Page 1

3Com® Switch 5500 Family

www.3Com.com

Part No. 10014925, Rev. AD

Published: August, 2007

Getting Started Guide

Switch 5500-EI

Switch 5500G-EI

Page 2

3Com Corporation

350 Campus Drive

Marlborough, MA

USA 01752-3064

Copyright © 2006-2007, 3Com Corporation. All rights reserved. No part of this documentation may be reproduced in any

form or by any means or used to make any derivative work (such as translation, transformation, or adaptation) without

written permission from 3Com Corporation.

3Com Corporation reserves the right to revise this documentation and to make changes in content from time to time

without obligation on the part of 3Com Corporation to provide notification of such revision or change.

3Com Corporation provides this documentation without warranty, term, or condition of any kind, either implied or

expressed, including, but not limited to, the implied warranties, terms or conditions of merchantability, satisfactory quality,

and fitness for a particular purpose. 3Com may make improvements or changes in the product(s) and/or the program(s)

described in this documentation at any time.

If there is any software on removable media described in this documentation, it is furnished under a license agreement

included with the product as a separate document, in the hard copy documentation, or on the removable media in a

directory file named LICENSE.TXT or !LICENSE.TXT. If you are unable to locate a copy, please contact 3Com and a copy will

be provided to you.

UNITED STATES GOVERNMENT LEGEND

If you are a United States government agency, then this documentation and the software described herein are provided to

you subject to the following:

All technical data and computer software are commercial in nature and developed solely at private expense. Software is

delivered as “Commercial Computer Software” as defined in DFARS 252.227-7014 (June 1995) or as a “commercial item”

as defined in FAR

license for the Software. Technical data is provided with limited rights only as provided in DFAR 252.227-7015 (Nov

FAR 52.227-14 (June 1987), whichever is applicable. You agree not to remove or deface any portion of any legend provided

on any licensed program or documentation contained in, or delivered to you in conjunction with, this User Guide.

Unless otherwise indicated, 3Com registered trademarks are registered in the United States and may or may not be registered

in other countries.

3Com and the 3Com logo are registered trademarks of 3Com Corporation.

Cisco is a registered trademark of Cisco Systems, Inc.

Funk RADIUS is a registered trademark of Funk Software, Inc.

Aegis is a registered trademark of Aegis Group PLC.

Intel and Pentium are registered trademarks of Intel Corporation. Microsoft, MS-DOS, Windows, and Windows NT are

registered trademarks of Microsoft

registered trademark in the United States and other countries, licensed exclusively through X/Open Company, Ltd.

IEEE and 802 are registered trademarks of the Institute of Electrical and Electronics Engineers, Inc.

All other company and product names may be trademarks of the respective companies with which they are associated.

2.101(a) and as such is provided with only such rights as are provided in 3Com’s standard commercial

Corporation. Novell and NetWare are registered trademarks of Novell, Inc. UNIX is a

1995) or

ENVIRONMENTAL STATEMENT

It is the policy of 3Com Corporation to be environmentally-friendly in all operations. To uphold our policy, we are committed

to:

Establishing environmental performance standards that comply with national legislation and regulations.

Conserving energy, materials and natural resources in all operations.

Reducing the waste generated by all operations. Ensuring that all waste conforms to recognized environmental standards.

Maximizing the recyclable and reusable content of all products.

Ensuring that all products can be recycled, reused and disposed of safely.

Ensuring that all products are labelled according to recognized environmental standards.

Improving our environmental record on a continual basis.

End of Life Statement

3Com processes allow for the recovery, reclamation and safe disposal of all end-of-life electronic components.

Regulated Materials Statement

3Com products do not contain any hazardous or ozone-depleting material.

Page 3

CONTENTS

ABOUT THIS GUIDE

Release Notes 8

Conventions 8

Related Documentation 8

Accessing the Documentation 9

Documentation Comments 10

1 INTRODUCING THE

SWITCH 5500 FAMILY

About the Switch 5500 Family 12

Switch 5500 Family — Front View 14

Switch 5500 — Rear View Detail 21

Default Settings 27

2 INSTALLING THE SWITCH

Package Contents 30

Choosing a Suitable Site 31

Rack-mounting 32

Connecting a Redundant Power Supply 35

Installing and Removing the Power Module 42

Placing Units On Top of Each Other 43

The Power-up Sequence 43

SFP Operation 47

Installing and Removing the Optional Interface Module 50

Packing and Shipping the Switch 5500 51

3 SETTING UP FOR MANAGEMENT

Methods of Managing a Switch 56

Setting Up Your Switch 58

Page 4

Manually Configuring the IP Information 61

Viewing Automatically Configured IP Information 67

Setting Up Command Line Interface Management 69

Setting Up Command Line Interface Management using SSH 70

Setting Up Web Interface Management 71

Setting Up SNMP Management 72

Changing the Default Passwords 73

Downloading the Configuration Conversion Utility 74

4 CREATING AN XRN STACKING FABRIC

How To Interconnect Units 75

Guidelines For Interconnecting Units 78

Unit Numbering within the Fabric 78

5 PROBLEM SOLVING

Solving Problems Indicated by LEDs 82

Solving Hardware Problems 83

Solving Communication Problems 84

Solving Fabric Formation Problems 86

6 UPGRADING SOFTWARE

The Contents of the Executable File 88

Upgrading from the Command Line Interface 88

Upgrading from the Bootrom Interface 95

Bootrom Upgrade 99

A SAFETY INFORMATION

Power Cord Set — Japan 104

Important Safety Information 104

L’information de Sécurité Importante 107

Wichtige Sicherheitsinformationen 110

Información de Seguridad Importante 112

Importanti Informazioni di Sicurezza 115

Wa¿ne informacje o zabezpieczeniach 118

Page 5

B PIN-OUTS

Null Modem Cable 123

PC-AT Serial Cable 123

Modem Cable 124

Ethernet Port RJ-45 Pin Assignments 124

C TECHNICAL SPECIFICATIONS

Switch 5500 (28 Port) 128

Switch 5500 PWR (28 Port) 129

Switch 5500 (52 Port) 130

Switch 5500 PWR (52 Port) 131

Switch 5500 FX (28 Port) 132

Switch 5500G-EI (24 Port) 133

Switch 5500G-EI PWR (24 Port) 134

Switch 5500G-EI (48 Port) 135

Switch 5500G-EI PWR (48 Port) 136

Switch 5500G-EI SFP (24-Port) 137

RPS 138

Earthing Lead 139

D OBTAINING SUPPORT FOR YOUR PRODUCT

Register Your Product 141

Purchase Value-Added Services 141

Troubleshoot Online 142

Access Software Downloads 142

Telephone Technical Support and Repair 142

Contact Us 143

E 3COM NETWORK MANAGEMENT

3Com Network Supervisor 145

3Com Network Director 146

3Com Network Access Manager 146

3Com Enterprise Management Suite 147

Integration Kit with HP OpenView Network Node Manager 147

Page 6

INDEX

REGULATORY NOTICES

Page 7

ABOUT THIS GUIDE

This guide provides all the information you need to install and use the

following switches in their default state:

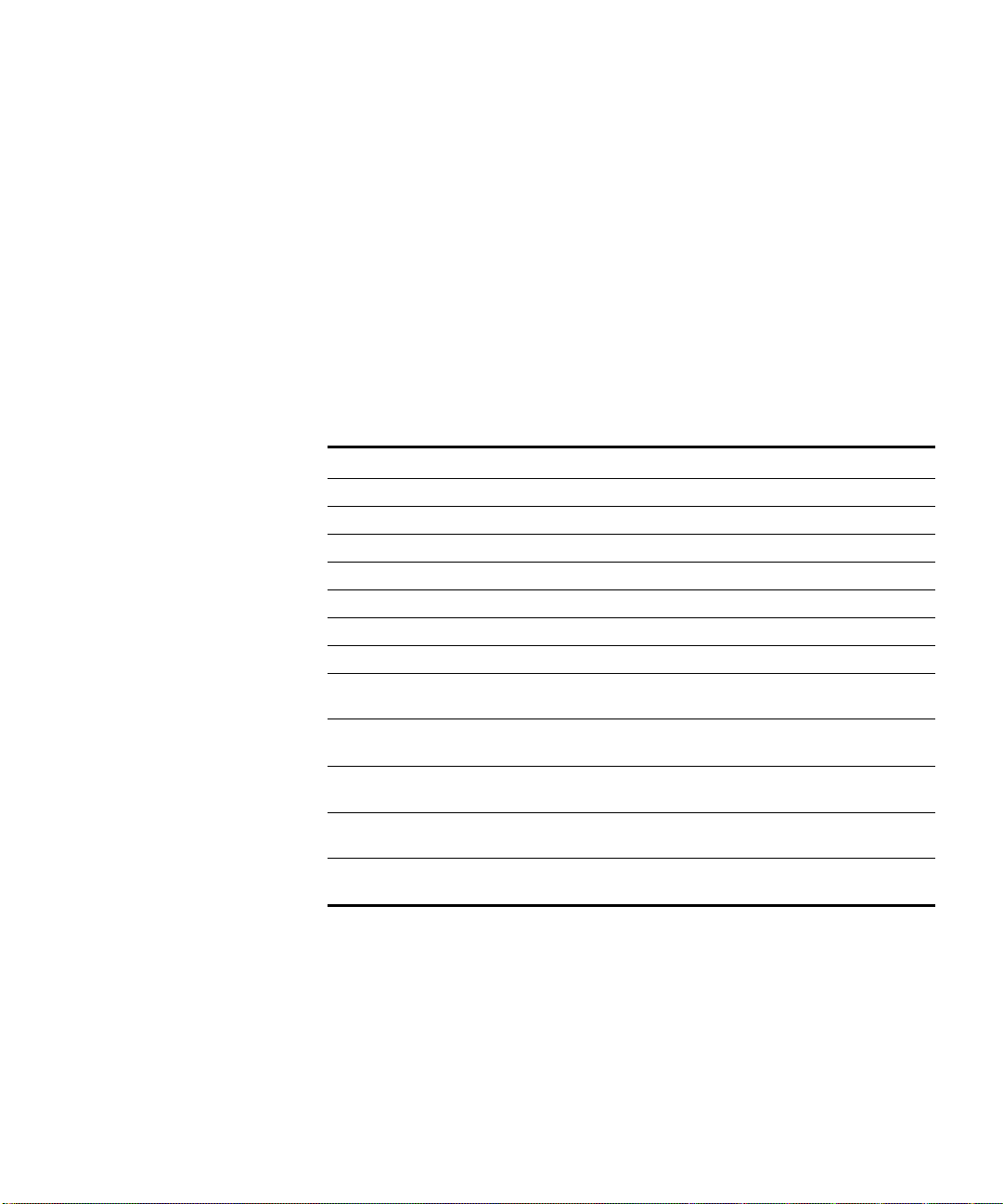

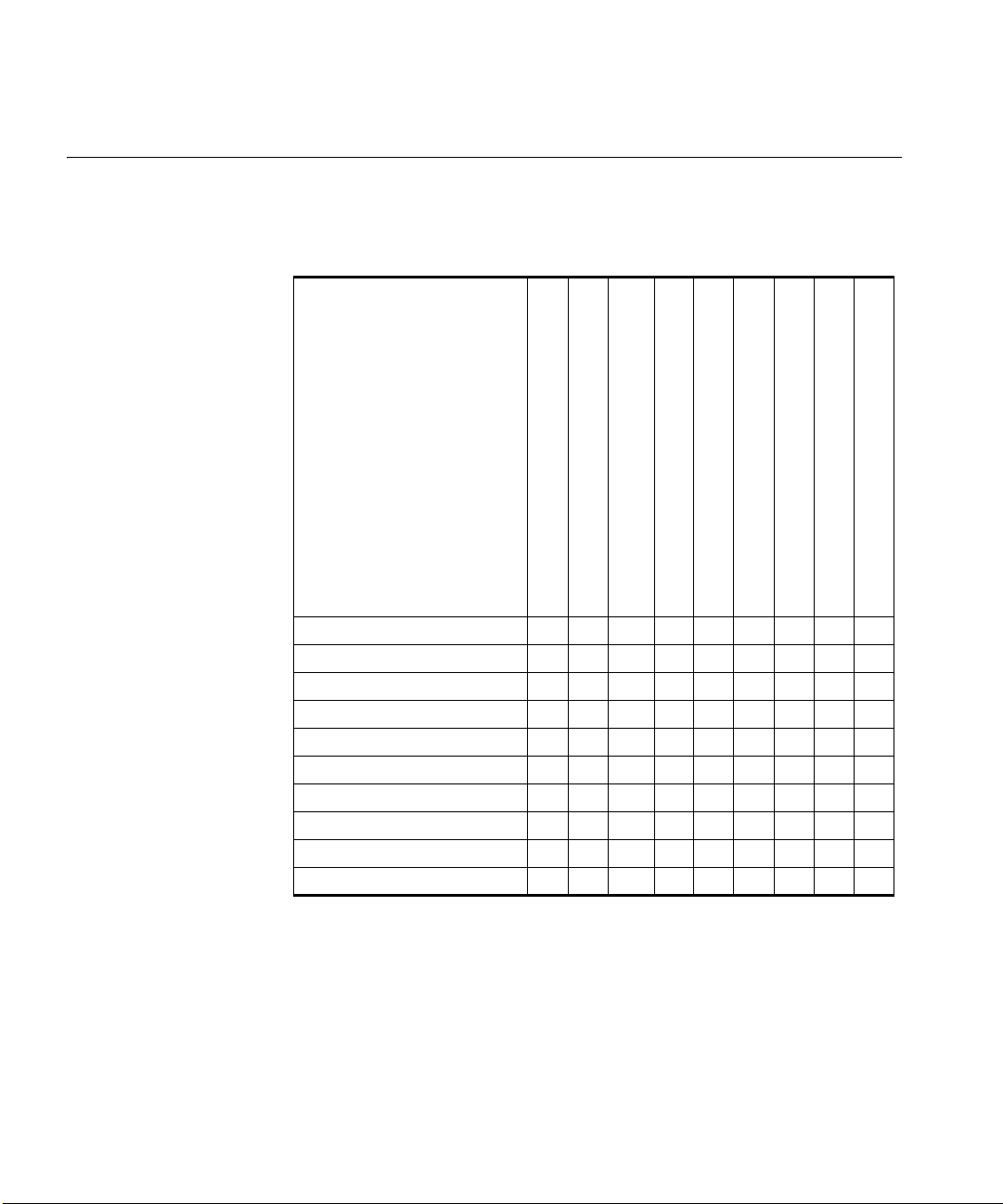

Ta bl e 1 Switch 5500 Family

Switch Model SKU Number

Switch 5500-SI 28-Port 3CR17151-91

Switch 5500-SI 52-Port 3CR17152-91

Switch 5500-EI 28-Port 3CR17161-91

Switch 5500-EI 52-Port 3CR17162-91

Switch 5500-EI PWR 28-Port 3CR17171-91

Switch 5500-EI PWR 52-Port 3CR17172-91

Switch 5500-EI 28-Port FX 3CR17181-91

Switch 5500G-EI 24-Port 3CR17250-91 Includes 3CR17254-91 (chassis)

Switch 5500G-EI 48-Port 3CR17251-91 Includes 3CR17255-91 (chassis)

Switch 5500G-EI PWR 24-Port 3CR17252-91 Includes 3CR17254-91 (chassis)

Switch 5500G-EI PWR 48-Port 3CR17253-91 Includes 3CR17255-91 (chassis)

Switch 5500G-EI 24-Port SFP 3CR17258-91 Includes 3CR17259-91 (chassis)

and 3C17266 (power supply)

and 3C17267 (power supply)

and 3C17264 (power supply)

and 3C17265 (power supply)

and 3C17266 (power supply)

All procedures described in this guide apply to all models except where

stated.

The guide is intended for network administrators who are responsible for

installing and setting up network equipment; consequently, it assumes a

basic working knowledge of LANs (Local Area Networks).

Page 8

8 ABOUT THIS GUIDE

Release Notes The Release Notes provide important information about the current

software release, including new features, modifications, and known

problems. You should read the Release Notes before installing the Switch

in your network.

If the information in the Release Notes differs from the information in this

guide, follow the instructions in the Release Notes.

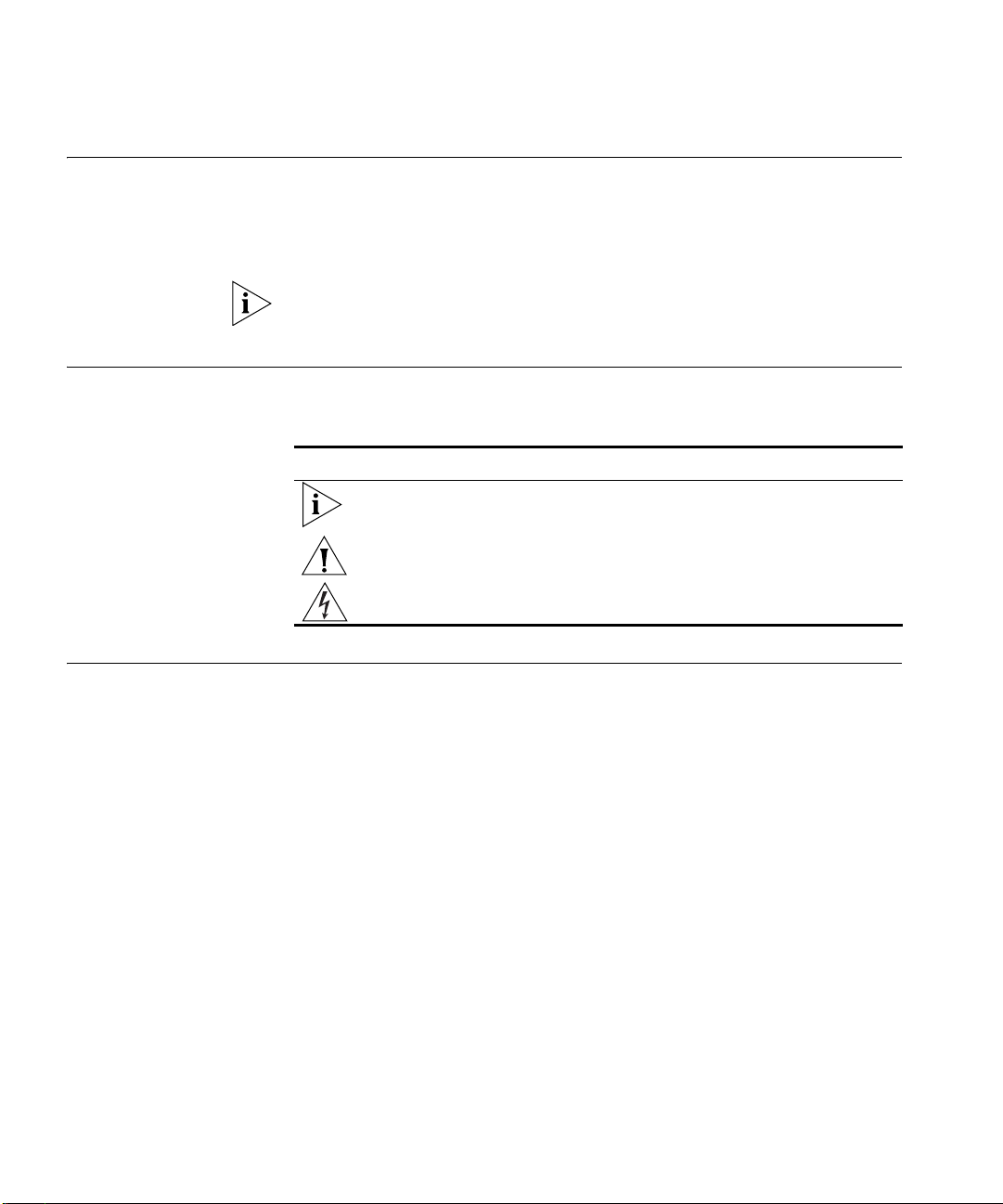

Conventions Ta bl e 2 lists conventions that are used throughout this guide.

Ta bl e 2 Notice Icons

Icon Notice Type Description

Information note Information that describes important features or

Caution Information that alerts you to potential data loss or

Warning Information that alerts you to potential personal injury

instructions

potential damage to an application, system, or device

Related Documentation

In addition to this guide, each Switch documentation set includes the

following:

■ Switch 5500 Family Configuration Guide

This guide contains information about the features supported by your

Switch and how you can use them to optimize your network.

■ Switch 5500 Family Quick Reference Guide

This guide contains a list of the features supported by the Switch 5500

Family and a summary of the command line interface commands

available for the Switch. This guide is also available under the Help

button on the web interface.

■ Switch 5500 Family Command Reference Guide

This guide provides detailed information about the web interface and

command line interface that enable you to manage the Switch.

Page 9

Accessing the Documentation 9

■ Release Notes

These notes provide information about the current software release,

including new features, modifications, and known problems. The

Release Notes are supplied in hard copy with your Switch.

Accessing the Documentation

The Switch 5500 Family documentation is available in Adobe Acrobat

Reader Portable Document Format (PDF) at www.3com.com.

Page 10

10 ABOUT THIS GUIDE

Documentation Comments

Your suggestions are very important to us. They will help make our

documentation more useful to you. Please e-mail comments about this

document to 3Com at:

pddtechpubs_comments@3com.com

Please include the following information when commenting:

■ Document title

■ Document part number and revision (on the title page)

■ Page number (if appropriate)

Example:

Part Number 10014925 rev. AC

Switch 5500 Family Getting Started Guide

Page 21

Please note that we can only respond to comments and questions about

3Com product documentation at this e-mail address. Questions related

to technical support or sales should be directed in the first instance to

your network supplier.

Page 11

1

INTRODUCING THE SWITCH 5500 FAMILY

This chapter contains introductory information about the Switch 5500

and how it to use it within a network. It includes hardware and software

feature summaries and contains the following section:

■ About the Switch 5500 Family

■ Switch 5500 Family — Front View

■ Switch 5500 — Rear View Detail

■ Default Settings

Page 12

12 CHAPTER 1: INTRODUCING THE SWITCH 5500 FAMILY

About the Switch 5500 Family

The Switch 5500 Family includes mixed media devices consisting of those

described in

Ta bl e 3 Switch 5500 Family Hardware

Switch 5500 Family

Switch 5500-SI 28 Port 24 4 1 1

Switch 5500-SI 52 Port 48 4 1 1

Switch 5500-EI 28 Port 24 4 1 1

Switch 5500-EI 52 Port 48 4 1 1

Switch 5500 PWR 28 Port 24 4 1 1

Switch 5500 PWR 52 Port 48 4 1 1

Switch 5500 FX 28 Port 2 24 2 1 1

Switch 5500G-EI 24 Port 24 24* 4† 2 1 1 1

Switch 5500G-EI 48 Port 48 48* 4† 2 1 1 1

Switch 5500G-EI SFP 24 Port 4 24 2 1 1 1

Ta bl e 3.

10BASE-T\100BASE-TX Ports

10BASE-T\1000BASE-TX\1000BASE-T Ports

10\100\1000 PoE Ports

100BASE-X SFP Ports

1000BASE-X SFP Ports

Stacking Ports

RJ-45 Console Port

-48V DC RPS Input

Module Slot

*Depending on Power Supply Unit Fitted

†Combo SFP and 10/100/100 Ports

The Switch 5500 Family provides high-performance workgroups with a

backbone to the server connection. You can also add the Switch 5500 to

any 3Com

system as your network grows.

Page 13

About the Switch 5500 Family 13

For information about using the software features of the Switch, refer to

the “Command Reference Guide” located at www.3com.com.

Summary of

Hardware Features

Ta bl e 4 summarizes the hardware features that are supported by the

Switch 5500.

Ta bl e 4 Hardware Features

Feature Switch 5500 Family

MAC Addresses Up to 16,000 supported

Forwarding Modes Store and Forward

Auto-negotiation Supported on all ports

Auto MDI/MDIX Supported on all ports. If fiber SFP transceivers are

used, Auto MDIX is not supported.

Duplex Modes Half and full duplex on all ports

Flow Control In full duplex mode, all ports are supported.

Smart Auto-sensing Supported on all copper ports

Traffic Prioritization Supported (IEEE Std 802.1D, 1998 Edition)

Eight traffic queues per port

Power over Ethernet

(Switch 5500)

Power over Ethernet

(Switch 5500G-EI)

Ethernet and Fast Ethernet

Ports

(Switch 5500)

Fast Ethernet and Gigabit

Ethernet Ports (Switch

5500G-EI)

100BASE-X SFP Ports Supports 100BASE-LX10 10km single-mode and

1000BASE-X Gigabit

Ethernet SFP Ports

Supported on front panel ports, except for the SFP

ports. (3CR17171 and 3CR17172 only)

Supported on all front panel ports, except for the

SFP ports, when fitted with PoE PSUs (3CR17254

and 3CR17255).

Auto-negotiating 10BASE-T/100BASE-TX ports or

100BASE-X ports.

Auto-negotiating

10BASE-T/100BASE-TX/1000BASE-T and SFP ports.

100BASE-FX 2km multi-mode transceivers.

Supports fiber Gigabit Ethernet short-wave (SX),

long-wave (LX), long-haul (LH70), and copper (T)

transceivers in any combination

Page 14

14 CHAPTER 1: INTRODUCING THE SWITCH 5500 FAMILY

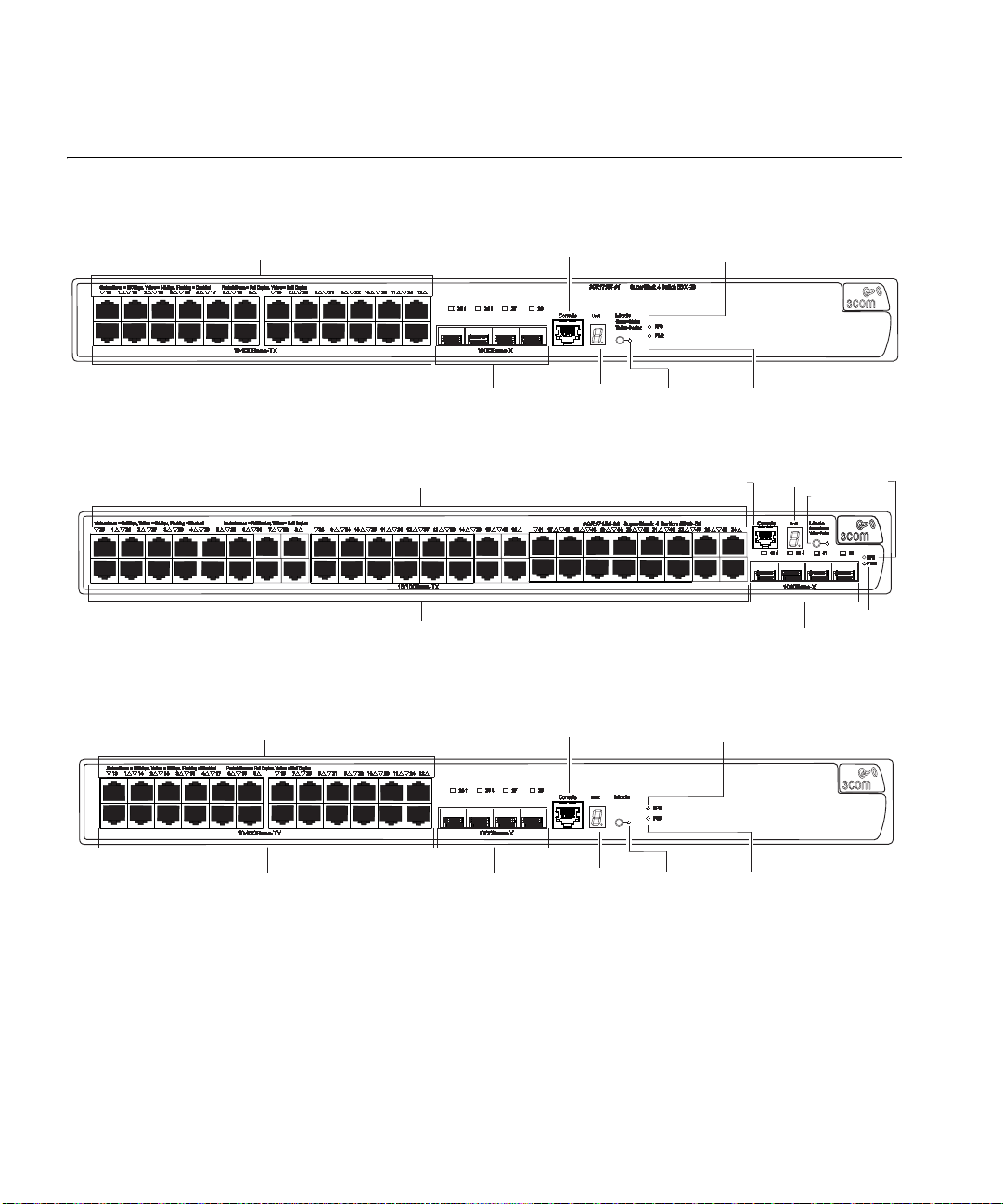

Unit LED

Console Port

Mode LED

Power LED

10/100BASE-TX Ports

Port Status LEDs

1000BASE-X Ports

RPS LED

Unit LED

Console Port

Mode LED

RPS LED

10/100BASE-TX Ports

Port Status LEDs

1000BASE-X Ports

PWR LED

Unit LED

Console Port

Mode LED

Power LED

10/100BASE-TX Ports

Port Status LEDs

1000BASE-X Ports

RPS LED

3CR17171-91

SuperStack 4 Switch 5500 PWR 28 Port

Green=Status

Yellow=Packet

Red=PoE

Switch 5500 Family

— Front View

Figure 1 Switch 5500-SI and EI 28-Port — front view

Figure 2 Switch 5500-SI and EI 52-Port — front view

Figure 3 Switch 5500-EI 28-Port PWR - front view

Page 15

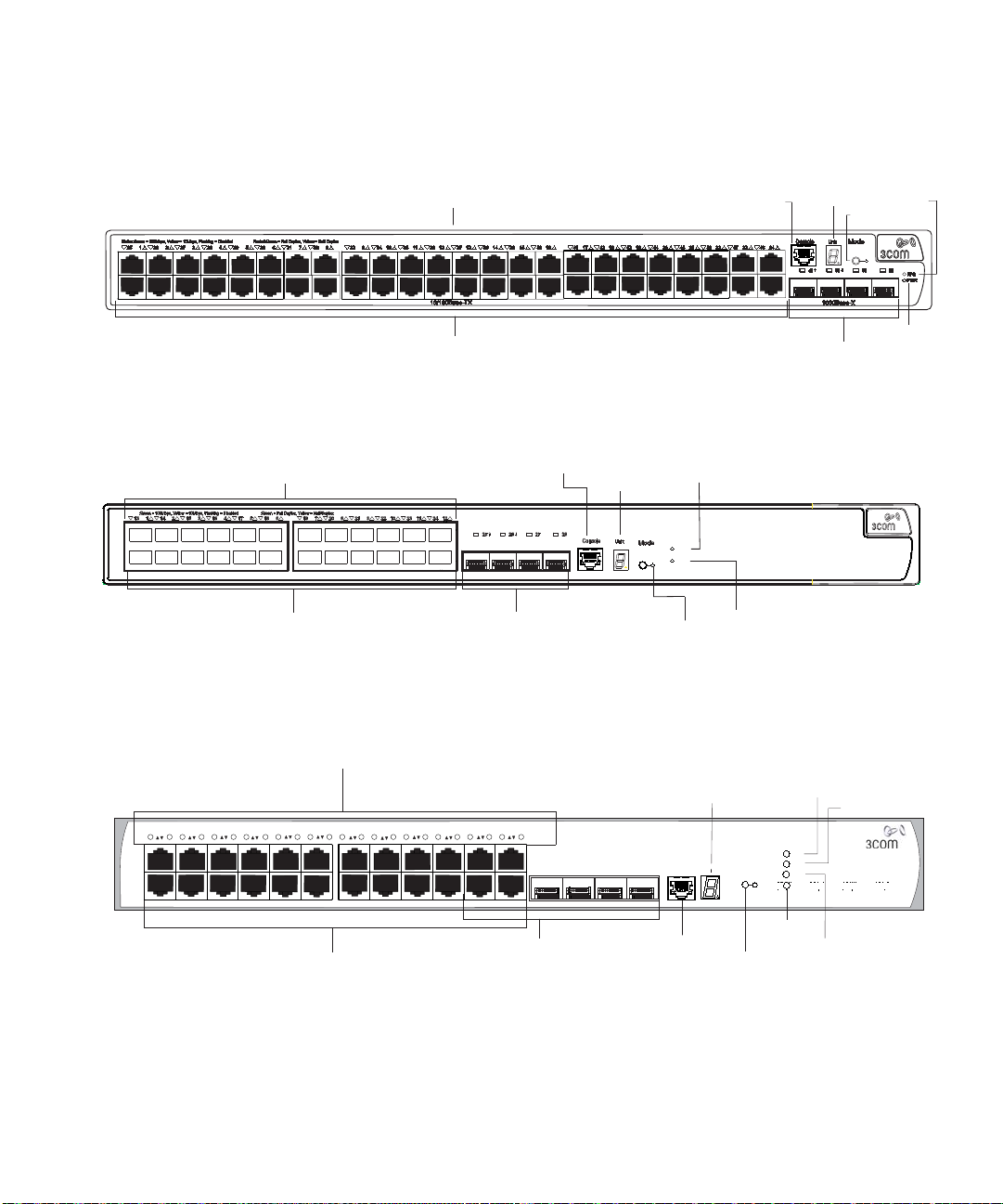

Switch 5500 Family — Front View 15

Unit LED

Console Port

Mode LED

RPS LED

10/100BASE-TX Ports

Port Status LEDs

1000BASE-X Ports

PWR LED

SuperStack 4 Switch 5500 PWR 52 Port

3CR17172-91

Green=Status

Yellow=Packet

Red=PoE

RPS

PWR

Green=Speed

Yellow=Duplex

Speed Duplex

100Base-FX

1000Base-X

Console Port

Two 10/100/1000BASE-T Ports

Two 1000BASE-X Ports

Unit LED

RPS LED

Power LED

Mode LED

Port Status LEDs

100BASE-X Ports

10/100/1000BASE-T Ports

Console Port

3CR17251-91 SuperStack4 Switch 5500G-EI 24-Port

Port Status LEDs

Unit LED

21

22 23

24

Dual Personality

10/100/1000BASE-T/

1000BASE-X SFP Ports

1 432 5 678 9 10 11 1213 161514 17 18 19 20 21 22 23 24

Console

PWR

RPS

MOD

STK

Unit

Stack LED

Module LED

RPS LED

Status:Green=10Mbps Yellow=10MbpsFlashing=Disabled Packet:Green=Full Duplex Yellow=Half Duplex Power:Green=Delivering Power Yellow=FaultFlashing Green=Over Budget

100%

80%

60%

40%

20%

Mode:

Green=Status

Yellow=Packet

Red=POE

Mode LED

PWR LED

Figure 4 Switch 5500-EI 52-Port PWR - front view

Figure 5 Switch 5500-EI FX 28-Port — front view

Switch 5500G-EI Figure 6 Switch 5500G-EI (24 port) — front view

Page 16

16 CHAPTER 1: INTRODUCING THE SWITCH 5500 FAMILY

10/100/1000BASE-T Ports

Console Port

SuperStack 4 Switch 5500G-EI 48-port

Port Status LEDs

Unit LED

45

46 47

48

Dual Personality

10/100/1000BASE-T/

1000BASE-X SFP Ports

1 432 5 678 9 10 11 1213 161514 17 18 19 20 21 22 23 24 25 282726 29 30 31 32 33 34 35 3637 403938 41 42 43 44 45 46 47 48

Status:Green=10Mbps Yellow=10MbpsFlashing=Disabled Packet:Green=Full Duplex Yellow=Half Duplex Power:Green=Delivering Power Yellow=FaultFlashing Green=Over Budget

PWR

RPS

MOD

STK

100%

80%

60%

40%

20%

Mode:

Green=Status

Yellow=Packet

Red=POE

Stack

LED

Mode LED

Power LED

RPS LED

Module LED

Unit LED

Console Port

10/100/1000BASE-TX Ports

Port Status LEDs

1000BASE-X Ports

1

13

3CR17259-91 SuperStack 4 Switch 5500G-EI SFP 24-Port

PWR

RPS

MOD

STK

11

23

10

22

8

20

7

19

12

24

9

21

6

18

5

17

4

16

3

15

2

14

1000BASE-X:

Green=1000Mbps Flashing Yellow=POST failed

10/100/1000BASE-TX:

S(Speed):Green=1000Mbps Yellow=10/100Mbps

D(Duplex):Green=Full Duplex Yellow=Half Duplex

Mode

LED

Stack

LED

RPS LED

Power LED

10/100/1000Base-TX

1000Base-X1000Base-X

S

D

25/11

S

D

26/12

S

D

27/23

S

D

28/24

Figure 7 Switch 5500G-EI (48 port) — front view

Figure 8 Switch 5500G-EI SFP (24 port) — front view

WARNING: The RJ-45 ports are shielded RJ-45 data sockets. You cannot

use them as standard traditional telephone sockets, or to connect the

unit to a traditional PBX or public telephone network. Only connect RJ-45

data connectors, network telephony systems, or network telephones to

these sockets. You can connect either shielded or unshielded data cables

with shielded or unshielded jacks to these data sockets.

10BASE-T/

100BASE-TX/

1000BASE-T Ports

The 10BASE-T/100BASE-TX/1000BASE-T ports have RJ-45 connectors and

are configured as Auto MDIX (cross-over).

The default state for these ports is auto-negotiation enabled, where the

link’s speed, duplex, and flow control modes are automatically detected

to provide the highest available bandwidth with the link partner.

Page 17

Switch 5500 Family — Front View 17

You can disable auto-negotiation. You can manually configure these

ports to 10 Mbps half duplex, 100 Mbps half duplex,

10 Mbps full duplex, or 100 Mbps full duplex. It is not possible to

manually configure a 1000 Mbps link because auto-negotiation is

mandatory in the 1000 Mbps standard. If you disable auto-negotiation,

Auto MDIX cannot function and the ports become fixed in MDIX

(cross-over) mode.

If you disable auto-negotiation on a 1000 Mbps port, the speed drops to

the highest available speed, which is 100 Mbps by default.

1000BASE-X SFP Ports The 1000BASE-X SFP (Small Form Factor Pluggable) ports support fiber

Gigabit Ethernet short-wave (SX), long-wave (LX), long-haul (LH70), and

copper (T) SFP Transceivers in any combination. This offers you the

flexibility of using SFP transceivers to provide connectivity between the

Switch and remote 1000 Mbps workgroups, or to create a high capacity

aggregated link backbone connection.

The default state for these ports is auto-negotiation enabled, where the

speed, duplex and flow control modes are negotiated. As the speed and

duplex modes are fixed by the media type, only the flow control is

negotiated with the link partner. Alternatively, auto-negotiation can be

disabled (except 1000BASE-T where auto-negotiation is mandatory) and

the flow control setting can be manually configured.

100BASE-X SFP Ports

(Switch 5500-EI FX

only)

Console Port The console port allows you to connect a terminal and perform remote or

You can also use these ports for stacking the 5500 SI and EI. For

information about stacking these switches, see the section entitled

“Guidelines For Interconnecting Units” on page 78.

The Switch 5500-EI FX has 24 100BASE-X SFP ports. These are 100Mbps

ports that can use multi-mode fiber optic cables of up to 2km and

single-mode fiber optic cables of up to 10km.

You must manually configure duplex and flow control.

The Switch 5500-EI FX supports copper transceivers on the Gigabit SFP

ports only.

local out-of-band management. As the console port on the Switch is an

RJ-45 port, you must connect an RJ-450 to DB9 converter cable to a

standard null modem cable in order to connect a terminal.

Page 18

18 CHAPTER 1: INTRODUCING THE SWITCH 5500 FAMILY

Unit LED The Unit LED is a seven segment display visible on the front of the Switch.

The Unit LED indicates the unit number in a fabric, POST test ID, and

software upgrade information. In the unlikely event of a hardware fault

occurring, you can use the Unit LED to help diagnose the problem. For

information on using the Unit LED for problem solving, see

Problems Indicated by LEDs” on page 82.

LEDs Ta bl e 5 lists the LEDs visible on the front of the Switch, and how to read

their status according to color. For information on using the LEDs for

problem solving, see

page 43.

Ta bl e 5 LED behavior

LED Color Indicates

10/100/1000BASE-TX Port LEDs

Speed Green A high speed (1000 Mbps) link is present, blinking off

Yellow A low speed (10/100 Mbps) link is present, blinking

Yellow flashing The port has failed POST.

Off No link is present.

Duplex Green Full duplex, blinking off for every packet received or

Yellow Half duplex, blinking off for every packet received or

Yellow flashing The port has failed POST.

Off No link is present.

PoE Green Power is being delivered to the port.

Green flashing Port power has exceeded limit or is unable to supply

Yellow PoE error, no power supplied on port.

Yellow flashing The port has failed post.

Off No power is being delivered.

10/100BASE-T/TX Ports LEDS

Speed Green A high speed (100 Mbps) link is present, blinking off

Yellow A low speed (10 Mbps) link is present, blinking off for

Yellow flashing The port has failed POST.

“Solving

“Checking for Correct Operation of LEDs” on

for every packet received or transmitted.

off for every packet received or transmitted.

transmitted.

transmitted.

power due to unit being over budget.

for every packet received or transmitted.

every packet received or transmitted.

Page 19

Switch 5500 Family — Front View 19

LED Color Indicates

Off No link is present.

Duplex Green Full duplex, blinking off for every packet received or

transmitted.

Yellow Half duplex, blinking off for every packet received or

transmitted.

Yellow flashing The port has failed POST.

Off No link is present.

PoE Green Power is being delivered to the port.

Green flashing Port power has exceeded limit or is unable to supply

power due to unit being over budget.

Yellow PoE error, no power supplied on port.

Yellow flashing The port has failed post.

Off No power is being delivered.

1000BASE-X SFP Port LEDs

Speed Green A 1000 Mbps link is present.

Yellow flashing The port has failed post.

Off No link is present.

Duplex Green Full duplex packets are being transmitted/received on

Yellow Half duplex packets are being transmitted/received on

Yellow flashing Port failed POST.

Off No links is present.

100BASE-X SFP Port LEDs

Speed Green A 100 Mbps link is present.

Yellow flashing The port has failed post.

Off No link is present.

Duplex Green Full duplex packets are being transmitted/received on

Yellow Half duplex packets are being transmitted/received on

Yellow flashing Port failed POST.

Off No links is present.

the port.

the port.

the port.

the port.

Page 20

20 CHAPTER 1: INTRODUCING THE SWITCH 5500 FAMILY

LED Color Indicates

Unit LED

Green Power on Self Test (POST) is in progress. During POST

Green flashing The Switch has failed POST. The Unit LED flashes the

Green flashing ‘f’ There has been a fan failure.

Green flashing ‘t’ The Switch is over temperature and unit temperature

Stack LED

Green The XRN stack is functioning in resilient mode. Loop

Green flashing Switch is not compatible with the other Switches in

Yellow The XRN stack is functioning without the loop

Off Stacking Cables are not connected.

Module LED (Switch 5500G-EI only)

Green The Module is installed and operating normally.

Yellow flashing The Module is installed but not supported or faulty.

Off The Module is not installed.

Mode LED

Duplex Yellow 10/100/1000 Duplex and Activity, 1000 SFP Duplex

Speed Green 10/100/1000 Port Speed and Activity, 1000 SFP

PoE Red 10/100/1000 port showing PoE information.

RPS LED

Green AC and RPS supply connected.

Yellow AC failed or not connected. RPS supply is OK.

Off There is no RPS supply connected.

a test ID number appears in the Unit LED (seven

segment display)

or

Software download is in progress. During software

download, a clockwise cycling bar appears in the Unit

LED.

number of the test that has failed.

is critical.

cable is attached.

the stack.

connection.

and Activity, or Stack Activity.

Status and Activity, or Stack Status and Activity.

Page 21

LED Color Indicates

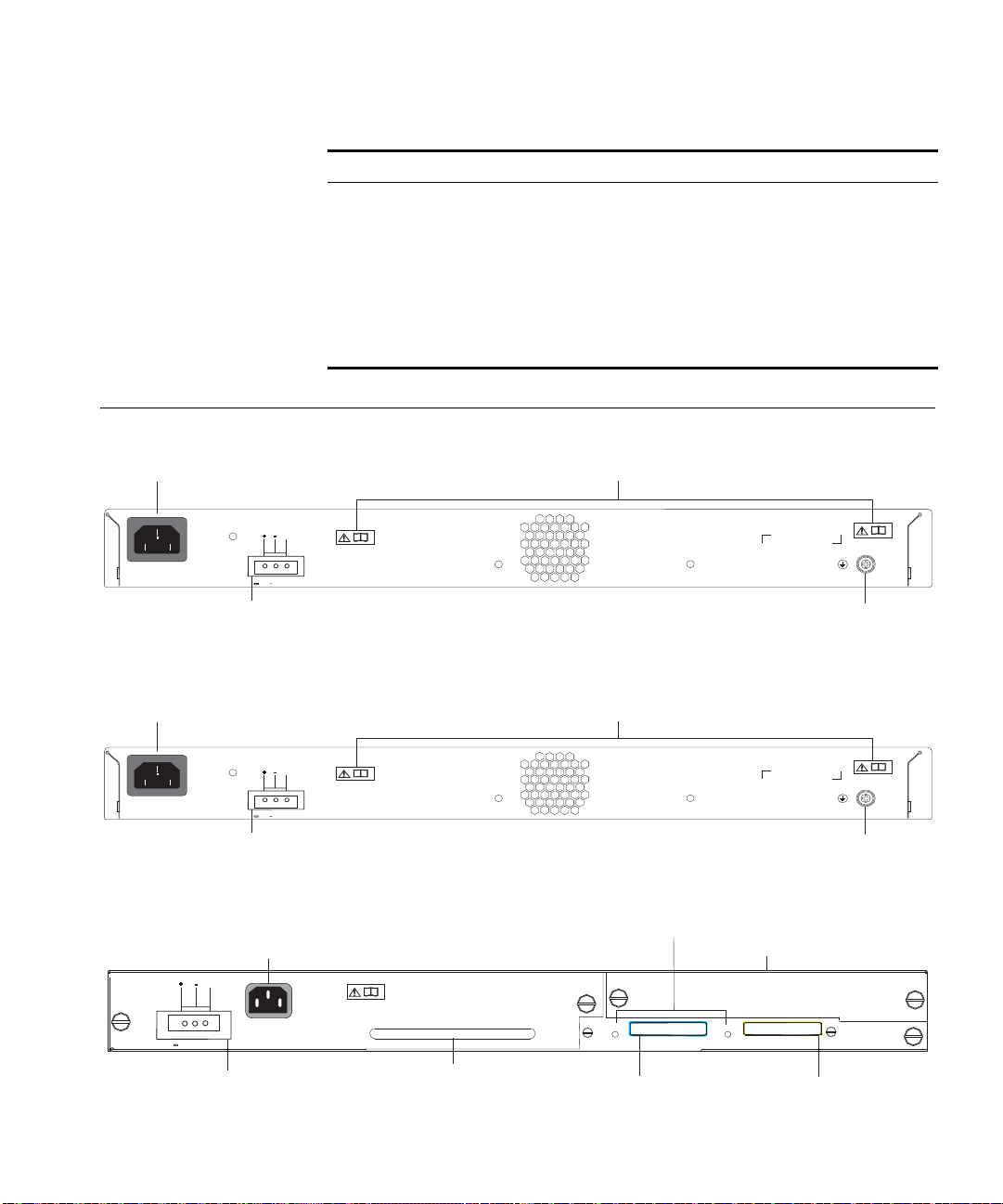

Power Socket

Redundant Power System Socket

100-240V; 50/60Hz; 2.5A

Open Book Warning Labels

NULL

Earthing Screw

~

-48 -60V;2.0A

Power Socket

Redundant Power System Socket

100-240V; 50/60Hz; 8.0A

Open Book Warning Labels

NULL

Earthing Screw

~

-53 -55V;19.5A

Redundant Power System Socket

Power Socket

Stacking Cable Port (Down)

Stacking Cable Port (Up)

Expansion Module Slot

Stacking: Green=OK, Flashing Green=Traffic,Yellow=Link Fault,

YellowFlashing=Stack Fault

Stack LEDs

Handle

-52 - -55V;19.5A

DOWN

UP

Switch 5500G PoE PSU 24-Port

NULL

PWR LED

Green The Switch is powered-up and operating normally.

Green flashing Self Test (POST) or Software Download is in progress.

Yellow flashing One or more ports have failed POST.

Red The Switch has failed its Power On Self Test.

Off The Switch is not receiving power or there is a fault

with the Power Supply Unit.

Switch 5500 — Rear View Detail 21

Switch 5500 — Rear

Figure 9 Switch 5500-SI, EI and FX — rear view

View Detail

Figure 10 Switch 5500-EI PWR - rear view

Switch 5500G-EI Figure 11 Switch 5500G-EI — rear view

Page 22

22 CHAPTER 1: INTRODUCING THE SWITCH 5500 FAMILY

Expansion Module

Slot (Switch 5500G-EI

Only)

You can use this slot to install an Expansion Module. The Switch 5500G

Family provides one expansion module slot on the rear panel in which you

can use an 8-port 1000 Mbps SFP module, a 1-port 10 Gbps XENPAK

module, or a 2-port 10 Gbps XFP module.

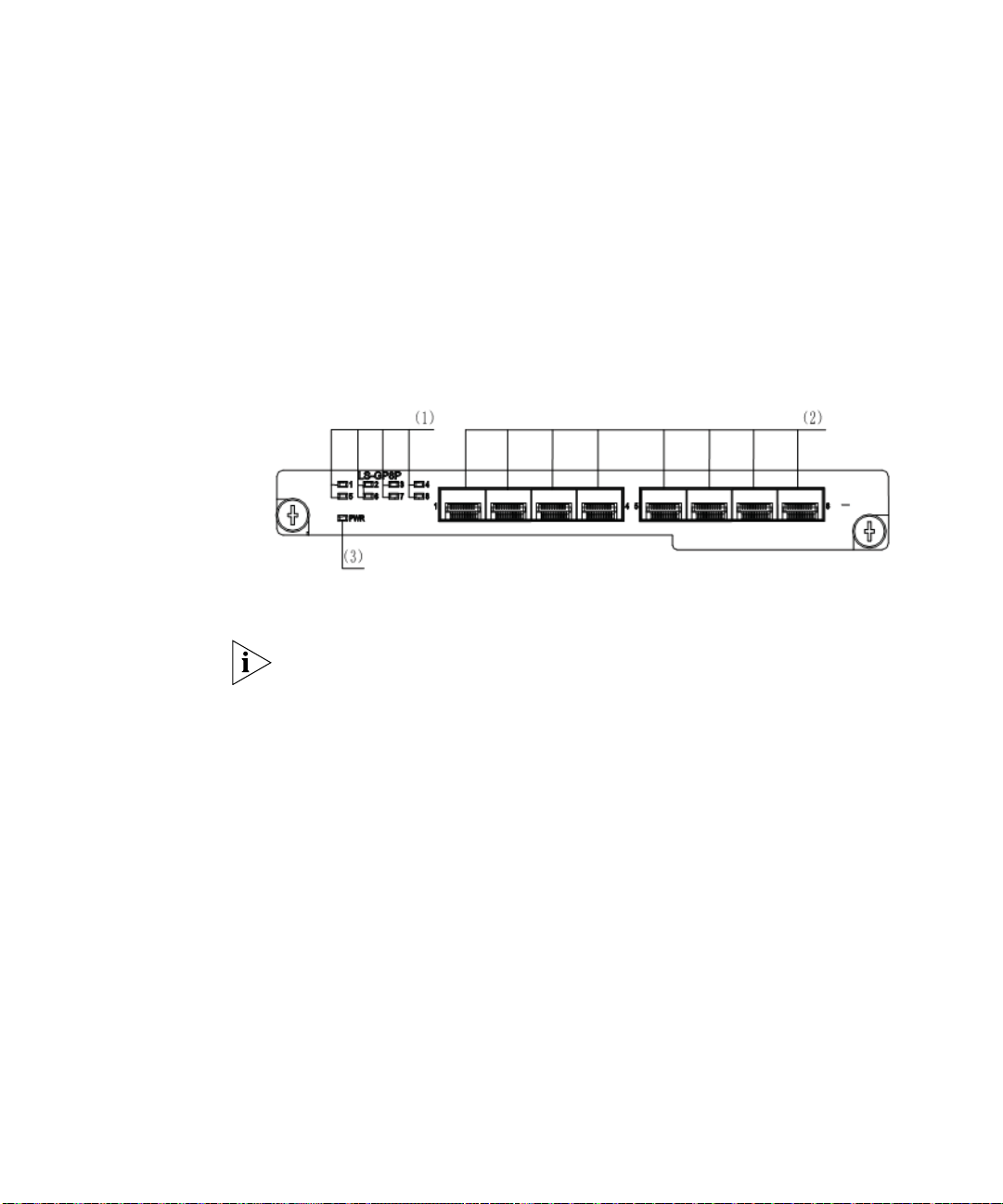

8-port 1000 Mbps SFP module

This module, shown in Figure 12, provides eight 1000 Mbps 1000Base-X

SFP transceiver ports.

Figure 12 8-port 1000 Mbps SFP module

(1) Port status LEDs 2) SFP ports 3) Module power LED

Notes:

■ The types of available SFP modules may change over time. Refer to

www.3com.com for the latest transceiver support.

■ For SFP module specifications, refer to 3Com Web site at

www.3com.com

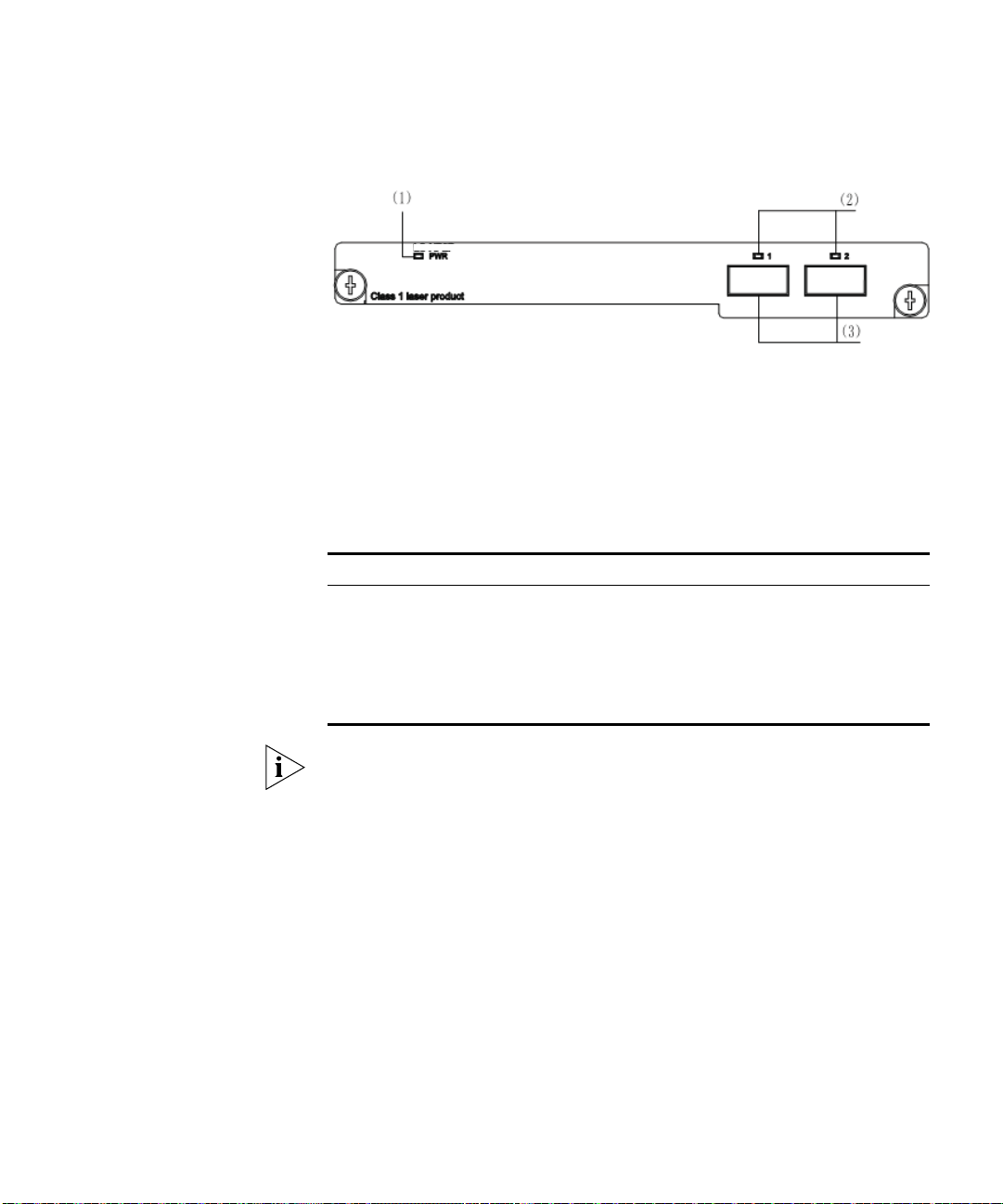

2-port 10 Gbps XFP module

This module, shown in Figure 13, provides two 10 Gbps XFP optical ports.

Page 23

Figure 13 2-port 10 Gbps XFP module

Switch 5500 — Rear View Detail 23

(1) Module power LED (2) 10 Gbps XFP optical

ports

(3) 10 Gbps XFP optical ports

Ta bl e 6 lists the available XFP transceivers.

Ta bl e 6 XFP transceivers supported by 2-port 10 Gbps XFP module

Ty pe Model

XFP transceivers 3CXFP90 10GBASE-LRM

3CXFP92 10GBASE-LR

3CXFP94 10GBASE-SR

3CXFP95 10GBASE-CX4

3CXFP96 10GBASE-ER

Notes:

■ The type of 10 Gbps XFP module may be different from those listed

above. For the most up-to-date information, refer to www.3com.com.

■ For XFP transceiver specifications, refer to 3Com’s Web site at

www.3Com.com.

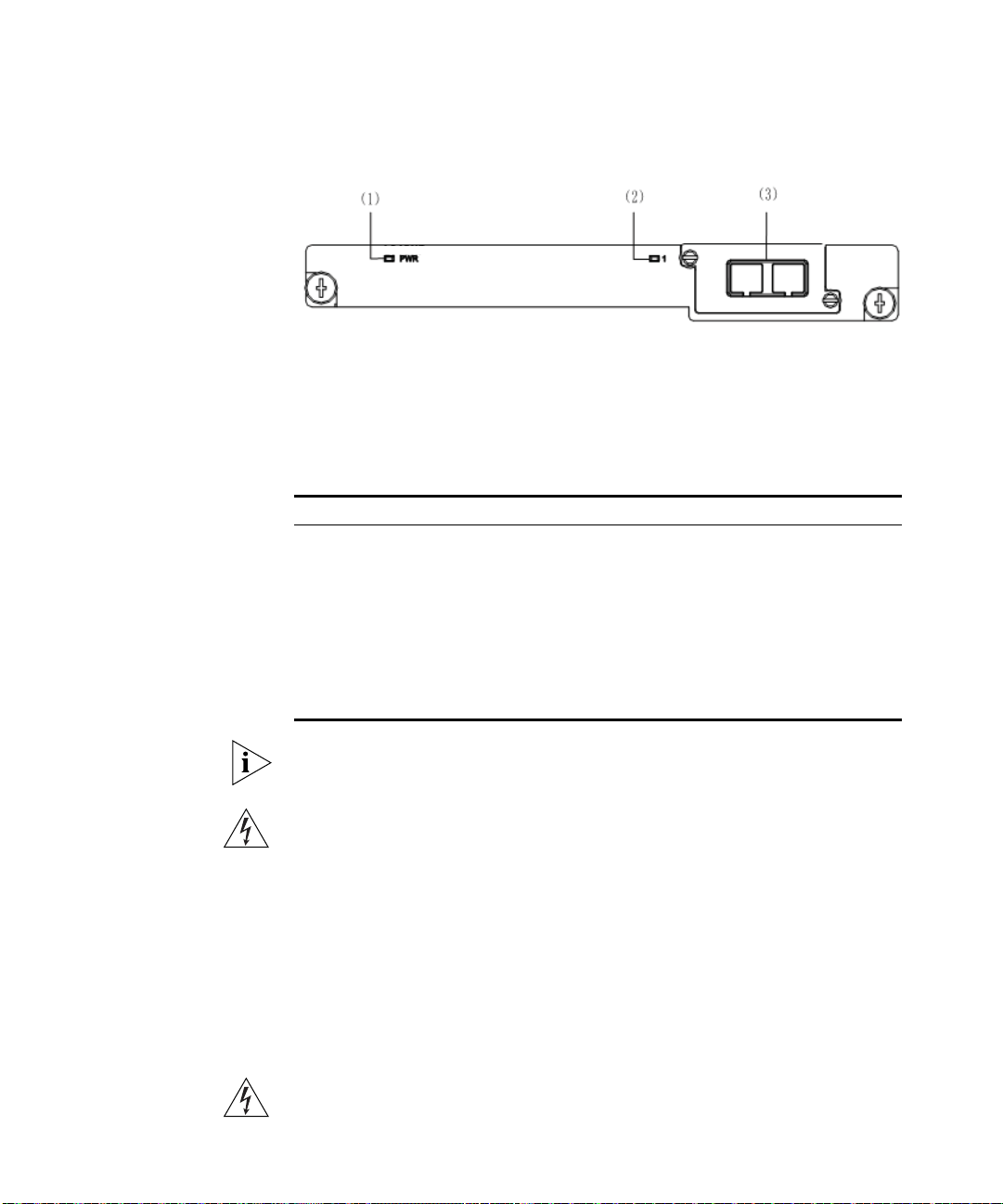

1-port 10 Gbps XENPAK module

This module, shown in Figure 14, provides one 10 Gbps XENPAK

transceiver port.

Page 24

24 CHAPTER 1: INTRODUCING THE SWITCH 5500 FAMILY

Figure 14 1-port 10 Gbps XENPAK module

(1) Module power

LED

(2) Port status LED (3) 10 Gbps XENPAK

optical/electrical port

The Table 7 lists the available XENPAK optical modules:

Ta bl e 7 XENPAK optical port module supported by 1-port 10 Gbps XENPAK

module

Ta bl e 8 Typ e Ta bl e 9 Model

XENPAKs that are supported

3CXENPAK91 10GBASE-LX4

3CXENPAK92 10GBASE-LR

XENPAK optical module

3CXENPAK93 10GBASE-T

3CXENPAK94 10GBASE-SR

3CXENPAK95 10GBASE-CX4

3CXENPAK96 10GBASE-ER

For specifications of XENPAK Transceivers, refer to 3Com’s Web site at

www.3Com.com.

WARNING: When an Expansion Module is not installed, ensure that the

blanking plate is fitted by tightening all screws with a suitable tool.

Failure to fit a blanking plate may void the product warranty.

Power Socket The Switch automatically adjusts its power setting to any supply voltage

Open Book Warning

Labels

in the range 100-240 VAC.

Before installing or removing any components from the Switch 5500

Family or carrying out any maintenance procedures, you must read the

safety information provided in

Appendix A of this guide.

AVERTISSEMENT: Avant d'installer ou d'enlever tout composant des

commutateurs de la gamme Switch 5500 ou d'entamer une procédure

Page 25

Switch 5500 — Rear View Detail 25

de maintenance, lisez les informations relatives à la sécurité qui se

trouvent dans l'annexe A de ce guide.

VORSICHT:Bevor Sie Komponenten der Switch 5500-Baureihe

installieren oder deinstallieren und bevor Sie Wartungsarbeiten

ausführen, müssen Sie die in Anhang A dieses Handbuchs aufgeführten

Sicherheitshinweise lesen.

ADVERTENCIA: Antes de instalar o extraer cualquier componente del

Switch 5500 Family o de realizar tareas de mantenimiento, debe leer la

información de seguridad facilitada en el Apéndice A de esta guía.

Page 26

26 CHAPTER 1: INTRODUCING THE SWITCH 5500 FAMILY

AVVERTENZA: Prima di installare o rimuovere qualsiasi componente

dello Switch 5500 Family o di eseguire qualsiasi procedura di

manutenzione, leggere le informazioni di sicurezza riportate

nell'Appendice A di questa guida.

OSTRZEŻENIE: Przed instalacją lub usunięciem jakichkolwiek elementów

z przełącznika z rodziny 5500 lub przeprowadzeniem prac

konserwacyjnych należy zapoznać się z informacjami o bezpieczeństwie

zawartymi w Załączniku A niniejszego podręcznika.

Redundant Power

System Socket

Stacking Cable Ports

(Switch 5500G-EI)

For protection against an internal power supply failure, you can use this

socket to connect the Switch to a -48 DC Redundant Power System.

You can use these ports to connect the following cables:

■ Stacking Cable (3C17262) — this cable enables you to stack together

two switches up to three rack units apart.

■ Resilient Stacking Cable (3C17263) — this cable enables you to stack

together two switches up to sixteen rack units apart.

You can stack together any combination of 5500G-EI 24 port and 48 port

units, up to a maximum of eight units.

For more information on how to connect a stacking cable to your Switch

units, refer to the Installation Guide that accompanies your cable.

You canno create a Fabric by interconnecting a 3Com Switch 5500G with

any other 3Com device (such as a 5500-EI) or mix Enhanced Image (EI)

Switch 5500 units with Standard Image (SI) units.

Page 27

Default Settings 27

Default Settings Ta bl e 10 shows the default settings for the Switch 5500 Family:

Ta bl e 10 Default Settings

Feature Switch 5500

Automatic IP Configuration Enabled

Port Status Enabled

Port Speed Auto-negotiated

Duplex Mode Auto-negotiated

Power over Ethernet Enabled (3CR17171-91 and 3CR17172-91 only)

Flow Control Auto-negotiated

Broadcast Storm Control Enabled

Virtual LANs (VLANs) All ports belong to the untagged Default VLAN

(VLAN

1) with IEEE Std 802.1Q-1998 learning

operational

Management VLAN Fixed as VLAN 1 on 5500-SI units. Can be any

VLAN for 5500-EI/5500G-EI units.

Link Aggregation Control

Protocol (LACP)

IP Multicast Filtering Filtering enabled

Rapid Spanning Tree Protocol Enabled

Fast Start Enabled on front panel ports

RMON Alarm Enabled

Webcache Support Disabled

Traffic Prioritization All ports prioritize NBX VoIP traffic (LAN and IP).

Port Security Disabled per port

Configuration Save and

Restore

Spanning Tree Protocol Enabled

Smart Auto-sensing Enabled

Disabled per port

All ports set to “best effort” for all other traffic.

Disabled

Page 28

28 CHAPTER 1: INTRODUCING THE SWITCH 5500 FAMILY

Page 29

2

INSTALLING THE SWITCH

This chapter contains the information you need to install and set up the

Switch 5500. It covers the following topics:

■ Package Contents

■ Choosing a Suitable Site

■ Rack-mounting

■ Connecting a Redundant Power Supply

■ Placing Units On Top of Each Other

■ The Power-up Sequence

■ SFP Operation

■ Packing and Shipping the Switch 5500

WARNING: Safety Information. Before installing or removing any

components from the Switch 5500 or carrying out any maintenance

procedures, you must read the safety information provided in Appendix

of this guide.

A

AVERTISSEMENT: Consignes de sécurité. Avant d'installer ou d'enlever

tout composant du Switch 5500 ou d'entamer une procédure de

maintenance, lisez les informations relatives à la sécurité qui se trouvent

dans l'Appendice A de ce guide.

VORSICHT: Sicherheitsinformationen. Bevor Sie Komponenten aus

dem Switch 5500 entfernen oder dem Switch 5500 hinzufuegen oder

Instandhaltungsarbeiten verrichten, lesen Sie die Sicherheitsanweisungen,

die in Appendix A (Anhang A) in diesem Handbuch aufgefuehrt sind.

ADVERTENCIA: Información de seguridad. Antes de instalar o extraer

cualquier componente del Switch 5500 o de realizar tareas de

mantenimiento, debe leer la información de seguridad facilitada en el

Apéndice A de esta guía del usuario.

Page 30

30 CHAPTER 2: INSTALLING THE SWITCH

AVVERTENZA: Informazioni di sicurezza. Prima di installare o

rimuovere qualsiasi componente dal Switch 5500 o di eseguire qualsiasi

procedura di manutenzione, leggere le informazioni di sicurezza riportate

nell'Appendice A della presente guida per l'utente.

OSTRZEŻENIE: Informacje o zabezpieczeniach. Przed instalacją lub

usunięciem jakichkolwiek elementów z product lub przeprowadzeniem

prac konserwacyjnych należy zapoznać się z informacjami o

bezpieczeństwie zawartymi w Załączniku A niniejszego podręcznika.

Package Contents The Switch 5500 packaging contains the following for all units:

■ Switch unit

■ Release Notes

■ RPS -48V DC Connector

■ Unit Information Labels

■ Warranty Information

■ RPS Flyer

■ Power Cord

■ Console Cable (RJ-45)

■ RPS Connector (and backshell)

■ RPS Connector Cable Tie

■ Earthing Lead

■ Mounting brackets

■ Screws

■ 4 x Rubber feet

Ta bl e 11 below details the packaging contents specific to each unit in the

Switch 5500 Family.

Page 31

Choosing a Suitable Site 31

Ta bl e 11 Package Contents

Switch 5500-SI 28 and 52 Port

Switch 5500-EI 28 and 52 Port

Switch 5500 PWR 28 and 52 Port

Switch 5500 FX 28 Port

Switch 5500G-EI 24 Port

Blanking Plate ✓ ✓ ✓

12A RPS Connector and Backshell

(incl. cable tie and earthing lead)

✓ ✓ ✓

Switch 5500G-EI 48 Port

Switch 5500G-EI SFP 28 Port

Choosing a Suitable Site

25A RPS Connector and Backshell

(incl. cable tie and earthing lead)

2 x Front Securing Brackets ✓ ✓ ✓ ✓ ✓ ✓ ✓

2 x Back Securing Brackets ✓ ✓ ✓ ✓

4 x Screws ✓ ✓ ✓

6 x Screws ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓

The Switch 5500 Family is suited for use in an internal wiring closet, a

network room, or telecommunications room, where you can mount it in a

standard 19-inch equipment rack or leave it free-standing.

CAUTION: Ensure that the ventilation holes are not obstructed.

When deciding where to position the switch, ensure that:

■ The cabling is located away from:

■ sources of electrical noise, such as radios, transmitters, and

broadband amplifiers.

■ power lines and fluorescent lighting fixtures.

■ The switch is accessible and cables can be connected easily.

■ Water or moisture cannot enter the switch’s case.

Page 32

32 CHAPTER 2: INSTALLING THE SWITCH

■ Air flow is not restricted around the switch or through the vents in the

■ The air temperature around the switch does not exceed 40 °C (104

If the switch is installed in a 19-inch rack or closed assembly, its local air

temperature may be greater than room ambient temperature.

■ The air is as free from dust as possible.

■ The switch is situated away from conductive (electrical) dust sources;

■ The unit is installed in a clean, air conditioned environment.

■ The AC supply used by the switch is separate from the AC supply used

■ No more than four switch units are placed on top of one another if

side of the switch. 3Com recommends that you provide a minimum of

25 mm (1 in.) clearance.

°F).

laser printers, for example.

by units that generate high levels of AC noise; air conditioning units,

for example.

the units are free-standing.

Rack-mounting The Switch 5500 is 1U high and will fit in most standard 19-inch racks.

CAUTION: Disconnect all cables from the switch before continuing.

Remove all self adhesive pads from the underside of the switch if they

have been fitted.

CAUTION: If you use a shelf or support, ensure that it will not obstruct

the air flow through the switch’s side panels.

Switch 5500 (non

PoE)

To rack-mount your Switch 5500 (non PoE):

1 Place the switch the right way up on a hard flat surface with the front

facing towards you.

2 Place a securing bracket over the mounting holes on one side of the front

of the switch, as shown in

Figure 15.

Page 33

Rack-mounting 33

3 Insert the two screws and tighten them with a suitable screwdriver.

Figure 15 Fitting a front bracket for rack-mounting

You must use the screws supplied with the securing brackets. Damage

caused to the unit by using incorrect screws invalidates your warranty.

4 Repeat steps 2 and 3 for the other side of the switch.

5 Insert the switch into the 19-inch rack and secure with suitable screws

(not provided). Ensure that the ventilation holes are not obstructed.

6 Connect the network cabling.

7 Place a unit information label on the unit in an easily accessible position.

The unit information label shows the switch’s:

■ 3Com product name

■ 3Com 3C number

■ Unique MAC address (Ethernet address)

■ Serial number

You may need this information if you contact 3Com for Technical

Support.

Page 34

34 CHAPTER 2: INSTALLING THE SWITCH

Switch 5500 and

Switch 5500G-EI (PoE)

To rack-mount the front of your Switch 5500 and Switch 5500G-EI (PoE):

1 Place the switch the right way up on a hard flat surface, with the front

facing towards you.

2 Place a securing bracket over the mounting holes on one side of the front

of the switch, as shown in

Figure 15.

3 Insert the two screws and tighten them with a suitable screwdriver.

4 Repeat steps 1 and 2 for the other front securing bracket.

You must use the screws supplied with the securing brackets. Damage

caused to the unit by using incorrect screws invalidates your warranty.

5 Insert the switch into the 19-inch rack and secure with suitable screws

(not provided). Ensure that the ventilation holes are not obstructed.

To rack mount the rear of your switch:

1 Place a rear rail bracket over the mounting holes on one side of the rear

of the switch, as shown in

Figure 16.

The bracket has two mounting positions. The one you choose depends

on the rack depth.

Ta bl e 12 describes the correct positions on which to

mount the bracket:

Ta bl e 12 Rear rail bracket mounting points

Distance from Front to Rear Mounting Positions

37cm — 25cm Middle mounting point

43cm — 56cm Rear mounting point

2 Insert the screw and tighten it with a suitable screwdriver.

3 Repeat steps 1 and 2 for the other rear securing bracket.

Page 35

Connecting a Redundant Power Supply 35

Figure 16 Fitting a rear rail bracket for rack-mounting

4 Insert the switch into the 19-inch rack and secure it with suitable screws

(not provided). Ensure that the ventilation holes are not obstructed.

Connecting a Redundant Power Supply

5 Connect the network cables.

6 Place a unit information label on the unit in an easily accessible position.

The unit information label shows the switch’s:

■ 3Com product name

■ 3Com 3C number

■ Unique MAC address (Ethernet address)

■ Serial number

You may need this information if you contact 3Com for Technical

Support.

The Switch 5500 Family has a -48V DC Redundant Power Supply socket.

WARNING: Only properly trained and qualified personnel should install

the Redundant Power Supply (RPS).

WARNING: Make sure to read these instructions in conjunction with the

RPS flyer and the safety and installation instructions supplied with your

RPS.

Page 36

36 CHAPTER 2: INSTALLING THE SWITCH

WARNING: When powering any Switch 5500 from an RPS, make sure

that the unit is earthed (grounded) by either connecting the power cord

to the unit or by connecting the earth terminal on the rear of the unit to

a reliable electrical earth (or by connecting both). Ensure that the earth

connection is made before connecting the DC supply from the RPS.

3Com switches that support -48V DC RPS inputs, and are PoE enabled,

can only be powered by an RPS that complies with the isolation

requirements of IEEE-Std 802.3af. Non PoE enabled switches do not have

this restriction.

WARNING: Do not use a standard 'positive-earthed' -48V redundant

power system suitable for use with telecommunications equipment with

the 3Com Power-over-Ethernet (PoE) network switches. In order to meet

the IEEE 802.3af (PoE) specification, the -48V output must be isolated

from earth (ground) and meet the isolation requirements in that

specification.

WARNING: Any RPS must be approved as a SELV output in accordance

with IEC 60950-1/UL 60950-1/EN 60950-1.

WARNING: The characteristics of the Switch 5500 DC supply input are

provided in Appendix C on page 127.

You can power the Switch 5500 using three methods:

■ AC Mains only — this does not offer any power redundancy. If the

AC mains supply or the AC power supply fails, the switch powers off.

■ AC Mains and -48V DC (primary supply) — the internal AC supply

acts as the backup in the event of a DC power failure.

■ DC only — the switch does not need an AC supply and the resiliency

is provided by the DC supply. This is useful in environments where only

DC power is available.

The RPS provides three main benefits:

■ Power Redundancy — if a switch is powered from the mains supply

unit, a failure of the internal power supply causes the switch to fail.

You can avoid this by connecting both the AC and DC RPS supplies to

the switch. You can also add redundancy to the DC power by using

(N+1) DC power supplies to further increase the availability of the

system.

Page 37

Connecting a Redundant Power Supply 37

■ Uninterruptable Power — the system allows easy connection and

maintenance of batteries to the RPS shelf to further increase the

availability of the system.

■ Additional Power to PoE Ports — the PoE switch’s internal AC

Power Supply provides enough power for most network applications.

You can use the RPS to supplement power (up to a maximum of

15.4W), including full backups of all PoE devices on the network.

Ta bl e 13 outlines the behavior of the switch when changes occur to the

power system, such as removing the AC mains cable when the RPS is

attached. The responses to the different power inputs are controlled by

the switch’s internal power supply and not by the RPS.

Ta bl e 13 Switch Power Inputs

Power Input before

User Intervention

AC mains and RPS RPS only The unit remains powered by the RPS.

AC mains and RPS AC mains only The unit is powered by the AC mains.

RPS only AC mains and RPS The unit remains powered by the RPS.

AC mains AC mains and RPS The unit is powered by the RPS. Full

Power Input after

User Intervention

Correct Response

PoE is dropped on all ports, however

the unit does not reset. PoE restarts

and is powered by the remaining

power from the AC mains. PoE ports

will be dropped depending on their

preset priority level.

The total power available to the

switch may be less than when

powered from the RPS. Some PoE

ports may be dropped because they

are unable to obtain the power they

require.

PoE power can be enabled on all

ports.

Page 38

38 CHAPTER 2: INSTALLING THE SWITCH

Specifying the

Redundant Power

System

3Com’s redundant power solution allows you to use any off-the-shelf

-48V DC RPS that meets the requirements defined in

Appendix C on

page 127.

For an approved vendor list, more details about purchasing the 3Com

recommended RPS, and a full set of requirements go to:

http://www.3Com.com/RPS

The 3Com recommended RPS generates -48V DC power using power

supply units (or rectifiers). The outputs of the rectifier(s) are connected

together so that you can increase the total -48V power available by

adding rectifiers. For example, three 1500W rectifiers can provide up to

4500W. Hot removal or insertion of a rectifier does not affect the -48V

DC output voltage.

Ta bl e 14 shows an example of the total power available from several

1500W rectifiers.

A minimum of two rectifiers are required for each shelf to provide N+1

rectifier redundancy.

Ta bl e 14 Power Availability

Rectifiers

1 2 3 4 5 6

No Rectifier

Redundancy

N+1 Rectifier

Redundancy

1500W 3000W 4500W 6000W 7500W 9000W

- 1500W 3000W 4500W 6000W 7500W

The unearthed -48V DC power distribution provides the mechanism to

connect to the Switch 5500. The distribution consists of several circuit

breakers and connection terminals for the positive (common) and

negative -48V outputs. Individually connect each Switch 5500 to a circuit

breaker terminal.

You can also connect a battery to battery terminals prior to the DC power

distribution to provide uninterrupted power and to be protected against

the loss of AC mains power.

Page 39

Connecting a Redundant Power Supply 39

3Com’s RPS solution uses -48V DC power distribution. The RPS system

provides bulk -48V DC power that is separately distributed to a number

of network switches.

Each RPS consists of a shelf that can house from one to six rectifiers, a

Distribution Module, and a Management Module.

Connecting the

Switch to the

Redundant Power

System

When connecting the RPS to the switch, the circuit breaker and 2-core

cables need to be matched to the switch’s power rating.

Ta bl e 15 shows

the recommended circuit breaker and cable rating for the Switch 5500.

The recommended cable length should not exceed three metres (9.84

feet).

Ta bl e 15 Switch 5500 Circuit Breaker and Cable Ratings

Circuit Breaker Minimum 2-Core Cable Diameter

Non PoE 6A C type 18 AWG (solid or stranded cable)

PoE 25A C type 12 AWG (solid or stranded cable)

WARNING: Make sure to follow the RPS Manufacturers

recommendations when connecting the cable to the RPS.

WARNING: Ensure that the circuit breaker in the RPS is in the open (off)

position when connecting the cable to the RPS and the cable and

connector to the switch.

WARNING: You must ensure that the positive terminal on the switch is

connected to the positive (common) terminal of the RPS and that the

negative terminal on the switch is connected to the negative (circuit

breaker) terminal of the RPS.

Figure 17 shows how to connect the power supply to the RPS socket in

the back of the switch. Use the cable tie supplied with your switch to

support the cable in the back of the RPS connector as shown in

Figure 17.

Page 40

40 CHAPTER 2: INSTALLING THE SWITCH

+

-

NULL

-48 -60V;2.0A

100-240V;50/60Hz;1.0A

~

NULL

-48 -60V;2 0A

Null

+

-

Pinout

Cable Tie

Figure 17 RPS Connection to the Switch

Connecting the

Earthing Cable

When the RPS is connected to the switch, you can move the circuit

breaker in the RPS to the closed (on) position and the switch will be

powered by the -48V DC power.

The -48V DC power takes priority over the AC mains and powers the

switch if it is connected.

Use the earthing cable that accompanies your switch if the length is

suitable. Alternatively use the earthing cable specification as defined in

Appendix C on page 127.

The earthing cable is only required if the switch is powered by the RPS

only.

The recommended cable length should not exceed three metres (9.84

feet).

Page 41

Connecting a Redundant Power Supply 41

RPS LED The RPS status LED on the front of the Switch 5500 indicates the status of

the RPS and AC supplies as shown in

Ta bl e 16 RPS LED Colors

Color State

Green The AC and RPS supply is connected.

Yellow The AC supply has failed or is not connected. The RPS

supply is connected.

Off There is no RPS supply connected.

Ta bl e 16.

Using Power over

Ethernet

The Switch 5500G-EI Power over Ethernet (PoE) units can supply power

to any IEEE 802.3af compliant device through any of its front panel ports

over a Category 5 or Category 5e Ethernet cable. The same cable

connects the device to the network.

The Switch 5500 units can supply power through the 10/100 ports only.

Power over Ethernet is a self-configuring protocol. When you plug a PoE

compliant device into one of the ports on the switch, the switch supplies

the power required to the device, providing that the total power budget

for the switch is not exceeded.

A PoE switch combines the functionality of a standard Ethernet switch

with a single power supply that can power multiple devices. Using a PoE

switch has the following advantages over an non-powered network.

■ Reduced Cabling — a PoE (802.3af) compliant device that has its

power supplied over its Ethernet cable does not require a separate

power supply. If, for example, you use the switch to connect a 3Com

11 Mbps Wireless LAN Access Point 8500 to the network, then only a

network cable is required to provide both power and network

connectivity.

■ Increased Reliability — a device powered by a PoE switch can take

advantage of the facilities available to the switch. You can fit the

switch with a redundant power supply or uninterruptible power

supply to increase its uptime.

The switch supports resistor detection according to IEEE 802.3af and

pre-standard detection methods.

Page 42

42 CHAPTER 2: INSTALLING THE SWITCH

The Switch 5500 supports 3Com 802.3af equipment. For the latest list of

supported devices, refer to the product page on the 3Com web site at

http://www.3com.com/

For additional information on Power over Ethernet, refer to the Power

over Ethernet Configuration chapter in the Configuration Guide available

on the 3Com Web site. Power over Ethernet management is available

using the web interface or the command line interface (CLI).

Installing and Removing the Power Module

Installing the Power

Module

Removing the Power

Module

The Switch 5500G Family Power Module is swappable. To install the

power module:

1 Wear an ESD wrist strip, and make that sure it is well grounded.

2 Verify that the Power Module is not installed upside-down (the module

should be installed according to the letters. If the module is installed

upside down, it will not be fully seated due the design of the chassis’

internal structure).

3 Use one hand to hold the handle on the front, and another to hold the

bottom. Slide it gently along the power slot. Push the module until it is

fully seated.

4 Use a Phillips screwdriver to fasten the screws at both sides of the

module.

To remove the Power Module:

1 Wear an ESD wrist strip, and make sure it is well grounded.

2 Disconnect all power to the switch.

3 Use a Phillips screwdriver to unscrew the screws on both sides of the

module.

4 Use one hand to hold the handle on the front, and another to hold the

top. Pull out the module stably towards you along the power slot until it

is completely apart from the chassis bottom.

Page 43

Placing Units On Top of Each Other 43

CAUTION: When you use the Phillips screwdriver or power screwdriver to

fasten captive screws on both sides of the module, make sure the captive

force moment is not larger than 0.4 Nom.

Placing Units On Top of Each Other

The Power-up Sequence

Powering-up the

Switch 5500

Checking for Correct

Operation of LEDs

If the switch units are free-standing, you can stack up to eight units. If

you are mixing a variety of switches, make sure to place the smaller units

at the top.

If you are stacking switch units, apply the supplied self-adhesive rubber

feet to the underside of each switch. Stick one in the marked area at each

corner. Place the switch units on top of each other, ensuring that the feet

of the upper unit sit fully on the lower unit.

The following sections describe how to prepare your Switch 5500 for

operation.

To power-up the switch:

1 Plug the power cord into the power socket at the back of the switch.

2 Plug the other end of the power cord into your power outlet.

The switch powers-up and runs through its Power On Self Test (POST),

which takes approximately one minute.

During the POST, all ports on the switch are disabled and the LEDs blink in

a rapid sequence.

When the POST has completed, check the Unit Status to make sure that

your switch is operating correctly.

colors.

Ta bl e 17 describes the possible LED

Page 44

44 CHAPTER 2: INSTALLING THE SWITCH

Ta bl e 17 Unit Status Colors

Color State

Green The switch is powered-up and operating normally.

Green flashing The Power On Self Test (POST) is in process, or

Red The switch has failed its Power On Self Test (POST).

Off The switch is not receiving power.

If you encounter a problem, see the section entitled “Solving Problems

Indicated by LEDs” on page 82 for a list of suggested solutions.

CAUTION: The switch has no ON/OFF switch; the only method of

connecting or disconnecting mains power is by connecting or

disconnecting the power cord.

software is downloading.

Choosing the Correct

Cables

All of the ports on the switch are Auto-MDIX, that is, they have a

cross-over capability. These ports can automatically detect whether to

operate in MDI or MDIX mode. Therefore, you can make a connection to

one of the ports with a straight-through (MDI) or a cross-over (MDIX)

cable.

The Auto-MDIX feature only operates with auto-negotiation enabled.

If auto-negotiation is disabled, all the switch ports are configured as

MDIX (cross-over). If you want to make a connection to another MDIX

port, you need a cross-over cable. Many ports on workstations and

servers are configured as MDI (straight-through). If you want to make a

connection to an MDI port, you need to use a standard straight-through

cable. See

Ta bl e 18.

3Com recommends that you use at least Category 5 twisted pair cable.

The maximum segment length for this type of cable is 100 m (328 ft.).

Page 45

The Power-up Sequence 45

Ta bl e 18 Cables required to connect the switch to other devices with

auto-negotiation disabled

Cross-over Cable Straight-through Cable

Switch-to-switch

(MDIX to MDIX)

Switch-to-hub

(MDIX to MDIX)

Switch-to-PC (NIC)

(MDIX to MDI)

✓ ✕

✓ ✕

✕ ✓

CAUTION: If you want to install the switch using a Category 5E or

Category 6 cable, 3Com recommends that you briefly connect the cable

to a grounded port before connecting network equipment, otherwise the

cable’s Electrostatic Discharge (ESD) may damage the switch's port.

You can create a grounded port by connecting all wires at one end of a

UTP cable to an earth ground point, and the other end to a female RJ-45

connector located, for example, on a switch rack or patch panel. The

RJ-45 connector is now a grounded port.

Choosing the Correct

Cables for the

1000BASE-X SFP Ports

WARNING: The Switch 5500G-EI supports Power over Ethernet on all

front ports. The Switch 5500 PWR supports Power over Ethernet on the

10/100 ports only. Use these ports for Ethernet wiring within the same

building only.

The 1000BASE-SX SFP transceiver supports a direct connection to a

multi-mode fiber-optic cable. The 1000BASE-LX SFP transceiver supports

a direct connection to single-mode and multi-mode fiber-optic cables.

The 1000BASE-LH70 SFP transceiver supports a direct connection to a

single-mode fiber-optic cable. The 1000BASE-T SFP transceiver uses

Category 5 copper cabling with RJ-45 connectors and supports segment

lengths of up to 100 m (328 ft). Table 14 describes the port cable range

for each connection.

Page 46

46 CHAPTER 2: INSTALLING THE SWITCH

Ta bl e 19 1000BASE-X SFP Port Cable Range

Choosing the Correct

Cables for the

100BASE-X SFP Ports

Fiber Type Diameter

(microns)

1000BASE-SX

Multi-mode 62.5 160 2m - 220m (6.6 ft - 721.8 ft)

Multi-mode 62.5 200 2m - 275m (6.6 ft - 902.3 ft)

Multi-mode 50 400 2m - 500m (6.6 ft - 1640.5 ft)

Multi-mode 50 500 2m - 550m (6.6 ft - 1804.6 ft)

1000BASE-LX

Multi-mode 62.5 500 2m - 550m (6.6 ft - 1804.6 ft)

Multi-mode 50 400 2m - 550m (6.6 ft - 1804.6 ft)

Multi-mode 50 500 2m - 550m (6.6 ft - 1804.6 ft)

Single-mode 9 - 2m - 10,000m (6.6 ft - 32, 810 ft)

1000BASE-LH70

Single-mode 9 core - 2m - 70 km (6.6 ft - 43 miles)

Modal

Bandwidth

(MHz . km)

Transmission Range in meters

(in feet)

The 100BASE-LX10 SFP transceiver supports a direct connection to a

single-mode fiber-optic cable. The 100BASE-FX SFP transceiver supports a

direct connection to multi-mode fiber-optic cable.

Ta bl e 20 describes the

port cable range for each connection:

Ta bl e 20 100BASE-X SFP Port Cable Range

Fiber Type Diameter

(microns)

100BASE-FX 2Km

Multi-mode 62.5 160 2m - 2000m (6.5 ft - 6,562 ft)

Multi-mode 50 400 2m - 2000m (6.5 ft - 6,562 ft)

100BASE-LX10 10Km

Single-mode 9 - 2m - 10,000m (6.5 ft - 32, 808 ft)

Modal

Bandwidth

(MHz . km)

Transmission Range in meters

(in feet)

Page 47

SFP Operation 47

SFP Operation The following sections describes how to select and use an SFP transceiver

in an SFP port.

Approved

1000BASE-X SFP

Transceivers

The approved Gigabit Ethernet SFP transceivers include:

■ 3CSFP91 SFP (1000BASE-SX)

■ 3CSFP92 SFP (1000BASE-LX)

■ 3CSFP93 SFP (1000BASE-T)

■ 3CSFP97 SFP (1000BASE-LH70)

3Com may approve additional SFP transceivers following the publication

of this document. The latest list of approved SFP transceivers for the

Switch 5500 Family is available on the 3Com Web site, at:

http://www.3com.com

You must match SFP transceivers with the correct cable type as follows:

■ 1000BASE-SX SFP transceiver

Use this transceiver to connect Gigabit Ethernet SFP ports on the

switch directly to a multimode fiber-optic cable.

■ 1000BASE-LX SFP transceiver

Use this transceiver to connect Gigabit Ethernet SFP ports on the

switch directly to a single-mode fiber-optic cable or to a multimode

fiber using a conditional launch cable.

■ 1000BASE-LH70 SFP transceiver

Use this transceiver to connect Gigabit Ethernet SFP ports on the

switch directly to a single-mode fiber-optic cable.

■ 1000BASE-T SFP transceiver

This transceiver uses Category 5 copper cabling with RJ-45 connectors

and supports segment lengths of up to 100 m (328 ft).

If the SFP transceiver is faulty, it will not operate within the switch. See

“Solving Hardware Problems” on page 83.

3Com recommends that you only use Gigabit Ethernet SFPs supplied by

3Com. If the SFP transceiver is invalid it will not be recognized by the

switch.

Page 48

48 CHAPTER 2: INSTALLING THE SWITCH

Approved 100BASE-X

SFP Transceivers

The following list of approved 100Mbps SFP transceivers is correct at the

time of publication.

■ 3CSFP81 100BASE-FX

■ 3CSFP82 100BASE-LX10

■ 3CSFP85 100BASE-BX10-D

■ 3CSFP86 100BASE-BX10-U

SFP transceivers must be matched with the correct cable type as follows:

■ 100BASE-FX

Use this transceiver to connect 100Mbps SFP ports on the switch

directly to a multi-mode fiber-optic cable.

■ 100BASE-LX10

Use this transceiver to connect 100Mbps SFP ports on the switch

directly to a a single-mode fiber-optic cable.

■ 100BASE-BX10-D

Use this transceiver to connect 100Mbps SFP ports on the switch

directly to a single strand of a single-mode fiber-optic cable on the

opposite end of a link that is connected to a 100BASE-BX10-U

transceiver.

■ 100BASE-BX10-U

Use this transceiver to connect 100Mbps SFP ports on the switch

directly to a single strand of a single-mode fiber-optic cable on the

opposite end of a link that is connected to a 100BASE-BX10-D

transceiver.

If the SFP transceiver is faulty, it will not operate within the switch. See

“Solving Hardware Problems” on page 83.

3Com recommends that you only use Gigabit Ethernet and Fast Ethernet

SFPs supplied by 3Com. If the SFP transceiver is invalid it will not be

recognized by the switch.

Page 49

SFP Operation 49

Product

label

Suitable port

on host Switch

Inserting an SFP

Transceiver

To activate the SFP ports:

SFP transceivers are hot-insertable and hot-swappable. You can remove

them from and insert them into an appropriate SFP port without having

to power down the switch.

1 The SFP transceiver (shown in Figure 18) is keyed so that there is only one

way that you can install it correctly. Hold the transceiver so that the

connector is toward you and the product label is visible. Ensure that the

wire release lever is closed (in the upright position).

2 Gently slide the transceiver into the SFP port until it clicks. If the

transceiver does not click into place, remove it, turn it over and re-insert

it.

3 Remove the plastic protective cover, if fitted.

CAUTION: The dual personality ports on the Switch 5500G-EI enable you

to activate an RJ-45 port, an SFP port, or a mixture of both (for example,

on the 24 Port switch, you can activate the RJ-45 ports 23 and 24 and the

SFP ports 21 and 22 at the same time). If you try to activate the same dual

personality RJ-45 port and SFP port (for example, RJ-45 port 23 and SFP

port 23 at the same time), the SFP port takes priority.

Figure 18 Inserting an SFP Transceiver

Page 50

50 CHAPTER 2: INSTALLING THE SWITCH

4 Check the LEDs on the front of the switch to ensure that it is operating

correctly. Refer to the section entitled

information.

“LEDs” on page 18 for more

Removing an SFP

Transceiver

Installing and Removing the Optional Interface Module

To remove the transceiver (it is not necessary to power-down your

switch):

1 Disconnect the cable from the transceiver.

2 Move the wire release lever downwards until it is pointing toward you.

3 Pull the wire release lever toward you to release the catch mechanism;

the transceiver will then easily slide out.

The Optional Interface Module is hot-swappable. To install the Optional

Interface Module:

1 Wear an ESD wrist strip that is well grounded and remove the module

from the package.

2 Using a Phillips screwdriver, remove the blank filler panel from the slot

where you plan to install the module.

3 Hold the module’s front panel with both hands, align the module with

the guides in the slot, and slide it gently into the slot. Push the module

until it is fully in position.

4 Fasten the captive screws to fix the module using the Phillips screwdriver.

Note: Keep the removed blank panel for future use. When you use the

Phillips screwdriver or power screwdriver to fasten captive screws on both

sides of the module, make sure the captive force momentum is not larger

than 0.4 Nom.

To remove the module,:

1 Wear an ESD wrist strip that is well grounded.

2 Use a Phillips screwdriver to unscrew the captive screws at both sides of

the module.

3 Pull the module towards you until it is completely apart from the chassis

bottom.

Page 51

Packing and Shipping the Switch 5500 51

CAUTION: When installing and removing an Optional Interface Module,

note that:

■ Do not exert excessive force on the module or touch the components

on the module surface.

■ If you are not installing a new module, insert a blank filler panel to

keep the dust out and to ensure normal ventilation within the switch.

Packing and

Shipping the Switch

This section describes how to correctly package your Switch 5500 should

you need to return the switch to 3Com.

5500

WARNING: If you are returning the unit to 3Com for repair, ensure that

you fit the rear blanking plates for the PSU and module. If 3Com receives

the unit without the blanking plates in place your warranty could be

invalidated.

WARNING: Package the unit correctly to ensure that you do not

invalidate the repair.

The Switch 5500G To package your Switch 5500G unit correctly:

1 For the 5500G unit, orientate your switch so that the PSU blanking plate

is on the left (looking down at the top of the unit) as shown in

2 Secure one of the polystyrene supports to side of the unit with the PSU

blanking plate, ensuring that the wider recess on the support is fitted

around the blanking plate. Secure the remaining support to the opposite

side of the unit in the same way.

3 Place the unit in the box with the PSU blanking plate side placed next to

the cable packaging.

Figure 19 Correct Orientation When Packing the Switch 5500G-EI

Figure 19.

Page 52

52 CHAPTER 2: INSTALLING THE SWITCH

Polystyrene Supports

Switch Unit

PSU Blanking Plate

Cable Packaging

PORT

SIDE

PSU

SIDE

The Switch 5500SI

and EI

To package your Switch 5500 unit correctly, orient the switch so that the

front of the unit faces the front of the box, rather than the right of the

Figure 20.

box as shown in

Page 53

Packing and Shipping the Switch 5500 53

Figure 20 Correct Orientation When Packing the Switch 5500SI and 5500EI

The Switch 5500-EI

PWRs

The 5500-EI PWRs should be orientated like the 5500G-EI (see Figure 19)

and not facing forward.

Page 54

54 CHAPTER 2: INSTALLING THE SWITCH

Page 55

3

SETTING UP FOR MANAGEMENT

To make full use of the features offered by your switch, and to change

and monitor the way it works, you use management software that

resides on the switch. Managing the switch can help you to improve its

efficiency and, therefore, the overall performance of your network.

This chapter explains the initial setup and the methods by which you can

access the management software to manage the switch. It includes the

following topics:

■ Methods of Managing a Switch

■ Setting Up Your Switch

■ Manually Configuring the IP Information

■ Viewing Automatically Configured IP Information

■ Setting Up Command Line Interface Management

■ Setting Up Command Line Interface Management using SSH

■ Setting Up Web Interface Management

■ Setting Up SNMP Management

■ Changing the Default Passwords

■ Downloading the Configuration Conversion Utility

Page 56

56 CHAPTER 3: SETTING UP FOR MANAGEMENT

Console Port

Connection

Workstation

(with terminal emulation

software installed)

Console Cable

Switch

Switch

Workstation

Connect over Network

via Telnet

Methods of Managing a Switch

Command Line

Interface

Management

You can manage your switch using one of the following methods:

■ Command line interface management

■ Command line interface management using SSH

■ Web interface management

■ SNMP management

Each switch has a command line interface (CLI) that allows you to

manage the switch from a workstation, either locally using a console port

connection (see

Figure 21 CLI Management via the Console Port

Figure 22 CLI Management over the Network

Figure 21), or remotely over the network (see Figure 22).

For a description on how you can set up command line interface

management using a local console port connection or over the network,

refer to

“Setting Up Command Line Interface Management” on page 69.

There are two main views in the CLI:

■ User View — this view displays when you first connect to the switch

and provides basic information about its operation and statistics. The

prompt for user view is <SW5500-XX> (where xx is either SI or EI).

■ System View — this view enables you to configure the system

parameters. To display this view, from user view enter system-view.

The prompt for system view is [SW5500-XX].

Page 57

Methods of Managing a Switch 57

Workstation

Switch

Connect over Network

via web browser

SNMP Network Management

Workstation

Switch

Connect over Network

using SNMP

Command Line

Interface

Management using

SSH

Web Interface

Management

The Switch 5500 supports Secure Shell version 2.0 (SSHv2), allowing

secure access to the Command Line Interface of the switch.

If you use SSH to administer your switch, and the network traffic is

intercepted, no passwords or configuration information are visible in the

data. To securely administer the switch using the Command Line Interface

you need a third party SSH client.

Each switch has an internal set of Web pages that allow you to manage

the switch using a Web browser remotely, over an IP network (see

Figure 23).

Figure 23 Web Interface Management over the Network

For more information about how to set up web interface management

over the network, refer to

“Setting Up Web Interface Management” on

page 71.

SNMP Management You can manage a switch using any network management workstation

running the Simple Network Management Protocol (SNMP) as shown in

Figure 24. For a description of 3Com Network Management applications,

please refer to Appendix E.

Figure 24 SNMP Management over the Network

For more information about managing your switch using a network

management application, refer to

“Setting Up SNMP Management” on

page 72.

Page 58

58 CHAPTER 3: SETTING UP FOR MANAGEMENT

Plug and Play Setup

Initial IP Information Setup

Feature Management

Power Up the Switch.

IP Information is automatically configured via

DHCP

See page 59

Do you want to manually

configure the IP information?

Connect to the console port and use the

Command Line Inter-

face.

See page 61

How do you want to manage your Switch? See page 56

SNMP

See page 72

Command Line Interface

Connect using the

console port.

See page 69

Web Interface

Connect over the

network using Telnet.

See page 69

Connect over the

network.

See page 72

How do you want to view the automatically

configured IP information?

How do you want to connect to the Switch?

Connect to a front panel port

and use the Web Interface or

Command Line

Interface.

See page 61

Use 3Com Network

Director (3ND).

See page 67

Connect to the console