Page 1

®

ONline Ethernet 10BASE-T

Module

User’s Guide

Document Number 17-00141-3

Printed March 1995

Model Number: 5108M-TP

3Com Co rporation

118 Turnpike Road

Southbo rough, MA 01772-1886

U.S.A.

(508) 46 0- 8900

FAX (508) 460-8950

Page 2

Federal Communications Comm ission

Notice

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment i s operated in a

commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to rad io communications. Operation of this equipment

in a residential area is likely to cause harmful interference, in which

case you must correct the interference at your own expense.

Canadian Emissions Requirements

This Class A digital apparatus meets all requirements of the

Canadian Interference-Causing Equipment Regulations.

Cet apparei l numérique de la classe A respecte toutes les exigences

du Règlement sur le matériel brouilleur du Canada.

VDE Class B Compl ianc e

Hiermit wird bescheinigt, dass der 5108M-TP in Üebereinstimmung

mit den Bestimmungen der Vfg 243/1991 funkentstöert ist.

Der Deutschen Bundespost wurde das Inverkehrbringen dieses

Geraetes angezeigt und die Berechtigung zur Üeberprüefung der

Serie auf Einhaltung der Bestimmungen eingeräeumt.

Einhaltung mit betreffenden Bestimmugen kommt darauf an, dass

geschirmte Ausfuehrungen gebraucht werden. Fuer die

Beschaffung richtiger Ausfuehrungen ist der Betreiber

verantwortlich.

This is to certify that the 5108M-TP is shielded against radio

interference in accordance with the provisions of Vfg 243/1991.

The German Postal Services have been advised that this equipment

is being placed on the market and that they have been given the

right to inspect the series for compliance with regulations.

Compliance with applicable regulations depends on the use of

shielded cables. The user is responsible for procuring the

appropriate cables.

EN55022/CISPR22 Com p lian ce

This equipment conforms to the Class A emissions limits for a

digital device as defin ed by EN55022 (CISPR22).

VCCI Class 1 Compliance

This equipment is in the 1st Class category (information equipment

to be used in commercial or industrial areas) and conforms to the

standards set by the V oluntary Control Council for Inter fere nce by

Information Technology Equipment aimed at preventing radio

interference in commercial or industrial areas.

Consequently, when the equipment is used in a residential area or

in an adjacent area, r adio interferenc e may be caused to radio and

TV receivers, and so on.

Read the instructions for correct handling.

UK General Approval Statem en t

The ONcore Switching Hub, ONline System Concentrator, and

ONsemble StackSyste m Hub are manufactur ed to the International

Safety Standard EN 60950 and are approve d in the UK under the

Genera l Approval Number NS/G/12345/J/100003 for indirect

connection to the public telecommunication network.

Disclaimer

The information in this document is subject to change without

notice and should not be construed as a commitment by 3Com

Corporation. 3Com Corporation assumes no responsibility for any

errors that may appear in this document.

Copyright Statement

©

1995, by Chipcom Corporation, a subsidiary of 3Com

Corporation. Printed in U.S.A. All rights reserved. 3Com is a

registere d trade mark of 3Com Corporat ion. ONcore is a registered

trademark of Chipcom Corporation. The information contained

herein is the exclusive and confidential property of 3Com

Corporation. No part of this manual may be disclosed or

reproduced in whole or in part without permission from 3Com

Corporation.

Trademarks

Because of the nature of this material, numerous hardware and

software products are mentioned by name. In most, if not all

cases, these product names are claimed as trademarks by the

companies that manufacture the products. It is not our intent to

claim these names or tradem arks as our own.

Artel, Chipcom, Ethermo d em, Galactica, ONcore, ORnet,

StarBridge, and Tr iChannel are reg ister e d tra demark s of C hipcom

Corporation.

Chipcom OpenHub, G-Man, LANsentry, MultiProbe, ONdemand,

ONline, ONsemble, PowerRing, SL2000, SL3000, SL4000,

StackJack, StackSystem, and SwitchCentral are trademarks of

Chipcom Corporation.

The Chipcom Multichannel Architecture Communications System is

registered under U.S. Patent Number 5,301,303.

DEC, DECnet, the Dig ital l ogo, DELNI, POLYCENTE R, VAX , VT100,

and VT220 are trademarks of Digital Equipment Corporation.

IBM is a registered trademark of Interna tional Business Machines.

NetView is a trademark of International Business Machi nes.

ii ONline Ethernet 10BASE-T Module User’s Guide

Page 3

XNS is a trade mark a nd Ethernet is a r egistered trademark of Xerox

Corporation.

3ComFacts, Ask 3Com, CardFacts, NetFacts, and CardBoard are

service marks of 3Com Corporation.

3Com, LANplex, BoundaryRouting, LanScanner, LinkBuilder,

NETBuilder, NETBuilderII, ParallelTasking, ViewBuilder, EtherDisk,

Etherl\Link, Ether Link Plus, EtherLink II, T ok enLink, T okenLink Plus,

and TokenDisk are registered trademarks of 3Com Corporation.

3ComLaser Library, 3TECH, CacheCard, FDDILink, FMS, NetProbe,

SmartAgent, Star-Tek, and Transcend are trademarks of 3Com

Corporation.

CompuServe is a registered trademark of CompuServe, Inc.

3Com registered trademarks are registered in the United Stat es,

and may or may not be register ed i n other countrie s. Other brand

and product names may be reg istered tradema rks or trademark s of

their respective holders.

Restricte d Righ ts

Use, duplication, or disclosure by the Government is s ubject to

restrictions as set forth in subparagraph (c)(1) (ii) of the Rights in

Technical Data and Compu ter Software clause at

DFARS 252.227-7013.

Printed on recycled paper.

ONline Ethernet 10BASE-T Module User’s Guide iii

Page 4

iv ONline Ethernet 10BASE-T Module User’s Guide

Page 5

How to Use This Guide

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii i

Structure of This Guid e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Related D ocuments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

3Com Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Reference Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Chapter 1 — Introduction

The ONline Ethernet 10BASE-T Module . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Dip Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Dip Switch SW1 (Port Status) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Dip Switch SW3 (Crossover Mode, Channel Select, Squelch) . . . . 1-6

Dip Switch SW6 (Link Integrity ) . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Related Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -10

LED and Channel Verification . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

The ONline Ethernet Network Management Mod ule . . . . . . . . . 1 -11

Contents

Chapter 2 — Designing and Expanding the Network

Understanding th e General Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Basic Network Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

LAN Equivalence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Fiber Backbone, Twisted Pair To-The-Desk . . . . . . . . . . . . . . . . . . . . . . . 2-7

Fiber Backbone, Twisted Pair To-The-Desk Example . . . . . . . . . . . 2-8

Twisted Pair Backbone, Twisted Pair To-The-Desk . . . . . . . . . . . . . . . . . 2-11

Redundant Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -12

Patch Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

ONline Ethernet 10BASE-T Module User’s Guide v

Page 6

Chapter 3 — Installing and Operating the Modu le

Precautionary Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Unpacking Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Chapter 4 — Troubleshooting

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Troubleshooting W ith the Status LEDs . . . . . . . . . . . . . . . . . . . . . . . 4-1

Troubleshooting W ith the Activity LEDs . . . . . . . . . . . . . . . . . . . . . . 4-5

Technical Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Appendix A — Specifications

ONline Ethernet 10BA S E-T Module Spec ific ations . . . . . . . . . . . . . . . . . . A-1

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Environmental Spec ific ation s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Mechanical Specificatio ns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Twisted Pair Connectors and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Twisted Pair Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Twisted Pair Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Connecting Twi sted P air Cable s . . . . . . . . . . . . . . . . . . . . . . . . .A-5

Appendix B — Technical Support

On-line Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Email Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

World Wide Web Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Support from Your Netw ork Sup plier . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Support from 3Com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Returning Produ cts for Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Accessing the 3Com MIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

3Com Technical Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Index

vi ONline Ethernet 10BA SE-T Module User’s Guide

Page 7

Figures

Figure 1-1. 10BASE-T Module Faceplate and ONline

Figure 1-2. 10BA S E-T Module and Dip Switc h Lo catio ns . . . . . . . . . . 1-5

Figure 2-1. Sample Conf iguration Distance Calculation . . . . . . . . . . . 2-9

Figure 2-2. Unshielded Twisted Pair Network . . . . . . . . . . . . . . . . . 2-11

Figure 2-3. Redundant Tw isted Pair Conf igu ration . . . . . . . . . . . . . 2-12

Figure 3-1. Installing a 10BA SE-T Modu l e . . . . . . . . . . . . . . . . . . . . . 3-3

Figure 3-2. 10BA S E-T Module Cable Co nn ectio n . . . . . . . . . . . . . . . 3-4

Figure A-1. RJ45 Connecto r Pin-out s . . . . . . . . . . . . . . . . . . . . . . . . .A-4

System Concentrato r . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

ONline Ethernet 10BASE-T Module User’s Guide vii

Page 8

viii ONline Ethernet 10BASE-T Module User’s Guide

Page 9

Tables

Table 1-1. Interpretation of the 10BASE-T Modu le LEDs . . . . . . . . . . 1-4

Table 1-2. Dip Switch SW1 Settings and Interpret ations . . . . . . . . . . 1-6

Table 1-3. Dip Switch SW3 Settings for Switches 1 and 4. . . . . . . . . 1-7

Table 1-4. Dip Switch SW3 Settings and Interpretation s for

Switches 2 and 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Table 1-5. Dip Switch SW6 Settings and Interpret ations . . . . . . . . . 1-10

Table 1-6. Channel Check Codes . . . . . . . . . . . . . . . . . . . . . . . . . . 1 -11

Table 2-1. Seven Basic Network Rules. . . . . . . . . . . . . . . . . . . . . . . . 2-3

Table 2-2. LAN Produc t Equi valent Distance s . . . . . . . . . . . . . . . . . . 2-6

Table 2-3. Maximum Link Distance on Twisted Pair. . . . . . . . . . . . . 2-10

Table 4-1. Troubleshooting With the Port Status LEDs . . . . . . . . . . . 4-2

Table 4-2. Troubleshooting With the Port Activ ity L EDs . . . . . . . . . . . 4-5

ONline Ethernet 10BASE-T Module User’s Guide ix

Page 10

Page 11

The ONline™ Ethernet 10BASE-T Module User’s Guide describes the

features, indicators, and installation procedures for the O Nline Ethernet

10BASE-T Module. Information on troubleshooting and diagnostics is

included for verifying operation. This guide also contains a configuration

section which will be helpful when you plan your netwo rk configuration.

Audience

This guide is intended for the following people at your site:

How to Use This Guide

❑ Network manager or administrator

❑ Hardware installer

ONline Ethernet 10BASE-T Module User’s Guide xi

Page 12

Structure of This Guide

This guide contains the following chapters:

Chapter 1, Introducti on –Introduces the principal features of the ONline

Ethernet 10BASE-T Module and provides views and descriptions of the front

panel and the dip switches on the module.

Chapter 2, Designing and Expanding the Network – Shows and

explains examples of possible network configurations using the ONline

System Concentrator and the ONline Ethernet 10BA SE- T M od ule. These

examples include both shielded and unshielded twisted pair configurations.

Chapter 3, Install ing and Operating the Module – Provides illustrated

procedures for installing the 10BASE-T Module into the ONline System

Concentrator.

Chapter 4, Troubleshooting –Provides help in isolating and correcting

problems that may arise during the installation process and during normal

operation.

Appendix A, Specifications – Provides electrical, environmental, and

mechanical specifications, as well as other information for the module.

Appendix B, Technical Support – Lists the various methods for

contacting the 3Com technical suppor t organization and for accessing

other product support services.

Index

xii ONline Ethernet 10BASE-T Module Us er’s Guide

Page 13

Document Conventions

The following document conventions are used in this manual:

Convention Indicates Example

Courier text User input In the Agent Information Form,

System output After pressing the Apply

enter MIS in the New Contact

field.

button, the system displays

the message

Transmi tt in g da ta .

Bold command

string

Italic text in braces User-substituted

Capitalized text in

plain brackets

Italics Text emphasis,

Path names Before you begin, read the

identifiers

Keyboard entry

by the user

document titles

readme.txt file located in

/usr/snm/agents.

Use the following command to

show port details:

SHOW PORT {

Type your password and press

[ENTER].

Ensure that you press the Apply

button after you add the new

search parameters.

slot

.all} VERBOSE

ONline Ethernet 10BASE-T Module User’s Guide xiii

Page 14

Convention Indicates Example

Note: A Note. The

Caution: A Caution. A

Warning: A Warning. A

Related Documents

This section provides in formation on supporting documentation, including:

❑ 3Com Documents

information is

important

condition may

damage

software or

hardware

condition may

threaten

personal safety

Note: Use STP lobe

cables for your system.

Caution: Do not put

your installation

diskettes on a

magnetic surfac e.

This may damage the

diskettes.

Warning: Wear eye

protection when

performin g these

maintenance

procedures.

❑ Reference Documents

xiv ONline Ethernet 10BASE-T Module User’s Guide

Page 15

3Com Documents

The following documents provide additional information on 3Com

products:

17-Slot ONlin e System Concen trator Ins tallatio n and O pera tion

Guide – Explains how to install, operate, and manage the 3Com ONline

17-Slot System Concentrator (Models 5017C-LS and 5017C with load

sharing).

6-Slot ONline System Concentrator Installation and Operation

Guide – Explains ho w to install, operate, and manage the 3Com ONline

6-Slot System Concentrator.

ONline Ethernet Management Module Installation and Operation Guide –

Describes how to install the ONline Ethernet Network Management

Module in the ONline System Concentrator and explains the LEDs on th e

module faceplate. This guide also provides instructions for connecting a

terminal to the module and describes the man agement commands

necessary to perform management tasks on the concentrator and on

remote devices.

ONline Management Commands Guid e – Provides an alph abetized

reference resource describing all ONline management commands.

For a complete list of 3Com documents, contact your 3Com representative.

Reference Documents

The following documents supply related background information:

Case, J., Fedor, M., Scoffstall, M., and J. Davin, The Simple Network

Management Protocol, RFC 115 7 , University of Tennessee at Knoxville,

Performance Systems International and the MIT Laboratory for Computer

Science, May 1990.

Rose, M., and K. McCloghrie, Structure and Identification of

Management Information for TCP/IP-based Internets, RFC 1155,

Performance Systems International and Hughes LAN Systems, May 1990.

ONline Ethernet 10BASE-T Module User’s Guide xv

Page 16

Page 17

Introduction

1

This chapter describes the features, indicators, and dip switch settings on

the ONline™ Ethernet 10BASE-T Module.

The ONline Ethernet 10BASE-T Module

The ONline™ Ethernet 10BA SE-T Modu le is an eight-port IEEE 802.3

repeater module that complies with the 10BASE-T standard. This module

works with the 3Com ONline System Concentrator using both unshielded

and shielded twisted pair wiring. The ONline 10BASE-T Module provides the

following features and benefits:

❑ supports up to 150 meter link distances on 22 gauge wire, up to 125

meters on 24 gauge wire, and up to 100 meters on 26 gauge wire

❑ supports up to 200 meter link distance on IBM Type 1 cabling

❑ complies fully with the 10BASE-T standard

❑ features “hot swap” capability so that you can install or remove the

module wit hout having to power down the concentr at or

The 10BASE-T Mod ule works with both unshielded and shielded twisted

pair wire. A single module can support any mix of shielded and unshielded

twisted pair connections. For example, ports 1, 2, and 6 can be unshielded

Introduction 1 - 1

Page 18

twisted pair connections while ports 3, 4, 5, and 7 are shielded twisted pair

connections.

In addition to complying with the 10BASE-T standard, each port provides

support for features that are beyond the scope of the 10BASE-T standard:

Before installing the Ethernet 10BASE-T Module, read the ONline System

Concentrator In stallation and Operation G uide.

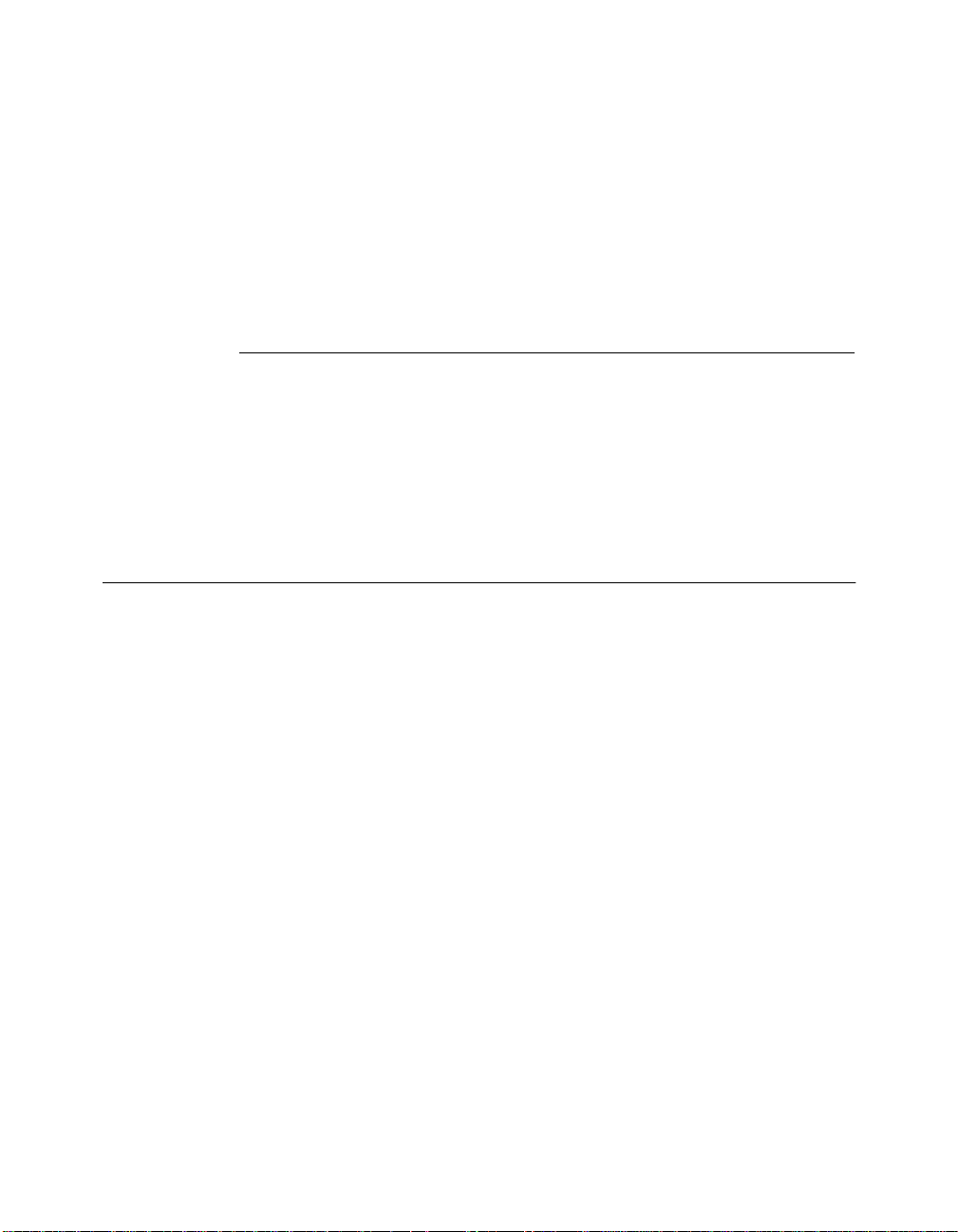

Indicators

The 10BASE-T Module has eight Activity and eight Status LEDs on the front

panel that indicate the state of each port on the module. Figure 1-1 shows

the locations of these indicators and T able 1-1 describes how to read them.

❑ supports shielded twisted pair cable

❑ allows Low Squelch level (which significantly increases achievable link

distances)

❑ allows Link Integrity to be disabled (which allows connection to some

equipment which does not conform to the 10BASE-T standard)

1 - 2 ONline Ethernet 10BASE-T Module User’s Guide

Page 19

Figure 1-1. 10BASE-T Module Faceplate and ONline

System Concentrator

Introduction 1 - 3

Page 20

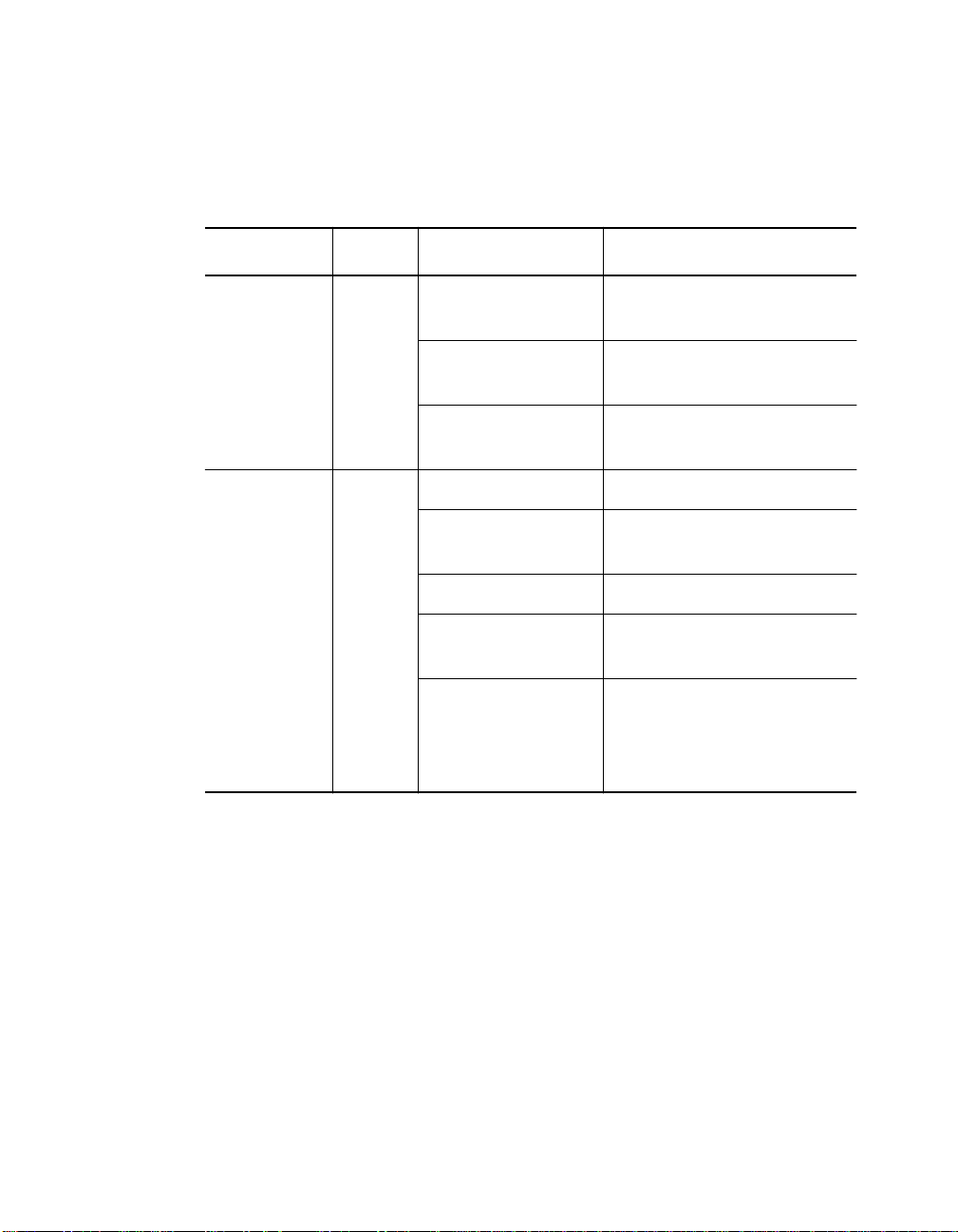

Table 1-1. Interpretation of the 10BASE-T Module LEDs

LED Name Color State Indicates

Activity

(Ports 1-8)

Status

(Ports 1-8)

yellow Off No packets are received on

the segment.

On Constant activity on the

segment.

Blinking Normal activity on the

segment.

green Off Port disabled.

On Port enabled and Link

Integrity is functional.

1 blink Link Integrity error.

2 blink s Jabber error or port

partition ing.

Timed blinks (LED

is on for 10

seconds, blinks

off for 400 msecs)

Link Integrity disabled for

this active port.

Dip Switches

The 10BASE-T Mod ule has three dip switches located on the module:

❑ 8-switch dip switch (SW1)

❑ 4-switch dip switch (SW3)

❑ 8-switch dip switch (SW6)

1 - 4 ONline Ethernet 10BASE-T Module User’s Guide

Page 21

Configure the switches to th e settings you want if different than the

default values. (Refer to Table 1-2, T able 1-3, T able 1-4, and T able 1-5 for an

explanation of the dip switch settings.) Figure 1-2 shows the location of the

dip switches.

Figure 1-2. 10BASE-T Module and Dip Switch Locations

Dip Switch SW1 (Port Status)

The eight switches on dip switch SW1 allow you to enable or disable each

of the eight ports. The switches are labeled 1 through 8 and correspond to

the respective eight ports. The Off position disables the port and the On

position enables the port. The switch settings are initially configured in the

Introduction 1 - 5

Page 22

On position, therefore, all ports are initially enabled. T able 1-2 describes the

settings and functions for switches 1 through 8.

Table 1-2. Dip Switch SW 1 Settings and Interpretations

Switch Function

Factory

Default

Switch Setting

Off On

1 - 8 Enable/disable port enable disable enable

If you have an ONline Ethernet Network Management Module installed in

your concentrator , you can remotely override these switch settings. Refer to

the ON line Ethernet Network Management Module Installation and

Operation Guide for informatio n on remotely managing the ports.

Dip Switch SW3 (Crossover Mode, Channel Select, Squelch)

The four switches on dip switch SW3 allow you to:

❑ set port 8 to uncrossed mode

❑ select a channel for the module

❑ set the Squelch level to high (normal) or low (sensitive)

The switches are labeled 1 through 4 and the settings affect all eight ports.

Switch 1 allows you to enable or disable crossover mode for port 8. The

channel is initially configured for channel 1 (default) and Squelch level is

initially configured for high (default). The following sections explain the

crossover, channel selection, and Squelch mode.

If you have an ONline Ethernet Network Management Module installed in

your concentrator, you can remotely overri de these switch settings.

1 - 6 ONline Ethernet 10BASE-T Module User’s Guide

Page 23

Table 1-3 explains crossover mode and squelch mode switch settings and

the sections following the table explain these features in more detail. The

channel selection switches are discussed in Table 1-4.

Table 1-3. Dip Switch SW 3 Settings for Switches 1 and 4

Switch Function

1 Enable/disable

crossover mode for

port 8 only

4 Squelch mode high low high

Crossover Mode Switch

All eight ports on the 10BASE-T Module are internally crossed over as per

10BASE-T standard. This enables the 10BASE-T Module to be connected to a

10BASE-T Transceiver. Port 8, however, can be uncrossed using the

crossover mode switch to connect the 10BASE-T Module directly to another

10BASE-T Module without the need for an external crossover adapter . One

port must be crossed over and the other port (port 8) must be uncrossed

when connecting a 10BASE-T Module to another 10BASE-T Module. If both

ports are crossed, you must use an external crossover adapter to provide a

proper connection.

The Off position disables crossover mode (uncrosses) and the On position

enables crossover mode (default), therefore, port eight is initially crossed

over .

Factory

Default

enable disable

Switch Setting

Off On

(uncrossed)

enable

(crossed)

Squelch Mode Switch

The Squelch mode switch allows you to set the Squelch level to high

(normal) or low (sensitive). The On position sets the Squelch level to high

(default). The High Squelch level conforms to the proposed 10BASE-T

standard. In general, 3Com recommends using Hig h Squelch.

Introduction 1 - 7

Page 24

The Off position sets the Squelch level to low. When the Squelch level is set

to low , the ports are able to r eceive weaker signals. Note that Low Squelch

mode does not conform to the 10BASE-T standard. If you change the

module's Squelch level to low, you must change the 10BASE-T T ransceiver

Squelch level to low also. Refer to the ONlin e Ethern et 10BASE-T

Transceiver Installation Guide for information on setting the transceiver

Squelch level.

On unshielded twisted pair cable, setting the Squelch level to low increases

the achievable link distance by approximately 25% to 50%, but with the

added risk of losing packets to impulse noise. Do not use Low Squelch

mode if your network should experience too many illegally short packets

(runts). This problem will occur if there is significant external noise ar ound

the link.

Setting the Squelch level to low in conjunction with shielded twisted pair

wiring increases the achievable link distan ce without sacrificing noise

immunity. Thus, there is no real drawback in using Low Squelch on shielded

twisted pair.

To gain the extended link distance achieved by using Low Squelch mode,

you must use qualified data grade shielded twisted pair cable or qualified

high performance unshielded cable. IBM Ty pe 1 shielded cable (with an

appropriate RJ45 to Type 1 connector), among others, meets this

requirement. If you are unsure of the grade of twisted pair cable to use, set

the Squelch level to high, or call 3Com for a list of qualified cables to use in

extended distance applicat ions.

Channel Select Switch Settings

The ONline Ethernet 10BASE-T Module is equipped with the technology to

work with the ON line System Concentrator's uniqu e TriChannel™

architecture. This feature allows you to assign the module to any of three

channels (or none) on the ONline System Concentrator backplane. Refer to

Chapter 1 in the ONline System Concentrator Installation and Operation

Guide for a co mplete discussion of ONline's TriChannel architecture.

The channel select switch settings (switches 2 and 3) on dip switch SW3 let

you select a channel. Switches 2 and 3 are factory set to On, therefore, the

1 - 8 ONline Ethernet 10BASE-T Module User’s Guide

Page 25

10BASE-T Mod ule is initially configured to channel 1. To recon figure the

module to a different channel, refer to the information in Table 1-4.

Table 1-4. Dip Switch SW3 Settings and Interpretations for

Switches 2 and 3

Switch 2 Switch 3 Channel Selection

Switch Setting On On 1 (default)

On Of f 2

Off On 3

Off Off Isolated (module

operates independent of

any channel)

If you have an ONline Ethernet Network Management Module installed in

your concentrator, you can remotely overri de these switch settings.

Dip Switch SW6 (Link Integrity)

The eight switches on dip switch SW6 allow you to enable or disable Link

Integrity for each port. The switches are labeled 1 through 8 and

correspond to the eight ports. The On position enables Link Integrity for

each port (default) and the Off position disables Link Integrity for each

port. The switch settin gs are init ially configured in the On posi tion,

therefore, all eight ports have Link Integrity enabled, as per the 10BASE-T

standard.

In general, you should enable Link Integrity . To conform to the 10BASE-T

standard, for example, a connection requires Link Integrity to be enabled.

Y o u must disable Link Integrity to connect to older equipment which does

not conform to the 10BASE-T standard. Link Integrity must either be

enabled at both ends of the link or disabled at both ends or the module will

report a Link Integrity error.

Introduction 1 - 9

Page 26

If you enable a port and disable Link Integrity, the Status LED is on for 10

seconds and blinks off for 400 msecs to indicate that Link Integrity is

disabled.

Table 1-5 lists the settings and functions for switches 1 through 8.

Table 1-5. Dip Switch SW 6 Settings and Interpretations

Switch Function

1 - 8 Enable/disable link integrity enable disable enable

If you have an ONline Ethernet Network Management Module installed in

your Concentrator, you can remotely override these switch settings.

Related Features

The following sections describe functions which allow you to:

❑ check the module's channel assignment and LED functionality

❑ remotely manage the 10BASE-T Module

LED and Channel Verification

The ONline Controller Module is equipped with an LED/Channel Check

button on the front panel. The LED/Channel Check button has two

functions: it causes all LEDs in all modules in the concentrator to light and it

causes each module to identify the channel to which it is assigned. When

you activate this button, it causes all module LEDs to light for

approximately five seconds. Any LED that does not light is defectiv e.

Factory

Default

Switch Setting

Off On

After the five seconds elapse, the diagnostic continues with a channel

check of all modules. This channel check causes each module's Status LEDs

to blink a number of times corresponding to the channel to which it is

1 - 10 ONline Ethernet 10BASE-T Module User’s Guide

Page 27

assigned. The channel check sequence repeats five times. T able 1-6 explains

the channel check codes.

Table 1-6. Channel Check Codes

LED Stat e Channe l Co n figuration

1 Blink Module is config ured for channel 1

2 Blinks Module is configured for channel 2

3 Blinks Module is configured for channel 3

Off Isolated (module operates independent of any

channel)

The LED/Channel Check button and the Controller Module are explained in

more detail in the ONline Controller Module Installation Guide.

The ONline Ethernet Network Management Module

The ONline Network Manag ement Module provides remote network

management capabilities for the ONline System Con centrator and its

modules. The Management Module can also remotely override the

following dip switch settings of the 10BASE-T Modu le:

❑ enable/disable each port

(SET PORT 6.5 MODE ENABLE)

❑ enable/disable Link Integrity for each port

(SET PORT 3.2 LINK_INTEGRITY ENABLE)

❑ set Squelch to high level o r low level per port

(SET PORT 5.1 SQUELCH LOW)

❑ enable/disable crossover mode for port 8

(SET MODULE 5 CROSSOVER DISABLE)

Introduction 1 - 11

Page 28

❑ change channel selectio n (per module)

(SET MODULE 4 CHANNEL 2)

The ONline Ethernet Management Module allows you to set redundancy

between the ports. Refer to Redundant Links in Chapter 2 for an example

of setting redundancy between concentrators using 10BA SE-T Modules.

Refer to the ONline Ethernet Network Management Module In st allation

and Operation Guide for additional information on the Network

Management features.

1 - 12 ONline Ethernet 10BASE-T Module User’s Guide

Page 29

2

Designing and

Expanding the Network

This appendix con tains configuration information that will help you to

design your network. Install all equipment using only approved cables for

proper operation. Refer to Appendix A in the T wisted Pair Connectors and

Cables section for in formation on twisted pair connector and cab le

requiremen ts.

This appendix describ es how to configu re you r network with the O Nline

System Concentrator and the ONline Ether net 10BASE-T Module. It also

provides examples of alternative network cabling structures and rules for

configuring Ethernet networks. There are five sections:

❑ Network Diamet er Calculations: General Rules

❑ Fiber Backbone, Twisted Pair To-The-Desk

❑ Twisted Pair Backbon e, Twisted Pair To-The-Desk

❑ Redundant Links

❑ Patch Panels

Designing and Ex panding the Network 2 - 1

Page 30

Understandi ng the General Rules

As part of your network design, it is important to consider your netwo rk

size. For instance, is the network (end-to-end) 100 meters, 1000 meters,

4000 meters, or more? What are your plans for expansion? Y our answers

play a role in how you configure your network. For exam ple, once the

network expands beyond a certain size, you need to add a bridge or other

internetw orking device.

This section describes general rules for configuring an Ethernet network

using fiber as the backbone medium. It also provides rules to ensure that

your network configuration conforms to distance limitations imposed by

Ethernet and networking equipment.

This section includes:

❑ Basic Network Rules

❑ LAN Equivalence

Basic Network Rules

This section outlines the basic network rules and 3Com recommendations

for these rules. For more hardware-specific information on the 10-Port

module, refer to Appendix A.

2 - 2 ONline Ethernet 10BASE-T Module User’s Guide

Page 31

T able 2-1 outlines the seven basic rules to keep in mind when you construct

your network.

Table 2-1. Seven Basic Network Rules

Rule Definition Recommendations/Notes

1 If possible, use

10BASE-FB as the

backbone medium.

2 Wire the backbone in

a star topology to

isolate faults.

3 The maximum Fiber

Ethernet network

diameter is 4200

meters of fiber cable.

Use 62.5 micron cable to conform

with the IEEE 10BA SE-F and

upcoming ANSI FDDI standards.

Use ST-type connect ors.

Make sure to lay extra fiber cables.

The extra cost is small and you will

find you need them as your network

grows.

The star topology conforms to FDDI

wiring as well -- ju st make sure to

run at least two fiber strands to

every backbone connection.

The 4200 meters is the maximum

distance between any two

transceivers on the network.

The 4200 meters does not include

the transceiver cable (that is, drop or

patch cable) that connects a device

with an external transceiver.

T ransceiver cables can extend up to

50 meters. Thus, total network

diameter can be as much as 4300

meters (4200 m + 2 * 50 m)

between any two nodes.

Designing and Ex panding the Network 2 - 3

Page 32

Table 2-1. Seven Basic Network Rules (Continued)

Rule Definition Recommendations/Notes

4 Certain LAN devices

on the network shrink

the maximum Fib er

Ethernet network

diameter to less than

4200 meters.

5 Assume that one

meter of coaxial or

twisted pair is equal to

one meter of fiber

cable.

Many LAN products delay the signal

that goes through them. This is

known as equivalent distance. Every

microsecond delay reduces the

maximum link distance . In fact,

every microsecond delay shrinks the

network diameter by approximately

200 meters of fiber cable. Table 2-2

lists the Equivalent Distances for

other 3Com products.

This is a conservative rule of thumb.

For example, the actual equivalence

is about 1.1 meters of coaxial for

every meter of fiber. For simplicity,

assume one meter.

2 - 4 ONline Ethernet 10BASE-T Module User’s Guide

Page 33

Table 2-1. Seven Basic Network Rules (Continued)

Rule Definition Recommendations/Notes

6 The fiber link distances

must not exceed the

limits imposed by the

optical power budget.

7 When in doubt, use a

bridge.

In general, on 62.5 micron cable,

you can go up to 4000 meters

point-to-point using the ONcore or

ONline Fiber Modules. If you have

poor quality cable or cross many

patch panels, you may have to

sacrifice some distance .

Some older Ethernet fiber optic

products are less powerful than

ONcore Fiber Module optics. So

when connecting to these products,

remember that the least powerful

device determines the maximum

point-to-point distance.

If you are not certain if you have

exceeded allowable network

distances, use a bridge to extend

the network.

Designing and Ex panding the Network 2 - 5

Page 34

LAN Equivalence

LAN equivalenc e is the sum of both the incoming and outgoing module

port signals. Different modules, however, have different equivalent

distances. Table 2-2 lists the LAN product equivalent distances.

Table 2-2. LAN Product Equivalent Distances

LAN Product

ONcore Ethernet 10-Port 10BASE-FB Module 190

Incoming sig nal to fiber port 140

Outgoing signal from fiber port 50

ONcore Ethernet 10BASE-T Module 585

Incoming signal to TP port 420

Outgoing signal from TP port 165

ONline Ethernet 10BASE-T M odules 585

Incoming signal to TP port 420

Outgoing signal from TP port 165

ONline Ethernet Fiber or 10BASE-FB Modules 190

Incoming sig nal to fiber port 140

Outgoing signal from fiber port 50

ONline Ethernet FOIRL Module 560

Equivalent

Distance (meters)

Incoming sig nal to fiber port 330

Outgoing signal from fiber port 230

ONline Ethernet Transceiver Module 0

10BASE-FB Star Coupler (8 or 14 port) 26 180

2 - 6 ONline Ethernet 10BASE-T Module User’s Guide

Page 35

Table 2-2. LAN Product Equivalent Distances (Continued)

LAN Pr o duct

ONline Ethernet BNC Module 900

Incoming signal to BNC port 450

Outgoing signal from BNC por t 450

ONline Ethernet Repeater Module 800

Incoming signal to AUI port 600

Outgoing signal from AUI port 200

IEEE Repeater 800

Distance (m eters)

Fiber Backbo n e, Twisted Pair To-The-Desk

When you confi gure a netwo rk with unshielded or shielded twisted pair

cabling to-the-desk and fiber for the backbone, there are only three

additional rules you need to be aware of:

Equivalent

❑ There can be no more than eight 10BASE-T Modules (5108M-TP) in

the path between any two transceivers due to Ethernet's

four -repeater rule (each 10 BASE-T Module counts as a 1/2 repeater).

You must add a bridge if you have more than eig ht 10BASE-T

Modules serially connected.

❑ There is an equivalent fiber distance for the ONline Fiber Modules

(see Rule 4). The equivalent is:

– 140 meters for signals that externally enter a Fiber Module

port

– 50 meters for signals that internally enter a Fiber Module

via the ONline Concentrator backplane

Designing and Ex panding the Network 2 - 7

Page 36

❑ There is an equivalent fiber distance for the 10BASE-T Modules (see

Rule 4). The equivalence is:

– 420 meters for signals that externally enter a 10BASE-T

Module port

– 165 meters for signals that internally enter a 10BASE-T

Module via the ONline Concentrator backplane

Thus, for every pair of 10BASE-T Modules that a signal goes through, ther e

is a fiber equivalent distance of 585 meters (420 m + 165 m = 585 m). This

is also true if a signal makes a r oundtrip through a single 10BASE-T Module,

i.e., enters a 10BASE-T port externally and exits through another port on

the same 10BASE-T Module. This counts as 585 meters of fiber equivalent

distance, and as a full repeater.

Fiber Backbone, Twisted Pair To-The-Desk Example

In the sample configuration shown in Figure 2-1, we determine if the

transceivers are within legal Ethern et limits. This example is applicable to

both unshielded and shielded twisted pair cables. Note that 22 gauge

unshielded twisted pair cable is used to connect 10BASE-T Transceivers to

the 10BASE-T Modules in the concentrators.

The first step is to identify the two transceivers that are likely to be the

greatest fiber equivalent distance apart. In this case, they are 10BASE-T

Transceivers A and B.

2 - 8 ONline Ethernet 10BASE-T Module User’s Guide

Page 37

.

Figure 2-1. Sample Configuration Distance Calculation

Use the following steps to determine whether your network configuration

is legal:

1. Begin with 4.2 km (4200 m) since th is is the maximum networ k

diameter for a pure fiber network (Rule 3).

2. Subtract 100 m for t he signal exiting the Fiber Modules in

concentrators A and C (2 * 50) and 280 m for the signal entering the

Fiber Modules in concentrators C and B (2 * 140) as explained in Rule

4 and defined in Table 2-2.

3. Subtract 420 m of fiber equivalent distance for the signal entering the

10BASE-T Module in concentrator A and 165 m for the signal exiting

the 10BASE-T Mod ule in concentrator B (Rule 4).

4. Subtract all cable lengths between the two transceivers and if t h e

result is greater than zero, the configuration is within legal Ethernet

limits (Rule 5).

Designing and Ex panding the Network 2 - 9

Page 38

For the configuration shown in F igure 2-1 to work, the fiber equivalent

distance between transceiver A and transceiver B must be less than 4200

meters. As you can see in the calculation, there are still 1510 meters left for

expansion in this configuration.

Be aware that the link from a 10BASE-T Module to a 10BASE-T T ransceiver

should not exceed the distances as defined in Table 2-3. In th is example,

the link cannot exceed 150 meters, using the 10BASE-T standard High

Squelch mode and 22 gauge wire.

Table 2-3. Maximum Link Distance on Twisted Pair

Cable Gauge Support s Link Distances Up To:

Unshielded T wisted Pair:

10BASE-T

22 (.6mm) 150m 200m

24 (.5mm) 125m 150m

Shielded Twisted Pair:

IBM Type 1

22 (.6mm) 200m 300m

In areas of low noise, the Squelch level can be low ered to accept weaker

signals. (Low Squelch does not con form to the 10BASE-T standard.) This

allows the acceptable link distance to increase to 200 meters. The 10BASE-T

standard limits link distance to approximately 200 m eters (equivalent to

1

µsec of delay) on unshielded twisted pair.

10BASE-T signaling can also be used on shielded twisted pair even though

the standard does not include shielded twisted pair in its specificat ion.

Since external noise does not affect signals on shielded twisted pair , there is

no restriction in using the Low Squelch level. Using Low Squelch on

shielded twisted pair allows link distances of up to 300 meters.

Nevertheless, 3Com recommends that you always use the High Squelch

setting except in situat ions where the link distance exceeds 200 meters.

High Squelch Low Squelch

High Squelch Low Squelch

2 - 10 ONline Ethernet 10BASE-T Module User’s Guide

Page 39

Twisted Pair B ackb one, Twisted Pair To -Th e-Des k

In constructing a twisted pair backbone, one additional configuration rule

must be considered:

❑ There can be no more than eight 10BASE-T Modules in the path

between any two transceivers due to the Ethernet four -repeater

rule (each 10BASE-T Module counts as a 1/2 repeater). Y ou must

add a bridge if you have more than eight 10BASE-T Modules

serially connected.

The configuration in Figure 2-2 illustrates a possible unshielded twisted pair

network using 2 2 gauge cable.

Figure 2-2. Unshielded T wiste d Pair Network

Note that when connecting two concentrators with twisted pair cable, use

port 8 on one of the 10BASE-T Modules and disable crossover mode for

that port. This allows a direct connec tion to another 10BASE-T Mod ule

without the need for an intervening adapter. (Refer to Dip Switch SW3

(Crossover Mode, Channel Select, Squelch) in Chapter 1 for information on

crossover mode and the crosso ver mode switch setting. )

Designing and Expanding the Network 2 - 11

Page 40

While there is no fiber in this configuration, the fiber equivalent distance

can be calculated a s follow s :

Total link distance: 150 m + 100 m + 100 m + 50 m + 20 m = 420 m

Total equivalent distance of 10BASE-T Modules:

4 * 420 m + 4 * 165 m = 2340 m

(signal externally enters four 10BASE-T Modules: 4 * 420 m)

(signal enters four 10BASE-T Modules from the backplane: 4 * 165 m)

Total equivalent distance: 420 m + 2340 m = 2760 m

Since the total equivalent distance (2760 m) is less than 4200 meters, this is

a legitimate configuration.

Note that if shielded twisted pair cabling is used, each link in the network

could run up to 300 meters using Low Squelch (refer to Dip Switch SW3

(Crossover Mode, Channel Select, Squelch) in Chapter 1 for information on

Squelch levels and the Squelch d ip switch setting). Low Squelch is

acceptable for all shielded twisted pair applications since external noise is

not a problem.

Redundan t Lin ks

You can implement twisted pair link redundancy between ONline System

Concentrators using Network Management. Figure 2-3 below shows an

example of a redundant configuration between concentrators using

10BASE-T Modules.

Figure 2-3. Redundant Twisted Pair Configuration

2 - 12 ONline Ethernet 10BASE-T Module User’s Guide

Page 41

To set redundancy between two 10BASE-T Modules, connect two links

between the modules. The redundant link must be connected to a port on

the same 10BASE-T Module as the primary link. Use a crossover adapter

between each link unless you choose to uncross port 8 on one of the

modules to make the connection. Refer to Chapter 1 for inf ormation on

using crossover mode. Then use the SET PORT <slot.port> MOD E

REDUNDANT <slot.port> command to specify which port is the primary link

and which is the backup link.

Note: If the 10BASE-T Modules are powered down, and then

brought back up without the Ethernet Man agement

Module present, a network loop could occur. To prevent a

potential failure, 3Com advises that you disable the Port

Enable dip switch setting for the backup port on one of the

10BASE-T Modules.

Once redundancy is con figured, a switchover will occur under three

conditions: a link failure; port partition; or a jabber condit ion. The

switchover occurs when the primary link fails . (Note that in the unlikely

event of a partial break in the link, a switchover may not occur. In this

situation, use Netwo rk Management to manually swit ch over the ports.)

Once the switchover occurs, and the primary link becomes operational, a

switch-over back to the primary link happens automatically if the cause of

the original switchover was a link failure. If a jabber condition causes the

switchover , the link will not automatically switch back to the primary once

the problem is resolved. In this case, use Network Management to

manually switch back to the primary link.

Refer to the ONline Ethern et Network Management Module Installation

and Operation Guide for information on setting redundan cy between

10BASE-T Module ports.

Designing and Expanding the Network 2 - 13

Page 42

Patch Panels

Patch panels weaken signals, thereby reducing achievable link distanc es.

3Com includes the use of one patch panel in the 150 meter link distance

calculation. However, each additional patch panel in the link reduces the

150 meter link distance by approximately 10 meters.

In the example in Figure 2-2, if two patch panels were used between the

top right PC and the top right concentrator, the link distance of 150 meters

would have to be shortened to 140 meters. This is because the maximum

allowable link distance on 22 gauge wire using 10BASE-T signaling with two

intervening patch panels is 150 meters minus approximately 10 meters.

Note that a patch panel installed b etween the bottom right PC and the

bottom left concentrator would not affect the link since it is only 20 meters.

2 - 14 ONline Ethernet 10BASE-T Module User’s Guide

Page 43

Installing and

Operating the Module

3

This chapter describes the precautionary, unpacking, and installation

procedures for the Ethernet 10BASE-T Module.

Precautionary Procedures

Electrostatic discharge (ESD) can damage static-sensitive devices on circuit

boards. Follow these precautions when you handle the 10BASE-T Module.

❑ Do not remove the board from its anti-static shielding bag until you

are ready to inspect it.

❑ Handle the board by the faceplate.

Use proper gr ounding techniques when you install the 10BASE-T Module.

These techniques include using a foot strap and grounded mat or wearing

a grounded static discharge wrist strap. An alternate method is to touch

the grounded rack or other source of ground just before you handle the

module.

Installing and Operating the Module 3 - 1

Page 44

Unpacking Procedures

Use the following procedure when unpacking your 10BASE-T Module.

1. Verify that the 10BASE-T Module is the correct model by matching

the model number listed on the side of the shipping cart on to the

model number you ordered (5108M-TP).

Note that the product model number printed on the shipping box

differs from the model number on the product. The model number

on the shipping box contains the prefix ’3C9’.

2. Remove the 10BASE-T Module from the shipping carton.

3. Remove the module from the anti-static shielding bag and inspect it

for damage. Always handle the 10BASE-T Module by the faceplate

being careful not to touch the components.

If the module appears to be damaged, replace it in the anti-static

shielding bag, return it to the shipping carton, and contact your local

supplier .

3Com suggests you keep the shipping carton and anti-static shielding bag

in which your module was shipped in case you later want to repackage the

module for storage or shipment.

We also suggest that you record the serial number of your 10BASE-T

Module. We have provided a log for this and other information specific to

your modules under the Slot Usage Chart in Appendix B of the ONline

System Concentrator Installation and Operation Guide.

Installatio n Procedures

Y ou do not need to power down the ONline System Concentrator to install

the 10BASE-T Module. Y ou can insert the module while the concentrator is

operating (called a hot insertion). Follow t he steps below to install the

10BASE-T Module.

3 - 2 ONline Ethernet 10BASE-T Module User’s Guide

Page 45

1. Set the dip switches on the board to the settings you want, if

different than the default values. (Refer to Table 1- 2 , Table 1- 3 ,

T able 1-4, and T able 1-5 for an explanation of the dip switch settings.)

2. Locate a blank slot in the concentrator. If there is no blank slot, you

must remove a blank panel on the concentrator to expose a slot for

the 10BASE-T Module.

3. Insert the module into the board guides at the top and bottom of the

slot and slide it into the concentrator . Make sure the connecto r is well

seated into the backplane of the concentrator.

Figure 3-1 shows the installation of the 10BASE-T Module.

Figure 3-1. Installing a 10BASE-T Module

Installing and Operating the Module 3 - 3

Page 46

4. Fasten the spring-loaded screws on the front of the 10BASE-T Module

face-plate to the concentrator with your fingers (do not overtighten).

5. Attach the twisted pair cable to the port on the fro nt of the 10BASE-T

Module as shown in Figure 3-2. Then attach the other end of the

cable to another 10BASE-T Mod ule, a 10BASE-T Transceiver, or a

10BASE-T Adapter Ca rd.

Figure 3-2 shows a cable attached to the 10BASE-T Module.

Figure 3-2. 10BASE-T Module Cable Connection

3 - 4 ONline Ethernet 10BASE-T Module User’s Guide

Page 47

Troubleshooting

4

This chapter describes troubleshooting procedures for the ONline Ethernet

10BASE-T Module. Information on troubleshooting will assist you in

verifying operation. Typical fault conditions are addressed in this chapter.

Troubleshooting

Diagnostic features are covered in Table 1-1 on page 1-4. Table 4-1 and

Table 4-2 in this chapter cover fault conditions and troubleshooting

suggestions for the 10BASE-T Module. This chapter is divided into the

following parts:

❑ Troubleshooting With the Port Status LEDs

❑ Troubleshooting With the Activity LEDs

❑ Technical Assistance

Troubleshooting 4 - 1

Page 48

Troubleshooting With the Status LEDs

A blinking Port Status ind icator may be a sign that the port detects a

potential problem. Once a port detects a problem, you can further analyze

the problem by counting the number of blinks. Table 4-1 provides

troubleshooting suggestions for each of the blinking sequences.

Table 4-1. Troubleshooting With the Port Status LEDs

LED State Indication

Off Port

Disabled

Possibl e

Problem

Port disabled Enable port.

10BASE-T

Module not

powered

Broken LED Press the LED/Channel

Bad 10BASE-T

Module

Troubleshooting

Suggestions

Check the Controller

Module Power LEDs.

Check button on the

Controller Module.

Replace module.

4 - 2 ONline Ethernet 10BASE-T Module User’s Guide

Page 49

Table 4-1. Troubleshooting With the Port Status LEDs (Continued)

LED State Indication

1 Blink Link

Integrity

Error

Possibl e

Problem

Cable no t

connected

Cable broken Check cable with cable

Cable too long Try a shorter cable.

Remote

connection has

Link Integrity

disabled

Weak or no

signal - link

distance too

long

Troubleshooting

Suggestions

Connect cable.

tester. Repair or replace

cable.

Enable Link Integrity at

remote connection or if

the remote link does not

have Link Integrity,

disable Link Integrity at

local connection.

Change Squelch level

from high to low (low

setting does not

conform to the

10BASE-T standard).

Bad port Try another port.

Device attached

to transceiver at

other end is not

powered on

This is not a problem.

Troubleshooting 4 - 3

Page 50

Table 4-1. Troubleshooting With the Port Status LEDs (Continued)

LED State Indication

2 Blinks Port

Partitioning

Jabber

condition

Timed

Blinks (LED

is on f or 10

seconds,

blinks off

for 40 0

msecs)

Link

Integrity

Disabled

Possibl e

Problem

Faulty cable Check cable with cable

Network

overloaded

Transceiver

attached to the

port is jabbering

or has DTE

jabber

None This is not a problem.

Troubleshooting

Suggestions

tester. Repair or replace

cable.

Reassign users to

another channel to

balance the load.

Try another port or

replace module.

You may want Link

Integrity disabled .

4 - 4 ONline Ethernet 10BASE-T Module User’s Guide

Page 51

Troubleshooting With the Activity LEDs

There may be situations where a port's Activity LED may not light. Use the

troubleshooting suggestions in Table 4-2 to help isolate why this has

occurred.

Table 4-2. Troubleshooting With the Port Activity LEDs

LED Name

Activity

(Ports 1 - 8)

LED

State

Off There is no traffic

Possible Problem

received from the

segme nt (normal)

The port is disabled Check the port enable dip

The power is off Check the Controller

The Activity LED has

burnt ou t

The 10BASE-T

Module port is

faulty

The module

connection to the

backplane is bad

Troubleshooting

Solutions

None.

switch setting.

Module Power LEDs.

Press the LED/Channel

Check button on the

Controller Module.

Connect the cable to a

different port.

Reinsert the 10BASE-T

Module. If this fails, try

another concentrator slot.

The 10BASE-T

Module i s faulty

Try a different 10BASE-T

Module.

Troubleshooting 4 - 5

Page 52

Technical Assistance

Y ou can receive assistance for installing and troubleshooting the 10BASE-T

Module by calling either your 3Com reseller or 3Com T echnical Support. Be

prepared to supply a representative with the following information:

❑ Description of the problem

❑ Steps you have tak en to try and correct the problem

❑ Type and softw a re version of the ONline network management

module being used

❑ Version of software installed on your 10BASE-T Module

❑ Status of the front panel LEDs

❑ Configuration of your concentrator

(you may find it helpful to refer to the Slot Usage Chart in Appendix B

of the ONline System Concentrator Installation and Operation Guide

for a record of this information)

Reber to Appendix B for instructions on c ontacting Technical Support for

your product .

4 - 6 ONline Ethernet 10BASE-T Module User’s Guide

Page 53

Specifications

A

ONline Ethe r net 10BASE-T Modul e Spec ifi cati ons

This appendix lists specifications for the 10BASE-T Module. There are five

subsections:

❑ Electrical Specifications

❑ Environmental Speci fications

❑ Mechanical Spec ifications

❑ General Specifications

❑ Twisted Pair Connectors and Cables

Electrical Specifications

Backplane Interface: 96-pin edge connector, compatible with the 3Com

ONline System Concentrators.

Power Requirements: 1.75 A for 5V

Fuse: 4.0 Amps Fast blow

Watts: 8.75

Specifications A - 1

Page 54

Environmental Specifications

Operating Temperature: 0° to 50° C (32° to 122° F)

Storage Temperature: -30° to 65° C (-22° to 149° F)

Humidity: less than 95%, non-conden sing

BTU/hr: 30

Mechanical Specification s

Dimensions : 1.0" W x 10.25" L x 8.5" H

(2.54 cm x 26.04 cm x 21.6 cm)

Weight: 1.25 lb. (0.57 kg.)

General Specifications

Data Rate: 10 Mbps (million bits per second)

Data modulation : Manchester

Diagnostic modulation: Link Integrity pulse

Collision detection: 100% deterministic

Maximum number of nodes: 1024

Configuration rules: supports IEEE 802.3 controllers and IEEE 802.3

repeaters

Jabber Protectio n: 6.5 milliseconds

Port Connectors: Shielded 8-pin modular telephone jack, compatible with

an unshielded connector

Cabling: 22, 24 , or 26 AWG un shielded or shielded twisted pair cable

Cable differential impedance: 85 ohms to 150 ohms over 1 to 16 MHz band

A - 2 ONline Ethernet 10BASE-T Module User’s Guide

Page 55

Cable propagation velocity: >.585c

Host Interface: 3Com ONline System Concentrator bus interface standard

Installation Att achment: Two thumbscrews on the mounting bracket

Twisted Pair C on necto rs an d Cabl es

There are many types of cables and connectors that you can u se to link

your 10BASE-T Module to your network. These cables and connectors are

explained in the following sections. Use this information to ensure that the

cables and connecting hardware meet requirements. For proper operation,

use only approved cables when yo u install all equipment. This section is

divided into the following parts:

❑ Twisted Pair Co nnectors

❑ Twisted Pair Cables

Twisted Pair Connectors

The IEEE 802.3 10BASE-T standard for pin-outs must be used. The following

cable standard must be used. 10BASE-T uses 2 pairs of wire: pins 1 & 2 and

pins 3 & 6. If the pairs are not configured this way, the connection will not

work properly. Datagrade cable should have the following pin pairings:

❑ pins 4 and 5 are pair 1

❑ pins 3 and 6 are pair 2

❑ pins 1 and 2 are pair 3

❑ pins 7 and 8 are pair 4

Specifications A - 3

Page 56

Refer to Figure A-1 for an example of this connector and the cable pin-outs.

Pair 2

W-G G W-O BL W-BL

Figure A-1. RJ45 C onnector Pin-outs

Some installations may have 50-pin Telco connectors at the wiring closet.

We recommend using a patch panel that converts from 50-pin to RJ45-type

connectors. This allows direct connection to the ONline Ethernet 10BASE-T

Module in your ONline System Concentrator.

Twisted Pair Cables

The cables that are supported must meet the following qu alifications:

Pair 3 Pair4

1 2 3 4 5 6 7 8

Pair 1

O BRW-BR

Jack Positions

❑ 22, 24, or 26 gauge twisted pair cable

❑ 80 to 150 ohm impedance

❑ minimum of 2 pairs

Usually, a pair on a twisted pair cable is designated by a solid color wire

twisted with a striped wire with the same color.

A - 4 ONline Ethernet 10BASE-T Module User’s Guide

Page 57

Connecting Twisted Pair Cables

We recommend that you connect cables first at the active concentrator

location, and co nnect transceivers second. Refer to the ONline System

Concentrator Installation and Operation Guide for more information about

the ONline System Concentrator conn ections.

Specifications A - 5

Page 58

Page 59

B

Technical Support

3Com provides easy access to technical support information through a

variety of services. This appendix describes the following services:

❑ On-line Technical Support

❑ Support from Your Network Supplier

❑ Support from 3Com

❑ Returning Products for Repair

❑ Accessing the 3Com MIB

❑ 3Com Technical Public at ions

On-line Technical Sup port

3Com offers world wide product support through the following on-line

systems:

❑ Email Technical Service

❑ World Wide Web Site

Technical Support B - 1

Page 60

Email Technical Support

Y ou can contact the Integrated Systems Division (formerly Chipcom) on the

Internet fo r technical support using the e-mail address

techsupp@chipcom.com.

World Wide Web Site

You can access the latest networking information on the 3Com World

Wide Web site by entering our URL into your Internet browser:

http://www.3Com.com/

This service features news and information about 3Com products,

customer service and support, the 3Com latest news releas es, selected

articles from 3TECH™, the 3Com award-winning technical journ al, and

more.

You can contact the Integrated Systems Division on the World Wide Web

by entering our URL into your Internet browser:

http://www.chipcom.com/

There are links between both WWW pages to view information from all

3Com divisio n s.

Support from Your Network Supplier

If additional assistance is required, contact your network supplier. Many

suppliers are authorized 3Com service partners who are qualified to provide

a variety of services, including network planning, installation, hardware

maintenance, application training, and support services.

B - 2 ONline Ethernet 10BASE-T Module User’s Guide

Page 61

When you contact your network supplier for assistance, have the following

information ready:

❑ Diagnostic error messages

❑ A list of system hardware and sof tware, inclu ding revision levels

❑ Details about recent configuration changes, if applicable

If you are unable to contact your network supplier, see the following

section on h ow to contact 3Com.

Support from 3Com

If you are unable to receive support from your network supplier, technical

support contracts are available from 3Com.

For direct access to customer service for Integrated Systems Division

products in:

❑ U.S.A. and Canada - call (800) 724-2447

❑ Asia Pacific - call (508) 787-5151

❑ Europe - Refer to the table below. For European countries not listed,

call 31 30 60 299 00.

Country Telephone Number Country Telephone Number

Belgium 0800 71429 Netherlands 06 0227788

Denmark 800 17309 Norway 800 11376

Finland 0800 113153 Spain 900 983125

Franc e 05 917959 Sweden 020 795482

Germany 0130 821502 U.K. 0800 966197

Ireland 1 800 553117 U.S. 800 876-3266

Italy 1678 79489

Technical Support B - 3

Page 62

For access to customer service for all 3Com products, call (800) 876-3266.

You can also contact the Integrated Systems Division (ISD) on the Internet

by using the e-mail address techsupp@chipcom.com.

Return i ng P roducts fo r Repa ir

A product sent directly to 3Com for repair must first be assigned a Return

Materials Authorization (RMA) number. A product sent to 3Com without

an RMA number will be returned to the sender unopened, at the sender’s

expense.

To obtain an RMA number for In tegrated Systems Divi si on products

(formerly Chipcom), use the following numbers.

Country Telephone Number Fax Number

U.S. and Canada (800) 724-2447 (508) 787-3400

Europe (44) (1442) 275860 No Fax

Asia Pacific (508) 787-5296 (508) 787-3400

Accessing the 3Com MIB

The 3Com Management Information Base (MIB) for the Integrated Systems

Division describe s commands that enable you to manage 3Com

SNMP-based products. The MIB is available over the Internet on an

anonymous FTP server. Up dates to these MIBs are released as new 3Com

products are introduced.

To access Internet versions:

1. FTP to ftp.chipcom.com (151.104.9.65).

2. Enter the login n ame anonymous.

B - 4 ONline Ethernet 10BASE-T Module User’s Guide

Page 63

3. Enter your full Internet e-mail address as the password

(for example, jdoe@company.com).

4. Change to the mib or schema directory using the cd /pub/mibs or

cd /pub/ mi bs /s ch em as command.

5. To view the 3Com MIB, OID, or schema entries, enter the dir

command.

❑ To pause the display, press [CTRL-S].

❑ To continue the display, press [CTRL-Q].

6. Copy the MIB, OID, or schema files to your current directory using the

appropriate command (for example, get chipcom.mib).

7. To exit the F TP session, invoke the quit command.

3Com Te chn ic al Pub lic atio ns

If you have comments or questions on 3Com Integrated Systems Division

T echnical Publications documents, please contact the T echnical Publications

group by FAX (508) 229-1551.

Technical Support B - 5

Page 64

Page 65

Index

Numerics

3Com Bulletin Board Service (3ComBBS), B-3

A

Audience of Manu al, xi

B

Backbone

Fiber Medium

bulletin board service, B-3

, 2-2

C

Cable Types

Shielded Twisted Pair

Unshielded Twisted Pair, 1-1

Cabling

Connectors

Fiber Backbone, 2-7, 2-8, 2-1 0

Redundant Links, 2-13

Twisted Pair Backbone, 2-11

Twisted Pair Connections, 2-10

Wire Types, A-4

Configuration Rules

Fiber Backbone

Configuration Rules

Fiber Backbone

General, 2-2, 2-3, 2-5

Twisted Pair Backbone, 2-11, 2-12

, A-3, A-4

, 1-1

, 2-9

, 2-7, 2-8

D

Dip Switch Settings

Channel Select

Crossover Mode, 1-6, 1-7

Link Integrity, 1-9, 1-1 0

Port Status, 1-5

Squelch Mode, 1-7, 1-8

Dip Switches, 1-4

, 1-8, 1-9

F

FCC notice, ii

Features, 1-1, 1-2

Fiber Link Distances, 2-5

Front Panel Indicators

Activity LEDs

Status Indicators, 1-2

Status LEDs, 1-4

, 1-2, 1-4

I

Installation

Cabling

Installing The M odule, 3-3, 3-4

, 3-4

L

LAN Product Equivalent Distances, 2-6

Link Distances

Configuration Rules

, 1-1

Index 1

Page 66

M

U

MIB, B-4

N

network supplier support, B-2

O

ONline Controller Mo dule, 1-10

ONline Ethernet Management Module, 1-11,

1-12

on-line technical service s, B-1

P

Patch Panels, 2-14

R

Redundancy, 2-13

returning products for repair, B-4

S

Shielded Twisted Pair, 2-10, 2-1 2

SNMP Commands, B-4

Star Topology, 2-3

Unshielded Twisted Pair, 2-8, 2-10, 2-11

V

VDE compliance, ii

W

Wire Types, 1-1

T

Technical Assistanc e, 4-6

Technical Support, 4-6, B-1

Troubleshooting

Port Activity LEDs

Port Status LEDs, 4-1, 4-3, 4-4

Technical Assistanc e, 4-6

Twisted Pair

, A-4, A-5

Cables

Connections, A-5

Connectors, A-3, A-4

2 Index

, 4-5

Loading...

Loading...