Page 1

3B SCIENTIFIC

Instruction sheet

12/08 ELWE/ALF

®

PHYSICS

Heat pump U8440600

1 On/off switch for Compressor

2 Condenser

3 Stirrer

4 Overpressure cut-out switch

5 Reset overpressure cut-out switch

6 Manometer for the high-pressure side

7 Manometer for the low-pressure side

8 Energy monitor

9 Expansion valve

10 Evaporator

11 Stirrer

12 Viewing window

13 Compressor

1. Safety instructions

If the heat pump is tipped to one side, it must remain in an upright position for at least seven hours

before being operated again.

• Always keep the heat pump in an upright posi-

tion during storage, transport and operation.

• Carry the heat pump only at the carrying handles.

• Do not lift the heat pump by its copper pipes or

they may get bent.

Caution: the voltage in the compressor circuit is

dangerous to touch!

• Do not thermally insulate the compressor or it

may overheat.

• After shut-down by the overpressure cut-out

switch wait for 10 minutes to press the green reset button.

2. Description

Demonstration model of an electrically powered

compressor heat pump for demonstrating how a

heat pump or a refrigerator operates. Can be operated as a water-air or water-water heat pump.

The demonstration model of an electrically powered

compressor heat pump consists of a compressor with

a drive motor, an evaporator, a condenser and an

expansion valve. These components are connected in

a closed system by means of pipes and built onto a

base.

The energy monitor allows to record and display the

electrical performance data of the compressor.

1

Page 2

Button Function

Zeit (Time) displays the time / operating time of

the compresor (ED)

(changes when you press the button)

Strom (Current)

Spannung

displays the current consumption of

the compresor

displays the mains voltage

(Voltage)

Leistung

(Power)

Energie

displays the momentary power consumption

displays the energy, (unit: Wh)

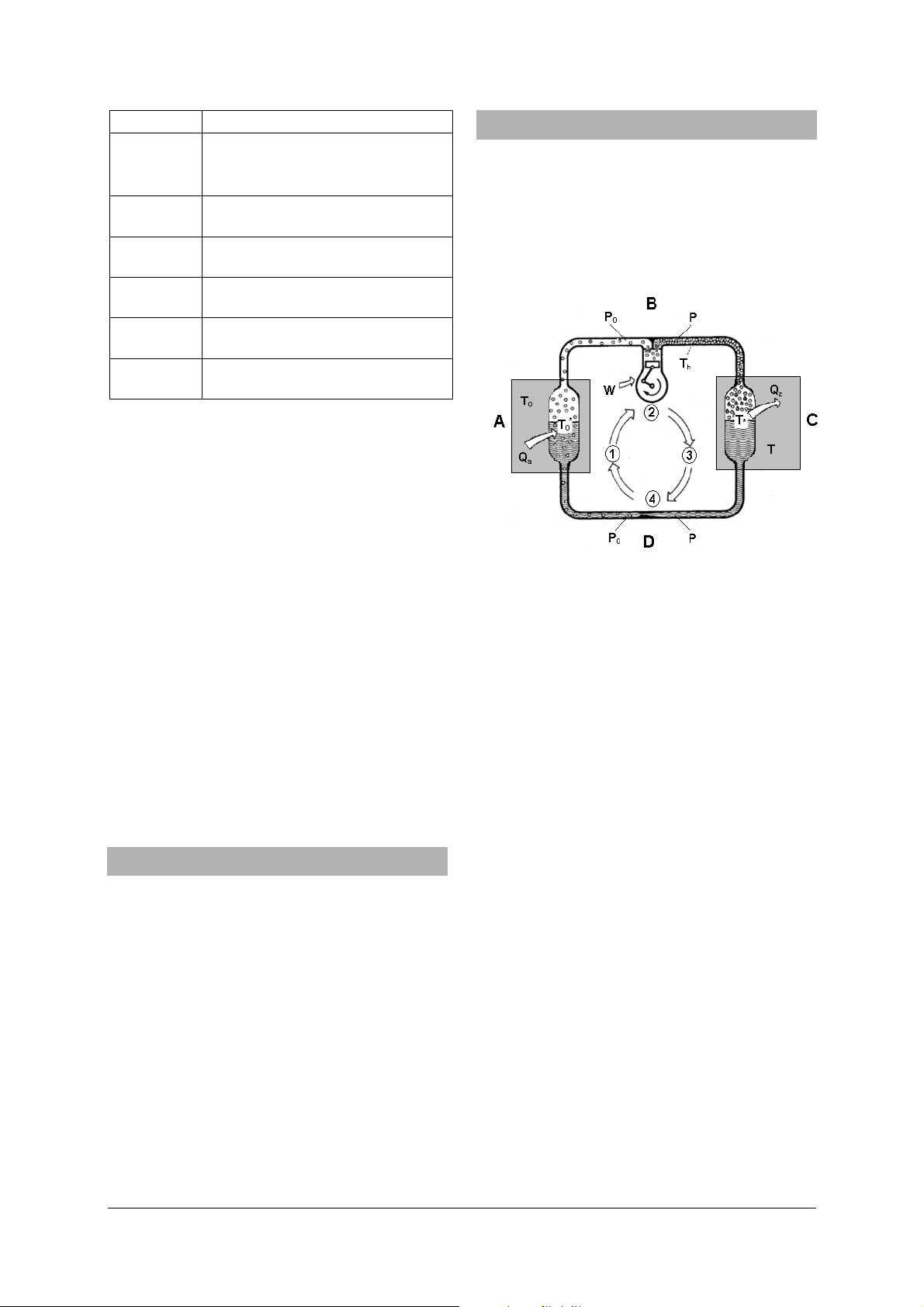

3.1 The processes in a heat pump circuit

In the most important and widely used type of heat

pump, the compressor heat pump, a substance in

the form of a liquid with a low boiling point circulates in a closed loop. It passes through four different processes. It is evaporated, compressed, condensed and then allowed to expand (see Fig. 1).

(Energy)

Zeit (Time)

> 6s

Reset function for time, ED and

energy

The evaporator and condenser are constructed as

coils of copper piping and each is immersed in a

beaker filled with 2000 ml of water that serves as a

reservoir of heat in order to determine the quantity

of energy absorbed or emitted. Two additional thermometers are required in order to measure the

temperature of the water in the beakers.

Two large manometers display the pressure of the

refrigerant in both heat exchangers. An overpressure

cut-out switch disconnects the heat pump from the

mains if the excess pressure reaches 15 bars.

So that the properties of the refrigerant in liquid and

gaseous states and the processes of conversion can

be viewed, the heat pump is equipped with viewing

Fig. 1 Circulation in a heat pump

A Evaporator

B Compressor

C Condenser

D Expansion valve

P

windows. These allow the interior of the pump to be

seen and the state of the refrigerant to be observed

immediately after the evaporator or condenser.

p High pressure in the condenser segment from

The heat pump is available for two different mains

volatages. U8440600-230 is designed for 230 V (±10

%), 50 Hz mains supplies, while the U8440600-115

T

model is for 115 V (±10 %), 60 Hz supplies.

T Temperature of the medium (usually centrally

3. Technical data

Compressor power: 120 W, power consump

tion dependent on operat ing state

Evaporator temperature: -10° C

Refrigerant (CFC-free): R 134A (Tetrafluorethan, C

2H2F4

Boiling point: -26° C

Manometer: 160 mm dia., evaporator

(suction intake) up to 9

bars; condenser (pressure

pipe) up to 24 bars

Overpressure cut-off: disconnects compressor

from the mains at 15 bars

T

rator at pressure p

T

after compression

)

T* Boiling point of the refrigerant in the con-

denser at pressure p

Q

Q

W Work performed by the compressor

3.1.1 Evaporation

Power supply: 115 V, 60 Hz or 230 V, 50 Hz

Dimensions: 750 x 350 x 540 mm

3

Weight: 21 kg approx.

4. Operating principle

Low pressure in the evaporator segment from

0

the outlet of the expansion valve to the input

of the compressor

the outlet of the compressor to the input of

the expansion valve

Temperature of the medium (soil, water, air)

0

surrounding the evaporator from which a

quantity of heat Q

is absorbed

a

heated water), surrounding the condenser

which absorbs a quantity of heat Q

* Boiling point of the refrigerant in the evapo-

0

Temperature of the refrigerant vapour

h

Heat absorbed by the evaporator

a

Heat emitted by the condenser

Z

0

z

In the evaporator the liquid refrigerant experiences a low pressure p

. The temperature T0 in

0

the medium surrounding the evaporator is higher

than the boiling point of the refrigerant T

responding to the pressure p

. This tempera-

0

* cor-

0

2

Page 3

ture gradient leads to heat being transferred

from the surroundings into the refrigerant, which

therefore boils and turns into vapour. The quantity of heat Q

required for this evaporation is

a

taken from the surroundings, which cool down as

a result.

3.1.2 Compression

The refrigerant vapour is constantly drawn into

the compressor where it is compressed. This

causes the vapour pressure to rise from p

to p.

0

The boiling point at pressure p is T*. The work W

performed by the compressor raises the temperature of the vapour to T

> T*. Th is the temperature

h

of the refrigerant vapour after it has been thus

raised, i.e. the temperature is above the boiling

point T* corresponding to the pressure p after the

compressor.

3.1.3 Condensing

The compressed vapour is forced into the condenser. The temperature of the surroundings

around the condenser is T and is lower than T*. This

means that heat is transferred from the refrigerant

into the environment. This corresponds to the

smaller fraction of Q

pour decreases from T

. The temperature of the va-

z

but the vapour does not con-

h

dense until the condensation temperature T* is

reached. At that point the vapour begins to condense (become liquid) and the heat of condensation, the greater component of Q

, is transferred to

z

the surroundings, the temperature of which therefore rises.

3.1.4 Expansion

The piping connecting the condenser and the

evaporator completes the circuit. The expansion

valve in this pipe allows the pressure difference to

even out. The liquid refrigerant at temperature T* is

allowed to expand so that its pressure decreases

from p in the condenser to p

in the evaporator. This

0

also causes the refrigerant to cool. The lower pressure p

results in a lower boiling point T0*. There-

0

fore the expansion also causes the boiling point to

drop so that the temperature T* at which the refrigerant leaves the evaporator is now above the

boiling point of the expanded fluid. Part of it therefore starts to evaporate. The heat of evaporation required for this is provided by the cooling of the refrigerant itself until pressure and temperature reach

p

and T0* and the refrigerant returns to its initial

0

state thus completing the cycle.

The heat energy required to evaporate the refrigerant

per unit time in the evaporator can be supplied either

by the extensive cooling of a small volume of air or by

lesser cooling of a large volume of air. The energy

associated with a material is dependent on its temperature and its quantity. In practice the cooling of

the medium around the evaporator, such as the cooling of air outdoors, only corresponds to a few degrees.

3.2 The processes in the circuit as a T, Q/T diagram

The heat pump cycle is often represented in a state

diagram with the «Temperature» T as its ordinate and

the quotient «Heat divided by absolute temperature»

Q/T, which is called entropy, as the abscissa (Fig. 2).

The value x in this diagram represents the ratio of

refrigerant vapour to liquid. When x = 0 and anywhere

to the left of this line (left-hand limit), all the refrigerant

is liquid. To the right of the line an increasing quantity

of the refrigerant is gaseous until a line with x = 1

(right-hand limit) is reached, after which the refriger-

ant is entirely vapour. The sequence of processes in

the cycle already described will now be explained

again in terms of this diagram:

Fig. 2 The process in a heat pump cycle as a T, Q/T diagram

A Evaporator, B Compressor, C Condenser, D Expansion

valve

Gaseous refrigerant at a pressure p

T

* (state 1) is sucked into the compressor and com-

0

and temperature

0

pressed. The amount of work done in this case is W.

This is converted into heat and transferred to the

refrigerant. The pressure p

increases to p. The higher

0

pressure p corresponds to a higher boiling point T*.

Temperature rises from T

* to Th (state 2).

0

The compressed refrigerant flows into the condenser.

The temperature of the condenser's surroundings T is

lower than T*. By emitting heat, the vapour cools

from T

down to the condensation temperature, the

h

boiling point T* corresponding to the pressure p (state

2'). It then condenses by emitting its heat of conden-

sation (Q

).

z

Now that the refrigerant is liquid at temperature T*

and pressure p (state 3) it is allowed to flow to the

evaporator via an expansion valve. During the course

of this, the pressure drops back to p

pressure causes the temperature to fall to T

, and the drop in

0

* (state 4).

0

3

Page 4

The low pressure in the evaporator allows the liquid

Δ

⋅

⋅=Δ

refrigerant to boil at a low temperature T

Q

required for this is absorbed from the surroundings

a

as long as they are at a temperature T

*. The heat

0

where T0 > T0*.

0

The refrigerant vapour then returns to a pressure and

temperature of p

and T0* (state 1) and is once again

0

sucked into the compressor.

In the T, Q/T diagram the quantities of energy are

indicated by areas

=Δ

. The area beneath

T/QTQ

the line between 4 and 1 where the refrigerant boils

(p

= const., T0* = const.), for example, represents the

0

heat of evaporation Q

transferred to the refrigerant.

a

If such a machine were to operate without losses, the

quantity of heat Q

emitted from the condenser would

z

be equal to the sum of the work W done by the

compressor and the heat Q

absorbed in the evapora-

z

tor.

4. Example experiment

Determining the efficiency ε

Two thermometers are required to measure the rise

or fall in temperature in the water vessels.

• Take the beakers from the heat pump and fill

them with water.

• Put back the reservoirs as follows:

• Place the beakers carefully on the base plate and

move them with the low edge first under the

evaporator and the condenser.

• Turn the beakers in such a way that the high

edge points to the back wall.

• Lift up the beakers and mount them into the

retaining plates.

• Connect the heat pump to the mains supply.

• Allow the compressor to run for about 10 min-

utes before starting the experiment until it

reaches its operating temperature. Then replace

the water and start the experiment.

• Push the button „Zeit“ (time) at the energy

monitor for 6 seconds and at the same time

switch on the compressor. (toggle switch to the

right)

The energy monitor starts the time measurement

and records the power consumption of the compressor.

• The water should be stirred thoroughly through-

out the experiment.

The efficiency ε is given by the ratio of the change in

energy ΔQ provided to the heat reservoir per unit

time Δt, to the power P supplied to the compressor

to perform its work:

Δ

=ε

.

tPQΔ⋅

ΔQ is given by

TmcQ Δ⋅

where c = specific

heat capacity and m = mass of water.

The efficiency ε decreases as the temperature differ-

ence between the evaporator and the condenser

increases.

To optimise efficiency the water beakers and the

pipes (but not the compressor) can be insulated with

foam strips, for example, in order to prevent radia-

tion losses.

Elwe Didactic GmbH • Steinfelsstr. 6 • 08248 Klingenthal • Germany • www.elwedidactic.com

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • www.3bscientific.com

Technical amendments are possible

© Copyright 2008 3B Scientific GmbH

Loading...

Loading...