Page 1

3B SCIENTIFIC® PHYSICS

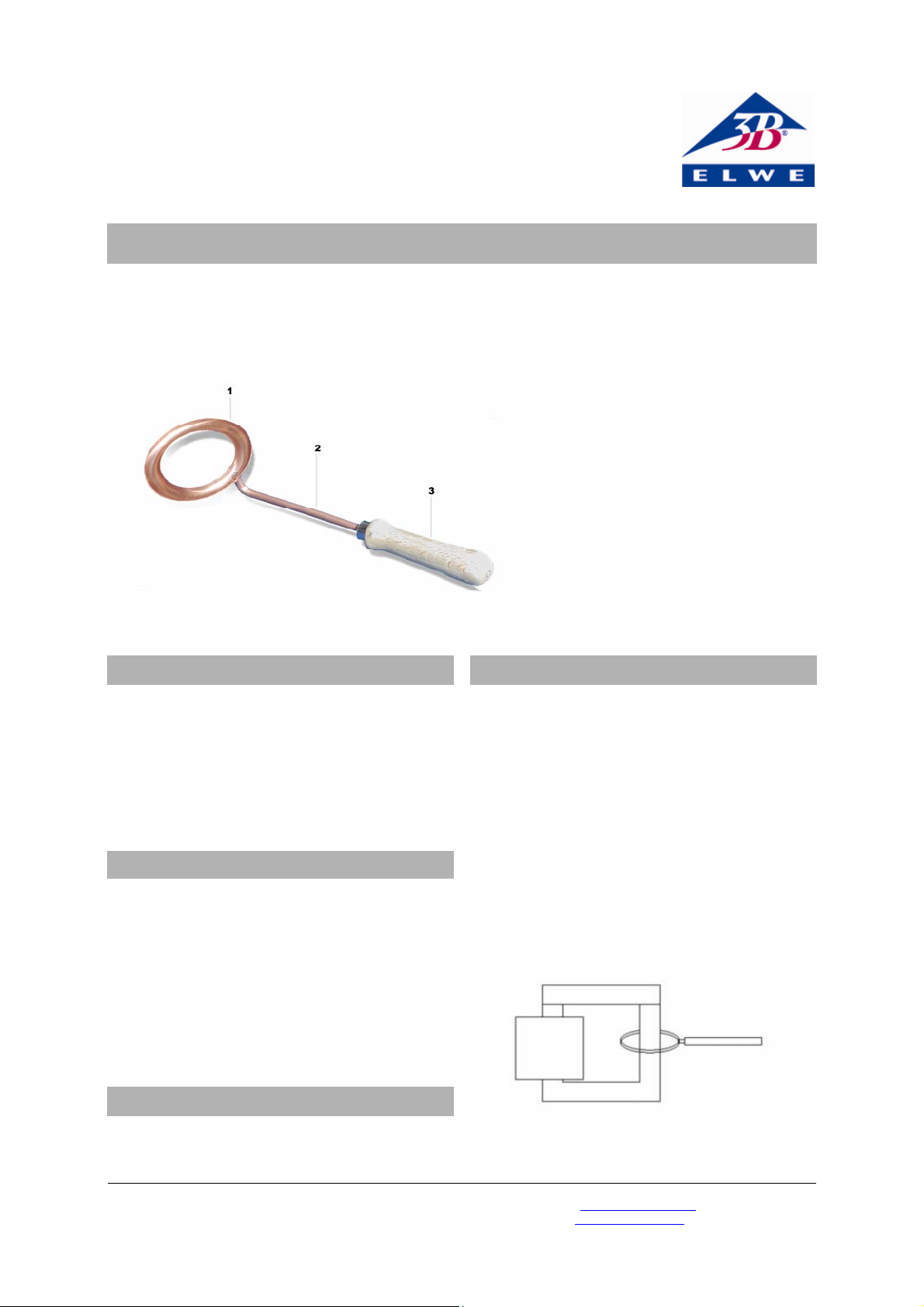

Fusion ring 8497310

Instruction sheet

06/06 SF

1 Fusion ring

2 Shaft

3 Wooden handle

Safety instructions

Caution: Build-up of high temperatures. Danger of

serious burns!

• Hold the apparatus only by the insulated handle.

• Set up the induction furnace on a heat-resistant

surface.

• Switch off the mains coil immediately after the

solder has melted.

2. Description

The fusion ring is used for demonstrating the application of the Joule effect (induction melting).

The fusion ring consists of copper sheet which is

formed into a circular groove and attached to a

wooden handle. In the experiment, the fusion ring

acts as a secondary coil with a single winding in conjunction with mains coil 8497420 and transformer

core with yoke 8497180 to form an induction furnace.

Ordinary tin-lead solder is well suited for use in the

experiment.

3. Technical data

Inner diameter: 57 mm

Length: 270 mm

Material: Copper

4. Operation

Additionally required:

1 Mains coil 8497420

1 Transformer core with yoke 8497180

Tin-lead solder

• Set up the experiment as shown in Fig. 1.

• Put the solder into the fusion ring.

• Switch on the mains coil.

• Switch off the mains coil immediately after the

solder has melted.

• Carefully remove the molten solder from the

fusion ring.

• Disposal of the solder must be in accordance with

local regulations.

Fig. 1: Schematic diagram of an induction oven

Elwe Didactic GmbH • Steinfelsstr. 6 • 08248 Klingenthal • Germany • www.elwedidactic.com

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • www.3bscientific.com

Subject to technical amendments

Loading...

Loading...