Page 1

ENGINE REMOVAL

ENGINE OVERHAUL

ENGINE REMOVAL

NOTE:

It is not necessary to remove the engine in order

to remove the following components:

??

Cylinder head

?? Cylinder

0

Piston

. Clutch

0

Water pump

?? A.C. magneto

LOWER COWLING, CENTER COWLING,

UPPER COWLING AND TOP COVER

1. Remove:

?? Lower cowlings (Left and right)

?? Center cowlings (Left and right)

0

Upper cowling

0 Seat

??

Top cover

Refer to the “COWLING REMOVAL

AND INSTALLATION - REMOVAL”

section in the CHAPTER 3.

FUEL TANK

1. Remove:

?? Fuel tank

Refer to the “CARBURETOR - REMOVAL” section in the CHAPTER 6.

ENGINE OIL

1. Drain:

??

Engine oil

Refer to the “ENGINE OIL REPLACE-

MENT” section in the CHAPTER 3.

COOLANT

1. Drain:

0

Coolant

Refer to the “COOLANT REPLACE-

MENT” section in the CHAPTER 3.

AIR FILTER CASE AND CARBURETOR

1. Remove:

??

Air filter case

??

Carburetor

Refer to the “CARBURETOR - RE-

MOVAL” section in the CHAPTER 6.

4-1

Page 2

ENGINE REMOVAL

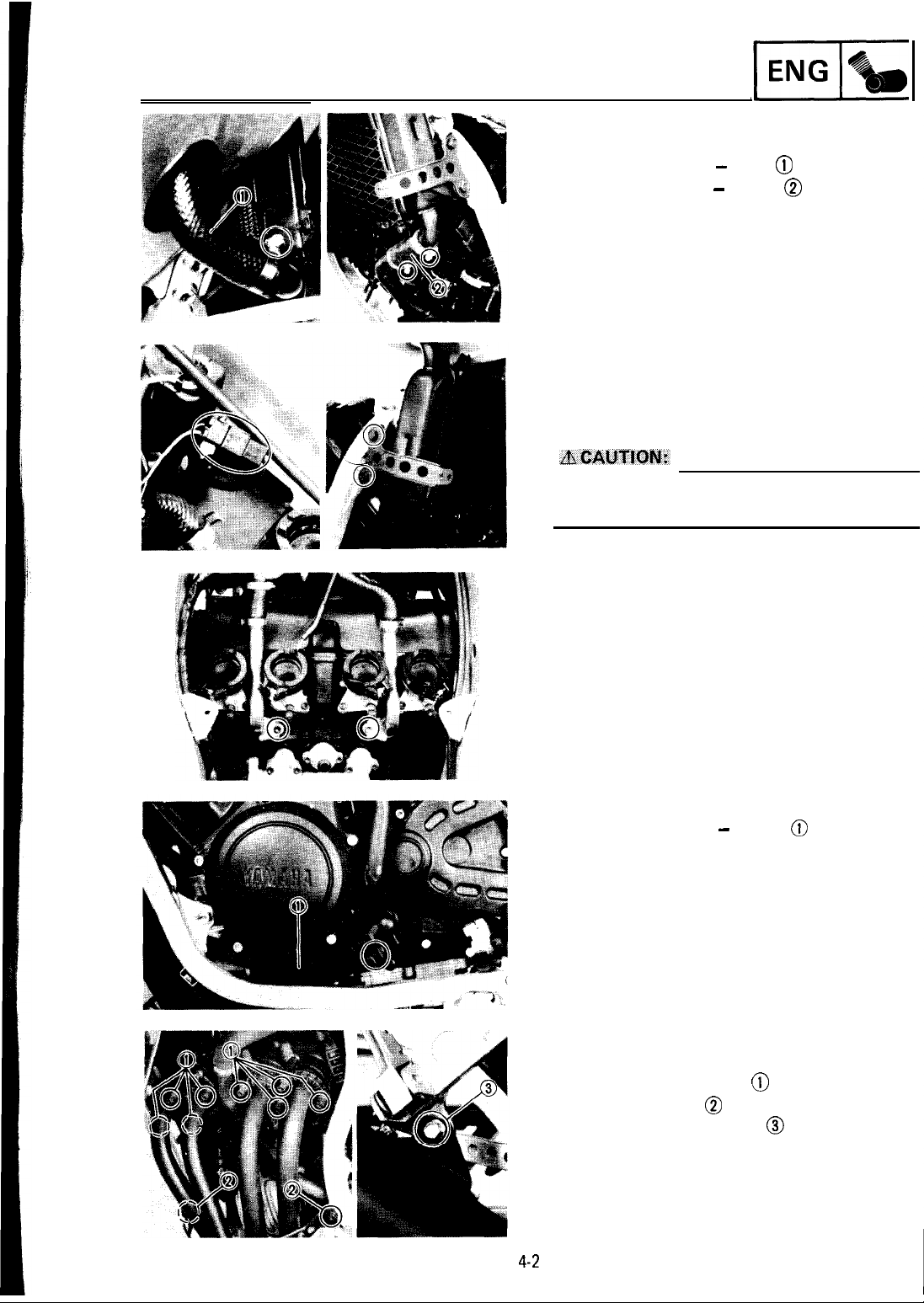

RADIATOR

1. Disconnect:

?? Hose (Radiator

?? Hose (Radiator

2. Disconnect:

?? Fan motor coupler

3. Remove:

??

Radiator assembly

Cover the cylinder head cover and the fender

with rugs to prevent a scratching.

-

Inlet)

-

Outlet)

@

@

4. Disconnect:

?? Pipes (Left and right)

5. Remove:

?? Pipes (Radiator

-

MUFFLER ASSEMBLY

1. Remove:

?? Nuts (Exhaust pipe)

?? Cowling stays

?? Bolt (Muffler bracket)

@

Outlet)

@

@

@

4-2

Page 3

ENGINE DISASSEMBLY

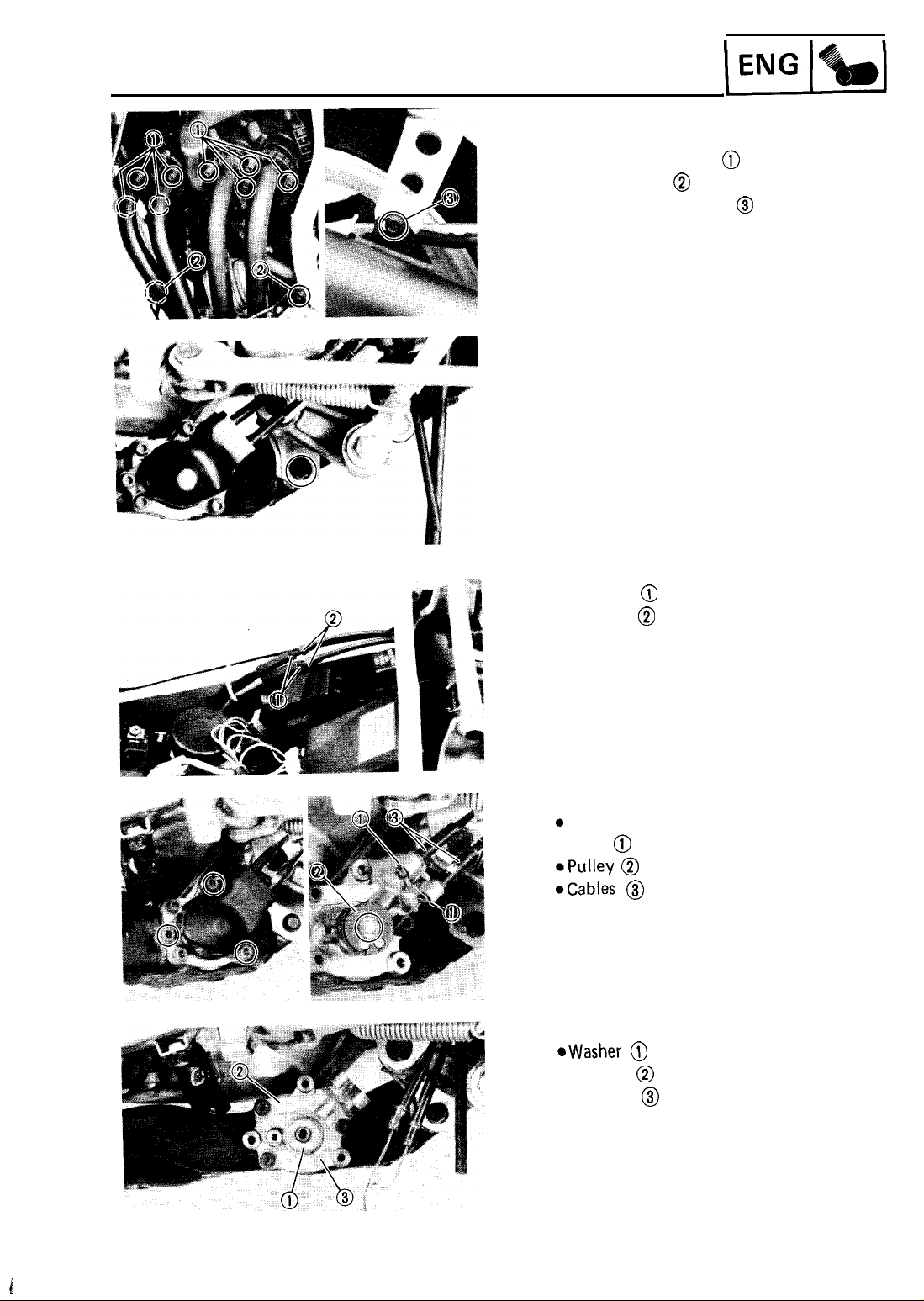

MUFFLER ASSEMBLY (For California only)

1. Remove:

?? Nuts (Exhaust pipe)

??

Cowling stays

?? Bolt (Muffler bracket)

2. Remove:

??

Bolt (Muffler stay)

@

@

@

3. Loosen:

?? Lock nut

?? Adjuster

4. Remove:

0

Cover

??

Clips

aPulley @

*Cables @

5. Remove:

*Washer @

??

Bracket

?? Housing

??

Gasket

(Left side)

??

Shaft arm

@

@

0

@

@

4-3

Page 4

ENGINE REMOVAL

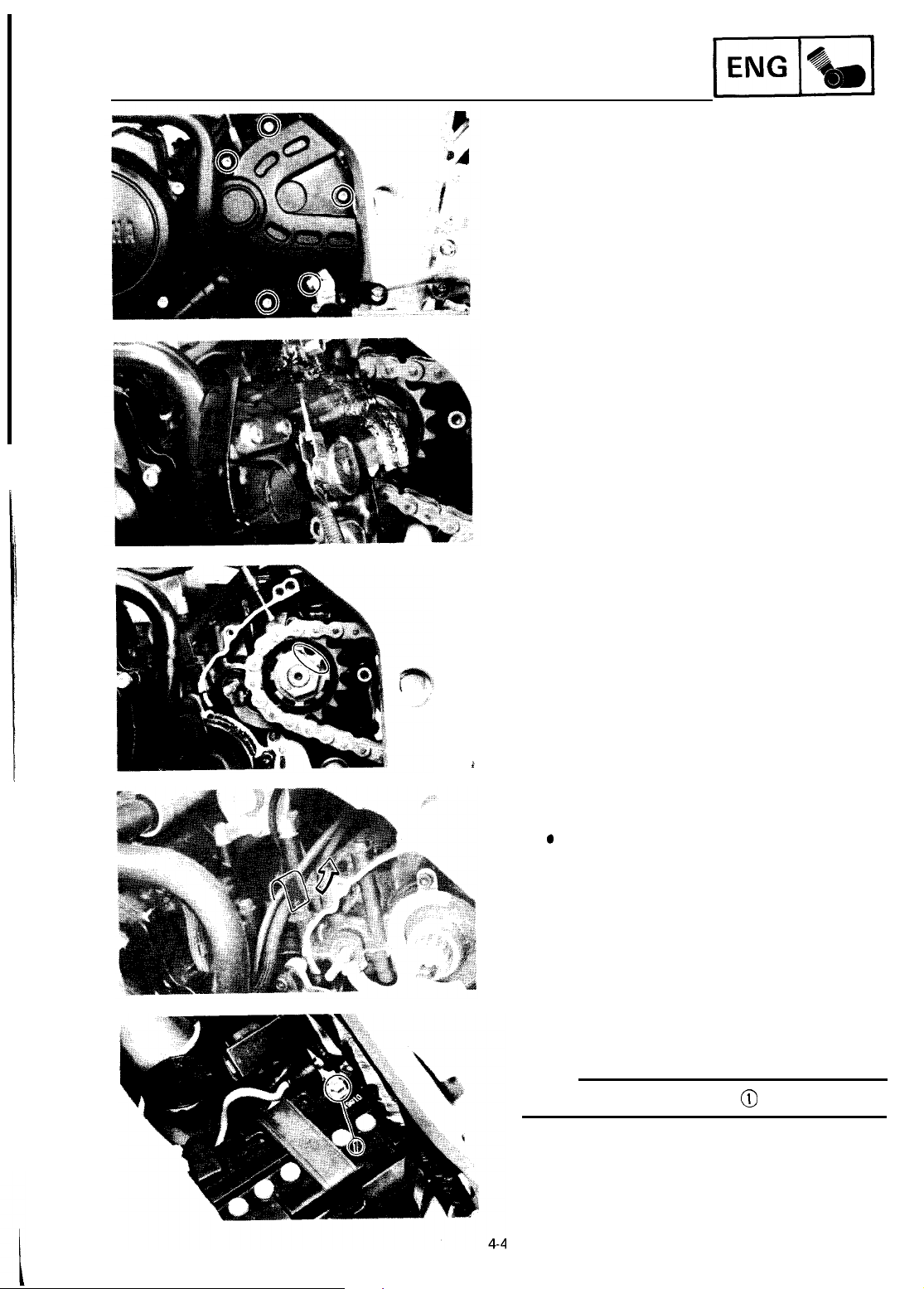

CLUTCH CABLE AND DRIVE CHAIN

1. Remove:

?? Shift arm

?? Crankcase cover (Left)

2. Remove:

?? Clutch cable

3. Straighten:

?? Lock washer tab

4. Remove:

?? Drive sprocket

LEADS

1. Straighten:

0

Clamp

2. Disconnect:

?? Battery leads

NOTE:

Disconnect the negative lead @ first.

Page 5

ENGINE REMOVAL

3. Disconnect:

?? Lead (Starter motor)

4. Remove:

0

Cover

5. Disconnect:

?? Coupler (Oil level Neutral switch)

?? Coupler (A.C. generator)

?? Coupler (Sidestand switch)

6. Remove:

??

Spark plug leads

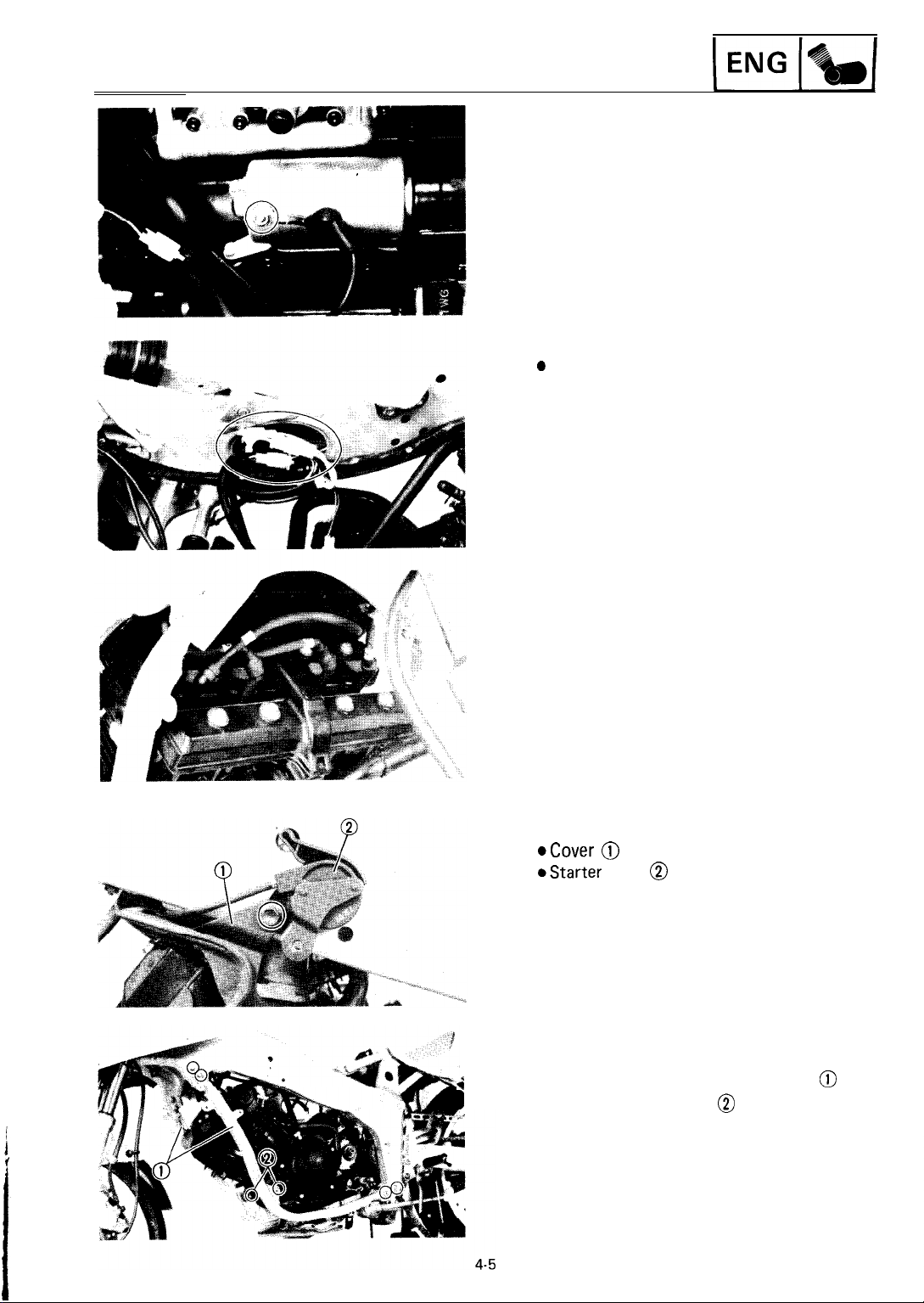

ENGINE REMOVAL

1. Remove:

@Cover @

aStarter

lever

0

2. Place a suitable stand under the engine.

3. Remove:

i

I

?? Down tube frames (Left and right)

?? Bolt (Engine-mount)

@

@

Page 6

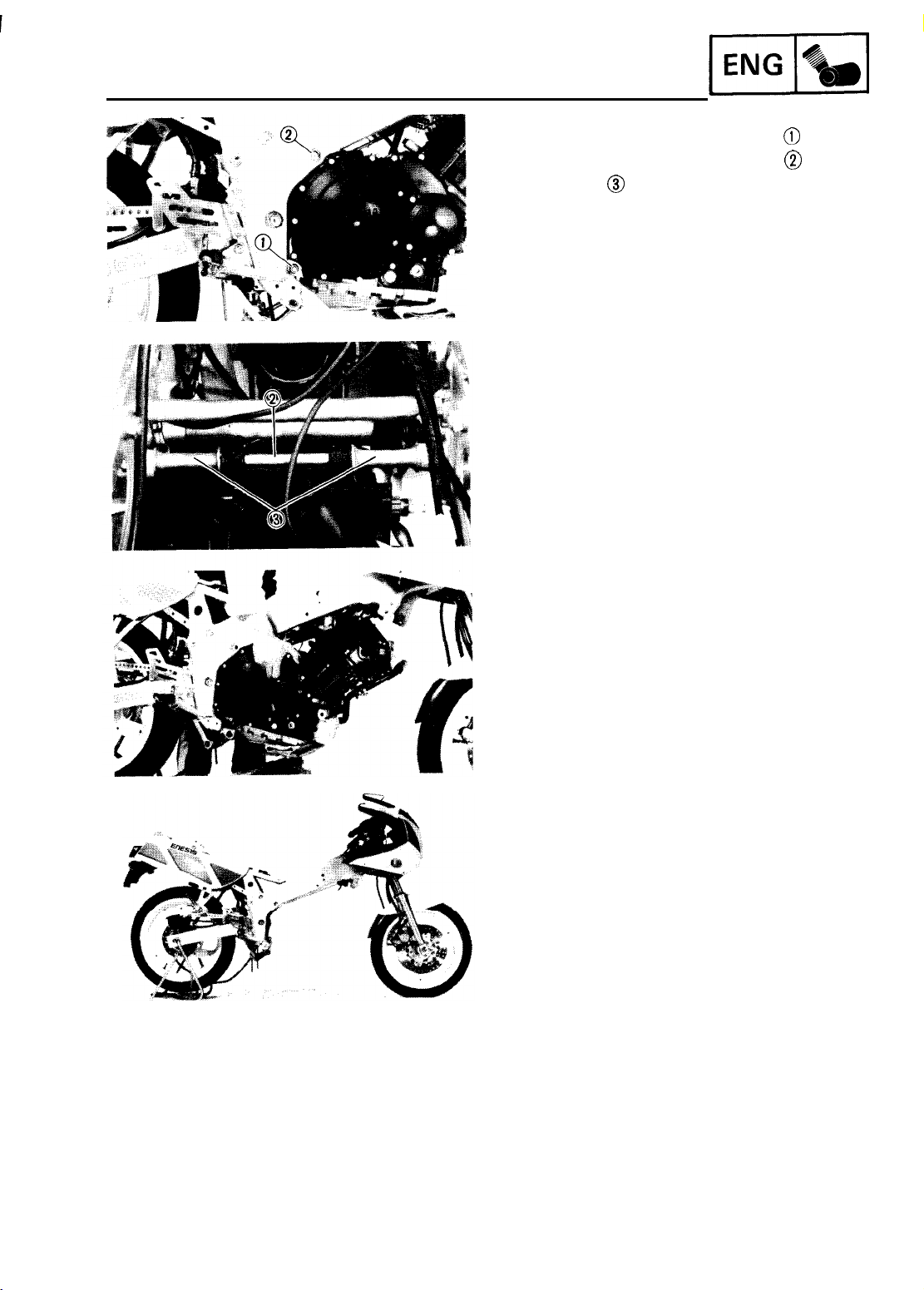

ENGINE REMOVAL

4. Remove:

?? Bolt (Engine-mounting Lower)

?? Bolt (Engine-mounting Upper)

??

Collars

@

@

@

5. Remove:

??

Engine assembly.

From right side.

4-6

Page 7

ENGINE DISASSEMBLY

ENGINE DISASSEMBLY

CYLINDER HEAD COVER, CAMSHAFT AND

CYLINDER HEAD

NOTE:

With the engine mounted, the cylinder head

cover,

maintained by removing the following parts.

?? Lower cowlings (Left and right)

?? Center cowlings (Left and right)

??

??

??

@Air

??

??

?? Down tube frame (Right)

camshaft and cylinder head can be

Seat

Top cover

Radiator

filter case

Carburetor

Muffler assembly

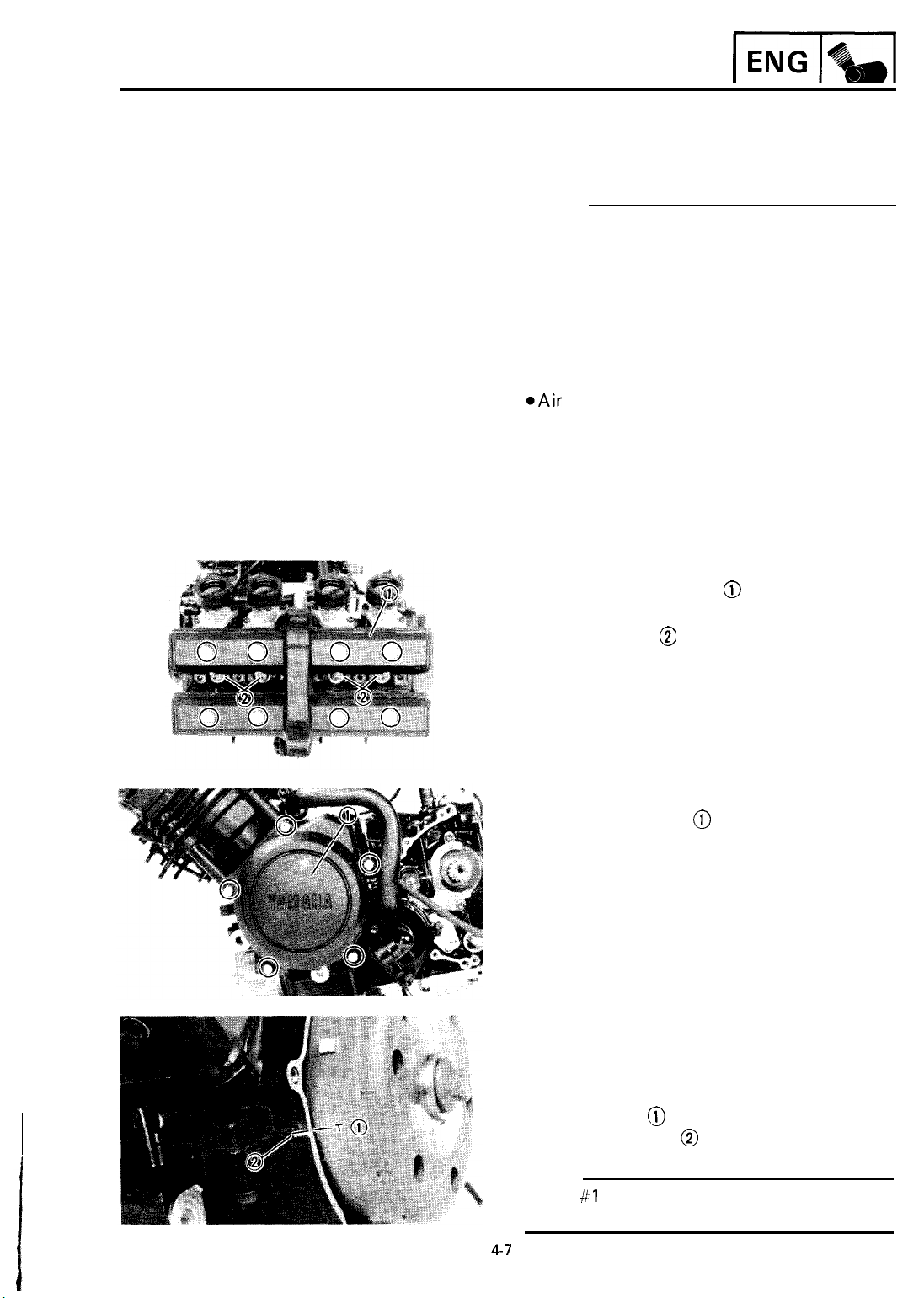

1. Remove:

@Cylinder head cover

??

Gasket (Cylinder head cover)

*Spark plugs

@

2. Remove:

@Generator cover

??

Dowel pins

3. Turn:

??

Crankshaft

Counterclockwise

4. Align:

?? “T” mark

??

Crankcase end

@

@

@

@

NOTE:

When #1 piston is at TDC on compression

stroke.

Page 8

ENGINE DISASSEMBLY

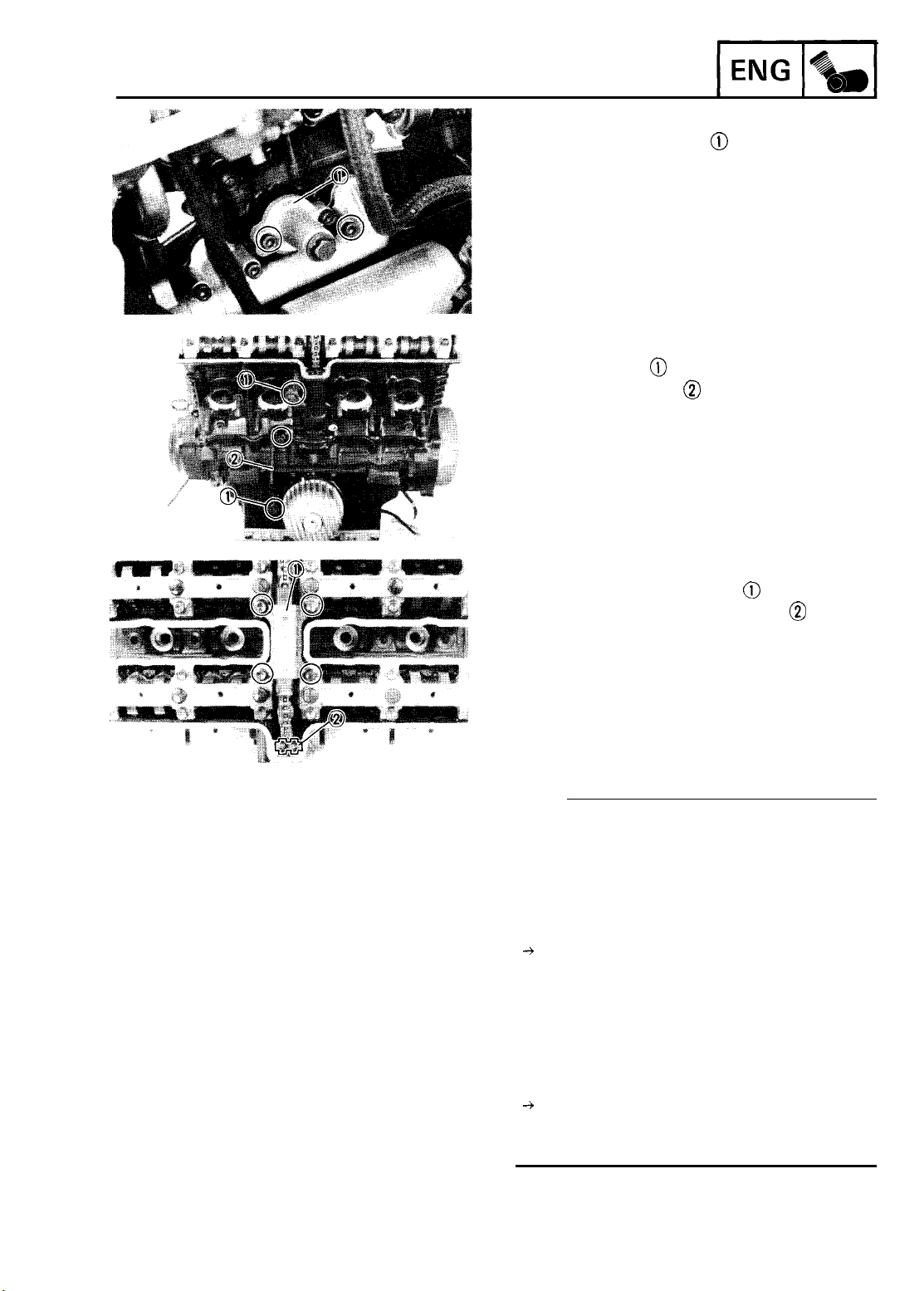

5. Remove:

??

Cam chain tensioner

?? Gasket (Cam chain tensioner)

6. Remove:

?? Union bolts

?? Oil delivery pipe

@

@

@

7. Remove:

??

Cam chain guide (Upper)

??

Cam chain guide (Exhaust side)

@

@

NOTE:

?? Select either of the two procedures explained

in this manual, as follows:

??

Procedure 1.

For engine service except cylinder head dis-

assembly.

-+

Disconnect the cam chain.

The pistons and cylinder can be removed

without removing the camshafts.

??

Procedure 2.

For engine service including cylinder head

disassembly.

--f

Remove the cam caps and camshafts.

The camshafts can be removed without disconnecting the cam chain.

4-8

Page 9

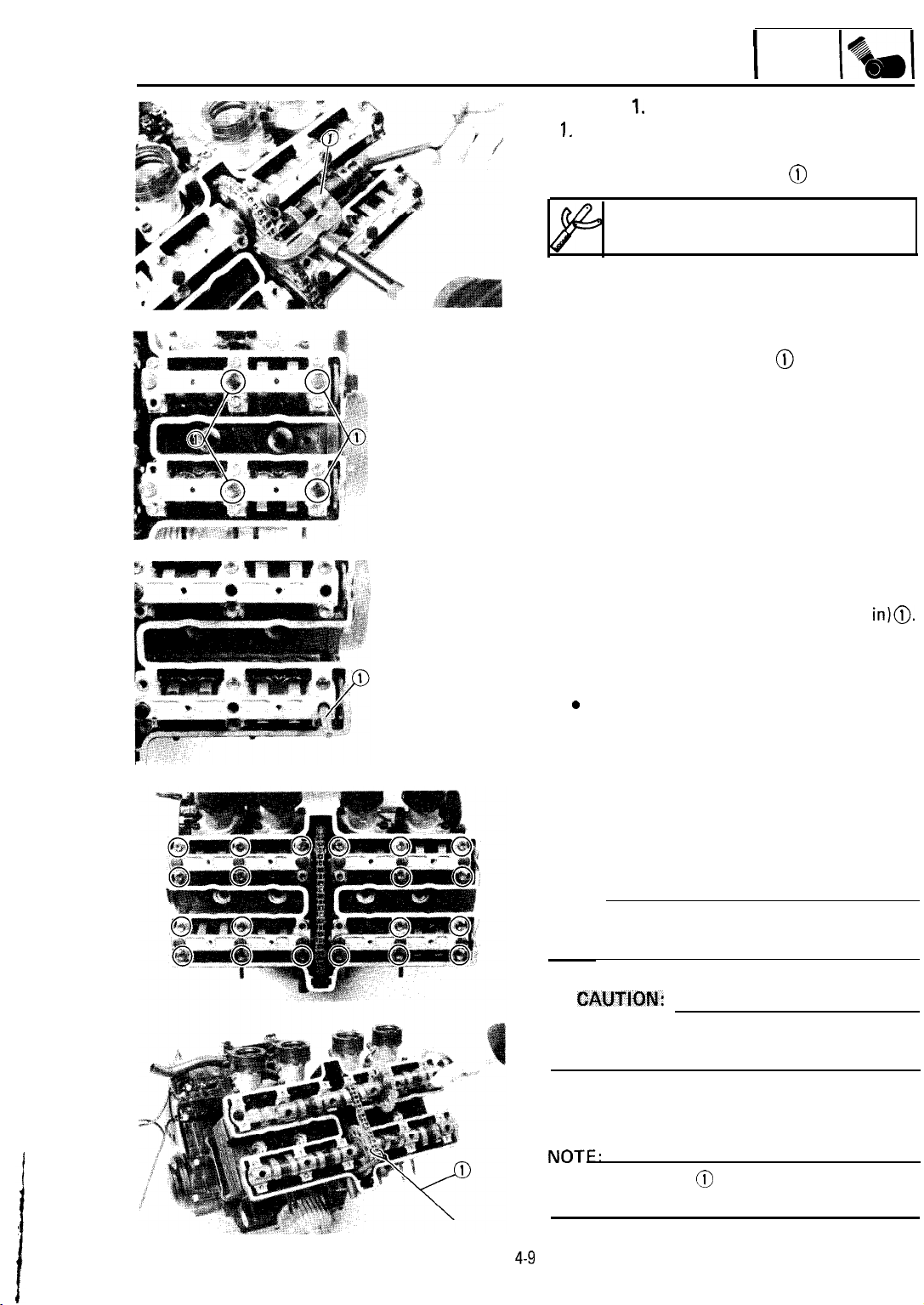

ENGINE DISASSEMBLY

)

ENG

lq-1

Procedure

1.

Disconnect:

??

2. Remove:

?? Rubbers (Camshaft cap)

3. Remove:

?? Nuts (Cylinder head)

4. Remove:

?? Cylinder head

?? Gasket (Cylinder head)

o

Dowel pins

5. Go to “CYLINDER AND PISTON”.

1.

Cam chain

Use the Cam Chain Cutter @ .

Cam Chain Cutter:

P/N YM-01112

@

Use the Hexagon Wrench 6 mm (0.24

in)@.

Procedure 2.

1. Remove:

??

Camshaft caps

??

Dowel pins

NOTE:

Remove the camshaft caps in a crisscross pattern

from outermost to inner caps.

A

CAUTIOM:

Do not rotate the camshaft or valve damage may

occur.

2. Remove:

??

Camshafts

Fasten safety wire @ to the cam chain to pre-

vent it from falling into the crankcase.

4-9

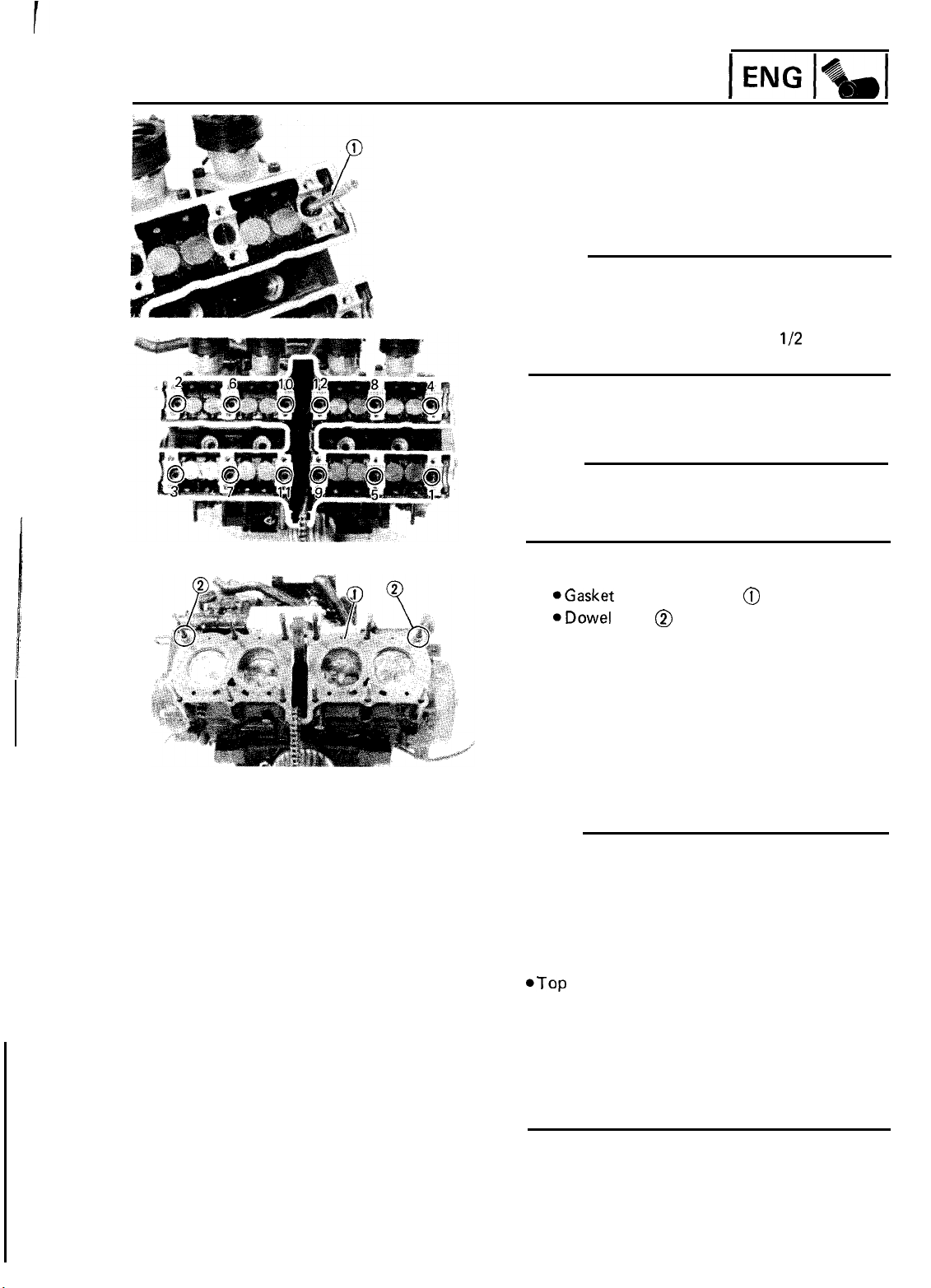

Page 10

ENGINE DISASSEMBLY

3. Remove:

?? Nuts (Cylinder head)

Use the Hexagon Wrench 6 mm (0.24 in)@.

NOTE:

?? Loosen the nuts in their proper loosening

sequence.

?? Follow numerical order shown in photo.

Start by loosening each nut

all are loose.

4. Remove:

??

Cylinder head

NOTE:

Remove the cylinder head as a whole to prevent

the valve lifters and adjusting pads from falling

into the crankcase.

l/2

turn until

5. Remove:

aGasket

@Dowel

(Cylinder head)

pins

@

@

CYLINDER AND PISTON

NOTE:

With the engine mounted, the cylinder and piston

can be maintained by removing the following

parts.

?? Lower cowlings (Left and right)

??

Center cowlings (Left and right)

??

Seat

*Top

cover

??

Radiator

??

Air filter case

??

Carburetor

??

Muffler assembly

?? Down tube frame (Right)

??

Cylinder head

4-10

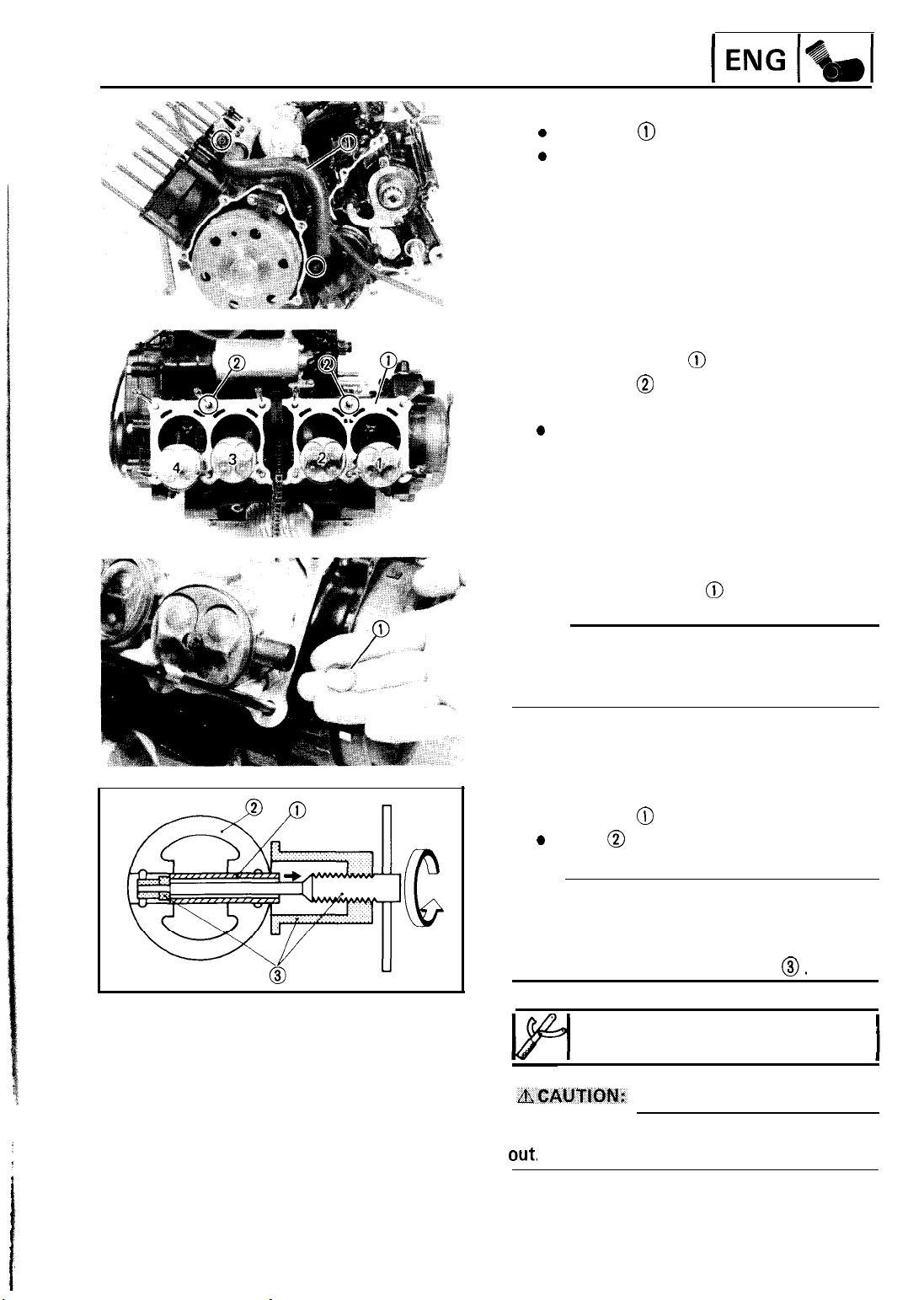

Page 11

ENGINE DISASSEMBLY

1. Remove:

0

Water pipe

0

O-rings

?? Cylinder

2. Remove:

?? Gasket (Cylinder)

?? Dowel pins

3. Mark:

0 Pistons

With the piston number designations as

shown.

@

@

@

4. Remove:

??

Circlips (Piston pin)

@

NOTE:

Before removing the piston pin circlip, cover the

crankcase with a clean rag to prevent the circlip

from falling into the crankcase cavity.

5. Remove:

??

Piston pins

0

Pistons

0

@

NOTE:

Before removing the piston pin, deburr the clip

grooved and pin hole area. If the piston pin

groove is deburred and piston pin is still difficult

to remove, use the Piston Pin Puller

0.

Piston Pin Puller:

P/N YU-01304

Do not use a hammer to drive the piston pin

out.

4-11

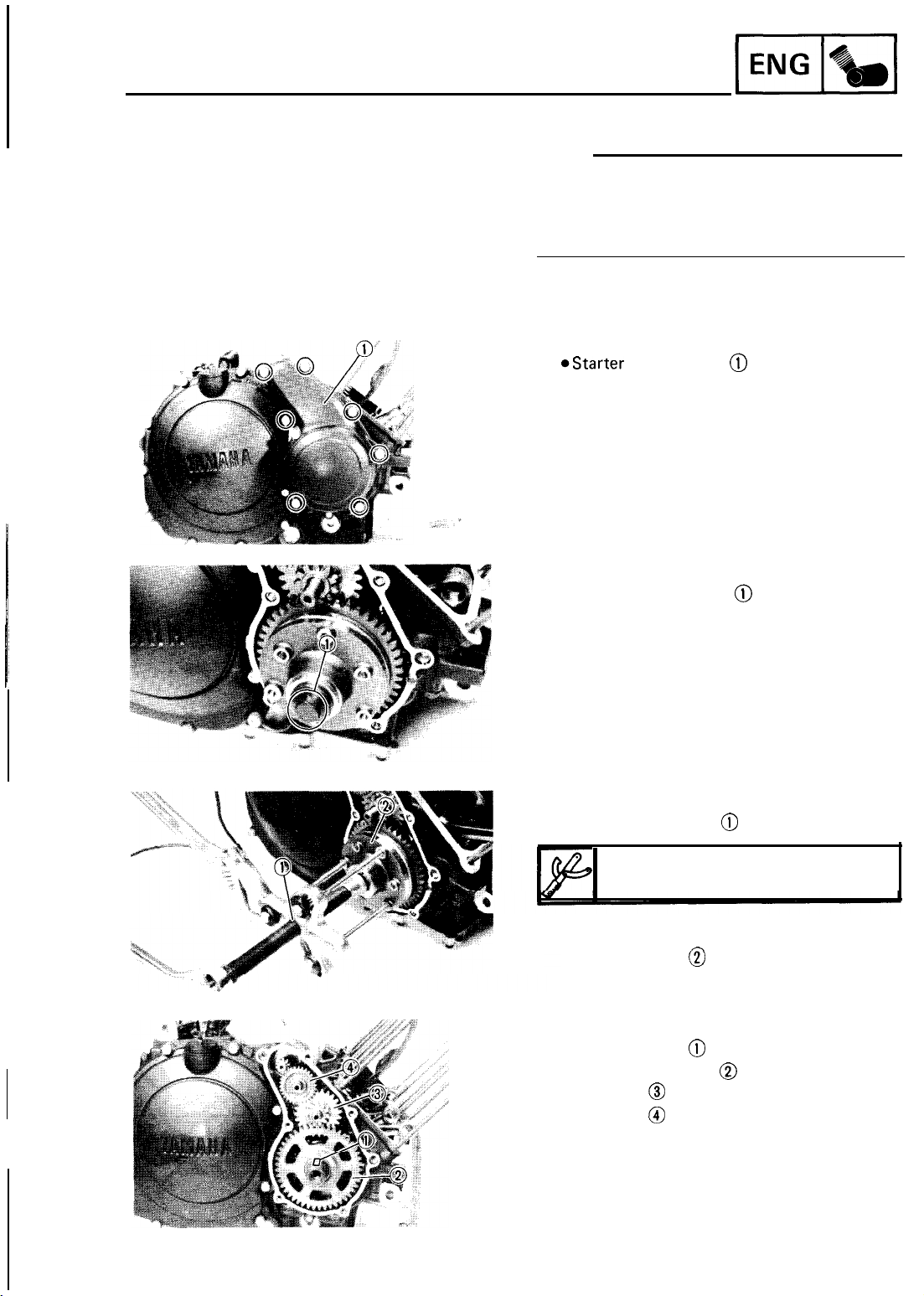

Page 12

ENGINE DISASSEMBLY

STARTER CLUTCH

NOTE:

With the engine mounted, the starter clutch can

be maintained by removing the following parts.

?? Lower cowling (Right)

?? Starter clutch cover

1. Remove:

*Starter

?? Gasket (Starter clutch cover)

??

clutch cover

Dowel pens.

@

2. Remove:

?? Bolt (Starter clutch)

??

Washer

3. Attach:

?? Heavy Duty Puller

Heavy Duty Puller:

Y U-33270

4. Remove:

?? Starter clutch

5. Remove:

?? woodruff key

??

Starter clutch gear

?? Idle gear

?? Idle gear

@I

@

@

@

@

@

@

4-12

Page 13

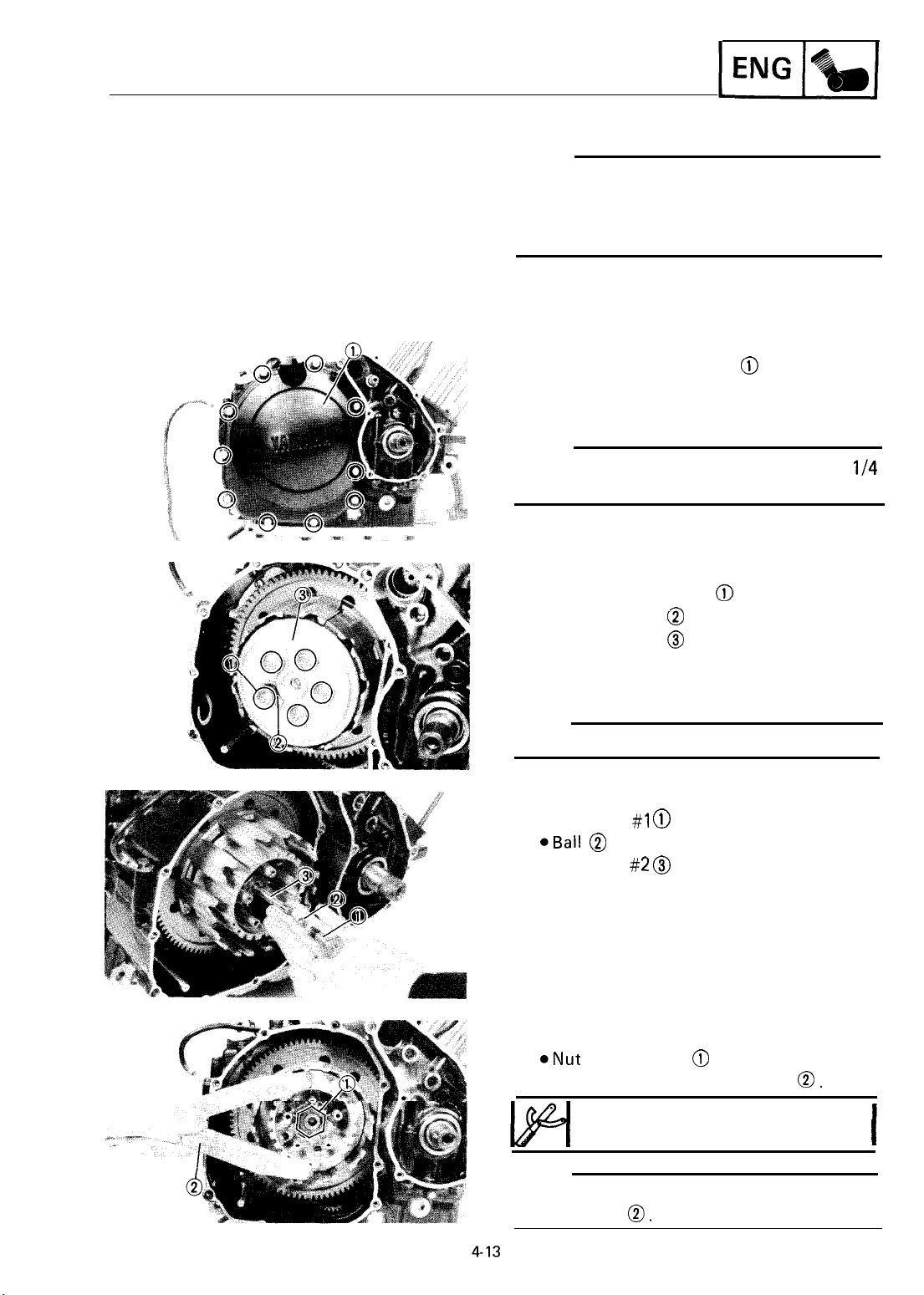

ENGINE DISASSEMBLY

CLUTCH

NOTE:

With the engine mounted, the starter clutch can

be maintained by removing the following parts.

?? Lower cowling (Right)

??

Crankcase cover (Right)

1. Remove:

?? Crankcase cover (Right)

??

Gasket (Crankcase cover)

??

Dowel pins

NOTE:

Working in a crisscross pattern, loosen bolts

turn each. Remove them after all are loosened.

@

l/4

2.

Remove:

?? Bolts (Clutch spring)

*Clutch springs

??

Pressure plate

??

Friction plates

??

Clutch plates

@

@

@

NOTE:

Loosen the bolts in a crisscross pattern.

3. Remove:

?? Push rod

#l @

aBall @

?? Push rod

#2 @

4. Straighten the lock washer tabs.

5. Loosen:

@Nut

(Clutch boss)

Use the Universal Clutch Holder

@

0.

Universal Clutch Holder:

P/N Y M-91 042

NOTE:

Hold the clutch boss loosen the nut by Universal

Clutch Holder

0.

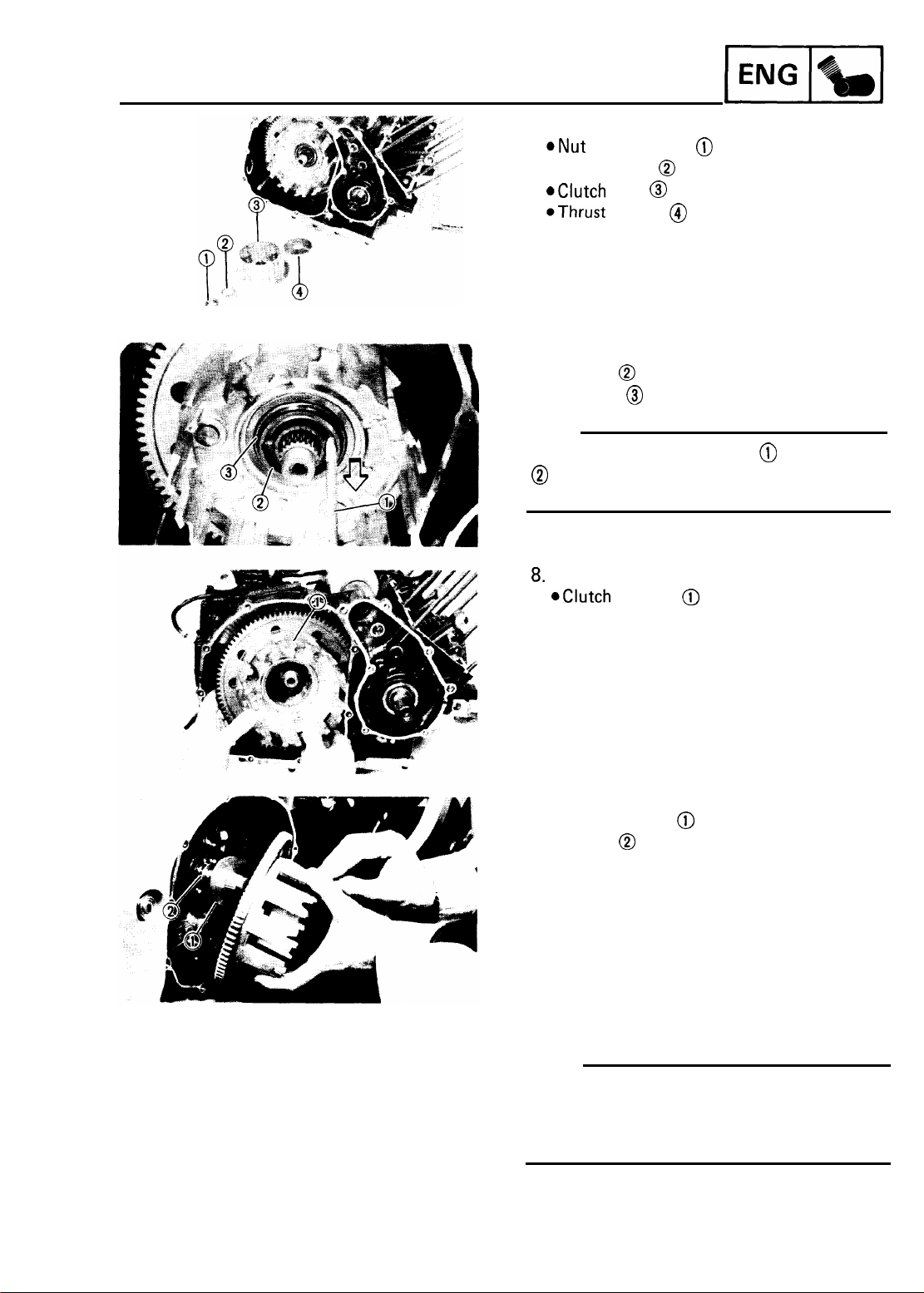

Page 14

ENGINE DISASSEMBLY

6. Remove:

.Nut

(Clutch boss)

??

Lock washer

@Clutch

thrust

boss

washer

7. Remove:

??

Spacer

@

??

Bearing

@

NOTE:

Install the 5 mm (0.2 in) screw @ on the spacer

@

then remove the spacer with pulling out

screw.

@

@

@

@

8.

Remove:

aClutch

housing

9. Remove:

??

Thrust washer

*Collar

@

A.C. MAGNETO

@

@

NOTE:

With the engine mounted, the A.C. Magneto can

be maintained by removing the following parts.

?? Lower cowling ( Left)

??

Generator cover

4-14

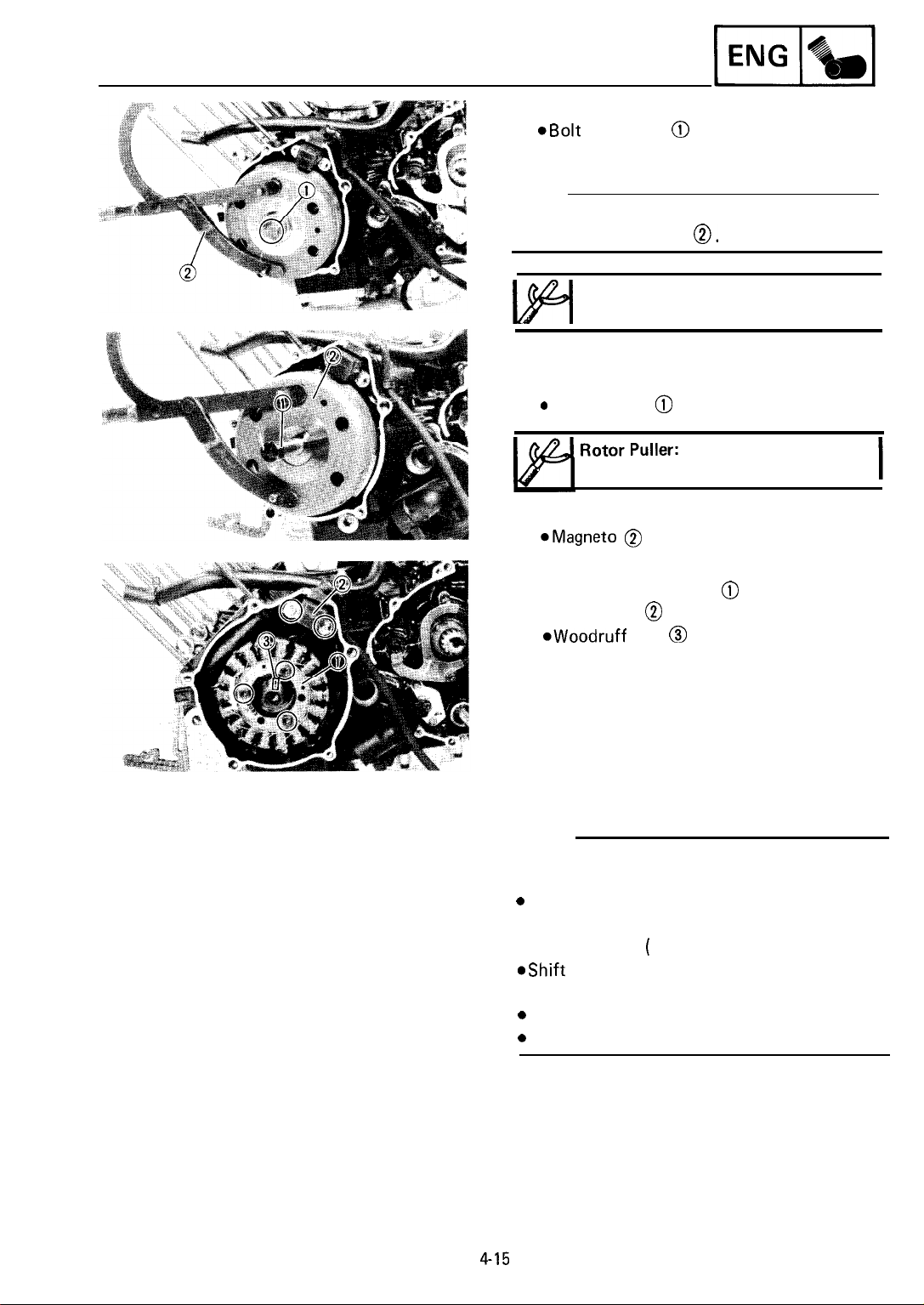

Page 15

ENGINE DISASSEMBLY

1. Remove:

@Bolt

(Magneto)

??

Washer

NOTE:

Hold the magneto to loosen the nut by the

Universal Rotor Holder

Universal Rotor Holder:

LFI

2. Attach:

0

3.

*Magneto @

P/N YU-01235

Rotor puller

P/N YM-01080

Remove:

@

0.

@

I

4. Remove:

??

Starter coil assembly

??

Pickup coil

@Woodruff

WATER PUMP

NOTE:

With the engine mounted, the water pump can

be maintained by removing the following parts.

0 Seat

??

Top cover

?? Lower cowling

aShift

arm

??

Crankcase cover (Right)

0 Water pipe

0

Water pump cover

@

key

(

Right)

@

@

4-15

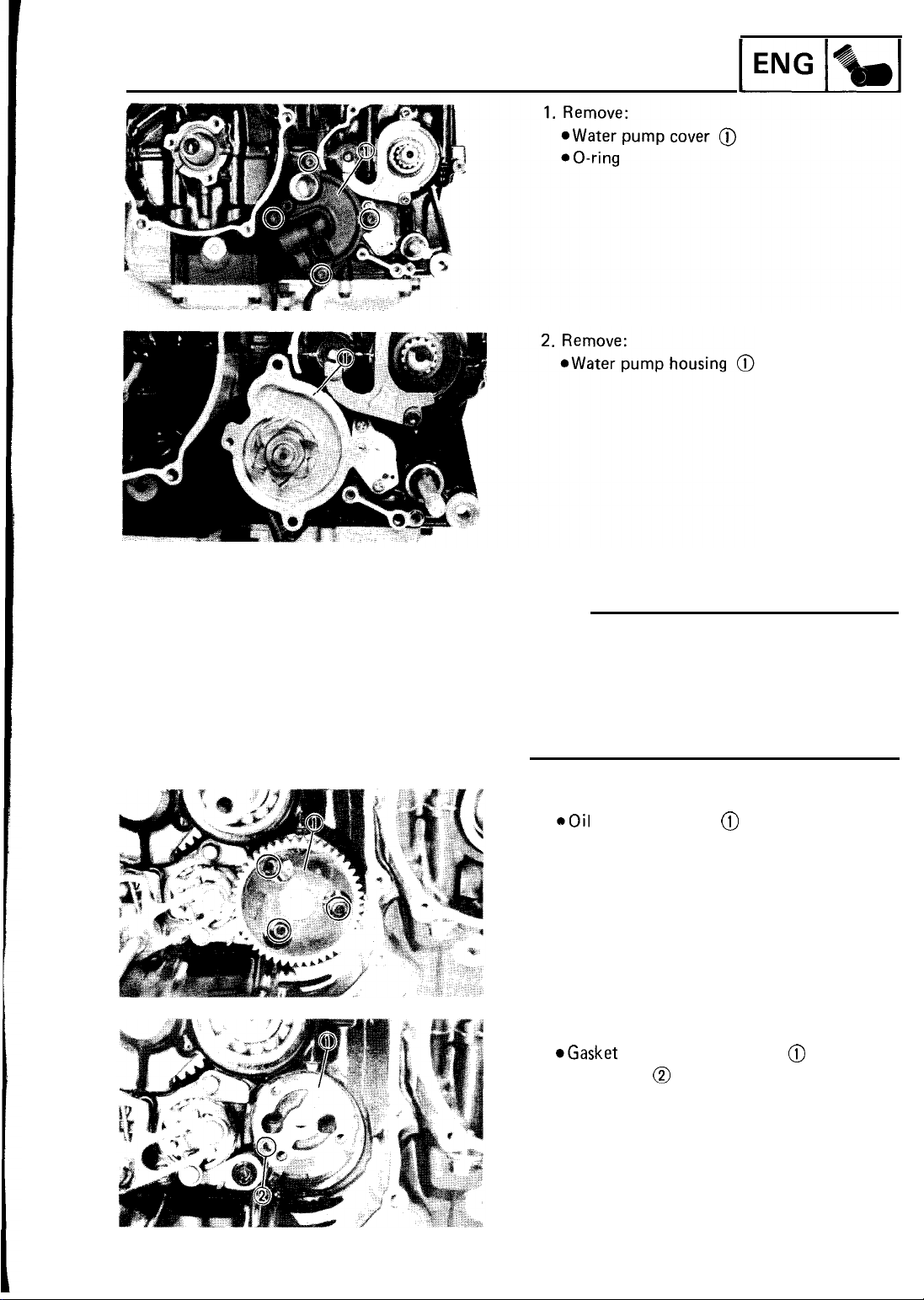

Page 16

ENGINE DISASSEMBLY

OIL PUMP AND SHIFT SHAFT

NOTE:

With the engine mounted, the oil pump and

shift shaft can be maintained by removing the

following parts.

?? Lower cowling (Right)

??

Crankcase cover (Right)

??

Clutch housing

1. Remove:

*Oil

pump assembly

2. Remove:

*Gasket

??

Dowel pin

(Oil pump assembly)

@

@

@

4-16

Page 17

ENGINE DISASSEMBLY

(ENG lb1

3. Remove:

??

Shift shaft assembly

@

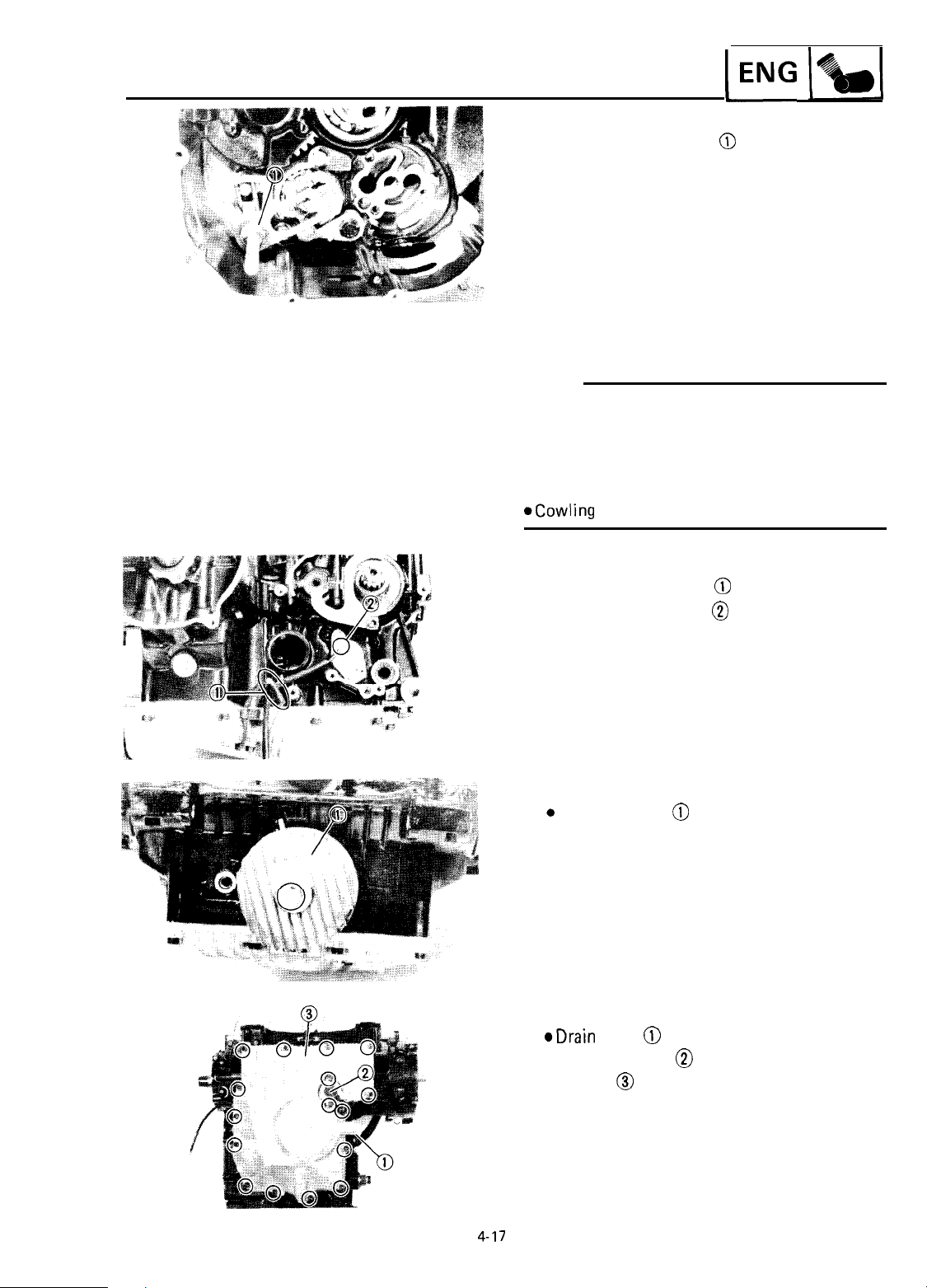

OIL PAN AND OIL STRAINER

NOTE:

With the engine mounted, the oil pan and oil

strainer can be maintained by removing the

following parts.

?? Lower cowlings (Left and right)

?? Muffler assembly

scowling

stay

1. Disconnect:

?? 0il level switch lead

?? Neutral switch lead

2. Remove:

0

Oil filter cover

??

Oil filter

3. Remove:

@Drain

plug

@

?? 0il level switch

??

Oil pan

@

??

Gasket (Oil pan)

??

Dowel pins

@

@

@

@

4-17

Page 18

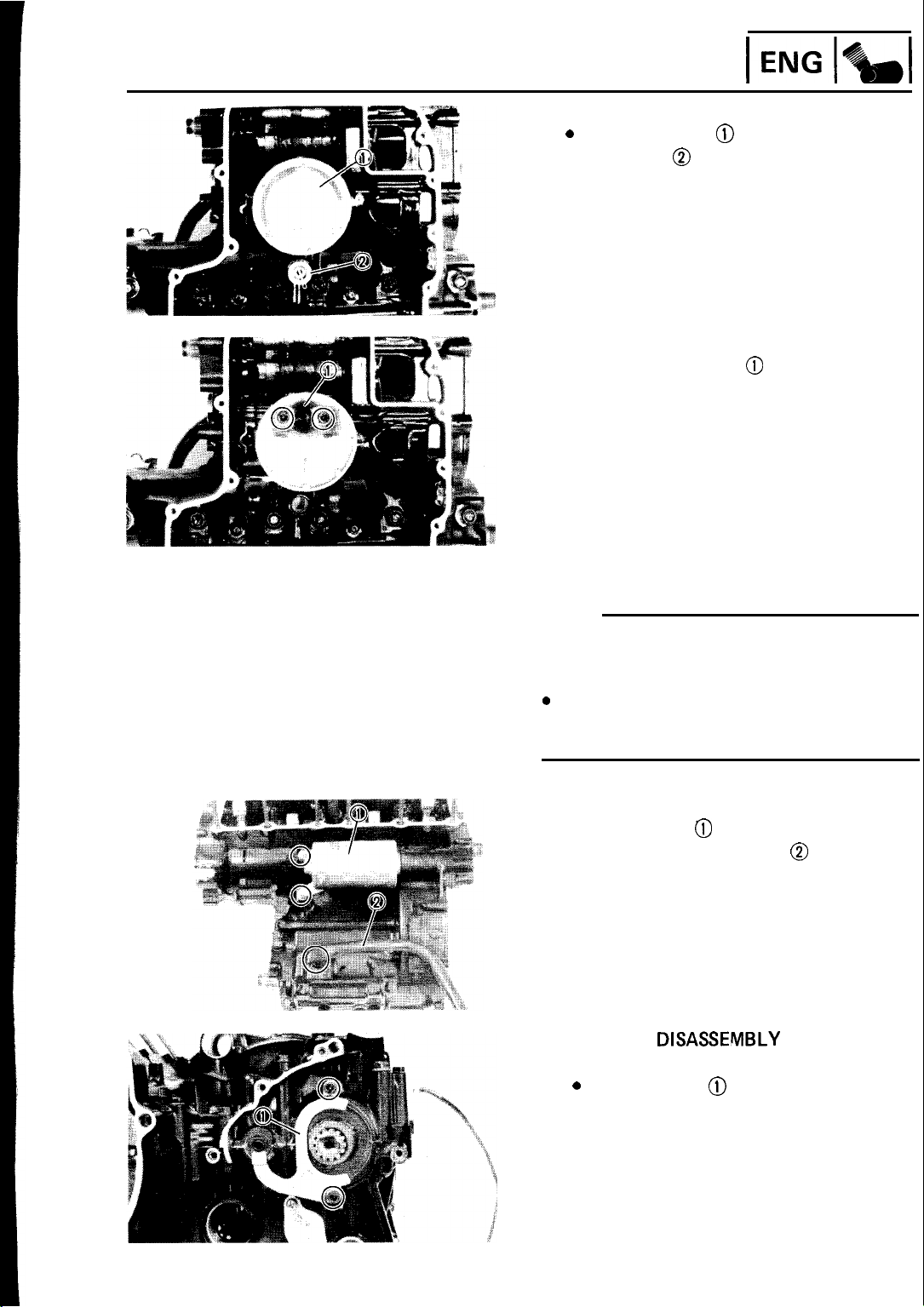

ENGINE DISASSEMBLY

4. Remove:

0

Oil strainer cover

?? Relief valve

5. Remove:

??

Oil strainer assembly

0

@

@

STARTER MOTOR

NOTE:

With the engine mounted, the starter motor,

can be maintained by removing the following

parts.

0

Seat

??

Top cover

??

Fuel tank

1. Remove:

??

Starter motor

??

crankcase ventilation hose

CRANKCASE

0

@

DlSASSErVlBLY

1. Remove:

0

Oil seal stopper

@

4-18

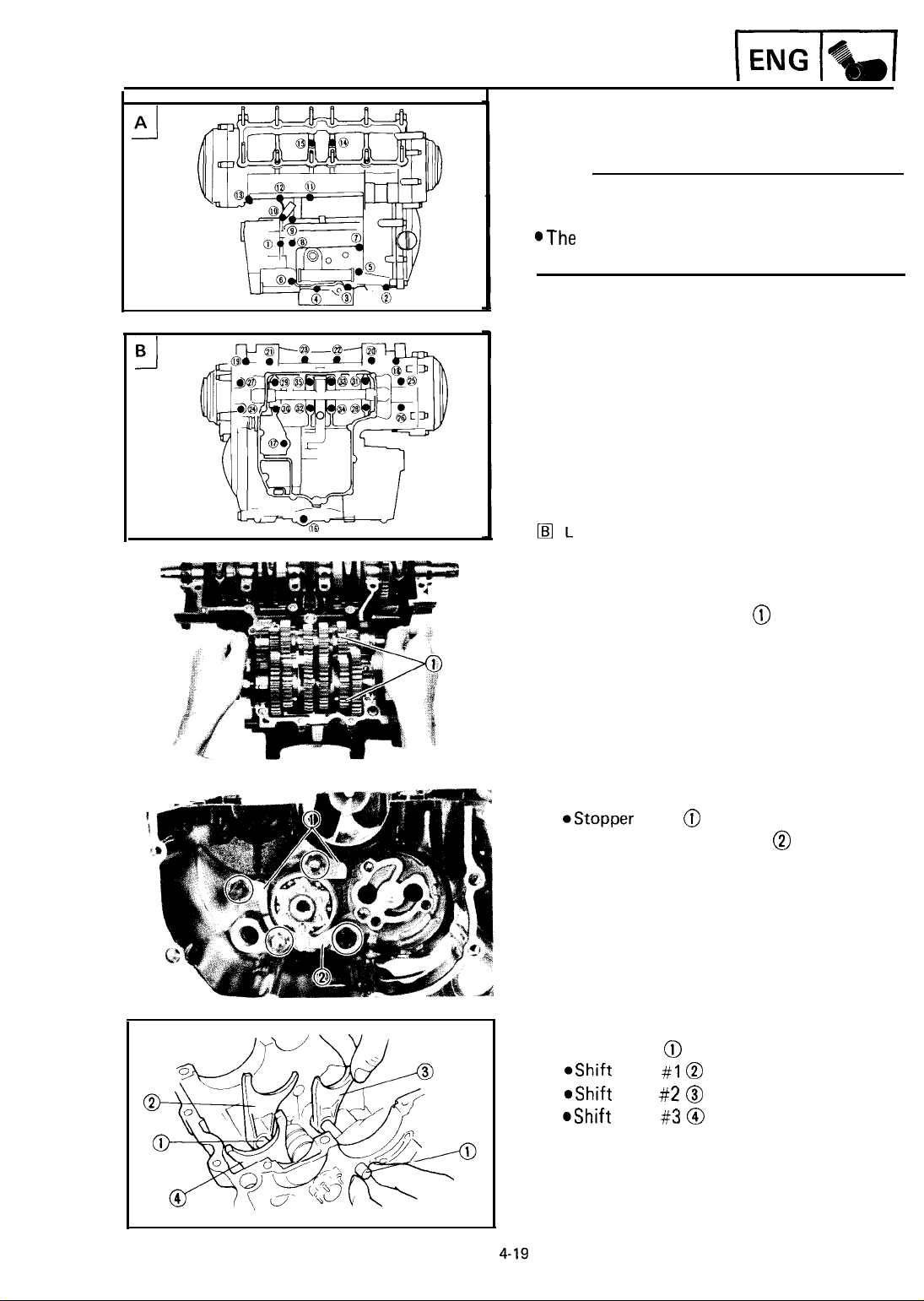

Page 19

ENGINE DISASSEMBLY

A

J

3. Remove:

??

Bolts (Crankcase)

NOTE:

G

?? Remove the bolts starting with the highest

numbered one.

*The

embossed numbers in the crankcase

designate the crankcase tightening sequence.

4. Place the engine upside down.

5. Remove:

?? Crankcase (Lower)

Use a soft hammer.

??

Upper case

ower case

[BIL

TRANSMISSION, SHIFTER AND SHIFT CAM

1. Remove:

??

Transmission assembly

??

Dowel pins

@

2. Remove:

@Stopper

lever

0

?? Stopper plate (Shift cam)

3. Remove:

?? Guide bars

@Shift

fork #l

*Shift

fork #2

aShift

fork #3

@

@

@

@

@

Page 20

ENGINE DISASSEMBLY

4. Remove:

??

Shift cam

CRANKSHAFT

1. Remove:

??

Crankshaft assembly

2. Remove:

??

Main journal bearing

NOTE:

Identify each main journal bearing position

very carefully so that it can be reinstalled in

its original place.

4. Remove:

??

Neutral switch

4-20

Page 21

ENGINE DISASSEMBLY

5. Remove:

??

Breather hose

@Oil

baffle plate

VALVE PAD AND VALVE

NOTE:

With the engine mounted, the valve pad and

valve can be maintained by removing the

following parts.

?? Lower cowlings (Left and right)

@Center cowlings (Left and right)

??

Fuel tank

??

Carburetor

??

Radiator

@Generator cover

?? Cylinder head cover

eCam

chain tensioner

@Cylinder head

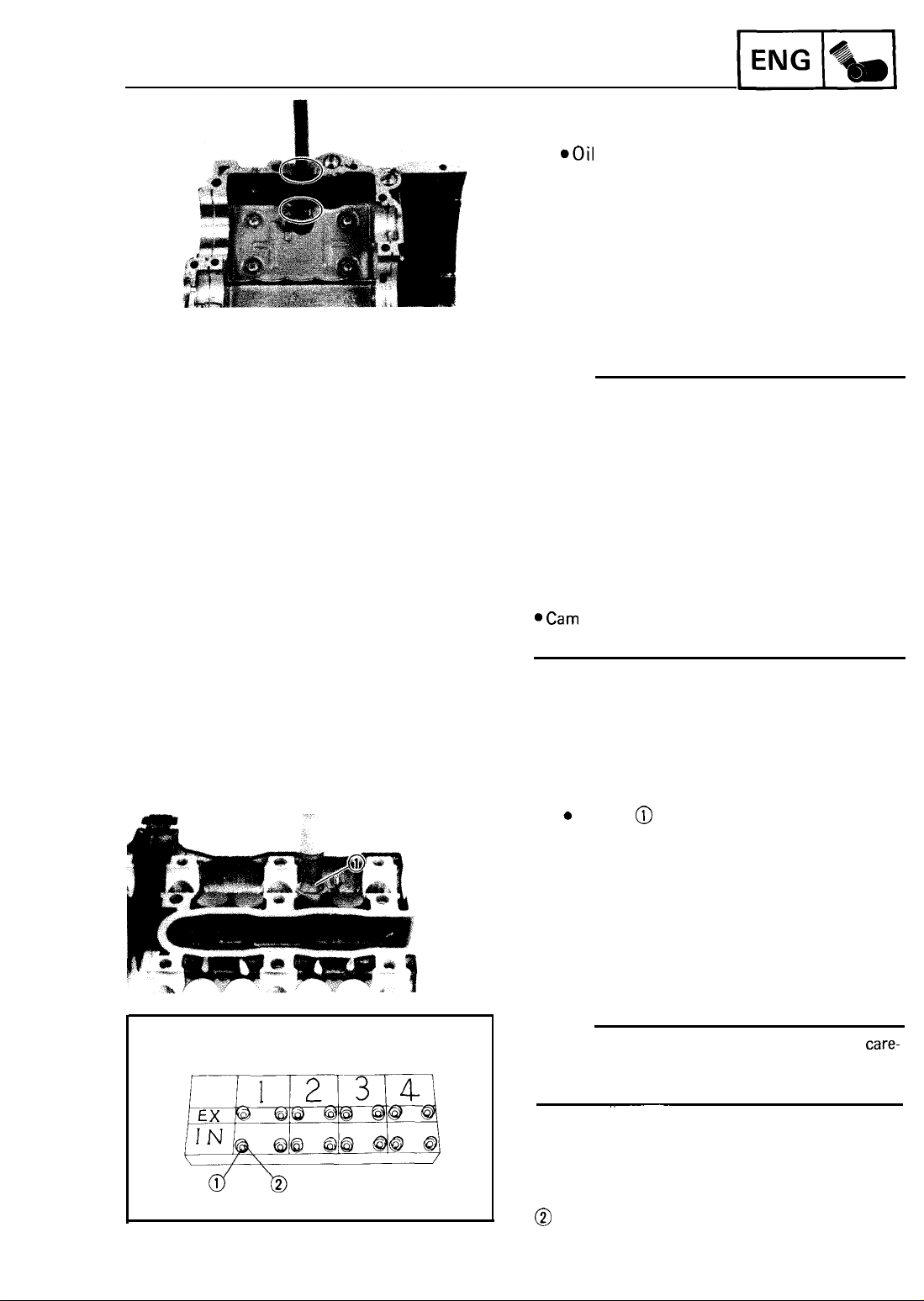

1. Remove:

0

Lifters

??

Valve pads

0

NOTE:

Identify each lifter and pad position very

fuly so that it can be reinstalled in its original

4-21

place.

@ Lifters

@

Valve pads

--

care-

Page 22

ENGINE DISASSEMBLY

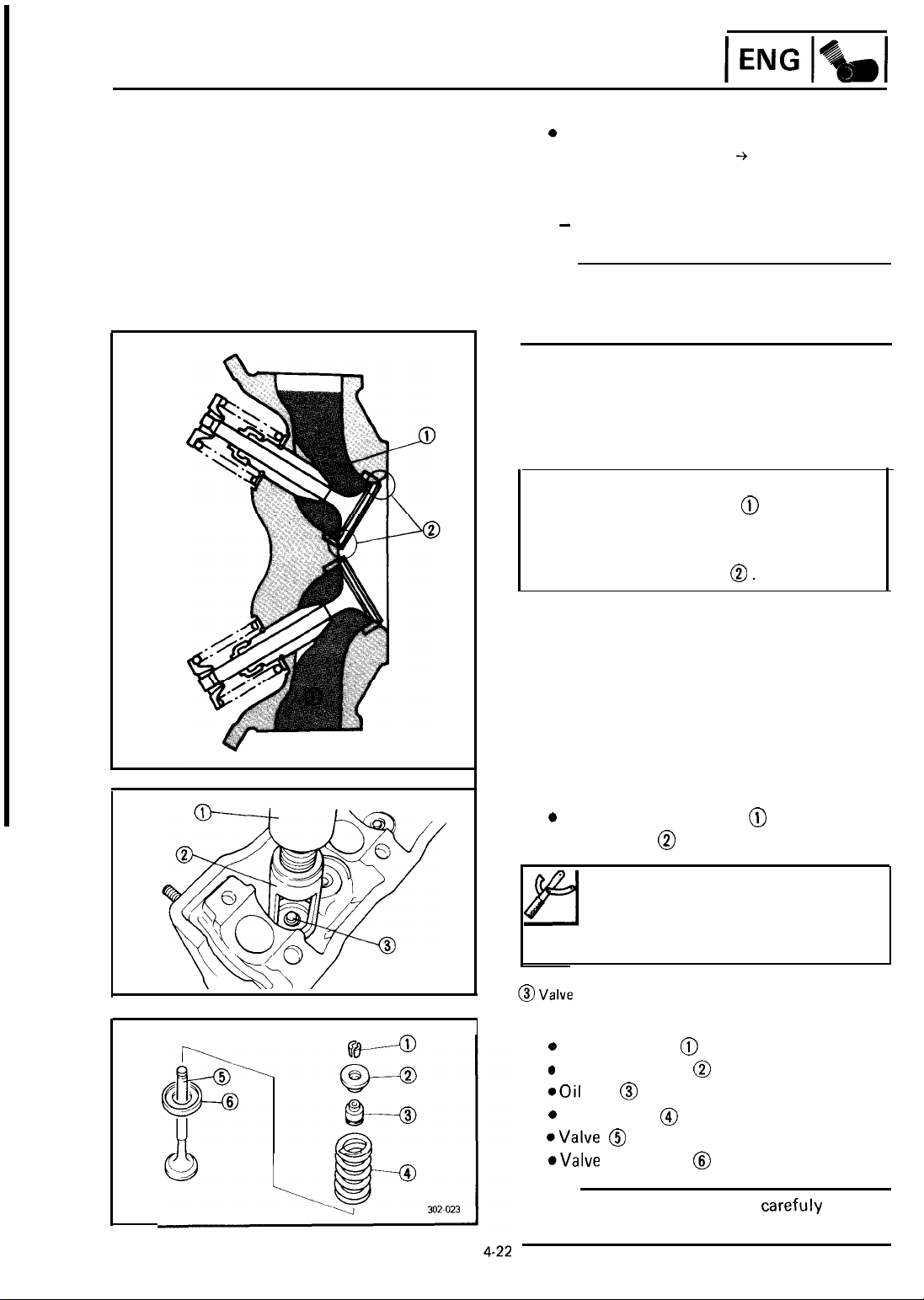

2. Check:

0

Valve sealing

Leakage at valve seat + inspect the valve

face, valve seat and valve seat width.

Refer to the “INSPECTION AND REPAIR

-

VALVE SEAT” section.

NOTE:

Before removing the internal parts (valve, valve

spring, spring seat, etc.) of the cylinder head, the

valve sealing should be checked.

Valve seal checking steps:

?? Supply a clean solvent

and exhaust ports.

?? Check the valve sealing. There should be no

leakage at the valve seats

@

into the intake

0.

3. Attach:

0

Valve spring compressor

?? Attachment

@

@

Valve Spring Compressor:

P/N YM-04019

Attachment:

P/N Y M-04108

@Valve

retainers

4. Remove:

0

Valve retainers

0

Valve spring seat

*Oil

seal

@I

0

Valve spring

@

@

@

*Valve @

*Valve

spring seat

@

NOTE:

Identify each part position very

carefuly

it can be reinstalled in its original place.

so that

Page 23

ENGINE DISASSEMBLY

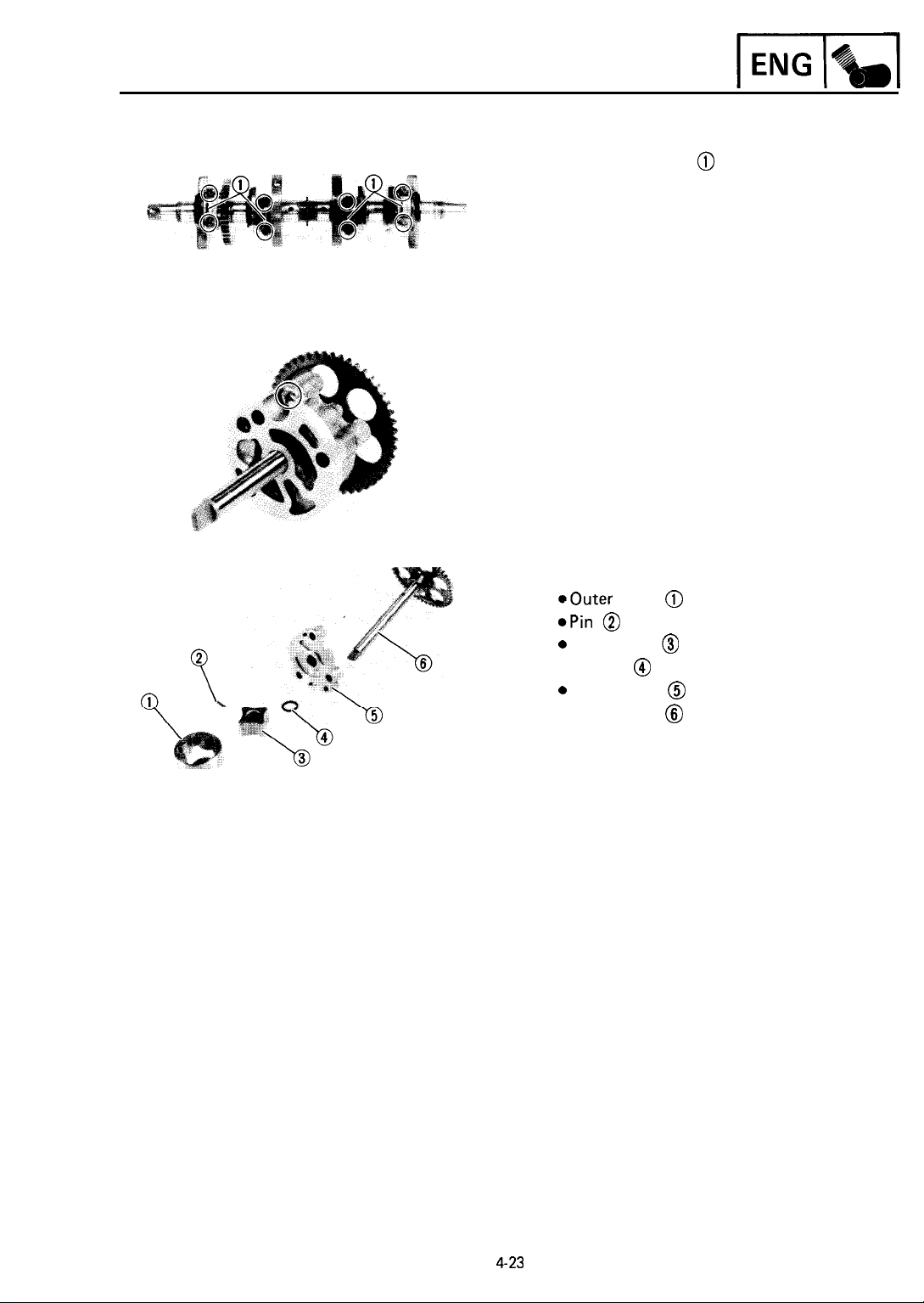

CONNECTING ROD

1. Remove:

??

connecting rod

?? Connecting rod bearing

INNER ROTOR (OIL PUMP)

1. Remove:

??

Pump housing

@

2. Remove:

*Outer

rotor

@Pin @

0

Inner rotor

??

Washer

0

Pump cover

?? Pump shaft

@

0

@

@

@

4-23

Page 24

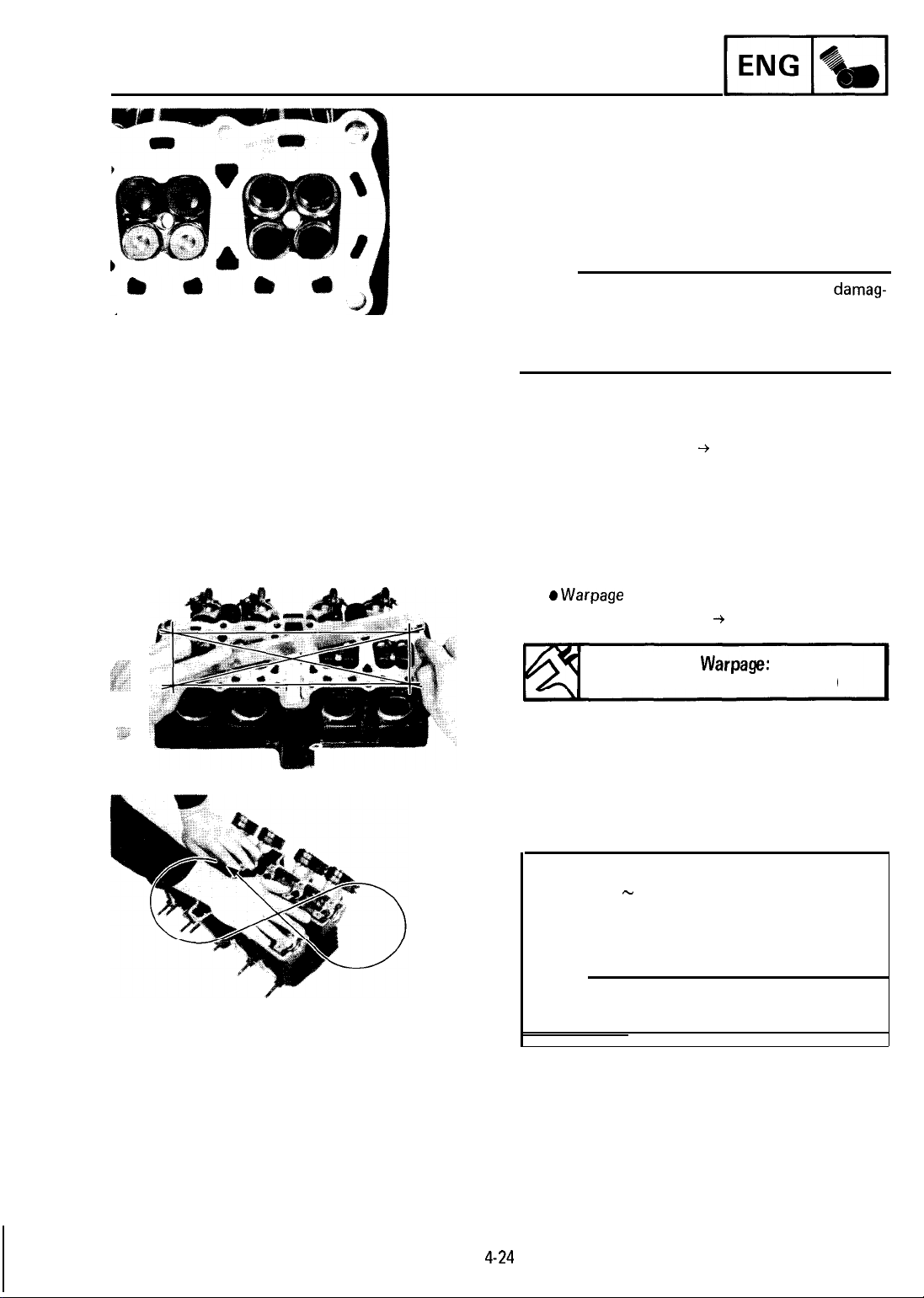

INSPECTION AND REPAIR

INSPECTION AND REPAIR

CYLINDER HEAD

1. Eliminate:

??

NOTE:

Do not use a sharp instrument and avoid

--

ing or scratching:

??

??

Va Ive seat

2. Inspect:

??

Carbon deposit

(from combustion chamber)

Use rounded scraper.

damag-

Spark plug threads

Cylinder head

Scratches/Damage + Replace.

3. Measure:

0 Warpage

Out of specification -+ Resurface.

Cylinder Head Warpage:

Less than 0.03 mm (0.0012 in)

4. Resurface:

??

Cylinder head

Resurfacement steps:

Place a 400

600 grit wet sandpaper on the

-

surface plate, and resurface the head using a

figure-eight sanding pattern.

NOTE:

Rotate the head several times to avoid remov-

ing too much material from one side.

I

I

4-24

Page 25

INSPECTION AND REPAIR

VALVE

1. Inspect:

0

Valve face

@Stem

end

Wear/Pitting + Reface.

Out of specification + Replace.

Face Width @ :

1.6 - 2.4 mm (0.0630 - 0.0945 in)

Seat Width @ :

0.9 - 1.1 mm (0.0354 - 0.0433 in)

< Limit

1.6 mm (0.063 in)

Margin Thickness @ :

0.6 - 0.8 mm (0.0236 - 0.0315 in)

< Limit >

0.4 mm (0.0157 in)

>

2. Measure:

0

Valve stem clearance

Valve stem clearance =

Valve guide inside diameter @

Valve stem diameter

Out of specification + Replace either valve

and/or guide.

Use a Micrometer and Bore Gauge

@

-

Valve Stem Clearance Maximum

Intake

Exhaust

3. Inspect:

?? Valve stem end

Mushroom shape/Larger diameter than rest

of stem +Replace valve, valve guide, and

oil seal.

0.010 - 0.037 mm

(0.0004 - 0.0015 in) (0.0031 in)

0.025 - 0.052 mm

(0.001 - 0.002 in)

0.08 mm

0.1 mm

(0.0039 in)

@

4-25

Page 26

INSPECTION AND REPAIR

4. Measure:

0

Valve stem

runout

Out of specification + Replace.

Maximum Runout:

0.02 mm

(0.0008 in)

VALVE GUIDE

NOTE:

?? Always replace the valve guide if the valve is

replaced.

?? Always replace the oil seal if the valve is

removed.

1,

Inspect:

??

Valve guide

Wear/Oil leakage into cylinder

--f

Replace.

302-019

302-020

2. Remove:

??

Valve guide

Use the Valve Guide Remover

0.

Valve Guide Remover (4.5 mm):

P/N YM-04116

3. Install:

?? Valve guide (New)

Use the Valve Guide Installer @ with the

valve Guide Remover @ .

p

Valve Guide Installer:

P/N YM-04117

Valve Guide Remover (4.5 mm):

P/N YM-04116

4. Bore valve guide @ to obtain proper valve

stem clearance.

Use the Valve Guide Reamer (4.5 mm) @ .

301013

Valve Guide Reamer (4.5 mm):

P/N YM-04118

NOTE:

Reface the valve seat after installing the valve

guide.

4-26

Page 27

INSPECTION AND REPAIR

VALVE SEAT

1. Clean:

?? Valve face

??

Valve seat

Remove carbon deposit.

2. Inspect:

??

Valve seat

Pitting/Wear + Reface valve seat.

3. Measure:

?? Valve seat width

Out of specification + Reface valve seat.

@

Valve Seat Width

302 027

302 017

Intake 0.9

Exhaust 0.9

-

1.1

mm

(0.035-0.043

-

1.1

mm

(0.035-0.043

in)

in)

Valve seat width measurement steps:

?? Apply the Mechanic’s bluing dye (Dykem)

@

to the valve face.

?? install the valve into the cylinder head.

?? Press the valve through the valve guide and

onto the valve seat to make a clean pattern.

?? Measure the valve seat width. Whether the

valve seat and valve face made contact,

bluing will have been removed.

elf the valve seat width is too wide, too

narrow, or seat has not centered. The valve

seat must be refaced.

4-27

4. Reface:

??

Valve seat

Use

20”,

45” and 60” Valve Seat Cutter.

Valve Seat Cutter Set

(ij

:

P/N YM-91043

Page 28

INSPECTION AND REPAIR

A

CAU’IIQN:

Remove just enough material to achieve satisfactory seat.

When twisting cutter, keep and even downward

pressure to prevent chatter marks.

Cut sections as follows

I

Section

I

Cutter

I

I

I

B

C

Valve seat refacing steps:

d

Valve face indicates that valve seat is

centered on valve face but is too wide.

J

4

VIa ve seat is in the middle of the valve

face but too narrow.

45”

60”

---I

4-28

down near the bottom edge of the valve

face.

increase its width.

Page 29

INSPECTION AND REPAIR

5. Lap:

0 Valve face

0 Valve seat

NOTE:

After refacing the valve seat or replacing the

valve and valve guide, the valve seat and valve

face should be lapped.

Valve lapping steps:

?? Apply a coarse lapping compound

valve face.

A

CAUTION:

Be sure no compound enteres the gap between

the valve stem and guide.

@

to the

1

1%

302 017

302 024

?? Apply a molybdnum disulfide oil to the

valve stem.

?? Install the valve into the cylinder head.

?? Turn the valve until the valve face and

valve seat are evenly polished, then clean

off all compound.

NOTE:

To obtain the best lapping result, lightly tap

the valve seat while rotating the valve back

and forth between your hand.

?? Apply a fine lapping compound to the valve

face and repeat the above steps.

NOTE:

Be sure to clean off all compound from the

valve face and valve seat after every lapping

operation.

302 017

?? Apply the Mechanic’s bluing dye

@

to the valve face.

?? Install the valve into the cylinder head.

4-29

(Dykem)

Page 30

INSPECTION AND REPAIR

?? Press the valve through the valve guide and

onto the valve seat to make a clear pattern.

@Measure

the valve seat width is out of specification,

reface and lap the valve seat.

VALVE SPRING

1. Measure:

302 “05

the valve seat width @ again. If

?? Valve spring free length

Out of specification

Valve Spring Free Length:

41.94 mm (1.65 in)

@

--f

Replace.

302 006

2. Measure:

?? Valve spring installed force

Out of specification + Replace.

@

Installed length

Valve Spring Installed Force:

37.5 mm (1.48 in)

I

3. Measure:

*Spring Tilt

Out of specification + Replace.

@

@

0

14.2 - 16.4 kg

(31.3 - 36.2

lb)

Spring Tilt:

Less than 1.8 mm (0.0709 in)

I

Page 31

INSPECTION AND REPAIR

VALVE LIFTER

1. I nspect:

0

Valve lifters

Scratches/Damage + Replace both lifters

and camshaft case.

CAMSHAFT, CAM CHAIN, AND CAM

SPROCKET

Camshaft

1. I nspect :

aCam

lobes

Pitting/Scratches/Blue discoloration

Replace.

2. Measure:

*Cam

lobes

Use the Micrometer.

Out of specification + Replace.

+

Cam Lobe

(iJ

(Limit)

Intake

Exhaust

3. Measure:

??

Camshaft

Use the Micrometer.

Out of specification + Replace.

32.51 mm 25.005 mm

(1.2799 in)

32.21 mm

(1.2681

runout

in)

Cam Lobe

@

(Limit)

(0.9844 in)

24.96 mm

(0.9827 in)

Camshaft Runout Limit:

0.03 mm (0.0012 in)

Camshaft/Cap Clearance Measurement

1. Install:

??

Camshaft

2. Position:

??

Strip of Plastigage@

Onto the camshaft.

@

4-31

Plastigage@

:

P/N W-33210

Page 32

INSPECTION AND REPAIR

3. Install:

??

Dowel pins

??

Camshaft caps

t

‘*

4. Tighten:

??

camshaft cap bolts

Bolts (Camshaft Cap) :

10 Nm (1.0

NOTE:

?? Tighten the camshaft caps in a crisscross

pattern from innermost to outer caps.

?? Do not turn the camshaft when measuring

clearance with the

5. Remove:

??

Camshaft caps

m-kg,

7.2

Plastigage@.

ftslb)

6. Measure:

?? Width of

Out of specification + Follow step 7.

Plastigage@ @

>

7. Measure:

?? Camshaft outside diameter

Use a micrometer.

Out of specification -+ Replace the camshaft.

Within specification -+ Replace the cam-

shaft case.

@

Camshaft Outside Diameter:

Standard: 22.967 - 22.980 mm

(0.9042 - 0.9047 in)

Cam Cap Inside Diameter:

Standard: 23.000 - 23.021 mm

(0.9056 - 0.9063 in)

4-32

Page 33

INSPECTION AND REPAIR

Cam Chain

1. Inspect:

*Cam

chain

Chain stretch/Cracks

Cam Sprockets

1. Inspect:

*Cam sprockets

Wear/Damage + Replace.

--f

Replace.

Cam Chain Guide

1. I

nspect:

?? Cam chain guide (Upper)

?? Cam chain guide (Exhaust side)

?? Cam chain guide (intake side)

Wear + Replace.

Cam Chain Tensioner

1. Check:

@One-way

Unsmooth operation + Replace.

2. Inspect:

@AlI

Damage/Wear -+ Replace.

as er

% :dhp’ug

@

Springs

cam 0 operation

parts

@

Collar

@

Tensioner body

@

Tensioner rod

CYLINDER AND PISTON

1. Inspect:

??

cylinder and Piston walls

Vertical scratches

cylinder and piston.

2. Measure:

?? Piston-to-cylinder clearance

--f

Rebore or Replace

@

@

@

4-33

Page 34

INSPECTION AND REPAIR

Piston-to-cylinder clearance measurement

steps:

First step:

D

Measure the cylinder bore “C” with a

Cylinder Bore Gauge.

NOTE:

Measure the-cylinder bore “C” in parallel to

and at right angles to the crankshaft. Then,

find the average of the measurements.

Standard Wear Limit

-.

Cylinder 56.000 - 56.005 mm

bore “C” (2.2047 - 2.2049 in)

56.05 mm

(2.2067 in)

C = Maximum D

T = (Maximum D, or D, )

-

(Maximum D, or D6 )

R =

(Maximum D,, D, or D,)

(Minimum D, , D4 or

?? If out of specification, rebore or replace

cylinder, and replace piston and piston rings

as a set.

2nd step:

r

Measure the piston skirt diameter “P” with

a micrometer.

@

5.0 mm

(0.2

in) from the piston bottom edge.

-

D,)

Piston Size P

D

If out of specification, replace piston and

piston rings as a set.

3rd step:

DCalculate

with following formula:

the piston-to-cylinder clearance

4-34

Piston-to-cylinder Clearance

Cylinder bore “C”

-

Piston skirt diameter “P”

=

Page 35

INSPECTION AND REPAIR

?? If out of specification, rebore or replace

cylinder, and replace piston and piston rings

as a set.

Piston-to-cylinder Clearance:

a

I

PISTON RING AND PISTON PIN

Piston Ring

1. Measure:

Limit: 0.15 mm (0.006 in)

??

Side clearance

Use the Feeler Gauge

Out of specification + Replace the piston

and/or rings.

0.

307.or6

20mm

(0.8in)

NOTE:

Decarbon the piston ring grooves and rings

before measuring the side clearance.

Side Clearance:

Standard

Top ring

I

2nd ring

I

2. Position:

0

Piston ring

Into cylinder.

NOTE:

Insert the ring into the cylinder, and push it

approximately 20 mm (0.8 in) into the cylinder.

Push the ring with the piston crown so that the

ring will be at a right angle to the cylinder bore.

0.03 - 0.07 mm

(0.0012 - 0.0028 in) (0.004 in)

0.02 - 0.06 mm

(0.0008 - 0.0024 in) (0.004 in)

Limit

0.10 mm

0.10 mm

4-35

3. Measure:

??

End gap

Out of specification + Replace.

Page 36

INSPECTION AND REPAIR

End Gap (Installed) :

Top ring

2nd ring

Oil control

(Rails)

Piston Ring Oversize

stop

and 2nd piston ring

Oversize top and middle ring size is stamped

on the top of ring.

0.15 0.30 mm

(0.0059 - 0.0118 in)

0.15 0.30 mm

(0.0059 - 0.0118 in)

0.2 - 0.8 mm

(0.0079 - 0.0315 in)

Standard

-

-

Oversize 2

I

*Oil control ring

Expander spacer of bottom ring (oil control

ring) is color-coded to identify sizes.

I

I

Size

Oversize 2 Red

0.50 mm (0.0197 in)

Color

Piston Pin

1.

Lubricate:

?? Piston pin (Lightly)

SAE

lOW30

Motor Oil

I

I

4-36

2. Install:

??

Piston pin

Into

the small end of connecting rod.

3. Check:

@Free

play

Free play -j Inspect the connecting rod for

wear.

Wear

--f

Inspect the connecting rod and

piston pin.

4. Position:

??

Piston pin

Into the piston.

Page 37

INSPECTION AND REPAIR

5. Check:

??

Free play

When the pin is in place in the piston.

Free play + Replace the piston pin and/or

piston.

CRANKSHAFT AND CONNECTING ROD

Crankshaft

1.

Measure:

??

Runout

Use the V-Blocks and Dial Gauge.

Out of specification

Out of specification + Replace.

--t

Replace.

308 005 I

Runout

la

2. Inspect:

?? Crankshaft journal surfaces

Wear/Scratches + Replace.

Limit:

0.03 mm (0.0012

in)

Main Journal Oil Clearance

1. Clean all parts.

2. Position:

?? Crankshaft journal surfaces

Place on a bench in an upside down position.

3. Install:

?? Main journal bearings

Into the upper crankcase.

acrankshaft

4. Attach:

0 Plastigage@ @

Onto the crankshaft journal surface.

I

4-37

Page 38

INSPECTION AND REPAIR

5. Install:

*Bearings

Into the lower crankcase.

?? Crankcase (Lower)

6. Tighten:

.Bolts

Tighten to full torque in torque sequence cast

on the crankcase.

1

Bolt @ - @ :

24 Nm (2.4

Bolt @ - @ :

12 Nm (1.2

m-kg,

m-kg,

I

7.

Remove:

.Bolts

Reverse assembly procedure.

??

crankcase (Lower)

Use care in removing.

17

8.7

ft*lb)

ftalb)

8. Measure:

?? Plastigage width

Out of specification

replace the crankshaft if necessary.

>]

Connecting Rod Bearings

1. I

nspect:

?? Connecting rod bearings

Burns/Flaking/Roughness/Scratches

Replace.

4-38

@

--f

Replace the bearings;

+

Page 39

INSPECTION AND REPAIR

Connecting Rod Oil Clearance

1. Clean all parts thoroughly.

2. Install:

??

Connecting rod bearings

Into the connecting rod and cap.

3. Attach:

0 Plastigage@ @

Onto the crank pin.

4. Install:

??

Connecting rod

?? Connecting rod cap

NOTE:

?? Be sure the “Y” marks

rods face toward left crankshaft end .

?? Be sure the letters on both components align

to form a perfect character.

@

on the connecting

5. Lubricate:

?? Bolt threads (Connecting rod)

?? Nut seats (Connecting rod)

Molybdenum Disulfide Grease

6. Tighten:

?? Nuts (Connecting rod cap)

Do not turn the connecting rod until the

clearance measurement has been completed.

Tighten to full torque specification without

pausing. Apply continuous torque between

1.2 and 2.3 m-kg. Once you reach 1.2 m-kg

DO NOT STOP TIGHTENING until final torque

is reached. If tightening is interrupted between

1.2 and 2.3 m-kg, loosen nut to less than

1.2 m-kg, and start again.

4-39

Nuts (Connecting Rod) :

23 Nm (2.3 m-kg, 17 ft-lb)

I

I

Page 40

INSPECTION AND REPAIR

7. Remove:

??

connecting rod cap

Use care in removing.

8. Measure:

??

Width of Plastigage@

Out of specification + Replace the bearings

and/or replace the crankshaft if necessary.

Connecting Rod Oil Clearance:

0.043 - 0.0066 mm

(0.0017 - 0.0026 in)

@

J2 J4 J6 P2 P4

Crankshaft Main Journal and Connecting Rod

Bearing Selection

?? Numbers used to indicate crankshaft journal

sizes are stamped on the LH crankweb. The

first six (6) are main journal bearing numbers,

starting with the left journal. The four (4)

connecting rod bearing numbers follow in the

same sequence.

?? The upper crankcase half is numbered

J3, J4, J5 and J6 on the rear right bosse as

shown.

Jl,

J2,

?? The numbers are stamped in ink on the rod

cap@.

BEARING COLOR CODE

No. 1

No. 2

No. 3

No. 4

*No.5

Blue

Black

Brown

Green

Yellow

4-40

3c

No. 5 applies only to the main journal bear-

ing selection.

Page 41

INSPECTION AND REPAIR

Example 1:

bearings:

@If

the crankcase Jl and crankshaft Jl sizes

are No. 4 and No. 1, respectively, the bearing

size No. is:

Bearing Size No.

Crankcase No. - Crankshaft No.

r

4 - 1 = 3 (Brown)

I

No. 1

Example 2: Selection of the connecting rod

bearing:

?? If the connecting rod

sizes are No. 5 and No. 1, respectively, the

bearing size No. is:

Bearing Size No. =

Connecting rod No. - Crankshaft No.

5 - 1 = 4 (Green)

Selection of the main journal

=

=

BEARING COLOR CODE

Blue

Pl

and crankshaft

1

Pl

=

BEARING COLOR CODE

1

01 L PUMP

1. Measure:

?? Tip clearance “A”

Between the inner rotor @ and the outer

rotor@ .

@Side

clearance “B”

Between the outer rotor @ and the pump

housing @ .

Use the Filler Gauge and Straight Edge.

Out of specification + Replace the oil

pump assembly.

4-41

Page 42

INSPECTION AND REPAIR

2. Lubricate:

0

inner rotors

0

Outer rotors

0 Oil seal

??

Pump shaft

SAE

lOW30

Motor Oil

3. Install:

Reverse removal procedure.

Alighn the pins in the pump shaft and the

groove on the inner rotors dualing assembly.

4. Check:

0

Oil pump operation

With a finger.

Unsmooth operation + Repeat step 2. or

replace.

PRIMARY DRIVE

1. Inspect:

?? Primary drive gear (Crank shaft)

?? Primary driven gear

Wear/Damage

Excessive noises during operation

Replace both gears.

4-42

@

--f

Replace both gears.

@

-+

Page 43

INSPECTION AND REPAIR

STARTER CLUTCH

1. Check:

?? Roller operation

Push the roller to arrow direction.

Unsmooth operation + Replace starter

clutch.

2. Inspect:

*Starter

@Starter

idle gear teeth

drive gear teeth

Burrs/Chips/Roughness/Wear -+ Replace.

@

@

3. Inspect:

??

Contacting surfaces

Pitting/Wear/Damage -+ Replace.

4. Check :

?? Starter clutch operation

Clutch operation checking steps:

?? Install the starter clutch gear to the starter

clutch, and hold the starter clutch.

?? When turning the starter clutch gear clock-

wise the starter clutch and the wheel gear

should be engaged.

If not, the starter clutch is faulty. Replace

it.

?? When turning the starter clutch gear counter-

clockwise, the starter clutch gear should

turn freely.

If not, the starter clutch is faulty. Replace it.

4-43

Page 44

INSPECTION AND REPAIR

CLUTCH

Clutch Housing

1 . Inspect :

??

Dogs on the housing

Cracks/Wear/Damage

?? Clutch housing bearing

Chafing/Wear/Damage + Replace.

NOTE:

Wear on the friction plate dogs of the clutch

housing will cause an erratic operation.

Clutch Boss

1 . Inspect :

?? Clutch boss splines

Scoring/Wear/Damage + Replace clutch

boss assembly.

NOTE:

Scoring on the clutch plate splines will cause

erratic operation.

@

pqq

--f

Deburr or replace.

4’1 )OL

Friction Plates

1. Inspect:

?? Friction plate

Damage/Wear -+ Replace the friction plates

as a set.

2. Measure:

?? Friction plate thickness

Measure at all four points.

Out of specification + Replace the friction

plates as a set.

2.8 mm (0.11

in)

Clutch Plates

1. Measure:

?? Clutch plate

Use the surface plate and Feeler Gauge @ .

Out of specification + Replace.

warpage

4-44

0.1 mm (0.004 in)

Page 45

INSPECTION AND REPAIR

2. Inspect:

??

Pressure plate

Damage + Replace.

Push Rod

1. I nspect :

@Push

rod 1

.Bofl @

@Push rod 2

Wear/Cracks/Damage -+ Replace.

@

@

Push Lever Assembly and Boll Screw Housing

1. I nspect :

??

Push lever assembly

Unsmooth + Replace.

2. Measure:

??

Push rod

runout

Use the V-Blocks and Dial Gauge.

Out of specification + Replace.

Clutch Spring

1.

Measure:

?? Clutch spring free length

Out of specification + Replace the springs

as a set.

Clutch Spring Minimum Free Length:

29.0 mm (1.14 in)

Page 46

INSPECTION AND REPAIR

TRANSMISSION

Shift Fork

1. Inspect:

?? Shift fork cam follower

?? Shift fork

Wear/Chafing/Bends/Damage + Replace.

2. Check:

?? Shift fork movement

On its guide bar @ .

Unsmooth operation + Replace the fork

and/guide bar.

Shift Cam

1. Inspect:

?? Shift cam grooves

Wear/Damage/Scratches + Replace.

?? Shift cam segment

Damage/Wear + Replace.

??

Shift cam bearing

Pitting/Damage + Replace.

paw1 @

@

Main and Drive Axles

1.

Measure:

?? Axle

runout @

Use the centering device and Dial Gauge@.

Out of specification + Replace.

Out of specification + Replace.

Runout

Limit: 0.08 mm (0.0031 in)

Gears

1. Inspect:

??

Gears

Damage/Wear + Replace.

2. Check:

?? Gear movement

Unsmooth operation + Replace.

3. Inspect:

??

Mating dogs

Cracks/Wear/Damage + Replace.

Shift Shaft Assembly

1. Inspect:

?? Shift shaft

Bends/Wear/Damage -f Replace.

0

Spring

Damage + Replace.

4-46

Page 47

INSPECTION AND REPAIR

RELIEF VALVE AND PIPE

1. Check:

?? Relief valve body

??

Cover

0

*Spring

??

Damage/Wear + Replace.

2. Check:

??

Damage + Replace.

Comtamination

the passage.

@

O-ring

@

Oii pipe

0

@

Wash and blow out

+

-1

3. Check:

??

Water pipe

??

Water jacket joint

??

O-rings

@

Damage

--f

Replace.

CRANKCASE

1. Inspect:

??

Case halves

??

Bearing seat

??

Fitting

Damage + Replace

BEARING AND OIL SEAL

1.

Inspect:

??

Bearings

Clean and lubricate, then rotate inner race

with finger.

Roughness + Replace the bearing (see Re-

moval).

2. Inspect:

@Oil seals

Damage/Wear + Replace the (see Removal).

4-47

@

@

Page 48

INSPECTION AND REPAIR

YAMAHA EXHAUST VARIABLE

(For California Only)

1. I

nspect

:

?? Shaft arm

Wear/Cracks/Damage -+ Replace.

2. Inspect:

.Bush @

Wear -+ Replace.

VAiVE

4-48

Page 49

ENGINE ASSEMBLY AND ADJUSTMENT

ENGINE ASSEMBLY AND

ADJUSTMENT

INNER ROTOR (OIL PUMP)

1. Install:

??

Pump shaft

0

Pump cover

@Washer @

0

inner rotor

*Pin

@

?? Outer rotor

NOTE:

Insert the inner rotor @ into the outer rotor

Then with the pump shaft dowel pin @ in the

inner rotor slit.

@

@

@

@

0.

-41

M

a

2. Install:

??

Pump housing

CONNECTING ROD

1. Clean:

??

Crankshaft

??

Connecting rods

2. Install:

*Connecting rod bearings

Into the connecting rod and

3. Lubricate:

@Connecting rod bolt threads

??

Connecting rod nuts

Molybdenum Disulfide Oil

cap.

4-49

4. Apply engine oil to the crankshaft pins.

Page 50

CRANKSHAFT

@Crankshaft

g ii1 se;1

ain

ournal bearing

@Connecting rod assembly

@Connecting rod bolt

@Connecting rod bearing

@Nut

ENGINE ASSEMBLY AND ADJUSTMENT

Page 51

ENGINE ASSEMBLY AND ADJUSTMENT

5. Install:

@Connecting rods

aconnecting

NOTE:

@The

stamped “Y” mark on the connecting rods

@

should face towards the left side of the

crankcase.

?? Be sure the letter on both components align to

form a perfect character.

6. Install:

@Connecting rod bolts

Align the bolt head and connecting rod cap.

7. Tighten :

??

Connecting rod nuts

Tighten to full torque specification without

pausing. Apply continuous torque between

1.2 and 2.3 m-kg. Once you reach 1.2 m-kg.

DO NOT STOP TIGHTENING until final torque

is reached. If the tightening is interrupted

between 1.2 and 2.3

less than 1.2 m-kg and start again.

rod caps

m*kg,

loosen the nut to

1

23 Nm (2.3 m-kg, 17

ftlb)

bA

VALVE PAD AND VALVE

Deburr any deformed valve stem end. Use an oil

stone to smooth the stem end.,

~Deburr

@Valve stem

1. Eliminate:

??

Carbon deposit

From the combustion chamber.

Use a rounded scraper.

NOTE:

Do not use a sharp instrument and avoid damaging or scratching:

@Spark

??

??

plug threads

Va Ive seat

Cylinder head

4-51

Page 52

ENGINE ASSEMBLY AND ADJUSTMENT

2. Install:

0

Valve spring seat

??

Oil seal

@

3. Install:

0

Valve

NOTE:

Apply molybdenum disulfide oil.

@

1 ENG I%1

4. Install:

0

Valve spring

@

NOTE:

Install springs with wider-gapped coils facing

upwards, as shown.

@

Larger

pitch

@Smaller pitch

5. Attach:

?? Valve spring compressor

?? Attachment

@

@

6. Install:

aValve

retainers

@

7. Settle the valve retainer by lightly patting

the valve seat with a piece of wood @ in

between.

NOTE:

Do not hit so much as to damage the valve.

4-52

Page 53

ENGINE ASSEMBLY AND ADJUSTMENT

8. Install:

@Valve

NOTE:

Apply molybdnum disulfide oil.

9. Install:

0

pads

Lifters

@

@

CRANKSHAFT

1. Install:

?? Oil baffle plate

??

Breather hose

Oil Baffle Plate Bolts:

10 Nm (1.0 m-kg, 7.2

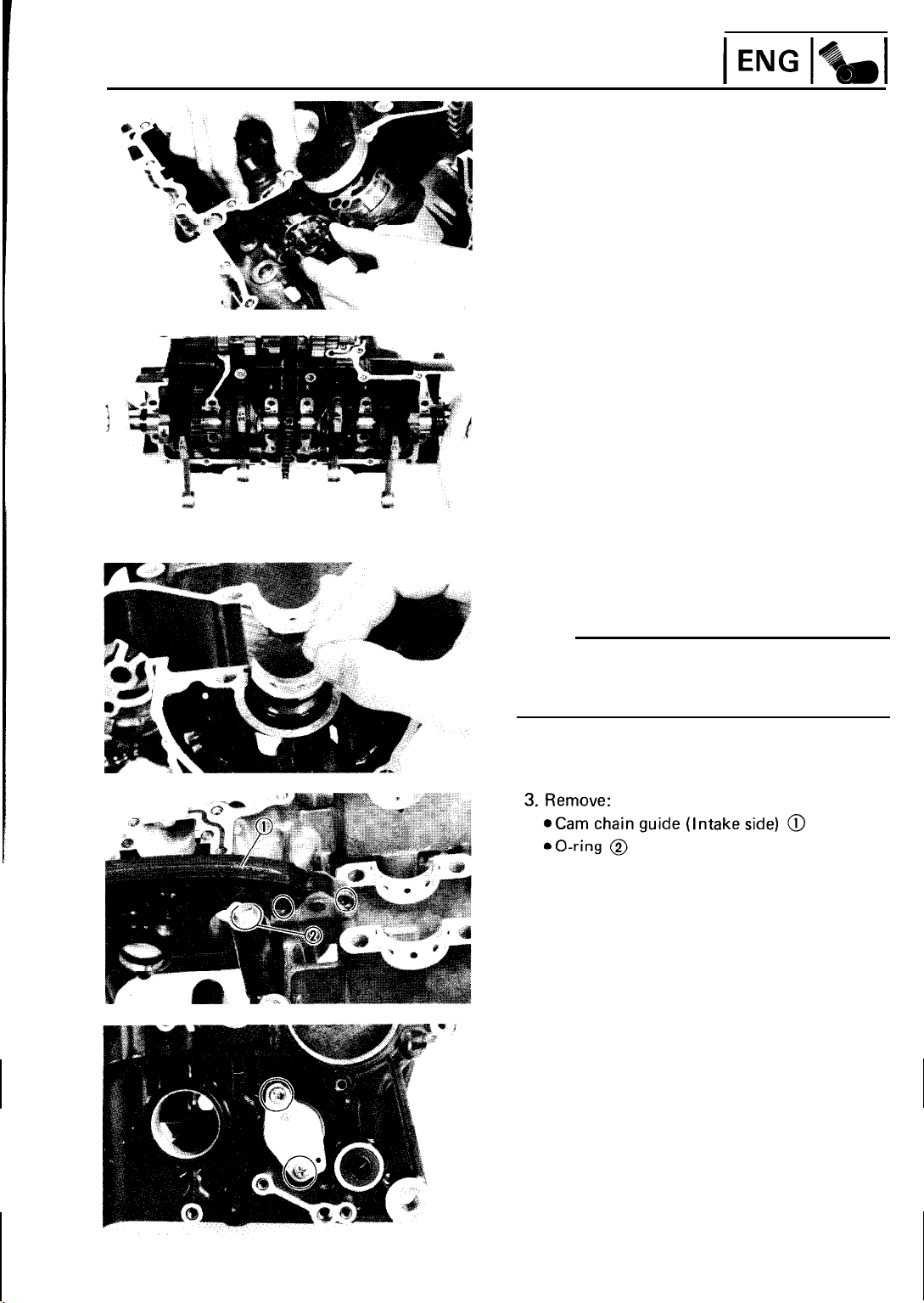

2. Install:

?? Neutral switch assembly

3. Install:

??

Cam chain guide (Intake side)

??

O-ring

@

ft.lb)

@

@

Bolts (Chain Guide):

10 Nm (1.0 m-kg, 7.2

ftalb)

Page 54

CRANKCASE

@Crankcase assembly

@Oil

level window

@Crankcase ventilation hose

(436

mm bolt

06

mm bolt

@6

mm bolt

06

mm bolt

@8

mm bolt

ENGINE ASSEMBLY AND ADJUSTMENT

@ 8

mm bolt

@

O-ring

0

8 mm bolt

@I@@@@:

12 Nm (1.2 m-kg, 8.7

00:

24 Nm (2.4 m-kg, 17

ft.lb)

ft. lb)

Page 55

TRANSMISSION

@

Main axle

@

5th pinion gear

@

Circlip

@

3rd pinion gear

@

6th pinion gear

@

2nd pinion gear

@

Bearing

@

Circlip

ENGINE ASSEMBLY AND ADJUSTMENT

@Drive axle

@2nd

wheel gear

06th

wheel gear

@3rd

wheel gear

04th

wheel gear

055th

wheel gear

@

1st wheel gear

@Washer

C USE NEW ONE

Page 56

ENGINE ASSEMBLY AND ADJUSTMENT

4. Install:

?? Main journal bearing

To crankcase (Lower)

NOTE:

Apply molybedenum disulfide oil.

5. Install:

?? Cam

?? Crankshaft assembly

NOTE:

@The

the left.

*Pass the cam chain through the cam chain

cavity. Be sure to attach a retaining wire @to

the cam chain.

cabin @

Onto the crankshaft

stepped crankshaft end @I should face to

@

@

@

TRANSMISSION, SHIFTER AND SHIFT CAM

1. Install:

?? Shift cam assembly

aGuide

?? Shift fork

?? Shift fork

?? Shift fork

bar

@

#I @

#2 @I

#3 @

@

NOTE:

All shift fork letters should face to the left side

and be in sequence (1, 2, 3) beginning from

the left.

4-56

Page 57

1

ENGINE ASSEMBLY AND ADJUSTMENT

2. Install:

?? Stopper plate (Shift cam)

?? Stopper lever

@

ENG

I

Bolts (Stopper Plate) :

10 Nm (1.0

Use

LOCTI

m-kg,

TE@

Bolt (Stopper Lever) :

10 Nm (1.0

m-kg,

Use LOCTITE@

3. Install:

??

Circlip

@

To crankcase ( Lower)

NOTE:

Be sure the circlips @ are inserted into the

lower crankcase positioning grooves.

@

7.2

7.2

ftslb)

ftslb)

le-1

I

4. Install:

?? Main axle assembly

?? Drive axle assembly

@Oil

seal

@

@

@

NOTE:

@Be

sure the main axle bearing pin @ should

face to front and the drive axle bearing pins

@

should face to rear.

?? Mesh the shift fork

@

and #2 with the 5th wheel gear @ on the

drive axle.

?? Mesh the shift fork

gear @ on the main axle.

*Carefully guide the shift forks so that they

mesh smoothly with transmission gears.

#l

with the 4th wheel gear

#2

with the 3rd pinion

CRANKCASE ASSEMBLY

1. Apply:

aQuick

Gasket@

To crankcase matching surfaces.

4-57

Quick Gasket@

P/N ACC-11001-05-01

Page 58

ENGINE ASSEMBLY AND ADJUSTMENT

Before tightening the crankcase bolts, check

the following points:

*Be sure the gear shifts correctly while

turning the shift cam.

2. Tighten:

o

Lower crankcase bolt

?? Upper crankcase bolt

(Follow the proper tightening sequence.)

8mmBolt@-@@J:

24 Nm (2.4

6mmBolt

12 Nm (1.2

@-

@I

a

m-kg,

@ @ - 8

m-kg,

17

8.7

hand-

ft*lb)

:

ft*lb)

NOTE:

nstall the ground lead @# on bolt No. @ .

nstall the copper washer @ on bolt No. @ .

NOTE:

?? Install the washer

@I

on bolt No. @ , @I ,

or 0.

3. Install:

@Oil

seal stopper

CiJ

4-58

Bolts (Oil Seal Stopper):

10 Nm (1.0

m-kg,

7.2

ftalb)

Page 59

ENGINE ASSEMBLY AND ADJUSTMENT

STARTER MOTOR

1. Check:

@O-ring

2. Install:

@Starter

OIL PAN AND OIL STRAINER

1. Install:

??

(Starter motor)

Damage + Replace.

motor

@

Bolt (Starter Motor) :

10 Nm (1.0 m-kg, 7.2

Oil strainer assembly

Bolts (Oil Strainer Assembly):

10

Nm (1.0 m-kg, 7.2

0

ft.lb)

ft-

lb)

I

2. Install:

?? Oil strainer cover

?? Relief valve

@

@

NOTE:

The element (window) must be installed vertically against housing arrow mark.

3.

Install:

??

Dowel pins

i

-

i

??

Gasket (New)

@Oil

pan

0

@Oil

level switch

?? Drain plug

@

@

Bolts (Oil Pan):

4. Install:

0

Oil filter

0

Oil filter cover

10 Nm (1.0

rn-

kg, 7.2 ft-lb)

@

I

4-59

Bolt (Oil Filter Cover):

15 Nm (1.5 m-kg, 11

Refer to the “ENGINE OIL FILTER RE-

PLACEMENT” section in the CHAPTER 3.

ft.lb)

I

Page 60

ENGINE ASSEMBLY AND ADJUSTMENT

OIL PUMP AND SHIFT SHAFT

1. Install:

??

Shift shaft

NOTE:

Insert the stopper between spring ends.

2. Install:

@Dowel

*Gasket (New)

pin

@

@

1 ENG lb1

3. Install:

@Oil

pump assembly

@

NOTE:

Align the oil pump arrow mark @ with crankcase arrow mark

0.

WATER PUMP

1. Install:

@Water

pump housing

@

Bolts (Water Pump Housing):

10 Nm (1.0 m-kg, 7.2

2. Install:

??

O-ring

?? Water pump cover

(iJ

ft.lb)

4-60

Bolts (Water Pump Cover) :

10 Nm (1.0 m-kg, 7.2

ft.lb)

I

Page 61

A.C. MAGNETO

@

Magneto

@ Stator

@

coil assembly

Pickup coil

ENGINE ASSEMBLY AND ADJUSTMENT

ST

PSOR COlC REs\sT ANCE-. I

0.44 -

0.66R

(White -White)

PICKUP COIL RESISTANCE:

85 -

115R

(White/Red -White/Black)

at

20°C (68’F)

at 20°C (68°F)

10 Nm (1.0

m-kg,

7.2

ftmlb)

4-61

80 Nm (8.0

m-kg,

58

ftelb)

Page 62

ENGINE ASSEMBLY AND ADJUSTMENT

A.C. MAGNETO

1. Install:

??

Stator

coil assembly

?? Pickup coil

*Woodruff key

Bolts (Stator Coil Assembly):

Screws (Pickup Coil):

NOTE:

@Clean

the tapered portions of the crankshaft

and magneto.

?? When installing the magneto, make sure the

woodruff key is properly seated in the key way

of the crankshaft.

@

@

10 Nm (1.0

Use LOCTITE@

5 Nm (0.5

rn.

@

m-kg,

7.2

kg, 3.6

ftslb)

ft. lb)

2. Install:

@Magneto @

?? Bolt (Magneto)

3. Attach :

?? Universal Rotor Holder

@

NOTE:

Hold the magneto to tighten the nut by the

Universal Rotor Holder @ .

Universal Rotor Holder:

P/N Y U-01 235

4. Tighten:

?? Bolt (Magneto)

4-62

Page 63

CLUTCH

@Primary driven gear

@Thrust washer

@

Clutch boss

@

Friction plate

@Clutch plate

@

Pressure plate

@Clutch spring

@

Push rod # 1

SPRING FREE LENGTH

LIMIT:

29.0 mm (1.142 in)

CLUTCH PLATE

B

WARP LIMIT:

0.1 mm (0.004 in)

FRICTION PLATE

C

WEAR LIMIT:

2.8 mm (0.11 in)

i

ENGINE ASSEMBLY AND ADJUSTMENT

@O-ring

@

Lock washer

@Boll

@Oil seal

@Push rod

@Push lever assembly

g:o:

1

0 ar

16

Nm

#2

screw housing

(Oik-,

0

Thrust washer

@I

Spacer

@

Bearing

4-63

16 Nm (1.6

m*kg,

11 ft-lb)

Page 64

ENGINE ASSEMBLY AND ADJUSTMENT

CLUTCH

1. Install:

*Collar

*Thrust

*Clutch

??

*Spacer

?? Thrust washer

.Clutch

?? Lock washer (New)

.Nut

NOTE:

Install the bearing @ and spacer @after installa-

tion of the clutch housing @ .

0

washer

housing

Bearing

@

@

boss

@

(Clutch boss)

@

@

@

@

@

2. Tighten:

.Nut

(Clutch boss)

@

Use the Universal Clutch Holder @ .

NOTE:

Hold the clutch boss to tighten the nut by

Universal Clutch Holder @ .

P/N Y M-91 042

Nut (Clutch Boss) :

70 Nm (7.0 m-kg, 50

ft.lb)

NOTE:

Bend the lock washer tab along the nut flat.

3. Install:

@Push rod #2

@

.Boll 0

*Push rod #l

??

Friction plates

??

Clutch plates

@

I

4-64

Page 65

ENGINE ASSEMBLY AND ADJUSTMENT

4. Install:

0

Pressure plate

Be sure the match mark @ on the clutch boss is

aligned with the match mark @on the pressure

plate.

5. Install:

@Clutch

?? Bolts (Clutch spring)

springs

Bolts (Clutch Spring) :

6 Nm (0.6 m-kg, 4.3

@

@

ft.

lb)

I

6. Install:

??

Dowel pins

?? Gasket (Crankcase cover)

*Crankcase cover (Right)

Bolts (Crankcase Cover) :

10 Nm (1.0 m-kg, 7.2

STARTER CLUTCH

1. Install:

,*

?? Idle gear

?? Idle gear

*Starter

?? Woodruff key

2. Install:

@Starter clutch

??

Washer

?? Bolt (Starter clutch)

@

@

clutch gear

@

@

@

@

ft.lb)

I

4-65

Bolt (Starter Clutch) :

80 Nm (8.0 m-kg, 58 ft-lb)

I

Page 66

STARTER CLUTCH

@

Starter drive gear

@

Idle gear

@

Idle gear

@

Shaft

@

Starter clutch assembly

ENGINE ASSEMBLY AND ADJUSTMENT

@

Starter clutch gear

@)

Woodruff key

@

Washer

4-66

Page 67

ENGINE ASSEMBLY AND ADJUSTMENT

PISTON AND CYLINDER

@Top ring @Dowel pin

@Oil ring (Lower) @Cylinder

@Oil ring (Upper)

@Second ring @Gasket (Cylinder)

@Circlip

@Piston pin

@Piston

@I

O-ring

@!

Piston ring

m

r

/ 7 Nm (0.7 m-kg, 5.1

ft.lb)

SIDE CLEARANCE

Top: 0.10 mm (0.004 in) I

2nd: 0.10 mm (0.004 in)

EN0 GAP:

8

/

1

Top: 0.15- 0.30 mm

B

(0.0059 - 0.0118 in)

2nd: 0.15 - 0.30 mm

PISTON-TO-CYLINDER

CLEARANCE:

0.04 - 0.06 mm

(0.0016 - 0.0024 in)

LIMV

I

JD( uSENEWONE

I

W _

4-67

Page 68

ENGINE ASSEMBLY AND ADJUSTMENT

3. Install:

??

Dowel pins

@Gasket

?? Stater clutch cover

(Stater

clutch cover) (New)

Bolts (Stater Clutch Cover):

10 Nm (1.0 m-kg, 7.2

@

-1

ft-lb)

I

PISTON AND CYLINDER

1. Install:

aPiston

NOTE:

Be sure to install rings so that Manufacturer’s

marks or numbers are located on the top side of

the rings. Oil the pistons and rings liberally.

2. Install:

0

0

??

NOTE:

@Be

sure the piston arrow mark @ face to ex-

haust side of the engine.

rings

Piston pins

Pistons

Circlips (Piston pin)

@

?? Before installing the piston pin circlip, cover

the crankcase with a clean rag to prevent the

circlip from falling into the crankcase cavity.

?? Be sure the marked piston numbers

be in sequence

left.

(1,

2, 3, 4) begining from the

@

should

Always use new circlips (Piston pin).

4-68

Page 69

ENGINE ASSEMBLY AND ADJUSTMENT

3. Install:

?? Gasket (Cylinder)

??

Dowel pins

4. Lubricate:

0 Pistons

0

Piston rings

?? Cylinder

NOTE:

Apply a liberal coating of

5. Position:

Offset the piston ring end gaps.

stop

ring end

?? Oil ring end (Lower)

*Oil

ring end (Upper)

??

2nd ring end

@

4stroke

@

@

@

@

engine oil.

6. Install:

??

Cylinder

NOTE:

?? Install pistons

#2

and #3 first.

?? Pass the cam chain and cam chain guide

haust side) through the cam chain cavity.

7. Install:

0

O-ring

*Water

8. Turn:

9. Align:

pipe

@

??

Crankshaft

Counterclockwise.

?? “T” mark

*Stationary pointer

Refer to “ENGINE DISASSEMBLY

CYLINDER HEAD AND CAMSHAFT”.

(E>

-

NOTE:

When # 1 piston is at TDC.

4-69

Page 70

ENGINE ASSEMBLY AND ADJUSTMENT

CYLINDER HEAD AND CAMSHAFT

Cylinder Head

@Washer

@

Rubber washer

@

Gasket (Cylinder head cover)

@ Spark plug

@ Nut

@Washer

@Valve

@

@Gasket (Cylinder head)

(@Cylinder

@Cylinder head assembly

guide

Circlip

head cover

1 10 Nm

10

(I.0

m-Kg,

Nm (1.0 m-kg, 7.2

I.L ~t-ll))

1 25 Nm (2.5

=:/CT\

ft.lb)

)

m-kg, 18 ft.7

4-70

c .

01

C 1 USE NEW

I

ON4

Page 71

Camshaft

@Camshaft (Intake)

@Cam chain sprocket

@

Valve lifter

@

Valve pad

@

Valve retainer

@Spring seat

0

Valve spring

ENGINE ASSEMBLY AND ADJUSTMENT

@

Spring seat

@

Oil seal

@

Intake valve

(@

Exhaust valve

@

Cam chain tensioner

@Gasket (Cam chain tensioner)

@Cam chain guide (Intake side)

@Camshaft (Exhaust)

@

Chain guide (Upper)

0

Cam chain

@Cam

chain guide (Exhaust side)

@

Match mark

VALVE CLEARANCE (COLD):

A

INTAKE:

B

0.11 - 0.20 mm

(0.004 - 0.008 in)

EXHAUST:

C

0.21 - 0.30 mm

(0.008 - 0.012 in)

F

-.-___

~____

__-___

I

.4 m*ka.

17

ft.lb)

Page 72

ENGINE ASSEMBLY AND ADJUSTMENT

CYLINDER HEAD AND CAMSHAFT

1. Install:

@Gasket (Cylinder head) (New)

?? Dowel pins

NOTE:

The gasket “HEAD” mark should face upward.

NOTE:

aSelect

??

@Procedure 2.

either of the two procedures explained

in this manual, as follows:

Procedure 1.

The cam chain is disconnected + Connect.

The camshafts are removed + Install.

@

@

Procedure 1

1. Install:

?? Camshafts, and cylinder head assembly

*Be sure the camshaft timing marks @ align

with the camshaft cap marks

aBe

sure the “T” mark on the magneto align

the stationary pointer when #l piston is

at TDC.

2. Tighten:

?? Nuts (Cylinder head)

Use the Hexagon Wrench 6 mm (0.24 in)

0.

0.

NOTE:

Tighten the nuts in their proper tightening

sequence and torque nuts in two stages.

Nuts (Cylinder Head):

25 Nm (2.5 m-kg, 18

4-72

ft-lb)

Page 73

ENGINE ASSEMBLY AND ADJUSTMENT

4. Connect:

??

Cam chain

With the chain joint (New).

Use the Cam Chain Cutter @ .

Cam Chain Cutter:

P/N YM-01112

NOTE:

Keep the cam chain as tense as possible on

exhaust side.

5. Go to “CAM CHAIN TENSIONER”.

Procedure 2.

1. Install:

??

Camshaft case and cylinder head assembly

2. Tighten:

?? Nuts (Cylinder head)

Use the Hexagon Wrench 6 mm (0.24 in).

the

Tighten the nuts in their proper

sequence and torque nuts in two stages.

Nuts (Cylinder Head):

25 Nm (2.5

3. Install:

??

Camshafts

Camshaft installation steps:

*Turn

the crankshaft counterclockwise.

@Align

the “T” mark @ on the magneto

the crankcase end @ when #l piston

at TDC.

A

CAfXl-KM:

I

Do not turn the crankshaft during the camshafts installation. Damage or improper valve

timing will result.

m-kg,

18

ft. lb)

tightenin<

wir

th

is

Page 74

ENGINE ASSEMBLY AND ADJUSTMENT

?? Lubricate the camshaft bearing surfaces,

cam lobes and cam journals.

Molybdeum Disulfide Oil

o

Install the exhaust camshaft

install the intake camshaft @ .

?? Be sure the timing marks

face upward.

II

Keep the cam chain as tense as possible on

the exhaust side.

?? Remove the retaining wire

Do not turn the camshaft separately or

damage to the piston and valve will result.

y

Install the dowel pins.

??

Install the camshaft caps.

@Align

the camshaft timing marks @ with the

camshaft cap marks @ .

pi&j

(IJ

first, then

@I

on the camshaft

@

.

NOTE:

*The numbers are punched on the camshaft

caps in increments from right to left.

?? Do not install the bolts at

this stage.

??

Tighten the bolts (Camshaft caps).

$6

marked place in

NOTE:

Tighten the camshaft caps in a crisscross

pattern from innermost to outer caps.

A

CAW-ION:

The cam caps must be tightened evenly or

damage to the cylinder head, camshaft caps

and cam will result.

Bolts (Camshaft Cap):

4. Install:

@Cam

??

Cam chain guide (Upper)

10 Nm (1 .O me kg, 7.2

chain guide (Exhaust side)

@

ft.

lb)

@

4-74

Page 75

ENGINE ASSEMBLY AND ADJUSTMENT

CAM CHAIN TENSIONER

1. Position:

??

Cam chain

Exhaust side -+ Tense.

Intake side + Slack.

2. Install:

??

Cam chain tensioner

Cam chain tensioner installation steps:

?? Remove the tensioner end cap bolt and

spring.

?? Release the cam chain tensioner one-way

cam @ and push the tension rod @ .

?? Install the tensioner with a new gasket into

the cylinder.

Bolts (Cam Chain Tensioner) :

10 Nm (1.0 m-kg, 7.2 ft-lb)

?? Install the collar

and end cap bolt

@

, springs @ , washer

0.

End Cap Bolt (Cam Chain Tensioner):

20 Nm (2.0 m-kg, 14

3. Turn:

??

Crankshaft

Counterclockwise for a several turns.

4. Inspect:

?? Camshaft timing marks

Align with the camshaft cap marks @ .

a

Crankshaft “T” mark

Align with the crankcase end

Out of alignment + Adjust.

Refer to “CAMSHAFT INSTALLATION

STEPS”.

5. Install:

?? Gasket (Cylinder head cover)

?? Cylinder head cover

ft.lb)

@

@

0.

@

4-75

Bolts (Cylinder Head Cover):

10 Nm (1.0 m-kg, 7.2 ft-lb)

I

Page 76

ENGINE ASSEMBLY AND ADJUSTMENT

6. Install:

??

Washers (New)

?? Oil delivery pipe

?? Union bolts

7. Install:

??

Dowel pins

?? Generator cover

Bolts (Generator Cover):

@I

@

10 Nm (1.0

@

m-kg,

7.2

ftslb)

I

REMOUNTING ENGINE

When remounting the engine, reverse the removal

procedure. Note the following points.

1. Install:

??

Engine assembly

@Bolt

(Engine mount - Rear Lower)

*Bolt

(Engine mount - Rear Upper)

@

@

Bolt (Engine Mount - Rear Lower):

45 Nm (4.5

m-kg,

32

ftslb)

Bolt (Engine Mount - Rear Upper):

55 Nm (5.5 me kg, 40

@Collars

ft.

lb)

2. Install:

?? Down tube frames (Left and right)

?? Bolt (Engine

-

Mount)

@

@

4-76

Bolts (Down Tube Frame

33 Nm (3.3

m-kg,

24

-

Lower):

ftmlb)

Bolts (Down Tube Frame - Upper):

60 Nm (6.0

m-kg,

43

ftalb)

Use LOCTITE@

Bolt (Engine Mount) :

55 Nm (5.5

rn.

kg, 40

ftslb)

Page 77

ENGINE ASSEMBLY AND ADJUSTMENT

3. Install:

*Starter lever

@Cover @

Bolt (Starter Lever) :

8 Nm (0.8 ma kg, 5.8

4. Install:

?? Drive chain

?? Drive sprocket

?? Lock washer (New)

?? Nut (Drive sprocket)

Nut (Drive Sprocket) :

70 Nm (7.0 me kg, 50

NOTE:

Adjust the drive chain slack if necessary.

@

@

@

@

ft. lb)

@

ft. lb)

5. Install:

*Cover (Crankcase Left)

*Shift arm

Bolts (Crankcase Cover) :

10 Nm (1.0

m-kg,

7.2

ft*lb)

Use LOCTITE@

Bolt (Shift Arm) :

10 Nm (1.0

m-kg,

7.2

ft-lb)

6. Install:

??

Muffler assembly

7. Tighten :

??

Flange nuts (Exhaust pipe)

8. Tighten:

?? Bolt (Muffler bracket)

@

?? Bolt (Muffler stay) (For California only

0

4-77

Bolt (Muffler Bracket):

20 Nm (2.0

Bolt (Muffler Stay

m-kg,

-

14

ftslb)

For California only):

20 Nm (2.0

m-kg,

14

ftelb)

Page 78

ENGINE ASSEMBLY AND ADJUSTMENT

YAMAHA EXHAUST VARIABLE VALVE (For California Only)

@

1 Exhaust pipe assembly

Gasket (Exhaust pipe)

Bush

Oil seal

Gasket

Shaft arm

Housing

1 20 Nm (2.0 m-kg, 14

Bracket

@

Cables

@Washer

@

Pulley

@

Valve cover

@

Gasket (Muffler)

@

Muffler assembly

lONm(

I”

1.0

m-kg

7.2

ft.lb)

5 Nm (0.5 m-kg, 3.6

A USE NEW ONE

ft.lb)

Page 79

ENGINE ASSEMBLY AND ADJUSTMENT

9. Install (For California only):

??

Shaft arm

*Gasket

@Housing @

IO. Install (For California only):

??

??

@

Washer

Bracket

Bolts (Bracket):

10 Nm (1.0

m-kg,

7.2

ftslb)

11. Install (For California only):

@Pulley @

@Cables

@Clips @

12. Adjust (For California only):

??

Refer to the “EXUP CABLE ADJUSTMENT” section in the CHAPTER 3.

13. Adjust:

*Throttle cable

@

Cable

4-79

Throttle Cable Free Play

(Throttle Gripe):

2 - 5 mm (0.08 - 0.20 in)

Refer to the “THROTTLE CABLE FREE

PLAY ADJUSTMENT” section in the

CHAPTER 3.

Page 80

ENGINE ASSEMBLY AND ADJUSTMENT

14. Adjust:

@Clutch

cable

Clutch Cable Free Play:

2 - 3 mm (0.08 - 0.12 in)

Refer to the “CLUTCH

section in the CHAPTER 3.

15. Fill:

??

Coolant

Total Amount:

1.0 L (0.9 Imp qt, 1.1 US qt)

Refertothe”COOLANT REPLACEME

section in the CHAPTER 3.

16. Fill:

??

Engine oil

6

KY

Total Amount:

0.8 L (0.7 Imp qt, 0.84 US

Refer to the “ENGINE OIL REPL

MENT” section in the CHAPTER 3.

ADJUSTMEI

qt)

4-80

Loading...

Loading...