Carrier 06E, 07E User Manual

06E,07E Compressors and Condensing Units

Installation, Start-Up and

Service Instructions

Hermetic, Water-Cooled

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Receive and Inspect Unit. . . . . . . . . . . . . . . . . . . . . . . . . 1

Place Unit in Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Check Compressor Mounting . . . . . . . . . . . . . . . . . . . . 1

Piping Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

PRE-START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7,8

Evacuate, Dehydrate, and Leak Test. . . . . . . . . . . . . . 7

Oil Charge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Start Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Timer Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

Protection Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Compressor Thermal Protection . . . . . . . . . . . . . . . . . 9

Capacity Control System . . . . . . . . . . . . . . . . . . . . . . . . . 9

Removing, Inspecting and Replacing

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Lubrication System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cylinder Heads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pressure Relief Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Suction and Discharge Valve Plate Assembly . . . 14

Terminal Plate Assembly . . . . . . . . . . . . . . . . . . . . . . . . 14

Compressor Running Gear Removal . . . . . . . . . . . . 14

Compressor Running Gear Replacement. . . . . . . . 15

Motor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Motor Burnout (Clean-Up Procedure). . . . . . . . . . . . 17

Condenser Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 17

SAFETY CONSIDERATIONS

Installing, starting up, and servicing this equipment can be hazardous due to system pressures, electrical components, and equipment location (roofs, elevated structures, etc.). Only trained, qualified installers and service mechanics should install, start up, and service this equipment.

When working on the equipment, observe precautions in the literature, tags, stickers and labels attached to the equipment, and other safety precautions that apply. Follow all safety codes. Wear safety glasses and work gloves. Use care when handling, rigging, and setting bulky equipment.

Electrical shock can cause personal injury and even death. Be sure power to equipment is shut off before installing or servicing this equipment. There may be more than one disconnect. Tag disconnect(s) to alert others not to turn power on until work is completed.

INSTALLATION

Receive and Inspect Unit — Inspect shipment for damage. File claim with the shipping company if shipment is damaged or parts are missing.

Local water conditions can cause excessive fouling or pitting of condenser tubes. If such conditions are anticipated, a water treatment analysis is recommended. Refer to Carrier System Design Manual, Part 5, for general water conditioning information.

Place Unit in Position — Locate unit on floor in a well-ventilated area. Install unit where it will be warmer than conditioned area. Position it to allow sufficient space for refrigerant and water connections and to service compressor. Allow space at one end of condenser for tube cleaning or replacement. Place unit so suction and discharge valves can be easily reached and so oil level can be checked.

Make provision in piping layout to drain and vent condenser if system is to be shut down in winter.

Level unit and bolt firmly to foundation.

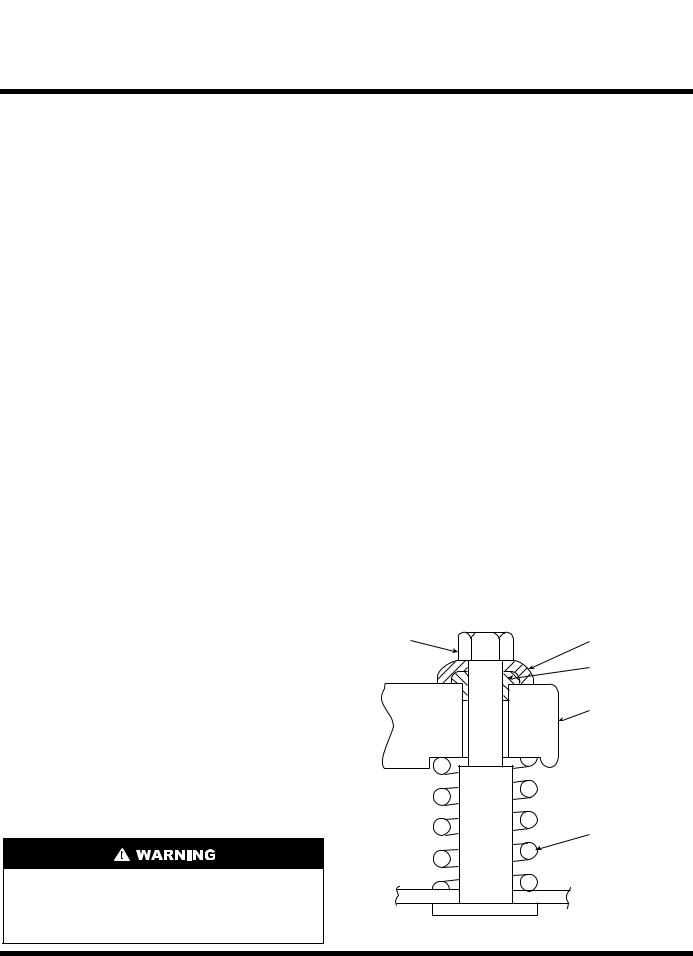

Check Compressor Mounting — Loosen compressor mounting bolts and remove shipping blocks from under compressor. Tighten all 4 bolts on compressor. Loosen each bolt just enough until the flanged washer can be moved sideways with finger pressure. See Fig. 1.

NOTE: Be sure that compressor floats freely on mounting springs.

SELF-LOCKING |

SNUBBER FLANGED |

BOLT |

WASHER |

|

NEOPRENE |

|

SNUBBER |

|

COMPRESSOR FOOT |

ISOLATION SPRING

Fig. 1 — Compressor Mounting

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book |

2 |

2 |

4 |

4 |

PC 802 |

Catalog No. 530-607 |

Printed in U.S.A. |

Form 06/07E-2SI |

Pg 1 |

7-02 |

Replaces: 06/07E-1SI |

Tab |

1b |

2a |

2b |

3a |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

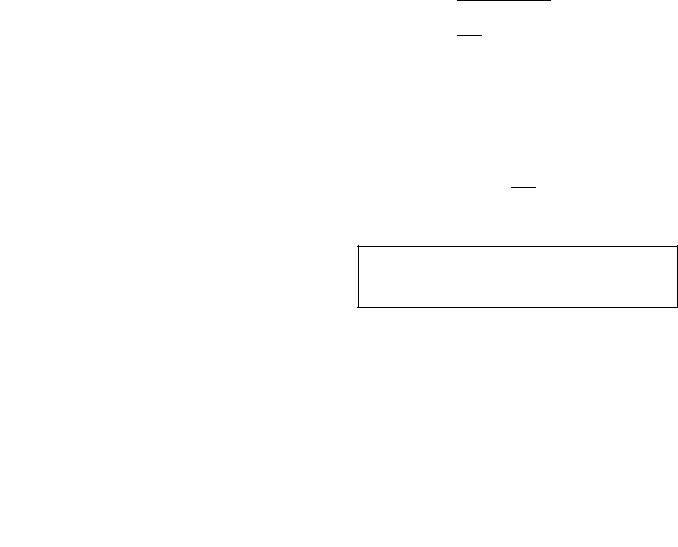

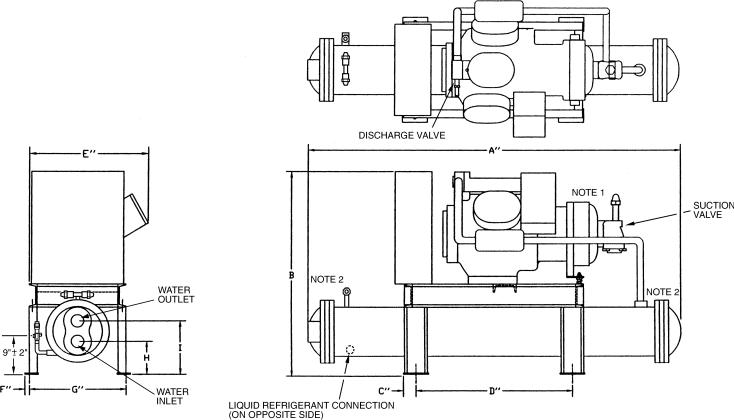

Piping Connections — Attach water supply and return lines to connections indicated on condensing unit (Fig. 2). Water leaving condenser should not be connected directly into sewer lines; check local codes.

Attach refrigerant liquid and suction lines to condensing unit (Fig. 2); suction and discharge lines to compressor unit (Fig. 3 and 4). Discharge line muffler and check valve are factory supplied with 06E compressor units. Install the muffler as close to shutoff valve as possible and install the check valve in the discharge line close to the muffler, on the downstream side. When soldering or brazing piping to valves, disassemble the valve or wrap it in wet cloth to prevent damage by heat. Allow flexibility in suction line so compressor suction valve may be moved aside for access to suction strainer.

A solenoid valve is necessary for single pumpout control used on 06E and 07E units. Install the valve (field supplied) in the liquid line, just before expansion valve. A filter drier of adequate size should be installed in liquid line between condenser and solenoid valve.

Pressure relief valve located on top of condenser will open to relieve excessive pressure, allowing refrigerant to escape. Most local codes require piping from valve to outdoors.

Refer to Carrier System Design Manual for standard piping techniques.

Electrical Connections

UNBALANCED 3-PHASE SUPPLY VOLTAGE — Never operate a motor where a phase imbalance in supply voltage is greater than 2%. Use the following formula to determine the % voltage imbalance:

% Voltage Imbalance =

100 x |

max voltage deviation from avg voltage |

|

average voltage |

Example: Supply voltage is 240-3-60

AB = 243 volts

BC = 236 volts

AC = 238 volts

Average Voltage =

243 + 236 + 238

3

717 = 3

= 239 volts

Determine maximum deviation from average voltage:

(AB) 243 – 239 = 4 volts (BC) 239 – 236 = 3 volts (AC) 239 – 238 = 1 volt

Maximum deviation is 4 volts. Determine % voltage imbalance:

% Voltage Imbalance = 100 x 2394 = 1.7%

This amount of phase imbalance is satisfactory as it is below the maximum allowable 2%.

IMPORTANT: If the supply voltage phase imbalance is more than 2%, contact your local electric utility company immediately. Allowing the unit to operate with a voltage imbalance in excess of 2% may void the warranty.

POWER SUPPLY — Field wiring must comply with local and national codes. See Table 1.

Install a branch circuit fused disconnect of adequate size to handle starting current. The disconnect must be within sight from the unit and readily accessible, in compliance with National Electrical Code (NEC), Section 440-14.

Line power is brought into control center through indicated opening. Connect line power supply to terminal block TB1; connect power leads to terminals L1, L2 and L3. Connect control circuit power supply (115 volts) to terminals 1 and 15 on terminal block TB2. Refer to Fig. 5.

Wiring connections for field-supplied equipment are shown on wiring diagram. See Fig. 6.

ACCESSORIES — Field-installed accessories for the 06E and 07E units are control circuit transformer and gage panel (3 gages). Refer to accessory literature for installation instructions.

2

DIMENSIONS (in.)

UNIT 07E |

VOLTS |

A |

B |

C |

D |

E |

F |

G |

H |

I |

|

A022 |

208/230 |

66 |

493/4 |

23/4 |

34 |

271/2 |

1 |

21 |

59/16 |

95/16 |

|

460, 575 |

66 |

433/4 |

23/4 |

34 |

26 |

1 |

21 |

59/16 |

95/16 |

||

|

|||||||||||

B027 |

208/230 |

78 |

493/4 |

23/4 |

34 |

271/2 |

1 |

21 |

59/16 |

95/16 |

|

460, 575 |

78 |

433/4 |

23/4 |

34 |

26 |

1 |

21 |

59/16 |

95/16 |

||

|

|||||||||||

B033 |

208/230 |

78 |

493/4 |

23/4 |

34 |

271/2 |

1 |

21 |

59/16 |

95/16 |

|

460, 575 |

78 |

433/4 |

23/4 |

34 |

26 |

1 |

21 |

59/16 |

95/16 |

||

|

|||||||||||

D044 |

208/230 |

691/2 |

493/4 |

23/4 |

34 |

271/2 |

1 |

21 |

41/8 |

85/8 |

|

460, 575 |

691/2 |

493/4 |

23/4 |

34 |

271/2 |

1 |

21 |

41/8 |

85/8 |

||

|

NOTES:

1.For standard service practices, such as trouble-

shooting and refrigerant charging, allow a minimum 2′-6″ clearance around the unit.

2.Recommended service space for condenser tube removal is one condenser length at either end.

3.For compressor removal, allow a minimum 3′ wide access aisle to and from the unit.

4.Local codes or jurisdiction may prevail for unit clearances.

3

Fig. 2 — 07E Water-Cooled Condensing Units

NOTES:

1. For standard service practices, such as troubleshooting and refrigerant charging, allow a minimum 2′-6″ clearance around the unit.

2. For compressor removal, allow a minimum 3′ wide access aisle to and from the unit.

3. Local codes or jurisdiction may prevail for unit clearances.

DIMENSIONS (in.)

06E UNIT |

VOLTAGE |

A |

B |

C |

D |

E |

F |

G |

|

V022 |

208/230 |

481/4 |

35 |

367/8 |

11/2 |

271/2 |

1 |

191/2 |

|

460,575 |

481/4 |

29 |

367/8 |

11/2 |

26 |

1 |

191/2 |

||

|

|||||||||

W027 |

208/230 |

501/4 |

35 |

367/8 |

11/2 |

271/2 |

1 |

191/2 |

|

460,575 |

501/4 |

29 |

367/8 |

11/2 |

26 |

1 |

191/2 |

||

|

|||||||||

W033 |

208/230 |

501/4 |

35 |

367/8 |

11/2 |

271/2 |

1 |

191/2 |

|

460,575 |

501/4 |

29 |

367/8 |

11/2 |

26 |

1 |

191/2 |

||

|

|||||||||

W044 |

208/230 |

501/4 |

35 |

367/8 |

11/2 |

271/2 |

1 |

191/2 |

|

460,575 |

501/4 |

35 |

367/8 |

11/2 |

271/2 |

1 |

191/2 |

||

|

Fig. 3 — 06E Hermetic Compressor Units

Fig. 4 — 06E Compressors

4

Table 1 — Electrical Data — Compressor Motor With Circuit Breaker

|

|

|

COMPRESSOR MOTOR DATA |

|

|

CIRCUIT BREAKER |

|||||||

Compressor |

Voltage |

|

Maximum |

Maximum |

|

LRA-PW |

Motor |

Recommended |

|

|

|

|

|

|

|

Winding |

|

|

|

Recommended |

|||||||

Part Number |

(3 Ph - 60 Hz) |

Hp |

Must Trip |

RLA |

LRA-XL |

(first |

Resistance |

Circuit Breaker |

MHA |

MTA |

LRA |

RLA |

|

06E* |

|

|

Amps |

|

|

winding) |

(Ohms) |

Part No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

250 |

208/230 |

|

108 |

87 |

345 |

207 |

0.32 |

HH83XB336 |

91 |

104 |

350 |

74.3 |

|

575 |

20 |

45 |

36 |

120 |

72 |

2.2 |

XA461 |

33 |

38 |

124 |

27.1 |

|

|

|

460 |

|

54 |

44 |

173 |

104 |

1.3 |

XA424 |

42 |

49 |

175 |

35.0 |

|

265 |

208/230 |

|

140 |

112 |

446 |

268 |

0.27 |

HH83XC509 |

110 |

127 |

420 |

90.7 |

|

575 |

25 |

57 |

46 |

164 |

98 |

1.6 |

XA469 |

46 |

53 |

164 |

37.9 |

|

A |

|

460 |

|

70 |

56 |

223 |

134 |

1.1 |

XA426 |

55 |

643 |

210 |

45.7 |

275 |

208/230 |

|

168 |

135 |

506 |

304 |

0.22 |

HH83XC539 |

142 |

163 |

507 |

116.4 |

|

|

|

||||||||||||

|

575 |

30 |

65 |

52 |

176 |

106 |

1.3 |

XA430 |

50 |

58 |

168 |

41.4 |

|

|

|

460 |

|

84 |

68 |

253 |

152 |

0.9 |

XA425 |

63 |

73 |

210 |

52.1 |

|

299 |

208/230 |

|

236 |

189 |

690 |

414 |

0.15 |

HH83XC537 |

187 |

215 |

636 |

153.6 |

|

575 |

40 |

94 |

75 |

276 |

165 |

1.0 |

XA551 |

74 |

85 |

236 |

60.7 |

|

|

|

460 |

|

118 |

95 |

345 |

207 |

0.58 |

XA550 |

92 |

106 |

295 |

75.7 |

|

LEGEND |

LRA |

— Locked Rotor Amps |

MHA — Must Hold Amps |

|

MTA |

— Must-Trip Amps |

PW |

— Part-Winding (Start) |

RLA |

— Rated Load Amps |

XL |

— Across-the-Line (Start) |

*Refer to physical data table to match compressor with correct compressor or water-cooled condensing unit.

NOTES:

1.Compressor MTA and RLA values are maximum figures.

2.LRA values for PW second winding = 1/2 the LRA – XL value.

3.3-Pole XL circuit breakers shown, other 3-Pole XL alternates and 6-Pole PW breakers available. Terminal lugs for circuit breakers available in package 06EA660152 (not shown).

|

LEGEND |

C1 |

— Compressor Contactor |

C2 |

— Compressor Contactor (PW) |

CCB |

— Compressor Circuit Breaker |

CHR |

— Crankcase Heater Relay |

CR |

— Control Relay |

FU |

— Fuse |

GND |

— Ground |

HPS |

— High-Pressure Switch |

LPS |

— Low-Pressure Switch |

NEC |

— National Electrical Code |

NEMA — National Electrical |

|

|

Manufacturer’s Association |

OPS |

— Oil Pressure Switch |

POR |

— Pumpout Relay |

TB |

— Terminal Block |

TDR |

— Time Delay Relay |

TM |

— Timer Motor |

TR |

— Timer Relay |

4.Recommended RLA value shown is determined by: circuit breaker must trip value 1.40. Use this recommended (and minimum) RLA value to determine nameplate stamping, minimum contactor sizing, and wire sizing. RECOMMENDED RLA FOR 06E COMPRESSORS EQUALS: MUST-TRIP (MTA) OF

CARLYLE APPROVED OVERCURRENT DEVICE BEING USED 1.40

5.Compressor operating amps at any specific condition can only be determined from a performance curve.

6.Ohm values for resistance are approximate and shown for reference purposes only. Motors from different vendors and motors of different efficiencies can differ up to 15% from data shown.

7.Electrical data for compressor part numbers 06ER, 06EM and 50 Hz models (not shown) are available from Carrier Sales Representative.

Fig. 5 — Component Location

5

|

|

|

LEGEND |

AUX |

— Auxiliary |

M1 |

— Evaporator Fan or |

C |

— Compressor Contactor |

|

Chilled Water Pump |

C1 |

— Compressor Contactor |

M2 |

— Cooling Tower Pump |

|

(XL start and first step of PW start) |

M3 |

— Cooling Tower Fan |

C2 |

— Compressor Contactor |

NEC |

— National Electrical Code |

|

(PW second step) |

OPS |

— Oil-Pressure Switch |

CH |

— Crankcase Heater |

POR |

— Pumpout Relay |

CHR |

— Crankcase Heater Relay |

PW |

— Part Wind |

CR |

— Control Relay |

SW |

— Start-Stop-Reset Switch |

DTS |

— Discharge Temperature Sensor |

TB |

— Terminal Block |

DX |

— Direct Expansion |

TDR |

— Time Delay Relay |

FU |

— Fuse |

TM |

— Timer Motor |

HPS |

— High-Pressure Switch |

TR |

— Timer Relay |

LLS |

— Liquid Line Solenoid Valve |

XL |

— Across-the-Line |

LPS |

— Low-Pressure Switch |

|

|

Terminal Block Connector

Unmarked Terminal

Marked Terminal

Factory Wiring

Field Control Wiring

To indicate common potential only; not to represent wiring.

Splice

NOTES:

1.Factory wiring is in compliance with NEC. Any field modifications or additions must be in compliance with all applicable codes. Use copper, copper-clad aluminum for field power supply only.

2.Field power supply wiring must be 75 C minimum.

3.Compressor thermally protected. Three-phase motors are protected against primary single-phasing condition.

4.Pilot duty control must be field supplied. Minimum contact rating must be 25 va.

5.60 Hz units have 120 volt control circuit. 50 Hz units have 230 volt control circuit. A separate source of supply at the correct voltage must be field supplied through a fused disconnect device with a

maximum rating of 15 A to TB2 connections L1 (Hot Side) and L2 (Neutral).

6.Open control circuit disconnect switch for servicing only. Disconnect must remain closed for crankcase heater to operate.

7.A transformer of the following rating may be field supplied for 60 Hz units: 350 va.

8.Transformer must be fused and grounded per applicable codes.

9.If any of the original wiring furnished must be replaced, it must be replaced with 90 C wire or its equivalent.

10.Wiring is shown for single pumpout control. Single pumpout control should not be used on direct-expansion (DX) cooler applications (see lower diagram for wiring when applied with DX cooler).

Fig. 6 — Control Circuit Wiring for 06E/07E Units

6

Loading...

Loading...