Zte ZXG10 BS21 Maintenance Manual

ZXG10 BS21

Compact Out door BTS for GSM

Maintenance Manual

V ersion 2.2

ZTE CORPORATION

ZTE Plaza, Keji Road South,

Hi-Tech Industrial Park,

Nanshan District, Shenzhen,

P. R. China

518057

Tel: (86) 755 26771900 800-9830-9830

Fax: (86) 755 26772236

URL: http://support.zte.com.cn

E-mail: doc@zte.com.cn

LEGAL INFORMATION

Copyright © 2005 ZTE CORPORATION.

The contents of this document are protected by copyright laws and international treaties. Any reproduction or distribution of

this document or any portion of this document, in any form by any means, without the prior written consent of ZTE

CORPORATION is prohibited. Additionally, the contents of this document are protected by contractual confidentiality

obligations.

All company, brand and product names are trade or service marks, or regis tered trade or service marks, of ZTE

CORPORATION or of their respective owners.

This document is provided “as is”, and all express, implied, or statutory warranties, representations or conditions are

disclaimed, including without limitatio n any implied warranty of merchantability, fitness f or a p a rticular purpose, title or noninfringement. ZTE CORPORATION and its lice nsors shall not be liable for damages resulting from the use of or reliance on

the information contained herein.

ZTE CORPORATION or its licensors may have current or pending intellectual property rights or applications covering the

subject matter of this document. Except as expressly provided in any written license between ZTE CORPORATIO N and its

licensee, the user of this document shall n ot acquire any license to the subject matter herein.

The contents of this document and all policies of ZTE CORPORATION, including without limitation policies related to support

or training are subject to change without notice.

Revision History

Date Revision No. Serial No. Description

05/17//2005 R1.0 sjzl20051442

05/19/2007 R1.1 sjzl20051442 Updated

ZTE CORPORATION

Values Your Comments & Suggestions!

Your opinion is of great value and will help us improve the quality of our

product documentation and offer better services to our customers.

Please fax to: (86) 755-26772236; or mail to Publications R&D

Department, ZTE CORPORATION, ZTE Plaza, A Wing, Keji Road South,

Hi-Tech Industrial Park, Shenzhen, P. R. China 518057.

Thank you for your cooperation!

Document

Name

ZXG10 BS21 (V2.2) Compact Outdoor BTS for GSM Maintenance Manual

Product

Version

V2.2

Document

Revision Number

R1.1

Equipment Installation Date

Presentation:

(Introductions, Procedures, Illustrations, Completeness, Level of Detail, Organization,

Appearance)

Good Fair Average Poor Bad N/A

Accessibility:

(Contents, Index, Headings, Numbering, Glossary)

Good Fair Average Poor Bad N/A

Your evaluation

of this

documentation

Intelligibility:

(Language, Vocabulary, Readability & Clarity, Technical Accuracy, Content)

Good Fair Average Poor Bad N/A

Your

suggestions for

improvement

of this

documentation

Please check the suggestions which you feel can improve this documentation:

Improve the overview/introduction Make it more concise/brief

Improve the Contents Add more step-by-step procedures/tutorials

Improve the organization Add more troubleshooting information

Include more figures Make it less technical Add more examples

Add more/better quick reference aids Add more detail Improve the index

Other suggestions

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

# Please feel free to write any comments on an attached sheet.

If you wish to be contacted regarding your comments, please complete the following:

Name Company

Postcode Address

Telephone E-mail

This page is intentionally blank.

Content s

About this Maintenance Manual ...............................................................xi

Purpose of this Maintenance Manual........................................................................ xi

Typographical Conventions.....................................................................................xii

Mouse Operation Conventions................................................................................xiii

How to Get in Touch .............................................................................................xiii

Customer Support .................................................................................................................xiii

Documentation Support ......................................................................................................... xiii

Chapter 1........................................................................................ 1

Maintenance Security.................................................................................1

Overview ...............................................................................................................2

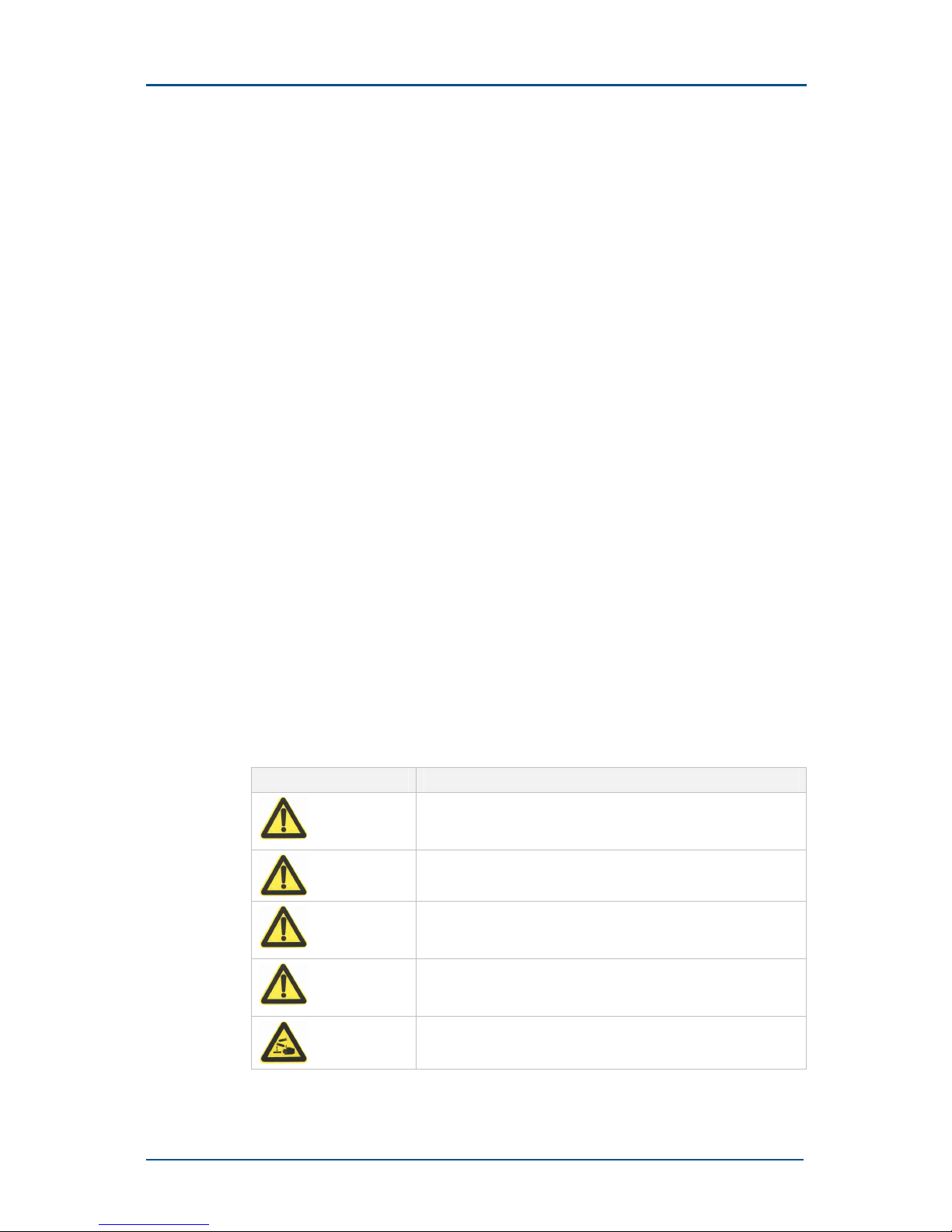

Symbol Description................................................................................................. 2

Toxic Substances.................................................................................................... 4

Beryllia ...................................................................................................................................4

Hydrochloride..........................................................................................................................4

Electrical Safety...................................................................................................... 5

Tools ......................................................................................................................................5

High Voltage ...........................................................................................................................5

Power Cord .............................................................................................................................5

Drilling ....................................................................................................................................5

Thunder ..................................................................................................................................6

Antistatic ............................................................................................................... 6

Storage Battery ...................................................................................................... 7

Short Circuit ............................................................................................................................ 8

Hazardous Gases .................................................................................................................... 8

High Temperature ...................................................................................................................8

Acid Liquid ..............................................................................................................................8

Storage Battery Replacement ..................................................................................................9

Electromagnetic Radiation ....................................................................................... 9

Working at Heights ............................................................................................... 10

Hoisting Heavy Objects..........................................................................................................10

Using Ladders .......................................................................................................................10

Fans .................................................................................................................... 11

High Temperature ................................................................................................ 11

Board Plugging/Unplugging ................................................................................... 11

Do-Nots ............................................................................................................... 12

Chapter 2...................................................................................... 13

Maintenance Overview............................................................................ 13

Categories of Daily Maintenance............................................................................. 14

Common Maintenance Methods ............................................................................. 14

Precautions on Daily Maintenance .......................................................................... 16

Chapter 3...................................................................................... 19

Routine Maintenance .............................................................................. 19

Daily Routine Maintenance .................................................................................... 20

Viewing Current Alarms .........................................................................................................20

Viewing Alarms in Each Module .............................................................................................. 22

Viewing Current Notification Information ................................................................................ 25

Viewing Real-time Attributes of a Carrier ................................................................................ 29

Creating Daily Performance Report......................................................................................... 30

Creating a Daily Traffic Report................................................................................................ 35

Weekly Routine Maintenance ................................................................................. 39

Viewing History Alarms ..........................................................................................................39

Collecting Alarm Frequency Statistics ..................................................................................... 44

Analyzing Performance Report ............................................................................................... 48

Monthly Routine Maintenance ................................................................................ 48

Creating Monthly Performance Report ....................................................................................48

Collecting Statistics of Bad Cells ............................................................................................. 53

Analyzing and Processing Reports ..........................................................................................57

Generating Monthly Operation Report..................................................................................... 58

Biannual Routine Maintenance ............................................................................... 58

Checking BS21 AC Power ...................................................................................................... 59

Checking Running Status of Heat Exchanger........................................................................... 60

Checking Dust-Proof Status ................................................................................................... 60

Checking Running Status of CMM Module ...............................................................................61

Checking Running Status of ETRM Module .............................................................................. 64

Checking Running Status of ECDU Module .............................................................................. 67

Measuring Amplifier Output Power ......................................................................................... 69

Measuring SWR of Antenna Feeder ........................................................................................ 69

Calibrating Clock ................................................................................................................... 71

Checking Fastness of Antennae and Towers ............................................................................ 72

Checking Obliquity of Directional Antennae ............................................................................. 72

Checking whether Antenna Feeder Connectors and Lightning Protection Grounding Kit are

Waterproof............................................................................................................................74

Checking E1 Interfaces ..........................................................................................................75

Checking Antenna Feeder Interfaces ......................................................................................76

Checking Whether Lightning Protection Arrester is in Good Condition .......................................76

Checking whether Grounding Cable is Reliable ........................................................................78

Grounding Resistance Test..................................................................................................... 78

Checking Running Status of Transmission Equipment.............................................................. 79

Checking Running Status of UPS ............................................................................................79

Chapter 4...................................................................................... 81

Notification and Handling ....................................................................... 81

Summary of Notification Information ...................................................................... 82

No Traffic Notification in BS Cell ............................................................................. 82

Chapter 5...................................................................................... 85

Alarms and Handling............................................................................... 85

Summary of Alarms.............................................................................................. 86

CMM Alarms......................................................................................................... 90

CMM Power Failure ................................................................................................................ 90

LAPD Long-Time Link Disconnection .......................................................................................91

CMM's FLASH Programming Failure ........................................................................................ 92

HW Long Time Link Disconnection .......................................................................................... 92

Power Over/Under-Voltage Alarms ......................................................................................... 93

Clock Exceptions (13M, FCLK, SYNCLK).................................................................................. 93

Software Accumulative Frame Number Inconsistent with Hardware Accumulative Frame Number

............................................................................................................................................94

Alarms of Communication Link to Main Rack...........................................................................95

Alarm with Communication Link between Master Rack and Left/Right Slave Rack ..................... 95

E1 Carrier Wave Receiving Alarm (A, D and E interfaces) ........................................................96

Out-of-Frame Alarm at Receiving End of E1 interfaces (A, D and E interfaces).......................... 97

Forward Slip Code Indication at Transmitting End of E1 Interfaces (A, D and E interfaces) ........97

Backward Slip Code Indication at Transmitting End of E1 Interfaces (A, D and E Interfaces) ..... 98

Forward Slip Code Indication at Receiving End of E1 Interfaces (A, D and E Interfaces) ............99

Backward Slip Code Indication at Receiving End of E1 Interfaces (A, D and E Interfaces) ........100

ETRM Alarm ....................................................................................................... 101

Dry Contact Alarm ............................................................................................................... 101

LNA (Low Noise Amplifier) Alarm.......................................................................................... 102

Power Alarm for Tower Mounted Amplifier ............................................................................102

AEM SWR Minor Alarm ........................................................................................................ 103

AEM SWR Major Alarm ........................................................................................................ 103

AEM Power Alarm ................................................................................................................ 104

AEM Type Alarm.................................................................................................................. 104

AEM Not-in-Position Alarm ................................................................................................... 105

TPU’s CHP DSP0 Initialization Failure ....................................................................................105

TPU’s CHP DSP1~3 Initialization Failure ................................................................................ 106

RFAD6620 Initialization Failure ............................................................................................. 107

RFAD6620 Resource Unavailable .......................................................................................... 107

CIP Resource Unavailable .................................................................................................... 108

TPU’s FLASH MEMORY Error ................................................................................................. 109

WATCHDOG Overflow in TPU’s CHP DSP0............................................................................. 109

WATCHDOG Overflow in TPU’s CHP DSP1~3 ........................................................................110

WATCHDOG Overflow in FUC ............................................................................................... 111

Parameter Configuration Error in TPU’s Channel 0~7 ............................................................ 111

Inconsistent Cell Parameter Configuration............................................................................. 112

Inconsistent FUC Software Versions ..................................................................................... 112

Inconsistent CHP Software Versions .....................................................................................113

Temporary No Response from FUC’s L3 Software.................................................................. 113

Disconnected LAPD Link between FUC and BSC ....................................................................114

Interrupted Communication between CMM and FUC ............................................................. 115

TPU’s CIP Initialization Failure .............................................................................................. 116

CIP Parameter Configuration Error ....................................................................................... 116

WATCHDOG Overflow in TPU’s CIP ....................................................................................... 117

Inconsistent CIP Software Versions ...................................................................................... 117

Alarm with Clock between TPU and CMM .............................................................................. 118

TPU Power Alarm ................................................................................................................ 119

TPU Frame Number Alarm ................................................................................................... 119

Receiving RF Local Oscillator PLL1~2 out of Lock .................................................................. 120

Transmitting RF Local Oscillator PLL1~2 out of Lock .............................................................. 121

52 M Reference Clock PLL Out of Lock .................................................................................. 121

Transmitting IF Local Oscillator PLL Out of Lock..................................................................... 122

PA Voltage SWR Alarm ........................................................................................................ 123

PA Overheat Minor Alarm..................................................................................................... 123

PA Overheat Major Alarm .................................................................................................... 124

PA Output Power Alarm ....................................................................................................... 124

PAS Power Amplifier Power Supply Over-voltage Alarm......................................................... 125

PAS Power Amplifier Power Supply Under-voltage Alarm ....................................................... 125

DLRC_AL Downward Link Check Error .................................................................................. 126

Chapter 6.................................................................................... 127

Troubleshooting .................................................................................... 127

Summary of Common Problems .......................................................................... 128

List of Major Faults.............................................................................................. 129

Troubleshooting Procedure of Components Failures ............................................... 129

Troubleshooting at BS Commissioning Stage......................................................... 130

BS Works Normally but Mobile Phone Has no Signals or Cannot Access Network .................... 130

Handling of SWR Major Alarms............................................................................................. 132

Poor Conversation Quality at BS........................................................................................... 134

Troubleshooting in BS Maintenance Stage............................................................. 137

Shrinkage of BS Coverage ................................................................................................... 137

Cell Carrier not Occupied ..................................................................................................... 140

LAPD Broken-Link of BS Carrier............................................................................................ 142

BS in Normal Status but BS Handover Is Abnormal............................................................... 147

Handling Lightning-Stricken BS Faults .................................................................................. 149

MS Signal is not Stable in Idle State .....................................................................................151

Unstable MS Signal in Conversation...................................................................................... 153

TCH Assigned with Low Success Ratio and Calls Are Difficult to Get through ........................... 154

MS Echo during Conversation............................................................................................... 156

Troubleshooting in BS Cutover and Expansion Stages............................................ 158

Unidirectional Mobile Phone Calls .......................................................................................... 158

SDCCH Occupied too Long ................................................................................................... 160

Call Drop Rate in Cell Rises Suddenly ................................................................................... 163

Chapter 7.................................................................................... 167

Collection of Maintenance Experience.................................................. 167

Reference for Wireless Parameters Adjustment during Commissioning .................... 168

Adjusting List of Adjacent Cells and List of Carrier-Sense Frequencies .................................... 168

Adjusting Wireless Parameters ............................................................................................. 170

Others ................................................................................................................................171

Analysis of Bird928 Mobile Phone’s Failure to Access Network................................. 172

Configuration Method for Intra-Cell Handover ....................................................... 174

Appendix A .................................................................................175

Replacement of Modules and Parts ...................................................... 175

Overview ........................................................................................................... 175

CMM Replacement .............................................................................................. 176

ETRM Replacement............................................................................................. 177

AEM Replacement............................................................................................... 178

PSM Replacement............................................................................................... 179

Power Lightning Protection Module Replacement ................................................... 180

Backplane Replacement ...................................................................................... 181

Heat Exchanger Replacement .............................................................................. 182

Trunk Cable Replacement.................................................................................... 183

RF Cable Replacement ........................................................................................ 184

Antenna Feeder Lightning Arrester replacement .................................................... 185

Cabinet-Bottom 1/2 Soft Jumper Replacement...................................................... 187

Tower Top 1/2” Soft Jumper Replacement ............................................................ 188

Feeder Connectors Replacement .......................................................................... 190

Tower Amplifier Replacement .............................................................................. 191

Antenna Replacement ......................................................................................... 192

Appendix B .................................................................................195

Common Maintenance Tables............................................................... 195

Daily Maintenance Record Table........................................................................... 195

Weekly Maintenance Record Table ....................................................................... 196

Monthly Maintenance Record Table ...................................................................... 197

Biannual Maintenance Record Table ..................................................................... 198

Emergency Failure Record Table .......................................................................... 199

Appendix C .................................................................................201

Use of Common Instruments and Meters ............................................ 201

SAGEM (OT35) Test Mobile Phone........................................................................ 201

Basic Functions ................................................................................................................... 201

Operation Description .......................................................................................................... 202

Engineering Test Mode of ZTE289 Mobile Phone .................................................... 211

Key Description ................................................................................................................... 211

How to Enter Engineering Mode ........................................................................................... 211

How to Close Engineering Mode ........................................................................................... 211

Instructions of Engineering Mode Menu ................................................................................ 211

BIRD Power Meter .............................................................................................. 214

BIRD Power Meter Components ...........................................................................................214

Usage .................................................................................................................................215

HP8954E Spectrum Analyzer ............................................................................... 217

Components ....................................................................................................................... 218

Usage .................................................................................................................................218

Antenna Feeder Tester (SITE MASTER S332B) ...................................................... 222

Procedure for Testing SWR .................................................................................................. 222

Test Procedure of DTF ......................................................................................................... 223

Appendix D.................................................................................225

Operation Maintenance Quality Indexes of Certain Telecom Network

(Wireless Part)...................................................................................... 225

Abbreviations .............................................................................227

Figures........................................................................................233

Tables .........................................................................................235

Confidential and Proprietary Information of ZTE CORPORATION xi

About this Maintenance

Manual

ZXG10 BS21 (V2.2) Base Station Transceiver Station Maintenance Manual

describes maintenance safety, routine maintenance items and methods,

handling of alarm and notification information, handling of common faults

and maintenance experience of the ZXG10 BS21 (V2.2). The manual

serves as a reference manual in the maintenance and fault handling of the

ZXG10 BS21 (V2.2) equipment.

The complete set of manuals is listed below:

ZXG10 BS21 (V2.2) Compact Outdoor BTS for GSM Guide to

Documentation

ZXG10 BS21 (V2.2) Compact Outdoor BTS for GSM Technical Manual

ZXG10 BS21 (V2.2) Compact Outdoor BTS for GSM Hardware Manual

ZXG10 BS21 (V2.2) Compact Outdoor BTS for GSM Installation Manual

ZXG10 BS21 (V2.2) Compact Outdoor BTS for GSM Maintenance Manual

Purpose of this Maintenance

Manual

Chapter 1, Maintenance Security, presents the meanings of the signs used

in this manual. It also covers some safety precautions related to the

installation procedure, such as precautions against high voltage,

thunderstorms and overhead operations.

Chapter 2, Maintenance Overview, introduces daily maintenance

categories, common maintenance methods and some precautions on

maintenance of ZXG10 BS21 (V2.2) base station controllers.

Chapter 3, Routine Maintenance, explains routine maintenance items of

the ZXG10 BS21 (V2.2) base station controller equipment and details

instrument requirements, check methods and fault handling of individual

maintenance items; among them, the version of the OMCR interface

diagram is the software OMCRV2.52.02a for the time being.

ZXG10 BS21 (V2.2) Compact Outdoor BTS for GSM Maintenance Manual

xii Confidential and Proprietary Information of ZTE CORPORATION

Chapter 4, Notification and Handling, provides notification messages

related to the ZXG10 BS21 (V2.2) base station controller in the ZXG10BSS base station subsystem so that the system maintenance personnel

can have a clear understanding of notification messages in the system,

including meanings causes and handling of notification messages.

Chapter 5, Alarms and Handling, covers the alarm information in the

ZXG10-BSS Base Station Subsystem related to ZXG10 BS21 (V2.2), in

order for system maintenance personnel to have a clear idea about the

alarm messages given by the system, including their meaning, cause and

way of handling.

Chapter 6, Troubleshooting, gives an introduction to the universal

methods for the common faults of the ZXG10 BS21 (V2.2), including fault

symptoms, source, analysis, location and troubleshooting.

Chapter 7, Collection of Maintenance Experience, provides some

experience derived from project maintenance for your reference.

Appendix A, Replacement of Modules and Parts, describes the procedure

for and precautions on the replacement of modules and backplanes.

Appendix B, Common Maintenance Tables, lists forms used in routine

maintenance.

Appendix C, Use of common Instruments and Meters, introduces the

instructions on common instruments and meters used for maintaining the

ZXG10 BS21 (V2.2) transceiver station.

Appendix D, Operation Maintenance Quality Indexes of Certain Telecom

Network (Wireless Part), describes the telecommunication network

operation maintenance quality indexes (wireless part) as required by a

certain carrier for your reference.

Typographical Conventions

ZTE documents employ the following typographical conventions.

TABLE 1 TYPOGRAPHICAL CONVENTIONS

Typeface Meaning

Italics References to other guides and documents; parameter values

“Quotes” Links on screens

Bold Menus, menu options, input fields, radio button names, check

boxes, drop-down lists, dialog box names, window names

Bold, with first

letter capitalized

Keys on the keyboard and buttons on screens and company

name

Constant width

Text that you type, program code, files and directory names,

and function names

About this Maintenance Manual

Confidential and Proprietary Information of ZTE CORPORATION xiii

Typeface Meaning

[ ] Optional parameters

{ }

Mandatory parameters

| Select one of the parameters that are delimited by it

Note: Provides additional information about a certain topic

Checkpoint: Indicates that a particular step needs to be checked

before proceeding further

Tip: Indicates a suggestion or hint to make things easier or

more productive for the reader

Mouse Operation Conventions

TABLE 2 MOUSE OPERATION CONVENTIONS

Typeface Meaning

Click Refers to clicking the primary mouse button (usually the left

mouse button) once.

Double-click Refers to quickly clicking the primary mouse button (usually the

left mouse button) twice.

Right-click Refers to clicking the secondary mouse button (usually the right

mouse button) once.

Drag Refers to pressing and holding a mouse button and moving the

mouse.

How to Get in Touch

The following sections provide information on how to obtain support for

the documentation and the software.

Customer Support

If you have problems, questions, comments, or suggestions regarding

your product, contact us by e-mail at support@zte.com.cn. You can also

call our customer support center at (86) 755 26771900 and (86) 8009830-9830.

Documentation Support

ZTE welcomes your comments and suggestions on the quality and

usefulness of this document. For further questions, comments, or

ZXG10 BS21 (V2.2) Compact Outdoor BTS for GSM Maintenance Manual

xiv Confidential and Proprietary Information of ZTE CORPORATION

suggestions on the documentation, you can contact us by e-mail at

doc@zte.com.cn; or you can fax your comments and suggestions to (86)

755 26772236. You can also explore our website at

http://support.zte.com.cn, which contains various interesting subjects like

documentation, knowledge base, forum and service request.

Confidential and Proprietary Information of ZTE CORPORATION 1

Chapter 1

Maintenance Security

In this chapter, you will learn about:

Safety regulations to be observed

Instructions on the safety symbols

ZXG10 BS21 (V2.2) Compact Outdoor BTS for GSM Maintenance Manual

2 Confidential and Proprietary Information of ZTE CORPORATION

Overview

To avoid any accident, please carefully read safety instructions in this

chapter before conducting any maintenance operation on the ZXG10 BS21

(V2.2) device. If there are local safety specifications to be followed, the

safety instructions here shall only serve as a supplement to the local

safety specifications. If there is any conflict between them, the local safety

specifications shall prevail.

Maintenance personnel of the ZTE BS21 (V2.2) device should have the

basic safe operation knowledge, pass the relevant technical training,

correctly grasp the device operation and maintenance methods as well as

obtain the corresponding qualification.

During operation and maintenance on the ZTE BS21 (V2.2) device, please

strictly observe the equipment precautions and special safety instructions

provided by ZTE Corporation.

In addition, the safety instructions listed in this manual are only those

calling for special attentions of users provided by ZTE. ZTE Corporation

shall not be liable for any behavior against the general safe operation

requirements or against the safety standards for the design, production

and use of the equipment.

Symbol Description

Safety symbols quoted in this manual are shown in Table 3, prompting

users to follow safety instructions during equipment maintenance.

TABLE 3 SAFETY SIGNS

Safety Signs Meaning

Danger: Indicates an imminently hazardous situation, which if

not avoided, will result in death or serious injury. This signal

word should be limited to only extreme situations.

Warning: Indicates a potentially hazardous situation, which if

not avoided, could result in death or serious injury.

Caution: Indicates a potentially hazardous situation, which if not

avoided, could result in minor or moderate injury. It may also

be used to alert against unsafe practices.

Note: Indicates a potentially hazardous situation, which if not

avoided, could result in injuries, equipment damage or

interruption of services.

Erosion: Beware of erosion.

Chapter 1 - Maintenance Security

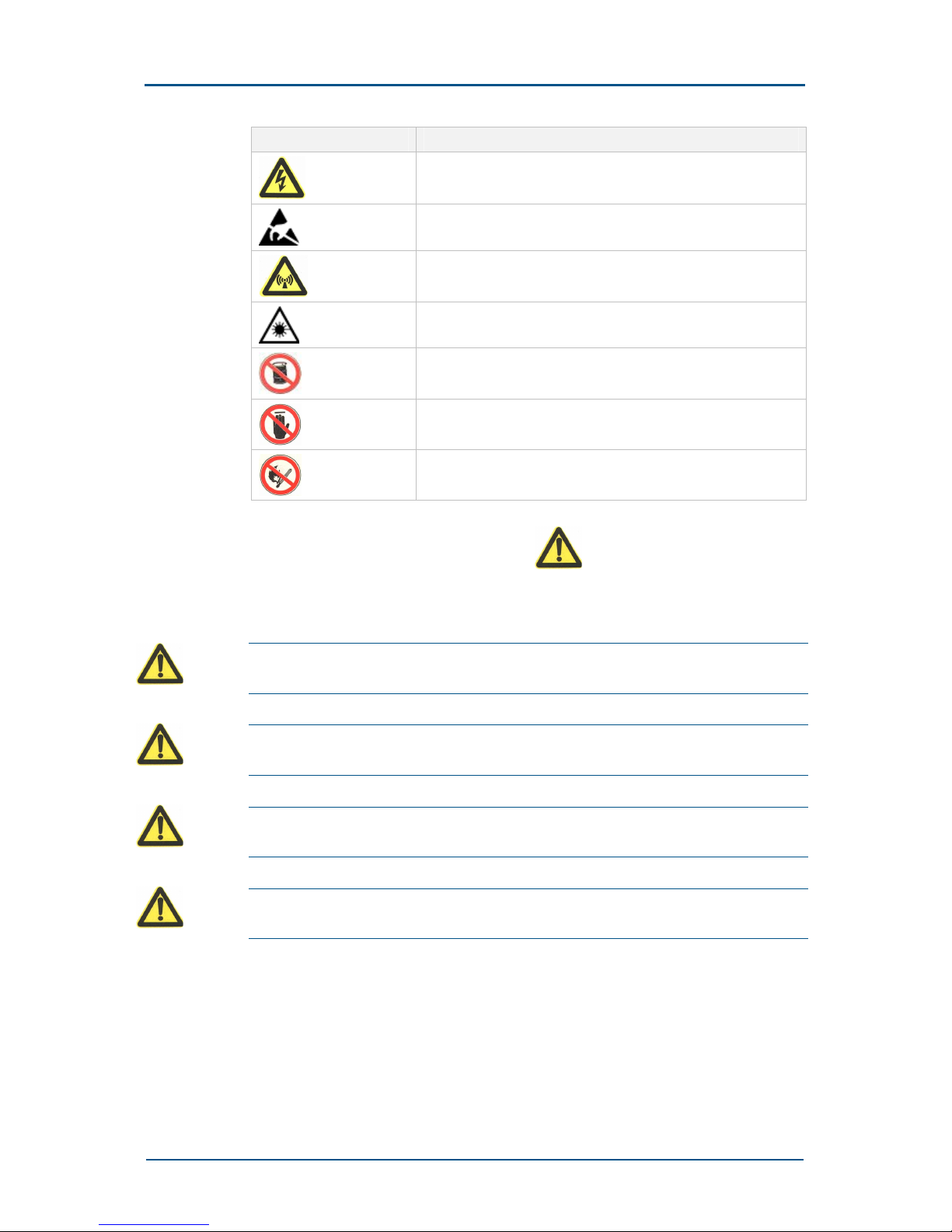

Confidential and Proprietary Information of ZTE CORPORATION 3

Safety Signs Meaning

Electric shock: There is a risk of electric shock.

Electrostatic: The device may be sensitive to static electricity.

Microwave: Beware of strong electromagnetic field.

Laser: Beware of strong laser beam.

No flammables: No flammables can be stored.

No touching: Do not touch.

No smoking: Smoking is forbidden.

Among them, universal alarm symbol adopts four grades. Based on

the descending order of the danger degree, they are: danger, warning,

caution and notes. Their respective formats and meanings are described

as below.

Danger: This sign means that personal death or major accidents such as

equipment damage or breakdown may occur if you ignore this safety warning.

Warning: This sign means that there may be a major or serious accident,

equipment damage or interruption of key services if you ignore this safety warning.

Caution: This sign means that serious injury or death, equipment damage or

interruption of some services may occur if you ignore this safety warning.

Notes: This sign means that an injury, equipment damage or interruption of local

services may occur if you ignore this safety warning.

To the right of a safety sign is a text indicating its safety level. Under the

sign is the detailed safety description.

ZXG10 BS21 (V2.2) Compact Outdoor BTS for GSM Maintenance Manual

4 Confidential and Proprietary Information of ZTE CORPORATION

Toxic Substances

Beryllia

Warning: Beryllia is a type of toxic chemical existing in the transistor and other

components. The power amplifier circuit and AEM circuit in the base station contain

Beryllia, so it is advised not to touch these components directly under any

circumstances.

Beryllium oxide dusts may be produced when a component containing

beryllium oxide is broken, frictionized or bruised. They may seriously hurt

human skin and membrane even life safety.

Beryllium oxide may hurt human bodies only when components containing

beryllium oxide are damaged. Therefore, be sure to take care when

replacing or handling such components and boards and avoid any

mechanical damage.

Do not discard components containing beryllium oxide randomly. Please

observe local regulations to make chemical treatment or special waste

material treatment for components containing beryllium oxide.

If you suspect that beryllium oxide has entered your skin or been

absorbed in your body, please thoroughly rinse the skin wound with water

and then see the doctor immediately.

The personnel contacting or handing such components should understand

the characteristics of such components and take the corresponding

preventive measures.

Hydrochloride

Warning: Chemicals containing hydrochloride have to be used in some

components of the BS21 (V2.2) device. Burning these components will generate

toxic gas.

Do not burn the components and take preventive measures to avoid

inhaling toxic gas.

Do not discard components containing hydrochloride randomly. Please

observe local regulations to make chemical treatment or special waste

material treatment for components containing hydrochloride.

Chapter 1 - Maintenance Security

Confidential and Proprietary Information of ZTE CORPORATION 5

Electrical Safety

Tools

Warning: Be sure to use special tools rather than common tools for high-voltage

and AC operations.

High Voltage

Danger: High voltage is hazardous. Direct or indirect contact with high voltage or

mains supply through a wet object could result in fatal danger.

Do follow the local safety regulations to install any AC power equipment.

Personnel who that installs AC devices must be qualified for high-voltage

and AC operations.

During operation, it is strictly forbidden to wear any conductive articles

such as watch, chain and ring.

Please prevent water from entering the equipment during operation and

maintenance in damp environments.

Power Cord

Notes: Do not install or remove power cables with power on. Contact of the power

cable with any conductor will generate electric spark or electric arc, which may

cause fire or eye injury.

Do turn off the power supply before connecting or disconnecting a power

cable.

Before connection, make sure the connecting cable and its label suit the

actual installation requirements.

Drilling

Warning: It is not allowed to drill the cabinet without permission.

Unqualified drilling could damage the wiring and cables inside the cabinet.

Additionally, metal pieces inside the cabinet created by the drilling could

result in a shorted circuit board.

When it is necessary to drill holes in the cabinet in some special cases,

please wear insulated protective gloves and move away the cables in the

ZXG10 BS21 (V2.2) Compact Outdoor BTS for GSM Maintenance Manual

6 Confidential and Proprietary Information of ZTE CORPORATION

cabinet before drilling. Take care to protect your eyes during drilling.

Flying metal scraps may harm your eyes. In addition, please promptly

clean and clear metal scraps after drilling.

Thunder

Danger: Operations concerned with high-voltage, AC, iron tower or mast are

strictly forbidden in thunderstorms.

Thunderstorms would give rise to a strong electromagnetic field in the

atmosphere. So, the equipment should be earthed and protected in time

against lightning strike.

Antistatic

Notes: The static electricity produced by the human body could damage the static-

sensitive components on the circuit board, such as large-scale integrated circuits

(IC).

Friction caused by human body’s activities is a source of accumulation of

static charge. When it is dry, the static voltage a human body carries may

be as high as 30kV, and may stay a long while. An operator with static

may cause damage to a device when in touch with it due to the discharge

from the device.

To avoid any damage to sensitive devices by human body static, an

operator should wear an antistatic wrist strap before touching devices,

plug-in boards, circuit boards and IC chips, and well ground the other end

of the antistatic wrist strap.

The cable between the wrist and the ground must be connected in series

with a more than 1M ohm resistance to protect operators from electric

shock. The static discharge from a 1M ohm-plus resistance is sufficiently

low.

Check the antistatic wrist strap regularly. Do not replace the cable of the

wrist strap with any other cable.

Static-sensitive board should not be in touch with any objects carrying

static electricity or easy to generate static electricity. For example, friction

of the package, conveyor box and conveyor belt made of insulation

materials will make the components statically electrified. These

components will discharge static electricity when touching human body or

the ground, thus being damaged.

Static-sensitive boards can only touch high quality discharging materials

such as static-protective packages. Use static-protective packages on

boards during storage and transportation.

Chapter 1 - Maintenance Security

Confidential and Proprietary Information of ZTE CORPORATION 7

Discharge the static electricity before connecting a measurement device

with a board. The measurement device should first be grounded.

Keep boards at least 10cm away from strong DC magnetic fields such as

the cathode-ray tube of a monitor.

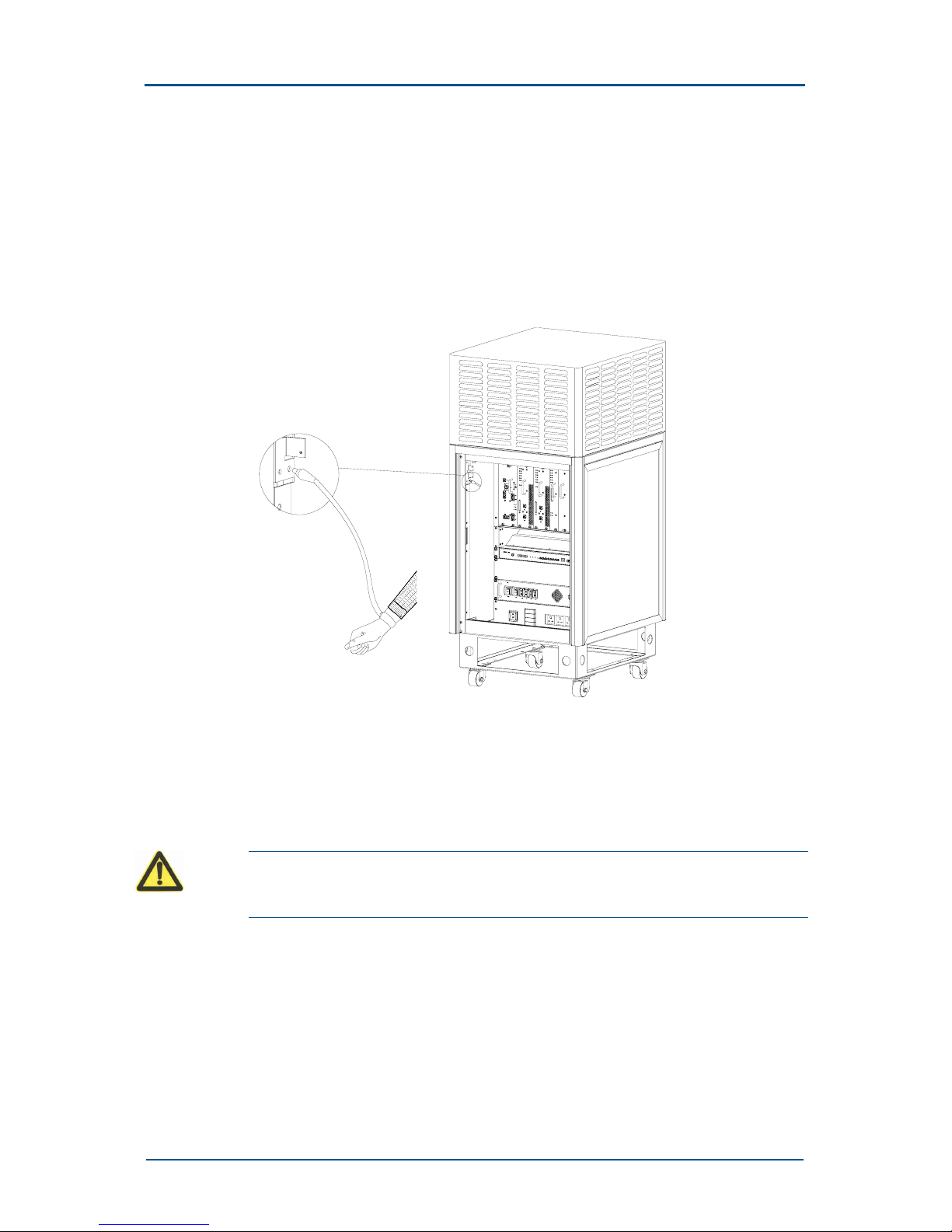

Figure 1 shows how to properly put on antistatic wrist straps.

FIGURE 1 CORRECTLY PUTTING ON ANTISTATIC WRIST STRAP

Storage Battery

If the BS21 is equipped with UPS, please pay due attention to the correct

use and maintenance of storage batteries.

Danger: Before battery-related operations, make sure you have carefully read the

safety precautions on carrying the battery and learned the correct battery

connection method.

Nonstandard operations on the battery will result in great danger. During

operation, short circuit or electrolyte spill/ drain of the batteries must be

prevented, As electrolyte spill will pose potential threat to the equipment

and erode the metal objects and circuit boards, thus damaging the

equipment and causing short circuits to the circuit board.

To ensure safety, please pay attentions to the following points before

battery installation and maintenance:

ZXG10 BS21 (V2.2) Compact Outdoor BTS for GSM Maintenance Manual

8 Confidential and Proprietary Information of ZTE CORPORATION

1. Handle the battery with care. Do not vibrate it violently.

2. Do not wear any object that contains metal, such as watch, chain,

bangle or ring.

3. Use special-purpose insulation tools.

4. Use eye-protecting devices and take preventive measures.

5. Use rubber gloves and aprons that protect against electrolyte overflow.

6. Always keep the front of the pole up during battery transportation. Do

not put it upside down or tilted.

Short Circuit

Danger: Battery short circuit may harm human bodies. Although battery voltage is

generally low, the transient current caused by short circuits will release high

energy.

Prevent metal objects from causing short circuit to the battery, such as

short circuits caused by improper use of operation tools. If allowed, please

first stop battery power supply before making other operations.

Hazardous Gases

Danger: Do not use unsealed LA batteries. Gases released by batteries may burn

or corrode the equipment. Batteries should be fixed and horizontally placed.

Batteries may release inflammable gases during working. Keep sound

ventilation and take fireproof measures where the batteries are placed. To

prevent high temperature caused by exposure to sunlight, windows of the

battery room should be installed with sun shields.

High Temperature

Danger: High temperature may distort and damage the battery or cause overflow

of acid liquid.

If the battery temperature is higher than 60oC, check whether there is any

acid liquid overflow.

If the acid liquid overflows, handle it promptly and properly.

Acid Liquid

Danger: If the acid liquid overflows, promptly and properly absorb and neutralize

the liquid.

Chapter 1 - Maintenance Security

Confidential and Proprietary Information of ZTE CORPORATION 9

When moving a leaking battery, pay attention to potential harms that may

be caused by the acid liquid. Once acid liquid overflow is detected, the

following materials may be used to absorb and neutralize the liquid:

NaHCO

3

, Na2CO3 and Na2CO3-10H2O.

Use manufacturer-recommended materials to absorb and neutralize the

acid liquid.

Storage Battery Replacement

After the storage battery group has run for a long time, its internal

resistance of one or more monomers will increase due to drifting of its

internal parameters. If serious, the monomer becomes an old battery. The

common preventative method and solution to this problem is to recharge

the batter group with high voltage so as to activate its interior. In some

cases, one monomer still cannot be activated after times of recharges, so

it cannot be used any longer and need be replaced.

Since the battery production conditions of different types, batches and by

different manufacturers are different, the internal parameters must be

different too. Therefore, it is required that the monomers of the battery

group should be of the same type, batch and from the same manufacturer

when it is replaced. In this way it is ensured that the parameters are

consistent and the battery group can be used for a long time.

Danger: Operation and maintenance personnel should not replace the specified

batteries with ones of different types. Otherwise, explosions may occur.

Electromagnetic Radiation

Since the antenna of operating equipment generates electromagnetic

radiation, if you are too close to the antenna, your safety may be

endangered. The equipment can be installed and maintained only by

professionals with adequate training and relevant qualifications. The

radiation design of the equipment complies with the IEEE C95.1-1991

standard.

Warning: The high intensity microwave may affect your body health when you

operate on the high-intensity RF equipment.

When close installation and maintenance operations are conducted to a

certain antenna in an iron tower or mast mounted with many transmitter

antennas, collaboration must be prepared so that the transmitter of the

antenna is shut down.

Warning: When conducting installation and servicing operations around the

operating antenna, keep adequate distance from the antenna.

ZXG10 BS21 (V2.2) Compact Outdoor BTS for GSM Maintenance Manual

10 Confidential and Proprietary Information of ZTE CORPORATION

Do not unplug the connector of the transmitter output feeder or of the

antenna feeder cable when the transmitter is operating.

Power off the corresponding transmitter when you need to unplug the

connector of the feeder cable or to work beside the transmitter antenna.

Working at Heights

Warning: When working at heights, take care to prevent objects from falling.

Working at heights should conform to the related national service

regulation requirements:

Operators working at heights must have been specially trained.

Take care of the operation machinery and tools to prevent them from

falling.

Take safety precautions, and wear helmet and safety belt.

In cold areas, wear cold-protection clothes before working at heights.

Before working at heights, check all hoisting equipment.

Hoisting Heavy Objects

Warning: Do not walk about right under the boom and hoisted objected when

heavy objects are hoisted.

When disassembling heavy equipment, or moving and replacing

equipment, make sure there are facilities of proper hoisting capability.

Personnel engaged in the hoisting work must have received relevant

trainings. The tools used for hoisting must have been inspected to ensure

they are tightly fixed on the weight-bearing object or the wall. Use brief

hoisting commands to prevent misoperations.

Using Ladders

Before using ladders, make sure they are in good condition and can be

used through inspection. Over-weight is forbidden during the use of

ladders.

When a ladder tilts more than 5 meters, or a straight two-foot ladder tilts

over 3 meters or when operations are conducted in a dangerous

environment, it is required to have the ladder supported or take other

security measures. A-shape ladders should be fully unfolded when used.

Chapter 1 - Maintenance Security

Confidential and Proprietary Information of ZTE CORPORATION 11

The proper tilt angle for ladders is 75°; the broader foot should always be

put downside or protective measures be taken at the bottom of the ladder

to prevent sliding. Ladders should be put at steady places instead of on

carton boxes, stones or other slippery objects.

Ladder-climbers should face the ladder; when working on tilted ladders,

they should keep their body barycenter within the edges of the ladder. It

is advisable to hold the ladder tightly with one hand and two feet stepping

fast, that is to say, with 3 parts of the body in contact with the ladder to

ensure security and reduce risks. It is suggested that the last 4 rails

should be left un-mounted as the limit of the climbing height. If work need

be carried out on the roof, the ladder should be at least 1 meter higher

than the eaves against which the ladder leans.

Fans

Warning:

Keep your fingers or body off any dangerous parts of the fan that is still

running.

Make sure not to stick your fingers or any tool into the running fan in case any

damage or injury done to the device or the human body.

While replacing the related parts, be sure to put away the parts, screws

and tools. Make sure they will not fall into the working fan and damage the

fan or related devices.

When replacing the devices around the fan, do not put your finger or a

board in the fan, to avoid damage to the equipment or your finger.

High Temperature

Warning: The surface temperature of some devices is quite high, so do not touch

them in case of being scalded.

Board Plugging/Unplugging

Notes:

Never plug a board too hard, so as not to deform the pins on the backplane.

Plug a board along the slot to avoid short circuit due to touch with the circuit of

the adjacent board.

ZXG10 BS21 (V2.2) Compact Outdoor BTS for GSM Maintenance Manual

12 Confidential and Proprietary Information of ZTE CORPORATION

When holding a board, keep your hands off the board circuit, components,

connectors and cable trough.

Do-Nots

Notes: Do not perform maintenance or debugging inside the equipment, unless a

qualified person is present for your help.

Replacing any parts or altering the equipment might result in unexpected

danger. Therefore, be sure not to replace any parts or alter the equipment

unless otherwise authorized.

To ensure your safety, if you have any question, please contact ZTE

Corporation.

Confidential and Proprietary Information of ZTE CORPORATION 13

Chapter 2

Maintenance Overview

In this chapter, you will learn about:

Categories of daily maintenance

Common maintenance methods

Precautions on daily maintenance

ZXG10 BS21 (V2.2) Compact Outdoor BTS for GSM Maintenance Manual

14 Confidential and Proprietary Information of ZTE CORPORATION

Categories of Daily Maintenance

Daily maintenance of the BS21 (V2.2) device can be divided into routine

maintenance, handling of notification information and alarm information as

well as troubleshooting.

1. Routine maintenance

Routine maintenance refers to daily and periodic maintenance to check

the running conditions of the equipment periodically and handle faults

in time. The routine maintenance is intended to find hidden troubles,

prevent accidents, locate faults in time and handle faults as early as

possible.

2. Notification information handling

Notification information handling refers to a process ranging from the

analysis of various notification messages arising from the running of

the system, judgment on whether there is anything abnormal to

appropriate handling.

3. Alarm information handling

Alarm information handling refers to the process ranging from the

analysis of various alarm messages that occur during the running of

the system, judgment on whether there is anything abnormal to

appropriate handling.

4. Troubleshooting

Troubleshooting is a process of analyzing, handling and resolving any

fault that is discovered.

Common Maintenance Methods

Some methods need to be adopted to locate faults during daily

maintenance. The common maintenance methods are as follows:

1. Alarm and operation log view

Alarm and operation log view is the first method to be adopted when a

fault is detected by maintenance personnel. It is implemented through

the alarm management and operation log view interface of the BSS

operation & maintenance subsystem OMCR.

Through the alarm management interface, we can observe and analyze

alarm messages reported from each NE such as the current alarm,

history alarm and general notification. In this way, we can detect any

fault during network running in time and then locate, isolate and

remove it.

By viewing operation logs in user management, we can investigate

modifications on system parameters, locate the relevant responsible

terminal and operator as well as detect faults caused by individual

operations in time.

Chapter 2 - Maintenance Overview

Confidential and Proprietary Information of ZTE CORPORATION 15

2. Indicator status analysis

Indicator status analysis is a frequently adopted method when a fault

is detected by maintenance personnel. With this method, we can locate

and remove faults by observing the indicator status on each board

panel in the rack.

This method requires maintenance personnel to be familiar with the

indicator status and meaning of each board.

3. Performance analysis

It is implemented through the performance management interface of

the BSS operation & maintenance subsystem OMCR. Through this

interface, maintenance personnel can implement performance

management and signaling tracing on the BSS system.

Through the performance management interface, users can create all

kinds of performance measurement tasks, product various

performance reports and grasp the performance indexes of the BSS

system, such as the traffic of each cell, congestion situation of SDCCH

and TCH, successful and failed switchover. By analyzing such

information, maintenance personnel can discover load allocation

situation in the network in time so as to adjust network parameters to

enhance network performances.

Through the signaling tracing interface, we can trace signaling involved

in BSS (including Gb interface signaling), thus facilitating consulting of

different signaling flows in the debugging and maintenance processes

as well as detecting problems in the signaling cooperation process.

4. Analyzing with instruments and meters

This method allows maintenance personnel to locate, analyze and

remove faults with the testing mobile, frequency spectrograph,

signaling analyzer, power meter and site master during base station

maintenance.

5. Plugging and pressing

When detecting a board fault, we can loosen the fixation screw in the

front panel and plug or unplug the board and external interface

connector. In this way, we can remove faults caused by poor contact

or processor faults.

In addition, we can also remove faults caused by poor contact by

pressing the cable connector after power-off.

6. Comparing and swapping

Comparing indicates to compare a possible faulty board with a board at

the similar position in the system (for example: a board at the same

slot in a multi-module system) from aspects such as the running status,

jumper and connection cables. We can judge whether the board fails

through comparison.

Swapping indicates to replace a possible faulty board with a standby

part or another board of the same type running normally in the system.

We can judge whether the board actually fails according to whether the

fault disappears after board replacement. It should be noted that no

matter the comparison or replacement method is adopted, the board

ZXG10 BS21 (V2.2) Compact Outdoor BTS for GSM Maintenance Manual

16 Confidential and Proprietary Information of ZTE CORPORATION

unplugging/plugging operation should be performed in accordance with

the relevant description in Appendix

A of this manual.

7. Isolating

When a part of the system fails, it can be isolated from other relevant

boards or racks to judge whether the fault is caused by mutual

influence. For example, the often-used isolating method is to remove

CMM module or transmission faults by self-looping the E1 interface of

the CMM module.

8. Self-test method

It refers to fault judgment through self-test after the system or module

is powered on again. Generally, by powering on common modules for

self-test, we can find the indicators on the panel will flash regularly,

from which we can judge whether there are any problems in the

modules.

Generally, during actual operation, the above methods and accumulated

experiences of maintenance personnel are combined to remove faults in

the maintenance process.

Precautions on Daily

Maintenance

Please pay attention to the following points during daily maintenance:

1. Normal temperature, humidity and a clean and tidy environment

should be kept for the equipment room, and the equipment room

should be dampproof and free of dust, rodents and insects.

2. The primary power of the system should be stable and reliable.

Periodic check should be performed on the system ground and

lightning-protection ground. Especially before thunderstorm seasons

and after thunderstorms, the lightning-protection system should be

checked to guarantee that the facilities are in sound conditions.

3. A perfect equipment room maintenance system should be formulated

to standardize daily work of the maintenance personnel. Detailed logs

should be prepared to record the daily running, version, data change,

upgrade and troubleshooting of the system for the convenience of fault

analysis and handling. In addition, shift records should be made to

differentiate individual responsibilities.

4. It is prohibited to play online games or surf on the Internet at the PC

terminal or install, operate or copy any software irrelevant to the

system in the PC terminal. It is forbidden to use PC terminals for other

purposes.

5. Right-based NMS (Network Management System) passwords should be

set, managed strictly and modified periodically. Such passwords are

available to the maintenance personnel only.

Loading...

Loading...