Zte NetNumen U31 R06 Hardware Installation Manual

NetNumen™U31R06

UniedElementManagementSystem

HardwareInstallationGuide

Version:V12.14.30

ZTECORPORATION

No.55,Hi-techRoadSouth,ShenZhen,P .R.China

Postcode:518057

Tel:+86-755-26771900

Fax:+86-755-26770801

URL:http://support.zte.com.cn

E-mail:support@zte.com.cn

LEGALINFORMATION

Copyright©2014ZTECORPORATION.

Thecontentsofthisdocumentareprotectedbycopyrightlawsandinternationaltreaties.Anyreproductionor

distributionofthisdocumentoranyportionofthisdocument,inanyformbyanymeans,withoutthepriorwritten

consentofZTECORPORATIONisprohibited.Additionally,thecontentsofthisdocumentareprotectedby

contractualcondentialityobligations.

Allcompany,brandandproductnamesaretradeorservicemarks,orregisteredtradeorservicemarks,ofZTE

CORPORATIONoroftheirrespectiveowners.

Thisdocumentisprovided“asis”,andallexpress,implied,orstatutorywarranties,representationsorconditions

aredisclaimed,includingwithoutlimitationanyimpliedwarrantyofmerchantability,tnessforaparticularpurpose,

titleornon-infringement.ZTECORPORATIONanditslicensorsshallnotbeliablefordamagesresultingfromthe

useoforrelianceontheinformationcontainedherein.

ZTECORPORA TIONoritslicensorsmayhavecurrentorpendingintellectualpropertyrightsorapplications

coveringthesubjectmatterofthisdocument.ExceptasexpresslyprovidedinanywrittenlicensebetweenZTE

CORPORATIONanditslicensee,theuserofthisdocumentshallnotacquireanylicensetothesubjectmatter

herein.

ZTECORPORA TIONreservestherighttoupgradeormaketechnicalchangetothisproductwithoutfurthernotice.

UsersmayvisittheZTEtechnicalsupportwebsitehttp://support.zte.com.cntoinquireforrelatedinformation.

TheultimaterighttointerpretthisproductresidesinZTECORPORATION.

RevisionHistory

RevisionNo.RevisionDateRevisionReason

R1.02014-12-20Firstedition

SerialNumber:SJ-20141121 113158-006

PublishingDate:2014-12-20(R1.0)

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

Contents

Chapter1InstallationFlow........................................................................1-1

Chapter2InstallationPreparations..........................................................2-1

2.1EnvironmentCheck............................................................................................2-1

2.2T oolsPreparation...............................................................................................2-2

2.3RequiredDocuments..........................................................................................

Chapter3UnpackingandCheckingEquipment.....................................

Chapter4RemovingCabinetDoors.........................................................4-1

Chapter5CabinetInstallation...................................................................5-1

5.1InstallingtheCabinetontheAdjustableBase.......................................................5-2

5.2InstallingtheCabinetontheFloor.....................................................................

Chapter6InstallationofExternalPowerCablesandGrounding

Cables.....................................................................................................

6.1PowerSupplySystemofaCabinet......................................................................6-1

6.2CablingRequirements........................................................................................6-3

6.3InstallingPowerCablesandGroundingCables....................................................

Chapter7AssemblyInstallationinaCabinet..........................................

7.1InstallinganE4140Shelf....................................................................................7-1

7.2InstallingBoards................................................................................................

7.2.1RemovingaBlankPanel...........................................................................7-4

7.2.2InstallingaBoard.....................................................................................7-6

2-5

3-1

5-18

6-1

6-7

7-1

7-3

Chapter8InstallationofInternalPowerCablesandGrounding

Cables.....................................................................................................8-1

8.1PowerSupplySysteminaCabinet......................................................................8-1

8.2InstallingCablesforanE4140Shelf....................................................................8-3

Chapter9SignalCableInstallation..........................................................9-1

9.1SignalCableInstallationRequirements................................................................9-1

9.2SettingJumpersandDIPSwitchesoftheUniedPDU........................................

9.3InstallingtheNetworkCables..............................................................................9-8

Chapter10CabinetAccessoryInstallation............................................10-1

10.1InstallingtheCabinetSideDoor......................................................................10-1

10.2InstallingtheFrontandRearDoors.................................................................10-3

Chapter11PeripheralDeviceInstallation..............................................11-1

I

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

9-4

11.1InstallingTerminalDevices...............................................................................11-1

11.2AlarmBoxInstallation......................................................................................11-2

11.2.1InstallingtheAlarmBox.........................................................................11-2

11.2.2ConnectingCables(ACPowerSupply)...................................................

11.2.3ConnectingCables(DCPower)..............................................................11-6

11-4

Chapter12InstallationInspection..........................................................12-1

12.1CheckingtheCabinets....................................................................................12-1

12.2CheckingtheAssembliesintheCabinets.........................................................12-2

12.3CheckingthePowerCablesandGroundingCables..........................................

12.4CheckingtheSignalCables............................................................................12-3

12.5CheckingtheOtherauxiliaryDevices...............................................................

Chapter13SystemPower-On.................................................................

13.1PoweringontheCabinet.................................................................................13-1

13.2PoweringontheE4140Shelves......................................................................

Chapter14SiteClean-Up.........................................................................

12-2

12-3

13-1

13-3

14-1

AppendixAMakingaPowerCableandaGroundingCable.................A-1

AppendixBMakingaNetworkCable......................................................

B-1

Figures.............................................................................................................I

Tables.............................................................................................................V

Glossary.......................................................................................................VII

II

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

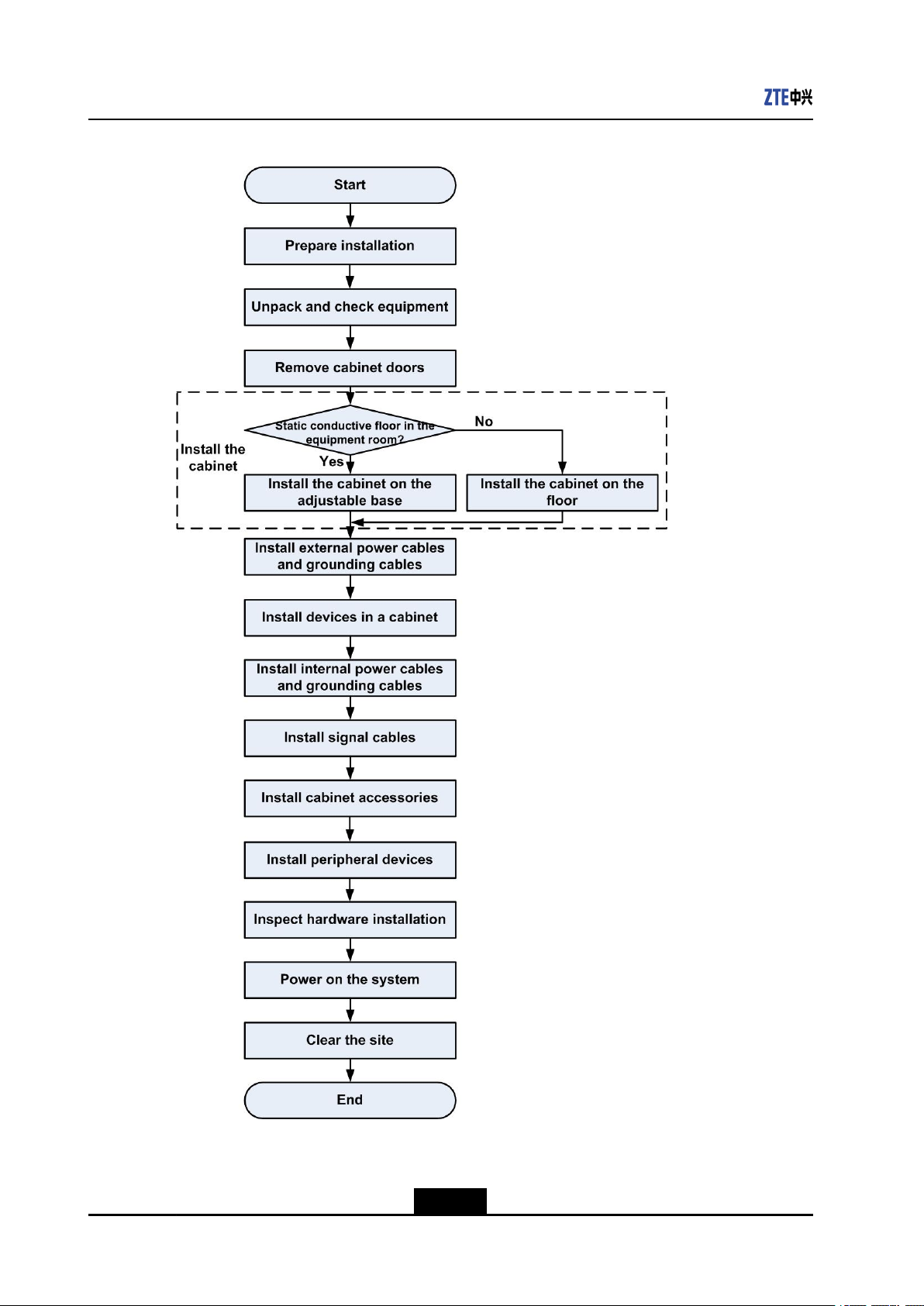

Chapter1

InstallationFlow

Beforestartinghardwareinstallation,youshallcompletecorrespondingpreparations,such

aspreparingconstructionconditions,checkinginstallationenvironment,andunpacking

andinspectinggoods,sothatthelaterinstallationprocesscanbesmoothandefcient.

Forthehardwareinstallationow,seeFigure1-1.

1-1

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

NetNumen™U31R06HardwareInstallationGuide

Figure1-1HardwareInstallationFlow

1-2

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

Chapter2

InstallationPreparations

Youmustknowtheprocedureforinstallingthehardware,andhaveknowledgeonsystem

networkstructure,powersupply,cableconnection,andhardwaremaintenance.

Beforeinstallation,youneedtochecktheenvironmentandpreparerequiredtoolsand

documents.

TableofContents

EnvironmentCheck....................................................................................................2-1

ToolsPreparation.......................................................................................................

RequiredDocuments..................................................................................................2-5

2.1EnvironmentCheck

Beforeinstallation,itisnecessarytochecktheequipmentroomtoensurethatthe

environmentmeetstheoperatingrequirementsoftheequipment.

2-2

Note:

Itisnotallowedtoinstalltheequipmentiftheinstallationenvironmentisunsatisfactory.

lArchitecturalconditions

Checkthesize,height,load-bearingcapacity,andlayoutoftheequipmentroom.

lEnvironmentalconditions

Checkillumination,air-conditioning,ventilation,antistaticmeasures,shockproof

measures,lightningprotectionmeasures,andre-ghtingdevicesoftheequipment

room.

lPowersupplyconditions

CheckACpowersupplyfacilities,DCpowersupplyfacilities,andaccumulator

batteries.

lGroundingconditions

Theequipmentroommusthavegoodgroundingconditions.Groundresistancemust

meetlocaltechnicalrequirements.Ingeneral,groundresistancecannotbegreater

than1Ω.

lAuxiliarydevices

2-1

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

NetNumen™U31R06HardwareInstallationGuide

CheckDigitalDistributionFrames(DDF),cabletrays,andcabledistributionframes.

lOtherfacilities

Checkworkbenches,poweroutlets,alarmboxes,andotherperipheraldevices.

Foradetailedenvironmentalchecklist,refertoEnvironmentAcceptanceReportofCore

NetworkProducts.

2.2ToolsPreparation

Foralistofthetoolsandmetersthatmustbepreparedbeforeinstallation,refertoT able

2-1.

Note:

Instrumentsandmetersaresubjecttolocalstandards.Thepicturesinthetablearefor

referenceonly.

Themeterscannotbeusedunlessstrictlycalibratedandprovenqualied.

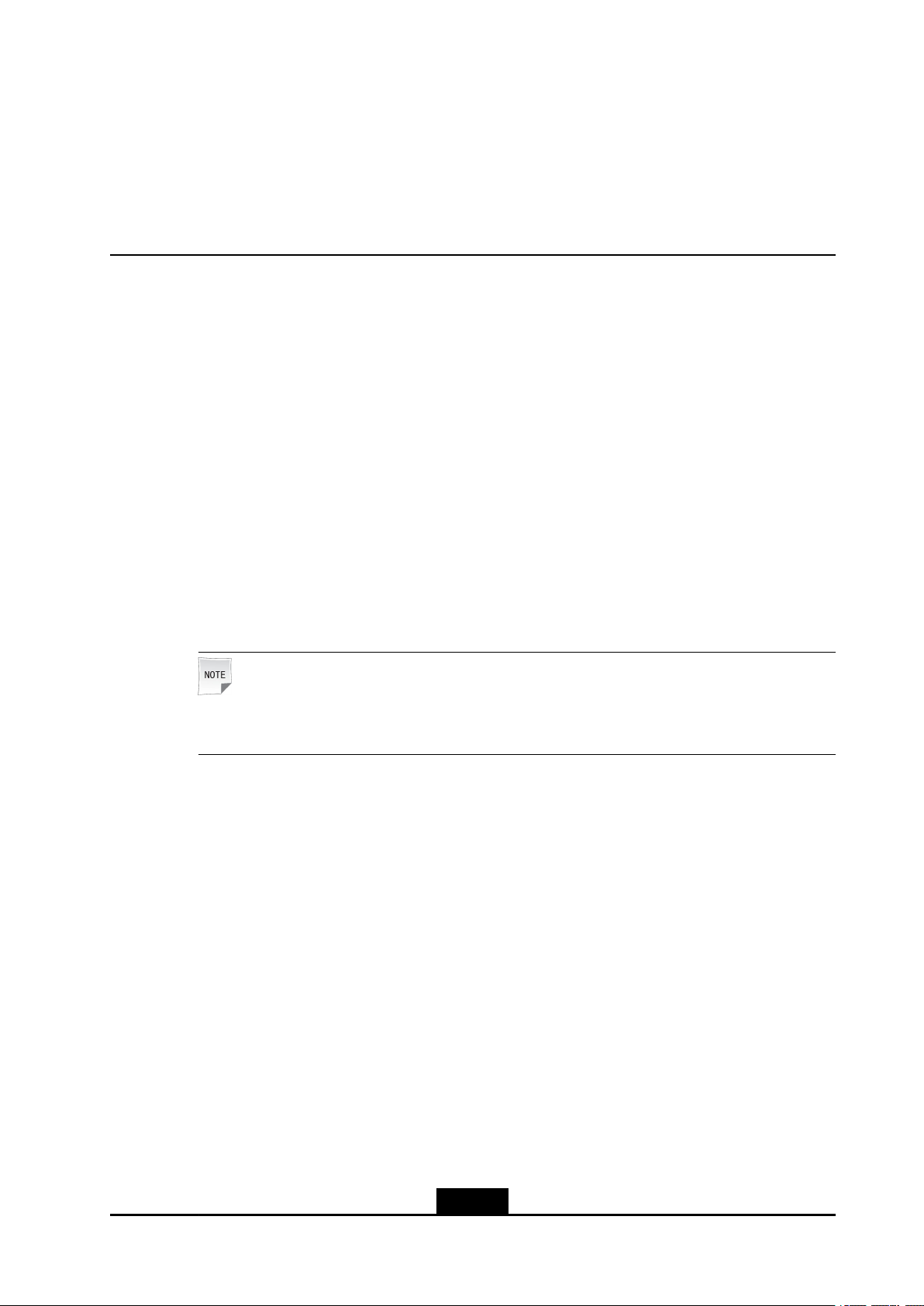

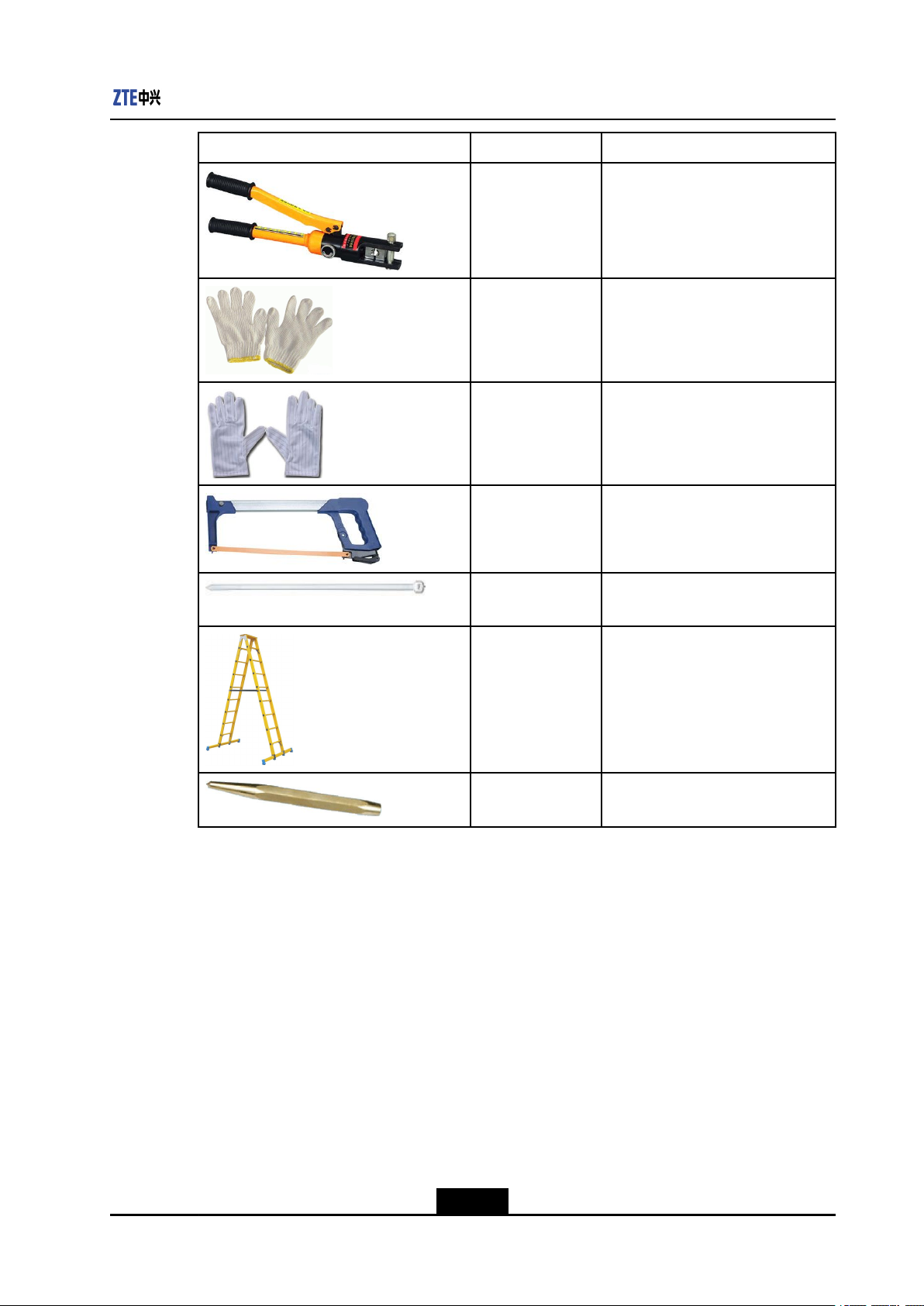

Table2-1ToolsandMeters

PictureNamePurpose

Crossheadscrew-

driver

Flatheadscrew-

driver

AdjustablewrenchTightensbolts.

TorquewrenchTightensbolts.

SocketwrenchsetLoosensortightensfastenerstoad-

Tightenscrossheadscrews.

Tightensatheadscrews.

justthelevelofthecabinet.

Floating-nutdriverInstallsoatingnuts.

2-2

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

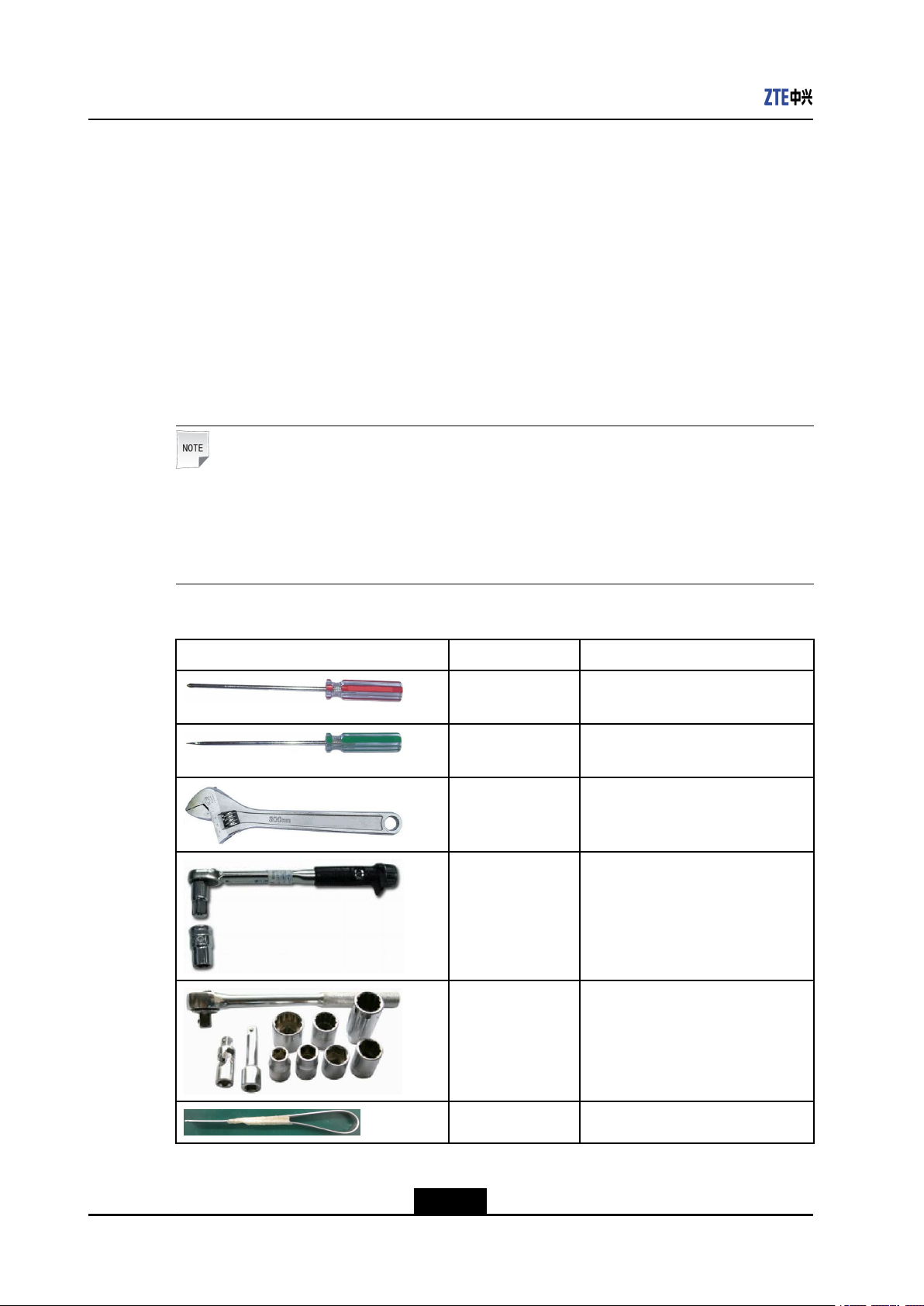

PictureNamePurpose

TapemeasureMeasureslength.

AnglesquareMeasureslengthordrawsrightan-

SpiritlevelChecksthelevelofadjustable

PlumblineChecksverticaldeviationofacabi-

Chapter2InstallationPreparations

gles.

basesandcabinets.

net.

MarkerpenMarksthepositionsofdrilledholes

ontheoor.

PowdermarkerMarkslinesonthegroundtode-

terminethepositionwhereasocket

boltisinstalled.

ClawhammerInstallssocketboltsandopens

woodencases.

PercussiondrillDrillsholes.

VacuumcleanerCleansinstallationholesandthe

oor.

2-3

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

NetNumen™U31R06HardwareInstallationGuide

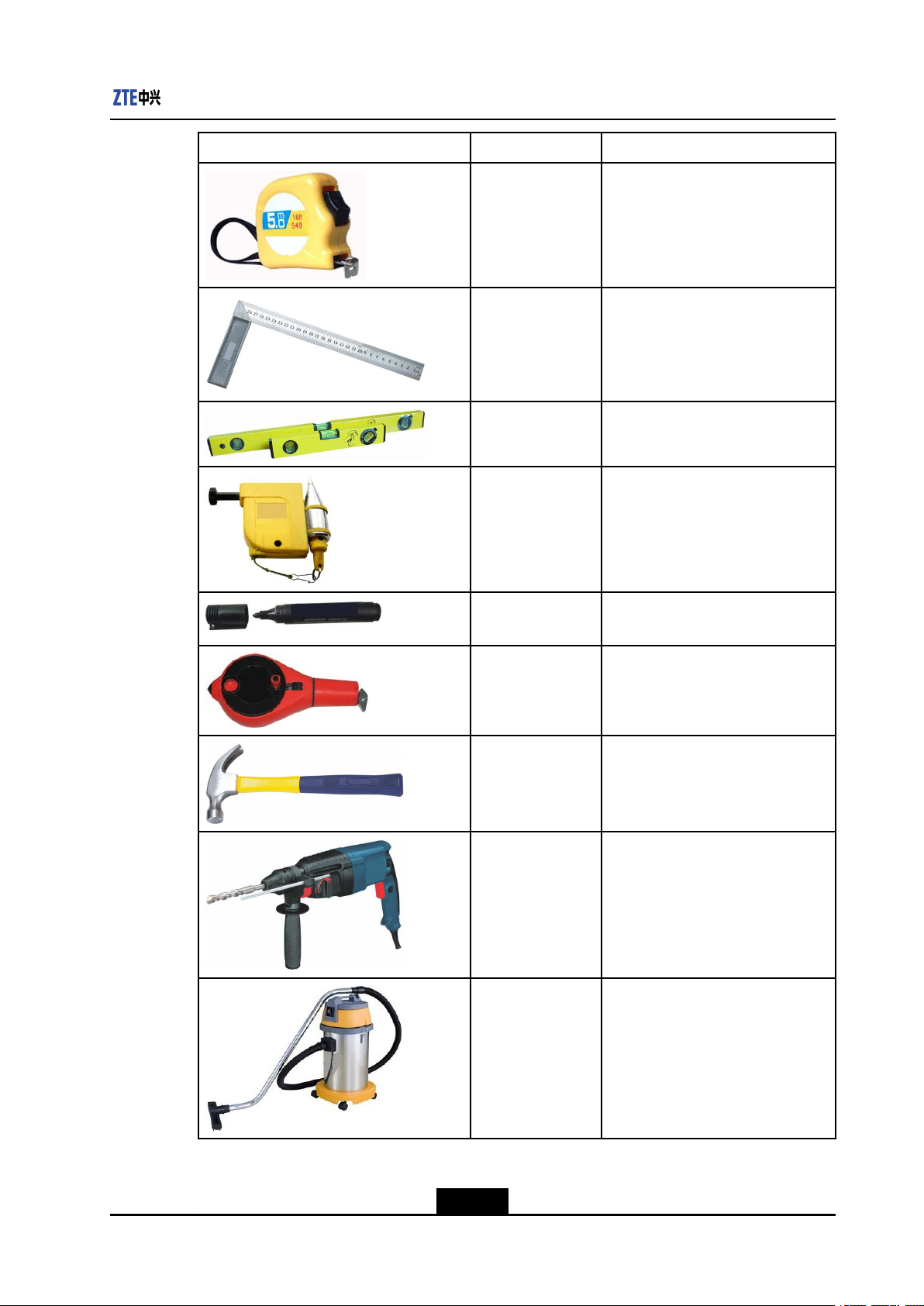

PictureNamePurpose

DiagonalpliersPrunescabletiesandcutspacking

strapsofcartons.

PaperknifeCutsadhesivetapesoncartons.

Networkcable

Testsnetworkcables.

tester

MultimeterT eststheinsulationconditionofcab-

inets,connectionconditionofca-

bles,andelectricperformancein-

dexesofdevices,suchasvoltage,

current,andelectricresistance.

Currentclampme-

ter

Measuresthecurrentinacableun-

dertheconditionthattheloadingop-

erationisnotinterrupted.

Crystalheadcrimp-

ingpliers

Crimpscrystalheadsofnetworkca-

bles.

Coaxial-cable

crimpingpliers

Crimpsthemetalsheathattheend

ofacoaxialcable.

WirestrippersStripsoffthecablesheath.

2-4

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

PictureNamePurpose

HydraulicpliersCrimpsO-typeterminalsandJGter-

WorkglovesUsedduringinstallation.

Anti-staticglovesUsedduringinstallation.

HacksawCutswoodoorormetal.

Chapter2InstallationPreparations

minals.

2.3RequiredDocuments

CabletieTiesuppowercables,protective

groundingwires,andsignalcables.

LadderUsedforworkingatheights.

PunchUsedtolocateadrillbitformaking

anindentationattheholelocation.

Thefollowingdocumentsmustbepreparedbeforeinstallation:

lEngineeringdesigndocumentsandpackinglists

lManualsshippedwiththeproducts

lUnpackingInspectionGuideofCoreNetworkProducts

lEnvironmentAcceptanceReportofCoreNetworkProducts

lCoreNetworkProductHardwareInstallationQualityStandard

2-5

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

NetNumen™U31R06HardwareInstallationGuide

Thispageintentionallyleftblank.

2-6

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

Chapter3

UnpackingandChecking

Equipment

Thisproceduredescribeshowtounpackwoodencases,cartons,andtheboardpackage.

Forhowtocountandcheckequipment,refertoUnpackingInspectionGuideofCore

NetworkProducts.

lAwoodencaseisusedtopackacabinet.

lAcartonisusedtopackboards,terminalequipment,andcables.

Prerequisite

Aatheadscrewdriver,aclawhammer,diagonalpliers,apaperknife,antistaticgloves(or

anESDwriststrap)areready .

Steps

1.CheckthetotalnumberofequipmentinaccordancewiththePackingList,andthen

verifythattheouterpackingiscomplete.

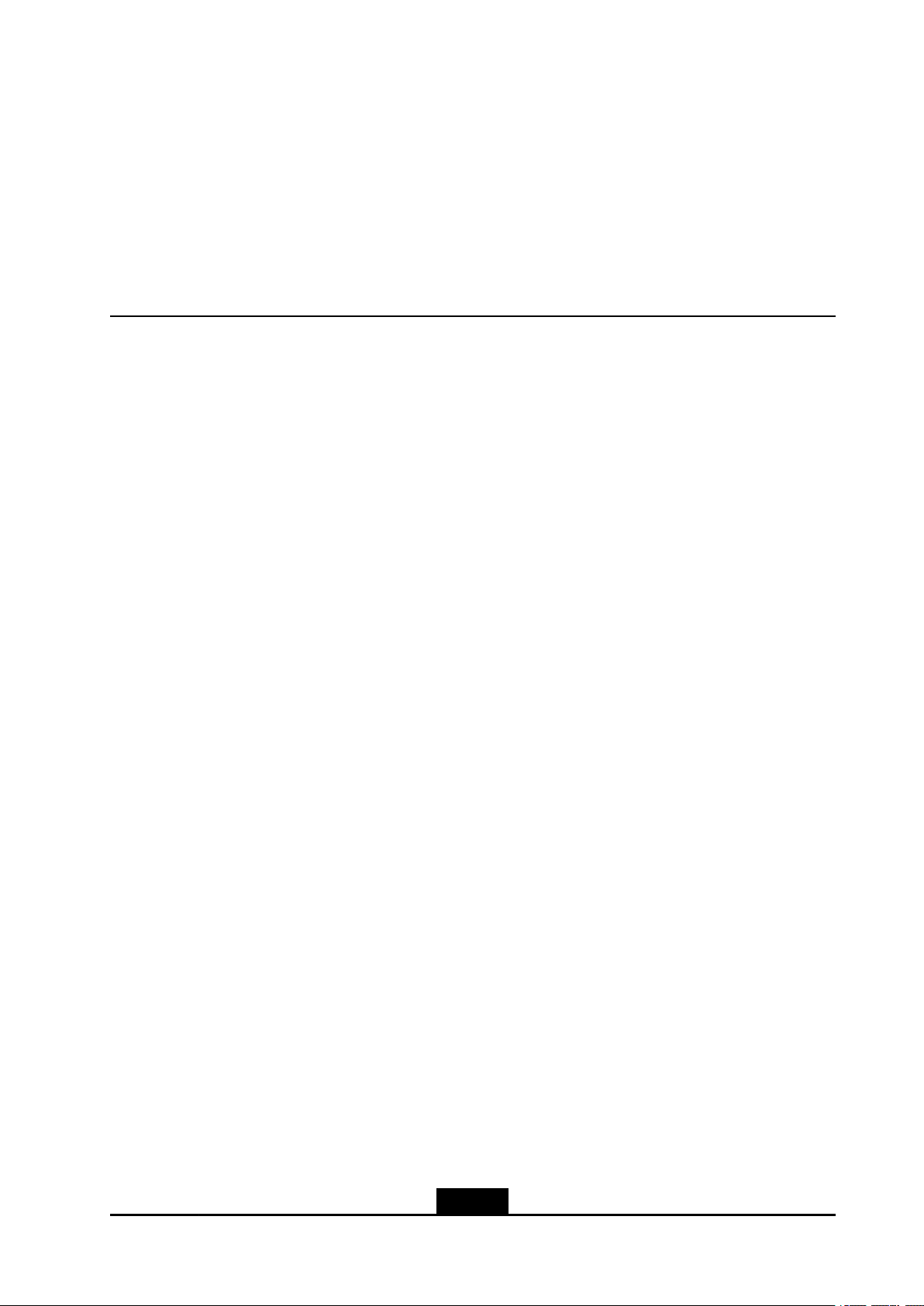

2.Removetheouterpackingofthewoodencase.

a.Movethewoodencasewithaforktrucktothecabinetinstallationsiteinthe

equipmentroom.

b.Openalltonguepieceswithaatheadscrewdriver,removetheuppercoverofthe

case,andthenremovethesideboards,seeFigure3-1.

3-1

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

NetNumen™U31R06HardwareInstallationGuide

Figure3-1UnpackingaWoodenCase

1.Flatheadscrewdriver2.Tongue

c.Takeouttheequipmentlist,technicaldocuments,andtoolsforequipment

installationfromPackage1.

d.Makethebottomofthecabinetdownwards.

e.Removefoamcornerprotectors,foamedgeprotectors,andplasticpackage.

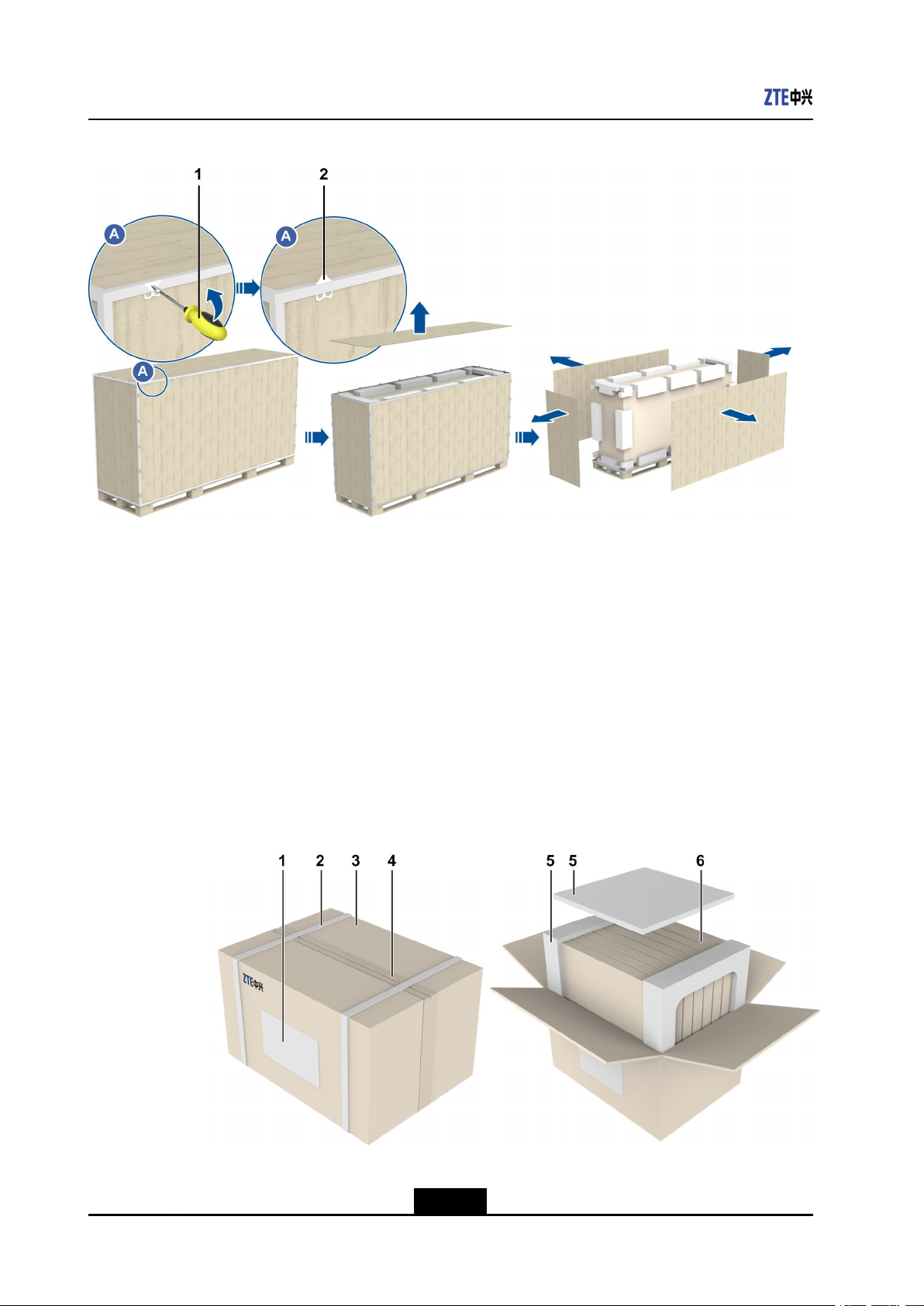

3.Removetheouterpackingofthecarton,seeFigure3-2.

a.Cutthepackingstrapsofacartonbyusingdiagonalpliers.

b.Cuttheadhesivetapessealingthecarton.

c.Openthecarton,andthentakeoutthefoamboardandboardboxes.

Figure3-2RemovingtheOuterPackingofaCarton

1.Cartonlabel2.Packingstrap3.Carton

3-2

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

Chapter3UnpackingandCheckingEquipment

4.Adhesivetape5.Foamboard6.Boardbox

4.Removetheboardpackage.

a.Wearantistaticgloves(oranESDwriststrap).

b.Removetheboardpackage,seeFigure3-3.

Figure3-3RemovingtheBoardPackage

1.ESDwriststrap

c.Fortheboardthatisnotinstalledimmediately,putitbackinitsoriginalpackage,

andthensealthepackage.

5.Checktoensurethattheequipmentisingoodconditionandthequantityiscorrect

beforeequipmenthand-overandstorage.

–EndofSteps–

3-3

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

NetNumen™U31R06HardwareInstallationGuide

Thispageintentionallyleftblank.

3-4

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

Chapter4

RemovingCabinetDoors

Thecabinetisdeliveredwithfrontandreardoorsinstalled.Tofacilitateinstallationofthe

accessoriesinthecabinet,youneedtoremovethefrontandreardoors.Thisprocedure

describeshowtoremovethecabinetdoors.

Note:

Thefrontdoorandthereardoorcanberemovedinthesameway.Removingthefront

doorisusedasanexampleinthisprocedure.

Prerequisite

Acrossheadscrewdriverisready.

Steps

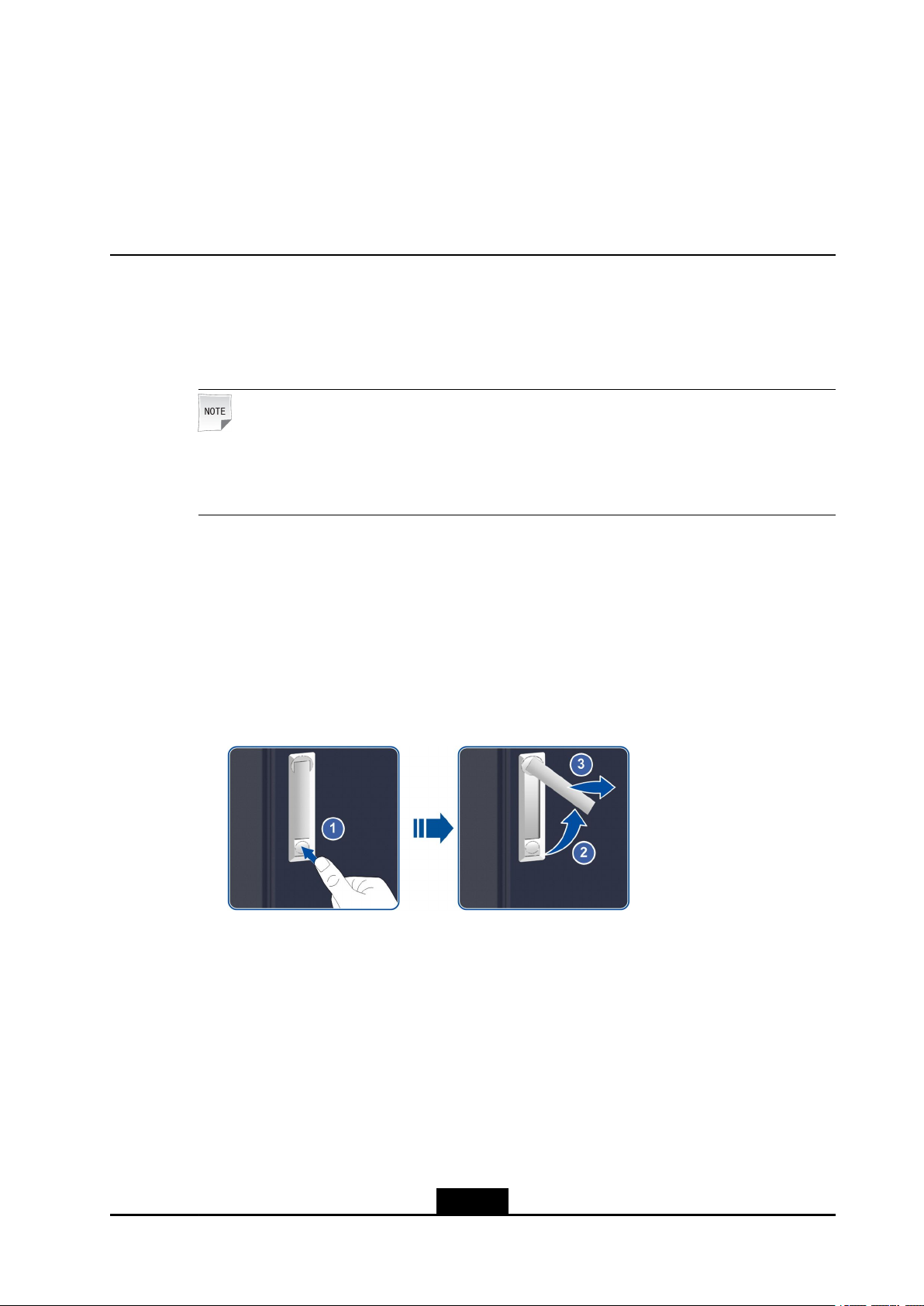

1.Openthedoorlock,andthenopenthecabinetdoor,seeFigure4-1.

Figure4-1OpeningtheDoorLock

2.Disconnecttheendofthegroundingcableonthecabinetbyusingacrosshead

screwdriver(itisrecommendedthatonlytheendconnectedtothecabinetis

disconnected),seeFigure4-2.

4-1

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

NetNumen™U31R06HardwareInstallationGuide

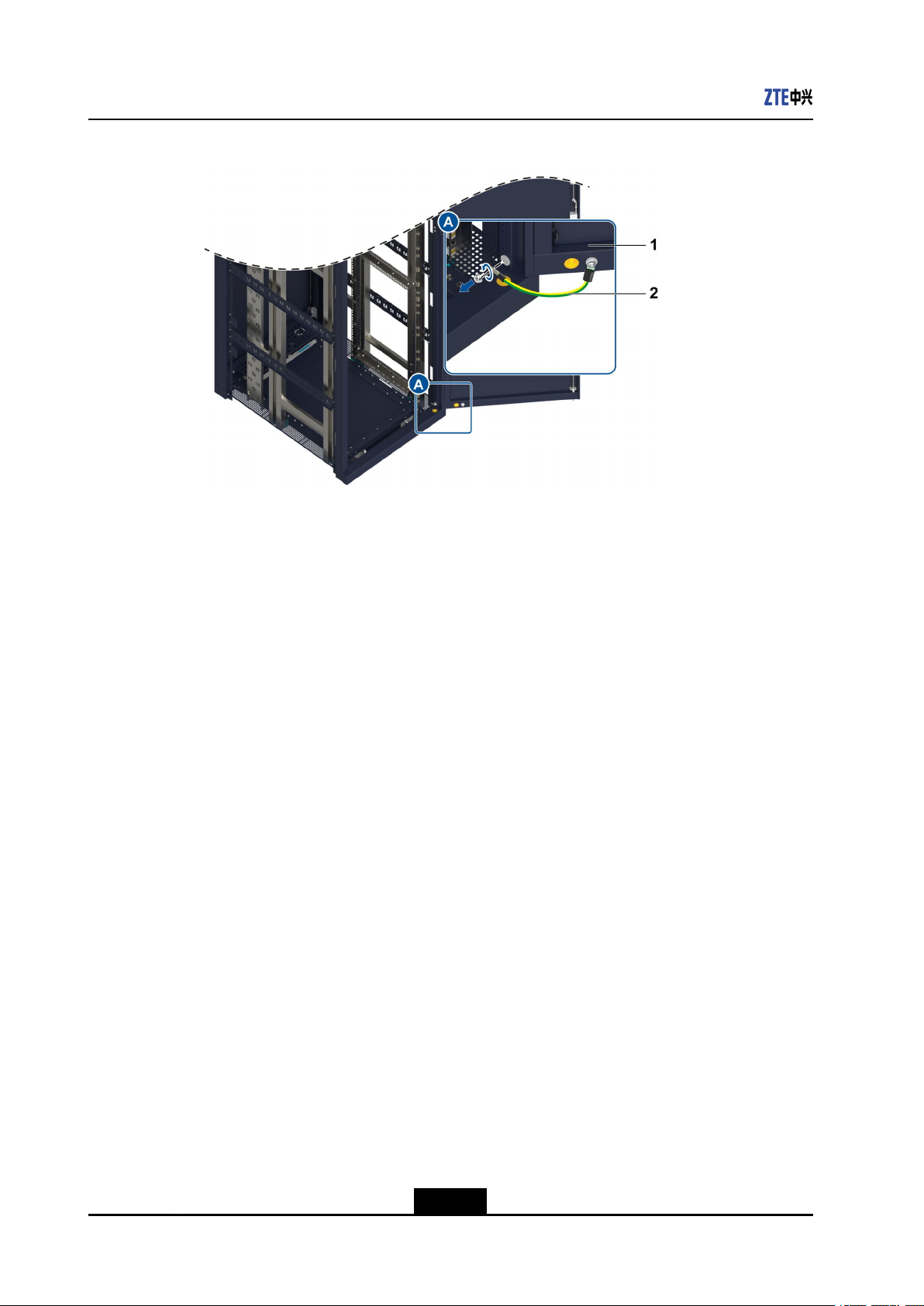

Figure4-2DisconnectingtheGroundingCable

1.Cabinetdoor2.Groundingcable

3.Installthescrewsbacktothecabinettoavoidlosingthem.

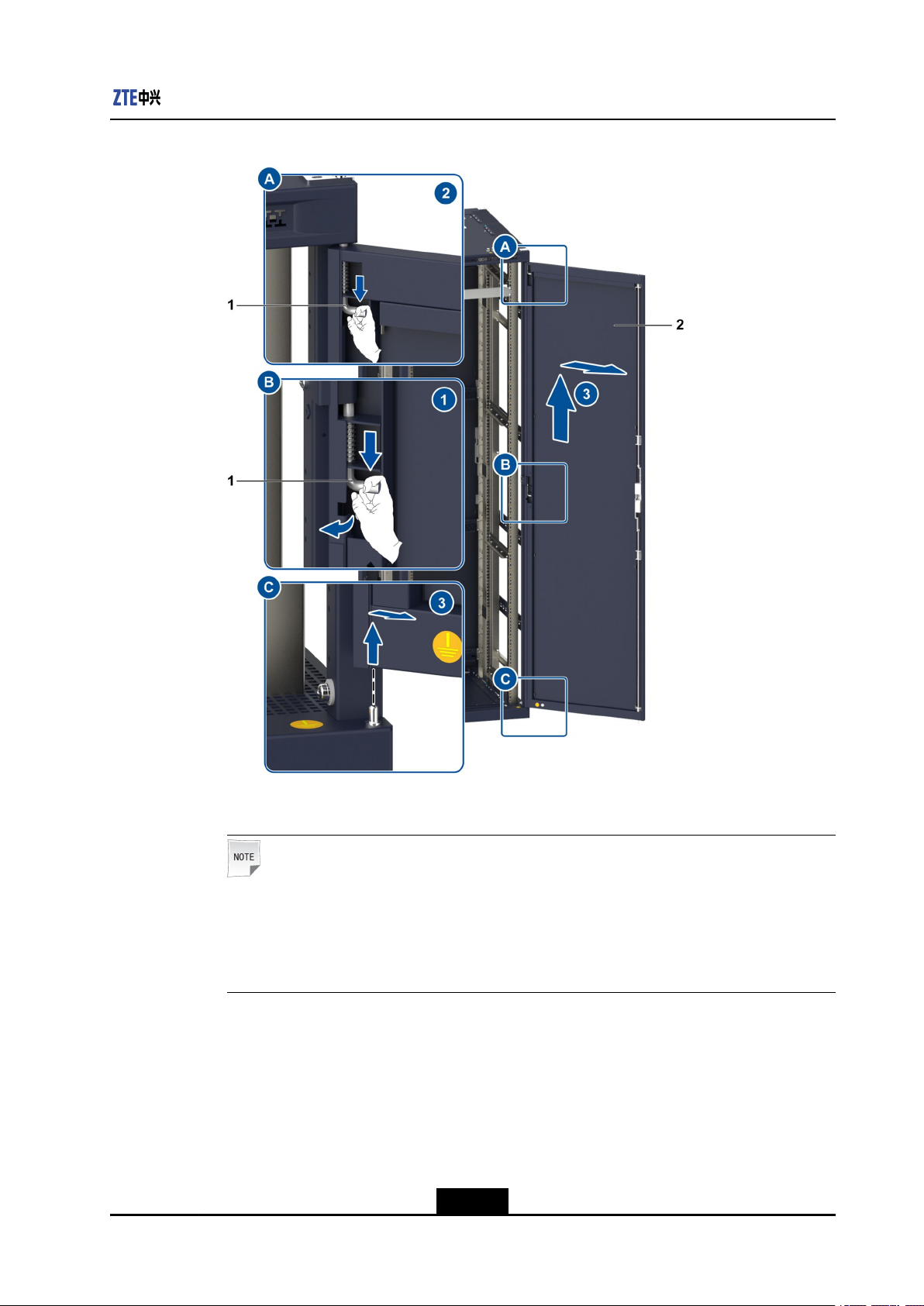

4.Disassemblethecabinetdoor,seeFigure4-3.

a.Holdthedoorwithyourrighthand.

b.Pulldownthespringpinlocatedinthemiddlepartofthedoorwithyourlefthand,

andthenhangthespringpininthegapononesideofthedoor.

c.Pulldownthespringpinontheupperpartofthedoor.

d.Liftthedoorupwards,andthenmovethedooroutwards.

4-2

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

Figure4-3DisassemblingtheCabinetDoor

Chapter4RemovingCabinetDoors

1.Springpin2.Frontdoor

Note:

Putthecabinetatasafeplace.

Ensurethatthelockofthecabinetdoorisopened,whichpreventsthelockrodonthe

lowerpartofthedoorfrombeingdistortedbecauseofpressure.

–EndofSteps–

4-3

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

NetNumen™U31R06HardwareInstallationGuide

Thispageintentionallyleftblank.

4-4

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

Chapter5

CabinetInstallation

Forselectingthecabinetinstallationmodeinaccordancewiththeequipment-room

conditions,refertoT able5-1.

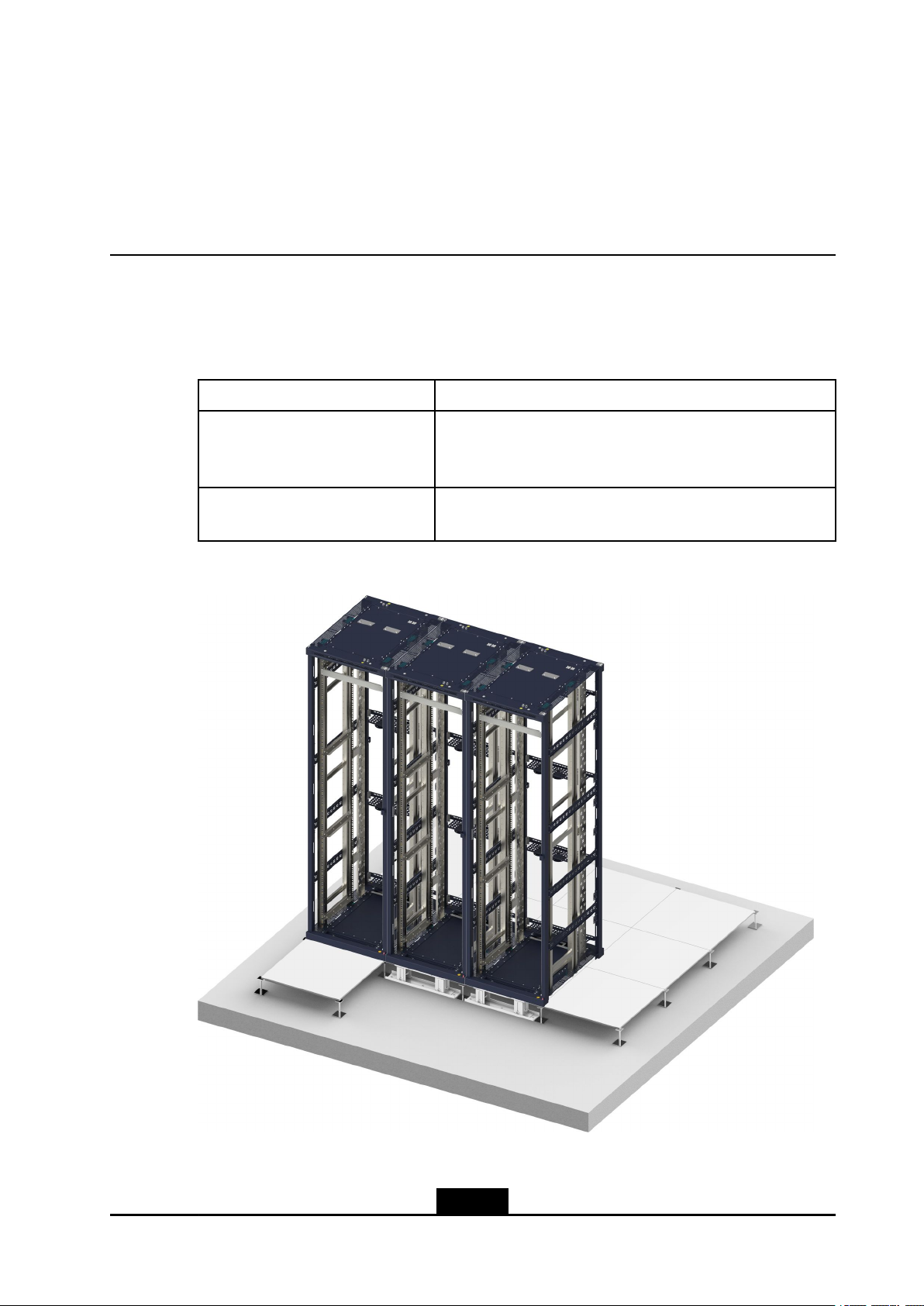

Table5-1SolutionsforInstallingtheCabinet

EquipmentRoomConditionInstallationSolution

Theequipmentroomhasstatic

conductiveoor.

Theequipmentroomhasnostatic

conductiveoor.

Figure5-1InstallingtheCabinetontheAdjustableBase

Installthecabinetontheadjustablebase.Usetheadjustable

basetoinstallthecabinetontheconcreteoorofthe

equipmentroom,seeFigure5-1.

Installthecabinetontheoor.Installthecabinetdirectlyon

theconcreteooroftheequipmentroom,seeFigure5-2.

5-1

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

NetNumen™U31R06HardwareInstallationGuide

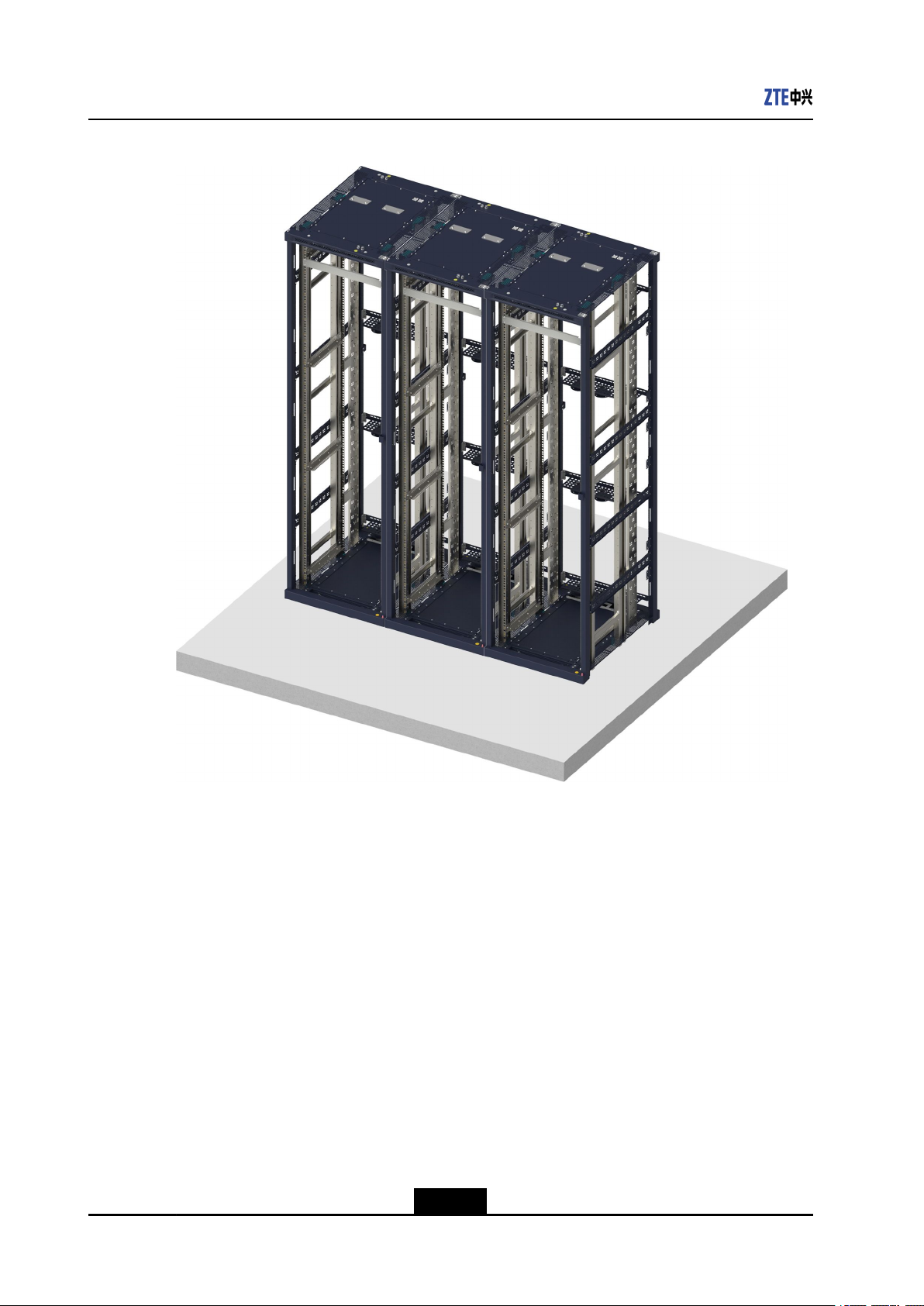

Figure5-2InstallingtheCabinetontheFloor

TableofContents

InstallingtheCabinetontheAdjustableBase.............................................................5-2

InstallingtheCabinetontheFloor............................................................................5-18

5.1InstallingtheCabinetontheAdjustableBase

Thisproceduredescribeshowtoinstallthecabinetontheadjustablebase.

Adjustthebaseheightandmountthebasetomakeitssurfaceinlevelwiththestatic

conductiveoor.

5-2

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

Chapter5CabinetInstallation

Note:

Ensurethattheengineeringoverthecabinet(suchascabletrayinstallation)iscompleted,

sothatdustormetalscrapswillnotdropintothecabinetfromthetopduringthecabinet

installationprocess.

Prerequisite

lTherelateddesigndocumentsareready.

lThedrillingtemplate(providedwiththecabinet)isready.

lTheadjustablebases,AN01socketboltsareready.

lInstrumentssuchascrossheadscrewdriver,tapemeasure,anglesquare,spiritlevel,

powdermarker,markerpen,percussiondrill,vacuumcleaner,adjustablespanner,

torquespanner,socketspanner,clawhammer,punch,multimeter,andladderare

ready.

lSpacershims,insulatinggaskets,M12×90bolts(anM12×90boltcontainsaspring

washer,agasket,andaninsulatingwasher),M12×35bolts(anM12×35boltcontains

aspringwasherandagasket)areready.

Context

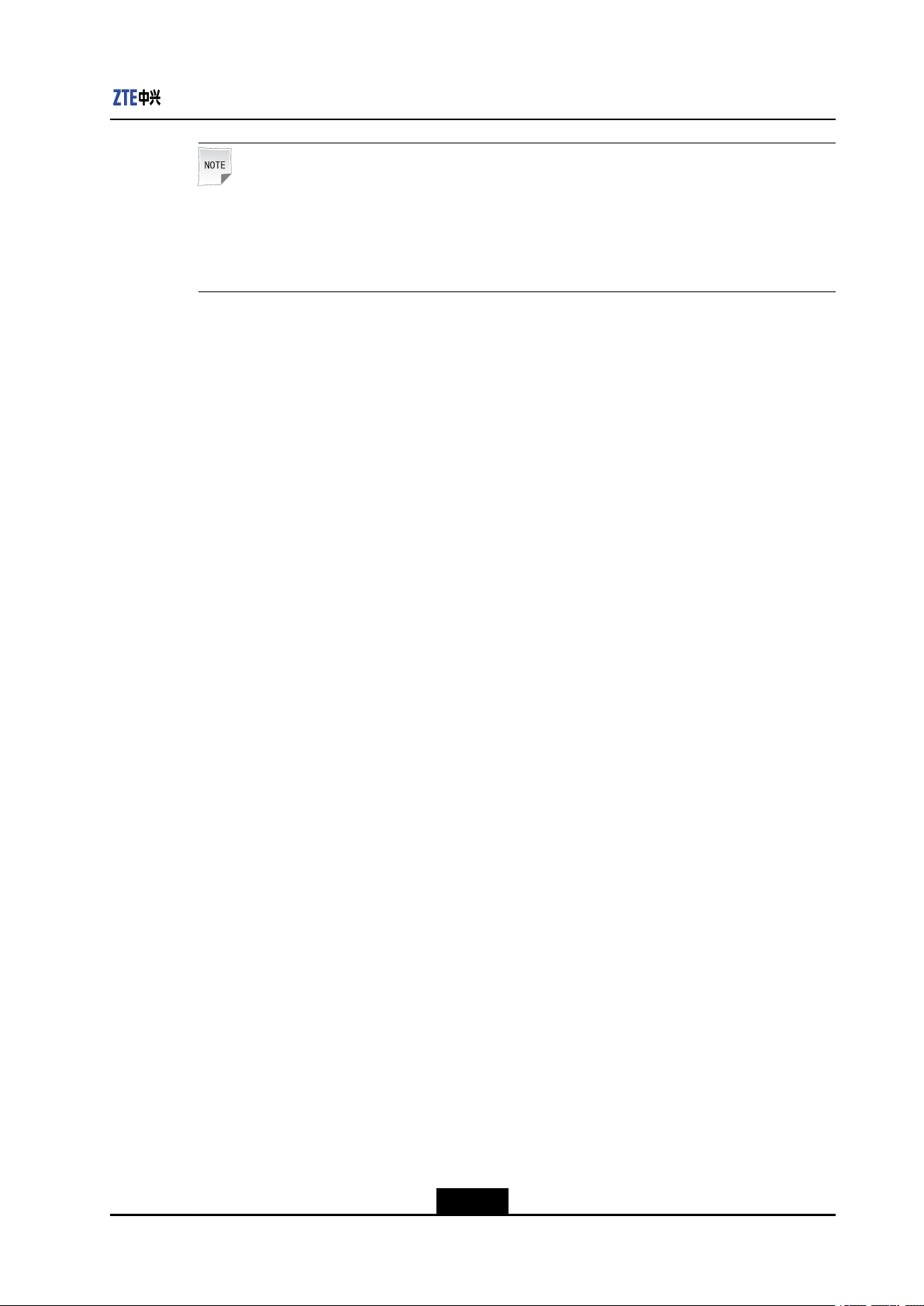

Fortheinstallationpositionofthecabinetintheequipmentroom,seeFigure5-3.

5-3

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

NetNumen™U31R06HardwareInstallationGuide

Figure5-3InstallationPositionoftheCabinet

Caution!

Themountingpositionoftheadjustablebaseshouldnotconictwiththeframeworkof

thestaticconductiveoor.Ifacollisionisunavoidable,removetheoorframeworkatthe

collidingposition.

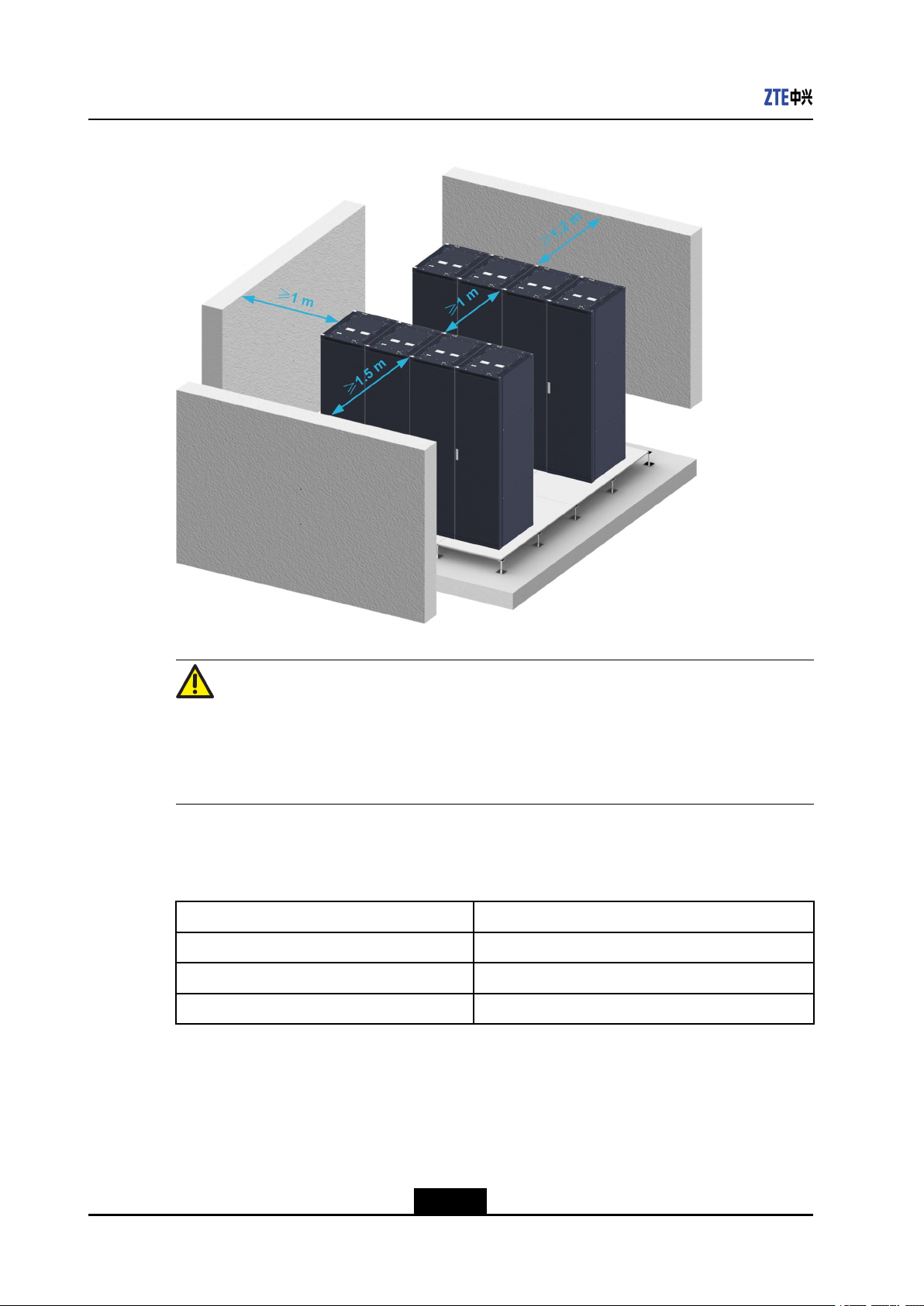

Adjustablebasesfallintothreetypes.Fortypesoftheadjustablebase,refertoTable5-2.

Table5-2AdjustableHeights

AdjustableBaseTypeAdjustableHeights

TypeA160mm-240mm

TypeB240mm-390mm

TypeC390mm-690mm

Thethreetypesofadjustablebaseshavethesamestructure.Fortheoverviewofan

adjustablebaseoftypeA,seeFigure5-4.

5-4

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

Figure5-4AdjustableBaseofTypeA

Chapter5CabinetInstallation

Steps

Positioningtheadjustablebase

1.Removethestaticconductiveooranditsbracesattheplacewherethecabinetisto

beinstalled.

2.Drawlinesbyusingmeasurementtoolsandline-drawingtoolstomarktheinstallation

holesfortheadjustablebase.

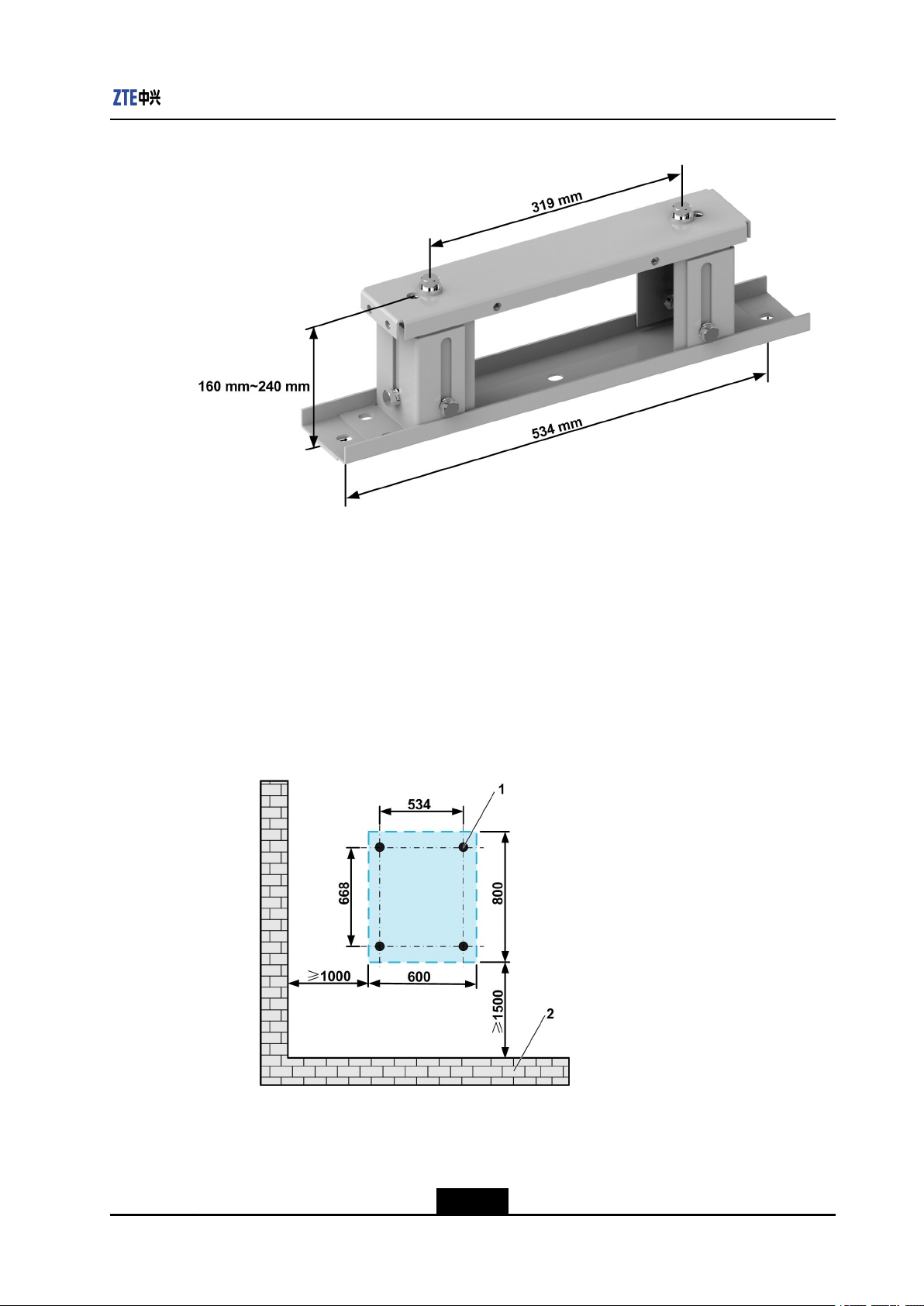

lForthepositionofholesforinstallingasinglecabinet,seeFigure5-5.

Figure5-5MarkingHolesforInstallingaSingleCabinet(Unit:mm)

1.Installationhole2.Wall

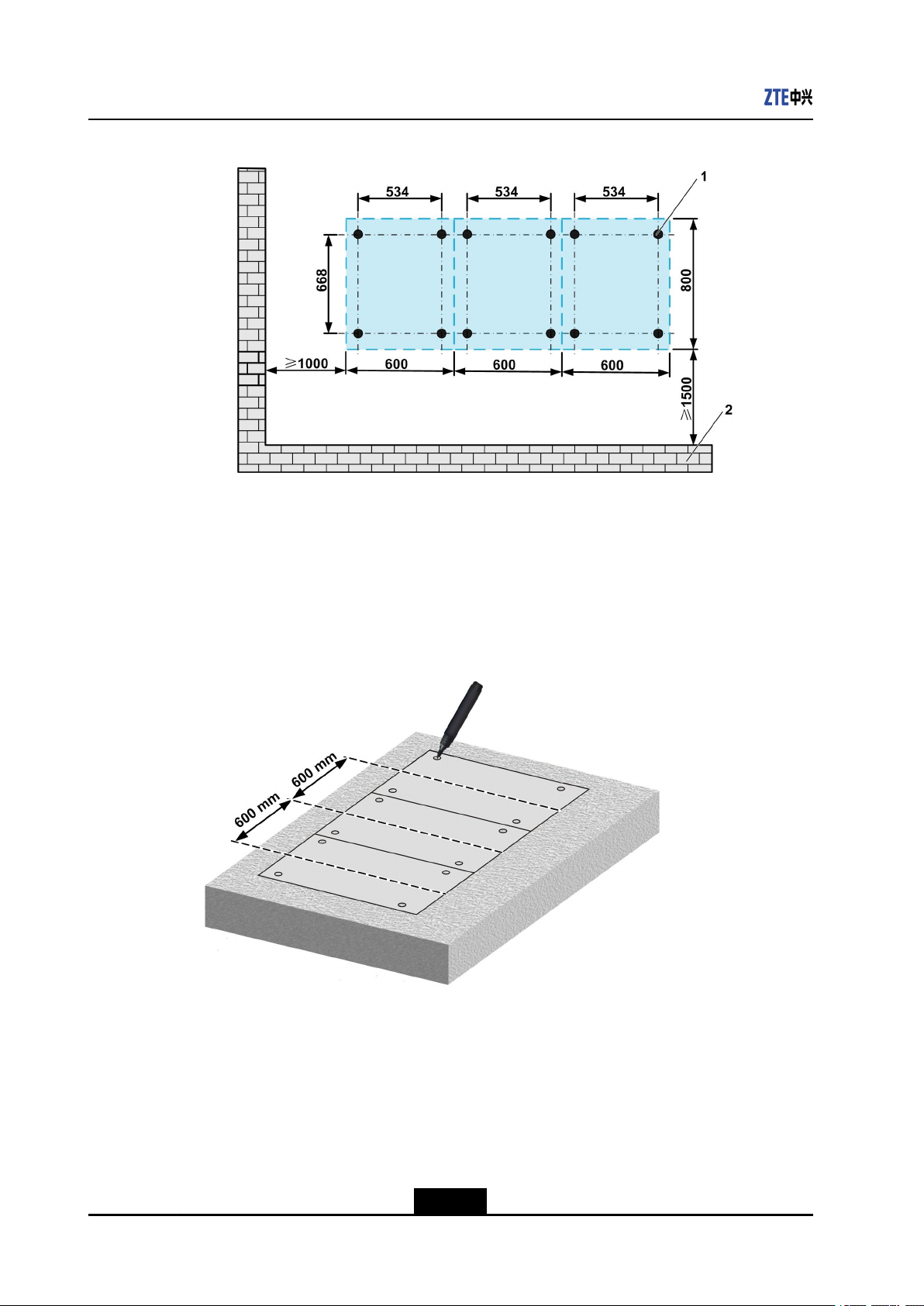

lFortheinstallationholesofsocketboltsfortheadjustablebasestoinstallmultiple

cabinets,seeFigure5-6.

5-5

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

NetNumen™U31R06HardwareInstallationGuide

Figure5-6MarkingHolesforInstallingMultipleCabinets(Unit:mm)

1.Installationhole2.Wall

3.Putthedrillingtemplateonthemarkedpositions.Iftheholesonthetemplatematch

theinstallationholesmarkedinstep2.,markallinstallationholesforthebasebyusing

amarkerpen,seeFigure5-7.

Iftheholesdonotmatch,adjusttheholessothatthelinesdrawninstep2.arecorrect.

Figure5-7MarkingInstallationHolesUsingtheDrillingTemplate

4.Inaccordancewiththepositionofthesocketboltmarkedontheoor,makean

indentationattheholelocationrstbyusingapunchtohelplocatethedrillbit,see

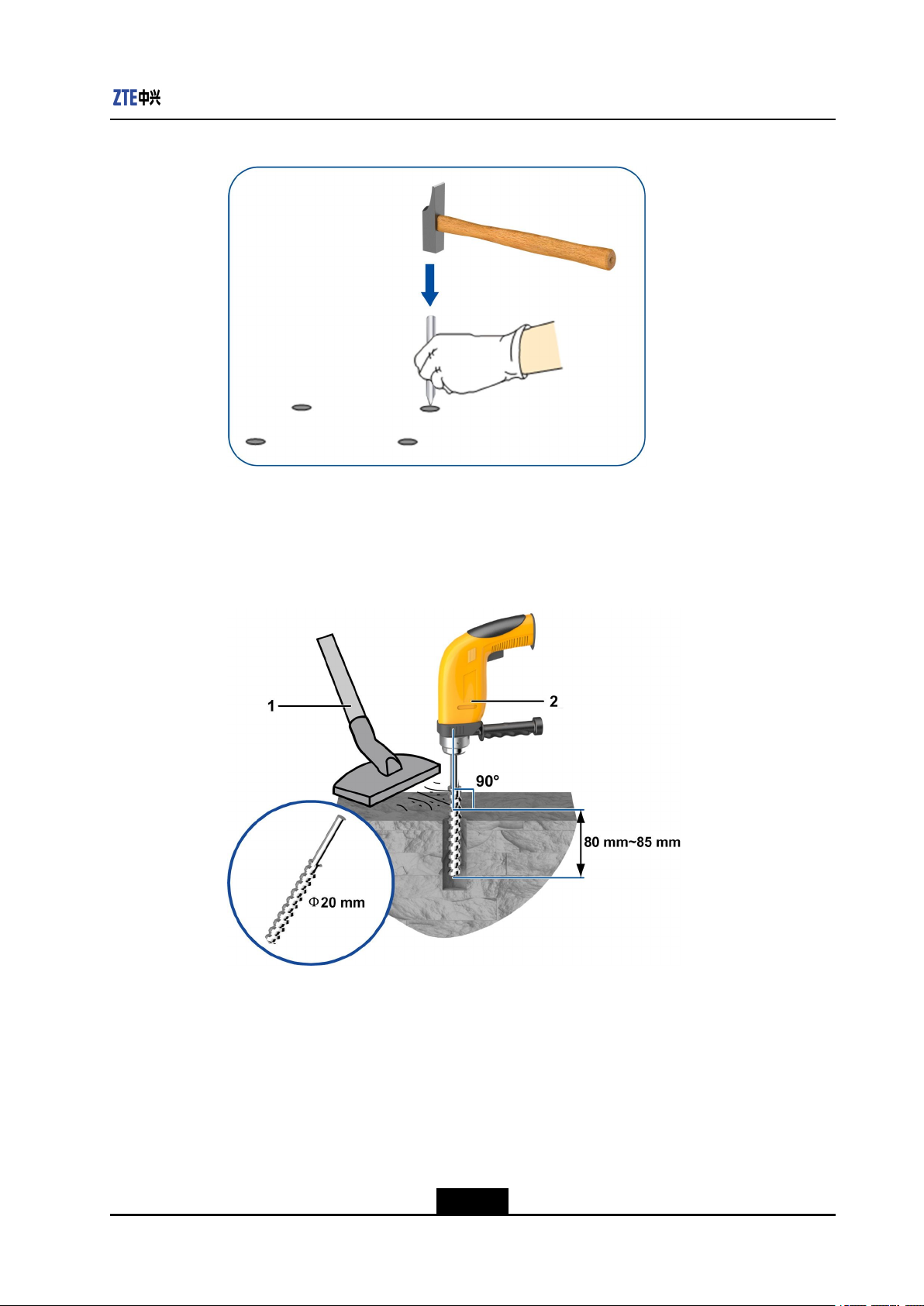

Figure5-8.

5-6

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

Chapter5CabinetInstallation

Figure5-8DrillingIndentations

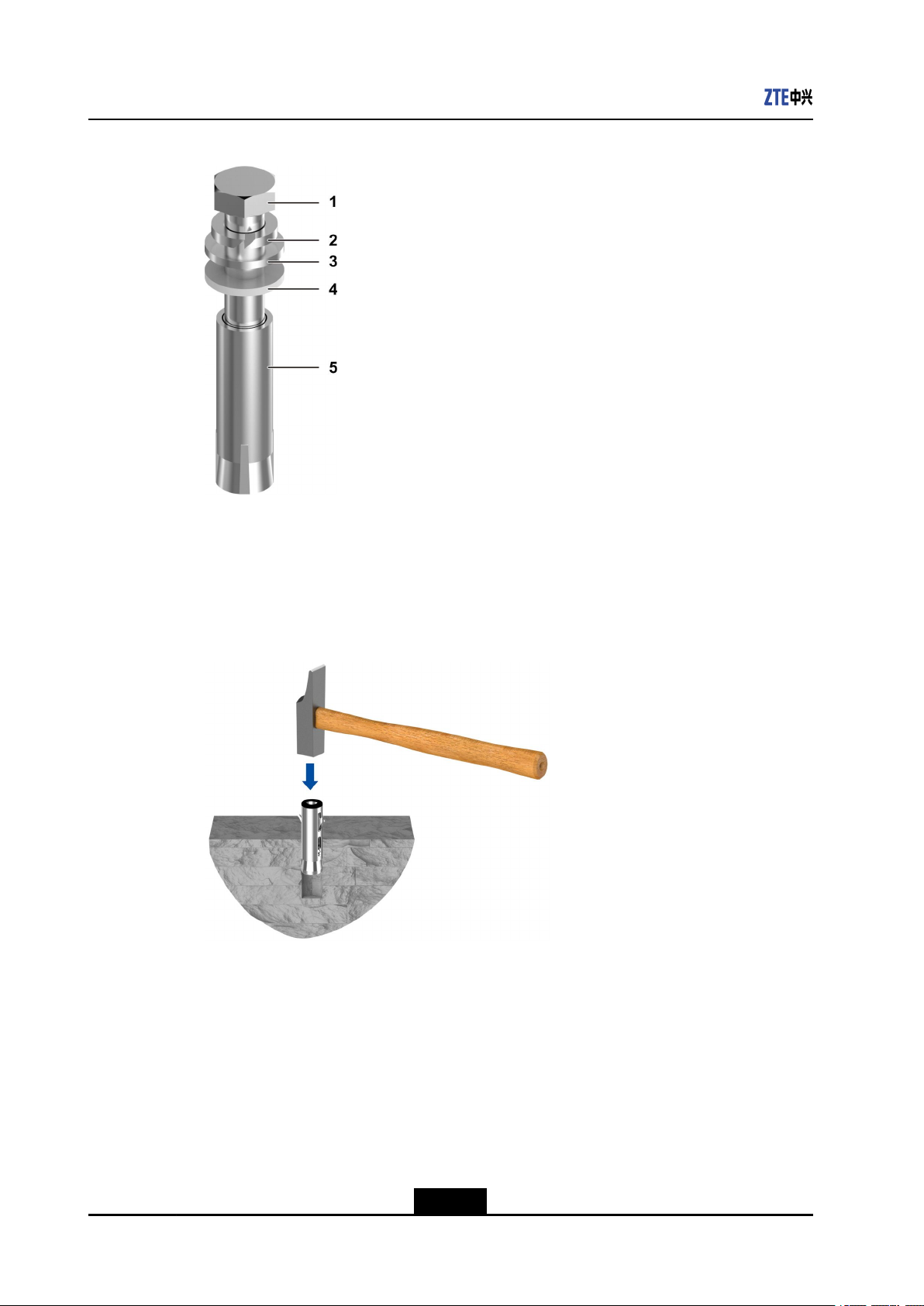

5.Adjustthescalethatdeterminesthedepthofthehole,andthenpressthepercussion

drilldownwardverticallytodrillholes.Usethevacuumcleanertoremovethedust

insideandoutsidetheholes,seeFigure5-9.

Figure5-9DrillingaHole

1.Vacuumcleaner2.Percussiondrill

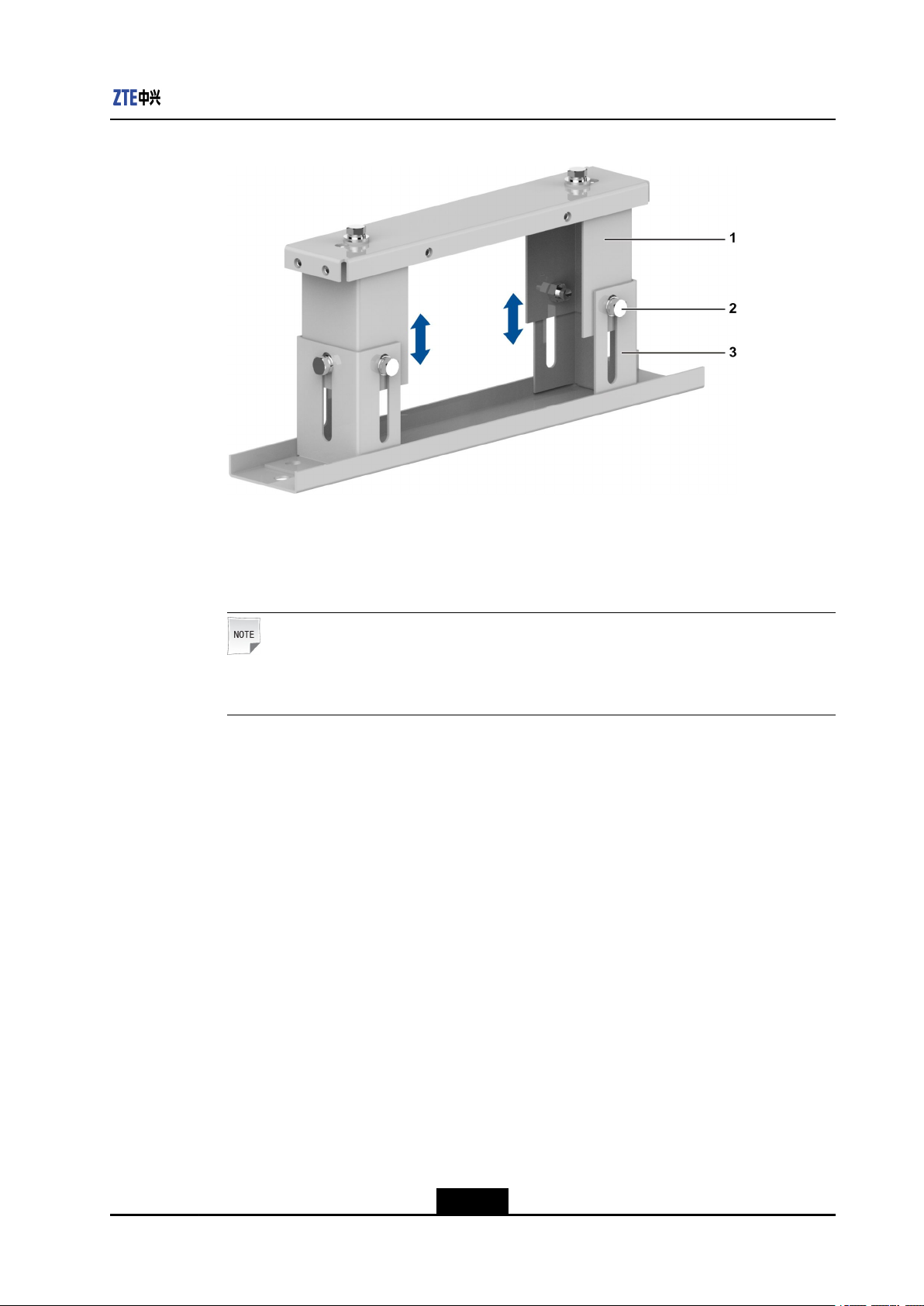

6.Removethebolt,springwasher,insulatingwasher,andgasketoftheAN01socket

bolt.

FortheoverviewofAN01socketbolt,seeFigure5-10.

5-7

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

NetNumen™U31R06HardwareInstallationGuide

Figure5-10AN01SocketBolt

1.M12×90bolt

2.Springwasher

3.Gasket

4.Insulatingwasher

5.Expansiontube

7.Installthesocketboltverticallyintothehole.Hammerthesocketboltbyusingthe

clawhammeruntiltheexpansiontubeenterstheholecompletely,seeFigure5-1 1.

Figure5-11HammeringaSocketBolt

Mountingtheadjustablebase

8.Measuretheheightbetweentheconcreteoorandthesurfaceofthestaticconductive

oorbyusingatapemeasure.

9.Adjusttheadjustablebasetomakethescaleindicationonthebaseequaltotheheight

ofthestaticconductiveoor,seeFigure5-12.

Thetighteningtorqueofaheight-lockingboltshouldreach40N·m.

5-8

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

Figure5-12AdjustingtheHeightofanAdjustableBase

Chapter5CabinetInstallation

1.Movablebracket2.Height-locking

M12×25bolt

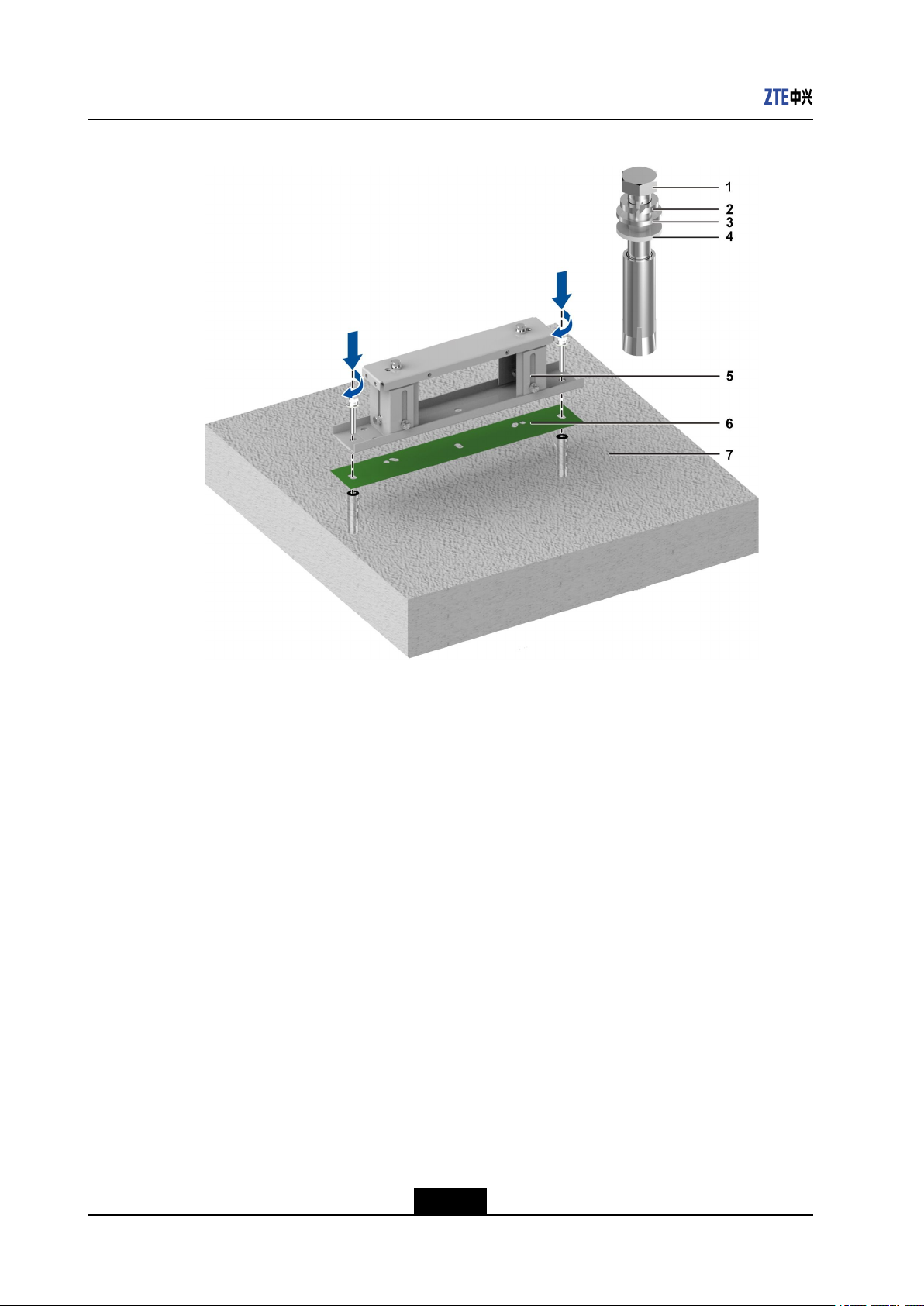

10.Securetheadjustablebase,seeFigure5-13.

Note:

Thetighteningtorqueofaboltshouldreach75N·m.

3.Fixedbracket

5-9

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

NetNumen™U31R06HardwareInstallationGuide

Figure5-13SecuringanAdjustableBase

1.M12×90bolt

2.Springwasher

3.Gasket

4.Insulatingwasher

5.Adjustablebase

6.Insulatinggasket

7.Concretefloor

11.RemoveM12×35boltsfromtheadjustablebasebyusinganadjustablewrench.

Removespringwashersandgasketsfromthebolts,seeFigure5-14.

5-10

SJ-20141121113158-006|2014-12-20(R1.0)ZTEProprietaryandCondential

Loading...

Loading...