Page 1

Operation Description

ME3000V2 Operation Description

Version:V1.0

ZTE CORPORTION

1

Page 2

Operation Description

Table of Contents

1 Mechanical Interface ...................................................................................................................... 3

1.1 Physical Features ........................................................................................................................................ 3

1.2 Mechanical size .......................................................................................................................................... 3

2 Electrical Interface ......................................................................................................................... 4

2.1 Pin Assignments ......................................................................................................................................... 4

3 Power Management ....................................................................................................................... 6

3.1 Power and Reset ......................................................................................................................................... 6

3.1.1 Power supply ..................................................................................................................................... 6

3.1.2 Power on ............................................................................................................................................ 6

3.1.3 Power off ........................................................................................................................................... 6

3.1.4 Reset .................................................................................................................................................. 6

4 Antenna Interface ........................................................................................................................... 7

4.1 Antenna Installation ................................................................................................................................... 7

4.2 Antenna Pad ............................................................................................................................................... 7

4.3 Antenna connector ..................................................................................................................................... 7

5 RF Interface ................................................................................................................................... 9

5.1 Overview .................................................................................................................................................... 9

5.2 Antenna Subsystem .................................................................................................................................... 9

5.2.1 Antenna Specifications .................................................................................................................... 10

5.2.2 Cable Loss ....................................................................................................................................... 10

5.2.3 Antenna Gain Minimum Requirements ........................................................................................... 10

5.2.4 Antenna Gain Maximum Requirements .......................................................................................... 10

5.2.5 Antenna Matching ........................................................................................................................... 10

5.2.6 PCB Design Considerations ............................................................................................................. 10

5.2.7 Other Precautions ............................................................................................................................. 10

5.2.8 Grounding .........................................................................................................................................11

6 Test Capabilities ........................................................................................................................... 12

6.1 Test Description ........................................................................................................................................ 12

6.2 GSM Test Equipment and Tools ............................................................................................................... 13

6.2.1 GSM RF Rx Specification ............................................................................................................... 14

6.2.2 GSM RF Tx Specification: .............................................................................................................. 14

6.2.3 High Temperature Operation Test .................................................................................................... 14

6.2.4 Low Temperature Operation Test .................................................................................................... 14

6.2.5 High Temperature Storage Test ....................................................................................................... 14

6.2.6 Low Temperature Storage Test ........................................................................................................ 15

6.2.7 High Temperature High Humidity Operation Test .......................................................................... 15

6.2.8 Temperature Concussion Test ......................................................................................................... 15

6.2.9 ESD Immunity Test ......................................................................................................................... 15

6.2.10 Radiated Emissions Test .................................................................................................................. 15

2

Page 3

Operation Description

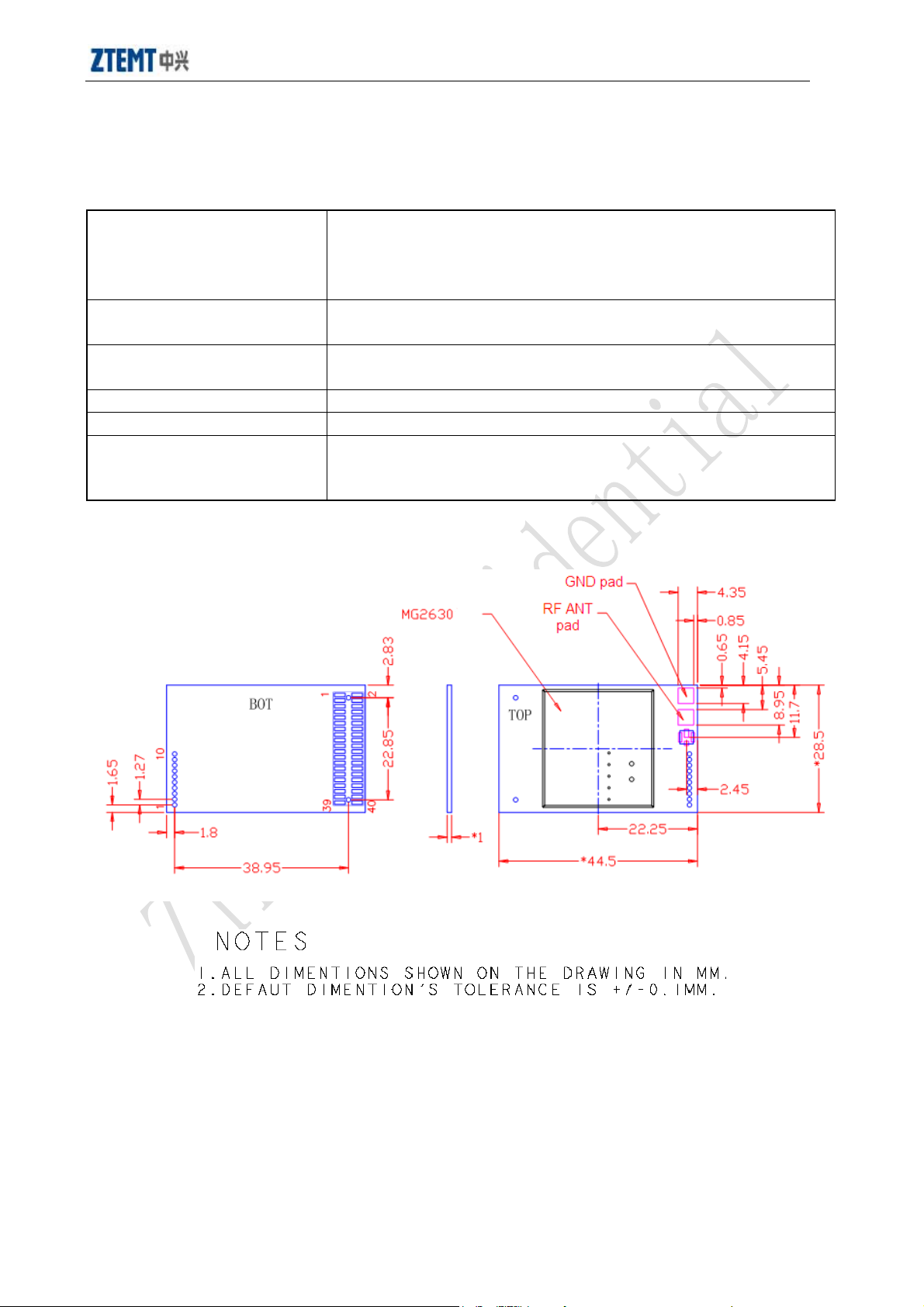

1 Mechanical Interface

1.1 Physical Features

Length: 44.5 mm

Dimensions & Weight

Operational

Temperature Range

Storage Temperature

Range

ROHS Yes

Antenna Connectors 50-Ohm ANT connectors for GSM

Power Supply

1.2 Mechanical size

Width: 28.5 mm

Thickness: 8.25 mm

Weight: 8 g

-20℃ to +65℃

-40℃ to +80℃

Two kinds of inputs:

1.external power supply (+4.75V~ +5.25V, typical value +5V)

2. battery power supply (+3.3V~ +4.2V, typical)

Figure 1-1: ME3000V2 T-viewgraph

3

Page 4

Operation Description

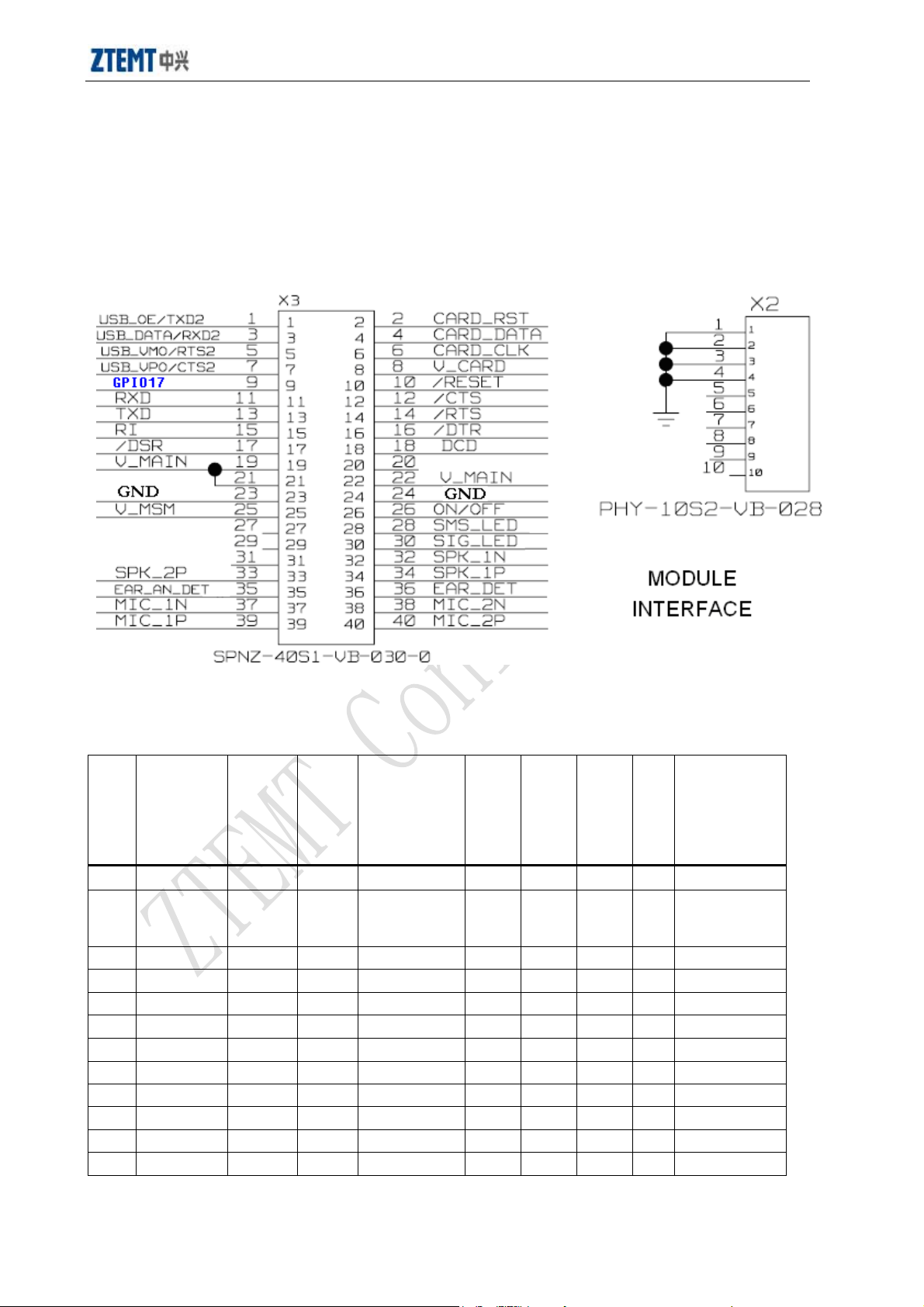

2 Electrical Interface

2.1 Pin Assignments

Figure 2-1 ME3000V2 Module interface ME3000V2 map

Table 2-1 ME3000V2 Module 40-pin Electrical Interface

Signeal

Pin

Name

6 SIM-CLK Digital O SIM clock 2.5 2.8 3.3 V 2.8VLevel

8 SIM-VCC Power O

4 SIM-DATA Digital I/O SIM data 2.5 2.8 3.3 V 2.8VLevel

2 SIM-RST Digital O SIM reset 2.5 2.8 3.3 V 2.8VLevel

30 SIG_LED Digital O LED control 2.5 2.8 3.3 V 2.8VLevel

3

11 RXD Digital O COM Port 2.5 2.8 3.3 V 2.8VLevel

1 TXD2 Digital I COM Port 2.5 2.8 3.3 V 2.8VLevel

13 TXD Digital I COM Port 2.5 2.8 3.3 V 2.8VLevel

30 SIG_LED Digital O LED control 2.5 2.8 3.3 V 2.8VLevel

28 SMS_LED Digital O LED control 2.5 2.8 3.3 V 2.8VLevel

22

RXD2

V_MAIN

Signal

Type

Digital

Power

Inpu

t/Out

put

O

P

Function Min Typ Max

SIM power

supply

COM Port 2.5 2.8 3.3 V 2.8VLevel

Main power 3.3 3.7 4.25 V

2.5 2.8 3.3 V 2.8VLevel

Uni

t

Comments

4

Page 5

Operation Description

25 V_MSM Power O

External

power supply

2.5 2.8 3.3 V

LED ON as

15 RI Digital O 2.5 2.8 3.3 V

the level is

high.

17 /DSR Digital O COM Port 3.3 3.8 4.2 V

14

/RTS

Digital

I

COM Port 3.3 3.8 4.2 V

16 /DTR Digital I COM Port 4.75 5 5.25 V

5

12

RTS2

/CTS

Digital

Digital

I

O

COM Port 3.0 3.8 4.25 V

COM Port 2.5 2.8 3.3 V

7 CTS2 Digital O COM Port 2.5 2.8 3.3 V

18 DCD Digital O COM Port 2.5 2.8 3.3 V

10 /RESET Digital I System reset 2.5 2.8 3.3 V

26 ON/OFF Digital I

EAR_ANT_D

35

ET

Analog

I

Power on/off

key control

EARPHONE

MIC KEY

2.5 2.8 3.3 V

36 EAR_DET Digital I

EARPHONE

insert detect

37 MIC_1N Analog AI Mic input-

39 MIC_1P Analog AI Mic input+

38 MIC_2P Analog AI Mic input+

40

MIC_2N

32 SPK_1N Analog AO

34 SPK_1P Analog AO

33

SPK_2P

Analog

Analog

AI

AO

Mic input-

Speaker

output-

Speaker

output-

Speaker

output-

Headset MIC

Earphone

MIC

Headset

Receiver

Earphone

Receiver

5

Page 6

Operation Description

3 Power Management

3.1 Power and Reset

3.1.1 Power supply

The module could work under two power modes: 1. Charger; 2 Battery.

When powered by the charger, you could perform constant current charge, constant voltage

charge and trickle current charge. Normally, trickle current charge starts when the voltage is

lower than 3.2V, constant current charge starts as the voltage is between 3.2V and 4.0V; and

constant voltage charge starts when the voltage reaches 4.0V. As the blackout happens, the

battery would be immediately used.

See table 4-1 for the module’s input voltage characteristics. If the input voltage is not in the

range, it must be converted to the voltage below:

Table4-1 Voltage Characteristics

1. External power supply

Status Max. voltage Typical voltage Min. voltage

Power supply +5.25 VDC +5.0VDC +4.75 VDC

2. Battery(currently the software supports Li battery)

Status Max. voltage Typical voltage Min. voltage

Power supply +4.25 VDC +3.8 VDC +3.3 VDC

3.1.2 Power on

The module is under power-off status after it’s normally powered on. To turn on the module,

provide a 1500-2000mS low level pulse to ON/OFF pin when the module is OFF.

3.1.3 Power off

To turn off the module, provide a 1500-2000mS low level pulse to ON/OFF pin when the

module is ON.

3.1.4 Reset

Use the above method to firstly “Power off” and then “Power on”, and by doing so the module

could be reset. ME3000V2 module does not lead the reset pin.

6

Page 7

Operation Description

4 Antenna Interface

The RF interface of the ME3000V2 Module has an impedance of 50 . The module is capable of sustaining a

total mismatch at the antenna connector or pad without any damage, even when transmitting at maximum RF

power.

The external antenna must be matched properly to achieve best performance regarding radiated power,

DC-power consumption, modulation accuracy and harmonic suppression. Antenna matching networks are not

included on the ME3000V2 Module PCB and should be placed in the host application.

Regarding the return loss, the Module provides the following values in the active band:

Table 4-1 Return Loss in the Active Band

State of Module Return Loss of Module Recommended Return Loss of

Receive ≥ 8dB ≥ 12dB

not applicable ≥ 12dB

Tran smit

The connection of the antenna or other equipment must be de coupled from DC voltage. This is necessary

because the antenna connector is DC coupled to ground via an inductor for ESD protection.

4.1 Antenna Installation

Application

To suit the physical design of individual applications, the ME3000V2 offers two alternative approached to

connecting the antenna:

■ Recommended approach:

component side of the PCB (top view on Module). See Section 4.3 for details.

■ Antenna pad and grounding plane placed on the bottom side. See Section 4.2 for details.

MM9329-2700B connector has been chosen as antenna reference point (ARP) for the ZTEMT reference

The

equipment submitted to type approve the ME3000V2 Module. All RF data specified throughout this manual are

related to the ARP. For compliance with the test results of the ZTEMT type approval you are advised to give

priority to the connector, rather than using the antenna pad.

Note: Both solutions can be applied alternatively. This means,if the antenna is connected to the pad, then the

connector on the Module must be left empty,and when the antenna is connected to the Module connector, the pad

is useless,

MM9329-2700B antenna connector manufactured by MURATA assembled on the

4.2 Antenna Pad

The antenna pad of the module is soldered to the board on the customer design to connect with RF line.

For proper grounding connect the RF line to the ground plane on the bottom of the MG2636 Module which

must be connected to the ground plane of the application.

Consider that according to GSM recommendations as 50Ω connector is mandatory for type approval

measurements. It must be ensured that the RF line which is connected to antenna pad should be controlled on

50Ω.

Notes on soldering

■ To prevent damage to the Module and to obtain long-term solder joint properties, you are advised to

maintain the standards of good engineering practice for soldering.

Material Properties

■ME3000V2 Module PCB: FR4

■ Antenna pad: Gold plated pad

4.3 Antenna connector

The ME3000V2 Module uses a microwave coaxial connector supplied by Murata Ltd. The product name is

MM9329-2700B. The position of the antenna connector on the Module PCB can be seen in Figure 4-1.

7

Page 8

Operation Description

Figure 4-1 Specification of MM9329-2700B connector

Part

Number

MM9329

-2700B

Impedance : 50 ohm

Rated

Voltag

e

(V)

250

Table 4-2 Product specifications of

Contact

Resistan

ce

(ohm)

0.015

max.

Withstandi

ng

Voltage

(rms)

300 (AC) 500 min. 100 DC - 6.0 -40~+90

Insulatio

n

Resistan

ce

(M ohm)

Durabili

ty

(cycles)

MM9329-2700B connector

Frequen

cy

Rating

(GHz)

Temperatu

re

Range

(degree C)

VSWR Center

1.2 max.

(DC~3GH

z)

Conta

ct

Copper

Alloy

Gold

plated

Outer

Conta

ct

Copper

Alloy

Silver

plated

Insulator

Engineeri

ng plastic

8

Page 9

Operation Description

5 RF Interface

5.1 Overview

A 50 ohm coaxial RF connector is provided for Module testing. However, we advise customers lead from the

antenna pad at the RF line to the antenna.

Figure 5-1 GSM Connector

The module must provide a suitable antenna that works in the desired frequency band of operation. The Antenna

connected to the GSM connector should be a dual band antenna supporting the GSM900 and DCS1800 bands.

Band TX Frequency RX Frequency

GSM 880~915 MHz 925~960 MHz

DCS 1710~1785 MHz 1805~1880 MHz

Note: TX refers to the transmit from the module into the antenna (Reverse Link of the GSM

system), and RX refers to the receive from the antenna into the module (Forward Link of the

GSM system).

5.2 Antenna Subsystem

The antenna sub-system and its design is a major part of the final product integration. Special attention and care

should be taken in adhering to the following guidelines.

9

Page 10

Operation Description

5.2.1 Antenna Specifications

Choice of the antenna cable (type, length, performance, RF loss, etc) and antenna connector (type + losses) can

have a major impact on the success of the design.

5.2.2 Cable Loss

All cables have RF losses. Minimizing the length of the cable between the antenna and the RF connectors on the

module will help obtain superior performance. High Quality/Low loss co-axial cables should be used to connect

the antenna to the RF connectors. Contact the antenna vendor for the specific type of cable that interfaces with

their antenna and ask them to detail the RF losses of the cables supplied along with the antenna. Typically, the

cable length should be such that they have no more than 1-2dB of loss. Though the system will work with longer

(loss) cables, this will degrade GSM system performance. Care should also be taken to ensure that the cable end

connectors/terminations are well assembled to minimize losses and to offer a reliable, sturdy connection to the

Module sub-system. This is particularly important for applications where the module is mounted on a mobile or

portable environment where it is subject to shock and vibration.

5.2.3 Antenna Gain Minimum Requirements

It is recommended that the antenna chosen have at least 2 dBi gain in the GSM900 band and 4 dBi in the PCS

band. The Antenna subsystem shall also have at least 8 dB of return loss at the input with respect to a 50-ohm

system.

5.2.4 Antenna Gain Maximum Requirements

Our FCC Grant imposes a maximum gain for the antenna subsystem: 7 dBi for the GSM900 band and 13dBi for

the DCS band.

Warning:

Excessive gain could damage sensitive RF circuits and void the warranty.

5.2.5 Antenna Matching

The module’s RF connectors are designed to work with a 50-ohm subsystem. It is assumed that the antenna

chosen has matching internal to it to match between the 50-ohm RF connectors and the antenna impedance.

5.2.6 PCB Design Considerations

• The antenna subsystem should be treated like any other RF system or component. It should be isolated as much

as possible from any noise generating circuitry including the interface signals via filtering and shielding.

• As a general recommendation all components or chips operating at high frequencies such as

micro controllers, memory, DC/DC converts and other RF components should not be placed too close to the

module. When such cases exist, correct supply and ground de-coupling areas should be designed and validated.

• Avoid placing the components around the RF connection and close to the RF line between the RF antenna and

the module.

• RF lines and cables should be as short as possible.

• If using coaxial cable it should not be placed close to devices operating at low frequencies. Signals like charger

circuits may require some EMI/RFI decoupling such as filter capacitors or ferrite beads.

• Adding external impedance matching to improve the match to your cable and antenna assemblies is optional.

Please contact the antenna vendor for matching requirements.

• For better ESD protection one can implement a shock coil to ground and place it close to the RF connector.

5.2.7 Other Precautions

It is essential to keep the voltage ripple to a minimum at this connection in order to avoid phase error. Insufficient

power supply voltage can dramatically affect some RF performance such as TX power, modulation spectrum

EMC performance, and spurious emissions and frequency error.

The RF connections are 50-ohm impedance systems and are a DC short to ground. Best effort should be made to

provide low insertion loss and shielding between the external antenna and RF connections over the frequency

band of interest.

10

Page 11

Operation Description

5.2.8 Grounding

On terminals including the antenna, poor shielding can dramatically affect the sensitivity of the terminal.Moreover

the power emitted through the antenna can affect the application.

11

Page 12

Operation Description

6 Test Capabilities

6.1 Test Description

1) ME3000V2 RF Connectors:

2) Operating instructions

12

Page 13

Operation Description

Connect the sector to access terminal antenna connectors as shown in the following figure 6-1

figure 6-1

Connect the sector to access terminal antenna connectors as shown in the following figure 6-2:

figure 6-2

6.2 GSM Test Equipment and Tools

Lease or purchase of test equipment is available from vendors who provide this equipment for GSM over the-air

simulation. Some suggested products include:

• Agilent 8960 Series 10 E5515C CDMA Mobile Station Tester

• Agilent E4440A Spectrum analyzer

• Agilent E4438C Signal Generator

• Agilent E4438C Signal Generator

• Programmable Temperature-Humidity Testor

• Programmable Temperature Concussion Testor

RF Performance Requirements

13

Page 14

Operation Description

6.2.1 GSM RF Rx Specification

Frequency range 925~960 MHz/1805~1880 MHz

Rx. Sensitivity

Rx. Signal Range

-109 dBm for GSM, -108dBm for DCS (BER≤2.4%)

-25 dBm~ -109dBm(BER≤2.4%)

6.2.2 GSM RF Tx Specification:

Max. frequency tolerance 880~915 MHz/1710~1785 MHz

Max. Tx. Power

Peak Phase Error

RMS Phase Error

Frequency Error GSM900: -90Hz< FE <90 Hz

Modulation Spectrum Mod +400kHz: <-60dBm

Switching Spectrum Switching +400kHz:<-22dBm

GSM900: 32.2±1 dBm

DCS1800:29.2±1 dBm

-20°< PPE < 20°

-5°< RMS < 5°

DCS1800: -180Hz< FE <180 Hz

Mod -400kHz: <-60dBm

Mod+1800kHz:<-63dBm

Mod-1800kHz:<-63dBm

Switching -400kHz:<-22dBm

Switching +1800kHz:<-27dBm

Switching -1800kHz:<-27dBm

Remarks:

RF technical specification conforms to the following standards:

3GPP2 Recommended Minimum Performance Standards for GSM Spread Spectrum Mobile Stations

3GPP2 Recommended Minimum Performance Standards for GSM High Rate Packet Data Access Terminal

Environmental Reliability Requirement

6.2.3 High Temperature Operation T es t

EUT Status Power-on

Temperature 70℃

Duration 24h

6.2.4 Low Temperature Operation Test

EUT Status Power-on

Temperature -30℃

Duration 24h

6.2.5 High Temperature Storage Test

EUT Status Power-off

Temperature 85℃

14

Page 15

Operation Description

Duration 24h

6.2.6 Low Temperature Storage Test

EUT Status Power-off

Temperature -40℃

Duration 24h

6.2.7 High Temperature High Humidity Operation Test

EUT Status Power-on

Temperature 55℃

Humidity 93%

Duration 48h

6.2.8 Temperature Concussion Test

EUT Status Power-off

High Temperature 85℃

High Temperature Duration 1h

Low Temperature -45℃

Low Temperature Duration 1h

Cycle Times 10

ElectroMagnetic Compatibility

6.2.9 ESD Immunity Test

EUT Status Idle mode and traffic mode

Test Voltage Air ±8KV; Contact ±6KV

Reference Standard IEC 61000-4-2 : 2001

6.2.10 Radiated Emissions Test

EUT Status Idle mode and traffic mode

Limits for radiated disturbance Class B ITE

Reference Standard FCC Part 22H&24E

15

Loading...

Loading...