Page 1

3G Mobile Communication cdma2000 System – All-IP Architecture

ZXC10 BTSB I1 (V1.0)

cdma2000 Base Transceiver Station

Installation Manual

ZTE CORPORATION

Page 2

ZXC10 BTSB I1(V1.0)

cdma2000 Base Transceiver Station

Installation Manual

Manual Version 20040615-R1.1

Product Version V1.0

Copyright © 2003 ZTE Corporation

All rights reserved.

No part of this documentation may be excerpted, reproduced, translated, annotated or

duplicated, in any form or by any means without the prior written permission of ZTE

Corporation.

ZTE CORPORATION

ZTE Plaza, Keji Road South, Hi-Tech Industrial Park, Nanshan District, Shenzhen, P.R.China

Website: http://www.zte.com.cn

Postcode: 518057

Customer Support Center: (+86755) 26771900 800-9830-9830

Fax: (+86755) 26770801

Email: support@zte.com.cn

* * * *

S.N.: sjzl20041524

Page 3

FAX: 0086-755-26770160

Suggestions and Feedback

To improve the quality of ZTE product documentation and offer better services to our

customers, we hope you can give us your suggestions and comments on our

documentation and fax this form to +86-755-26770160; or mail to “Marketing center

rd

3

floor ZTE Plaza, Keji Road South, Hi-Tech Industrial Park, Nanshan District,

Shenzhen, P. R. China”. Our postcode is 518057.

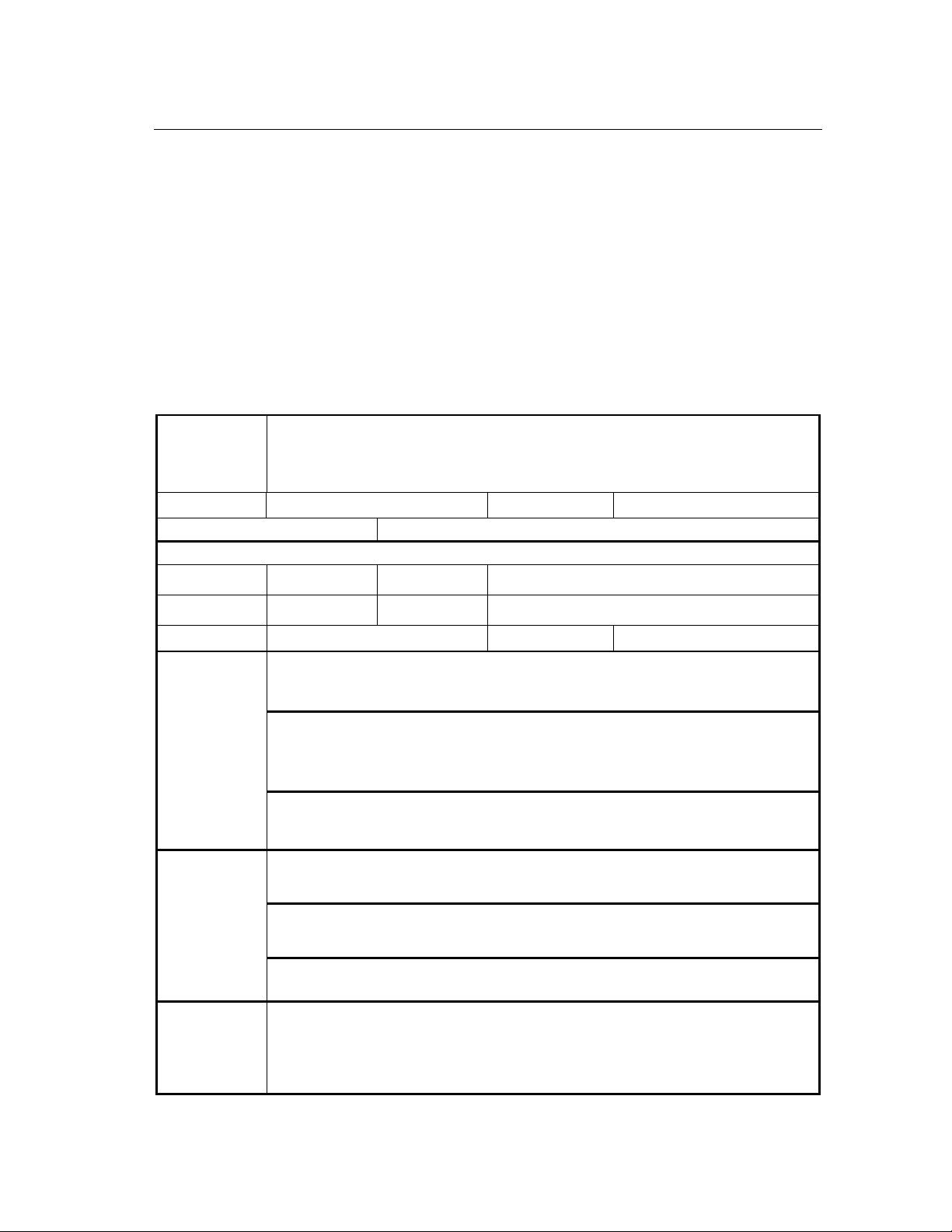

Document name

Product version

Equipment installation time

Your information

Name

Postcode

Telephone

Your evaluation

of this

documentation

Presentation: How is information presented? (Introductions, procedures, illustrations, others)

Good Fair Average Poor Bad

Accessibility: Can you find the information you want? (Table of contents, Index, headings,

numbering, others)

Good Fair Average Poor Bad

Intelligibility: Can you understand it when you find it? (Language, vocabulary, readability, others)

Good Fair Average Poor Bad

Presentation:

V1.0

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station

Installation Manual

Document version 20040615-R1.1

Company

Company address

E-mail

Your suggestions

for improvement

of this

documentation

Your other

suggestions on

ZTE product

documentation

Accessibility:

Intelligibility:

Page 4

Page 5

Preface

About This Manual

This manual introduces the hardware installation flow and method of the ZXC10

BTSB I1.

It is one of the manuals of the CDMA cellular mobile communication system of ZTE.

This manual is intended to provide basic installation operation guide to the engineering

staff that install the ZXC10 BTSB I1 of ZTE. Operation and maintenance staff of the

equipment can also use it as reference.

Standardized hardware installation is the basis for the normal and stable operation of

the BS and is thus important in the project engineering. To guide the hardware

installation of ZXC10 BTSB I1, this manual is arranged in the order of engineering

installation. This manual first briefs the equipment composition, which enables the

engineering staff to have an overall understanding of the ZXC10 BTSB I1 of ZTE.

Then it details the installation flow of the equipment and the installation check.

How to Use This Manual

This manual comprises 15 chapters:

Chapter 1 Installation Overview briefs the equipment installation and commissioning

flow, the hardware installation flow and the hardware installation precautions for the

BTSB system.

Chapter 2 Installation Preparations

installation, including installation environment check, and preparation for tools,

instruments and technical documentation.

Chapter 3 Unpacking and Acceptance describes unpacking, acceptance and handover

of the goods.

Chapter 4 Cabinet Installation describes the installation of the BTSB cabinet, and the

layout, connection and fixing of multiple cabinets.

Chapter 5 Power System Installation

BTSB power system.

introduces the preparations prior to the BTSB

describes the installation procedure of the

Page 6

Chapter 6 Grounding System Installation describes the installation procedure of the

BTSB grounding system.

Chapter 7 Cable Installation in Cabinet introduces the types of BTSB cabinet

internal cables, and describes the installation procedure of them.

Chapter 8 Trunk Cable Installation describes the installation procedure of the BTSB

trunk cables, and explains how to prepare the E1 cables and how to convert the 75 Ω

trunk cables into the 120 Ω trunk cables.

Chapter 9 Monitoring System Installation introduces the composition of the

monitoring system and describes its installation procedure.

Chapter 10 Main Antenna Feeder System Installation describes the installation

preparation, the installation flow and the specific installation procedure of the main

antenna feeder system, and explains how to check and test the antenna feeder and how

to conduct waterproof treatment on the connector.

Conventions

Chapter 11 GPS Antenna Feeder System Installation

preparation, the installation flow and the specific installation procedure of the GPS

antenna feeder system.

Chapter 12 Board Installation describes the types and functions of boards used in the

BTSB system, and how to install and replace them.

Chapter 13 Hardware Installation Check describes the hardware installation check

requirements of the BTSB system.

Chapter 14 Power-on/Power-off

the detailed power-on and power-off operation procedures.

Appendix A - Appendix D gives supplementary information on the BTSB technical

performance indices and board indicators, and an abbreviation form.

Describing notational conventions, keyboard operation convention, mouse operation

convention and four safety signs.

describes the check prior to the BTSB power-on, and

describes the installation

1. Notational conventions

Angular brackets "<and>" identify names of keys and buttons, and the

information typed by an operator from a terminal. Square brackets "[and]"

Page 7

indicate a man-machine interface, menu item, data list, or field name. The

symbol "-->" separates a multi-level menu, e.g., [File --> New --> Folder]

indicates the [Folder] menu item under the [New] submenu of the menu [File].

2. Keyboard operation conventions

Format Description

Character within angular

brackets

<key 1+key 2>

<key 1, key 2>

Indicating a key or button name, e.g., <Enter>, <Tab>,

<Backspace>, and <a>

Indicating to hold several keys down at the same time. For

example, <Ctrl+Alt+A> indicates to hold down “Ctrl”, “Alt”

and “A” three keys

Press Key 1 first. Then release Key 1 and press Key 2. For

example, <Alt, F> indicates to press and release <Alt> key, and

then press <F> key

3. Mouse operation conventions

Format Description

Click Refers to clicking the primary mouse button (usually the left

mouse button) once

Double-click Refers to quickly clicking the primary mouse button (usually the

left mouse button) twice

Right-click Refers to clicking the secondary mouse button (usually the right

mouse button) once

Drag Refers to pressing and holding a mouse button and move the

mouse

4. Signs

Four eye-catching signs are used in this manual to emphasize important and

critical information.

Note, Caution, Warning, and Danger: Used to

indicate the precautions during the operation.

Statement: The actual product may differ from what is described in this

manual due to frequent update of ZTE products and fast development of

technologies. Please contact the local ZTE office for the latest updating

information of the product.

Page 8

FCC & IC STATEMENT

Before using this product, read this important RF energy awareness and control information and operational

instructions to ensure compliance with the FCC and IC RF exposure guidelines.

NOTICE: Working with the equipment while in operation, may expose the technician to RF

electromagnetic fields that exceed FCC rules for human exposure. Visit the FCC website at

www.fcc.gov/oet/rfsafety

Changes or modifications to this unit not expressly approved by the party responsible for compliance will

void the user’s authority to operate the equipment. Any change to the equipment will void FCC and IC

grant.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to the FCC and IC Rules. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation.

For OUTDOOR use, a PNALE Antenna with a maximum gain of 17dBi is authorized for use with this unit.

Outside antennas must be positioned to observe minimum separation of 3.0M (9.84 feet.) for 800MHz unit

and 2.5M (8.2 feet.) for 1900MHz unit from all users and bystanders. For the protection of personnel

working in the vicinity of outside (uplink) antennas, the following guidelines for minimum distances

between the human body and the antenna must be observed.

The installation of an OUTDOOR antenna must be such that, under normal conditions, all personnel cannot

come within 3.0M (9.84 feet.)for 800MHz unit and 2.5M (8.2 feet.) for 1900MHz unit from the outside

to learn more about the effects of exposure to RF electromagnetic fields.

antenna. Exceeding this minimum separation will ensure that the worker or bystander does not receive

RF-exposure beyond the Maximum Permissible Exposure according to section 1.1310 i.e. limits for

Controlled Exposure.

Page 9

Contents

1 Installation Overview.............................................................................................................................. 1-1

1.1 BTSB Installation Overview .......................................................................................................... 1-1

1.2 BTSB Installation Flow Chart........................................................................................................1-3

1.3 BTSB Precautions for Hardware Installation ................................................................................. 1-6

2 Installation Preparations ........................................................................................................................2-1

2.1 Checking the Installation Environment..........................................................................................2-1

2.1.1 Checking the Equipment Room .......................................................................................... 2-1

2.1.2 Checking the Indoor Environment of the Equipment Room ............................................... 2-2

2.1.3 Checking the Power Supply System ...................................................................................2-3

2.1.4 Checking the Grounding System......................................................................................... 2-5

2.1.5 Checking the Outdoor Installation Environment for the Antenna Feeder System ..............2-6

2.1.6 Checking the Safety Conditions .......................................................................................... 2-7

2.1.7 Checking Other Auxiliary Equipment.................................................................................2-7

2.2 Preparing Tools and Instruments....................................................................................................2-7

2.3 Preparing Technical Documentation .............................................................................................. 2-9

3 Unpacking and Acceptance ....................................................................................................................3-1

3.1 Checking Goods against the Packing List......................................................................................3-1

3.2 Unpacking the Wooden Box........................................................................................................... 3-2

3.2.1 Wooden Box Structure ........................................................................................................3-2

3.2.2 Unpacking Procedure .......................................................................................................... 3-2

3.2.3 Checking the Rack Appearance...........................................................................................3-2

3.3 Unpacking the Carton ....................................................................................................................3-3

3.3.1 Carton.................................................................................................................................. 3-3

-i-

Page 10

3.3.2 Unpacking Procedure.......................................................................................................... 3-4

3.3.3 Checking the Boards ........................................................................................................... 3-4

3.4 Goods Acceptance and Handover.................................................................................................. 3-4

4 Cabinet Installation ................................................................................................................................ 4-1

4.1 Cabinet Types ................................................................................................................................ 4-1

4.2 RFS Cabinet Installation................................................................................................................ 4-2

4.2.1 RFS Installation Flow ......................................................................................................... 4-2

4.2.2 Support Installation Mode .................................................................................................. 4-3

4.2.3 Base Installation Mode ....................................................................................................... 4-9

4.2.4 Cabinet Stacking Mode.....................................................................................................4-14

4.2.5 Installing Cabinet Accessories.......................................................................................... 4-17

4.2.6 Cabinet Installation Specifications ................................................................................... 4-20

5 Power Supply System Installation......................................................................................................... 5-1

5.1 Introduction to Power Cables ........................................................................................................ 5-1

5.2 Installation Flow of Power Cables................................................................................................. 5-2

5.3 Cable Installation Procedure.......................................................................................................... 5-2

6 Grounding System Installation.............................................................................................................. 6-1

6.1 Grounding System Overview ........................................................................................................ 6-1

6.2 Installing the Grounding System ................................................................................................... 6-3

6.2.1 Installing the Outdoor Grounding Copper Bar ................................................................... 6-3

6.2.2 Installing the Feeder Grounding Clip ................................................................................. 6-3

6.2.3 Installing the Indoor Lightning Arrester ............................................................................. 6-6

7 Cable Installation in Cabinet................................................................................................................. 7-1

7.1 BTSB Cable Installation Overview ............................................................................................... 7-1

7.2 Installing Cables in the BDS Cabinet ............................................................................................ 7-2

7.2.1 BDS Cable Types................................................................................................................ 7-2

-ii-

Page 11

7.2.2 Installing Power Cables in the BDS .................................................................................... 7-2

7.2.3 Installing Optical Fibers ......................................................................................................7-2

7.2.4 Installing Monitoring Cables in the BDS ............................................................................ 7-3

7.2.5 Internal Cabling Table of the BDS...................................................................................... 7-3

7.2.6 Internal Cabling of the BDS................................................................................................7-5

7.3 RFS Installing Cables in the RFS Cabinet ..................................................................................... 7-6

7.3.1 Installing Power Cables.......................................................................................................7-6

7.3.2 Installation Interconnection Signal Cables.......................................................................... 7-8

7.3.3 Installing Monitoring Cables...............................................................................................7-9

7.3.4 Installing RF Cables .......................................................................................................... 7-12

7.3.5 Connecting Optical Fibers.................................................................................................7-16

7.4 Types and Installation of Inter-Cabinet Cables ............................................................................ 7-17

7.4.1 Installing BDS-RFS Interconnection Cable...................................................................... 7-17

7.4.2 Installing Optical Fibers ....................................................................................................7-18

7.4.3 Installing Interconnection Cables with BPWS .................................................................. 7-18

8 Trunk Cable Installation ........................................................................................................................ 8-1

8.1 Installing E1 Cables ....................................................................................................................... 8-1

8.2 Making E1 Cables.......................................................................................................................... 8-4

8.3 Converting 75 Ω Trunk Cable to 120 Ω Trunk Cable.................................................................... 8-7

8.3.1 Appearance of the Impedance Converter ............................................................................ 8-8

8.3.2 Wiring of the Impedance Converter .................................................................................... 8-8

8.3.3 Technical Parameters of the Impedance Converter .............................................................8-9

9 Monitoring System Installation ............................................................................................................. 9-1

9.1 Composition of the Monitoring System .........................................................................................9-1

9.2 Installing the Monitoring System................................................................................................... 9-2

9.2.1 Installing the Indoor Smog Sensor ...................................................................................... 9-2

-iii-

Page 12

9.2.2 Installing the Indoor Temperature/Humidity Sensor........................................................... 9-3

9.2.3 Installing the Infrared Sensor.............................................................................................. 9-4

10 Main Antenna Feeder System Installation ....................................................................................... 10-1

10.1 Preparation for Installing the Antenna Feeder System .............................................................. 10-1

10.1.1 Preparation by Installation Personnel ............................................................................. 10-2

10.1.2 Checking the Installation Environment .......................................................................... 10-2

10.1.3 Checking the Safety Measures........................................................................................ 10-3

10.1.4 Preparing Installation Tools............................................................................................ 10-4

10.2 Structure of the Antenna Feeder System.................................................................................... 10-4

10.3 Installation Content and Flow.................................................................................................... 10-6

10.3.1 Technical Parameters for Antenna Installation ............................................................... 10-6

10.3.2 Antenna Installation Flow............................................................................................... 10-7

10.4 Installing the Parts ..................................................................................................................... 10-8

10.4.1 Determining the Antenna Installation Position ............................................................... 10-8

10.4.2 Moving and Hoisting the Antenna .................................................................................. 10-8

10.4.3 Installing and Adjusting the Directional Antenna........................................................... 10-9

10.4.4 Installing and Adjusting the Omni-antenna .................................................................. 10-12

10.4.5 Sealing the Connection between Jumper and Antenna ................................................. 10-12

10.4.6 Installing the Feeder Window....................................................................................... 10-13

10.4.7 Installing the Feeders .................................................................................................... 10-14

10.4.8 Installing the Indoor Jumpers ....................................................................................... 10-25

10.5 Checking and Testing the Installation of the Antenna Feeder Part .......................................... 10-25

10.5.1 Lightning Protection for the Outdoor Antenna ............................................................. 10-25

10.5.2 Testing the Antenna SWR............................................................................................. 10-26

10.6 Waterproof Treatment for the Connectors ............................................................................... 10-26

11 GPS Antenna Feeder System Installation ..........................................................................................11-1

-iv-

Page 13

11.1 Preparation for Installing the Antenna Feeder System ............................................................... 11-1

11.2 Structure of the Antenna Feeder System .................................................................................... 11-1

11.3 Installation Flow......................................................................................................................... 11-2

11.4 Installing the Parts...................................................................................................................... 11-2

11.4.1 Preparing the GPS Coaxial Cable Connectors ................................................................ 11-2

11.4.2 Installing the Lightning Arrester ..................................................................................... 11-4

12 Board Installation ...............................................................................................................................12-1

12.1 BTSB Board Types.....................................................................................................................12-1

12.2 RF Cabinet Boards .....................................................................................................................12-2

12.2.1 Receiver Front End (RFE)............................................................................................... 12-2

12.2.2 Power Amplifier (PA)......................................................................................................12-3

12.2.3 Transceiver (TRX) .......................................................................................................... 12-4

12.3 Cabinet Front Boards ................................................................................................................. 12-5

12.3.1 Board Overview ..............................................................................................................12-5

12.3.2 Installing and Replacing the Boards................................................................................ 12-6

12.4 Interface Boards at the Back of the Baseband Cabinet .............................................................. 12-7

12.4.1 Interface Board Overview ............................................................................................... 12-7

12.4.2 Interface Board Diagram .................................................................................................12-9

12.4.3 Interface Board Structure .............................................................................................. 12-10

12.4.4 Installing and Replacing the Interface Boards .............................................................. 12-10

12.5 Board Installation Sequence..................................................................................................... 12-10

13 Hardware Installation Check.............................................................................................................13-1

13.1 Checking the Cabinet .................................................................................................................13-1

13.2 Checking the Cable Racks ......................................................................................................... 13-2

13.3 Checking Cable Laying, Binding and Identifying......................................................................13-2

13.4 Checking the Power Cables and Grounding Cables................................................................... 13-3

-v-

Page 14

13.5 Checking the E1 Cables............................................................................................................. 13-5

13.6 Checking the Sensors................................................................................................................. 13-5

13.7 Checking the Internal Connections of the Cabinet .................................................................... 13-6

13.8 Checking Indoor 1/2" Jumpers .................................................................................................. 13-6

13.9 Checking the Lightning Arrester................................................................................................ 13-6

13.10 Checking the Lightning Arrester Rack .................................................................................... 13-7

13.11 Checking the Primary Feeder Cables and GPS Feeder Cables ................................................ 13-7

13.12 Checking the Feeder Cable Window and Water-Blocking Curve of the Primary Feeder Cable

........................................................................................................................................................... 13-9

13.13 Checking the Three-Way Feeder Cards ................................................................................... 13-9

13.14 Checking the Outdoor 1/2" Jumpers ...................................................................................... 13-10

13.15 Checking the Antenna............................................................................................................ 13-11

13.16 Checking Feeders of SWR..................................................................................................... 13-14

13.17 Checking Indoor & Outdoor Environments........................................................................... 13-15

13.18 Base Station Information Table.............................................................................................. 13-15

14 Power-on/Power-off ............................................................................................................................ 14-1

14.1 Checking before Power-on ........................................................................................................ 14-1

14.1.1 Checking the External Connections of the Rack ............................................................ 14-1

14.1.2 Checking the Internal of the Rack .................................................................................. 14-2

14.2 Procedure of Power-on .............................................................................................................. 14-3

14.2.1 Initial Power-on .............................................................................................................. 14-3

14.2.2 Normal Power-on............................................................................................................ 14-4

14.3 Procedure of Power-off.............................................................................................................. 14-4

14.4 Hot Swap ................................................................................................................................... 14-5

Appendix A Technical performance indices of the BTSB...................................................................... A-1

A.1 Mechanical indices ...................................................................................................................... A-1

A.2 Power indices............................................................................................................................... A-1

-vi-

Page 15

Appendix B Using SiteMaster .................................................................................................................. B-1

B.1 Selecting a frequency range.......................................................................................................... B-1

B.2 Checking SiteMaster .................................................................................................................... B-1

B.3 Inputting feeder parameters.......................................................................................................... B-2

B.4 Installing the tester ....................................................................................................................... B-2

B.5 Measuring SWR ........................................................................................................................... B-2

B.6 Measuring DTF ............................................................................................................................ B-3

Appendix C BTSB board indicators........................................................................................................ C-1

C.1 RMM indicators ........................................................................................................................... C-1

C.2 Board indicators ........................................................................................................................... C-2

Appendix D Abbreviations ...................................................................................................................... 14-1

-vii-

Page 16

Page 17

List of Figures

Fig. 1.1-1 BTSB Cabinet Composed of RF Chassis/BDS Chassis/PWS Chassis 1-2

Fig. 1.1-2 Appearance of BTSB Macro Base Station and PWS/BDS/RFS Chassis 1-2

Fig. 1.1-3 BTSB Installation Hardware 1-3

Fig. 1.2-1 Hardware Installation Flow 1-5

Fig. 3.2-1 Structure of the Wooden Box 3-2

Fig. 3.3-1 Packing Box of Modules 3-4

Fig. 4.1-1 Flexible Combination of ZXC10 BTSB I1 Subracks 4-2

Fig. 4.2-1 Cabinet Installation Flow 4-3

Fig. 4.2-2 Zoom-in Diagram of Support Fixing 4-4

Fig. 4.2-3 Support Installation Flow 4-4

Fig. 4.2-4 Position of Caster Wheels and Supports 4-5

Fig. 4.2-5 Rotating Supports Downward 4-6

Fig. 4.2-6 Positions of Installation Holes of Cabinet Supports 4-7

Fig. 4.2-7 Installing Supports and Pressure Plate 4-8

Fig. 4.2-8 Cabinet after Installation 4-9

Fig. 4.2-9 Installation on Universal Base 4-10

Fig. 4.2-10 Base Installation Flow 4-11

Fig. 4.2-11 Locations of the Installation Holes for the Four Bases 4-12

Fig. 4.2-12 Installing Pressure Plate of the Base 4-13

Fig. 4.2-13 Fixation of Supports, Pressure Plate and Base 4-14

Fig. 4.2-14 Installation of BDS Unit 4-15

Fig. 4.2-15 Installation of PWS Unit 4-16

Fig. 4.2-16 Appearance of the BDS and PWS Units after Installation 4-17

-i-

Page 18

Fig. 4.2-17 Installation of Feeder Fixing Rack 4-18

Fig. 4.2-18 Feeder Fixing Rack after Installation 4-19

Fig. 4.2-19 Installation and Replacement of Dust Filters 4-19

Fig. 5.1-1 BDS Power Cable Installation on BTSB 5-1

Fig. 5.2-1 Installation Flow of RFS Power 5-2

Fig. 5.3-1 RFS Power Cabling 5-3

Fig. 5.3-2 BDS Power Cabling 5-3

Fig. 5.3-3 Connection between Busbar and Backplane 5-4

Fig. 5.3-4 Connecting Power Cable (1) 5-5

Fig. 5.3-5 Connecting Power Cable (2) 5-6

Fig. 6.1-1 Wiring for the BTSB Grounding.............................................................................. 6-2

Fig. 6.2-1 Appearance of the Grounding Copper Bar 6-3

Fig. 6.2-2 Structure of the Grounding Clip............................................................................... 6-4

Fig. 6.2-3 Wrapping the Grounding Cable of the Grounding Clip with Waterproof Tape 6-5

Fig. 6.2-4 Installing the Lightning Arrester Frame 6-7

Fig. 7.2-1 Internal Cabling of BDS 7-5

Fig. 7.3-1 Power Cabling in RFS 7-8

Fig. 7.3-2 RFS Backplane Layout 7-10

Fig. 7.3-3 Layout of the Interface Board on the Top of RFS Cabinet 7-11

Fig. 7.3-4 Signal and Monitoring Cabling in the RFS 7-12

Fig. 7.3-5 RF Cable Interface in RFS ..................................................................................... 7-15

Fig. 7.3-6 RF Cabling in the RFS 7-16

Fig. 7.4-1 Interconnection Cables between BDS and RFS Cabinets 7-18

Fig. 8.1-1 D_SUB44-core Connector Connecting BDS 8-1

Fig. 8.1-2 Structure of 75 Ω E1 Cable 8-2

Fig. 8.1-3 Structure of 120 Ω E1 Cable .................................................................................... 8-3

-ii-

Page 19

Fig. 8.2-1 Assembly of thCC4Y-J32 Coaxial Cable Connector 8-5

Fig. 8.2-2 Coaxial Connector of the DDF 8-6

Fig. 8.2-3 Assembling DDF Coaxial Cable Plug 8-7

Fig. 8.3-1 Appearance and Wiring of an Impedance Converter 8-8

Fig. 8.3-2 Wiring of the Impedance Converter 8-9

Fig. 9.1-1 Structure of External Monitoring Cable of RFS 9-1

Fig. 9.2-1 Installing the Smog Sensor Base 9-3

Fig. 9.2-2 Installation of Temperature-Humidity Converter 9-4

Fig. 9.2-3 Location of the Infrared Sensor 9-5

Fig. 9.2-4 Structure of Infrared Sensor 9-6

Fig. 9.2-5 Structure of Infrared Sensor Cable 9-7

Fig. 10.2-1 Typical Structure of the Antenna Feeder System with Three Sectors 10-5

Fig. 10.3-1 Antenna Installation Flow 10-7

Fig. 10.4-1 Hoisting an Antenna 10-9

Fig. 10.4-2 Installing the KATHRAIN Antenna.................................................................... 10-11

Fig. 10.4-3 Adjusting the Pitch Angle of the Antenna 10-12

Fig. 10.4-4 Structure of the Feeder Window 10-14

Fig. 10.4-5 Structure of a BTSB Feeder 10-15

Fig. 10.4-6 Cutting Tool for the 7/8" Feeder Connector 10-16

Fig. 10.4-7 Cutting the Feeder with a Cutter 10-17

Fig. 10.4-8 Checking the Cutting Length of the Feeder 10-17

Fig. 10.4-9 Expanding the External Conductor of the Feeder with a Tube Expander 10-18

Fig. 10.4-10 Connecting the Front Part and the Back Part of the Feeder Connector 10-18

Fig. 10.4-11 Fixing the Front Part and the Back Part of the Feeder 10-19

Fig. 10.4-12 Pulling the Feeder Cable up the Iron Tower ..................................................... 10-21

Fig. 10.4-13 Three-feeder Clip 10-22

-iii-

Page 20

Fig. 10.4-14 Introducing Feeders into the Equipment Room (Method 1) 10-23

Fig. 10.4-15 Introducing Feeders into the Equipment Room (Method 2) 10-23

Fig. 10.5-1 Installation and Lightning Protection of Arrester 10-25

Fig. 10.6-1 Wrapping the Waterproof Adhesive Tapes (1) 10-27

Fig. 10.6-2 Wrapping the Waterproof Adhesive Tapes (2) 10-27

Fig. 10.6-3 Wrapping the Waterproof Adhesive Tapes (3) 10-28

Fig. 11.2-1 Composition of the GPS Antenna Feeder System 11-2

Fig. 11.4-1 Stripping GPS Cable 11-3

Fig. 11.4-2 Welding GPS Connector Pin 11-3

Fig. 11.4-3 Structure of the N-J7A Cable Connection Part 11-3

Fig. 12.3-1 Board Mechanical Structure 12-5

Fig. 12.3-2 Picture of a Board................................................................................................. 12-6

Fig. 12.3-3 Loosening the Screws and Unplugging the RFE 12-7

Fig. 12.4-1 BIM Interface Board Structure............................................................................. 12-8

Fig. 12.4-2 Structure of a Back Interface Board 12-10

Fig. 12.5-1 Positions of Boards ............................................................................................ 12-11

Fig. 13.14-1 Waterproof Outdoor 1/2” Jumper 13-11

Fig. 13.15-1 Antenna Installation Checking the Feeder SWR 13-14

Fig. B.5-1 SWR Test for the Antenna Feeder B-3

Fig. B.6-1 Antenna Feeder DTF Measurement B-4

Fig. C.1-1 Indicators on the RMM C-1

-iv-

Page 21

List of Tables

Table 2.1-1 DC Power Supply Indices for the Normal Operation of BTSB ..................................... 2-4

Table 2.1-2 Power Consumption Indices for the Normal Operation of BTSB.................................. 2-4

Table 2.2-1 Tools...............................................................................................................................2-7

Table 2.2-2 Instruments..................................................................................................................... 2-9

Table 7.2-1 Internal Cabling Table of BDS ....................................................................................... 7-3

Table 7.2-2 Internal Optical Fiber Cabling of BDS .......................................................................... 7-4

Table 7.3-1 Connection Relationship of RFS Power Cables............................................................. 7-6

Table 7.3-2 Interconnection Signal Cabling in RFS Cabinet..........................................................7-9

Table 7.3-3 Monitoring Cabling in RFS Cabinet .............................................................................. 7-9

Table 7.3-4 RF Cable Connection in the RFS Cabine..................................................................... 7-13

Table 7.3-5 Optical Fiber Connection Table in RFS Cabinet.......................................................... 7-17

Table 7.4-1 Optical Fiber Connection between BDS and RFS ....................................................... 7-18

Table 7.4-2 Signal Connection Relationships of the Interconnecting Cable with BPWS ...............7-19

Table 8.1-1 Internal Connection Relationship of a 75 Ω E1 Cable................................................... 8-2

Table 8.1-2 Internal Connection Relationship of the 120 Ω E1 Cable.............................................. 8-3

Table 8.1-3 Correspondence between Cable Pairs at End B and Signals..........................................8-4

Table 8.3-1 Wiring Correspondence of the Impedance Converter .................................................... 8-9

Table 9.1-1 Content of Labels Placed on the Connectors ................................................................. 9-1

Table 9.2-1 Terminal Connection of the Smog Sensor Cable Connector..........................................9-3

Table 9.2-2 Terminal Connection of the Temperature/Humidity Sensor Cable Connector...............9-4

Table 12.4-1 BIM Interface Board Interfaces .................................................................................12-8

Table A.1-1 Weight of the Integrated Machine ................................................................................ A-1

Table A.2-1 BTS Power Consumption Indices in Normal Operation .............................................. A-2

-i-

Page 22

Table C.2-1 BTSB Board Indicators.................................................................................................C-2

-ii-

Page 23

1 Installation Overview

Summary:

z Hardware installation flow of the BTSB system

z Precautions for BTSB installation

1.1 BTSB Installation Overview

The cabinet of ZXC10 BTSB I1 comprises three basic chassis: RF chassis (RFS),

baseband chassis (BDS) and power chassis (PWS). These chassis can be combined in

different ways in a cabinet, as shown in Fig. 1.1-1. The appearance of the BTSB macro

base station of ZTE is shown in Fig. 1.1-2.

The BTSB system installation involves the following parts:

1. The BTSB cabinet, including the cabinet, internal cables and boards.

2. The power system, which provides -48V operating power for the system.

3. The grounding system, which provides protection ground for the parts of the

BTSB.

4. The antenna system, including the antenna, jumpers and feeders (a test of the

antenna & feeder system is necessary).

5. The GPS system, including the GPS and the feeder.

6. The trunk cable, that is, connecting the cables with the connectors.

7. The monitoring system, including the temperature, humidity and other

environment sensors.

BTSB system installation is shown in Fig. 1.1-3.

1-1

Page 24

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station Installation Manual

Power chassis

Slave baseband

chassis

Slave baseband

chassis

Slave baseband

chassis

Power chassis

Slave baseband

chassis

Master baseband

chassis

Master baseband

chassis

Master baseband

chassis

RF chassis

Fig. 1.1-1 BTSB Cabinet Composed of RF Chassis/BDS Chassis/PWS Chassis

RF chassis

PWS

BDS

RFS

RF chassis

Fig. 1.1-2 Appearance of BTSB Macro Base Station and PWS/BDS/RFS Chassis

1-2

Page 25

Chapter Error! Style not define

d. Error! Style not defined.

GPS installation

Power supply

system installation

Grounding system

installation

Fig. 1.1-3 BTSB Installation Hardware

1.2 BTSB Installation Flow Chart

The normal operation of ZXC10 BTSB I1 depends heavily on the quality of the

installation engineering. The equipment must be installed in a systematic and

standardized way to eliminate stability problems caused by improper installation and

improve the reliability of the system.

Antenna system

installation

BTSB cabinet installation

Rack

installation

Internal cable

installation

Board

installation

Trunk cable

installation

Monitoring system

installation

This manual introduces the installation of BTSB and its parts step by step in an attempt

to guide the engineering staff in their equipment installation.

The indoor installation of ZXC10 BTSB I1 includes cabinet installation and indoor

cable connection and cabling. Please strictly follow these steps for installation:

1. Fix the rack base to the rack.

2. Position the rack and score & drill to fix it.

3. Install the power cable of the cabinet.

4. Install the monitoring cables and temperature/humidity sensors of the BTSB.

5. Install and connect the trunk cable.

6. Install boards and modules in the cabinet.

7. Connect the RF cable of the cabinet.

1-3

Page 26

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station Installation Manual

The detailed hardware installation flow of the BTSB system is shown in Fig. 1.2-1.

This manual describes the specific installation procedure by chapters according to this

flow.

1-4

Page 27

Chapter Error! Style not define

d. Error! Style not defined.

Start

Survey report

Engineering design file

Environment acceptance

report

Cabling rack, power supply

system, grounding system

and other accessories

Packing list

Engineering installation

preparation

Construction condition

checking

Unpacking and

acceptance

Consistence

Yes

Cabinet installation

Power supply system

installation

Grounding system

installation

Cable installation in

cabinet

Delivery error feedback

form

Replacement

application form

Trunk cable installation

Monitoring system

installation

Main antenna feeder

system installation

GPS installation

Board installation

Hardware

installation checking

End

Fig. 1.2-1 Hardware Installation Flow

1-5

Page 28

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station Installation Manual

1.3 BTSB Precautions for Hardware Installation

Precautions for the BTSB hardware installation include:

1. Take careful precautions for the safety of yourself and the equipment during the

installation.

2. Avoid hot swap during module installation.

3. In case of lightning, never install the antenna & feeder system.

4. Before the thunderstorm season every year, check whether the lightning arrester

is in proper contact. In case any lightning arrester is damaged, replace it

immediately.

5. Lock the door right after cabinet installation.

1-6

Page 29

2 Installation Preparations

Summary:

z Environment check prior to the BTSB installation

z Tool and instrument preparation prior to the BTSB installation

z Technical documentation preparation prior to the BTSB installation

2.1 Checking the Installation Environment

Check the following environment items before installation:

Before installation, the customer should prepare the equipment room, power supply

and grounding cables, and provide necessary facilities for the project implementation.

The area and height of the equipment room should satisfy the requirements of the

equipment layout. Otherwise, reconstructions are required to eliminate the problems

faced during the installation, operation and maintenance of the equipment.

The BTSB should not be used in the environment with high temperature, thick dust,

harmful gases, explosive articles or low air pressure. It shall be put far from

transformer stations and traction substations, and shall not be in places with frequent

shaking or great noises.

As the equipment of BTSB cannot be moved easily, the equipment room construction

should be under a long-term plan.

The BTSB equipment room should comply with fire prevention regulations.

2.1.1 Checking the Equipment Room

The items for the equipment room inspection include:

1. The civil engineering of the equipment room and corridor has been completed,

and the wall is fully dry.

2. The height and width of the doors in the equipment room should not cause any

inconvenience for transporting the equipment. Usually, the height of the main

2-1

Page 30

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station Installation Manual

doors in the equipment room should be no less than 2.2 meters, and the width

should be no less than 1 meter. The net height of the equipment room should be

no less than 3 meters. The equipment room should have a sufficient area for the

equipment with extra free space. For easy equipment operation and maintenance,

the space for opening the front door should be no less than 1 meter, and the

space at the rack rear should be no less than 0.8 meter.

3. The equipment room floor should be able to bear the weight over 450kg/m2.

4. The wall and ceiling of the equipment room should not chalk or peel off and

should be free of dust accumulation. Fire-retardant materials should be used for

decoration.

5. The shock-proof design of the equipment room should be one degree higher than

the local anti-seismic requirements. Generally, the equipment room should be

able to bear the earthquake of 7 on the Ritcher Scale. Otherwise, shock-proof

reinforcement measures must be adopted for the equipment.

6. Air-conditioning facilities should be provided to maintain desired temperature

and humidity in the equipment room.

7. Lightning screen or lightning arrester should be installed for the places in the

equipment room vulnerable to the lightning. Outdoor metal pipelines should be

grounded when being led into the equipment room.

2.1.2 Checking the Indoor Environment of the Equipment Room

The inspection of the indoor equipment room environment includes the inspection of

humidity, temperature, air pressure, antistatic protection, anti-interference requirement,

air conditioning, ventilation, dust proof, rodent proof, fire protection, lighting, and

drainage facilities.

1. Requirements for the ambient temperature and humidity

Working temperature: -5 °C ~ +55 °C

Relative humidity: 15% ~ 93% RH

2. Requirements for the equipment room floor

The level difference per square meter of the floor should not be more than 2

mm.

2-2

Page 31

Chapter Error! Style not defined.

Error! Style not defined.

3. Cleanness

Cleanness is related to the amount of dust and harmful gases in the air. The

equipment room should meet the following cleanness requirements:

z No explosive, conductive, magnetic or corrosive dust.

z Density of the dust whose diameter is larger than 5µm must be less than or equal

4

to 3*10

particles/m3.

z No corrosive metal or gas that is harmful to insulations, such as SO2, NH3.

z The equipment room should be always kept clean, with the doors and windows

properly sealed.

4. Lighting

The equipment room should be equipped with 3 types of lighting facilities:

Common lighting, guaranteed lighting and emergency lighting.

5. Fire-proof requirements

The paint and decoration materials in the equipment room should be fire-proof.

The cabling holes through the wall should be filled with fire-retardant materials.

Fire-fighting devices should be equipped at the appropriate positions.

2.1.3 Checking the Power Supply System

1. DC power supply requirements:

1) BTSB employs -48V DC power supply so the equipment room should be

equipped with an AC/DC power supply converter for working power supply.

The DC voltage is allowed to range from -57V to -40V.

2) To guarantee uninterrupted operation of the BTSB even in case of mains supply

failure, uninterrupted power supply facilities such as diesel engine generator

group and storage battery should be available.

3) The noise level indices of DC power voltages shall meet the technical

specifications by the former Ministry of Posts and Telecommunications.

4) The DC power supply should be provided with over-voltage/over-current

protection and indicators.

2. AC power requirements (including the AC power for construction purpose and

2-3

Page 32

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station Installation Manual

that used for local operation & maintenance consoles)

1) Three-phase power supply: 380V, with the voltage fluctuation range of no more

than 10%, frequency fluctuation range of no more than 5%, line voltage

waveform distortion factor of less than 5%.

2) Single-phase power supply: 220V, with the voltage fluctuation range of no more

than 10%, frequency fluctuation range of no more than 5%, line voltage

waveform distortion factor of less than 5%.

3. Cabling requirements of the power supply system

Cabling of the power supply system should be correct, tidy and in good order,

and has excellent insulation and reasonable arrangement. To prevent the power

supply system from interfering with other signal lines, power cables and other

cables should be laid separately, with special cabling troughs preferred.

In addition, during the cabling of the power supply system, the cross sections of

the cable feeders and the busbars shall be able to meet the requirements for the

medium-term or long-term capacity expansion.

2.1.3.1 Power System Range

Please see Table 2.1-1 for the DC power indices for the normal operation of ZXC10

BTSB I1 (supporting 24V DC power supply).

Table 2.1-1 DC Power Supply Indices for the Normal Operation of BTSB

Item DC Voltage

Nominal value

Allowed fluctuation

-48V

-

40 ~ -57V

2.1.3.2 Power Consumption

Power supply and power consumption: The power consumption of ZXC10 BTSB I1

refers to the overall power consumption when the operating voltage is -48V and the

output power of each power amplifier is 20W, as shown in Table 2.1-2.

Table 2.1-2 Power Consumption Indices for the Normal Operation of BTSB

Configuration

1-carrier 1-sector 40W/carrier -48V About 1400W About 1400W

Amplification

Output

Working

Voltage

1X Maximum Power

Consumption (W)

DO Maximum Power

Consumption (W)

2-4

Page 33

Chapter Error! Style not defined.

Error! Style not defined.

Configuration

2-carrier 1-sector 40W/carrier -48V About 1400W About 1400W

3-carrier 1-sector 40W/carrier -48V About 1400W About 1400W

5-carrier 1-sector 40W/carrier -48V About 2000W About 2000W

7-carrier 1-sector 40W/carrier -48V About 2000W About 2100W

1-carrier 3-sector 40W/carrier -48V About 2500W About 2600W

2-carrier 3-sector 40W/carrier -48V About 2600W About 2600W

3-carrier 3-sector 40W/carrier -48V About 2600W About 2700W

4-carrier 3-sector 40W/carrier -48V About 2600W About 2700W

5-carrier 3-sector 40W/carrier -48V About 4400W About 4500W

7-carrier 3-sector 40W/carrier -48V About 4500W About 4600W

8-carrier 3-sector 40W/carrier -48V About 4500W About 4700W

1-carrier 6-sector 40W/carrier -48V About 4300W About 4400W

2-carrier 6 -sector 40W/carrier -48V About 4400W About 4500W

3-carrier 6-sector 40W/carrier -48V About 4500W About 4600W

4-carrier 6-sector 40W/carrier -48V About 4500W About 4700W

Amplification

Output

2.1.4 Checking the Grounding System

Wor ki ng

Voltage

1X Maximum Power

Consumption (W)

The grounding regulations and resistance requirements (including the lightning

protection requirements) are as follows:

DO Maximum Power

Consumption (W)

The communication equipment should be well grounded for reliable operation. Good

grounding ensures lightning protection and interference resistance. The grounding

cables in the equipment room should be routed in a radiating or flat way. Three

independent grounding cables should be used: The protection ground of the DC power

distribution system, the work ground of the power system and the lightning protection

ground.

The equipment adopts joint grounding with the grounding resistance less than 1 Ω.

Generally, the grounding resistance of BTSB should be less than 5 Ω. The engineering

requires the grounding resistance to be the smallest possible. The magnitude of

grounding resistance is affected by grounding post resistance, leading wire resistance,

contact resistance between the grounding post and soil as well as the soil type. The

greatest impact on grounding resistance comes from soil type. In areas with poor soil

conditions, some resistance-reducing agent (such as propenamide) may be added

around the grounding stake to meet the requirements. Changes in temperature will also

cause variations in resistance. In cold areas, the impact of temperature on the resistance

2-5

Page 34

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station Installation Manual

may be reduced by burying the stake deeply into the ground. Grounding stakes are

usually made of galvanized materials in proper size. The connection cables from the

grounding stake to the equipment should adopt copper-sheathed wires of good

2

conductivity (core wire section area less than 50 mm

, and length as short as possible).

If necessary, anti-erosion protection can be provided to the grounding connection parts

to guarantee low-resistance connection.

The working ground refers to the loop formed through the earth to transmit energy and

information. For instance, the 3-phase AC power supply neutral line ground and the

positive battery ground are both working grounds. This grounding approach can resist

electromagnetic interference and cross talk.

The protection ground refers to the grounding of the metal shell of the power supply

equipment to prevent hazards to human body due to power leakage.

In addition, the ground for lightning protection should be used to prevent lightning

stroke from damaging the equipment and to protect the safety of lives and properties.

2.1.5 Checking the Outdoor Installation Environment for the Antenna Feeder

System

1. Check whether the height and size of the feeder window comply with the

requirements of the BTSB equipment and the engineering design drawing.

2. Check whether the height, weight bearing and grounding of the outdoor cabling

rack comply with the engineering design.

3. Check whether the height, weight bearing and grounding of the indoor cabling

rack comply with the engineering design.

4. Check the height, diameter, weight bearing, wind resistance, grounding,

lightning protection and position of the antenna pole of the BTSB on the roof to

make sure they comply with the BTSB equipment requirements and the

engineering design drawing.

5. Check the height, diameter, weight bearing, wind resistance, grounding,

lightning protection and position of the antenna pole of the BTSB on the iron

tower to make sure they comply with the BTSB equipment requirements and the

engineering design drawing.

2-6

Page 35

Chapter Error! Style not defined.

2.1.6 Checking the Safety Conditions

Appropriate fire-fighting devices should be equipped in the equipment room, such as a

certain quantity of portable powder fire-extinguishers. As for a large equipment room, a

complete set of automatic fire-fighting system should be equipped. No inflammable or

explosive articles should be placed in the equipment room.

1. Storage of flammable and explosive materials in the equipment room is strictly

prohibited and necessary firefighting equipment must be installed.

2. Different outlets in the equipment room shall bear noticeable marks, and

dynamic electricity and lighting electricity should be noticeably differentiated.

3. The equipment room should be far from high-voltage power lines, strong

magnetic fields, strong electric sparks, or other factors that may threaten the

security of the equipment room.

4. Reserved holes in the floors should be covered with safety cover plates.

5. Proper lightning protection facilities should be in place before the power lines

and transmission lines are led into the equipment room.

Error! Style not defined.

2.1.7 Checking Other Auxiliary Equipment

Check the following items against the configuration requirements specified in the

contract:

1. Check whether the external power supply and the power cable connecting the

racks are ready.

2. Check whether the E1 cable connecting the BTSB and the BSCB is ready.

2.2 Preparing Tools and Instruments

A number of tools and instruments are to be used during the BTSB installation process.

Prepare the tools and instruments as given in Table 2.2-1 and Table 2.2-2 below.

Table 2.2-1 Tools

Category Name

One feeder connector knife

Special tools

One wire skinner for 75 Ω coaxial cables

One crimping pliers for 75 Ω coaxial cables

2-7

Page 36

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station Installation Manual

Category Name

One multi-functional crimping pliers

One multimeter

One SiteMaster VSWR tester

Earth resistance tester

One electric percussion drill

Several drill bits

Concrete drilling tools

One cleaner

One power terminal block (at least three 2-phase sockets and three

3-phase sockets, with the power capacity more than 15A)

Philips screwdrivers (4″, 6″ and 8″ each)

Flathead screwdrivers (4″, 6″ and 8″ each)

Adjustable wrenches (6″, 8″, 10″ and 12″ each)

Dual-purpose spanners (17″ and 19″ each)

General-purpose tools

One set of socket wrench

One 5 kg nail hammer

One 300 W iron

One 40 W iron

One roll of solder wire

One 50 m tape measure

One 5 m steel tape

One 400 mm level bar

Measurement tools

One angle meter

One compass

Level

Plumb

Protection tools

Anti-static wrist strap

Safety helmet, slip-proof glove

One hacksaw (with several saw blades)

One pair of sharp-nose pliers (8″)

One pair of diagonal pliers (8″)

One pair of slip joint pliers (8")

One pair of vices (8″)

One needle file set (medium sized)

Small tools

Tweezers

One paint brush

One pair of scissors

One hot blower

One solder sucker

One pair of hydraulic pliers

Crowbar

2-8

Page 37

Chapter Error! Style not defined.

Error! Style not defined.

Category Name

Pulley block

Auxiliary tools

Instrument Name Manufacturer

Spectrum analyzer (needed in some

special cases)

Base station tester SITE MASTER

Testing MS Qualcomm

Compass

Multimeter

Field strength tester (needed in some

special cases)

Rope

Ladder

Forklift

Table 2.2-2 Instruments

HP

2.3 Preparing Technical Documentation

The technical documents to be prepared before the commissioning of the equipment

include:

1. Project Survey Report, BTSB System Project Design and Engineering Drawing,

and Environment Acceptance Report.

Project Survey Report should be completed by the engineering staff sent by the

equipment supplier during the onsite survey. If engineering staff cannot conduct

the survey in time, he should entrust the equipment user to fill in the report and

mail it back after the survey for the preparation of engineering materials.

BTSB System Project Design and Engineering Drawing should be completed by

the design party entrusted by the equipment user, and its copy should be

provided by the equipment user to the equipment supplier before equipment

delivery.

Environment Acceptance Report is used for the first engineering environment

inspection during the project survey. If the environment is found to fail the

inspection, the equipment user is requested to make improvement and solve the

problem. The second environment inspection is conducted before the

engineering starts.

2-9

Page 38

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station Installation Manual

2. ZXC10BTSB (V 1.0) cdma2000 Base Transceiver Station Installation Manual

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station Technical Manual

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station Hardware Manual

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station Maintenance Manual

3. Installation Acceptance Report and Test Acceptance Report.

Installation Acceptance Report and Test Acceptance Report are the engineering

materials for acceptance after the BTSB commissioning. They are provided by

the equipment supplier to the equipment user at the time of delivery. They

should be completed properly after the commissioning of the BTSB.

2-10

Page 39

3 Unpacking and Acceptance

Summary:

z Unpacking of BTSB

z Acceptance of BTSB

3.1 Checking Goods against the Packing List

1. Check the Delivery Checklist of ZTE Corporation.

2. Unpacking inspection is conducted by the Project Supervising Committee and

representatives from the user. First, check the total number of goods, the

intactness of the packing boxes, and check whether the arrival place is the

actual installation place against the packing list number attached to the packing

boxes;

3. The packages can be opened if they are not damaged. Each package has a

Packing List. The engineering supervisor should check item by item according

to the Packing List. The Unpacking Inspection Report is placed in the packing

box numbered 1#. First open the 1# packing box and take out the Unpacking

Inspection Report. To check the total number of the goods against the

inspection list and record it for filing.

4. During the unpacking inspection process, if there is any short and wrong

shipment or goods damage, you should contact the ZTE headquarters.

5. The goods of ZTE may be packed in crate or carton. Different tools are

required to open them on site.

Caution:

The ZXC10 BTSB I1 equipment is relatively expensive. During transportation, it shall

be well packaged with clear waterproof and quake-resistant marks. Handle the

equipment with care and protect it from sunshine and rain.

3-1

Page 40

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station Installation Manual

3.2 Unpacking the Wooden Box

3.2.1 Wooden Box Structure

The wooden boxes are generally used for packing heavy goods like rack.

The structure of the BTSB rack-packing box is shown in Fig. 3.2-1.

860mm

m

m

0

6

2060mm

8

3.2.2 Unpacking Procedure

1. Prepare appropriate tools such as nail hammer, pliers, straight screwdriver and

crowbar.

2. First skin the packing sheet iron. Insert a flat-tip screwdriver into the slit

between the box and the front cover board to make it loose; then insert the

crowbar to unclench the cover board.

3. Keep the box on end and the legs downward, and pull the rack out of the box.

Make sure not to remove the antistatic bag of the rack before pulling the rack

out.

4. Remove the packing adhesive tape of the rack.

Note: The BTSB rack is equipped with casters for easy movement. However, you

should control the moving direction with your hands during the move to avoid any

damages or accidents.

Fig. 3.2-1 Structure of the Wooden Box

3.2.3 Checking the Rack Appearance

Put the rack vertically on the solid ground. The rack should be erected upright without

3-2

Page 41

Chapter Error! Style not defined.

tilting. Visually there is no dent, bump, scratches, peel, bubbling, stains or other similar

damaged signs. The captive screws should not be loose, missing or misplaced. The

installation slots for plug-in boxes are intact and the slot guide rails are not missing,

damaged or broken. All fittings and accessories required for rack installation are

complete. The labels of installation slots are intact and eligible. The busbar, the exhaust

fan and the installation positions are not damaged or deformed. There is no rack

surface paint flake-off or scratches.

3.3 Unpacking the Carton

3.3.1 Carton

Error! Style not defined.

Caution:

1. Avoid taking any circuit board out of the antistatic bags during the unpacking and

acceptance. Do not open the antistatic bags until the board is to be mounted into the

rack. In addition, avoid damaging any antistatic bag and keep it for future use when

storing spare boards and packing the faulty boards for repair.

2. When the equipment is moved from a colder and drier place to a hotter and

damper place, wait for 30 minutes before unpacking the equipment. Otherwise,

moisture may appear on the surface of the equipment and cause damage.

3. Properly recycle the desiccants lest children may eat them by accident. Cartons

are generally used to pack circuit boards and terminal equipment.

The circuit boards are placed in the anti-static protective bags during transportation.

Before unpacking the boards, take proper anti-static protective measures to avoid

damages. In addition, attention should be paid to the ambient temperature. Usually

some desiccant is placed in the anti-static protective bag to absorb moisture and keep

the bag dry.

The packing box of modules is shown in Fig. 3.3-1.

3-3

Page 42

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station Installation Manual

Fig. 3.3-1 Packing Box of Modules

3.3.2 Unpacking Procedure

Take the following steps to unpack a carton:

1. Use the diagonal pliers to cut the straps.

2. Use a paper knife to cut the adhesive tape along the slits on the box covers. Note

that the cut shall not be too deep and damage the goods inside.

3. Count the quantity and types of boards inside the carton against the packing list

attached and sign for the acceptance with the customer on site.

3.3.3 Checking the Boards

Check the boards against the delivery list and contact the equipment supplier in time if

any incompliance is found.

3.4 Goods Acceptance and Handover

After the unpacking acceptance, both parties sign on the Unpacking Acceptance Report.

after which the goods shall be handed over to the customer if they are to be kept by the

customer after acceptance according to the contract terms. Each party shall hold a copy

of the Unpacking Inspection Report and the Project Supervisor shall feedback the

Acceptance Conclusion of the Report to be archived by the equipment supplier.

3-4

Page 43

4 Cabinet Installation

Summary:

z Appearance and structure of the BTSB cabinet

z Installation procedure of a single BTSB cabinet

z Arrangement of the BTSB cabinets

z Connection and fixation between BTSB cabinets

z Standard of installing the BTSB cabinets

4.1 Cabinet Types

ZXC10 BTSB I1 is composed of three types of subracks, PWS, BDS and RFS, that can

be combined flexibly into super base stations, as shown in Fig. 4.1-1These subracks

provide powerful functions with lighter weight and small footprint, allowing easy

movement and installation.

4-1

Page 44

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station Installation Manual

PWS

BDS

RFS

Fig. 4.1-1 Flexible Combination of ZXC10 BTSB I1 Subracks

4.2 RFS Cabinet Installation

The RFS cabinet supports base installation and support installation. The following

sections detail the procedures of these two installations.

4.2.1 RFS Installation Flow

The base installation mode is to mount the cabinet on an adjustable base provided by

ZTE in the case that there is antistatic floor in the equipment room. The support

installation mode is to fix the cabinet with the pressure plate assembly to the floor in

the cast that there are feet under the cabinet (the four feet of the cabinet). The cabinet

installation flow is shown in Fig. 4.2-1.

4-2

Page 45

Chapter Error! Style not

defined. Error! Style not defined.

Support

installation mode

Support

installation

Fig. 4.2-1 Cabinet Installation Flow

Base installation

mode

Base installation

Fixing the cabinet to

the base

Cabinets fixing

Cabinet accessories

installation

Installation check

End

4.2.2 Support Installation Mode

4.2.2.1 Support and Pressure Plate Assembly

The support fixing amplification is shown in Fig. 4.2-2.

4.2.2.2 Support Installation Flow

Firstly, install the pressure plate assembly on the support as shown in Fig. 4.2-3.

4-3

Page 46

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station Installation Manual

1. Locking nut 2. Pressure plate 3. M10X25 bolt 4. Support 5. Insulating washer

Fig. 4.2-2 Zoom-in Diagram of Support Fixing

Start

Support installation

Pressure plate

assembly positioning

Expansion bolts

installation

Cabinet positioning

Pressure plate

assembly installation

Insulation test

Y

End

N

Fig. 4.2-3 Support Installation Flow

4-4

Page 47

Chapter Error! Style not

4.2.2.3 Adjusting the Supports

The cabinet base is equipped with supports and caster wheels. The supports should be

suspended so that the cabinet can move with the caster wheels. Fig. 4.2-4

defined. Error! Style not defined.

1. Cabinet 2. Caster wheels 3. Support

Fig. 4.2-4 Position of Caster Wheels and Supports

In the equipment room, screw off the support to make it 80 mm lower than the cabinet

bottom. Thus, there is room for the baffle and the caster wheels. Rotate the supports

downward , as shown in Fig. 4.2-5.

4-5

Page 48

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station Installation Manual

80mm

Fig. 4.2-5 Rotating Supports Downward

4.2.2.4 Positioning the Pressure Plate Assembly

1. Scoring

Decide the position to install the base according to the basic size and cabinet

size given in the construction plane design drawing; measure a few marking

points with a tape measure, and mark two lines spaced 670 mm and parallel to

the base line with an ink fountain; according to the design, mark the positions of

the four installation holes for the first cabinet on the two lines; then mark the

installation holes for other cabinets one by one. This is shown in Fig. 4.2-6.

4-6

Page 49

Chapter Error! Style not

defined. Error! Style not defined.

Support area

M10X40 embedded expansion nut

ф 12 drill bit is recommended for

Rack area

Fig. 4.2-6 Positions of Installation Holes of Cabinet Supports

holes of 43 mm deep

2. Drilling

After the scoring in Fig. 4.2-6, select φ12 bit for drilling. Keep the bit vertical to

the floor. Use both hands to hold the drill handle tightly and straightly without

swing to avoid damaging floor and incline the hole.

The hole depth should be equal to the length of the expansion tube of expansion

nut (or bolt) plus the flare head length. While drilling holes, use a vacuum

cleaner to remove dust. Suck the dust in the holes once again after the holes are

drilled. Measure the space between holes and place the base to check whether

the holes are matched. For holes with large deviation, it is necessary to

reposition and re-drill the holes before installing the expansion bolts (expansion

nuts).

4.2.2.5 Installing the Embedded Expansion Nuts

Place the embedded expansion bolts in a drilled hole and hammer it fully into the

4-7

Page 50

ZXC10 BTSB (V1.0) cdma2000 Base Transceiver Station Installation Manual

ground with a dedicated hammer or a rubber hammer.

4.2.2.6 Positioning the Cabinet

Move the cabinet to the right position, revolve the screws of the cabinet feet to adjust