Page 1

ZXSDRBS8800C200

CDMAIndoorBasestation-8800

InstallationManual

ZTECORPORATION

ZTEPlaza,KejiRoadSouth,

Hi-TechIndustrialPark,

NanshanDistrict,Shenzhen,

P .R.China

518057

Tel:(86)75526771900

Fax:(86)75526770801

URL:http://ensupport.zte.com.cn

E-mail:support@zte.com.cn

Page 2

LEGALINFORMATION

Copyright©2006ZTECORPORATION.

Thecontentsofthisdocumentareprotectedbycopyrightlawsandinternationaltreaties.Anyreproductionordistributionof

thisdocumentoranyportionofthisdocument,inanyformbyanymeans,withoutthepriorwrittenconsentofZTECORPORATIONisprohibited.Additionally ,thecontentsofthisdocumentareprotectedbycontractualcondentialityobligations.

Allcompany ,brandandproductnamesaretradeorservicemarks,orregisteredtradeorservicemarks,ofZTECORPORATION

oroftheirrespectiveowners.

Thisdocumentisprovided“asis”,andallexpress,implied,orstatutorywarranties,representationsorconditionsaredisclaimed,includingwithoutlimitationanyimpliedwarrantyofmerchantability ,tnessforaparticularpurpose,titleornon-infringement.ZTECORPORATIONanditslicensorsshallnotbeliablefordamagesresultingfromtheuseoforrelianceonthe

informationcontainedherein.

ZTECORPORATIONoritslicensorsmayhavecurrentorpendingintellectualpropertyrightsorapplicationscoveringthesubject

matterofthisdocument.ExceptasexpresslyprovidedinanywrittenlicensebetweenZTECORPORA TIONanditslicensee,

theuserofthisdocumentshallnotacquireanylicensetothesubjectmatterherein.

ZTECORPORATIONreservestherighttoupgradeormaketechnicalchangetothisproductwithoutfurthernotice.

UsersmayvisitZTEtechnicalsupportwebsitehttp://ensupport.zte.com.cntoinquirerelatedinformation.

TheultimaterighttointerpretthisproductresidesinZTECORPORATION.

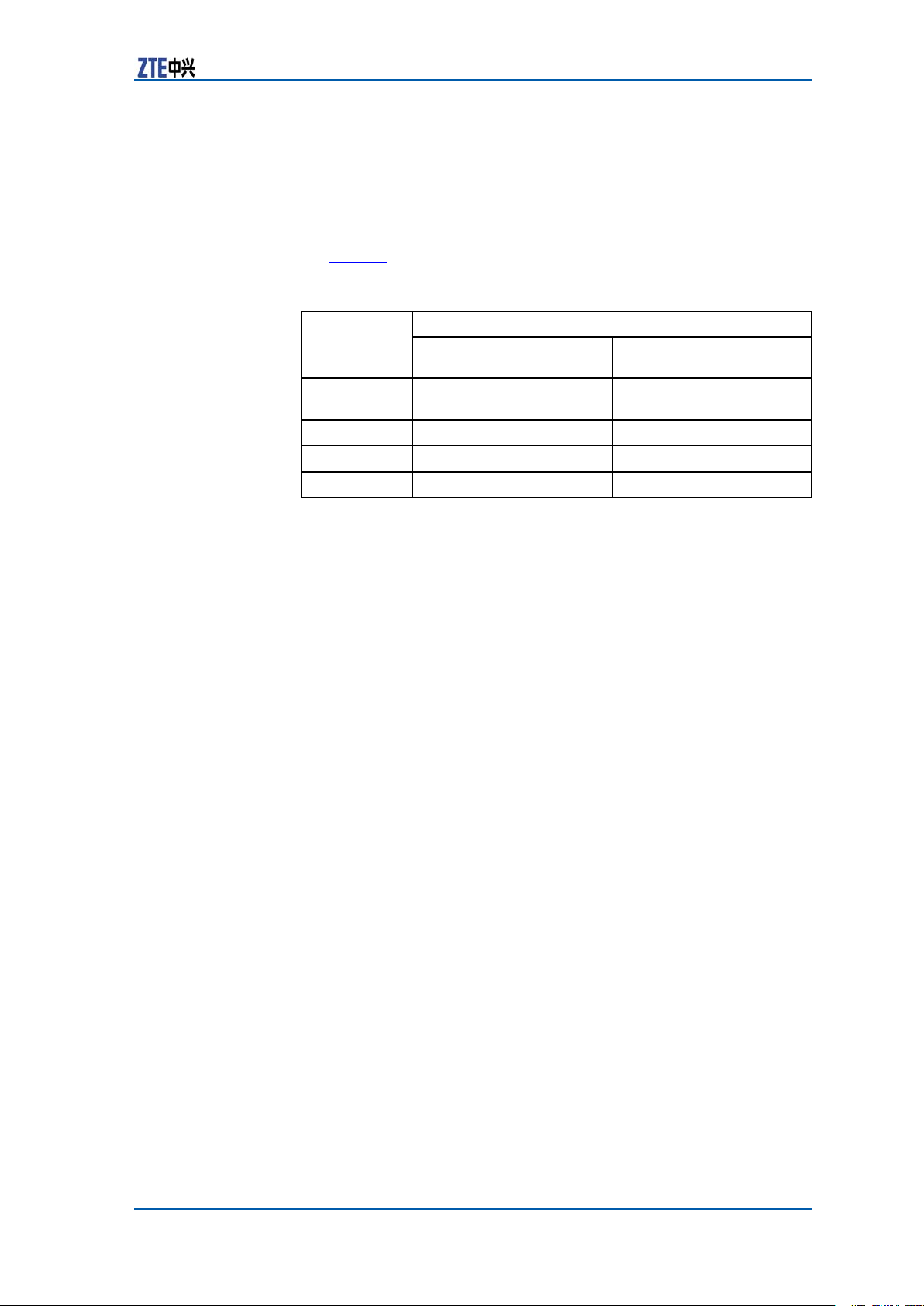

RevisionHistory

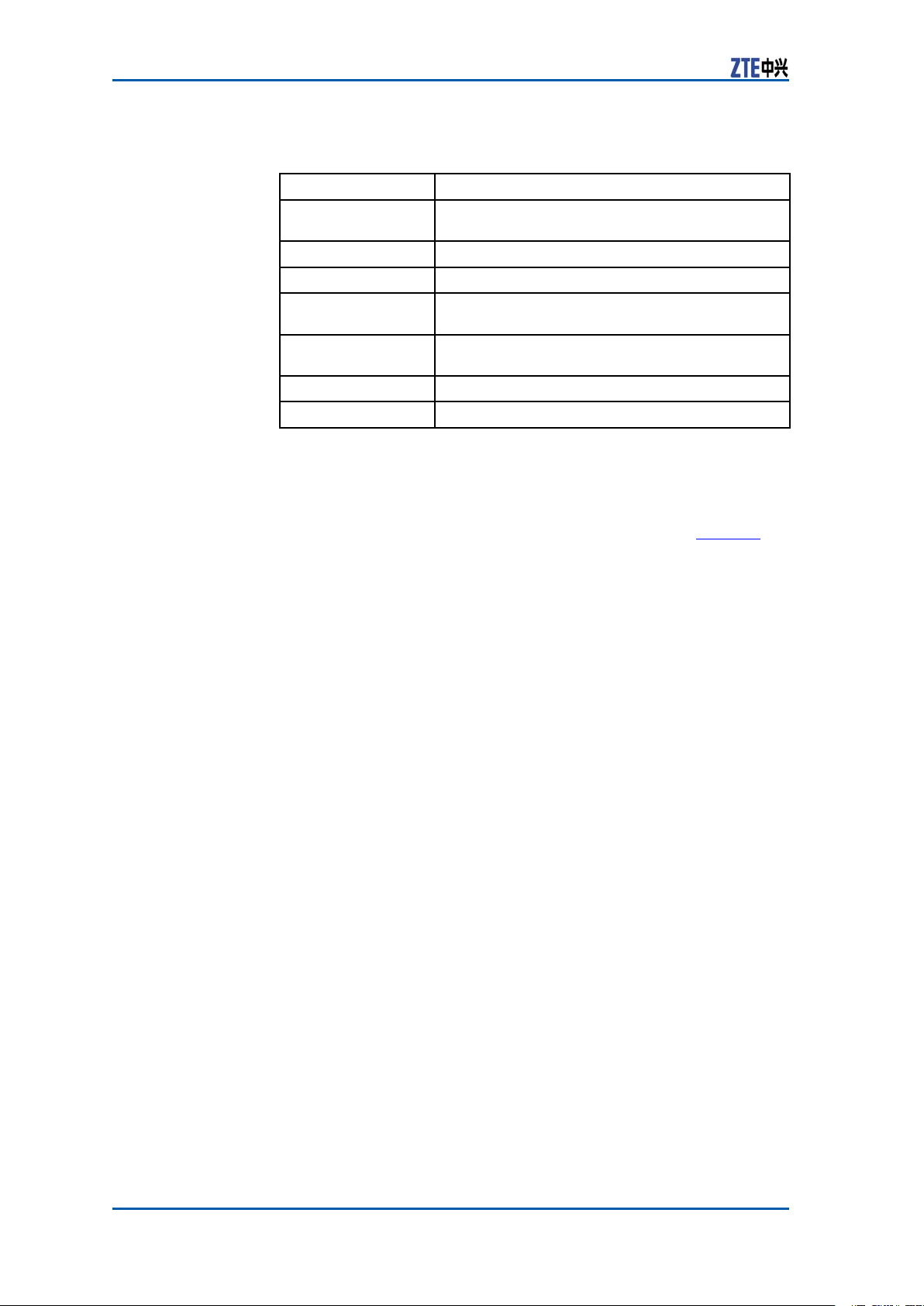

RevisionNo.RevisionDateRevisionReason

R1.1

R1.0

01/30/2009OptimizeManual

09/30/2008FirstEdition

SerialNumber:sjzl20083046

Page 3

Contents

Preface...............................................................i

SafetyInstruction.............................................1

SafetySpecicationsGuide..............................................1

SafetySymbols..............................................................2

SafetyInstructions.........................................................3

InstallationOverview........................................7

Appearance...................................................................7

EngineeringIndices........................................................7

InstallationFlow.............................................................8

InstallationPrecautions...................................................9

InstallationPreparation..................................11

CabinetInstallationEnvironmentCheck............................11

EquipmentRoomSpaceRequirements..........................11

EquipmentRoomEnvironmentRequirements................13

EquipmentRoomPowerSupplyRequirements...............14

LightningandGroundingRequirements........................15

TransmissionRequirements.........................................15

WiringRequirements..................................................16

TechnicalMaterialPreparation.........................................17

PersonnelRequirements.................................................18

ToolsandInstrumentsPreparation...................................18

UnpackingAcceptance....................................................20

CountingGoods.........................................................20

CrateUnpacking........................................................20

CartonUnpacking......................................................21

AcceptanceandGoodsHandover.................................22

InstallingCabinet............................................23

CabinetInstallationFlow................................................23

InstallingSingle-cabinet.................................................24

InstallingComponents....................................31

ModulePositionSchematicDiagram.................................31

Page 4

InstallingRSUModule....................................................33

InstallingBBU...............................................................35

InstallingBBUHorizontalModule.....................................37

InstallingBBUVerticalModule.........................................38

InstallingCable...............................................41

On-siteCableInstallationList..........................................41

CableInstallationFlow...................................................42

InstallingDCPowerCable...............................................43

InstallingGroundingCable..............................................46

InstallingDataCable......................................................47

Installing75ΩE1Cable..................................................49

Installing120ΩE1Cable................................................51

Installing100ΩT1Cable................................................52

InstallingAbisInterfaceEthernetCable............................53

InstallingDryContactInput/outputCable.........................55

InstallingRS232/RS485MonitoringCable.........................58

InstallingFiberbetweenBBUandRSU..............................59

InstallingAISGControlCable..........................................59

InstallingGPSJumper....................................................61

InstallingRFJumper......................................................63

InstallingGPSAntennaFeederSystem...........65

GPSAntennaFeederSystemInstallationFlow...................65

GPSAntennaFeederSystemInstallationPreparation..........66

InstallingGPSAntenna...................................................66

GPSAntennaInstallationPosition................................66

InstallingGPSAntennainVerticalPlacement.................67

InstallingGPSAntennainHorizontalPlacement.............69

InstallingGPSAntennainWall-mountMode..................71

InstallingGPSFeeder.....................................................73

GPSFeederSelectionPrinciple....................................73

WiringGPSFeeder.....................................................73

InstallingGPS1/4”FeederGroundingKit......................75

LeadingGPSFeederintoRoom....................................77

InstallingMainAntennaFeederSystem..........79

AntennaFeederSystemInstallationPreparation................79

FoundationalFacilityRequirements..............................79

CheckingIncomingMaterial........................................80

MakingFeederConnector...........................................81

AssemblingOmnidirectionalAntenna............................83

AssemblingDirectionalAntenna...................................86

Page 5

HoistingAntennaandFeeder......................................89

InstallingIndoorGroundingBar.......................................90

InstallingAntenna.........................................................93

InstallingDirectionalAntennaonTop-tower..................93

InstallingDirectionalAntennaonRoof........................100

InstallingOmnidirectionalAntennaonTop-tower..........111

InstallingOmnidirectionalAntennaonRoof.................115

InstallingAntennaJumper........................................123

InstallingFeederHermetic-window................................125

InstallingandGroundingFeederandJumper...................127

FeederCuttingPrinciple............................................127

FeederLayoutPrinciple............................................128

InstallingFeederonT ower........................................128

InstallingFeederonRoof..........................................130

FeederGroundingPrinciple.......................................132

InstallingFeederGroundingKit.................................134

FeederIndoorIngoing..................................................135

FeederIndoorArrangementPrinciple..........................135

LeadingMainFeederintoRoom................................136

InstallingTop-equipmentJumper...............................138

PerformingAntennaFeederSystemTest.........................139

PerformingOutdoor-connectorWaterproofProcess-

ing....................................................................140

PerformingFeederHermetic-windowWaterproof

Processing..........................................................142

InstallationCheck.........................................147

CheckingEquipmentInstallation....................................147

CabinetInspectionItems..........................................147

CableCheckItems...................................................147

Socket,PlugandLockingPieceInspectionItems..........148

LabelInspectionItems.............................................148

On-siteEnvironmentInspectionItems........................149

CheckingAntennaFeederSystemInstallation..................149

CheckingFeeder......................................................149

VSWRTest..............................................................150

CheckingWater-proofProcessing...............................150

CheckingPoweron......................................................151

Figures..........................................................153

Tables...........................................................157

Page 6

ListofGlossary..............................................159

Page 7

PrerequisiteSkill

andKnowledge

Whatisinthis

Preface

PurposeTheZXSDRBS8800C200isaradiotransceiverdevicetoprovide

serviceforacertaincell.TheZXSDRBS8800C200canfulll

mostfunctionsconcerningCDMApatenttechnologies.TheprimaryfunctionsofZXSDRBS8800C200are:basebandmodulation

anddemodulation,RFsignaltransmissionanddemodulation,radioresourcesdistribution,callprocessing,powercontrolandsoft

handoff.

Thismanualprovidesfundamentalinstallationoperationguidefor

ZXSDRBS8800C200hardwareinstallationengineersandatthe

sametimeactsasareferencematerialforoperationmaintenance

personnel.

Intended

Audience

Manual

ThisdocumentisintendedforengineersandtechnicianswhoperforminstallationactivitiesonZXSDRBS8800C200.

Tousethisdocumenteffectively ,usersshouldhaveageneralunderstandingofZXSDRBS8800C200equipmentanditscomponents.Familiaritywiththefollowingishelpful:

�cdma2000fundamental

�ZXSDRBS8800C200hardwarestructure

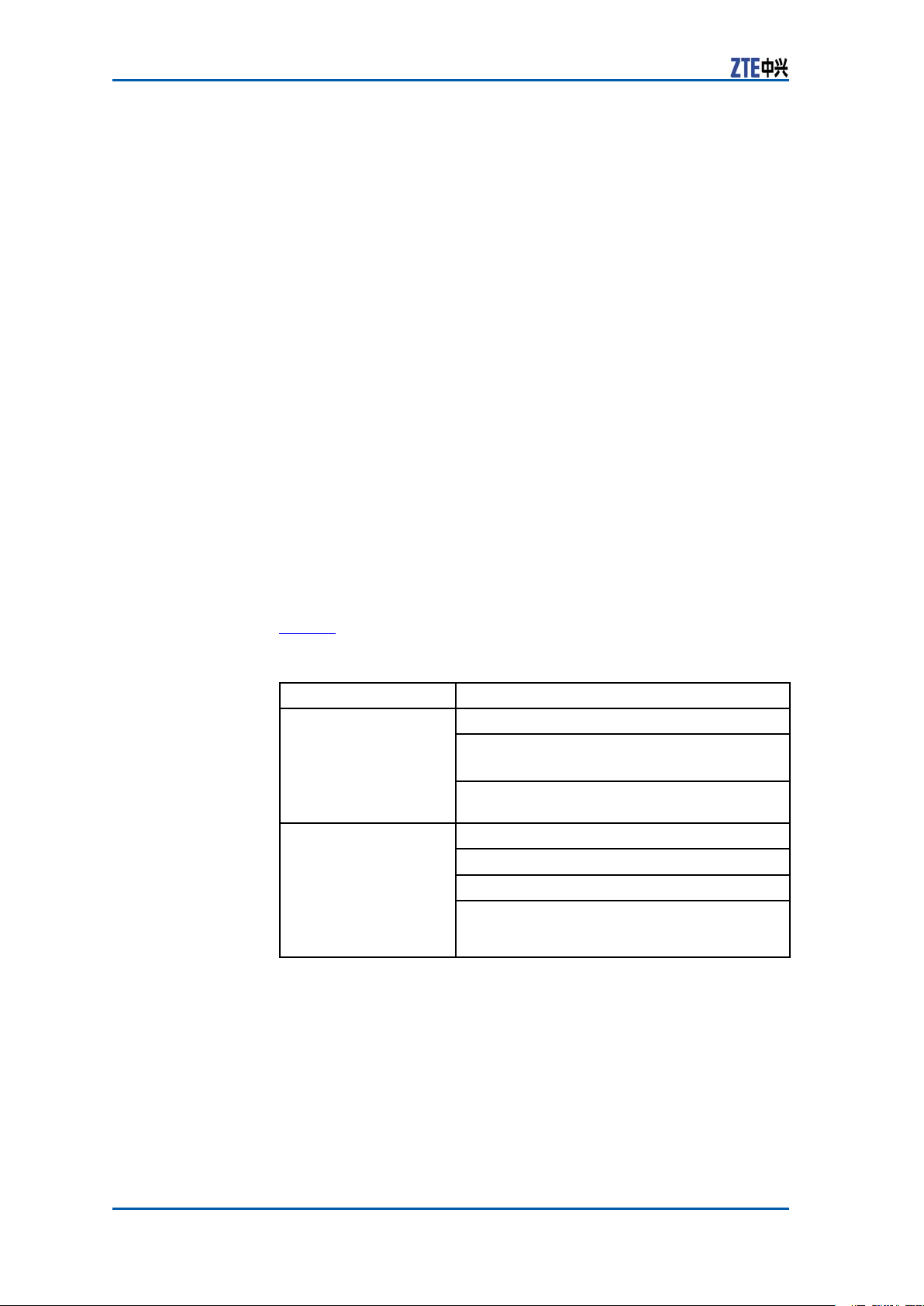

Thismanualcontainsthefollowingchapters:

Chapter

Chapter

1Safety

Instruction

Chapter2

Installation

Overview

Chapter3

Installation

Preparation

Chapter4

Installing

Cabinet

Chapter5

Installing

Components

Chapter6

Installing

Cable

Summary

DescribessafetyprecautionsduringZXSDRBS8800

C200installationoroperationmaintenanceaswellas

meaningsofvarioussafetysymbols.

DescribestheZXSDRBS8800C200installationows

andinstallationprecautions.

Describesinstallationenvironmentinspection,

requirementsofinstallationpersonnel,toolsand

documents,aswellasunpackingandacceptance

beforeinstallation.

DescribesinstallationmodesofZXSDRBS8800C200

cabinetandtheinstallationprocess.

DescribesinstallationmethodsofZXSDRBS8800

C200modulesandsubrack.

Describestheinstallationprocessofcables.

ConfidentialandProprietaryInformationofZTECORPORATIONi

Page 8

ZXSDRBS8800C200InstallationManual

Chapter

Chapter7

Installing

GPSAntenna

Feeder

System

Chapter8

Installing

MainAntenna

Feeder

System

Chapter9

Installation

Check

Summary

DescribestheinstallationmethodsofGPSantenna

feedersystem.

Describestheinstallationmethodsofmainantenna

feedersystem.

Describestheinspectionprocessafterinstallation

completion.

iiConfidentialandProprietaryInformationofZTECORPORATION

Page 9

Page 10

ZXSDRBS8800C200InstallationManual

Note:

ZTECorporationdoesnotbearanyliabilitiesincurredbecauseof

violationoftheuniversalsafetyoperationrequirements,orviolationofsafetystandardsfordesigning,manufacturingandusing

theequipment.

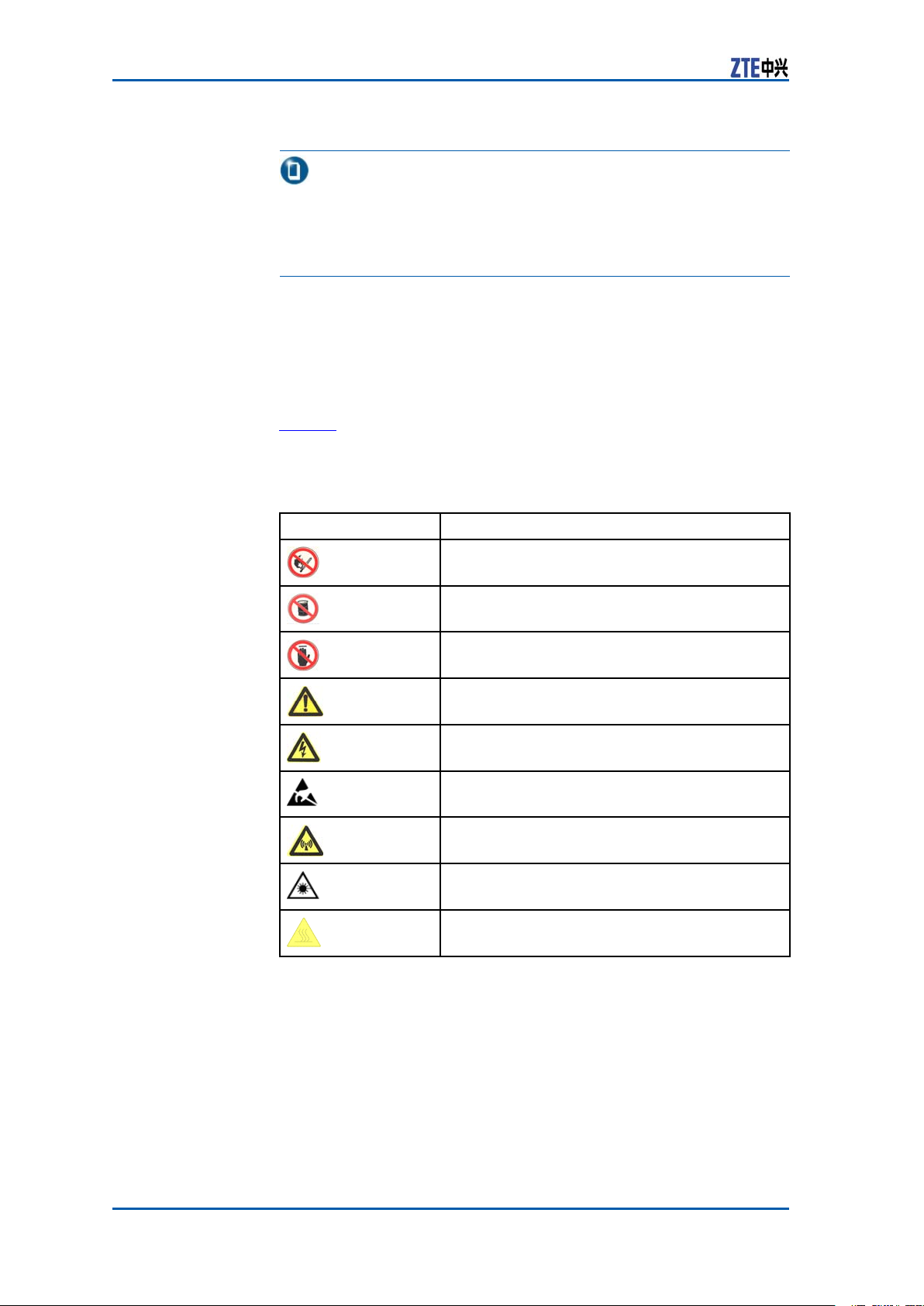

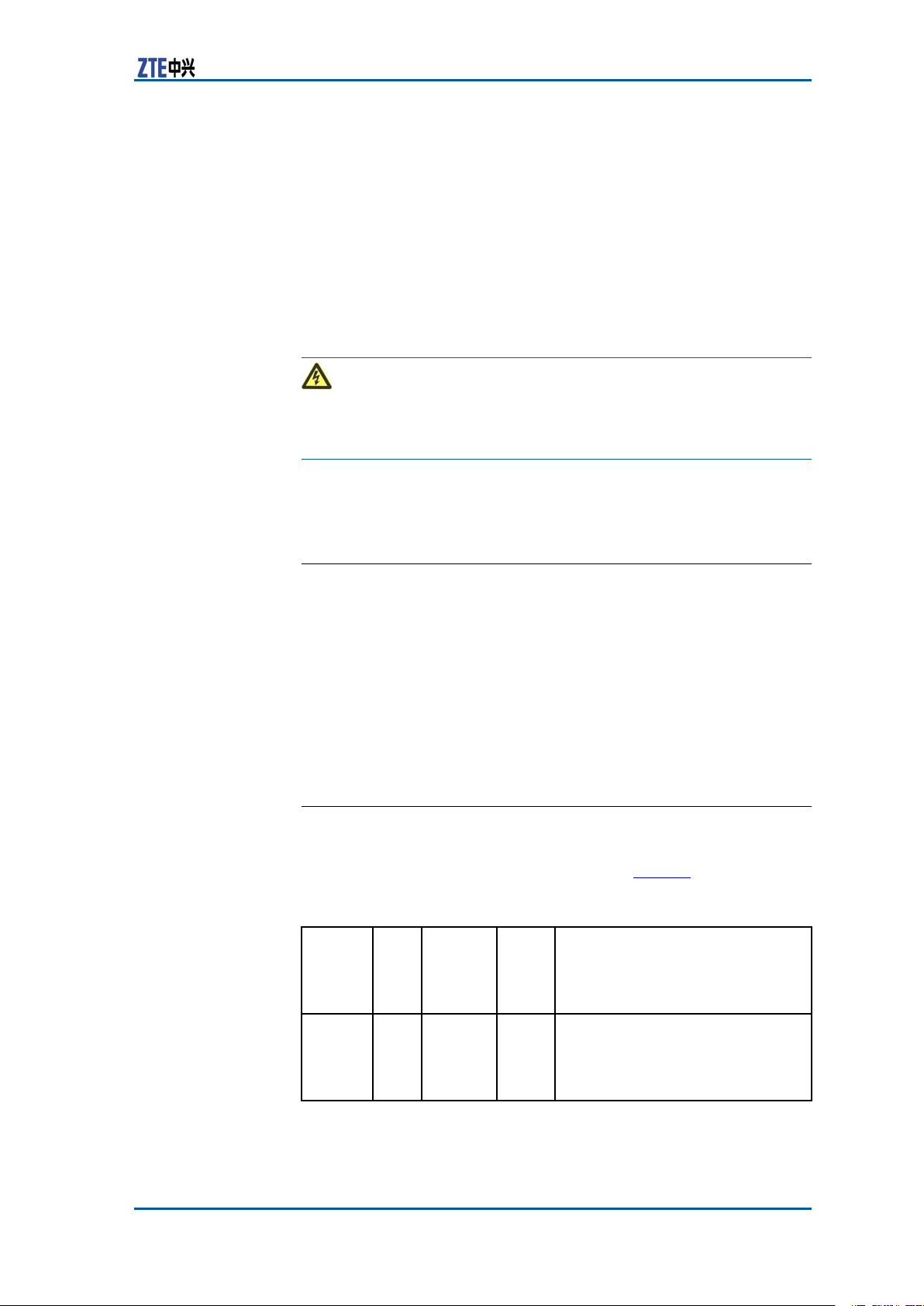

SafetySymbols

a b l e 1 listssafetysymbols.Theyaretoprompttheuserofthe

T

safetyprecautionstobeobservedduringZXSDRBS8800C200

operationandmaintenance.

TABLE1SAFETYSYMBOLSDESCRIPTION

SafetySymbols

Meaning

Nosmoking:Smokingisforbidden

Noflammables:Noflammablescanbestored.

Notouching:Donottouch.

Universalalertingsymbol:Generalsafety

attentions.

Electricshock:Riskofelectricshock.

Electrostatic:Thedevicemaybesensitiveto

staticelectricity.

Microwave:Bewareofstrongelectromagnetic

field.

Laser:Bewareofstronglaserbeam.

Scald:Bewareofscald.

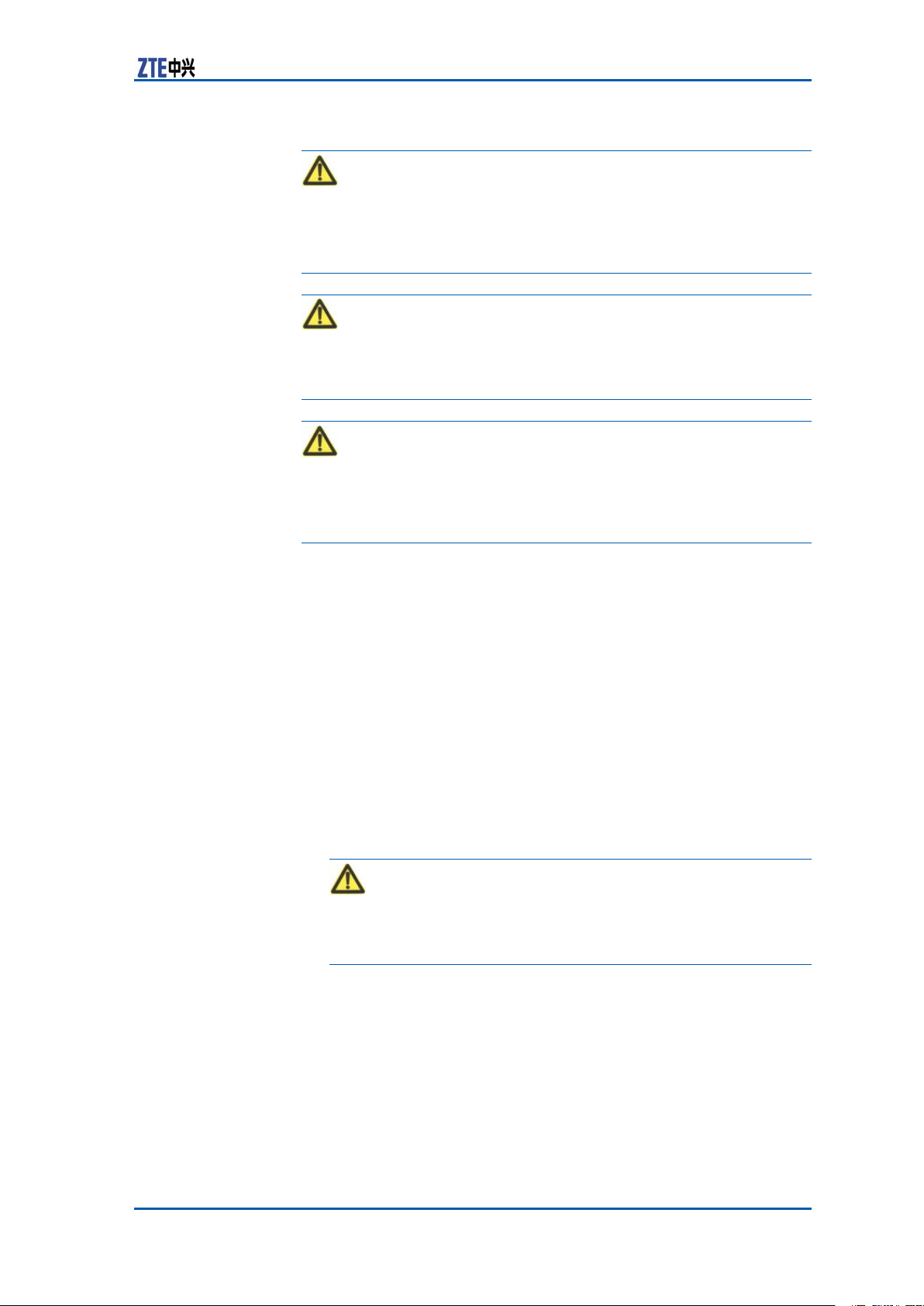

Amongstthesesafetysymbols,theuniversalalarmsymbolsare

classiedintothreelevels:danger ,warning,andcaution.The

formatsandmeaningsofthethreelevelsaredescribedasbelow:

2ConfidentialandProprietaryInformationofZTECORPORATION

Page 11

Chapter1SafetyInstruction

Danger:

Indicatesapotentiallyhazardoussituationwhich,ifnotavoided,

willresultindeathorseriousinjuryofpeople,orequipmentdamagesandbreakdown.

Warning:

Indicatesapotentiallyhazardoussituationwhich,ifnotavoided,

couldresultindeathorseriousinjury.

Caution:

Indicatesapotentiallyhazardoussituationwhich,ifnotavoided,

couldresultinseriousinjuries,equipmentdamagesorinterruption

ofpartservices.

ElectricalSafety

SafetyInstructions

Thissectiondescribesthesafetyinstructionsrelatedtoelectrical

safety,antistatic,heavyobjectsandmodules.

Instructions

Thefollowingaretheelectricalsafetyinstructionsabouttools,high

voltage,powercables,holesandlightning:

�Tools

Usespecialtoolsratherthancommontoolsforhigh-voltage

andACoperations.

�HighVoltage

Danger:

Highvoltageishazardous.Directorindirectcontactwithhigh

voltageormainsupplyusingawetobjectcouldresultindeath.

�StrictlyfollowlocalsafetyrulestoinstallACpowerequip-

ments.

�Installationstaffmustbequaliedforperforminghigh-volt-

ageandACoperations.

�Donotwearanywatch,handchain,bracelet,ringorany

otherconductiveobjectduringsuchoperations.

�Preventmoisturefromaccumulatingontheequipmentdur-

ingoperationsinadampenvironment.

�PowerCable

ConfidentialandProprietaryInformationofZTECORPORATION3

Page 12

ZXSDRBS8800C200InstallationManual

Warning:

Neverinstalloruninstallpowercableswhiletheyarelive.Otherwise,thepowercable,whencontactingaconductor ,mayresultinsparksorelectricarccausingareorevendamageto

eyes.

�Makesuretoshutoffpowersupplybeforeinstallingordis-

connectingapowercable.

�Beforeconnectingthepowercable,makesurethatthecon-

nectingcableanditslabelisappropriatefortheactualinstallationrequirements.

�DrillingHoles

Warning:

Itisnotallowedtodrillcabinetholeswithoutpermission.

AntistaticSafety

�Unqualieddrillingcoulddamagewiringandcablesinside

thecabinet.Additionally ,metalpiecesinsidethecabinet

createdbythedrillingcouldresultinashortcircuit.Use

insulationprotectionglovesandrstmovecablesinsidea

cabinetawaywhendrillingisnecessaryonacabinet.

�Protecteyesduringdrillingasdustoryingdebrismay

damageeyes.

�Cleananydebrisintimeafterdrilling.

�Lightning

Danger:

Donotperformhigh-voltage,AC,irontowerormastoperations

inathunderstorm.

Thunderstormswouldgiverisetoastrongelectromagnetic

eldintheatmosphere.Therefore,theequipmentmustbe

groundedandprotectedintimeagainstlightningstrikes.

Instructions

Electrostatic:

Staticelectricityproducedbyhumanbodycandamagestatic-sensitivecomponentsoncircuitboard,suchaslarge-scaleintegrated

circuits.

�Frictioncausedbyhumanbodyactivitiesistherootcauseof

electrostaticchargeaccumulation.Staticvoltagecarriedbya

humanbodyinadryenvironmentcanbeupto30kV ,and

canremaininthereforalongtime.Anoperatorwithstatic

electricitymaydischargeelectricitythroughacomponentwhen

he/shetouchestheconductorandcausingdamage.

4ConfidentialandProprietaryInformationofZTECORPORATION

Page 13

HoistingHeavy

Chapter1SafetyInstruction

�Wearanantistaticwriststrap(theotherendofwriststrapmust

bewellgrounded)beforetouchingtheequipmentorholding

aplug-inboard,circuitboard,IntegratedCircuit(IC)chipor

otherdevices,topreventhumanstaticelectricityfromdamagingsensitivecomponents.

�Aresistorover1MΩshouldbeconnectedinseriesonthecable

betweentheantistaticwriststrapandthegroundingpoint,to

protecttheoperatoragainstaccidentalelectricshock.Resistanceover1MΩislowenoughtodischargestaticvoltage.

�Theantistaticwriststrapusedmustbesubjecttoregular

check.Donotreplacethecableofanantistaticwriststrap

withanyothercable.

�Donotcontactstatic-sensitivemoduleswithanyobjectthat

easilygeneratesstaticelectricity .Forexample,frictionofpackagebag,transferboxandtransferbeltmadefrominsulation

plasticmaycausestaticelectricityoncomponents.Discharge

ofstaticelectricitymaydamagecomponentswhentheycontactahumanbodyortheground.

�Modulesshouldonlycontactmaterialssuchasantistaticbag.

Keepmodulesinantistaticbagsduringstorageandtransportation.

�Dischargestaticelectricityofthetestdevicebeforeuse,that

is,groundthetestdevicerst.

�DonotplacethemodulenearastrongDCmagneticeld,such

asthecathode-raytubeofamonitor .Keepthemoduleatleast

10cmaway.

Objects

Warning:

Whenhoistingheavyobjects,ensurethatnobodyisstandingor

walkingunderthehoistedobject.

�Ensurethehoistercanmeethoistingrequirementswhendis-

assemblingheavyequipment,ormovingandreplacingequipment.

�Theinstallationpersonnelmustbedulytrainedandqualied

forhoistingoperations.

�Hoistingtoolsmustbeinspectedandcompletebeforeservice.

�Makesurethathoistingtoolsarexedrmlyonasufciently

securedobjectorwallbeforethehoistingoperation.

�Givebrieforalinstructionsduringhoistingoperationstopre-

ventanymishap.

Unplugging/Plug-

gingaModule

�Neverplugamodulewithexcessiveforce,toensurethatthe

pinsonthebackplanedonotgetdeformed.

�Plugthemodulerightintotheslotandmakesuremodulecir-

cuitfacesdonotcontacteachotherlestanyshortcircuitmay

occur .

�Keephandsoffthemodulecircuit,components,connectors

andcabletroughwhenholdingamodule.

ConfidentialandProprietaryInformationofZTECORPORATION5

Page 14

ZXSDRBS8800C200InstallationManual

OtherSafety

Instructions

Note:

Donotperformmaintenanceordebuggingindependently,unless

aqualiedpersonispresent.

�Replacinganypartsormakinganychangestotheequipment

mightresultinanunexpecteddanger .Therefore,besurenot

toreplaceanypartsorperformanychangestotheequipment

unlessauthorizedotherwise.

�DuetothatRRUisinhightemperatureduringrunning,theRRU

shouldbeinstalledinsomeregionsoutofoperators’reachor

strictlyrestricted.

�DuetothatRRUisinhightemperatureduringrunning,theRRU

shouldbeinstalledinsomeregionsoutofoperators’reachor

strictlyrestricted.

�ContactZTEofceifyouhaveanyquestion,toensureyour

safety.

6ConfidentialandProprietaryInformationofZTECORPORATION

Page 15

C h a p t e r 2

InstallationOverview

TableofContents:

Appearance.......................................................................7

EngineeringIndices............................................................7

InstallationFlow.................................................................8

InstallationPrecautions.......................................................9

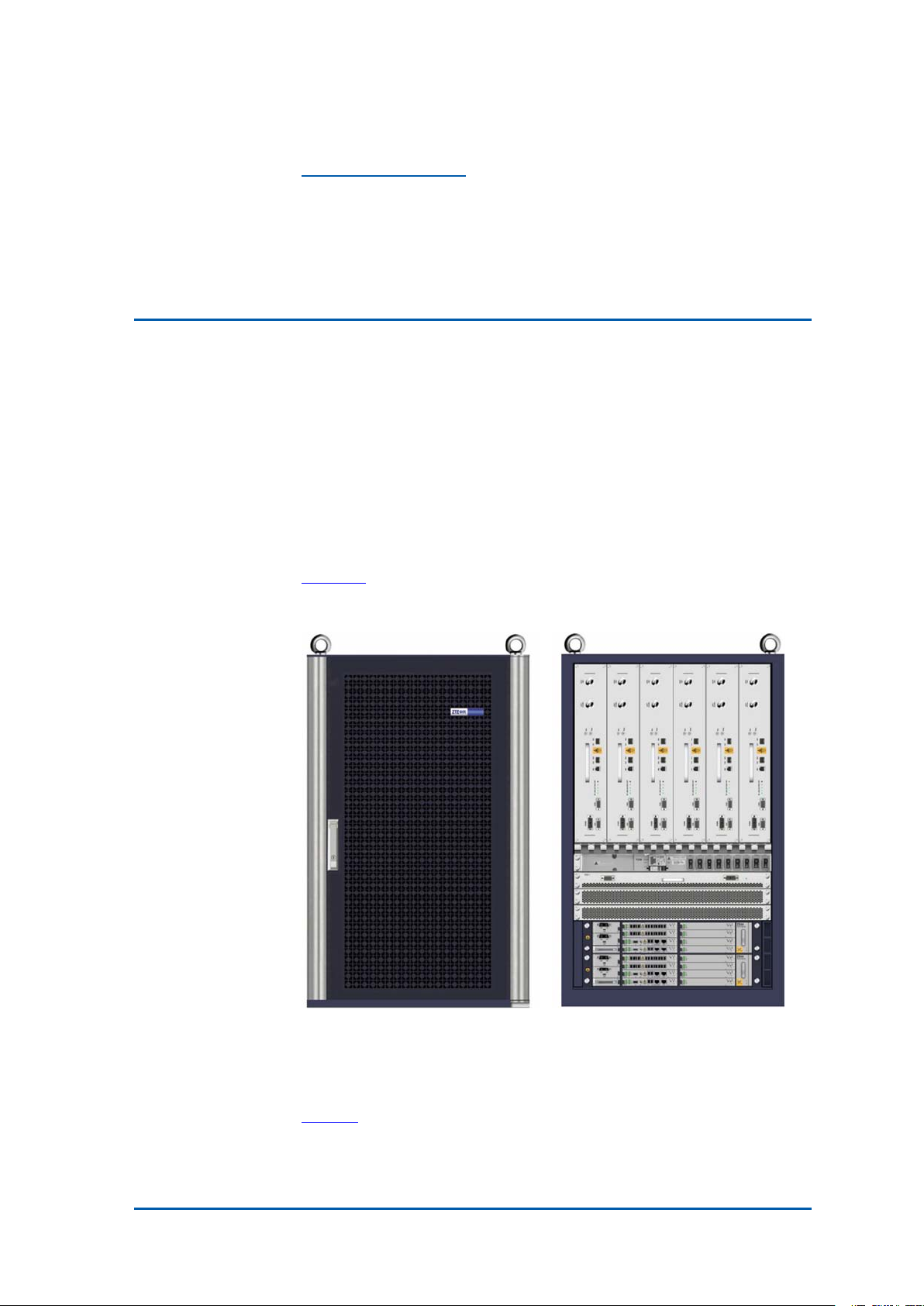

Appearance

i g u r e 1 showstheappearanceofZXSDRBS8800C100.

F

FIGURE1ZXSDRBS8800C200APPEARANCE

EngineeringIndices

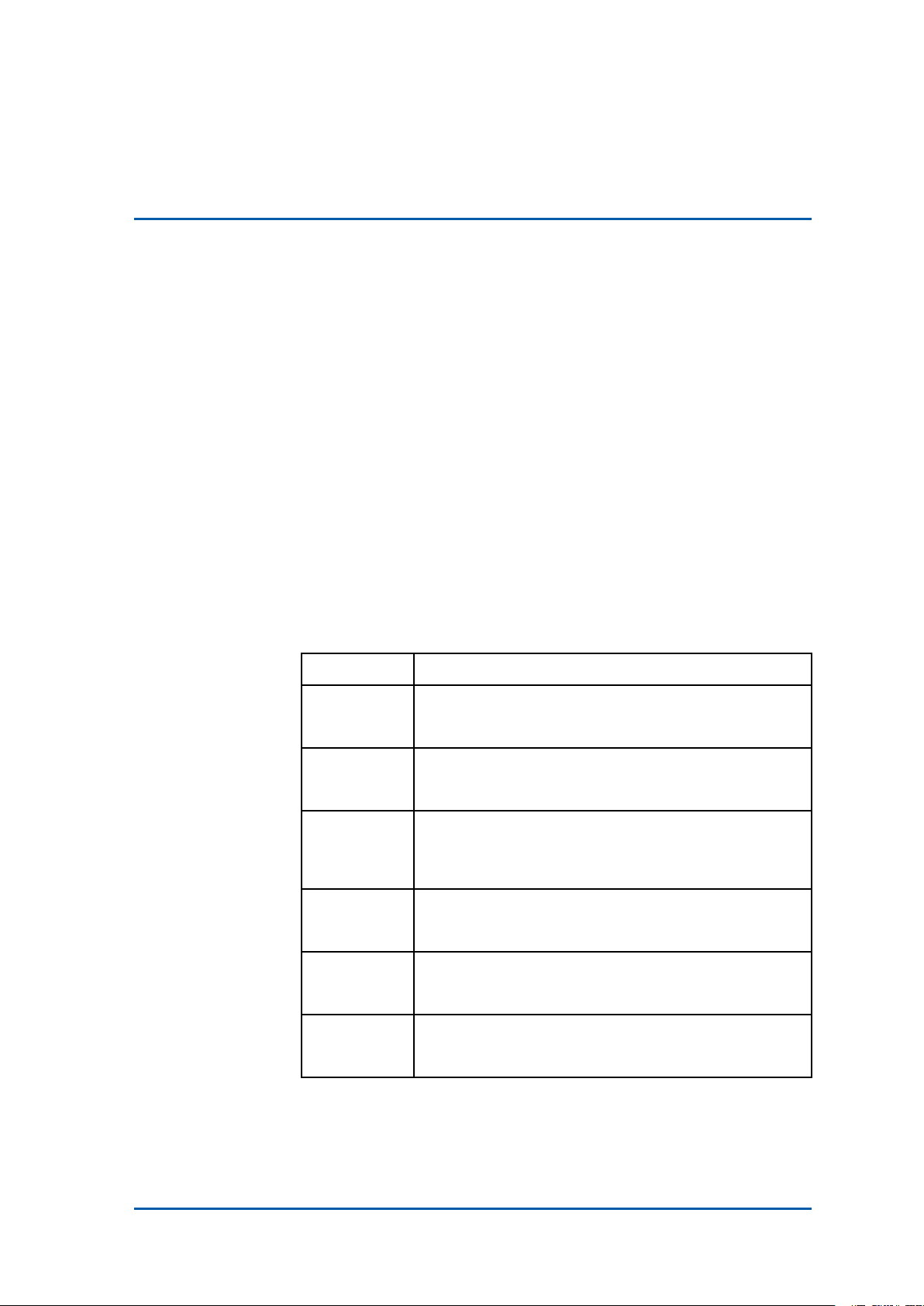

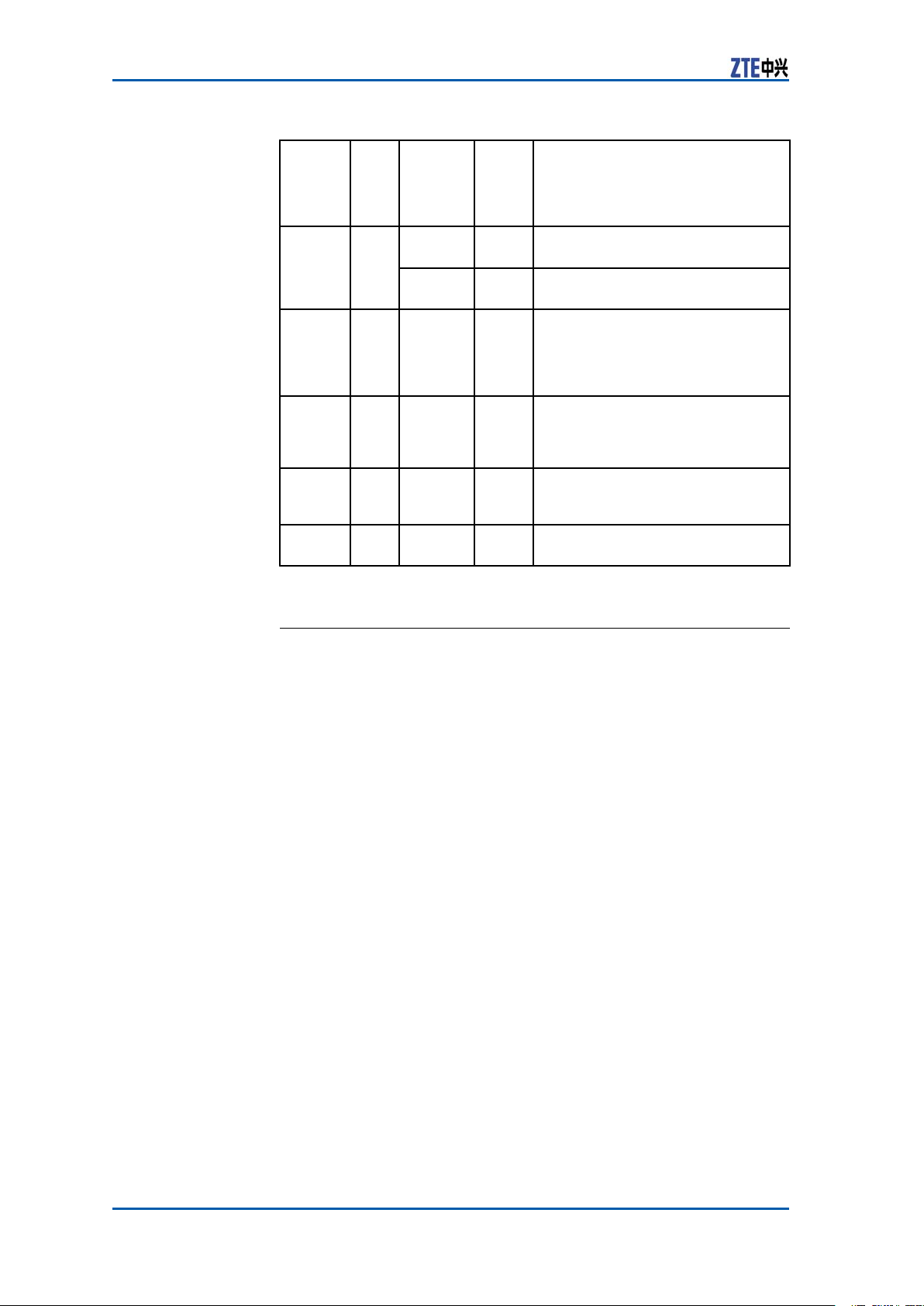

a b l e 2 liststheengineeringindicesofZXSDRBS8800C200.

T

ConfidentialandProprietaryInformationofZTECORPORATION7

Page 16

ZXSDRBS8800C200InstallationManual

TABLE2ZXSDRBS8800C200ENGINEERINGINDICES

Item

Dimension

Weight<200kg

PowerSupply

WorkingTemperat

ure

OverallPower

Consumption

WorkingHumidity

Grounding

Index

950mm×600mm×450mm(height×width

×depth)

-48VDC:-40V~-57V

-40℃to55℃(-40℉to131℉)

<3000W(fullconfiguration)

5%RH~95%RH

<5Ω

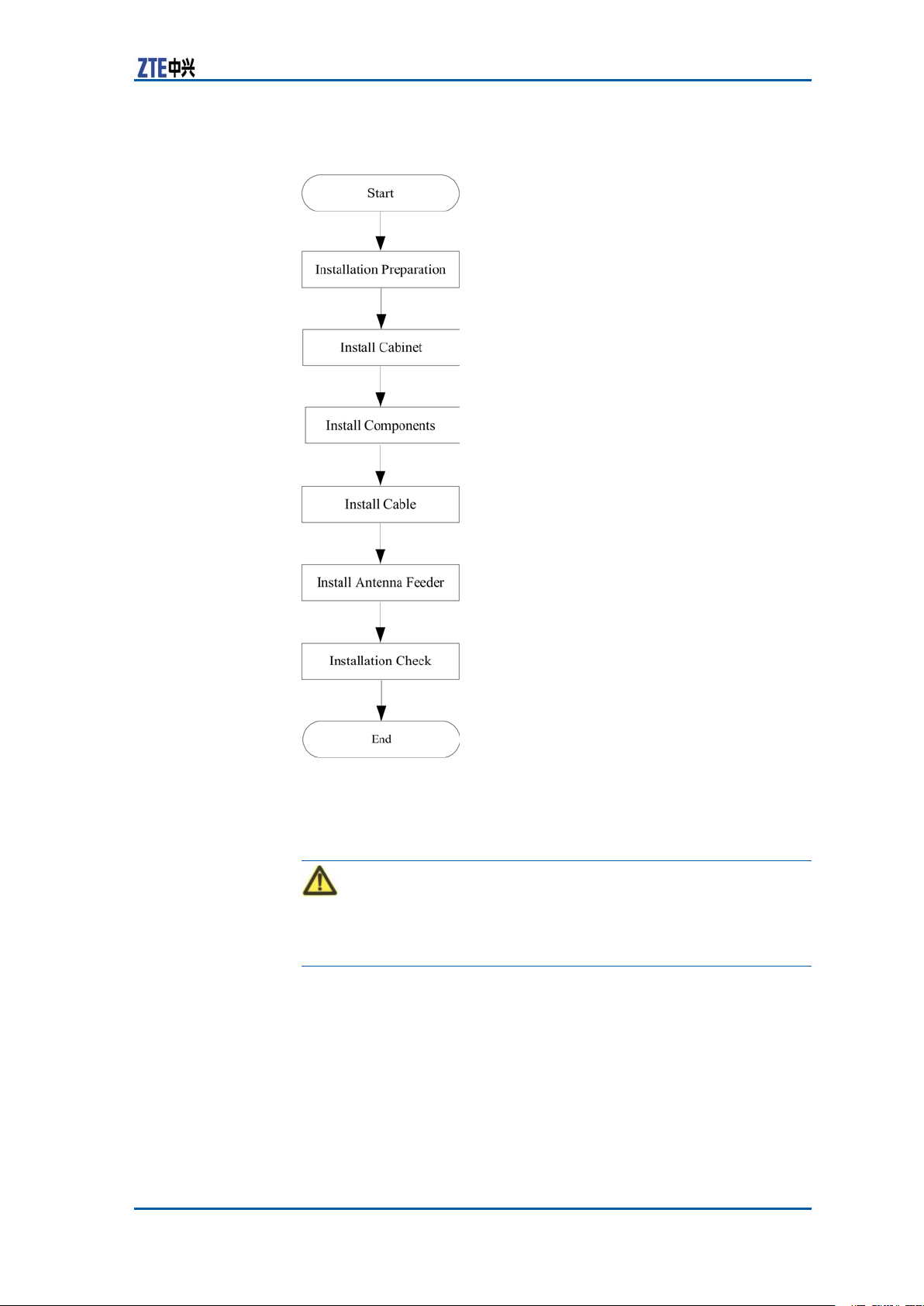

InstallationFlow

TheZXSDRBS8800C200installationowislistedinF

i g u r e 2 .

8ConfidentialandProprietaryInformationofZTECORPORATION

Page 17

FIGURE2INSTALLATIONFLOW

Chapter2InstallationOverview

InstallationPrecautions

Warning:

Nonprofessionalpersonnelprohibitsinstallinganddebuggingdevicesalone,exceptwithguideofprofessionalpersonnel.

�Readthismanualaswellascorrespondingmanualscarefully

beforeinstallationandperforminstallationaccordingtotheinstallationowandspecicationsinthismanual.

�ZXSDRBS8800C200hardwareinstallationpersonnelmust

participateinsometrainingrelatedtocommunicationequipmentinstallationandownskilledinstallationtechnique.

�Duringinstallation,ensurepersonalsafetyandavoidaccidents

suchaselectricshockorbruise.

ConfidentialandProprietaryInformationofZTECORPORATION9

Page 18

ZXSDRBS8800C200InstallationManual

�Duringinstallationintheequipmentroom,installationper-

sonnelshouldwearinsulationshoesandtakeoffnecklaces,

braceletsandwatches.

�Duringinsertingandextractingboards,installationpersonnel

shouldwearantistaticwriststrapsandmakesuretheother

endofitgrounding.

�Duringinstallationandmaintenanceofopticalber ,prohibit

directlystaringatasectionofopticalberorasocketofoptical

terminalincasethatlaserbeamsdamageeyes.

�Insertboardsalongslots,avoidcontactbetweenparalleled

boardscausingshortcircuit.Makeproperforceincaseofpins

distorted.

�Takeholdoftheedgeofboardsandnottouchthecircuit,com-

ponentsandwires.

�Replacingcomponentsormodifyingdevicesmaybringextra

risks.Withoutauthorization,prohibitreplacingormodifying

devices.

10ConfidentialandProprietaryInformationofZTECORPORATION

Page 19

C h a p t e r 3

InstallationPreparation

TableofContents:

CabinetInstallationEnvironmentCheck................................11

TechnicalMaterialPreparation.............................................17

PersonnelRequirements.....................................................18

ToolsandInstrumentsPreparation.......................................18

UnpackingAcceptance........................................................20

CabinetInstallation

EnvironmentCheck

EquipmentRoomSpace

Requirements

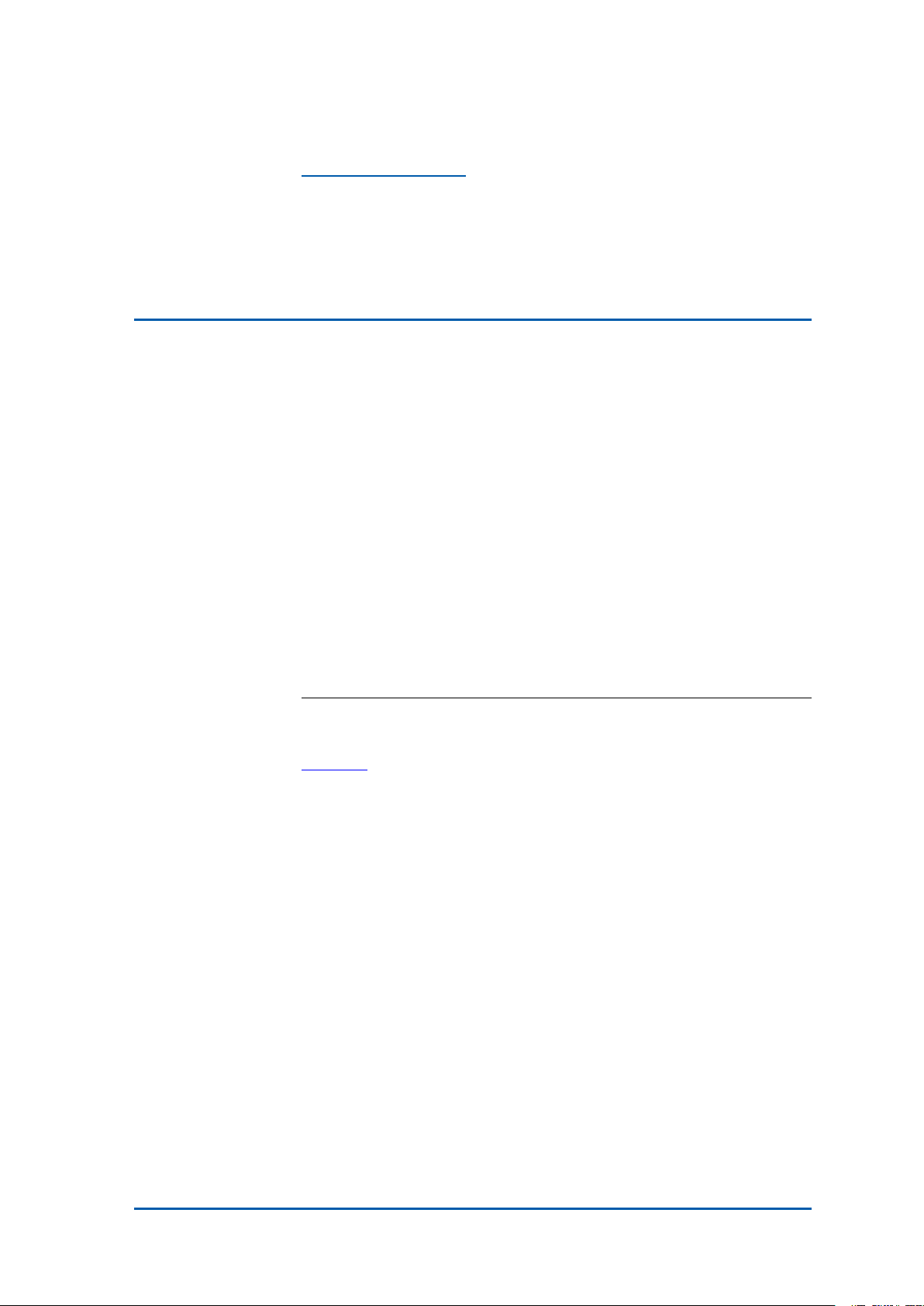

Theminimuminstallationspaceofcabinetisrequiredasshownin

i g u r e 3 .

F

ConfidentialandProprietaryInformationofZTECORPORATION11

Page 20

ZXSDRBS8800C200InstallationManual

FIGURE3INSTALLATIONSPACEREQUIREMENT

Thedetailedrequirementsisasfollows:

�Thisequipmentcanbeinstalledalongsideawallandperform

maintenanceforallboardsundertheconditionthattheback

doorisclosed;keepthecabinetadistanceofmorethan100

mmfromthewall.

�Whenthereareotherequipmentatbothsidesoftheequip-

ment,makeitabuttingagainstotherequipment;whenthere

arewallsatbothsidesoftheequipment,keepadistanceof

morethan100mmfromthebothwalls.

�Keepamorethan800mmspacefromthefaceofequipment.

12ConfidentialandProprietaryInformationofZTECORPORATION

Page 21

EquipmentRoomEnvironment

Requirements

Chapter3InstallationPreparation

RoomLayout

Requirements

EquipmentRoom

Equipment

Building

Thelayoutofequipmentroomincludescabletraylayoutandcabinetlayout.Accordingtotheengineeringdesigndrawing,installationpersonnelshouldmarkandlocatebasedonequipmentroom

spaceandcabinetdimension.

Thedirectionfromfeedertocabinetshouldbeconsideredenough

duringcabinetlayout.Thefeedershouldbeshortaspossibleas

itcan,andthebendingradiusoffeedershouldbenottoosmall.

Iftwocabinetsormorearerequired,themaincabinetshouldbe

putinthemiddleofallcabinets.

Cabinetlayoutadoptingarowormulti-rows(putinthesame

equipmentroomwithBSCorMSC)isdeterminedbythesizeof

equipmentroomandcabinetquantity .

Inordertobeconvenientforoperation,suggestthatcabinetlayout

shouldmeetthefollowingrequirements:

�Thedistancefromcabinettowallshouldbemorethan10cm.

�Arowofcabinetskeeps1mdistanceatleastfromanother

neighboringrowofcabinets.

�Whenmultiplecabinetsareputsidebyside,thesecabinets

shouldkeepinline.

�Thefaceofcabinetkeeps1mdistanceatleastfromanob-

struction.

Theengineeringforequipmentroommustmeetthefollowingrequirements:

�Theleveloordifferencepersquaremeterisnotmorethan2

mm.

�Theoor ,wall,ceiling,reservedinstallationholesandgrooves

ofequipmentroomshouldaccordwiththedesignrequirements.

�Preventwaterontheoutdooroorintotheindooroorwhilein-

stallationholespassesanoutdoorwall.T akemeasuresagainst

dampnessforthegrooves.

�Selectsomematerialwhichisdifculttodeformandcrackfor

hiddenpipes,holesandslotsbetweencoverplates.

�Prepareatemporaryroomtostoreinstallationmaterialsand

devices.

ConfidentialandProprietaryInformationofZTECORPORATION13

Page 22

ZXSDRBS8800C200InstallationManual

Note:

High-voltagepowerwire,strongmagneticled,strongelectrical

sparkaswellasotherfactorsbringingdangerforequipmentroom

mustbeawayfromtheequipmentroom.

Temperatureand

Humidity

NoiseConsideringmaintenancepersonnel’sphysicalandmentalhealth,

FireProtectionThereprotectionconditionsofequipmentroommustmeet:

DustproofThedustproofrequirementsofequipmentroomshouldmeetthe

LightingThelightingconditionsofequipmentroomshouldreachthere-

WaterSupplyand

Draining

Theair-conditiondevicesshouldmeetthefollowingconditions:

�EnvironmentT emperature:-5℃~+45℃(Suggestmaintain-

ingtheenvironmenttemperaturebetween15℃and30℃).

�RelativeHumidity:15%~90%(Suggestmaintainingtherela-

tivehumiditybetween15%and90%).

noiseintheequipmentroomshouldbelowerthan70dB.

�Theindoorwallshouldmaintaindryness,andthewallsurface

andceilingarecoatedwithwhitenoncombustiblelusterless

paintorotherame-retardantmaterials.

�Prohibitstoringammableandexplosivesubstancesandequip

necessaryreprotectiondevices.

following:

�Alldoorsandwindowsshouldbeclosed.

�Ventilationpipelinesintheequipmentroomshouldbecleaned,

andairconditiondevicesshouldbeinstalledwithdustscreens.

�HolesCommunicatingbetweenequipmentroomsandpassage

forcablelayoutshouldbeclosedtodecreasedustowbetween

rooms.

quirementsofequipmentmaintenance.Dailylighting,standby

lightingandemergencylightingsystemsshouldbeprepared.

Pipelinesofwaresupply ,drainingandreprotectionshouldnotbe

equippedinsidetheequipmentroom.

EquipmentRoomPowerSupply

Requirements

Thepowersupplyofequipmentroommustmeetthefollowingrequirements:

�Equipadieselenginetoprovidestandbypower .TheACpower

isresponsibleforpowersupplyalone.Thevoltagerange:380

V±10%;220V±10%.

�ThesupplypowervoltageofDCdistributiondeviceshouldbe

stableandthenominalvalueis-48V(-57V~-40V).

�Thebatterycapacityshouldbeadequate.

14ConfidentialandProprietaryInformationofZTECORPORATION

Page 23

Chapter3InstallationPreparation

�Differentpowersocketsintheequipmentroomshouldhave

obviousmarks.Thepowerelectricityshouldbedistinguished

fromthelightingelectricityobviously .

�Whenthephenomenaofpowerundercurrent,under-voltage

andover-voltageoccur ,thereshouldbesound-and-light

alarms.

�Whileusing220Vor380VACvoltage,paygreatattentionin

caseofelectricshock.

�WhileinstallingDCpower ,makesurepowerpolaritiesconsis-

tent.

ElectricShock:

Whilecheckingpowers,examinethecurrentstatusofallswitches

andwatchoutelectricshock.

LightningandGrounding

Requirements

Thelightningandgroundingintheequipmentroomshouldmeet

thefollowingrequirements:

�Thegroundingresistanceisnotmorethan5Ω.

�Theindoorgroundingsystemconnectsdirectlywithaground-

ingbar .Alldevicegroundingconnectstothisgroundingbar .

Andthenthegroundingbarconnectswiththeprimarygroundingbarofthebuilding.

TransmissionRequirements

TheexternalinterfacesofZXSDRBS8800C200locateontheRSU

modulesandBBUsubsystem,referringtoT

TABLE3ZXSDRBS8800C200EXTERNALINTERFACEINDEXDESCRIPTION

Tran

smis

sion

Categ

ory

E1/T1

M

odule

S

A-d

ata

cable

Inte

rface

Name

B2inter

face

Conn

ector

DB44

Description

ConnectstheZXSDRBS8800

C200withtheBSC;

E1provides75Ωand120Ωload

interfaces;

T1provides100Ωloadinterface.

a b l e 3 .

ConfidentialandProprietaryInformationofZTECORPORATION15

Page 24

ZXSDRBS8800C200InstallationManual

Tran

smis

sion

Categ

ory

Ethe

rnet

cable

RS232/

RS485

monit

oring

cable

Dry

contact

cable

AISG

control

cable

GPS

jumper

M

odule

CC

S

A-d

ata

cable

S

A-d

ata

cable

RSUAISGDB9

CC

Inte

rface

Name

ETH0

ETH1RJ45

B4

B3DB25

ANT

Conn

ector

RJ45

DB9

SMA

Description

ConnectstheZXSDRBS8800

C200withtheBSC.

ConnectstheZXSDRBS8800C200

andPCforLMTmaintenance.

Providesinternalandexternal

environmentmonitoringfor

ZXSDRBS8800C200.

Importdrycontactsignalfrom

externaldevices;

Exportdrycontactsignalfromthis

device.

Controlselectricaladjustment

antenna.

Importsatellitesignalintothe

cabinet.

WiringRequirements

Requirements

Wiring

�Beforelayoutofpowercableandprotectivegroundcable,wrap

cableconnectorswellwithinsulationadhesivetape.

�Thepowercableandprotectivegroundcableshouldbesepa-

ratefromthesignalcable.

�Whenthepowercableandprotectivegroundcableareparallel

withthesignalcable,thedistancefromthesignalcablekeeps

10mmatleastinsidethecabinetand100mmatleastoutside

thecabinet.

�Ifthesignalcableiscrossedwiththepowercable,thecrossed

anglemustbe90°.

�Attheturningofcable,thebendingradiusshouldbemorethan

vetimesofthecablediameter .

�Whenthepowercableconnectstoaconnectingterminalof

distributionpowerboxinsidethecabinet,thewiringshouldbe

straightandtheradianofturningshouldbesmooth.

�Theactualinstallationpositionofcablesshouldbeconsistent

withrequirementsofengineeringsurveyanddataconguration.

�Theroutofcablelayoutshouldbeclearandreasonable,ac-

cordingtotheengineeringdesigndrawing.

�Thelayoutofsignalcableshouldbeorderly ,smoothandnon-

crossed.

�Thelayoutofcablesshouldbeconvenientformaintenanceand

capacityexpansion.

16ConfidentialandProprietaryInformationofZTECORPORATION

Page 25

Chapter3InstallationPreparation

�。Beforefeederlayout,learnofthewiringrouteanddrawa

practicalwiringrouteonthepaperincasefeedercrossed

�Theminimumbendingradiumoffeederisnotlessthan20

timesofthefeederradium.

�Therequirementsoffeederbendingradiumareasshownin

T

a b l e 4 .

TABLE4BENDINGRADIUMREQUIREMENTS

Bending

Super–soft

1/2"Feeder

1/2"Feeder

7/8"Feeder

5/4"Feeder

Requirements

Binding

�Thebindingtapeisboundneatlyandproperly,andthespaces

betweenwirefastenersanddirectionsoffastenerskeepconsistent.

�Cutredundantbindingtapeandmakeitatandtidy.

�Thepowercableandprotectivegroundcableareboundsepa-

ratelyfromthesignalcable.

�Thecablesinsidethecabinetisboundontoawirebushing.

�Whilelayingoutcablesalongthecabletray ,thecableshould

beboundtogetherclose.

�Remainproperlengthincableforinsertingandextractingcon-

nectors.

TheMinimumBendingRadius(recommended) Feeder

BendingforOnce

15cm

50cm125cm

90cm250cm

150cm380cm

ConsecutiveBending

(<=15times)

30cm

TechnicalMaterial

Preparation

Itisnecessarytopreparethefollowingtechnicalmaterialfor

ZXSDRBS8800C200installation:

�ZXSDRBS8800C200CDMAIndoorBasestation-8800Engi-

neeringSurveyReport

�ZXSDRBS8800C200CDMAIndoorBasestation-8800Environ-

mentAcceptanceReport

ZXSDRBS8800C200kitmaterialsinclude:

�ZXSDRBS8800C200CDMAIndoorBasestation-8800T echnical

Manual

�ZXSDRBS8800C200CDMAIndoorBasestation-8800Hard-

wareManual

ConfidentialandProprietaryInformationofZTECORPORATION17

Page 26

ZXSDRBS8800C200InstallationManual

�ZXSDRBS8800C200CDMAIndoorBasestation-8800Installa-

tionManual

�ZXSDRBS8800C200CDMAIndoorBasestation-8800Opera-

tionandMaintenanceManual

�ZXSDRBS8800C200CDMAIndoorBasestation-8800Commis-

sioningandCongurationManual

PersonnelRequirements

InstallationpersonnelshouldparticipateinZTE’strainingandexamination,andhandleknowledgeofinstallationanddebugging.

Afterobtainingjobcerticate,installationpersonnelarequalied

forinstallationanddebugging.

ToolsandInstruments

Preparation

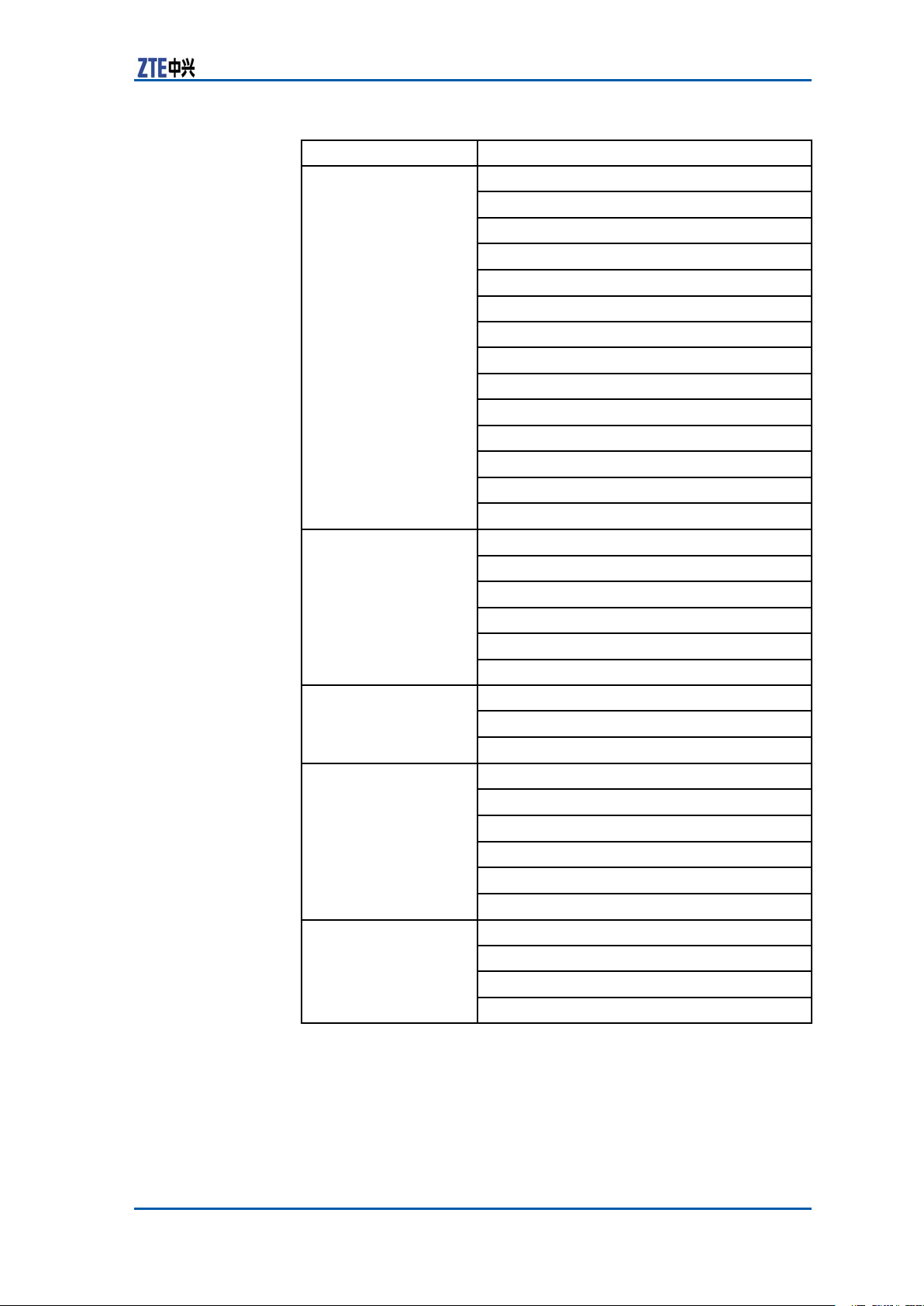

T

a b l e 5 showstoolsandmeterslistrequiredduringinstallation.

TABLE5TOOLANDMETERLIST

Category

Special-purposetools

Concretedrillingtools

Name

Onefeederconnectorknife

Onewirestripper

Onecrimpingpliers

Onemulti-functionalcrimpingpliersEarth

resistancetester

Oneelectricpercussiondrill

Auxiliaryandsamplebits

Onevacuumcleaner

Powersocket(two-phaseandthree-phase

socket,withcurrentcapacitygreaterthan15

A)

18ConfidentialandProprietaryInformationofZTECORPORATION

Page 27

Chapter3InstallationPreparation

Category

General-purposetools

Measurementtools

Protectiontools

Clamptools

Auxiliarytools

Name

Crossscrewdrivers(4”,6”and8”each)

Flatheadscrewdrivers(4,6”and8”each)

Adjustablewrenches(6” ,8” ,10”and12)

Dual-purposespanners(17”and19”each)

Onesetofsocketwrench

5kg(11lb)nailhammer

One300Wiron

One40Wiron

Solderwires

Hotblower

Oilpaintbrush

Pliers

Scissor

Paperknife

One50m(164feet)tapemeasure

One5m(16feet)steeltape

One400mm(16inches)levelbar

Oneanglemeter

Onecompass

Plumb

Antistaticwriststrap

Safetyhelmet

Pairofgloves

Onehacksaw(withseveralsawblades)

Onepairofsharp-nosepliers(8″)

Onepairofdiagonalpliers(8″)

Onepairofslipjointpliers(8″)

Onepairofvices(8″)

Crowbar

Chainwheel

Rope

Ladder

Forklift

ConfidentialandProprietaryInformationofZTECORPORATION19

Page 28

ZXSDRBS8800C200InstallationManual

UnpackingAcceptance

CountingGoods

PrerequisiteThetransportedcargoshouldhavereachedtheinstallationsite.

ContextTherepresentativeofcustomerandtheprojectsupervisormustbe

presentonsiteduringcountingofgoodsreceived.Ifanypartyis

notpresentatthattime,transportermustholdtheresponsibility

foranydifferenceingoods.

Thestepsinvolvedincountinggoodsareasfollows:

Steps1.CheckDeliveryChecklistofZTECorporation.Checktotalnum-

berofgoods,intactnessofpackingboxes,andcheckwhether

arrivalplaceistheactualinstallationplaceagainstpackinglist

numberattachedtopackingboxes.Ifgoodsareintact,start

tounpackandinspectthem.

Note:

Itisrecommendedtounpackthegoodsafterabout30minutes

ofreceivingthecargo,sincethereisapossibilityofmoisture

contentduetotemperaturevariationsifany .

2.Equipmentinspectionlistandunpackingacceptancereportare

presentintherstpackingcarton.Firstly,openrstpacking

cartonandtakeouttheUnpackingAcceptanceReporttocheck

whetherthegoodsreceivedareinaccordancewiththeinspectionlist.

3.Duringthecountingandunpackinginspectionprocess,ifany

materialisfoundshort,orgoodsdamaged,thenll-inUnpack-

ingAcceptanceFeedbackTableandcontactZTEpromptly.

ENDOFSTEPS.

CrateUnpacking

PrerequisitePreparetheappropriatetoolssuchasstraightscrewdriver ,pliers,

andcrowbar .

ContextPerformthefollowingstepstoopenthecrate:

Steps1.Insertastraightscrewdriverintotheslitbetweencrateand

frontcoverboardtomakeitloose;theninsertcrowbartounclenchcoverboard.

2.Pullthecoverboardoutfromthecrate.

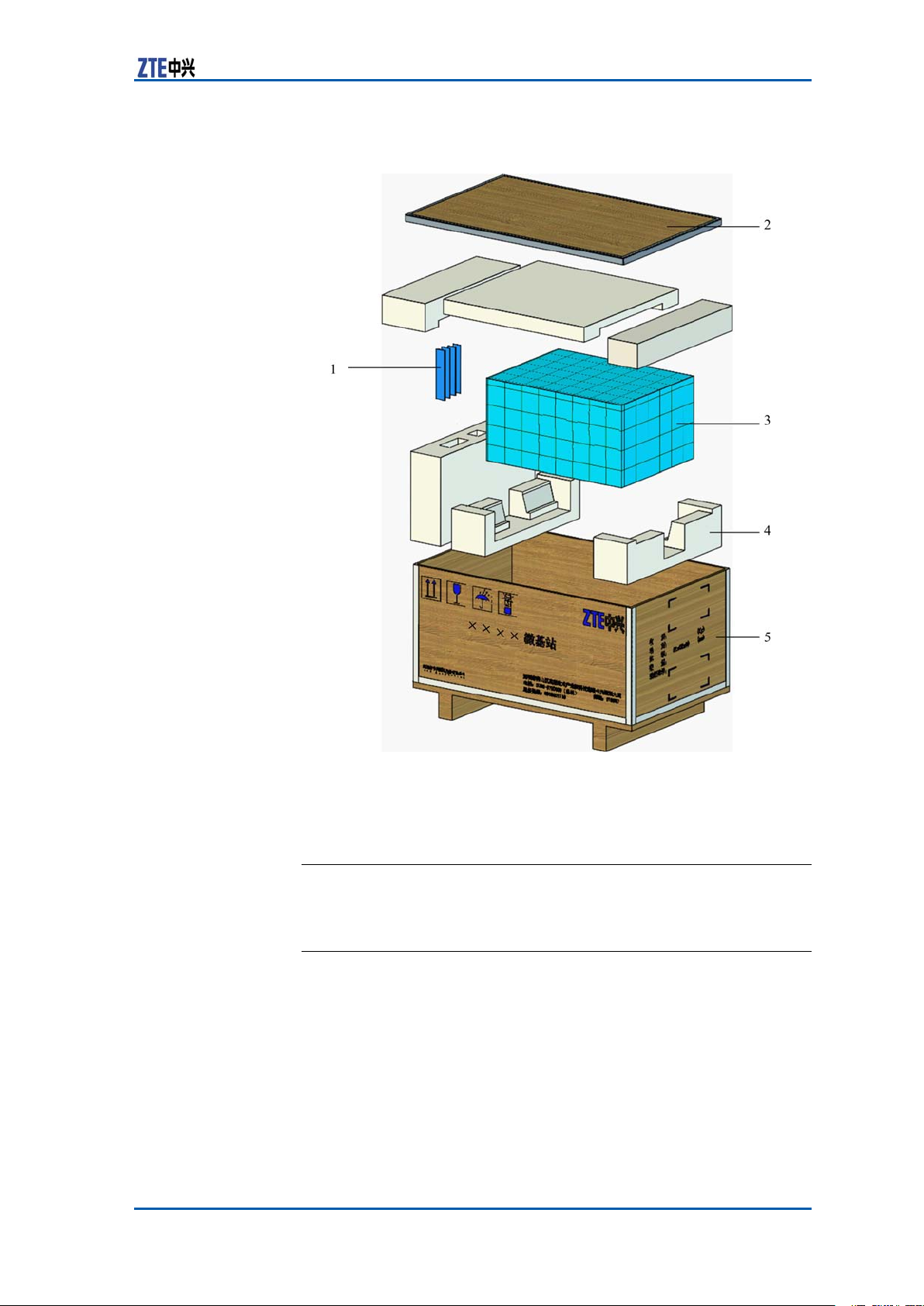

3.Removetheotherboardsofthecrate,asshowninF

i g u r e 4 .

20ConfidentialandProprietaryInformationofZTECORPORATION

Page 29

FIGURE4CRATEUNPACKING

Chapter3InstallationPreparation

1.Accessories

2.Coverplate

3.Equipment

4.Foampiece

5.Crate

ENDOFSTEPS.

CartonUnpacking

PrerequisitePreparetheappropriatetoolssuchasstraightscrewdriver ,diago-

nalpliers,andpaperknife.

ContextPerformthefollowingstepstounpackthecarton:

Steps1.Usediagonalplierstocutpackingstraps.

2.Useapaperknifetocutadhesivetapealongtheslitsoncarton

cover ,avoiddamaginggoodsinside.

3.Openthecarton,andremovethefoamboard.

ConfidentialandProprietaryInformationofZTECORPORATION21

Page 30

ZXSDRBS8800C200InstallationManual

4.Checkthegoodswithinthecarton.

Note:

�Avoiddamagingtheantistaticbag(Itcanbeusedinthe

futureforstorageofspareparts)duringunpacking.

�Whiletheequipmentismovedtoahotteranddamper

place,waitfor30minutesbeforeunpackingtheequipment.

Otherwise,moisturemaycondenseonthesurfaceofthe

equipmentandcausedamage.

�Properlydisposeofrecycledesiccants.

ENDOFSTEPS.

AcceptanceandGoodsHandover

ContextPerformthisprocedureforacceptinggoods,andhandingthem

overtooperators.

Steps1.Acceptance

Baseduponthename,categoryandnumbermentionedonthe

shippinglist,carefullycheckthegoodspiecebypiece.Make

surethatgoodsfullthefollowingconditions:

i.Makesurethattherearenobubbly,peeling,nickandlth

markonthesurfaceofthechassis.

ii.Ensurethatoilpaintonthechassissurfaceisintact.

iii.Ensureclampingscrewsaretightandintact.

iv.Allthecomponentsareproperlyinstalledattheirrespective

positions.

v.Laydowntheinspectedgoodsaccordingtocategories.

2.Handover

Aftercompletingtheunpackingprocedure,representativeof

customerandprojectsupervisorshouldapproveandsignUn-

packingforInspectionReport.Eachpartyshouldhaveacopy

ofUnpackingforInspectionReport.Ifthegoodsarestillunderthesupervisionoftheoperatorevenafteracceptance,then

goodswillnotbehandedovertotheoperatoruntilbothparties

signonthereport.

ENDOFSTEPS.

22ConfidentialandProprietaryInformationofZTECORPORATION

Page 31

C h a p t e r 4

InstallingCabinet

TableofContents:

CabinetInstallationFlow....................................................23

InstallingSingle-cabinet.....................................................24

CabinetInstallationFlow

ZXSDRBS8800C200cabinetinstallationowislistedinF

i g u r e 5 .

ConfidentialandProprietaryInformationofZTECORPORATION23

Page 32

ZXSDRBS8800C200InstallationManual

FIGURE5CABINETINSTALLATIONFLOW

InstallingSingle-cabinet

Steps1.Conrmtheinstallationpositionofcabinetbasedontheref-

erencedimensionandcabinetdimensiongivenbytheengineeringdesigndrawing.Measuresomemarkingpointswitha

measuringtapeanddrawtwostraightlinesparalleledwiththe

referencelinewithaninkingpot.Makesuretheholepositions

forcabinetinstallationonthestraightlinesaccordingtothe

designdrawing.Thepositionofsingle-cabinetisasshownin

i g u r e 6 .

F

24ConfidentialandProprietaryInformationofZTECORPORATION

Page 33

FIGURE6SINGLE-CABINETINSTALLATIONPOSITION

Chapter4InstallingCabinet

2.Drillsomeφ12holeswith60mmdepthbasedontheexpansion

boltmarks,asshowninF

FIGURE7HOLING

i g u r e 7 .

Note:

�Whileusingahammerdrilloranelectrichammer ,make

surethedrillbitverticalwiththehorizontalground,clasp

thedrillstockwithhandsandpressitverticallydownwards.

�Whileholing,useacleanertocleandustandmakesure

cleanoutallgarbageafterconstruction.

�Ifthedrillbitisunabletoxduetotoosmoothoor ,in

ordertohelppositioningdrillbit,rstcutaholeonthe

markedpositionswithapunch.

3.Installexpansionnuts.

i.Beforeinstallation,usethecleanertogetridofalldust

insideandoutsideholes.

ConfidentialandProprietaryInformationofZTECORPORATION25

Page 34

ZXSDRBS8800C200InstallationManual

ii.Installfourinsulationsleevesontheinstallationholesto

makesuretheexpansionnutsinsulatedwiththeground,

asshowninF

FIGURE8INSULATIONSLEEVEINSTALLATION

i g u r e 8 .

iii.Inserttheexpansionnutsverticallyintotheinsulation

sleeves,andknockthenutswitharubberhammerto

makethemcompletelyintotheground,asshowninF

9 .

i g u r e

FIGURE9EXPANSIONNUTINSTALLATION

4.Adjustaninsulationsheetandaligntwoholesontheinsulation

sheetwiththoseontheground,asshowninF

FIGURE10INSULATIONSHEETINSTALLATION

i g u r e 1 0 .

26ConfidentialandProprietaryInformationofZTECORPORATION

Page 35

Chapter4InstallingCabinet

5.Aligninstallationholesonthebaseinstallationassemblywith

holesofexpansionnuts.InserttheM10boltthroughabig

washer ,insulationwasher ,installationholeofbaseinstallation

assemblyandinsulationwasherinturn.Screwdownthebolts

andxtheinstallationassemblyonthecementoor ,asshown

i g u r e 1 1 andF i g u r e 1 2 .

inF

FIGURE11BASEINSTALLATIONASSEMBLY(1)

FIGURE12BASEINSTALLATIONASSEMBLY(2)

6.Implementaninsulationtest.

i.Adjustthemultimetertotheresistancegrade.

ii.Forresistancemeasurement,onemeasuringprobeofthe

multimetercontactswiththemetalpartofbaseassembly

andtheotherwiththeexpansionnuts.Ifthecircuitdis-

ConfidentialandProprietaryInformationofZTECORPORATION27

Page 36

ZXSDRBS8800C200InstallationManual

playsanopenstatus,theinsulationtestcompletes.Ifnot,

continuethenext.

iii.Checkwhethertheinsulationsleevesaredamagedorfor-

gottentoinstall.Suchasthissituation,repeattheabove

ow(installthebaseassembly)andperformaninsulation

testagain.

7.Fixthecabinet.

i.Movethecabinettothefrontofbaseassemblyandthe

backofcabinetfacestothebaseassembly .

Note:

Consideringtheweightofcabinet,thetopofcabinetprovidesliftingeyesandsuggestahoistinginstallationmode.

ii.Alignthelocationholesatthebottomofcabinetwiththe

orientationpinboltsonthebaseassembly ,andmovethe

cabinetslowlyandcarefullytomaketwoanglesupports

insertingtheslotsatthebottomofcabinet,asshownin

i g u r e 1 3 .

F

FIGURE13FIXINGCABINET(1)

1.LocationHole

2.OrientationPinBolt

3.AngleSupport

28ConfidentialandProprietaryInformationofZTECORPORATION

Page 37

Chapter4InstallingCabinet

Caution:

Prohibitdrillingholeonthecabinetbyself.Drillinghole

thatdoesnotmeetrequirementswilldamagethecables

andcableconnectioninsidethecabinet.Themetaldust

causedbydrillingwillresultinshortcircuit.

iii.Measurewhetherthecabinetislevelwithalevelbar .Ifnot,

addalevellingsheetunderthecabinettoadjusttolevel.

iv.Openthefrontdoorofcabinetanddisplaytwocircularholes

atthebottom,asshowninF

i g u r e 1 4 .InserttheM10bolt

throughawasher ,insulationwasherandovalhole,and

screwdownthebolt.

FIGURE14FIXINGCABINET(2)

1.CircularHole

Note:

Theinsulationwasherhasbeenrivetedatthebottomof

cabinet.

8.AccordingtoStep6,performasolutiontestformetalcomponentsatthefrontofcabinet.

9.Closethefrontdoorandxthecabinet,asshowninF

ConfidentialandProprietaryInformationofZTECORPORATION29

i g u r e 1 5 .

Page 38

ZXSDRBS8800C200InstallationManual

FIGURE15CABINETINSTALLATIONCOMPLETION

ENDOFSTEPS.

30ConfidentialandProprietaryInformationofZTECORPORATION

Page 39

C h a p t e r 5

InstallingComponents

TableofContents:

ModulePositionSchematicDiagram.....................................31

InstallingRSUModule........................................................33

InstallingBBU...................................................................35

InstallingBBUHorizontalModule.........................................37

InstallingBBUVerticalModule.............................................38

ModulePositionSchematic

Diagram

ZXSDRBS8800

C200Baseband

ThemainmodulesofZXSDRBS8800C200areinstalledintheRF

layerandbasebandlayer .Theinternalstructureisasshownin

ConfidentialandProprietaryInformationofZTECORPORATION31

Page 40

ZXSDRBS8800C200InstallationManual

andRFCabinet

InternalStructure

F

i g u r e 1 6 .

FIGURE16BASEBAND-RFCABINETINTERNALSTRUCTURE

1.RFSubrack

2.CableTray

3.PowerDistributionSubrack

4.FanSubrack

5.Wind-guidePlace

6.BasebandSubrack

RFModuleLayoutTheRFmodulesareconguredintherstsubrack,asshownin

F

i g u r e 1 7 .

32ConfidentialandProprietaryInformationofZTECORPORATION

Page 41

BasebandMoudle

Chapter5InstallingComponents

FIGURE17RFSUBRACKAPPEARANCE

1.RFUnit

SixRSUmulti-carrierRFunitscanbeconguredinSlot1~Slot6.

Layout

ZXSDRBS8800C200basebandsubrackisasshowninF

FIGURE18BASEBANDSUBRACKAPPEARANCE

i g u r e 1 8 .

1.PM

2.FS

3.CC

4.SA

5.CHV

6.FA

7.CHD

InstallingRSUModule

Prerequisite�InstalltheZXSDRBS8800C200cabinetcompletely .

�WearanantistaticwriststraptoavoiddamagingtheRSU.

Steps1.Conrmslotsofmoduletobeinstalled.

2.Holdpartofametalpanelwiththerighthandandsupportthe

lowerpartofRSUwiththelefthand.Inthisway,keepthe

metalpanelerect.

3.Pushthemodulegentlyintoaslotalongaguideway,keepit

erectandlocateupperandlowerendsintotheslots.

4.Holdthemoduleatmiddleandpushitslowlyonce2/3rdof

boardisinserted.Whenthemoduletouchestoabackplane

socket,pushitlittleforciblyandmakeitintothesocketof

backplane.

ConfidentialandProprietaryInformationofZTECORPORATION33

Page 42

ZXSDRBS8800C200InstallationManual

5.ScrewdownsixM5X20panheadassemblyscrewsontheRF

module.

ThepositionsofsixscrewsareasshowninF

FIGURE19SCREWPOSITIONSONRFMODULE

i g u r e 1 9 .

1.M5X20panheadassembly

screw

6.ScrewdownallscrewsasshowninF

RSUgroundingsheet.

i g u r e 2 0 andconnectthe

34ConfidentialandProprietaryInformationofZTECORPORATION

Page 43

FIGURE20SCREWPOSITION

Chapter5InstallingComponents

1.M5*10panheadscrewwith

crossrecessed

ENDOFSTEPS.

InstallingBBU

Prerequisite�InstalltheZXSDRBS8800C200cabinet.

�WearanantistaticwriststraptoavoiddamagingtheBBU.

Steps1.InsertthemoduleintotheZXSDRBS8800C200cabinetalong

theguidewayandxitwithfourM5×16combinedscrews(two

respectivelyatleftandright),asshowninF

i g u r e 2 1 .

ConfidentialandProprietaryInformationofZTECORPORATION35

Page 44

ZXSDRBS8800C200InstallationManual

FIGURE21BBUINSTALLATION

1.M5×16screw

2.ConnectthegroundinglugofBBUtothecabinetwithaM6×16

screw.ThepositionofM6×16screwisasshowninF

FIGURE22M6×16SCREWPOSITION

i g u r e 2 2 .

1.Groundinglug

2.M6×16screw

36ConfidentialandProprietaryInformationofZTECORPORATION

Page 45

Chapter5InstallingComponents

ENDOFSTEPS.

InstallingBBUHorizontal

Module

PrerequisiteBeforeinstallation,makesurewearinganantistaticwriststrapto

avoiddamagingthePCBboard.

ContextThehorizontalmodulesofZXSDRBS8800C200includeasfollows:

�Controlandclockmodule(CC)

�Channelmodule(CH)

�Fabricswitchmodule(FS)

�Sitealarmmodule(SA)

�Powermodule(PM)

Steps1.InsertthemodulesintotheZXSDRBS8800C200subrackalong

theleftandrightguideways,asshowninF

i g u r e 2 3 .

FIGURE23HORIZONTALMODULEINSTALLATION

1.HorizontalInsertionandExtractionHandle

ConfidentialandProprietaryInformationofZTECORPORATION37

Page 46

ZXSDRBS8800C200InstallationManual

2.Holdhandlesatbothsidesofsubracktopushintothemodule

andmakesurethehandlelockedwiththeZXSDRBS8800C200

subrack.

ENDOFSTEPS.

InstallingBBUVertical

Module

PrerequisiteMakesurewearinganantistaticwristwrapincaseofdamaging

thePCBboard.

ContextTheZXSDRBS8800C200verticalmodulesincludethefanarray

(FA)anddustproofassembly.

Steps1.FastentheFAmodulewiththefourself-clinchingboltslocating

atthebottomplateofthefansubrackwithM3×8combination

screws.

2.InsertthedustproofassemblyalongtherightguidewayofFA

subrackandmakesurethatthespringplateontheFAsubrack

isfastenedwiththedustproofassembly ,asshowninF

2 4 .

i g u r e

FIGURE24DUSTPROOFASSEMBLYINSTALLATION

38ConfidentialandProprietaryInformationofZTECORPORATION

Page 47

Chapter5InstallingComponents

3.PushtheequippedFAsubrackanddustproofassemblyintothe

ZXSDRBS8800C200untilhearinglockingsound,asshownin

i g u r e 2 5 .

F

FIGURE25VERTICALMODULEINSTALLATION

ENDOFSTEPS.

ConfidentialandProprietaryInformationofZTECORPORATION39

Page 48

ZXSDRBS8800C200InstallationManual

Thispageisintentionallyblank.

40ConfidentialandProprietaryInformationofZTECORPORATION

Page 49

C h a p t e r 6

InstallingCable

TableofContents:

On-siteCableInstallationList..............................................41

CableInstallationFlow.......................................................42

InstallingDCPowerCable...................................................43

InstallingGroundingCable..................................................46

InstallingDataCable..........................................................47

Installing75ΩE1Cable......................................................49

Installing120ΩE1Cable....................................................51

Installing100ΩT1Cable....................................................52

InstallingAbisInterfaceEthernetCable................................53

InstallingDryContactInput/outputCable.............................55

InstallingRS232/RS485MonitoringCable.............................58

InstallingFiberbetweenBBUandRSU..................................59

InstallingAISGControlCable..............................................59

InstallingGPSJumper........................................................61

InstallingRFJumper..........................................................63

On-siteCableInstallation

List

Internalcablesinstalledonsitearelistedasfollows:

�Internalopticalber

�Receivingdiversitycable

�CascadingEthernetcable

�SApanelcable

Externalcablesinstalledonsitearelistedasfollows:

�Externalpowercable

�Protectivegroundcable

�E1/T1externalcable

�Abis/Iubinterfaceopticalber

�Abis/IubinterfaceEthernetcable

�Drycontactcable

�RS232/RS485cable

�Antennafeederandjumper

ConfidentialandProprietaryInformationofZTECORPORATION41

Page 50

ZXSDRBS8800C200InstallationManual

�GPSjumper

CableInstallationFlow

ThecableinstallationowislistedinF

FIGURE26CABLEINSTALLATIONFLOW

i g u r e 2 6 .

42ConfidentialandProprietaryInformationofZTECORPORATION

Page 51

Chapter6InstallingCable

Note:

�Thetrunkshouldbeselectedaccordingtotheon-sitesituation.

�Generally,theGPSjumperisinstalledbeforedelivery.

InstallingDCPowerCable

Prerequisite1.Layouttherouteandlengthofcablesalongacabletraybe-

tweenthepowercabinetandtheZXSDRBS8800C200.The

powercableandtheprotectivegroundcableshouldbeseparatelyarrangedandbandedfromothercables.Thebanding

distancepersegmentis200mm.The0.2m~0.5lengthat

bothendsisreserved.

Note:

Thepowercableandtheprotectivegroundcableshouldbe

intactandavoidjointsappearinginthemiddleofcables.

2.Makesurethepowersupplyoutputcutoff.

Danger:

Makesurecheckingthestatusofcircuitbreakerinsidethe

powercabinet.Prohibitinstallingpowercablesinalivestatus.

ContextTherearetwoDCpowercables,madeupofstrandsofame-

retardantwire.ThecrosssectionalareaofDCpowercableis16

2

mm

.Oneisa-48Vbluepowerinputcableandtheotherisa

blackgroundcable.

TheappearanceofDCpowercableisasshowninF

FIGURE27DCPOWERCABLEAPPEARANCE

i g u r e 2 7 .

Steps1.Makeblueandblackcableswith16mm

andconnecttheironeendstothepowercabinet.Theother

endsofblueandblackcablesarereservedforstandby.

ConfidentialandProprietaryInformationofZTECORPORATION43

2

crosssectionalarea

Page 52

ZXSDRBS8800C200InstallationManual

2.Leadthe-48VDC(blue)and-48VRTN(black)cablesthrough

thecableinletontheequipmenttop,asshowninF

FIGURE28DCPOWERCABLEINLET

i g u r e 2 8 .

3.Layoutthepowercabletothepowerdistributionsubrackalong

theverticalcabletrayontheleftsideofcabinet.

4.Screwoffthescrewsontheprotectivecoverattheleftsideof

powerdistributionsubrackwithascrewdriver ,andtakeoffthe

protectivecover .

5.Installrespectivelythe–48VDC(blue)and–48VRTN(black)

cablestotheconnectionterminalsofthepowerdistribution

subrack,theconnectionrelationshipasshowninF

i g u r e 2 9 .

44ConfidentialandProprietaryInformationofZTECORPORATION

Page 53

Chapter6InstallingCable

FIGURE29POWERDISTRIBUTIONSUBRACKCONNECTION

1.—48VRTN2.—48VDC

Caution:

RefertoF

i g u r e 2 9 toconnectthepositiveandnegativeelec-

trodesofpowercableandmakesurenotconnectioninreverse.

6.Rextheprotectivecovertothepowerdistributionsubrack.

ENDOFSTEPS.

ResultTheinstallationofpowercableiscompleted,asshowninF i g u r e

3 0 .

ConfidentialandProprietaryInformationofZTECORPORATION45

Page 54

ZXSDRBS8800C200InstallationManual

FIGURE30POWERCABLEINSTALLATIONCOMPLETION

InstallingGroundingCable

Steps1.Basedonthedistancefromthecabinettotheprotective

ground,cutaproperlengthofprotectivegroundcable.

46ConfidentialandProprietaryInformationofZTECORPORATION

Page 55

Chapter6InstallingCable

Note:

Makesuresomecablesleftwhilecutting.

2.InstalltheprotectivegroundcabletothePEbindingposton

theequipmenttop,asshowninF

FIGURE31GROUNDCABLEINSTALLATION

i g u r e 3 1 .

ENDOFSTEPS.

InstallingDataCable

PrerequisiteInstalltheBBUandtheFSboardcompletely.

ContextDuetoahigh—integrationdesignfortheBBU,interfacesonthe

panelarelimited.Adoptadatacablefortransfer ,foritisconvenientforaccessoftheinternal/externalenvironmentmonitoring,

drycontactmonitoringandE1/T1(Abisinterface).Thereisone

interfacetoconnecttheSAmoduleatEndAofdatacable.There

aremultipletri-interfaceatEndB,connectingtheinternal/externalenvironmentmonitoring,drycontactmonitoringandE1/T1.

TheexplodedviewofdatacableisasshowninF

i g u r e 3 2 .

ConfidentialandProprietaryInformationofZTECORPORATION47

Page 56

ZXSDRBS8800C200InstallationManual

FIGURE32DATACABLEAPPEARANCE

1.Groundterminal

2.E1/T1cable

Steps1.Connectthedatacabletothe“Monitoring/Abis”interfaceofFS

3.RS232/RS485

4.Drycontactinput/output

moduleandscrewdowntwoboltsatthejunction.

2.ConnectEndB1tothegroundterminalofcabinet.

3.ConnectEndB2totheDB44connectorofE1/T1cableand

screwdowntwoboltsatthejunction.

4.ConnectEndB3totheDB9connectorofRS485/RS232environmentmonitoringcableandscrewdowntwoboltsatthe

junction.

5.ConnectEndB4totheDB25connectoroftheexternaldrycontactcableandscrewdowntwoboltsatthejunction.

ENDOFSTEPS.

ResultThedatacableisinstalledcompletely ,asshowninF i g u r e 3 3 .

48ConfidentialandProprietaryInformationofZTECORPORATION

Page 57

FIGURE33DATACABLEINSTALLATIONCOMPLETION

Chapter6InstallingCable

1.Groundterminal

2.E1/T1cable

PostrequisiteContinuetoinstalltheE1/T1,RS232/RS485,drycontactin-

3.RS232/RS485

4.Drycontactinput/output

put/outputcables.

Installing75ΩE1Cable

PrerequisiteInstalltheSAmoduleanditspanelconnectioncable.

ContextAbis-interface75ΩE1cableisthetransmissioncablebetween

ZXSDRBS8800C200andBSC,transmittingtheinterfacemessage

betweenZXSDRBS8800C200andBSC.

Theappearanceof75ΩE1cableisasshowninF

ofthecableisaDB44straightconnector .Therearetwotypesof

cable:inF

i g u r e 3 4 ,theabovecablesupportseightE1cablesand

thefollowingsupportsfourE1cables.

i g u r e 3 4 .Enda

ConfidentialandProprietaryInformationofZTECORPORATION49

Page 58

ZXSDRBS8800C200InstallationManual

Note:

IneightE1cable,1–4E1cablesareafxedwithlabelsandothers

arenot.

FIGURE34ABIS/IUBINTERFACE75ΩE1CABLEAPPEARANCE

Steps1.Leadthe75ΩE1cablethroughacableslotonthetopintothe

cabinet.

2.Layoutthe75ΩE1cablealongtheverticalcabletrayatthe

rightsideofcabinettotheB2connector(E1cableconnector)

ofdatacablebelongingtothebaseband.

RefertoI

n s t a l l i n g D a t a C a b l e fortheinstructionofdatacable.

3.ConnecttheDB44connectorof75ΩE1cabletotheB2interface(E1cableinterface)ofdatacablethroughtheSAmodule.

ENDOFSTEPS.

ResultAfterinstallationcompleted,theappearanceof75ΩE1cableis

asshowninF

i g u r e 3 5 .

50ConfidentialandProprietaryInformationofZTECORPORATION

Page 59

FIGURE3575ΩE1CABLEINSTALLATIONCOMPLETION

Chapter6InstallingCable

Installing120ΩE1Cable

PrerequisiteInstalltheSAmoduleanddatacable.

ConfidentialandProprietaryInformationofZTECORPORATION51

Page 60

ZXSDRBS8800C200InstallationManual

ContextThe120ΩE1cableisthetransmissioncablebetweenZXSDR

Steps1.Leadthe120ΩE1cablethroughaslotonthetopintothe

BS8800C200andBSC,transmittingtheinterfacemessagebetweenZXSDRBS8800C200andBSC.

Theappearanceof120ΩE1cableisasshowninF

AofcableisaDB44straightplug.

FIGURE36120ΩE1CABLEAPPEARANCE

Therearetwotypesof120ΩE1:onesupports8E1cablesand

theothersupports4E1cables.Theappearancesoftwocablesare

similar ,butthenumberofcorewireisdifferent.

cabinet.

2.Layoutthe120ΩE1cablealongtheverticalcabletrayatthe

rightsideofcabinettotheB2connector(E1/T1cableconnector)ofdatacable.

RefertoI

3.ConnecttheDB44connectorof120ΩE1cabletotheB2interface(E1/T1cableinterface)ofdatacablethroughtheSA

panel.

ENDOFSTEPS.

n s t a l l i n g D a t a C a b l e fortheinstructionofdatacable.

i g u r e 3 6 .End

ResultAfterinstallationcompleted,theappearanceof120ΩE1cableis

asshowninF

Installing100ΩT1Cable

PrerequisiteInstalltheSAmoduleanddatacable.

ContextThe100ΩT1cableisthetransmissioncablebetweenZXSDR

BS8800C200andBSC,transmittingtheinterfacemessagebetweenZXSDRBS8800C200andBSC.

Theappearanceof100ΩT1cableisasshowninF

AofcableisaDB44straightplug.

52ConfidentialandProprietaryInformationofZTECORPORATION

i g u r e 3 5 .

i g u r e 3 7 .End

Page 61

Chapter6InstallingCable

FIGURE37100ΩT1CABLEAPPEARANCE

Steps1.Leadthe100ΩT1cablethroughaslotonthetopintothe

cabinet.

2.Layoutthe100ΩT1cablealongtheverticalcabletrayatthe

rightsideofcabinettotheB2connector(E1/T1cableconnector)ofdatacable.

RefertoI

3.ConnecttheDB44connectorof100ΩT1cabletotheB2interface(E1/T1cableinterface)ofdatacablethroughtheSA

module.

ENDOFSTEPS.

n s t a l l i n g D a t a C a b l e fortheinstructionofdatacable.

ResultAfterinstallationcompleted,theappearanceof120ΩE1cableis

asshowninF

i g u r e 3 5 .

InstallingAbisInterface

EthernetCable

Prerequisite�ThetransmissionbetweenBTSandBSCisbasedontheIP

bearernetwork.

�InstalltheCCmodule.

ContextBothendsofEthernetcablearecrimpedwiththeRJ45connector ,

asshowninF

i g u r e 3 8 .

ConfidentialandProprietaryInformationofZTECORPORATION53

Page 62

ZXSDRBS8800C200InstallationManual

Steps1.LeadtheAbisinterfacethroughawireinletattherightsideof

FIGURE38ETHERNETCABLEAPPEARANCE

cabinet.

2.LayouttheAbisinterfaceEthernetcablealongtheverticalcabletrayattherightsideofcabinettoCCmoduleofthebase-

band,asshowninF

i g u r e 3 9 .

54ConfidentialandProprietaryInformationofZTECORPORATION

Page 63

FIGURE39ABISINTERFACEETHERNETCABLELAYOUT

Chapter6InstallingCable

3.ConnecttheRJ45connectorofEthernetcabletotheETH0interfaceontheCCmodule.

ENDOFSTEPS.

InstallingDryContact

Input/outputCable

PrerequisiteInstalltheSAmoduleanddatacable.

ConfidentialandProprietaryInformationofZTECORPORATION55

Page 64

ZXSDRBS8800C200InstallationManual

ContextThedrycontactinput/outputcableisusedtoimport/exportdry

Steps1.Leadthedrycontactcablethroughaslotonthetopintothe

contactsignalsfromexternalequipment.

Theappearanceofdrycontactinput/outputcableisasshownin

F

i g u r e 4 0 .EndAofthecableisaDB25straightplugandEndBis

nakedwire.

FIGURE40DRYCONTACTINPUT/OUTPUTCABLEAPPEARANCE

cabinet.

2.Layoutthedrycontactcablealongtheverticalcabletrayat

therightsideofcabinettoSAmoduleofthebaseband.

3.ConnecttheDB25connectorofdrycontactcabletotheB4

interface(DB25)ofdatacablefromtheSAmodule.

ENDOFSTEPS.

ResultAfterinstallationcompleted,theappearanceofdrycableisas

showninF

i g u r e 4 1 .

56ConfidentialandProprietaryInformationofZTECORPORATION

Page 65

FIGURE41DRYCONTACTINSTALLATIONCOMPLETION

Chapter6InstallingCable

ConfidentialandProprietaryInformationofZTECORPORATION57

Page 66

ZXSDRBS8800C200InstallationManual

Prerequisite�InstalltheSAmodule.

ContextTheRS232/RS485monitoringcableprovidesfunctionsofinter-

InstallingRS232/RS485

MonitoringCable

�ConnecttheSApanelconnectioncable(datacable)totheSA

module.

nalandexternalenvironmentmonitoringfortheZXSDRBS8800

C200.Theenvironmentmonitoringinvolvesthesmogmonitoring,

accesscontrolmonitoring,temperatureandhumiditymonitoring,

andoodingmonitoring.TheappearanceofRS232/RS485monitoringcableisasshowninF

signalsisdescribedinT

FIGURE42RS232/RS485MONITORINGCABLE

i g u r e 4 2 .Thedenitionofcore-cable

a b l e 6 .

TABLE6RS232/RS485MONITORINGCABLEDESCRIPTION

Signal

Definit

ion

EndA

PinNo.

Cable

Color

EndB

Name

GNDD0_RS

1

WhiteWhite&Blue

B1

485

–RX_EM

6

Steps1.ConnectEndA(DB9connector)ofRS232/RS485monitoring

0_RS4

85–RX

+_EM

74

cabletotheB3connector(DB9)ofSApanelconnectioncabledatacable.

2.Fastenjunctionsoftheconnectorswithtapes.

ENDOFSTEPS.

GNDD1_RS

Green

485

–RX_EM

8923

White&

Orange

1_RS4

85–RX

+_EM

0_UA

RT-RX

_EM

Blue

B2

1_UA

RT-TX

_EM

O

range

G

NDD

5

W

hite

GND

DB9

metal

sheath

Shie

lding

Layer

Shie

lding

Layer

58ConfidentialandProprietaryInformationofZTECORPORATION

Page 67

InstallingFiberbetween

BBUandRSU

Prerequisite�Installthecabinetcompletely .

�InstalltheZXSDRBS8800C200andallmodules.

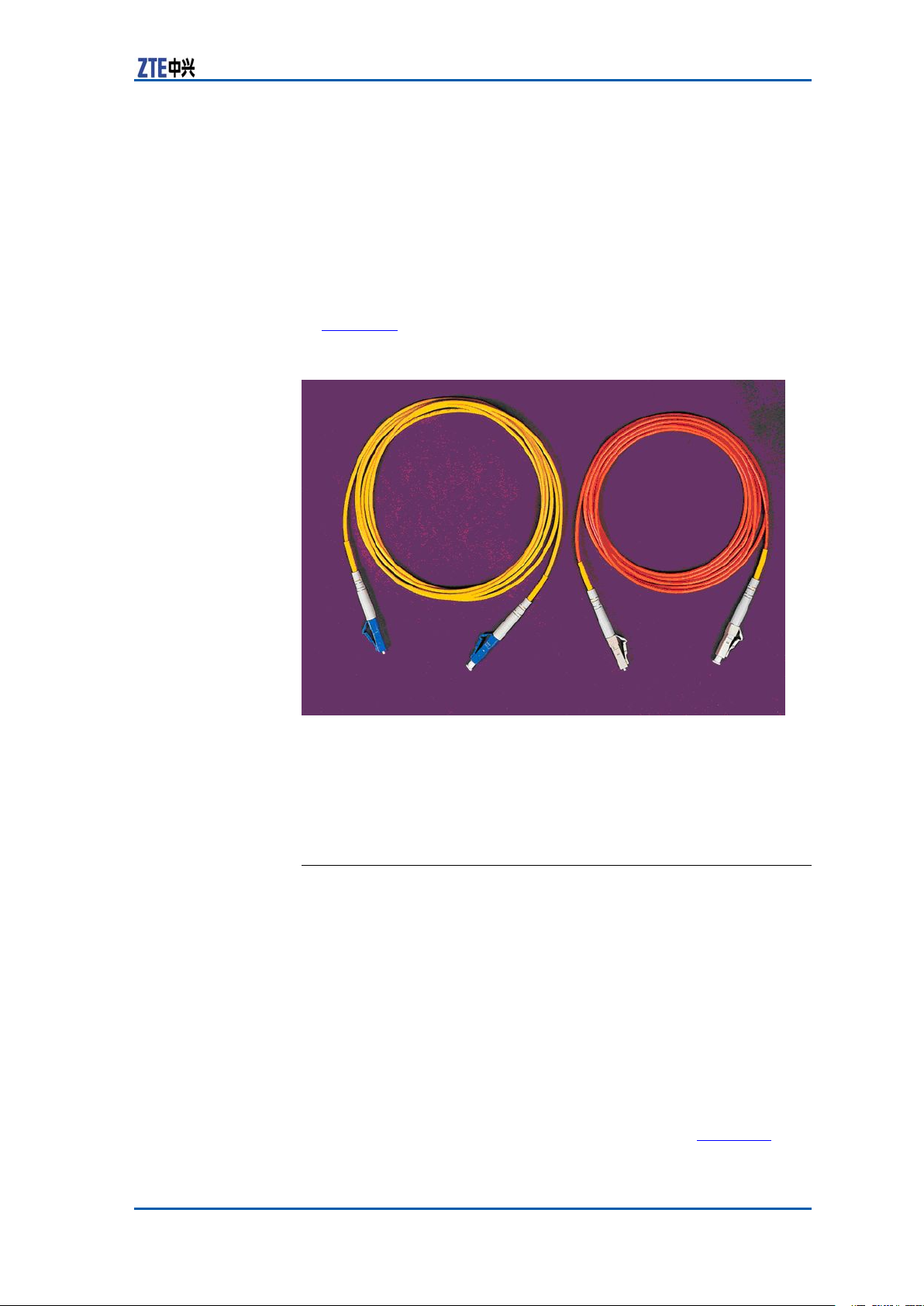

ContextTheappearanceofZXSDRBS8800C200opticalberisasshown

inF

i g u r e 4 3 .

FIGURE43OPTICALFIBERAPPEARANCE

Chapter6InstallingCable

Steps1.Connectoneendofopticalbertotheopticalinterfaceofthe

FSmoduleintheZXSDRBS8800C200.

2.ConnecttheotherendofopticalbertotheTX1/RX1optical

interfaceofRSU.

ENDOFSTEPS.

InstallingAISGControl

Cable

ContextTheAISGcontrolcableisusedforcontroloftheelectric-adjust-

mentantenna.Thecablecanfulllalong-distancecontrolofdip

anglesorphasesofantennatoadjustthecoveragerangeofwirelesssignal.

ThestructureofAISGcontrolcableisasshowninF

ConfidentialandProprietaryInformationofZTECORPORATION59

i g u r e 4 4 .

Page 68

ZXSDRBS8800C200InstallationManual

Steps1.ConnectEndAofAISGcontrolcabletothedebugginginter-

ResultTheAISGcontrolcableisinstalledcompletely,asshowninF i g u r e

FIGURE44AISGCONTROLCABLESTRUCTURE

face(AISG)ofZXSDRBS8800C200andfastenscrewsofthe

interface.

2.ConnectEndBofAISGcontrolcabletothecontrolinterfaceof

electric-adjustmentantennaandfastenscrewsoftheinterface.

ENDOFSTEPS.

4 5 .

FIGURE45AISGCONTROLINSTALLATIONCOMPLETION

60ConfidentialandProprietaryInformationofZTECORPORATION

Page 69

InstallingGPSJumper

Prerequisite�Installthecabinetcompletely .

�InstalltheZXSDRBS8800C200andmodules.

�InstalltheGPSarrester .

ContextTheGPSjumperisasectorofcabletoconnecttheGPSinterface

ofCCmodulewiththeGPSarrester ,theappearanceasshownin

F

i g u r e 4 6 .

FIGURE46GPSJUMPERAPPEARANCE

Chapter6InstallingCable

Steps1.ConnectEndAofjumpertothe“REF”antennainterfaceofCC

module.

2.ConnectEndBtotheGPSarrester .

ENDOFSTEPS.

ResultTheGPSjumperisinstalledcompletely ,asshowninF i g u r e 4 7 .

ConfidentialandProprietaryInformationofZTECORPORATION61

Page 70

ZXSDRBS8800C200InstallationManual

FIGURE47GPSJUMPERINSTALLATIONCOMPLETION

62ConfidentialandProprietaryInformationofZTECORPORATION

Page 71

Chapter6InstallingCable

InstallingRFJumper

ContextTheRFjumperisasectionofcabletoconnectthemainfeederwith

theantennafeederinterfaceofZXSDRBS8800C200.Usually,

installtheRFjumperafterthemainfeederinstalledcompletely.

TheRFjumperadoptsanished1/2″typewith5m.

TheinstallationpositionofRFjumperisasshowninF

FIGURE48RFJUMPERINSTALLATIONPOSITION

i g u r e 4 8 .

Steps1.ConnectthemaleDINconnectorofRFjumperwiththefemale

DINconnectorofmainfeeder .

2.ConnectthemaleDINconnectorofRFjumpertotheRFantennainterfaceofRSU.

3.Carryoutwaterproofhandlingforconnectors.

ENDOFSTEPS.

ConfidentialandProprietaryInformationofZTECORPORATION63

Page 72

ZXSDRBS8800C200InstallationManual

Thispageisintentionallyblank.

64ConfidentialandProprietaryInformationofZTECORPORATION

Page 73

C h a p t e r 7

InstallingGPSAntenna

FeederSystem

TableofContents:

GPSAntennaFeederSystemInstallationFlow.......................65

GPSAntennaFeederSystemInstallationPreparation..............66

InstallingGPSAntenna.......................................................66

InstallingGPSFeeder.........................................................73

GPSAntennaFeeder

SystemInstallationFlow

TheinstallationowofGPSantennafeedersystemislistedinF

u r e 4 9 .

FIGURE49GPSANTENNAFEEDERSYSTEMINSTALLATIONFLOW

i g -

ConfidentialandProprietaryInformationofZTECORPORATION65

Page 74

ZXSDRBS8800C200InstallationManual

GPSAntennaFeeder

SystemInstallation

Preparation

TheinstallationpreparationoftheGPSantennafeedersystemis

asfollows:

�PreparetheGPSantenna.

�Assigninstallationpersonnel.

�Preparetechnicaldocuments,toolsandmeasureinstrument.

�MakeconnectorsofGPSfeederandjumper .

InstallingGPSAntenna

GPSAntennaInstallationPosition

GPSAntenna

Installation

Positioning

TheGPSantennainstallationpositionshouldmeetthefollowing

requirements:

�Theinstallationpositionshouldbefarawayfromhighandlarge

buildingsaswellassomebuildingsonthetopofwhichsmall

afliatedconstructionslocate.Theupward—verticallyvisual

angleofantennaismorethan90°.Theinstallationpositionof

antennaisasshowninF i g u r e 5 0 .

FIGURE50GPSANTENNAINSTALLATIONPOSITION

1.Ambientconstructionorother

obstructions

2.GPSantenna

�Theinstallationpositioncannotberadiatedinaneardistance

byafaceofmainlobeofmobilecommunicationantenna.Do

notlocatetheantennaundermicrowavesignalfrommicrowave

antenna,high-voltagecablesandstrongradiationfromaTV

emissiontower .

66ConfidentialandProprietaryInformationofZTECORPORATION

Page 75

Chapter7InstallingGPSAntennaFeederSystem

�Consideringfromlightning,selectthecenterofroofforanin-

stallationposition.Donotinstalltheantennaonthesunkfence

aroundtheroofaswellasatacorneroftheroof,inorderto

preventfromlightning.

�Thereshouldbeotherspecialandsimilarequipmentnearto

theinstallationposition,suchasotheroperation’stower .Make

suretheantennawithinaprotectiveareaofarrester .Ifthereis

noirontowerorarrester ,installaspecialarrestertomeetthe

requirementoflightningdesign.Theleveldistancebetween

arresterandGPSantennashouldkeep2~3mandbe0.5m

higherthanthereceivingconnectorofGPSantennaatleast.

InstallingGPSAntennainVertical

Placement

PrerequisiteFollowingtoolsmustbeready.

�Adjustablespanner

�NormalSpanner

Itisrecommendedtohaveapolewithadiameterbetween30mm

~60mm(48mmisrecommended).Theantennashouldnotbe

installedduringrainandheavywind.

Steps1.OpenthepackageandtakeoutGPSantennaandtheGPSrack.

2.UsetheU-shapeclamptoinstalltheGPSracktothemounting

pole.InsertspringwasherandwasherbetweentheU-shaped

clampandmountingpole.

3.UseM6nuttoxtheU-shapeclampandthepoletogether

rmly.

F

i g u r e 5 1 showsthexingprocess.

ConfidentialandProprietaryInformationofZTECORPORATION67

Page 76

ZXSDRBS8800C200InstallationManual

FIGURE51U-SHAPEDCLAMPINSTALLATION

1.GPSsettledclamp

2.Cablestrip

3.Mountingpole

4.U-shapeclamp

4.FixtheGPSantennatotheGPSsettledclamp.Screwthebolt

(M4x14)tormlyxtheantenna.

ENDOFSTEPS.

ResultF i g u r e 5 2 showstheantennaxedintheverticalposition.

68ConfidentialandProprietaryInformationofZTECORPORATION

Page 77

FIGURE52GPSANTENNAVERTICALINSTALLATION

Chapter7InstallingGPSAntennaFeederSystem

1.GPSsettledclamp

2.Feeder

3.Feederstrip

4.GPSantenna

5.Mountingpole

6.U-shapeclamp

InstallingGPSAntennainHorizontal

Placement

PrerequisiteConrmtheinstallationmodeandinstallationpositionofGPSan-

tenna.

Followingtoolsmustbeready:

�Adjustablespanner

�NormalSpanner

Context�Itisrecommendedtohaveapolewithadiameterbetween30

mm~60mm(48mmisoptimal).

�ThepoleusedtoxGPSantennamustbegroundedwell.

�Theantennacannotbeinstalledduringrainandheavywind.

Steps1.OpenthepackageandtakeoutGPSantennaandtheGPSrack.

2.UsetheU-shapeclamptoinstalltheGPSracktothemounting

pole.

3.TheinstallationsupportofGPSantennaisasshowninF

5 3 .AlignholesontheU-shapeclampwithHole1andHole3,

orHole4andHole6ontheinstallationsupport.Thencover

i g u r e

ConfidentialandProprietaryInformationofZTECORPORATION69

Page 78

ZXSDRBS8800C200InstallationManual

aspringwashandatwasherrespectivelyontheseholesand

fastenthemwithM6screws,asshowninF

FIGURE53GPSANTENNARACKINSTALLATIONSUPPORT

i g u r e 5 4 .

–1~6holeposition

FIGURE54GPSRACKINSTALLATION(HORIZONTALPLACEMENT)

4.FixtheGPSantennatotheGPSsettledclamp.Screwdown

thebolt(M4x14)tormlyxtheantenna.

ENDOFSTEPS.

ResultF i g u r e 5 5 showstheGPSantennaxedhorizontally .

70ConfidentialandProprietaryInformationofZTECORPORATION

Page 79

FIGURE55GPSANTENNAFIXEDHORIZONTALLY

Chapter7InstallingGPSAntennaFeederSystem

1.GPSsettledclamp

2.Feeder

3.Feederstrip

4.GPSantenna

5.Mountingpole

6.U-shapeclamp

InstallingGPSAntennainWall-mount

Mode

PrerequisiteFollowingtoolsmustbeready.

�Adjustablespanner

�NormalSpanner

�Hammer

�ExpansionAnchorBolts(M5x30orM5x40)

ContextForinstallingtheGPSAntennaonthewall,theU-shapeclampis

notnecessary.

Steps1.OpenthepackageandtakeoutGPSantennaandtheGPSrack.

2.UsetheDesigntemplateformarkingholesonthewall.Then

drillholesonthewallaccordingthesizeoftheexpansionanchorboltsthattobeused.

F

i g u r e 5 6 showsthedesigntemplate.

ConfidentialandProprietaryInformationofZTECORPORATION71

Page 80

ZXSDRBS8800C200InstallationManual

FIGURE56DESIGNTEMPLATEFORMARKINGHOLES

3.Inserttheexpansionbolts,andhammerthemtoxproperly.

4.InstallGPSantennaracktothecorrespondingboltposition.

5.Insertaspringwasherandatwasherontoexpansionbolts

andusetheM6nuttoxtherackonthewallrmly.

Note:

Thetorqueusedtoxtheclampis45Nm.

6.FixtheGPSantennatotheGPSsettledclampandscrewthe

M4x14bolttightly.

ENDOFSTEPS.

ResultF i g u r e 5 7 showstheGPSantennaxedonthewall.

72ConfidentialandProprietaryInformationofZTECORPORATION

Page 81

Chapter7InstallingGPSAntennaFeederSystem

FIGURE57GPSANTENNAFIXEDONWALL

InstallingGPSFeeder

GPSFeederSelectionPrinciple

GPSfeederselectioncomplieswiththefollowingprinciples:

�WhenthelengthofGPSfeederislessthan100m,select1/4"

feeder .

�WhenthelengthofGPSfeederismorethan100m,please

contactwithZTElocalofce.

WiringGPSFeeder

PrerequisiteBeforefeederlayout,checklayoutenvironmentsuchastheiron

towerandroof;accordingtotherequirementsofengineeringdesigndrawing,makesuretheplanningandproceduresoflayout.

ContextTakenoticeofthefollowingitemswhileperforminglayoutofthe

GPSfeeder:

�Thefeederpassagefromtheinstallationpositiontotheequip-

mentroomshouldbeunhinderedandaccordswiththewiring

requirements;takesomemeasurementsforrainprotection

andanticorrosion.

�Makeawateravoidancecrookwhilethefeederisimported

fromoutdoorstoindoors;thelowestpointofwateravoidance

crookkeepsaverticaldistanceof200mmatleastfromthe

inletforwaterproof.

�Unusedfeederconnectorsshouldbeprotectedwithsolidma-

terial,suchaspackingbags,fromdamagingthereconnectors

duringcablelayout.

ConfidentialandProprietaryInformationofZTECORPORATION73

Page 82

ZXSDRBS8800C200InstallationManual

Steps1.Attachamarkrespectivelyatthebothendsoffeeder .

�Unfoldthefeederandlayoutit;avoidtwistingaspossibleas

youcan;ifitisnecessaryforbending,makesuretheradiusof

bendingnotlessthantheminimumradiusofbendingpermitted

bycables.

�IftheGPSantennaisinstalledontheroof,xthefeederalong

thewallfootontheroofwithplasticclipswhichsteelnails

areattachedto;keepandistanceof1mbetweenplasticclips;

thedirectionsofplasticclipheadarestaggeredmutuallyand

regularly;twofeedersafterjunctionshouldbeboundtogether

incaseoftwistingmutuallyandbending.

2.Protectthefeederconnectorwithlinen(alsoadoptaantistatic

pagingbagwithprotectivefoam)andfastenthebagwitha

bandingtape.

3.MovetheGPSfeederneartotheGPSantenna.

4.MakeanGPSfeederconnectoratoneendthroughthebiding

tape,connectwiththeGPSantennaandscrewdowntheconnectorclockwise,asshowninF

i g u r e 5 8 .

FIGURE58CONNECTIONBETWEENFEEDERTOGPSANTENNA

1.GPSAntenna

2.Pole

3.HoopIron

4.GPSMountingPanel

5.GPSFeeder

6.FeederBindingT ape

Note:

Whilexingthefeeder ,itisrequiredtoscrewdownthefeeder

clockwise.Soconsideringthesituation,aftercompletingthe

abovestep,layoutthefeeder ,orelseitisinconvenientfor

installation.

5.Accomplishtheperformancemeasureofantennaandfeeder ,

makesurethatthesystemoperationisnormal,andthenmake

74ConfidentialandProprietaryInformationofZTECORPORATION

Page 83

Chapter7InstallingGPSAntennaFeederSystem

awaterproofprotectionatthebackofGPSmountingpanelas

wellasatthejunctionofGPSfeederandGPSantenna.

6.FixtheGPSfeederwiththebindingtapeandcutaredundant

partatlyafterbinding.

ENDOFSTEPS.

InstallingGPS1/4”FeederGrounding