Page 1

OPERATOR'S MANUAL FOR

RT60 ROUGH TERRAIN CRANE

Address:Quantang Indust=rial Park, 2nd Yuanda Road,

Changsha Economic and Technological Development

Zone, Hunan Province, China

Postcode: 410131

Website: www.zoomlion.com

Page 2

RT60 ROUGH TERRAIN CRANE

OPERATOR’S

MANUAL

Edition 1

Dec. 2013

Page 3

Page 4

Zoomlion Cranes appreciates your selection of the ZOOMLION Rough Terrain Crane

for your application.

No one should operate the crane unless they read and understand the information in

this manual.

When you follow the instructions in this manual, your crane can operate at MAXIMUM

EFFICIENCY.

The operator must keep this manual in the cab of the crane.

If there is anything in the manual that you do not understand, speak with us. We

(Zoomlion Cranes) are NOT responsible for damages from an operator who does not

obey the instructions in the OPERATOR’S MANUAL.

The OPERATOR’S MANUAL is an important part of the crane. If the crane becomes the

property of a different person, make sure that the manual stays in the cab of the crane.

THANK YOU!

Mobile Crane Branch Company of ZOOMLION Heavy Industry Science and Technology

Co., Ltd.

Copyright

Under the copyright laws, this manual may not be copied, photocopied, reproduced,

translated, or reduced to any electronic medium or machine readable form, in whole or

part, without the prior written consent of Zoomlion Heavy Industry Science and

Technology Co., Ltd.

Copyright © 20XX, Zoomlion Heavy Industry Science and Technology Co., Ltd.

All rights reserved.

RT60 Rough Terrain Crane I

Page 5

Hazard Indicators

Attention

Note

Caution

Warning

Danger

Important

DANGER, WARNING, CAUTION, ATTENTION, NOTE, and IMPORTANT labels are on

signs and decals, and as you read this manual to show important instructions. In this

manual, DANGER, WARNING, and CAUTION labels are before the paragraph or item to

which they apply. ATTENTION, NOTE, and IMPORTANT follow the paragraph or item

they apply to. The markers are as follows:

Refers to a dangerous situation which, if you do not prevent, will cause death or

injury.

Refers to a possible dangerous situation which, if you do not prevent, could cause

death or injury.

Refers to a possible dangerous situation which, if you do not prevent, may cause

light or moderate injury.

Refers to a situation which, if you do not prevent, may cause property or equipment

damage.

Refers to a tip or hint in the operation instructions.

Emphasizes the importance of the data in this manual.

This symbol shows a step or procedure that is not approved and can cause a dangerous

situation.

II RT 60 Rough Terrain Crane

Page 6

To owners, users and operators ............................................................................................... I

Safety ......................................................................................................................................... II

1 Foreword ......................................................................................................................... 01-1

2 Nomenclature . ................................................................................................................ 02-1

3 Introduction .................................................................................................................... 03-1

4 Safety .............................................................................................................................. 04-1

5 Operating conditions and points for attention ........................................................... 05-1

5.1 Operating conditions ..................................................................................................... 05-1

5.2 Pre-departure checks (to job-site) ................................................................................ 05-3

6 Controls and instruments . ............................................................................................ 06-1

6.1 Upper controls and instruments . .................................................................................. 06-1

6.1.1 Air conditioner control panel . ............................................................................ 06-6

6.1.2 Media player ...................................................................................................... 06-9

6.2 Controls and instruments . .......................................................................................... 06-10

6.3 Monitor ........................................................................................................................ 06-15

6.4 Boom mode selection .................................................................................................. 06-36

7 Operating instructions ................................................................................................... 07-1

7.1 Safety equipment .......................................................................................................... 07-1

7.2 Starting the engine ........................................................................................................ 07-2

7.3 Operating the engine ..................................................................................................... 07-2

7.4 Cold weather starting .................................................................................................... 07-2

7.5 Starting off and parking operation . ................................................................................ 07-3

7.6 Economical driving ........................................................................................................ 07-4

7.7 Steering operation ......................................................................................................... 07-5

7.8 Braking operation .......................................................................................................... 07-6

7.9 Transmission operation ................................................................................................. 07-7

7.10 Towing ......................................................................................................................... 07-8

7.11 PTO operation ............................................................................................................. 07-8

7.12 Outrigger operation ................................................................................................... 07-10

7.13 Hoist operation .......................................................................................................... 07-13

7.14 Operation of main boom and its telescoping system ................................................ 07-23

7.15 Luffing operation ....................................................................................................... 07-26

7.16 Swing operation ........................................................................................................ 07-28

7.17 Simultaneous crane movements . ............................................................................. 07-31

7.18 Jib operation .............................................................................................................. 07-37

7.19 Rooster sheave ......................................................................................................... 07-45

7.20 Vehicular operation ................................................................................................... 07-47

RT60 Rough Terrain Crane III

Page 7

7.21 “On tires” lifts ............................................................................................................. 07-50

7.22 Unusual operating conditions . .................................................................................. 07-51

8 Transportation and storage . ......................................................................................... 08-1

8.1 Transportation ............................................................................................................... 08-1

8.2 Storage.......................................................................................................................... 08-3

9 Specifications ................................................................................................................. 09-1

9.1 Conversion tables ......................................................................................................... 09-1

9.2 Average weight of materials . ........................................................................................ 09-3

9.3 Torque ratings ............................................................................................................... 09-5

9.4 Technical specification .................................................................................................. 09-6

IV RT60 Rough Terrain Crane

Page 8

Page 9

Page 10

The owner of this crane must know federal, state and loc al rules. When your

equipment is in operation, the area must be safe for employees and non-employees.

Do not cause damage to other equipment or local structures while you operate this

crane. The rules change by location and this manual does not give that data.

ZOOMLION makes manuals for different construction and industrial equipment. It is

policy to include applicable national consensus, industry standards and safety data

with the manuals. Use these data to give applicable training to personnel who are to

operate, do the maintenance and supervise the equipment correctly and safely.

We make equipment for heavy-duty labor. Do the periodic inspections regularly

because the equipment wears. This prevents accidents, decreases downtime and

helps equipment work satisfactorily. The goal of these inspections is to find worn,

cracked, damaged parts and loose or missing fasteners before they cause a problem.

Correct training and inspection procedures are necessary to prevent injury to persons,

property damage and high maintenance costs.

Read and understand the data that comes with this crane. Help is available from the

distributors of your ZOOMLION crane and from the ZOOMLION Mobile Crane Branch

Company.

This manual contains the instructions and data on the operation, maintenance,

lubrication, and adjustments of the Rough Terrain Crane. Do not operate the crane

before you understand the data in this manual.

RT60 Rough Terrain Crane 01 - 1

Page 11

Page 12

Page 13

Page 14

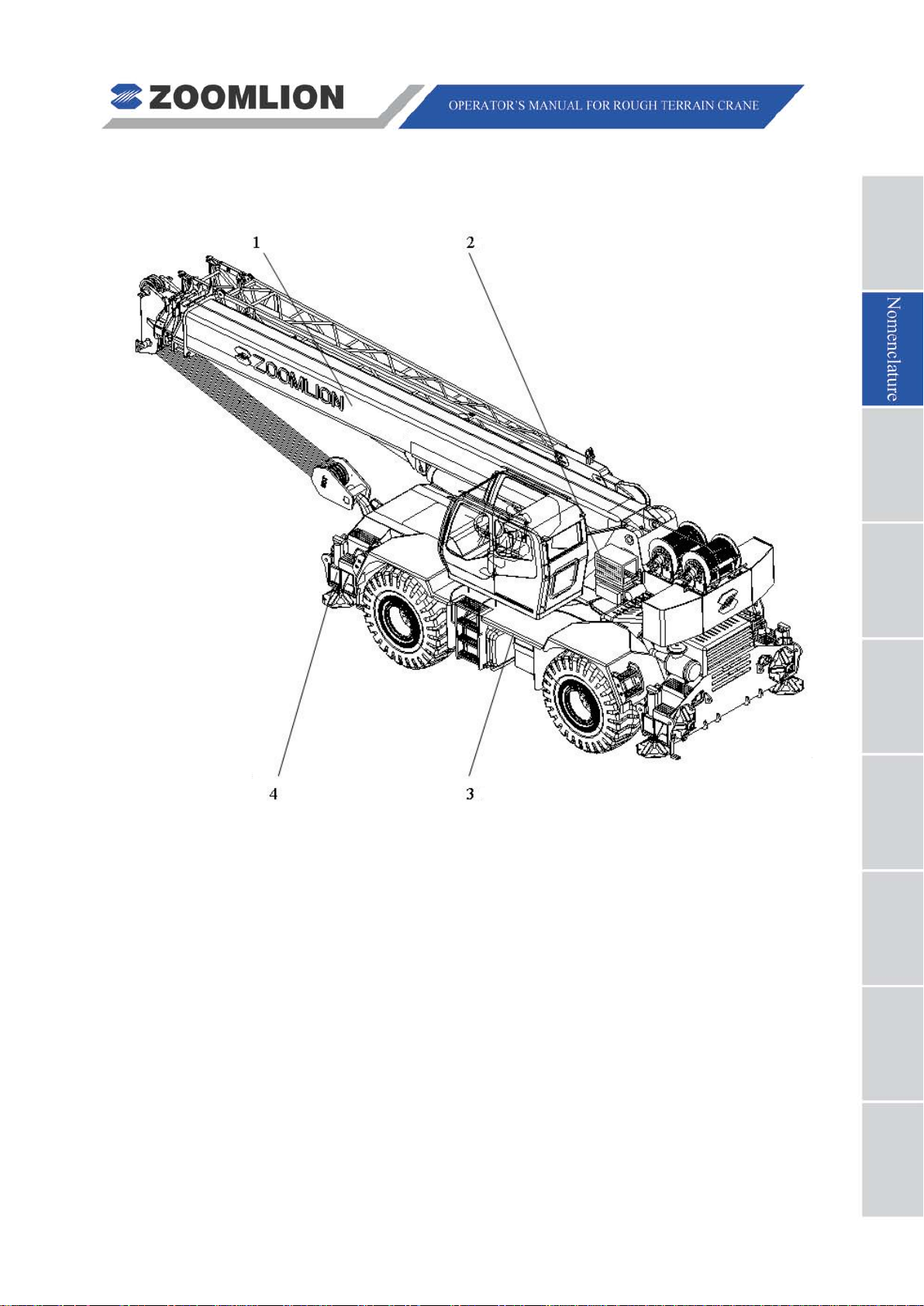

To help you understand the contents of this manual, refer to the figure below. Each

numbered term can represent several components of the same main part.

LEGEND

1. BOOM SYSTEM = Main boom assy., jib assy., telescoping mechanism, hook block,

auxiliary hook, hoist rope.

2. SWING SYSTEM = Superstructure, counterweight, main and auxiliary winches,

swing bearing, swing reducer, derricking cylinder, cab, air

conditioner and cab heater.

3. CHASSIS = Power system, drive system, steering system, air intake system,

exhaust system, cooling system, fuel supply system, chassis

frame assy. and vehicle body system.

4. OUTRIGGERS = Outrigger beams, outrigger jacks, cylinders and outrigger floats.

RT60 Rough Terrain Crane 02 - 1

Page 15

Page 16

Page 17

Page 18

CRANE PERIODIC INSPECTION CHECKLIST

This inspection checklist provides supplementary data to facilitate the correct operation

and maintenance of the crane.

Component

Inspected

Interval

Function

Adjusting

Condition

Maintenance

condition

Component

Inspected

Inspection

Code

Function

Adjusting

Condition

Maintenance

Condition

RT60 Rough Terrain Crane 03 - 1

Page 19

MAINTENANCE LOG

Item

Adjusting Condition

Date

03 - 2 RT60 Rough Terrain Crane

Page 20

About This Manual

General

The data (data, specifications, illustrations) in this manual is for cranes in production at the

time of this manuals publication. We reserve the right to make changes to this manual at

any time, without obligation.

This manual contains the instructions to move and operate the RT75 Crane in the field.

Follow the operation and maintenance procedures to make sure that your machine

operates at MAXIMUM EFFICIENCY. Use the CRANE PERIODIC INSPECTION

CHECKLIST. Keep a maintenance log to monitor all maintenance work on the machine.

An example of a Maintenance Log and Crane Periodic Inspection Checklist is at the

beginning of this section.

Again, we appreciate your selection of our crane. User safety is most important. To

complete on-site tasks safely, operators must be responsible. Obey the instructions that

follow:

Comply – with Occupational Safety and Health Administration (OSHA), Federal, State,

and Local Regulations.

Read, Understand, and Follow – the instructions in this and other manuals and

documents that come with the crane.

Use Good, Safe Work Practices – in a common sense way.

Only have trained operators – directed by informed and knowledgeable job-site

supervisors.

Do not use this crane – before the portable fire extinguisher, installed in the cab,

agrees with local fire protection rules.

Note

OSHA prohibits the alteration or modification of this crane without written

manufacturer’s approval. Use only factory approved parts to service or repair

the crane.

If you make modifications/additions "which affect the safe operation of the

equipment" to the crane before you use it, the crane owner must make sure

that the modifications/additions agree with OSHA 1926:1412.

RT60 Rough Terrain Crane 03 - 3

Page 21

Speak with us if special data is necessary for the maintenance or operation of your RT75

Crane. Send your machine model and a serial number to make sure that you receive the

correct data.

If there is anything in this manual that is not clear or which you think is necessary, write to

the address that follows:

Rough Terrain Crane R & D Institute

Zoomlion Mobile Crane Branch Company

nd

Quantang Industrial Park, 2

Yuanda Road,

Economic and Technological Development Zone,

Changsha, Hunan Province, China, 410131

You can also speak to us by telephone at 0086-84671987 (international), 0731-84671987

(domestic).

03 - 4 RT60 Rough Terrain Crane

Page 22

Page 23

Page 24

4.1 HAZARD INDICATORS

Caution

Warning

Danger

DANGER, WARNING, CAUTION, ATTENTION, NOTE, and IMPORTANT labels are on

signs and decals, and as you read this manual to show important instructions. In this

manual, DANGER, WARNING, and CAUTION labels are before the paragraph or item to

which they apply. ATTENTION, NOTE, and IMPORTANT follow the paragraph or item they

apply to. The markers are as follows:

Refers to a dangerous situation which, if you do not prevent, will cause

death or injury.

Refers to a possible dangerous situation which, if you do not

prevent, could cause death or injury.

Refers to a possible dangerous situation which, if you do not

prevent, may cause light or moderate injury.

Attention

Refers to a situation which, if you do not prevent, may cause property or

equipment damage.

Note

Refers to a tip or hint in the operation instructions.

Important

Emphasizes the importance of the data in this manual.

This s ymbol shows a step or procedure that is not approved and can

cause a dangerous situation.

RT60 Rough Terrain Crane 04 - 1

Page 25

4.2 SAFETY SYMBOL

Caution

Warning

Danger

The safety symbol, used on the Danger, Warning, and Caution labels, tells personnel

of possible death, inj ury, or property damage. Obey all safety data that follows this

symbol to prevent dangerous conditions.

4.3 Hazard classification

Hazard classification is a system to show different classes of possible injury levels. A

safety symbol and a signal word show how dangerous the level of possible injury can be.

A signal word without a safety symbol refers to property damage, protection devices, or

important data. You will find this system used in this manual and on signs on the crane to

help find and prevent dangerous situations.

4.4 SAFETY

This section contains the safety rules that you must follow. You must read and understand

the Operator’s Manual. It contains the instructions for the specified machine.

All personnel must be safe at the work location.

Attention

A. Moving personnel

Only use a crane to lift personnel when it is the less dangerous mode to move them to

areas that are hard to access.

B. Operator’s responsibilities

Read and understand the Operator's Manual.

The operator must always think about the safety of all personnel in the area.

Only personnel who show that they can safely control a RT75 crane can operate the

crane.

Comply with the requirements, that apply, as follows:

Occupational Safety and Health Administration (OSHA) standards

American National Standards Institute (ANSI)

China National Standards GB/T3811.

Make sure that all the mechanical functions of the crane can operate.

04 - 2 RT60 Rough Terrain Crane

Page 26

Make sure that the system operating gauges and indicators, and warning signals

function.

Keep all the glazed surfaces, instruments, windows, and lights clean.

Remove all oil, grease, mud, ice, and snow from walkway surfaces.

Read and understand all Decals and Warnings.

Keep all tools and other necessary items in the toolbox.

Do not lift a load without a Load Ratings in the cab.

Read and understand the Load Ratings.

Make sure that the load to lift is less than the capacity of the crane.

Be in good physical condition and free from effects of alcohol, drugs and medications.

Be sure to not decrease vision, hearing, or reaction time.

Keep personnel, equipment and material that are not necessary for your task at the

job-site out of the area.

The operator must know the hand signals.

When the view of the operator is blocked or if the task is in a dangerous area, use

signal personnel to give directions.

If a signal person is necessary, the operator must obey only the signals from the

approved signal person. You must obey the STOP signal from all personnel in the

area.

Keep a fully charged fire extinguisher and first aid kit in the cab at all times. The

operator must know how to use the fire extinguisher and how to apply the items in the

first aid kit.

Look for the movement of other equipment, trucks, and personnel at the job-site.

Personnel must stay off the crane platform while the crane is in operation.

All personnel must be in a safe area before you move the hook, boom, load, or

outriggers.

Stop and start the movement of the load smoothly and move at a speed that keeps the

load in your control.

Keep a minimum of three full wraps of wire rope on the drum.

Use the tag lines to keep the load in control.

Keep the load near the ground.

Use the shortest boom possible.

If a load is off the ground or the crane is on, you must stay in the cab.

Always use outriggers as the Load Ratings and Operator’s Manual tells.

RT60 Rough Terrain Crane 04 - 3

Page 27

C. Signal personnel responsibilities

Use and understand all standard hand signals.

Help the operator to operate safely and satisfactorily. Keep safe all personnel and

property .

Understand the work you must do.

Stay where you can see the full operation and where personnel can see you.

D. Responsibilities of all crew members

Correct the conditions and procedures that are not safe.

Obey WARNING signs.

Do your work safely and do not make dangerous conditions.

Know and understand correct procedures for crane erection and rigging.

Tell the operator and the signal person of dangerous conditions (power lines/cables,

work surface that is not stable etc.).

E. Management responsibilities

The operator must be competent, in good physical condition and have applicable

licenses.

The operator, signal person, and riggers must receive training in correct crane

operation.

The operator and the signal person must know all standard hand signals.

Have a supervisor at the job-site to be responsible for safety.

Give crew members the safety instructions and tell them to report conditions that are

not safe to the supervisors.

Supply the operator with accurate data on the load that they have to lift.

Make sure that all personnel know applicable OSHA and ANSI B30.5 requirements

and the instructions in manuals.

F. Planning the job

Understand the work that you must do.

Think of all possible dangerous conditions/risks at the job-site.

Know the type of personnel that is necessary.

Give the tasks to personnel.

Know the weight of the load that you must lift.

Find the lift-radius, boom angle, and the rated lift limits of the crane.

Tell the signal person how to communicate with the operator.

04 - 4 RT60 Rough Terrain Crane

Page 28

Use equipment which does the work safely.

Make a decision on how to safely move equipment to the job-site.

Find gas lines, power lines and structures.

Make sure that the work surface can hold the crane and load.

Find out how to rig the load.

If necessary, make the special safety precautions.

Know the weather conditions.

Keep equipment that is not necessary away from the job-site.

Set the crane to use the shortest possible boom and radius.

G. Operator safety check

Safety related items must be in position.

Look at the crane logbook for maintenance and inspection records.

Make sure to complete necessary repairs.

Examine the wire rope for damage (kinks, broken wires etc.).

Make sure that all field modifications are approved.

Do an inspection for air and hydraulic oil leaks.

Examine the control positions before you start the engine.

After you start the engine, examine all the instruments and indicators for the correct

values.

Do a test on the controls.

Check brakes.

Lift and hold a load 2 inch (50 mm) off of the work s urface to ex amine the load brakes.

H. Operator aids check

Anti-Two Block devices

Boom angle indicator

Backup alarms

Swing lockout device

Rated capacity indicator (RCI)

rd

3

wrap indicator.

I. Operation overload prevention

Know the weight of the load.

Decrease radius at the start of the lift to let the load radius increase during lift.

RT60 Rough Terrain Crane 04 - 5

Page 29

Know the weight of the hook and rigging.

Know the boom length, jib length, and the area where you have to move the load.

Use next lower rated capacity when working at the boom length or radius between the

figures on the rated lifting capacity chart.

Do not lift a load until you know if the load is less than the capacity limit of the crane.

Only operate with the recommended counterweights. It is dangerous if you do not use

the approved charts to calculate the decrease or increase in counterweight.

Do not lift the load if winds are dangerous. If necessary, lower the boom.

See the Load Ratings for possible restrictions.

Avoid side loading.

Do not let the load or other objects hit the boom.

Release the load slowly, be sure the boom does not tighten against back stops.

Put the boom point directly above the load.

Be sure that the load hangs freely.

J. Operation setup

Be sure the load-bearing surface can hold the weight of the crane and load.

Make crane level, check frequently, and re-level them when necessary.

Assemble barricades to keep personnel out of the load move radius.

K. Power line safety

Find power lines in the area before you start a task. Follow national and local

regulations and ANSI B30.5 when you operate around power lines.

Do not remove the material from below power lines if the boom or crane can touch the

lines.

Do not let the crane or load touch electrical lines. Do not go near the minimum

permitted clearance for operation of a crane near electrical lines.

If you touch the electrical lines, stay on the crane until the boom moves of f the lines or

until the power line current is of f .

Keep all personnel off the crane if it touches power lines. If you must move from the

crane, JUMP, DO NOT STEP OFF. Jump with feet together.

Use a signal person when you operate around power lines

L. Slip and fall prevention

Make sure that you stop the crane before you move on and off the equipment. Do not

jump.

Do not use the controls and the steering-wheel as hand holds.

04 - 6 RT60 Rough Terrain Crane

Page 30

Keep the equipment clean and dry.

Replace all broken ladders.

Keep the non-slip surfaces in good condition.

Wear a safety harness when you climb the counterweight and attach the harness in

the necessary points. Do not walk on the boom!

M. Travel

Be careful when you move cranes on or off the job-site.

Look for personnel, power lines, low or narrow clearance, bridge or road load limits,

steep hills, or rough terrain.

Correctly stow the boom before you move the crane.

Inflate the tires to the specified pressure.

Move slowly and prevent sudden movement.

Wear seat belt correctly when you move the crane.

Make sure that the travel surface can hold the weight of the crane and load.

Always use the park brake when you park the crane.

N. Safety sign maintenance

During the daily inspection, make sure that the decals show and are in good condition.

Replace all missing or damaged safety signs. The safety of the operator is always

important.

Use a weak soap and water to clean the safety signs. Do not use solvent-based cleaners.

Solvents can cause damage to the safety sign material.

The graphics, on the pages that follow, give an example of each safety decal and its

location.

RT60 Rough Terrain Crane 04 - 7

Page 31

Left-hand side

Right-hand side

Figure 04 – 1 Overview of the Safety Signs on the Machine

04 - 8 RT60 Rough Terrain Crane

Page 32

1

Figure 04 – 2 Danger – Crush Hazard

2

Figure 04 – 3 Danger – Electrocution Hazard

RT60 Rough Terrain Crane 04 - 9

Page 33

3

Figure 04 – 4 Hand Signals for Crane Operation

04 - 10 RT60 Rough Terrain Crane

Page 34

4

Figure 04 – 5 Danger – Explosion / Burn Hazard

5

Figure 04 – 6 Danger – Crush Hazard

RT60 Rough Terrain Crane 04 - 11

Page 35

6

Figure 04 – 7 Danger – Burn Hazard

7

Figure 04 – 8 Prohibited – No Thoroughfare

8

Figure 04 – 9 Prohibited - No Access / Only Authorized Personnel

9

Figure 04 – 10 CAUTION - Risk of Falling

04 - 12 RT60 Rough Terrain Crane

Page 36

10

Figure 04 – 11 CAUTION - Swinging Load

11

Figure 04 – 12 No Swing over the Rear with -3°

12

Figure 04 – 13 Entanglement Hazard

Keep all open flames and

sparks away.

13

Figure 04 – 14 Keep All Open Flames and Sparks Away – RH Only

RT60 Rough Terrain Crane 04 - 13

Page 37

14

Figure 04 – 15 Be Careful in the Working Radius – RH Only

15

Figure 04 – 16 No Walk – RH Only

04 - 14 RT60 Rough Terrain Crane

Page 38

Page 39

Page 40

5.1 OPERATING CONDITIONS

Warning

A. Always use the correct light diesel fuel and engine oil. Make your selection on the

lowest ambient temperature where you are to do the work. Refer to the table below for

more data on diesel and engine oil. Obey the Engine Manual if the data in this table is

incorrect.

Engine Emission Oil Brand Specification

According to guidelines

per US EPA T ier 3

Emission Standards

According to guidelines

per EURO Stage III A

Emission Standards

The fuel sulfur content in the fuel must be less than 15 PPM to obey US EPA

Sulfur content < 15 PPM,

according to US EPA2007

regulations

Sulfur content < 50 PPM,

according to EN 590

regulations

CH – 4 stage, API classification

CH – 4 stage, API classification

Tier 3 Emission Standards.

The fuel sulfur content must be less than 50 PPM to obey EURO Stage III A

Emission Standards.

Do not use fuel that is mixed with a lubricant or accredited additives.

B. All mechanical components are in a break-in state during initial crane operation (less

than 100 operating hours). You must follow the below instructions during this time

period:

The working load and working speed must not be too high.

The maximum lift capacity should not be larger than 80% of the rate one.

Do not operate the crane at a speed that is more than the maximum limits.

C. Make sure that you do all of the work on level ground that is hard. The ground must

hold more than the load bearing capacity (permissible ground pressure ≥ 507.6 psi

(3.5 MPa)). Use material (such as wooden timbers) below the outrigger floats if the

work area is soft or not flat.

D. Before you operate the crane that is supported on outriggers, all wheels must not

touch the ground. Before "On tires lifts", make sure that you align the crane wheels to

the middle.

E. Do not operate the crane if the temperature at the job-site is more than -4°F to 104°F

(-20°C to +40°C).

F. If wind speed is greater than the permissible value of 45 ft/s (13.8 m/s), while the

crane is in operation, do the tasks that follow:

Stop the work (safely lower the load).

RT60 Rough Terrain Crane 05 - 1

Page 41

Retract the boom.

Beaufort

Scale

Correctly stow the boom.

To make an estimate of the wind speed, use the table that follows:

Wind Force Wind Speed

Effect of the wind on the land

Description

ft-in/s m/s

0 Calm 0 - 8″ 0 - 0.2 No wind, smoke rises vertically

1

2

3

Light Air 1′-4″ - 4′-7″ 0.4 - 1.4

Light Breeze 5′-3″ - 9′-10″ 1.6 - 3

Gentle

Breeze

4 Moderate

Breeze

5 Fresh

Breeze

6

Strong Wind 35′-5″ - 45′-0″ 10.8 - 13.7

7

8

Near Gale 45′-7″ - 60′-9″ 13.9 - 17

Gale 56′-5″ - 67′-7″ 17.2 - 20.6

9

Strong Gale 68′-3″ - 80′-5″ 20.8 - 24.5

11′-2″ - 17′-5″ 3.4 - 5.3

18′-1″ - 25′-7″ 5.5 - 7.8

26′-3″ - 34′-9″ 8 - 10.6

Wind direction shown by smoke

drift but not by wind vanes

Wind felt on face, leaves rustle,

vanes move by wind

Leaves and small twigs in

constant motion, wind extends

light flag

Small branches move

Small trees in leaf begin to sway

Large branches in motion;

difficult to use umbrellas,

whistling heard in telegraph

wires

Whole trees in motion, difficult

to walk against the wind

Breaks twigs off trees, impedes

progress

Slight structural damage (roof

tiles and chimney covers, etc.

blown off)

10

Storm 81′-0″ - 92′-10″ 24.7 - 28.3

Trees uprooted, considerable

damage occurs

G. Do not operate the crane until the conditions are safe.

05 - 2 RT60 Rough Terrain Crane

Page 42

5.2 PRE-DEPARTURE CHECKS (TO JOB-SITE)

Caution

A. VEHICLE CHECKS (PRIOR TO ENGINE START)

(1) Do a check of the level of coolant and add more if below the cold engine level.

(2) Do a check of the fuel level and make sure that you have more than is necessary

to complete the task.

(3) Make sure that the parts in the steering and brake systems are flexible, safe, and

reliable.

(4) Make sure that the parts that follow are tight:

Bolts in universal joints for steering axles

Front and rear axles mounting bolts

Wheel bolts

Drive shaft mounting bolts

Engine and transmission mounting bolts.

(5) Examine all tires for the correct pressure.

(6) Examine the items that follow for damage:

Condition of tires

Door locks

Doors

Windows

Crane control mechanisms.

(7) Examine the fittings of oil pipes, air pipes and water pipes for leakage.

(8) Examine the air pressure tank for condensation (drain the water as necessary).

(9) Examine the battery terminals for too much corrosion and make sure that the

power wires are tight.

(10) Examine the level of the battery electrolyte (adjust as necessary).

(11) Examine the air filter indicator. If the indicator is red, clean or replace the filter

cartridge.

The air filter system must be clean prior to starting the engine.

(12) Examine the air filter assembly. Clean the contamination from the bottom of the

air filter.

(13) Turn the ignition switch to stage “I” and examine the functions of the items that

follow:

RT60 Rough Terrain Crane 05 - 3

Page 43

Caution

Caution

Instrument panel

Switches

All lights

Turn signals

Wipers

Miscellaneous displays.

(14) Adjust the mirrors for clear vision to the rear.

B. GENERAL CHECKS A T VEHICLE START UP

Before you start the vehicle on a steep slope or a muddy road, move the

transmission gear selector into “F1” position.

Do not turn the power supply OFF while the engine in ON. If you turn the power

supply OFF, the electrical system does not operate and you remove the data

from the ECU.

Examine the controls and instruments.

((11))

Examine the engine oil pressure gauge.

((aa))

1 The engine oil pressure must be between 240 PSI (1.7 MPa) – 310 PSI

(2.1 MPa).

Examine the compressed air supply.

((bb))

Examine the engine coolant temperature gauge.

((cc))

1 After the engine has the time to warm-up, the pointer must point to the

green range (between 158° F (70° C) and 203° F (95°C)).

) Make sure that the transmission gears shift correctly.

((dd)

Make sure that the 360° superstructure lock moves correctly.

((ee))

Make sure that each indicator operates.

((22))

Make sure that the generator operates.

((33))

Make sure that the park brake is not ON.

((44))

Move the transmission gear selector to the “F1” position and slowly increase the

((55))

speed.

05 - 4 RT60 Rough Terrain Crane

Page 44

C. MOVE THE CRANE TO THE JOB-SITE

Caution

Caution

Warning

Danger

Do not let the vehicle move forward when transmission is in neutral.

Do not operate a vehicle if a warning indicator illuminates. Stop the vehicle and

have it repaired.

If a warning indicator illuminates, decrease your speed immediately and stop at a

((11))

safe location for maintenance checks.

Do not skip a gear when you move through the gear cycle.

((22))

During driving, if there is any abnormal sound, smell, vibration or acceleration,

((33))

bring the vehicle to a standstill immediately and check. If the cause of problem is

unclear or if the problem cannot be rectified, send the vehicle to the specialized

repair factory.

Stop the vehicle if there are unusual conditions with the items in the below list:

((44))

Steering

Braking

Sounds or smells

Vibrations

Sudden speed increase or decrease.

If you cannot find or correct the problem, send the vehicle for repair.

Check the following instruments for functions:

((55))

Monitor the indicators / gauges that follow:

((66))

Stop the engine if the engine oil pressure low indicator illuminates.

The engine oil pressure low indicator illuminates if the engine oil filter

screen is dirty. If this occurs, examine the engine oil pressure. If it is in the

correct pressure range, check and clean the engine oil filter screen.

Engine oil pressure low indicator:

((aa))

1 Not illuminated.

2 When the engine runs at idle, the minimum oil pressure is 55.1 psi (0.38

MPa). When the engine runs without a load, the minimum oil pressure is

10 psi (0.069 MPa). If the pressure is less than the minimum value, the

indicator illuminates. If this occurs, stop the engine. Measure the level of

RT60 Rough Terrain Crane 05 - 5

Page 45

the oil in the engine and check for leaks. If the oil level is at the correct

Caution

Caution

Caution

level and there are no leaks, it is an unserviceable lubricating system.

Send the crane to the factory for repair.

Engine coolant temperature gauge

((bb) )

1 The coolant temperature must be between 158°F and 203° F (70°C and

95°C). Do not move the crane at high speed when the coolant

temperature is less than 158°F (70°C).

2 Do not operate the engine at high speeds without a load for extended

periods of time.

Do not move the crane at high speeds with a heavy load until the engine

coolant temperature is a minimum 158°F (70°C).

3 When the coolant temperature is in the yellow area, between 203°F and

212°F (95°C - 100°C), the engine is too hot. Park the crane. Operate the

engine at a RPM immediately above idle to help cool the engine. Or, as

you move, put the transmission in a lower gear range to decrease the

load on the engine.

Do not stop the engine immediately when the engine coolant temperature is

above the maximum limit. If y ou stop the engine, the coolant temperature

increases suddenly and damage to the engine occurs. Operate the engine

at a RPM immediately above idle to help decrease the coolant temperature.

4 When the coolant temperature gauge points to the red area, between

212°F and 248°F (100°C - 120°C) continuously, it shows that the engine

is above limits. If you stop the engine, the coolant temperature increases

suddenly and damage to the engine occurs. Operate the engine at a RPM

immediately above idle to help decrease the coolant temperature.

5

When the coolant temperature goes back to the green or yellow area, do

the items that follow:

Examine the engine area for leaks.

Examine the function of the thermostat.

Check the coolant level.

Check the fan belt for damage.

Make sure that the fan belt is not too loose.

Do not add a large quantity of cold water to the engine if the engine coolant

05 - 6 RT60 Rough Terrain Crane

Page 46

temperature is above the maximum limit. This can kill or blind you and

Caution

Caution

Caution

cause damage to the engine.

Low engine coolant:

((cc))

Use soft water, e. g. tap water, for coolant. Do not use hard water (river

water).

1

Do not add a large quantity of cold water too quickly. When it is

necessary to add cold water, put the water in slowly. Follow the below

instructions to add coolant:

Put together water, antifreeze and/or anti-rust fluid in the correct

ratio.

Loosen the cap to the coolant tank with a wet rag to release the

pressure in the tank. After you release the pressure, continue to

remove the cap. The fluid released is hot and pressurized and can

cause burns or blindness. Always keep your face away from the cap

on the coolant tank.

Add the water mix to the applicable coolant tank fill-line and then

install the cap.

Do not operate the engine continuously at high speeds without a load.

Put the crane in a lower gear before you move up a s l ope to decrease the

((77))

load on the engine and drive-line.

Note

Make sure that the RPM of the engine is around maximum when you move up a

slope.

Do not bypass gears when you move to a lower gear.

Slow the crane down before you change to a lower gear.

Do the items that follow before you go down a long hill slope:

((88))

Make sure that the brake system can stop the crane before you go onto the

slope.

Put the transmission in the ”F1” position before you go down the slope.

Know the below data while you steer the crane:

((99))

When you go into a corner, put the transmission in a lower gear and apply a

small quantity of pressure on the brakes.

RT60 Rough Terrain Crane 05 - 7

Page 47

The steering wheel has a mechanical limit. Do not continue to turn the wheel

Caution

when at the limit. Do not keep the wheel at the limit for long periods of time.

0)) If the engine stops because the fuel tank is empty, air can go into the fuel system.

((110

When this occurs, you remove the air from the fuel lines.

When you move the crane between locations, only one person is approved to be

((1111))

in the cab.

D. CRANE MOVEMENT IN OFF-ROAD CONDITIONS

When the rear axle is in the mud (no traction) or on rough terrain, follow these steps:

Put the transmission in the ”F1” position. This applies more torque to the drive

system.

Put the vehicle in the "4-wheel drive" mode.

Tow the vehicle or put rigid materials, e.g. pieces of wood or iron plates, below

the wheels.

E. PARK THE VEHICLE

Make sure that the hazard indicator illuminates when the vehicle is parked on the

road at night.

When you park the vehicle, follow the instructions below:

((11))

In bad weather condition (rain, snow, ice) or on a slope, make sure that there

is a lot of clearance in front and to the aft of the vehicle.

Put the park brake switch to the "P" position and put the chocks against the

wheels.

Put the transmission in the "neutral" position.

Before you stop the engine, do the items that follow:

((22))

Push the accelerator pedal 2 or 3 times to increase the engine RPM. This

makes the oil flow into each part of the engine.

Let the engine idle while you monitor the coolant temperature.

Stop the engine, when the coolant temperature is in the correct range.

Put the battery master switch to the OFF position.

F. EMERGENCY STOP ON THE ROADWAY

If the crane malfunctions on the roadway, do the items that follow:

Set the hazard lights to ON and put the safety triangles in position.

Set the park brake if you stop because of a drive train (drive shaft, axle) failure or

you make an emergency stop on a slope. Put the chocks on the wheels.

05 - 8 RT60 Rough Terrain Crane

Page 48

Examine the vehicle to find the part that caused the malfunction. Be careful of the

road conditions while you move around the vehicle.

If you cannot repair the vehicle, tell the servicing and repair facility.

G. PREPARE THE CRANE FOR OPERATION

Examine the items that follow:

((11))

Engine oil for correct level and make sure that it is clean.

Coolant for correct level.

Fuel tank for correct level.

Hydraulic oil tank for correct level.

Start the engine and check for noises and vibrations that are not usual. If

((22))

necessary, engage the PTO.

H. WHEN THE CRANE IS IN OPERATION

(11)) Personnel must stay away from the area below the boom.

(

(22)) Do not let personnel on the superstructure while you operate the crane.

(

(33)) Personnel must stay away from the reach of the boom.

(

(44)) The crane, with extended outriggers, must be on the ground with a slope of less

(

than 1°.

Do not move a load above personnel.

((5 5))

RT60 Rough Terrain Crane 05 - 9

Page 49

6)) Do not move personnel on the load or other equipment used to lift.

((6

Do not use the crane for the tasks that follow:

((77))

Lift a load that is above the capacity of the crane.

Pull a load at an angle.

Lift a load that is not in balance.

Do not try to lift a load that is buried or frozen on the ground.

((8 8))

Do not extend / retract the boom with a suspended load.

((9 9))

05 - 10 RT60 Rough Terrain Crane

Page 50

Keep no less than 3 wraps of wire rope on the drum.

((110 0))

1)) When the load is off the ground, do not adjust the hoist mechanism brake.

((111

When the load is off the ground, the operator must stay in the cab.

((1122))

When the job-site is near live power lines, you must keep a safe distance. Make

((113 3))

sure that the dangerous area has a cover or is fenced off.

4)) When the load is off the ground, move the load in a slow and smooth direction.

((114

Constantly monitor the system gauges and indicators, when the crane is in

((1155))

operation. If you find a malfunction, stop the operation.

A noise sounds when the load is at 90% of the capacity of the crane. When this

((1166))

occurs, be careful as you continue to lift.

If the crane was changed, do not operate the crane until approved personnel

((1177))

examine the changed part.

RT60 Rough Terrain Crane 05 - 11

Page 51

Stop the operation or do not start to lift a load, if one of the items that follows

((118 8))

occurs:

An overload or if the weight of the load is unknown.

The load lift moves out of position, the rigging becomes too loose or the load

is out of balance.

The protective material between the edges of load and wire rope is missing.

The light level at the job-site goes below a safe work condition.

Equipment malfunction or damage to the crane that decreases the safe

operation of the crane.

05 - 12 RT60 Rough Terrain Crane

Page 52

I. TROUBLESHOOTING – ENGINE

Caution

Caution

Caution

If failures occur during crane operation, stop working immediately and remove the

safety hazards. At the same time, disengage the PTO for transmission and make the

engine run at idle speed. After that, check control instruments, e.g. transmission oil

pressure gauge and engine coolant temperature gauge, etc. for functional work.

It is a normal phenomenon that the engine oil pressure low indicator lights up

when starting the engine with the PTO engaged. The warning indicator will go

off after the oil pressure increases to the specified value.

The illumination of the engine oil pressure low indicator indicates that the engine

((11))

oil pressure decreases abnormally. Bring the vehicle to a standstill immediately

and contact the manufacturer or specialized repair factory.

Do not turn off the engine immediately when it is overheated. Otherwise, the

engine will be sintered caused by sudden raising coolant temperature. Check

for leaks when the engine is running for cooling. Stop the engine after the

coolant temperature decreases. At this time, reinspect engine coolant level and

check fan belt for damages and loosening.

When the engine coolant temperature gauge points to the red area, cool down

((22))

the engine at the RPM a little higher than the idle RPM.

Points for attention when adding coolant:

Use proper coolant.

When the coolant temperature is extremely high, hot water will spray.

Therefore, tighten or loosen the radiator cover using a piece of cloth.

Otherwise, there is a risk of burn hazard.

RT60 Rough Terrain Crane 05 - 13

Page 53

Page 54

Page 55

Page 56

This part of the chapter is to show you the controls and instruments on the crane. This is

only a small part of the data that you must know before you can safely operate the crane.

Do not operate the crane until you are trained in all the other sections of this manual.

1 2 3 4 5 6 7 8 9 10 11

12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

Figure 06 – 1 Upper Controls and Instruments

RT60 Rough Terrain Crane 06 - 1

Page 57

LEGEND

1. High / Low Speed Select Switch for

Main Winch

2. Steering Switch

3. Camera Display

4. High / Low Speed Select Switch for

Aux Winch

5. Air Conditioner Control Panel

6. A/C Fan Speed / Mmaster Switch

7. Cab Heater Power Switch

8. Cab Cooler Power Switch

9. Monitor Display

10. Media Player

11. Rated Capacity Indicator (RCI)

Display

12. Left Front Outrigger Switch

13. Left Rear Outrigger Switch

14. Emergency Stop Button

15. Right Front Outrigger Switch

16. Right Rear Outrigger Switch

17. Work Light Switch

18. Hazard Lights Switch

19. Cigarette Lighter

20. Ignition Switch

21. Outrigger Extend / Retract Master

Switch

22. Swing Lock Switch

23. 2-Wheel / 4-Wheel Drive Switch

24. Hand / Foot Throttle Select Switch

25. Bypass Switch

26. Hand Throttle

06 - 2 RT60 Rough Terrain Crane

Page 58

1 2 3 4 5 6 7

8 9 10 11

Figure 06 – 2 Left Dash

1. LEFT REAR OUTRIGGER SWITCH –

to be extended / retracted with

SWITCH (21)

(See Figure 06 – 1).

Used to select outrigger cylinder (jack or beam)

OUTRIGGER EXTEND / RETRACT MASTER

2. LEFT FRONT OUTRIGGER SWITCH – Used to select outrigger cylinder (jack or

beam) to be extended / retracted with OUTRIGGER EXTEND / RETRACT MASTER

SWITCH (21) (See Figure 06 – 1).

3. HIGH / LOW SPEED SELECT SWITCH FOR MAIN WINCH – Sets the main winch

speed to OFF, LOW or HIGH.

4. RIGHT REAR OUTRIGGER SWITCH – Used to select outrigger cylinder (jack or

beam) to be extended / retracted with OUTRIGGER EXTEND / RETRACT MASTER

SWITCH (21) (See Figure 06 – 1).

5. RIGHT FRONT OUTRIGGER SWITCH – Used to select outrigger cylinder (jack or

beam) to be extended / retracted with OUTRIGGER EXTEND / RETRACT MASTER

SWITCH (21) (See Figure 06 – 1).

RT60 Rough Terrain Crane 06 - 3

Page 59

Set the steering switch to crab or 4-wheel steer only when the axles are

in the center position. If you do not this, the range of steering

decreases and it can lock.

If the wheels lock, set the steering switch to 2-wheel steer and turn

front wheels. Move the switch to crab or 4-wheel steer and then put the

wheels to the center position.

Be careful when the superstructure is not in the travel position. The

steering is opposite when the boom is in the rear position.

6. STEERING SWITCH – The 4 modes are as follows:

2-wheel steer (front wheel) 2-wheel steer (rear wheel) Crab steer 4-wheel steer

7. HIGH / LOW SPEED SELECT SWITCH FOR AUX. WINCH – Sets the auxiliary winch

speed to OFF, LOW or HIGH.

8. EMERGENCY STOP BUTTON – In an emergency, push this button to immediately

STOP all crane functions. Turn the button clockwise to release the button.

9. WORK LIGHTS SWITCH – Push down to turn on the headlights and boom work lights ,

up to turn off.

10. HAZARD LIGHTS SWITCH – Push down to turn on the rotating beacon and flash the

turn signals and boom head light.

11. CAB HEATER POWER SWITCH –

adjust heat are on the

1).

AIR CONDITIONER CONTROL PANEL (5)

Used to turn on the cab heater. The controls to

(See Figure 06 –

06 - 4 RT60 Rough Terrain Crane

Page 60

1 2 3 4 5

Figure 06 – 3 Right Dash

1. OUTRIGGER EXTEND / RETRACT MASTER SWITCH – Used with switches (12, 13,

15, 16 in Figure 06 – 1) to extend and retract the outrigger beams and jacks. Push

down to retract, up to extend.

You must set the swing lock switch to LOCK, when the boom is in the

travel position.

2. SWING LOCK SWITCH - Push down to disengage swing lock, up to engage.

Do not use this switch until you stop the crane.

3. 2-WHEEL / 4-WHEEL DRIVE SWITCH – Push up to engage 2-wheel drive, down to

engage 4-wheel drive.

4. HAND / FOOT THROTTLE SELECT SWITCH - Push up to select foot throttle, down

to select hand throttle.

5. BYPASS SWITCH – Push down to bypass the switch-off when the RCI sounds the

alarm and switches off the movements. (BYPASS SWITCH not used with Greer LMI

system.)

06 - 5 RT60 Rough Terrain Crane

Page 61

6.1.1 AIR CONDITIONER CONTROL PANEL

Figure 06 – 4 Air Conditioner Control Panel

FUNCTIONS

1. A/C FAN SPEED / MASTER SWITCH – Used to control the fan blower modes: OFF,

HI, MID, LOW.

2. FAN POWER INDICAT OR

3. COOL MODE INDICATOR

4. CAB COOLER POWER SWITCH – Refrigeration ON / OFF. Starts or stops the

function of the compressor.

RT60 Rough Terrain Crane 06 - 6

Page 62

Table 06 – 1 Air Conditioner Maintenance Requirements

Every month or increase the

conditions

Every quarter or increase the

conditions

Item Requirements Maintenance interval

Condenser fan

motor

Evaporator fan

motor

Examine and repair. Every quarter

Examine and repair. Every quarter

Condenser Examine and clean.

Evaporator Examine and clean.

Electromagnetic

clutch

Connector

Make sure that it operates

smoothly and is clean.

Make sure that the connector is

set in place.

A. Component Location

Evaporator – Air outlet in the cab

Condenser – In front of the engine

maintenance frequency

according to the working

maintenance frequency

according to the working

Every quarter

Every month

Condenser fan – On the front of the engine (also the radiator fan)

B. Cab Temperature Control Functions:

(1) Refrigeration

The first time you use the COOL function, do the items that follow:

– Start the engine.

– Set the A/C FAN SPEED / MASTER SWITCH (1) to blow air.

RESULT: -

FAN POWER INDICATOR (2) (red) illuminates.

– Set the CAB COOLER POWER SWITCH (4) to position "COOL".

RESULT: -

COOL MODE INDICATOR (3) (green) illuminates.

– Turn the A/C FAN SPEED / MASTER SWITCH (1) counter-clockwise to 3

fan speed (HI, MID, LOW) to get the necessary temperature.

(2) A/C FAN SPEED / MASTER SWITCH – Used to change between the 4 fan

speeds (OFF, HI, MID, LOW).

When the switch is set to blow air, the FAN POWER INDICATOR (red)

illuminates.

06 - 7 RT60 Rough Terrain Crane

Page 63

Note

The switch is the master power to the COOL function and must be ON (HI,

MID, LOW) for the COOL function to operate.

(3) HEAT mode

Turn on the A/C FAN SPEED / MASTER SWITCH (1) after the engine is

started:

– Set the A/C FAN SPEED / MASTER SWITCH (1) to blow air.

RESULT: -

The FAN POWER INDICATOR (red) illuminates.

– Push down the CAB HEATER POWER SWITCH on the dash.

RESULT: -

The heater is ON.

– Turn the A/C FAN SPEED / MASTER SWITCH (1) counter-clockwise

between 3 fan speed (HI, MID, LOW) to get the correct temperature.

Do not disassemble an A/C system that is in the Warranty Period

without consent from the A/C manufacturer.

Examine the condition and tension of the compressor belt at a regular

interval. If necessary, adjust the tension on the belt.

You must clean the condenser at a regular interval.

You must use the same type of refrigerant and compressor oil to

complete the repairs on the A/C.

Set the FAN mode to HI when you first start to cool the cab.

Do not use the parts to repair the A/C system that are not approved by

the manufacturer.

When you use the A/C function where it is cool and has a high level of

humidity, examine the evaporator at a regular interval. In these

conditions, the evaporator freezes and causes a blockage for the air

that goes through it.

If you operate the crane in a cold area or in the winter season, set the

A/C system to ON for 10 minutes each month.

Make sure that the A/C is in the OFF mode when the engine is OFF or at

idle speed for a long time. The battery drains in these conditions.

When you move the crane a long distance at low speed, with the A/C in

the ON mode, put the transmission in a low gear. This increases the

engine RPM and decreases the load on the transmission.

RT60 Rough Terrain Crane 06 - 8

Page 64

Set the A/C to the OFF position when you do one of the items that

follow:

• Move the crane quickly.

• Move up a long hill slope.

Make sure that the refrigerant in the A/C system is at the correct level at

regular intervals.

If there are unusual vibrations, noises or smells during operation, stop

and examine the crane immediately. Do not operate the crane that has a

malfunction.

Keep the surface of the condenser clean. When you clean the

condenser, do not use steam.

Before you disassemble the A/C system, correctly remove the

refrigerant.

Do not disassemble the A/C system in an area with high humidity.

06 - 9 RT60 Rough Terrain Crane

Page 65

6.1.2 MEDIA PLAYER

Figure 06 – 5 Media Player

LEGEND

1. Power Button Press power button turn on/off the Media Player

2. SD CARD Port

3. USB Port

4. LCD Display

5. Band Selector AM / FM function selection

6. Setting Button Sound menu function selection

7. Mute Button Telephone mute function

8. Dsp Button Time display, Short press display time; long press

seconds to adjust the time

9. Volume/Function knob Clockwise feature adds/counterclockwise rotation,

10. Mode Button Press mode button to select radio and SD or USB

11.▲ Button Low-Scan (radio) / on a (playback)

12.

13.

14.

15. Button Prefabricated key 3 (radio)/previous folder selection (Playback)

16. Button Prefabricated key 4 (radio) / Shuffle (Playback)

17. Button Prefabricated key 5 (radio) / Repeat Play (Playback)

18. Button Prefabricated key 6 (Broadcasting) / next folder selection (Playback)

Button High-end scanning (radio) / Next (playback)

▼

Button Prefabricated key 1(radio) / pause playback (playback).

Button Prefabricated key 2(radio)/10seconds browsing (playback)

button for 3

▲

▼

reduced functionality

Set the ignition switch to "I", when you use the CD player with the

engine in the OFF position.

RT60 Rough Terrain Crane 06 - 10

Page 66

6.2 CONTROLS AND INSTRUMENTS

1 2 3 4 (3) 5 6 7 8 9 10

Figure 06 – 6 Controls and Instruments

1. SWING / AUX. WINCH CONTROL – Move the joystick forward to reel-off the aux.

winch rope. Move the joystick backward to spool-up the aux. winch rope. Move the

joystick to the left to move the boom to the left side. Move the joystick to the right to

move the boom to the right side.

Free

Swing

Figure 06 – 7 Left Joystick (Swing / Aux. Winch Control)

Horn – Push and hold-in to make a sound. (Located on right side of joystick)

Free swing – Push to operate the FREE SWING. Push again to release this function.

(Located on left side of joystick)

Note

Only when the operator’s seat is

occupied and the icon on the

display lights up, the joysticks can initiate various movements.

06 - 11 RT60 Rough Terrain Crane

Page 67

2. BOOM EXTEND / RETRACT PEDAL

Figure 06 – 8 Boom Extend / Retract Pedal

Note

Only when the operator’s seat is occupied and the icon on the

display lights up, can the boom extend / retract function be operated

3. CIGARETTE LIGHTER

Push-in the cigarette lighter for 3 to 5 sec. Pull it out to use it. After you use it, put it in

its initial position.

Note

To use the cigarette lighter, the engine must be ON or the ignition must be in

the "I" position.

4. STEERING WHEEL AND COMBINATION SWITCHES

The crane has a hydraulic booster system which makes it easy to turn the crane in all

conditions.

You can adjust the steering wheel height and angle when you push the pedal at the

bottom of the steering wheel.

DO NOT adjust the steering wheel while you move the crane. This can

kill you. Lock the steering wheel after adjustment.

RT60 Rough Terrain Crane 06 - 12

Page 68

Figure 06 – 9 Combination Switches

A GEAR SELECTOR - Use to control the transmission gear selection. Pull in the

direction of the operator for forward. Push in the direction of the dash for reverse.

Turn the handle to set the speed.

B PARKING BRAKE INDICATOR – Not used.

C TURN SIGNAL INDICATOR - Not used.

D PARKING BRAKE SWITCH - Set the switch to the “P” position when the crane is

in the correct position to operate.

Note

If you park the crane on a slope, you must put the chocks before and behind

the wheels.

E HAZARD LIGHTS SWITCH - Push-in to set the warning hazard lights to ON. The

indicator illuminates (flashes).

F CORNER MARKER LIGHTS / LOW BEAM SWITCH - Push the switch up, to

turn ON the corner marker lights. Push the switch down, illuminate the low beam

lights.

G SERVICE BRAKE INDICATOR – Not used.

H WIPER CONTROL - Windshield wiper operation (4-speed settings: J - Timed

Interval (Intermittent), I - Low Speed, II - High Speed, O - OFF). Push the button,

on the end of the handle, to spray washer fluid onto the window. Pull in the

direction of the operator for high beam. Push in the direction of the dash for low

beam.

06 - 13 RT60 Rough Terrain Crane

Page 69

The spray of washer fluid stops after 15 seconds or if the washer fluid

tank is empty. Do not operate the wipers on hot sunny days unless you

use spray the window with wiper fluid. When the temperature is below

freezing, make sure that the wiper blades are not stuck to the window

before you set the wipers to ON.

5. BRAKE PEDAL – Push the brake pedal to decelerate or stop the crane.

6. IGNITION SWITCH – The 4 positions of the switch are as follows:

"I" - All circuits, this does not include the starter, are ON

"II" - This position does not have a function

"III" - A temporary position, use it to operate the starter

"O" - All circuits are OFF.

Note

Make sure that you release the ignition ("III" position) when the engine starts.

You cannot remove the key from the ignition until the switch is in the

"O" position (OFF).

7. THROTTLE PEDAL – Push the pedal to increase the engine RPM, release the pedal

to decrease it. The movement of the items that follow can increase or decrease as the

speed of the engine changes:

Boom swing

Increase or decrease the angle of the boom

Extend or retract the boom

Hoist movements (raise or lower a load).

Note

You can use the throttle pedal with the joysticks and boom extend / retract

pedal to increase / decrease the speed of the items in (7).

8. HAND THROTTLE – You can use the hand throttle after the HAND / FOOT

THROTTLE SELECT SWITCH is activated.

9. BUBBLE LEVEL –

You use this to make sure that the crane is level.

RT60 Rough Terrain Crane 06 - 14

Page 70

10. BOOM HOIST / MAIN WINCH CONTROL - Move the joystick forward to reel-off main

winch rope. Move the joystick rearward to spool-up main winch rope. Move the

joystick left to lift the boom. Move the joystick right to lower the boom.

Horn – Push and hold-in to make a sound. (Located on left side of joystick).

Free swing – Push to operate the FREE SWING. Push again to release this function.

(Located on right side of joystick)

Free

Swing

Figure 06 – 10 Right Joystick (Boom Hoist / Main Winch Control)

Note

Only when the operator’s seat is occupied and the icon on the

display lights up, the joysticks can initiate various movements.

06 - 15 RT60 Rough Terrain Crane

Page 71

6.3 Monitor

Figure 06 – 11 Overview

Figure 06 – 12 System Start-up

After being switched on:

a) The monitor system runs up. See Figure 06 – 12.

b) The Work Mode Screen (when the parking brake is ON) or Travel Mode Screen (when

the parking brake is OFF) appears on the monitor. See Figures 06 – 13 and 06 – 14

respectively.

RT60 Rough Terrain Crane 06 - 16

Page 72

Figure 06 – 13 Work Mode

Under Work Mode Screen, the virtual tachometer will be displayed on the screen. See

Table 06 – 2.

Figure 06 – 14 Travel Mode

Trip Distance is the crane travel distance from the departure place to the destination.

Press the function key “TRIP DIS” to begin to record the travel distance. At this time, the

key turns to grey. Press the key again to finish the travel distance recording and the key

turns to green.

Under Travel Mode Screen, the virtual gauges such as odometer, tachometer, fuel gauge

and engine coolant temperature gauge will be displayed on the screen. See Table 06 – 2.

Under any screen, the function keys at the bottom are available for switching between

various screens.

06 - 17 RT60 Rough Terrain Crane

Page 73

For the icons displayed on the screen, please refer to Table 06 – 3.

Table 06 – 2 Gauges

DESCRIPTION FUNCTION

Tachometer

Odometer

Engine coolant

temperature gauge

Fuel gauge

The engine should not operate for a long interval if the coolant

temperature indication is in the red area. Decrease the speed of the

engine or decrease the load on the engine. If the temperature does not

go down, stop the crane and examine the engine coolant system. The

engine can be damaged, if you cannot find a solution to the problem.

Displays engine speed (RPM) and equipment operating time.

Displays the speed of the crane in kilometers per hour (km/h)

when the crane is moving.

Displays the engine coolant temperature in degrees Celsius

(C°).

GREEN - normal range

RED - the engine has a large load on it.

Displays, as a percent full, the amount of fuel in the tank.

Always use clean fuel.

Before you stop the engine, operate the engine at idle for a short period

of time. This helps the engine coolant temperature to be stable.

Do not move the crane when the indicator for the service or parking

brake system illuminate.

Do not move the crane when the engine oil pressure low indicator

illuminates. Stop the engine to prevent damage to the engine.

RT60 Rough Terrain Crane 06 - 18

Page 74

Table 06 – 3 Indicators – Universal Symbol Identification

INDICATOR SYMBOL DESCRIPTION FUNCTION

ENGINE COOLANT

Illuminates:

LOW INDICATOR

Shows that the engine coolant level is

too low.

Illuminates:

ENGINE OIL

PRESSURE LOW

INDICATOR

Shows that the engine oil pressure is too

low or the oil filter screen is dirty.

Stop the engine immediately to prevent

damage.

Illuminates:

Shows that the engine coolant

ENGINE COOLANT

TEMPERATURE HIGH

INDICATOR

temperature is high.

Examine the coolant temperature

indication and find the cause of the

out-of-tolerance indication. Do the steps

to decrease the coolant temperature.

Illuminates:

FUEL RESERVE LOW

INDICATOR

Shows that the fuel reserve is lower than

the permitted value (1/4 of the total).

LEFT TURN SIGNAL

Crane moves to the left.

Flashes:

Flashes:

RIGHT TURN SIGNAL

HIGH PRESSURE

FILTER DIRTY

INDICATOR

CHARGE

MONITORING

INDICATOR

CORNER MARKER

LIGHTS INDICATOR

LOW BEAM

INDICATOR

HIGH BEAM

INDICATOR

Crane moves to the right.

Illuminates:

Shows that the high pressure filter is

dirty.

Illuminates:

Battery charging system fault.

Illuminates:

The corner marker lights are ON.

Illuminates:

Low beam lights are ON.

Illuminates:

High beam lights are ON.

06 - 19 RT60 Rough Terrain Crane

Page 75

INDICATOR SYMBOL DESCRIPTION FUNCTION

AIR CONDITIONER

INDICATOR

FAULTY OUTRIGGER

OPERATION

INDICATOR

TRANSMISSION OIL

PRESSURE LOW

INDICATOR

SERVICE BRAKE

INDICATOR

PARKING BRAKE

INDICATOR

SWING LOCKOUT

DEVICE PRESSURE

LOW INDICATOR

EMERGENCY BRAKE

SYSTEM PRESSURE

LOW INDICATOR

Illuminates:

Air conditioner is ON.

Illuminates:

Shows that the outrigger system has a

malfunction.

Illuminates:

Shows that the transmission oil pressure

is too low.

Illuminates:

The service brake is ON.

Illuminates:

The parking brake is ON.

Illuminates:

Shows that the pressure to the swing

lockout device is too low.

Illuminates:

Shows that the pressure in the

emergency brake system is too low.

Use the service brake system to bring

the crane to a stop.

SERVICE BRAKE

SYSTEM PRESSURE

LOW INDICATOR

PARKING BRAKE

SYSTEM PRESSURE

LOW INDICATOR

CLUTCH

DISENGAGING

INDICATOR

PTO INDICATOR

Illuminates:

Shows that the pressure in the service

brake system is too low.

DO NOT move the crane.

Illuminates:

Shows that the pressure in the parking

brake system is too low.

DO NOT move the crane.

Illuminates:

The clutch is disengaged and the

service brake indicator illuminates when

the service brake is applied.

Illuminates:

Shows that the PTO is engaged.

RT60 Rough Terrain Crane 06 - 20

Page 76

INDICATOR SYMBOL DESCRIPTION FUNCTION

AXLE CENTERED

INDICATOR

SUPERSTRUCTURE

POSITION INDICATOR

MAIN WINCH

APPROACHING

LOWER LIMIT

INDICATOR

AUXILIARY WINCH

APPROACHING

LOWER LIMIT

INDICATOR

2-WHEEL DRIVE

INDICATOR

4-WHEEL DRIVE

INDICATOR

Illuminates:

Shows that the rear axle is centered.

Illuminates:

Shows that the superstructure is in the

initial position.

Illuminates:

Shows that the main winch is near the

minimum wire rope wrap limit (3 turns on

the drum).

Illuminates:

Shows that the auxiliary winch is near

the minimum wire rope wrap limit (3

turns on the drum).

Illuminates:

Shows that the crane is in the

2-wheel-drive mode.

Illuminates:

Shows that the crane is in the

4-wheel-drive mode.

AXLE SUSPENSION

LOCKED INDICATOR

AXLE SUSPENSION

SET TO SPRUNG

INDICATOR

SWING LOCK

INDICATOR

SWING UNLOCK

INDICATOR

NEUTRAL 0

POSITION INDICATOR

NEUTRAL 1

POSITION INDICATOR

Illuminates:

Shows that the axle suspension is

locked.

Illuminates:

Shows that the axle suspension is not in

the locked position.

Illuminates:

Shows that the swing lock is engaged.

Illuminates:

Shows that the swing lock is NOT

engaged.

Illuminates:

Shows that the transmission is in the

"N0" position.

Illuminates:

Shows that the transmission is in the "N

1" position.

06 - 21 RT60 Rough Terrain Crane

Page 77

INDICATOR SYMBOL DESCRIPTION FUNCTION

NEUTRAL 2

POSITION INDICATOR

FORWARD SPEEDS

INDICATOR

REVERSE SPEEDS

INDICATOR

CRAB-STEER

INDICATOR

4-WHEEL STEER

INDICATOR

2-WHEEL STEER

(FRONT WHEEL)

INDICATOR

Illuminates:

Shows that the transmission is in the "N

2" position.

Illuminates:

Shows that the gear selector is in the

forward direction.

Illuminates:

Shows that the gear selector is in the

reverse direction.

Illuminates:

Shows that the Crab steer steering

program is switched to ON.

Illuminates:

Shows that the 4-wheel steer steering

program is switched to ON.

Illuminates:

Shows that the 2-wheel steer (front

wheel) steering program is switched to

ON.

2-WHEEL STEER

(REAR WHEEL)

INDICATOR

ENGINE STOP

INDICATOR

ENGINE WARNING

INDICATOR

WAIT TO START

INDICATOR

WATER IN FUEL

INDICATOR

Illuminates:

Shows that the 2-wheel steer (rear

wheel) steering program is switched to

ON.

Illuminates:

ECU detects a serious failure and you

must stop the engine immediately.

Illuminates:

Shows that the ECU detects a common

failure.

Illuminates:

Shows that the engine is cool and the

glow plugs must have time to heat up

properly to start the engine.

Shows that the glow plugs are hot

enough, the light goes out.

Illuminates:

Shows that the fuel contains water.

RT60 Rough Terrain Crane 06 - 22

Page 78

INDICATOR SYMBOL DESCRIPTION FUNCTION

HAZARD LIGHTS

When driving the crane, the joysticks and boom extend / retract

pedal remain active. Crane operations can occur if either joysticks

or pedal are used unintentionally .

INDICATOR

HIGH-SPEED

INDICATOR

LOW-SPEED

INDICATOR

SEAT OCCUPIED

INDICATOR

Illuminates:

Shows that the crane is in operation and

the hazard lights are ON.

Illuminates:

Shows that the transmission high-low

speed valve is connected.

Illuminates:

Shows that the transmission high-low

speed valve is disconnected.

Illuminates:

Only when the indicator lights up, can

the superstructure movements be

initiated.

06 - 23 RT60 Rough Terrain Crane

Page 79

6.3.1 VEHICLE STATUS

Under Travel Mode Screen or Work Mode Screen, press the function key “STATUS” to

enter the Vehicle Status Screen. You can consult the basic information about the vehicle.

Press the key “BACK” to return the Travel Mode Screen or Work Mode Screen. Press the

key “MENU" to enter the Main Menu Screen. Press the key “HOME” to return to the Travel

Mode Screen.

Figure 06 – 15 Vehicle Status

RT60 Rough Terrain Crane 06 - 24

Page 80

6.3.2 SYSTEM WARNING

Under Travel Mode Screen or Work Mode Screen, press the function key “WARN” to enter

the System Warning Screen. You can consult the current warning information about the

vehicle. Remedy the malfunctions immediately according the displayed information.

Press the key “BACK” to return the Travel Mode Screen or Work Mode Screen. Press the

key “MENU" to enter the Main Menu Screen. Press the key “HOME” to return to the Travel

Mode Screen.

Figure 06 – 16 System Warning

06 - 25 RT60 Rough Terrain Crane

Page 81

6.3.3 MAIN MENU

Under Travel Mode Screen or Work Mode Screen, press the function key “MENU” to enter

the Main Menu Screen. Press the relevant function keys to move the cursor left and right to

select the items as follows: Monitoring, Real-time warning, Parameter settings,

Maintenance,

“ENTER” to enter the required screen.

简体中文

(Chinese), Information and Password etc. And then press the key

Figure 06 – 17 Main Menu

6.3.3.1 LANGUAGE SWITCHING

You can make the monitor displaying all information in English or Chinese mode under

Main Menu Screen.

(1) Switch to English mode

In Chinese mode, under Travel Mode Screen or Work Mode Screen, press “

(MENU) to enter Main Menu Screen.

Under Main Menu Screen, press

select the “English” item, see Figure 06 – 18, and press “

operating, monitor displays all information in English mode, see Figure 06 – 19.

(2) Switch to Chinese mode

In English mode, under Travel Mode Screen or Work Mode Screen, press “MENU” to

enter Main Menu Screen.

Under Main Menu Screen, press

select the “

this operating, monitor displays all information in Chinese mode, see Figure 06 – 18.

简体中文