Page 1

2824

2844

Thermal Printer

User’s Manual

User’s Manual No. 980381-001 Rev. A

©2002 ZIH Corp.

Page 2

FOREWORD

This manual provides installation and operation information for the 2824 and the 2844 series print

ers, manufactured by Zebra Technologies Corporation, Camarillo, California.

COPYRIGHT NOTICE

This document contains information proprietary to Zebra Technologies Corporation. This docu

ment and the informationcontained within is copyrighted byZebra Technologies Corporation and

may not be duplicated in full orinpartbyanyperson without written approval from Zebra Technol

ogies Corporation. While every efforthasbeenmade to keep the information contained withincur

rent and accurate as of the date of publication, no guarantee is given or implied that the document

is error-free or that it is accurate with regard to any specification. Zebra Technologies Corporation

reserves the right to make changes, for the purpose of product improvement, at any time.

TRADEMARKS

LP 2824, TLP 2824, LP 2844 and TLP 2844 are service marks of Zebra Technologies Corporation.

Windows and MS-DOS are registered trademarks of Microsoft Corp. All other marks are trade

marks or registered trademarks of their respective holders.

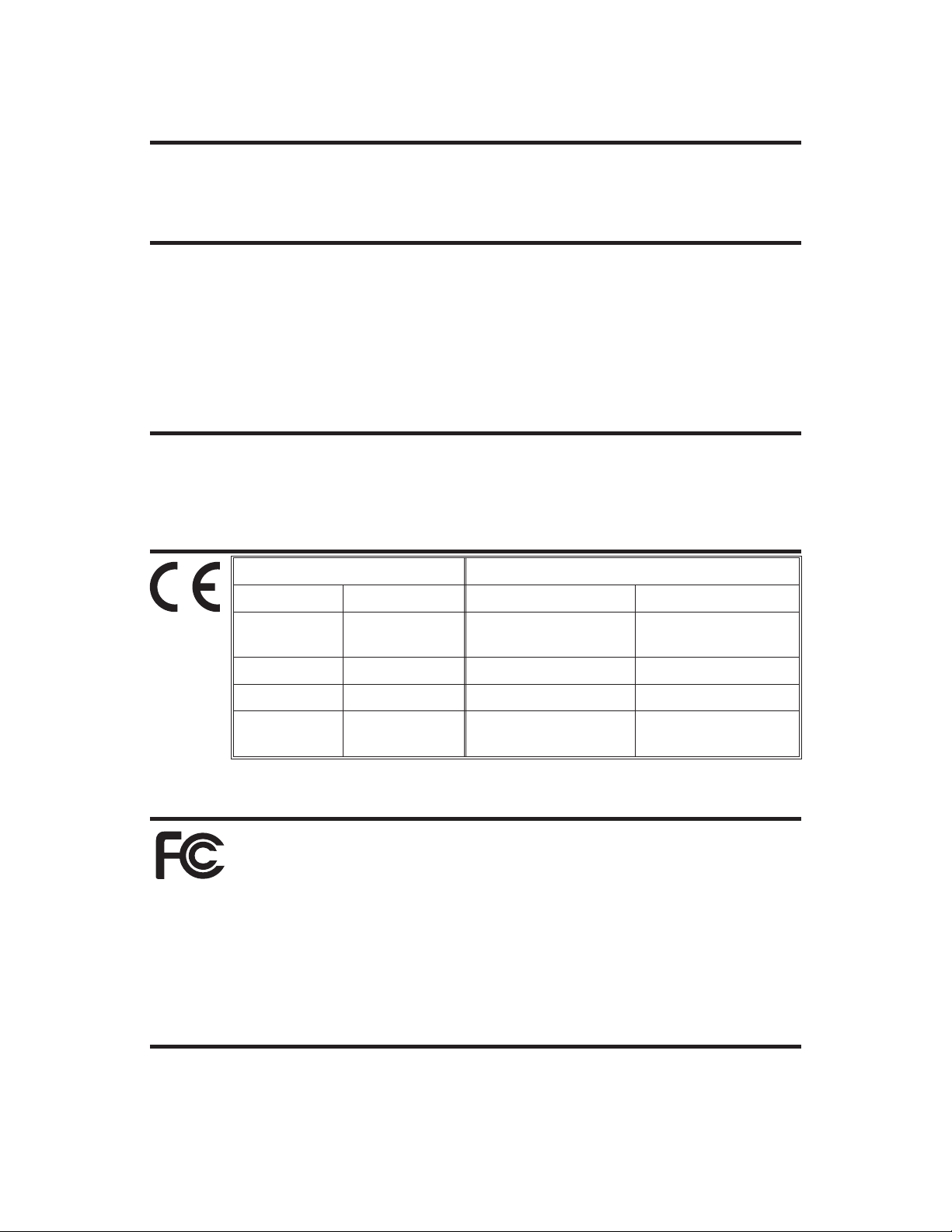

LP 2824, TLP 2824, LP 2844 and TLP 2844 Thermal Printers

European Council Directive Compliance to Standards

89/336/EEC EMC Directive EN 55022-B 1998 RF Emissions control

-

-

-

-

-

EMC Directive EN 55024 1998

92/31/EE EMC Directive EN 61000-3-2 Harmonic Emissions

92/31/EE EMC Directive EN 61000-3-3 Voltage Variation

CB Scheme

EN 60950 1991

A1, A2, A3, A4

Immunity to Electro-

magnetic Disturbances

Safety

FCC - DECLARATION OF CONFORMITY:

Models: LP 2824, TLP 2824, LP 2844 and TLP 2844 conform to the follow

ing specification:

FCC Part 15, Subpart B, Section 15.107(a) and Section 15.109(a) Class B

digital device

Supplemental Information:

This device complies with Part 15 of the FCC Rules. Operation is subject to the following Two

Conditions: (1) This device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

INDUSTRY CANADA NOTICE:

This device complies with Industry Canada ICS-003 class B requirements.

-

Cet equipement est conforme a l’ICS-003 classe B de la norm Industrielle Canadian

ii 980381-001 Rev. A

Page 3

WE NEED TO HEAR FROM YOU

We Need To Hear From You!

To Establish Your Warranty Period And Provide Access To Technical Support,

Send Us Your Product Registration Card Today!

To establish your warranty period and provide access to technical support, send us your product

registration card today.

RETURN MATERIALS AUTHORIZATION

Before returning any equipment to Zebra for in warranty or out of warranty repair, contact Repair

Administration for a Return Materials Authorization (RMA) number. Repack the equipment in the

original packing material and mark the RMA number clearly on the outside. Ship the equipment,

freight prepaid, to the address listed below:

Zebra RMA, USA

1001 Flynn Road

Camarillo, CA. 93012

Phone: +1 (805) 579-1800

repair@zebra.com

Label Printers: Card Printers:

Zebra Technologies, Europe Zebra Technologies, Europe

Zebra House Zone Indutrielle, Rue d'Amsterdam

The Valley Centre, Gordon Road 44370 Varades, France

High Wycombe Phone: +33 (0) 240 097 070

Buckinghamshire HP13 6EQ, UK FAX: +33 (0) 240 834 745

Phone: +44 (0) 1494 472872

FAX: +44 (0) 1494 450103

980381-001 Rev. A iii

Page 4

SHOCK HAZARD WARNING:

The printer and power supply should never be operated in a

location where either one can get wet. Personal injury could

result.

MEDIA AND RIBBON WARNING:

Always use high quality, approved labels, tags and ribbons. If

adhesive backed labels are used that DO NOT lay flat on the

backing liner, the exposed edges may stick to the label guides

and rollers inside the printer, causing the label to peel off from

the liner and jam the printer. Permanent damage to the print

head may result if a non-approved ribbon is used as it may be

wound incorrectly for the printer or contain chemicals

corrosive to the print head. Approved supplies can be ordered

from your dealer.

RELOADING HINT:

If labels or ribbon run out while printing, DO NOT turn the

power switch OFF (0) while reloading or data loss may result.

The printer automatically restarts after you load a new label or

ribbon roll.

STATIC DISCHARGE:

The discharge of electrostatic energy that accumulates on the

surface of the human body or other surfaces can damage or

destroy the print head or electronic components used in this

device. DO NOT TOUCH the print head or the electronic

components under the top cover.

THERMAL PRINTING:

The print head becomes hot while printing. To protect from

damaging the print head and risk of personal injury, avoid

touching the print head. Use only the cleaning pen to perform

maintenance.

iv 980381-001 Rev. A

Page 5

TABLE OF CONTENTS

Installation and Operation

Unpack Your Printer . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Attach Power . . . . . . . . . . . . . . . . . . . . . . . . 4

Attach Interface Cable . . . . . . . . . . . . . . . . . . . 5

Load Media . . . . . . . . . . . . . . . . . . . . . . . . 6

AutoSense Media Gap Sensing . . . . . . . . . . . . . . . 9

Install Software . . . . . . . . . . . . . . . . . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Using Options

Using Transfer Ribbon . . . . . . . . . . . . . . . . . . . . . 14

Using the Label Dispenser . . . . . . . . . . . . . . . . . . . 19

Using Fan-Fold Media . . . . . . . . . . . . . . . . . . . . . 20

Using the Media Cutter . . . . . . . . . . . . . . . . . . . . 21

Troubleshooting

Problems and Solutions . . . . . . . . . . . . . . . . . . . . 23

Serial Interface Cable Wiring. . . . . . . . . . . . . . . . . . 26

Parallel Interface Cable Wiring . . . . . . . . . . . . . . . . . 27

Universal Serial Bus (USB). . . . . . . . . . . . . . . . . . . 28

Cash Drawer Cable Wiring. . . . . . . . . . . . . . . . . . . 28

Internal ZebraNet PrintServer II . . . . . . . . . . . . . . . . 29

Alternative Serial Interface Input . . . . . . . . . . . . . . . . 30

Cleaning the Print Head . . . . . . . . . . . . . . . . . . . . 31

Cleaning the Platen . . . . . . . . . . . . . . . . . . . . . . 32

Preparing Media, Paper, and Labels Before Loading . . . . . 33

980381-001 Rev. A v

Page 6

vi 980381-001 Rev. A

Page 7

1

Installation and Operation

This section provides information on the

installation and operation of the printer.

The printer is a low cost, desktop thermal

printer. The printer is specifically designed for

printing labels, tags or continuous receipts (with

or without bar codes) from any DOS™, Windows™or ASCII-based compatible host.

There are four models of printer. Many illustrations in this manual show the wide printer.

While there are some physical differences

among them, you can operate all printers using

the same procedures.

980381-001 Rev. A 1

Page 8

Installation and Operation

Unpack Your

Printer

There are four models of printer. You have

received one of these printers:

2 980381-001 Rev. A

Page 9

Installation and Operation

980381-001 Rev. A 3

Page 10

Installation and Operation

Installation The following steps will guide you through the

installation of the printer and software.

Step Attach Power Supply To The Printer

Power OFF

Check Voltage

Plug in

Power

Module

Plug in

Power

Cord

Plug Power Cord

into a Suitable

AC Outlet

See the SHOCK HAZARD WARNING on page

iv.

4 980381-001 Rev. A

Page 11

Step Attach Interface Cable

Serial

Parallel

Installation and Operation

Universal Serial Bus

(USB)

Internal ZebraNet

PrintServer II

(optional)

For details regarding

this interface and its

operation, refer to the

user guide supplied

with your ethernet

print server.

See Appendix A for cable wiring information.

980381-001 Rev. A 5

Page 12

Installation and Operation

Step Load Media

Open Cover

MOVIE

SHOW ME

TLP 2844 LP 2844

TLP 2824 LP 2824

Open Guides

Adjust Holders

1.0 inch

2.5 cm

MOVIE

SHOW

ME

1.5 inch

3.8 cm

6 980381-001 Rev. A

Page 13

Load Media - continued

Remove the outside

length of media

SHOW

MOVIE

For more information

on media preparation,

refer to Appendix A.

preparing media in

ME

Install Roll

Note: Find the

instructions for

Appendix A.

Installation and Operation

Close Guides to the

Width of the Media

Note: When using

linerfree labels,

adjust the guides to

the widest position

980381-001 Rev. A 7

Page 14

Installation and Operation

Load Media - continued

Release Cover

MOVIE

SHOW ME

TLP 2844 TLP 2824

Note: This step

applies to thermal

transfer printers

Close Cover

8 980381-001 Rev. A

Page 15

Step AutoSense Media Gap Sensing

Installation and Operation

MOVIE

SHOW ME

TLP 2844 LP 2844

TLP 2824 LP 2824

Power OFF

Hold

Feed Button

Perform this procedure when loading a new

roll. If your printer has the label dispenser

option, turn OFF the label taken sensor.

Power ON

980381-001 Rev. A 9

Page 16

Installation and Operation

age

000,

024

avl

AutoSense Gap Sensor Adjustment - continued

When Indicator

Flashes, Release

Feed Button

Printer Advances

Media and Prints

Status Summary

UKQ1935 16 V3.21

Serial port : 96,N,8,1

Note: Printer is in

diagnostic dump mode

Tap Feed Button

To Begin Normal

Operation

Note: Printer prints

“out of DUMP”

Image buffer size:1032K

Fmem:000.0K,016.4K avl

Gmem:000K,0593K avl

E

mem:000K,0593K avl

I8,0,001 rY

S2 D10 R016,000 ZT UN

q800 Q01225,026

Option:

04 08 13

now in DUMP

now in DUMP

04 08 13

Option:

q800 Q1029,025

S2 D10 R016,000 ZT UN

I8,0,001 rY

E

mem:000K,0241K

Gmem:000K,

Fmem:

Im

If the indicator remains orange or red, see the

troubleshooting steps.

10 980381-001 Rev. A

Page 17

Step Install Software

Installation and Operation

Start your computer and follow the installation

instructions on the compact disc (CD).

980381-001 Rev. A 11

Page 18

Installation and Operation

Operation The following information helps you get the

most from your printer.

Programming

Commands

You must use programming to control many of

the printer's functions. See the EPL2 program

mer's manual for details. For example, the Q

command controls form length and gap.

Printer Driver Theprinter driver provides a convenient control

to improve print quality. For example, Print

density (darkness) is affected by the heat energy

(density setting) applied and by the print speed.

Changing both Print Speed and Density may be

required to achieve the desired results.

Thermal Printing:

Direct or

Transfer?

You must use the correct media for the type of

printing you require. When printing without a

ribbon, you must use direct thermal media.

When using ribbon, you must use thermal transfer media. The printer's ribbon sensor detects

motion of the supply spindle.

-

Replacing Supplies Whenreplacing media or ribbon, do not turn off

the printer or data loss occurs. The printer auto

matically resumes printing after you load new

supplies.

12 980381-001 Rev. A

-

Page 19

Using Options

2

Using Options

This section provides information on the

printer's optional features:

• thermal transfer printing

• label dispenser

• fan-fold media

• media cutter

980381-001 Rev. A 13

Page 20

Using Options

Using

Transfer

Ribbon

The TLP printer supports both direct thermal

media (chemically treated to darken when

heated) and thermal transfer media (accepts

wax and/or resin transferred off a ribbon).

Step Prepare Ribbon

Pull Adhesive

MOVIE

SHOW ME

TLP 2844 TLP 2824

Strip Free

14 980381-001 Rev. A

Page 21

Step Install Supply Roll

Thread

Ribbon

Through

Carriage

Press

onto Hub

Using Options

Align Notches

onto Hub Spokes

980381-001 Rev. A 15

Loading...

Loading...