Page 1

___________________________________________________________________________

WhereLAN III User’s Guide

WhereLAN III

LOS-5000

User’s Guide

DRAFT

___________________________________________________________________________ 1

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 2

___________________________________________________________________________

WhereLAN III User’s Guide

Typographical Conventions

_____________

_____________

____________

____________

____________

Note

____________

Warnings call attention to a procedure or practice that could result in

personal injury if not correctly performed. Do not proceed until you fully

understand and meet the required conditions.

Cautions call attention to an operation procedure or practice that could

damage the product, or degrade performance if not correctly performed.

Do not proceed until understanding and meeting these required

conditions.

Notes provide information that can be helpful in understanding the

operation of the product.

___________________________________________________________________________ 2

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 3

___________________________________________________________________________

WhereLAN III User’s Guide

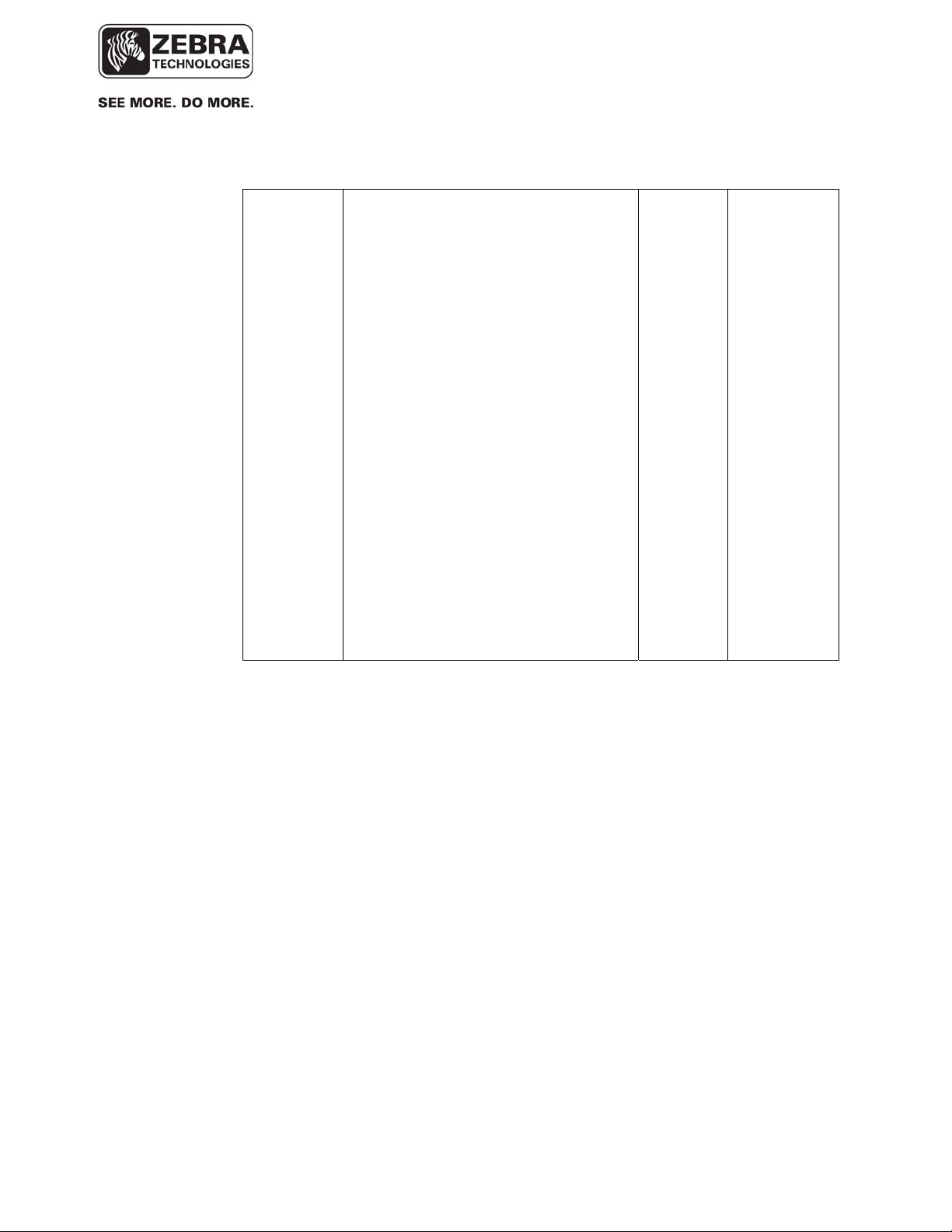

Document Revision History

Revision Description of Changes Date Approved

A Initial Release 10/20/10 GLC

B Per ECO C02532 05/09/11 GLC

C Addition of Secure Shell, Wi-Fi

8/28/11 SR

configuration, Network Autoconfiguration (DHCP), and general

errata.

D Per ECO C02834 04/04/12 GC

E Per ECO C02879 05/21/12 GC

___________________________________________________________________________ 3

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 4

___________________________________________________________________________

WhereLAN III User’s Guide

Table of Contents Page

TABLE OF FIGURES .................................................................................................................. 5

1 DOCUMENT OVERVIEW ................................................................................................. 8

2 PRODUCT DESCRIPTION AND FEATURES ................................................................ 8

3 PRODUCT SPECIFICATIONS ........................................................................................ 11

3.1 MECHANICAL ................................................................................................................. 11

3.2 ELECTRICAL ................................................................................................................... 11

3.3 ENVIRONMENTAL ........................................................................................................... 11

3.4 EXTERNAL CONNECTIONS .............................................................................................. 12

4 ACCESSORIES .................................................................................................................. 13

5 CONFIGURATION & CONTROL .................................................................................. 14

5.1 WHERELAN III SELF BOOT ........................................................................................... 14

5.2 WHERELAN III INTERFACE ........................................................................................... 16

5.3 WHERELAN III MAC/ IP ADDRESS CONFIGURATION ................................................... 23

5.4 WI-FI CLIENT CONFIGURATION (LOS-5000-00AB ONLY) ............................................ 39

5.5 WPA SUPPLICANT UPLOAD ........................................................................................... 44

6 INSTALLATION AND MOUNTING .............................................................................. 50

6.1 SAFETY AND INSTALLATION WARNINGS AND CAUTIONS ............................................... 50

6.2 MOUNTING ..................................................................................................................... 51

6.3 3/8THS THREADED ROD ................................................................................................. 53

6.4 POLE MOUNT KIT .......................................................................................................... 55

7 ANTENNAS......................................................................................................................... 61

7.2 VERTICAL DIVERSITY MOUNTING ................................................................................. 65

7.3 WI-FI 802.11 B/G ANTENNAS......................................................................................... 68

8 CABLING ............................................................................................................................ 69

8.1 POWER, AC ................................................................................................................... 70

8.1 ETHERNET ...................................................................................................................... 71

8.2 WI-FI ANTENNA KIT ...................................................................................................... 71

8.3 TIMING CABLE INTERCONNECTION GUIDELINES ............................................................ 77

8.4 LOCATION SENSOR OPERATIONAL VERIFICATION ......................................................... 84

REGULATORY INFORMATION ........................................................................................... 86

APPENDIX A: LOS-5000 EFFECTIVE PROJECTED AREA (EPA) ................................. 89

___________________________________________________________________________ 4

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 5

___________________________________________________________________________

WhereLAN III User’s Guide

APPENDIX B: LOS-5000 WEIGHT ....................................................................................... 90

APPENDIX C: WI-FI REGULATORY COMPLIANCE ..................................................... 91

APPENDIX D: FIRMWARE UPGRADE ............................................................................... 93

APPENDIX E: HYPERTERMINAL BOOT SEQUENCE ................................................... 98

Table of Figures

Figure 1 LOS-5000 LED's ............................................................................................................ 14

Figure 2 Example of LOS-5000-00AB Label ......................................................................... 36

Figure 3 Safety and Warnings ....................................................................................................... 50

___________________________________________________________________________ 5

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 6

___________________________________________________________________________

WhereLAN III User’s Guide

Figure 4 Mounting Points ............................................................................................................. 51

Figure 5 Safety Lanyard................................................................................................................ 52

Figure 6 Threaded-Rod ................................................................................................................. 53

Figure 7 Safety Lanyard................................................................................................................ 54

Figure 8 Pole Mount Kit ............................................................................................................... 55

Figure 9 Bracket Mount ................................................................................................................ 56

Figure 10 Retaining Bolts ............................................................................................................. 57

Figure 11 Location Sensor Mounted ............................................................................................. 58

Figure 12 Pole mount on Pole ....................................................................................................... 59

Figure 13 Location Sensor on Pole ............................................................................................... 60

Figure 14 Office Omni .................................................................................................................. 61

Figure 15 All Weather Omni ........................................................................................................ 61

Figure 16 Minimum clearance to metallic structures ................................................................ 62

Figure 17 Corner mount industrial application ......................................................................... 63

Figure 18 Office omnidirectional in corridor ............................................................................ 64

Figure 19 Vertical Diversity 5ft, ................................................................................................... 66

Figure 20 Vertical Diversity +11ft. ............................................................................................... 67

Figure 21 Vertical Diversity Connections .................................................................................... 68

Figure 22 Location Sensor Connections ....................................................................................... 69

Figure 23 Drip Plug ...................................................................................................................... 69

Figure 24 CBK-020-00 ................................................................................................................. 71

Figure 25 Wi-Fi Cable 1 ............................................................................................................... 72

Figure 26 Wi-Fi Cables Drip Plug ................................................................................................ 73

Figure 27 Wi-Fi Bracket ............................................................................................................... 74

Figure 28 2.2 dBi Dipole .............................................................................................................. 75

Figure 29 2.2 dBi Installed............................................................................................................ 75

Figure 30 Wi-Fi Bracket Remote Antenna ................................................................................... 76

Figure 31 Remote Antenna Clamp ............................................................................................... 76

Figure 32 Timing cable wiring pin out ...................................................................................... 78

Figure 33 Timing Cable Trim ....................................................................................................... 79

Figure 34 Timing Cable Jacket ..................................................................................................... 79

Figure 35 Timing Cable Trim ....................................................................................................... 80

Figure 36 Timing Cable Pull Jacket.............................................................................................. 80

Figure 37 Timing Cable Crimp ..................................................................................................... 81

Figure 38 Test setup for CAT5 cable using Fluke 620 ............................................................. 82

Figure 39 Correct readout when testing 2 pair cable. ................................................................ 83

Figure 40 Location Sensor LED indicators ............................................................................... 84

Figure 41 Ftproot Directory .......................................................................................................... 93

___________________________________________________________________________ 6

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 7

___________________________________________________________________________

WhereLAN III User’s Guide

Figure 42 VSS Firmware 4.0.5.2 Directory .................................................................................. 94

___________________________________________________________________________ 7

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 8

___________________________________________________________________________

WhereLAN III User’s Guide

1 DOCUMENT OVERVIEW

This document describes the basic configuration and recommendations on

physical installation of the WhereLAN III product, which is part of the

Location Sensor product line. The site design and placement is detailed in the

Location Sensor Placement Guide D0406 and WhereLAN III Instruction

Sheet (26913), provide with each unit.

2 PRODUCT DESCRIPTION AND FEATURES

The WhereLAN III is the next generation of WhereLAN product that receives

the signals transmitted by WhereTags (ISO 24730-2), and provides data to the

Location Algorithm processor. The received tag blinks are decoded, time

stamped, and routed to a Windows Server or ZLA (Zebra Location Appliance)

for additional processing. The locate algorithm running on the Windows

Server or ZLA calculates the tag position based on the time stamps of multiple

Location Sensors, and reports that position to the database where it is

displayed by Resource Manager.

The WhereLAN III Location Sensor supports the same Real Time Locating

System (RTLS) functions as the previous sensor, known as the WhereLAN

Location Sensor (LOS). WhereLAN III is fully backwards compatible and

may be used, as outlined herein, as a drop-in replacement for any existing

LOS. However, the WhereLAN III incorporates modern and patent-pending

techniques that result in superior accuracy performance over the current LOS

product. In addition, WhereLAN III supports a number of other value-added

features, as follows:

Time Synchronization: Like the LOS, WhereLAN III supports wireless and

wired time synchronization. However, the product can operate in two distinct

time synchronization modes, known as “Legacy” and “Time Synch II” As

shipped, the product defaults to Legacy time synchronization. In Legacy

mode, WhereLAN III is drop-in compatible with LOS and is backwards

compatible with VSS release 3.8. The Legacy Time service relies on various

user-defined entities, such as Line-of-Sight lists and Timing Islands. Time

Synch II no longer exposes these entities to the end user. A site must run

either the Legacy Time service or the Time Synch II service, but not both. In

Time Synch II mode, WhereLAN III furnishes additional data required by a

new Time Synchronization Process, scheduled for release in Q4 2012, which

runs on the Windows Server or ZLA. The Time Synch II service reduces site

design complexity and post-install support. It accomplishes this by being

“self-configuring” and “self-adjusting”; it hides its configuration details from

___________________________________________________________________________ 8

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 9

___________________________________________________________________________

WhereLAN III User’s Guide

the end user, automatically self configures and automatically adjusts to a wide

range of Radio Frequency environmental changes. The new Time Synch II

service is substantially different from and is not backwards compatible with

the Legacy Time Synch service. In Legacy mode, the embedded wireless time

beacons are transmitted over the right channel whereas both the left and right

channels are used in Time Synch II mode. Time Synch II can operate in an all

WhereLAN IIIs network, an all LOSs network, or a network with mixed

WhereLAN IIIs and LOSs. However, in order for Time Synch II to work with

LOSs, they must operate in “dual-posting” mode.

Wi-Fi: A variant of the LOS, known as a Locating Access Point (LAP),

supports an integral 802.11 b/g/a Access Point. WhereLAN III does not

support an integral Access Point. Instead, a variant of WhereLAN III supports

establishing an 802.11 b/g Wi-Fi client side connection to any industrystandard Access Point. Unlike WhereLAN III, the LOS does not support

establishing Wi-Fi client side connections.

Network Auto-Configuration (DHCP) and IPv6: The WhereLAN III, with the

release of VSS 4.0.5.2 support both DHCP IP and IPv6 address assignment.

However, the methods used by system software to establish connectivity with

the sensors on start-up preclude the full use of (dynamic) DHCP IP addresses.

This restriction is being eliminated, in the VSS 4.0.5.2 release, for WhereLAN

III sensors by a new process, referred to as Network AutoConfig. This

process conveys the IP address of the RTLS server to the WhereLAN IIIs as

part of the standard DHCP IP address assignment message exchange. In turn,

the WhereLAN IIIs “check-in” with the RTLS server by passing it the MAC

address of their Ethernet port. The RTLS server uses the MAC address to

“authenticate” the identity of the WhereLAN IIIs by checking for the MAC

addresses to be present in the site configuration file.

IEEE 802.3af Power of Ethernet (PoE): WhereLAN III supports industrystandard PoE. This allows for easier installation as it removes the need to run

DC power cabling to the unit. PoE may be supplied by any standardscompliant network switch. Alternatively, Zebra offers a single-line PoE

injector.

Power Consumption: WhereLAN III consumes just 12 watts, a 31% and 57%

reduction relative to the LOS and LAP, respectively.

___________________________________________________________________________ 9

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 10

___________________________________________________________________________

WhereLAN III User’s Guide

The WhereLAN III product line contains the following product skews:

LOS-5000-00AA: This is a “base” WhereLAN III unit, with an integral

802.3af compliant Ethernet interface, supporting wireless and wired timing

options.

LOS-5000-00AB: This version adds 802.11 b/g Wi-Fi support, in client

mode, to the base unit. This part number is approved for sale to U.S. Federal

Government procurements.

LOS-5000-00CA: This is a “base” WhereLAN III unit approved for sale to

U.S. Federal Government procurements.

LOS-5000-01AA: This is a “base” WhereLAN III unit incapable of

transmitting a wireless time beacon and is approved for sale to U.S. Federal

Government procurements.

___________________________________________________________________________ 10

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 11

___________________________________________________________________________

WhereLAN III User’s Guide

3 PRODUCT SPECIFICATIONS

3.1 Mechanical

Size: 10.3 x 1.7 x 12.0

261 x 43 x 305

Weight: 7.0

3.2

in (HxDxW)

mm

Lbs

Kg

3.2 Electrical

Voltage: 36 to 57

48V nominal

Current: .350 (max) Amps

Power Dis.: 12.0 (max) Watts

Power:

Can be powered by a Zebra

approved, Limited AC to DC Power

Supply or Power Over Ethernet

(POE). See Accessories List

Vdc

3.3 Environmental

Operating Temp.1:

Ingress Protection: 55 IP

Humidity

1

See power supply limits

___________________________________________________________________________ 11

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

-40 to +60 ºC

5 to 95% Non-condensing

Page 12

___________________________________________________________________________

WhereLAN III User’s Guide

3.4 External Connections

Antenna (2): MCX (Jack)

DC Power: 2.5 ID/ 5.5 OD mm (Jack)

Opt. Wi-Fi Antenna: SMB (Jack)

Ethernet: RJ45 (Jack) 10/100 and 802.3af POE

Timing (3): RJ-22 (4 wire telephone handset, Jack)

With the exception of the LOS-5000-00AB model (Wi-Fi backhaul), the

WhereLAN III must be wired to a nearby 10/100BaseT Ethernet switch or

hub. In addition, the network to which the switch or hub connects must allow

full access to a number of standard communication protocols and port ranges

(TCP/IP, UDP, ftp, etc). See the Zebra VSS Software Installation Guide for

further detail on the interconnecting network requirements. The maximum

Ethernet cable run is 328 ft (100 m). If additional distance is required, hubs,

repeaters, and fiber (with 10baseT converters) can be used to extend the

distance. Refer to IEEE guidelines for Ethernet cabling. The LOS-500000AB must be configured to connect to an IEEE 802.11 b/g Wi-Fi network, as

outlined in this document.

___________________________________________________________________________ 12

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 13

___________________________________________________________________________

WhereLAN III User’s Guide

4 ACCESSORIES

The accessories indicated below are required to complete the installation of

the Location Sensor. Ordering information is supplied where applicable.

Note: Not all accessories are listed or globally available. Check with local sales

representative regarding availability.

Accessories Model Number

• All Weather Omni Antenna1

(standard)

• Office Omni Antenna1 (indoor

only)

• DC power cable extender, 50 ft,

Plenum Rated (Indoor Only)

• DC power cable extender, 50ft.,

Outdoor Rated.

• Power Over Ethernet injector

• Power Supply

• Pole Mount Kit:

• Wi-Fi Antenna Kit

• Wi-Fi Indoor Omni Antenna,

2.2dBi

AK-210-10

AK-110-10

PX-010-00

PX-050-00

EP-025-00

PS-040-00 or PS-045-00

RM-510-00

CBK-020-00

AK-170-00

• Wi-Fi Outdoor Omni Antenna,

5.2dBi

• Wi-Fi Outdoor Directional

Antenna, 13.5dBi

AK-151-00

AK-153-00

___________________________________________________________________________ 13

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 14

P

H

___________________________________________________________________________

WhereLAN III User’s Guide

5 CONFIGURATION & CONTROL

5.1 WhereLAN III Self Boot

Upon power up, WhereLAN III executes a self-boot process. The boot

process takes between 45 to 60 seconds. If a fault occurs during the boot

process, the unit may reset and restart the boot process. During that process,

the four LEDs blink in a sequence to indicate the current stage of the power

up boot process. The LED Process is as follows after initial power is applied.

• 1 LED (Power): The Boot Loader is loading the Kernel.

• 4 LED’s : The Kernel is initialized and is loading the applications,

JFFS2 and CRAM File system

• 1 LED (Power): The Application is loading the FPGA’s and DSP’s

• 2 LED’s (Power and Tag Reception): The unit is initializing the

FPGA’s and DSP’s.

• 1 LED (Power): Unit is booted and ready for operations.

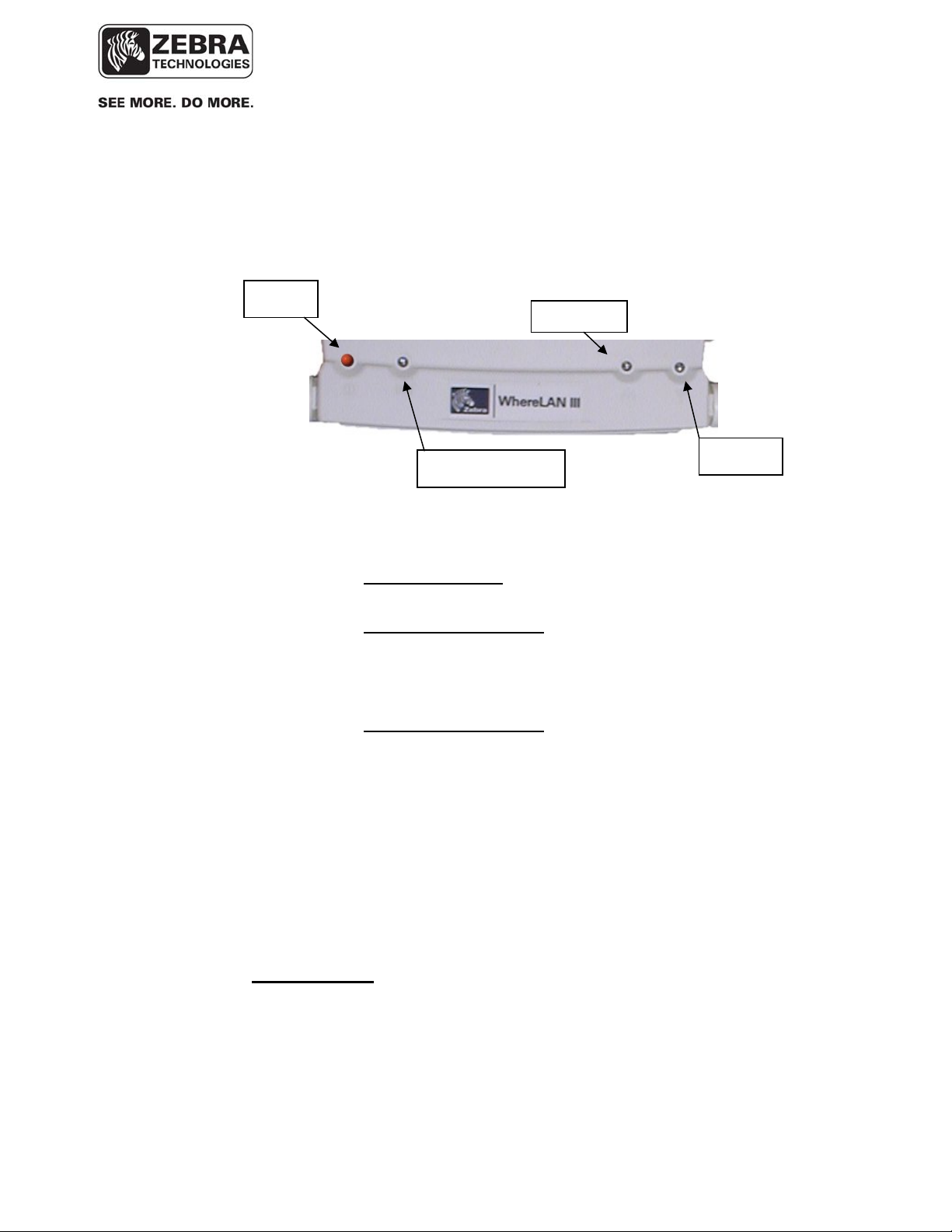

Location Sensor

ower/

ealth

Tag

Reception

Ethernet

WLAN

Outdoor

Omni

Antenna

Figure 1 LOS-5000 LED's

___________________________________________________________________________ 14

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 15

___________________________________________________________________________

WhereLAN III User’s Guide

5.1.1 LED Functions

Once the boot process is complete, the LEDs revert to their standard

functions indicating power/health, tag status, Ethernet, and Wi-Fi.

Power

Ethernet

Tag Reception

WLAN

• Power/Health LED: Indicates unit has power and general health of

unit.

o State 1 Steady ON: When the Power LED is steady on, the

unit is healthy and sitedata has been received and is correct.

o State 2 80% Duty Cycle: The Power LED is ON for close to

80% of the time and OFF for a brief period. This indicates

either sitedata has not been received or that there is a

problem with site data.

o State 3 50% Duty Cycle: The Power LED blinks ON for 1

Second and OFF for 1 Second. This indicates a health check

has failed and possible hardware problem. For example, the

unit is either not blinking its embedded tag or is not receiving

its embedded tag.

• Tag Reception LED: Blinks when WhereTag signals are received.

• Ethernet LED: Is on solid when has connection to an Ethernet

network.

• WLAN LED: Is on solid when Wi-Fi connection is established.

See Appendix F

: For Complete Boot Sequence details.

___________________________________________________________________________ 15

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 16

___________________________________________________________________________

WhereLAN III User’s Guide

5.2 WhereLAN III Interface

After the WhereLAN III has completed its boot process, it is possible to

communicate with the unit via the following methods.

____________

Note

____________

Do not attempt to communicate with the WhereLAN III it has completed

the first stage of the boot process (i.e., left LED is solid). Doing so will

stop the boot process. The unit must be reset to clear this condition.

These units are configured using:

• SSH (Secure Shell 2) via Ethernet (preferred)

____________

Note

____________

• WhereWand

• Hyperterminal (or any terminal emulation software) via serial port

SSH is the preferred method of communicating with the WhereLAN III.

Use the HyperTerminal is for initial set-up before being installed on a

network for setting static IP addresses, if DHCP is not used. In addition

to SSH, WhereLAN III also supports Telnet, but this protocol is disabled

by default. To use Telnet, you must first enable it via accessing the

WhereLAN III configuration menu via SSH or a serial port connection.

However, enabling Telnet is not recommended as it sends user name and

passwords across the network in the clear.

The Ethernet Communication Parameters are:

• 10/100 Mb/s

• CAT 5 cable/ RJ-45 plug

___________________________________________________________________________ 16

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 17

___________________________________________________________________________

WhereLAN III User’s Guide

Hyperterminal via Serial Port

Communication Parameters:

• Null-modem cable, 9-pin female to 9-pin female

• 19200 baud, RS-232c

• 8 data bits, 1 stop bit, no parity, no hardware flow control

HyperTerminal may be used to configure the sensor before connecting it to a

network with a DHCP server, or when a rare fault occurs during the first stage

of the boot process, or if visibility to the boot process is needed for debugging

installation problems.

5.2.1 Establishing an SSH Connection

WhereLAN III supports Secure Shell (SSH), SSH2 being preferred over

SSH1. Either the IP address or host name of the unit must be known in order

to establish an SSH session.

An SSH session may be established using a freely available application called

OpenSSH (supplied by your Zebra Professional Services staff or visit

http://openssh.com for further details, but requires the ssh_zebra_rsa_key

available from Professional Services). Alternatively, other applications, such

as PuTTY, may be used as well, but will require the conversion on the

ssh_zebra_rsa_key into the appropriate format.

To establish the SSH session, you must use Zebra-supplied key, called

“ssh_host_rsa_key” and the “blowfish” passphrase.

The following section shows how to use the OpenSSH application.

___________________________________________________________________________ 17

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 18

___________________________________________________________________________

WhereLAN III User’s Guide

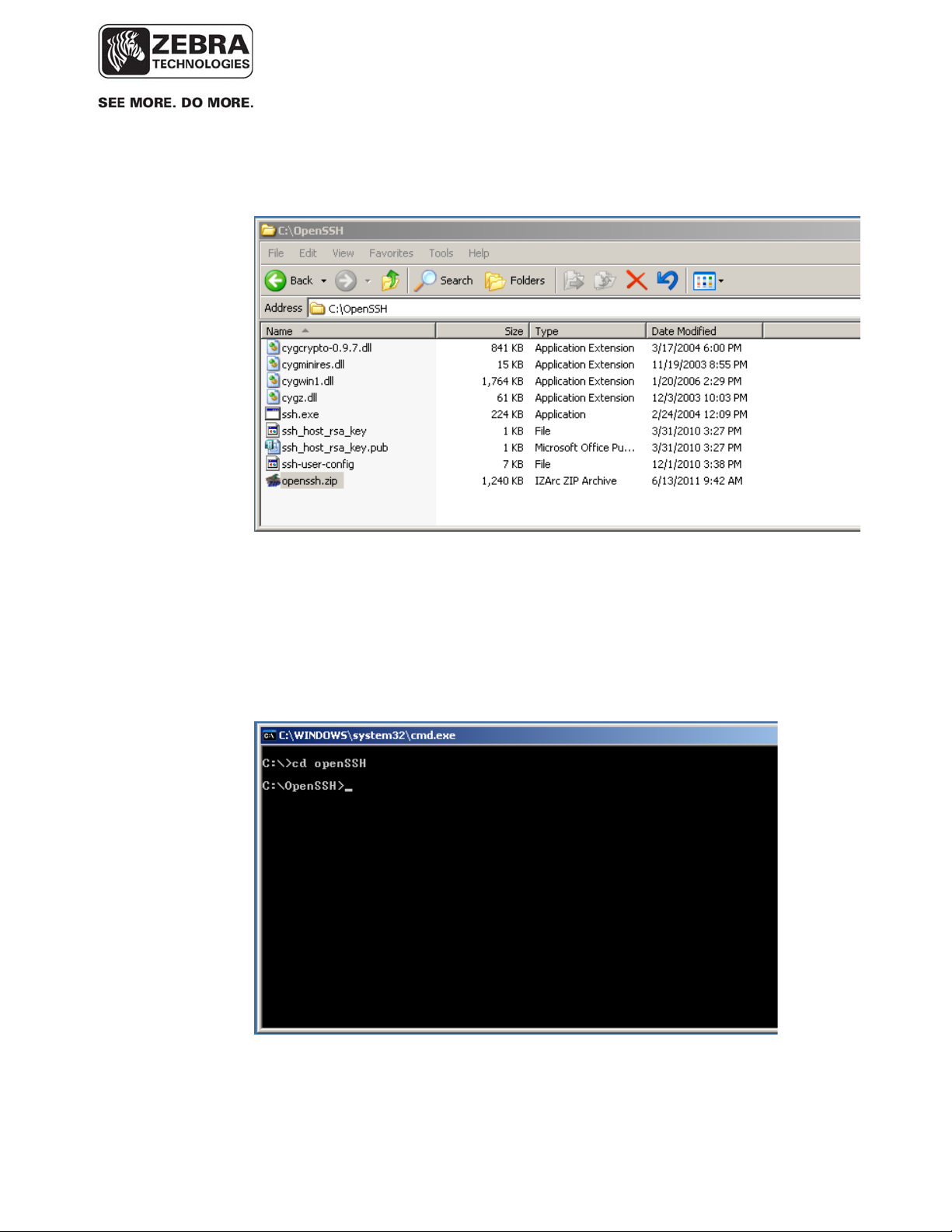

The provided zip archive contains all you need to use OpenSSH. Unzip the

file and put it anywhere on your hardrive.

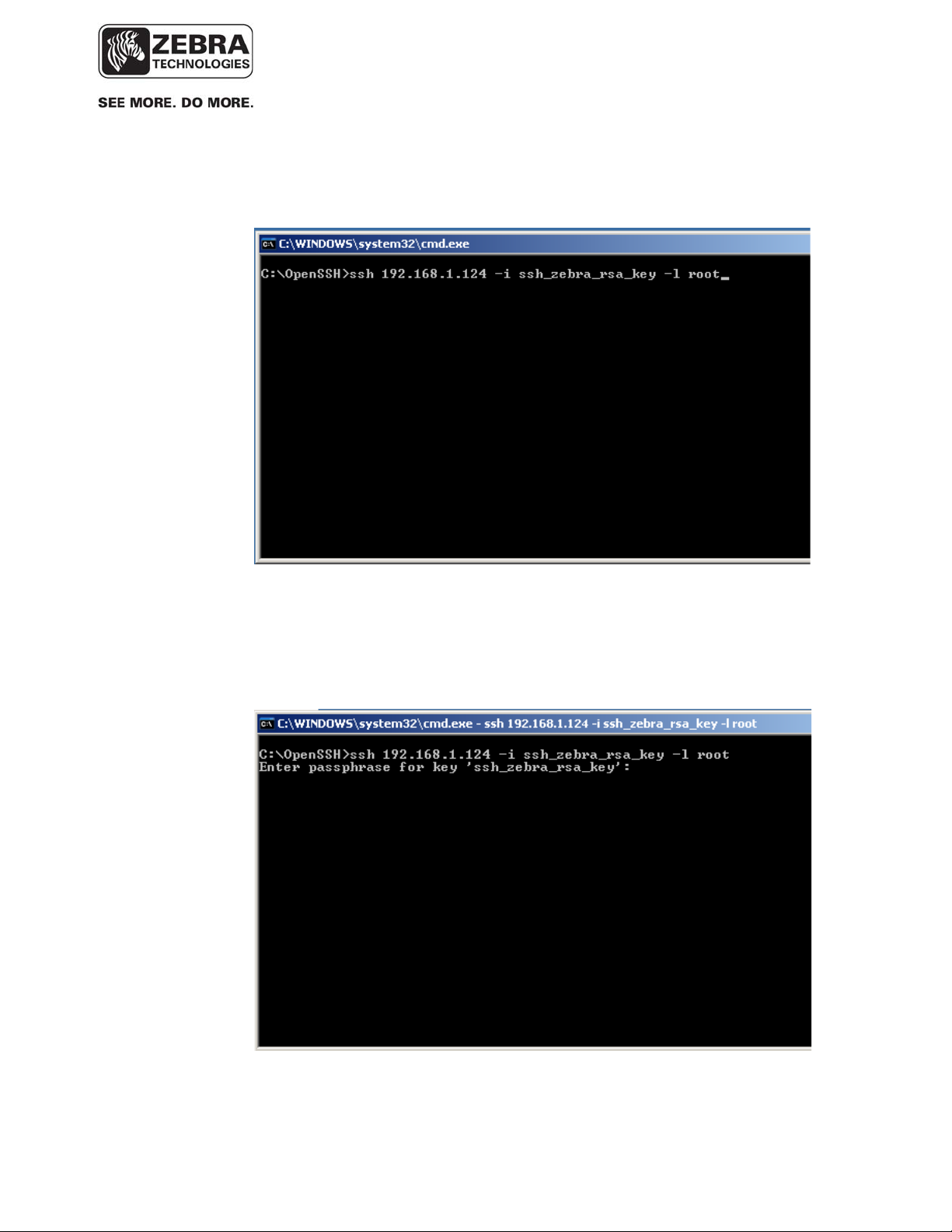

1. Launch a command prompt, and change directory to the folder where you

placed the executable ssh.exe file, for example, “C\OpenSSH”.

___________________________________________________________________________ 18

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 19

___________________________________________________________________________

WhereLAN III User’s Guide

2. Enter the following command at the command prompt:

‘ssh <ip-address> -i ssh_zebra_rsa_key –l root’

Note: The first time you do this from most computers you will be told

“can’t establish….” And it will ask you “are you sure?”…enter ‘yes’

3. The application will prompt you for a passphrase, use: ‘blowfish’

___________________________________________________________________________ 19

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 20

___________________________________________________________________________

WhereLAN III User’s Guide

4. WhereLAN III then presents secure access to its Configuration menu.

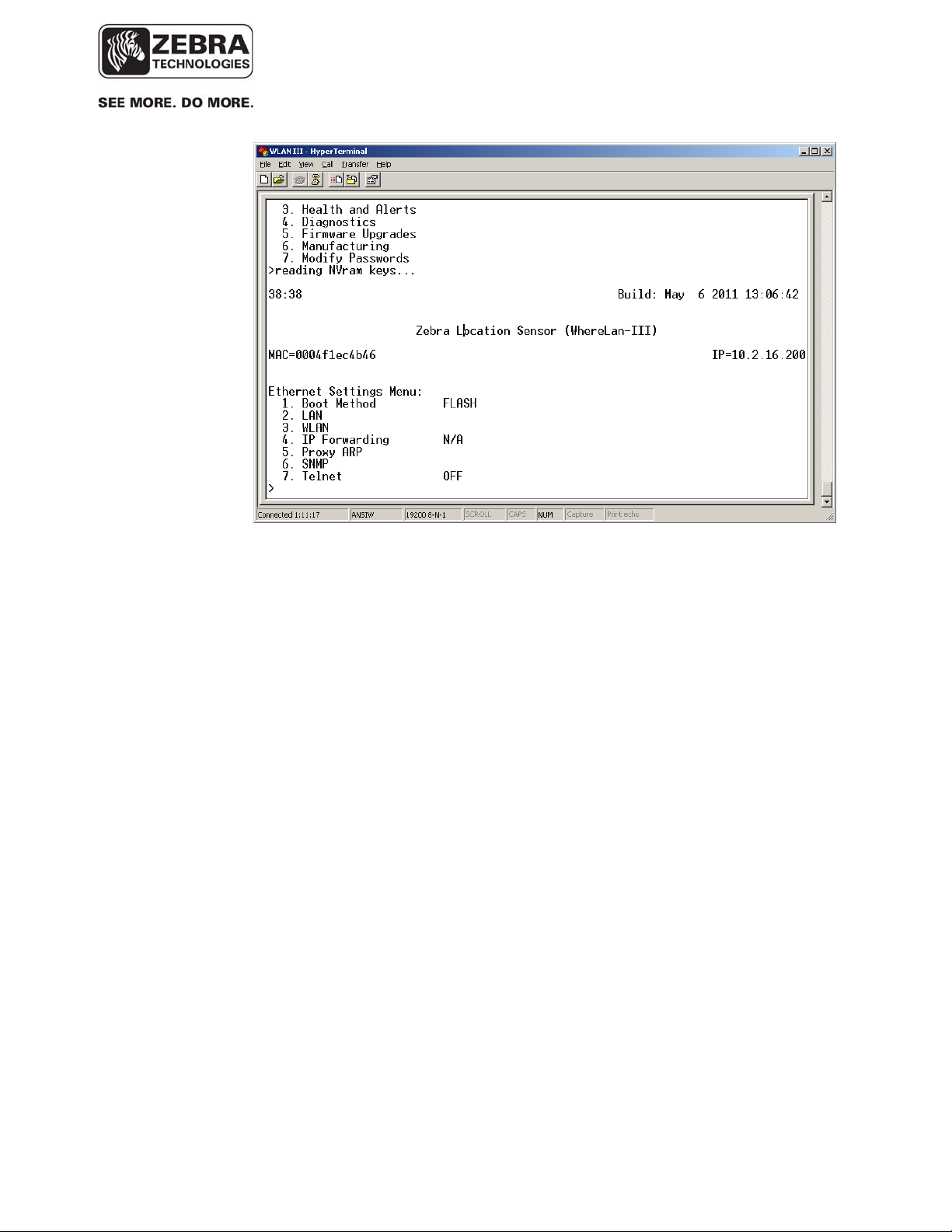

5.2.2 Enabling Telnet

The WhereLAN-III comes shipped with Telnet Disabled as added network

security. However for certain installation and/or customers Telnet may be

Enabled via the Menu System.

The enabling of Telnet is done via the numbered menu system either through

HyperTerminal or SHH, either will method will provide the same Menu

structure. The following example is shown using a direct connection with a

Null Modem Serial cable and HyperTerminal Session.

• From the Main Menu select the number that corresponds to ‘Ethernet

Settings’. The WhereLAN III application shows the following submenu:

___________________________________________________________________________ 20

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 21

___________________________________________________________________________

WhereLAN III User’s Guide

• Next select the number that corresponds to ‘Telnet’ and respond with y

to enable (or n to disable) Telnet.

___________________________________________________________________________ 21

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 22

___________________________________________________________________________

WhereLAN III User’s Guide

Press the ESC key and enter the “ff2” password when prompted. The unit

will update NVRAM, save your changes, and ask if you wish to reset the unit.

After reset, the unit will boot with Telnet support.

Note Telnet User and Password are as follows.

User: root

Password: password

___________________________________________________________________________ 22

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 23

___________________________________________________________________________

WhereLAN III User’s Guide

5.3 WhereLAN III MAC/ IP Address Configuration

WhereLAN IIIs connect to an IP network over an Ethernet or Wi-Fi interface

using TCP/IP, UDP, and other standard network protocols. For the LOS5000-00AB, both the Location Sensor and the embedded Client Card must be

independently configured with its own unique IP addresses or for DHCP

address assignment. The IP address of each LS must be recorded and entered

into the site configuration file, which contains the configuration information

for each LS, including its location, and MAC address. This is for versions of

VSS prior to the 4.0.5.2 release.

5.3.1 Activating IPv6 Transport

The WhereLAN-III device, running appropriate firmware V5.0.1 or later, will

automatically generate a link-local IPv6 address after booting up. However,

in order to acquire a global IPv6 address, which is needed for IPv6

communication with the VSS server, there must be an IPv6 router on the

network having the following configuration:

• Allow local IPv6 traffic with a global.

• IPv6 network prefix (such as, for example, 2001:470:87c4:1000::/64)

• Enable neighbor discovery/route advert. protocol

NOTE: The global IPv6 network prefix is a globally unique address and

can be used inside or outside of internal networks. You need to apply for

and obtain a global IPv6 network prefix for your network (for example,

see www.tunnelbroker.net

personnel responsible for the network.

If additionally you would like to assign a fixed IPv4 address to a

WhereLAN-III, you can do so via the sensor menu, which can be accessed

via Telnet (if enabled) or SSH client, or direct connect with serial cable.

). This is a task typically performed by IT

___________________________________________________________________________ 23

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 24

___________________________________________________________________________

WhereLAN III User’s Guide

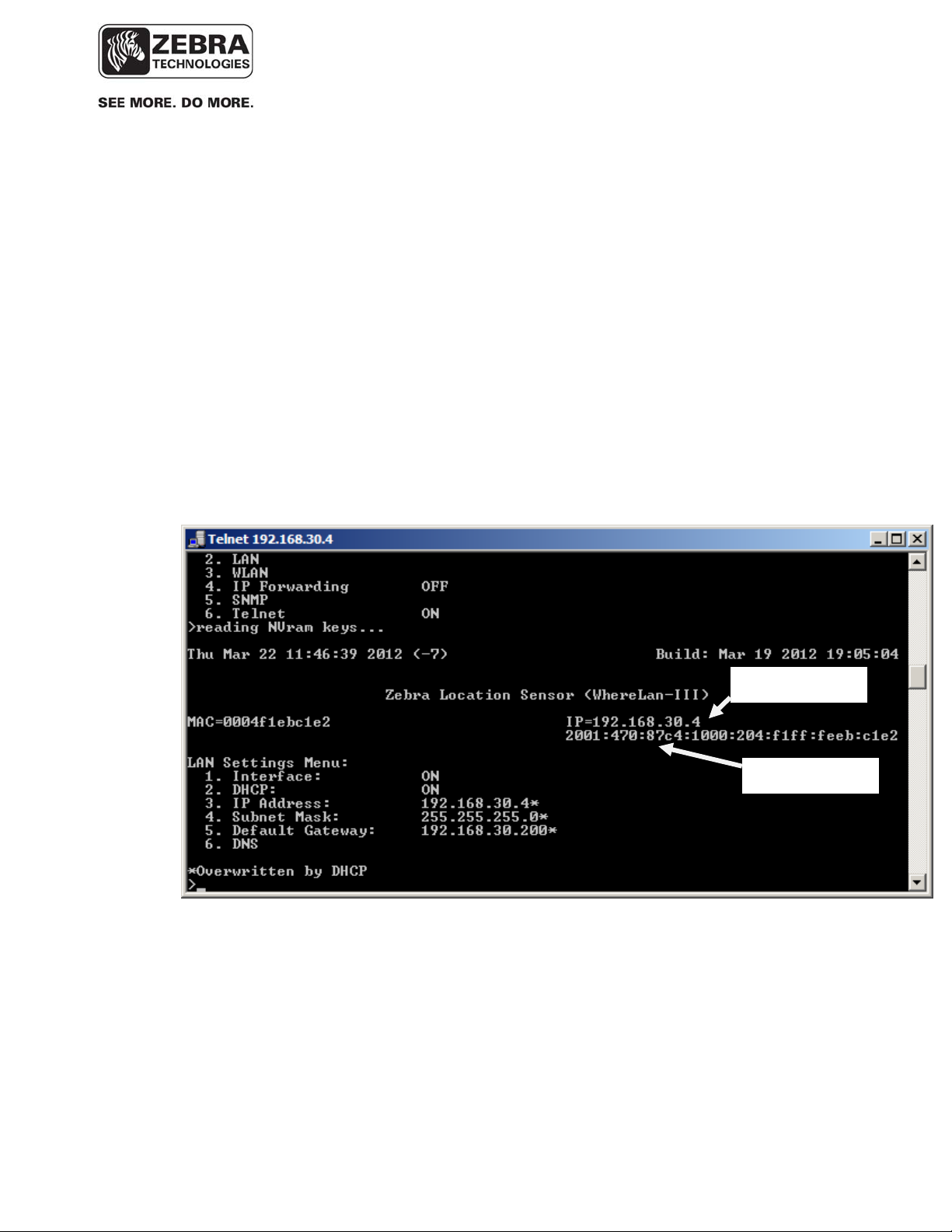

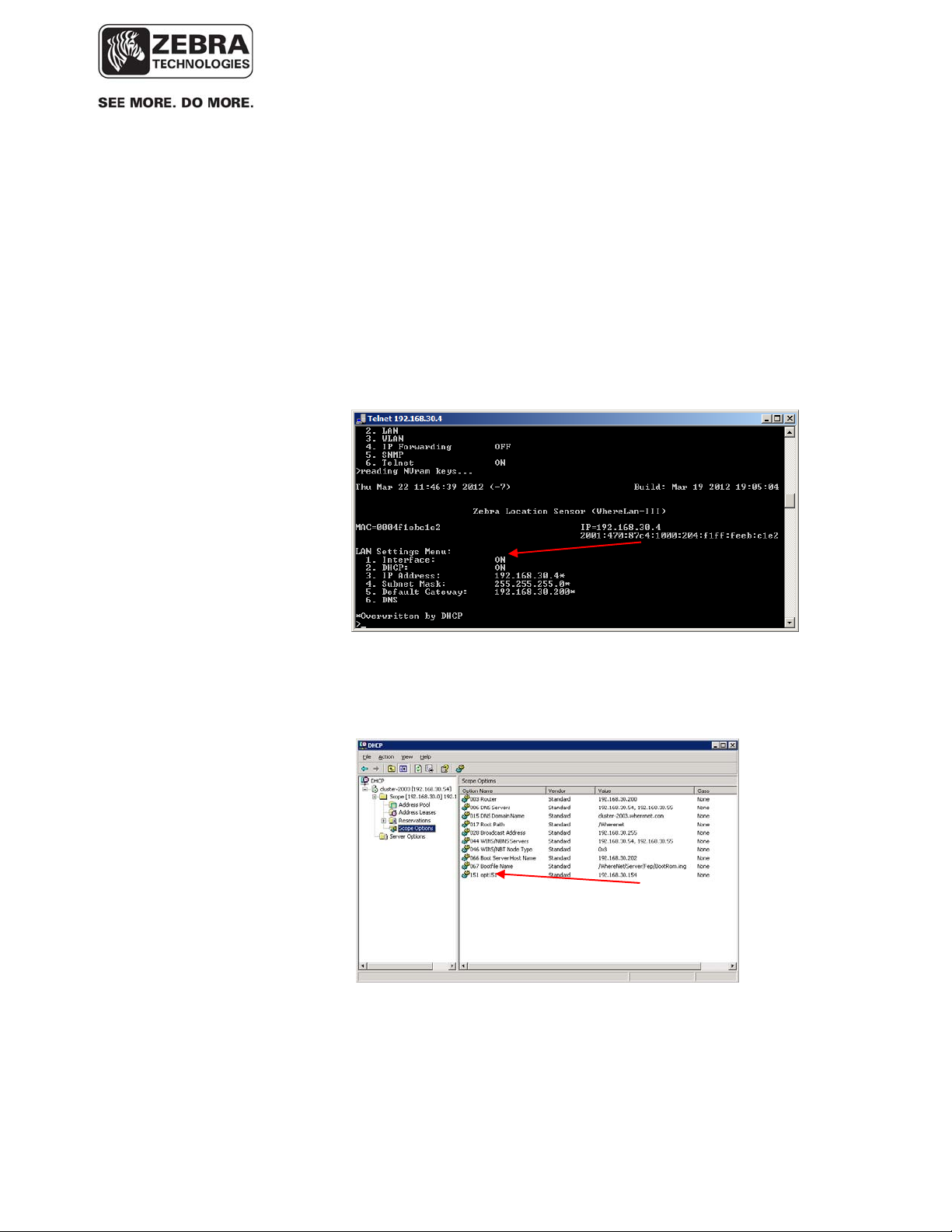

For example, if you Telnet to a sensor, you may see three IP addresses at

the top right of the window, as shown in the screenshot below:

• An IPv4 address, if one has been configured using the ‘Ethernet

Settings’ in the sensor menu (see screenshot).

• A global IPv6 address. This is the IPv6 address required for

communication with the VSS server using IPv6 transport.

• A link-local IPv6 address, automatically generated at boot up time

from the MAC address of the device

IPv4 address

IPv6 address

___________________________________________________________________________ 24

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 25

___________________________________________________________________________

WhereLAN III User’s Guide

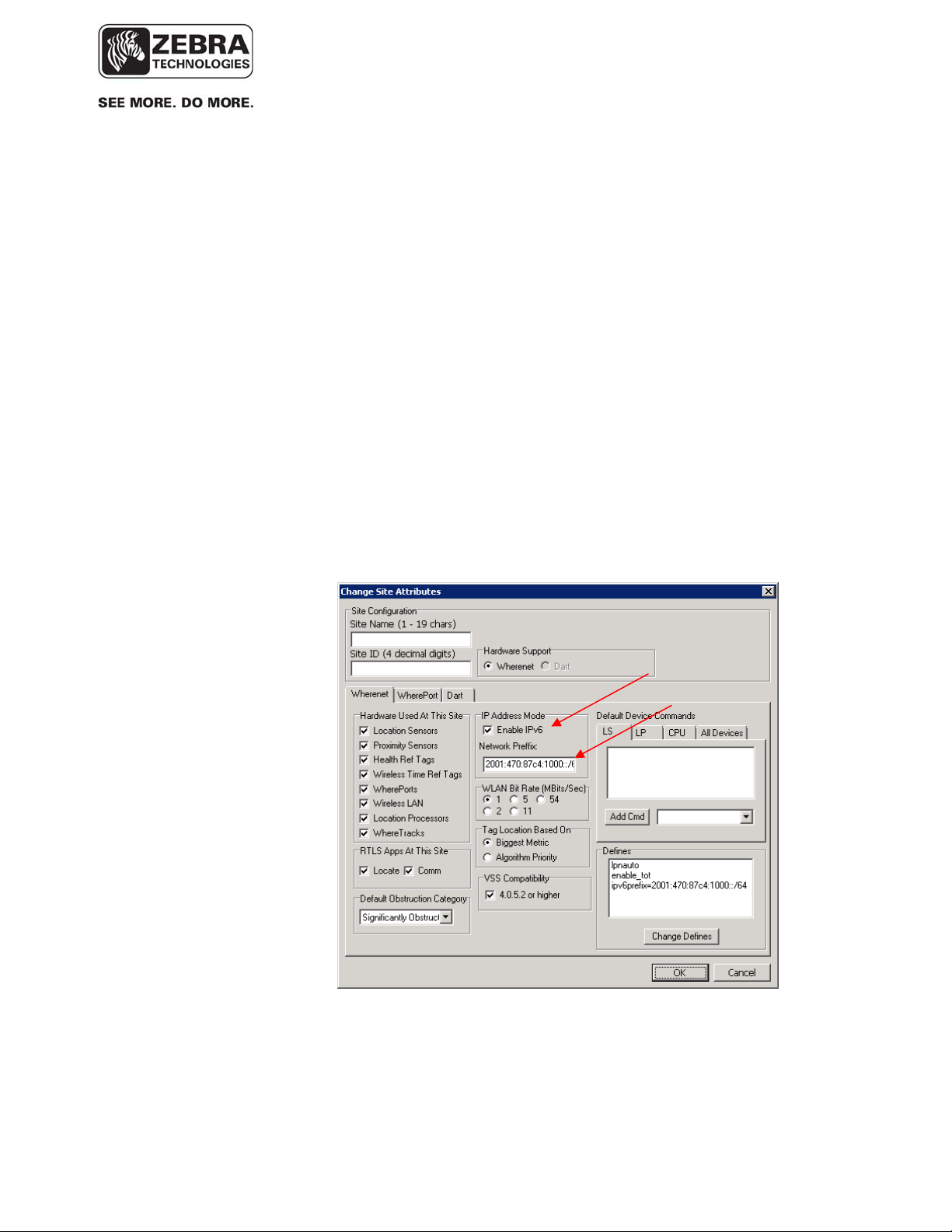

In order to have IPv6 network traffic (blinks, status information, etc.) between

the WhereLAN-III devices and the VSS server, the following requirements

must be fulfilled:

• The WhereLAN-III device must be able to acquire a global IPv6

address as described above.

• IPv6 must be enabled in the operating system (Windows) on the VSS

server.

• The following steps must be followed in System Builder, which is the

tool that generates the sitedata.dat configuration file parsed by the VSS

services and the WhereLAN-III devices:

• Activate IPv6 in the ‘Change Site Attributes’ dialog window and enter the

global IPv6 network prefix that the IPv6 router on that network is using:

___________________________________________________________________________ 25

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 26

___________________________________________________________________________

WhereLAN III User’s Guide

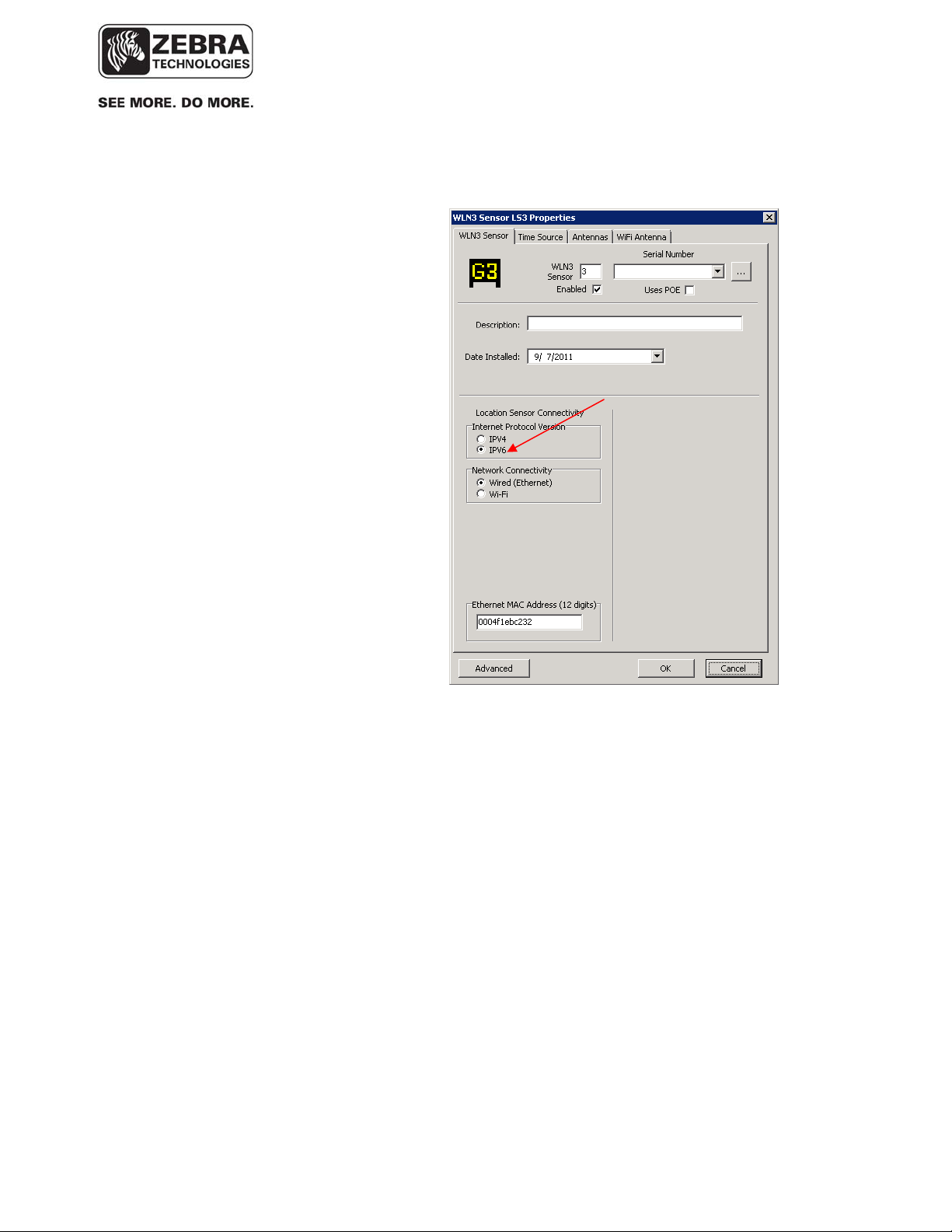

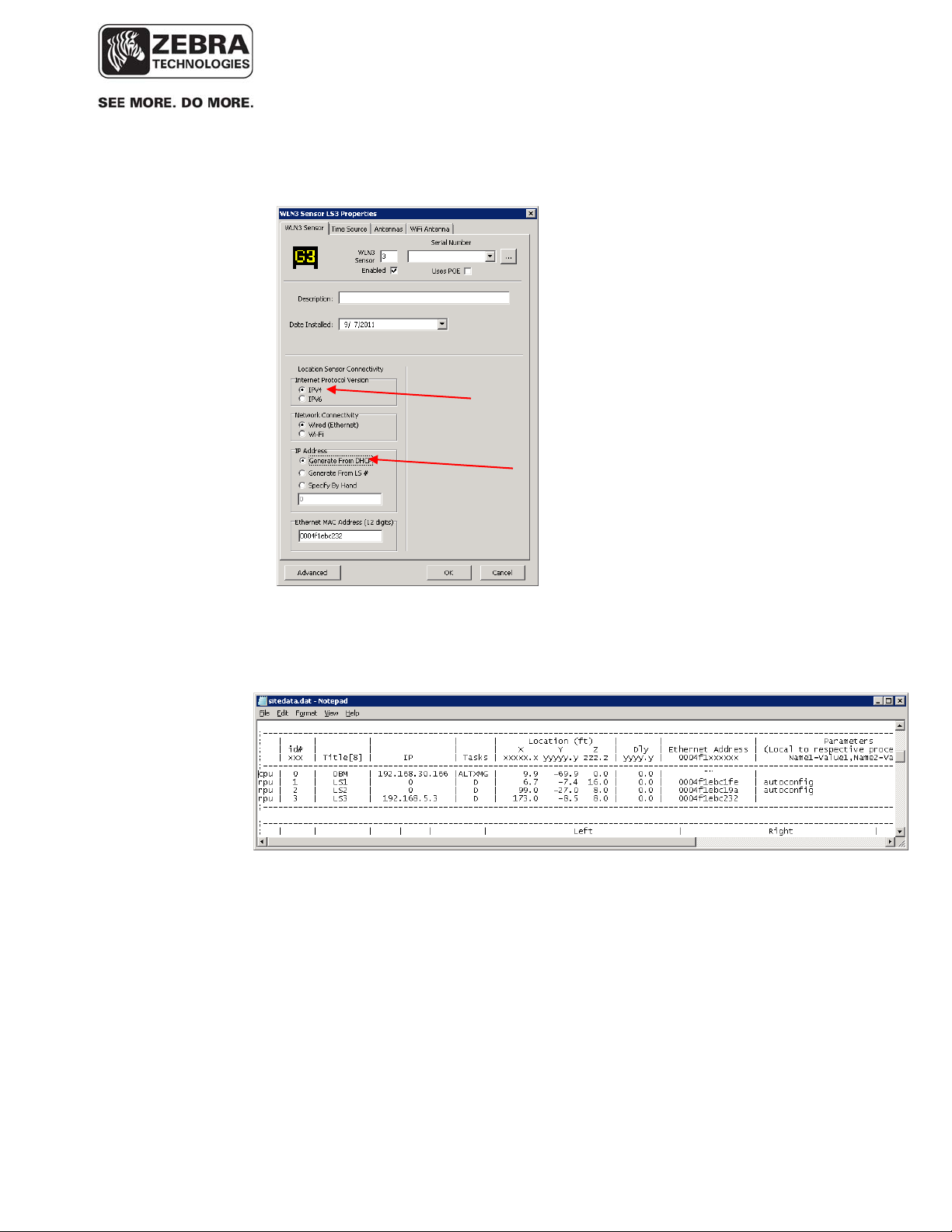

• Select IPv6 option in the Sensor Properties window:

___________________________________________________________________________ 26

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 27

___________________________________________________________________________

WhereLAN III User’s Guide

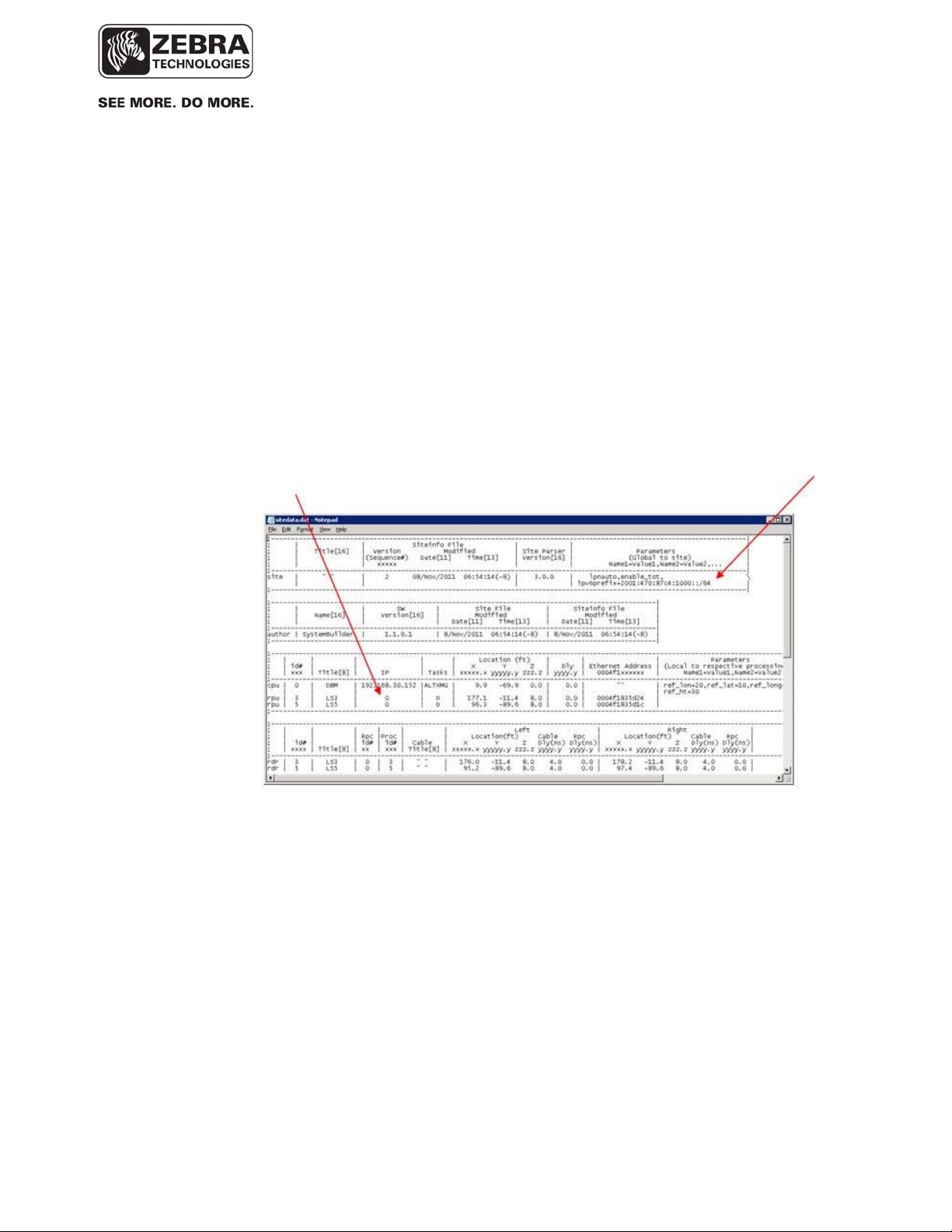

The resulting sitedata.dat generated by System Builder will include the following:

o A site define ipv6prefix specifying the global IPv6 network prefix used by

the IPv6 router on that network

o 0 (zero) IP address for all WhereLAN-III units that will communicate using IPv6

An example sitedata.dat is shown in the screenshot below:

NOTE: As usual, you need to restart the VSS services on the VSS server for

changes in sitedata.dat to take effect. Some changes require rebooting the

WhereLAN-III devices as well.

___________________________________________________________________________ 27

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 28

___________________________________________________________________________

WhereLAN III User’s Guide

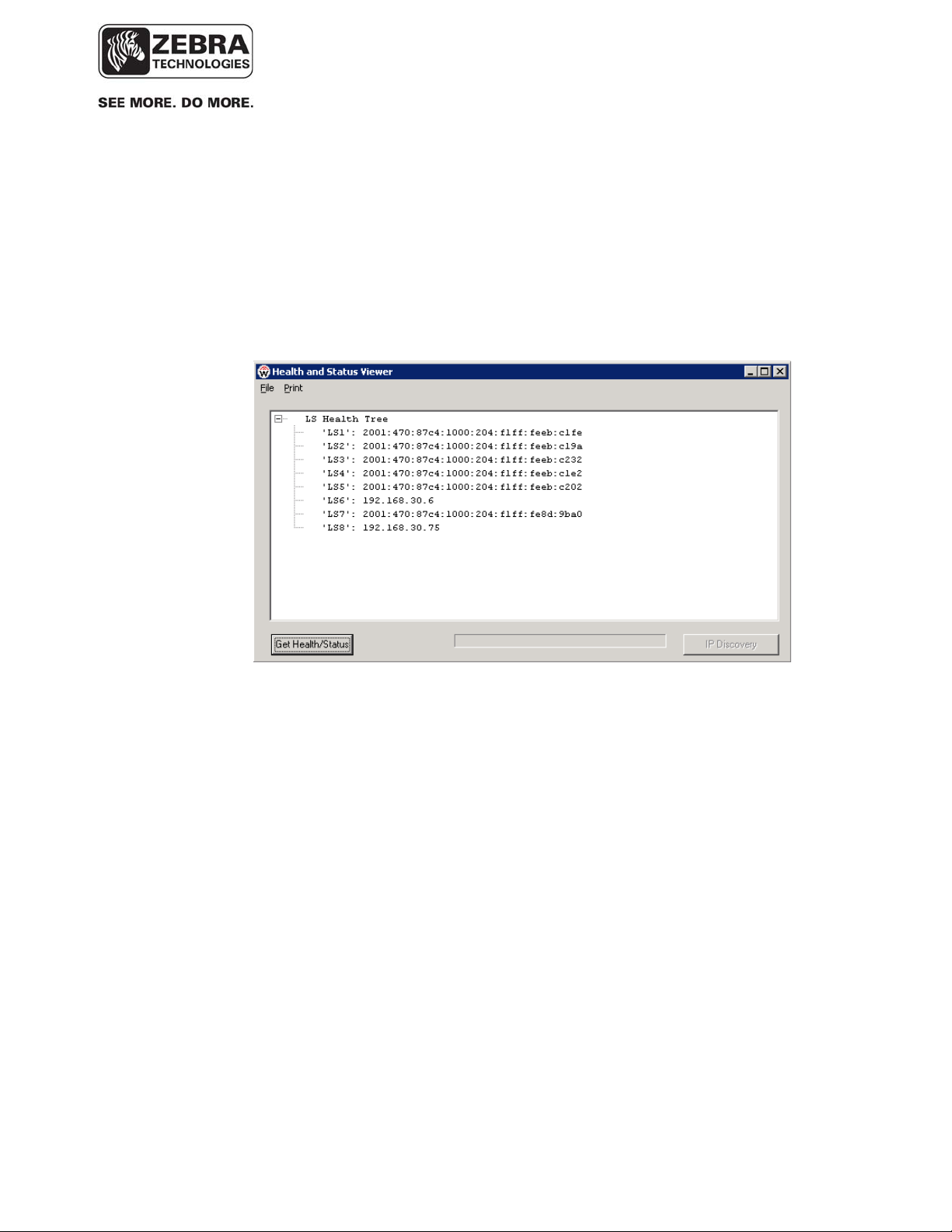

5.3.2 VSS Tool Support for IPv6

Once IPv6 transport between the VSS server and the WhereLAN-III devices

has been activated as described above, you can use the VSS diagnostics and

status tools as usual, but you will notice that the IPv6 address is used for

devices configured with the IPv6 option in System builder, as shown in the

Sensor Analyzer screenshot below:

___________________________________________________________________________ 28

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 29

___________________________________________________________________________

WhereLAN III User’s Guide

5.3.3 IPv4 DHCP Dynamic IP for WhreLAN-III Devices

It is possible to have a WhereLAN-III device automatically acquire an IPv4

address from a DHCP server. This IP assignment is dynamic and therefore the

assigned IP may change the next time the device is rebooted. To enable the

device to do so, the following steps are required:

o The DHCP option in the sensor menu needs to be turned ON:

o On the DHCP server, add scope option 151 (IP Address type) and point it to the IP

address of the VSS server:

___________________________________________________________________________ 29

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 30

___________________________________________________________________________

WhereLAN III User’s Guide

o In the Sensor Properties window in System Builder, select the IPv4 – DHCP option:

This will result in an entry for this sensor in sitedata.dat with a ‘0’ IP address and the

‘autoconfig’ define, as shown in the example below:

___________________________________________________________________________ 30

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 31

___________________________________________________________________________

WhereLAN III User’s Guide

5.3.4 SNMP and DNS Support in WHERELAN-III Devices

The WhereLAN-III firmware version 5.0.1 includes support for the SNMP

and DNS network protocols. The ‘Ethernet Settings’ menu in the sensor menu

includes menus to enable and configure these protocols, as shown in the

screenshots below:

___________________________________________________________________________ 31

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 32

___________________________________________________________________________

WhereLAN III User’s Guide

5.3.5 WhereLAN-III MAC Legacy Compatibility

The WhereLAN-III MAC address is not directly compatible for replacing a

WhereLAN-II at an existing site that is running a version of VSS prior to

4.0.5.2, and WhereWAND’s that are running software that is from VSS prior

to 4.0.5.2.

Location Sensors use 4 unique embedded tags id’s, for Timing and Health.

These 4 unique embedded tag Id’s correspond to the Rf Transmit and TIC

ports (1, 2, and 3). The upper 32 bits of these four tag-ID’s MATCH bits 31

down to 2 of the unit’s MAC address. For this reason MAC addresses of

Location Sensor with, WhereLAN-II or WhereLAN-III, skip in a modulus of

4.

• For Example: In a WhereLAN-2 a MAC address might look like

0004F1AAA120, then the next MAC address of a WhereLAN-2,

in sequence, would be 0004F1AAA124.

• So this means for a WhereLAN-2 that there MAC address will

always end in either a 0, 4, 8, or C.

• For the above Example: Embedded tags for 0004F1AAA120:

Rf Port: F1AAA120

Tic1: F1AAA121

Tic2; F1AAA122

TIic3:F1AAA123

• The WhereLAN-III MAC addresses now ends in either 2, 6, A, and E.

___________________________________________________________________________ 32

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 33

___________________________________________________________________________

WhereLAN III User’s Guide

WhereLAN-III MAC addresses now ends in either 2, 6, A, and E. This new

MAC scheme allows more efficient use of the MAC space defined for this

product and easy recognition by users and the system in identify a unit as a

WhereLan-III or II by just looking at its MAC.

• However the embedded tags still follow the format of the WhereLAN-

II, meaning they MATCH bits 31 down to 2 of the unit’s MAC address

in order of RF Tag thru wired time ports.

• Older versions of the WhereWand FW assume that the lower 32-bits

MATCH between the MAC and the RF tag-ID. To fit WhereLan-III

into the MAC space it is now that sensors MATCH bits 31 down to 2.

• The embedded tags not matching the MAC address is causing issues,

because the WhereWAND uses the Rf embedded tag id to

communicate with the Location sensor.

The differences described above cause three main issues with the WhereLANIII MAC address and running an older version of VSS prior to VSS 4.0.5.2,

cause.

1. The Blink Service auto-generates a list of expected/known system

embedded tags based on the MAC address in SiteData. Entering the

MAC as listed on the unit, a legacy BlinkService will not generate a

proper list of embedded reference tags, and the Time Service will not

receive the embedded tag blinks it needs from the WhereLAN-III.

2. iSensor validates the MAC addresses in sitedata.dat match the MAC of

the Location sensors. With legacy iSensor, this causes red-lights on

the health and status display.

3. The WhereWAND’s download of the site configuration contain the

MAC addresses of each Location Sensor. The WhereWAND must use

the Rf embedded tag Id to communicate with the location sensor and

legacy WhereWand FW calculates the tag-ID incorrectly, resulting in

no-response from the specific sensor.

___________________________________________________________________________ 33

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 34

___________________________________________________________________________

WhereLAN III User’s Guide

There are three ways to fix these issues.

1. The best is to have the customer site upgrade to VSS 4.0.5.2 or later,

which has the tools and system builder that take care of the issues

directly.

2. The next best is to see if the customer will allow new tools to be

loaded onto their system, if they require an approval time for full VSS.

The tools will be the System Builder and iSensor from the VSS 4.0.5.2

release. This will work with legacy version of VSS.

a. With this the MAC of the WhereLAN-III can be entered

accurately (as it is shown on the WHERELAN-III label) into

system builder, in the Location Sensor, WLN3 of the tree view.

Under the ‘Site Attributes’ tab, make sure the 4.0.5.2 VSS

Compatibility box is unchecked for legacy VSS systems. This

will save and publish the sitedata.dat in the correct form.

___________________________________________________________________________ 34

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 35

___________________________________________________________________________

WhereLAN III User’s Guide

3. Otherwise, In legacy VSS systems using legacy tools, the MAC

address must be adjusted by subtracting 2 from the MAC address that

is listed on the unit, see table below.

ActualWLANIIIMAC SystemBuilder

MACEntry

00‐04‐f1‐xx‐xx‐02 00‐04‐f1‐xx‐xx‐00

00‐04‐f1‐xx‐xx‐06 00‐04‐f1‐xx‐xx‐04

00‐04‐f1‐xx‐xx‐0A 00‐04‐f1‐xx‐xx‐08

00‐04‐f1‐xx‐xx‐0E 00‐04‐f1‐xx‐xx‐0C

NOTE:ThistableonlyappliestolegacyVSS,versionpriortoVSS

4.0.5.2

This will allow the WhereLAN-III’s to function in the Blink Service and have

the Time Service looking for the correct embedded tag Id’s. However with

legacy iSensor this will still display the unit as Red in Health and Status, for

the MAC mismatch. To fix the health indicator, you can consider just

replacing the iSensor executable with the one from VSS 4.0.5.2.

____________

Note

____________

Failure to configure the WhereLAN III prior to operation may result in

an inoperative unit. Ethernet connected units installed on an operational

and reliable network with DHCP IP address assignment may be

configured post installation. All Wi-Fi connected units must be

configured with the appropriate Wi-Fi network parameters before

installation.

___________________________________________________________________________ 35

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 36

___________________________________________________________________________

WhereLAN III User’s Guide

Each WhereLAN III is shipped with a label set containing one label (Figure 2)

with the bar coded MAC address of the unit and its Wi-Fi client (as

applicable) and three labels with the last six characters of the Location

Sensor’s MAC address in large type. Ensure that the label is correct by

matching the MAC address(es) on the loose label set with the MAC

address(es) listed on the back of the unit. Place the loose bar code label in the

site design document where indicated, and place one or more of the large type,

six character labels on the exterior of the Location Sensor in positions that are

visible after installation.

____________

Note

The MAC address label must be clearly marked on the exterior of the

Location Sensor housing in a position visible after installation.

____________

Last 6 LS

MAC digits

Location Sensor

Serial Number

Wi-Fi Client

MAC Address

Location Sensor

`

MAC Address

Figure 2 Example of LOS-5000-00AB Label

___________________________________________________________________________ 36

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 37

___________________________________________________________________________

WhereLAN III User’s Guide

While there is no restriction to the IP address, it must match the address in the

Site file for that particular WhereLAN III. The IP address(es) can be static

assigned, or dynamically assigned via DHCP. If assigned through DHCP, the

DHCP server must contain the MAC address and corresponding IP address for

each of the Location Sensors (and Wi-Fi Client).

____________

Note

For networks utilizing DHCP, the IP address or host name of the site’s

RTLS server must be entered in the DHCP server. See the VSS User

Guide for more details on Network Autoconfig.

____________

To configure the IP address of the Location Sensor:

Note the following configuration examples are done thru HyperTerminal.

• Connect to the Location Sensor using SSH, or HyperTerminal.

• Select the number that corresponds to ‘Ethernet Settings”1 and

confirm the unique MAC address for the Location Sensor.

___________________________________________________________________________ 37

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 38

___________________________________________________________________________

WhereLAN III User’s Guide

• Select 1 for setting Boot Method, Flash for internal image or Network

for image. (Flash is default and most commonly used).

• Select 2 for wired LAN Port IP setting or 3 WLAN client IP/DHCP

setting.

• Save the configuration changes by using ESC key entering the

password “ff2”.

• Note Changes take effect on unit reboot/reset.

• Confirm communication to the Location Sensor by “pinging” the

device from a DOS prompt.

___________________________________________________________________________ 38

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 39

___________________________________________________________________________

WhereLAN III User’s Guide

5.4 Wi-Fi Client Configuration (LOS-5000-00AB only)

The Wi-Fi client card embedded in the WhereLAN III must be configured

with the proper IP address or for DHCP set and the Interface must be ON. In

addition, the Wi-Fi network parameters, such as the SSID, and authentication

and encryption methods, must be configured in the wpa_supplicant, (See

sections 5.4.2 Configuring the Wi-Fi Network Parameters and 5.4.3

WPA_Supplicant Cautions)

From the Main Menu:

• Select Ethernet Settings.

• Under Ethernet Menu select 3 WLAN.

• Set 1. Interface to ON, then IP/DHCP settings.

___________________________________________________________________________ 39

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 40

___________________________________________________________________________

WhereLAN III User’s Guide

• Save the configuration changes by using ESC key entering the

password “ff2”.

• Select either ‘yes’ or ‘no’ at this point, depending on if further

configuration needs to take place.. (A reset/reboot will be

required thought for all the changes to take effect.)

Note: Although the LOS-5000-00AB has two network interfaces (its Ethernet

and Wi-Fi ports) in the vast majority of cases, only its Wi-Fi port is actually

connected to an operational network. If enabled, the Ethernet port must be

configured to be on a different subnet than the Wi-Fi port. In this case, it is

recommended that a non-routable IP address be used such as

192.168.5.0/255.255.255.0, to enable local diagnostics via the Ethernet port.

5.4.1 Setting Wi-Fi Antenna Type

The Wi-Fi antenna setting is available in firmware versions V5.0.2 or later

(Build Date Apr 30 2012 or later). The antenna selection is set under

802.11Client Menu, which is reached from the Main Menu via the

Diagnostics Menu. There are currently three antenna choices to select from,

and these match the Wi-Fi antennas that are offered on the marketing price

list. The selection is entered under the “Select Antenna” menu item.

Antenna Options:

• AK-170-00 2.2dBi Dipole Antenna (Rubber Duck) , Selection ANT4941

• AK-151-00 5.2dBi Omni Antenna, Selection ANT2506

___________________________________________________________________________ 40

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 41

___________________________________________________________________________

WhereLAN III User’s Guide

From the Main Menu, select Diagnostics, and from the Diagnostics Menu select

802.11 Client. Then, in the 802.11 Client Menu, select the number that

corresponds to “Select Antenna”, and enter the value that corresponds to the

antenna that will be attached to the WhereLAN-III.

Escape “ESC” to save selection, ‘ff2’ is the password. The unit will need to be

rebooted for the setting to take effect.

5.4.2 Configuring the Wi-Fi Network Parameters

All the Wi-Fi network parameters are under the control of a file called

wpa_supplicant.conf. In order to configure the WhereLAN III Wi-Fi client

card to access your network, you must first edit or create this file to match

your Wi-Fi network configuration and then upload the file onto the

WhereLAN III unit. The wpa_supplicant.conf file must be created or edited

with a Linux friendly text editor. Do not use Notepad or similar. A popular

free Linux editor is called VIM and is found at http://vim.sourceforge.net/.

___________________________________________________________________________ 41

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 42

___________________________________________________________________________

WhereLAN III User’s Guide

The process will be illustrated assuming a sample Wi-Fi network with the

following parameters.

a. SSID = ZEBRA

b. Security = WPA2, Pre-Shared Key (WPA2-PSK)

c. WPA2 passphrase = ZebraPassphrase2011

To match these Wi-Fi parameters, the wpa_supplicant.conf file is very simple

and is shown below:

# A simple script file for WPA2-PSK with AES CCMP mode.

# The following line should not be changed. Otherwise, Wi-Fi will not work.

ctrl_interface=/var/run/wpa_supplicant

# Let wpa_supplicant take care of scanning and AP selection

ap_scan=2

# Network Block

network={

ssid="ZEBRA"

proto=WPA2

key_mgmt=WPA-PSK

pairwise=CCMP

group=CCMP

psk="ZebraPassphrase2011"

}

Create your wpa_supplicant.conf file with your Linux-friendly editor and

place a copy of it on the RTLS Server’s ftproot directory. Placing the file in

this directory facilitates the upload process.

Uploading the wpa_supplicant.conf file onto the WhereLAN III Unit.

5.4.3 WPA_Supplicant Cautions

___________________________________________________________________________ 42

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 43

___________________________________________________________________________

WhereLAN III User’s Guide

Important: The wpa_supplicant file, which controls security of the wireless

client card, is currently over written when upgrading the firmware on a

WhereLAN-III.

• Over writing the wpa_supplicant file can lead to loss of network

connection if the WhereLAN-III is wirelessly connected to the

network.

• Once upgraded the wpa_supplicant file will revert to its original

configuration.

• Recovery WILL require direct connection to the unit.

Solution: The issue of over writing the wpa_supplicant file can be avoided by

editing the WhereLAN-III ‘upgrade.txt’ script file that is distributed with the

WhereLAN-III firmware files. The files will be located in a directory under the

/inetpub/ftproot/server\G3v501.

• The script file is the first to be read by the WhereLan-III and is

subsequently used by the WhereLan-III to control which of the four

firmware files (bootloader.bin, uImage, rootfilesys, and JFFS2) are to

be uploaded to the WhereLan-III during the upgrade process.

• The wpa_suplicant.conf file is stored within the JFFS2 image. When

JFFS2 is upgraded, the site specific wpa_suplicant.conf file is replaced

with the default found in the released JFFS2 image.

• Modifications to the upgrade.txt script file are supported to enable the

WhereLan-III to temporarily save the site specifc wpa_supplicant.conf

file and restore it after the upgrade of JFFS2 completes.

• The necessary command line for saving and restoring the

wpa_suplicant.conf file is present in the upgrade.txt script, but is

commented out and therefore causes no effect.

• Modifying the wpa_supplicant.conf file can be done by removing the

“#” (indicator for a comment line)from in front of the

F1=”wpa_supplicant/conf” line.

o Note ‘#’ is the script’s language for indicating the line is a

comment and contains no instructions. Removing the ‘#’

causes the script to execute the instruction on that line.

o The upgrade.txt file must be edited with a Linux friendly text

editor. Do not use Notepad or similar as it WILL corrupt the

___________________________________________________________________________ 43

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 44

___________________________________________________________________________

WhereLAN III User’s Guide

file. A popular free Linux editor is called VIM and is found at

http://vim.sourceforge.net/ .

Example excerpt from a default upgrade.txt script file:

###############################################################

# List JFFS2 files and/or directories (F0-FN, N<10) to be restored

###############################################################

#F0="wpa_supplicant.conf_reference"

#F1="wpa_supplicant.conf"

Modified example excerpt from a default upgrade.txt script file to cause the

wpa_supplicant.conf file to be save d and later restored:

###############################################################

# List JFFS2 files and/or directories (F0-FN, N<10) to be restored

###############################################################

#F0="wpa_supplicant.conf_reference"

F1="wpa_supplicant.conf"

NOTE the removed “#” (from the fourth line) in front of the F1 as shown above.

Engineering is in planning on how to deliver a standard set of firmware files and

scripts that may default to automatic save/restore.

5.5 WPA Supplicant Upload

The following instructions will demonstrate on how to upload a

wpa_supplicant.conf file to the WhereLAN-III.

From the Main Menu, select the number that corresponds to ‘Firmware

Upgrade’.

___________________________________________________________________________ 44

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 45

___________________________________________________________________________

WhereLAN III User’s Guide

Now Select the ‘Transfer Protocol’ (either TFTP default, FTP, or NFS) and set

the ‘Server IP Address’ of the server where the files are locate. Ensure the

tftp and/or ftp service is enabled on the computer that contains the

wpa_supplicant.conf file.

Now, select the item number that corresponds to ‘Advanced’, and enter the ff2

password. The WhereLAN II present the following menu.

___________________________________________________________________________ 45

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 46

___________________________________________________________________________

WhereLAN III User’s Guide

___________________________________________________________________________ 46

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 47

___________________________________________________________________________

WhereLAN III User’s Guide

• Now, select 7, ‘Get remote file’. The WhereLAN III asks for the path

to the remote file. As you have placed the file in the server’s root

directly, simply enter ‘wpa_supplicant.conf’.

• Now, the WhereLAN III asks for a local path, i.e., where the file

should be placed in the WhereLAN III itself. Enter

‘/mnt/jffs2/wpa_supplicant.conf’. Be sure to enter the path and file

names correctly, as an error here will prevent normal Wi-Fi operations.

WhereLAN III asks you to confirm before the file is uploaded. Accept

by entering y. When the operation completes, your screen should

look like this.

• Now, that the wpa_supplicant.conf file has been uploaded, you must

enable wpa_supplicant processing on the WhereLAN III itself.

___________________________________________________________________________ 47

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 48

___________________________________________________________________________

WhereLAN III User’s Guide

• From the Main Menu, select the number that corresponds to,

‘Diagnostics’. This will display the Diagnostic menu as shown below.

• Next select the number that corresponds to, ‘802.11 client’.

___________________________________________________________________________ 48

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 49

___________________________________________________________________________

WhereLAN III User’s Guide

• And now, the item that corresponds to, ‘WPA Supplicant’, respond

‘yes’ to enable wpa_supplicant operation.

• Press ESC to save changes, and enter the ff2 password, and space to

continue.

• The unit must be reset in order for wpa_supplicant processing to take

effect.

Verify the unit’s Wi-Fi network connection is operation.

• From the Main Menu select the number that corresponds

‘Diagnostics’.

• In the Diagnostics Menu, select the number that corresponds to

‘802.11 Client’.

• In the 802.11 Client Menu, select the item that corresponds to ‘WPA

Supplicant Status’ and WhereLAN III will display its Wi-Fi

association status, as shown below.

Important: It is good practice to verify the operation of the Wi-Fi before

having the unit installed.

___________________________________________________________________________ 49

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 50

___________________________________________________________________________

WhereLAN III User’s Guide

6 INSTALLATION AND MOUNTING

Read Installation and Instruction sheet included with the Location Sensor as

well as all Safety and Installation Warnings/Cautions before installing. Follow

the Site Design document for installed location.

6.1 Safety and Installation Warnings and Cautions

Warning - Warning - Electrical Shock: A protective earthing

conductor with green and yellow insulation, minimum of 18 AWG, shall be

installed to the protective earthing terminal of the metal enclosure when I/O or

power cables are routed outdoors. National electrical codes shall be followed

to install facility protective earthing conductor to the protective earthing

terminal.

Earth Ground Locations.

Bolt Size 8mm. Max

Length 25mm.

Figure 3 Safety and

Warnings

Warning - Electrical Shock: No operator serviceable parts inside. Refer

servicing to qualified personnel. To prevent electrical shock, do not remove

covers.

Caution - The Location Sensor hardware must be installed by a qualified

service technician

Caution - Use of Zebra external power supply is limited to indoor use

and a max 40° C environment. Only use Zebra approved power supplies.

Caution - The Timing Sync cable use is limited to indoor only.

___________________________________________________________________________ 50

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 51

___________________________________________________________________________

WhereLAN III User’s Guide

6.2 Mounting

The site design specifies the location of the Location Sensor(s) to provide

optimum system performance. It is critical that the Location Sensor is

mounted in a position which provides good RF visibility to the tracked assets.

Thus the Location Sensor must be mounted exactly in the position specified in

the site design document

The Location Sensor has two methods of mounting .The first can be hung

using nut pocket on top for attachment to accept a 3/8 in (10 mm) threaded

rod and jam nut, useful when using a beam clamp type of hanger. The second

method of mounting is a pole mount hardware kit is available separately, ZES

Part Number RM-510-00 Mounting Bracket, Pole Mount.

____________

Note

Nut Pocket

Safety Lanyard Points

Mounting Bracket Points

Figure 4 Mounting Points

Failure to mount the Location Sensor in the exact position specified in the

site design will result in erroneous or non-locates of the tracked assets.

___________________________________________________________________________ 51

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 52

___________________________________________________________________________

WhereLAN III User’s Guide

____________

For safety it is strongly recommend that a Safety Lanyard be employed with

either mounting method. The Safety Lanyard points are large enough to

accept a 3/16” loop style wire rope. Stainless Steel Rope is recommended.

____________

Figure 5 Safety Lanyard

___________________________________________________________________________ 52

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 53

___________________________________________________________________________

WhereLAN III User’s Guide

6.3 3/8ths Threaded Rod

The Location Sensor can be hung via a 3/8 inch (10 mm) threaded rod per the

following instructions. This type of mounting is intended for indoor

installations only, if mounting outdoors use the Pole Mount Kit described in

Sections 6.4. The required supports, threaded rod, nuts, etc., are not included.

• Cut the threaded rod to the desired length and install it directly above

the desired Location Sensor position.

• Thread one nut up 2 in (50 mm) from the bottom of the threaded rod,

with Lock Washer and Washer.

• Place the second nut onto threaded rod, flush with the end of the

threaded rod and install the Location Sensor.

• Tighten the upper nut down on top of the Location Sensor housing.

Figure 6 Threaded-Rod

___________________________________________________________________________ 53

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 54

___________________________________________________________________________

WhereLAN III User’s Guide

6.3.1 Safety Lanyard with Threaded Rod

For Location Sensor installation using the Threaded Rod Mounting, it must

also be secured to the building infrastructure with a safety lanyard through the

one of the rectangular loops on top the casting. See below in Figure 7 Safety

Lanyard.

Figure 7 Safety Lanyard

___________________________________________________________________________ 54

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 55

___________________________________________________________________________

WhereLAN III User’s Guide

6.4 Pole Mount Kit

The pole mount kit, catalog number RM-510-00, must be ordered separately.

The pole mount kit will allow the Location Sensor to be mounted to either a

pole or 1-1/4” metal channel framing, per the instructions included with the

pole mount kit.

Top of Bracket

Figure 8 Pole

Mount Kit

___________________________________________________________________________ 55

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 56

___________________________________________________________________________

WhereLAN III User’s Guide

6.4.1 Pole Mount on Metal Frame

First mount bracket to metal frame in location, orientation and height

specified in the site design, with support hooks up and retaining slots down,

using supplied clamp.

Figure 9 Bracket Mount

___________________________________________________________________________ 56

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 57

___________________________________________________________________________

WhereLAN III User’s Guide

Loosen the retaining bolts on each side of the Location Sensor, but do not

remove them.

Retaining Bolts

Figure 10 Retaining Bolts

___________________________________________________________________________ 57

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 58

___________________________________________________________________________

WhereLAN III User’s Guide

Hang the Location Sensor on the bracket and tighten retaining blots securely.

Next install safety lanyard through one of the Location Sensor’s lanyard

points, and the other end of the lanyard to a point above the Location Sensor.

Figure 11 Location Sensor Mounted

___________________________________________________________________________ 58

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 59

___________________________________________________________________________

WhereLAN III User’s Guide

6.4.2 Pole Mount on Pole

First mount bracket to Pole at height location, orientation and height specified

in the site design, with support hooks up and retaining slots down, using

supplied clamp.

Figure 12 Pole mount on Pole

Loosen the retaining bolts on each side of the Location Sensor, but do not

remove them (See Figure 10 Retaining Bolts).

___________________________________________________________________________ 59

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 60

___________________________________________________________________________

WhereLAN III User’s Guide

Hang the Location Sensor on the bracket and tighten retaining blots securely.

Next install safety lanyard through one of the Location Sensor’s lanyard

points, and the other end of the lanyard to a point above the Location Sensor.

Figure 13 Location Sensor on Pole

___________________________________________________________________________ 60

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 61

g

n

___

__

s

n

wan

be

i

W

n

2

T

S

n

n

L

I

i

w

s

m

s

f

-

ff

r

t

i

A

a

F

o

s

c

f

r

o

a

r

Where

AN III User’

Guide

7

T

AN

o different

tenna is the

th

e Location

in

door only i

specified i

ENNAS

antennas ar

All Weathe

ensor hous

stallations

the site de

e available

r Omni AK

ng. The O

here appea

ign.

or the Loca

210-10, wh

ice Omni

ance critic

ion Sensor.

ch can be b

-110-10 i

l. The choi

The standa

lted directl

available f

e of antenn

d

y to

r

will

F

gure 15 All

Weather O

ni

igure 14 O

fice Omni

© Copyri

Zebra Co

ht Zebra Tech

fidential

U

er’s Guide,

ologies, 201

hereLAN II

draft D1675

61

rev F

Page 62

___________________________________________________________________________

WhereLAN III User’s Guide

7.1.1 All Weather Omni

As its name suggests, the All Weather Omni provides omni-directional

coverage and is suitable for outdoor environments. It should be attached

directly to the Location Sensor housing, and therefore requires no additional

mounting. For this reason, it is the preferred antenna for the Location Sensor.

Because it is an omni-directional antenna, the coverage pattern of the All

Weather Omni can be degraded if mounted too close to metallic structures.

Therefore, the All Weather Omni must be mounted a minimum 12 inches (305

mm) from nearby metallic structures.

_____________

_____________

Min 12 inches

I Beam

(305 mm) from

metal wall

Left

antenna

Figure 16 Minimum clearance to metallic structures

The All Weather (and Indoor Office) Omni antennas must be mounted a

minimum of 12 inches (305 mm) away from metal walls.

Right

antenna

___________________________________________________________________________ 62

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 63

___________________________________________________________________________

WhereLAN III User’s Guide

For best diversity reception, the Location Sensor should be mounted in an

orientation in which the antennas are at a diagonal (45 deg) orientation with

respect to surrounding walls and aisles. The RM-250 Wall Mount Bracket

can be utilized to provide the necessary clearance from nearby metallic

surfaces.

Wall

Mount

Bracket

Location

Sensor

Min 12 inches

(305 mm) from

metal wall

Right

Antenna

Left

Antenna

Figure 17 Corner mount industrial application

___________________________________________________________________________ 63

User’s Guide, WhereLAN III draft D1675 rev F

© Copyright Zebra Technologies, 2012

Zebra Confidential

Page 64

inimu

m12i

n

___________________________________________________________________________

WhereLAN III User’s Guide

7.1.2 Indoor Omni

The indoor omni is designed to be mounted directly to the ceiling. It has a

small profile designed to be unobtrusive in an office environment. Like the

All Weather Omni antenna, it must be mounted a minimum of 12 inches from