Page 1

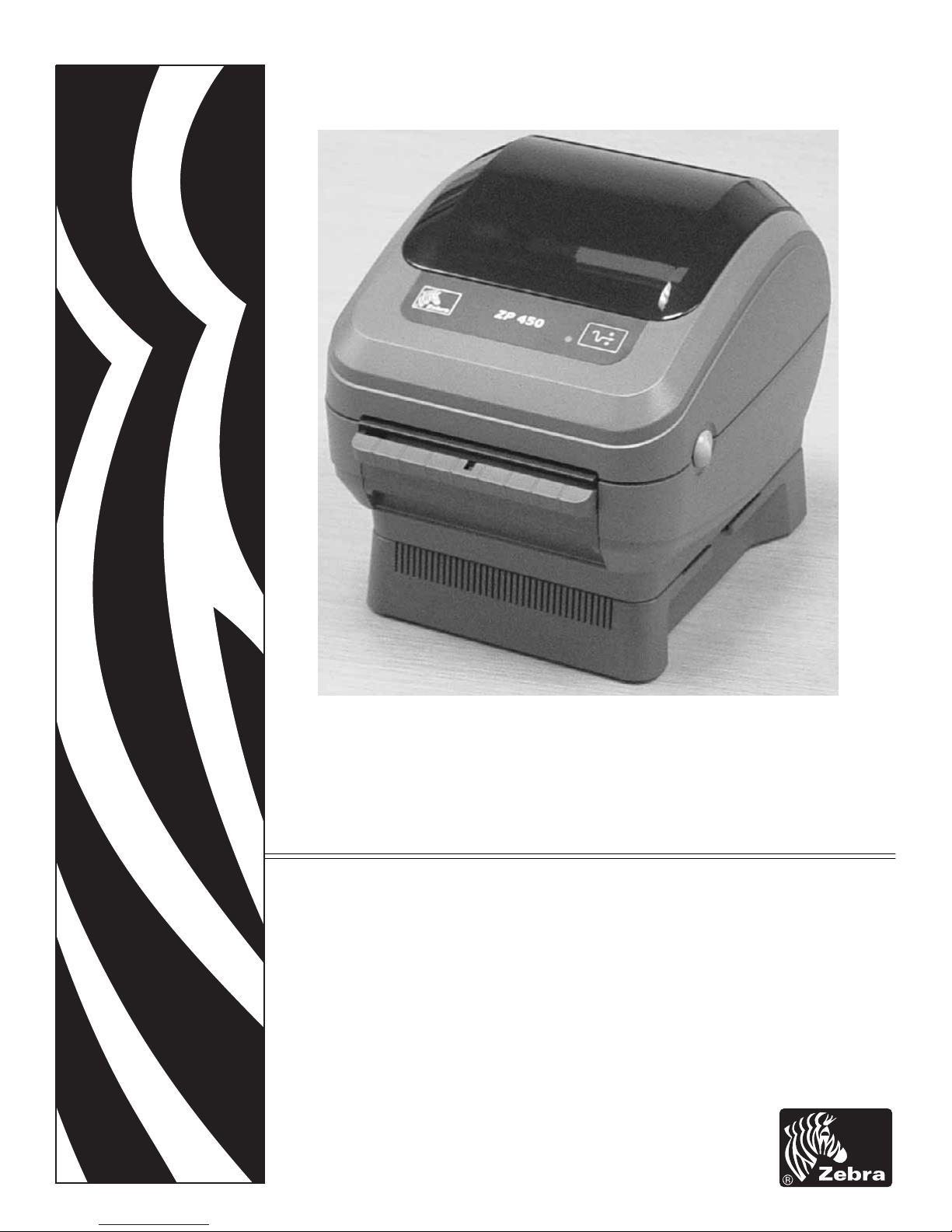

Zebra ZP 450™

Desktop Thermal Printer

User Guide

Page 2

ii

© 2008 ZIH Corp.. All trademarks and registered trademarks are property of their

respective owners. All rights reserved.

This manual contains proprietary information of Zebra Technologies Corporation and its

subsidiaries (“Zebra Technologies”). It is intended solely for the information and use of

parties operating and maintaining the equipment described herein. Such proprietary

inform ation may not be used, reproduced, or disclosed to any other parties for any other

purpose without the express written permission of Zebra Technologies.

The copyrights in this manual and the software and/or firmware in the label printer

described therein are owned by ZI H Corp. Unauthorized reproduction of this manual or

the software and/or firmware in the label printer may result in imprisonm ent of up to one

year and fines of up to $10,000 (17 U.S.C.506). Copyright violators may be subject to

civil liability.

This product may contain ZPL ®, Z PL II®, and Z ebraLink™ programs; element Energy

3

Equalizer™ Circuit; E

®; and AGFA fonts. Software ©ZIH corp. All rights reserved

worldwide.

ZebraLink and all product names and numbers are trademarks, and Zebra, the Z ebra logo,

ZPL , ZPL II, Element Energy Equalizer circuit, and E3 Circuit are registered trademarks

of ZIH Corp. All rights reserved worldwide.Monotype®, Intellifont® and UFST® are

trademarks of Monotype Imaging, Inc. registered in the United States Patent and

Trademark Office and may be registered in certain jurisdictions.

CG Triumvirate is trademarks of Monotype Imaging, Inc. and may be registered in some

jurisdictions.

TrueType® is a trademark of Apple Computer, I nc. registered in the United States Patent

and Tradem ark Office and may be registered in certancertain jurisdictions.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications

and designs are subject to change without notice.

Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and

manuals are correct; however, errors do occur. Zebra Technologies reserves the right to

correct any such errors and disclaims liability resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production,

or delivery of the accompanying product (including hardware and software) be liable for

any damages whatsoever (including, without limitation, consequential damages including

loss of business profits, business interruption, or loss of business information) arising out

of the use of, the results of use of, or inability to use such product, even if Zebra

Technologies has been advised of the possibility of such damages. Some jurisdictions do

not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

Canadian DOC Compliance Statement

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 3

FCC Compliance Statement

This device complies with Part 15 rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause

undesired operation.

This equipment has been tested and found to comply with the limits for Class B Digital

Devices, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a residential

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the product manuals, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television

reception, the user is encouraged to do one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

iii

• Consult the dealer or an experienced radio/TV technician for help.

The user is cautioned that any changes or modifications not expressly approved by Zebra

Technologies could void the user’s authority to operate the equipment. To ensure compliance,

this printer must be used with fully shielded communication cables.

ZP Family Printers

DO NOT VIEW DIRECTLY WITH OPTICAL INSTRUMENTS

Maximum output power:

Caution • CLA SS 1M LAS ER PRODUCT

INVISIBLE LASER RADIATION.

CLASS 1M LASER PRODUCT.

Wavelength:

Pulse duration:

0.657mW.

850nm.

Gap (Web) Sensor

moving.

Dispenser (Peel) Sensor

when the printer is in dispense mode and a label has

been printed but not removed. The Dispenser Sensor

laser is OFF when printer is not printing.

- ON continuously when motor is

- 5ms ON, 10.2ms OFF only

IEC 60825-1: 1993+A1:1997+A2:2001

• Vi ewin g th e laser ou tput wi th certai n opt ical i nstru ment s (f or exampl e, ey e loops, magnifiers and m i croscopes) within

a dis tance of 100mm m ay pose an ey e haz ard.

• Use of cont rol s or adjustm ent s or perf ormance of procedu res other than th ose speci f ied herei n may resul t in hazardous

radi ati on exposu re.

• Do not tam per or attem pt to repai r any se nsor i nsi de this product. No servi ceabl e sensors i nsi de.

• Do not star e into Gap ( Web) or Dispenser (Peel ) sen sors. Avoid possibl e exposure t o haz ardous laser radi ation s.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 4

iv

Notes • ___________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 5

Contacts

Preface

This section provides y ou with contact information, document structure and organization, and

additional reference documents.

You can contact Zebra Technologies at any of the following:

Visit us at: www.zebra.com

Our Mailing Addresses:

Zebra Techn ologies Corporation

333 Corporate Woods Parkway

Vernon Hills, Illinois 60061.3109 U.S.A

Telephone: +1 847.793.2600

Toll-free (USA) +1 800.423.0422

Fax: +1 847.913.8766

Zebra Technologies Europe Limited

Zebra House

The Valley Centre, Gordon Road

High Wycombe

Buckinghamshire HP13 6EQ, UK

Telephone: +44 (0)1494 472872

Fax: +44 (0)1494 450103

12/17/07 ZP 450™ User Guide 980546-003 B

Page 6

Preface

vi

Environmental Management

Support

You can contact Zebra support at:

Web Address: www.zebra.com/SS/service_support.htm

Note • The web address is case-sensitive.

US Phone Number +1 847.913.2259

UK/International Phone Number +44 (0) 1494 768289

Environmental Management

Do not dispose of this product in unsorted municipal waste. This product is recy clable, and

should be recycled according to y our local standards.

For more information, please see our website at:

Web address: www.zebra.com/environment

Document Conventions

The following conventions are used throughout this document to convey certain information:

s

Alternate Color (online only) Cross-references contain links to other sections in this guide.

If you are viewing this guide online, click the blue text

to jump to its location.

Command Line Examples All command line examples appear in Courier New font.

For example, type the following to get to the Post-Install scripts in the

bin directory:

Ztools

Files and Directories All file names and directories appear in Courier New font. For

example, the

Zebra<version number>.t ar file and the /root directory.

Cautions, Important, Note, and Example

Caution • Warns you of the potential for electrostatic discharge.

Caution • Warns you of a potential electric shock situation.

Caution • Warns you of a situation where excessive heat could cause a burn.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 7

Preface

Related Documents

Caution • Advises you that failure to take or avoid a specific action could result in physical

harm to you.

Caution • Advises you that failure to take or avoid a specific action could result in physical

harm to the hardware.

Caution • Advises you need to wear protectiv e eyeware.

Important • Advises y ou of information that is essential to complete a task.

Note • Indicates neutral or positive information that emphasizes or supplements important

points of the main text.

vii

Example • Provides an example, often a scenario, to better clarify a section of text.

Tools • Tells you what tools you need to complete a given task.

Related Documents

The following documents might be helpful references:

• ZPL Programming Guide

• EPL Programm ing Guide

12/17/07 ZP 450™ User Guide 980546-003 B

Page 8

Preface

viii

Related Documents

Notes • ___________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 9

Contents

• Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Environmental Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Document Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

1 • Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

What’s in the Box? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Inspecting the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Mini-CD on Printer Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 • Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Modes of Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Attaching Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Loading Roll Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Preparing Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Placing the Roll in the Media Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operator Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Printing a Test Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Hooking Up the Printer and Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Interface Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Communicating with the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Adjusting the Print Width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Adjusting the Print Quality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3 • Operations & Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Thermal Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Replacing Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

12/17/07 ZP 450™ User Guide 980546-003 B

Page 10

Contents

x

Printing in Dispenser Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Printing on Fan-Fold Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

ZebraNet® 10/100 Internal Print Server Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Printer Network Configuration Status Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Liner-less Media Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Sending Files to the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Transferring files with the Firmware Downloader . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Media Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4 • Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Printhead Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Media Path Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Platen Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Replacing the Platen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Replacing the Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5 • Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Resolutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Print Quality Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Manual Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Troubleshooting Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Printing a Configuration Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Recalibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Resetting the Factory Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Feed Button Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Repackaging the Printer for Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6 • Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Universal Serial Bus (USB) Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Ethernet Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Serial Port Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 11

1

Introduction

This section describes what you get in your shipping box and provides an overview of printer

parts. This section also has procedures that describe how to open and close the printer and

report any problems.

Hello!

Thank you for choosing a Zebra® desktop printer, a high-quality on-demand printer

manufactured by the industry leader in quality, service, and value—Zebra Technologies

Corporation. For over 25 years, Zebra Technologies Corporation has provided customers with

the highest caliber of products and support.

Your printer is a high-quality on-demand printer. The printer provides direct-thermal printing.

This manual provides all of the information you will need to operate y our printer on a daily

basis. To create label formats, refer to your programming guide. This guide is available by

contacting y our distributor or dealer.

Your printer, when connected to a host computer, functions as a complete sy stem for printing

labels and tags.

Note • Many printer settings may also be controlled by your printer’s driver or label

preparation software. Refer to the driver or software documentation for more information.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 12

Intro duction

2

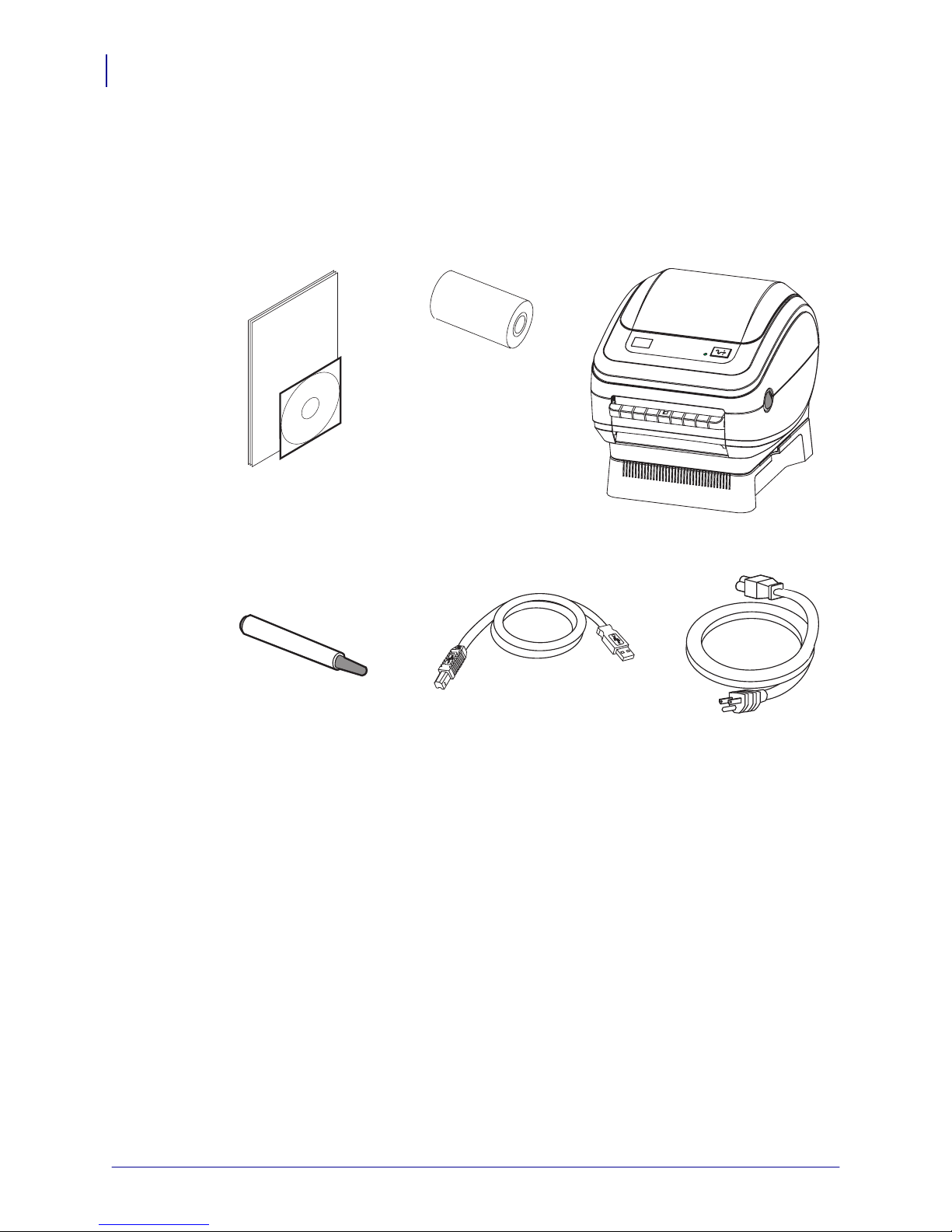

What’s in the Box?

What’s in the Box?

Save the carton and all packing materials in case y ou need to ship or store the printer later.

After unpacking, make sure you have all parts. Follow the procedures for inspecting the printer

to familiarize yourself with printer parts so you can follow the instructions in this book.

Prin ter

Sample

Labels

Documentation

and Software

Cl eaning

Pen

Interface

Cable

Powe r

Base

Power

Cord

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 13

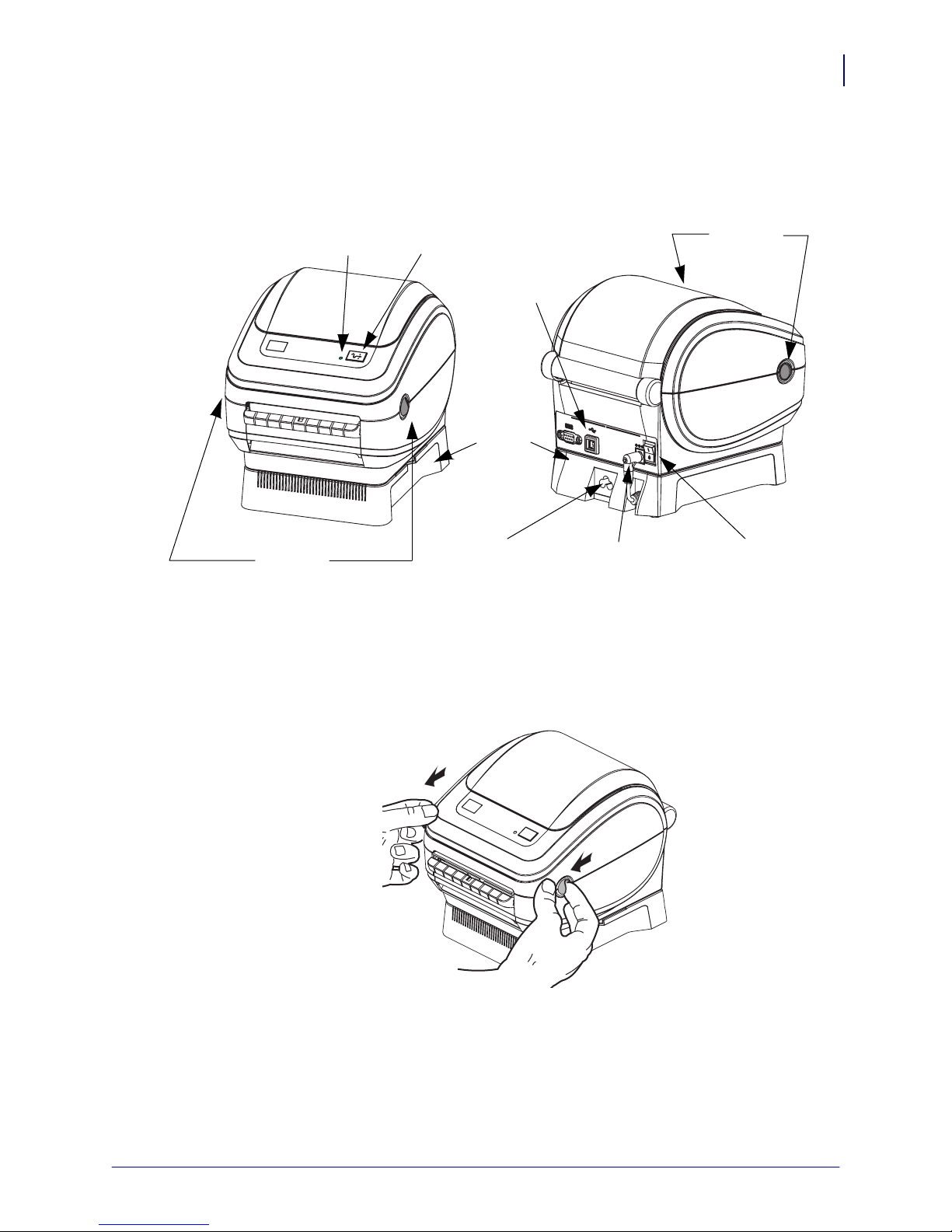

Inspecting the Printer

Look at the outside of the printer and make sure that all parts are present.

Introduction

Inspecting the Printer

3

Status

Light

Release

Latches

Opening the printer

Feed

Button

Interface

Connectors

Power

Base

Power

Supply

Receptacle

Active

Power

Light

Release

Latches

Power

Switch

To access the media compartment, you must open the printer. Pull the release latches towards

you and lift the cover.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 14

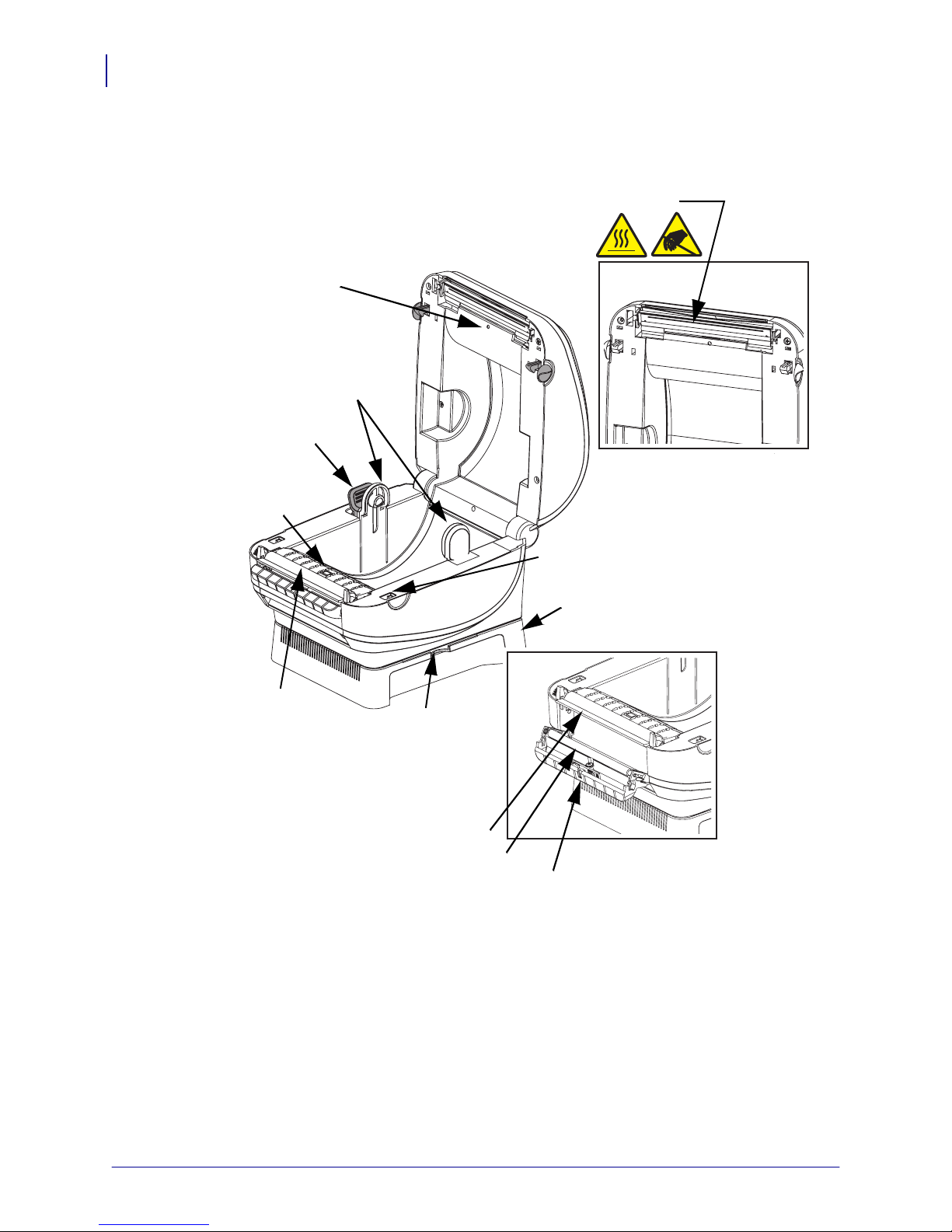

Intro duction

4

Inspecting the Printer

After opening the printer, check the media compartment.

Printhead

Gap

Sensor

Media

Hangers

Pull

Black-Line

Sensor

Platen

Roller

Head-Up Sensor

(inside)

Power Base

Dispenser Open

Mini-CD Storage

Bar

Roller

Sensor

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 15

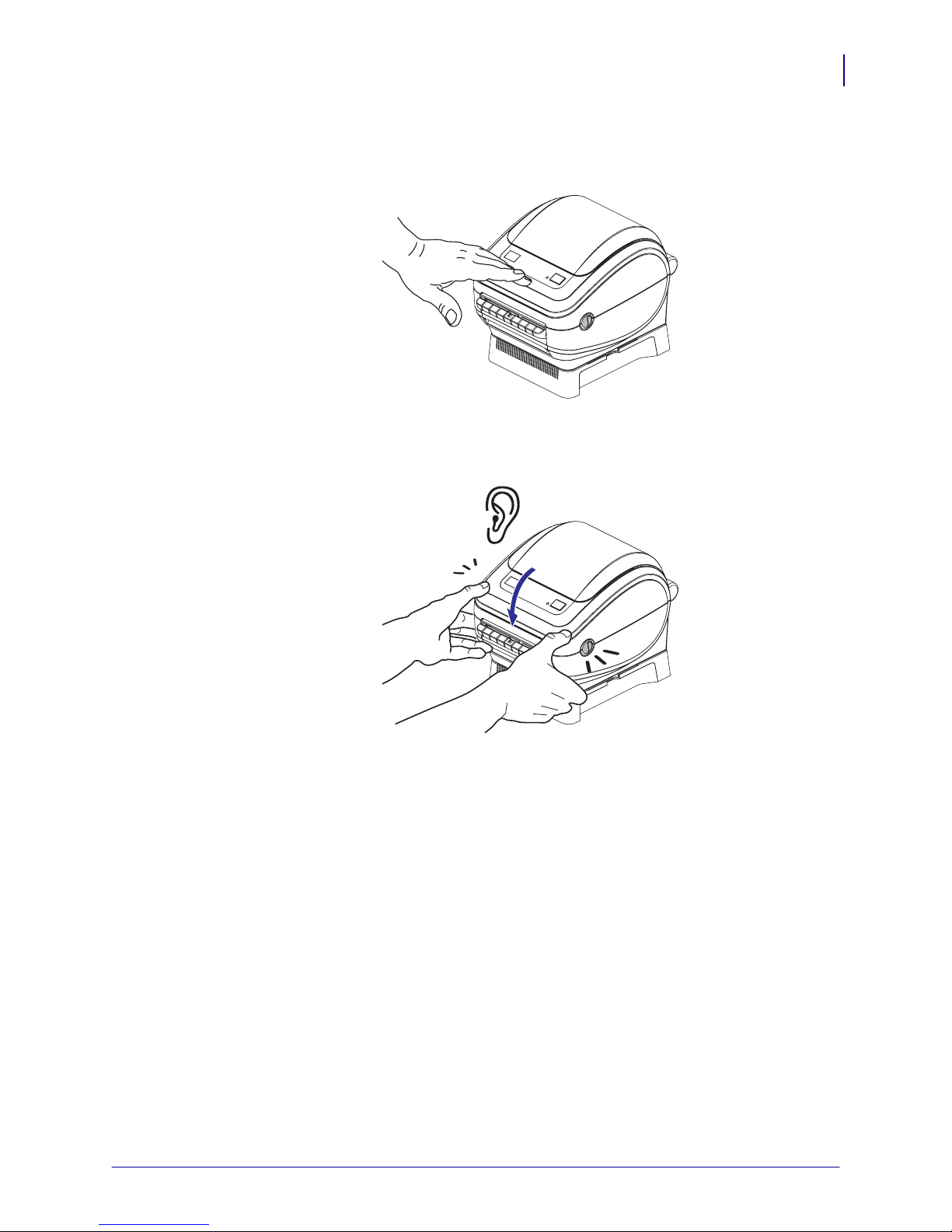

Closing the printer

1. Lower the top cover.

2. Press down until the cover snaps closed.

Introduction

Inspecting the Printer

5

Reporting Damage

If you discover damage or missing parts:

• Immediately notify and file a shipping damage report.

• Keep the carton and all packing material for inspection.

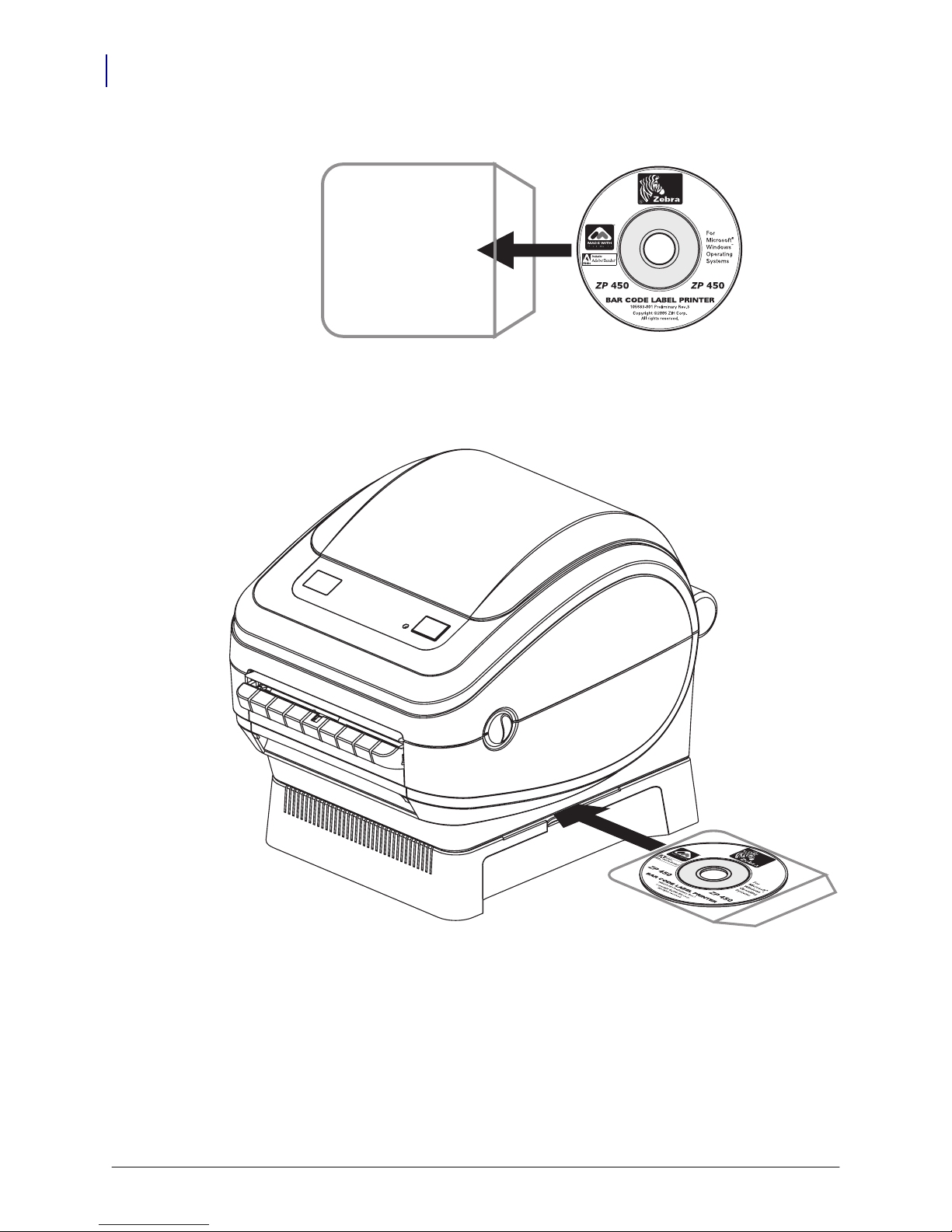

Mini-CD on Printer Storage

The printer has a mini-CD storage slot molded between the printer and its power base. Please

keep the mini-CD there for quick access to maintenance, troubleshooting, printer usage

animations, media, contact information and more.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 16

Intro duction

6

Inspecting the Printer

1. Always place the mini-CD in its plastic sleeve to protect th e mini-CD from damage.

2. Slide the plastic sleeve with the m ini-CD inside, into the printer.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 17

This section describes how to set up your printer for the first time and use the most common

operating procedures for loading media in tear-off mode.

Modes of Printing

2

Getting Started

You can operate this printer in different modes:

• Standard tear-off mode allows you to tear off each label (or a strip of labels) after it is

printed.

• Dispense mode will peel the backing material away from the label as it is printed. After

this label is removed, the next one is printed.The printer typically uses roll media, but you

can use fan-fold or other continuous media as well.

For procedures to use optional equipment and features, refer to Operations & Options

on page 21.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 18

Getting Started

8

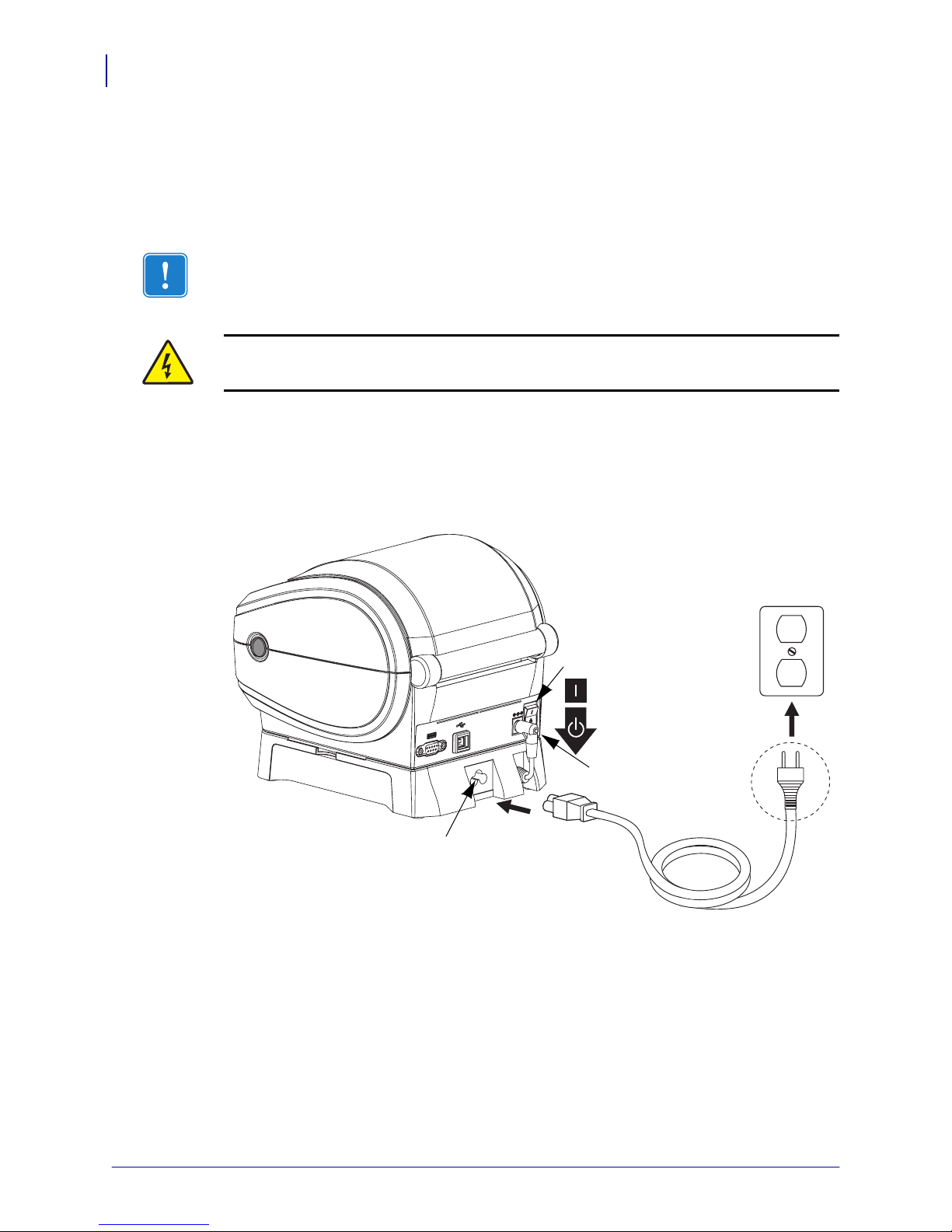

Attaching Power

Attaching Power

Important • Set up your printer so that you can handle the power cord easily if needed. To

make certain the printer cannot carry electrical current, you must separate the power cord from

the power supply receptacle or AC electrical outlet.

Caution • Never operate the printer an d power supply in an area where they can get wet.

Serious personal i njury could result!

1. Make sure the power switch is in the off position (down).

2. Insert the AC power cord into the power supply.

3. Plug the other end of the cord into an appropriate A C electrical outlet.

Printer

Power

Base

Power

Supply

Receptacle

Power

Switch

Act ive

Power

Light

Power

Connector

Plug Varies

by Country

AC Power

Cord

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 19

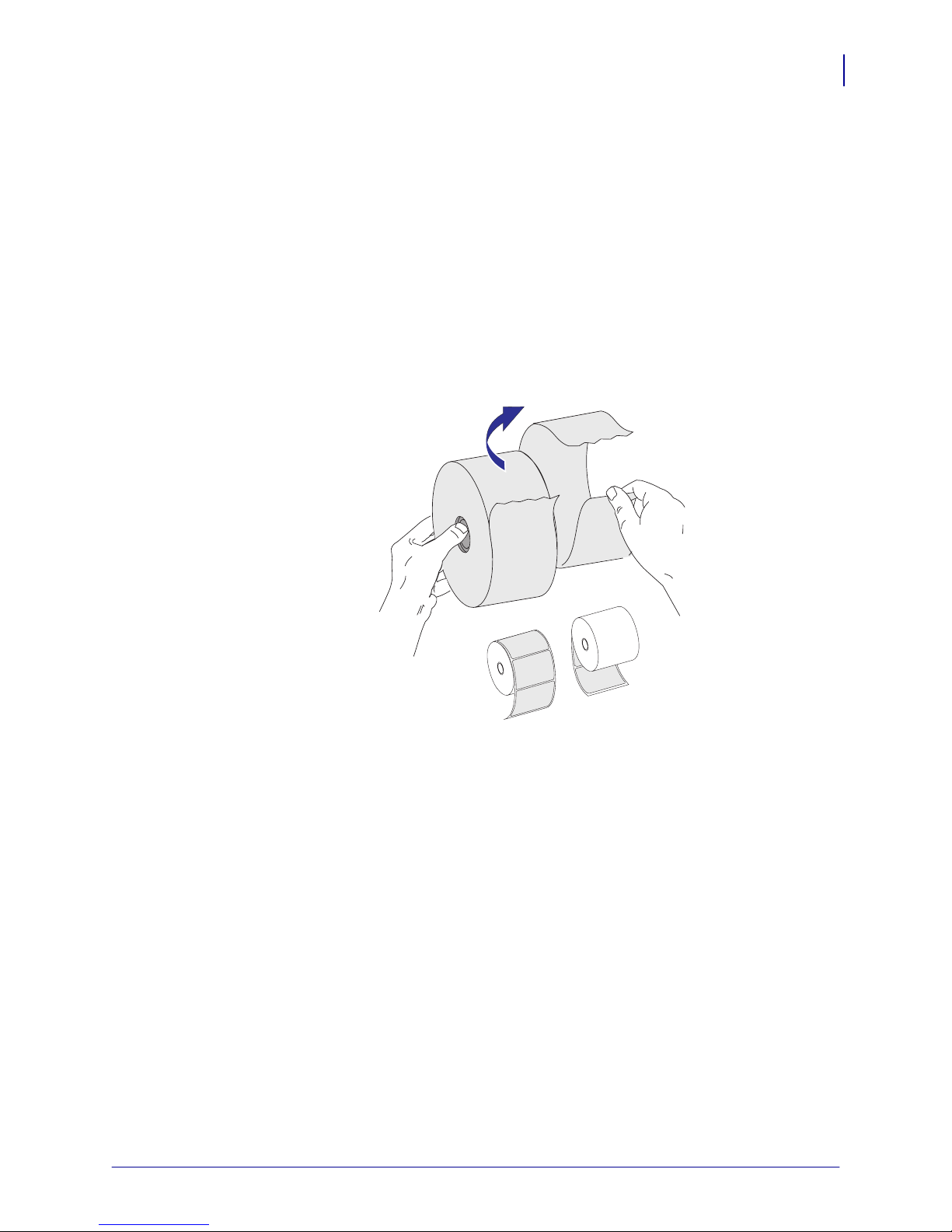

Loading Roll Media

When you load media, y ou must place the roll on the media hangers.

You must use the correct media for the type of printing you require. You must use direct

thermal media.

Preparing Media

Whether your roll media is inside or outside wound you load it into the printer the same way.

• Remove the outside length of media. During shipment, the roll may become dirty when

handled or dusty when stored. Removing the outside length avoids dragging adhesive or

dirty media between the printhead and platen.

Getting Started

Loading Roll Media

9

12/17/07 ZP 450™ User Guide 980546-003 B

Page 20

Getting Started

10

Loading Roll Media

Placing the Roll in the Media Compartment

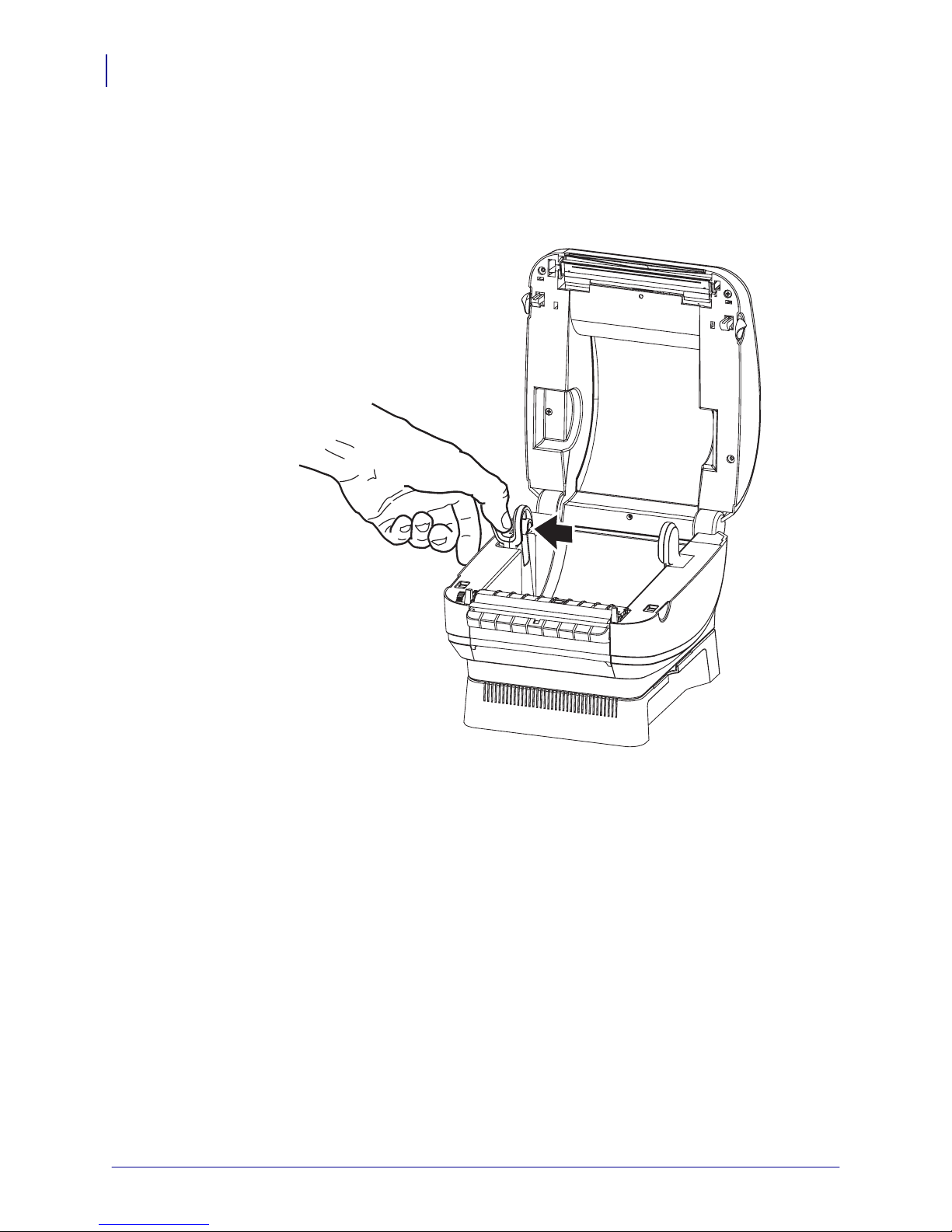

1. Open the printer. Remember that you need to pull the release levers toward the front of the

printer.

2. Pull the left media hanger to the side.

3. Orient the media roll so that its printing surface will be up as it passes over the platen.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 21

Getting Started

Loading Roll Media

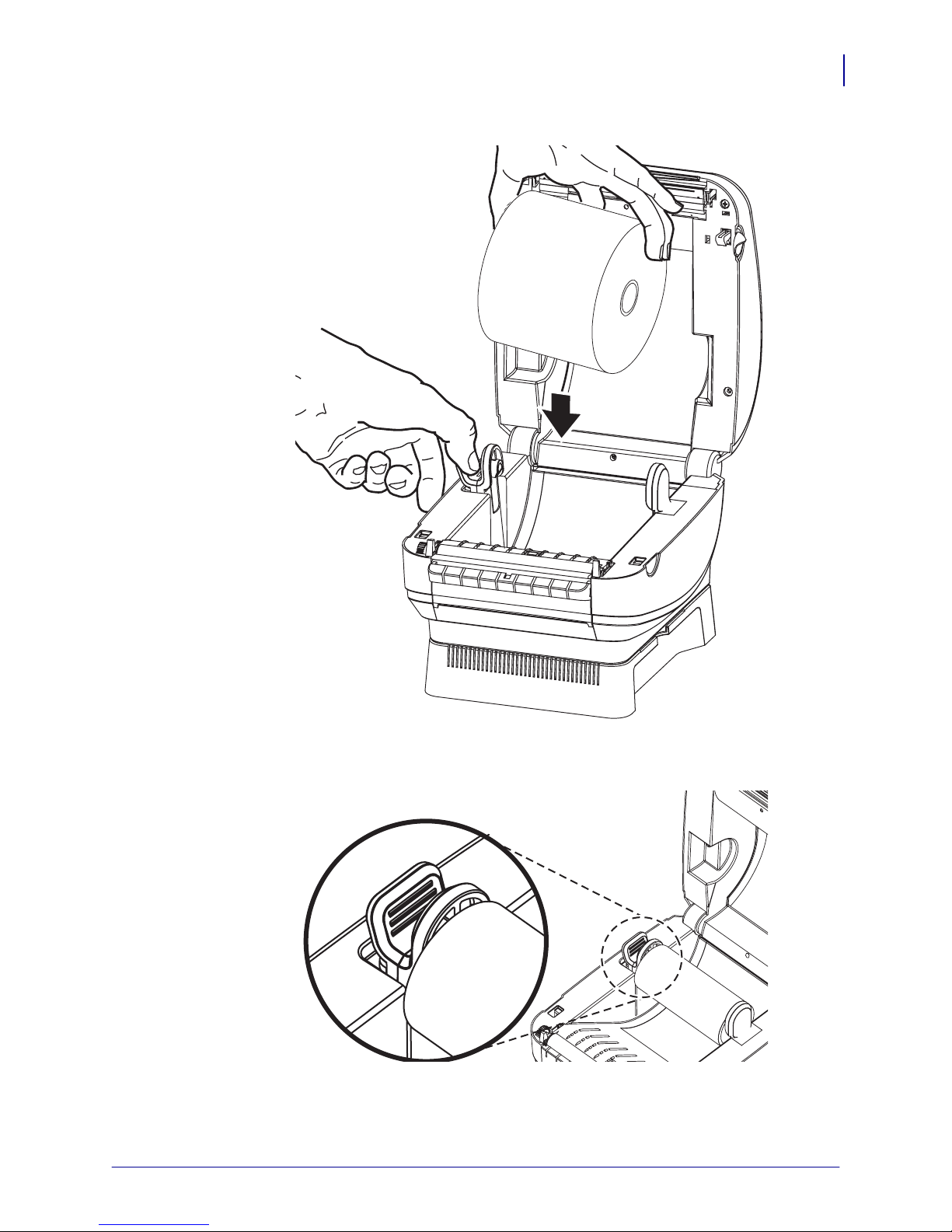

4. Lower the roll between the hangers and release the left hanger onto the core.

11

5. Verify the core rests on the hangers and the roll turns freely. The roll must not sit in the

bottom of the media compartment.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 22

Getting Started

12

Operator Controls

Operator Controls

Power Switch

Press up to turn ON or down to turn OFF the printer.

Important • To make certain the printer cannot carry electrical current, you must separate the

power cord from the power supply receptacle or AC electrical outlet. Set up y our printer so

that you can handle the power cord easily if needed.

Caution • The power should be turned off before connecting or disconnecting the

communication s and power cables.

Active Power Light

Located at the rear of the printer, the active power light indicates that electrical power is

energizing the printer.

Power

Switch

Active

Power

Light

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 23

Feed Button

• Tap the Feed button once to force the printer to feed one blank label.

• Press the Feed button to take the printer out of a “pause” condition. The printer is put into

“pause” by either a programming command or an error condition. See What the Status

Light is Telling You on page 45 in the Troubleshooting chapter.

• Use the Feed button for printer setup and status (see Feed Button Modes on p age 53 in the

Troubleshooting chapter).

Status Light

Located on the top case next to the feed button, the status light functions as a printer

operational indicator (see See What the Status Light is Telling You on page 45 in the

Troubleshooting chapter).

Feed

Button

Getting Started

Operator Controls

13

Status

Light

12/17/07 ZP 450™ User Guide 980546-003 B

Page 24

Getting Started

14

Printing a Test Label

Printing a Test Label

Before you connect the pri nter to your computer, make sure that the printer is in proper

working order.

You can do this by printing a configuration label.

1. Make sure the media is properly loaded and the top cover of the printer is closed. Then,

turn the printer power on if you have not already done so. If the printer initializes with the

status light blinking green (pause mode), press the Feed button once to set the printer in

Ready (to print) mode. See the What the Status Light is Telling You on page 45 if the

printer’s status light does not turn solid green (Ready).

2. Press the Feed button two to three times to allow the printer to calibrate the printer for the

installed media. The printer may feed several labels during this process.

3. When the status light is solid green, press and hold the Feed button until the status light

flashes once. Release the Feed button. A configuration label will print. If you cannot get

this label to print, refer to Getting Started on page 7.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 25

Hooking Up the Printer and Computer

Your printer will have a combination of interfaces: USB and Serial or USB and Ethernet.

Caution • Keep the power switch in the OFF position when attaching the interface cable.

The power cord must be inserted into the power ba se on the back of the printer before

connecting or disconnecting the communications cables.

Getting Started

Hooking Up the Printer and Computer

15

Important • This printer complies with FCC “Rules and Regulations,” Part 15, for Class B

Equipment, using fully shielded data cables. Use of unshielded cables may increase radiated

emissions above the Class B limits.

Interface Cable Requirements

Data cables must be of fully shielded construction and fitted with metal or metallized

connector shells. Shielded cables and connectors are required to prevent radiation and

reception of electrical noise.

To minimize electrical noise pickup in the cable:

• Keep data cables as short as possible (6’ [1.83 m] recommended).

• Do not tightly bundle the data cables with power cords.

• Do not tie the data cables to power wire conduits.

USB Interface Requirements

Universal Serial Bus (version 2.0 compliant) provides a fast interface that is compatible with

your existing PC hardware. USB’s “plug and play” design makes installation easy. Multiple

printers can share a single USB port/hub.

.

When using USB cable not supplied with your printer, verify that the cable or cable packaging

bears the “Certified USB™” mark (see below) to guarantee USB 2.0 compliance.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 26

Getting Started

16

Hooking Up the Printer and Computer

Serial Communications

The required cable must have a nine-pin “D” type (DB-9P) male connector on one end, which

is plugged into the mating (DB-9S) serial port located on the back of the printer. The other end

of this signal interface cable connects to a serial port at the host computer. Depending on the

specific interface requirements, this will most likely be a Null Modem (cross-over) cable.

Early models of Zebra printers running the EPL programming ty pically utilized a straight

through signal connections cable (no cross-over). For pinout information, refer to Appendix A.

Note • The printer design does not allow for the use non-molded cables such as hand-made

cables with large clam shell connector covers.

The serial port communication settings between the printer and host (typically a PC) must

match for reliable communication. The Bits per second (or Baud rate) and Flow control are the

most common settings that get changed. The hosts (typically a Windows PC) needs to have the

data Flow control changed to match the printer’s default communication method: Hardware

and is noted by the Host Handshake setting DTR/Xon/Xoff. This combined hardware

(DTR) and software (Xon/Xoff) mode may need to change depending upon the non-Zebra

application software and the serial cable variation in use.

Serial communications between the printer and the host computer can be set by :

• Autobaud synchronization

• ZPL programming ^SC command

• EPL programming Y command

• Resetting the printer to its default printer configuration.

Autobaud

Autobaud synchronization allows the printer to automatically match the communication

parameters of the host computer. To autobaud:

1. Press and hold the feed button until the green status LED flashes once, twice, and then

three times.

2. While the status LED flashes, send the ^XA^XZ command sequence to the printer.

3. When the printer and host are synchronized, the LED changes to solid green. (No labels

will print during autobaud synchronization.)

ZPL ^SC Command

Use the Set Communications (^SC) command to change the communications settings on the

printer.

1. With the host computer set at the same communications settings as the printer, send the

^SC command to change the printer to the desired settings.

2. Change the host computer settings to match the new printer settings.

Refer to the ZPL Programming Guide for more information about this command.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 27

Getting Started

Hooking Up the Printer and Computer

EPL Y Co mm and

Use the serial port setup (Y) command to change the communications settings on the printer.

1. With the host computer set at the same communications settings as the printer, send the

Y command to change the printer to the desired settings. Note: the Y command does not

support setting the data flow control, use the Xon/Xoff setting.

2. Change the host computer settings to match the new printer settings.

Refer to the EPL Page Mode Programming Guide for more information about this command.

Resetting the Default Serial Port Parameters

Do the following to reset the communications parameters on the printer to the factory defaults

(serial communication settings are: 9600 baud, 8 bit word length, NO parity, 1 stop bit, and

DTR/XON/XOFF data flow control).

1. Press and hold the feed button until the green status LED flashes once, waits a moment

and flashes twice, and then waits again before flashing three times (release immediately).

2. While the status LED rapidly flashes amber and green, press the feed button. Serial

communications between the printer and the host computer can be set by the ZPL ^SC

command or the EPL Y command.

17

Note • Early models of Z ebra printers running the EPL programming language had 9600

baud, NO

parity, 8 data bits, 1 stop bit and a HARDWARE and SOFTWARE (merged) data

control (essentially DTR/Xon/Xoff) as the default serial port settings. The Windows operating

system flow control setting was Hardware for most applications.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 28

Getting Started

G

LED Amb

LED

18

Hooking Up the Printer and Computer

Ethernet

The printer requires UTP RJ45 Ethernet cable rated CAT-5 or better.

For more information on configuring y our printer to run on a compatible Ethernet based

network, see the ZebraNet® 10/100 Internal Print Server manual. The printer must be

configured to run on y our LAN (local area network). The print server on board your printer

can be accessed through the printer’s web pages.

(RJ45 Connector)

Ethernet Cable

Ethernet Status/Activity Indicators

LED Status Description

Both OFF No Ethernet link detected

Green 100 Mbps link detected

Green with the Amber

100 Mbps link and Ethernet activity detected

flickering on and off

Amber 10 Mbps link detected

Amber with the Green

10 Mbps link and Ethernet activity detected

flickering on and off

reen

er

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 29

Hooking Up the Printer and Computer

Communicating with the Printer

Universal Serial Bus (USB) Communications

The printer is a terminal device when using a universal serial bus interface. You can refer to

the Universal Serial Bus Specification for details regarding this interface.

USB Printer Detection and Windows® operating systems.

Windows 98 Second Edition, Windows 2000 and Windows XP and later operating systems

support the USB communications with printers. The Zebra Windows Driver supports your

printer in these operating systems.

These operating systems automatically detect the printer when connected via the USB

interface. The operating system automatically starts a “Add new hardware’ wizard when

connecting the printer for the first time to the PC. Close the wizard. Install the Zebra Windows

Driver found on the user’s CD. Select the USB port and media size (closest match). Click on

the ‘Print test page’ button to verify a successful installation.

Getting Started

19

The Windows operating sy stem will detect and relink a previously installed printer if it is

reconnected to the USB interface or power is turned on after the PC has finished it’s restart of

the operating system. Ignore the new device detected warnings and close the Task bar prompts.

Wait several seconds for the operating system to match the printer to the driver software. The

warnings will quit and the printer now should be ready to begin printing.

Serial Port and Windows® operating systems

The Windows operating sy stem default settings for the serial port communication closely

match the printer’s defaults settings with one exception; the data Flow Control settings. The

Windows default data Flow Control setting is NONE. The printer requires data Flow Control

set to Hardware.

Note • The printer does not support Windows Serial Port Plug and Play (PnP) device

detection at this time.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 30

Getting Started

20

Adjusting the Print Width

Adjusting the Print Width

Print width must be set when:

• You are using the printer for the first time.

• There is a change in media width.

Print width may be set by:

• The Windows printer driver or application software such as Zebra Designer.

• The five-flash sequence in Feed Button Modes on p age 53.

• Controlling printer operations with ZPL programming; refer to the Print Width (^PW)

command (consult your ZPL Programming Guide).

Controlling printer operations with EPL Page Mode programming, refer to the Set Label

Width (

q) command (consult your EPL Programmer’s Guide).

Adjusting the Print Quality

Print quality is influenced by the heat of the printhead, the speed of the media and the type of

media y ou are using. Only by experimenting will you find the optimal mix for your

application.

The relative darkness (or density) setting can be controlled by:

• The six-flash sequence in Feed Button Modes on page 53. This will overwrite any ZPL

and EPL programmed darkness/density settings.

• The Set Darkness (

• The Density (D) EPL command (consult your EPL Programmer’s Guide).

If you find that the print speed needs to be adjusted, use:

• The Windows printer driver.

• The Print Rate (^PR) command (consult your ZPL Programming Guide).

The Speed Select (

~SD) ZPL command (consult your ZPL Programming Guide).

S) command (consult your EPL Programmer’s Guide).

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 31

Operations & Options

This section helps you get the most from your printer.

You must use programming to control many of the printer’s functions.

Example • The ~JL command controls label length.

3

^XA^JUS^XZ command saves the new settings to flash memory.

The

For detailed information about creating labels using ZPL, refer to the ZPL Programming

Guide or visit our web site at www.zebra.com

To improve print quality, changing both print speed and density may be required to achieve the

desired results. Your application’s printer driver provides control of the speed and heat

(density).

.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 32

Operations & Options

22

Thermal Printing

Thermal Printing

Caution • The prin thead becomes hot while prin ting. To protect from damaging the

printhead an d risk of personal injur y, avoid touching the printhead. Use only the cleaning pen

to perform maintenance.

Caution • The discharge of elect rostatic energy that accumula tes on the surface of the

human body or other surfaces can damage or destroy the printhead or electronic

components used in t his device. You must observe stati c-safe procedures when working with

the printh ead or the electronic components u nder the top cover.

You must use the correct media for the type of printing you require. You must use direct

thermal media.

Replacing Supplies

If labels run out while printing, leave the printer power on while reloading (data loss results if

you turn off the printer).

Alway s use high quality, approved labels and tags. If adhesive backed labels are used that

don’t lay flat on the backing liner, the exposed edges may stick to the label guides and rollers

inside the printer, causing the label to peel off from the liner and jam the printer. Approved

supplies can be ordered from your dealer.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 33

Printing in Dispenser Mode

The factory installed label dispenser option allows you to print a label with backing (liner/

web) being removed from the label as it prints, ready for application. When printing multiple

labels, removing the dispensed (peeled) label notifies the printer to print and dispense the next

label.

To use dispenser-mode correctly, use your printer driver to activate the label (taken) sensor

along with these typical label settings which include but are not limited to length, noncontinuous (gap), and web (liner). Otherwise, you must send the ZPL or EPL programming

commands to the printer.

When programming in ZPL, you can use the following command sequences shown below

and refer to your ZPL Programming Guide for more information on ZPL programming.

When programming in EPL, send the Options (O) command with the ‘P’ command

parameter (

included with the Options command string. Refer to your EPL Programmer’s Guide for more

information on programming with EPL and the Options (

OP) to enable the Label Taken sensor. Other printer option parameters may also be

^XA ^MMP ^X Z

^XA ^JUS ^XZ

Operations & Options

Printing in Dispenser Mode

O) command behaviors.

23

12/17/07 ZP 450™ User Guide 980546-003 B

Page 34

Operations & Options

24

Printing in Dispenser Mode

1. Load y our labels into the printer. Close the printer and press the feed button until a

minimum of 4 inches or 100 millimeters of exposed labels exit the printer. Remove the

exposed labels from the liner.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 35

Printing in Dispenser Mode

2. Lift the liner over the top of the printer and open the dispenser door.

Operations & Options

25

12/17/07 ZP 450™ User Guide 980546-003 B

Page 36

Operations & Options

26

Printing in Dispenser Mode

3. Insert the label liner between the dispenser door and the printer body.

4. Close the dispenser door.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 37

5. Press the Feed button to advance the media.

Operations & Options

Printing in Dispenser Mode

27

6. Set the label (taken) sensor to detect removed labels. This is set by the Windows printer

driver (a configuration setting), y our application software or via the printer’s EPL or ZPL

programming languages.

7. During the print job, the printer will peel off the backing and present a single label. Take

the label from the printer to allow the printer to print the next label. Note: If you skipped

step six, the printer will stack and eject peeled labels.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 38

Operations & Options

28

Printing on Fan-Fold Media

Printing on Fan-Fold Media

Printing on fan-fold media requires y ou to prepare the media hangers.

1. Open the top cover.

2. Place an empty core between the media hangers.

3. Insert the media through the slot at the rear of the printer.

4. Run the media between the hangers and above the empty core.

5. Close the top cover.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 39

ZebraNet® 10/100 Internal Print Server Option

ZebraNet® 10/100 Internal Print Server Option

Operations & Options

29

The ZebraNet® 10/100 Internal Print Server (PS) is an optional factory installed device that

TM

connects the network and your ZebraLink

with a browser interface for printer and print server settings. If you use the ZebraNet

-enabled printer. The print server provides y ou

TM

Bridge

Zebra network printer management software, y ou can easily access the specialized features of

TM

a ZebraLink

enabled printer.

Printer with 10/100 Internal PS—10/100 Internal PS gives y our printer these features:

• Print server and printer setup using a browser

• Remote monitoring and configuration capability of the 10/100 Internal PS using a

browser

•Alerts

• The ability for you to send unsolicited printer status messages via E-mail-enabled

devices

TM

ZebraNet

Bridge — ZebraNetTM Bridge is a software program that works with the

10/100 Internal PS and enhances the features of ZebraLink resident within ZPL-based printers.

The features include the following:

TM

• ZebraNet

Bridge allows you to locate printers automatically. ZebraNetTM Bridge

searches on parameters such as IP address, subnet, printer model, printer status, and

many other user-defined characteristics.

• Remote Configuration — Manage all your Zebra label printers throughout the

enterprise without having to travel to remote sites or physically handle any printers.

Any Zebra printer connected to the enterprise network can be accessed from the

TM

ZebraNet

Bridge interface and configured remotely through an easy-to-use

graphical user interface.

TM

• Printer Alerts, Status, Heartbeat Monitoring and event Notification — ZebraNet

Bridge lets you configure multiple event alerts per device with different alerts directed

to different people. Receive alerts and notifications by e-mail, cell phone/pager, or

TM

through the ZebraNet

Bridge Events tab. View alerts by printer or group, and filter

by date/time, severity, or trigger.

• Configure and Copy Printer Profiles — Copy and paste settings from one printer to

another or broadcast them to an entire group. ZebraNet Bridge allows you to copy

printer settings, printer-resident files (formats, fonts, and graphics), and alerts with a

click of the mouse. Create printer profiles—virtual “golden printers”—with desired

settings, objects, and alerts, and clone or broadcast them as if they were real printers,

providing extensive savings in setup time. Printer profiles are also an excellent way to

back up a printer’s configuration for crisis recovery.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 40

Operations & Options

30

ZebraNet® 10/100 Internal Print Server Option

Printer Network Configuration Status Label

ZP-Series printers with the ZebraNet® 10/100 Internal Print Server option on-board print an

additional printer configuration status label for information needed to establish and trouble

shoot network printing. The following printout is printed with the ZPL

~WL command.

The regular printout of the configuration status label has some of the printer’s network settings

such as IP Address, on the lower half of the printout.

The printer’s IP address is needed to identify and configure the printer for operations on your

network. See the ZebraNet® 10/100 Internal Print Server manual for more information.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 41

Liner-less Media Printing

The ZP-Series printer includes a liner-less media printing option. The liner-less media printer

includes a non-stick platen (drive) roller. The liner-less platen roller has a sponge-like wavy

surface with a thin layer on the outer surface impregnated with silicon. The silicon is

continuously squeezed out of the roller when printing and feeding media. When the printer is

paired with specially formulated, Zebra approved liner-less media; the operator can print, tearoff and apply labeling without removing any label backing or liner.

The specially formulated Zebra approved liner-less media has a printing surface that does not

allow the specially formulated acry lic adhesive stick to media (or the liner-less platen roller).

Only use Zebra approved liner-less media with liner-less printers.

Note • Keep a spare liner-less platen available. The liner-less platen has a limited life. The

thin layer of silicon is eventually squeezed out of the liner-less platen with use and will begin

jamming media.

The liner-less platen is normally self cleaning. Foreign materials, dust and adhesive will be

removed by the media’s adhesive backing.

Cleaning a liner-less platen shortens or ends the platen’s usable life.

Operations & Options

Liner-less Media Printing

31

See Platen Considerations on page 39 for more information on your printer’s platen and

maintenance.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 42

Operations & Options

32

Sending Files to the Printer

Sending Files to the Printer

Files can be sent to the printer from the Microsoft Windows operating systems by using the

Zebra Firmware (and File) Downloader found on the user's CD or at

method is common for both programming languages, all wired interfaces (including USB) and

wired network printers.

Transferring files with the Firmware Downloader

1. Install the printer. Verify communication is working properly by using the drivers Pr i n t

Test Page located on the printer driver properties window.

2. Install the Zebra Firmware Downloader on your system.

3. Find the Firmware Downloader by selecting start > Programs > Z ebra.

www.zebra.com. This

4. Select the Pri n ter menu and run the Auto-Detect.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 43

Operations & Options

Sending Files to the Printer

5. Click on your Zebra printer to select the printer for download.

6. Select the File menu and click on the Select Fir mware Fil e.. . . Use the Browser window

to select your file for download to your printer.

33

7. Select the Pri n ter menu and click on the Download to Selected (printer). The

downloader may display a download status indicator to show download progress of larger

files.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 44

Operations & Options

34

Media Sensing

Media Sensing

The printer has automatic media sensing capability. The printer is designed to continuously

check and adjust media length sensing for minor variations. Once the printer is printing or

feeding media, the printer continually checks and adjusts the media sensing to accommodate

for minor changes in media parameters from label to label on a roll and from roll to roll of

media. The printer will automatically initiate a media length calibration if the expected media

length or the label to label gap distance has exceeded the acceptable variation range when

starting a print job or Feeding media. The automatic media sensing in the ZP-Series printers

works the same for printer operations that use EPL and ZPL label formats and programming.

If the printer does not detect labels or blacklines (or notches with blackline sensing) after

feeding the media the ZP 450 printer’s default maximum label length distance of 13 inches,

then the printer will switch to continuous (receipt) media mode. The printer will keep these

settings until changed by software, programming or a manual calibration with different media.

Optionally, the printer can be set to do a short media calibration after printer power up or when

closing the printer with power on. The printer will then feed up to three labels while

calibrating.

The printer’s media settings can be verified by printing a Printer Configuration label. See the

Printing a Test Label on page 14 for more details.

The maximum distance that the automatic media type detection and sensing will check can be

reduced by using the ZPL Maximum Label Length command (^ML). It is recommended that

this distance be set to no less than two times the longest label being printed. If the largest label

being printed was a 4 by 6 inch label, then the maximum label (media) length detection

distance can be reduced from the ZPL default distance of 39 inches down to 12 inches. Your

printer has a default distance of 13 inches

If the printer has difficulty automatically detecting the media type and auto-calibrating, see

Manual Calibration on page 49 to perform an extensive calibration. It includes a printed graph

of sensor operation for your media. This method disables the printer’s automatic media

sensing capability until the printer’s default parameters are reset to the factory defaults with

the four flash Feed button mode. See the Feed Button Modes on page 53 for more details.

The automatic media calibration can be modified, turned on or turned off to meet your needs.

Sometimes print job conditions require that the printer use all the media on a roll. The two

automatic media conditions, power up with media loaded and closing the printer with power

on, can be controlled individually with the ZPL Media Feed command, ^MF. The feed action

discussed in the ZPL programmers guide for the ^MF command is primarily for automatic

media sensing and calibration. The automatic media calibration that controls the dynamic

media (label to label) calibration is the ^XS command. If multiple media types of different

lengths, material or detection methods (web/gap, blackline or continuous) are used, you should

not change these settings.

The media calibration and detection process can also be refined to match the media type

loaded into the printer. Use the ZPL Media Tracking command (^MN) to set the media type.

Sometimes the printer can detect preprinted media as the gap between labels or the liner

backing with print as a blackline marks. If the ^MN parameter for continuous media is set, then

the print does not preform the automatic calibration. The ^MN command also includes an

automatic calibration parameter (^MNA) to return the printer to its default setting to

automatically detect all media ty pes.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 45

Cleaning

4

Maintenance

When you clean the printer, use one of the following supplies that best suits your needs:

:

Cleaning Supplies Order Quantity Intended Purpose

Cleaning pens Set of 12 Clean printhead

Cleaning swabs Set of 25 Clean media path, guides and sensors

The cleaning process takes just a couple of minutes using the steps outlined below.

Printer Part Method Interval

Printhead Let the printhead to cool for a minute, then use a

new cleaning pen to swab the dark line on the

printhead from end to end.

Platen roller See “Platen Considerations” in the Maintenance

chapter. Manually rotate the platen roller. Clean it

thoroughly with 90% medical-grade alcohol and a

fiber-free cleaning swab (such as a alcohol filled

Texpad swab or alcohol moistened lint-free

cloth).

Peel bar Clean it thoroughly with cleaning swab (such as a

Media path

Exterior Water-dampened cloth.

Interior Gently brush out printer.

alcohol filled Texpad swab or alcohol moistened

lint-free cloth).

Let alcohol dissipate and the printer dry

completely.

When using direct

thermal: after every

roll of media.

As needed.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 46

36

Maintenance

Cleaning

Caution • Adhesives an d coatings of media can over time transfer onto the printer

components along the media path including the platen and printhead. This build-up can

accumulate dust and debris. Failure to clean the printhead, media path and platen roller

could result in inadvertent loss of labels, l abel jams and possible damage to the printer.

Important • Using too much alcohol can result in contamination of the electronic components

requiring a much longer drying time before the printer will function properly.

Printhead Cleaning

Alway s use a new cleaning pen on the printhead (an old pen carries contaminants from its

previous uses that may damage the printhead).

Caution • The prin thead becomes hot while prin ting. To protect from damaging the

printhead an d risk of personal injur y, avoid touching the printhead. Use only the cleaning pen

to perform maintenance.

When you load new media, y ou can also clean the printhead.

1. Rub the cleaning pen across the dark area of the printhead. Clean from the middle to the

outside. This will move adhesive transferred from the edges of media to the printhead

outside of media path.

2. Wait one minute before closing the printer.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 47

Media Path Cleaning

Use a cleaning swab (such as a Texpad swab or alcohol moistened lint-free cloth) to remove

debris, dust or crust that has built-up on the holders, guides and media path surfaces. Do not

touch or clean the printhead with the same cleaning swab or cloth.

1. Use the alcohol in the cleaning swab (or cloth) to soak the debris so that it breaks up.

2. Wipe the ridges to remove accumulated debris.

3. Wipe the inside edges of both label edge guide walls to remove any built-up residue.

4. Wipe the label guide’s curved surface to remove accumulated debris. Do not wipe debris

or alcohol into the gap sensor. Tamp the gap sensor with a dry swab to remove any excess

alcohol that may get onto the sensor.

5. Wait one minute to dry before closing the printer.

Discard the cleaning swab or cloth after use.

Label Guide

(curved surface)

Gap Sensor

Maintenance

Cleaning

37

Platen

Ridges

Label Edge

Guides

(Walls)

12/17/07 ZP 450™ User Guide 980546-003 B

Page 48

38

Maintenance

Cleaning

Sensor Cleaning

Dust can accumulate on the media sensors.

1. Gently blow away dust; if necessary, use a dry swab to brush away dust. If adhesives or

other contaminates remain, use an alcohol moistened cleaning swab (such as a Texpad

swab) to break up the foreign material.

2. Use a dry swab several times to remove any residue that may be left from the first

cleaning.

.

Gap

Sensor

Black-Line

Sensor

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 49

Platen Considerations

The standard platen (drive roller) normally does not require cleaning. Paper and liner dust can

accumulate without effecting print operations. Contaminates on the platen roller can damage

the printhead or cause the media to slip when printing. Adhesive, dirt, general dust, oils and

other contaminates should be cleaned immediately off the platen.

Clean the standard platen (and media path) whenever the printer has significantly poorer

performance, print quality or media handling. The platen is the print surface and drive roller

for your media. If sticking or jamming continues even after cleaning, you must replace the

platen.

Cleaning the liner-less platen removes the outer layer of silicon. If contaminates other than

adhesive and paper dust are on your platen, you may need to clean your platen. This will

shorten your platen’s usable life.

Reminder - Always clean the printhead before installing a new media roll to help prevent

adhesive buildup on the printhead and adhesive transfer to the platen. Adhesive buildup on the

printhead should always be cleaned from the middle of the printhead to the outside. Any

adhesive residue will be moved outside of the media feed and print area. Discard the cleaning

pen after each cleaning to keep diluted adhesive from building up on the pen and transferring

to the printhead surface. This is the most common cause of media feed (jamming, slippage and

stalls) and print quality issues.

Maintenance

Cleaning

39

Standard Media Platen Cleaning

The platen can be cleaned with a fiber-free swab (such as a Texpad swab) or a lint free, clean,

damp cloth very lightly moistened with medical grade alcohol (90% pure or better).

1. Open the media door and remove the media.

2. Remove the platen from the printer (see Replacing the Platen on page 41).

3. Clean the platen surface with the alcohol moistened swab. Rotate the platen while

swabbing. Repeat this process two to three times with a new swab to remove residual

contaminates. Adhesives and oils, for example, may be thinned by the initial cleaning but

not completely removed.

4. Install the platen in the printer (see Replacing the Platen on page 41).

5. Discard the cleaning swab after use.

Allow the printer to dry for one minute before loading labels.

Liner-less Platen Cleaning

Normal Cleaning: If the liner-less platen roll has adhesive or paper dust build-up at the edges

of the media path, use the following procedure to remove the material. Do not use this

procedure to remove foreign contaminates (oils, dirt, etc.), see the Foreign Contaminates

Cleaning procedure.

1. Open the printer and remove the liner-less media.

2. Remove the platen roller. Use the platen replacement procedure.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 50

40

Maintenance

Lubrication

3. Remove several inches of new liner-less media from the roll.

4. Gently tamp the adhesive and paper dust off of the platen roller with the adhesive side of

the liner-less media.

5. Clean the printhead. Use the printhead cleaning procedure. Remember to clean the

adhesive buildup on the head from the middle of the printhead to the outside.

6. Replace the platen roller.

7. Load the media. Let it extend out of the printer. Press the Feed button to verify that it is

operating correctly. Remove excess media.

Liner-less Platen Foreign Contaminates Cleaning: This is an stop gap procedure only to

remove foreign contaminates (oils, dirt) from the liner-less platen that can damage the

printhead or other printer components. This procedure will shorten or even exhaust the

platen’s useable life!

The liner-less platen can be cleaned with a fiber-free swab (such as a Texpad swab) or a lintfree, clean, damp cloth very lightly moistened with medical grade alcohol (90% pure or

better).

1. Open the printer and remove the liner-less media.

2. Liner-less platen rollers can damage easily. Gently swab the platen surface with the

alcohol moistened swab to clean. Rotate the platen or remove the platen while swabbing.

Repeat this process two to three times with a new swab to remove residual contaminates.

Adhesives and oils, for example, may be thinned by the initial cleaning but not completely

removed.

3. Discard the used cleaning swabs.

4. Allow the printer to dry for one minute before loading media. Load the liner-less media

roll. Let it extend out of the printer.

5. All of the non-stick coating was removed from the surface by cleaning. Feed a meter (39

inches) or more of media while gently pulling the media. This keeps the media from

wrapping around the platen roller and jamming in the printer. Feeding media causes the

roller to leach more silicon to the surface.

Note: If the liner-less media continues to jam after cleaning and feeding 1 to 2 meters (3 to 5

feet) of media, replace the liner-less platen.

Lubrication

Caution • No lubrica ting agents of any kind should be used on this printer. Some

commercially available lubricants, if used, will damage the finish and the mechanical parts

inside the prin ter.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 51

Replacing the Platen

Removal

Open the printer and remove any media.

1. Press the tabs on the right and left sides out. Then rotate them up.

Maintenance

Replacing the Platen

41

2. Lift the platen out of the printer’s bottom frame.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 52

Maintenance

42

Replacing the Platen

Installation

1. Make sure the bearings are on the shaft of the platen.

2. Align the platen with the gear to the left and lower it into the printer’s bottom frame.

3. Rotate the tabs back and snap them into place.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 53

Replacing the Printhead

In the event you need to replace the printhead, read the procedure and review the removal and

installation steps before actually replacing the printhead.

Caution • Prepare your work area by protecting against static discharge. Your work area

must be static-sa fe and include a properly gr ounded conductive cushioned mat to hold the

printer and a conductive wrist strap for yourself.

Caution • Turn th e printer power off and un plug the power cord before replacing the

printhead.

Removal

1. Open the cover. Press the printhead to the left; then, release the right side catch.

Maintenance

Replacing the Printhead

43

2. Let the printhead fall forward; pull it free of the top case if necessary.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 54

Maintenance

44

Replacing the Printhead

3. Unplug both bundles of printhead wires from their connectors.

Installation

1. Align the printhead to plug the left and right connectors into the wire bundles.

2. Slide the printhead into the left side and jog it into the right side catch.

Clean the printhead as described under Printhead Cleaning on page 36.

Reload media. Plug in the power cord, turn on the printer and print a status report to ensure

proper function.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 55

5

Troubleshooting

What the Status Light is Telling You

LED Status and Color Printer Status

Off Off 1

Solid Green On 2

Solid Amber Stopped 3

Flashing Green Normal Operation 4

Flashing Red Stopped 5

Double Flashing Green Paused 6

Flashing A mber Paused 7

Alternately Flashing Green and Red Needs Service 8

Flashing Red, Red and Green Needs Service 9

Resolutions

1. The printer is not receiving power.

• Have y ou turned on the printer power?

• Check power connections from the wall outlet to the power supply, and from the power

supply to the printer.

For a Resolution,

Refer to Number:

• Disconnect the printer from the wall outlet for 30 seconds and then reconnect the printer to

the wall outlet.

2. The printer is on and in an idle state.

No action necessary.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 56

Troubles hooting

46

Resolutions

3. The printer has failed its power on self test (POST).

• If this error occurs right after y ou turn on the printer, contact an authorized reseller for

assistance.

There is a memory error.

• If this error occurs after you have been printing, turn the printer power off and on. Then,

resume printing.

The printer needs to cool or requires service.

• If this error continues, turn the printer power off for five minutes or more. Then, turn on. If

the amber light persists, then the printer requires service.

4. The printer is receiving data.

• As soon as all of the data has been received, the status LED will turn green; then, the

printer will automatically resume operation.

5. The media is out.

• Follow the instructions for Loading Roll Media on p age 9 in the Getting Started section.

Then, press the feed button to resume printing.

The printhead is open.

• Close the top cover. Then, press the feed button to resume printing.

6. The printer is paused.

• Press the feed button to resume printing.

7. The printhead is under temperature.

• Continue printing while the printhead reaches the correct operating temperature.

The printhead is over temperature.

• Printing will stop until the printhead cools to an acceptable printing temperature. When it

does, the printer will automatically resume operation.

8. FLASH memory is not programmed.

• Return the printer to an authorized reseller.

9. The printhead or motor has had a critical failure.

• Return the printer to an authorized reseller.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 57

Print Quality Problems

No print on the label.

• You must use direct thermal media for printing. Direct thermal media is chemically treated

to print (expose) when heat is applied. A finger nail or pen cap may be used to test for

direct thermal media by pressing firmly and quickly dragging it accross the media surface.

This test method uses friction heat to expose the media.

• Is the media loaded correctly? The media’s print surface must face up to make contact

with the printhead. Follow the instructions for Loading Roll Media on page 9 in the

Getting Started section.

The printed image does not look right.

• The printhead is dirty. Clean the printhead.

• The printhead is under temperature.

• Adjust the print darkness and/or print speed.

Troubleshooting

Print Quality Problems

47

•Use the

Programming Guide.

•Use the

Guide.

• Manually adjust print darkness with the six-flash sequence of Feed Button Modes

on page 53.

• The Windows printer driver or application software may change these settings and

may require a change to optimize print quality.

• The media being used is incompatible with the printer. Be sure to use the recommended

media for y our application, and always use Zebra-approved labels and tags.

• The printhead has worn out. The printhead is a consumable item and will wear out due to

friction between the media and printhead. Using unapproved media may shorten life or

damage your printhead. Replace the printhead.

• The platen may need cleaning or replacement. The platen (driver) roller maybe losing

traction due to:

• Foreign objects attached to its surface,

• The rubbery smooth surface has become polished and slippery, or

• There is damage to the normally smooth and flat print surface such as box knife cuts.

^PR (speed) and ~SD (darkness) commands referenced in the ZPL

D (darkness/density) and S (speed) commands in the EPL Programmer’s

There are long tracks of missing print (blank vertical lines) on

several labels.

• The printhead is dirty. Clean the printhead.

• The printhead elements are damaged. Follow the instructions for Replacing the Printhead

on page 43 in the Maintenance section).

12/17/07 ZP 450™ User Guide 980546-003 B

Page 58

Troubles hooting

48

Print Quality Problems

The printing does not start at the top of the label, or misprinting of

one t o three labels.

• The printer needs to be calibrated for the media. Refer to the two-flash sequence of Feed

Button Modes on page 53 in this section.

• The correct media sensor may not be activated. Manual calibration selects the media

sensing method for the labels being used (refer to the

Programming Guide).

^MN command in the ZPL II

• Verify that the Label Top (

ZPL II Programming Guide).

^LT) command is correctly set for y our application (consult the

A ZPL label format was sent to, but not recognized by, the printer.

• Is the printer in pause mode? If so, press the feed button.

• If the status LED is on or flashing, refer to Feed Button Modes on page 53 in this chapter.

• Make sure the data cable is correctly installed.

• A communications problem has occurred. First, make sure that the correct

communications port on the computer is selected. Refer to Hooking Up the Printer and

Computer on page 15 in the Getting Started section.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 59

Manual Calibration

Manual calibration is recommended whenever you are using pre-printed media or if the printer

will not correctly auto calibrate.

1. Make sure media is loaded.

2. Turn on the printer power.

3. Press and hold the Feed button until the green status light flashes once, then twice and

then continuing until the flash groups reach the group of seven flashes. Release the Feed

button.

4. The printer will set the media sensor for the label backing being used. After it is done

making this adjustment, the roll will automatically feed until a label is positioned at the

printhead. A profile of the media sensor settings (similar to the example below) will print.

Upon completion, the printer will save the new settings in memory and the printer is ready

for normal operation.

5. Press the Feed button. One entire blank label will feed. If this does not happen, try

defaulting (refer to the four-flash sequence in “Feed Button Modes” later in this chapter)

and recalibrating the printer..

Troubleshooting

Manual Calibration

49

Note • Performing a manual calibration disables the automatic media type detection the is

part of the automatic media sensing (and calibration) function. To return to auto calibration,

default the printer (refer to the four-flash sequence in Feed Button Modes on page 53 in this

section).

12/17/07 ZP 450™ User Guide 980546-003 B

Page 60

Troubles hooting

50

Troubleshooting Tests

Troubleshooting Tests

Printing a Configuration Label

To print out a listing of the printer’s current configuration, refer to the one-flash sequence in

Feed Button Modes on page 53 in this section

Recalibration

Recalibrate the printer if it starts to display unusual symptoms, such as skipping labels. Refer

to the two-flash sequence in Feed Button Modes on page 53 in this section.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 61

Resetting the Factory Default Values

Sometimes, resetting the printer to the factory defaults solves some of the problems. Refer to

the four-flash sequence in Feed Button Modes on page 53 in this section.

Communications Diagnostics

If there is a problem transferring data between the computer and printer, try putting the printer

in the communications diagnostics mode. The printer will print the ASCII characters and their

respective hexadecimal values (a sample is shown below) for any data received from the host

computer. To find out how,

There are multiple ways to enter hex data dump mode:

•The ~JD ZPL command

•The dump EPL command

• On power up with the Feed button pressed. Refer to the power off mode procedure in Feed

Button Modes on page 53 in this section.

Troubleshooting

Resetting the Factory Default Values

51

The printer will print ‘Now in DUMP’ (see below) and advance to the top of the next label.

12/17/07 ZP 450™ User Guide 980546-003 B

Page 62

Troubles hooting

52

Communications Diagnostics

The following example of a communications DUMP mode printed out. The printout displays

hexadecimal data 00h-FFh (0-255 decimal) with a unique character for each hexadecimal

value displayed above the hexadecimal data.

The blank lines between the lines of data are where serial port and Bluetooth data handling

errors get logged. The errors are:

• F = Frame Error

• P = Parity Error

• N = Noise Error

• O = Data Overrun Error

To exit the diagnostic mode and resume printing, turn off and then turn on the printer. An

alternate method for exiting the diagnostic mode is to press the Feed button as many times as it

takes to clear the printer’s command buffer and print ‘Out of DUMP’ on the label.

980546-003 B ZP 450™ User Gu ide 12/17/07

Page 63

Feed Button Modes

With th e print er power of f , press and h old th e Feed button while you turn on the power.

Flash Sequence Action

Rapid Red

Flashing

Amber

Green

Troubleshooting

Feed Button Modes

Power O ff Mode (Communications Diagnostics Mode)