Page 1

MPACT

Bluetooth Smart Beacon

Hardware Installation

Guide

‘MN-002606-05EN

Page 2

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corporation, registered in

many jurisdictions worldwide. All other trademarks are the property of their respective owners.

© 2022 Zebra Technologies Corporation and/or its affiliates. All rights reserved.

Information in this document is subject to change without notice. The software described in this document

is furnished under a license agreement or nondisclosure agreement. The software may be used or copied

only in accordance with the terms of those agreements.

For further information regarding legal and proprietary statements, please go to:

SOFTWARE:http://www.zebra.com/linkoslegal

COPYRIGHTS:http://www.zebra.com/copyright

WARRANTY:http://www.zebra.com/warranty

END USER LICENSE AGREEMENT: http://www.zebra.com/eula

Terms of Use

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries

(“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced,

or disclosed to any other parties for any other purpose without the express, written permission of Zebra

Technologies.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications and designs are

subject to change without notice.

Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and manuals are

correct; however, errors do occur. Zebra Technologies reserves the right to correct any such errors and

disclaims liability resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever

(including, without limitation, consequential damages including loss of business profits, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to

use such product, even if Zebra Technologies has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

Apple iBeacon

Use of the Works with Apple iBeacon badge means that a product has been designed and certified by the

manufacturer to meet Apple performance standards. Apple is not responsible for the operation of this

device or its compliance with safety and regulatory standards. Please note that the use of this product with

iPod, iPhone, or iPad may affect wireless performance.

i

Page 3

Zebra Technologies Corporation ("Zebra") End-User Software

License Agreement

BY INSTALLING AND/OR USING THIS PRODUCT, YOU ACKNOWLEDGE THAT YOU HAVE

READ THIS AGREEMENT, UNDERSTAND IT AND AGREE TO BE BOUND ITS TERMS. IF YOU

DO NOT AGREE TO THE TERMS OF THIS AGREEMENT, ZEBRA IS NOT WILLING TO

LICENSE THE PRODUCT TO YOU, AND YOU MUST NOT INSTALL OR USE THIS PRODUCT.

Definitions

Grant of License

Zebra Technologies Corporation ("Zebra") grants you ("Licensee" or "you") a personal,

nonexclusive, nontransferable, revocable, nonassignable, limited license to use the software and

documentation ("Product(s)") subject to the terms and conditions of this Agreement. You shall use

the Products only for your internal business purposes, exclusively to support Zebra devices. Any

use of the Products outside of the conditions set forth herein is strictly prohibited and will be deemed

a breach of this Agreement resulting in immediate termination of your License. In the event of a

breach of this Agreement, Zebra will be entitled to all available remedies at law or in equity

(including immediate termination of the license without notice, immediate injunctive relief and

repossession of all Products unless Licensee is a Federal agency of the United States

Government).

You shall not distribute, sublicense, rent, loan, lease, export, re-export, resell, ship or divert or

cause to be exported, re-exported, resold, shipped or diverted, directly or indirectly, the Products

under this Agreement. You shall not, and shall not permit others to: (i) modify, translate, decompile,

bootleg, reverse engineer, disassemble, or extract the inner workings of the Products, (ii) copy the

look-and-feel or functionality of the Products; (iii) remove any proprietary notices, marks, labels, or

logos from the Products; (iv) rent or transfer all or some of the Products to any other party without

Zebra's prior written consent; or (v) utilize any computer software or hardware which is designed to

defeat any copy protection device, should the Products be equipped with such a protection device.

Title to all copies of Products will not pass to Licensee at any time and remains vested exclusively

in Zebra. All intellectual property developed, originated, or prepared by Zebra in connection with the

Products remain vested exclusively in Zebra, and this Agreement does not grant to Licensee any

intellectual property rights.

Portions of the Products are protected by United States patent and copyright laws, international

treaty provisions, and other applicable laws. Therefore, you must treat the Products like any other

copyrighted material (e.g., a book or musical recording) except that you may make one copy of the

Product solely for back-up purposes. Unauthorized duplication of the Products constitutes copyright

infringement, and in the United States is punishable in federal court by fine and imprisonment.

ii

Page 4

Limited Warranty

Zebra warrants for a period of ninety (90) days from your receipt of the Products to you that the

Software, under normal use, will perform substantially in accordance with Zebra's published

specifications for that release level of the Software. The written materials are provided "AS IS" and

without warranty of any kind. Zebra's entire liability and your sole and exclusive remedy for any

breach of the foregoing limited warranty will be, at Zebra's option, the provision of a downloadable

patch or replacement code, or a refund of the unused portion of your bargained for contractual

benefit up to the amount paid for the Products.

Disclaimer

THIS LIMITED WARRANTY IS THE ONLY WARRANTY PROVIDED BY ZEBRA, AND ZEBRA

MAKES, AND YOU RECEIVE, NO OTHER WARRANTIES OF ANY KIND, WHETHER EXPRESS,

IMPLIED, STATUTORY, OR IN ANY COMMUNICATION WITH YOU. ZEBRA SPECIFICALLY

DISCLAIMS ANY WARRANTY INCLUDING THE IMPLIED WARRANTIES OF

MERCHANTABILTY, NONINFRINGEMENT, OR FITNESS FOR A PARTICULAR PURPOSE.

ZEBRA DOES NOT WARRANT THAT THE PRODUCTS WILL MEET YOUR REQUIREMENTS,

OR THAT THE OPERATION OF THE PRODUCTS WILL BE UNINTERRUPTED OR ERROR

FREE, OR THAT DEFECTS IN THE PRODUCTS WILL BE CORRECTED. ZEBRA MAKES NO

WARRANTY WITH RESPECT TO THE CORRECTNESS, ACCURACY, OR RELIABILITY OF THE

PRODUCTS. Some jurisdictions do not allow the exclusion of implied warranties, so the above

exclusion may not apply to you.

Limitation of Liability

THE TOTAL LIABILITY OF ZEBRA UNDER THIS AGREEMENT FOR DAMAGES SHALL NOT

EXCEED THE FAIR MARKET VALUE OF THE PRODUCTS LICENSED UNDER THIS

AGREEMENT. IN NO EVENT WILL ZEBRA BE LIABLE IN ANY WAY FOR INCIDENTAL,

CONSEQUENTIAL, INDIRECT, SPECIAL OR PUNITIVE DAMAGES OF ANY NATURE,

INCLUDING WITHOUT LIMITATION, LOST BUSINESS PROFITS, OR LIABILITY OR INJURY TO

THIRD PERSONS, WHETHER FORESEEABLE OR NOT, REGARDLESS OF WHETHER ZEBRA

HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Some jurisdictions do not

permit limitations of liability for incidental or consequential damages, so the above exclusions may

not apply to you. This Limitation of Liability provision survives the termination of this Agreement and

applies notwithstanding any contrary provision in this Agreement. Licensee must bring any action

under this Agreement within one (1) year after the cause of action arises.

iii

Page 5

Maintenance

Unless provided for in a separate agreement, Zebra shall not be responsible for maintenance or

field service of the Products.

High Risk Activities

The Products are not fault-tolerant and are not designed, manufactured or intended for use or

resale as on-line control software in hazardous environments requiring fail-safe performance, such

as in the operation of nuclear facilities, aircraft navigation or communication systems, air traffic

control, direct life support machines, or weapons systems, in which the failure of the Products could

lead directly to death, personal injury, or severe physical or environmental damage ("High Risk

Activities"). Zebra and its suppliers specifically disclaim any express or implied warranty of fitness

for High Risk Activities, and if you elect to use the Products in any High Risk Activities, you agree

to indemnify, defend, and hold Zebra harmless from and against any and all costs, damages, and

losses related to that use.

U.S. Government

If you are acquiring the Products on behalf of any unit or agency of the U.S. Government, the

following shall apply. Use, duplication, or disclosure of the Products is subject to the restrictions set

forth in subparagraphs (c) (1) and (2) of the Commercial Computer Software - Restricted Rights

clause at FAR 52.227-19 (JUNE 1987), if applicable, unless being provided to the Department of

Defense. If being provided to the Department of Defense, use, duplication, or disclosure of the

Products is subject to the restricted rights set forth in subparagraph (c) (1) (ii) of the Rights in

Technical Data and Computer Software clause at DFARS 252.227-7013 (OCT 1988), if applicable.

Products may or may not include a Restricted Rights notice, or other notice referring specifically to

the terms and conditions of this Agreement. The terms and conditions of this Agreement shall each

continue to apply, but only to the extent that such terms and conditions are not inconsistent with the

rights provided to you under the aforementioned provisions of the FAR and DFARS, as applicable

to the particular procuring agency and procurement transaction.

Assignment

Except as otherwise provided in this section, neither party may assign this Agreement, or any of its

rights or obligations under this Agreement, without the prior written approval of the other party,

which will not be unreasonably withheld. Any attempted assignment, delegation, or transfer without

the necessary approval will be void. Notwithstanding the foregoing, for any Zebra acquisition,

merger, consolidation, reorganization, or similar transaction, or any spin-off, divestiture, or other

separation of a Zebra business, Zebra may, without the prior written consent of the other party: (i)

assign its rights and obligations under this Agreement, in whole or in part, or (ii) split and assign its

rights and obligations under this Agreement so as to retain the benefits of this Agreement for both

Zebra and the assignee entity(ies) (and their respective Affiliates) following the split.

iv

Page 6

Governing Law

This Agreement shall be governed by the laws of the United States of America to the extent that

they apply and otherwise by the laws of the State of New York without regard to its conflict of laws

provisions or by the internal substantive laws of the country to which the Products is shipped if end-

user customer is a sovereign governmental entity. The terms of the U.N. Convention on Contracts

for the International Sale of Goods do not apply. In the event that the Uniform Computer information

Transaction Act, any version of this Act, or a substantially similar law (collectively "UCITA")

becomes applicable to a Party's performance under this Agreement, UCITA does not govern any

aspect of this End User License Agreement or any license granted under this End-User License

Agreement, or any of the parties' rights or obligations under this End User License Agreement. The

governing law will be that in effect prior to the applicability of UCITA.

Compliance with Laws

Licensee will comply with all applicable laws and regulations, including export laws and regulations

of the United States. Licensee will not, without the prior authorization of Zebra and the appropriate

governmental authority of the United States, in any form export or re-export, sell or resell, ship or

reship, or divert, through direct or indirect means, any item or technical data or direct or indirect

products sold or otherwise furnished to any person within any territory for which the United States

Government or any of its agencies at the time of the action, requires an export license or other

governmental approval. Violation of this provision will be a material breach of this Agreement,

permitting immediate termination by Zebra.

Third-Party Software

The Products may contain one or more items of Third-Party Software. The terms of this Agreement

govern your use of any Third-Party Software UNLESS A SEPARATE THIRD-PARTY SOFTWARE

LICENSE IS INCLUDED, IN WHICH CASE YOUR USE OF THE THIRD-PARTY SOFTWARE

WILL THEN BE GOVERNED BY THE SEPARATE THIRD-PARTY LICENSE.

Open Source Software

The Products may contain one or more items of Open Source Software. Open Source Software is

software covered by a publicly available license governed solely under Copyright law, whereas the

complete terms and obligations of such license attach to a licensee solely through the act of

copying, using and/or distribution of the licensed software, such obligations often include one or

more of attribution obligations, distribution obligations, copyleft obligations, and intellectual property

encumbrances. The use of any Open Source Software is subject to the terms and conditions of this

Agreement as well as the terms and conditions of the corresponding license of each Open Source

Software package. If there is a conflict between the terms and conditions of this Agreement and the

v

Page 7

terms and conditions of the Open Source Software license, the applicable Open Source Software

license will take precedence. Copies of the licenses for the included Open Source Software, if any,

as well as their attributions, acknowledgments, and software information details, are provided in the

electronic copy of this Agreement, which is available in the Legal Notices or README file

associated with the Product. Zebra is required to reproduce the software licenses,

acknowledgments and copyright notices as provided by the authors and owners, thus, all such

information is provided in its native language form, without modification or translation. Depending

on the license terms of the specific Open Source Software, source code may not be provided.

Please reference and review the entire Open Source Software information to identify which Open

Source Software packages have source code provided or available. For instructions on how to

obtain a copy of any source code made publicly available by Zebra related to Open Source

Software distributed by Zebra, you may send your request (including the Zebra Product name and

version, along with the Open Source Software specifics) in writing to: Zebra Technologies

Corporation, Open Source Software Director, Legal Department, 3 Overlook Point, Lincolnshire, IL

60069 USA.

vi

Page 8

Contents

About This Document ....................................................................................................................... 1

Introduction ..................................................................................................................... 1

Icon Conventions ............................................................................................................ 2

Related Documents ......................................................................................................... 2

Service Information ......................................................................................................... 2

Feedback ........................................................................................................................ 2

Hardware Specifications and Installation ........................................................................................ 3

Lozier® Shelves .............................................................................................................. 3

MB1000 Beacon: MPACT-T1B20-000-WR ..................................................................... 3

MB1000 Beacon: MPACT-T1B10-000-WR ..................................................................... 4

Replacing MB1000 Battery ............................................................................... 6

MPACT-MB2000-01-WR, MPACT-MB1000-01-WR, MPACT-MB2001-01-WR,

MPACT-SB2000-01-WR, MPACT-SB2100-01-WR ........................................................ 8

USB Beacon: MPACT-MB3000-01-WR ........................................................................ 13

Beacon Part Numbers: MPACT-MB4000-01-WR and MPACT-MB4001-01-WR ......... 14

Mounting using Tape ....................................................................................... 15

Mounting using Screws ................................................................................... 15

Beacon: MPACT-MB1000-01-WR and MPACT-SB1100-01-WR ................................ 17

Mounting using Tape ....................................................................................... 19

Mounting using a Beacon Accessory .............................................................. 20

Fixed IoT Bridge (hub): MPACT-MB5000-01-WR, MPACT-SB5200-01-WR................. 22

Mobile IoT Bridge (badge): MPACT-MB6000-01-WR ................................................... 25

Usage .............................................................................................................. 29

Charging .......................................................................................................... 30

Disposing ........................................................................................................ 30

Cradle Charger: MPACT-MB6000-CHRGR ................................................................. 31

Cleaning the Badge Contacts ......................................................................... 34

Cleaning the Cradle Connectors .................................................................... 34

Troubleshooting ............................................................................................................ 35

1

Page 9

About This Document

Introduction

MPact utilizes Bluetooth Smart beacons in various modes to unify Wi-Fi and Bluetooth Smart Technology

to capture analytics, accuracy and insight.

Beacon placements can be adjusted within a deployment floor plan, and depending on the mode selected,

their battery life can be tracked over time. Administrators can cursor over a beacon on a site’s floor plan to

assess the beacon’s remaining battery life. This guide covers a variety of indoor, outdoor and USB type

beacons, mounting options, and operational instructions for each beacon type.

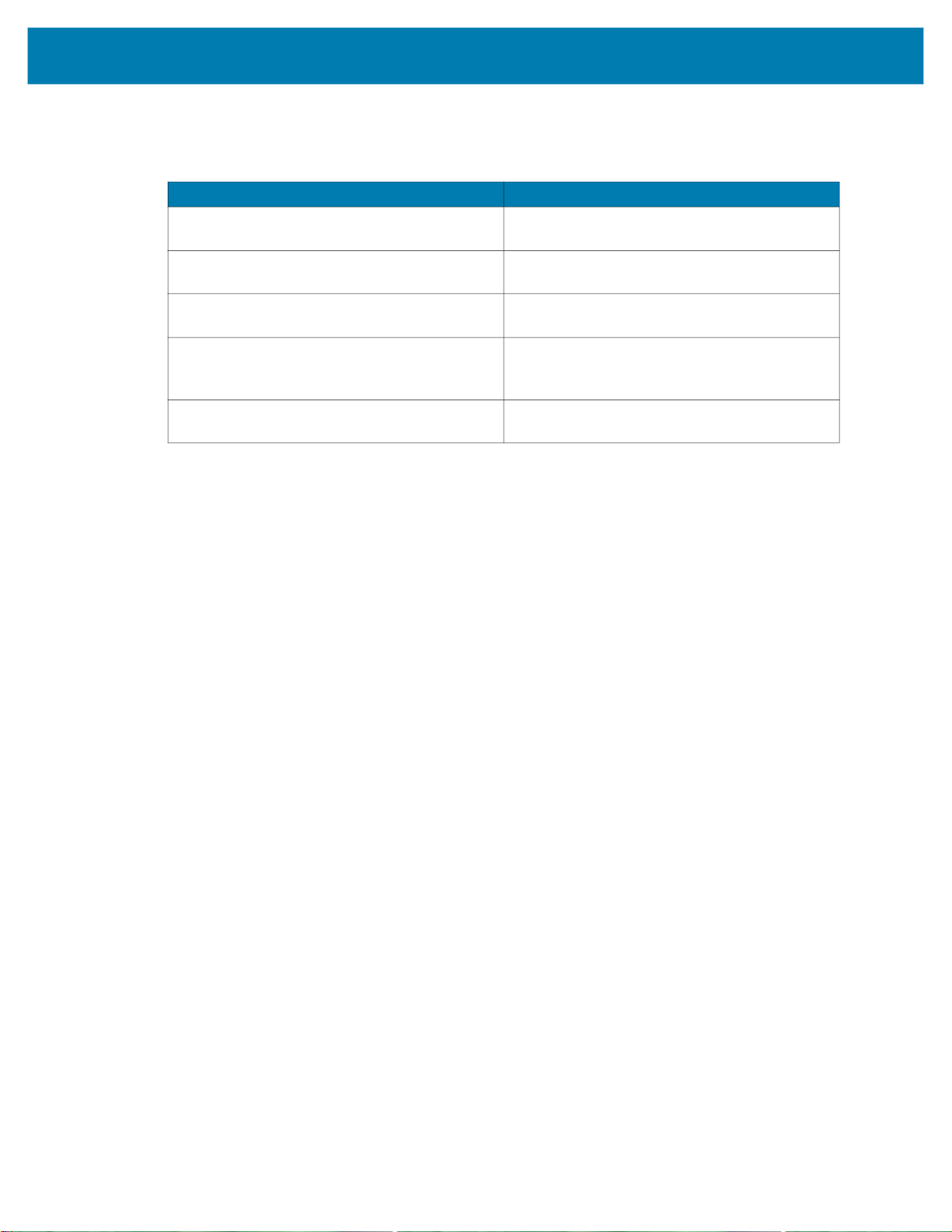

This guide supports the following product families, parts, and regulatory models:

PRODUCT FAMILY PART NAME REGULATORY MODEL

MB 1000 MPACT-T1B10-000-WR ALTS-T1B

MB 1000 MPACT-T1B20-000-WR ALTS-T1B

MB 1000 MPACT-MB1000-01-WR MPACT-INDR2

MB 1000 MPACT-SB1100-01-WR MPACT-INDR3

MB 1000 MPACT-MB1000-01-ACC Lanyard mounting plate

MB 1000 MPACT-MB1001-01-ACC Wrist mounting plate

MB 2000 MPACT-MB2000-01-WR MPACT-INDR1

MB 2000 MPACT-MB2001-01-WR MPACT-INDR1

MB 2000 MPACT-MB2001-01-KIT MPACT-INDR1

MB 2000 MPACT-MB2001-01-ACC MPACT-INDR1

MB 2000 MPACT-SB2000-01-WR MPACT-INDR1

SB 2100 MPACT-SB2100-01-WR MPACT-INDR1

MB 2000 MPACT-MB2002-01-ACC RF enhancement plate

MB 3000 MPACT-MB3000-01-WR MPACT-USB1

MB 4000 MPACT-MB4000-01-WR MPACT-OUTR1

MB 4000 MPACT-MB4001-01-WR MPACT-OUTR1

MB 5000 MPACT-MB5000-01-WR MPACT-HUBFXD

SB 5200 MPACT-SB5200-01-WR MPACT-HUBFXD

MB 6000 MPACT-MB6000-01-WR MPACT-BRDGM

MB 6000 MPACT-MB6000-CHRGR MPACT-CRDLE

MB 6000 MB6000-01-ACC Replacement clip

MB 6000 MB6000CABLE-US Power cable

MB 6000 MB6000CABLE-EU Power cable

MB 6000 MB6000CABLE-UK Power cable

1

Page 10

Icon Conventions

The following graphic icons are used throughout the documentation set; these icons and their associated

meanings are described below:

NOTE: The text here indicates information that is supplemental for the user to know and that is not

required to complete a task.

IMPORTANT: The text here indicates information that is important for the user to know.

Related Documents

• MPACT Hardware Installation Guide

• IOT Bridge CLI Document

• JSON Schema for Receiver Operations

• Wi-Fi Connectivity Settings

• Integration with Receivers

• Receiver Indicators, Actions, and Details

About This Document

• Hostname Support

• Beacon Toolbox User Guide

• Superbeacon Toolbox User Guide

These and other guides are available at: www.zebra.com/support

management.

Service Information

If you have a problem with your equipment, contact Zebra Global Customer Support for your region.

Contact information is available at www.zebra.com/support

When contacting support, please have the following information available:

• Serial number of the unit

• Model number or product name

• Software/firmware type or version number

Zebra responds to calls by email, telephone or fax within the time limits set forth in support agreements.

If your problem cannot be solved by Zebra Customer Support, you may need to return your equipment for

servicing and will be given specific directions. Zebra is not responsible for any damages incurred during

shipment if the approved shipping container is not used. Shipping the units improperly can possibly void

the warranty.

or contact Zebra’s product line

Feedback

If you purchased your Zebra business product from a Zebra business partner, contact that business

partner for support.

If you have comments, questions, or suggestions about this guide, send an email to

EVM-techdocs@zebra.com

.

2

Page 11

Hardware Specifications and Installation

Bluetooth Low Energy beacons from Zebra can be used with Zebra Location Solutions (MotionWorks and

MPact) or other third-party solutions.

Lozier® Shelves

Beacon brackets for the MPACT-T1B20-000-WR and MPACT-T1B10-000-WR are used with the following

Lozier products:

• TL Shelf

• DL Shelf

• HL Shelf

• Standard Base Deck

MB1000 Beacon: MPACT-T1B20-000-WR

As a prerequisite, the following hardware items are required to mount the tie-wrap style beacon housing to

a pole or similar structure:

• Beacon (tie-wrap style housing) part number MPACT-T1B20-000-WR

• Plastic tie wraps for attaching each beacon housing to the shelf

Mounting and Installing

Tie-wrap beacon housings are designed to attach to vertical or horizontal poles or similar mounting

surfaces. As shown in Figure 1, there are openings on the back of the beacon housing allowing a tie wrap

through the openings and wrapped around a pole or similar structure.

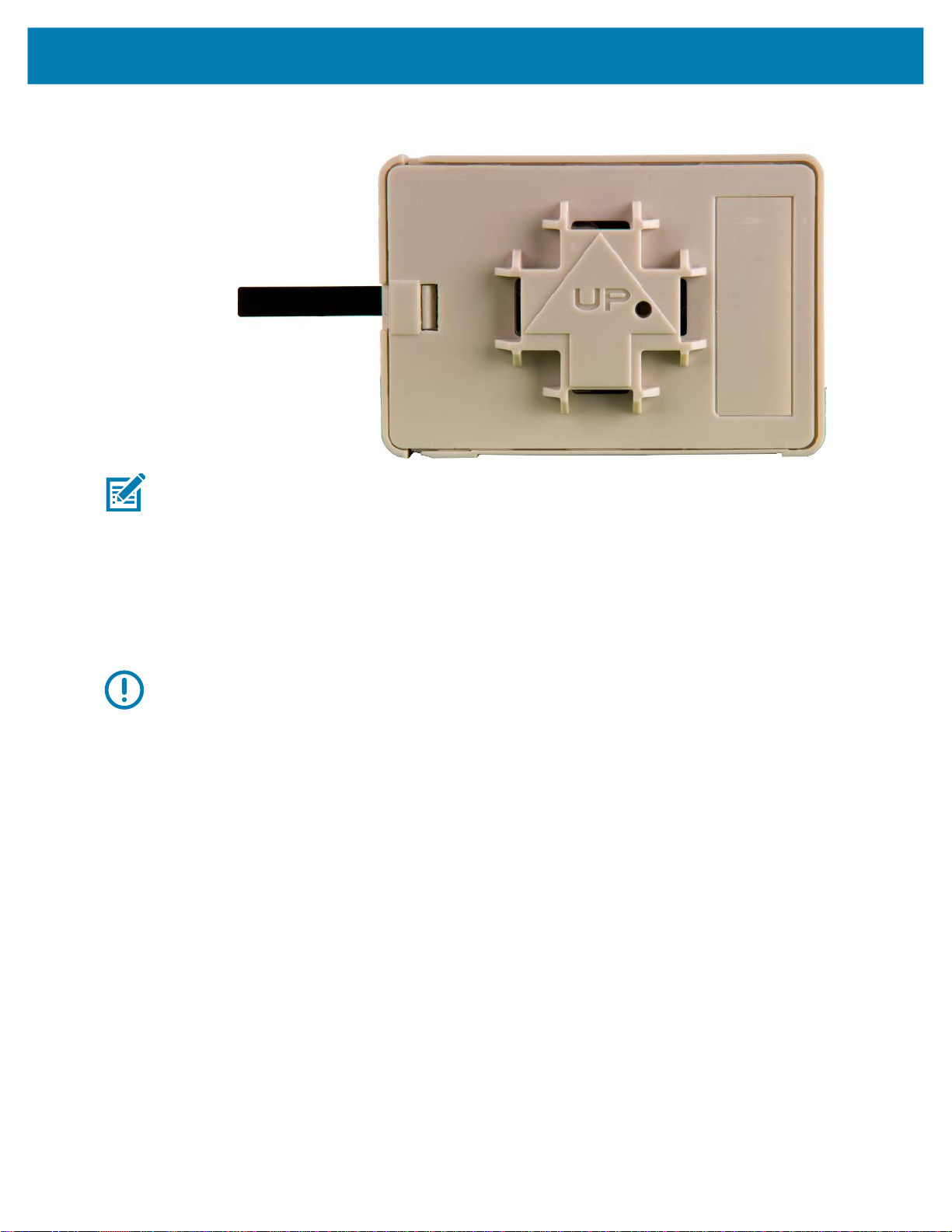

Notice the up arrow located on the middle of the beacon housing, this arrow indicates the optimal

orientation for the beacon to function properly. Additionally, the smooth front of the beacon should face

outward toward the aisle.

Figure 1 shows a beacon with the mylar strip attached to the left-hand side of the housing.

3

Page 12

Hardware Specifications and Installation

Figure 1 Tie Wrap Style Beacon

NOTE: When installing numerous beacons, group beacons by category and activate them prior to

scanning the barcodes and associating them with positions in the Toolbox.

From the MPact Toolbox, select a site floor plan and an unassigned position for the beacon. Refer to the

MPact Location & Analytics Deployment Guide for information on how to install and deploy the beacon

from the Toolbox.

Mount the beacon to a pole or similar structure using the plastic tie wrap. Tie can be placed vertically or

horizontally but the arrow should still point up.

To activate a beacon part number MPACT-T1B20-000-WR, pull the mylar strip off the beacon housing.

IMPORTANT: After pulling off the last mylar strip, you have 20 seconds to associate the beacon in either

off-line or on-line mode using the Toolbox application.

MB1000 Beacon: MPACT-T1B10-000-WR

As a prerequisite, the following hardware items are required to mount beacon brackets to a Lozier style

shelf:

• Lozier Shelves

• Beacon part number MPACT-T1B10-000-WR

• Bracket mount (one of either):

• MPACT Metal Lozier Bracket: MPACT-A1O10-004-WR

• MPACT Plastic Lozier Bracket: MPACT-A1O10-001-WR

• Phillips screwdriver

Mounting and Installing

Figure 2 shows a universal style beacon. While there is no up arrow on this beacon’s housing, the beacon

should be oriented similar to the tie wrap style of beacon housing (see MB1000 Beacon:

MPACT-T1B20-000-WR on page 3).

4

Page 13

Hardware Specifications and Installation

Notice the up arrow located on the middle of the beacon housing. This arrow indicates the optimal

orientation for the beacon to function properly. Additionally, the smooth front of the beacon should face

outward toward the aisle.

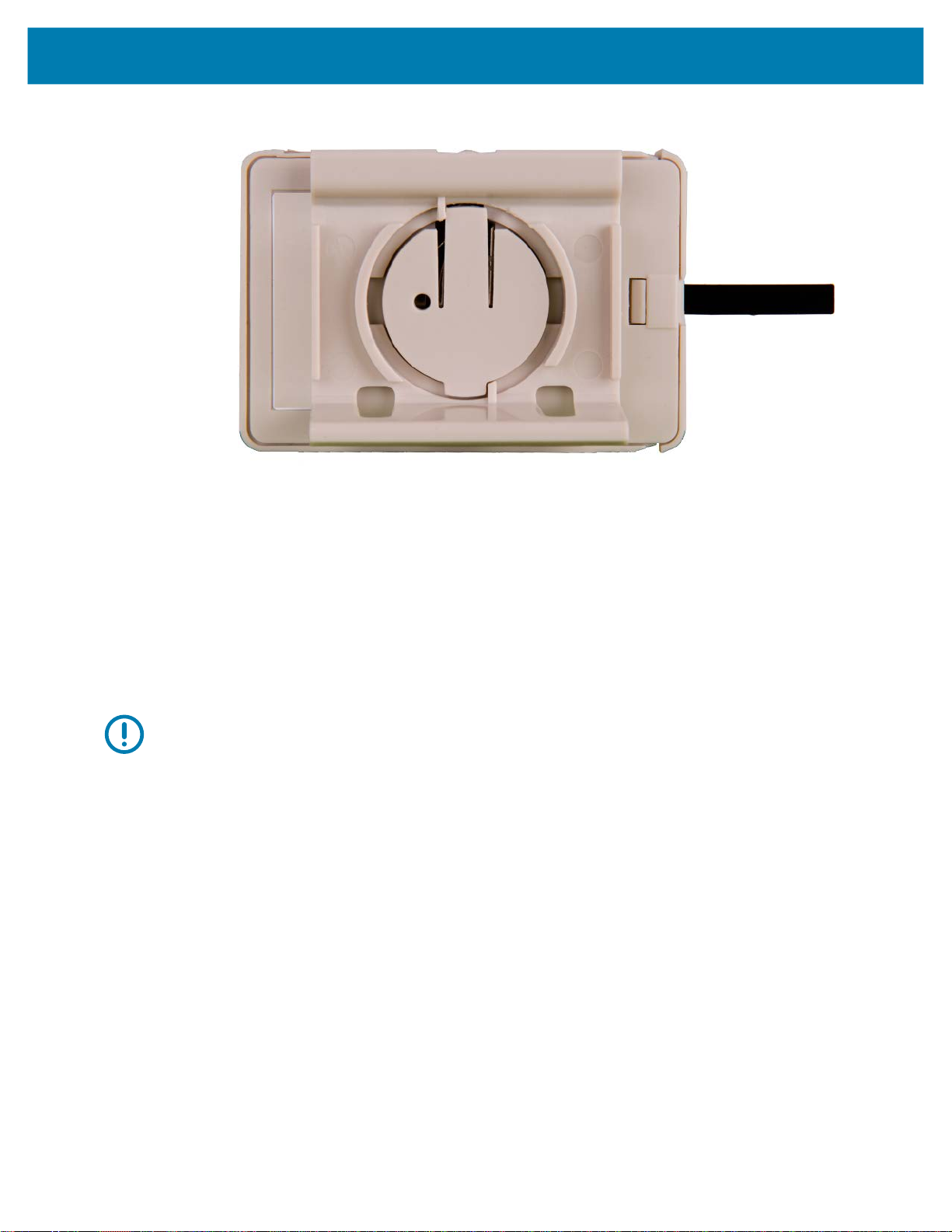

Figure 2 Universal Style Beacon

NOTE: When installing numerous beacons, group beacons by category and activate them prior to

scanning the barcodes and associating them with positions in the Toolbox.

From the MPact Toolbox, select a site floor plan and an unassigned position for the beacon. Refer to the

MPact Location & Analytics Deployment Guide for information on how to install and deploy the beacon

from the Toolbox.

There are two styles of bracket mounts:

• Universal Style Metal Bracket: MPACT-A1O10-004-WR

Figure 3 Universal Style Metal Bracket

• Universal Style Plastic Bracket: MPACT-A1O10-001-WR

5

Page 14

Hardware Specifications and Installation

Figure 4 Universal Style Plastic Bracket

To mount the universal style beacon to Lozier shelves:

1. Place the universal beacon shelf-bracket on the shelf:

• Metal brackets: Fit in place and tighten onto the shelving unit using a Phillips screwdriver.

• Plastic brackets: Fit in place and snap onto the shelving unit.

2. Fit the beacon’s universal style housing into the bracket (mylar strip pointing up) and turn the beacon

housing clockwise 90 degrees.

The barcode label should face up toward the ceiling and the smooth front of the beacon should face out

toward the aisle.

Activate one or MPACT-T1B10-000-WR model beacons by pulling the mylar strip off the beacon housing.

IMPORTANT: After pulling off the last mylar strip, you have 20 seconds to associate the beacon in either

off-line or on-line mode using the Toolbox application.

Battery Replacement

When a the battery life is less than 20%, the beacon should be prioritized for immediate replacement.

This section includes procedures for replacing batteries for the following part numbers:

• MPACT-T1B20-000-WR

• MPACT-T1B10-000-WR

Replacing MB1000 Battery

The battery is located within a tray in the beacon housing.

1. Remove the beacon from the shelving unit.

2. With the bottom of the beacon facing up, gently lift each corner of the beacon’s battery tray.

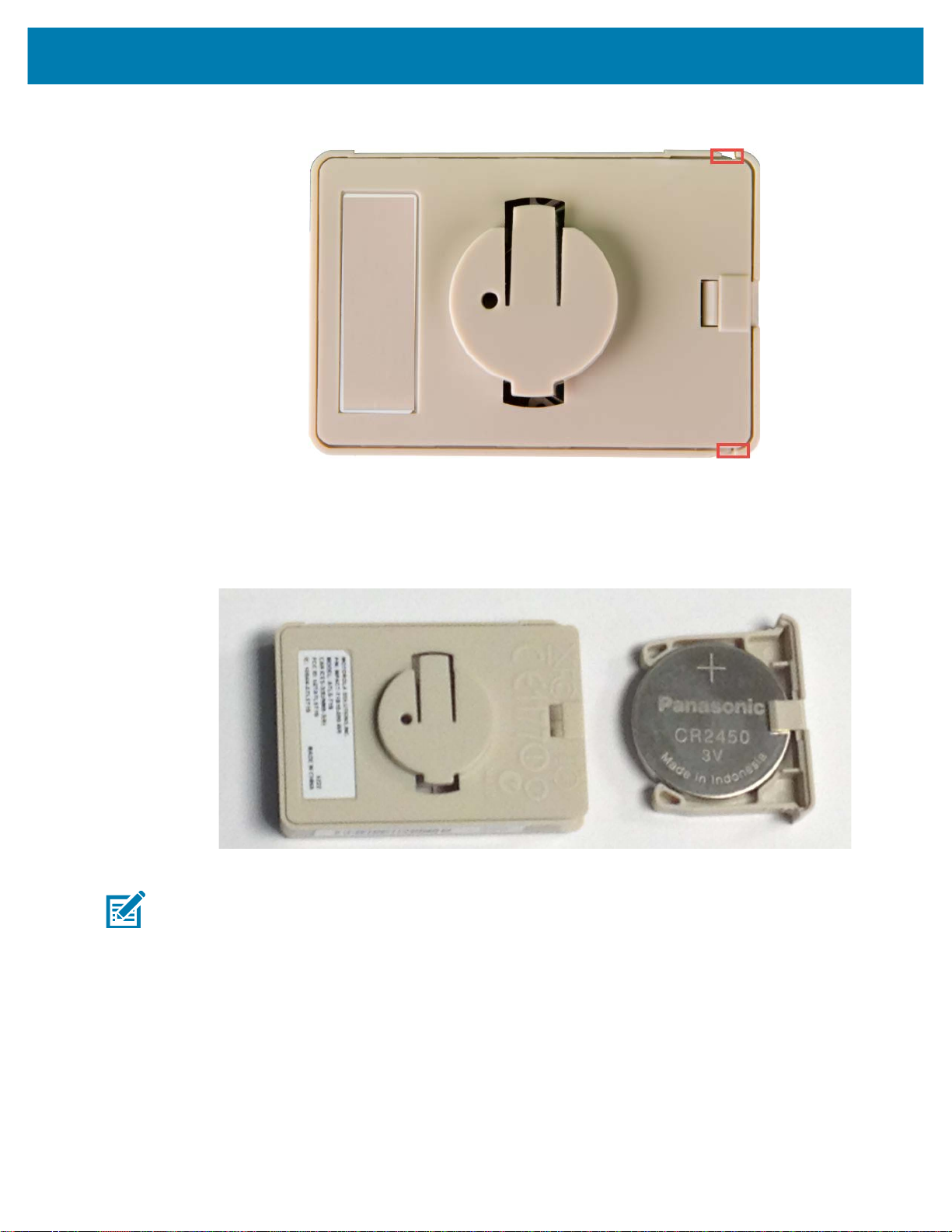

Figure 5 shows the beacon battery housing for part number MPACT-T1B20-000-WR,

MPACT-T1B10-000-WR, and MPACT-T1B10-000-WR. In this example, the battery tray is on the right

and the corners of the battery tray are marked in red. When gently lifting each tray corner, slightly push

the each corner out to dislodge corners of the tray.

6

Page 15

Hardware Specifications and Installation

Figure 5 Beacon Battery Housing

3. With both tray corners dislodged, gently slide the battery tray open, being careful not to drop the tray.

Figure 6 shows an open battery housing. In this example, the battery tray is a separate piece, along

with the battery, on the right-hand side.

Figure 6 Battery Tray

4. Remove the old battery, dispose properly, and replace with a Panasonic CR2450 model battery.

NOTE: Pay attention to the position of the + on the battery. Installing the battery backwards may damage

the Beacon.

1. Close the tray, ensuring the latch is secure.

7

Page 16

Hardware Specifications and Installation

MPACT-MB2000-01-WR, MPACT-MB1000-01-WR, MPACT-MB2001-01-WR, MPACT-SB2000-01-WR, MPACT-SB2100-01-WR

As a prerequisite, the following hardware is required to wall mount a beacon:

• Beacon part numbers: MPACT-MB2000-01-WR and MPACT-MB2001-01-WR

• Bracket mount kit (included with part number MPACT-MB2000-01-WR):

• Metal bracket

• Two 1-inch Phillips head tap screws, and two 1inch plastic wall inserts

Figure 7 Metal Beacon Wall Mount Bracket

NOTE: Ensure the beacon is positioned correctly, Once the beacon is mounted on the bracket it will be

difficult to remove.

Activate one or more MPACT-MB2000-01-WR or MPACT-MB2001-WR beacons by pulling the mylar strip

out from inside the beacon housing.

IMPORTANT: After pulling off the last mylar strip, you have 20 seconds to associate the beacon in either

off-line or on-line mode using the Toolbox application.

8

Page 17

Hardware Specifications and Installation

Figure 8 Indoor Style Beacon

The MPACT-SB2000-01-WR is a unique device. It operates as a BLE beacon but also captures and

broadcasts (using BLE) the information of other nearby Zebra BLE beacons. It is packaged the same as

other Zebra beacons including two AA batteries.

Figure 9 shows the basic operation of the SB2000.

Figure 9 SB2000 Basic Operation

The SB2000 is configures via the Superbeacon Toolbox application which is available from Zebra product

line management. The configuration of the product is done with the toolbox application and related settings

in the Zebra MB5000. Refer to the JSON Schema for Receiver Operations document for more information.

Mounting and Installing

Adhere to the following prerequisites when mounting an MPACT-MB2000-01-WR,

MPACT-MB2001-01-WR, or MPACT-SB2000-01-WR model beacon:

• Do not install the cover on the unit until the beacon has been initialized and configuration verified.

• Ensure the planned installation location matches your physical deployment plans.

• Beacon mounting heights my vary by deployment but should be mounted 2 meters or lower from the

supporting surface.

• Ensure the intended deployment location has good Wi-Fi coverage.

9

Page 18

Hardware Specifications and Installation

To mount a MPACT-MB2000-01-WR, MPACT-MB2001-01-WR, or MPACT-SB2000-01-WR model beacon

using the MPACT-MB2001-01-ACC:

1. Before peeling the cover tape off the adhesive mounting pads, hold the wall plate portion of the

accessory in its intended mounting location and mark the spot on the wall. You can use masking tape to

mark the bottom of the unit. Make sure the orientation arrow on the back plate is pointing up.

2. Ensure the mounting surface is clean and dry. Clean the surface with a 50:50 mixture of isopropyl

alcohol (IPA) and water. Ensure the surface is completely dry before applying the mounting tape.

3. Peel the cover tape from the adhesive pads on the rear of the wall plate, align and press to the wall.

4. Snap the beacon into the accessory wall plate.

Figure 10 Wall Mount and attached beacon

NOTE: If the surface is clean and smooth, use the tape to mount the beacon. However, if the surface is

wood, brick or other non-smooth surface use appropriately sized screws for mounting (not included).

5 Snap the top cover in place with the small gap showing on the right side and ensuring logos are

correctly oriented.

10

Page 19

Hardware Specifications and Installation

Figure 11 Cover and Wall Mount Installed

NOTE: Ensure the beacon is positioned correctly, Once the beacon is mounted on the bracket it will be

difficult to remove.

If the beacon is moved, the adhesive pads (MBWALL-TAPE) must be replaced.

Figure 12 Beacon Replacement Adhesive

The cover can be removed to service the beacon by placing a small flathead screwdriver into the gap on

the right side as shown in the picture.

Figure 13 Cover Removal

11

Page 20

Hardware Specifications and Installation

Beacon Operating Modes

Refer to the following for beacon operating modes for MPACT-MB2000-01-WR, MPACT-MB2001-01-WR,

and MPACT-MB1000-01-WR model beacons:

Mode Definition

Sleep The beacon is not transmitting or accepting client connections.

Configuration The beacon accepts connections from clients. Clients can configure the device

when connected.

Broadcast The beacon is transmitting packets that conform to one of the supported

beacon formats (iBeacon, MPact, Battery Save and SecureCast).

Refer to the following for Indoor Style Beacon operating modes:

Mode Sleep Configuration Broadcast LED Behavior

0-2 seconds No action No action No action

2+ -5 Broadcast Broadcast Broadcast Slow flash when

5+ - 10 Move to

configuration

+ 10 Sleep Sleep Sleep Solid light

Remain in

configuration

Move to

configuration

button flashes 300

ms on / 300ms off.

Fast flash – 100ms

/on & off

Battery Replacement

When a beacon’s battery life is less than 20%, the beacon battery should be prioritized for immediate

replacement. The beacon’s battery is located within a battery tray in the beacon’s housing.

1. Remove the beacon from the cover and wall mount.

2. With the bottom of the beacon facing up, use your finger nail to gently lift the clip up to remove the back

off the beacon’s battery enclosure.

3. Remove the old batteries and dispose of properly and replace it with two new 2AA batteries.

IMPORTANT: Pay attention to the polarity (+ and -) of the batteries. Installing the batteries incorrectly may

damage the Beacon.

WARNING: A battery subject to extremely low air pressure may result in explosion or leakage of

flammable or liquid gas.

12

Page 21

Figure 14 Open Battery Enclosure

4. Close the battery enclosure, ensuring the clip is secure.

Battery Disposal

Hardware Specifications and Installation

• Always dispose of batteries according to local laws.

• NEVER dispose of batteries in fire as they may explode.

• Where available, please recycle to reduce the impact on our environment.

USB Beacon: MPACT-MB3000-01-WR

A USB powered interface is required to power the USB Beacon. No additional hardware is required.

Installing

To activate a MPACT-MB3000-01-WR model beacon:

1. Insert the beacon into any standard USB power source—the beacon moves into connect mode

automatically after insertion.

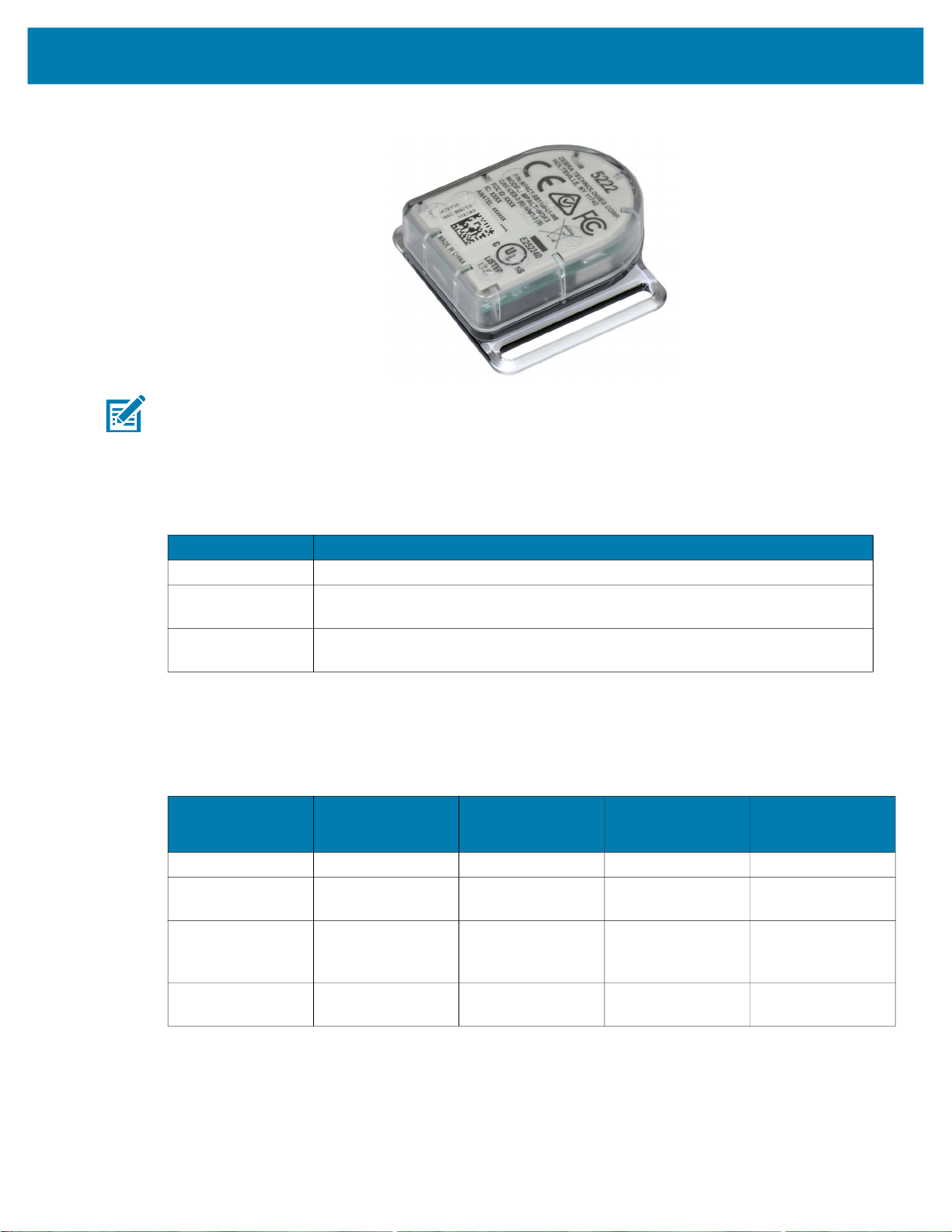

Figure 15 USB Style Beacon

13

Page 22

Hardware Specifications and Installation

NOTE: When installing numerous beacons, group beacons by category and activate them prior to

scanning the barcodes and associating them with positions in the Toolbox.

The USB beacon barcode is not on the beacon itself but on the on its plastic packaging.

1. After inserting the beacon(s) into any standard USB power source, associate the beacon in either

offline or online mode in the Toolbox application.

2. From the MPact Toolbox, select a site floor plan and an unassigned position for the beacon. Refer to

the MPact Location & Analytics Deployment Guide for information on how to install and deploy the

beacon from the Toolbox. The guides are available at www.zebra.com/support.

Beacon Part Numbers: MPACT-MB4000-01-WR and MPACT-MB4001-01-WR

As a prerequisite, the following hardware items are required to mount a beacon using screws:

• Beacon part number MPACT-MB4000-01-WR

• Two No. 6 gauge or M3.5 screws (not included) for use on the intended surface

• Phillips screwdriver compatible with No. 6 gauge screws for mounting the Outdoor Style beacon

Antennae Positions

The following are antennae positions for the MPACT-MB4000-01-WR Outdoor Beacon:

• MPACT-MB4000-01-WR orients its antenna down at a 20 degree angle.

• MPACT-MB4001-01-WR orients its antenna down to the side at a 20 degree angle.

Figure 16 Antennae Positions

14

Page 23

Hardware Specifications and Installation

Mounting and Installing

1. From the MPact Toolbox, select a site floor plan and an unassigned position for the beacon. Refer to

the MPact Location & Analytics Deployment Guide for information on how to install and deploy the

beacon from the Toolbox.

To prepare the Outdoor style beacon for mounting:

a. Prepare a surface with 3M VHB double-sided tape.

or

b. Prepare to mount the Outdoor style beacon with two No. 6 gauge or M3.5 screws (not included).

2. Beacon mounting heights my vary by deployment but should be mounted 2 meters or lower from the

supporting surface.

NOTE: If the surface is clean and smooth, use the tape to mount the beacon. However, if the surface is

wood, brick or other non-smooth surface use appropriately sized screws for mounting (not included).

Mounting using Tape

1. Clean the surface with a 50:50 mixture of isopropyl alcohol (IPA) and water before applying 3M ™

VHB ™ tape.

Some surfaces may require additional preparation such as the following:

• Use a degreaser or solvent-based cleaner to remove heavy oil or grease from a surface followed by

cleaning with IPA/water

• Scrape the surface, followed by cleaning with IPA/water to remove heavy dirt or oxidation and

increases surface area to improve adhesion.

• Prime the surface to improve initial and ultimate adhesion to many materials such as plastics and

paints.

• Seal porous and fibered materials such as wood, particleboard, and concrete to provide a unified

surface. Mount with two No. 6 gauge or M3.5 screws (not included).

2. Peel the plastic off from the tape.

3. Press the backside of the Outdoor style beacon firmly to a smooth, flat and clean mounting surface.

Mounting using Screws

1. Press the backside of the beacon to the mounting surface.

2. Insert screws into the screw holes (see Figure 18).

Zebra recommends not removing the plastic backside of the 3M tape when mounting the beacon with

screws.

3. Hand tighten the screws to firmly secure the beacon.

NOTE: Ensure the beacon is positioned correctly. Once the beacon is mounted it will be difficult to remove.

15

Page 24

Hardware Specifications and Installation

Figure 17 Back of Outdoor Style Beacon

Figure 18 Top of Outdoor Style Beacon

NOTE: On MPACT-MB4000-01-WR model outdoor beacons, the large red antenna pattern indicates that

the antenna is pointing down.

NOTE: When installing numerous beacons, group beacons by category and activate them prior to

scanning the barcodes and associating them with positions in the Toolbox.

Activating

1. Swipe your finger across the capacitive switch several times to wake the beacon out of shipping mode

Figure 19 Activating Outdoor Style Beacon

into broadcast mode. The under surface LED light becomes solid and then turns off.

2. Put the beacon in connect mode. Press your finger on the capacitive switch for about five seconds. The

under surface LED will flash slowly. Refer to the table below for information about operating modes and

LED blink patters.

NOTE: When installing numerous beacons, group beacons by category and activate them prior to

scanning the barcodes and associating them with positions in the Toolbox.

16

Page 25

Hardware Specifications and Installation

The barcode label should face up toward the ceiling and the smooth front of the beacon should face out to

where the mobile client is expected to engage.

Mode Shipping Sleep Configuration Broadcast LED Behavior

0-2 seconds No action No action No action No action

2+ -7 Broadcast Broadcast Broadcast Broadcast Solid light

7+ - 12 Move to

configuration

+ 12 Sleep Sleep Sleep Fast flash –

Remain in

configuration

Move to

configuration

Slow flash when

button flashes

300 ms on /

300ms off.

100ms /on & off

Beacon: MPACT-MB1000-01-WR and MPACT-SB1100-01-WR

The MPACT-MB1000-01-WR and MPACT-SB1100-01-WR beacon is a small beacon designed to be

affixed to assets. The beacon and the optional mounting accessory are used to attach the asset beacon to

an object lacking a flat mounting surface.

On the side of the asset beacon is a switch used to place the device in different operating modes.

Figure 20 Beacon and Mounting Accessory

17

Page 26

Hardware Specifications and Installation

Figure 21 Beacon with Adhesive Strip

Adhere to the following prerequisites when mounting an MPACT-MB1000-01-WR and

MPACT-SB1100-01-WR model beacon:

• The asset beacon should be mounted on any smooth, flat, clean, prepared dry surface.

• There should be no structures immediately in front or to the sides that would block signals from this

unit.

• There should be no material, metal or surfaces over or covering the beacon.

• Before peeling the cover off the mounting tape, hold the asset beacon in its intended mounting location

and ensure it will fit as desired.

Figure 22 shows the beacon attached to a piece of equipment in the preferred orientation. The antenna

pattern is omni-directional and the unit operates sufficiently in any vertical orientation.

Figure 22 Preferred Orientation

18

Page 27

Hardware Specifications and Installation

To mount a MPACT-MB1000-01-WR or MPACT-SB1100-01-WR model beacon:

1. Peel the tape from the adhesive pads on the rear of the asset beacon (as shown below) and press the

unit to the mounting surface.

Figure 23 Adhesive Tape

NOTE: If the surface is clean and smooth, use the tape to mount the beacon. However, if the surface is

wood, brick or other non-smooth surface use appropriately sized screws for mounting (not included).

NOTE: Ensure the beacon is positioned correctly, Once the beacon is mounted on the bracket it will be

difficult to remove.

If the beacon is moved, the adhesive pads must be replaced.

Initialize the unit per the operating instruction.

Mounting using Tape

1. Clean the surface with a 50:50 mixture of isopropyl alcohol (IPA) and water before applying tape.

Some surfaces may require additional preparation such as the following:

• Use a degreaser or solvent-based cleaner to remove heavy oil or grease from a surface followed by

cleaning with IPA/water

• Scrape the surface, followed by cleaning with IPA/water to remove heavy dirt or oxidation and

increases surface area to improve adhesion.

• Prime the surface to improve initial and ultimate adhesion to many materials such as plastics and

paints.

• Seal porous and fibered materials such as wood, particleboard, and concrete to provide a unified

surface. Mount with two No. 6 gauge or M3.5 screws (not included).

2. Peel the plastic off from the tape.

3. Press the backside of the Outdoor style beacon firmly to a smooth, flat and clean mounting surface.

19

Page 28

Hardware Specifications and Installation

Mounting using a Beacon Accessory

The MPACT-MB1000-01-WR and MPACT-SB1100-01-WR can be mounted on non-flat objects using the

MPACT-MB1000-01-ACC beacon accessory. Figure 24 shows a tool with the asset beacon attached to

the mounting accessory. The optional accessory is ordered separately from MPACT-MB1000-01 asset

beacon. The beacon is attached to the mounting plastic using the adhesive strip, then a tie wrap wire or

something similar is used to connect the mounting plastic to the hand tool.

Figure 24 Beacon Accessory attached to Tool

1. Peel the tape from the adhesive pads on the rear of the asset beacon and press the unit to the

mounting surface on the accessory MPACT-MB1000-01-ACC. The adhesive bonds immediately and

reaches full adhesion within an hour.

Figure 25 MPACT-MB1000-01-ACC Beacon

NOTE: Ensure the beacon is positioned correctly, Once the beacon is mounted on the bracket it will be

difficult to remove.

If the beacon is moved, the adhesive pads must be replaced.

The MPACT-SB1100-01-WR is a small, waterproof (IP67), BLE 5.0 version of the MB1000. An NFC

application for Android is available for Zebra product management and is used to turn the beacon on and

off, switch modes, and change operating configurations.

20

Page 29

Figure 26 MPACT-SB-1100-01-WR Beacon

NOTE: MPACT-SB1100-01-WR mounted to the optional MPACT-MB1001-01-ACC wrist mount

accessory.

Operating Modes

Refer to the following for operating modes for MB1000-01-WR asset beacon operating modes:

Hardware Specifications and Installation

Mode Definition

Sleep The beacon is not transmitting or accepting client connections.

Configuration The beacon accepts connections from clients. Clients can configure the device

when connected.

Broadcast The beacon is transmitting packets that conform to one of the supported

beacon formats (iBeacon, MPact, Battery Save and SecureCast).

The MPACT-MB1000-01-WR is delivered in shipping mode. To initiate beacon operation, press the button

three times quickly (within 2 seconds), if unsuccessful, wait 5 seconds and repeat. The LED flashes

several times and the beacon begins to broadcast. Using the table below, hold the button for the length of

time shown to change modes. The LED displays a different light pattern depending on the mode it is

entering.

Current

Operation Mode /

Button Press

0-2 seconds No action No action No action

2+ -5 Moves to

5+ - 10 Moves to

+ 10 Moves to Sleep

Sleep Configuration Broadcast LED Behavior

Broadcast mode

Configuration

mode

mode

Moves to

Broadcast mode

Moves to

Configuration

mode

Moves to Sleep

mode

Moves to

Broadcast mode

Moves to

Configuration

mode

Moves to Sleep

mode

Slow Flash

Fast Flash

Solid LED

Cleaning

Cleaning frequency is discretionary in respect to the environments the BLE devices are deployed. They

may be cleaned as frequently as required.

21

Page 30

Hardware Specifications and Installation

Prolonged exposure to Metrex CaviWipes or similar chemicals may degrade the clear PC9925A material

used in the asset beacon (and associated mounting accessory) and should be used with care and in small

amounts per the manufacturers recommended instructions. Contact Zebra for specific product and

cleaning agent information.

Fixed IoT Bridge (hub): MPACT-MB5000-01-WR, MPACT-SB5200-01-WR

Installing

1. Select your desired mounting location for the unit. Verify the USB cable can reach the power supply

and it’s electrical outlet (nearby the device). Clean the surface with a 50:50 mixture of isopropyl alcohol

(IPA) and water.

2. Peel backing tape from adhesive on the back of the rear cover and place firmly on a wall. Make sure the

arrow is pointing up. Optionally, use #8 or #10 Pan Head screws to mount the unit to rough mounting

surfaces The distance between the horizontal screw hole mounting positions is 109 mm. The screw

hole diameters are 5.2 mm.

3. Insert the USB cable into the unit and carefully route the cable through the cable strain lock features

outlined in yellow (see Figure 27).

Figure 27 Install Hub Components

4. Snap the cover on. Ensuring the logo is oriented correctly. The USB cable should be in the cable notch

and not pinched by the cable cover. The unit’s cover access slot will be on the right side if cover and

unit are mounted correctly.

22

Page 31

Hardware Specifications and Installation

Figure 28 Hub Mounted

5. Plug the power supply into an A/C outlet and plug the other end of USB cable into the power supply.

Figure 29 Hub with Power Connected

23

Page 32

Initializing

The factory default programming is set to allow compliant operation across global regulatory domains.

When the hub is turned on, the unit will use the default “world safe” settings until or unless it receives

802.11d probes identifying the country of operation. The unit will automatically reconfigure for enhanced

performance in that country, otherwise the factory settings remain.

The badge and hub product are tested and receive EMC regulatory certifications on a per country basis.

Zebra provides a list of all approved countries where the units are able to be sold to end-customers and

used by end-users. By design, the operation of the units is controlled by firmware in accordance with the

approved regulatory domains (i.e., approved countries). The initial production release product (Rev. A) has

a default country domain with somewhat reduced RF performance to ensure compliance with most

domains globally. The units will initially operate in this “world safe” default scanning for Wi-Fi access point

802.11d country information. The units will either set the country operation to the 802.11d information (if an

approved country), or if not and approved country, the units will continue to operate in the “world safe”

default mode. The unit never allows use of 2.4 GHz channels 12 and 13.

The hub scans for Bluetooth Smart beacon emissions. The hub filters based on its scanning configuration

for known devices and forwards scan results to its defined administration (posting) server.

The hub ships with a default software load, but without its configuration. When the hub is initialized for the

first time, it conducts an internal scan diagnostic but is unable to properly provision itself. Consequently,

the hub needs to be provisioned with both an initial configuration and a scanning configuration before it

can filter beacons and forward relevant scanning information.

Hardware Specifications and Installation

Figure 30 IoT Bootstrapping

Figure 31 IoT Bridge Operation as Deployed

24

Page 33

Hardware Specifications and Installation

To provide the hub its initial and scanning configurations:

1. Initialize the hub. The hub scans for its initial configuration. The hub has a fixed SSID of mpact_init and

a preset WPA2 password of mpact123. When unable to provision itself the hub connects to

192.168.1.100 (a fixed location) and downloads its initial configuration file (badge_config.json).

NOTE: The 192.168.1.100 location must be reachable from the hub’s connected Access Point mpact_init

SSID to receive its required badge_config.json file.

The hub obtains its badge_config.json file and self-configures its initial configuration. Once completed,

the hub connects to its posting server to obtain its scanning configuration. The scanning configuration is

required to define the hub’s scan interval and beacon profile determining how beacon data is

forwarded, based on the beacon’s UUID and Major values, and posted to the server for administration.

2. If you encounter issues with the setup of the hub, there’s several file restoration options available.

• Reboot the badge - Press and hold button 2 (see Figure 33) between 10–20 seconds, then release.

LED 1 will blink slowly twice to confirm. Any in-process configuration activity will need to be

re-started.

• Erase to factory default configuration and reboot - Press and hold button 2 between 30–40 seconds,

then release. LED 1 will blink slowly twice to confirm. The deletion of the initial configuration could

be warranted if the configuration was not successfully applied on the first attempt. Once reverted to

factory configuration, the initial config and scanning config can be re-applied.

• Shutdown the badge - Press and hold button 2 between 20–30 seconds, then release. LEDs will

blink 5 times to confirm the badge shutdown. Use this process when brining a deployed badge

off-line.

3. For additional information about the configuration process and JSON files, contact your product line

manager.

Cleaning

Use alcohol to clean this product. When using sodium hypochlorite (bleach) based disinfectants to clean

the product, always follow the manufacturers recommended instructions regarding the use of gloves during

application and to remove the residue afterwards with a damp cloth to avoid prolonged skin contact while

handling the scanner. Please note that due to the powerful oxidizing nature of sodium hypochlorite the

metal surfaces on the product are prone to oxidation (corrosion) when exposed to this disinfectant in the

liquid form and should be removed promptly after cleaning with a damp cloth.

Use pre-moistened wipes to clean the unit. Do not allow liquid cleaners to pool or remain on the unit.

Cleaning frequency is discretionary in respect to the environments the MPACT-MB5000-01-WR is

deployed and may be cleaned as frequently as required.

Mobile IoT Bridge (badge): MPACT-MB6000-01-WR

The factory default programming for the badge is set to allow compliant operation across global regulatory

domains. When the hub is turned on, the unit will use the default “world safe” settings until or unless it

receives 802.11d probes identifying the country of operation. The unit will automatically reconfigure for

enhanced performance in that country, otherwise the factory settings remain.

25

Page 34

Hardware Specifications and Installation

The badge and hub product are tested and receive EMC regulatory certifications on a per country basis.

Zebra provides a list of all approved countries where the units are able to be sold to end-customers and

used by end-users. By design, the operation of the units is controlled by firmware in accordance with the

approved regulatory domains (i.e., approved countries). The initial production release product (Rev. A) has

a default country domain with somewhat reduced RF performance to ensure compliance with most

domains globally. The units will initially operate in this “world safe” default scanning for Wi-Fi access point

802.11d country information. The units will either set the country operation to the 802.11d information (if an

approved country), or if not and approved country, the units will continue to operate in the “world safe”

default mode. The unit never allows use of 2.4 GHz channels 12 and 13.

The badge is a wearable beacon that’s clipped to one’s body, typically in the mid section or belt area.

The badge needs to be attached to a person in a manner directing RF radiation away from the body. The

RF antennas radiate out from one side of the badge. An MPACT-MB6000-01-WR badge is designed to

enhance personal safety.

Figure 32 Correct Clothing Mount

NOTE: The clip portion of the badge is replaceable. Refer to Part No. MB6000-01-ACC when ordering a

replacement clip for a MB6000-01-WR model badge.

To mount an MPACT-MB6000-01-WR model badge:

1. Clip an initialized badge to your midsection or belt area

2. If you encounter issues with the setup of the badge, there’s several file restoration options available.

26

Page 35

Hardware Specifications and Installation

BUTTON 1

LED 1

LED 2

BUTTON 2

Figure 33 LEDs and Buttons

NOTE: With the badge clip side facing you and the buttons facing up, button 1 is on the left top and button

2 is on the top right.

• Reboot the badge - Press and hold button 2 between 10–20 seconds, then release. LED 1 will blink

slowly twice to confirm. Any in-process configuration activity will need to be re-started.

• Erase to factory default configuration and reboot - Press and hold button 2 between 30–40 seconds,

then release. LED 1 will blink slowly twice to confirm. The deletion of the initial configuration could be

warranted if the configuration was not successfully applied on the first attempt. Once reverted to factory

configuration, the initial config and scanning config can be re-applied.

Initializing

• Shutdown the badge - Press and hold button 2 between 20–30 seconds, then release. All LEDs will

blink 5 times to confirm the badge shutdown. Use this process when brining a deployed badge off-line.

The factory default programming is set to allow compliant operation across global regulatory domains.

When the hub is turned on, the unit will use the default “world safe” settings until or unless it receives

802.11d probes identifying the country of operation. The unit will automatically reconfigure for enhanced

performance in that country, otherwise the factory settings remain.

The badge and hub product are tested and receive EMC regulatory certifications on a per country basis.

Zebra provides a list of all approved countries where the units are able to be sold to end-customers and

used by end-users. By design, the operation of the units is controlled by firmware in accordance with the

approved regulatory domains (i.e. approved countries). The initial production release product (Rev. A) has

a default country domain with somewhat reduced RF performance to ensure compliance with most

domains globally. The units will initially operate in this “world safe” default scanning for Wi-Fi access point

802.11d country information. The units will either set the country operation to the 802.11d information (if an

approved country), or if not and approved country, the units will continue to operate in the “world safe”

default mode. The unit never allows use of 2.4 GHz channels 12 and 13.

The hub scans for Bluetooth Smart beacon emissions. The hub filters based on its scanning configuration

for known devices and forwards scan results to its defined administration (posting) server.

The hub ships with a default software load, but without its configuration. When the hub is initialized for the

first time, it conducts an internal scan diagnostic but is unable to properly provision itself. Consequently,

the hub needs to be provisioned with both an initial configuration and a scanning configuration before it

can filter beacons and forward relevant scanning information.

27

Page 36

Hardware Specifications and Installation

Figure 34 IoT Bootstrapping

Figure 35 IoT Bridge Operation as Deployed

To provide the hub its initial and scanning configurations:

1. Initialize the hub. The hub scans for its initial configuration. The hub has a fixed SSID of mpact_init and

a preset WPA2 password of mpact123. When unable to provision itself the hub connects to

192.168.1.100 (a fixed location) and downloads its initial configuration file (badge_config.json).

NOTE: The 192.168.1.100 location must be reachable from the hub’s connected Access Point mpact_init

SSID to receive its required badge_config.json file.

The hub obtains its badge_config.json file and self-configures its initial configuration. Once completed,

the hub connects to its posting server to obtain its scanning configuration. The scanning configuration is

required to define the hub’s scan interval and beacon profile determining how beacon data is

forwarded, based on the beacon’s UUID and Major values, and posted to the server for administration.

2. If you encounter issues with the setup of the hub, there’s several file restoration options available.

• Reboot the badge - Press and hold button 2 (see Figure 33) between 10–20 seconds, then release.

LED 1 will blink slowly twice to confirm. Any in-process configuration activity will need to be

re-started.

• Erase to factory default configuration and reboot - Press and hold button 2 between 30–40 seconds,

then release. LED 1 will blink slowly twice to confirm. The deletion of the initial configuration could

be warranted if the configuration was not successfully applied on the first attempt. Once reverted to

factory configuration, the initial config and scanning config can be re-applied.

28

Page 37

Cleaning

Hardware Specifications and Installation

• Shutdown the badge - Press and hold button 2 between 20 and 30 seconds, then release. LEDs will

blink 5 times to confirm the badge shutdown. Use this process when brining a deployed badge

off-line.

3. For additional information about the configuration process and JSON files, contact your product line

manager.

Use alcohol to clean this product. When using sodium hypochlorite (bleach) based disinfectants to clean

the product, always follow the manufacturers recommended instructions regarding the use of gloves during

application and to remove the residue afterwards with a damp cloth to avoid prolonged skin contact while

handling the scanner. Please note that due to the powerful oxidizing nature of sodium hypochlorite the

metal surfaces on the product are prone to oxidation (corrosion) when exposed to this disinfectant in the

liquid form and should be removed promptly after cleaning with a damp cloth.

NOTE: Use pre-moistened wipes to clean the unit. Do not allow liquid cleaners to pool or remain on the

unit.

Cleaning frequency is discretionary in respect to the environments the MPACT-MB6000-01-WR and the

MPACT-MB6000-CHRGR are deployed. They may be cleaned as frequently as required.

Battery Safety Precautions

Usage

Misusing the battery may cause the battery to get hot, rupture or ignite causing serious injury. Be sure to

follow the safety rules listed below:

Read and follow all guidelines in the Regulatory Guide included with every shipment:

• Do not open or attempt to remove the battery from the MB6000-01-WR housing

• Do not place the battery in fire or heat the battery.

• Do not install the battery backwards so that the polarity is reversed.

• Do not connect the battery’s positive terminal and the negative terminal to each other with any metal or

conductive object (such as a wire).

• Do not carry or store batteries together with necklaces, hairpins or other metal objects

• Do not pierce a battery with nails, strike the battery with a hammer, step on the battery or subject it to

strong impacts or shocks.

• Do not apply solder to the battery

• Do not expose the battery to water or allow the battery to get wet or exposed to moisture.

• Do not disassemble or modify the battery. The battery contains safety and protection devices which, if

damaged, may cause the battery to generate heat, rupture or ignite.

• Do not place the battery on or near fires, stoves or other high temperature locations.

• Do not place the battery in direct sunlight for prolonged periods.

• Do not store the battery or use the unit in a car. Doing so may cause the battery to generate heat,

rupture or ignite.

• Device is not for use by children.

• When the battery is worn out, insulate the terminals with adhesive tape or similar material before

disposal.

29

Page 38

• Immediately discontinue battery use if, while charging or storing, the battery emits an unusual smell,

• Do not place batteries in microwave ovens, high-pressure containers or induction cookware.

• In the event the battery leaks, and fluid gets into one’s eye, do not rub the eye. Rinse the eye with water

Charging

Be sure to follow the rules listed below when charging the battery. Failure to do so may cause the battery

to become hot, rupture, ignite and cause serious injury.

• Read and follow all guidelines in the Regulatory Guide included with every shipment

• Operating temperature for charging: 50–104°F (10–40°C)

• When charging the battery, only use the specified battery charger.

• Do not attach the battery to a power supply plug or directly to a car’s cigarette lighter.

• Do not place the battery in or near fire or in direct sunlight. When the battery becomes hot, its built-in

Hardware Specifications and Installation

feels hot, changes color, shape or appears abnormal in any other way.

and immediately seek medical attention. If left untreated, the battery fluid could cause permanent

damage to the eye.

safety measure are activated, preventing the battery from charging. Heating the battery can destroy its

safety equipment and result in an overheat or ignition.

• Do not continue charging the battery if it does not charge within its specified charging time. Doing so

The mobile badge design includes dedicated, internal circuitry and logic for battery management, charging

and reporting. The unit self-protects against various over-charging, shorting and rapid discharge

conditions. If a unit is not operating as expected, it may be due to a self-protection condition. The badge

may need to be manually reset with button pushes and/or placed in the charger to clear the condition

before resuming normal operation. If for some reason a unit is not responding or operating normally after

being reset and recharged, please contact Zebra Support.

Disposing

The battery may only be replaced by a Zebra Authorized Repair Center and requires special handling

when discarding. Always follow all local laws and regulations when discarding batteries. Fully discharge

the battery before discarding it. The temperature range through which the battery should be discharged is

32–104°F (0–40°C). Discharging the battery outside of this range may damage the battery’s performance

or reduce its life expectancy.

Do not discharge the battery using any device except its designated original device. When the battery is

used in devices aside from its designated device it may damage the performance of the battery and

potentially reduce its useful expectancy. If the device causes an abnormal current flow it may result in the

battery becoming hot, rapture or ignite resulting in serious injury.

may cause the battery to become hot, rupture or ignite.

30

Page 39

Hardware Specifications and Installation

Cradle Charger: MPACT-MB6000-CHRGR

Initial Charging and Use

When a brand new badge is received it should be inserted into the badge cradle before its initial use. The

badge should be charged fully before its first use. The badge will automatically update its firmware and

configuration profile if connected to the Wi-Fi network and the gateway (if there is a profile update on the

server).

The badge will blink green while charging and solid green when fully charged.

The badge cradle can charge one to ten badges at a time. The AC powered charger is a wall or desk

mounted cradle platform providing 5Vdc to each badge placed in individual charging slots. The charger

feeds electric current through battery inside the badge. The cell inside retains the energy passing through

them.

Figure 36 Charger

Each slot has spring contacts that mate with the contacts on the badge. Badges have battery chargers and

fuel gages built into each device so the charger is a power supply platform and no battery knowledge

exists in the charger itself, everything to charge and protect a lithium Ion battery is built into the badge

itself.

The charger's primary function is providing 5Vdc at 900 mA to each badge holder re-charge badge

batteries. The charger holds badges when not in use. When badges are in the charger, they begin to

charge using the 5Vdc supplied in the charger base. If there is sufficient charge detected, the badge uses

the charger as a holder (without charging).

31

Page 40

Hardware Specifications and Installation

While in the charger, the badge could conduct a software or configuration update if required and a status

update.

Specification Value

Charger Capacity 1–10 badges simultaneously

Voltage 5Vdc ± 5%

Current Each Badge requires 900 mA during charging, total 5Vdc power is 10 Amps

Power

Consumption

Power Supply External 12 Vdc, 5 Amps max, 60 watts total, enclosed power supply

Power Cord AC power cord connecting external power supply to AC power

Power Supply

Connector

Power Indicator All Badges within the charger platform have LEDs indicating charging state

Temperature 32–104°F (0–40°C) (operating), -40–158°F (-40–70°C) (storage)

Humidity 5–95% RH (operating) 85% RH (storage)

Altitude 8,000 ft @ 82.4°F (28°C) (operating), 30,000 ft @ 53.6°F (12°C) (storage)

50–60 Watts

Barrel connector (2.5mm outside diameter). The plastic enclosure has built-in

strain relief to prevent accidental disconnects.

Installation

The charger can be wall mounted using the screw holes on the back or placed on a flat surface. The screw

holes are 5.36 inches (136 mm) apart. When selecting a deployment location, ensure the power adapter

cables reach from the electrical outlet to the charger. The charger and its power adapter must be deployed

in a well ventilated location. The charger and power adapter should have a 1-inch clearance on each side

from surrounding objects. It must only be deployed indoors, in a dry area free from spills or potential

contamination. The temperature should be between 60–80°F (15–27°C).

The charger is designed so DC power cable can be installed from the rear of the charger housing without

removing the base. The cable and connector do not interfere with the base lying flat on any surface. The

DC cord snakes through strain relief features in the housing to prevent accidental disconnects. The

external power adapter DC cable terminates with a right-angle connector at the charger interface.

32

Page 41

Hardware Specifications and Installation

Figure 37 Routing Power Cable

Battery Charging Guidelines

Failure to follow these guidelines may result in fire, explosion or other hazard.

• The MPACT-MB6000-CHRGR in intended for use with the MB6000-01-WR only and should not be

used with other products or batteries.

• The area in which the units are charged should be clear of debris and combustible materials or

chemicals. Particular care should be taken when charging in a non commercial environment.

• To charge the battery, the battery and charger temperatures must be between 32–104°F (0–40°C).

• Do not use incompatible batteries and chargers. Use of an incompatible battery or charger may present

a risk of fire, explosion, leakage or other hazard. If you have any questions about the compatibility of a

battery or a charger, contact Zebra Support.

• Do not disassemble, open, crush, bend or deform, puncture or shred the badge or charger.

• Impact from dropping the badge and charger on a hard surface could cause the battery to overheat.

• Do not short circuit a battery or allow metallic or conductive objects to contact the battery terminals.

• Do not modify, re-manufacture, insert foreign objects into the battery, immerse or expose to water or

other liquids, or expose to fire, explosion or other hazard.

• Do not leave or store the equipment in or near areas that might get very hot, such as in a parked vehicle

or near a radiator or other heat source. Do not place battery into a microwave oven or dryer

• If you suspect damage to your equipment or battery, contact Zebra Support to arrange for inspection.

• See Battery Safety Information in section 2.11.1.

33

Page 42

Hardware Specifications and Installation

Cleaning the Charging Cradle

The following materials are required to clean the charging cradle:

• Alcohol wipes

• Cotton tipped applicators

• Can of compressed air

Cleaning frequency is discretionary in respect to the environments the charger and the badges are

deployed. They may be cleaned as frequently as required.

When using sodium hypochlorite (bleach) based disinfectants to clean the product, always follow the

manufacturers recommended instructions regarding the use of gloves during application and to remove

the residue afterwards with a damp cloth to avoid prolonged skin contact while handling the scanner.

Please note that due to the powerful oxidizing nature of sodium hypochlorite the metal surfaces on the

product are prone to oxidation (corrosion) when exposed to this disinfectant in the liquid form and should

be removed promptly after cleaning with a damp cloth.

Cleaning frequency is discretionary in respect to the environments the MPACT-MB6000-01-WR and the

MPACT-MB6000-CHRGR are deployed. They may be cleaned as frequently as required.

Use pre-moistened wipes to clean the unit. Do not allow liquid cleaners to pool or remain on the unit.

Cleaning the Badge Contacts

To clean the contacts on a badge before inserting into the charging cradle:

1. Dip the cotton portion of the cotton tipped applicator in isopropyl alcohol.

2. Rub the cotton portion of the cotton tipped applicator back-and-forth across the contacts. Do not leave

any cotton residue on the contacts (repeat at least three times).

3. Use a dry cotton tipped applicator to clean any moisture or residue remaining on the contacts.

4. Spray compressed air on the contact area by pointing the nozzle about ½ inch away from the surface.

5. Inspect the area for any grease or dirt, repeat this process if required.

Cleaning the Cradle Connectors

To clean the connectors within the cradle:

1. Unplug the unit from the AC wall outlet and remove the DC power cable from the cradle.

2. Dip the cotton portion of the cotton tipped applicator in isopropyl alcohol.

3. Rub the cotton portion of the applicator along the connector pins. Slowly move the applicator

back-and-forth on the connector to the other. Do not leave any cotton residue on the connector. All

sides of the connector should also be rubbed with the cotton tipped applicator.

4. Spray compressed air in the connector area by pointing the tube/nozzle about ½ inch away from the

surface.

5. Ensure there is no lint left by the cotton tipped applicator, remove any lint if found.

6. If grease or other dirt can be found on other areas of the cradle, use a lint free cloth and alcohol to

remove.

7. Allow at least 10–30 minutes (depending on ambient temperature and humidity) for the alcohol to air

dry before applying power to cradle. If the temperature is low and the humidity is high, a longer drying

time is required. Warm temperatures and dry humidity require less drying time.

34

Page 43

Troubleshooting

Refer to the following to troubleshoot issues with charging badges in the charger cradle:

Cradle is not receiving power Ensure the power cable is connected securely

The badge is not fully seated in the cradle Remove and re-insert the badge into the

The badge was placed in the cradle upside

down

All badges are in the cradle correctly, the

cradle is plugged in, but none of the badges

are charging

Badge battery is faulty (solid red light is On) Verify other badges charge properly. If so,

Hardware Specifications and Installation

Issue Solution

to both the cradle and its AC power source

cradle, ensuring it is correctly seated

Remove the badge from the cradle and

re-insert in its proper orientation

Unplug the cradle from the AC outlet and plug

back in again

contact system administrator.

35

Page 44