ZE511/ZE521

Industrial Print Engine

Quick Reference Guide

P1126553-01EN

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corporation, registered in

many jurisdictions worldwide. All other trademarks are the property of their respective owners.

© 2021 Zebra Technologies Corporation and/or its affiliates. All rights reserved.

Information in this document is subject to change without notice. The software described in this document

is furnished under a license agreement or nondisclosure agreement. The software may be used or copied

only in accordance with the terms of those agreements.

For further information regarding legal and proprietary statements, please go to:

SOFTWARE:zebra.com/informationpolicy

COPYRIGHTS:zebra.com/copyright

WARRANTY:zebra.com/warranty

END USER LICENSE AGREEMENT: zebra.com/eula

Terms of Use

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries

(“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced,

or disclosed to any other parties for any other purpose without the express, written permission of Zebra

Technologies.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications and designs are

subject to change without notice.

Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and manuals are

correct; however, errors do occur. Zebra Technologies reserves the right to correct any such errors and

disclaims liability resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever

(including, without limitation, consequential damages including loss of business profits, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to

use such product, even if Zebra Technologies has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

Publication Date

November 4, 2021

2

Print Engine Orientation

The ZE511 and ZE521 print engines are available in a left-hand configuration (the print mechanism is on

the left) and a right-hand configuration (the print mechanism is on the right).

Left-hand (LH) print engine

ZE511/ZE521 Quick Reference Guide

1

2

3

1

Power switch location

2

Control panel

3

Media cover

Right-hand (RH) print engine

1

2

3

3

ZE511/ZE521 Quick Reference Guide

Print Engine Components

The following shows the components inside the media compartment of a right-hand (RH) print engine. A

left-hand (LH) unit contains a mirror image of these components. Familiarize yourself with these

components before continuing.

1

2

12

11

1

Ribbon take-up spindle

2

Ribbon supply spindle

3

Printhead-release latch

4

Printhead assembly (shown open)

5

Peel bar

6

Platen roller

910 7

8

6

7

Peel roller assembly (hidden when closed)

8

Peel roller latch

9

Media guide

10

Pinch roller assembly

11

Lower guide post

12

Upper guide post

3

4

5

4

Control Panel

All controls and indicators for the print engine are located on the control panel.

ZE511/ZE521 Quick Reference Guide

1 2 4

5

6

7

1

Power switch Toggles the print engine on/off.

2

Display Shows the print engine’s operating status and allows the user to navigate

3

8

the menu system.

3

NFC logo Used for the Print Touch feature.

4

USB host ports Allows you to connect USB devices such as memory sticks, keyboards, or

handheld scanners to the printer.

5

PAUSE button Starts or stops print engine operation when pressed.

6

FEED button Forces the print engine to feed one blank label each time the button is

pressed.

7

CANCEL button Cancels print jobs when the print engine is paused.

8

Indicator lights Communicate the printer’s status. For more information, see Indicator

Lights on page 20.

5

ZE511/ZE521 Quick Reference Guide

MEDIA SUPPLY

MEDIA BACKING

OPEN

SUPPLIES LOADING

PRESS

TO OPEN

WHEN OPEN

MEDIA BACKING

WHEN CLOSED

DETAIL VIEW

LABEL

www.zebra.com/ze511-info

Ribbon and Media Loading

Use the instructions in this section to load ribbon (if used) and media in a ZE511/ZE521 print engine.

NOTE: The majority of the graphics in this section show a right-hand (RH) unit with ribbon that is coated

with ink on the outside. Graphics for other options are included in some places for clarity.

Loading Ribbon

Do I need to use ribbon? The media itself determines if you need to use ribbon. Thermal Transfer media

requires ribbon while Direct Thermal media does not.

How can I tell if media is Direct Thermal or Thermal Transfer? The easiest way is to scratch the surface

of the media rapidly with your fingernail. If a black mark appears where you scratched, the media is Direct

Thermal, and you do not need to use ribbon.

What kind of ribbon can I use? Ribbon can be wound with the coated side on the inside or outside. This

print engine can use either type. Contact your authorized Zebra reseller for ordering information.

How can I tell which side of the ribbon is coated? Press a corner of the sticky side of a label to the outer

surface of the roll of ribbon, and then peel the label off of the ribbon. If ink particles adhere to the label, the

outer side of the roll is coated. Repeat this test with the inner surface if necessary to confirm the coated

surface.

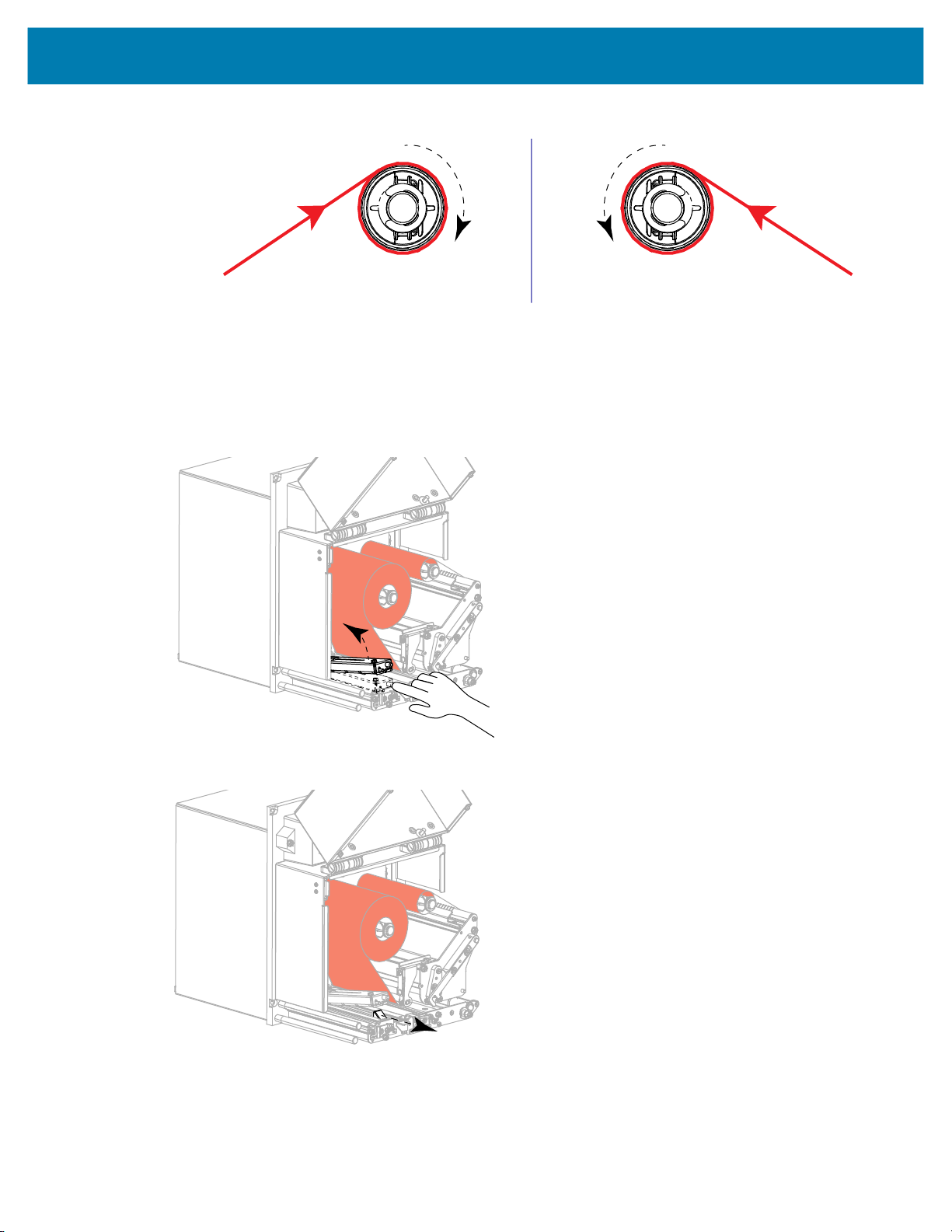

Ink on the Outside Ink on the Inside

An alternate method is to unroll a short length of ribbon, place the outer surface against a piece of paper,

and scratch the inner surface of the ribbon with your fingernail. Lift the ribbon and check for marks on the

paper. If the ribbon left a mark, the outer side is coated.

6

ZE511/ZE521 Quick Reference Guide

Determine which side of the ribbon is coated with ink, and then position the ribbon roll with the loose

1.

end unrolling in the direction shown.

LH (ink side out)

RH (ink side in)

2.

If necessary, update the ribbon ink side setting (touch Print > Print Quality > Ribbon Tension).

3.

Open the media cover.

RH (ink side out)

LH (ink side in)

4.

Release the printhead assembly.

7

ZE511/ZE521 Quick Reference Guide

Place the roll of ribbon on the ribbon supply spindle. Push the roll back as far as it will go.

5.

LH (ink side out) RH (ink side out)

LH (ink side in) RH (ink side in)

6.

Place an empty ribbon core on the ribbon take-up spindle. Push the core back as far as it will go.

8

ZE511/ZE521 Quick Reference Guide

CAUTION—HOT SURFACE: The printhead may be hot and could cause severe burns. Allow the

printhead to cool.

7.

Thread the ribbon under the lower ribbon guide roller (1), under the printhead assembly (2), and then

over the upper ribbon guide roller (3).

3

1

2

LH (ink side out)

3

1

RH (ink side out)

1

1

3

2

3

2

LH (ink side in) RH (ink side in)

9

2

Wind the ribbon around the core on the ribbon take-up spindle in the direction shown.

8.

Loading Media

1.

Load media on the media supply reel of the applicator (refer to the applicator’s documentation for more

information).

2.

Press the release button on the pinch roller assembly. Allow the assembly to pivot upward.

ZE511/ZE521 Quick Reference Guide

RHLH

3.

Slide the media guide all the way out.

10

ZE511/ZE521 Quick Reference Guide

Thread the media under the upper guide post (1), below the pinch roller assembly (2), and under the

4.

printhead assembly (3).

2

1

3

LH RH

5.

Extend approximately 30 in. (75 cm) of media past the peel bar. Remove and discard the labels from

2

1

the liner on this exposed media.

3

6.

Slide in the media guide until it just touches the edge of the media.

11

ZE511/ZE521 Quick Reference Guide

Press down on the pinch roller assembly until it locks closed.

7.

8.

Raise the peel roller latch so that the peel roller assembly pivots downward.

LH RH

9.

Thread the liner around the peel bar (1) and through the peel roller assembly (2).

IMPORTANT: If the applicator has an air tube, route the liner between the air tube and the peel bar. Do not

thread the liner over the air tube.

LH RH

121 2

12

ZE511/ZE521 Quick Reference Guide

Lock the printhead assembly.

10.

.

11.

Rotate the peel roller assembly up until it locks into the closed position.

LH RH

12.

Thread the liner around the take-up spindle of the applicator (refer to the applicator’s documentation for

more information).

13.

Close the media cover.

13

Removing Used Ribbon

Remove used ribbon from the ribbon take-up spindle each time you change the roll of ribbon.

1.

Has the ribbon run out?

• Yes—Continue with step 2.

• No—Cut or break the ribbon before the ribbon take-up spindle.

ZE511/ZE521 Quick Reference Guide

LH RH

2.

Slide the core with the used ribbon off of the ribbon take-up spindle.

LH RH

3.

Discard the used ribbon. Reuse the empty core from the ribbon supply spindle by moving it to the

ribbon take-up spindle.

14

Alert and Error States

If the background color of the Home screen changes, you may need to take an action to restore the printer

to a Ready status. Red and yellow backgrounds typically halt printing until the issue is resolved.

Informational messages with a green background usually disappear without user intervention, and printing

continues as normal.

Diagnostics and Troubleshooting

Touch the icons in the bar at the top of the Home screen to view the error, alert, or informational message.

See Alerts and Error Messages on page 16 for recommended actions.

15

Diagnostics and Troubleshooting

Alerts and Error Messages

Display/Indicator Lights Possible Causes Recommended Solutions

The printhead is not fully closed. Close the printhead completely.

Head Open

Printhead is open.

Close the printhead.

The printhead open sensor is not

working properly.

Call a service technician to replace the

sensor.

Media Out

Media is out.

Load additional media.

Paper Jam

Media jammed.

Check the media.

The media is not loaded or is loaded

incorrectly.

Load media correctly. See Ribbon and

Media Loading on page 6.

Misaligned media sensor. Check the position of the media

sensor.

The print engine is set for

noncontinuous media, but continuous

media is loaded.

1. Install the proper media type, or

reset print engine for the current

media type.

2. Calibrate the printer. On the control

panel, touch Print > Sensors >

Manual Calibration to initiate

calibration.

There is an issue with the media in the

media path.

1. Check for media that is loaded

incorrectly or stuck to components

in the media path.

2. Check if media is wrapped around

the platen roller. Carefully remove

any labels.

3. If necessary, clean the platen roller

to remove adhesive. See Cleaning

the Printhead and Rollers on

page 23.

16

Diagnostics and Troubleshooting

Display/Indicator Lights Possible Causes Recommended Solutions

1. Load ribbon correctly. See Ribbon

and Media Loading on page 6.

2. Calibrate the printer. On the control

panel, touch Print > Sensors >

Manual Calibration to initiate

calibration.

1. Touch Print > Sensors > Print:

Sensor Profile to print a sensor

profile image (which extends

across several actual labels or

tags).The ribbon out threshold (1)

is likely too high, above the line

that indicates where the ribbon is

detected (2).

Ribbon Out

Ribbon is out.

Replace the ribbon.

In thermal transfer mode:

• ribbon is not loaded

• ribbon is loaded incorrectly

• the ribbon sensor is not detecting

ribbon

• media is blocking the ribbon sensor

In thermal transfer mode, the print

engine did not detect the ribbon even

though it is loaded correctly.

2

1

If you are using direct thermal media,

the print engine is waiting for ribbon to

be loaded because it is incorrectly set

for thermal transfer mode.

2. Calibrate the printer or load print

engine defaults. On the control

panel, touch Print > Sensors >

Manual Calibration to initiate

calibration, or touch System >

Settings > Restore Defaults >

Restore Printer to load print engine

defaults

Set the print engine for Direct Thermal

mode. Touch Print > Print Quality >

Print Type > Direct Thermal.

17

Diagnostics and Troubleshooting

Display/Indicator Lights Possible Causes Recommended Solutions

Ribbon In

Ribbon was detected in

Direct Thermal mode.

Remove the ribbon.

Head Identification Failed

Printhead is not a Zebra

Certified Product

Replace the Printhead

Ribbon is loaded, but the print engine

is set for direct thermal mode.

The printhead was replaced with one

that is not a genuine Zebra printhead.

Ribbon is not required with direct

thermal media. If you are using direct

thermal media, remove the ribbon.

This error message will not affect

printing.

If the message persists with no ribbon

in the printer, calibrate the printer. On

the control panel, touch Print >

Sensors > Manual Calibration to

initiate calibration.

If you are using thermal transfer

media, which requires ribbon, set the

print engine for Thermal Transfer

mode. Touch Print > Print Quality >

Print Type > Thermal Transfer.

Install a genuine Zebra printhead.

Head Element Out

A printhead element failed.

The printhead may need to be replaced.

Replace Printhead

Replace the printhead.

Head Maintenance Needed

Clean the printhead.

A printhead element is no longer

working.

The printhead is nearing the end of its

If the location of the failed element

affects printing, replace the printhead.

Replace the printhead.

life and should be replaced.

The printhead needs to be cleaned. Clean the printhead. See Cleaning the

Printhead and Rollers on page 23.

18

Diagnostics and Troubleshooting

Display/Indicator Lights Possible Causes Recommended Solutions

CAUTION—HOT SURFACE: The printhead may be hot enough to

Head Over Temp

Printhead is too hot.

All printing is halted.

Head Under Temp

Printhead is too cold.

All printing is halted.

Head Thermistor Fault

Faulty thermistor detected.

Replace the printhead.

The printhead is over temperature. Allow the print engine to cool. Printing

The printhead data cable is not

properly connected.

The printhead has a faulty thermistor. Replace the printhead.

cause severe burns. Allow the printhead to cool.

automatically resumes when the

printhead elements cool to an

acceptable operating temperature.

If this error persists, consider

changing where the printer is located

or using a slower print speed.

CAUTION—HOT SURFACE: An improperly connected printhead data

or power cable can cause these error messages. The printhead may be

hot enough to cause severe burns. Allow the printhead to cool.

Make sure that the printhead is fully

seated. If necessary, call a service

technician to check the cable.

The print engine shows one of these

messages or cycles between them.

Head Under Temp

Printhead is too cold.

All printing is halted.

Out of Memory Storing XXX

XXX not stored.

Out of memory.

CAUTION—HOT SURFACE: An improperly connected printhead data

or power cable can cause this error message. The printhead may be hot

enough to cause severe burns. Allow the printhead to cool.

The printhead temperature is

approaching its lower operating limit.

Continue printing while the printhead

reaches the correct operating

temperature. If the error remains, the

environment may be too cold for

proper printing. Relocate the print

engine to a warmer area.

The printhead data cable is not

properly connected.

Make sure that the printhead is fully

seated. If necessary, call a service

technician to check the cable.

The printhead has a faulty thermistor. Replace the printhead.

There is not enough memory to

perform the function specified.

Free up some of the print engine’s

memory by adjusting the label format

or print engine parameters. One way

to free up memory is to adjust the print

width to the actual width of the label

instead of leaving the print width set to

the default.

Ensure that the data is not directed to

a device that is not installed or is

unavailable.

If the problem persists, call a service

technician.

19

Indicator Lights

The indicator lights communicate the printer’s status.

Diagnostics and Troubleshooting

STATUS light

PAUSE light

DATA light

SUPPLIES light

NETWORK light

Table 1 Status of Printer As Shown by Indicator Lights

• STATUS light steady green (other lights steady yellow for 2 seconds

during printer power-up)

The printer is ready.

• PAUSE light steady yellow.

The printer is paused.

• STATUS light steady red

• SUPPLIES light steady red

The media supply is out. The printer needs attention and cannot

continue without user intervention.

• STATUS light steady red

• SUPPLIES light flashing red

The ribbon supply is out. The printer needs attention and cannot

continue without user intervention.

20

Diagnostics and Troubleshooting

Table 1 Status of Printer As Shown by Indicator Lights (Continued)

• STATUS light steady yellow

• SUPPLIES light flashing yellow

The printer is in Direct Thermal mode, which does not require ribbon;

however, ribbon is installed in the printer.

• STATUS light steady red

• PAUSE light steady yellow

The printhead is open. The printer needs attention and cannot continue

without user intervention.

• STATUS light steady yellow

The printhead is over temperature.

CAUTION—HOT SURFACE: The printhead may be hot and could

cause severe burns. Allow the printhead to cool.

• STATUS light flashing yellow

One of the following:

• The printhead is under temperature.

• The power supply is over temperature.

• The main logic board (MLB) is over temperature.

• STATUS light steady red

• PAUSE light steady red

• DATA light steady red

The printhead was replaced with one that is not a genuine Zebra ™

printhead. Install a genuine Zebra ™ printhead to continue.

• STATUS light flashing red

The print engine is unable to read the dpi setting of the printhead.

Printers with a ZebraNet wired Ethernet option

• NETWORK light off

No Ethernet link is available.

• NETWORK light steady green

A 100 Base-T link was found.

• NETWORK light steady yellow

A 10 Base-T link was found.

• NETWORK light steady red

An Ethernet error condition exists. The printer is not connected to your

network.

21

Diagnostics and Troubleshooting

Table 1 Status of Printer As Shown by Indicator Lights (Continued)

Printers with a ZebraNet wireless option

• NETWORK light off

A radio was found during power-up. The printer is attempting to

associate with the network. The light flashes red while the printer

associates with the network. The light then flashes yellow while the

printer is authenticating with the network.

• NETWORK light steady green

The radio is associated with your network and authenticated, and the

WLAN signal is strong.

• NETWORK light flashing green

The radio is associated with your network and authenticated, but the

WLAN signal is weak.

• NETWORK light steady red

A WLAN error condition exists. The printer is not connected to your

network.

22

Diagnostics and Troubleshooting

Cleaning the Printhead and Rollers

Inconsistent print quality, such as voids in the barcode or graphics, may indicate a dirty printhead. Clean

the printhead and rollers at these intervals:

• Direct Thermal Mode: After every roll of media (or 500 feet of fanfold media).

• Thermal Transfer Mode: After every roll of ribbon.

CAUTION—ESD: Before touching the printhead assembly, discharge any built-up static electricity by

touching the metal printer frame or by using an anti-static wriststrap and mat.

1.

Turn Off (O) the print engine.

2.

Open the media cover.

3.

Remove the media and ribbon.

4.

Release the printhead assembly.

23

Diagnostics and Troubleshooting

Press the release button on the upper pinch roller assembly, and allow the assembly to pivot upward.

5.

CAUTION—HOT SURFACE: The printhead may be hot and could cause severe burns. Allow the

printhead to cool.

6.

Clean the printhead.

a.

Using the swab from the Preventive Maintenance Kit (p/n 47362 or p/n 105950-035 for a multipack),

wipe the print elements (gray strip) from end to end. In place of this kit, use a lint-free cloth dipped in

99.7% isopropyl alcohol.

b.

Allow the solvent to evaporate.

24

Diagnostics and Troubleshooting

Clean the rollers.

7.

a.

Use the swab or the lint-free cloth to clean the pinch roller (1), peel roller (2), and platen roller (3).

Rotate the rollers while cleaning them.

b.

Allow the solvent to evaporate.

1 2 3

NOTE: If print quality does not improve after you perform this procedure, clean the printhead with Zebra’s

Save-a-Printhead cleaning film. Call your authorized Zebra distributor for more information.

8.

Reload the ribbon and media (if used).

9.

Close the upper pinch roller assembly.

10.

Lock the printhead assembly.

.

25

Close the media cover.

11.

Diagnostics and Troubleshooting

26

zebra.com

Loading...

Loading...