Page 1

ZE500 Quick Reference Guide

1

2 3

1

3

2

Use this guide to operate your print engine on a daily basis. For more detailed information,

refer to the User Guide.

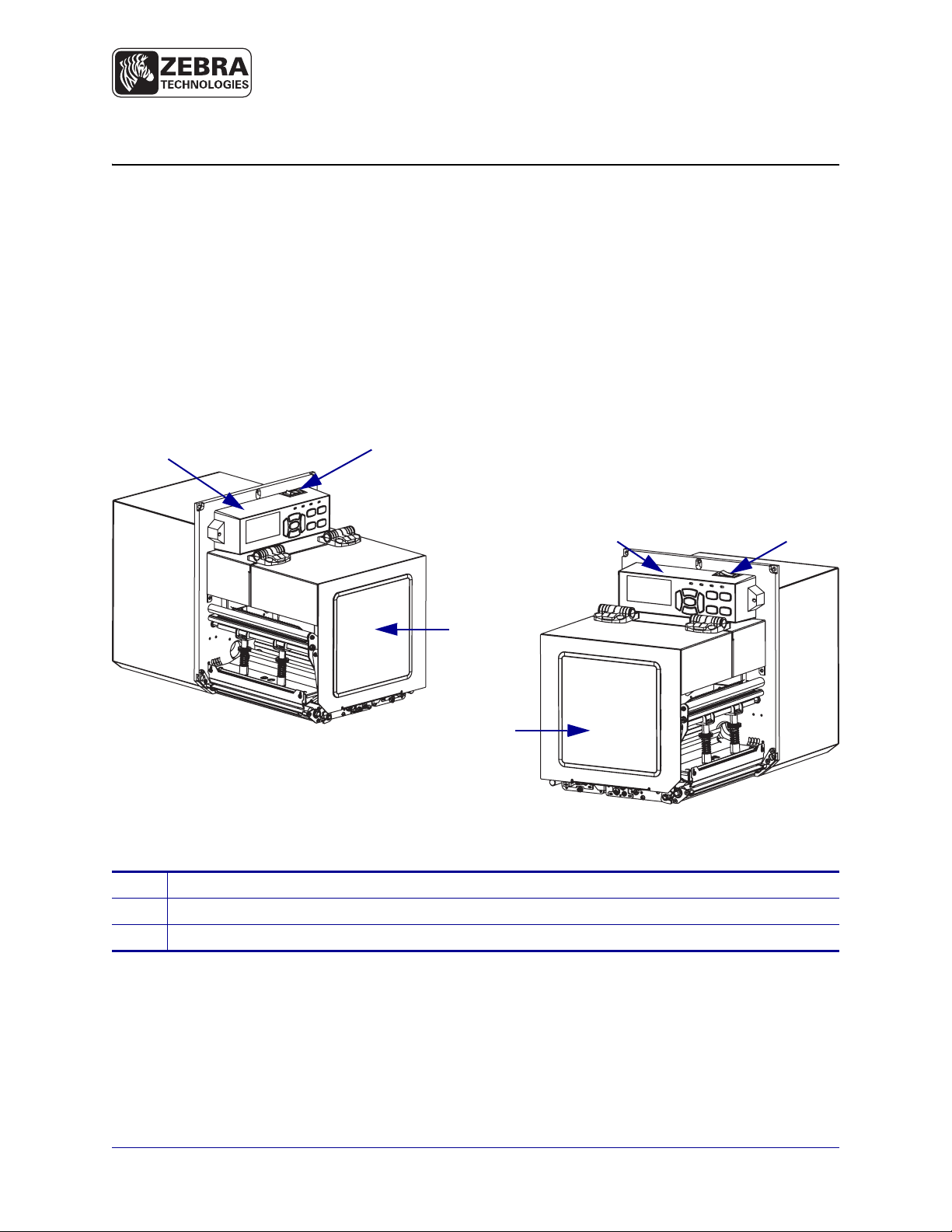

Print Engine Orientation

The ZE500 print engines are available in a right-hand configuration (the print mech anism is on

the right) and a left-hand configuration (the print mechanism is on the left).

Figure 1 • Left-Hand (LH) Print Engine

Figure 2 • Right-Hand (RH) Print Engine

© 2011 ZIH Corp. All pro duct names and numb ers are Zebra trademar ks, and Zebra

and the Zebra logo are registered trademarks of ZIH Corp. All rights reserved.

1

2

3

media door

control panel

power switch

P1047597-001 Rev . A

03/08/2012

Page 2

ZE500 Quick Reference Guide

3

4

910 7

5

6

12

11

8

1

2

2

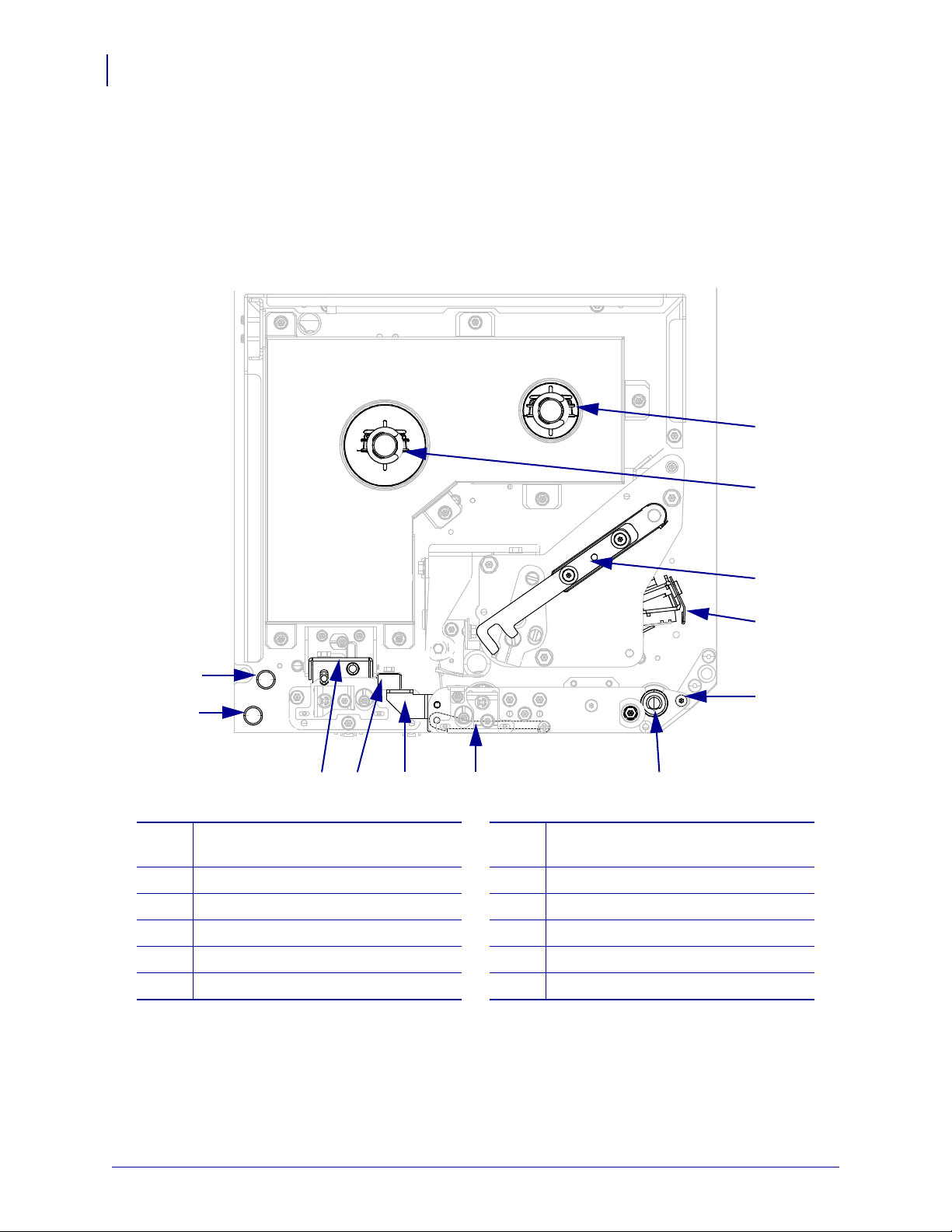

Print Engine Components

Print Engine Components

Figure 3 shows the components inside the media compartment of a right-hand print engine. A

left-hand unit contains a mirror image of these components. Familiarize yourself with these

components before continuing with the print engine setup procedure.

Figure 3 • Print Engine Components (RH model shown)

a222

ribbon take-up spindle

1

ribbon supply spindle

2

printhead-release latch

3

printhead assembly

4

peel bar

5

platen roller

6

P1047597-001 03/08/2012

peel roller assembly (hidden when

7

closed)

peel roller latch

8

media guide

9

pinch roller assembly

10

lower guide post

11

upper guide post

12

Page 3

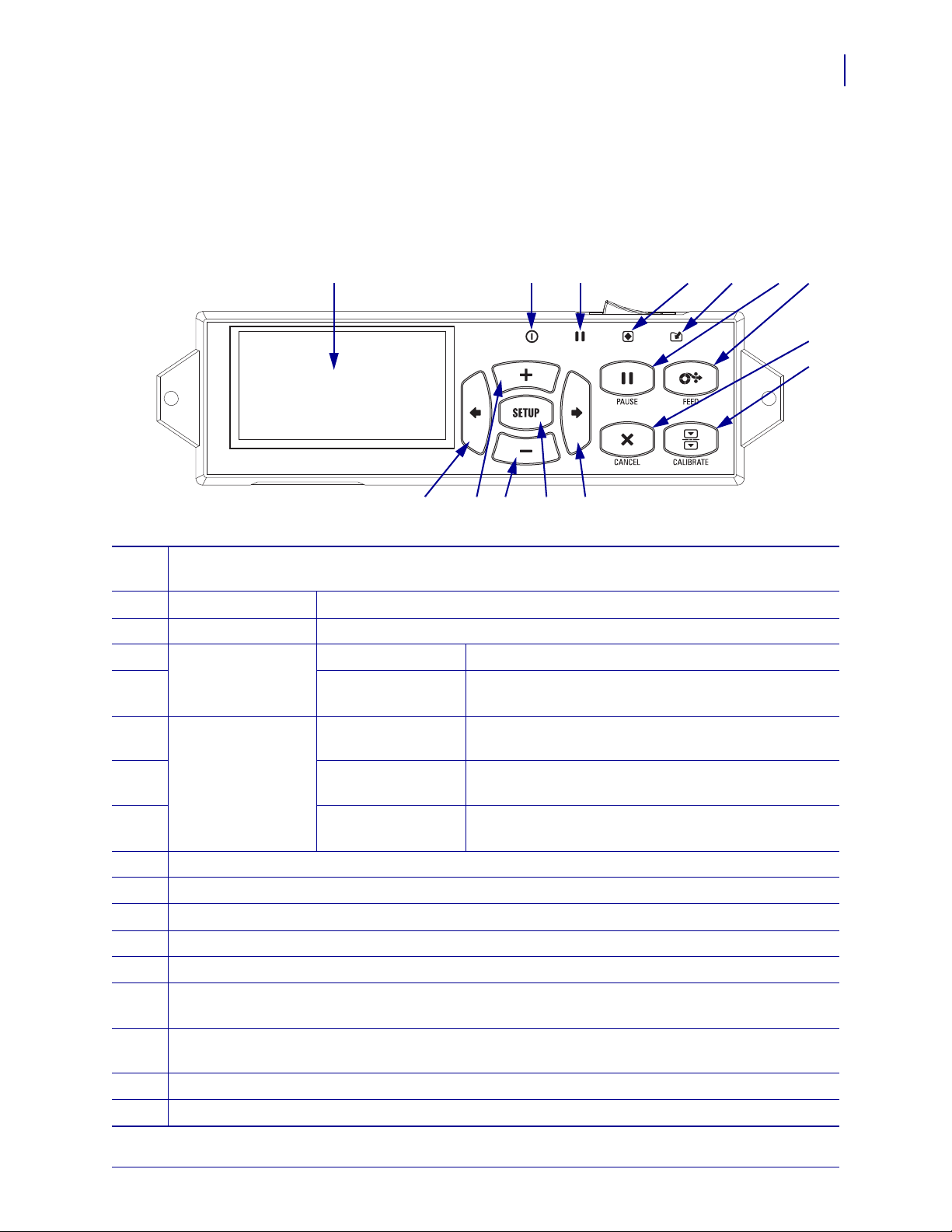

Control Panel

POWER PAUSE STATUS DATA

1

2 3 4 5

10 11 12 13 14

6 7

9

8

All controls and indicators for the print engine are locate d on the co ntrol pan el ( Figure 4). The

power switch is located on top of the control panel.

Figure 4 • Control Panel

ZE500 Quick Reference Guide

Control Panel

3

The display shows the print engine’s operating status and allows the user to navigate the menu

1

system.

POWER light On when the print engine is on.

2

PAUSE light On when the print engine is paused.

3

STATUS light Off Normal operation—no print engine errors.

4

Blinking A print engine error exists. Check the display for more

information.

DATA light Off Normal operation. No data being received or

5

processed.

On The print engine is processing data or is printing. No

data is being received.

Blinking The print engine is receiving data from or sending

status information to the host computer.

The PAUSE button starts or stops print engine operation when pressed.

6

The FEED button forces the print engine to feed one blank label each time the button is pressed.

7

The CANCEL button cancels print jobs when the print engine is paused.

8

The CALIBRATE button calibrates the print engine for media length and sensor values.

9

The LEFT ARROW navigates to the previous parameter in the menus.

10

The PLUS (+) button changes the parameter values. Common uses are to increase a value, to scroll

11

through choices, or to change values while entering the print engine password.

The MINUS (-) button changes the parameter values. Common uses are to decrease a value, to scroll

12

through choices, or to change the cursor position wh ile entering the print engine password.

The SETUP/EXIT button enters and exits configuration mode.

13

The RIGHT ARROW navigates to the next parameter in the menus.

14

03/08/2012 P1047597-001

Page 4

ZE500 Quick Reference Guide

4

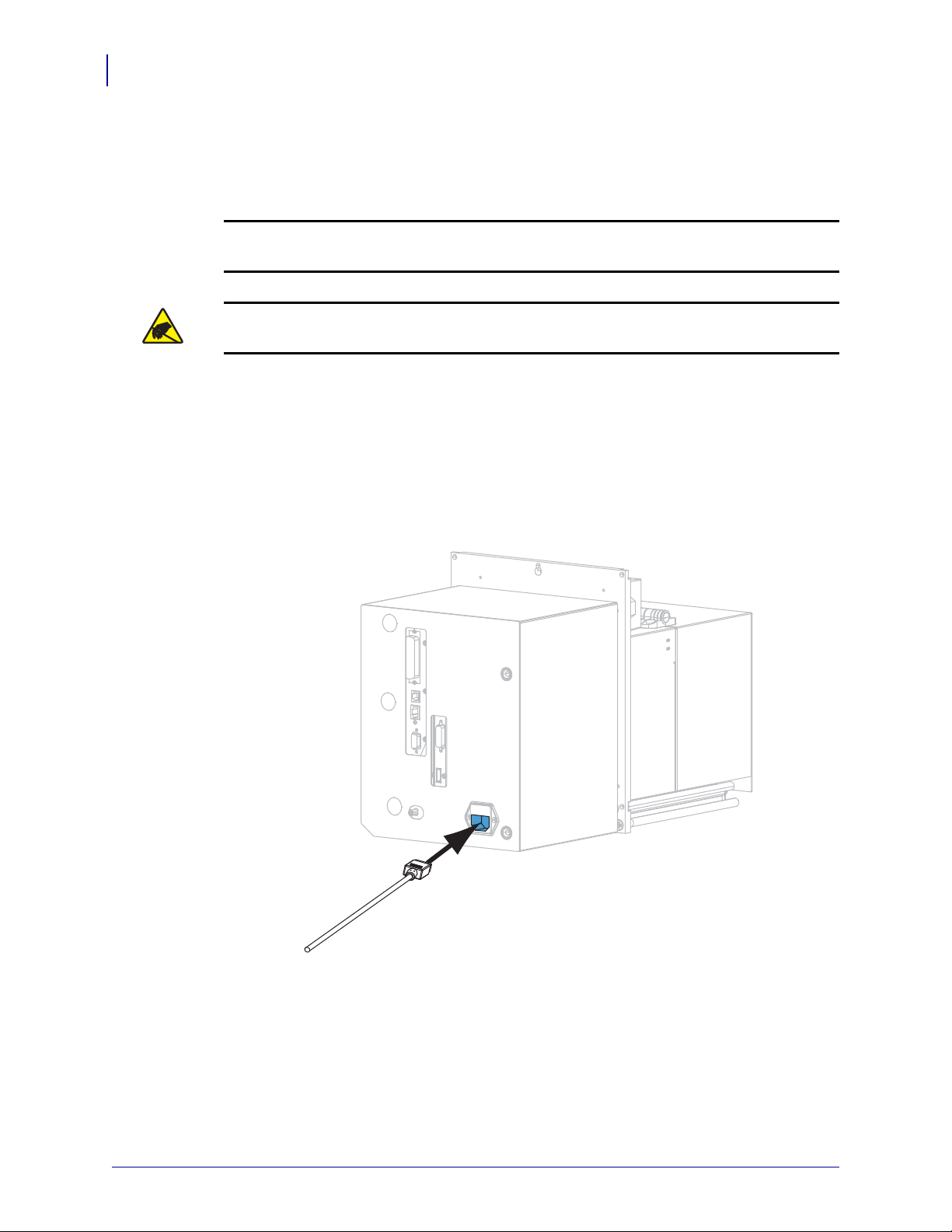

Preparing the Print Engine for Use

Preparing the Print Engine for Use

After you have familiarized yourself with the print engine components and the control panel,

prepare the print engine for use.

Caution • When you are loading media or ribbon, remove all jewelry that could come into

contact with the printhead or other

Caution • Before touching the printhead assembly, discharge any built-up static electricity

by touching the metal

To set up the print engine, complete these steps:

1. Unpack and inspect the print engine. If necessary, report any shipping damage. For more

information, refer to the User Guide.

2. Mount the print engine in the preselected location or applicator.

print engine frame or by using an anti-static wriststrap and mat.

print engine parts.

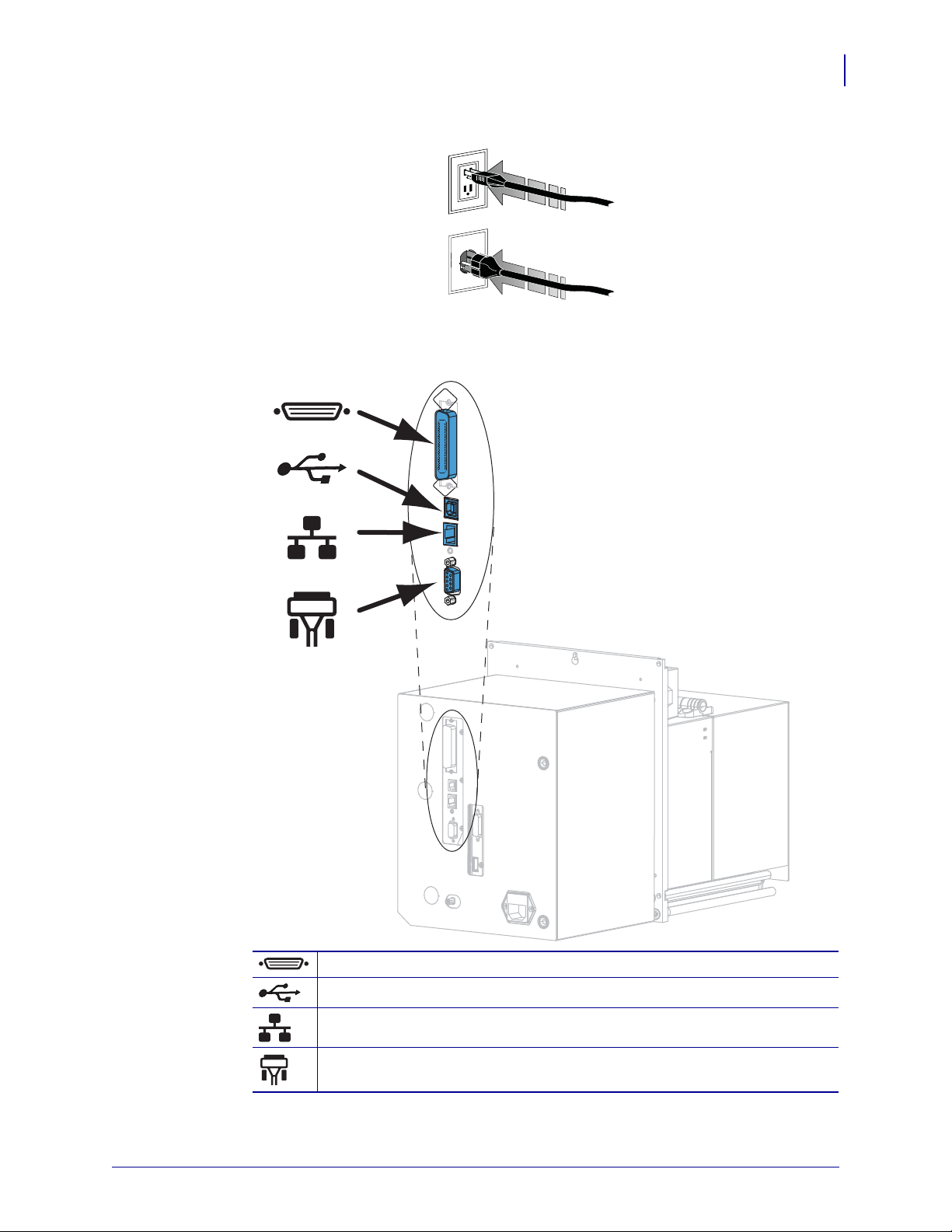

3. Plug the female end of the A/C power cord into the A/C power connector on the back of

the print engine.

P1047597-001 03/08/2012

Page 5

ZE500 Quick Reference Guide

115 V AC

230 V AC

Preparing the Print Engine for Use

4. Plug the male end of the A/C power cord into an appropriate power outlet.

5. Connect the print engine to a computer using one or more of the available connections.

The standard connections are shown here. A ZebraNet wireless print server option ‘may

also be present on your print engine.

5

parallel port

USB 2.0 port

wired Ethernet port

serial port

03/08/2012 P1047597-001

Page 6

ZE500 Quick Reference Guide

6

Preparing the Print Engine for Use

6. Raise the media door.

7. Load ribbon (if using Thermal Transfer mode) and media into the print engine (see Load

Ribbon and Media on page 7).

8. Turn on (I) the print engine.

The print engine boots up and performs a self-test.

P1047597-001 03/08/2012

Page 7

Load Ribbon and Media

LH RH

Use the instructions in this section to load ribbon (if used) and media in a ZE500 print engine.

Ribbon is used with thermal transfer labels. For direct thermal la bels, do not l oad ribbon in th e

print engine. For instructions for loading in different print modes, refer to the User Guide.

Caution • When you are loading media or ribbon, remove all jewelry that could come into

contact with the printhead or other

Important • Use ribbon that is wider than the media to protect the printhead from wear.

Ribbon must be coated on the outside (refer to the User Guide for more information).

Note • For optimal printing quality and proper printer performance across our product line,

Zebra strongly recommends the use of genuine Zebra™ supplies as part of the total solution.

Specifically, the ZE500 print engines are designed to work only with genuine Zebra™

printheads, thus maximizing safety and print quality.

To load ribbon and media, complete these steps:

print engine parts.

ZE500 Quick Reference Guide

Load Ribbon and Media

7

Loading Ribbon

1.

Caution • The printhead may be hot and could cause severe burns. Allow the

printhead to cool.

Rotate the printhead-release latch to the open position.

03/08/2012 P1047597-001

Page 8

ZE500 Quick Reference Guide

LH RH

LH RH

LH RH

8

Load Ribbon and Media

2. Position the ribbon roll with the loose end unrolling in the direction shown.

3. Place the roll of ribbon on the ribbon supply spindle. Push the roll back as far as it will go.

4. Place an empty ribbon core on the ribbon take-up spindle. Push the core back as far as it

will go.

P1047597-001 03/08/2012

Page 9

ZE500 Quick Reference Guide

2

3

1

LH RH

2

3

1

RHLH

Load Ribbon and Media

5.

Caution • The printhead may be hot and could cause severe burns. Allow the

printhead to cool.

Thread the ribbon under the lower ribbon guide roller (1), under the printhead

assembly

(2), and then over the upper ribbon guide roller (3).

9

Wind the ribbon around the core on the ribbon take-up spindle.

6.

03/08/2012 P1047597-001

Page 10

ZE500 Quick Reference Guide

LH RH

LH RH

10

Load Ribbon and Media

Loading Media

7. Load media on the media supply reel of the applicator (refer to the applicator’s

8. Press the release button on the pinch roller assembly. Allow the asse mbly to pivot upward .

documentation for more information).

9. Slide the media guide all the way out.

P1047597-001 03/08/2012

Page 11

ZE500 Quick Reference Guide

LH RH

1

2

3

12

3

RH

LH

Load Ribbon and Media

10. Thread the media under the upper guide post (1), below th e pinch roller assembly (2), and

under the printhead assembly

11. Extend approximately 30 in. (75 cm) of media past the peel bar. Remove and discard the

(3).

labels from the liner on this exposed media.

11

03/08/2012 P1047597-001

Page 12

ZE500 Quick Reference Guide

LH RH

LH RH

LH RH

12

Load Ribbon and Media

12. Slide in the media guide until it just touches the edge of the media.

13. Press down on the pinch roller assembly until it locks closed.

14. Rotate the printhead-release latch to the closed position.

P1047597-001 03/08/2012

Page 13

ZE500 Quick Reference Guide

LH RH

LH RH

Load Ribbon and Media

15. Raise the peel roller latch so that the peel roller assembly pivots downward.

16. Thread the liner around the peel bar, under the platen roller, and through the peel roller

assembly.

Important • If the applicator has an air tube, route the liner between the air tube and the

peel bar. Do not thread the liner over the air tube.

13

03/08/2012 P1047597-001

Page 14

ZE500 Quick Reference Guide

LH RH

14

Load Ribbon and Media

17. Rotate the peel roller assembly up until it locks into the closed position.

18. Thread the liner around the take-up spindle of the applicator (refer to the applicator’s

19. Close the media door.

documentation for more information).

P1047597-001 03/08/2012

Page 15

Remove Used Ribbon

LH RH

LH RH

Remove used ribbon from the ribbon take-up spindle each time you change the roll of ribbon.

To remove used ribbon, complete these steps:

1. Has the ribbon run out?

If the ribbon... Then

Ran out Continue with step 2.

ZE500 Quick Reference Guide

Load Ribbon and Media

15

Did not run out

2. Slide the core with the used ribbon off of the ribbon take-up spindle.

a. Cut or break the ribbon before the ribbon take-up spindle.

b. Continue with step 2.

3. Discard the used ribbon. Y ou may reuse the empty core from the ribbon supply spindle by

moving it to the ribbon take-up spindle.

03/08/2012 P1047597-001

Loading...

Loading...