Page 1

R

4

02

Smart Label Printer and Encoder

User s

Guide

'

980389-001 Rev. A

Page 2

Page 3

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation. It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced, or disclosed to any other parties for any other purpose

without the expressed written permission of Zebra Technologies Corporation.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies Corporation. All specifications and signs are subject to change without notice.

FCC Compliance Statement

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that the interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

■

Reorient or relocate the receiving antenna.

■

Increase the separation between the equipment and the receiver.

■

Connect the equipment into an outlet on a circuit different than that to which the receiver is connected.

■

Consult the dealer or an experienced Radio/TV technician for help.

NOTE: This unit was tested with shielded cables on the peripheral devices. Shielded cables must be used with the unit to insure compliance.

“The user is cautioned that any changes or modifications not expressly approved by Zebra Technologies Corporation could void the user’s authority to operate

the equipment.”

Liability Disclaimer

Zebra Technologies Corporation takes steps to assure that its published Engineering specifications and Manuals are correct; however, errors do occur. Zebra

Technologies Corporation reserves the right to correct any such errors and disclaims liability resulting therefrom.

No Liability for Consequential Damage

In no event shall Zebra Technologies Corporation or anyone else involved in the creation, production, or delivery of the accompanying product (including

hardware and software) be liable for any damages whatsoever (including, without limitation, damages for loss of business profits, business interruption, loss of

business information, or other pecuniary loss) arising out of the use of or the results of use of or inability to use such product, even if Zebra Technologies

Corporation has been advised of the possibility of such damages. Because some states do not allow the exclusion or limitation of liability for consequential or

incidental damages, the above limitation may not apply to you.

Trademarks

The Zebra logo and the zebra head design are both registered trademarks and R402 is a service mark of ZIH Corp. Windows and MS-DOS are registered

trademarks of Microsoft Corp. All other marks are trademarks or registered trademarks of their respective holders.

Copyrights

This copyrighted manual and the label printer described herein are owned by Zebra Technologies Corporation. All rights are reserved. Unauthorized

reproduction of this manual or the software in the label printer may result in imprisonment of up to one year and fines of up to $10,000 (17 U.S.C.506).

Copyright violators may be subject to civil liability.

©2002 ZIH Corp. All rights reserved.

Page 4

Page 5

Introduction

Hello! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

What’s in the Box?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Inspecting the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Opening the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Closing the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Reporting Damage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Getting Started

Modes of Printing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Attaching Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Loading Roll Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Placing the Roll in the Media Compartment . . . . . . . . . . . . . . . . . . . . 9

Adjusting the Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Using the Media Adapter Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

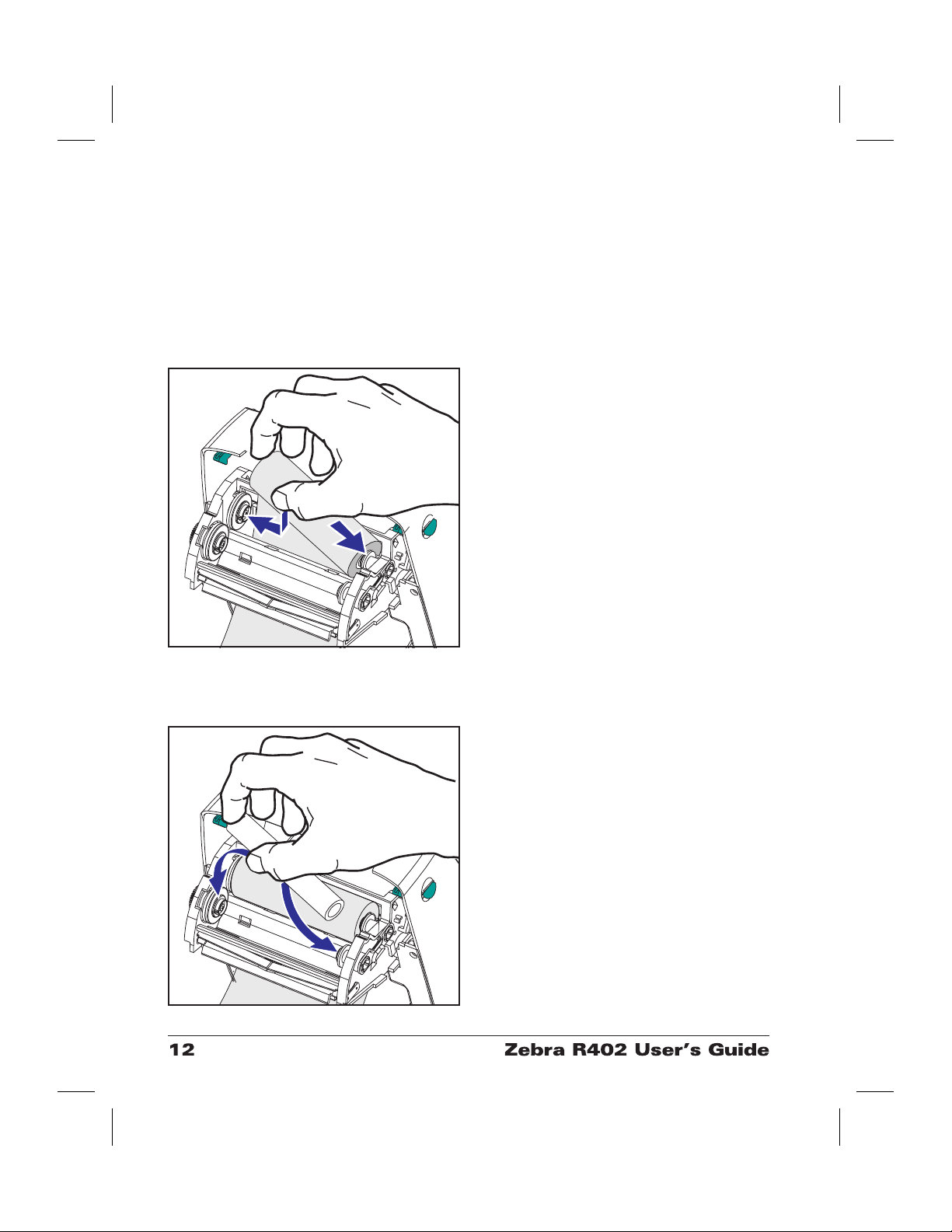

Loading Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Install the Ribbon Supply Roll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Install the Take-Up Core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Attach and Tighten the Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Auto Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operator Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Feed Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Status Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Printing a Test Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Hooking Up the Printer and Computer . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Parallel Interface Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Interface Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Communicating with the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adjusting the Print Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adjusting the Print Darkness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adjusting the Print Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Contents

Page 6

Operation & Options

Thermal Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Replacing Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Adding a New Transfer Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Replacing a Partially Used Transfer Ribbon. . . . . . . . . . . . . . . . . . . 20

Printing in Peel-Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Printing on Fan-Fold Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

RFID Guidelines

Supported Transponders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Texas Instruments Tag-it™ Transponders . . . . . . . . . . . . . . . . . . . . 25

Philips I•Code Transponders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Inside Technologies Picotag® Transponders . . . . . . . . . . . . . . . . . . 27

ISO-15693 Transponders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

ZPL II Commands for RFID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

^WT – Write Tag. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

^RT – Read Tag. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

^RS – RFID Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

^RI – RFID Get Tag Unique ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Sample of RFID Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Maintenance

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Replacing the Print Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Cleaning the Print Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Troubleshooting

Resolutions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Print Quality Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

RFID Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

RFID tags generally not programmed . . . . . . . . . . . . . . . . . . . . . . . . 48

VOID messages are printed across media. . . . . . . . . . . . . . . . . . . . . 48

Nothing is printed.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Manual Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Troubleshooting Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Printing a Configuration Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Recalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Page 7

Resetting the Factory Default Values . . . . . . . . . . . . . . . . . . . . . . . . . 51

Communications Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Feed Button Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Appendix

Page 8

980389-001 Rev. A

Page 9

Hello!

Introduction

This section describes what you get in your shipping box and provides an

overview of printer parts. This section also has procedures that describe

how to open and close the printer and report any problems.

Thank you for choosing the Zebra®R402™Printer, a high-quality thermal

transfer on-demand printer with RFID capability manufactured by the

industry leader in quality, service, and value—Zebra Technologies

Corporation. For over 25 years, Zebra Technologies Corporation has

provided customers with the highest caliber of products and support.

This manual provides all of the information you will need to operate your

printer on a daily basis. RFID specific ZPL II commands are contained in

this manual. To create label formats, refer to the ZPL II Programming

Guide (part # 46530L). This guide is available by contacting your

distributor or Zebra Technologies Corporation.

NOTE: Many printer settings may also be controlled by your printer’s

driver or label preparation software. Refer to the driver or

software documentation for more information.

The Zebra R402 printer, when connected to a host computer, functions as a

complete system for printing and encoding “smart” labels, tickets, and tags.

Page 10

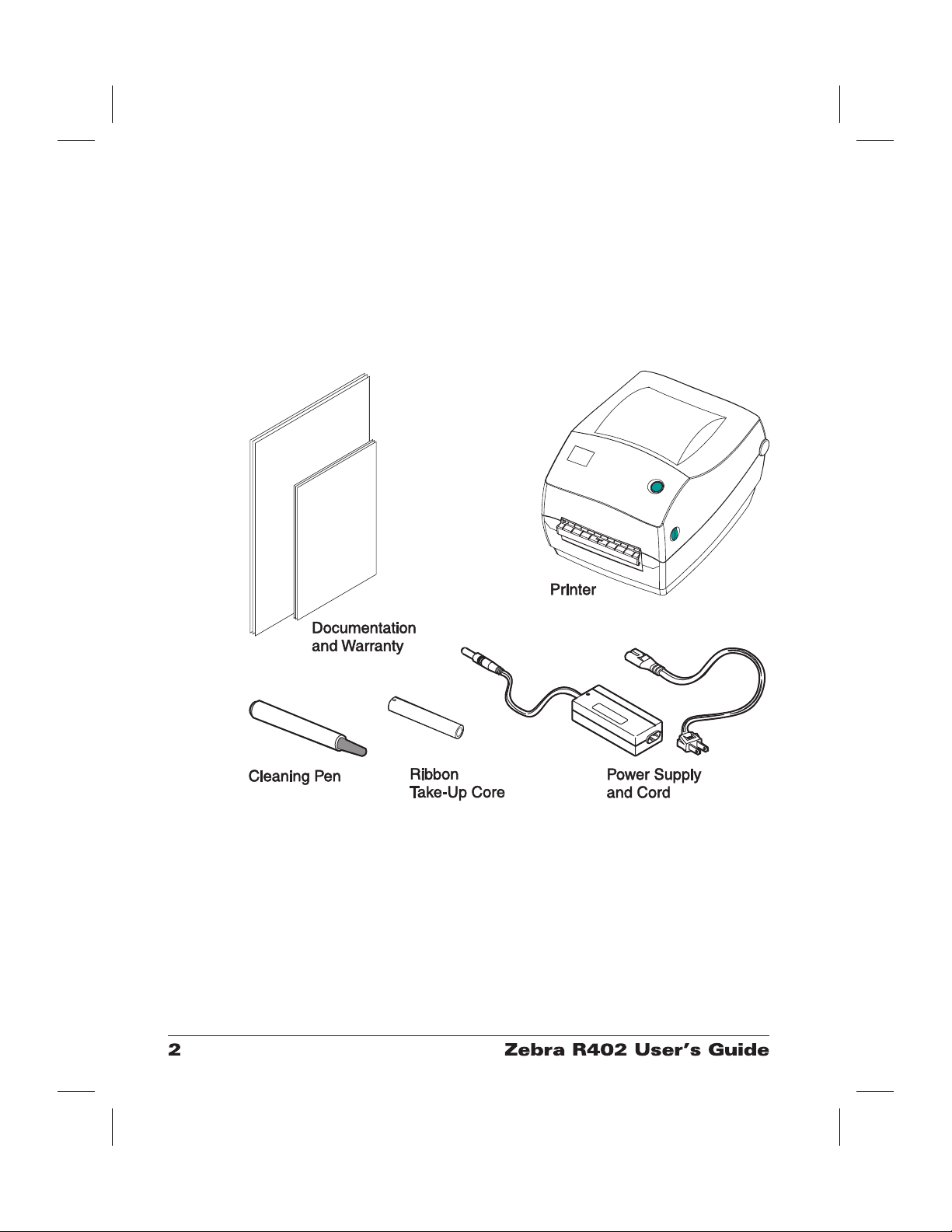

What’s in the Box?

Save the carton and all packing materials in case you need to ship or store

the printer later. After unpacking, make sure you have all parts. Follow the

procedures for inspecting the printer to familiarize yourself with printer

parts so you can follow the instructions in this book.

Page 11

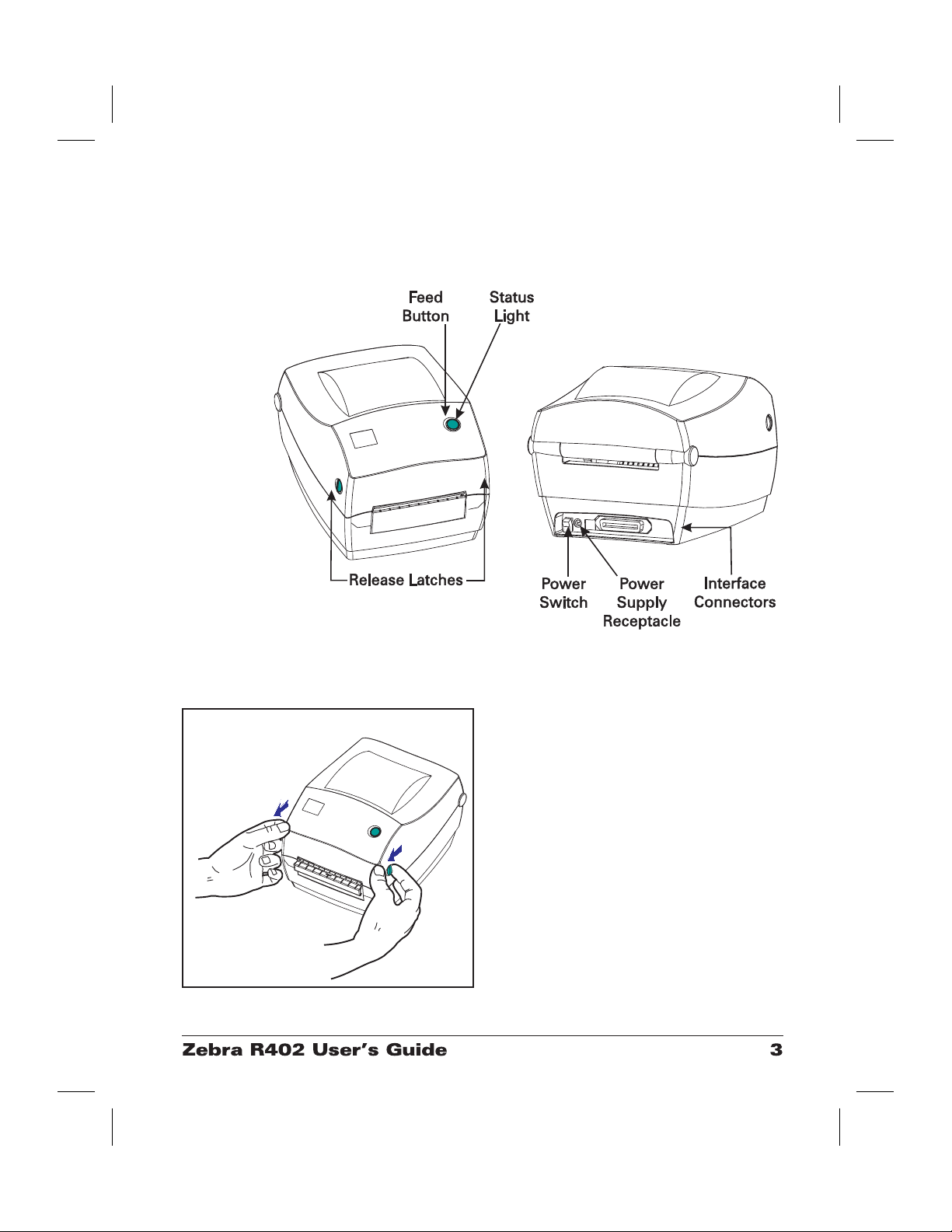

Inspecting the Printer

Look at the outside of the printer and make sure that all parts are present.

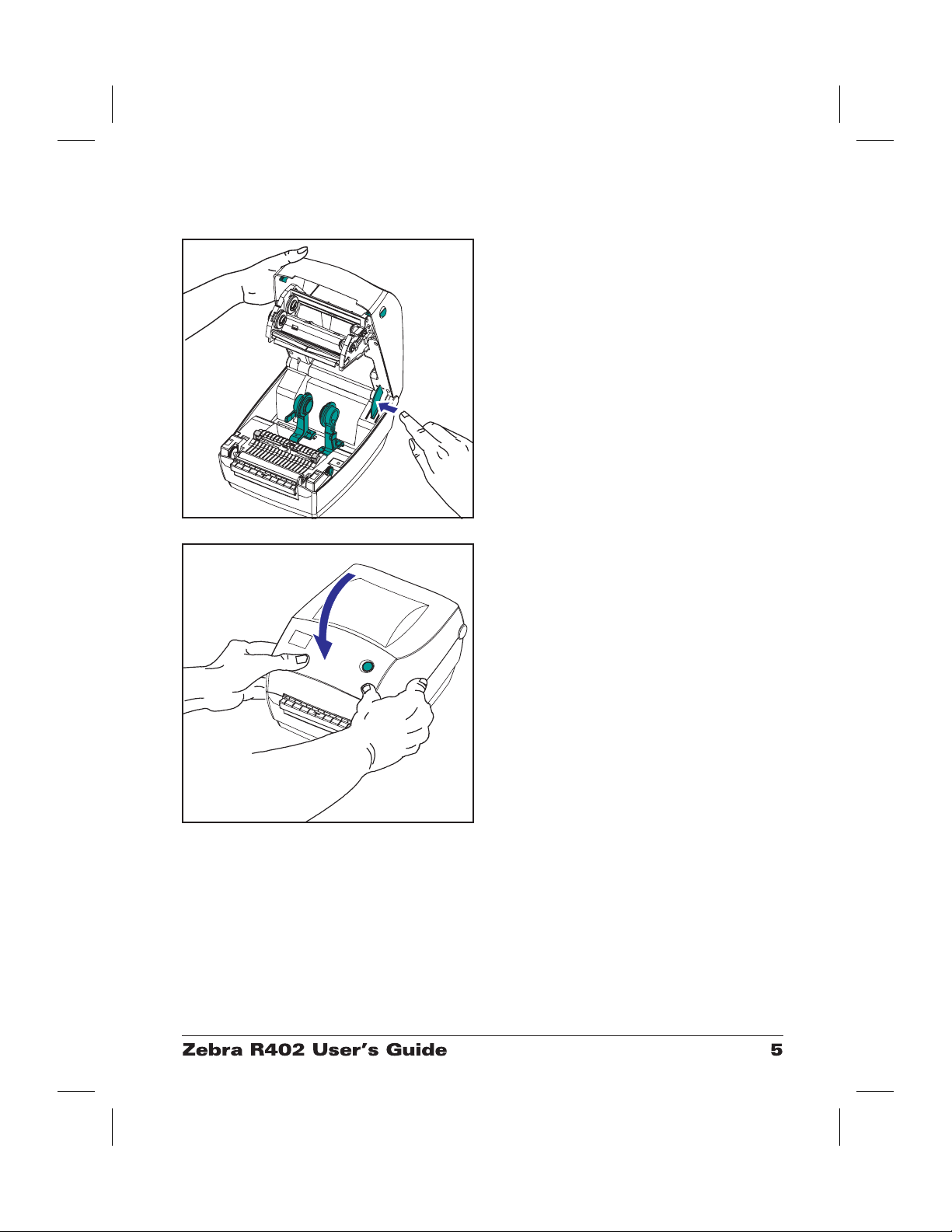

Opening the printer

To access the media compartment, you

must open the printer.

Pull the release levers towards you and lift

the cover.

Page 12

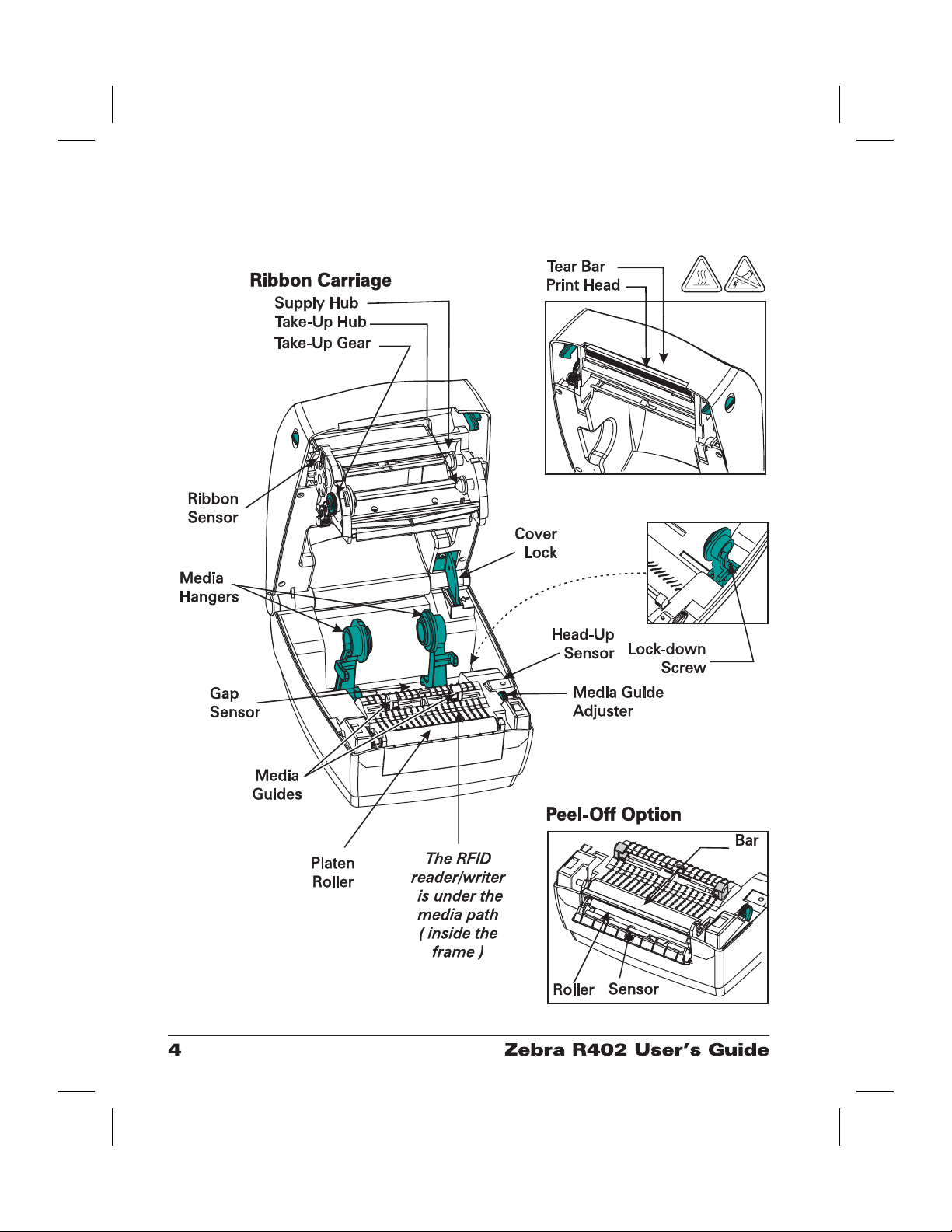

INSPECTING THE PRINTER (continued)

After opening the printer, check the media compartment.

Page 13

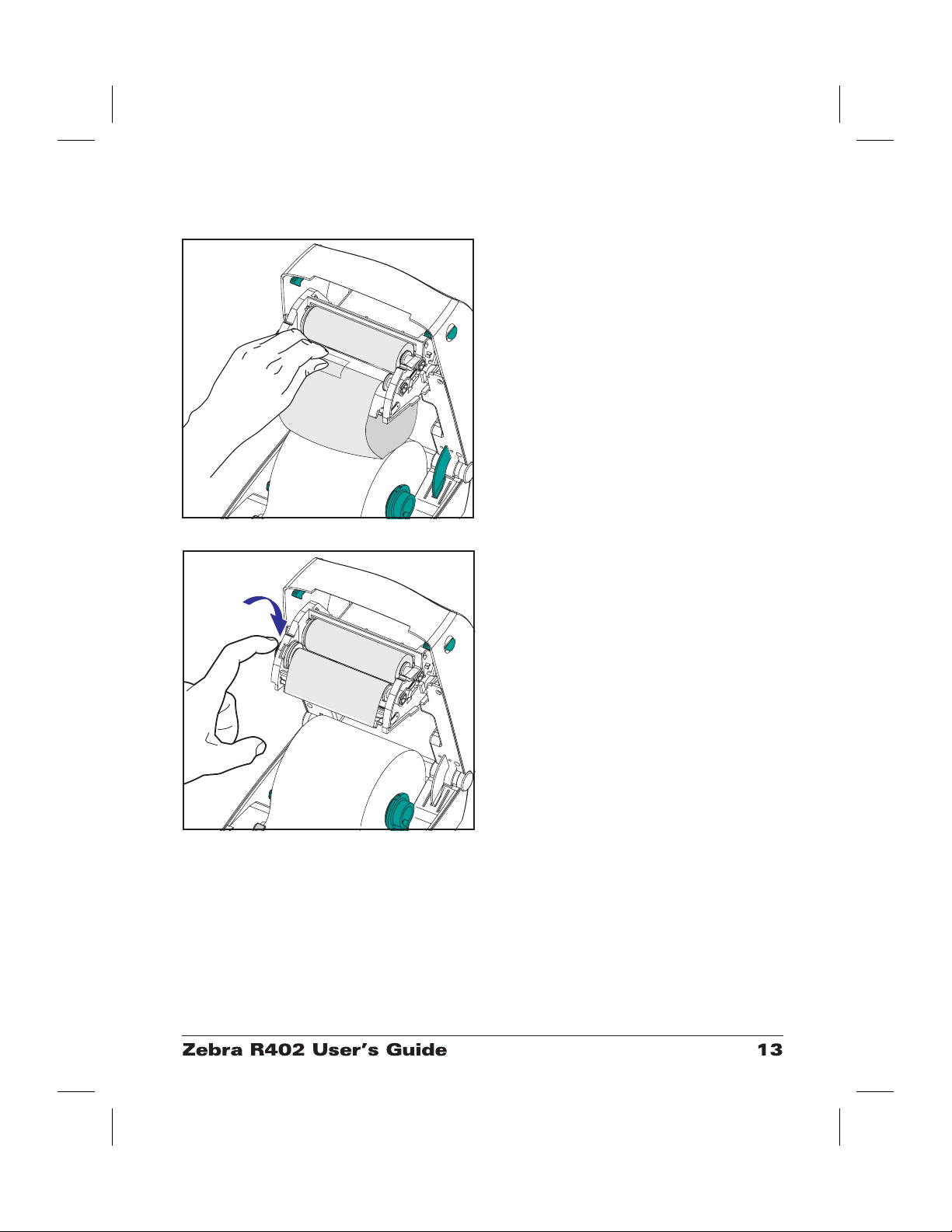

Closing the printer

Hold the top cover and press the cover

lock to release.

Lower the top cover. The ribbon carriage

automatically folds up into place.

Press down until the cover snaps closed.

Page 14

Reporting Damage

If you discover damage or missing parts:

■

Immediately notify and file a damage report with the shipping company.

Zebra Technologies Corporation is not responsible for any damage

incurred during shipment of the printer and will not cover the repair of

this damage under its warranty policy.

■

Keep the carton and all packing material for inspection.

■

Notify the authorized reseller

Page 15

This section describes how to set up your printer for the first time and use

the most common operating procedures for loading media in tear-off mode

and loading ribbon.

Modes of Printing

You can operate this printer in two different modes: tear-off or peel-off.

■

Standard tear-off mode allows you to tear off each label (or a strip of

labels) after it is printed.

■

In optional peel-off mode, the backing material is peeled away from the

label as it is printed. After this label is removed, the next one is printed.

The printer typically uses roll media, but you can use fan-fold media as

well.

For procedures to use optional modes and features, refer to the Operation

and Options section.

Getting Started

Page 16

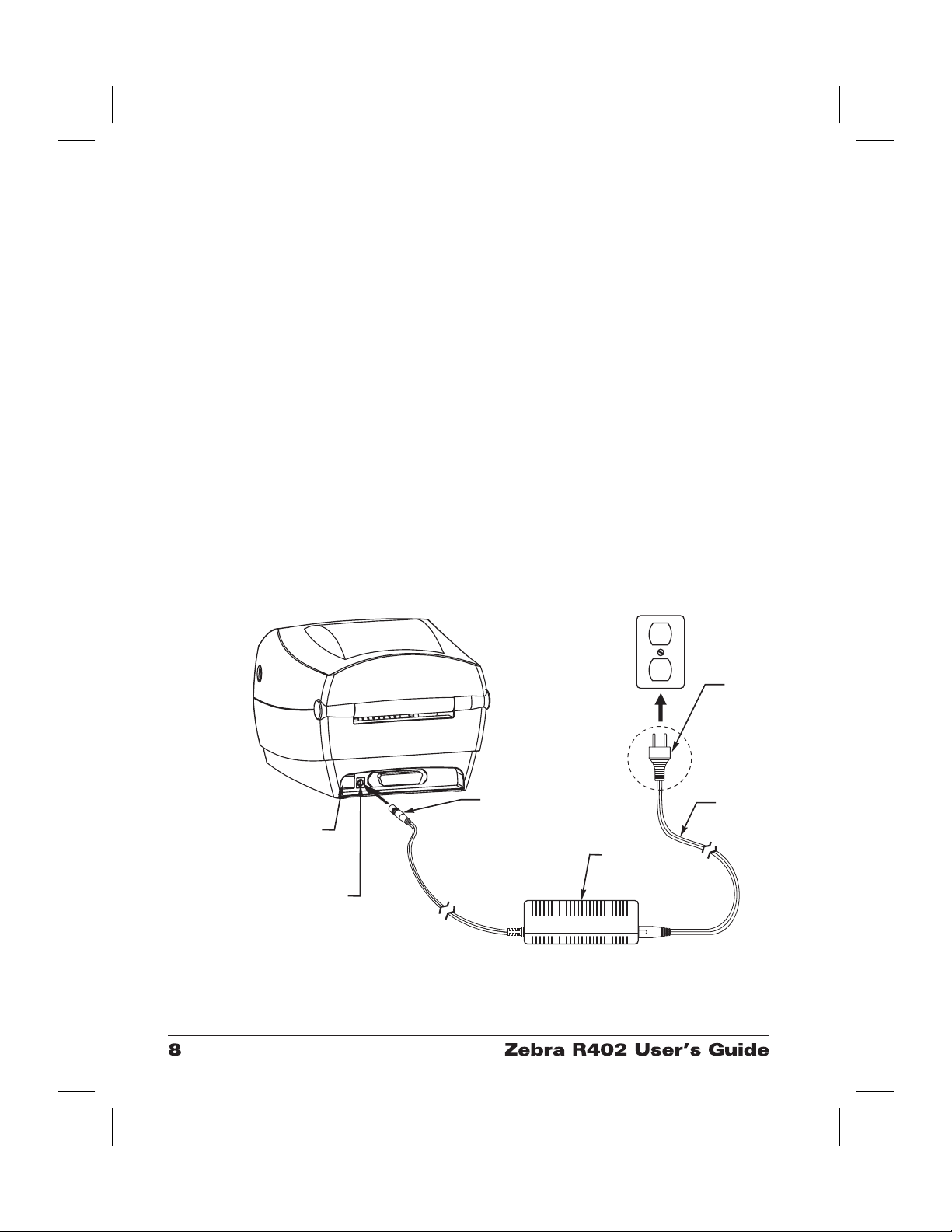

Attaching Power Supply

y

Check the power supply to make certain it is appropriate for your input

voltage.

Warning: Use the Zebra-supplied power supply that came

with your printer.

Never operate the printer and power supply in

an area where they can get wet. Serious

personal injury could result!

1. Make sure the power switch is in the off position (down).

2. The DC power supply has a barrel connector on one end that must be

inserted into the power supply receptacle on the back of the printer.

3. Insert the separate AC power cord into the power supply.

4. Plug the other end of the cord into an appropriate AC electrical outlet.

Power

Switch

Power

Supply

Receptacle

Barrel

Connector

Plug

Vari es b

Country

AC

Power

Cord

Power

Supply

Page 17

Loading Roll Media

When you load media, you must place the roll on the media hangers and

then adjust the media guides.

Placing the Roll in the Media Compartment

Whether your roll media is inside or

outside wound you load it into the printer

the same way.

1. Open the printer. Remember that you

need to pull the release levers toward

the front of the printer.

2. Remove the outside length of media.

During shipment, the roll may become

dirty when handled or dusty when

stored. Removing the outside length

avoids dragging adhesive or dirty

media between the print head and

platen.

3. Separate and hold open the media

hangers.

4. Orient the media roll so that its

printing surface will be up as it passes

over the platen.

5. Lower the roll between the hangers

and close them onto the core.

Page 18

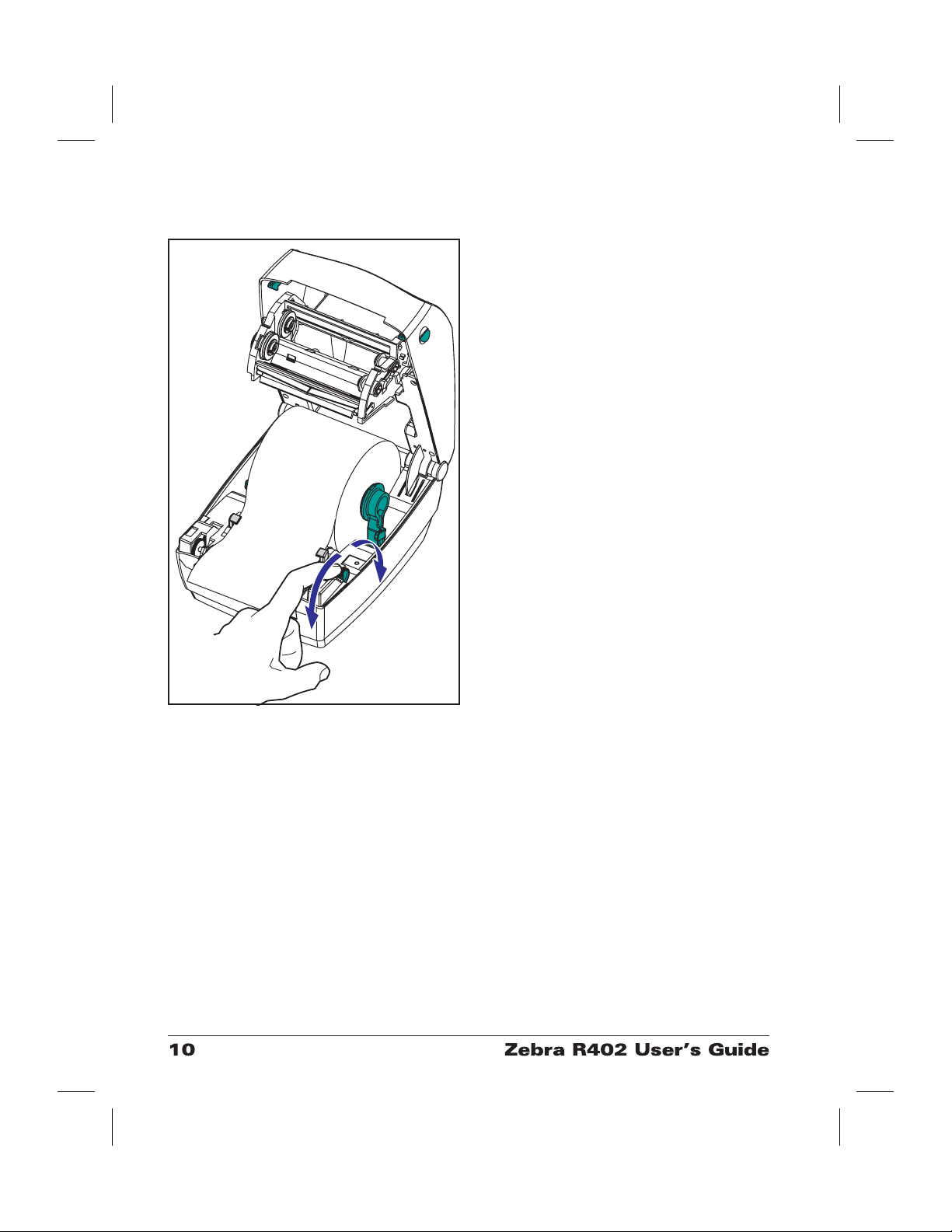

Adjusting the Guides

The adjustable guides direct the media

toward the platen and print head.

1. Open the media guides by turning the

guide adjuster knob to the rear.

2. Thread the media through the guides.

3. Close the media guides by turning the

guide adjuster knob to the front. They

should just touch, but not restrict, the

edges of the media.

4. Unless you need to load ribbon, close

the top cover. Remember that you

need to release the cover lock, lower

the top cover, and press down until the

latches snap into place.

Page 19

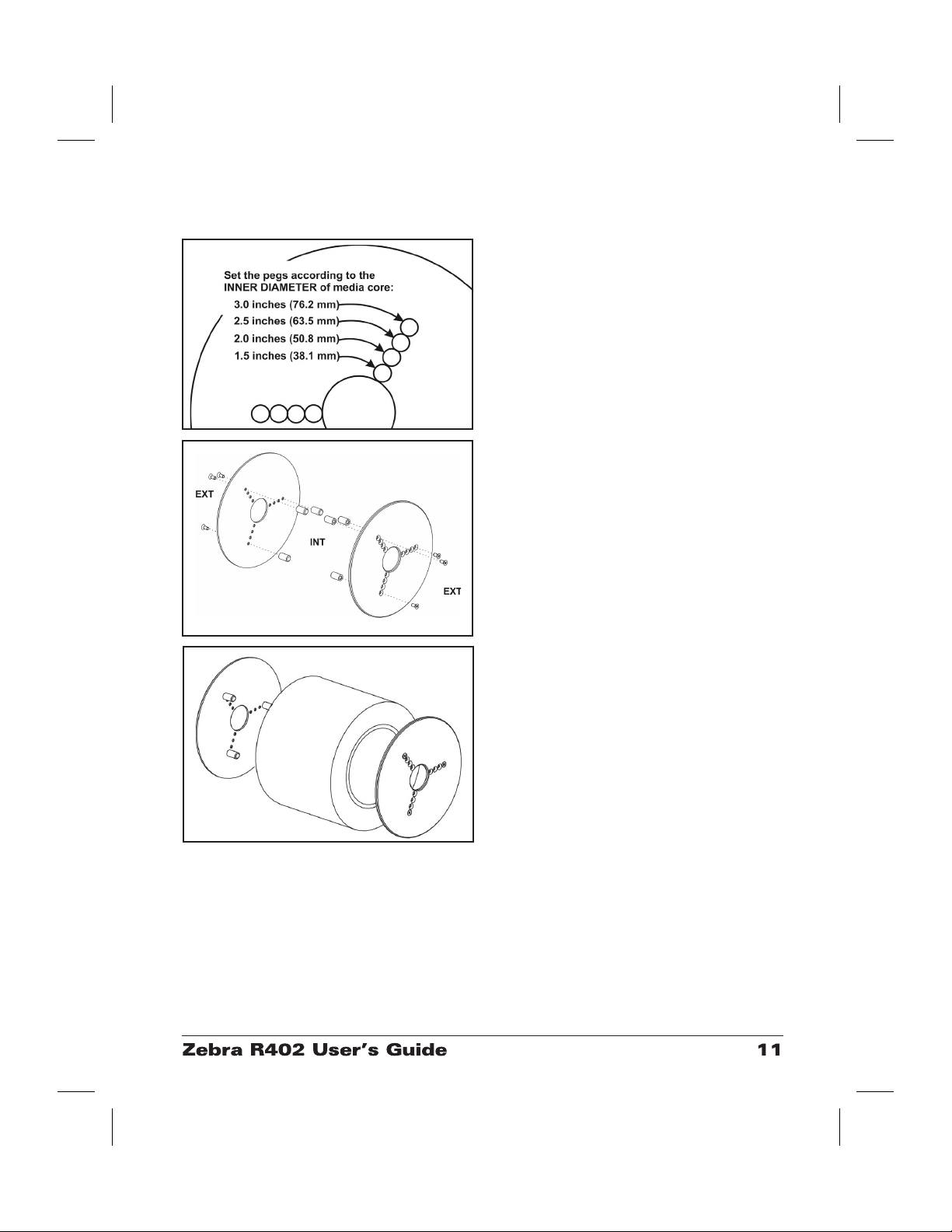

Using the Optional Media Adapter Plates

If your media roll has a larger diameter

core, you can use an accessory (part

number 105810-002) to adapt the core to

the media holders.

1. Note which position will fit the

diameter of the roll core.

2. On the left side plate, align the pegs

with the screws and use a small

Phillips driver to tighten them.

3. On the right side plate, align the pegs

with the screws and use a small

Phillips driver to tighten them.

4. Align the plates so that the pegs hold

the roll core and press together.

5. Place the roll into the media

compartment.

Page 20

Loading Ribbon

You must use thermal transfer media (accepts wax and/or resin transferred

off a ribbon) when you use a ribbon. When loading ribbon, you install the

supply and take-up rolls, then tighten the ribbon on the carriage.

Install the Ribbon Supply Roll

Before following these steps, prepare the

ribbon by removing its wrapping and

pulling its adhesive strip free.

1. Thread the ribbon through the

carriage.

2. Press the right side onto the supply

hub.

3. Align the notches on the left side and

mount onto the spokes of the left hub.

Install the Take-Up Core

1. Press the right side onto the take-up

hub.

2. Align the notches on the left side and

mount onto the spokes of the left hub.

You can find your first ribbon take-up

core in the packing box. Subsequently,

use the empty supply core to take up the

next roll of ribbon.

Page 21

Attach and Tighten the Ribbon

You must align the ribbon so that it will

be taken straight onto the core.

1. Attach the ribbon to the take up core.

Use the adhesive strip on new rolls;

otherwise, use tape.

2. Turn the ribbon take-up gear

counter-clockwise (top moves toward

rear) to remove slack from the ribbon.

3. Close the top cover. Remember that

you need to release the cover lock,

lower the top cover, and press down

until the latches snap into place.

Page 22

Auto Calibration

NOTE: If you are using pre-printed labels, pre-printed label backing, or

continuous media, see “Manual Calibration” on page 49.

An auto calibration is performed when the printer is turned on (if media is

loaded) or after a media error is cleared. When it is auto calibrating, the

printer sets the sensor levels for, and determines the length of, the label you

are using.

If the status light flashes red, refer to “Manual Calibration” on page 49.

Page 23

Operator Controls

Power Switch

Press up to turn ON or down to turn OFF the printer.

CAUTION: The power should be turned off before connecting or

disconnecting the communications and power cables.

Feed Button

Forces the printer to feed one blank label.

Takes the printer out of a “pause” condition. (The printer is put into

“pause” by either a ZPL II command or an error condition.) See “What the

Status Light is Telling You” on page 43.

Use the Feed button for printer setup and status (see “Feed Button Modes”

on page 52).

Status Light

Functions as a printer operational indicator (see “What the Status Light is

Telling You” on page 43).

Page 24

Printing a Test Label

SCO

Before you connect the printer to your computer, make sure that the printer

is in proper working order. You can do this by printing a configuration

label.

1. Make sure the media is properly loaded and the top cover of the printer

is closed. Then, turn the printer power on if you have not already done

so.

2. When the status light is solid green, press and hold the feed button until

the status light flashes once.

3. Release the feed button. A configuration label will print.

If you cannot get this label to print, refer to Troubleshooting on page 43.

PRI NTER CONFI GURATI ON

Zebr a Technol ogi es

ZTC R402- 200dpi

................

+1 0 DARKNESS

...............

+000 TEAR OFF

...........

TE AR OFF PRI NT MODE

NON- CONTI NUOUS MEDI A T YPE

................

WEB SENSOR TYPE

THERMAL- TRANS. PRI NT METHOD

104 0/ 8 MM PRI NT WIDTH

...............

1233 LABEL L ENGTH

22. 0I N 557MM MAXI MUM LENGTH

..............

38400 BAUD

.............

8 BITS DATA BITS

...............

NONE PARI TY

...........

XON/ XOF F HOST HANDSHAKE

...............

NONE PROT OC OL

................

000 NETWORK I D

NORMAL MODE COMMUNI CAT I ONS

...........

< ~ > 7EH CONT ROL P R E F I X

...........

<^ > 5 EH FORMAT PREFI X

...........

<, > 2 CH DEL I MI TER CHAR

.............

ZPL I I ZPL MODE

...............

FEED MEDI A POWER UP

...............

FEED HEAD CLOSE

............

DEFAULT BACKFEED

...............

+0 2 0 LABEL TOP

..............

+0000 LEFT POSI TI ON

................

029 WEB S.

................

068 MEDI A S.

................

050 RI BBON S.

................

050 MARK S.

................

0 0 1 MA R K MED S.

.................

CS MODES ENABL E D

.................

. . MODES DI SABLED

832 8/ MM FULL RESOLUTI ON

SP. 814. B <- FI RMWARE

V2.2.6.98.C HARDWARE I D

CUSTOMI ZED CONFI GURATI ON

1024.............R: RAM

0000.............B: MEMORY CARD

0768.............E: ONBOARD FLASH

...............

NONE FORMAT CONVERT

...............

NONE OPTI ON

...............

NONE ZEBRA NET I I

AUT O DETE CT RF I D TA G TYPE

oem- 400: Ver . 2. 00 RFI D VERSI ON

FI RMWARE I N THISPRI NTER I

.....

.....

.........

.....

........

......

.....

........

.........

........

PYRIGHTE D

Page 25

Hooking Up the Printer and Computer

This printer comes with a bidirectional parallel data interface. You must

supply the required interface cable for your application.

CAUTIONS:Keep the power switch in the OFF position when

attaching the interface cable.

The power supply barrel connector must be inserted

into the power supply receptacle on the back of the

printer before connecting or disconnecting the com

munications cables.

-

This printer complies with FCC “Rules and Regula

tions,” Part 15, for Class B Equipment, using fully

shielded six-foot data cables. Use of longer cables or

unshielded cables may increase radiated emissions

above the Class B limits.

Parallel Interface Requirements

The required cable (IEEE 1284-compliant is recommended) must have a

standard 36-pin parallel connector on one end, which is plugged into the

parallel port located on the back of the printer. The other end of the parallel

interface cable connects to the printer connector at the host computer.

For pinout information, refer to page 57.

Interface Cable Requirements

Data cables must be of fully shielded construction and fitted with metal or

metalized connector shells. Shielded cables and connectors are required to

prevent radiation and reception of electrical noise.

To minimize electrical noise pickup in the cable:

Keep data cables as short as possible (6’ [1.83 m] recommended).

-

Do not tightly bundle the data cables with power cords.

Do not tie the data cables to power wire conduits.

Page 26

Communicating with the Printer

When using the parallel port, typically there is no setup is required once the

cable is plugged in. If you should encounter any problems, consult the

user’s guide that came with your computer.

Adjusting the Print Width

Print width must be calibrated when:

■

You are using the printer for the first time.

■

There is a change in the width of the media.

Print width may be set by way of the five-flash sequence in “Feed Button

Modes” (see page52) or refer to the Print Width (^PW) command (consult

your ZPL II Programming Guide).

Adjusting the Print Darkness

The relative darkness setting is controlled by either the six-flash sequence in

“Feed Button Modes” (see page 52) or the Set Darkness (~SD) ZPL II

command (follow the instructions in the ZPL II Programming Guide).

Adjusting the Print Speed

Print quality is affected by print speed and the media you are using. Only

by experimenting will you find the optimal mix for your application.

If you find that the print speed needs to be adjusted, refer to the Print Rate

(^PR) command in the ZPL II Programming Guide.

Page 27

Operation & Options

This section helps you get the most from your printer.

You must use programming to control many of the printer’s functions. A

few examples:

■

The ~JL command controls label length.

■

The ^XA^MTD^XZ command changes the printing mode to direct

thermal; the ^XA^MTT^XZ command changes the printing mode to

thermal transfer.

■

The ^XA^JUS^XZ command saves the new settings to flash memory.

For detailed information about creating labels using ZPL II, refer to the ZPL

II Programming Guide or visit our web site at www.zebra.com.

To improve print quality, changing both print speed and density may be

required to achieve the desired results. Your application’s printer driver

provides control of the speed and heat (density).

Thermal Printing

The print head becomes hot while printing. To protect from damaging the

print head and risk of personal injury, avoid touching the print head. Use

only the cleaning pen to perform maintenance.

The discharge of electrostatic energy that accumulates on the surface of the

human body or other surfaces can damage or destroy the print head or

electronic components used in this device. You must observe static-safe

procedures when working with the print head or the electronic components

under the top cover.

You must use the correct media for the type of printing you require. When

printing without a ribbon, you must use direct thermal media. When using

ribbon, you must use thermal transfer media. The printer’s ribbon sensor

detects motion of the supply spindle.

Page 28

Replacing Supplies

If labels or ribbon run out while printing, leave the printer power on while

reloading (data loss results if you turn off the printer). After you load a new

label or ribbon roll, the printer flashes double-green until you press the Feed

button to restart .

Always use high quality, approved labels, tags and ribbons. If adhesive

backed labels are used that don’t lay flat on the backing liner, the exposed

edges may stick to the label guides and rollers inside the printer, causing the

label to peel off from the liner and jam the printer. Permanent damage to the

print head may result if a non-approved ribbon is used as it may be wound

incorrectly for the printer or contain chemicals corrosive to the print head.

Approved supplies can be ordered from your dealer.

Adding a New Transfer Ribbon

If ribbon runs out in the middle of a print job, the indicator lights orange

and the printer waits for you to add a fresh roll.

1. Keep the power on as you change ribbon.

2. Open the top cover, then cut the used ribbon so you can remove the

cores.

3. Load a new ribbon roll. If necessary, review the Ribbon Loading steps.

4. Close the top cover.

5. Press the Feed button to restart printing.

Replacing a Partially Used Transfer Ribbon

To remove used transfer ribbon, perform the following steps.

1. Cut the ribbon from the take-up roll.

2. Remove the take-up roll and discard used ribbon.

3. Remove the supply roll and tape the end of any fresh ribbon to prevent

it from unwrapping.

When reinstalling a partially used supply roll, tape the cut end onto the

empty take-up roll.

Page 29

Printing in Peel-Mode

ON OFF

The optional dispenser allows you to print

in “peel-mode” where the label backing

follows a different path and the labels are

presented one at a time for subsequent

placement.

Before using peel-mode, you must send

the programming commands

^XA ^MMP ^XZ

^XA ^JUS ^XZ

to the printer. Refer to your ZPL II

Programmer’s Manual.

1. Remove several labels from the

backing material.

2. Open the top cover.

3. Open the dispenser door.

4. Switch on the label-taken sensor.

5. Insert the backing in front of the peel

bar and behind the peel roller.

6. Close the dispenser door.

7. Close the top cover.

8. Press the Feed button to advance the

label.

During the print job, the printer will peel

off the backing and present a single label.

Take the label from the printer so it will

print the next label.

Page 30

Printing on Fan-Fold Media

Printing on fan-fold media requires you to

set both the media hangers and the media

guides in position.

Lock-down

Screw

1. Open the top cover.

2. With a sample of your media, adjust

the media hangers to the width of the

media. The hangers should just touch,

but not restrict, the edges of the

media.

3. Tighten the screw using a small

Phillips driver #1.

4. With a sample of your media, adjust

the guides to the width of the media.

The guides should just touch, but not

restrict, the edges of the media.

5. Insert the media through the slot at the

rear of the printer.

6. Run the media between the hangers

and guides.

7. Close the top cover.

Page 31

RFID Guidelines

The Zebra R402 Smart Label Printer and Encoder serves as dynamic tool

for both printing and programming smart labels, tickets and tags. Smart

labels are usually made from two components, media and a RFID (radio

frequency identification) transponder. The media will usually be comprised

of synthetic- or paper-based material that can be printed upon using direct

thermal or thermal transfer printing techniques. The media is typically

made from the same materials and adhesives standard a non-RFID barcode

printer would use. The second component of smart label is the transponder,

sometimes known as the RFID tag. The transponder is usually comprised

of an antenna coil that is bonded to an integrated circuit (IC) chip. The IC

contains the RF drivers, coders, decoders and memory. At a minimum,

RFID tags have memory that can be read, while the vast majority also have

memory that can be programmed by the user as well.

Page 32

The communication between the RFID tag and R402 printer is established

when the transponder lines up with the printer’s antenna. Note that

transponder position, prior to encode/decode, is critical. The optimal

transponder position varies with antenna coil size and type of RFID IC

used. It is important to use media and tags that have been specifically

designed for use in the R402. Failure to do so may result in the

inability to read or program the embedded RFID tags.

Printing and programming of smart labels in handled through the use of

Zebra's printer programming language, ZPL. The printer segments the

received ZPL's RFID and non-RFID related commands. The R402 will

execute the RFID commands first, followed by the others (like the printing

commands for barcodes or human readable text). Each transponder has

blocks of addressable memory that are written to and read from through

ZPL commands. Many transponders also contain a pre-programmed unique

ID/serial number. The ZPL commands also provide for exception handling,

such as setting the number of read/write retries before declaring the

transponder defective. If an RFID tag is declared defective (fails to

program correctly or cannot be detected) the printer ejects it and prints the

word "void" across the entire label. This process will continue for two more

RFID tags using the same data and format, assuming the problems persist.

After the third tag is ejected the printer removes the customer format from

the print queue, and proceeds with the next format (if one exists in the

buffer).

Supported Transponders

The R402 supports several transponder types:

■

Texas Instruments Tag-it™

■

Philips I•Code

■

Inside Technologies Picotag® 2K

■

ISO 15693

Page 33

Texas Instruments Tag-it™ Transponders

Texas Instruments transponders are high frequency (13.56MHz) RFID

devices. Each transponder has 256 bits of memory. Data is segmented into

4 byte (32 bit) blocks that are uniquely addressable, for a total of 8 blocks.

Each memory block is lockable using the write protect function during the

writing process.

Texas Instruments Tag-it™ Blocks

Block # Description Bytes

0 User Data

1 User Data

2 User Data

3 User Data

4 User Data

5 User Data

6 User Data

7 User Data

32 User

Page 34

Philips I•Code Transponders

Philips I•Code transponders are high frequency (13.56MHz) RFID devices.

Each transponder has 512 bits of memory. Data is segmented into 4 byte

(32 bit) blocks that are uniquely addressable for a total of 16 blocks. Each

memory block is lockable using the write protect function during the

writing process. The first two blocks of data (block 0 and 1) are

pre-programmed, non-changeable, and are used for storage of a unique 64

bit serial number. The next two blocks (blocks 2 and 3) are used for storage

of configuration information; block 4 is used for family or application

identification and blocks 5 to 15 are free for user application use.

If you are using these transponders for your own use, and don’t require

universal special function or family codes, then you can program blocks 3

through 15.

Block # Description Bytes

0 Serial Number (write protected)

1 Serial Number (write protected)

2 Write Protect Block (Caution*)

3 Special Function Block

4 Family Code

5 User Data

6 User Data

7 User Data

8 User Data

9 User Data

10 User Data

11 User Data

12 User Data

13 User Data

14 User Data

15 User Data

Philips I•Code Blocks

8 Optional

40 User

* The bits in block 2 determine the write access conditions for itself and

each of the remaining blocks. You can leave blocks 2 through 15 open or

you can write-protect them. Write-protected blocks (included block 2) can

never be written to from the moment they are locked

Page 35

Inside Technologies Picotag® Transponders

Inside Technologies Picotag® transponders are high frequency (13.56MHz)

RFID devices. Each transponder has 2048 bits of memory. Data is

segmented into 8 byte (64 bit) blocks that are uniquely addressable for a

total of 31 blocks. Blocks 6 to 12 are lockable using the write protect

function during the writing process. The first block of data (block 0) is

pre-programmed and is used for storage of a unique 64 bit serial number.

The next two blocks (blocks 2 and 3) are used for storage of configuration

information; blocks 3 to 31 are free for user application use.

Inside Technologies Picotag® 2K

Block

0 Serial Number (64 bits)

1

2 Application Issuer Area

3

5

6

7

8

9

10

11

12

13

31

0123456 7

FFh

Application

16-bit OTP

Byte number within a block

Block

Area

Block Write Lockable Application Area

Write

Lock

Application Area4

Application Area...

Tun-

ing

Cap

1Fh

E.A.

S.

Fuses

Page 36

ISO-15693 Transponders

ISO-15693 is an international standard for 13.56 MHz RFID devices. As

this is a public standard, tags and integrated circuits may be produced by a

wide variety of manufacturers. The current standard stipulates that

manufacturers may configure memory in various ways ( up to 256 blocks

comprising a block size up to 256 bits (32 bytes)). The standard also

stipulates that a manufacturer may, or may not, use the recommend methods

of reading and writing to the tag as stipulated in the standard. For these

reasons, the R402 may not be compatible with every manufacturers

ISO-15693 transponders. Contact your technical support representative for

the latest list of supported ISO-15693 transponders.

Page 37

ZPL II Commands for RFID

^WT – Write Tag

The format for the ^WT instruction is:

where

^WT = Write Tag command

b = Block Number

Default value: 0

Other values: 1 to n, where n is the maximum number of

blocks for the tag

This is the starting block number. If the user sends more than a block of

data it will overflow into the next block. If the user overflows the block and

subsequent blocks cause errors (write protects, beyond range, etc.), the

write will be aborted, but blocks already written will not revert to original

contents. It’s up to the caller to ensure blocks aren’t accidentally

overwritten.

r = Retries

Default value: 0

Other values: 1 to 10, number of retries

m = motion

Default value: 0 (Feed label after writing)

Other value: 1 (No Feed after writing, other ZPL may cause

a feed)

^WTb,r,m,w,s

w = Write protect

Default value: 0 (NOT write protected)

Other value: 1 (Write protect)

s = Special mode

Reserved

Page 38

^RT – Read Tag

The format for the ^RT instruction is:

where

^RT = Read Tag command

# = Number to be assigned to the Field

Default value: 0

Other Values: 1 to 9999

b = Starting Block Number

Default value: 0

Other values: 1 to n, where n is the maximum number of

blocks for the tag

n = Number of blocks to read

Default value: 1

Other values: 2 to n, where n is maximum number of blocks

minus starting block number. In other words, if the tag has 8

blocks (starting with block 0) and you’re starting with block 6,

n can be 2. This would give you block 6 and block 7

information.

f = Format

Default value: 0 ASCII

Other values: 1 Hexadecimal

^RT#,b,n,f,r,m,s

r = Retries

Default value: 0

Other values: 1 to 10, number of retries

m = motion

Default value: 0 (Feed label after writing)

Other value: 1 (No Feed after writing, other ZPL may cause

a feed)

s = Special Mode

Default value: 0

Other values: 1 to 255, to specify more detailed mode control.

Page 39

^RT – Read Tag (continued)

Example: This reads a block from a tag, and prints it on a label:

^XA

^FO20,120^A0N,60^FN1^FS

^FO20,100^A0N,20^FN2^FS

^RT1,0,7,3,0,5,0,0^FS

^RT2,0,2,2,0,5,0,0^FS

^XZ

The first ^RT command automatically detects the tag type, starting at block

7, reads three blocks of data in ASCII format. It will retry the command 5

times if necessary. A “void” label will be generated if the read is

unsuccessful after ‘r’ retries. The data read will go into the ^FN1 location

of the recalled format.

The second ^RT command automatically detects the tag type, string at

block 2, reads two blocks of data in ASCII format. It retries up to 5 times.

The data read will go into the ^FN2 location of the recalled format.

The data can be sent back to the host via the ^HV command.

Page 40

^RS – RFID Setup

The format for the ^RS instruction is:

where

t = tag type

Default value: 0 –NONE (No tags available)

Other values:

1- Auto detect (automatically determine the

tag type, by querying the tag)

2- Texas Instruments Tag-it™ tags

3- Philips I•Code tags

4- Inside Technologies Picotag® 2K

5- ISO 15693 tag*

# = read/write position of transponder in rows of dots

Set to 0 (zero) to not move the media.

Default value: Label length minus eight dot rows

(one millimeter)

Other values: 0 (zero) to label length

Use caution when using this function in combination with ^RI (reading the

unique ID number) or ^RT (reading tag data). Problems can occur if the

data read from the tag is going to be printed on the label. Any data read

from the transponder must be positioned to be printed above the read/write

position. Failure to do this will prevent read data from being printed on the

label, ticket or tag.

^RSt,#

* ISO-15693 is an international standard for 13.56 MHz RFID devices. As

this is a public standard, tags and integrated circuits may be produced by a

wide variety of manufacturers. The current standard stipulates that

manufacturers may configure memory in various ways ( up to 256 blocks

comprising a block size up to 256 bits (32 bytes)). The standard also

stipulates that a manufacturer may, or may not, use the recommend

methods of reading and writing to the tag as stipulated in the standard. For

these reasons, the R402 may not be compatible with every manufacturers

ISO-15693 transponders. Contact your technical support representative for

the latest list of supported ISO-15693 transponders.

Page 41

^RI – RFID Get Tag Unique ID

The format for the ^RI instruction is:

where

n = field number to store the unique ID

The unique ID will be read from the tag and available to

print or return to the host computer.

The example below reads the unique ID/serial number from a tag, and prints

it on a label:

^XA

^FO100,100^A0N, 60^FN0^FS

^RI0^FS

^FD ^FS

^XZ

^RIn

Page 42

Sample of RFID Programming

ZPL IITMis Zebra Technologies Corporation’s Zebra Programming

Language II label design language. ZPL II lets you create a wide variety of

labels from the simple to the very complex, including text, bar codes, and

graphics.

This section is not intended as an introduction to ZPL II. If you are a new

ZPL II user, order a copy of the ZPL II Programming Guide (part# 46530L)

or go to the internet address http://support.zebra.com and select the

Documentation Button to download the guide.

For your programming, do the following:

1. Set up the printer and turn the power on.

2. Use any word processor or text editor capable of creating ASCII-only

files (ex: Microsoft Word® and save as a .txt file) and type in the label

format exactly as shown in the sample label format that follow.

3. Save the file in a directory for future use. Use the “.zpl” extension.

4. Copy the file to the printer.

From the DOS command window, use the “COPY” command to send a

file to the Zebra printer. For example, if your file name is

then type, “COPY FORMAT 1.ZPL XXXX”, where “XXXX” is the

port to which your Zebra printer is connected, for example, “LPT1.”

format1.zpl

5. Compare your results with those shown. If your printout does not look

like the one shown, confirm that the file you created is identical to the

format shown, then repeat the printing procedure. If nothing prints,

refer to the “Getting Started” section to make sure your system is set up

correctly, otherwise refer to the “Troubleshooting and Diagnostics”

section.

Page 43

Line # Type this label format Resulting printout

1.

2.

3.

4.

5.

6.

7.

^XA

^WT6^FDZebra^FS

^FO100,100^A0n,60^FN0^FS

ZEBRA

^FO100,200^A0n,40^FN1^FS

5A65627261000000

^RT0,6,2^FS

^RT1,6,2,1

^XZ

Line 1 Indicates start of label format.

Line 2 Writes the data “Zebra” to block 6 for the tag (one byte will

spill into block 7, since we have 4 bytes/block.

Line 3 Print field number ‘0’ at location 100,100.^FN0 is replaced

by what we read on line #5.

Line 4 Print field number ‘1’ at location 100,200. ^FN1 is replaced

by what we read on line #6.

Line 5 Read Tag into field number 0, starting at block 6, lasting for 2

blocks in ASCII format (default).

Line 6 Read Tag into field number 1, starting at block 6, lasting for 2

blocks in hexadecimal format.

Line 7 End of label format.

Page 44

Page 45

Cleaning

Use only the cleaning agents indicated. Zebra Technologies Corporation

will not be responsible for damage caused by any other cleaning materials

used on this printer.

Printer Part Method Interval

Print head

Platen roller

Peel bar

Tear bar

Exterior Water-dampened cloth

Interior Brush or air blow

Maintenance

After allowing the print head to cool for approximately

one minute, use 70% isopropyl alcohol on a cotton

swab to clean the print elements from end to end (the

print elements are located in the thin gray line on the

print head). NOTE: You do not have to turn off the

printer to do this.

If print quality has not improved after performing this

procedure, try cleaning the print head with Save-a-Print

Head cleaning film. This specially coated material

removes contamination buildup without damaging the

print head. Call your authorized reseller for more

information.

Manually rotate the platen roller. Clean it thoroughly

with 70% isopropyl alcohol and a cotton swab or

lint-free cloth.

Clean it thoroughly with 70% isopropyl alcohol and a

cotton swab.

Clean it thoroughly with 70% isopropyl alcohol and a

cotton swab.

After every

five rolls of

media

As needed

Lubrication

No lubricating agents of any kind should be used on this printer! Some

commercially available lubricants, if used, will damage the finish and the

mechanical parts inside the printer.

Page 46

Parts List

ITEM DESCRIPTION

1 Latch Assembly 105910-052

2 Feed Switch/Sensor Assy (set of 3) 105910-128

3 Upper Cover Support (set of 3) 105910-066

4

5 Head Up Sensor 105910-129

6 Gap/Blackline Sensor PCBA (set of 3) 105910-054

7 Platen Kit (standard set of 3) 105910-055

8

10 Rubber Foot Kit (set of 24) 105910-007

11 Main Control PCBA (RFID) 105910-133

12 Bottom Frame Assy 105910-130

13 Upper Cover Assy 105910-131

14 Ribbon Out Sensor (set of 3) 105910-134

15 Ribbon Carriage w/o printhead 105910-132

Not

Shown

Manuals

Print Head Assy - 4” TLP

Print Head Cable Assy.

Front Bezel (standard set of 10)

Front Bezel, Dispenser (single)

Motor (set of 2)

Power Supply, 100V-240V

Power Cord, U.S. 120V IEC320C13 (set of 5)

PCBA, RFID Reader

PCBA, Antenna, Type 2

Ribbon Core, 4” (set of 50)

Accessory, Media Adapter Plates

User’s Manual, R402

ZPL II Programmer’s Manual

PART

NUMBER

105910-053

105910-065

105910-057

105910-022

105910-051

105950-043

105950-014

105903-135

105950-136

105903-053

810059-001

980389-001

46530L

Page 47

14

15

1

2

13

11

12

3

4

5

6

8

7

9

10

Page 48

Replacing the Print Head

In the event you need to replace the print

head, make sure your work area is

prepared by protecting against static

discharge. Your work area must be

static-safe and include a properly

grounded conductive cushioned mat to

hold the printer a conductive wrist strap

for yourself.

Removal

Before following the steps in this

procedure, open the printer by pulling the

release latches forward then lifting the top

cover. Remove any ribbon from the

carriage.

1. Grasp the print head spring and pull it

to the left; then, slide it free of the

carriage.

2. Use the spring to pry the print head

clip off the right side of the carriage.

3. Pull the print head and bracket

forward.

4. Use a #2 Phillips driver to remove the

screw that holds the ground wire.

5. Unplug both bundles of print head

wires from their connectors.

Page 49

REPLACING THE PRINT HEAD (Continued)

Assembly

The new print head comes with the clip

and ground screw attached.

1. Align the print head and bracket to

2. Attach the ground wire and secure it

3. Insert the bracket pegs into the left

4. Align the right side of the bracket and

Cleaning the Print Head

plug the left and right connectors into

the black and white wire bundles.

with the screw. Use a #2 Phillips

driver to tighten it.

side of the carriage.

insert the print head clip through the

right side of the ribbon carriage into

the bracket.

5. Slip the left end of the print head

spring into the left side of the ribbon

carriage; then slide the right end into

the other side. The angle of the “v”

fits into the indent on top of the print

head bracket.

6. Clean the print head with the cleaning

pen.

Reload media and ribbon. Plug in the

power cord, turn on the printer and run an

automatic or manual calibration to ensure

proper function.

Page 50

Page 51

Troubleshooting

What the Status Light is Telling You

Status LED

Condition and Color

Off Off 1

Solid Green On 2

Flashing Yellow Stopped 3

Flashing Green Normal Operation 4

Flashing Red Stopped 5

Double Flashing Green Paused 6

Solid Yellow Various 7

Alternately Flashing Green and Red Needs Service 8

Printer

Status

Resolutions

1. The printer is not receiving power.

For a Resolution,

Refer to number:

■

Have you turned on the printer power?

■

Check power connections from the wall outlet to the power supply, and

from the power supply to the printer.

2. The printer is on and in an idle state.

■

No action necessary.

Page 52

3. The printer has failed its power on self test (POST).

■

If this error occurs right after you turn on the printer, contact an

authorized reseller for assistance.

There is a shortage of memory.

■

If this error occurs after you have been printing, turn the printer power

off and on. Then, resume printing.

4. The printer is receiving data.

■

As soon as all of the data has been received, the status LED will turn

green; then, the printer will automatically resume operation.

5. Either the media or ribbon is out.

■

Load a roll of media, following the instructions in “Loading the Media”

on page 9. Then, press the feed button to resume printing.

■

Load a roll of ribbon, following the instructions in “Loading the Ribbon”

on page 12. Then, press the feed button to resume printing.

The print head is open.

■

Close the top cover. Then, press the feed button to resume printing.

6. The printer is paused.

■

Press the feed button to resume printing.

Page 53

7. The print head is under temperature.

■

Continue printing while the print head reaches the correct operating

temperature.

The print head is over temperature.

■

Printing will stop until the print head cools to an acceptable printing

temperature. When it does, the printer will automatically resume

operation.

8. FLASH memory is not programmed.

■

Return the printer to an authorized reseller.

Page 54

Print Quality Problems

No print on the label.

■

You must use the correct media for the method of printing you require.

When printing without a ribbon, you must use direct thermal media.

When using ribbon, you must use thermal transfer media. The printer's

ribbon sensor detects motion of the supply spindle.

■

Is the media loaded correctly? Follow the instructions in “Loading the

Media” on page 9.

The printed image does not look right.

■

The print head is dirty. Clean the print head according to the

instructions on page 41.

■

The print head is under temperature.

■

Adjust the print darkness and/or print speed. Refer to the six-flash

sequence in “Feed Button Modes” on page 52, or the ^PR and ~SD

commands in the ZPL II Programming Guide.

■

The media being used is incompatible with the printer. Be sure to use

the recommended media for your application, and always use

Zebra-approved labels and tags.

There are long tracks of missing print (blank vertical lines) on

several labels.

■

The print head is dirty. Clean the print head according to the

instructions on page 41.

■

The print head elements are damaged. Replace the print head (see

“Replacing the Print Head” on page 40).

The ribbon sensor settings did not print.

■

The printer is set for direct thermal printing; use the ^XA^MTT^XZ

command to reset the printer for thermal transfer printing and calibrate

again.

Page 55

The printing does not start at the top of the label, or misprinting of

one to three labels.

■

The media may not be threaded under the media guides. Refer to

“Loading the Media” on page 9.

■

The printer needs to be calibrated. Refer to “Auto Calibration” on page

14.

■

The correct media sensor may not be activated. Manual calibration

selects the media sensing method for the labels being used (refer to the

^MN command in the ZPL II Programming Guide).

■

Verify that the Label Top (^LT) command is correctly set for your

application (consult the ZPL II Programming Guide).

A label format was sent to, but not recognized by, the printer.

■

Is the printer in pause mode? If so, press the feed button.

■

If the status LED is on or flashing, refer to “What the Status LED is

Telling You” on page 43.

■

Make sure the data cable is correctly installed.

■

A communications problem has occurred. First, make sure that the

correct communications port on the computer is selected. Refer to

“Communicating with the Printer” on page 18.

Page 56

RFID Symptoms

RFID tags generally not programmed

■

Is the printer set up correctly? Print a configuration label to verify RFID

version. See “Auto Calibration” on page 14.

■

Check if supported RFID media is loaded correctly.

VOID messages are printed across media.

■

Verify tag type is properly selected in ZPL II. Use RFID media with

supported tag type. Edit ZPL II to select proper tag type or increase

retries.

■

ZPL II is attempting to write to a non-existent block. Some tags’ blocks

are identified as 0-7. If ZPL II attempts to write to block “8,” it will fail.

■

Verify voided tag on external reader. Discard bad tags if this is a media

problem.

Nothing is printed.

■

See if the correct media is loaded or load new, fresh media.

■

See if tags can be read/programmed using other hardware.

■

Verify ZPL II RFID commands. Debug the printing program.

■

Tag is out of reach of the antenna or too close. Verify tag alignment.

■

Wrong type of tag was selected. Check ZPL II.

■

Block is write protected. Ensure that the tag is not write protected.

■

Aluminum and other metals within tag may interfere with read/write.

Make sure media meets requirements.

■

Increase the number of retries in the ZPL II commands.

■

Time out may have occurred during internal communication. Cycle

power and try printing label again.

Call a service technician if you have been unsuccessful in getting your

expected print out and data.

Page 57

Manual Calibration

Manual calibration is recommended whenever you are using pre-printed

labels (or label backing) or if the printer will not correctly auto calibrate.

1. Turn on the printer power.

2. Remove approximately 4" (102 mm) of labels from a section of backing

material. Load the media so that only the backing material is threaded

through the printer and under the print head.

3. Press and hold the feed button until the green status LED flashes once,

then twice. Release the feed button.

4. The printer will set the media sensor for the label backing being used.

After it is done making this adjustment, the roll will automatically feed

until a label is positioned at the print head.

5. A profile of the media sensor settings (similar to the example below)

will print. Upon completion, the printer will save the new settings in

memory and the printer is ready for normal operation.

6. Press the feed button. One entire blank label will feed. If this does not

happen, try defaulting (refer to the four-flash sequence in “Feed Button

Modes” on page 52) and recalibrating the printer.

NOTE: Performing a manual calibration disables the auto calibration

function. To return to auto calibration, default the printer (see the

four-flash sequence in “Feed Button Modes” on page 52).

Page 58

Troubleshooting Tests

SCO

Printing a Configuration Label

To print out a listing of the printer’s current configuration, refer to the

one-flash sequence in “Feed Button Modes” on page 52.

Recalibration

Recalibrate the printer if it starts to display unusual symptoms, such as

skipping labels. See “Auto Calibration” on page 14.

PRI NTER CONFI GURATI ON

Zebr a Technol ogi es

ZTC R402- 200dpi

................

+1 0 DARKNESS

...............

+000 TEAR OFF

...........

TE AR OFF PRI NT MODE

NON- CONTI NUOUS MEDI A TYPE

................

WEB SENSOR TYPE

THERMAL - TRANS. PRI NT MET HOD

104 0/ 8 MM PRI NT WIDTH

...............

1233 LABEL L ENGT H

22. 0I N 557MM MAXI MUM LENGTH

38400 BAUD

8 BITS DATA BITS

...............

NONE PARI TY

XON/ XOF F HOST HA NDSHA KE

...............

NONE PROT OCOL

................

000 NETWORK I D

NORMAL MODE COMMUNI CAT I ONS

< ~ > 7 E H CONT ROL PRE F I X

<^ > 5EH FORMAT PREFI X

<, > 2 CH DEL I MI T ER CHAR

ZPL I I ZPL MODE

...............

FEED MEDI A POWER UP

...............

FEED HEAD CLOSE

DEFAULT BACKFEED

...............

+0 2 0 LABEL TOP

+0000 LEFT POSI TI ON

................

029 WEB S.

................

068 MEDI A S.

................

050 RI BBON S.

................

050 MARK S.

................

0 0 1 MA R K MED S.

.................

CS MODES ENA BL ED

.................

. . MODES DI SABLED

832 8/ MM FULL RESOLUTI ON

SP. 814. B <- FI RMWARE

V2.2.6.98.C HARDWARE I D

CUSTOMI ZED CONFI GURATI ON

1024.............R: RAM

0000.............B: MEMORY CARD

0768.............E: ONBOARD FLASH

...............

NONE FORMAT CONVERT

...............

NONE OPTI ON

...............

NONE ZEBRA NET I I

AUT O DETE CT RF I D TA G TYPE

oem- 400: Ver . 2. 00 RFI D VERSI ON

FI RMWARE I N T HISPRI NTER I

.....

.....

.........

.....

..............

.............

...........

........

...........

...........

...........

.............

............

..............

......

.....

........

.........

........

PYRIGHTE D

Page 59

Resetting the Factory Default Values

Sometimes, resetting the printer to the factory defaults solves some of the

problems. Follow the four-flash sequence instructions in “Feed Button

Modes” on page 52.

Communications Diagnostics

If there is a problem transferring data between the computer and printer, try

putting the printer in the communications diagnostics mode. The printer

will print the ASCII characters and their respective hexadecimal values (a

sample is shown below) for any data received from the host computer. To

find out how, refer to the power off mode procedure in “Feed Button

Modes” on page 52.

Page 60

Feed Button Modes

Power Off Mode (Communications Diagnostics Mode)

With the printer power off, press and hold the feed button while you turn on the power. The printer

prints out a listing of its current configuration (see Figure 22). After printing the label, the printer will

automatically enter a diagnostic mode in which the printer prints out a literal representation (see Figure

23) ofall datasubsequently received. To exit the diagnostic modeand resume printing,turn off and then

turn on the printer.

Power On Modes

With theprinter power on and topcover closed, press and holdthe feed button for severalseconds. The

green status LED will flash a number of times in sequence. The explanation at the right (Action) shows

what happens when you release the key after the specific number of flashes.

Flash

Sequence

* A configuration label prints.

*

**

*

**

***

*

**

***

****

*

**

***

****

*****

*

**

***

****

*****

******

If the feed button remains pressed after a 7-flash sequence, the printer will ignore the button when it

is released.

The media sensor calibrates and a media sensor profile prints (see “Manual

Calibration” on page 49).

To reset the communication parameters. Press and release the feed button while

the LED rapidly flashes yellow and green.

For autobaud synchronization: Send a ZPL II format to the printer while the LED

rapidly flashes yellow and green. When the printer and host are synchronized, the

LED changes to solid green. NOTE: No labels will print during autobaud

synchronization.

Resets the factory defaults, auto calibrates, and saves settings into memory.

The print width calibrates. While the status LED alternately flashes green and

yellow, a series of stacking rectangles print on the label. When the rectangle prints

to the outer edges of the label, press and release the feed button. The label width

and current communication parameters will be saved into memory.

The print darkness calibrates. A series of nine samples print, starting with the

lightest and ending with the darkest image. When the desired print darkness is

achieved, press and release the feed button. The print darkness will be saved into

memory.

Action

Page 61

Appendix

All specifications are subject to change without notice.

Physical Specifications

Size 7.8 inches wide / 6.8 inches tall / 9.4 inches long (depth)

200 mm wide / 173 mm tall / 240 mm long (depth)

Weight 3.6 pounds / 1.6 kilograms

Environmental Guidelines

Operating temp. 40 to 104 degrees Fahrenheit / 5 to 40 degrees Celsius

Operating humidity 10 to 90 percent non-condensing

Storage temp. -40 to 140 degrees Fahrenheit / -40 to 60 degrees Celsius

Storage humidity 5 to 90 percent non-condensing

Electrical Autoranging external power supply

Printing Specifications

Print Density 203 dots per inch / 8 dots per millimeter

Print Speed 2 inches / 51 millimeters per second

Print Width 1.0 to 4.09 inches / 25.4 to 104 millimeters

Print Length 0.005 to 22 inches / 0.125 to 559 millimeters

Registration

Tolerance

FLASH Memory

(user available)

DRAM Memory

(user available)

Input: 100-240VAC; 50-60 Hz

Output: 20VDC; 2.5A

3 inches / 76 millimeters per second

4 inches / 102 millimeters per second

with standard memory

Horizontal: +/- 0.0591 inches (1.5 millimeters)

Vertical: +/- 0.0393 inches (1.0 millimeters)

768K

1 MB

Page 62

Media Specifications

Width 1 to 4.25 inches / 25.4 to 108 millimeters)

1 to 2.25 inches / 25.4 to 57 millimeters (tag stock)

Length 0.5 to 22 inches / 13 to 559 millimeters with standard memory

Gap 0.08 to 0.16 inch (2.0 to 4.0 millimeters)

0.118 inch / 3.0 millimeters recommended

Thickness 0.003 to 0.007 inch / 0.08 to 0.18 millimeter

Roll Size Maximum outer diameter: 5 inches (127 millimeters

Inner Core diameters: 1 or 1.5 inches (25.4 or 38 millimeters)

Optional media hangers available for larger inner core

diameters

Requirements

Transponder

Requirements

User Zebra-brand direct thermal or thermal transfer media

✔

that is outside wound. Media may be reflective (black mark)

sensing or transmissive sensing, die-cut, notched, or

continuous)

For die-cut labels, use only full auto dies.

✔

Notched media must have a 0.5 inch (13 mm) wide by 0.094

✔

inch (2.5 mm) long cutout located in the center of the roll.

✔ The reflective media black marks must be located in the

center of the roll. Mark width 0.5 inch (13 mm) centered and

perpendicular to the edge of the media; mark length 0.094

inch (2.4 mm) parallel to the bottom edge of the media.

✔ Phillips I•Code

✔ Texas Instruments Tag-It™

✔ Inside Technologies PicoTag®

✔ ISO-15693

Always thoroughly test your desired media for your specific application

before buying in large quantities.

Ribbon Specifications

Roll Size Maximum outer diameter: 1.3 inches / 33 millimeters

Length 2,900 inches / 74 meter capacity; provides 1:1 media roll to

Width At least as wide as media

Setup Ink-side out

Requirements User Zebra-brand ribbon that is outside wound.

ribbon ratios

Page 63

Font/Code Specifications

Fonts

1D Bar Codes

2D Bar Codes

Rotation Angles 0°, 90°, 180° and 270°

CG Triumvirate Bold Condensed scalable smooth (0)

✔

Zebra fonts A-H, GS, P-V

✔

IBM Code Page 850 international Symbols

✔

Codabar (supports ratios of

✔

2:1 to 3:1)

Code 11

✔

Code 128/USD 8 (supports

✔

serialization in all subsets

and UCC Case Codes)

Code 39 (supports ratios of

✔

2:1 to 3:1)

Code 93

✔

EAN 8/JAN 8

✔

EAN 13/JAN 13

✔

EAN 14/UPC-A

✔

Codeblock

✔

Code 49

✔

Data Matrix

✔

✔ MaxiCode

Zebra Programming Language (ZPL II®)

✔ Downloadable graphics, scalable and

bitmap fonts, and label formats

✔ Object copying between memory areas

(RAM and internal FLASH)

✔

Code Page 850 character set

✔

Adjustable print cache

✔

Data compression

✔

Automatic virtual input buffer

management

✔

Automatic memory allocation

✔

Format inversion

✔

Mirror image printing

✔

Four-position field rotation

0°, 90°, 180° and 270°

✔ Slew command

✔ Programmable quantity with print and

pause

✔

Communicates in printable ASCII

characters

✔

Error-checking protocol

✔

Controlled via mainframe,

mini-computer, PC, portable data

terminal

✔

In-spec OCR-A and OCR-B

✔

UPC/EAN

✔

User-programmable password

✔

Status message to host upon request

Industrial 2 of 5

✔

Standard 2 of 5

✔

Interleaved 2 of 5 (supports

✔

ratios of 2:1 to 3:1,

Modulus 10 Check Digit)

LOGMARS

✔

MSI

✔

Plessey

✔

POSTNET

✔

UPC-E

✔

UPC-EAN Extensions

✔

MicroPDG417

✔

PDF 417

✔

QRcode

✔

Page 64

Agency Approvals

The Thermal Printer Model R402, manufactured by Zebra Technologies

Corporation, complies with the applicable requirements:

Emissions and susceptibility: FCC 15.225, FCC Part 15 Class B, RSS-210, EN300-330,

✔

EN300-683, IECS-003, EN61000-3-2, EN61000-3-3.

rd

Safety: UL 1950 3

✔

Ed., CSA C22.2 No. 950-95 3rdEd., IEC950/EN60950

Options

Adjustable core diameter media holders

✔

Dispenser for “peel-off mode”

✔

Page 65

Parallel Interface Technical Information

Pin No. Description

1 NStrobe/Host Clk

2-9 Data Bits 1-8

10 nACK/PtrClk

11 Busy/Per Busy

12 PError/ACK Dat Req.

13 Select/Xflag

14 NAuto Fd/Host Busy

15 Not Used

16-17 Ground

18 +5 V @ 0.75 A Fused

19-30 Ground

31 nInit

32 NFault/nData Avail.

33-34 Not Used

35 +5 V throught 1.8 K Ohms Resistor

36 NSelectin/1284 active

The maximum current available through the interface port is not to exceed a

total of 0.75 amps.

Page 66

Page 67

Index

A

adapter plates . . . . . . . . . . . . . . . . . . . 11

agencies . . . . . . . . . . . . . . . . . . . . . . . 56

attaching power . . . . . . . . . . . . . . . . . . 8

auto calibration. . . . . . . . . . . . . . . . . . 14

B

bar codes. . . . . . . . . . . . . . . . . . . . . . . 55

barrel connector . . . . . . . . . . . . . . . . . . 8

box, contents. . . . . . . . . . . . . . . . . . . . . 2

button, feed. . . . . . . . . . . . . . . . . . . . . 15

C

cable . . . . . . . . . . . . . . . . . . . . . . . . . . 17

calibration

manual . . . . . . . . . . . . . . . . . . . . . . 49

calibration, auto . . . . . . . . . . . . . . . . . 14

cleaning . . . . . . . . . . . . . . . . . . . . . . . 37

cleaning the print head . . . . . . . . . . . . 41

closing printer. . . . . . . . . . . . . . . . . . . . 5

communicating . . . . . . . . . . . . . . . . . . 18

Communications diagnostics . . . . . . . 51

configuration label . . . . . . . . . . . . 16, 50

controls, operator . . . . . . . . . . . . . . . . 15

copyrights . . . . . . . . . . . . . . . . . . . . . . iii

cover lock . . . . . . . . . . . . . . . . . . . . . . . 4

E

environmental guidelines . . . . . . . . . . 53

F

factory defaults, resetting . . . . . . . . . . 51

Factory defaults, resetting . . . . . . . . . 52

fan-fold media . . . . . . . . . . . . . . . . . . 22

FCC . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

feed button . . . . . . . . . . . . . . . . . . . 3, 15

feed button modes . . . . . . . . . . . . . . . 52

fonts . . . . . . . . . . . . . . . . . . . . . . . . . . 55

G

get tag ID command . . . . . . . . . . . . . . 33

getting started . . . . . . . . . . . . . . . . . . . . 7

guides, media . . . . . . . . . . . . . . . . . . . 10

H

holders, media . . . . . . . . . . . . . . . . . . . 4

I

I-Code. . . . . . . . . . . . . . . . . . . . . . . . . 26

inspecting printer . . . . . . . . . . . . . . . . . 3

interface . . . . . . . . . . . . . . . . . . . . . . . 17

interface connectors . . . . . . . . . . . . . . . 3

ISO-15693 . . . . . . . . . . . . . . . . . . . . . 28

D

damage, reporting . . . . . . . . . . . . . . . . . 6

defaulting the printer . . . . . . . . . . . . . 51

diagram, parts . . . . . . . . . . . . . . . . . . . 39

dispenser. . . . . . . . . . . . . . . . . . . . . . . 21

L

light, status . . . . . . . . . . . . . . . . . . . . . 15

loading media . . . . . . . . . . . . . . . . . . . . 9

loading ribbon. . . . . . . . . . . . . . . . . . . 12

lock-down screw. . . . . . . . . . . . . . . 4, 22

Page 68

lubrication. . . . . . . . . . . . . . . . . . . . . . 37

M

maintenance . . . . . . . . . . . . . . . . . . . . 37

manual calibration . . . . . . . . . . . . . . . 49

media . . . . . . . . . . . . . . . . . . . . . . . . . 22

media adapters . . . . . . . . . . . . . . . . . . 11

media guides. . . . . . . . . . . . . . . . . . 4, 10

media specifications . . . . . . . . . . . . . . 54

media, loading . . . . . . . . . . . . . . . . . . . 9

media, outside length . . . . . . . . . . . . . . 9

O

opening . . . . . . . . . . . . . . . . . . . . . . . . . 3

operation. . . . . . . . . . . . . . . . . . . . . . . 19

operator contols . . . . . . . . . . . . . . . . . 15

options . . . . . . . . . . . . . . . . . . . . . . . . 19

outside length, media . . . . . . . . . . . . . . 9

P

parallel . . . . . . . . . . . . . . . . . . . . . . . . 17

parallel interface . . . . . . . . . . . . . . . . . 57

parts list . . . . . . . . . . . . . . . . . . . . . . . 38

peel-mode . . . . . . . . . . . . . . . . . . . . . . 21

peel-off mode . . . . . . . . . . . . . . . . . . . . 4

physical characteristics. . . . . . . . . . . . 53

Picotag . . . . . . . . . . . . . . . . . . . . . . . . 27

plates, media adapter . . . . . . . . . . . . . 11

plug, power. . . . . . . . . . . . . . . . . . . . . . 8

power supply . . . . . . . . . . . . . . . . . . . . 8

power switch. . . . . . . . . . . . . . . . . . 3, 15

print darkness . . . . . . . . . . . . . . . . . . . 18

Print darkness, adjusting. . . . . . . . . . . 52

print head . . . . . . . . . . . . . . . . . . . . . . . 4

cleaning . . . . . . . . . . . . . . . . . . . . . 41

replacing . . . . . . . . . . . . . . . . . . . . 40

print quality . . . . . . . . . . . . . . . . . . . . 46

print speed . . . . . . . . . . . . . . . . . . . . . 18

print width . . . . . . . . . . . . . . . . . . . . . 18

Print width, adjusting . . . . . . . . . . . . . 52

printing modes . . . . . . . . . . . . . . . . . . . 7

printing specifications . . . . . . . . . . . . 53

programming language. . . . . . . . . . . . 55

programming, RFID . . . . . . . . . . . . . . 34

Q

quality problems . . . . . . . . . . . . . . . . . 46

R

read tag command . . . . . . . . . . . . . . . 30

recalibrating the printer . . . . . . . . . . . 50

release latches. . . . . . . . . . . . . . . . . . . . 3

replace the print head . . . . . . . . . . . . . 40

replacing supplies . . . . . . . . . . . . . . . . 20

resetting the factory defaults . . . . . . . 51

Resetting the factory defaults . . . . . . . 52

rewriting . . . . . . . . . . . . . . . . . . . . . . . 24

ribbon . . . . . . . . . . . . . . . . . . . . . . . . . 20

ribbon carriage . . . . . . . . . . . . . . . . . . . 4

ribbon sensor printout. . . . . . . . . . . . . 46

ribbon specifications. . . . . . . . . . . . . . 54

ribbon, loading . . . . . . . . . . . . . . . . . . 12

S

setup command. . . . . . . . . . . . . . . . . . 32

spares . . . . . . . . . . . . . . . . . . . . . . . . . 38

Status LED . . . . . . . . . . . . . . . . . . . . . 43