Page 1

Ht-146

H Series

Thermal Printer

User’s Manual

User’s Manual No. 980342-001 Rev. A

©2001 Zebra Technologies Corporation

Page 2

COPYRIGHT NOTICE

This document contains information proprietary to Zebra Technologies Corporation. This docu

ment and the information contained within is copyrighted by Zebra Technologies Corporation and

may not be duplicated in full or in part by any person without written approvalfromZebraTechnol

ogies Corporation. While every effort has been made to keep the information contained within cur

rent and accurate as of the date of publication, no guarantee is given or implied that the document

is error-free or that it is accurate with regard to any specification. Zebra Technologies Corporation

reserves the right to make changes, for the purpose of product improvement, at any time.

TRADEMARKS

Ht-146 is a service mark and Zebra is a trademark of Zebra Technologies Corporation. Windows

and MS-DOS are registered trademarks of Microsoft Corp. All other marks are trademarks or regis

tered trademarks of their respective holders.

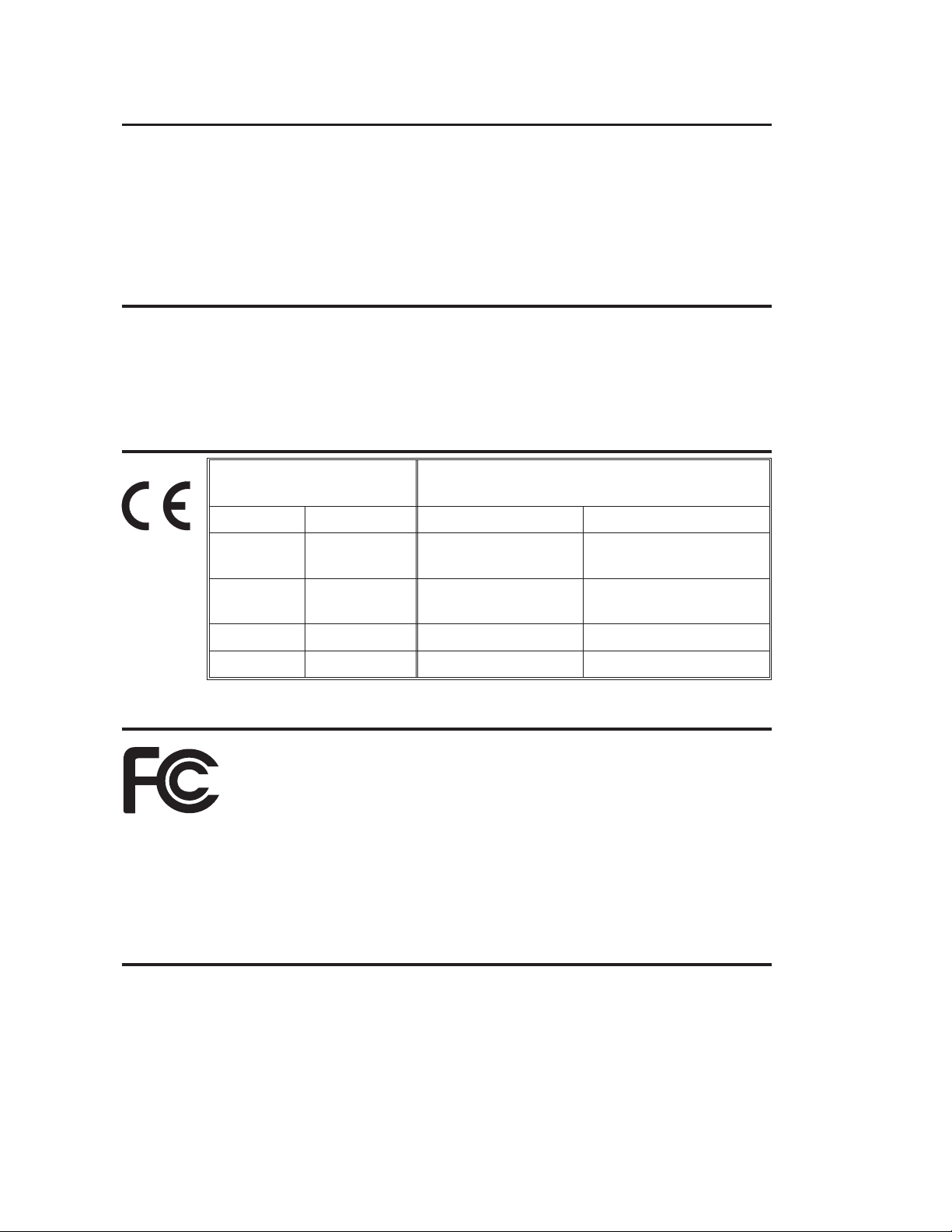

Ht-146 Thermal Printer

European Council

Directive

89/336/EEC EMC Directive EN55022-B, 1998 RF Emissions control

92/31/EE EMC Directive EN55024, 1998

Compliance to Standards

Immunity to Electromag-

netic Disturbances

-

-

-

-

73/23/EEC

Low Voltage

Directive

EMC Directive EN61000-3-2 Harmonic Emissions

EMC Directive EN61000-3-3 Voltage Variation

EN60950 IEC950 Product Safety

FCC - Declaration Of Conformity:

Model: Ht-146 conforms to the following specification:

FCC Part 15, Subpart B, Section 15.107(a) and Section

15.109(a) Class B digital device

Supplemental Information:

This device complies with Part 15 of the FCC Rules. Operation is subject to the following Two Con

ditions: (1) This device may not cause harmful interference , and (2) this device must accept any

interference received, including interference that may cause undesired operation.

Industry Canada Notice:

This device complies with Industry Canada ICS-003 class B requirements.

Cet equipement est conforme a l’ICS-003 classe B de la norm Industrielle Canadian

-

ii 980342-001 Rev.A

Page 3

Table of Contents

Installation & Operation . . . . . . . . . . . . . . . . . . . . . . . 1

Unpacking Your Printer. . . . . . . . . . . . . . . . . . . . . . . . . . 1

Getting To Know Your Printer . . . . . . . . . . . . . . . . . . . . . . 2

Controls & Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Media Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Before You Load Media in the Printer . . . . . . . . . . . . . . . . . . 9

Using AutoSense . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Thermal Transfer Printer Features . . . . . . . . . . . . . . . . . . . . 19

Loading Transfer Ribbon . . . . . . . . . . . . . . . . . . . . . . . . 19

Configuring Thermal Transfer Printing . . . . . . . . . . . . . . . . . 21

Operator Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 23

Cleaning Your Printer . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Extending Print Head Life . . . . . . . . . . . . . . . . . . . . . . . . 24

Print Head Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Cleaning the Print Head. . . . . . . . . . . . . . . . . . . . . . . . . 26

Platen Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Front Bezel Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Using the Label Dispense Option . . . . . . . . . . . . . . . . . . 31

Label Dispense Features. . . . . . . . . . . . . . . . . . . . . . . . . 31

Label Dispenser Mounting. . . . . . . . . . . . . . . . . . . . . . . . 32

Using Label Dispense . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Label Dispenser Removal. . . . . . . . . . . . . . . . . . . . . . . . 40

Peel Bar Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Printing with the Label Dispenser . . . . . . . . . . . . . . . . . . . . 42

Using the Liner Take-Up Option . . . . . . . . . . . . . . . . . . . 43

Liner Take-Up Features . . . . . . . . . . . . . . . . . . . . . . . . . 43

Liner Take-Up with Automatic Label Dispense . . . . . . . . . . . . . 44

Manual Label Dispense with Liner Take-up . . . . . . . . . . . . . . . 48

Using the Media Cutter . . . . . . . . . . . . . . . . . . . . . . . 49

Media Cutter Features . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Cutter Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Cutter Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Cleaning and Clearing the Media Cutter. . . . . . . . . . . . . . . . . 52

Clearing Cutter Jams . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Miscellaneous Printer Options . . . . . . . . . . . . . . . . . . . . 55

Factory Installed Printer Options . . . . . . . . . . . . . . . . . . . . 55

Add-On Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Liner-free Media Printing . . . . . . . . . . . . . . . . . . . . . . . . 56

Programming with the Real Time Clock Option . . . . . . . . . . . . . 57

980342-001 Rev.A iii

Page 4

Asian Language Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

High Resolution 300 dpi Printers . . . . . . . . . . . . . . . . . . . . . . . . 58

Keyboard Display Unit (KDU) . . . . . . . . . . . . . . . . . . . . . . . . . 58

The PrintServer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Narrow Media Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Where to Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Printer Configuration Settings. . . . . . . . . . . . . . . . . . . . . . . . . . 64

Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Media Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Reflective Sensor Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Top Of Form Sensing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Black Mark and Index Hole Sensing Range . . . . . . . . . . . . . . . . . . . 67

Print Head Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Serial Interface Communication Configuration . . . . . . . . . . . . . . . . . 68

RS-232 Serial Interface Cable Wiring . . . . . . . . . . . . . . . . . . . . . . 68

Parallel Interface Cable Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 69

USB Interface Cable Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Printer Option: RS-422 Serial Interface Cable Wiring . . . . . . . . . . . . . . 70

Print Head Replacement Procedures. . . . . . . . . . . . . . . . . 71

Identifying Print Head Problems . . . . . . . . . . . . . . . . . . . . . . . . 72

Print Head Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Cover Removal Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

iv 980342-001 Rev.A

Page 5

General Cautions and Warnings

This page describes general safety and maintenance warnings and cautions for the printer and

are referenced throughout the manual.

Warning - Shock Hazard

The printer should never be operated in a location where it can

get wet. Personal injury could result.

Warning - Static Discharge

The discharge of electrostatic energy that accumulates on the

surface of the human body or other surfaces can damage or

destroy the print head or electronic components used in this

device. DO NOT TOUCH the print head or the electronic

components under the print head assembly.

Caution - Printer Setup & Handling

1)When installing or modifying the printer setup or

configuration, ALWAYS TURN POWER OFF Before

A) Connecting any cables.

B) Performing any cleaning or maintenance operations.

C) Moving the printer.

2) Damage to the printer interface connector, accessories or

door may result from placing the printer on it’s front bezel or

backside during unpacking or handling.

:

Media Warning

Media Reload Hint

Print Quality Tip

Always use high quality approved labels and tags. If adhesive

backed labels are used that DO NOT lay flat on the backing

liner, the exposed edges may stick to the label guides and

rollers inside the printer, causing the label to peel off from the

liner and jam the printer.

If you should run out of labels while printing, DO NOT turn the

power switch OFF (0) while reloading or data loss may occur.

The printer will automatically resume printing when a new label

or ribbon roll is loaded.

Print density (darkness) is affected by the heat energy (density

setting) applied and by the print speed. Changing both Print

Speed and Density may be required to achieve the desired

results.

980342-001 Rev.A

v

Page 6

vi 980342-001 Rev.A

Page 7

Installation & Operation

1

Installation & Operation

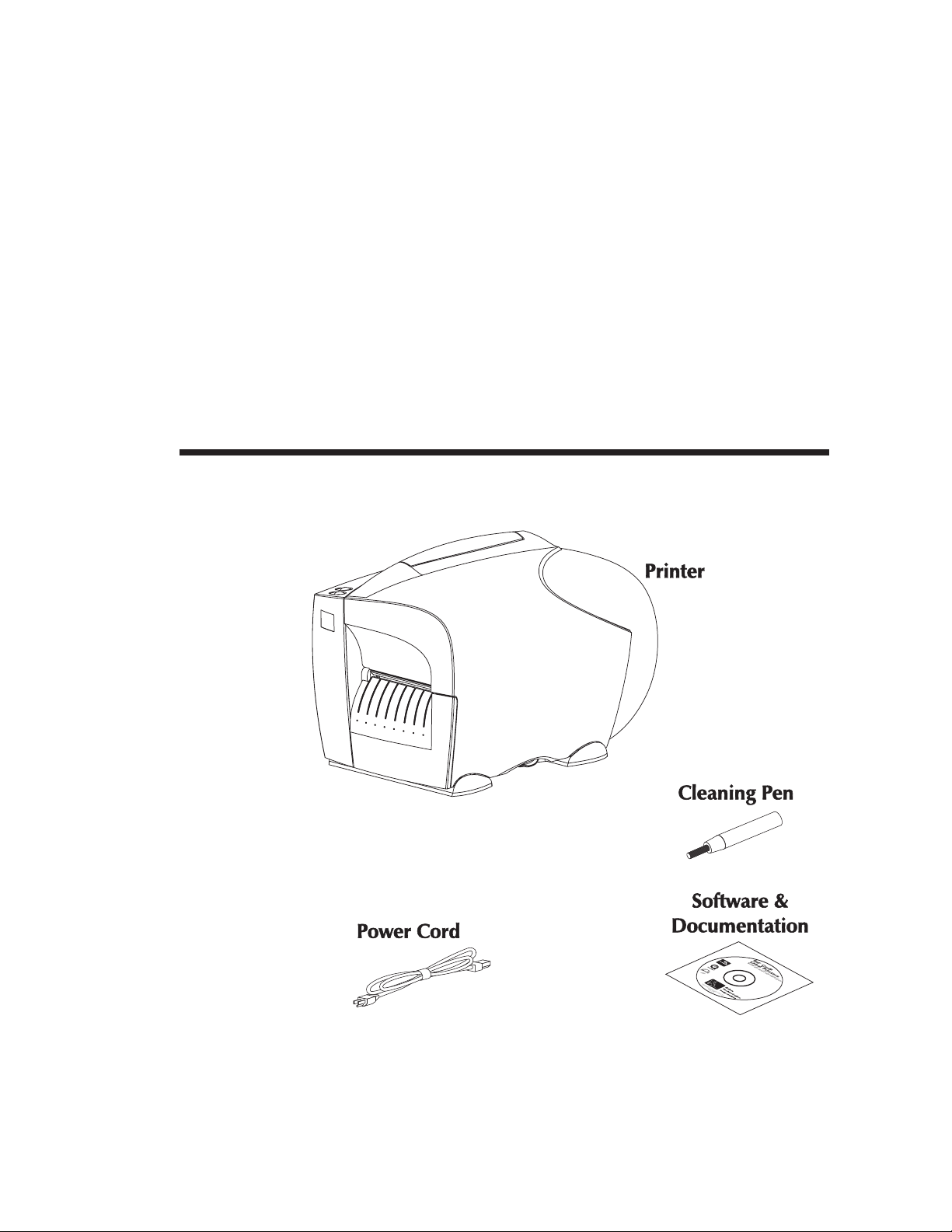

Unpacking Your

Printer

Open the shipping carton and remove the

printer and its accessories.

B

L

a

S

a

r

o

b

f

C

t

w

e

o

a

l

r

e

d

P

a

e

n

r

d

i

n

D

o

t

c

e

u

m

r

s

e

n

t

a

t

i

o

©2001 Zebra Technologies Corporation

105551-006

n

980342-001 Rev.A 1

Page 8

Installation & Operation

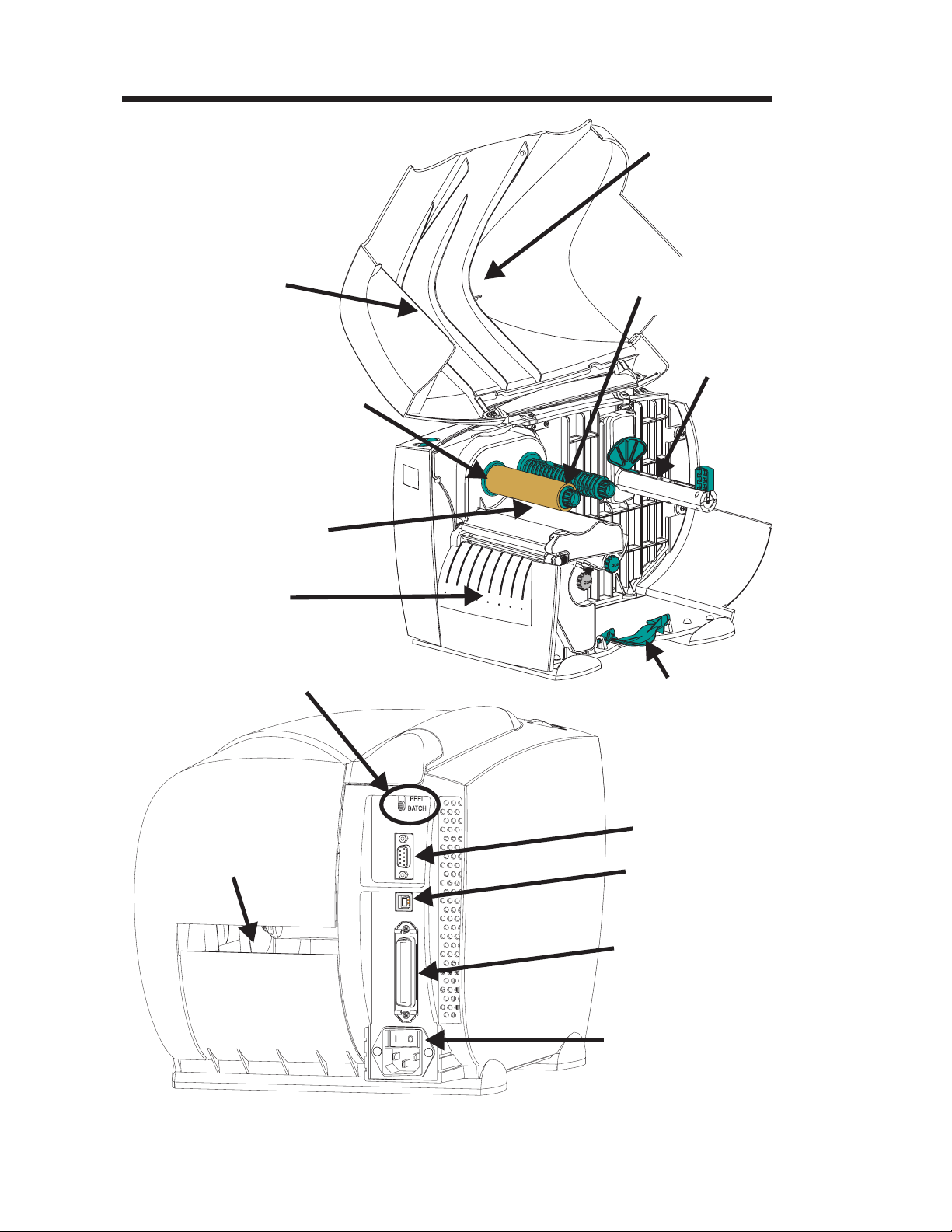

Getting To Know

Your Printer

Tear Edge

Ribbon Take-Up

Tube

Ribbon Core

(Shipped mounted on

Ribbon Tube)

Cover

(Open)

Ribbon Supply

Tube

Media Roll

Holder

Front Bezel

Label Mode

Switch

Auxiliary Media Access

(Opening for Fan Fold &

External Media)

Cover Latch

(Lift to Open)

Serial Interface

Connector

USB Interface

Connector

Parallel Interface

Connector

Power Switch and

Power Cord

Module

2 980342-001 Rev.A

Page 9

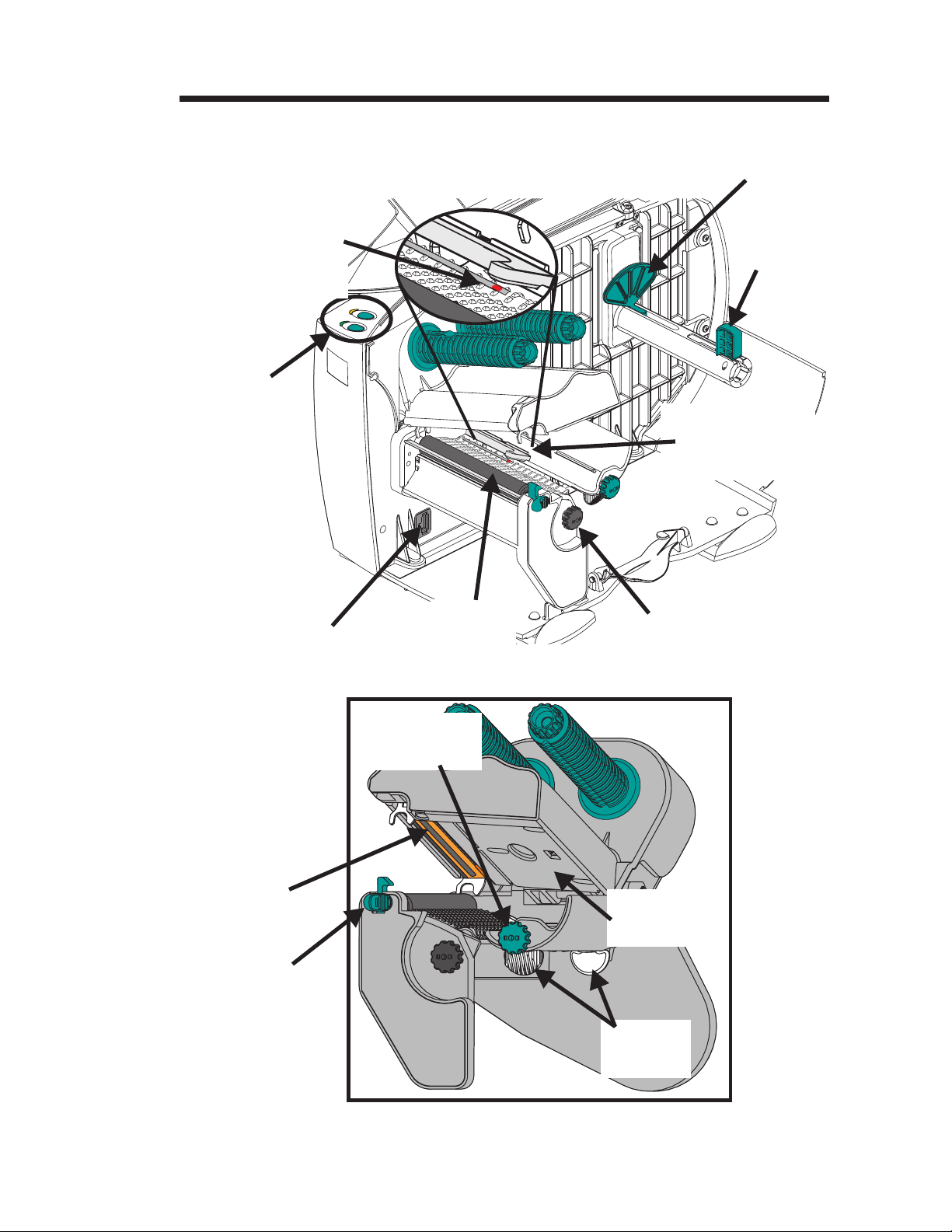

Installation & Operation

Getting To Know

Your Printer

Red Light

Position Indicator

(Position for Gap

Sensing Shown)

Controls

&

Indicators

Roll

Guide

Roll

Keeper

Transmissive

(Gap) Sensor

(Fixed Position)

Modular

Accessory Plug

Print

Head

Print Head

Release Lever

Platen

Roller

Media Guide

Adjustment

Reflective

(Blackline & Hole)

Sensor Adjustment

Ribbon Out

Sensor

Media

Guides

Print Mechanism

980342-001 Rev.A 3

Page 10

Installation & Operation

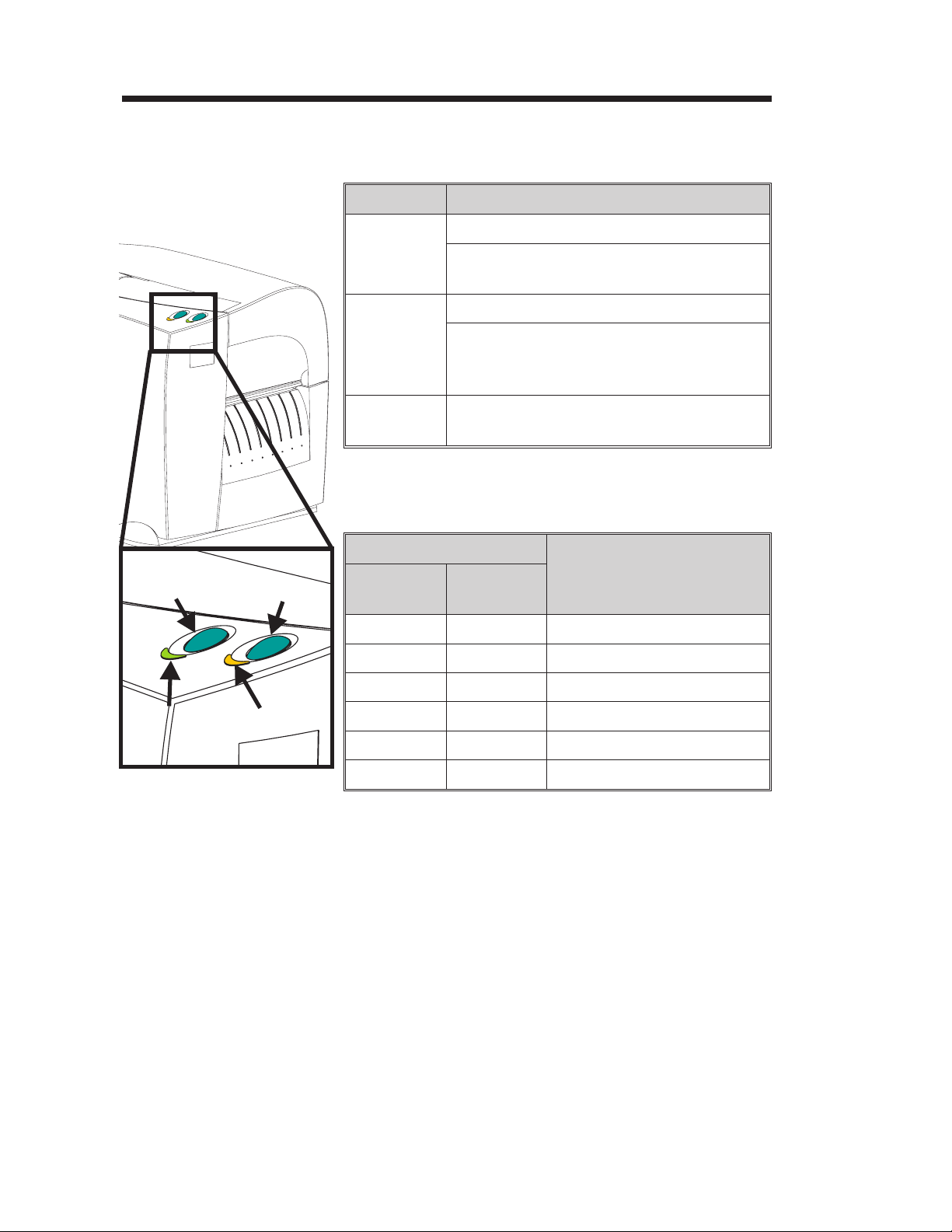

Controls &

Indicators

Button Function

Press Once - Halt batch printing.

PAUSE

Press Second Time - Resume batch

printing operation.

Press Once - Feed one label or “form”.

Feed

Button

Power

Indicator

Pause

Button

Error

Indicator

FEED

PAUSE &

FEED

Indicator LEDs

POWER

(Green)

On Solid OFF

Flashing OFF

OFF

OFF On Solid Hardware Error

OFF Flashing

On Solid On Solid

Press & Hold - Feed a single label, stop,

feed a single label, stop, and so on until the

FEED button is released.

Press & Hold a minimum of 3 seconds

to reset the printer.

ERROR

(Amber)

On Solid

Condition Report

Power On

Pause

Media/Ribbon Out

Head Open or Rewind Full

Data/Command Syntax Error

4 980342-001 Rev.A

Page 11

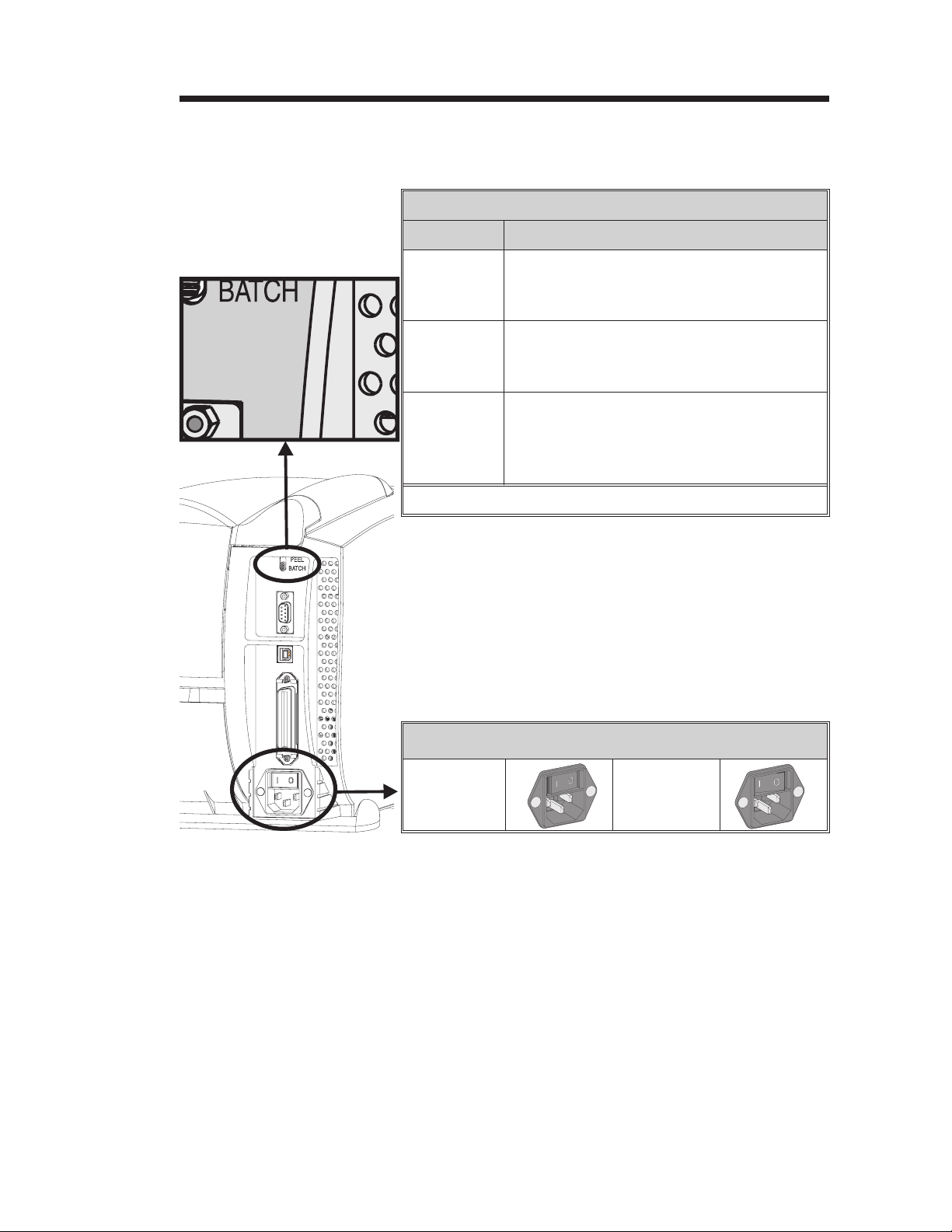

Controls &

Indicators

Installation & Operation

Label Mode Switch

Mode Description

Standard operation - Prints one or more

Batch

labels until the batch form (label) print op

eration is complete.

-

Peel with

Label Taken

Sensor

Peel with

out a Label

Taken

Sensor

Note: Reset the printer to initialize the mode change.

Print one label and pause. Remove label.

Prints next label. Repeats until print opera

tion is completed.

Print one label and pause. Remove label.

Press Feed to print next label. Repeat until

print operation is completed. (See EPL2 O

command with L parameter).

Power Switch

0 = OFF

(8 seconds

to power off)

1 = ON

-

980342-001 Rev.A 5

Page 12

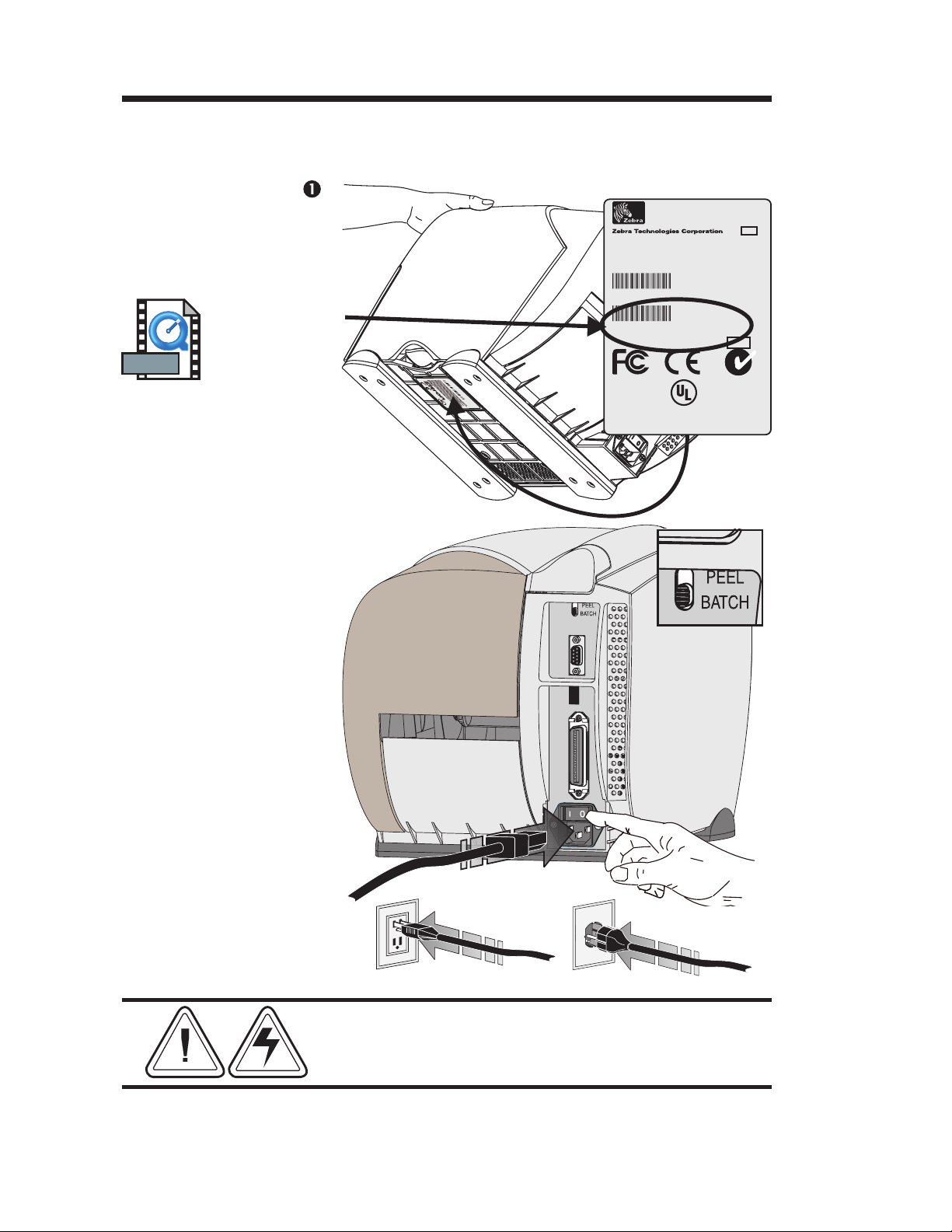

Installation & Operation

Installation The following steps will guide you through the

installation of the printer.

MOVIE

Step

Attach Power

Check

Printer

Voltage

Set Batch Mode

Pat. No.

5.813,343

6,068,415

EPL

TLP 2746

Model:

02/01/01

Mfg. Date:

Part Number:

Serial No.:

Input Power:

For home or office use

I

S

Part N

Hd-146

np

e

r

ut P

i

al

No

o

o

.:12

we

.:

r

XX

:1

0

XXX

15

X

XXX

V

A

X

C

XX

X

6.3

X

A

50

/6

0H

z

I.T.E.

8T34

2746-120XXX-001

12345678912

115-230 VAC,2-1 Amps, 50/60 Hz

C

®

US

MADE IN USA

with foreign and domestic parts

N2557

Batch Mode

Set Printer

Power OFF

(OFF = 0)

Attach the

Power Cord

See Warnings - Page v

6 980342-001 Rev.A

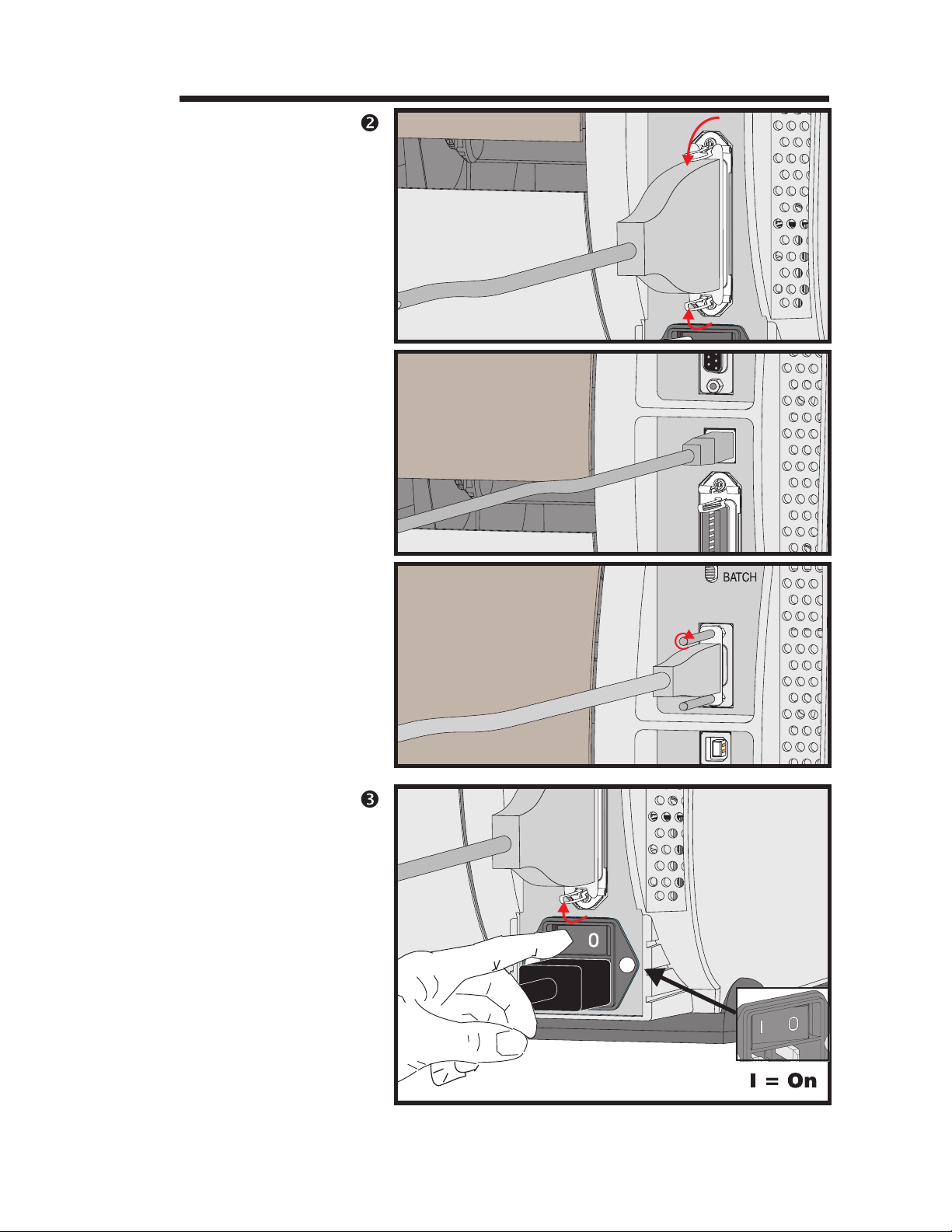

Page 13

Step

Attach Interface

Cable

Parallel

Interface

Installation & Operation

USB

Interface

Serial

Interface

Step

Apply Power

980342-001 Rev.A 7

Page 14

Installation & Operation

Media Loading

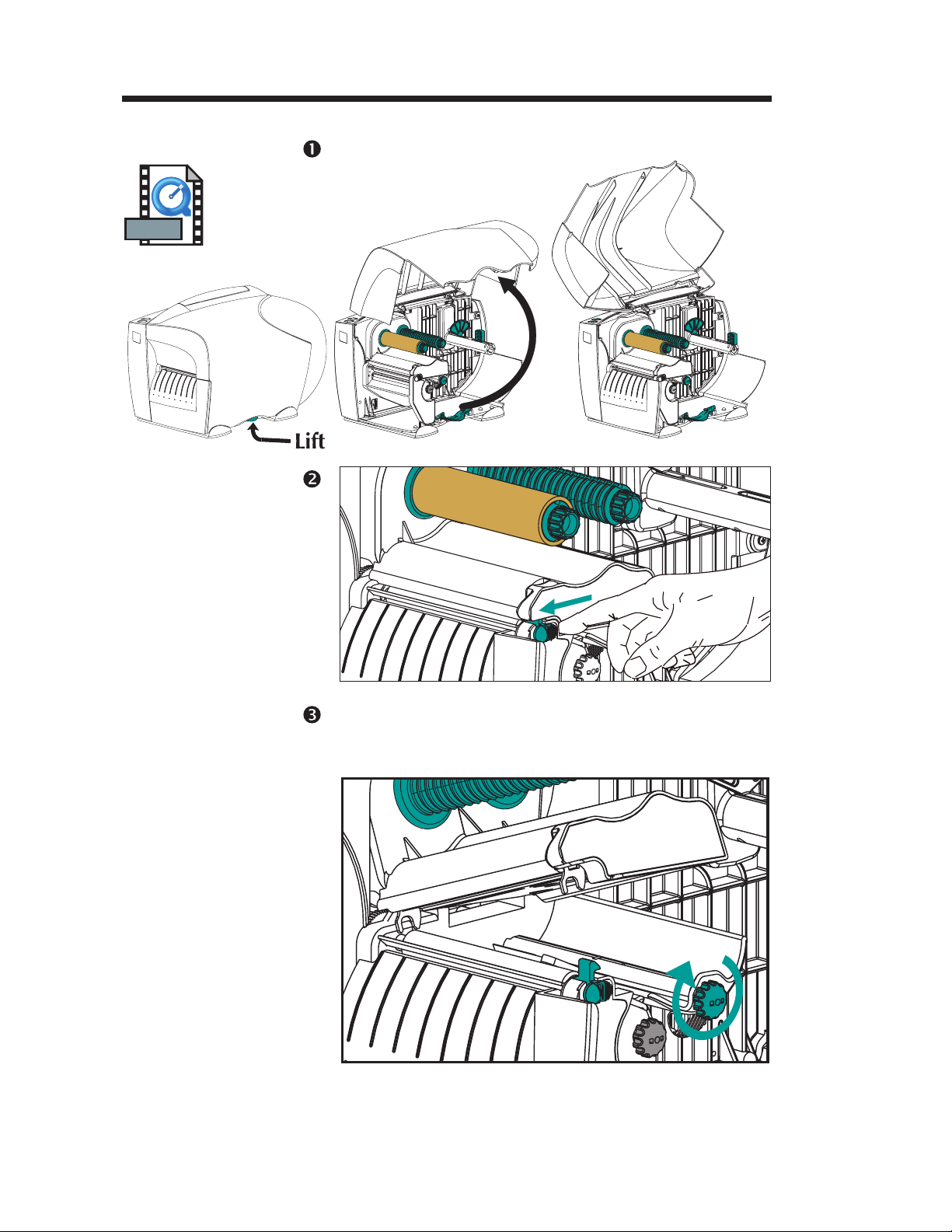

MOVIE

Print Head

Step

Step

Open the

Open the cover. Lift the green latch to unlock

the cover.

Step Turn the green adjustment knob clockwise to

Open the

Media Guides

open. Verify the media sensor indicator light is

directly under the transmissive sensor.

8 980342-001 Rev.A

Page 15

Installation & Operation

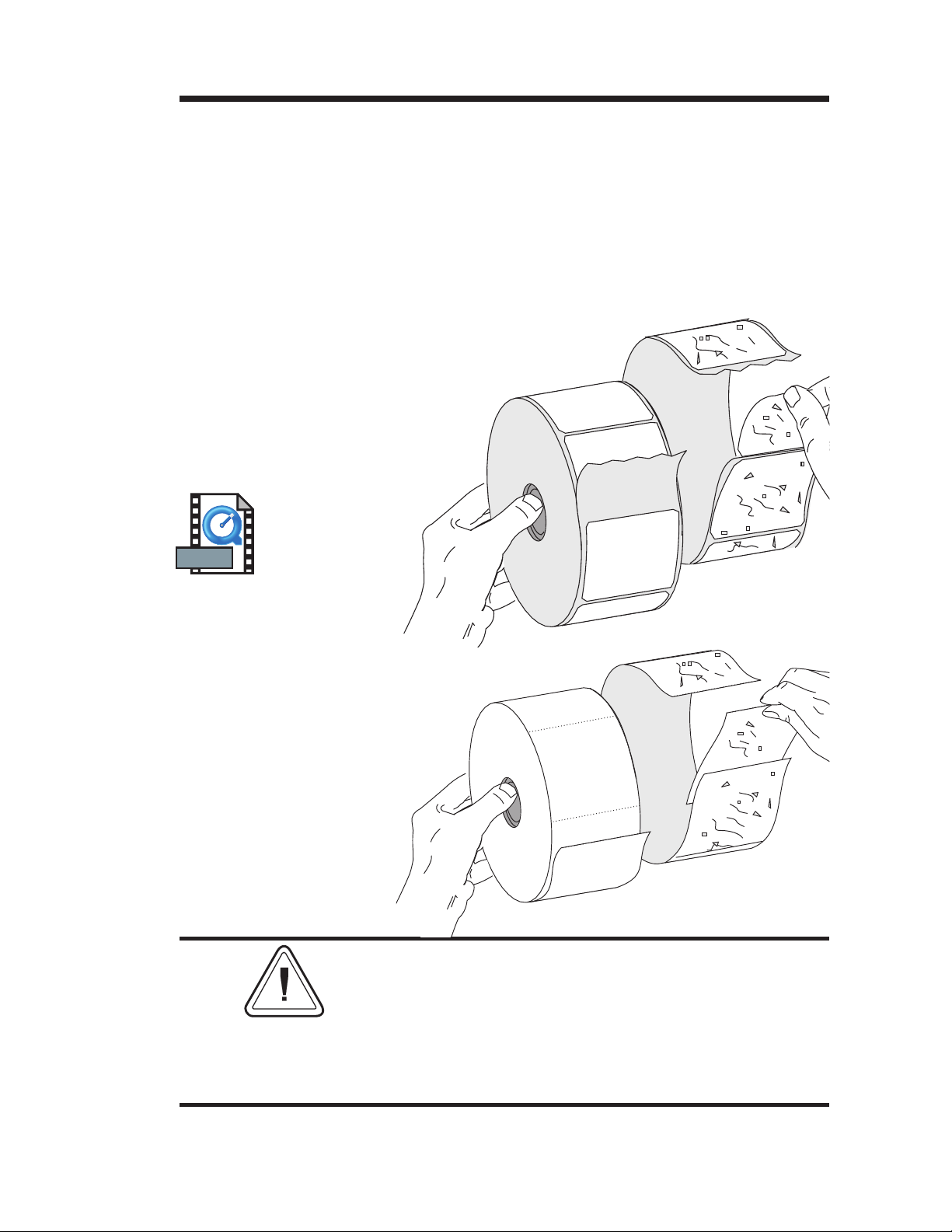

Before You Load

Media in the

Printer

Remove all labels

that are held by

adhesives or tape

MOVIE

Labels

You must remove the outside length of media

(that is, one, full revolution of labels and any

liner). When you remove this part of the me

dia, you remove the oils, dust, and adhesives

that contaminate it. Tape or adhesive holds the

loose end and the outside length of media

becomes contaminated when handled or

stored.

-

Tag Stock

Detach both ends of

the bottom tag

You must avoid dragging adhesive or dirty

media between the print head and platen. Such

an occurrence damages the print head and is

not covered under your warranty. Using clean

media prevents damage and reduces wear on

the print head and platen.

980342-001 Rev.A 9

Page 16

Installation & Operation

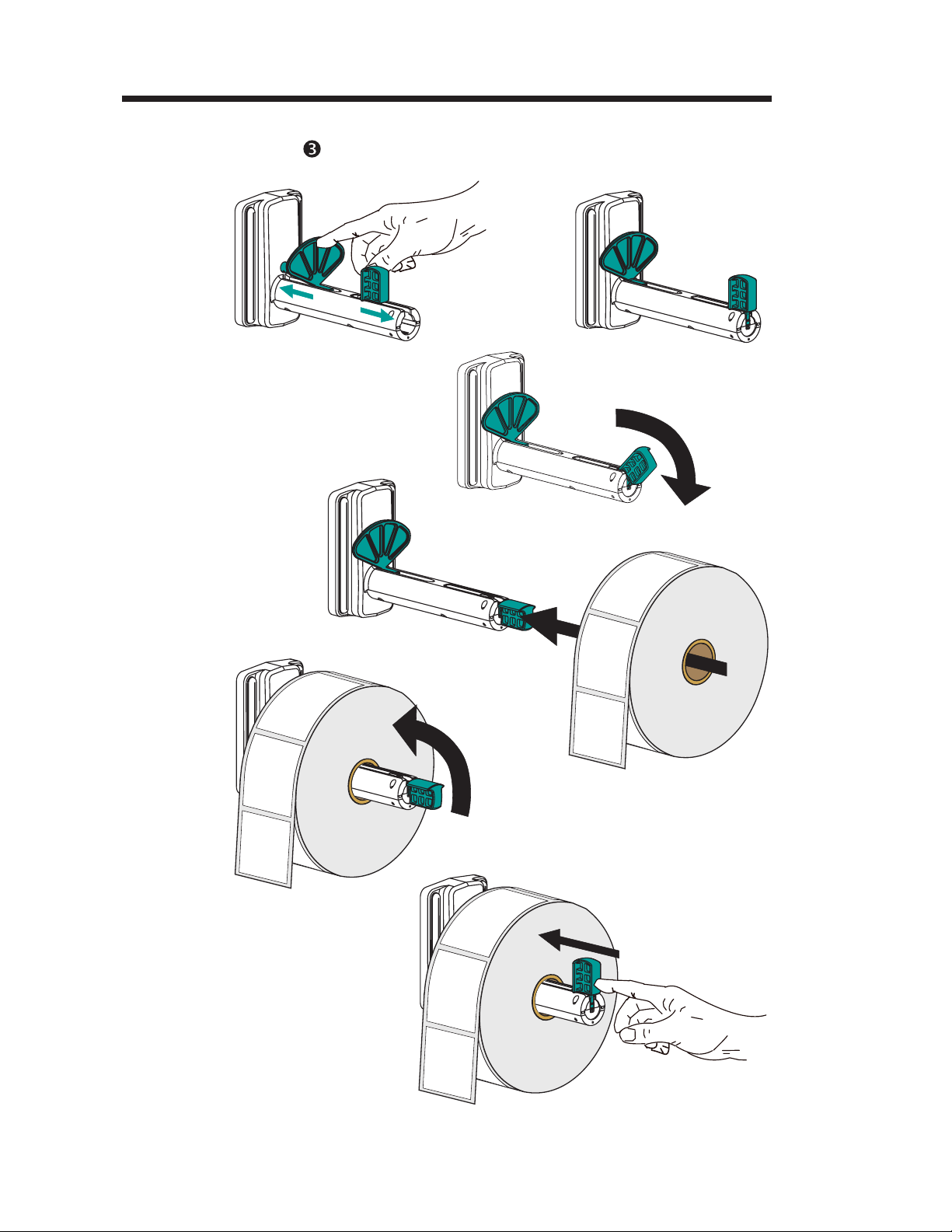

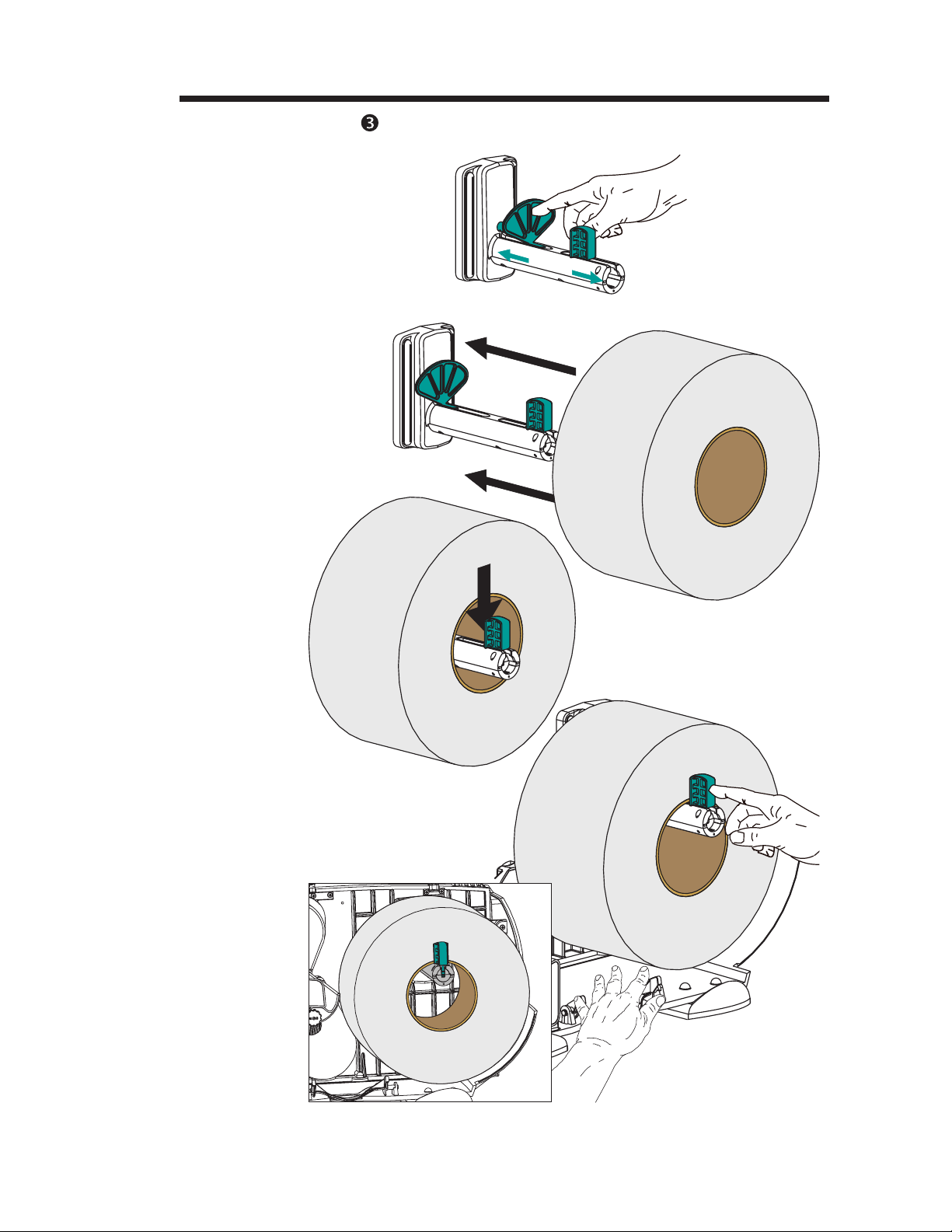

Media Loading

Open

Roll

Guide

Open

Keeper

Insert Roll

Load the media roll - 1 inch inner diameter.

Step

Close

Keeper

Hold the

Printer

and

Push the

Keeper

Tight

Against

the Roll

10 980342-001 Rev.A

Page 17

Open

Roll Guide

Insert Roll

Lift Roll

Over

Keeper

Installation & Operation

Step Load the media roll - 3 inch inner diameter.

Set Roll On

Holder

Between

Roll Guide

and Keeper

Hold the

Printer

and

Push the

Keeper

Tight

Against

the Roll

980342-001 Rev.A 11

Page 18

Installation & Operation

Media Loading

Step

Thread Media

Thread the media between the media guide

and platen assembly. Center media over the

platen roller and under the media sensor.

Center Media

12 980342-001 Rev.A

Page 19

Step Note the media orientation for the different

Outside Wound

Installation & Operation

media delivery methods.

Inside Wound

Fan Fold

980342-001 Rev.A 13

Page 20

Installation & Operation

Media Loading

Step

Pull Media Taut

Adjust

Media Guides to

Media Width

Step Close the print head.

Adjust media guides to match the media width.

Turn the adjustment knob clockwise to narrow

the guides.

Close

Print Head

Step Press the Feed button once (with the power ap

Power ON

Labels Loaded

Press FEED

-

plied and the power switch “ON”).

14 980342-001 Rev.A

Page 21

Installation & Operation

Step Close the cover. Remove excess media. Use the

tear edge in the cover, directly above the me

dia.

Close

Cover

-

Remove

Push

Excess

Media

Step Set label detection parameters for media:

· Use the AutoSense procedure (page 16) for

first time use of new media to set transmissive

(gap) sensor.

· Use the AutoSense procedure for detection

of label and gap lengths.

· Use programming to set continuous media

mode. See the Q command in the EPL2 pro

grammer's manual for details.

-

DO NOT turn the power switch OFF (0) while

reloading media or data loss may result. Load

new media and press the FEED button to

automatically resume printing.

980342-001 Rev.A 15

Page 22

Installation & Operation

Using AutoSense AutoSense sets the sensitivity of the

transmissive (gap) sensor, measures and stores

the form (label) and gap lengths. For more

details on media sensing and sensors see page

65. To activate the AutoSense feature:

MOVIE

Load Labels

Visually Verify

Reflective Sensor

Step Load labels into the printer. Verify that the re

flective sensor’s location (red light) is under the

transmissive sensor for label mode operations.

Position

Step Turn OFF printer power. Set Batch mode.

Do not use the peel mode.

-

Batch Mode

0

Power OFF

0

16 980342-001 Rev.A

Page 23

Installation & Operation

Step Press and hold the FEED button while turning

ON printer power.

Press and

Hold the

FEED Button

Power ON

Step Release the FEED button when the power

indicator begins to flash and the label will begin

to advance.

Release the

FEED Button

980342-001 Rev.A 17

Page 24

Installation & Operation

Step The printer will advance 3-4 labels while per

forming the sensor adjustment. When the

adjustment is complete, a status summary label

will be printed and the printer will be placed in

Diagnostic Dump mode.

P

M

U

D

n

i

w

3

o

1

n

2

6

N

1

3

U

0

1

D

,

T

:

1

5

Z

n

3

o

0

i

2

t

0

1

p

0

Q

,

O

2

2

3

3

l

0

8

v

R

0

a

q

2

K

1

Y

3

l

r

D

9

v

5

8

a

1

0

S

0

,

l

K

0

v

K

3

,

a

0

9

0

,

0

5

K

8

0

0

4

I

:

,

.

K

1

m

0

6

e

K

0

0

5

,

m

0

4

:

K

E

2

0

:

m

,

e

e

0

z

0

i

m

s

0

G

:

r

e

m

f

f

e

u

m

1

b

,

F

8

e

,

g

N

a

,

6

m

I

9

:

1

0

t

.

r

4

o

0

p

.

l

4

a

i

r

7

e

3

S

2

s

I

"

4

Sample: DUMP Mode

Printout

4" Is-237 4.04.01

Serial port : 96,N,8,1

Image buffer size:245K

Fmem:000,0K,061.4K avl

Gmem:000K,0593K avl

E

mem:000K,0593K avl

I8,0,001 rY

S8 D12 R032,000 ZT UN

q0832 Q1235,036

Option:D

11 12 13

now in DUMP

-

Step Press the FEED button to exit the Dump mode.

Remove excess labels.

Press FEED

Prints:

out of DUMP

outof DUMP

18 980342-001 Rev.A

Page 25

Installation & Operation

Thermal Transfer

Printer Features

Ribbon Core

(Shipped mounted on

Ribbon Tube)

Print Head

The thermal transfer printer supports wax,

resin, and wax resin ribbons in 1 inch

(24.5mm) inner (nominal) and 2.53 inch

(64mm) maximum outer diameters.

Ribbon Take-Up

Tube

Ribbon Supply

Tube

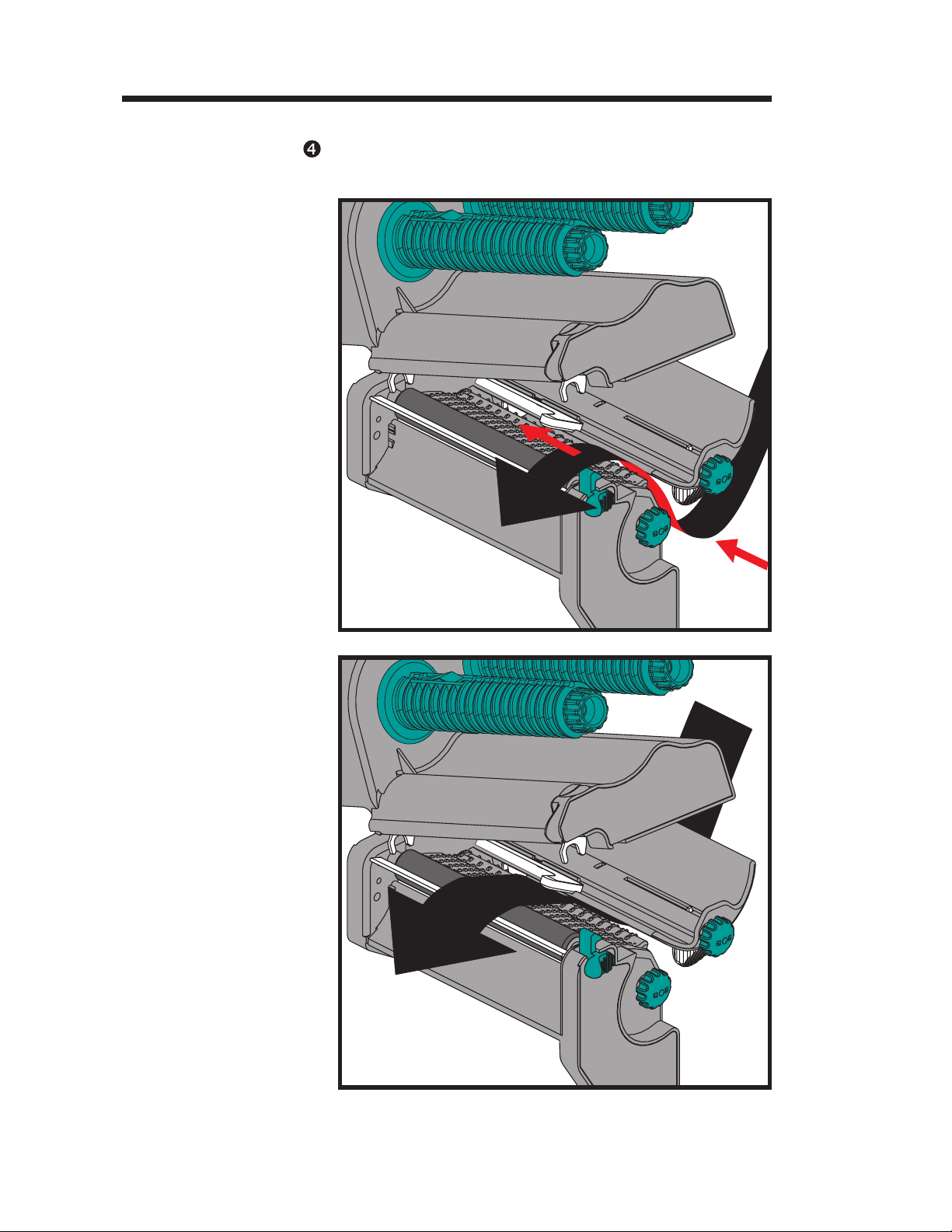

Loading Transfer

Ribbon

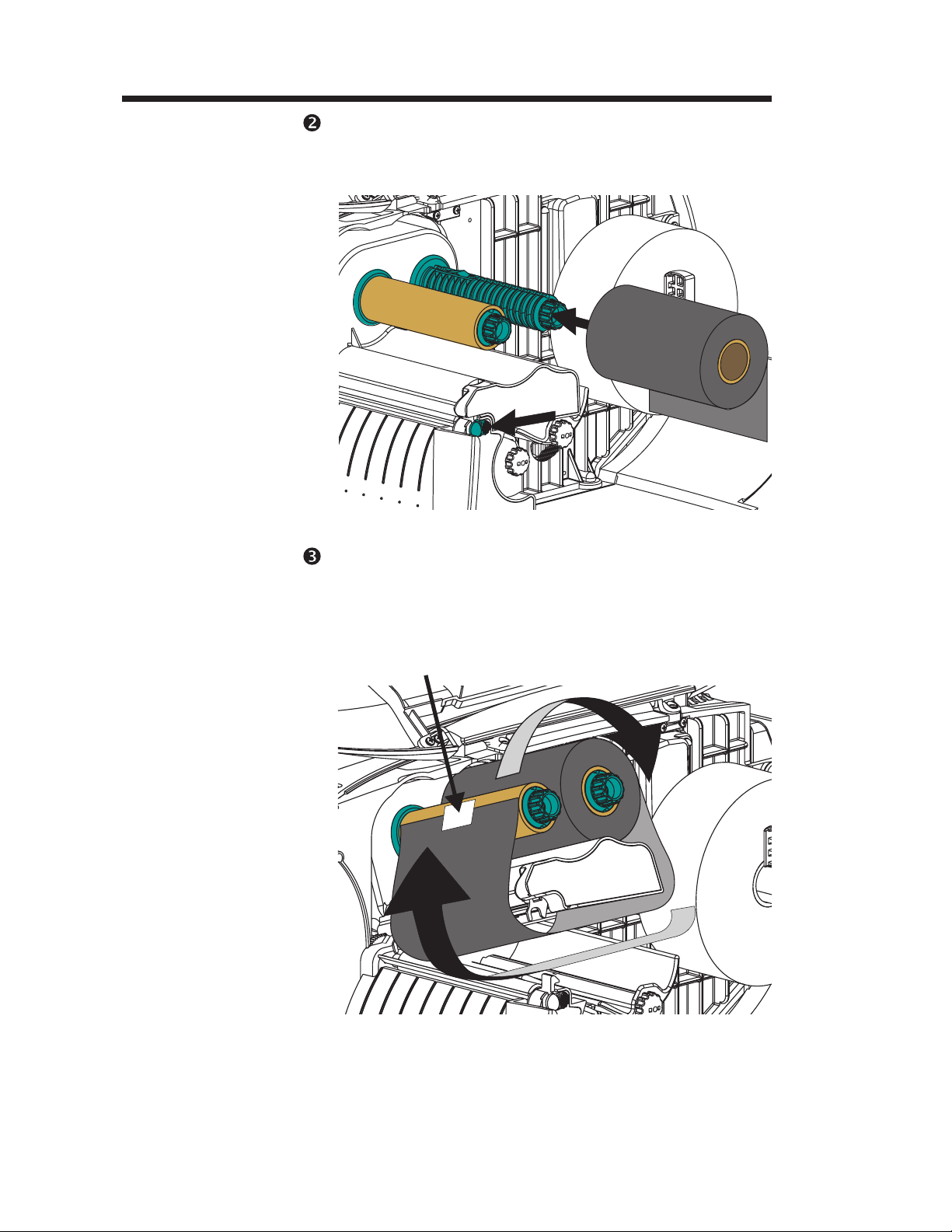

Step Insert an empty ribbon core on the ribbon

MOVIE

Insert Ribbon Core

Ribbon Out

Sensor

Refer to the following instructions for installation of the ribbon.

take-up tube.

Ribbon

Core

980342-001 Rev.A 19

Page 26

Installation & Operation

Step Insert a transfer ribbon roll on the ribbon supply

Insert Ribbon Roll

Open Print Head

tube. The transfer ribbon unwinds clockwise.

Open the print head.

Step Thread the transfer ribbon under the print head

Thread Ribbon

Attach Ribbon to

Ribbon Core

assembly and clockwise around the ribbon

core and take-up tube. Attach the ribbon to the

core.

Tape

20 980342-001 Rev.A

Page 27

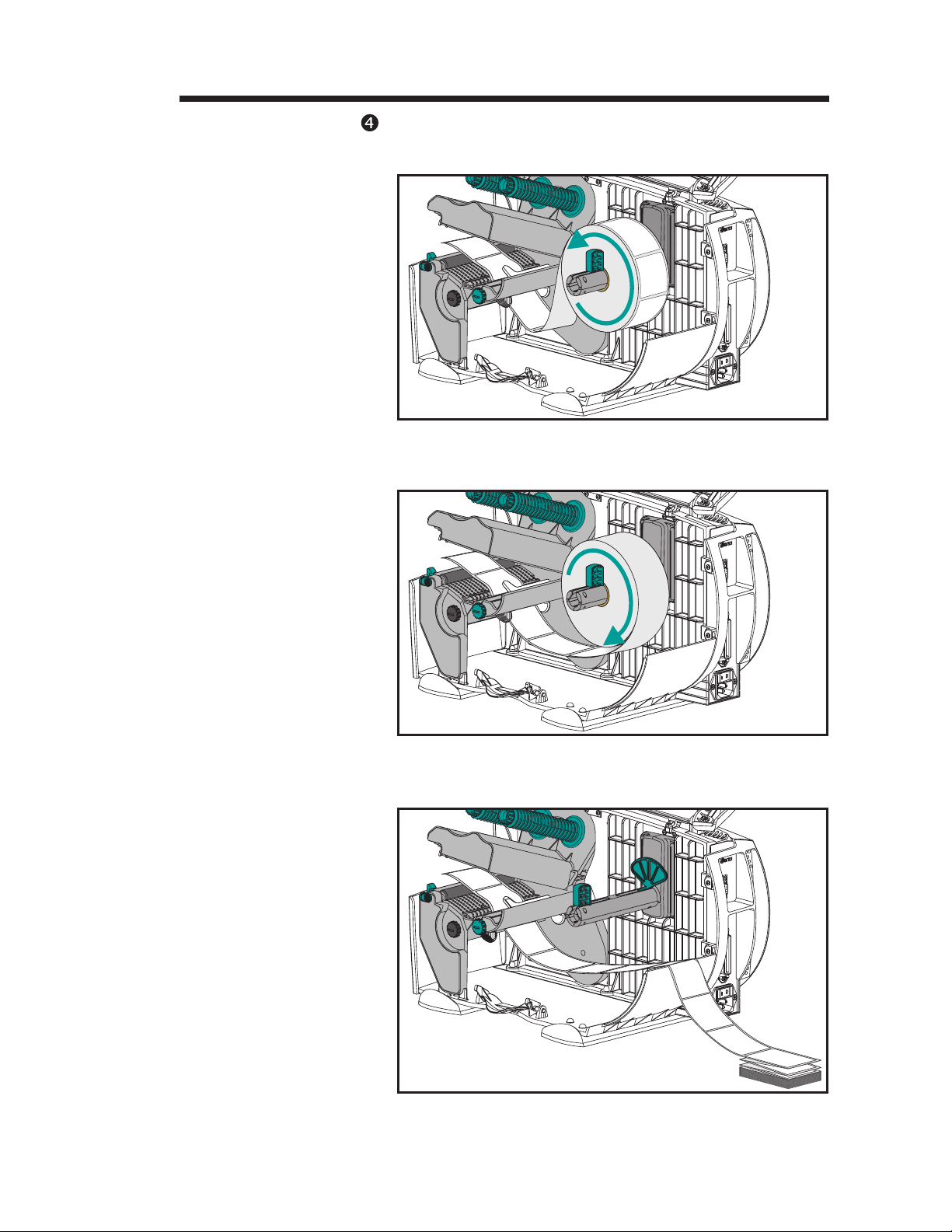

Installation & Operation

Loading Transfer

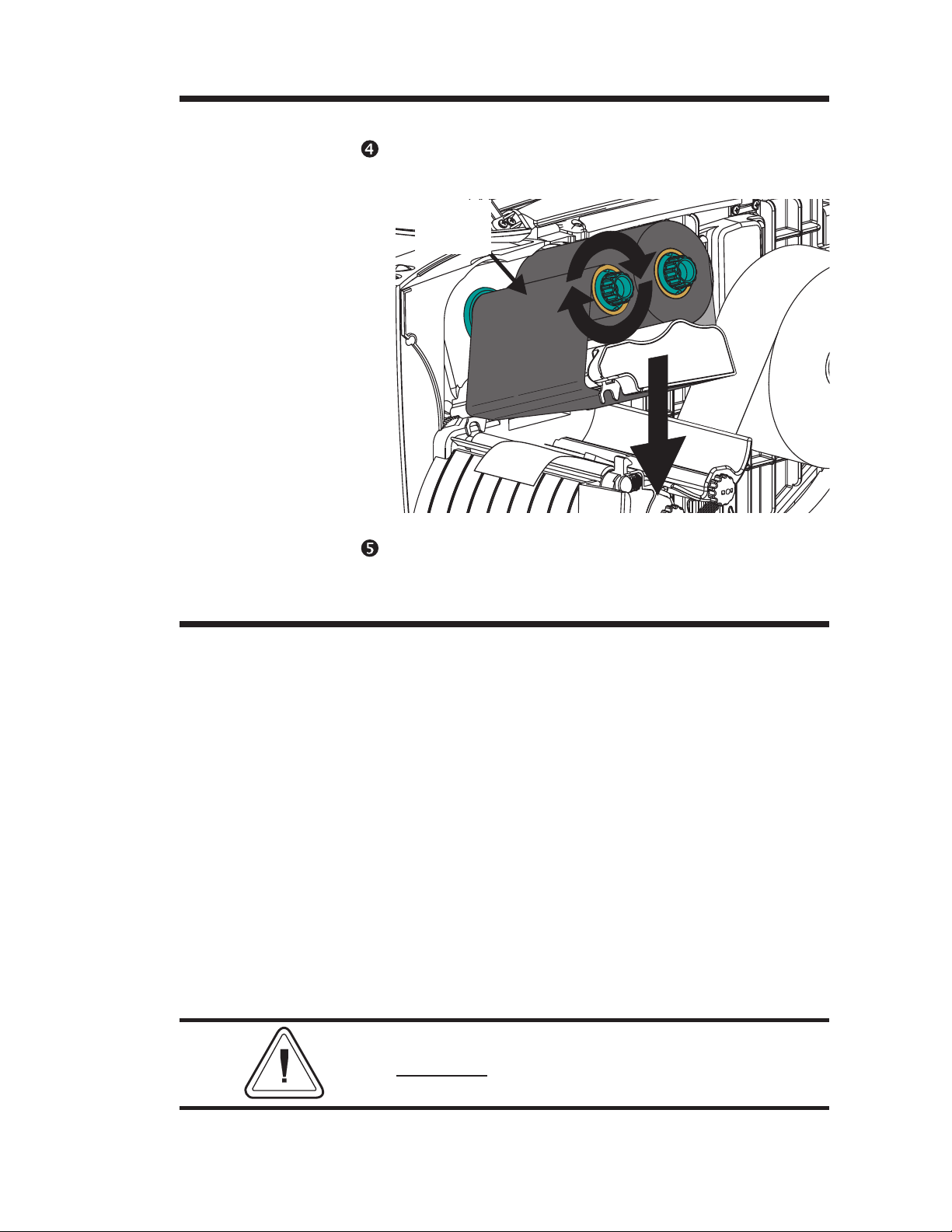

Ribbon - Step

Turn Ribbon

Take-Up Tube

Close Print Head

Close the Printer

Step With printer power ON and media loaded,

Turn the ribbon take-up tube clockwise a mini

mum of two (2) times to lock the ribbon on the

core.

Ribbon

Core

press the FEED button until approximately 6

inches or 150 mm of media has advanced.

-

Configuring

Thermal Transfer

Printing

By default, the thermal transfer printer is set to

the direct thermal print mode as configured

"Out of the Box". The printer will print thermal

transfer media in direct thermal mode, but it

will not sense a ribbon out media condition.

The most common method of changing the

print mode is to use the Windows printer driver.

Select the Ht-146 printer and print a label.

To configure thermal transfer printing with pro

gramming, use the O (thermal transfer) and

OD (direct thermal) commands. The print

mode will be set until changed by program

ming.

See the EPL2 programmer's manual for

important

details on printer programming and

printing using the Option (O) command.

-

-

980342-001 Rev.A 21

Page 28

Installation & Operation

22 980342-001 Rev.A

Page 29

Operator Maintenance

2

Operator Maintenance

This section provides information on operator

maintenance procedures for your printer.

Cleaning Your

Printer

The printer’s media path allows for cleaning

and clearing of media jams. The user can clean

the print head, platen roller and areas adjacent

to the media path surfaces.

Warning -Shock Hazard - See page v.

Always turn the printer off before cleaning.

The media path surfaces (except the print

head) can be cleaned with a lint free, clean,

damp cloth very lightly moistened with medical

grade alcohol. Alcohol may be used to help re

move any adhesive or label material buildup.

If a label has become jammed in the printer,

remove the label and any adhesive residue,

immediately. Adhesive may spread through out

the printer’s media path if not completely

removed. Many adhesives are permanent and

have short “set” times.

-

980342-001 Rev.A 23

Page 30

Operator Maintenance

Extending Print

Head Life

The print head is the most critical component in

your printer, and possibly the most delicate. It

is a consumable item just like the brakes on

your car, which will eventually wear over time.

However, with ongoing careful attention and

maintenance, you can extend the life of the

print head!

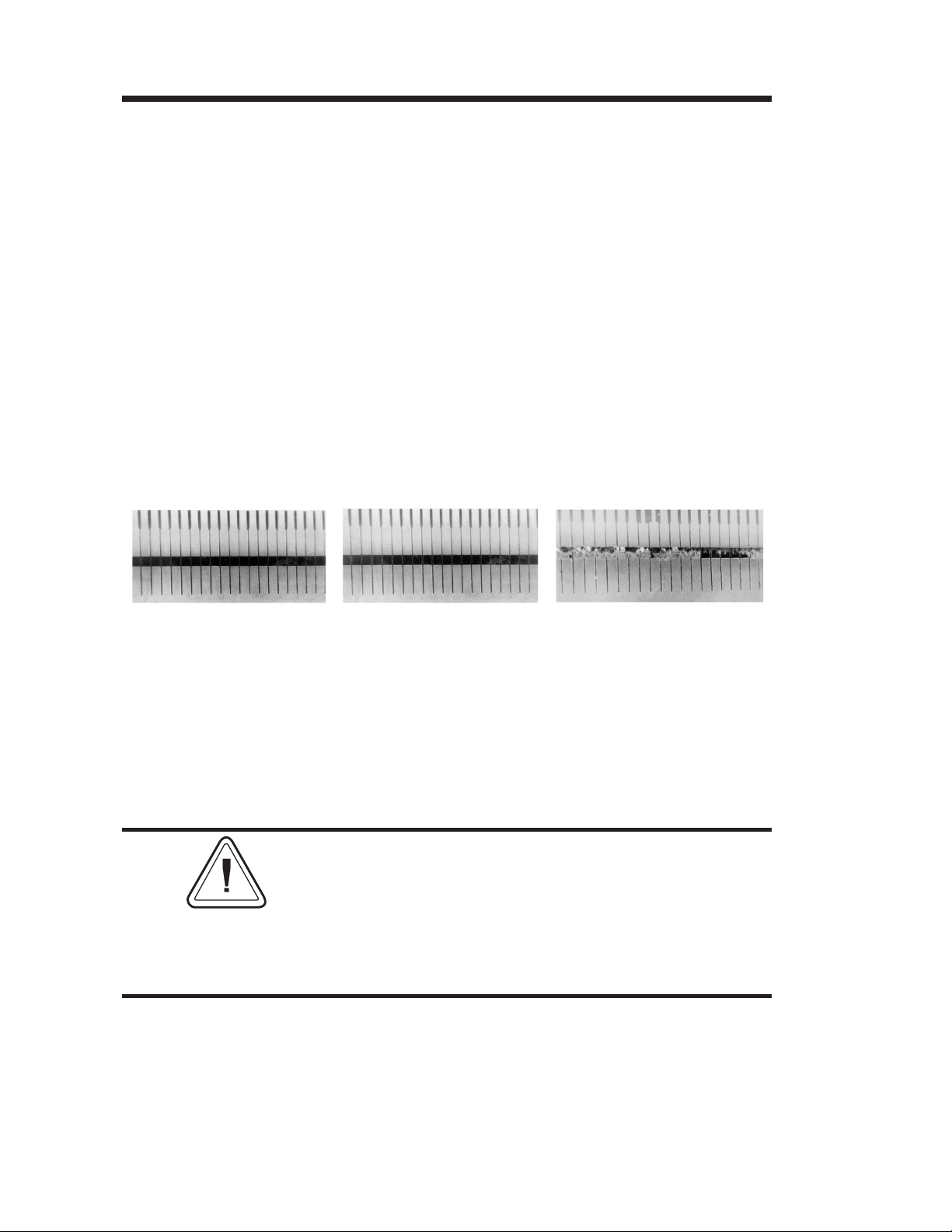

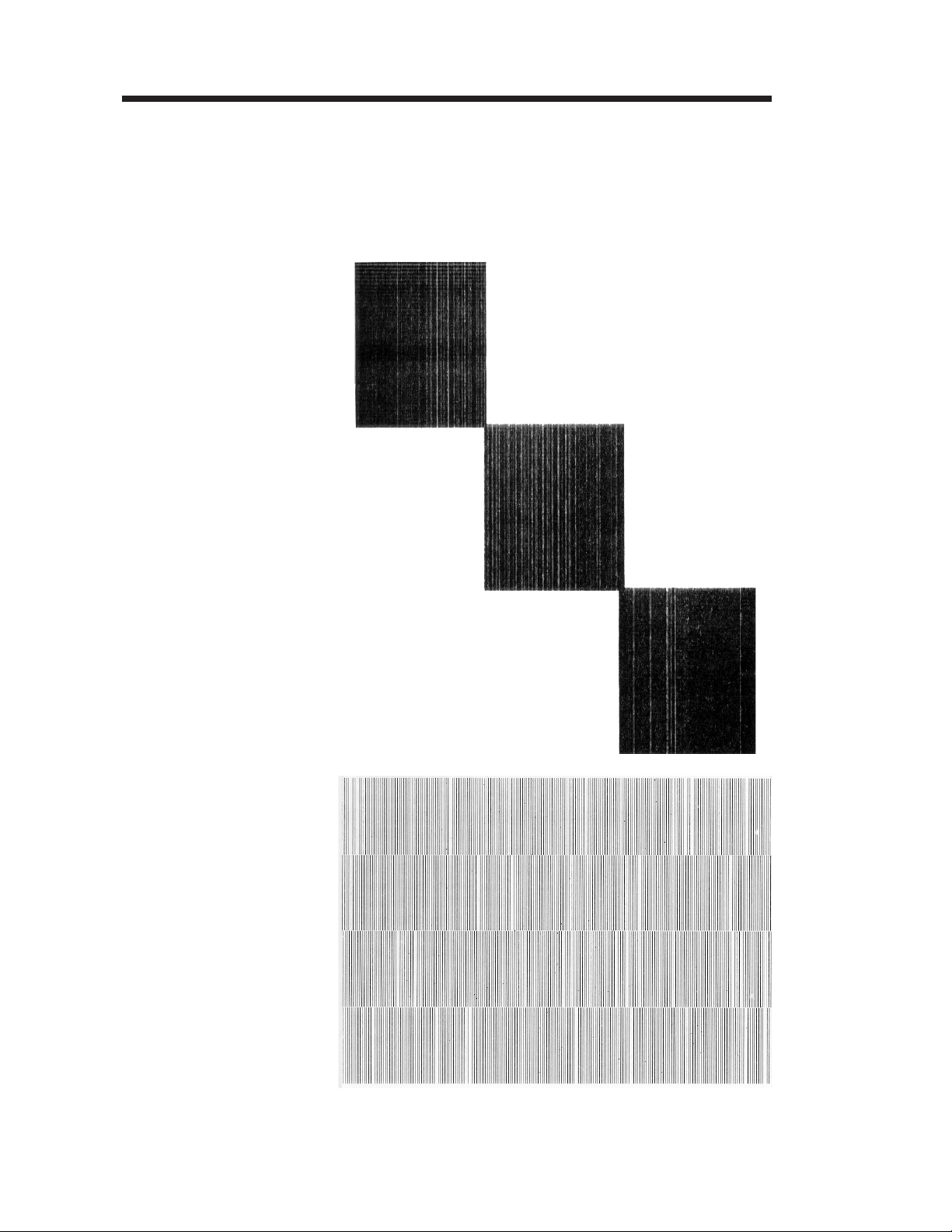

Below are photographs of three print heads.

The first print head is brand new. The second

has printed over 1 million linear inches of ther

mal transfer labels and has been properly main

tained. The third print head has printed far

fewer labels, but without proper care and main

tenance, signs of abrasion and contamination

build-up are evident.

-

-

-

New Over 1 Million Less Than 1 Million

Inches Inches

(Properly Maintained) (Without Proper Care)

Contaminant buildup occurs gradually and results in poor print quality that may look like

faded print or failed print element(s). This build

up is very resistant to cleaning with the

pre-soaked swabs and is difficult to remove.

Note - The one million inches of print head

usage shown in the illustration above is used for

reference only. The actual print head life will

vary due to enviromental conditions, printer

setup and the properties of the media used. See

Print Head Care for more details.

24 980342-001 Rev.A

Page 31

Operator Maintenance

Print Head Care The main factors that contribute to reduced

head life are:

Touching the print head! Static electricity

·

can discharge and damage the print head.

The body's oils and acids also damage the

print head.

Cleaning - For optimum performance,

·

clean the print head regularly after every roll

of thermal transfer ribbon or after every roll of

direct thermal labels.

Abrasion - Over time, the movement of me

·

dia/ribbon across the print head will wear

through the protective ceramic coating, ex

posing and eventually damaging the print el

ements (dots).

-

-

-

· Use of proper media - Use only approved

Zebra Technologies Corportation media.

Non-approved media may contain

chemicals that can destroy or dramatically

reduce the print head's life. Approved

thermal transfer ribbons have a special

anti-stick back coating that helps to dissipate

static and provide lubrication.

· Ribbon Width - Ensure that the thermal

transfer ribbon is as wide or wider than the la

bel media to prevent exposing the elements

to the more abrasive label material.

·

Temperature - Print head density (heat) set

ting. Set the density to the lowest possible set

ting that prints a good image.

·

Print Speed - Fast print speeds have higher

friction levels on the print head's surface.

-

-

-

·

Regular Print Head Conditioning - Use

our Save-a-Print head cleaning film to re

move print head contamination buildup

quickly and easily. (Part No.105950-047)

980342-001 Rev.A 25

-

Page 32

Operator Maintenance

MOVIE

Cleaning the

Print Head

Step Open the printer and the print head carriage.

As you use your printer, the print head may be

come contaminated resulting in poor print

quality. Whenever new labels are loaded into

the printer, the print head should be cleaned

with a cleaning pen.

Warning - Static Discharge - See page v.

Never touch the print head. Always clean the

print head with a cleaning pen (to protect the

print head from static discharge and fibers).

-

Print

Head

Cleaning

Pen

Don’t use the cleaning

pen for cleaning other

printer surfaces

Step Gently rub the cleaning pen across the surface

of the print head. Clean the black surface to

wards the front edge of the print head.

Allow the print head to dry for 1 minute before

loading labels.

Do Not Clean the Print Head with sharp

objects! Only used approved cleaning

materials.

-

26 980342-001 Rev.A

Page 33

Operator Maintenance

Platen Cleaning Liner-free platen printers require periodic

cleaning. Adhesive and particles can build up

and cause the media to stick.

The standard printer platen does not normally

require cleaning. Normal operation leaves label

liner particles which is normal. Clean the platen

only to remove adhesive (or other contami

nates).

Step Open the print head and remove the media.

Step Place a cleaning card on the platen (and all of

lower print mechanism).

-

Cleaning

Card

Step Press the FEED button and the media will feed.

Repeat until the cleaning card has ejected from

the front. If the card stops feeding with a media

out error, press the PAUSE and then the FEED

button to clear the error. Press the FEED but

ton. Repeat button sequence as necessary.

Step Repeat steps 2 and 3 until the platen is clean.

Do not re-use cleaning cards.

-

980342-001 Rev.A 27

Page 34

Operator Maintenance

Front Bezel Access The printer’s front bezel is designed for easy re

moval and replacement. Some printer mainte

nance operations are facilitated by the removal

of the front bezel.

Standard

Front Bezel

-

-

Inside of

Front Bezel

Bezel Guide Tabs in Slots

The front bezel should be installed for normal

print operations. The front bezel helps to keep

the printer clean. Some printer options

supercede the use of the standard front bezel.

Bezel

Retaining Tabs

Bezel Guide Slots

28 980342-001 Rev.A

Page 35

Operator Maintenance

MOVIE

Front Bezel

Removal

Step Open cover.

Step Slide the blade of the screwdriver between the

Pry Bezel

Arm Open with

Screwdriver

Swing Bezel

Down and Off

The front bezel can be easily removed with a

small blade screwdriver.

front bezel’s retaining tab arm and the inside

wall of the lower print mechanism.

While gently pulling on the top right corner of

the front bezel, gently pry the tab away from

the inside wall of the print mechanism.

980342-001 Rev.A 29

Page 36

Operator Maintenance

MOVIE

Replacing the

Front Bezel

Bezel

Retaining Slots

Step Align the bezel guide slots to the bezel guide

To replace the bezel, simply snap it onto the

printer.

Bezel

Guide Tabs

tabs on the bottom of the printer.

Insert Bezel Guide

Slot onto Tabs

Snap Retainer Tabs

into Retainer Slots

Step 2 Swing the bezel up while pivoting on the guide

tabs and into the print mechanism. The bezel

will snap in place with a gentle push. The re

tainer tabs will lock the bezel in place at the

print mechanism’s retainer slots.

-

30 980342-001 Rev.A

Page 37

Using the Label Dispense Option

3

Using the Label Dispense Option

This section provides information on the

printer’s Automatic Label Peel and Print option.

Label Dispense

Features

Peel Bar

Pinch

Roller

The printer can dispense a single peeled label

in the Label Dispense (Peel) mode. Removing

the presented label will prompt the printer to

print the next label.

Label Dispense

Bezel

980342-001 Rev.A 31

Modular Accessory

Socket and Plug

Label Taken

Sensor

Page 38

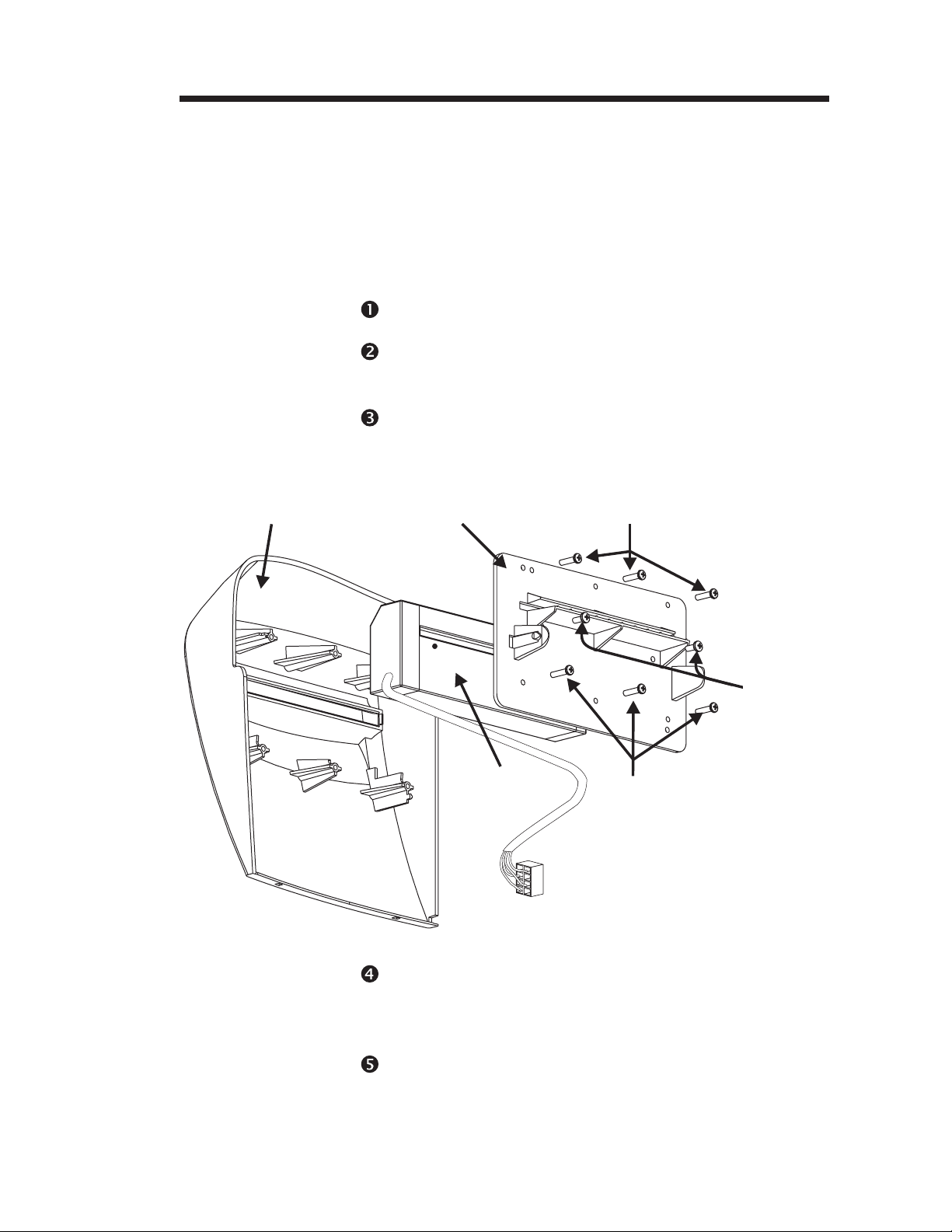

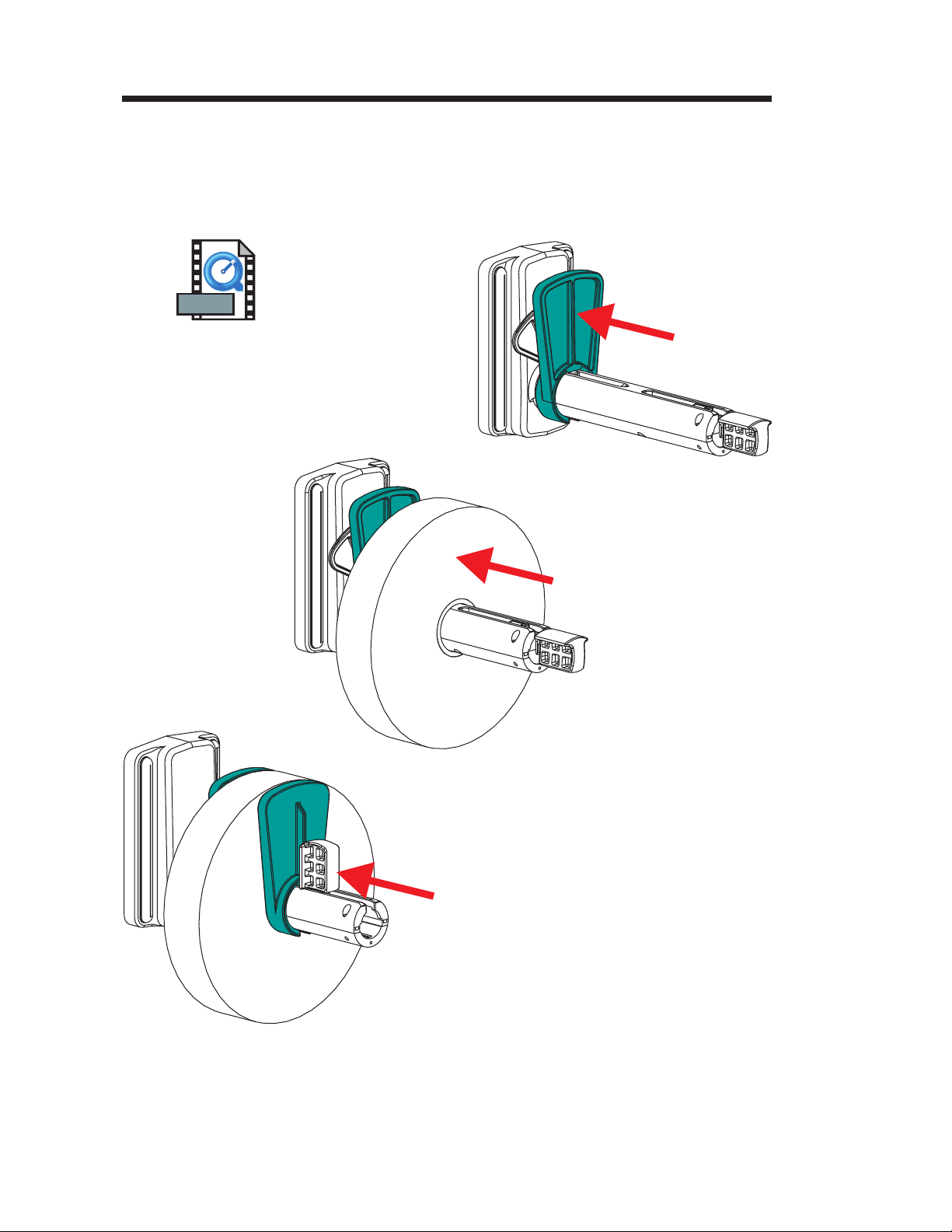

Using the Label Dispense Option

Label Dispenser

Mounting

Step Turn the power off. Open the cover. Remove

MOVIE

Step Open the print head. Insert the right side of the

Print Head

Right Side of

Peel Bar

The label dispenser is mounted in place of the

front bezel.

the bezel, see “Front Bezel Removal”, page 29.

peel bar into the print mechanism’s right peel

bar mounting slot. Note that the left side has the

beveled tab.

Open

Insert

Peel Bar

Mounting

Slot

Insert

Left Side of

Peel Bar

Swing the left side of the peel bar’s tab into the

peel bar guide channel and down into the left

mounting slot.

32 980342-001 Rev.A

Page 39

Using the Label Dispense Option

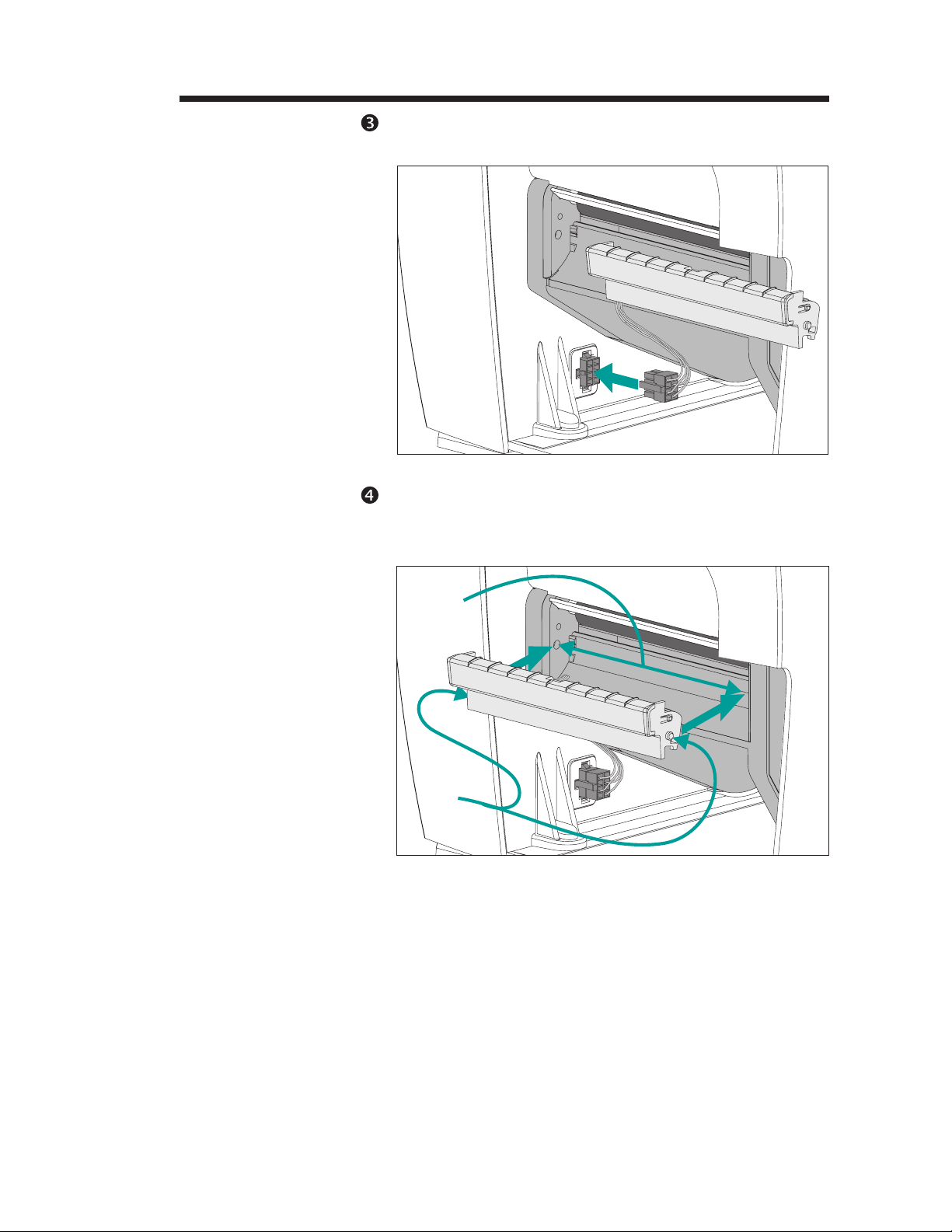

Step Connect the label dispenser’s (accessory) cable

plug into the accessory socket.

Plug-in Label

Dispenser

Step Slide the left tab of the label dispenser into the

left slot on the print mechanism. Swing the right

tab into the right slot.

Insert Label

Dispenser

Slots

Tabs

980342-001 Rev.A 33

Page 40

Using the Label Dispense Option

Label Dispenser

Mounting

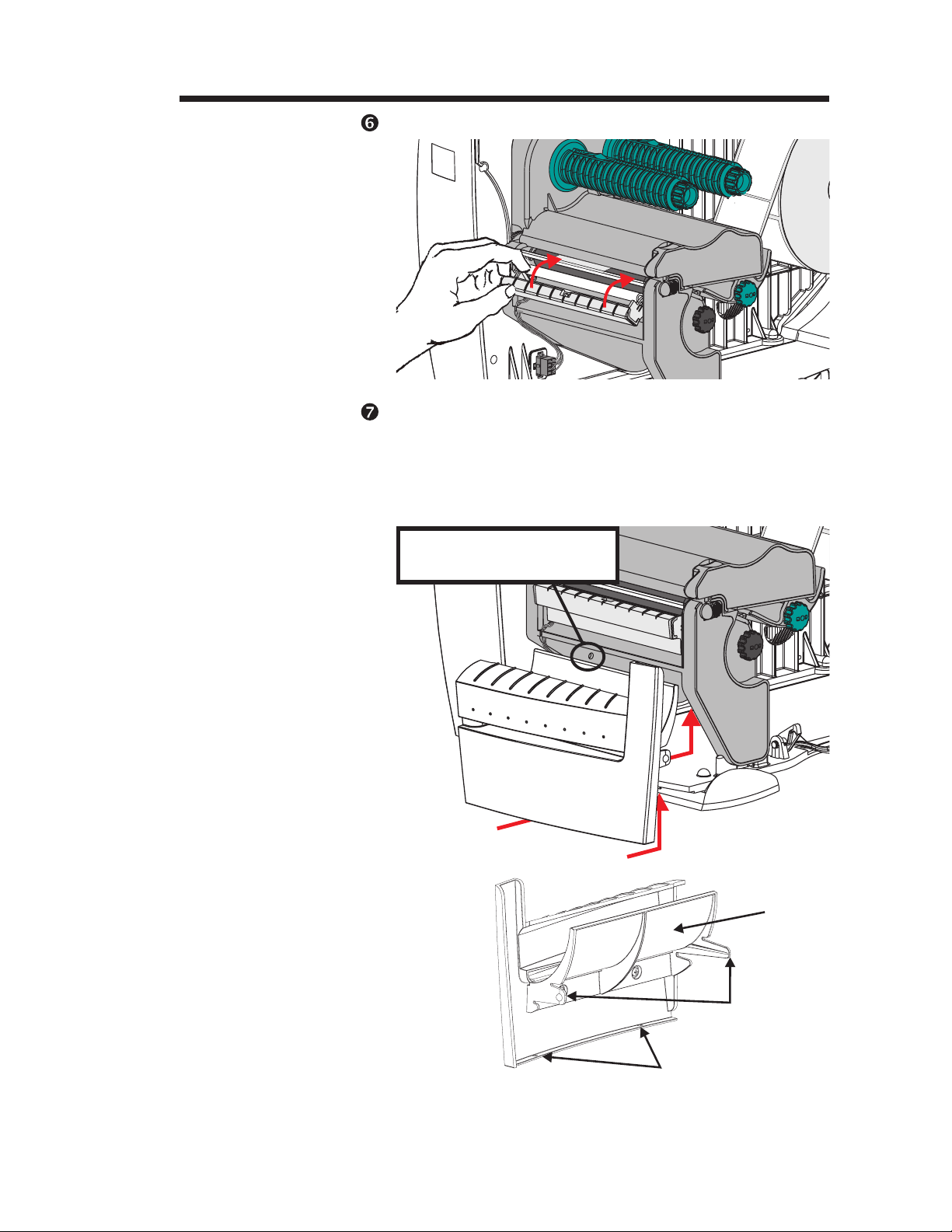

Step

Open

Label

Dispenser

Pull the label dispenser door open.

Slide the label dispenser’s cable into the slot immediately under the left end of the label dispenser.

Insert Cable

in the Slot

Pull Cable

Taut

Pull the cable gently down to remove slack

from the under side of the open label dispenser.

34 980342-001 Rev.A

Page 41

Using the Label Dispense Option

Step Close the label dispenser.

Step Insert the liner guide (on the inside of the label

dispenser bezel) into the area below the print

mechanism. Insert the bezel guide slots onto

the guide tabs on the bottom of the printer, see

page 29. Slide the bezel up to snap it in place.

Insert Bezel Guide

Slot onto Tabs

Snap Retainer Tabs

into Retainer Slots

Label Dispenser Bezel

Retainer Slot

(both sides)

Liner

Guide

Retaining

Tabs

Guide Slots

980342-001 Rev.A 35

Page 42

Using the Label Dispense Option

Using Label

Dispense

Step Open the cover.

Power ON

Labels Loaded

The printer can dispense a single peeled label

without the liner in the “Automatic” Label Dis

pense (Peel) mode. Removing the presented la

bel will prompt the printer to print the next

label.

Load and set label parameters (via AutoSense

or programmed with the Q command).

-

-

Press FEED

Step Press the FEED button until approximately 8

inches (20 cm) of media has exited the printer.

Step Remove the exposed labels from the media

liner (backing).

Peel

Exposed

Labels

36 980342-001 Rev.A

Page 43

Using the Label Dispense Option

Step Swing the label dispenser down to open.

Open the

Label

Dispenser

Step Thread the media liner (backing) below the

platen roller and above the pinch roller into the

liner slot.

Thread Media Liner

(Label Dispenser Bezel

Not shown)

980342-001 Rev.A 37

Page 44

Using the Label Dispense Option

Using Label

Dispense - Step

Thread the

Pull the

Liner Taut

Liner

Pull the liner taut and close the label dispenser.

The label dispenser will snap

into place.

Close Label

Dispenser

38 980342-001 Rev.A

Page 45

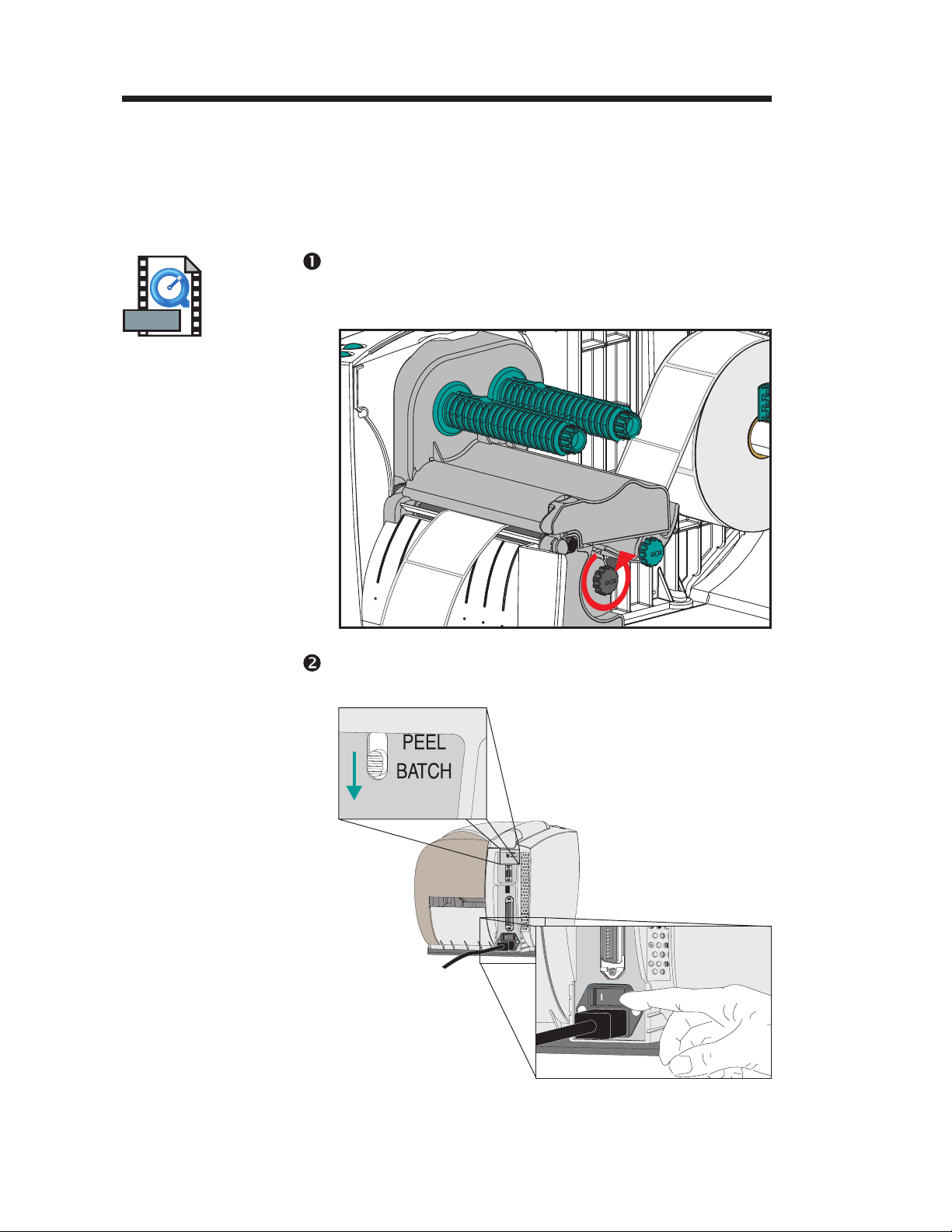

Step Change the printer mode switch to the “Peel”

MOVIE

Switch to Peel Mode

Remove Liner Slack

(Press FEED)

Using the Label Dispense Option

position at the rear of the printer. Reset the

printer or cycle the power.

Remove Label

Step Press the FEED button to remove liner slack

Step Close and latch the printer's cover.

Close Printer

Printer is Ready to

Dispense Labels

and peel a label from the liner backing. Remove the peeled label.

980342-001 Rev.A 39

Page 46

Using the Label Dispense Option

Label Dispenser

Removal

Step Disconnect the label dispenser plug. Press the

Step Open the label dispenser.

Step While holding the label dispenser in the open

Pinch, Hold

and

Lift Up to

Remove

Label

Dispenser

The label dispenser is designed for easy re

moval for cleaning and reconfiguration.

release and pull it out of the socket.

position on the right side, push the dispenser

from the bottom with a gentle steady pressure

to pop it off.

-

40 980342-001 Rev.A

Page 47

Using the Label Dispense Option

Peel Bar Removal The peel bar is easily removed without tools.

Using tools is not recommended. Personnel in

jury or damage to the printer could result from

using screwdrivers or other sharp objects to

wedge the bar out.

Step Open the print head.

-

Step Remove the bezel (see page 29) or label dis

Step Push the peel bar into the right side of print

Push the Peel Bar

to the Right

Swing the Peel Bar

Up and Out

penser (32), if present, to allow easier access to

the bottom of the peel bar.

mechanism and swing the bar up and out of the

bar’s guide slot. Hold the printer down with the

other hand. The peel bar may need some gentle downward pressure to slightly bend bar up

to slip the left end past the lip.

980342-001 Rev.A 41

Page 48

Using the Label Dispense Option

Printing with the

Label Dispenser

The printer can be programmed to print single

or multiples of a single label (form). Parameter

fields in the printer’s Print (P and PA) com

mands control the print quantity of a single

form (or job).

The P command can interact with the Counter

(C) command to make sequencing data fields

for serialization of labels. The printer also sup

ports printing multiples of a single number and

then sequencing the number. See the Page

Mode (EPL2) programmer’s for details.

The software controlling the printer may finish

printing with the printer storing the last label in

buffer memory. The printer will print the first

label and wait for it to be removed before allowing the second label to print.

-

-

42 980342-001 Rev.A

Page 49

Using the Liner Take-Up Option

4

Using the Liner Take-Up Option

This section provides information on the

printer’s liner take-up option.

Liner Take-Up

Features

Label Dispenser &

Sensor Assembly

The liner take-up option supports liner take-up

in Label Dispense (Peel) mode. The printer can

wind the label liner and present peeled labels

with or without the label dispenser option. Label dispensing without the label dispenser option must programmed into the printer with the

O,L command. This configuration uses the

FEED button to initiate printing.

Liner Take-Up

Tube

Media

Clip

Media Full

Sensor

980342-001 Rev.A 43

Page 50

Using the Liner Take-Up Option

Liner Take-Up

with Automatic

Label Dispense

MOVIE

The printer with the liner take-up mechanism

and the label dispenser option can dispense a

single peeled label and wind the backing in the

Dispense (Peel) mode. Removing the pre

sented label will prompt the printer to print the

next label.

Liner Take-Up Capacity - The quantity of

media liner wound will vary due to

environmental conditions and liner properties.

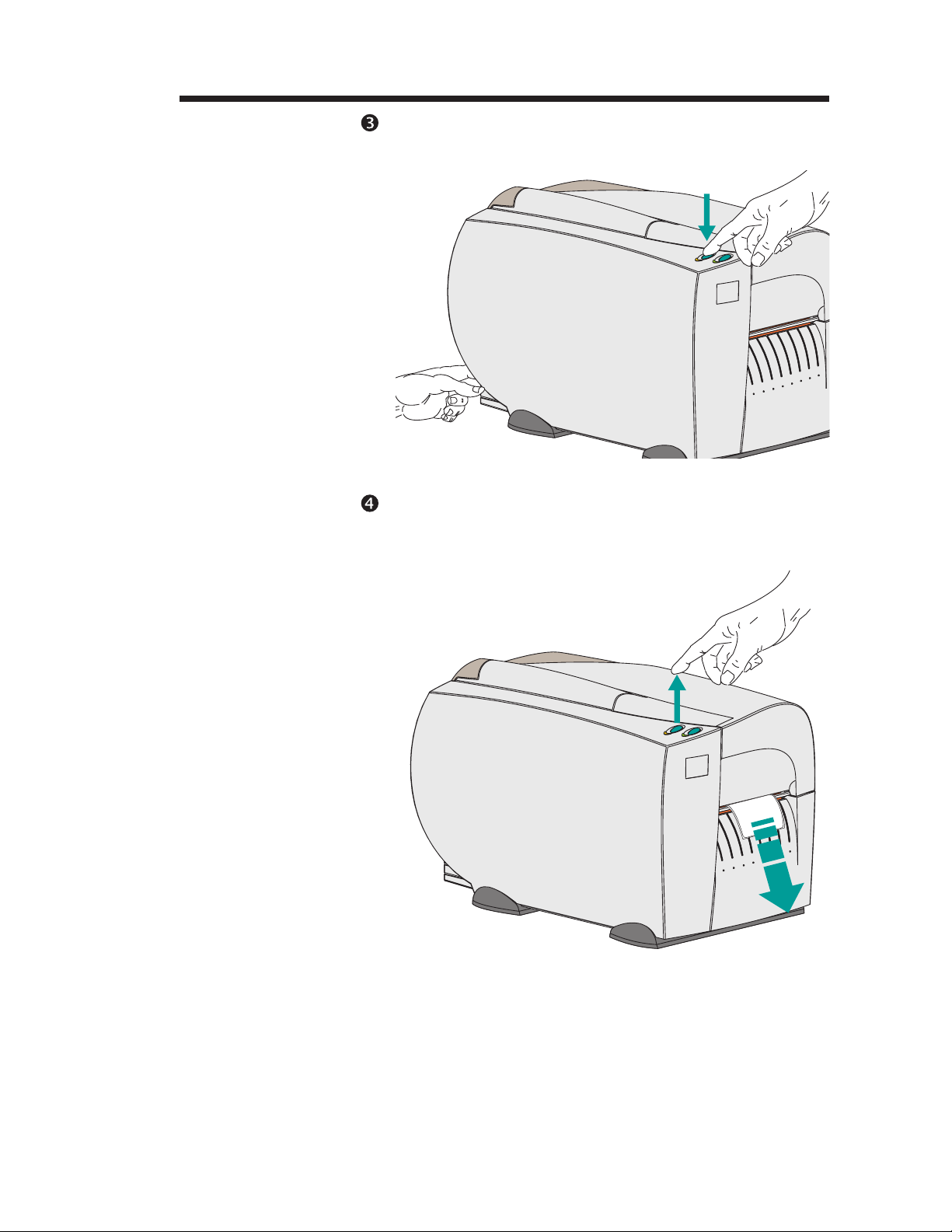

Step Open the printer cover. Remove front bezel, if

present. See Front Bezel Removal, page 29.

Step Load media and set media parameters (via

AutoSense, see page 16, or programming with

the Q command) in the printer.

StepStep Press the FEED button until approximately 16

inches (40 cm) of media has exited the printer.

-

Remove

Front Bezel

Load Media

FEED Labels

44 980342-001 Rev.A

Page 51

Using the Liner Take-Up Option

Liner Take-Up

Step

Peel Exposed Labels

Step Open the label dispenser door. Thread the me-

Remove the exposed labels from the media

liner (backing).

dia liner (backing) below the platen roller into

the liner slot.

Open the

Label Dispenser

Thread the Liner

980342-001 Rev.A 45

Page 52

Using the Liner Take-Up Option

Step Remove the media clip and thread the liner un

Remove

Media Clip

Thread Liner

Around the

Liner Take-Up Tube

-

der the liner take-up tube.

Media

Clip

Step Attach the liner to the liner take-up tube with

Attach Liner to

Liner Take-Up Tube

Remove

Liner Slack

the clip. Turn the liner take-up tube counter-clockwise to remove liner slack.

46 980342-001 Rev.A

Page 53

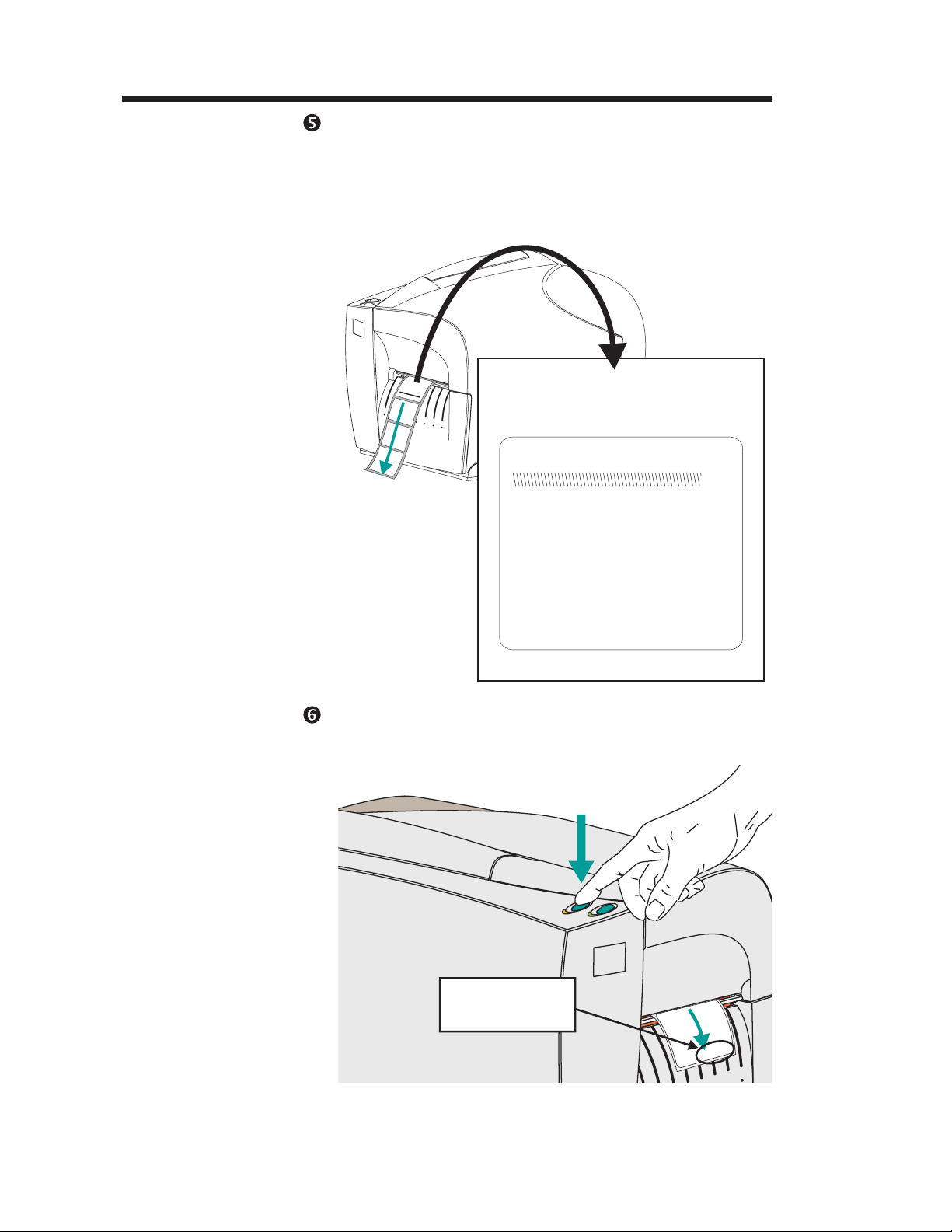

Using the Liner Take-Up Option

MOVIE

Liner Rewind

Step

Set Peel

Mode

Step If necessary, press the FEED button to remove

Change the printer mode switch to “Peel”

mode. Reset the printer or cycle the power.

slack and to wind minimum of one full revolution of liner around the liner take-up tube.

Press FEED

Step Close the printer.

Close Printer

Ready for

Press and

Print Label

Dispense

980342-001 Rev.A 47

Page 54

Using the Liner Take-Up Option

Manual Label

Dispense with

Liner Take-up

Step Load and thread the labels, see page 8.

Step Press FEED and remove labels until approxi

The printer with the liner take-up mechanism

can dispense a single peeled label and wind the

backing without the Label Dispenser Assembly

in the Dispense (Peel) mode. Remove the

presented label and press the FEED button to

print the next label. This configuration must

programmed into the printer with the O,L

command.

mately 16 inches (40 mm) of liner has been ex

posed.

-

-

Step Pull the liner under the print mechanism and

liner take-up tube. Attach the liner to the liner

take-up tube with the clip. Turn the liner

take-up tube counter-clockwise to remove liner

slack. See page 46 for more details and

illustration.

Step Close the printer and press FEED to present a

blank label. Remove the label.

Step Change the printer mode switch to “Peel”

mode. Reset the printer or cycle the power.

Step Send the EPL2 O,L command to finish config

uring the printer.

48 980342-001 Rev.A

-

Page 55

Using the Media Cutter

5

Using the Media Cutter

This section provides information on the

printer’s Media Cutter option.

Media Cutter

Features

Cutter & Bezel

Assembly

Printers with the cutter option have a detachable cutter with a motorized blade. The cutter is

a self cleaning tag and label liner cutter.

Modular Accessory

Socket and Plug

980342-001 Rev.A 49

Page 56

Using the Media Cutter

Cutter Guidelines Use the media cutter to cut through continuous

paper or the label liner in the gaps between la

bels. Never cut the portion of media that has

adhesive or adhesive backing.

You can switch cutting on and off by using the

OC command. You can set form length and

gap distances by using the Q command. A sin

gle cut can be made anytime the printer is not

printing with the C (Cut Immediate) command.

Refer to the Page Mode (EPL2) programmer’s

manual for complete programming informa

tion.

Keep the cutter dry. Never use any solutions or

solvents to clean the blade. If there is a jam, follow the steps for Clearing Cutter Jams.

-

-

-

Specifications

Warranty 90 Days

Mean Time To

Failure (MTBF)

Cutting Method Rotating, double edged blade

Media

Media Type Paper, Thermal Paper, Paper Tags, Paper Label Liners

Max. Density 200 grams/meter

Min. Width 1.0 inch (25 mm)

Max. Width 4.13 inches (105 mm)

500,000 cut cycles

2

(approximately 0.010 inches (0.254 mm) thick)

50 980342-001 Rev.A

Page 57

Using the Media Cutter

MOVIE

Mounting the

Cutter

Step Turn the power off. Remove the front bezel

Step Insert the cutter plug into the accessory socket.

Bezel

Retainer

Tabs

Use this procedure to attach cutter onto the

printer.

(and peel bar if present). See Front Bezel Re

moval, page 29.

Bezel

Retainer

Slots

-

Bezel Guide

Slots

Accessory

Socket

980342-001 Rev.A 51

Bezel Guide

Tabs

Cutter Plug

Page 58

Using the Media Cutter

Step Align and insert the bezel guide tabs to the bezel

Step Load media as required. Configure the printer

guide slots and insert. Swing the cutter bezel re

taining tabs into the print mechanism’s retain

ing slots. The cutter bezel will snap and lock into

place. See “Replacing the Front Bezel”, page

30, for more details.

for the selected media with the AutoSense rou

tine or programming. Continuous media and

black line or mark media required program

ming for proper configuration.

-

-

-

-

Step Configure the printer for cutting with program

ming or software. See the programmer’s man

ual for details on setting or canceling cutter

printer command settings.

Close the cover, if open.

Cutter Removal The cutter bezel is removed like the standard

front bezel, see page 29 for the “Front Bezel Removal” procedure.

Cleaning and

Clearing the

Media Cutter

The media cutter is designed to be self cleaning

and sharpening. Occasionally, the cutter needs

to have a cleaning cycle of 5 cuts to clean and

sharpen the blade. This cleaning should be af

ter use and prior to new periods of use. This is

the only approved method for cleaning the cut

ter blade. Do not use solutions or solvents to

clean the blade.

-

-

-

-

A single cut can be made anytime the printer is

not printing with the C (Cut Immediate) com

mand. Refer to the EPL2 programmer’s man

ual for complete programming information.

52 980342-001 Rev.A

-

-

Page 59

Using the Media Cutter

Clearing Cutter

Jams

Step Remove the media cutter assembly.

Step Remove the six (6) cutter bezel retaining screws

Step Remove the two (2) screws holding the cutter

Cutter Bezel

Always turn the printer power off. The only

tool required to clear a jam is a pair of small

tweezers. Never use your fingers or sharp ob

jects to clear jams.

If you cannot remove the jammed media with

tweezers, the media cutter may be opened.

on the back of the media cutter assembly.

mechanism to the cutter mounting bracket.

Cutter Mounting

Bracket

Bezel Retaining

Screws

-

Cutter

Mounting

Screws

Cutter

Mechanism

Bezel

Retaining

Screws

Step Clean the cutter bezel and mounting bracket as

required. Do not clean the cutter mechanism

with any liquid or moistened material!

Step Reassemble the cutter assembly and then re

mount the media cutter.

-

980342-001 Rev.A 53

Page 60

Using the Media Cutter

54 980342-001 Rev.A

Page 61

Miscellaneous Printer Options

6

Miscellaneous Printer Options

This section provides information on the printer

options that do not require physical interaction

by the operator to configure or use.

Factory Installed

Printer Options

The following options are factory installed options. They can not be added in the field.

· Liner-free Label Printing

(Non Stick Platen Roller)

· Real Time Clock (RTC)

· Asian Language Printing

·

300 dot per inch print resolution

·

RS-422 Serial Port Interface

(See Appendix A)

Add-On Options The following options can easily be added to

provide added features to your printer.

·

Keyboard Display Unit (KDU) - Used for

stand alone printer operation.

·

PrintServer - Ethernet/LAN adapter

·

Narrow Roll Media Adapters

980342-001 Rev.A 55

Page 62

Miscellaneous Printer Options

Liner-free Media

Printing

Real Time Clock

Features

Liner-free printing utilizes a special platen roller

and media path design for tear and print label

ing applications. The unique liner-free media is

normally a roll of continuous media. Liner-free

printing allows the programmer to provide vari

able lengths of labels without changing the me

dia roll.

Liner-free printer’s require more frequent

cleaning of the media path, platen roller and

print head due to accumulation of small

amounts of adhesive. See Section 2 for more

details on printer maintenance procedures.

The printer’s Real Time Clock has a ten (10)

year, self contained battery power source. The

time and data are adjustable, including the displayed format. The use, access and configuration of the Real Time Clock is done through

software or programming. See the EPL2 Programmer’s manual for more details.

-

-

-

Checking for

Time & Date

Use the printer’s AutoSense procedure to generate a Dump Mode (status) printout. A printer

U command will also print a Dump Mode status

printout.

RTC Dump Mode Status Information:

·

Use it to check for the RTC option in printer.

When time and date are displayed, it shows

the presently set Time & Date and that the

RTC is installed in the printer.

·

Display presently set Time & Date.

56 980342-001 Rev.A

Page 63

Miscellaneous Printer Options

Programming with

the Real Time

Clock Option

The list below is for quick reference when pro

gramming the RTC option features:

TS - Set Time & Date

·

TT - Define Time Layout as a command or

·

Insert Time Function as a variable in a

“DATA” field.

TD - Define Date Layout as a command or

·

Insert a Date Function as a variable in a

“DATA” field.

A - ASCII or Asian (double byte ASCII text)

·

as a variable function within the “DATA”

string.

· B - Bar Code as a variable function within the

“DATA” string.

· Simple Math Functions as part of the A

(text) or B (bar code) commands.

-

Asian Language

Printers

See the EPL2 Programmer’s manual for more

details.

The Asian language capable printer supports

one of the three (3) available Asian languages:

Chinese, Korean or Japanese. The Ht-146

Asian printer, offered as a factory option only,

requires a special PCBA with additional mem

ory to support the large pictographic Asian

character sets. The standard character sets are

also supported by these printers. See the Page

mode (EPL2) Programmer’s manual for more

details.

-

980342-001 Rev.A 57

Page 64

Miscellaneous Printer Options

High Resolution

300 dpi Printers

Keyboard Display

Unit (KDU)

The high resolution 300 dots per inch printing

is available as a factory option only.

When programming, be aware that the 300 dpi

printer has 11.8 dots per millimeter verses the 8

dots per millimeter of the standard 203 dpi

printer. Multiply all 203 dpi dot measurements

(command parameters) by 1.5 to recreate ex

isting label formats. External graphics or logos

(PCX files) must be recreated or scaled to 1.5

times the original dot size to remain the same

size.

The Keyboard Display Unit allows the operator

to print label formats previously stored into the

printer’s flash memory. The operator can call

forms to print to type or scan data. The KDU

has a scanner serial port for including a third

party scanning device.

-

KDU

Setup

Printer

KDU

Scanner

(3rd Party)

See the KDU manual and the EPL2 Program

mer’s manual for details.

The KDU supports multiple languages.

-

58 980342-001 Rev.A

Page 65

Miscellaneous Printer Options

The PrintServer The PrintServer is a 10Base-T Ethernet adapter

that includes a suite of IT management and in

stallation tools. The PrintServer will work on

networks that utilize TCP/IP and/or IPX proto

cols.

The PrintServer Supports:

TCP/IP and IPX protocols

·

Windows™ 95/98

·

Windows™ NT

·

Netware

·

Peer to Peer Networking

·

· HP JetAdmin

-

-

· SNMP

See the PrintServer data sheet and the installation and operator’s guide at the Zebra web site

(http://www.zebra.com) or on the printer’s software and documentation CDROM for this

printer.

980342-001 Rev.A 59

Page 66

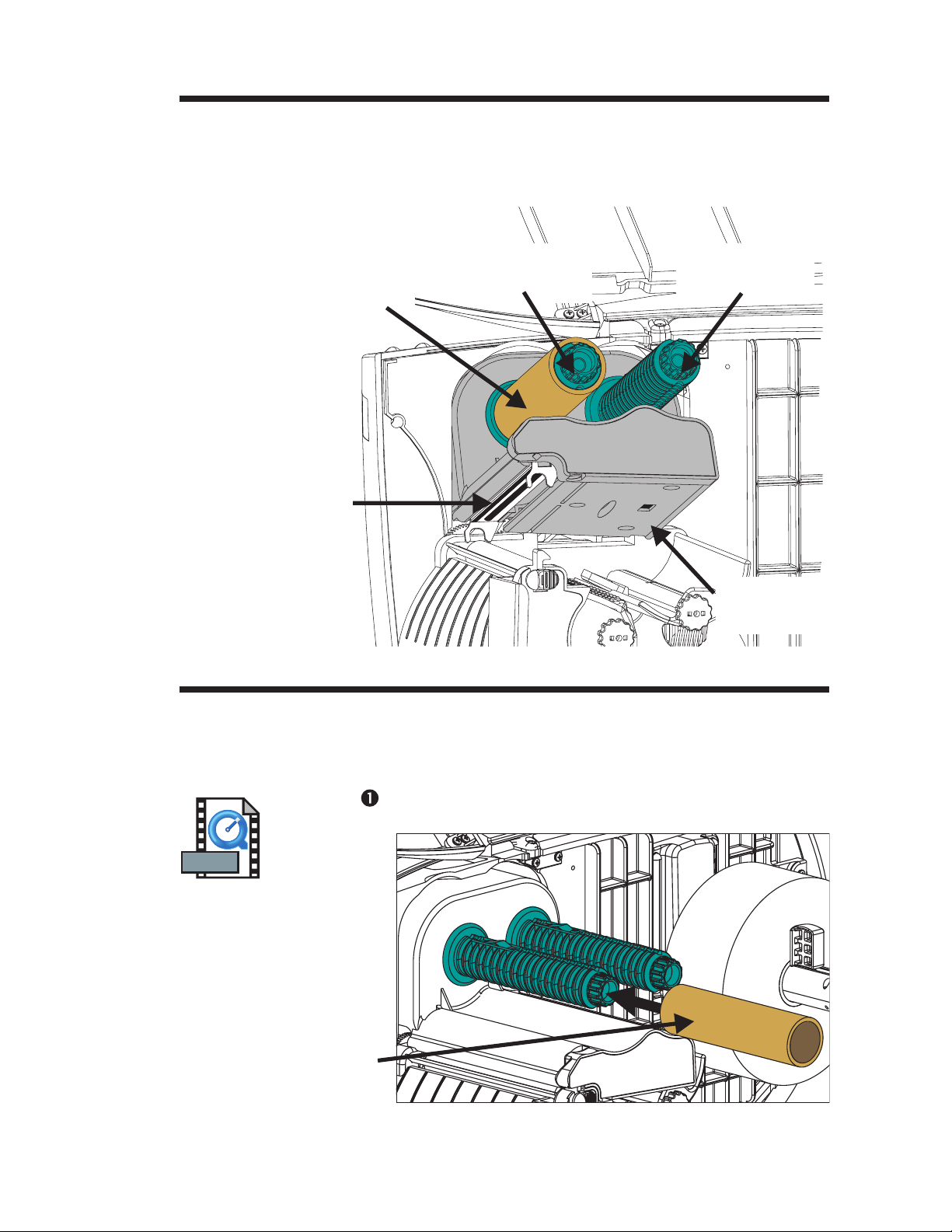

Miscellaneous Printer Options

Narrow Media

Adapters

MOVIE

The printer has media roll adapters for media

that is less than 2 inches wide to a minimum

width of 1 inch. Slide the adapters on the media

roll holder and around the roll. The tall sides of

the adapters face the media roll, see below.

60 980342-001 Rev.A

Page 67

Troubleshooting

Appendix A

Troubleshooting

This section addresses the most common issues

you may face with operation, maintenance and

configuration of the printer.

Where to Start Your first troubleshooting reference source is

the Common Problems Troubleshooting table

on the following page.

980342-001 Rev.A 61

Page 68

Troubleshooting

Common Printing Problems

Troubleshooting Guide

Problem Solution or Reason

Status indicators do not

light with printer power

ON (=1).

With the POWER

indicator GREEN, the

printer appears to be

working, but nothing is

printed.

Printing stops and the

indicators are:

Power - Off

Error - Amber

1. Check power connections from the printer to

the outlet.

1. Verify that the labels are the correct type.

2. Check the roll and verify that the print surface

faces up for printing.

3. Check that the transfer ribbon is correctly

routed and has the ink side out for thermal

transfer printing, only.

1. Check for Out-of-Media or Ribbon condition,

missing labels in the middle of a roll, ribbon

damage or label jam.

2. Possible problem sensing labels.

a) For labels, verify the reflective sensor (light

source with red dot) is positioned under the

Transmissive sensor.

b) Perform AutoSense adjustment.

3. Possible problem with media.

a) Gap between the bottom of a label and the

top of the next label should be at least 1/16"

(1.6mm).

b) For tags, see Gap and Index Hole Sensing

Range, page A-70.

c) Use only Zebra approved labels and tags.

4. Possible software/programming problem.

Refer to the Page Mode (EPL2) Programming

manual for the correct data syntax.

The printer has issued

a command and the

indicators are:

Power - Off

Error - Amber

1. Media is not loaded or properly loaded.

2. When direct thermal printing, verify that the

programmed mode (or printer driver) is set for

direct thermal printing. See the programmer’s

manual for details. The printer maybe detect

ing the absence of transfer ribbon.

-

62 980342-001 Rev.A

Page 69

Problem Solution or Reason

Troubleshooting

The printer has issued

a command, media

moves and then stops.

The indicators are:

Power - Green

Error - Amber

Printing is faded or

poor quality.

Printer cuts (melts)

through the transfer

ribbon. The ribbon is

advancing normally,

i.e. at the same rate as

the media.

1. Verify that the adjustable reflective media sen

sor is correctly positioned to detect an inter la

bel gap, index holes (notches), or black marks

(stripes). See page 15 for sensor location and

setting.

2. Not detecting label gaps properly. Perform

AutoSense.

1. Clean the print head with cleaning pen.

2. Adjust print speed/darkness in software or

with programming.

3. Check the roll and verify that the media print

surface is facing up.

4. Verify that the correct combination thermal

transfer ribbon and media are in use.

5.- The print head life may have been exceeded

if quality is still poor after cleaning, see Print

Head Replacement on page 74.

1. Verify the density (heat) setting. If this is unknown reduce setting several levels the until

the transferred ink is clear and the ribbon is

not damaged.

2. Verify that the correct media is in use.

3. Verify that the ink (transfer material) side is

out on the transfer ribbon roll.

-

-

Label Dispense Mode:

Printing does not stop

between labels.

Label Dispense Mode:

Prints one label and

stops.

Cutter Option:

Cutting labels instead

of cutting between

labels.

980342-001 Rev.A 63

1. The Peel/Batch switch in the rear of the

printer is not set to peel.

2. The dispenser door is open (down position).

1. Programming - Verify the quantity has been

correctly set.

1. Programming - Verify form length setting.

2. Check that peel switch is in the "batch" posi

tion (towards outside of printer).

-

Page 70

Troubleshooting

Printer

Configuration

Settings

The printer has flash (non-volatile) memory to

store printer configuration settings. The settings

are stored in flash memory and are set by

programing, printer drivers or the AutoSense

routine. The settings are shown on the Dump

mode printout or can be reported back to the

host via the serial port.

The following are the basic settings stored in the

printer:

Print Mode - Direct (OD) or Thermal Transfer

(O)

Speed (S)

Density (D) or heat applied

Form (label) length and gap in dots (Q)

Form (label) width in dots (q)

Serial Port (Y)

Margin (R)

Buffer Mode (r)

Dump Mode

Printout

(See the U command in

the Programmer’s manual

for details)

Options: D

Print Mode is Direct Thermal (OD)

64 980342-001 Rev.A

Page 71

Troubleshooting

Media The two types of printing methods supported

by the Ht-146 printer family are direct thermal

and thermal transfer. Direct thermal media is

chemically treated to produce print without a

ribbon. Thermal transfer printing uses heat to

transfer wax, resin or a combination of both

from the transfer ribbon to the media.

The printer is set by default to direct thermal

printing. Set the printer to thermal transfer

mode to activate a ribbon out sensor.

Media Sensing The printer is equipped with a transmissive

(gap) sensor, reflective (black mark) sensor,

and a reflective ribbon out sensor. The

transmissive and ribbon out sensors are fixed

position sensors. The reflective sensor is adjustable. Printers with the label dispense option,

have a reflective (label taken) sensor.

The transmissive (gap) sensor is set by

AutoSense and it adjusts the sensitivity and detection levels for the media in use. The

transmissive sensor also detects the media out

condition. The sensor’s light source comes

from the adjustable reflective sensor when set

immediately below the gap sensor (under the

media).

The reflective (black mark) sensor senses light

(media) and dark (black marks) on the media

backing (or liner). The reflective sensor is ad

justable from a near center position to the out

side edge of the media (towards the inside

wall).

The ribbon out sensor reflects light off the rib

bon’s reflective end marker (trailer). When rib

bon is present (and unused), the light is stopped.

-

-

-

-

The label taken sensor detects light reflected

from a peeled label waiting to be removed.

980342-001 Rev.A 65

Page 72

Troubleshooting

Reflective Sensor

Positioning

Top Of Form

Sensing

Gap Sensing The gap sensing feature depends on the ability

The printer has a moveable sensor to detect

black lines (or marks) or index holes (or

notches) from the back side of the media. The

sensor includes a red targeting light for ease of

use. The sensor should be centered on the

black mark or index hole (or notch). Move the

sensor position by turning the black adjustment

knob on the lower print mechanism. Typically,

the media does not require a sensor position

adjustment.

To accommodate different media and media

dimensions, your printer is equipped with sen

sors capable of detecting the top of form for la

bels or tags. Two methods are used by the

printer for top of form sensing: gap sensing and

black mark sensing.

of the transmissive (gap) sensor to “see

through” the label liner between labels. Label

and label backing opacity vary due to manufacturing differences in label stock. The sensor

may have difficulty distinguishing the difference between labels and the liner. This may require the user to AutoSense the media. Set the

gap sensor’s sensitivity with the AutoSense fea

ture. Verify that the reflective sensor’s position

(note the red light) is immediately below the

transmissive (gap) sensor. For all gap sensing

operations, the sensor must be in this position.

-

-

-

Black Mark

Sensing

66 980342-001 Rev.A

The black mark uses a reflective (black mark)

sensor to detect a black line (mark) on the

media backing. The black mark sensor is used

with special labels that have a black mark

printed on the back of the label liner or tag

between each label or tag. When printing with

black mark media, the sensor does not need to

be aligned with the upper transmissive (gap)

sensor to work and can be moved.

Page 73

Troubleshooting

Black Mark and

Index Hole

Sensing Range

Sensor

Adjustment

Range

Inside Edge

of Tag Stock

The reflective sensor’s position is indicated by a

red light that is visible through the media with

the print head open. The sensor can be moved

by rotating the black knob on the lower portion

of the print mechanism. For proper sensing, en

sure that the sensor is aligned with the center

portion of the black mark or index hole/notch.

The following dimensions show the required

position of the index hole or notch on tag stock

.

C

min. max.

B

A

Tag Tear-away

-

.314 Nominal Sensor Location

Dimension Min. Max. Nominal

A .236" None .512"

B .079" .512" .118"

C .098" 1.520" N/A

Print Head Life The print head has a limited life and is consid

ered a consumable item. The media rubs

across the print head print elements and wears

away the surface. This process is affected by

many factors relating to the media material, op

erational settings and environment.

-

-

980342-001 Rev.A 67

Page 74

Troubleshooting

Serial Interface

Communication

Configuration

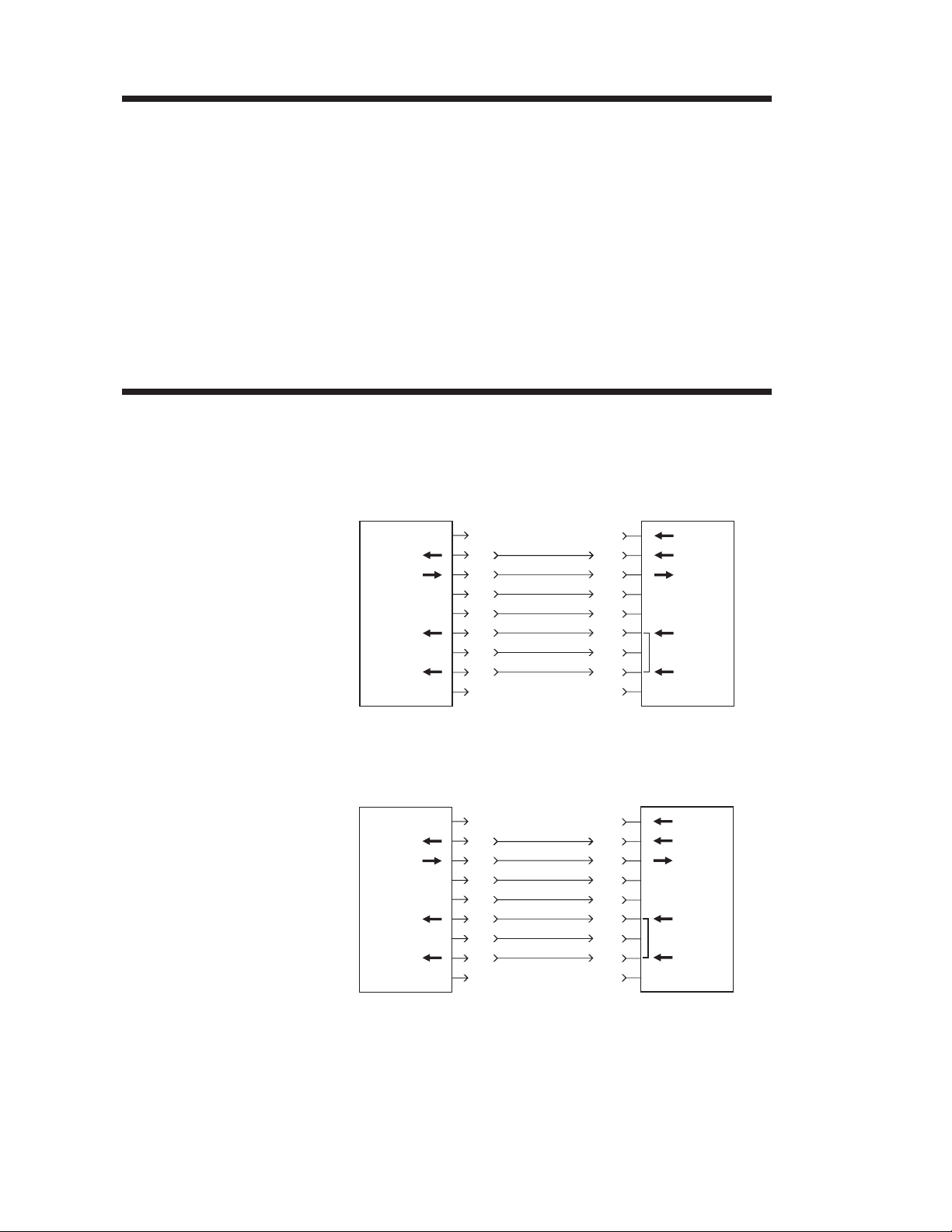

RS-232 Serial

Interface Cable

Wiring

The printer’s serial port is configured with the

Y command for the printer. The printer sup

ports interface data rates from 1200 to 38,400

baud. See the EPL2 programmer's manual for

details.

The printer’s serial port default configuration is:

9600 baud

8 bit data

1 stop bit

No parity

The figure below displays the cable wiring re

quired to use the printer’s serial interface.

DB-9

Pin #

N/C

RxD

TxD

DTR

GND

DSR

RTS

CTS

RI

Female DB-9 to Male DB-9

Cable P/N 300017-006 (6') or 300017-010 (10')

DB-9

Pin #

11

22

33

44

55

66

77

88

99

PrinterHost

+5 Volts*

TxD

RxD

N/C

GND

RDY

N/C

RDY

N/C

-

-

DB-25

Pin #

N/C

RxD

TxD

DTR

GND

DSR

RTS

CTS

RI

Female DB-25 to Male DB-9

Cable P/N 300018-006 (6')

*+5 volts at 150 mA for external device (e.g. KDU or scanner)

DB-9

Pin #

18

23

32

420

57

66

74

85

922

PrinterHost

+5 Volts*

TxD

RxD

N/C

GND

RDY

N/C

RDY

N/C

68 980342-001 Rev.A

Page 75

Troubleshooting

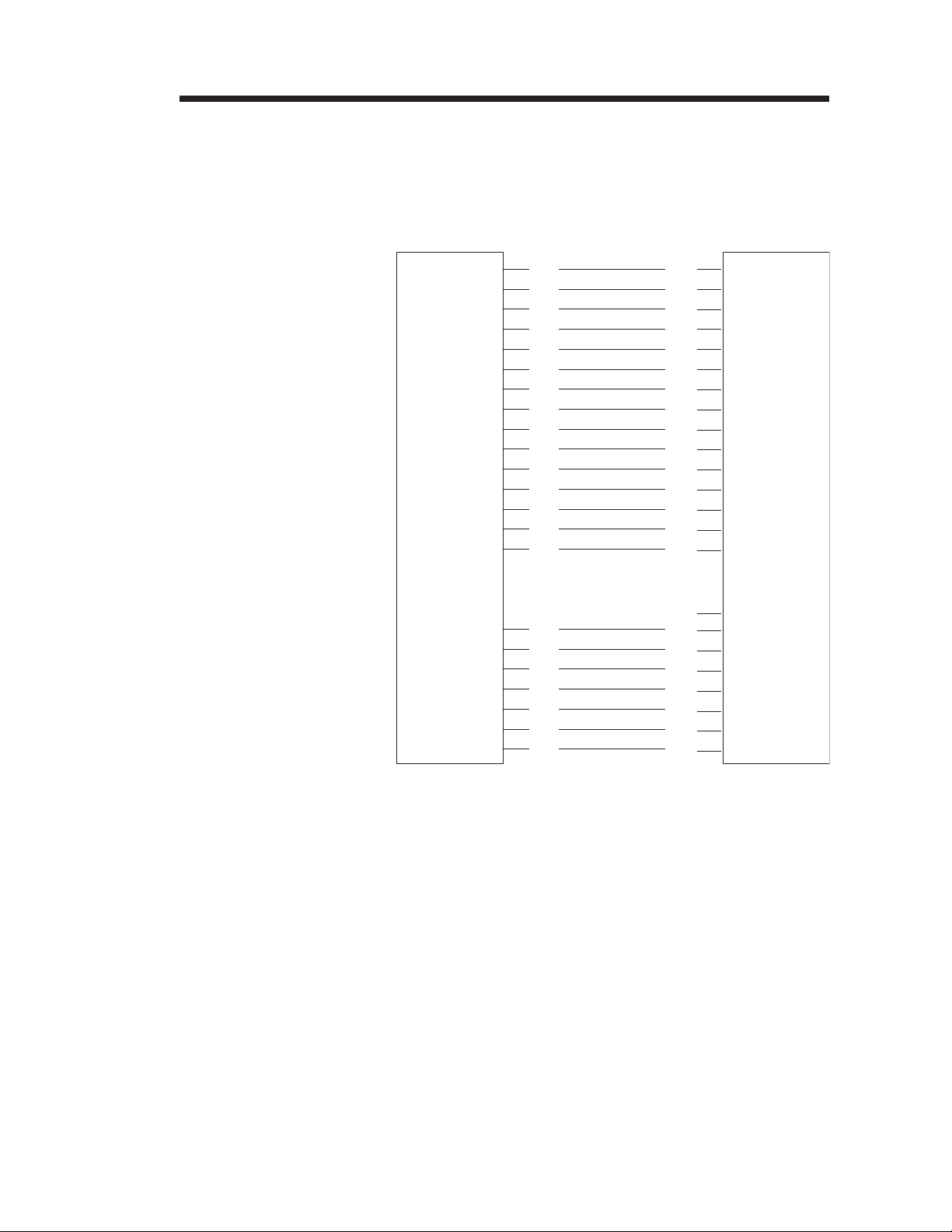

Parallel Interface

Cable Wiring

The figure below displays the cable wiring

required to use the printer's Centronics parallel

interface.

HOST

STROBE

DATA 0

DATA 1

DATA 2

DATA 3

DATA 4

DATA 5

DATA 6

DATA 7

ACK/

BUSY

PAPER ERR.

READY

INIT

ERROR/

N/A

N/A

N/A

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

DB-25

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Centronics

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

PRINTER

STROBE

DATA 0

DATA 1

DATA 2

DATA 3

DATA 4

DATA 5

DATA 6

DATA 7

ACK/

BUSY

PAPER ERR.

READY

INIT

ERROR/

N/A

N/A

+5V

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

SIG. GND

Female DB-25 to Male Centronics

980342-001 Rev.A

(Cable)

+5 volts at 300 mA for external device (e.g. PrintServer)

69

Page 76

Troubleshooting

USB Interface

Cable Wiring

USB

Connector

The figure below displays the cable wiring

required to use the printer's USB interface.

Pin Signal

2

3

1

4

1 Vbus - N/C

2D-

3D+

4 Ground

Shell

Shield /

Drain Wire

For printer supported operating systems and

USB drivers, see the software and documenta

tion CD or visit the Zebra printer web site at:

http://www.zebra.com

For information on the USB interface go to the

USB web site, at:

http://www.usb.org

-

Printer Option:

RS-422 Serial

Interface Cable

Wiring

The figure below displays the cable wiring required to use the printer’s optional RS-422 serial interface.

DB-9

Printer

Pin #

1

2

3

4

5

6

7

8

9

+5V *

+T

+R

–R

N/C

–T

N/C

–T

N/C

*+5 volts at 150 mA for external device

70 980342-001 Rev.A

Page 77

Print Head Replacement Procedures

Appendix B

Print Head Replacement Procedures

The following section has print head evaluation

information and print head replacement procedure.

Warning - Static Discharge - The discharge

of electrostatic energy that accumulates on the

surface of the human body or other surfaces can

damage or destroy the print head or electronic

components used in this device.

DO NOT TOUCH the print head or the

electronic components under the print head

assembly accept during replacement.

Prepare a static-safe work area for repair. The

area must include a properly grounded

conductive cushioned mat to hold the printer

and a conductive wrist strap for the technician.

ESD protective devices are available from most

electronic supply stores or by contacting 3M

corporation at (800) 328-1368.

980342-001 Rev.A 71

Page 78

Print Head Replacement Procedures

Identifying Print

Head Problems

Weak or Damaged

Print Elements

(Full-On Print

Pattern)

The print head wears with printer use. If the

print quality does not improve after cleaning,

the print head may require replacement. Print

ing with worn damaged print elements may

create unreadable bar codes. The following are

examples of print head wear or damage.

-

Weak or Damaged

Print Elements or

Print Logic

(Rotating Print

Element Pattern)

72 980342-001 Rev.A

Page 79

Print Head Replacement Procedures

Print head damage can be caused by: improper

cleaning with unapproved fluids or imple

ments, electro static discharge (ESD), and

touching the print head (contaminates, ESD

and body oil acids).

-

980342-001 Rev.A 73

Page 80

Print Head Replacement Procedures

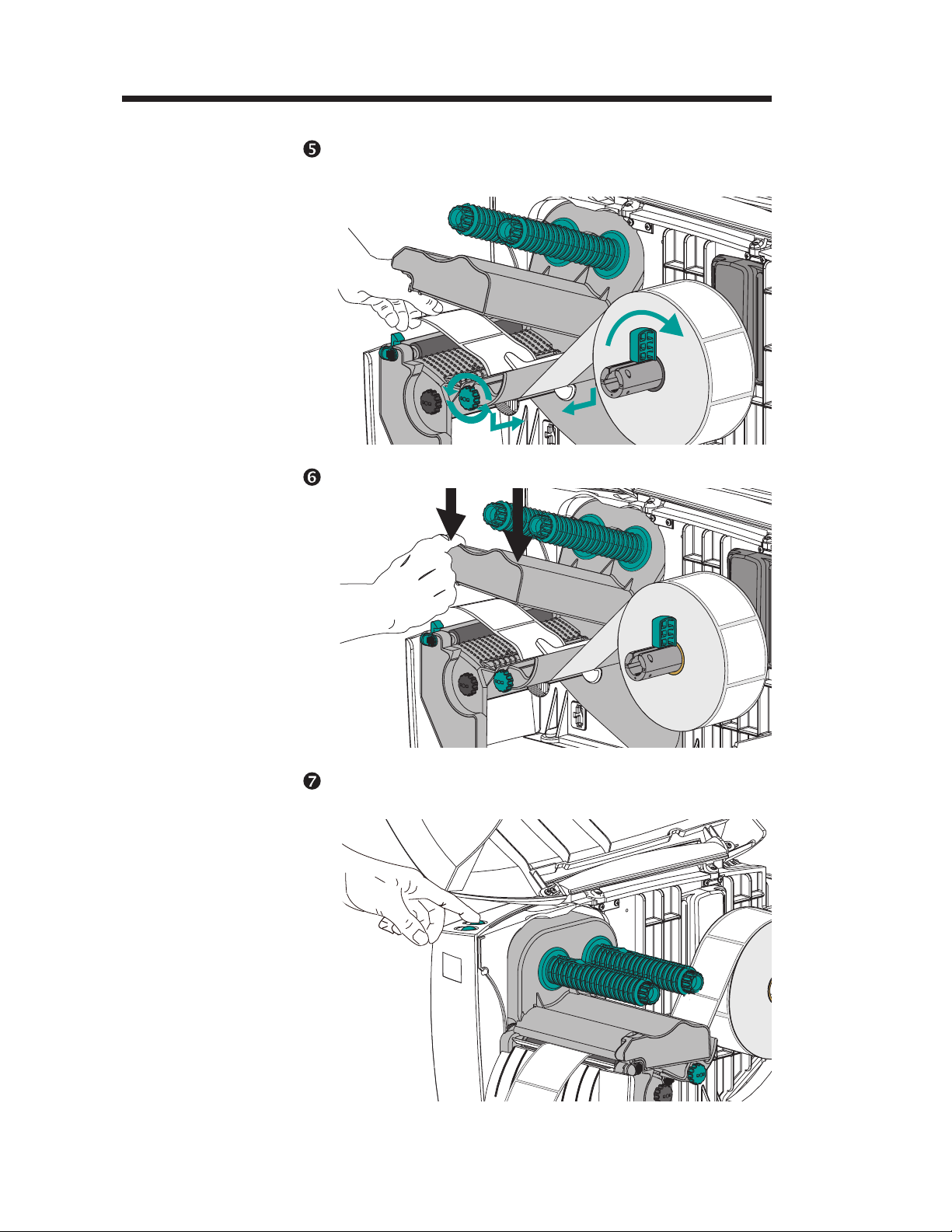

Print Head

Replacement

MOVIE

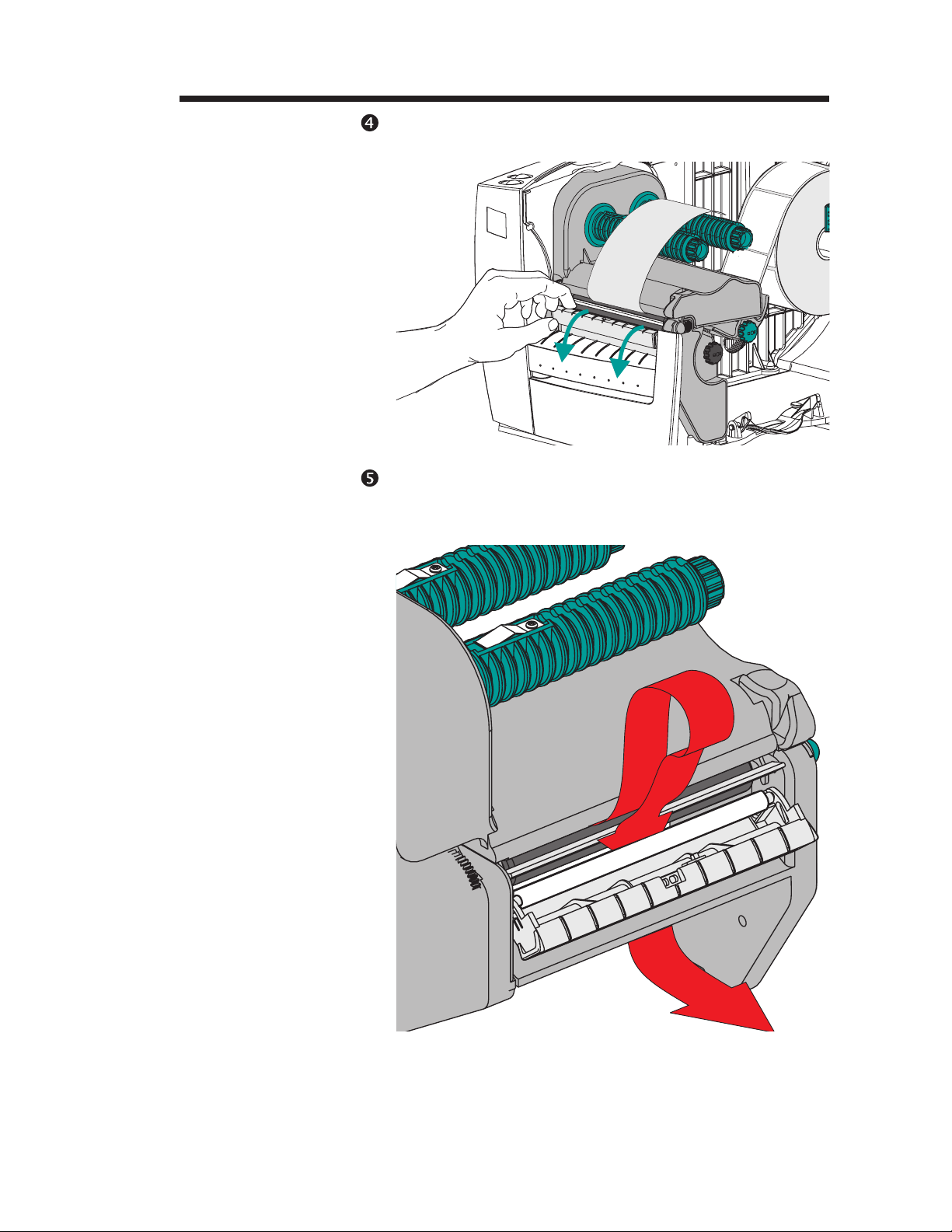

Step 1

Turn printer power off. Open the print head.

Remove any thermal transfer ribbon, if present.

Step 2 Remove the print head shroud. Slide the

shroud forward to detach (unsnap) it from the

print head mechanism.

Slide Shroud

Forward

Push

Here

Wiggle the

Shroud

Set Shroud

Aside

74 980342-001 Rev.A

Page 81

Print Head Replacement Procedures

Step 3 Push the print head up into the print mecha

Push The Print Head

Bracket to the Back

(Cables Not Shown)

Spring Action Pops

Bracket Out

-

nism and slide it to the back of the printer.

Step 4 Disconnect the print head cables. Avoid pulling

the cables.

980342-001 Rev.A 75

Page 82

Print Head Replacement Procedures

Step 5 Disconnect the ground wire lug on the top of

the print head bracket with a Philips screw

driver. Discard old print head and bracket.

Disconnect

Ground Wire

-

Step 6 Reconnect the new print head and bracket as-

sembly to the ground wire.

Step 7 Reconnect the print head cable to the print

head. The connectors are keyed to go together

one way. Do not force the connectors. The connector with the black wires goes on the outside

and the connector with the white wires goes on

the inside toward the center panel of the

printer.

76 980342-001 Rev.A

Page 83

Print Head Replacement Procedures

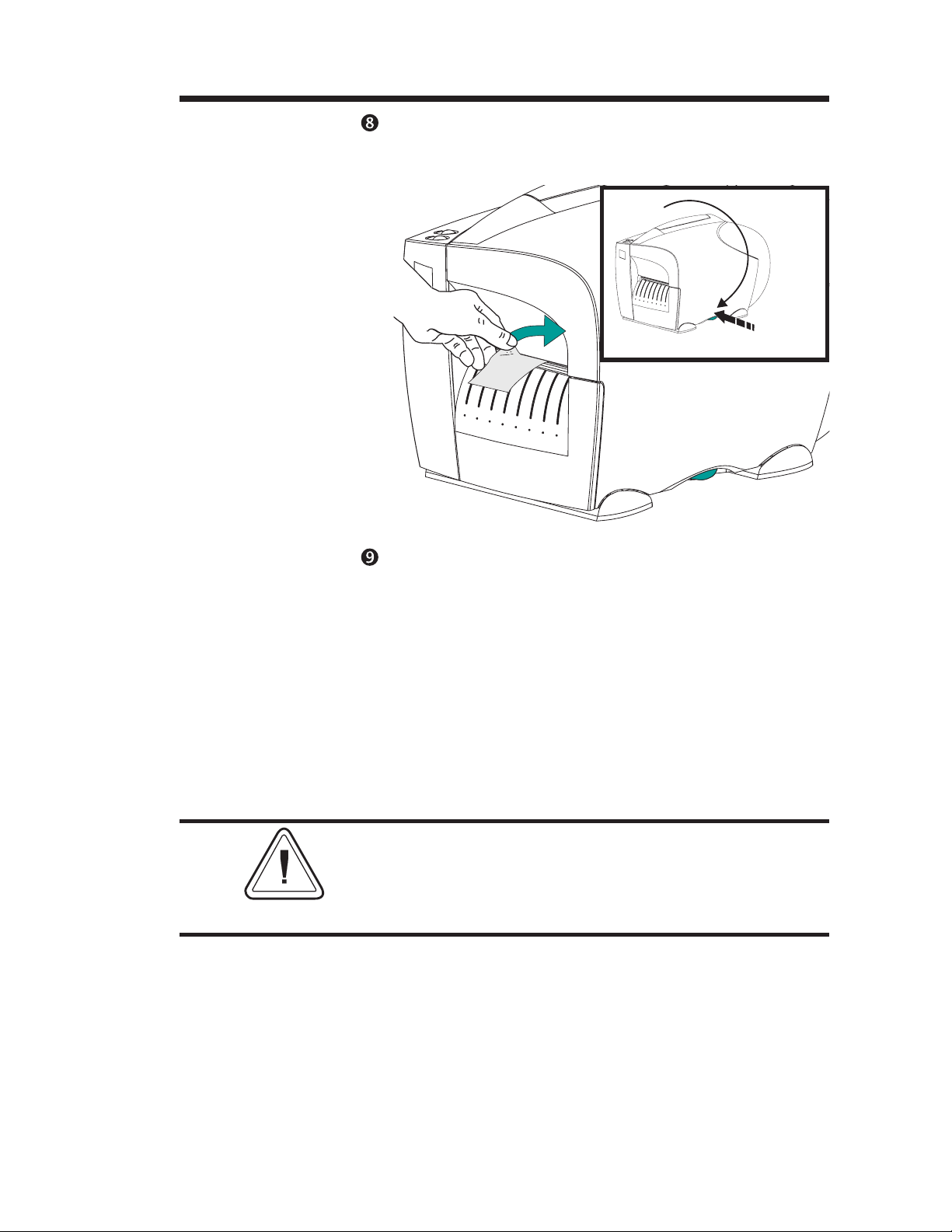

Step 8 Align the center of the print head bracket with

the center (V) of the print head spring. Push the

bracket's center slot onto the shroud's center

post (and screw).

Spring

Center

Print Head

on Spring

Tabs

Retainers

(colored for reference)

Place Bracket

onto

Center Post

Centering

Guide

Center

Post

980342-001 Rev.A 77

Page 84

Print Head Replacement Procedures

Step 9 While pressing up on the print head, slide the

bracket's tabs over the upper print mechanism's

print head retainer lip. Even upward pressure

on both sides of the print head is required to

clear the front edge of the retainer lip. Slide the

bracket to the front of printer.

Press Print Head

Tabs over the

top of the

Bracket

Retainers

Step 10 Dress the print head cable away from the print

head bracket and replace the print head

shroud. Align the shroud to the three (3) posts

(and screws) and slide to the back. The shroud

will snap in place.

Step 11 Clean the print head. See page 26 for more

details.

78 980342-001 Rev.A

Page 85

Cover Removal

Appendix C

Cover Removal

The following section describes the cover removal for service.

Cover Removal

Procedure

This procedure is intended for the field service

engineer or technician.

The printer's cover is not designed to be removed repeatedly.

Prepare a static-safe work area before opening

the printer for repair. The area must include a

properly grounded conductive cushioned mat

to hold the printer and a conductive wrist strap

for the technician. ESD protective devices are

available from most electronic supply stores or

by contacting 3M corporation at (800)

328-1368.

Shock Hazard

Always turn off the printer before performing

any maintenance or repair operations. Wait for

the indicator light to be dark, then unplug the

power cord.

980342-001 Rev.A 79

Page 86

Cover Removal

MOVIE

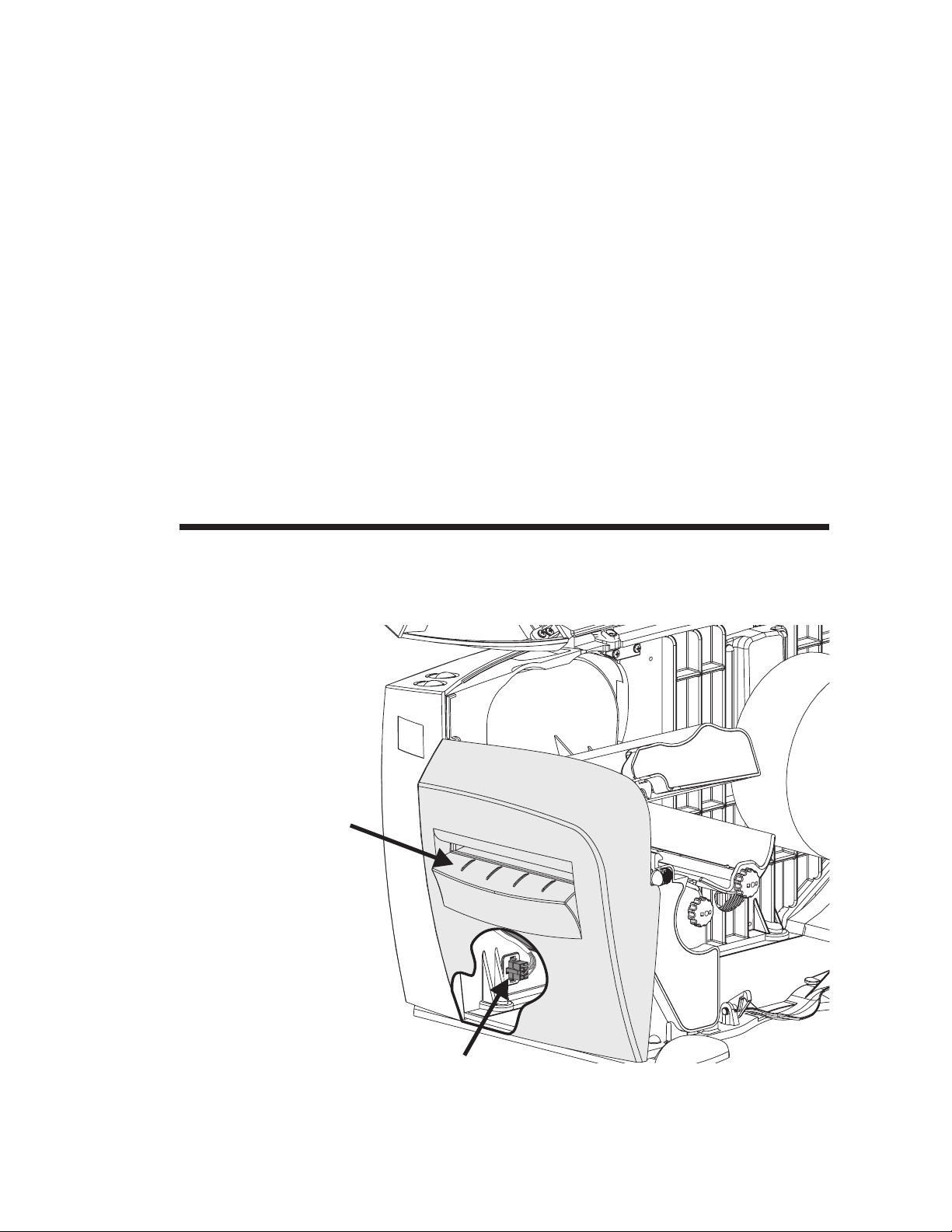

Step 1 Remove the top cover (door). Remove the two

screws on the cover's front hinge bracket.

Swing the top cover off the back hinge bracket

and set it aside.

80 980342-001 Rev.A

Page 87

Cover Removal

Step 2 Remove the six screws retaining the left side

cover to the printer's center panel.

Step 3 Serial Port - Remove the two 3/16" hex screws.

Remove

Remove

980342-001 Rev.A 81

Page 88

Cover Removal

Step 4 Pry the cover off with your hands. Do not use

tools. Start at the front corner working around

to the top and then to the rear of the printer.

Step 5 Slip the left cover and I/O plate off the main

Replacing the

Cover

PCBA in the rear of the printer.

Set the cover down next to the left side of the

printer. Note that the cover is attached to the

main PCBA by the control panel's cable.

Reverse the cover removal process. Do not

over tighten the screws. Do not cross-thread the

pre-existing threads made during the original

assembly of the printer. Use a torque setting of

4.7 ±1 inch pounds (0,531 ± 0,113 Nm).

82 980342-001 Rev.A

Loading...

Loading...