Page 1

Omnii HDK

User Manual

(Omnii XT10)

December 8, 2010 P/N 8100210.A

ISO 9001 Certified

Quality Management System

Page 2

© Copyright 2010 by Psion Teklogix Inc.

2100 Meadowvale Boulevard, Mississauga, Ontario, Canada L5N 7J9

http://www.psionteklogix.com

This document and the information it contains is the property of Psion Teklogix Inc., is issued in strict confidence, and is not to be reproduced or copied, in whole or in part, except for the sole purpose of promoting the

sale of Psion Teklogix manufactured goods and services. Furthermore, this document is not to be used as a

basis for design, manufacture, or sub-contract, or in any manner detrimental to the interests of

Psion Teklogix Inc.

Disclaimer

Every effort has been made to make this material complete, accurate, and up-to-date. In addition, changes

are periodically added to the information herein; these changes will be incorporated into new editions of

the publication.

Psion Teklogix Inc. reserves the right to make improvements and/or changes in the product(s) and/or the program(s) described in this document without notice, and shall not be responsible for any damages, including

but not limited to consequential damages, caused by reliance on the material presented, including but not

limited to typographical errors.

Omnii™ is a trademark of Psion Teklogix Inc.

Windows

®

and the Windows Logo are trademarks or registered trademarks of Microsoft Corporation in the

United States and/or other countries.

The Bluetooth

®

word mark and logos are owned by Bluetooth SIG, Inc. and any use of such marks by Psion

Teklogix Inc. is under license.

All trademarks and trade names are the property of their respective holders.

Page 3

Return-To-Factory Warranty

Psion Teklogix Inc. provides a return to factory warranty on this product for a period of twelve (12) months in

accordance with the Statement of Limited Warranty and Limitation of Liability provided at:

www.psionteklogix.com/warranty

The warranty on Psion Teklogix manufactured equipment does not extend to any product that has been tampered with, altered, or repaired by any person other than an employee of an authorized Psion Teklogix service

organization. See Psion Teklogix terms and conditions of sale for full details.

Important: Psion Teklogix warranties take effect on the date of shipment.

Service and Information

Psion Teklogix provides a complete range of product support services and information to its customers worldwide. Services include technical support and product repairs. To locate your local support services, please go

to

www.psionteklogix.com/service-and-support.htm

To access further information on current and discontinued products, please go to http://community.psiontek-

logix.com/login.aspx?ReturnUrl=%2fdefault.aspx and log in. A section of archived product information is available

online.

Page 4

Page 5

TABLE OF CONTENTS

Chapter 1: Introduction

1.1 About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Text Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.3 About the HDK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Development Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Contents of the HDK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5.1 Files in the HDK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6 Obtaining the HDK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.7 About the Omnii Hand-Held Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 2: Getting Started

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 What Can I Do With the Omnii HDK? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Expansion Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Expansion Device Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4.1 Device EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4.2 Device Registry Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 3: Hardware

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 Hardware Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.1 Display Variants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.2 Keyboard Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.3 Back Cover Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2.4 Scanner/Imager Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3 Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.4 Identifying Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5 The LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.6 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.6.1 Connector Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.7 Power Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.7.1 Batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 4: Software

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.1 Windows Drivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.2 Non-Psion Teklogix Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.3 System Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4 Registry Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4.1 Registry Settings for Expansion Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4.1.1 Device Information Registry Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.4.1.2 Device Driver Registry Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.4.2 Software Registry Entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Psion Teklogix Omnii HDK User Manual i

Page 6

Contents

4.5 Device Detection and Driver Loading Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.6 Serial (COM) Port Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.7 Omnii HDK Application Development Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.7.1 Windows Embedded CE 6.0 Development Platform for Visual Studio . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.7.2 Psion Teklogix Mobile Devices SDK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.7.3 Omnii HDK Development Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.7.4 Omnii HDK API Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.7.4.1 Hdk7545_ExpansionSlotFromActiveRegKey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.7.4.2 Hdk7545_Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.7.4.3 Hdk7545_Close . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.7.4.4 Hdk7545_SetPower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.7.4.5 Hdk7545_GetPower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.7.4.6 Hdk7545_SetPowerMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.7.4.7 Hdk7545_GetPowerMode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.7.4.8 Hdk7545_ExpansionSetPinDirection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.7.4.9 Hdk7545_ExpansionGetPinDirection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.7.4.10 Hdk7545_ExpansionSetPinMode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.7.4.11 Hdk7545_ExpansionGetPinMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.7.4.12 Hdk7545_ExpansionSetPinFunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.7.4.13 Hdk7545_ExpansionGetPinFunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.7.4.14 Hdk7545_ExpansionSetPinState . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.7.4.15 Hdk7545_ExpansionGetPinState . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.7.4.16 Hdk7545_ExpansionSetPullUpDown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.7.4.17 Hdk7545_ExpansionGetIrq . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.7.4.18 Hdk7545_ReadEepromHeader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.7.4.19 Hdk7545_WriteEepromHeader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.7.4.20 Hdk7545_ReadEepromExtendedData . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.7.4.21 Hdk7545_WriteEepromExtendedData. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.7.5 API Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.7.5.1 Hdk7545_Eeprom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.7.6 API Enumerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.7.6.1 Hdk7545_PowerMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.7.6.2 Hdk7545_Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.7.6.3 Hdk7545_PinDirection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.7.6.4 Hdk7545_PinFunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.7.6.5 Hdk7545_PinState . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.7.6.6 Hdk7545_PullUpDown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.7.6.7 Hdk7545_PinMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.7.7 Omnii HDK API Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

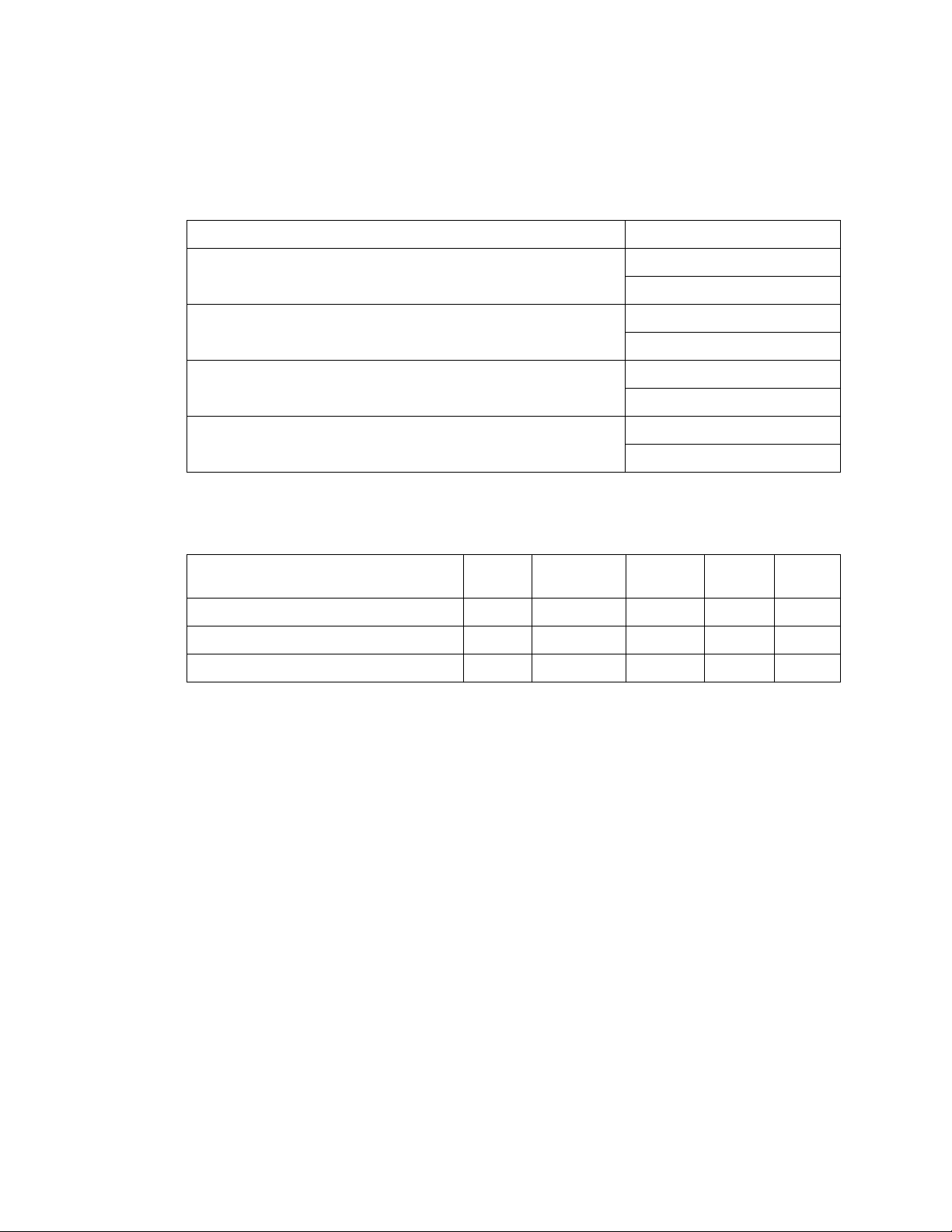

Chapter 5: Mechanical Considerations

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.2 Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.3 HDK Mechanical Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.3.1 3D Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.3.2 2D Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.4 Expansion Module and Device Design and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.4.1 Physical Space Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.4.2 End-Cap Modules and Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.4.3 Pod Expansion Modules and Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.4.4 Back Cover Modules and Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.4.5 Pistol Grip Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

ii Psion Teklogix Omnii HDK User Manual

Page 7

Contents

5.4.6 Keyboard Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.4.6.1 Keyboard Overlays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.4.6.2 Keyboard Hard Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.5 Installing Devices Inside Existing Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.5.1 Standard Scanner Pod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.5.2 Large/Auto-Range Standard Back Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.5.3 End-Cap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Chapter 6: Omnii Expansion Ports and Connectors

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.2 Connector Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

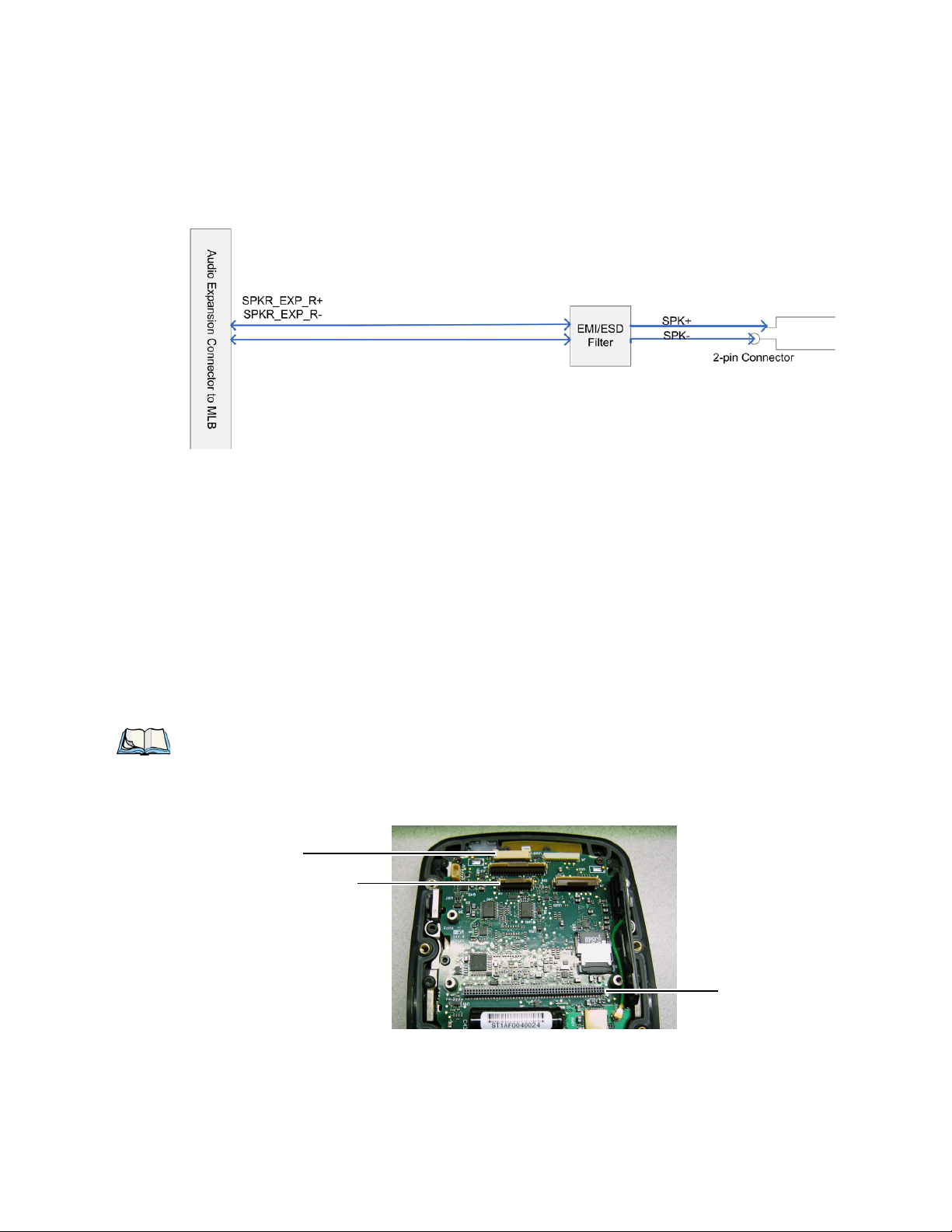

6.3 Audio Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.3.1 Audio Reference Designs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

6.3.1.1 Single-Ended Headset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

6.3.1.2 Push-to-Talk Handset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.3.1.3 External Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

6.4 Expansion Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

6.4.1 Expansion Port Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6.4.2 Expansion Port 1 (End-Cap Connector). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.4.3 Expansion Port 2 (Pod Expansion Connector) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6.4.4 Expansion Port 3 (100-pin Multi-Function Connector) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.4.5 Expansion Port Standard Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.4.5.1 Serial (UART) Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.4.5.2 USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6.4.5.3 GPIO (General Purpose Input/Output) Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6.4.5.4 SPI (Serial Peripheral Interface) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.5 100-Pin Multi-Function Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Chapter 7: Docking Stations

7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

7.2 Desktop Docking Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

7.2.1 Docking Station USB Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

7.2.2 Docking Station RS-232 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.2.3 Docking Station Ethernet RJ45 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.2.4 Docking Station Expansion Module (X-Mod) Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Chapter 8: EEPROM Specifications

8.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

8.2 EEPROM Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

8.3 EEPROM Data Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

8.3.1 Common EEPROM Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

8.4 EEPROM Reading/Writing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Chapter 9: Breakout Board

9.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

9.2 Contents of the Breakout Board Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

9.3 Board Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

9.4 Connecting to Omnii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

9.5 Power Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

9.6 GPIO Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Psion Teklogix Omnii HDK User Manual iii

Page 8

Contents

9.6.1 GPIO Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

9.6.2 GPIO Data Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

9.6.3 GPIO Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

9.7 RS-232 / UART Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

9.7.1 RS-232 / UART Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

9.7.2 RS-232 / UART Data Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

9.8 USB Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

9.8.1 USB Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

9.8.2 USB Data Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

9.9 1-Wire EEPROM Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

9.9.1 1-Wire EEPROM Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

9.9.2 1-Wire EEPROM Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

9.10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Chapter 10: HDK Demo Application

10.1 About The HDK Demo Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

10.2 Installing the HDK Demo Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

10.3 Modifying and Compiling the HDK Demo Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

10.4 Creating Registry Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

10.5 Connecting the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

10.5.1 Remove the Omnii Back Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

10.5.2 Attach the Omnii Back Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

10.5.3 Connect the Test Module to an Expansion Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

10.6 Using the HDK Demo Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

10.6.1 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

10.6.2 Main Tabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

10.6.2.1 USB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

10.6.2.2 UART. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

10.6.2.3 GPIO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

10.6.2.4 EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Appendix A: Resources

A.1 Psion Teklogix User Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.2 Psion Teklogix Downloadable Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.3 Psion Teklogix Accessory And Parts Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B: Omnii Specifications

B.1 The Omnii XT10 Hand-Held Computer (Model No. 7545XV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B.1.1 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B.1.2 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

B.1.3 Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

B.2 Lithium-ion Smart Battery 5000 mAh (ST3000) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

B.3 Wireless Radios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

B.4 Internal Scanners and Imagers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

B.4.1 SE1223LR - Long Range (Decoded) Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

B.4.2 SE1224HP - High Performance Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

B.4.3 SE1524ER – Extended Range Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

B.4.4 EV15 Imager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

B.4.5 5080 Imager/Decoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

B.5 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

iv Psion Teklogix Omnii HDK User Manual

Page 9

Contents

B.6 Camera (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-13

B.7 GPS (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-13

Appendix C: HDK License Agreement

C.1 HARDWARE DEVELOPER KIT LICENSE AGREEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

C.2 GRANT OF LICENSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

C.3 REQUIREMENTS, RESTRICTIONS, RIGHTS AND LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

C.4 HIGH RISK ACTIVITIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

C.5 DISCLAIMER OF WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

C.6 LIMITATION OF LIABILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

C.7 COPYRIGHTS, OWNERSHIP AND PROPRIETARY RIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

C.8 CONFIDENTIALITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

C.9 ENDING THIS AGREEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

C.10 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

Psion Teklogix Omnii HDK User Manual v

Page 10

Page 11

INTRODUCTION 1

1.1 About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Text Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 About the HDK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Development Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Contents of the HDK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5.1 Files in the HDK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6 Obtaining the HDK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.7 About the Omnii Hand-Held Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Psion Teklogix Omnii HDK User Manual 1

Page 12

Page 13

1.1 About This Manual

This manual provides guidance on creating expansion devices for Psion Teklogix Omnii devices

using the Omnii HDK. The manual is organised into the following chapters:

Chapter 1: Introduction

provides an overview of the Omnii Hand-Held Computer and the Omnii HDK.

Chapter 2: Getting Started

provides at-a-glance information about the capabilities of the HDK.

Chapter 3: Hardware

describes, in general terms, the hardware of Omnii.

Chapter 4: Software

gives an overview of the registry entries and API for controlling expansion devices and the

installation of device drivers.

Chapter 5: Mechanical Considerations

describes the physical aspects of designing and mounting expansion modules.

Chapter 6: Omnii Expansion Ports and Connectors

describes the connectors on Omnii, including the three standard expansion ports and docking

adaptors.

Chapter 1: Introduction

About This Manual

Chapter 8: EEPROM Specifications

describes the details of programming I2C and 1-wire EEPROMs for expansion modules.

Chapter 9: Breakout Board

describes the features and functions of the Omnii HDK breakout board kit (sold separately).

Chapter 10: HDK Demo Application

describes the features and functions of the HDK Demo application program.

Appendix A: Resources

lists extra resources which may be of use in conjunction with the HDK.

Appendix B: Omnii Specifications

lists the specifications of Omnii.

Appendix C: HDK License Agreement

provides the license agreement that is assumed by using the Omnii HDK.

Psion Teklogix Omnii HDK User Manual 3

Page 14

Chapter 1: Introduction

Text Conventions

1.2 Text Conventions

The following conventions and syntax are followed throughout this document:

Note: Notes highlight additional helpful information.

Important: These statements provide important instructions or additional information that is

critical to the operation of the computer or other equipment.

Warning: These statements provide important information that may prevent injury, damage to

the equipment, or loss of data.

An arrow next to field description information (usually in tables) indicates a recommended or

suggested configuration setting.

1.3 About the HDK

The Omnii HDK (Hardware Development Kit) provides the software tools and technical

information necessary to design and integrate your own expansion modules for your Omnii

hand-held computer.

Three dedicated expansion ports provide access to USB, serial and GPIO (General Purpose

Input/Output) interfaces for connecting to standard devices (bar code scanners, imagers, RFID

readers, etc.). An audio expansion port is also available for attaching speaker and/or

microphone devices.

3D model files and schematic drawings are provided which give the precise measurements needed

for designing custom back-cover, end-cap and pod expansion modules that fit and seal perfectly

with the main housing.

Finally, the Omnii HDK API library provides the software tools necessary to access and control

the expansion ports, and the devices attached to them.

1.4 Development Platform

The Omnii API library is designed for application development using Visual Studio 9 (2008).

1.5 Contents of the HDK

The HDK (Hardware Development Kit) for Omnii includes the following items:

• This manual.

• Installer for development files, including C header files for managing expansion devices and

HDK Demo application. See Section 4.7: “Omnii HDK Application Development Software”

and Chapter 10: “HDK Demo Application” for more details on these files.

• 2D drawings and 3D models of the areas of Omnii where devices and modules can

be mounted.

4 Psion Teklogix Omnii HDK User Manual

Page 15

1.5.1 Files in the HDK

The following files are included with the Omnii Hardware Development Kit:

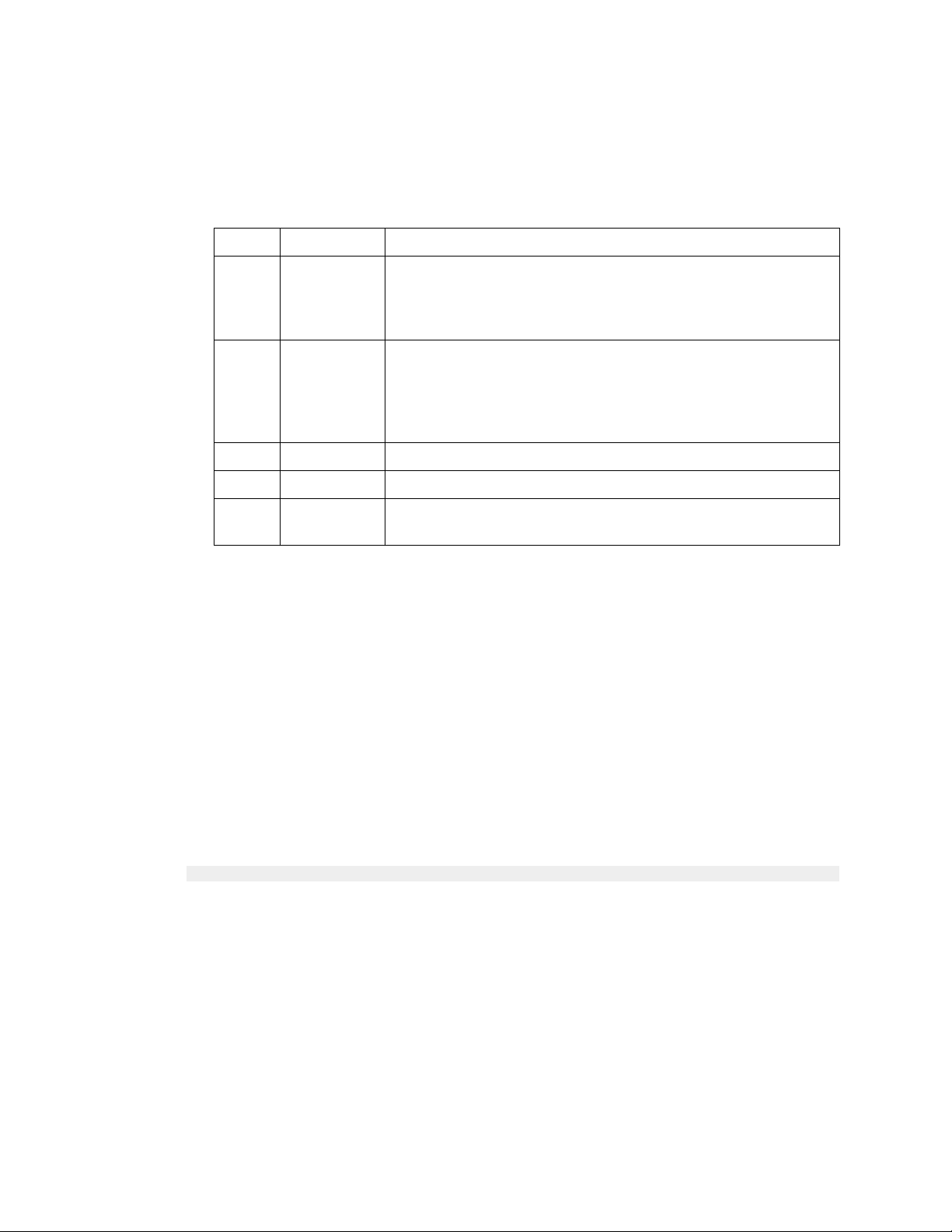

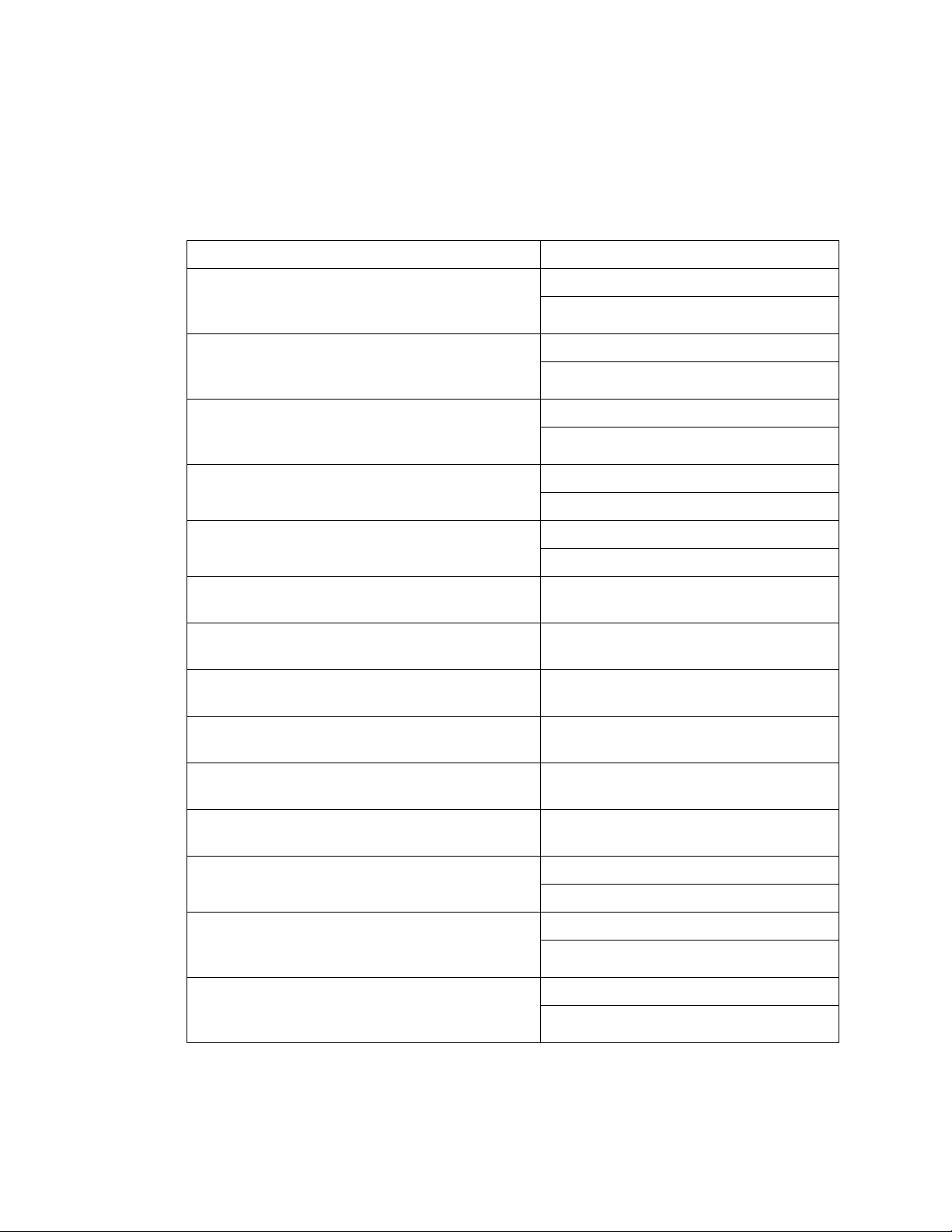

Table 1.1 Files in the HDK

Filename Description

OmniiHDK_Setup Installer for the Omnii HDK development files. Installs the fol-

Hdk7545.h C header file containing API functions for the Omnii HDK

Hdk7545Structs.h C header file containing API structures for the Omnii HDK

Hdk7545Consts.h C header file containing API constants for the Omnii HDK

7545HDK.dll

7545HDK.exp

7545HDK.lib

7545HDK.pdb

HDKDemo.exe Demo application for testing and demonstrating features and

Chapter 1: Introduction

Files in the HDK

lowing files on a PC:

components of the HDK

Audio_External_Speaker.pdf Reference design for an external speaker audio expansion

Audio_PTT.pdf Reference design for a push-to-talk handset audio expansion

Audio_Single-Ended_Headset.pdf Reference design for a single-ended headset audio expansion

Back_Cover_Auto_Std_2D.dwg 2D line drawing of the auto-range standard back cover with loca-

tions of mounting points for the back cover and pistol grip

Back_Cover_Auto_Std_2D.pdf 2D line drawing of the auto-range standard back cover with loca-

tions of mounting points for the back cover and pistol grip

Back_Cover_Auto_Std_3D.igs 3D CAD model of the auto-range standard back cover

Back_Cover_Auto_Std_3D.stp 3D CAD model of the auto-range standard back cover

Back_Cover_Expan_2D.dwg 2D line drawing of the expansion back cover with locations of

mounting points for the back cover, pistol grip, end-cap and

pod expansion

Back_Cover_Expan_2D.pdf 2D line drawing of the expansion back cover with locations of

mounting points for the back cover, pistol grip, end-cap and

pod expansion

Back_Cover_Expan_3D.igs 3D CAD model of the expansion back cover, showing end-cap

and pod expansion openings with sealing overmoulds, and keepaway areas for camera and speaker options

Back_Cover_Expan_3D.stp 3D CAD model of the expansion back cover, showing end-cap

and pod expansion openings with sealing overmoulds, and keepaway areas for camera and speaker options

Back_Cover_Large_Std_2D.dwg 2D line drawing of the large standard back cover with locations

of mounting points for the back cover and pistol grip

Back_Cover_Large_Std_2D.pdf 2D line drawing of the large standard back cover with locations

of mounting points for the back cover and pistol grip

Psion Teklogix Omnii HDK User Manual 5

Page 16

Chapter 1: Introduction

Files in the HDK

Table 1.1 Files in the HDK

Back_Cover_Large_Std_3D.igs 3D CAD model of the large standard back cover

Back_Cover_Large_Std_3D.stp 3D CAD model of the large standard back cover

Breakout_Sch.pdf Schematic diagrams of the HDK breakout board

DS2431.pdf Data sheet for the Maxim DS2431 1-wire EEPROM

Endcap_GPS_2D.dwg 2D line drawing of the end-cap with GPS antenna

Endcap_GPS_2D.pdf 2D line drawing of the end-cap with GPS antenna

Endcap_GPS_3D.igs 3D CAD model of the end-cap with GPS antenna

Endcap_GPS_3D.stp 3D CAD model of the end-cap with GPS antenna

Endcap_Standard_2D.dwg 2D line drawing of the standard end-cap

Endcap_Standard_2D.pdf 2D line drawing of the standard end-cap

Endcap_Standard_3D.stp 3D CAD model of the standard end-cap

KB_HardCaps_36ModNumCal12.pdf Artwork for the 36-key, alpha modified, numeric calculator,

Filename Description

12 Fn keyboard hard caps

KB_HardCaps_36NumTel12.pdf Artwork for the 36-key numeric telephony, 12 Fn keyboard

hard caps

KB_HardCaps_59ABCTel6.pdf Artwork for the 59-key, alpha ABC, numeric telephony,

6 Fn keyboard hard caps

KB_Overlay_36ModNumCal12.pdf Artwork for the 36-key, alpha modified, numeric calculator,

12 Fn keyboard overlay

KB_Overlay_36NumTel12.pdf Artwork for the 36-key numeric telephony, 12 Fn

keyboard overlay

KB_Overlay_59ABCTel6.pdf Artwork for the 59-key, alpha ABC, numeric telephony,

6 Fn keyboard overlay

Omnii_Connectors_NoRadio_2D.dwg 2D line drawing of Omnii chassis and MLB showing locations of

expansion ports with no GPS or WWAN radio installed

Omnii_Connectors_NoRadio_2D.pdf 2D line drawing of Omnii chassis and MLB showing locations of

expansion ports with no GPS or WWAN radio installed

Omnii_Connectors_NoRadio_3D.stp 3D CAD model of Omnii chassis with back cover removed

showing keep-away areas, with no GPS or WWAN

radio installed

Omnii_Connectors_Radio_2D.dwg 2D line drawing of Omnii chassis and MLB showing locations of

expansion ports with GPS and WWAN radio installed

Omnii_Connectors_Radio_2D.pdf 2D line drawing of Omnii chassis and MLB showing locations of

expansion ports with GPS and WWAN radio installed

Omnii_Connectors_Radio_3D.stp 3D CAD model of Omnii chassis with back cover removed

Scanner_Pod_Std_2D.dwg 2D line drawing of the standard scanner pod with locations of

6 Psion Teklogix Omnii HDK User Manual

showing keep-away areas, with GPS and WWAN radio installed

mounting points for the pod and for the scanner assembly

Page 17

Table 1.1 Files in the HDK

Filename Description

Scanner_Pod_Std_2D.pdf 2D line drawing of the standard scanner pod with locations of

Scanner_Pod_Std_3D.igs 3D CAD model of the standard scanner pod

Scanner_Pod_Std_3D.stp 3D CAD model of the standard scanner pod

1.6 Obtaining the HDK

The Omnii HDK is available for download on the Psion Teklogix Community website

(

http://community.psionteklogix.com). You will need an account on the website in order to down-

load files. An account can be easily created by clicking on the Join link in the upper right corner

of the home page.

To download the HDK:

1. Click on the Downloads link in the top bar of the Community home page.

2. Click on Psion Teklogix HDK in the list that appears.

3. Click on Hardware Development Kit (HDK) for Omnii.

Chapter 1: Introduction

Obtaining the HDK

mounting points for the pod and for the scanner assembly

4. Click on the link to view the license agreement and download the .zip file containing the

HDK files.

5. Open the .zip file and extract the files within to a folder on your PC hard drive.

To continue with installing the HDK files required for developing applications to work with your

expansion devices, see Section 4.7: “Omnii HDK Application Development Software”.

1.7 About the Omnii Hand-Held Computer

Omnii is an industrial hand-held computer. It has a modular design that allows for many variations

and combinations of the component modules. Currently, Omnii XT10 is the only model available;

information on future Omnii models will be added to this document as they are released.

For more information on the Omnii XT10 operation and hardware variants, refer to the Omnii

XT10 Hand-Held Computer User Manual (P/N 8100190).

Omnii XT10 uses the Microsoft® Windows® CE 6.0 operating system.

Psion Teklogix Omnii HDK User Manual 7

Page 18

Page 19

GETTING STARTED 2

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 What Can I Do With the Omnii HDK? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Expansion Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Expansion Device Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4.1 Device EEPROM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4.2 Device Registry Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Psion Teklogix Omnii HDK User Manual 9

Page 20

Page 21

2.1 Overview

This section gives a brief look at what the Omnii HDK can be used for, some quick links to the relevant sections of this manual for each task, as well as some basic information on what is required

to develop working devices using the HDK.

2.2 What Can I Do With the Omnii HDK?

The information provided in the Omnii HDK allows you to:

• design custom end-cap, pod and back cover expansion modules that fit and seal precisely with

your Omnii hand-held computer.

- Section 5.4: “Expansion Module and Device Design and Installation”

• install non-Psion Teklogix serial, USB or GPIO devices in existing Psion Teklogix end-cap,

pod and back cover modules.

- Section 5.5: “Installing Devices Inside Existing Modules”

- Section 6.4: “Expansion Ports”

- Section 4.4.1: “Registry Settings for Expansion Devices”

- Chapter 8: “EEPROM Specifications”

• design custom keyboard overlay and hard cap artwork.

- Section 5.4.6: “Keyboard Modules”

• design custom audio devices.

- Section 6.3: “Audio Connector”

• design custom pistol grips.

- Section 5.4.5: “Pistol Grip Modules”

• design custom devices that connect to Psion Teklogix desktop docking stations.

- Chapter 7: “Docking Stations”

Chapter 2: Getting Started

Overview

Psion Teklogix Omnii HDK User Manual 11

Page 22

Chapter 2: Getting Started

Expansion Areas

2.3 Expansion Areas

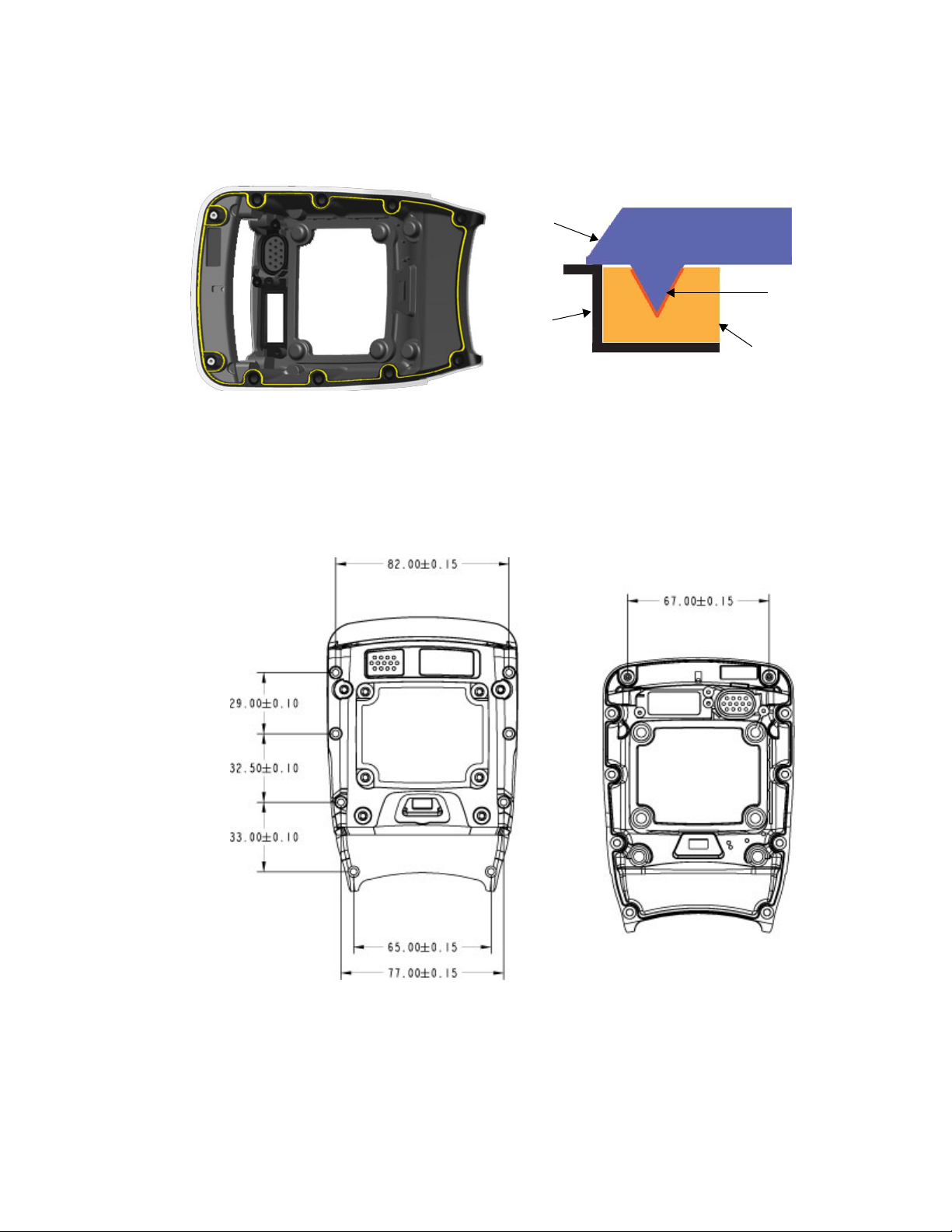

The following illustrations show the areas where custom expansion modules can be mounted on

your Omnii hand-held computer:

End-Cap Pod

Back Cover

12 Psion Teklogix Omnii HDK User Manual

Page 23

2.4 Expansion Device Requirements

2.4.1 Device EEPROM

It is highly recommended that any expansion device attached to an Omnii expansion port be

equipped with a Maxim DS2431 EEPROM. This 1-wire EEPROM is used to store specific data

that identifies the expansion device to Omnii. On boot-up, Omnii reads the EEPROM of all

devices attached to the expansion ports, and searches for corresponding entries in the registry that

specify the device driver(s) and port configuration to use for that device.

Details on this EEPROM can be found in Chapter 8: “EEPROM Specifications”, and instructions

on reading and writing the EEPROM using the HDK Demo application can be found in

Section 10.6.2.4: “EEPROM”.

2.4.2 Device Registry Keys

For each expansion device, certain registry keys and values must be added to the Omnii registry.

These registry keys provide Omnii with the information needed to load the required device

driver(s) and to configure the data pins of the expansion port appropriately.

Details on these registry keys can be found in Section 4.4: “Registry Keys”, and specific examples

are given in Section 10.4: “Creating Registry Keys”.

Chapter 2: Getting Started

Expansion Device Requirements

Psion Teklogix Omnii HDK User Manual 13

Page 24

Page 25

HARDWARE 3

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 Hardware Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.1 Display Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.2 Keyboard Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.3 Back Cover Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2.4 Scanner/Imager Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3 Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.4 Identifying Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5 The LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.6 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.6.1 Connector Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.7 Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.7.1 Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Psion Teklogix Omnii HDK User Manual 15

Page 26

Page 27

3.1 Overview

This chapter gives an overview of the hardware of Omnii.

3.2 Hardware Variants

Omnii has variant modules for the display, keyboard, back cover and bar code scanner or imager

pod attachment.

3.2.1 Display Variants

Omnii has two standard variants for the LCD touchscreen display:

High Impact Display

The high impact display withstands impacts up to 1.2 joules and consists of separate overlaid

panels for the LCD display and touchscreen surface.

High Visibility Display

The high visibility display withstands impacts up to 0.4 joules provides increased visibility in

sunlight and uses a single combined LCD and touchscreen panel.

3.2.2 Keyboard Variants

Chapter 3: Hardware

Overview

Omnii has three standard variants for the keyboard module: two numeric variants, and one full

alphanumeric variant.

36-Key, Numeric Telephony, 12Fn Keyboard

This numeric keyboard has the number keys arranged telephone-style, with the numbers 1,2,3

along the top row. The alphabetic characters are also arranged telephone-style, in groups of 3 or 4

[FN]-shifted characters above the number keys. It has 24 function keys (12 single-press and

12 shifted), and five macro keys available.

36-Key, Alpha Modified, Numeric Calculator, 12 Fn Keyboard

This numeric keyboard has the number keys arranged calculator-style, with the numbers 7,8,9

along the top row. The alphabetic characters are located as single [FN]-shifted characters

on individual keys across the entire keyboard. It has 24 function keys (12 single-press and

12 shifted) available.

59-Key, Alpha ABC, Numeric Telephony, 6 Fn Keyboard

This full alphanumeric keyboard has the numeric keys arranged telephone-style with the numbers

1,2,3 along the top row, and the alphabetic keys arranged in order from A to Z. It has 30 function

keys (6 single-press and 24 shifted), and 6 macro keys available.

Psion Teklogix Omnii HDK User Manual 17

Page 28

Chapter 3: Hardware

p

y

Back Cover Variants

3.2.3 Back Cover Variants

Omnii has three standard variants for the back cover module.

• Expansion Back Cover - a slim back cover with separate end-cap, and a back plate that can be

removed for an optional pod expansion module (see Section 3.2.4: “Scanner/Imager Variants”). This back cover can also have an optional built-in speaker and/or camera, which need

to be considered when designing modules.

• Large Standard Back Cover - a single-piece back cover module that also covers the end-cap

area and accommodates an integrated scanner or imager (see Section 3.2.4: “Scanner/Imager

Variants”).

• Auto-Range Standard Back Cover - similar to the Large Standard Back Cover but with

different options for the integrated scanner or imager (see Section 3.2.4: “Scanner/Imager

Variants”).

3.2.4 Scanner/Imager Variants

Omnii comes standard with no scanner or imager installed. A scanner or imager engine can be installed in a pod expansion module and mounted to the expansion back cover. Alternatively, a

scanner or imager could be mounted in the end-cap of the unit, with an appropriately designed

end-cap. The scanner or imager engine attaches to an expansion port on the Omnii main logic

board through a flex cable.

36-Key Alpha Modified36-Key Numeric Telephony 59-Key Alpha ABC

Numeric Calculator Numeric Tele

hon

Only one internal bar code scanner or imager can be installed in Omnii at a time. The internal

scanner or imager can be activated from the trigger switch on the Omnii pistol grip (if present),

from the [SCAN] buttons on the Omnii keyboard and side panels, or from another softwareassigned key on the keyboard.

The following scanner/imager options are currently available to order from the factory:

Expansion Back Cover with Scanner Pod Module

• SE1223LR long range bar code scanner

• SE1224HP high performance bar code scanner

• EV15 1D imager

• 5080 2D imager

18 Psion Teklogix Omnii HDK User Manual

Page 29

Auto-Range Standard Back Cover

• SE1223LR long range bar code scanner

• SE1524ER auto-range bar code scanner

Large Standard Back Cover

• SE1224HP high performance bar code scanner

• EV15 1D imager

• 5080 2D imager

3.3 Processor

Omnii XT10 is built around a Texas Instruments OMAP3515 600MHz ARM Cortex-A8 dualcore processor.

Chapter 3: Hardware

Processor

Psion Teklogix Omnii HDK User Manual 19

Page 30

Chapter 3: Hardware

Identifying Hardware

3.4 Identifying Hardware

An overview of the operating system and the installed hardware on Omnii can be viewed by

opening the System applet in the Windows Control Panel.

3.5 The LEDs

Omnii has four LEDs in the top left corner of the display bezel. From left to right the colors of

the LEDs are green/red/yellow, yellow, blue, and green/red/yellow. The yellow LED (second

from the left) can be controlled by applications with the Windows API; the name of this LED for

programming purposes is “Application”.

3.6 Connectors

In addition to the external docking connector on the base of the Omnii hand-held computer, the

following connectors exist on the main logic board:

• Audio Expansion Connector

• End-cap Expansion Connector (Expansion Port 1)

• Pod Expansion Connector (Expansion Port 2)

• 100-Pin Multi-Function Connector (includes Expansion Port 3)

These connectors are described in detail in Chapter 6: “Omnii Expansion Ports and Connectors”.

3.6.1 Connector Locations

The following illustration shows the positions of the electrical connectors on the Omnii XT10

main logic board. These locations are shown in more precise detail in the drawing and model files

included with the HDK. See Section 5.4.1: “Physical Space Considerations” for details.

20 Psion Teklogix Omnii HDK User Manual

Page 31

Figure 3.1 Connector Locations of the Omnii XT10 Main Logic Board

Chapter 3: Hardware

Power Management

Note: The camera and scanner/imager connectors are not intended for third-party expansion on

Omnii XT10, and are shown here for reference only.

3.7 Power Management

Omnii is powered by a lithium-ion rechargeable battery pack and can also be powered from

external power. When Omnii is powered from external power, the battery pack also charges.

Use only power sources recommended or sold by Psion Teklogix for Omnii.

3.7.1 Batteries

The battery is a custom 5000 mAh lithium-ion cylindrical multi-cell pack that fully implements

a Smart Battery Specification and is CTIA approved (Model No. ST3000). The battery is fully

sealed and designed to survive in rugged environments. For more details, refer to the Omnii

Hand-Held Computer User Manual (P/N 8000190).

Psion Teklogix Omnii HDK User Manual 21

Page 32

Page 33

SOFTWARE 4

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.1 Windows Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.2 Non-Psion Teklogix Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.3 System Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4 Registry Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4.1 Registry Settings for Expansion Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4.1.1 Device Information Registry Keys . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.4.1.2 Device Driver Registry Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.4.2 Software Registry Entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.5 Device Detection and Driver Loading Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.6 Serial (COM) Port Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.7 Omnii HDK Application Development Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.7.1 Windows Embedded CE 6.0 Development Platform for Visual Studio . . . . . . . . . . . . 34

4.7.2 Psion Teklogix Mobile Devices SDK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.7.3 Omnii HDK Development Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.7.4 Omnii HDK API Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.7.4.1 Hdk7545_ExpansionSlotFromActiveRegKey . . . . . . . . . . . . . . . . . . . . 36

4.7.4.2 Hdk7545_Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.7.4.3 Hdk7545_Close . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.7.4.4 Hdk7545_SetPower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.7.4.5 Hdk7545_GetPower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.7.4.6 Hdk7545_SetPowerMode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.7.4.7 Hdk7545_GetPowerMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.7.4.8 Hdk7545_ExpansionSetPinDirection . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.7.4.9 Hdk7545_ExpansionGetPinDirection . . . . . . . . . . . . . . . . . . . . . . . . 42

4.7.4.10 Hdk7545_ExpansionSetPinMode . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.7.4.11 Hdk7545_ExpansionGetPinMode . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.7.4.12 Hdk7545_ExpansionSetPinFunction . . . . . . . . . . . . . . . . . . . . . . . . 46

4.7.4.13 Hdk7545_ExpansionGetPinFunction . . . . . . . . . . . . . . . . . . . . . . . . 47

4.7.4.14 Hdk7545_ExpansionSetPinState . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.7.4.15 Hdk7545_ExpansionGetPinState . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.7.4.16 Hdk7545_ExpansionSetPullUpDown . . . . . . . . . . . . . . . . . . . . . . . . 50

4.7.4.17 Hdk7545_ExpansionGetIrq . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.7.4.18 Hdk7545_ReadEepromHeader . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.7.4.19 Hdk7545_WriteEepromHeader . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.7.4.20 Hdk7545_ReadEepromExtendedData. . . . . . . . . . . . . . . . . . . . . . . . 55

4.7.4.21 Hdk7545_WriteEepromExtendedData . . . . . . . . . . . . . . . . . . . . . . . 56

4.7.5 API Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.7.5.1 Hdk7545_Eeprom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.7.6 API Enumerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.7.6.1 Hdk7545_PowerMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.7.6.2 Hdk7545_Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.7.6.3 Hdk7545_PinDirection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Psion Teklogix Omnii HDK User Manual 23

Page 34

4.7.6.4 Hdk7545_PinFunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.7.6.5 Hdk7545_PinState . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.7.6.6 Hdk7545_PullUpDown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.7.6.7 Hdk7545_PinMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.7.7 Omnii HDK API Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

24 Psion Teklogix Omnii HDK User Manual

Page 35

4.1 Overview

This chapter describes the software aspects of controlling expansion modules for Omnii.

4.2 Drivers

4.2.1 Windows Drivers

The Peripherals Driver

Psion Teklogix provides the peripherals driver for all expansion and docking peripherals. The

peripherals driver is a stream driver activated very early at boot up time.

The Serial Port Driver

The full-function UART (Universal Asynchronous Receiver/Transmitter) serial port driver is

loaded if required, as determined by the registry settings for any expansion devices detected. For

details on the registry settings, see Section 4.4.1 on page 26.

4.2.2 Non-Psion Teklogix Drivers

The Psion Teklogix platform loads some standard device drivers. If the expansion module uses

standard drivers such as serial or USB, there is no need to load custom drivers.

Chapter 4: Software

Overview

There must be a registry entry for the driver and its parameters. For details see Section 4.4:

“Registry Keys”.

4.3 System Initialization

During system startup on Omnii, the following sequence occurs:

1. The expansion module EEPROMs are initialized and read.

2. If the registry entry for a detected expansion device indicates it is a serial device, the

full-function UART (FFUART) serial port driver is loaded and activated.

3. If the USB flag is set in the registry entry for a detected expansion device, the USB hub

is activated.

4. All drivers are identified from the EEPROM data and activated. For more details see

Section 4.4.1: “Registry Settings for Expansion Devices”.

Psion Teklogix Omnii HDK User Manual 25

Page 36

Chapter 4: Software

Registry Keys

4.4 Registry Keys

4.4.1 Registry Settings for Expansion Devices

For an expansion device to be properly detected by the peripherals driver, and to have the correct

drivers loaded to support the device, registry keys must be added to the Omnii registry.

Creating Registry Entries for a Device

The basic steps for creating registry entries for a device are outlined below. The individual features

of each step are explained in more detail in the sections that follow.

1. Using a registry editor, locate the following key in the Omnii registry:

[HKLM\Drivers\BuiltIn\Peripherals\devices]

2. Create a subkey for the type of connector to which the device connects.

(0=Expansion Port, 1=WWAN (not on Omnii XT10), 2=GPS, 4=Docking)

For example:

[HKLM\Drivers\BuiltIn\Peripherals\devices\0]

3. Create the DeviceId subkey as a concatenation of the device manufacturer and model

names, separated by a space.

For example, for a device made by Psion Teklogix with the model name “Exp1_UART”

the subkey should be:

[HKLM\Drivers\BuiltIn\Peripherals\devices\0\Psion Teklogix Exp1_UART]

4. Program the expansion device EEPROM Manufacturer and Model fields to match the

DeviceID subkey (case sensitive).

For example:

Manufacturer: Psion Teklogix

Model: Exp1_UART

See Section 8.4: “EEPROM Reading/Writing” for more details.

5. Add the following registry values under the DeviceID subkey (see “Device Registry

Values” on page 28 for more details on these values):

a. Name: a descriptive name for the device.

b. ConnectorId: optional field restricting devices to a specific expansion port.

c. PinFunctions: specify the GPIO/Serial/SPI pin functions.

d. PowerMode: set power management for the device.

e. Notifications: set user notification behaviour for device.

f. LoadFlags: specifies default device driver(s).

26 Psion Teklogix Omnii HDK User Manual

Page 37

Chapter 4: Software

Registry Settings for Expansion Devices

Sample Device Registry Entries

Serial Device Registry Entry Sample

; Registry entry for a serial device

;

[HKLM\Drivers\BuiltIn\Peripherals\devices\0\Psion Teklogix Exp1_UART]

“Name”=”Exp1_UART”

“ConnectorId”=dword:0 ;ConnectorId_Expansion1: 0

;ConnectorId_Expansion2: 1

;ConnectorId_Expansion3: 2

“PinFunctions”=dword:0F ;Pin GPIO0_TXD: bit 0 [1]

;Pin GPIO1_RXD: bit 1 [1]

;Pin GPIO2_CTS: bit 2 [1]

;Pin GPIO3_RTS: bit 3 [1]

;Pin GPIO4_MOSI: bit 4 [0]

;Pin GPIO5_MISO: bit 5 [0]

;Pin GPIO6_SCLK: bit 6 [0]

;Pin GPIO7_CS_N: bit 7 [0]

“PowerMode”=dword:1 ;PowerMode_Auto: 1

;PowerMode_Manual: 2

“Notifications”=dword:0

“LoadFlags”=dword:1 ;Flags_Uart: 0x01, load default UART driver

;Flags_UsbHost: 0x02, load default USB host driver

;Flags_UsbClient: 0x04, load default USB client driver

;Flags_Spi: 0x08, load default SPI driver

;Flags_UsbOtg: 0x10, load default USB OTG driver

;Flags_None: 0x00, load vendor supplied driver

SPI Device Registry Entry Sample

(SPI not available on Omnii XT10):

; Registry entry for an SPI device

;

[HKLM\Drivers\BuiltIn\Peripherals\devices\0\Psion Teklogix Exp1_SPI]

“Name”=”Exp1_SPI”

“ConnectorId”=dword:0 ; ConnectorId_Expansion1: 0

; ConnectorId_Expansion2: 1

; ConnectorId_Expansion3: 2

“PinFunctions”=dword:F0 ; Pin GPIO0_TXD: bit 0 [0]

; Pin GPIO1_RXD: bit 1 [0]

; Pin GPIO2_CTS: bit 2 [0]

; Pin GPIO3_RTS: bit 3 [0]

; Pin GPIO4_MOSI: bit 4 [1]

; Pin GPIO5_MISO: bit 5 [1]

; Pin GPIO6_SCLK: bit 6 [1]

; Pin GPIO7_CS_N: bit 7 [1]

“PowerMode”=dword:1 ; PowerMode_Auto: 1

; PowerMode_Manual: 2

“Notifications”=dword:0

“LoadFlags”=dword:0 ; Flags_Uart: 0x01, load default UART driver

; Flags_UsbHost: 0x02, load default USB host driver

; Flags_UsbClient: 0x04, load default USB client driver

; Flags_Spi: 0x08, load default SPI driver

; Flags_UsbOtg: 0x10, load default USB OTG driver

; Flags_None: 0x00, load vendor supplied driver

Psion Teklogix Omnii HDK User Manual 27

Page 38

Chapter 4: Software

Registry Settings for Expansion Devices

4.4.1.1 Device Information Registry Keys

This section describes the registry keys required by the peripherals driver to identify and define

the behaviour of expansion devices. The parent key for all of the device-specific subkeys is:

[HKLM\Drivers\BuiltIn\Peripherals\devices]

Within that key, create a subkey (if it does not already exist) for the type of connector that the

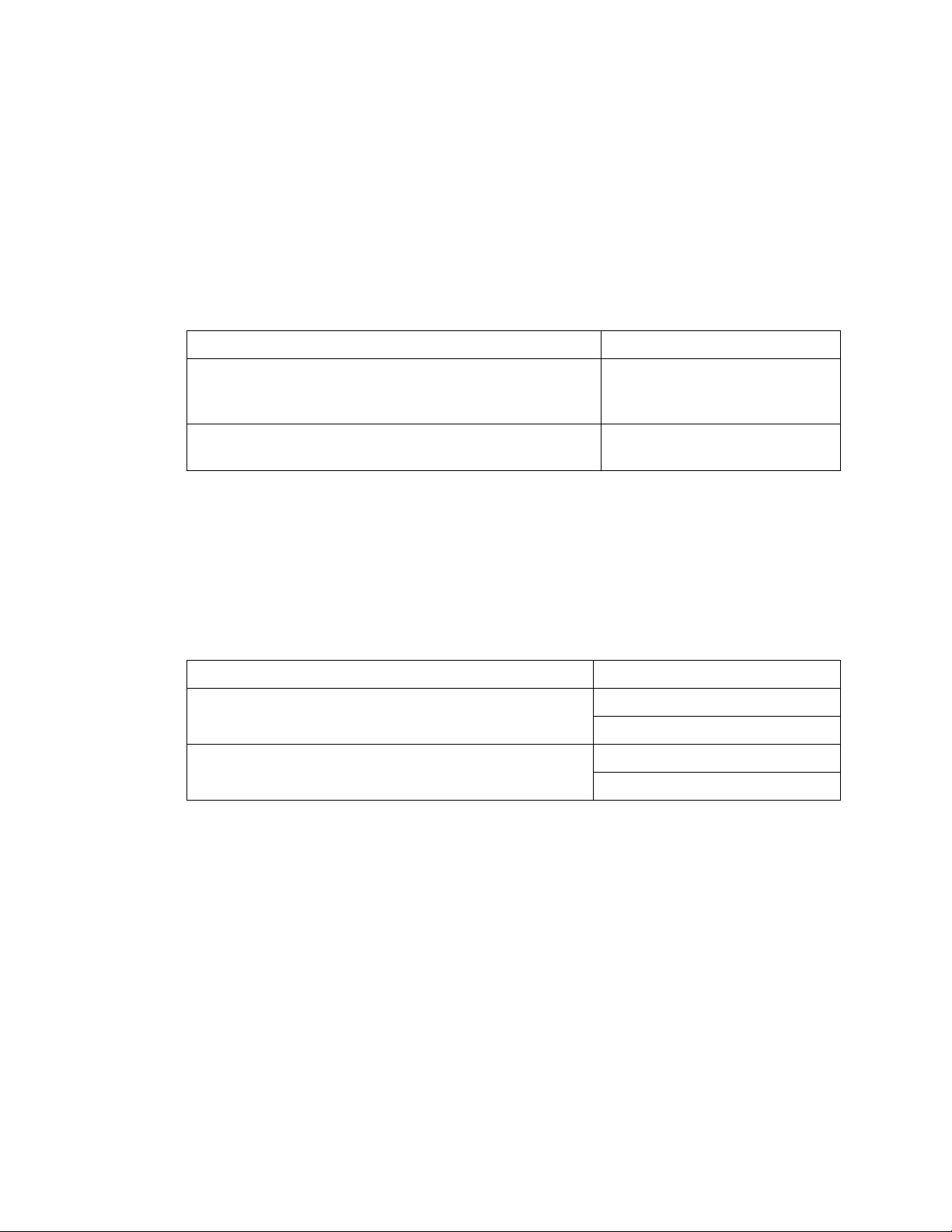

device will attach to. The connector types are defined in the following table:

Table 4.1 Connector Type Definitions

Subkey

Number

0 Expansion Port

1WWAN

2 GPS

4 Docking

1

WWAN is not available on Omnii XT10, and is included here for development on future products.

1

Connector Type

For example, the registry keys that describe devices connecting to the expansion port would be

stored in the subkey:

[HKLM\Drivers\BuiltIn\Peripherals\devices\0]

Within the connector type subkey create a further subkey using the Device ID reported by the

device. For devices that attach to the docking connector, an integer value based on a resistor ID in

the device is used for identification. For example, the Device Name (resistor ID) for the desktop

dock device is 18, therefore the correct registry key for parameters pertaining to that device is:

[HKLM\Drivers\BuiltIn\Peripherals\devices\4\18]

For all expansion devices with EEPROMs, the Device Name is a concatenation of the

Manufacturer and Model fields in the EEPROM (see Section 8.3.1: “Common EEPROM

Fields” for more details). For example, if an end-cap expansion device manufactured by

Psion Teklogix with the model field defined as “Endcap” was connected to the end-cap expansion

port, the correct registry key for parameters pertaining to that device would be:

[HKLM\Drivers\BuiltIn\Peripherals\devices\0\Psion Teklogix Endcap]

Note: Because the model and manufacturer fields in the EEPROM are used as part of the registry

key, they cannot contain any characters that are not permitted in registry key names (null,

backslash, etc.).

Device Registry Values

Within the subkey for the specific device, add the following device registry values:

• Name (REG_SZ): A descriptive name for the device.

• ConnectorId (REG_DWORD): An optional field that restricts a device to be recognized only

on a specific expansion slot. The possible values are 0 (Expansion Port 1), 1 (Expansion Port

2) and 2 (Expansion Port 3).

If this field is not specified, the device will be recognized on all logical connectors with the

same Connector Type (e.g. if the Connector Type of the device is 0, it will be recognized on

all expansion ports).

28 Psion Teklogix Omnii HDK User Manual

Page 39

Chapter 4: Software

Registry Settings for Expansion Devices

• PinFunctions (REG_DWORD): A one-byte value that configures the communication mode

of the dual-purpose GPIO / UART and GPIO / SPI pins for the type of device attached.

Each of the three major expansion ports have eight pins that can be configured to communicate to a GPIO device (General Purpose Input/Output), or to a serial RS-232/UART or SPI

(not available on Omnii XT10) device. If no PinFunctions value is specified, the pins default

to the non-GPIO (serial / SPI) function.

• To set the communication mode of these pins, set the PinFunctions value according to the

following bit field:

Table 4.2 PinFunctions Registry Value Definitions

Bit Pin Name Description

0 (LSB) EXP1_TXD_GPIO0 0 = GPIO pin 0, 1 = Serial TXD

1 EXP1_RXD_GPIO1 0 = GPIO pin 1, 1 = Serial RXD

2 EXP1_CTS_GPIO2 0 = GPIO pin 2, 1 = Serial CTS

3 EXP1_RTS_GPIO3 0 = GPIO pin 3, 1 = Serial RTS

4 EXP1_MOSI_GPIO4 0 = GPIO pin 4, 1 = SPI MOSI

5 EXP1_MISO_GPIO5 0 = GPIO pin 5, 1 = SPI MISO

6 EXP1_SCLK_GPIO6 0 = GPIO pin 6, 1 = SPI SCLK

7 (MSB) EXP1_CS_N_GPIO7 0 = GPIO pin 7, 1 = SPI chip select

For example, to configure the pins for serial communication, set the PinFunctions value to 0F.

• PowerMode (REG_DWORD): This value determines how and when the device hardware is

powered by the peripherals driver. The possible values are 1 (Auto) and 2 (Manual). If the

power mode is set to Auto, the device power is managed by the peripherals driver; the device

is powered off when the computer enters suspend mode and powered on when the computer

resumes activity.

The default setting for this value is 2, which is the recommended setting. Under this setting,

power to the device must be controlled by a loaded device driver or application.

• Notifications (REG_DWORD): The notifications registry value determines how the user is

notified about expansion devices.

This value is a bit field as defined in the following table:

Table 4.3 Notifications Registry Value Definitions

Bit Functionality Description