Page 1

980588-001 Prelim 1

®

Zebra

F680

Photo Printer

User’s Manual

Page 2

Page 3

This manual contains installation and operation information for the Zebra F6 80 Photo

Printer, manufactured by Zebra Technologies Corporation, Camarillo, California.

Return Materials Authorization

Before returning any equipment to Zebra Technologies Corporation for in-warranty or outof-warranty repair, contact Repair Administration for a Return Materials Authorization

(RMA) number. Repack the equipment in the original packing materia l and mark the RMA

number clearly on the outside. Ship the equipment, freight prepaid, to the address listed

below:

• For USA, Latin America, and Asia / Pacific:

Zebra Technologies Corporation

Zebra Card Printer Solutions

1001 Flynn Road

Camarillo, CA. 93012-8706.USA

Phone: +1 (805) 578-5001

FAX: +1 (805) 579-1808

Foreword

• For Europe and Middle East:

Zebra Technologies Corporation

Zebra Card Printer Solutions

Pittman Way, Fulwood

Preston, PR2 9ZD

Lancashire, U.K.

Phone: +44 - 1 - 772 - 797555

FAX: +44 - 1 - 772 - 693000

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual iii

Page 4

Foreword

Copyright Notice

© 2007 ZIH Corp.

This document contains information proprietary to Zebra Technologies Corporation. This

document and the information contained within is Copyrighted by Zebra Technologies

Corporation and may not be duplicated in ful l or in part by any person without written

approval from Zebra. While every effort has been made to keep the information contained

within current and accurate as of the date of publication, no guarantee is given that the

document is error-free or that it is accurate with regard to any specificat ion. Zebra reserves the

right to make changes, for the purpose of product improvement, at any time.

Trademarks

F680 is a trademark and Zebra is a registered trademark of Zebra Technologies Corporation.

Windows and MS.DOS are registered trademarks of Microsoft Corp. All other trademarks or

registered trademarks are marks of their respective holders.

Product Disposal

Product Disposal Information • Do not dispose of this product in unsorted municipal

waste. This product is recyclable, and should be recycled according to your local

standards. For more information, please see our web site at:

http://www.zebra.com/environment

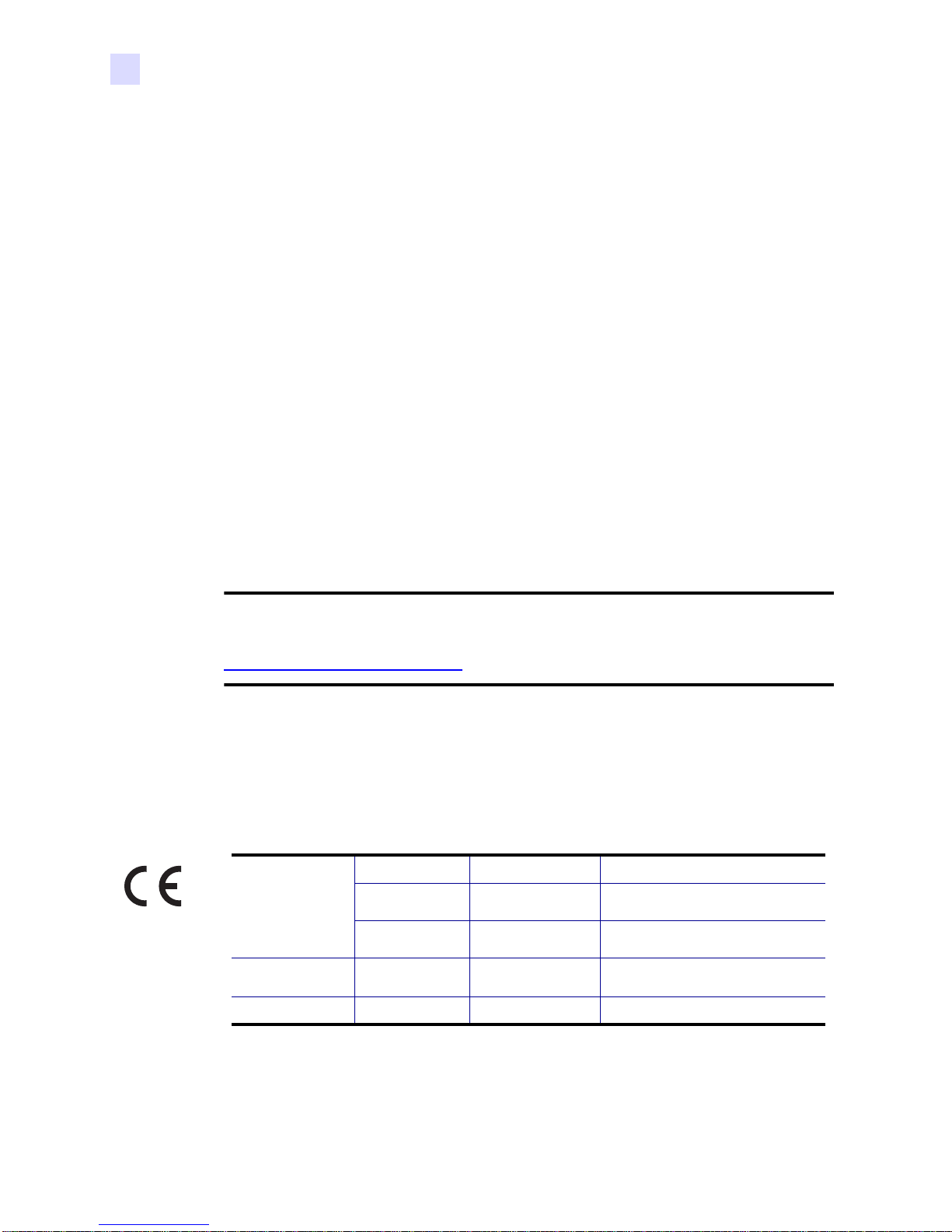

Declarations of Conformity

89/336/EEC

modified by

92/31/EEC and

93/68/EEC

73/23/EEC modified

by 93/68/EEC

1999/5/CE

EMC Directive

EMC Directive

EMC Directive EN55024 (2001)

Low voltage

Directive

R&TTE Directive

EN 55022 (1998) RF Emissions control

EN 301489-3 V1.4.1

EN 60950-1 (2001) Product safety

EN300330-2 V1.1.1 Radio Frequency Interferences

RF Emissions and Immunity for radio

equipment

Immunity to Electro-Magnetic

Disturbances

For a formal certificate, please contact the Compliance Office at Zebra’s Camarillo facility.

iv F680 User’s Manual 980588-001 Prelim 1

Page 5

EUROPE: Norway Only: This product is also designed for IT power system with phase to phase

voltage 230V. Earth grounding is via the polarized, 3-wire power cord.

FI: “Laite on liitettävä suojamaadoitus koskettimilla varustettuun pistorasiaan”

SE: “Apparaten skall anslutas till jordat uttag”

NO: “Apparatet må tilkoples jordet stikkontakt”

FCC Regulations

Model F680 has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and operated in accordance with the F680 User’s Manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Pursuant to Part 15.21 of the FCC Rules, any changes or modifications to this equipment not

expressly approved by Zebra may cause harmful interference and void the FCC authorization

to operate this equipment.

Foreword

Industry Canada Notice

This device complies with Industry Canada ICES-003 class A requirements.

Cet equipement est conforme a l’ICES-003 classe A de la norm Industrielle Canadian.

980588-001 Prelim 1 F680 User’s Manual v

Page 6

Foreword

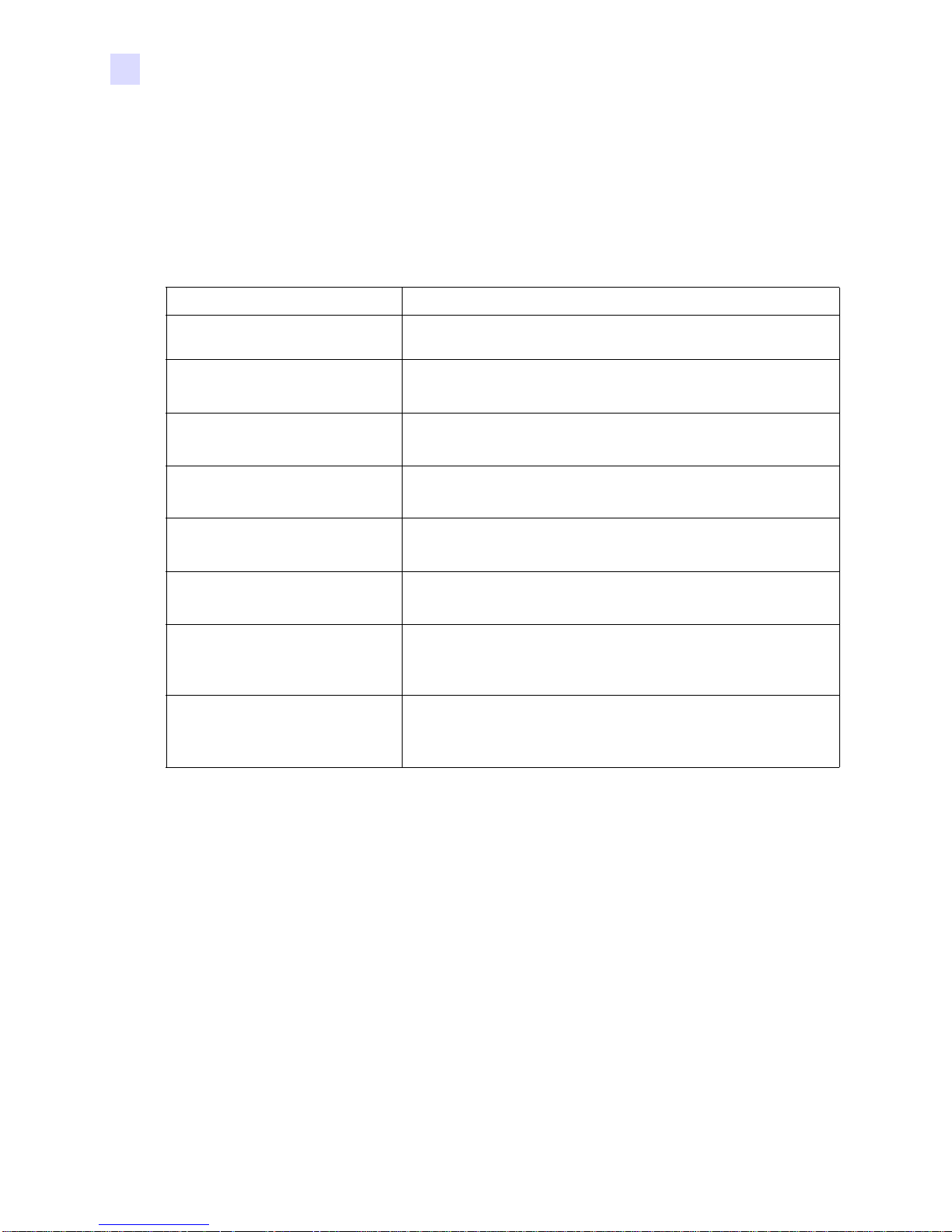

F680 Printer Model

The Zebra Product Number tells a story:

Here is a quick review of the Zebra Card Prin ter Seri es numbering and letterin g system to help

you.

Model numbers include identifiers that specify options using the following lettering

conventions:

Part Number Description

F 6 8 0 - _ _ _ _ _ - _ _ _

_ _ _ _ - 0 _ _ _ _ - _ _ _

_ _ _ _ - _ 0 _ _ _ - _ _ _

_ _ _ _ - _ _ 0 _ _ - _ _ _

_ _ _ _ - _ _ _ 0 _ - _ _ _

_ _ _ _ - _ _ _ _ A - _ _ _

_ _ _ _ - _ _ _ _ _ - A _ _

_ _ _ _ - _ _ _ _ _ - I _ _

_ _ _ _ - _ _ _ _ _ - _ D 0

Base Printer

F680 Digital Photo Printer

Built-in Options

None

Reserved

None

Reserved

None

Reserved

None

Interface

USB

Power Cord(s) Included

US 120 VAC

US 120 VAC and European 220 VAC

Windows Drivers and User Documentation CD

Included

vi F680 User’s Manual 980588-001 Prelim 1

Page 7

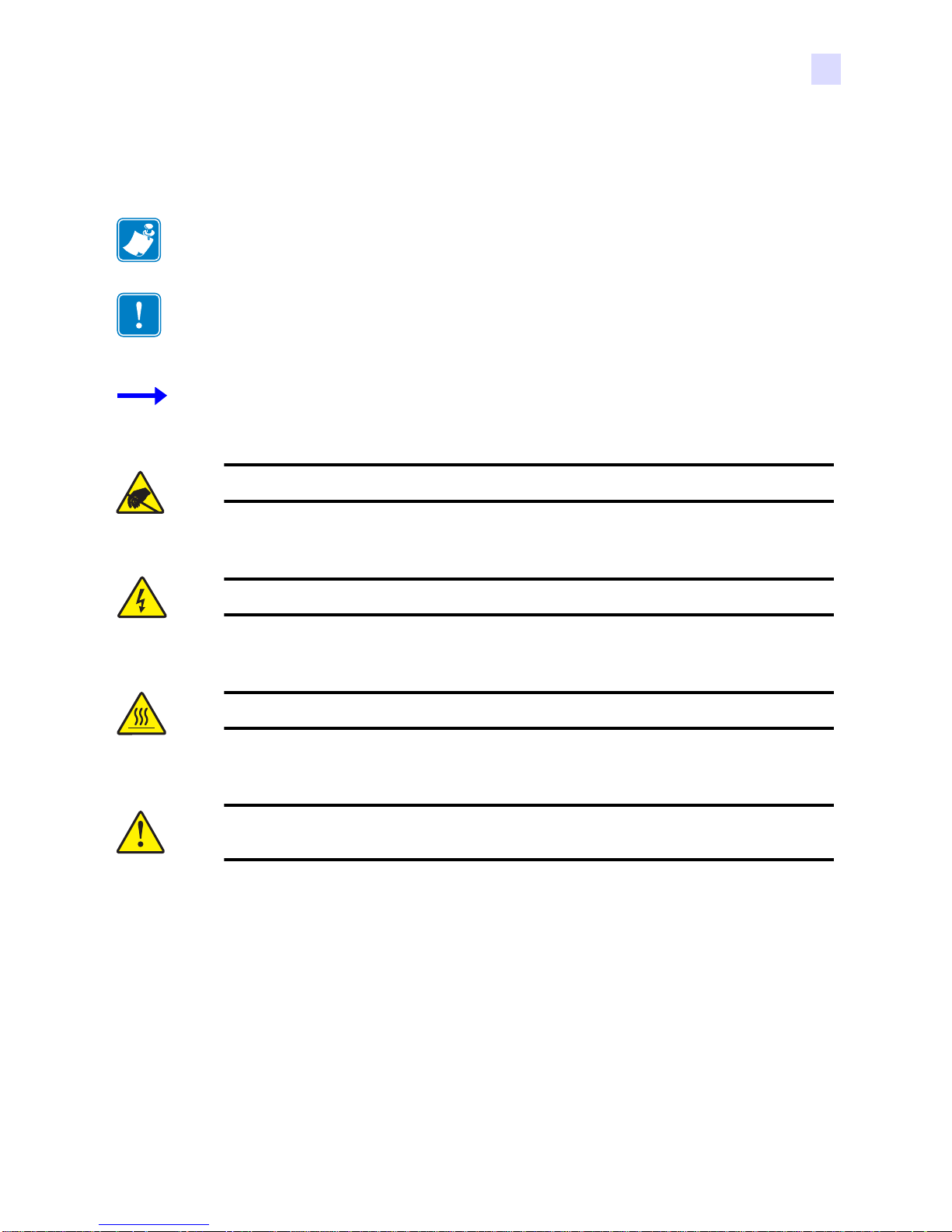

Icons

Foreword

Throughout this manual, different icons highlight important information, as follows:

Note • Indicates information that emphasizes or supplements important points of the main

text.

Important • Advises you of information that is essential to complete a task, or points out the

importance of specific information in the text.

Provides an example or scenario to demonstrate or clarify a section of text.

Electrostatic Discharge Caution • W arns you of the potential for electrostatic discharge.

Electric Shock Caution • Warns you of a potential electric shock situation.

Caution • Warns you of a situation where e xcessive heat could cause a burn.

Caution • Advises you that failure to take or avoid a specific action could result in

physical harm to you, or could result in physical damage to the hardware.

980588-001 Prelim 1 F680 User’s Manual vii

Page 8

Foreword

viii F680 User’s Manual 980588-001 Prelim 1

Page 9

Table of Contents

1 • Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Printer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Controls, Connectors, and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 • Installation and Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operating Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Opening the Printer Cover and Paper Door. . . . . . . . . . . . . . . . . . . . . . . 10

Loading Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Initial Steps - 6 inch (15.3 cm) Wide Paper . . . . . . . . . . . . . . . . . . . . .11

Initial Steps - 5 inch (12.7 cm) Wide Paper . . . . . . . . . . . . . . . . . . . . 12

Subsequent Steps - Either Width Paper Roll . . . . . . . . . . . . . . . . . . . 15

Loading a Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Closing the Paper Door and Printer Cover. . . . . . . . . . . . . . . . . . . . . . . . 27

Installing the Print Driver Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Connecting Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Connecting the Printer to the Computer. . . . . . . . . . . . . . . . . . . . . . . . . . 30

Attaching the Print Catcher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Making a Test Print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Packing the F680 Photo Printer for Shipment . . . . . . . . . . . . . . . . . . . . . 34

3 • Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Setting Printer Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Calibrating the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

980588-001 Prelim 1 F680 User’s Manual ix

Page 10

Table of Contents

4 • Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Cleaning the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5 • Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Resolving Potential Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Resolving Operator Panel Error Messages . . . . . . . . . . . . . . . . . . . . . . . 45

Clearing a Paper Jam. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Recovering from a Power Interruption . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6 • Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Computer System Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Photo Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Cleaning the Platen Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cleaning the Thermal Print Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Appendix A • Worldwide Service & Support . . . . . . . . . . . . . . . . . 49

Service and Support Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Website . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

x F680 User’s Manual 980588-001 Prelim 1

Page 11

Thank you for choosing the Zebra F680 Photo Printer. This manual guides you to efficient start

up and operation of your new Photo Printer.

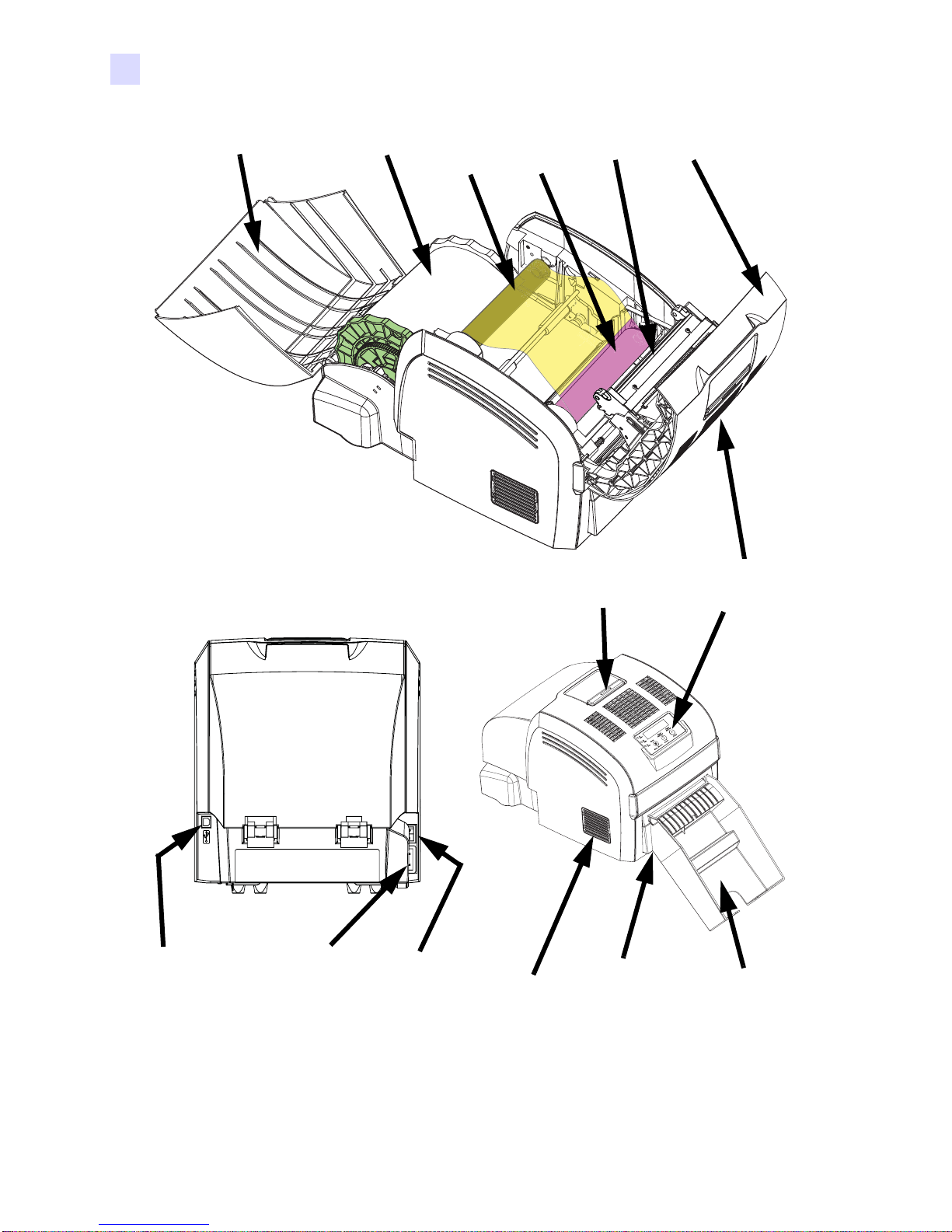

Printer Features

1

Introduction

The following figure shows the main features of your F680 Printer. Section 2 of this manual

describes how to load the paper and ribbon, how to connect the Printer to your computer, and

how to install the Driver software onto your computer.

980588-001 Draft 1 Zebra F680 Photo Printer User’s Manual 1

Page 12

Introduction

Printer Features

Paper Door (Open)

Paper Roll

Ribbon

Takeup

Spool

Ribbon

Supply

Spool

Print

Head

Cover

Release

Cover

(Open)

Operator

Control

Panel

USB 2.0

Connecctor

2 Zebra F6 80 Photo Printer User’s Manual 980588-001 Draft 1

AC Power

Connector

Power

Switch

Air

Filter

Trim Tray

(under Print

Catcher)

Print

Catcher

Page 13

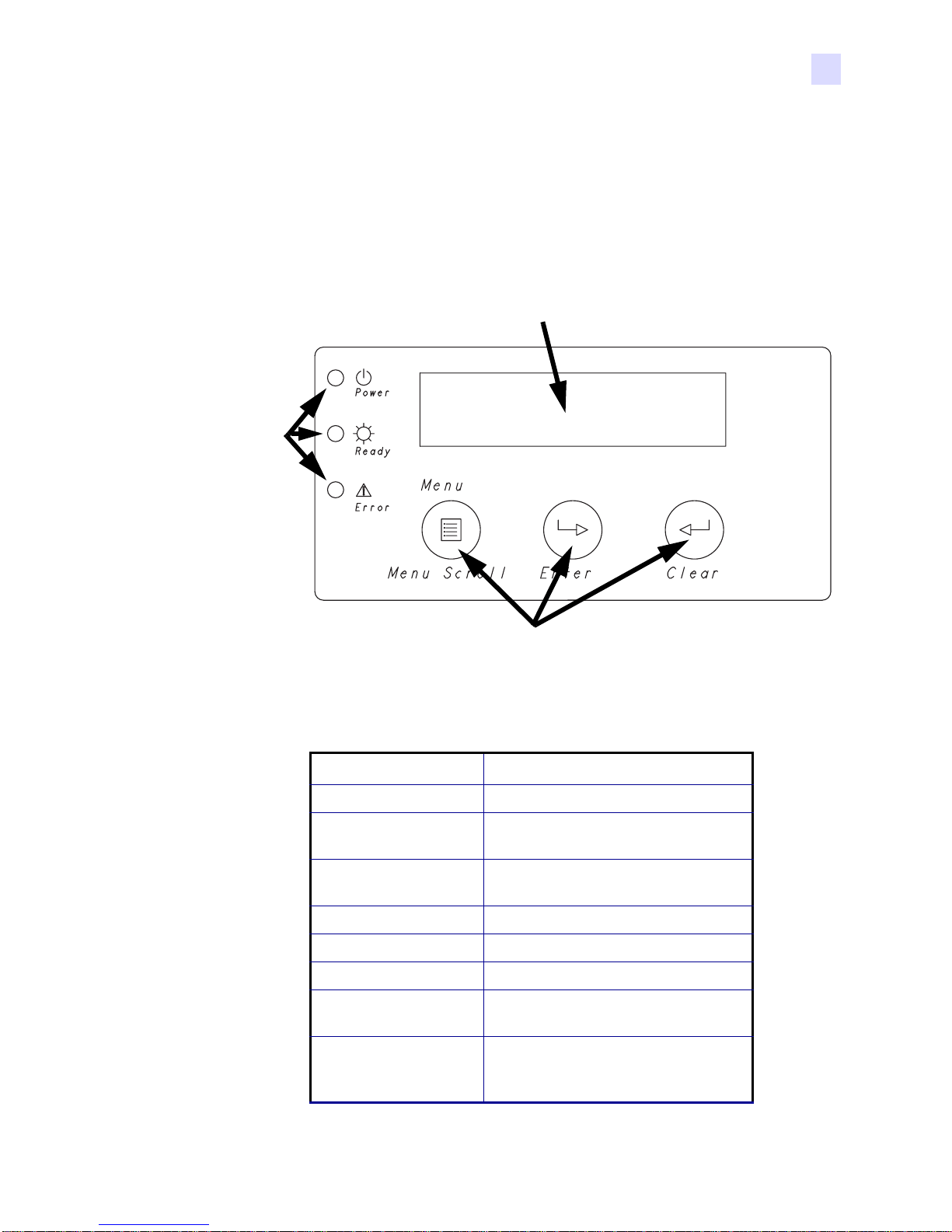

Controls, Connectors, and Indicators

The AC Power Connector, Power Switch, and USB 2.0 Connector are located on the rear of

the Printer, as shown in the previous figure.

The Operator Control Panel (shown below ) includes three Indicator LEDs that indi cate system

status, three Control Buttons for scrolling through and selecting commands and options, and

an LCD Display Screen that indicates status and/or fault information.

Display Screen

Indcator

LEDs

Introduction

Controls, Connectors, and Indicators

Control Buttons

The LCD Display on the Operator Control Panel can display the following messages:

Message Meaning

Ready Printer is ready to print.

Warming Up Printer is not ready to print; allow it to

complete warming up.

Cooling Printer (typically the Print Head) is

too hot; allow it to cool down.

Cover Open Make sure Cover is evenly closed.

Check Ribbon Out of Ribbon - Load New Ribbon.

Paper Empty Load Paper.

Cutter Jam Check for paper jam where paper exits

printer.

Incorrect Ribbon Check for possible Ribbon Jam. Also

possible that Ribbon Barcode not

detected or incorrect.

980588-001 Draft 1 Zebra F680 Photo Printer User’s Manual 3

Page 14

Introduction

Controls, Connectors, and Indicators

Service 3.40.1

Service 3.40.5

Service 3.41.1

Service 3.41.2

Service 3.41.3

Service 3.41.4

Service 3.41.5

Service 3.41.6

Service 3.41.7

Service 3.42.1

Service 3.42.2

Service 3.42.3

Service 3.42.4

Service 3.42.5

Service 3.42.6

Service 3.42.7

Service 3.42.8

Service 3.42.9

Service 3.43.2

Service 3.43.4

Service 3.43.5

Service 3.43.7

Service 3.43.8

Service 3.43.9

Service 3.43.A

These Service Codes indicate an

internal problem. Report the code

number to your Zebra service

representative.

4 Zebra F6 80 Photo Printer User’s Manual 980588-001 Draft 1

Page 15

Installation and Setup

General Information

This section will guide you through the installation and setup of you r F680 Photo Printer.

This consists of the following procedures, which should be performed in the order

presented.

• Unpacking the Printer

• Connecting the Printer to the Power Source

• Connecting the Printer to the Computer

• Opening the Printer Cover and Paper Door

• Loading Paper

• Loading a Ribbon

• Closing the Printer Cover and Paper Door

• Attaching the Print Catcher

• Applying Power

• Loading the Printer Driver Software

• Making a Test Print

2

Instructions on packing the Printer for shipment are given at the end of this section.

The printer should be placed in a location that allows easy access to all sides. The printer

should never be operated while resting on its side or upside down.

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 5

Page 16

Installation and Setup

Unpacking the Printer

Electric Shock Caution • Limit AC power supplied to the F680 Printer to 110 ~ 230

volts, 60 ~ 50 Hz. Never operate the printer in a location where operator, computer, or

printer can get wet. Personal injury could result. The printer must be connected to a

grounded electrical power source and properly protected against electrical surges

and grounding faults; the electrical reliability of the printer is based on the reliability of

the power source and with ground connection.

The printer’s power supply is an internal unit that can only be serviced or replaced by

trained and authorized personnel.

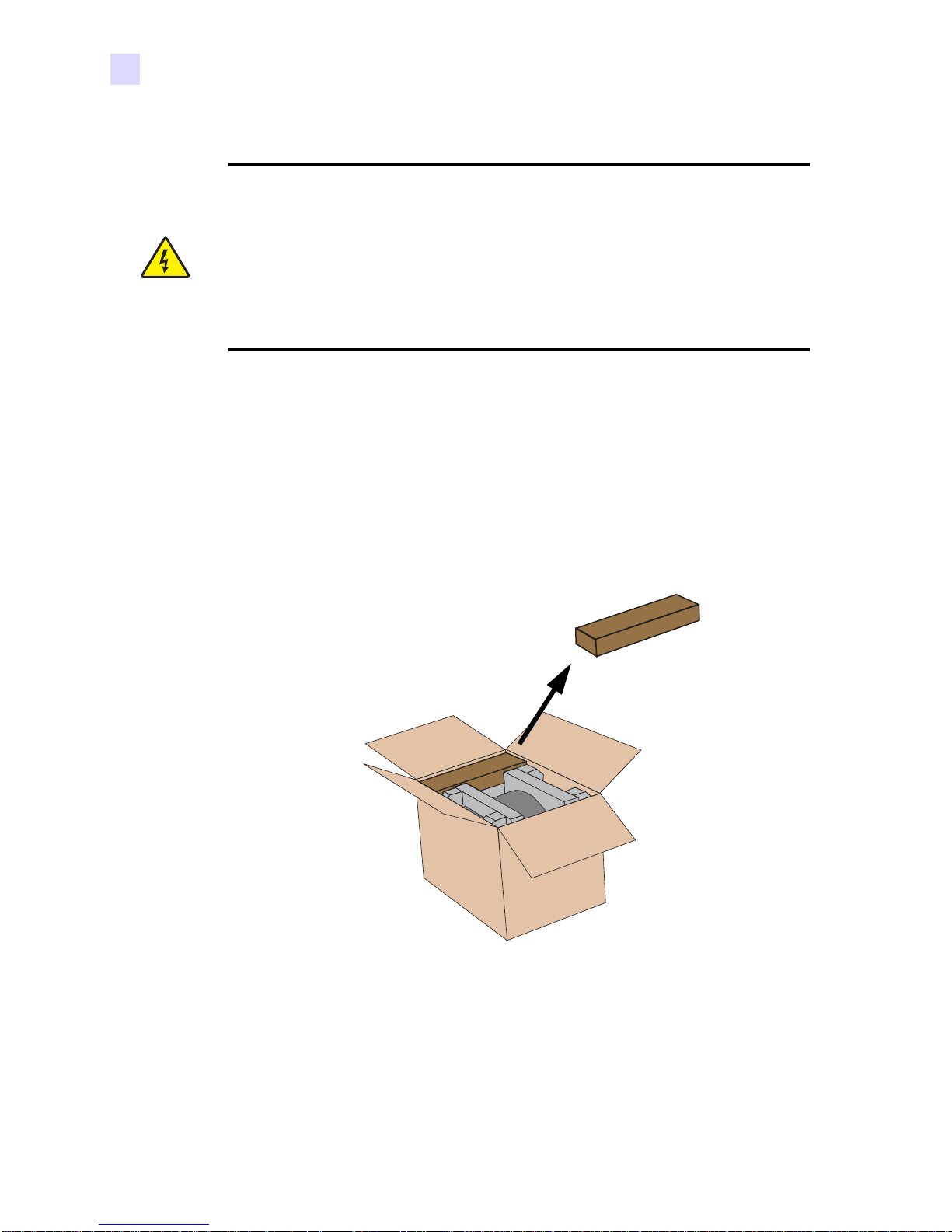

Unpacking the Printer

Your F680 Photo Printer ships in a carton and protective anti-static bag. Keep all packaging

material in case you need to move or re-ship the printer.

1. Inspect the shipping container to ensure that no damage has occurred during shipment. If

any damage is apparent, file a claim with the shipper.

2. Open the shipping carton. Remove the Accessories Box.

Accessories

Box

6 Zebra F6 80 Photo Printer User’s Manual 980588-001 Prelim 1

Page 17

Installation and Setup

Unpacking the Printer

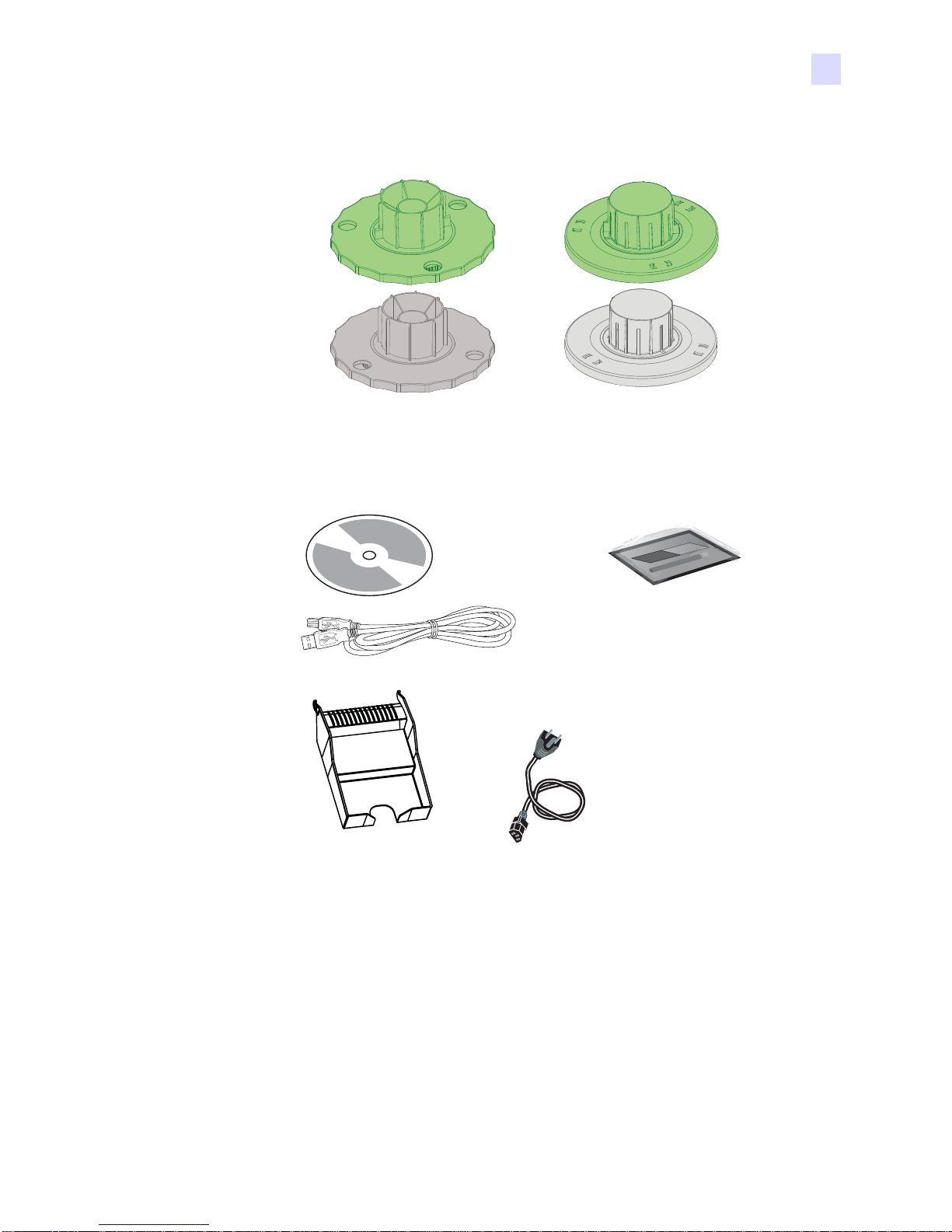

3. Open the Accessories Box, and verify that the following nine items are included:

Hubs

(Used for loading

either 6” or 5” wide

paper rolls)

Catch Tray

Driver &

Documentation

CD

USB

Cable

Spacers

(Used in addition

to Hubs for loading

of 5” wide paper

rolls only)

Cleaning Kit

(Includes a Cleaning

Card and a Cleaning

Swab)

AC Power Cord

(Type depends on

Printer Model

oredered)

If any items are missing, please contact your dealer. To reorder, please refer to Appendix D of

this manual.

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 7

Page 18

Installation and Setup

Unpacking the Printer

4. Use both hands to lift the Printer (in the foam inserts) from the shipping carton.

Caution • The F680 Printer weighs approximately 20 lbs (9 kg).

Keep all the packing and shipping material in case you have to transport the Printer. If the

shipping material is damaged or misplaced, replacement material can be ordered at nominal

cost (refer to Appendix D of this manual).

8 Zebra F6 80 Photo Printer User’s Manual 980588-001 Prelim 1

Page 19

Operating Location

1. Please ensure that you have a clean and nearly dust free environment for proper operation

and storage of the printer.

2. The following figure shows minimum space requirements for the Printer (including space

for installing the paper and ribbon, and allowing space for sufficient free air circulation).

In addition, the front of Printer should be located with in appproximate ly 2 inches (50 mm)

of the work surface, since the Catch Tray extends below the bottom of the Printer.

Installation and Setup

Operating Location

Approx. 34" (860 mm)

Approx. 17.5" (440 mm)

Approx. 17.7"

(450 mm)

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 9

Page 20

Installation and Setup

Opening the Printer Cover and Paper Door

Opening the Printer Cover and Paper Door

1. With the heel of your hand, press down on the rectangular bar as shown in the figure

below. You will hear a “click” and the rear edge of the Printer Cover wil l raise sli gh tly, as

shown.

2. Swing the Cover forward, then lift and swing the Paper Door by its front edge.

1

2

10 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Page 21

Loading Paper

Important • The initial steps for loading paper are diff eren t fo r 6 inch (1 5. 3 cm) wide or 5

inch (12.7 cm) paper rolls.

The initial steps for 6 inch (15.3 cm) wide paper are given below.

Initial steps for 5 inch (12.7 cm) wide paper are given starting on page 12.

Subsequent steps that are the same for either width paper are gi ven starting on .

Initial Steps - 6 inch (15.3 cm) Wide Paper

1. Note that there is a green hub and a gray hub (if necessary, see the figure on page 7 to

make sure you have the hubs and not the spacers).

2. In the drawing below, note that there are “lugs” on the green hub and no lugs on the gray

hub. Otherwise the gray and green hubs are identical. There a re not che s on one end of the

paper core, and no notches on the other end.

Installation and Setup

Loading Paper

Lugs

Notches

No Notches

No Lugs

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 11

Page 22

Installation and Setup

Loading Paper

3. Press the green hub into the paper roll so the lugs are fully engaged in the notches and the

flat (inner) surface of the hub is flush against the paper roll. Similarly, press the gray hub

into the other end of the paper roll.

Initial Steps - 5 inch (12.7 cm) Wide Paper

To use 5 inch (12.7 cm) wide paper rolls in the F680 Photo Printer, spacers are used between

the hubs and either side of the paper spool to make the effective width the same as for 6 inch

(15.3 cm) paper rolls.

1. Note that the green hub and spacer have lugs, and the gray hub and spacer do not have

lugs, as shown below.

Green Hub has Lugs

Gray Hub has no Lugs

12 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Green Spacer has Lugs

Gray Spacer has no Lugs

Page 23

Installation and Setup

Loading Paper

2. Snap the green hub and space r together, and snap the gray hub and spacer together, as

shown below.

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 13

Page 24

Installation and Setup

Loading Paper

3. Insert the green hub/spacer into the paper core so the lugs on the spacer engage the

notches on the paper core. Similarly, insert the gray hub/spacer into the other end of the

paper core.

14 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Page 25

Subsequent Steps - Ei ther Width Paper Roll

1. Slide the Paper Width Guides to the appropriate position for the width of the paper roll

you will be loading. If your paper roll is six inches (15.3 cm) wide, slid e the guides to the

outer (“6”) position; if your paper roll is five i nches (12.7 cm) wide, slide the guides to the

inner (“5”) position.

Installation and Setup

Loading Paper

6” (15.3 cm) Paper

Width Position

5” (12.7 cm) Paper

Width Position

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 15

Page 26

Installation and Setup

Loading Paper

2. Note the location of the paper spool slots on either side of the Printer.

Paper Spool Slots

16 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Page 27

Installation and Setup

Loading Paper

3. Put the Paper Roll (with its hubs or hubs and spacers, depending on the width of the paper

roll) so the round axle ends of the hubs fit within the Pape r Spool Slots, as shown in the

following figure. The end of the Paper Roll in the green hub (with the lugs/not ches) must

go into the slot on the near side of the Printer, as shown below. Make sure the Paper Roll

seats fully and evenly in the slots.

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 17

Page 28

Installation and Setup

Loading Paper

4. Remove the sticker securing the end of the Paper Roll, and lift the leading edge of the

paper.

18 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Page 29

Installation and Setup

Loading Paper

5. T o guide the paper through its path, it is preferable to unroll the paper by turning the green

hub. (It is ok to pull the leading edge of t he p ap er d urin g t he in iti al l oa din g, but its a good

habit to get into to avoid touching the surface of the paper.)

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 19

✓

Page 30

Installation and Setup

Loading Paper

6. Feed the paper under the Pinch Rollers and the Paper Guide, as shown below.

Pinch Rollers

Paper Guide

20 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Page 31

Installation and Setup

Loading Paper

7. Continue feeding the paper until approximately one to three inches (25 to 75 mm) of paper

sticks out from the front of the Printer.

1 - 3 "

(25 - 75 mm)

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 21

Page 32

Installation and Setup

Loading a Ribbon

Loading a Ribbon

Important • Use only genuine Zebra ribbons in the F680 Photo Printer; use of other ribbons

can result in poor-quality prints and can even damage the Printer.

Important • Images remain on the ribbon after printing. If you need to maintain

confidentiality, dispose of the used ribbon appropriately.

1. If you are replacing a ribbon, remove the old ribbon and the supply and takeup spools.

2. Remove the protective wrapping and the paper band from the ribbon. Unroll about 7

inches (175 mm) of ribbon from the supply spool, as shown in the figure below.

22 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

7 ± 1 in

(175 ± 25 mm)

Page 33

Installation and Setup

Loading a Ribbon

3. Note that one end of the supply spool extends from the ribbon and has a bar-code pattern

on it. That end of the supply spool will be placed into po siti on first, follo wed b y th e ot her

end of the supply spool.

No barcode

on this end

End of Supply

Spool with

Barcode goes

onto this spindle

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 23

Page 34

Installation and Setup

Loading a Ribbon

4. See the following figures and position the ribbon supply spool on i ts spindles.

1. While holding the ribbon

takeup spool with one hand

(typically the left hand for a righthanded person), use your right

hand to press the barcode end of

the ribbon supply spool onto the

spindle on the right.

2. As the spool

compresses the

spindle spring,

lower the other end

of the ribbon supply

spool so it can

engage the spindle

on the left side.

24 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

3. Rotate the spool back

and forth so it fully

engages both spindles

and is pressed against

the left side spindle.

Page 35

Installation and Setup

Loading a Ribbon

5. Check that the ribbon supply spool is fully engaged on both spindles (especially the one

on the left side.)

✓

X

X

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 25

Page 36

Installation and Setup

Loading a Ribbon

6. Then position the ribbon take-up spool on the other spindles.

X

7. If there is an excessive amount of slack in the ribbon (i.e., it appears that the ribbo n will

become tangled with the paper or elsewhere in the Printer), take up the slack by turning

the ribbon supply spool only. Do not turn the ribbon takeup spool in either direction.

26 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Page 37

Closing the Paper Door and Printer Cover

Closing the Paper Door and Printer Cover

Swing the Paper Door to its closed position, then swing the Printer Cover closed. Press down

evenly until the Printer Cover snaps closed.

Installation and Setup

1

2

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 27

Page 38

Installation and Setup

Installing the Print Driver Software

Installing the Print Driver Software

Printing with the F680 Photo Printer requires the Windows Printer Driver and your card

design/issuing software or printer command level programming through the printer interface.

To install the Windows Printer Driver onto your computer, insert the included Driver and

Documentation CD into your computer’s CD-ROM drive and follow the screen prompts.

Connecting Power

The F680 Printer contains an auto-detecting and switching power supply. Input voltage and

frequency can be in either of the following ranges:

• 90 - 132 VAC at 48 - 62 Hz

• 180 - 264 VAC at 48 - 62 Hz

A three-wire (grounding) Power Cord is included with the Printer. If the in cl uded Power Cord

is not appropriate for your voltage and/ or source out let, be sure to obtain an appropri ate Power

Cord before proceeding.

Important • Verify that the Power Switch is set to OFF (O).

Caution • The AC power outlet must be grounded and a three-wire Power Cord must be

used. An ungrounded outlet can cause fire, electric shock, or harmful interference to

nearby electrical devices.

28 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Page 39

Installation and Setup

Connecting Power

Power Switch

AC Power

Connector

1. Connect the Power Cord to the AC Power Connector on the back of the Printer (see above

figure) and to a grounded AC power outlet.

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 29

Page 40

Installation and Setup

Connecting the Printer to the Computer

Connecting the Printer to the Computer

The F680 Printer includes a standard USB 2.0 interface.

Important • Verify that the Power Switch is set to OFF (O)

USB

1. Connect the USB Cable included with the Printer to the USB 2.0 Connector o n the back of

the Printer and to the USB 2.0 Connector on the computer.

30 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Page 41

Attaching the Print Catcher

The Print Catcher attaches to the front of the Printer and provides a receptacle for completed

prints.

The Print Catcher simply hooks into slots in the front of the Printer. Note that when the Print

Catcher is attached, it extends below the bottom level of the Printer; the Print Catcher would

normally hang over a desk or table edge.

Installation and Setup

Attaching the Print Catcher

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 31

Page 42

Installation and Setup

Applying Power

Applying Power

1. Verify that the Printer’s power cord is plugged into a grounded AC outlet, and that the

USB 2.0 Connector on the Printer is connected to a USB 2.0 Port on your computer.

2. Set the Power Switch to On ( I ).

USB

90 - 264 VAC

3. The Power LED on the Operator Control Panel will light. The Printer will perform an

initialization and self-test routine; at successful complet ion of this ro utine the Rea dy LED

will light and the message Ready will display.

32 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Ready

Page 43

Making a Test Print

Making a test print is a simple way to verify basic operation of the Printer.

1. Set the Printer power to ON (I). The Power LED on the front panel will glow orange.

2. The Printer will run through an initialization and self-test. At successful completion, the

Ready LED on the front panel will glow green and the message Ready will display on the

LCD panel.

Installation and Setup

Making a Test Print

Ready

3. Press the Menu Scroll button several times, until Test Print Mode displays on the LCD

Panel, then press the Enter button.

Test Print Mode

4. Press the Menu button several times, until Pattern appears on the LCD Panel, then press

the Enter button.

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 33

Page 44

Installation and Setup

Packing the F680 Photo Printer for Shipment

5. Press the Menu button several times to scroll through the choices of pattern. The choices

are::

•Mid Gray

• Grid on Gray

• 1 Pixel Grid

• 2 Pixel Grid

• Max (maximum) Gray

•Offset Dots

• Smear

Pattern

6. When the desired pattern is displayed on the LCD Panel, press the Enter button. The

Printer will print a “picture” with that pattern.

Packing the F680 Photo Printer for Shipment

If the F680 Photo Printer is to be shipped, it is important to use the original packing and

shipping material to prevent damage to the Printer. If the original material is lost, a

replacement Shipping Kit can be ordered from Zebra; please refer to the Media List on the

Windows Drivers and User Documentation CD supplied with this printer.

34 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Page 45

3

Printing

Printing with the F680 Photo Printer is similar to printing with any other printer in a

Windows environment.

Setting Printer Properties

Printer Properties can be set either at the Operating System level or within the application

software program used for printing.

Calibrating the Printer

The provided Calibration Utility (on the Driver and Documentation CD) will help you get

the best quality prints from the P680 Phot o Printer.

The factory default calibration values generally provide excellent prints. However, if you

are dissatisfied with the color of your prints, run the Calibration Utility.

To run the Calibration Utility, insert the CD, click on Calibration Software, and follow

the on-screen prompts.

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 35

Page 46

Printing

Calibrating the Printer

36 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Page 47

4

Cleaning

To ensure good performance and high-quality prints, make sure that the F680 Photo

Printer and its environment are clean and dust free.

Caution • Never use abrasives or harsh chemicals to clean an y parf of the Prin ter. Do not

allow any foreign objects or liquids to fall or spill inside the printer. Fire or electric shock

could result. If any foreign object enters the printer , turn of f the printer power imme diately,

disconnect the power cord, and contact your supplier or Zebra Technologies.

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 37

Page 48

Cleaning

Cleaning the Printer

Cleaning the Printer

Clean the exterior of the Printer and the filter opening regular to eliminate dust buildup and

prevent dirt from entering the Printer.

1. Wipe the exterior of the Printer with a damp, lint-free clot h.

2. Vacuum the filter opening and the area above the Print Head to remove any dust.

Area Above the

Print Head

Filter Opening

Routine Maintenance

Note • If paper and/or ribbon are loaded in the Printer, remove them before performing

maintenance procedures.

To maintain good print quality:

1. Clean the Platen Roller if you notice artifacts (tiny spots; usually white) on your prints.

2. Clean the Thermal Print Head if directed to do so by a Zebra service representative.

38 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Page 49

Cleaning the Platen Roller

Clean the Platen Roller and Pick Rollers if you notice artifacts (tiny spots; usually white) on

your prints.

1. Make sure the printer power is set to OFF (O).

2. Open the Cover and the Paper Doo r.

3. If Ribbon and Paper are installed in the Prin ter, remove them both and set aside (they will

be re-installed in the Printer after the Platen Roller and Pick Rollers are cleaned).

4. In turn, slide the Paper Guides toward th e center and remove them by lifting up on the

back edge of the Guide.

Paper

Guides

Cleaning

Routine Maintenance

Lift

Back

Edge

5. Peel off the protective covering from both sides of the Cleaning Card.

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 39

Page 50

Cleaning

Routine Maintenance

6. Slide the white (adhesive) end of the Cleaning Card under one of the white Pick Rollers.

Note • The Cleaning Card will be a VERY snug fit under the Pick Roller.

Pick

Rollers

Cleaning

Card

7. Slide the Cleaning Card straignt inward over the Platen Roller so the adhesive surface of

the Cleaning Card remains under the Pick Roller.

Pick

Rollers

Platen

Roller

40 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Page 51

Cleaning

Routine Maintenance

8. Remove the Cleaning Card by sliding it straight out.

9. Using the same Cleaning Card, repeat steps 6 through 8 for the other Pick Roller.

10. Replace the Paper Guides by engaging the lip on the inside of the back edge and then

rotating it forward and down until it snaps into place.

11. Replace the Paper and Ribbon.

Cleaning the Thermal Print Head

Important • Do not perform this procedure unless you have been directed to do so by a Zebra

service representative.

1. Make sure the printer power is set to OFF (O).

2. Open the Printer Cover.

Caution • The Thermal Print Head becomes extremely hot during normal o peration. W ait

five minutes after you open the Printer Cover before you begin cleaning the head.

Caution • Oil from fingerprints can damage the Print Head, which looks like a glass bar .

Never touch it with your bare hands or fingers.

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 41

Page 52

Cleaning

Routine Maintenance

3. Remove the Cleaning Swab from the Cleaning Kit. Bend the Swab to release alcohol to

the tip.

4. Move the tip of the Cleaning Swab along the entire length of the Thermal Print Head and

the Peel Bar. (Note that the picture below shows the inside of the Printer with the Ribbon

and Paper removed; they do not need to be removed to perform this cleaning.)

Peel

Bar

Thermal

Print

Head

5. Wait five minutes for any residual alcohol to evaporate befo re applying power.

42 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Page 53

5

Troubleshooting

The table on the next page offers causes and solutions to symptoms related to improper

operation. Check the table when experiencing any loss of operation o r print quality.

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 43

Page 54

Troubleshooting

Resolving Potential Problems

Resolving Potential Problems

Problem / Symptom Description or Cause Possible Solution

Paper jam; Error indicator is on,

Printer does not operate.

Prints have linear streaks. Thermal Print Head is dirty. If directed by your Zebra service

Prints have streaks of small dots. The Platen Roller is dirty. Clean the Platen Roller. See

Print size or aspect ratio is not

what you expected.

Paper is jammed in the Printer. Clear the paper jam. See

“Clearing a Paper Jam” on

page 46

representative, clean the Thermal

Print Head. See “Cleaning the

Thermal Print Head” on page 41

“Cleaning the Platen Roller” on

page 39

The image file or printing options

need to be adjusted in your photo

printing software program.

In your photo printing software

program:

• Use Fit To Page or Clip

options if available.

• Adjust the image size to match

the paper size.

• Makes sure the Portrait /

Landscape setting matches the

orientation of the image.

• For more information, see the

help file or documentation for

your photo printing software

program.

Note: It is not necessary to adjust

the image resolution (dpi) to

match the printer resolution. The

Printer Driver automatically

scales your image to match the

Printer resolution.

Insufficient Memory errors

occur on your computer after

making a substantial number of

prints.

44 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Your computer may be low on

RAM (Random Access Memory)

and/or disc caching memory.

This occurs when you rotate,

scale, or retouch high resolution

images (i.e., over 72 dpi).

• Minimize the number of

images open at the same time.

• Delete the contents of the

clipboard frequently.

• Close all programs except the

photo printing software

program.

• See the help f ile or

documentation for your photo

printing software program for

tips on memory optimization.

•See page 48 of this document

for system requirements.

Page 55

Resolving Operator Panel Error Messages

Resolving Operator Panel Error Messages

Error Message Description or Cause Possible Solution

Troubleshooting

Paper Empty The paper roll has been

completely used up or is not

loaded.

Check Ribbon The ribbon is completely used

up, is not loaded, or is stuck to

the paper.

Check Paper The paper is stuck in the Printer

or paper path.

Cover Open The Printer cover is open. Make sure that the cover is

Incorrect Ribbon The Printer could not read the bar

code on the ribbon supply spool.

W a rming Up The Printer is warming up, and is

not ready to print.

Cooling The Printer is too hot to print, and

is cooling down.

Cutter Jam The paper cutter did not move

completely to one side.

Load the paper. See “Loading

Paper on page 11.

Load the ribbon. See “Loading a

Ribbon” on page 22.

Clear the Paper Jam. See

“Clearing a Paper Jam” on

page 46

completely and securely closed.

Check that the ribbon has a bar

code and/or replace the ribbon.

See”Loading a Ribbon” page 22

Wait for the Printer to complete

warming up.

Wait for the Printer to complete

cooling.

Check the paper path for a jam.

Service XX.YY.ZZ The Printer requires service. Contact your Zebra service

representative. Have available:

•Error Code Number

(XX.YY.ZZ)

• Printer Model Number and

Serial Number (shown on the

Printer’s data plate)

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 45

Page 56

Troubleshooting

Clearing a Paper Jam

Clearing a Paper Jam

1. Turn off the Printer and then turn it back on.

2. If a Paper Jam message appears on the Operator Panel after the Printer reaches the Ready

state, continue with this procedure.

3. Turn off the Printer, and open the cover.

4. Remove the ribbon.

Caution • Do not pull abruptly on the paper. This could cause damage to the Printer.

5. Open the paper door.

6. Slowly and carefully pull the damaged paper out of the Printer.

7. Use a pair of scissors to cut off any damaged, wrinkled, or torn portion of the paper. Cut

the paper smoothly and reasonably close to straight across the paper.

Note • Do not damage or mark any of the rollers.

8. Reload the paper.

9. Reload the ribbon.

10. Closee the paper door and the cover. Turn on the Printer and resume printing.

Recovering from a Power Interruption

Caution • If the Printer loses power while printing, the Printer will stop with the Thermal

Print Head positioned against the platen roller. The platen roller could become deformed

and damaged if the Thermal Print Head is left in this position.

If a power interruption occurs:

1. Open the cover immediately to release the pressure on the platen roller. Leave the cover

open until power is restored.

2. When power is restored, restart the Printer by following the procedure for Clearing a

Paper Jam on page .

3. Send the print job to the Print er again.

46 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Page 57

Technical Specifications

Physical Specifications

Dimensions: Width 11.4 in. (290 mm)

6

Depth 19.6 in. (496 mm)

Height (13.6 in.) (346 mm)

Weight 20 lbs (9 kg) (without ribbon and paper)

Operating Environment

Temperature: 50 to 95° F (+10 to +35° C)

Relative Humidity:20 to 80%

Power Requirements

Voltage/Frequency (auto detection of the following ranges):

90 V to 132 V / 48 Hz to 62 Hz

180 V to 264 V / 48 Hz to 62 Hz

Power Consumption: 320 watts maximum

980588-001 Prelim 1 Zebra F680 Photo Printer User’s Manual 47

Page 58

Technical Specifications

Computer System Requirements

Computer System Requirements

• Microsoft Windows 2000 or Microsoft Windows XP Operating System

• Minimum 1.0 GHz Pentium III Microprocessor

• Minimum 128 MB of RAM

• Minimum 2GB of available hard disk space

• USB 2.0 compliant host device

Photo Dimensions

• 4 x 6 in. (10 x 15 cm)

• 6 x 8 in. (15 x 20 cm) with border

• 6 x 8 in. (15 x 20 cm) borderless

48 Zebra F680 Photo Printer User’s Manual 980588-001 Prelim 1

Page 59

Worldwide Service &

Service and Support Locations

North America Region

APPENDIX A

Support

Zebra Technologies

Card Printer Solutions Headquarters

1001 Flynn Road

Camarillo, CA 93012-8706 USA

Phone: 800-511-9909

e-mail: techsupport@zebra.com

Europe, Middle East, and Africa Region

Zebra Technologies

Card Printer Solutions, Europe, Middle East, Africa

The Valley Centre, Gordon Road, High Wycombe

Buckinghamshire HP13 6EQ, England

Phone: + 44 (0) 870 241 1527 (from outside U.K.)

Phone: 0870 241 1527 (from inside U.K.)

e-mail: cardts@zebra.com

980588-001 Draft 1 Zebra F680 Photo Printer User’s Manual 49

Page 60

Worldwide Service & Support

Website

Latin America Region

Zebra Technologies

Card Printer Solutions, Latin America

9800 NW 41st Street, Suite 220

Doral, FL 33178 USA

Fax: + 1 (305) 558-8485

e-mail: techsupport@zebra.com

Asia Pacific Region

Zebra Technologies Asia Pacific, LLC

16 New Industrial Road

#05-03 Hudson TechnoCentre

Singapore 536204

Phone: + 65 6885 0833

Website

Fax: + 65 6885 0836

e-mail: esoh@zebra.com

www.zebracard.com

50 Zebra F680 Photo Printer User’s Manual 980588-001 Draft 1

Loading...

Loading...