Page 1

Page 2

Page 3

FORE WORD

This man ual con tains Pro gram ming in for ma tion for Ze bra Se ries Card Print ers man u fac tured by

Ze bra Tech nol o gies Cor po ra tion, Camarillo, Cal i for nia.

Pro pri etary State ment

This man ual con tains pro pri etary in for ma tion of the man u fac turer. It is in tended solely for the in for ma tion and use of par ties op er at ing and main tain ing the equip ment de scribed herein. Such pro pri etary in for ma tion may not be used, re pro duced, or dis closed to any other par ties for any other

pur pose with out the ex pressed writ ten per mis sion of the man u fac turer.

Prod uct Im prove ments

Con tin u ous im prove ment of prod ucts is a pol icy of the man u fac turer. All spec i fi ca tions and signs

are sub ject to change with out no tice.

Li a bil ity Dis claimer

The man u fac turer takes steps to as sure that its pub lished En gi neer ing spec i fi ca tions and Man u als

are cor rect; how ever, er rors do oc cur. The man u fac turer re serves the right to cor rect any such er rors and dis claims li a bil ity re sult ing there from.

No Li a bil ity for Con se quen tial Dam age

In no event shall the man u fac turer or any one else in volved in the cre ation, pro duc tion, or de liv ery

of the ac com pa ny ing prod uct (in clud ing hard ware and soft ware) be li a ble for any dam ages what so ever (in clud ing, with out lim i ta tion, dam ages for loss of busi ness prof its, busi ness in ter rup tion,

loss of busi ness in for ma tion, or other pe cu ni ary loss) aris ing out of the use of or the re sults of use of

or in abil ity to use such prod uct, even if the man u fac turer has been ad vised of the pos si bil ity of such

dam ages. Be cause some states do not al low the ex clu sion or lim i ta tion of li a bil ity for con se quen tial

or in ci den tal dam ages, the above lim i ta tion may not ap ply to you.

Trade marks and Copy rights

The Ze bra logo and the ze bra head de sign are both reg is tered trade marks of ZIH Corp.

Win dows and MS-DOS are reg is tered trade marks of Microsoft Corp.

Soft ware® Ze bra Tech nol o gies Cor po ra tion; all rights re served world wide.

All other marks are trade marks or reg is tered trade marks of their re spec tive hold ers.

This copy righted man ual and the software de scribed herein are owned by the man u fac turer. All

rights are re served. Copy right vi o la tors may be sub ject to civil li a bil ity.

©2006 ZIH Corp. All rights re served.

i

Page 4

ii

Page 5

Ta ble of Con tents

IN TRO DUC TION .........................1-1

......................................1-2

Com mon Fea tures ............................1-2

Pro gram ming Ob jec tives .........................1-2

Ba sic Com mand Syn tax .........................1-7

Com mand Ed i tor.............................1-8

Im age Mem ory Ar range ments ......................1-8

Bit-Map Com pres sion Al go rithm .....................1-9

Data-to-Card Map ping .........................1-13

Con trol Com mands ...........................1-19

Card Han dling Pro cess .........................1-20

Com mand Link ing ...........................1-20

Sam ple Card ..............................1-21

Par al lel Port Sig nals...........................1-22

Er ror Line Cod ing............................1-22

COM MAND REF ER ENCE .....................2-1

A - Print Test Card............................2-6

!AO - Check Patch Sen sors .......................2-7

!AT - Check Heat Off set .........................2-8

ATM - Set Card Feed ing Mode .....................2-9

&B - Load Mag netic En coder Track Write Buffer ............2-10

+B - Se rial In ter face Rate .......................2-12

+BS - Set Black Syn chro........................2-13

B/vB - Write Bar Code .........................2-14

&C - Set Coercivity ..........................2-16

+C - Ad justs Mono chrome In ten sity ..................2-17

+$C - Ad just Color Con trast ......................2-18

!CC - Get Num ber of Cards Printed ..................2-19

!CCLN - Check Clean ing Pa ram e ters .................2-20

+CCLN - Set Clean ing Pa ram e ters ..................2-21

%CDER - Get Mag netic En coder Read Set tings ............2-22

&CDER - Set Mag netic En coder Track Read En code Pa ram e ters ...2-23

&CDEW - Set Mag netic En coder Track Write En code Pa ram e ters ...2-25

+CDOTS - Im age Print Qual ity Com pen sa tion Fac tor .........2-27

+CH - Ad just Ho lo gram In ten sity ...................2-28

CHECK - Re turn Checksum ......................2-29

CLEAN - Set Clean ing Card Se quence.................2-30

!CLEAN - Clean the Laminator ....................C-31

%CLN - Check Due-for-Clean ing Pa ram e ters .............2-32

CLNCARD - Set Clean ing Pa ram e ters .................2-33

CRB - Set Re ject Box Card Count Warn ing Thresh old .........2-34

!CT - Check Cool ing Time .......................2-35

+CT - Set Cool ing Time ........................2-36

+CV - Ad just Clear Var nish In ten sity..................2-37

C/vC - Write Box (Mono chrome)....................2-38

!D - Move Print Head Down ......................2-39

&D - Change Track Den sity ......................2-40

iii

Page 6

+DLAMI - Set Lam i na tion Con fig u ra tion ...............2-41

+DLAMI - Set Lam i na tion Con fig u ra tion (Con tin ued) ........2-42

+DLAMI - Set Lam i na tion Con fig u ra tion (Con tin ued) ........2-43

+DLAMI - Set Lam i na tion Con fig u ra tion (Con tin ued) ........2-44

D/vD - Draw Di ag o nal Line (Mono chrome/Over lay)..........2-45

E - Re trans mit Last Re sponse .....................2-46

&E - Write Sin gle Track .......................2-47

&E* - Write Track Buff ers ......................2-48

+EC - End of Print ..........................2-49

$F - Clear Color Im age Buff ers ....................2-50

!FF - Set Rib bon Color Se quence ..................2-51

$FP - Clear Spec i fied Bit-Maps ....................2-52

FS - Con trol Use of Card Feed Sen sor ................2-53

F/vF - Clear Mono chrome Im age Buff ers ...............2-54

GS - Down load Color Graphic ....................2-55

G/vG - Ini tial ize Mono chrome Graphic (B/W).............2-56

%HEAD - Get Print Head Se rial Num ber ...............2-57

I - Print Mono chrome Panel .....................2-58

IH - Print Ho lo gram Over lay .....................2-59

IM - Print Color Test Card ......................2-60

IMB - Print Gray Test Card ......................2-61

IS - Print Card Panel .........................2-62

IV - Print Clear Var nish ........................2-63

+ISC - Set Smart Card Se rial Port Data Rate.............2-64

+ISC2 - Set Smart Card Se rial Port Data Rate (Ad vanced)......2-65

ISERIES - i-Se ries Printer Test ....................2-66

J - Print Mul ti ple Mono chrome Cards .................2-67

!L - Check Sta tus: P720 Laminator Sen sor Lev els ..........2-68

!L - Check Sta tus of Printer Sen sors .................2-69

$L - Draw a Hor i zon tal Line/Rect an gle in a Color Buffer .......2-71

&L - Read Sin gle Track .......................2-72

+$L - Ad just Spec i fied Color In ten sity ................2-74

!LC - Check Lam i na tion Coun ter ..................2-75

$LD - Ini tial ize a Color Buffer to a Spec i fied In ten sity Level .....2-76

!LT - Check Lam i na tion Tem per a ture ................2-77

+LT - Set Lam i na tion Tem per a ture .................2-78

!LTI - Check Lam i na tion Time ....................2-79

+LTI - Set Lam i na tion Time .....................2-80

L/vL - Draw Hor i zon tal Line (Mono chrome/Over lay) .........2-81

!M - Move Print Head Up .......................2-82

MB - Re turn Card To Card Feeder ..................2-83

MC - Clear Me dia Path ........................2-84

MCL - Move Contactless .......................2-85

ME - Exit Card To Out put Hop per ..................2-86

MF - Flip Card ............................2-87

MI - Move Card Into Print Ready Po si tion ..............2-88

MIB - Move Card Back To Print Ready Po si tion ...........2-89

MM - Move Card Through Printer ..................2-90

M/m - Mul ti ple Com mand .......................2-91

MO - Move Card To Out put Hop per .................2-92

MR - Check for Card Pres ence ....................2-93

iv

Page 7

MRB - Move Card to Re ject Box ....................2-94

MS - Move Card To Smart Card Pro gram mer .............2-95

MS - Move Card To Smart Card Pro gram mer .............2-96

&– Se lect Mag netic En cod ing Stan dard ................2-97

!NL - Get Printer Im pres sion and Er ror Coun ters ............2-98

!O - Check Card Off set .........................2-99

+O - Print Off set X-Axis .......................2-100

+OCL - Off set Contactless ......................2-101

!OFP - Check X-Axis Patch Off set ..................2-102

+OFP - Ad just X-Axis Laminator Patch Off set ............2-103

+OLP - Off set Overlaminate Patch ..................2-104

!OP - Check Patch Off sets ......................2-105

+OP - Ad just Laminator Patch X and Y Off set ............2-106

+OS - Smart Card X-axis Off set ...................2-107

O/vO - Load Sin gle Line Bit-map (Mono chrome) ...........2-108

+OY - Print Off set Y-axis .......................2-110

!P - Move Card For ward 8 cm ....................2-111

&P - Check Card Pres ent - En coder .................2-112

+PRF - Pre-Feed a Card Close to the Print Area ...........2-113

PS - Down load Color Im age Buffer ..................2-114

P/vP - Draw Sin gle Dot (Mono chrome/Over lay) ............2-115

R - Re set ...............................2-116

!R - Print Head Re sis tance ......................2-117

&R - Re set Mag netic En coder ....................2-118

>R - Read Data From Smart Card Se rial In ter face ..........2-119

+RB - Set Re ject Box Us age .....................2-120

>RB - Read Data From Smart Card Se rial In ter face in ASCII hex Form

....................................2-121

RCBC - Re set Re jected Card Box Coun ter ..............2-122

>RG - Con tact In ter nal Gemplus Smart Card Read Com mand....2-123

+RIB - Set Rib bon Type .......................2-124

!RIB BON - Check Rib bon Type ...................2-125

!RIB BON - Get rib bon type in stalled..................2-126

+RIB BON - Set Rib bon Type ....................2-127

!RIBPN- Get rib bon part num ber ...................2-128

!RIBLEN- Get num ber of re main ing pan els on rib bon . 2-129

+RO - X-Axis Off set, Rel a tive.....................2-130

+ROY - Y-Axis Offet, Rel a tive ....................2-131

!SA - Self Ad just ...........................2-132

!SAN - Per form pre-cal i bra tion base line test ing ............2-134

!SB - Check Stand-By Mode Set tings .................2-135

+SB - Con fig ure Laminator Stand-By Mode .............2-136

SDATA - Force im me di ate save of pa ram e ters ............2-137

!SERIE - Get Laminator Se rial Num ber ................2-138

%SERIE - Get Printer Se rial Num ber .................2-139

SF - Syn chro nize Film (Overlaminate) ................2-140

!SIDE - Check Lam i na tion Mode ...................2-141

+SIDE - Set Lam i na tion Mode ....................2-142

&SVM - Dis able/En able Mag netic En cod ing Ver i fi ca tions .......2-143

&T - Mag netic En coder Card Eject ..................2-144

+TC - Set Laminator Head Tem per a ture ...............2-145

v

Page 8

TF - Film Type ...........................2-146

T/vT - Draw Text (Mono chrome/Over lay) ..............2-147

T/vT - ASCII Text (Con tin ued) ....................2-148

V - Check Printer Type/Ver sion ...................2-149

!V - Re turn Op er a tional Pa ram e ter .................2-150

+V - Black Print Speed .......................2-151

+VL - Set Lam i na tion Speed ....................2-152

!W - Move Card Back ward 8 cm ..................2-153

&W - Change En cod ing Di rec tion .................2-154

>W - Write Data To Smart Card Se rial Port.............2-155

>WB - Write Data For mat ted in ASCII HEX To Smart Card Se rial Port

...................................2-156

>WG - Con tact In ter nal Gemplus Smart Card Write Com mand ..2-157

!X - Check Com mand Ini ti a tor....................2-158

+X - Change Com mand Ini ti a tion Char ac ter ............2-159

!Z - Re-Syn chro nize Card ......................2-160

Z/vZ - Load Bit-map (Mono chrome) .................2-161

. - Clear Er ror Sta tus Lines .....................2-163

Ap pen dix A ............................A-1

Res i dent Fonts ..............................A-2

Code 39

(Code 3 of 9) ..............................A-2

Stan dard 2 of 5

(Code 2/5) ................................A-4

In ter leaved 2 of 5

(Code I 2/5) ...............................A-5

UPC-A ..................................A-6

EAN-8 ..................................A-7

EAN-13 .................................A-8

Code 128

Sub sets B & C ..............................A-9

EAN In ter na tional Reg u la tion Agen cies .................A-11

Ap pen dix B ............................B-1

Par al lel Port Printer Data Hand shake Sig nal Lines.............B-1

Par al lel Port Printer Er ror Re sponse ....................B-1

Se rial Port Printer Data Hand shake ....................B-1

Se rial Port Printer

Er ror Re sponse .............................B-2

Ap pen dix C ............................C-1

Mag netic Encoders............................C-1

En coder Op er a tion ...........................C-1

Data Er rors ...............................C-3

En coder De fault Con fig u ra tion......................C-3

Ba sic Com mands ............................C-4

Ad vanced En coder Com mands .....................C-4

Re set ting The En coder To ANSI/ISO Track De faults ............C-5

Change Track Den sity ..........................C-5

vi

Page 9

Chang ing Read Con fig u ra tion ......................C-5

Chang ing Write Con fig u ra tions .....................C-5

Cus tom ISO Data ............................C-6

Unique Cus tom Data For mats ......................C-7

vii

Page 10

viii

Page 11

IN TRO DUC TION

This man ual de scribes pro gram ming com mands that

con trol op er a tions and de liver data for the fol low ing

card printer mod els:

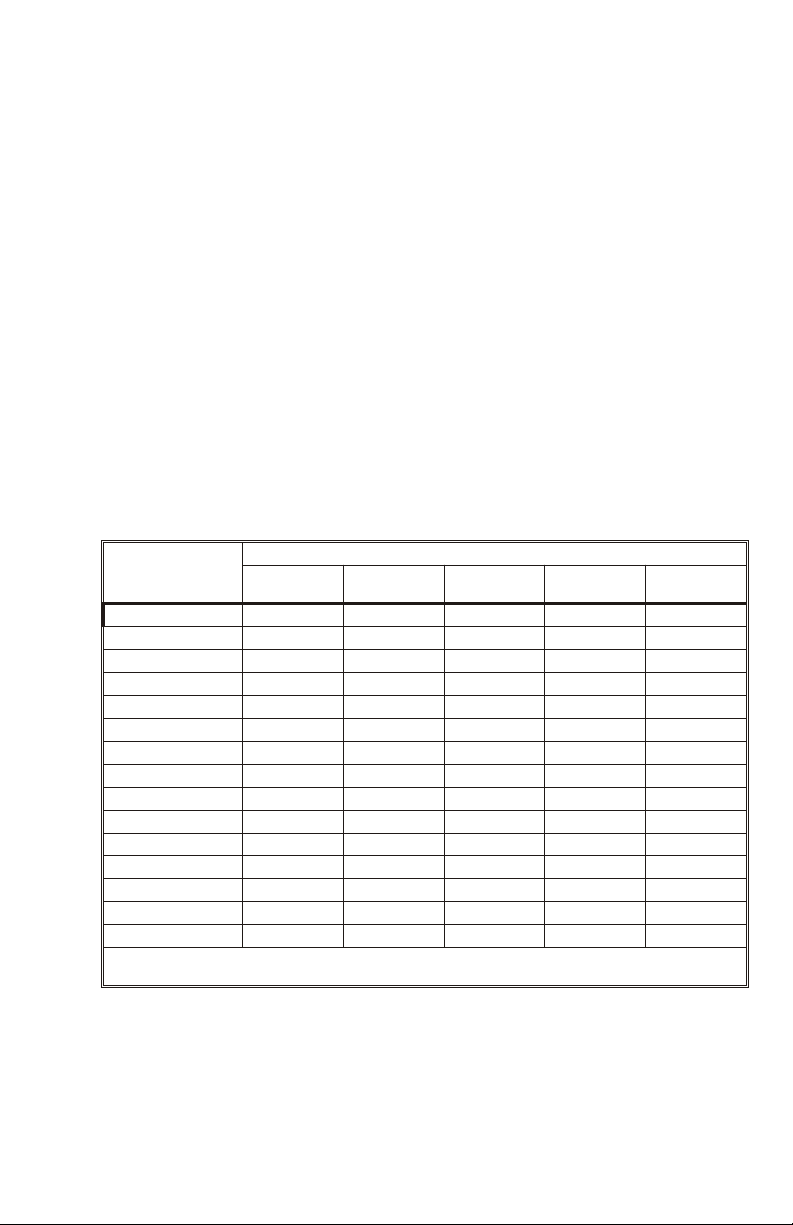

Mod els

P110i • •

P120i • • •

P205

P210 • •

P310F

P310C •

P310i • •

P320i • • •

P330i • •

P420 • •

P420i • • • •

P430i • • •

P520 • • •*

P520i • • • •* •

P720 • • • •†

* Model that laminates duplex using same lamination patch type for both card sides

† Model ca pa ble of ap ply ing different upper and lower lamination patch types onto cards

RFID

Color

Print ing

Fea tures

Du plex

Print ing

Du plex

Lam i na tion

Log-On

Se cu rity

All mod els em ploy a Com mon Com mand Set plus

ad di tional Com mand Sets for any model-specific

fea tures. All mod els ship with Win dows driv ers.

As so ci ated pro gram ming for use in the Win dows

en vi ron ment is not nec es sary.

1-1

Page 12

Common Features All cov ered mod els can print bar-codes in sev eral for mats

and have res i dent scal able font de scrip tions. Also, all

mod els can in clude a Smart-Card Docking Sta tion. P310

and P420 vari ants can have a Prox im ity Card dock ing

Sta tion. All mod els are of fered with or with out a Mag netic

Stripe En coder. A Se rial Host In ter face is op tional on the

P205, P210, P310, and P420 vari ants, where an

as so ci ated RS-232C Setup Com mand ex ists. All mod els

can have USB Ports, ei ther stan dard or as an option.

The pro gram ming com mands con trol the print ing pro cess

by color and by rib bon ma te rial, al low ing over print ing

and sep a rate con trol of var i ous pro tec tive cov er ings.

Pro gramming

Objectives

The Es cape Com mands al low printer set ups, many of

which de ter mine how a Printer Mod ule El e ment re acts

upon re ceiv ing an in com ing card. For ex am ple, a data

down load must oc cur be fore the Printer Mod ule can print

a card or en code a mag netic stripe.

Ex cept for the Card Feeder, each mod ule has an In put

Sen sor that trig gers the re sponses de ter mined pre vi ously

by setup com mands.

Card Sen sors also al low the Firm ware to keep track of the

po si tion of the card in the Card Path. There fore, the need

for card po si tion ing oc curs as an au to matic re sponse to

re lated com mands. For ex am ple, with no card in the

Card Path, a Print Com mand pro duces a Card Feed.

Sim i larly, if a Print Com mand oc curs af ter a card has

passed be yond the Print Head, the card first re turns to the

Print Head.

Rib bons come in dif fer ent panel con fig u ra tions, and how

the printer re sponds to a Print Com mand var ies

ac cord ing to the Rib bon Type Com mand Pa ram e ters

spec i fied. For each rib bon type, a re lated print se quence

ex ists. How ever, all mod els equipped with the RFID

fea ture sense the rib bon type, and firm ware takes care of

this pa ram e ter.

While some com mands af fect just one printer mod ule,

oth ers can pro duce re sponses from more than one. Also,

some com mands serve as set ups for a par tic u lar printer

and, there fore, need not be re es tab lished for each print

job. No ta bly, all com mand pa ram e ters end up in Flash

mem ory.

1-2

Page 13

Rib bons Rib bon types ex ist in the fol low ing con fig u ra tions:

• Con tin u ously Coated Mono chrome Rib bons are

Ther mal Trans fer Rib bons hav ing a resin coat ing and no

panel sep a ra tions. Ze bra of fers these in sev eral rib bon

col ors along with a Scratch-Off Gray, us able in all mod els but an ob vi ous choice for use in Mono chrome

Printers.

• Black Sublimination Dye al ter nated with Var -

nish Panels that im age black and white gray-scale el e ments. An ex cel lent choice for im ag ing black-and-white

photo im ages, fol lowed by an ap pli ca tion of a UV pro tec tive coat ing.

• Black Resin al ter nated with Var nish Panels that

im age fully sat u rated black and ap ply a pro tec tive coat ing. Ideal for im ag ing solid graphic el e ments such as

Text and Bar Codes.

• Yel low, Ma genta, and Cyan Panels for im ag ing

only Dye Sublimination Color. Typically used in print ers

with no re quire ment for Resin or Var nish. No ta bly, Yel low, Ma genta, and Cyan Panels can com bine to pro duce Black, and a Laminator re moves a need for

Var nish.

• Yel low, Ma genta, and Cyan Panels for im ag ing

Dye Sublimination Color fol lowed by Black

Resin and Var nish Panels. Dye Sublimination Im -

ages should have a pro tec tive coat ing, and Black Resin

serves as an ex cel lent choice for Text and Bar Codes.

Thus, Color Printers with out Laminators typ i cally use

these rib bons.

• Yel low, Ma genta, and Cyan Panels for im ag ing

Dye Sublimination Color fol lowed by a sin gle

Black Resin Panel. While a Laminator pre cludes the

need for var nish, a solid resin black pro duces the best

Bar Codes and of fers an other, some times better, way to

im age Black Text and other black graphic el e ments.

• Yel low, Ma genta, and Cyan Panels for im ag ing

Dye Sublimination Color fol lowed by a two

Black Resin Panels. This rib bon of fers im ag ing for

color plus resin on one card side and only resin on the

other side while us ing sin gle set of rib bon pan els.

1-3

Page 14

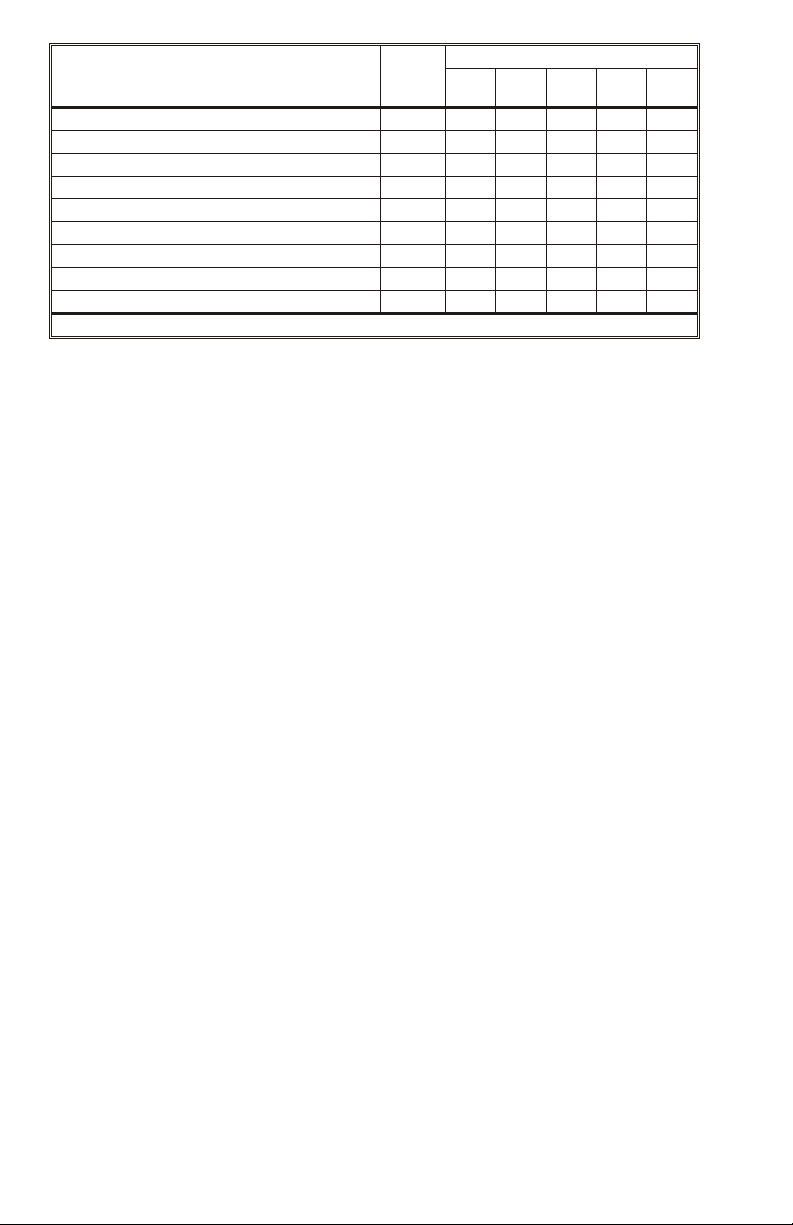

Printer Rib bons

K

(all monochrome colors) 1 • • • • •

resin

Scratch-off Gray 1 • • • •

K

O 2 • • •

resin

K

O 2 • • •

dye

YMC 3 • •

YMCK 4 • •

YMCK

YMCK

YMCK

* P310 monochrome and P205 printers only use 1-panel ribbons.

O 5 • • •

resin

resinKresin

resinOKresin

*Panel

Count

P205

P210

5 • •

6 •

Mod els

P310

P420 P520 P720

P320

Mod u lar El e ments:

• Print En gine—Be ing the pri mary con trol ling el e ment in

all printer mod els, the Print En gine CPU re ceives Host

Com mands. Re ceived com mands can en com pass op er a tions that di rectly con trol the Print En gine and op er a tions that draw on other Printer El e ments for ex e cu tion.

Whereas some el e ments have their own CPUs, the Print

En gine CPU ex er cises com plete con trol over other el e ments. Only in P520s and P720s can a com mand be di rected to an other el e ment (the Laminator CPU). An

as so ci ated El e ment-Spe cific Com mand Pre fix ex ists for

this pur pose. Be sides its print func tion, Print Engines

have Op tions that in clude a Mag netic Stripe En coder

and/or a Smart Card Docking Sta tion. Some Models also

of fer Prox im ity (Contactless) Card Docking as an al ter na tive to Smart Card Docking.

• Card Feeder—This el e ment de livers cards placed in the

Card In put Hop per to the Card Path in side the Printer un der con trol of the Print En gine CPU.

• Card Flip—Printers with this el e ment can flip cards in

prep a ra tion for du plex print ing or, in the case of a P520,

Sec ond Side Lam i na tion. Card Flip Sta tions can also de liver cards with sensed flaws to the Re jected Card Box.

This el e ment has its own CPU that car ries out the de tails

of in struc tions re ceived.

• Sin gle Side Laminator—P520 Printers can place a

pro tec tive trans par ent patch on one card sur face at a

time. This el e ment also has its own CPU that car ries out

the de tails of in struc tions re ceived.

• Du plex Laminator—Printers with this el e ment lam i -

nate both card sur faces in a sin gle lam i na tion pass. This

el e ment also has its own CPU that car ries out the de tails

of in struc tions re ceived.

• Op er a tor LCD Con trol Panel—Printers with this el e -

ment con vey mes sages to op er a tors via a 1- or 2-line by

1-4

Page 15

16- char ac ter LCD screen and al low op er a tor re sponses

and Printer Con trol. Power and Alert LEDs also ap pear.

This el e ment also has its own CPU that car ries out the

de tails of in struc tions re ceived.

Sig nif i cant model/con fig u ra tion dif fer ences

re lated to pro gram ming in clude the fol low ing:

• P310 Mono chrome card print ers have a smaller com -

mand set along with an im age buffer suf fi cient for a

one-bit im age map ping depth. Im aging us ing Ther mal

Trans fer Meth od ol ogy oc curs, sup ported by Ther mal

Trans fer Printer Rib bons. (Only fully-saturated dots im age in a sin gle print pass.) Any gray-scale im ag ing re quires host data mapped into mul ti ple-dot ma trixes,

sized for the de sired gray-scale range (e.g., a

four-by-four dot pixel ma trix can pro duce 16 lev els of

gray plus white, [(4 x 4)2/16 + white]). Gray Levels de rive from the num ber of dots im aged in side the ma trix.

• P310 Color card print ers em ploy dye sub li ma tion

meth od ol ogy for color im ag ing and ther mal trans fer

meth od ol ogy for im ag ing from Resin Mono chrome Rib bons or Rib bon Panels. A yel low, ma genta, and cyan

im ag ing se quence oc curs. Each rib bon panel pro duces

im ages from five-bit-per-dot data.

The black pan els on Ze bra-sup plied rib bons with color

pan els have a resin coat ing that par tic u larly suits

bar-code and other solid im age print ing (i.e., no gray

scale). How ever, resin re sponds poorly as a dye sub li ma tion print me dium. There fore, the black used for

gray-scale im ag ing co mes from for mu la tions of yel low,

ma genta, and cyan (YMC), which means

dye-sublimation black also has a five-bit-per-dot range

(32 lev els of gray). If the need for a

resin-panel-generated gray scale should ever be come

nec es sary, as so ci ated host data must be mapped into

mul ti ple-dot pixel ma trixes as noted in the P310 Mono chrome de scrip tion.

1-5

Page 16

• P310 Color Card Print ers have five im age buff -

ers—three for color and an other for two for mono chrome. The color buffer re ceives down loads of Cyan,

Ma genta, and Yel low im age data, each five bits deep.

The Mono chrome Buffer re ceives black and/or var nish

data one bit deep. Sep a rate data for Resin Black and

Over lay Var nish can of ten be avoided. Be cause of its du ra bil ity, card ar eas with resin im ages may not re quire var nish for the as so ci ated ul tra vi o let pro tec tion. There fore,

by us ing a re verse im ag ing for var nish, the same bit-map

used for resin pro duces a var nish over lay that omits the

ar eas with resin. Also, through re verse im ag ing, a Clear

Com mand can pre pare Mono chrome Mem ory for a

full-cov er age var nish.

• P420s em ploy the same Print Engines as the P310 Color

de scribed above. Be cause P420s also have a Card-Flip

as sem bly and a Re jected Card Box, these mod els have

some ad di tional re lated com mands. P420s also have an

in ter face that sup ports the pro gram ming of Prox im ity

Cards (also called Contactless Cards). Mem ory size is

dou bled to sup port two-sided print ing.

• P520s have all the same im ple men ta tions as a P420, in -

clud ing Smart Card sta tions, and Mag netic Encoders as

op tions. How ever, P520s also have a Card Laminator

Sta tion. Laminators serve as heat-transfer de vices for

ma te rial or pan els con tained on Lam i na tion Rib bons. A

va ri ety of these kinds of rib bons ex ist, as fol lows:

• Rib bons with trans par ent die-cut patches that of fer

near edge-to-edge card cov er age

• Die cuts with cut outs for Smart Card Con tacts, and

smaller die cuts that serve to avoid Mag netic Stripes

• Preprinted Patches that con tain se cu rity de vices such

as graph ics, ho lo grams, or other op ti cally-encoded

safe guards

1-6

P520 Laminators can also serve a heat-transfer func tion for rib bons con tain ing a coat ing in stead of

die-cut pan els. How ever, only a to tal card ap pli ca tion

can oc cur. Be cause the Print Sta tion can have a Dye

Sub li ma tion Rib bon with Var nish Panels, many

choices ex ist for se lec tion of pro tec tive coat ings. Ad di tional com mands ex ist to im ple ment Laminator

use.

• In stead of just an <Esc>, a P520 Com mand meant

for the Laminator needs a pre ced ing:

<Esc>#<Space>1<Space>

Page 17

• P720s have P420 el e ments plus a Laminator mod ule

<Esc>T p1 p2 p3 p4 p5 p6 p7 data<Rtn>

Command Name

Command

Parameters

WRITE TEXT

ASCII Programming Code

Text

Hexadecimal Programming Code

Escape (Command Initiator)

Carriage Return (Command Terminator)

1B54203130302031303020302031203230203330203120546578740D

<Esc>T 100 100 0 1 20 30 1 Text<Rtn>

Space (Delimiters)

that fully im ple ments si mul ta neous near edge-to-edge

patch ap pli ca tions from above and be low the Card

Path. In te gral sen sors as sure ac cu rate patch place ments

and sig nal the Rib bon Types in use and the amount re main ing on their cores.

Basic Command

Syntax

Each com mand be gins with a Com mand Ini ti a tor (the

Es cape Char ac ter). For P520s, di rect ing char ac ters can

fol low the Es cape Char ac ter.

The Com mand Ini ti a tor serves to mark the char ac ter(s)

im me di ately fol low ing as com mand char ac ters.

Com mand char ac ters vary be tween one and seven

char ac ters (or up to seven bytes of hex a dec i mal data).

Some Com mands then have one or more Pa ram e ters to

sup ply the printer with in for ma tion nec es sary to

com plete the com mand. A Space Char ac ter de lin eates

in di vid ual Com mand Con trol Pa ram e ters. The fol low ing

Text Com mand shows a typ i cal ex am ple.

Each Com mand Line re quires a Car riage Re turn

Char ac ter (13 dec. or 0D hex.). The Printer ig nores a

sin gle Line Feed (LF) char ac ter (Dec. 10 or 0A Hex.)

when it im me di ately fol lows the com mand ter mi nat ing

Car riage Re turn. Most PC Based Sys tems send a CR/LF

when the En ter Key is pressed.

1-7

Page 18

Command Editor Any ASCII based Text Ed i tor can serve to cre ate sim ple

com mand files. In the DOS en vi ron ment, MS-DOS EDIT

of fers a good choice. To ex e cute the file, use the Print

Com mand from the ed i tor, or from DOS, the COPY

Com mand, to send the file to the printer. Ex am ples us ing

the COPY Com mand are:

COPY file name.ext LPT1

For more in for ma tion on the use of the COPY com mand,

re fer to a DOS Soft ware Man ual.

Some text ed it ing pro grams can cause printer er rors by add ing ex tra char ac ters or by chang ing ex ist ing char ac ters

when gen er at ing a near ASCII for mat ted file.

Ex am ple: A com mon ASCII ed i tor, BRIEF, changes all NUL

char ac ters to the SPACE or TAB char ac ters with a File

Save. The graphic data for print in ten sity level “0" is the

NUL char ac ter. This causes the re sult ing file to print with

hor i zon tal lines in all graph ics with solid white (i.e.,

no-print) ar eas. Other ed i tors may add a SUB char ac ter

(Dec. 26 or 1A Hex.), which causes the printer to er ror.

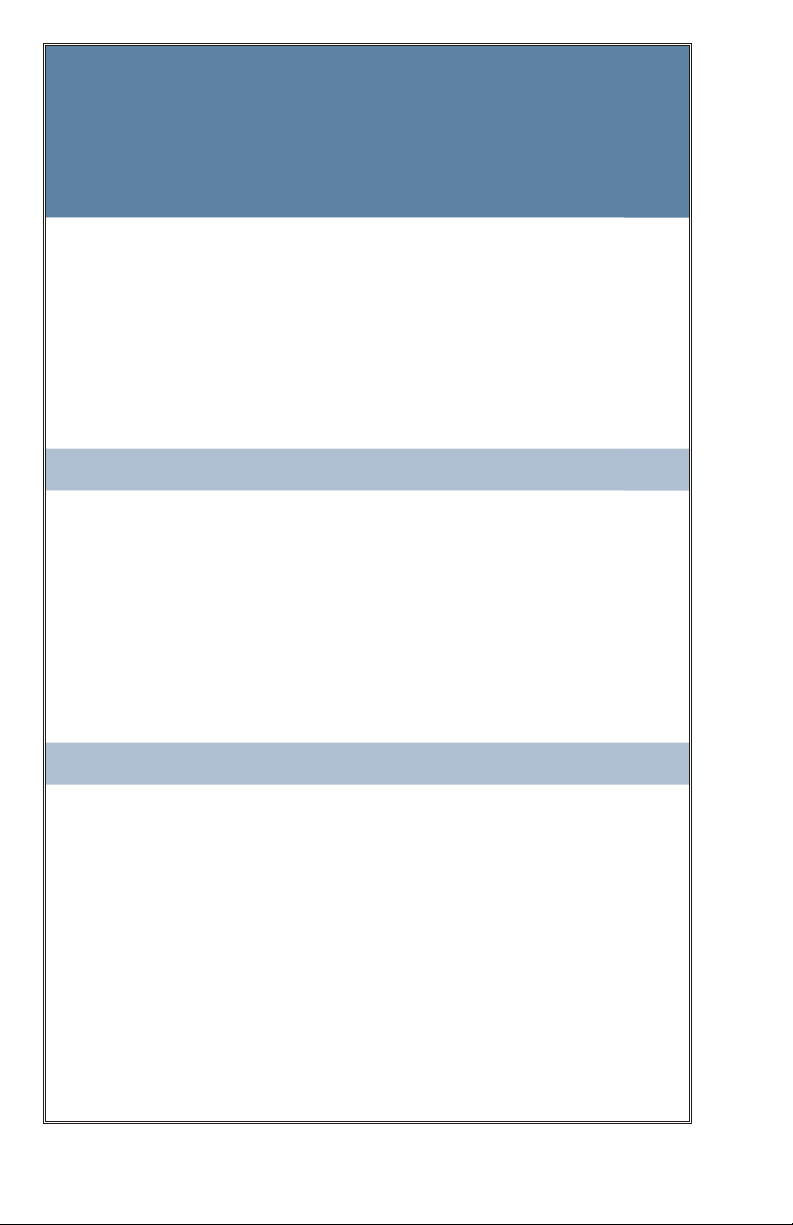

Image Mem ory

Ar range ments

1-8

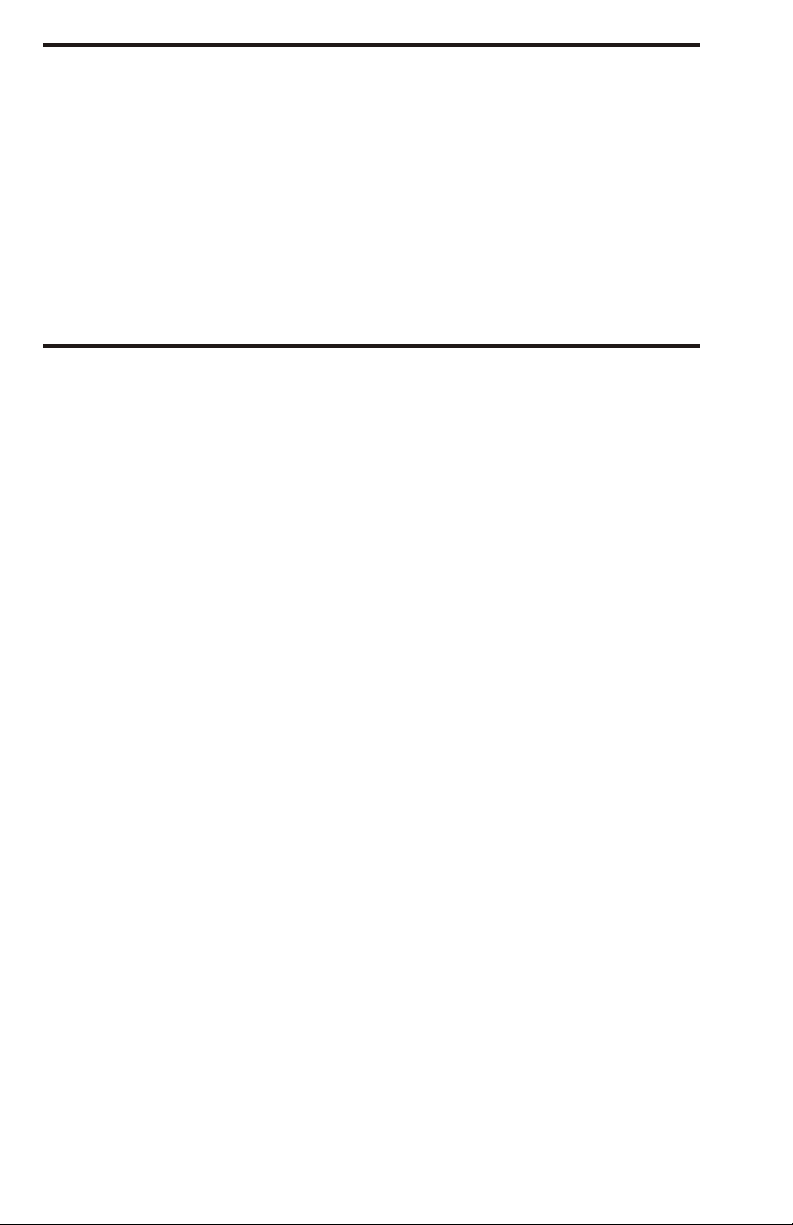

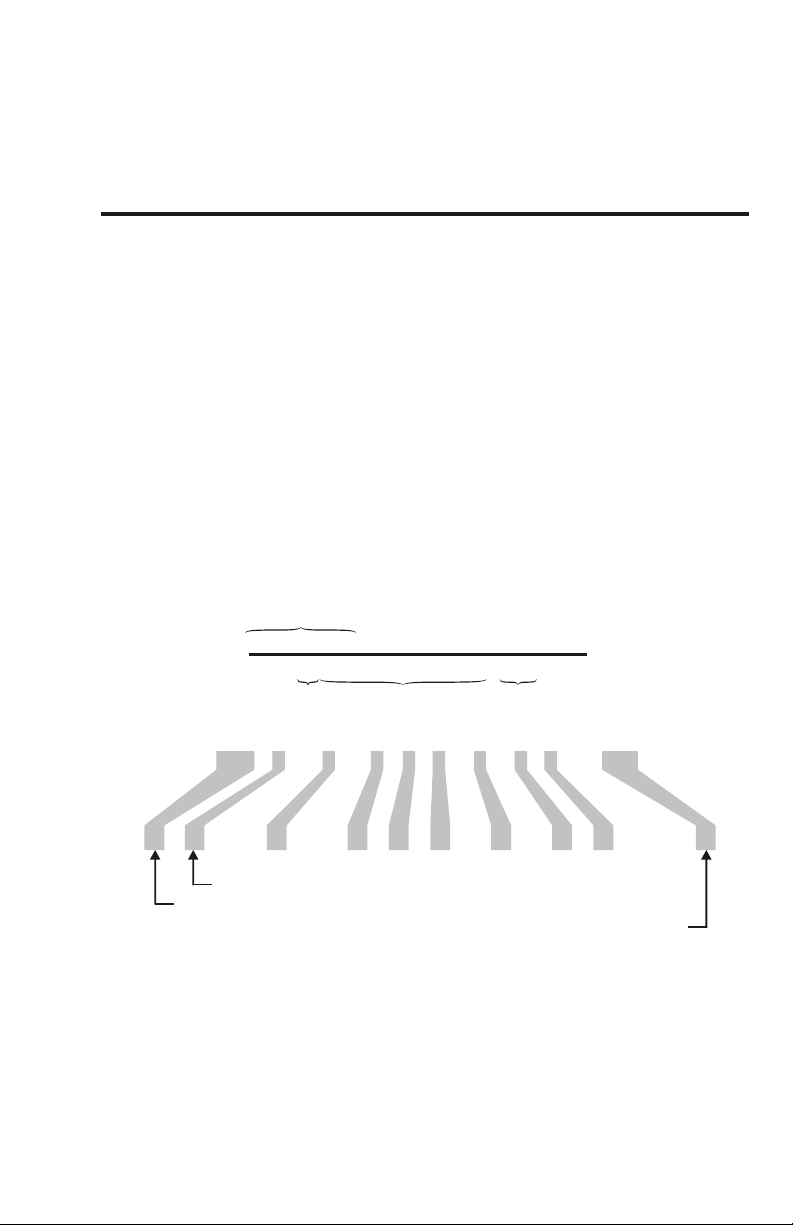

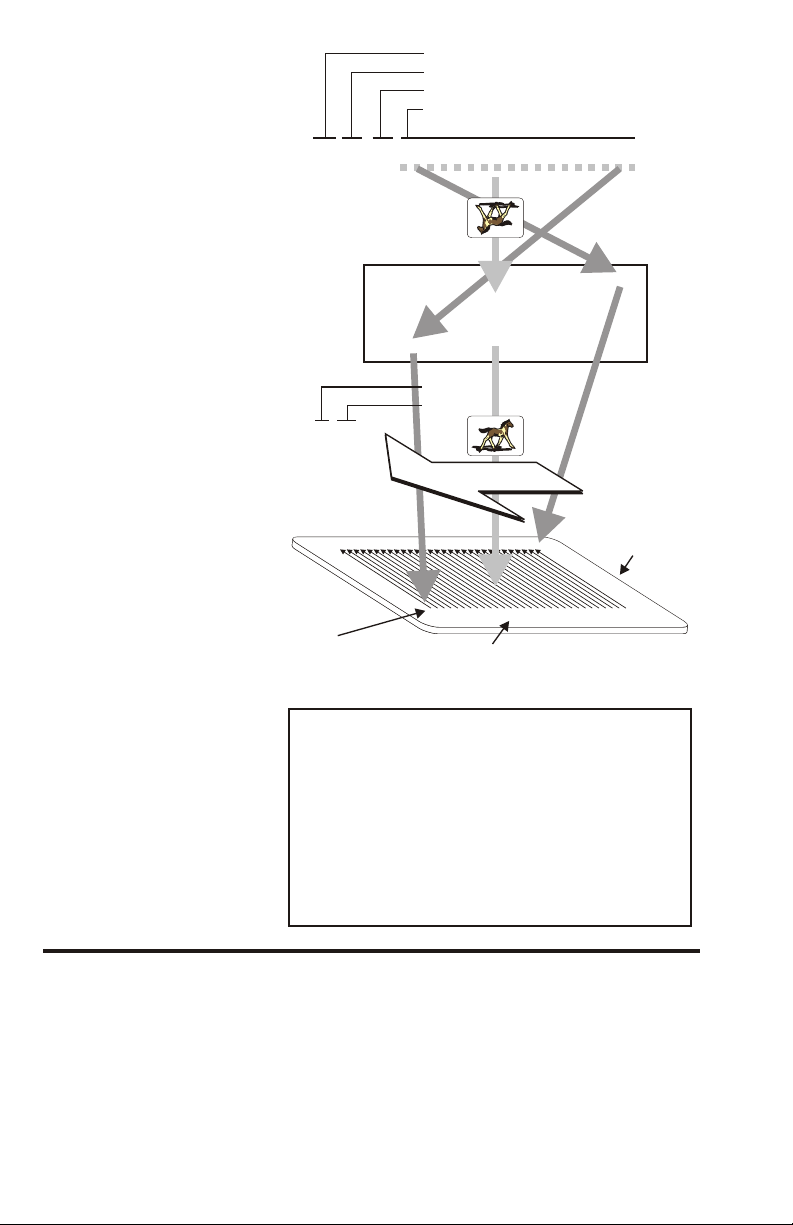

Fig ure 1-1 shows el e ments in volved in im age data flow.

Note that two Im age Mem ory Con fig u ra tions ex ist and

that Im age Mem ory al ways con tains com pressed data.

Ideally, hosts should send com pressed data, which

re quires a com pat i ble com pres sion al go rithm. This can

sub stan tially re duce the data trans fer times of most im age

files.

Mono chrome Print ers need no Color Buff ers and of fer

less mem ory ca pac ity. Color Print ers may need as many

as five buff ers and, there fore, have a greater mem ory

ca pac ity. In most cases, com pressed data for an en tire

card im age fits into avail able mem ory in a sin gle

down load se quence.

Color-sep a rated data en ters re lated buff ers due to a

buffer-spec i fy ing pa ram e ter in the Color Data Com mand.

Page 19

Host Computer

Image Data

Compression

Algorithm

Image

Buffers

Image Data

Decompression

Algorithm

Print Head

Registers

CARD PRINTER

Bypassed

when Host

Compressed

Color Printer

Memory

Monochrome

Printer Memory

Mono.

Buffer

Yellow

Buffer

Magenta

buffer

Cyan

Buffer

Black

Buffer

Varnish

Buffer

Yellow

Buffer

Magenta

buffer

Cyan

Buffer

Black

Buffer

Varnish

Buffer

SINGLE

DUPLEX

Figure 1-1

Image Memory

Arrangements

Bit- Map

Com pres sion

Al go rithm

Char ac ter is tically, a Bit-Map Com pres sion Al go rithm

flags data seg ments as ei ther re peat ing or non-repeating,

spec i fies the bytes re peated, and the num ber of re peats.

For these card print ers, com pres sion ap plies to

byte-wide bit-map seg ments, which the host sends with

the PS, GS, Z, and vZ com mands. The PS and GS

com mands in clude pa ram e ters spec i fy ing a buffer

(YMCK). Mono chrome com mands Z and vZ send

as so ci ated bit-map data to the Black (K) and Var nish

Buffers, re spec tively. All of these com mands in clude

pa ram e ters that spec ify whether or not the com mand

ap plies to com pressed data. For rec og ni tion by the card

printer, com pressed data must con form to the fol low ing

rules:

Rule 1. When high, the most sig nif i cant bit (the Flag

Bit) of a two-byte se quence in di cates that the sec ond

byte re peats. The re main ing seven bits of the first byte

spec ify the num ber of re peats, al low ing a

field-specification range of from zero to 127 re peats.

1-9

Page 20

Rule 2. When low, the Flag Bit of a data se quence

in di cates that the re main ing seven bits of the byte spec ify

the num ber of fol low ing bytes that rep re sent

non-re peat ing im age data. Here, how ever, the range

al lows a spec i fi ca tion of from zero to 31 bytes of data.

Rule 3. The first byte in the Data Field of any com mand

spec i fy ing a Com pressed Bit-Map must have the

Com pres sion Flag high, even if a one must be en tered as

the num ber of bytes re peated.

Rule 4. No other al go rithm can be used to com press

im age data for this card printer.

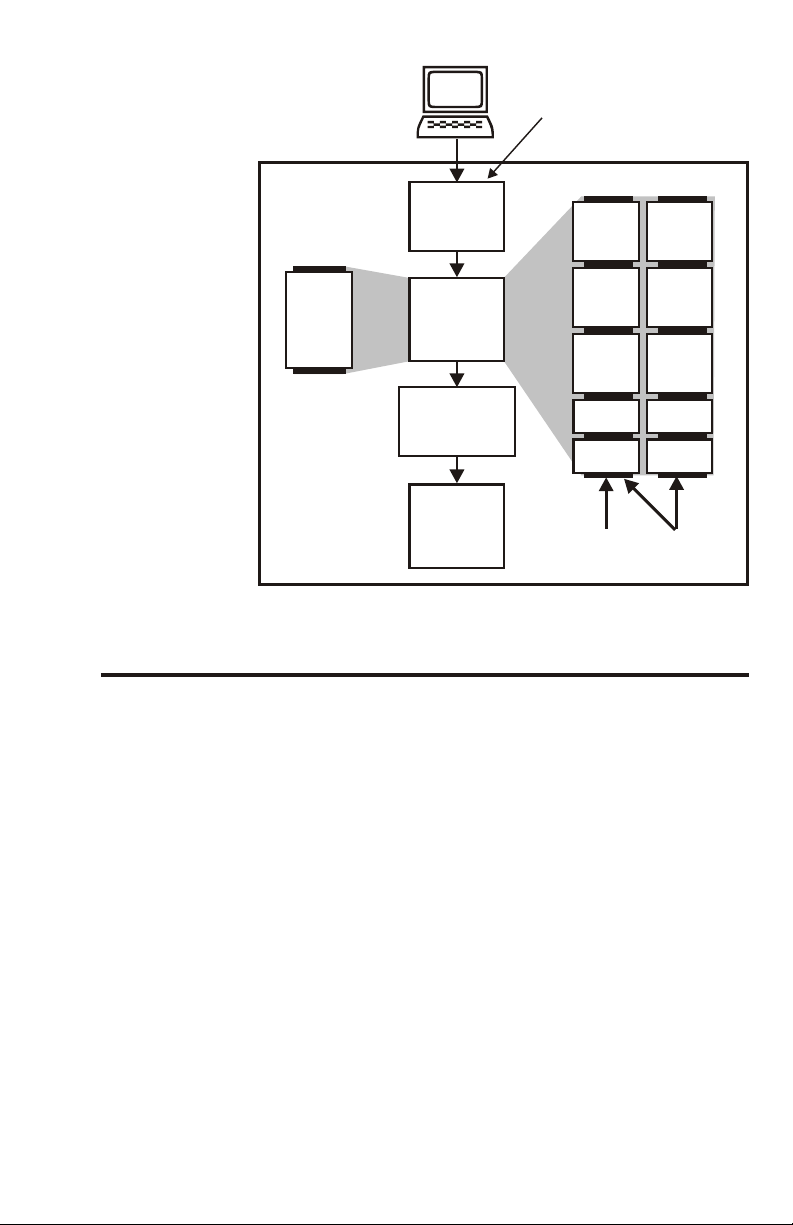

Fig ure 1-2 in cludes ex am ples of data strings em ploy ing

com pres sion.

1-10

Page 21

1XXX XXXX XXXX XXXX

Data Compression Flag Set

No. of Repeats (1~127)

Data Byte Repeated

Dye Sub. Panel 1-Dot Data Field

1XXX XXXX XXXX XXXX

Data Compression Flag Set

No. of Repeats (1~127)

Data Byte Repeated

Mono. Panel 8-Dot Data Field

0XXX XXXX

Data Compression Flag Off

No. of Non-Compressed Bytes

Non-Compressed Data

---Bytes (0~31)---

0001 1111 0001 1111 0001 1111 0001 1111 0001 1111 0000 0011 0000 0011 0000 0011

1F Hex (5 repeats) 03 Hex (3 repeats)

85 1F 83 03

Compressed Data

1000 0101 0001 1111 1000 0011 0000 0011

Compression Example 1

0001 1111 0001 1111 0001 1111 0001 1111 0001 1111 0000 0100 0000 1011 0000 0011

1F Hex (5 repeats) 04 0B 03 Hex (0 repeats)

85 1F 03 04 0B 03

Compressed Data

1000 0101 0001 1111 0000 0011 0000 0100 0000 1011 0000 0011

Compression Example 2

Figure 1-2

Bit-Map

Compression

1-11

Page 22

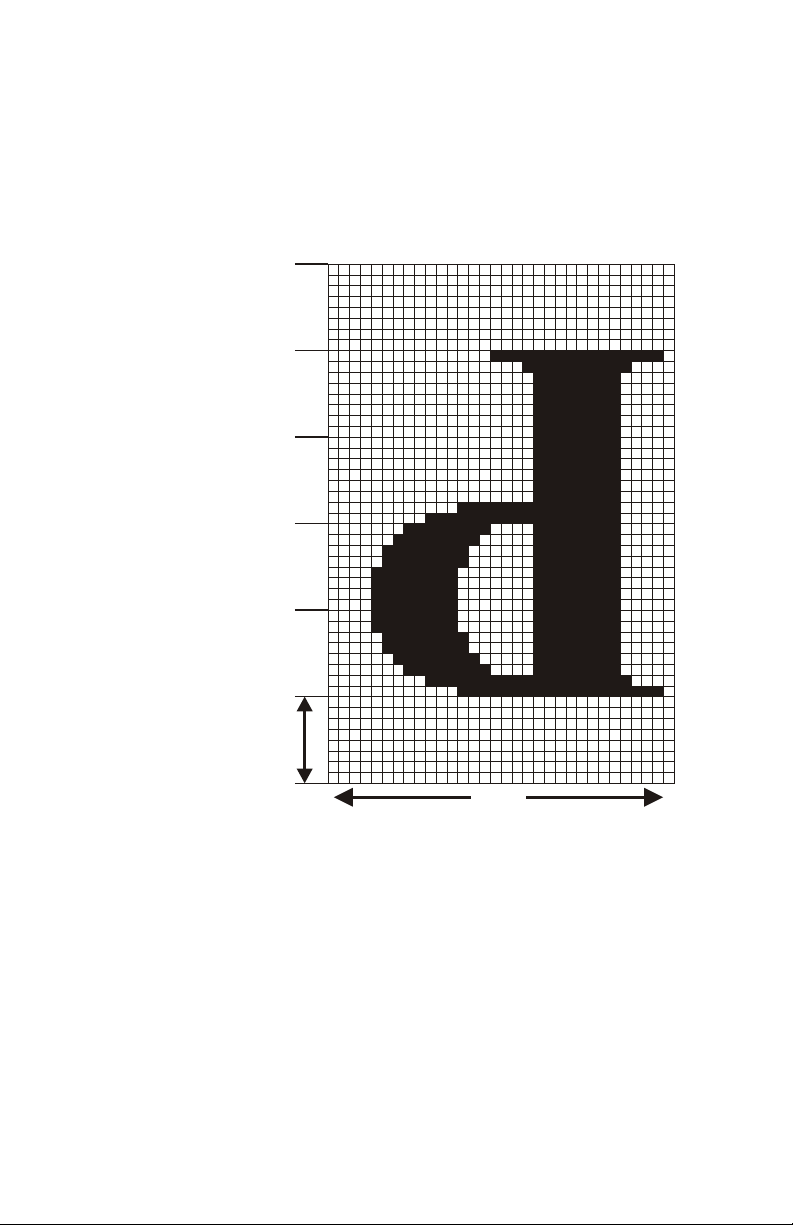

Fig ure 1-3 shows how a bit-map re lates to as so ci ated

1B 5A

00 00 00 00 00 00

00 00 00 00 00 00

00 00 00 00 00 00

00 00 00 00 00 00

00 03 F0 00 00 00

00 0F FC 00 00 00

00 1F FE 00 00 00

00 3F FF 00 00 00

00 3F FF 00 00 00

00 7F FF 80 00 00

00 7F FF 80 00 00

00 7F FF 80 00 00

00 FC 0F C0 00 00

00 F0 03 C0 00 00

00 E0 01 C0 00 00

00 C0 00 C0 01 00

00 C0 00 C0 01 00

00 C0 00 C0 01 00

00 C0 00 C0 03 00

00 FF FF FF FF 00

00 FF FF FF FF 00

00 FF FF FF FF 00

00 FF FF FF FF 00

00 FF FF FF FF 00

00 FF FF FF FF 00

00 FF FF FF FF 00

00 FF FF FF FF 00

00 C0 00 00 03 00

00 80 00 00 01 00

00 80 00 00 01 00

00 80 00 00 01 00

00 00 00 00 00 00

0D

1 Byte

x axis

non-compressed data. Fig ure 1-4 shows the same

bit-map in as so ci a tion with com pressed data.

Figure 1-3

Non-Compressed

Bit-Map

1-12

Page 23

1B 5A

99 00 02

03 F0 84 00 02

0F FC 84 00 02

1F FE 84 00 02

3F FF 84 00 02

3F FF 84 00 3C

7F FF 80 00 00

00 7F FF 80 00 00

00 7F FF 80 00 00

00 FC 0F C0 00 00

00 F0 03 C0 00 00

00 E0 01 C0 00 00

00 C0 00 C0 01 00

00 C0 00 C0 01 00

00 C0 00 C0 01 00

00 C0 00 C0 03 00

00 84 FF 02 00

00 84 FF 02 00

00 84 FF 02 00

00 84 FF 02 00

00 84 FF 02 00

00 84 FF 02 00

00 84 FF 02 00

00 84 FF 18 00

00 C0 00 00 03 00

00 80 00 00 01 00

00 80 00 00 01 00

00 80 00 00 01 87

00

0D

1 Byte

Figure 1-4

Compressed

Bit-Map

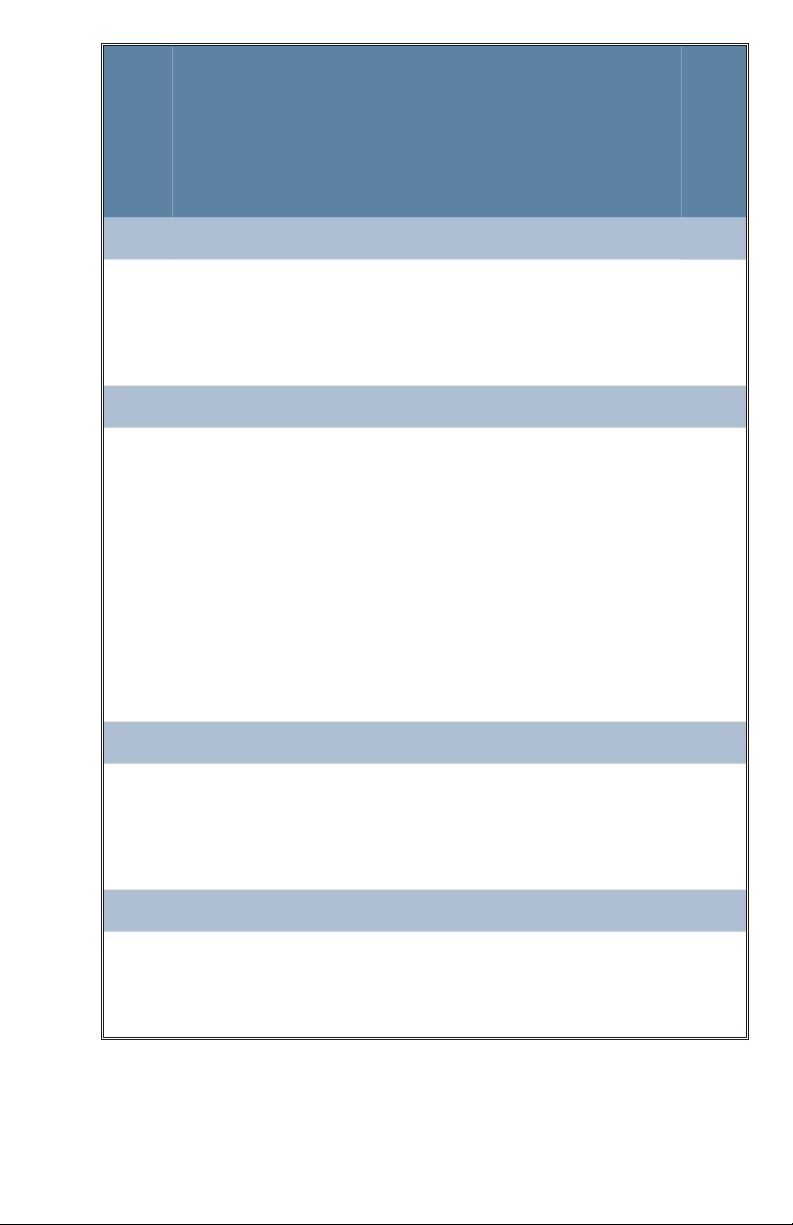

Data- to-Card

Map ping

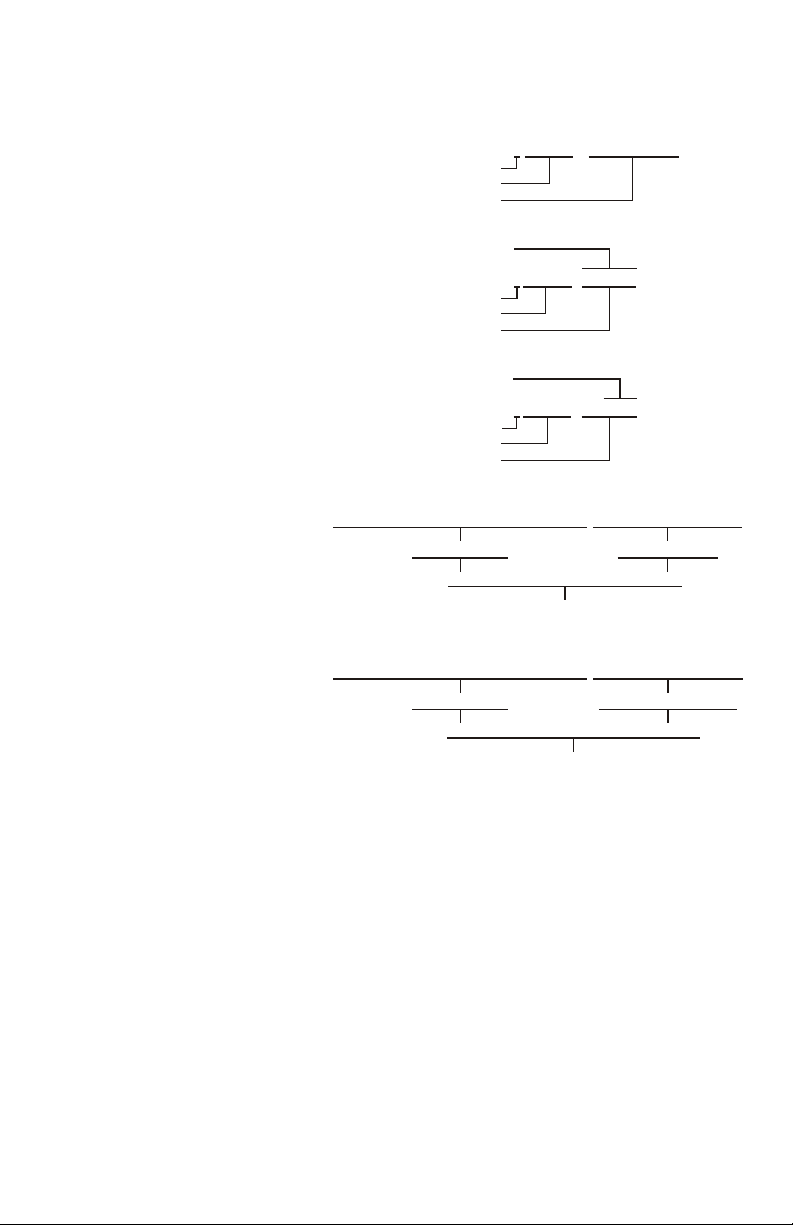

Fig ure 1-5 shows a card con sis tent with the ori en ta tion

of a card trav el ing right to left in the Card Path of a

printer. From this per spec tive, the data field of the PS,

GS, Z, and vZ com mands first be comes a

mem ory-res i dent im age in a des ig nated im age buffer.

The Im age Buffer, as shown, fills from top to bot tom and

from right to left. Be cause the Im age Buffer has a

last-in-first-out (LIFO) ar range ment, card im ages build

from bot tom to top and from left to right. This suits the

front-to-back load ing of Print Head Reg is ters and the

right-to-left card move ment dur ing print cy cles. As noted

in the fig ure, an ob ject mir rored in both axis in the data

sent to the buffer would print nor mally on the card.

1-13

Page 24

PS p1 p2 data.............................data

Download Buffer Data Command

Buffer Select (YMCK) Parameter

Compressed vs. Uncompressed Parameter

Data Downloaded (300dpi/11,8dpmm)

Last In

First Out

MAXIMUM CARD IMAGING

646 Line Bytes by 1030 Lines

Image Buffer

IS p1

Print Buffer Command

Buffer Select (CMYK) Parameter

Print Direction

Card Size

3.375 x 2.125 in

85,7 x 53,9 mm

PartialImage

Origin

ASSOCIATED COMMANDS

Monochrome

G

O

Z

P

L*

C*

D*

T

B

I

Overlay

IH

IV

vZ

vP

vL*

vC*

vD*

vT

vB

Color

PS

GS

IS

* Objects drawn with these commands have an upper-left origin.

Figure 1-5

Data Sent verses

Card Mapping

Laminator Data

Considerations

1-14

As so ci ated print ers have no need to print var nish.

How ever, the Var nish Buffer stores mono chrome data.

There fore, all data com mands for mono chrome data

re quire the “v” pref ace. A sub se quent “I” com mand

prints data stored in the Var nish Buffer. Note that the IV

Com mand serves to in di cate the pres ence of a rib bon

with var nish pan els that then get by passed.

Page 25

Color Printer Data

Con sid era tions

When con vert ing from another color sys tem to CMY, the

best pos si ble re sults oc cur when a ta ble maps each

source color to a vi su ally equiv a lent CMY printer color.

Such a ta ble must convert all pos si ble printer col ors.

Also, the con ver sions must be fine-tuned to produce

optimum re sults. How ever, for RGB data, a sim ple

con ver sion can oc cur via the fol low ing:

Y = 255 - B

M = 255 - G

C = 255 - R.

Color data al ways en ters a color im age buffer, ei ther as

Yel low, Ma genta, or Cyan. This is also true for K

rib bon, which im ages with black dye. The com mand

des ig nates the buffer dif fer ently ac cord ing to the Buffer

Spec i fi ca tion Pa ram e ter in the com mand. Note that the

spec i fi ca tion for Dye Sub li ma tion only ap plies to im ages

pro duced us ing a Dye Sub li ma tion Black Rib bon. All

data as so ci ated with these com mands rep re sent im ag ing

con sist ing of five-bits-per-dot.

Whether down loading data for a par tial im age (GS

com mand) or for a com plete card im age (PS com mand)

the data must match the as so ci ated card area. For par tial

im ages (some times called lo gos be cause of a typ i cal

ap pli ca tion) the GS Com mand Pa ram e ters spec ify the

area im aged. This as sures proper line breaks. Any ei ther

over- or un der-flow pro duces an er ror. For proper

ap pear ance, color im ages should not over print other

card print ing.

dye

O

1-15

Page 26

Mono chrome Data

Considerations

P-Series Printers al ways down load mono chrome data

into a Mono chrome Im age Buffer. In print ers with out

Laminators, mono chrome data com mands pref aced with

a “v” des ig nate the Var nish Buffer. Com mands with out

the “v” pref ace des ig nate the buffer used for resin

print ing. If only one Mono chrome Im age Buffer ex ists, the

com mand des ig nates the buffer dif fer ently de pend ing on

the as so ci ated data.

How ever, most color im ag ing does not need a

pre-established Var nish Buffer to ap ply the var nish

coat ing. If no Var nish Buffer is down loaded, the printer

de faults to the Resin Buffer for the ap pli ca tion of var nish.

This works for three rea sons. First, color rib bons have

resin black fol lowed by var nish pan els, both lim ited to

mono chrome data. Sec ond, the pri mary use of var nish is

to pro tect the dye sub li ma tion im ag ing from ul tra vi o let

ra di a tion. Third, be cause resin may need no var nish

pro tec tion, an in verted-resin bit-map can ap ply var nish.

The IV com mand has a pa ram e ter set ting to pro duce an

in verted data print. There fore, when suit able, leave the

Resin Buffer un changed af ter print ing resin. Then, is sue

an IV com mand to print the var nish.

Note that full-coverage var nish, as re quired for ul tra vi o let

pro tec tion us ing dye-sublimation black rib bons, re quires

only a buffer clear com mand (F) fol lowed by the in verted

print com mand (IV).

A wa ter mark sim u la tion can re sult by, in ef fect, punch ing

holes in the var nish im age. Sim i larly, suit able holes in the

var nish ap pli ca tion are nec es sary to pre vent cov er age

over Mag netic Stripes or Smart Card Con tacts. How ever,

this con cern can be avoided by lim it ing im ages re quir ing

var nish to the card sides with out con tacts or stripes.

A ho lo gram trans fer from an as so ci ated rib bon oc curs by

print ing a Var nish Buffer that im ages the area of the

rib bon con tain ing the ho lo gram. Both of these im ages

re quire data pre vi ously down loaded into the Var nish

Buffer.

1-16

Page 27

Mono chrome graphic ob jects can down load into

ei ther a Resin or Var nish Buffer. As with the pre ced ing,

a “v” pref ace des ig nates a buffer that prints with the

“IV” Com mand, and com mands with out the “v” pref ace

des ig nate a buffer that prints with the “I” Com mand.

Com mands ex ist for down loads of the fol low ing graphic

ob jects:

P/vP Write Dot

L/vL Write Line

C/vC Write Box

D/vD Write Di ag o nal Line

T/vT Write Text

B/vB Write Bar-Code

The fol low ing Graphic Com mands have Ro ta tional

Pa ram e ters (clock wise):

D/vD (Di ag o nal Line) 0, 90, or 180°

Cen ter of Ro ta tion lower-left

T/vT (Text) 90° In cre ments (0~270)

Cen ter of Ro ta tion lower-left or ob ject cen ter

B/vB (Bar Code) 90° In cre ments (0~270)

Cen ter of Ro ta tion lower-left or ob ject cen ter

Mono chrome bit-maps re quire en try of two

com mands—first an initializing com mand (G) and then

an as so ci ated data com mand. The “G” Com mand

spec i fies im age place ments as so ci ated with the fol low ing

com mands:

O/vO Down load Sin gle Line

Z/vZ Down load Mul ti ple Lines

Fig ure 1-5 shows the re la tion ship be tween data sent by

“O” or “Z” com mands and an area pre vi ously

es tab lished by a “G” com mand. The “G” com mand can

also de fine data as sin gle bits (i.e., im age dots).

With dots se lected as the Data Mode in the G

Com mand, data sent to the printer must, nev er the less,

fin ish on an even byte bound ary. When nec es sary, fill in

zero bits to bytes that do not reach the bound ary

spec i fied in the G Com mand.

Data is han dled in bytes dec i mal (0~255) or

hex a dec i mal (00~FF) by the printer.

1-17

Page 28

Bar Codes Bar Codes vary in ca pac ity, size, char ac ter sets, and

den sity. Sev eral in dus tries have adopted spe cific cod ing

and bar code for mats. A se lected Bar Code must match a

code sup ported by the scan ning equip ment.

All the Bar Codes of fered by the card print ers have the

data char ac ters, 2 quiet zones, and Start and Stop

Char ac ters. The Bar Codes can in clude Text as part of

the Printed Bar Code. Some of the Bar Codes in clude a

printer-generated Check Digit (or Data Check Sum)

Char ac ter au to mat i cally or as an op tion.

A com mand er ror con di tion oc curs when Im age Data

ex tends be yond the ad dress able range of the Im age Buffer.

The Bar Code and Text Fields must re main within the ad dress able area of the Im age Buffer. Each of the Bar Codes,

in the Com mand B and Ap pen dix-A De scrip tions have a

for mula to de ter mine a Bar Code Length.

Se lecting a larger Bar Code Width Mul ti plier and a higher

ra tio of the nar row to wide bars (and spaces, where ap pli ca ble) im proves the gen eral read abil ity of a Bar Code. Also,

wider bars and spaces in crease the depth of field for im proved per for mance with Moving-Beam La sers and other

non-contact scan ning de vices.

1-18

Page 29

Control

Commands

The card print ers can per form a va ri ety of print, card,

rib bon, head move ment, and other con trol com mand

op er a tions.

Print Controls

Card Movement

In ten sity—Ad justs the amount of heat used to trans fer

Max i mum In ten sity Color or Mono chrome Dots.

Con trast (Color Only)—Ad justs the min i mum

amount of heat used to print dots at the low est color

set ting.

Im age Po si tioning—Lo cates the print able im age on

the card.

Head—Raises the Print Head for card moves and

low ers the head to print. These com mands are nested

within Print Com mands and typ i cally only sup port

test ing.

Print Test Cards—Ini ti ates a print se quence us ing

printer-resident data.

Print Ready Po si tion—The card moves to a po si tion

just prior to the Card Edge Sen sor.

Exit Card—The printer sends the card to the Out put

Hop per. For print ers with mul ti ple sta tions, cards exit to

the next sta tion.

Du plex—Flips cards us ing the Card-Flip Sta tion,

ini ti ated by the MF com mand.

Ready Smart Card—Po si tions a Smart Card un der the

Smart Card Docking Sta tion, where Smart Card Chip

Con tacts make con tact and be come avail able at a

rear-mounted printer con nec tor.

En code Ready po si tion—The card moves to a

po si tion just prior to the Read Write Head of the

Mag netic En coding Sta tion.

Re ject Card—Sends a card to the Re jected Card Box

Ribbon

Re set Rib bon—Ad vances rib bon to pre pare for the

first im ag ing pass (for color, Yel low) or cy cles a

con tin u ous color Mono chrome Rib bon.

Se lect Panel—Re sets, then ad vances rib bon to a

com mand-specified panel.

1-19

Page 30

Card Handling

Process

The fol low ing out lines a rec om mended card han dling

se quence:

1. Smart Card Pro gram ming - Op tion

2. Mag net i cally En code Card - Op tion

3. Print Card

For color, print:

Yel low

Ma genta

Cyan

Black

Clear Var nish

4. Du plex - Flip Card - Op tion

5. Print Card Back side - Op tion

For color, print:

Yel low

Ma genta

Cyan

Black

Clear Var nish

Ho lo gram Lam i na tion

6. Eject Card

Never im age or lam i nate over mag netic stripes or Smart

Card Con tacts. En coding and/or Smart Card Pro gramming

Er rors can result. Those with lamination capabilities can

order patches that leave these ar eas un cov ered.

Command Linking The “M” and “m” Com mands serve as Com mand

Linking Op er a tors. A string of linked com mands may

ex e cute one or mul ti ple times. The “[” char ac ter serves as

the de lim iter for Linked Com mands in the as so ci ated

syn tax.

For the com plete “M” Com mand Syn tax, and an

ex am ple, see M/m in the Com mand Ref er ence.

1-20

Page 31

Sam ple Card Fig ure 5-6 shows a printed card along with the

Commands

Descriptions

+RIB

+C 4

F

B 512 600 4 0 2 4 100 1 TEST

T 512 75 4 0 0 35 1 Company Name, Incorporated

T 200 200 0 1 0 50 1 FIRST NAME

T 200 300 0 1 0 50 1 LAST NAME

T 200 400 0 1 0 50 1 ACCOUNT NUMBER

T 65 320 7 1 0 50 0 Reverse text

L 15 80 970 4 1

I

Ribbon Type, Monochrome

Thermal Intensity

Clear Mono. Buffer

Write Bar Code

Write Text

Write Text

Write Text

Write Text

Write Text

Write Line

Print Monochrome

Figure 1-6

Sample Monochrome

Card

com mands used.

1-21

Page 32

Parallel Port Signals P205, P210, P310 and P420 Printers have a Se rial Port

Op tion. Se rial equipped print ers com mu ni cate with the

host over an RS-232C in ter face us ing ACK/NAK flow

con trol. Par al lel Ports are stan dard. The other card printer

mod els have no Se rial Port Op tion.

Card print ers with Par al lel Ports com mu ni cate with the

host us ing the fol low ing sig nal lines:

DATA (0~7) Eight bits of par al lel data.

STROBE (Pin 1) A host sig nal that in di cates sta ble data.

ACK/ (Pin 10) A printer sig nal that in di cates data re ceived. The

host drops the STROBE sig nal in re sponse.

BUSY (Pin 11) A printer sig nal that in di cates an in abil ity to ac cept

com mands due to on go ing pro cess ing. In print ers

with more than one pro ces sor, a BUSY re sponse

from one pro ces sor does not im ply a BUSY at the

an other pro ces sor.

READY (Pin 13) A printer sig nal that in di cates its avail abil ity to re -

ceive Host Com mands.

PAPER ER ROR (Pin 12)

Card print ers re port er rors to the host by en cod ing

the PAPER ER ROR and ER ROR lines (see Er ror

Line Coding be low).

ER ROR/ (Pin 15) Card print ers re port er rors to the host by en cod ing

the PAPER ER ROR and ER ROR lines (see Er ror

Line Coding be low).

INIT (Pin 14) Not used.

Er ror Line Cod ing

1-22

Pa per Er ror Er ror De scrip tion

0 1 No Error

0 0 Syn tax Error

1 1 Rib bon End/Empty Feeder

1 0 Me chani cal Error

Page 33

Esc

#

Space

Enter

Command Initiator—Press <Esc> to

indicate Command String follows.

Command String Delimiter—Use Spaces

<Sp> between Commands and Parameters.

Send Key—Press <Rtn> to send Command

String to Printer.

Placed after and followed by number (n)

(<Esc>#<sp>n<Sp>) directs Command

to Station n.

P1~Pn

{P1~Pn}

data

Indicates Required Parameter(s) in String

Indicates Optional Parameter(s) in String

Indicates Data Position in String

Figure 2-1

Command Entry

COM MAND REF ER ENCE

This sec tion con tains in di vid ual com mand de scrip tions

for data down loads, print ing, lam i na tion, mag netic

en codes, and card move ment con trol. An in cluded

command list groups com mands by func tion and shows

the as so ci ated ap pli ca ble printer models.

2-1

Page 34

Com mand List

DNA MMOC

DE SCRIP TION

Setup Com mands

+BS Set Black Speed

+C Ad justs Monochrome In ten sity 2-17

+$C Ad just Color Con trast 2-18

+CCLN Set Cleaning Parameters 2-21

+CDOTS Image Print Quality Compensation Factor 2-27

+CH Ad just Holo gram In ten sity 2-28

CRB Set Card Count Warning Threshold 2-34

+CT Set Cooling Time 2-36

+CV Ad just Clear Varnish In ten sity 2-37

+EC End of Print 2-49

!FF Set Rib bon Color Se quence 2-51

+$L Ad just Specified Color In ten sity 2-74

+LC Set Lamination Counter

+LT Set Lamination Roller Temperature 2-78

+LTI Set Lamination Time 2-80

MCL Move Contactless 2-85

+O Print Off set X- axis 2-100

+OCL Offset Contactless 2-101

+OFP Adjust X-Axis Laminator Patch Offset 2-102

+OLP Offset Overlaminate Patch 2-104

+OP Adjust Laminator Patch X and Y Offset 2-106

+OS Smart Card X- axis Off set 2-107

+OY Print Off set Y- axis 2-110

!R Print Head Re sis tance 2-117

+RB Set Reject Box Usage 2-120

+RIB Set Rib bon Type 2-124

+RIB BON Set Ribbon Type 2-127

+RO Set X-Axis Offset, Relative 2-130

+ROY Set Y-Axis Offset, Relative 2-131

+SB Configure Laminator Stand-By Mode 2-136

+SIDE Set Lamination Mode 2-142

SXY Center Image Maps

+V Black Print Speed 2-151

A Print Test Card 2-6

IM Print Color Test Card 2-60

egaP

2-2

Page 35

DNA MMOC

DE SCRIP TION

Tests

IMB Print Gray Test Card 2-61

!SA Self Adjust 2-132

ISERIE i-Se ries Printer Test 2-66

Ini tial ize Com mands

ATM Set Card Feeding Mode 2-9

+B Se rial In ter face Rate 2-12

+DLAMI Set Lami na tion Con figu ra tion 2-41

FS Set Mag netic En coder Track Write En code Pa ram e ters 2-53

F/vF Clear Mono chrome Im age Buff ers 2-54

$LD Ini tial ize a Color Buffer to a Spec i fied In ten sity Level 2-76

R Re set 2-116

RCBC Reset Rejected Card Box Counter 2-122

SF Syn chro nize Film (Overlaminate) 2-140

+TC Set Laminator Head Tem pera ture 2-145

TF Film Type 2-146

+VL Set Lami na tion Speed 2-152

+X Change Command Initiation Character 2-159

Printer Query Com mands

!AO Check Patch Sensors 2-7

!AT Check Heat Offset 2-8

!CCLN Check Cleaning Parameters 2-20

CHECK Return Checksum 2-29

%CLN Check Due-for-Cleaning Parameters 2-32

!CC Get Number of Cards Printed 2-19

!CT Check Cooling Time 2-35

E Re trans mit Last Re sponse 2-46

%F Return Font Names

!L Check Status: P720 Laminator Sensor Levels 2-68

!L Check Status of Printer Sensor 2-68

!LC Check Lamination Counter 2-75

!LT Check Lamination Temperatures 2-77

!LTI Check Lamination Time 2-79

%N Return Number of Loaded Fonts

!NL Get Printer Impression and Error Counter 2-98

!O Get State of Cover Sensor

!O Check Card Offset 2-99

!OFP Check X-Axis Patch Offset 2-102

!OP Check Patch Offsets 2-105

&P Check Card Pre sent - En coder 2-112

egaP

2-3

Page 36

DNA MMOC

!RIB BON Check Ribbon Type 2-125

!RLEVEL Check Patches Remaining

!SB Check Stand-By Mode Settings 2-135

%SERIE Get Printer Serial Number 2-139

%HEAD Get Print Head Serial Number 2-57

!SERIE Get Laminator Serial Number 2-138

!SIDE Check Laminator Mode 2-141

V Check Printer Type/Ver sion 2-149

!V Return Operational Parameter 2-150

!W Move Card Backward 8 cm 2-153

!X Check Com mand Ini tia tor 2-158

DE SCRIP TION

Im age Data Down load Com mands

B/vB Write Bar Code 2-14

C/vC Write Box (Monochrome) 2-38

D/vD Draw Di ago nal Line (Monochrome) 2-45

G/vG Ini tial ize Mono chrome Graphic (B/W) 2-56

GS Down load Color Graphic 2-55

$L Draw a Horizontal Line/Rectangle in a Color Buffer 2-71

L/vL Draw Horizontal Line (Monochrome/Overlay) 2-81

O/vO Load Sin gle Line Bitmap (Monochrome) 2-108

PS Down load Color Im age Buffer 2-114

P/vP Draw Single Dot (Monochrome/Overlay) 2-115

T/vT Draw Text (Monochrome/overlay) 2-147

Z/vZ Load Bitmap (Monochrome) 2-161

Card Po si tioning Com mands

egaP

!M Move Print Head Up 2-82

MB Return Card to Card Feeder 2-83

MC Clear Me dia Path 2-84

MCL Move Contactless 2-85

ME Exit Card to Out put Hop per 2-86

MF Flip Card 2-87

MI Move Card to Print Ready Po si tion 2-88

MIB Move Card Back to Print Ready Position 2-89

MM Move Card Through Printer 2-90

MO Move Card to Out put Hopper 2-92

MR Check for CArd Presence 2-93

MRB Move Card to Reject Box 2-94

MS Move Card to Smart Card Programmer 2-96

!P Move Card Forward 8 cm 2-111

SF Synchronize Film (Overlaminate) 2-140

&T Mag netic En coder Card Eject 2-144

2-4

Page 37

DNA MMOC

DE SCRIP TION

Print Com mands

I Print Mono chrome Panel 2-58

IH Print Holo gram Over lay 2-59

IS Print Card Panel 2-62

IV Print Clear Var nish 2-151

J Print Mul ti ple Monochrome Cards 2-67

!Z Re-Synchronize Card 2-160

Mag netic Stripe En coder Com mands

&B Load Magnetic En coder Track Write Buffer 2-11

&C Set Coercivity 2-16

&CDER Set Magnetic Encoder Track Read Encode Parameters 2-24

&CDEW Set Mag netic En coder Track Write En code Pa ram e ters 2-25

&D Change Track Den sity 2-40

&E Write Sin gle Track 2-47

&E* Write Track Buffers 2-48

$F Clear Color Image Buffers 2-50

$FP Clear Specified Bit Maps 2-52

&L Read Sin gle Track 2-73

&N Select Magnetic Encoding Standard 2-97

&R Re set Magnetic En coder 2-118

&SVM Disable/Enable Magnetic Encoding Verifications 2-143

&W Change En cod ing Di rec tion 2-154

Smart Card Com mands

egaP

+ISC Set Smart Card Se rial Port Data Rate 2-64

+ISC2 Set Smart Card Se rial Port Data Rate (Advanced) 2-65

>R Read Data From Smart Card Serial Interface 2-119

>RB Read Data From Smart Card Serial Interface in ASCII hex Form 2-121

>W Write Data From Smart Card Serial Port 2-155

>WB Write Data From Smart Card Serial Port in ASCII hex Form 2-156

Mis cel la neous Com mands

. Clear Er ror Sta tus Lines 2-126

CLEAN Start Cleaning Card Se quence 2-30

CLNCARD Set Cleaning Card Parameters 2-33

!D Move Print Head Down 2-39

M/m Multiple Command 2-91

2-5

Page 38

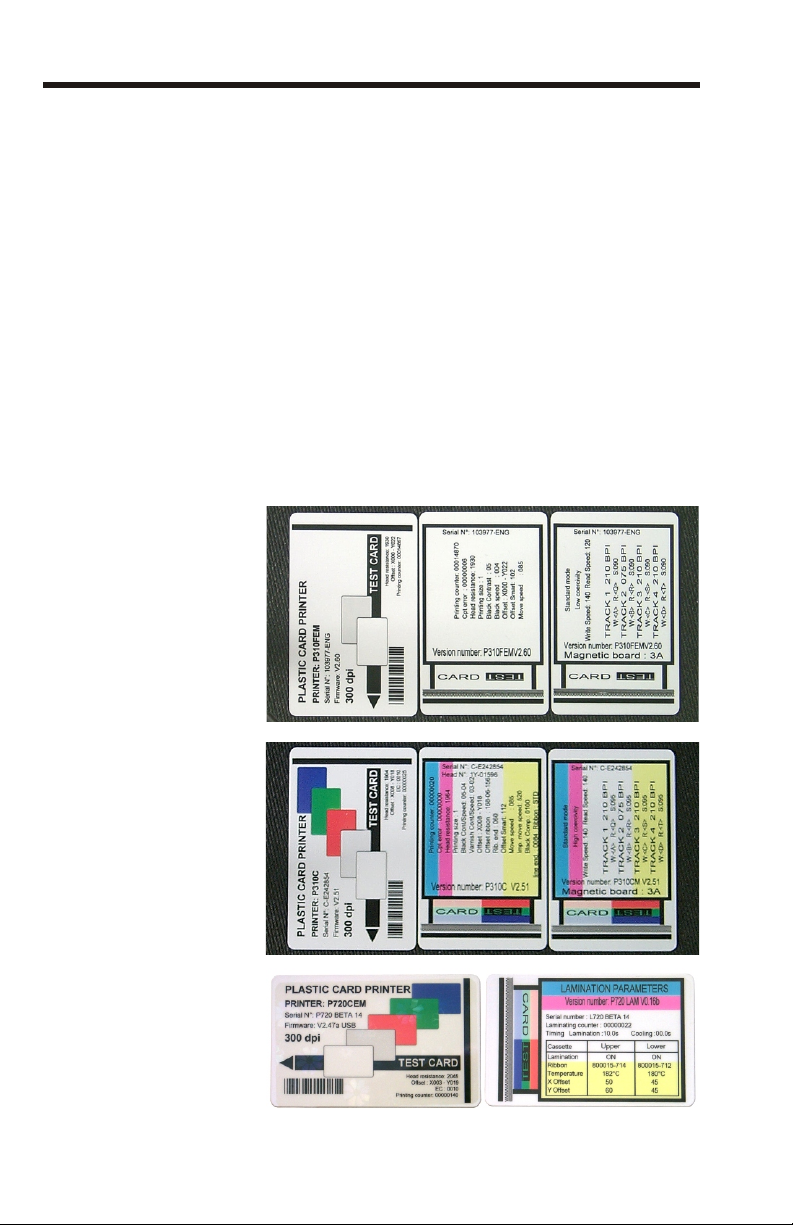

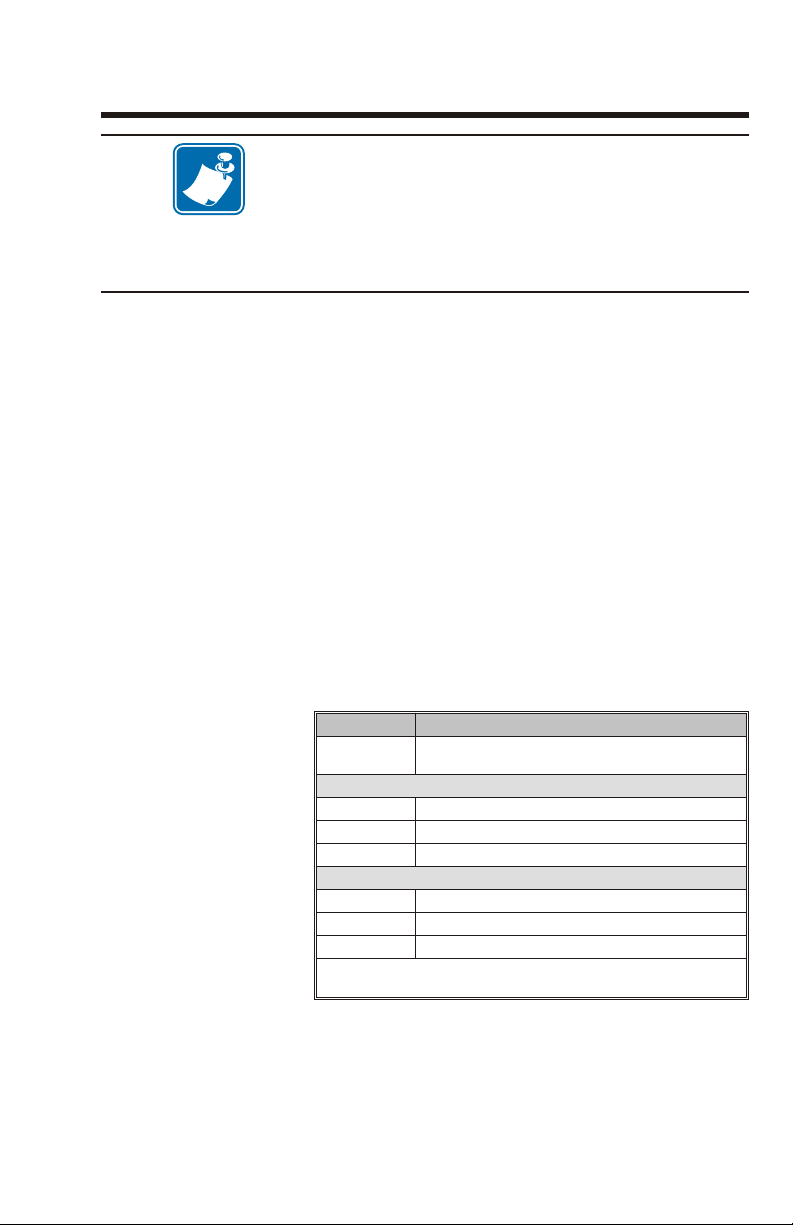

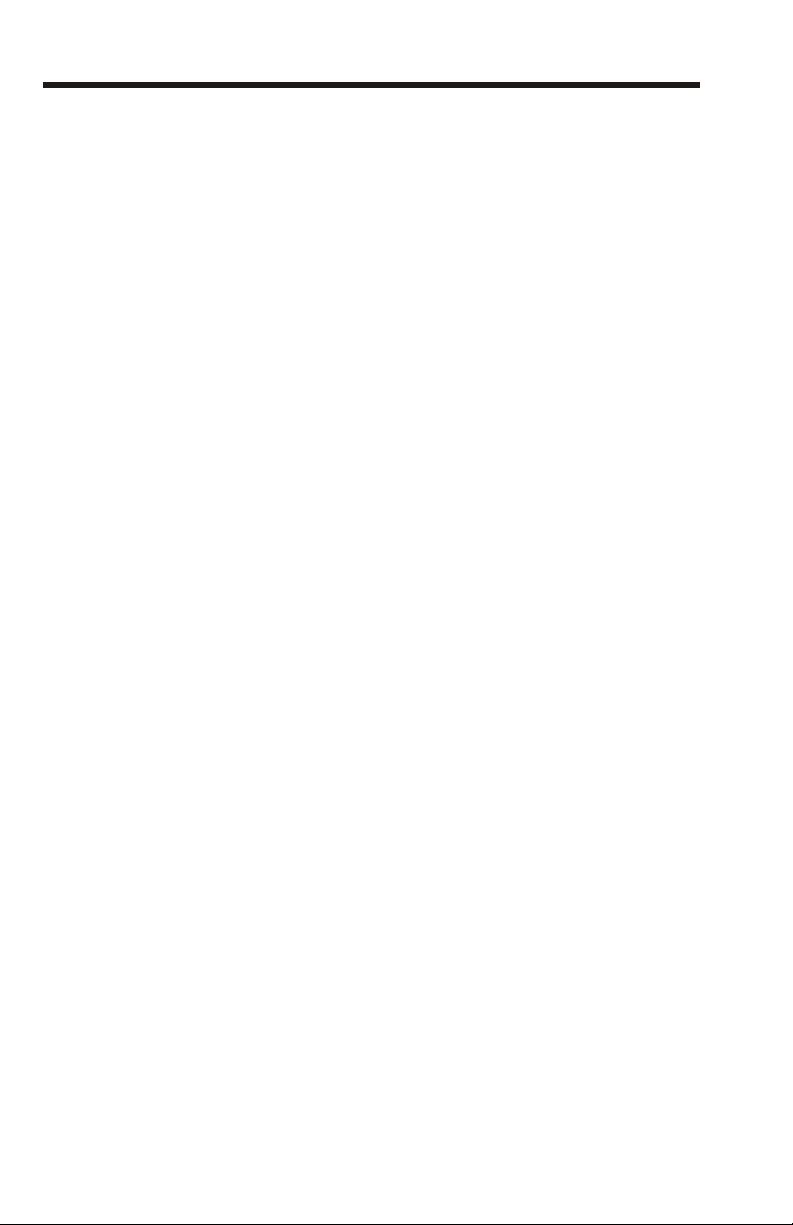

A - Print Test Card

Models Supported P110i, P120i, P205, P210i, P310c, P310f, P310i, P320i,

P330i, P420c, P420i, P430i, P520c, P520i, P720c

Description Prints a Stan dard Test Card with Printer Pa ram e ters,

Ver sion Num ber, and Test Pat tern. Sys tems with

Laminators print two cards—one for the Printer the other

for the Laminator (if con nected).

Syntax <Esc>A{ p1}

Parameters p

= Test Card

1

Where:

None =

Stan dard Test Card(s)

1 = Printer Test Card

2 = Mag netic En coder Test Card

3 = Lam i na tion Test Card

Figure 2-2

Standard

Monochrome

Test Cards

Color Test Cards

2-6

Figure 2-3

Standard

Figure 2-4

Printer and

Laminator

Card Sides

Page 39

!AO - Check Patch Sen sors

Models Supported P520c, P520i, P720c

De scrip tion Re turns val ues for se lected laminator patch po si tion

sen sor

Syn tax <Esc>#-1-!AO p1{ p2}

Pa ram e ters p

= Card Side

1

Where:

0 = Up per laminator patch po si tion sen sors

1 = Lower laminator patch po si tion sen sors

p2 = laminator patch po si tion sen sor se lec tion

Where:

None = De fault set tings

0 = X-Axis Sen sor

1 = Y-Axis Sen sor

2-7

Page 40

!AT - Check Heat Off set

Models Supported P520c, P520i, P720c

De scrip tion Re turns any vari a tion from the Fac tory Set Laminator

Roller Heat. For ex am ple, for a Fac tory Set ting of 180°

and a Roller Heat of 190°, the !AT Com mand re turns a

+10.

Syn tax <Esc>#-1-!AT p

Pa ram e ters p

= Roller Se lec tion

1

Where:

0 = Top Heat Roller

1 = Bot tom Heat Roller

1

2-8

Page 41

ATM - Set Card Feed ing Mode

Models Supported P110i, P120i, P330i, P430i

Description Se lect card feed ing mode and con trol how printer re acts

to an out-of-card con di tion.

Syntax <Esc>ATM p

Parameters p

= Feed Mode as fol lows:

1

0 = Nor mal mode (de fault). This mode is in tended for

use with print ers equipped with a card feeder hop per.

When the hop per is empty, the printer will sig nal that it

is out of cards and wait for the user to add more. The

printer will not en ter a ready state (and re sume print ing)

un til the er ror state is cleared by press ing the <se lect>

but ton.

1 = ATM Mode (de fault). This mode is in tended for use

with print ers equipped with a front sin gle-card feed ing

slot. In this mode, the printer will sig nal that it is out of

cards as mode 0 does, but will au to mat i cally clear this

er ror sta tus when a card is fed in; the user does not have

to press <se lect> to clear the er ror.

ATM mode, when en abled, is most ef fec tive when used in

con junc tion with an en abled card feed sen sor (con trolled

by the FS com mand).

1

2-9

Page 42

&B - Load Magnetic En coder Track Write Buffer

Models Supported P110i, P120i, P205, P210i, P310c, P310f, P310i, P320i,

P330i, P420c, P420i, P430i, P520c, P520i, P720c

Description Load data into the write buffer for a sin gle se lected track

of en cod ing

Syntax <Esc>&B p1 data

Parameters p

= Track Num ber and data for mat

1

Where:

1 = Track 1 ASCII data

2 = Track 2 ASCII data

3 = Track 3 ASCII data

11= Track 1 hex a dec i mal data*

12= Track 2 hex a dec i mal data*

13= Track 3 hex a dec i mal data*

data =

Each track has unique char ac ter and length

lim i ta tions due to for mat ting, and each has its own

data buffer. When <p1> = 1..3, <data> should be

ex pressed as a sim ple string of ASCII char ac ters. If

<p1> = 11..13, <data> should be ex pressed as a

vari able length se quence of 2-digit ASCII

hex a dec i mal num bers.

In hex mode, only dig its 0..9 and up per case al pha

char ac ters A..F are al lowed. No er ror check ing is

per formed on the <data> field; the data loaded into

the track write buffer will be in de ter mi nate if the

<data> string con tains in valid char ac ters. The

printer au to mat i cally in serts the re quired ISO Con trol

Char ac ters (start and stop sen ti nel, lon gi tu di nal

re dun dancy check char ac ter, etc.) into the data.

2-10

The ac tual data en coded onto the card is con verted from

ASCII to an ISO track-spec i fied en cod ing for mat. See Ap pen dix C for de fault ANSI/ISO data for mats and cus tom

data en cod ing com mands.

Page 43

&B - Load Mag En coder Track Write Buffer (Con tin ued)

Track

1

2 0 through 9 = 37

3 0 through 9 = 104

11* Hexa deci mal N/A *

12* Hexa deci mal N/A *

13* Hexa deci mal N/A *

* - See Ap pen dix C for Ex tended En coder Com mand Set and

Cus tom Track Data and Con trol Pa rame ters.

Char ac ters

(De fault ANSI/ISO)

<Sp> $ ( ) - . /

0 through 9

A through Z (All Caps)

Field

Sep a ra tor

^ 76

Length

2-11

Page 44

+B - Se rial In ter face Rate

The card printer re sponds to com mands (with data or er ror

codes) via the bi-di rec tional se rial in ter face only. Print ers

with par al lel in ter faces can not re spond to this com mand,

(other than flag ging an er ror). In a test en vi ron ment, card

print ers can op er ate with both in ter faces at tached and com mu ni cat ing with the printer. The printer CPU board has as so ci ated con nec tors.

Models Supported P205, P210i, P310c, P310f, P310i, P420c, P420i

Description This com mand changes the bit rate (Baud) of print ers

with RS232 se rial in ter faces. RFID-equipped mod els may

not of fer the RS232 op tion.

NOTE: Baud set ting re mains in ef fect un til power is

cy cled, af ter which printer re turns to de fault.

Syntax <Esc>+B p1{ p2}

Parameters p

= Se rial In ter face baud rate op tions

1

Where:

0 = 9600 (De fault)

1 = 19200

2 = 38400

3 = 57600

p2 = Com mand re ply time

Where:

None = ACK af ter Baud switch

1 = ACK be fore Baud switch

2-12

Page 45

+BS - Set Black Synchro

Models Supported P110i, P120i, P205, P210i, P310c, P310f, P310i, P320i,

P330i, P420c, P420i, P430i, P520c, P520i, P720c

Description Sets the ac cu racy of card po si tion ing, when set to high

qual ity, the printer print po si tion ing is more ac cu rate.

Syntax <Esc>+BS p

Parameters p

= Speed

1

Where:

0 = High speed print ing

1 = High qual ity print ing

1

2-13

Page 46

B/vB - Write Bar Code

Models Supported P110i, P120i, P205, P210i, P310c, P310f, P310i, P320i,

P330i, P420c, P420i, P430i, P520c, P520i, P720c

Description This com mand down loads stan dard bar codes. See

Ap pen dix A for char ac ter maps and unique pa ram e ter

set tings for each bar code type. The B com mand writes to

the mono chrome buffer, while the vB com mand writes to

the var nish buffer.

Syntax <Esc>B p1 p2 p3 p4 p5 p6 p7 p8 data

Parameters p

= Hor i zon tal (X-axis) Start Po si tion, in dots

1

p2 = Ver ti cal (Y-axis) start po si tion, in dots

p3 = Ro ta tion:

Where:

Value De scrip tion Or i gin

0 No ro ta tion Lower Left

1 90 de grees Lower Left

2 180 de grees Lower Left

3 270 de grees Lower Left

4 No ro ta tion Cen tered

5 90 de grees Cen tered

6 180 de grees Cen tered

7 270 de grees Cen tered

Figure 2-5

Bar Code Rotation

Samples

2-14

p4 = Bar Code se lec tion - See Ap pen dix A

Where:

0 = Code 39 (3 of 9—Al pha nu meric)

1 = 2/5 In ter leaved (Nu meric, Even No Count

2 = 2/5 In dus trial (Nu meric) no Check Digit

3 = EAN8 (Nu meric, 12 dig its en coded)

4 = EAN13 (Nu meric, 12 dig its en coded)

5 = UPC - A (Nu meric, 12 dig its en coded)

6 = Re served for MON ARCH

7 = Code 128 C w/o Check Dig its* (Nu meric

only, Even Num ber Printed)

8 = Code 128 B w/o Check Dig its*

(Al pha nu meric)

s

Page 47

B/vB - Write Bar Code (Con tin ued)

107 = Code 128 C w/Check Dig its*

* Not sup ported in some Mono chrome Printerp5 = Bar

NOTE: Some bar code types have a selectable bar code

width ra tio. See Ap pen dix A for sup ported ra tio and

set tings.

p6 = Bar Code Bar Width Mul ti plier. Range 3~9 for all

p7 = Bar Code Height in dots

(Nu meric only, Even Num ber printed)

108 = Code 128 B w/Check Dig its*

(Al pha nu meric)

Width Ra tio

Where:

Value Nar row Bar Wide Bar Ra tio

0 1 dot 2 dots 2:1

1 1 dot 3 dots 3:1

2 2 dots 5 dots 2.5:1 or 2:5

Ze bra card bar codes ex cept UPC-A, EAN-8 and

EAN-13 which have a range of 4~7. For a se lected

bar width ra tio of 2:5, the range is 2~4.

Note: Each bar code type has a spec i fied stan dard

for the width range of a nar row bar width. See

Ap pen dix A for op ti mal val ues.

Note: Each Bar Code Type has an in dus try

spec i fied min i mum height stan dard. See Ap pen dix

A for op ti mal val ues.

p8 = Print Text ver sion of Bar Code un der Bar Code

Where:

1 = yes

0 = no.

data =

Rep re sents a fixed data field. Each bar code type

has a dif fer ing data field length and al low able

char ac ter re quire ments. See Ap pen dix A.

A printer er ror oc curs when a bar code ex tends be yond the

ad dress able area of the im age buffer. See Ap pen dix A for

field size cal cu la tions for to tal bar code length and height.

2-15

Page 48

&C - Set Coercivity

Models Supported P110i, P120i, P205, P210i, P310c, P310f, P310i, P320i,

P330i, P420c, P420i, P430i, P520c, P520i, P720c

De scrip tion This com mand sets the en coder for high- or

low-coercivity mag netic stripe re cord ing.

Syn tax <Esc>&C p

Pa rame ters p

Where:

= Coercivity

1

0 = Low

1 = High

1

2-16

Page 49

+C - Ad justs Mono chrome In ten sity

Models Supported P110i, P120i, P205, P210i, P310c, P310f, P310i, P320i,

P330i, P420c, P420i, P430i, P520c, P520i, P720c

Description Sets the mono chrome rib bon trans fer in ten sity (heat)

level. Vary ing the in ten sity level af fects the dot gain, or

the size of the dot and the den sity (opaque ness) of the

trans ferred ma te rial. note that higher val ues raise the

trans fer heat.

Syntax <Esc>+C p

Parameters p

Where:

= In ten sity

1

5 = Printer de fault

0~10 = range

1

2-17

Page 50

+$C - Ad just Color Con trast

Models Supported P110i, P120i, P210i, P310c, P310f, P310i, P320i, P330i,

P420c, P420i, P430i, P520c, P520i, P720c

Description Sets the range from the max i mum to min i mum color

in ten sity (heat) level ap plied to a se lected dye sub li ma tion

rib bon panel

Syntax <Esc>+$C p1 p

Parameters p

= 4 : Set con trast for all col ors (0 - 3)

1

Where:

0 = Yel low (Y)

1 = Ma genta (M)

2 = Cyan ©)

3 = Dye Sub li ma tion Black (K

p2 = Con trast:

Where:

5 = Printer de fault

0~10 = p2 range

2

)

dye

2-18

Page 51

!CC - Get Num ber of Cards Printed

Models Supported P110i, P120i, P210i, P310i, P320i, P330i, P420i, P430i,

P520i

De scrip tion Ev ery time the printer fin ishes print ing an en tire card, it

in cre ments its cards printed coun ter. This coun ter is

saved in non-vol a tile mem ory. This com mand will

re turn the to tal num ber of cards that have been printed

since the printer en tered ser vice. The value is re ported

to the host as an ASCII dec i mal num ber.

Syn tax <Esc>!CC

Pa ram e ters None

2-19

Page 52

!CCLN - Check Clean ing Pa ram e ters

Models Supported P720c

De scrip tion Re turns Card Count and Max i mum Heat Val ues set by

Syn tax <Esc>#-1-!CCLN

Pa ram e ters None

the +CCLN Com mand

2-20

Page 53

+CCLN - Set Clean ing Pa ram e ters

Models Supported P720c

De scrip tion Es tab lishes lam i na tion count and max i mum tem per a ture

value for laminator cleanings

Syn tax <Esc>#-1-+CCLN p1 p

Pa ram e ters p

= Num ber of cards lam i nated

1

p2 = Tem per a ture be low which clean ing is al lowed

2

De fault +CCLN 1000 60

2-21

Page 54

%CDER - Get Mag netic En coder Read Set tings

Models Supported P110i, P120i, P205, P210i, P310c, P310f, P310i, P320i,

P330i, P420c, P420i, P430i, P520c, P520i, P720c

Description Re turns the mag netic en coder read set tings that are pres ently in

ef fect, as set by the &CDER com mand. The string re turned is

for mat ted like this:

“TRACK 1”* “TRACK 2”# “TRACK 3”*

where * and # are sub sti tuted with the de code set tings

that take the same form as those used by the &CDER

com mand. the ex am ple be low shows the string that

would be re turned if tracks 1 and 3 were set to the de fault

ISO de code set tings, and the set tings for track 2 had been

changed by ex e cut ing the com mand: &CDER 2 V 6 :

“TRACK 1”A “TRACK 2”V 6 “TRACK 3”C

Syntax <Esc>%CDER

Parameters None

2-22

Page 55

&CDER - Set Mag netic En coder Track Read En code Pa ram e ters

The card printer re sponds to com mands (with data or er ror

codes) via the bi-di rec tional se rial in ter face only. The card

printer can not re spond to this com mand, (other than flag ging an er ror), through a par al lel in ter face. In a test en vi ron ment, card print ers can op er ate with both in ter faces

at tached and com mu ni cat ing with the printer. The printer

CPU board has as so ci ated con nec tors.

Models Supported P110i, P120i, P205, P210i, P310c, P310f, P310i, P320i,

P330i, P420c, P420i, P430i, P520c, P520i, P720c

De scrip tion Set the en coder to read a se lected data for mat

Syntax <Esc>&CDER p1 p2

<Esc>&CDER p1 p2

Parameters p

= Track Se lect: (val ues 1, 2, 3, or 0 (zero)

1

Where:

0 = Re set of ALL tracks to ISO de fault

con fig u ra tion pa ram e ters

p2 = Cus tom Data Se lect, as fol lows:

Value De scrip tion - ISO For mat Data

Re sets ALL tracks to ISO de fault con figu ra tion

0

pa rame ters.

De fault For mat Se lect

Q ISO Track 1 Data For mat to Track 1

R ISO Track 2 Data For mat to Track 2

S ISO Track 3 Data For mat to Track 3

Cus tom ISO Track For mat Lo ca tion

qX Track 1 with ISO Track “X” For mat

rX Track 2 with ISO Track “X” For mat

sX Track 3 with ISO Track “X” For mat

X = 1, 2, or 3 as the ISO de fault track for mat ap plied to the

se lected track (e.g., Q=q1, R=r2, and S=s3.

2-23

Page 56

&CDER - Set Mag netic En coder Track Read En code Pa ram e ters (Con tin ued)

p2 = Cus tom Data Se lect, as fol lows:

Value De scrip tion - Raw Data For mat

Read For ward - “Raw” Data

U Track 1

U_ Track 1 read data with NULs in data string

V Track 2

V_ Track 2 read data with NULs in data string

W Track 3

W_ Track 3 read data with NULs in data string

Read Re verse - “Raw” Data

u Track 1

u_ Track 1 read data with NULs in data string

v Track 2

v_ Track 2 read data with NULs in data string

w Track 3

w_ Track 3 read data with NULs in data string

2-24

p3 = Data Block Size Se lect in Bits

Where:

Ac cept able val ues = 3, 4, 5, 6, and 7

The en coder can not de code and con vert raw data into

ASCII data. The en coder only re ports data read af ter the

pro cess has com pleted.

Page 57

&CDEW - Set Mag netic En coder Track Write En code Pa ram e ters

The card printer re sponds to com mands (with data or er ror

codes) via the bi-di rec tional se rial in ter face only. The card

printer can not re spond to this com mand (other than flag ging an er ror) through a par al lel in ter face. In a test en vi ron ment, card print ers can op er ate with both in ter faces

at tached and com mu ni cat ing with the printer. The printer

CPU board has as so ci ated con nec tors.

Models Supported P110i, P120i, P205, P210i, P310c, P310f, P310i, P320i,

P330i, P420c, P420i, P430i, P520c, P520i, P720c

Description Con fig ure the write data to en code a sin gle, se lected

track of data

Syntax <Esc>&CDEW p1 p2

<Esc>&CDEW p1 p2 p3

Parameters p

= Track Se lect: (val ues 1, 2, 3 or 0 (zero)

1

Where:

0 = Re set of ALL tracks to ISO de fault

con fig u ra tion pa ram e ters

p2 = Data For mat Se lect, as fol lows:

Value De scrip tion - ISO For mat Data

Re set ALL tracks to ISO de fault con figu ra tion

0

pa rame ters.

De fault For mat Se lect

A ISO Track 1 Data For mat to Track 1

B ISO Track 2 Data For mat to Track 2

C ISO Track 3 Data For mat to Track 3

Cus tom ISO Track For mat Se lect

aX Track 1 with ISO Track “X” For mat

bX Track 2 with ISO Track “X” For mat

cX Track 3 with ISO Track “X” For mat

X = ISO de fault track for mat ap plied to the se lected track

(e.g., A=a1, B=b2, and C=c3.

2-25

Page 58

&CDEW - Write Cus tom Track Data (Con tin ued)

p2 = Cus tom Data Se lect, as fol lows:

Value De scrip tion - Raw Data For mat

Read For ward - “Raw” Data

E Track 1

E_ Track 1 write data with NULs in data string

F Track 2

F_ Track 2 write data with NULs in data string

G Track 3

G_ Track 3 write data with NULs in data string

p3 = Data Block Size Se lect in Bits

Where:

Ac cept able val ues = 3, 4, 5, 6, and 7