Page 1

HOST API FOR

BARCODE

SCANNERS

WITH RFID

Programming Interface

72E-154791-05EN Rev. A

Page 2

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corporation, registered in

many jurisdictions worldwide. All other trademarks are the property of their respective owners. ©2021

Zebra Technologies Corporation and/or its affiliates. All rights reserved.

Information in this document is subject to change without notice. The software described in this document

is furnished under a license agreement or nondisclosure agreement. The software may be used or copied

only in accordance with the terms of those agreements.

For further information regarding legal and proprietary statements, please go to:

SOFTWARE:www.zebra.com/linkoslegal

COPYRIGHTS:www.zebra.com/copyright

WARRANTY:www.zebra.com/warranty

END USER LICENSE AGREEMENT: www.zebra.com/eula

Terms of Use

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries

(“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced,

or disclosed to any other parties for any other purpose without the express, written permission of Zebra

Technologies.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications and designs are

subject to change without notice.

Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and manuals are

correct; however, errors do occur. Zebra Technologies reserves the right to correct any such errors and

disclaims liability resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever

(including, without limitation, consequential damages including loss of business profits, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to

use such product, even if Zebra Technologies has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

2

Page 3

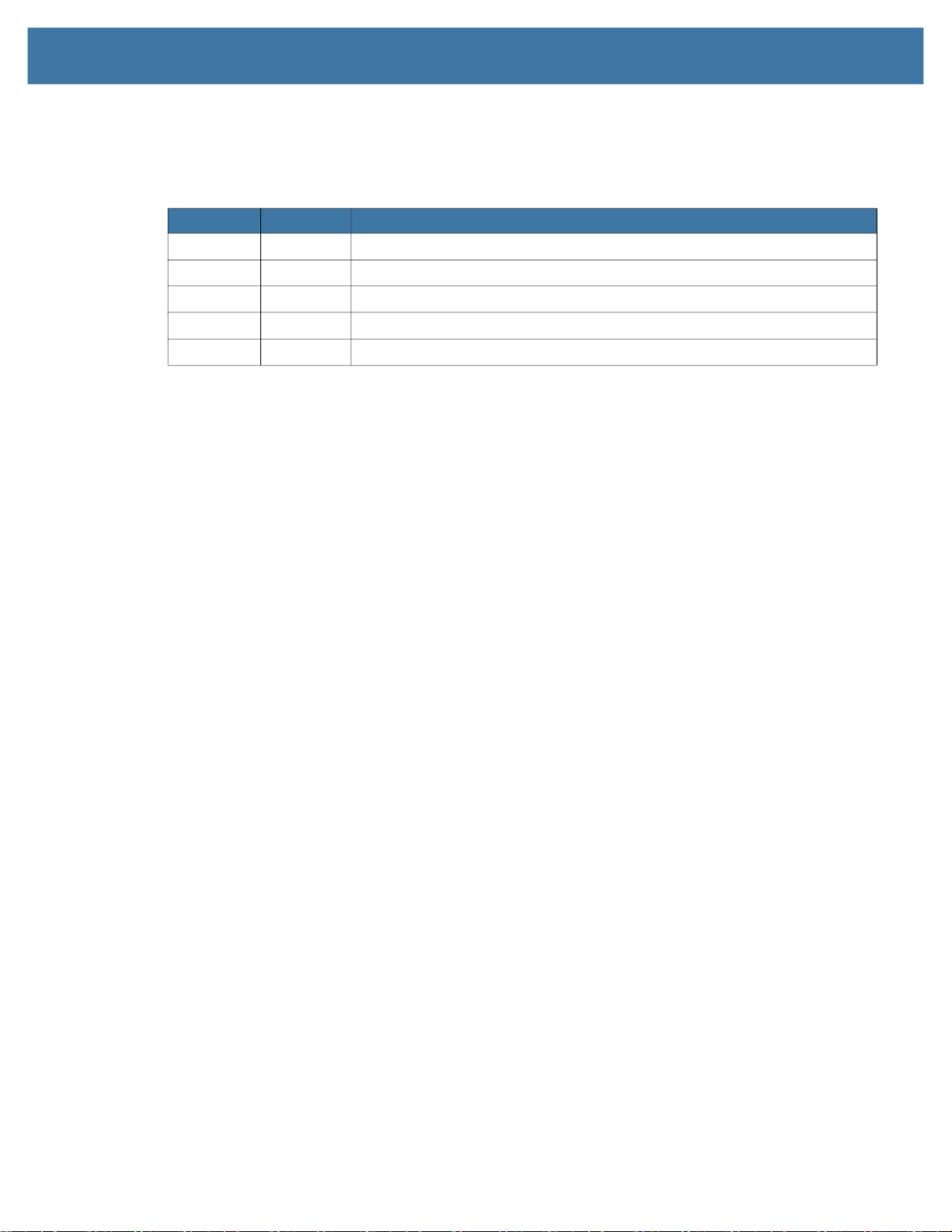

Revision History

Changes to the original guide are listed below:

Change Date Description

-01 Rev A 9/21/11 Initial release.

-02 Rev A 1/18/12 Update tables on pages 8, 9, 11, 13, and 14.

-03 Rev A 3/31/2015 Zebra rebranding.

-04 Rev A 2/27/2019 Add DS9908R.

-05 Rev A 8/23/2021 Remove patent-pending wording on page 8.

3

Page 4

Contents

Terms of Use ................................................................................................................... 2

Proprietary Statement .............................................................................................. 2

Product Improvements ............................................................................................ 2

Liability Disclaimer ................................................................................................... 2

Limitation of Liability ................................................................................................ 2

Revision History .............................................................................................................. 3

About This Document ....................................................................................................................... 6

Introduction ..................................................................................................................... 6

Notational Conventions ................................................................................................... 6

Related Documents and Software .................................................................................. 7

Service Information ......................................................................................................... 7

Provide Documentation Feedback .................................................................................. 7

Host API for RFID ............................................................................................................................... 8

Overview ......................................................................................................................... 8

DS9808R Corded Hybrid Imager with RFID ............................................................ 8

DS9908R Next Generation Corded Hybrid Imager with RFID ................................. 8

Setup ............................................................................................................................... 9

Using with USB OPOS ............................................................................................ 9

RSM Attributes for RFID ................................................................................................. 9

RFID_LAST_TAG_ID – Last Reported Tag ........................................................... 10

RFID_CMD_STATUS - Common Operation Response ........................................ 11

RFID_COMMAND ................................................................................................. 11

Tag Read Operation ........................................................................................ 11

Tag Write Operation ........................................................................................ 16

Example Write ................................................................................................. 17

Tag Lock Operation ......................................................................................... 18

Tag Kill Operation ........................................................................................... 21

RFID_TAG_CACHE – Tag Cache Operations ....................................................... 23

Example Read Cache Size ............................................................................. 23

Example Clear Tag Cache .............................................................................. 23

4

Page 5

List of Tables

About This Document ........................................................................................................................ 6

Host API for RFID ................................................................................................................................ 8

RSM Attributes ................................................................................................................ 9

Example Read - Read Entire EPC Bank ....................................................................... 12

Example Read - Read PC Word ................................................................................... 14

Example Write ............................................................................................................... 17

Example Tag Lock Operation ........................................................................................ 20

Example - Tag Kill Operation ........................................................................................ 22

Example - Read Cache Size ......................................................................................... 23

Example - Clear Tag Cache .......................................................................................... 23

5

Page 6

About This Document

Introduction

This document describes the host Application Program Interface (API) for the advanced reading and

writing of Radio Frequency Identification (RFID) tags using the Durango RFID Module with the DS9808

Sierra digital scanner and the DS9908R (DS9908 with RFID) imager.

Notational Conventions

The following conventions are used in this document:

• The

• Bold text is used to highlight the following:

• Bullets (•) indicate:

Consolas font is used to denote code.

• Dialog box, window and screen names

• Drop-down list and list box names

• Check box and radio button names

• Icons on a screen

• Key names on a keypad

• Button names on a screen.

• Action items

• Lists of alternatives

• Lists of required steps that are not necessarily sequential.

• Sequential lists (e.g., those that describe step-by-step procedures) appear as numbered lists.

6

Page 7

About This Document

Related Documents and Software

The following documents provide more information about the DS9X08 scanners.

• DS9808 Digital Scanner Product Reference Guide, part number 72E-112999-xx

• DS9808R Digital Scanner Product Reference Guide Supplement, part number 72E-132822-xx

• DS9908 Hands-Free Imaging Scanner Product Reference Guide, part number MN-003185--xx.

• DS9908R Hands-Free Imaging Scanner Product Reference Guide Supplement, part number

MN-003377-xx.

• Zebra Scanner SDK

www.zebra.com/us/en/products/software/scanning-systems/scanner-drivers-and-utilities.html

• EPC Tag Data Standard Standard version 1.11

www.gs1.org/standards/epcrfid-epcis-id-keys/epc-rfid-tds/1-11

For the latest version of this guide and all guides, go to: zebra.com/support.

Service Information

If you have a problem with your equipment, contact Zebra Global Customer Support for your region.

Contact information is available at: zebra.com/support

When contacting support, please have the following information available:

• Serial number of the unit

• Model number or product name

• Software type and version number.

Zebra responds to calls by email, telephone or fax within the time limits set forth in support agreements.

If your problem cannot be solved by Zebra Customer Support, you may need to return your equipment for

servicing and will be given specific directions. Zebra is not responsible for any damages incurred during

shipment if the approved shipping container is not used. Shipping the units improperly can possibly void

the warranty.

If you purchased your Zebra business product from a Zebra business partner, contact that business

partner for support.

Provide Documentation Feedback

If you have comments, questions, or suggestions about this guide, send an email to

EVM-Techdocs@zebra.com

.

.

7

Page 8

Host API for RFID

Overview

DS9808R Corded Hybrid Imager with RFID

The DS9808R is the first combination 1D/2D barcode scanner and RFID reader and the first combination

hand-held/hands-free UHF RFID reader. The DS9808R offers the flexibility to accommodate virtually any

type of data capture application, including support for: 1D and 2D paper and mobile barcodes, mobile

coupons, mobile loyalty cards, mobile boarding passes, PDF417 barcodes, and reading/writing RFID tags.

The read range for the RFID antenna can be adjusted to suit the environment. For example, the RFID read

range in presentation mode can be decreased to prevent inadvertent reading of RFID tags in a nearby

cash-wrap, while the range in hand-held (triggered) mode can be increased to read RFID tags that are

further away.

DS9908R Next Generation Corded Hybrid Imager with RFID

The DS9908R replaces the DS9808R. The DS9908R offers several enhanced features that includes the

following.

• A capacitive touch sensor and accelerometer that work together to instantly switch to hand-held mode

as soon as an associate picks up the scanner. There are no mechanical components to wear out,

providing fail-proof switching throughout the scanner’s life.

• The reader operates with just 5 VDC and does not require an external power supply.

• Built-in RFID data conversion software reports the tags EPC data as:

• Raw - the EPC buffer transmits as a hexadecimal string. This format can include the protocol control

bytes.

• GS1-128 - for GS1 encoded tags. This option converts EPC data to a GS1-128 barcode as per the

GS1 EPC Tag Data Standard.

• EPC URI - the EPC data is represented as a Universal Resource Identifier (URI) as defined in the

EPC Tag Data Standard version 1.11.

• Zebra’s ScanSpeed Analytics provides detailed performance metrics on each barcode captured enabling you to identify and eliminate poor performing barcodes that slow down the checkout process.

You can also view the number of decodes performed in hand-held and hands-free modes to better

understand how associates are using the scanner.

8

Page 9

Setup

Using with USB OPOS

To use the RFID control with the Zebra Scanner SDK you may use the Scanner WMI Sample Application

(Scanner_WMI_test.exe). Refer to Zebra Scanner SDK for Windows at:

www.zebra.com/scannersdkforwindows

This program offers the “SetAttributes” and “GetAttributes” methods which are needed to access the RFID

attributes. All examples in this document assume you are using this sample application.

The DS9X08R scanner must have a USB cable connection and should be configured with the USB Device

Type set to one of the following:

• USB OPOS Handheld

• IBM Handheld USB

• IBM Table Top USB

Refer to the scanner Product Reference Guides for details and configuration barcodes (see Related

Documents and Software on page 7).

Host API for RFID

.

RSM Attributes for RFID

The RFID API is expressed in a series of RSM attributes.

Table 1 RSM Attributes

Attribute

Number

35001 RFID_LAST_TAG_ID ‘A’ 34 R The EPC Tag ID of the last tag

35002 RFID_TAG_ID ‘A’ 34 W The EPC Tag ID of the tag to be

35003 RFID_BANK ‘B’ 1 W Desired Tag Bank:

35004 RFID_DATA ‘A’ 66 RW Buffer for read, write, and lock

35005 RFID_OFFSET ‘W’ 2 W Word offset into tag buffer

35006 RFID_LENGTH ‘W’ 2 W Words of data to read from tag

35007 RFID_PASSWORD ‘A’ 4 W Binary password for privileged

Attribute Name

RSM

Type

Size

(Bytes)

Access Descroption

reported. (size-encoded binary)

operated upon. (size-encoded

binary)

0 = reserved,

1 = EPC,

2 = TID,

3 = User

(size-encoded binary)

buffer. 0 means entire bank

operations

9

Page 10

Host API for RFID

Table 1 RSM Attributes (Continued)

Attribute

Number

35008 RFID_COMMAND ‘B’ 1 W Execute command:

35009 RFID_CMD_STATUS ‘W’ 2 R Resulting status from executing a

35010 RFID_TAG_CACHE ‘W’ 2 RW Internal Tag Cache Size:

For size-encoded binary data, the first two bytes contain the length (MSB, LSB) for the data to be

considered (needed because the RSM attributes are fixed size).

Attribute Name

RSM

Type

Size

(Bytes)

RFID_LAST_TAG_ID – Last Reported Tag

As a convenience, the RFID_LAST_TAD_ID may be used to get the raw EPC of the last tag reported by

normal tag reading operation of the D9x08R (normally for an RFID_READ event, the scanner issues a

2-tone beep).

Access Descroption

1 = Read

2 = Write

3 = Lock

4 = Kill

command

Read for current cache size

Write 0 to clear the cache

As an example, to get the RFID_LAST_TAD_ID attribute after the scanner reports the tag

3005FB63AC1F3681EC880469.

Method Input attValueList

GetAttributes <attrib_list>35001</attrib_list> <attrib_list>

<attribute>

<id>35001</id>

<datatype>A</datatype>

<permission>R</permission>

<value>0x00 0x0c 0x30 0x05

0xfb 0x63 0xac 0x1f 0x36 0x81

0xec 0x88 0x04 0x69 0x00 0x00

0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 0x00 0x00 0x00 0x00

</value>

</attribute>

</attrib_list>

In raw RSM protocol:

Send: 00 08 02 00 88 B9 FF FF

Recv: 00 33 02 00 88 B9 41 01 42 00 22 00 00 00 0C 30 05 FB 63 AC 1F 36 81 EC 88 04 69

00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 FF FF FF FF

10

Page 11

Host API for RFID

RFID_CMD_STATUS - Common Operation Response

All operations (read, write, kill, lock) return a status in the RFID_CMD_STATUS attribute:

0x0000 Success

0x0001 No RFID module

0x0002 Tag Not Found

0x0003 Timeout

0x0004 Tag CRC Error

0x01xx Tag Backscatter Error, LSB indicates the error_code as per EPC

Protocol

0x02xx Tag Access error. LSB indicates the error code

0x03xx Bad Parameter, the LSB indicates which parameter:

1 = Command

2 = Tag_ID

3 = Bank

4 = Data

5 = Offset

6 = Password

7 = Length

RFID_COMMAND

The RFID_COMMAND attribute is used to execute the various tag operations. Each operation has

parameter attributes that should be setup prior to executing the command.

Tag Read Operation

The Tag Read operation requires the following attributes to be set using RSM SetAttributes:

Attribute Number Attribute Description

35002 RFID_TAG_ID EPC code of desired tag.

35003 RFID_BANK Desired memory bank of tag.

35005 RFID_OFFSET Word offset into the memory bank.

35006 RFID_LENGTH Number of words to read.

35007 RFID_PASSWORD Optional access password.

35008 RFID_COMMAND 1 = Read.

The Tag Read operation is activated by the SetAttribute of the RFID_COMMAND attribute.

The result of the operation may be retrieved by the RSM GetAttributes of the following attributes. If the

RFID_CMD_STATUS attribute indicates success, then the RFID_DATA attribute will have the requested

data.

11

Page 12

Attribute Number Attribute Description

35009 RFID_CMD_STATUS Resulting status from the read.

35004 RFID_DATA Buffer for read.

Example Read

Table 2 is an example to read the entire EPC bank of the tag with EPC of 3005FB63AC1F3681EC880469.

Table 2 Example Read - Read Entire EPC Bank

Method Input attValueList

Host API for RFID

SetAttributes <attrib_list>

<attribute>

<!--RFIDTagID-->

<id>35002</id>

<datatype>A</datatype>

<value>0x00 0x0c 0x30 0x05 0xFB

0x63 0xAC 0x1F 0x36 0x81 0xEC 0x88 0x04

0x69 </value>

</attribute>

<attribute>

<!--RFIDBank-->

<id>35003</id>

<datatype>B</datatype>

<value>1</value>

</attribute>

<attribute>

<!--RFIDOffset-->

<id>35005</id>

<datatype>W</datatype>

<value>0</value>

</attribute>

<attribute>

<!--RFIDLength-->

<id>35006</id>

<datatype>W</datatype>

<value>0</value>

</attribute>

<attribute>

<!--RFIDCommand-->

<id>35008</id>

<datatype>B</datatype>

<value>1</value>

</attribute>

</attrib_list>

n/a

12

Page 13

Host API for RFID

Table 2 Example Read - Read Entire EPC Bank (Continued)

Method Input attValueList

GetAttributes <attrib_list>35009,35004</attrib_list> <attrib_list>

<attribute>

<id>35009</id>

<name>"RFIDCmdStatus"</name>

<datatype>W</datatype>

<permission>R</permission>

<value>0</value>

</attribute>

<attribute>

<id>35004</id>

<name>"RFIDData"</name>

<datatype>A</datatype>

<permission>R W P</permission>

<value>0x00 0x10 0xA0 0x4B 0x30

0x00 0x30 0x05 0xFB 0x63 0xAC 0x1F

0x36 0x81 0xEC 0x88 0x04 0x69 0x00

0x00 0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 0x00 0x00 0x00 </value>

</attribute>

</attrib_list>

In raw RSM protocol:

Send: 00 33 05 00 88 BA 41 00 42 00 0E 00 00 00 0C 30 05 FB 63 AC 1F 36 81 EC 88 04 69

88 BB 42 00 01 88 BD 57 00 00 00 88 BE 57 00 00 00 88 C0 42 00 01 FF FF

Recv: 00 04 05 00

Send: 00 0A 02 00 88 C1 88 BC FF FF

Recv: 00 59 02 00 88 C1 57 01 00 00 88 BC 41 03 42 00 42 00 00 00 10 AE 57 30 00 30 05

FB 63 AC 1F 36 81 EC 88 04 69 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

FF FF FF FF

13

Page 14

Host API for RFID

Table 3 is a second example to read the PC word (second word, whose value is 0x3000) from the EPC

buffer of the same tag:

Table 3 Example Read - Read PC Word

Method Input attValueList

SetAttributes <attrib_list>

<attribute>

<!--RFIDTagID-->

<id>35002</id>

<datatype>A</datatype>

<value>0x00 0x0c 0x30 0x05

0xFB 0x63 0xAC 0x1F 0x36 0x81

0xEC 0x88 0x04 0x69 </value>

</attribute>

<attribute>

<!--RFIDBank-->

<id>35003</id>

<datatype>B</datatype>

<value>1</value>

</attribute>

<attribute>

<!--RFIDOffset-->

<id>35005</id>

<datatype>W</datatype>

<value>1</value>

</attribute>

<attribute>

<!--RFIDLength-->

<id>35006</id>

<datatype>W</datatype>

<value>1</value>

</attribute>

<attribute>

<!--RFIDCommand-->

<id>35008</id>

<datatype>B</datatype>

<value>1</value>

</attribute>

</attrib_list>

n/a

14

Page 15

Host API for RFID

Table 3 Example Read - Read PC Word (Continued)

Method Input attValueList

GetAttributes <attrib_list>35009,35004</attrib_

list>

<attrib_list>

<attribute>

<id>35009</id>

<name>"RFIDCmdStatus"</name>

<datatype>W</datatype>

<permission>R</permission>

<value>0</value>

</attribute>

<attribute>

<id>35004</id>

<name>"RFIDData"</name>

<datatype>A</datatype>

<permission>R W

P</permission>

<value>0x00 0x02 0x30 0x00

0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 0x00 0x00 0x00 0x00

0x00 0x00 </value>

</attribute>

</attrib_list>

In raw RSM protocol:

Send: 00 33 05 00 88 BA 41 00 42 00 0E 00 00 00 0C 30 05 FB 63 AC 1F 36 81 EC 88 04 69

88 BB 42 00 01 88 BD 57 00 00 01 88 BE 57 00 00 01 88 C0 42 00 01 FF FF

Recv: 00 04 05 00

Send: 00 0A 02 00 88 C1 88 BC FF FF

Recv: 00 59 02 00 88 C1 57 01 00 00 88 BC 41 03 42 00 42 00 00 00 02 30 00 00 00 00 00

00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

FF FF FF FF

15

Page 16

Tag Write Operation

The Tag Write operation requires the following attributes to be set using RSM SetAttributes:

Attribute Number Attribute Description

35002 RFID_TAG_ID EPC code of desired tag

35003 RFID_BANK Desired memory bank of tag

35004 RFID_DATA data to write

35005 RFID_OFFSET Word offset into the memory bank

35007 RFID_PASSWORD Optional access password

35008 RFID_COMMAND 2 = “write”

The Tag Write operation is activated by the SetAttribute of the RFID_COMMAND attribute.

The result of the operation may be retrieved by the RSM GetAttributes of the RFID_CMD_STATUS

attribute.

Attribute Number Attribute Description

35009 RFID_CMD_STATUS Resulting status from the Write

Host API for RFID

16

Page 17

Host API for RFID

Example Write

Table 4 is an example to write 0x1234 into the second word of the user bank of the tag with EPC of

3005FB63AC1F3681EC880469.

Table 4 Example Write

Method Input attValueList

SetAttributes <attrib_list>

<attribute>

<!--RFIDTagID-->

<id>35002</id>

<datatype>A</datatype>

<value>0x00 0x0c 0x30 0x05 0xFB

0x63 0xAC 0x1F 0x36 0x81 0xEC 0x88 0x04

0x69 </value>

</attribute>

<attribute>

<!--RFIDBank-->

<id>35003</id>

<datatype>B</datatype>

<value>3</value>

</attribute>

<attribute>

<!--RFIDOffset-->

<id>35005</id>

<datatype>W</datatype>

<value>1</value>

</attribute>

<attribute>

<!--RFIDData-->

<id>35004</id>

<datatype>A</datatype>

<value>0x00 0x02 0x12 0x34

</value>

</attribute>

<attribute>

<!--RFIDCommand-->

<id>35008</id>

<datatype>B</datatype>

<value>2</value>

</attribute>

</attrib_list>

n/a

17

Page 18

Host API for RFID

Table 4 Example Write

Method Input attValueList

GetAttributes <attrib_list>35009</attrib_list> <attrib_list>

<attribute>

<id>35009</id>

<name>"RFIDCmdStatus"</name>

<datatype>W</datatype>

<permission>R</permission>

<value>0</value>

</attribute>

</attrib_list>

In raw RSM Protocol:

Send: 00 33 05 00 88 BA 41 00 42 00 0E 00 00 00 0C 30 05 FB 63 AC 1F 36 81 EC 88 04 69

88 BB 42 00 03 88 BD 57 00 00 01 88 BC 41 00 42 00 04 00 00 00 02 12 34 88 C0 42 00 02

FF FF

Recv: 00 04 05 00

Send: 00 08 02 00 88 C1 FF FF

Recv: 00 0E 02 00 88 C1 57 01 00 00 FF FF FF FF

Tag Lock Operation

The Tag Lock operation requires the following attributes to be set using RSM SetAttributes:

Attribute Number Attribute Description

35002 RFID_TAG_ID EPC code of desired tag

35004 RFID_DATA Lock configuration

35007 RFID_PASSWORD Access password (required)

35008 RFID_COMMAND 3 = “Lock”

The Lock Configuration is 4 bytes, defined in the EPC Protocol Spec as:

18

Page 19

Host API for RFID

The password is required for the Tag Lock operation and must match the access password of the tag

(bytes 4-7 of the reserved bank).

The Tag Lock operation is activated by the SetAttribute of the RFID_COMMAND attribute.

The result of the operation may be retrieved by the RSM GetAttributes of the RFID_CMD_STATUS

attribute.

Attribute Number Attribute Description

35009 RFID_CMD_STATUS Resulting status from the Kill

Example Tag Lock Operation

Table 5 is an example to hide the kill password (bytes 0-3 of the reserved bank) of the tag with EPC of

3005FB63AC1F3681EC880469, assuming the access password (bytes 4-7 of the reserved bank) is

0x87654321.

To setup the lock configuration, set:

“kill pwd” mask = 11

“kill pwd” action = 10

Therefore the lock configuration is 0x000c0200.

19

Page 20

Host API for RFID

Table 5 Example Tag Lock Operation

Method Input attValueList

SetAttributes <attrib_list>

<attribute>

<!--RFIDTagID-->

<id>35002</id>

<datatype>A</datatype>

<value>0x00 0x0c 0x30 0x05 0xFB 0x63

0xAC 0x1F 0x36 0x81 0xEC 0x88 0x04 0x69

</value>

</attribute>

<attribute>

<!--RFIDData-->

<id>35004</id>

<datatype>A</datatype>

<value>0x00 0x04 0x00 0x0c 0x02 0x00

</value>

</attribute>

<attribute>

<!--RFIDPassword-->

<id>35007</id>

<datatype>A</datatype>

<value>0x87 0x65 0x43 0x21</value>

</attribute>

<attribute>

<!--RFIDCommand-->

<id>35008</id>

<datatype>B</datatype>

<value>3</value>

</attribute>

</attrib_list>

n/a

GetAttributes <attrib_list>35009</attrib_list> <attrib_list>

<attribute>

<id>35009</id>

<name>"RFIDCmdStatus"</name>

<datatype>W</datatype>

<permission>R</permission>

<value>0</value>

</attribute>

</attrib_list>

20

Page 21

Tag Kill Operation

The Tag Kill operation requires the following attributes to be set using RSM SetAttributes:

Attribute Number Attribute Description

35002 RFID_TAG_ID EPC code of desired tag

35007 RFID_PASSWORD Kill password (required non-zero)

35008 RFID_COMMAND 4 = “kill”

The password is required for the Tag Kill operation and must match the kill password of the tag (bytes 0-3

of the reserved bank). Note that, as per the EPC protocol spec, if the kill password is zero the tag cannot

be killed.

The Tag Kill operation is activated by the SetAttribute of the RFID_COMMAND attribute.

The result of the operation may be retrieved by the RSM GetAttributes of the RFID_CMD_STATUS

attribute.

Attribute Number Attribute Description

35009 RFID_CMD_STATUS Resulting status from the Kill

Host API for RFID

Example Tag Kill Operation

Table 6 is an example to kill the tag with EPC of 3005FB63AC1F3681EC880469, assuming the kill

password (bytes 0-3 of the reserved bank) is 0x12345678.

21

Page 22

Table 6 Example - Tag Kill Operation

Method Input attValueList

Host API for RFID

SetAttributes <attrib_list>

<attribute>

<!--RFIDTagID-->

<id>35002</id>

<datatype>A</datatype>

<value>0x00 0x0c 0x30 0x05 0xFB

0x63 0xAC 0x1F 0x36 0x81 0xEC 0x88 0x04

0x69 </value>

</attribute>

<attribute>

<!--RFIDData-->

<id>35004</id>

<datatype>A</datatype>

<value>0x00 0x04 0x00 0x0c 0x02

0x00 </value>

</attribute>

<attribute>

<!--RFIDPassword-->

<id>35007</id>

<datatype>A</datatype>

<value>0x12 0x34 0x56

0x78</value>

</attribute>

<attribute>

<!--RFIDCommand-->

<id>35008</id>

<datatype>B</datatype>

<value>4</value>

</attribute>

</attrib_list>

n/a

GetAttributes <attrib_list>35009</attrib_list> <attrib_list>

<attribute>

<id>35009</id>

<name>"RFIDCmdStatus"</name>

<datatype>W</datatype>

<permission>R</permission>

<value>0</value>

</attribute>

</attrib_list>

22

Page 23

Host API for RFID

RFID_TAG_CACHE – Tag Cache Operations

As a diagnostic tool, the RFID_TAG_CACHE may be used to read the current tag cache size or to flush the

tag cache. Reading this attribute returns the current number of the unique RFID tags in the cache. Writing

any value to this attribute causes the cache to be cleared (flushed).

NOTE:

Use caution when clearing the tag cache as all tags in range will be read on the very next inventory. If

automatic reading is enabled, this will be immediately.

Example Read Cache Size

Table 7 Example - Read Cache Size

Method Input attValueList

GetAttributes <attrib_list>35010</attrib_list> <attrib_list>

<attribute>

<id>35010</id>

<name>""</name>

<datatype>W</datatype>

<permission>R W</permission>

<value>2</value>

</attribute>

</attrib_list>

In raw RSM protocol:

Send: 00 08 02 00 88 C2 FF FF

Recv: 00 0E 02 00 88 C2 57 03 00 02 FF FF FF FF

Example Clear Tag Cache

Table 8 Example - Clear Tag Cache

Method Input attValueList

SetAttributes <attrib_list>

<attribute>

<id>35010</id>

<datatype>W</datatype>

<value>0</value>

</attribute>

</attrib_list>

In raw RSM protocol:

Send: 00 0A 05 00 88 C2 57 03 00 00

Recv: 00 04 05 00

23

Page 24

www.zebra.com

Loading...

Loading...