Page 1

YSI incorporated

YSI Profiler System

User’s Manual

Page 2

Table of Contents

Page

Section 1 Introduction

1.1 System Overview 1-1

1.2 System Description 1-1

1.3 Getting Started 1-4

Section 2 Profile Routine

2.1 Software Installation 2-1

2.2 Using Profile Wizard to Create a Profile Routine 2-4

2.3 How the CR10X Executes a Profile Routine 2-17

Section 3 Equipment Staging – Sonde & Components

3.2 Setting Sonde Parameters 3-1

3.3 Connecting & Checking Profiler Components 3-9

Section 4 Equipment Staging – PC / CR10X Communications

4.1 Introduction 4-1

4.2 Setting Up Communication from PC to Station 4-1

4.3 Downloading Program File to Station 4-10

Section 5 Pre-Deployment Testing

5.1 Setting Up LoggerNet for System Testing 5-1

5.2 Testing with Ports and Flags 5-6

5.3 Start a Profiling Sequence 5-12

Section 6 Deployment & Maintenance

6.1 Transporting Platform to Profile Location 6-1

6.2 Testing Communications 6-3

6.3 Maintenance – Servicing Sonde 6-4

6.4 Maintenance – Servicing Other System Components 6-5

6.5 Maintenance Schedule 6-7

Section 7 Data Collection & Analysis

7.1 Data Collection 7-1

7.2 YSI Profile Data Manager 7-1

7.3 Data Analysis 7-2

7.4 Automation Setup 7-6

7.5 FTP Site Test 7-13

3.1 Introduction 3-1

i

Page 3

Section 8 Appendices

A

B Software File Reports

C I/O Module Configuration

D YSI Parameter ID Numbers (CR10X)

E Required Notice

F Material Safety Data Sheet(s)

G Data File Array Numbers

H Supplementary Information

Warranty & Service Information

ii

Page 4

YSI Profiler System USER Manual

Section 1

Introduction

1.1 System Overview

The YSI Profiler is an integrated system of hardware and software, typically mounted to a

floating platform (pontoon or buoy). The Profiler is anchored at a predetermined site on a lake,

reservoir or bay, and used for vertical profiling a column of water. The system employs a YSI

sonde to periodically measure water parameters in the column. The user inputs information

through YSI Profile Wizard (PC-based) to create a program that is downloaded to a Campbell

Scientific CR10X data logger that resides on the Profiler platform. The CR10X controls the

Profiler winch to move the sonde up and down through the water column and command data from

sensors at specified intervals. The system may also include a depth sounder (or fixed reference

sonde), compass and meteorological sensors for collecting additional data at the site. The remote

data collection system operates on programmed software instructions, and when polled, it sends

data via a wireless communication link back to one or more base stations. LoggerNet™ is a PCbased program used to communicate with the CR10X data logger, which keeps track of the last

samples uploaded. The YSI Profile Data Manager™ is a PC-based program that may be used to

analyze and manage profile data.

1.2 System Description

The YSI Profiler pontoon version consists of the YSI 6960 Controller Assembly and the YSI

6955 Winch Assembly, both mounted to a T-Frame support. Figure 1-1 should help you to

visualize the hardware. The software programs are described in later sections.

Figure 1-1 Profiler Platform: On Boat Ramp for Pre-deployment Check (Panels Removed)

YSI Environmental 669523 Rev B Page 1-1

Page 5

YSI Profiler System USER Manual

The YSI Profiler System may be configured in a fixed station version as shown in Figure 1-2.

Here the YSI 6955 Winch Assembly is mounted to a pylon and the YSI 6961 Controller

Assembly is rail-mounted and housed inside a NEMA enclosure.

Figure 1-2 YSI Profiler Fixed Mount Version: mounted to pylon and guard rail

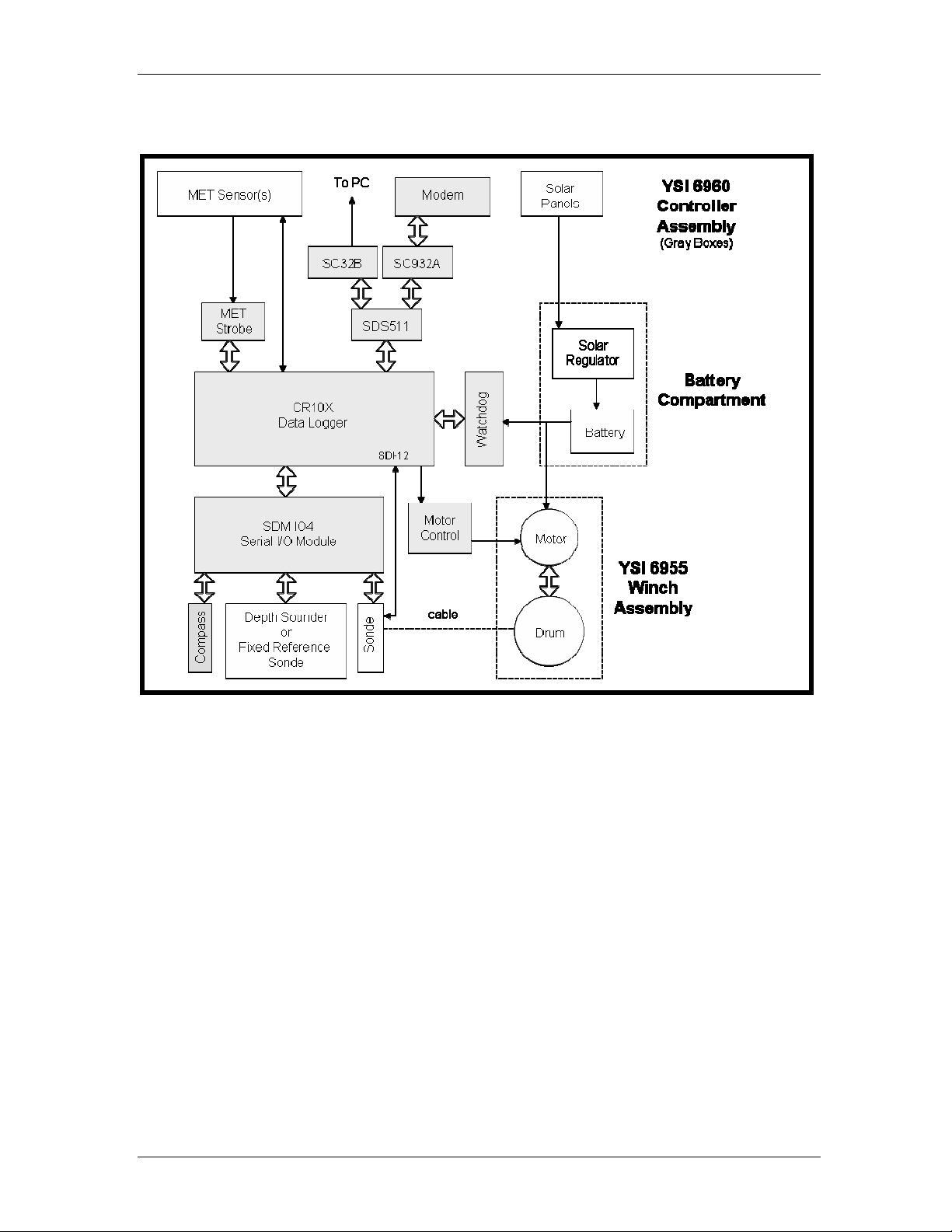

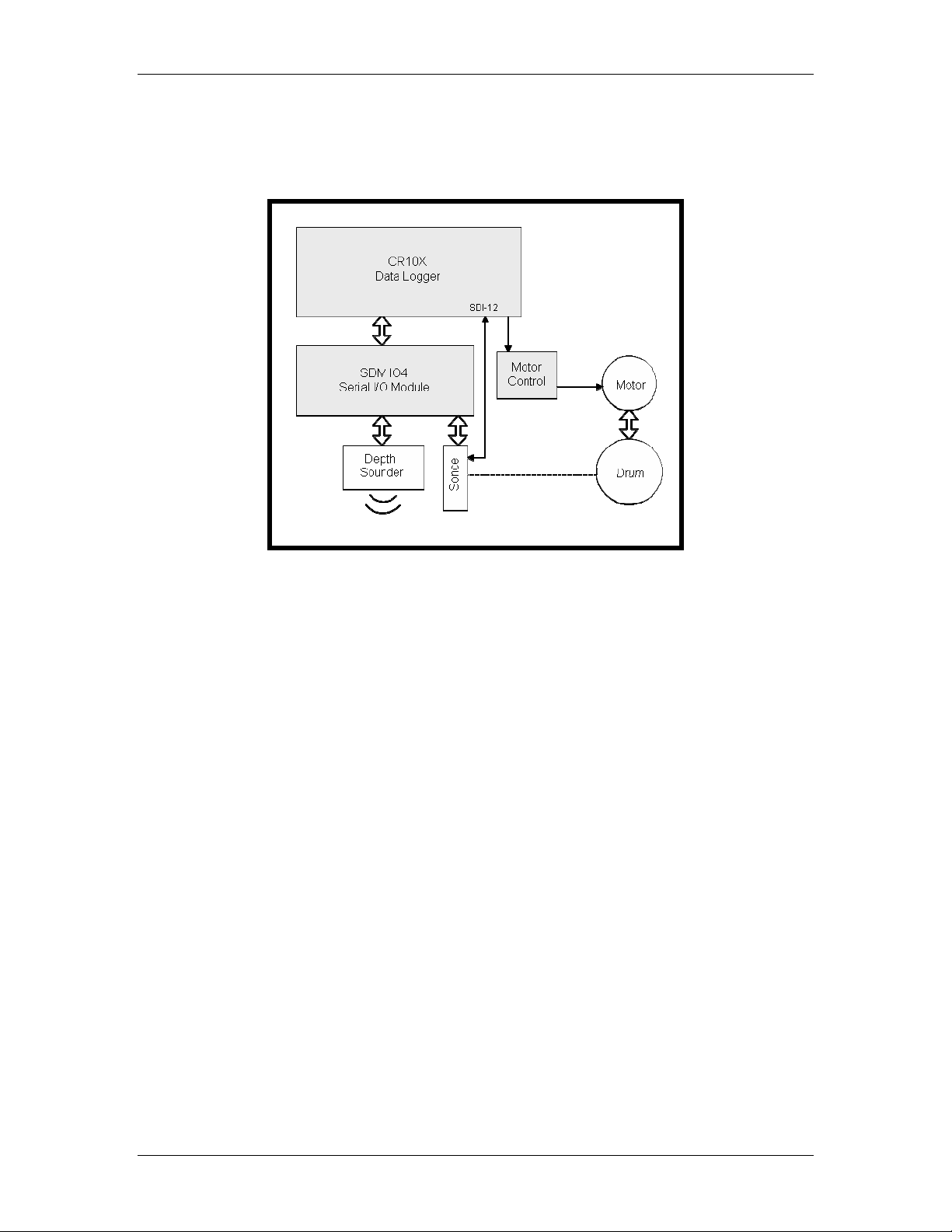

The YSI 6960 (or 6961) Controller is the heart of the system. It includes a Campbell Scientific

CR10X-2M data logger, an SDM SIO4 module, a motor control system (with two relays), a

watchdog timer and a communication module. These components are housed within a watertight

enclosure to protect the electronics from the environment. In Figure 1-4, gray shaded

components are those housed within the enclosure. Note that variable water depth can be

monitored by the Depth Sounder or a Fixed Reference Sonde depending on the deployment

requirements.

The CR10X program executes commands that collect information from the sonde and various

peripherals. This information is then used by the CR10X to strobe its I/O ports and performs

mechanical actions, such as energize the power relay that controls the winch motor to move the

sonde to a new location in the water column.

The YSI 6955 Winch Assembly is driven by a 12 VDC motor. The Winch Assembly includes a

reinforced Kevlar® sonde cable that is approximately 0.3 inch in diameter and 15 meters in

length for vented cables. For non-vented cables sonde cables the diameter is approximately 0.25

inch with lengths from 30 to 100 meters. The Winch Assembly is primarily composed of PVC

and Delrin® parts to maximize resistance to environmental damage. The motor is a small

horsepower motor geared down to lift the required weight of a YSI sonde (including attached

weight and cable). The total weight of the sonde in water is about 8 lbs. The motor is coupled to

the drum axle via a robust planetarium gear assembly that incorporates a 90 degree gear coupler.

The Motor Control Circuit Breaker module is controlled by the CR10X. It functions as the main

power OFF/ON to the motor and as a current limiter. In the event the motor draws excessive

power, the current increases. Once it reaches a set threshold the module terminates motor power.

YSI Environmental 669523 Rev B Page 1-2

Page 6

YSI Profiler System USER Manual

The program makes a second and third attempt to run the motor. If current threshold is still

exceeded, the program aborts to SETUP mode.

Figure 1-3 Block Diagram – YSI Profiler Control and Winch Assemblies

The Watch Dog circuit provides a 90 to 120 second power interrupt to the CR10X in the unlikely

event the program fails to execute as expected. It takes approximately 36 hours of no SDM I/O

port activity for the Watch dog to time out. After 36 hours the program will re-initialize to

SETUP mode which then requires manual operator intervention to restart the profiling program.

A belt-driven diamond screw and a V-roller suspension assembly help guide the sonde cable as it

moves in and out of the winch drum. This level wind mechanism is powered and synchronized

by the motor drive timing pulley. The design of the driving pulley, the speed reducing pulley,

and the reverse screw allows the cable carriage guide to move laterally at the correct speed to

properly lay the cable on the drum. See Section 3 for details.

Other components required for the system include a 12 volt battery, solar panels, and solar

charger/regulator. Optional equipment includes a depth sounder (or a fixed reference sonde) to

measure the water level, meteorological sensors, beacons, telemetry modules, antennas, compass,

and counter weights for stabilizing the platform.

YSI Environmental 669523 Rev B Page 1-3

Page 7

YSI Profiler System USER Manual

When connected the Winch and Controller assemblies perform the required steps to collect sonde

data from the water column. The sequence at which it collects data depends on how the software

program is set up. Information in the following sections provides step-by-step instructions that

take you through pre-deployment setup operations, some tips on deployment, and routine

maintenance of the Profiler system.

1.3 Getting Started

Core components of the YSI Profiler are assembled and tested at the factory. Some assembly will

be required after delivery depending on what you ordered and what arrangements you made when

the system was purchased. In addition, some components specific to your application may need

to be installed. Contact information for YSI and Endeco/YSI can be found in Appendix A.

Initial Inspection

Carefully unpack components and accessories of the system. Visually inspect all parts for

damage. Compare received parts with materials listed on the packing list included with your

system. If any parts or materials are missing or damaged, contact Endeco/YSI .

Sonde

The Profiler system requires the use of a YSI 6-Series Sonde with a depth sensor. Please refer to

the Operations Manual accompanying the sonde for configuration and calibration details. You

will be prompted to enter specific sonde information that can only be set in the sonde menu. To

communicate with the sonde you need a terminal emulator program on your PC such as YSI

EcoWatch™, Microsoft ® HyperTerminal, or the equivalent. You may also use the YSI 650

MDS handheld monitor. Specific instructions can be found in Section 3 of this manual. You will

be prompted by Profile Wizard to verify these sonde settings during pre-deployment

configuration.

Software

Three PC software programs are available with your system. In Section 2 there are specific

instructions for installing these programs on your PC. The first, YSI Profile Wizard provides you

with step-by-step screens that allow entry of key parameters that define your profiling routine.

These parameters are then used to configure the controlling software. If you have not done so,

take time to sketch out your vertical profiling objectives, including depths, parameters to be

measured, intervals, up/down or down/up preferences, and any other information you think

relevant. The second software program is LoggerNet™ (licensed from Campbell Scientific Inc.).

This program allows you to communicate with the CR10X data logger that resides on the Profiler

platform. It is used to download profile information that you defined in Profile Wizard.

LoggerNet™ comes with a separate manual. You should take time to review this manual prior to

setting up your system. The third software program is Profile Data Manager™. You use this

program for data analysis once data is collected. You will learn more about this program in

Section 7.

Hardware & Electronics

The major hardware/electronics components of the system are preassembled and tested at the

factory. Most of these components mount to the T-frame that you see in Figure 1-1. The T-frame

assembly is shipped to you, and must be mounted to the deck of the float. After factory testing

YSI Environmental 669523 Rev B Page 1-4

Page 8

YSI Profiler System USER Manual

some components are dismounted for safe shipping. These will need to be remounted. More

about hardware components are covered in Sections 3, 4 and the Appendix.

Once your software is installed, you are ready to proceed with a profile routine, equipment

staging, and pre-deployment checks. As always, the extra time you spend to verify that your

system is properly working prior to deployment, results in a successful working system after

deployment.

Examples of Deployed Profiler Systems

Below are examples of the most common Profiler deployments. In many setups meteorological

sensors are employed along with the sonde, especially in coastal applications. Anchoring

techniques vary with application. In Section 6, you will find information related to deploying a

Profiler system.

Figure 1-4 YSI Profiler with MET sensors on Pontoon Float

Figure 1-5 YSI Profiler at Fixed Station Figure 1-6 YSI Profiler on Buoy Float

YSI Environmental 669523 Rev B Page 1-5

Page 9

YSI Profiler System USER Manual

This Page Intentionally Left Blank

YSI Environmental 669523 Rev B Page 1-6

Page 10

YSI Profiler System USER Manual

Section 2

Profile Routine

2.1 Software Installation

The Floating Profiler System comes with three PC-based software programs. The minimum

required PC operating system is Windows 2000, however we recommend Windows XP. Install

all three programs on a single computer for optimal performance. The following instructions

assume that drive D: is a CD-ROM drive on the computer to which the software is being

installed. If your drive letter is different, substitute the appropriate CD-ROM drive letter into

the instructions below.

Profile Wizard

Load the installation disk into the CD-ROM drive. This activates the Profile Wizard

Installation Utility. Follow the prompts on the screen to complete the installation.

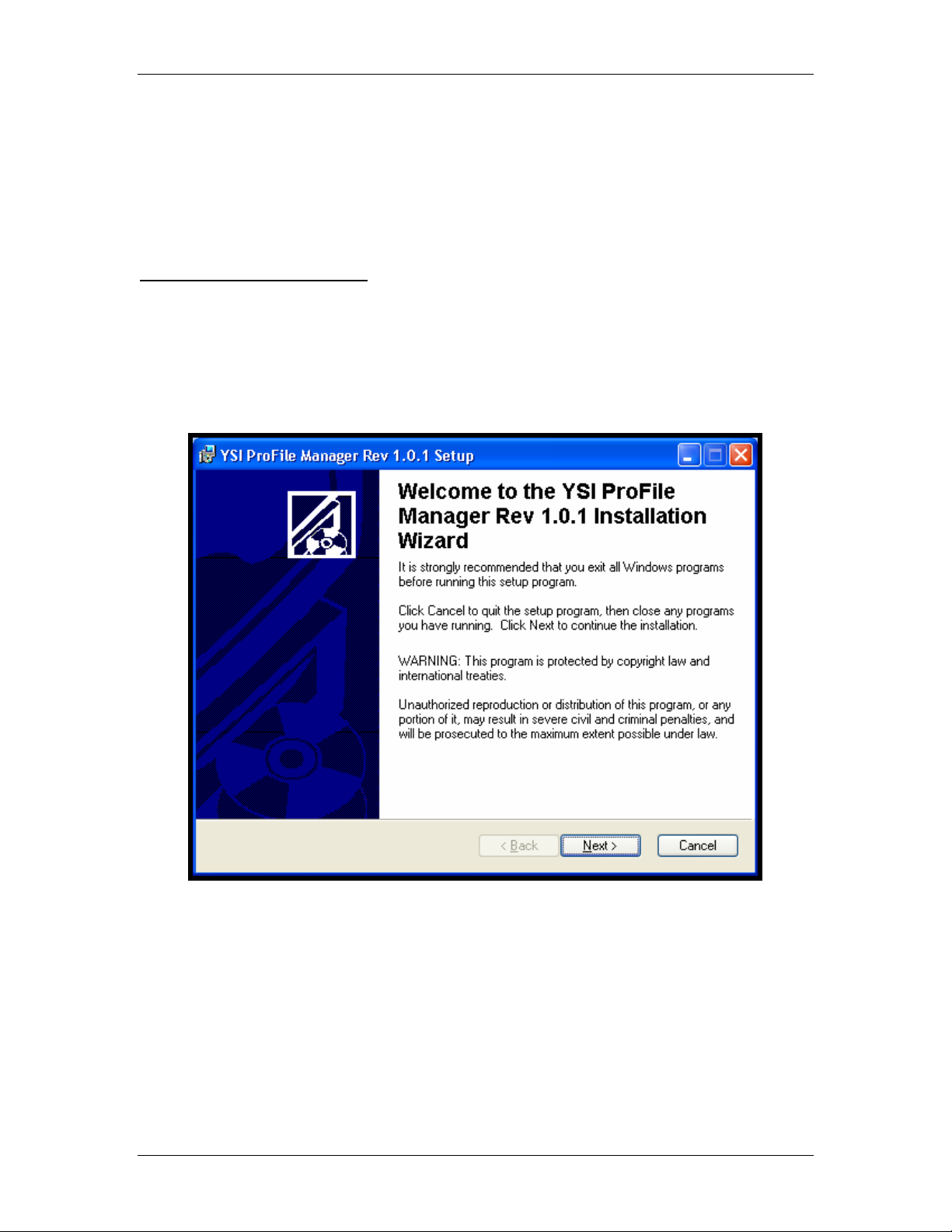

Figure 2-1 Opening Screen for Profile Wizard Installation

If the screen shown above does not appear, go to the Windows system menu. Select Start | Run.

Type D:\Setup.exe in the open field, and then press OK.

During installation items are added to your computer’s Start menu under Programs | YSI |

Profile Wizard that start the wizard. If the default directories are used, Profile Wizard

YSI Environmental 669523 Rev B Page 2-1

Page 11

YSI Profiler System USER Manual

executable files and help files are placed in the C:\Program Files\YSI\ Profile Wizard\

directory.

Once installed, Profile Wizard allows you to create a profiling routine. It contains simple

instructions (enhanced by graphics) that are easy to follow. If you enter inconsistent

information, pop-up messages provide messages to get you back on track. The end result is a

file that you name and save. This file contains specific profiling information that will be

downloaded to the CR10X data logger that resides on the floating platform.

LoggerNet™

Load the installation disk into the CD-ROM drive. This activates the LoggerNet™ Installation

Utility.

Figure 2-2 Opening Screen for LoggerNet™ Installation

Follow the prompts on the screen to complete the installation. You may need to access the

Internet to complete the installation. This activates the LoggerNet Installation Utility.

If the installation program does not start, then go to Windows system menu, select Start | Run.

Type D:\Disk1\Setup.exe in the open field or use the Browse button to access the CD-ROM

drive and select the setup executable file in Disk1 folder.

Items are added to your computer’s Start menu under Programs | LoggerNet that start the

Toolbar and other selected utilities. If the default directories are used, LoggerNet™ executable

files and help files are placed in the C:\ Program Files\ CampbellSci\ LoggerNet directory.

The directory C:\ CampbellSci\ LoggerNet is a working directory and contains the user

YSI Environmental 669523 Rev B Page 2-2

Page 12

YSI Profiler System USER Manual

programs and data files, along with files maintained by LoggerNet™ such as the binary data

cache and configuration files.

Once installed, LoggerNet™ allows you to communicate with the Campbell Scientific CR10X

Data Logger via RS-232 direct or wireless. Instructions from Profile Wizard will be downloaded

to the CR10X. Pre-deployment checks using LoggerNet™ may also be performed.

Profile Data Manager™

YSI Profile Data Manager is a third program that you may have purchased with your Profiler

system. Contact Endeco/YSI for pricing information if it was not included in your original

order.

Load the installation disk into the CD-ROM drive. This activates the Profile Wizard

Installation Utility. Follow the prompts on the screen to complete the installation.

Figure 2-3 Opening Screen for YSI Profile Data Manager Installation

If the install does not start, then go to Windows system menu, select Start | Run. Type

D:\Setup.exe in the open field or use the Browse button to access the CD-ROM drive and select

the setup executable file.

YSI Environmental 669523 Rev B Page 2-3

Page 13

YSI Profiler System USER Manual

Items are added to your computer’s Start menu under Programs | YSI | ProFile Manager that start

the program. If the default directories are used, Profile Data Manager executable files and help

files are placed in the C:\ Program Files\ YSI\ ProFile Manager Directory. YSI recommends a

separate subfolder for each deployment site.

Once installed, Profile Data Manager™ allows you to organize, report, and plot data from your

profiling routine. You will learn more about Profile Data Manager in later sections of this

manual.

Your PC-based programs should now be installed and ready to use. You will next create a file

that defines your profiling routine. In order to create this file using Profile Wizard, you will

need to verify that certain sonde parameters are set properly. Refer to instructions below that

describe how certain sonde parameters must be set. You may also refer to Section 3 in this

manual for more detail on these sonde settings.

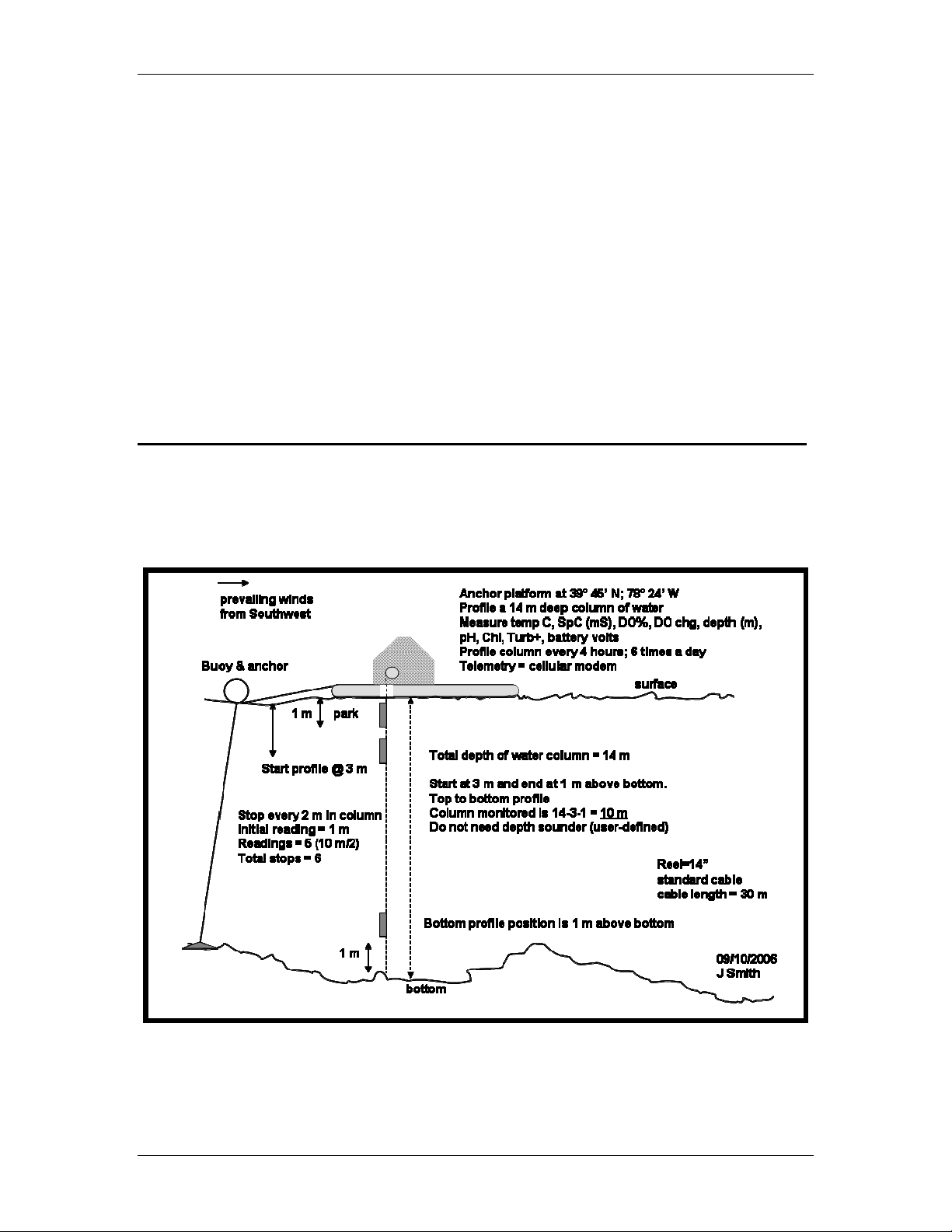

2.2 Using Profile Wizard to Create a Profiling Routine

You are now ready to create a file with information that describes your profiling routine. Make

certain your YSI sonde is configured properly, and calibrated for parameters you wish to

measure. It is recommended that you sketch out your profile plans. This will help you work

through Profile Wizard minimizing the need to backtrack and recalculate. See the example in

Figure 2-4.

Figure 2-4 Pre-Deployment Sketch; Information for Executing Profile Wizard

YSI Environmental 669523 Rev B Page 2-4

Page 14

YSI Profiler System USER Manual

SETTING UP A PROFILING ROUTINE

With basic configurations set in your sonde, use your notes on your profiling objectives to

proceed with Profile Wizard. There are several parts to setting up the file and each will be

discussed below. Following this description a step-by-step setup example will be described with

screen shots of each step of Profile Wizard. Below are some definitions of key terms used in the

setup. In addition to knowing the water depth at your profiling site, you also need to define the

column you want to profile and where you want to park the sonde between profile routines. You

will need to know where to START, where to END, and where to PARK. All must be defined in

units of meters relative to the surface of the water.

The PARK depth (required entry) can be anywhere in the water column. This is where the

sonde will reside when it is not actively profiling a water column.

The START position (required entry) is the first point in the water column where data is

collected. This can be close to the surface, near the bottom or anywhere in between. The Profile

Wizard program also requires an entry selection to profile from TOP TO BOTTOM or

BOTTOM TO TOP.

The END position (required entry) is the last step the Profiler can take. If the sonde goes any

further, it may come out of the water or hit bottom. The END step is the only step that will vary

in size from the other steps and is typically less than a full step size.

The PROFILE DURATION is the time it takes to go from PARK to START, perform all

measurements at each interval step, and then return to PARK.

Park position is where the sonde typically spends most of its time. For example, a profile may

take 45 minutes to complete. So if you configure your system to profile every four (4) hours

that would be six (6) times a day. If the profile takes 45 minutes, then the sonde resides in park

position (idle) for 3 hours and 15 minutes of each profile. So the sonde is idle about 80% of any

given day in this example.

If Profile Wizard is not open, do that next. Either double click on the Profile Wizard icon on

your Desktop; or click on Start | Open | and then Browse to search for YSI Profile Wizard.exe.

The opening screen (welcome screen) is shown below.

Note that there are two options in the welcome screen - Create new station and Modify existing

station. Since you are creating a new station in this example, verify the tick is in the Create box.

If you have a profiling routine defined by name, you may elect to open an existing file to modify

it by using the ‘Modify existing station’ option.

YSI Environmental 669523 Rev B Page 2-5

Page 15

YSI Profiler System USER Manual

Click on New… to view the Save As screen, and then type in a filename for your site. We

recommend creating a new folder for each site configuration. In this example assume that this is

Site 12 on Clark Reservoir. Click the ‘create new folder’ icon in upper right hand corner and

rename the folder ‘Site 12’. Open the new ‘Site 12’ folder and type in ‘CLK Res Site12’ for the

filename … click Save. The “.pfw” file will save in C:\ Program Files\ YSI\ Profile Wizard\

Shared\Site 12\.

YSI Environmental 669523 Rev B Page 2-6

Page 16

YSI Profiler System USER Manual

Once you click on Save the welcome screen reappears, this time with the Next … button active

to proceed to the next step in Profile Wizard. Note also that Units are Metric, which at this time

is the only option. English units (feet) can not be used in your calculations and setup. (One

meter is approximately 3.281 feet). Finally, take note that the directory path and filename you

assigned is shown near the bottom of the screen

Now Click on N

ext > to proceed to one of five ‘General Information Steps’. This is where you

will enter critical information to define your profiling routine. Have your notes on hand before

proceeding.

Information (Steps 1-5)

In the first Step (General Information), you must indicate if you will use a depth sounder or

fixed reference sonde in your operation. In this example assume there is no depth sounder

sensor or fixed sonde in the system. Below are examples of applications where you may choose

using a depth sounder or fixed sonde, including its advantages in those specific applications.

You must also indicate in Step 1 if you have meteorological (MET) sensors or a compass in your

system. If there were a solar radiation sensor, a constant will be provided by YSI. In this

example, assume there are no MET sensors in use.

YSI Environmental 669523 Rev B Page 2-7

Page 17

YSI Profiler System USER Manual

There are three bottom depth options: 1) user-defined; 2) using a depth sounder sensor; and 3)

using a fixed reference sonde. The descriptions and the table below should help you choose the

appropriate setup for your application.

User defined

applications are typically employed when the winch and electronics can be

mounted to a fixed structure. The water level should not change significantly in depth and

extreme bottom monitoring is not important.

Depth sounder

applications are often used to track the bottom of a body of water and adjust the

program to get within a specified distance from the bottom.

Fixed reference sonde

applications are used to track water level and adjust the program to a

specified distance from the bottom, but it is always used with fixed mount winch and electronics.

Type Mounted to Water dynamics Monitoring…

User defined

Pier

Bridge

Slow change in water level Near surface area only

Pilling

Float

Depth sounder

Pontoon

Float

Variable water depth Track bottom

Buoy

Fixed reference

sonde

Pier

Bridge

Pilling

Variable water depth Track water level

YSI Environmental 669523 Rev B Page 2-8

Page 18

YSI Profiler System USER Manual

In Step 2 (Winch Information) you must enter the reel size, cable type and length. The Reel

diameter of the Winch Assembly is 14 inch (35.56 cm) in this system and the Cable type is

Standard. These two questions have default answers at this time. Future options are planned.

The Cable length in this example is 30 meters. You order the cable length that best fits your

application. Typically there is at least one extra meter of cable shipped to allow some amount of

cable to remain on the reel at all times for proper winding. If you order 30 or 50 meter cable,

you will receive at least 33 meters or 53 meters, respectively.

In Step 3 (Site Information) enter your choice of profiling direction; ‘Bottom to Top’ or ‘Top to

Bottom’ profiling. Refer to your notes and you will see that ‘Top to Bottom’ was declared as

the Profiling direction in the example application.

The maximum depth of water in the profiling area is 14 meters. The predetermined park depth

was noted at one (1) meter below the surface. Type in these numbers and proceed by clicking on

N

ext >.

YSI Environmental 669523 Rev B Page 2-9

Page 19

YSI Profiler System USER Manual

Step 4 (Study Information), shown below, deals with defining the actual column length of water

to step through and the time interval at which you intend to monitor.

Since the sonde starts at three (3) meters below the surface and proceeds through five-plus steps,

stopping no further than one (1) meter above the bottom, the actual monitored column of water

is ten (10) meters, start at 3 meters and end at 13 meters below the surface. You must enter the

Start and End depths (relative to the surface

) in the appropriate boxes (see below).

In addition, you must enter the profiling step interval. In this example two (2) meter steps are

used, meaning the cable will complete one set of measurements, then pay out two meters, stop

and repeat these measurements. This will be repeated until it reaches the bottom of the profiling

column (13 meters below the surface). The last step is often less than the defined interval if the

profiling depth is not evenly divisible by the number of steps. In this case 10 meters divided by

2 meter intervals work out to be a whole number.

The Profiles per day are 6, indicating that a profiling routine will be initiated every four (4)

hours beginning with local time of 00:00:00 (midnight). Enter six (6) into the appropriate box.

YSI Environmental 669523 Rev B Page 2-10

Page 20

YSI Profiler System USER Manual

At this point you are ready to move to the next screen to verify specific information in the sonde

menu and then to assign sonde report parameters. However, before moving to these last two

screens, make note of how profile setup screens would differ if a Depth Sounder or a Fixed

Reference Sonde were used to determine sonde vertical position relative to the top or bottom of

the water column. After these examples, Profile Wizard setup screens will be displayed for the

original example application.

Depth Sounder Option

The General Information Step 1 screen would appear as follows, marking the Depth Sounder

with a click of the mouse. Step 2 and Step 3 related to cable/reel and site information,

respectively would remain unchanged. Step 4 takes on a very different look since the final depth

reading is referenced from the bottom. See figures below.

Fixed Reference Sonde Option

The General Information Step 1 screen would appear as follows, marking the Depth Sounder

with a click of the mouse. Step 2 and Step 3 related to cable/reel and site information,

respectively would remain unchanged. Step 4 takes on a very different look since the final depth

reading is referenced from the bottom.

On the next two pages see the differences in setup screens when using the depth tracking options

listed immediately above.

YSI Environmental 669523 Rev B Page 2-11

Page 21

YSI Profiler System USER Manual

NOTE:

Step 2 (Cable/Reel Information) and Step 3 (Site Information) screens would appear the

same as above in the User defined example. Steps 1 and 4 appear differently.

YSI Environmental 669523 Rev B Page 2-12

Page 22

YSI Profiler System USER Manual

NOTE:

Steps 2 (Cable/Reel Information) and Step 4 (Profile Information) screens would appear

the same as above in the Depth Sounder example. Steps 1 and 3 appear differently.

YSI Environmental 669523 Rev B Page 2-13

Page 23

YSI Profiler System USER Manual

Although infrequently used in this way the Fixed Sonde Reference may be positioned on the

bottom of the water column. In this case the Fixed Reference sonde distance is entered as zero

(0). If mounted above the bottom, you will need to determine a true measured distance from

bottom to the “fixed point”. This distance can be determined by lowering the sonde to the

bottom, record the instant depth reading, and then move the sonde to the desired fixed (or

attached) location. You then subtract the two values and enter the result in location (c) on the

screen.

IMPORTANT:

The Fixed Reference Sonde must be set to have only two Report parameters enabled:

Temp in C, and Depth in Meters. They must appear in the order shown and in the

units of measurement shown. Also, do not set date or time.

After completing the above steps for User defined depth, Depth sounder or Fixed Reference

Sonde, click on Next > and you will see a screen that asks you to verify that specific information

in the sonde configuration is entered as stated.

The boxes are not ‘checked’ when the screen appears. You must verify that these sonde

configurations have been set before the Next button becomes active. That is, you can not

proceed until you click on each box. Once you confirm the sonde settings, click N

ext > and

proceed to the final step in defining your profiling routine.

YSI Environmental 669523 Rev B Page 2-14

Page 24

YSI Profiler System USER Manual

In Step 5 (Sonde parameters) you must record in the box on the right all parameters you have

chosen to monitor. You probably have jotted these down in notes. If not, return to the sonde

menu and check the Report setup to make sure you have listed all parameters, in the same order

as in Step 5 of the setup wizard.. Depth in meters is a given, and in fact, is listed by default in

the Sonde report output column. You now click on each parameter and then click Add >> to add

it to the list on the right. You may do this one at a time, or you may press and hold the Control

key (Ctrl) on your keyboard and click on the appropriate parameters in the list on the left. The

Add button becomes active. Click Add >> and the list on the right appears as shown below for

this example. You may now need to rearrange the order of this list to match the sonde Report

setup.

It is essential that the list of parameters you create matches the parameters set in your sonde

(exact parameter, including units chosen and the order listed). For example, SpCond (mS/cm) is

not the same as SpCond (uS/cm) this does make a difference when the CR10X data logger and

sonde communicate during profiling routines. This makes a difference later on during post data

processing

The screen below shows an example list of parameters. There are nine (9) parameters total.

Depth in meters is a requirement. In Profile Wizard there is a maximum of twelve (12)

parameters that you may list, counting Depth in meters as one of the twelve.

IMPORTANT:

The order of parameters listed must match the Report setup in the sonde.

In the following figure Depth (meters) was moved so that it occurs after DO Chrg but before pH.

Parameters may be moved up and down the list by left clicking and dragging up or down.

YSI Environmental 669523 Rev B Page 2-15

Page 25

YSI Profiler System USER Manual

The final screen summarizes all information that you entered. Check this carefully, make

changes if necessary, and then click on Finish to complete the setup of your profile. Note the

parameter ID numbers in brackets just to the left of the parameters; this information will be

imbedded in the data file as Array 88.

YSI Environmental 669523 Rev B Page 2-16

Page 26

YSI Profiler System USER Manual

You should at this time also print the ‘*.rpt’ and ‘*.pfw’ files for your hard copy records. See

Appendix B for examples.

2.3 How the CR10X Executes the Profile Routine

Using Profile Wizard you have now created a profile routine file. In Section 3 you will learn to

send this file to the CR10X data logger using LoggerNet™ software. Once in the CR10X this

program controls the movement of the winch, sonde data collection, and other actions. Prior to

moving to Pre-Deployment checks, and in order to better understand how the ‘controller’

software executes the profile routine, consider the description and example below.

Since a depth sounder was not used in the example above, it will be considered part of the

routine below. In coastal applications, the tide can raise or lower the water level two or more

meters at times. The importance of knowing the total depth of the water column at all times is

essential. In tidal applications the use of a depth sounder is necessary if you intend to monitor

close to the bottom or to the surface.

EXAMPLE & DESCRIPTION OF PROFILE ROUTINE WITH DEPTH SOUNDER

For better understanding of the steps in a profiling routine, consider a new example where the

mean water depth is ten (10) meters and the daily tide is about two (2) meters. Assume the

system has a depth sounder and the Profile Wizard setup has been programmed accordingly.

The use of a depth sounder enables the system to track the overall water depth before the start of

a profile and again during the last 20% of the water column that is being profiled.

Profile Parameters

Profiles per day 4

Step Size 1 m

PARK (relative to surface) 5 m

START (relative to surface) 1 m

END (relative to bottom) 1 m

Top to Bottom Profile

In terms of ‘profile logic’, the CR10X goes through the following steps to ensure that depth and

parameters are measured as intended by the profile program. This is done through RS-232

communications using a serial I/O interface that connects to the CR10X to various sensors and

accessories.

Every six (6) hours starting at 00:00:00 (midnight) the program requests a PARAMeter check

from the sonde. This information is collected to insure that the sonde is operational and the

sonde parameters are unchanged. Once this information is received from the sonde and verified

as correct, the program requests a sonde water depth. The sonde should be in Park position five

(5) meters (+/- 0.2 m) below the surface. The information is collected, and then the overall

depth is measured by the depth sounder. The overall water depth is collected and recorded as a

reference to insure that the sonde will never hit the bottom during the profile.

The program next decides if the PARK to START move distance is greater than two (2) meters.

It turns the motor on to move up or down while monitoring the sonde depth to see how close it is

to the one meter depth (START). In this example the sonde was parked at 5 meters and was

moving up 4 meters to the start position. As a result the “move to” distance is 4 meters. If the

“move to” distance is less than two (2) meters, it calculates the time the motor needs to be

YSI Environmental 669523 Rev B Page 2-17

Page 27

YSI Profiler System USER Manual

powered to travel the required distance. It then powers the motor for the calculated time and

checks again to see if the sonde depth is within the +/- 0.2 meter tolerance. If not, the motor is

powered again until the sonde reaches the specified depth. The rate of movement is 0.1

meter/second, so a “step” may take a couple of minutes to reach its target.

Figure 2-5 Block Diagram: Sonde Control with Depth Sounder

When the sonde reports it is within the START depth position of one (1) meter +/- the tolerance,

it stops to stabilize for 60 seconds and then warms up for the specified DO warm-up time.

Depending on the sonde default DO warm-up time values are set at 40 or 60 seconds. After

about 100-120 seconds have expired, the CR10X sends an SDI-12 command directly to the

sonde to start parameter measurement. When completed, the CR10X stores the sample data in a

designated memory location. Therefore, all data in this memory array are SDI-12 measurements

taken directly from the sonde to the CR10X data logger memory. This array 105 includes the

Julian day, time stamp and sonde data. The time stamp indicates the end (not the beginning) of

the sample collection.

Once the data is stored in CR10X memory, a command turns the motor on for a calculated

period of time. This duration is the time it takes to move the sonde to the next step location (+/the specified tolerance). The sequence described above repeats until the END step is completed.

While profiling up or down the program keeps track of the sonde depth. When it reaches

approximately 80% of the overall water depth, the system checks the depth sounder again and

determines the distance to the bottom. From this point on the program continually checks depth

to insure it can do a full one meter step. Eventually, the step size of one meter is no longer

possible without hitting the bottom. At this point a calculation by the program determines a

partial step (typically 0.3 to 0.8 meters). When this step is completed, the CR10X issues the

command for the sonde to return to PARK position, where it waits for the next profile time.

Since this example location has a tidal influence, the overall depth will change from profile to

profile. The distance and/or steps may be more or less than a previous profile. Because this

sequence started at the surface, all of the steps are referenced from the surface down. The

opposite would be the case when starting at the bottom for a ‘bottom to top’ profile.

YSI Environmental 669523 Rev B Page 2-18

Page 28

YSI Profiler System USER Manual

The data collected into the CR10X memory is then uploaded by LoggerNet™ either as forced

upload or by the LoggerNet™ schedule. The data is archived in ASCII text, comma delimited

format. Profile Data Manager™ software can then be used to view or FTP the data.

Alternatively, you can import the ASCII text data file into a spreadsheet program like Microsoft

Excel® as comma separated values. See Figure 2-6 for example data. Using Excel’s filters you

can then display particular array numbers for quick data analysis. See Figure 2-7 for an example

with Array Number 60 (hourly MET reading). Refer to Appendix G for Data File Array

Descriptions.

99 2006 220 1000 10 5407 0 99 0

88 7 11 124 1 6 12 14 15 96 22 …

6 1 2 7.3 3 7.4 7.86 9 0

105 2006 220 1002 43.5 25.32 45.21 29.24 88.8 6.18 44.1

105 2006 220 1004 35.38 25.43 45.11 29.17 89.9 6.25 43.1

105 2006 220 1006 24 25.63 45.06 29.12 92.1 6.38 43.1

105 2006 220 1008 14.5 25.78 45.05 29.12 93.3 6.45 42

…

…

…

…

99 2006 220 1009 6.125 5407 0 99 0

99 2006 220 1030 9.88 5407 0 99 0

88 711691 61214159622…

6 1 2 7.1 3 7.1 7.56 9 0

105 2006 220 1032 36.88 25.34 45.18 29.22 90 6.26 43.1

105 2006 220 1034 28.63 25.53 45.08 29.15 90.1 6.25 44.1

105 2006 220 1036 27.75 25.76 45.05 29.11 92.5 6.39 43.1

105 2006 220 1038 15.38 25.83 45.05 29.11 93.3 6.44 43.1

99 2006 220 1039 17.38 5407 0 99 0

160 2006 220 1058 29.25 25.45 45.11 29.16 93.3 6.48 44.1

…

…

…

…

…

…

60 2006 220 1100 25.58 54.71 744 1016 5.668 357.7 0

Figure 2-6 Example data file imported into Microsoft Excel®

60 2006 220 1000 24.87 61.16 602.4 1016 5.542 0.68 0 13.76 0 1

60 2006 220 1100 25.58 54.71 744 1016 5.668 357.7 0 13.46 0 1

60 2006 220 1200 26.12 49.13 817 1016 4.021 356.8 0 13.45 0 1

60 2006 220 1300 26.73 44.6 760 1016 4.254 332.2 0 13.57 0 1

Figure 2-7 Example data file filtered for hourly MET data (Array 60)

YSI Environmental 669523 Rev B Page 2-19

Page 29

YSI Profiler System USER Manual

This Page Intentionally Left Blank

YSI Environmental 669523 Rev B Page 2-20

Page 30

YSI Profiler System USER Manual

Equipment Staging – Sonde & Platform

3.1 Introduction

In this section and the following section you will configure your sonde to insure proper

operation with the CR10X data logger, assemble components and connect cables (as required),

and manually verify operation of the Winch Assembly. In Section 4 you will establish

communication between LoggerNet™ and the CR10X and download your Profile Wizard file

with the profiling instructions.

You should proceed through the above mentioned steps in a stable environment if possible. If

you configure and test your profiling system in this manner, you are less likely to make an error

that would cost you valuable time once in the field.

3.2 Setting Sonde Parameters

The Campbell Scientific CR10X data logger program relies heavily on information obtained

from the YSI sonde both prior to the start of a profile, and during a profile sequence. Therefore,

it is imperative that you configure the YSI sonde correctly for successful winch operation. In

this section you will learn how to check for key settings in the sonde. These settings apply

primarily to proper configuration of the Profiler system. If required consult your YSI 6-series

sonde operations manual for more detailed information.

WARNING!

Do not disconnect the sonde from Profiler while it is actively running a profile sequence.

Wait for it to finish, or if necessary, disconnect power to Profiler.

You can access the sonde menu using any terminal emulator program, or if available the YSI

650 MDS handheld monitor. One such terminal emulator program is YSI EcoWatch™.

Common to most Windows-based computers is Microsoft ® HyperTerminal. If you use the YSI

650 make certain that you ‘escape’ all of the way out of the Sonde menu before

disconnecting the YSI 650 from the sonde.

A YSI sonde field cable is needed for connection to the YSI 650 MDS. A RS-232 cable with

MS-8 connector will be needed to connect from your PC COM port to the YSI sonde (YSI Part #

6067). An adapter may be needed, and in some cases a power supply if the sonde is not powered

by batteries. Refer to your 6-series sonde manual for cable connection details.

In the example below, a terminal emulator connection is described. Once you establish a

connection with the sonde you should see the # sign. You may type ‘ver’ <ENTER> to display

the version number of the sonde software; and in a similar manner, Esc to # and type ‘reset’

<ENTER> to display more detailed information about the sonde model and version number.

Refer to the displays below. Your sonde version number must be 2.25 or higher

.

YSI Environmental 669523 Rev B Page 3-1

Page 31

YSI Profiler System USER Manual

# ver

2.25

# reset

OK

YSI Water Quality Systems Model 6600

Version 2.25 07-01-2004 15:00:58

Copyright (c) 1992-2003 YSI Incorporated.

All rights reserved.

At the same # prompt type

Main menu.

-----------------Main-----------------1-Run 5-System

2-Calibrate 6-Report

3-File 7-Sensor

4-Status 8-Advanced

‘MENU’ <ENTER> to access the sonde menu. You should now see the

To navigate the menus, type ‘0’ or “Esc” to move back to previous levels, or type the number of

the submenu you desire to enter. In this section you will want to check, and possibly change,

settings in the Advanced, Sensor, Report, System and Status submenus. The displays below lead

you through the exercise of accessing each of these menus to check settings. Relevant

comments along the way should help you prepare your sonde for connection to Profiler.

First, check Sensor by typing in ‘7’. Remember that you may need up to twelve (12) sensors in

your setup. This depends on your sonde model and your profile. Sensors that are enabled have

an asterisk to their left. Verify that these are the measurement sensors that you need for your

profile routine. To enable or disable a sensor, type the character to the left of the name (1-9, AJ), making certain that an asterisk appears if you want that sensor enabled.

Under the sensor menu Time may be enabled

. However, in the Report menu, time and date must

be disabled to work with YSI Profiler. See more information below. Note also that the Pressure

sensor is present and enabled. This is the sensor that is used in measuring depth. A depth sensor

is required in the YSI Profiler application. Now type ‘0’ to return to the Main menu.

-----------------Main-----------------1-Run 5-System

2-Calibrate 6-Report

3-File 7-Sensor

4-Status 8-Advanced

Next, select 6-Report to view the parameters, including the units of measurement that you have

chosen. Make note of the three highlighted parameters. In the setup of the profiling routine,

both date and time must be disabled

. In addition, Depth in meters must be enabled. Profiler

software does not calculate properly when depth is set in feet. Double-check to make certain

that you have set these parameters as required. Now take a look at other parameters that are

enabled to be reported. Are these the parameters that you have chosen for your profiling

routine? If not, now is the time to change them. There is a maximum of twelve (12) parameters

for display and depth must be one of them. Another useful parameter to report is Battery volts.

YSI Environmental 669523 Rev B Page 3-2

Page 32

YSI Profiler System USER Manual

Since you depend on power to the sonde for proper calibration and measurements in the field,

we recommend this in the report choices.

-------------Report setup-------------1-( )Date B-(*)DOchrg

2-( )Time hh:mm:ss C-( )Press psig

3-(*)Temp C D-(*)Depth meters

4-(*)SpCond mS/cm E-(*)pH

5-(*)Cond mS/cm F-(*)pH mV

6-( )Resist G-(*)Turbid+ NTU

7-( )TDS H-(*)Chl ug/L

8-(*)Sal ppt I-(*)Fluor %FS

9-( )DOsat % J-(*)Battery volts

A-(*)DO mg/L

Next, type ‘0’ to return to the Main menu, and then select 5-System to check on the SDI-12

address. The sonde SDI-12 address must be set to 0 in order to communicate with the Profiler.

-----------------Main-----------------1-Run 5-System

2-Calibrate 6-Report

3-File 7-Sensor

4-Status 8-Advanced

-------------System setup-------------1-Date & time

2-Comm setup

3-Page length=25

4-Instrument ID=99F0932 AA

5-Circuit board SN:0001066E

6-GLP filename=0001066E

7-SDI-12 address=0

8-Language:English

While you are in System menu, check 2-Comm setup to make certain that the parameters Auto

baud and 9600 baud rate are enabled. Once you verify this, type ‘0’ two times to back out to the

Main menu.

--------------Comm setup--------------1-(*)Auto baud 5-( )2400 baud

2-( )300 baud 6-( )4800 baud

3-( )600 baud 7-(*)9600 baud

4-( )1200 baud 8-( )19200 baud

YSI Environmental 669523 Rev B Page 3-3

Page 33

YSI Profiler System USER Manual

-----------------Main-----------------1-Run 5-System

2-Calibrate 6-Report

3-File 7-Sensor

4-Status 8-Advanced

Next, select 4-Status to make certain that the sonde is not set for logging. Item number seven

should read Logging: Inactive

. Check your sonde manual for details on turning off the logging

activity, or see below during the final sonde menu checks. Normally the active logging

parameter would not be set.

----------------Status----------------1-Version:2.25

2-Date=11/17/05

3-Time=16:24:36

4-Bat volts:12.3

5-Bat life 20.0 days

6-Free bytes:295424

7-Logging:Inactive

Note that battery voltage for the sonde is 12.3 volts and has an expected battery life of more than 20 days

based on parameters that are set. Although you see Date and Time in this screen, this does not necessarily

mean that Report setup has date and time enabled. You confirmed that these parameters were turned off

when you displayed the Report setup menu above.

Next, type 0 to return to Main menu.

-----------------Main-----------------1-Run 5-System

2-Calibrate 6-Report

3-File 7-Sensor

4-Status 8-Advanced

Type 8-Advanced, to view a submenu that takes you into a variety of settings from calibration

constants to timing of activities. In addition to checking some of the timing settings, it is

important to verify that the Auto sleep function is enabled. This is one of the requirements of

monitoring in the Profiler routine.

---------------Advanced---------------1-Cal constants

2-Setup

3-Sensor

4-Data filter

YSI Environmental 669523 Rev B Page 3-4

Page 34

YSI Profiler System USER Manual

------------Advanced setup------------1-(*)VT100 emulation

2-( )Power up to Menu

3-( )Power up to Run

4-( )Comma radix

5-(*)Auto sleep RS232

6-(*)Auto sleep SDI12

7-( )Multi SDI12

8-( )Full SDI12

Note that both RS232 and SDI12 Auto sleep functions are enabled. If not, change these settings

by typing the number of the function to toggle on or off the asterisk. Next, return to the

Advanced menu and then type 3-Sensor.

---------------Advanced---------------1-Cal constants

2-Setup

3-Sensor

4-Data filter

Note in the Advanced sensor screen below that DO warm up time is set to 60 seconds, which is

the appropriate setting for the profiling routine. Since there are sensors with wiping mechanisms

in this sonde, keep in mind that the SDI12-M/wipe=1 means that the sensor will wipe before

each reading (turbidity or chlorophyll). If you set this number to two (2), a wipe will occur

before every other measurement. Choose the number appropriate for your water conditions.

------------Advanced sensor-----------1-TDS constant=0.65

2-Latitude=40

3-Altitude Ft=0

4-DO temp co %/C=1.1

5-DO warm up sec=60

6-( )Wait for DO

7-Wipes=1

8-Wipe interval=5

9-SDI12-M/wipe=1

A-Turb-6136 temp co %/C=0.6

B-(*)Turb-6136 spike filter

C-Chl temp co %/C=0

Next, make a quick check of other Advanced settings, specifically Data filter Cal and constants.

Type ‘0’ to return to Advanced.

---------------Advanced---------------1-Cal constants

2-Setup

3-Sensor

4-Data filter

YSI Environmental 669523 Rev B Page 3-5

Page 35

YSI Profiler System USER Manual

Select 4-Data filter, then select 3-Time constant… The time constants should resemble those

shown below for Turbidity and Chlorophyll sensors at 12 seconds, while Other defaults to 4

seconds.

-----------Data filter setup----------1-(*)Enabled

2-( )Wait for filter

3-Time constant...

4-Threshold...

-------------Time constant------------1-Turbid=12

2-Chl=12

3-Other=4

Return to Data filter setup and select 4-Threshold…

-----------Data filter setup----------1-(*)Enabled

2-( )Wait for filter

3-Time constant...

4-Threshold...

---------------Threshold--------------1-Turbid=0.01

2-Chl=1

3-Other=0.001

The above readings are typical and appropriate for the profiling routine. Please see the sonde

manual for additional information on this and other advanced settings. Next, type ‘0’ two times

to return to the Advanced menu.

---------------Advanced---------------1-Cal constants

2-Setup

3-Sensor

4-Data filter

Cal constants are shown in the next screen. For the sensors enabled the constants should appear

similar in value to those seen in this screen.

YSI Environmental 669523 Rev B Page 3-6

Page 36

YSI Profiler System USER Manual

-------------Cal constants------------1-Cond:4.99584

2-DO gain:1.01064

3-Pressure offset PSI:0.011

4-pH offset (pH-7)*K:19.7162

5-pH gain (pH-7)*K/mV:-5.12062

6-Turb-6136 Offset:7.01061

7-Turb-6136 A1:122.378

8-Turb-6136 M1:125.241

9-Turb-6136 A2:244.757

A-Turb-6136 M2:250.482

B-Chl Offset:-1.88556

C-Chl A1:100

D-Chl M1:69.9475

E-Chl A2:200

F-Chl M2:139.895

G-Fluor Offset:-0.44621

Type ‘0’ to back out to the Main menu.

-----------------Main-----------------1-Run 5-System

2-Calibrate 6-Report

3-File 7-Sensor

4-Status 8-Advanced

Now type 1-Run to view the Run setup options and then type 1-Discrete sample.

---------------Run setup--------------1-Discrete sample

2-Unattended sample

When you type 1-Start sampling you will now be able to view data from sonde sensor

measurements. Evaluate your data based on where the sonde resides at this time (air, bucket,

environmental water). Regardless of readings you can confirm that all sensors are working and

the sonde is actively measuring parameters in the correct units.

------------Discrete sample-----------1-Start sampling

2-Sample interval=0.5

3-File=

4-Site=

5-Open a file

Several lines of results are shown in the screen below.

YSI Environmental 669523 Rev B Page 3-7

Page 37

YSI Profiler System USER Manual

===============================================================

Temp SpCond Cond Sal DO DOchrg Depth pH pH Turbid+ Chl Fluor Battery

C mS/cm mS/cm ppt mg/L meters mV NTU ug/L %FS volts

----------------------------------------------------------------------------------------*** 1-LOG last sample 2-LOG ON/OFF, 3-Clean optics ***

Stabilizing:4 3 2 1

16.93 0.001 0.001 0.00 8.35 53.2 0.000 1.77 300.2 428.2 0.2 0.0 12.3

16.92 0.001 0.001 0.00 8.35 53.1 0.000 2.04 284.9 428.2 0.2 0.0 12.3

16.91 0.001 0.001 0.00 8.36 53.2 0.000 2.19 276.4 428.2 0.2 0.0 12.3

16.91 0.001 0.001 0.00 8.36 53.1 0.000 2.36 266.9 428.1 0.2 0.0 12.3

16.91 0.001 0.001 0.00 8.36 53.2 0.000 2.47 260.7 428.1 0.2 0.0 12.3

16.91 0.001 0.001 0.00 8.36 53.2 0.000 2.56 255.6 428.1 0.2 0.0 12.3

Type 2-Stop sampling to discontinue sampling data, then type ‘0’ several times until you return

to Main menu, and then finally to the # sign. You have now exited the sonde menu and you may

now disconnect the sonde from the cable to the PC.

-----------------Main-----------------1-Run 5-System

2-Calibrate 6-Report

3-File 7-Sensor

4-Status 8-Advanced

# xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx

You have now completed checking the YSI sonde for proper configuration. In addition, you have

become generally familiar with all submenus in the sonde Main menu. If you have yet to

calibrate the sonde, refer to your sonde user manual and use the 2-Calibrate function to enter the

submenus to complete this operation.

Once calibration setup is complete ensure

the sonde has new batteries installed and the

sensor guard has the provided standard

weight attached. The top of the weight,

inside the sensor guard, should be painted

black to ensure proper operation of the

optical sensors. Refer to Figure 3.1.

Figure 3-1 Sonde Sensor Guard with

standard weight

NOTE:

Sonde must be equipped with provided sonde weight for the YSI Profile system to work

properly.

YSI Environmental 669523 Rev B Page 3-8

Page 38

YSI Profiler System USER Manual

3.3 Connecting and Checking Profiler Components

The YSI Profiler Platform block diagram in Figure 3-1 depicts the major components in the

system. Except for the PC, all components are located on the floating platform. In gray boxes

are the Controller components, in addition to communication and power devices. These are all

located within the waterproof PVC cylindrical housing.

Figure 3-2 Block Diagram – YSI Profiler System

Now refer to the figures on the next several pages. The Winch Assembly, including drive motor,

is mounted on the bow side of the T-frame, while the Controller Assembly is mounted on the

stern side of the T-frame (See Figures 3-2, 3-3, 3-4). The battery and solar regulator are housed

in a separate waterproof compartment on the stern side of the float deck, just below the

Controller (Figure 3-6). Meteorological sensors, antenna, beacons and miscellaneous devices

may be mounted elsewhere on the platform, as determined by the configuration that you ordered.

The solar panels are mounted on both bow and stern faces of the two covers that protect all of

the assemblies (See Figure 3-9).

See Figure 3-2 below for a photograph of the floating platform during final assembling and predeployment testing.

YSI Environmental 669523 Rev B Page 3-9

Page 39

YSI Profiler System USER Manual

Figure 3-3 YSI Profiler Platform inside during Pre-Deployment Checkout

Figure 3-4 Winch Assembly mounted to T-frame; Winch motor to right of drum

The sonde cable from the controller connects to the drum on the left side in Figure 3-3 (not

visible in photo); while the winch motor/gear assembly is mounted to the right side. The orange

sonde cable routes through the opening in the deck. A diamond screw helps guide cable to wind

evenly on the drum. The cable passes through a V-roller suspension assembly that helps to

prevent possible snags or tangles as the sonde pays out or reels in during profiling.

YSI Environmental 669523 Rev B Page 3-10

Page 40

YSI Profiler System USER Manual

Figure 3-5 PVC Electronics Housing, correct orientation

The mounting orientation of the pressure case is critical when an internal compass is installed.

Figure 3-4 shows the correct orientation with the magnetic switch located at 11 O’Clock when

looking at the faceplate. Another easy orientation check is to make sure the antenna connector

(see white cap in Figure 3-4) is the closest connector to the T-Frame back plate. A secondary

benefit to this orientation is that the internal modem lights (if installed) will be perpendicular to

the deck for easy viewing (back side of housing).

Figure 3-6 PVC Electronic Housing; Port Locations

1

The T-frame Assembly should arrive largely assembled. You and/or your YSI representative

will need to mount the T-frame to the float deck. The Winch Assembly faces the bow of the

1

Port J6 in Fig 3-5. A second sonde connector may appear on this housing if a fixed reference sonde

(attached sonde) is used to establish depth relative to the bottom of the water column.

YSI Environmental 669523 Rev B Page 3-11

Page 41

YSI Profiler System USER Manual

float and the motor power cable connects to J2 of the Controller Assembly. The PVC cylindrical

housing (Controller Assembly) and the battery enclosure face the stern of the float. Depending

on your configuration, there may be several components that were disconnected and packaged

for safe shipping. You will need to make these connections to complete the assembly, however,

do not connect power to the system until you read the procedure in the next subsection below.

CONNECT POWER TO SYSTEM

Insure that the battery enclosure is secured to the T-frame and then install the battery. Measure

the battery voltage and confirm that it is charged. The voltage should be at least 12.0 VDC.

CAUTION!

Observe polarity when making power connections! Red to red. Black to black.

Connect the red and black leads from the Solar regulator (housed inside the battery enclosure) to

the battery posts. RED TO RED, and BLACK TO BLACK.

Figure 3-7 Battery and Solar Regulator: Connections

Next connect the Battery power cable to the PVC-housed Controller Assembly, J4 port

connector. This is a 3-pin connector. Then connect the Winch motor power cable to the

Controller Assembly, J2. This is a 4-pin connector. See Figure 3-7 below.

YSI Environmental 669523 Rev B Page 3-12

Page 42

YSI Profiler System USER Manual

Figure 3-8 Connect Winch Motor Cable to Controller (J2)

VERIFY WINCH OPERATION

First, verify that the motor power cable is connected to J2 of the Controller Assembly. After you

make the battery power connection to the controller, use the special magnetic slide switch to test

if the winch will pay out and reel in when the switch is activated. Placing the magnet side down

in the groove should result in movement of the winch drum. You should hear a click from the

relay contacts. The winch drum should move. Next slide the switch in the groove to control

direction of the cable movement. The sonde need not be attached for this test. To stop winch

movement, pull the magnetic slider away from the groove. This manual test verifies winch

movement. If the winch does not behave as described above, check all connections, check

battery voltage and repeat the procedure.

Figure 3-9 Magnetic Slide Switch to Test Winch System

YSI Environmental 669523 Rev B Page 3-13

Page 43

YSI Profiler System USER Manual

Figure 3-10 Housing with Solar Panel (one of two that mounts to T-frame)

CHECKING & Connecting OTHER COMPONENTS

SONDE

If you do not have the YSI sonde prior to receiving the YSI Profiler System, you will receive

your sonde separately. The YSI sonde pre-deployment configuration was described in Section

3.2, Setting Sonde Parameters. If not yet configured, you can easily check it with the YSI 650

MDS. Alternatively, you may use a PC and terminal emulator program as described in the

previous section. IMPORTANT: The sonde must be configured to work with the Profiler. If you

skipped the configuration steps, take time to read Section 3.2

Figure 3-11 Checking Sonde Configuration during Equipment Staging

ANTENNA

YSI Environmental 669523 Rev B Page 3-14

Page 44

YSI Profiler System USER Manual

The antenna will typically be shipped with the Profiler T-frame assembly. The antenna cable

will already be connected to the Controller System, Port J5 as shown in Figure 3-5. Unpack and

reattach the antenna base to the top plate of the T-frame. Mounting holes and hardware are

included.

Figure 3-12 Remounting the Cellular Antenna during Equipment Staging

DEPTH SOUNDER (optional)

The Depth Sounder is a sensor that periodically confirms water depth as directed by the profiling

program downloaded to the Campbell CR10X data logger. The sensor unit, if ordered, will be

mounted to the platform deck and the cable will be plugged into Port J6 on the Controller

Assembly (PVC cylindrical enclosure). Check to make certain the sensor unit is securely

fastened and the cable is appropriately routed and connected.

METEOROLOGICAL SENSORS (optional)

Some or the entire MET suite of sensors may be mounted to your Profiler System. Check that

the sensors you ordered are present and mounted. Some sensor units will need to be remounted

if they were separately packed for shipping. The MET suite cabling will typically require a PVC

breakout box to connect cables from separate units. One cable then plugs into Port J7 (installed

as needed) of the Controller Assembly. The cabling should be in place. Insure secure mounting

of sensor units and proper routing and connection of all cables. Live testing will be described

prior to final deployment.

Unless you have additional options for your Profiler platform, such as beacons or other optional

equipment, the indoor staging procedure is complete. The next step will be to setup and connect

the CR10X in the Controller Assembly via direct and/or wireless connection using the

LoggerNet™ software.

YSI Environmental 669523 Rev B Page 3-15

Page 45

YSI Profiler System USER Manual

This Page Intentionally Left Blank

YSI Environmental 669523 Rev B Page 3-16

Page 46

YSI Profiler System USER Manual

Section 4

Equipment Staging – PC / CR10X Communication

4.1 Introduction

You will now open LoggerNet™ and set up a connection between your PC and the CR10X data

logger. You will also set up your modem. Finally, you will proceed to download the program

(*.dld) that you created with YSI Profile Wizard. Communication with the CR10X will allow

you to perform important pre-deployment tests before locating the Profiler at a monitoring site.

To connect your PC to the CR10X (housed within the Profiler Controller Assembly) you will

need a Diagnostic Cable (provided with your system). One end is a 9-pin standard RS-232

connector; the other connector fits the Diagnostics port (J3) of the Controller. In addition, you

will learn to use LoggerNet™ to set up modem communication using the Setup function. The

most commonly used means of wireless communications in this system are either a cellular

modem or an IP address. Refer to your LoggerNet manual for detailed instructions. Below you

will see a sample setup.

You should proceed through the above mentioned steps in a stable environment if possible. If you

configure and test your profiling system in this manner, you are less likely to make an error that

would cost you valuable time once in the field.

4.2 Setting Up Communication from PC to Station (CR10X)

Use this section in conjunction with the LoggerNet™ manual. After installation, LoggerNet™

will appear in the Programs folder of the Start Menu or as an icon on Windows Desktop.

Double click the LoggerNet™ icon to open the following window.

Click Setup (far left button above) to open the Setup screen shown below. At any time you may

click the Undo button to reverse changes you have made.

Now proceed with the setup.

YSI Environmental 669523 Rev B Page 4-1

Page 47

YSI Profiler System USER Manual

SET UP MODEM CONNECTION

Use the Add Root… button and the Add… button on the Setup screen to ‘build’ a

communications tree in the left field of the screen. As you see below you begin with

ComPort_1. Highlight the port, click on A

screen, and then click on a device (PhoneBase). Click on A

You just established the first link in the communications setup. Notice at the bottom of the

screen it reads ‘Connect a PhoneBase to ComPort_1’.

dd… (green plus sign) to show the Add Device

dd Now… and the ‘tree grows’.

If multiple ComPorts are shown under Place to Add Device (right field on screen), then click the

port location you prefer before clicking A

YSI Environmental 669523 Rev B Page 4-2

dd Now. Click the Close button.

Page 48

YSI Profiler System USER Manual

The Setup screen now appears as shown below. It shows PhoneBase under ComPort_1 in the

left field (see tree diagram on next page). The software will automatically select Modem Type

to be <default modem>. Click the down arrow to the right of the field to change modems as

appropriate for your system.

Ensure that Communications Enabled is checked. To edit the modems available, click the Edit

Modem Database.... button. Set the Maximum Baud Rate to 9600 and the Extra Response

Time to 5 sec. Click Ap

ply to confirm any changes.

Now, click to highlight PhoneBase in the left field (tree) and click the A

dd… button just as

before to proceed with your setup.

YSI Environmental 669523 Rev B Page 4-3

Page 49

YSI Profiler System USER Manual

Now highlight PhoneRemote. Note that PhoneBase is now in the ‘Place to Add Device’. Click

the A

dd Now… button and then click Close to complete this step. Enter the Delay1 (ms) and

the appropriate phone number for your connection, then click on the Ap

ply… button.

1

5 ms is an appropriate delay time for the YSI Profiler system

YSI Environmental 669523 Rev B Page 4-4

Page 50

YSI Profiler System USER Manual

The final step is to connect the PhoneBase to the CR10X device listed in the pop-up screen. As

before, with PhoneBase highlighted, click on Add… (green plus sign) to complete the tree for

modem communications.

IMPORTANT:

Only one CR10X can be assigned to a PhoneRemote at a given time.

NOTE:

In the screen above, both ComPort_1 and PhoneRemote are choices to add the CR10X.

For direct line communications this is an option with a Diagnostics Cable.

YSI Environmental 669523 Rev B Page 4-5

Page 51

YSI Profiler System USER Manual

As you can see in the screen below you now have a path from PC to data logger represented by a

tree. Next you will enter or confirm some timing information.

Under the Hardware tab, ensure that Communications Enabled is checked.

Adjust the Maximum Time On-line and Extra Response Time to the desired interval (10 minutes

ON; 0 sec Extra).

Set the default Maximum Packet Size to 2048, and the Maximum Baud Rate to 9600.

More information regarding the Security Code and Call-Back ID can be found in the LoggerNet

user manual. Click the A

pply to confirm changes.

YSI Environmental 669523 Rev B Page 4-6

Page 52

YSI Profiler System USER Manual

You are now ready to move to the Schedule tab to enter information on collection intervals,

retries and related scheduling parameters. Your left field tree should remain with CR10X

highlighted. It is customary to rename ‘CR10X’ to something that helps you identify this field

station. Use the Ren

ame button or simply highlight the box and rename your station.

Although unchecked in the screen below, you would check the Scheduled Collection Enabled

box to set up automated data collection.

When using scheduled collection, set the Base Date & Time, Collection Interval, Primary Retry

Interval, and Number of Primary Retries (defaults shown below of one minute collection

interval, 5 minutes on retry interval, and 3 retries).

If you choose to use Secondary Retry Interval, check the box and set the interval in the field to

the right (1 day in this example).

Now check Collect Ports and Flags. This allows you to collect troubleshooting information.

Ports and Flags will be explained in more detail in the next section of this manual. Click A

to confirm changes. If required, click A

pply to other stations to confirm configurations to any

pply

other profilers on the system. In this example, there is just one CR10X.

Under the Final Storage Area 1 (FS Area 1) tab change the Output File Name (and path) from

the default value (shown below) to the station filename assigned when the DLD file was created.

YSI Environmental 669523 Rev B Page 4-7

Page 53

YSI Profiler System USER Manual

In addition, save this new DAT file to the same directory where the DLD file is located. For

example, if the station filename assigned during Profile Wizard setup was GSI-lab600.dld, then

the final storage filename would be GSI-lab600.dat; and it would be stored in the same directory

as the DLD file.

To learn more about information under the tabs Final Storage Area 1, Final Storage Area 2, and

Clock you should refer to you LoggerNet user manual.

Once all changes are made, click on the A

pply button to confirm changes. After confirming

changes, click on the X at the upper right of the window to close the setup screens.

YSI Environmental 669523 Rev B Page 4-8

Page 54

YSI Profiler System USER Manual

CONNECT PC TO CR10X DATA LOGGER

In the example below let us assume that you correctly set your connection path (see above) and

the profiling routine that you created with Profile Wizard resides in a directory. The remote

station is Clark Reservoir Site 12, which was defined in Section 2 of this manual. You have

renamed the CR10X station to be GSI-lab600 and there is a DLD file in the Profile Wizard

Shared directory (or site specific folder) by this name. You are able to directly connect

ComPort_1 to the data logger by the Diagnostic Cable and you are set to test the remote

connection via IP address information that was set in LoggerNet Setup.

Open the LoggerNet™ tool bar window. Click on the C

Screen.

onnect button to open the Connect

YSI Environmental 669523 Rev B Page 4-9

Page 55

YSI Profiler System USER Manual

Note that GSI-lab600 now appears with YSI Direct as CR10X options in the left field of the

screen. Highlight GSI-600lab. Assume the phone base is directed to an active cellular modem

or IP address.

Now click the C

onnect button. The image of ‘two cables aligned and ready to connect’ appears

in the lower left field. A space remains between the two connector images until the

communication link is established. Activity begins during dialing and then the connection

closes with a successful connection.

The button reading Connect changes to read Disconnect after the connection is completed.

Clock time may differ, but you can synchronize the station time to the PC time using the Set

Station Clock

button.

Note in particular that both the Data Collection and Program buttons are now active. If you have

not yet sent your DLD program that defines the profiling routine to the CR10X, then the S

end

button can be used to do this. If the DLD program has been sent, you may click on the Collect

N

ow button to query the data logger for information and data.

You will learn more about Ports and Flags in the next section of this manual.

Let us assume that you need to send the DLD program to the CR10X. Refer to instructions

below.

YSI Environmental 669523 Rev B Page 4-10

Page 56

YSI Profiler System USER Manual

4.3 Downloading Profile Program to Station

Before deployment, the file you created from YSI Profile Wizard must be sent to the profiling

system for proper system data collection to occur. Under the Program section you may see the

default setting (-Unknown-‘) if no program exists in the data logger. Click the S

You should now see a browse window open that allows you to locate the *.dld file that you

created in Profile Wizard. The file contains the information for the profiling routine, and must

be downloaded to the CR10X.

end button.

In the browse window, locate the folder where you saved the .dld file during the Profile Wizard

setup. The default directory is C:\ Program Files\ YSI\ Profile Wizard\ Shared. The .dld file will

have the same name as the station location created initially with Profile Wizard. Highlight the

file that will appear under Shared and click Open. The following warning should appear.

YSI Environmental 669523 Rev B Page 4-11

Page 57

YSI Profiler System USER Manual

Click OK to initiate the transfer of the file to the CR10X. This may take a couple of minutes. A

status screen appears showing you the status of the transfer and then the completion of

compiling of the program. After this a screen appears confirming that the file has been

‘downloaded to the station’ (CR10X).

Click OK to continue.

YSI Environmental 669523 Rev B Page 4-12

Page 58

YSI Profiler System USER Manual

The screen will now show the current Profiler setup filename under Program in the Connect

Screen window. The filename used in this example was GSI-lab600.

You have now successfully established communication between the PC (LoggerNet) and the

Station (CR10X data logger, residing within the Controller Assembly of the Profiler system.

In Section 5 you will perform pre-deployment tests that will test your system and prepare you

for taking a fully operational system to the field site.

YSI Environmental 669523 Rev B Page 4-13

Page 59

YSI Profiler System USER Manual

This Page Intentionally Left Blank

YSI Environmental 669523 Rev B Page 4-14

Page 60

YSI Profiler System USER Manual

Section 5

Pre-Deployment Testing

5.1 Setting Up LoggerNet™ for System Testing

In this section you will use LoggerNet™ control of the CR10X profiler program to test various

components of the Profiler System prior to deployment activities. The following components

will be tested, unless the component is optional and not present.

Sonde response (RS-232 and SDI-12)

Winch motor control

Depth sounder or Fixed reference sonde

Compass

Meteorological sensors