Page 1

PC6000 SOFTWARE

Operations

Manual

PC6000

+

+

-

-

Page 2

Page 3

CONTENTS

SECTION 1 INTRODUCTION 1

SECTION 2 GETTING STARTED 2

2.1

2.2

2.3

2.4

SECTION 3 CAPTURE, RETREIVE AND ANALYZE DATA 7

SECTION 4 PC6000 MENUS 12

4.1 File Menu 12

4.2 Setup Menu 21

4.3 Data Capture/ Real Time Setup 22

SECTION 5 ADVANCED SETUP 25

Installing PC6000 Software 2

Running Software 3

Software Setup 3

Communicating with a Sonde 5

4.1.1 Modify 13

4.1.2 View 18

4.1.3 System 19

SECTION 6 TROUBLESHOOTING 28

SECTION 7 CONTACT INFORMATION 29

SECTION 8 SENSOR DRIFT APPLICATION NOTE 30

SECTION 9 ACCESSORIES 33

i

Page 4

ii

Page 5

SECTION 1 INTRODUCTION

The PC6000 program is very useful in the operation of the YSI Sondes, and is prov ided as an option

with every sonde. This PC-based software can be used with any I B M-compatible computer.

PC6000 enables you to:

!

Configure and deploy the sonde

!

Capture data from the sonde

!

Create a variety of reports and plots

!

Print reports and plots

!

Save reports and plots to disk

!

Export data to other programs

The PC6000 program is completely menu-driven and easy to use. You can:

•

Use the arrow keys to move the cursor and hig hlig ht menu options.

•

Use the Enter key to select a highlighted m enu option.

•

Use the Esc key to return to a previous screen.

When each menu option is highlighted, a short, descriptive help line is displayed at the bottom of

the screen.

In Section 2 of this manual, you w ill learn how to:

•

Install the software to your PC

•

Run the software and set up the Com ports, and the display and plot colors

•

Establish communication between your sonde and com puter using PC6000

Section 3 of the manual provides the basics on how to:

•

Capture data from the sonde to your computer using PC6000

•

Upload data from your sonde to your computer

•

Report, plot, and analyze data files using PC 6000 software

Sections 4 through 9 provide complete details of the capability of PC 6000 as well as prov iding YSI

Customer Service contact information and a list of YSI sonde and software accessories.

Page 6

SECTION 2 GETTING STARTED

2.1 INSTALLING PC6000 SOFTWARE

PC6000 software can be used with an IBM-compatible PC with at least 256KB of RAM and

DOS 3.0 or later. If your system is not IBM-compatible, any terminal emulation program can be

used with your computer. PC6000 software is an optional accessory that can be requested at no

charge with each Sonde. The diskette is located in the back of this instruction manual.

You need a graphics adapter for operation of the plotting feature. You need one RS-232 port (also

called a Com port or serial port) to communicate with the sonde and to capture data files. This port

must be either Com1 or Com2.

For IBM-compatible computer systems with a hard disk drive:

your floppy disk drive. At the C:\ prompt, type the letter of the drive in which the disk was

inserted followed by a colon, then press

Example: “A:

To install PC6000 software execute the following command from the DOS prompt:

“INSTALL <destination>”

the PC6000 files to be installed.

Example: “INSTALL C:\PC6000”

If you have a non-standard video adapter

will also need to:

1. Put your video adapter into a compatible (standard) video mode. Typically the manufacturer of

the video adapter provides a program or utility to set the v ideo mode.

2. Type PC6000-V to run the program. This tells PC6000 to send video output through the

computer BIOS (built-in firmware), rather than directly to video memory. This procedure

slows down the video output somewhat, but g uarantees com p atibility .

Enter

”

where

Enter

.

<destination>

and monitor (rare except on CAD work stations) you

is the drive and directory in which you want

Insert the PC 6000 disk into

Page 7

Getting Started Section 2

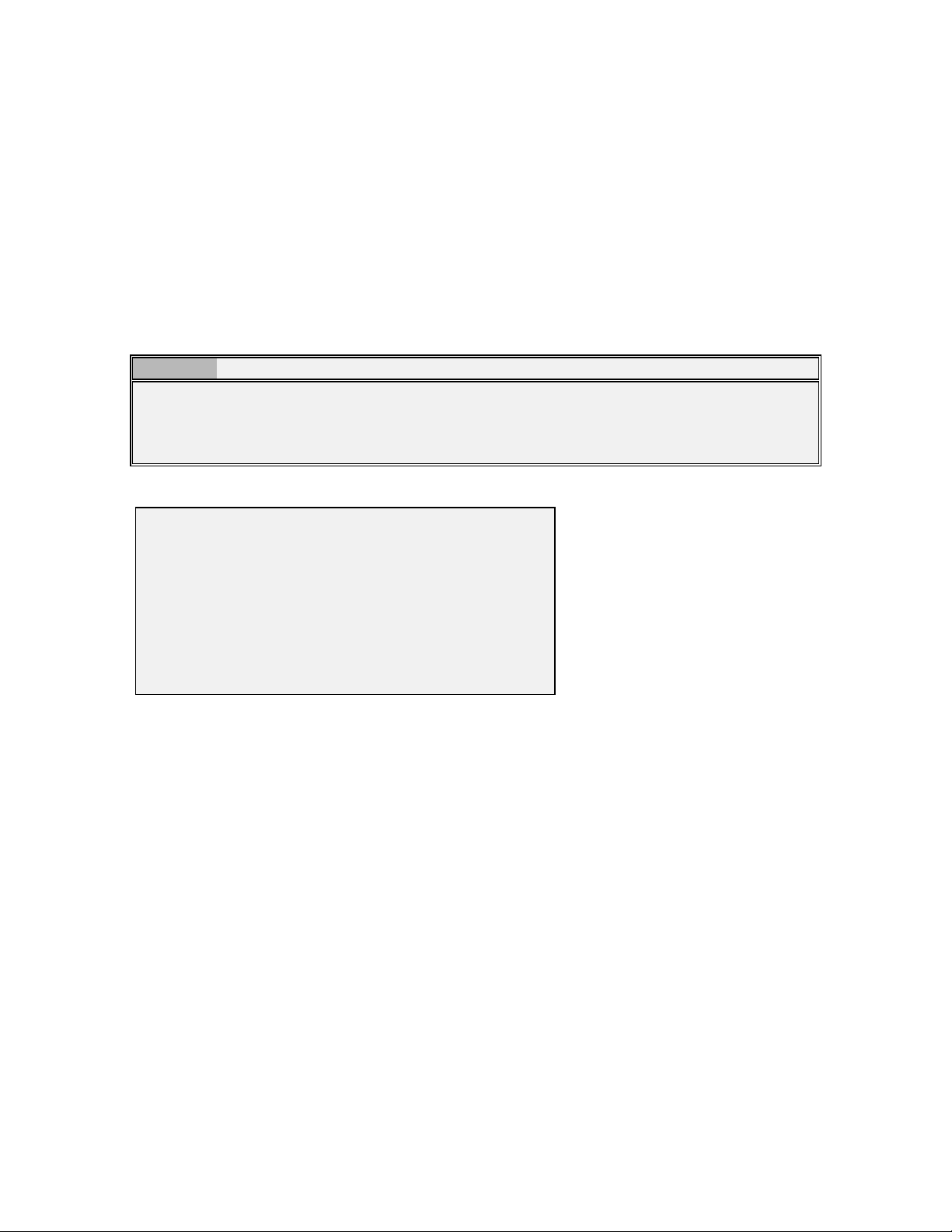

2.2 RUNNING SOFTWARE

To start the software, make your current drive C:\PC6000 (or another directory where you have

installed PC6000). Then type “

PC6000”

and press

the menu bar will appear at the top of the computer screen.

Enter

. The PC6000 software will load and

Use the arrow keys to move the cursor and to highlight different menu options. Press

select a highlighted option. Press

PC6000 Main Menu Bar

Esc

to cancel an entry.

Enter

Sonde File Setup Real-Time Exit PC6000

2.3 SOFTWARE SETUP

To begin setting up your computer to communicate with a sonde, highlight

Enter.

Check the default setup values by referring to the following instructions and/or the

PC6000 Setup Screen below.

Setup

and then press

to

---DISPLAY -FORMATS---------COMPUTER-CONNECTIONS------------------Date format: MDY Comm port: 1

Date separator: / Baud rate 9600

Time separator: : Printer Port 1

Radix mark: . Printer type HP LaserJet laser

-------MORE-SETUP-------------COMPUTER-DISPLAY--------------------Data capture setup... Menu colors: User-defined menu colors

Advanced Setup... Plot colors: User-defined plot colors

Graphics mode: Automatic selection hi-res

Select the

connected. Press

Comm

option to enter the number of the Com port (1 or 2) to which your sonde is

Enter

to confirm a new entry. If the default setting is correct, it does not need

to be changed.

YSI Incorporated PC6000 Software Operations Manual 3

Page 8

Getting Started Section 2

Select the

highlight it and press

and press

Select the

printer is connected. If no printer is connected, select LPT1. Press

Baud

option to check the baud rate. The baud rate should be 9600. If it is not,

Enter

. A list of possible baud rates will appear. Select 9600 from the list

Enter

.

Printer

option to specify the parallel port (LPT1, LPT2 or LPT3) to which your

Enter

after making your

selection.

Printer type

Select

to select the type of printer connected to your computer system. From the

list, choose the selection that best describes your printer. If your printer is not on the list, refer to

your printer's instruction manual to determine what type of printer your printer emulates. Press

Enter

after making your selection.

Select the

the cursor between color schemes, the screen changes to display your selection. Press

Menu colors

option to choose a color scheme for the PC6000 menus. As you move

Enter

to

confirm a selection.

Select the

cursor between color schemes, the screen changes to display your selection. Press

Plot colors

option to choose a color scheme for the PC6000 plots. As you move the

Enter

to

confirm a selection.

Other setup functions are described in Section 4.2,

necessary for a quick start into the sondes operations. Press

Setup Menu

Esc

, but are usually are not

to exit the Setup Menu. The

cursor will return to the PC6000 Menu bar.

YSI Incorporated PC6000 Software Operations Manual 4

Page 9

Getting Started Section 2

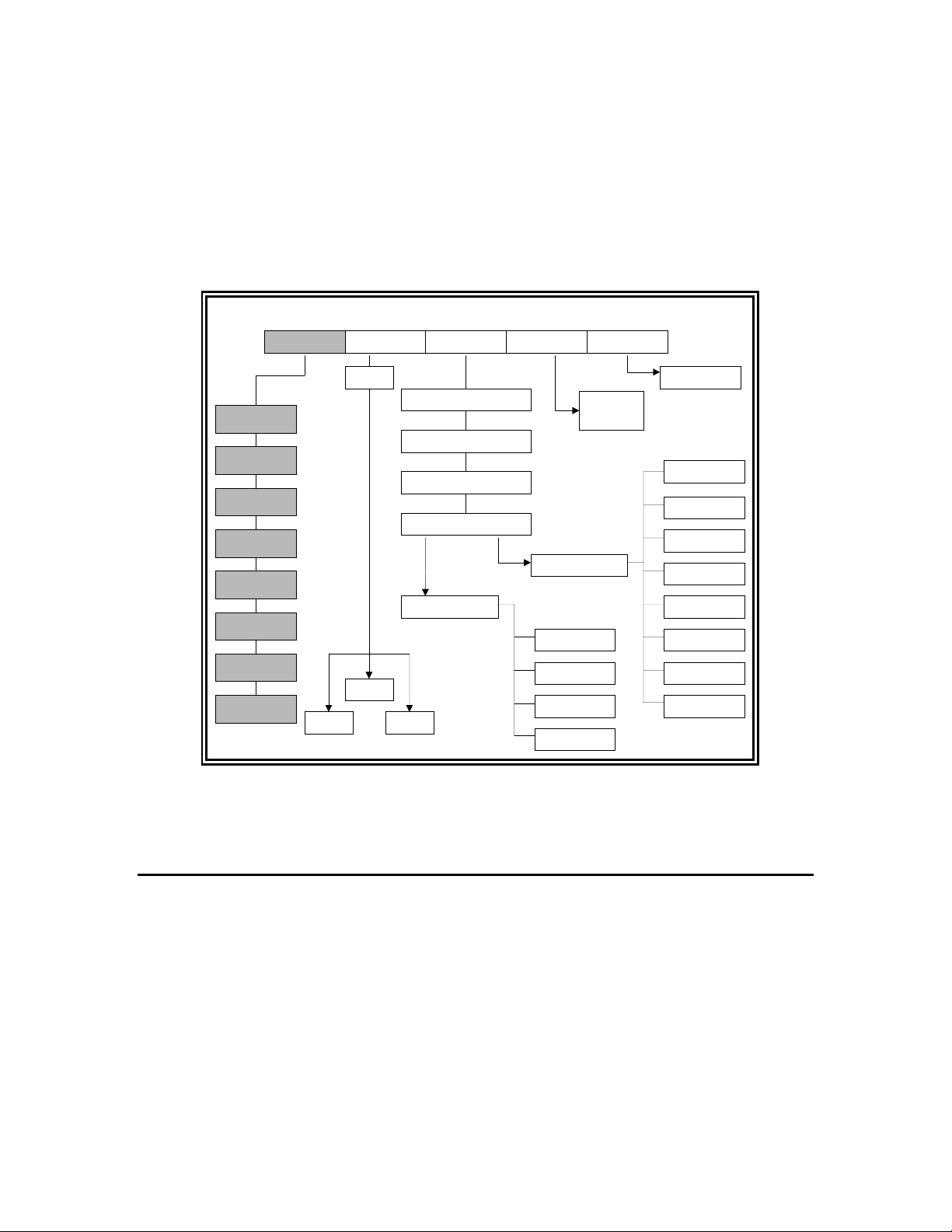

The PC6000 menu flow chart will help you visualize the relationship between the most often used

options in this PC-based software. To better understand the relationship between Sonde software

and PC6000 PC software, the sonde software menu items are listed in the shaded areas. Refer to

this chart as you learn more about the specific functions of these menu items in the following

descriptions.

PC6000 Menu Flow Chart for Sondes (Some choices in the sonde menu are not available with all sondes)

PC6000 MENU FLOW

Sonde File Setup Real-Time Exit

1. Run

2. Calibrate

3. File

4. Status

5. System

6. Report

7. Sensor

8. Advanced

Filename

View

Display Format

Computer Connection

Computer Display

More Setup

Advanced Setup

Advanced Setup

SystemModify

Readings

Displayed

Data Cap ture

Global Switch

Data Files

User-defined

Export

Return to DOS

Parser

Site Name

Instrument ID

Filename

Autoconfigure

X-axis Time

Parameter/Plo

Beep Notify

2.4 COMMUNICATING WITH YOUR SONDE

There are two sets of software at work within the YSI sonde. PC6000 is resident in your PC, while

the other software is resident in the sonde itself. When you select

menu the PC based software begins direct comm unication with the sonde-based software via

standard VT100 terminal emulation.

Using the arrow keys, highlig ht and select

instructed, type “

menu

” after the # sign and the Main sonde menu will appear.

Sonde

from the Main menu bar. Press

To use PC6000 to establish communication between your computer and sonde:

YSI Incorporated PC6000 Software Operations Manual 5

Sonde

from the PC6000 Main

Enter

as

Page 10

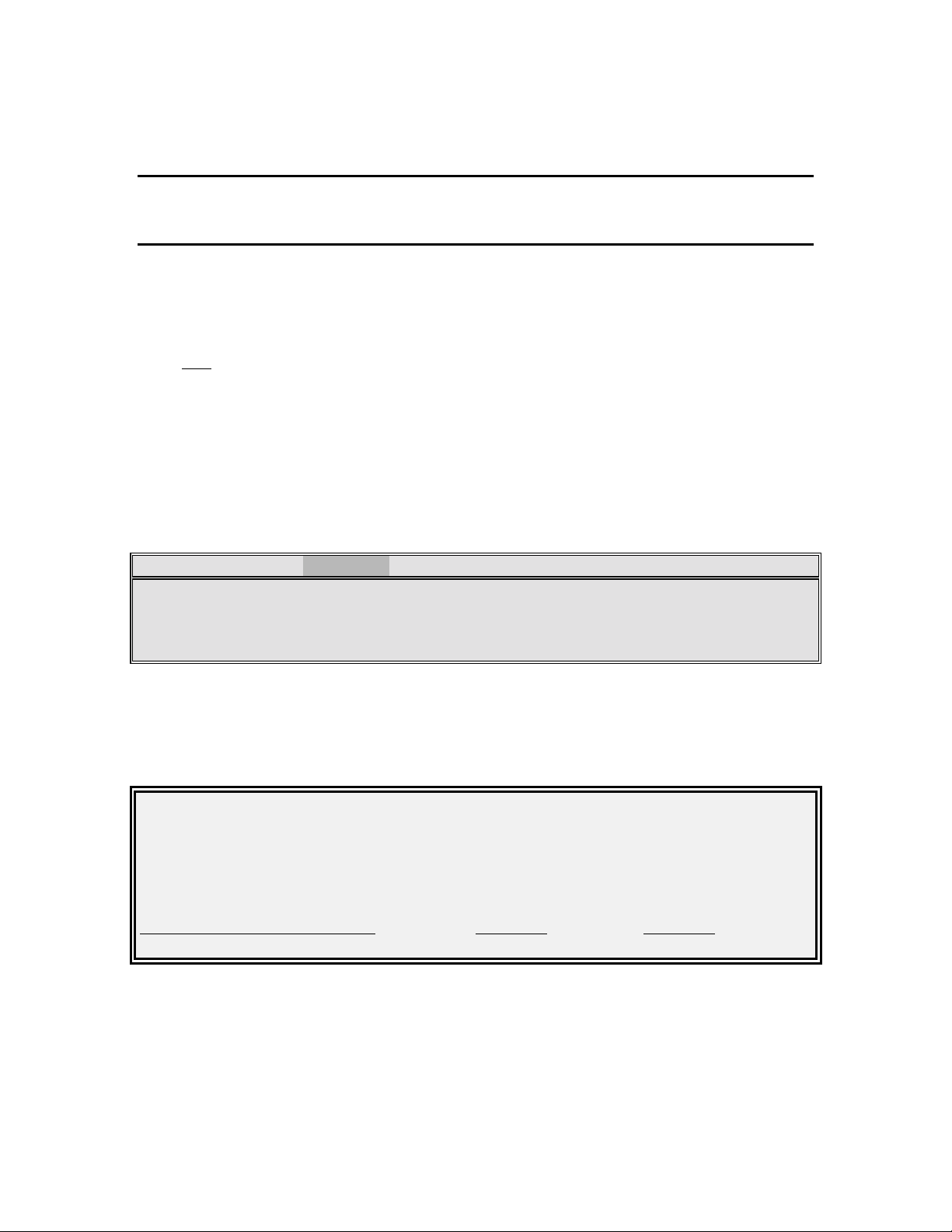

Getting Started Section 2

1. Connect one end of your YSI cable to the sonde and the other to the computer ‘s Com port

that was selected above.

2. Make certain that your sonde is powered either with batteries or a power supply.

3. Using the arrow keys, highlight the

Enter

.

Sonde

selection in the top menu bar of PC6000 and press

A display similar to that shown below will appear, followe d by a # si gn. As i n s t ructed, t ype

menu

“

” after the # sign and the Main sonde menu will appear.

PC6000 Main Menu Bar

Sonde

File Setup Real-Time PC6000

# menu

Sonde Main Menu

------------------Main----------------1-Run 5-System

2-Calibrate 6-Report

3-File 7-Sensor

4-Status 8-Advanced

Select option (0 for previous menu):

After establishing sonde communication proceed to Section 2 of the Sonde’s Operations manual

supplied with your sonde to learn about the basics of Sonde setup. Pay particular attention to

leaning low to set up Discrete Sampling and Unattended Sampling studies from the Run menu.

Then proceed to the next section of this manual to learn how to capture data from the sonde to

the computer in real time, to upload data from sondes containing memory, and to analyze the

captured or uploaded data.

YSI Incorporated PC6000 Software Operations Manual 6

Page 11

SECTION 3

USING PC6000 TO CAPTURE, RETRIEVE AND

ANALYZE DATA

CAPTURE – ALL SONDES

Once you have learned how to carry out Discrete Sampling studies using the sonde software

(Section 2 of your Sonde Operations Manual), you can capture that information into a data file

on your computer hard drive. This function is particularly useful when using sondes with no

internal memory (600R, 600XL, and 6820).

place only after the PC6000 software has been properly configured to match your parameter

selection as described in the following paragraphs.

PC6000 uses the date and time from your PC’s internal clock to stamp each incoming data point.

It is important, therefore, to make sure that the date and time are set up correctly inside your

computer. Consult your computer instruction manual if you are unsure how to set the internal

clock.

To set up for data capture return to the PC6000 menu bar by pressing F10.

Note, however, that this capture function can take

Sonde

# menu

Highlight

Select

menu will be displayed.

Parser: 6000

Site name: Clear Lake X-axis time per screen: 1

Instr ID: 96E12345 Parameters per plot: 2

Filename: CLRLAKE3 Auto-configure Beep notification: Both

ColumnParameter & Units Minimum Maximum

Use the arrow keys to highlight the

data on the computer hard drive or diskette. Remember that while you can type up to 15

characters in the name, MS-DOS will only recognize the first 8 for file designation.

File Setup Real-Time PC6000

Setup

from the top-line menu and press

Data Capture Setup

from the Setup menu and press

Filename:

Enter

.

Enter

. The Data Capture Setup

then type in a name that you will use to store the

Now highlight

PC6000 software has the same parameters as selected in the Report setup of the Sonde software.

Auto-configure

and press

Enter

. This makes sure that the Data Capture setup in

Page 12

Capture, Retrieve and Analyze Data Section 3

The parameters listed in the lower part of the display (not shown) are likely to change during the

Auto-configure execution.

IMPORTANT

may display error messages that refer to “differing parameters” that prohibit you from

proceeding.

Leave all of the other selections with their default settings intact and then press

return to the menu bar of PC6000.

To capture data, use the arrow keys to select

# sign type “

from the Main menu, and

Discrete Sample menu (600XLM, 6600 or 6920). Lines of data will be displayed to the screen

and updated at the interval specified.

Now press the

wish to create. Select

OK to create new data file?”

“

designated file will begin.

As noted above, a change in the format of the displayed data in that both date and time will now

be displayed. In this mode, data appearing on the screen will be saved to your computer memory

until you press either

returns the display to the original data scrolling. A second press of

and return the display to the Run menu.

: Without the execution of the Auto-Configure command, the PC6000 software

Esc

twice to

Sonde

from the main menu and press

menu

”. This command returns you to the Main Sonde menu. Next select

1-Start sampling

F3

key and a message appears on the screen asking for the type of data file you

PC6000

Esc

and press

Press

or F3. When you press either of these keys, data capture halts and

from the Setup Menu (600R, 600XL or 6820) or the

Enter

. A message now appears on the screen asking,

Enter

to indicate ‘yes’ and data capture to your

Esc

will stop the sampling

Enter

1-Run

. At the

You may view and/or analyze the data by pressing F10, and then following the instructions in the

Section 3, Analyzing Data

.

RETRIEVE – 600XLM, 6600 AND 6920 SONDES

PC6000 Software can also be used as the interface to transfer (upload) data logged to sonde

memory from the sonde to the computer hard drive. This function only applies to sondes with

internal memory (6920, 6600 and 600XLM).

To carry out this operation, consult Section 2 of your Sonde’s Operations Manual on the logging

of data to sonde memory using the Discrete Sample and Unattended Sample features of the sonde

software. Make certain that you have logged at least one file (or study) to the sonde memory.

After logging is complete and the studies terminated, attach the sonde to the computer via the

YSI cable as described above.

You may now retrieve data files using the following procedure. Remember these are not files in

the PC6000 directory, but are in the sonde file directory.

Run PC6000 software on your PC and select

keys. At the # sign, type “

menu

” to enter the Sonde Main menu. Next select

Sonde

from the PC6000 menu bar using the arrow

3-File

.

YSI Incorporated PC6000 Software Operations Manual 8

Page 13

Capture, Retrieve and Analyze Data Section 3

------------------File----------------1-Directory 4-View file

2-Upload 5-Quick view file

3-Quick Upload 6-Delete all files

Select option (0 for previous menu): 1

Select number

1-Directory

to view all files currently stored in the sondes flash disk memory, the

screen below shows 5 files. File 4-CLRLAKE2 is a 2-week study from August that can be

uploaded to PC6000 for viewing or plotting. The other 4 files are related to different studies.

You do not need to upload all files in the directory.

File Samples First sample Last sample Interval Site

1-BRIDGE1 20 07/10/96 09:42:52 07/10/96 09:44:12 Discrete Kenton Rd.

2-BRIDGE2 20 07/10/96 10:15:20 07/10/96 10:16:40 Discrete Lakeview Dr.

3-UPLAKE 672 07/10/96 12:00:00 07/14/96 12:00:00 00:15:00 Lake Site A

4-CLRLAKE2 1672 08/14/96 11:00:00 08/28/96 11:00:00 00:10:00 Clear Lake

5-DWNLAKE2 21 08/31/96 12:42:31 08/31/96 12:43:54 Discrete Lake Site B2

Select option (0 for previous menu):

Esc

Press

Select number

to return to the previous menu, File.

2-Upload

to view file lists in memory, and uploads the data to PC-based software.

With YSI PC6000 software you can produce reports, plots, data manipulation, statistics, and

more.

Prior to upload, a “

logged data to upload. You may select

Time window

” display appears that will allow you to select portions of the

1-Proceed

to upload all logged data from the dates and

times displayed.

--------------Time window-------------1-Proceed

2-Start date=08/14/96

3-Start time=18:00:00

4-Stop date=08/28/96

5-Stop time=11:00:00

Select option (0 for previous menu):

1-Proceed

Select

. Choose the appropriate file transfer protocol (in this example, PC6000) and a

status box will appear in the lower right quadrant of the screen. Verification of a successful

transfer is indicated when all of the requested data are transferred.

YSI Incorporated PC6000 Software Operations Manual 9

Page 14

Capture, Retrieve and Analyze Data Section 3

---------------File type--------------1-PC6000

2-Comma & ' ' Delimited

3-ASCII Text

Select option (0 for previous menu):

In the File menu, when you select

performed, except only the most recent flash disk file is uploaded in its entirety. You still must

choose the transfer format.

4-View File

Select

memory. You will first view the same screen as viewed in the Directory menu. From this menu

choose the file of interest, then, using the Time window menu, choose the dates and/or times of

interest. If you choose dates or times that are not within the designated start and stop times, no

data will be displayed.

You also may choose the entire file. You can use the

at any time. Use the

Select number

memory. This feature is particularly useful to quickly review any recently acquired data so that

system performance can be assessed.

Select number

memory. It is critical not to use this option until all relevant data from sonde memory is

transferred to your computer via one of the upload options. There is a verification screen that

appears, so that pressing the number 6-key does not immediately delete all files.

Now proceed to the next section to get the basics relevant to analyzing your captured or uploaded

data.

to examine the data in any file currently stored in the sondes flash disk

Esc

key to stop the view.

5-Quick view file

6-Delete

all files to

3-Quick Upload,

to view the last page of data from the last data file in flash disk

IRREVERSIBLY

the same operation as

Space Bar

removes all files from the sonde flash disk

to stop and restart the scrolling

2-Upload

is

ANALYZE

This section provides only basic information on obtaining reports, plots, and analysis of your

uploaded or captured data files. Detailed information on the many powerful functions

associated with these aspects of PC6000 software are found in

manual.

To begin your data analysis, select

A box will appear on the screen asking you to enter a filename. You may type a filename or press

Enter

for a directory listing all PC6000 format files on your hard drive. Use the arrow keys to

YSI Incorporated PC6000 Software Operations Manual 10

File

from the PC6000 menu bar.

Section 4, PC6000 Menus

of this

Page 15

Capture, Retrieve and Analyze Data Section 3

highlight the desired file and then press

Enter

to access the selected file. If only one file resides

in the directory, it will automatically load into PC6000.

Filename:

CLRLAKE2.DAT

MODIFY VIEW SYSTEM

Parameters...

Control Info...

Scaling Info...

Header

Report

Plot

Statistics

Print Report

Print Plot

Definitions

Export

Any changes you make from this menu will affect only the file listed, in this case

CLRLAKE2.DAT. To change default values for all files, see

Section 4.1, File Menu.

To view general information on the screen including filename, site description, a list of active

sensors, logging information, and more use the arrow keys to highlight

Esc

Press

Using the arrow keys highlight

to return to the File menu.

Report,

press

Enter

and the information will scroll by. You can

Header

view a time-stamped report of the entire set of data collected in the study. Press

stop the report and press

Enter

to resume. Press

Esc

to return to the File menu.

and press

Pause/Break

Enter

.

to

Plot

Select

to view a graphical expression of the data from the study. All Reports and Plots can

be customized to your preference.

Esc

Press

until the menu of the PC6000 program appears. You have now completed Basic

Operation of the sonde, which included basic calibration procedures, basic sampling and

deployment procedures, data capture, and data retrieval and viewing using PC6000 software.

YSI Incorporated PC6000 Software Operations Manual 11

Page 16

SECTION 4 PC6000 MENUS

4.1 FILE MENU

File

The

based on data that has been captured from the sonde. Select

press

Sonde File Setup Real-Time Exit PC6000

The following prompt appears on the monitor screen.

Filename: *.dat

menu option of PC6000 software allows you to specify and customize reports and plots

File

from the PC6000 menu bar, and

Enter

.

At this prompt, press

Highlight the file you wish to retriev e from the list. If only one data file exists, that file will be

loaded automatically.

SAMPLE.DAT 38046 2/06/92 11:11 am

CLRLAKE.DAT 21035 10/30/93 6:00 am

RIVER2.DAT 1926 7/23/96 10:22 pm

NOTE:

source drive and directory, then press

prompt, you will view a list of all files located in the directory named PC6000 and stored on a disk

in the A: drive.

When you choose a file, the following screen will appear. Highlig ht the option y ou prefer, then

press

first being “Parameters”. MODI FY, VIEW and SYSTEM are column headers only. The figure

below shows “Parameters” is highlighted as an example.

To retrieve files stored on another drive or directory, at the

Enter

. Use the Tab or Arrow keys to move through the options. There are 10 options, the

Enter

. A list of all data files in the current directory will be displayed.

filename:

Enter

. For example, when you type A:\PC6000\ at the

prompt, type the

Page 17

PC6000 Menus Section 4

Filename: SAMPLE.DAT

MODIFY VIEW SYSTEM

Parameters... Header Print Report

Control Info... Report Print Plot

Scaling Info... Plot Definitions...

Statistics

The following descriptions are the various options under the

then VIEW, and finally SYSTEM.

File

menu, beginning with MODIFY,

4.1.1 MODIFY

Any modifications performed w ith these functions w ill allow y ou to customize data and format

reports and plots for a selected file only. See

permanently. Select

X-axis parameter

----------------------- Date + Time

Y-axis parameter

----------------------- Temperature C

Specific Cond mS/cm

DO mg/L

pH

ORP mV

Parameters

from the Modify menu.

Setup

later in this section to change default values

Add parameter here

Delete this parameter

Move parameter up

Move parameter down

Detail this parameter

The Parameters menu helps you define the way you want your reports and plots to appear. When

you highlight any parameter on this display and press

submenu functions is described below. You may select one parameter for the X-axis, and up to

twelve parameters for the Y- axis.

Add parameter here

Select

that can be added will be displayed. Choose those parameters that you want to be included in

reports and plots.

Delete this parameter

Select

Select

down one position. By using these options all parameters within a report and plot can be displayed

in the order you prefer.

YSI Incorporated PC6000 Software Operations Manual 13

Move parameter up or Move parameter down

to add a parameter to a report or plot. A list of all available parameters

to delete the highlighted parameter from reports and plots.

Enter

, the submenu appears. Each of the

to shift the highlighted parameter up or

Page 18

PC6000 Menus Section 4

Detail this parameter

Select

to view the detailed information of a highlighted parameter. PC6000

has many built-in formulae. Each formula accepts certain inputs and produces a single output. An

example of this is the formula for specific conductance, which is calculated from temperature and

conductivity. Most formula inputs must be in the input data file from the sonde, but some can be

entered as constants. For example, the total dissolved solids (TDS) constant can be manually

entered.

Parameter: TDS (g/L)

Formula: Temp(C) Cond(mS/cm) TDScoef

Inputs: Temperature (C) from 6030 probe, channel 0

Conductivity (mS/cm) from 6030 probe, channel 3

TDS coeff source not selected

Compensate:

Parameter

Select

identifies the parameter you just chose.

Formula

to view and change the formula used by PC6000 to calculate the selected

parameter. This option will allow you to change formulae and input sources only in circumstances

where multiple formulae or input sources exist. If formula options for the highlighted parameter

exist, they will be displayed when pressing En ter while the formula is highlighted.

Inputs

The

Select

option is reserved for future software enhancements.

Compensate

to compensate a data file for long term sensor drift. This compensation

procedure is also commonly called Post- C alibration.

Compensation Example:

Dissolved oxygen data can be collected periodically

throughout a long-term deployment using a separate, freshly calibrated DO meter.

This independent data can then be used to compensate the sondes data for any

sensor drift that may occur over tim e.

NOTE:

The setup menu options for date format, date separator, time separator, and radix separator,

all apply here. The date, time and value are separated from each other by spaces. Lines that do not

match the above format are ig nored.

To create a compensation file, use a word processing program or follow the procedure below. The

file must be simple ASCII. In WordPerfect you use the DOS Text Out feature. In Word, save as

file type Text Only (*.TXT). From DOS, proceed as follows:

1. Issue the DOS command "COPY CON DO.CMP". The DO designation reminds you

that you are compensating DO % data in this exercise.

2. Type the compensation data into your file, placing each independently acquired reading

on a separate line. Make sure each line is correct before you press

YSI Incorporated PC6000 Software Operations Manual 14

Enter

for that line.

Page 19

PC6000 Menus Section 4

Example:

12/31/92 23:59:59 100

1/15/93 16:02:00 98

2/15/93 18:00:00 94

In this example, an independent DO reading taken at 4:02 PM on 1/15/93 showed a value

of 98 % air-saturation.

3. After the last line has been typed and entered, hold down Ctrl and press Z, then press

Enter

.

4. The message “1 File(s) copied” should appear.

If only one data point is entered into the compensation file, all data after that date and time will be

corrected. If more than one data point is included in the compensation file, data between points will

be corrected linearly.

To enter the compensation filename, press TAB while the highlight cursor is on Compensate. The

highlight cursor will mov e to the right. Enter the path and file name.

Example:

C:\DO.CMP Enter

.

When you enter a compensation filename, the program performs a test load of that compensation

file. A summary is displayed so you can verify the file structure. The summary includes how many

lines were accepted, rejected, or blank, the total number of lines, and the earliest and latest date.

If you compensate a constant used in calculating one param eter, you must also compensate the same

constant if you use it to calculate other parameters. A total of 1000 compensation points are

allowed for any single report or plot.

Control Info

Select

from the Modify menu. The Control I n fo m enu w ill be display ed.

Enter title line

SAMPLE.DAT

First sample was at: 02/05/92 13:58:00

Enter start time: begin

Enter stop time: end

Last sample was at: 02/06/92 11:42:00

Logging interval was: 60 seconds

Enter averaging interval: 0

X-axis time per screen: 1304

Cross-parameter style: AVG

Cross-parameter bins: 100 (maximum 2350)

Parameters per plot: 2

YSI Incorporated PC6000 Software Operations Manual 15

Page 20

PC6000 Menus Section 4

The Control Info menu allows you to report or plot an entire file, or any portion of a file. Other

options on the Control Info menu allow you to average several data points together and set up

reports and plots to display data in the format you choose.

Below the prompt,

Enter title line

, assign a title that will appear on all reports and plots.

SAMPLE.DAT is shown in the example screen above.

Select the four options below to view start and stop times of the file, and specify portions of the file

to report or plot.

First sample was at:

Enter start time:

Enter stop time:

Last sample was at:

The first and last line of this block of information indicates the actual start and stop times of the

current file. You can identify any segment of time from within a file to report and plot data. For

example, if the duration of the deployment was five days, but you wish to see a report and plot for

only the third day, simply enter the start and stop dates and times associated with day three. Even

though all five days of data are retained, reports and plots will show only day three.

The following two options show the sampling interval which was in effect throughout the

deployment and a method by which you can consolidate readings to improve report and plot

appearance.

Logging interval was:

Enter averaging interval:

You may choose to average several data points together for reporting and plotting. For example, if

the sondes readings were captured every 900 seconds (15 minutes) during the deployment, you

might want the reports and plots to average four of these readings together so that the information

can be reported or plotted on an hourly basis. To do this, define an averaging interval of 3600

seconds.

X-axis time per screen

Select

option to specify the time interval on the X-axis. This line is only

applicable when Date + Time have been defined for the X-axis. You can define the width of a given

plot screen in minutes by changing the num ber of minutes in this option.

Cross-parameter style

Select

to choose one of four plot styles. This option is only applicable if a

parameter other than Date + Time is selected for the X-axis (see Parameters above).

An averaged plot (

AVG

) assumes a correlation between the X-axis and the Y-axis parameters. The

averaged plot divides the X-axis into equal-sized memory bins. Each sample is tallied into the

appropriate memory bin based on its X-axis value. When finished, the average value for each

Y-axis parameter in each m emory bin is displayed.

A sequential plot (

SEQ

), plots each point successively as it comes from the data file. A sequential

plot provides more detail on the data than an averaged plot, but can appear rather messy.

YSI Incorporated PC6000 Software Operations Manual 16

Page 21

PC6000 Menus Section 4

The increase (

INC

) and decrease (

DEC

) plots are types of sequential plots. An increasing plot only

displays points when the X-axis values are increasing. A decreasing plot only displays points when

the X-axis values are decreasing. The increasing and decreasing sequential plots are especially

useful if you are profiling and display depth on the X-axis. Thus the plot shows only the time in

which the sonde is being lowered or raised.

Cross-parameter bins

Select

to set up the number of bins that will appear on the X-axis. This

feature only applies to reports and averaged plots (see descriptions above) with a parameter other

than Date + Time on the X-axis. Changing this value modifies the number of bins into which the

X-axis is divided. The smaller the number of bins, the wider and more general is the plotted

information. The maximum number of allowable bins varies with the capability of your computer

system, and is displayed in parentheses. For example, 100 is selected, and the maximum is 2350 as

shown in the screen above.

Parameters per plot

Select

option to setup the number of parameters that will be plotted together.

If you choose 1, there will be an individual X and Y-axis displayed for each selected parameter.

Select any number of parameters per plot, (from 1 to 4) which provides your data with the best plot

presentation.

Scaling Info

Select

from the Modify menu.

Scaling technique: automatic

Copy default to manual

Copy automatic to manual

Default

Scaling

Parameter Units Minimum Maximum Minimum Maximum Minimum Maximum

Manual

Scaling

Automatic

Scaling

------------ ------ ------ ------ ------ ------ ------ -----Temperature C -5 45 -5 45 4.6 2.1

Conductivity mS/cm 0 100 0 100 0 100

pH 2 14 2 14 2 14

ORP mV -1000 1000 -1000 1000 -1000 1000

DO mg/L 0 20 0 20 6.1 15

There are three scaling options.

Default Scaling

offers fixed limits. These limits correspond to the range of each parameter

as defined by the sensor specifications, so your plot will always fit within these limits.

Manual Scaling

allows you to enter custom limits for each parameter.

The computer scans the data file and determines the limits, then displays those limits on the

plot in

NOTE:

When entering a scaling technique, you need only type the first letter of the desired

technique and press

Copy default to manual or Copy automatic to manual

Select

Automatic scaling.

Enter

. PC6000 will fill in the rest.

to provide a quick way to copy

from either the default or automatic limits columns to the Manual scaling column.

YSI Incorporated PC6000 Software Operations Manual 17

Page 22

PC6000 Menus Section 4

Once you copy data into the manual scaling column, it can be modified. After copying is

complete, you will lose “manual limits” that were defined previously.

!

You can not change Default Scaling limits.

!

You can change Manual Scaling limits.

!

You can not change Automatic Scaling limits, but they are updated each time an automatically

scaled plot is generated.

4.1.2 VIEW

All of the

Filename: SAMPLE.DAT

Select

current file.

Select

portion of the menu) from the current file to the screen. As the report is scrolled onto the screen,

you can pause at any time by pressing any key. Once the entire report has been displayed, use the

Arrow ke ys, t he Pa ge Up a nd Pa ge Do wn keys , o r th e H ome a nd En d ke ys to move t o an y l o ca ti o n

within the report. If your computer system has limited RAM, early data points within a report may

become unavailable for viewing. To redisplay unavailable data points, simply redisplay the Report

from the beginning.

Select

Parameters and Control Info above. A plot can be abandoned at any time by pressing Esc, or

paused by striking any other key. If a plot is too large to fit on one screen, it will automatically

move to a new screen.

VIEW

Parameters... Header Print Report

Control Info... Report Print Plot

Scaling Info... Plot Definitions...

Header

Report

Plot

file options allow you to view file data on the screen.

MODIFY VIEW SYSTEM

Statistics Export

to display complete information about the sonde, probes, and configuration of the

to display a complete list of all readings (as defined by the settings in the Modify

to display a plot of the current data file to the screen. The plot can be customized, see

Statistics

Select

the displayed statistics are affected by the choices you make in the Parameters, and the Control info

menus described previously. To view statistics for a portion of a file enter the start and stop times

in Control Info. Statistics are only available after a report or plot is run.

YSI Incorporated PC6000 Software Operations Manual 18

to view statistics of a data file, or portion of a data file. As with reports and plots,

Page 23

PC6000 Menus Section 4

Sensor Type Minimum Maximum Mean Std.Dev.

Temperature (C) 4.69 21.00 5.88 2.877

Conductivity (mS/cm) 0.01 29.94 0.41 1.934

pH 6.32 9.44 7.64 0.200

ORP (mV) 75.7 313.5 156.7 36.45

DO (mg/L) 6.12 14.97 6.70 0.696

Number of samples = 1305

To print a copy of the Statistics screen, press the F2 key.

4.1.3 SYSTEM

SYSTEM

software program. The specific setup format of the report or plot can also be frozen for future use.

Filename: SAMPLE.DAT

Select the

prompt appears on the screen asking if your printer is ready. Press

operation. If more than 8 parameters are to be printed, PC6000 will assume you have a

wide-carriage printer. If your printer is not wide-carriage, set your printer to compress mode before

printing (see your printer manual for instructions). The printer port option, in the setup menu,

specifies the computer port to which the report will be sent.

Select the

appears on the screen asking if your printer is ready. Press

operation. The printer port option, in the setup menu, specifies the computer port to which the plot

will be sent.

menu options allow you to print the report and plot the data, or export the data to another

MODIFY VIEW SYSTEM

Parameters... Header Print Report

Control Info... Report Print Plot

Scaling Info... Plot Definitions...

Statistics Export

Print Report

Print Plot

option to send your report to the printer. After you select this option, a

Enter

to proceed with the print

option to send your plot to the printer. After you select this option, a prompt

Enter

to proceed with the print

Definitions

Select

Each file contains all options and setup information you defined in the Modify menus, see the

MODIFY options section, described earlier. After you have selected Definitions from the

SYSTEM menu.

YSI Incorporated PC6000 Software Operations Manual 19

to create and save different report or plot configurations from the same data file.

Page 24

PC6000 Menus Section 4

Active definition: default report/plot

Select an action: Select a definition

Create new definition

Rename active definition

Delete active definition

Clear active definition

Active definition

Highlight

Highlight

Select a definition

Create new definition

displays the name of the current active definition.

and press

Enter

and press

to retrieve an old definition.

Enter

to create a new report and plot format. You will

need to name the new definition, then specify the new definition by v ariation of the current format.

Example:

if you want to report and plot only dissolved oxygen readings in mg/L

for your study instead of all parameters, first create a new definition at the prompt

by typing “DO”. Then exit the definition menu by pressing

Parameters

menu and eliminate all parameters except DO, mg/L. This data

Esc

. Scroll to the

presentation can then be reported, plotted, or exported, but more importantly, if

you return to this data file at a later time, the “DO” definition can always be

selected to provide this same data format since it has been saved under its own

designation.

Remember: Always name the new definition in the “create new designation” option prior to making

changes that will define the new format.

Rename active definition

Select

Delete active definition

Select

option to change the name of the active definition.

option to remove the active definition from the file.

Select

Clear active definition

option to reset the active definition to default values. Thus all

customization features that you previously set up are reset to the default v a lues.

Export

Select

menu option to export a data file to another program. After selecting the Export

option you will be asked to name the file to be exported. The default name is the same as the

current data file with the extension .PRN, .CDF, or .SDF, depending on the export format selected,

ASCII, Comma & Quote Delimited or Space Delimited, respectively. Export formats are selected

in the Advanced Setup menu, see

Section 4.2, Setup Menu

). After the file has been exported to

disk, it can be retrieved using any program you choose. This feature is especially useful when

exporting to a database or a spreadsheet program. Follow the importing instructions outlined in the

destination program to retrieve the export file you hav e created.

YSI Incorporated PC6000 Software Operations Manual 20

Page 25

4.2 SETUP MENU

Highlight

specifications.

------DISPLAY-FORMATS---- ---------COMPUTER-CONNECTIONS-------Date format: mdy Comm port: 2

Date separator: / Baud rate: 9600

Time separator: : Printer port: 1

Radix mark: . Printer type: HP LaserJet laser

--------MORE-SETUP------- -----------COMPUTER-DISPLAY---------Data capture setup... Menu colors: Pacific Ocean (color)

Advanced setup... Plot colors: Danube River (color)

Other than the Comm port and Printer port options, the default values should be adequate to

perform virtually every function of the Sondes.

Under the COMPUTER-CONNECTIONS heading, sel ect

if the default value is not correct. This option must be properly set before you can communicate

with the software inside the Sonde. See

sonde and PC software. If you have difficulty communicating with the sonde, change the Com port

and try again. PC6000 allows only Com port 1 or 2.

Setup

from the PC6000 menu bar and press

Graphics mode: Automatic selection

Section 4.1.3, System

Enter

to configure the PC program to your

Comm port

to make necessary changes

, to verify agreement between the

Change the baud rate by highlighting

baud rates that are displayed. The baud rate you select here must match the baud rate set in the

sonde (which defaults to 9600).

Printer port

Select

printing, specify a different printer port (1, 2, or 3) and try again.

Printer type

Select

best describes your system's printer. If you have difficulty printing, try a different selection here.

You may need to consult the printer instruction manual to determine what type of printer your

printer emulates. The printer type option only affects plot

printing.

to specify where your computer’s printer is connected. If you have difficulty

to provide a list of printers that are supported by PC6000. Select a printer that

Baud rate

, then press

Enter

. Select from the list of possible

output, having no effect on report

Page 26

PC6000 Menus Section 4

Under DISPLAY-FORMATS change any default values that are not appropriate by typing in the

correct format.

Date format: mdy

Date separator: /

Time separator: :

Radix mark: .

Users may specify any order of day (d), month (m), and year (y) by selecting Date format. The

other options are used primarily outside of the US where other characters are sometimes used to

separate numbers in dates, times, or decimals.

Use the options below to specify what type of monitor your computer has, and change the colors of

both menus and plots as they are displayed on the screen.

Menu colors

Plot colors

Graphic Mode

The color selections have no effect on the printed output of reports and plots. Simply press

to activate either the Menu or Plot color selections, scroll through the choices with the Arrow keys,

and after selecting a color scheme, confirm it by pressing

are to your liking, you can setup a User Defined color schem e. See

From the list provided, choose a graphics mode which best matches your video adapter and

monitor. If you hav e difficulty , consult y our v ideo adapter's instruction manual.

Under

subsection. Section,

configure your sonde to provide “real-time” graphical display of in the discrete sample m ode.

MORE-SETUP

there are two important menu options. Each has been given a separate

Data Capture/ Real-Time Setup

Enter

again. If none of the color schemes

Section 5, Advanced Setup

, provides the instructions for you to

Enter

.

4.3 DATA CAPTURE / REAL-TIME SETUP

Real-time

When

is taken in the Discrete sample mode by the sonde. Each reading is display ed at the bottom of the

real-time screen, and plots are updated with the arrival of each data point. In addition, the data will

be automatically stored to the disk drive that y ou select.

mode has been properly set up, you will be able to v iew the data in real-time as it

YSI Incorporated PC6000 Software Operations Manual 22

Page 27

PC6000 Menus Section 4

Data capture setup

The

screen will appear similar to the one shown below.

Parser: 6000 X-axis time per screen: 1

Site name: YSPRINGS Parameters per plot: 2

Instr ID: 96K12345 Beep notification: off

Filename: CLRLAKE2 Auto-configure

Column Parameter & Units Minimum Maximum

------- ----------------- -------- -------1 Temperature (C) -5 45

2 Specific Cond (mS/cm) 0 235

3 DO (%) 0 200

4 DO (mg/L) 0 20

5 DO Charge 0 110

6 pH 2 14

The Data capture setup process is not difficult, but you must

carefully

follow the instructions below

to be sure of successful operation.

STEP 1.

Verify parameters in the Report setup (sonde software). Select

main menu bar and, if required, type “menu” at the # sign. Select

1-Start sampling

then

. Make certain that the parameters that you want to view in real-time are

1-Run

Sonde

, then

from the PC6000

1-Discrete

sample,

displayed correctly. Adjust these parameters, if necessary, via the Report Setup menu in the Sonde

software. Check these parameters again by viewing what is displayed on the screen. Exit the

Sonde menu by pressing

STEP 2.

menu bar select

Choose parameters in Data capture setup (PC6000 software). From the PC6000 main

Setup

F10

and return to the main menu bar of the PC6000 software.

Data capture setup

, then

. Verify that the Parser setting is “6000” for

600XLM, 6600 and 6920 sondes or “600” for 600R, 600XL and 6820 sondes. If not, type “6000”

in at the prompt and press

Enter

. Enter an appropriate site name, then press

Enter

.

The Site Name identifies the sampling location and is displayed on the File Header and Real-Time

screens and printouts. Enter an appropriate file name, then press

8 characters. Next highlight

Auto-configure

, then press

Enter

Enter

. The filename is limited to

. There will be a 5-10 second delay

while the PC6000 software examines the sonde software to determine the parameters that you have

decided to view in real-time. When the process is complete, these parameters appear in the list in

the lower portion of the Data capture setup screen.

STEP 3

Enter

per plot

. Set up display parameters which you wish to view (or hear) in real-time. Be sure to press

after each entry. First, set the

X-axis time per screen

that can be a value from 1 to 4. Finally, set the

in minutes. Next, set the

Beep notification

Parameters

to indicate the

acquisition of good data, bad data, or all data (both). Bad data contains errors in the communication

protocol when arriving from the sonde. This is rarely observed. If you prefer, you can eliminate the

beep function completely by selecting “off”. Simply type in one of the 4 notifications (good, bad,

both, off) indicated above, and press

Enter

.

STEP 4.

Set the scaling for each of the parameters in the lower right portion of the menu. There is

no automatic scaling in this mode, so you should select the manual scaling ranges that will result in

YSI Incorporated PC6000 Software Operations Manual 23

Page 28

PC6000 Menus Section 4

a meaningful display of your data. These selections will become easier with experience. Use the

Tab key to move from Minimum to Maximum, and the arrow keys to move vertically within the

scaling limits. Be sure to press

Enter

after each scaling entry.

STEP 5.

menu bar by pressing Esc twice. Then access

Type “

Start sampling

discrete sample mode is still operative, exit to the PC6000 main menu bar by pressing

Start sampling with the sonde. After entering scaling factors, exit to the PC6000 main

Menu

” at the # prompt and press

and begin sampling at the sample interval that is suitable for your study

Sonde

Enter

from the PC6000 main menu and press

. Select

1-Run

, then

1-Discrete

sample, then

Enter

. While the

Do not

F10.

1-

press Esc or the sampling will be terminated.

STEP 6

Enter

. View the data in real-time. From the PC6000 main menu bar, select Real-Time

. The Discrete Sample data from the sonde will be plotted on the display and will be logged

and press

to disk automatically under your desig n ated file nam e.

COMMON CAUSES OF ERRORS IN Real-Time MODE

The Parser is not set correctly.

sondes, and “600” for 60R, 600XL and 6820 sondes.

You have selected more parameters in the Sonde Report setup than can be viewed on the

computer screen.

Remove Time and Date and/or other less important parameters in the Report

setup menu so that all selected parameters are visible in Discrete Sam ple display .

The name that you entered for your file name already exists on your storage disk, but the file

format for the initial study is different from the current file format.

data file or delete the existing data file of this name from y our disk .

Set the Parser by typing in “6000” for 600XLM, 6600 and 6920

Change the name of the

.

You exited the Discrete sample mode of the sonde software using Esc rather than F10.

Return

to the Sonde menu and select 1-Run. Restart the Start sampling mode and exit with F10 to the

PC6000 menu bar. Choose Real-Time and press

YSI Incorporated PC6000 Software Operations Manual 24

Enter

.

Page 29

SECTION 5 ADVANCED SETUP

These options are provided for the advanced user who has special requirements of PC6000. It is

important to remember that the default values assigned to these options will be appropriate for most

operations.

Select

Advanced Setup menu appears.

Default scaling technique: automatic Export file format: prn

Default parameters per

plot:

Full screen sonde menu: no Export header

Multiple formula query: yes CDF delimiter: ,

Default data directory:

User-defined menu

colors...

User-defined plot

colors...

User-defined printer control codes...

Setup

from the PC6000 main menu bar, highlight

-------------GLOBAL-SWITCHES---------

---

2 Export date format: form

---------------DATA-FILES------------

---

--------------USER-DEFINED-----------

---

Advanced Setup

------------EXPORT---------

format:

and press

--

Enter

-

.

Full-screen sonde menu: yes

Select

PC screen, or should take place within the usual border drawn by the PC software.

Export date format: FORM

Select

data.

FORM (formatted):

MM/DD/YY and HH:MM:SS.

SEP (separated):

6 numeric values (m,d,y ,h,m ,s).

COMB (combination):

YYYYMMDD and a string of the form HH:MM:SS.

JUL (Julian):

to specify whether terminal emulation should use the entire

to choose from a variety of date formats for the exported

Page 30

Advanced Setup Section 5

A ten-digit integral number of seconds past midnight March 1, 1984.

NUM (numeric):

A fixed point number of the form DDDDDD.TTTTTT where DDDDDD is the number of days past

December 31 1899, and where TTTTTT is the fractional part of the day which has elapsed (.750000

is 6 PM).

REL (relative):

A fixed-point number of the form HHHH.HHHH giving the number of hours elapsed since the firs t

sample in the file.

NOTE:

The export date format only applies to CDF and SDF export files. The date and time

formats displayed on the PC6000 screen are determined in the SETUP m enu.

Export header format: --

Select

to specify what header lines (if any) should be included at the

top of CDF and SDF export files. The header can contain up to three lines.

(-): No header lines.

P: One header line, containing the name of each Parameter.

U: One header line, containing the name of each Unit.

T: One header line, containing the name of the report Title.

Multiple formula query: N

Select

to change the characteristics of a derived parameter. This

option should be set to N for no, except for advanced users.

User-Defined menu colors

Select

using this option permanently modifies the color scheme of

to customize the menu colors of PC6000. Changing the colors

User Defined Colors

in the Setup

menu. To use this feature, select a menu item to be changed from the lists provided. Find the box

that has the same title as the item you selected. Stop scrolling when the desired color is displayed

and press

Esc

.. Continue this process until all colors appear to your liking .

Select

User-Defined plot colors

to modify the plot colors of PC6000. As detailed in the

User-defined menu colors section above, select plot items to be changed from the list provided and

press

Enter

. Watch the sample plot as you repeatedly press

Enter

. Press

Esc

when the item color

you prefer is displayed. Repeat this process until all plot colors are to your liking .

Default Data Directory:

Select

to specify the drive and directory to which you want all PC6000

files to be stored. Type the drive and directory to which you wish all PC6000 data files to be stored

when captured from the sonde.

Example:

Typing C:\PC6000 would save all data files to the C:\ drive and to a

directory called PC6000.

User-defined printer control codes:

Select

to manually enter special printer commands. Consult

your printer's instruction manual for the specific com mands compatible with your printer.

YSI Incorporated PC6000 Software Operations Manual 26

Page 31

Advanced Setup Section 5

Select

program. See

Export file format: PRN

Section 4.1, File Menu

for more information. The software determines the correct

to setup a format if you wish to export data to another

format to specify to which you want to export data. Consult the manual of the destination software

to determine the compatible form at.

The three export format choices PC6000 allows are:

Printer format (PRN):

Select this option to export data in exactly the same format as it would be sent to a printer. All page

headings, column headings, and form feeds are present in the export file.

Comma & Quote (“ “) delimited format (CDF):

Select this option to export data in a format that encases all strings of data in double quotes, and

separates each option on each line with a comma (or other delimiter character). There will be no

spaces on any line unless they are inside a string.

Example:

"12/31/92","23:59:59",123.45,12.3,123

Space delimited format (SDF):

Select this option to export data in a format with fixed-column fields, which can be string or

numeric. Strings and dates are left justified in their field, numbers are right justified. Strings are

not encased in quotes. Lines are fixed width, and columns are apparent when viewing the file.

Field widths are as follows:

•

title is 80 characters

•

parameter names and units are 8 characters each

•

numbers are 8 digits including the radix separator and decim al dig its

•

formatted dates are two 8 character strings separated by 1 space

•

separated dates are six 3-digit values

•

combined dates are an 8-digit num ber and an 8 character string separated by 1 space

•

Julian dates are 10 digits

•

numeric dates are 13 digits

•

relative dates are 9 digits

Example:

Default scaling technique: or Automatic

Select

default values for reports and plots. These options are described in detail in

12/31/92 23:59:59 123.45 12.3 123

or

Default parameters per plot:

Section 4.1.1, Modify

2

to modify the

The Setup menu determines what the default scaling technique and parameters per plot should be

for each new data file. Change the values here to modify these options for future reports and plots.

To modify these options only for a current file, see

YSI Incorporated PC6000 Software Operations Manual 27

Section 4.1, The File Menu

.

.

Page 32

SECTION 6 TROUBLESHOOTING

This section contains a troubleshooting table that will be helpful to identify the causes of the

most common difficulties that may occur while operating the PC6000 software. The

column describes the type of difficulty that you might experience. The

describes the conditions that might cause the stated symptom. The

simple steps that can be followed to correct for the "possible cause" and cure the "symptom"

being experienced. The column entitled

subsection in the manual where you may find additional information.

If you need assistance that this Troubleshooting section can not provide, please contact YSI or

your authorized dealer. See Section 7 for specific contact information.

SYMPTOMS POSSIBLE CAUSE ACTIONS REF

PC6000 software

operates but no data

are captured to disk.

PC6000 displays data,

no files found.

Expected parameters

are not displayed on

reports or plots

Unable to print

reports or plots

Data capture not set up Move cursor to data capture

Will not auto configure. Enter parser, site name , ID 5

After auto configure, no data

arrives

Data directory path not

recognized

Data files not readable Export file as PRN, CDF, SDF 6

Parameters not added to Yaxis list

Sensor disabled Check sensor setup instructions

Printer port improperly

configured

Ref

is the number of the reference section and

setup and make proper

selections.

Return to sonde menu and start

sonde

Move cursor to PC6000

Advanced setup and establish a

directory

Add parameter 3

in the sonde manual

Try a screen print out to the

printer (print scrn)

Possible cause

Action

column provides

Symptom

column

3

2

Video screen of PC is

not readable

When selecting

“sonde” from PC6000

top line, sonde menu

not shown

Printer port improperly set Check setup 6

Printer type improperly

selected

Print cable improperly

connected

Incorrect menu color option

has been selected

Incorrect graphic mode Select compatible graphic mode 5

Prompt # appears in place of

menu

Communication problem Make certain com port

Check setup 6

Check connections at both ends

Select appropriate menu

parameter

Type “menu” and press (enter) 4

selection is correct.

Page 33

SECTION 7 CONTACT INFORMATION

For any questions regarding PC6000 software, or any YSI equipment, please contact YSI Technical

Support at (800) 897-4151 or e-mail at ysi@support.com. For ordering YSI equipment or

accessories, please see your YSI dealer, or the contact inform ation below.

1700/1725 Brannum Lane

Yellow Springs, Ohio 45387 USA

(800) 765-4974 (937) 767-7241

FAX: (937) 767-9320

Website: http://www.ysi.com

E-mail: info@ysi.com

Page 34

SECTION 8 SENSOR DRIFT APPLICATION NOTE

SENSOR DRIFT COMPENSATION

The following application note is designed to facilitate the use of the sensor drift software included

in the PC6000 package by providing the user with a specific exam ple.

After laboratory calibration, a user deployed their sonde in a readily accessible stream on 10/14/92

with the instrument set to capture data to memory at 15-minute intervals. The study was nam ed

SRUN7. The instrument was left in place for approximately 2 weeks and during this time period,

the user visited the site 3 times, took a water sam ple in a sealed bottle, and, on returning to the

laboratory, measured the dissolved oxyg en and pH w ith recently calibrated instruments. The user

also collected a water sample when the instrument was retrieved (10/26/92) and m easured dissolved

oxygen and pH in the laboratory. The following records were kept.

Laboratory Measurements

Date Time DO (mg/L) pH

10/17/92 8:00 5.40 7.62

10/29/92 8:00 7.50 7.63

10/23/92 10:00 7.30 7.58

10/26/92 8:15 6.32 7.60

The user now has everything required to compensate the DO and pH readings for field drift:

"

The data file captured by the computer or data collection platform.

"

The correct DO and pH readings at various times during the study based on grab samples of

water which were analyzed with recently calibrated laboratory instruments.

PC6000 software for retrieval and manipulation of the data from the sonde m emory.

"

COMPENSATION PROCEDURE

1- For this example, make certain that the data file is present in a subdirectory of the hard

drive (C:\PC6000).

2- "Exit" from PC6000 software using the top menu bar. The "C:\PC6000" prompt

should be displayed.

Page 35

Sensor Drift Compensation Section 8

3- The user must now write compensation files which contain the above data points and

which will be accessed automatically by the PC 6000 software. If the "C:\PC6000" prompt is

displayed, the files will be located in the same subdirectory as the SRU N7.D A T data file

compensation file for each parameter (DO and pH, in this example) must be written.

overall filename is SRUN7.D AT, the DO compensation file will be called SRUN7DO.CMP

and the pH compensation file will be called SRUN7PH.C MP. No te that for accurate record

keeping, the compensation file nam e should somehow be related to the name of the overall

study. For example, it will becom e extremely confusing if all dissolved oxyg en compensation

files are named "DO.CMP" as shown in the brief example in the manual.

. A

Since the

4- To compose the DO compensation file, ty pe the following at the "C:\PC6000" prompt

C:\PC6000

COPY CON SRUN7DO.CMP --

:

(Return)

10/17/92 8:00:00 5.40

10/20/92 8:00:00 7.50

10/23/92 10:00:00 7.30

10/26/92 8:15:00 6.32

Control Z

The screen will display "1 File Copied" if all is correct and the file SRUN7D O .CMP will now

be in the "PC6000" subdirectory of the C drive. Note that the data must be entered in exactly the

above format:

5- To compose the pH compensation file, ty pe the following at the "C:\ PC6000" prom pt:

C:\PC6000

(Return)

(1) The time must contain a designation for seconds ev en if the user does not

(2) There must be a space between the date, time, and param eter v alue entries.

COPY CON SRUN7PH.CMP

(Return)

(Return)

(Return)

(Return)

know this value exactly; an entry of XX:XX

--

:00

is suggested for all time inputs

(Return)

10/17/92 8:00:00 7.62

10/20/92 8:00:00 7.63

10/23/92 10:00:00 7.58

10/26/92 8:15:00 7.60

Control Z

(Return)

(Return)

(Return)

(Return)

(Return)

The screen will display "1 File Copied" if all is correct and the file SRUN7P H.C MP w ill now

be in the "PC6000" subdirectory of the C drive.

6- After writing the DO and pH comp ensation files to the C:\ PC 6000 directory , ty pe

"PC6000" at the "C:\PC6000" prompt to re-enter the PC6000 software package. Just as would

be done for no compensation, prepare the plot and report output format desired by m anipulation

of the "Parameters", the "Control Inform ation", and the "Scaling Information".

7- After the format is finalized, re-enter the "Parameters" section of the software. Place

YSI Incorporated PC6000 Software Operations Manual 31

Page 36

Sensor Drift Compensation Section 8

the cursor on the "DO (mg/L)" entry, press "Return", and then select the "Detail this parameter"

option within the window.

8- Move the cursor to the "Compensate" entry and press "Return". Move the cursor to

the "DO, mg/L" entry and press "Return" to activate the com pensation of this parameter.

9- Press the "Tab" key once to move the cursor to the rig ht portion of the screen and then enter the

location and designation of the DO compensation file in this bar. I n this case, the entry is:

C:\PC6000\SRUN7DO.CMP

procedure has been followed:

. Press "Return" and the screen should appear as follows if the

Parameter: DO (mg/L)

Formula: Temp (C) Cond (mS/cm) DO (%)

Inputs: Temperature (C) from 6030* probe, channel 0

Conductivity (mS/cm) from 6560 probe, channel 1

DO (%) from 6560 probe, channel 2

Compensate: DO (mg/L) c:\pc6000\srundo.cmp

10- Carry out the same procedure for pH:

(a) Activation of the compensation, and

(b) Entry of the location and designation of the pH compensation file.

YSI Incorporated PC6000 Software Operations Manual 32

Page 37

SECTION 9 ACCESSORIES

STANDARD EQUIPMENT WITH YSI SONDES

"

600R, 600XL, 600XLM, 6820, 6600 or 6920 Sonde with Calibration Cup

"

EcoWatch for Windows Software

"

Operations Manual

"

Guard for Probe Compartment

"

6570 Maintenance Kit

"

6560 Conductivity/Temperature Probe ( not supplied with the 600R)

PROBES FOR THE SONDES

"

6560 Conductivity/Temperature Probe

"

6561 pH Probe

"

6562 Rapid Pulse DO Probe

"

6565 Combination pH/ORP Probe

"

6026 Turbidity Probe, wiped

"

6036 Turbidity Probe, unwiped

"

6882 Chloride Probe

"

6883 Ammonium Probe

"

6884 Nitrate Probe

OPTIONAL ACCESSORIES FOR THE SONDES

"

PC6000 Software (Available at no cost)

"

6027 Turbidity Wiper Kit

"

6035 Probe Reconditioning Kit for 6562 Dissolved Oxyg en Probe

"

062655 Carrying case

"

6038 12 VDC power supply with 110 VAC input

"

6037 12 VDC Power Supply with 220 VAC input

"

6100 External Power Connector, attaches to 6095B Field Cable

"

6570 Maintenance Kit

"

5775 Membrane Kit

"

6108 Desiccant Cartridge Kit

"

6109 Desiccant Canister Kit

"

065802 Replacement Desiccant

CABLES FOR THE SONDES

"

6093 Field Cable, 100 ft (30 m)

"

6092 Field Cable, 50 ft (15 m)

"

6091 Field Cable, 25 ft (7.5 m)

"

6090 Field Cable, 8 ft (2.4 m)

"

6191 Field Cable, Vented, 25 ft (7.5 m)

"

6192 Field Cable, Vented, 50 ft (15 m)

"

6067B Low Cost Calibration Cable, Dry use only; 10 ft (3m)

Page 38

Accessories Section 9

"

6077B CE Calibration Cable, 10 ft. (3m)

"

SP6093-L Special field cables available in 25 ft (7.6 m) increm ents; Maximum 1000 ft (305 m)

"

6098B Field Cable to 610-D/610-DM adapter

"

6096 Field Cable to Flying Lead (wire) adapter, 15 ft (5m)

"

6095B Field Cable to Female DB-9 (PC Serial with Power Connector)

"

6099: 610 to Female DB-9 (PC Serial)

"

6100 External Power Connector, attaches to 6095B Field Cable (6ft)

"

6102: 610 to Portable Power Pack Adapter

"

6103 MS-8 Dust Cover (caps connector when not in use)

CONDUCTIVITY REAGENTS

"

3161 Calibrator Solution, 1,000 uS/cm (quart)

"

3163 Calibrator Solution, 10,000 uS/cm (quart)

"

3165 Calibrator Solution, 100,000 uS/cm (quart)

"

3167 Calibrator Solution, 1,000 uS/cm (box of 8 pints)

"

3168 Calibrator Solution, 10,000 uS/cm (box of 8 pints)

"

3169 Calibrator Solution, 100,000 uS/cm (box of 8 pints)

pH REAGENTS

"

3821 pH 4 Buffer (box of 6 pints)

"

3822 pH 7 Buffer (box of 6 pints)

"

3823 pH 10 Buffer (box of 6 pints)

ORP REAGENTS

"

3682 Zobell Solution (125 ml)

AMMONIUM REAGENTS

"

3841 1 mg/L ammonium-nitrogen standard solution

"

3842 10 mg/L ammonium-nitrogen standard solution

"

3843 100 mg/L ammonium-nitrogen standard solution

NITRATE REAGENTS

"

3885 1 mg/L nitrate-nitrogen standard solution

"

3886 10 mg/L nitrate-nitrogen standard solution

"

3887 100 mg/L nitrate-nitrogen standard solution

TURBIDITY REAGENTS

"

3845 0 NTU standard

"

6073 100 NTU standard suspension

"

3846 200 NTU standard suspension

"

3847 800 NTU standard suspension

YSI Incorporated PC6000 Software Operations Manual 34

Page 39

Accessories Section 9

DISPLAYS, LOGGERS, AND ACCESSORIES

"

610-D Handheld Field Display with Accessories

"

610-DM: 610-D with 128K of memory

"

610-DM: 610-D with 512K of memory

"

614 Ultraclamp, C-clamp Mount for 610

"

615 Leather Carrying Case for 610

"

616 Cigarette lighter adapter (powers and charges 610s)

"

617 Replacement Battery Pack for 610

"

6099: 610 to Female DB-9 (PC serial)

"

6097 Blank port plug for 610

"

6104 Replacement Charger Jack for 610

"

6042 Battery Charger for 610

"

6101 Portable Power Pack for 610 or sondes

LOGGER/TELEMETRY

"

1240: SDI-12 Logger for interfacing as many as 10 6-Series devices. Can also serve as RF

telemetry platform (RF radio, battery, interface cable, junction box not included)

"

1240B1: 7 amp hour, lead acid 12 VDC rechargeable battery

"

1240B2: 20 amp hour, alkaline 6 VDC battery (2 required)

"

1240AC: 110 VAC charger/transformer assembly, charges 1240B1

"

1240SO: 1240 Solar Panel Assembly, includes panel, mount, cable

"

1240SE: 1240 Serial data interface cable, connects 1240 to PC

"

1240JU: 1240/6 series Junction Box, provides input of multiple SDI-12 devices (standard

configuration is for 5 devices)

Note: For RF radio frequency telemetry system applications, contact YSI Customer Support @ 1800-363-3269 (USA) or 508-748-0366 or fax 508-748-2543.

SOFTWARE

"

PC6000: MS-DOS compatible communication, upload, plotting

"

610SOFT: Software upgrade for Model 610 D/DM

"

6920SOFT: Software upgrade for Model 6920

"

EW-DOS EcoWatch for MS-DOS Applications

"

EW-WIN EcoWatch for Windows (Use EW-WIN for 6-Series Applications)

YSI Incorporated PC6000 Software Operations Manual 35

Page 40

Accessories Section 9

YSI Incorporated PC6000 Software Operations Manual 36

Page 41

Page 42

1700/1725 Brannum Lane

Yellow Springs, Ohio 45387 USA

(800) 765-4974 (937) 767-7241

FAX: (937) 767-9320

Website: http://www.ysi.com

E-MAIL: INFO@YSI.COM

Item # 069305

Drawing # A69305

July 1998

Loading...

Loading...