Page 1

User Manual

DOCUMENT #606335

EcoSense® ODO200

Dissolved oxygen & temperature

instrument

USER MANUAL

English, Français, Español, Português

Page 2

Item #606335

Rev B, September 2014

For the latest version of this manual,

visit ysi.com

©2014 YSI Incorporated.

The YSI logo and EcoSense are registered trademarks of YSI

Incorporated.

Page 3

CONTENTS

Warranty ................................................................................................i

Introduction .........................................................................................1

Getting Started ....................................................................................1

Initial Inspection .....................................................................1

Precautions .............................................................................1

The Probe .........................................................................1

Initial Setup ............................................................................2

Preparing the Probe ........................................................2

Battery Installation ...........................................................3

Key Pad ....................................................................................4

Main Display ..........................................................................5

Operational Procedures - Taking Measurements .............................6

Measurement Modes - % or mg/L ........................................7

Sampling modes - Continuous or Manual ...........................7

Saving, Viewing and Deleting Data ......................................7

Calibration ..............................................................................8

Temperature .....................................................................8

Dissolved Oxygen ...........................................................8

Maintenance and Troubleshooting ...................................................9

Sensor Maintenance - Dissolved Oxygen ............................9

Cleaning the Sensor Cap ................................................9

Sensor Cap Replacement ............................................10

Entering Sensor Cap Coefficients into the EcoSense

ODO200 .........................................................................11

Rehydrating the Sensor Cap ......................................12

Sensor Maintenance - Temperature ...................................12

Sensor Storage .....................................................................12

Short-term Storage ......................................................12

Long-term Storage ........................................................13

Page 4

Troubleshooting ...................................................................13

Specifications .....................................................................................14

Accessories / Part Numbers .............................................................15

Contact Information and Service .....................................................16

Ordering and Technical Support ........................................16

Service Information ..............................................................16

Recycling ...............................................................................16

Appendix A-DO% Calibration Values ..............................................17

Page 5

WARRANTY

The EcoSense® ODO200 Instrument, probe, cable and sensor cap are

warranted for one year from date of purchase by the end user against

defects in materials and workmanship, exclusive of batteries and any

damage caused by defective batteries. Within the warranty period, YSI will

repair or replace, at its sole discretion, free of charge, any product that YSI

determines to be covered by this warranty.

To exercise this warranty, write or call your local YSI representative, or

contact YSI Customer Service in Yellow Springs, Ohio at +1 937 767-7241,

800-765-4974 or visit YSI.com for a Product Return Form. Send the product

and proof of purchase, transportation prepaid, to the Authorized Service

Center selected by YSI. Repair or replacement will be made and the

product returned, transportation prepaid. Repaired or replaced products

are warranted for the balance of the original warranty period, or at least 90

days from date of repair or replacement.

Limitation of Warranty

This Warranty does not apply to any YSI product damage or failure caused

by: (i) failure to install, operate or use the product in accordance with

YSI’s written instructions; (ii) abuse or misuse of the product; (iii) failure

to maintain the product in accordance with YSI’s written instructions or

standard industry procedure; (iv) any improper repairs to the product; (v)

use by you of defective or improper components or parts in servicing or

repairing the product; or (vi) modification of the product in any way not

expressly authorized by YSI.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY WARRANT Y OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. YSI’s LIABILITY UNDER THIS WARRANTY

IS LIMITED TO REPAIR OR REPLACEMENT OF THE PRODUCT, AND THIS

SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY DEFECTIVE

PRODUCT COVERED BY THIS WARRANTY. IN NO EVENT SHALL YSI BE

LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES RESULTING FROM ANY DEFECTIVE PRODUCT COVERED BY

THIS WARRANTY.

i

Page 6

THIS PAGE LEFT INTENTIONALLY BLANK

ii

Page 7

INTRODUCTION

Thank you for purchasing the EcoSense ODO200, a precise handheld

instrument that measures temperature and dissolved oxygen in % and

mg/L. The EcoSense ODO200 measures dissolved oxygen in water

using optical, lifetime luminescence technology and uses a digital

signal to send information between the instrument and probe. Key

advantages of the EcoSense ODO200 include the elimination of sensor

flow dependence (stirring) and sensor warm-up time, greater stability,

less frequent calibrations, and the elimination of frequent membrane/

electrolyte changes. This instrument uses one 9V battery.

For additional product specification information, please visit ysi.com

or contact Technical Support at 800-897-4151 (+1 937 767-7241) or

environmental@ysi.com.

GETTING STARTED

INITIAL INSPECTION

Carefully unpack the instrument and accessories and inspect for

damage. Compare received parts with items on the packing list. If any

parts are damaged or missing, contact YSI Customer Service at 800897-4151 (+1 937 767-7241) or the authorized YSI distributor where

the instrument was purchased.

PRECAUTIONS

THE PROBE

Sensor caps last longer if stored in a moist environment and kept clean

and free of scratches in the paint layer. Erratic readings can result from

damaged or dirty caps. If unstable readings occur from large scratches

in the paint or dye layer, replace the sensor cap. See the Maintenance

and Troubleshooting section of this manual for information on how to

clean or replace the sensor cap. The average sensor cap replacement

interval is 12 to 18 months, although they may last longer.

Avoid substances that may damage probe materials such as

concentrated acid, caustics and strong solvents. Probe materials

include urethane (cable), Xenoy (probe body), acrylic (sensor cap) and

acetal and stainless steel (probe guard).

1

Page 8

To prevent the sensor cap from drying out, store the probe in the gray

calibration/storage sleeve with a moistened, clean sponge. In the event

the sensor cap dries out, rehydrate it following the instructions in the

Maintenance and Troubleshooting section of this manual.

INITIAL SETUP

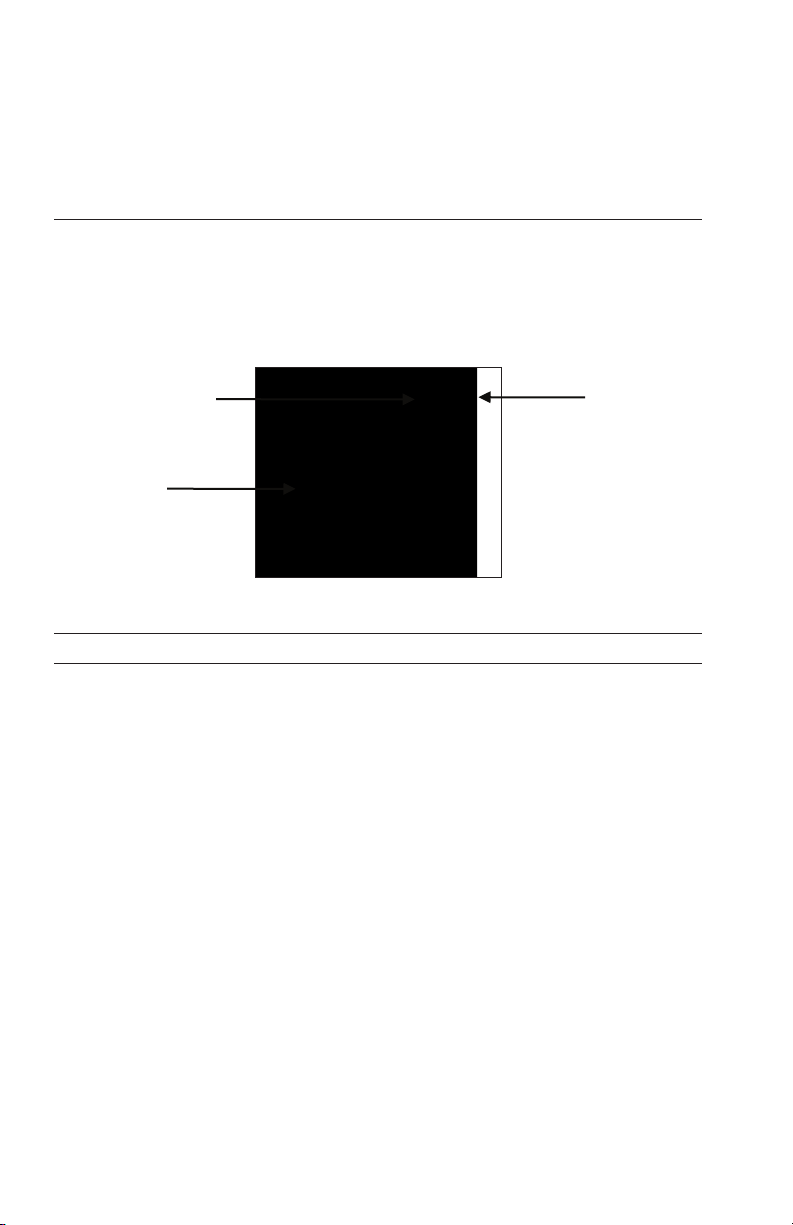

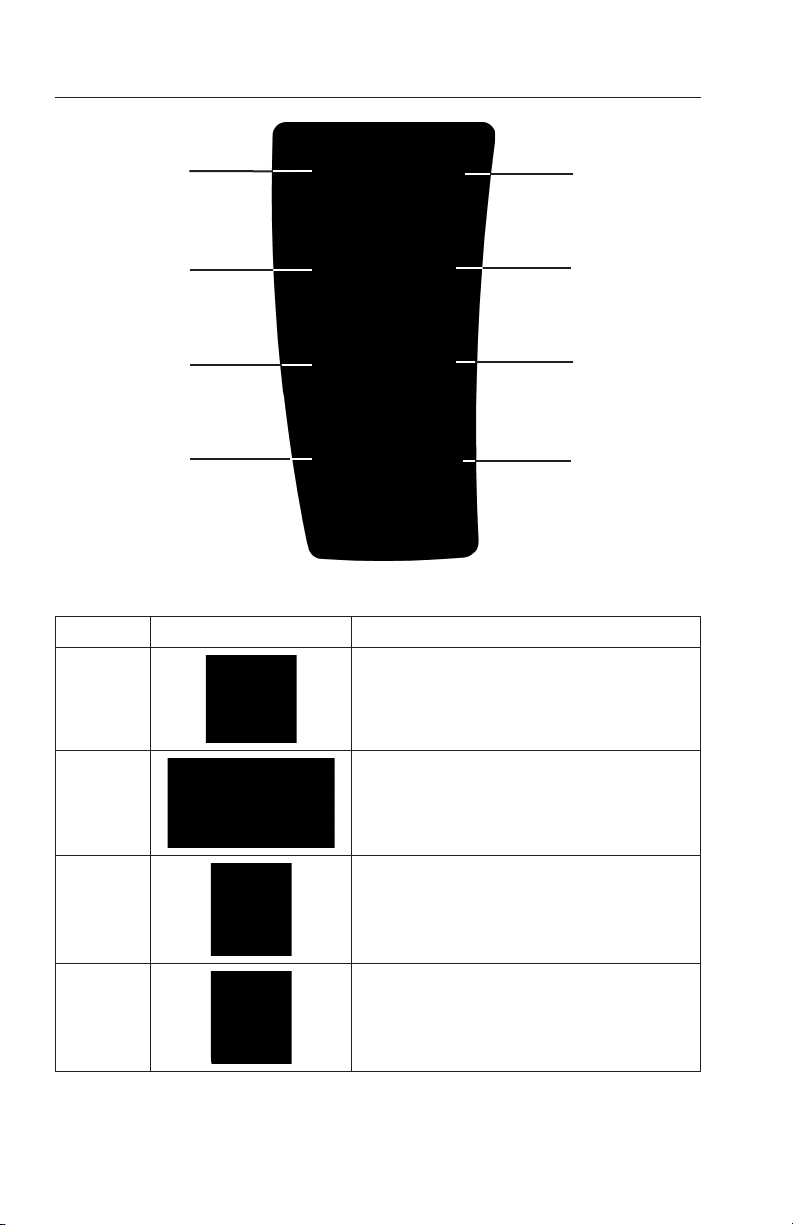

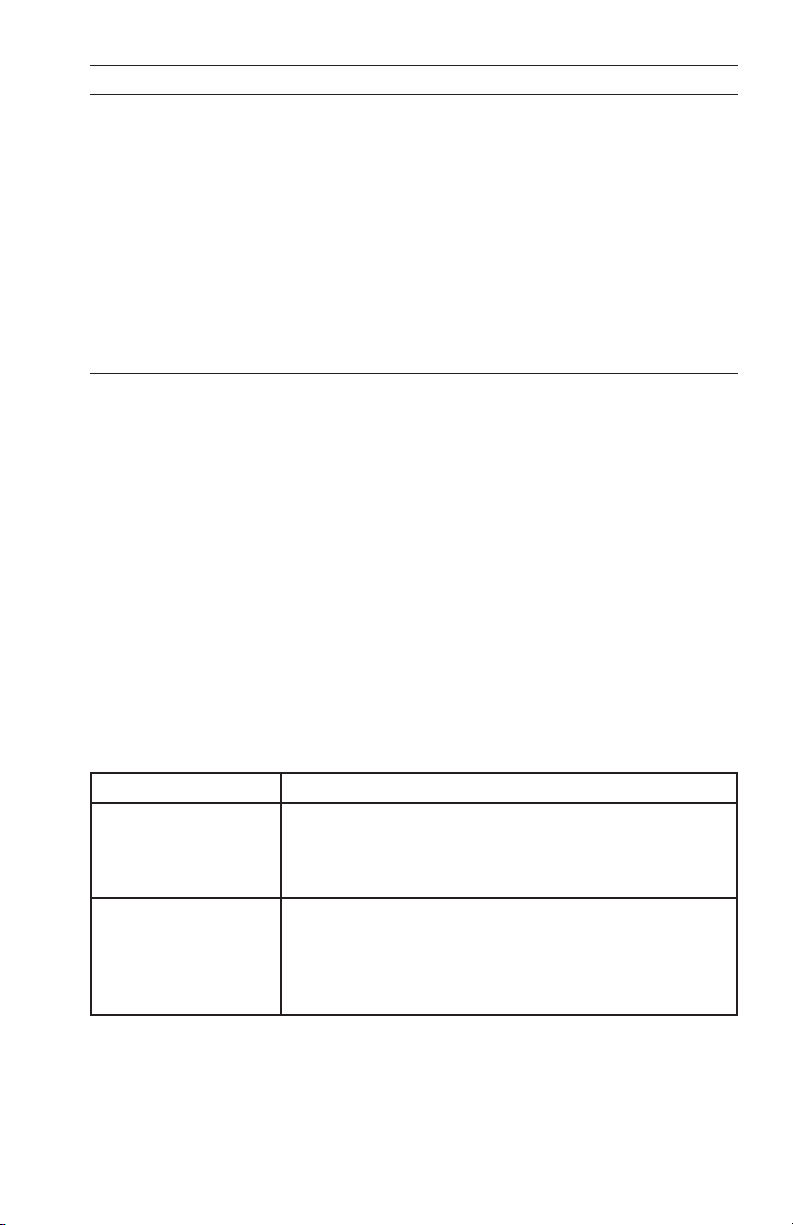

Throughout the manual, the term “probe” refers to the end of the cable

where the sensor is located, the term “sensor” refers to the Optical

Dissolved Oxygen sensing portion of the cable/probe assembly, and

the term “sensor cap” refers to the removable sensing cap that is

replaced about once per year (Figure 1).

Sensor

Probe

Figure 1

PREPARING THE PROBE

Sensor Cap

Each EcoSense ODO200 sensor cap has unique calibration coefficients

associated with it. These coefficients are labeled on the instruction

sheet included with each EcoSense ODO200 cable/probe assembly

and replacement ODO200 sensor cap.

Remove the probe/cable assembly from the shipping container and

locate the sensor cap instruction sheet. Be sure to save the instruction

sheet in case you need to reload these calibration coefficients.

New probe/cable assemblies have the sensor cap installed and

coefficients loaded into the probe at the factory. When a cable is

installed, the coefficients are automatically sent to the instrument.

Preparing the probe for the first time:

1. Remove the probe guard from the probe by turning it

counterclockwise.

2. Remove the red storage cap which contains a moist sponge from

the end of the probe by pulling it straight off the sensor. Save this

to use later for long term storage.

2

Page 9

3. Reinstall the probe guard by sliding it carefully over the sensor and

then threading it onto the cable/probe assembly with a clockwise

rotation (Figure 2).

4. Locate the gray calibration/storage sleeve that was shipped with

your probe/cable assembly. Moisten the sponge in the gray

calibration/storage with a small amount of clean water.

5. Slide the calibration/storage sleeve over the probe guard to keep

the probe in a moist environment for storage and calibration

(Figure 3). It is important to always keep your sensor in a moist

environment so the sensor cap does not dry out.

6. Connect the cable to the instrument by aligning the connectors,

pushing them together and then screwing down the retainer

clockwise.

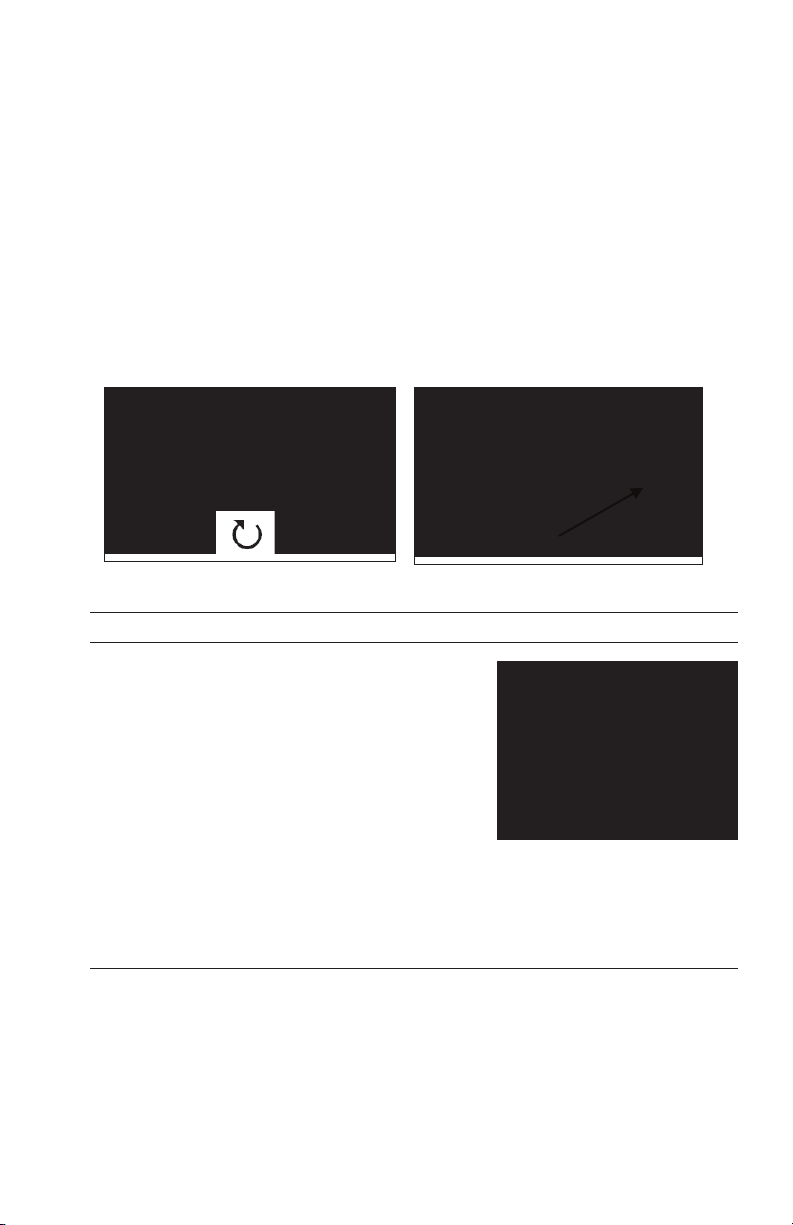

Figure 2 Figure 3

BATTERY INSTALLATION

To install (or replace) the battery, remove

the two battery cover screws and battery

cover. Replace the 9V battery. Replace the

battery cover and o-ring (be sure to align

the o-ring correctly to prevent a bad seal)

and fasten the two battery cover screws.

An initial display of “LOW BAT” on the

LCD indicates approximately one hour of

Figure 4

battery life for unit operation within specifications. Replace battery

when “LOW BAT” appears on the LCD.

Battery Disposal

This instrument is powered by a 9 volt battery, which the user must

remove and dispose of when the battery no longer powers the

instrument. Disposal requirements vary by country and region, and

users are expected to understand and follow the battery disposal

requirements for their specific locale.

3

Page 10

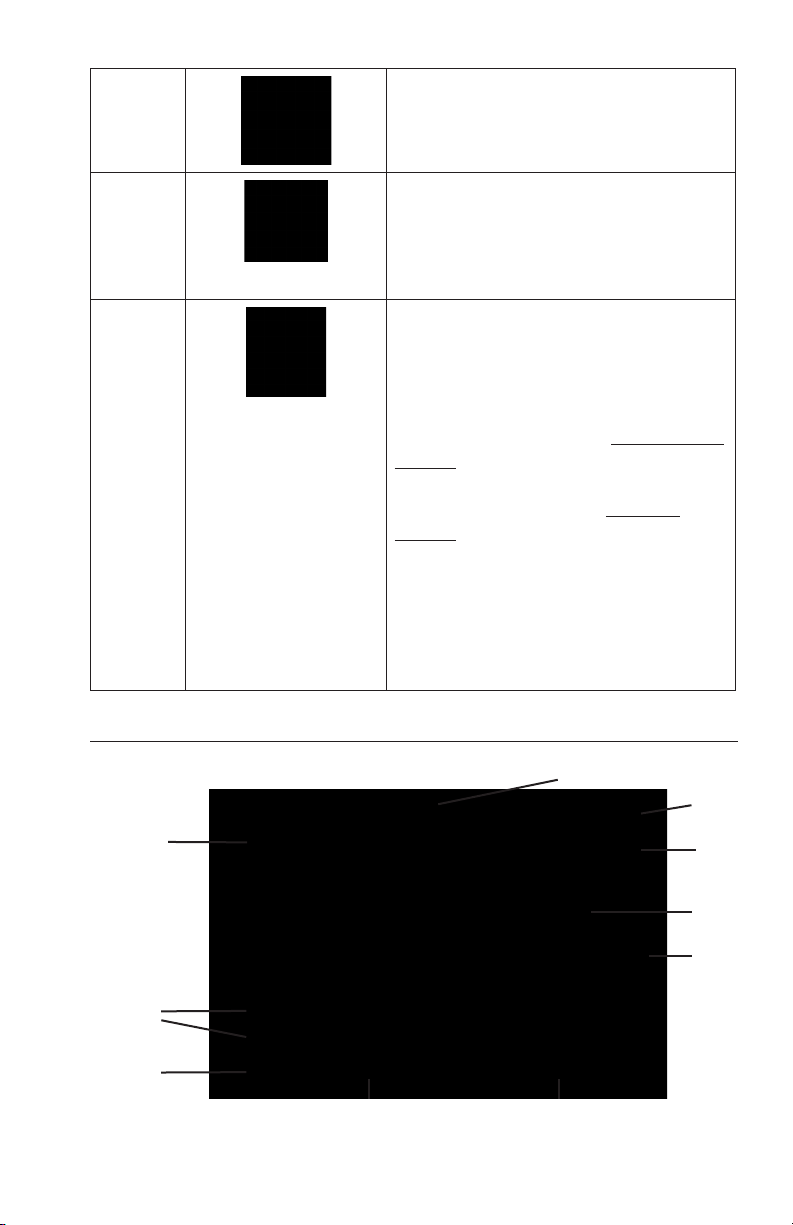

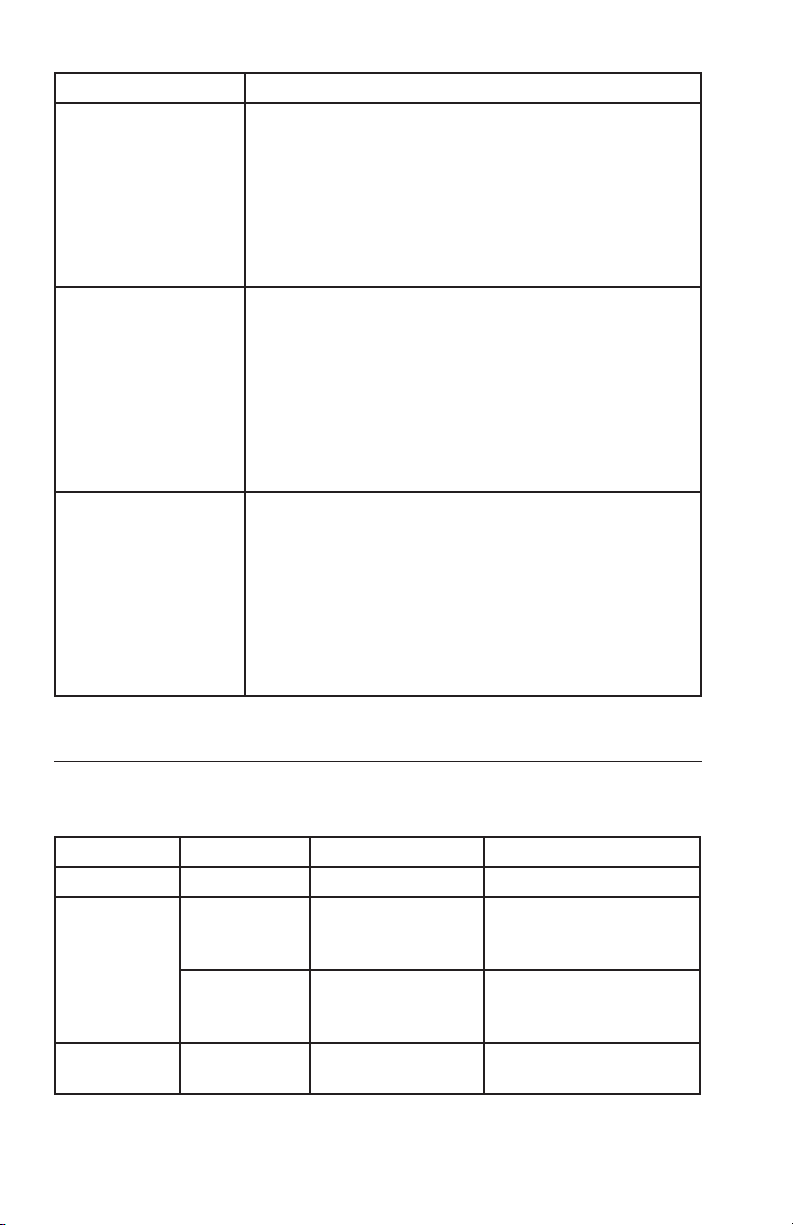

KEY PAD

1

2

3

4

Figure 5

Number Key Description

1

Power key. Turns the unit on or off.

5

6

7

8

2, 6

3

4

Up and down arrow key. Used

to adjust inputs for salinity

correction, calibration and

sensor cap coefficients

Calibration key. Press to calibrate

the dissolved oxygen sensor.

Cap key. Press to enter new

sensor cap coefficients.

4

Page 11

5

Mode key. Adjusts between

measurement modes (%, mg/L),

recalling saved data (rCL) and

deleting saved data (dEL).

7

Enter key. Used to confirm

calibration, to save data

from run screen, to select

data mode (rCL/dEL), and

confirm coefficient entries.

8

Sample/Mode key. Press and

hold for 3 seconds to switch

between continuous and manual

measurement modes. Press and

release to restart the measurement

when in manual mode. Continuous

mode: the instrument will

continuously update the dissolved

oxygen measurement. Manual

mode: the instrument will update

the DO reading until reaching a

stable measurement. The stable

measurement will be ‘locked’ on

the display until the user initiates

a new measurement reading by

pressing the Sample/Mode key.

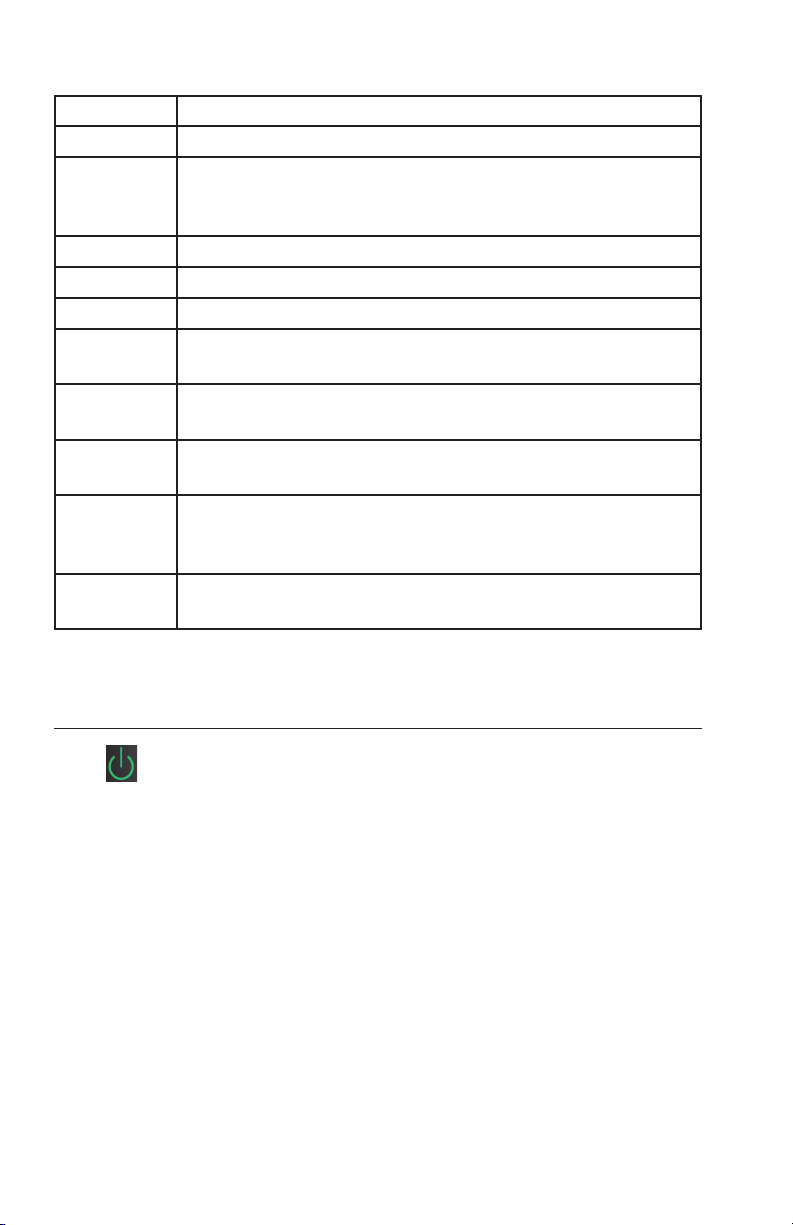

MAIN DISPLAY

1

2

3

10

9

8

7

6

4 5

5

Page 12

Number Description

1

2

BAT: Low battery indicator.

Continuous or Manual sampling mode indicator.

When in Manual mode, manual will blink until the

measurement is stable.

3

4

5

6

CAL: Calibration mode indicator.

Data record indicator.

Temperature reading in Celsius.

mbar: Displays during calibration to prompt user for

true barometric pressure.

7

Main display for dissolved oxygen measurements in

either % or mg/L.

8

9

Save, Full, Recall, Each, All, Delete: Instrument’s data

storage indicators.

Figure 6

SAL ppt: Displays during calibration when user is

prompted for the approximate salinity (in ppt) of the

sample to be tested.

10

CAP, K1, K2, K3, K4, K5, KC: Sensor cap coefficient

indicators when entering new sensor cap coefficients.

OPERATIONAL PROCEDURES TAKING MEASUREMENTS

Press to turn the unit on or off. When turned on, the instrument will

perform a self-diagnostic test during which an error message may

display. This is normal. After the self-diagnostic test completes, the

temperature displays in the lower right and the dissolved oxygen

measurement displays in the center of the display (figure 6). The unit is

ready for operation. If necessary, perform a 1-point dissolved oxygen

calibration. The digital instrument and probe can hold its calibration

for many months but should be verified regularly.

Immerse the probe into the sample solution to take a measurement.

When the unit is not in use, turn it off to save battery life. It is not

necessary to recalibrate the instrument after turning it off and back on.

The instrument has a 30 minute auto shut off feature when not in use.

6

Page 13

MEASUREMENT MODES - % OR MG/L

This unit provides three distinct measurements: Temperature and

Dissolved Oxygen in either % or mg/L.

The dissolved oxygen measurement unit is indicated on the right side

of the display. Press Mode to switch between % and mg/L.

SAMPLING MODES - CONTINUOUS OR MANUAL

The ODO200’s sampling mode can be set to Manual or Continuous.

Press and hold the Sample/Mode key for 3 seconds to switch between

Continuous and Manual mode. When in Manual mode, press and

release Sample/Mode to initiate a new measurement.

Continuous mode: the instrument will continuously update the

dissolved oxygen measurement.

Manual mode: the instrument will update the DO reading until

reaching a stable measurement. The stable measurement will ‘lock’ on

the display until the user initiates a new measurement by pressing the

Sample/Mode key. Manual mode conserves battery power.

SAVING, VIEWING AND DELETING DATA

The ODO200 can save 50 data records. When in measurement mode,

press Enter to save a record. The instrument will confirm saving

the data by displaying SAVE and the data record number for one

second. “Full” is displayed when trying to save data and memory is full.

To view saved data, press Mode until Recall (rCL) is displayed and then

press Enter. Use the Up or Down arrow keys to review different saved

records. Press Mode to escape back to measurement mode.

To delete data records, press Mode while in measurement mode

until Delete (dEL) is displayed. Press Enter. “All” will be displayed and

blinking. Press the Up or Down arrow key to switch between delete ‘All’

or ‘Each’ options. Select either ‘All’ or ‘Each’ by pressing Enter while

that option is displayed.

If ‘All’ is selected, all records will be deleted from memory and ‘None’

will be displayed. Press Mode twice to return to the measurement

mode.

7

Page 14

If ‘Each’ is selected, the Up and Down arrow keys will allow you to scroll

through the saved data records. Press Enter to delete the selected

record. All records after the deleted record will shift up to keep the

records in sequential order. For example, if record 3 is deleted, record

4 will become record 3 and record 5 will become record 4. Press Mode

twice to return to the measurement mode.

CALIBRATION

TEMPERATURE

All EcoSense ODO200 cables have a built-in thermistor. Temperature

calibration is not available or required. To verify the temperature sensor,

compare it to a NIST traceable thermistor by touching the thermistors

together and observing the measurements.

DISSOLVED OXYGEN

The ODO200 sensor is an optical luminescent sensor which has greater

stability and is less susceptible to calibration drift than traditional

electrochemical sensors. This increased stability means the instrument

can hold its calibration for many months; however, calibration should

be verified regularly for highest data accuracy.

To verify the instrument’s calibration, place the sensor in its calibration

environment and check to see that the DO% is reading its calibration

value based on the barometric pressure. Refer to Appendix A for the

DO% calibration values based on barometric pressure.

Calibration Requirements:

• The approximate true barometric pressure in millbars (mBar) of the

location at the time of calibration.

True Barometric Pressure (mmHg) =

[Corrected BP mmHg] – [2.5 * (Local Altitude in ft. above sea level/100)]

mBar = mmHg *1.333

• The approximate salinity of the water to be analyzed. Fresh

water’s salinity value is approximate zero parts per thousand (ppt).

Seawater has an approximate salinity of 35 ppt.

1. Moisten the sponge in the gray storage sleeve with a small

amount of clean water. The moistened sponge creates a 100%

water-saturated air environment for the probe, which is ideal

8

Page 15

for calibration, transport, and storage of the EcoSense ODO200

probe.

2. Make sure there are no water droplets on the sensor cap or

temperature sensor and then install the storage sleeve over the

guarded probe. Make sure the DO and temperature sensors are

not touching the sponge or immersed in water. Turn the instrument

on and wait approximately 5 to 10 minutes for the storage sleeve

to become completely saturated and to allow the temperature and

dissolved oxygen sensors to stabilize.

3. Press CAL.

4. The display prompts for the local, true barometric pressure in

mBar (millibars). Use the Up and Down Arrow keys to increase or

decrease the barometric pressure value, then press Enter.

5. The display will show the current dissolved oxygen measurement

on the main display and the calibration value in the lower right

corner. Wait for the DO measurement to stabilize, then press Enter.

6. The display prompts for the approximate salinity of the water

to be analyzed. Use the Up and Down Arrow keys to increase or

decrease the salinity compensation value to the salinity value of

your sample (between 0 to 40 parts per thousand [ppt]). When the

correct salinity displays, press Enter.

7. The unit holds calibration for several months, even when powered

off and on.

MAINTENANCE AND

TROUBLESHOOTING

SENSOR MAINTENANCE - DISSOLVED OXYGEN

CLEANING THE SENSOR CAP

The Sensor Cap should be kept clean since some types of fouling can

consume or produce oxygen or block the water sample from reaching

the sensor which could affect the dissolved oxygen measurements.

To clean the Sensor Cap, gently wipe away any fouling with a lens

cleaning tissue that has been moistened with water. Do not use organic

solvents to clean the Sensor Cap. Using an organic solvent to clean the

Sensor Cap may cause permanent damage to the cap. For example,

alcohol will dissolve the outer paint layer and other organic solvents

will likely dissolve the dye in the cap. Dissolving or scratching the paint

or dye layer will cause erratic dissolved oxygen measurements.

To disinfect the probe, soak the probe in 3% hydrogen peroxide for 15

to 30 minutes and then rinse it with clean water.

9

Page 16

SENSOR CAP REPLACEMENT

The sensor cap should be replaced about once per year but may last

longer. It should also be replaced if it is cracked or damaged (see

Troubleshooting section for instructions on how to inspect the cap for

damage). The instruction sheet shipped with the replacement ODO

sensor cap includes the calibration coefficients specific to your sensor

cap.

The replacement ODO sensor cap is shipped in a humidified container.

The package should not be opened until ready for use. Once the sensor

cap has been installed on the sensor as described below, it is important

to keep the sensor in a 100% humid environment. Therefore, the

sensor should be stored in either the gray calibration/storage sleeve

with a moistened sponge or immersed in water, see Sensor Storage

for more information. If the sensor dries out, refer to the Rehydration

procedure in this manual.

Refer to Figure 7 below when following the instructions for replacing

the cap.

Figure 7

Caution: Avoid touching the sensing end of the sensor cap during the

following maintenance procedures.

1. Remove the old sensor cap assembly from the sensor by grasping

the probe body with one hand and then rotating the sensor cap

counterclockwise until it is completely free. Do not use any tools

for this procedure.

2. Inspect the o-ring on the probe for damage. If there is any indication

of damage, carefully remove the o-ring and replace it with the new

o-ring included with the replacement sensor cap. Do not use any

tools to remove the o-ring.

10

Page 17

3. Ensure that the o-ring installed on the probe is clean. If necessary,

wipe clean with a lint free cloth or replace the o-ring as described

in the previous step.

4. Locate the o-ring lubricant included with the new sensor cap.

Apply a thin coat of o-ring lubricant to the installed o-ring. Remove

any excess o-ring lubricant from the o-ring and/or probe with a

lens cleaning tissue.

5. Remove the new sensor cap from its hydrated container and dry

the inside cavity of the sensor cap with lens cleaning tissue. Next,

clean the clear surface of the sensor on the end of the probe with

lens cleaning tissue.

6. Using clockwise motion, thread the new sensor cap onto the probe

assembly until it is finger-tight. The o-ring should be compressed

between the sensor cap and probe. Do not over-tighten the sensor

cap and do not use any tools for the installation process.

7. After installing the new sensor cap, store the sensor in the gray

calibration/storage sleeve with a moistened sponge.

8. Follow the procedures below for entering in the new sensor cap’s

coefficients into the EcoSense ODO200 instrument.

ENTERING SENSOR CAP COEFFICIENTS INTO THE ECOSENSE

ODO200

After installing a new sensor cap, connect the probe/cable assembly to

the instrument and turn the instrument on. Locate the Calibration Code

Label at the top of the instruction sheet and note the six numbers which

are listed as K1 through K5 and KC. These six numbers contain the

calibration code for this particular sensor cap. Follow these instructions

to enter the new calibration coefficients into your instrument:

1. Press and hold the CAP key for 3 seconds. The CAP key is located

in the lower left corner of the keypad.

2. The instrument will prompt for K1 and show 8 alpha/numeric

values with the first value blinking.

3. Use the up and down arrow keys to adjust the first value to match

the first value of the new cap’s K1. Press the Enter key to accept.

4. Continue using the up and down arrow keys to adjust all 8 alpha/

numeric values for K1 pressing the Enter key to confirm each entry.

5. After confirming the last value for K1, the instrument will prompt

you for K2. Follow the instructions in step 3 and 4 to enter and

confirm the value for K2. Continue with K3, K4 and K5.

6. After confirming K5, the EcoSense ODO200 will prompt you for KC.

KC has two values. Follow the instructions in step 3 and 4 to enter

the coefficients. After confirming KC, the instrument will return to

the measurement screen.

11

Page 18

7. After entering the Sensor Cap Coefficients, perform a 1-point

calibration as described in the Calibration Section.

8. Press and hold the CAP key for 3 seconds at any time to exit and

cancel the cap coefficient update.

If errors are made in entering the Sensor Cap Coefficients, the

instrument will block the update and an error message will appear

on the display and the instrument will return to the K1 entry screen. If

you see this error message, re-enter the coefficients and check them

carefully for correct transcription from the Calibration Coefficient Label.

The coefficient values are hexadecimal. Due to the EcoSense ODO200’s

display, 6 and b look very similar. Hexadecimal values on the ODO200

will be displayed as: A, b, C, d, E, F, 0, 1, 2, 3, 4, 5, 6, 7, 8, and 9.

If you continue to get an error message after several entry attempts,

contact YSI Technical Support for assistance.

REHYDRATING THE SENSOR CAP

The Sensor Cap must remain in a moist environment; see Sensor

Storage for storage recommendations. If the sensor cap is allowed to

dry out, it is likely to drift slightly at the beginning of your next study

unless it is rehydrated. If the cap dries out, you can rehydrate it by

soaking the probe tip with the sensor cap installed in room temperature

tap water for 24 hours. After rehydration is complete, recalibrate and

be sure to store the probe in a moist environment.

SENSOR MAINTENANCE - TEMPERATURE

You must keep the temperature portion of the sensor free of build

up. Other than that, the sensor requires no maintenance. A soft bristle

brush, like a tooth brush can be used to scrub the temperature sensor

if needed.

SENSOR STORAGE

SHORT-TERM STORAGE

When the ODO sensor is not in use, store it in a moist environment.

For short-term storage (less than 30 days), moisten the sponge in the

calibration/storage sleeve with a small amount of clean water and place

this over the probe with the sensor cap and sensor guard installed. This

will provide a 100% saturated air environment.

12

Page 19

LONG-TERM STORAGE

For long-term storage (>30 days), remove the battery from the

instrument. Moisten the sponge in the calibration/storage sleeve with

a small amount of clean water and place this over the probe with the

sensor cap and sensor guard installed. Inspect the sponge every 30

days to make sure it is still moist.

Alternatively, you can place the probe with sensor cap directly in a

beaker or other container of water, making sure that the water does

not evaporate over time.

TROUBLESHOOTING

Erroneous dissolved oxygen readings typically indicate a need to

clean the sensor cap, replace the sensor cap, and/or recalibrate the

instrument. First, clean the sensor cap following the instructions in

the Maintenance section and then perform a calibration. If erroneous

readings persist, inspect the sensor cap for damage (cracks, large

scratches in paint or dye layer), replace if necessary, enter new

coefficients and then attempt to recalibrate the instrument.

If the sensor cap is not damaged, try to rehydrate the sensor cap then

recalibrate.

If you are still getting erroneous dissolved oxygen readings, try replacing

the sensor cap, enter the new coefficients and then recalibrate. If the

erroneous readings continue, contact YSI Technical Support to help

determine the next step.

Symptom Possible Solution

Instrument will not

turn on, the BAT

symbol displays

on the screen.

Temperature values

display Over or

Undr on Run screen.

1. Low battery voltage, replace batteries.

2. Batteries installed incorrectly,

check battery polarity.

3. Return system for service.

1. Sample temperature is less than 0° C or more

than +50°C. Increase or decrease the sample

temperature to bring within the allowable range.

2. Contact YSI Tech Support. Possible temperature

sensor failure.

13

Page 20

Symptom Possible Solution

Instrument will

not calibrate

dissolved oxygen.

DO readings are

inaccurate.

Dissolved Oxygen

values display

Over or Undr on

Run screen.

1. Verify calibration routine - correct

barometric pressure, salinity input,

and calibration environment.

2. Allow sufficient stabilization time for

dissolved oxygen and temperature.

3. Check sensor cap. Clean, rehydrate

or replace as necessary.

4. Contact YSI Tech Support.

1. Verify temperature readings are accurate.

2. Sample temperature should be

between 0 and 45 ºC, the temperature

compensation range for DO mg/L.

3. DO sensor not properly calibrated,

recalibrate the sensor.

4. Check sensor cap. Clean, rehydrate or

replace as necessary. Recalibrate.

5. Contact YSI Tech Support.

1. Sample dissolved oxygen concentration

is more than 20 mg/L or 200%, or

less than 0.0 mg/L or 0.0%.

2. Verify temperature readings are accurate.

3. DO sensor not properly calibrated,

recalibrate the sensor.

4. Check sensor cap. Clean, rehydrate or

replace as necessary. Recalibrate.

5. Contact YSI Tech Support.

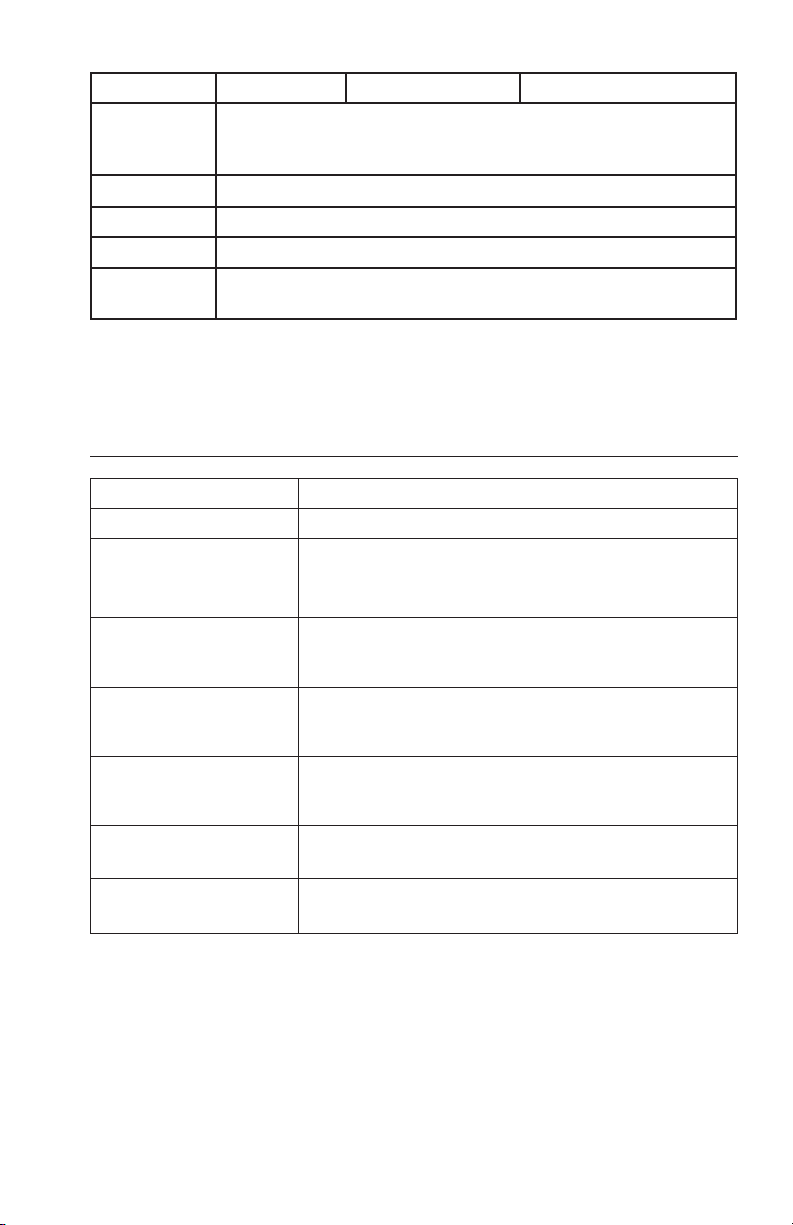

SPECIFICATIONS

These specifications represent typical performance and are subject to

change without notice. For the latest product specification information,

please visit YSI’s website at ysi.com or contact YSI Tech Support.

Parameter Range Resolution Accuracy

Temperature 0 to 50°C* 0.1°C ± 0.3°C

Dissolved

Oxygen

Barometer 500 to 1125

0.0 to 200%

air saturation

0.00 to

20.0 mg/L

mBar

1% or 0.1%, user

selectable

0.1 or 0.01 mg/L ± 1.5% of reading

1.0 mBar manual entry

14

± 1.5% of reading or

± 1.5% air saturation,

whichever is greater

or ± 1.5 mg/L,

whichever is greater

Page 21

Parameter Range Resolution Accuracy

Temperature

Operating

Range

Certifications

Memory 50 data sets

Salinity 0 to 40 ppt, manual entry

Battery 9 volt alkaline, 100 hour battery life

0 to 50ºC

RoHs, WEEE, CE, IP-67

in manual sampling mode

* Automatic dissolved oxygen temperature compensation range is 0

to 45°C

ACCESSORIES / PART NUMBERS

Part Number Description

606326 EcoSense ODO Sensor Cap Kit

606327 1 meter (approximately 3.3 feet)

probe and cable assembly*

606328 4 meter (approximately 13 feet)

probe and cable assembly*

606304 10 meter (approximately 33 feet)

probe and cable assembly*

606329

605139

EcoSense ODO200 instrument

Carrying case, small, soft-sided (holds instrument

and up to a 4 meter cable/probe assembly

606330 ODO200 hard-sided carrying case with form

fitted foam inserts

*All cables include optical-based dissolved oxygen sensor and

temperature sensor.

15

Page 22

CONTACT INFORMATION AND

SERVICE

ORDERING AND TECHNICAL SUPPORT

Telephone: 800 897 4151 (US)

+1 937 767 7241 (Globally)

Monday through Friday, 8:00 AM to 5:00 ET

Fax: +1 937 767 9353 (orders)

+1 937 767 1058 (technical support)

Email: environmental@ysi.com

Mail: YSI Incorporated

1725 Brannum Lane

Yellow Springs, OH 45387

USA

Web address: ysi.com

When placing an order please have the following available:

1.) YSI account number (if available)

2.) Name and phone number

3.) Purchase Order or Credit Card

4.) Model Number or brief description

5.) Billing and shipping addresses

6.) Quantity

SERVICE INFORMATION

YSI has authorized service centers throughout the United States and

Internationally. For the nearest service center information, please visit

ysi.com and click ‘Support’ or contact YSI Technical Support directly at

800-897-4151.

When returning a product for service, include the Product Return form

with cleaning certification. The form must be completely filled out for a

YSI Service Center to accept the instrument for service. The form may

be downloaded from ysi.com by clicking on the ‘Support” tab, then the

Product Return Form button.

RECYCLING

YSI is committed to reducing the environmental footprint in the course

of doing business. Even though materials reduction is the ultimate

goal, we know there must be a concerted effort to responsibly deal

with materials after they’ve served a long, productive life-cycle. YSI’s

recycling program ensures that old equipment is processed in an

16

Page 23

environmentally friendly way, reducing the amount of materials going

to landfills.

• Printed Circuit Boards are sent to facilities that process and reclaim

as much material for recycling as possible.

• Plastics enter a material recycling process and are not incinerated

or sent to landfills.

• Batteries are removed and sent to battery recyclers for dedicated

metals.

When the time comes for you to recycle, follow the easy steps outlined

at ysi.com.

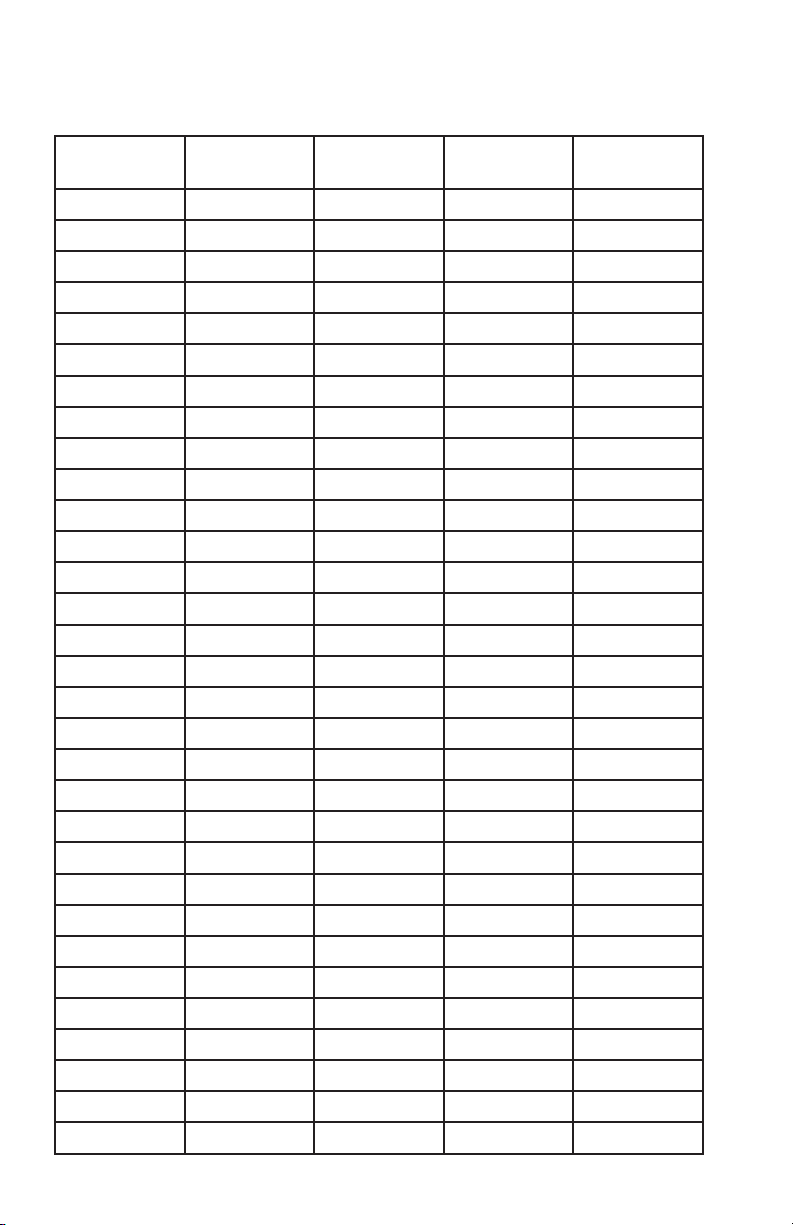

APPENDIX A-DO% CALIBRATION

VALUES

Calibration

Value

D.O. % in Hg mmHg kPa mbar

101% 30.22 767.6 102.34 1023.38

100% 29.92 760.0 101.33 1013.25

99% 29.62 752.4 100.31 1003.12

98% 29.32 744.8 99.30 992.99

97% 29.02 737.2 98.29 982.85

96% 28.72 729.6 97.27 972.72

95% 28.43 722.0 96.26 962.59

94% 28.13 714.4 95.25 952.46

93% 27.83 706.8 94.23 942.32

92% 27.53 699.2 93.22 932.19

91% 27.23 691.6 92.21 922.06

90% 26.93 684.0 91.19 911.93

89% 26.63 676.4 90.18 901.79

88% 26.33 668.8 89.17 891.66

87% 26.03 661.2 88.15 881.53

86% 25.73 653.6 87.14 871.40

85% 25.43 646.0 86.13 861.26

84% 25.13 638.4 85.11 851.13

83% 24.83 630.8 84.10 841.00

Pressure

17

Page 24

82% 24.54 623.2 83.09 830.87

81% 24.24 615.6 82.07 820.73

80% 23.94 608.0 81.06 810.60

79% 23.64 600.4 80.05 800.47

78% 23.34 592.8 79.03 790.34

77% 23.04 585.2 78.02 780.20

76% 22.74 577.6 77.01 770.07

75% 22.44 570.0 75.99 759.94

74% 22.14 562.4 74.98 749.81

73% 21.84 554.8 73.97 739.67

72% 21.54 547.2 72.95 729.54

18

Page 25

Guide d’Utilisation

DOCUMENT nº 606335

EcoSense® ODO200

Appareil de mesure de l’oxygène

dissous et de la température

GUIDE D’UTILISATION

English, Français, Español, Português

Page 26

Article nº 606335

Rév. B, septembre 2014

Pour obtenir la dernière version de ce manuel,

visitez ysi.com

©2014 YSI Incorporated.

Le logo YSI et EcoSense sont des marques déposées d’YSI Incorporated.

Page 27

CONTENTS

Garantie ................................................................................................. i

INTRODUCTION ..................................................................................1

PREMIERS PAS .....................................................................................1

Inspection initiale ...................................................................1

Précautions .............................................................................1

Sonde ...............................................................................1

Configuration initiale ............................................................2

Préparation de la sonde ..................................................2

Installation de la pile .......................................................4

Clavier .....................................................................................4

Affichage principal ...............................................................6

PROCEDURES D’UTILISATION – PRISES DE MESURES ...................7

Modes de mesure –% ou mg/l .............................................7

Modes d’échantillonnage – Continu ou Manuel .................7

Enregistrement, affichage et suppression des données ....8

Étalonnage ..............................................................................8

Température ..................................................................... 8

Oxygène dissous .............................................................8

ENTRETIEN ET DÉPANNAGE ...........................................................10

Entretien des capteurs – Oxygène dissous .......................10

Nettoyage de l’embout du capteur .............................10

Remplacement de l’embout du capteur ...................10

Saisir les coefficients de l’emboutdecapteurdans

l’EcoSenseODO200 .....................................................12

Réhydratation de l’embout du capteur ....................13

Entretien des capteurs – Température ...............................13

Stockage du capteur............................................................13

Stockage à court terme ..............................................13

Stockage à long terme ..................................................13

Page 28

Dépannage ...........................................................................13

CARACTÉRISTIQUES .........................................................................15

ACCESSOIRES / NUMÉROS DEPIECES ............. 16

COORDONNÉES ET SERVICE ..........................................................16

Commande et assistance technique ..................................16

Informations sur le service ..................................................17

Recyclage ..............................................................................17

ANNEXE A – VALEURS DE CALIBRAGE DU POURCENTAGE

D’OD ...................................................................................................18

Page 29

GARANTIE

L’appareil EcoSense® ODO200, la sonde, le câble et l’embout de capteur

sont garantis pour une période de un an à compter de la date d’achat par

l’utilisateur final contre les défauts matériels et de fabrication, à l’exception

des piles et des dommages causés par des piles défectueuses. Pendant la

période de garantie, YSI s’engage à réparer ou à remplacer, gratuitement

et à sa discrétion, tout produit qu’YSI peut établir comme étant couvert

par la garantie.

Pour faire valoir cette garantie, écrivez à votre représentant YSI ou appelezle, ou contactez le service clientèle d’YSI à Yellow Springs, Ohio, États-Unis,

aux numéros +1937 767-7241, 800-765-4974, ou visitez YSI.com pour obtenir

un formulaire de retour de produit. Envoyez le produit et son justificatif

d’achat, en port payé, au Centre de service homologué sélectionné par

YSI. La réparation ou le remplacement seront effectués et le produit

vous sera retourné en port payé. Les produits réparés ou remplacés sont

garantis jusqu’à expiration de la période de garantie initiale ou pour une

période d’au moins 90 jours, à compter de la date de réparation ou de

remplacement.

Limitation de garantie

Cette garantie ne s’applique pas aux produits YSI endommagés ou

présentant des dysfonctionnements pour les raisons suivantes : (i)

installation, exploitation ou utilisation du produit d’une façon non

conforme aux instructions écrites d’YSI; (ii) abus ou mésusage du produit;

(iii) manquement à l’entretien du produit conformément aux instructions

écrites d’YSI ou aux procédures industrielles normales; (iv) réparation non

conforme du produit; (v) utilisation par vous de pièces ou de composants

défectueux ou non conformes lors de l’entretien ou de la réparation du

produit, ou; (vi) modification du produit d’une façon non expressément

autorisée par YSI.

CETTE GARANTIE REMPLACE TOUTES LES AUTRES GARANTIES,

EXPRESSES OU INDUITES, Y COMPRIS LES GARANTIES DE QUALITÉ

MARCHANDE OU D’ADAPTATION À UN USAGE PARTICULIER. LA

RESPONS ABILITÉ D’ YSI SELON LES TERME S DE CETT E GARANT IE SE LIMITE

À LA RÉPARATION OU AU REMPLACEMENT DU PRODUIT, CONSTITUANT

VOTRE SEUL ET UNIQUE RECOURS POUR TOUT PRODUIT DÉFECTUEUX

COUVERT PAR CETTE GARANTIE. YSI NE POURRA EN AUCUN CAS

ÊTRE TENU RESPONSABLE DE DOMMAGES SPÉCIAUX, INDIRECTS,

ACCIDENTELS OU CONSÉCUTIFS RÉSULTANT DE L’UTILISATION DE TOUT

PRODUIT DÉFECTUEUX COUVERT PAR CETTE GARANTIE.

i

Page 30

CETTE PAGE EST LAISSÉE VIERGE DE FAÇON

INTENTIONNELLE

ii

Page 31

INTRODUCTION

Nous vous remercions d’avoir acheté l’EcoSense ODO200, un appareil

manuel précis qui mesure la température et l’oxygène dissous en

pourcentage (%) et milligrammes par litre (mg/l). L’EcoSense ODO200

mesure l’oxygène dissous dans l’eau à l’aide d’une technologie optique

de luminescence durant toute la vie et utilise un signal numérique pour

envoyer des informations entre l’appareil et la sonde. Les avantages

principaux de l’EcoSense ODO200 comprennent notamment l’élimination

de la dépendance au flux du capteur (agitation) et à la durée de chauffage

du capteur, une plus grande stabilité, des étalonnages moins fréquents,

et l’élimination des changements fréquents de membrane et d’électrolyte.

Pour obtenir davantage d’informations sur les caractéristiques du produit,

visitez ysi.com ou contactez l’assistance technique au 800-897-4151

(+1937 767-7241) ou environmental@ysi.com.

PREMIERS PAS

INSPECTION INITIALE

Déballez soigneusement l’appareil et les accessoires et vérifiez qu’ils n’ont

pas été endommagés. Comparez les pièces reçues aux articles répertoriés

dans le bordereau d’emballage. Si des pièces sont endommagées ou

manquantes, contactez l’assistance à la clientèle d’YSI au 800-897-4151

(+1937 767-7241) ou le distributeur agréé par YSI chez qui l’appareil de

mesure a été acheté.

PRÉCAUTIONS

SONDE

Les embouts de capteur durent plus longtemps s’ils sont entreposés

dans un milieu humide et s’ils restent propres et que la couche de

peinture n’est pas rayée. Les mesures risquent d’être irrégulières si les

embouts sont endommagés ou sales. Si les mesures sont instables alors

que la couche de peinture ou de teinture présente de grandes rayures,

remplacez l’embout de capteur. Reportez-vous à la section Entretien et

dépannage de ce manuel pour obtenir des informations sur le nettoyage

ou le remplacement de l’embout de capteur. L’intervalle de remplacement

moyen des embouts de capteur est de 12 à 18 mois, bien qu’ils puissent

durer plus longtemps.

Évitez les produits pouvant endommager les matériaux de la sonde, tels

que l’acide concentré et les solvants puissants et caustiques. Les matériaux

de sonde comprennent de l’uréthane (câble), du Xenoy (corps de la sonde),

1

Page 32

de l’acrylique (embout du capteur) et de l’acétaldéhyde-diéthylacétal et

de l’acier inoxydable (protection de la sonde).

Pour éviter que l’embout de capteur se dessèche, entreposez la sonde

dans le manchon d’étalonnage/stockage gris avec une éponge propre et

humide. Si l’embout de capteur se dessèche, réhydratez-le en suivant les

instructions de la section Entretien et dépannage de ce manuel.

CONFIGURATION INITIALE

Dans tout le manuel, le terme «sonde» se rapporte à l’extrémité du câble

où se trouve le capteur, le terme «capteur» se rapporte à la portion de

détection optique de l’oxygène dissous de l’assemblage du câble et de la

sonde, et le terme «embout de capteur» se rapporte à l’embout sensible

amovible qui est remplacé à peu près tous les ans (Figure 1).

Capteur

Sonde

Figure 1

Embout

decapteur

PRÉPARATION DE LA SONDE

Chaque embout de capteur de l’EcoSense ODO200 possède des

coefficients d’étalonnage uniques. Ces coefficients sont indiqués sur la

fiche d’instructions expédiée avec chaque assemblage de câble et de

sonde de l’EcoSense ODO200 et l’embout de capteur de remplacement

ODO200.

Retirez l’assemblage du câble et de la sonde de l’emballage d’expédition et

localisez la fiche d’instructions de l’embout de capteur. Veillez à conserver

cette fiche d’instructions dans l’éventualité où vous devriez recharger les

coefficients d’étalonnage.

L’embout de capteur est installé et les coefficients sont chargés à l’usine

dans la sonde des nouveaux assemblages de câble et de sonde. Lorsque

le câble est installé, les coefficients sont envoyés automatiquement à

l’appareil.

Préparation de la sonde pour la première fois:

1. Retirez la protection de la sonde en la tournant dans le sens inverse

des aiguilles d’une montre.

2. Retirez le capuchon de stockage rouge qui contient une éponge

humide de l’extrémité de la sonde en le tirant tout droit hors du

2

Page 33

capteur. Mettez-le de côté pour l’utiliser ultérieurement lors d’un

entreposage à long terme.

3. Réinstallez la protection de la sonde en la glissant soigneusement sur

le capteur et en la vissant sur l’assemblage de câble et de sonde dans

le sens des aiguilles d’une montre (Figure 2).

4. Localisez le manchon d’étalonnage/stockage gris expédié avec

l’assemblage du câble et de la sonde. Humidifiez l’éponge située dans

le manchon d’étalonnage/stockage gris avec un peu d’eau propre.

5. Glissez le manchon d’étalonnage/stockage sur la protection de

la sonde afin de conserver la sonde dans un milieu humide lors

de l’entreposage et de l’étalonnage (Figure 3). Il est important de

conserver toujours le capteur dans un milieu humide afin que l’embout

de capteur ne se dessèche pas.

6. Connectez le câble à l’appareil en alignant les connecteurs, puis en les

poussant l’un dans l’autre et en vissant le dispositif de retenue dans le

sens des aiguilles d’une montre.

Figure 2 Figure 3

3

Page 34

INSTALLATION DE LA PILE

Pour installer (ou remplacer) la pile, retirez

les deux vis du couvercle du compartiment

de la pile et le couvercle du compartiment

de la pile. Remplacez la pile de 9 V. Replacez

le couvercle et le joint torique (veillez à

aligner le joint correctement afin d’assurer

une bonne étanchéité) et revissez les deux

vis du couvercle.

Figure 4

Lorsque l’écran à cristaux liquides affiche pour la première fois «LOW

BAT », il reste environ une heure de fonctionnement sur pile selon les

spécifications. Remplacez la pile lorsque l’indication «LOW BAT» s’affiche

sur l’écran.

Mise au rebut de la pile

L’appareil est alimenté par une pile de 9 V que l’utilisateur doit retirer et

jeter lorsque la pile n’alimente plus l’appareil. Les exigences concernant

la mise au rebut sont différentes en fonction du pays et de la région, et

il est attendu de l’utilisateur qu’il comprenne et suive les règlements

spécifiques à sa juridiction concernant la mise au rebut des piles.

CLAVIER

1

2

3

4

Figure 5

4

5

6

7

8

Page 35

Numéro Touche Description

1

Touche Marche/Arrêt. Met l'appareil hors

ou sous tension.

2, 6

3

4

5

7

8

Touches fléchées Haut et Bas. Utilisées

pour ajuster les saisies de correction

de salinité, d’étalonnage et des

coefficients de l’embout du capteur.

Touche Cal (Étalonnage). Appuyez

sur cette touche pour étalonner

le capteur d’oxygène dissous.

Touche Cap. Appuyez sur cette

touche pour saisir les nouveaux

coefficients de l’embout de capteur.

Touche Mode. Permet de

sélectionner le mode de mesure

(%, mg/l), de récupérer les données

enregistrées (rCL) et de supprimer

les données enregistrées (dEL).

Touche Entrée. Utilisée pour confirmer

l’étalonnage, enregistrer les données

de l’écran d’exécution, sélectionner

le mode de données (rCL/dEL) et

confirmer la saisie des coefficients.

Touche Sample/Mode. Maintenez la

touche enfoncée pendant 3 secondes

pour passer entre les modes de

mesure continu et manuel. Appuyez et

relâchez pour recommencer la mesure

lorsque vous êtes en mode manuel.

Mode continu (Continuous):l'appareil

met continuellement à jour la mesure

de l’oxygène dissous. Mode manuel

(Manual): l'appareil met à jour la

mesure d’oxygène dissous jusqu’à

ce qu’elle soit stable. La mesure

stable est «verrouillée» sur l’écran

jusqu’à ce que l’utilisateur lance

une nouvelle mesure en appuyant

sur la touche Sample/Mode.

5

Page 36

AFFICHAGE PRINCIPAL

10

9

1

2

3

4 5

Figure 6

Numéro Description

1

2

BAT (PILE): Indicateur de pile déchargée.

Indicateur d’échantillonnage en mode continu

(Continuous) ou manuel (Manual). En mode manuel, le

mot Manual clignote jusqu’à ce que la mesure soit stable.

3

CAL (ÉTALONNAGE): Indicateur de mode d'étalonnage

(Calibration).

4

5

6

Indicateur d’enregistrement de données.

Mesure de température en degrés Celsius.

mbar: S'affiche lors de l'étalonnage pour inviter l'utilisateur

à indiquer la pression barométrique réelle.

7

Affichage principal des mesures d’oxygène dissous,

exprimées en pourcentage (%) ou milligrammes par litre

(mg/L).

8

Save (Enregistrer), Full (Plein), Recall (Rappeler), Each

(Chacun), All (Tous), Delete (Supprimer): Indicateurs du

stockage des données de l’appareil.

9

SAL ppt : S'affiche lors de l'étalonnage pour inviter

l'utilisateur à indiquer la salinité approximative de

l'échantillon à tester, exprimée en parties par millier.

10

CAP, K1, K2, K3, K4, K5, KC: Indicateurs des coefficients

de l’embout de capteur lors de la saisie de nouveaux

coefficients.

8

7

6

6

Page 37

PROCEDURES D’UTILISATION –

PRISES DE MESURES

Appuyez sur pour mettre l’appareil hors ou sous tension. Lorsqu’il est

mis en marche, l’appareil réalise un test d’autodiagnostic pendant lequel

un message d’erreur peut s’afficher. Cette condition est normale. Une fois

que le test d’autodiagnostic est terminé, la température s’affiche dans

l’angle droit et la mesure d’oxygène dissous s’affiche au centre de l’écran

(figure 6). L’appareil est prêt à l’emploi. Le cas échéant, réalisez un

étalonnage d’oxygène dissous à 1 point. L’appareil numérique et la sonde

peuvent conserver leur étalonnage pendant des mois, mais l’étalonnage

doit être vérifié régulièrement.

Plongez la sonde dans la solution à examiner pour prendre une mesure.

Lorsque l’appareil n’est pas utilisé, mettez-le hors tension pour économiser

la pile. Il n’est pas nécessaire de ré-étalonner l’appareil après l’avoir arrêté

puis remis en marche. L’appareil s’éteint automatiquement s’il n’est pas

utilisé après 30 minutes.

MODES DE MESURE –% OU MG/L

Cet appareil permet trois mesures distinctes: température et oxygène

dissous exprimé en pourcentage (%) ou milligrammes par litre (mg/L).

L’unité de mesure de l’oxygène dissous est indiquée à droite de l’écran.

Appuyez sur la touche Mode pour passer entre% et mg/L.

MODES D’ÉCHANTILLONNAGE – CONTINU OU MANUEL

Le mode d’échantillonnage de l’ODO200 peut être défini sur Manual

(Manuel) ou Continuous (Continu).

Maintenez la touche Sample/Mode enfoncée pendant 3 secondes pour

passer entre le mode continu (Continuous) et le mode manuel (Manual).

En mode manuel, appuyez et relâchez la touche Sample/Mode pour lancer

une nouvelle mesure.

Mode continu (Continuous) : l’appareil met continuellement à jour la

mesure de l’oxygène dissous.

Mode manuel (Manual): l’appareil met à jour la mesure d’oxygène dissous

jusqu’à ce qu’elle soit stable. La mesure stable est «verrouillée» sur l’écran

jusqu’à ce que l’utilisateur lance une nouvelle mesure en appuyant sur la

touche Sample/Mode. Le mode manuel permet d’économiser la pile.

7

Page 38

ENREGISTREMENT, AFFICHAGE ET

SUPPRESSION DES DONNÉES

Le ODO200 enregistre jusqu’à 50 jeux de données. En mode de mesure,

appuyez sur

l’enregistrement des données en affichant SAVE (Enregistrer) et le numéro

du jeu pendant une seconde. Si la mémoire est pleine, l’appareil affiche

« Full » (Pleine) lorsque vous essayez d’enregistrer des données. Pour

afficher les données enregistrées, appuyez sur la touche Mode jusqu’à ce

que Recall (rCL) (Rappeler) s’affiche, puis appuyez sur Entrée. Utilisez les

touches fléchées Haut et Bas pour examiner différents enregistrements.

Appuyez sur Mode pour revenir au mode de mesure.

Pour supprimer des jeux de données, appuyez sur Mode en mode de

mesure jusqu’à ce que Delete (dEL) (Supprimer) s’affiche. Appuyez sur la

touche Entrée. «All» (Tous) s’affiche et clignote. Appuyez sur les touches

fléchées Haut ou Bas pour basculer entre les options All (Tous) à Each

(Chacun). Sélectionnez «All» (Tous) ou «Each» (Chacun) en appuyant sur

Entrée alors que l’option souhaitée est affichée.

Si vous choisissez All (Tous), tous les enregistrements seront supprimés

de la mémoire et None (Aucun) sera affiché. Appuyez deux fois sur Mode

pour revenir au mode de mesure.

Si vous sélectionnez Each (Chacun), faites défiler les jeux de données

enregistrés à l’aide des touches fléchées Haut et Bas. Appuyez sur

Entrée pour supprimer l’enregistrement sélectionné. La suppression d’un

enregistrement modifie le classement des jeux suivants, de manière à

garder les jeux en suite ordonnée. Par exemple, si le jeu 3 est supprimé, le

jeu 4 deviendra le jeu 3, le jeu 5 deviendra le jeu 4, etc. Appuyez sur Mode

pour revenir au mode de mesure.

Entrée pour enregistrer un jeu. L’appareil confirme

ÉTALONNAGE

TEMPÉRATURE

Tous les câbles de l’EcoSense ODO200 possèdent une thermistance intégrée.

L’étalonnage de la température n’est ni disponible ni nécessaire. Pour vérifier

le capteur de température, comparez-la à une thermistance NIST traçable en

mettant en contact les thermistances et en observant les mesures.

OXYGÈNE DISSOUS

Le capteur ODO200 est un capteur optique luminescent plus stable

et moins susceptible aux glissements d’étalonnage que les capteurs

électrochimiques traditionnels. Cette stabilité accrue signifie que l’appareil

peut conserver son étalonnage pendant de nombreux mois. Cependant,

l’étalonnage doit être vérifié régulièrement pour assurer une précision

optimale des données.

8

Page 39

Pour vérifier l’étalonnage de l’appareil, placez le capteur dans son milieu

d’étalonnage et vérifiez que la mesure du pourcentage d’oxygène dissous

rapporte sa valeur d’étalonnage en fonction de la pression barométrique.

Reportez-vous à l’Annexe A pour connaître les valeurs d’étalonnage du

pourcentage d’oxygène dissous en fonction de la pression barométrique.

Conditions requises pour l’étalonnage:

• la pression barométrique réelle approximative (en millibar [mbar]) à

l’endroit et au moment de l’étalonnage.

Pression barométrique réelle (mmHg) =

[PB corrigée enmmHg] – [2,5 * (Altitude locale en pieds au-dessus du niveau de la mer/100)]

mBar = mmHg *1.333

• La salinité approximative de l’eau devant être analysée. La salinité de

l’eau douce est approximativement de zéro partie par millier. La salinité

de l’eau de mer est approximativement de 35 parties par millier.

1. Humidifiez l’éponge située dans le manchon de stockage gris avec

un peu d’eau propre. L’éponge humide permet d’obtenir un milieu

atmosphérique saturé à 100% d’humidité pour la sonde, ce qui est

optimal pour l’étalonnage et le stockage de la sonde du modèle

EcoSense ODO200.

2. Veillez à ce qu’aucune gouttelette d’eau ne soit déposée sur l’embout

de capteur ou le capteur de température, puis placez le manchon

de stockage sur la sonde protégée. Assurez-vous que les capteurs

d’oxygène dissous et de température ne touchent pas l’éponge et ne

sont pas immergés dans l’eau. Mettez l’appareil en marche et attendez

environ 5 à 10 minutes que le manchon de stockage soit complètement

saturé et que les capteurs de température et d’oxygène dissous se

stabilisent.

3. Appuyez sur la touche CAL.

4. L’affichage vous invite à indiquer la pression barométrique réelle

locale enmbar (millibar). Utilisez les touches fléchées Haut et Bas pour

augmenter ou diminuer la pression barométrique, puis appuyez sur

Entrée.

5. L’écran affiche la mesure d’oxygène dissous actuelle sur l’écran

principal et la valeur d’étalonnage dans l’angle inférieur droit. Attendez

que la mesure d’oxygène dissous se stabilise, puis appuyez sur Entrée.

6. L’écran vous invite à indiquer la salinité approximative de l’eau

devant être analysée. Utilisez les touches fléchées Haut et Bas pour

augmenter ou diminuer la valeur de compensation de la salinité afin

qu’elle corresponde à la valeur de l’échantillon (entre 0 et 40 parties

par millier). Une fois que la salinité correcte est affichée, appuyez sur

Entrée.

7. L’unité conserve l’étalonnage pendant plusieurs mois, même si elle est

arrêtée et mise en marche.

9

Page 40

ENTRETIEN ET DÉPANNAGE

ENTRETIEN DES CAPTEURS – OXYGÈNE DISSOUS

NETTOYAGE DE L’EMBOUT DU CAPTEUR

L’embout du capteur doit rester propre, car certains types de saleté

peuvent consommer ou produire de l’oxygène ou empêcher l’échantillon

d’eau d’atteindre le capteur, ce qui pourrait affecter les mesures d’oxygène

dissous.

Pour nettoyer l’embout du capteur, essuyez doucement toute saleté à

l’aide d’une serviette de nettoyage pour lentilles humidifiée avec de

l’eau. N’utilisez pas de solvants organiques pour nettoyer l’embout du

capteur. Les solvants organiques peuvent endommager l’embout de

façon permanente. Par exemple, l’alcool dissout la couche de peinture

externe et d’autres solvants organiques risquent de dissoudre la teinture

de l’embout. Des mesures d’oxygène dissous irrégulières peuvent se

produire si la couche de peinture ou de teinture est dissoute ou rayée.

Pour désinfecter la sonde, trempez la sonde dans de l’eau oxygénée à 3%

pendant 15 à 30 secondes, puis rincez-la avec de l’eau propre.

REMPLACEMENT DE L’EMBOUT DU CAPTEUR

L’embout du capteur doit être remplacé environ tous les ans, mais peut

durer plus longtemps. Il doit également être remplacé s’il est fendu ou

endommagé (reportez-vous à la section Dépannage pour savoir comment

vérifier si l’embout est endommagé). La fiche d’instructions expédiée

avec l’embout de capteur ODO de remplacement indique les coefficients

d’étalonnage spécifiques à votre embout de capteur.

L’embout de capteur ODO de remplacement est expédié dans un

conteneur humidifié. Le paquet ne doit pas être ouvert avant que vous

soyez prêt à l’utiliser. Une fois que l’embout de capteur a été installé sur

le capteur comme décrit ci-dessous, il est important de garder le capteur

dans un milieu saturé d’humidité. En conséquence, le capteur doit être soit

entreposé dans le manchon d’étalonnage/stockage gris avec une éponge

humide, soit plongé dans l’eau. Reportez-vous à la section Stockage

du capteur pour davantage d’informations. Si le capteur se dessèche,

reportez-vous à la procédure de réhydratation décrite dans ce manuel.

Reportez-vous à la Figure 7 ci-dessous lorsque vous suivez les instructions

de remplacement de l’embout.

10

Page 41

JOINT

Figure 7

JOINT TORIQUE

EMBOUT DE CAPTEUR

Attention: évitez de toucher l’extrémité sensible de l’embout du capteur

pendant les procédures d’entretien suivantes.

1. Retirez l’ancien assemblage de l’embout de capteur du capteur en

empoignant le corps de la sonde d’une main et en tournant l’embout

de capteur dans le sens inverse des aiguilles d’une montre jusqu’à

ce qu’il soit complètement libéré. N’utilisez aucun outil lors de cette

procédure.

2. Vérifiez que le joint torique de la sonde n’est pas endommagé. S’il existe

des traces de dommage, retirez soigneusement le joint torique et

remplacez-le avec le nouveau joint torique inclus avec l’embout de capteur

de remplacement. N’utilisez aucun outil pour retirer le joint torique.

3. Assurez-vous que le joint torique installé sur la sonde est propre. Le

cas échéant, nettoyez-le en l’essuyant avec un chiffon non pelucheux

ou remplacez le joint torique comme décrit à l’étape précédente.

4. Localisez le lubrifiant de joint torique expédié avec le nouvel embout

de capteur. Appliquez une légère couche de lubrifiant de joint torique

au joint torique. Enlevez tout excès de lubrifiant du joint torique et/ou

de la sonde à l’aide d’une serviette de nettoyage de lentilles.

5. Retirez le nouvel embout de capteur de son conteneur hydraté et

séchez la cavité intérieure de l’embout de capteur à l’aide d’un tissu

de nettoyage de lentilles. Ensuite, nettoyez la surface transparente

du capteur, située à l’extrémité de la sonde, à l’aide d’un tissu de

nettoyage de lentilles.

6. En tournant dans le sens des aiguilles d’une montre, vissez le nouvel

embout de capteur sur l’assemblage de la sonde et serrez-le à la main.

Les joints toriques doivent être compressés entre l’embout de capteur

et la sonde. Ne serrez pas trop l’embout de capteur et n’utilisez aucun

outil lors du processus d’installation.

7. Après avoir installé le nouvel embout de capteur, stockez le capteur dans

le manchon d’échantillonnage/stockage gris avec une éponge humide.

8. Suivez la procédure ci-dessous pour saisir les nouveaux coefficients

de l’embout de capteur dans l’appareil EcoSense ODO200.

11

Page 42

SAISIR LES COEFFICIENTS DE L’EMBOUTDECAPTEURDANS

L’ECOSENSEODO200

Après avoir installé un nouvel embout de capteur, connectez l’assemblage

du câble et de la sonde à l’appareil et mettez l’appareil en marche. Localisez

l’étiquette de code d’étalonnage située en haut de la fiche d’instructions et

notez les six nombres répertoriés comme K1 à K5 et KC. Les six nombres

contiennent le code d’étalonnage de cet embout de capteur particulier.

Suivez ces instructions pour saisir les nouveaux coefficients d’étalonnage

dans votre appareil:

1. Maintenez la touche CAP enfoncée pendant 3 secondes. La touche

CAP se trouve dans l’angle inférieur gauche du clavier.

2. L’appareil vous invite à indiquer la valeur K1 et montre 8 valeurs

alphanumériques, la première valeur clignotant.

3. Utilisez les touches fléchées Haut et Bas pour ajuster la première valeur

afin qu’elle corresponde à la première valeur K1 du nouvel embout.

Appuyez sur la touche Entrée pour accepter.

4. Continuez d’utiliser les touches fléchées Haut et Bas pour ajuster

toutes les valeurs alphanumériques de K1, en appuyant sur la touche

Entrée pour confirmer chaque saisie.

5. Après avoir confirmé la dernière valeur de K1, l’appareil vous invite à

saisir celle de K2. Suivez les instructions des étapes 3 et 4 pour saisir

et confirmer la valeur de K2. Continuez avec K3, K4 et K5.

6. Après avoir confirmé K5, l’EcoSense ODO200 vous invite à saisir KC.

KC possède deux valeurs. Suivez les instructions des étapes 3 et 4

pour saisir les coefficients. Après avoir confirmé KC, l’appareil retourne

à l’écran de mesure.

7. Après avoir saisi les coefficients de l’embout de capteur, réalisez un

étalonnage à 1 point, comme décrit dans la section Étalonnage.

8. Maintenez la touche CAP enfoncée pendant 3 secondes à n’importe

quel moment pour quitter et annuler la mise à jour des coefficients de

l’embout.

Si des erreurs sont commises lors de la saisie des coefficients de l’embout

de capteur, l’appareil bloque la mise à jour, un message d’erreur s’affiche

et l’appareil retourne à l’écran de saisie K1. Si vous voyez ce message

d’erreur, entrez à nouveau les coefficients et vérifiez soigneusement que

leur transcription depuis l’étiquette des coefficients d’étalonnage est

correcte.

Les valeurs des coefficients sont hexadécimales. Le chiffre 6 et la lettre b

se ressemblent beaucoup sur l’écran de l’EcoSense ODO200. Les valeurs

hexadécimales s’affichent comme suit sur l’ODO200: A, b, C, d, E, F, 0, 1,

2, 3, 4, 5, 6, 7, 8 et 9.

Si vous continuez à recevoir un message d’erreur après plusieurs tentatives,

contactez l’assistance technique YSI.

12

Page 43

RÉHYDRATATION DE L’EMBOUT DU CAPTEUR

L’embout du capteur doit rester dans un milieu humide; reportez-vous

à la section Stockage du capteur pour obtenir des recommandations sur

l’entreposage. Si l’embout du capteur se dessèche, il est probable que

les mesures glissent légèrement au début de votre prochaine étude, à

moins que vous le réhydratiez. Si l’embout se dessèche, vous pouvez le

réhydrater en trempant le bout de la sonde dans de l’eau du robinet à

température ambiante pendant 24 heures, alors que l’embout du capteur

est installé. Après la réhydratation, effectuez un nouvel étalonnage et

veillez à entreposer la sonde dans un milieu humide.

ENTRETIEN DES CAPTEURS – TEMPÉRATURE

Vous devez éviter la formation d’accumulations sur la portion du capteur

devant mesurer la température. Autrement, le capteur ne nécessite pas

d’entretien particulier. Une brosse à poils souples, comme une brosse à dents,

peut être utilisée pour brosser le capteur de température, le cas échéant.

STOCKAGE DU CAPTEUR

STOCKAGE À COURT TERME

Lorsque le capteur ODO n’est pas utilisé, entreposez-le dans un milieu humide.

Pour un stockage à court terme (moins de 30 jours), humidifiez l’éponge

qui se trouve dans le manchon d’étalonnage/stockage avec un peu d’eau

claire et placez le manchon sur la sonde alors que l’embout de capteur

et la protection du capteur sont installés. Cela fournira un milieu ambiant

saturé d’eau.

STOCKAGE À LONG TERME

Pour un stockage à long terme (> 30 jours), retirez la pile de l’appareil.

Humidifiez l’éponge qui se trouve dans le manchon d’étalonnage/stockage

avec un peu d’eau claire et placez le manchon sur la sonde alors que

l’embout de capteur et la protection du capteur sont installés. Inspectez

l’éponge tous les 30 jours pour vous assurer qu’elle est toujours humide.

Vous pouvez autrement placer la sonde avec l’embout de capteur

directement dans un bécher ou autre récipient d’eau, en vous assurant

que l’eau ne s’évapore pas au fil du temps.

DÉPANNAGE

Des valeurs d’oxygène dissous erronées indiquent généralement que

l’embout du capteur doit être nettoyé ou remplacé et/ou que l’appareil doit

être ré-étalonné. Tout d’abord, nettoyez l’embout du capteur en suivant

13

Page 44

les instructions de la section Entretien, puis effectuez un étalonnage. Si

les mesures erronées persistent, vérifiez que l’embout du capteur n’est

pas endommagé (fentes, grosses rayures de la couche de peinture ou de

teinture), remplacez-le, le cas échéant, entrez les nouveaux coefficients,

puis tentez de ré-étalonner l’appareil.

Si l’embout du capteur n’est pas endommagé, essayez de réhydrater

l’embout du capteur, puis effectuez un nouvel étalonnage.

Si vous obtenez toujours des valeurs d’oxygène dissous erronées, essayez

de remplacer l’embout du capteur, saisissez les nouveaux coefficients,

puis effectuez un nouvel étalonnage. Si vous obtenez toujours des valeurs

erronées, contactez l’assistance technique d’YSI afin de déterminer l’étape

suivante.

Symptôme Solution possible

L’appareil ne démarre

pas, le symbole BAT

s’affiche à l’écran.

Les valeurs de

température affichent

Sur ou Sous dans

l’écran d’exécution.

Impossible d’étalonner

l’oxygène dissous

Les mesures d’oxygène

dissous ne sont

pas précises.

1. La tension de la pile est trop faible; remplacez la pile.

2. La pile n’est pas installée correctement;

vérifiez sa polarité.

3. Retournez le système au centre de service.

1. La température de l’échantillon est inférieure à 0 ºC

ou supérieure à 50 ºC. Augmentez ou diminuez la

température de l’échantillon pour qu’elle se trouve

dans la plage autorisée.

2. Contactez l’assistance technique d’YSI. Défaillance

possible du capteur de température.

1. Vérifiez la procédure d’étalonnage:

pression barométrique correcte, saisie de

la salinité et milieu d’étalonnage.

2. Laissez les mesures d’oxygène dissous et de

température se stabiliser suffisamment.

3. Vérifiez l’embout de capteur. Nettoyez-le,

réhydratez-le ou remplacez-le, le cas échéant.

4. Contactez l’assistance technique d’YSI.

1. Vérifiez que les mesures de température sont précises.

2. La température de l’échantillon doit se situer

entre 0 et 45ºC, la plage de compensation

de la température pour les mesures

d’oxygène dissous exprimées en mg/l.

3. Le capteur d’oxygène dissous n’est pas étalonné

correctement. Étalonnez le capteur.

4. Vérifiez l’embout du capteur. Nettoyezle, réhydratez-le ou remplacez-le, le cas

échéant. Effectuez un nouvel étalonnage.

5. Contactez l’assistance technique d’YSI.

14

Page 45

Symptôme Solution possible

Les valeurs d’oxygène

dissous affichent

Sur ou Sous dans

l’écran d’exécution.

1. La concentration en oxygène dissous de

l’échantillon est supérieure à 20 mg/l ou

200%, ou inférieure à 0,0 mg/l ou 0,0%.

2. Vérifiez que les mesures de température sont précises.

3. Le capteur d’oxygène dissous n’est pas étalonné

correctement. Étalonnez le capteur.

4. Vérifiez l’embout du capteur. Nettoyez-

le, réhydratez-le ou remplacez-le, le cas

échéant. Effectuez un nouvel étalonnage.

5. Contactez l’assistance technique d’YSI.

CARACTÉRISTIQUES

Ces caractéristiques représentent des performances typiques et

sont sujettes à modification sans préavis. Pour obtenir les dernières

caractéristiques du produit, visitez le site Web d’YSI à ysi.com ou contactez

l’assistance technique d’YSI.

Paramètre Plage Résolution Précision

Température 0 à 50ºC* 0,1ºC ± 0,3ºC

Oxygène

dissous

Baromètre 500 à 1125

Plage de

température de

fonctionnement

Homologations

Mémoire 50 jeux de données

Salinité De 0 à 40 parties par millier, saisie manuelle

Pile Alcaline 9 volts, 100 heures d’autonomie

Saturation

de l’air de

0,0 à 200%

0,00 à

1% ou 0,1%,

sélectionnable

par l’utilisateur

0,1 ou 0,01 mg/l Le plus grand de

20mg/l

1,0 mbar Saisie manuelle

mBar

0 à 50ºC

RoHs, WEEE, CE, IP-67

en mode d’échantillonnage manuel

Le plus grand de

±1,5% de la mesure

ou ±1,5% de la

saturation de l’air

±1,5% de la mesure

ou ±1,5 mg/l

* La plage de compensation automatique de la température pour l’oxygène

dissous s’étend de 0 à 45ºC.

15

Page 46

ACCESSOIRES / NUMÉROS DEPIECES

Code de pièce Description

606326 Kit d’embout de capteur EcoSense ODO

606327 Assemblage câble (environ 1 mètre, 3,3 pieds)

et sonde*

606328 Assemblage câble (environ 4 mètres, 13 pieds)

et sonde*

606304 Assemblage câble (environ 10 mètres, 33 pieds)

et sonde*

606329 Appareil EcoSense ODO200

605139 Sacoche à fond et dessus souples, petite

(contient l’appareil et un assemblage de câble

et de sonde de 4 mètres maximum)

606330 Sacoche de transport à flancs durs ODO200

avec inserts de mousse formée

*Tous les câbles sont dotés d’un capteur d’oxygène dissous optique et

d’un capteur de température.

COORDONNÉES ET SERVICE

COMMANDE ET ASSISTANCE TECHNIQUE

Téléphone: 800 897 4151 (États-Unis)

+1937 767 7241 (monde entier)

Du lundi au vendredi, de 8h00 à 17h00,

heure de l’Est des États-Unis

Télécopie: +1937 767 9353 (commandes)

+1937 767 1058 (assistance technique)

Courrier électronique: environmental@ysi.com

Adresse postale: YSI Incorporated

1725 Brannum Lane

Yellow Springs, OH 45387

États-Unis

Adresse Web: ysi.com

Lorsque vous passez une commande, veuillez

fournir les informations suivantes:

1.) Numéro de compte YSI (le cas échéant)

2.) Nom et numéro de téléphone

16

Page 47

3.) Bon de commande et carte de crédit

4.) Numéro de modèle ou brève description

5.) Adresses de facturation et de destination

6.) Quantité

INFORMATIONS SUR LE SERVICE

YSI dispose de centres de service autorisés à travers les États-Unis et dans

le monde. Pour connaître le centre de service le plus proche, veuillez visiter

ysi.com et cliquez sur «Support» ou contactez l’assistance technique au

800-897-4151.

Lorsque vous retournez un produit pour réparation, accompagnez-le du

formulaire de retour de produits avec la certification de nettoyage. Le

formulaire doit être entièrement rempli pour qu’un centre de service d’YSI

accepte de réparer l’appareil. Le formulaire peut être téléchargé à partir

de ysi.com en cliquant sur l’onglet «Support», puis sur le bouton Product

Return Form (Formulaire de retour des produits).

RECYCLAGE

YSI s’est engagé à réduire son impact sur l’environnement dans le cadre

de ses activités. Bien que la réduction des matériaux soit le but ultime,

nous savons qu’un effort concerté doit être fourni pour gérer de façon

responsable le traitement des matériaux après un cycle de vie long

et productif. Le programme de recyclage d’YSI garantit que l’ancien

équipement est traité d’une manière écologique, réduisant la quantité de

matériaux allant vers les sites de décharge contrôlée.

• Les cartes de circuit imprimé sont envoyées aux usines qui traitent et

récupèrent le plus grand nombre de matériaux possible en vue de

leur recyclage.

• Les matières plastiques entrent dans un processus de recyclage et ne

sont pas incinérées ou envoyées vers des sites de décharge.

• Les piles sont enlevées et envoyées à des recycleurs de piles pour la

récupération des métaux.

Lorsque le moment viendra pour vous de recycler, suivez les étapes faciles

indiquées à ysi.com.

17

Page 48

ANNEXE A – VALEURS DE CALIBRAGE

DU POURCENTAGE D’OD

Valeur

d’étalonnage

% OD po Hg mmHg kPa mbar

101% 30,22 767,6 102,34 1023,38

100% 29,92 760,0 101,33 1013,25

99% 29,62 752,4 100,31 1003,12

98% 29,32 744,8 99,30 992,99

97% 29,02 737,2 98,29 982,85

96% 28,72 729,6 97,27 972,72