Page 1

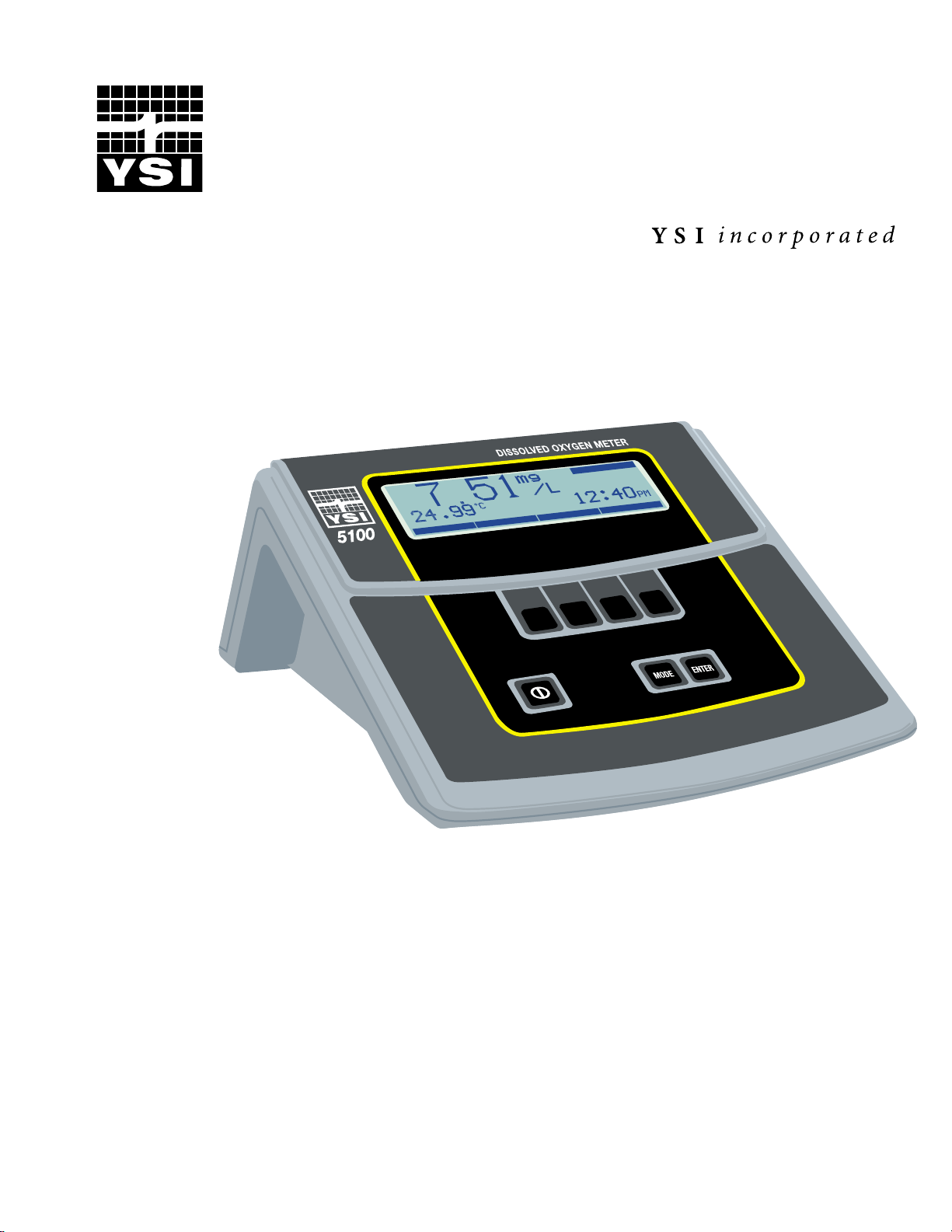

YSI Model 5000

YSI Model 5100

Dissolved Oxygen

Temperature

Operations Manual

Page 2

Table of Contents

1. General Description..............................................................................................................................1

2. Specifications........................................................................................................................................3

3. Quick Start.............................................................................................................................................5

4. Controls .................................................................................................................................................6

4.1 Front Panel...................................................................................................................................................... 6

4.2 Software Flow Chart....................................................................................................................................... 7

4.3 Rear Panel....................................................................................................................................................... 9

5. Setup....................................................................................................................................................11

5.1 Display Setup................................................................................................................................................ 12

5.2 Report Setup ................................................................................................................................................. 14

5.3 Autostable Setup........................................................................................................................................... 16

5.4 System Setup................................................................................................................................................. 17

6. Calibration ...........................................................................................................................................19

6.1 Dissolved Oxygen Calibration...................................................................................................................... 19

Auto Cal........................................................................................................................................................ 20

DO Cal (manual)........................................................................................................................................... 21

Barometer ..................................................................................................................................................... 22

Salinity.......................................................................................................................................................... 23

6.2 Zero Calibration............................................................................................................................................ 24

7. Operation.............................................................................................................................................26

7.1 Main Mode ................................................................................................................................................... 26

Making Measurements .................................................................................................................................. 26

Store.............................................................................................................................................................. 27

Review.......................................................................................................................................................... 28

Send .............................................................................................................................................................. 30

7.2 Application Mode ......................................................................................................................................... 32

OUR.............................................................................................................................................................. 32

SOUR............................................................................................................................................................ 37

Remote.......................................................................................................................................................... 42

8. Diagnostics..........................................................................................................................................44

History .......................................................................................................................................................... 45

Sensor ........................................................................................................................................................... 46

Reset Ps......................................................................................................................................................... 47

9. Principles of Operation.......................................................................................................................48

10. Understanding Dissolved Oxygen Error Factors......................................................................49

i

Page 3

11. Maintenance..................................................................................................................................52

Batteries........................................................................................................................................................ 52

12. Troubleshooting...........................................................................................................................54

Error Messages ............................................................................................................................................. 54

13. Warranty & Repair ........................................................................................................................56

Cleaning Instructions .................................................................................................................................... 57

Packing Instructions...................................................................................................................................... 58

14. Required Notice............................................................................................................................59

15. Accessories and Replacement Parts..........................................................................................60

16. Appendix A - Oxygen Solubility Table........................................................................................61

17. Appendix B - Pressures and Altitudes.......................................................................................63

18. Appendix C - Conversion Factors...............................................................................................64

19. Appendix D - Remote Command Language...............................................................................65

ii

Page 4

1. General Description

Model 5000 Features

The Model 5000 is a microprocessor based, menu-driven, dissolved oxygen meter designed to

perform laboratory measurement of dissolved oxygen and Biochemical Oxygen Demand (BOD).

The instrument’s menu system makes it simple to use.

The Model 5000 has a new case design which facilitates laboratory measurement. The angled

profile makes these instruments both functional and attractive. A large graphical display provides

on-screen menus, and large data fields for ease of operation and readability. The angle and

position of the keypad make operation of the 5000 comfortable. The tactile and audio response

from each key stroke give you the confidence that every command has been received.

The Model 5000 is compatible with all existing YSI dissolved oxygen probes when used with the

YSI Model 5011 adapter. The new YSI Model 5010 self-stirring BOD Probe allows you to

operate the probe from the instrument’s power supply, eliminating the need for a separate power

cable for the probe.

Internal memory for storing up to 100 sets of data, and an RS232 port allow you to upload data

from the Model 5000 directly to your computer. Or you can use your Model 5000 with YSI BOD

Analyst software.

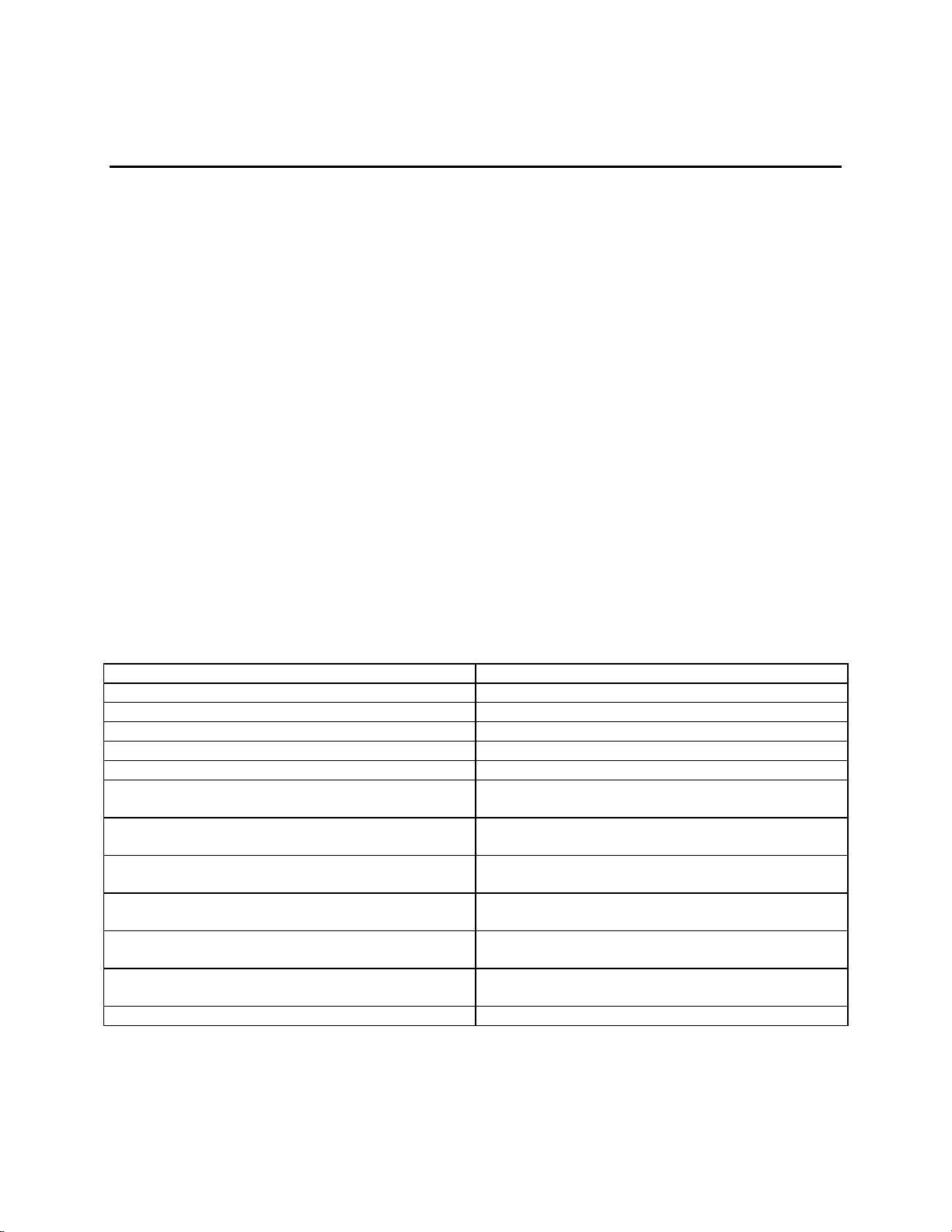

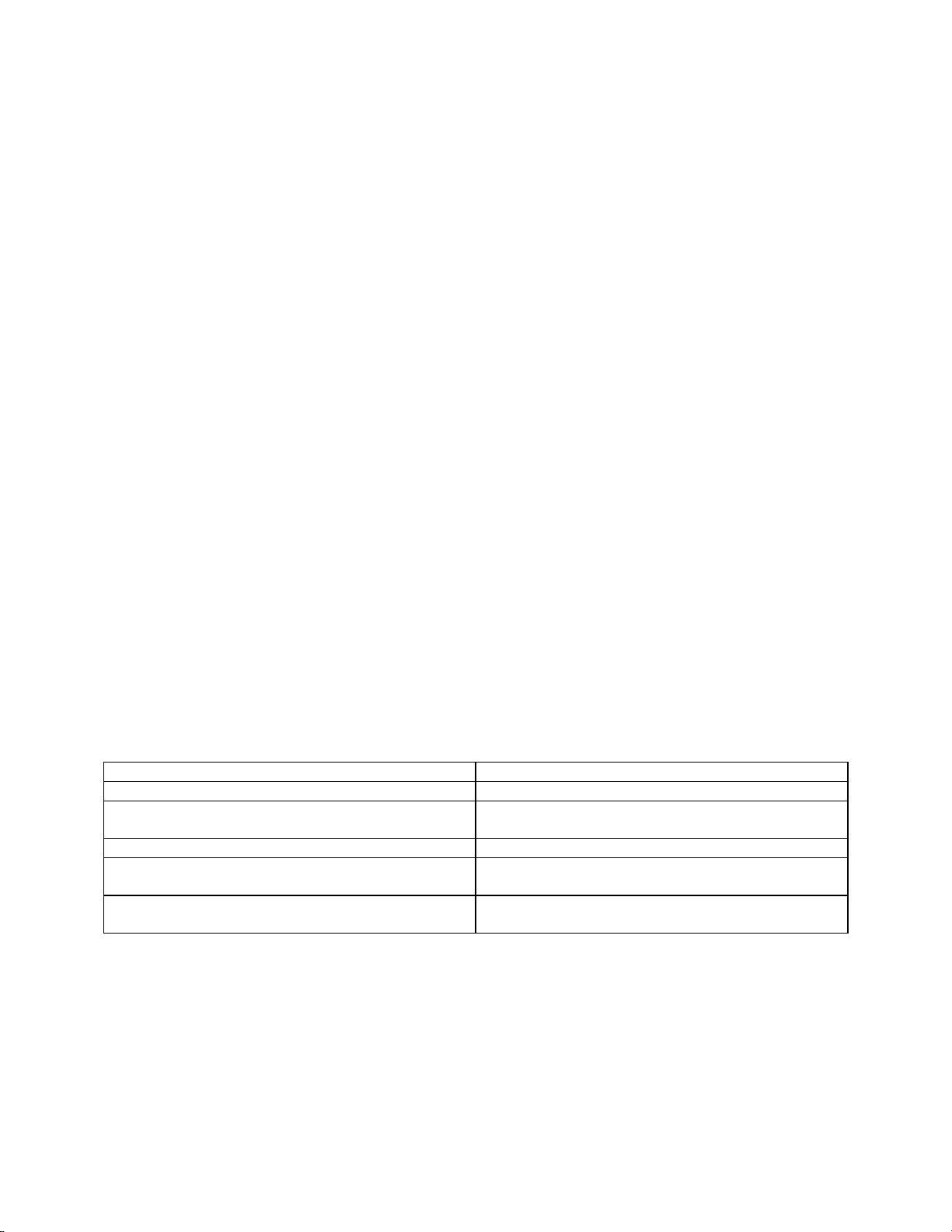

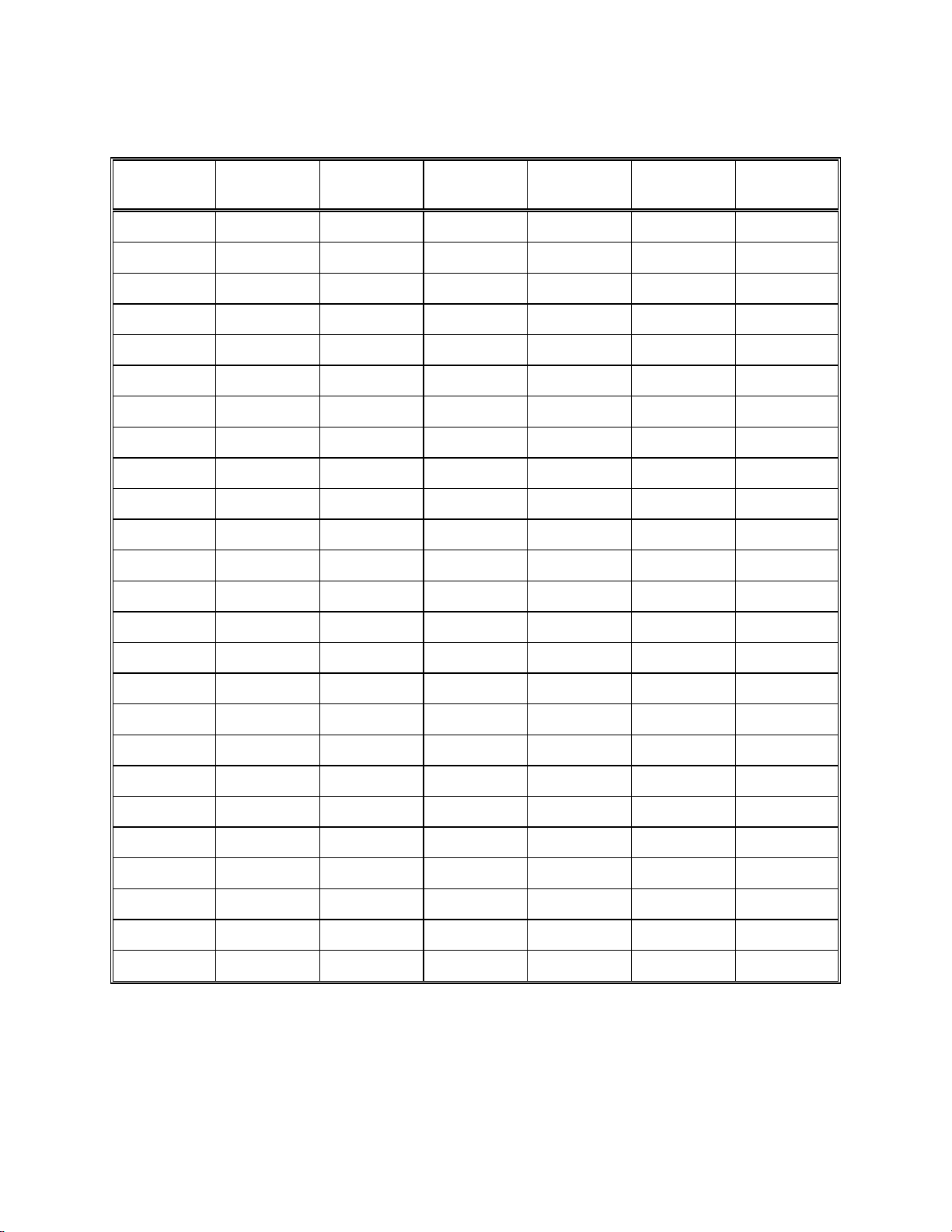

Model 5000 Features & Benefits

Feature Benefit

1. Menu driven operation for ease of use Ease of use -- little need for instruction manual.

2. Compatible with all existing YSI probes No need to re-invest in probes. (5011 adapter required)

3. Large graphic liquid crystal display Easy to read.

4. Internal memory for 100 data points No need to write down readings.

5. Auto stabilization feature You are alerted when stable DO reading is reached.

6. Compatible with YSI BOD Analyst Software Software does all the BOD calculations -- no chance for

math errors.

7. User upgradable internal software No fear that an instrument purchased today will be out of

date tomorrow.

8. RS232 interface Computer uploads to spreadsheets eliminates

transcription errors, & increases regulatory confidence.

9. 8-pin DIN connector which allows the instrument to

power the YSI 5010 self-stirring BOD probe

10. Computer interface control Allows you to control the functions of the instrument

11. Audio & tactile keypad response Affirmation of successful key strokes reduces errors and

12. Real-time clock For recalling or downloading data, this is essential.

No power supply needed for the DO probe which means

one less cable to clutter your work space.

from a computer.

uncertainty.

1

Page 5

Model 5100 Features

The YSI Model 5100 has all of the same functionality of the Model 5000 and much more.

The YSI Model 5100 is a state-of-the-art, microprocessor-based, dissolved oxygen instrument

with many automated and application specific features.

The YSI 5100 DO instrument contains built-in application software for the calculation of Oxygen

Uptake Rate (OUR) and Specific Oxygen Uptake Rate (SOUR). These application features

simplify compliance with USEPA 503 regulations for vector attraction and provide useful tools

for plant operation decisions.

For laboratories with larger volumes, the Model 5100 offers an optional bar code reader and

BOD Analyst software capability. These tools greatly reduce the labor required for processing

BODs and calculating BOD values. The RS232 serial port makes it easy to capture data

electronically.

The model 5000 and 5100 software can be upgraded easily using your computer. When YSI

upgrades these instruments, you’ll be able to get a floppy disk from YSI and simply upgrade the

software in a few minutes.

Calibration of the Model 5100 has been greatly simplified when compared to other dissolved

oxygen instruments. With its internal barometer, the Model 5100 is able to automatically

compensate for changes in barometric pressure so there is no need for charts, altitude information

or external barometric pressure information. The 5100 also has a membrane integrity feature

which will notify you when the membrane needs to be changed.

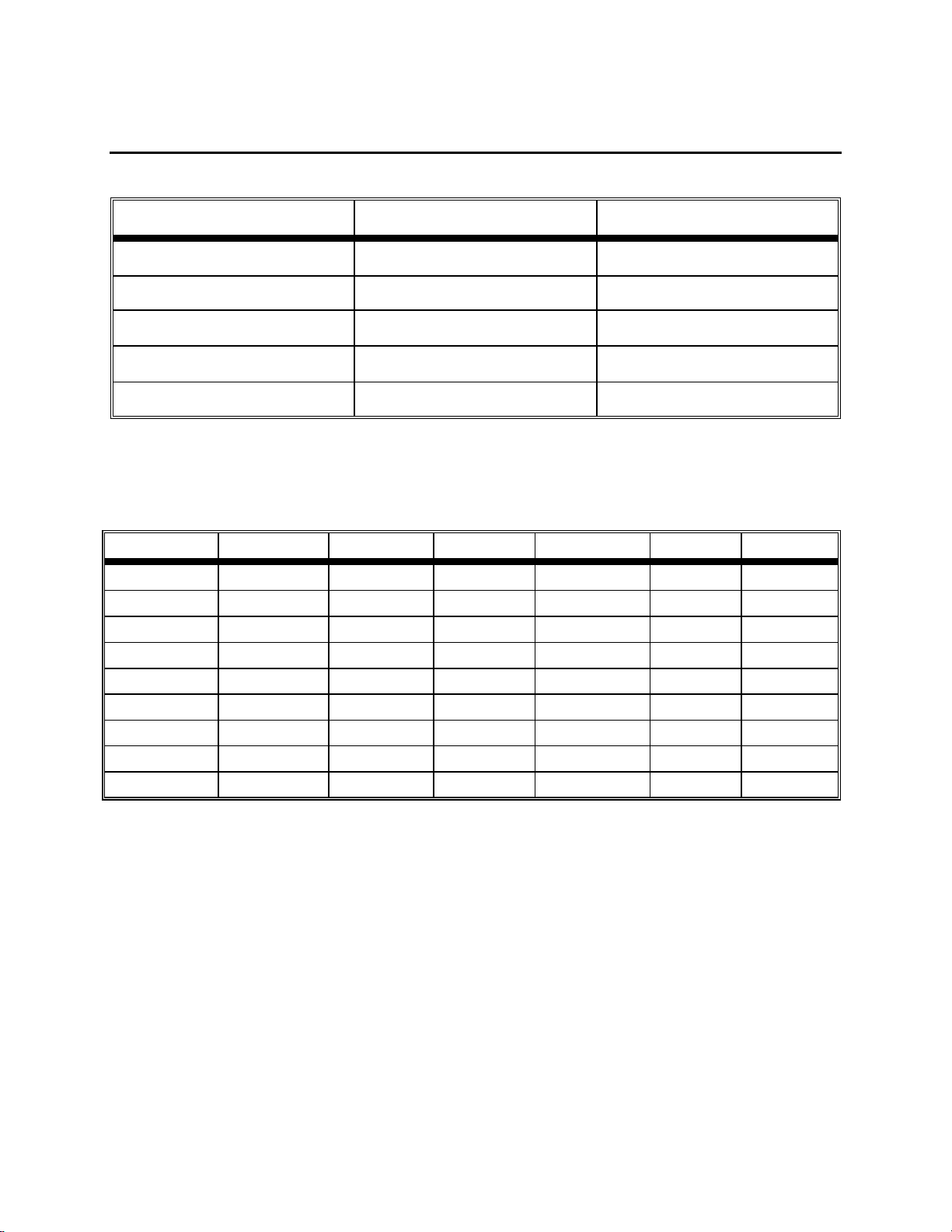

Model 5100 Features & Benefits

The Model 5100 has all the same functionality as the Model 5000, but with these additional

features:

Additional Feature Benefit

1. Built-in application software for OUR/ SOUR Easy compliance with USEPA 503 regulations.

2. Internal barometer No need to consult external barometer and perform

manual barometric pressure compensation.

3. Automated calibration Saves time and extra steps of manual calibration.

4. Bar-code capability No need to manually type or write the bottle number on

your bench sheet.

5. Port for computer keyboard For some applications, using a keyboard for data entry

will be faster than using the instrument keypad.

2

Page 6

2. Specifications

Oxygen Measurement

Ranges: mg/L: 0.0 to 60.0 mg/L

% air saturation: 0.0 to 600.0% air saturation

mbar: 0 to 1500

Accuracy: mg/L: ±0.1% plus 1 Least Significant Digit (LSD)

% air saturation: ±0.1% plus 1 LSD

mbar: ±±±±1% plus 1 LSD

Resolution: mg/L: 0.1%, or 0.01 mg/L , whichever is greater

% air saturation: 0.1% air saturation

mbar: 1 mbar

Temperature Measurement

Range: -5.0 to +50.0°C

Accuracy: ±0.1°C

Resolution: 0.01°C

Barometric Pressure Measurement

Range: 450 to 825 mmHg (600 to 1100 mbar)

Accuracy: ±1% plus 1 LSD within ±10°C ambient temperature from calibration point

Resolution: 1 mmHg

Temperature Compensation

The mg/L mode is automatically temperature-compensated to an accuracy of ±1% of DO

readings between 0 and 5°C, and to an accuracy of ±0.6% of readings between 5 and 45°C.

The % air saturation mode is automatically temperature-compensated to an accuracy of ±0.5% of

calibration values between 0 and 5°C, and to an accuracy of ±0.3% of values between 5 and

45°C.

3

Page 7

Salinity Compensation

Range: 0.0 to 40.0 ppt

Accuracy: ±.02 mg/L

Operating Environment

0 to 45°C, 10 to 90% relative humidity, non-condensing

Water Resistance

The Model 5000 and 5100 are designed exclusively for indoor use and are NOT waterproof.

Power

The Model 5000 & 5100 are powered by an AC adapter or 4 C-size alkaline batteries. A new set

of alkaline batteries will power the selected instrument for approximately 30 hours (not including

stirring).

Size and Weight

22.9 by 24.1 by 11.2 cm; 1.1 kg (with batteries)

9 by 9.5 by 4.4 inches; 2.6 pounds (with batteries)

4

Page 8

3. Quick Start

When you unpack your new Model 5000 or 5100 there are several things you’ll want to do to set

the instrument up.

1. Inspect the product to assure that it has not been damaged during shipment.

2. Check the packing list to make sure you have received everything you should have.

3. Install the batteries (see 11. Maintenance, Batteries).

4. Plug the power supply into its mating connector on the back of the meter (see 4.3

Rear Panel).

5. Prepare the DO probe, as discussed in the Probe Operations Manual, and plug it into

the connector on the back of the instrument.

6. Depress the (on/off ) key (see 4.1 Front Panel).

7. Set the date and time (see 5.4 System Setup).

8. Calibrate the system in a known oxygen environment (see 6.1 Dissolved Oxygen

Calibration).

You are now ready to make dissolved oxygen and temperature readings.

5

Page 9

4. Controls

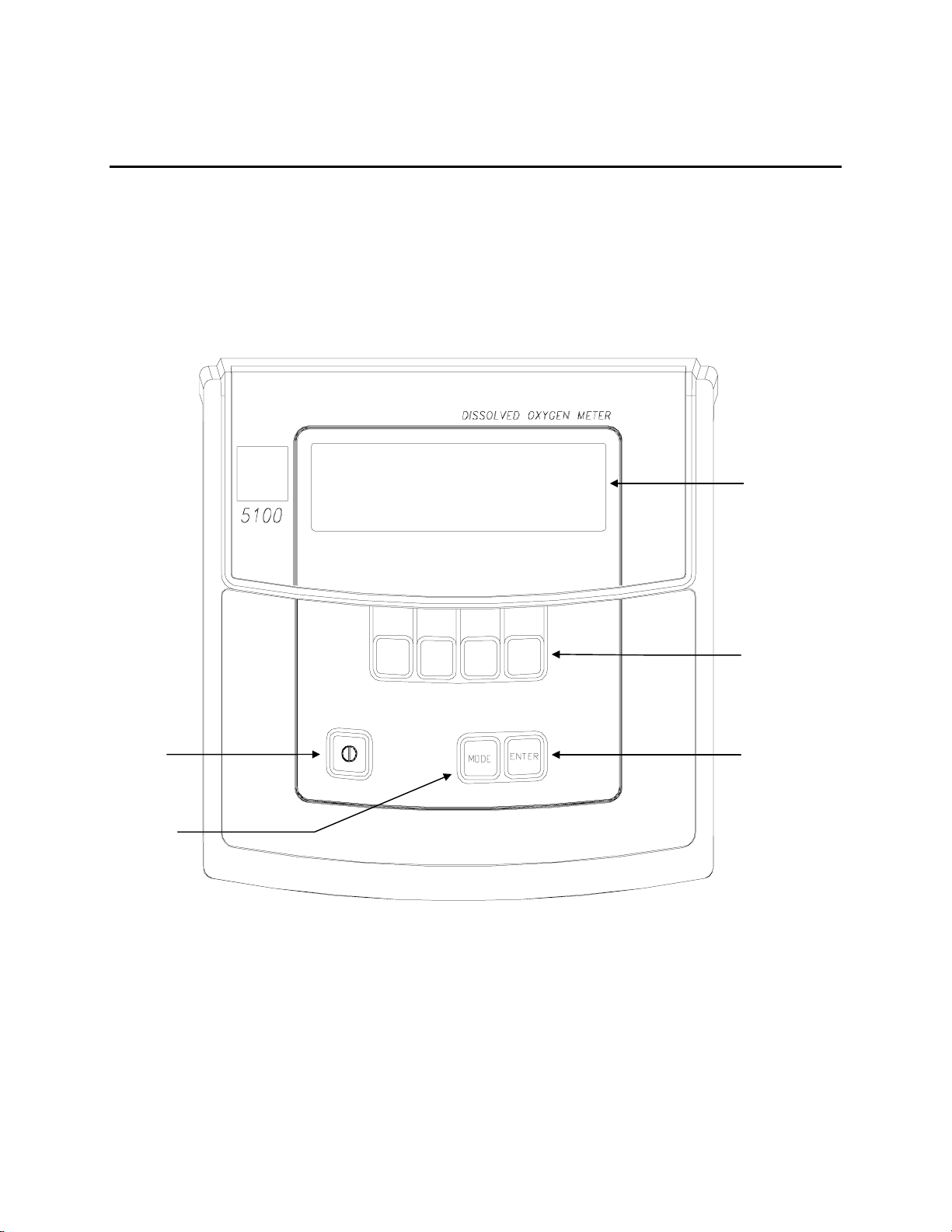

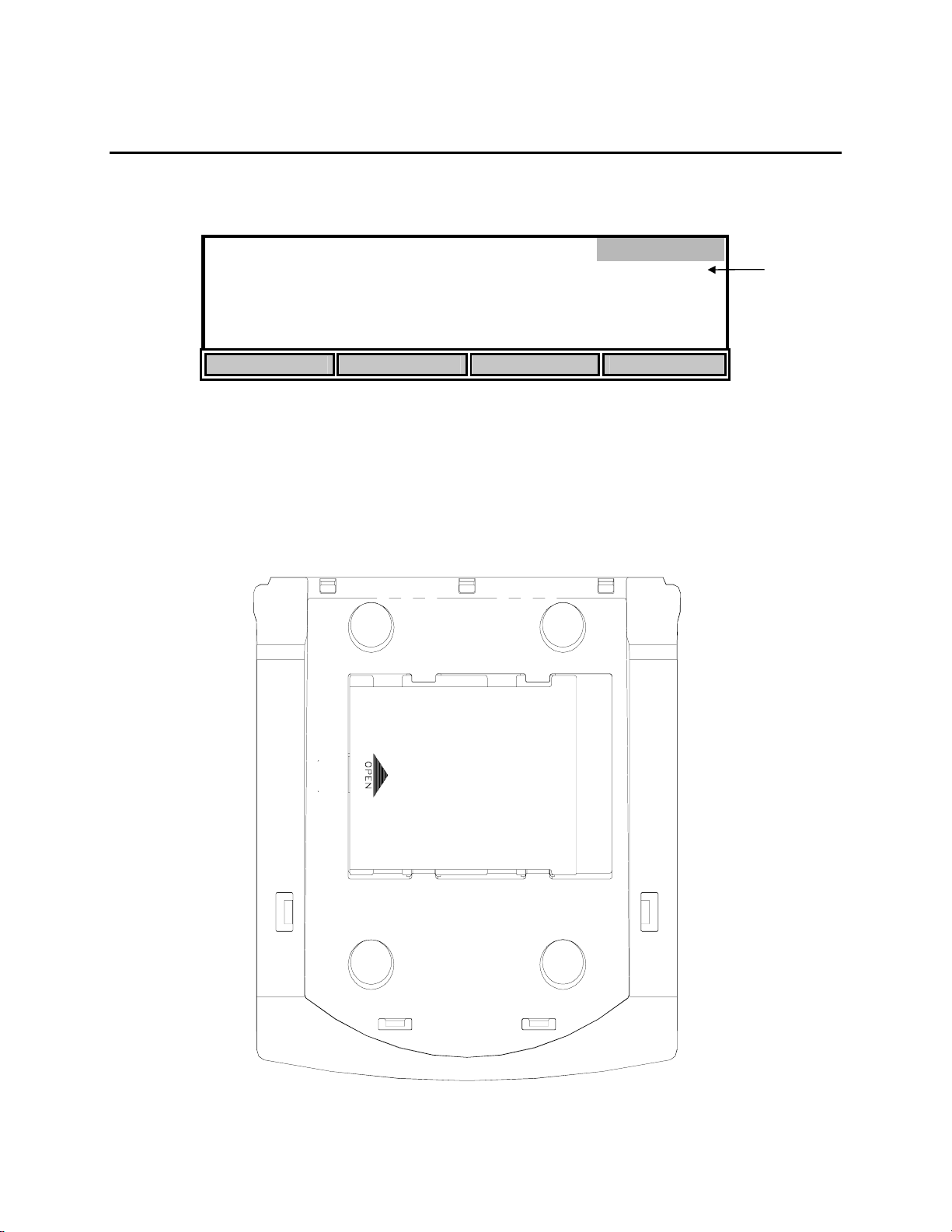

4.1 Front Panel

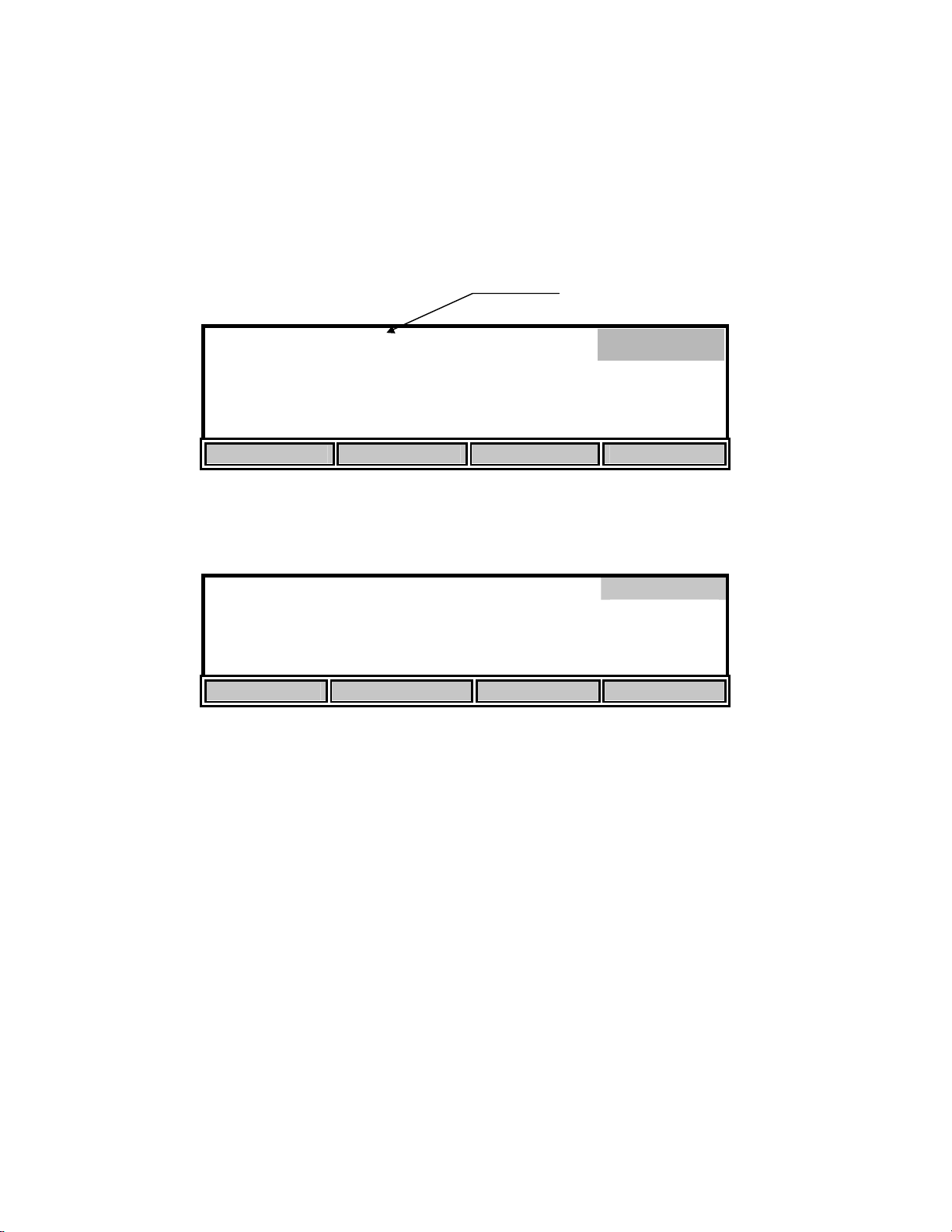

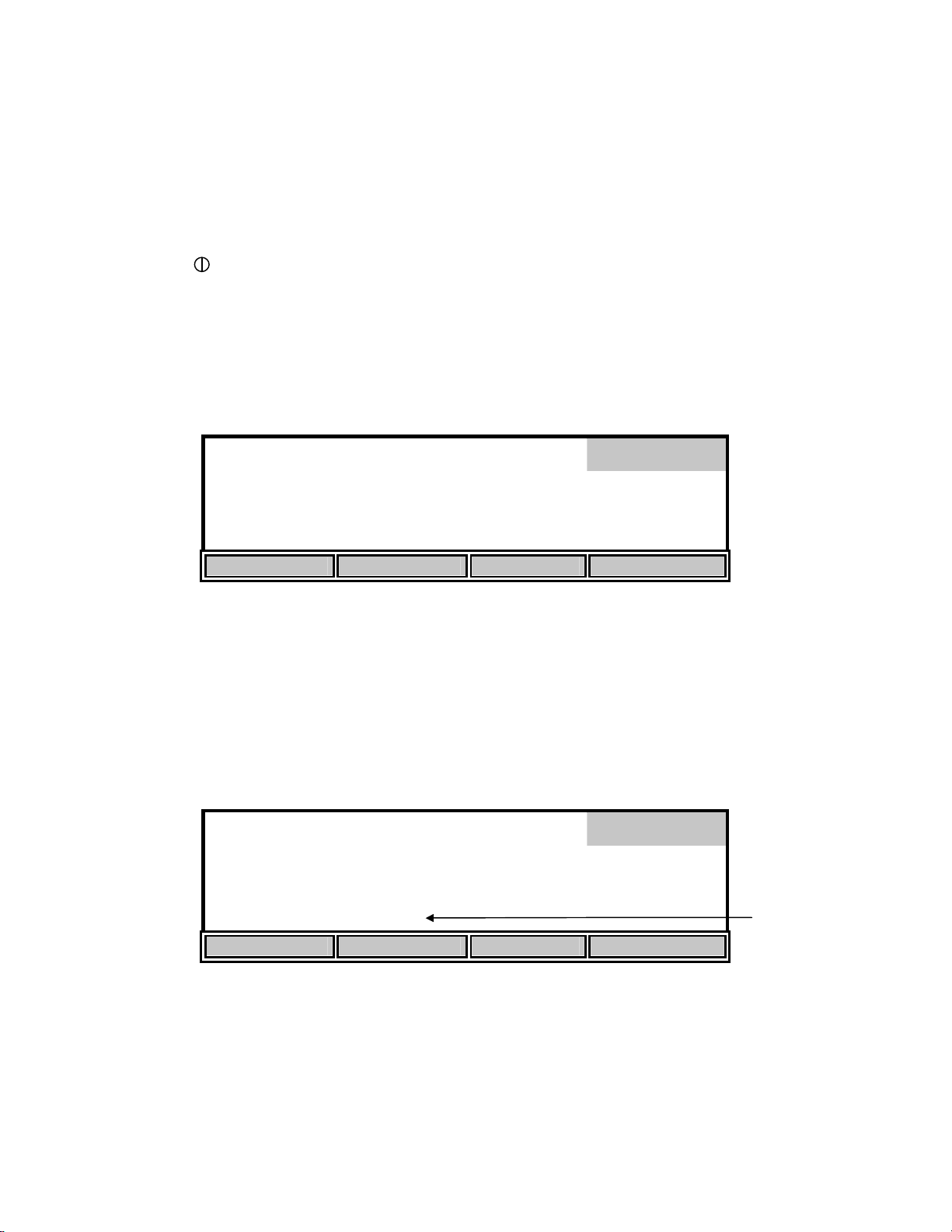

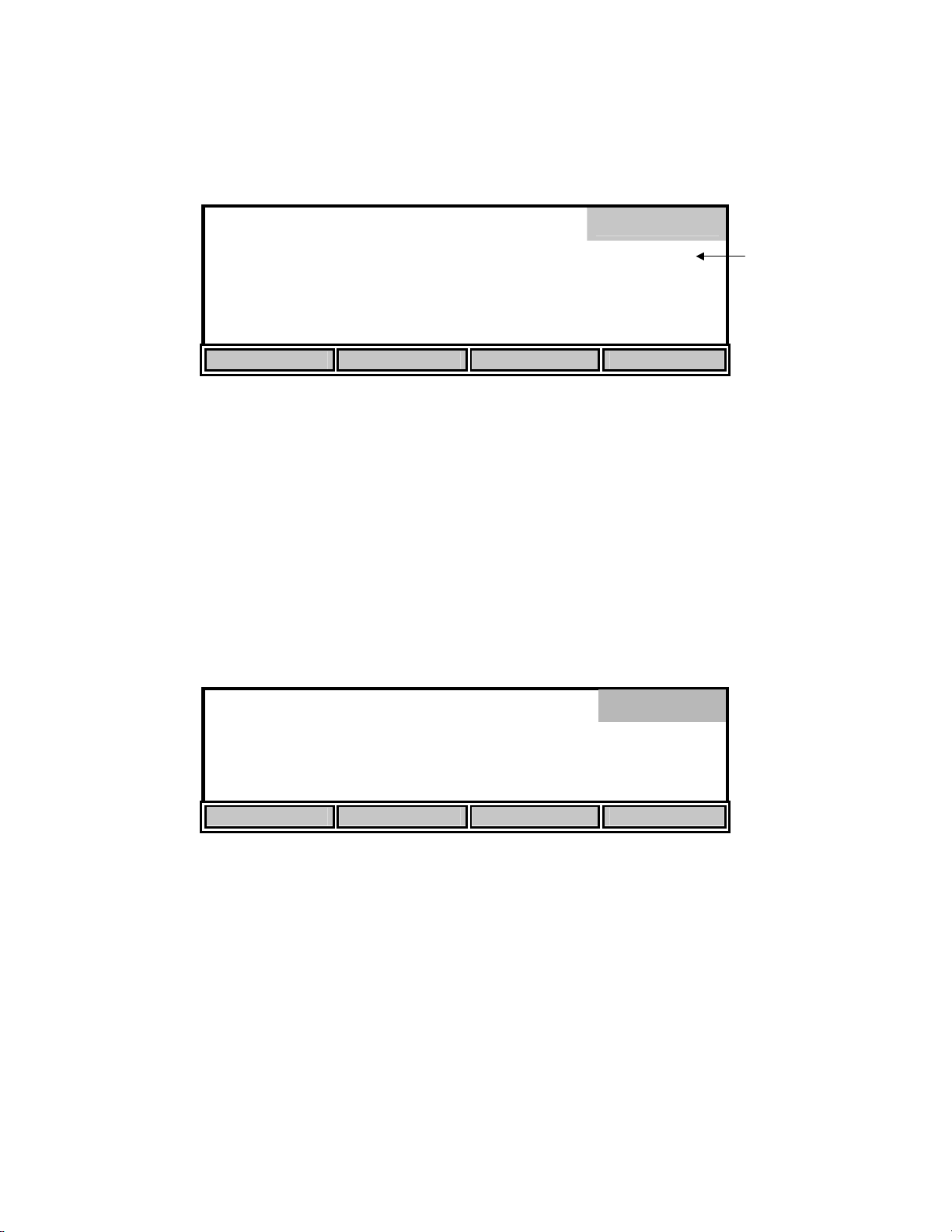

The front panel of the instrument contains the display and keypad as shown below. The front

panel display and controls of the 5000 and 5100 are identical.

Display

Power

ON/OFF

MODE Key

Soft-Keys

ENTER Key

6

Page 10

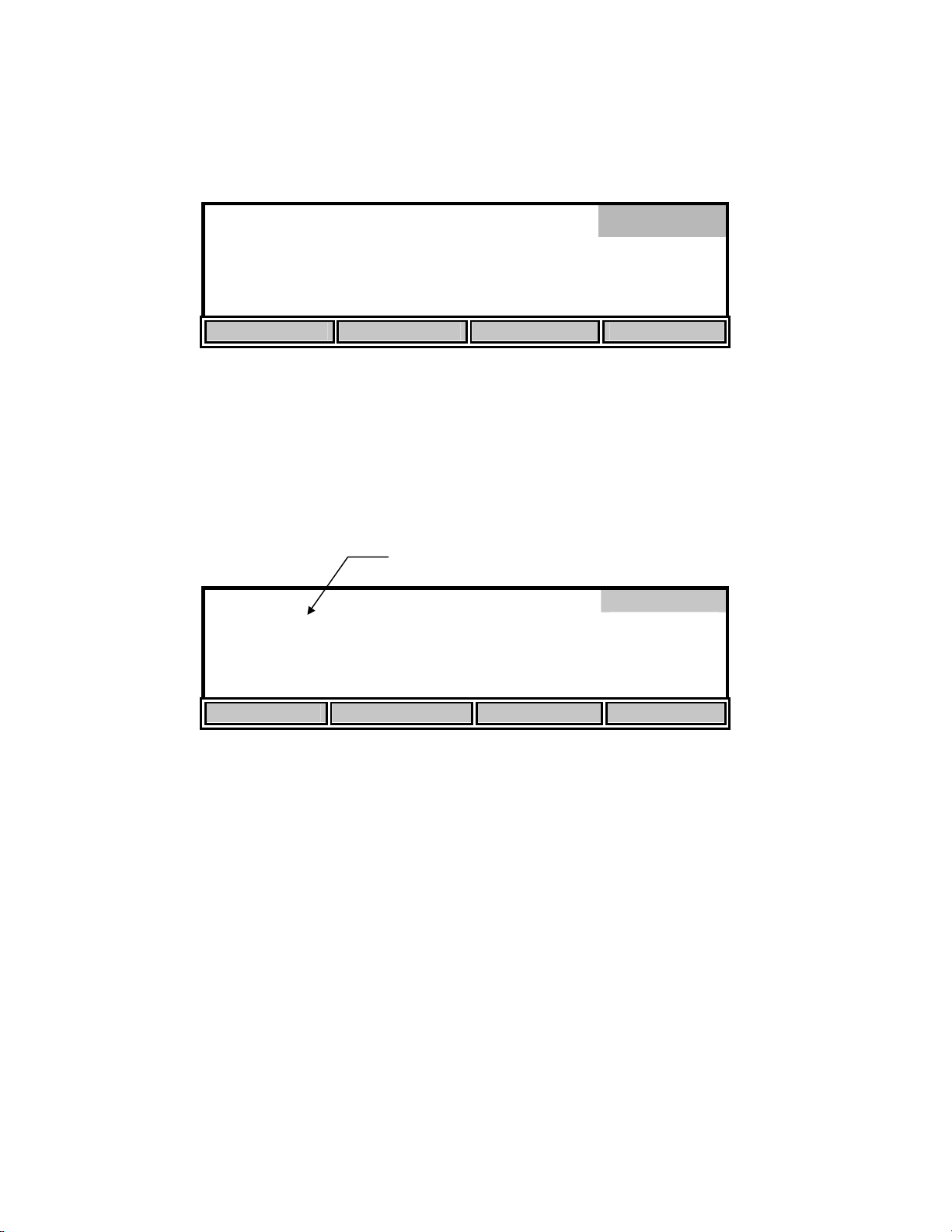

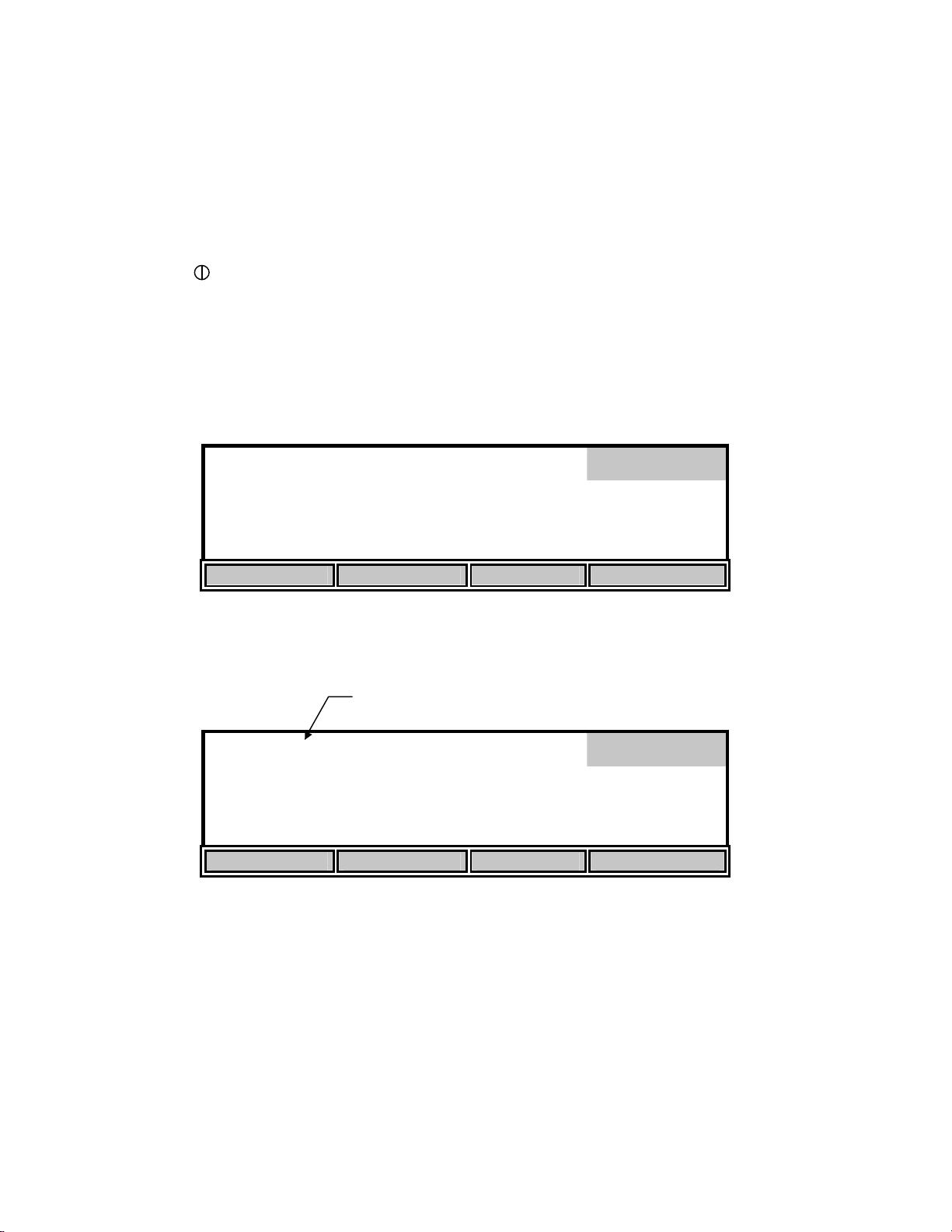

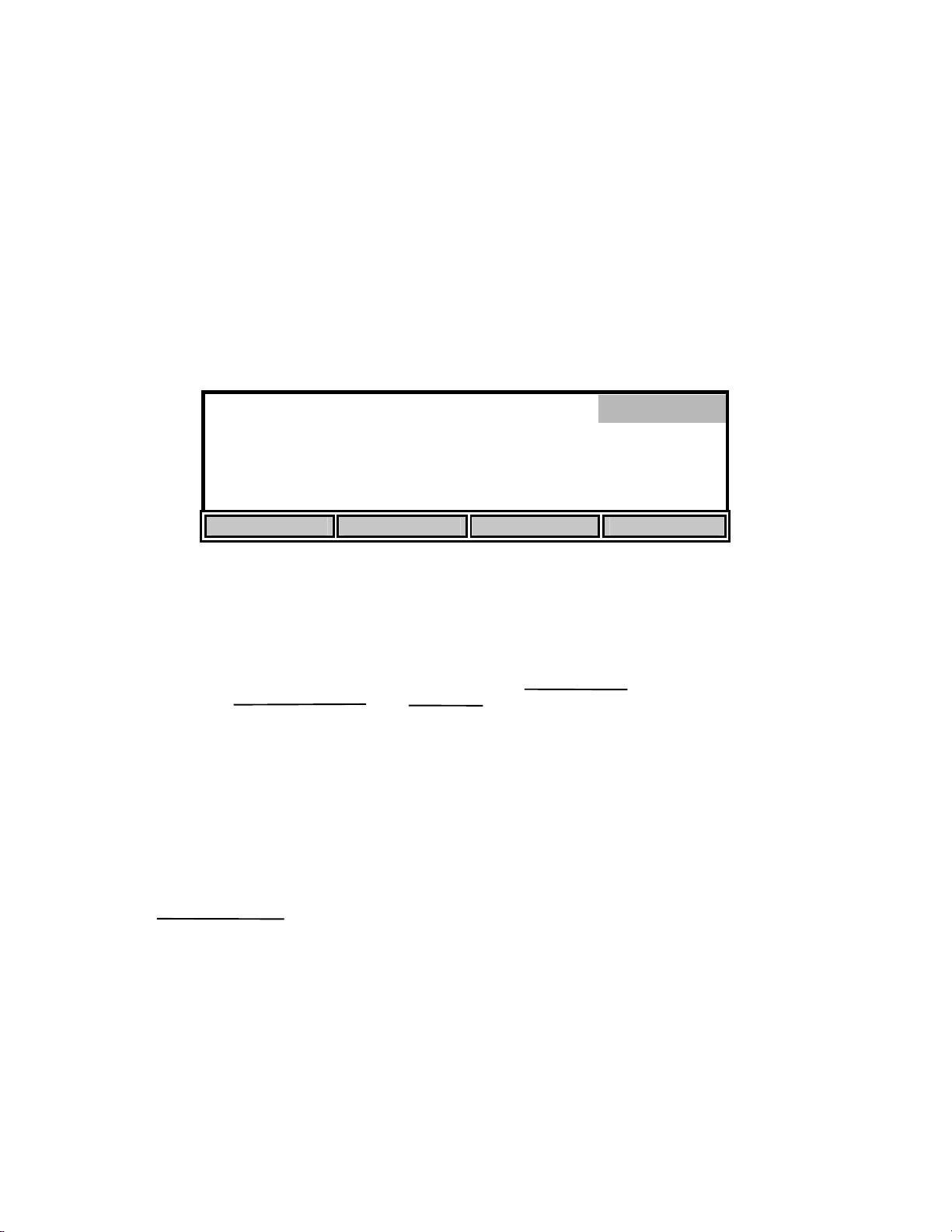

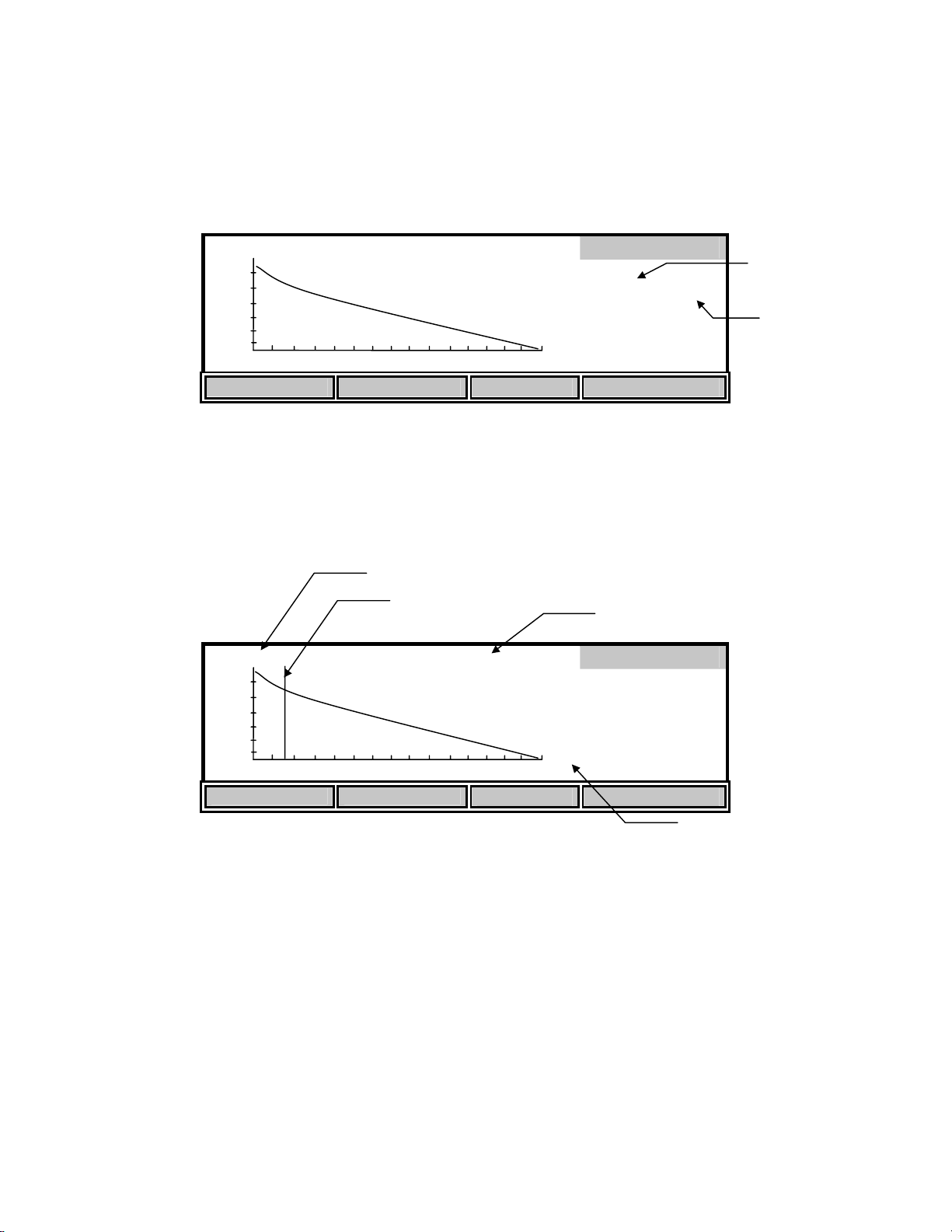

The 5000/5100 has two main operating modes, Main and Application. The current mode is

displayed in the dark bar at the top right corner of the display. The following diagram shows the

display while the instrument is in the Main mode.

Main

Mode

mg

8.15*

/L

24.38°C 11:33AM

STORE REVIEW SEND CALIBRATE

The bottom row of the display identifies the function of the four soft-keys which are located on

the keypad below the display. The function of each of these keys changes with each mode.

The [Mode] key and soft-keys are used to navigate through the menus. The [Mode] key is used to

cycle between the two main operating modes. Pressing a soft-key will bring up a new set of softkey functions (menu). The [Mode] key is also used to backup through the menus to the top level.

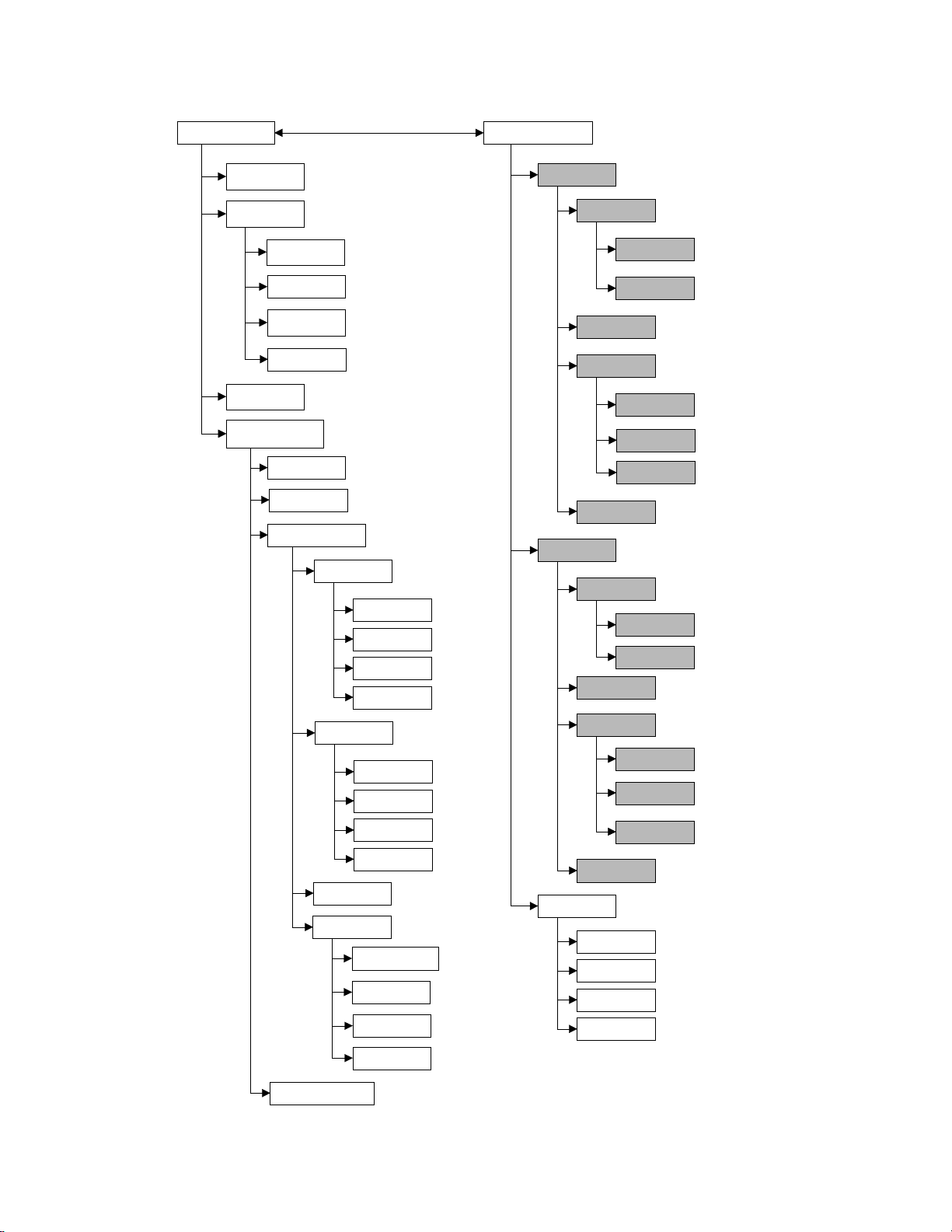

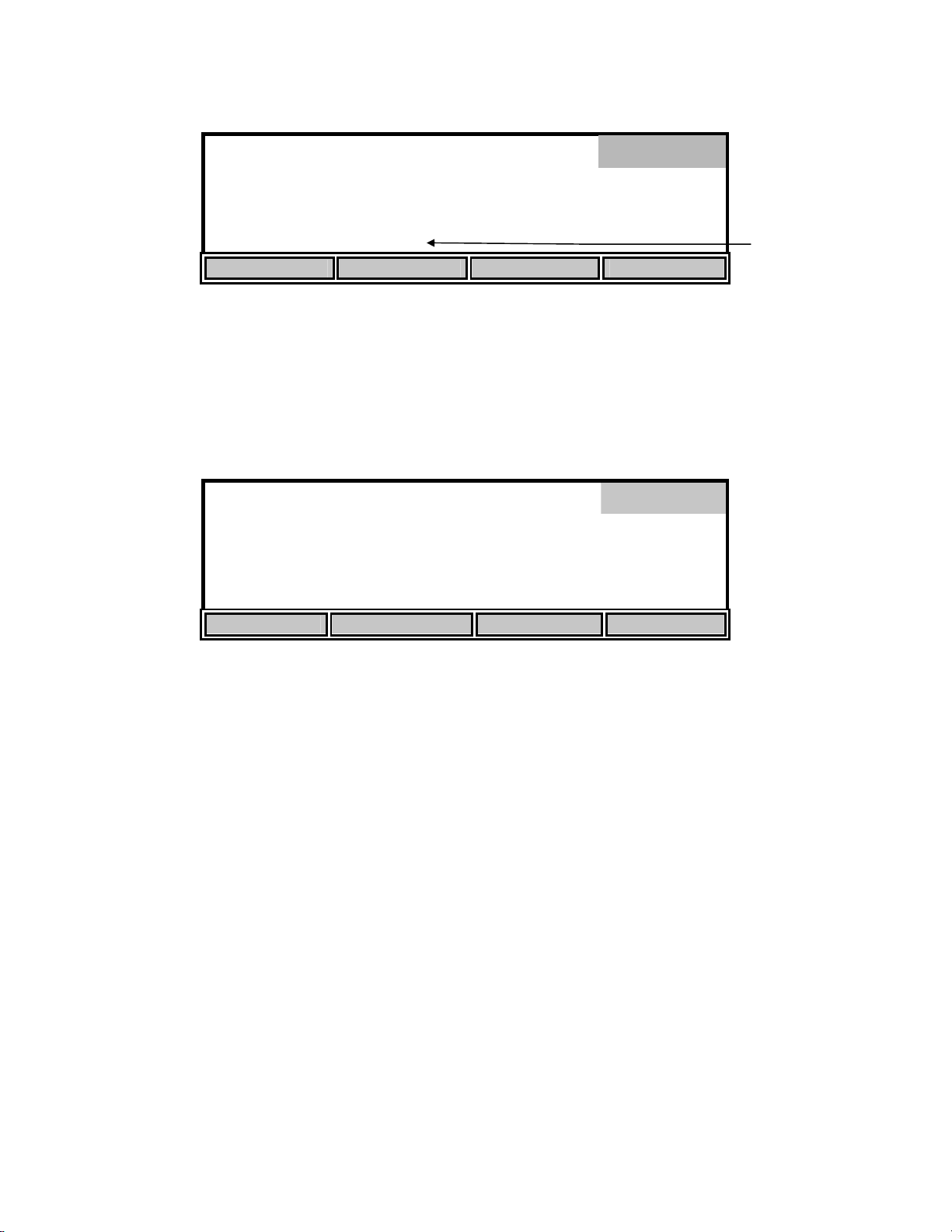

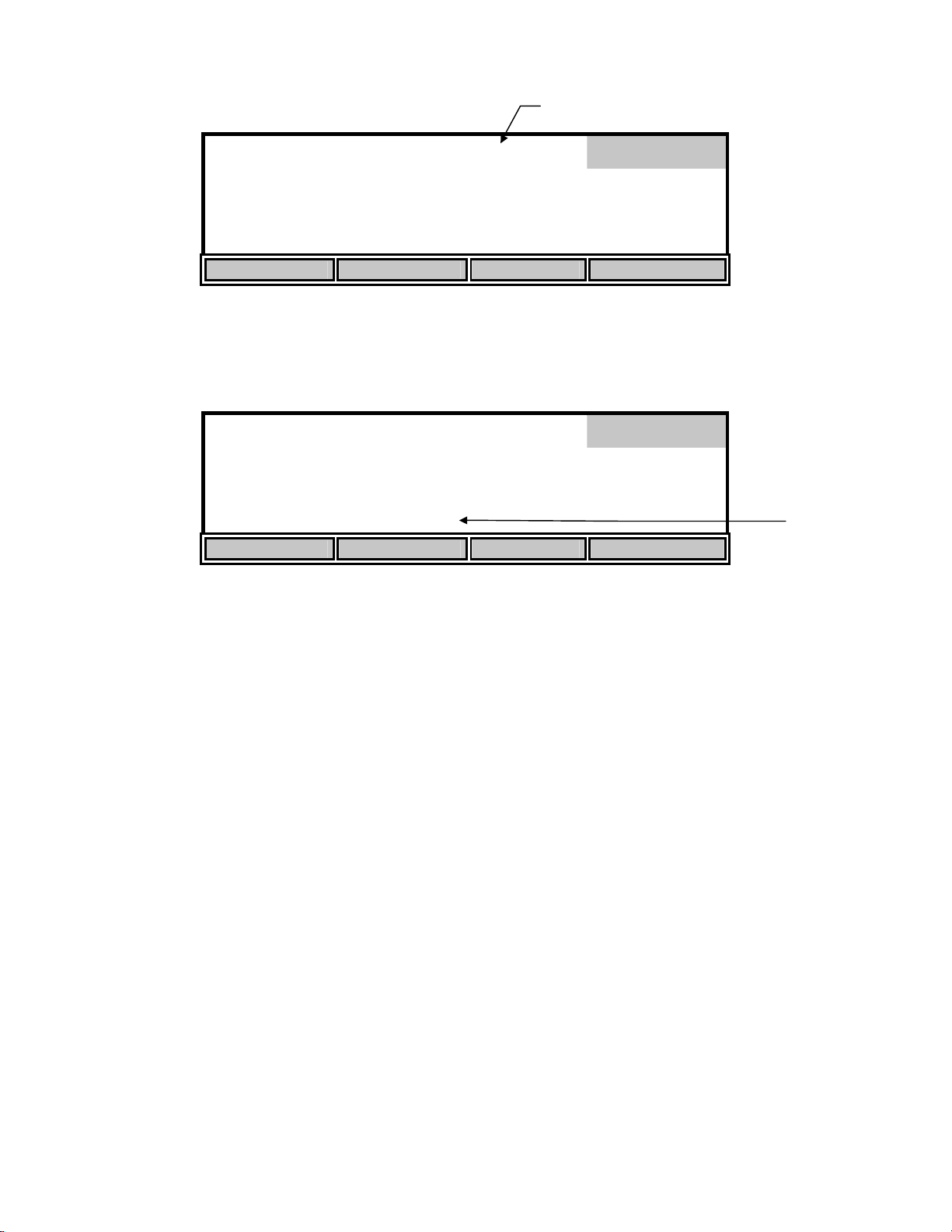

4.2 Software Flow Chart

The following section shows the software flow chart for the 5000/5100. The two operating

modes, Main and Application, are shown at the top with the soft-key functions that are accessed

in each mode below them. Functions in shaded boxes are only available on the model 5100.

Soft-key

functions

7

Page 11

5000/5100 Software Flow Chart

A

A

MAIN

Store

Review

Send

Calibrate

Recall

Send All

Clear

Delete All

uto Cal

DO Cal

Setup

Display

Size

Unit

Contrast

Last Digit

APPLICATION

OUR

Start

End

Send on/off

Setup

Review

Next Rec.

Modify

Send

Send

SOUR

Start

End

Send on/off

Setup

Report

SDF

CDF

Range

Next

Stable

System

udio On/Off

Time/Date

Version

RS-232

Diagnostic

NOTE: Shaded boxes are only available

on the model 5100

8

Review

Next Rec.

Modify

Send

Send

Remote

Skip

Up

Down

Confirm

.

Page 12

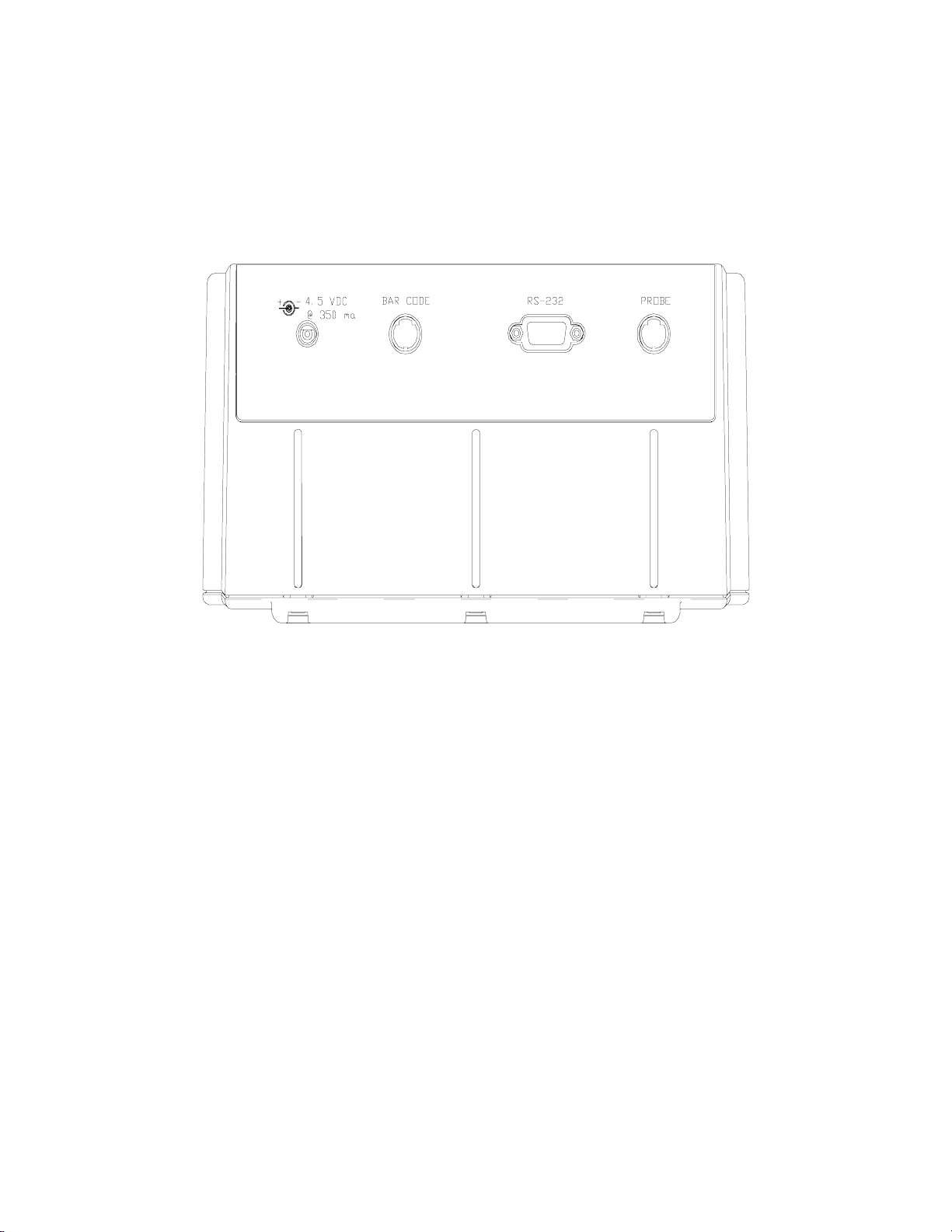

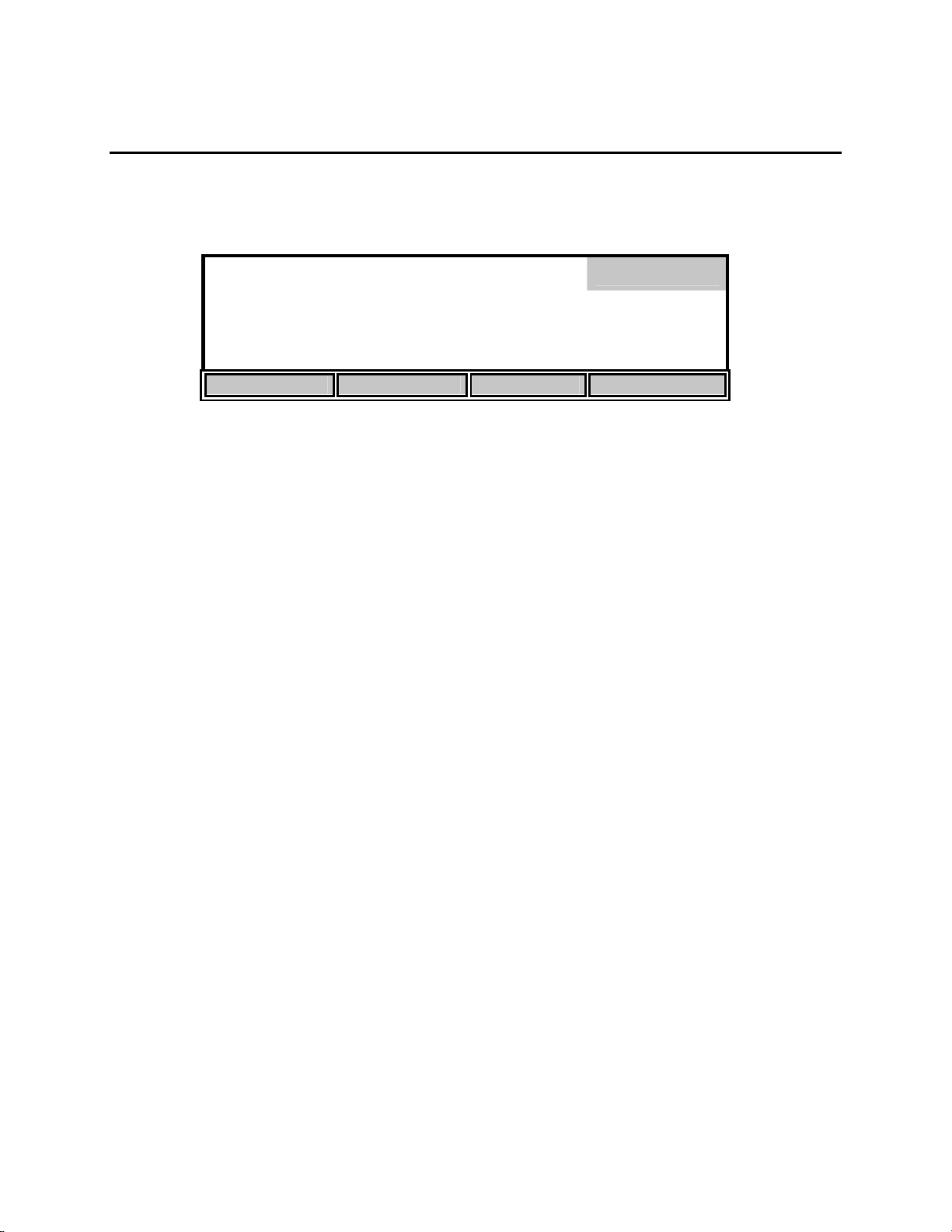

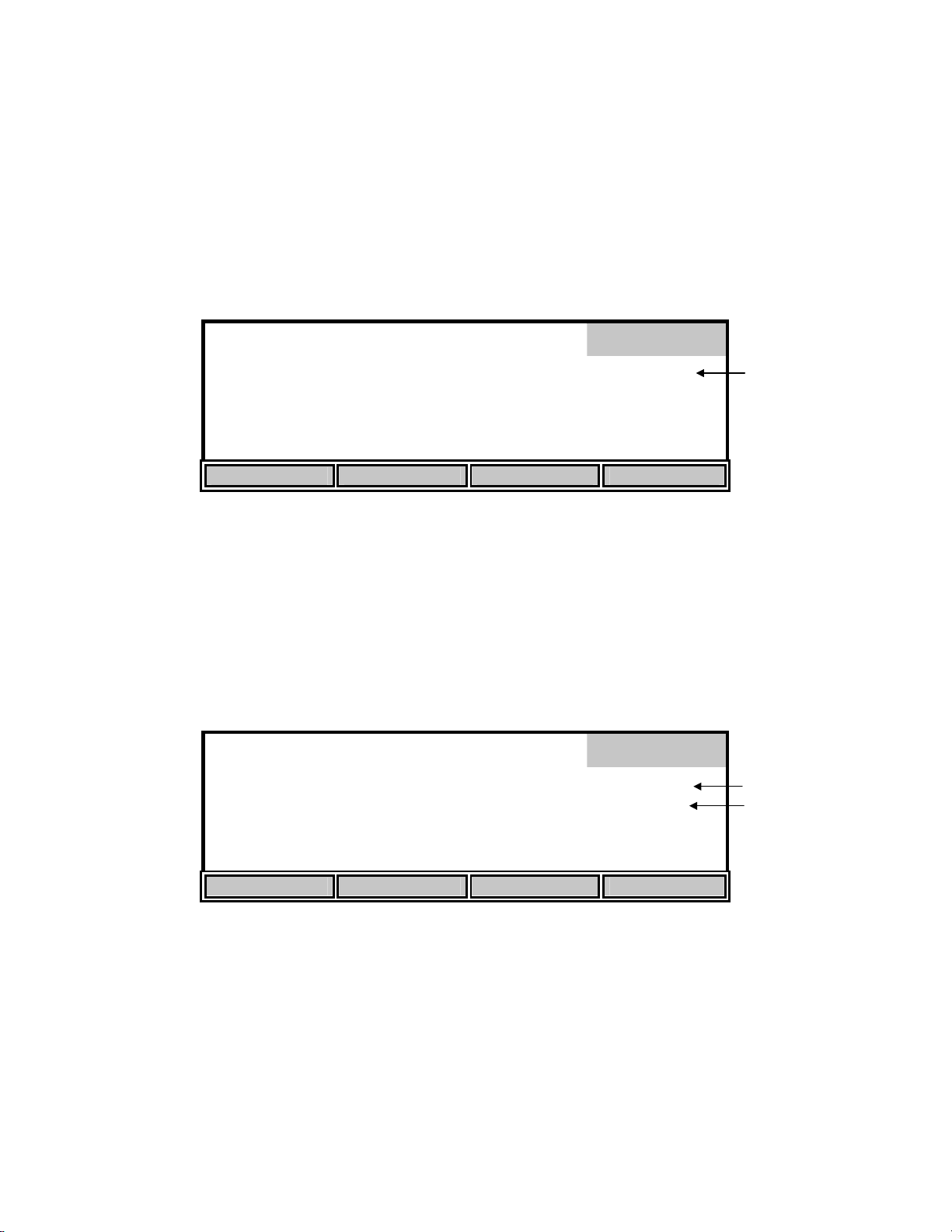

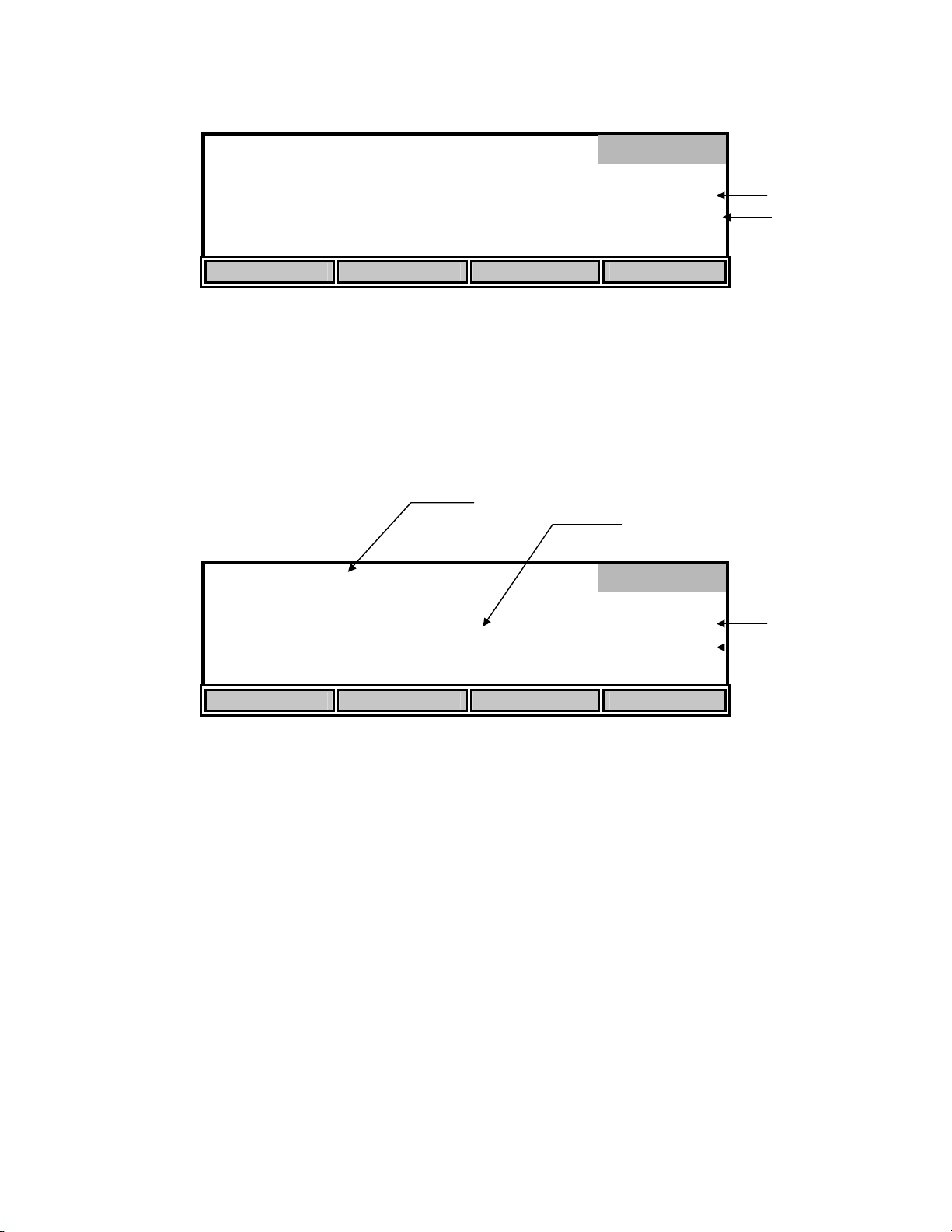

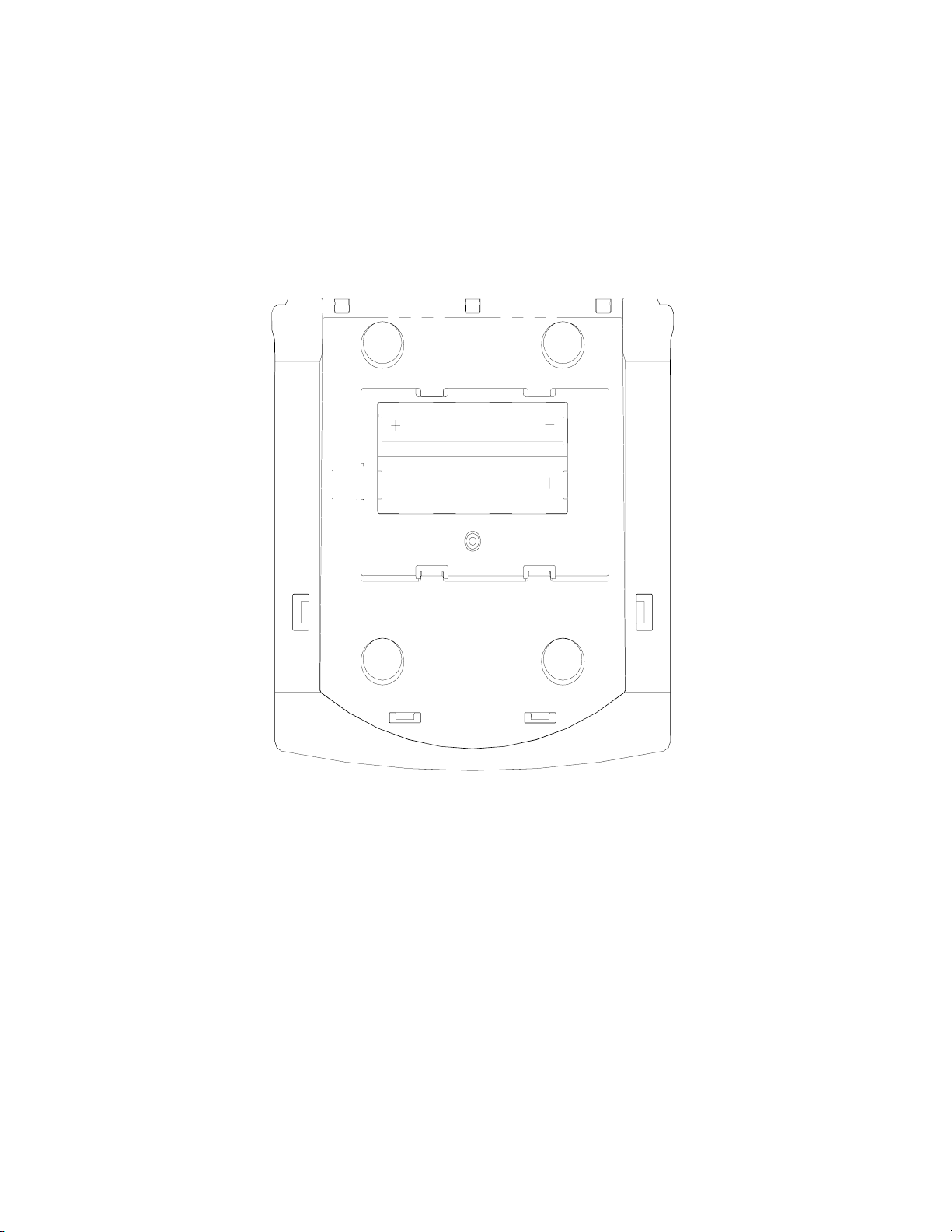

4.3 Rear Panel

The rear panel contains the connections for the power supply, probe, bar code reader, external

computer keyboard and RS232 serial port as shown below. The bar code reader and external

computer keyboard share the same socket and are only available on the model 5100.

Power Supply Connection

The power supply connection requires a 4.5 to 5.5 VDC power supply with at least 350 mA

current (6.0 VDC 800 mA when using the YSI 5015 bar code reader).

Probe Connection

The connector for the probe is an 8-pin mini DIN connector and is marked with an arrow to show

proper alignment. Be sure to align the arrows when plugging in the probe.

YSI 5000 series probes, such as the YSI 5010 BOD probe, will plug directly into the 5000/5100.

If you have an older YSI 5700 or 5900 series probe, the YSI 5011 adapter will be required.

The YSI 5011 adapter has a mini-DIN connector at one end and a 5-pin MS connector and probe

power connector at the other end. The 8-pin mini-DIN connector plugs into the 5000/5100 probe

socket and the 5-pin MS connector plugs into a 5700 or 5900 series probe/cable. The power

connector plugs into the matching connector on a self stirring BOD probe. This allows the

5000/5100 to power the BOD probe, eliminating the need for a separate probe power supply.

NOTE: Do NOT plug the 5011 adapter power connector into the 5000/5100 power supply

socket. Doing so will prevent the 5000/5100 from operating.

9

Page 13

Bar Code Reader Connection

The YSI 5015 bar code reader connects to this 6-pin mini DIN connector. The connector is

marked with an arrow to show proper alignment. Be sure to align the arrows when plugging in

the YSI 5015 bar code reader (see 7.2 Application Mode, Remote,

Bar Code Reader).

The bar code connector is also used for attaching an external computer keyboard. Using a

keyboard simplifies data entry when using the 5100 in the remote mode, such as with YSI BOD

Analyst software (see 7.2 Application Mode, Remote).

RS232 Connection

The RS232 connection is a standard DB9 connector. See 7.2 Application Mode, Remote, System

Setup for details.

10

Page 14

5. Setup

Before operating the 5000/5100 for the first time, you should set the instrument parameters. Once

set, these parameters are maintained in memory. These parameters are discussed below.

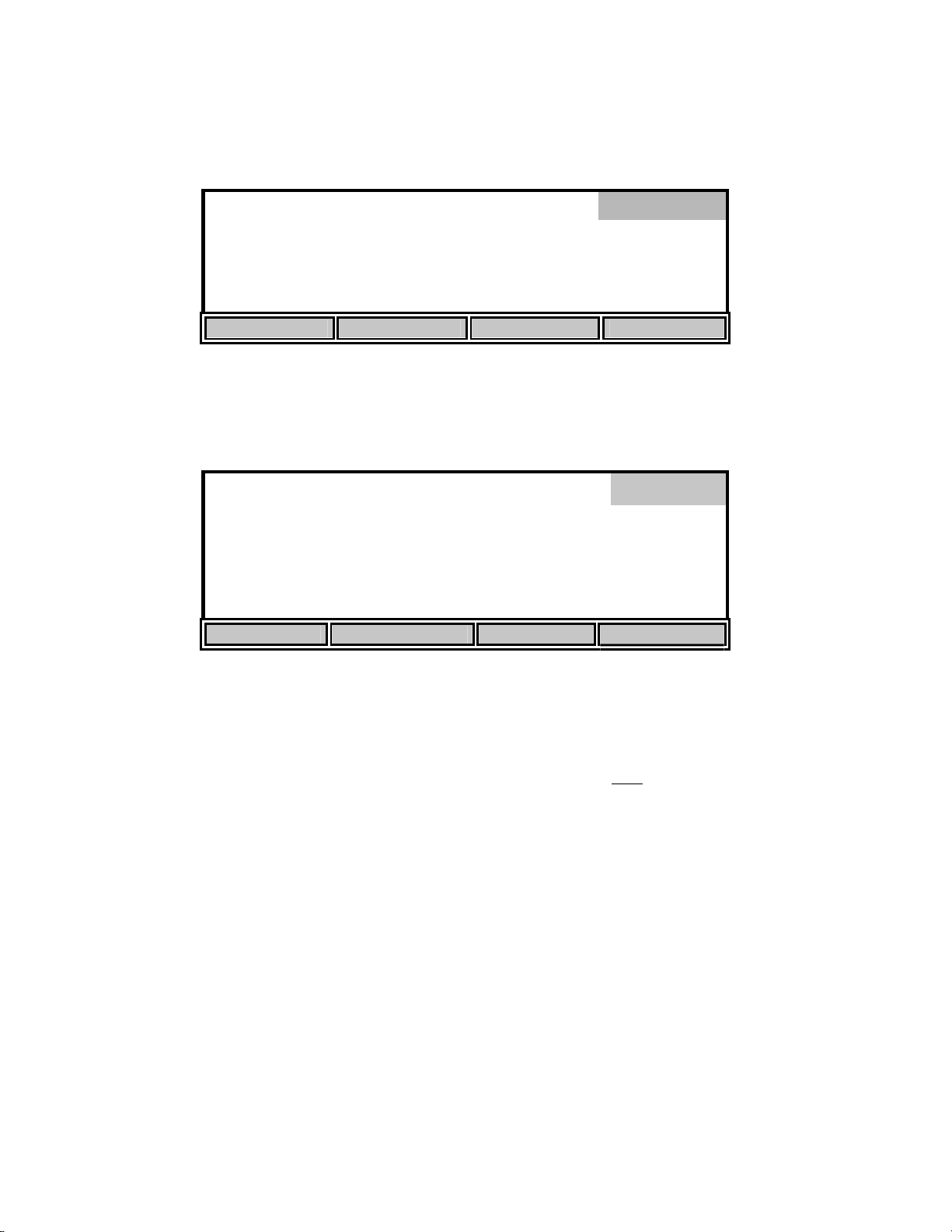

From Main mode, press the [CALIBRATE] soft-key to enter the calibration menu. Notice that

the dark bar in the top right corner of the display shows the current mode.

98.0 % 8.15

ppt

0.0

740

mg/L

mmHg

Calibrate

24.38°C 11:33AM

AUTO CAL DO CAL SETUP DIAGNOSTICS

Next, press the [SETUP] soft-key to enter the Setup menu. The bottom row of the display will

show the following soft-key setup selections.

Setup

mg

8.15*

/L

24.38°C 11:33AM

DISPLAY REPORT STABLE SYSTEM

These four selections are used to change the instrument setup.

11

Page 15

5.1 Display Setup

Press the [DISPLAY] soft-key to show the following menu.

Display

mg

8.15*

/L

24.38°C 11:33AM

SIZE UNITS CONTRAST LAST DIG.

The [SIZE] soft-key cycles among the two possible display arrangements for Main mode. One

selection shows as many parameters as possible, the other shows Dissolved Oxygen in large type

with temperature and time in small type. These different display arrangements are for Main mode

only. The display will show all parameters in Calibration mode.

98.0% 8.15

ppt

0.0

740

mg/L

mmHg

Display

24.38°C 11:33AM

SIZE UNITS CONTRAST LAST DIG.

The [UNITS] soft-key brings you to the [UNITS] menu. Use the [UP] and [DOWN] soft-keys to

change the measurement units. If you have selected the size to be large, only the DO units

selected on the [UNITS] screen will be shown. When the size is set to small, both % and mg/L

will be shown. The Date Format is also used to change from a 2 digit year to 4 digit year. The

Sal – 78 scale give salinity in unitless values as the measurements are in reference to the

conductivity of standard seawater at 15 °C. The HOUR units switch from a 12 to 24 hour day.

Press the [MODE] key to return to the Display menu.

12

Page 16

[

[

[

[

[

[

]

DISPLAY UNIT SETUP

D.O.

Barometer

Salinity

Temperature

Date Format

UP DOWN NEXT

The [CONTRAST] soft-key allows the user to change the display contrast. The display contrast

will change slightly each time the [UP] or [DOWN] soft-key is pressed.

The [LAST DIG.] soft-key allows the user to suppress the last digit of the DO reading. This

function is only available when the large size display has been selected. The small size display

will not be affected.

% ]

in Hg ]

Sal – 78 ]

C ]

MM/DD/YY ] HOUR

mg

8.2*

/L

Units

12H

Display

24.38°C 11:33AM

SIZE UNITS CONTRAST LAST DIG.

Press the [MODE] key to return to the Setup menu. If you wish to return to Main mode, press

[MODE] two more times.

13

Page 17

[*]

[*]

[*]

[*]

[*]

[*]

[*]

]

5.2 Report Setup

From the Setup menu, press [REPORT] to display the following soft-keys.

[SDF] Space Delimited Format

SAMPLE ID #

DO%

DO mg/L

DATE

TIME

BAROMETER

TEMPERATURE [*] SALINITY

SEND Record from [ 0] to [99

SDF CDF RANGE NEXT

The display lists the parameters that can be included in the output string at the RS232 serial port,

the default set has everything selected for inclusion.

You can select the report format that you wish to use by pressing the [SDF] or [CDF] soft-key.

Select [SDF] for Space Delimited Format (standard text). If you are going to import the data to a

spreadsheet, select [CDF] for Comma Delimited Format. The following are examples of each

format:

Report

Space Delimited Format

SAMPLE ID mg/L % C ppt mmHg TIME DATE

ID: 0 7.95 97.3 25.6 0.0 786 15:06:34 01/23/96

ID: 1 7.94 97.1 25.6 0.0 786 15:06:36 01/23/96

ID: 2 7.95 97.2 25.6 0.0 785 15:06:44 01/23/96

14

Page 18

[*]

[*]

[*]

[*]

[*]

[*]

[*]

Comma Delimited Format

"SAMPLE ID","mg/L","%","C","ppt","mmHg","TIME","DATE"

"ID: 0", 7.95, 97.3,25.6, 0.0, 786,"15:06:34","01/23/96"

"ID: 1", 7.94, 97.1,25.6, 0.0, 786,"15:06:36","01/23/96"

"ID: 2", 7.95, 97.2,25.6, 0.0, 785,"15:06:44","01/23/96"

The asterisk character in front of each parameter indicates that the parameter will be included in

the report. Press the [NEXT] soft-key to select the parameter that you want to change. Then press

[ENTER] to turn the asterisk character on or off.

NOTE: After pressing [SDF] or [CDF] to choose the report format, press the [MODE] key to exit

the Report menu. Do NOT press [ENTER] as this will change the currently selected parameter.

To return to Main mode, press [MODE] two more times.

The [RANGE] soft-key brings up the following soft-key menu.

[SDF] Space Delimited Format

SAMPLE ID #

DO%

DO mg/L

DATE

TIME

BAROMETER

Report

TEMPERATURE [*] SALINITY

SEND Record from [ 00] to [99]

UP DOWN DIGIT NEXT

Flashing Cursor

This menu allows specifying a specific range of memory locations for the report. The default

range is 00 - 99 and empty locations will not be sent to a computer or serial printer.

The display digit that has the flashing cursor below it is increased or decreased by pressing the

[UP] or [DOWN] soft-key. If the [UP] or [DOWN] soft-key is held down, the digit will continue

to change until the key is released. The [DIGIT] soft-key makes it easy to make large changes by

selecting the digit you wish to change. Press the [NEXT] soft-key to change between the

minimum and maximum parameter. When the desired number is obtained, pressing [ENTER]

will accept the number and exit the RANGE sub-menu. The RANGE sub-menu can be left

without making any changes by pressing the [MODE] key. Operation returns to the report setup

menu.

To return to Main mode, press [MODE] three more times.

15

Page 19

[

[

)

5.3 Autostable Setup

The autostable feature indicates when readings are stable by emitting a single beep and

displaying an asterisk (*) to the right of the dissolved oxygen reading. The instrument uses

criteria that you input to determine what a stable reading is. You select the maximum percent of

change that may occur during a selected time duration. The default values are 10 seconds and

0.4% variation. The instrument will display an asterisk (*) only when these criteria are met.

mg

Stable reading indication

Main

8.20*

/L

24.38°C 11:33AM

STORE REVIEW SEND CALIBRATE

From the Setup menu, press the [STABLE] soft-key to display the following menu.

PARAMETERS

10] Time Duration (3-19) Seconds

0.4] DO % variation (0.0-1.9

UP DOWN DIGIT NEXT

This menu is used to change the autostable criteria. Press the [NEXT] soft-key to select between

the time duration and the percent variation. Use the [DIGIT] soft-key to select the digit you wish

to change by pressing [UP] or [DOWN]. When you have finished setting the parameters, press

[ENTER] to confirm. The STABLE sub-menu can be left without making any changes by

pressing the [MODE] key instead of [ENTER]. Operation returns to the setup menu.

Stable

If you wish to disable the autostable feature, set the DO% variation to 0.0.

To return to Main mode, press [MODE] two more times.

16

Page 20

5.4 System Setup

From the Setup menu, press the [SYSTEM] soft-key to display the following menu.

mg

System

8.38*

/L

24.38°C 11:47AM

AUDIO off TIME / DATE VERSION RS232

The [AUDIO on/off] soft-key allows setting the beeper on or off. The key toggles between an

[AUDIO off] soft-key and an [AUDIO on] soft-key. The present state of the beeper would be the

OPPOSITE of the function shown on the soft-key. If the beeper is currently on, the soft-key

shows “AUDIO off”; i.e., your alternate choice.

The [TIME/DATE] soft-key brings up the following menu to allow setting of the date and time.

Flashing Digit

Time/Date

09:58:04

01/20/96

UP DOWN DIGIT NEXT

Use the UP, DOWN, DIGIT and NEXT soft-keys to enter the time in 24-hour format. The

display digit that is flashing is increased or decreased by pressing the [UP] or [DOWN] soft-key.

If the [UP] or [DOWN] soft-key is held down, the digit will continue to change until the key is

released. The [DIGIT] soft-key makes it easy to make large changes by selecting the digit you

wish to change. After you have set the hour, press the [NEXT] soft-key to move to the next

parameter, minutes. Repeat the process for the remaining parameters.

When you have finished entering the time and date, press [ENTER] to confirm and return to the

system setup menu. The message

at the bottom of the screen. The Time/Date sub-menu can be left without making any changes by

pressing the [MODE] key instead of [ENTER]. Operation returns to the system setup menu.

“TIME SETTING SAVED” will be displayed on the message line

17

Page 21

mg

System

8.38*

/L

24.38°C 9:59AM

TIME SETTING SAVED

AUDIO off TIME / DATE VERSION RS232

If you wish to return to Main mode, press [MODE] three times.

The [VERSION] soft-key displays the instrument software version on the message line of the

display just above the soft-key descriptions.

The [RS232] soft-key displays the RS232 setup.

[ 2 ] BAUD RATE 19200

0. 4. 4800

1. 5. 2400

2. 19200 6. 1200

3. 9600

UP DOWN

RS232

Message

Select the baud rate by pressing the [UP] or [DOWN] soft-keys. The first two choices, 0 and 1,

are not currently available.

The remaining RS232 parameters are fixed as follows:

Data Length: 8 bits

Parity: None

Stop Bits: 1

Press [ENTER] to confirm. The RS232 sub-menu can be left without making any changes by

pressing the [MODE] key instead of [ENTER]. Operation returns to the system setup menu.

Press [MODE] to return to the previous menu, Setup. To return to Main mode, press [MODE]

two more times.

18

Page 22

6. Calibration

From the Main mode, press the [CALIBRATE] soft-key to enter Calibration mode. The bottom

row of the display shows the soft-key menu.

98.0*% 8.15

ppt

0.0

740

mg/L

mmHg

Calibrate

24.38°C 11:33AM

AUTO CAL DO CAL SETUP DIAGNOSIS

6.1 Dissolved Oxygen Calibration

Dissolved oxygen calibration can be done automatically with the push of one button (see Auto

Cal) or manually by entering the desired value in milligrams per liter or percent saturation (see

DO Cal).

BEFORE YOU CALIBRATE you must Setup the meter, as discussed in the Setup section of

this manual, and Prepare the DO probe as discussed in the Probe Operations Manual. Before

performing an AUTO CAL on a Model 5100, you must check the barometric pressure reading

and calibrate the barometer, if necessary, as shown under 6.1 Dissolved Oxygen Calibration,

Barometer. The Model 5000 does not contain a barometer, therefore, the current barometric

pressure must be entered before an AUTO Cal is performed.

Dissolved oxygen calibration must be done in an environment with a known oxygen content.

Three such environments will be discussed here: calibration in air (water saturated), calibration

in air-saturated water and calibration by Winkler titration. Choose the one which best fits your

application. Calibration in air is the simplest and most accurate method of calibration.

• For air calibration, place the probe in air at 100% relative humidity. To achieve this, the

probe can be placed in a BOD bottle containing 1″ of water. No stirring is required in air.

• For air-saturated water calibration, air-saturate a volume of water (300 to 500 mL) by

aerating for at least 15 minutes at a relatively constant temperature. Place the probe in the

aerated water and provide adequate stirring (at least 1 foot per second) while calibrating, such

as that provided by the 5010 self-stirring BOD Probe.

• To calibrate to a Winkler-titrated sample, determine the dissolved oxygen value of a

sample by Winkler titration. Place the probe in the sample and provide adequate stirring (at

least 1 foot per second) while calibrating in the manual mode.

NOTE: If you choose calibration by Winkler titration, you cannot use AUTO CAL, you must use

DO CAL (manual) mode, since AUTO CAL assumes the probe is in a saturated environment.

19

Page 23

Auto Cal

1. Prepare the probe according to the instructions in the Probe Operations Manual.

2. Connect the probe to the meter.

3. Place the probe in a BOD bottle containing about 1″ of water to provide a 100% relative

humidity environment.

4. Press [ ] to turn the instrument on.

5. Allow the probe to polarize and the temperature to stabilize for at least 15 minutes. If

calibration is performed prematurely the values will drift and may be out of specification.

6. Press the [CALIBRATE] soft-key to change to Calibration mode. The following display will

appear.

98.0*% 8.15

ppt

0.0

740

mg/L

mmHg

Calibrate

24.38°C 11:33AM

AUTO CAL DO CAL SETUP DIAGNOSIS

7. Model 5100: Verify that the barometer reading is correct. Calibrate the barometer, if

necessary, as shown under 6. Dissolved Oxygen Calibration, Barometer.

Model 5000: Enter the current barometric pressure as shown under 6. Dissolved Oxygen

Calibration, Barometer.

8. Make sure that the display readings are stable, then press the [AUTO CAL] soft-key to

calibrate Dissolved Oxygen. The message “

a few seconds.

98.0*% 8.15

ppt

0.0

740

D.O. CALIBRATION SAVED” will be displayed for

mg/L

mmHg

Calibrate

24.38°C 11:33AM

D. O. CALIBRATION SAVED

AUTO CAL DO CAL SETUP DIAGNOSIS

9. Press [MODE] to return to the Main mode. The instrument is now calibrated and ready to

measure dissolved oxygen and temperature. See 7.1 Main Mode, Making Measurements.

20

Message

Page 24

DO Cal (manual)

1. Prepare the probe according to the probe instructions.

2. Connect the probe to the meter.

3. Place the probe in a known oxygen environment, such as a BOD bottle containing about 1″ of

water to provide a 100% relative humidity environment or a Winkler-titrated sample.

4. Press [ ] to turn the instrument on.

5. Allow the probe to polarize and the temperature to stabilize for at least 15 minutes. If

calibration is performed prematurely the values will drift and may be out of specification.

6. Press the [CALIBRATE] soft-key to change to Calibration mode. The following screen will

be displayed.

98.0*% 8.15

ppt

0.0

740

mg/L

mmHg

Calibrate

24.38°C 11:33AM

AUTO CAL DO CAL SETUP DIAGNOSTICS

7. Press the [DO CAL] soft-key to enter the manual DO calibration menu.

98.0*% 8.15

ppt

0.0

Flashing digit

mg/L

740

mmHg

Cal %

24.38°C 11:33AM

UP DOWN DIGIT NEXT

8. Make sure that the display readings are stable, then enter the calibration value in percent

saturation, using the [UP], [DOWN] and [DIGIT] soft-keys. See Appendix A - Oxygen

Solubility Table and Appendix B - Pressures and Altitudes for manual calibration data.

If you wish to calibrate in milligrams per liter (instead of percent), verify that the salinity is set to

the salinity value of the calibration environment (0.0 ppt for air calibration, see 6.1 Dissolved

Oxygen Calibration, Salinity). Then, use the [NEXT] soft-key to select mg/L and enter the

calibration value in milligrams per liter as shown below.

21

Page 25

98.0*% 08.15

0.0

ppt

740

mmHg

Flashing digit

mg/L

Cal mg/L

24.38°C 11:33AM

UP DOWN DIGIT NEXT

9. Press [ENTER] to confirm your calibration. The screen will momentarily display

CALIBRATION SAVED”

98.0*% 8.15

as shown below.

ppt

0.0

740

mg/L

mmHg

Calibration

24.38°C 11:33AM

D. O. CALIBRATION SAVED

UP DOWN DIGIT NEXT

“D.O.

Message

NOTE: If you wish to abort calibration before you have pressed [ENTER], you may press

[MODE] to return to the calibrate menu without saving the new calibration value. You may

also press [NEXT] to select a different parameter (any change made will not be saved).

10. Press [MODE] to return to the Main mode. The instrument is now calibrated and ready to

measure dissolved oxygen and temperature. See 7.1 Main Mode, Making Measurements.

Barometer

The YSI Model 5100 has an internal barometer for pressure compensation during AUTO

Dissolved Oxygen Calibration. This barometer only needs to be calibrated when it is no longer

reading the correct barometric pressure. If the 5100 is kept at a fairly constant ambient

temperature (±10°C), the barometer calibration should be accurate for approximately 30 days.

The Model 5000 does not contain a barometer, therefore, the current barometric pressure must be

entered before an AUTO Cal is performed. The pressure value displayed is the setting that was

entered and stored during the previous calibration.

From the calibration menu press the [DO CAL] soft-key, then press the [NEXT] soft-key until

the barometric pressure is flashing and “Barometer” appears in the top right corner of the display

as follows:

22

Page 26

mg/L

98.0*% 8.15

0.0

ppt

0740

mmHg

Flashing digit

Barometer

24.38°C 11:33AM

Press ENTER to SAVE SETTING

UP DOWN DIGIT NEXT

Using the [UP], [DOWN] and [DIGIT] soft-keys, enter the true local barometric pressure. This

corresponds to a reading from a mercury barometer. Do NOT use the pressure reported by the

weather bureau. Weather bureaus correct pressures to sea level.

NOTE: You may estimate

and Altitudes.

Press [ENTER] to confirm. The message

the model 5100, as shown below. The model 5000 will display

since it does not contain an internal barometer.

the standard pressure at your altitude by using Appendix B - Pressures

“PRESSURE CALIBRATION SAVED” will be displayed, on

“PRESSURE SETTING SAVED”,

98.0*% 8.15

ppt

0.0

740

mg/L

mmHg

Calibrate

24.44°C 11:34AM

PRESSURE CALIBRATION SAVED

AUTO CAL DO CAL SETUP DIAGNOSIS

NOTE: If you wish to abort before pressing [ENTER], you may press [MODE] to return to the

calibrate menu without saving the new value for barometric pressure. You may also press

[NEXT] to select a different parameter (any change made will not be saved).

Salinity

Salt reduces the ability of water to hold oxygen in solution. Enter the salinity of the sample you

are measuring and the meter will automatically compensate for the effect of salinity on dissolved

oxygen. The default setting for salinity is 0.0 ppt. You can enter any value between 0.0 and 40.0

ppt.

From the Calibration menu press the [DO CAL] soft-key, then press the [NEXT] soft-key until

the salinity value is flashing. The top right corner of the screen will display “Salinity” as shown

in the following screen. Remember, if you are manually calibrating in mg/L in water saturated

air, salinity is 0.0 ppt.

Message

23

Page 27

98.0

*

% 8.15

ppt

0.0

Flashing digit

mg/L

740

mmHg

Salinity

24.55°C 11:35AM

Press ENTER to SAVE SETTING

UP DOWN DIGIT NEXT

Using the [UP], [DOWN] and [DIGIT] soft-keys, enter the salinity value.

Press [ENTER] to confirm. The message

below.

10.0

*

% 8.15

ppt

740

98.0

“SALINITY SETTING SAVED” will be displayed as shown

mg/L

mmHg

Calibrate

24.57°C 11:36AM

SALINITY SETTING SAVED

AUTO CAL DO CAL SETUP DIAGNOSIS

Message

NOTE: For accurate DO readings, the salinity setting MUST match the salinity of each sample

measured.

6.2 Zero Calibration

In rare applications, the accuracy of the calibration can be improved by performing a zero

calibration along with one of the procedures discussed previously.

All oxygen probes have a small background current, even in the absence of oxygen. Model

5000/5100 compensation is based on the average background current of YSI probes. This is the

default zero value. Using this average will result in errors with probes whose background current

differs from the average.

Note: Errors will be insignificant in most applications. See 10. Understanding Dissolved

Oxygen Error Factors.

For highest accuracy measurements, a zero calibration should be performed to compensate for

the specific background current of the probe in use.

To calibrate to a true zero, place the probe in a zero oxygen environment and adjust the

calibration value to zero.

24

Page 28

A standard method for creating such an environment is to dissolve excess sodium sulfite

(Na

the sample to be measured. These chemicals will remove all oxygen from the sample (See

Standard Methods for the Examination of Water & Wastewater, method 4500-O G, 19th edition).

Alternatively, you may place the probe in 100% nitrogen gas.

1. Place the probe in the zero oxygen sample and allow at least 20 minutes for the probe to

2. Press the [CALIBRATE] soft-key to change to Calibration mode. The following screen will

) and a trace of cobalt chloride (CoCl2) in water. Preferably, the water should come from

2SO3

come to equilibrium.

be displayed.

98.0*% 8.15

ppt

0.0

740

mg/L

mmHg

Calibration

24.38°C 11:33AM

AUTO CAL DO CAL SETUP DIAGNOSTICS

3. Press the [DO CAL] soft-key to enter the manual DO calibration menu.

000.0*% 0.00

ppt

0.0

740

mg/L

mmHg

Cal %

24.38°C 11:33AM

UP DOWN DIGIT NEXT

4. Make sure that the display readings are stable, then use the [UP], [DOWN] and [DIGIT] softkeys to enter the calibration value of 0.0% (or 0.00 mg/L).

NOTE: The instrument will not except any value other than zero for the first point of a two-point

calibration.

5. Press [ENTER] to confirm your calibration. The screen will momentarily display “D.O.

CALIBRATION SAVED

The Model 5000/5100 is calibrated at two points: the calibration value you select, and its default

zero.

NOTE: When you change the zero calibration point, you offset the other value, so that after

zeroing the probe for zero oxygen, you must recalibrate in an oxygen environment.

6. You must now recalibrate in an oxygen environment (see 6.1 Dissolved Oxygen Calibration,

Auto Cal or DO Cal).

”.

25

Page 29

7. Operation

7.1 Main Mode

When the instrument is turned on it is in the Main mode. The following chart shows the display

during Main mode operation.

8.15*

mg

/L

Main

24.38°C 12:13AM

STORE REVIEW SEND CALIBRATE

The bottom row of the display shows the functions of the four soft-keys used during Main mode.

Main mode is used to make measurements, store or review readings and send the current

readings to a computer or serial printer.

Making Measurements

Main mode is used to make dissolved oxygen and temperature measurements as follows:

1. Make sure that the instrument has been properly calibrated (see 6. Calibration).

NOTE: If the instrument has just been turned on, allow at least 15 minutes for the probe to

polarize and the temperature to stabilize before calibrating.

2. Verify that the salinity of the sample matches the salinity setting of the instrument (see 6.1

Dissolved Oxygen Calibration, Salinity).

3. Place the probe in the sample.

4. Provide adequate stirring (at least 1 foot per second), such as that provided by the 5010 selfstirring BOD Probe.

5. Allow time for the temperature and dissolved oxygen readings to stabilize. The amount of

time varies with temperature, the condition of the probe and the dissolved oxygen level.

6. Read the dissolved oxygen and temperature.

NOTE: Temperature compensation of the dissolved oxygen reading is automatically

determined.

26

Page 30

Store

Press the [STORE] soft-key to enter Store mode and display the following menu.

Store

mg

8.15*

/L

Record: 01

Record number

24.38°C 11:33AM

UP DOWN DIGIT SAVE

The Store menu is used to control the storing of data. The current record number is shown in the

display on the right side.

Press the [SAVE] soft-key to store the values currently displayed. The message

(where

number will increase to the next memory location.

X is the record number) will momentarily be displayed on the screen and the record

Store

mg

8.15*

/L

Record: 02

“Record X SAVED”

Record number

24.38°C 11:33AM

Record 1 SAVED

UP DOWN DIGIT SAVE

Message

If you wish to store a record at a location other than the current one, use the [UP], [DOWN] and

[DIGIT] soft-keys to select the memory location desired.

If the current record location contains data, you will see the following display to warn you that

the current memory location contains data.

8.15*

mg

/L

Store

Record: 01

Record Full

WARNING

24.38°C 11:33AM

UP DOWN DIGIT SAVE

27

Page 31

If the current memory location already contains data and you press [SAVE], the current readings

will be stored and the previous readings will be erased.

NOTE: There is NO way to restore previous data once it has been deleted.

When you have finished storing records, press [MODE] to return to Main mode.

Review

Press the [REVIEW] soft-key to enter Review mode and display the following menu.

98.0 % 8.15

ppt

0.0

740

mg/L

mmHg

Review

Record: 01

Record Full

24.38°C 11:33AM 02/06

RECALL SEND ALL CLEAR DEL. ALL

Recall

From the Review menu, press the [RECALL] soft-key to enter Recall mode and display the

following menu.

98.0 % 8.15

ppt

0.0

740

mg/L

mmHg

Recall

Record: 01

Record Full

Record number

24.38°C 11:33AM 02/06

UP DOWN DIGIT SEND

The Recall menu is used to recall or send data that was previously stored. The current record

number is shown on the right side of the display.

Use the [UP], [DOWN] and [DIGIT] soft-keys to view a different record number.

Press the [SEND] soft-key to send the currently displayed record to a computer or serial printer

via the RS232 port.

When you have finished recalling records, press [MODE] two times to return to Main mode.

28

Page 32

Send All

From the Review menu, you may send ALL stored data to a computer or serial printer by

pressing the [SEND ALL] soft-key. See 5.2 Report Setup for format.

Clear

From the Review menu, press the [CLEAR] soft-key to enter Clear mode and display the

following menu.

98.0 % 8.15

ppt

0.0

740

mg/L

mmHg

Clear

Record: 01

Record Full

Record number

24.38°C 11:33AM 02/06

UP DOWN DIGIT DELETE

The Clear menu is used to delete data that was previously stored. The current record number is

shown in the display on the right side.

Use the [UP], [DOWN] and [DIGIT] soft-keys to select the record that you want to delete. Press

the [DELETE] soft-key to delete the selected record.

NOTE: It is not necessary to clear records before new data can be stored. The new data will

overwrite the previous data.

%

mg/L

Clear

ppt

mmHg

Record: 01

Deleted

Record number

Status of record

°C

Record 1 DELETED

UP DOWN DIGIT DELETE

NOTE: There is NO way to restore data once it has been deleted.

When you have finished deleting records, press [MODE] two times to return to Main mode.

29

Page 33

Delete All

To delete ALL stored data, press the [DEL. ALL] soft-key to display the following:

98.0 % 8.15

ppt

0.0

740

mg/L

mmHg

Delete All

Record: 01

Record Full

Record number

24.38°C 11:33AM 02/06

Press ENTER to DELETE ALL

RECALL SEND ALL CLEAR DEL. ALL

Press [ENTER] to confirm your decision and delete ALL stored data. Press [MODE], instead of

[ENTER], if you wish to abort.

NOTE: There is NO way to restore data once it has been deleted.

Press [MODE] to return to Main mode.

Send

While in the Main menu, the [SEND] soft-key is used to send the current live display readings to

a computer or serial printer via the RS232 port. This is an alternative to storing results, recalling

them, and then printing them.

Main

mg

8.15*

/L

24.38°C 11:33AM

STORE REVIEW SEND CALIBRATE

Each time you press the [SEND] soft-key, on the model 5100, the current display values are sent,

along with the salinity setting, date and barometric pressure reading. The model 5000 prints the

same information, however, the barometric pressure is the current setting and not a reading. The

output format can be changed under 5.2 Report Setup. The following are examples of the send

format:

Space Delimited Format

mg/L % C ppt mmHg TIME DATE

8.69 98.5 21.5 0.0 797 10:17:30 02/06/96

30

Page 34

Comma Delimited Format

"mg/L","%","C","ppt","mmHg","TIME","DATE"

12.19,138.2,21.6, 0.0, 790,"10:20:56","02/06/96"

NOTE: If you want to send stored records, you must first enter Recall mode (see 7.1 Main Mode,

Review, Recall).

31

Page 35

7.2 Application Mode

The YSI Model 5100 DO instrument contains built-in application software for the calculation of

Oxygen Uptake Rate (OUR) and Specific Oxygen Uptake Rate (SOUR). These application

features may simplify compliance with USEPA 40 CFR Part 503 regulations for vector attraction

and provide useful tools for plant operation decisions. With the Model 5100 complete sets of

data from five OUR tests and five SOUR tests can be stored to memory and later reviewed.

From the Main mode, press the [MODE] key to enter the Application mode. The bottom row of

the display shows the soft-key menu of the Model 5100. The Model 5000 does not support OUR

or SOUR applications. The 5000 does, however, support Remote mode which allows the

instrument to be controlled via computer.

mg

8.99*

/L

23.22°C 11:01AM

OUR SOUR REMOTE

OUR

The 5100 uses the following formula to calculate the OUR value:

OUR =

Where:

DO

DO

START

END

DO

T

START

ELAPSED

- DO

END

3600 Sec

x

x

1 Hour

= Dissolved oxygen level at start of test

= Dissolved oxygen level at end of test

Total

Volume

Sample

Volume

Application

mg/L/h

=

T

Total Volume

= Elapsed time of test in seconds

ELAPSED

= Dilution factor of sample (entered in setup screen as Sample / Total)

Sample Volume

32

Page 36

]

[

]

[

[

[

f

From the Model 5100 Application mode menu press the [OUR] (Oxygen Uptake Rate) soft-key.

The following screen will be displayed.

OUR

mg

4.7

23.21°C 8.92 0:00

START SETUP REVIEW SEND

Press [SETUP] to change the OUR parameters. The following screen shows the default

parameters.

PARAMETERS

Sample / Total 1 / [ 1

Min. Time

Max. Time

Min. Beginning DO

Min. Ending DO

UP DOWN DIGIT NEXT

/L /h

mg

/L

1

15] min. SEND: off

5.00] mg/L

2.00] mg/L

min.

SEND: of

OUR

Use the [UP], [DOWN], [DIGIT] and [NEXT] soft-keys to change the following parameters as

necessary:

Sample / Total: Enter the ratio of sample volume to total volume. For example, if

you are diluting 1 to 10 (1 part sample plus

then enter the number 10. This would be a 10-fold dilution.

Min. Time: Enter the minimum time (in minutes).

Max. Time: Enter the maximum time (in minutes). When the maximum time is

reached, the test will end.

Min. Beginning DO: Enter the minimum level of DO allowed at the start of the test.

Min. Ending DO: Enter the minimum level of DO allowed during the test. If the DO

level falls below this value, the test will end.

SEND: on/off This sets the RS232 status at the beginning of the test.

After the parameters have been set, press [ENTER] to save them and return to the OUR menu.

9 parts dilution water),

33

Page 37

f

OUR

mg

2.6

23.21°C 8.92 0:00

OUR SETTING SAVED

START SETUP REVIEW SEND

Once the parameters have been set, you are ready to begin. Place the probe in the prepared

sample and make certain no air bubbles are trapped, then turn on the stirring and wait a few

seconds for the temperature readings to stabilize.

NOTE: It is normal for the OUR reading to oscillate for the first few seconds.

Press [START] to begin the OUR measurement. The following screen shows the available softkeys after the test is started.

/L /h

mg

/L

OUR

SEND: of

Current DO

OUR

RS232 status

Elapsed Time

mg

348.7

23.20°C 6.97 0:32

END SEND ON

/L /h

mg

/L

SEND: off

RS232 status

Elapsed Time

The OUR value is displayed on the screen and is updated approximately once per second.

The [SEND ON/OFF] soft-key toggles the RS232 status. Press [SEND ON] if you want to send

the readings to a computer or serial printer during the OUR measurement. The RS232 status is

displayed just above the elapsed time. During the OUR measurement, data will be sent every 15

seconds until the OUR measurement ends or the [SEND OFF] soft-key is pressed. The following

is an example of the format:

NOTE: Once pressed, the [SEND ON] soft-key toggles and becomes a [SEND OFF] soft-key.

Second mg/L/h C mg/L 11:04:10 09/21/98

0 0.23 23.20 8.52

15 595.27 23.20 7.28

30 369.63 23.20 6.98

45 275.23 23.20 6.80 . . .

34

Page 38

If you want to stop the OUR measurement before the maximum time or minimum ending DO

(entered in OUR setup) is reached, press [END]. The final OUR reading will be displayed on the

screen.

OUR

Mg

50.5

21.21°C 0.54 14:20

PROCESS COMPLETE

START SETUP STORE SEND

NOTE: The DO and temperature readings do not stop updating on the screen.

After the OUR measurement has ended, the [SEND] soft-key can be used to send all of the DO

values and the final OUR reading to a computer or serial printer via the RS232 port. The format

is as follows:

Time stamp: 11:04 AM

Date stamp: 09/21/98

Reference point: 105 (sec.)

Second mg/L

/L /h

mg

/L

SEND: on

0 8.52

15 7.28

30 6.98

45 6.80

60 6.66

75 6.53 . . .

863 1.99

OUR = 50.53 mg/L/h

Dilution ration: 1 / 2(Sample/Total)

NOTE: If you have run an OUR measurement, but did not enter the appropriate sample dilution,

you will get uncorrected results. However, after running the OUR measurement, you

may return to the OUR setup screen, change the Sample/Total ratio, then press [ENTER]

to save the changes. The recalculated OUR value will be displayed. Press [SEND] to

send the new OUR value to a computer or serial printer via the RS232 port.

35

Page 39

If you want to save these values press the [STORE] soft-key. A record number will then show

up under the REVIEW menu. If the record slot contains a set of data, an indicator saying FULL

will appear beside the test number. If the record slot does not contain a set of data, the indicator

will say EMPTY.

62.9 mg /L /hr 8.5 mg /L

mg

/L

0

NEXT REC. MODIFY SAVE SEND

870

REVIEW

REC:1 EMPTY

11:04 AM

09/21/98

Record Number

FULL or EMPTY

indicator

Press the [NEXT REC.] soft-key to change the record number to find an empty slot, or pick a slot

to overwrite (you cannot delete records, you must overwright). Press the [SAVE] soft-key to

save the current test data into that slot. Once you have saved the data you can press the

[MODIFY] soft-key to change some parameters of the test.

OUR

Time Reference

50.0 mg /L /hr 5.6 mg /L

mg

/L

0

DO (at Reference

MODIFY

REC:1 FULL

11:04 PM

870

09/21/98

! "

SETTINGS

Test time

Press the ! or " soft-keys to move the start time reference point to an optimal place on the

curve. The reference point is represented by a vertical line. Only data to the right of the

reference point will be used to calculate the OUR value. Moving this reference point allows you

to start the test at anytime and trim off unwanted data after the test has run. The DO reading at

the reference point is shown at the top. The reference point cannot move closer than the

minimum time to the end of the test.

The [SETTINGS] soft-key allows you to modify or input values for the Dilution factor. Changes

to the Dilution factor are saved if you save the record again.

36

Page 40

SOUR

The 5100 uses the following formula to calculate the SOUR value:

OUR =

DO

T

START

ELAPSED

- DO

END

3600 Sec

x

1 Hour

Total Volume

x

Sample Volume

=

mg/L/h

Where:

DO

DO

T

ELAPSED

Total Volume

= Dissolved oxygen level at start of test

START

= Dissolved oxygen level at end of test

END

= Elapsed time of test in seconds

= Dilution factor of sample (entered in setup screen as Sample/Total)

Sample Volume

SOUR =

OUR

Solids Weight

mg/h/g (mg O

=

/ hour / g solids)

2

Where:

Solids Weight = Total Solids or Volatile Suspended Solids in g/L

From the Model 5100 Application mode menu press the [SOUR] (Specific Oxygen Uptake Rate)

soft-key. The following screen will be displayed.

SOUR

mg

2.8

25.37°C 9.12 0:00

START SETUP REVIEW SEND

/h /g

SEND: off

mg

/L

37

Page 41

[

[

[*]

[

[

[

Press [SETUP] to change the SOUR parameters. The following screen shows the default

parameters.

Sample / Total 1 / [ 1]

Min. Time

Max. Time

Min. Beginning DO

Min. Ending DO

Solids Weight

UP DOWN DIGIT NEXT

1] min.

15] min.

5.00] mg/L SEND: off

2.00] mg/L

1.000] g/L

SOUR

SOUR@20

Use the [UP], [DOWN], [DIGIT] and [NEXT] soft-keys to change the following parameters as

necessary:

Sample / Total: Enter the ratio of sample volume to total volume. For example, if

you are diluting 1 to 10 (1 part sample plus

9 parts dilution water)

then enter the number 10. This would be a 10-fold dilution.

Min. Time: Enter the minimum time (in minutes).

Max. Time: Enter the maximum time (in minutes). When the maximum time is

reached, the test will end.

Min. Beginning DO: Enter the minimum level of DO allowed at the start of the test. If the

DO falls below this level, the test will not start.

Min. Ending DO: Enter the minimum level of DO allowed during the test. If the DO

level falls to this value, the test will end.

Solids Weight: Enter the Total Solids or Volatile Suspended Solids concentration of

the sample in g/L. The maximum acceptable value is 31.999 g/L.

SOUR@20: This applies the calculation for temperature correction to 20°C

according to the Farrell and Bhide equation as follows:

SOUR

= SOURT x Θ

20

(20-T)

Where:

Θ = 1.05 above 20°C

1.07 below 20°C

This calculation is only valid for temperature ranges from 10° - 30°C

SEND: on/off This sets the RS232 status at the beginning of the test.

After the parameters have been set, press [ENTER] to save them and return to the SOUR menu.

38

Page 42

SOUR

mg

7.7

25.35°C 8.09 0:00

SOUR SETTING SAVED

START SETUP REVIEW SEND

Once the parameters have been set, you are ready to begin. Place the probe in the prepared

sample and make certain no air bubbles are trapped, then turn on the stirring and wait a few

seconds for the temperature readings to stabilize.

NOTE: It is normal for the SOUR reading to oscillate for the first few seconds.

Press [START] to begin the SOUR measurement. The following screen shows the available softkeys .

40.7

25.35°C 6.57 1:09

END SEND ON

/h /g

mg

/h /g

SOUR

mg

/L

mg

/L

@20

SEND: off

Current DO

SOUR

SEND: off

RS232 status

RS232 status

The SOUR value is displayed on the screen and is updated approximately once per second.

The [SEND ON/OFF] soft-key toggles the RS232 status. Press [SEND ON] if you want to send

the readings to a computer or serial printer during the SOUR measurement. The RS232 status is

displayed just above the elapsed time. During the SOUR measurement, data will be sent every 15

seconds until the SOUR measurement ends or the [SEND OFF] soft-key is pressed. The

following is an example of the format:

NOTE: Once pressed, the [SEND ON] soft-key toggles and becomes a [SEND OFF] soft-key.

Second mg/h/g C mg/L 10:32:36 09/21/98

1 .36 25.35 7.35

15 92.57 25.35 6.99

30 64.55 25.34 6.83

45 42.54 25.35 6.71

60 45.76 25.35 6.60 . . .

39

Page 43

If you want to stop the SOUR measurement before the maximum time or minimum ending DO

(entered in SOUR setup) is reached, press the [END] soft-key. The final SOUR reading will be

displayed on the screen.

mg

20.07

/h /g

25.33°C 1.29 11:38

PROCESS COMPLETE

START SETUP STORE SEND

NOTE: The DO and temperature readings do not stop updating on the screen.

After the SOUR measurement has ended, the [SEND] soft-key can be used to send all of the DO

values and the final SOUR to a computer or serial printer via the RS232 port. The format is as

follows:

Time stamp: 10:32 AM

Date stamp: 09/21/98

@20

mg

/L

SOUR

SEND on

Reference point: 30 (sec.)

Second mg/L

1 7.35

15 6.99

30 6.83

45 6.71

60 6.60 . . .

701 1.98

SOUR = 26.04 mg/h/g

SOUR@20 = 20.07 mg/h/g Tavg = 25.34 C

Dilution ratio: 1 / 1(Sample/Total)

Solids Weight : 1.000 g/L

NOTE: If you have run a SOUR measurement, but did not enter the appropriate sample dilution,

you will get uncorrected results. However, after running the SOUR measurement, you

may return to the SOUR setup screen, change the Sample / Total ratio or Solids Weight,

then press [ENTER] to save the changes. The recalculated SOUR value will be

displayed. Press [SEND] to send the new SOUR value to a computer or serial printer via

the RS232 port.

If you want to save these values press the [STORE] soft-key. A record number will then show

up under the REVIEW menu. If the record slot contains a set of data, an indicator saying FULL

will appear beside the test number. If the record slot does not contain a set of data, the indicator

will say EMPTY.

SOUR@20 Indicator

40

Page 44

20.1 mg /h /g @20 6.8 mg /L

mg

/L

0

NEXT REC. MODIFY SAVE SEND

705

REVIEW

REC:1 EMPTY

10:32 AM

09/21/98

Record Number

FULL or EMPTY

indicator

Press the [NEXT REC.] soft-key to change the record number to find an empty slot, or pick a slot

to overwrite (you cannot delete results, you must overwrite). Press the [SAVE] soft-key to save

the current test data into that slot. Once you have saved the data you can press the [MODIFY]

soft-key to change the parameters of the test.

20.1 mg /h /g @20 6.8 mg /L

mg

/L

0

SOUR

Time Reference

DO (at Reference

MODIFY

REC:1 FULL

10:32 AM

705

09/21/98

! "

SETTINGS

Test time

Press the ! or " soft-keys to move the start time reference point to an optimal place on the

curve. The reference point is represented by a vertical line. Only data to the right of the

reference point will be used to calculate the SOUR value. Moving this reference point allows

you to start the test at anytime and trim off unwanted data after the test has run. The DO reading

at the reference point is shown at the top. The reference point cannot move closer than the

minimum time to the end of the test.

The [SETTINGS] soft-key allows you to modify or input values for the Dilution factor and

Solids Weight. These changes are saved if you save the record again.

41

Page 45

Remote

From the Model 5000/5100 Application mode menu press the [REMOTE] soft-key. The

following screen will be displayed.

STIR

ON

SKIP UP DOWN CONFIRM

ID: 1680 MODE :0

96.4% 24.94 C

REMOTE

The Remote mode is used in conjunction with YSI 5910 BOD Analyst software to greatly reduce

the labor required for processing BODs and calculating BOD values.

Remote mode is also used to control the 5000/5100 via computer. This can be done using any

standard communications program. See Appendix D - Remote Command Language for details.

RS232 Serial Port

The RS232 serial port uses a standard DB9 connector. Use a straight serial cable (not a null

modem) to connect the 5000/5100 to a computer serial port or a serial printer. See

15. Accessories and Replacement Parts for the YSI item number. A 9 to 25 pin adapter will also

be needed if the computer has a 25 pin serial port. Port settings are 9600 baud, 8 bits, Parity

None, Stop bits 1, and Flow Control set to Xon / Xoff.

Bar Code Reader

The YSI Model 5015 bar code reader may be connected to the Model 5100 while in the Remote

mode. This greatly improves data entry when entering sample ID numbers used with YSI BOD

Analyst software. The YSI 5015 has a 6-Pin Mini DIN connector that connects to the rear of the

5100 (see section 4.3 for the location of the socket). The model 5000 does not support a bar code

reader. Before using the 5015 bar code reader for the first time, it must be programmed as

follows:

1. Plug the bar code reader into the connector labeled “BAR CODE” on the rear of the 5100.

2. Turn on the 5100.

The YSI 5015 bar code reader may be either an Imageteam 3800/3900 or Laser Wedge 300 scanner.

**Please check which scanner you have by locating the scanner’s operations manual. If your Bar Code

Scanner is an Imageteam 3800/3900 then you will follow the first set of instructions to initialize.

Follow the second set of instructions if you have a Laser Wedge 300 scanner.

A) Imageteam 3800/3900 scanner

The following instructions involve the IMAGETEAM 3800/3900 User’s Guide:

42

Page 46

1. Prepare the scanner by installing the ferrite bead on the scanner’s cable near to where it plugs

into the 5100 meter as shown in the following diagram:

2. Turn to page 1-7 and scan the “Keyboard Wedge Interface for IBM PC AT and compatibles”

bar code label. The scanner should beep, indicating that it is ready to be used.

3. Test the bar code reader configuration by selecting Remote mode from the Application menu

of the 5100 and scanning a BOD bottle label. The bar code reader and 5100 meter will beep

and the 5100 will briefly display ”BC” along with the bar code number.

B) Laser Wedge 300 scanner

The following instructions involve the Laser Wedge 300 Bar Code Reader Programming Menus

booklet:

1. Turn to the page entitled “Bar Codes For Menus”, the last page in the booklet. Fold out the

page so that the list of bar codes is scanable. Keep this page unfolded for later use as it

contains the numbers and letters that will be used to program the bar code reader in the

following steps.

2. Turn to the page entitled “Status Check”, the second to last page. Scan the DEFAULT ALL

PARAMETERS bar code to load the factory default parameters. The bar code reader will

beep to indicate a successful scan.

43

Page 47

3. Turn to the page entitled “Terminal Selection”, the first page in the booklet.

3.1. Scan the ENTER TERMINAL SELECTION bar code.

3.2. Scan the 0 code on the “Bar codes for menus” page that you unfolded earlier.

Hold the reader close to the page to prevent scanning more than one code at a

time.

3.3. Scan the 1 code on the “Bar codes for menus” page.

3.4. Go back to the “Terminal Selection” page and scan the EXIT TERMINAL

SELECTION bar code.

4. Turn to the page entitled “General III Control Parameters”, the sixth page in the booklet.

4.1. Scan the ENTER GENERAL III SELECTIONS bar code.

4.2. Scan the POSTAMBLE bar code.

4.3. Scan the 0 code on the “Bar codes for menus” page that you unfolded earlier.

4.4. Scan the D code.

4.5. Scan the 0 code again.

4.6. Scan the A code.

4.7. Go back to the “General III Control Parameters” page and scan the EXIT

GENERAL III SELECTIONS bar code.

5. Test the bar code reader configuration by selecting Remote mode from the Application menu

of the 5100 and scanning a BOD bottle label. The bar code reader should beep, the 5100

should beep (if the beeper is enabled) and the 5100 should briefly display ”BC” and the bar

code number.

External Computer Keyboard

An external computer keyboard may be connected to the Model 5100 while in the Remote mode.

This greatly improves data entry when entering sample ID numbers used with YSI BOD Analyst

software (when a bar code reader is not available). The computer keyboard must be PC

compatible and have a 6-Pin Mini DIN connector. A commercially available adapter may be used

if necessary (5-Pin DIN to 6-Pin mini DIN). See 4.3 Rear Panel for the location of the socket.

The model 5000 does not support an external computer keyboard.

8. Diagnostics

The YSI 5000/5100 has a diagnostic mode that is used primarily during troubleshooting. In

Diagnosis mode you can view information from specific sensors, such as DO probe current, DO

background current and pressure sensor offset. This information is useful when trying to isolate

problems or monitor sensor conditions. When the 5000/5100 senses a problem, it displays an

error code and message. Diagnosis mode can be used to determine when membrane/probe service

is needed, before the instrument displays an error code. Refer to section

44

Page 48

12. Troubleshooting for additional information on error codes.

From the Main mode, press the [CALIBRATE] soft-key to enter Calibration mode, then press the

[Diagnosis] soft-key to enter Diagnosis mode. The following screen will be displayed.

Diagnosis

HISTORY SENSOR HELP RESET Ps

History

Press the [HISTORY] soft-key to display the following information.

Date Time DO uA %/uA C

Diagnosis

02/01 14:12 16.8 5.98 21.9

02/02 08:42 16.3 7.90 28.0

02/05 09:55 17.0 6.42 23.0

02/06 10:58 17.1 7.47 27.9

02/07 13:08 16.9 6.43 22.8

HISTORY SENSOR HELP RESET Ps

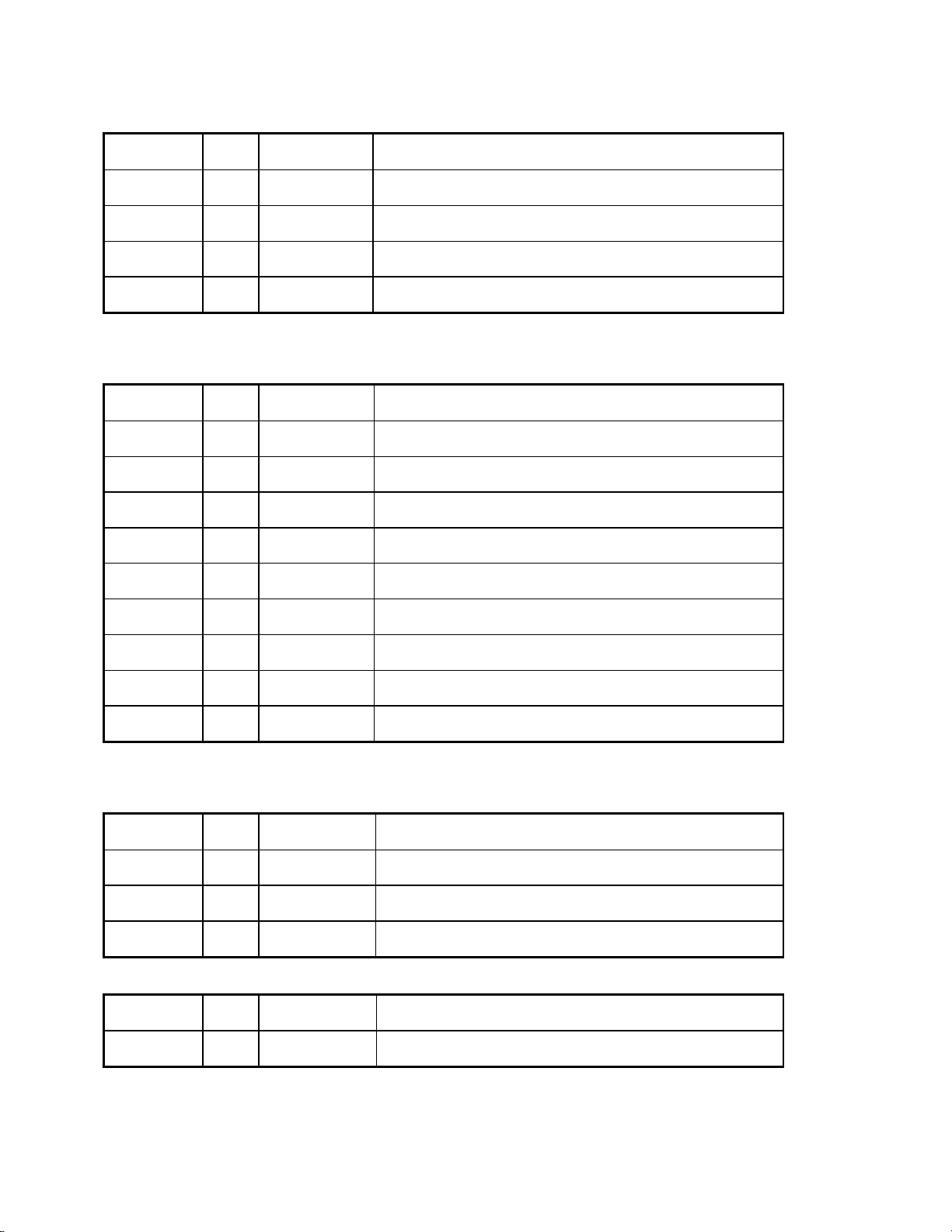

The History screen displays information about the last five DO calibrations. This information is

useful for tracking the performance of the DO probe/membrane. The following parameters are

displayed:

Date: The date the calibration was performed.

Time: The time the calibration was performed.

DO uA: The dissolved oxygen calibration current in microamps. The calibration

current (100% saturation at sea level) of an ideal probe using a 1 mil

(standard) membrane is 13.7uA @ 20°C. If the probe current (100%

saturation @ 20°C, 1 mil membrane) is greater than 17.0uA or lower than

8.0uA, the membrane/probe may need service. See 12. Troubleshooting,

Error Codes, E3 and E4.

%/uA: The slope of the dissolved oxygen probe in percent per microamp

corrected to 20°C. The slope of an ideal probe using a 1 mil membrane is

45

Page 49

7.3 %/uA @ 20°C. If the probe slope (1 mil membrane) is greater than

12.6 %/uA or lower than 5.9 %/uA, the membrane/probe may need

service. See 12. Troubleshooting, Error Codes, E3 and E4.

C: The temperature at the time of calibration in °C.

Sensor

Press the [SENSOR] soft-key to display the following sensor diagnostics screen:

System Parameters

Sensor

Cal. Temperature = 22.85 C

Probe Slope = 6.43 %/uA @20C

Probe Offset = 0.000 uA

Probe Current = 16.91 uA

Pressure Offset = 830 mbar P = 981

Cal. Temperature: The temperature at the time of the last calibration in °C.

Probe Slope: The slope of the dissolved oxygen probe in percent per microamp

corrected to 20°C. The slope of an ideal probe using a 1 mil

membrane is 7.3%/uA @ 20°C. If the probe slope (1 mil

membrane) is greater than 12.6 %/uA or lower than 5.9 %/uA, the

membrane/probe may need service. See 12. Troubleshooting, Error

Codes, E3 and E4.

Probe Offset: The zero offset current (background current) of the DO probe in

microamps. The factory default value is 0.000 uA. This value will

only change after a zero calibration is performed (see 6.2 Zero

Calibration). If this value is greater than 0.15uA (after a zero

calibration) the membrane/probe may need service. See 12.

Troubleshooting, Error Code E2.

Probe Current: The present (real time) DO probe current in microamps.

Pressure Offset: The offset of the barometer in millibars. This value will change

whenever the barometer is calibrated. The normal range is 300 to

1300 mbar.

P: Current barometer reading in millibars.

Press [MODE] to return to the Diagnosis menu. Press [MODE] two more times to return to the

Main menu.

46

Page 50

Reset Ps

The [RESET Ps] soft-key (Reset Parameters) is used to reset all instrument parameters to the

factory default values. This is useful when the parameters have been changed or corrupted, such

as when new software is loaded. Press the [RESET Ps] soft-key to display the following:

Reset

Press ENTER to RESET Parameters

HISTORY SENSOR HELP RESET Ps

Press [ENTER] to confirm. All parameters, including calibration values, will be reset. If you do

NOT wish to reset the parameters, press [MODE], instead of [ENTER], to return to the

Diagnosis menu.

WARNING: Resetting the instrument parameters to the factory default values will clear

the barometer calibration/setting. You MUST recalibrate the barometer before performing

an autocal. See 6.1 Dissolved Oxygen Calibration Barometer.

47

Page 51

9. Princip l es o f Operation

YSI dissolved oxygen probes use membrane-covered, Clark-type polarographic sensors with

built-in thermistors for temperature measurement and compensation. A thin permeable

membrane, stretched over the sensor, isolates the sensor elements from the environment, but

allows oxygen and certain other gases to enter. When a polarizing voltage is applied across the

sensor, oxygen that has passed through the membrane reacts at the cathode, causing a current to

flow. This current is read and interpreted by the YSI dissolved oxygen meter utilizing customized