York GY8S'UH, LY8S'UH User Manual

TECHNICAL GUIDE

MODELS: GY8S*UH / LY8S*UH

GAS-FIRED

HIGH EFFICIENCY SINGLE STAGE

UPFLOW/HORIZONTAL FURNACES

STANDARD & Low NOx

NATURAL GAS

40 - 130 MBH INPUT

EFFICIENCY

RATING

CERTIFIED

ISO 9001

Certified Quality

Management System

Due to continuous product improvement, specifications are subject to change without notic e.

Visit us on the web at www.york.com for the most

up-to-date technical information.

Additional information can be found at

www.gamanet.org.

278436-YTG-A-0407

DESCRIPTION

These high efficiency, compact units employ induced combustion, reliable hot surface ignition and high heat transfer

aluminized tubular heat exchangers. The units are factory

shipped for installation in upflow or horizontal applications.

These furnaces are designed for residential installation in a

basement, closet, alcove, attic, recreation room or garage

and are also ideal for commercial applications. All u nits are

factory assembled, wired and tested to assure safe dependable and economical installation and operation.

These units are Category I listed and may be common vented

with another gas appliance as allowed by the National Fuel

Gas Code.

WARRANTY

20-year limited warranty on the heat exchanger.

10-year heat exchanger warranty on commercial applica-

tions.

5-year limited parts warranty.

FEATURES

• Easily applied in upflow, horizontal left or horizontal right

installation with no conversion necessary.

• 100% shut off main gas valve for added safety.

• Rollout safety control.

• Low unit amp requirement for easy application.

• High quality inducer motor for quiet operation.

• Built-in self diagnostics with fault code display.

• Electronic Hot Surface Ignition saves fuel cost with

increased dependability and reliability.

• Standard terminals for controlling humidifiers and EAC's.

• 40 VA control transformer fuse protected.

• Easy to connect power and control wiring.

• Efficiency ratings of 80 AFUE attained by using tubular

heat exchangers.

• Cooling relay supplied for easy installation of add-on

cooling.

• Multi-speed PSC, large, quiet direct-drive blower motor

to match cooling requirements.

• Adjustable fan-off settings to eliminate “cold-blow”.

• Compact 40-in height allows installation in small space

confines.

• Low NOx models have been designed to meet specific

code requirements.

• All models are propane convertible.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

278436-YTG-A-0407

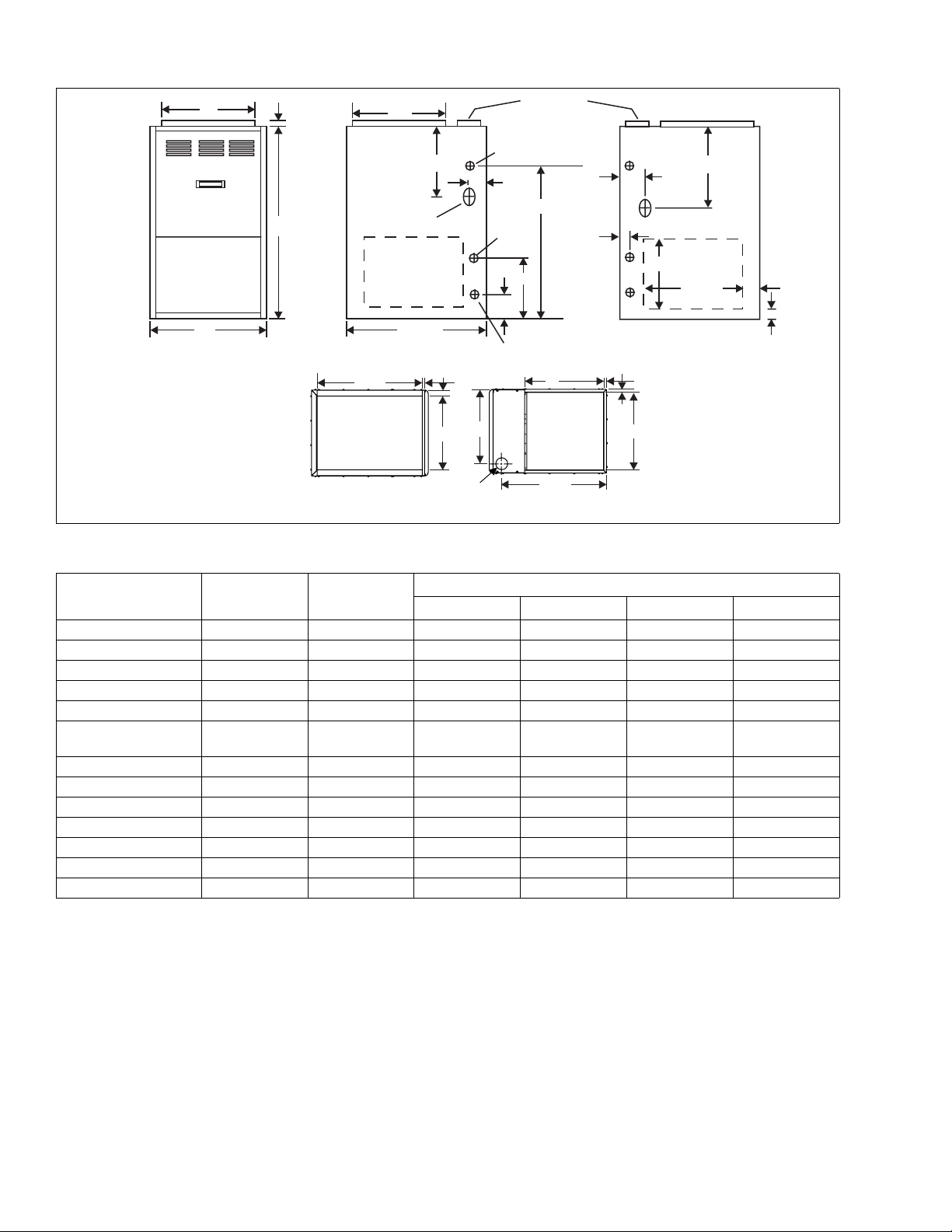

B

A

FRONT

3/4

40

20

13-3/4

GAS INLET

1-1/4 x 2-1/2

28-1/2

LEFT SIDE

26-1/2

BOTTOM IMAGE

RETURN END

1-1/2

1-1/4

C

4” Diameter

D

4” Diameter

(VENT CONNECTIONS)

POWER WIRING

7/8” HOLE

2-1/2

32-1/2

ACCESS

WIRING

7/8” K.O.

16

8-3/4

T’STAT WIRING 7/8” K.O.

20

24-3/4

TOP IMAGE

SUPPLY END

5/8

5-3/8

2

5/8

B

14

23-1/2

RIGHT SIDE

14-3/4

2-1/4

1-1/8

CABINET AND DUCT DIMENSIONS

Models CFM

Cabinet

Size

ABCD

(G,L)Y8S040A12UH11 1200 A 14 1/2 13 1/4 11 1/2 10 1/8

(G,L)Y8S060A12UH11 1200 A 14 1/2 13 1/4 11 1/2 10 1/8

(G,L)Y8S080A12UH11 1200 A 14 1/2 13 1/4 11 1/2 10 1/8

(G,L)Y8S080B16UH11 1600 B 17 1/2 16 1/4 14 1/2 11 5/8

(G,L)Y8S080C16UH11 1600 C 21 19 3/4 18 13 3/8

GY8S080C22UH11

LY8S080C20UH11

2200

2000

C 21 19 3/4 18 13 3/8

(G,L)Y8S100B12UH11 1200 B 17 1/2 16 1/4 14 1/2 11 5/8

(G,L)Y8S100B16UH11 1600 B 17 1/2 16 1/4 14 1/2 11 5/8

(G,L)Y8S100C16UH11 1600 C 21 19 3/4 18 13 3/8

(G,L)Y8S100C20UH11 2000 C 21 19 3/4 18 13 3/8

GY8S115C16UH11 1600 C 21 19 3/4 18 13 3/8

(G,L)Y8S115C20UH11 2000 C 21 19 3/4 18 13 3/8

(G,L)Y8S130D20UH11 2000 D 24 1/2 23 1/4 21 1/2 15 1/8

Cabinet Dimension

2 Unitary Products Group

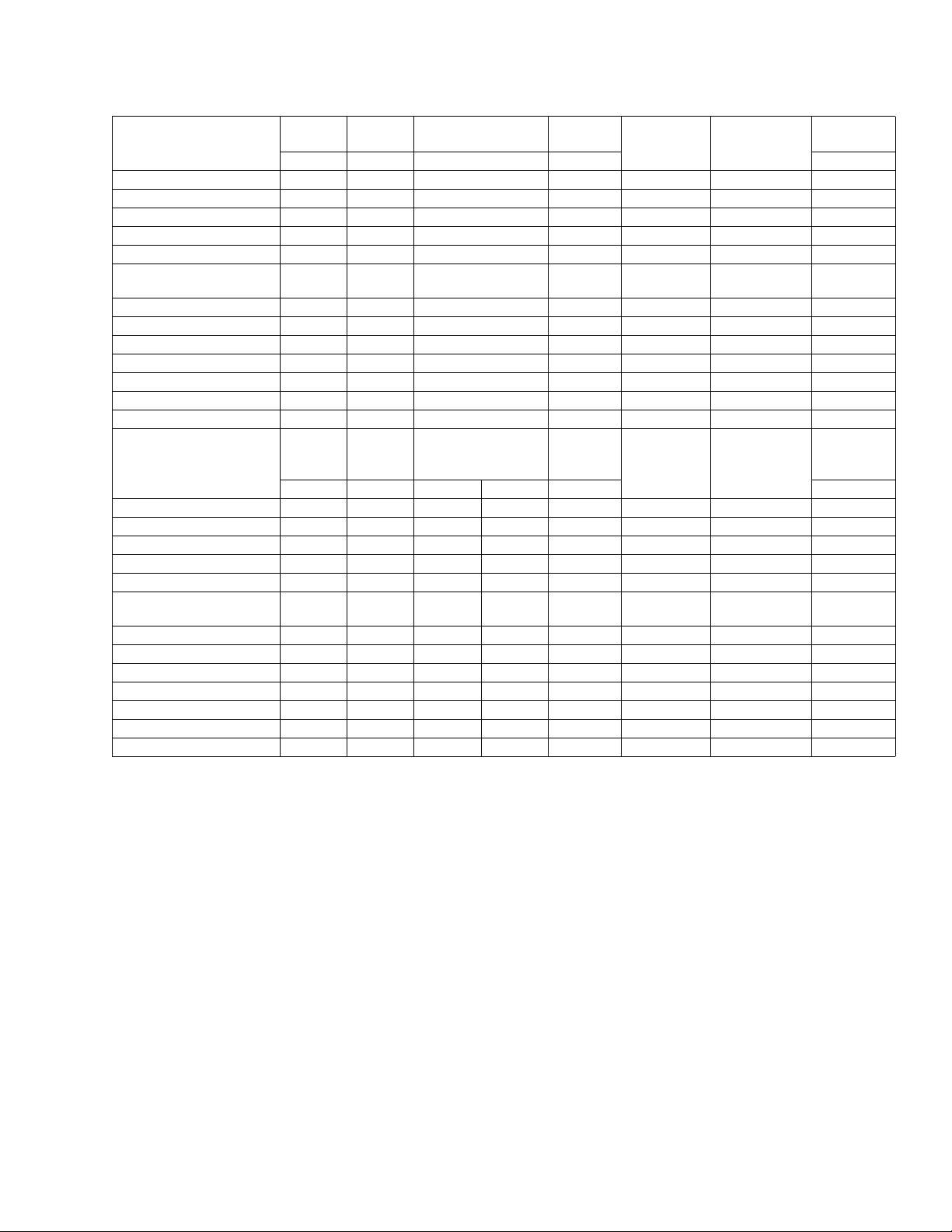

RATINGS & PHYSICAL / ELECTRICAL DATA - UPFLOW MODELS

278436-YTG-A-0407

Models

(G,L)Y8S040A12UH11 40 32 1200 14-1/2 9.0 80.0 25-55

(G,L)Y8S060A12UH11 60 48 1200 14-1/2 9.0 80.0 25-55

(G,L)Y8S080A12UH11 80 64 1200 14-1/2 9.0 80.0 35-65

(G,L)Y8S080B16UH11 80 64 1600 17 1/2 12.0 80.0 25-55

(G,L)Y8S080C16UH11 80 64 1600 21 12.0 80.0 25-55

GY8S080C22UH11

LY8S080C20UH11

(G,L)Y8S100B12UH11 100 80 1200 17 1/2 12.0 80.0 40-70

(G,L)Y8S100B16UH11 100 80 1600 17 1/2 12.0 80.0 35-65

(G,L)Y8S100C16UH11 100 80 1600 21 12.0 80.0 35-65

(G,L)Y8S100C20UH11 100 80 2000 21 14.0 80.0 25-55

GY8S115C16UH11 115 92 1600 21 12.0 80.0 35-65

(G,L)Y8S115C20UH11 115 92 2000 21 14.0 80.0 30-60

(G,L)Y8S130D20UH11 130 104 2000 24-1/2 14.0 80.0 35-65

Models

(G,L)Y8S040A12UH11 40 155 1/2 7.1 10 x 8 20 14 105

(G,L)Y8S060A12UH11 60 155 1/2 7.1 10 x 8 20 14 110

(G,L)Y8S080A12UH11 80 170 1/2 7.1 10 x 8 20 14 117

(G,L)Y8S080B16UH11 80 155 3/4 11.5 11 x 8 20 14 126

(G,L)Y8S080C16UH11 80 155 3/4 11.5 10 x 10 20 14 130

GY8S080C22UH11

LY8S080C20UH11

(G,L)Y8S100B12UH11 100 170 1/2 7.1 10 x 8 20 14 128

(G,L)Y8S100B16UH11 100 165 3/4 11.5 11 x 8 20 14 134

(G,L)Y8S100C16UH11 100 165 3/4 11.5 10 x 10 20 14 140

(G,L)Y8S100C20UH11 100 155 1.0 14.0 11 x 11 20 12 145

GY8S115C16UH11 115 170 3/4 11.5 10 x 10 20 14 145

(G,L)Y8S115C20UH11 115 170 1.0 14.0 11 x 11 20 12 147

(G,L)Y8S130D20UH11 130 165 1.0 14.0 11 x 11 20 12 158

Nominal external static pressure is 0.50” w.c. at furnace outlet ahead of cooling coils.

Annual Fuel Utilization Efficiency (AFUE) numbers are determined in accordance with DOE Test procedures.

Wire size and over current protection must comply with the National Electrical Code (NFPA-70-latest edition) and all local codes.

Input Output

MBH MBH CFM In. °F

80 64

Input

MBH °F Hp Amps In. LBS

80 165 1.0 14.0 11 x 11 20 12 140

Max.

Outlet

Air Temp

Nominal

Airflow

2200

2000

Blower

Cabinet

Width

21 14.0 80.0 25-55

Blower

Size

Total Unit

Amps

Max

Over-Current

Protect

AFUE

Min. wire Size

(awg) @ 75 ft

one way

Operation

Air Temp.

Rise

Weight

Unitary Products Group 3

Loading...

Loading...