Page 1

WT1800

Precision Power Analyzer

Features Guide

IM WT1801-01EN

2nd Edition

Page 2

Notes

Thank you for purchasing the WT1800 Precision Power Analyzer. This manual contains useful

information about the features of the WT1800. To ensure correct use, please read this manual

thoroughly before beginning operation.

After reading the manual, keep it in a convenient location for quick reference whenever a question

arises during operation. The following manuals, including this one, are provided as manuals for the

WT1800. Please read all the manuals.

Manual Title Manual No. Description

WT1800 Precision Power Analyzer

Features Guide

WT1800 Precision Power Analyzer

User’s Manual

WT1800 Precision Power Analyzer

Getting Started Guide

WT1800 Precision Power Analyzer

Communication Interface

User’s Manual

IM WT1801-01EN This manual. The supplied CD contains the PDF

file of this manual. This manual explains all the

WT1800 features other than the communication

interface features.

IM WT1801-02EN The supplied CD contains the PDF file of this

manual. The manual explains how to operate the

WT1800.

IM WT1801-03EN The manual explains the handling precautions and

basic operations of the WT1800 and provides an

overview of its features.

IM WT1801-17EN The supplied CD contains the PDF file of this

manual. The manual explains the WT1800 series

communication interface features and instructions

on how to use them.

• The contents of this manual are subject to change without prior notice as a result of continuing

improvements to the instrument’s performance and functionality. The figures given in this manual

may differ from those that actually appear on your screen.

•

Every ef

fort has been made in the preparation of this manual to ensure the accuracy of its

contents. However, should you have any questions or find any errors, please contact your

nearest YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this m

anual without the permission of

YOKOGAWA is strictly prohibited.

TCP/IP software of this product and the documents concerning it have been developed/

• The

created by YOKOGAWA based on the BSD Networking Software, Release 1 that has been

licensed from the Regents of the University of California.

Trademarks

• Microsoft, Internet Explorer, MS-DOS, Windows, Windows NT, and Windows XP are either

registered trademarks or trademarks of Microsoft Corporation in the United States and/or other

countries.

•

Adobe and

Acrobat are either registered trademarks or trademarks of Adobe Systems

Incorporated.

• In this manual, the ® and

TM symbols do not accompany their respective registered trademark

or trademark names.

• Other company and product names are trademarks or register

holders.

Revisions

• 1st Edition: February 2011

• 2nd Edition: August 2011

2nd Edition: August 2011(YMI)

All Rights Reserved, Copyright © 2011 Yokogawa Meters & Instruments Corporation

IM WT1801-01EN

ed trademarks of their respective

i

Page 3

ii

IM WT1801-01EN

Contents

1 Items That This Instrument Can Measure

Measurement Functions Used in Normal Measurement............................................................... 1-1

Harmonic Measurement Functions (Option) ................................................................................. 1-3

Delta Computation Functions (Option).......................................................................................... 1-5

Motor Evaluation Functions (Option) ............................................................................................ 1-5

Auxiliary Input Measurement Functions (Option) .......................................................................... 1-5

High Speed Data Capturing (Option) ............................................................................................ 1-5

What Is a Measurement Function? ............................................................................................... 1-6

Measurement Period..................................................................................................................... 1-6

2 Fundamental Measurement Conditions

Wiring System Settings (WIRING) ................................................................................................ 2-1

Wiring System (Wiring) ................................................................................................................. 2-1

Efciency Equation (η Formula) .................................................................................................... 2-4

Independent Input Element Conguration (Element Independent) ............................................... 2-5

Delta Computation (Δ Measure; option) ........................................................................................ 2-6

Selecting an Element Whose Measurement Range You Want to Specify (ELEMENT) ................ 2-8

Selecting All Input Elements (ALL)................................................................................................ 2-9

Voltage Range (RANGE UP/DOWN (V)) ...................................................................................... 2-9

Auto Voltage Range (AUTO (V)) ................................................................................................. 2-10

Current Range (RANGE UP/DOWN (A)) .....................................................................................2-11

Auto Current Range (AUTO (A)) ..................................................................................................2-11

Power Range .............................................................................................................................. 2-12

External Current Sensor Range (EXT SENSOR; option) ........................................................... 2-12

External Current Sensor Conversion Ratio (SENSOR RATIO; option) ....................................... 2-13

External Current Sensor Range Display Format (DIRECT/MEASURE; option) ......................... 2-14

Scaling (SCALING) ..................................................................................................................... 2-14

Valid Measurement Range (CONFIG(V)/CONFIG(A)) ................................................................ 2-16

Crest Factor (Crest Factor) ......................................................................................................... 2-17

Measurement Period (SYNC SOURCE) ..................................................................................... 2-18

Line Filter (LINE FILTER) ............................................................................................................ 2-19

Frequency Filter (FREQ FILTER) ............................................................................................... 2-19

Data Update Interval (UPDATE RATE) ....................................................................................... 2-20

Averaging (AVG) ......................................................................................................................... 2-20

Displaying the Setup Parameter List (INPUT INFO) ................................................................... 2-22

3 Harmonic Measurement Conditions (Option)

Harmonic Measurement Conditions (HRM SET) .......................................................................... 3-1

PLL Source (PLL Source) ............................................................................................................. 3-1

Measured Harmonic Orders (Min Order/Max Order) .................................................................... 3-2

Distortion Factor Equation (Thd Formula)..................................................................................... 3-3

Input Element Group (Element Settings) ...................................................................................... 3-3

Anti-Aliasing Filter ......................................................................................................................... 3-4

Page 4

4 Motor Evaluation Conditions (Option)

Motor Evaluation Conditions and Auxiliary Input Conditions (MOTOR/AUX SET) ....................... 4-1

Scaling Factor (Scaling) ................................................................................................................ 4-1

Unit (Unit) ...................................................................................................................................... 4-2

Input Signal Type (Sense Type) .................................................................................................... 4-2

Analog Input Range ...................................................................................................................... 4-3

Linear Scaling of Analog Input ...................................................................................................... 4-3

Line Filter (Line Filter) ................................................................................................................... 4-4

Synchronization Source (Sync Source) ........................................................................................ 4-5

Pulse Input Range ........................................................................................................................ 4-5

Torque Signal Pulse Rating........................................................................................................... 4-5

Revolution signal pulses per revolution (Pulse N) ........................................................................ 4-7

Synchronous Speed (Sync Speed) ............................................................................................... 4-7

Electrical Angle Measurement (Electrical Angle Measurement) ................................................... 4-8

Motor Efciency and Total Efciency Computation ....................................................................... 4-9

5 Auxiliary Input Conditions (Option)

Auxiliary Input Conditions (MOTOR/AUX SET) ............................................................................ 5-1

Input Signal Name (Aux Name) .................................................................................................... 5-1

Scaling Factor (Scaling) ................................................................................................................ 5-1

Unit (Unit) ...................................................................................................................................... 5-1

Analog Input Range ...................................................................................................................... 5-1

Linear Scaling of Analog Input ...................................................................................................... 5-2

Line Filter (Line Filter) ................................................................................................................... 5-3

Contents

6 Holding Measured Values and Performing Single Measurements

Holding Measured Values (HOLD) ................................................................................................ 6-1

Single Measurement (SINGLE) .................................................................................................... 6-1

7 Numeric Data Display

Numeric Data Display (NUMERIC) ............................................................................................... 7-1

Display Format (FORM) ................................................................................................................ 7-1

Numeric Data Display Format ....................................................................................................... 7-1

Switching the Displayed Page (PAGE UP/PAGE DOWN) ............................................................ 7-3

Jumping to the First or Last Page (PAGE TOP/PAGE END) ........................................................ 7-3

Number of Displayed Digits (Display Resolution) ......................................................................... 7-4

Display Item (ITEM) ...................................................................................................................... 7-4

4-, 8-, and 16-Value Displays (4 Items/8 Items/16Items) .............................................................. 7-5

Matrix display (Matrix) ................................................................................................................... 7-7

All Items Display (All Items) .......................................................................................................... 7-8

Single Harmonics and Dual Harmonics Lists (Hrm List Single/Dual; option) ................................ 7-9

Custom Display (Custom) ........................................................................................................... 7-10

IM WT1801-01EN

iii

Page 5

iv

IM WT1801-01EN

Contents

8 Computation

Computation (MEASURE) ............................................................................................................ 8-1

User-Dened Functions (User Dened Function) ......................................................................... 8-1

Measuring the Average Active Power ........................................................................................... 8-5

MAX Hold (Max Hold) ................................................................................................................... 8-5

User-Dened Events (User Dened Event) .................................................................................. 8-6

Apparent Power, Reactive Power, and Corrected Power Equations (Formula) ............................ 8-8

Sampling Frequency (Sampling Frequency)................................................................................. 8-9

Phase Difference Display Format (Phase) .................................................................................. 8-10

Master/Slave Synchronization Measurement (Sync Measure) ................................................... 8-10

Voltages or Currents Whose Frequencies Will Be Measured (FREQ MEASURE) ......................8-11

9 Integrated Power (Watt hours)

Integration-Related Display Indications ........................................................................................ 9-1

Number of Displayed Digits (Display Resolution) ......................................................................... 9-2

Enabling or Disabling Independent Integration (Independent Control) ......................................... 9-4

Independently Integrated Elements (Element Object) .................................................................. 9-4

Starting, Stopping, and Resetting Integration (Start/Stop/Reset) ................................................. 9-5

Integration Conditions (Integ Set) ................................................................................................. 9-7

Integration Mode (Mode)............................................................................................................... 9-7

Integration Timer (Integ Timer).................................................................................................... 9-10

Scheduled Times for Real-Time Integration (Real-time Control) ................................................ 9-10

Integration Auto Calibration On/Off (Auto Cal) .............................................................................9-11

Watt Hour Integration Method for Each Polarity (WP ± Type) ......................................................9-11

Current Mode for Current Integration (q Mode) ...........................................................................9-11

Rated Time of Integrated D/A Output (D/A Output Rated Time; Option) ..................................... 9-12

10 Waveform Display

Waveform Display (WAVE) ......................................................................................................... 10-1

Display Format (FORM) .............................................................................................................. 10-2

Number of Windows (Format) ..................................................................................................... 10-2

Time Axis (Time/div) .................................................................................................................... 10-2

Vertical Axis (Amplitude) ............................................................................................................. 10-4

Trigger (Trigger Settings) ............................................................................................................ 10-5

Advanced Waveform Display Settings (Display Settings) ........................................................... 10-7

Waveform Mapping (Wave Mapping) .......................................................................................... 10-8

Display Item (ITEM) .................................................................................................................... 10-8

11 Trend Display

Other Displays (OTHERS) ...........................................................................................................11-1

Trend Display (Trend) ..................................................................................................................11-1

Display Format (FORM) ...............................................................................................................11-2

Display Item (ITEM) .....................................................................................................................11-3

12 Bar Graph Display (Option)

Bar Graph Display (OTHERS (Bar)) ........................................................................................... 12-1

Display Format (FORM) .............................................................................................................. 12-1

Display Item (ITEM) .................................................................................................................... 12-2

Page 6

13 Vector Display (Option)

Vector Display (OTHERS (Vector)) ............................................................................................. 13-1

Display Format (FORM) .............................................................................................................. 13-2

Display Item (ITEM) .................................................................................................................... 13-2

14 Split Display

Split Display (OTHERS) .............................................................................................................. 14-1

Split Displays with the Numeric Display (Numeric+***) ............................................................... 14-1

Split Displays with the Waveform Display (Wave+***) ................................................................ 14-1

Split Displays with the Trend Display (Trend+***) ....................................................................... 14-1

Split Display Settings .................................................................................................................. 14-1

15 Cursor Measurement

Cursor Measurement (CURSOR) ............................................................................................... 15-1

Turning Cursor Measurement On and Off (Cursor) .................................................................... 15-1

Waveform Measured by Cursor 1 (+; C1+ Trace) ....................................................................... 15-1

Waveform Measured by Cursor 2 (x; C2x Trace) ....................................................................... 15-1

Cursor Path (Cursor Path) .......................................................................................................... 15-2

Position of Cursor 1 (+; C1+ Position) ........................................................................................ 15-2

Position of Cursor 2 (x; C2x Position) ......................................................................................... 15-2

Linking Cursor Movement (Linkage) ........................................................................................... 15-2

Measured Items .......................................................................................................................... 15-2

Cursor Movement ....................................................................................................................... 15-4

Contents

16 High Speed Data Capturing

High Speed Data Capturing (OTHERS(High Speed Data Capturing)) ....................................... 16-1

High Speed Data Capturing (HS) Settings (FORM).................................................................... 16-4

Number of Data Captures (Capture Count) ................................................................................ 16-4

Viewing and Optimizing the Maximum Capturing Count (Optimize Count) ................................ 16-4

Capture Control Settings (Control Settings)................................................................................ 16-5

Recording to a File (Record to File) ............................................................................................ 16-7

Save Conditions (File Settings)................................................................................................... 16-8

Starting and Stopping High Speed Data Capturing (Start/Stop) ................................................. 16-9

Display Items (ITEM) .................................................................................................................16-11

17 Data Storage

Storage-Related Display Indications ........................................................................................... 17-1

Storage Conditions (STORE SET) .............................................................................................. 17-1

Storage Control (Control Settings) .............................................................................................. 17-2

Stored Items (Item Settings) ....................................................................................................... 17-4

Save Conditions (File Settings)................................................................................................... 17-5

Starting, Stopping, and Resetting Storage (STORE START, STORE STOP, and STORE RESET) ...

17-6

Storage Operations in Each Storage Mode ................................................................................ 17-8

IM WT1801-01EN

v

Page 7

Contents

18 Saving and Loading Data

Storage Media............................................................................................................................. 18-1

Saving Setup Data (Save Setup) ................................................................................................ 18-2

Saving Waveform Display Data (Save Wave) ............................................................................. 18-2

Saving Numeric Data (Save Numeric) ........................................................................................ 18-2

File Save Conditions ................................................................................................................... 18-3

Loading Setup Data (Load Setup) .............................................................................................. 18-5

File Operations (Utility) ............................................................................................................... 18-6

19 Saving Screen Images

Conditions for Saving Screen Image Data (IMAGE SAVE MENU) ............................................. 19-1

Saving a Screen Image (IMAGE SAVE) ..................................................................................... 19-1

20 Printing Screen Images and Numeric Data (Option)

Printing Conditions (PRINT MENU) ............................................................................................ 20-1

Output Format (Format) .............................................................................................................. 20-1

Automatic Printing Execution (Auto Print ON) ............................................................................ 20-2

Automatic Printing (Auto Print Settings)...................................................................................... 20-2

Comment (Comment) ................................................................................................................. 20-3

Paper Feed (Paper Feed) ........................................................................................................... 20-3

Print Timing for Different Print Modes ......................................................................................... 20-4

Printing (PRINT).......................................................................................................................... 20-6

21 Ethernet Communication (Network)

TCP/IP (TCP/IP) ......................................................................................................................... 21-2

FTP Server (FTP Server) ............................................................................................................ 21-3

Network Drive (Net Drive) ........................................................................................................... 21-4

SNTP (SNTP) ............................................................................................................................. 21-5

22 Utility

Utility (UTILITY) .......................................................................................................................... 22-1

Overview (System Overview)...................................................................................................... 22-2

Initializing the Settings (Initialize Settings) .................................................................................. 22-2

Remote Control (Remote Control) .............................................................................................. 22-3

System Conguration (System Cong) ....................................................................................... 22-5

D/A Output (D/A Output Items; option) ........................................................................................ 22-8

Self-Test (Selftest)......................................................................................................................22-11

23 Other Features

Zero-Level Compensation (CAL) ................................................................................................ 23-1

NULL Feature (NULL SET) ......................................................................................................... 23-1

Enabling and Disabling the NULL Feature (NULL) ..................................................................... 23-3

Clearing Remote Mode (LOCAL) ................................................................................................ 23-3

Key Lock (KEY LOCK) ................................................................................................................ 23-3

Index

vi

IM WT1801-01EN

Page 8

1 Items That This Instrument Can Measure

Click here.

The items that you can measure with this instrument are listed below. For details about how the values of the

measurement functions are determined, see appendix 1 in the getting started guide, IM WT1801-03EN. For

explanations of the terms measurement function, input element, and wiring unit, see “What Is a Measurement

Function?”

The input elements and wiring units referred to in each measurement function table are listed below. However,

the input elements and wiring units that you can measure vary depending on how many input elements are

installed in the WT1800.

•

Input elements:

• Wiring units: ΣA,

Measurement Functions Used in Normal Measurement

Voltage

Function Description Input Element Wiring Unit

Urms True rms voltage Yes Yes

Umn Rectified mean voltage calibrated to

Udc Simple voltage average Yes Yes

Urmn Rectified mean voltage Yes Yes

Uac AC voltage component Yes Yes

U+pk Maximum voltage Yes No

U−pk Minimum voltage Yes No

CfU Voltage crest factor Yes No

Element1, Element2, Element3, Element4, Element5, Element6

ΣB, ΣC

Yes Yes

the rms value

Current

Power

Frequency

1 On models with the harmonic measurement option or the simultaneous dual harmonic measurement

2 Only on models with the simultaneous dual harmonic meas

IM WT1801-01EN

Function Description Input Element Wiring Unit

Irms True rms current Yes Yes

Imn Rectified mean current calibrated to the

rms value

Idc Simple current average Yes Yes

Irmn Rectified mean current Yes Yes

Iac AC current component Yes Yes

I+pk Maximum current Yes No

I−pk Minimum current Yes No

CfI Current crest factor Yes No

Function Description Input Element Wiring Unit

P Active power Yes Yes

S Apparent power Yes Yes

Q Reactive power Yes Yes

λ

Φ

Pc Corrected Power Yes Yes

P+pk Maximum power Yes No

P−pk Minimum power Yes No

Function Description Input Element Wiring Unit

fU Voltage frequency Yes No

fI Current frequency Yes No

fPLL1 Frequency of PLL1

fPLL2 Frequency of PLL2

Power factor Yes Yes

Phase difference Yes Yes

1

2

Yes Yes

No No

No No

option.

urement option.

1-1

Page 9

1-2

IM WT1801-01EN

1 Items That This Instrument Can Measure

Integrated Power (Watt hours)

Function Description Input Element Wiring Unit

Time Integration time Yes No

WP Sum of positive and negative watt

hours

WP+ Sum of positive P values Yes Yes

WP− Sum of negative P values Yes Yes

q Sum of positive and negative ampere

hours

q+ Sum of positive I values Yes Yes

q− Sum of negative I values Yes Yes

WS Volt-ampere hours Yes Yes

WQ Var hours Yes Yes

Efficiency

Function Description

η1 to η4 Efficiency

User-Defined Functions

Function Description

F1 to F20 User-defined functions

Yes Yes

Yes Yes

User-defined events

Function Description

Ev1 to Ev8 User-defined events

Page 10

1 Items That This Instrument Can Measure

Harmonic Measurement Functions (Option)

Function Description Input Element Wiring Unit

U(k) Rms voltage of harmonic order k Yes Yes

I(k) Rms current of harmonic order k Yes Yes

P(k) Active power of harmonic order k Yes Yes

S(k) Apparent power of harmonic order k Yes Yes

Q(k) Reactive power of harmonic order k Yes Yes

λ(k) Power factor of harmonic order k Yes Yes

Φ(k) Phase difference between the voltage

and current of harmonic order k.

ΦU(k) Phase difference between the

fundamental signal, U(1), and

harmonic voltage U(k)

ΦI(k) Phase difference between the

fundamental signal, I(1), and harmonic

current I(k)

Z(k) Impedance of the load circuit Yes No

Rs(k) Series resistance of the load circuit Yes No

Xs(k) Series reactance of the load circuit Yes No

Rp(k) Parallel resistance of the load circuit Yes No

Xp(k) Parallel reactance of the load circuit Yes No

Uhdf(k) Harmonic voltage distortion factor Yes No

Ihdf(k) Harmonic current distortion factor Yes No

Phdf(k) Harmonic active power distortion factor Yes No

Uthd Total harmonic voltage distortion Yes No

Ithd Total harmonic current distortion Yes No

Pthd Total harmonic active power distortion Yes No

Uthf Telephone harmonic factor of the

voltage

Ithf Telephone harmonic factor of the

current

Utif Telephone influence factor of the

voltage

Itif Telephone influence factor of the

current

hvf Harmonic voltage factor Yes No

hcf Harmonic current factor Yes No

K−factor K factor Yes No

1

ΦUi−Uj

ΦUi−Uk

ΦUi−Ii

ΦUj−Ij

ΦUk−Ik

Phase difference between the

fundamental voltage of element i,

Ui(1), and the fundamental voltage of

element j, Uj(1).

1

Phase difference between Ui(1) and

the fundamental voltage of element k,

Uk(1)

1

Phase difference between Ui(1) and

the fundamental current of element i,

Ii(1)

1

Phase difference between Uj(1) and

the fundamental current of element j,

Ij(1)

1

Phase difference between Uk(1) and

the fundamental current of element k,

Ik(1)

1 i, j, and k are input element numbers. For example, when the number of input elements in wiring unit ΣA is

six and the wiring system of elements 1, 2, and 3 is three phase, four wire, i is 1, j is 2, and k is 3. ΦUi – Uj

represents ΦU1 – U2, the difference between the fundamental voltage signal of element 1, U1(1), and the

fundamental voltage signal of element 2, U2(1). In the same way ΦUi – Uk, ΦUi – Ii, ΦUj – Ij, and ΦUk−Ik

represent to ΦU1 – U3, ΦU1 – I1, ΦU2 – I2, and ΦU3 – I3, respectively.

2

Setting i to an input element, is the same as setting k to 1 in Φ

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

No Yes

No Yes

2

Yes

No Yes

No Yes

Yes

(k).

IM WT1801-01EN

1-3

Page 11

1-4

IM WT1801-01EN

1 Items That This Instrument Can Measure

Harmonic Measurement Function Orders

The harmonic orders that you can specify are indicated below.

Input Element Harmonic Measurement Functions

Measurement

Function

U( ) Yes Yes Yes 2 to 500

I( ) Yes Yes Yes 2 to 500

P( ) Yes Yes Yes 2 to 500

S( ) Yes Yes Yes 2 to 500

Q( ) Yes Fixed at 0 Yes 2 to 500

λ( ) Yes Yes Yes 2 to 500

Φ( ) Yes No Yes 2 to 500

ΦU( ) No No No 2 to 500

ΦI( ) No No No 2 to 500

Z( ) No Yes Yes 2 to 100

Rs( ) No Yes Yes 2 to 100

Xs( ) No Yes Yes 2 to 100

Rp( ) No Yes Yes 2 to 100

Xp( ) No Yes Yes 2 to 100

Uhdf( ) No Yes Yes 2 to 500

Ihdf( ) No Yes Yes 2 to 500

Phdf( ) No Yes Yes 2 to 500

Uthd Yes No No No

Ithd Yes No No No

Pthd Yes No No No

Uthf Yes No No No

Ithf Yes No No No

Utif Yes No No No

Itif Yes No No No

hvf Yes No No No

hcf Yes No No No

K-factor Yes No No No

Functions with parentheses will produce different values depending on which of the following is contained in their

parentheses.

• T

otal: Total value (The total value of all harmonic components from the minimum order to N.

about how the value is determined, see appendix 1 in the getting started guide, IM WT1801-03EN.)

• 0(DC):

DC value

• 1: Fundamental harmonic value

• k: The value of any order from 2 to N.

Characters or Numbers in Parentheses

Total 0 (DC) 1 k

*

*

For information

* N is the maximum measurable order. The maximum measurable harmonic order is the smallest of the three

orders listed below.

• The specified maximum measurable harmonic order

•

The value determined automatically according to the PLL source frequency (see section 6.4 in the getting

started guide, IM WT1801-03EN)

• When the data update interval is 50 ms, the maximum measur

able harmonic order is 100.

Page 12

Click here.

1 Items That This Instrument Can Measure

Wiring Unit Harmonic Measurement Functions (Σ functions)

Measurement

Function

UΣ( ) Yes Yes

IΣ( ) Yes Yes

PΣ( ) Yes Yes

SΣ( ) Yes Yes

QΣ( ) Yes Yes

λΣ( ) Yes Yes

Characters or Numbers

in Parentheses

Total 1

Functions with parentheses will produce different values depending on which of the following is contained in their

parentheses.

• T

otal: Total value

• 1: Fundamental harmonic value

Delta Computation Functions (Option)

Function Description

U1

Δ

U2

Δ

U3

Δ

ΔUΣ

I

Δ

P1

Δ

P2

Δ

P3

Δ

ΔPΣ

For details about delta computation functions, see “Delta Computation (Δ Measure; optional).”

The values returned by the delta computation

functions vary depending on the specified delta

computation type.

Motor Evaluation Functions (Option)

Function Description

Speed Motor rotating speed

Torque Motor torque

SyncSp Synchronous speed

Slip Slip (%)

Pm Mechanical output of the motor (mechanical power)

EaU1 to 6

EaI1 to 6

*

Electrical angle: Phase angles of U1 to I6 with the

*

falling edge of the signal received through the Z

terminal of the motor evaluation function as the

reference.

* On models with the harmonic measurement option or the simultaneous dual harmonic measurement

option.

Auxiliary Input Measurement Functions (Option)

Function Description

Aux1 Auxiliary input 1

Aux2 Auxiliary input 2

High Speed Data Capturing Measurement Functios (Option)

• For the U and I of each input element and wiring unit: Select rms, mean, dc, or r-mean.

• The P of each input element and wiring unit

• Motor evaluation function (option) speed, torque, and Pm

• Auxiliary inputs (option) Aux1 and Aux2

• The maximum and minimum values of the above measurement functions

IM WT1801-01EN

1-5

Page 13

Click here.

Click here.

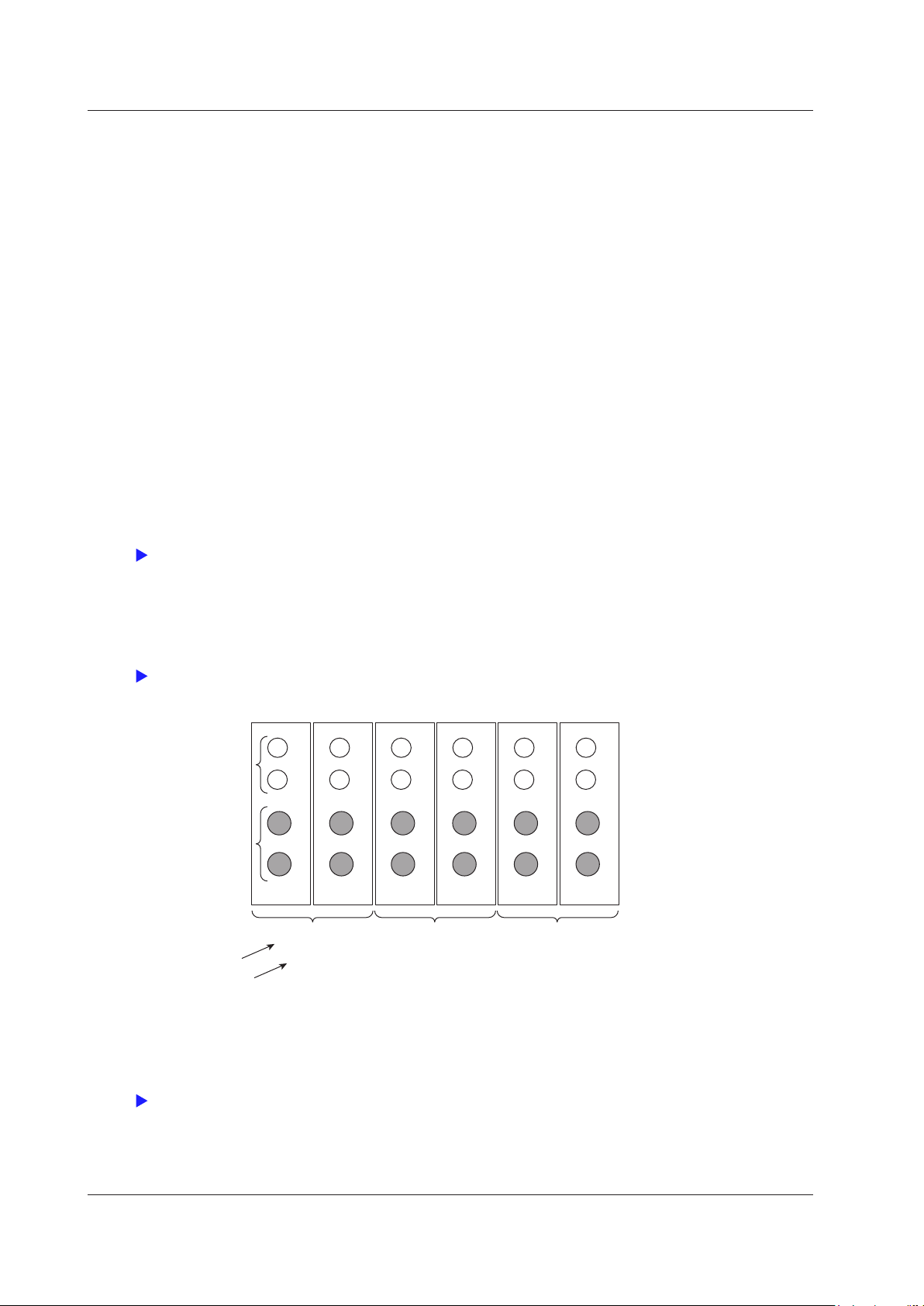

Three-phase,

three-wire

Σ

A

Element

1

Element2Element3Element

4

Three-phase,

three-wire

Σ

B

Wiring system

Wiring unit

Voltage input

Current input

Element5Element

6

Three-phase,

three-wire

Σ

C

Click here.

1 Items That This Instrument Can Measure

What Is a Measurement Function?

Measurement Function

The physical values (such as rms voltage, average current, power, and phase difference) that the WT1800

measures and displays are called measurement functions. Each measurement function is displayed using

symbols that correspond to its physical value. For example, “Urms” corresponds to the true rms voltage.

Element

Element refers to a set of input terminals that can receive a single phase of voltage and current to be measured.

The WT1800 can contain up to six elements, numbered from 1 to 6. An element number is appended to the

measurement function symbol for the measured data that the WT1800 displays, so that you can tell which data

belongs to which element. For example, “Urms1” corresponds to the true rms voltage of element 1.

Wiring System

You can specify five wiring systems on the WT1800 to measure the power of various single-phase and three-

phase power transmission systems: single-phase, two-wire; single-phase, three-wire; three-phase, three-wire;

three-phase, four-wire; and three-phase, three-wire with three-voltage, three-current method.

Wiring Unit

The wiring unit is a set of two or three input elements of the same wiring system that are grouped to measure

three-phase power. There can be up to three wiring units: ΣA, ΣB, and ΣC.

Σ Functions

The measurement function of a wiring unit is called a Σ function.

For example, “UrmsΣA” corresponds to the average of the voltages of the input elements that are assigned to

the wiring unit ΣA. The average value represents the true rms value.

Measurement Period

For information about the measurement period for computing measurement functions, see “Measurement Period

(SYNC SOURCE).”

1-6

IM WT1801-01EN

Page 14

2 Fundamental Measurement Conditions

Wiring System Settings (WIRING)

The wiring system settings are listed below.

• Wiring system (Wiring)

• Efficiency equation (η Formula)

• Independent input element configuration (Element Independent)

• Delta computation (Δ Measure; option)

Wiring System (Wiring)

There are five wiring systems available on the WT1800. The selectable wiring systems vary depending on the

number of installed input elements.

• 1P2W

• 1P3W: Single-phase, three-wire system

• 3P3W: Three-phase, three-wire system

• 3P4W: Three-phase, four-wire system

• 3P3W(3V3A): Three-voltage, three-current method

Wiring Unit

Wiring units are sets of two or three input elements of the same wiring system that are grouped together. You

can define up to three wiring units: ΣA, ΣB, and ΣC.

• When there is one wiring unit, that unit is ΣA.

• When there are two wiring units, those units are ΣA and ΣB. You cannot make ΣC one of the first two wiring

• When there are three wiring units, those units are ΣA, ΣB, and

• When there are multiple wiring units, element numbers are assigned to them in ascending order. The element

• Wiring units are composed of input elements that are next to e

• A

: Single-phase, two-wire system

You cannot make ΣB or ΣC the first wiring unit.

units.

ΣC.

numbers are assigned to ΣA, ΣB, and then ΣC.

ach other. Wiring units cannot consist of input

elements that are not next to each other.

wiring unit must either be composed of only 50 A input elements or only 5 A input elements. Wiring units

cannot consist of different types of input elements.

Σ Functions

The measurement function of a wiring unit is called a Σ function.

For example, “UrmsΣA” corresponds to the average of the voltages of the input elements that are assigned to

the wiring unit ΣA. The average value represents the true rms value.

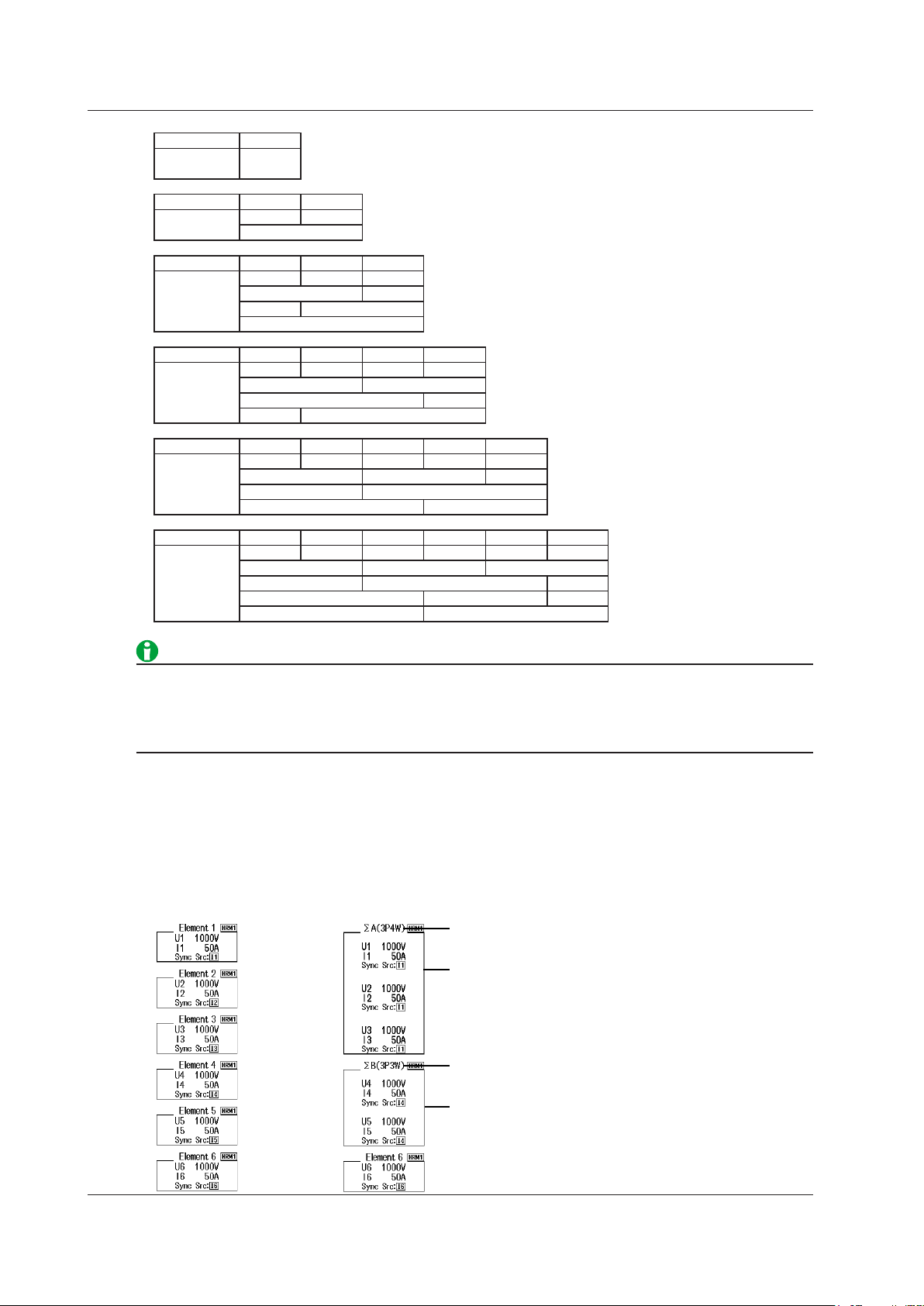

Wiring System Combinations

The following tables provide examples of the wiring system combinations that you can use and the input

elements that you can assign to wiring system ΣA, ΣB, or ΣC depending on the number of installed input

elements. In addition to the combinations indicated in the tables below, you can also configure any pattern that

meets the conditions for wiring units described above.

For details about the relationship between wiring systems and how the values of the measurement functions are

determined, see appendix 1 in the getting started guide, IM WT1801-03EN.

IM WT1801-01EN

2-1

Page 15

2-2

IM WT1801-01EN

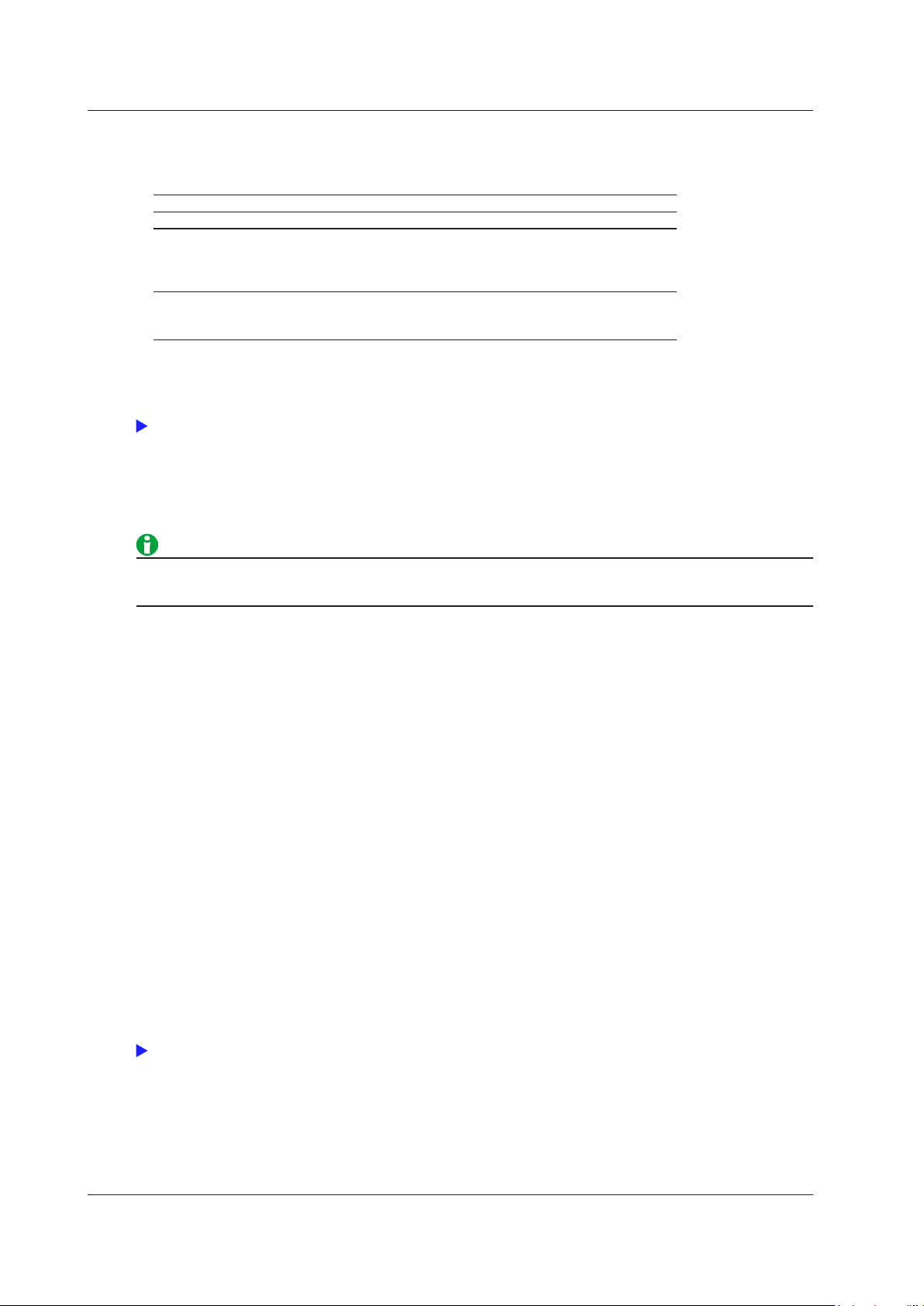

When the wiring systems

of elements 1 to 6 are set

to single-phase, two-wire

When the wiring system of elements 1, 2,

and 3 is set to three-phase, four-wire and the

wiring system of elements 4 and 5 is set to

three-phase, three-wire

Wiring unit and system

The elements that compose

the wiring unit are shown

in the frame.

Wiring unit and system

The elements that compose

the wiring unit are shown

in the frame.

2 Fundamental Measurement Conditions

Input Element 1

Wiring system

combination

Input Element 1 2

Wiring system

combination

Input Element 1 2 3

Wiring system

combination

Input Element 1 2 3 4

Wiring system

combination

Input Element 1 2 3 4 5

Wiring system

combination

Input Element 1 2 3 4 5 6

Wiring system

combination

1P2W

1P2W 1P2W

1P3W or 3P3W:ΣA

1P2W 1P2W 1P2W

1P3W or 3P3W:ΣA 1P2W

1P2W 1P3W or 3P3W:ΣA

3P4W or 3P3W:ΣA

1P2W 1P2W 1P2W 1P2W

1P3W or 3P3W:ΣA 1P3W or 3P3W:ΣB

3P4W or 3P3W:ΣA 1P2W

1P2W 3P4W or 3P3W:ΣA

1P2W 1P2W 1P2W 1P2W 1P2W

1P3W or 3P3W:ΣA 1P3W or 3P3W:ΣB 1P2W

1P3W or 3P3W:ΣA 3P4W or 3P3W(3V3A):ΣB

3P4W or 3P3W:ΣA 1P3W or 3P3W:ΣB

1P2W 1P2W 1P2W 1P2W 1P2W 1P2W

1P3W or 3P3W:ΣA 1P3W or 3P3W:ΣB 1P3W or 3P3W:ΣC

1P3W or 3P3W:ΣA 3P4W or 3P3W(3V3A):ΣB 1P2W

3P4W or 3P3W:ΣA 1P3W or 3P3W:ΣB 1P2W

3P4W or 3P3W:ΣA 3P4W or 3P3W(3V3A):ΣB

Select the wiring system to match the actual wiring of the circuit under measurement. The method in which

the Σ functions (wiring unit measurement functions) are determined varies depending on the wiring system. If

the selected wiring system does not match the wiring of the actual circuit, measurements and computation will

not be correct.

Wiring System Display

The wiring system configuration is displayed on the right side of the screen. Because it is displayed behind the

menu, to view it, you need to press the ESC key to hide the menu. The figure below shows wiring system display

examples for a model with six input elements installed.

Page 16

Click here.

2 Fundamental Measurement Conditions

Settings of Elements Grouped in a Wiring Unit

If independent input element configuration is off and a wiring system other than 1P2W is selected when the

measurement range, valid measurement range, or valid synchronization source settings of each input element

are different, these settings are changed in the manner described below:

•

The measurement range is set to the greatest of the measurement ranges of the input elements assigned to

the same wiring unit. The external current sensor input range has precedence over the direct input current

range.

• The auto range on/of

f settings are changed to match the setting of the input element whose measurement

range is highest. If multiple input elements are set to a common highest measurement range, the setting of

the input element with the smallest input element number takes precedence.

• In the valid measurement range settings, all measurement ran

ges are enabled (selected).

• The synchronization source for a wiring unit is set to the input element whose number is the smallest of the

elements in the unit.

At the same time that you press ELEMENT to select the element that you want to set the voltage or current

range of, the indicators for the input elements that have been assigned to the same wiring unit illuminate.

Wiring System during High Speed Data Capturing

IM WT1801-01EN

2-3

Page 17

2-4

IM WT1801-01EN

Converter

(inverter, etc.)

Input power: P1

Output power: P2

2 Fundamental Measurement Conditions

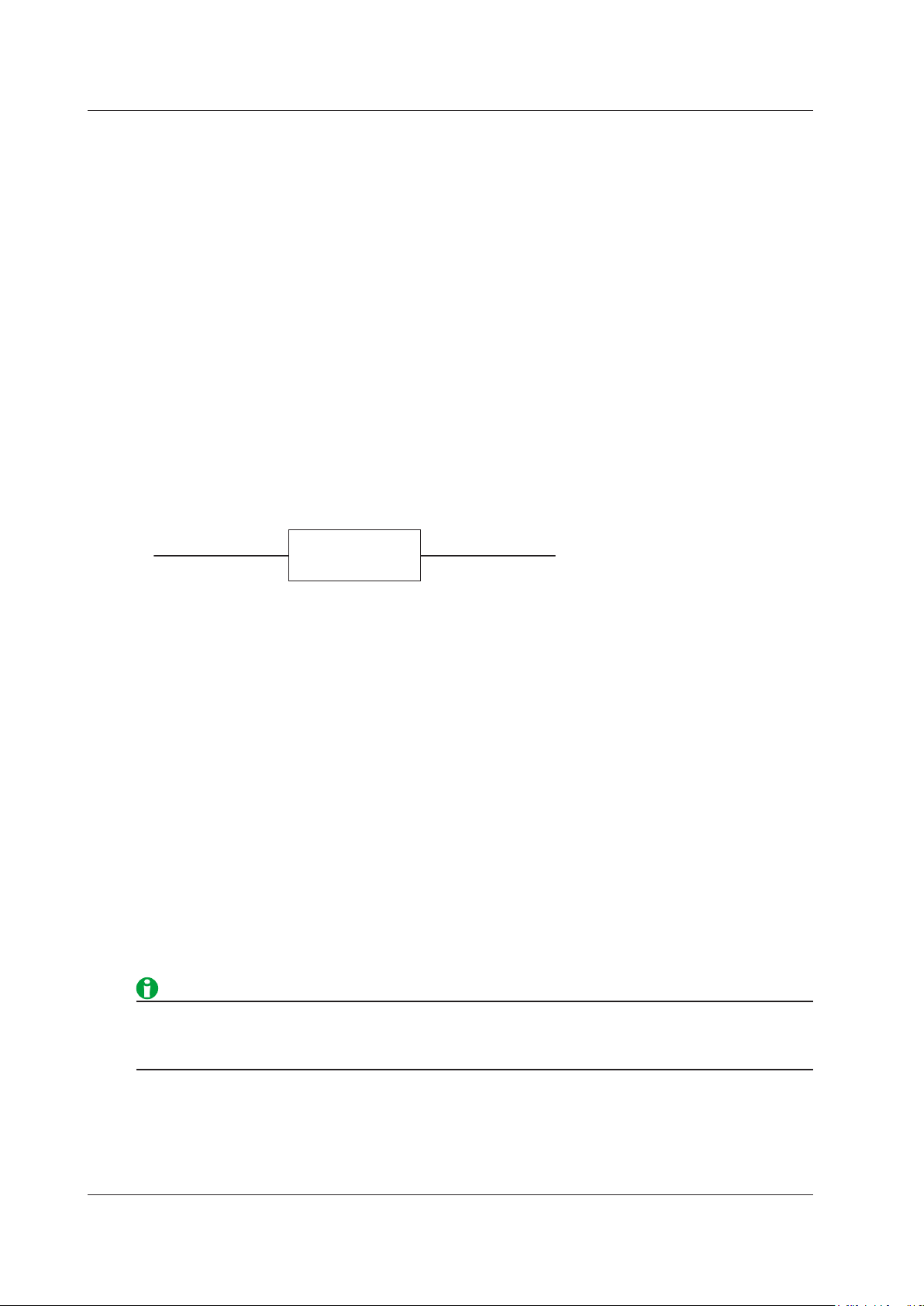

Efficiency Equation (η Formula)

You can create an efficiency equation by combining measurement function symbols. The WT1800 can determine

the energy conversion efficiency of the device using the numeric values of the measurement functions.

η1 to η4

You can create four efficiency equations (η1 to η4), using the following measurement functions as operands.

• The active powers of each element (P1 to P6)

•

The active powers of the Σ functions (PΣA to PΣC)

• The motor output (Pm; on models with the motor evaluation option)

• Udef1 and Udef2

Udef1 and Udef2

To add active powers and motor output and use them in η1 to η4, use Udef1 and Udef2. You can add up to four

operands consisting of the measurement functions listed above.

Equation Examples

•

Efficiency of a Single-Phase, T

Input: Power of element 1 (P1)

Output: Power of element 2 (P2)

Efficiency equation: P2/P1 × 100 (%)

wo-Wire Input/Single-Phase, Two-Wire Output Device

• Efficiency of a Single-Phase, Two-Wire Input/Three-Phase, Three-Wire Output Device

Input: Power of element 1 (P1)

Output: Σ power of elements 2 and 3 (PΣA)

Efficiency equation: PΣA/P1 × 100 (%)

• Efficiency of a Three-Phase, Three-Wire Input/Three-Phase, Three-Wire Output Device

Input: Σ power of elements 1 and 2 (PΣA)

Output: Σ power of elements 3 and 4 (PΣB)

Efficiency equation: PΣB/PΣA × 100 (%)

• Efficiency of a Motor with a Single-Phase, Two-Wire Input

Input: Power of element 1 (P1)

Output: Motor output (Pm)

Efficiency equation: Pm/P1 × 100 (%)

• Efficiency of a Motor with a Three-Phase, Three-Wire Input

Input: Σ power of elements 1 and 2 (PΣA)

Output: Motor output (Pm)

Efficiency equation: Pm/PΣA × 100 (%)

To correctly compute the efficiency, set the power coefficients of all elements so that all power units used in

the computation are the same. For example, the efficiency cannot be computed correctly if elements or wiring

units used in the computation have different power units, such as W (watt) and J (joule).

Page 18

2 Fundamental Measurement Conditions

Independent Input Element Configuration (Element Independent)

In the wiring system settings, you can select whether to set the measurement range or sync source of input

elements in the same wiring unit collectively or independently.

Turning Independent Input Element Configuration On or Off

For example, assume that the wiring system on a model with three input elements is set as follows:

Input elements 1 to 3: Three-phase, four-wire system (3P4W). Input elements 1 to 3 are assigned to a single

wiring unit ΣA.

•

ON

The measurement range and sync source can be set indepen

wiring unit.

• OFF

The

measurement range and sync source of input elements 1 to 3 are set to the same setting.

convenient because when you are measuring a three-phase device, you can set the range and sync source

settings of all input elements included in a wiring unit simultaneously.

Settings That Are Shared between Input Elements When Independent Input Element Configuration Is

Turned Off

• Measurement range (including auto range on or of

• Direct current input or external current sensor input

• Valid measurement range

• Synchronization source

• Input element group for harmonic measurement (applies to models with the simultaneous dual harmonic

measurement option).

f)

dently for each input element included in a

This is

Settings That Can Be Configured Independently Even When Independent Input Element Configuration Is

Turned Off

• External current sensor conversion ratio (option)

•

Scaling values (VT ratio, CT ratio, and power coefficient)

• Input filters (line filter and frequency filter)

These settings can be configured independently for each input element regardless of whether independent input

element configuration is turned on or off.

How Settings Are Aligned When You Turn Independent Input Element Configuration from On to Off

When independent input element configuration is switched from on to off, the measurement range, valid

measurement range, and sync source settings of each input element in a wiring unit (ΣA, ΣB, or ΣC) are

changed as follows:

•

The measurement range is set to the greatest of the measurem

the same wiring unit. The external current sensor input range has precedence over the direct input current

range.

• The auto range on/of

range is highest. If multiple input elements are set to a common highest measurement range, the setting of

the input element with the smallest input element number takes precedence.

• In the valid measurement range settings, all measurement ran

• The synchronization source for a wiring unit is set to the input element whose number is the smallest of the

elements in the unit.

f settings are changed to match the setting of the input element whose measurement

ent ranges of the input elements assigned to

ges are enabled (selected).

IM WT1801-01EN

2-5

Page 19

2-6

IM WT1801-01EN

Click here.

T

R

ST

R

S

±

±

±

±

I

R

S

T

U

U

I

N

I1

I2

U2

U1

Urs

It

Click here.

2 Fundamental Measurement Conditions

Delta Computation (Δ Measure; option)

The sum or difference of the instantaneous voltage or current values (sampled data) between the elements in

a wiring unit can be used to determine various types of data such as the differential voltage and phase voltage.

This operation is called delta computation.

Types of Delta Computation (ΔMeasure Type)

The following types of delta computation are available:

•

ferential voltage and differential current (Difference)

Dif

• Line voltage and phase current (3P3W > 3V3A)

• Star-delta transformation (Star>Delta)

• Delta-star transformation (Delta>Star)

The delta computation types that you can select vary as indicated below according to the wiring system.

Wiring System Delta Computation Type

1P3W Difference, 3P3W>3V3A

3P3W Difference, 3P3W>3V3A

3P4W Star>Delta

3P3W(3V3A) Delta>Star

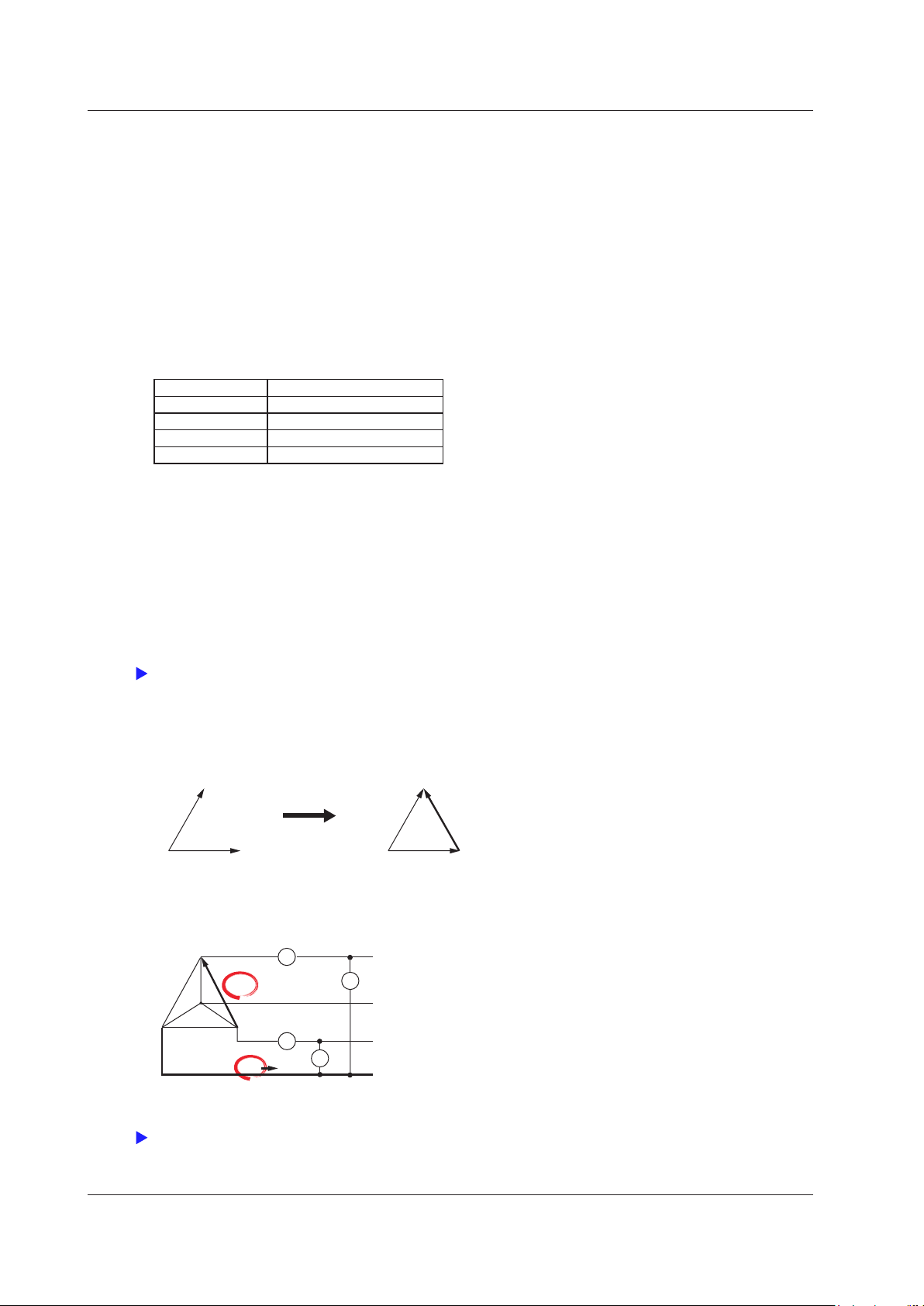

• Differential Voltage and Differential Current (Difference)

The differential voltage and differential current between two elements can be computed on a single-phase,

three-wire system or on a three-phase, three-wire system.

When you perform delta computation on wiring unit ΣA, the available measurement functions are as follows.

ΔU1rms[Udif

fA], ΔU1mn[UdiffA], ΔU1dc[UdiffA], ΔU1rmn[UdiffA], ΔU1ac[UdiffA]

ΔIrms[IdiffA], ΔImn[IdiffA], ΔIdc[IdiffA], ΔIrmn[IdiffA], ΔIac[IdiffA]

* In the measurement functions,

rms, mn(mean), dc, rmn(r-mean), and ac are the delta computation modes.

A indicates the wiring unit.

• Line Voltage and Phase Current (3P3W > 3V3A)

You can compute unmeasured line voltages and phase currents by converting the data of a three-phase,

three-wire system to the data of the three-voltage, three-current method (3V3A).

When you perform delta computation on wiring unit ΣA, the available measurement functions are as follows.

ΔU1rms[UrsA], ΔU1mn[UrsA], ΔU1dc[UrsA], ΔU1rmn[UrsA], ΔU1ac[UrsA]

ΔIrms[ItA], ΔImn[ItA], ΔIdc[ItA], ΔIrmn[ItA], ΔIac[ItA]

* In the measurement functions, rms, mn(mean), dc, rmn(r-mean), and ac are the delta computation modes.

A indicates the wiring unit.

Page 20

R

ST

R

ST

I

I

R

S

T

U

U

U

I

N

I1

I2

I3

U1

U2U3

Urs

Utr

Ust

In

±

±

±±

±

±

Click here.

R

ST

R

ST

2 Fundamental Measurement Conditions

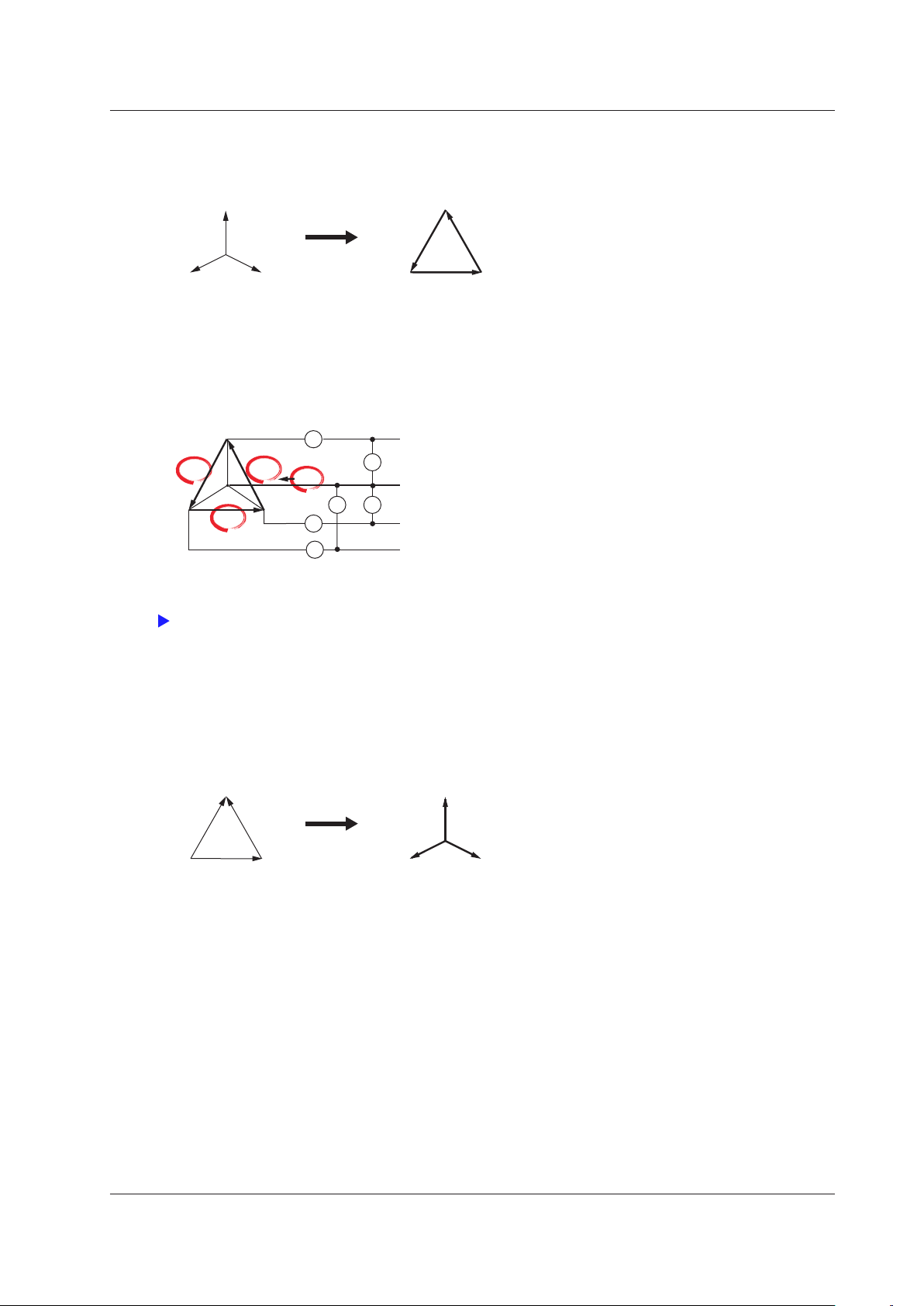

• Star-delta transformation (Star>Delta)

You can use the data from a three-phase, four-wire system to compute the data of a delta connection from the

data of a star connection.

When you perform delta computation on wiring unit ΣA, the available measurement functions are as follows.

ΔU1rms[UrsA], ΔU1mn[UrsA], ΔU1dc[UrsA], ΔU1rmn[UrsA], ΔU1ac[UrsA]

ΔU2rms[UstA], ΔU2mn[UstA], ΔU2dc[UstA], ΔU2rmn[UstA], ΔU2ac[UstA]

ΔU3rms[UtrA], ΔU3mn[UtrA], ΔU3dc[UtrA], ΔU3rmn[UtrA], ΔU3ac[UtrA]

ΔUΣrms[UΣA], ΔUΣmn[UΣA], ΔUΣdc[UΣA], ΔUΣrmn[UΣA], ΔUΣac[UΣA]

ΔIrms[InA], ΔImn[InA], ΔIdc[InA], ΔIrmn[InA], ΔIac[InA]

* In the measurement functions, rms, mn(mean), dc, rmn(r-mean), and ac are the delta computation modes.

A indicates the wiring unit.

• Delta-star transformation (Delta>Star)

Using the data from a three-phase, three-wire system that uses a three-voltage, three-current method, you

can compute the data of a star connection from the data of a delta connection. This function is useful when

you wish to observe the phase voltage of an object that has no neutral line, such as a motor. The center

N of the star connection is computed as the center of the delta connection. If the actual center of the star

connection does not match the center of the delta connection, an error results.

When you perform delta computation on wiring unit ΣA, the available measurement functions are as follows.

ΔU1rms[UrA], ΔU1mn[UrA], ΔU1dc[UrA], ΔU1rmn[UrA], ΔU1ac[UrA]

ΔU2rms[UsA], ΔU2mn[UsA],

ΔU3rms[UtA], ΔU3mn[UtA],

ΔU

Σrms[UΣA], ΔUΣmn[UΣA], ΔUΣdc[UΣA], ΔUΣrmn[UΣA], ΔUΣac[UΣA]

ΔIrms[InA], ΔImn[InA],

ΔU2dc[UsA], ΔU2rmn[UsA], ΔU2ac[UsA]

ΔU3dc[UtA], ΔU3rmn[UtA], ΔU3ac[UtA]

ΔIdc[InA], ΔIrmn[InA], ΔIac[InA]

ΔP1[PrA]

ΔP2[PsA]

ΔP3[PtA]

ΔPΣ[PΣA]

IM WT1801-01EN

2-7

Page 21

2-8

IM WT1801-01EN

I

I

R

S

T

UU

U

I

N

I1

I2

I3

U3U2U1

Ur

Ut

Us

In

±

± ±

±

±

±

Click here.

Click here.

2 Fundamental Measurement Conditions

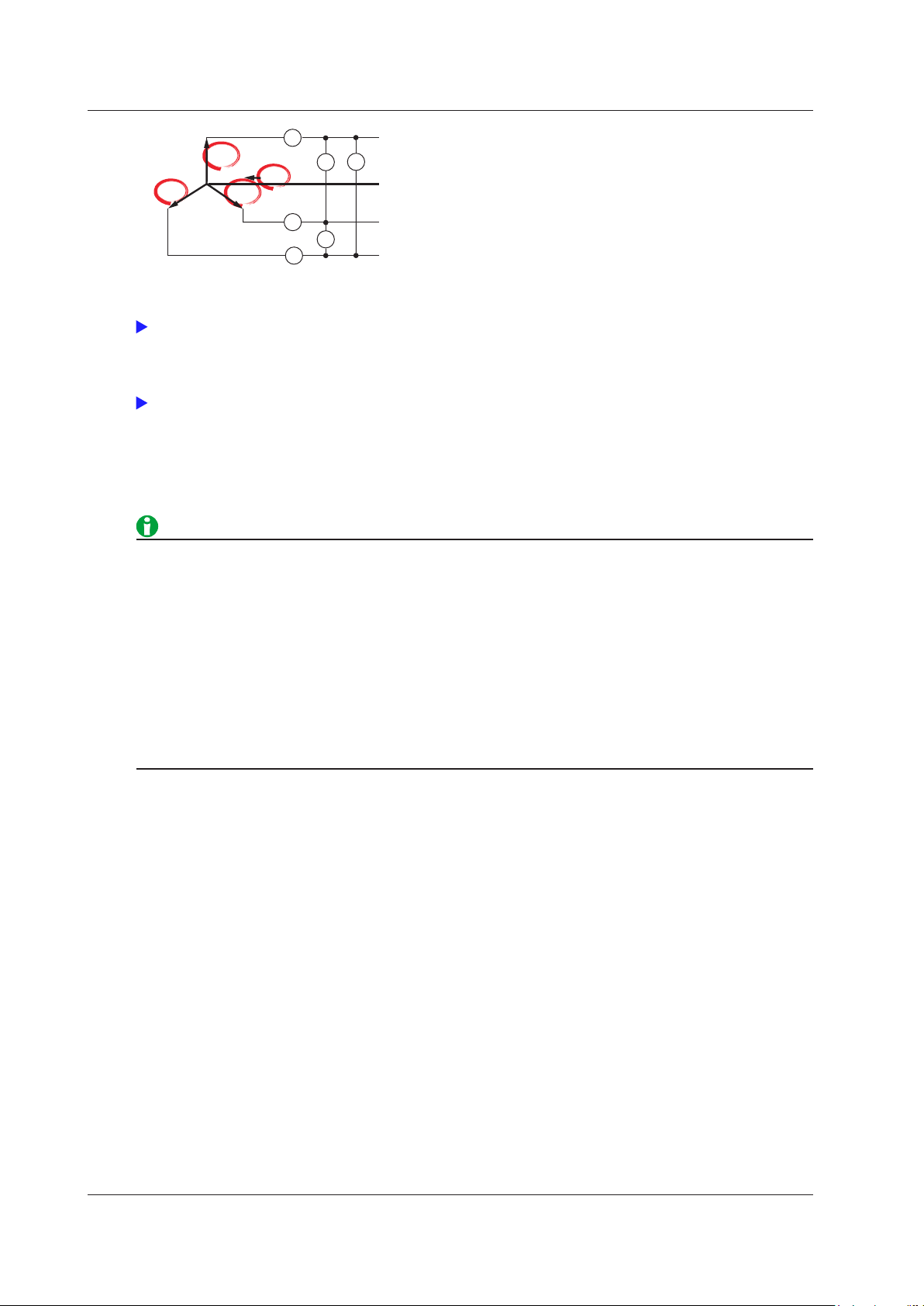

* In the measurement functions, rms, mn(mean), dc, rmn(r-mean), and ac are the delta computation modes.

A indicates the wiring unit.

For information about equations, see appendix 1 in the getting started guide, IM WT1801-03EN.

For information about the measurement period, see “Measurement Period.”

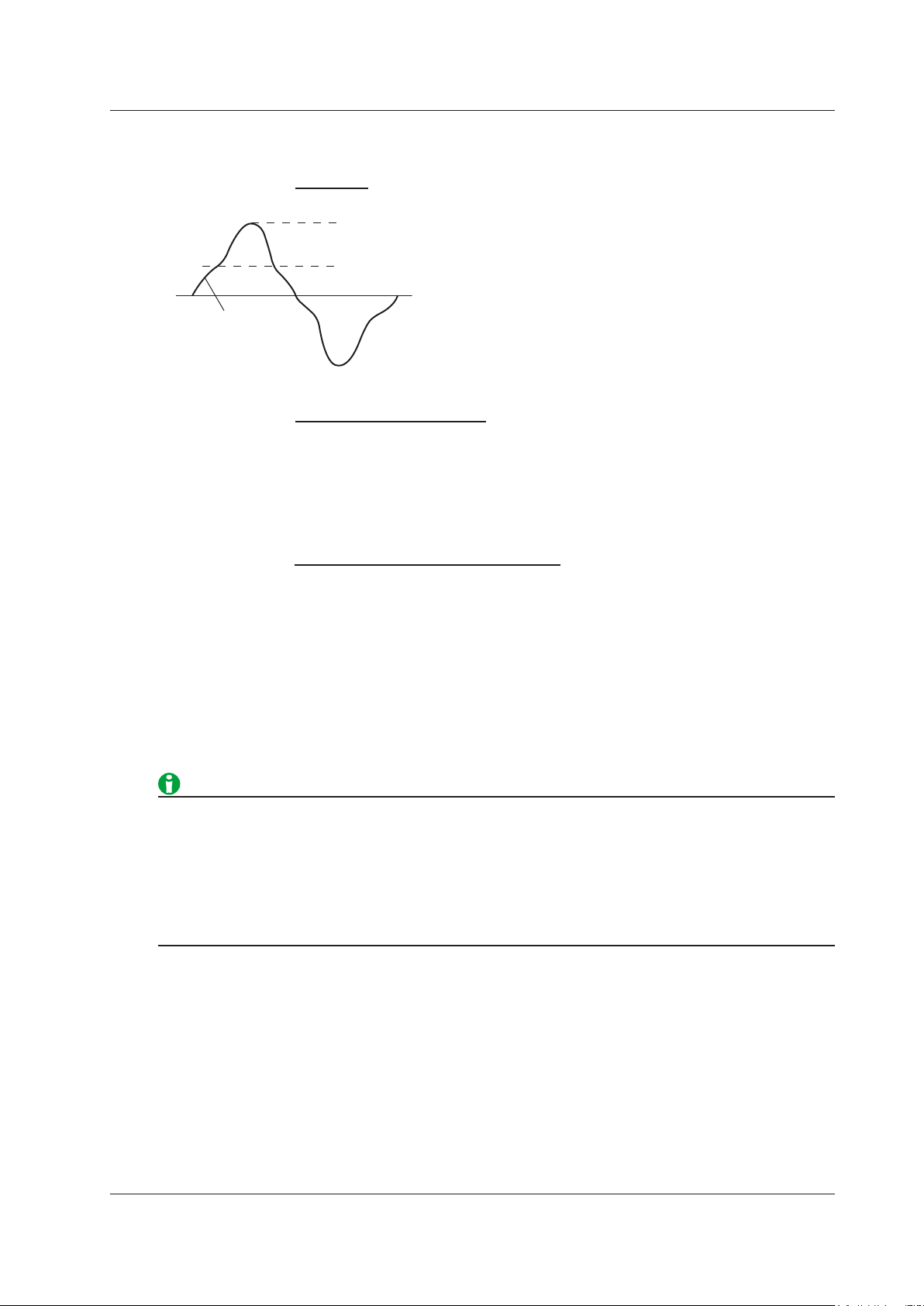

Delta Computation Modes (ΔMeasure Mode)

You can select the voltage or current mode to be displayed as delta computation values from the following:

rms, mean, dc, r−mean, ac

• We recommend that you set the measurement range and scaling (VT/CT ratio and coefficients) of the

elements that are undergoing delta computation as closely as possible. Using different measurement

ranges or scaling causes the measurement resolutions of the sampled data to be different. This results in

errors.

•

The numbers (1, 2, and 3) that are attached to delta computat

ion measurement function symbols have no

relation to the element numbers. The computation of all delta measurement functions, from ΔU1 to ΔPΣ,

varies depending on the wiring system and the delta computation type. For details, see appendix 1 in the

getting started guide, IM WT1801-03EN.

•

When only one element is installed in the WT1800, this feature

cannot be used, and its settings do not

appear.

• Delta computation cannot be performed on a single-phase, tw

o-wire (1P2W) wiring system.

Selecting an Element Whose Measurement Range You Want to Specify (ELEMENT)

Select an element whose measurement range you want to specify. Press ELEMENT to switch in order between

the indicators of the installed elements. When independent input element configuration is off, the selected

elements will switch by wiring unit, according to the wiring system.

Page 22

Click here.

2 Fundamental Measurement Conditions

Selecting All Input Elements (ALL)

At the same time, you can select the currently selected element and all elements that meet the following

conditions. You can set their voltage and current ranges at the same time.

Conditions for Simultaneous Element Selection

• Only input elements of the same type (50

• Only input elements whose valid measurement range settings are the same can be selected.

Initial Values for Simultaneously Selected Elements

The voltage range, current range, and auto range on/off settings of the element that was selected before you

selected the other elements are copied to all the other selected elements.

After you have selected all the input elements, changes that you make to the voltage range, current range, and

auto range on/off settings affect all the selected input elements.

To disable simultaneous selection and specify independent input element settings, press ELEMENT.

A input or 5 A input) can be selected.

Voltage Range (RANGE UP/DOWN (V))

The voltage range can be fixed (when auto range is set to off) or determined automatically (when auto range is

set to on).

Fixed Ranges

When the voltage range is fixed, you can select a range from the available options. The selected voltage range

does not change even if the amplitude of the input signal changes. Set the range in reference to the rms value of

the input signal.

When the Crest Factor Is Set to CF3

You can select from 1.5 V, 3 V, 6 V, 10 V, 15 V, 30 V, 60 V, 100 V, 150 V, 300 V, 600 V, and 1000 V.

When the Crest Factor Is Set to CF6

You can select from 0.75 V, 1.5 V, 3 V, 5 V, 7.5 V, 15 V, 30 V, 50 V, 75 V, 150 V, 300 V, and 500 V.

Auto Range

• Set the range in reference to the rms value of the input signal. For example, if you are applying a 100-Vrms

sinusoidal signal, set the range to 100 V.

• When measuring a signal other than a sine wave (such as a d

measurements by selecting the smallest measurement range that does not produce any of the conditions

below.

• The input peak over-range indicator at the top center of the screen illuminates or blinks in red.

• The measured values of the voltage and current are indicated as being overload values (“-OL-”).

• The peak over-range indicator may not illuminate or blink in the following cases.

• If the pulse width is narrow, and the peak value of the waveform cannot be acquired at the sampling rate

of the WT1800 (approximately 2 Ms/S).

• If the high frequency components of the pulse waveform atten

of the WT1800 measurement circuit, causing the waveform peak value to be less than the peak overrange detection level.

• When a signal with the peak which becomes more than about 10 times of the range is input, it takes about

1 second to change the range.

• When the secondary output of a VT

the voltage range according to the maximum value of the VT output. Then, use the scaling feature to set

the VT ratio.

(voltage transformer) is being applied to the voltage input terminal, set

istorted wave), you can obtain accurate

uate due to the bandwidth limitations

IM WT1801-01EN

2-9

Page 23

2-10

IM WT1801-01EN

Click here.

2 Fundamental Measurement Conditions

• To display a list of the range settings of all input elements, see “Displaying the Setup Parameter List.” You

can change measurement ranges from the list.

Auto Voltage Range (AUTO (V))

When you press AUTO, the AUTO key illuminates, and the range is set automatically. The measurement range is

switched automatically depending on the amplitude of the input signal as described below. The different ranges

used in the auto range are the same as those available for the fixed range.

Range Increase

The measurement range is increased when any of the following conditions is met.

• The data of measurement function Urms or Irms exceeds 110% of the measurement range.

• The crest factor is set to CF3 and the data of Upk* or Ipk* exceeds 330% of the current measurement range.

• The crest factor is set to CF6 and the data of Upk* or Ipk* exceeds 660% of the current measurement range.

• If all the installed input elements are selected (all the element indicators are illuminated), the measurement

range is increased on all input elements when any of the elements meets the range-increase conditions

described above.

•

When a wiring unit is configured, the measurement range is in

when any of the elements in the unit meets the range-increase conditions described above.

creased on all input elements in the wiring unit

Range Decrease

The measurement range is decreased when all the following conditions are met.

• The data of Urms or Irms is less than or equal to 30% of the measurement range.

• The data of Urms or Irms is less than or equal to 105% of the next lower range.

• The crest factor is set to CF3 and the data of Upk* or Ipk* is less than or equal to 300% of the next lower

range.

• The crest factor is set to CF6 and the data of Upk* or Ipk* is less than or equal to 600% of the next lower

range.

* Even if the NULL

• If all the installed input elements are selected (all the element indicators are illuminated) and meet the rangedecrease conditions described above, all their measurement ranges are decreased.

• When a wiring unit is configured and all the elements in the unit meet the range-increase conditions described

above, all their measurement ranges are increased.

• If you disable a measurement range in the valid measurement range settings, that measurement range is

skipped, and the auto range feature operates using only the valid measurement ranges.

• When non-periodic pulse waveforms are applied, the range m

the fixed range setting.

feature is on, the values are determined as if it were off.

ay not remain constant. If this happens, use

Page 24

Click here.

Click here.

2 Fundamental Measurement Conditions

Current Range (RANGE UP/DOWN (A))

The current range can be fixed (when auto range is set to off) or determined automatically (when auto range is

set to on).

Fixed Ranges

When the current range is fixed, you can select a range from the available options. The selected current range

does not change even if the amplitude of the input signal changes. Set the range in reference to the rms value of

the input signal.

For 5 A Input Elements

• When the Crest Factor

You can select from 10 mA, 20 mA, 50 mA, 100 mA, 200 mA,

• When the Crest Factor Is Set to CF6

You can select from 5 mA, 10 mA, 25 mA, 50 mA, 100 mA, 250 mA, 500 mA, 1 A, and 2.5 A.

For 50 A Input Elements

• When the Crest Factor Is Set to CF3

ou can select from 1 A, 2 A, 5 A, 10 A, 20 A, and 50 A.

Y

• When the Crest Factor Is Set to CF6

You can select from 500 mA, 1 A, 2.5 A, 5 A, 10 A, and 25 A.

Is Set to CF3

500 mA, 1 A, 2 A, and 5 A.

Auto Range

This is the same as the auto range feature for voltage.

• When the secondary output of a CT (current transformer) or a clamp-type current sensor that outputs

current is being applied to the current input terminal, set the current range according to the maximum value

of the CT or current sensor output. Then, use the scaling feature to set the CT ratio or the conversion ratio

of the clamp-type current sensor that outputs current.

Auto Current Range (AUTO (A))

This is the same as the auto range feature for voltage.

IM WT1801-01EN

2-11

Page 25

2-12

IM WT1801-01EN

Click here.

Click here.

2 Fundamental Measurement Conditions

Power Range

The measurement ranges (power ranges) of active power (P), apparent power (S), and reactive power (Q) are

as follows:

Wiring System Power Range

1P2W (single-phase, two-wire system) Current range × voltage range

1P3W (single-phase, three-wire system)

3P3W (three-phase, three-wire system)

3P3W (3V3A; three-voltage, three-

current method)

3P4W (three-phase, four-wire system) Voltage range × current range × 3

• When the result of the equation voltage range × current range exceeds 1000 W (VA or var), the displayed unit

changes to kW (kVA or kvar).

• Number of displayed digits (display resolution)

For a detailed list of the available voltage and current range combinations and power ranges when all the

elements have the same voltage or current range, see appendix 4 in the getting started guide, IM WT180103EN.

Voltage range × current range × 2

(when the voltage and current ranges on the

elements in the wiring unit are set to the same range)

(when the voltage and current ranges on the

elements in the wiring unit are set to the same range)

In auto range mode, because the voltage and current ranges switch independently according to range

increase and decrease conditions, different power ranges may be set for the same power value.

External Current Sensor Range (EXT SENSOR; option)

The output of current sensors that produce voltage, such as shunts and clamps, can be applied to an element’s

external current sensor input connector (EXT) and measured. Press EXT SENSOR so that it illuminates, and

then set the external current sensor range.

The external current sensor range can be fixed (when auto range is set to off) or determined automatically (when

auto range is set to on).

Fixed Ranges

When the current range is fixed, you can select a range from the available options. The selected current range

does not change even if the amplitude of the input signal changes. Set the range in reference to the rms value of

the input signal.

•

When the Crest Factor Is Set to CF3

ou can select from 50 mV, 100 mV, 200 mV, 500 mV, 1 V, 2 V, 5 V, and 10 V.

Y

• When the Crest Factor Is Set to CF6

You can select from 25 mV, 50 mV, 100 mV, 250 mV, 500 mV, 1 V, 2.5 V, and 5 V.

Auto Range

This is the same as the auto range feature for voltage.

Page 26

Click here.

2 Fundamental Measurement Conditions

External Current Sensor Conversion Ratio (SENSOR RATIO; option)

Set the conversion ratio used to measure the signal received by the external current sensor input connector (EXT)

from a current sensor that produces voltage. Set how many millivolts the current sensor transmits when 1 A of

current is applied (conversion ratio). Then, the input signal can be made to correspond to the numeric data or

waveform display data that is obtained when the current is directly applied to the input terminals. When using a

current sensor that produces current, set the conversion ratio as the CT ratio.

Measurement Function Conversion

Ratio

Current I E I

Active power P E P

Apparent power S E S

Reactive power Q E Q

Max./min. current Ipk E Ipk

Data before

Transformation

(current sensor output) IS/E

S

S

S

S

(current sensor output) IpkS/E

S

Transformation

Result

PS/E

SS/E

QS/E

Element1 to Element6

Use the soft keys to select an element, and then set the element’s external current sensor conversion ratio to a

value within the following range.

0.0001 to 99999.9999

Copying the External Current Sensor Conversion Ratio (Exec Copy Σ)

Copy the external current sensor conversion ratio of the selected input element to the other input elements in the

same wiring unit.

External Current Sensor Range and Conversion Ratio Configuration Example

When you measure a current with a maximum value of 100 A using a current sensor that produces 10 mV

when 1 A of current is flowing, the maximum voltage that the current sensor produces is 10 mV/A × 100 A = 1 V.

Therefore, configure the settings as indicated below.

•

External current sensor range: 1 V

External current sensor conversion ratio: 10 mV/A

•

• When you want to divide the external current sensor output by the conversion ratio and read the current of

•

When you are measuring a signal other than a sine wave (suc

• The input peak over-range indicator at the top center of the

• The measured values of the voltage and current are indicated as being overload values (“-OL-”).

IM WT1801-01EN

the circuit under measurement directly, turn the external VT/CT scaling feature off. If the feature is turned

on, the value will be further multiplied by the CT ratio.

h as a distorted wave), you can obtain

accurate measurements by selecting the smallest measurement range that does not produce any of the

conditions below.

screen illuminates or blinks in red.

2-13

Page 27

2-14

IM WT1801-01EN

2 Fundamental Measurement Conditions

External Current Sensor Range Display Format (DIRECT/

MEASURE; option)

You can select the external current sensor range display format from the following options.

• DIRECT (direct input value display)

Values are displayed within the external current sensor range (voltage). This setting is useful when you want

to set the external current sensor range using the voltage received by the WT1800 from the external current

sensor as a guide.

•

MEASURE (measurement range display)

The external current sensor range is divided by the external cu

(current) range is displayed. This setting is useful when you want to set the external current sensor range

using the current measured by the external current sensor as a guide. For example, if you are using a current

sensor that produces 10 mV when it receives 1 A (external current sensor conversion ratio: 10 mV/A) and you

set the external current sensor range to 1 V, the displayed current range is 100 A.

rrent sensor conversion ratio, and the resulting

Scaling (SCALING)

You can set coefficients for when you apply a voltage or current signal from an external VT (voltage transformer)

or CT (current transformer).

Turning Scaling On and Off (Scaling)

You can select whether to apply the VT ratio, CT ratio, and power coefficient to applicable measurement

functions.

When reading measured values directly by using a VT or CT (or current sensor), select ON. When you select

ON, the SCALING key and the Scaling indicator at the top of the screen illuminate.

Applicable Measurement Functions

Voltage (U), current (I), power (P, S, and Q), maximum and minimum voltages (U+pk and U-pk), and maximum

and minimum currents (I+pk and I-pk)

•

ON:

The measurement functions above are multiplied by the VT ratio, CT ratio, or power coefficient.

• OFF:

The measurement functions above are not multiplied by the VT ratio, CT ratio, or power coefficient. The

output values of the VT and CT are displayed directly as numeric data.

VT Ratio (VT Scaling)

Set the VT ratio when applying the secondary output of a VT to the voltage input terminal. Then, set the voltage

range according to the maximum VT output.

Element1 to Element6

Use the soft keys to select an element, and then set the element’s VT ratio to a value within the following range.

0.0001 to 99999.9999

Copying the VT Ratio (Exec Copy Σ)

Copy the VT ratio of the selected input element to the other input elements in the same wiring unit.

CT Ratio (CT Scaling)

Set the CT ratio (or the conversion ratio of the current sensor that produces current) when applying the

secondary output of a CT or clamp-type current sensor that produces current to the current input terminal. Then,

set the current range according to the maximum CT or current sensor output.

Element1 to Element6

Use the soft keys to select an element, and then set the element’s CT ratio to a value within the following range.

0.0001 to 99999.9999

Copying the CT Ratio (Exec Copy Σ)

Copy the CT ratio of the selected input element to the other input elements in the same wiring unit.

Page 28

Click here.

2 Fundamental Measurement Conditions

Power Coefficient (SF Scaling; scaling factor)

By setting the power coefficient (SF), you can display the measured active power, apparent power, and reactive

power after they have been multiplied by a coefficient.

Measurement Function Data before Transformation Transformation

Result

Voltage U U

Current I I

Active power P P

Apparent power S S

Reactive power Q Q

Max./min. voltage Upk Upk

Max./min. current Ipk Ipk

Element1 to Element6

Use the soft keys to select an element, and then set the element’s power coefficient to a value within the

following range.

0.0001 to 99999.9999

Copying the Power Coefficient (Exec Copy Σ)

Copy the power coefficient of the selected input element to the other input elements in the same wiring unit.

(secondary output of the VT) U2 × V V: VT ratio

2

(secondary output of the CT) I2 × C C: CT ratio

2

2

2

2

(secondary output of the VT) Upk2 × V

2

(secondary output of the CT) Ipk2 × C

2

P2 × V × C × SF SF: Power coefficient

S2 × V × C × SF

Q2 × V × C × SF

• If the value of the result of multiplying the measured value by the VT ratio, CT ratio, or power coefficient

(scaling factor) exceeds 9999.99 M, “-OF-” will appear in the numeric data display frame.

• Y