Page 1

Digital Power Meter

Yokogawa Electric Corporation

IM253401-01E

3rd Edition

Page 2

Foreword

Notes

Revisions

AThank you for purchasing the YOKOGAWA WT110 or WT130 Digital Power Meter.

This User’s Manual contains useful information regarding the instrument’s functions and

operating procedures, as well as precautions that should be observed during use. To ensure

proper use of the instrument, please read this manual thoroughly before operating it.

Keep the manual in a safe place for quick reference whenever a question arises.

• The peak measurement function and the MATH function described in this manual apply to

WT110/WT130 with ROM version 2.01 or later.

• The contents of this manual are subject to change without prior notice.

• Every effort has been made in the preparation of this manual to ensure the accuracy of its

contents. However, should you have any questions or find any errors, please contact your

dealer or YOKOGAWA sales office.

• Copying or reproduction of all or any part of the contents of this manual without

YOKOGAWA’s permission is strictly prohibited.

First edition: September 1995

2nd edition: March 1997

3rd edition: March 1998

Disk No. BA12

3rd Edition:March 1998(YK)

All Rights Reserved, Copyright © 1995 Yokogawa Electric Corporation

IM 253401-01E

1

Page 3

Checking the Contents of the Package

Unpack the box and check the contents before operating the instrument. In case the wrong

instrument or accessories have been delivered, or if some accessories are not present, or if they

seem abnormal, contact the dealer from which you purchased them.

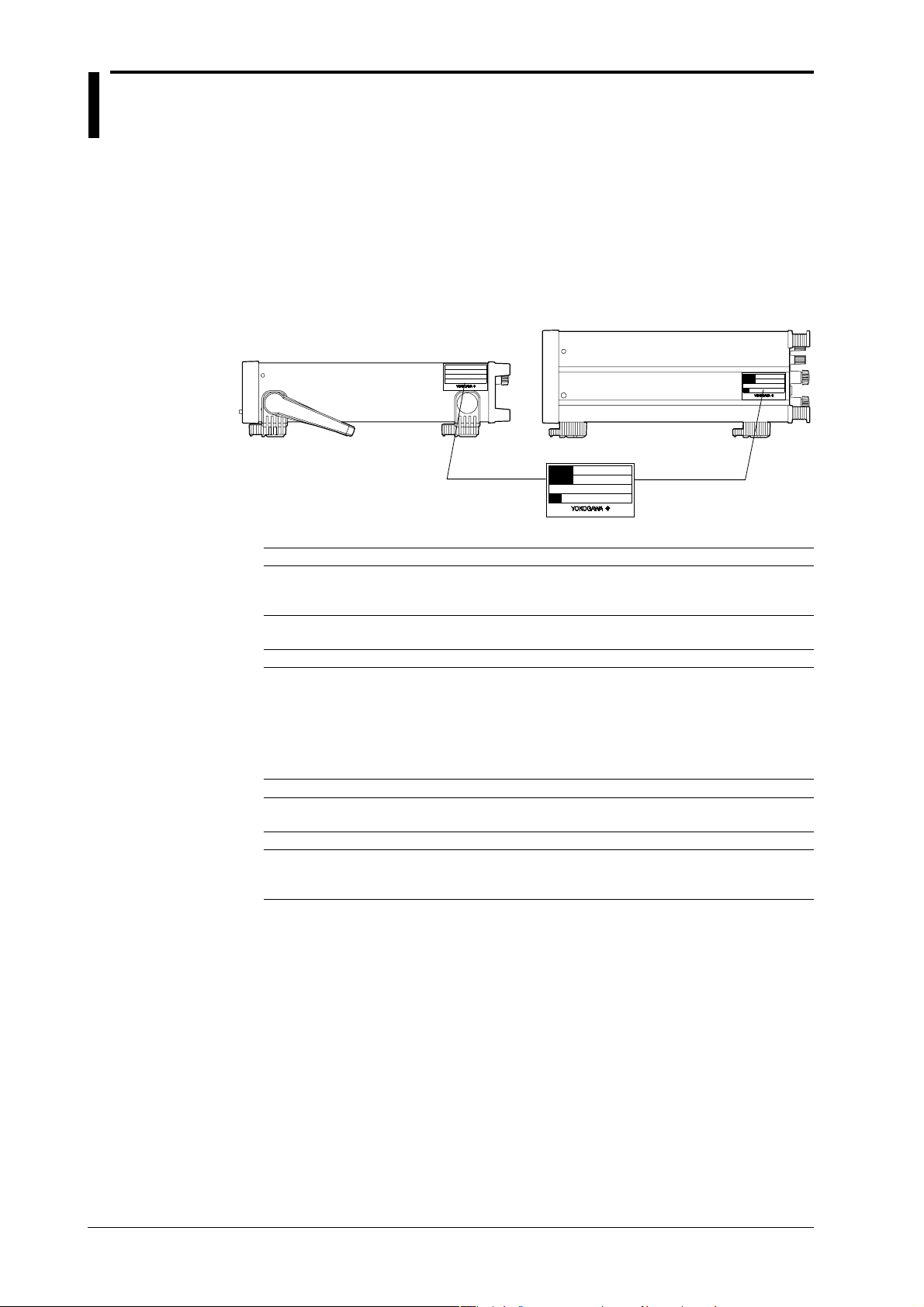

WT110/WT130 Main Body

Check that the model code and suffix code given on the name plate located at the right side of

the main body are according to your order.

WT110 (model code: 253401) WT130 (model code: 253502, 253503)

MODEL

SUFFIX

NO.

Madein Japan

MODEL

SUFFIX

NO.

Made in Japan

Model and Suffix codes

Model code Suffix code Specifications

253401 WT110 Single-phase model

253502 WT130 Three-phase, three-wire model

253503 WT130 Three-phase, four-wire model

Interface -C1 GP-IB interface

-C2 RS-232-C interface

Power voltage -0 100-120V/220-240V

Power cord -D [Maximum rated voltage: 125V; Maximum rated current: 7A]

Options

External sensor input function /EX1 ... 2.5/5/10V range

Harmonic analysis function /HRM .. –

External input/output function /DA4 ... 4 channels D/A output (for 253401)

Ex: WT130 Three-phase, three-wire model, GP-IB interface, with UL/CSA power cord, with

external sensor input 50/100/200mV range, with harmonic analysis function, and 12 channels

D/A output →253202-C1-0-D/EX2/HRM/DA12

-F VDE Standard Power Cord (Part No.: A1009WD)

[Maximum rated voltage: 250V; Maximum rated current: 10A]

-J BS Standard Power Cord (Part No.: A1023WD)

[Maximum rated voltage: 250V; Maximum rated current: 5A]

-R SAA Standard Power Cord (Part No.: A1024WD)

[Maximum rated voltage: 240V; Maximum rated current: 10A]

/EX2 ... 50/100/200mV range

/DA12 . 12 channels D/A output (for 253502/253503)

/CMP .. Comparator 4 channels, D/A output 4 channels

MODEL

SUFFIX

NO.

Madein Japan

NO. (instrument number)

When contacting the dealer from which you purchased the instrument, please quote the

instrument No.

2

IM 253401-01E

Page 4

Standard Accessories

The following standard accessories are supplied with the instrument. Make sure that all items

are present and undamaged.

Name Part No. Q’ty Remarks

1 Power cord see page 2 1 —

2 Power fuse A1346EF 1 only for the three-phase model

3 24-pin connector A1004JD 1 For remote, D/A output

4 User’s Manual IM253401-01E 1 this manual

5 Rubber feed A9088ZM 1 set

6 Clamp filter (Ferrite core) A1179MN 1 for WT110 only

Checking the Contents of the Package

Time lag, 0.5A, 250V

(located in the fuse holder)

Not provided with the single-phase model

(only provided with options /DA4, /DA12 or

/CMP)

1. One of the power cords is supplied according

to the instrument's suffix code

2. 5. 6.

Optional Equipment

The following optional equipment is available. Upon receiving any optional equipment, make

sure that all the items ordered have been supplied and they are in good condition.

If you have any questions regarding optional equipment, or if you wish to place an order,

contact the dealer from whom you purchased the instrument.

Name Parts No. Minimum Q’ty Remarks

Digital printer 740921 1 ESC/P compatible, RS-232-C/Centronics

Note

DFJ R

3. 4.

It is recommended that the packing box be kept in a safe place. The box can be used for transporting the

instrument.

IM 253401-01E

3

Page 5

Safety Precautions

This instrument is a IEC safety class I instrument (provided with terminal for protective

grounding).

The following general safety precautions must be observed during all phases of operation,

service and repair of this instrument. If this instrument is used in a manner not sepecified in this

manual, the protection provided by this instrument may be impaired.

Also,YOKOGAWA Electric Corporation assumes no liability for the customer’s failure to

comply with these requirements.

The fullowing symbols are used on this instrument.

To avoid injury, death of personnel or damage to the instrument, the operator must refer to an

explanation in the User's Manual or Service Manual.

Danger, risk of electric shock

Alternating current

ON(power)

OFF(power)

In-position of a bistable push control

Out-position of a bistable push control

Ground

4

IM 253401-01E

Page 6

Safety Precautions

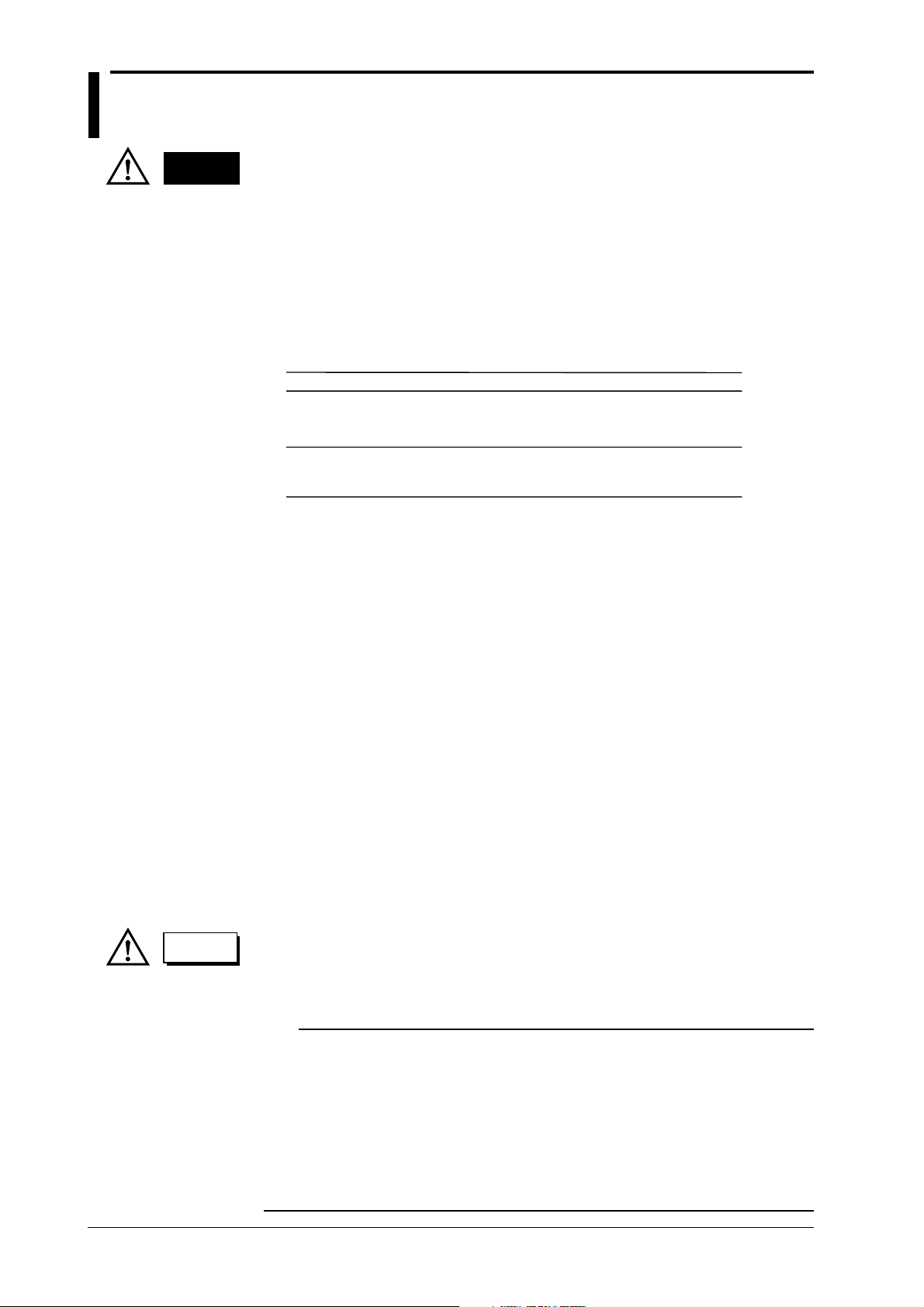

WARNING

Do not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable liquids or

vapors.

Operation of any electrical instrument in such an environment constitutes a

safety hazard.

Protective Grounding

Make sure to connect the protective grounding to prevent an electric shock

before turning ON the power.

Necessity of Protective Grounding

Never cut off the internal or external protective grounding wire or

disconnect the wiring of protective grounding terminal. Doing so poses a

potential shock hazard.

Defect of Protective Grounding

Do not operate the instrument when protective grounding or fuse might be

defective.

Power Cord and Plug

To prevent an electric shock or fire, be sure to use the power cord supplied

by YOKOGAWA. The main power plug must be plugged in an outlet with

protective grounding terminal. Do no invalidate protection by using an

extension cord without protective grounding.

Power Supply

Ensure the source voltage matches the voltage of the power supply before

turning ON the power.

External Connection

To ground securely, connect the protective grounding before connecting to

measurement or control unit.

Fuse

To prevent a fire, make sure to use fuses with specified standard (current,

voltage, type). Before replacing the fuse, turn OFF the power and

disconnect the power source. Do not use a different fuse or short-circuit the

fuse holder.

Do not Remove any Covers

There are some areas with high voltage. Do not remove any cover if the

power supply is connected. The cover should be removed by qualified

personnel only.

IM 253401-01E

5

Page 7

How to Use this Manual

This User’s Manual consists of 15 chapters, an Appendix and an Index as described below.

Chapter 1 What this Instrument Can Do

Chapter 2 Nomenclature, Keys and Displays

Chapter 3 Before Operation

Chapter 4 Setting Measurement Conditions

Chapter 5 Measuring/Displaying Voltage, Current, and Active Power and Frequency

Chapter 6 Computing/Displaying Apparent Power, Reactive Power, Power Factor and

Chapter 7 Integrating

Chapter 8 Using the Harmonic Analysis Function (option)

Chapter 9 Storing/Recalling

Chapter 10 Using External In/Output

Chapter 11 GP-IB Interface

Chapter 12 RS-232-C Interface

Chapter 13 Other Useful Functions

Chapter 14 Adjustment, Calibration and Trouble-Shooting

Chapter 15 Specifications

Appendix Describes communication commands and sample programs.

Index Gives the index in alphabetic order.

Explains the flow of the measurement input signals and gives an outline of the

functions.

Gives the name of each part and each key, and describes how to use it. This

chapter also gives the displays in case of overrange/error during measurement.

Describes points to watch during use and describes how to install the instrument,

wire the measuring circuits, connect the power cord and switch the power ON/OFF.

Explains settings such as measurement mode, filter ON/OFF, measurement range,

scaling in case of external PT/CT or external sensor (such as shunt or clamp),

averaging and measurement conditions.

Explains the procedures for measuring and displaying voltage, current and active

power.

Phase Angle.

Explains the procedures for measuring and displaying apparent power, reactive

power, power factor and phase angle.

Explains the procedures for integration of active power and current.

Explains the procedures when using the harmonic analysis function.

Explains the procedures when storing or recalling measured data or setting

parameters from the internal memory.

Explains the procedures for remote control, D/A output (option), external plotter/

printer output and comparator (option).

Explains the procedures for controlling the instrument by personal computer and for

sending measurement/computed data to a personal computer using the GP-IB

interface.

Explains the procedures for controlling the instrument by personal computer/

controller and for sending measurement/computed data to a personal computer/

controller using the RS-232-C interface.

Explains the procedures such as backing up set-up information and initializing

settings.

Explains the procedures for calibration, adjustment, the way to verify trouble, the

contents of error messages and the way to replace the fuse.

Describes the specifications of the instrument.

6

IM 253401-01E

Page 8

Conventions Used in this Manual

Symbols Used

The following symbol marks are used throughout this manual to attract the operator’s attention.

To avoid injury or death of personnel, or damage to the instrument, the

operator must refer to the User's Manual. In the User's Manual, these

symbols appear on the pages to which the operator must refer.

WARNING

CAUTION

Note

serious injury or death to the user.

Describes precautions that should be observed to prevent the danger of

minor or moderate injury to the user, or the damage to the property.

Provides information that is important for proper operation of the

instrument.

Displayed Characters on the 7-Segment LED

Describes precautions that should be observed to prevent the danger of

In order to display all numbers and alphabetic characters on the 7-segment LED, some of them

are displayed in a slightly altered format. For details, refer to section 1.3.

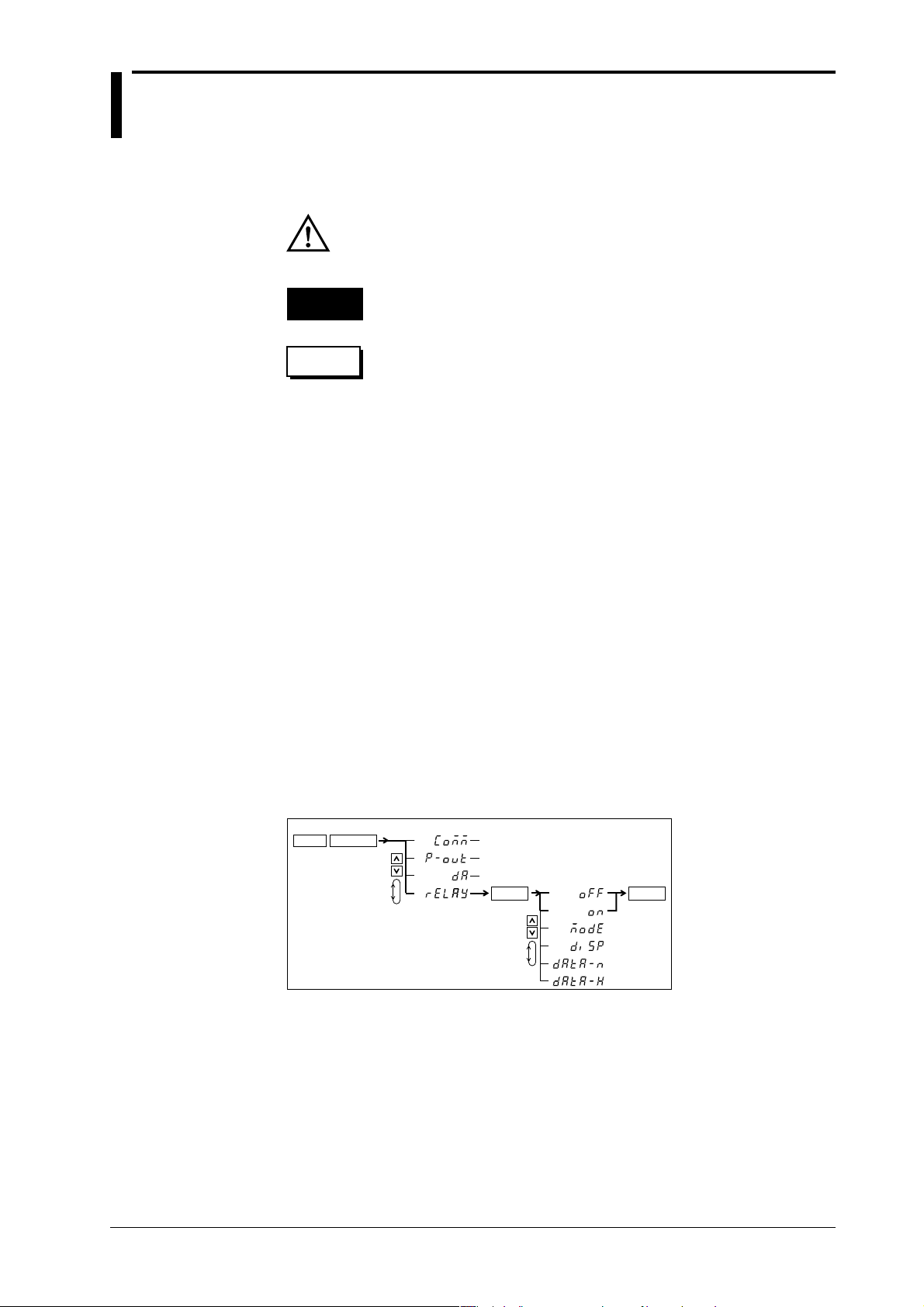

Markings used for Descriptions of Operations

Relevant Keys

Operating Procedure

Indicates the relevant panel keys and indicators to carry out

the operation.

The procedure is explained by a flow diagram. For the

meaning of each operation, refer to the example below. The

operating procedures are given with the assumption that you

are not familiar with the operation. Thus, it may not be

necessary to carry out all the steps when changing settings.

Explanation

Describes settings and restrictions relating to the operation.

An example of an Operating Procedure

2.

(Di splay C)

3.

ENTER

4.

(Di splay C)

5.

ENTER

End of

setting

1.

SETUP

OUTPUT

SHIFT

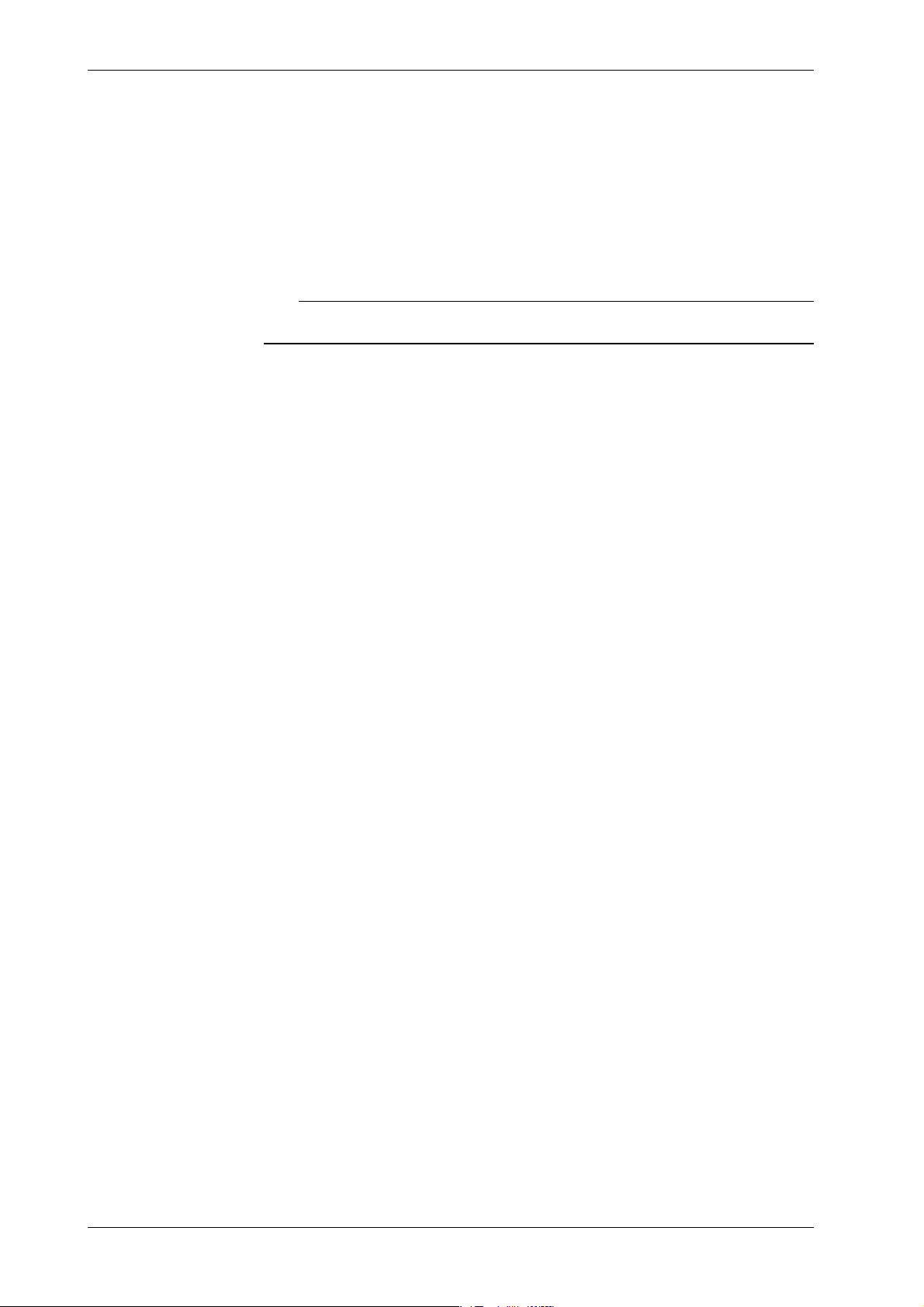

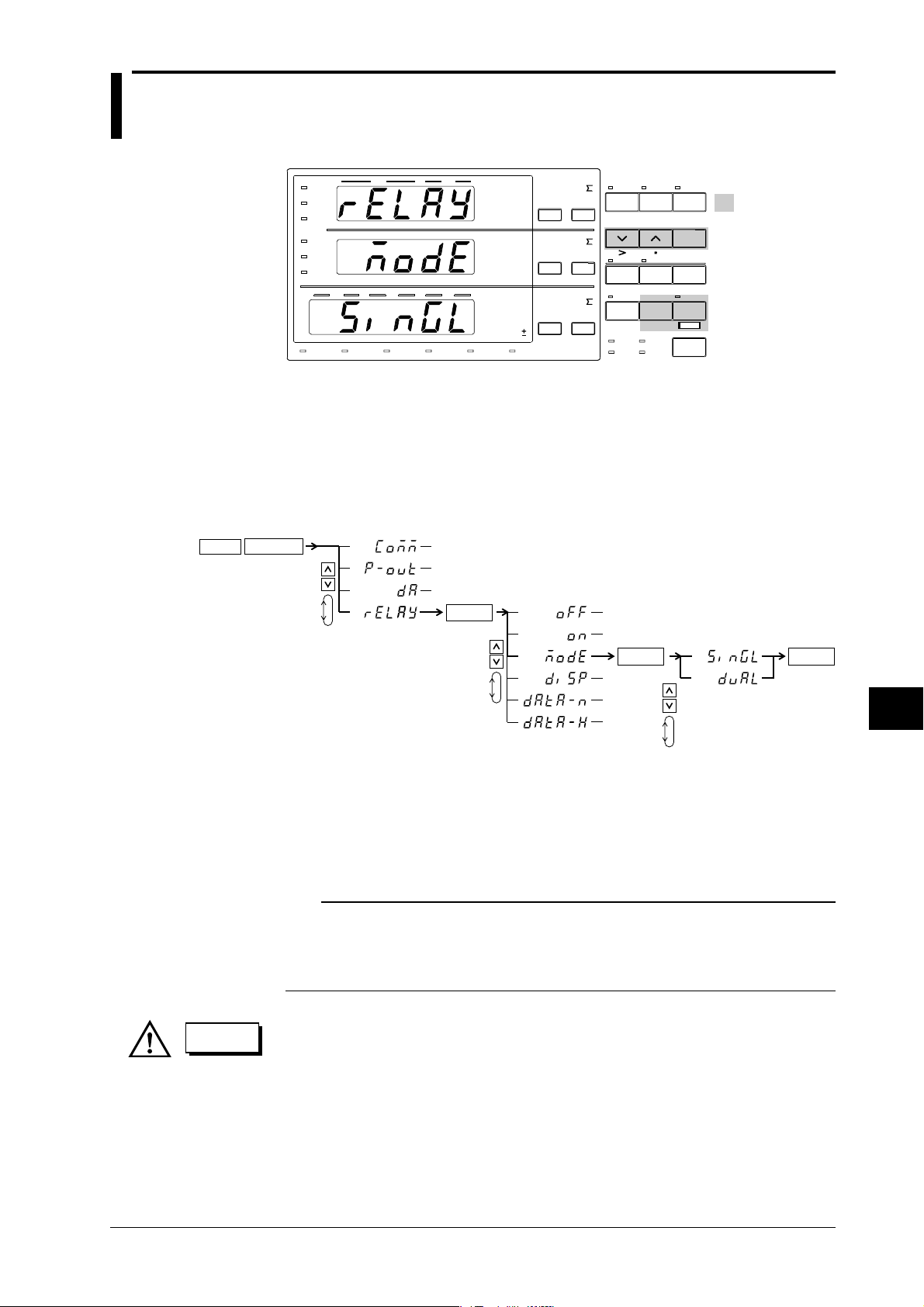

The items in this figure are obtained by the following setting procedures. The blinking part of

the display can be set.

1. After pressing the SHIFT key and the SHIFT indicator is lit, press the SETUP (OUTPUT)

key. The output setting menu will appear on display C.

2. Select rELAY using the up/down keys.

Pressing either key, 4 selectable items will be displayed consecutively.

3. Verify the setting by pressing the ENTER key.

The setting menu corresponding to the item selected at step 2 will appear at display C.

4. Select oFF or on using the up/down keys.

Pressing either key, 6 selectable items will be displayed consecutively.

5. Verify the setting by pressing the ENTER key.

IM 253401-01E

7

Page 9

Contents

Foreword ............................................................................................................................................................................. 1

Checking the Contents of the Package..................................................................................................... 2

Safety Precautions...................................................................................................................................................... 4

How to Use this Manual .......................................................................................................................................... 6

Conventions Used in this Manual .................................................................................................................. 7

Chapter 1 What this Instrument Can Do

1.1 System Configuration and Block Diagram ..................................................................................1-1

1.2 Functions ...................................................................................................................................... 1-2

1.3 Digital Numbers/Characters, and Initial Menus .......................................................................... 1-5

Chapter 2 Nomenclature, Keys and Displays

2.1 Front Panel, Rear Panel and Top View........................................................................................ 2-1

2.2 Operation Keys and Function/Element Display .......................................................................... 2-2

2.3 Displays in case of Overrange/Error during Measurement ......................................................... 2-4

Chapter 3 Before Operation

3.1 Usage Precautions ........................................................................................................................3-1

3.2 Installing the Instrument .............................................................................................................. 3-2

3.3 Wiring Precautions ...................................................................................................................... 3-4

3.4 Wiring the Measurement Circuit ................................................................................................. 3-5

3.5 Wiring the Measurement Circuit when Using External PT/CT ................................................... 3-7

3.6 Wiring the Measurement Circuit when Using the External Sensor ............................................. 3-9

3.7 Connecting the Power Supply.................................................................................................... 3-12

3.8 Turning the Power ON/OFF ...................................................................................................... 3-13

3.9 Selecting the Wiring Method (for WT130) .............................................................................. 3-15

3.10 Improving the Measurement Accuracy...................................................................................... 3-16

Chapter 4 Setting Measurement Conditions

4.1 Selecting the Measurement Mode................................................................................................ 4-1

4.2 Turning the Filter ON/OFF .......................................................................................................... 4-3

4.3 Selecting the Measurement Range in case of Direct Input ..........................................................4-4

4.4 Setting the Scaling Value when External PT/CT is Used ............................................................ 4-6

4.5 Selecting the Measurement Range and Setting the Scaling Value when External Sensor is

Used (option) ............................................................................................................................... 4-8

4.6 Using the Averaging Function ...................................................................................................4-10

4.7 Using the Four Arithmetical Operation Function (Applies to WT110/WT130 with ROM

Version 2.01 or later) .................................................................................................................4-12

4.8 Computing the Crest Factor (Applies to WT110/WT130 with ROM Version 2.01 or later) ....4-15

4.9 Computing the Efficiency (Applies to WT130 with ROM Version 2.01 or later) .................... 4-16

Chapter 5 Measuring/Displaying Voltage, Current, Active Power, Frequency,

Four Arithmetic Operation Value, Crest Factor and Peak Value

5.1 Measuring/Displaying Voltage, Current and Active Power ........................................................5-1

5.2 Measuring/Displaying Frequency ................................................................................................ 5-3

5.3 Measuring/Displaying Four Arithmetic Operation Value, Crest Factor and Peak Value ........... 5-4

8

IM 253401-01E

Page 10

Contents

Chapter 6 Computing/Displaying Apparent Power, Reactive Power, Power

Factor and the Phase Angle

6.1 Computing/Displaying Apparent Power, Reactive Power and Power Factor ............................. 6-1

6.2 Computing/Displaying the Phase Angle ...................................................................................... 6-2

Chapter 7 Integration

7.1 Integrator Functions .....................................................................................................................7-1

7.2 Setting Integration Mode and Integration Timer .........................................................................7-4

7.3 Displaying Integrated Values....................................................................................................... 7-5

7.4 Precautions Regarding Use of Integrator Function...................................................................... 7-7

Chapter 8 Using the Harmonic Analysis Function (optional)

8.1 Harmonic Analysis Function ....................................................................................................... 8-1

8.2 Setting the Element, PLL Source and Harmonic Distortion Method .......................................... 8-3

8.3 Switching the Harmonic Analysis Function ON/OFF .................................................................8-5

8.4 Setting the Harmonic Order and Displaying the Results of Harmonic Analysis......................... 8-6

1

2

3

4

5

Chapter 9 Storing/Recalling

9.1 Storing/Recalling Measured Data ................................................................................................9-1

9.2 Storing/Recalling Set-up Parameters ...........................................................................................9-4

Chapter 10 Using External In/Output

10.1 Remote Control and D/A Output Connector (optional)............................................................. 10-1

10.2 Remote Control (optional) .........................................................................................................10-2

10.3 D/A Output (optional)................................................................................................................ 10-3

10.4 Comparator Function (optional) ................................................................................................ 10-7

10.5 Setting the Comparator Mode (optional) ...................................................................................10-9

10.6 Setting the Comparator Limit Values (optional) ..................................................................... 10-10

10.7 Comparator Display (optional) ................................................................................................ 10-14

10.8 Turning the Comparator Function ON/OFF (optional) ........................................................... 10-16

10.9 Outputting to an External Plotter/Printer .................................................................................10-17

Chapter 11 GP-IB Interface

11.1 Using the GP-IB Interface ......................................................................................................... 11-1

11.2 Responses to Interface Messages ............................................................................................... 11-2

11.3 Status Byte Format (before the IEEE488.2-1987 Standard)...................................................... 11-3

11.4 Output Format for Measured/Computed Data, Harmonic Analysis Data, Set-up

Parameters and Error Codes ......................................................................................................11-4

11.5 Setting the Address/Addressable Mode .....................................................................................11-9

11.6 Setting the Output Items .......................................................................................................... 11-10

11.7 Commands (before the IEEE488.2-1987 Standard) ................................................................ 11-12

6

7

8

9

10

11

12

13

Chapter 12 RS-232-C Interface

12.1 Using the RS-232-C Interface.................................................................................................... 12-1

12.2 Connecting the Interface Cable.................................................................................................. 12-2

12.3 Setting the Mode, Handshaking Method, Data Format and Baud Rate ..................................... 12-4

12.4 Format and Commands of Output Data (brefore the IEEE488.2-1987 Standard)..................... 12-7

Chapter 13 Other Useful Functions

13.1 Back-up of Set-up Parameters ................................................................................................... 13-1

13.2 Initializing Set-up Parameters.................................................................................................... 13-2

IM 253401-01E

14

15

App

Index

9

Page 11

Chapter 14 Adjustment, Calibration and Trouble-Shooting

14.1 Adjustments ............................................................................................................................... 14-1

14.2 Calibration ................................................................................................................................. 14-4

14.3 In Case of Malfunctioning ....................................................................................................... 14-10

14.4 Error Codes and Corrective Actions ........................................................................................14-11

14.5 Replacing the Fuse (for WT130) ............................................................................................. 14-13

Chapter 15 Specifications

15.1 Input ...........................................................................................................................................15-1

15.2 Measurement Functions .............................................................................................................15-1

15.3 Frequency Measurement ............................................................................................................15-1

15.4 Communication .......................................................................................................................... 15-1

15.5 Computing Functions ................................................................................................................. 15-2

15.6 Display Functions ...................................................................................................................... 15-2

15.7 Integrator Functions ...................................................................................................................15-2

15.8 Internal Memory Function .........................................................................................................15-2

15.9 D/A Converter (optional) ........................................................................................................... 15-2

15.10 External Input (optional) ............................................................................................................ 15-3

15.11 Comparator Output (optional) ................................................................................................... 15-3

15.12 External Control and Input Signals

(in combination with the D/A converter and comparator options) ............................................15-3

15.13 General Specifications ............................................................................................................... 15-3

15.14 Total Harmonic Analysis Function (optional) ...........................................................................15-3

15.15 External Dimensions ..................................................................................................................15-4

Contents

Appendix 1 Communication Commands (before the IEEE488.2-1987

Standard)

App.1.1 Commands ....................................................................................................................... App1-1

App.1.2 Sample Program............................................................................................................. App1-10

App.1.3 For Users Using Communication Commands of Digital Power Meter 2533E ............. App1-15

Appendix 2 Communication Commands (according to the IEEE488.2-1987

Standard)

App.2.1 Overview of IEEE 488.2-1987 ........................................................................................ App2-1

App.2.2 Program Format ............................................................................................................... App2-2

2.2.1 Symbols Used in Syntax Descriptions ................................................................ App2-2

2.2.2 Messages ............................................................................................................. App2-2

2.2.3 Commands ...........................................................................................................App2-4

2.2.4 Responses ............................................................................................................ App2-5

2.2.5 Data ..................................................................................................................... App2-5

2.2.6 Synchronization with the Controller ................................................................... App2-7

App.2.3 Commands ....................................................................................................................... App2-8

2.3.1 Command List ..................................................................................................... App2-8

2.3.2 AOUTput Group ............................................................................................... App2-11

2.3.3 COMMunicate Group ....................................................................................... App2-12

2.3.4 CONFigure Group .............................................................................................App2-14

2.3.5 DISPlay Group .................................................................................................. App2-17

2.3.6 HARMonics Group ........................................................................................... App2-18

2.3.7 INTEGrate Group ..............................................................................................App2-19

2.3.8 MATH Group .................................................................................................... App2-20

2.3.9 MEASure Group ............................................................................................... App2-21

2.3.10 RECall Group .................................................................................................... App2-27

2.3.11 RELay Group .................................................................................................... App2-28

10

IM 253401-01E

Page 12

Contents

2.3.12 SAMPle Group ..................................................................................................App2-30

2.3.13 STATus Group ..................................................................................................App2-31

2.3.14 STORe Group.................................................................................................... App2-32

2.3.15 Common Command Group ...............................................................................App2-33

App.2.4 Status Report .................................................................................................................. App2-35

2.4.1 Overview of the Status Report .......................................................................... App2-35

2.4.2 Status Byte ........................................................................................................ App2-36

2.4.3 Standard Event Register .................................................................................... App2-37

2.4.4 Extended Event Register ................................................................................... App2-38

2.4.5 Output Queue and Error Queue .........................................................................App2-39

App. 2.5 Sample Program .............................................................................................................App2-40

App. 2.6 ASCII Character Codes ................................................................................................. App2-42

App. 2.7 Communication-related Error Messages ....................................................................... App2-43

1

2

3

4

Index

5

6

7

8

9

10

11

IM 253401-01E

12

13

14

15

App

Index

11

Page 13

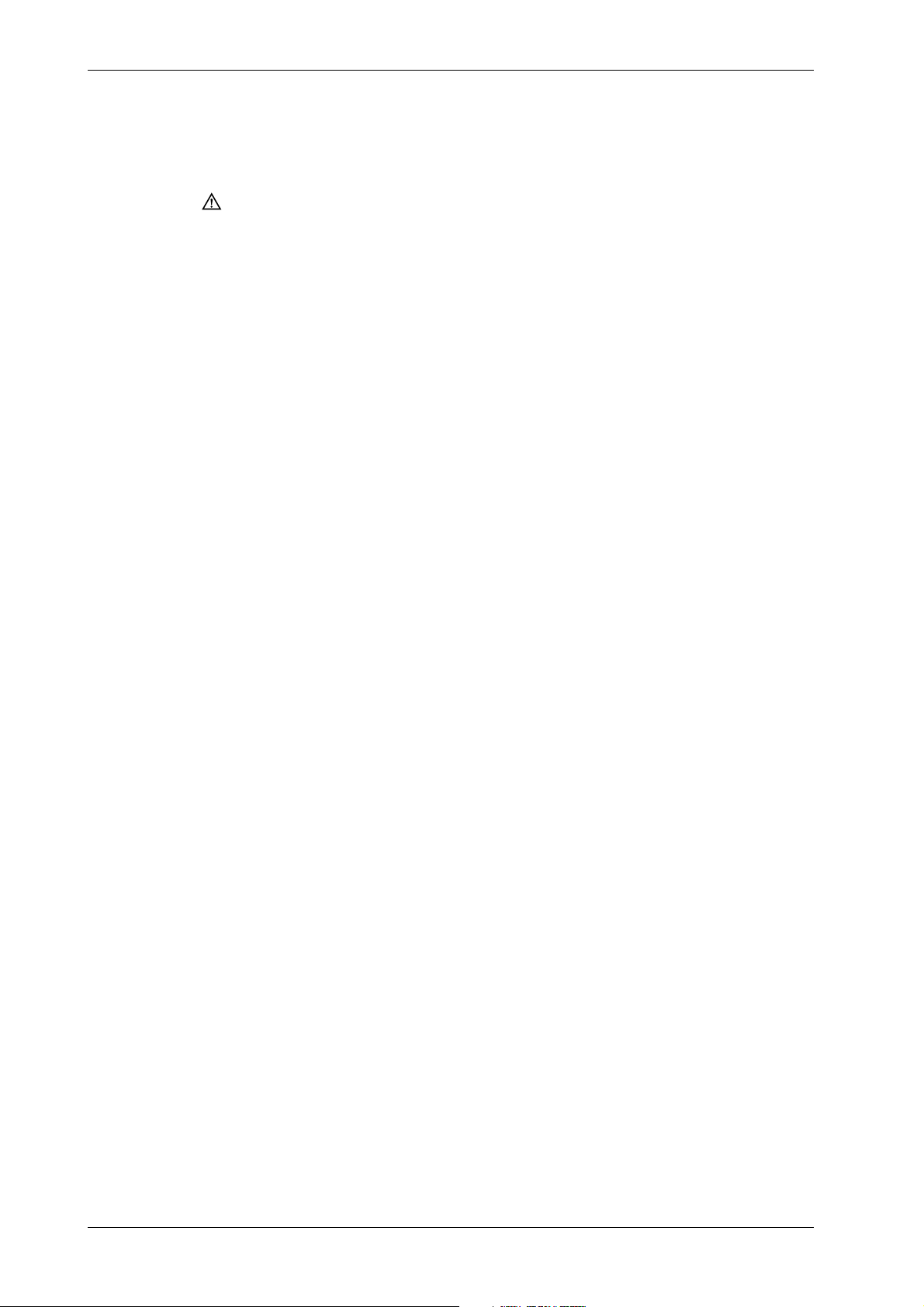

1.1 System Configuration and Block Diagram

System Configuration

PT

Voltage

input

Input

either

one

Digital

power meter

Contact / relay output

1

What this Instrument Can Do

Block Diagram

Model INPUT Section

253401 ELEMENT 1

253502

253503

VOLTAGE INPUT

CURRENT INPUT

Equipment

under

test

ELEMENT 1,3

ELEMENT 1,2,3

INPUT ELEMENT 1

A/D

Zero Cross

A/D

Detector

Zero Cross

Detector

LPF

LPF

INPUT ELEMENT 2

CT

Ext.

sensor

ISO

ISO

Current

input

A/D

interface

Lead/Lag

Detector

EEPROM

Input

either

one

DSP

WT110

(253401)

WT130

(253502,253503)

SAMPLING

Bus

Arbiter

FREQUENCY

COUNTER × 2

CLOCK

HARMONICS

PLL

DMAC

RAM

(Option)

Analog output

GP-IB or

RS-232-C

CPU

CLOCK

Bus

Arbiter

Recorder

Computer

Ext. printer

or plotter

CPU

Personal

ROM

RAM

KEY&DISPLAY

CONTROLLER

GP-IB

or

RS-232-C

D/A OUTPUT

EEPROM

(Option)

COMPARATOR

(Option)

INPUT ELEMENT 3

This instrument consists of various sections: input (voltage input and current input circuits),

DSP, CPU, display and interface section.

In the voltage input circuit, the input voltage is formalized by a voltage divider and operational

amplifier, then sent to the A/D converter.

In the current input circuit, one shunt resistor is used to form a closed circuit. The voltage

between both ends of the shunt resistor is amplified and formalized by an operational amplifier

and then sent to the A/D converter. This method enables switching of the current range without

opening the current measurement circuit, so the current range can be switched while electricitiy

is supplied to the circuit. This also enables remote control via communications outputs.

The output from the A/D converter in the current input and voltage input circuits is sent to the

DSP (Digital Signal Processor) via a photo-isolator, which is used to provide insulation between

the current input circuit (or voltage circuit) and the DSP. One DSP is provided for each input

element (current/voltage). For example, a total of 3 DSP’s are used for the three-phase, fourwire model (model 253503). The DSP performs averaging of voltage, current and active power

for each sampled data sent from the A/D converter. After processing of a certain number of sets

of data has been completed, computation of apparent power, reactive power, power factor and

phase angle starts.

Computation results are then sent from the DSP to the CPU, where computation such as range

conversion, sigma computation and scaling is carried out. Control of display and outputs is also

performed by the CPU.

IM 253401-01E

1-1

Page 14

1.2 Functions

Input Functions

Voltage and Current Input Sections

A voltage or current supplied to each input terminal is normalized then sent to the A/D

converter, where the voltage or current is converted into digital signals. The digital signals are

then sent via photo-isolator to a 16-bits high-speed DSP (Digital Signal Processor) or CPU,

where computation of the measured value is carried out.

Frequency Measuring Range

Measurement of DC voltage, current and power as well as AC voltage and current in the

frequency range 10Hz to 50kHz.

Filter

This instrument carries out various measurements after synchronizing the frequency of the input

signals. Therefore, correct measurements are necessary. Thus, a filter is being applied to the

frequency measurement circuit to eliminate noise of waveforms, such as inverted and distortion

waveforms.

Wiring Method

The input units for voltage or current measurement are located on the rear panel of this

instrument. These units are called input elements. The number of input elements depends on the

model, and the possible wiring methods are as follows. The wiring method demonstrates the

circuit configuration to measure voltage, current and power and this circuit configuration varies

by phase and number of electrical wires.

model number of elements wiring method

253401 1 single-phase, two-wire (1Φ2W)

253502 2 single-phase, two-wire (1Φ2W); single-phase, three-wire

253503 3 single-phase, two-wire (1Φ2W); single-phase, three-wire

Display Functions

This function enables display of measured/computed values using three red high-intensity 7segment LED displays. A total of three values can be displayed at once.

Computing Functions

Apparent Power, Reactive Power, Power Factor and Phase Angle

Based on the measurement values of voltage, current and active power, the values of apparent

power, reactive power, power factor and phase angle can be computed.

Scaling Function

When performing voltage or current measurements with an external PT, CT, shunt, external

sensor (clamp) or such connected, you can set a scaling factor to the primary/secondary ratio.

This is called scaling. This function enables display of the measured values of voltage, current,

active power, reactive power, integrated current and integrated power factor in terms of

primary-side values.

(1Φ3W); three-phase, three-wire (3Φ3W)

(1Φ3W); three-phase, three-wire (3Φ3W); three-phase, fourwire (3Φ4W); three-voltage, three-current (3V3A)

1-2

Averaging Function

This function is used to perform exponential or moving averaging on the measured values

before displaying them in cases where the measured values are not stable.

IM 253401-01E

Page 15

Four Arithmetic Operation Function (Applies to WT110/WT130 with ROM

Version 2.01 or later)

Results from six types of arithmetic operations can be displayed. (A+B, A-B, A*B, A/B, A2/B,

A/B2)

Crest Factor Computing Function (Applies to WT110/WT130 with ROM

Version 2.01 or later)

Crest factor is determined by peak value/RMS value. Crest factor of the voltage and current are

computed and displayed on models that have the peak measurement function.

Peak Measurement Function (Applies to WT110/WT130 with ROM Version

2.01 or later)

This function measures the peak value of the voltage and current. Crest factor (peak value/RMS

value) can also be computed and displayed.

Integrator Functions

This function enables integration of active power and current. All measurement values (and

computed values) can be displayed, even when integration is in progress, except for the

integrated values (watt hour and ampere hour) and elapsed integration time. Since also

integrated values of negative polarity can be displayed, the consumed watt hour (ampere hour)

value of the positive side and the watt hour value returning to the power supply of the negative

side can be displayed seperately.

1.2 Functions

1

What this Instrument Can Do

Frequency Measurement Function

This function enables measurement of the frequency of input voltage and current.

Measuring range is from 10Hz to 50kHz (however, depending on the internal timing of the

instrument, measurement might be carried out in the range from 4Hz to 10Hz also).

Harmonic Analysis Function (option)

This function enables computation of voltage, current, active power and so forth of up to the

50th order, the relative harmonic content of harmonic orders and the phase angle of each order

compared to the fundamental (first order). This is for one selected input element. Furthermore,

the total rms value (fundamental + harmonic) of the voltage, current and active power, and the

harmonic distortion factor (THD) can be calculated.

Storage/Recalling of Measured data and Setting Parameters

This function enables the storage of measured data and setting parameters into the internal

memory. Furthermore, after recalling measured data or setting parameters, these data can be

displayed or output by communication interface.

D/A Output Function (option)

This function enables output of measured values of voltage, current, active power, apparent

power, reactive power, power factor and phase angle as a DC analog signal with full scale of

±5V. Output items up to 12 output channels (253401: 4 channels) can be selected.

Comparator Function (option)

This function compares the measured values of voltage, current, active power, apparent power,

reactive power, power factor and phase angle and such with preset limit values. When the

measured values cross those preset limits, a contact output relay will be activated. Output items

up to 4 channels can be set.

IM 253401-01E

1-3

Page 16

1.2 Functions

Remote Control Functions (option)

External Input

This instrument can be controlled using the following TTL-level, low pulse, logic signals.

EXT HOLD (when options /DA4, /DA12, /CMP are installed)

Holds updating of the displayed values or releases the hold status.

EXT TRIG (when options /DA4, /DA12, /CMP are installed)

Updates the displayed values in hold mode.

EXT START (when options /DA4, /DA12 are installed)

Starts integration.

EXT STOP (when options /DA4, /DA12 are installed)

Stops integration.

EXT RESET (when options /DA4, /DA12 are installed)

Resets the integration results.

External Output

This instrument can output the following TTL-level, low pulse, logic signals.

EXT BUSY (when options /DA4, /DA12 are installed)

Outputs continuously from integration start through integration stop.

Communication Functions

Either a GP-IB or RS-232-C interface is provided as standard according to the custormer’s

preference. Measured/computed data of up to 14 channels can be output. It is also possible to

control this instrument from the personal computer.

Output Function to an External Plotter / Printer

Measured/computed data can be printed on an external plotter or printer using the GP-IB or RS232-C interface.

Other Useful Functions

Backup Function of Set-up Parameters

This instrument backs up the set-up parameters (including computed values) in case power is

cut off accidentally as a result of a power failure or for any other reason.

Initializing Set-up Parameters

This function enables you to reset the set-up parameters to initial (factory) settings.

1-4

IM 253401-01E

Page 17

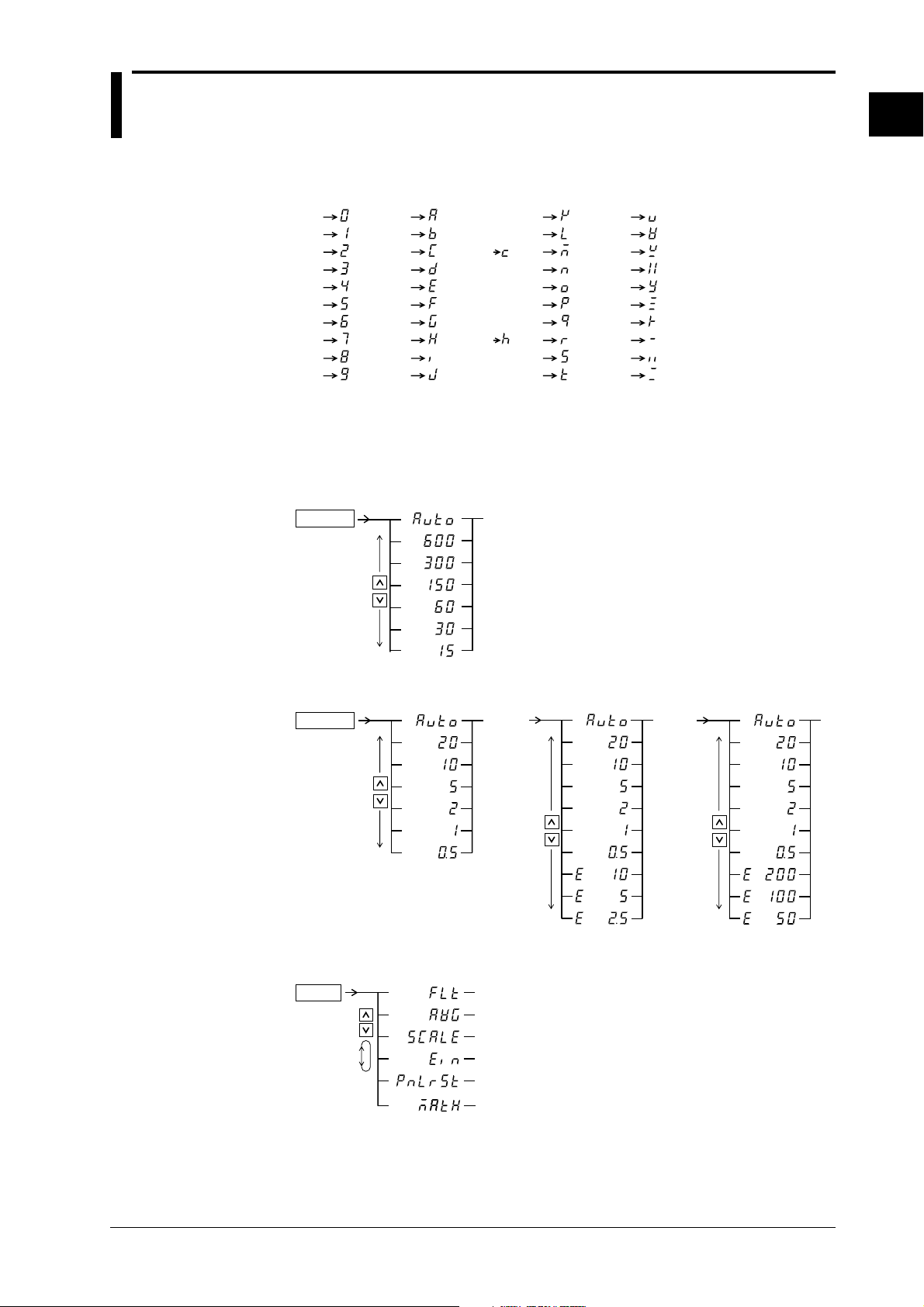

1.3 Digital Numbers/Characters, and Initial Menus

Digital Numbers/Characters

This instrument is equipped with a 7-segment LED which imposes some restrictions on the

usable characters. The numbers/characters are styled as follows.

0

1

2

3

4

5

6

7

8

9

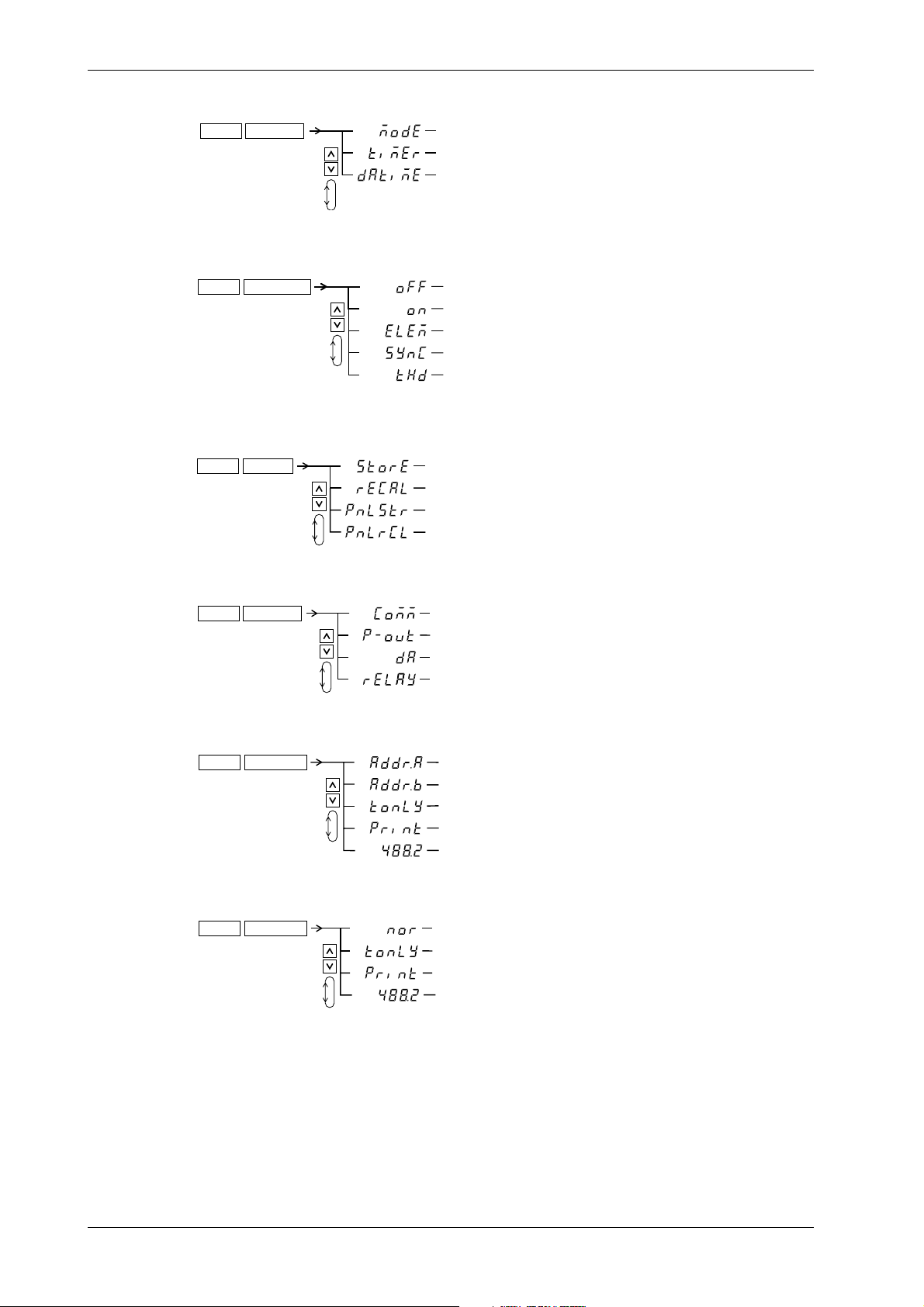

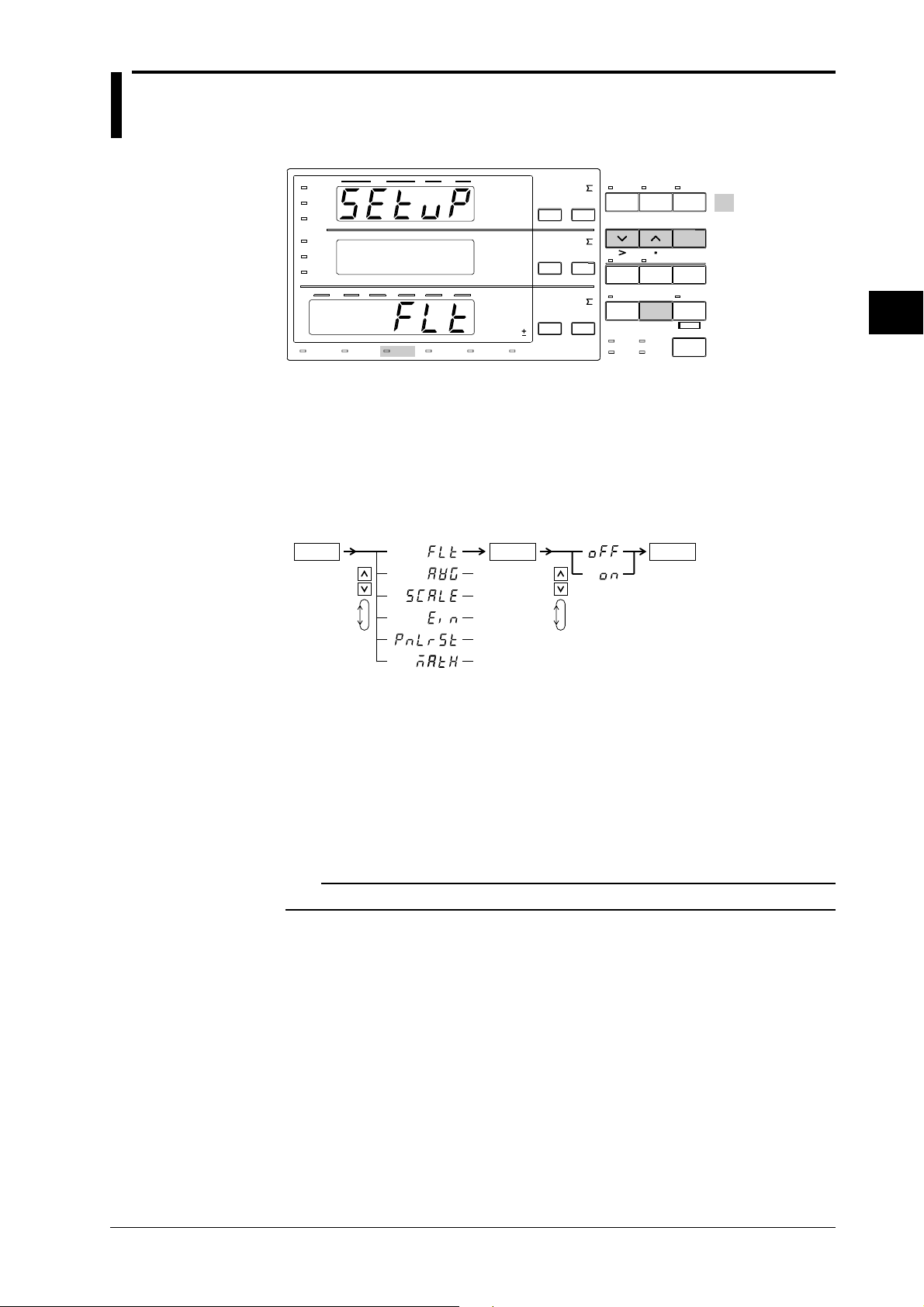

Initial Menus

Every function of this instrument can be set using the menus on the display. The initial displays

which appear when the operation keys are pressed, are shown below.

• Voltage Range Setting

1.

V RANGE

2.

A

B

C

D

E

F

G

H

I

J

(Display C)

Small c

Small h

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

+

−

×

÷

1

What this Instrument Can Do

• Current Range Setting

1.

A RANGE

(Display C)

2.

When equipped with

option /EX1

(Display C)

2.

When equipped with

option /EX2

(Display C)

2.

• Filter/Scaling/Averaging/Ext. Sensor Input/Initializing Set-up Parameters

2.

(Display C)

(Filter setting)

(Averaging setting)

(Scaling setting)

(Ext. sensor input setting)

(Initiallizing set-up parameters)

(Computation, crest factor settings)

1.

SETUP

IM 253401-01E

1-5

Page 18

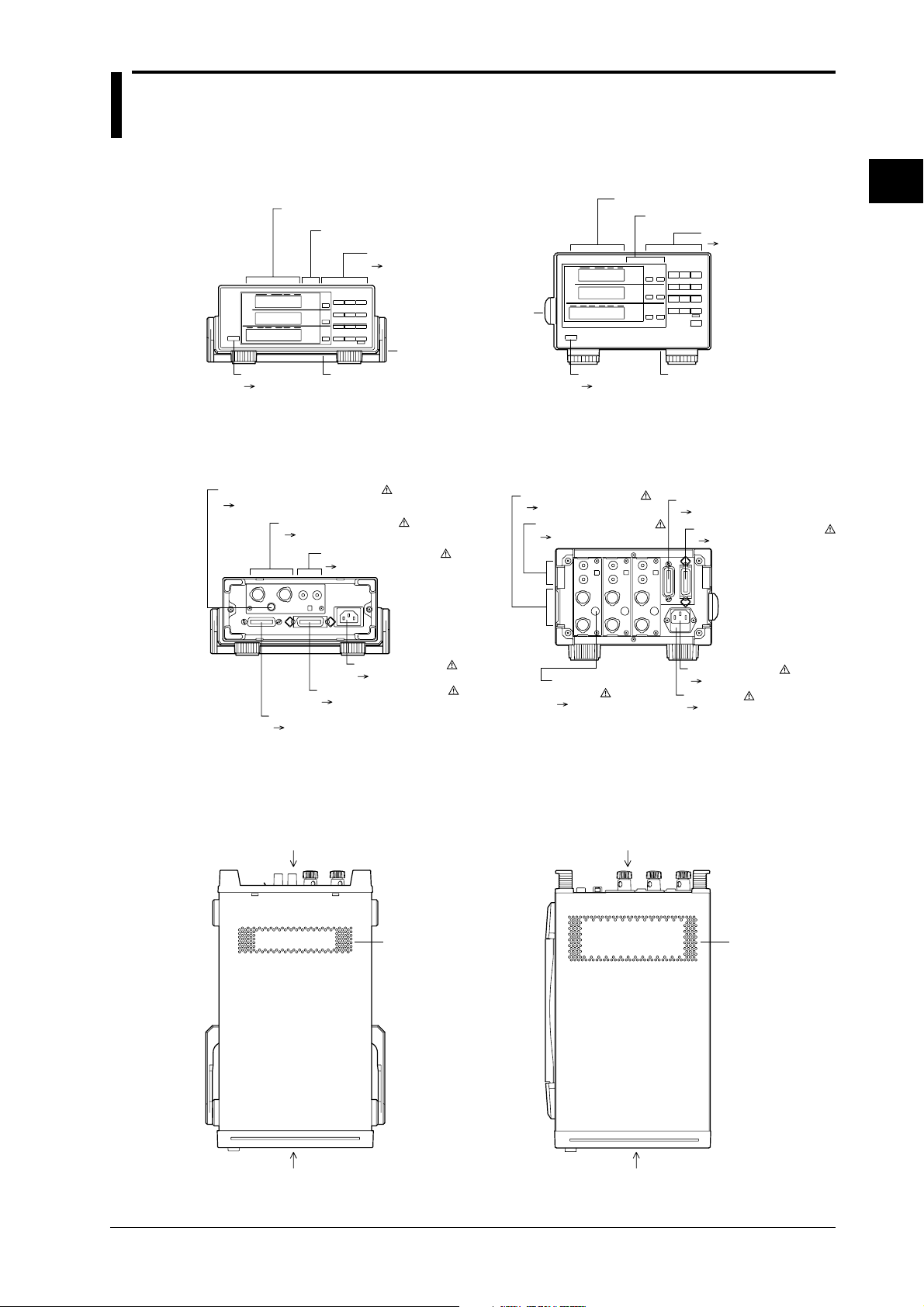

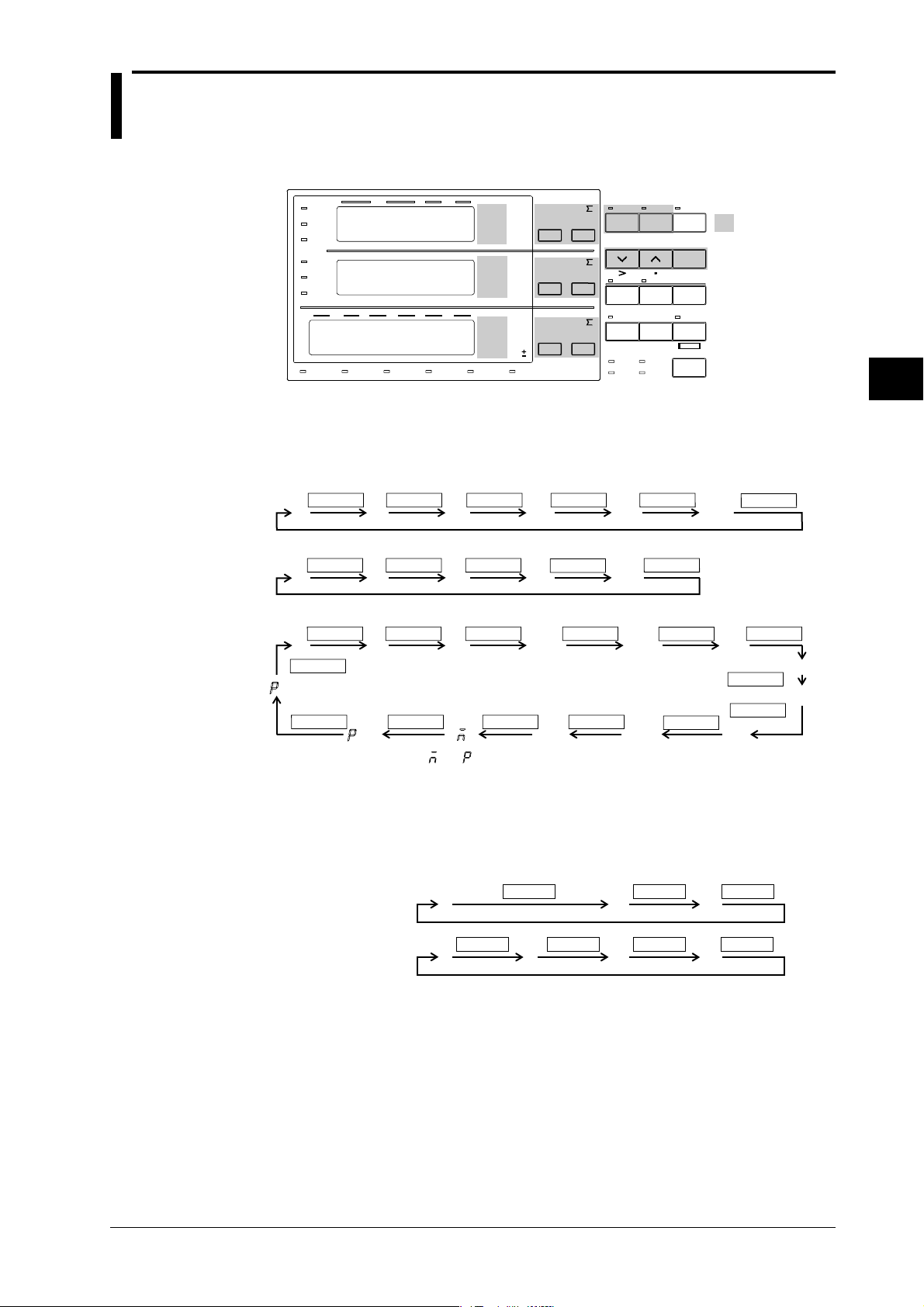

1.3 Digital Numbers/Characters, and Initial Menus

• Integration Setting

1.

SHIFT

RESET

INTEG SET

( Display C )

2.

• Turning the Harmonic Analysis Function ON/OFF

(Setting integration mod)

(Setting integration timer)

(Setting integration preset time)

1.

SHIFT

START

HARMONICS

(Display C)

2.

(Setting the element)

(Setting PLL source)

(Setting computation methood

of harmonic distortion)

• Storing/Recalling to/from Internal Memory

1.

SHIFT

STOP

MEMORY

2.

( Display C )

(Storing measurement data)

(Recalling measurement data)

(Storing set-up parameters)

(Recalling set-up parameters)

• Setting Output

2.

( Display C )

(Setting comm./plotter/printer output)

(Execute plotter/printer output)

(Setting D/A output)

(Comparator setting:relay output setting)

1.

SHIFT

SETUP

OUTPUT

• Setting Communication Interface (GP-IB)

1.

SHIFT

LOCAL

INTERFACE

2.

( Display C )

(Setting addressable mode A)

(Setting addressable mode B)

(Setting talk-only mode)

(Print mode setting:setting plotter/printer output)

(Setting communication commands according to IEEE 488.2-1987)

• Setting Communication Interface (RS-232-C)

1.

SHIFT

LOCAL

INTERFACE

2.

( Display C )

(Setting normal mode)

(Setting talk-only mode)

(Print mode setting:setting plotter/printer output)

(Setting communication commands according to IEEE 488.2-1987)

1-6

IM 253401-01E

Page 19

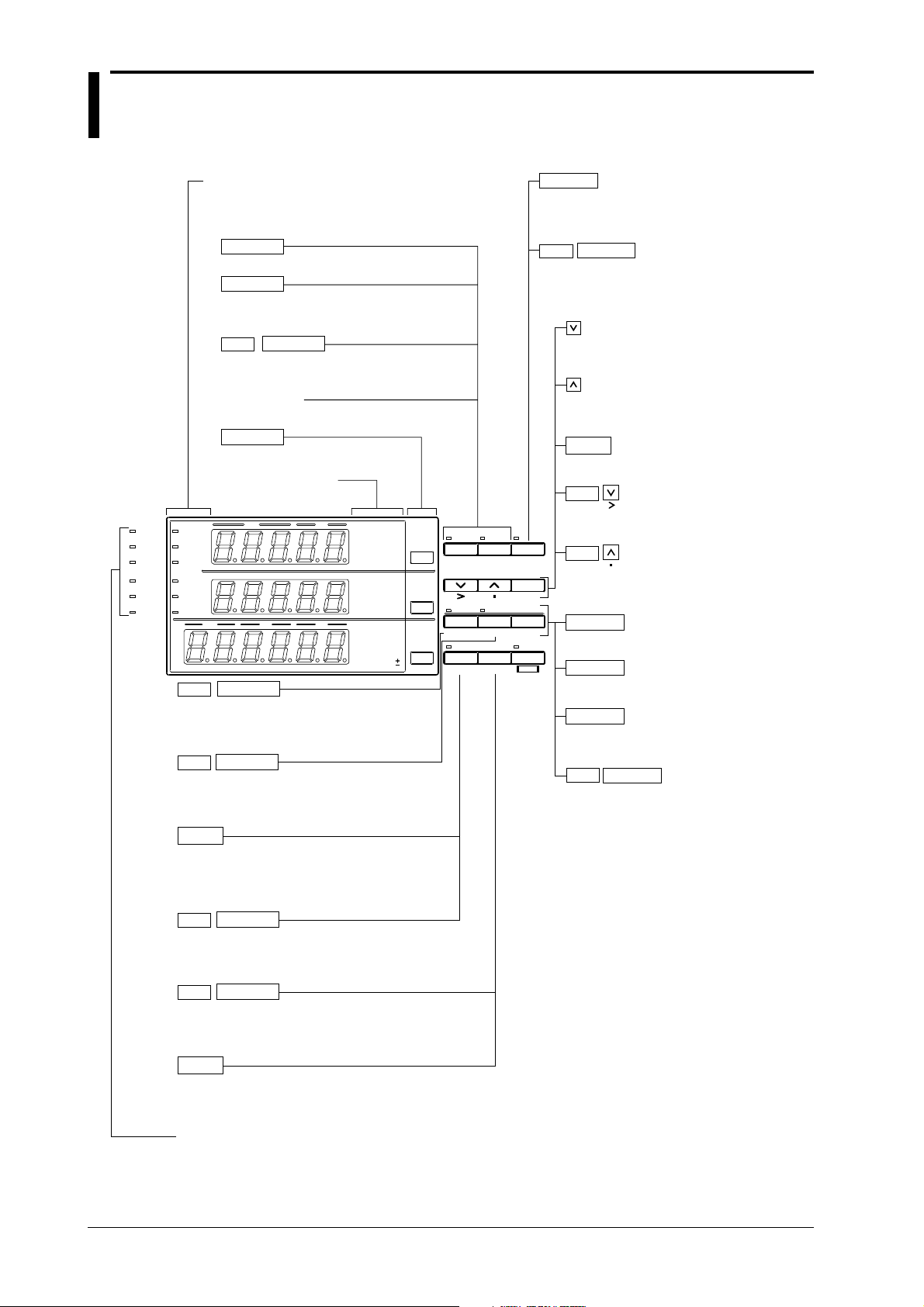

2.1 Front Panel, Rear Panel and Top View

Front Panel

WT110 (253401) WT130 (253502, 253503)

7-segment display

power switch

page 3-13

function/unit/element display

ventilation slot

GP-IB or RS-232-C connector

Rear Panel

7-segment display

function/unit display

operation keys

page 2-2

handle

handle

power switch

page 3-13

ventilation slot

WT110 (253401) WT130 (253502, 253503)

External sensor input terminal

page 3-9, 3-10

Current input terminal

page 3-5 to 3-8

Voltage input terminal

page 3-5 to 3-8

Current input terminal

page 3-5 to 3-8

Voltage input terminal

page 3-5 to 3-8

operation keys

page 2-3

chapter 11, 12

Ext. in/output connector

chapter 10

2

Nomenclature, Keys and Displays

Top View

power connector

Ext. in/output connector

GP-IB or RS-232-C connector

chapter 11, 12

page 3-12

chapter 10

External sensor input

terminal

page 3-9, 3-10

power connector

page 3-12

power fuse

page 14-13

WT110 (253401) WT130 (253502, 253503)

rear panelrear panel

ventilation slot ventilation slot

IM 253401-01E

front panel front panel

2-1

Page 20

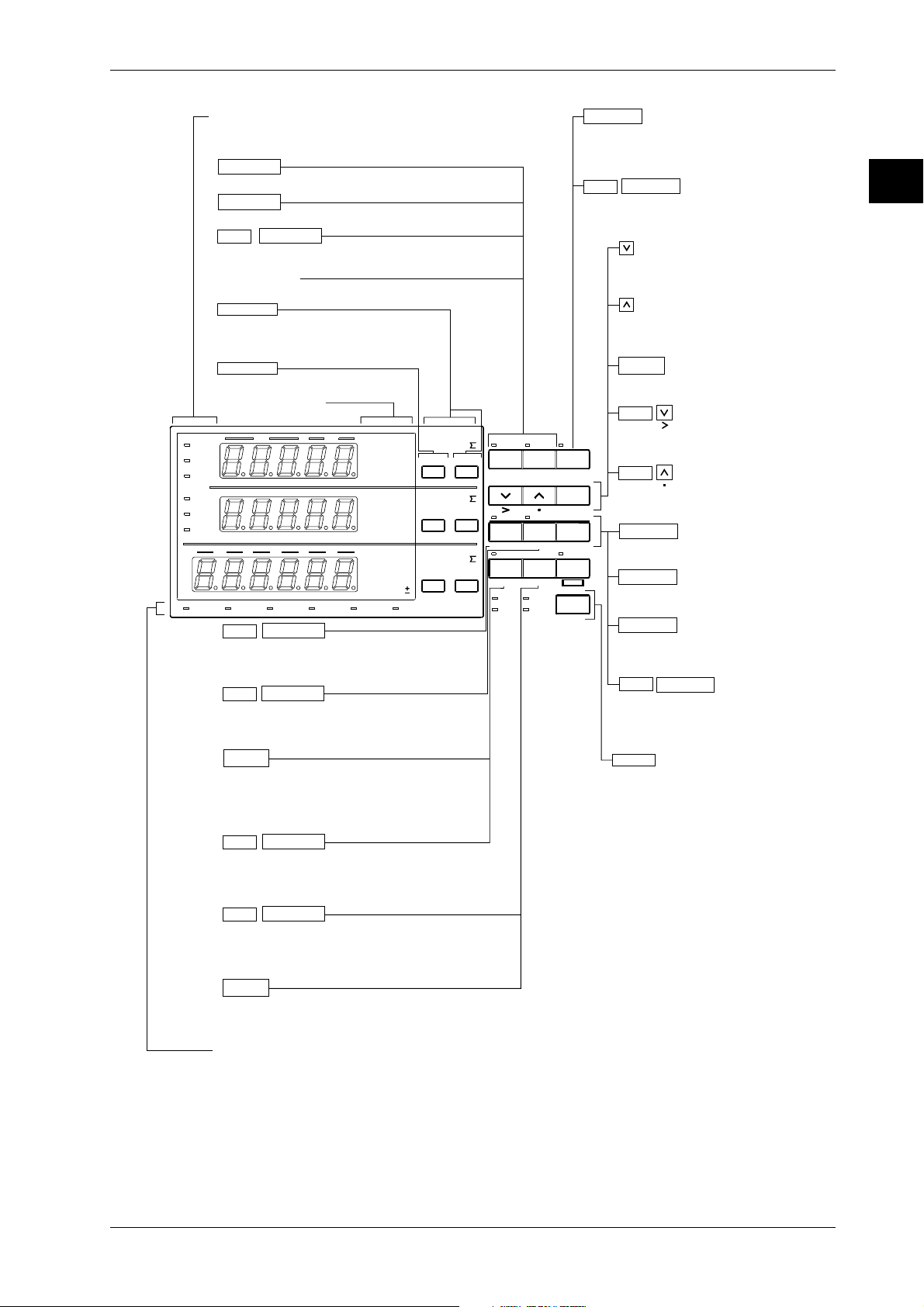

2.2 Operation Keys and Function/Element Display

WT110 (253401): Operation keys and function display

Indicators for operation conditions

Shows sampling, voltage/current overrange and

measurement mode

V RANGE

Shows the voltage range setting menu (page 4-4)

A RANGE

Shows the current range setting menu (page 4-4,

4-8)

V RANGE

SHIFT

MODE

Switches between modes (page 4-1)

AUTO indicator

Lights up when range is AUTO

FUNCTION

Sets the displayed function (Ch. 5, 6)

Function/unit display

SCALING

AVG

FILTER

STORE

RECALL

HARMONICS

MODE

C

SAMPLE

V OVER

A OVER

RMS

V MEAN

DC

hour

A

B

hour

min sec

min

START

HARMONICS

SHIFT

Shows the setting menu for harmonics ON/OFF,

PLL source, and element selection (Ch. 8)

STOP

SHIFT

MEMORY

Shows the setting menu for storing/recalling

measurement data and set-up information (Ch. 9)

LOCAL

When the REMOTE indicator is lit, the remote

function will be canceled. When the REMOTE

indicator is not lit, the setting menu for

communication/printing will appear

m

VVA

Ak

MW

m

VPF

Ak

MW

m

VHz

Ak

MW

var

TIME

deg

h

FUNCTION

FUNCTION

%

FUNCTION

h

AUTO AUTO

V RANGE A RANGE HOLD

MODE

STOP RESET

START

HARMONICS MEMORY INTEG SET

REMOTE

LOCAL

SETUP

INTERFACE OUTPUT

HOLD

Keeps the displayed value, and the HOLD

indicator will light up. Pressing once again will

result in canceling HOLD

HOLD

SHIFT

When in the HOLD situation this results in

updating the displayed value

TRIG

For decreasing the voltage/current range,

and for setting of functions/values

For increasing the voltage/current range,

and for setting of functions/values

ENTER

For verifying the set range/function/value

SHIFT

Moves the cursor of a value from left to right

TRIG

SHIFT

ENTER

INTEGRATOR

Moves the decimal point from left to right

START

Starts integration

SHIFT

STOP

Stops integration

RESET

Integration value and elapsed time of

integration are set to zero(0)

SHIFT

Shows the setting menu for integration

mode/time, and rated integration time (Ch. 7)

RESET

INTEG SET

2-2

LOCAL

INTERFACE

SHIFT

Shows the setting menu for communication/printing

(Ch. 11, 12)

SETUP

SHIFT

Shows the setting menu for communication output items, D/A

output, plotter /printer output and comparator output (Ch. 10 to

12)

OUTPUT

SETUP

For settings such as initializing settings, filter, average, scaling,

computing and ext. sensor input (Ch. 4)

Indicators for operating functions

When a function is set and in operation, this indicator will light up

IM 253401-01E

Page 21

2.2 Operation Keys and Function/Element Display

WT130 (253502, 253503): Operation keys and function / element display

Indicators for operation conditions

Shows sampling, voltage/current overrange and

measurement mode

V RANGE

Shows the voltage range setting menu (page 4-4)

A RANGE

Shows the current range setting menu (page 4-4, 4-8)

V RANGE

SHIFT

Switches between modes (page 4-1)

MODE

AUTO indicator

Lights up when range is AUTO

ELEMENT

Sets the input element for

measurement/integration. The corresponding

indicator will light up (Ch. 5, 6)

FUNCTION

Sets the displayed function (Ch. 5, 6)

Function/unit display

MODE

C

SAMPLE

V OVER

A OVER

RMS

V MEAN

DC

SCALING

A

B

hour

AVG FILTER

hour

min sec

STORE

min

m

VVA

Ak

MW

m

VPF

Ak

MW

m

VHz

Ak

MW

RECALL

START

HARMONICS

SHIFT

Shows the setting menu for harmonics ON/OFF, PLL

source, and element selection (Ch. 8)

STOP

SHIFT

MEMORY

Shows the setting menu for storing/recalling

measurement data and set-up information (Ch. 9)

LOCAL

When the REMOTE indicator is lit, the remote

function will be canceled. When the REMOTE

indicator is not lit, the setting menu for

communication/printing will appear

var

FUNCTION

TIME

deg

FUNCTION ELEMENT

%

FUNCTION ELEMENT

h

h

HARMONICS

123

ELEMENT

123

123

AUTO AUTO

V RANGE A RANGE HOLD

MODE

START

STOP RESET

HARMONICS MEMORY INTEG SET

REMOTE

LOCAL

SETUP

INTERFACE OUT PU T

3Φ3W

1Φ3W

3Φ4W

3V3A

HOLD

Keeps the displayed value, and the HOLD

indicator will light up. Pressing once again will

result in canceling HOLD

HOLD

SHIFT TRIG

When in the HOLD situation this results in

updating the displayed value

For decreasing the voltage/current range,

and for setting of functions/values

For increasing the voltage/current range,

and for setting of functions/values

ENTER

For verifying the set range/function/value

SHIFT

Moves the cursor of a value from left to right

TRIG

ENTER

INTEGRATOR

SHIFT

Moves the decimal point from left to right

START

Starts integration

SHIFT

WIRING

STOP

Stops integration

RESET

Integration value and elapsed time of

integration are set to zero(0)

SHIFT

RESET

INTEG SET

Shows the setting menu for integration

mode/time, and rated integration time (Ch.7)

WIRING

Sets the connection format matching the

connection to the voltage/current input

terminals at the rear (page 3-15)

2

Nomenclature, Keys and Displays

IM 253401-01E

LOCAL

INTERFACE

SHIFT

Shows the setting menu for

communication/printing (Ch. 11, 12)

SETUP

SHIFT

OUTPUT

Shows the setting menu for communication output items, D/A

output, plotter / printer output and comparator output (Ch. 10

to 12)

SETUP

For settings such as initializing settings, filter, average,

scaling and ext. sensor input (Ch. 4)

Indicators for operating functions

When a function is set and in operation, this indicator will light up

2-3

Page 22

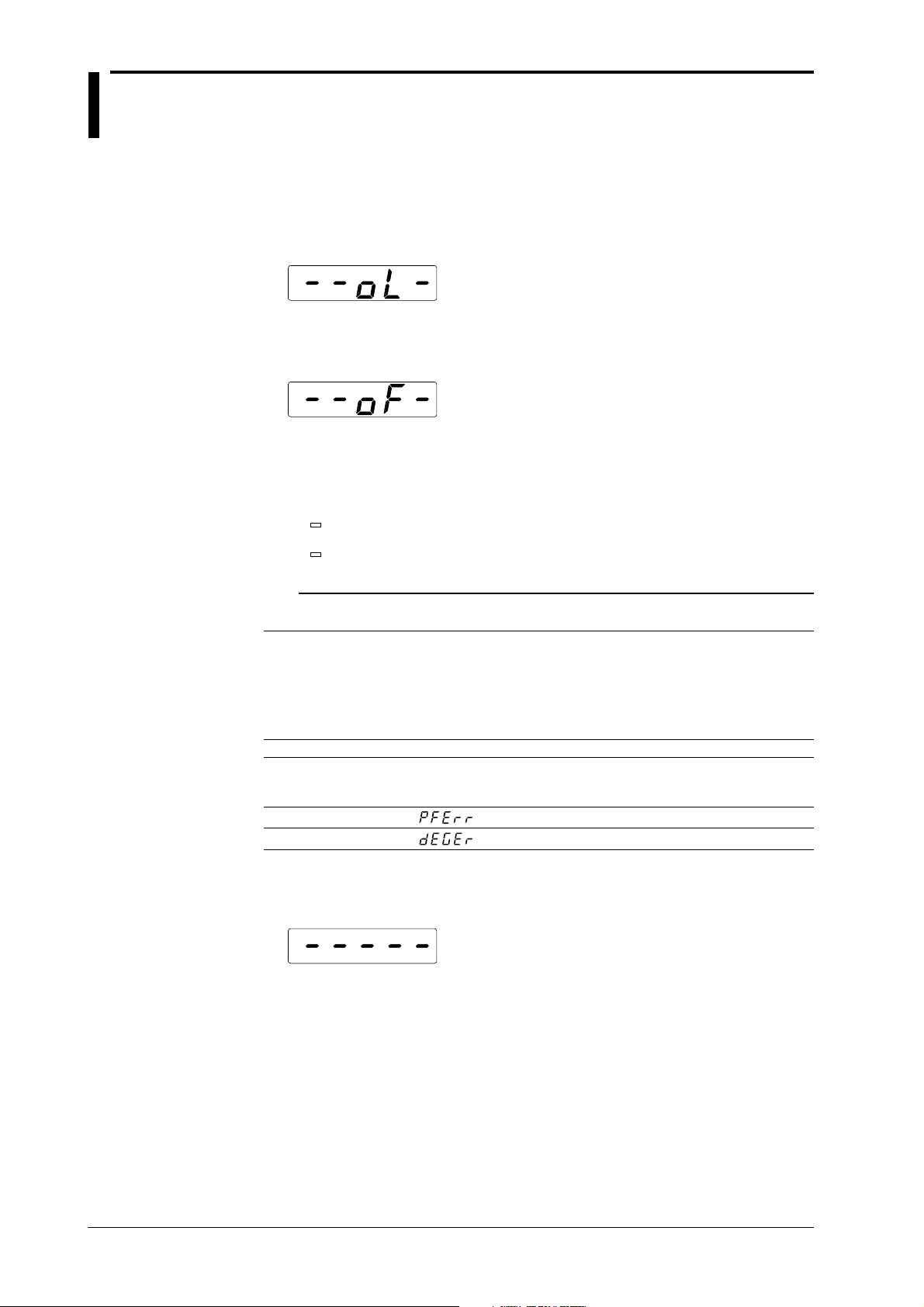

2.3 Displays in case of Overrange / Error during Measurement

Overrange display

Overrange occurs when the measured voltage or current exceeds 140% of the rated

measurement range. In that case the range will automatically be increased, however up to 140%

of the maximum range. When this level is exceeded, the overrange display wil appear, which

looks as follows.

Computation over display

When the computed value becomes too high during the computation process, the following

display will appear.

Peak over display

When the sampled data (instantaneous voltage or instantaneous current) exceed approx. 300%

of the measurement range, the “V over” or “A over” indicators at the front panel will light up.

V OVER

A OVER

Note

The “V over” and “A over” indicators at the front panel will light up in case of overrange or peak-over of

any signal which is input to the elements.

Display in case the measurement value is too small

In case either the measured voltage or measured current drops below 0.5% of the measurement

range, the display will indicate as follows. This is only in case the measurement mode is RMS

or V MEAN.

Function Display

V(voltage)

A(current) displays zero

var(reactive power)

PF(power factor)

deg(phase angle)

Interruption during measurement

If the measurement range, or function/element is changed and the contents of the display

changes, the display will indicate as follows.

2-4

IM 253401-01E

Page 23

3.1 Usage Precautions

Safety Precautions

Before using the instrument for the first time, make sure you have read the safety precautions on

page 4 and 5.

Do not remove the case from the instrument.

Some areas in the instrument use high voltages, which are extremely dangerous.

When the instrument needs internal inspection or adjustment, contact your nearest

YOKOGAWA representative. Addresses may be found on the back cover of this manual.

If you notice smoke or unusual odors coming from the instrument, immediately turn OFF the

power and unplug the power cord. Also turn OFF the power to all the objects being measured

that are connected to the input terminals. If such an irregularity occurs, contact your nearest

YOKOGAWA representative. Addresses may be found on the back cover of this manual.

Do not place anything on the power cord and keep it away from any heat generating articles.

When unplugging the power cord from the power outlet, always hold the plug and pull it, never

pull the cord itself. If the power cord becomes damaged, contact your nearest YOKOGAWA

representative. Addresses may be found on the back cover of this manual.

General Handling Precautions

Never place anything on top of the instrument, especially objects containing water. Entry of

water into the instrument may result in breakdowns.

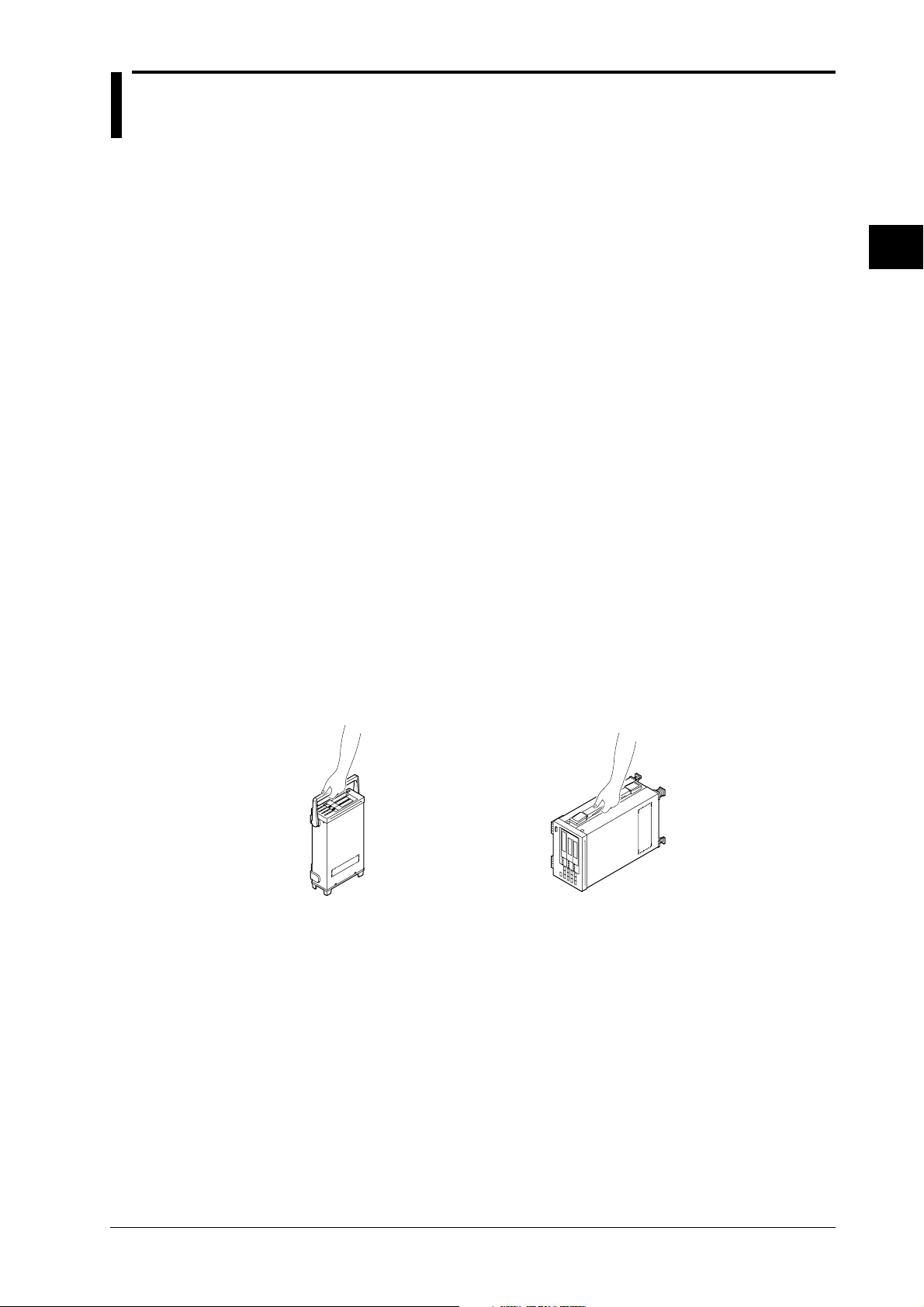

When Moving the Instrument

First turn off the power of the objects to be measured and disconnect the connected cables such

as for measurement and communication. Then turn off the power switch and unplug the power

cord from the power outlet. Always carry the instrument by the handles as shown below.

3

Before Operation

WT110 (253401) WT130 (253502, 253503)

To prevent internal temperature rise, do not block the vent holes in the instrument case.

Keep input terminals away from electrically charged articles as they may damage internal

circuits.

Do not allow volatile chemicals to come into contact with the case or operation panel. Also do

not leave any rubber or vinyl products in contact with them for prolonged periods. The

operation panel is made of thermoplastic resin, so take care not to allow any heated articles such

as a soldering iron to come in contact with it.

For cleaning the case and the operation panel, unplug the power cord first, then gently wipe

with a dry, soft and clean cloth. Do not use chemicals such as benzene or thinner, since these

may cause discoloration or damage.

IM 253401-01E

If the instrument will not be used for a long period, unplug the power cord from the AC outlet.

3-1

Page 24

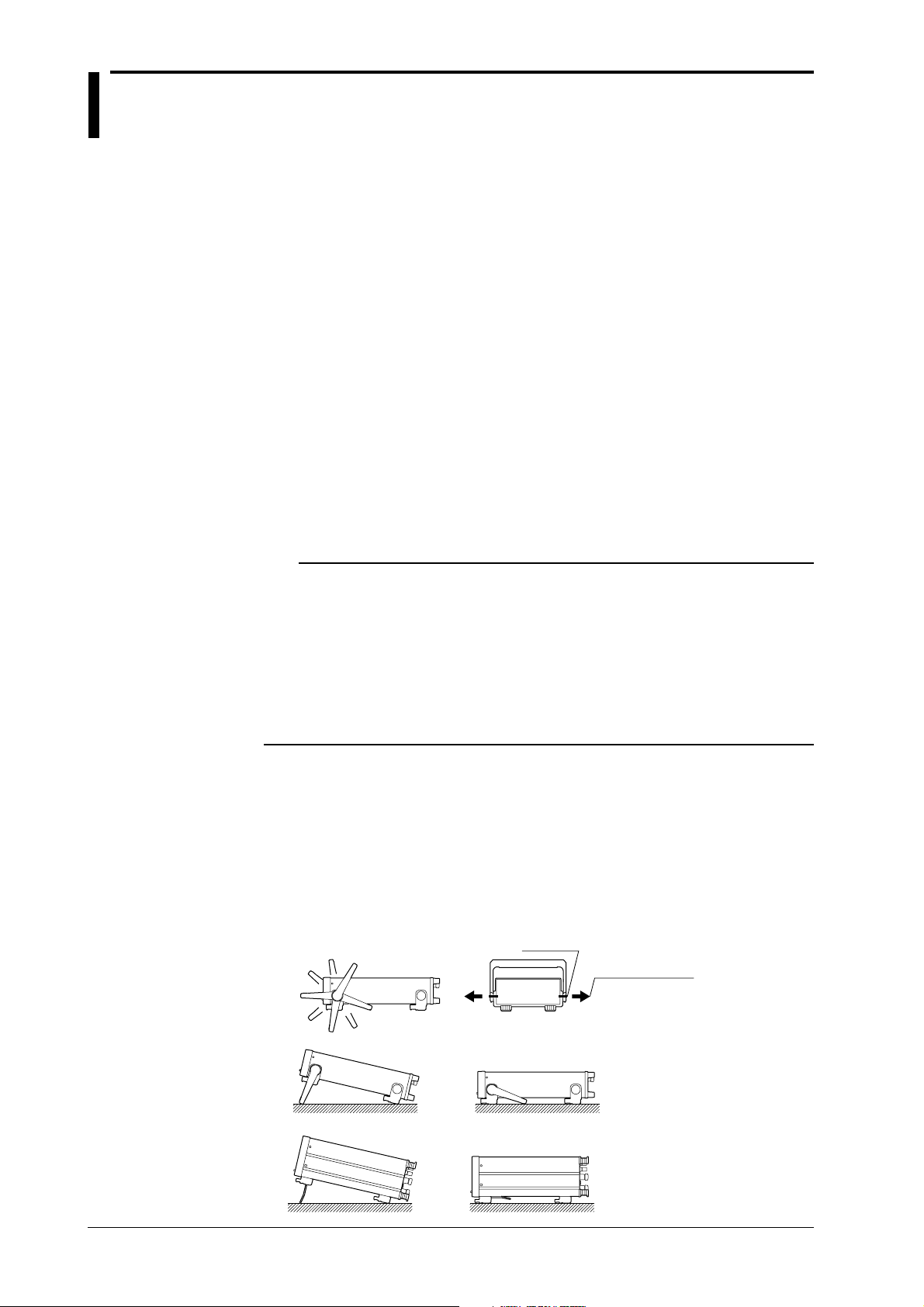

3.2 Installing the Instrument

1

2

3

4

5

6

7

8

1

3

Turning axis

Fixed positions of the handle

(We recommend the positions 1, 3, 5, or 8. When

using no 4, don´t put any weight on the instrument.)

Turn the stands after

pulling them approx.

2-3 mm on both sides.

Installation Conditions

The instrument must be installed in a place where the following conditions are met.

Ambient temperature and humidity

Ambient temperature: 5 to 40˚C

Ambient humidity: 20 to 80% RH (no condensation)

Horizontal position

The instrument must be installed horizontally. A non-horizontal or inclining position can

impede proper measurement of the instrument.

Well-ventilated location

Vent holes are provided on the top and bottom of the instrument. To prevent rise in internal

temperature, do not block these vent holes.

In case you removed the feet for rack-mounting the instrument, make sure to keep a space of at

least 20mm as not to block the vent holes.

Never install the instrument in any of the following places

• In direct sunlight or near heat sources;

• Near noise sources such as high voltage equipment or power lines ;

• Where an excessive amount of soot, steam, dust or corrosive gases is present;

• Where the level of mechanical vibration is high;

• Near magnetic field sources;

• In an unstable place.

Note

• To ensure high measurement accuracy, the instrument should only be used under the following

conditions.

Ambient temperature: 23 ± 5˚C

Ambient humidity: 30 to 75% RH (no condensation)

When using the instrument in the temperature ranges of 5 to 18 or 28 to 40˚C, add the temperature

coefficient to the accuracy as specified in chapter 15 “Specifications”.

• If the ambient humidity of the installation site is 30% or below, use an anti-static mat to prevent

generation of static electricity.

• Internal condensation may occur if the instrument is moved to another place where both ambient

temperature and humidity are higher, or if the room temperature changes rapidly. In such cases

acclimatize the instrument to the new environment for at least one hour before starting operation.

Installation Position

3-2

Desktop

Place the instrument in a horizontal position or tilted using the stand, as shown below.

• WT110 (253401)

When installing using the handle, verify that the handle is in a fixed position. While pulling the

handle approx. 2 to 3mm from the turning axes on both side, slowly turn the handle until it slips

into the fixed position.

•WT130 (253502, 253503)

IM 253401-01E

Page 25

3.2 Installing the Instrument

Rack mount

To install the instrument in a rack, use one of the following optional rack mount kits.

• Rack mount kit (option)

Specifications

WT110 EIA standard

WT110 JIS standard

WT110 EIA standard

WT110 JIS standard

Kit

751533-E2

751533-J2

751534-E2

751534-J2

Specifications

WT130 EIA standard

WT130 JIS standard

WT130 EIA standard

WT130 JIS standard

Kit

751533-E3

751533-J3

751534-E3

751534-J3

• Mounting procedure

1. Remove the handle. For the WT110, turn the handle to position 8 (refer to the picture on the

previous page) and remove the handle by pulling it approx. 10mm from the turning axes on

both sides. For the WT130, remove the handle by first removing the covers of the handle, and

then unfastening the screws.

WT110 (253401) WT130 (253502, 253503)

Turn the handle to

Turning axis

position 8 and remove

it by pulling it approx.

10 mm from the turning

axes on both sides.

Cover

3

Before Operation

Cover

Handle

For more detailed information regarding the rack mount procedure, refer to the instruction

manual accompanied with the rack mount kit.

2. Remove the feet from the instrument.

3. Remove the seals covering the mounting holes from the front side of the instrument.

4. Mount the rack mount brackets.

5. Mount the instrument in the rack.

Note

When mounting the instrument in a rack, make sure not to block the vent holes. Refer to page 3-2.

IM 253401-01E

3-3

Page 26

3.3 Wiring Precautions

Max allowable input Voltage input

Current input

Instantaneous max

(for 1s)

The peak value is 2000V

or the RMS value is 1500V,

whichever is less

The peak value is 150A

or the RMS value is 40A,

whichever is less

Continuous The peak value is 1500V

or the RMS value is 1000V,

whichever is less

The peak value is 100A

or the RMS value is 30A,

whichever is less

WARNING

CAUTION

Note

3-4

• To prevent hazards, make sure to apply a ground protection before

connecting the object being measured.

• Always turn OFF the power to the object being measured before

connecting it to the instrument. Never connect or disconnect the

measurement lead wires from the object while power is being supplied to it,

otherwise a serious accident may result.

• When the power switch is ON, never apply a voltage or current exceeding

the level specified in the table below to the voltage input or current input

terminal. When the power switch is OFF, turn off the power of the

instrument under measurement as well.

For details regarding the other terminals, such as the external input

terminal, refer to chapter 15 “Specifications”.

• In case you are using an external potential transformer (PT) or current

transformer (CT), use one which has a sufficient withstand voltage against

the voltage to be measured (a withstand voltage of 2E + 1000V is

recommended, where E is the measurement voltage.) Also be sure not to

allow the secondary side of the CT to go open-circuit while power is

supplied, otherwise an extremely dangerous high voltage will be generated

on the secondary side of the CT.

• If the instrument is used in a rack, provide a power switch so that power to

the instrument can be shut off from the front of the rack in an emergency.

• For safety reasons, make sure that the bare end of the measurement lead

wire connected to each input terminal does not protrude from the terminal.

Also make sure that the measurement lead wires are connected to the

terminals securely.

• The voltage ratings across the measuring (voltage and current) input and

the ground for this instrument varies under operating conditions.

• When protective covers are used on GP-IB or RS-232-C and external

input/output connectors;

Voltage across each measuring input terminal and ground 600Vrms max.

• When protective covers are removed from GP-IB or RS-232-C and from

external input/output connectors; or when connectors are used;

Voltage across A, ±(V and A side) input terminals and ground 400Vrms max.

Voltage across V terminal and ground 600Vrms max.

• The lead wires must have a sufficient margin in both withstand voltage and

current against those to be measured. They must also have insulation

resistance appropriate to their ratings. Ex. If measurement is carried out on

a current of 20A, use copper wires with a conductor cross-sectional area of

at least 4mm

• After completing the wiring of the WT130, the WIRING key needs to be used to select the wiring

system before starting measurements. Refer to section 3.9, page 3-15.

• When measuring high currents, or currents or voltages that contain high-frequency components, wiring

should be made with special attention paid to possible mutual interference and noise problems.

• Keep the lead wires short as possible.

• For current circuits indicated by thick lines in the wiring diagrams shown in section 3.3, use thick lead

wires appropriate for the current to be measured.

• The lead wire to the voltage input terminal should be connected as close to the load of the object under

measurement as possible.

• To minimize stray capacitance to ground, route both lead wires and grounding wires so that they are as

away from the instrument's case as possible.

2

.

IM 253401-01E

Page 27

3.4 Wiring the Measurement Circuit

• When applying a current to be measured directly to the input terminals of

WARNING

CAUTION

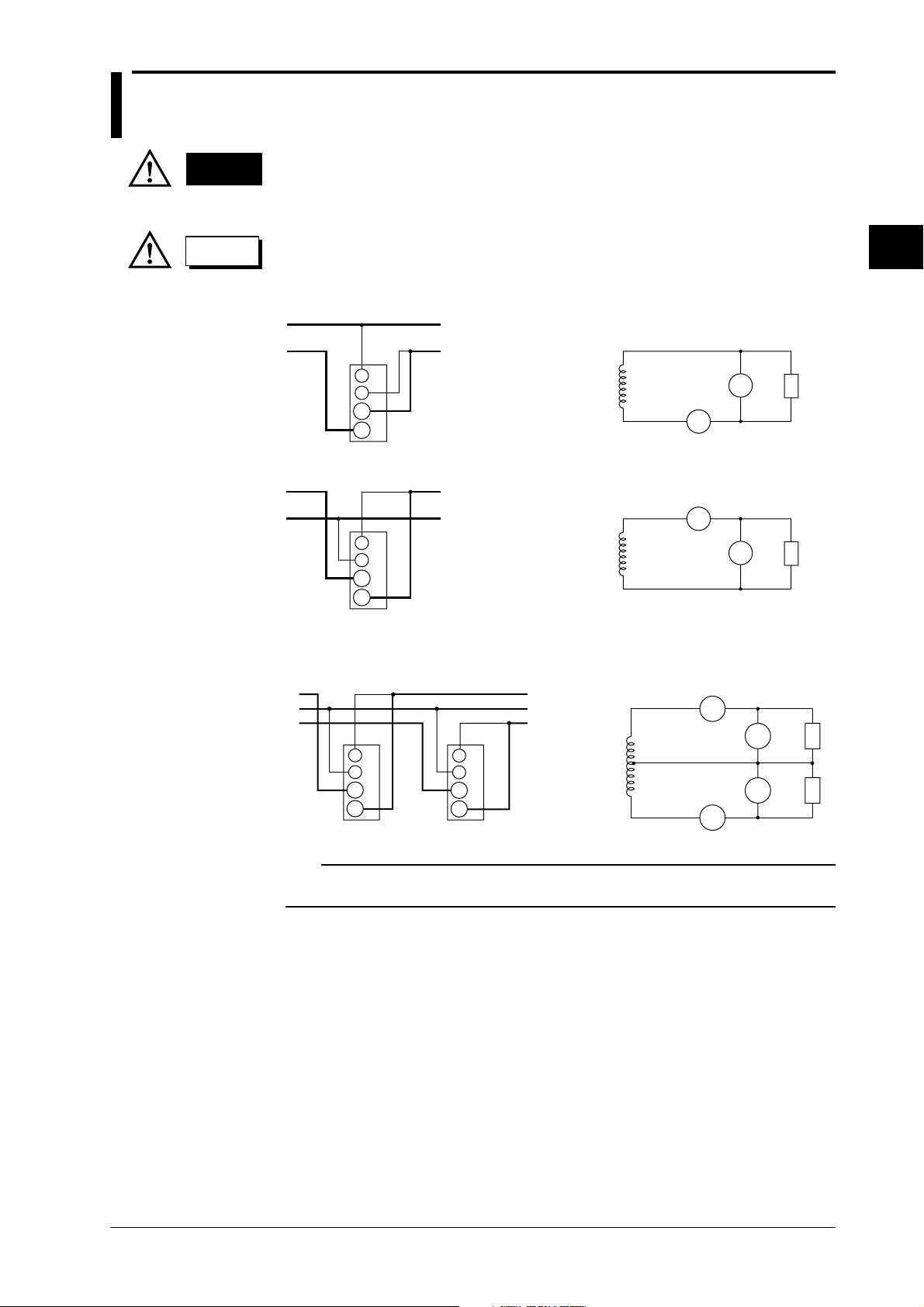

Wiring diagram for single-phase, two-wire system (253401, 253502, 253503)

the instrument, disconnect the input cable of the external sensor. A voltage

might be generated by the external sensor input terminal when connected.

• A load current flows in the thick lines show in the diagrams; therefore, a

wire with sufficient current capacity must be used for these lines.

SOURCE

LOAD

3

Before Operation

SOURCE

SOURCE

± A

A

A

A

±

SOURCE

V

±

A

±

Input terminal

(ELEMENT)

V

±

A

±

Input terminal

(ELEMENT)

LOAD

Wiring diagram for single-phase, three-wire system (253502, 253503)

SOURCE

N

V

±

A

±

Input terminal

(ELEMENT1)

Input terminal

(ELEMENT3)

Note

The wire connected from the source the ± current terminal must be routed as close as possible to the

ground potential in order to minimize measurement error.

LOAD

SOURCE

V

±

A

±

N

A

1

A

3

A

A

V

±

V

±

±

V

V

±

LOADV

LOADV

V

1

±

±

3

V

LOAD

IM 253401-01E

3-5

Page 28

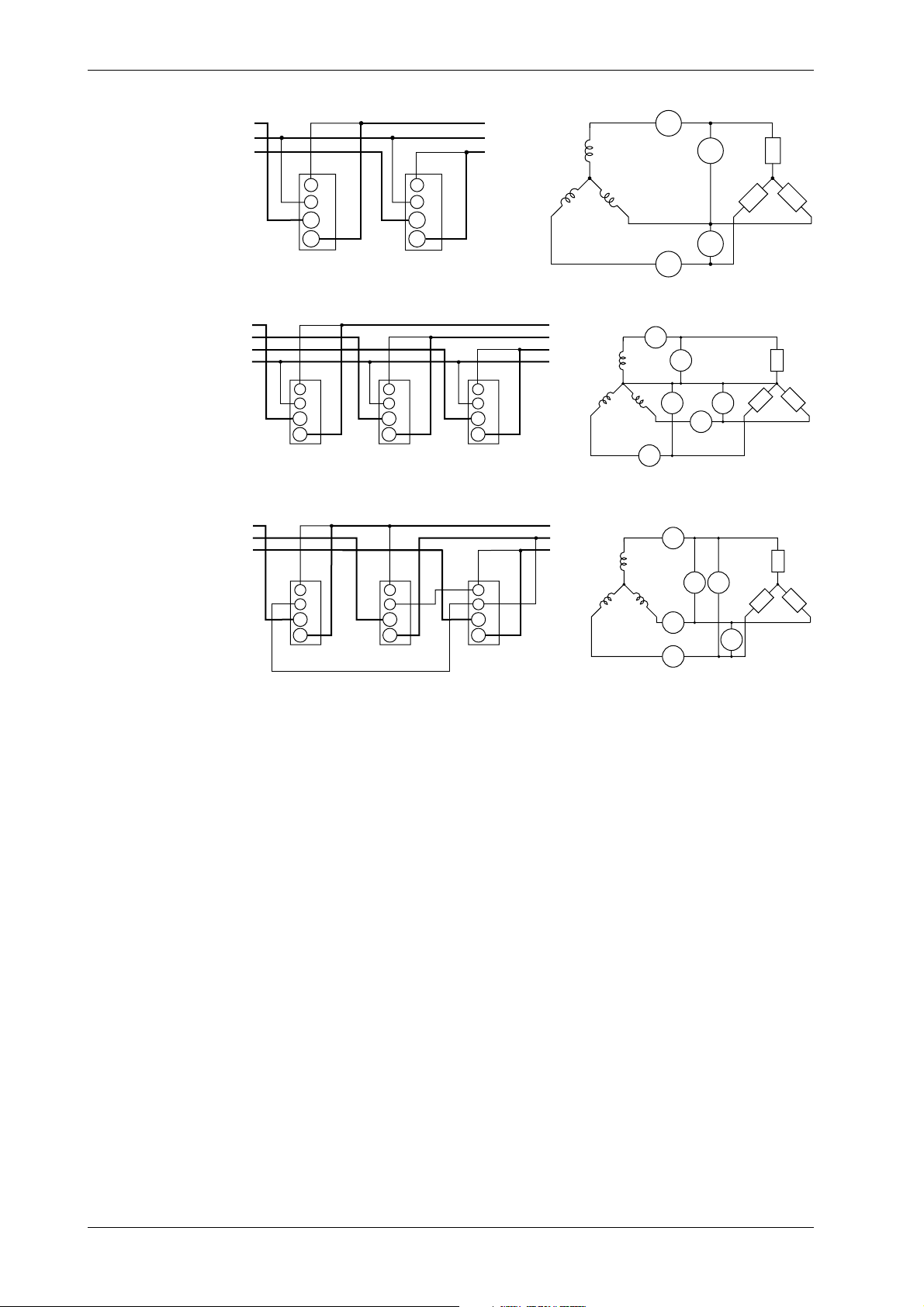

3.4 Wiring the Measurement Circuit

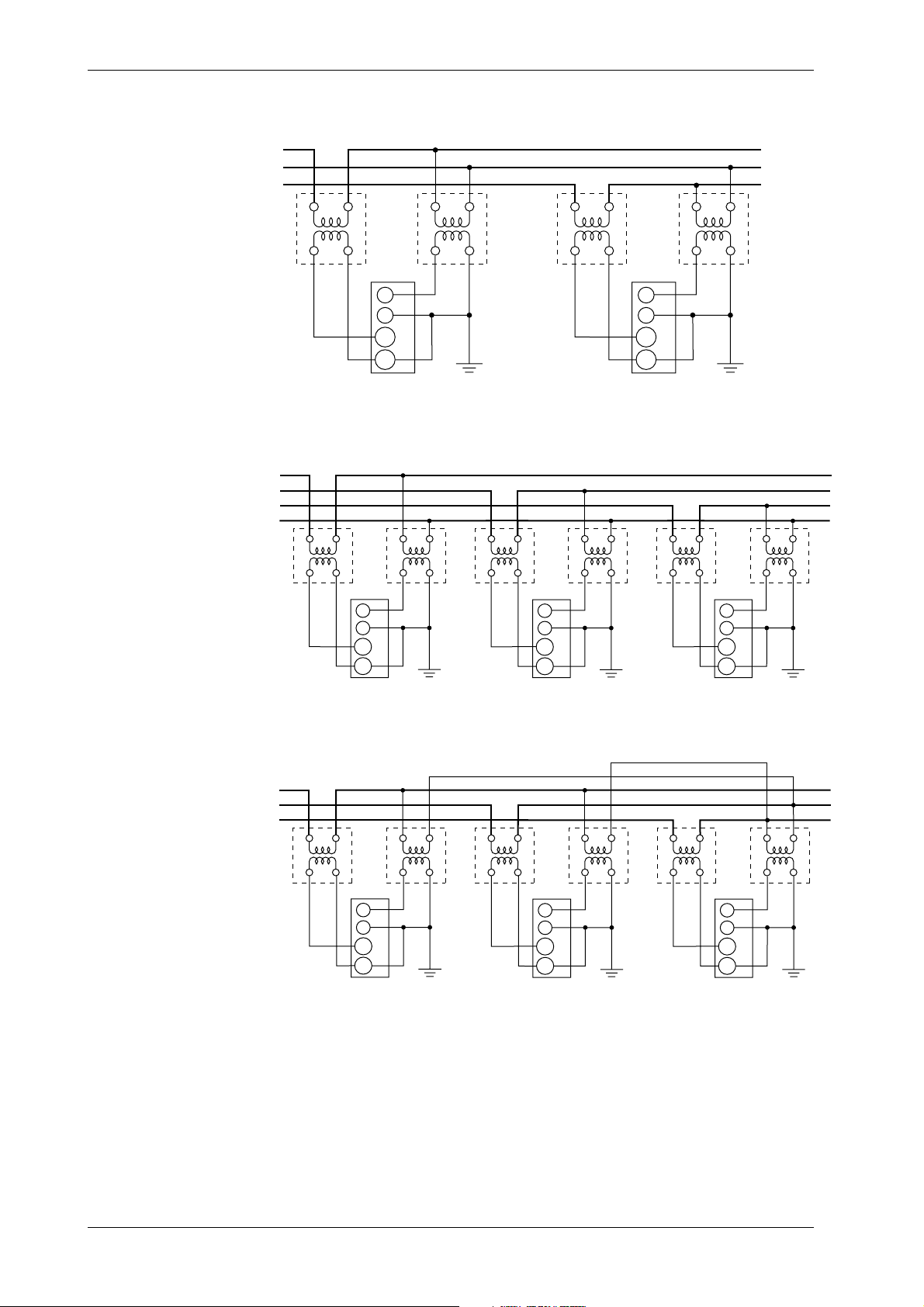

Wiring diagram for three-phase, three-wire system (253502, 253503)

SOURCE

R

S

T

V

±

A

±

Input terminal

(ELEMENT1)

V

±

A

±

Input terminal

(ELEMENT3)

LOAD

R

SOURCE

A

ST

A

Wiring diagram for three-phase, four-wire system (253503)

SOURCE

R

S

T

N

V

±

A

±

Input terminal

(ELEMENT1)

V

±

A

±

Input terminal

(ELEMENT2)

V

±

A

±

Input terminal

(ELEMENT3)

LOAD

SOURCE

A

R

N

ST

A

A

Wiring diagram for three-voltage, three-current system (253503)

SOURCE

R

S

T

V

±

A

±

Input terminal

(ELEMENT1)

V

±

A

±

Input terminal

(ELEMENT2)

V

±

A

±

Input terminal

(ELEMENT3)

LOAD

R

SOURCE

ST

±

1

A

V

1

V

±

LOAD

±

V

3

3

A

±

1

A

±

V

3

V

3

±

A

A

A

A

A

A

V

±

V

1

V

±

±

V

2

V

2

A

A

±

±

1

V

±

2

3

V

1

V

2

V

±

±

V

3

±

LOAD

LOAD

±

V

3-6

IM 253401-01E

Page 29

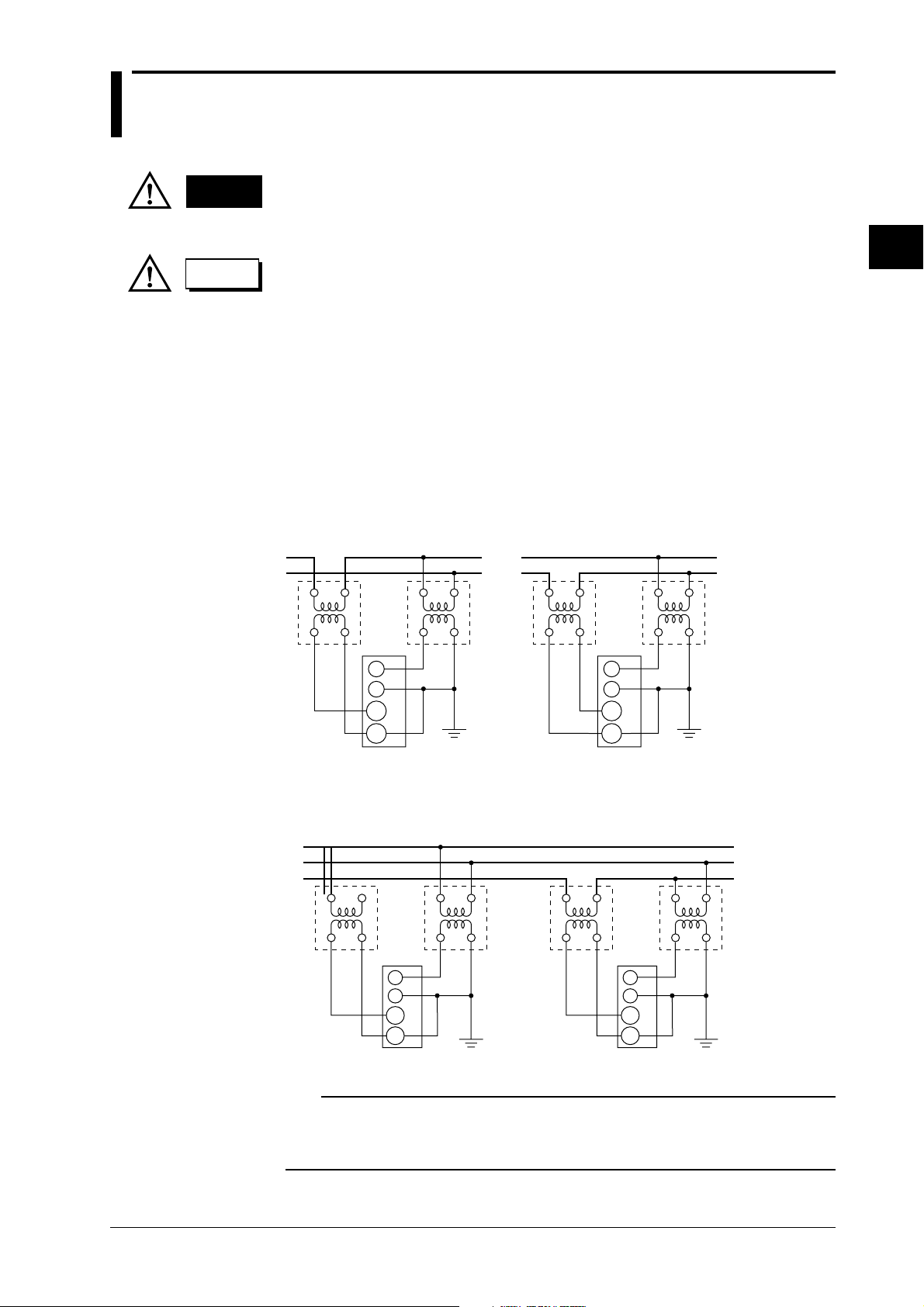

3.5 Wiring the Measurement Circuit when Using External PT/CT

• When using an external CT, do not allow the secondary side of the CT to

WARNING

go open-circuit while power is supplied, otherwise an extremely high

voltage will be generated on the secondary side of the CT.

• A load current flows in the thick lines shown in the diagrams; therefore, a

CAUTION

wire with sufficient current capacity must be used for these lines.

Use of a PT (or CT) enables measurement of voltage or current even if the maximum voltage or

maximum current of the object to be measured exceeds the maximum measuring range.

• If the maximum voltage of the object to be measured exceeds 600V, connect an external

potential transformer (PT), and connect the secondary side of the PT to the voltage input

terminals.

• If the maximum current of the object to be measured exceeds 20A, connect an external

current transformer (CT), and connect the secondary side of the CT to the current input

terminals.

Wiring diagram for single-phase, two-wire system with PT and CT connected

(253401, 253502, 253503)

SOURCE LOAD

CT

L

l

V

±

A

±

Input terminal

(ELEMENT)

V

v

PT

SOURCE LOAD

CT

L

l

V

±

A

±

Input terminal

(ELEMENT)

V

v

PT

3

Before Operation

Wiring diagram for single-phase, three-wire system with PT and CT connected

(253502, 253503)

IM 253401-01E

SOURCE

N

CT PT

L

l

V

±

A

±

Input terminal

(ELEMENT1)

V

v

CT PT

L

l

V

±

A

±

Input terminal

(ELEMENT3)

Note

• Using the scaling function enables direct reading of measured values on the display. Refer to section 4.4

on page 4-6.

• It must be noted that measured values are affected by the frequency and phase characteristics of PT and

CT.

LOAD

V

v

3-7

Page 30

3.5 Wiring the Measurement Circuit when Using External PT/CT

Wiring diagram for three-phase, three-wire system with PT and CT connected

(253502, 253503)

SOURCE

R

S

T

CT PT

L

V

CT PT

L

LOAD

V

l

V

±

A

±

Input terminal

(ELEMENT1)

v

l

V

±

A

±

v

Input terminal

(ELEMENT3)

Wiring diagram for three-phase, four-wire system with PT and CT connected

(253503)

SOURCE

R

S

T

N

L

CT PT

l

V

±

A

±

Input terminal

(ELEMENT1)

V

v

L

CT

l

V

±

A

±

Input terminal

(ELEMENT2)

V

PT

v

L

CT

l

V

±

A

±

Input terminal

(ELEMENT3)

LOAD

V

PT

v

Wiring diagram for three-voltage, three-current system with PT and CT

connected (253503)

SOURCE LOAD

R

S

T

L

CT

l

V

±

A

±

Input terminal

(ELEMENT1)

V

PT

v

L

CT

l

V

±

A

±

Input terminal

(ELEMENT2)

V

PT

v

L

CT

l

Input terminal

(ELEMENT3)

V

PT

v

V

±

A

±

3-8

IM 253401-01E

Page 31

3.6 Wiring the Measurement Circuit when Using the External Sensor

• Use an external sensor that is enclosed in a case which has sufficient

WARNING

withstand voltage against the voltages to be measured. Use of bare sensor

may cause an electric shock if the sensor is touched accidentally.

• Before connecting an external shunt, make sure the power to the shunt is

turned OFF. Always make sure to turn OFF the power switch of the source.

When the power is supplied a voltage will be present at the shunt, so don't

touch the shunt with your hands.

• When using the clamp sensor, make sure to fully understand the

specifications/instruction manual regarding voltages of the measurement

circuit and the clamp sensor, and verify that no hazard exists.

• Do not touch the current terminal of the input element and not connect any

measurement lead. When power is applied to the measurement circuit, a

voltage will be generated at the current terminal, which constitutes a

hazard.

• The connector to the input terminal for the external sensor should not have

bare wires protruding; make sure to make connections to this terminal

according to safety measures, since voltages will be present at the bare

wires, which constitutes a hazard.

3

Before Operation

CAUTION

• A load current flow in the thick lines shown in the diagrams; therefore, a

wire with sufficient current capacity must be used for these lines.

Note

• The external sensor must be selected carefully and its frequency and phase characteristics taken into

account.

• The external sensor must be wired so that the area between the wires connected to both ends of the

sensor is minimized, in order to reduce the effect of the magnetic field generated by the current to be

measured. Measurement is affected by field lines entering this area. Minimizing this area also reduces

the effects of external noise.

• Connect the external shunt as in the figures below. To avoid the effects of common-mode voltage, the

external shunt must be connected using AWG18 wires (cross sectional area of 1mm2).

• Since measurement accuracy decreases as an effect of an increase of wiring resistance and floating

capacity, keep the wiring between the external sensor and this instrument as short as possible.

V

Voltage input terminal

±

A

Current input terminal

±

Ext. sensor input terminal

Ext. shunt

• If the measuring object is high frequency and high power and is not grounded, use an isolation sensor

(CT, DC-CT, clamp)

Clamp sensor

V

Voltage input terminal

±

A

Current input terminal

±

Ext. sensor input terminal

LOAD

LOAD

IM 253401-01E

3-9

Page 32

3.6 Wiring the Measurement Circuit when Using the External Sensor

In cases where the maximum current of the object under measurement exceeds 20A,

measurement becomes possible by connecting an external sensor. The range for external sensor

input is either 2.5/5/10V or 50/100/200mV. Either range is available as an option.

In the following wiring diagrams, the external shunt is grounded. When using the clamp sensor,

replace the shunt with the clamp sensor.

Note

• When using the external sensor or the clamp sensor, take care not to reverse the polarity when applying

the clamp to the measurement circuit.

• Using the scaling function enables direct reading of measured values on the display. Refer to section 4.5

on page 4-8.

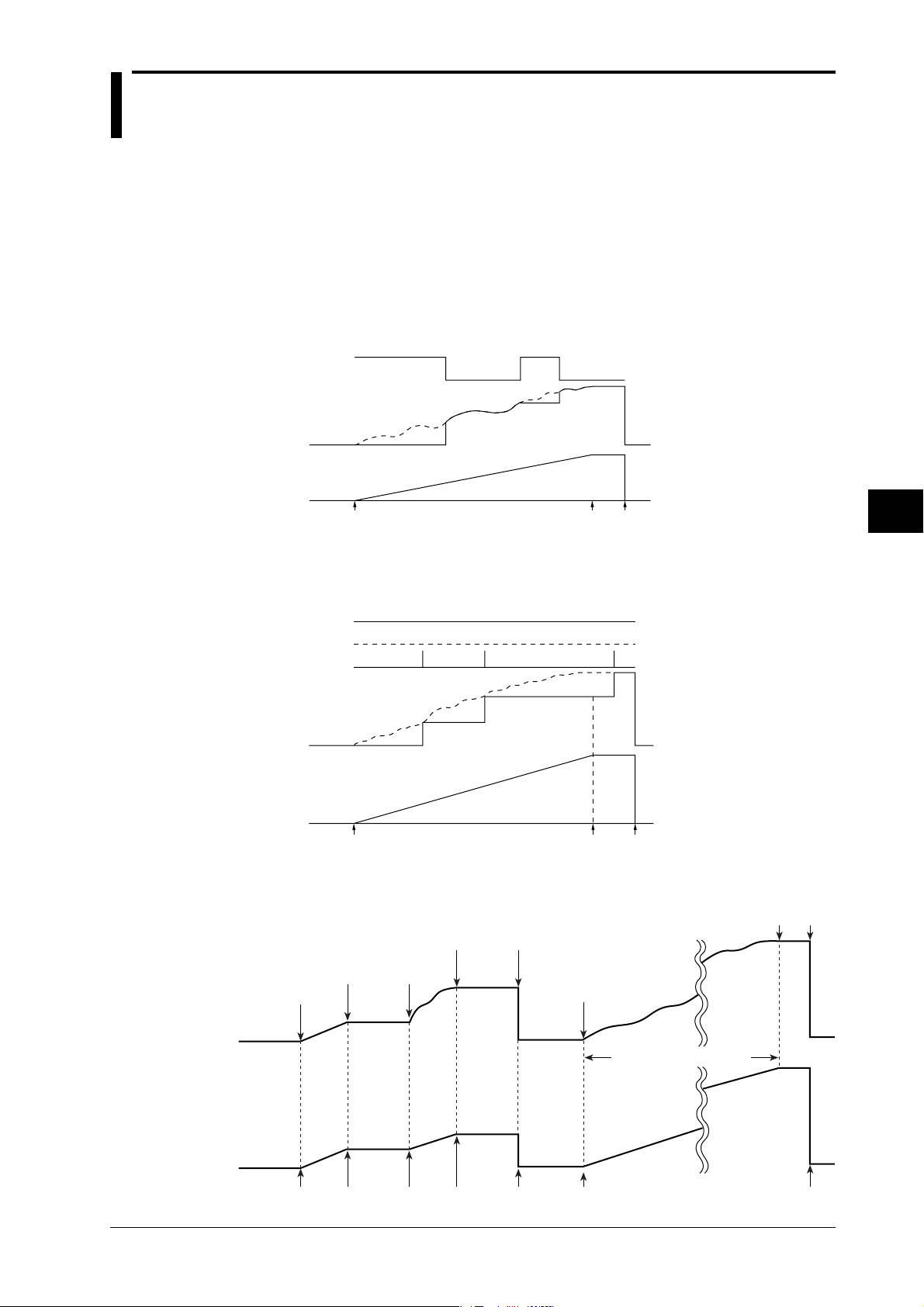

Wiring diagram for single-phase, two-wire system with external shunt