Page 1

User’s

Manual

Models SR10001/SR10002/SR10003/SR10004/

SR10006

SR10000 Recorder

Yo kogawa Electric Corporation

IM 04P03B01-01E

2nd Edition

Page 2

Foreword

Thank you for purchasing the YOKOGAWA SR10000 Recorder.

This user’s manual explains how to use the SR10000 recorder excluding the

communication functions. To ensure correct use, please read this manual thoroughly

before operation.

The following three manuals including this manual are available for the SR10000

Recorder.

• Paper Manual

Manual Title Manual No. Description

SR10000 Recorder IM 04P03B01-02E Explains concisely the operations of the

Operation Guide SR10000 Recorder. It is also provided in the

CD-ROM.

• Electronic Manuals Provided on the Accompanying CD-ROM

Manual Title Manual No. Description

SR10000 Recorder IM 04P03B01-02E Explains concisely the operations of the

Operation Guide SR10000 Recorder. This is the electronic

version of the paper manual.

SR10000 Recorder IM 04P03B01-01E This manual.

User’s Manual

SR10000 IM 04P03B01-17E Explains the communication functions of the

Communication Interface SR10000 Recorder using Ethernet interface and

User’s Manual the RS-422A/485 communication interface.

Notes

Trademarks

• The contents of this manual are subject to change without prior notice as a result of

continuing improvements to the instrument’s performance and functions.

• Every effort has been made in the preparation of this manual to ensure the accuracy

of its contents. However, should you have any questions or find any errors, please

contact your nearest YOKOGAWA dealer as listed on the back cover of this manual.

• Copying or reproducing all or any part of the contents of this manual without the

permission of Yokogawa Electric Corporation is strictly prohibited.

• The TCP/IP software of this product and the document concerning the TCP/IP

software have been developed/created by YOKOGAWA based on the BSD

Networking Software, Release 1 that has been licensed from the University of

California.

• All the brands or names of Yokogawa Electric’s products used in this manual are

either trademarks or registered trademarks of Yokogawa Electric Corporation.

• Microsoft, MS-DOS, Windows, Windows NT, and Windows XP are either registered

trademarks or trademarks of Microsoft Corporation in the United States and/or other

countries.

• Adobe, Acrobat, and PostScript are trademarks of Adobe Systems incorporated.

• For purposes of this manual, the TM and ® symbols do not accompany their

respective trademark names or registered trademark names.

• Company and product names that appear in this manual are trademarks or registered

trademarks of their respective holders.

Revisions

1st Edition February 2006

2nd Edition October 2006

2nd Edition: October 2006 (YK)

All Rights Reserved, Copyright © 2006 Yokogawa Electric Corporation

IM 04P03B01-01E

i

Page 3

How to Use This Manual

Structure of the Manual

Read the Operation Guide first to familiarize yourself with the basic operation, and

then read this manual. For a description of the communication function, see the

SR10000 Communication Interface User's Manual (IM 04P03B01-17E)

This user's manual consists of the following sections.

Chapter Title and Description

1 Functional Explanation and Setup Guide

Describes the functions of the SR10000 Recorder and provides a function setup

guide. Refer to this chapter when you are unsure of the details of the function that

you are operating.

2 Frequently Used Setup Operations (Setting Mode)

Describes how to change the input range, alarms, chart speed, etc.

3 Setup Operations for Convenient Functions (Setting Mode)

Describes the setup operations for convenient functions such as how to assign tags

to channels and how to set message strings that are to be printed.

4 Setup Operations for Changing/Adding Functions (Basic Setting Mode)

Describes the setup operations for changing or adding functions such as setting the

recorder to detect sensor burnouts and changing the contents that are printed on the

chart paper.

5 Troubleshooting

Describes error message and troubleshooting measures of the SR10000 Recorder.

6 Maintenance

Describes periodic inspection, calibration, and pen adjustment/printer carriage

adjustment.

7 Specifications

Gives the specifications of the SR10000 Recorder.

Appendix Describes the printout contents.

Index

.

Note

• This user’s manual covers information regarding the recorders with English as the printout

font (suffix code “2”).

Recorder’s Version and Functions Described in This Manual

The contents of this manual corresponds to the recorder with version 1.31.

SR10000 Versions and Functions

Version

1.21 or earlier

1.31

Suffix Code

–

/BT1

• Checking the Version Number

Press the

Hold down the

FUNC

key, key, or key to select VER ( ), then press the key.

FUNC

Software (Sold Separately)

The table below shows the relationship between the RXA10 Configuration Software

revisions and the SR10000 recorder versions.

RXA10 Configuration

Software revision

Yes: Compatible

Added or Modified Functions

–

(Added) Header printout

key to return to Operation mode.

Recorder version

1.21 or earlier

R3.01

1.31

YesYes

Reference

–

Section 1.3

ii IM 04P03B01-01E

Page 4

How to Use This Manual

Conventions Used in This Manual

Unit

K ........ Denotes 1024. Example: 768 KB (file size)

k ........ Denotes 1000.

Safety Markings

The following markings are used in this manual.

WARNING

CAUTION

Improper handling or use can lead to injury to the user or

damage to the instrument.

instrument to indicate that the user must refer to the user’s

manual for special instructions. The same symbol appears in

the corresponding place in the user’s manual to identify those

instructions. In the manual, the symbol is used in conjunction

with the word “WARNING” or “CAUTION.”

Calls attention to actions or conditions that could cause serious

or fatal injury to the user, and precautions that can be taken to

prevent such occurrences.

Calls attentions to actions or conditions that could cause light

injury to the user or damage to the instrument or user’s data,

and precautions that can be taken to prevent such occurrences.

This symbol appears on the

1

2

3

4

5

6

7

Note

Subheadings

On pages that describe the operating procedures in Chapter 2 through 4 and 6, the

following symbols are used to distinguish the procedures from their explanations.

Procedure

Explanation

Calls attention to information that is important for proper

operation of the instrument.

Follow the numbered steps. All procedures are written with

inexperienced users in mind; depending on the operation, not

all steps need to be taken.

This subsection describes the setting parameters and the

limitations on the procedures. It does not give a detailed

explanation of the function. For details on the function, see

chapter 1.

App

Index

IM 04P03B01-01E

iii

Page 5

Contents

Foreword ......................................................................................................................................... i

How to Use This Manual ................................................................................................................. ii

Chapter 1 Functional Explanation and Setup Guide

1.1 Measuring Input Section .................................................................................................. 1-1

1.2 Alarms .............................................................................................................................. 1-6

1.3 Recording ......................................................................................................................... 1-8

1.4 Remote Control Function (/R1 Option) .......................................................................... 1-19

1.5 Other Functions ............................................................................................................. 1-21

1.6 Function Setup Guide .................................................................................................... 1-23

Chapter 2 Frequently Used Setup Operations (Setting Mode)

2.1 Setting the Input Range ................................................................................................... 2-1

2.2 Setting the Alarm.............................................................................................................. 2-9

2.3 Setting the Unit on Linearly Scaled Channels ................................................................ 2-11

2.4 Changing the Chart Speed ............................................................................................ 2-12

2.5 Setting the Date/Time .................................................................................................... 2-13

Chapter 3 Setup Operations for Convenient Functions (Setting Mode)

3.1 Setting the Trend Recording Interval (Dot Model)............................................................ 3-1

3.2 Setting the Filter (Pen Model) .......................................................................................... 3-2

3.3 Setting the Moving Average (Dot Model) ......................................................................... 3-3

3.4 Setting Recording Zones for Each Channel (Zone Recording) ........................................ 3-4

3.5 Setting the Partial Expanded Recording .......................................................................... 3-5

3.6 Turning Trend Recording (Dot Model) and Periodic Printout ON/OFF for Each Channel 3-6

3.7 Setting Tags on Channels ................................................................................................ 3-7

3.8 Setting the Message String .............................................................................................. 3-8

3.9 Setting the Secondary Chart Speed (Remote Control Function, /R1) ............................. 3-9

3.10 Applying a Bias on the Measuring Input Signal ............................................................. 3-10

3.11 Performing Calibration Correction (/CC1 Option) .......................................................... 3-11

3.12 Setting Up Start Printout and End printout (/BT1 Option) .............................................. 3-13

3.13 Regarding the Message Format (/BT1 Option) .............................................................. 3-18

3.14 Setting the Date/Time for Switching between Standard Time and DST ......................... 3-20

Chapter 4 Setup Operations for Changing/Adding Functions

(Basic Setting Mode)

4.1 Changing the Auxiliary Alarm Function ............................................................................ 4-1

4.2 Changing the Integration Time of the A/D Converter ....................................................... 4-3

4.3 Setting the Burnout Detection Function ........................................................................... 4-4

4.4 Setting the RJC Function on TC Input Channels ............................................................. 4-5

4.5 Changing the Channel Recording Color (Dot Model) ...................................................... 4-6

4.6 Recording by Compensating for the Pen Offset along the Time Axis (Pen Model) .......... 4-7

4.7 Turning Printouts ON/OFF (Selecting the Channel/Tag Printout and Turning ON/OFF the

Channel, Alarm, Recording Start, New Chart Speed, Scale, and Pen Color

Printouts) .............................................................................................................. 4-8

4.8 Turning Periodic Printout ON and OFF and Setting the Interval .................................... 4-10

4.9 Setting the Key Lock ...................................................................................................... 4-12

4.10 Enabling the Moving Average Function (Dot Model)...................................................... 4-15

4.11 Enabling the Filter Function (Pen Model) ....................................................................... 4-16

iv IM 04P03B01-01E

Page 6

Contents

4.12 Enabling the Partial Expanded Recording Function ...................................................... 4-17

4.13 Changing the Printout Font ............................................................................................ 4-18

4.14 Changing the Print/Display Format of the Date ............................................................. 4-19

4.15 Enabling the Bias, Low-Cut, and Calibration Correction (/CC1 Option) Functions ........ 4-20

4.16 Changing the Time Printout Format ............................................................................... 4-22

4.17 Initializing the Settings ................................................................................................... 4-24

4.18 Assigning Functions to the Remote Control Input Terminals (/R1 Option) ..................... 4-25

4.19 Selecting to Show/Hide the FUNC Key Menus .............................................................. 4-27

4.20 Selecting to Show/Hide Setting Mode Menus ................................................................ 4-29

4.21 Enabling/Disabling the Customized Menu ..................................................................... 4-31

4.22 Setting the Calibration Correction Function (/CC1 Option) ............................................ 4-34

4.23 Enabling Start Printout, End printout, and Message Format (/BT1 Option) ................... 4-35

4.24 Changing the Temperature Unit ..................................................................................... 4-37

Chapter 5 Troubleshooting

5.1 A List of Error Messages .................................................................................................. 5-1

5.2 Troubleshooting Flow Charts ........................................................................................... 5-4

Chapter 6 Maintenance

6.1 Periodic Inspection ........................................................................................................... 6-1

6.2 Cleaning the Recorder ..................................................................................................... 6-2

6.3 Calibrating the Recorder .................................................................................................. 6-3

6.4 Adjusting the Pen Position (Pen Model) .......................................................................... 6-5

6.5 Adjusting the Dot Printing Position (Dot Model) ............................................................... 6-7

1

2

3

4

5

6

7

Chapter 7 Specifications

7.1 Input Specifications .......................................................................................................... 7-1

7.2 Alarm Function Specifications .......................................................................................... 7-3

7.3 Recording Function Specifications ................................................................................... 7-4

7.4 Display Function Specifications ....................................................................................... 7-7

7.5 Specifications of Optional Functions ................................................................................ 7-9

7.6 General Specifications ................................................................................................... 7-13

Appendix

Appendix 1 Periodic Printout Interval ................................................................................ App-1

Index

App

Index

IM 04P03B01-01E

v

Page 7

Chapter 1 Functional Explanation and Setup Guide

1.1 Measuring Input Section

Input Section

Number of Measurement Channels and Scan Interval

The recorder samples the input signals on the measurement channels at the scan

interval to obtain the measured values.

Model Number of Channels Scan Interval

1-pen model 1 125 ms

2-pen model 2 125 ms

3-pen model 3 125 ms

4-pen model 4 125 ms

Dot model 6 1 s

Input Type, Measurable Range, and Computation

The recorder can measure the following types of inputs.

Input Type Measurable Range

DC voltage DC voltage in the range of ±20 mV to ± 50 V

1-5V See “1-5V” below.

Thermocouple Temperature range corresponding to each type: R, S, B, K, E, J, T, N, W, L, U,

and WRe

RTD Temperature range corresponding to each type: Pt100Ω and JPt100Ω

ON/OFF input Contact input: Open contact is OFF (0). Closed contact is ON (1).

Voltage input: Less than 2.4 V is OFF (0). Greater than or equal to 2.4 V is ON (1).

Within ±6 V.

1

Functional Explanation and Setup Guide

(However, the scan interval is 2.5 s when the

integration time of the A/D converter is 100 ms.)

• 1-5V

1-5V is scaled to values in the appropriate unit to be used as measured values. Also,

the low-cut function (input less than 0% is fixed to 0% (scale left value)) can be used.

• Current Input

A shunt resistor is attached to the input terminal. The current signal is converted to a

voltage signal and measured. The measurable range is the range equivalent to the

“DC voltage” range indicated above after converting the current to the voltage signal.

Note

Three types of shunt resistors (250 Ω, 100 Ω, and 10 Ω) are available for current input (See

“Optional Accessories (Sold Separately)” in the

shunt resistor is used to convert the signal to the range of 1 to 5 V for 4 to 20 mA input.

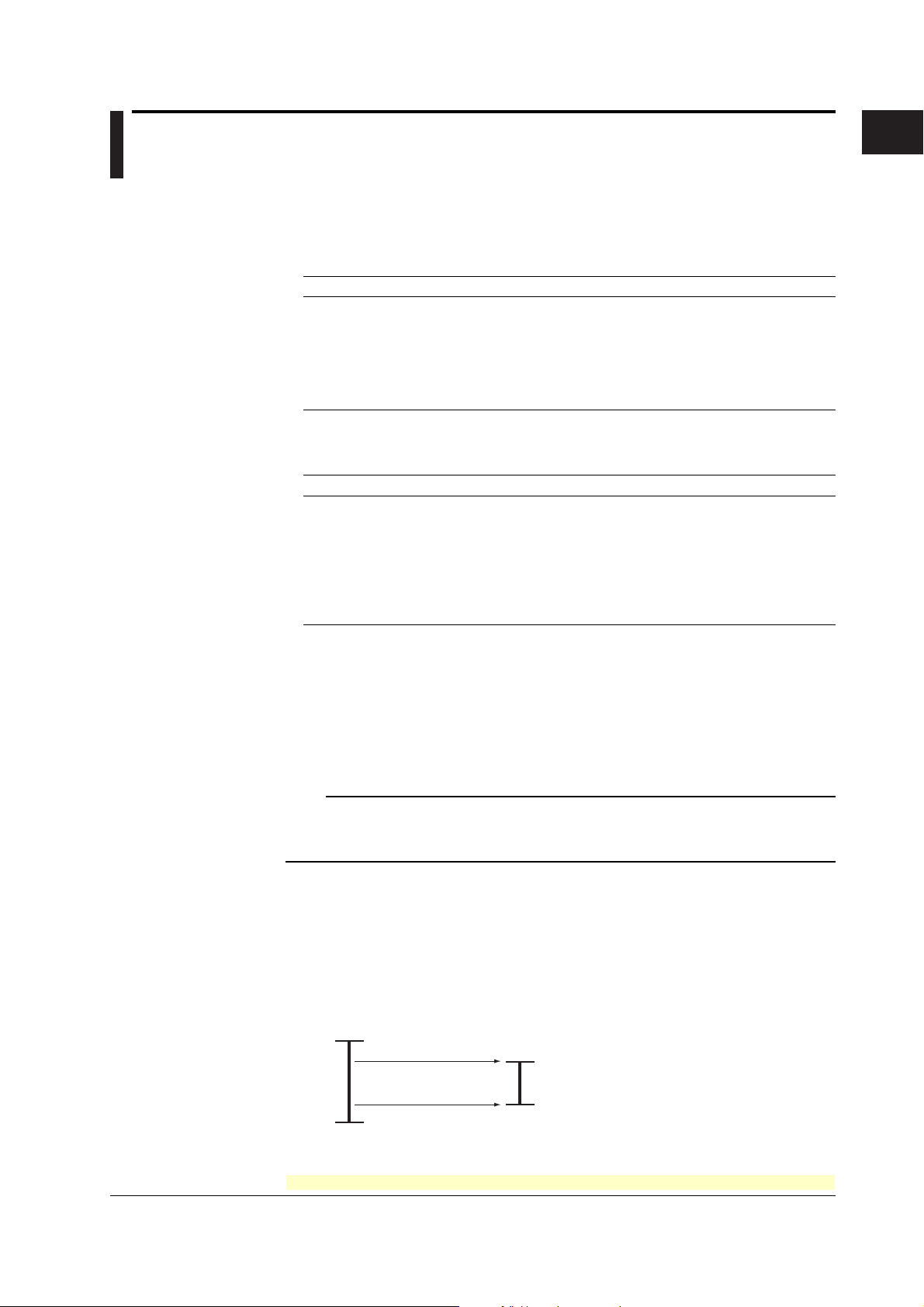

• Range Type, Measurable Range, and Recording Span

Various “range type” are available for the different types of inputs (for example

thermocouple type R). Each range type has a preset measurable range (0.0 to

1760.0°C for thermocouple type R). Measurement can be made by specifying an

arbitrary range within the measurable range as the

in the input range are recorded on the chart paper. The range of measured values

that are recorded is called the

Measurable range (Thermocouple Type R example)

1760.0°C

recording span

Input range or recording span

Operation Guide

input range

). For example, a 250-Ω

. The measured values

.

1500.0°C (rightmost value of span)

IM 04P03B01-01E

300.0°C (leftmost value of span)

0.0°C

<Related Topics> Setting the input range: Section 5.1

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

1-1

Page 8

1.1 Measuring Input Section

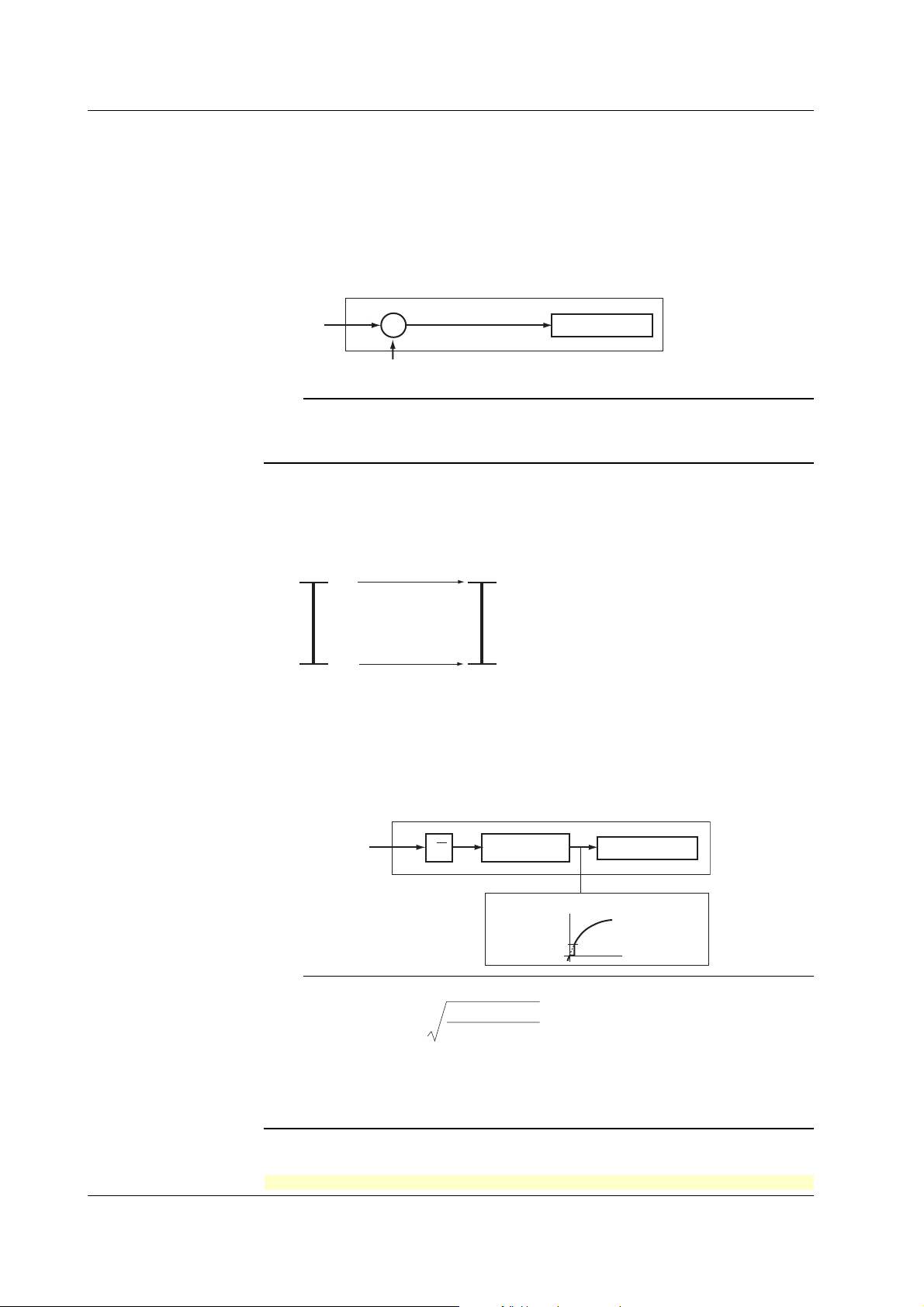

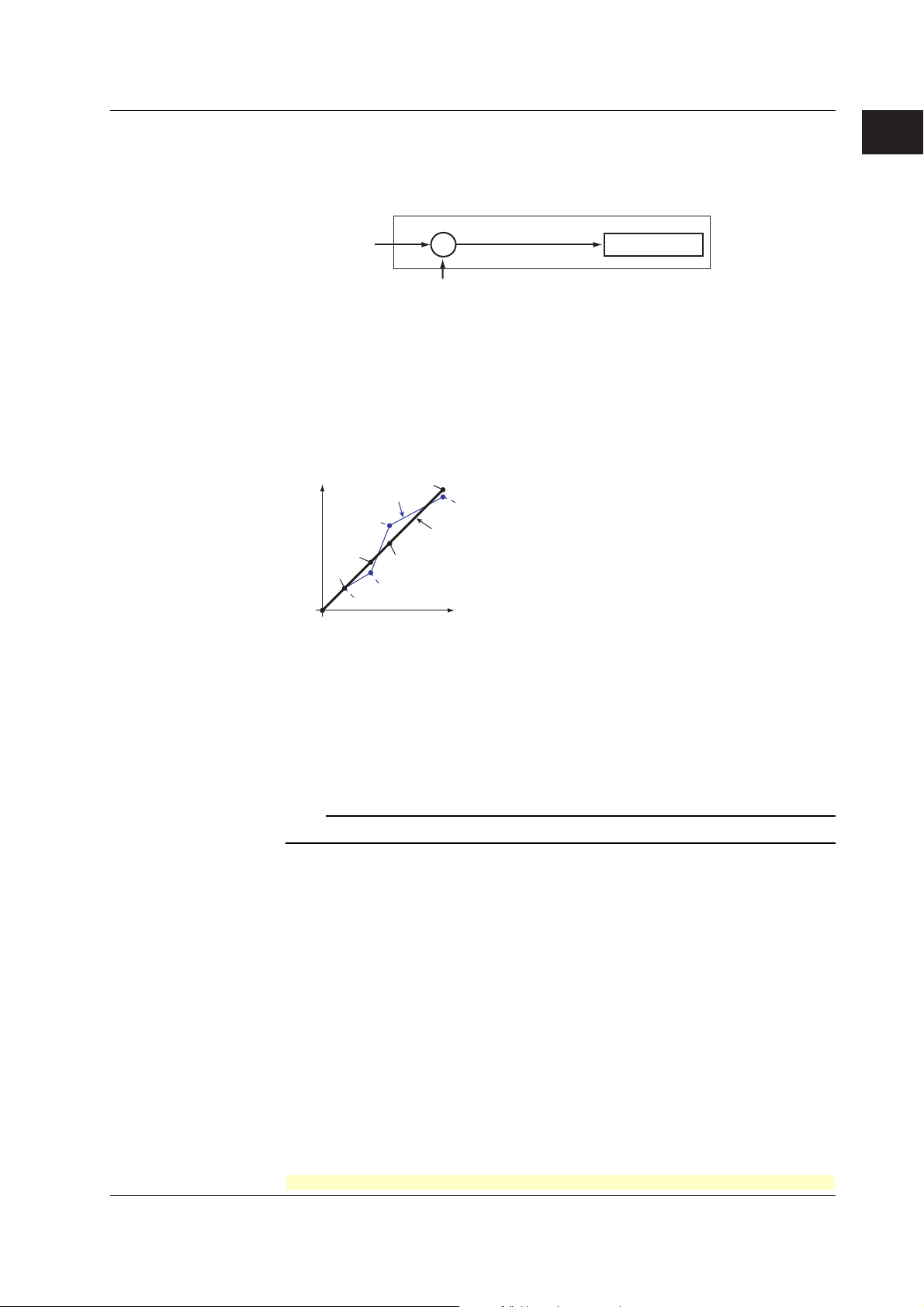

• Delta Computation

The value obtained by subtracting the measured value of another channel (called the

reference channel

) from the input value of the channel set to delta computation is used

as the measured value of that channel. The reference channel must be assigned to a

channel whose channel number is less than that of the channel on which delta

computation is specified. The channel on which delta computation is specified is

automatically set to the same range type as the reference channel.

Channel set to delta computation

Input

value

–

Measured value on the reference channel

Measured value

Note

A channel whose input type is set to DC voltage, TC, or RTD can be designated as a

reference channel. However, channels set to scaling or square root computation cannot be

designated.

• Scaling

The input values are scaled to values in the appropriate unit to be used as measured

values.

Measured valueInput value

10 V

0 V −100.0°C

• Square Root Computation

When the input type is DC voltage, the square root of the input value is calculated, the

result is scaled to a value in the appropriate unit, and used as the measured value of

the channel. Also, the low-cut function (input less than a given measured value is

fixed to 0% (scale left value)) can be used.

300.0°C

1-2

Channel set to square root computation

Input value

√

Scaling

Measured value

Low-cut value

Measured value

Result of square

root computation

Input value

Note

The square root computation on the recorder uses the following formula.

min

V - V

F = ( F - F )

x

max

min min

where V

min

(leftmost value of span) < V

F

min

(leftmost value of scale after scaling) < F

scaling)

Vx is the input voltage and Fx is the scaled value

x

max min

V - V

<Related Topics> Setting the input range: Section 5.1

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

+ F

max

(rightmost value of span)

max

(rightmost value of scale after

IM 04P03B01-01E

Page 9

1.1 Measuring Input Section

• Bias

A given value (bias value) is added to the input value and used as the measured

value of that channel.

Biased channel

Input value

+

Bias value

Measured value

<Related Topics> Setting the bias: Sections 4.15 and 3.10

• Calibration Correction (/CC1 Option)

Corrects the measured value of each channel using segment linearizer approximation

and makes the resultant value the measured value of the channel. You can set

arbitrary correction values for 2 to 16 points of arbitrary measured values. Linear

approximation is used between two segment points. Correction values can be

assigned using revise values or absolute values.

Scale value

Measured value

B3

B2

B1

A2

A1

A4

A3

B4

B5

A5

Correction

value

Calibration point

Correction using

revise values

Measured value = A

Correction value = B – A

A1 to A5: Measured value (measured value before correction)

B1 to B5: Correction value (measured value after correction)

Correction using

absolute values

Measured value = A

Correction value = B

<Related Topics> Setting the calibration correction function: Sections 4.15, 4.22, and

3.11

1

Functional Explanation and Setup Guide

Burnout Detection of Thermocouples

This function makes the recording go off the scale to the right or left when the

thermocouple burns out while measuring temperature with a thermocouple. This function

can also be used on 1-5V. The burnout detection function can be set for each channel.

By default, this function is disabled.

Note

For 1-5V, a burnout occurs when the input value is less than or equal to 0.2 V.

<Related Topics> Setting the burnout detection function: Section 4.3

Reference Junction Compensation of Thermocouple Input

When measuring the temperature using a thermocouple, the reference junction

compensation on the recorder can be used. When using external reference junction

compensation, you can set the reference voltage. The reference junction compensation

can be set for each channel.

By default, the recorder is configured to use the internal reference junction compensation

function.

IM 04P03B01-01E

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

1-3

Page 10

1.1 Measuring Input Section

Note

When using external reference junction compensation, set an appropriate reference junction

compensation voltage. For example, if the reference junction temperature of the external

reference compensation is T0 °C, set the reference compensation junction voltage to the

thermoelectromotive force of the 0°C reference of T0 °C.

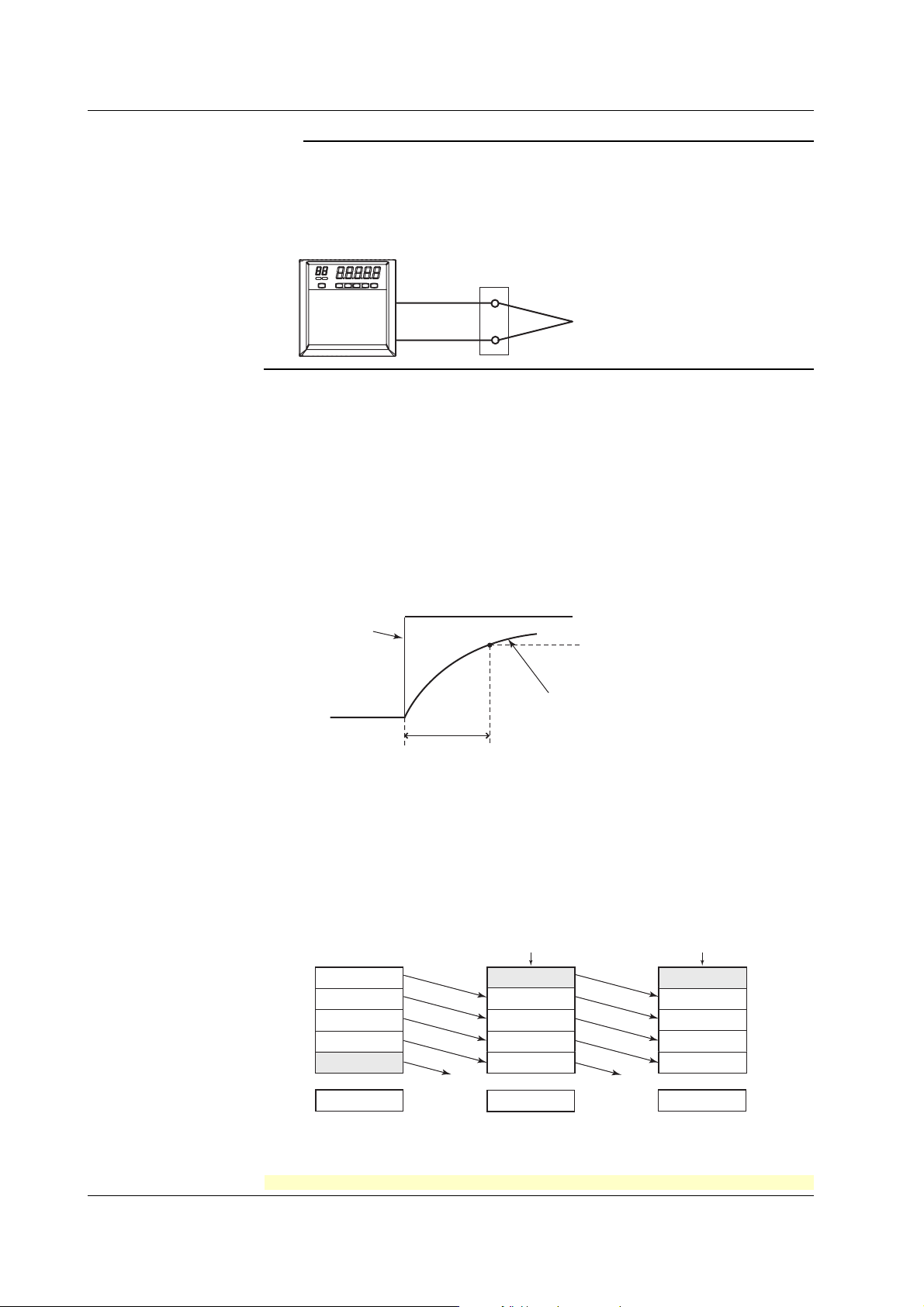

Example when using external reference junction compensation

Recorder

<Related Topics> Setting the reference junction compensation function: Section 4.4

Noise Elimination from Input Signals

Filter and Moving Average

This function used to suppress the effects of noise that is riding on the signal. The pen

model and dot model are equipped with a filter function and a moving average function,

respectively. The function can be set for each measurement channel. However, it does

not operate on channels set to ON/OFF input.

• Filter (Pen Model)

The filter is a low-pass filter. The time constant can be set to 2 s, 5 s, or 10 s.

Filter result (output for a step input)

Copper wire

External reference junction compensation

(Hold the contact point of the thermocouple

and copper wire at T

0

°C)

Thermocouple

Input signal

2, 5, 10 s (time constant, the time it takes

to reach 63.2% of the output value)

63.2% of the output value

Output response curve

(when using the filter)

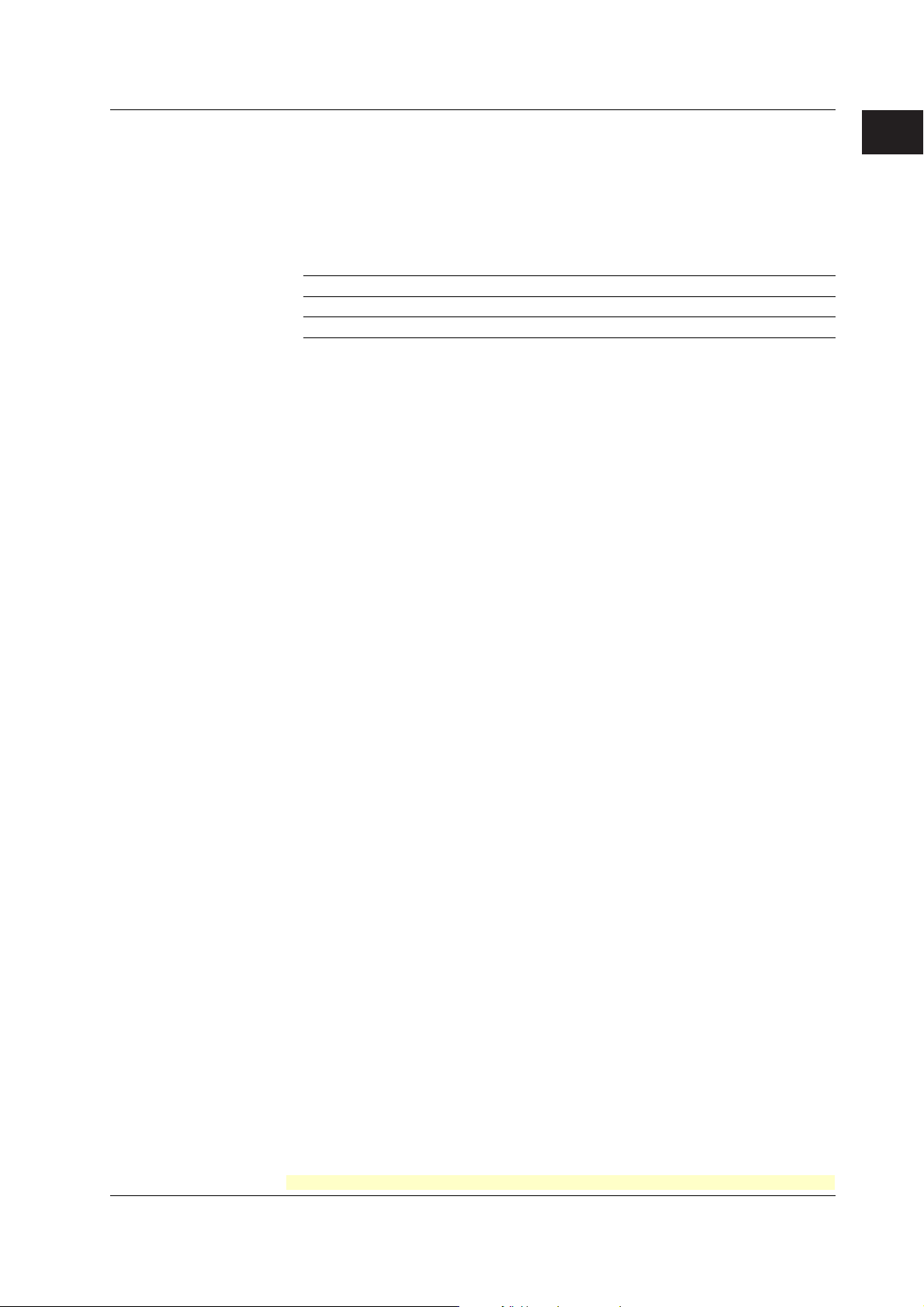

• Moving Average (Dot Model)

The average value of the m most recent values acquired at the scan interval is used

as the measured value of the channel. The number of moving-averaged data points

(m) can be set in the range 2 to 16. The figure below shows an example indicating the

operation of the buffer for the moving average computation when the number of

moving averaged data points is set to 5.

Buffer data for the

n+2th sampling time

10.0 mV

15.0 mV

10.0 mV

5.0 mV

0.0 mV

Deleted

8.0 mV

Moving

average

Buffer data for the

nth sampling time

10.0 mV

1

5.0 mV

2

0.0 mV

3

–5.0 mV

4

–10.0 mV

5

0.0 mV

Buffer data for the

n+1th sampling time

Most recent data Most recent data

15.0 mV

10.0 mV

5.0 mV

0.0 mV

–5.0 mV

Deleted

5.0 mV

1-4

<Related Topics> Setting the filter: Sections 4.11 and 3.2

Setting the moving average: Sections 4.10 and 3.3

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

IM 04P03B01-01E

Page 11

1.1 Measuring Input Section

Integration Time of the A/D Converter

The recorder uses an A/D converter to convert the sampled analog signal to a digital

signal. By setting the integration time of the A/D converter to match the time period

corresponding to one cycle of the power supply or an integer multiple of one cycle, the

power supply frequency noise can be effectively suppressed.

The integration time of the A/D converter is selected according to the model from the

table below.

Model Integration Time of the A/D Converter

Pen model Select 16.7 ms (60 Hz), 20 ms (50 Hz), or Auto

Dot model Select 16.7 ms (60 Hz), 20 ms (50 Hz), 100 ms or Auto

• If Auto is selected, the recorder detects the power supply frequency and automatically

selects 16.7 ms or 20 ms.

• If Auto is specified when using the 24-VDC power supply on a recorder with the 24VDC/AC power supply (/P1 option), the integration time is fixed to 20 ms (50 Hz).

• Because 100 ms is an integer multiple of 16.7 ms and 20 ms, this setting can be used

to suppress the power frequency noise for either frequency, 50 Hz or 60 Hz.

• The scan interval on the dot model is 1 s when the integration time is set to 16.7 ms or

20 ms and 2.5 s when the integration time is set to 100 ms.

<Related Topics> Setting the A/D integration time: Section 4.2

1

Functional Explanation and Setup Guide

IM 04P03B01-01E

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

1-5

Page 12

1.2 Alarms

This function generates an alarm when the measured data meets a certain condition.

The alarm status is displayed on the screen while recording the alarm occurrence/

release on the chart paper.

Also, alarm output relays can be used to output contact signals when alarms occur (/A1,

/A2, and /A3 options).

Alarm Types

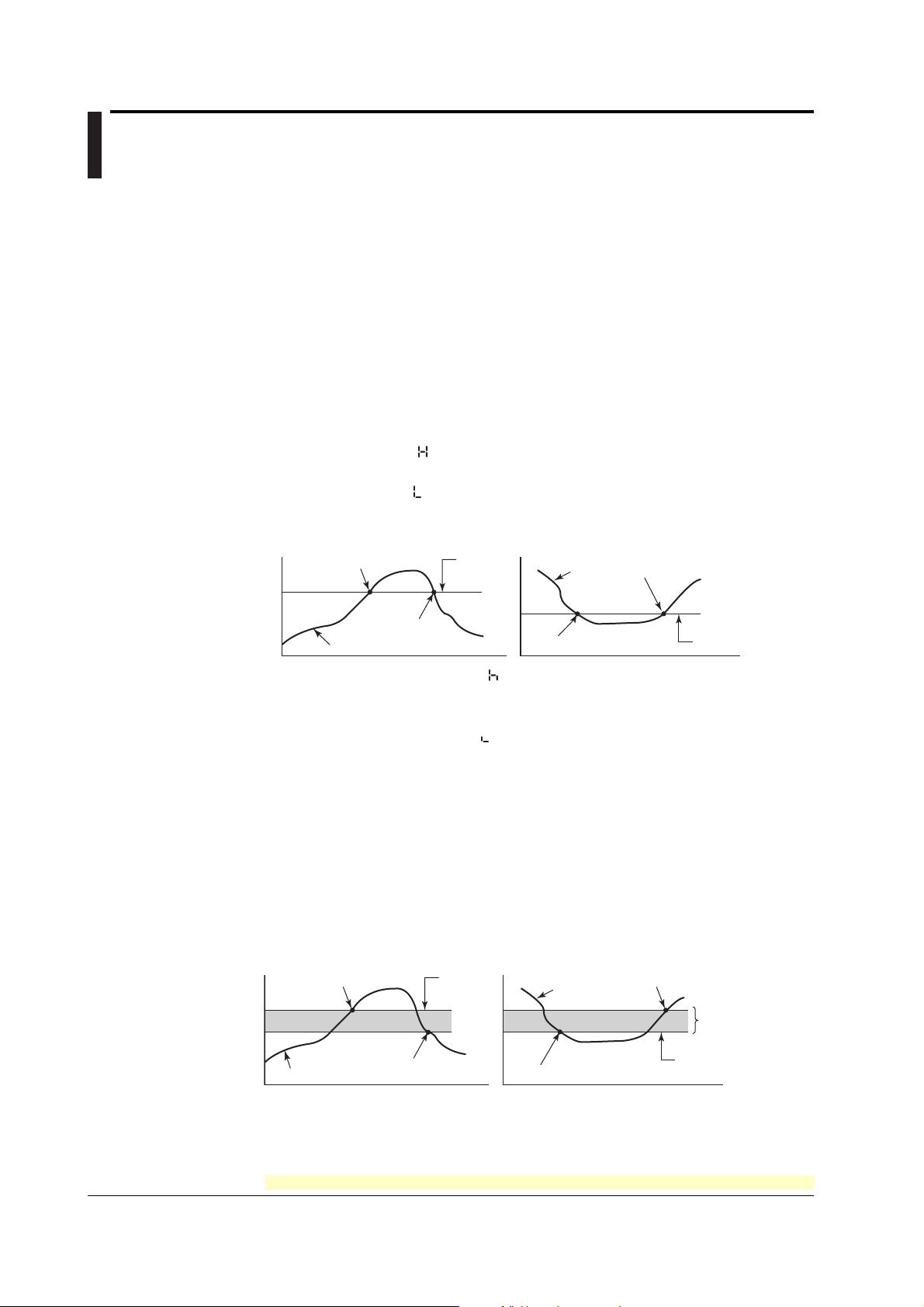

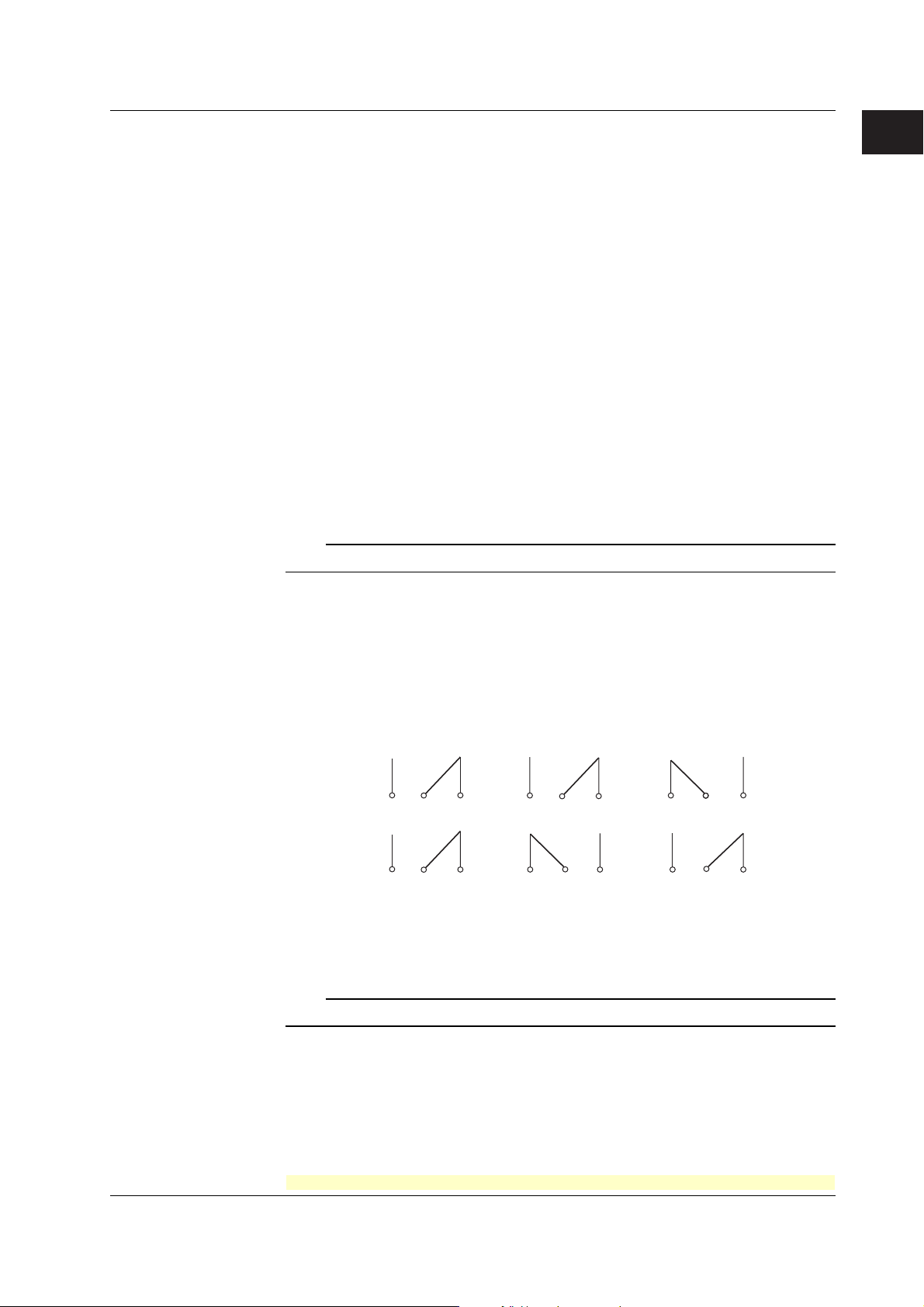

Number of Alarm Point Marks

Up to four alarms can be set for each channel.

Alarm Conditions

The following four conditions are available: The alphanumeric character or symbol inside

the parentheses is used on the recorder to denote each alarm.

• High Limit Alarm (H/

• Low Limit Alarm (L/

)

An alarm occurs when the input value exceeds the alarm value.

)

An alarm occurs when the input value falls below the alarm value.

High limit alarm

Alarm occurrence

Measured value

Alarm

value

Alarm release

Low limit alarm

Measured

value

Alarm occurrence

Alarm release

Alarm value

• Difference High Limit Alarm (h/ )*

An alarm occurs when the difference in the input values of two channels is greater

than or equal to the specified value.

• Difference Low Limit Alarm (l/

)*

An alarm occurs when the difference in the input values of two channels is less than

or equal to the specified value.

* Can be specified on channels set to delta computation.

Alarm Hysteresis

Hysteresis can be specified to the values for activating and releasing the alarm. The

hysteresis applies only to high limit alarm (H) and low limit alarm (L). The hysteresis

width can be set in the range of 0.0% (OFF) to 1.0% of the recording span in 0.1 steps.

The setting applies to all high limit alarms and low limit alarms. By default, the hysteresis

width is set to 0.5%.

High limit alarm

Alarm occurrence

Measured value

Alarm

value

Alarm release

Low limit alarm

Measured

value

Alarm occurrence

Alarm release

Hysteresis

(1% or less)

Alarm value

1-6

<Related Topics> Setting alarms: Section 2.2

Setting the alarm hysteresis: Section 4.1

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

IM 04P03B01-01E

Page 13

1.2 Alarms

Alarm Indication

When an alarm occurs, the ALM indicator in the status display section illuminates, and

nd

the 2

digit of the LED shows the alarm status for each channel. When the alarm clears,

the indicator and the LED turn OFF.

Alarm Recording

The alarm occurrence/release can be recorded on the chart paper. See section 1.3.

Alarm Output Relay (/A1, /A2, and /A3 Options)

Contact signals can be generated from alarm output relays when alarms occur. The

number of output relays is 2 (/A1), 4 (/A2), or 6 (/A3). The alarm output relays are

denoted as I01 to I06 on the recorder.

The following functions can be assigned to the alarm output relay.

Diagnosis Output

The diagnosis output can be assigned to alarm output relay I01.

The relay is activated when there is an error in the plotter operation on the pen model,

when a burnout is detected, or when there is an error in the A/D converter. Output relay

I01 is normally energized and de-energizes when an error is detected (de-energized

operation).

Note

If diagnosis output is enabled, I01 becomes a relay dedicated to diagnosis output.

1

Functional Explanation and Setup Guide

<Related Topics> Setting the diagnosis output: Section 4.1

Energized/De-energized Operation of Alarm Output Relays

You can select whether the alarm output relay is energized or de-energized when an

alarm occurs. If de-energized is selected, the status of the alarm output relay when an

alarm occurs is the same as the status that results when the recorder is turned OFF

(including power failures). The setting applies to all alarm output relays.

The default setting is energized.

NO

Energize

De-energize

NO : Normally Opened, C : Common, NC : Normally Closed

CNC NOCNC NO C NC

NC

When power is

turned OFF

NO C NC NO C NCNO C

When an alarm

is not occurring

(During normal

operation)

When an alarm

is occurring

(During a

malfunction)

Note

If diagnosis output is enabled, I01 is fixed to de-energized operation.

IM 04P03B01-01E

<Related Topics> Setting the energized/de-energized operation of alarm output relays:

Section 4.1

Alarm Output Relay Operation

When the output destination of multiple alarms is assigned to a single alarm output relay,

the relay is activated when any of the assigned alarms is occurring (OR operation).

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

1-7

Page 14

1.3 Recording

The recorder is capable of recording the measured values with pens or dots (trend

recording) as well as various other types of information.

Trend Recording

The measured values are printed within a width of 100 mm.

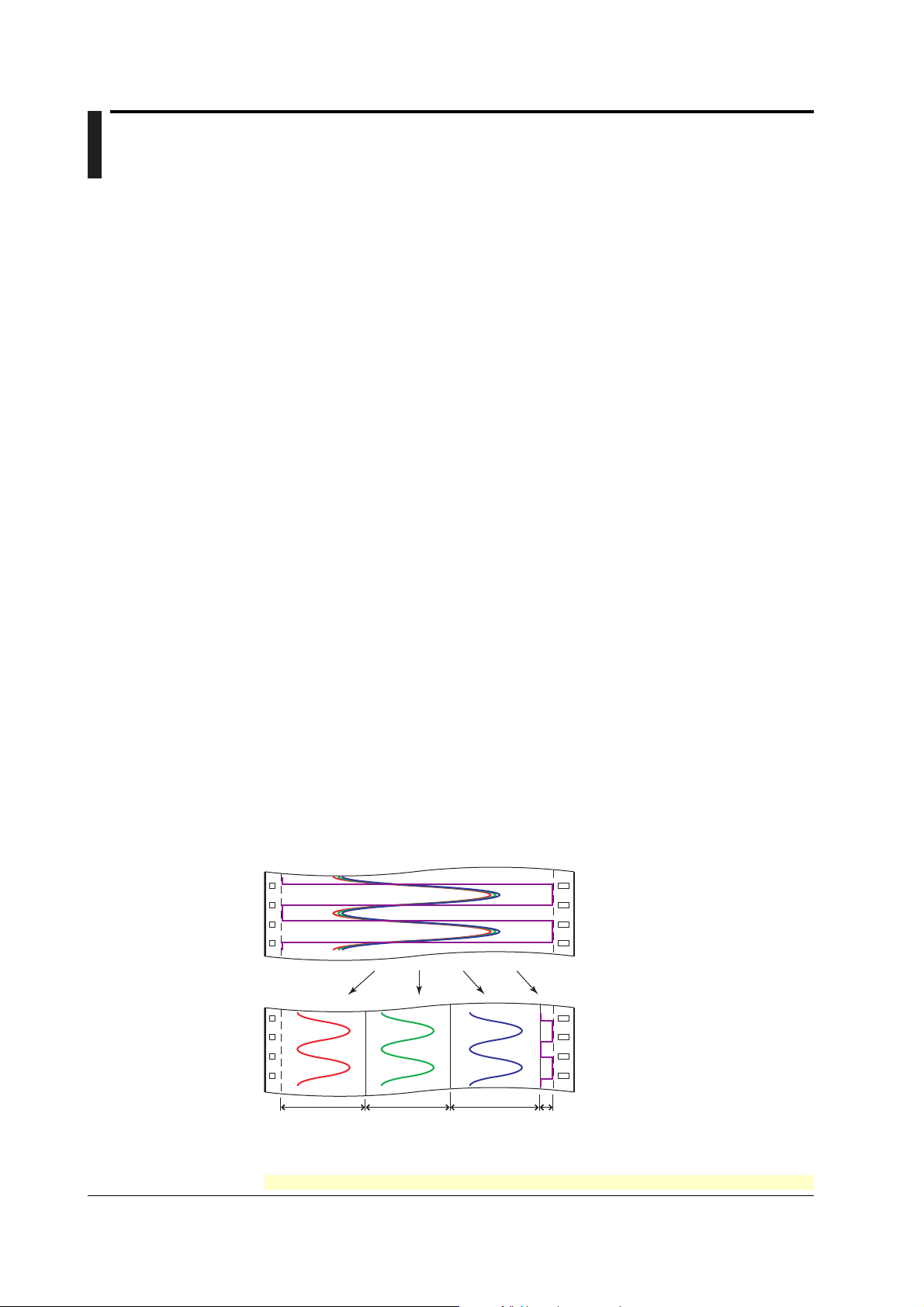

Recording Method (Pen Model)

• The measured value is updated every scan interval and continuously recorded.

• The recording colors in order from channel 1 are red, green, blue, and violet.

Recording Method (Dot Model)

• The most recent measured value is recorded with a dot every dot printing interval.

The dot printing interval is in the range of 10 s to 90 s. There are two recording

methods from which you can select. One method automatically adjusts the dot

printing interval according to the chart speed so that the dots do not overlap. The

other method records at the fastest dot printing interval at all times.

• The recording colors in order from channel 1 are purple, red, green, blue, brown, and

black. The recording color of each channel can be changed among these six colors.

• For each channel, trend recording can be enabled or disabled.

<Related Topics> Setting the trend recording interval: Section 3.1

Changing the recording color: Section 4.5

Enabling/Disabling trend recording for each channel: Section 3.6

Chart Speed

On the pen model, the chart speed can be selected from 40 settings in the range of 10 to

12000 mm/h.

On the dot model, the chart speed can be selected from 28 settings in the range of 10 to

1500 mm/h.

The default setting is 20 mm/h.

<Related Topics> Setting the chart speed: Section 2.4

Zone Recording

A recording zone is assigned to each channel. This function is useful such when the

recording results overlap making them difficult to be viewed.

1-8

Zone 1 Zone 2 Zone 3 Zone 4

<Related Topics> Setting the zone recording: Section 3.4

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

IM 04P03B01-01E

Page 15

1.3 Recording

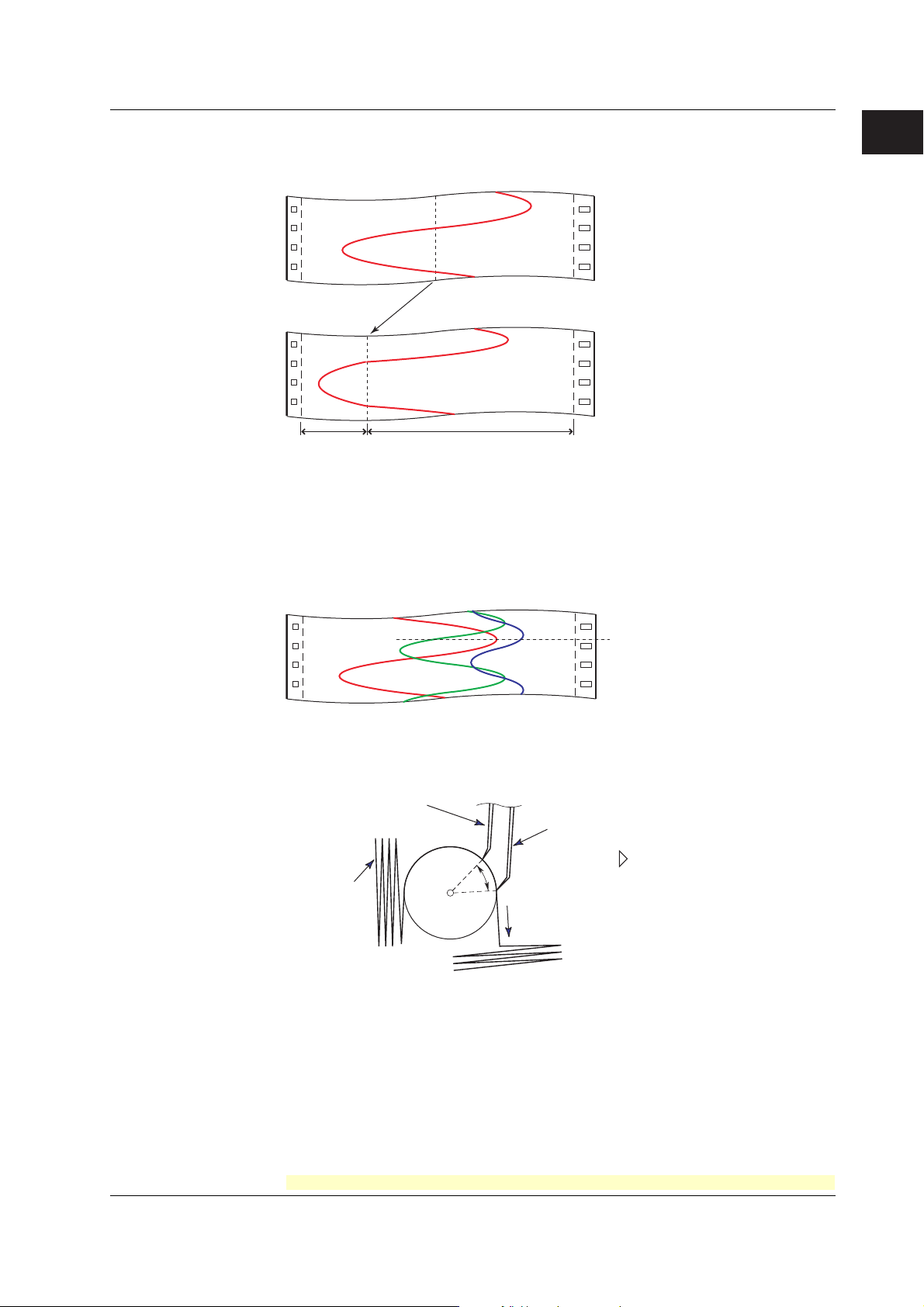

Partial Expanded Recording

This function expands a section of the recording range. By default, partial expanded

recording is disabled.

Compressed Expanded

<Related Topics> Setting the partial expanded recording: Sections 4.12 and 3.5

Pen Offset Compensation (Pen Model)

This function compensates for the pen offset (phase difference) along the time axis.

On 2-pen, 3-pen, and 4-pen recorders, there are offsets along the time axis (phase

difference) between the pens. This offset is corrected when pen offset compensation is

used.

1

Functional Explanation and Setup Guide

Same time

Below is an explanation for the 2-pen model.

The recording of these two pens are offset by an amount of phase P. If pen offset

compensation is enabled, the measured values of pen 1 are stored in the memory, and

recorded when the chart paper is fed by an amount corresponding to P.

Reference pen (pen 2)

Pen 1

Recorder front panel

Chart paper

P

Chart feeding direction

By default, this function is disabled.

<Related Topics> Setting the pen offset compensation: Section 4.6

IM 04P03B01-01E

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

1-9

Page 16

1.3 Recording

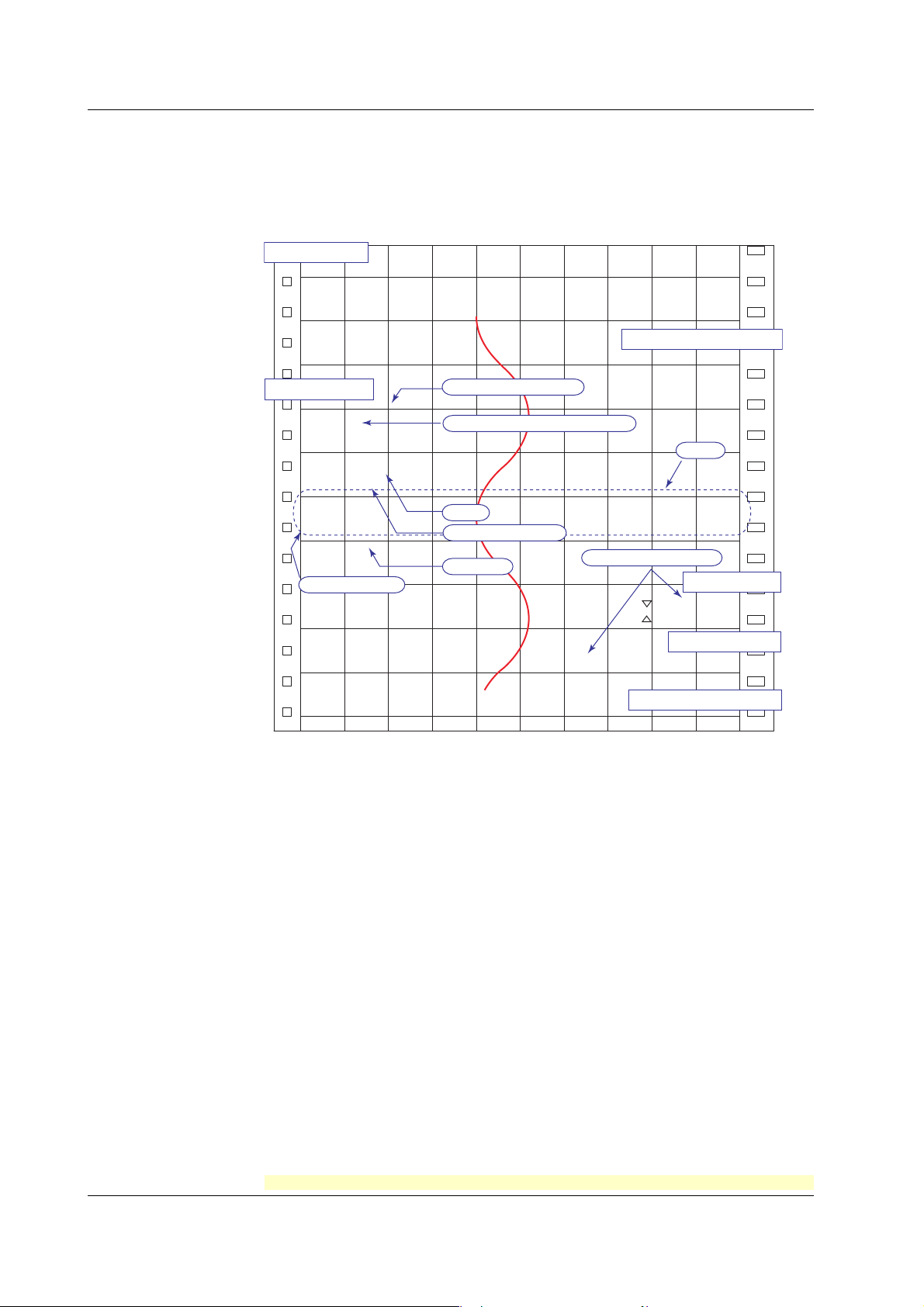

Printout

The figure below is used to explain the printout contents. The actual printout and font are

different from those illustrated in the figure. The printout positions are also slightly

different.

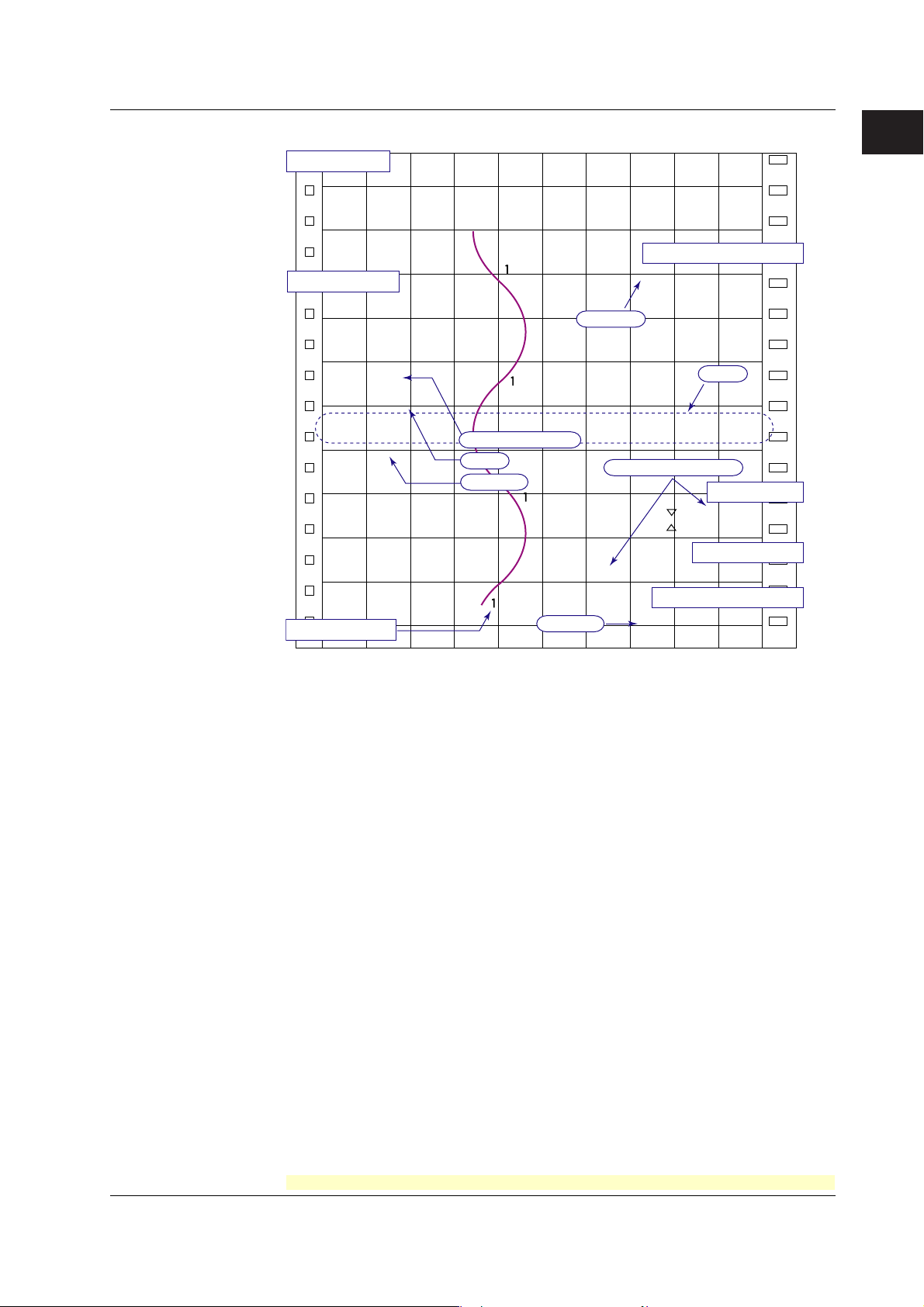

Printout Example on the Pen Model

Manual printout

Jan.31.05 15:00

1 223.5mg/cm

3

2 437.2µS/cm

3 H 591.6˚C 4d −0.222V

New chart speed printout

50mm/h 14:55

Periodic printout

Time tick cancel mark

Jan.31.05!

13:50*

1 218.7mg/cm

2 390.6µS/cm

Pen offset compensation mark

3

Scale

3 H 598.4˚C

4 d −0.222V

0.0 500.0

1CH mg/cm

RED

50mm/h_

Recording color

Alarm

Delta computation

Time tick

Buffer overflow mark

3

Alarm printout

1H3*10:09

1H3 10:05

Message printout

09:52*START#205 ABCDEF

Recording start printout

08:00 25mm/h

Time tick

The time ticks are marks that indicate the positions of the date/time on the chart paper.

Time tick cancel mark

An exclamation point (!) is printed when the periodic printout time tick was not printed at the

correct position.

Channel number or tag printout

Channel numbers or tags can be printed.

1-10

<Related Topics>

Switching between channel number printout and tag printout: Section 4.7

Setting the periodic printout

Turning printout ON/OFF

printout for periodic printout, and recording color printout for periodic printout)

(interval, reference time, and periodic printout ON/OFF): Section 4.8

(alarm printout, recording start printout, new chart speed printout, scale

: Section 4.7

Setting the time format (alarm printout, message printout, recording start printout, and new chart

speed printout): Section 4.16

Turning periodic printout ON/OFF for each channel: Section 3.6

Setting the message string: Section 3.8

Executing manual printouts, executing message printouts, clearing the alarm printout

buffer, and printing out settings: see the

Operation Guide

)

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

IM 04P03B01-01E

Page 17

1.3 Recording

Printout Example on the Dot Model

Manual printout

Jan.31.05 16:00

1 223.5mg/cm

3

2 437.2µS/cm

3 H 591.6˚C 4d −0.222V

5 −0.665V 6 L −0.448V

New chart speed printout

Periodic printout

_50mm/h 14:55

Jan.31.05

13:50

1 218.7mg/cm

3

Time tick

2 390.6µS/cm

3 H 598.4˚C

4 d −0.222V

5 −0.995V

6 L −0.448V

0.0 500.0

1CH mg/cm

50mm/h_

Delta computation

Alarm

Time tick

Buffer overflow mark

09:52*START#205 ABCDEF

1

Functional Explanation and Setup Guide

Scale

3

Alarm printout

1H3*10:09

1H3 10:05

Message printout

Recording start printout

Channel printout

Channel Printout (Dot Model Only)

Prints the channel No. or tag by the trend recording. The channel No. or tag is printed every

approximately 25 mm on the chart paper. The channel printout can be enabled or disabled. By

default, the channel printout is enabled.

Time tick

_08:00 25mm/h

<Related Topics>

Switching between channel number printout and tag printout: Section 4.7

Setting the periodic printout (interval, reference time, and periodic printout ON/OFF): Section 4.8

Turning printout ON/OFF

speed printout, and scale printout for periodic printout): Section 4.7

(channel printout, alarm printout, recording start printout, new chart

Setting the time format (alarm printout, message printout, recording start printout, and new chart

speed printout): Section 4.16

Turning recording and printout ON/OFF for each channel (trend recording and periodic

printout): Section 3.6

Setting the message string: Sections 3.8

Executing manual printouts, executing message printouts, clearing the alarm printout

buffer, and printing out settings: see the

Operation Guide

)

IM 04P03B01-01E

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

1-11

Page 18

1.3 Recording

Channel data

Recording color

Chart speed

Date

Time

Scale

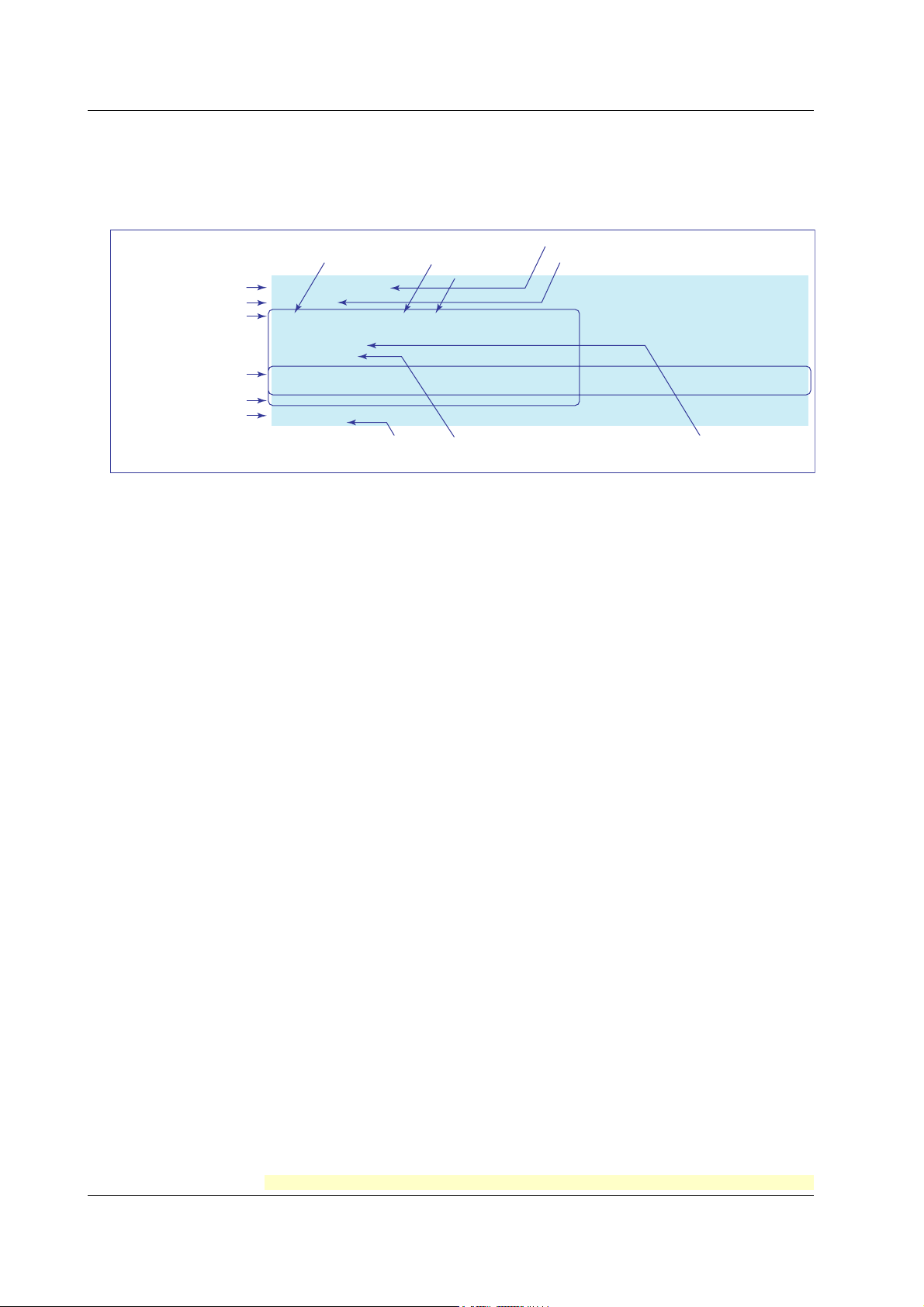

Periodic Printout

Values such as the measured values are printed at a determined interval. The contents

of the printout vary between the pen model and dot model.

Printout cannot be performed at the following chart speeds.

Pen model: 1800 mm/h or higher; Dot model: 120 mm/h or higher

Channel No.

or tag

Measured

value

Unit

Time tick cancel mark

Offset compensation mark

Mar.31.2006!

15:50*

TAG-001 1.000V

2 -1.000V

3 H-2.1050UNIT03

4 d 2.000V

0.000 2.000

TAG-001 V

RED

50mm/h_

Time tick

The font used in the figure differs from that of the actual printout. The printout positions may

also differ from those of the actual printout.

Prints the letter “d” for channels set to

delta computation.

Alarm

• Printout Contents

• Date/Time: The date/time when the periodic printout was executed.

• Time ticks: Marks that indicate the first pen position of the date/time on the

chart paper. If the time tick is not printed in the correct position, the

pen model prints a time tick cancel mark (!), and the dot model does

not print the time tick.

• Offset compensation mark: When pen offset is being executed on the pen model,

asterisks (∗) are printed.

• Channel data: Prints the channel numbers or tags, measured values

(instantaneous values), and units.

• Alarm status: Prints the alarm that is occurring. Prints the letter “d” on channels

set to delta computation. If multiple alarms are occurring, the alarm

with the highest precedence is printed.

Alarm printout precedence: (Higher) H, L, h, and l (lower)

• Scale: Prints the leftmost and rightmost values of the recording span and

the channel number or tag for channels that have scale printout

specified. The scale is printed for one channel at each periodic

printout. The channel whose scale is printed changes in ascending

order. The scale of channels that are being zone recorded is printed

within the recording range of the zone for 40 mm or greater.

• Recording color (pen model): Prints the recording colors of channels that have

scale printout and recording color printout specified.

• Chart speed: The chart speed can be printed.

• For the measured values and alarm status, you can select whether to print them for

each channel. For the scale and recording color (pen model), you can select

whether to print them.

1-12

• Interval (for details, see appendix 1)

The printout interval can be set by specifying the value or set automatically in sync

with the chart speed.

• Turning ON/OFF the Periodic Printout

Periodic printout can be turn ON/OFF. By default, periodic printout is enabled with the

interval synchronized to the chart speed.

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

IM 04P03B01-01E

Page 19

1.3 Recording

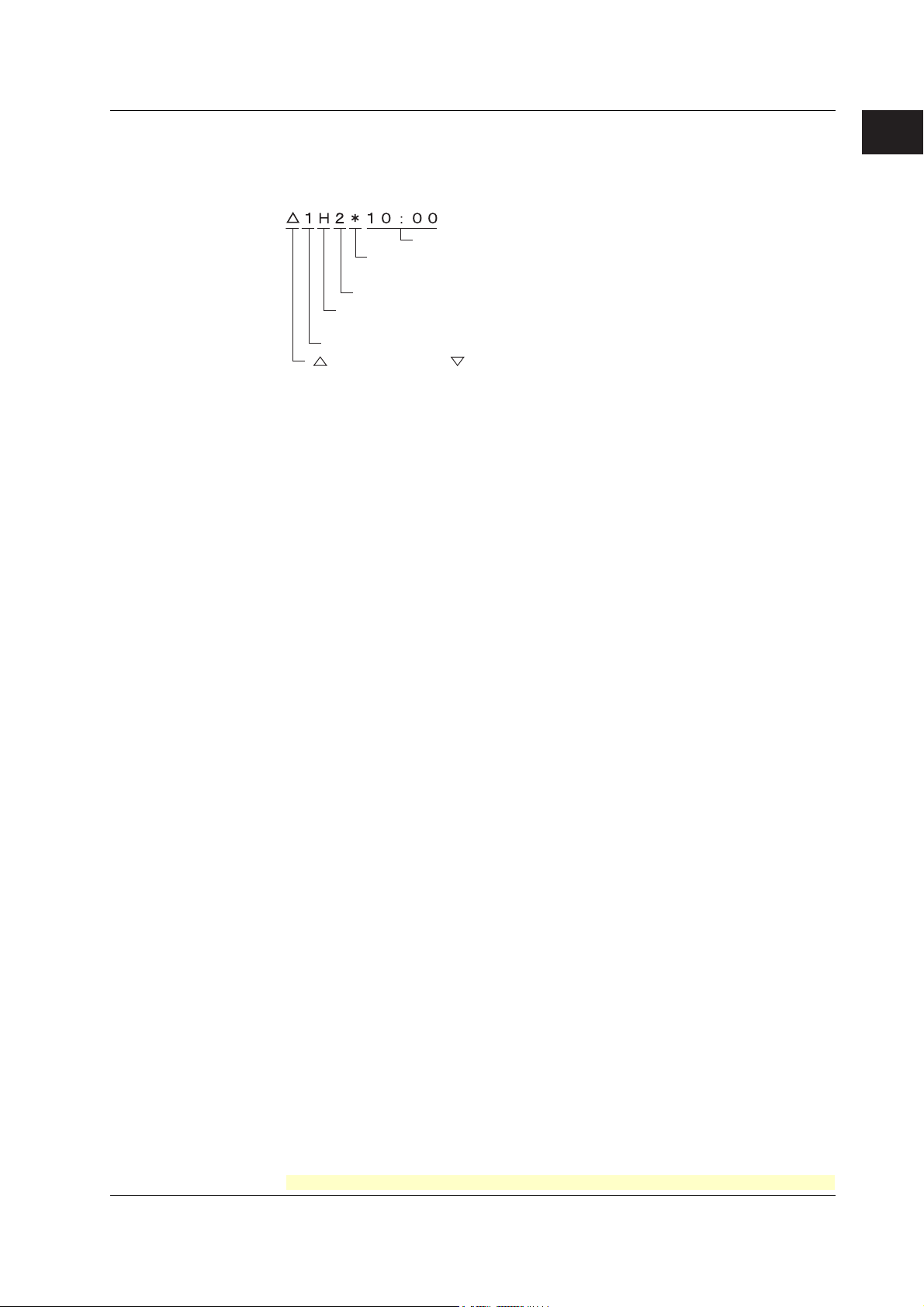

Alarm Printout

Alarm information is printed when an alarm occurs or releases.

Printout cannot be performed at the following chart speeds.

Pen model: 1800 mm/h or higher; Dot model: 120 mm/h or higher

Time of alarm occurrence/release

Indicates that there are alarms that are not

printed because the alarm printout buffer is full.

Level number

Alarm type (H: high limit, L: low limit, h: difference high limit,

and l: difference low limit)

Channel No. or tag

: Alarm occurrence, : Alarm release

• The print condition can be set to (1) print when alarms occur and release, (2) print

only when alarms occur, or (3) do not print.

• Alarms that occur while an alarm printout is in progress are temporarily saved to the

buffer memory in a printout-wait condition. Alarms are cleared from the buffer memory

when they are printed.

• The number alarms that can be stored in the buffer is 8 and 12 on the pen model and

dot model, respectively. Alarms that occur while the buffer is full are not printed. A

buffer overflow mark is printed when there are alarms that cannot be printed because

the buffer is full.

• The time printout format can be selected.

1

Functional Explanation and Setup Guide

Manual Printout

Measured values and alarm status can be printed manually using the keys. When

manual printout is executed, trend recording stops and restarts when manual printout is

complete.

<For the operation procedure, see the

Operation Guide

.>

Message Printout

Printout cannot be performed at the following chart speeds.

Pen model: 1800 mm/h or higher; Dot model: 120 mm/h or higher

Preset messages can be printed on the chart paper using the keys. Five messages,

each within 16 characters, can be registered in advance.

• If message printout is executed while another message is being printed, the most

recent message is temporarily stored to the buffer memory in a printout-wait condition.

Messages are cleared from the buffer memory when they are printed.

• The number of messages that can be stored in the buffer is 5. If message printout is

executed when the buffer is full, the message is not printed. A buffer overflow mark is

printed when there are messages that cannot be printed because the buffer is full.

• The time printout format can be selected.

New Chart Speed Printout

Printout cannot be performed at the following chart speeds.

Pen model: 1800 mm/h or higher; Dot model: 120 mm/h or higher

• When the chart speed is changed, the time tick (dot model), the date/time of change,

and the new chart speed are printed. An asterisk (∗) shows there are messages that

cannot be printed.

• The time printout format can be selected.

IM 04P03B01-01E

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

1-13

Page 20

1.3 Recording

Recording Start Printout

Printout cannot be performed at the following chart speeds.

Pen model: 1800 mm/h or higher; Dot model: 120 mm/h or higher

When recording is started, the time tick (dot model), the time, and the chart speed can

be printed. An asterisk (∗) shows there are messages that cannot be printed.

• The recording start printout can be enabled or disabled. By default, the recording start

printout is disabled.

• The time printout format can be selected.

Printout/Display Format of the Date.

The printout/display format of the date can be selected from the list below.

Selectable Type Printout Format Display Format Notes

Settings Example Example

Year/Month/Day 2006/03/31 06 03 31 Default value

Month/Day/Year 03/31/2006 03 31 06

Day/Month/Year 31/03/2006 31 03 06

Day.Month.Year 31.03.2006 31 03 06

Month.Day.Year Mar.31.2006 03 31 06

*1 These do not apply for the date printout format for message printouts that include measured

values (/BT1 option). Specify that in the message format.

Printout Format of the Time

The printout format of the time can be selected from the list below.

Selectable Type Printout Format Notes

Settings Example

Hour:Minute 10:00 Default value

Hour:Minute:Second 10:00:00

Month/Day Hour:Minute 03/31 10:00

Month/Day Hour:Minute:Second 03/31 10:00:00

Year/Month/Day Hour:Minute:Second 2006/03/31 10:00:00

*1: The year/month/day format varies depending on the printout/display format of the date.

*2: Can be set to the alarm printout, message printout, recording start printout, and new chart

speed printout.

*3 These do not apply for the date printout format for message printouts that include measured

values (/BT1 option). Specify that in the message format.

1-14

<Related Topics> Setting the printout/display format of the date: Section 4.14

Setting the printout format of the time: Section 4.16

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

IM 04P03B01-01E

Page 21

1.3 Recording

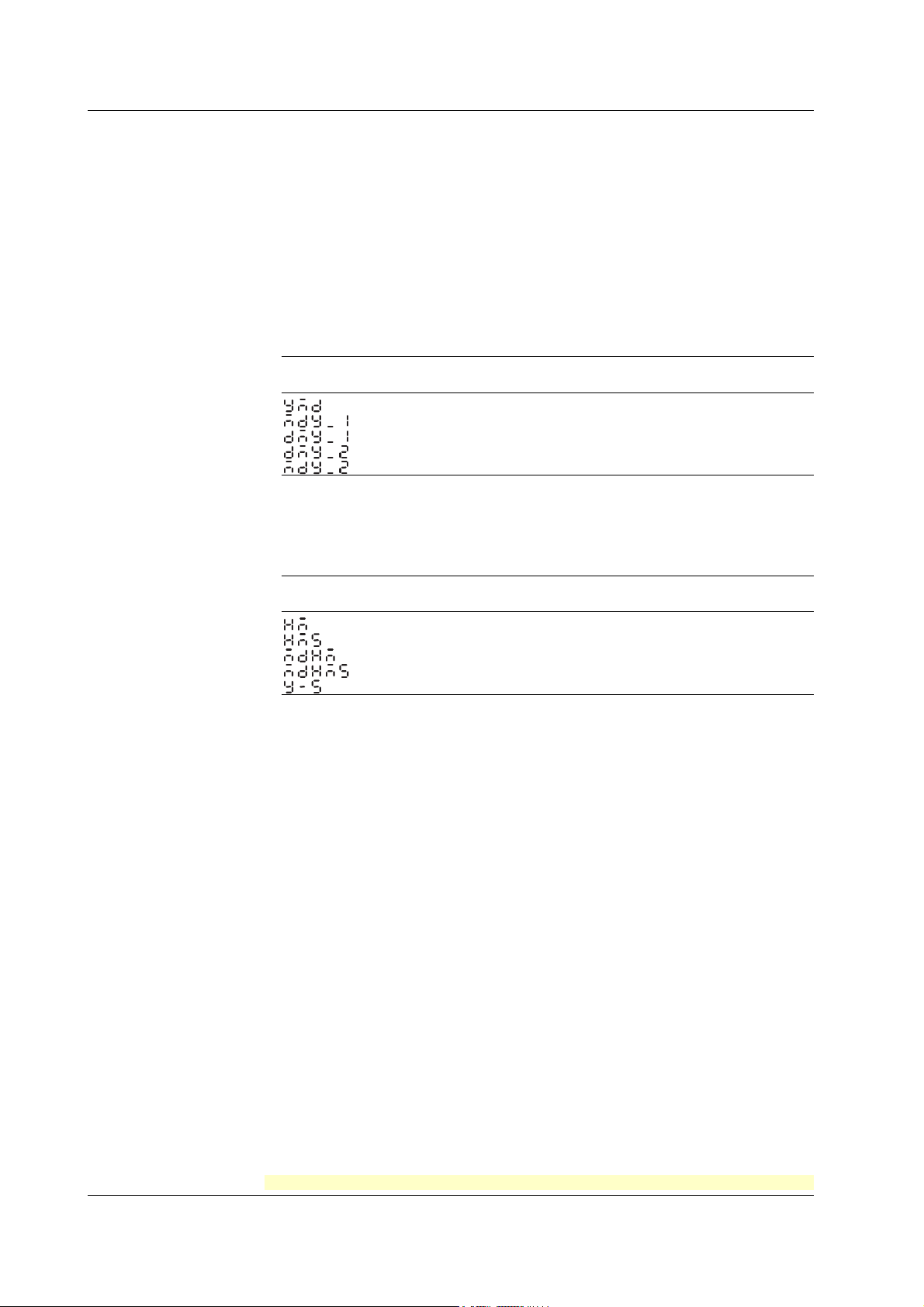

Setting Printout

List or setup list can be printed. When setting printout is executed, trend recording stops

and restarts when the printout is complete.

List printout contains Setting Mode settings such as the input range and alarm for each

channel.

Setup List contains Basic Setting Mode settings such as the alarm output relay operation

and printout method.

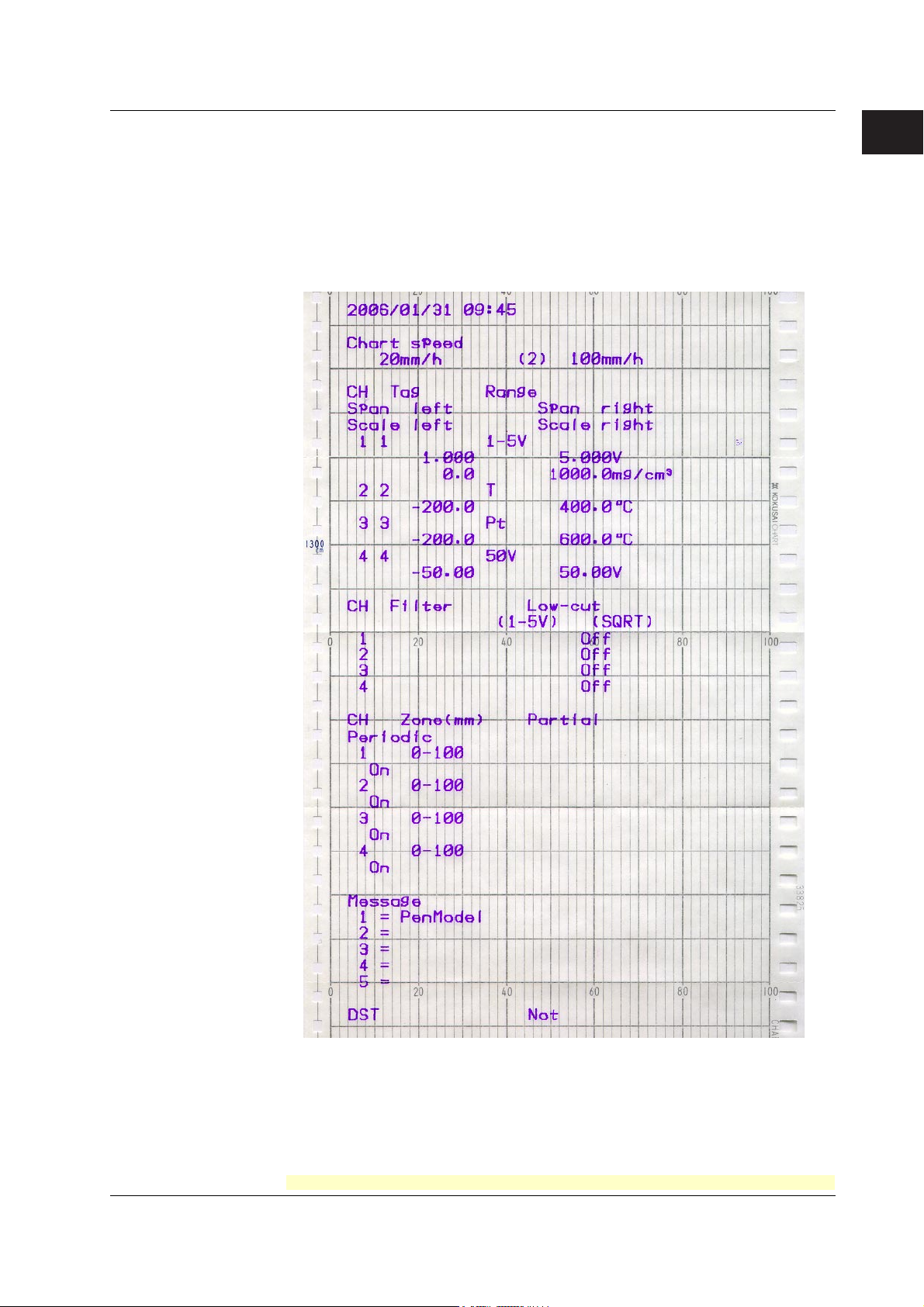

• Printout Example of List on the Pen Model

1

Functional Explanation and Setup Guide

IM 04P03B01-01E

The printout examples may appear differently from the actual printout as a result of functional

improvements made on the recorder after this manual was written.

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

1-15

Page 22

1.3 Recording

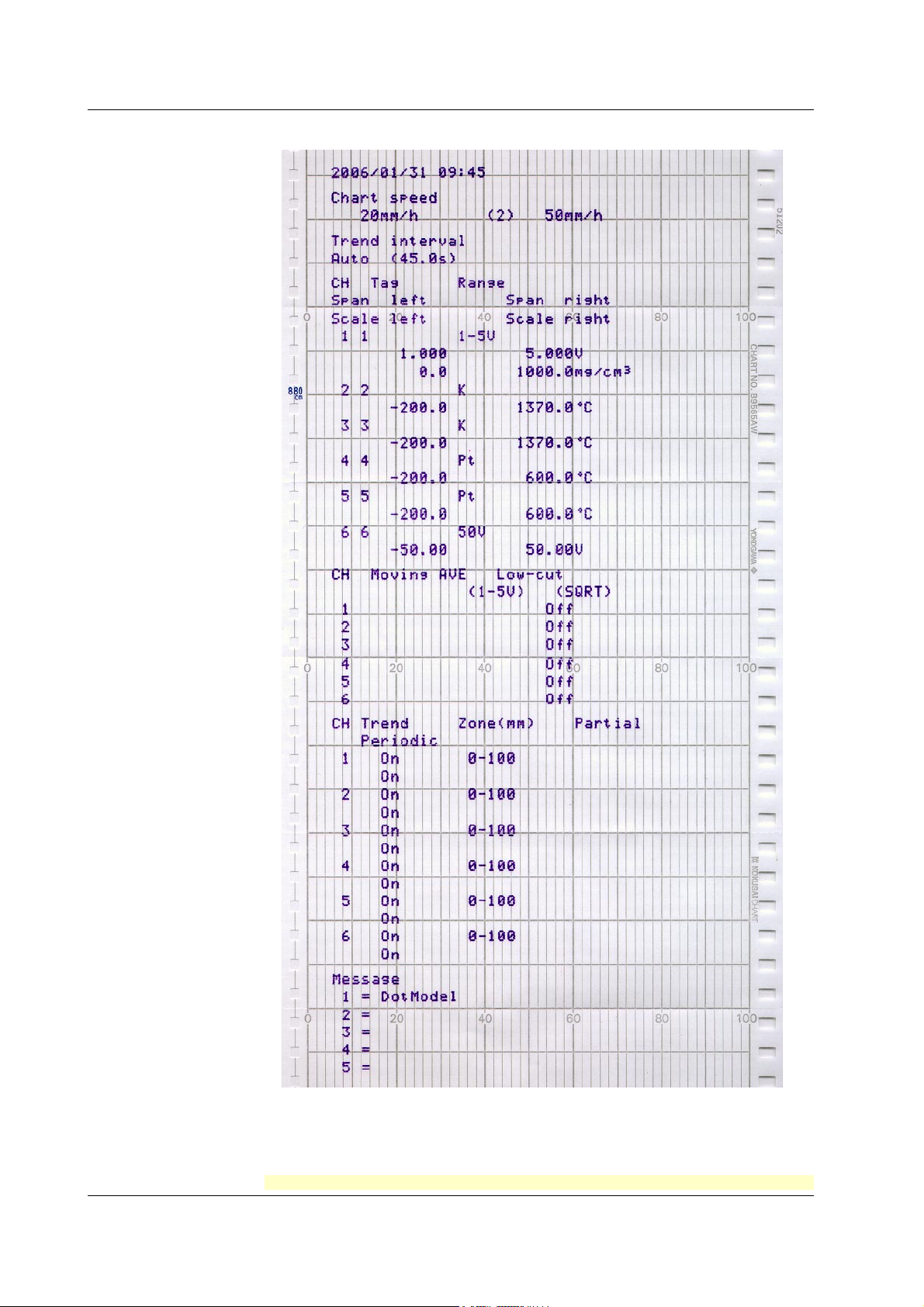

• Printout Example of List on the Dot Model

1-16

The printout examples may appear differently from the actual printout as a result of functional

improvements made on the recorder after this manual was written.

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

IM 04P03B01-01E

Page 23

1.3 Recording

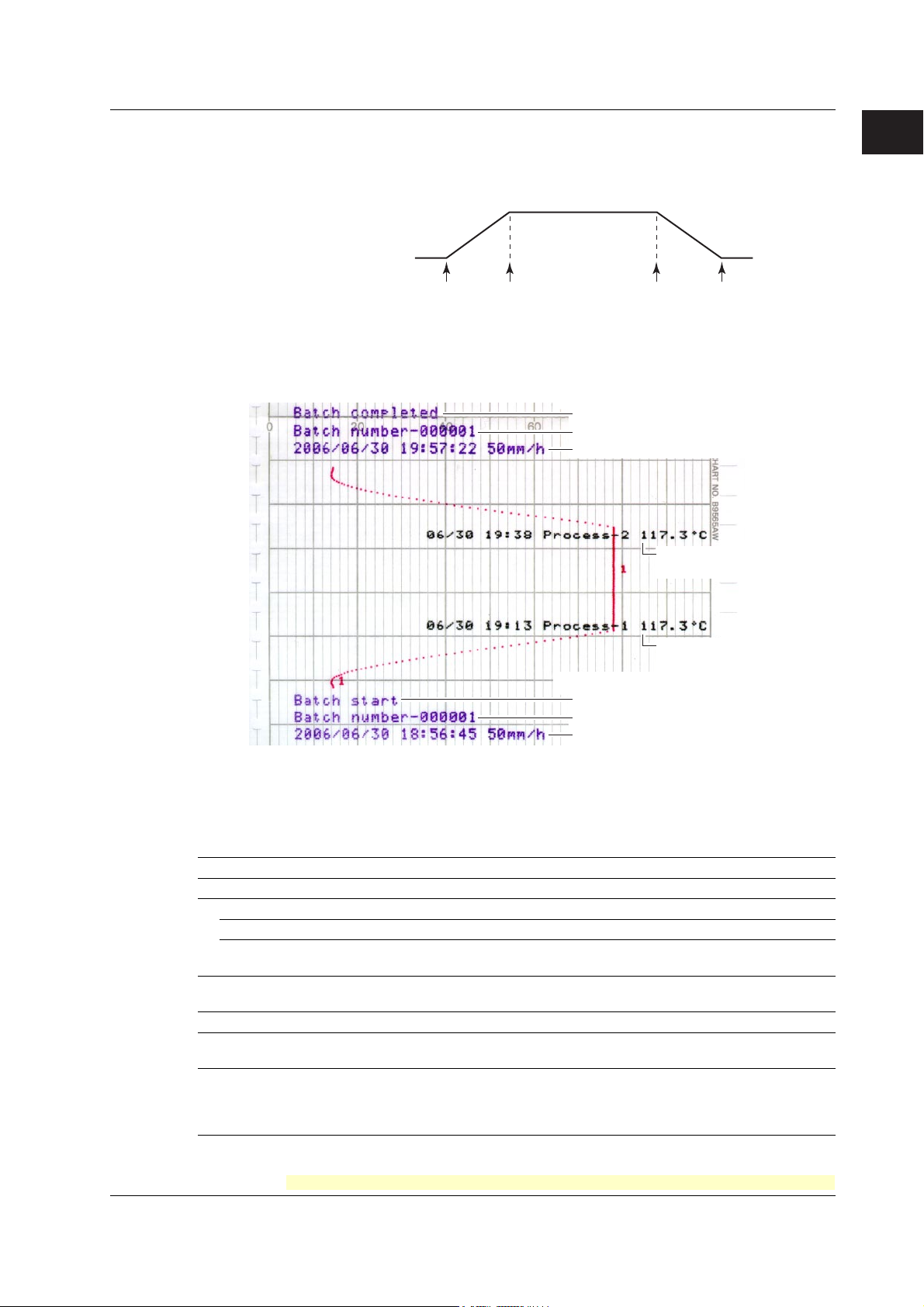

Header Printout (/BT1 Option)

When recording is started, the Start printout is performed, and recording starts. During

trend recording, you can print out messages (up to 5) that include measured values.

When recording is stopped, End printout is performed.

Operation

(Operation

instruction)

• Example Printout (Dot Model)

1. Chart paper feed

2. Start printout

3. Recording start

(Record start)

Message printout 1

including measured

values

(Message printout 1)

End printout

Comment

Batch name (batch number and lot number)

date/time, and chart speed

Message printout 2

including measured

values

(Message printout 2)

Message printout 2 including

measured values

1

Functional Explanation and Setup Guide

1. Recording stop

2. End printout

3. Chart paper feed

(Recording stop)

Message printout 1 including

measured values

Start printout

Comment

Batch name (batch number and lot number)

date/time, and chart speed

The printout examples may appear differently from the actual printout as a result of functional

improvements made on the recorder after this manual was written.

Start Printout and End printout

You can set “Start printout” and “Start printout 2” for the printout when recording starts.

Also, you can set “End printout” and “End printout 2” for the printout when recording stops.

Printout/Operation Description Notes

Comment Prints 32 characters x 5 lines or less.

Batch name

Batch number Prints up to 26 characters.

Lot number Prints a number from 4-digits or 6-digits. You can automatically increment

Date/time The date format prints out according to the date Date and time cannot be turned

printout/display format. On/Off independently.

Chart speed Prints the current chart paper feed speed.

Chart paper feed Feeds the chart paper 50 mm or less before Start printout. Steps of 1 mm

Feeds the chart paper 50 mm or less after End printout. Steps of 1 mm

Ejection of pen offset You can record the portion of the data that remains after When pen offset compensating

compensating data recording stops. Also, when recording the remaining is On (pen model).

portion of the data, you can change the chart speed to

450 mm/h (fixed).

by 1 when recording stops.

IM 04P03B01-01E

You can select whether to print out the batch name, date/time, and chart speed. By default, the printout is enabled.

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

1-17

Page 24

1.3 Recording

• Switching between Start Printout and Start printout 2, and between End printout

and End printout 2

With the remote control function (/R1 option), you can change the items that are

printed out.

For example, when a process ends successfully, End printout is performed and the lot

number is updated. If the process fails, you can have End printout 2 be carried out

and the lot number remain not updated.

Depending on the status of the “batch comment switching signal,” the following

switches occur when the “record start/stop signal” switches:

Batch Comment Switching Signal Status

Record start/Stop Signal Status Level: 0 (Open) Level: 1 (Closed)

Upon start Edge (rising) Start printout Start printout 2

Upon stop Edge (falling) End printout End printout 2

Remote Control Signal

Record start/stop

signal

Start Stop

Batch comment

switching signal

Start printout End printout

Concluded

successfully

Start Stop

Start printout End printout 2

Concluded

unsuccessfully

Message Printout Including Measured Values

Following the specified message format, the date/time, message strings of the standard

function (5 strings of up to 16 characters), and measured instantaneous values are

printed out together.

• Up to 5 messages of 35 characters can be entered.

• Messages are printed out in the order in which they are set.

• The specified number of characters specified for standard function messages is used,

then if a subsequent character string has been set, it is used next. Also, it can only be

used once for the message format.

Message Example

06/30 10:10 Process-1 134.8°C

Measured value on CH1 (no units)

Character string set for message 1

of the standard function

Date/time

<Related Topics> Setting start printout and stop printout: Sections 4.23 and 3.12

Assigning functions to the remote control input terminals: Section 4.18

Setting the message string: Section 3.8

Enabling the message format: Section 4.23

Regarding the message format: Section 3.13

1-18

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

IM 04P03B01-01E

Page 25

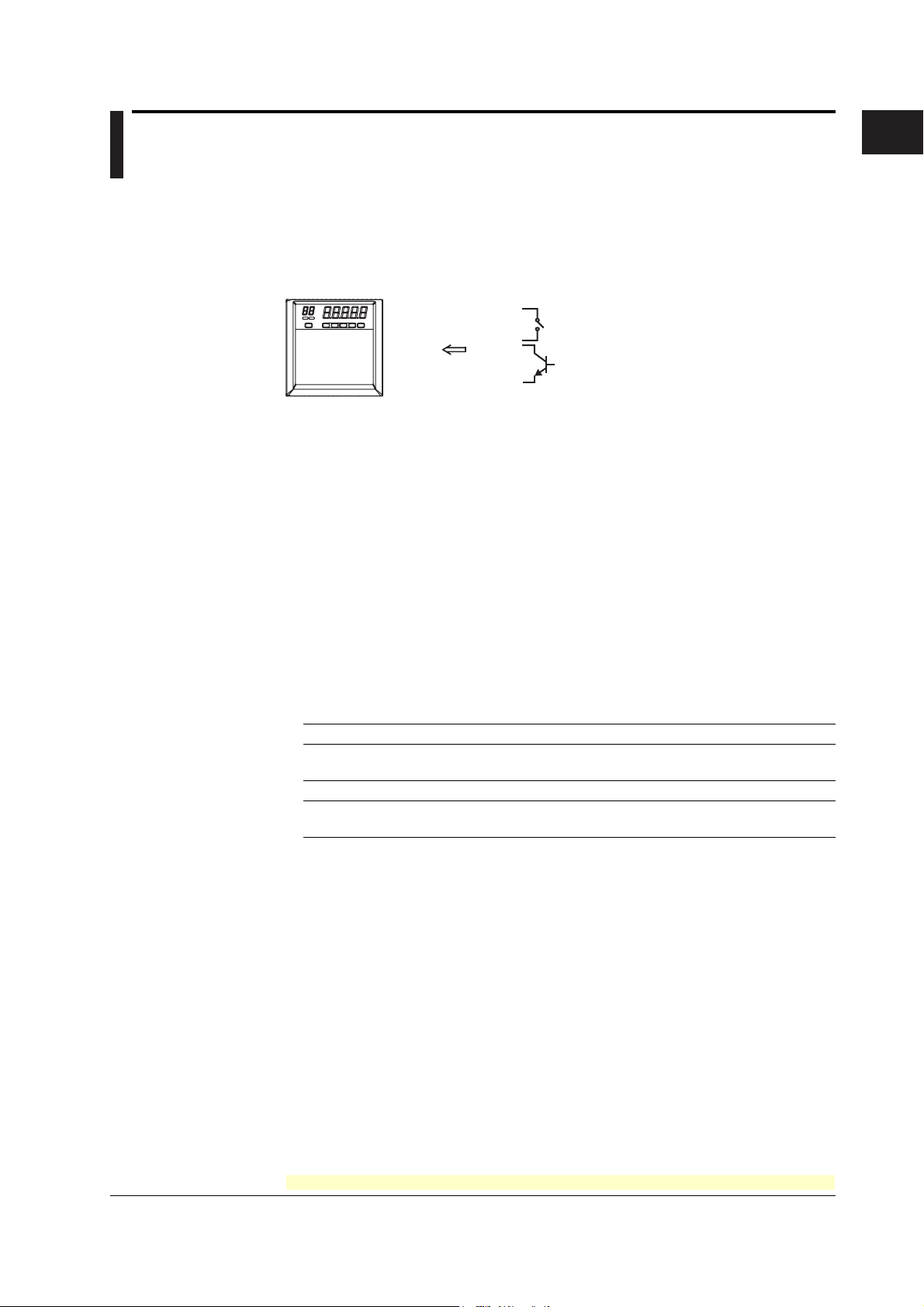

1.4 Remote Control Function (/R1 Option)

Specified operations can be carried out by applying remote signals (contact or open

collector signals) to the remote control input terminals.

There are five remote control input terminals. An action can be assigned to each

terminal.

Recorder

Contact

Open collector

Assignable Functions

• Recording start/stop

• Remote input signal: Rising edge signifies start; falling edge signifies stop

• Starts/stops recording.

• Applying a rising edge signal when recording is already in progress produces no

effect. Applying a falling edge signal when recording is stopped produces no effect.

• Chart Speed Switch

• Remote input signal: Level

• The chart paper is fed at the secondary chart speed while a level signal is applied

to the terminal. The secondary chart speed is set in advance.

1

Functional Explanation and Setup Guide

• Internal Clock Adjustment

• Remote input signal: Trigger

• The internal clock of the recorder is adjusted to the nearest hour depending on the

time when the remote signal is applied.

Time When Signal Is Input Adjustment

00 min 00 s to 01 min 59 s Truncates the minutes and seconds.

02 min 00 s to 57 min 59 s The time is not changed.

58 min 00 s to 59 min 59 s Rounds up the minutes and seconds.

• Message 1 Printout to Message 5 Printout

• Remote input signal: Trigger

• Manual Printout

• Remote input signal: Trigger

• Priority to Remote Recording (/BT1 Option)

• Remote input signal: Edge (rising/start or falling/stop)

• Starts/stops recording.

• When started with a remote signal (on a remote signal rise), stop per key operation

or communication is disabled.

Example: 10 hours 01 min 50 s becomes 10 hours 00 min 00 s.

Example: 10 hours 59 min 50 s becomes 11 hours 00 min 00 s.

IM 04P03B01-01E

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

1-19

Page 26

1.4 Remote Control Function (/R1 Option)

• Switching Batch Comment (/BT1 Option)

• Remote input signal: Level

• Switches between Start printout and Start printout 2, and between End printout and

End printout 2 depending on the status of the batch comment switching signal

when recording is started/stopped remotely.

• When starting/stopping by key operation, performs Start printout and End printout.

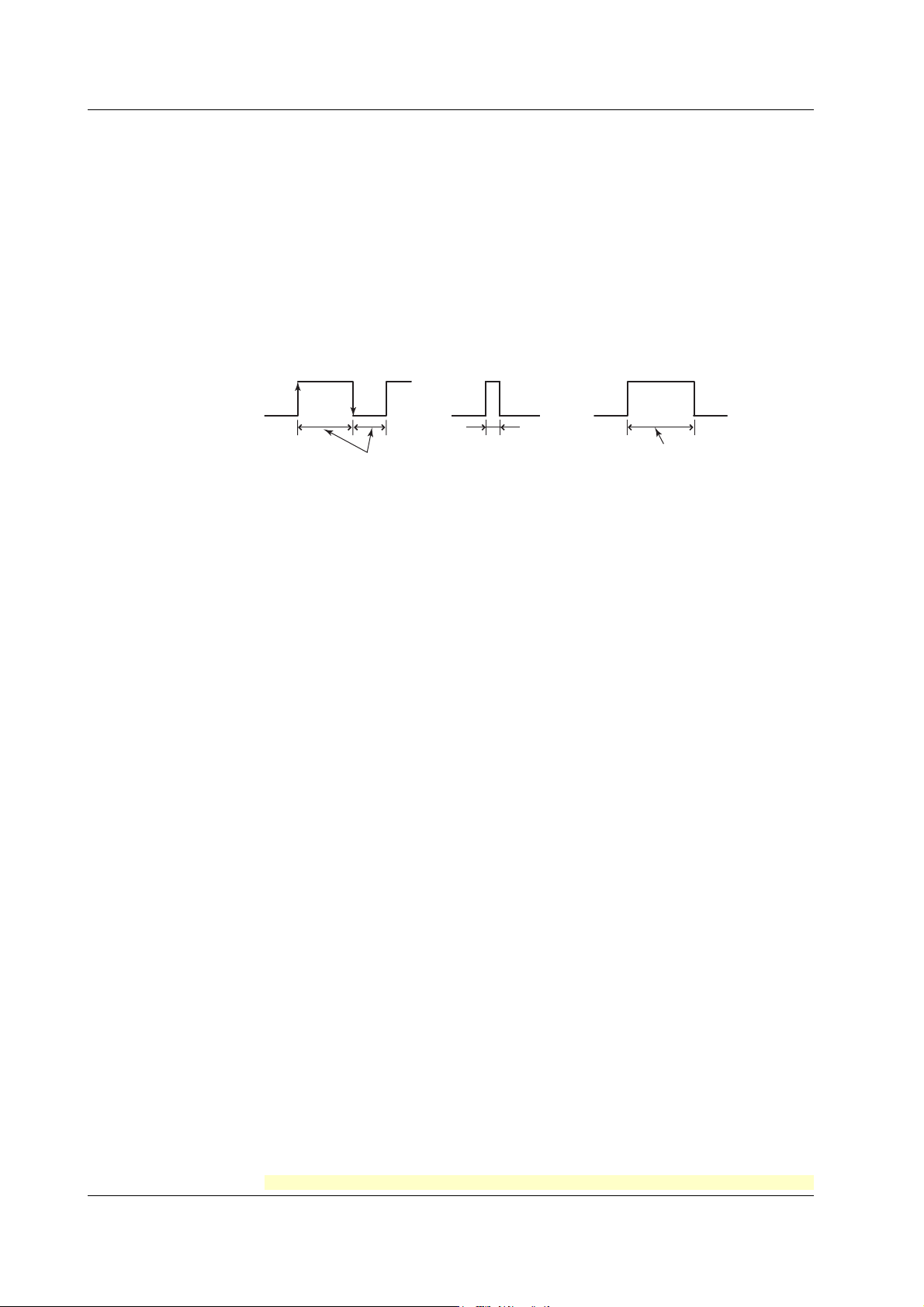

Remote Signal (Edge, Trigger, and Level)

The above actions are carried out on the rising or falling edge of the remote signal

(edge), the ON signal lasting at least 250 ms (trigger), or the ON/OFF signal (level).

Rising/Falling edge Trigger Level

Rising

Falling

For contact inputs, the remote signal rises when the contact switches from open to

closed and falls when the contact switches from closed to open. For open collector

signals, the remote signal rises when the collector signal (voltage level of the remote

control terminal) goes from high to low and falls when the collector signal goes low to

high.

250 ms or more

250 ms or more

Operates at the

secondary chart speed

<Related Topics> Assigning functions to the remote control input terminals: Section 4.18

Setting the secondary chart speed: Section 3.9

1-20

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

IM 04P03B01-01E

Page 27

1.5 Other Functions

Key Lock

Key lock is a function that prohibits key operations. When key lock is enabled, pressing

keys produces no effect. To release the key lock, a password is entered.

Key Lock Items

Each of the following keys can be included or excluded from the key lock function.

In the case of the FUNC key, each function of the FUNC key can be included or

excluded from the key lock function.

FUNC key functions: Manual printout, list printout, setup list printout, message printout,

<Related Topics> Setting the key lock function: Section 4.9

Using the key lock function: see the

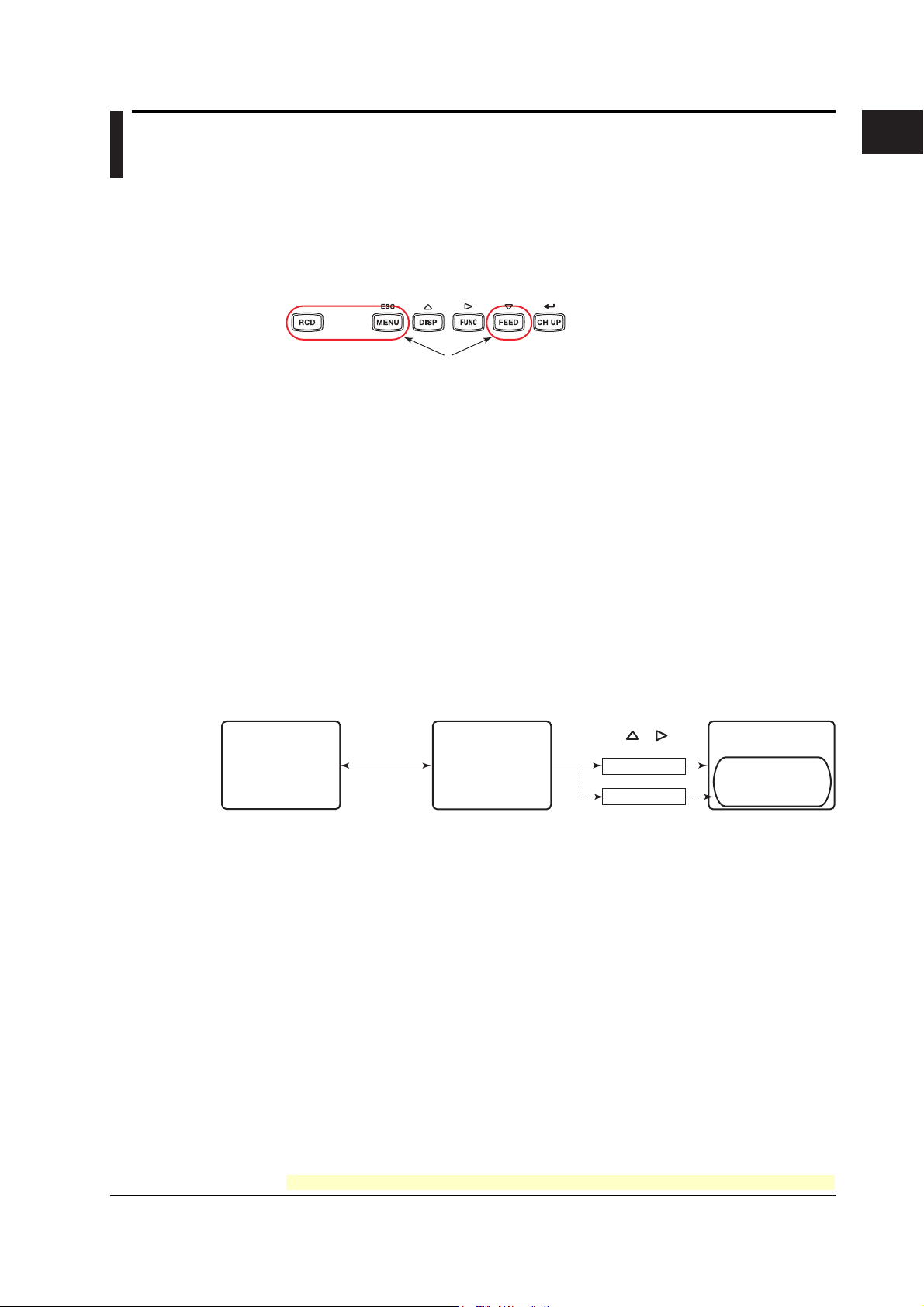

Customize Menu

The menu can be customized to display only the menus that you use.

• Display only the items that you use on the FUNC key menu.

• Display only the items that you use on the Setting mode menu.

• Lock Basic Setting mode (use a password to enter the mode).

The pen position adjustment (pen model) and dot printing position adjustment (dot

model) can be set so that they can be used without the password.

Keys that can be locked

printout buffer clear, pen exchange (pen model), and ribbon

cassette exchange (dot model)

Operation Guide

)

1

Functional Explanation and Setup Guide

Font

Operation mode

Displays only the

FUNC key menu

items to be used

<Related Topics> Setting the FUNC key menu: Section 4.19

The characters used in the printout can be set to English, Japanese, German, or French.

The characters that are available vary depending on the selected font.

English: Alphabet, numbers, and symbols

Japanese: Alphabet, numbers, Katakana, and symbols

German: Alphabet (German), numbers, and symbols

French: Alphabet (French), numbers, and symbols

<Related Topics> Changing the language: Section 4.13

Hold down

MENU for 3 s

Setting the Setting mode menu: Section 4.20

Enabling/Disabling the customized menu: Section 4.21

Setting mode

Displays only the

setup menu items

to be used

Hold down +

for 3 s

Password

No password

Basic Setting mode

Pen and dot

printing position

adjustment

IM 04P03B01-01E

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

1-21

Page 28

1.5 Other Functions

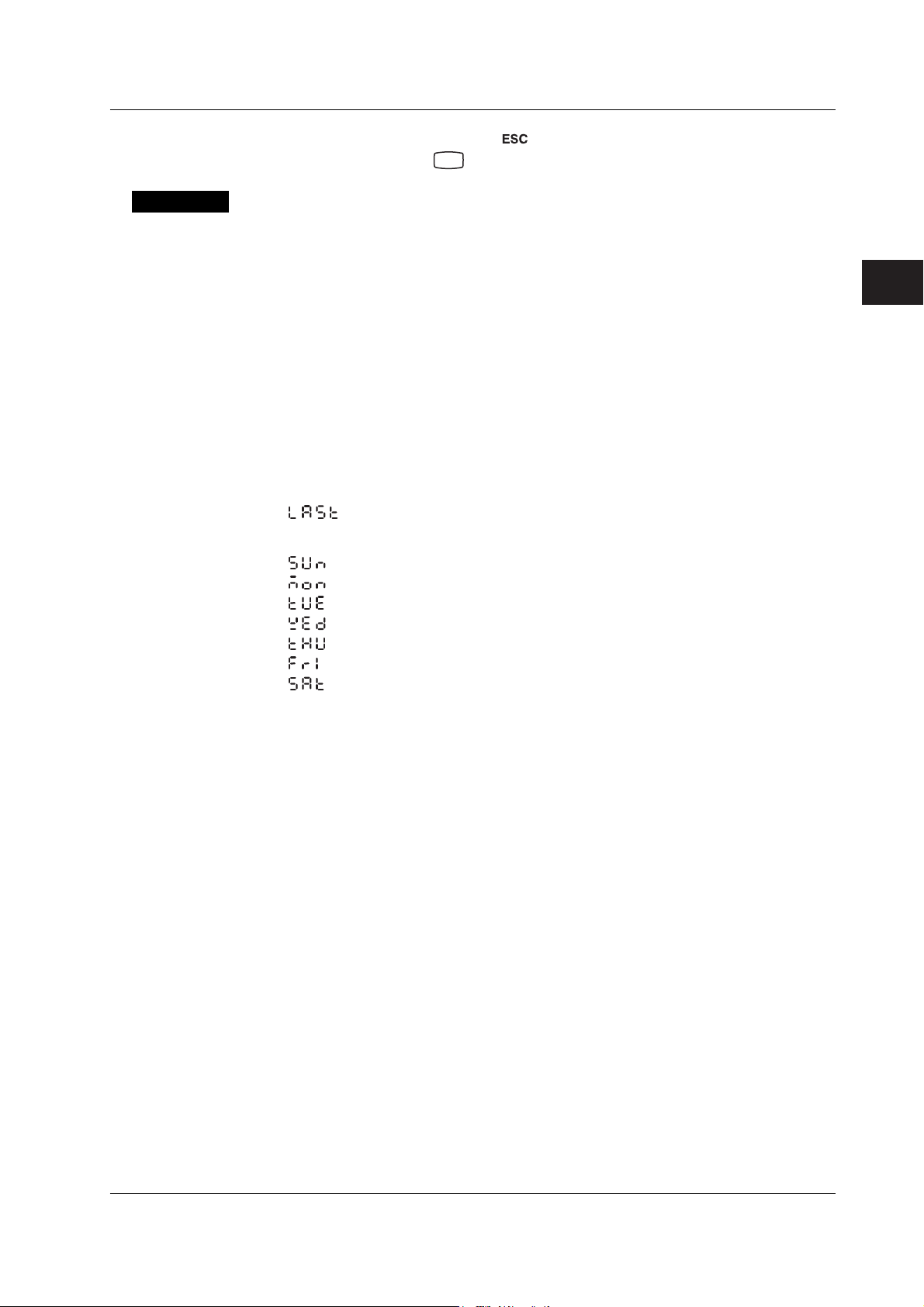

DST

Temperature Unit

If the recorder is used in a region that has DST, time can be switched automatically

between DST and standard time by setting the date/time when switching from the

standard time to DST and the date/time when switching back from DST to standard time.

When switching from standard time to DST, the clock is set ahead by 1 hour. When

switching back from DST to standard time, the clock is set back by 1 hour.

<Related Topics> Using the DST: Section 3.14

The temperature unit can be set to Celsius or Fahrenheit. The setting applies to all

channels.

<Related Topics> Changing the temperature unit: Section 4.24

1-22

For the procedure to set the functions, see section 1.6, “Function Setup Guide.”

IM 04P03B01-01E

Page 29

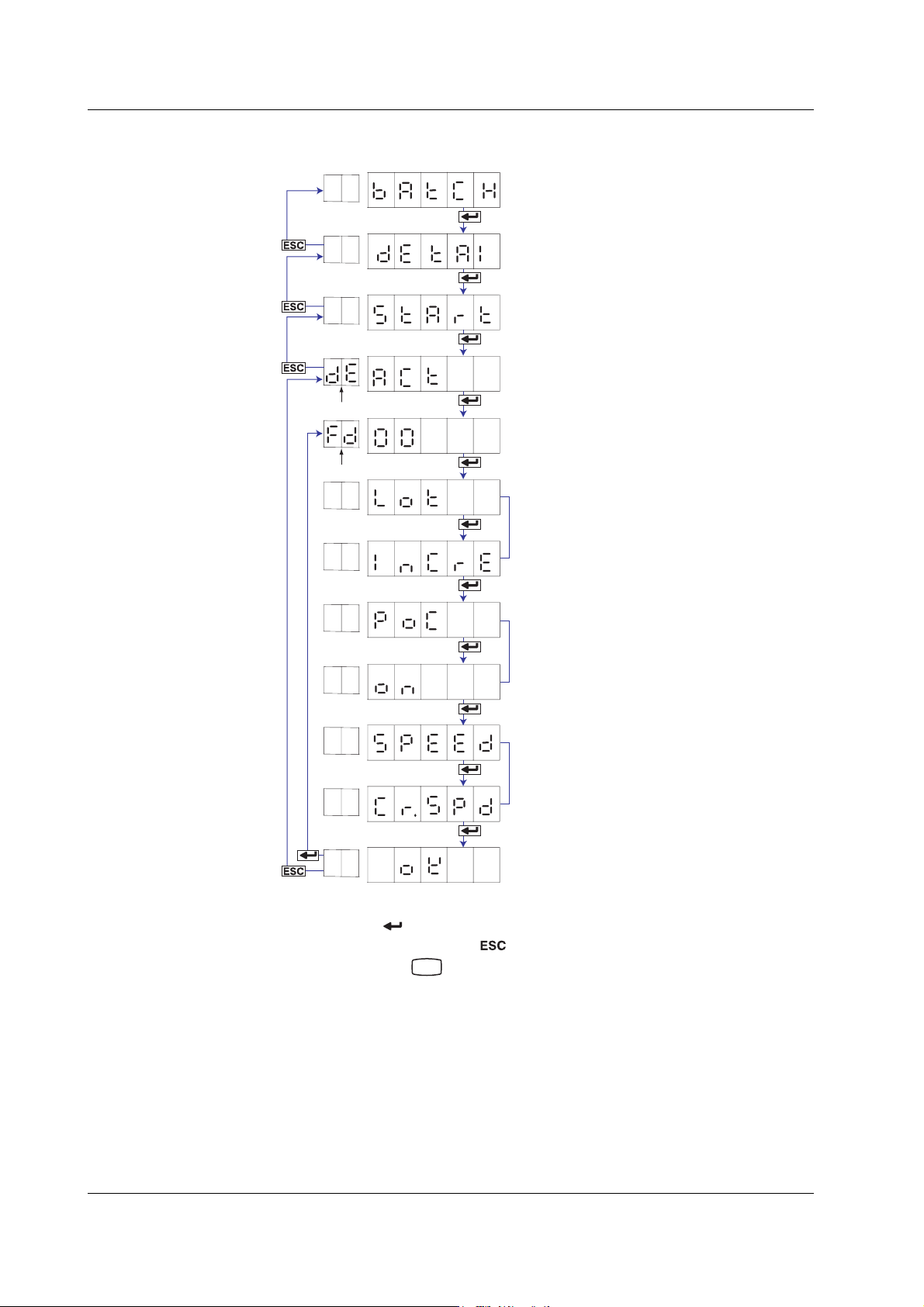

1.6 Function Setup Guide

This section explains the settings necessary to use various functions of the recorder.

Read the section corresponding to the function you wish to use.

Note

This section contains all the settings related to each item. If the desired setting is the same as

the default value, you do not have to set it.

1

Functional Explanation and Setup Guide

Item Description Reference

Date/Time setting Use CLOCK in Setting mode 2.5

DST Sets the date/time for switching between DST and standard time using 3.14

AUX > DST in Setting mode.

Setting initialization Use INIT in Basic Setting mode to initialize the settings of Setting mode 4.17

and Basic Setting mode to their default values.

Measuring input functions

Item Description Reference

Range and span of the TC, RTD, or DC voltage

Use RANGE in Setting mode. 2.1

1-5V • Range, span, and scale 2.1

Use RANGE in Setting mode.

• Unit 2.3

Use UNIT in setting mode to set the unit after scaling.

• Low-cut 4.15

Use PERS. > 1-5V low-cut in Basic Setting mode and select Use or Not.

If Use is selected, turn ON/OFF the low-cut function using RANGE in Setting 2.1

mode.

If Not is selected, the Low-cut item does not appear in the RANGE setting.

Scaling • Range, span, and scale 2.1

Use RANGE in Setting mode.

• Unit 2.3

Use UNIT in setting mode to set the unit after scaling.

Square Root Computation • Range, span, and scale 2.1

Use RANGE in Setting mode.

• Unit 2.3

Use UNIT in setting mode to set the unit after scaling.

• Low-cut 4.15

Use PERS. > SQRT low-cut in Basic Setting mode and select Use or Not.

If Use is selected, set the low-cut value using RANGE in Setting mode. 2.1

If Not is selected, the Low-cut item does not appear in the RANGE setting.

Unused channels Use RANGE > SKIP in Setting mode to disabling the trend recording (dot model) 2.1

and periodic printout of the target channel.

Bias Use PERS. > BIAS in Basic Setting mode and select Use or Not. 4.15

If Use is selected, set the bias value that is added to the input using BIAS in 3.10

Setting mode. If Not is selected, the BIAS item does not appear.

Calibration Correction (/CC1 option)

Use PERS. > CALIB in Basic Setting mode and select Use or Not 4.15

If Use is selected,

• Use CALIB in Basic Setting mode to set the correction mode and the number 4.22

of calibration points.

• Use CALIB in Setting mode to set the measured value and correction value 3.11

for each channel.

If Not is selected, the CALIB item does not appear.

Burnout detection function (TC input and 1-5V input) 4.3

Use B_OUT in Basic Setting mode to set the burnout detection function for each

channel.

Section

Section

IM 04P03B01-01E

1-23

Page 30

1.6 Function Setup Guide

Item Description Reference

RJC of TC input Use RJC in Basic Setting mode to select whether to use the internal 4.4

RJC function or an external RJC function.

Filter (pen model) Use FILTR in Basic Setting mode and select Use or Not. 4.11

If Use is selected, set the filter time constant using AUX > FILTR in Setting mode. 3.2

If Not is selected, the AUX > FILTR item does not appear.

Moving average (dot model)

Use M_AVE in Basic Setting mode and select Use or Not. 4.10

If Use is selected, set the number of samples of moving average using AUX > 3.3

M_AVE in Setting mode.

If Not is selected, the AUX > M_AVE item does not appear.

Integration time of the A/D converter 4.2

Use INTG in Basic Setting mode to set the integration time of the A/D converter.

Temperature Unit Select the temperature unit using TEMP in Basic Setting mode. 4.24

Alarm functions

Item Description Reference

Alarms for each channel Use ALARM in Setting mode. 2.2

Set a hysteresis on the alarm occurrence/release value of high limit alarm and low limit alarm

Use ALARM > HYS in Basic Setting mode to set the hysteresis to be applied 4.1

to the high limit alarm and low limit alarm of measurement channels.

Diagnosis output Use ALARM > DIAG in Basic Setting mode to set the function. 4.1

Change the alarm output relay operation

If ALARM > RELAY in Basic Setting mode set to “DE_EN”, alarm output relay is 4.1

energized during normal operation and de-energized when an alarm occurs.

Section

Section

Recording functions

Item Description Reference

Section

Recording interval (dot model)

Change the recording color of measurement channels (dot model).

Turn trend recording ON/OFF (dot model)

Chart speed Use CHART in Setting mode to set the chart speed. 2.4

Record by setting recording zone

Partial expanded recording Use PART in Basic Setting mode and select Use or Not. 4.12

Record by compensating for the pen offset along the time axis (pen model)

Date format Use DATE in Basic Setting mode to set the printout/display format 4.14

Time format Use T_PRN in Basic Setting mode to set the printout format of the time. 4.16

Use AUX > TREND in Setting mode to set the recording interval to AUTO or FIX. 3.1

Use COLOR in Basic Setting mode to set the recording color of measurement 4.5

channels.

Use AUX > PRINT in Setting mode to turn ON/OFF the trend recording for each 3.6

measurement channel.

Use AUX > ZONE in Setting mode to set the recording zone for each channel. 3.4

If Use is selected, set the display mode using AUX > PART in Setting mode. 3.5

If Not is selected, the AUX > PART item does not appear.

Use POC in Setting mode to turn ON/OFF offset compensation. 4.6

of the date.

1-24

IM 04P03B01-01E

Page 31

1.6 Function Setup Guide

Item Description Reference

Periodic printout

Mar.31.2006!

15:50*

1 1.000V

2 -1.000V

0.000 2.000

1 V

RED

50mm/h_

• Enable/Disable the periodic printout 4.8

Use PER. in Basic Setting mode to turn ON/OFF the periodic printout.

• Printout interval 4.8

Use PER. in Basic Setting mode to set the periodic printout interval.

• Turn ON/OFF periodic printout for each channel 3.6

Use AUX > PRINT in Setting mode to turn ON/OFF the periodic printout for

each measurement channel.

• Scale printout and recording color printout (pen model) 4.7

Use PRINT > SCALE in Basic Setting mode to turn scale printout ON/OFF.

Use PRINT > PEN color in Basic Setting mode to turn pen color printout

ON/OFF (pen model).

Tag printout • Select channel printout or tag printout 4.7

Use PRINT > TAG.CH in Basic Setting mode to select whether to use channel

numbers or tags in printouts.

• Set the tag 3.7

Use AUX > TAG in Setting mode to set the tag name.

Alarm occurrence/release printout

• Turn printout ON/OFF 4.7

Use PRINT > ALARM in Basic Setting mode to select whether to print the alarm

occurrence and release, print only the alarm occurrence, or not print.

• Time printout format 4.16

Use T_PRN > ALARM in Basic Setting mode to set the time printout format

when printing alarm occurrence/release.

Message printout • Set the message string 3.8

Use AUX > MSG to set the message string to be printed.

• Time printout format 4.16

Use T_PRN > MSG in Basic Setting mode to set the time printout format.

• Execute the message printout Operation Guide

Use FUNC key > MSG in Operation mode to execute the message printout. Printing a Message

New chart speed printout • Turn printout ON/OFF 4.7

Use PRINT > SPEED in Basic Setting mode to set whether to print the new

chart speed when the chart speed is changed.

• Time printout format 4.16

Use T_PRN > SPEED in Basic Setting mode to set the time printout format.

Recording Start Printout • Turn printout ON/OFF 4.7

Use PRINT > RCD in Basic Setting mode to enable/disable the recording

start printout.

• Time printout format 4.16

Use T_PRN > RCD in Basic Setting mode to set the time printout format.

Setting Start printout/End printout (/BT1 option)

Use BATCH > DUAL (Dual comment) in Basic Setting mode, and select a LOT 4.23

from 4 or 6 digits.

Use BATCH > B.NUM in Setting mode to set the batch number. 3.12

Use BATCH > LOT in Setting mode to set the lot number. 3.12

Use BATCH > DETAI > START, END, STAT2, and END2 in Setting mode to set 3.12

the various comments, printout ON/OFF, and chart paper feed amount for each.

Also, in END and END2, enter the settings for lot number update and ejection of

pen offset compensating data (Pen model).

Channel number

or tag

Measured value

Scale

Recording color

(pen model)

Section

1

Functional Explanation and Setup Guide

IM 04P03B01-01E

1-25

Page 32

1.6 Function Setup Guide

Item Description Reference

Section

Switching between Start printout and Start printout 2, and between End printout and End printout 2 (/BT1, /R1 option)

• Switching settings

Assign DUAL (Batch comment switching) to the remote control input terminal. 4.18

Use BATCH > DUAL (Dual comment) in Basic Setting mode and select Use. 4.23

Set BATCH > DETAI > STAT2, and END2 in Setting mode. 3.12

• Executing the switch

The switch occurs according to the status of the DUAL (Batch comment 1.3

switching) signal when RCD or PR.RCD signal assigned to the remote control

input terminal rises or falls.

Printout of messages including measured values (/BT1 option)

• Setting message strings 3.8

Use AUX > MSG in Setting mode to enter the message to print out.

• Setting the message format 4.23

Use BATCH > MSG_F in Basic Setting mode and select Use.

Set the message format using the PC software (sold separately) or a

communication command.

• Executing the message printout

Execute the message printout by choosing FUNC key > MSG in Operation Guide

Operation mode. Printing a Message

Display functions

Item Description Reference

Section

Date format Same as the Date format in “Recording functions.” 4.14

Other functions

Item Description Reference

Section

Key lock • Target keys and password 4.9

Use LOCK in Basic Setting mode to set the keys to be key-locked and the

password.

• Enable the key lock Operation Guide

Use FUNC key > LOCK in Operation mode to turn key lock ON/OFF. Activating/Releasing

the Key Lock

Customize menu • FUNC key target menu selection 4.19

Use S.MENU > FUNC in Basic Setting mode to select the menus to be displayd.

• Setting mode target menu selection 4.20

Use S.MENU > SET in Basic Setting mode to select the menus to be displayd.

• Customize menu execution 4.21

Use CUST.M in Basic Setting mode to select whether to use the customized menu.

Font Use FONT in Basic Setting mode to set the characters used in the recording. 4.13

Remote control function • Assign functions to the remote control input terminals 4.18

(/R1 option) Use REM in Basic Setting mode to set the function to be assigned to the

remote control input terminal.

• Secondary chart speed 3.9

If “chart speed switching” is assigned, use AUX > SPD_2 in Setting mode to

set the secondary chart speed.

• Switching between Start printout and Start printout 2, and between End

printout and End printout 2 (/BT1 option)

If DUAL (Batch comment switching) is assigned, 4.23

Use BATCH > DUAL (Dual comment) in Basic Setting mode. Set BATCH > 3.12

DETAI > STAT2, and END2 in Setting mode.

1-26

IM 04P03B01-01E

Page 33

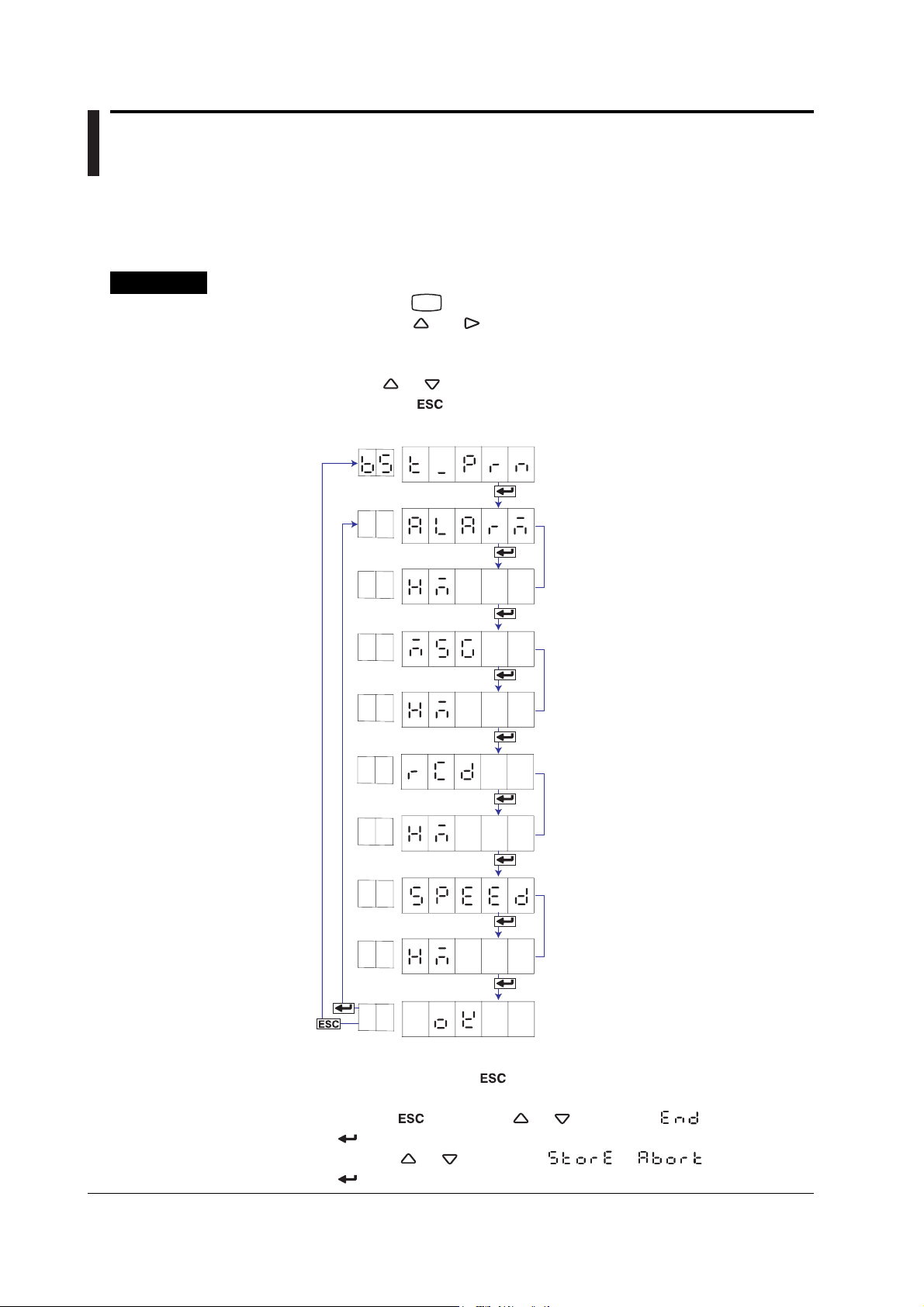

Chapter 2 Frequently Used Setup Operations (Setting Mode)

2.1 Setting the Input Range

Procedure

TC, RTD, and DC Voltage

Input range can be set for each measurement channel. Set unused channels to Skip.

If you change the input range, set the bias, alarm, partial expanded recording, and

calibration correction again.

1. Hold down the

key for 3 seconds to enter Setting mode.

MENU

2. Carry out the procedure shown in the figure below.

Press the or key to select the value.

For the procedure on how to enter values or characters, see page 19 in the

Operation Guide

.

To change the polarity, press the or key when the leftmost digit of the

value is blinking.

If you press the

key, the operation is cancelled, and the display returns to a

higher level menu.

Select “RANGE.”

(RANGE)

Select the channel number.

(CH1)

2

Frequently Used Setup Operations (Setting Mode)

Select the input type.

(TC)

Channel number

Select the range.

(R)

Set the left span value.

Span left

Set the right span value.

Span right

The settings are activated.

(OK)

3. Press the key to set other channels.

If you are done, press the key.

4. Hold down the

key for 3 seconds to return to Operation mode.

MENU

IM 04P03B01-01E

2-1

Page 34

2.1 Setting the Input Range

Description

• Selectable Range of Input Range, Span Left, and Span Right

The input range, span left, and span right can be set in the range shown below. Span

left and span right cannot be set to the same value.

DC voltage ( )

Range Type Selectable Span Range

20 mV( ) –20.00 to 20.00 mV

60 mV( ) –60.00 to 60.00 mV

200 mV( ) –200.0 to 200.0 mV

2 V( ) –2.000 to 2.000 V

6 V( ) –6.000 to 6.000 V

20 V( ) –20.00 to 20.00 V

50 V( ) –50.00 to 50.00 V

Thermocouple ( )

Range Type Selectable Span Range (°C) Selectable Span Range (°F)

R ( ) 0.0 to 1760.0°C 32 to 3200°F

S ( ) 0.0 to 1760.0°C 32 to 3200°F

B ( ) 0.0 to 1820.0°C 32 to 3308°F

K ( ) –200.0 to 1370.0°C –328 to 2498°F

E ( ) –200.0 to 800.0°C –328.0 to 1472.0°F

J ( ) –200.0 to 1100.0°C –328.0 to 2012.0°F

T ( ) –200.0 to 400.0°C –328.0 to 752.0°F

N ( ) 0.0 to 1300.0°C 32 to 2372°F

W ( ) 0.0 to 2315.0°C 32 to 4199°F

L ( ) –200.0 to 900.0°C –328.0 to 1652.0°F

U ( ) –200.0 to 400.0°C –328.0 to 752.0°F

WRe ( ) 0.0 to 2400.0°C 32 to 4352°F

RTD ( )

Range Type Selectable Span Range (°C) Selectable Span Range (°F)

PT (Pt100) ( ) –200.0 to 600.0°C –328.0 to 1112.0°F

JPT(JPt100) ( ) –200.0 to 550.0°C –328.0 to 1022.0°F

/N1 option /N3 option

Selectable

Settings

Cu1

Cu2

Cu3

Cu4

Cu5

Cu6

Cu25

Input Type

Cu10 (GE)

Cu10 (L&N)

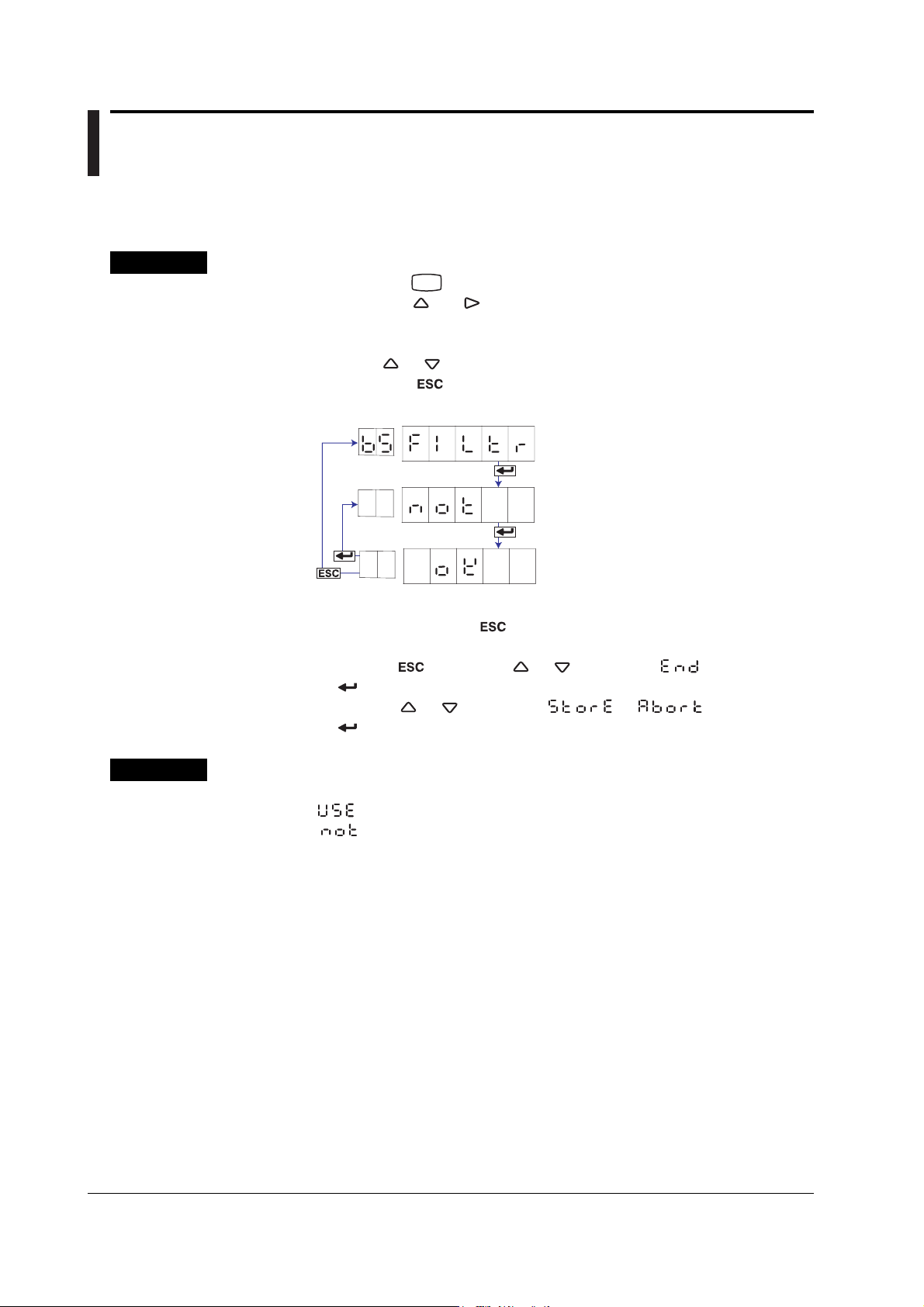

Cu10 (WEED)