Page 1

Instruction

Y

Manual

Model SC4A

19mm Conductivity Sensors

OKOGAWA

IM 12D7J4-E-E

7th edition

Page 2

TABLE OF CONTENTS

1. GENERAL ...................................................................................................................... 1

1-1. Type number ......................................................................................................... 1

1-2. General specifications SC4A-AD .......................................................................... 1

1-3. General specifications SC4A-SA/SB/SC ............................................................... 2

1-4. General specifications SC4A-PR .......................................................................... 3

1-5. Labelling ................................................................................................................ 3

2. INSTALLATION ............................................................................................................. 6

2-1. connection ............................................................................................................. 6

2-2. Mounting ............................................................................................................... 6

2-3. Safety warning ....................................................................................................... 6

3. OPERATION AND MAINTENANCE ............................................................................. 7

3-1. Checking the cell ................................................................................................... 7

3-2. Calibration of the cell ............................................................................................. 7

3-3. Cleaning of the cell ................................................................................................ 7

3-4. Spare parts list ...................................................................................................... 8

IM 12D7J4-E-E

Page 3

ºC

1. GENERAL

1-1. Type number

The type number of the conductivity cell, shown on the cable, gives coded information on

the cell constant, the materials of construction etc.

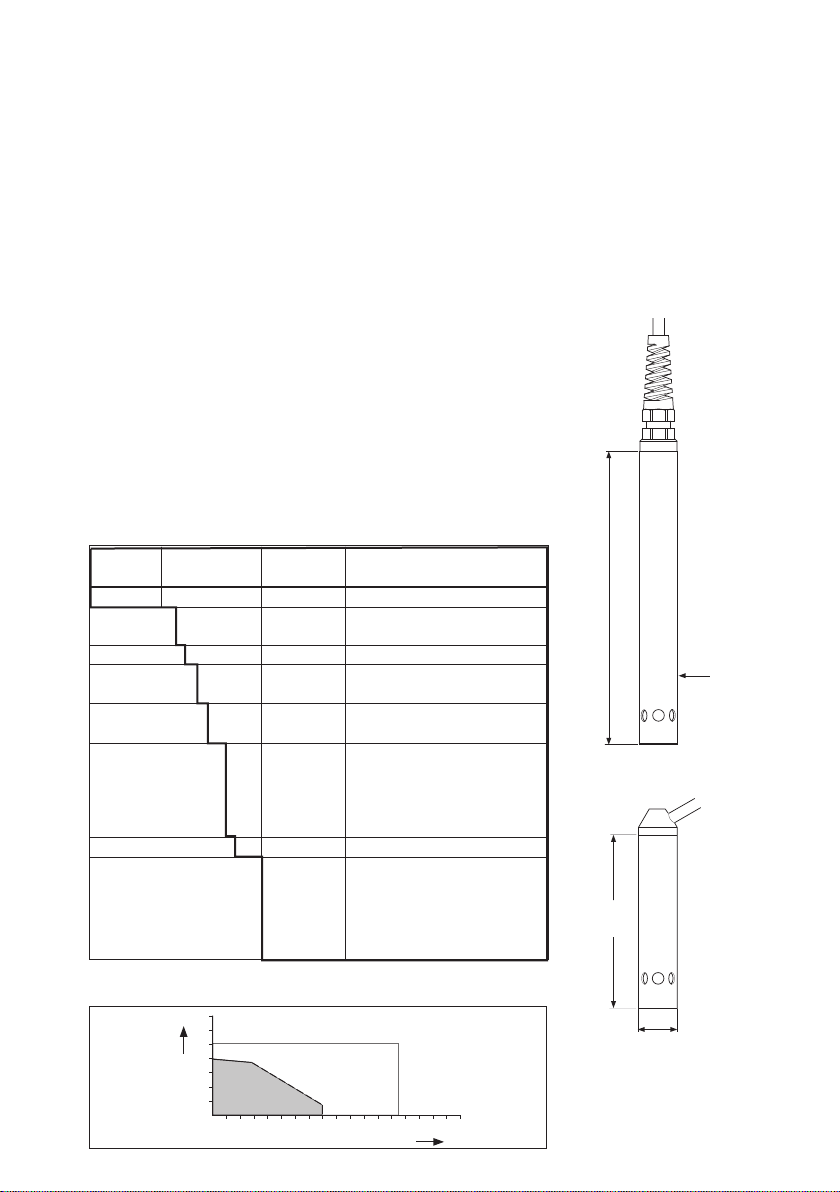

1-2.General specifications SC4A-AD

Materials Wetted Parts

3 ro 2 edarg muinatiT ro 613 ISIA leets sselniatS : sedortcele & ydoB

O-rings : Viton

613 ISIA leets sselniatS ro FDVP : retpada gnitnuoM

Insulation : PEEK (Poly Ether Ether Ketone)

Operating Specifications (Sensor)

Measuring system : 2-electrode (4-wire)

Maximum pressure : 10 Bar (142 PSIG)

Maximum temperature : 110 °C (230 °F)

egnahc pets a fo %09 rof etunim 1 < : esnopser erutarepmeT

Sterilize : At 135°C (275 °F)

Shipping details

Package size : wxhxd 220 x 220 x 90 mm

wxhxd 215 x 150 x 55 mm

package weight : Approx. 1.6 kg. 3.5 Ib

Model Suffix Option Description

Code code

SC4A

-T Titanium

19 mm conductivity sensor

152 (5.98")

-S Stainless steel

Fitting-type -AD For adapter mounting

Sensor-length -09 9 cm

-15 15 cm

Cellconstant -002 0.02/cm

-010 0.1/cm

Cable length -03 3 meter

-05 5 meter

-10 10 meter

-AD -15cm

-15 15 meter

-20 20 meter

-T1 Pt1000

AD only /PS

/PF

3

/4

” stainless steel adapter

3

/4

” PVDF adapter

gnittifwolF SS FF/

(option /PS required)

Certificates /Q Quality Inspection Certificate

90 (3.55)

Note: 3.1 Material certificate according to EN 10024 is standard

delivered with this sensor.

BAR

12

10

8

6

4

2

0 10 20 30 40 50 60 70 80 100 120 140 160

Operating Specifications (Adapters)

PVDF

SS

Ø19,1

(0.75)

-AD -09cm

IM 12D7J4-E-E

1

Ø 19,1 (0.75")

Page 4

2

(1.50 x 0.20)

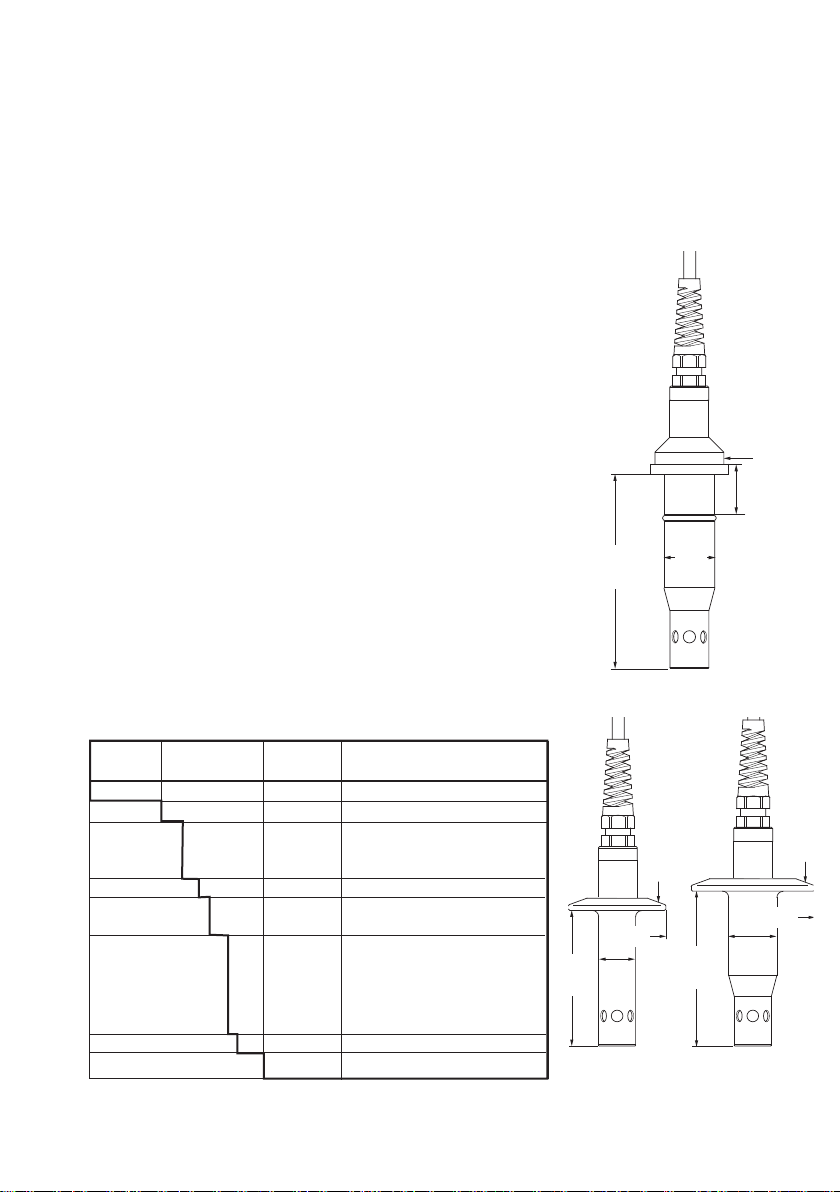

1-3 General specifications SC4A-SA/SB/SC

Materials Wetted Parts

Body & electrodes : Stainless steel AISI 316 (1.4435), Ro < 0.5

O-rings : EPDM, FDA migration tested

Mounting adapter : Stainless steel AISI 316 Triclamp acc. to ISO2852-1993

Insulation : PEEK (Poly Ether Ether Ketone), FDA migration tested

Operating Specifications (Sensor)

Measuring system : 2-electrode (4-wire)

Maximum pressure : 10 Bar (142 PSIG)

Maximum temperature : 110 °C (230 °F)

a fo %09 rof etunim 1 < : esnopser erutarepmeT

step change

Sterilize : At 135°C (275 °F)

Operating Specifications

Stainless Steel

Maximum pressure : 10 Bar (142 psig)

Maximum temperature : 135 °C (275 °F)

Shipping details

Package size : wxhxd 220 x 220 x 90 mm

wxhxd 215 x 150 x 55 mm

package weight : Approx. 1.6 kg. 3.5 Ib

95 (3.74")

Ø 25

(1.00")

Ø 38 x 5

25

Model Suffix Option Description

Code code

SC4A 19 mm conductivity sensor

-E EPDM FDA

Fitting-type -SA 25mm port

-SB 1-1

1/2

” tri-clamp

-SC 2” tri-clamp

Always -NN fixed length

Cellconstant -002 0.02/cm

-010 0.1/cm

Cable length -03 3 meter

-05 5 meter

-10 10 meter

-15 15 meter

-20 20 meter

-T1 Pt1000

Certificates /Q Quality Inspection Certificate

Note: dradnats si 42001 NE ot gnidrocca etacifitrec lairetaM 1.3

delivered with this sensor.

IM 12D7J4-E-E

70 (2.75")

Ø19

(0.75")

Ø50,4

(1.98")

-SA

1 - 1.5 " tri-clamp

80 (3.15")

2 " tri-clamp

Ø63,9

(2.52")

Ø25

(1.00")

-SC-SB

Page 5

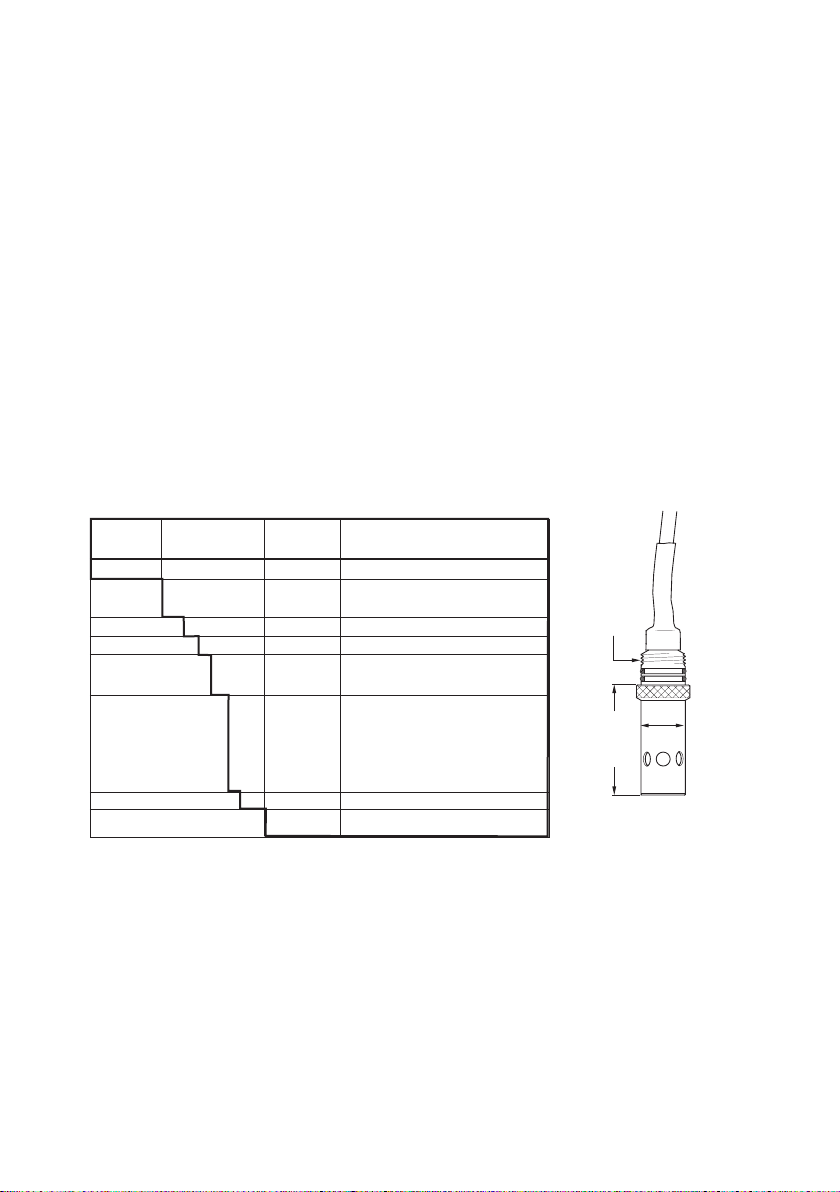

1-4 General specifications SC4A-PR

Materials

Wetted Parts

613 ISIA leets sselniatS : sedortcele & ydoB

or Titanium grade 2 or 3

O-rings : Viton

gnittif elbatcarteR : retpada gnitnuoM

Insulation : PEEK (Poly Ether Ether Ketone)

Operating Specifications (Sensor)

Measuring system : 2-electrode (4-wire)

Maximum pressure : 10 Bar (142 PSIG)

Maximum temperature : 110 °C (230 °F)

a fo %09 rof etunim 1 < : esnopser erutarepmeT

step change

Sterilize : At 135°C (275 °F)

Shipping details

Package size : wxhxd 220 x 220 x 90 mm

wxhxd 215 x 150 x 55 mm

package weight : Approx. 1.6 kg. 3.5 Ib

Model Suffix Option Description

Code code

SC4A 19 mm conductivity sensor

-T Titanium

-S Stainless steel

Fitting-type -PR For retractable mounting

Always -NN fixed length

Cellconstant -002 0.02/cm

-010 0.1/cm

Cable length -03 3 meter

-05 5 meter

-10 10 meter

-15 15 meter

-20 20 meter

-T1 Pt1000

Certificates /Q Quality Inspection Certificate

M19x1.5

Ø19

(0.75")

48 (1.89")

-PR

3

Note: dradnats si 42001 NE ot gnidrocca etacifitrec lairetaM 1.3

delivered with this sensor.

1-5. Labelling

In addition to the type number, information is given regarding:

queries.

.noitarbilac tnatsnoc llec laudividnI -

ecnanetniam ro ecivres yna ni detouq eb dluohs rebmun sihT .)7P .g.e( rebmun hctab ehT -

IM 12D7J4-E-E

Page 6

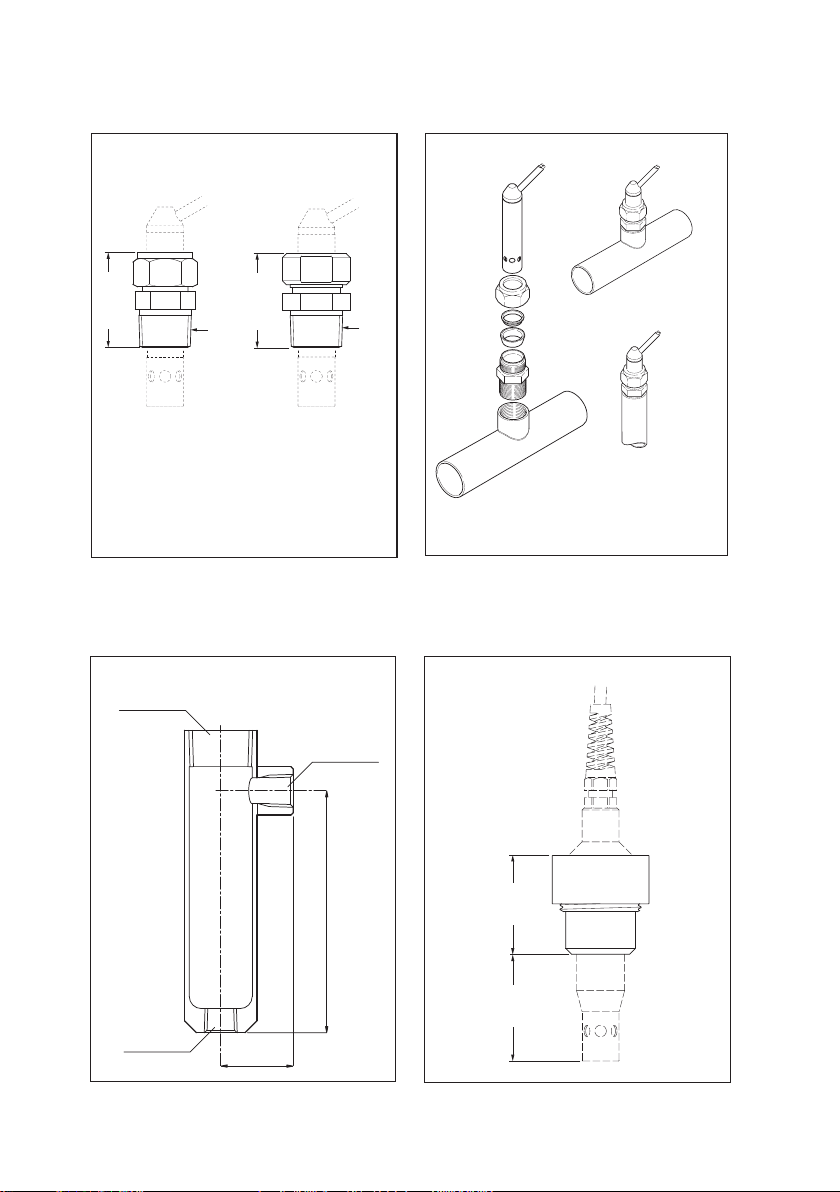

4

12D7J4-19

OPTIONS

OPTIONS

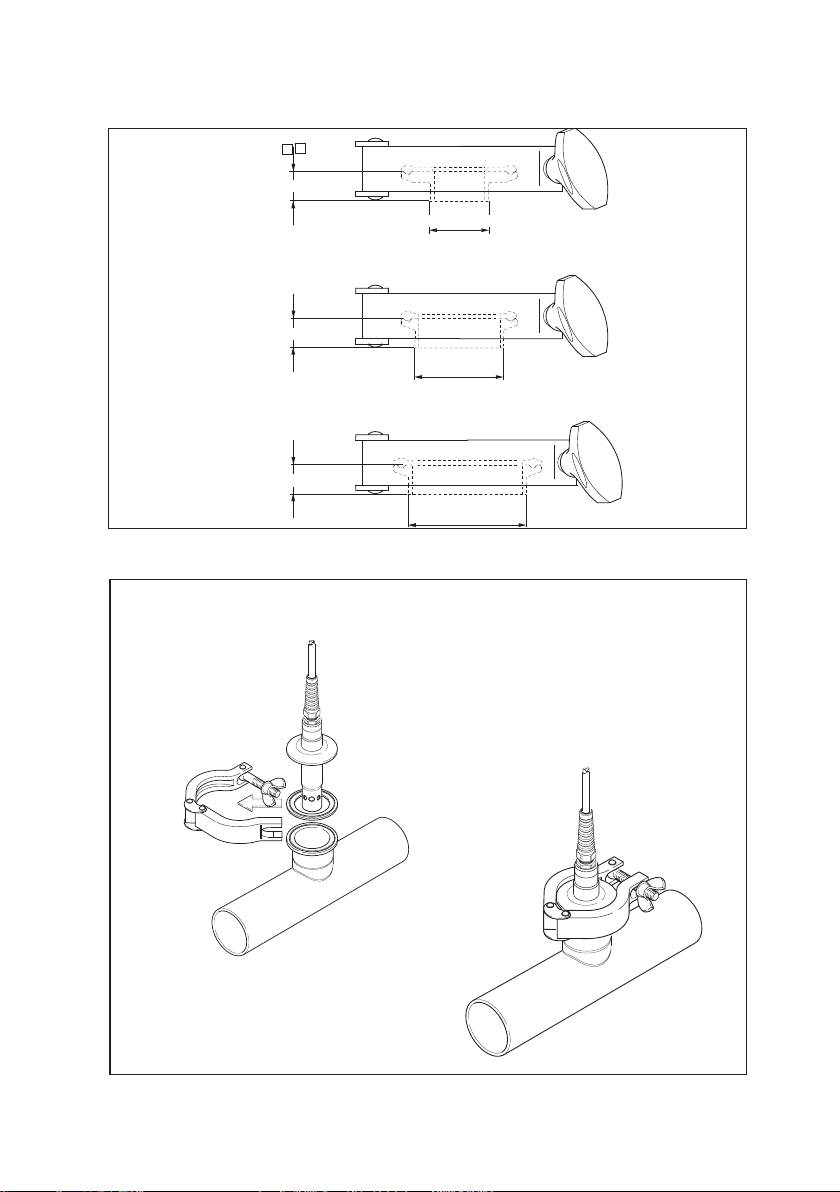

ca 49 (1.95")

/PS

3/4 NPT

ca 49 (1.95")

/PF

Figure 1-1. Adapters for SC4A-AD...

units in mm (inch)

3/4” NPT

1/4” NPT

Ø30

3/4 NPT

Figure 1-2. Mounted sensor with the

option /PS and /PF

1/4” NPT

30 (1.18”)

Figure 1-3. Flow fitting option /FF

K1598 AC (incl. 3.1 certificate)

IM 12D7J4-E-E

100 (3.94”)

51 (2.00")

55 (2.16")

Figure 1-4. Welding socket

for SC4A-SA...

Page 7

/SB2

/SC1

/SB1

12,7 (0.5")

Ø25,4(1.0")

12,7 (0.5")

Ø38,1(1.5")

12,7 (0.5")

Ø50,8(2.0")

Tri-clamps for SC4A -SB...

Tri-clamp for SC4A-SC...

Figure 1-5. Tri-clamp dimensions

5

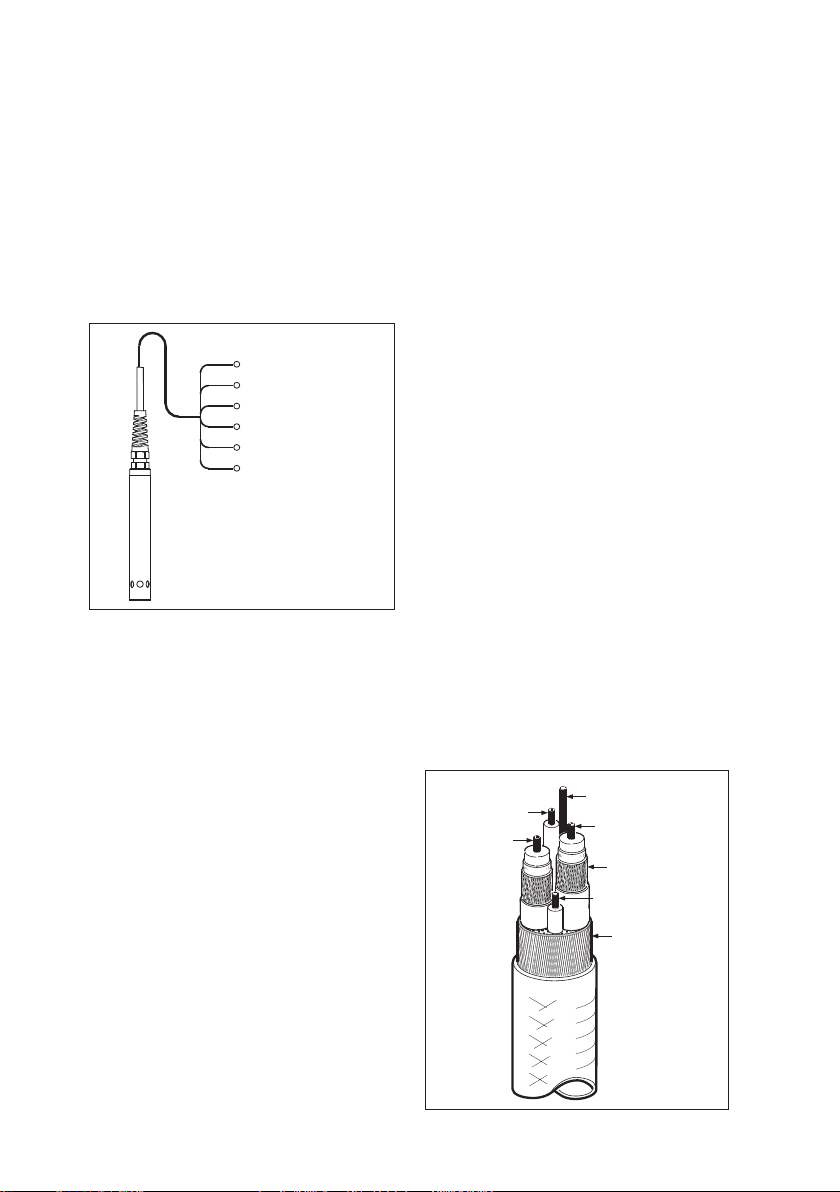

Figure 1-6. Mounted Sensor SC4A -SB / - SC

IM 12D7J4-E-E

Page 8

6

2. INSTALLATION

2-1. Connection

The cable is six wire multicore and covered

with a thermoplastic TPE. The wires are also

covered with thermoplastic TPE individually

and coloured. The cable connections

are supplied with 2 mm terminations for

connection to the transmitter, or connection

box: these pins quarantee a correct and

simple connection to the terminals.

11 Temperature

12 Temperature

13 Outer electrode

14 Outer electrode

15 Inner electrode

16 inner electrode

Figure 2-0. Sensor Wiring

At the instrument end the cable termination

tags are numbered to correspond with their

respective terminals of the transmitters.

NOTE:

If the cable is used with a connection box,

type BA10 then special purpose cable, type

WF10 must be used between connection

box and transmitter connected to the same

terminals as the cell cable. A maximum of

50 metres total cable length is permissable.

2-2. Mounting

The mounting is by a compression gland or

sanitary adapter, giving a simple effective

method of direct insertion in process

pipework. For mounting the retractable

sensor refer to the instruction manual of the

PR4A retractable holder. Before mounting

a cell in a process plant environment the

following points should be considered:

ssecorp fo wolf ,evitatneserper ,doog a liquid through the cell should exist. Hence,

the cell must

be mounted in the process

IM 12D7J4-E-E

in such a way that the flow through it

represents the true composition of the

liquid. The flow through the cell should be

uninterrupted and the cell should not be

mounted at a “dead” angle.

ssecorp eht ni desremmi eb tsum llec a liquid to a level above the outlet to ensure

an uninterrupted liquid path between the

electrodes.

to allow easy removal for

maintenance. It is recommended that

the cell is mounted in a ‘by-pass’ directly

behind a drain valve.

2-3. Safety warning

For SC4A..AD to avoid the sensor

shooting out, never install in application

where pressure can exceed specified

maximum. Never loosen mounting nut while

system is pressurised.

2-4. Commisioning

The sensor cable is marked with a label

specifying complete MS mode, Serialnumber

and calibrated cell constant*. This cell

constant must be entered in the EXA

transmitter to achive an accurate

measurement.

* Always specify complete MS code

and serialnumber in communication with

Yokogawa organisation with regards to

performance issues or warranty matters.

C

A

E

B

screen

D

overall

shield

Figure 2-1. WF10 Cable

yaw a hcus ni detnuom eb dluohs llec eht -

Page 9

3. OPERATION AND MAINTENANCE

7

3-1. Checking the cell

If a fault occurs, first check the cell for

visible damage. If damage is not apparent, check the cell resistances measuring

between the cable connections.

a. 11 and 12 (or connector pins 1 and 2)

b. 11 and 13 (or connector pins 1 and 3)

c. 12 and 13 (or connector pins 2 and 3)

d. 12 and 15 (or connector pins 4 and 5)

e. 15 and 16 (or connector pins 5 and 6)

f. 13 and 14 (or connector pins 3 and 4)

g. 13 and 15 (or connector pins 3 and 5)

Celltype a, b, c, d, g e, f

SC4A Pt1000 value > 100MΩ < 2Ω

If the cell has become fouled resistance will

be developed across the electrodes. These

resistances can be measured by making

contact directly with the electrode and the

relevant pin of the connector.

3-2. Calibration of the cell

The cell constant is determined under

laboratory conditions. It is possible that

slight variations in the cell constant may

occur dependant on the installation.

This possible error can be corrected by

recalibrating with a solution of known

conductivity value. The procedure is

descibed in ASTM D1125 or OIML

recommendation 56. Sensors with

long

cables may exhibit an offset in the

temperature readings. This can be

adjusted in the transmitter or converter.

A calibrated thermometer should be used

as reference measurement.

3-3. Cleaning of the cell

If the cell becomes fouled an insulating

layer may be formed on the electrodes and

consequently, an apparent increase in cell

constant may accur, giving a measuring

error. This error is:

2 • x 100 %

(Rv)

(Rcel)

Where:

Rv = the resistance of the fouling layer

Rcel = the cell resistance.

Cleaning methods

htiw retaw toh snoitacilppa lamron roF .1

domestic washing-up liquid added will

be effective.

%01...5 a .cte ,sedixordyh ,emil roF .2

solution of hydrochloric acid is

recommended.

easily removed with acetone.

a esu ,sdluom ro airetcab eagla roF .4

chlorinated solution (domestic bleach*).

dna dica cirolhcordyh esu reveN *

domestic bleach simultaneously.

The liberation of the very poisonous

gas Chlorine will result.

eb nac ).cte ,staf ,slio( sgniluof cinagrO .3

NOTES:

The specific conductivity value of the

solution of known value must be near the

value of the liquid to be measured. Specific

conductivity is highly temperature

dependent, therefore in the above

calibration procedure the temperature of

the cell and the liquid should be allowed

to equalise and should be accurately

measured with a calibrated thermometer.

IM 12D7J4-E-E

Page 10

8

3-4. SPARE PARTS AND ACESSOIRES

3-4-1- Spare parts and acessories for SC4A-S- AD and SC4A-T-AD

K1542DF Compression fitting in Stainless Steel ( /PS)

K1500DY Ferrule set for K1542DF

K1542CW Compression fitting in PVDF (/PF)

K1598AC Flowfitting with 3.1 material certificate

3.4.2. Spare parts and acessories for SC4A-E-SA

K1542FA Straight welding socket and mounting nut Stainless Steel

K1500BJ O-rings in EPDM (5), FDA migration tested

3.4.3. Spare parts and acessories for SC4A-E-SB

K1500HN Sealing gasket in EPDM for K1542FC (3), FDA migration tested

(welding socket, sealing gasket and clamp ring) (/SB1)

(welding socket, sealing gasket and clamp ring) (/SB2)

K1500BN Sealing gasket in EPDM for K1542FF (3), FDA migration tested

3.4.3. Spare parts and acessories for SC4A-E-SC

(welding socket, sealing gasket and clamp ring) (/SC1)

K1500BP Sealing gasket in EPDM for K1542FE (3), FDA

3.4.4. Spare parts and acessories for SC4A-T-PR and SC4A-S-PR

K1500BE O-rings in Viton (10)

K1500ED O-rings in Kalrez (2)

pmalcirt ”1 rof tes gnitnuom pmalC-irT CF2451K

pmalcirt ”5,1 rof tes gnitnuom pmalC-irT FF2451K

pmalcirt ”2 rof tes gnitnuom pmalC-irT EF2451K

migration tested

IM 12D7J4-E-E

Page 11

9

IM 12D7J4-E-E

Page 12

YOKOGAWA

YOKOGAWA EUROPE B.V.

Euroweg 2

3825 HD AMERSFOORT

The Netherlands

Tel. +31-88-4641 000

Fax +31-88-4641 111

www.yokogawa.com/eu

YOKOGAWA CORPORATION OF AMERICA

2 Dart Road

Newnan GA 30265

United States

Tel. (1)-770-253-7000

Fax (1)-770-251-2088

www.yokogawa.com/us

YOKOGAWA ELECTRIC ASIA Pte. Ltd.

5 Bedok South Road

Singapore 469270

Singapore

Tel. (65)-241-9933

Fax (65)-241-2606

www.yokogawa.com.sg

YOKOGAWA HEADQUARTERS

9-32, Nakacho 2-chome,

Musashinoshi

Tokyo 180

Japan

Tel. (81)-422-52-5535

Fax (81)-422-55-1202

www.yokogawa.com

Yokogawa has an

extensive sales and

distribution network.

Please refer to the

European website

(www.yokogawa.com/eu)

to contact your nearest

representative.

YOKOGAWA ELECTRIC CORPORATION

World Headquarters

9-32, Nakacho 2-chome, Musashino-shi

Tokyo 180-8750

Japan

www.yokogawa.com

YOKOGAWA CORPORATION OF AMERICA

2 Dart Road

Newnan GA 30265

USA

www.yokogawa.com/us

Euroweg 2

3825 HD AMERSFOORT

The Netherlands

www.yokogawa.com/eu

IM 12D7J4-E-E Copyright ©

Subject to change without notice

YOKOGAWA ELECTRIC ASIA Pte. LTD.

5 Bedok South Road

Singapore 469270

Singapore

www.yokogawa.com/sg

YOKOGAWA CHINA CO. LTD.

3F Tower D Cartelo Crocodile Building

No.568 West Tianshan Road Changing District

Shanghai, China

www.yokogawa.com/cn

YOKOGAWA MIDDLE EAST B.S.C.(c)

P.O. Box 10070, Manama

Building 577, Road 2516, Busaiteen 225

Muharraq, Bahrain

www.yokogawa.com/bh

Yokogawa has an extensive sales and

distribution network.

Please refer to the European website

(www.yokogawa.com/eu) to contact your

nearest representative.

Printed in The Netherlands

07-901 (A) I

Loading...

Loading...