Page 1

Instruction

YOKOGAWA

Manual

Model SC4A, SC41 SC42,

SC49, SX42

Specific Conductivity

sensors

IM 12D07J01-10E-E

11th edition

Page 2

(BG)

Всички улътвания за продукти от серията

ATEX Ex ce лредлагат на английски език.

Ако се нуждаете oт улътвания за продукти oт

серията Ex на родния ви eзик, ce свържете c

най-близкия oфис или представителство на

фирма Yokogawa.

(CZ)

Všechny uživatelské příručky pro výrobky, na

něž se vztahuje nevýbušné schváleni ATEX Ex,

jsou dostupné v angličtině. Požadujete-li pokyny

týkající se výrobků s nevýbušným schválením ve

vašem lokálním jazyku, kontaktujte prosím vaši

nejbližší reprezentačni kancelář Yokogawa.

(E)

Todos los manuales de instrucciones para

los productos antiexplosivos de ATEX están

disponibles en inglés. Si desea solicitar las

instrucciones de estos artículos antiexplosivos en

su idioma local, deberá ponerse en contacto con

la oficina o el representante de Yokogawa más

cercano.

(F)

Tous les manuels d’instruction des produits ATEX

Ex sont disponibles en langue anglaise. Si vous

nécessitez des instructions relatives aux produits

Ex dans votre langue, veuillez bien contacter votre

représentant Yokogawa le plus proche.

(D)

Alle Betriebsanleitungen für ATEX Ex bezogene

Produkte stehen in den Sprachen Englisch. Sollten

Sie die Betriebs- anleitungen für Ex-Produkte in

Ihrer Landessprache benötigen, setzen Sie sich

bitte mit Ihrem örtlichem Yokogawa-Vertreter in

Verbindung.

(DK)

Alle brugervejledninger for produkter relateret til

CE er tilgængelige på engelsk. Skulle De ønske

yderligere oplysninger om håndtering af CE

produkter på eget sprog, kan De rette henvendelse

herom til den nærmeste Yokogawa afdeling eller

forhandler.

(EST)

Kõik ATEX Ex toodete kasutamisjuhendid on

esitatud inglise keeles. Ex seadmete muukeelse

dokumentatsiooni saamiseks pöörduge lähima

lokagava (Yokogawa) kontori või esindaja poole.

IM 12D07J01-10E-E

(GB)

All instruction manuals for ATEX Ex related

products are available in English. Should you

require Ex related instructions in your local

language, you are to contact your nearest

Yokogawa office or representative.

(GR)

Ολα τα εγχειριδια λειτουργιας των προιοντων

με ATEX Ex διατιθενται στα Αγγλικα. Σε

περιπτωση πον χρειαζεοτε οδηγιεξ σχετικα με Ex

στην τοπικη γλωσσα παρακαλονμε επικοινωνηστε

με το πλησιεστερο γραφειο τηζ Yokogawa η

αντιπροσωπο τηξ.

(H)

Az ATEX Ex mûszerek gépkönyveit angol

nyelven adjuk ki. Amennyiben helyi nyelven kérik

az Ex eszközök leírásait, kérjük keressék fel a

legközelebbi Yokogawa irodát, vagy képviseletet.

(I)

Tutti i manuali operativi di prodotti ATEX

contrassegnati con Ex sono disponibili in inglese.

Se si desidera ricevere i manuali operativi di

prodotti Ex in lingua locale, mettersi in contatto

con l’ufficio Yokogawa più vicino o con un

rappresentante.

Page 3

(LV)

Visas ATEX Ex kategorijas izstrâdâjumu

Lietoðanas instrukcijas tiek piegâdâtas

angïu valodâs. Ja vçlaties saòemt Ex ierîèu

dokumentâciju citâ valodâ, Jums ir jâsazinâs ar

firmas Jokogava (Yokogawa) tuvâko ofisu vai

pârstâvi.

(PL)

Wszystkie instrukcje obsługi dla urządzeń w

wykonaniu przeciwwybuchowym Ex, zgodnych

z wymaganiami ATEX, dostępne są w języku

angielskim. Jeżeli wymagana jest instrukcja obsługi

w Państwa lokalnym ję zyku, prosimy o kontakt z

najbliższym biurem Yokogawy.

(LT)

Visos gaminiø ATEX Ex kategorijos

Eksploatavimo instrukcijos teikiami anglø

kalbomis. Norëdami gauti priestaisø Ex

dokumentacijà kitomis kalbomis susisiekite su

artimiausiu bendrovës Yokogawa biuru arba

atstovu.

(M)

Il-manwali kollha ta’ l-istruzzjonijiet għal prodotti

marbuta ma’ ATEX Ex huma disponibbli bl-Ingliż.

Jekk tkun teħtieģ struzzjonijiet marbuta ma’ Ex

fil-lingwa lokali tiegħek, għandek tikkuntattja lilleqreb rappreżentan jew uffiććju ta’ Yokogawa.

(NL)

Alle handleidingen voor producten die te maken

hebben met ATEX explosiebeveiliging (Ex)

zijn verkrijgbaar in het Engels. Neem, indien u

aanwijzingen op het gebied van explosiebeveiliging

nodig hebt in uw eigen taal, contact op met de

dichtstbijzijnde vestiging van Yokogawa of met

een vertegenwoordiger.

(P)

Todos os manuals de instruções referentes aos

produtos Ex da ATEX estão disponíveis em

Inglês. Se necessitar de instruções na sua língua

relacionadas com produtos Ex, deverá entrar em

contacto com a delegação mais próxima ou com

um representante da Yokogawa.

(RO)

Toate manualele de instructiuni pentru produsele

ATEX Ex sunt in limba engleza. In cazul in care

doriti instructiunile in limba locala, trebuie sa

contactati cel mai apropiat birou sau reprezentant

Yokogawa.

(S)

Alla instruktionsböcker för ATEX Ex

(explosionssäkra) produkter är tillgängliga på

engelska. Om Ni behöver instruktioner för dessa

explosionssäkra produkter på annat språk, skall

Ni kontakta närmaste Yokogawakontor eller

representant.

(SF)

Kaikkien ATEX Ex-tyyppisten tuotteiden

käyttöhjeet ovat saatavilla englannin-. Mikäli

tarvitsette Ex-tyyppisten tuotteiden ohjeita

omalla paikallisella kielellännne, ottakaa yhteyttä

lähimpään Yokogawa-toimistoon tai -edustajaan.

(SK)

Všetky návody na obsluhu pre prístroje s ATEX

Ex sú k dispozícii v jazyku anglickom. V prípade

potreby návodu pre Ex-prístroje vo Vašom

národnom jazyku, skontaktujte prosím miestnu

kanceláriu firmy Yokogawa.

(SLO)

Vsi predpisi in navodila za AEX Ex sorodni

pridelki so pri roki v anglišèini. Èe so Ex sorodna

navodila potrebna v vašem tukejnjem jeziku,

kontaktirajte vaš najbliši Yokogawa office ili

predstaunika.

IM 12D07J01-10E-E

Page 4

CONTENTS

1. PREFACE 1

1.1 Introduction 1

1.2 Unpacking and Checking 1

1.3 Warranty and Service 1

1.4 Serial Number definition 2

2. MODEL SC4A 3

2.1. General Specifications 3

2.1.1. Measuring elements 3

2.1.2. Materials 3

2.1.3. Functional specifications (at 25°C) 4

2.1.4. Dynamic specifications 4

2.1.5. Operating range 4

2.1.6. Regulatory standards (only for SC4A with fixed cable) 5

2.1.7. Shipping details 7

2.1.8. Environmental conditions 7

2.1.9. Mechanical specifications 7

2.2. Installation of SC4A sensors 7

2.2.1. Typical installation SC4A-*-AD with standard options 7

2.2.2. Typical installation SC4A-E-SA (SB, SC) with standard options / spare parts 8

2.2.3. Typical installation SC4A-*-PR 9

2.3. Dimensions SC4A sensors 9

2.4. Wiring SC4A sensors 10

2.5. Modelcode SC4A sensors 11

2.6. Spare parts SC4A 12

3. MODEL SC41, SC42 AND SC49 13

3.1. General Specifications 13

3.1.1. Measuring elements 13

3.1.2. Materials 13

3.1.3. Functional specifications (at 25°C) 14

3.1.4. Dynamic specifications 14

3.1.5. Operating range 14

3.1.6. Regulatory standards (only for SC42 with Amphenol connector) 15

3.1.7. Shipping details 16

3.1.8. Environmental conditions 16

IM 12D07J01-10E-E

Page 5

3.2. Installation of SC41/SC42/SC49 sensors 17

3.2.1. Typical installation of SC41/SC42/SC49 sensor

in FF40 Flow fittings/ FS40 Flow fitting assemblies 17

3.2.2. Typical installation of SC41/SC42/SC49 sensor in FD40 Immersion fitting 22

3.3 Dimensions SC41/SC42/SC49 sensors. 23

3.4. Wiring SC41/SC42/SC49 sensors 25

3.5 Modelcode SC41/SC42/SC49 25

4. MODEL SX42 26

4.1. General Specifications 26

4.1.1. Measuring elements 26

4.1.2. Materials 26

4.1.3. Functional specifications (at 25°C) 26

4.1.4. Operating range 26

4.1.5. Regulatory standards (not applicable for sensors with suffix code -BV or -NV) 28

4.1.6. Shipping details 29

4.1.7. Environmental conditions 29

4.2. Installation of SX42 sensors 29

4.3. Dimensions SX42 sensors 29

4.4. Wiring SX42 sensors 29

5. GENERAL CALIBRATION AND MAINTENANCE PROCEDURE 31

5.1. Calibration of the sensor 31

5.2. Periodic maintenance of the sensor 31

6. PROTECTION OF ENVIRONMENT (USE IN CHINA) 32

7. CHEMICAL COMPATABILITY CHART 33

IM 12D07J01-10E-E

Page 6

IM 12D07J01-10E-E

Page 7

1. PREFACE

1.1 Introduction

The sensor, model SC4A, SC41, SC42, SC49 and SX42, and associated fitting program is

designed to meet the most common installation requirements in terms of material compatibility,

process connections and flow dynamics. The various installation possibilities are described and

illustrated in this Instruction Manual.

Model SC4A sensors, available in a Stainless Steel or Titanium version with fixed cable or

Variopin connector, in combination with WU10/WE10-cable are intended for the low conductivity

applications. These sensors are designed in a convenient compact style, and can be inserted

directly in process pipework using available fittings or adapters.

Model SC41, SC42 and SC49 sensors, available in various materials such as Epoxy, Stainless

Steel, PTFE and PVDF, are intended to suit most process conditions. The sensors are provided

either with a Amphenol connector to fit the Yokogawa WU40 cable or Variopin connector to fit with

Yokogawa WU10/WE10-cable. A wide range of flow and immersion fittings makes it possible to

install the sensors in a permanent or semi-permanent location.

Model SX42 sensors have a Stainless Steel body and ceramic insulation, especially designed to

withstand high temperatures and high pressures. The flanged model has an integral connection box,

the threaded models are provided with a Amphenol connector to fit the Yokogawa WU40 cable or

Variopin connector to fit with Yokogawa WU10/WE10-cable.

1

All sensors have a pre-calibrated cell constant and a built-in temperature element for automatic

temperature compensation. Sensors with the Variopin connector are equipped with an ID-chip

in which callibration information is stored for easy setup when connected to a SENCOM Smart

Adapter model SA11-C1. For metal sensors a 3.1 material certificate is included. The sensors,

except those equipped with Variopin connector, are ATEX certified for installation in zone 0

environments when connected to a certified intrinsically safe Yokogawa analyser, model SC202S

or FLXA21 or a certified intrinsically safe circuit with defined output parameters (see General

Specifications of each sensor for details).

1.2 Unpacking and Checking

Upon delivery, unpack the sensor carefully and inspect it to ensure that it is not damaged during ship-

ment. If damage is found, retain the original packing material and immediately notify the carrier and the

relevant local Yokogawa Sales office. Make sure the Model Code and Serial Number on the sensor are

the same as on the packing list. Also check if option(s) that were ordered, are included and correct.

1.3 Warranty and Service

Yokogawa products are guaranteed free from defects in workmanship and materials under

normal use and service for a period of (typically) 12 months from the date of shipment from the

manufacturer. Individual Sales organizations can deviate from the typical warranty period, and the

IM 12D07J01-10E-E

Page 8

2

conditions of sale relating to the original purchase order should be consulted. Damage caused

by wear and tear, inadequate maintenance, corrosion, or by the effects of chemical processes is

excluded from this warranty coverage. In the event of a warranty claim, the defective goods should

be sent (freight paid) to the Service Department of the relevant Yokogawa Sales office for repair or

replacement (at Yokogawa’s discretion).

The following information must be included in the letter accompanying the returned goods:

• Model Code and Serial Number.

• Original Purchase Order and Date.

• Length of time in service and description of the process.

• Description of the fault and circumstances of the failure.

• Process/environmental conditions that may be related to the failure of the sensor.

• Statement as to whether warranty or nonwarranty service is requested.

• Complete shipping and billing instructions for return of material, plus the name and phone number

of a contact person that can be reached for further information.

• Clean Statement Returned goods that have been in contact with process fluids must be

decontaminated and disinfected prior to shipment. Goods should carry a certificate to this effect,

for the health and safety of our employees. Material Safety Data sheets must be included for all

components of the process to which the sensor (options) have been exposed.

1.4 Serial Number definition

The serial number is defined by nine (9) alphanumeric characters:

X1X2 Production location, N3 for Yokogawa Process Analyzers Europe B.V.

X3X4 Year/Month code

X5X6X7X8X9 Tracking number

Example: N3P600028

Method used for year/month numbering

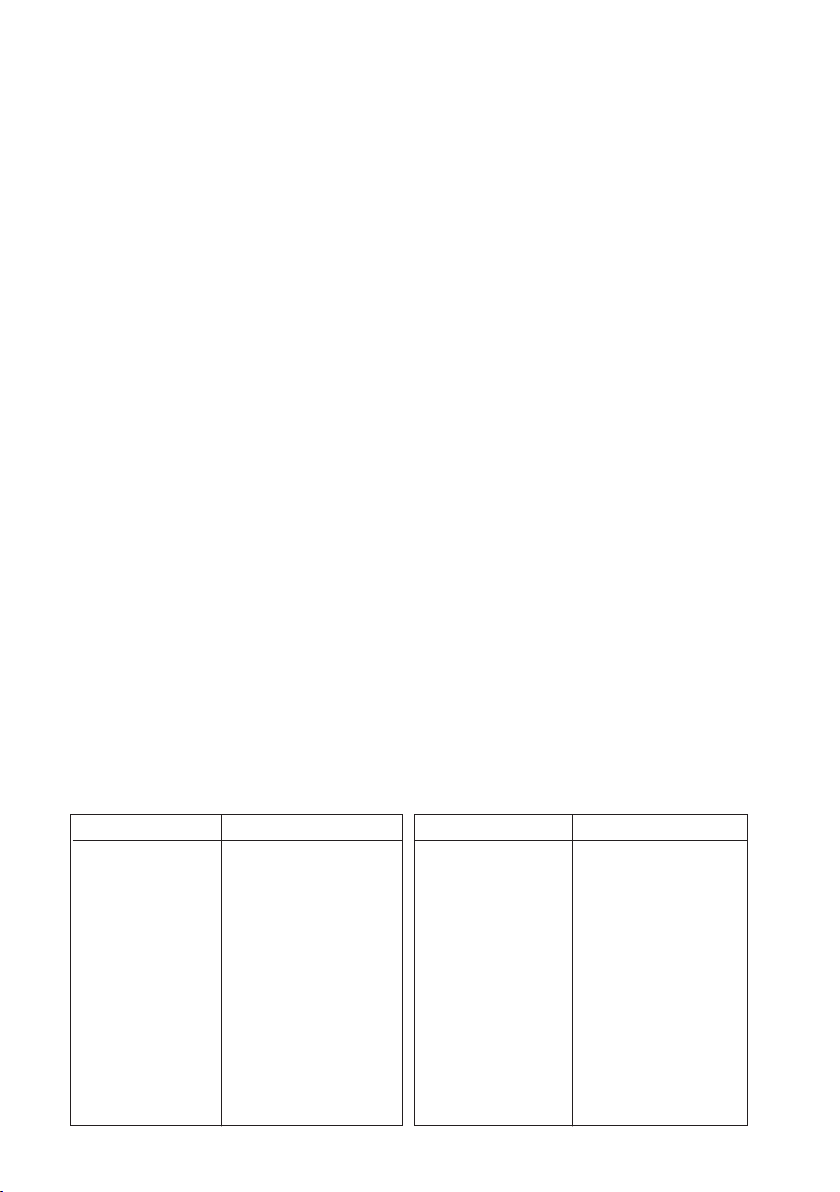

Table 1: Production Year code Table 2: Production Month code

Year Year code Year Year code Month Month code

2014 P 2026 3 January 1

2015 R 2027 4 February 2

2016 S 2028 5 March 3

2017 T 2029 6 April 4

2018 U 2030 7 May 5

2019 V 2031 8 June 6

2020 W 2032 9 July 7

2021 X 2033 A August 8

2022 Y 2034 B September 9

2023 Z 2035 C October A

2024 1 2036 D November B

2025 2 2037 E December C

IM 12D07J01-10E-E

Page 9

2. MODEL SC4A

2.1. General Specifications

2.1.1. Measuring elements

2-electrode measuring system

Pt1000 temperature sensor

2.1.2. Materials

Wetted parts sensor:

Body & electrodes SC4A-T-AD : Titanium grade 2 or 3

SC4A-S-AD : Stainless Steel AISI 316L

SC4A-E-SA (SB, SC) : Stainless Steel AISI 316L

SC4A-T-PR : Titanium grade 2 or 3

SC4A-S-PR : Stainless Steel AISI 316L

O-ring SC4A-*-AD : Viton

SC4A-E-SA (SB, SC) : EPDM FDA approved

SC4A-*-PR : Viton

Insulation : PEEK 450G, FDA migration tested

Wetted parts adapters/fitting:

/PS, /FF SC4A-*-AD : Stainless Steel AISI 316L

/PF SC4A-*-AD : PVDF

/SA1(2), /SB1(2), /SC1 SC4A-E-SA (SB, SC) : Stainless Steel AISI 316L

3

Cable:

Versions with integrated cable only:

Conductors : tinned copper 0.6 mm

2

Outside shield : braid, tinned copper, 85% coverage

Insulator : Polyester for conductors, for colors see

Section 2.4

TPE-O for outer jacket, color black

Variopin connector:

Contacts : Gold plated

Material : Nickel plated brass

Insulation : Peek, UL94-VO

IP class : IP67

IM 12D07J01-10E-E

Page 10

4

2.1.3. Functional specifications (at 25°C)

Temperature element : Pt1000 to IEC 751

Nominal Cell Constant (C.C.) : 0.02 cm-1 or 0.1 cm

-1

Note: The SC4A temperature sensor is designed for measurement compensation and for

indication. It is NOT designed for process temperature control.

2.1.4. Dynamic specifications

Response time temperature t90 : < 1 min.

2.1.5. Operating range

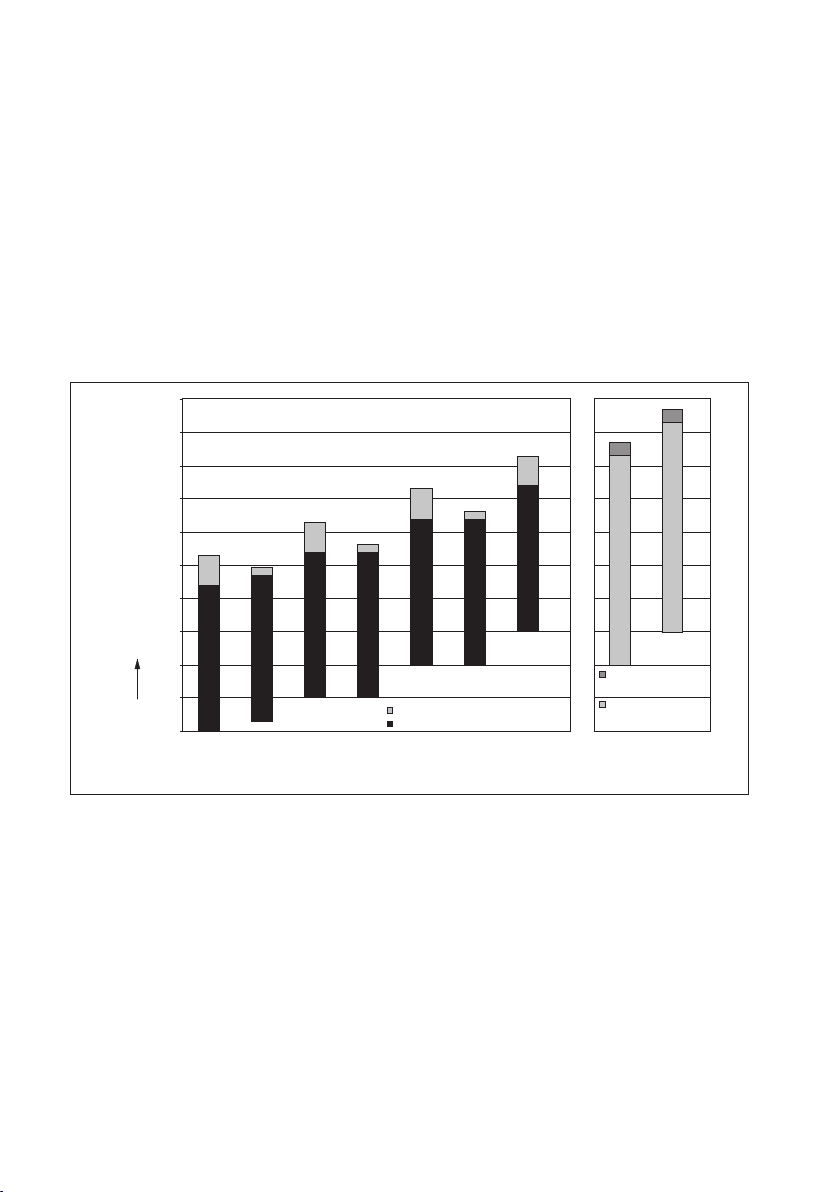

Conductivity at actual process temperature : 1 µS * C.C. – 50 mS * C.C.

100 000 000.00

10 000 000.00

1 000 000.00

100 000.00

10 000.00

1 000.00

100.00

10.00

µS/cm

1.00

0.10

0.01

SC42-SP34

SX42-SX34

(0.01/cm)

SC4A-002

(0.02/cm)

SC42-SP24

SX42-SX24

(0.1/cm)

SC450/SC202/FLXA21/ FLXA202

DC402

SC4A-010

SC42-EP14

(0.1/cm)

(1/cm)

SC42EP15/EP16

(1/cm)

SC42-EP04

SC42-FP04

SC42-TP04

(10/cm)

SC450/FLXA21/

FLXA202

SC202

SC42-EP18

SC42-EP08

SC42-FP08

(1/cm)

SC42-TP04

(10/cm)

Fig. 1 Measuring range of conductivity sensors

Process temperature Stainless Steel : 0°C to 110°C (32°F to 230°F)

& Titanium type : 135°C (275°F) for a short period of time during

sterilization.

Process temperature in combination : 0°C to 80°C (32°F to 176°F)

with PVDF fitting

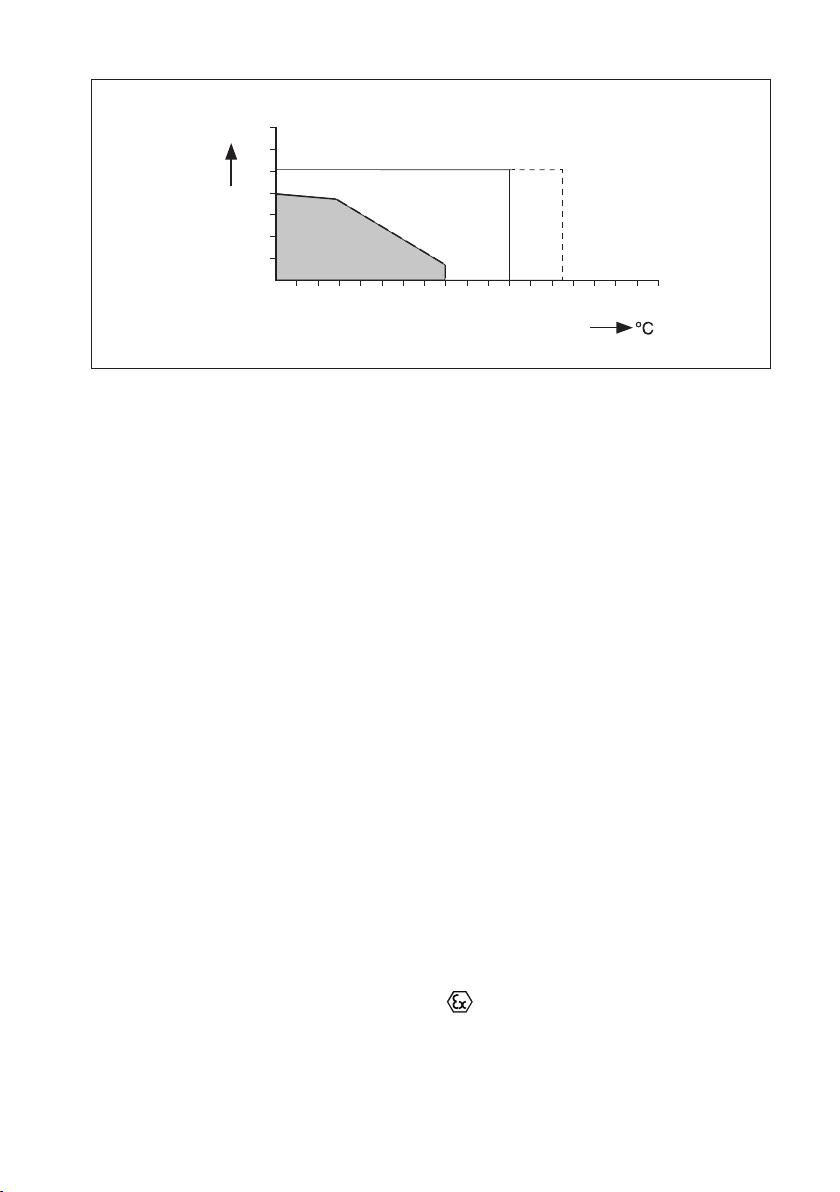

Process pressure Stainless Steel & Titanium type : 0 to 10 bar (0 to 142 PSIG)

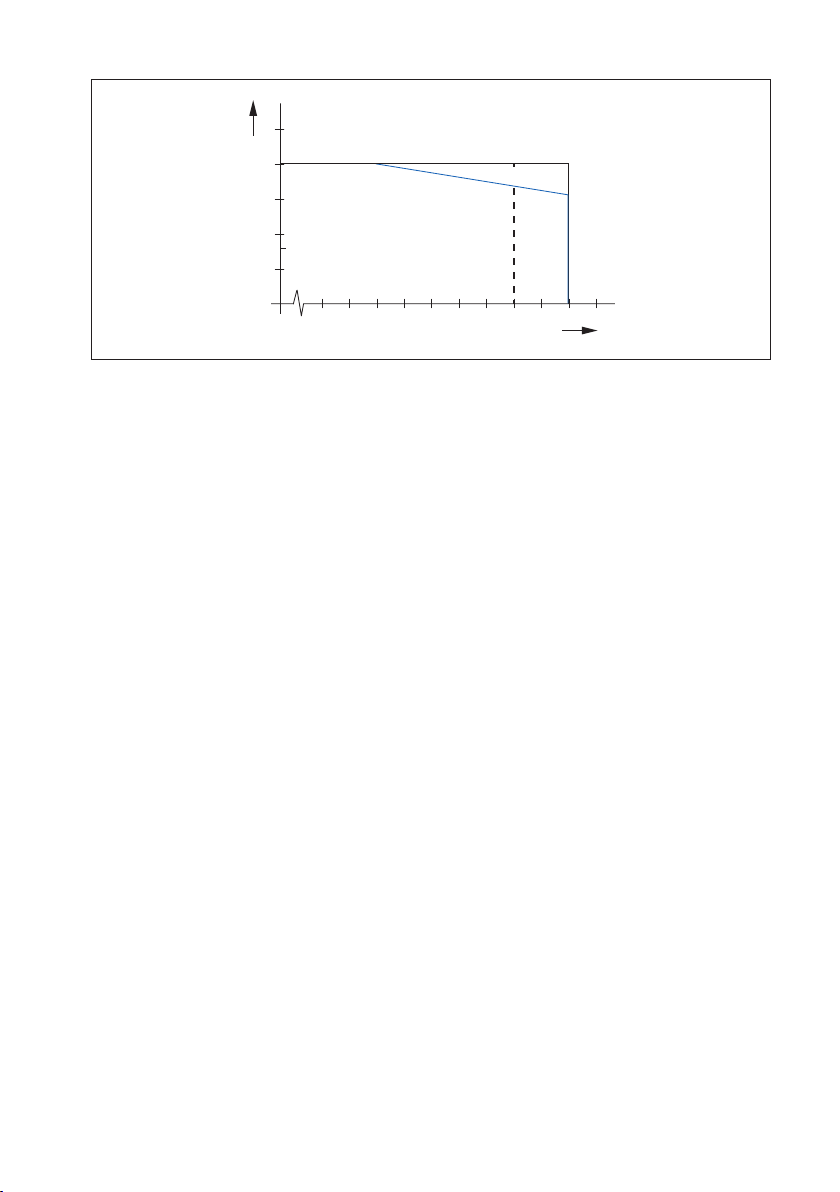

Process Pressure in combination with PVDF fitting: See Fig. 2

IM 12D07J01-10E-E

Page 11

bar

12

10

8

6

4

2

0 10 20 30 40 50 60 70 80 100 120 140 160

SS / Ti

PVDF

Fig. 2 Pressure vs temperature

Cable length for

• SC4A with fixed cable or SC4A with Variopin

directly connected to Flexa analyzer : max. 60 meter with WU10/WE10

(possibly in combination with WF10 cable

and BA10 junction box}

• For suffix -VS combined with SA11 : 3 meter WE10 cable (as option) combined

with SA11 Smart Adapter

SA11 Smart Adapter : Directly connected to the analyzer using a

WU11 cable up to 100 meters

or

Connected to a BA11 connetion box

using WU11 cable upto 100 m. The BA11

connection box is connected to the analyzer

using a WU11 cable up to 100m.

5

2.1.6. Regulatory standards (only for SC4A with fixed cable)

- ATEX : Directive 2014/34/EU

by applying:

EN 60079-0

EN 60079-11

EN 60079-26

Certificate no. : DEKRA 14ATEX0074 X

II 1 G Ex ia IIC T4… T6 Ga

IM 12D07J01-10E-E

Page 12

6

- IECEx

Applying standards : IEC 60079-0

: IEC 60079-11

: IEC 60079-26

Certificate no. : IECEx DEK 14.0032X

Ex ia IIC T4…T6 Ga

Conformity : EAC (Eurasia)

TS (Taiwan)

- Electrical data for ATEX/IECEx : For sensor input circuit connected to

A certified intrinsically safe circuit with the following

maximum values:

Ui = 14.4 V; Ii = 116.5 mA; Pi = 0.342 W

or

Certified intrinsically safe Yokogawa Contact

Conductivity transmitter Model FLXA21 series or

Model SC202S series.

The effective internal capacitance Ci and the

effective internal inductance Li of the sensor depends only

upon the properties and length of the integral cable.

Special conditions (X) : T6 for Tamb. -30°C to 40°C

T5 for Tamb. -30°C to 95°C

T4 for Tamb. -30°C to 130°C

Impact on the product shall be avoided.

Electrostatic charges on the enclosure shall be avoided.

From the safety point of view the circuits shall be

assumed to be connected to earth.

Regulatory standards (all types)

CE : Decision 768/2008/EC

- Pressure : Directive 2014/68/EU

Applying article : 4.3 (Sound Engineering Practice)

- RoHS2 : Directive 2011/65/EU

Applying category : 9 (Industrial monitoring and control instruments)

IM 12D07J01-10E-E

Page 13

2.1.7. Shipping details

Package size (LxWxH) : 220 x 220 x 90 mm (8.7 x 8.7 x 3.6 inch)

Package weight : 0.5 to 1.7 kg (1.1 to 3.8 lbs), depends on sensor type

and cable length

2.1.8. Environmental conditions

Storage temperature : -30°C to 50°C (-22°F to 122°F)

2.1.9. Mechanical specifications

Surface roughness SC4A-*-AD : 0.8 µm

SC4A-E-SA (SB, SC) : 0.5 µm

SC4A-*-PR : 0.8 µm

2.2. Installation of SC4A sensors

For optimum measurement results, the SC4A sensor should be installed in a location that

offers an acceptable representation of the process composition and DOES NOT exceed the

specifications of the sensor.

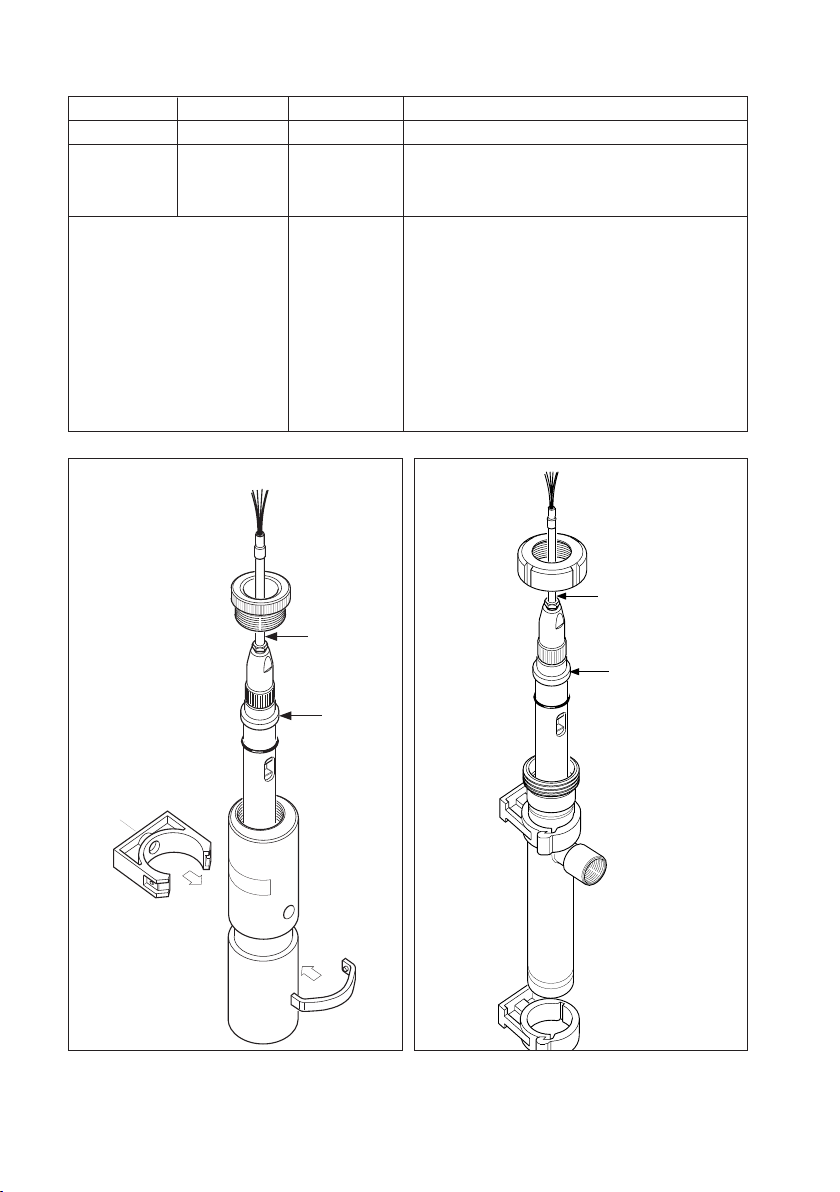

2.2.1. Typical installation SC4A-*-AD with standard options

The SC4A-*-AD sensor can be installed in the process using optional ¾” NPT adapters. These

adapters are available in Stainless Steel (/PS) and in PVDF (/PF); see figure 3 for the mounting

sequence. The sensor can also be installed in an optional Stainless Steel flow fitting (/FF) using

option /PS, see figure 4 for details.

3/4 “NPT

1/4 “NPT

7

Fig. 3 Mounted sensor

with the option /PF and /PS

100 (3.94”)

1/4 “NPT

30(1.18”)

Fig. 4 Dimensional drawing /FF

with the option /PS

IM 12D07J01-10E-E

Page 14

8

2.2.2. Typical installation SC4A-E-SA (SB, SC) with standard options / spare parts

The typical installation of the SC4A-E-SA sensor is done by using a standardized 25 mm port.

Stainless Steel welding sockets are available as straight version (spare part /SA1) or 15° angled

version (spare part /SA2). Both versions are delivered with mounting nut.

In figure 5 an example is shown how to install the sensor using spare part /SA1.

Sensors SC4A-E-SB and SC4A-E-SC are installed by tri-clamp method.

For the SB version two Stainless Steel tri-clamps are available, in a 1” size

(spare part /SB1) or in a 1½“ size (spare part /SB2).

The SC version has just one Stainless Steel tri-clamp in a 2” size (spare part /SC1).

/SA1

51 (2.00")

55 (2.16")

Fig 5. Mounted SC4A-E-SA sensor

with sparepart/ SA1

IM 12D07J01-10E-E

Fig 6 Mounted SC4A-E-SB sensor

Page 15

Ø 19,1

(0.75")

90 (3.55")

Ø 25

(1.00")

Ø 38 x 5

(1.50 x 0.20)

95 (3.74")

25

(1.00”)

M19x1.5

48 (1.89")

19.8

Ø 24.9

Ø 19.1

152 (5.98")

152 (5.98")

95 (3.74")

41

52

Ø

27.5

Ø 19.1

M19x1.5

48 (1.89")

41

52

Ø

27.5

Ø 19.1

Ø 19,1

(0.75")

90 (3.55")

Ø 25

(1.00")

Ø 38 x 5

(1.50 x 0.20)

95 (3.74")

25

(1.00”)

Ø50,4

(1.98")

Ø19

(0.75")

1 - 1.5 "

tri-clamp

2 "

tri-clamp

Ø25

(1.00")

80 (3.15")

Ø63,9

(2.52")

M19x1.5

48 (1.89")

19.8

Ø 24.9

Ø 19.1

152 (5.98")

152 (5.98")

95 (3.74")

70 (2.75")

41

52

Ø

27.5

Ø 19.1

Ø 64

Ø 25

Ø 50.5

Ø 19.1

Ø 19.1

2 "

tri-clover

1" - 1

1

/2"

tri-clover

70

80

M19x1.5

48 (1.89")

19.8

Ø 24.9

Ø 19.1

95 (3.74")

41

52

Ø

27.5

Ø 19.1

Ø 64

Ø 25

Ø 50.5

Ø 19.1

Ø 19.1

2 "

tri-clover

1" - 1

1

/2"

tri-clover

70

80

2.2.3. Typical installation SC4A-*-PR

The installation of the SC4A-*-PR sensor is done using the Model PR10 retractable fitting.

The mounting procedure of the sensor is explained in the Instruction Manual of this fitting.

2.3. Dimensions SC4A sensors

units in mm (inch)

Fig 7. SC4A-AD Fig. 8. SC4A-SA Fig. 9. SC4A-PR

9

Fig. 10 : Dimensions of SC4A-SB/SC sensor

IM 12D07J01-10E-E

Page 16

10

2.4. Wiring SC4A sensors

The SC4A sensors are provided with a fixed sensor cable or Variopin connector to fit the WU10/WE10

cable up to 20 meters. When a longer cable run is necessary (maximum cable run is 60 meters), this

can be done by using the WF10 extension cable in combination with the BA10 connection box. The

connection of the integral cable and WF10 cable to the Yokogawa Contact Conductivity analyser are

given in table 3.

Table 3. Definition fixed sensor cable, WF10 cable and analyser

Cable wire color Cable wire color WF10 SC terminal # Signal description

White Red 11 Temperature

Brown Blue 12 Temperature

Green Clear (Core of Brown coax) 13 Inner electrode

Yellow Yellow 14 Outer electrode

Black Clear (Core of White coax) 15 Inner electrode

Pink White (Shield of White coax) 16 Outer electrode

Table 4. Definition VP sensor cable, WU10/WE10 cable and analyser

WU10/WE10 Color SC

A Core brown Ui

B Shield brown Ii

C Core white Uo

D Shield white Io

E Red T1

F Blue T2

G Yellow VCC ID chip

H Green Data ID chip

Drain wire Black Shield

Note: Sensors with Variopin contain an embedded ID chip which is recognized to work with

SA11 Smart Adapter model SA11-C1

Note: WU10-V-D type

IM 12D07J01-10E-E

Page 17

2.5. Modelcode SC4A sensors

Model Suffix Code Option code Description

SC4A 19 mm conductivity sensor

material -T Titanium Grade 2 or 3

-S Stainless steel AISI 316L (SS)

-E EPDM FDA

fitting-type -AD For adapter mounting

-PR For retractable mounting

-SA For sanitary purposes

-SB 1-1½” tri-clamp

-SC 2” tri-clamp

sensor-length -09 9 cm

1)

-15 15 cm

-NN Fixed length

cellconstant -002 0.02/cm

-010 0.1/cm

connection type -03 Fixed cable with wirepins, 3 m

-05 Fixed cable with wirepins, 5 m

-10 Fixed cable with wirepins, 10 m

-15 Fixed cable with wirepins, 15 m

-20 Fixed cable with wirepins, 20 m

-VS No Cable; Variopin connector

with SENCOM ID-chip

2)

-T1 Pt1000

/PS 3/4” stainless steel adapter

/PF 3/4” PVDF adapter

/FF Flow fitting stainless steel AISI 316L

11

3)

Note 1: Suffix -AD-09 not available with -VS.

Note 2: Suffix -VS not ATEX/IECEx certified.

Note 3: With option /FF: option /PS is mandatory.

IM 12D07J01-10E-E

Page 18

12

2.6. Spare parts SC4A

Adapters SC4A-*-AD sensor

Part no. Description Process connection Material Quantity

K1542DF /PS 3/4” NPT adapter Stainless Steel 1

K1542CW /PF 3/4” NPT adapter PVDF 1

K1598AC /FF Flow fitting Stainless Steel 1

Adapters SC4A-E-SA sensor

Part no. Description Process connection Material Quantity

K1542FA /SA1 Straight welding socket Stainless steel 1

K1542FB /SA2 Angled welding socket Stainless steel 1

Spare parts for adapters SC4A-E-SA sensor

Part no. Description Quantity

K1520EJ Straight weld-in adapter without mounting nut, Stainless Steel 1

K1520EK Angled weld-in adapter without mounting nut, Stainless Steel 1

Spare parts for SC4A-E-SA sensor

Part no. Description Quantity

K1542DL O-ring set, EPDM FDA, 20.3 x 2.62 3

K1542DK O-ring set, Viton, 20.3 x 2.62 3

Adapters SC4A-E-SB sensor

Part no. Description Process connection Material Quantity

K1542FC /SB1 Tri-clamp 1” Stainless Steel 1

K1542FF /SB2 Tri-clamp 1½“ Stainless Steel 1

Spare parts for adapters SC4A-E-SB sensor

Part no. Description Quantity

K1500BN Clamp seal ring, EPDM FDA, 1” ~ 1½“ 1

K1542DG Clamp seal ring, Viton, 1“ 3

K1542DH Clamp seal ring, Viton, 1½“ 3

Adapters SC4A-E-SC sensor

Part no. Description Process connection Material Quantity

K1542FE /SC1 Tri-clamp 2” Stainless Steel 1

Spare parts for adapters SC4A-E-SC sensor

Part no. Description Quantity

K1500BP Clamp seal ring, EPDM FDA, 2“ 1

K1542DJ Clamp seal ring, Viton, 2“ 3

Spare parts for SC4A-*-PR sensor

Part no. Description Quantity

K1500BE O-ring set, Viton, 15.6 x 1.78 10

K1500ED O-ring set, Kalrez, 15.6 x 1.78 1

IM 12D07J01-10E-E

Page 19

3. MODEL SC41, SC42 AND SC49

3.1. General Specifications

3.1.1. Measuring elements

2-electrode for SC41/SC42-SP series; SC41/SC42-EP04 (EP14); SC41/SC42-EP15 (EP16) series

4-electrode for SC42/SC49-EP08 (EP18); SC42/SC49-FP08 (TP08)

Pt1000 temperature sensor

3.1.2. Materials

Wetted parts sensor:

Body SC41/SC42/SC49-SP/SV : Stainless Steel AISI 316L

SC41/SC42/SC49-EP : Glass filled epoxy resin

SC41/SC42/SC49-FP/FV : PVDF, Glass

SC41/SC42/SC49-TP/TV : Glass filled PTFE, Glass

Electrodes SC41/SC42/SC49-SP/SV : Stainless Steel AISI 316L

SC41/SC42/SC49-EP : Graphite impregnated with epoxy resin

SC41/SC42/SC49-FP/FV : Platinum

SC41/SC42/SC49-TP/TV : Platinum

O-ring SC41/SC42/SC49-SP/SV : Viton

SC41/SC42/SC49-FP/FV : Viton

SC41/SC42/SC49-TP/TV : Kalrez™

13

For the -FP/FV and -TP/TV the supplied O-ring for sealing in the fitting is Viton.

Insulation -SP/SV : PEEK 450G, FDA migration tested

Connector:

Amphenol: Contacts : gold plated

Plug : Polyamide

Variopin: Contacts : gold plated

Material : Nickel-plated brass

Insulation : PEEK, UL94-V0

IP class : IP67

IM 12D07J01-10E-E

Page 20

14

3.1.3. Functional specifications (at 25°C)

Temperature element SC41, SC49 : Ni100

Temperature element SC42 : Pt1000 to IEC 751

Nominal Cell Constant SC41/SC42/SC49-SP/SV24 : 0.1 cm

SC41/SC42/SC49-SP/SV34 : 0.01 cm

SC41/SC42/SC49 (EP08) : 10 cm

SC41/SC42/SC49-EP14 (EP18) : 1 cm

SC41/SC42/SC49-EP15 (EP16) : 1 cm

SC41/SC42/SC49-FP/FV : 10 cm

SC41/SC42/SC49-TP/TV : 10 cm

-1

-1

-1

-1

-1

-1

-1

Note: The SC41/SC42/SC49 temperature sensor is designed for measurement compensation

and for indication. It is NOT designed for process temperature control.

3.1.4. Dynamic specifications

Response time temperature t90

SC41/SC42/SC49-SP/SV24 : < 3 min.

SC41/SC42/SC49-SP/SV34 : < 1 min.

SC41/SC42/SC49-EP04 (EP08) : < 3 min.

SC41/SC42/SC49-EP14 (EP18) : < 2 min.

SC41/SC42/SC49-EP15 (EP16) : < 3 min.

SC41/SC42/SC49-FP/FV : < 1 min.

SC41/SC42/SC49-TP/TV : < 1 min.

3.1.5. Operating range

Conductivity at actual process temperature : 1 µS * C.C. – 200 mS * C.C.

See Fig. 2: Measuring range of conductivity sensors section 2.1.5

Temperature SC41/SC42/SC49-SP/SV : 0°C to 150°C (32°F to 302°F)

SC41/SC42/SC49-EP : 0°C to 110°C (32°F to 230°F)

SC41/SC42/SC49-FP/FV : 0°C to 110°C (32°F to 230°F)

SC41/SC42/SC49-TP/TV : 0°C to 110°C (32°F to 230°F)

Pressure SC41/SC42/SC49-SP/SV : 0 to 10 bar (0 to 142 PSIG)

SC41/SC42/SC49-EP : 0 to 10 bar (0 to 142 PSIG)

SC41/SC42/SC49-FP/FV : 0 to 10 bar (0 to 142 PSIG)

SC41/SC42/SC49-TP/TV : 0 to 2 bar (0 to 28 PSIG)

Cable length for

Sensors with Amphenol connector or

Variopin connector directly connected

to Flexa analyzer : max. 60 meter with WU10 or WU10 in

combination with WF10 cable and BA10

junction box

For sensors with suffix -VS combined with SA11 : Optional 3 meter WE10 cable combined with

SA11 Smart Adapter

IM 12D07J01-10E-E

Page 21

SA11 Smart Adapter : Directly connected to the analyzer using a

WU11 cable up to 100 meters

or

Connected to a BA11 connetion box

using WU11 cable upto 100 m. The BA11

connection box is connected to the analyzer

using a WU11 cable up to 100m

3.1.6. Regulatory standards (only for SC42 with Amphenol connector)

- ATEX : Directive 2014/34/EU

by applying:

EN 60079-0

EN 60079-11

EN 60079-26

Certificate no. : DEKRA 14ATEX0074 X

II 1 G Ex ia IIC T4… T6 Ga

- IECEx

Applying standards : IEC 60079-0

: IEC 60079-11

: IEC 60079-26

Certificate no. : IECEx DEK 14.0032X

Ex ia IIC T4…T6 Ga

Conformity : EAC (Eurasia)

TS (Taiwan)

15

- Electrical data for ATEX/IECEx : For sensor input circuit connected to

A certified intrinsically safe circuit with the following

maximum values:

Ui = 14.4 V; Ii = 116.5 mA; Pi = 0.342 W

or

Certified intrinsically safe Yokogawa Contact

Conductivity transmitter Model FLXA21 series or

Model SC202S series.

The effective internal capacitance Ci and the

effective internal inductance Li of the sensor depends only

upon the properties and length of the integral cable.

Special conditions (X) : T6 for Tamb. -30°C to 40°C

T5 for Tamb. -30°C to 95°C

T4 for Tamb. -30°C to 130°C

IM 12D07J01-10E-E

Page 22

16

Impact on the product shall be avoided.

Electrostatic charges on the enclosure shall be avoided.

From the safety point of view the circuits shall be

assumed to be connected to earth.

Regulatory standards (all types)

CE : Decision 768/2008/EC

- Pressure : Directive 2014/68/EU

Applying article : 4.3 (Sound Engineering Practice)

- RoHS2 : Directive 2011/65/EU

Applying category : 9 (Industrial monitoring and control instruments)

3.1.7. Shipping details

Package size (LxWxH) : 300 x 95 x 73 mm (11.8 x 3.7 x 2.9 inch)

Package weight : 0.3 to 0.8 kg (0.7 to 1.8 lbs), depends on

sensor type

3.1.8. Environmental conditions

Storage temperature : -30°C to 50°C (-22°F to 122°F)

bar

12

10

8

6

4

2

0 10 20 30 40 50 60 70 80 100 120 140 160

Fig. 11 Pressure vs temperature

IM 12D07J01-10E-E

FP/FV

TP/TV

EP

SP/SV

Page 23

17

3.2. Installation of SC41/SC42/SC49 sensors

To install the SC41/SC42/SC49 conductivity sensors in a permanent or semi-permanent location,

Yokogawa can supply a range of flow and immersion fittings. These fittings and sub-assemblies are

available in different materials to give the best solution for any process considering chemical resistance,

pressure and temperature specifications (see figure 11). Flow fittings are available with optional flange

adapters. When installing the SC41/SC42/SC49 sensor in a fitting, an O-ring is necessary. This O-ring is

available in different materials to improve chemical resistance (see Section 3.6 for ordering information).

If the SC41/SC42/SC49 sensor is supllied with an O-ring, the O-ring in the fitting must be

removed.

3.2.1. Typical installation of SC41/SC42/SC49 sensor in FF40 Flow fittings/ FS40 Flow

fitting assemblies

From a practical point of view, the best mounting place for a conductivity sensor is in a by-pass

with a sample valve. For these applications the following Flow fittings/Flow fitting subassemblies

are ideal: Model FF40: Flow fitting

Model FS40: Flow fitting subassembly

When using the sensor in combination with a Flow fitting or Flow fitting subassembly, the process

flow has to be taken into account when mounting the sensor. For an example see figure 12

Reasonable

Bad

Fig. 12 Mounting position SC41/SC42/SC49 sensor

Bad

Good

Good

IM 12D07J01-10E-E

Page 24

18

Modelcode FF40 Flowfitting:

Model code Suffix code Option code Description

FF40 Flow fitting

Material - P22 Polypropylene (PP)

- S22 Stainless steel (AISI 316)

- V22 Polyvinylchloride (PVC)

Optional Flange adapters /FP1 DN15 PN10 PP

(NPT ½” Male lap joint) /FP2 DN25 PN10 PP

/FP3 ½” ANSI 150 lbs PP

/FP4 1” ANSI 150 lbs PP

/FS1 DN15 PN10 SS AISI 316

/FS2 DN25 PN10 SS AISI 316

/FS3 ½” ANSI 150 lbs SS AISI 316

/FS4 1” ANSI 150 lbs AISI 316

Material Certificate /M 3.1 according to EN-10024 on wetted parts

Sensor cable

Sensor cable

Plug-in

sensor

Plug-in

sensor

M8 thread

Fig. 13 Installation SC41/SC42/SC49

Fig. 14 Installation SC41/SC42/SC49

in FF40-P22/FF40-V22 *)

Note: Not possible for sensors with suffix code -EP16

IM 12D07J01-10E-E

in FF40-S22 *)

Page 25

Ø 35

(1.38)

Ø 54 (2.76)

32

(1.26)

IN

Ø 40 (1.57)

120 (4.72)

(adj.)

153 (6.0)

231 (9.09)

OUT

Units in mm (inch)

19

Ø 60

(Ø 2.36)

245 (9.65)

125 (4.92)

FLOW Direction IN

Ø 12

87 (3.42)

OUT

231 (9.09)

(adj.)

120 (4.72)

IN

Ø 40 (1.57)

32

(1.26)

Ø 35

(1.38)

Ø 54 (2.76)

OUT

153 (6.0)

Fig. 15 Dimensions FF40-P22 (V22) Fig. 16 Dimensions FF40-S22

Flange adapters are available for the FF40-P22 (option /FP*) and for the FF40-S22 (option /FS*)

D

ø 115

ø 85

4x 13.5

ø 16

k

dg

1

/2Inch 1 Inch

ø 88.9

ø 108

ø 60.5

ø 79.2

ø 15.7

ø 15.7

ø 11.2

ø 17.5

b

231

Ø 54

OUT

32

Ø 36

L1

DN15 DN25

D

ø 95

k

ø 65

dg

4x 13.5

B

ø 11.5

L2

IN

Type DN15PN10 DN25-PN10 1/2” 150 lbs 1” 150 lbs

L1 L2 L1 L2 L1 L2 L1 L2

FF40-S22 226 123 236 133 8 7/8” 4 13/16” 9 5/16” 5 1/4”

FF40-P22 247 123 236 112 9 3/4” 4 7/8” 9 5/16” 4 7/16”

Fig. 17 Dimensions of optional Flange adapters

IM 12D07J01-10E-E

Page 26

20

Modelcode FS40 Subassembly for Flow fitting

Model code Suffix code Option code Description

FS40 Subassembly for Flow fitting

Material - F22 Polyvinylidenefluoride (PVDF)

- S22 Stainless steel (AISI 316)

- S23 Stainless steel (AISI 316) for EP16 model sensor

- V22 Polyvinylchloride (PVC)

Mounting - WE Weld-in socket for - S22 and - S23

Glue-in socket for - V22

- PA Parallel thread, only for - F22, (ISO 228/1-G11/4”)

- TP Tapered pipe thread (11/4” NPT)

- DF For insertion type sensor with collar piece

DN25 in combination with - S23

Material Certificate /M 3.1 according to EN-10024 on wetted parts

Sensor

(EP16 model)

FS40-S23-DF

Fig. 18 Installation example of the SC41/SC42/-EP16 sensor

with a FS40-S23-DF subassembly

IM 12D07J01-10E-E

Page 27

21

24 (0.95)

27 (1.06)

36 (1.42)

27 (1.06)

52 (2.05)

19 (0.75)

FS40-S23-DF

FS40-S22-WE

FS40-F22-PA

Ø 63

(2.48)

Ø 31

(1.22)

Ø 28

(1.10)

Ø 54

(2.12)

Ø 38

(1.50)

Ø 36

(1.42)

Ø 55

(2.16)

1 1/4" ISO

228/1-G 1

1/4

36 (1.42)

61 (2.40)

50 (1.97)

41 (1.61)

32 (1.26)

57 (2.25)

27 (1.06)

FS40-F22-TP

FS40-V22-TP

FS40-S22-TP

24 (0.95)

FS40-V22-WE

Ø 55

(2.16)

1 1/4"-11.5

NPT

Ø 54

(2.12)

1 1/4" NPT

Ø 50

(1.97)

Ø 40

(1.57)

Fig. 19 Dimensions FS40 Flow fitting subassemblies

IM 12D07J01-10E-E

Page 28

22

3.2.2. Typical installation of SC41/SC42/SC49 sensor in FD40 Immersion fitting

The immersion fittings are for installing the SC41/SC42/SC49 sensor in tanks, open vessels or drains.

If the fitting is mounted in a tank with agitator or if it is placed in a fast flowing process, care must be

taken that the fitting is adequately supported. For this reason mounting several flanges can be ordered.

Modelcode FD40 FD40 Immersion fitting

Model code Suffix code Option code Description

FD40V28 Immersion fitting PVC

FD40S28 Immersion fitting Stainless Steel AISI 316

Immersion - Between 05 and 20 decimeter

depth (Example 06 = 6 dm. = 0.6 m.)

- NC

Flange - FN No flange

- F1 PVC flange DN50 PN10

- F2 PVC flange ANSI 2” 150 lbs

- F3 Stainless Steel flange DN50 PN10

- F4 Stainless Steel flange ANSI 2” 150 lbs

Style code * B

Protection hose /PH5 For 5.5 meter mounting cable

/PH10 For 10 meter mounting cable

Mounting cable /C05 Length 5,5 meter*

/C10 Length 10 meter*

Material Certificate /M 3.1 according to EN-10024 on SS wetted parts

Note: If it is necessary to use the fitting with another mounting cable length, this cable can be

ordered separately as WU40 model (Amphenol connector) or WU10/WE10 (Variopin

connector). This is not applicable for sensors with suffix V (Variopin model).

Model code Suffix code Description

WU40 Sensor cable

Cable length - LH01 1 meter

- LH02 2 meters

- LH05 5½ meters

- LH10 10 meters

- LH15 15 meters

- LH20 20 meters

- LH25 25 meters

IM 12D07J01-10E-E

Model code Suffix code Description

WU10 Universal sensor

cable

Conn. type -V Variopin

Cable type -D Dual Coax

Cable length -02 2 meters

-05 5 meters

-10 10 meters

-15 15 meters

-20 20 meters

Page 29

3.3 Dimensions SC41/SC42/SC49 sensors.

SC4 -SP34 (L=164 mm)

SC4 -SP24 (L=111 mm)

SC4 -SV34 (L=164 mm)

SC4 -SV24 (L=111 mm)

23

4.37

111

2.24

0.47

12

0.39

10

57

30

1.18

*

*

0.47

6.46

- * = Minimum submersion depth.

- Dimensions in millimeters [Inches].

5.67

144

164

7.76

197

12

7.19

182.6

9.28

235.6

ø 36

20

10

56

L

12

ø 30

Fig. 20 Dimensions SC4 -SP Fig. 21 Dimensions SC4 -SV

30

1.18

2.24

0.39

57

10

30

1.18

IM 12D07J01-10E-E

Page 30

24

12D7J1-15

INSERTION SENSORS

SC4.-EP15

12D7J1-16

INSERTION SENSORS

SC4.-EP15D

SC4 -FP08

SC4 -TP08

ø 36

(1.42")

46

(1.81")

30

(1.18")

ø 29

(1.14")

26

(1.02")

ø 5

(0.20")

SC4 -FV08

SC4 -TV08

20

(0.78")

10

(0.40")

194

SC42-FV08

SC42-TV08

1.18

30

0.39

10

1.14

1.18

30

8.94

227

7.64

194

29

1.8

46

1.16

29

*

1.02

26

- * = Minimum submersion depth.

- Dimensions in millimeters [Inches].

10.46

266

Fig. 22 Dimensions SC4 -FP/TP

20

10

100

ø 36

ø 25

15

Fig. 23 Dimensions SC4 -FV/TV

20

10

65

ø 44

ø 25

15

Fig. 24 SC41/SC42-EP15 Fig. 25 SC41/SC42-EP16

IM 12D07J01-10E-E

20

(0.78")

ø 36

(1.42")

ø 30

(1.18")

43

(1.69")

30

(1.18")

10

(0.40")

L

ø d

SC4 -EP04 (L= 193 mm)

SC4 -EP14 (L= 160 mm)

SC4 -EP08 (L= 193 mm)

SC4 -EP18 (L= 160 mm)

Fig. 26 SC4 -EP14 (EP18),

SC4 -EP04 (EP08)

Page 31

3.4. Wiring SC41/SC42/SC49 sensors

The SC41, SC42 and SC49 sensors are provided with a fixed connector. The standard cable

used to connect the sensor with Amphenol connector to the analyser is the WU40. The standard

cable used to connect the sensor with VP connector to the analyzer is the WU10. These cables

are available up to 25/20 meters. When a longer cable run is necessary (maximum cable run

is 60 meters), this can be done by using the WF10 extension cable in combination with the

BA10 connection box. The connection of the WU40 cable, WU10 cable and WF10 cable to the

Yokogawa Contact Conductivity analyser are given in table 4.

11

CELL

16

12

15

13

temp.

14

element

Amphenol

connector

CELL

11

16

12

15

13

temp.

14

element

Amphenol

connector

25

Variopin

connector

Fig. 27 Top view connector system SC41/

SC42 2-electrode

Variopin

connector

Fig. 28 Top view connector system SC42/

SC49 4-electrode

3.5 Modelcode SC41/SC42/SC49

Model Suffix Code Option code Description

SC41 (SC49) Conductivity Sensor 2- or 4- electrodes + Ni100

SC42 Conductivity Sensor 2- or 4- electrodes + Pt1000

Materials -E Epoxy / graphite

-S Stainless steel AISI 316L / PEEK

-F PVDF / Glass / Platinum

-T PTFE / Glass / Platinum

Mounting P Plug-in type, plug-socket connector

V1) Plug-in type, VarioPin connector with SENCOM

ID-chip 1)

Cell constant 0 Cell constant

1 C = 1 cm-1

2 C = 0,1 cm-1

3 C = 0,01 cm-1

Type 4 2-electrode, flow cell

5 2-electrode, insertion cell

6 2-electrode, insertion cell with DN25 collar

8 4-electrode, flow cell

Options N/A

Note: Suffix V not ATEX/IECEx certified. Suffix V not in combination with suffix -E (Epoxy).

IM 12D07J01-10E-E

Page 32

26

4. MODEL SX42

4.1. General Specifications

4.1.1. Measuring elements

2-electrode measuring system

Pt1000 temperature sensor

4.1.2. Materials

Wetted parts sensor:

Body : Stainless Steel AISI 316L

Electrodes : Stainless Steel AISI 316L

Insulation : Ceramic (aluminium oxide)

Connector:

Amphenol: Contacts : gold plated

Plug : Polyamide

Variopin: Contacts : gold plated

Material : Nickel-plated brass

Insulation : PEEK, UL94-V0

IP class : IP67

Terminal box flanged models:

Housing : Aluminium

Insulation : Ceramic

4.1.3. Functional specifications (at 25°C)

Temperature element : Pt1000 to IEC 751

Nominal Cell Constant (C.C.) SX42-SX24 : 0.1 cm

SX42-SX34 : 0.01 cm

-1

-1

Note: The SX42 temperature sensor is designed for cell compensation and for indication.

It is NOT designed for process temperature control.

4.1.4. Operating range

Conductivity at actual process temperature : 1 μS * C.C. – 200 mS * C.C.

See Fig. 2: Measuring range of conductivity

sensors section 2.1.5

Temperature Threaded models (-BS,-NS) : 0°C to 200°C (32°F to 392°F)

Threaded models (-BV,-NV) : 0°C to 125°C (32°F to 257°F)

Flanged models : 0°C to 250°C (32°F to 482°F)

Pressure Threaded models : 0 to 40 bar (0 to 363 PSIG)

Flanged model PN63 : 0 to 40 bar (0 to 580 PSIG)

Flanged model PN40 : 0 to 30 bar (0 to 435 PSIG)

IM 12D07J01-10E-E

Page 33

27

ºC

50

bar

40

30

25

20

16

10

0

0

50 100 150 200 250

Flange PN63

Flange PN40

dedaerhT

Fig. 29 Pressure vs. process temperature flanged / threaded models SX42

Cable length:

Threaded models (-BS,-NS) : max. 60 meter with WU40 cable in combination

with WF10 cable and BA10 junction box

Threaded models (-BV,-NV)

Variopin connector directly connected : max. 60 meter with WU10/WE10

(possibly in combination with WF10 cable

and BA10 junction box}

For sensors with suffix -BV/NV : 3 meter WE10 cable (as option) combined

with SA11 Smart Adapter

combined with SA11 Smart Adapter Smart Adapter directly connected to the

analyzer using a WU11 cable up to 100 meters

or

Connected to a BA11 connetion box

using WU11 cable upto 100 m. The BA11

connection box is connected to the analyzer

using a WU11 cable up to 100m

Flanged models : max. 60 meter with customer specified high

temperature cable

IM 12D07J01-10E-E

Page 34

28

4.1.5. Regulatory standards (not applicable for sensors with suffix code -BV or -NV)

- ATEX : Directive 2014/34/EU

by applying:

EN 60079-0

EN 60079-11

EN 60079-26

Certificate no. : DEKRA 14ATEX0074 X

II 1 G Ex ia IIC T4… T6 Ga

- IECEx

Applying standards : IEC 60079-0

: IEC 60079-11

: IEC 60079-26

Certificate no. : IECEx DEK 14.0032X

Ex ia IIC T4…T6 Ga

Conformity : EAC (Eurasia)

TS (Taiwan)

- Electrical data for ATEX/IECEx : For sensor input circuit connected to

A certified intrinsically safe circuit with the following

maximum values:

Ui = 14.4 V; Ii = 116.5 mA; Pi = 0.342 W

or

Certified intrinsically safe Yokogawa Contact

Conductivity transmitter Model FLXA21 series or

Model SC202S series.

The effective internal capacitance Ci and the

effective internal inductance Li of the sensor depends only

upon the properties and length of the integral cable.

Special conditions (X) : T6 for Tamb. -30°C to 40°C

T5 for Tamb. -30°C to 95°C

T4 for Tamb. -30°C to 130°C

Impact on the product shall be avoided.

Electrostatic charges on the enclosure shall be avoided.

From the safety point of view the circuits shall be

assumed to be connected to earth.

Regulatory standards (all types)

CE : Decision 768/2008/EC

- Pressure : Directive 2014/68/EU

Applying article : 4.3 (Sound Engineering Practice)

- RoHS2 : Directive 2011/65/EU

Applying category : 9 (Industrial monitoring and control instruments).

IM 12D07J01-10E-E

Page 35

4.1.6. Shipping details

SX42-SX24-BS

SX42-SX24-NS

SX42-SX24-DF

SX42-SX24-AF

SX42-SX34-DF

SX42-SX34-AF

SX42-SX34-BS

SX42-SX34-NS

225 (10.04)

ø 28 (1.10)

ø 28 (1.10)

91 (3.58) 110 (4.33)

98 (3.86)

164 (6.42) 91 (3.58)

150 (5.90)

35 (1.38)

ø 34

(1.34)

23 (0.90)

169 (6.65)

110 (4.33)

169 (6.65)

ø 34

(1.34)

3.78

96 *

0.83

21 *

282

1.1

243

9.57

138

5.43

28

11.09

T

h

r

e

a

d

t

yp

e

7.48

190

28

1.1

229

3.35

85

9

T

h

r

e

a

d

t

yp

e

SX42-SX34-BV

SX42-SX34-NV

SX42-SX34-BV

SX42-SX34-NV

8X

Package size (LxWxH) Threaded models : 300 x 95 x 73 mm (11.8 x 3.7 x 2.9 inch)

Flanged models : 480 x 275 x 235 mm (18.9 x 10.8 x 9.3 inch)

Package weight Threaded models : 0.5 to 0.7 kg (1.1 to 1.5 lbs)

Flanged models : 5.7 to 6.0 kg (12.6 to 13.2 lbs)

4.1.7. Environmental conditions

Storage temperature : -30°C to 50°C (-22°F to 122°F)

4.2. Installation of SX42 sensors

SX42 threaded models are installed by screw-in (ISO 7/1-R 1” or 1” NPT), and the SX42 flanged

models by using the pre-mounted flange (DN50 PN63, DN50 PN40 or ANSI 2” 600 lbs).

Flange dimensions of DN50 PN40 (in red) to be included

ANSI 2”600LBS

ø 165 (6.5)

ø 127 (5.0)

ø 91.9 (3.62)

ø 19.1 (0.75)

20

(0.79)

DN50 PN40

ø 165 (6.5)

ø 125 (4.92)

ø 18 (0.71)

4X

26

(1.02)

3 (0.12)

DN50 PN63

ø 180 (7.1)

ø 135 (5.3)

ø 102 (4.0)

ø 22 (0.87)

4X

31.8

(1.25)

6.4 (0.25)

Fig. 30 Flange dimensions SX42 flanged model according EN 1092-1

4.3. Dimensions SX42 sensors

29

Fig. 31 Dimensions SX42 threaded models and flanged models

4.4. Wiring SX42 sensors

The SX42 threaded models are provided with a fixed connector. The standard cable used to

connect the sensors with Amphenol connector to the analyser is the WU40. The standard cable

used to connect the sensor with VP connector to the analyzer is the WU10/WE10. These cables

are available up to 25/20 meters. When a longer cable run is necessary (maximum cable run

is 60 meters), this can be done by using the WF10 extension cable in combination with the

BA10 connection box. The connection of the WU40 cable, WU10 cable and WF10 cable to the

Yokogawa Contact Conductivity analyser are given in table 5.

The sensors with VP connector contain an embedded ID chip allowing direct connection to

our SA11 Smart Adapter. The SA11 Smart Adapter can be applied in processes with ambient

temperature upto 125°C.

If ambient temperature is higher than 125°C the connection to Smart Adapter should be made

using the WE10 extension cable in between the Smart Adapter and the sensor.

IM 12D07J01-10E-E

Page 36

30

Table 5: Defintion of WU10 cable, WE10 cable, WU40 cable and WF10 cable

VP connector Cable wire color SC analyser Signal

WU10-V-D-** / WE10-H-D-** Terminal # description

A Core brown coax 15 Ui (inner electrode)

B Shield brown coax 16 Ii (inner electrode

C Core white coax 13 Uo (outer electrode)

D Shield white coax 14 I0 (outer electrode)

E Red 11 Temperature

F Blue 12 Temperature

G Yellow N/A

H Green N/A

Note: For the WU40 and WF10 cable the labelled wires must be connected to the corresponding

terminal # of the SC analyser.

The SX42 flanged models are provided with a connection box. The cable used to connect these

sensors to the analyser has to be a high temperature shielded cable. This cable is not supplied by

Yokogawa. The wiring diagram of the flanged models is given in fig.32.

(12)

CELL

11

16

15

14

Amphenol

connector

(11)

E

F

temp.

G

H

12

13

element

B

A

Variopin

connector

D

C

(15)

Use WF10 cable or a customer

specific high temperature cable

(13)

Shield

Interconnect #15 with #16,

and #13 with #14 in analyser

11

12

13

14

15

16

Fig. 32 SX42 threaded models connector (top view)

Model Suffix Code Option code Description

SX42 High temp. conductivity sensor with Pt1000 sensor

-SX24 Cell constant 0.1/cm

-SX34 Cell constant 0.01/cm

-BS ISO 7/1-R1 screw thread, plug-socket conn.

-BV

1)

ISO 7/1-R1 screw thread, VarioPin conn.

with SENCOM ID-chip 1)

-NS 1-11½ NPT screw thread, plug-socket conn.

-NV

1)

1-11½ NPT screw thread, VarioPin conn.

with SENCOM ID-chip 1)

-DF DN50-PN63 EN flange

-EF DN50-PN40 EN flange

-AF 2” 600 LBS ANSI flange

Style *A Always *A style

Option N/A

Note: Suffix -BV and -NV not ATEX/IECEx certified.

IM 12D07J01-10E-E

Page 37

5. GENERAL CALIBRATION AND MAINTENANCE PROCEDURE

31

5.1. Calibration of the sensor

The conductivity sensors are factory calibrated

traceable to NIST standards. The cell constant

values are indicated on the sensor or on the

integral cable of the sensor. The cell constant

value can be entered directly in the Yokogawa

analyser. The procedure is explained in the

Instruction Manual of the analyser. If the sensor

has been subject to abrasion (erosion or coating)

in the process, re-calibration of the sensor may

be necessary. Refer to the Instruction Manual of

the analyser for a detailed description.

Note: During calibration the temperature

compensation is still active. This means

that the display reading refer to the

default reference temperature (25 °C).

Calibration is normally carried out by measuring

a solution with a known conductivity value at

a known temperature. These solutions are

commercially available. You can make your own

solution by dissolving an amount of salt in water.

Table 6 and 7 show some typical conductivity

values for Sodium Chloride (NaCl) and Potassium

Chloride (KCl) solutions which can be made,

preferably in a laboratory. The tables are derived

from the standards laid down in ‘International

Recommendation No. 56 of the Organisation

Internationale de Métrologie Legale’.

Table 6. KCl values at 25 °C (OIML)

Weigth % molal (m) mg of KCl / Conductivity

kg of solution

0.3 0.001 74.66 0.1469 mS/cm

0.5 0.002 149.32 0.2916 mS/cm

1 0.005 373.29 0.7182 mS/cm

3 0.01 745.263 1.4083 mS/cm

5 0.1 7419.13 12.852 mS/cm

10 1.0 71135.2 111.31 mS/cm

Table 7. NaCl values at 25 °C (IEC 746-1)

Weigth % mg/kg Conductivity

0.001 10 21.4 μS/cm

0.003 30 64.0 μS/cm

0.005 50 106 μS/cm

0.01 100 210 μS/cm

0.03 300 617 μS/cm

0.05 500 1.03 mS/cm

0.1 1000 1.99 mS/cm

0.3 3000 5.69 mS/cm

0.5 5000 9.48 mS/cm

1 10000 17.6 mS/cm

3 30000 48.6 mS/cm

5 50000 81.0 mS/cm

10 100000 40 mS/cm

5.2. Periodic maintenance of the sensor

In general conductivity sensors do not need

much periodic maintenance. In case the sensor

has become fouled, an insulating layer may be

formed on the surface of the electrodes, and

consequently giving a measuring error. Cleaning

the sensor will solve this problem. Effective

cleaning methods are given below:

1. Normal applications: hot water with some

commercially available washing-up liquid.

2. Lime, hydroxides or similar applications:

5 % solution of hydrochloride acid.

3. Organic (e.g. oils, fats) applications: alcohol

or iso-propanol.

4. Algae, bacteria or fungus: solution of

commercially available bleach (hypochlorite).

Note: Read the instructions on the package of

the cleaning agents for safe use.

IM 12D07J01-10E-E

Page 38

32

SB20, SC24V, SC25V, SC25F, SM60, SR20

FC20, BA10, BA11, SM29, SA11,

WE10, WF10, WF20, WP20, WU10, WU11, WU40

SC41, SC42, SC49, SC4A, SX41, SX42

ISC40

Protection of Environment (Use in China)

中華人民共和国国内でのみ有効です。

个志是基于SJ/T11364 ,在中国(不包括台湾,香港,澳门)售的子器

品所适用的境保期限,6种有害物的含有量都低于GB/T26572所定的限

量要求以下。

Production date

关于生日期

生日期在品牌上9位数的序列号中,用以下形式表示生日期。

从左数第3位数:生年份

R:2015 ,S:2016 ,T:2017 ,U:2018,V:2019 ,W:2020,X:2021 ,Y:2022 ,Z:2023 ,

1:2024 ,2:2025 ,3:2026 ,…

从左数第4位数:生月份

1:1月,2:2月,3:3月,…,9:9月,A:10月,B:11月,C:12月

(示例)N3S700001:2016 年 7 月

Subject to change without notice

Instruction

Manual

3

rd

edition April 2019

P

rinted in The Netherlands

Copyright©2016 YPA Europe B.V

Euroweg 2, 3825 HD, Amersfoort The Netherlands

SC24V, SC25V, SC25F, SM60, SR20,

FC20, BA10, BA11, IB100, SA11,

WE10, WF10, WU10, WU11, WU40

SC41, SC42, SC4A, SX41, SX42

ISC40

Protection of Environment (Use in China)

Instruction

Manual

6. PROTECTION OF ENVIRONMENT (USE IN CHINA)

7KLVPDQXDOLVYDOLGRQO\LQ&KLQD

中華人民共和国国内でのみ有効です。

Production date

关于生产日期

生产日期在产品铭牌上9位数的序列号中,用以下形式表示生产日期。

从左数第3位数:生产年份

R:2015,S:2016,T:2017,U:2018,V:2019,W:2020,X:2021,Y:2022,Z:2023,

1:2024,2:2025,3:2026,…

从左数第4位数:生产月份

1:1月,2:2月,3:3月,…,9:9月,A:10月,B:11月,C:12月

(示例)N3S700001:2016 年 7 月

这个标志是基于SJ/T11364,在中国(不包括台湾,香港,澳门)贩售的电子电器

产品所适用的环境保护期限,6种有害物质的含有量都低于GB/T26572所规定的限

量要求以下。

YPA Europe

IM 12D07J01-10E-E

Page 39

7. CHEMICAL COMPATABILITY CHART

Chemical Compatibility Chart Chemical Compatibility Chart

Material

Conc.%

Temp. °C

20601002060

1002060

1002060

1002060

1002060

1002060

1002060

1002060

10020602060

1002060

100

Acetic acid O O O O O O O O O O O O O X O O O

Formic acid O O O X X X O O O O O X - - O O O

Citric acid O O O O O O O O O O O X - - O O O

Calcium hydroxide O O O O O O O O O O O O O O O O O

Potassium hydroxide O O O O O O O O X O O O O X O O X

Sodium hydroxide O O O O O O O O X O O O O X O O X

Ammonia in water O

Ammonium chloride O O O O O O O O O O O O X X O O O

Zinc chloride O O O O O O O O O O O O O X O O O

Iron(III) chloride O O O O O O O O O O O O O X O O O

Sodium sulfite O O O O O O O O O O O O O O O O O

Sodium carbonate O O O O O O O O O O O O O X O O O

Potassium chloride O O O O O O O O O O O O O O O O O

Sodium sulfate O O O O O O O O O O O O O O O O O

Calcium chloride O O O O O O O O O O O O O O O O O

Sodium chloride O O O O O O O O O O O O O O O O O

Sodium nitrate O O O O O O O O O O O O O O O O O

Aluminium chloride O O O O O O O O O O O O O O O O O

Hydrogen peroxide O O O O O O O O O O O O O X O O O

Sodium Hypochloride O O O O O O O O O X X O X X O O O

Potassium dichromate O O O O O O O X - O O O X X O O O

Chlorinated lime O O O X X X O O O - - O X X O O O

Ethanol O O O O O O O O X O O O O X O O O

Cyclohexane O O O O O O O O X - - O O X O O O

Toluene O O O O O O O O O X - O O X O O O

Trichloroethane O O O O O O X X X - - X - - O O O

Water O O X O O O O O O O O O O X O O O

Note: Information in this list is based on our general experience and literature data and given in good faith. Note: Information in this list is based on our general experience and literature data and given in good faith.

However, Yokogawa is unable to accept responsibility for claims related to this information.

PVDF

(Kynar)

PP

Epoxy

Glass

Organic

solvent

Neutral salt

sat.50sat.

30

Oxidizing

agent

50

sat.

80

Acid salt

sat.5050

sat.

Basic salt

sat.

sat.

sat.

sat.

Organic acid

10

glacial8050

Alkali

sat.5040

30

Phosphoric acid

255095

Hydrofluoric acid

40

75

Hydrochloric acid

10

sat.

Nitric acid

255095

fuming

PTFE

(teflon)

PEEK

O = can be used; X = shortens useful life; - = cannot be used; Blank = no data available

Inorganic acid

Sulfiric acid

105095

fuming

Phosphoric acid

95

25

50

Sulfiric acid

50

Nitric acid

Hydrofluoric acid

Organic acid

50

Hydrochloric acid

sat.

40

40

sat.

fuming

sat.

glacial

sat.

sat.

80

sat.

Silicon

Rubber

33

SS 316(l)Viton Kalrez

TiEPDM

10

95

10

sat.

50

fuming

25

95

Acetic acid - - - O O O O O O O O O O O O O O X

Formic acid - - - O O X O O X O O O X X - X X X

Citric acid O O O O O O O O O O O O X X X O O O

Calcium hydroxide O O O O O O O O O O O O O O O O O O

Potassium hydroxide O O O O O O O X - O O O O X - O O O

Sodium hydroxide X X X O O O O X - O O O X X - O O O

AlkaliAcid salt Inorganic acid

Ammonia in water X X X O O O O O O O O O X X - O O O

Ammonium chloride O O O O O O O O O O O O O O O X X X

Zinc chloride O O O O O O O O O O O O O O O X X X

Iron(III) chloride O O O O O O O O O O - - -

Sodium sulfite - - - O O O O O O O O O O O O O O O

Sodium carbonate O O O O O O O O O O O O O O O O O O

Potassium chloride O O O O O O O O O O O O O O X X X X

Sodium sulfate O O O O O O O O O O O O O O O O O O

Basic salt

Calcium chloride O O O O O O O O O O O O O O O X X X

Sodium chloride O O O O O O O O O O O O O O O X X X

Sodium nitrate O O O O O O O O O O O O O O O X X X

Aluminium chloride O O O O O O O O O O O O O O X - - -

Neutral salt

Hydrogen peroxide O O O O O O O O X X X X O O O O O O

Sodium Hypochloride O O X O O O O O O O O O X - - X X X

Potassium dichromate O O O O O O O O O O O O O O O O O O

Chlorinated lime X - - O O O X X X

agent

Oxidizing

Ethanol X - - O O O O O O O O O O O O O O O

Cyclohexane O O O O O O - - - - - - O O O O O O

Toluene - - - O O O - - - - - - O O O O O O

Trichloroethane X X X X - - - - - - - - O O O O O X

solvent

Organic

Water O O O O O X O O O O O O O O O O O O

O = can be used; X = shortens useful life; - = cannot be used; Blank = no data available

However, Yokogawa is unable to accept responsibility for claims related to this information.

75

10

80

sat.

50

30

50

50

sat.

sat.

sat.

50

30

50

O O O O O O O O O O O O - - - X X X

O O O O O O O X - - - - - - - X X X

O O O O O O X - - - - - - - - X X X

O O O O O O - - - - - - - - - - - -

O O O O O X O O O X - - - - - - - -

O O O O O X X X X X - - - - - - - -

O O X O O O O X - O O X O O O X X X

- - - O O O - - - X - - O O O X X X

- - - O O X - - - - - - O O O O O O

- - - O O X - - - - - - O O O

O O O O O O O O O O O X X X - - - -

O O O O O O O O O O O X X - - X X X

X X - O O O O O O O X X X - - O O O

O O O O O X - - - - - - - - - - - -

O O X O O X - - - - - - - - - - - -

- - - O O O X X X O O O O O O O O X

IM 12D07J01-10E-E

Page 40

Conc.%

Temp. °C

20601002060

1002060

10020602060

1002060

100

(Kynar)

PP

Epoxy

Glass

50

sat.

50

80

sat.5050

sat.

sat.

sat.

Organic acid

10

80

50

504030

Phosphoric acid

255095

Hydrofluoric acid

40

sat.

50

95

PTFE

(teflon)

PEEK

Sulfiric acid

105095

fuming

PVDF

O O O O O O O O O O O O X X O O O

O O O O O O O O O O O X X X O O O

O O O - - - O X - X - - - - O O O

Hydrochloric acid

Nitric acid

10

25

O O O - - - - - - - - - - - O O O

O O O O O X O O O O O O X - O O O

O O O O O X O O O O O O X - O O O

O O O O O O O O X O O O X - O O O

O O O X X X O O X X - X - - O O O

Inorganic acid

fuming

O O O - - - O X - - - - - - O O O

O O O - - - - - - - - - - - O O O

O O O O O O O O O O O O O X O O O

O O O O O O O O O O O O O X O O O

O O O O O O O O O O O O O X O O O

O O O - - - O O O O O X X - X X X

75

O O O - - - O O O O O X X - - - -

Acetic acid O O O O O O O O O O O O O X O O O

glacial

O O O O O X O X - O X X - - O O O

Formic acid O O O X X X O O O O O X - - O O O

Citric acid O O O O O O O O O O O X - - O O O

Calcium hydroxide O O O O O O O O O O O O O O O O O

sat.

Potassium hydroxide O O O O O O O O X O O O O X O O X

Sodium hydroxide O O O O O O O O X O O O O X O O X

Alkali

Ammonia in water O

O O O O O O O O O O O O O O O X

Ammonium chloride O O O O O O O O O O O O X X O O O

Zinc chloride O O O O O O O O O O O O O X O O O

Iron(III) chloride O O O O O O O O O O O O O X O O O

Acid salt

Sodium sulfite O O O O O O O O O O O O O O O O O

sat.

Sodium carbonate O O O O O O O O O O O O O X O O O

Potassium chloride O O O O O O O O O O O O O O O O O

Sodium sulfate O O O O O O O O O O O O O O O O O

Basic salt

Calcium chloride O O O O O O O O O O O O O O O O O

Sodium chloride O O O O O O O O O O O O O O O O O

sat.

sat.

Sodium nitrate O O O O O O O O O O O O O O O O O

Aluminium chloride O O O O O O O O O O O O O O O O O

Neutral salt

Hydrogen peroxide O O O O O O O O O O O O O X O O O

30

Sodium Hypochloride O O O O O O O O O X X O X X O O O

Potassium dichromate O O O O O O O X - O O O X X O O O

Chlorinated lime O O O X X X O O O - - O X X O O O

agent

Oxidizing

Ethanol O O O O O O O O X O O O O X O O O

sat.

Cyclohexane O O O O O O O O X - - O O X O O O

Toluene O O O O O O O O O X - O O X O O O

Trichloroethane O O O O O O X X X - - X - - O O O

solvent

Organic

Water O O X O O O O O O O O O O X O O O

O = can be used; X = shortens useful life; - = cannot be used; Blank = no data available

YOKOGAWA ELECTRIC CORPORATION

World Headquarters

9-32, Nakacho 2-chome, Musashino-shi

Tokyo 180-8750

Japan

www.yokogawa.com

YOKOGAWA CORPORATION OF AMERICA

2 Dart Road

Newnan GA 30265

USA

www.yokogawa.com/us

YOKOGAWA EUROPE BV

Euroweg 2

3825 HD AMERSFOORT

The Netherlands

www.yokogawa.com/eu

YOKOGAWA ELECTRIC ASIA Pte. LTD.

5 Bedok South Road

Singapore 469270

Singapore

www.yokogawa.com/sg

YOKOGAWA CHINA CO. LTD.

3F Tower D Cartelo Crocodile Building

No.568 West Tianshan Road Changing District

Shanghai, China

www.yokogawa.com/cn

YOKOGAWA MIDDLE EAST B.S.C.(c)

P.O. Box 10070, Manama

Building 577, Road 2516, Busaiteen 225

Muharraq, Bahrain

www.yokogawa.com/bh

Yokogawa has an extensive sales and

distribution network.

Please refer to the European website

(www.yokogawa.com/eu) to contact your

nearest representative.

However, Yokogawa is unable to accept responsibility for claims related to this information.

IM 12D07J01-10E-E

Subject to change without notice Printed in The Netherlands, 11-1904 (A) I

Copyright ©

Loading...

Loading...