Page 1

Instruction

YOKOGAWA

Manual

Model SC25V

Combined 12mm sensor;

pH, Ref, LE and Temperature

IM12B6J1-40E-E

2nd edition

Page 2

2

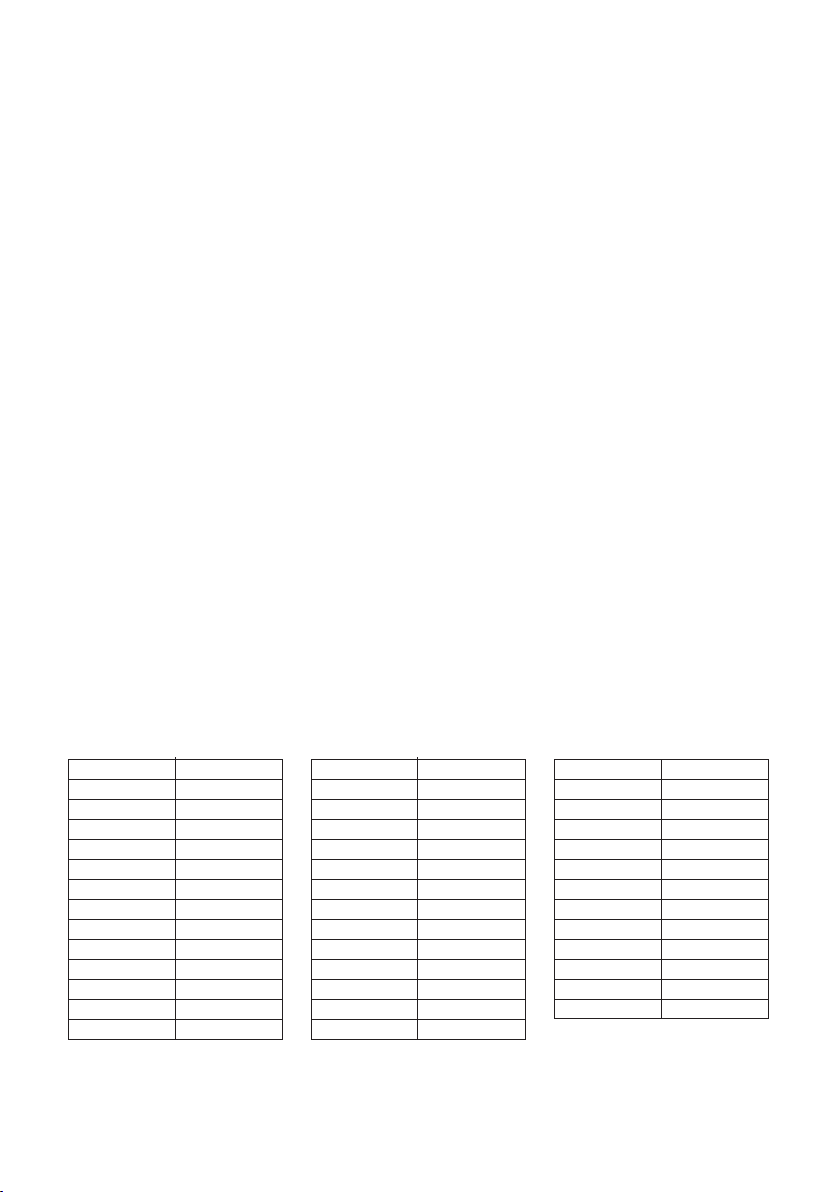

Table 1

Production year according to

DIN. IEC 60062

Year Yearcode

2010 A

2011 B

2012 C

2013 D

2014 E

2015 F

2016 G

2017 H

2018 J

2019 K

2020 L

2021 M

2022 N

IM12B6J1-40E-E

Year Yearcode

2023 P

2024 Q

2025 R

2026 S

2027 T

2028 U

2029 V

2030 W

2031 X

2032 A

2033 B

2034 C

2035 D

Table 2

Production month according to

DIN. IEC 60062

Month Monthcode

January 1

February 2

March 3

April 4

May 5

June 6

July 7

August 8

September 9

October O

November N

December D

Page 3

TABLE OF CONTENTS

1. Preface 4

1.1 Introduction 4

1.2 ATEX/IECEx compliance 4

1.3 Unpacking and checking 4

1.4 Warranty and service 4

2. General Specifications 5

2.1 Measuring elements 5

2.2 Construction materials 5

2.3 Functional specifications 5

2.4 Operating range 5

2.5 Dynamic specification 5

2.6 Sensor dimensions 6

2.7 Equipment and protective systems 6

3. Installation 7

3.1 Typical installation 7

3.2 Preparing the sensor for use 7

3.3 Mounting the sensor 7

4. Wiring to the pH analyzer 9

4.1 Cable marking and pin allocation 9

4.2 Instrument connection of sensor 9

4.3 Instrument connection setting for PH402G and PH202G(S) 9

4.4 Instrument connection setting for PH150, PH450 and FLXA21 9

4.5 Sensor VP connection 10

3

5. General calibration and maintenance procedure 10

5.1 Calibration for pH measurement 10

5.2 Maintenance 10

5.3 Chemical cleaning HCN 11

6. Model and suffix codes 12

6.1 SC25V sensor 12

6.2 Cable for Sensor with Variopin Connector 12

7. Spare parts 12

8. Appendix 13

Chemical Compatibility Chart 13

EC DECLARATION OF CONFORMITY 14

Application datasheet SC25V 15

IM12B6J1-40E-E

Page 4

4

1. PREFACE

1.1 Introduction

This instruction manual provides information

for the installation and use of the SC25V,

combined 12mm glass sensor; pH, Ref, LE

and Temperature. The SC25V is the best

choice for the majority of typical processand waste water applications. The sensor is

designed with titanium liquid earth, increased

electrolyte reservoir and large surface area PTFE

diaphragm combined with a long pathway inner

junction resulting in a longtime stability and

prolonged lifetime.

1.2 ATEX/IECEx compliance

The model SC25V is intended for use in

potentially explosive atmospheres. A number of

restrictions apply on the use of this sensor.

All varieties of SC25V are ATEX certified:

II1G Ex ia IIC T3...T6 Ga (see chapter 2.7).

EC-type Examination Certificate Number:

DEKRA 11ATEX0014 X

IECEx-type Examination Certificate Number:

IECEx DEK 11.0064x

Special conditions for safe use:

For ambient temperature see chapter 2.7.

Electrostatic charges on the enclosure and

cable shall be avoided.

1.3 Unpacking & Checking

Upon delivery, unpack the sensor carefully and

inspect it to ensure it was not damaged during

shipment. If damage is found, retain the original

packing materials (including outer box) and

immediately notify the carrier and the relevant

Yokogawa sales office. Make sure the Model

Code on the sensor is the same as on the

packing list. The Model Code and Serial Number

are found on the VP-connector of the sensor.

Check that option(s) that were ordered are also

included.

1.4 Warranty & Service

Yokogawa products and parts are guaranteed

free from defects in workmanship and materials

under normal use and service for a period of

twelve months from the date of shipment from

the manufacturer. Individual sales organizations

can deviate from the typical warranty period,

and the conditions of sales relating to the

original purchase order should be consulted.

Damage caused by wear and tear, inadequate

maintenance, corrosion, or by the effects of

chemical processes are excluded from this

warranty coverage. In the event of warranty

claim, the defective goods should be sent

(freight paid) to the Service Department of

the relevant sales Organization for repair or

replacement (at Yokogawa’s discretion).

The following information must be included in

the letter accompanying the returned goods:

• Model Code and Serial Number.

• Original Purchase Order and Date.

• Length of time in service and description of

the process.

• Description of the fault and circumstances of

the failure.

• Process/environmental conditions that may be

related to the failure of the sensor.

• Statement as to whether warranty or

nonwarranty service is requested.

• Complete shipping and billing instructions for

return of material, plus the name and phone

number of a contact person that can be

reached for further information.

Returned goods that have been in contact with

process fluids must be decontaminated

and disinfected prior to shipment. Goods

should carry a certificate to this effect, for the

health and safety of our employees. Material

Safety Data sheets must be included for all

components of the process to which the

sensors/fittings have been exposed.

IM12B6J1-40E-E

Page 5

2. GENERAL SPECIFICATIONS

5

2.1 Measuring elements

pH glass electrode

Silver/Silver Chloride reference

Titanium liquid earth

Pt1000 temperature sensor.

2.2 Construction materials

Wetted materials:

O-ring : Viton

Earth Ring : Titanium

Reference Junction : Porous PTFE

Measuring Sensor : Glass

Body Sensor : Glass, PEEK

2.3 Functional specifications

Isothermal point : pH 7

Glass impedance G-Glass

: 225 MΩ

Glass impedance L-Glass

: 600 MΩ

Reference system : Double junction, Ag/

AgCl with saturated KCI,

including Ag+ ion trap

Junction resistance : 0.2 to 10 kΩ

Temp. element : Pt1000 to IEC 751

Asymmetry potential : 8 ±15 mV

Slope : > 96 %

(of theoretical value)

Sensor length : 120 mm and 225 mm

2.4 Operating range

pH : 0 to 14

Temperature

Type G-glass : -10 to 80°C

(14 to 176°F)

Type L-glass : +15 to 130°C

(59 to 266°F)

Pressure : 0 to 10 bar (0 to 145 psi)*

Conductivity : > 10 μS/cm

Storage temp. : -10 to 50°C (14 to 122°F)

* Damaging the screw thread might influence

the max process pressure.

Note: Specifications should not be considered

in isolation. For example the pH range

can be 2-12pH, where the measurement

is at elevated temperatures. For advice

about specific applications please contact

your local sales office.

2.5 Dynamic specifications

Response time pH step (7 to 4)

: < 5 sec for 90%

Response time temp step (25°C)

: < 90 sec for 90%

Stabilization time (0.02 pH unit/10 s)

: < 30 seconds

Note: The temperature sensor included in the

SC25V is intended to provide indication

and cell compensation. The construction

has not been tested to the pressure

vessel standards required for plant

temperature control.

IM12B6J1-40E-E

Page 6

6

2.6 Sensor Dimensions

Dimension according to DIN 19263:2007-05

Criteria : 120 mm version

L (below plug head) : 120 ± 2 mm

Ø shaft : 11.9 ± 0.1 mm

Criteria : 225 mm version

L (below plug head) : 225 ± 2 mm

Ø shaft : 11.9 ± 0.1 mm

Concentricity : < 0,25 mm (centerline plug

head - 25 mm from tip)

Perpendicularity : < 0,5 mm (plug head

- 25 mm from tip)

Cilindricity : < 0,5 mm (centerline

sensor)

2.7 Equipment and protective systems

intended for use in potentially explosive

atmospheres

ATEX II1G Ex ia IIC T3...T6 Ga.

EC-type Examination Certificate Number:

DEKRA 11ATEX0014 X

IECEx-type Examination Certificate Number:

IECEx DEK 11.0064x

Description

pH sensor series SC25V for connection to a

certified associated pH/ORP transmitter are

used for measurement of pH, redox(ORP) and

temperature.

Criteria : All types

All measuring elements within 25mm from tip.

Wrench 19

PG13.5

YOKOGAWA

Made in the netherlands NL-3825 HD-2

173 / 278

II 1 G EX ia IIC T3/T4/T5/T6 Ga

DEKRA 11ATEX0014X

Ø12

0344

0344

S

-

A

C

5

2

V

X

6

1

-

1

0

0

120 / 225

< Ø11.8

25.0

Ambient temperature range:

-40°C to +40°C for temp. class T6,

-40°C to +55°C for temp. class T4 and T5,

-40°C to +105°C for temp. class T3,

Electrical data

Sensor input circuits (connector):

In type of protection intrinsic safety Ex ia IIC,

only for connection to a certified intrinsically safe

circuit, with the following maximum values:

Ui = 18V; Ii =170 mA; Pi = 0,4 W; Ci = 0 nF

(connector) or 3,6 nF (permanently connected

cable); Li = 0 mH;

Or for connection to the certified intrinsically

safe YOKOGAWA pH/ORP Transmitter Model

FLXA21 series or Model PH202S series.

Special conditions for safe use:

For ambient temperature see above.

Electrostatic charges on the enclosure and

cable shall be avoided.

pH sensor series SC25V is suitable for use with

the PH202S, FLXA21-EA conform to ATEX.

Note: When the sensor has been connected

to none intrinsically safe equipment or

equipment which exceeds the restrictions

regarding the sensor input circuit, the

sensor is not suitable for intrinsically safe

use anymore.

Figure 1

IM12B6J1-40E-E

Page 7

3. INSTALLATION

3.1 Typical installation

The SC25V sensor can be installed in-line, in a

bypass loop or in an immersion assembly. For

best results the SC25V should be mounted with

the process fluid flowing towards the sensor

and positioned at least 15° above the horizontal

plane to eliminate air bubbles in the glass bulb.

See fig. 6 section 3.3

7

SC25V

O-RING VITON 11x3

PR10

3.2 Preparing the sensor for use

Remove the sensor from its shipping box and

slide off the “wet pocket” (the flask including the

rubber ring). This wet pocket is filled with a weak

acid and saline solution to prevent the sensor

from drying out during storage and making sure

it is ready for immediate use.

Before mounting the sensor, it should be

validated with buffer solutions and calibrated

when necessary. The specific calibration

procedure is described in the Instruction Manual

of the pH transmitter, but a general procedure is

also provided in section 5 of this manual.

3.3 Mounting the sensor

The SC25V can be mounted using:

• PR10 retractable fitting (see fig 2).

• FF20 flow fitting / FS20 subassembly / FD20

immersion fitting (see fig 4)

• For mounting in Yokogawa fittings, a PG13.5

to M25 adapter is available in different

materials (see fig 3) more information in

chapter 7.

• PD20 immersion fitting / PF20 flow fitting /

PS20 flow fitting (see fig 5)

• FF40 fitting with PG13,5 adapter (K1523JA)

or the small flow fitting K1598AC with PG13,5

adapter (K1523JB), (see fig 7).

Figure 2

Figure 3

Figure 4

SC25V

SLIDE RING

RYTON

O-RING 11 x 3

SC25V

K1520JN

2 x O-RING 11x3

FD20 / FF20 / FS20

SC25V

Figure 5

SLIDE RING

RYTON

O-RING 11 x 3

PD20 / PF20 / PS20

IM12B6J1-40E-E

Page 8

8

Position

23

30

Position

15°

.

Minimum

Figure 6 Figure 7

ø

PG13.5

PG13,5 adapter

10

5

ø30

ø36

20

K1523JA

1

Flow fitting FF40 with K1523JA

Adapter to fit sensors with a PG13,5

process connection in FF40/FS40 and

FD40 fittings. Material: Polypropylene.

Conductivity

Flow Fitting

FF40

K1523JA

32

Ø 36

Ø 54

PG13,5 adapter

K1523JB

153 (6.0”)

PG 13,5

60

1/4” NPT

3/4” NPT

SC4A

option

Ø30

/FF

100 (3.94”)

1/4” NPT

30 (1.18”)

K1598AC

Flow fitting option /FF K1598AC

(incl. 3.1 certificate) with Adapter

K1523JB to fit sensors with PG13,5

process connection.

IM12B6J1-40E-E

Page 9

4. WIRING TO THE PH ANALYZER

4.1 Cable marking and pin allocation

Signal description VP connector

(Using WU10-V-S)

pH A Transparent (core coax)

pH-shield C Black

Reference B Brown (shield coax)

Liquid earth D Yellow (cable shield)

Temp -1 E Red

Temp -2 F Blue

4.2 Instrument connection of sensor

Instrument Terminal for Measurement

pH

pH&ORP ORP only

Signal description pH&rH

pH 15 - 13

pH-shield 16 - 17

Reference 13 13 Liquid earth / (ORP) 14 15 15

Temp -1 11 11 11

Temp -2 12 12 12

Jumper - 13-14 14-15

The settings for the pH instruments should follow the instruction Manual of the instrument

The following tables summarize these settings:

4.3 Instrument connection settings for PH402G and PH202G(S)

Function pH pH compensated

Setting (default)

code 01 0(pH) 0(pH) 0(pH) 1(ORP) 1(ORP)

code 02 0(off) 1(ORP) 2(rH) 0(off) 0(off)

code 03 1.1.1 1.1.1 1.1.1 0.0.1 0.0.1

code 04 0.0.1 0.0.1 0.0.1 0.0.1 1.1.1

code 31 0 2 2

Jumper input 1 no no no yes yes

Jumper input 2 yes yes yes yes no

pH&ORP pH&rH ORP

Cable Wire Colour

pH-compensated

ORP

ORP

9

4.4 Instrument connection settings for PH150, PH450 and FLXA21

Function pH pH compensated

Setting (default)

sensor setup pH pH + ORP pH + ORP ORP ORP

measurement setup pH + ORP pH+rH

Impedance settings

input 1 High High High Low Low

input 2 Low Low Low Low High

jumper input 1 no no no yes yes

jumper input 2 yes yes yes yes no

pH&ORP pH&rH ORP

ORP

IM12B6J1-40E-E

Page 10

10

4.5 Sensor VP connection

VP-Connector

(Temp 2) F

(Temp 1) E

(LE) D

(pH) A

(Ref.) B

Figure 8

5. GENERAL CALIBRATION AND MAINTENANCE PROCEDURE

5.1 Calibration for pH measurement

To calibrate a pH sensor, at least two buffer

solutions with known pH values are required. It

is recommended to use one buffer solution with

a value of pH=7. The second buffer solution

should be either acidic (pH<7) or alkaline

(pH>7), depending on the process value to be

measured. Example buffer solutions are the IEC

buffers with pH=4.01, pH=6.87 and pH=9.18.

The following is a general 2-point calibration

procedure:

1 Clean the sensor (deposits may be removed

using a 5% HCl-solution).

2 Rinse sensor thoroughly with clean water.

Carefully slap out residual fluid drops.

3 Immerse the sensor in the first buffer (pH=6.87

buffer is recommended).

4 Refer to appropriate Instrument Instruction

Manual for detailed instrument calibration input

settings (Auto; Manual; Sample, etc.),

5 Rinse sensor thoroughly with clean water.

Carefully slap out residual fluid drops.

6 Immerse the sensor in the second buffer

(pH=4.01 buffer or pH=9.18 buffer

recommended).

7 Repeat Step 3.

Most instruments automatically correct the

measured pH value at process temperature to

a pH-value at a standard temperature of 25°C.

After the calibration is complete, replace or

re-install the sensor into the process.

5.2 Maintenance

Cleaning the electrodes

When the sensitivity of the electrode has

decreased or the response has slowed down,

the electrode should be cleaned. If cleaning

with hot water is not sufficient, more aggressive

water based agents should be used.

Examples:

• Deposits of lime, hydroxides or carbonates

can be removed by immersing the sensor in

or a dilute solution of hydrochloric acid (5% is

recommended). Afterwards rinse with water.

• Deposits of oils and fats can be removed with

hot water in conjunction with a detergent.

When the results are unsatisfactory, a mild

(carbonate based) abrasive can be used.

IM12B6J1-40E-E

Page 11

5.3 Chemical cleaning HCN

The chemical cleaning system is effective in

processes where deposits can be removed by

a suitable solvent. Good cleaning effects can

be obtained from periodically spraying of an

electrode. EXA PH450G has a built-in wash

timer with programmable wash time, interval

time and relaxation time for automatic cleaning

of the electrodes, preventing pollution of the

pH sensitive parts. After washing, it is possible

to check the response time of the electrodes.

A built-in (no return) nozzle in the spray unit

prevents penetration of the process liquid in the

cleaning system. The standardized dimensions

allow mounting in all flow-, insertion- and

immersion fittings of Yokogawa as well as

back-end mounting on the 4-in-one pH/Redox

electrodes.

Specifications

Materials

Nozzle : Hastelloy

O-rings : EPDM rubber

Mounting set : Stainless steel

Tubing : 1/4” (OD Ø) Nylon tubing

Process cond. : Max. 1 MPa (10 bar) at 100 ºC

Part no.

K1547PA : /HCN3, 3-hole flow-, insertion-,

immersion fitting

K1547PB : /HCN4, 4-hole flow-, insertion-,

immersion fitting

Chemical cleaning

Tubing

O-rings

(11x3)

11

Figure 9

K1547PP

(spare tubing, EPDM)

IM12B6J1-40E-E

Page 12

12

6. MODEL AND SUFFIX CODES

6.1 SC25V sensor

Model Suffix Code Option code Description

SC25V Combined 12mm sensor: pH, Ref, LE, Temp.

Equiped with Variopin connector

Sensor type -AGP25 General purpose

-ALP25 High temp: Chemical resistant.

Sensor length -120 120 mm

-225 225 mm

6.2 Cable for Sensor with Variopin Connector

Cable Model Suffix code Description

WU10-V-S Cable-Variopin-Single COAX

Cable length -02 2 meters

-05 5 meters

-10 10 meters

-15 15 meters

-20 20 meters

7. SPARE PARTS

Sealings

Prod. No. Description

K1500BV O-RINGS EPDM 11X3 (6 PCS.)

K1500BZ O-RINGS VITON 11X3 (6 PCS.)

K1500GR O-RINGS SILICON 11X3 (8PCS)

K1524AA O-ring 10.77X2.62 SILICON 70°sh

FP20-R12 Blind plug set for 1-hole

FP20-R12M Blind plug set for 1-hole (x12)

Adapters

Prod. No. Description

K1523JA Adapter for mounting Pg13,5-sensors in F*40

K1520JN Adapter M25x1.5 - PG13.5 PVC

K1520JP Adapter M25x1.5 - PG13.5 RVS

K1500DV Adapter M25x1.5 - PG13.5 PVDF

K1523JB Adapter PG13.5 to ¾"NPT

K1598AC Flow fitting (3.1), for SC4A (In combination with K1523JB)

K9148NA Adapter for mounting Pg13,5-sensors in HA405-120-S3

K9148NB Adapter for mounting Pg13,5-sensors in HA405-120-PP

K9148NC Adapter for mounting Pg13,5-sensors in HA405-120-PV

IM12B6J1-40E-E

Page 13

8. APPENDIX

CHEMICAL

COMPATIBILITY

CHART

Material

Viton EPDM Ti PTFE PEEK Glass

(teflon)

13

Conc.%

Sulfiric acid 10 o o o o o o - - - o o o o o o o o o

50 o o o o x - - - - o o o o o o o o o

95 o o o x - - - - - o o o - - - o o o

fuming o o o - - - - - - o o o - - - o o o

Hydrochloric acid 10 o o o o o o - - - o o o o o x o o o

sat. o o o x x x - - - o o o o o x o o o

Nitric acid 25 o o x o x - o o o o o o o o o o o o

50 - - - - - - o o o o o o x x x o o o

95 - - - - - - o o o o o o - - - o o o

fuming - - - - - - o o o - - - o o o

Phosphoric acid 25 o o o o o o x x - o o o o o o o o o

50 o o o o o o x - - o o o o o o o o o

95 x x - o o o x - - o o o o o o o o o

Hydrofluoric acid 40 o o o - - - - - - o o o - - - x x x

75 o o x - - - - - - o o o - - - - - Acetic acid 10 - - - o o o o o o o o o o o o o o o

glacial - - - x x x o o o o o o o o x o o o

Formic acid 80 - - - o o x x x - o o o x x x o o o

Citric acid 50 o o o o o o x x x o o o o o o o o o

Calcium hydroxide sat. o o o o o o o o o o o o o o o o o o

Potassium hydroxide 50 o o o o x - o x - o o o o o o o o x

Sodium hydroxide 40 x x x o x - x x - o o o o o o o o x

Ammonia in water 30 x x x o o o x x - o o o o o o o o x

Ammonium chloride sat. o o o o o o o o o o o o o o o o o o

Zinc chloride 50 o o o o o o o o o o o o o o o o o o

Iron(III) chloride 50 o o o o o o o o o o o o o

Sodium sulfite sat. - - - o o o o o o o o o o o o o o o

Sodium carbonate sat. o o o o o o o o o o o o o o o o o o

Potassium chloride sat. o o o o o o o o x o o o o o o o o o

Sodium sulfate sat. o o o o o o o o o o o o o o o o o o

Calcium chloride sat. o o o o o o o o o o o o o o o o o o

Sodium chloride sat. o o o o o o o o o o o o o o o o o o

Sodium nitrate 50 o o o o o o o o o o o o o o o o o o

Aluminium chloride sat. o o o o o o o o x o o o o o o o o o

Hydrogen peroxide 30 o o o o o x o o o o o o o o o o o o

Sodium Hypochloride 50 o o x o o o x - - o o o o o o o o o

Potassium dichromate sat. o o o o o o o o o o o o o o o o o o

Chlorinated lime o o o x x x o o o

Ethanol 80 x - - o o o o o o o o o o o o o o o

Cyclohexane o o o - - - o o o o o o o o o o o o

Toluene - - - - - - o o o o o o o o o o o o

Trichloroethane x x x - - - o o o o o o o o o o o o

Organic Oxidizing Neutral Basic Acid Alkali Organic Introganic

acid agent salt salt salt acid acid

Water o o o o o o o o o o o x o o o o o o

o = can be used / x = shortens useful life / - = cannot be used / Blank = no data currently available

Note: Information in this list is based on our general experience and literature data and given in good

faith. However Yokogawa is unable to accept responsebility for claims related to this information.

Temp. °C2060

1002060

1002060

1002060

1002060

1002060

IM12B6J1-40E-E

100

Page 14

14

EC DECLARATION OF CONFORMITY

IM12B6J1-40E-E

Page 15

APPLICATION DATA SHEET SC25V COMBINED PH SENSOR

Yokogawa has an

extensive sales and

distribution network.

Please refer to the

European website

(www.yokogawa.com/eu)

to contact your nearest

representative.

A5 formaat

YOKOGAWA ELECTRIC CORPORATION

World Headquarters

9-32, Nakacho 2-chome, Musashino-shi

Tokyo 180-8750

Japan

www.yokogawa.com

YOKOGAWA CORPORATION OF AMERICA

2 Dart Road

Newnan GA 30265

USA

www.yokogawa.com/us

YOKOGAWA ELECTRIC ASIA Pte. LTD.

5 Bedok South Road

Singapore 469270

Singapore

www.yokogawa.com/sg

YOKOGAWA CHINA CO. LTD.

3F Tower D Cartelo Crocodile Building

No.568 West Tianshan Road Changing District

Shanghai, China

www.yokogawa.com/cn

YOKOGAWA MIDDLE EAST B.S.C.(c)

P.O. Box 10070, Manama

Building 577, Road 2516, Busaiteen 225

Muharraq, Bahrain

www.yokogawa.com/bh

Customer Please complete a separate form for each

Address process stream to be analyzed and return,

marked for the attention of:

Contact

Telephone

Fax

Serial no. Date received Date returned

1. Process data

Description

15

Application

Operation

Type of

solution

pH Value Nor Min Max

Temperature ( ºC, ºF) Nor Min Max

Pressure (psig, bar, kg/cm²) Nor Min Max

Flow Rate (m/s : ft/s) Nor Min Max

Conductivity (mS/cm) Nor Min Max

Concentration of salts Concentration of organics

Type(s) Type(s)

Problems with Present

measuring procedure

Description

Yokogawa

Confidential

Pulp & Paper Power

Pharmaceutical

Batch

Fouling

Other

Continuous Monitor

Poisoning

Chemical

Other

Control

Coating

YOKOGAWA

Euroweg 2

3825 HD Amersfoort

The Netherlands

www.yokogawa.com/eu

IM12B6J1-40E-E

Page 16

A5 formaat

YOKOGAWA ELECTRIC CORPORATION

World Headquarters

9-32, Nakacho 2-chome, Musashino-shi

Tokyo 180-8750

Japan

www.yokogawa.com

YOKOGAWA CORPORATION OF AMERICA

2 Dart Road

Newnan GA 30265

USA

www.yokogawa.com/us

Euroweg 2

3825 HD Amersfoort

The Netherlands

www.yokogawa.com/eu

YOKOGAWA ELECTRIC ASIA Pte. LTD.

5 Bedok South Road

Singapore 469270

Singapore

www.yokogawa.com/sg

YOKOGAWA CHINA CO. LTD.

3F Tower D Cartelo Crocodile Building

No.568 West Tianshan Road Changing District

Shanghai, China

www.yokogawa.com/cn

YOKOGAWA MIDDLE EAST B.S.C.(c)

P.O. Box 10070, Manama

Building 577, Road 2516, Busaiteen 225

Muharraq, Bahrain

www.yokogawa.com/bh

Yokogawa has an

extensive sales and

distribution network.

Please refer to the

European website

(www.yokogawa.com/eu)

to contact your nearest

representative.

YOKOGAWA

IM12B6J1-40E-E 02-1106 (G) I

Subject to change without notice Printed in The Netherlands

Copyright ©

Loading...

Loading...