Page 1

General

A

Model MLX

Specifications

Loop Powered Process Indicator

-

-

The Model MLX Loop-Powered Process

Indicator receives DC current signals from

electronic transmitters and indicates process

measurement values. Standard models are

general purpose.

STANDARD SPECIFICATIONS

□

FUNCTIONAL SPECIFICATIONS

Input: 4-20mA DC 2-wire

Voltage Drop: 3.5V at 20mA

LCD Display

Numerical: Six 7-segment digits

Alpha-numerical: Six 14-segment characters

Bar graph: 20-segment Bar graph.

Symbols: P, SP, T, F, %, √, x10, x100, x1000

Configuration: User configurable for desired

engineering units.

Method: User configurable from front panel

Zero & Span: Zero and span can be set between

±999999.

Turn-on Time: 12 second (includes power on self-test

and memory integrity check)

Update Time: 1 second

Isolation: Input/Output/Ground isolated to 500V DC

□

PERFORMANCE SPECIFICATIONS

Accuracy: ± 0.05% of full scale +1 digit

Operating Current: 3.6mA to 28mA

Ambient Temperature: -30 to +60°C (-22 to 140°F)

Ambient Humidity: 0 to 100%RH at 23°C (73°F)

Ambient Temperature Effect: 0.1°C per 10°C

Over range: 200mA without damage

Maximum error: +0.02%, -0.03% (of full scale)

Conformity (Linearity): 0.03%

Hysteresis error: 0.03%

Repeatability: 0.03%

Vibration: 3G @ 10-150Hz

Shock: 50G

Explosion Protection: FM, CSA, ATEX, and IEC

□

PHYSICAL SPECIFICATIONS

Enclosure

Material

Housing: Low copper cast aluminum alloy with

Polyurethane resin baked finish - Deep sea moss

green (equivalent of Munsell 0.6GY3.1/2.0) or

SUS316 cast stainless steel (ASTM CF-8M)

Name plate: Black anodized aluminum or 316 SST

Tag: 304 SST

Wired tag: 304 SST

Degrees of Protection: NEMA 4X, IP67

Mounting: Nominal 2” (50mm) pipe mount or

surface. (horizontal or vertical)

Weight: 1.25kg (2.70 lbs)*

*: Without mounting bracket

Add 0.8 kg (0.35 lbs) for mounting bracket

Electrical Connection: ½ NPT female or M20 female

FEATURES

User interface

A front panel push button switch combined with four

touch switches allows easy configuration of the indicator

(calibration, span, zero and engineering units).

Root extraction

For applications where the process variable is non-linear

and based on the square root, 3/2 root or 5/2 root, the

MLX can be configured to display the root function of the

input.

Field Configurable

Via the front panel user interface, the process variable

parameters can be modified as desired in the field.

LCD Display features

The LCD display includes a bar graph for an analog

indication of the process variable magnitude. The 6 digit

display and 6 character display (combined with several

symbols) give an instant view of all process variable

parameters. A menu system allows customizing

parameters such as decimal point position, engineering

units, status of symbols and state of bar graph.

Self-diagnostics

Built-in diagnostics operate at power-up and during

operation for ease of maintenance and troubleshooting.

Yokogawa Corporation of America

2 Dar t Ro ad, Ne wna n, GA 30265

770-254-0400

GS 6 0A02S01-01E-

©Copyright Februa ry 2012

2nd Edit ion

Page 2

A

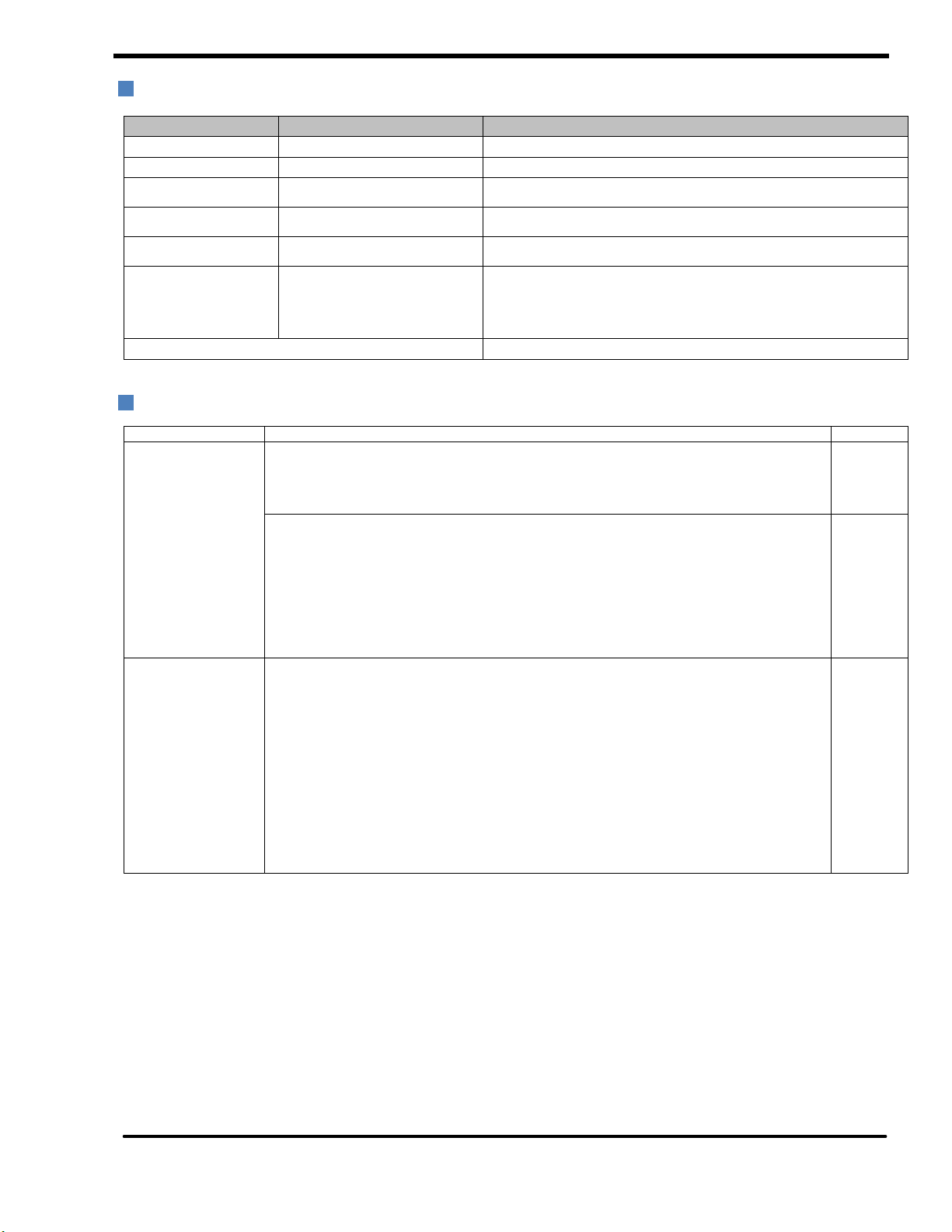

MODEL AND SUFFIX CODES

Model Suffix Codes Description

MLX ………………………………........... Loop Indicator

Input signal -A…………………………………... 4 to 20mA DC

Mounting

Housing

Communication -1………………….

Electrical Connection

Optional Codes

OPTIONAL SPECIFICATIONS (For Explosion Protected Type)

1…………………………............

2…………………………............

1…………………………........

2…………………………........

-2………………….

0……………..

1……………..

2……………..

3……………..

4……………..

2 inch Horizontal Pipe

2 inch Vertical Pipe (or wall mount)

Cast aluminum alloy

SUS316 cast stainless steel and ASTM CF-8M

Standard

HART Communications (To be announced later)

ANSI ½ NPT female, two electrical connections without blind plugs

ANSI ½ NPT female, two electrical connections and a 304 SST blind plug

ANSI ½ NPT female, two electrical connections and a 316 SST blind plug

ISO M20 female, two electrical connections without blind plugs

ISO M20 female, two electrical connections and a 316 SST blind plug

/ □Optional specification

Item Description Code

Factory Mutual (FM)

CENELEC ATEX

FM Explosion-proof Approval

Applicable Standard: FM3600, FM3615, FM3810, ANSI/NEMA 250

Explosionproof for Class I, Division 1, Groups A, B, C and D, Dust-ignitionproof for Class II/III,

Division 1, Groups E, F and G, in Hazardous locations, indoors and outdoors (NEMA 4X)

Temperature class: T5, Ambient Temperature: –30 to 60°C (–22 to 140°F)

FM Intrinsically Safe/FM Explosion-proof/FM Non-incendive Approval (Pending)

Applicable Standard: FM3600, FM3610, FM3611, FM3615, FM3810, ANSI/NEMA 250

Intrinsically Safe for Class I, Division 1, Groups A, B, C & D, Class II, Division 1,

Groups E, F & G and Class III, Division 1, Class I, Zone 0, in Hazardous Locations, AEx ia IIC

Non-incendive for Class I, Division 2, Groups A, B, C & D, Class II, Division. 2,

Groups E, F & G, and Class III, Division 1, Class I, Zone 2, Group IIC, in Hazardous Locations

Enclosure: "NEMA 4X", Temp. Class: T5, Amb. Temp.: –40 to 85°C (–40 to 185°F)

Intrinsically Safe Apparatus Parameters

[Groups A, B, C, D, E, F and G] Vmax=30 V, Imax=200 mA, Pmax=0.9 W, Ci=6 nF, Li=0 _H

[Groups C, D, E, F and G] Vmax=30 V, Imax=200 mA, Pmax=0.9 W, Ci=10 nF, Li=0 mH

ATEX Intrinsically Safe/ATEX Flameproof/Non-incendive Approval (Pending)

Flameproof

Applicable Standard: EN 60079-0, EN 60079-1, EN 60079-31

II 2G, 2D Ex d IIC T5 Ex tD A21 IP6X T85 Degree of protection : IP66 and IP67

Temperature class: T5, Ambient Temperature: –40 to 85°C (–40 to 185°F)

Intrinsically safe

Applicable Standard: EN 60079-0, EN 60079-11, EN 60079-26

II 1G, 1D Ex ia IIC T5 Degree of protection : IP66 and IP67

Temperature class: T5, Ambient Temperature: –40 to 85°C (–40 to 185°F)

Entity parameters : Ui=30 V, Ii=200 mA, Pi=0.9 W, Ci=10 nF, Li=0 mH

Non-incendive

Applicable Standard: EN 60079-0, EN 60079-11

II 3G Ex ic IIC T5

Temperature class: T5, Ambient Temperature: –40 to 85°C (–40 to 185°F)

Entity parameters : Ui=30 V, Ii=200 mA, Pi=0.9 W, Ci=10 nF, Li=0 mH

FF1

FU1

KU21

ll Rights Reserved. Copyright © 2012, Yokogawa Corporation of America GS 60A02S01-01E-A February 2012

Page 3

A

Item Description Code

Canadian Standards

Association (CSA)

Canadian Standards

Association (CSA)

IECEx Scheme

Combination of

Approvals

INMETRO (Brazil)

Certificate

GOST (Russian)

Certificate

CSA Intrinsically Safe/CSA Explosionproof Approval (Pending)

Applicable C22.2 No.25, C22.2 No.30, Standard: FM 3600, FM 3615, UL 1203, UL 50, UL

50E, C22.2 No.94, C22.2 No. 94.2

Explosionproof for Class I, Division 1, Groups A, B, C and D, Dust-ignitionproof for Class II/III,

Division 1, Groups E, F and G

Enclosure: TYPE 4X, Temp. Code: T5

Ex d IIC T5 Enclosure: IP66 and IP67

Amb.Temp.:–40 to 85°C(–40 to 185°F) for T5

Applicable Standard: C22.2 No.0, FM 3600, FM 3610, FMRC 3611, UL 60079-0, UL 60079-11,

C22.2 No.60079.0, CAN/CSA E60079-11, C22.2 No.213, CAN/CSA C22.2 No.157

Intrinsically Safe for Class I, Division 1, Groups A, B, C & D, Class II, Division 1, Groups E, F &

G, Class III, Division 1, Non-incendive for Class I, Division 2, Groups A, B, C & D, Class II,

Division 2, Groups E, F & G, Class III, Division 1

Enclosure: Type 4X, Temp. Code: T5 Amb. Temp.:–40 to 85°C(–40 to 185°F)

Electrical Parameters: [Intrinsically Safe] Vmax=30V, Imax=200mA, Pmax=0.9W, Ci=10nF,

Li=0

[Non-incendive] Vmax=30V, Ci=10nF, Li=0

[For CSA E60079]

Ex ia IIC T5, Ex ic IIC T5 Enclosure: IP66 and IP67

Amb. Temp.:–40 to 85°C(–40 to 185°F)

Electrical Parameters: [Ex ia] Ui=30V, Ii=200mA, Pi=0.9W, Ci=10nF, Li=0

[Ex ic] Ui=30V, Ci=10nF, Li=0

IEC Intrinsically Safe/IEC Flameproof Approval (Pending)

Intrinsically safe and type n

Applicable Standard: IEC 60079-0, IEC 60079-1, IEC 60079-11, IEC 60079-26, IEC 60079-31

II 1G, 1D Ex ia IIC T5, II 3G Ex ic IIC T5 Degree of protection : IP66 and IP67

Amb. Temp.:–40 to 85C(–40 to 185F)

Electrical Parameters: [Ex ia] Ui=30V, Ii=200mA, Pi=0.9W, Ci=10nF, Li=0

[Ex ic] Ui=30V,Ci=10nF, Li=0

Flameproof

Applicable Standard: IEC 60079-0, IEC60079-1

II 2G, 2D Ex d IIC T5 Ex tD A21 IP6X T85 Degree of protection : IP66 and IP67

Amb.Temp.:–40 to 85°C(–40 to 185°F) for T5

Combination of FU1, CU1 and KU21 Approvals (Pending) V1U

INMETRO Intrinsically Safe/INMETRO Flameproof Approval (Pending) BU1

Russian GOST certifícate (Pending) QR1

OPTIONAL SPECIFICATIONS

CU1

SU2

Item Description Code

Paint Epoxy resin paint

Calibration Calibration range and scale ENG

Stainless steel tag

plate

Polyurethane-Epoxy combination paint (Anti-corrosion coating)

Stainless steel tag screw attached to housing

Stainless steel tag wired to housing

X1

X2

SST

SSW

ORDERING INFORMATION OPTIONS

Specify the following when ordering:

1. Model and suffix codes. The MLX is fully field configurable from the front panel. To order a

2. Option codes.

3. Tag number

4. Calibration range desired (optional)

□

Example Ordering Information:

MLX-A11-10/FF1/ENG/SST

(Field Mounted Loop Indicator, 4 to 20mA DC, 2” Horizontal Pipe mount, aluminum housing, standard communication, ANSI ½ NPT electrical

connection without blind plugs, FM Explosion-proof approval)

0-200 InH2O Scale in Engineering Units. Please specify Scale and Engineering units when ordering /ENG.

FT-201 Specify Tag Number when ordering /SST and/or /SSW.

ll Rights Reserved. Copyright © 2012, Yokogawa Corporation of America GS 60A02S01-01E-A February 2012

pre-configured unit, specify the /ENG option followed by the desired

setpoints (zero, full scale, and engineering units).

Page 4

A

DIMENSIONS

MOUNTING

ll Rights Reserved. Copyright © 2012, Yokogawa Corporation of America GS 60A02S01-01E-A February 2012

Page 5

A

WIRING

The loop powered indicator series is powered by the current output loop and does not require external power. All devices must

be wired in series with the current loop. Twisted pair shielded cable is recommended.

The following is a typical wiring example of the MLX Loop Indicator connected to an EJA Pressure Transmitter (Note: The EJA

Transmitter below can be replaced with any 4-20mA 2 wire device.

ll Rights Reserved. Copyright © 2012, Yokogawa Corporation of America GS 60A02S01-01E-A February 2012

Loading...

Loading...