Page 1

User’s

Manual

Model MLX

Loop Powered Process Indicator

IM 60A02S01-01E-A

IM 60A02S01-01E-A

2

nd

Edition

Page 2

Page 2 of 28

Contents

Loop Powered Process Indicator ............................................................................................ 1

Contents .......................................................................................................................................................... 2

1. Introduction ............................................................................................................................................... 3

■ Regarding This Manual ........................................................................................................ 3

1.1 Safe Use of This Product ........................................................................................................ 4

1.2 Warranty ............................................................................................................................... 5

2. Handling Cautions ..................................................................................................................................... 6

2.1 Model and Specifications Check ............................................................................................. 7

2.2 Unpacking ............................................................................................................................. 7

2.3 Storage .................................................................................................................................. 7

2.4 Selecting the Installation Location .......................................................................................... 7

2.5 Insulation Resistance and Dielectric Strength Test .................................................................. 8

2.6 Installation of an Explosion-Protected Instrument .................................................................. 9

2.6.1 Factory Mutual (FM) Certification .................................................................................. 9

2.7 EMC Conformity Standards ............................................................................................. 10

3. Installation .............................................................................................................................................. 11

3.1 Mounting Examples ............................................................................................................. 12

4. Wiring ....................................................................................................................................................... 13

4.1 Wiring Precautions .............................................................................................................. 13

4.2 Selecting the Wiring Materials ............................................................................................. 13

4.3 Wiring ................................................................................................................................. 13

4.3.1 Loop Configuration ....................................................................................................... 13

5. Operation .................................................................................................. Error! Bookmark not defined.

5.1 Overview ................................................................................ Error! Bookmark not defined.

6. Maintenance ............................................................................................................................................. 22

6.1 Overview ............................................................................................................................. 22

6.2 Calibration Instruments Selection ........................................................................................ 22

6.3 Calibration .......................................................................................................................... 22

6.4 Rotating Display Direction ................................................................................................... 23

6.5 Cleaning .............................................................................................................................. 23

7. General Specifications ............................................................................................................................. 24

7.1 Standard Specifications ........................................................................................................ 24

7.2 Model and Suffix Codes ....................................................................................................... 25

7.5 Dimensions .......................................................................................................................... 27

Revision Record ........................................................................................................................................... 28

IM 60A02S01-01E-A

Page 3

Page 3 of 28

1. Introduction

Thank you for purchasing the Model MLX Loop Powered Process Indicator. Your Model MLX Process

Indicator was precisely calibrated at the factory before shipment. To ensure both safety and efficiency,

please read this manual carefully before you operate the instrument.

The Model MLX field mounted indicator receives DC current signals from electronic transmitters and

indicates process measurement values. This instruction manual gives instructions on handling, mounting,

and wiring of the indicator.

■ Regarding This Manual

• This manual should be provided to the end user.

• The contents of this manual are subject to change without prior notice.

• All rights reserved. No part of this manual may be reproduced in any form without Yokogawa’s

written permission.

• Yokogawa makes no warranty of any kind with regard to this manual, including, but not limited to,

implied warranty of merchantability and fitness for a particular purpose.

• If any question arises or errors are found, or if any information is missing from this manual, please

inform the nearest Yokogawa sales office.

• The specifications covered by this manual are limited to those for the standard type under the

specified model number break-down and do not cover custom-made instruments.

• Please note that changes in the specifications, construction, or component parts of the instrument

may not immediately be reflected in this manual at the time of change, provided that postponement

of revisions will not cause difficulty to the user from a functional or performance standpoint.

• Yokogawa assumes no responsibilities for this product except as stated in the warranty.

• If the customer or any third party is harmed by the use of this product, Yokogawa assumes no

responsibility for any such harm owing to any defects in the product which were not predictable, or

for any indirect damages.

• The following safety symbols are used in this manual:

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

IM 60A02S01-01E-A

Page 4

Page 4 of 28

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. It

may also be used to alert against unsafe practices.

IMPORTANT

Indicates that operating the hardware or software in this manner may damage it or lead to system failure.

NOTE

Draws attention to information essential for understanding the operation and features.

1.1 Safe Use of This Product

For the safety of the operator and to protect the instrument and the system, please be sure to follow this

manual’s safety instructions when handling this instrument. If these instructions are not heeded, the

protection provided by this instrument may be impaired. In this case, Yokogawa cannot guarantee that the

instrument can be safely operated. Please pay special attention to the following points:

(a) Installation

• This instrument may only be installed by an engineer or technician who has an expert knowledge of

this device. Operators are not allowed to carry out installation unless they meet this condition.

• All installation shall comply with local installation requirements and the local electrical code.

(b) Wiring

• The instrument must be installed by an engineer or technician who has an expert knowledge of this

instrument. Operators are not permitted to carry out wiring unless they meet this condition.

• Before connecting the power cables, please confirm that there is no current flowing through the

cables and that the power supply to the instrument is switched off.

(c) Operation

• Do not open the covers when an explosive atmosphere is present.

(d) Maintenance

• Please carry out only the maintenance procedures described in this manual. If you require further

assistance, please contact the nearest Yokogawa office.

• Care should be taken to prevent the build up of dust or other materials on the display glass and the

name plate.

(e) Modification

IM 60A02S01-01E-A

Page 5

Page 5 of 28

• Yokogawa will not be liable for malfunctions or damage resulting from any modification made to

this instrument by the customer.

1.2 Warranty

• The warranty shall cover the period noted on the quotation presented to the purchaser at the time of

purchase. Problems occurring during the warranty period shall basically be repaired free of charge.

• If any problems are experienced with this instrument, the customer should contact the Yokogawa

representative from which this instrument was purchased or the nearest Yokogawa office.

• If a problem arises with this instrument, please inform us of the nature of the problem and the

circumstances under which it developed, including the model specification and serial number. Any

diagrams, data and other information you can include in your communication will also be helpful.

• The party responsible for the cost of fixing the problem shall be determined by Yokogawa

following an investigation conducted by Yokogawa.

• The purchaser shall bear the responsibility for repair costs, even during the warranty period, if the

malfunction is due to:

− Improper and/or inadequate maintenance by the purchaser.

− Malfunction or damage due to a failure to handle, use, or store the instrument in accordance

with the design specifications.

− Use of the product in question in a location not conforming to the standards specified by

Yokogawa, or due to improper maintenance of the installation location.

− Failure or damage due to modification or repair by any party except Yokogawa or an approved

representative of Yokogawa.

− Malfunction or damage from improper relocation of the product in question after delivery.

− Reason of force majeure such as fires, earthquakes, storms/floods, thunder/lightening, or other

natural disasters, or disturbances, riots, warfare, or radioactive contamination.

IM 60A02S01-01E-A

Page 6

Page 6 of 28

2. Handling Cautions

This chapter provides important information on how to handle the MLX Loop Powered Process Indicator.

Read this carefully before using the indicator.

The MLX indicator is thoroughly tested at the factory before shipment. When taking delivery of an

instrument, visually check it to make sure that no damage occurred during shipment.

Also check that the indicator mounting hardware shown in figure 2.1 is included. After checking the

indicator, carefully repack it in its box and keep it there until you are ready to install it.

Figure 2.1 MLX Mounting Hardware

IM 60A02S01-01E-A

Page 7

Page 7 of 28

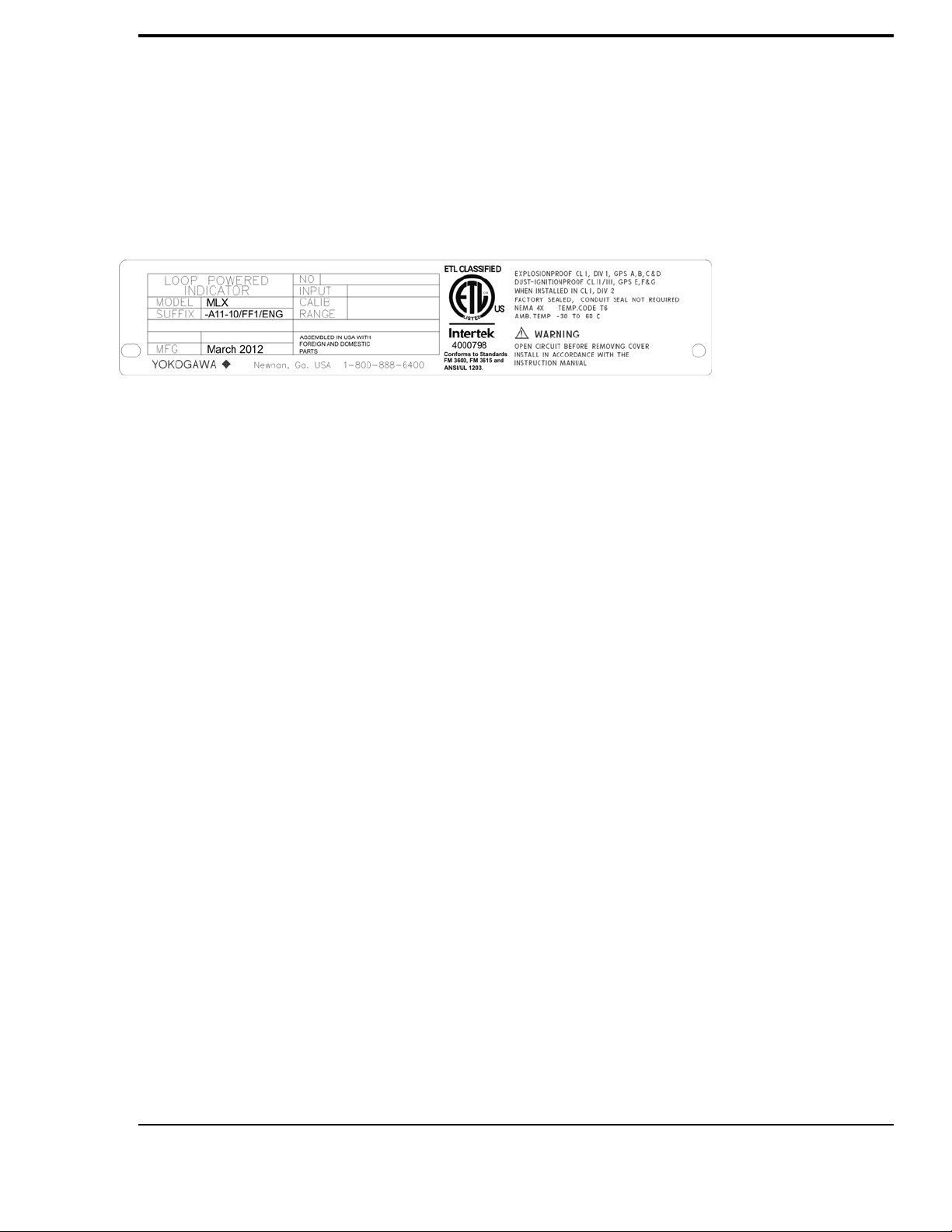

2.1 Model and Specifications Check

The model name and specifications are written on the name plate attached to the case.

MODEL: Specified model code.

SUFFIX: Specified suffix code.

MFG: Year of manufacture.

NO.: Serial number.

INPUT: Input signal (4-20mA).

CALIB RANGE: Specified calibration range.

Figure 2.2 MLX Name Plate

2.2 Unpacking

Keep the indicator in its original packaging to prevent it from being damaged during shipment. Do not

unpack the indicator until it reaches the installation site.

2.3 Storage

The following precautions must be observed when storing the instrument, especially for a long period.

(a) Select a storage area which meets the following conditions:

• It is not exposed to rain or subject to water seepage/leaks.

• Vibration and shock are kept to a minimum.

• It has an ambient temperature and relative humidity within the following ranges.

Ambient temperature: –40 to 85°C (approval codes may affect limits)

Relative humidity: 0% to 100% R.H.

Preferred temperature and humidity: approx. 25°C and 65% R.H.

(b) When storing the indicator, repack it carefully in the packaging that it was originally shipped with.

2.4 Selecting the Installation Location

(1) The MLX is designed to withstand severe environmental conditions. However, to ensure that it will

provide years of stable and accurate performance, take the following precautions when selecting the

installation location.

(2) Ambient Temperature

IM 60A02S01-01E-A

Page 8

Page 8 of 28

(3) Avoid locations subject to wide temperature variations or a significant temperature gradient. If the

location is exposed to radiant heat from plant equipment, provide adequate thermal insulation

and/or ventilation.

(4) Ambient Atmosphere

(5) Do not install the indicator in a corrosive atmosphere. If this cannot be avoided, there must be

adequate ventilation as well as measures to prevent the leaking of rain water and the presence of

standing water in the conduits.

(6) Shock and Vibration

(7) Although the MLX is designed to be relatively resistant to shock and vibration, an installation site

should be selected where this is kept to a minimum.

2.5 Insulation Resistance and Dielectric Strength Test

Since the MLX has undergone insulation resistance and dielectric strength tests at the factory before

shipment, normally these tests are not required. If the need arises to conduct these tests, heed the following:

(1) Do not perform such tests more frequently than is absolutely necessary. Even test voltages that do

not cause visible damage to the insulation may degrade the insulation and reduce safety margins.

(2) Never apply a voltage exceeding 500 V DC (100 V DC with an internal lightning protector) for the

insulation resistance test, nor a voltage exceeding 500 V AC (100 V AC with an internal lightning

protector) for the dielectric strength test.

(3) Before conducting these tests, disconnect all signal lines from the transmitter terminals. The

procedure for conducting these tests is as follows:

• Insulation Resistance Test

(1) Short-circuit the + and – SUPPLY terminals in the terminal box.

(2) Turn OFF the insulation tester. Then connect the insulation tester plus (+) lead wire to the

shorted SUPPLY terminals and the minus (–) lead wire to the grounding terminal.

(3) Turn ON the insulation tester power and measure the insulation resistance. The voltage

should be applied as briefly as possible to verify that the insulation resistance is at least 20

MΩ.

(4) After completing the test and being very careful not to touch exposed conductors disconnect

the insulation tester and connect a 100 kΩ resistor between the grounding terminal and the

short-circuiting SUPPLY terminals. Leave this resistor connected at least one second to

discharge any static potential. Do not touch the terminals while it is discharging.

• Dielectric Strength Test

(1) Short-circuit the + and – SUPPLY terminals in the terminal box.

(2) Turn OFF the dielectric strength tester. Then connect the tester between the shorted

SUPPLY terminals and the grounding terminal. Be sure to connect the grounding lead of the

dielectric strength tester to the ground terminal.

(3) Set the current limit on the dielectric strength tester to 10mA, then turn ON the power and

gradually increase the test voltage from ‘0’ to the specified voltage.

(4) When the specified voltage is reached, hold it for one minute.

(5) After completing this test, slowly decrease the voltage to avoid any voltage surges.

IM 60A02S01-01E-A

Page 9

Page 9 of 28

2.6 Installation of an Explosion-Protected Instrument

WARNING

If a customer makes a repair or modification and the instrument is not restored to its original

condition, its safety may be compromised and the instrument may be hazardous to operate. Please

contact Yokogawa before making any repair or modification to an instrument.

CAUTION

This instrument has been tested and certified as being Explosionproof. Please note that severe

restrictions apply to this instrument’s construction, installation, external wiring, maintenance and

repair. A failure to abide by these restrictions could make the instrument a hazard to operate.

WARNING

Maintaining the safety of Explosionproof equipment requires great care during mounting, wiring,

and piping. Safety requirements also place restrictions on maintenance and repair. Please read the

following sections very carefully.

2.6.1 Factory Mutual (FM) Certification

1) Technical Data

a. FM Explosionproof Type

Caution for FM Explosionproof type.

Note 1. Model MLX Loop Process Indicator with optional code /FF1 for potentially

explosive atmospheres:

• Certificate No. 4000798

• Applicable Standard: FM 3600, FM 3615, FM 3810, NEMA 250

• Explosionproof for Class I, Division 1, Groups A, B, C, and D.

• Dust-ignitionproof for Class II/III, Division 1, Groups E, F and G.

• Enclosure rating: NEMA 4X.

• Temperature Class: T5

• Ambient Temperature: –30 to 60°C

Note 2. Wiring

• All wiring shall comply with National Electrical Code ANSI/NEPA70 and Local Electrical

Codes.

• “FACTORY SEALED, CONDUIT SEAL NOT REQUIRED”.

IM 60A02S01-01E-A

Page 10

Page 10 of 28

Note 3. Installation

• Strictly observe the “WARNING” on the attached nameplate.

WARNING: OPEN CIRCUIT BEFORE REMOVING COVER. “FACTORY

SEALED, CONDUIT SEAL NOT REQUIRED”. INSTALL IN ACCORDANCE

WITH THE INSTRUCTION MANUAL.

Note 4. Maintenance and Repair

• The instrument modification or parts replacement by other than authorized representative of

Yokogawa Electric Corporation is prohibited and will void Factory Mutual Explosionproof

Approval.

Note 5. Special Conditions for Safe Use

• In the case where the enclosure of the MLX is made of aluminum, it must be installed such,

that, even in the event of rare incidents, ignition sources due to impact and friction sparks are

excluded.

2.7 EMC Conformity Standards

EN61326-1 Class A, Table 2 (for use in industrial locations)

EN61326-2-3

IM 60A02S01-01E-A

Page 11

Page 11 of 28

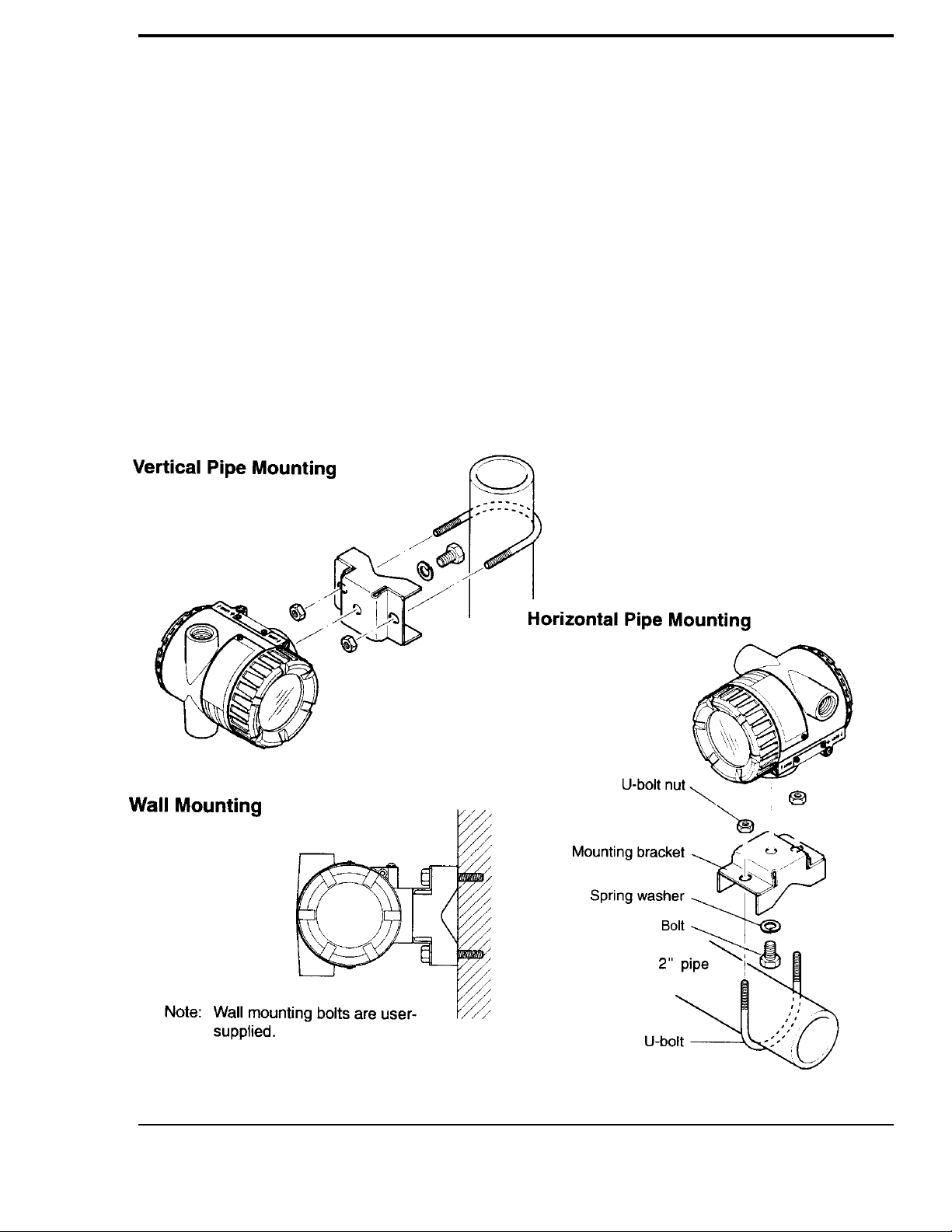

3. Installation

The MLX can be mounted on a wall or a 2” pipe. The housing is NEMA 4X rated so it can be mounted

outside in the field.

"0 Ring" seals MUST be carefully examined after opening to ensure that the NEMA 4X protection is

maintained. Damaged seals MUST be replaced.

The complete electrical circuit in the hazardous area MUST be capable of withstanding an AC test voltage

of 500V RMS to earth or frame of the apparatus.

Where there is a possibility of attack by aggressive substances, the MLX must be protected by a suitable

enclosure, capable of protecting it from the environment and the effects of impact, thermal or mechanical

stress.

Do not install the MLX in the following conditions:

• Extreme Temperatures beyond the temperature rating of the instrument.

• High vibration areas above the vibration rating of the instrument.

• Extremely corrosive environments.

Installation MUST comply with the requirements specified in FM 3600 and must be performed by suitably

qualified staff only.

IM 60A02S01-01E-A

Page 12

Page 12 of 28

3.1 Mounting Examples

Figure 3.1 Mounting configurations

IM 60A02S01-01E-A

Page 13

Page 13 of 28

4. Wiring

4.1 Wiring Precautions

IMPORTANT

• Lay wiring as far as possible from electrical noise sources such as large capacity transformers,

motors, and power supplies.

• Remove the electrical connection dust cap before wiring.

• To prevent noise pickup, do not pass signal and power cables through the same ducts.

• Explosion-protected instruments must be wired in accordance with specific requirements (and, in

certain countries, legal regulations) in order to preserve the effectiveness of their explosionprotected features.

The MLX is powered by the current output loop and does not require external power. All devices must be

wired in series with the current loop. Twisted pair shielded cable is recommended.

4.2 Selecting the Wiring Materials

(a) Use stranded leadwires or cables which are the same as or better than 600 V grade PVC insulated

wire or its equivalent.

(b) Use shielded wires in areas that are susceptible to electrical noise.

(c) In areas with higher or lower ambient temperatures, use appropriate wires or cables.

(d) In environment where oils, solvents, corrosive gases or liquids may be present, use wires or cables

that are resistant to such substances.

(e) It is recommended that crimp-on solderless terminal lugs (for 4 mm screws) with insulating sleeves

be used for leadwire ends.

4.3 Wiring

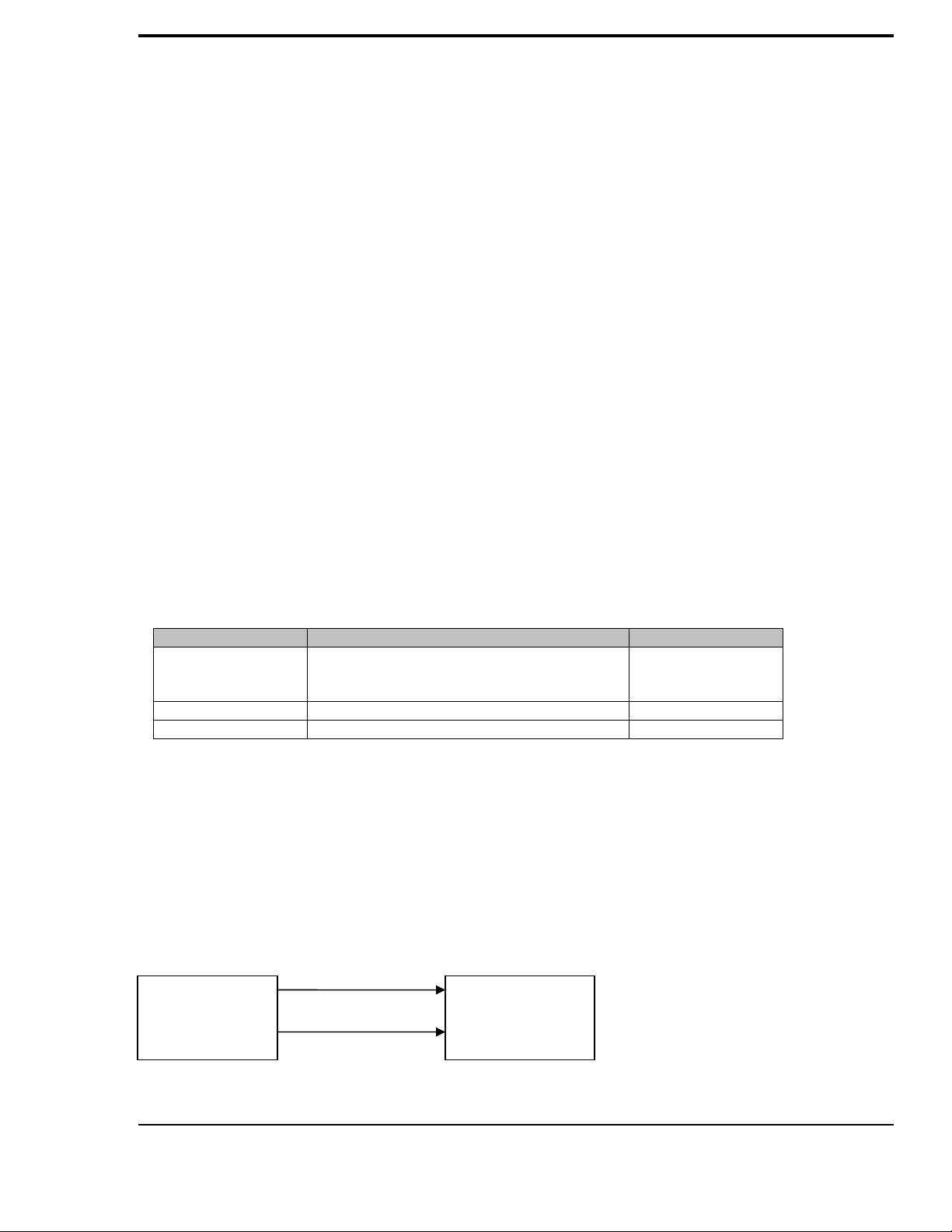

4.3.1 Loop Configuration

The following is a typical wiring example of the MLX connected to an EJA Pressure Transmitter.

IM 60A02S01-01E-A

Page 14

Page 14 of 28

(1) General-use Type

(Note: The EJA Transmitter below can be replaced with any 4-20mA 2 wire device. )

Figure 4.1 General-use Type wiring examples

IM 60A02S01-01E-A

Page 15

Page 15 of 28

5. Operation

5.1 Overview

The MLX is loop powered. Connect it in series with a 4-20mA loop as per Section 4 “Wiring”. Observe

correct polarity as the indicator is protected against reversed connections but will not display a reading.

After properly connecting the indicator to a transmitter or other 4-20mA source, the display will indicate

the value of the current flowing in the loop (0-100% for the standard model or other specified engineering

units can be user defined).

IMPORTANT

Connecting directly across a 24 V supply without a transmitter or similar device to regulate the loop

current will result in damage to either the power supply or the MLX.

The MLX can easily be ranged to display virtually any engineering units by properly calibrating and

selecting the desired units to be displayed.

The MLX uses a 4-key touchpad for operator input. Each key may have multiple functions assigned to it

based a particular menu operation. These keys allow the user to access setup parameters, enter engineering

units, zero and full-scale values, select display symbols and modify display functions. Figure 5.1 illustrates

the keyboard.

Figure 5.1 MLX 4-key Touch keypad.

Each key serves to navigate the menu systems and select a particular value or function. The overall

function of each key is shown in Table 5.1.

Table 5.1 MLX key functions

Key Function

Selects the previous menu item or menu level

Selects the next menu item or menu level

Selects the current menu item or menu level

Exits the menu item or menu level and returns the MLX to normal functions.

IM 60A02S01-01E-A

Page 16

Page 16 of 28

MLX Menu Tree (Calibrate) (Set Units) (Common)

(Setup)

(Response) (FS value)

(Indicators) (Alphabetical)

(Dec places)

(Scroll) (Speed)

(Real-time)

(Demo)

1. Setup

2. Demo

1. Calibrate

2. Eng units

3. Response

4. Indicators

5. Decimal pt

6. Scroll

7. Return

1. Real

2. Simulated

3. Return

(Eng Units)

(Simulated)

1. Start Cal

2. Return

1. Set Units

2. Eng unit 0

value

3. Eng unit

FS value

4. Return

1. Linear

2. Sqrt

3. 3/2

4. 5/2

5. Custom

6. Return

1. Bar

2. x10

3. x100

4. x1000

5. %

6. P

7. SP

8. T

9. F

10. Sqrt

11. Return

1. 0 Dec pt

2. 1 Dec pt

3. 2 Dec pt

4. 3 Dec pt

5. Return

1. Auto

2. Off

3. All

4. Speed

1. Start Real

2. Return

1. Start

Simulated

2. Return

1. Common

2. Alphabetical

3. Clear Units

4. Return

(Zero value)

1. Zero unit

value

2. Return

1. FS unit

value

2. Return

1. Fast scroll

2. Medium scroll

3. Slow scroll

4. Return

1. %

2. bar

3. barg

4. degC

5. degF

6. inH20

7. kg/h

8. kNm3/h

9. m

10. m3/h

11. Nm3/h

12. t/h

13. Return

1. % - %.

2. 1 - 1

3. A – F

4. G – L

5. M – R

6. S – Z

7. Return

IM 60A02S01-01E-A

Page 17

Page 17 of 28

3

etu

MLX Menu Tree (cont.)

(Bar)

From Indicators

(x10)

(x100)

(x1000)

(%)

(P)

(SP)

(T)

(F)

1. Bar on

2. Bar off

3. Return

1. x10 on

2. x10 off

3. Return

1. x100 on

2. x100 off

3. Return

1. x1000 on

2. x1000 off

3. Return

1. % on

2. % off

3. Return

1. P on

2. P off

3. Return

1. SP on

2. SP off

3. Return

1. T on

2. T off

3. Return

1. F on

2. F off

. R

rn

IM 60A02S01-01E-A

Page 18

Page 18 of 28

MLX Menu Tree (cont.)

%

%C

%CH4

%CO

%CO2

%CP

%H2

%H2O

%LEL

%N2

%O2

%R.H.

%RF

%RH

%RV

%VH

1/min

1/s

A

ABS

at

ata

atg

atm

BACARA

bar

BARA

barabs

bare

bareG

barG

bbl/d

bbl/h

bbl/min

bbl/s

bbl_b/d

bbl_b/h

bbl_b/min

bbl_b/p

bbl_b/s

bbl_o/d

bbl_o/h

bbl_o/min

bbl_o/p

bbl_o/s

Bq/cm2

Bq/cm3

BRIX

BTU/SCF

c/s

cal

cal/kWh

CC/MIN

Cel

CelD.P.

cf/d

cf/h

cf/min

cf/p

cf/s

CFM

cft/min

cm

cm/min

cm/s

cm2

cm3

cm3/d

cm3/h

cm3/min

cm3/p

cm3/s

cmAq

cmAqabs

cmAqG

cmH2O

cmH2Oabs

cmH2OG

cmHg

cmHgabs

CO2ppm

COS

cP

cpm

cps

cSt

d

D.P.

dB

deg

degF

degR

degree

DEWPOINT

dm2

ELm

List of alphabetical engineering units (from Alphabetical)

F

FNU

foot

foot/p

foot/s

footAq

footAqabs

footH2O

footH2Oabs

ftH2O

ftH2Oabs

g

g/cm2

g/cm2G

g/cm3

g/d

g/h

g/l

g/m2

g/m3

g/min

g/ml

g/mm2

g/mm2G

g/Nm3

g/p

g/s

G/T

gal/d

gal/h

gal/min

gal/p

gal/s

GBq

Gcal/h

gf

gf.m

gf/cm2

GHz

GJ

GJ/h

GOhm

GPM

gpm

GW

GW.h

h

H2%

HL/H

hPa

hPaabs

hPaG

Hz

in

in/s

inAq

inAqabs

inAqG

inH2O

inH2Oabs

inH2OG

inHg

inHgabs

inWC

inWCabs

inWG

inWGabs

J

K

kA

kbbl/d

kbbl/h

kbbl/min

kbbl/s

kbbl_b/d

kbbl_b/h

kbbl_b/min

kbbl_b/p

kbbl_b/s

kbbl_o/d

kbbl_o/h

kbbl_o/min

kbbl_o/p

kbbl_o/s

KC/NM3

kcal

kcal/Nm3

kcf/d

kcf/h

kcf/min

kcf/p

kcf/s

kg

kg/cm2

kg/cm2abs

kg/cm2G

kg/d

kg/h

kg/l

kg/m2

kg/m2G

kg/m3

kg/min

kg/mm2

kg/mm2G

kg/p

kg/s

kgal/d

kgal/h

kgal/min

kgal/p

kgal/s

kgf

kgf.m

kgf/cm2

kgf/cm2abs

kgf/cm2G

kgf/m2

kgf/m2G

kgf/mm2

kgf/mm2G

kgfm

kHz

kJ

kl

kl/d

kl/h

kl/min

kl/p

kl/s

klb/d

klb/h

klb/min

klb/p

klb/s

KLEENH

klx

km

km/h

km3

km3/d

km3/h

km3/min

km3/s

IM 60A02S01-01E-A

Page 19

Page 19 of 28

km3N/h

KMHO

kN

kN.m

kN/m2

kN/m2abs

kN/m2G

kNm3/h

knot

kOhm

kPa

kPaabs

kPaG

kt

kt/h

kV

kvar

kW

kW.h

kW.m-2

kW/m2

KWH/M3

l

L.E.L.

l/d

l/h

l/min

l/p

l/s

lb

lb/cf

lb/d

lb/gal

lb/h

lb/in2

lb/min

lb/p

lb/s

lbf/in2

lbf/in2abs

lbw/in2

lx

m

m/h

M/H2

m/min

m/p

m/s

m/s2

m2

m3

m3/d

m3/h

m3/min

m3/p

m3/s

m3N/h

mA

mAq

mAqabs

mAqG

mb

mbar

mbarabs

mbare

mbareG

mbarG

mbbl/d

mbbl/h

mbbl/min

mbbl/s

mbbl_b/d

mbbl_b/h

mbbl_b/min

mbbl_b/p

mbbl_b/s

mbbl_o/d

mbbl_o/h

mbbl_o/min

mbbl_o/p

mbbl_o/s

mBq

mcf/d

mcf/h

mcf/min

mcf/p

mcf/s

mF

Mg

mg

mg/cm2

mg/l

MG/LO2

MG/LT

mg/m3

mg/Nm3

Mgal/d

mgal/d

Mgal/h

mgal/h

Mgal/min

mgal/min

Mgal/s

mgal/s

Mgal_p

mgal_p

mGy/h

mH2O

mH2Oabs

mH2OG

mHg

mHgabs

MHO

MHO/CM

MHz

micron

min

min-1

MJ

mJ

MJ.m-2

MJ/m2

MJ/Nm3

mK

ml

Ml/d

Ml/h

ml/h

Ml/min

ml/min

Ml/p

Ml/s

ml/s

MLB/H

mm

mm/h

mm/min

mm/s

mm2

mm3

mmAq

mmAqabs

mmAqG

MMAT

MMCE

mmH2O

mmH2Oabs

mmH2OG

mmHg

mmHgabs

MMHO

mmol/l

mmP-P

MMSCFD

mmWC

mmWCabs

mmWG

mmWGabs

MN

mN

mN.m

MN/m2

MN/m2G

MNGF

MOhm

mOhm

MOhm.cm

MOhm/cm

mol

MOLWT

MPa

mPa

mPa.s

MPaabs

mPaabs

MPaG

mPaG

MPM

mR/h

mS

ms

mS/cm

mS/m

MSCFD

MSI/CM

mSv/h

Mt/h

MV

mV

Mvar

MW

mW

MW.h

MW/m2

mWC

mWG

N

N.m

N/m2

N/m2abs

N/m2G

N2ppm

nA

nF

nGy/h

Nkm3/d

Nkm3/h

Nl/h

Nl/min

Nl/s

Nm3/d

Nm3/h

Nm3/min

Nm3/s

ns

nSv/h

NTU

Ohm

Ohm.cm

Ohm-1

OPm

P

Pa

pA

Paabs

PaG

pF

pF/m

pH

ppb

PPHM

ppm

ppmCO

ppmCO2

ppmH2S

ppmN2

ppmNOX

ppmO2

ppmSO2

psi

psia

psiabs

psig

R.M゚

R/h

R/min

rad

rpm

rps

S

s

S.G.

s-1

SCFH

SCFM

Sm3/h

St

Sv/h

t

t/d

IM 60A02S01-01E-A

Page 20

Page 20 of 28

t/h

t/min

t/p

t/s

TF

THz

TM

Torr

TPm

TR/min

uA

ubbl/d

ubbl/h

ubbl/min

ubbl/s

ubbl_b/d

ubbl_b/h

ubbl_b/min

ubbl_b/p

ubbl_b/s

ubbl_o/d

ubbl_o/h

ubbl_o/min

ubbl_o/p

ubbl_o/s

uF

ug

ug/l

ug/m3

uGy/h

uHg

um

UMHO

UMHO/CM

umP-P

uOhm

uPa

uS

us

uS/cm

uS/m

USI/CM

uSv/h

uV

uW/cm2

V

VAC

var

vol%

vol%O2

volpct

W

W.h

W.s

W/m2

wt%

wtpct

wtpctS

wtppb

wtppm

X10L

5.2 Setting Engineering Units

The standard configuration of the MLX sets the engineering units to 0-100%. Also, after calibration, the

MLX will be set to 0-100%. (Refer to the Maintenance section for instructions on calibrating the MLX.) If

other engineering units are desired, they must be setup. The following procedure illustrates an example of

using units of 200-400 m3/h.

(a) Touch the “Menu” button to enter the menu system.

The alphanumeric display reads “Setup”.

(b) Touch

The alphanumeric display reads “Calibrate”.

to begin the setup routine.

(c) Touch to advance to the next menu item.

The alphanumeric display reads “Eng units”.

(d) Touch to select the Eng units routine.

The alphanumeric display reads “Units”.

(e) Touch to select the Units routine.

The alphanumeric display reads “Alphabetical”. The choices here are:

1. Alphabetical – Use to select units from an alphabetical list

2. Units of Measure – Use to select units by specifying the units of measure (i.e, volume, time,

etc.)

3. Common units – Use to select units from a common set of units

4. Custom – Allows a custom unit to be specified

Touch

to select alphabetical or to select another desired method. In this example, we

will use Common units.

(f) Touch

to display the Units of Measure routine.

IM 60A02S01-01E-A

Page 21

Page 21 of 28

The alphanumeric display reads “Units of Measure”.

(g) Touch to display the Common units routine.

The alphanumeric display reads “Common units”.

(h) Touch to select the Common units routine.

(i) Touch

(j) When the desired unit is shown (in this case, m

to scroll forward through the units (or to scroll backwards).

3

/h), touch to select the unit.

The alphanumeric display shows “Eng units 0 value”. The numeric display shows the current

engineering unit zero value with the least significant digit blinking. At this point, the menu buttons

are redefined as in Table 5.2.

Table 5.2 MLX key functions (when in Engineering units mode)

Key Function

Selects the digit to modify (digits advance from least significant to most

significant to the sign symbol and back to least significant – 6 digits plus

sign).

Increments the selected digit (values roll over from 9 to 0).

Decrements the selected digit (values roll over from 0 to 9).

Accepts the modified value as the current engineering unit zero or full-scale

(FS) value.

(k) Touch to increment the least significant digit to the desired valued (the digits roll over from 9

to 0).

(l) Touch to move to the next digit.

(m) Touch to increment the selected (blinking) digit to the desired valued.

(n) Repeat Steps (l) and (m) until desired value is indicated (including sign value).

(o) Touch to accept the entered value as the engineering units zero value.

The alphanumeric display shows “Eng units 0 value”. The numeric display shows the current

engineering unit zero value.

(p) Touch

to move to the next menu item.

The alphanumeric display reads “Eng units FS value”. The numeric display shows the current

engineering unit FS value with the least significant digit blinking.

(q) Repeat Steps (k) through (o) set the engineering units FS value.

(r) Touch to exit the setup routine and resume measurements.

IM 60A02S01-01E-A

Page 22

Page 22 of 28

6. Maintenance

6.1 Overview

The electronics of the MLX is maintenance free. This chapter describes the procedures for calibration and

rotating the display within the enclosure. Please carefully and thoroughly read the following sections for

information on how to perform these maintenance procedures.

6.2 Calibration Instruments Selection

Table 6.1 lists the instruments that can be used to calibrate the MLX. When selecting an instrument,

consider the required accuracy level. Exercise care when handling these instruments to ensure they

maintain the specified accuracy.

6.3 Calibration

The MLX is factory calibrated to 0-100%. Products ordered with the /ENG Engineering Units option other

than 0-100% use 0-100% as the basis for the desired engineering units. Use the procedure below to check

instrument operation and accuracy during periodic maintenance or troubleshooting.

(2) Connect the instruments as shown in Figure 6.1 (red wire to + OUT on current source, black wire to

- OUT on current source) and warm up the instruments for at least five minutes.

Table 6.1 Instruments Required for Calibration

Name Yokogawa-recommended Instrument Remarks

Current Standard Model CA11 Voltage/Current Calibrator

or

Model CA71 Multifunction Calibrator

Current Source MLX Loop Indicator

4-20mA source

+ (Out)

- (Out)

Figure 6.1 Calibrating the MLX

+ (Red)

- (Black)

IM 60A02S01-01E-A

Page 23

Page 23 of 28

(3) Using the values in Table 6.2, check the MLX readings by setting the current source to each of the

table values. Check all points in the table and verify unit is within specification.

Table 6.2 Percent vs. Current Values

Value Current

0%

25%

50%

75%

100%

4.0mA

8.0mA

12mA

16mA

20mA

(4) If a re-calibration is required, use the following method:

(a) Touch the “Menu” button to enter the menu system.

The alphanumeric display reads “Setup”.

(b) Touch to begin the setup routine.

The alphanumeric display reads “Calibrate”.

(c) Touch to begin the calibrate routine. Follow the instructions given on the

display. For each calibration point, after adjusting the current standard to the value

indicated, press the “Menu” button.

6.4 Rotating Display Direction

The MLX display is designed so that it can be rotated in increments of 90 degrees. When there is a need to

change the orientation of the display, use the following procedure:

(1) Remove power from the MLX.

(2) Remove the glass cover from the display side.

(3) Remove the two anchor nuts from the MLX module assembly.

(4) Remove and rotate the display assembly to the desired orientation.

(5) Re-install and tighten the two nuts on the module assembly.

(6) Replace the glass cover.

6.5 Cleaning

Cleaning should be restricted to wiping with a damp cloth or approved anti-static cleaner to avoid the

danger of ignition due to electrostatic charges.

IM 60A02S01-01E-A

Page 24

Page 24 of 28

7. General Specifications

7.1 Standard Specifications

□FUNCTIONAL SPECIFICATIONS

Input: 4-20mA DC 2-wire

Voltage Drop: 3.5V at 20mA

LCD Display

Numerical: Six 7-segment digits

Alpha-numerical: Six 14-segment characters

Bar graph: 20-segment Bar graph.

Symbols: P, SP, T, F, %, √, x10, x100, x1000

Configuration: User configurable for desired engineering units.

Method: User configurable from front panel

Zero & Span: Zero and span can be set between ±999999.

Turn-on Time: 12 second (includes power on self-test and memory integrity check)

Update Time: 1 second

Isolation: Input/Output/Ground isolated to 500V DC

□PERFORMANCE SPECIFICATIONS

Accuracy: ± 0.05% of full scale +1 digit

Operating Current: 3.6mA to 28mA

Ambient Temperature: -30 to +60°C (-22 to 140°F)

Ambient Humidity: 0 to 100%RH at 23°C (73°F)

Ambient Temperature Effect: 0.1°C per 10°C

Over range: 200mA without damage

Maximum error: +0.02%, -0.03% (of full scale)

Conformity (Linearity): 0.03%

Hysteresis error: 0.03%

Repeatability: 0.03%

Vibration: 3G @ 10-150Hz

Shock: 50G

Explosion Protection: FM (CSA, ATEX, and IEC pending)

□PHYSICAL SPECIFICATIONS

Enclosure

Material

Housing: Low copper cast aluminum alloy with Polyurethane resin baked finish - Deep sea moss green

(equivalent of Munsell 0.6GY3.1/2.0) or SUS316 cast stainless steel (ASTM CF-8M)

Name plate: Black anodized aluminum or 316 SST

Tag: 304 SST or 316 SST

Wired tag: 304 SST or 316 SST

Degrees of Protection: NEMA 4X, IP67

Mounting: Nominal 2” (50mm) pipe mount or

surface. (horizontal or vertical)

Weight: 1.25kg (2.70 lbs)*

*: Without mounting bracket

Add 0.8 kg (0.35 lbs) for mounting bracket

Electrical Connection: ½ NPT female or M20 female

IM 60A02S01-01E-A

Page 25

Page 25 of 28

7.2 Model and Suffix Codes

MODEL AND SUFFIX CODES

Model Suffix Codes Description

MLX ………………………………........... Loop Indicator

Input signal -A…………………………………... 4 to 20mA DC

Mounting

Housing

Communication -1………………….

Electrical Connection

Optional Codes / □Optional specification

OPTIONAL SPECIFICATIONS (For Explosion Protected Type)

1…………………………............

2…………………………............

1…………………………........

2…………………………........

-2………………….

0……………..

1……………..

2……………..

3……………..

4……………..

2 inch Horizontal Pipe

2 inch Vertical Pipe (or wall mount)

Cast aluminum alloy

SUS316 cast stainless steel and ASTM CF-8M

Standard

HART Communications (To be announced later)

ANSI ½ NPT female, two electrical connections without blind plugs

ANSI ½ NPT female, two electrical connections and a 304 SST blind plug

ANSI ½ NPT female, two electrical connections and a 316 SST blind plug

ISO M20 female, two electrical connections without blind plugs

ISO M20 female, two electrical connections and a 316 SST blind plug

Item Description Code

Factory Mutual (FM)

CENELEC ATEX

FM Explosion-proof Approval

Applicable Standard: FM3600, FM3615, FM3810, ANSI/NEMA 250

Explosionproof for Class I, Division 1, Groups A, B, C and D, Dust-ignitionproof for Class II/III,

Division 1, Groups E, F and G, in Hazardous locations, indoors and outdoors (NEMA 4X)

Temperature class: T5, Ambient Temperature: –40 to 85°C (–40 to 185°F)

FM Intrinsically Safe/FM Explosion-proof/FM Non-incendive Approval (Pending)

Applicable Standard: FM3600, FM3610, FM3611, FM3615, FM3810, ANSI/NEMA 250

Intrinsically Safe for Class I, Division 1, Groups A, B, C & D, Class II, Division 1,

Groups E, F & G and Class III, Division 1, Class I, Zone 0, in Hazardous Locations, AEx ia IIC

Non-incendive for Class I, Division 2, Groups A, B, C & D, Class II, Division. 2,

Groups E, F & G, and Class III, Division 1, Class I, Zone 2, Group IIC, in Hazardous Locations

Enclosure: "NEMA 4X", Temp. Class: T5, Amb. Temp.: –40 to 85°C (–40 to 185°F)

Intrinsically Safe Apparatus Parameters

[Groups A, B, C, D, E, F and G] Vmax=30 V, Imax=200 mA, Pmax=0.9 W, Ci=6 nF, Li=0 _H

[Groups C, D, E, F and G] Vmax=30 V, Imax=200 mA, Pmax=0.9 W, Ci=10 nF, Li=0 mH

ATEX Intrinsically Safe/ATEX Flameproof/Non-incendive Approval (Pending)

Flameproof

Applicable Standard: EN 60079-0, EN 60079-1, EN 60079-31

II 2G, 2D Ex d IIC T5 Ex tD A21 IP6X T85 Degree of protection : IP66 and IP67

Temperature class: T5, Ambient Temperature: –40 to 85°C (–40 to 185°F)

Intrinsically safe

Applicable Standard: EN 60079-0, EN 60079-11, EN 60079-26

II 1G, 1D Ex ia IIC T5 Degree of protection : IP66 and IP67

Temperature class: T5, Ambient Temperature: –40 to 85°C (–40 to 185°F)

Entity parameters : Ui=30 V, Ii=200 mA, Pi=0.9 W, Ci=10 nF, Li=0 mH

Non-incendive

Applicable Standard: EN 60079-0, EN 60079-11

II 3G Ex ic IIC T5

Temperature class: T5, Ambient Temperature: –40 to 85°C (–40 to 185°F)

Entity parameters : Ui=30 V, Ii=200 mA, Pi=0.9 W, Ci=10 nF, Li=0 mH

FF1

FU1

KU21

IM 60A02S01-01E-A

Page 26

Page 26 of 28

Item Description Code

Canadian Standards

Association (CSA)

Canadian Standards

Association (CSA)

IECEx Scheme

Combination of

Approvals

INMETRO (Brazil)

Certificate

GOST (Russian)

Certificate

CSA Intrinsically Safe/CSA Explosionproof Approval (Pending)

Applicable C22.2 No.25, C22.2 No.30, Standard: FM 3600, FM 3615, UL 1203, UL 50, UL

50E, C22.2 No.94, C22.2 No. 94.2

Explosionproof for Class I, Division 1, Groups A, B, C and D, Dust-ignitionproof for Class II/III,

Division 1, Groups E, F and G

Enclosure: TYPE 4X, Temp. Code: T5

Ex d IIC T5 Enclosure: IP66 and IP67

Amb.Temp.:–40 to 85°C(–40 to 185°F) for T5

Applicable Standard: C22.2 No.0, FM 3600, FM 3610, FMRC 3611, UL 60079-0, UL 60079-11,

C22.2 No.60079.0, CAN/CSA E60079-11, C22.2 No.213, CAN/CSA C22.2 No.157

Intrinsically Safe for Class I, Division 1, Groups A, B, C & D, Class II, Division 1, Groups E, F &

G, Class III, Division 1, Non-incendive for Class I, Division 2, Groups A, B, C & D, Class II,

Division 2, Groups E, F & G, Class III, Division 1

Enclosure: Type 4X, Temp. Code: T5 Amb. Temp.:–40 to 85°C(–40 to 185°F)

Electrical Parameters: [Intrinsically Safe] Vmax=30V, Imax=200mA, Pmax=0.9W, Ci=10nF,

Li=0

[Non-incendive] Vmax=30V, Ci=10nF, Li=0

[For CSA E60079]

Ex ia IIC T5, Ex ic IIC T5 Enclosure: IP66 and IP67

Amb. Temp.:–40 to 85°C(–40 to 185°F)

Electrical Parameters: [Ex ia] Ui=30V, Ii=200mA, Pi=0.9W, Ci=10nF, Li=0

[Ex ic] Ui=30V, Ci=10nF, Li=0

IEC Intrinsically Safe/IEC Flameproof Approval (Pending)

Intrinsically safe and type n

Applicable Standard: IEC 60079-0, IEC 60079-1, IEC 60079-11, IEC 60079-26, IEC 60079-31

II 1G, 1D Ex ia IIC T5, II 3G Ex ic IIC T5 Degree of protection : IP66 and IP67

Amb. Temp.:–40 to 85C(–40 to 185F)

Electrical Parameters: [Ex ia] Ui=30V, Ii=200mA, Pi=0.9W, Ci=10nF, Li=0

[Ex ic] Ui=30V,Ci=10nF, Li=0

Flameproof

Applicable Standard: IEC 60079-0, IEC60079-1

II 2G, 2D Ex d IIC T5 Ex tD A21 IP6X T85 Degree of protection : IP66 and IP67

Amb.Temp.:–40 to 85°C(–40 to 185°F) for T5

Combination of FU1, CU1 and KU21 Approvals V1U

INMETRO Intrinsically Safe/INMETRO Flameproof Approval (Pending) BU1

Russian GOST certifícate (Pending) QR1

OPTIONAL SPECIFICATIONS

CU1

SU2

Item Description Code

Paint Epoxy resin paint

Stainless steel tag

plate

Polyurethane-Epoxy combination paint (Anti-corrosion coating)

Stainless steel tag screw attached to housing

Stainless steel tag wired to housing

ORDERING INFORMATION OPTIONS

Specify the following when ordering:

1. Model and suffix codes.

2. Option codes.

3. Tag number

4. Calibration range desired (optional)

The MLX is fully field configurable from the front

panel. To order a pre-configured unit, specify the

/ENG option followed by the desired setpoints (zero,

full scale, and engineering units).

X1

X2

ENG Calibration Calibration range and scale

SST

SSW

IM 60A02S01-01E-A

Page 27

Example Ordering Information:

□

MLX-A11-10/FF1/ENG/SST

(Field Mounted Loop Indicator,

communication, ANSI ½ NPT electrical connection without blind plugs, FM Explosion-proof approval)

0-200 InH2O Scale in Engineering Units. Please specify Scale and Engineering units when ordering

FT-201 Specify Tag Number when ordering /SST and/or /SSW.

4 to 20mA DC, 2” Horizontal Pipe mount, aluminum housing, standard

.5 Dimensions

7

/ENG.

IM 60A02S01-01E-A

nd

Page 28

Revision Record

Title: MLX Loop Powered Process Indicator

Manual No.: IM 60A02S01-01E-A

Edition Date Page Revised Item

1st January 2012 -- New publication

2nd March 2012 14, 21 Removed J12 reference; modified Specifications

Page 28 of 28

IM 60A02S01-01E-A

Loading...

Loading...