Page 1

IM 61A01A01-01E-A

4th Edition

Model MLD

Loop Powered Process Indicator

User’s

Manual

IM 61A01A01-01E-A

Page 2

IM 61A01A01-01E-A

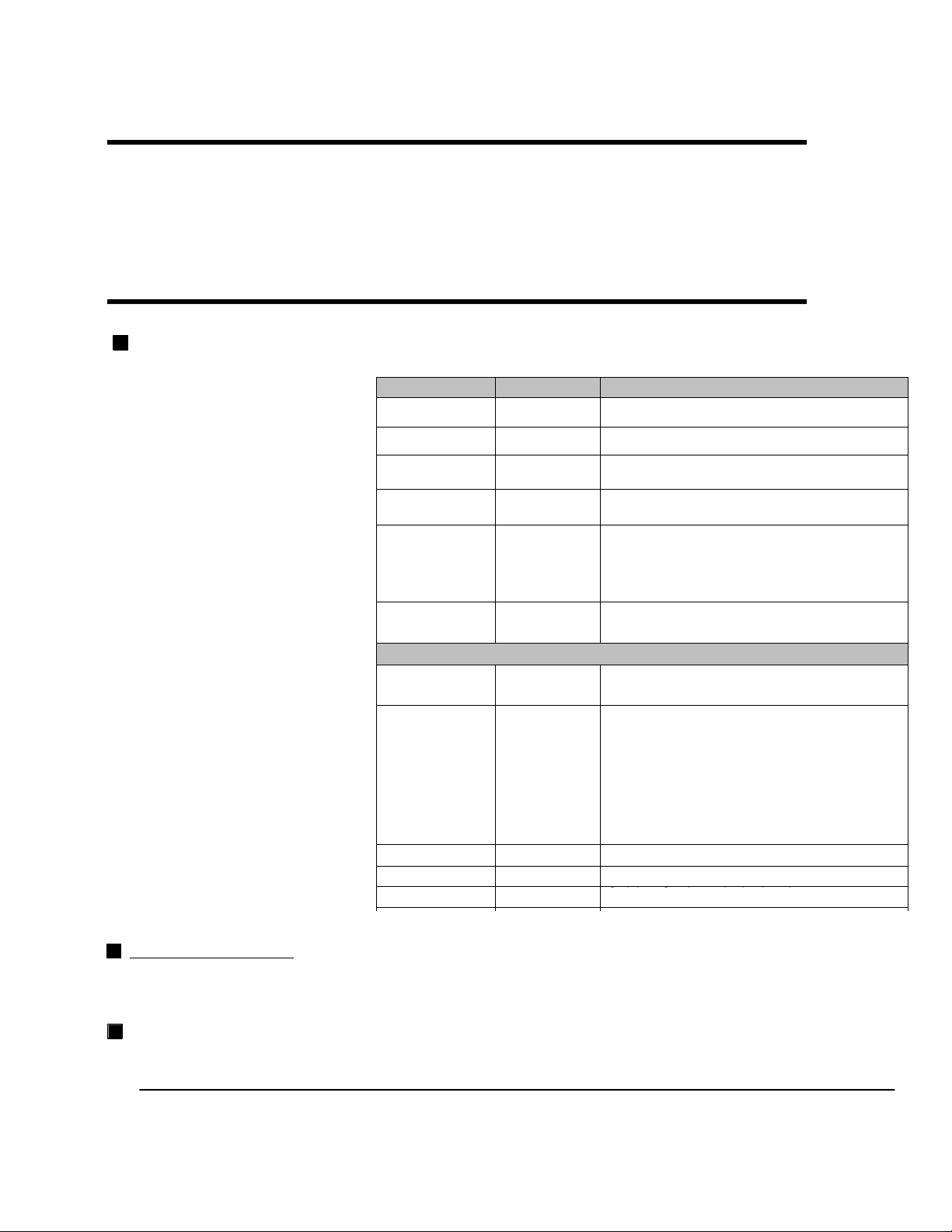

Model

Suffix Codes

Description

MLD Field Mounted Loop Indicator (Digital)

Input Signal

-A

4 to 20 mA DC

Mounting

1

2

2” Horizontal Pipe

2” Vertical Pipe (or wall mount)

Housing

/1

/2

Cast Aluminum Alloy - (Standard Housing)

SUS316 Cast Stainless Steel and ASTM CF-8M

Electrical

Connection

/00

/20

/30

/40

ANSI ½ NPT female, without blind plug

ANSI ½ NPT female, 316 Stainless Steel blind plug

ISO M20 female, without blind plug

ISO M20 female, 316 Stainless Steel blind plug

Ex Protection

/FF1

/CF1

FM Explosion Proof

CSA Explosion Proof

Optional Specifications

Coating

/X1

/X2

Epoxy resin coating

Polyurethane-Epoxy Anti-corrosion coating

Paint

/P1

/P2

/P3

/P4

/P5

/P6

/P7

Light Blue (RAL # 5012)

Orange (RAL # 2008)

Red (Munsell # 7.5 R4/14)

Mint Green

Silver (RAL # 9006)

Yellow (RAL # 1018)

Gray (RAL # 7046)

Calibration

/ENG

Engineering Unit Calibration (MLD Only)

Stainless Steel Tag

/SST

Stainless Steel tag screw attached to housing

Stainless Steel Tag

/SSW

Stainless Steel tag wired to housing

1. PREFACE

The Model MLD field mounted indicator receives a DC current signal from electronic transmitters and

indicates process measurement values. This instruction manual gives instructions on handling, mounting,

and wiring of the MLD indicator.

2. MODEL CODE AND SPECIFICATIONS

STANDARD SPECIFICATIONS

Voltage Drop:

1.8V typ., 2V max.

Scale:

0- 1999 w/decimal

Accuracy:

± 0.05% of full scale (1999) ±1 count

Operating Temperature Range:

-20 to 60°C

Temperature drift: ±0.3 Count/°C

Insulation

terminals and case 100 Mohm at 500 V DC

Dielectric

and case: 1000 VAC for 1 minute.

Mounting:

surface.

Explosion Protection Type:

EXPLOSIONPROOF

A,B,C,D,

GROUPS E,F,G

Case and Cover: Die cast aluminum or 316

Stainless Steel, baked polyurethane paint. Moss

Green (Stainless Steel is unpainted); NEMA 4X

Electrical

M20 x 1.5

Weight: 2.7 lbs

ORDERING INSTRUCTIONS

Example Ordering Instructions:

MLD-A1/1/00/FF1/ENG/SST Field Mounted Indicator (Digital), 4 to 20 mA DC, 2” Horizontal Pipe, FM Explosion Proof

0-200 InH2O Scale in Engineering Units. Please specify Scale and Engineering units when ordering /ENG

FT-201 Specify Tag Number when ordering /SST or /SSW

Resistance: Between input

Strength: Between input terminals

Nominal 2” (50mm) pipe mount or

FM, CSA,

CL1, DIV1, GROUPS

DUST-IGNITIONPROOF

Connection: ½ x 14 NPT or

1. Model and Suffix codes.

2. Option Codes

CLII / III,

Page 3

IM 61A01A01-01E-A

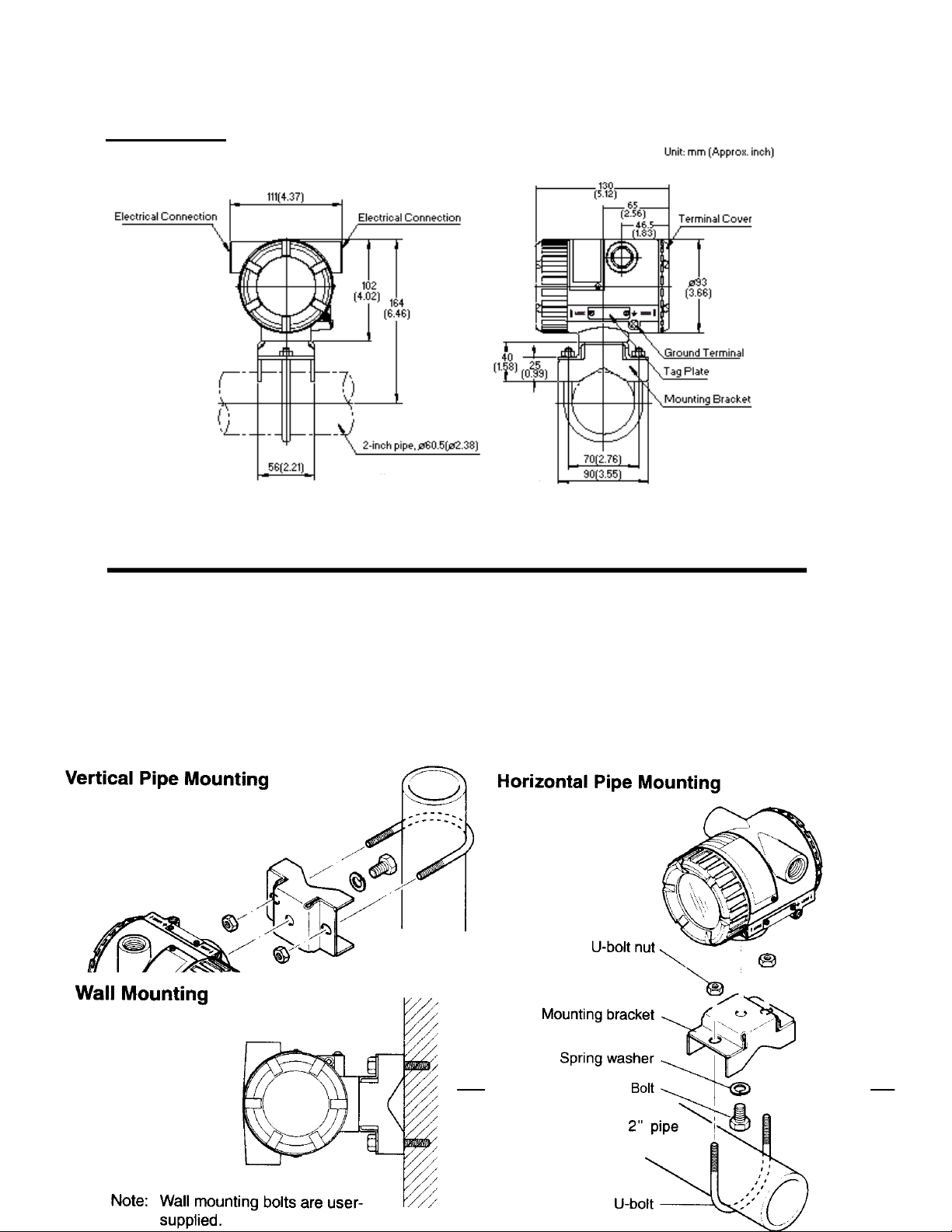

DIMENSIONS

3. INSTALLATION

The Loop Powered Indicator can be mounted on a wall or a 2” pipe. The housing is a NEMA 4X Explosion Proof housing so it c an be mounted

outside in the field.

Do not install the unit in the following conditions:

• Extreme Temperatures beyond the temperature rating of the instrument.

• High vibration areas above the vibration rating of the instrument.

• Extremely corrosive environments.

MOUNTING EXAMPLES

Page 4

IM 61A01A01-01E-A

4. WIRING

The loop powered indicator series is powered by the current output loop and does not require external power. All devices must be wired in series

with the current loop. Twisted pair shielded cable is recommended.

The following is an example of the MLD Loop Indicator connected to an EJA Pressure Transmitter (Note: The EJA Transmitter below can be

replaced with any 4-20mA 2 wire device.)

The Loop Indicator is available in FM Explosion Proof and CSA Explosion Proof types for hazardous locations. Wire sealing is required for these

approvals. The following diagrams show som e wire sealing examples .

For Flameproof type, use Flameproof Packing Adapter or Flameproof Conduit in connection above.

Page 5

IM 61A01A01-01E-A

MOUNTING IN HAZARDOUS LOCATIONS

Page 6

IM 61A01A01-01E-A

5. CALIBRATION

Desired Display Reading

4mA

Adjustment

20mA

Adjustment

Minimum

20mA

Adjustment

Maximum

SW1

SW2

SW3

SW4

SW5

000

1200

1999

OFF

OFF

OFF

OFF

OFF

000

600

1200

ON

OFF

OFF

OFF

OFF

000

400

600

OFF

OFF

ON

OFF

OFF

000

200

400

ON

ON

ON

OFF

OFF

000

100

200

ON

ON

ON

ON

OFF

Suffix –A

4-20mA

0%

4.0mA

25%

8.0mA

50%

12mA

75%

16mA

100%

20mA

Calibration of MLD Units

(1) The MLD model ships with a calibration range of 0-100% unless ordered with the /ENG

Engineering Units option.

(2) If adjustments are needed the 2 screws holding the plate will need to be removed

(3) Connect unit to a Current Standard (red to +, black to -). Current Standards can be purchased

through Yokogawa Corporation of America. Recommended models are CA310 (Voltage/Current

Calibrator) or CA71 (Multifunction Calibrator).

(4) Set range switches based on the following table (for standard 0-100% unit set SW1 and SW8 to

ON):

(5) Set the Decimal value as follows:

a. If tenths (ex. XXX.X) set SW8 on.

b. If hundredths (ex. XX.XX) set SW7 on.

c. If thousandths (ex. X.XXX) set SW6 on.

(6) The values to check are shown in the table below.

(7) Set the Current standard to the 0% value. Adjust the Zero Pot (top one) to read the minimum value

needed.

(8) Set the Current Standard to the 100% value. Adjust the Span Pot (bottom one) to read the

maximum value needed.

(9) Check all points in the table above and verify unit is within specification.

Page 7

IM 61A01A01-01E-A

6. ROTATING DISPLAY DIRECTION

The loop indicator display is designed so that it can be rotated in 90 degree increments. This is

accomplished by ordering the unit as a horizontal pipe mount or a vertical pipe mount. However there

may be the need for the customer to change the angle of the display. The following are procedures for

the display rotation:

Display Rotation:

(1) Remove power from the unit.

(2) Remove the glass cover from the display side.

(3) Remove the 2 screws holding the mounting plate to the standoffs.

(4) Rotate the display to the desired position (can be rotated in 90 degree increments).

(5) Replace and tighten firmly the 2 screws into the standoffs.

(6) Replace the glass cover.

Loading...

Loading...