Page 1

User’s

Manual

Model MLA & MLD

Model MLD (Digital) Model MLA (Analog)

Loop Powered Process Indicators

Page 2

1. PREFACE

The Model MLA and MLD field mounted indicators receive DC voltage or current

signals by electronic transmitters and indicate process measurement values. This

instruction manual gives instructions on handling, mounting, and wiring of the MLA

(analog type) and MLD (digital type) indicators.

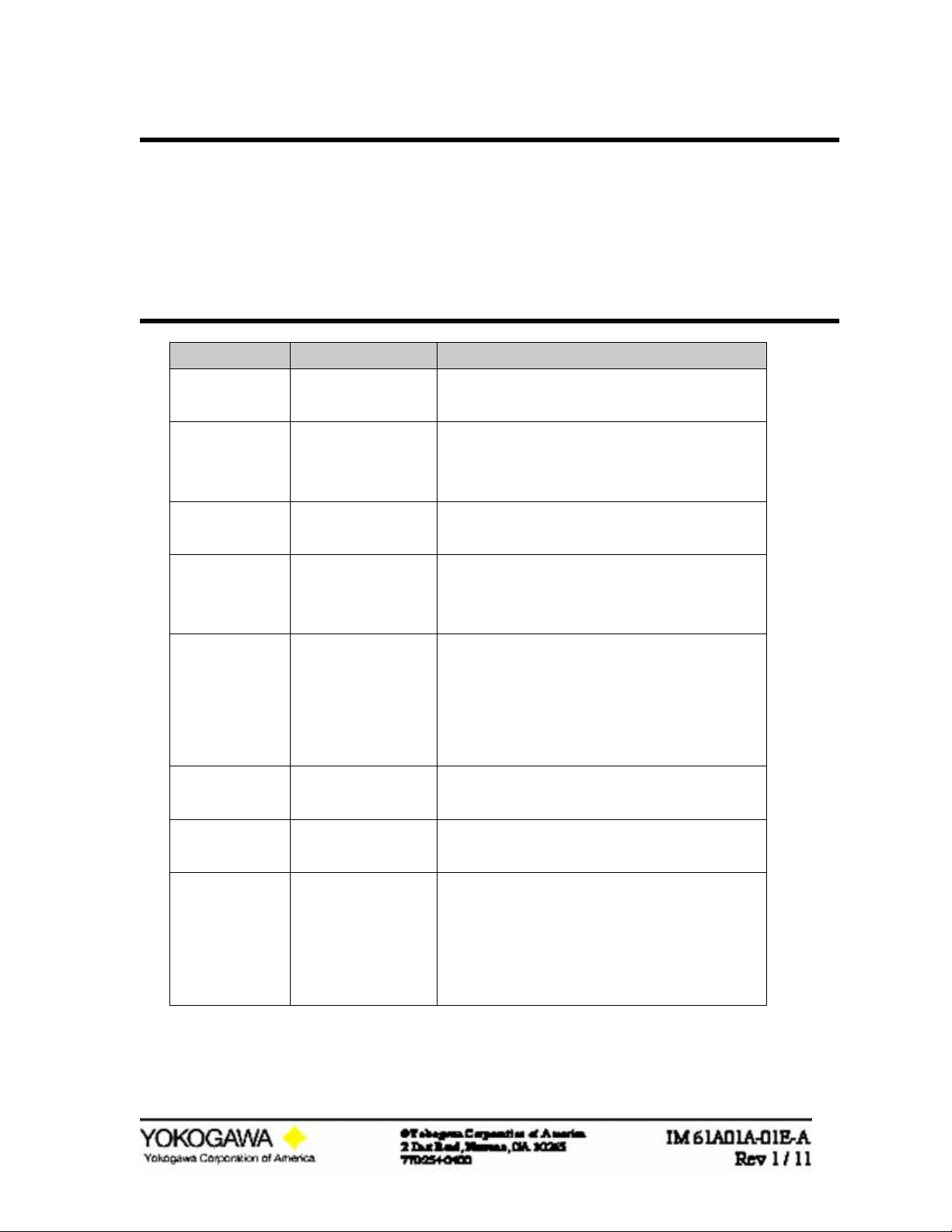

2. MODEL CODE AND SPECIFICATIONS

Model Suffix Codes Description

MLA ………………. Field Mounted Loop Indicator (Analog)

MLD ………………. Field Mounted Loop Indicator (Digital)

Input Signal -A ………….. 4 to 20 mA DC

-B ………….. 10 to 50 mA DC (MLA only)

-C ………….. 1 to 5 VDC (MLA only)

Mounting 1.............. 2” Horizontal Pipe

2 ……….. 2” Vertical Pipe (or wall mount)

Housing /1……….. Cast Aluminum Alloy –(Standard Housing)

/2……….. SUS316 Cast Stainless and ASTM CF-8M

(/FF1 and /CF1 are pending.)

Electrical /00…….. NPT Female; No Plugs

Connection /10…….. NPT Female; (2) 304 SST Blind Plugs

/20…….. NPT Female; (2) 316 SST Blind Plugs

/30…….. M20 Female; No Plugs

/40…….. M20 Female; (2) 316 SST Blind Plugs

Explosion

Protection /CF1 CSA Explosion Proof

Paint Option /X1 Epoxy Resin Paint

/X2 Polyurethane-Epoxy(Anti-Corrosion Paint)

Options /E NG Engineering Unit Calibration (MLD Only)

/ WHT White scale or face plate (MLA Only)

/ SC Scale in Engineering Units (MLA Only)

/ SST SST Tag - Attached to Housing

/SSW SST Tag – Wired to Housing

/FF1 FM Explosion Proof

Page 3

STANDARD SPECIFICATIONS

Input Resistance: < 6.5 ohm (MLA-A 4-20mA), < 13.5 ohm (MLA-B 10-50mA),

~4K ohm (MLA-C 1-5V)

Voltage drop: 1.8V typical, 2V max. (MLD)

Scale: : Black. Analog single graduations 0-100% std. Digital 0-100.0% w/decimal std.

Accuracy: ± 1.5% of full scale (MLA), ± 0.05% of full scale (1999) +1 digit (MLD)

Operating Temperature Range: -20 to 60°C

Temperature drift: ±0.3digit/°C (MLD)

Vibration: 1G @ 10-150Hz (MLA), 3G @ 10-150Hz (MLD)

Insulation Resistance: Between input terminals and case 100 Mohm at 500 V DC

Dielectric Strength: Between input terminals and case: 1000 V AC for 1 minute.

Mounting: Nominal 2” (50mm) pipe mount or surface.

Electrical Classification: NEMA4X, FM, CSA, EXPLOSIONPROOF CL1, DIV1, GPS

A,B,C,D, DUST-IGNITIONPROOF CLII / III, GPS E,F,G

Case and Cover: Die cast aluminum, baked polyurethane paint. Dark green. NEMA4X ;

Optional SUS316 Stainless Steel

Electrical Connection: ” NPT or M20

Weight: 3.0 lbs (MLA), 2.7 lbs (MLD) – Based on Standard Housing

OPTIONS

Scale: MLA: Special range scale in Engineering Units (/SC).

MLD: Custom lasered faceplate available on request. (/ENG)

Scale or Faceplate color: White on request (/WHT)

Scaling: Digital: Special calibration in Engineering Units (/ENG). Max. value = 1999

Other Optional Items: Stainless Steel Tag, Electrical Connections, SUS316 Housing,

and /X1 or /X2 Paint. /SST (limited to 12 Characters) or /SSW Tag.

Page 4

ORDERING INSTRUCTIONS

1. Model and Suffix codes.

2. Option Codes

3. Scale range and unit markings desired.

4. Tag number.

Example Ordering Instructions:

MLD-A1/1/00/FF1/ENG/SST (Field Mounted Indicator (Digital), 4 to 20 mA DC, 2”

Horizontal Pipe, FM Explosion Proof,

0-200 InH2O scale in Engineering Units.) Please specify Scale and Engineering

units when ordering /ENG.

FT-201 Specify Tag Number when ordering /SST; Up to 12 Characters.

DIMENSIONS

Page 5

3. INSTALLATION

The Loop Powered Indicator can be mounted on a wall or a 2” pipe. The housing is a

Nema4X Explosion Proof housing so it can be mounted outside in the field.

Do not install the unit in the following conditions:

• Extreme Temperatures beyond the temperature rating of the instrument.

• High vibration areas above the vibration rating of the instrument.

• Extremely corrosive environments.

MOUNTING EXAMPLES

Page 6

4. WIRING

The loop powered indicator series is powered by the current output loop and does not

require external power. All devices must be wired in series with the current loop. Twisted

pair shielded cable is recommended.

The following is a typical wiring example of the MLA (Analog type) Loop Indicator

connected to an EJA Pressure Transmitter. The impedance of the MLA is low

enough that you can connect it across the Check Terminals

The following is another wiring example of the MLA (Analog type) or MLD (Digital type) Loop Indicator

connected to an EJA Pressure Transmitter (Note: The EJA Transmitter below can be replaced with any 420mA 2 wire device.

Page 7

The Loop Indicator is available in FM Explosion Proof and CSA Explosion Proof types

for hazardous locations. Wire sealing is required for these approvals. The following

diagrams show some wire sealing examples.

For Flameproof type use Flameproof Packing Adapter or Flameproof Conduit in

connection above.

Page 8

MOUNTING IN HAZARDOUS LOCATIONS

Page 9

5. CALIBRATION

The Loop Indicators are factory calibrated to 0-100% unless the /SC (for MLA) or /ENG

(for MLD) options are specified.

Calibration check for MLA Analog Type Units

(1) The MLA model ships with a 0-100% scale unless ordered with the /SC Special

Scale option.

(2) Connect unit to Voltage/Current Standard (red to +, black to -). Voltage/Current

Standards can be purchased through Yokogawa Corporation of America.

Recommended models are CA11 (Voltage/Current Calibrator) or CA71

(Multifunction Calibrator).

(3) The values to check are shown in the table below. Apply the minimum value and

adjust the zero manually first. The zero adjustment can be performed by using a

special tool or small needle nose pliers and twisting the white Teflon piece in the

center of the meter element. Be careful not to damage the meter movement

Suffix –A

4-20mA

0% 4.0mA 10mA 1.0VDC

20% 7.2mA 18mA 1.8VDC

40% 10.4mA 26mA 2.6VDC

60% 13.6mA 34mA 3.4VDC

80% 16.8mA 42mA 4.2VDC

100% 20.0mA 50mA 5.0VDC

Suffix –B

10-50mA

Suffix –C

1-5V

(4) Verify the meter readings are within specification.

Calibration of MLD Digital Type Units

(1) The MLD model ships with a calibration range of 0-100% unless ordered with the

/ENG Engineering Units option.

(2) If adjustments are needed the 2 screws holding the plate will need to be removed

(3) Connect unit to Voltage/Current Standard (red to +, black to -). Voltage/Current

Standards can be purchased through Yokogawa Corporation of America.

Recommended models are CA11 (Voltage/Current Calibrator) or CA71

(Multifunction Calibrator).

.

Page 10

(4) Set range switches based on the following table (for standard 0-100% unit set

SW1 and SW8 to ON):

Desired Display Reading

4mA

Adjustmen

t

000 1200 1999 OFF OFF OFF OFF OFF

000 600 1200 ON OFF OFF OFF OFF

000 400 600 OFF OFF ON OFF OFF

000 200 400 ON ON ON OFF OFF

000 100 200 ON ON ON ON OFF

20mA

Adjustmen

t Minimum

20mA

Adjustmen

t Maximum

SW1 SW2 SW3 SW4 SW5

(5) Set the Decimal value as follows:

a. If tenths (ex. XXX.X) set SW8 on.

b. If hundredths (ex. XX.XX) set SW7 on.

c. If thousandths (ex. X.XXX) set SW6 on.

(6) The values to check are shown in the table below.

Suffix –A

4-20mA

0% 4.0mA 10mA 1.0VDC

25% 8.0mA 20mA 2.0VDC

50% 12mA 30mA 3.0VDC

75% 16mA 40mA 4.0VDC

100% 20mA 50mA 5.0VDC

Suffix –B

10-50mA

Suffix –C

1-5V

(7) Set the voltage standard to the 0% value. Adjust the Zero Pot (top one) to read the

minimum value needed.

(8) Set the Voltage Standard to the 100% value. Adjust the Span Pot (bottom one) to

read the maximum value needed.

(9) Check all points in the table above and verify unit is within specification.

Page 11

6. ROTATING DISPLAY DIRECTION

The loop indicator display is designed so that it can be rotated in 90 degree

increments. This is accomplished by ordering the unit as a horizontal pipe mount or a

vertical pipe mount. However there may be the need for the customer to change the

angle of the display. The following are procedures for the display rotation:

Display rotation of MLA Analog type

WARNING: The MLA loop indicator contains a very delicate meter movement

which can easily be damaged if care is not taken. When performing the following

modification avoid contact with the pointer and any of the internal meter

movement to avoid damage.

(1) Remove power from the unit.

(2) Remove the glass cover from the display side.

(3) Remove the 2 small screws holding the scale plate onto the meter.

(4) Carefully remove the scale from the unit (avoid touching the pointer).

(5) You will notice 2 screws at the 9 and 3 o’clock positions in the bottom of the

housing. Remove these screws.

(6) Rotate the meter to the position desired.

(7) Replace screws in the 9 and 3 o’clock positions and tighten firmly.

(8) Carefully put the scale back on the unit (avoid touching the pointer).

(9) Replace the 2 scale mounting screws.

(10) Replace the glass cover.

Display rotation of MLD Digital type

(1) Remove power from the unit.

(2) Remove the glass cover from the display side.

(3) Remove the 2 screws holding the mounting plate to the standoffs.

(4) Rotate the display to the desired position (can be rotated in 90 degree increments).

(5) Replace and tighten firmly the 2 screws into the standoffs.

(6) Replace the glass cover.

Loading...

Loading...