Page 1

User’s

Manual

Positioning Modules

(with Pulse Output)

IM 34M6H57-01E

Yokogawa Electric Corporation

IM 34M6H57-01E

2nd Edition

Page 2

Applicable Product

● Range-free Multi-controller F A-M3

Model : F3NC11-0N, F3CN12-0N

Name: Positioning Module with Pulse Output

The document number and document model code for this manual are giv en below:

Refer to the document number in all communications; also ref er to the document n umber or

the document model code when purchasing additional copies of this manual.

Document No. : IM 34M6H57-01E

Document Model Code : DOCIM

i

Media No. IM 34M6H57-01E (CD) 2nd Edition : July, 2001 (YK)

All Right Reserved Copyright © 1999, Yokogawa Electric Corporation

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 3

Important

About This Manual

- This Manual should be passed on to the end user.

- Bef ore using the controller , read this manual thoroughly to ha v e a clear understanding

of the controller.

- This manual e xplains the functions of this product, but there is no guar antee that they

will suit the particular purpose of the user.

- Under absolutely no circumstances ma y the contents of this manual be transcribed or

copied, in part or in whole, without permission.

- The contents of this manual are subject to change without prior notice.

- Ev ery effort has been made to ensure accuracy in the preparation of this manual.

Howev er , should any errors or omissions come to the attention of the user, please

contact the nearest Yokogawa Electric representative or sales office .

Safety Precautions when Using/Maintaining the Product

ii

- The f ollowing saf ety symbols are used on the product as well as in this manual.

Danger. This symbol on the product indicates that the operator must follow the instructions laid out in this instruction manual to avoid the risk of personnel injuries,

fatalities, or damage to the instrument. The manual describes what special care the

operator must exercise to prevent electrical shock or other dangers that may result in

injury or the loss of life.

Protective Ground Terminal. Before using the instrument, be sure to ground this

terminal.

Function Ground Terminal. Before using the instrument, be sure to ground this

terminal.

Alternating current. Indicates alternating current.

Direct current. Indicates direct current.

IM 34M6H57-01E 2nd Edition : July 2001-00

Page 4

The following symbols are used only in the instruction manual.

W ARNING

Indicates a “W arning”.

Draws attention to information essential to prevent hardware damage, software damage

or system failure.

CAUTION

Indicates a “Caution”

Draws attention to information essential to the understanding of operation and functions.

TIP

Indicates a “TIP”

Gives information that complements the present topic.

SEE ALSO

Indicates a SEE ALSO reference.

Identifies a source to which to refer.

iii

- F or the protection and saf e use of the product and the system controlled by it, be sure

to follow the instructions and precautions on safety stated in this man ual whenev er

handling the product. Take special note that if you handle the product in a manner

other than prescribed in these instructions, the protection feature of the product may

be damaged or impaired. In such cases , Y okoga w a cannot guarantee the quality,

performance, function and safety of the product.

- When installing protection and/or saf ety circuits such as thunderbolt protection devices and equipment for the product and control system as well as designing or

installing separate protection and/or safety circuits for f ool-proof design and f ail-saf e

design of processes and lines using the product and the system controlled by it, the

user should implement it using devices and equipment, additional to this product.

- If component parts or consumable are to be replaced, be sure to use parts specified

by the company.

- This product is not designed or man ufactured to be used in critical applications which

directly affect or threaten human lives and saf ety — such as nuclear po wer equipment,

devices using radioactivity, railway facilities, a viation equipment, air navigation f acilities, aviation facilities or medical equipment. If so used, it is the user’s responsibility to

include in the system additional equipment and devices that ensure personnel safety.

- Do not attempt to modify the product.

Exemption from Responsibility

- Yokogaw a Electric Corporation (hereinafter simply referred to as Yokogawa Electric)

makes no warranties regarding the product e xcept those stated in the W ARRANTY

that is provided separately.

- Yokogaw a Electric assumes no liability to any party for any loss or damage, direct or

indirect, caused by the user or any unpredictable def ect of the product.

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 5

Software Supplied by the Company

- Yokogaw a Electric makes no other warranties e xpressed or implied e xcept as provided in its warranty clause for software supplied b y the company.

- Use the softw are with one computer only. You must purchase another copy of the

software for use with each additional computer .

- Cop ying the software f or an y purposes other than backup is strictly prohibited.

- Store the original media, such as floppy disks , that contain the software in a saf e

place.

- Re verse engineering, such as decompiling of the softw are, is strictly prohibited.

- No portion of the software supplied by Y ok ogaw a Electric may be transf erred, e xchanged, or sublet or leased for use b y any third party without prior permission by

Yokogawa Electric.

iv

IM 34M6H57-01E 2nd Edition : July 2001-00

Page 6

General Requirements for Using the FA-M3

● Avoid installing the FA-M3 in the following locations:

- Where the instrument will be exposed to direct sunlight, or where the oper ating temperature exceeds the range 0°C to 55°C (0°F to 131°F).

- Where the relativ e humidity is outside the range 10 to 90%, or where sudden temperature changes may occur and cause condensation.

- Where corrosiv e or flammab le gases are present.

- Where the instrument will be exposed to direct mechanical vibr ation or shock.

- Where the instrument ma y be exposed to e xtreme le vels of r adioactivity.

● Use the correct types of wire for external wiring:

- Use copper wire with temperature r atings greater than 75°C.

● Securely tighten screws:

- Securely tighten module mounting scre ws and terminal screws to av oid problems

such as faulty eration.

v

- Tighten terminal bloc k screws with the correct tightening torque as giv en in this

manual.

● Securely lock connecting cables:

- Securely loc k the connectors of cables , and check them thoroughly bef ore turning on

the power.

● Interlock with emergency-stop circuitry using external relays:

- Equipment incorporating the FA-M3 must be furnished with emergency-stop circuitry

that uses external relays. This circuitry should be set up to interlock correctly with

controller status (stop/run).

● Ground for low impedance:

- F or saf ety reasons, connect the [FG] g rounding terminal to a Japanese Industrial

Standards (JIS) Class 3 Ground. F or compliance to CE Marking, use cables such as

twisted cables which can ensure low impedance ev en at high frequencies f or grounding.

● Configure and route cables with noise control considerations:

- Perform installation and wiring that segregates system parts that may likely become

noise sources and system parts that are susceptible to noise. Seg regation can be

achieved b y measures such as segregating by distance , installing a filter or segregating the grounding system.

● Configure for CE Marking Conformance:

- F or compliance to CE Marking, perform installation and cable routing according

to the description on compliance to CE Marking in the “Hardware Manual”

(IM34M6C11-01E).

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 7

● Keep spare parts on hand:

- Stoc k up on maintenance parts including spare modules, in advance.

● Discharge static electricity before operating the system:

- Because static charge can accumulate in dry conditions, first touch grounded metal to

discharge any static electricity before touching the system.

● Never use solvents such as paint thinner for cleaning:

- Gently clean the surf aces of the FA-M3 with a cloth that has been soaked in water or a

neutral detergent and wringed.

- Do not use v olatile solv ents such as benzine or paint thinner or chemicals for cleaning,

as they may cause def ormity, discoloration, or malfunctioning.

● Avoid storing the FA-M3 in places with high temperature or humidity:

- Since the CPU module has a built-in battery, avoid storage in places with high

temperature or humidity .

- Since the service life of the battery is drastically reduced by e xposure to high

temperatures, take special care (storage temperature should be from –20

- There is a b uilt-in lithium battery in a CPU module and temperature control module

which serves as backup power supply for prog rams, de vice inf ormation and

configuration information. The service life of this battery is more than 10 years in

standby mode at room temperature. Take note that the service life of the battery may

be shortened when installed or stored at locations of extreme low or high

temperatures. Theref ore, w e recommend that modules with built-in batteries be stored

at room temperature.

°C to 75°C).

vi

● Always turn off the power before installing or removing modules:

- F ailing to turn off the power supply when installing or remo ving modules, ma y result in

damage.

● Do not touch components in the module:

- In some modules y ou can remov e the right-side cover and install R OM packs or

change switch settings. While doing this, do not touch any components on the printedcircuit board, otherwise components may be damaged and modules may f ail to work.

IM 34M6H57-01E 2nd Edition : July 2001-00

Page 8

Introduction

■ Overview of the Manual

This user’s man ual, “P ositioning Module (with Pulse Output),” explains the specifications

and provides information necessary for operation of the positioning modules, F3NC11-0N

and F3NC12-0N, used with an F A-M3 controller .

Before using the modules, read this manual thoroughly to ha ve a clear understanding f or

proper operation. K eep this manual on hand f or future ref erence.

■ Other Manuals

Refer to the follo wing manuals.

● For sequence CPU functions:

- Sequence CPU Modules - Functions (f or F3SP21, F3SP25 and F3SP35)

(IM 34M6P12-02E)

- Sequence CPU Modules - Functions (f or F3SP28, F3SP38, F3SP53 and F3SP58)

(IM 34M6P13-01E)

vii

● For sequence CPU instructions:

- Sequence CPU Modules - Instructions (IM 34M6P12-03E)

● For creating programs using ladders:

- FA-M3 Programming Tool WideField (IM 34M6Q14-01E)

- FA-M3 Programming Tool WideField - Application (IM 34M6Q14-02E)

● For the F A-M3 specifications and configurations*1, installation and wir -

ing, maintenance, and module installation limits f or the whole

system:

- Hardw are Manual (IM 34M6C11-01E)

*1: Refer to the relev ant product manuals f or specifications e xcept for po wer supply modules , base modules, input/

output modules, cables and terminal units.

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 9

Copyrights and Trademarks

■ Copyrights

Copyrights of the programs and online manual included in this CD-ROM belong to

Yokogawa Electric Corporation.

This online manual may be printed but PDF security settings have been made to prevent

alteration of its contents.

This online manual may only be printed and used for the sole purpose of operating this

product. When using a printed copy of the online manual, pay attention to possible

inconsistencies with the latest version of the online manual. Ensure that the edition agrees

with the latest CD-ROM version.

Copying, passing, selling or distribution (including transferring over computer networks) of

the contents of the online manual, in part or in whole, to any third party, is strictly prohibited.

Registering or recording onto video tapes and other media is also prohibited without

expressed permission of Yokogawa Electric Corporation.

■ Trademarks

viii

The trade names and company names referred to in this manual are either trademarks or

registered trademarks of their respective companies.

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 10

FA-M3

Positioning Modules

(with Pulse Output)

IM 34M6H57-01E 2nd Edition

CONTENTS

Applicable Product ............................................................................................... i

Important...............................................................................................................ii

Introduction.........................................................................................................vii

Copyrights and Trademarks ..............................................................................viii

1. Overview ................................................................................................. 1-1

2. Specifications ......................................................................................... 2-1

2.1 General Specifications ................................................................................... 2-1

2.2 Operating Envir onment .................................................................................. 2-2

2.3 Model and Suffix Codes.................................................................................. 2-2

2.4 Components.................................................................................................... 2-3

2.5 External Dimensions ...................................................................................... 2-4

2.6 Terminal Assignments and Connection ........................................................ 2-4

2.7 Applicable External Interface Connectors..................................................... 2-5

Toc-1

3. Function Overview.................................................................................. 3-1

3.1 Positioning Operation..................................................................................... 3-2

3.2 Change in Target Position during Positioning............................................... 3-3

3.3 Change in V elocity during P ositioning .......................................................... 3-4

3.4 Velocity Contr ol............................................................................................... 3-5

3.5 Change in V elocity during Velocity Control ................................................... 3-6

3.6 Velocity-to-P osition Contr ol Mode Switching ............................................... 3-7

3.7 Jog Stepping ................................................................................................... 3-8

3.8 Emergency-stop Input .................................................................................... 3-9

3.9 Contact Inputs............................................................................................... 3-10

3.10 Z-phase Encoder Input ................................................................................. 3-11

3.11 Origin-search Operation............................................................................... 3-12

3.12 Linear-interpolated Operation...................................................................... 3-13

3.13 On-Route Operation...................................................................................... 3-14

3.14 Arc-interpolated Operation........................................................................... 3-15

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 11

Toc-2

4. Parameters.............................................................................................. 4-1

4.1 List of Parameters........................................................................................... 4-1

4.1.1 Registered parameters ..................................................................... 4-4

4.1.2 Operation Pa rameters....................................................................... 4-4

4.1.3 Common Par ameters........................................................................ 4-6

4.2 List of Required Parameters f or each Command.......................................... 4-7

4.3 Description of Parameters.............................................................................. 4-8

4.3.1 Entry parameters .............................................................................. 4-8

4.3.2 Operation Pa rameters....................................................................... 4-9

4.3.3 Common Par ameters...................................................................... 4-12

4.4 Entry Parameters Setting Example.............................................................. 4-13

5. Status ...................................................................................................... 5-1

5.1 List of Status ................................................................................................... 5-1

5.2 Description of Status ...................................................................................... 5-3

6. List of Input/Output Relays .................................................................... 6-1

6.1 Output Relays.................................................................................................. 6-1

6.2 Input Relays .................................................................................................... 6-2

7. Accessing Modules ................................................................................ 7-1

7.1 Accessing from Sequence CPU ..................................................................... 7-1

7.1.1 Reading the Module Status............................................................... 7-2

7.1.2 Setting Parameters........................................................................... 7-3

7.1.3 Error Reset ....................................................................................... 7-5

7.1.4 Jog Stepping .................................................................................... 7-7

7.1.5 Origin-Search ................................................................................... 7-9

7.1.6 Write Current Position..................................................................... 7-14

7.1.7 Position Control Mode Operation .................................................... 7-16

7.1.8 V elocity Control Mode Operation..................................................... 7-24

7.1.9 Switch Velocity to Position Control................................................... 7-30

7.1.10 Request to Decelerate and Stop ..................................................... 7-33

7.1.11 Request to Stop Immediately .......................................................... 7-35

7.1.12 On-route Operation......................................................................... 7-37

7.1.13 Arc-Interpolated Operation ............................................................. 7-41

7.1.14 Backlash Correction........................................................................ 7-44

7.2 Accessing from BASIC CPU......................................................................... 7-46

7.2.1 Reading the Module Status............................................................. 7-47

7.2.2 Set Par ameter ................................................................................ 7-48

7.2.3 Error Reset ..................................................................................... 7-49

7.2.4 Jog-Stepping .................................................................................. 7-50

7.2.5 Origin-Search ................................................................................. 7-51

7.2.6 Write Current Position..................................................................... 7-54

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 12

Toc-3

7.2.7 Position-Control-Mode Operation.................................................... 7-55

7.2.8 V elocity-Control Mode Operation .................................................... 7-60

7.2.9 Switch Velocity to Position Control................................................... 7-64

7.2.10 The Request to Decelerate and Stop .............................................. 7-66

7.2.11 Request to Stop Immediately .......................................................... 7-67

7.2.12 On-route Operation......................................................................... 7-68

7.2.13 Arc-Interpolation Operation............................................................. 7-71

7.2.14 Backlash-Correction Operation....................................................... 7-73

8. List of Error Codes ................................................................................. 8-1

9. External Contact Signals........................................................................ 9-1

9.1 Pulse Output (Line Driver) .............................................................................. 9-1

9.2 Pulse Output (Open-Collector)....................................................................... 9-3

9.3 External Contact Input.................................................................................... 9-5

9.4 Emergency Stop Input .................................................................................... 9-6

9.5 Encoder Input Z-phase ................................................................................... 9-7

10. Examples of Connections to Servo Driver s......................................... 10-1

10.1 Example of Connecting with Sanyo Denki’ s P-Series Driver

(Incremental Encoder Type).......................................................................... 10-1

Appendix ....................................................................................................Appx.-1

Revision Information ............................................................................................ i

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 13

Blank Page

Page 14

1. Overview

The Models F3NC11-0N and F3NC12-0N are advanced positioning modules (hereinafter

simply referred to as “the modules” or “positioning modules”) used to control servo drivers

and thereby the velocity and position of pulse-driven motors. Just one module can control

different types of motors/drivers, including uniaxial (F3NC11-0N module) and biaxial

(F3NC12-0N module) pulse and servo motors. When in use, the positioning modules are

attached to the base module of an FA-M3 controller. According to commands from the

CPU module of the FA-M3 controller, the positioning modules generate trajectories for

positioning and issue position-control commands in the form of pulse trains.

■ Features

- Provided with multi-axial simultaneous control capabilities. Driven by commands from

the CPU module, the modules can carry out smooth and versatile position control,

such as one based on multi-axial linear interpolation, velocity control, and control for

switching between the velocity- and position-control modes.

- Can quickly bring motor up to synchronous speed thanks to the shorter startup time (6

ms maximum) and operate motor in synchronization with peripheral equipment Allows

the “on-the-route” operation, and provides the capability of conditional control mode

selection using external triggers.

1-1

Host CPU

module

FA-M3 controller

Positioning module

Trajectory

generation

Pulse

output

Pulse

counter

Servo driver

Computing

for servo

position

control

Pulse

counter

Velocity

detector

Computing

for servo

speed

control

Motor

Encoder

F0101.EPS

Figure 1.1 Operating Principle of Positioning Module (with Pulse Output)

CAUTION

When connecting a servo motor to the positioning module, choose a position-control servo

driver. Velocity-control and torque-control servo drivers do not meet the needs of this

application.

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 15

Blank Page

Page 16

2. Specifications

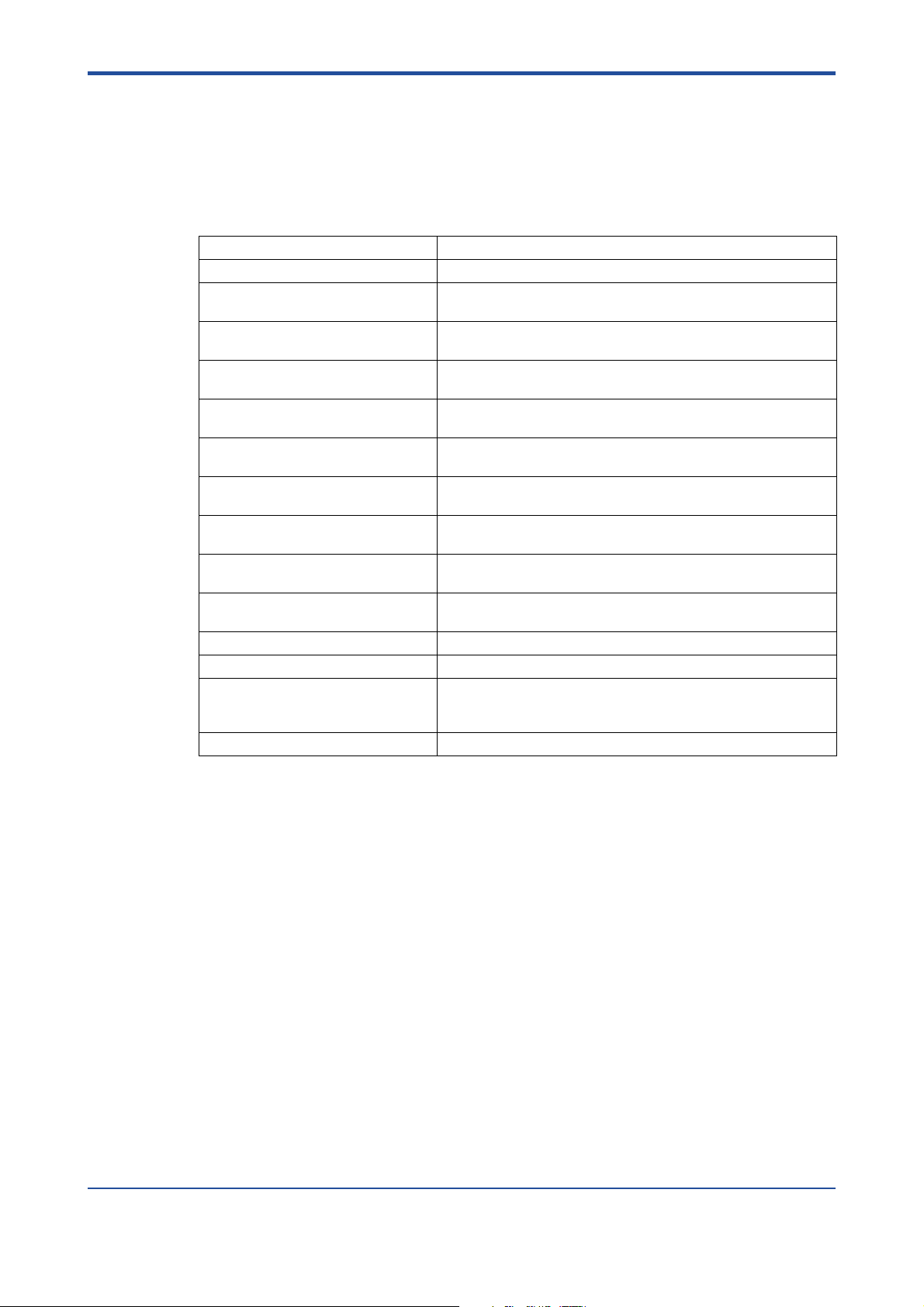

2.1 General Specifications

2-1

Item

Control

Control mode

Position

control

Velocity

control

Acceleration/

deceleration

Origin search

External contact input

Data backup

Startup time

Current consumption

External power supply

External wiring

External dimensions

Weight

Note: Excluding protrusions (see the external dimension diagram f or more details).

Method

Output pulse

Interpolation

method

Command position

in pulse count

Command speed in

pulse count per sec

Functionality

Command speed in

pulse count per sec

Functionality

Acceleration/

deceleration method

Acceleration/

deceleration time

Search method

Search speed

Open-loop control based on positioning pulse output

• RS422A-based differential output (249.75 kpps max.)

• Open-collector output

(The maximum available pulse rate is limited by such factors as the

load capacity. A maximum of 50 kpps is recommended.)

Position control, speed control, and control for switching between

position control and speed control modes

Axis-by-axis independent interpolation

Multiaxial linear interpolation (set from CPU module)

Biaxial arc interpolation (set from CPU module)

-8,388,608 to 8,388,608 pulses

0.1 to 249,750 pulses/s

On-the-route operation

Change in target position during operation

Change in speed during operation

-249,750 to 249,750 pulses/s

Change in velocity during operation

Trapezoidal tracking

0 to 32,767 ms each for acceleration/deceleration

User-definable by entering an origin setpoint, near-origin setpoint or

limit setpoint; the Z-phase of the encoder is available for this

purpose.

User-definable

LIMIT SWITCH, ORIGIN, NEAR-ORIGIN (external trigger), READY,

and EMERGENCY STOP contacts

By CPU module

6 ms max.

180 mA (5V DC)

5 V DC, 200 mA

40-pin connector (one unit)

28.9 (W) 3 100 (H) 3 83.2 (D) (mm) (Note)

100 g

F3NC11-0N F3NC12-0N

OneNumber of axes Two

Specifications

F0201.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 17

2.2 Operating Envir onment

No restrictions apply to CPU modules with which the positioning modules can be used.

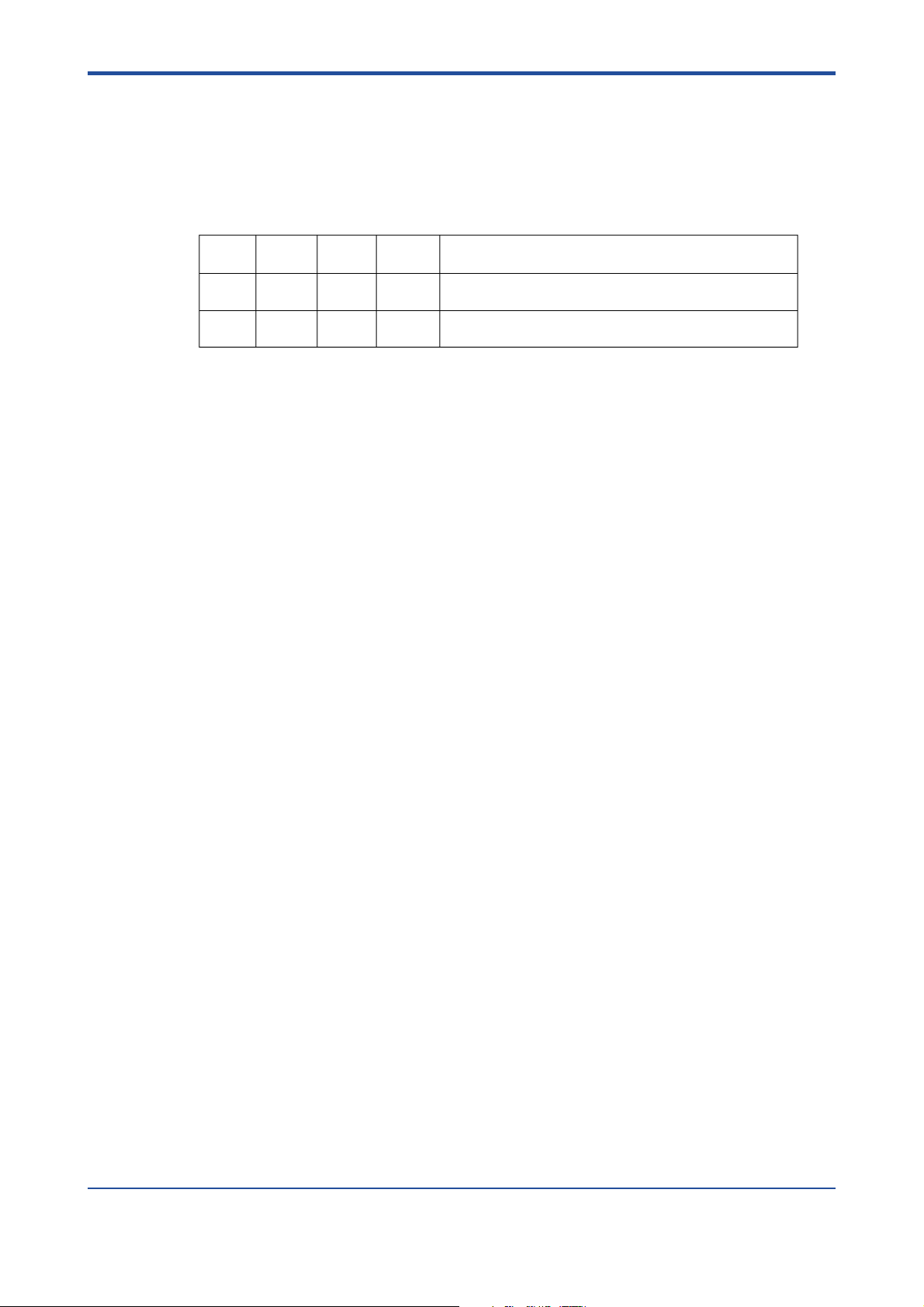

2.3 Model and Suffix Codes

2-2

Model

Code

F3NC11

F3NC12

Suffix

Code

-0N

-0N

Style

Code

. . .

. . .

Option

Code

. . .

. . .

Remarks

Uniaxial, advanced model with pulse-mode output for positioncontrol commands; maximum velocity of 249.75 kpps

Biaxial, advanced model with pulse-mode output for positioncontrol commands; maximum velocity of 249.75 kpps

F0203.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 18

2.4 Components

- F3NC11-0N module (uniaxial model)

2-3

B1S2Y

NC11-0N

RDY

34

POSIT

RDY indicator:

Remains lit when the internal circuitry is in normal operation.

Axis indicators:

Show the state of the axis as noted below:

"BSY" indicator: Remains lit when positioning is in progress.

"1 to 4" indicators: Light up if a given error or errors occur.

External I/O connector:

Connects to external I/O devices such as servo motors and

limit switches.

- F3NC12-0N module (biaxial model)

A

X

B

S

1

2

NC12-0N

RDY

1

Y

34

A

X

2

B

S

Y

1

2

34

POSIT

RDY indicator:

Remains lit when the internal circuitry is in normal operation.

AX1- and AX2-axis indicators:

Show the states of the respective axes as noted below:

"BSY" indicator: Remains lit when positioning is in progress.

"1 to 4" indicators: Light up if a given error or errors occur.

F0204_1.EPS

External I/O connector:

Connects to external I/O devices such as servo motors and

limit switches.

F0204_2.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 19

2.5 External Dimensions

2-4

Unit: mm

83.2 (3.27)

1.3 (0.05)

2 (0.08)

28.9 (1.14)

100

(3.94)

2.6 T erminal Assignments and Connection

A×2A×1

BA

20

20

19

19

18

18

17

17

16

16

15

15

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

External interface

connector

Pulse output B/line driver (-)

Pulse output B/line driver (+)

Pulse output A/line driver (-)

Pulse output A/line driver (+)

Pulse output B/open collector (-)

Pulse output B/open collector (+)

Pulse output A/open collector (-)

Pulse output A/open collector (+)

External power input/5 V DC (-)

External power input/5 V DC (+)

(Unused)

(EMERGENCY STOP)

Encoder input/Z-phase (-)

Encoder input/Z-phase (+)

READY

CCW limit input

CW limit input

NEAR-ORIGIN

ORIGIN

12–24V DC

Driver or external

switch

12–24V DC

12–24V DC

F0206.EPS

F0205.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 20

2.7 Applicable External Interface Connectors

Connection Applicable Connector Remarks

Soldered

Crimp-on

Pressure-welded

FCN-361J040-AU connector and FCN-360C040-B

connector cover (Fujitsu Limited)

FCN-363J040 housing, FCN-363J-AU contacts and

FCN-360C040-B connector cover (Fujitsu Limited)

FCN-367J040-AU/F connector (Fujitsu Limited)

Purchase the

desired connector

kit separately

when ordering the

positioning

module.

F0207.EPS

2-5

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 21

Blank Page

Page 22

3. Function Overview

This chapter explains the major functions of the positioning modules. F or details on ho w to

use each function, see Chapter 7. Table 3.1 summarizes the functions discussed in this

chapter.

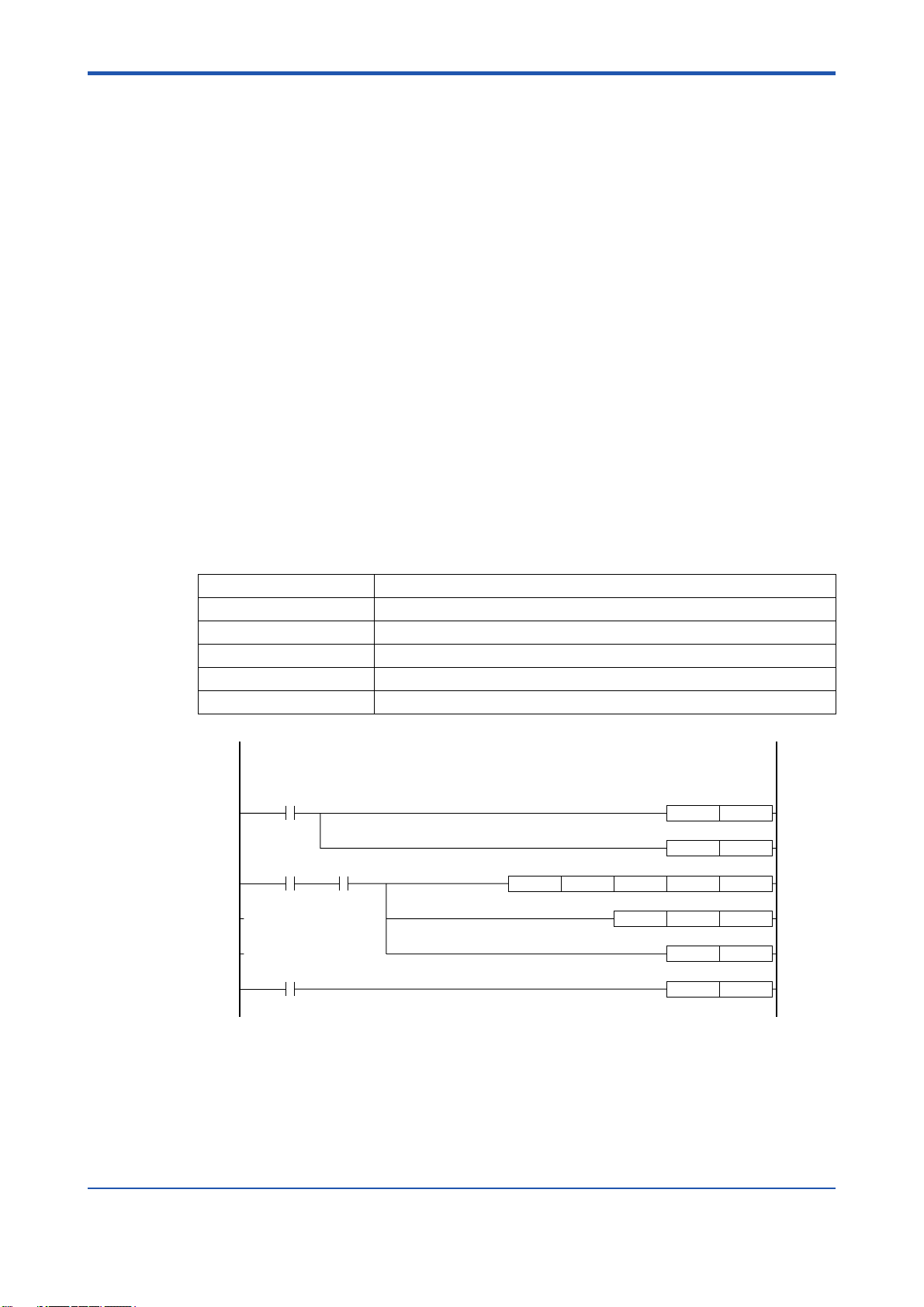

T able 3.1 Major Functions

Positioning operation

Change in target position during

positioning

Change in velocity during positioning

Carries out positioning in the normal position-control mode.

Changes the target position while positioning is in progress.

Changes the speed of rotation while positioning is in progress.

3-1

DescriptionMajor Function

Velocity control

Change in velocity during velocity

control

Velocity-to-position control mode

switching

Jog stepping

Emergency-stop input

Contact input

Z-phase encoder input

Origin-search operation

Linear-interpolated operation

On-route operation

Arc-interpolated operation

A function that works in the velocity-control mode. This

function keeps the motor rotating in the same direction.

Changes the speed of rotation while velocity control is in

progress.

Switches to position control while velocity control is in

progress.

Allows a motor to be rotated manually when, for example,

issuing positioning commands to the module.

Brings a motor to an immediate stop using an external contact

input.

Accepts such external contact signals as a limit-switch signal

or an ORIGIN contact signal.

Accepts a Z-phase encoder signal used to search for the

origin.

Searches for the origin using an external contact input.

Carries out multiaxial, linear-interpolated operation.

Carries out on-route operation (path operation) in which the

tracking path under control passes by the vicinity of a given

target position.

Carries out biaxial, arc-interpolated operation.

T0301.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 23

3.1 Positioning Operation

To initiate the positioning operation:

- first write the target velocity, target position, acceleration time, deceleration time and

other necessary parameters from the CPU module, and then

- change the state of the output relay defined as “Start Operation Command” from OFF

to ON.

When the positioning operation is complete, the input relay defined as “End of Positioning”

changes to the ON state. The trace of the acceleration/deceleration curve is trapezoidal,

where the acceleration/deceleration times are set separately.

3-2

Figure 3.1 Velocities and Acceleration/Deceleration Times in Trapezoidal and Trigonometric Drives

Figure 3.2 Comparison of Theoretical and Actual Behaviors of a Motor in Position Control

Figure 3.3 Acceleration/Deceleration Times Where Starting Velocity Is Set

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 24

3.2 Change in Target P osition during P ositioning

To change the target position using the module:

- first write the parameters necessary for another positioning operation, and then

- change the state of the output rela y defined as “Request to Change Target Position”

from OFF to ON while the positioning operation is in progress.

The speed of rotation can also be changed at the same time you change the target position. The module is also able to change the target position when the direction in which the

motor rotates changes. (In that application, the module quickly slo ws down the motor to a

complete stop and enters the positioning operation where it searches for a new target

position.)

3-3

Velocity

Start

command

Time

Request to change

target position

Case Where Direction of Rotation

Does Not Change

Figure 3.4 Behaviors When the Target Position Is Changed

Velocity

Start

command

Request to change

target position

Case Where Direction of Rotation

Changes

Time

F0304.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 25

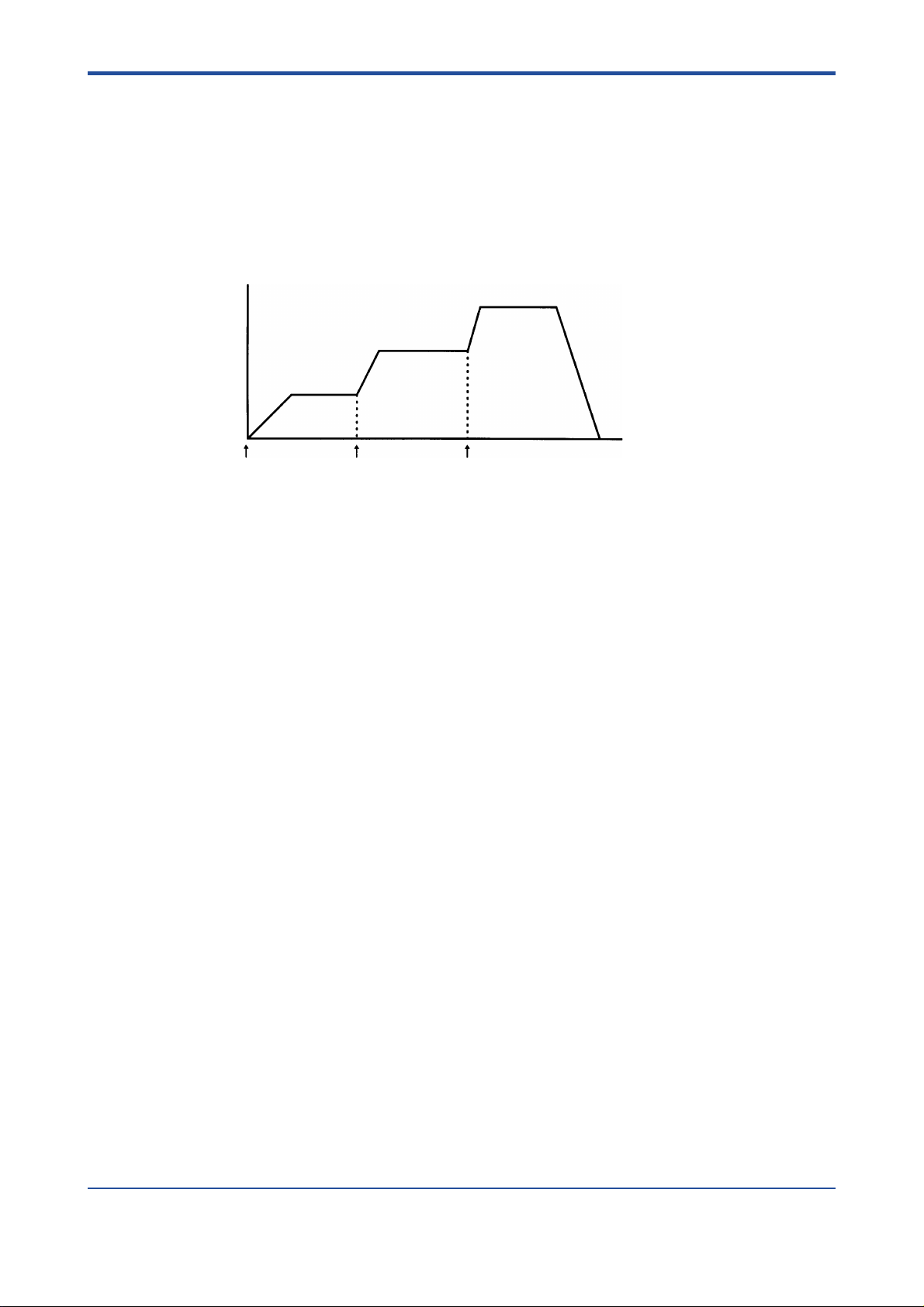

3.3 Change in V elocity during P ositioning

To change the velocity using the module, you must:

- first write the new target v elocity and other necessary parameters, and then

- change the state of the output rela y defined as “Request to Change Velocity” from

OFF to ON

while the positioning operation is in progress:

Velocity

3-4

Startup

Request to

change velocity

Figure 3.5 Behaviors When the Velocity Is Changed

Request to

change velocity

Time

F0305.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 26

3.4 V elocity Control

To initiate the velocity-control operation:

- first write the v elocity setpoint (a value with the min us sign if rotating the motor in the

negative direction), acceleration time, deceleration time and other necessary parameters from the CPU module, and then

- change the state of the output rela y defined as “Start Operation Command” from OFF

to ON.

The velocity-control operation continues until the output rela y defined as “Request to

Decelerate and Stop” or “Request to Stop Immediately” is turned on.

The trace of the acceleration/deceleration curve is trapezoidal, where the acceleration/

deceleration times are set separately.

3-5

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 27

3.5 Change in V elocity during V elocity Contr ol

To change the velocity using the module you must:

- first write the new target v elocity, and then

- change the state of the output rela y defined as “Request to Change Velocity” from

OFF to ON

while the velocity-control operation is in progress.

The change-in-velocity operation does not allow y ou to change the velocity in such a

manner that the direction in which the motor rotates changes. To change the direction, you

must first decelerate and stop the motor and then initiate the velocity-control operation after

setting a new target velocity.

Velocity

3-6

Startup

Request to

change velocity

Figure 3.6 V elocity Contr ol and Change-in-V elocity Operation

Request to

change velocity

Request to

change velocity

Time

Request to

decelerate and stop

F0306.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 28

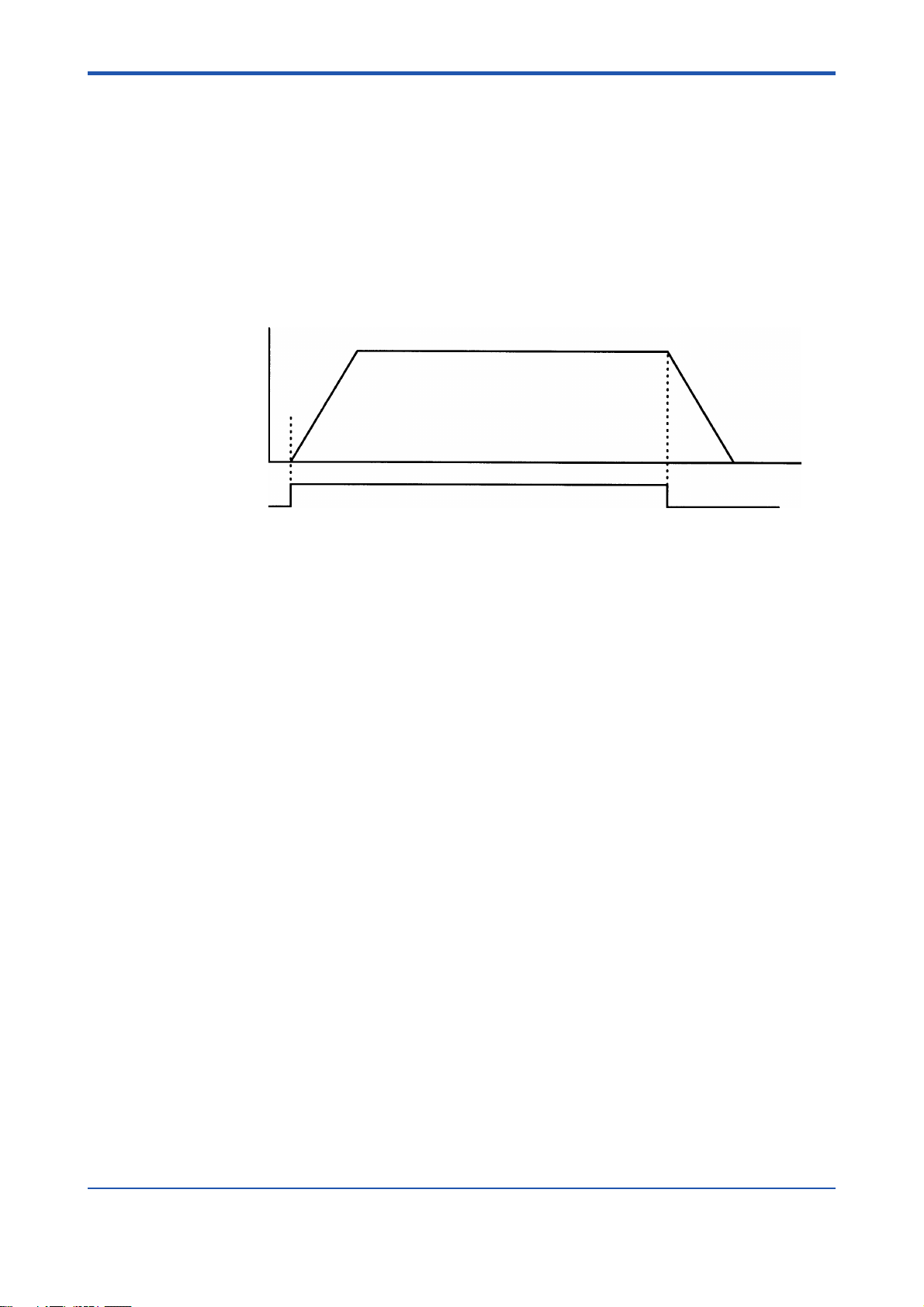

3.6 Velocity-to-Position Control Mode Switching

The module switches to position control while it is in the velocity-control operation and

enters the positioning operation where the position at which the switch was made is set as

“0.” This action takes place while velocity-control operation is in progress and requires you

to:

- first write the target velocity, target position, acceleration time, deceleration time and

other necessary parameters from the CPU module, and then

- change the control mode from velocity control to position control.

The trace of the acceleration/deceleration curve is trapezoidal, where the acceleration/

deceleration times are set separately.

In addition to the normal switching (where switching takes place immediately after the given

command is executed), you can set such a switching mode in which the module waits for

an external trigger before it switches to position control. To switch to position control after

detecting a Z-phase input signal, specify the polarity of the Z-phase, as well as the frequency of Z-phase pulse counting.

Case where no Z-phase pulse counting is specified

Velocity

3-7

Target position (travel)

Startup

Case where Z-phase pulse counting is specified (twice during the rise time)

Velocity

Target position (travel)

Startup

Request to switch to

position control

Z-phase

signal

Figure 3.7 Behaviors When Switching from Velocity Control to Position Control

Time

Time

F0307.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 29

3.7 Jog Stepping

To carry out jog stepping:

- first write the target velocity, acceleration time, deceleration time and other necessary

parameters from the CPU module, and then

- change the state of the output relay defined as “Positive-direction Jog Stepping” or

“Negative-direction Jog Stepping” from OFF to ON.

To quit the jog-stepping operation, change the ON-state output relay to an OFF state.

Velocity

Start

Positive-direction

jog stepping

3-8

End

Time

F0308.EPS

Figure 3.8 Jog-stepping Operation (Positive Direction)

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 30

3.8 Emergency-stop Input

The positioning module has one emergency-stop input common to the uniaxial and biaxial

models. The input is designed f or e xclusive use as a type-b contact input. Be SURE to wire

the input when using the module. If the input is left open, the module does not operate at

all. You can read the state of the emergency-stop input like you read the states of other

contact inputs.

3-9

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 31

3.9 Contact Inputs

The positioning module has five external contact inputs defined as “POSITIVE-DIRECTION

LIMIT,” “NEGA TIVE-DIRECTION LIMIT, ” “ORIGIN,” “NEAR-ORIGIN” (e xternal trigger) and

“READY,” separately for both the uniaxial and biaxial models.

You can read the state of each contact input using an application program. In addition, you

can set the polarity of each contact input separately .

3-10

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 32

3.10 Z-phase Encoder Input

For the improv ed repeatability of origin searches, you can use the Z-phase encoder input.

You can read the state of the encoder input like you read the states of the contact inputs.

Likewise, y ou can set the polarity of the encoder input like you set the polarities of the

contact inputs.

3-11

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 33

3.11 Origin-search Operation

To start an origin search:

- first write the direction of the search, the search v elocity, the type of operation when an

external contact input is detected (origin-search mode), the direction of the edge for

detecting the Z-phase, and other necessary parameters, and then

- change the state of the output rela y defined as “Origin Search” from OFF to ON.

If the positioning module detects a change in the state of a preset external contact input

after the start of an origin-search operation, the module either stops the motor or checks

the Z-phase, depending on the setting of the contact input. When checking the Z-phase ,

the module detects the preset Z-phase pulse count and stops the motor immediately,

defining the position where the motor has stopped as the origin. F or this reason, if a servo

motor is used, the position where the motor actually stops is off from where the origin was

detected by as much as a distance equivalent to the offset pulse count (diff erence between

the pulse counts of a momentary command position and a current motor position) given

during an origin-search operation.

There is an application in which an origin search is carried out at two different speeds or a

change is made to the direction of rotation while checking for an e xternal contact input

during an origin search. In that case, split the origin search process into se ver al cycles

while varying parameters for each cycle, and do the searches separately. This strategy

enables you to customize y our origin-search operation to conduct searches using your

desired search patterns.

3-12

CAUTION

An offset in the origin due to an offset pulse count becomes greater as the velocity of origin

search becomes higher.

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 34

3.12 Linear-interpolated Operation

To carry out a linear-interpolated operation:

- first write the target v elocity, target position, acceleration time, deceleration time and

other necessary parameters for each axis from the CPU module, and then

- change the state of the output rela y defined as “Start Operation Command” from OFF

to ON for both axes sim ultaneously.

When the positioning operation for each axis is complete, the input rela y defined as “End of

Positioning” for each axis changes to the ON state.

In this operation, set the same acceleration and deceleration times for both ax es that are

brought into linear-interpolated operation. Calculate and set the ratio between the target

velocities of the two ax es so it equals the ratio between their respectiv e trav els .

3-13

Velocity

X-axis travel

Y-axis travel

Acceleration time Deceleration time

Figure 3.9 Multiaxial Linear-interpolated Operation (Example of Biaxial Application)

X-axis speed setpoint

Y-axis speed setpoint

Time

Y-axis

Y-axis travel

X-axis travel

X-axis

F0309.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 35

3.13 On-Route Operation

If you initiate another positioning operation while the current positioning operation is in

progress, the positioning module begins the new operation before the current operation

ends. The module therefore carries out a combination of these two operations until the

current operation ends. This mode of positioning operation is referred to as an on-route

operation. The interval at which the two operations overlap is called the on-route interval.

Using the on-route operation, you can continue your position finding toward the new target

position without stopping at the target position set for the current positioning operation. It is

also possible to define a mode of on-route operation where the direction of rotation may be

changed.

• Normal positioning operation

X-axis velocity

3-14

Startup Startup

• On-route operation

On-route

X-axis velocity

Startup Startup Startup

• Example of on-route operation in biaxial linear-interpolated operation

Y-axis

interval

On-route

interval

Time

Time

X-axis

Figure 3.10 Normal Position-finding Operation and On-Route Operation

F0310.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 36

3.14 Arc-interpolated Operation

The biaxial arc-interpolated operation can be implemented by converting a positioning

command from the CPU module into a trigonometric function within the positioning module.

To bring the positioning module into arc-interpolated operation:

- first define the center of the X-Y plane , radius, starting angle, angular tra vel and other

necessary parameters from the CPU module, and then

- change the state of the output rela y defined as “Start Operation Command” from OFF

to ON.

Y-axis

Angular travel (270°)

Y-axis radius

3-15

Path for arc interpolation

Y-axis center

Starting positionTarget position

X-axis center

Figure 3.11 Arc-interpolated Operation

Zero-angle direction

Starting angle

(-45° [or 315°])

X-axis radius

X-axis

F0311.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 37

Blank Page

Page 38

4. Parameters

4.1 List of Parameters

Among the parameters listed in Figures 4.2 through 4.6, the ones with two data position

numbers are two-word data. The data with the smaller numbers are low-order words, and

those with the larger numbers are high-order words. Data position numbers are specified

for each word. The WRITE and READ instructions used for accessing from a sequence

program must be on word-basis. Long-word based instructions cause inappropriate access.

You should also use word-based instructions when you access from BASIC programs.

Data whose setting units are [(1/65536) pulses/ms], [(1/65536) degrees], or [(1/65536)

degrees/ms] (

bits) and 1 decimal part-word (16 bits). The data with the smaller numbers are low-order

words, and those with the larger numbers are high-order words.

Fixed-point data

The digits in the integer part of the binary data are sequentially defined as 1, 2, 4 ... , and

the digits in the decimal part are defined as 1/2, 1/4, 1/8, and so forth. If both the integer

part and the decimal part consist of 16 bits, the least significant bit is 1/65536, which means

that it is a 32 bit (long-word) datum whose setting unit is 1/65536. Negative numbers are

expressed as complements of 2 like ordinary binary data.

1 in Tables 4.2 through 4.6) are fixed point data with 1 integer part-word (16

*

4-1

Tabl e 4. 1

Bit

Value

31 (MSB)

Sign bit

30

16384

High-order word Low-order word

. . .

. . .

17216115

1/2141/4

. . .

. . .

1

1/32768

0 (LSB)

1/65536

T0401.EPS

[Example of fixed point data]

When setting 123.45 [pulses/ms] (=123450 [pulses/sec]),

123.45x65536 = 8090419.2 [(1/65536) pulses/ms]

Thus, we should set 8090419 as a long-word data. The high-order word of this data is 123

since 8090419 / 65536 = 123. The low-order word is the remainder, i.e., 29491.

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 39

4-2

(Reference)

An example of sequence programs which convert data in [pulses/s] into data to used for

setting a positioning module

Let D0001 (long-word data) be the original data (pulses/s).

(1) Divide D0001 by 1000 (long-word division) and put the result into D0011. In this case,

since the maximum value of D0001 is 249750 (249.75 kpps) and it is positive, the

maximum value of the result is 249 and thus the high-order word (D0012) is always 0.

The low-order word of the result of the division (D0011) is the high-order word (the

integer part which is 16 bits long) of the value [(1/65536) pulses/ms] to be calculated.

The remainder is put into D0013 (the low-order word) and D0014 (the high-order

word). Since the maximum value of the remainder is 999 because the divisor is 1000,

the high-order word of the remainder (D0014) is always 0.

(2) Then, multiply the remainder by 65536 and divide it again by 1000. A useful trick here

is this: the remainder in D0013 and D0012 is 0; thus, if we treat D0012 as long-word

data, its value is already the result of multiplication of the remainder by 65536. (D0012

as lower-order word, D0013 as high-order word.) Therefore, in order to divide the

result of multiplication of the remainder by 65536 by 1000, all we have to do is divide

D0012 by 1000 (long-word division). Put the result of this division into D0021.

D0012 (long word) is 999*65536 at a maximum, and it is divided by 1000 is 65470 at

maximum and high-order word (D0022) and always becomes 0. Thus D0021 is the

value [(1/65536) pulse/ms] of low-order word (the decimal part of 16 bits) and the

remainder will be discarded as truncation.

(3) Now, we are going to combine the operation results D0011 and D0021 calculated in

(1) and (2) above into a long word data [(1/65536) pulses/ms]. To do this, we only have

to do long-word division twice and transfer the resulting high-order word and low-order

word individually to the area (D0032, D0031). D0011-D0014 and D0021-D0024 are

the work areas.

(1) Long-word division

D0011 D0001 / 1000

Operation results

D0014

0

=

D0013

Remainder

D0012

0

D0011

High-order of

[(1/65536) pulses/ms]

(2) Long-word division

D0021 = D0012 / 1000

Operation results

D0024

0

D0023

Remainder

D0022

0

D0021

Low-order of

[(1/65536) pulses/ms]

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 40

MOV D0011 D0032

MOV D0021 D0031

Operation results

D0032

High-order of [(1/65536)]

pulses/ms

in the case of 123450 [pulses/s]

*

D0031

Low-order of

[(1/65536) pulses/ms]

(1) D0011 = 123450/1000 (long-word division)

4-3

D0014

0

D0013

450

29491200 (450*65536)

D0012

0

D0011

123

(2) D0021 = 29491200/1000 (long word division)

D0024

0

D0023

200

D0022

0

D0021

29491

The high-order word of the [1/65536) pulses/ms] data is 123, and the low-order word is

29491.

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 41

4.1.1 Registered parameters

Entry parameters are usually set only once after turning the power on. You can set them by

writing from the CPU module and then executing the Set Parameter command.

Table 4.2 Registered parameters

4-4

Data Position Number

Axis 1 Axis 2

030/031 230/231 Positive-direction Limit Value 0 to 8388608 [pulses]

032/033 232/233 Negative-direction Limit Value -8388608 to 0 [pulses]

034/035 234/234 Velocity Limit Value 0 to 16367616 [1/65536) pulses/ms]

036 236 Rotation Direction

037 237 Pulse Output Mode

038 238 Contact Input Polarity Specified for each point as a bit

Parameter Name Setup Range

0: CW pulse in positive direction

1: CW pulse in negative direction

0: Pulse and direction signal

1: CW pulse and CCW pulse

4.1.2 Operation Parameters

Operation parameters are referred to when starting operations like position control or

velocity control. These parameters do not have initial values. It is necessary to write all the

required parameters when executing a command.

(1) In Position Control Mode (excluding Arc Interpolation)

Table 4.3 Position Control Mode Operation Parameters (excluding arc interpolation)

1

*

T0402.EPS

Data Position Number

Axis 1 Axis 2

001 to 008 001 to 008

009/010 209/210

011/012 211/212 Target velocity -16367616 to 16367616 [(1/65536) pulses/ms]

013 213 Acceleration Time 0 to 32767 [ms]

014 214 Deceleration Time 0 to 32767 [ms]

015 215 (not used)

016/017 216/217 Target Position

018 218 Interpolation Mode 0

019 219 Control Mode Switching Parameter Set by a bit pattern

(not used)

Initial velocity 0 to 16367616 [(1/65536) pulses/ms]

Parameter Name Setup Range

-8388608 to 8388608 [pulses]

1

*

1

*

T0403.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 42

(2) In Velocity Control Mode

Table 4.4 Velocity Control Mode Operation Parameters

4-5

Data Position Number

Axis 1 Axis 2

001 to 008 201 to 208

009/010 209/210 Initial Velocity 0 to 16367616 [(1/65536) pulses/ms]

011/012 211/212 Target Velocity -16367616 to 16367616 [(1/65536) pulses/ms]

013 213 Acceleration Time 0 to 32767 [ms]

014 214 Deceleration Time 0 to 32767 [ms]

015 215 Time Interval for Velocity Change Time 0 to 32767 [ms]

016 to 018 216 to 218

019 219

(not used)

(not used)

Control Mode Switching Parameter Set by a bit pattern

Parameter Name Setup Range

1

*

(3) In Position Control Mode (Arc Interpolation)

Table 4.5 Position Control Mode (Arc Interpolation) Operation Parameters

Data Position Number

Axis 1 Axis 2

001/002 201/202 Center Position -8388608 to 8388608 [pulses]

003/004 203/204 Radius 1 to 8388608 [pulses]

005/006 205/206 Starting Angle

007/008 207/208 Angular Travel

009/010 209/210 Starting Angular Velocity

011/012 211/212 Angular Velocity Setpoint

013 213 Acceleration Time 0 to 32767 [ms]

014 214 Deceleration Time 0 to 32767 [ms]

015 215 (not used)

016/017 216/217 Target Position -8388608 to 8388608 [pulses]

018 218 Interpolation Mode 1: X Axis 2: Y Axis

2: If the set range is beyond the limits specified, the module will not operate correctly.

*

Parameter Name Setup Range

-23592960 to 23592960 [(1/65536) degrees]

(-360 to 360 [degrees])

-2123366400 to 2123366400 [(1/65536) degrees]

(-90 to 90 [rotation])

0 to 23592960 [(1/65536) degrees/ms]

360 [degrees])

0 to 23592960 [(1/65536) degrees/ms]

[degrees])

*1*

*1*

1

*

T0404.EPS

1

*

1

*

2 ( up to

2 ( to 360

T0405.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 43

4.1.3 Common Parameters

Common parameters are referred to when starting special operations like backlash correction or origin-search. These parameters do not have initial values. It is necessary to write all

the required parameters when executing the commands.

Table 4.6

4-6

Data Position Number

Axis 1 Axis 2

020 220 Origin-Search Mode Set by a bit pattern

021 221 Origin-Search Direction 0: negative direction 1: positive direction

022 222 Z-phase Edge Selection 0: OFF to ON edge 1: ON to OFF edge

023 223 Z-phase Pulse Count 0 to 32767 [times]

024/025 224/225 Z-phase Search Range 0 to 8388608 [pulses]

026/027 226/227 Backlash Correction Value -8388608 to 8388608 [pulses]

028/029 228/229 Backlash Correction velocity 0 to 16367616 [(1/65536) pulses/ms]

Parameter Name Setup Range

*

1

T0406.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 44

4-7

4.2 List of Required Parameters for each Command

To execute a command for the positioning module from the CPU module, it is necessary to

write all the required parameters in advance.

The list below shows the required parameters for each command.

The Set Parameter command is not included in this list because it changes all the entry

parameters.

● Mandatory parameters.

: Parameters which are required or not depending on the values of other parameters.

- : Non-required parameters (have no effect on the operation of the commands).

Table 4.7 List of Required Parameters for Each Command

Command name (output relay name)

→ velocity control)

Parameter name

→ position control)

Center position

Radius

Starting angle

Angular travel

Initial (angular velocity)

Target velocity (angular velocity)

Acceleration time

Deceleration time

Time interval for velocity change

Target position

Interpolation mode

Control mode switching para.

Origin position search mode

Origin position search direction

Z-phase edge selection

Z-phase pulse count number

Z-phase search area

Backlash correction value

Backlash correction speed

Start operation command

(in position control made)

Start operation command

(in velocity control mode)

Start operation command

(in arc-interpolated operation)

-

-

-

-

-

-

-

-

●

●

●

●

●●

●

●

-

-

●

-

-

●

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

●

-

●

-

●

●

-

-

●

●

-

●

-

●

-

-

-

●

-

●

-

●

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Request to switch control mode

(position control

Request to switch control mode

(velocity control

Start origin search

Backlash correction

Request to change target pos.

Request to change velocity

(during position control operat.)

Request to change velocity

(during velocity control oper.)

Request to change velocity

during arc interpolation

Positive-direction Jog stepping

Negative-direction Jog stepping

Write current position

Request to decelerate & stop

Request to stop Immediately

Error reset

-

-

-

-

----

-

-

●

●

●

●

●

●●

●

●

-

-

-

●

-

-

●

-

-

●

●

-

-

-

--

-

-

-

-

-

-

-

-

-

●

-

●●●

-

-

●

-

-

-

●

-

-

-

-

-

-

-

-

-

-

--

-

-

-

●

-

●

--

-

-

--

--

●-●

-

-

-

●

-

-

---

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

--

-

---

-

--

-

--

-

●

●

-

-

-

●

-

-

-

●

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

T0407.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 45

4.3 Description of Parameters

4.3.1 Entry parameters

When the power is switched on, all entry parameters are cleared. Please set all entry

parameters using the Set Parameter command in a application program. When the parameter value set is invalid, data error results. When this happens, execute Error Reset and

execute the Set Parameter command again with the valid values.

Table 4.8 Entry parameters

Parameter Type: Setting Content: Data Range: Remarks:

Positive-direction

Limit Value

Negativedirection Limit

Value

Velocity Limit

Value

Rotation

Direction

Control Output

Mode

Sets the operation

limit position in

positive/negative

direction as the

number of pulses

from the origin.

Sets the limit of

the target velocity

Sets the relation

between the

positive and

negative signs of

the position and

the direction of the

pulse output from

the CPU module

Sets the mode of

the position

command pulse

output.

0 to 8388608 [pulses]

-8388608 to 0 [pulses]

0 to 16367616 [(1/65536) pulse/ms] If you start the system after

0: CW pulse in the positive direction

1: CW pulse in the negative direction

0: pulse-and-direction signal 1: CW pulse and

CCW pulse. In the pulse-and-direction signal

mode, pulse output A is the pulse and B is the

polarity signal. In the CW pulse and CCW pulse

mode, pulse output A is the CCW pulse and B is

the CW pulse.

If the origin search is not

executed, then the position at

the moment when the main

switch was turned on is

defined as the origin. When

these limits are exceeded, an

error results. If you start the

system after setting a target

position beyond this range,

an error results and the motor

does not start. The detection

of the limit values in both

directions is not performed

during origin-search or in

velocity control mode. (Error

does not occur.)

setting a velocity beyond this

range, an error results and

the motor does not start.

During an operation (e.g. arcinterpolated operation), if this

value is exceeded, an error

results.

The direction of the operation

(positive or negative) is

defined by the direction of the

position set from the CPU

module.

4-8

Contact Input

Polarity

Defines the logic

of the external

contact input and

the Z-phase input.

Specified for each point as a bit. "0" indicates

an "a" contact "a" and "1" indicates a "b"

contact.

15- -543210

x----XXXXXX

Origin Input

Near-origin Input

(External Trigger Input

Positive-direction limit Input

Negative-direction limit Input

Ready Input

Z-phase Encoder Input

a" contact input is an input

which is effective when signal

input exists, and "b" contact

input is an input which is

effective without signal input.

For example, a "limit input of

'b' contact" detects a limit

when there is no signal input,

but does not detect a limit

when signal input exists.

T0408.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 46

4.3.2 Operation Parameters

Table 4.9 Operation Parameters

Parameter Type: Setting Cantact: Data Range: Remarks:

Center Position

Radius Refer to the section for arc-

Starting Angle Refer to the section for arc-

Angular Travel Refer to the section for arc-

Starting Velocity

Starting Angular

Velocity

Target velocity Sets operation velocity in

Setting Angular

Velocity

Acceleration Time Sets the time it takes to reach the

Deceleration Time Set the time from target velocity

Time Interval for

velocity change

Target Position Set the target position for the

Interpolation Mode Be sure to set [0] for usual

Control Mode

Switching

parameter

Refer to the section for arcinterpolation

interpolation

interpolation

interpolation

This is the starting velocity of the

operation at the start of the

positioning operation and the

velocity just before stopping at

end of positioning. When using, a

pulse motor and accelerating

from velocity [0], at the low

velocity portion during

acceleration, resonance may

occur resulting in detachment.

(same as in deceleration). Set a

velocity faster than the resonance

point to prevent this from

happening. When using a servo

motor, it is normally set to [0].

Position Control and Velocity

Control mode. For arc

interpolation, refer to the section

on arc-interpolation.

target velocity from the starting

Velocity at operation startup

to Decelerate and Stop.

Set the acceleration

(deceleration) time from the

preset speed to the new velocity

during execution of the Change

Velocity command in Velocity

Control mode.

positioning operation. For arcinterpolation, refer to the section

on arc-interpolation.

positioning operation in position

control mode, For arc

interpolation, refer to the section

on arc-interpolation.

This is referred during execution

of Switch Control Mode

command. It sets the mode or

conditions for switching.

-8388608 to 8388608 [pulses]

1 to 8388608 [pulses]

-23592960 to 23592960 [(1/65536) degrees]

(-360 to 360 [degrees])

-2123366400 to 2123366400

[(1/65536) degrees] (-90 to 90 [rotation])

0 to 16367616 [(1/65536) pulses/ms]

0 to 23592960 [(1/65536) degrees/ms]

(up to 360 [degrees])*1

0to 16367616 [(1/65536) pulses/ms]

(in position control mode)

-16367616 to 16367616 [(1/65536) pulses/ms]

(in velocity control mode)

0 to 23592960 [(1/65536) degrees/ms]

(to 360 [degrees])*1

0 to 32767 [ms] In target point change and

0 to 32767 [ms]

0 to 32767 [ms]

-8388708 to 8388608 [pulses]

0: normal operation

1: Arc Interpolation X axis

2: Arc Interpolation Y axis

Specified by bit pattern

15 down to 10

x-xx

• Waiting for external contract input

(during Velocity Control to Position

Control Switching)

• waiting for Z-phase encoder input

(during Velocity Control to Position

Control switching)

When using this parameter,

parameter values that are too

large may cause deregulation

at startup or stop because of

impact. Therefore, take care.

Setting starting velocity is

also possible in arcinterpolation. However, when

reversing the operation

direction in this case, each

axis decelerates/accelerates

slowly to velocity [0], so it is

less effective at preventing

deregulation of the pulse

motor.

If the value of the target velocity

(angular velocity) specified is

smaller than the starting

velocity (angular velocity), the

operation is performed with

target velocity [0]. Normally, set

a value larger than the starting

velocity (angular velocity).

velocity change, it has

different meaning. Refer to

the explanations of each

command for details

Set [0] for switching to

velocity control mode and

either [$8000], [$8001],

[$8002], or [$8003] for

switching to positioning

control depending on the

conditions for switching.

4-9

• 0: Position Control to Velocity Control

switching

1: Velocity Control to Position Control

switching

T0409.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 47

■ About Arc Interpolation

At positioning startup, when you specify the Arc Interpolation X Axis or the Arc Interpolation

Y Axis in "Interpolation Mode", arc-interpolated positioning is performed. The positioning

module generates the following command position and operates in the following way.

Note:

The X axis and Y axis which perform the arc interpolation are not related to axis 1 and axis

2 of the positioning module. It is not necessary that the X axis and Y axis are in the same

positioning module.

The trajectory of the arc interpolation is generated by:

X axis Center Position + Radius × COS (Starting Angle + Angular Velocity Set point × Time)

Y axis Center Position + Radius × SIN (Starting Angle + Angular Velocity Set point × Time)

When (Angular velocity Setpoint × time) is equal to Angular Travel, the operation ends. If

Acceleration Time and Deceleration Time are both 0, the actual path is the same as the one

defined by the above formulas. Otherwise, as Angular Velocity increases / decreases with

time, the term (Angular Speed Setpoint

the basic idea is the same. In the case of arc interpolation, Acceleration Time is the time

interval in which the angular velocity changes from 0 to Angular Velocity Setpoint when

starting, Deceleration Time is the time interval in which the angular velocity changes from

Angular Velocity Setpoint to 0 when stopping.

4-10

×

time) is not the same as that in the formulas. But

The arc interpolation operation is realized by setting the parameters to X axis and Y axis

independently , and then starting them simultaneously. So, it is necessary to specify the

same value on both axes for Starting Angle, Angular Travel, Angular Velocity Setpoint,

Acceleration Time and Deceleration Time.

Here “Angle” is defined in the X-Y plane with the positive part of the X axis as 0 degree ,

and to increase in the counterclockwise direction. For example, the positive part of the Y

axis is 90 degrees, and the negative part of the X axis is 180 degrees.

In the following, we will explain the case for X axis. For Y axis, change COS to SIN.

When the system starts, in the positioning module, the starting position of the arc interpolation operation can be computed using the above formulae with Time set as 0, that is,

Center Position + Radius

This position must coincide with the current position of the axis when starting the system.

(Set the parameters so that the above condition is satisfied.) If not, the positioning module

outputs the difference pulses at once when starting the system. If the velocity of the output

pulses exceeds the velocity limit value, an error occurs.

The position where the arc interpolation operation ends is calculated with the following

formula:

Center Position + Radius

Thus, this position must coincide with Target Position. (Set the parameters so that the

above condition is satisfied.) If not, the positioning module outputs the difference pulses at

once when the arc-interpolation operation ends. If the Velocity of the output pulses exceeds

the velocity limit value, an error occurs.

×

COS (Starting Angle).

×

COS (Starting Angle + Angular Travel)

Note: When starting the operation, the difference pulses at the end of the operation are all

output within 2 ms.

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 48

Y-axis

Angular travel (270°)

Y-axis radius

Y-axis center

X-axis center position

Figure 4.1 Arc-Interpolated Operation

4-11

Path for arc interpolation

Zero-angle direction

Starting angle

(-45° [315°])

Starting positionTarget position

X-axis radius

X-axis

F0401.EPS

CAUTION

The X axis and Y axis move independently also when performing arc interpolation. So

when an error occurs at one axis, the other axis continues moving. If it is necessary to stop

the other axis, stop the motor by applying the immediate stop command to the moving axis

after detecting the error with an application program (and checking the input relay labeled

“Error Notification”).

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 49

4.3.3 Common Parameters

Table 4.10 Common Parameters

Parameter Type Data Range Setting Contents Remarks

Origin-search Mode Sets the motion of the motor for each

contact input after detecting the edges

of each contact input during originsearch using bit patterns. For details,

refer to "3.11, "Origin-search

Operation."

Origin-search Direction

Sets the motor rotation direction

during origin-search.

Z-phase Edge Selection Sets the polarity of the Z-phase input

when detecting Z-phase during originsearch or during speed to position

control switching.

Z-phase Pulse Count Sets which nth Z-phase is effective

when detecting Z-phase during originsearch or during speed to position

control switching.

Z-phase Search Range Error occurs if the Z-phase cannot be

detected after operating the number

of pulses which was set by this

parameter when detecting Z-phase

during origin-search or during speed

to position control switch.

Backlash Correction Value

This is used to correct the backlash

between the motor shaft and the

Backlash Correction

moving parts (looseness of gears,

etc.).

Set using bit pattern

of the data.

0: negative direction

1: positive direction

0: OFF to ON edge

1: ON to OFF edge

0 to 32767 [times]

0 to 8388608 [pulses] This parameter is used to

prevent continued operation

of the motor when Z-phase

cannot be detected

because of Z-phase signal

disconnection, etc. Usually,

this is set close to the

period of the Z-phase.

-8388608 to 8388608

[pulses]

0 to 16367616

[(1/65536) pulses/ms]

When executing backlash

correction, outputs the

backlash correction value

pulse at the backlash

correction without changing

the current position status.

In this case, there is no

acceleration and

deceleration. Refer to

Figure 4.2, "Execution

Example of Backlash

Correction."

4-12

T0410.EPS

Velocity

Backlash correction

Execution

Startup

Backlash correction velocity

Backlash correction Value

Figure 4.2 Backlash Correction Execution Example

Startup

Time

F0402.EPS

IM 34M6H57-01E 2nd Edition : July, 2001-00

Page 50

4.4 Entry Parameters Setting Example

The following example shows the minimum setting of the entry parameters for controlling

the motor using the positioning module. The underlined values are set.

■ The motor used

Rated number of revolutions: 3000 rpm

Encoder pulse count: 8192 pulses/rotation

CAUTION

You can set and change the ratio of the command pulses and encoder pulses on the servo

driver side. In these cases, the parameters set in the positioning module must match the

setting of the servo driver. So calculate the values of the entry parameters after confirming

the setting of the servomotor.

■ Mechanism

4-13

Direct shaft drive using ball screws

Ball screw pitch: 5 mm/rot

Operation Range: -500 mm to +1000 mm (operates in the positive direction with the positive velocity command voltage)

Maximum speed: 6000 mm/min (100 mm/s)