Page 1

Model CX1006/CX1206

DAQSTATION CX1000

IM 04L31A01-03E

IM 04L31A01-03E

1st Edition

Page 2

Page 3

Notes

Trademarks

Revisions

Thank you for purchasing the CX1000. This manual describes the functions (excluding

the communications functions), installation and wiring procedures, operating procedures,

and handling precautions of the CX1000. To ensure correct use, please read this

manual thoroughly before beginning operation. The following four manuals are also

provided in addition to this manual. Read them along with this manual.

Electronic Manuals Provided on the Accompanying CD-ROM

Manual Title Manual No. Description

CX1000/CX2000 IM 04L31A01-17E Describes the communications functions of the

Communications Interface CX1000/CX2000 using the Ethernet/serial

interface.

User’s Manual

DAQSTANDARD for CX IM 04L31A01-61E Describes the functions and operating

User’s Manual procedure of the software “DAQSTANDARD

for CX” that comes with the package.

Paper Manuals

Manual Title Manual No. Description

CX1000 Installation and IM 04L31A01-73E Describes concisely the installation

Connection Guide procedures and wiring procedures of the

CX1000.

Precautions on the Use of IM 04L31A01-72E Precautions regarding the use of the CX1000/

the CX1000/CX2000 CX2000. The same information is written on

pages ii and iii of this user’s manual.

• This manual describes the CX1000, style number “S1.”

• The contents of this manual are subject to change without prior notice as a result of

continuing improvements to the instrument’s performance and functions. Note that

the program control operation described in this manual is not supported by this

version of the CX1000. Therefore, the information regarding the program control

operation may not be correct.

• Every effort has been made in the preparation of this manual to ensure the accuracy of

its contents. However, should you have any questions or find any errors, please contact

your nearest YOKOGAWA dealer as listed on the back cover of this manual.

• Copying or reproducing all or any part of the contents of this manual without the

permission of Yokogawa Electric Corporation is strictly prohibited.

• The TCP/IP software of this product and the document concerning the TCP/IP

software have been developed/created by YOKOGAWA based on the BSD

Networking Software, Release 1 that has been licensed from the Regents of the

University of California.

• Microsoft, MS-DOS, Windows, and Windows NT are either registered trademarks

or trademarks of Microsoft Corporation in the United States and/or other countries.

• Zip is either a registered trademark or trademark of Iomega Corporation in the

United States and/or other countries.

• Adobe and Acrobat are trademarks of Adobe Systems incorporated.

• Company and product names that appear in this manual are trademarks or registered

trademarks of their respective holders.

1st Edition March, 2002

Disk No. RE36

1st Edition : March 2002 (YK)

All Rights Reserved, Copyright © 2002 Yokogawa Electric Corporation

IM 04L31A01-01E

i

Page 4

Safety Precautions

About This Manual

• This manual should be read by the end user.

• Read this manual thoroughly and have a clear understanding of the product before operation.

• This manual explains the functions of the product. YOKOGAWA does not guarantee that the product will suit

a particular purpose of the user.

• Under absolutely no circumstances may the contents of this manual be transcribed or copied, in part or in

whole, without permission.

• The contents of this manual are subject to change without prior notice.

• Every effort has been made in the preparation of this manual to ensure the accuracy of its contents.

However, should you have any questions or find any errors or omissions, please contact your nearest

YOKOGAWA dealer.

Precautions Related to the Protection, Safety, and Alteration of the Product

• The following safety symbols are used on the product and in this manual.

“Handle with care.” (To avoid injury, death of personnel or damage to the instrument, the

operator must refer to the explanation in the manual.)

Functional ground terminal. (Do not use this terminal as a protective ground terminal.)

Protective grounding terminal

Alternating current

• For the protection and safe use of the product and the system controlled by it, be sure to follow the

instructions and precautions on safety that are stated in this manual whenever you handle the product.

Take special note that if you handle the product in a manner that violate these instructions, the protection

functionality of the product may be damaged or impaired. In such cases, YOKOGAWA does not

guarantee the quality, performance, function, and safety of the product.

• When installing protection and/or safety circuits such as lightning protection devices and equipment for

the product and control system or designing or installing separate protection and/or safety circuits for

fool-proof design and fail-safe design of the processes and lines that use the product and the control

system, the user should implement these using additional devices and equipment.

• If you are replacing parts or consumable items of the product, make sure to use parts specified by

YOKOGAWA.

• This product is not designed or manufactured to be used in critical applications that directly affect or

threaten human lives. Such applications include nuclear power equipment, devices using radioactivity,

railway facilities, aviation equipment, air navigation facilities, aviation facilities, and medical equipment. If

so used, it is the user’s responsibility to include in the system additional equipment and devices that

ensure personnel safety.

• Do not modify this product.

ii IM 04L31A01-03E

Page 5

Safety Precautions

WARNING

Power Supply

Ensure that the source voltage matches the voltage of the power supply before turning ON the

power.

Protective Grounding

Make sure to connect the protective grounding to prevent electric shock before turning ON the

power.

Necessity of Protective Grounding

Never cut off the internal or external protective earth wire or disconnect the wiring of the protective

earth terminal. Doing so invalidates the protective functions of the instrument and poses a potential

shock hazard.

Defect of Protective Grounding

Do not operate the instrument if the protective earth or fuse might be defective. Make sure to

check them before operation.

Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable liquids or vapors. Operation in such

environments constitutes a safety hazard.

Do Not Remove Covers

The cover should be removed by YOKOGAWA’s qualified personnel only. Opening the cover is

dangerous, because some areas inside the instrument have high voltages.

External Connection

Connect the protective grounding before connecting to the item under measurement or to an

external control unit.

Damage to the Protective Structure

Operating the CX1000 in a manner not described in this manual may damage its protective structure.

Exemption from Responsibility

• YOKOGAWA makes no warranties regarding the product except those stated in the WARRANTY that is

provided separately.

• YOKOGAWA assumes no liability to any party for any loss or damage, direct or indirect, caused by the

user or any unpredictable defect of the product.

Handling Precautions of the Software

• YOKOGAWA makes no warranties regarding the software accompanying this product except those

stated in the WARRANTY that is provided separately.

• Use the software on a single PC.

• You must purchase another copy of the software, if you are to use the software on another PC.

• Copying the software for any purposes other than backup is strictly prohibited.

• Please store the original media containing the software in a safe place.

• Reverse engineering, such as decompiling of the software, is strictly prohibited.

• No portion of the software supplied by YOKOGAWA may be transferred, exchanged, sublet, or leased for

use by any third party without prior permission by YOKOGAWA.

IM 04L31A01-01E

iii

Page 6

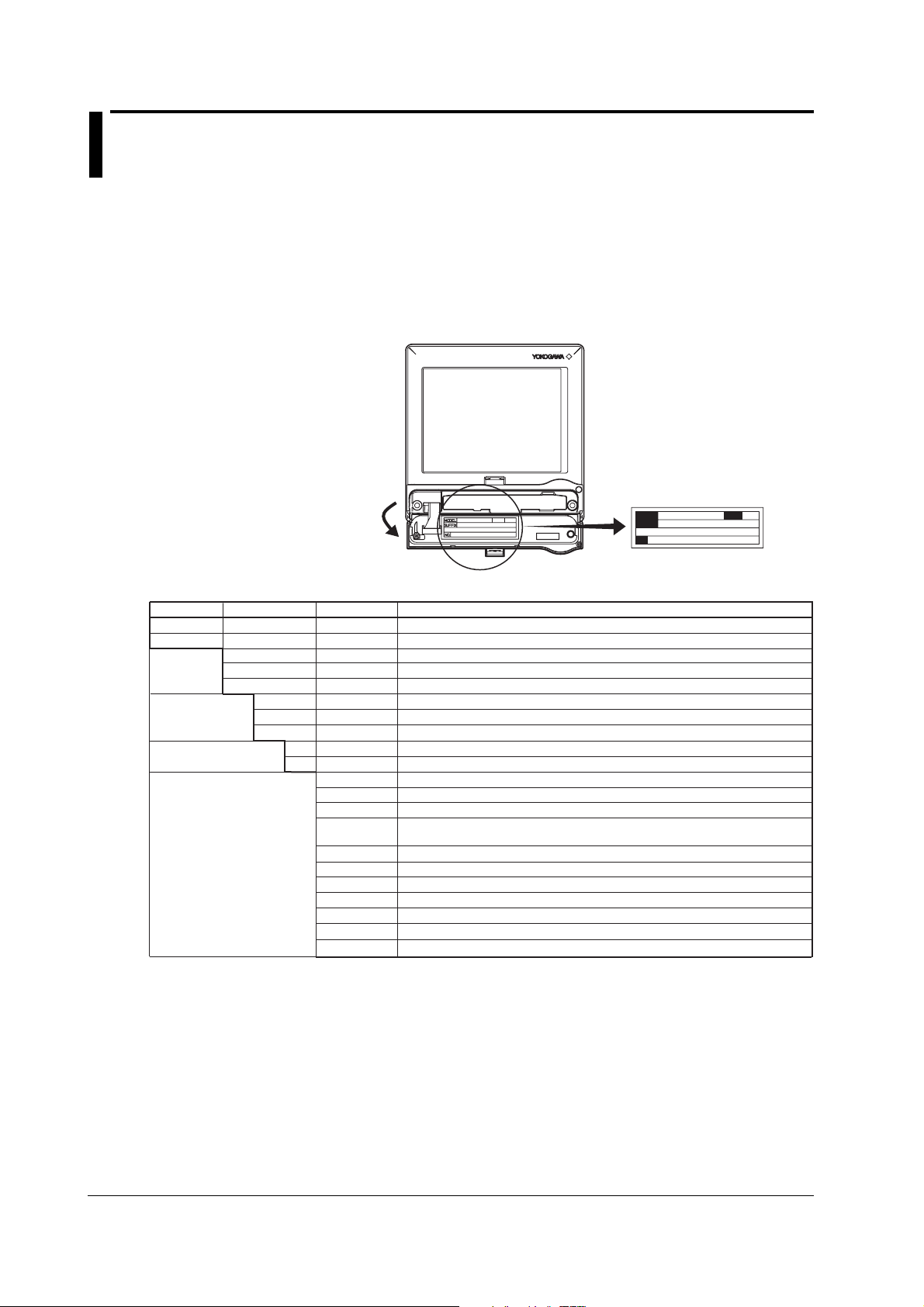

Checking the Contents of the Package

Unpack the box and check the contents before operating the instrument. If some of the

contents are not correct or missing or if there is physical damage, contact the dealer

from which you purchased them.

CX1000

When you open the operation cover on the front panel, a name plate is located on the

back side of the cover. Check that the model name and suffix code given on the name

plate on the rear panel match those on the order.

Open the operation

cover

STYLE

MODEL

SUFFIX

NO

STYLE

MODEL and SUFFIX

Model

CX1006

CX1206

External

storage

medium

Communication

interface

Displayed language

Options

*1

Suffix Code –2 (Ethernet + RS-422A/485 serial interface port) must be selected for the communication interface and

/CM1 (Green series communications) must be selected for the Optional Code.

*2

Includes the Modbus master/slave function. However, to use the Modbus master function, /M1 must be selected for the

Optional Code.

*3

Only one of the options can be specified on the CX1006. Cannot be specified on the CX1206.

*4

Suffix Code –1 (with RS-232 serial interface port) or –2 (with RS422/485 interface port) must be selected for the

communication interface. Either one can be specified on the CX1206. Ladder communication (/CM2) cannot be

specified on the CX1006.

*5

Either one can be specified on the CX1206.

Suffix Code Optional Code Description

*1

Number of internal control loops: 0, number of inputs for measurement: 6 ch

Number of internal control loops: 2, number of inputs for measurement: 6 ch

–1

–2

–3

–0

–1

–2

–1

–2

/A6

/A6R

/A4F

/A4FR

Floppy disk

Zip disk

ATA flash memory card

Only Ethernet

Ethernet + RS-232 serial interface port

Ethernet + RS-422A/485 serial interface port

Japanese

English

6 measurement alarm outputs

6 measurement alarm output, 8 remote inputs

4 measurement alarm outputs, 1 FAIL output, 1 memory end output

4 measurement alarm outputs, 1 FAIL output, 1 memory end output,

8 remote inputs

/M1

/N2

/P1

/CM1

/CM2

/PG1

/PG2

Computation function

Three-wire isolated RTD (input for measurement)

24-VDC/AC power supply driven

Green series communications

Ladder communications

Program control (number of program patterns: 4)

Program control (number of program patterns: 30)

*2

*3

*3

*3

*3

*4

*4

*5

*5

NO. (Instrument Number)

When contacting the dealer from which you purchased the instrument, please give them

the instrument number.

iv IM 04L31A01-03E

Page 7

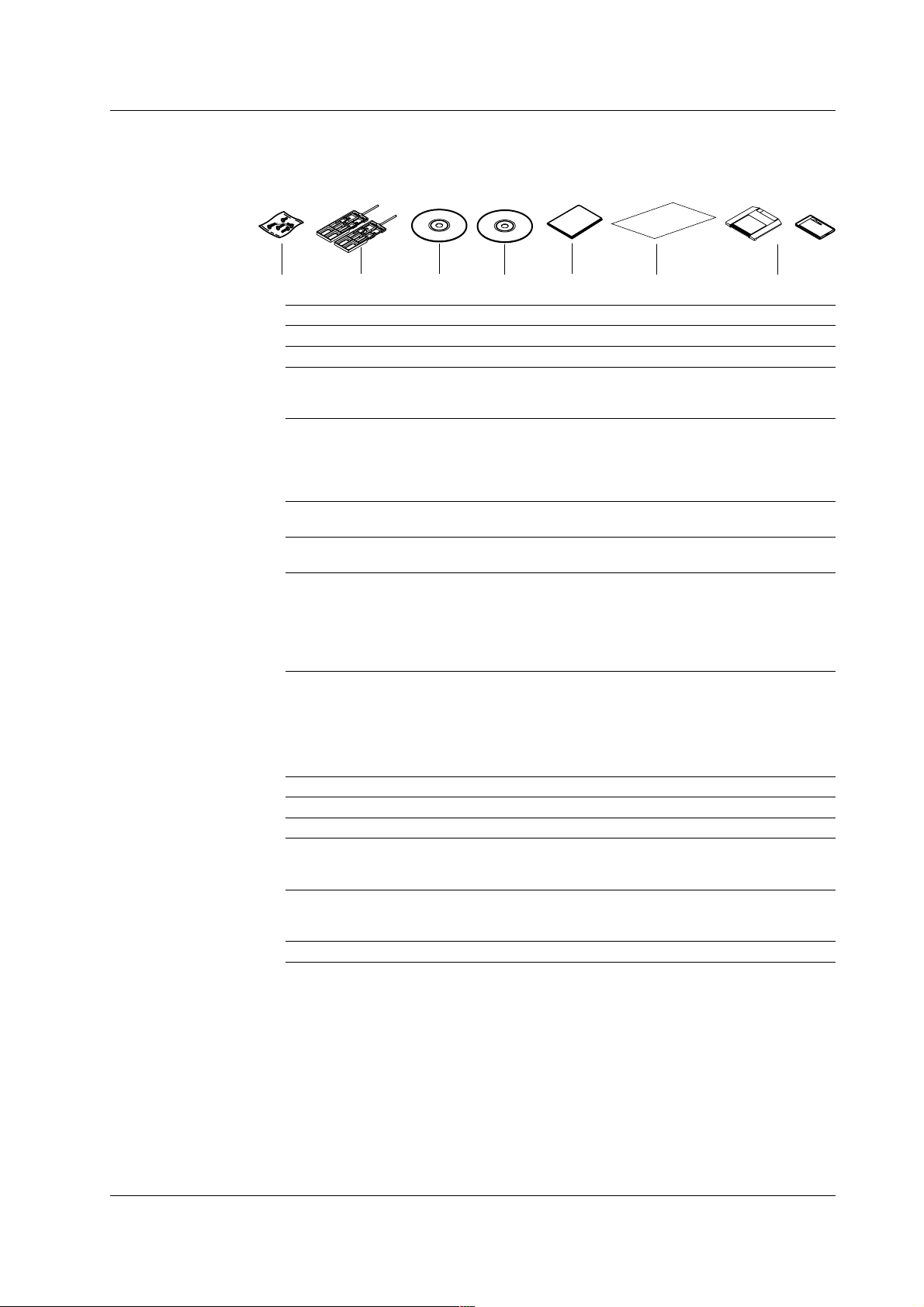

Standard Accessories

The standard accessories below are supplied with the instrument. Check that all

contents are present and that they are undamaged.

Checking the Contents of the Package

or

1

No. Name Part Number/Model Q’ty Note

1 Terminal screws 5 M4

2 Mounting bracket B9900BX 2 For panel mounting

3 DAQSTANDARD CXA100-01 1 Software for setting the CX and

4 CX1000/CX2000 B8700MA 1 CD-ROM containing the PDF files of this

5 CX1000 Installation and IM 04L31A01-73E 1 Abridged paper manual

6 Precautions on the Use IM 04L31A01-72E 1 Paper stating the precautions.

7 External storage medium A1053MP 1 Zip disk (provided only when the external

2

for CX displaying data CD-ROM used to install

electronic manual manual, the CX1000/CX2000

Connection Guide

of the CX1000/CX2000

3

Optional Accessories (Sold Separately)

The following optional accessories are available for purchase separately. When you

receive the order, check that all contents are present and that they are undamaged.

For information and ordering, contact your nearest YOKOGAWA dealer.

Part Name Part Number/Model Q’ty Note

3.5" floppy disk 7059 00 10 2HD

Zip disk A1053MP 1 100 MB

ATA flash memory card B9968PK 1 24 MB (The size and model may

Shunt resistance 4159 20 1 250 Ω±0.1%

(for the screw terminal) 4159 21 1 100 Ω±0.1%

Mounting bracket B9900BX 2

4

B9968PK 1 ATA flash memory card, provided only

4159 22 1 10 Ω±0.1%

5

6

“DAQSTANDARD for CX”

Communication Interface User’s Manual,

DAQSTANDARD for CX User’s Manual,

and other files.

storage medium suffix code is “-2”)

when the external storage medium suffix

code is “-3” (the size and model may

change in the future)

change in the future. Check with your

YOKOGAWA dealer when ordering.)

7

IM 04L31A01-01E

v

Page 8

How to Use This Manual

Structure of the Manual

This user’s manual consists of the following sections. For details on the communications

functions and the software “DAQSTANDARD for CX” provided with the package, see the

respective manuals (IM 04L31A01-17E and IM 04L31A01-61E).

Chapter Title and Description

1 Explanation of Functions

Describes in detail the functions of the instrument. The chapters that explain the

operation of the CX1000 only describe the operating procedures. For more detailed

information about the functions, see this chapter.

2 Installation and Wiring

3 Names of Parts, Display Modes, and Common Operations

4 Control Function Related Setup Operations

5 Program Control Related Setup Operations (Only on Models with the Program

6 Operations during Control Operation

7 Measurement Function Related Setup Operations

8 Operations for Changing the Displayed Contents

9 Data Save/Load Operations

10 Computation and Report Function Related Operations (Only on Models with the

11 Operations of Other Functions

12 Troubleshooting

13 Maintenance

14 Specifications

Appendix Describes the acquisition function of measured data to the internal memory, additional

Index

Describes the installation and wiring procedures of the CX1000.

Describes the names of the parts of the CX1000, the basic key operations, the basic

operations carried out initially, and how to use the external storage medium drive.

Describes setup operations related to the control function that are carried out before

starting control operations.

Control Option)

Describes the setup operations related to program control that are carried out before

starting control operations on models with the program control option.

Describes how to switch operation mode during control operation, how to change the

setpoints of setting mode, how to tune the control parameters, and the operations on the

program control screen (operations only on models with the option).

Describes how to set the PV input of the measurement function and alarms

(measurement alarms).

Describes how to change the operating display of both the control function and the

measurement function and the display format.

Describes how to write various data to the internal memory, how to save and load from

the external storage medium, and the file operations on the external storage medium.

Computation Function Option)

Describes how to set and execute operations related to the computation function and

report function of the computation function option.

Describes the USER key, key lock, login/logout of key operation, log display, and

remote input setting.

Describes the error messages and the troubleshooting measures of the CX1000.

Describes periodic inspection, calibration, and recommended replacement period for

worn parts.

Describes the specifications of the CX1000.

information on the computation and report functions, the ASCII file format, and initial settings.

Note

• This user’s manual covers information regarding CX1000s that have a suffix code for

language “-2” (English).

• For details on setting the displayed language, see

vi IM 04L31A01-03E

section 3.6

.

Page 9

Conventions Used in This Manual

Unit

K........ Denotes “1024.” Example: 768 KB (file size)

k........ Denotes “1000.”

Safety Markings

The following markings are used in this manual.

How to Use This Manual

Danger. Refer to corresponding location on the instrument.

This symbol appears on dangerous locations on the instrument

which require special instructions for proper handling or use. The

same symbol appears in the corresponding place in the manual to

identify those instructions.

WARNING

CAUTION

Note

Symbols Used on Pages Describing Operating Procedures

On pages that describe the operating procedures in Chapter 3 through 11, the following

symbols are used to distinguish the procedures from their explanations.

[ ] ................ Indicates character strings that appear on the screen.

Procedure

Calls attention to actions or conditions that could cause serious

injury or death to the user, and precautions that can be taken to

prevent such occurences.

Calls attentions to actions or conditions that could cause damage to

the instrument or user’s data, and precautions that can be taken to

prevent such occurrences.

Calls attention to information that is important for proper operation

of th instrument.

Example: [Space] soft key, [Volt]

This subsection contains the operating procedure used to carry out

the function described in the current section. All procedures are

written with inexperienced users in mind; experienced users may

not need to carry out all the steps.

IM 04L31A01-01E

Setup Items

Describes the details of the settings and the restrictions that exist with

the operating procedure. It does not give a detailed explanation of

the function. For details on the function, see chapter 1.

vii

Page 10

Contents

Safety Precautions ..........................................................................................................................ii

Checking the Contents of the Package ..........................................................................................iv

How to Use This Manual ................................................................................................................vi

Chapter 1 Explanation of Functions

1.1 CX1000 Overview ............................................................................................................ 1-1

1.2 Control Function Overview............................................................................................... 1-2

1.3 Basic Settings of Control................................................................................................ 1-13

1.4 PV Input Related Settings .............................................................................................. 1-18

1.5 Contact Input/Output Related Settings .......................................................................... 1-22

1.6 Target Setpoint Related Settings ................................................................................... 1-25

1.7 PID Parameter Settings ................................................................................................. 1-27

1.8 Control Output Suppression Settings............................................................................. 1-31

1.9 Settings for ON/OFF Control.......................................................................................... 1-33

1.10 Control Alarm Related Settings ...................................................................................... 1-34

1.11 Program Control Related Settings ................................................................................. 1-36

1.12 Tuning ............................................................................................................................ 1-50

1.13 Measurement Function Overview .................................................................................. 1-52

1.14 Measurement Function > Measurement Input Related Settings .................................... 1-54

1.15 Measurement Function > Measurement Alarm Related Settings .................................. 1-57

1.16 Display Function............................................................................................................. 1-62

1.17 Data Storage Function ................................................................................................... 1-81

1.18 Computation and Report Functions (Option) ................................................................. 1-86

1.19 Other Functions ............................................................................................................. 1-90

Chapter 2 Installation and Wiring

2.1 Handling Precautions ....................................................................................................... 2-1

2.2 Installation ........................................................................................................................ 2-2

2.3 Wiring ............................................................................................................................... 2-5

2.4 Connecting the Power Supply ........................................................................................ 2-13

Chapter 3 Names of Parts, Display Modes, and Common Operations

3.1 Names and Functions of Sections ................................................................................... 3-1

3.2 Basic Key Operations ....................................................................................................... 3-4

3.3 Setting the Date and Time ............................................................................................. 3-11

3.4 Setting the Brightness of the Display and the Backlight Saver Function........................ 3-13

3.5 Initializing the Setup Data and Clearing the Internal Memory ........................................ 3-14

3.6 Changing the Displayed Language ................................................................................ 3-15

3.7 Changing the Time Zone................................................................................................ 3-16

3.8 Inserting and Ejecting the External Storage Medium ..................................................... 3-17

Chapter 4 Control Function Related Setup Operations

4.1 Control > Control action ................................................................................................... 4-1

4.2 Control > Input setting (Burnout and RJC) ....................................................................... 4-4

4.3 Control > Contact input-registration ................................................................................. 4-6

4.4 Control > AUX (Remote setting, Alarm mode, SP No. selection source) ....................... 4-11

4.5 Control > Output processing .......................................................................................... 4-13

4.6 Control > Relay .............................................................................................................. 4-15

4.7 Control > Tuning setting ................................................................................................. 4-17

viii IM 04L31A01-03E

Page 11

Contents

4.8 Control input range ........................................................................................................ 4-19

4.9 Control alarm ................................................................................................................. 4-23

4.10 Operation-related parameters/Zone PID........................................................................ 4-25

4.11 PID parameters .............................................................................................................. 4-27

4.12 Control group setting ...................................................................................................... 4-29

4.13 Ten-segment linearizer I/O ............................................................................................. 4-31

4.14 Detailed setting (Control function/Hysteresis) ................................................................ 4-33

Chapter 5 Program Control Related Setup Operations

5.1 Program Pattern Setup Procedure................................................................................... 5-1

5.2 Program parameter setting > Pattern initial setting .......................................................... 5-2

5.3 Program parameter setting > Wait action setting ............................................................. 5-4

5.4 Program parameter setting > Program start setting ......................................................... 5-5

5.5 Program parameter setting > Program pattern setting..................................................... 5-6

5.6 Program parameter setting > Event setting...................................................................... 5-8

5.7 Program parameter setting > Repeat action setting ...................................................... 5-10

5.8 Event output setting ....................................................................................................... 5-11

5.9 AUX (Auto message, Display position) .......................................................................... 5-12

Chapter 6 Operations during Control Operation

6.1 Operations on the Control Group Display (Switching Displayed Information and

Control Operation Modes) ................................................................................................ 6-1

6.2 Switching Displays on the Overview Display.................................................................... 6-6

6.3 Tuning Operation .............................................................................................................. 6-7

6.4 Operations on the Program Control Display (Only on Models with the Program

Control Option)............................................................................................................... 6-10

1

2

3

4

5

6

7

8

Chapter 7 Measurement Function Related Setup Operations

7.1 Settings Related to Measurement Inputs ......................................................................... 7-1

7.2 Settings Related to Measurement Alarms ....................................................................... 7-6

7.3 Setting the Temperature Unit ......................................................................................... 7-11

Chapter 8 Operations for Changing the Displayed Contents

8.1 Using the Information Display (Alarm Summary, Message Summary, Memory

Summary, and Control Summary) .................................................................................... 8-1

8.2 Measurement Function > Measurement Group Setup Operation .................................... 8-2

8.3 Measurement Function > Settings Related to Tag Display for Channels ......................... 8-4

8.4 Measurement Function > Operations When Displaying Trend, Digital, and Bar

Graph Displays................................................................................................................. 8-6

8.5 Measurement Function > Operations When Displaying the Overview ............................. 8-8

8.6 Measurement Function > Operations When Displaying the Historical Trend ................... 8-9

8.7 Measurement Function > Changing the Display Update Rate of the Trend Display ...... 8-10

8.8 Measurement Function > Settings Related to Messages Displayed on the

Trend Display and Write Operation ................................................................................ 8-11

8.9 Measurement Function > Changing the Trip Line of the Trend Display .......................... 8-13

8.10 Measurement Function > Changing the Channel Display Color .................................... 8-14

8.11 Measurement Function > Changing the Zone Display of the Trend Display .................. 8-16

8.12 Measurement Function > Setting the Scale Division, Bar Graph Base Position,

Scale Position of Trend Displays .................................................................................... 8-17

8.13 Measurement Function > Setting the Partial Expanded Display on the Trend Display .. 8-21

8.14 Measurement Function > Setting the Display Direction, Background Color,

Waveform Line Width, Trip Line Width, Grid, and Scroll Time ........................................ 8-23

9

10

11

12

13

14

App

IM 04L31A01-01E

Index

ix

Page 12

Contents

Chapter 9 Data Save/Load Operations

9.1 Acquiring Measurement Data to the Internal Memory and Saving Data to

the External Storage Medium .......................................................................................... 9-1

9.2 Saving Measured/Computed Data at Arbitrary Times (Manual Sample) ......................... 9-7

9.3 Saving and Loading Setup Data ...................................................................................... 9-8

9.4 Loading the Stored Display/Event Data (Historical Trend) ............................................. 9-10

9.5 Managing Files and Checking the Free Space on the External Storage Medium.......... 9-11

9.6 Saving the Screen Image Data ...................................................................................... 9-13

9.7 Clearing the Data in the Internal Memory ...................................................................... 9-14

Chapter 10 Computation and Report Function Related Operations

(Only on Models with the Computation Function Option)

10.1 Assigning Computation Channels and Setting Computing Equations,

Constants and Tags ....................................................................................................... 10-1

10.2 Starting, Stopping, and Resetting the Computation ....................................................... 10-4

10.3 Setting Computation Channel Alarms ............................................................................ 10-5

10.4 Setting TLOG Computations .......................................................................................... 10-8

10.5 Setting the Rolling Average .......................................................................................... 10-11

10.6 Creating Reports .......................................................................................................... 10-12

10.7 Starting/Stopping the Report Function......................................................................... 10-14

Chapter 11 Operations of Other Functions

11.1 USER Key Assignment and Operation .......................................................................... 11-1

11.2 Key Lock......................................................................................................................... 11-3

11.3 Key Operation Login/Logout .......................................................................................... 11-5

11.4 Displaying Logs (Checking Operations) and System Information Display

(Checking the System Specifications)............................................................................ 11-8

11.5 Setting the Measurement Remote Input (/A6R option or /A4FR option) ...................... 11-11

Chapter 12 Troubleshooting

12.1 Messages ....................................................................................................................... 12-1

12.2 Troubleshooting Flow Chart ......................................................................................... 12-11

Chapter 13 Maintenance

13.1 Periodic Inspection ......................................................................................................... 13-1

13.2 Calibration ...................................................................................................................... 13-2

13.3 Replacement of Parts .................................................................................................... 13-4

Chapter 14 Specifications

14.1 Input Section Specifications ........................................................................................... 14-1

14.2 Control Function ............................................................................................................. 14-3

14.3 Alarm Function ............................................................................................................... 14-4

14.4 Display Function............................................................................................................. 14-5

14.5 Storage Function............................................................................................................ 14-7

14.6 Communication Functions ........................................................................................... 14-10

14.7 Options ......................................................................................................................... 14-11

14.8 General Specifications ................................................................................................. 14-14

14.9 Dimensional Drawings ................................................................................................. 14-18

x IM 04L31A01-03E

Page 13

Contents

Appendix

Index

Appendix 1 Supplementary Explanation of the Acquisition of Display Data/Event Data

to the Internal Memory .......................................................................................App-1

Appendix 2 Supplementary Explanation of the Computation Function ................................App-6

Appendix 3 Meaning and Syntax of Equations ..................................................................... App-9

Appendix 4 Additional Explanation of the Report Function ................................................App-13

Appendix 5 Data Format of ASCII Files ..............................................................................App-16

Appendix 6 Initial Values ..................................................................................................... App-20

Appendix 7 Control Function Block Diagram ...................................................................... App-33

Appendix 8 Explanation of Engineering Units (EU and EUS)............................................. App-39

1

2

3

4

5

6

7

8

9

10

11

12

13

14

IM 04L31A01-01E

App

Index

xi

Page 14

Page 15

Chapter 1 Explanation of Functions

1.1 CX1000 Overview

The CX1000 consists of a control function and a measurement function. The control

function executes control through PID control and ON/OFF control. The measurement

function displays and acquires measured data and control-output data.

Control Function

The CX1000 supports thee control modes: single-loop control, cascade control, and loop

control with PV switching. It can handle up to two loops of PID control. In addition, the

UT Series controllers made by Yokogawa M&C Corporation can be connected and

controlled simultaneously as external loops (four loops max.). You can check the control

status on the controller style and faceplate style displays and the hybrid style display that

is a mixture of the two styles. Furthermore, the overview display allows monitoring of all

control loops including external loops. In addition, the CX1000 provides auto-tuning of

PID constants as well as manual tuning, which enables you to adjust the control

parameters such as PID constants while checking the control status.

Measurement Function

In addition to the measured data for the control function, the CX1000 can acquire up to

six channels of measured data. The data can be displayed as waveforms, numeric

values, and bar graphs. The measured data along with the control data can be stored to

a floppy disk, Zip disk, or ATA flash memory card using the built-in drive.

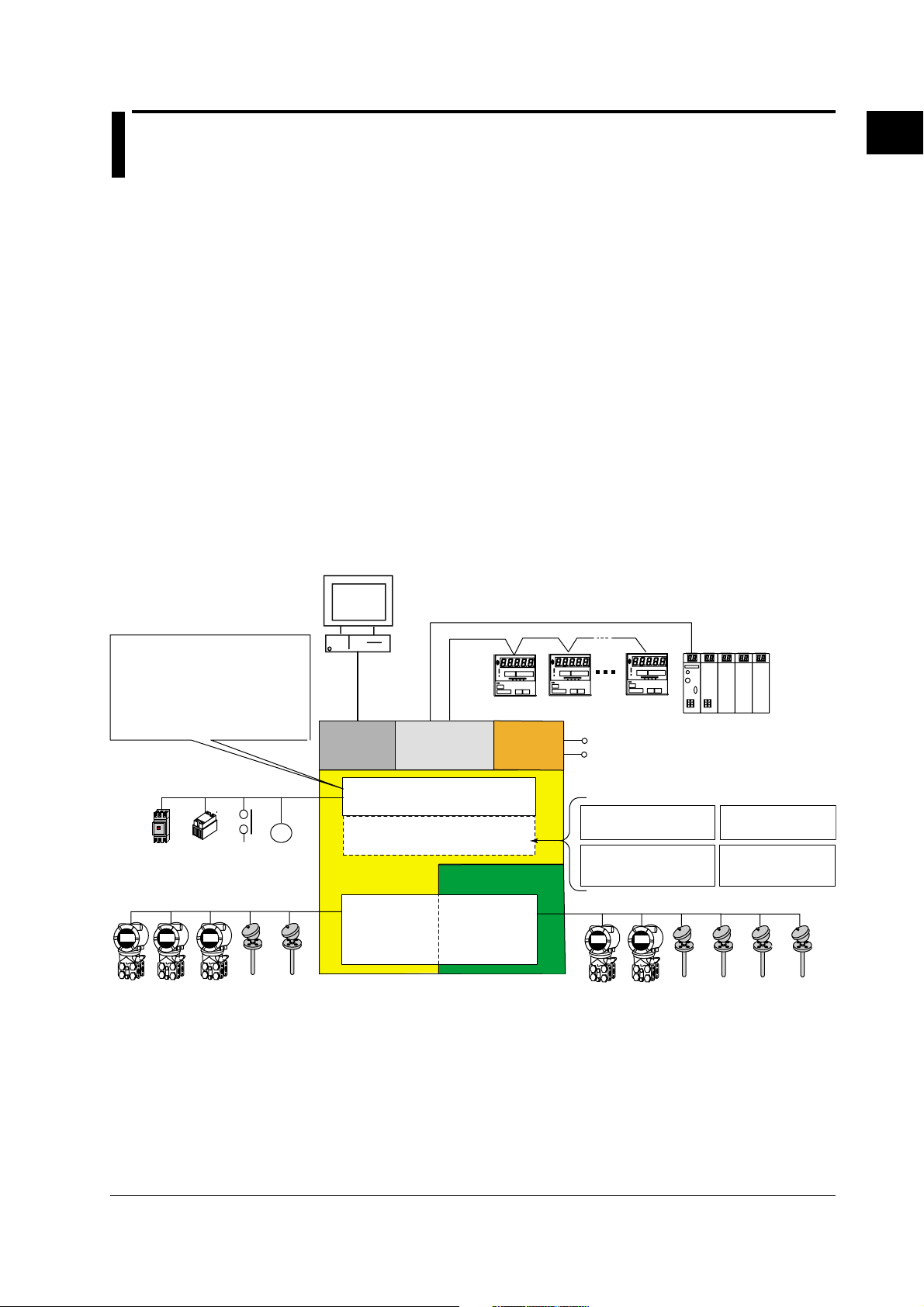

Conceptual Input/Output Diagram

1

Explanation of Functions

PC

• Universal control output: for 2 loops

Select current, voltage pulse, or

relay output.

• Control contact input: 6 inputs

• Control contact input

Relay output: 2 outputs

Transistor output: 4 outputs

R1

Magnet

switch

5 universal measurement inputs 6 universal measurement inputs

SSR

Contact

input

6 inputs

Contact

output

6 outputs

LAN

(Ethernet)

CX1000

Ethernet

the control output terminal block)

Control loop

(select 0 or 2 loops)

Serial interface

port

RS-422/485/232

Control output terminal

block (Loops 1 and 2)

Option terminal block

(Can be installed in place of

section

Control/measurement input

Control input

terminals

Measurement input

terminal block

Measurement input

Supply

section

terminals

CH1 to CH6

Power

Controllers (up to

4 loops)

100 VAC to 240 VAC

24 VDC/AC (/P1 option)

Select one from the following option

terminal blocks.

Measurement alarm output

(/A6 option)

Measurement alarm output +

FAIL/memory end output

(/A4F option)

PLC

(such as the FA-M3

by YOKOGAWA)

Measurement alarm

output + remote input/

output

(/A6R option)

Measurement alarm

output + FAIL/memory

end output + remote

input/output

(/A4FR option)

IM 04L31A01-03E

1-1

Page 16

1.2 Control Function Overview

Control Signal Input/Output

As shown in the following figure, the CX1000 can control up to two loops.

Control PV input

Control output

• Relay

• Voltage pulse

DISP/

ENTER

• Current

CX

The UT Series controllers made by Yokogawa M&C Corporation can be connected via

the serial interface and controlled simultaneously as external loops (four loops max.)

(see the

CX1000/CX2000 Communication Interface User’s Manual

Analog Input for Loop Control

PV input and remote setpoint input (RSP) are available as control signal inputs. You can

select thermocouple, resistance temperature detector, standard signal, or DC voltage for

both PV input and RSP input. The RSP input is used as a terget setpoint (SP). There

are five input terminals on the control/measurement input terminal block. The figure

below shows their assignments according to the number of loops used and the control

mode (see the

[Control mode setting]

During single-loop control

During cascade control

During loop control with

PV switching

You can apply scale conversion, bias, input filter, ten-segment linearizer bias, tensegment linearizer approximation, and square-root computation on the control signal

input. For thermocouple inputs, you can set reference junction compensation. In

addition, ratio setting can be specified against RSP inputs.

(number of analog inputs: 5)

[Up to 2 loops]

Controls

and

switches

··· ···

• SSR

• Magnet switch

etc.

next page

).

LOOP2

21321

PV, PV1, PV2: PV input, (RSP): RSP input

(not used during program control), : unused terminal

Object of

control

(RSP)

LOOP1

(RSP)(RSP)

(RSP)

• TC

• RTD

etc.

).

Measurement input terminals

PVPV

PVPV

PV1PV1 PV2PV2

Control Signal Output

The terminal provides universal output. Two loops can be controlled (except cascade control

which uses two loops for one control). The following types of control output can be selected.

• PID control output

• Time proportional PID Outputs ON/OFF signals with a pulse width that is proportional

relay contact output: to the time as relay contact signals according to the computed

PID value.

• Time proportional PID Outputs ON/OFF signals with a pulse width that is proportional to

voltage pulse output: the time as voltages according to the computed PID value.

• Current output (continuous Continuously outputs a current (analog signal) that is

PID control output): proportional to the computed PID value.

• On/off control relay Outputs on/off control relay contact signals according to the

contact output: polarity (positive/negative) of the deviation between the SP

and the PV.

1-2 IM 04L31A01-03E

Page 17

SP

PV

OUT

SP

PV

OUT

PV derivative type PID

(with output bump)

Deviation derivative type PID

(with output bump)

1.2 Control Function Overview

Control Methods

PID control and ON/OFF control are available. The following control modes can be

selected for both PID control and ON/OFF control.

Control Mode

In PID control, the following three control modes are available in relation to the PV input

selection.

• Single-loop control

Basic control consisting of a single system of controller CPU.

PV

PIDSP

OUT

• Cascade control

Control consisting of two systems of controller CPUs that use the primary control

output as the secondary control SP.

PV1

PIDSP

PV2

PID

OUT

• Loop control with PV switching

Single-loop control that is switched between two PV inputs (PV1 and PV2) according

to a specified condition.

PV1

PV2

1

Explanation of Functions

IM 04L31A01-03E

PIDSP

OUT

In PID control, you can also select the PID control mode.

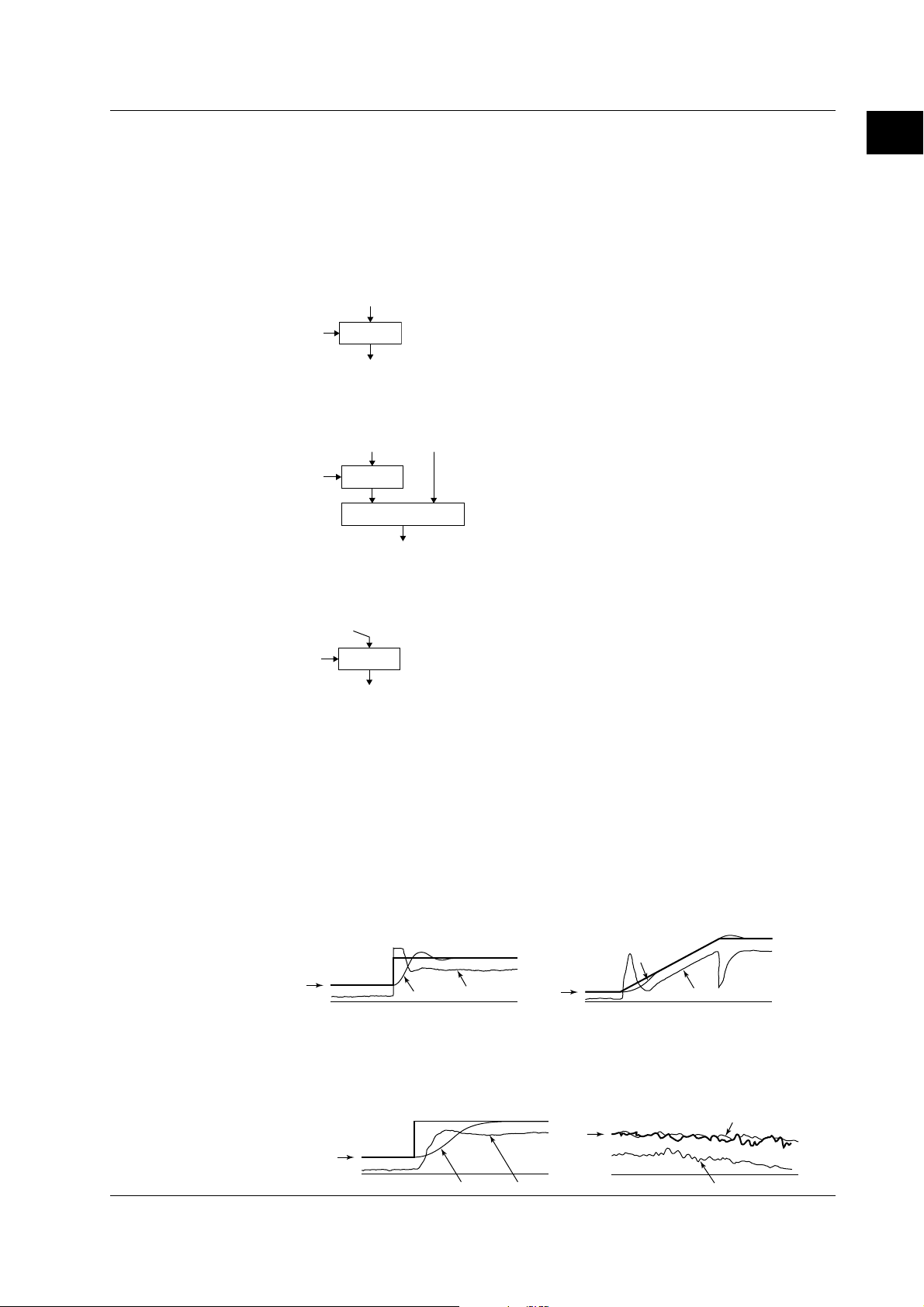

PID Control Mode

Depending on the desired operation at the time the SP is changed, you can select the

PID control mode from below. The selections between the PV derivative type and

deviation derivative type as well as the presence or absence of the control output bumps

are automatically made according to the PID control mode and operation mode (fixedpoint control or program control).

• Standard PID control

Controlled so that the control output reaches the new SP quickly after the SP is

changed.

• Fixed-point control

Select this mode if you wish to avoid the control OUT from reacting sensitively to the

SP change causing a disturbance in the control such as in the case with a continuous

fixed-point control.

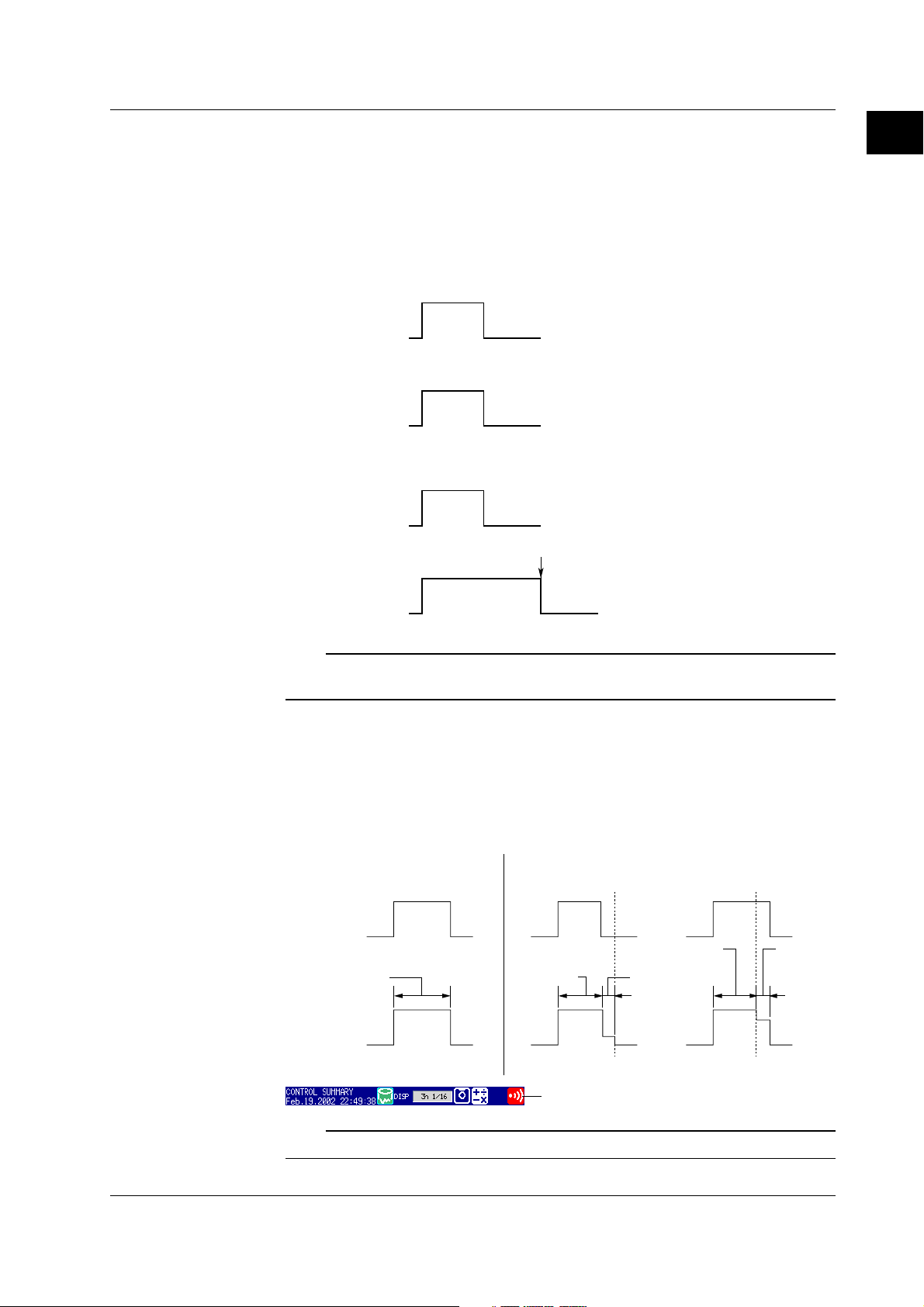

PV derivative type PID (without output bump) PV derivative type PID (with output bump)

SP

SP

PV OUT

PV

OUT

1-3

Page 18

1.2 Control Function Overview

Control Parameters

The following control parameters are available. For each group, you can enter up to

eight sets of SPs and PID parameters as underlined below.

SP,

value, relay hysteresis, control action direction, preset output, SP tracking, PV tracking,

setpoint limiter, output velocity limiter, auto/manual switching of the over-integration

prevention function (anti-reset windup), ON/OFF of the control output suppression

function, and SP ramp-rate.

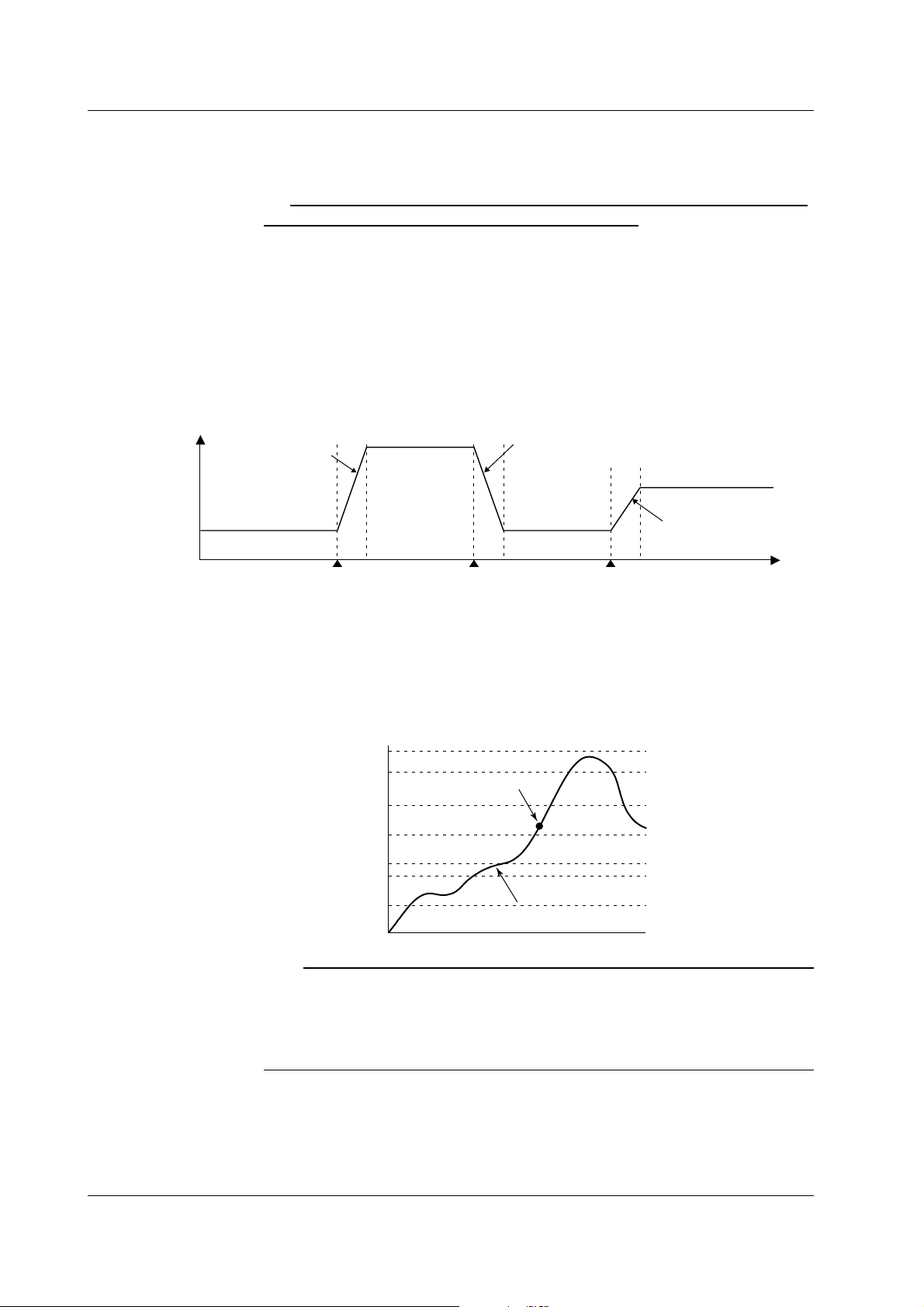

PID Selection Method

The following two methods are available.

• Target setpoint selection method

PV

Rise according to the

setpoint ramp-up

SP1

(No.1 PID)

Switch from SP1 to SP3 Switch from SP3 to SP1 Switch from SP1 to SP2

• Zone PID method

Maximum value of

measurement span

Reference point 6

Reference point 5

Reference point 4

Reference point 3

Reference point 2

Reference point 1

Minimum value of

measurement span

Note

PID constant, control output limiter, ON/OFF of the shutdown function, manual reset

A group (up to 8 groups) consisting of a SP and PID parameters is registered to a PID

number (SP number). By specifying the SP number using keys on the front panel,

external contact input, or via communications, the SP and PID parameters are

switched.

SP3

(No.3 PID)

setting

Fall according to the

setpoint ramp-down

setting

SP1

(No.1 PID)

SPn: Target setpoint number

SP2

(No.2 PID)

Rise according to the

setpoint ramp-up

setting

Time

The measurement span is divided into a maximum of seven zones using reference

points. The optimum PID constant is preassigned to each zone, and the PID constant

(in actuality, other control parameters that are registered using the PID number are

included) is automatically switched according to the PV. This method is suited for

controlling equipment such as reactors in which the chemical reaction gain varies

depending on the temperature.

If the current PV is here, PID

constant of PID No. 5 is used

for control.

Change in the

PV.

• When performing program control operation on models with the program control option,

you will select between segment PID method (zone PID selection OFF) and zone PID

method.

• For a description on auto tuning, which automatically sets the optimum PID constant, see

section 1.12, “Tuning.”

No.7 PID

No.6 PID

No.5 PID

No.4 PID

No.3 PID

No.2 PID

No.1 PID

1-4 IM 04L31A01-03E

Page 19

1.2 Control Function Overview

Alarm Output

When the control action status matches the preset status (up to 4 points per loop), the

CX1000 can output a relay contact signal from the control output terminal block or the DIO

expansion terminal block or display the alarm occurrence status on the screen. In relay

contact output, you can select and assign the type of alarm you wish to output at each

output terminal of the control output terminal block or the control DIO extension terminal

block.

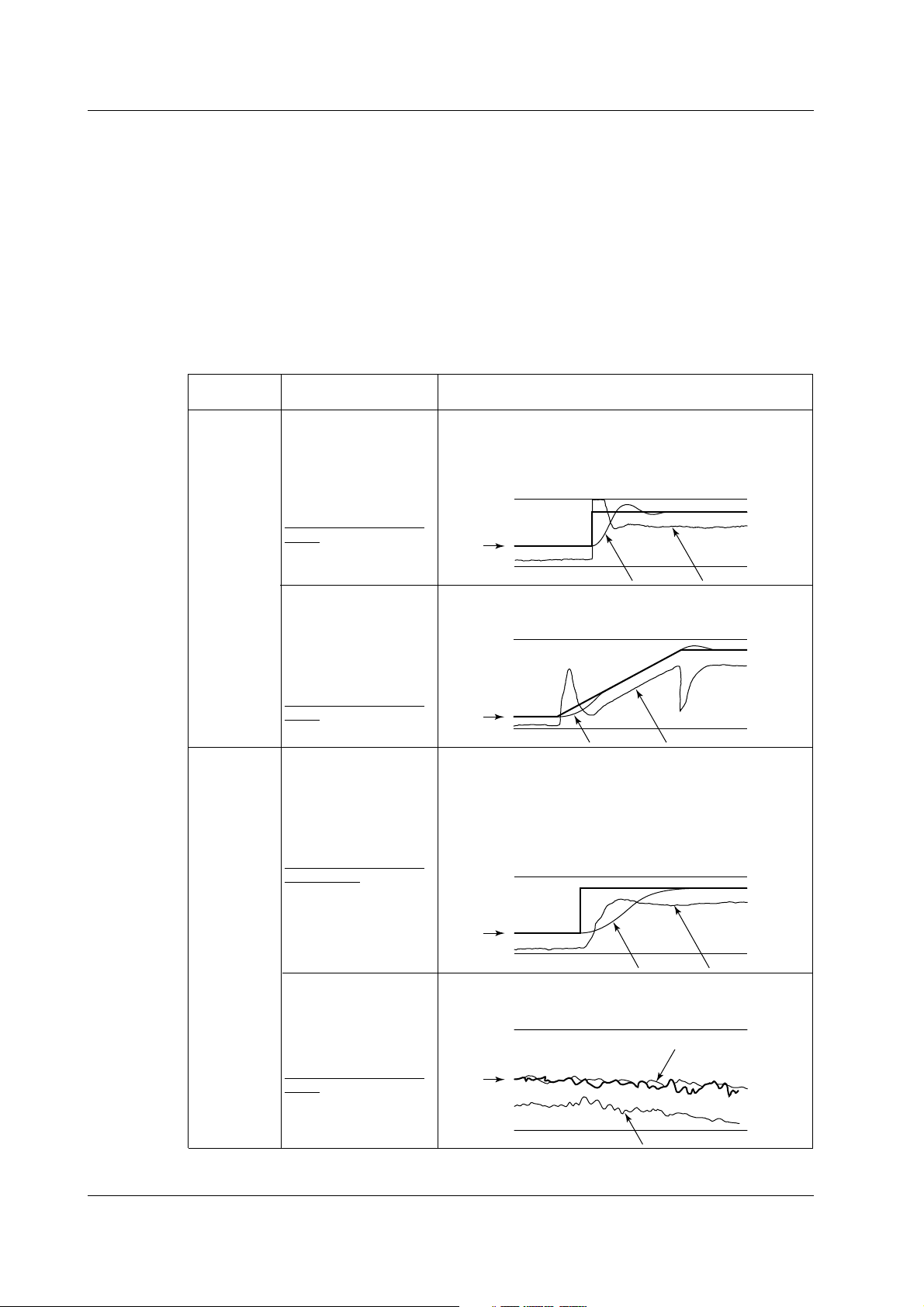

Alarm Type

You can select the alarm type from below. For a detailed explanation on each alarm

output, see

section 1.10, “Control Alarm Related Settings.”

PV high-limit alarm, PV low-limit alarm, deviation high-limit alarm, deviation low-limit

alarm, deviation high & low limit alarm, deviation within high & low limits alarm, SP highlimit alarm, SP low-limit alarm, output high-limit alarm, and output low-limit alarm.

Alarm Hysteresis

You can set a hysteresis to the setpoints used in the activation and releasing of the alarm.

Example of PV high limit alarm

OFF

PV

Time

ON

Alarm setpoint

Hysteresis

Alarm ON

OFF

ON

OFF

1

Explanation of Functions

Alarm Standby

You can put the alarm output on standby at the initial stage of control operation until the

PV input reaches the SP.

PV

Power up

Normal

handling

Alarm Mode

You can set the condition for disabling the alarm output (such as when the operation is stopped).

FAIL Output/Self Diagnosis Output

In addition to the alarm output described above, the following relay contact signal for

failure detection can be output from the control output terminal block.

• FAIL output

Output when a failure is detected in the CX1000 CPU. When a failure is detected, the

CX1000 is put in the following condition.

Control: Stopped (preset output if in the middle of operation, control output is off or

0% when power is turned ON)

• Self diagnosis output

Output when an input burnout, A/D converter failure, or RJC failure occurs. If an input

burnout or A/D converter failure is detected, the control output is set to the preset

output value. For RJC, PID control continues as though RJC is 0 °C.

Normal

Alarm is not output during this

period even if the PV is below

the alarm low limit.

Failure

Alarm output ON

Hysteresis

Alarm low limit value

Time

IM 04L31A01-03E

1-5

Page 20

1.2 Control Function Overview

Control Operation Mode

The following control operation switching is available. The control operation can be

switched using keys on the CX1000 control group display (see

inputs, or via communications. For a description of the control operation modes on

models with the program control option, see “

control function block diagram in the explanation below is a simplified one. For a

detailed control function block diagram for each control mode, see appendix 7.

Switching between Remote (REM) and Local (LOC)

Select whether control is executed using the SPs set on the CX1000 or using the

external analog signal (RSP) as the SP.

PV input RSP input

PV

SP

Local

(LOC)

Controller CPU

RSP

Remote

(REM)

(Analog signal)

Program Control

page 1-12

), using contact

” in the next section. The

Control output

OUT

Switching between Auto (AUT), Manual (MAN), and Cascade (CAS)

When set to auto, the control output value (OUT) is computed from the deviation between the PV

input and the SP. When set to manual, the control output value (OUT) that is set manually is

used rather than the computed control output value (OUT). Switching to “cascade (CAS)” is

possible only when the control mode is set to “cascade control.” In cascade control, the primary

PID control output is used as the SP of the secondary PID control.

Switching between Run (RUN) and Stop (STP)

When the operation is stopped, the control output value (OUT) is set to the preset value.

Single-loop control

Manual operation

Manual (MAN)

Preset output

Stop (STP)

PV input

PV

Controller CPU

Output limiter

Run (RUN)

Control output

SP

Auto (AUT)

OUT

Cascade control

PV input 1

(Cascade primary)

PV1 PV2

Controller CPU 1

Cascade

Manual (MAN)

SP1

PV input 2

(Cascade secondary)

SP2

Auto/

Manual

Controller CPU 2 Manual operation

Cascade/

Auto

(CAS/AUT)

Output limiter Preset output

Run (RUN)Stop (STP)

Control output

OUT

Enabling/Disabling Auto-Tuning

In PID control, the optimum PID constant is set automatically when auto-tuning (see

page 1-52

) is performed. Auto-tuning is possible only during auto operation.

Contact Input

Contact input can be used to carry out operations such as running/stopping operation,

switching operation modes, changing SPs, switching PV inputs (during loop control with

PV switching). For a description on the possible operations, see “Contact Input

Information Registration” on

1-6 IM 04L31A01-03E

page 1-23

.

Page 21

1.2 Control Function Overview

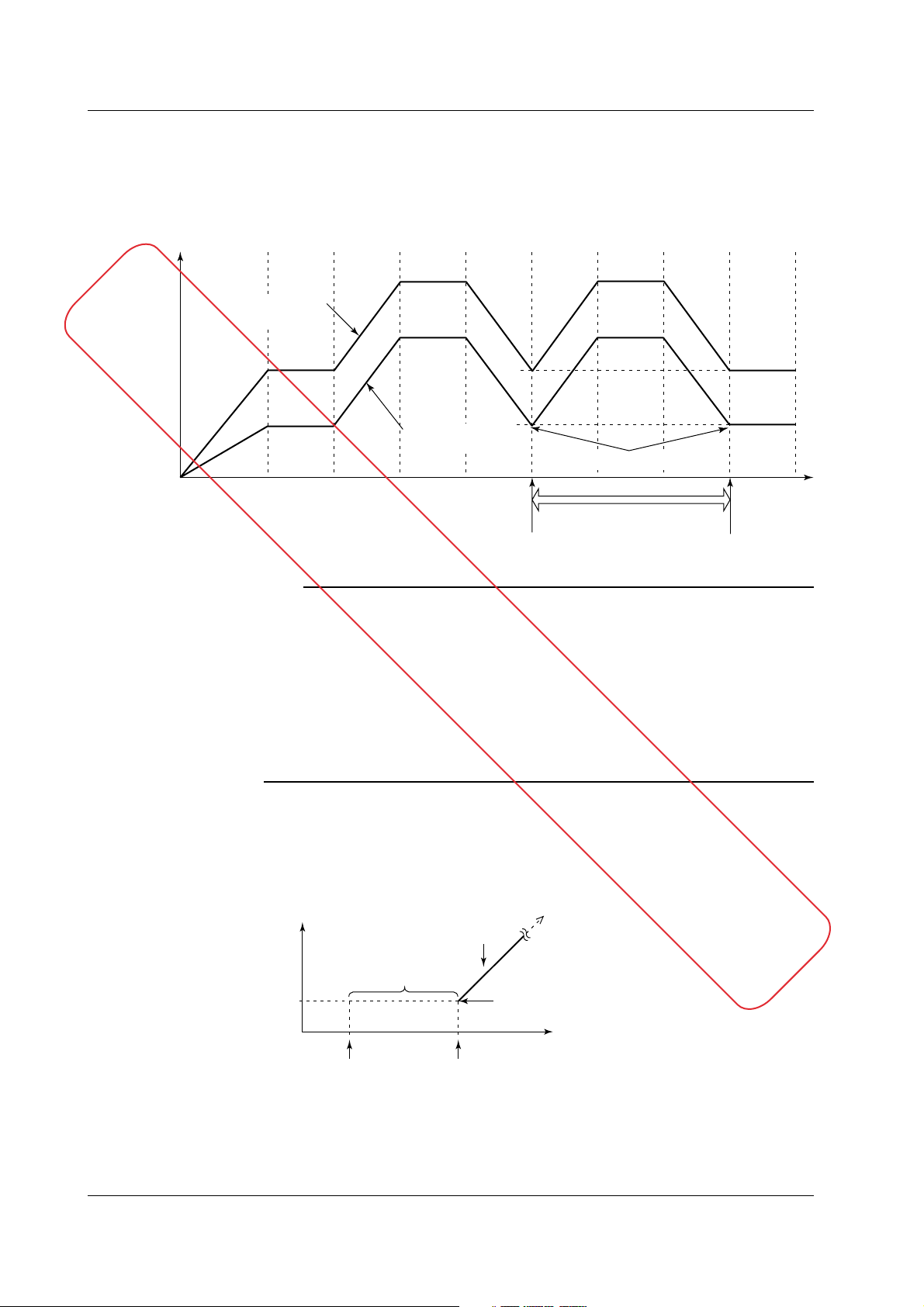

Program Control (Optional Function)

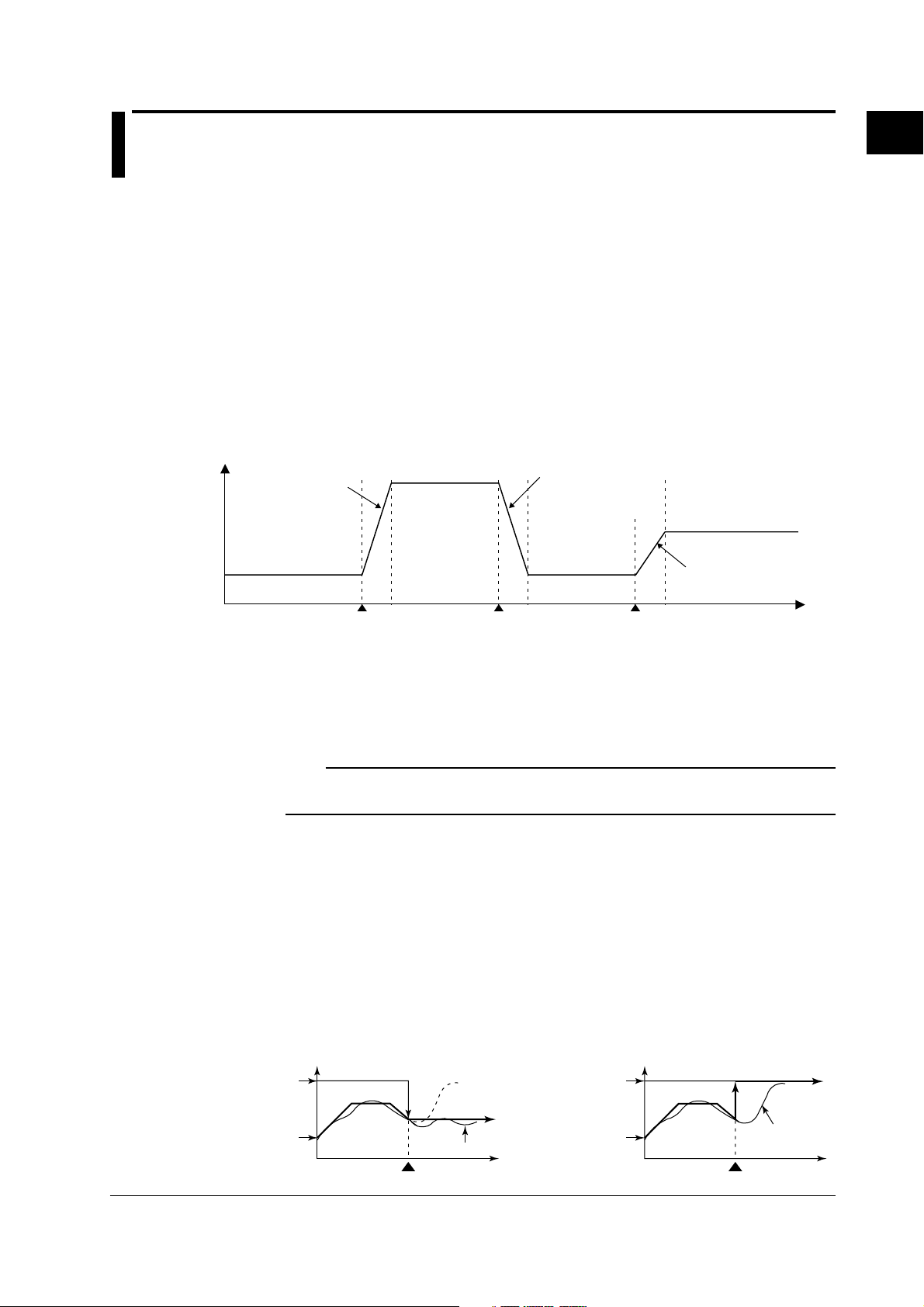

This function is used to ramp-up or ramp-down the SP according to a program pattern. You can

set multiple program patterns (up to 30) and switch among them according to the operating

condition. A program pattern consists of multiple program segments.

There are two methods in selecting the PID constant in program control. One is the

“segment PID method” in which the PID constant is switched every segment according to

the program pattern setting; the other is the “zone PID method” in which the PID

This function cannot be used on the current version of the CX1000.

The infomation given here may change in the future.

constant is automatically switched according to the PV. The “segment PID method” is

used when a different PID constant is required in the same PV region when the

temperature is rising and when the temperature is falling.

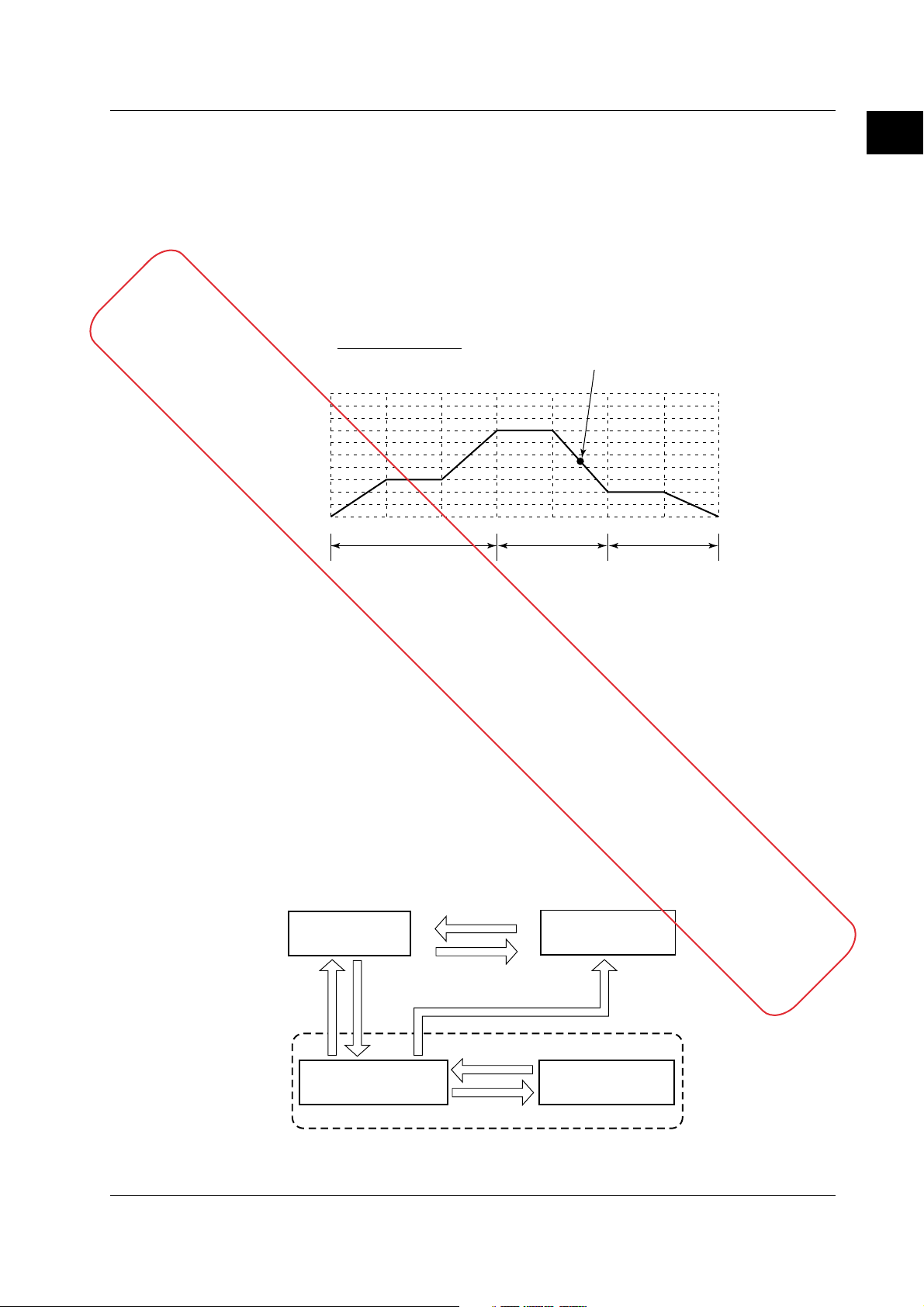

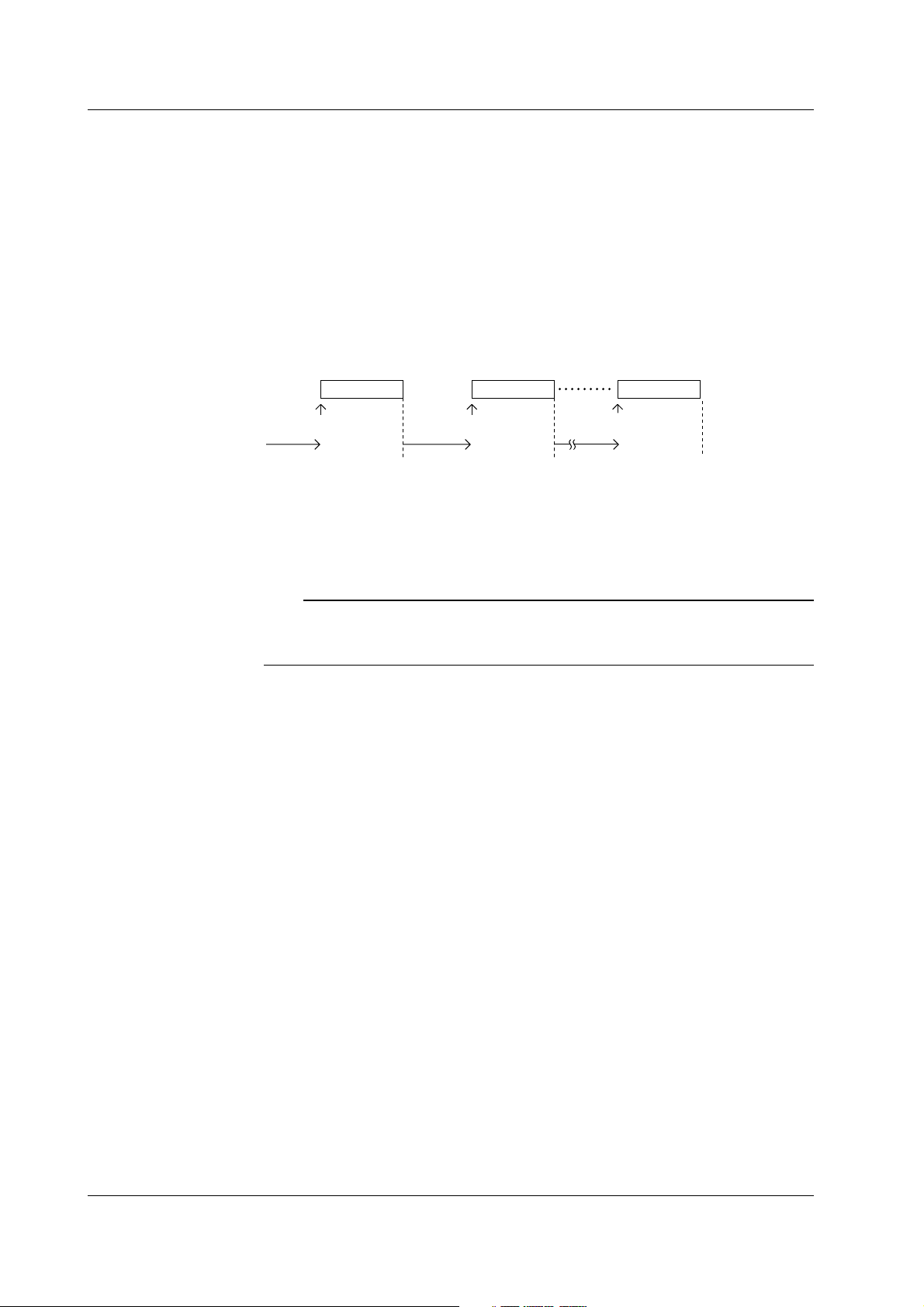

Segment PID method

PV

1000.0

500.0

0.0

SEG1 SEG2 SEG3 SEG4 SEG5 SEG6 SEG7

No.2 PID

Setting the Operation for Program Control

Settings include the number of repetitions of the program pattern (repeat function), delay

function (wait function) for the case when the PV cannot follow up the SP, and alarm

output/event output assignments (contact output assignments) according to the program

progression.

Operation Mode during Program Control

The following 4 types of operation modes are available.

• Program operation mode

Condition in which control is carried out according to the program pattern.

• Hold operation mode

Condition in which program operation is paused.

• Reset mode

Condition in which program operation is stopped. All event outputs are cleared (off).

• Local operation mode

Mode in which fixed-point control is performed independently from the program

operation condition.

No.1 PID No.3 PID

The PID constant of PID No. 1

is used in the 5th segment (SEG5).

1

Explanation of Functions

IM 04L31A01-03E

RESET

Reset mode

RESET

Program operation mode Hold operation mode

Since the remote input cannot be used for the SP during program control, there is no

remote/local switching operation.

RUN

RUN per

loop

Release HOLD

HOLD

Program operation

Local operation mode

LOC

1-7

Page 22

/

1.2 Control Function Overview

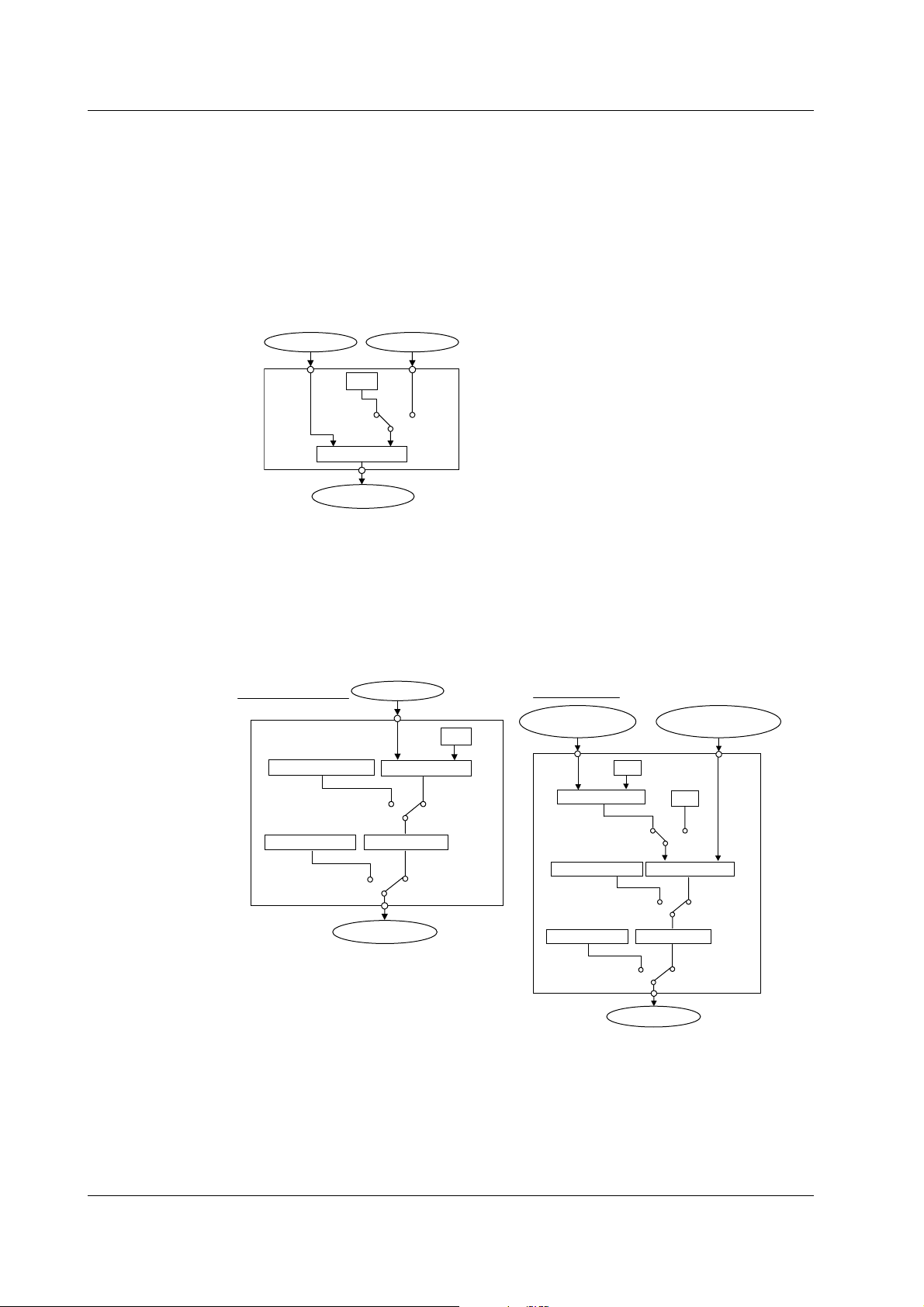

Flow of Setup Procedure

Below is a standard flow of setup procedure in executing control for the first time using

auto operation.

Power ON

Initial settings include the following

parameters.

Set SP

Set relay hysteresis

Set other control

parameters

Set alarm-related

parameters

Operating condition

Stop control

Initial settings

PID control or

ON/OFF control?

Set SP

Section 1.10

Set PID parameters

Set alarm-related

parameters

Start a test run

Operating condition

Adjust control

Start actual operation

Initial settings

Basic control settings

PV input related settings

Contact input/output

*

*

Set in

"Control Output Type"

PID controlON/OFF control

of basic control settings

related settings

Control output

suppression

→ Section 1.3

→ Section 1.4

→ Section 1.5

→ Section 1.6

→ Section 1.7

→ Section 1.10

• Auto tuning

• Manual tuning → Section 1.12

• Other adjustments

(Parameters that cannot be changed

during operation → section 6.1)

When using program control, set the items that include “Program control: On” in “Basic

control settings” indicated above. Then, carry out the following settings in addition to

“Target setpoint/PID parameter settings.”

Settings for program control

This function cannot be used on the current version of the CX1000.

The infomation given here may change in the future.

Pattern initial setting

Wait operation setting

Pattern start setting

Program pattern setting

Event setting

Event output setting

Repeat action setting

Operation start time

Start segment number

*

The operation start time and start segment number is set using key

operations on the operation screen.

→ Section 1.11

Pattern initial setting:

Set the pattern numbers, pattern off/on, number of

segments used, segment assignment method, and

edit segment number.

Wait operation setting:

Set wait zone off/on, wait zone settings, and timer.

Pattern start setting:

Set starting target setpoint and start code (operation

start condition).

Program pattern setting:

Set segment numbers, ramp/soak, final target setpoint,

segment time, ramp-rate-time unit, ramp-rate, segment

PID group numbers, operation at the time of segment

switching, wait operation type, and wait numbers.

Event setting:

Set event types, loop number/type/setpoint (only when

PV event is selected), time event ON/OFF, and ON time

OFF time (only when time event is selected).

Event output setting:

Set the event type, relay output ON/OFF, and relay

output number.

*

Repeat action setting:

Set the repeat function, number of repetitions, start

*

segment number, and end segment number.

1-8 IM 04L31A01-03E

Page 23

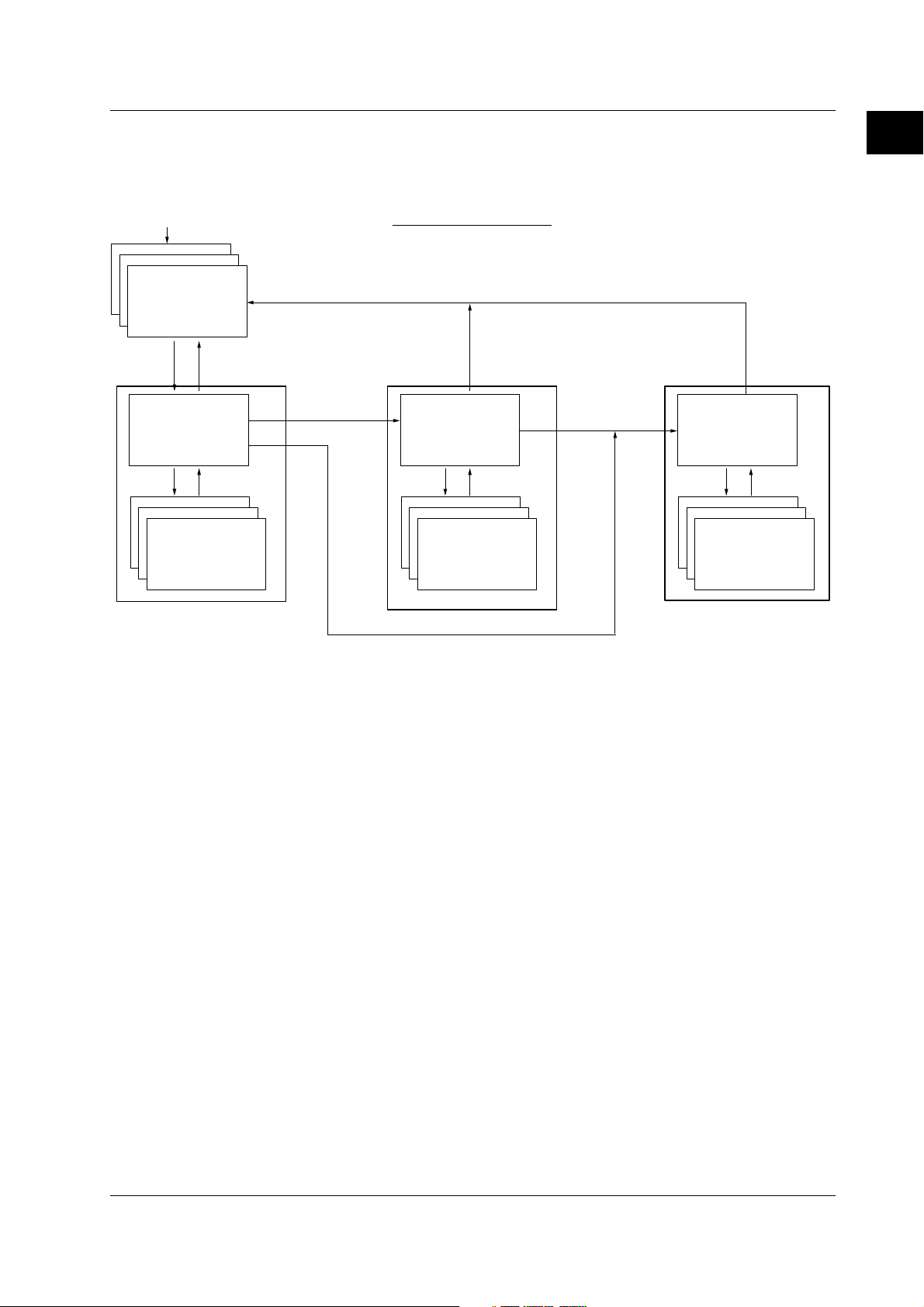

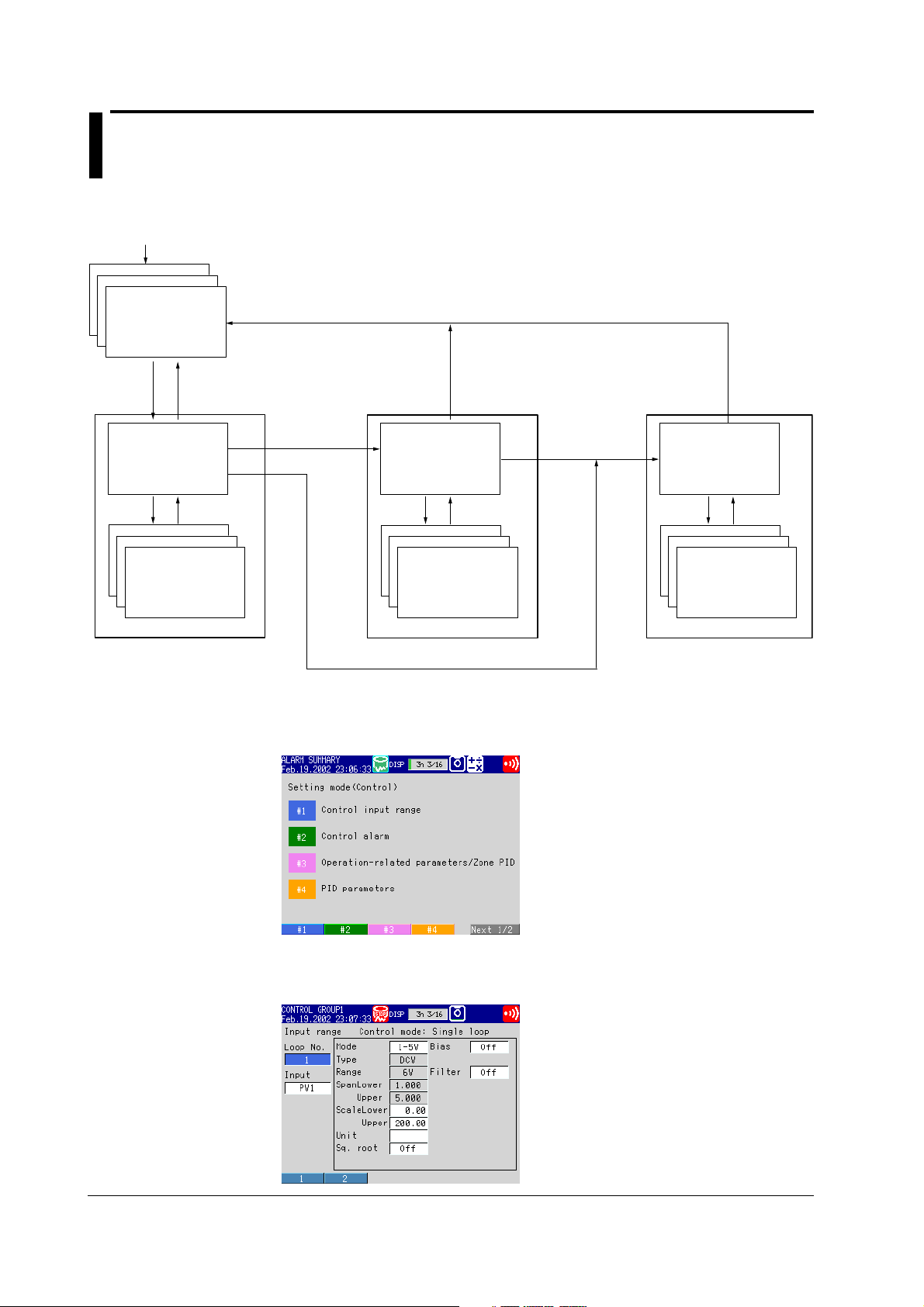

1.2 Control Function Overview

Switching Displays

Power ON

Operation display

MENU key

Soft keys

Operation mode

ESC key

Control setting mode

[Setting mode (Control)]

Menu

MENU key or

ESC key

Setup display

(#1 to #7

*

)

Control-related settings are entered in basic setting mode and control setting mode. In

addition, settings common to control and measurement are entered in the common and

measurement setting mode.

Display Transition Diagram

[End] soft key -> DISP/ENTER key

(This operation saves the settings made

in the basic setting mode.)

MENU key or ESC key

MENU key

Press the FUNC

key for 3 s

Soft keys

Common and measurement setting mode

[Set mode]

Press the FUNC

Menu

MENU key or

ESC key

Setup display

(#1 to #11)

key for 3 s

Soft keys

Basic setting

mode

Menu

ESC key

Setup display

(#1 to #12

**

)

1

Explanation of Functions

*

#1 to #8 when program control

is ON.

**

#1 to #11: Basic common and

measurement settings

#12: Basic control settings

Basic Control Setup Items in Basic Setting Mode

#1 Control action

PID number, control period, zone PID, restart mode, restart mode (program) (only on

models with the control option), initial PID, auto tuning, control mode, method (only

during loop control with PV switching), program control ON/OFF (only on models with

the program control option), and PID control mode.

#2 Input setting

Burnout and RJC.

#3 Contact input-registration

Contact input registration

#4 AUX

Remote setting, alarm mode, and SP number selection source.

#5 Output processing

Control output, cycle time, and analog-output type

#6 Relay

FAIL ON/OFF, self diagnosis ON/OFF, and relay action/behavior (energize/deenergize, hold/nonhold)

#7 Tuning setting

Tuning item selection

#8 External loop setting (For details on the settings, see the

Communication Interface User’s Manual

.)

CX1000/CX2000

Setup Items in the Control Setting Mode

#1 Control input range

Input type, mode, type, range, span, scale, unit, square root, low-cut, bias, filter, and ratio.

#2 Control alarm

Type, standby, relay output ON/OFF, and alarm value

IM 04L31A01-03E

1-9

Page 24

1.2 Control Function Overview

#3 Operation-related parameters/Zone PID

#4 PID parameters

#5 Control group setting

#6 Ten-segment linearizer I/O

#7 Program control (only when program control is ON)

#8 Detailed setting (“#7” when program control is OFF)

Suppressing function, ramp-rate-time unit, SP ramp-down-rate/SP ramp-up-rate, tag,

tag comment, reference point (when zone PID is selected), switching hysteresis

(when zone PID is selected), and reference deviation (when zone PID is selected).

SP, PID constant, output limit, shutdown ON/OFF, manual reset, relay hysteresis

(only during ON/OFF control), reverse/direct, and preset output.

Group name, kind (internal loop/external loop/measurement channel), and number.

Input type, mode, and biasing or approximation input/output values.

#1Program parameter setting

Pattern initial setting, wait action setting, program start setting, program pattern

setting, event setting, and repeat action setting.

#2Event output setting

Event kind, relay output ON/OFF, number, and program pattern end signal relay

output ON/OFF.

#3AUX (Auto message, Display position)

Auto message for program Run/Reset and Program display position.

#1Control function

SP tracking, PV tracking, SP limiter, output velocity limiter, and anti-reset windup

auto/manual.

#2Hysteresis (Alarm and PV event)

Alarm hysteresis and PV event hysteresis

1-10 IM 04L31A01-03E

Page 25

1.2 Control Function Overview

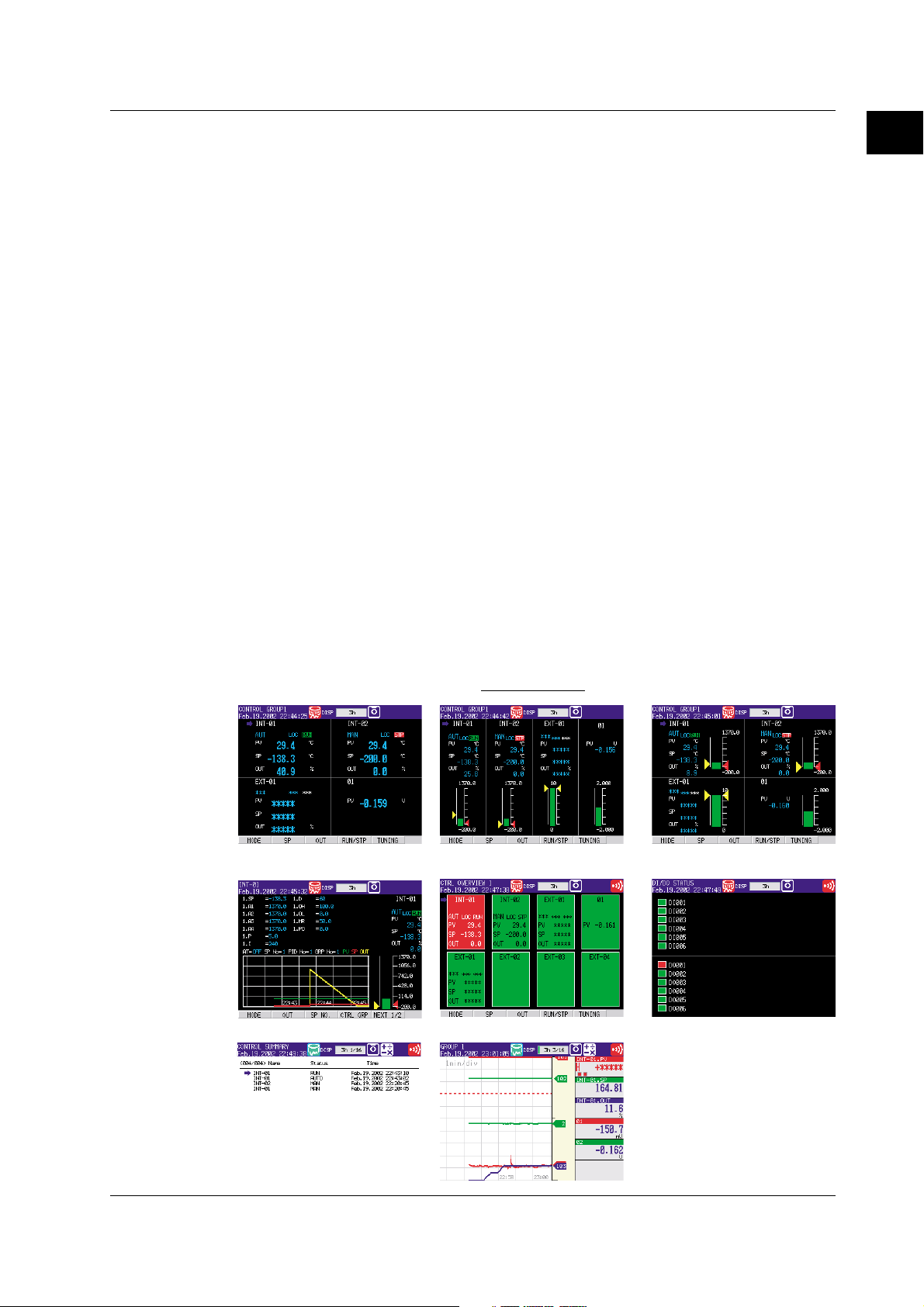

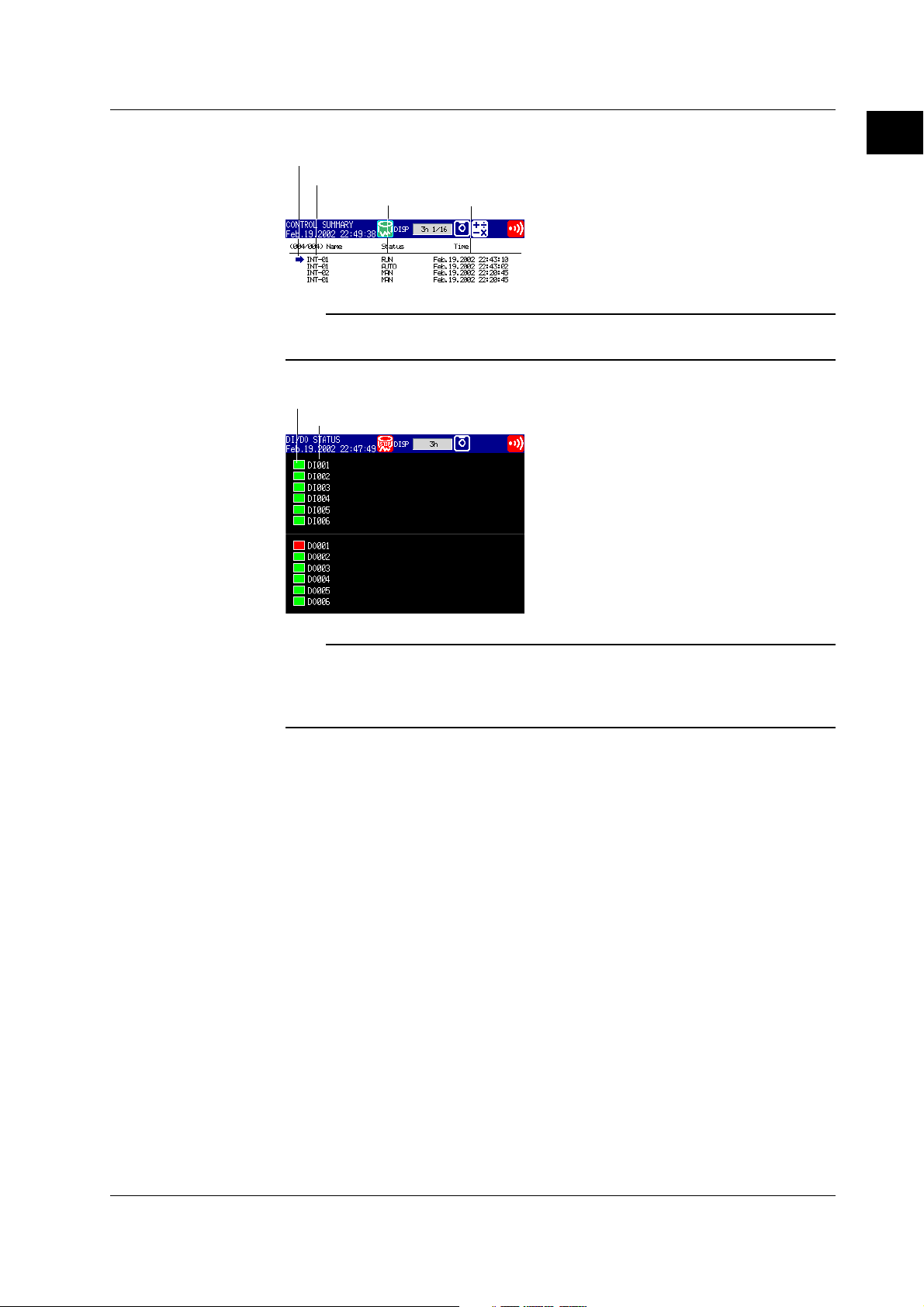

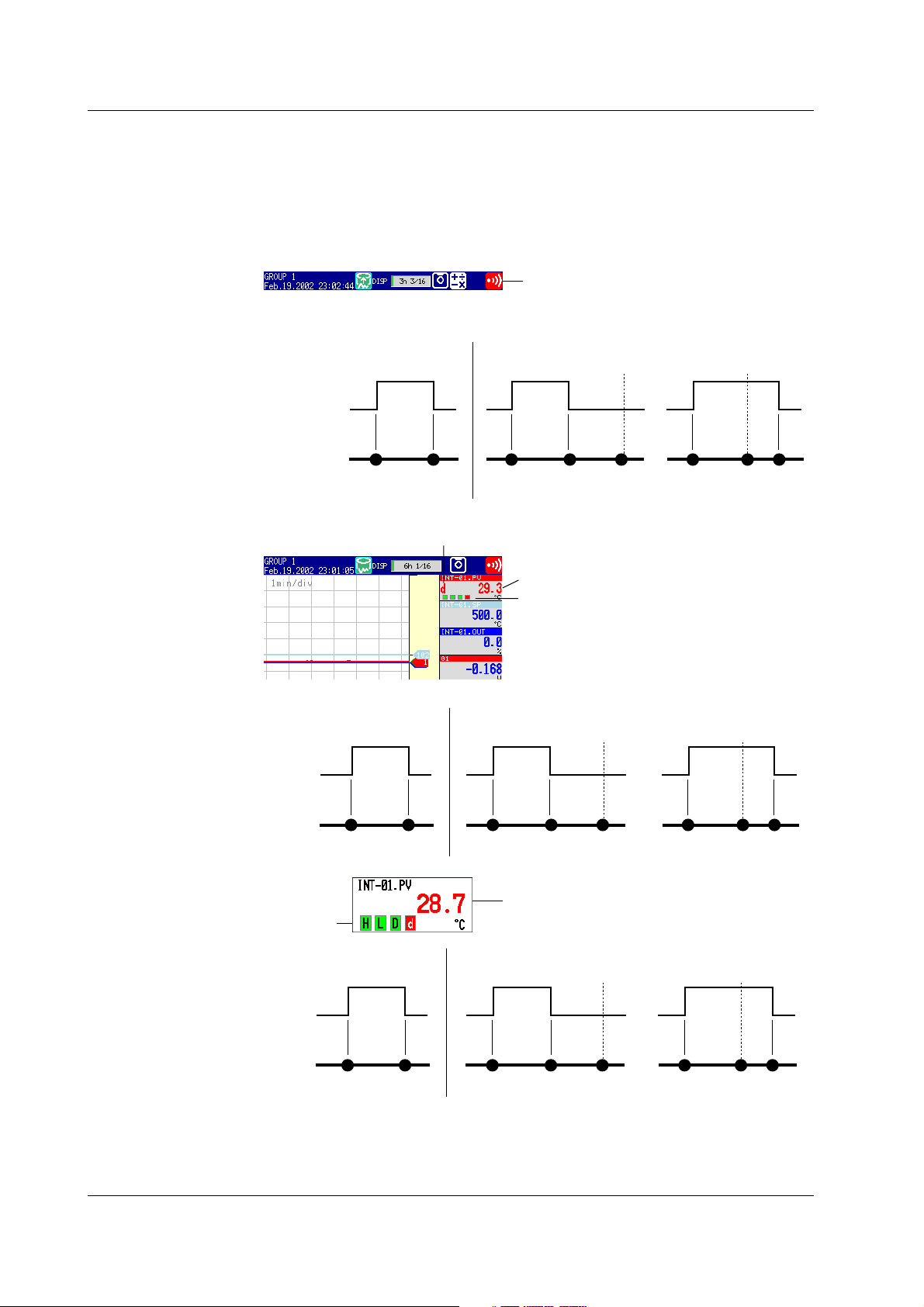

Control Operation Display

In operation mode, the following control operation displays can be shown.

• Control group display

This display is used to monitor the control status of multiple loops simultaneously

including external loops. You can select from three display styles as shown in the

display example in the figure below. If you include the measurement channels for the

measurement function in the group, you can also monitor the measured values on the

measurement channels at the same time on this display.

• Tuning display

This display is used to optimize (tune) the control parameters such as PID constants.

• Overview display

This display is used to monitor the alarm status of all control loops.

• DI/DO status display

Displays the ON/OFF status of the current contact input (DI) and contact output (DO).

• Control action summary display

Displays a log of control actions such as operation run/stop and auto/manual

operation switching.

On models with the program control function option, the following additional displays are

available: 1) the program operation display, which can show the pattern and current PV

accumulated on the screen during program operation and 2) the program event

summary display, which shows a log of time events and PV events that occurred during

program operation. Displays common with the measurement function include: 1) the alarm

summary display, which shows a log of alarm occurrence status and 2) the memory summary

display, which shows the file information of the internal memory. In addition, the values of PV,

SP, and OUT can be assigned to channels, and the trends of these channels can be displayed

along with the trends of measurement channels on the trend display of the measurement

function.

• Control group display

1

Explanation of Functions

Display Examples

IM 04L31A01-03E

• Tuning display

• Control operation summary display

Faceplate style Hybrid styleController style

• Overview display

• Trend display

• DI/DO status display

1-11

Page 26

1.2 Control Function Overview

Saving Data

Acquisition to the Internal Memory

Along with the measurement data, the data of SPs, PVs and OUT, and event information

for control are acquired to the internal memory.

Saving Data to the External Storage Medium

You can save the data acquired in the internal memory to an external storage medium

(floppy disk, Zip disk, or ATA flash memory card).

Floppy disk

Communications

CX

1

6

26

21

16

11

2

7

27

22

17

12

DISP

3

8

4

9

5

10

/ENTER

28

23

18

13

29

24

19

14

30

25

20

15

• Control setup data

• Measurement setup data

Zip disk

ATA flash memory card

• Measured data

The following communications functions are available. For a description on the handling

of the communications function and the software “DAQSTANDARD for CX” that comes

with the package, see the respective manuals.

Communications with Controllers

The CX1000 can communicate with UT Series Controllers made by Yokogawa M&C

Corporation to transmit/receive control parameters and receive PV data. Up to four

external loops can be constructed.

CX

1

6

26

21

16

11

2

7

27

22

17

12

DISP

3

8

4

9

5

10

/ENTER

28

23

18

13

29

24

19

14

30

25

20

15

Controllers

Up to four units (four loops)

Communications with PLCs

The CX1000 can carry out ladder communications between PLCs (sequencers).

PLCs (such as the FA-M3 by YOKOGAWA)

CX

1

6

26

21

16

11

2

7

27

22

17

12

DISP

3

8

4

9

5

10

/ENTER

28

23

18

13

29

24

19

14

30

25

20

15

CX

11

16

21

26

6

1

12

17

22

27

7

2

8

3

9

4

10

5

DISP

/ENTER

13

18

23

28

14

19

24

29

15

20

25

30

Up to 32 units

Communications with PCs

The CX1000 can communicate with PCs.

• Modbus master/slave

CX

1

6

26

21

16

11

2

7

27

22

17

12

DISP

3

8

4

9

5

10

/ENTER

28

23

18

13

29

24

19

14

15

30

25

20

PC

• Dedicated protocol communications

with the PC (Command communications)

• Display settings/data of the CX using

“DAQSTANDARD for CX”

1-12 IM 04L31A01-03E

Page 27

1.2 Control Function Overview

1.3 Basic Settings of Control

PID Group Number

You can set up to eight groups of control parameters (“PID parameters” on the setting

display) that you wish to change collectively through control. You set the number of

groups to be used from 1 to 8. For example, if you set a value of 4, the selectable PID

numbers will be 1 through 4. The parameters that are included in a single control

parameter group vary depending on the control method (“Control output” in the settings).

During PID control: SP, PID constant, output lower/upper limit, shutdown ON/OFF

(only when outputting 4-20 mA of current), manual reset, reverse/

direct, and preset output

During ON/OFF control: SP, relay hysteresis, reverse/direct, and preset output

Control Period

The following control periods can be selected:

250 ms (initial value), 500 ms, and 1 s.

The control period is common to all loops. When the A/D integral time is set to 100 ms,

the control period is fixed to 1 s.

The scan interval of control PV input is the same as the control period.

PID Selection Method (Zone PID ON/OFF)

Select either one from below. When program control is ON on models with the program

control option, the selection is between the segment PID method (zone PID OFF) and

the zone PID method.

• Target setpoint selection method (zone PID: OFF) (initial value)

In the target setpoint selection method, the operator can switch up to 8 SPs as

necessary. There are two methods in switching the SPs. One method is to specify

the SP number (SPs are registered to PID numbers (= SP numbers) along with PID

constants and other parameters) using keys on the front panel. The other is to use

external contact input or communications. The SP can be switched at any time.

During switching, the setpoint ramp-up-rate or setpoint ramp-down-rate setting is

activated. In addition, when a switch is made, control computation is performed using

the PID constant group that corresponds to the SP at that point.

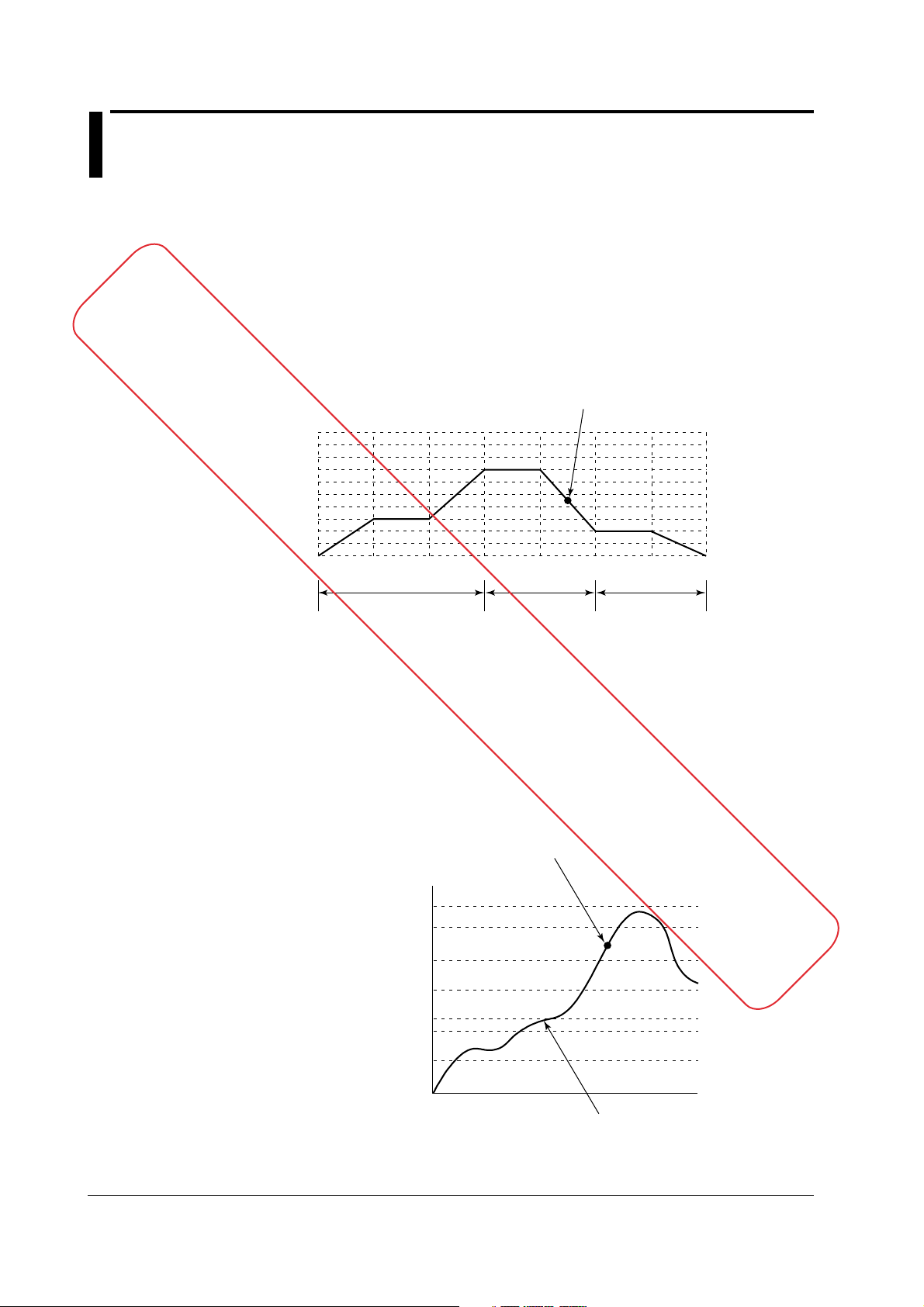

PV

Rise according to

ramp-up setting

(No.1 PID)

the setpoint

SP1

Switch from SP1 to SP3 Switch from SP3 to SP1 Switch from SP1 to SP2

SP3

(No.3PID)

Fall according to

the setpoint

ramp-down setting

SP1

(No.1 PID)

1

Explanation of Functions

SPn: SP number

SP2

(No.2PID)

Rise according to the

setpoint ramp-up setting

Time

IM 04L31A01-03E

1-13

Page 28

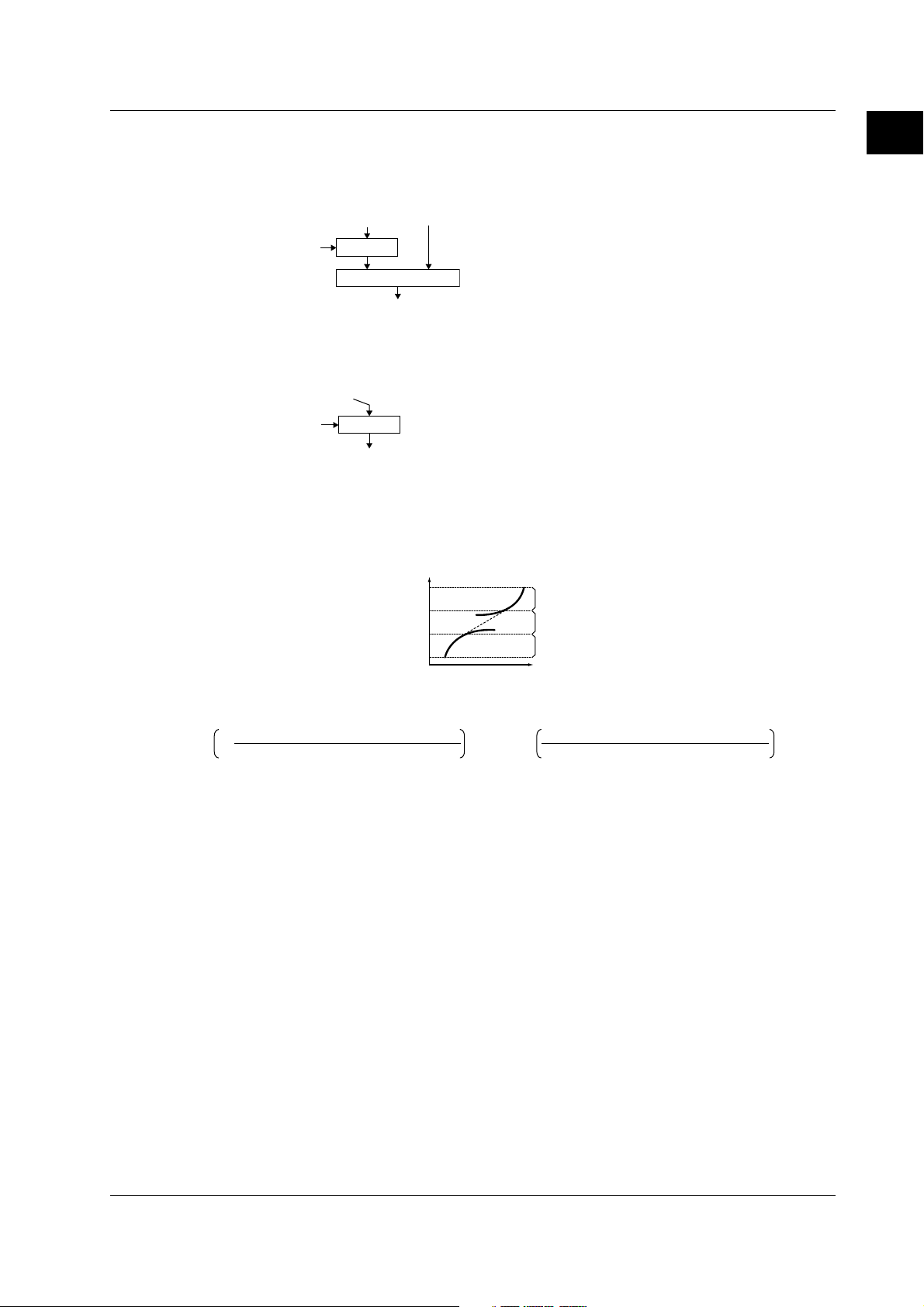

1.3 Basic Settings of Control

• Zone PID method

In the zone PID method, the measurement span is divided into a maximum of seven zones

using reference points. The optimum PID constant is preassigned to each zone, and the

PID constant (in actuality, other control parameters that are registered using the PID

number are included) is automatically switched according to the PV.

The number of reference points that can be specified is “PID group number – 2.” As shown in

the figure below, if the PID group number is 7, the number of reference points is 5. If the

number of reference points is 5, there are 6 zones. For example, if zones 1 through 6

correspond to PID numbers 1 through 6 and if the PV is within the zones of reference points 3

and 4, the control parameters of PID number 4 are selected. The control parameters of PID

number 7, which cannot be assigned to a zone, are selected when the deviation between the

SP and PV becomes greater than the preset reference deviation.

Maximum value of

measurement span

Reference point 5

Reference point 4

Reference point 3

Reference point 2

Reference point 1

Minimum value of

measurement span

If the current PV here,

control using thePID

constant of No. 4.

Restart and Restart for Program Control

Select how the CX1000 is to behave when an extended power failure occurs during control

operation (power failure period of 5 s or more) and the power recovers.

• Continue (initial setting):

Continue the operation before the power failure occurred.

• Manual operation:

Start from the manual operation condition.

• Auto operation (only during fixed-point operation):

Auto operation by continuing the operation before the power failure occurred.

• Reset (only during program operation):

Stop the program operation.

Change in the

PV.

No.6 PID

No.5 PID

No.4 PID

No.3 PID

No.2 PID

No.1 PID

Note

If the duration of the power failure is less than or equal to 2 s (a short power disruption), the

operation before the disruption continues. If the duration is between 2 to 5 s, the behavior for a

short power disruption or an extended power failure is carried out depending on the condition.

Initial PID

Select whether the initial PID constant in PID parameter settings (see

optimized to temperature control, pressure control, or flow control. Below are the initial

values of PID constants.

Initial values for temperature: P = 5.0%, I = 240 s, and D = 60 s.

Initial values for pressure/flow: P = 120.0%, I = 20 s, and D = 0 s.

page 1-28

) is

Control Mode

The following three control modes are available. The mode is selected for each control loop.

• Single-loop control

Basic control consisting of a single system of controller CPU.

PV

PIDSP

OUT

1-14 IM 04L31A01-03E

Page 29

1.3 Basic Settings of Control

Process value = 1–

• Cascade control

Control consisting of two systems of controller CPUs that uses the primary control

output as the secondary control SP. Continuous PID control is only possible for

primary control.

PV2

PID

OUT

SP

PV1

PID

• Loop control with PV switching

Single-loop control that switches between two PV inputs (PV1 and PV2) according to

the following conditions.

PV1

PV2

PIDSP

OUT

Input Switching Condition ([Method] on the setting display)

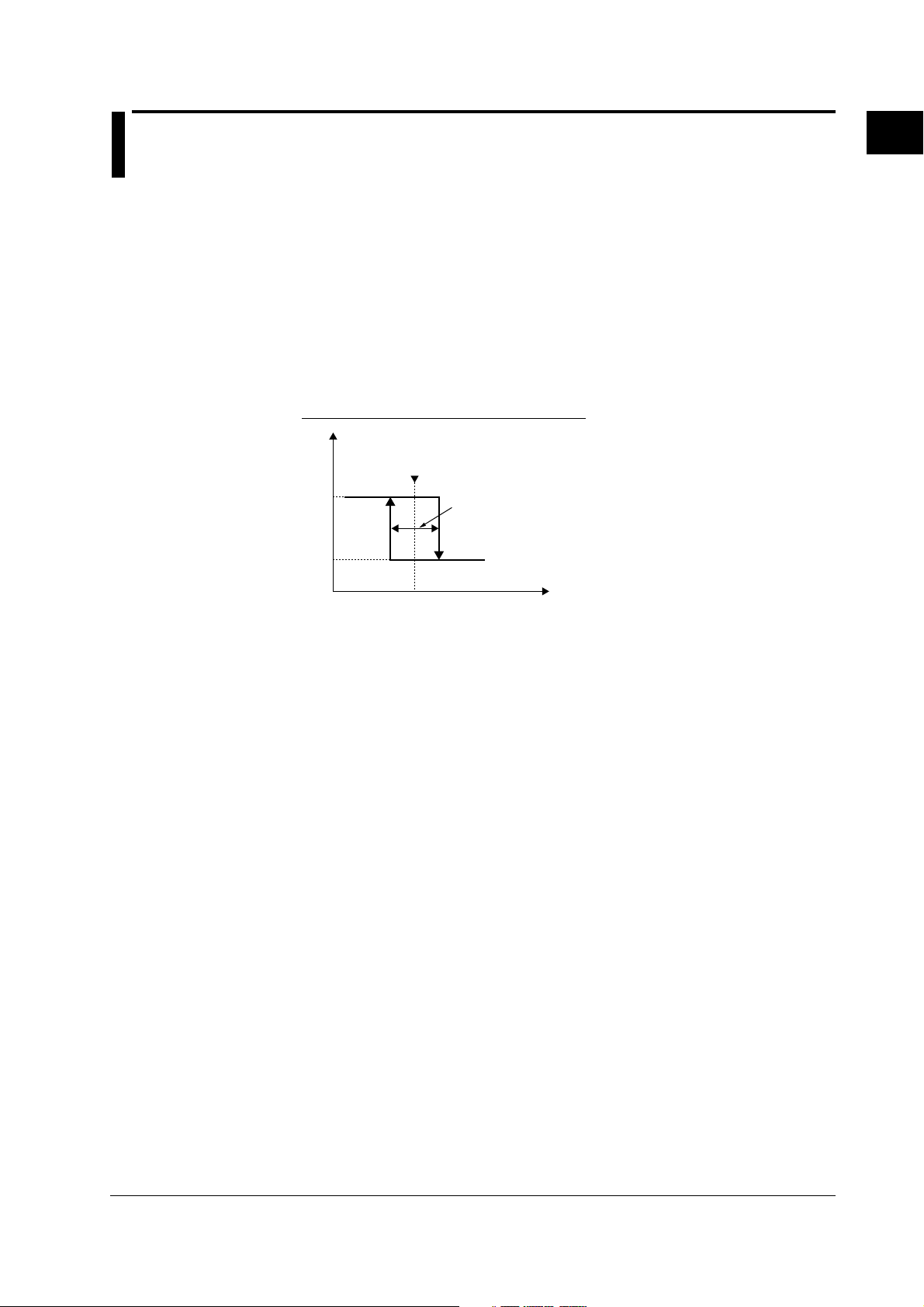

• Auto switching according to the PV range ([Range] on the setting display)

Switches PV inputs (PV1 and PV2) automatically according to the preset “PV

switching low-limit” and “PV switching high-limit” as shown in the following figure.

However, PV1 must be less than PV2.

PV range high limit

PV switching high limit

PV switching low limit

PV range low limit

PV

The PV value is computed using the following equation when “PV switching lower limit

< PV1 ≤ PV switching upper limit” and “PV switching lower limit ≤ PV2 < PV switching

upper limit.”

PV input 1 – PV switching low limit

PV switching high limit – PV switching low limit

• Auto switching according to the PV switching upper limit ([PVHigh] on the setting display)

The preset “PV switching upper limit” and PV1 are compared. Auto switching is

performed according to the following conditions. The switching hysteresis is

approximately 0.5% of the PV range span.

When PV1 ≤ PV switching upper value: Switch to PV1

When PV1 > PV switching upper value: Switch to PV2

• Switching through control input ([Signal] on the setting display)

Input is switched using “PV switching (loops 1 and 2)” (see page 1-23) as follows:

Contact input is OFF: Switch to PV1. Contact input is ON: Switch to PV2.

PV2

Process value according

to the equation

PV1

× PV input 1+ × PV input 2

PV input 1 – PV switching low limit

PV switching high limit – PV switching low limit

1

Explanation of Functions

Program Control ON/OFF (only on models with the program control option)

Select whether to use the program control function. For a description on the settings for

program control, see

IM 04L31A01-03E

section 1.11, “Program Control Related Settings.”

1-15

Page 30

1.3 Basic Settings of Control

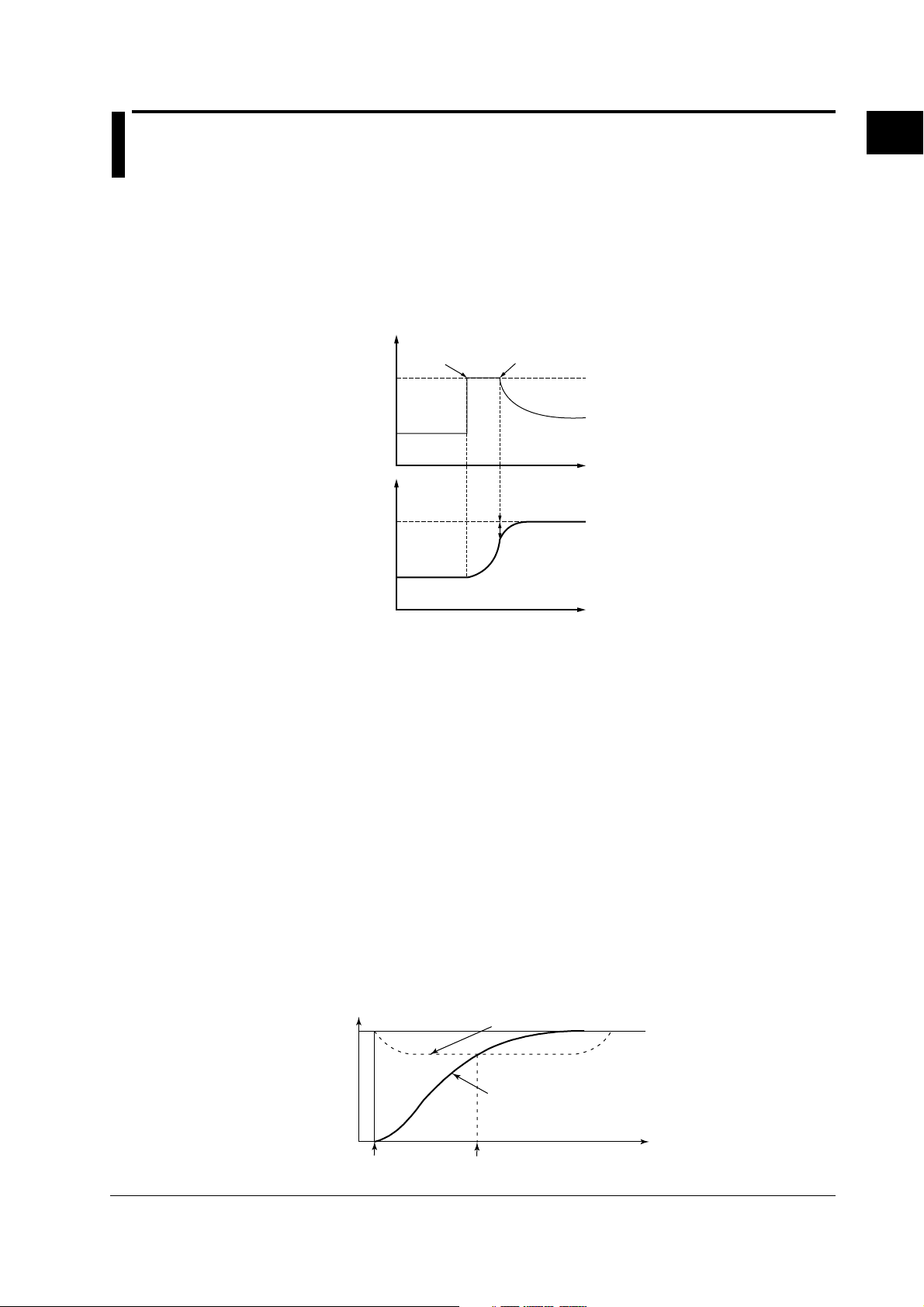

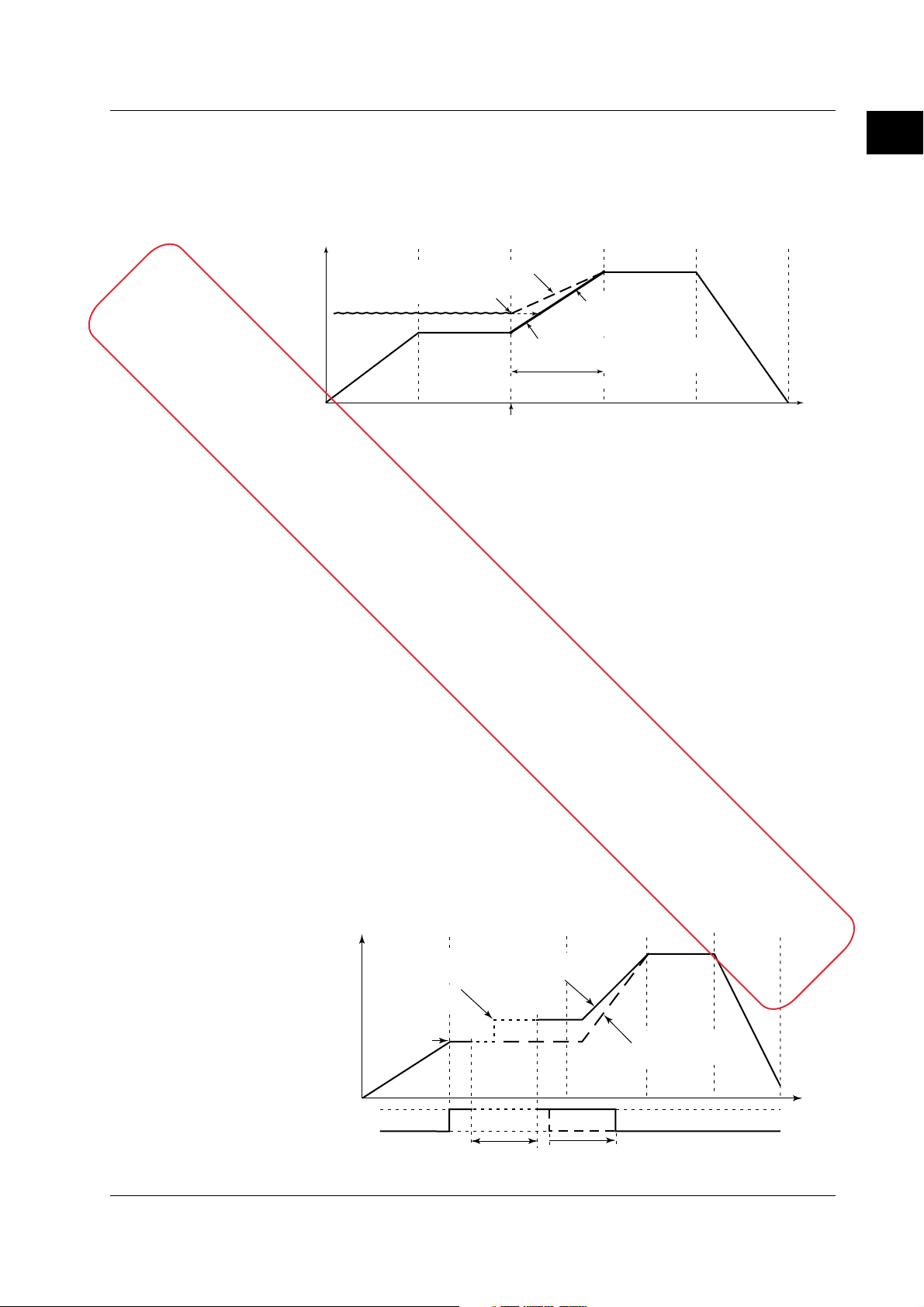

PID Control Mode

There are two PID control modes: standard PID control mode and fixed-point control mode. To

control the output so that the PV reaches the new SP quickly after the SP is changed, select

“standard PID control mode.” To perform a continuous fixed-point control, select “fixed-point

control.” As shown in the figure below, the control behavior varies depending on the selected

PID control mode. There are two control methods: PV derivative type PID control method and

deviation derivative type PID control method. As shown in the figure below, the control method is

automatically selected. In addition, the presence or absence of the control output bump at the

point of change of the SP is automatically selected. When performing program control in

standard PID control mode on models with the program control option, deviation derivative type

PID control is used during operation (except during hold and soak) and on the secondary loop of

cascade control. For all other cases, PV derivative type PID control is used.

Type of PID

Control Mode

Standard PID

control mode

(Initial value)

Control Method Description of the Control Operation

PV derivative type PID

During operation in local

mode or auto mode

(only the primary side

during cascade control)

With bumps in the control

output at the time the SP

is changed

Deviation derivative

type PID

During operation in remote

mode (secondary side

during cascade control)

Employs a PV derivative type PID so that the output reaches

the new SP quickly after the target setpoint is changed. In PV

derivative type PID, the proportional terms (P) that are

proportional to the deviation that occurred due to the SP change

are output immediately, forcing the process value to quickly reach