Page 1

User's

Manual

CW500

Power Quality Analyzer

User’s Manual

IM CW500-01EN

1st Edition

Page 2

Thank you for purchasing the CW500 Power Quality Analyzer. This user’s

manual explains the features and operating procedures of the CW500.

To ensure correct use, please read this manual thoroughly before

beginning operation. Keep this manual in a safe place for quick reference

in the event that a question arises.

The following five manuals, including this one, are provided as manuals

for the CW500.

Please read all manuals.

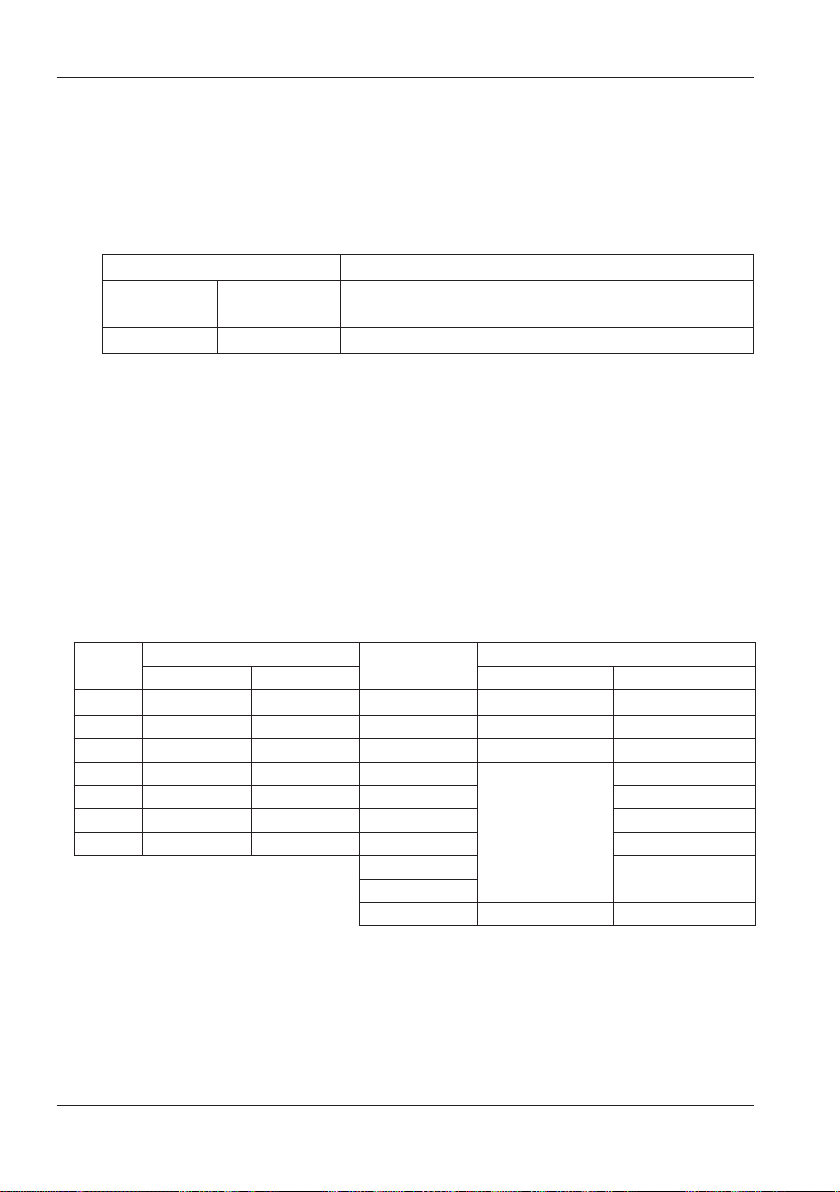

Manual Title Manual No. Description

CW500

Power Quality Analyzer

User’s Manual

IM CW50001EN

This guide. This manual

explains the CW500’s standard

features and how to use these

features.

Application Software

User’s Manual

IM CW50061EN

The supplied CD contains the

PDF file of this manual. This

manual explains how to use the

application software.

CW500

Power Quality Analyzer

Getting Started Guide

IM CW50002EN

The guide explains the

handling precautions and basic

operations of the CW500 and

provides a list of specifications.

Application Software

Installation Manual

CW500

IM CW500-62JA This manual describes how to

install the application software.

IM CW500-92Z1 Chinese document

Power Quality Analyzer

User’s Manual

The “-EN” in the manual number is the language code.

Contact information of Yokogawa offices worldwide is provided on the

following sheet.

Manual No. Description

PIM113-01Z2 List of worldwide contacts

1st Edition : September 2015 (YMI)

All Rights Reserved, Copyright © 2015 Yokogawa Meters & Instruments Corporation

IM CW500-01EN

i

Page 3

Notes

• The contents of this manual are subject to change without prior notice

as a result of continuing improvements to the software’s performance

and functionality. The figures given in this manual may differ from those

that actually appear on your screen.

• Every effort has been made in the preparation of this manual to ensure

the accuracy of its contents. However, should you have any questions

or find any errors, please contact your nearest YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual

without the permission of YOKOGAWA is strictly prohibited.

•

Trademarks

• Microsoft, Windows, Windows 7, and Windows 8 are either registered

trademarks or trademarks of Microsoft Corporation in the United States

and/or other countries.

• Adobe, Acrobat, and PostScript are either registered trademarks or

trademarks of Adobe Systems Incorporated.

• In this manual, the TM and ® symbols do not accompany their

respective registered trademark or trademark names.

• Other company and product names are trademarks or registered

trademarks of their respective companies.

Revisions

September 2015 1st Edition

ii

IM CW500-01EN

Page 4

Contents

Chapter 1 Product Outline

1.1 Feature Outline .....................................................1-1

1.2 Features ................................................................1-3

1.3 System Configuration Diagram .............................1-5

1.4 Measurement Procedure ......................................1-6

Chapter 2 Component Names

2.1 Display (LCD) and Control Keys ...........................2-1

2.2 Connectors ...........................................................2-2

2.3 Side Panel ............................................................2-3

2.4 Voltage Probe and Current Clamp-on Probe ........2-4

Chapter 3 Basic Operation

3.1 Description of Control Keys ..................................3-1

3.2 Marks Displayed in the Top Area of the LCD ........ 3-3

3.3 Display Symbols ...................................................3-4

3.4 Backlight and Contrast Adjustment .......................3-5

3.5 Screens and Screen Configuration .......................3-6

Chapter 4 Recording

4.1 Starting and Stopping Recording ..........................4-1

4.2 Starting to Record with “Quick start guide” ...........4-3

Chapter 5 Setup

5.1 Settings .................................................................5-1

5.2 Basic Setup ...........................................................5-2

5.3 Measurement Setup ...........................................5-12

5.4 Recording Setup .................................................5-25

5.5 Other Settings .....................................................5-31

5.6 Saved Data .........................................................5-36

IM CW500-01EN

iii

Page 5

Contents

Chapter 6 Display Items of Each Screen

6.1 Instantaneous Value (W) ......................................6-1

6.2 Integrated Value (Wh) ........................................... 6-9

6.3 Demand .............................................................. 6-11

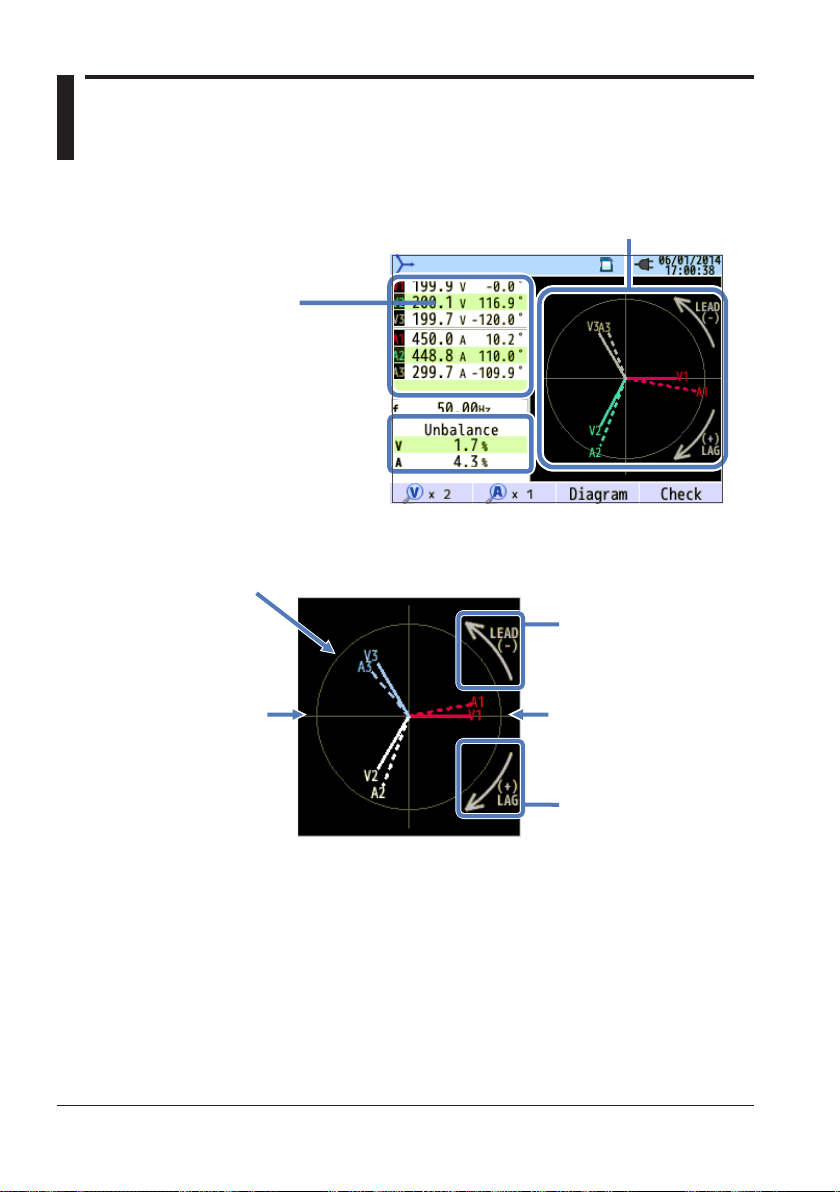

6.4 Vector ..................................................................6-14

6.5 Waveform............................................................6-17

6.6 Harmonics ...........................................................6-19

6.7 Power Quality .....................................................6-25

Chapter 7 Other Features

7.1 Other Features ......................................................7-1

Chapter 8 Connecting to Peripheral Devices

8.1 Transferring Data to a PC .....................................8-1

8.2 Signal Control with External Devices ....................8-2

8.3 Supplying Power through Measurement Lines .....8-5

Chapter 9 PC Software for Configuration and Analysis

9.1 PC Software for Configuration and Analysis .........9-1

Chapter 10 Troubleshooting

10.1 Troubleshooting ..................................................10-1

10.2 Error Messages and Corrective Actions .............10-3

iv

Appendix

When Using 96030, 96033, or 96036 ......................... App-1

Index

IM CW500-01EN

Page 6

Chapter 1 Product Outline

1.1 Feature Outline

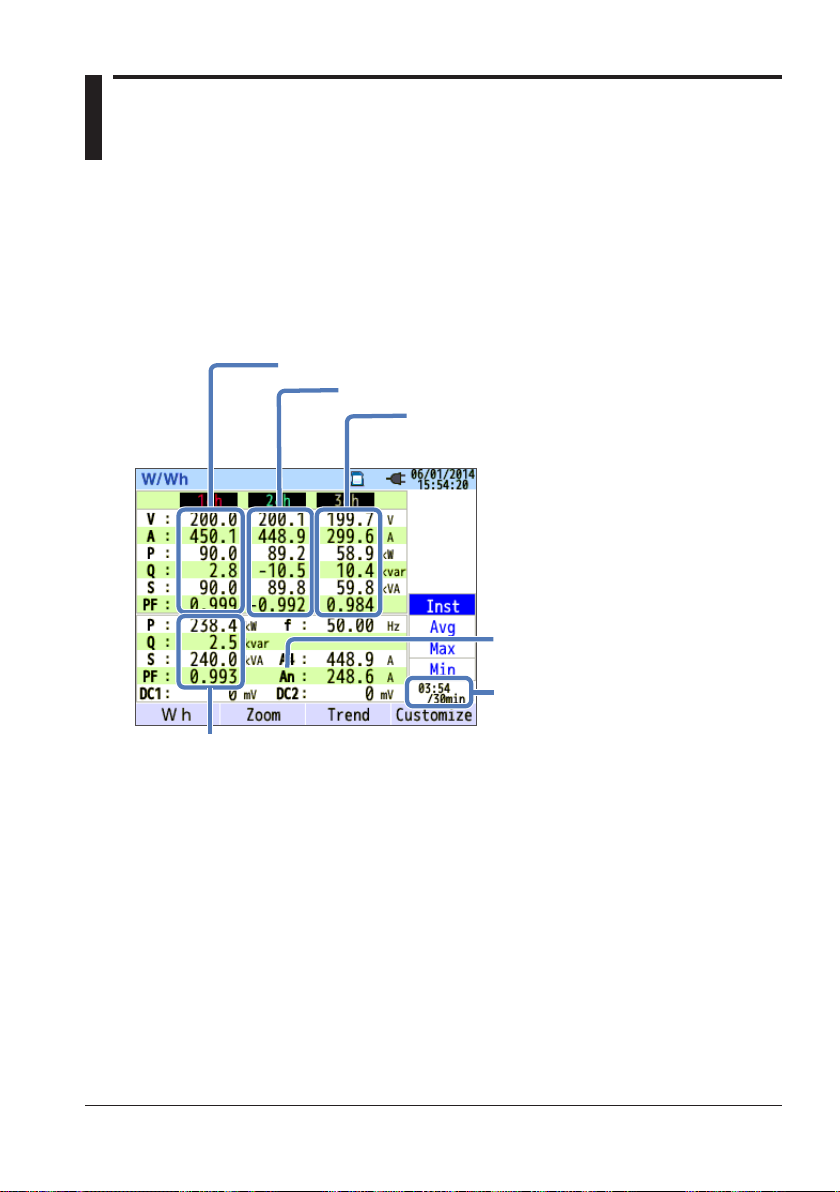

Displaying Instantaneous,

Integrated, and Demand

Displays instantaneous, average,

maximum and minimum values for

current, voltage, active power,

apparent power, and reactive power.

Switch the screen to display

integrated values. Set a demand

target value and display the demand

values from start to finish.

See “Displaying Instantaneous,

Integrated, and Demand.”

Starting and Ending Recording

Start recording normally or start by

following the Quick Start Navigation, which guides you through the

necessary setup for recording.

See “Starting and Stopping

Recording.”

IM CW500-01EN

Displaying Vectors and

Checking the Wiring

Displays a vector diagram of

voltage and current for the

measurement channel and

checks the wiring.

See “Vector.”

1-1

Page 7

1.1 Feature Outline

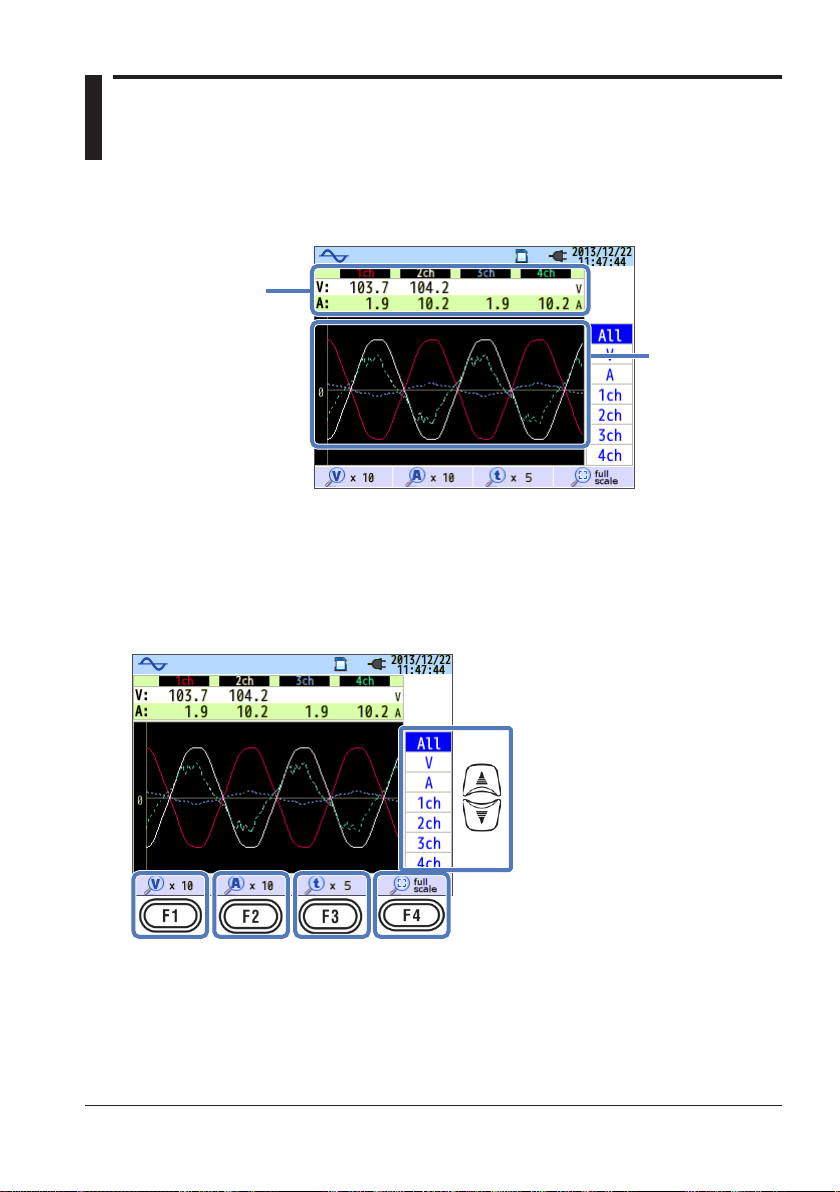

Displaying Waveforms

Displays waveforms of voltage

and current for the measurement

channel. See “Waveforms.”

Harmonic Analysis

Displays harmonic components

superimposed on the voltage and

current for the measurement channel.

See “Harmonic Analysis.”

Displaying Power Supply

Quality Events

Displays the swell, dip,

interruption, transient, inrush

current, and flicker of the

measured voltage.

See “Power Supply Quality.”

1-2

Setup (SET UP)

Configures the CW500 and

measurement.

See “Setup.”

IM CW500-01EN

Page 8

1.2 Features

This product is a clamp-type power quality analyzer that supports a

variety of wiring systems. It simultaneously performs simulations of

instantaneous values, integrated values, demand values for power

management, harmonic analysis, power quality events, and phase lead

capacitor values for improving the power factor. Voltage and current can

be displayed as waveforms and vectors.

Measured data can be saved to files in SD memory cards or internal memory,

and the files can be transferred to a PC through USB communication.

Safety Design

This product complies with safety standard IEC 61010-1 CAT. IV 300V/

CAT. III 600V/CAT. II 1000V.

Power Quality Measurement

This product supports international power quality measurement standard

IEC61000-4-30 Class S. It can perform highly accurate frequency

and rms voltage measurements and harmonic analysis as well as

simultaneously measure without gaps swell, dip, interruption, transient,

inrush current, and flicker that are necessary for capturing and monitoring

power abnormalities.

Power Measurement

This product can measure active, reactive, and apparent powers as well

as watt-hour, power factor, rms current, phase angle, and neutral line

current.

Wiring Systems

This product supports single-phase two-wire (four systems), single-phase

three-wire (two systems), three-phase three-wire (two systems), and

three-phase four-wire measurement lines.

Demand Measurement

You can monitor in a simplified form the usage condition so that the

specified target value (contract demand) is not exceeded.

IM CW500-01EN

1-3

Page 9

1.2 Features

Waveform and Vector Displays

Voltage and current can be displayed as waveforms and vectors.

Saving Measured Data

This product is equipped with a logging function whose recording interval

can be specified. Measured data can be saved manually or by specifying

the date and time. Further, the print screen function can be used to save

image data to SD memory cards.

Dual Power System

This product can be driven by AC power or batteries. For batteries, AA

alkaline batteries (LR6) or off-the-shelf rechargeable AA nickel-metal

hydride batteries (Ni-MH) can be used. For rechargeable AA nickel-metal

hydride (Ni-MH) batteries, use the battery manufacturer’s charger to

charge them. You cannot charge them on the CW500. If a power failure

occurs while the CW500 is running off of AC power, the power supply is

automatically switched to battery power.

Display Screen

This product has a color TFT LCD.

Easy Wiring and Compact, Lightweight Design

Wiring is easy as this product is a clamp type. Its compact, lightweight

design makes it convenient to install and carry around.

Application

Files saved in SD memory cards and internal memory can be downloaded

to a PC through USB. Downloaded files can be analyzed easily using the

accompanying PC software. It is also possible to configure the CW500

from a PC.

Auxiliary I/O Function

The 2-channel analog input (DC voltage) can be used to simultaneously

measure analog signals from thermometers, lux meters, and the like.

If a power quality event occurs, a contact signal can be sent to an alarm

through the 1-channel digital output.

1-4

IM CW500-01EN

Page 10

1.3 System Configuration Diagram

電流入力

Current input

AC voltage input

Digital output (1 ch) to

recorder or alarm

Analog input (2 ch) from

AA alkaline

batteries (LR6)

AA Ni-MH batteries

thermometer or illuminometer

USB

Power cord

IM CW500-01EN

SD memory

PC

card

(Option)

1-5

Page 11

1.4 Measurement Procedure

Getting Started Guide, “Making Preparations for Measurements” Page 5

Connecting cords and sensors to the CW500

Getting Started Guide, “Connecting a Voltage Probe and Clamp-on Probe”

Getting Started Guide, “Power Supply” Page 7

Setting common measurement items

5.2, “Basic Settings” Page 5-3

Getting Started Guide, “Safety Precautions” Page vii

Configuring measurement settings and save method

5.3, “Measurement Settings” Page 5-12 and 5.4, “Record Settings” Page

6.1, “Instantaneous Value W” Page 6-1 and 6.4, “Vectors” Page 6-14

Measurement preparation

Page 15

Turning the power on

Loading CW500 settings

5.6, “Save Data” Page 5-36

Wiring measurement lines

Checking the wiring

6.4, “Vectors” Page 6-14

5-25.

Checking measured values

4.6, “Starting and Stopping Recording” Page 4-12

Starting and stopping recording

Checking Measured Data

Chapter 6, “Display Items of Each Screen” Page 6-1

Removing cords and sensors from the measurement line and turning the

power off

Analyzing recorded data on a PC

8.1, “Transferring Data to a PC” Page 8-1

Chapter 9, “PC Software for Configuration and Analysis” Page 9-1

1-6

IM CW500-01EN

Page 12

Display (LCD)

Chapter 2 Component Names

2.1 Display (LCD) and Control Keys

IM CW500-01EN

Control keys

2-1

Page 13

2.2 Connectors

AC voltage input terminals

Power inlet

(VN, V1, V2, V3)

Current input terminals

(A1, A2, A3, A4)

Terminal covers

Wiring System

Single-phase two-wire (1 system)

Single-phase two-wire (2 system)

Single-phase two-wire (3 system)

Single-phase two-wire (4 system)

Single-phase three-wire (1 system)

Single-phase three-wire (2 system)

Three-phase three-wire (1 system)

Three-phase three-wire (2 system)

Three-phase three-wire 3A

Three-phase four-wire

1P2W×1

1P2W×2

1P2W×3

1P2W×4

1P3W×1

1P3W×2

3P3W×1

3P3W×2

3P3W3A

3P4W×1

AC Voltage

Input Terminal

VN, V1 A1

VN, V1 A1, A2

VN, V1 A1, A2, A3

VN, V1 A1, A2, A3, A4

VN, V1, V2 A1, A2

VN, V1, V2 A1, A2, A3, A4

VN, V1, V2 A1, A2

VN, V1, V2 A1, A2, A3, A4

V1, V2, V3 A1, A2, A3

VN, V1, V2, V3 A1, A2, A3

Current Input

Terminal*

* Current terminals that are not used in wiring can measure only rms values

and harmonics.

2-2

IM CW500-01EN

Page 14

2.3 Side Panel

Analog input/digital output area

Analog input/digital output terminals

With the Connector Cover Closed

SD memory card area

With the Connector Cover Open

SD memory card slot USB port

USB area

IM CW500-01EN

2-3

Page 15

2.4 Voltage Probe and Current Clamp-on Probe

Alligator Clip (the end of the voltage probe)

Barrier

Current Clamp-on Probe

Barrier

Barrier: A mark for securing the minimum required creep and spatial

distance to prevent electric shock during operation.

When taking a measurement, be careful that your finger or the like does

not cross over the barrier.

2-4

IM CW500-01EN

Page 16

Chapter 3 Basic Operation

3.1 Description of Control Keys

Display

Function keys

Selects or executes the menu

items at the screen bottom.

PRINT SCREEN key

Saves the LCD screen as a

BMP file.

DATA HOLD/

KEY LOCK key

DATA HOLD

Holds the display.

But, measurement

continues.

KEY LOCK

Hold down for 2 s to lock all

keys. Hold down for 2 s

again to release.

Power key

Turns the power

on and off.

Display switch key

See page 3-2.

SETUP Key

Changes basic, measurement,

recording, saved data, and

other settings.

START/STOP key

Starts or stops recording.

Status LED

Shows the recording status.

Green solid: Recording

Green blinking: Standby

Red blinking: Backlight off

LCD key

Turns on/off backlight, adjust

contrast and brightness.

ENTER key

Confirms the operation or

setting.

Arrow keys

Selects items, changes

displays.

ESC/RESET key

Resets to the original setting.

IM CW500-01EN

3-1

Page 17

Display Switch Key

W/Wh key

Displays instantaneous

values, integrated

values, and “demand”

Vector key

Displays phases

Waveform key

Displays voltage and current

waveforms

Harmonic analysis key

Displays harmonic voltage,

harmonic current, and

harmonic power

QUALITY key

Displays the occurrence of

swell, dip, interruption,

transient, inrush current, and

flicker

3-2

IM CW500-01EN

Page 18

3.2 Marks Displayed in the Top Area of the LCD

Mark Status When Displayed

Running on batteries. Shows the battery level using four

levels.

Running on AC power.

Screen updating is held.

Keys are locked.

The buzzer is turned off.

SD memory card can be used.

Recording to SD memory card.

Not enough space in SD memory card to record.

Unable to access SD memory card.

Possible to record to internal memory. This appears when

recording is started without an SD memory card inserted.

IM CW500-01EN

Recording to internal memory.

Not enough space in internal memory to record.

Waiting to record.

Recording measurement values.

Recording medium is full.

USB can be used.

Bluetooth® can be used.

3-3

Page 19

3.3 Display Symbols

Display Symbol

1

V

P

PF

DC1

2

An

WP+

WP-

THD

Pst

(1min)

Phase voltage

+

Active

power

power

factor

Consumption

Regeneration

–

+ Lag

– Lead

Analog input

channel 1 voltage

Neutral line current

Active energy

(consumption)

Active energy

(regeneration)

Voltage/current distortion

1-minute voltage flicker

1 The V and VL displays can be customized when 3P4W is selected.

2 An appears only when 3P4W is selected.

3 PA and C can be displayed by customization.

VL

Q

f

DC2

PA

WS+

WS-

Pst

1

Line voltage

Reactive

power

+ Lag

– Lead

Frequency

Analog input

channel 2 voltage

3

Phase

angle

+ Lag

– Lead

Volt-ampere hours

(consumption)

Volt-ampere hours

(regeneration)

Short term voltage

flicker

A

S

3

C

WQi+

WQc+

Plt

Apparent power

Phase advance

capacitance

Reactive energy

Reactive energy

Long term voltage

Current

capacitor

(lag)

(lead)

flicker

3-4

IM CW500-01EN

Page 20

3.4 Backlight and Contrast Adjustment

Backlight brightness can be changed

Brightness adjustment

to any of the 11 available levels.

Holding down the LCD key for 2 seconds when the backlight is on

displays slide bars for adjusting the backlight brightness and display

contrast. To adjust the brightness or contrast, use the arrow keys to move

the slide bars. After adjusting, press ENTER to confirm. To cancel the

adjustment, press ESC or LCD again.

to any of the 11 available levels.

Contrast adjustment

Contrast can be changed

IM CW500-01EN

3-5

Page 21

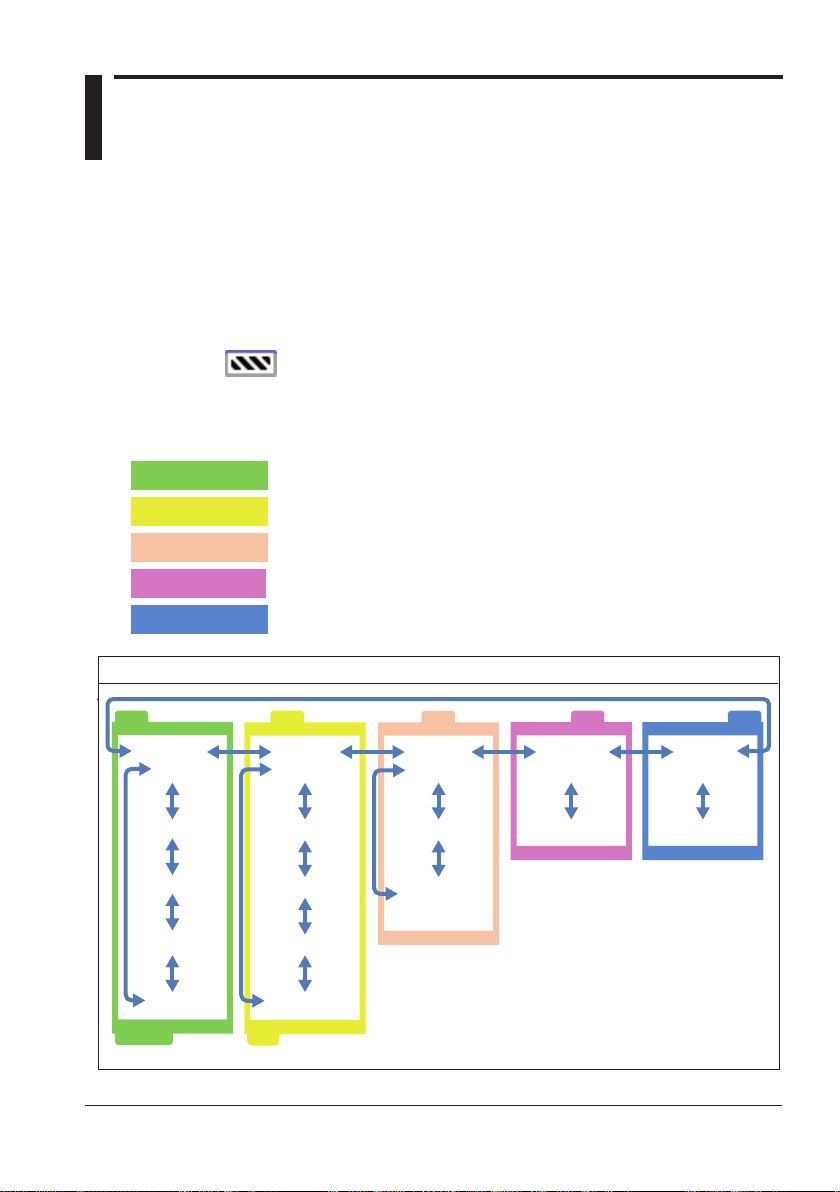

3.5 Screens and Screen Configuration

Demand

Wh (Integrated value)W (instantaneous value)

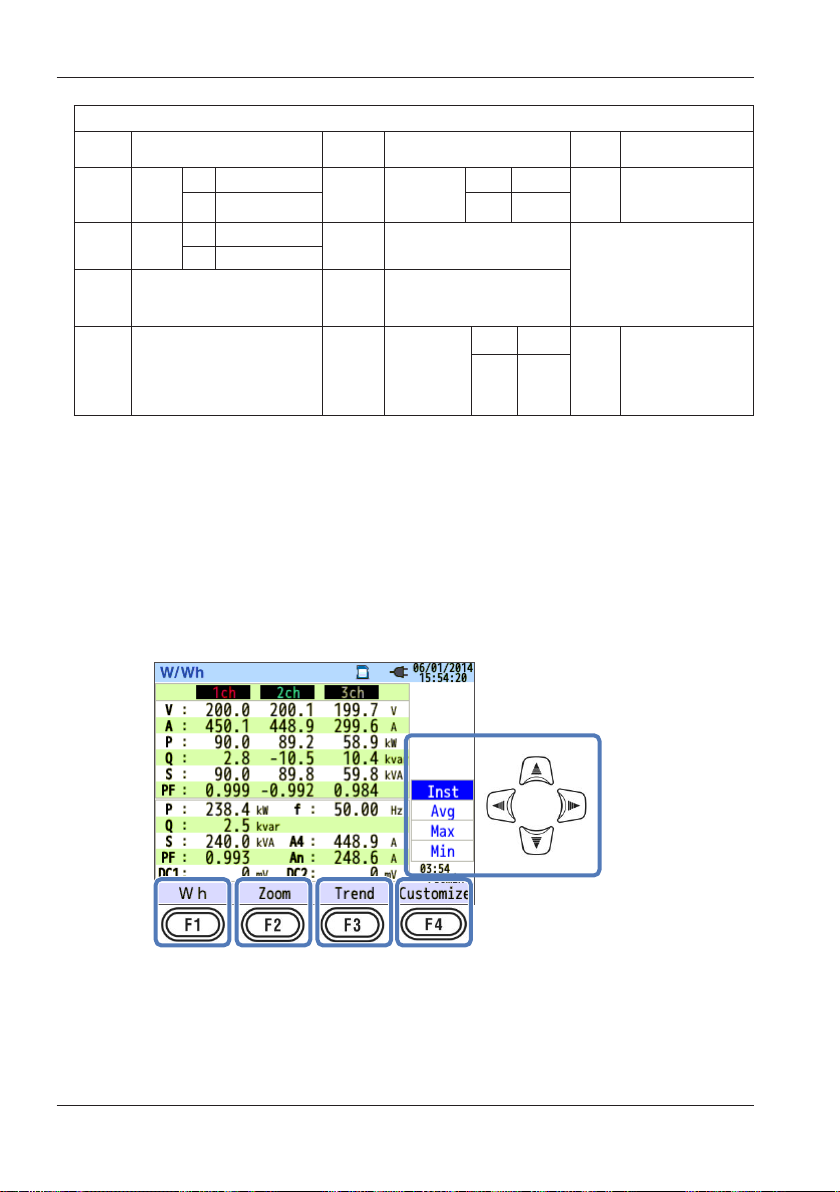

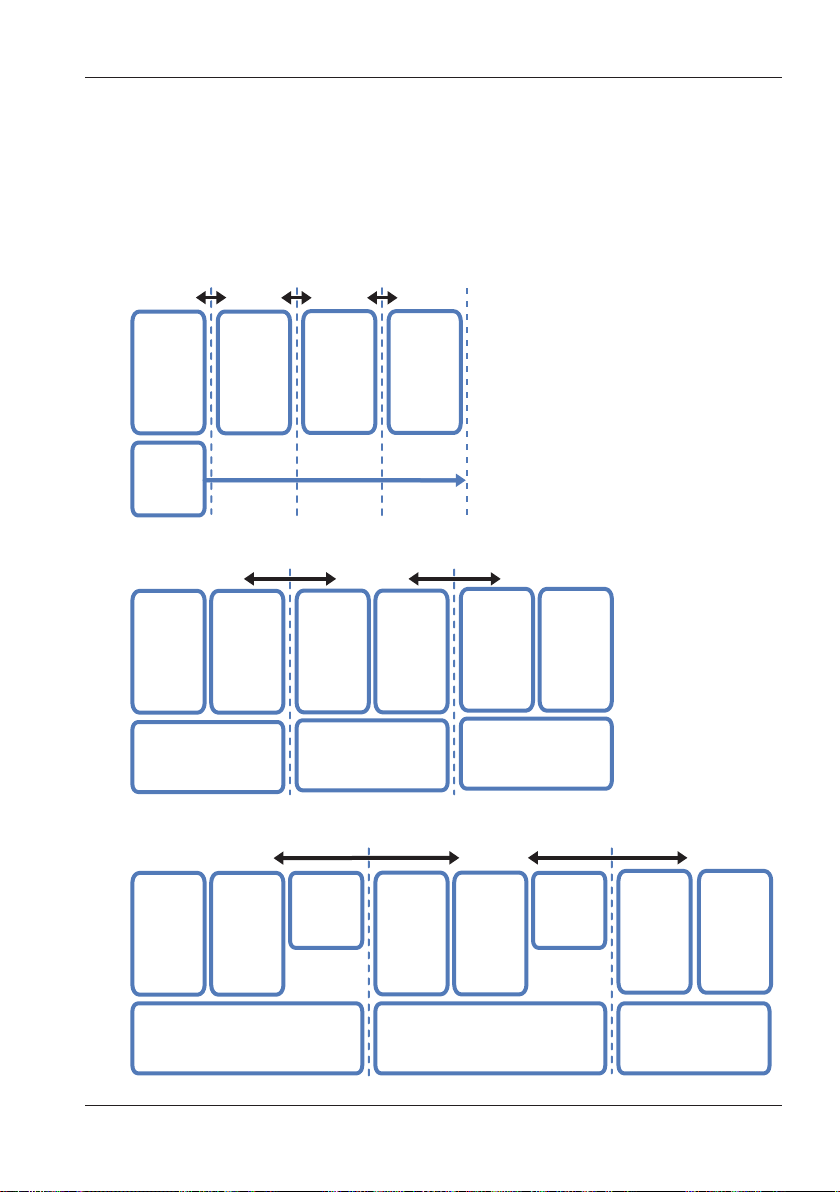

Instantaneous, Integrated, and Demand

Switching the W/Wh Screen

Each time you press function key F1, the display screen changes.

Select and change the items to be displayed.

Zoom

Zoom in on selected items.

4 windows 8 windows

Customize

Trend

Measurement variation trends

are displayed on a graph.

3-6

IM CW500-01EN

Page 22

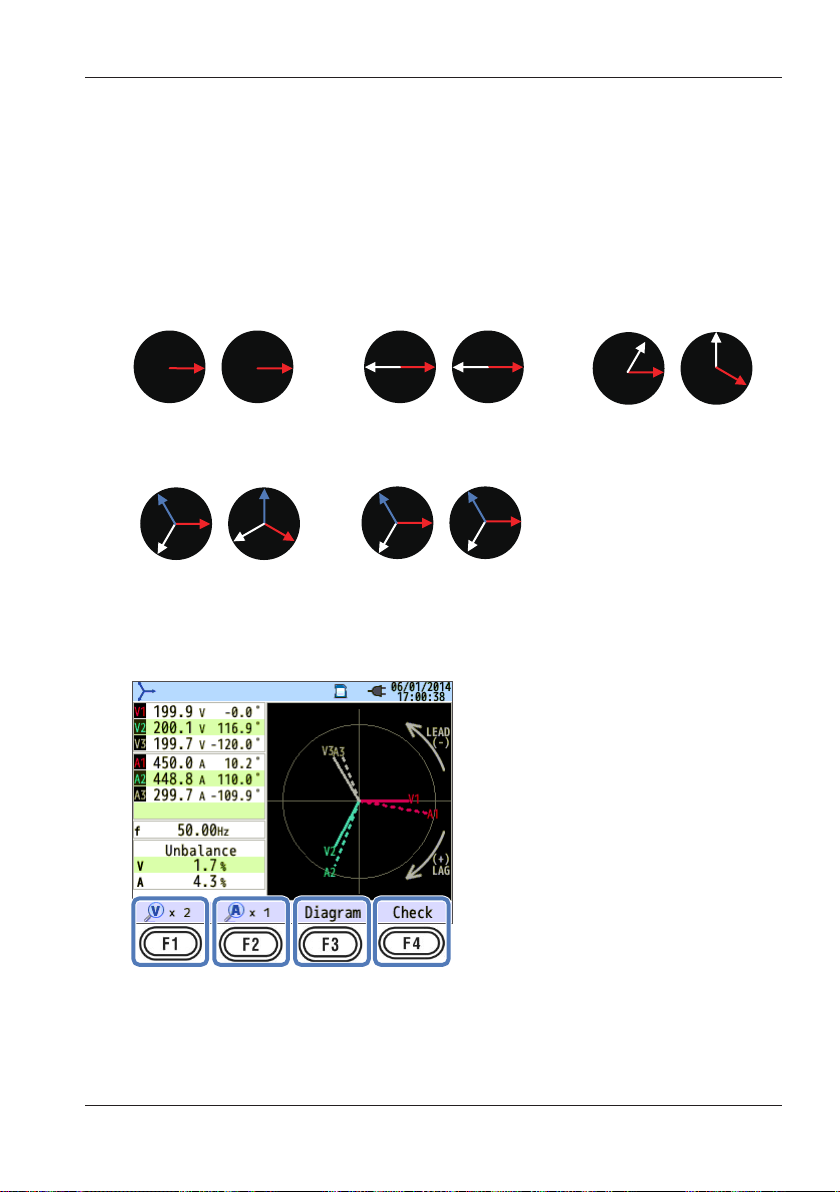

Vector

Switching the Vector Screen

Wiring diagram

Displays the diagram of the

selected wiring

3.5 Screens and Screen Configuration

Wiring check

Displays the results of

check items

Waveform

Switching the Waveform Screen

IM CW500-01EN

3-7

Page 23

3.5 Screens and Screen Configuration

Voltage, Linear, Overall display

Harmonics

Switching the Harmonic Analysis Display Items

Current Power

List, percentage content

Logarithm Zoom

Phase angle Rms value

Current Power

3-8

IM CW500-01EN

Page 24

Power Quality

Event Flicker

Use the left and right arrow keys

Switching the Quality Display Items

Setup

Switching the Setup Display Items

3.5 Screens and Screen Configuration

IM CW500-01EN

switch between screens.

3-9

Page 25

Chapter 4 Recording

4.1 Starting and Stopping Recording

Starting Recording

Press START/STOP.

You can select the recording start method from “Quick start guide” and

“Start now.”

Quick start guide

You can easily start recording by setting the items by following the

instructions displayed on the screen. However, the items that you can

set are those related to wiring and recording. If you need to specify other

settings, set them from the SETUP menu.

Start now

Recording starts immediately using the current settings.

<Procedure>

Using the up and down arrow keys, select “Quick start guide” or “Start

now,” and press ENTER.

To cancel, press ESC.

IM CW500-01EN

4-1

Page 26

Recording method

4.1 Starting and Stopping Recording

Stopping Recording

While recording is in progress, press START/STOP.

Data number

Record items

Recording information is displayed, and recording stops.

Display Items

Recorded

data

number

Elapsed time Elapsed time from the start of recording is displayed.

Recording

method

Save to

Record items Measurement items being recorded are displayed.

The ID number of the recorded data is displayed. This is

also used as the name of the folder in which measured

data is saved.

Manual

Constant

rec.

Time period

rec.

The recording start date and time are

displayed.

The recording start/end date and time are

displayed.

The recording start date and time, recording

period, and recording time are displayed.

The location where measured data is being recorded to is

displayed.

<Procedure>

Using the up and down arrow keys, select CANCEL or STOP, and then

press ENTER.

You can also cancel by pressing ESC.

4-2

IM CW500-01EN

Page 27

4.2 Starting to Record with “Quick start guide”

Set the

record items.

Set the

wiring system.

Select the item you want to record.

* Greater the number of items, the greater the file

size, which means shorter recording time.

Connect to the circuit to be

measured.

* Read and follow the safety precautions.

See the Getting Started Guide (IM CW500-02EN).

Check wiring

connection.

Check the test

environment.

Select the wiring system to be measured.

* Select a proper wiring system for accurate

measurements.

See page 4-5.

Check the test environment.

* Performs a CW500 self-diagnosis, wiring status

* We recommend that you execute this check in

IM CW500-01EN

check, and connected sensor identification.

order to record in the correct conditions. The

test takes about 10 seconds.

See page 4-6.

4-3

Page 28

4.2 Starting to Record with “Quick start guide”

Select the

rec interval

Select the

rec method

Select a recording interval.

* Selecting a short interval results in a large

See page 5-29.

Ready. Recording will start.

When recording starts, the screen shows

REC, and the Logging LED turns green.

To stop recording, press START/STOP, and

follow the instructions on the screen.

Confirm to

start recording.

file size preventing long-term recording.

Start

recording

Select the rec. method.

See page 4-9.

4-4

IM CW500-01EN

Page 29

be reversed.

4.2 Starting to Record with “Quick start guide”

Setting the Wiring System

You can select from the following wiring systems.

L

Power

supply

N

A1

VN

V1

A2

V2

VN

V1

L1(R)

Power

supply

L2(S)

L3(T)

L1(R)

Power

supply

L2(S)

L3(T)

N N

A3

A1

A4

A2

L

Load

(1)

N

1P2W

L

Load

(2)

N

1P2W

L

Load

(3)

N

1P2W

L

Load

(4)

N

1P2W

L1(R)

L2(S)

L3(T)

L1(R)

L2(S)

L3(T)

A3

A4

L1(R)

L2(S)

L3(T)

1P2W×2

1P2W×3

1P2W×4

Load

(1)

3P3W

Load

(2)

3P3W

Load

3P4W

1P2W×1

3P3W×1

3P3W×2

3P4W

L1

Power

supply

N

L2

V1

Power

supply

Orientation of the current clamp-on probe

Power

V2

L1(R)

L2(S)

L3(T)

VN

A1

V1

V2

L1

Load

N

1P3W

L2

L1

Load

N

1P3W

L2

A2

A3

A4

L1(R)

L2(S)

L3(T)

A1

A2

A3

V3

Load

(1)

1P3W×2

(2)

Load

3P3W

Arrow: load

1P3W×1

3P3W3A

V1

IM CW500-01EN

A1

A2

V2

V3

VN

A3

* If clamped in the reverse direction, the

polarity of the active power (P) value will

4-5

Page 30

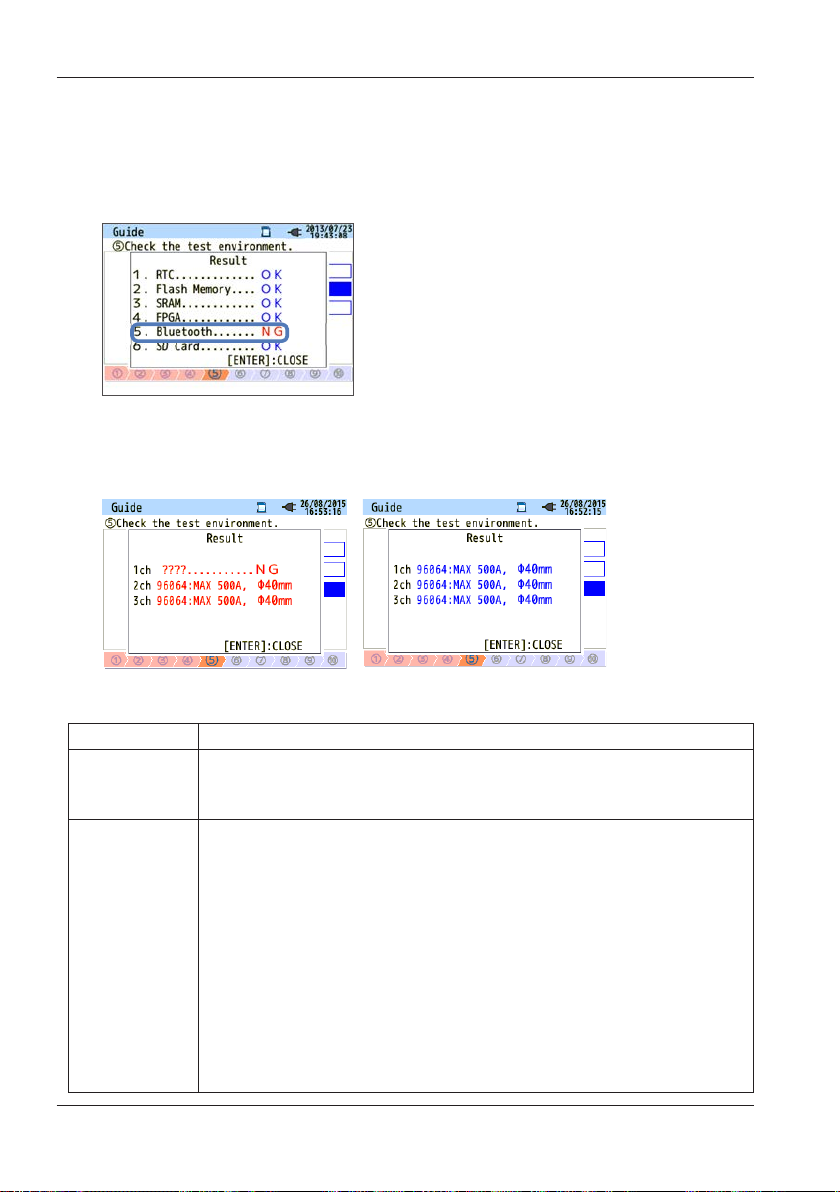

Test environment check

Automatically detects connected current probes

4.2 Starting to Record with “Quick start guide”

Test Environment Check

Select Start test and press ENTER

to check the test environment and

display the results.

Select the OK or NG of a test result

to see the details.

Wiring check

Displays the test results of each item.

* If measuring at site with extremely poor

power factor, this check may fail even

if the wiring is correct.

Self-diagnosis

Displays the results of a system operation

check.

4-6

Sensor detection

and sets the range to their maximums.

IM CW500-01EN

Page 31

Closing the test results causes the NG

values and vectors to blink. If everything

4.2 Starting to Record with “Quick start guide”

NG Judgment

Wiring Check

is OK, the ideal vector diagram will be

displayed in the lower left corner.

Wiring Check Criteria and Failure Cause

Check Judgment Criteria Failure Cause

Frequency

AC

voltage

input

Voltage

balance

Voltage

phase

Current

input

Current

phase

• The V1 frequency is

between 40 to 70 Hz.

• AC voltage input

is 10% of (nominal

voltage × VT) or

higher.

• AC voltage input

is within ±20% of

reference voltage V1.

* Not checked for

single-phase wiring

• AC voltage input

phase is within ±10%

of the reference value

(appropriate vector).

• Current input is 5% or

higher and 110% or

less of (current range

× CT).

• Power factor (PF,

absolute value) of

each channel is 0.5

or higher.

• Active power (P)

of each channel is

positive.

• The voltage clip is not firmly connected

to the DUT.

• Harmonic components are large.

• The voltage clip is not firmly connected

to the DUT.

• Voltage probe is not correctly inserted

into the AC voltage input terminal of

this instrument.

• Settings are not appropriate for the

measurement line wiring system.

• The voltage clip is not firmly connected

to the DUT.

• Voltage probe is not correctly inserted

into the AC voltage input terminal.

• Voltage probe is not connected

correctly.

(The connected channel is incorrect.)

• Current clamp-on probe is not

correctly inserted into the AC power

input terminal of this instrument.

• Current range setting is too high or

too low for the input level.

• Current direction mark of the current

clamp-on probe is not matched with

the current-to-load direction.

• Clamp-on probe is not connected

correctly.

IM CW500-01EN

4-7

Page 32

4.2 Starting to Record with “Quick start guide”

Self-Diagnosis

If NG is displayed frequently, the instrument may be malfunctioning. Stop

using it immediately, and see chapter 10, “Troubleshooting,” on page

10-1.

Sensor Detection

If detection fails, current clamp-on probe types are displayed in red.

Detection Failure Cause

Check Cause

Current

clamp-on

probe type

???

(cause

unknown)

4-8

• Different types of current clamp-on probes are connected

to each channel. Use the same type of current clamp-on

probes for measurement.

• Current clamp-on probe is not firmly connected to the

instrument.

• Troubleshooting

Connect the current clamp-on probe that failed to be

detected to a channel that detection was successful, and

test again. If the same channel fails again, the instrument

may be malfunctioning. If detection fails on the channel

connected to the current clamp-on probe that failed to

be detected the last time, the clamp-on probe may be

malfunctioning. If you suspect a malfunction, stop using

it immediately, and see chapter 10, “Troubleshooting,” on

page 10-1.

IM CW500-01EN

Page 33

4.2 Starting to Record with “Quick start guide”

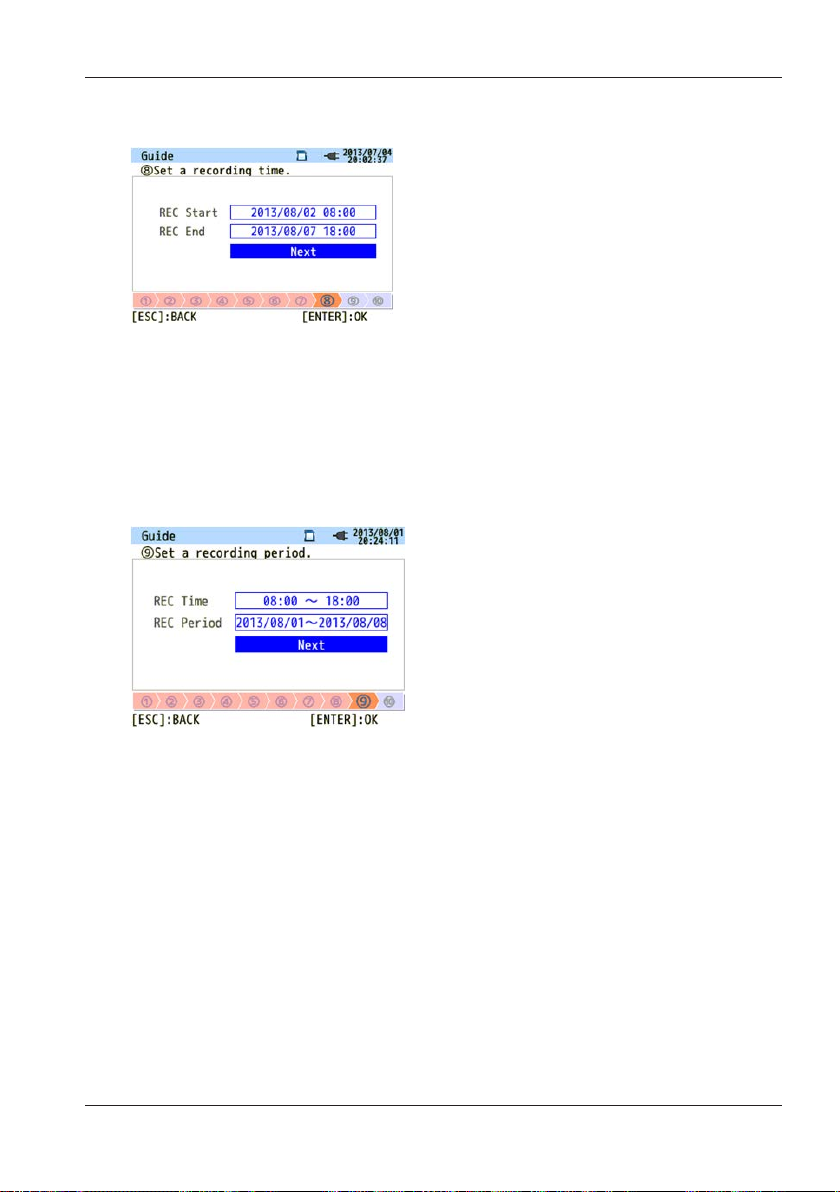

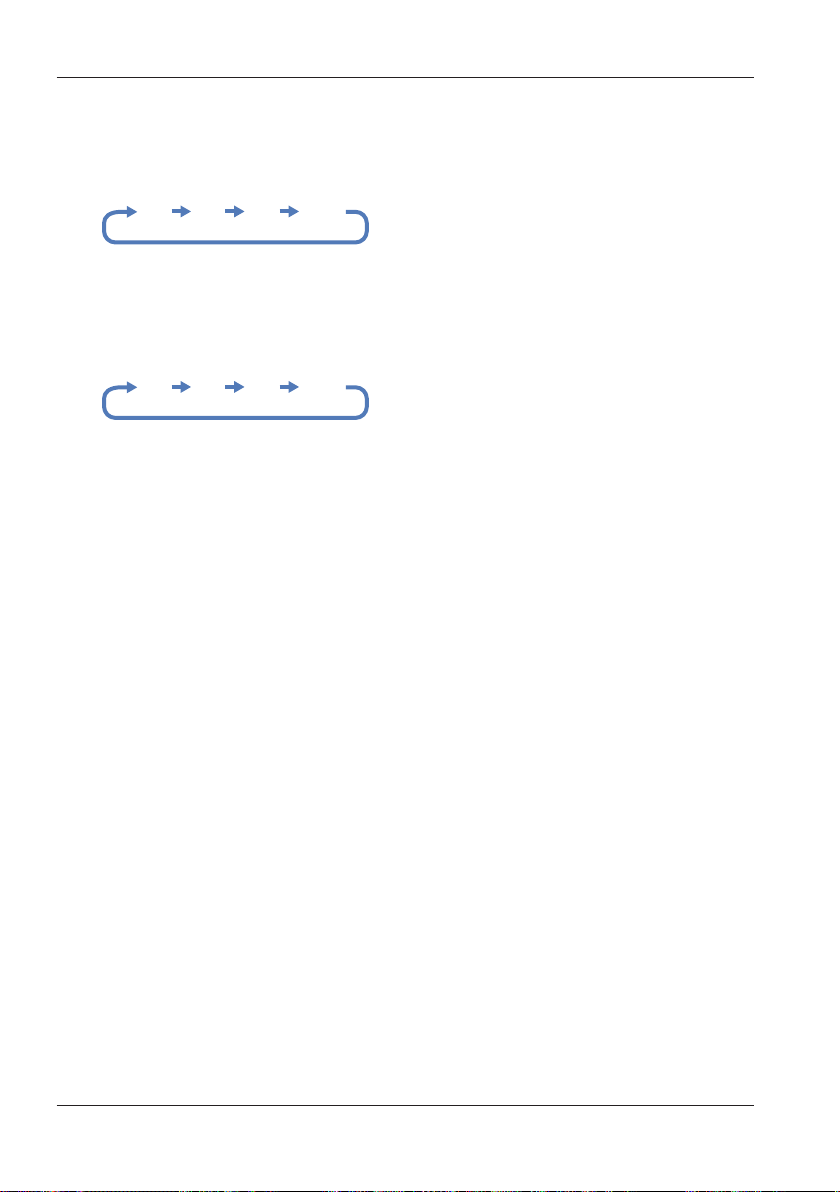

Reserving by Specifying the Date and Time

From the specified start date and time to the end date and time, recording

is performed at a given interval.

If the date and time are set as shown above, recording will be performed

during the following period.

8:00 on August 2, 2013 to 18:00 on August 7, 2013

Reserving a Repetitive Recording

Recording is repeated during the specified time slot at a given interval for

the specified period.

If the date and time are set as shown above, recording will be performed

during the time slots (i) to (viii) below. Recording is not performed from

18:00 to 8:00 of the next day.

(i) 8:00 to 18:00 on August 1, 2013

(ii) 8:00 to 18:00 on August 2, 2013

(iii) 8:00 to 18:00 on August 3, 2013

(iv) 8:00 to 18:00 on August 4, 2013

(v) 8:00 to 18:00 on August 5, 2013

(vi) 8:00 to 18:00 on August 6, 2013

(vii) 8:00 to 18:00 on August 7, 2013

(viii) 8:00 to 18:00 on August 8, 2013

IM CW500-01EN

4-9

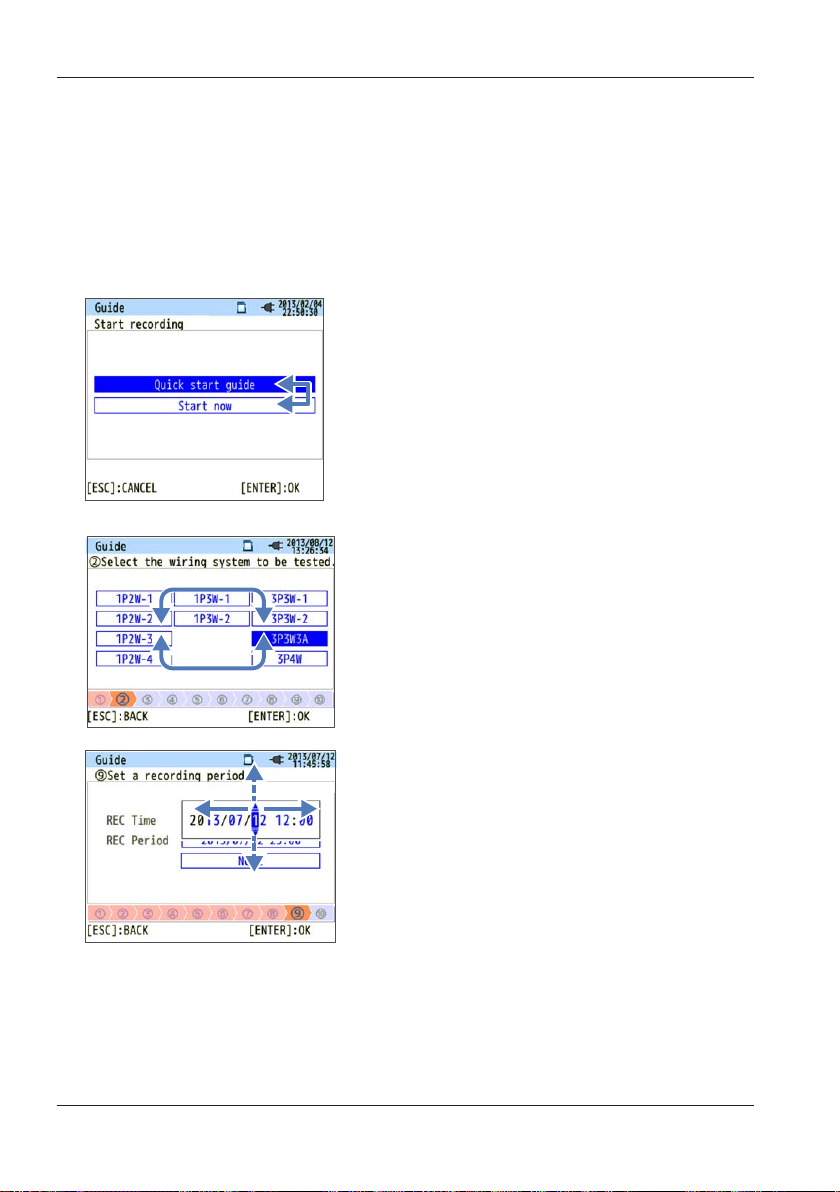

Page 34

screen shown on the left, you can use the up

the settings and close the Quick start guide,

On a screen that shows selectable items in a

To enter values such time, use the left and

down arrow keys will increment or decrement

the previous screen, press ESC.

4.2 Starting to Record with “Quick start guide”

Operation

The basic procedure to operate this instrument is to use the arrow keys

to select an item or value, the ENTER key to confirm, and the ESC key to

cancel. As an example, the operation is explained for entering settings in

Quick start guide. The operation is similar for entering settings on other

display screens.

Using arrow keys, you can select the items

in blue letters (unselected) and the

highlighted item with blue background and

white letters (selected). On the Record start

and down arrow keys to select the recording

method and ENTER to confirm. To cancel

table form, you can use the up, down, left,

and right arrow keys to select an item. On

the wiring selection screen shown on the

left, you can use the up, down, left, and right

arrow keys to select the wiring system to be

measured and ENTER to confirm. To cancel

4-10

right arrow keys to select the digit and the up

and down arrow keys to change the number.

On the recording time selection screen

shown on the left, left and right arrow keys

were used to select the tenth digit of the

date. In this condition, pressing the up and

the tenth digit. To confirm the change, press

ENTER. To cancel the settings and return to

IM CW500-01EN

Page 35

4.2 Starting to Record with “Quick start guide”

Notes on Settings

If the current range is set to AUTO, only “Power + Harmonics” or “Power

only” can be selected with “1. Select desirable recording item.” If you want

to record power quality, change the current range to a fixed range before

starting to record. Only wiring and recording settings can be specified in

“Quick start guide.” Nominal voltage, nominal frequency, threshold for

power quality events (included in the measurement settings), and filter

coefficient (ramp) for flicker measurement must be set in advance. Set

these items from the SETUP menu. Note that the “+ Clamp” option clampon probe setting is automatically set to OFF.

IM CW500-01EN

4-11

Page 36

Chapter 5 Setup

5.1 Settings

Before starting measurement, you need to set measurement conditions

and data saving conditions.

To set these conditions, press SET UP to enter the SET UP mode.

The SET UP mode is divided into the following five categories. Use the

arrow keys to move between the categories.

The settings that you change take effect after you exit from the SET UP

mode and appears in the upper left of the screen.

Note that even if you change the settings, if you turn off the power while

in SET UP mode, the settings will not take effect.

Basic

Measurement

Recording

Saved Data

Others

Basic

(Wiring)

(Voltage)

(Current)

(External

input DC)

(Frequency)

Set common measurement items.

Set specific measurement items.

Set the saving method.

Edit recorded data or change the instrument settings.

Configure environmental settings.

Settings

Measurement

(Demand)

(Harmonics)

(Power quality)

(Flicker)

(Phase advance

capacitor)

Recording

(REC item)

(Rec method)

(Manual/

Constant rec.

Time period rec.)

Saved Data

(Rec data)

(System settings)

Others

(Environment)

(System settings)

IM CW500-01EN

5-1

Page 37

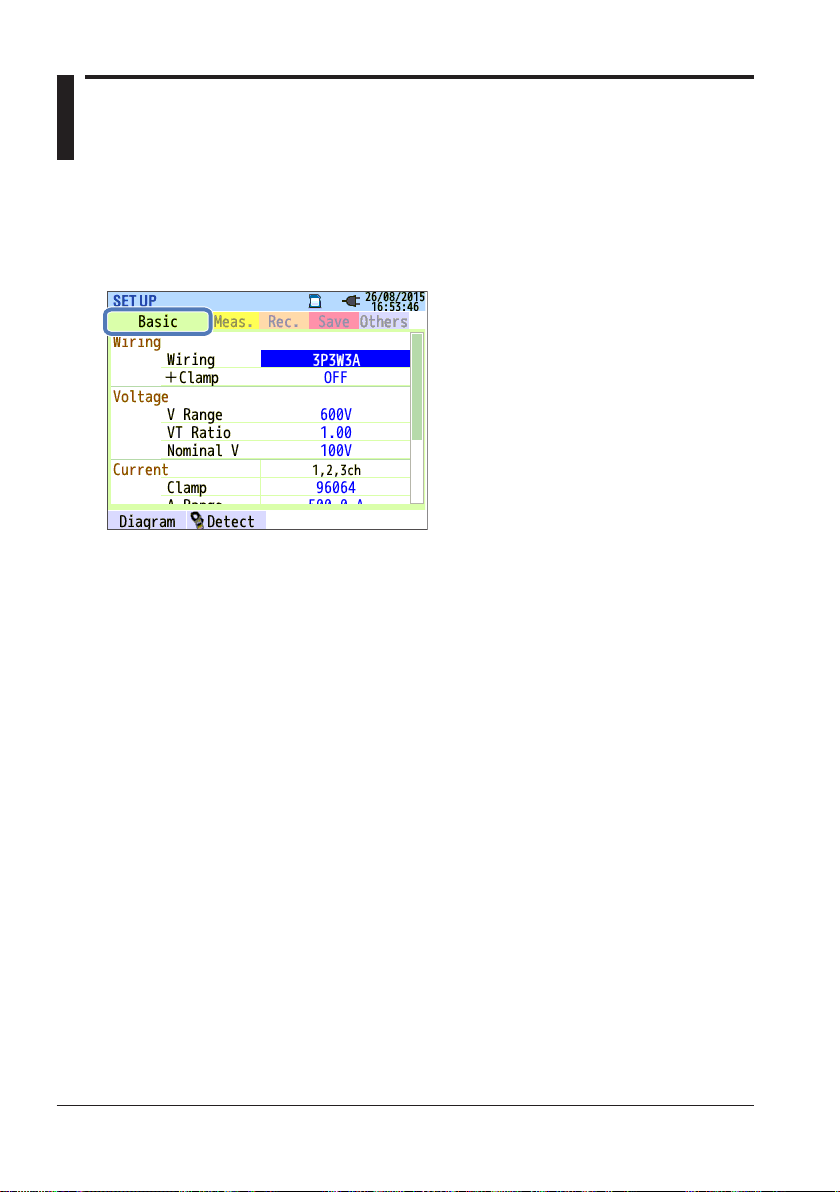

5.2 Basic Setup

<Procedure>

Press SETUP.

tab.

Use the left and right arrow keys to select the Basic

→

5-2

IM CW500-01EN

Page 38

5.2 Basic Setup

Wiring System Settings

Wiring

From the 10 available wiring systems, select the appropriate one for the

wiring system to be measured.

Settings

1P2W×1 1P2W×2 1P2W×3 1P2W×4

1P3W×1 1P3W×2

3P3W×1 3P3W×2 3P3W3A 3P4W (default setting)

*Current terminals that are not used in “+Clamp” wiring can measure only

rms values and harmonics.

<Procedure>

Use the up and down arrow keys to move to Wiring. → Press ENTER to

show a pull-down menu. → Select the wiring system. → Press ENTER

to confirm or ESC to cancel.

+Clamp (optional clamp-on probe)

<Procedure>

Use the up and down arrow keys to move to +Clamp.

to show a pull-down menu. → Use the up and down arrow keys to select

the optional clamp. → Press ENTER to confirm or ESC to cancel.

IM CW500-01EN

Press ENTER

→

5-3

Page 39

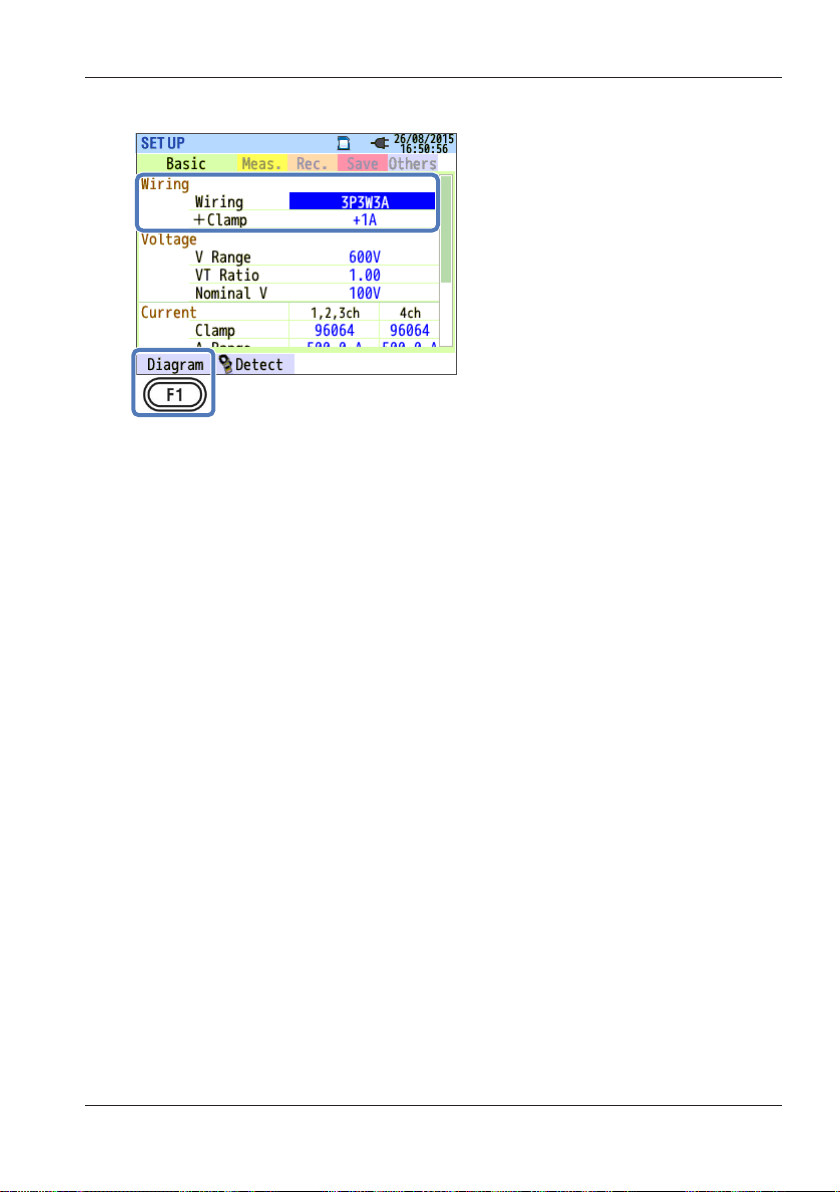

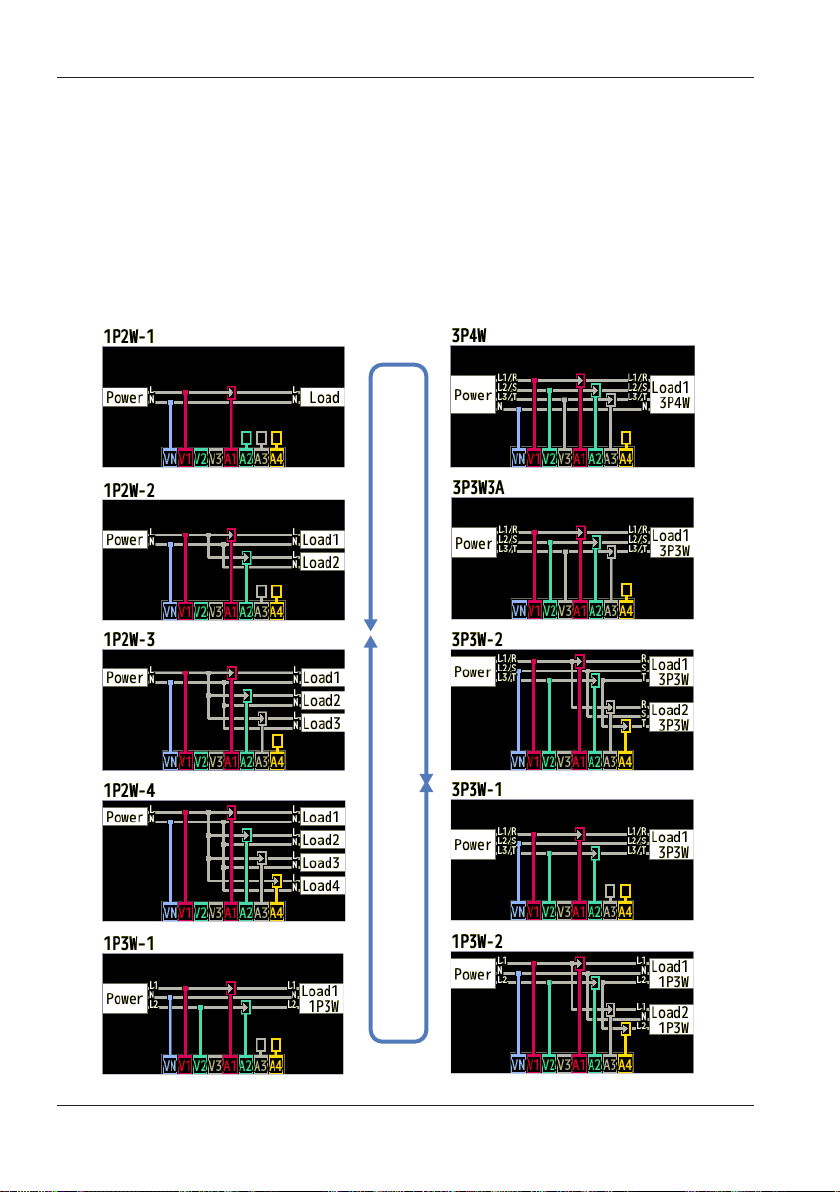

5.2 Basic Setup

Wiring Diagrams

When you move to the Wiring item, you can use the F1 (Diagram) key to

show the wiring diagram of the selected wiring system.

<Procedure>

After showing the wiring diagram, press F1 (previous wiring system) or

F2 (next wiring system) to change the wiring system. → Press ENTER to

confirm or ESC to cancel.

5-4

IM CW500-01EN

Page 40

5.2 Basic Setup

Voltage Measurement Settings

V Range

Select the voltage range to use.

To perform a measurement according to the international power quality

standard IEC61000-4-30 Class S, select 600V.

Settings

*

/1000V

600V

* Default value

<Procedure>

Use the up and down arrow keys to move to V Range.

Press ENTER

→

to show a pull-down menu. → Use the up and down arrow keys to select

the voltage range. → Press ENTER to confirm or ESC to cancel.

VT Ratio

Set this when an external VT (voltage transformer) is installed in the

system. The VT ratio will be applied to all voltage measurements.

*

Default value

IM CW500-01EN

Settings

0.01 to 9999.99 (1.00

*

)

5-5

Page 41

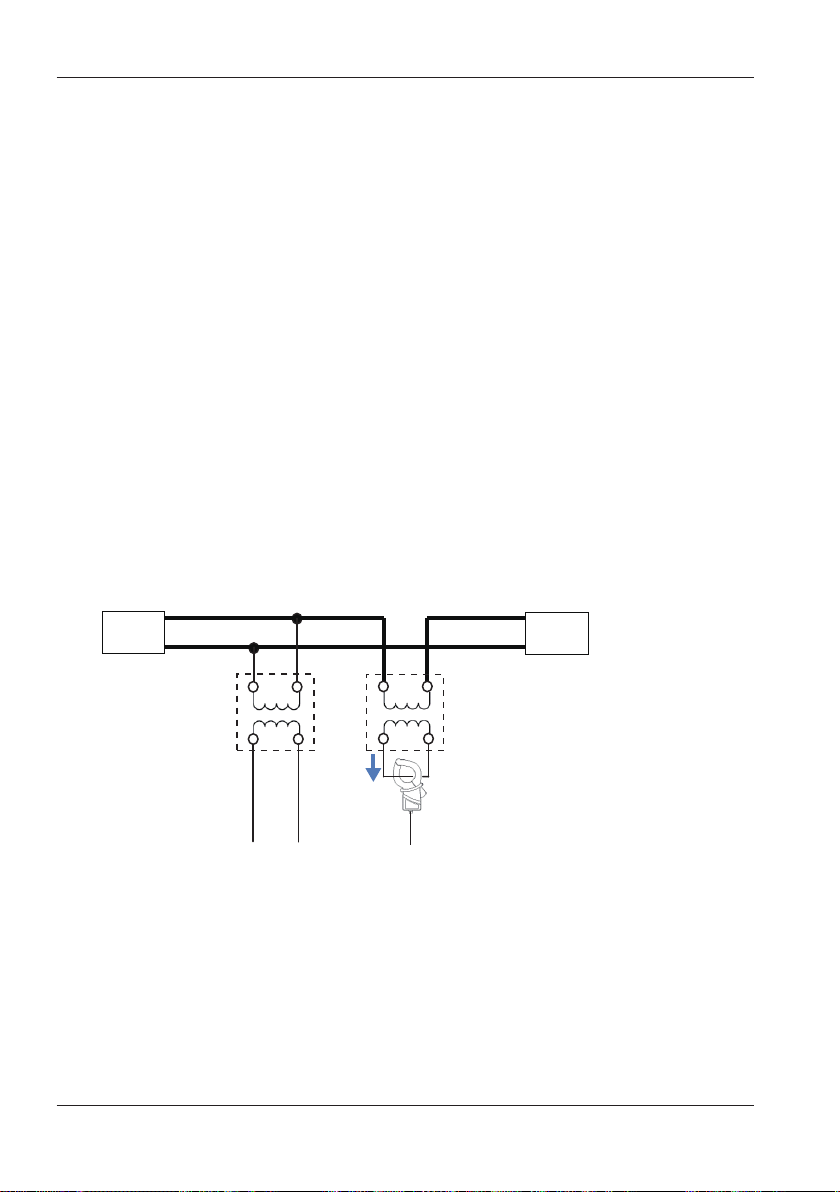

VN V1 A1

L

5.2 Basic Setup

<Procedure>

Use the up and down arrow keys to move to VT Ratio.

Press ENTER

→

to show a value entry window.* → Use the arrow keys to select the VT

ratio. → Press ENTER to confirm or ESC to cancel.

* The input range is shown in a pop-up.

VT/CT

The measurement accuracy of this instrument when VT or CT is used

is not guaranteed. When using a VT or CT, take into consideration the

VT or CT accuracy, phase characteristics, and the like in addition to the

instrument accuracy.

If the voltage or current on the measurement line exceeds the maximum

measurement range of this instrument, you can use a VT or CT with

specifications appropriate for the measurement line voltage and current to

measure the secondary side and display the value on the primary side.

Example of single-phase two-wire (1 system) (1P2W × 1)

5-6

Power

N

VT

CT

i

Load

IM CW500-01EN

Page 42

5.2 Basic Setup

If the rating of the secondary side of the CT is 5 A, We recommend that

you use a 50 A type clamp-on probe and measure at the 5 A range.

Make sure to set the appropriate VT and CT ratios.

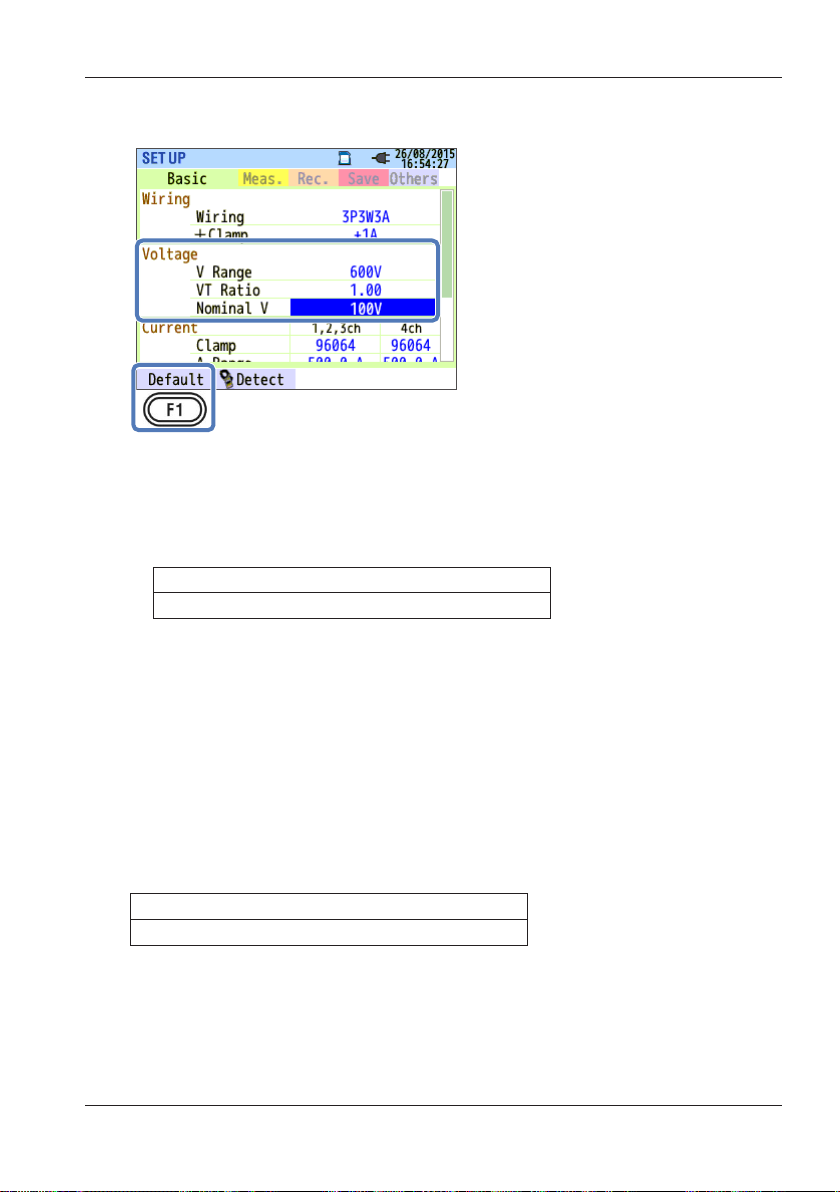

Nominal V

Set the nominal voltage applied from the DUT.

Settings

*

)

*

Default value

50V~600V(100V

<Procedure>

Use the up and down arrow keys to move to Nominal V. → Press ENTER

to show a value entry window.* → Use the arrow keys to enter the

nominal voltage. → Press ENTER to confirm or ESC to cancel.

* The input range is shown in a pop-up.

Default Values

When you move to the Nominal V item, you can press F1 (default values)

to show a list of typical nominal voltages that you can choose from.

Settings

100V/101V/110V/120V/200V/202V/208V/220V/230V/

240V/277V/346V/380V/400V/415V/480V/600V

<Procedure>

Use the arrow keys to select nominal voltage.

confirm or ESC to cancel.

Press ENTER to

→

IM CW500-01EN

5-7

Page 43

5.2 Basic Setup

Current Measurement Settings

Clamp (Current clamp-on probe)

Select the current clamp-on probe you want to use. If you selected an

optional clamp-on probe for “+Clamp,” you can select a current clampon probe that is of a different type than the current clamp-on probe

connected to the DUT only for channel 4. If you select a current clamp-on

probe from the pull-down menu, the rated current and the conductor size

are displayed in a pop-up.

Settings

96060: 0.2/2A/AUTO$3 Leak current clamp-on probe

96061:5/50A/AUTO

96062:10/100A/AUTO

96063:20/200A/AUTO

*

96064

:50/500*A/AUTO

96066:100/1000A/AUTO

96065:300/1000/3000

*

Default value

<Procedure>

Use the arrow keys to move to Clamp. → Press ENTER to show a pulldown menu. → Use the arrow keys to select the current clamp-on probe.

Press ENTER to confirm or ESC to cancel.

→

Power measurement clamp-on probe

5-8

IM CW500-01EN

Page 44

5.2 Basic Setup

Current Range

Select the current range to use. If power quality events are set to be

recorded, AUTO is not available.* If you want the current range to switch

automatically, set power quality events to “Do not record.” For details

on power quality event settings, see “Power Quality (Event) Threshold

Settings” on page 5-18.

* If AUTO range is selected, measurements according to international

power quality standard IEC61000-4-30 Class S cannot be performed.

<Procedure>

Use the arrow keys to move to A Range. → Press ENTER to show a pulldown menu. → Use the up and down arrow keys to select the range. →

Press ENTER to confirm or ESC to cancel.

CT Ratio

Set this when an external CT (current transformer) is installed in the

system. The CT ratio will be applied to all current measurements. For

details on CT, see “VT/CT” on page 5-6.

Settings

*

0.01~9999.99(1.00

)

* The default value is 1.00.

<Procedure>

Use the arrow keys to move to CT Ratio.

Press ENTER to show a

→

value entry window.* → Use the arrow keys to select the CT ratio. →

Press ENTER to confirm or ESC to cancel.

* The input range is shown in a pop-up.

IM CW500-01EN

5-9

Page 45

5.2 Basic Setup

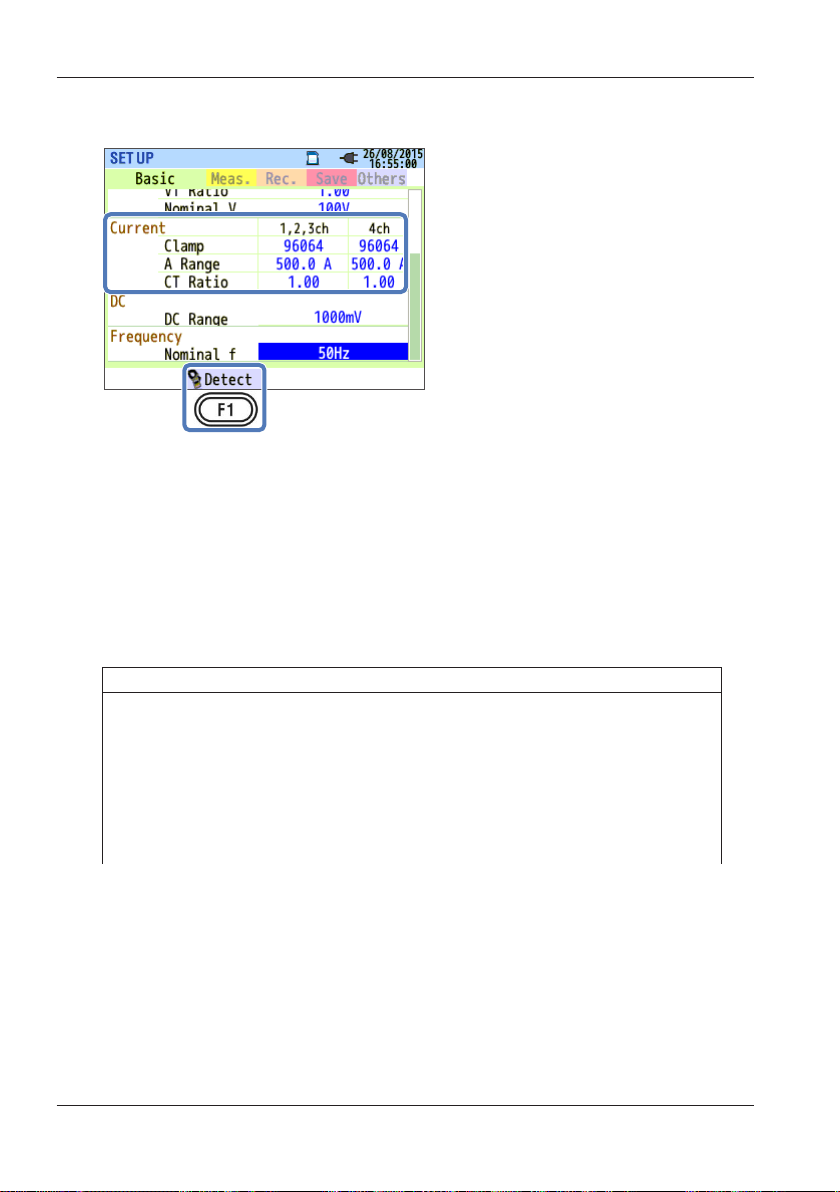

Sensor Detection

Press F2 (sensor detection) to automatically set the connected current

clamp probe. However, if a current clamp-on probe whose type is not

appropriate for the DUT is connected or if the type fails to be detected,

this will not work. If this happens, an error message appears in a pop-up,

and Clamp, A Range, and CT ratio settings will be cleared. For details on

sensor detection, see section 4.2, “Sensor Detection.”

5-10

IM CW500-01EN

Page 46

5.2 Basic Setup

External Input Terminal and Reference Frequency

Settings

DC Range

Select the DC range according to the input DC voltage signal.

Settings

100mV/1000mV

* Default value

<Procedure>

Use the up and down arrow keys to move to DC Range.

to show a pull-down menu. → Use the up and down arrow keys to select

the range. → Press ENTER to confirm or ESC to cancel.

*

/10V

Press ENTER

→

Frequency

Set the nominal frequency for the DUT. If the voltage frequency cannot be

determined, such as during a power failure, the CW500 measures based

on the preset nominal frequency.

Settings

*

/60Hz

50Hz

* Default value

<Procedure>

Use the up and down arrow keys to move to Nominal f.

to show a pull-down menu. → Use the up and down arrow keys to select

the frequency. → Press ENTER to confirm or ESC to cancel.

IM CW500-01EN

Press ENTER

→

5-11

Page 47

5.3 Measurement Setup

<Procedure>

Press SETUP.

Measurement tab.

Demand Measurement Settings

Use the left and right arrow keys to select the

→

5-12

IM CW500-01EN

Page 48

5.3 Measurement Setup

Measurement

Disable demand measurement or select the demand measurement cycle.

When demand measurement is started, the demand value is determined

every measurement interval and recorded. In demand measurement,

the recording interval can be set only to the times shown below. If the

interval is set to some other value and the measurement interval is set,

the interval is automatically set to the same value as the measurement

interval.

Selectable intervals: 1 s, 2 s, 5 s, 10 s, 15 s, 20 s, 30 s, 1 min, 2 min, 5

min, 10 min, 15 min,* 30 min

* The interval cannot be set to a value longer than the measurement

interval.

*

Settings

Not be used, 10 min, 15 min, 30 min

*

* Default value

<Procedure>

Use the up and down arrow keys to move to Measurement. → Press

ENTER to show a pull-down menu. → Use the up and down arrow keys

to select the time. → Press ENTER to confirm or ESC to cancel.

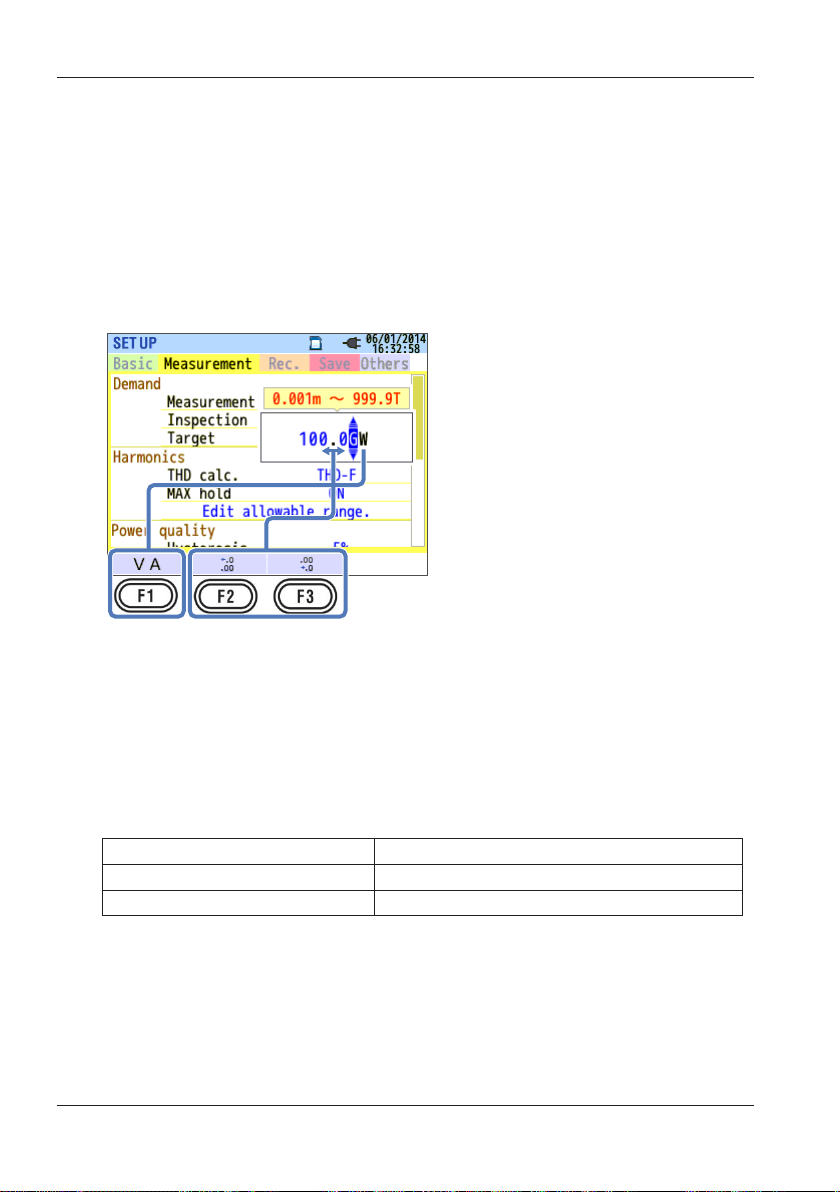

Target

Set the demand measurement target value.

Settings

0.001mW~999.9TW(100.0kW

* Default value

<Procedure>

Use the arrow keys to move to Target.

entry window.* → Use the arrow keys to enter the target value. → Press

ENTER to confirm or ESC to cancel.

* The input range is shown in a pop-up.

*

)

Press ENTER to show a value

→

IM CW500-01EN

5-13

Page 49

5.3 Measurement Setup

When the target value entry window is displayed, the following operations

become valid. You can specify an active power or apparent power for

the demand target value. To switch between active power and apparent

power, press F1 (VA/W) to change to the appropriate power unit.* To

change the unit,* use the left and right arrow keys to move to the unit, and

use the up and down arrow keys to change it. Press F2 and F3 to move

the decimal point.

*

Apparent power:mVA, _VA, kVA, MVA, GVA, TVA

Active power:mW, _W, kW, MW, GW, TW

Inspection cycle

Select the cycle (time) during which a buzzer is sounded when the

estimated value exceeds the target value during demand measurement.

You cannot set the inspection cycle longer than the measurement

cycle. The inspection cycles that can be selected depending on the

measurement cycle are shown below.

Measurement cycle setting Selectable inspection cycles

10 min or 15 min 1 min, 2 min, 5 min

30 min 1 min, 2 min, 5 min, 10 min,

* Default value

<Procedure>

Use the up and down arrow keys to move to Inspection.

to show a value entry window.* → Use the arrow keys to select the time.

Press ENTER to confirm or ESC to cancel.

→

* The input range is shown in a pop-up.

5-14

Press ENTER

→

*

15 min

IM CW500-01EN

Page 50

(kW)

0

5.3 Measurement Setup

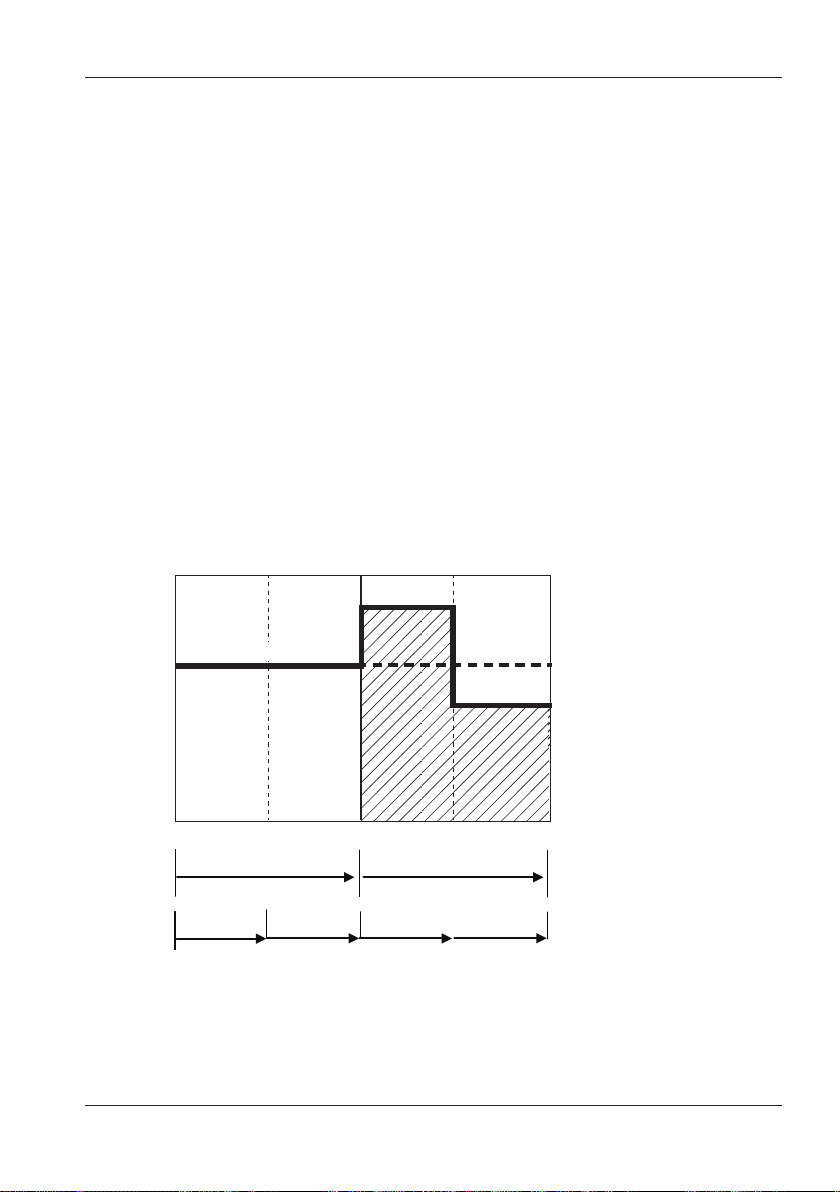

Demand Measurement Overview

The average power over 30 minutes (measurement cycle) is typically

called the demand. Contract demand for factories and the like is

determined by this demand. A method to suppress demand is explained

below using an example. Assuming that the maximum demand needs

to be suppressed to 500 kW (target value), measurement cycle 1 is not

a problem because the demand is 500 kW, but measurement cycle 2 is

because 600 kW of power is consumed in the first 15 minutes. In this

case, the demand for measurement cycle 2 can be suppressed to 500 kW

(the same as measurement cycle 1) by reducing the power of the last 15

min to 400kW. Note that if the power consumption during the first half of

cycle 2 is 1000 kW and the last 15 minutes is 0 kW (no load), the average

power is also 500 kW. If Inspection is set to 15 min, the buzzer will sound

after 15 minutes at measurement cycle 2.

600

500

0 15 30

IM CW500-01EN

500kW

600kW

Interval 2Interval 1

15

500kW

400kW

3

5-15

Page 51

5.3 Measurement Setup

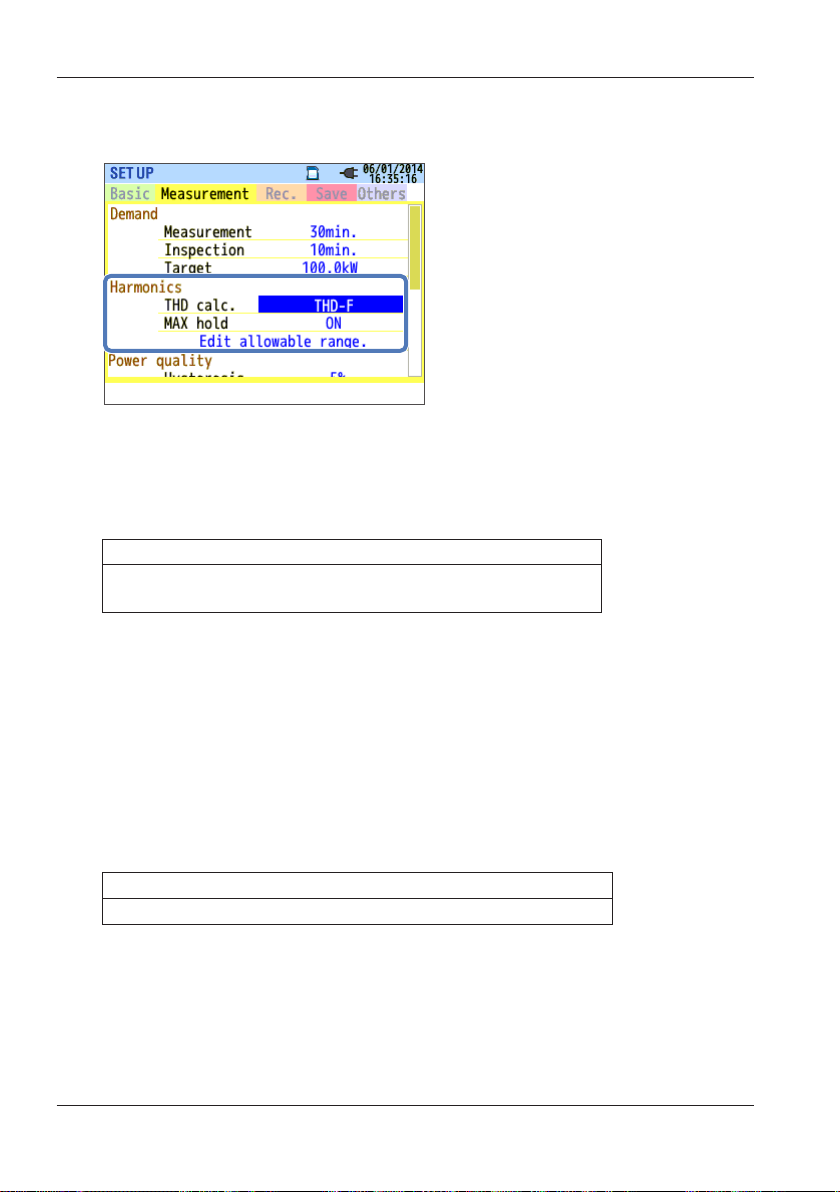

Harmonic Analysis Settings

THD calculation

Select the THD (total harmonic distortion) calculation method. Select

THD-F to calculate the total harmonics distortion based on the

fundamental waveform and “THD-R” to calculate based on all rms values.

Settings

THD-F (fundamental waveform as reference)

(all rms values as reference)

*

Default value

<Procedure>

Use the up and down arrow keys to move to THD calc. → Press ENTER

to show a pull-down menu. → Use the up and down arrow keys to select

the calculation method. → Press ENTER to confirm or ESC to cancel.

*

/THD-R

MAX hold

If MAX hold is set to ON, the maximum percentage content from the start

of measurement is marked on the harmonics graph.

Settings

*

/OFF

ON

*

Default value

<Procedure>

Use the up and down arrow keys to move to MAX hold. → Press ENTER

to show a pull-down menu. → Use the up and down arrow keys to select

ON or OFF. → Press ENTER to confirm or ESC to cancel.

5-16

IM CW500-01EN

Page 52

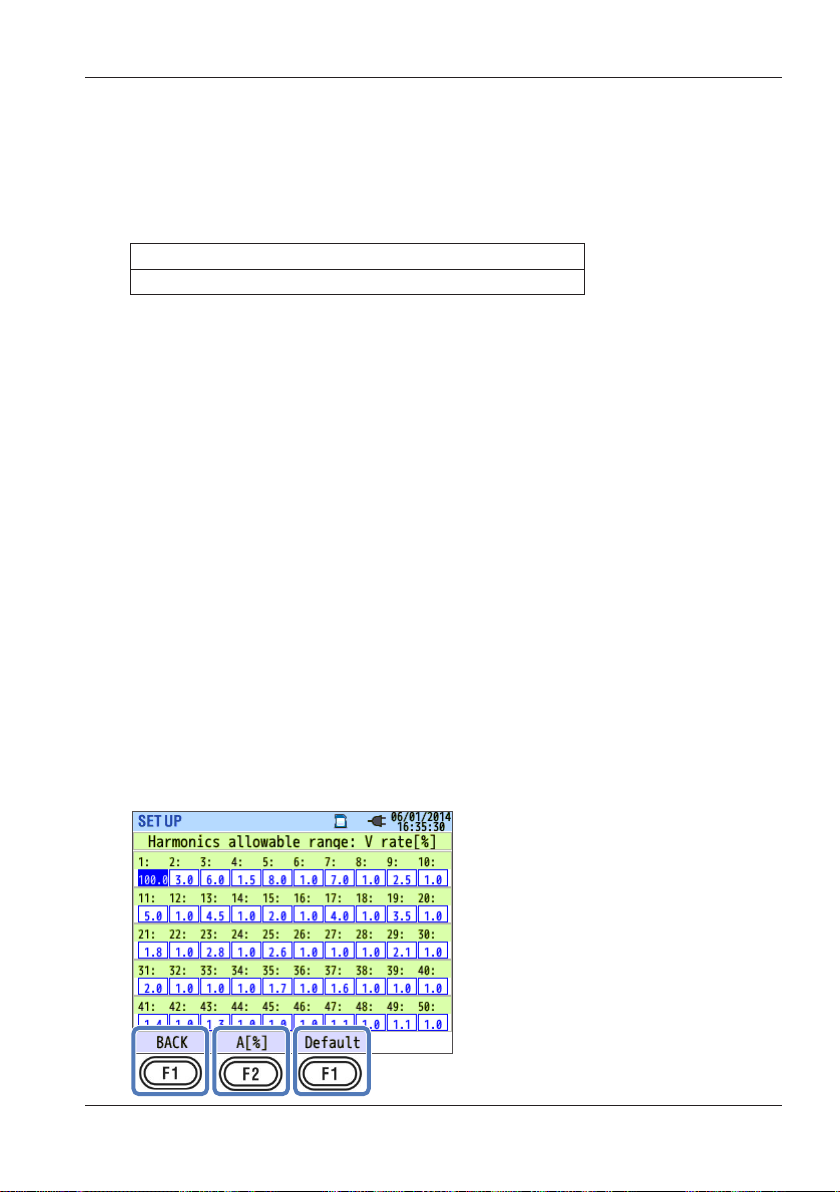

5.3 Measurement Setup

Editing the Allowable Range

Set the EMC allowable range (percentage content) for harmonics for

each order. The specified ranges are displayed as a bar graph on the

harmonics graph.

Settings

*

Specified value

*

Default value

<Procedure>

Use the up and down arrow keys to move to Edit allowable range. →

Press ENTER to display the allowable range entry window. → Use

the arrow keys to select the harmonic order you want to set. → Press

ENTER to open a value entry window.* → Use the arrow keys to enter

the allowable values. → Press ENTER to confirm or ESC to cancel.

* The input range is shown in a pop-up.

When the allowable range entry window is displayed, the following

operations become valid. The default allowable values of each harmonic

order are the values of the international EMC standard IEC61000-47: industrial environment Class 3. If you change the values and want to

reset to their defaults, press F3 (default). Press F2 (A/V [%]) to switch

between the allowable value entry window of harmonic current and that of

harmonic voltage. To return to the measurement setup screen, press F1

(return).

/customize (voltage/current)

IM CW500-01EN

5-17

Page 53

5.3 Measurement Setup

Power Quality (Event) Threshold Settings

Press F1 (OFF/ON) to enable the threshold of each event to be entered.

Even if a threshold is specified, the event will not be detected if it is set

to OFF. When you set an event back to ON, the threshold set previously

appears.

Notes on Setting the Thresholds

Because the SWELL, DIP, and INT thresholds are set as percentages

of the nominal voltage, if the nominal voltage is changed, the threshold

voltages also change. The default value is the peak voltage (300%).

Because the InrushCurrent threshold is set as a percentage of the

current range, if the current range is changed, the threshold current also

changes. Keep these in mind.

5-18

IM CW500-01EN

Page 54

(Voltage)

Voltage waveform

5.3 Measurement Setup

Hysteresis

Set the measurement area where events will not be detected as a

percentage of the threshold. Setting a proper hysteresis will help to

prevent unnecessary detections of events that are caused by voltage or

current fluctuations near the threshold values.

Settings

1 to 10% (5%*) of the threshold

*

Default value

<Procedure>

Use the arrow keys to move to Hysteresis. → Press ENTER to show a

value entry window.* → Use the arrow keys to enter the hysteresis [%].

Press ENTER to confirm or ESC to cancel.

→

* The input range is shown in a pop-up.

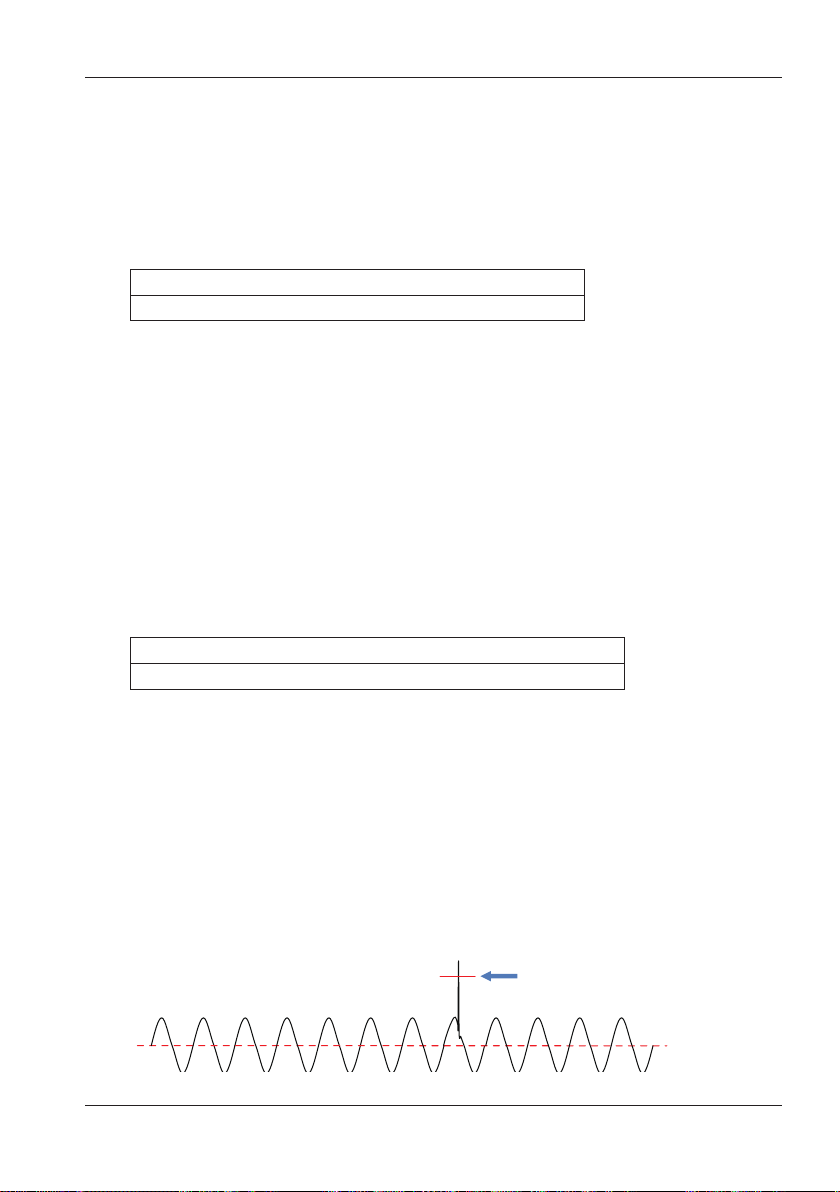

Transient (Over-voltage (Impulse))

Set the transient threshold as an instantaneous voltage. The selectable

range varies depending on the VT ratio.

IM CW500-01EN

Settings

*

±50 to ±2200 Vpeak (300% of the nominal voltage

)

* Default value

<Procedure>

Use the arrow keys to move to Transient.

Press ENTER to show a

→

value entry window.* → Use the arrow keys to enter the voltage. →

Press ENTER to confirm or ESC to cancel.

* The input range is shown in a pop-up.

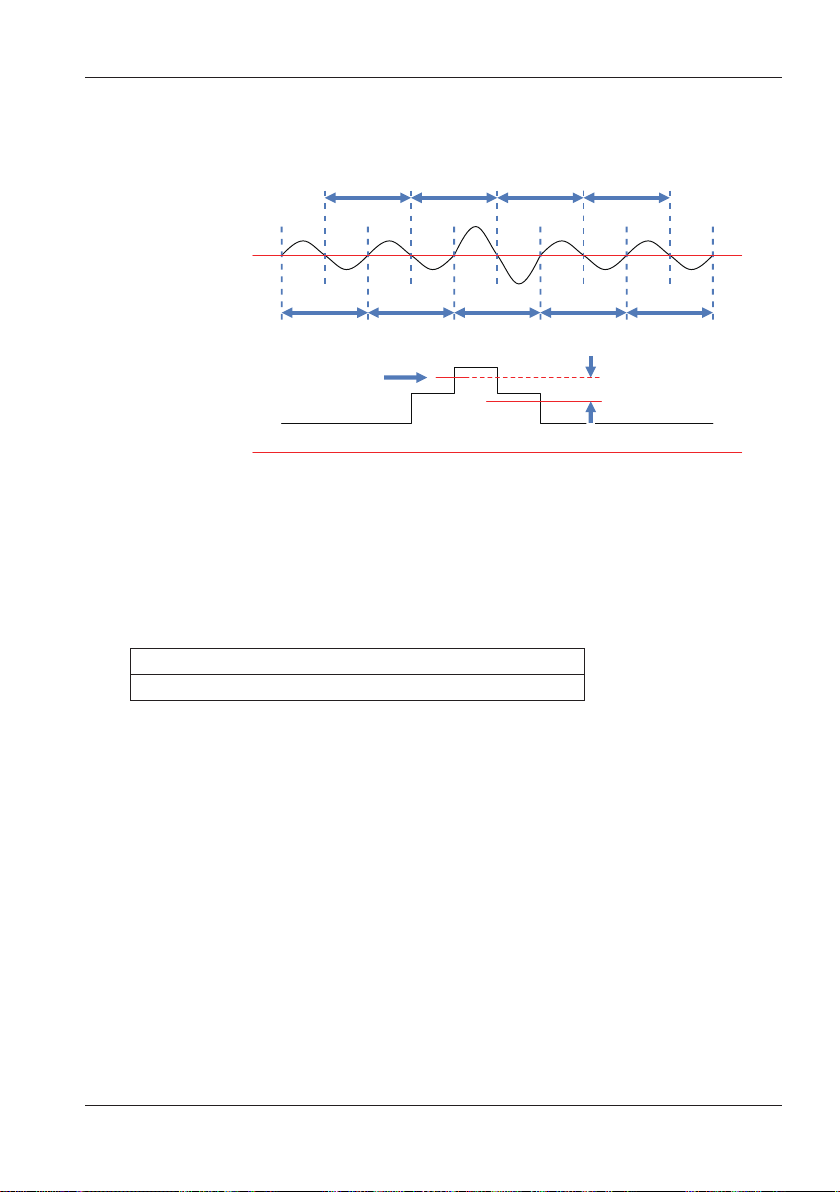

Example of Transient Detection

For details, see “Displaying Recorded Events” on page 6-27.

Threshold

5-19

Page 55

5.3 Measurement Setup

Swell (Instantaneous voltage rise)

Set the swell threshold (rms voltage in one cycle) as a percentage of the

nominal voltage. The selectable range varies depending on the VT ratio.

Hysteresis is applied to this threshold.

Settings

*

100 to 200% (110%

*

Default value

) of the nominal voltage

<Procedure>

Use the up and down arrow keys to move to SWELL. → Press ENTER to

show a value entry window.* → Use the arrow keys to enter a percentage

of the nominal voltage.

* The input range is shown in a pop-up.

Inrush current (Instantaneous current rise)

Set the inrush current threshold (rms current in one cycle) as a

percentage of the maximum value of the current range. The selectable

range varies depending on the CT ratio. Hysteresis is applied to this

threshold.

Settings

0 to 110% (100%*) of the current range

*

Default value

<Procedure>

Use the up and down arrow keys to move to InrushCurrent. → Press

ENTER to show a value entry window.* → Use the arrow keys to enter a

percentage of the maximum value of the current range.

* The input range is shown in a pop-up.

5-20

IM CW500-01EN

Page 56

Rms value (2)

Rms value (4) Rms value (6) Rms value (8)

Voltage/current

waveform

5.3 Measurement Setup

Example of Swell and Inrush Current Detection

For details, see “Displaying Recorded Events” (section 6.7).

Rms value (1)

Threshold

Rms waveform

Rms value (3) Rms value (5) Rms value (7) Rms value (9)

(5)

(4)

(6)

Hysteresis

(7) (8) (9)(1) (2) (3)

Dip (Instantaneous voltage drop)

Set the dip threshold (rms voltage in one cycle) as a percentage of the

nominal voltage. The selectable range varies depending on the VT ratio.

Hysteresis is applied to this threshold.

Settings

*

0 to 100 % (90 %

*

Default value

<Procedure>

Use the up and down arrow keys to move to DIP. → Press ENTER to

show a value entry window.* → Use the arrow keys to enter a percentage

of the nominal voltage.

* The input range is shown in a pop-up.

) of the nominal voltage

IM CW500-01EN

5-21

Page 57

Rms value (2)

Rms value (4) Rms value (6) Rms value (8)

Rms waveform

5.3 Measurement Setup

Interruption (Instantaneous power interruption)

Set the interruption threshold (rms voltage in one cycle) as a percentage

of the nominal voltage. The selectable range varies depending on the

VT ratio. Hysteresis is applied to this threshold. To detect events at rms

voltages of 10 V or less, be sure to enable the interruption event. Proper

detection may not be possible by setting a similar threshold for dip.

Settings

*

0 to 100 % (10 %

* Default value

<Procedure>

Use the up and down arrow keys to move to INT.

show a value entry window.* → Use the arrow keys to enter a percentage

of the nominal voltage.

* The input range is shown in a pop-up.

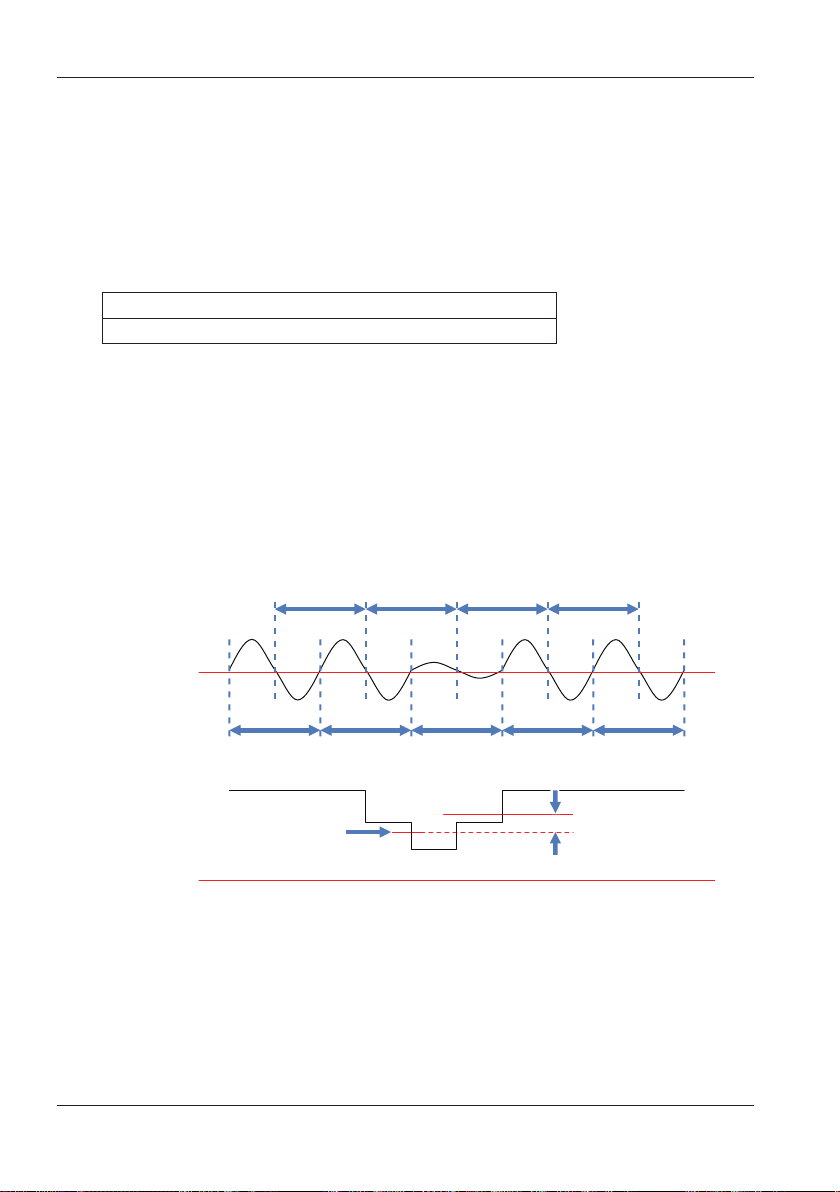

Example of Dip and Interruption Detection

For details, see “Displaying Recorded Events” on page 6-27.

) of the nominal voltage

Press ENTER to

→

5-22

Voltage

waveform

Rms value (1)

Threshold

Rms value (3) Rms value (5) Rms value (7) Rms value (9)

(4)

(5)

(6)

(7) (8) (9) (1) (2) (3)

Hysteresis

IM CW500-01EN

Page 58

5.3 Measurement Setup

Flicker Filter Coefficient Settings

Filter Coefficient

Select an appropriate filter coefficient according to the nominal voltage.

To accurately measure flicker, the nominal voltage, nominal frequency,

and filter coefficient must be set properly for the actual DUT. If possible,

use the same voltage for the nominal voltage and filter coefficient.

Settings

*

/220V/120V/100V

230V

*

Default value

<Procedure>

Use the up and down arrow keys to move to Filter. → Press ENTER to

show a pull-down menu. → Select the appropriate filter coefficient. →

Press ENTER to confirm or ESC to cancel.

IM CW500-01EN

5-23

Page 59

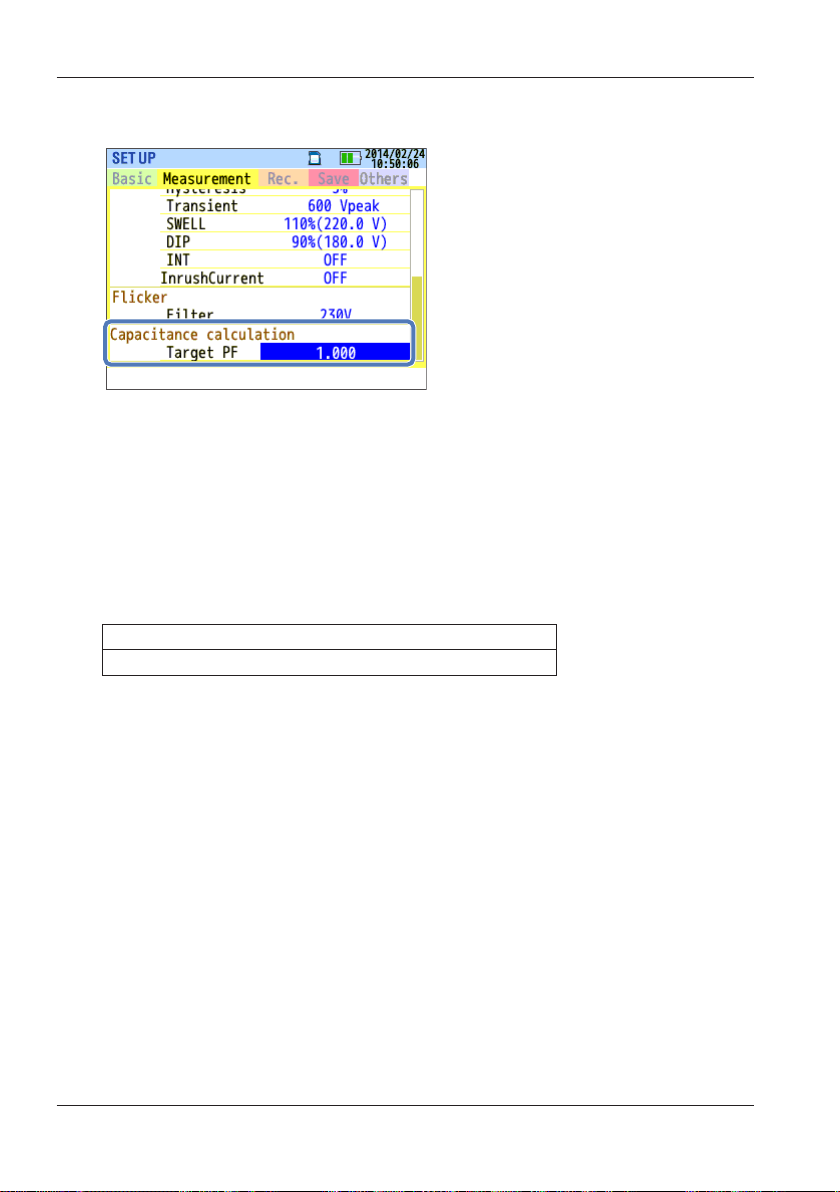

5.3 Measurement Setup

Target Power Factor for Phase Advance Capacitor

Target Power Factor

Set the power factor for when phase advance capacitors are installed.

The power factor degrades if inductive loads, such as motors, are

connected to the power supply because current phases lag behind the

voltage phases. Usually, phase advance capacitors are installed in highvoltage-receiving installations, to improve this situation.

Settings

*

)

*

Default value

0.5 to 1 (1.000

<Procedure>

Use the up and down arrow keys to move to Target PF. → Press ENTER

to show a value entry window.* → Use the arrow keys to enter the target

power factor.

* The input range is shown in a pop-up.

5-24

IM CW500-01EN

Page 60

5.4 Recording Setup

<Procedure>

Press SETUP.

Recording tab.

Recording Item Settings

Use the left and right arrow keys to select the

→

The length of time that measured data can be recorded to an SD

memory card or internal memory varies depending on the number of

recorded items and interval. Recording time can be extended by setting

unnecessary record items to “Do not record.” For details, “Possible

Recording Time” on page 5-30.

Power

This is fixed to “Record.” Power measurement items are always recorded.

IM CW500-01EN

5-25

Page 61

5.4 Recording Setup

Harmonics

Select whether to record the harmonic data of voltage, current, and

power.

Settings

*

/Not record

*

Default value

Record

Event

Select whether to record detailed data when a power quality event

occurs. If the current range is set to AUTO, “Record” cannot be selected.

To select “Record,” change the current range to a fixed range first.

* If AUTO range is selected, measurements according to international

power quality standard IEC61000-4-30 Class S cannot be performed.

Settings

Record*/Not record

*

Default value

<Procedure>

Use the up and down arrow keys to move to Harmonics or Event. →

Press ENTER to show a pull-down menu. → Use the up and down arrow

keys to select Record or Do not record. → Press ENTER to confirm or

ESC to cancel.

5-26

IM CW500-01EN

Page 62

5.4 Recording Setup

Record Items

The following data measured on each channel is recorded according to

the selected record method.

Record items vary depending on the record method and wiring system.

Record file Record items

RMS voltage (line/ phase)

Rms current

Active power

Reactive Power

Apparent power

Power factor

Frequency

Neutral line current (3P4W)

Voltage/current phase angle (1st order)

Analog input voltage, 1CH, 2CH

Power

measurement

data

Harmonic

measurement

data

Voltage/current

fluctuation

data

Event type

data

Waveform data Voltage/current waveforms

Voltage/current unbalance ratio

1-minute voltage flicker

Short term voltage flicker (Pst)

Long term voltage flicker (Plt)

Phase advance capacitor capacitance

Active energy (consumption/regeneration)

Reactive power (consumption) lag/lead

Volt-ampere hours (consumption/regeneration)

Reactive power (regeneration) lag/lead

Demand (W/VA)

Target demand (W/VA)

Total harmonic voltage distortion (F/R)

Total harmonic current distortion (F/R)

Harmonic voltage/current (1 to 50th order)

Voltage/current phase angle (1 to 50th order)

V/A phase difference (1 to 50th order)

Harmonic power (1 to 50th order)

Rms voltage per half-cycle

Rms current per half-cycle

Event detection date and time

Event type

Measured values at event detection

Recording setup

Power +Harmonics +Event

● ● ●

●

●

●

●

IM CW500-01EN

5-27

Page 63

5.4 Recording Setup

Record Method Settings

Interval

Set the interval to record the measured data to the SD memory card

or internal memory. Seventeen different intervals are available, but if

the measurement interval of demand measurement is already set, the

record interval cannot be set longer than the measurement interval.

To set a longer interval, change the measurement interval of demand

measurement to “Not be used” first. If you set the measurement interval of

demand measurement after you set the record interval, the record interval

is automatically set to the same setting as the measurement interval. For

details, see “Demand Measurement Settings” (page 5-12).

Settings

1s/2s/5s/10s/15s/20s/30s/

1min/2min/5min/10min/15min/20min/30min

*

/

1h/2h/150, 180 cycle (approx. 3 s)

*

Default value

The intervals 150, 180 cycles (approx. 3 sec) are defined in the

international power quality standard IEC61000-4-30. Data will be

collected for 150 cycles for 50 Hz nominal frequency and 180 cycles for

60 Hz nominal frequency.

<Procedure>

Use the arrow keys to move to Interval. → Press ENTER to show a

selection window.* → Use the arrow keys to enter the recording interval.

Press ENTER to confirm or ESC to cancel.

→

5-28

IM CW500-01EN

Page 64

5.4 Recording Setup

Start

Select the method to start recording.

Settings

Manual*/Constant rec./Time period rec.

* Default value

<Procedure>

Use the up and down arrow keys to move to Start.

show a pull-down menu.

the recording start method. → Press ENTER to confirm or ESC to cancel.

Use the up and down arrow keys to select

→

Manual

The CW500 records during the period from when you start recording to

when you stop recording using the START/STOP key.

Constant rec.

Set the time to start and stop recording. The CW500 records repeatedly

during the period between the start and stop times at the specified

interval. For details see “Reserving by Specifying the Date and Time” or

“Reserving a Repetitive Recording” (page 4-9).

Press ENTER to

→

Settings Settings

Start date/time Day/Month/Year Hour:Minute (00/00/0000 00:00)

Stop date/time Day/Month/Year Hour:Minute (00/00/0000 00:00)

<Procedure>

Use the arrow keys to move to REC Start/REC End.

show a time entry window. → Use the arrow keys to select the date and

time. → Press ENTER to confirm or ESC to cancel.

IM CW500-01EN

Press ENTER to

→

5-29

Page 65

5.4 Recording Setup

Time Period Recording

Set the recording period by specifying the start date and stop date, and

the common time slot during which recording will take place on each day

of the recording period. During each time slot, recording is performed at

the specified interval. For details see “Reserving by Specifying the Date

and Time” or “Reserving a Repetitive Recording” (page 4-9).

Settings Settings

REC Period Start—Stop

REC Time Start—Stop Hour:Minute (hh:mm) - Hour:Minute(hh:mm)

<Procedure>

Use the arrow keys to move to REC Period.

a time entry window. → Use the arrow keys to enter the date and time.

Press ENTER to confirm or ESC to cancel. → Use the arrow keys to

→

move to Time period rec. → Press ENTER to show a time entry window.

Use the arrow keys to enter the time. → Press ENTER to confirm or

→

ESC to cancel.

Day/Month/Year (DD/ MM/ YYYY) -

Day/Month/Year (DD/ MM/ YYYY)

Press ENTER to show

→

Possible Recording Time

Estimated recording time for a 2GB SD memory card

Interval

1 s 13 days 3 days 1 min 1 year or more 3 months

2 s 15 days 3 days 2 min 2 year or more 6 months

5 s 38 days 7 days 5 min 6 year or more 1 year or more

10 s 2.5 months 15 days 10 min

15 s 3.5 months 23 days 15 min 3 year or more

20 s 5 months 1 months 20 min 5 year or more

30 s 7.5 months 1.5 months 30 min 7 year or more

* The above figures do not include power quality event data. If events

are recorded, the possible recording time will decrease by the amount

of such events. The maximum event data size that can be saved per

recording is 1 GB.

* The SD memory cards that can be used with this instrument are those

provided by YOKOGAWA.

5-30

REC item

Power

+Harmonics

Interval

10 year or more

1 hour

2 hours

150/180 cycle 23 days 4 days

Power

REC item

+Harmonics

2 year or more

10 year or more

IM CW500-01EN

Page 66

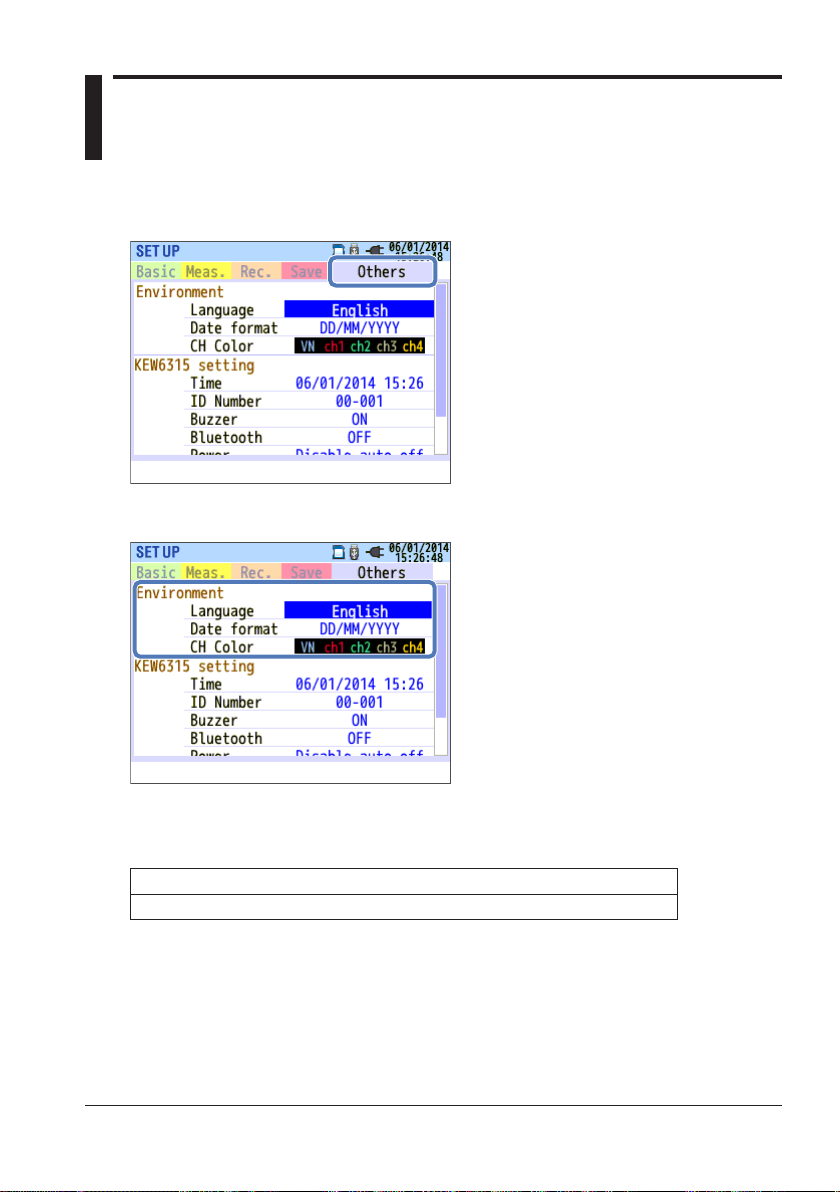

5.5 Other Settings

<Procedure>

Press SETUP.

System Environment Settings

Use the left and right arrow keys to select the Others tab.

→

Language

Select the language to be displayed.

*

English

*

Default value. However, this setting will not be initialized even when the

system is reset.

<Procedure>

Use the up and down arrow keys to move to Language. → Press ENTER

to show a pull-down menu. → Use the up and down arrow keys to select

the language. → Press ENTER to confirm or ESC to cancel.

IM CW500-01EN

/Japanese/French/Spanish/Polish/Korean/Chinese

Settings

5-31

Page 67

5.5 Other Settings

Date format

Select the date display format. You can change the display format of all

displayed dates, such as the current date shown in the upper right of the

screen and the recording start and stop dates that are shown and that

you edit.

Settings

*

YYYY/MM/DD / MM/DD/YYYY

*

Default value. However, this setting will not be initialized even when the

/ DD/MM/YYYY

system is reset.

<Procedure>

Use the up and down arrow keys to move to Date format. → Press

ENTER to show a pull-down menu. → Use the up and down arrow keys

to select the format. → Press ENTER to confirm or ESC to cancel.

CH color

Specify the colors for voltage and current of each channel. You can

change the item label text colors, graph colors, wiring diagram’s channel

colors, and so on.

Settings

White*

VN is only supported in wiring diagrams.

* The default color settings are VN: Yellow, 1CH: Red, 2CH: White, 3CH:

Blue, 4CH: Green. However, these setting will not be initialized even

when the system is reset.

<Procedure>

Use the arrow keys to move to CH color. → Press ENTER to show a

selection window.* → Use the arrow keys to select the color. → Press

ENTER to confirm or ESC to cancel.

Yellow*

Orange

Red* Gray Blue*

Green*

// / / / /

5-32

IM CW500-01EN

Page 68

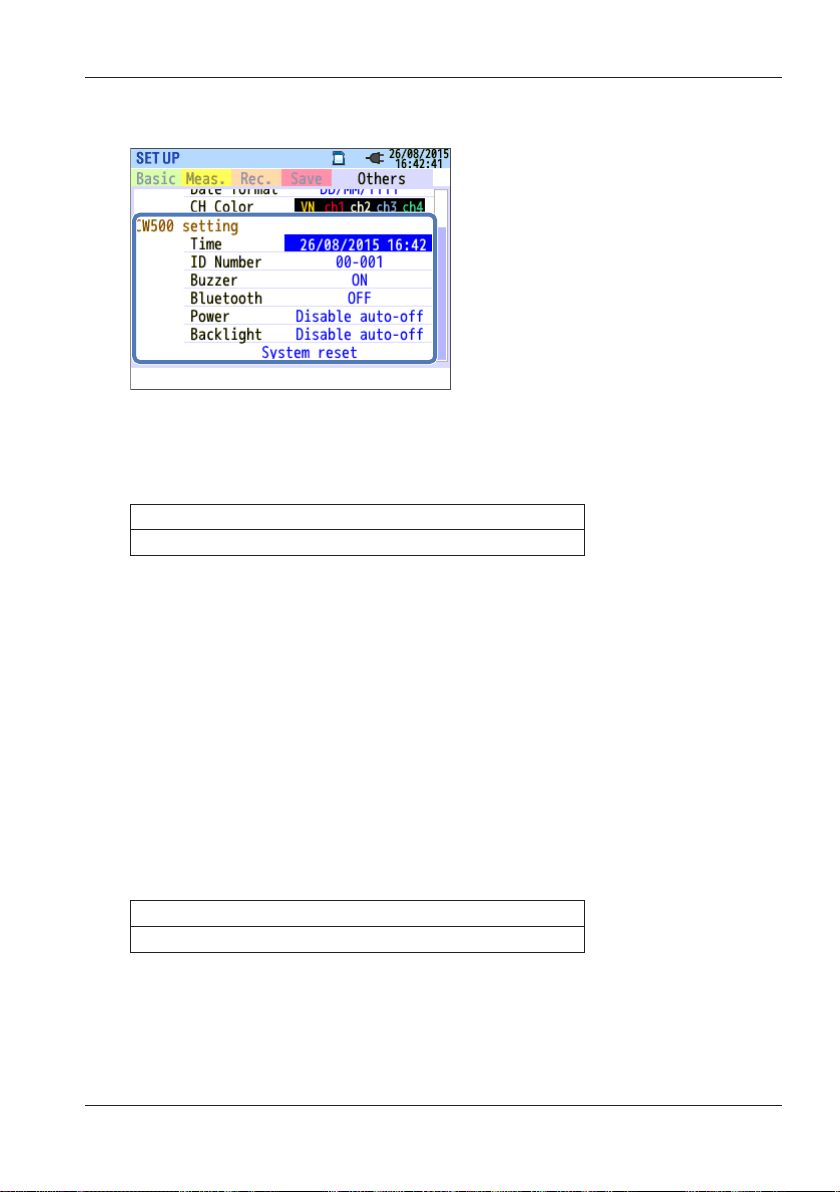

5.5 Other Settings

CW500 System Settings

Time

Set the system clock to the current time.

Settings

yyyy/mm/dd hh:mm

* The input format is synchronized with the Date format setting.

<Procedure>

Use the arrow keys to move to Time.

entry window. → Use the arrow keys to select the date and time. →

Press ENTER to confirm or ESC to cancel.

Press ENTER to show a time

→

ID Number

Set the CW500 ID number. Assigning numbers in an organized manner

will make it convenient to analyze recorded data when several CW500s

are used or when several locations are measured periodically using a

single CW500.

Settings

00-001~99-999(00-001

* Default value

<Procedure>

Use the arrow keys to move to ID Number.

value entry window. → Use the arrow keys to enter the ID number. →

Press ENTER to confirm or ESC to cancel.

IM CW500-01EN

*

)

Press ENTER to show a

→

5-33

Page 69

5.5 Other Settings

Buzzer

Turn on or off the keypad sound. Warning buzzers for demand judgment

and low battery are not affected by this setting.

Settings

*

On

/Off

* Default value

<Procedure>

Use the up and down arrow keys to move to Buzzer.

Press ENTER to

→

show a pull-down menu. → Use the up and down arrow keys to select on

or off. → Press ENTER to confirm or ESC to cancel.

Bluetooth® (option)

Enable or disable the built-in Bluetooth® function. Disable it when you are

not using Bluetooth® communication.

Settings

*

On/Off

* Default value

<Procedure>

Use the up and down arrow keys to move to Bluetooth®. → Press

ENTER to show a pull-down menu. → Use the up and down arrow keys

to select on or off. → Press ENTER to confirm or ESC to cancel.

5-34

IM CW500-01EN

Page 70

5.5 Other Settings

Power

Enable or disable the auto-power-off function. If the CW500 is running off

of batteries, “Disable auto-off” cannot be selected in order to save battery

power.

Mode Settings

AC power Power off in 5 min./Disable auto-off*

Battery Power off in 5 min.

* Default value

<Procedure>

Use the up and down arrow keys to move to Power.

show a pull-down menu. → Use the up and down arrow keys to enable

auto-power-off. → Press ENTER to confirm or ESC to cancel.

Press ENTER to

→

Backlight

Select whether to turn off the backlight automatically when there is no

user interaction for a given period. If the CW500 is running off of batteries,

“Disable auto-off” cannot be selected in order to save battery power.

Mode Settings

AC power Power off in 5 min./Disable auto-off*

Battery Power off after 2 min.

* Default value

<Procedure>

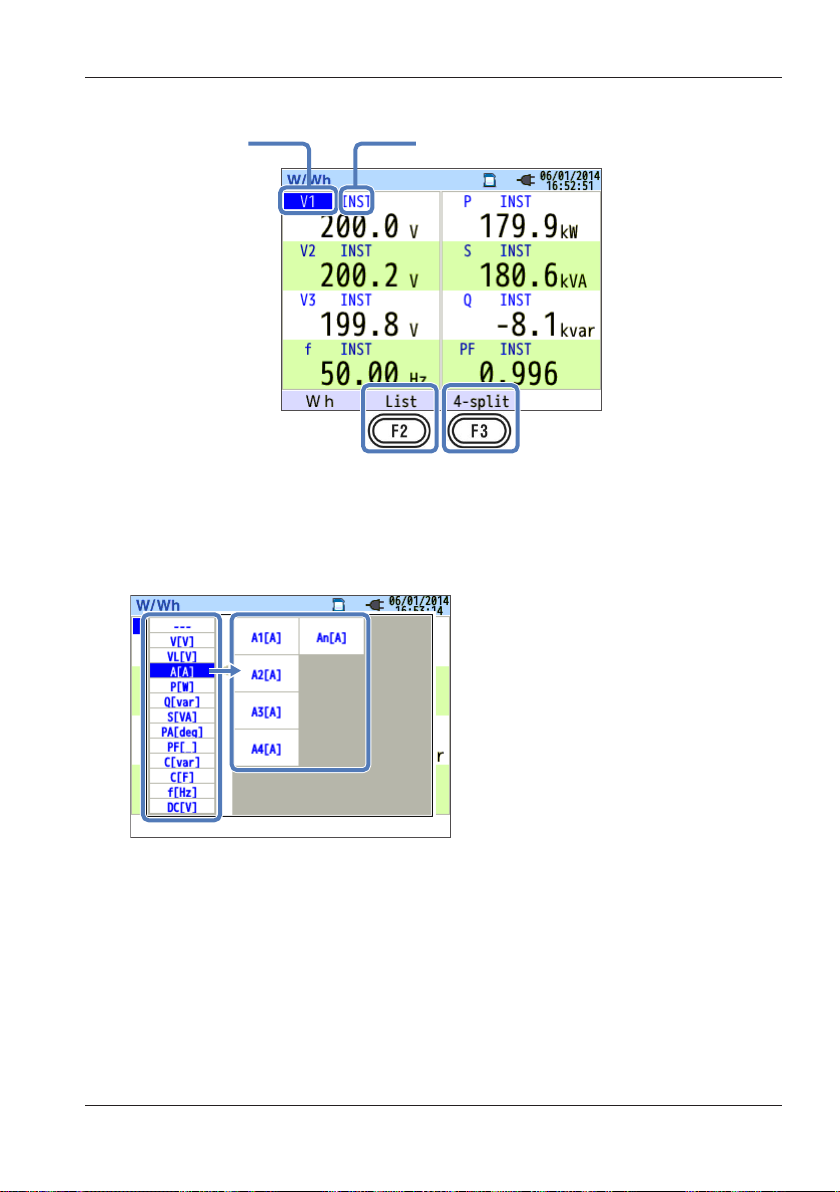

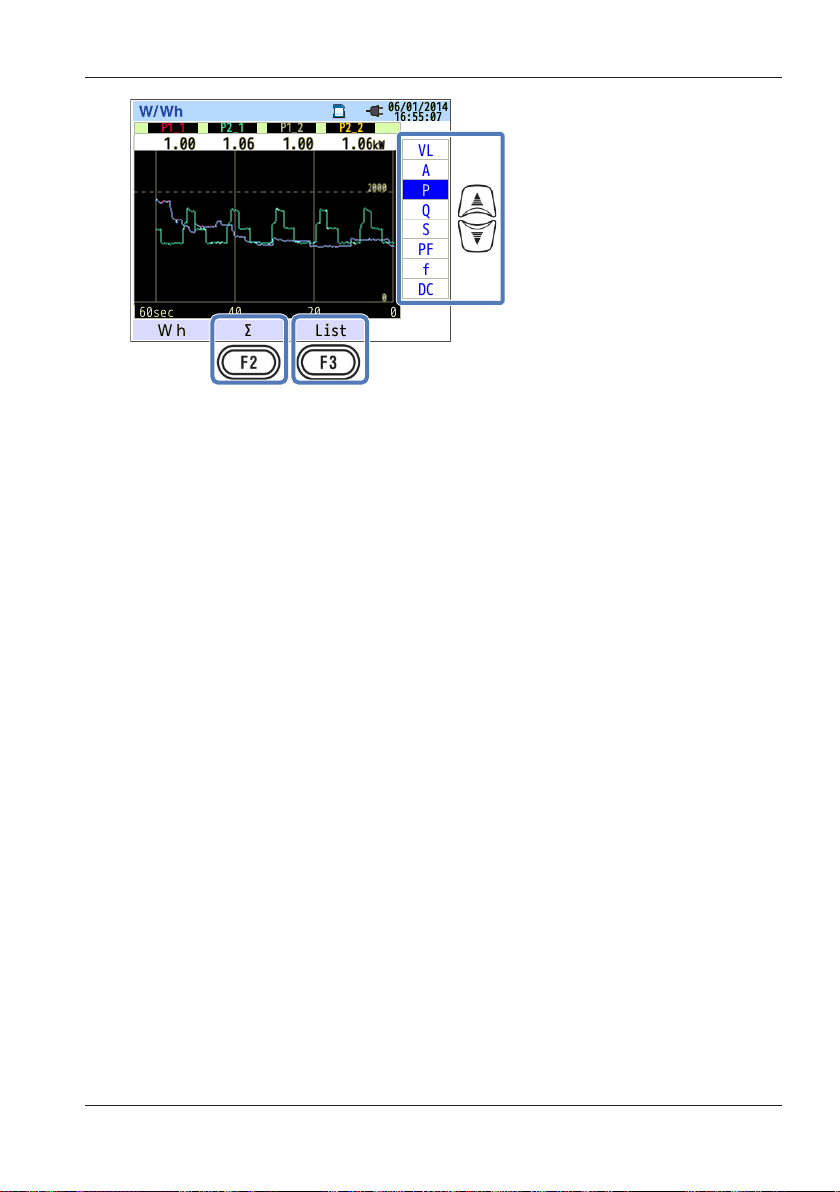

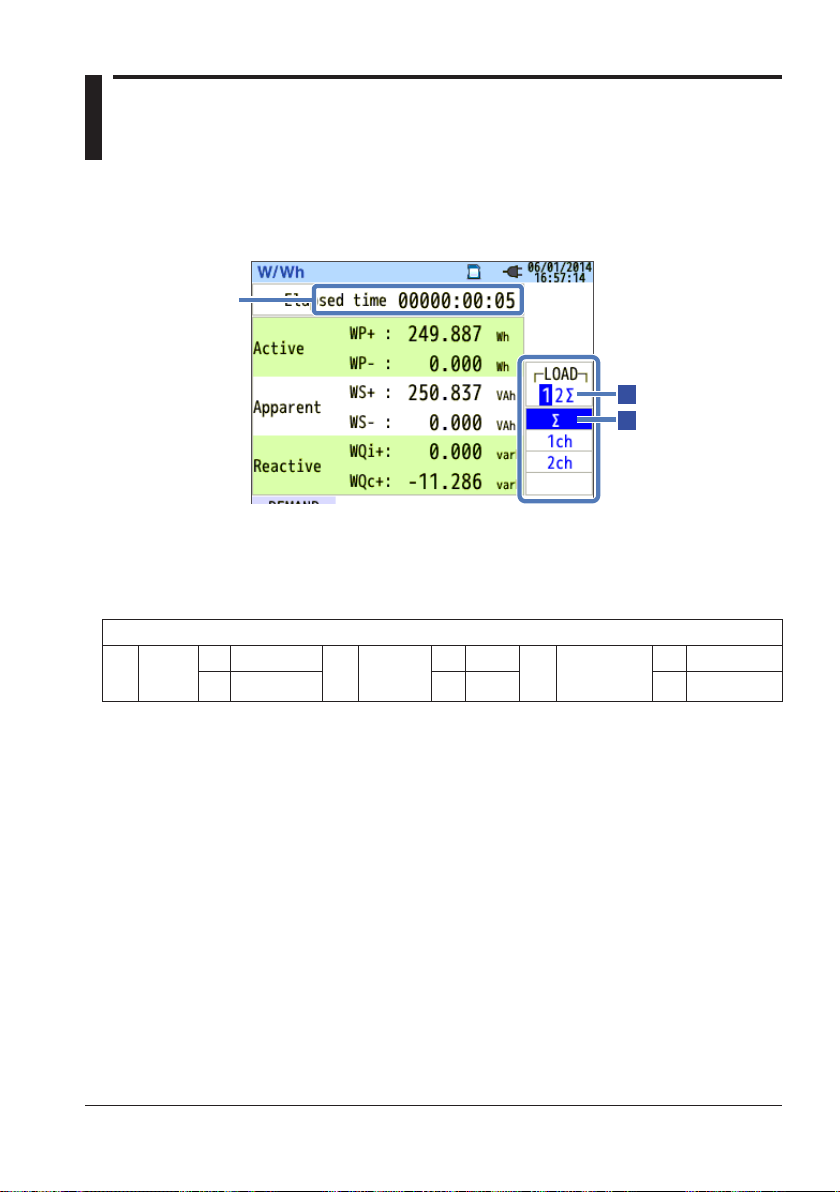

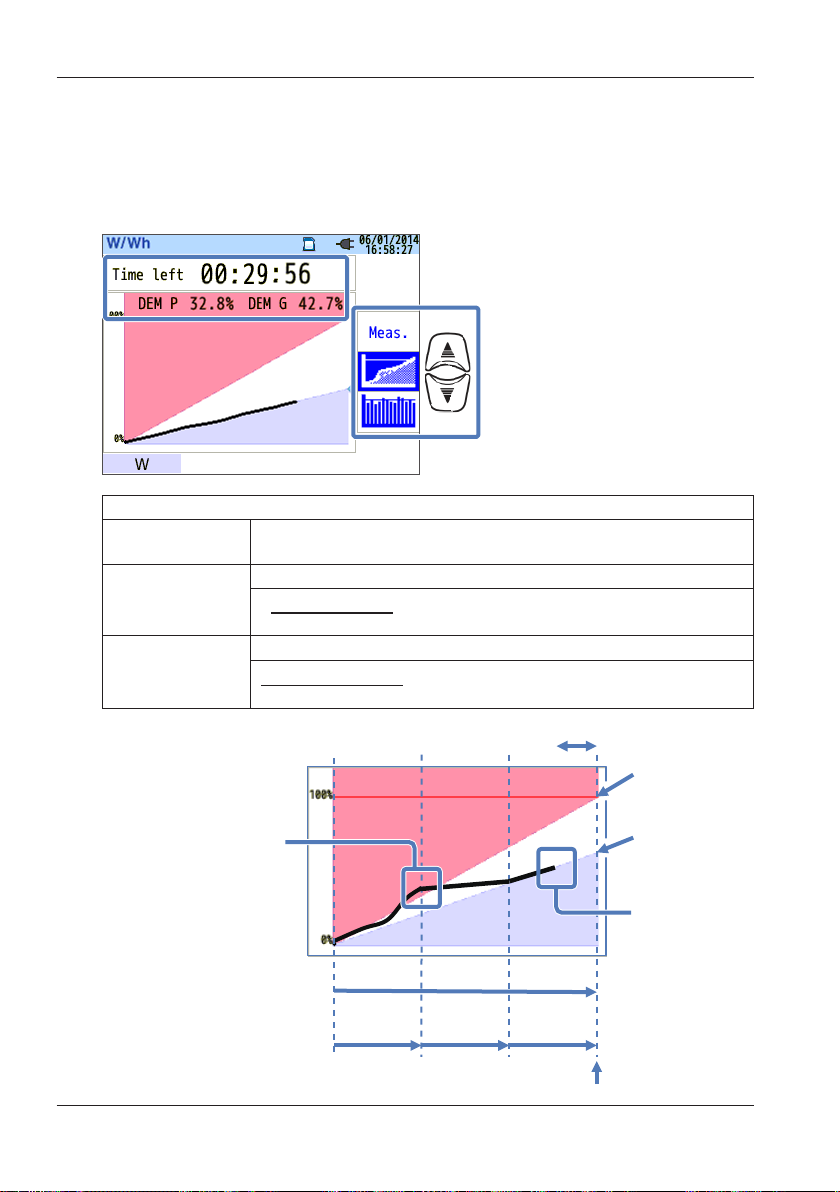

Use the up and down arrow keys to move to Backlight.

to show a pull-down menu. → Use the up and down arrow keys to enable

or disable the backlight auto-off function. → Press ENTER to confirm or

ESC to cancel.

Press ENTER

→

System reset

This restores all the settings to their defaults except for Language, Date

format, CH Color, and Time.

<Procedure>

Use the up and down arrow keys to move to System reset. → Press

ENTER to show a confirmation message. → Use the left and right arrow

keys to select Yes or NO. → Press ENTER to confirm.

IM CW500-01EN

5-35

Page 71

5.6 Saved Data

<Procedure>

Press SETUP.

data tab.

You can save measured data, screenshots, and setup data to the SD

memory card or internal memory. If an SD memory card is inserted in the

instrument, data will be automatically saved to the card. Do not insert an

SD memory card if you want to save to the internal memory. You cannot

set the save destination.

We recommend that you save data to an SD memory card. Up to three

measured data files and eight other files can be saved to the internal

memory.

Use the left and right arrow keys to select the Saved

→

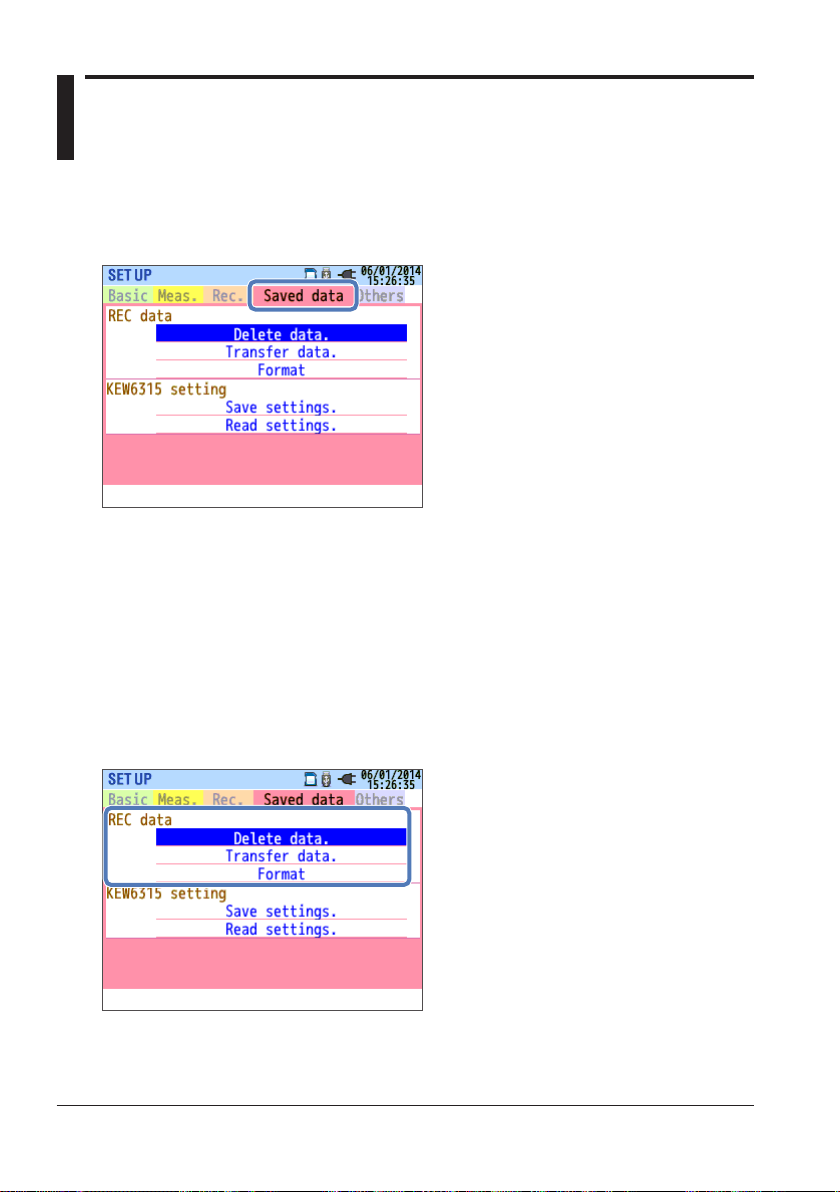

Recorded Data Operation

<Procedure>

Use the up and down arrow keys to move to the desired operation. →

Press ENTER to confirm.

5-36

IM CW500-01EN

Page 72

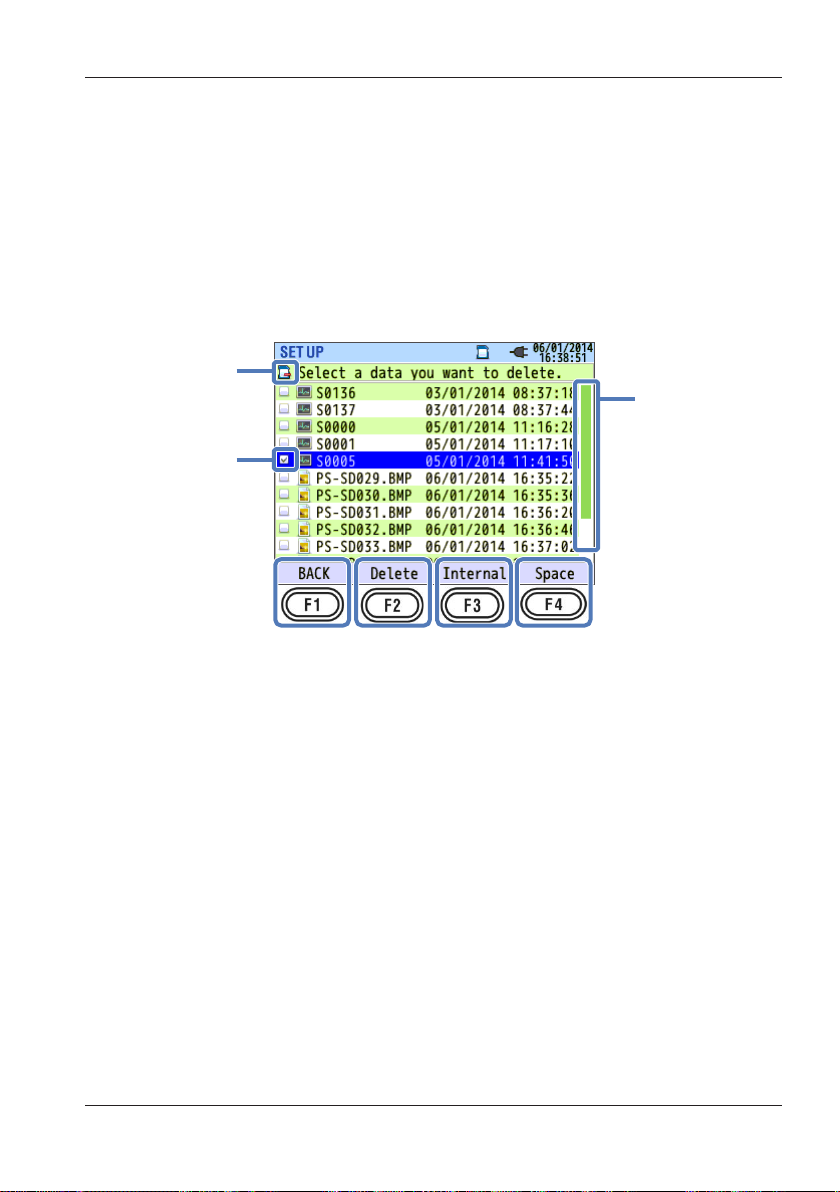

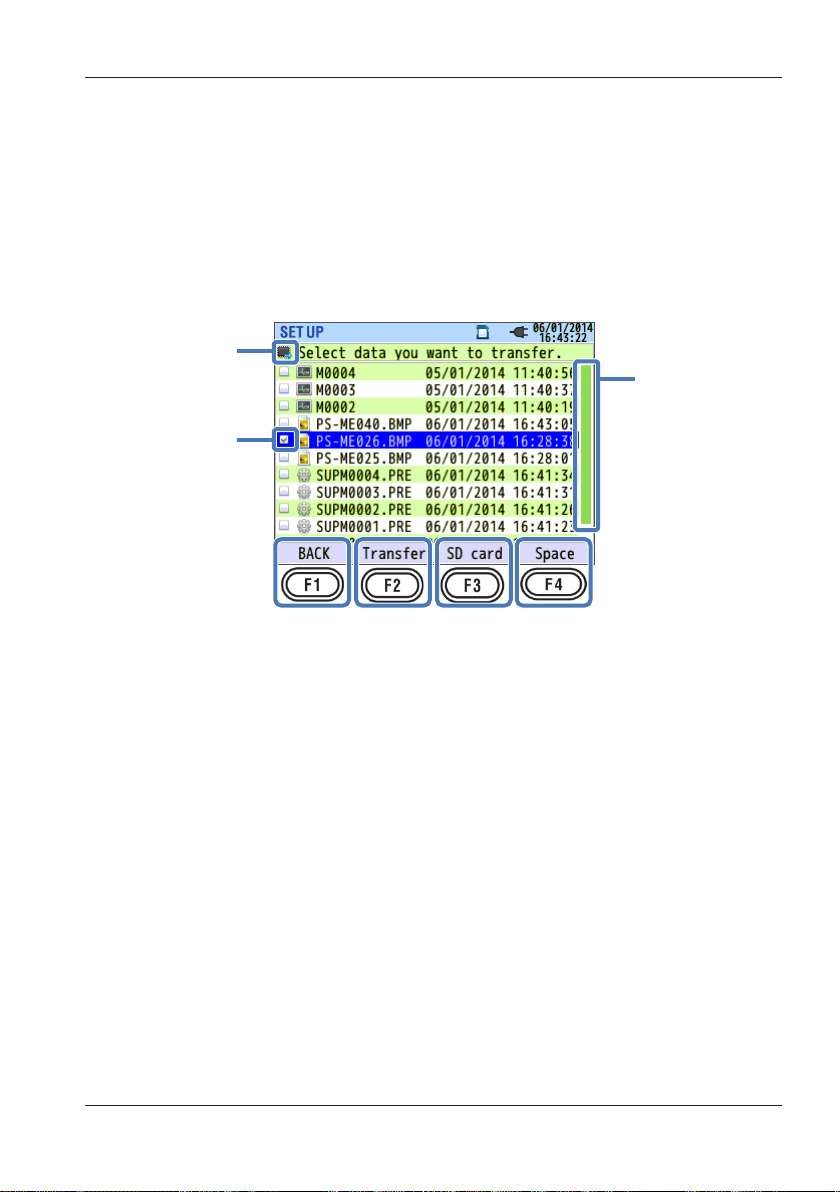

Data location

Scroll bar

5.6 Saved Data

Delete data

This is used to delete measured data, screenshots, and setup data from

the SD memory card or internal memory. Be careful when deleting data

files because they are not sorted by recording date. The data recording

dates are listed to the right of file names. Note that dates of data files

transferred from the internal memory to an SD memory card are the dates

when they were transferred. A scroll bar appears when not all the data

can be displayed on the screen.

Check box

<Procedure>

Use the up and down arrow keys to move to the data you want to delete.

Press ENTER to select it. → Press F2 to show a delete confirmation

→

message. → Use the left and right arrow keys to select Yes or NO. →

Press ENTER to confirm.

When you select a data file, the corresponding check box is selected. You

can delete several data files at once.

Delete

Press F2 (delete) to show a confirmation message. Select “Yes” to delete

the data.

Internal/SD card

Press F3 to switch between the SD memory card and internal memory.

The selected medium is displayed in the upper left of the screen.

Switching the screen clears all the selected check boxes.

IM CW500-01EN

5-37

Page 73

5.6 Saved Data

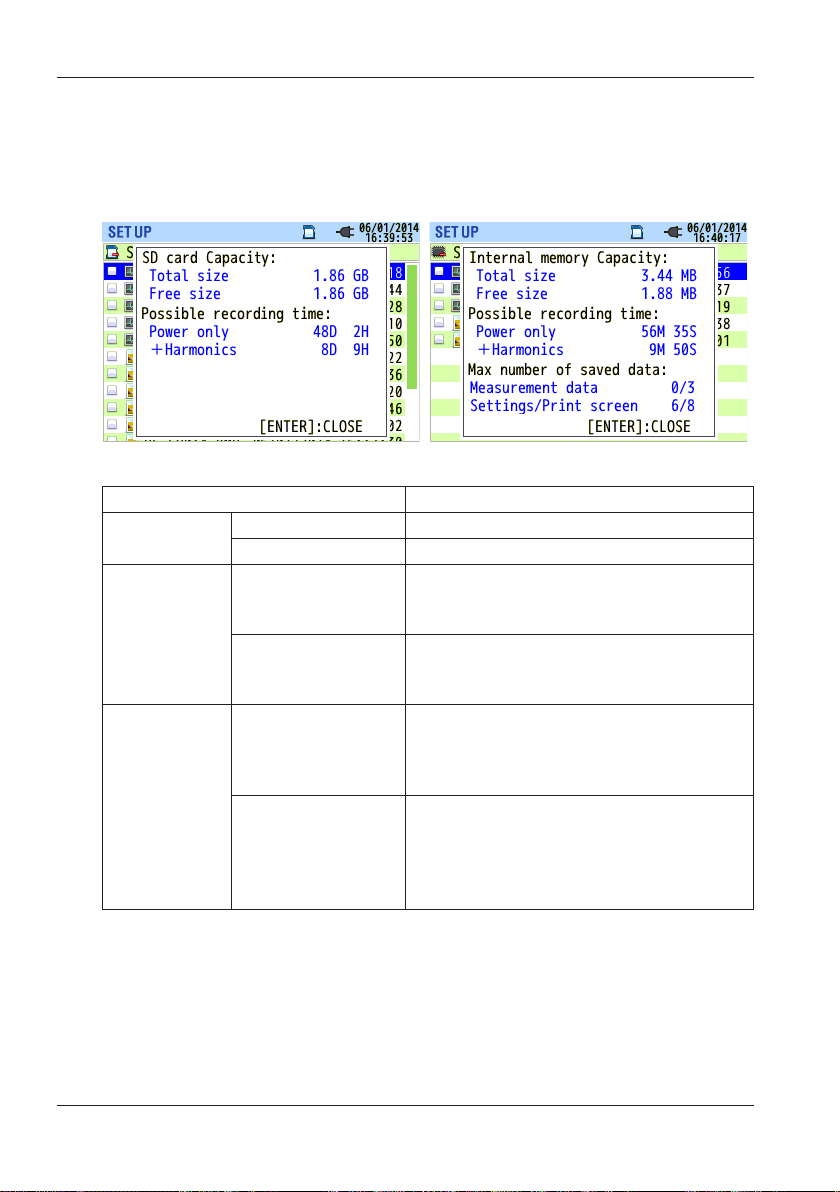

Space

Press F4 (free space) to display a pop-up screen showing the selected

medium information. Press ENTER to return to the data deletion screen.

Item Displayed Information

Capacity

Possible

recording

time

Max number

of saved data

* Internal

memory only

Total size

Free size

Power only

Power+Harmonics

Measured data

Settings/

Print

screen

Size of used space + free space

Size of free space only

Estimated possible recording time

when only power parameters are

recorded

Estimated possible recording time

when power and harmonic parameters

are recorded

Number of completed measurements

* The maximum number of files that

can be saved in the internal memory is

three.

Number of recorded settings and

screenshots

* The maximum number of files that

can be saved in the internal memory is

eight.

Back

Press F1 (back) to return to the Saved data screen.

5-38

IM CW500-01EN

Page 74

Data location

Scroll bar

5.6 Saved Data

Transfer data

This is used to transfer measured data, screenshots, and setup data from

the internal memory to an SD memory card. Be careful when transferring

data files because they are not sorted by recording date. The data

recording dates are listed to the right of file names. Note that dates of

data files transferred from the internal memory to an SD memory card are

the dates when they were transferred. A scroll bar appears when not all

the data can be displayed on the screen.

Check box

<Procedure>

Use the up and down arrow keys to move to the data you want to transfer.

Press ENTER to select it. → Press F2 to show a delete confirmation

→

message.

→ Use the left and right arrow keys to select Yes or NO. → Press

ENTER to confirm.

When you select a data file to be transferred, the corresponding check

box is selected. You can transfer several data files at once.

Transfer

Press F2 (transfer) to show a confirmation message. Select “Yes” to

transfer the data.

SD card

Press F3 (SD memory card) to view the data stored in the transfer

destination SD memory card. To return to the transfer data selection

screen, press F3 (internal memory) again. Switching the screen clears all

the selected check boxes.

IM CW500-01EN

5-39

Page 75

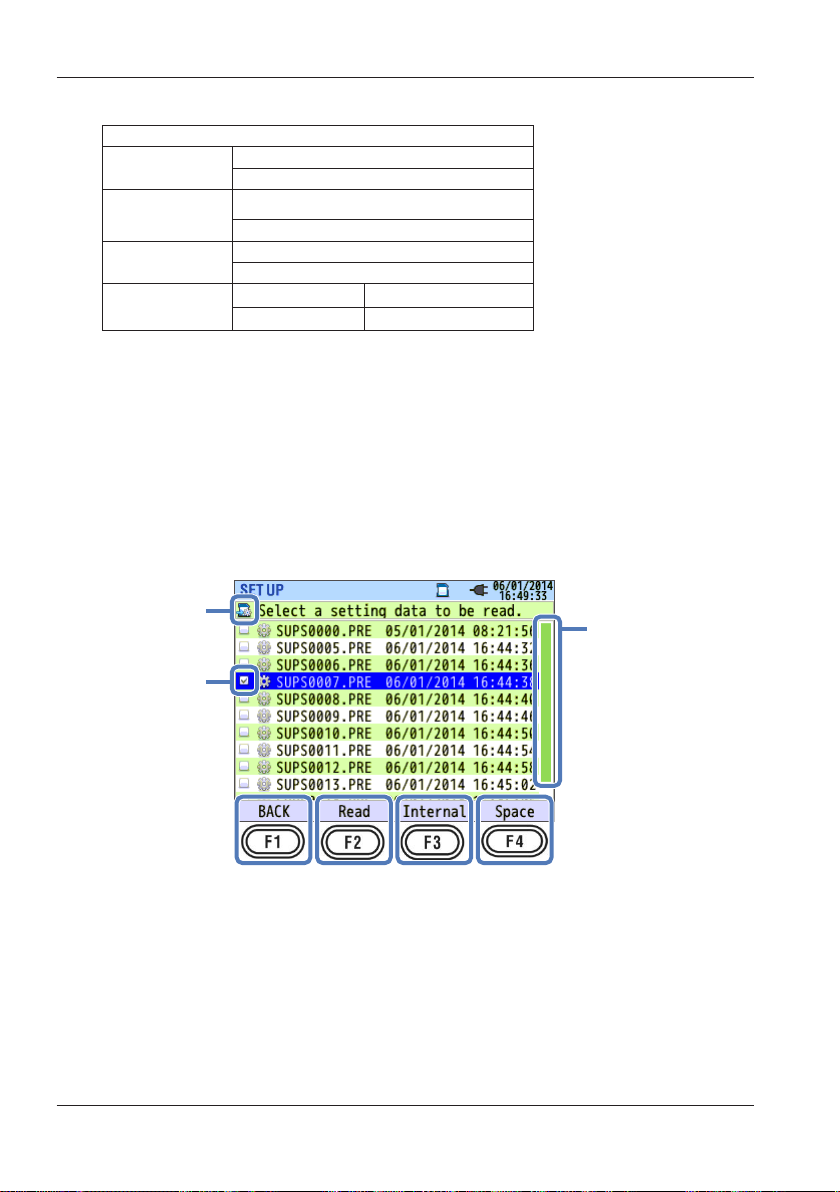

Data location

Scroll bar

5.6 Saved Data

Free size

Press F4 (free space) to display a pop-up screen showing the selected

medium information. Press ENTER (close) to return to the data transfer

screen.

For details, see “Space” on page 5-38.

Back

Press F1 (back) to return to the Saved data screen.

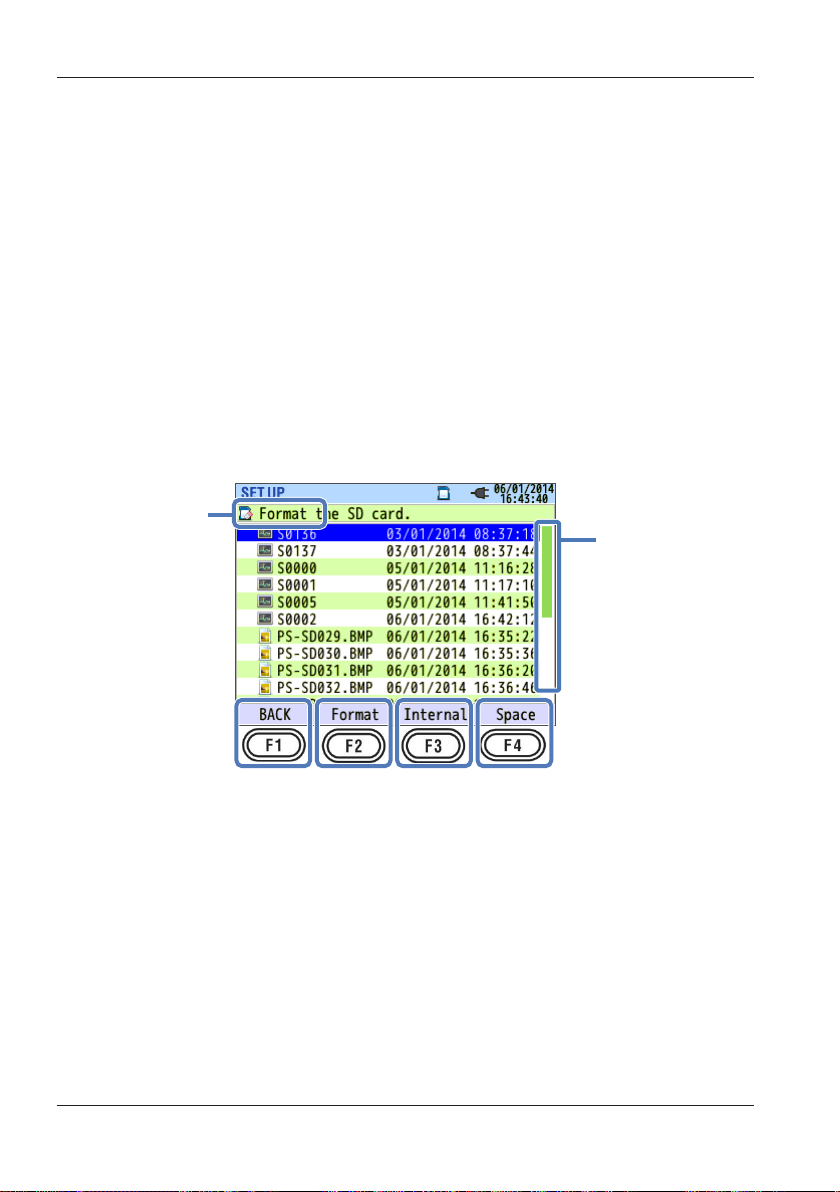

Format

This is used to format an SD memory card or internal memory.

When you format, all the saved data will be deleted. Save necessary data

to a different storage medium before formatting.

5-40

<Procedure>