Page 1

User's

Manual

IM CW240E

CW240

Clamp-on Power Meter

1st Edition: June 2004 (KP)

IM CW240E

Page 2

Index

Introduction .....................................................................................1

Checking the Contents of the Package........................................ 2

Precautions for Safe Use of the Instrument ................................ 6

Utilisation en Toute Securite ......................................................... 9

Chapter 1 Product Overview ................................... 1-1

1.1 Product Overview .............................................................. 1-2

1.2 System Configuration Diagram ........................................ 1-4

Chapter 2 Part Names and How to Use Parts ......... 2-1

2.1 Front Panel and Connector Block .................................... 2-2

2.2 Operation Keys .................................................................. 2-3

2.3 Side Faces .......................................................................... 2-4

2.4 Screen Configuration ........................................................ 2-5

2.5 Overrange/Error Indication during Measurement ........... 2-6

2.6 Description of Mark Indication ....................................... 2-11

Chapter 3 Preparation for Safe Measurements ...... 3-1

3.1 Precautions for Use ........................................................... 3-2

3.2 Connecting a Power Supply ............................................. 3-4

3.3 Connecting Voltage Probes ............................................ 3-14

3.4 Connecting Clamp-on Probes ........................................ 3-15

3.5 Connection Diagrams of Voltage Probes and

Clamp-on Probes ............................................................. 3-17

3.6 Turning ON the Power Switch ......................................... 3-22

3.7 Performing Measurements with Greater Precision ...... 3-24

IM CW240E

Toc-1

Page 3

Index

Chapter 4 Wiring ........................................................ 4-1

4.1 Precautions for Wiring to the Measurement Circuit ....... 4-2

4.2 Installing the CW240 .......................................................... 4-3

4.3 Setting up Wiring ............................................................... 4-5

4.4 Setting up the Number of Loads ...................................... 4-6

4.5 Carrying out Wiring ........................................................... 4-7

4.6 Wiring the Measurement Circuit

Using External VT/CT ...................................................... 4-23

4.7 Checking Wiring ............................................................... 4-24

Chapter 5 Setting Ranges Using the Direct Keys... 5-1

5.1 Setting the Voltage Range ................................................. 5-2

5.2 Setting the Current Range ................................................ 5-4

5.3 Ranges and Number of Digits ........................................... 5-6

Chapter 6 Configuring Settings ............................... 6-1

6.1 Settings ............................................................................... 6-2

6.2 General Settings 1/2 .......................................................... 6-6

6.3 General Settings 2/2 ........................................................ 6-21

6.4 Save Data Settings 1/2 ..................................................... 6-46

6.5 Save Data Settings 2/2 ..................................................... 6-62

6.6 Communication Settings ................................................. 6-67

6.7 Voltage Quality Settings .................................................. 6-72

6.8 Hardware Settings ........................................................... 6-76

6.9 Analog I/O Settings .......................................................... 6-88

Toc-2

IM CW240E

Page 4

Index

Chapter 7 Measurements ..........................................7-1

7.1 Measurements .................................................................... 7-2

7.2 Measure Screens ............................................................... 7-3

7.3 Measuring Electric Energy .............................................. 7-13

7.4 Measuring Demand .......................................................... 7-17

7.5 Displaying Zoom (Expanded View) ................................ 7-21

7.6 Measuring Harmonics ..................................................... 7-24

7.7 Displaying Waveform ....................................................... 7-34

7.8 Measuring Voltage Quality (Voltage Dip,

Voltage Swell, or Instantaneous Interruption) ............... 7-40

7.9 Checking Settings ............................................................ 7-43

7.10 Clearing Integrated Data ................................................. 7-45

7.11 Measurement Data ........................................................... 7-46

Chapter 8 Saving Measured Data............................. 8-1

8.1 Data Save ............................................................................ 8-2

8.2 Saving Measured Data ....................................................... 8-6

8.3 Memory (Reference) ........................................................ 8-11

8.4 Backup Memory ............................................................... 8-13

8.5 Copying Screen Data (Hard copy) .................................. 8-15

Chapter 9 Processing File(s) .................................... 9-1

9.1 File Processing .................................................................. 9-2

9.2 Changing a File Name ....................................................... 9-4

9.3 Deleting a File ..................................................................... 9-6

9.4 Formatting .......................................................................... 9-9

9.5 Data Copy ......................................................................... 9-10

9.6 Setting Files (Load/Save/Delete/Name Change) ........... 9-14

9.7 Backup Memory Copy ..................................................... 9-24

9.8 Backup Memory Delete ................................................... 9-25

Chapter 10 Using the Communication Function

(RS-232) .................................................. 10-1

10.1 Description of the Communication Function ................ 10-2

10.2 Using a Personal Computer ............................................ 10-4

10.3 Using a Printer ................................................................. 10-6

IM CW240E

Toc-3

Page 5

Index

Chapter 11 PC Card ................................................... 11-1

11.1 PC Card Specifications ................................................... 11-2

11.2 Inserting and Removing the PC Card ............................ 11-3

11.3 Formatting the PC Card ................................................... 11-4

11.4 Saving in the PC Card ..................................................... 11-5

Chapter 12 Using External Control Input/Output ... 12-1

12.1 External Control Input/Output ........................................ 12-2

12.2 Connecting External Control Terminals ......................... 12-3

12.3 Using Multiple CW240 Units in Synchronization .......... 12-4

Chapter 13 Using Analog Input/Output

(Optional) ................................................ 13-1

13.1 Analog Output (DA Output) ............................................. 13-2

13.2 Analog Input ..................................................................... 13-6

13.3 Connecting Analog Input/Output Terminals .................. 13-8

Chapter 14 Power Failure Processing Function ..... 14-1

Chapter 15 Other Functions ..................................... 15-1

15.1 Holding the Display Value ............................................... 15-2

15.2 Turning the LCD Backlight ON and OFF ........................ 15-3

15.3 Locking the Keys ............................................................. 15-4

15.4 Resetting the System ...................................................... 15-5

Chapter 16 Maintenance Troubleshooting .............. 16-1

16.1 Things to Check When There is a Malfunction ............. 16-2

16.2 Error Message Content and Actions ............................. 16-4

Chapter 17 CW 240 Specifications ........................... 17-1

17.1 CW 240 Specifications ..................................................... 17-2

17.2 Specifications of Current Clamps

(Clamp-on Probe) ........................................................... 17-17

Toc-4

IM CW240E

Page 6

Index

Appendix 1 Block Diagram .................................. App.1-1

Appendix 2 File/Print Item Descriptions ............ App.2-1

Appendix 3 Polarity (Active Power, Reactive Power,

Power Factor, Phase Angle) ............ App.3-1

Appendix 4 Polarity

(Harmonic Measurement) ................App.4-1

Appendix 5 Reactive Power Method ................... App.5-1

Appendix 6 Sampling Method ............................. App.6-1

Appendix 7 Terminology ...................................... App.7-1

IM CW240E

Toc-5

Page 7

Introduction

Thank you for purchasing our CW240 Clamp-on Power Meter. This User's

Manual describes the functions of the CW240 as well as its operating methods

and handling precautions. Read this manual thoroughly before using the

CW240, to ensure correct use.

In addition to this manual, the Quick Setup Manual and Communication

Function Manual (CD-ROM) are available separately. The Quick Setup Manual

briefly describes the basic procedures for performing such tasks as setup and

measurement operations. Use the Quick Setup Manual together with this indepth User's Manual. For more information on the communication functions,

see the Communication Function Manual (CD-ROM).

After reading this manual, always keep it in an easily accessible convenient

place for later reference. This manual will come in handy when you are unsure

of how to operate the product.

Notices

The contents of this manual are subject to change without prior notice. In

addition, figures and illustrations representing display views in this manual may

differ from actual views.

Every effort has been made to ensure accuracy in the preparation of this

manual. However, should any doubts arise or errors come to your attention,

please contact one of the Yokogawa M&C sales offices listed on the back cover

of this manual, or the sales representative from whom you purchased the

product.

The contents of this manual may not be transcribed or reproduced, in part or in

their entirety, without prior permission.

Introduction

Trademark Acknowledgments

The company and product names referred to in this document are either

trademarks or registered trademarks of their respective holders.

Revision Information

First Edition: June, 2004

Disk No. CW240E

1st Edition: June, 2004 (KP)

All Rights Reserved. Copyright © 1999, Yokogawa M&C Corporation

IM CW240E

1

Page 8

Checking the Contents of the

Package

After opening the package, be sure to check the product as instructed below

before use. Should the product you have received be the wrong model, lack any

items, or show any problems in its appearance, contact the vendor from whom

you purchased the product.

Instrument Main Unit

Check the model name where MODEL is printed on the nameplate located at

the back of the CW240 to ensure that the CW240 is exactly as specified in your

purchase order.

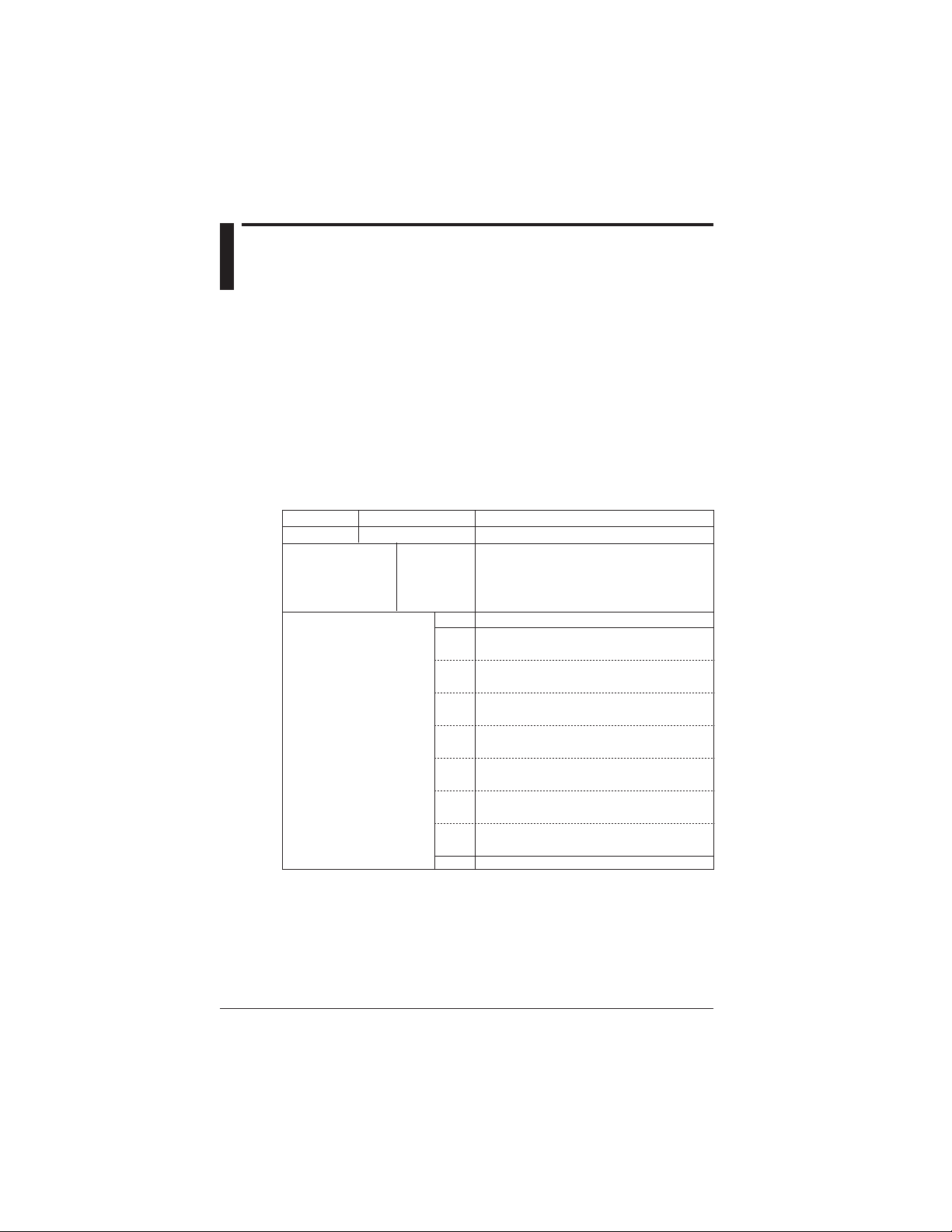

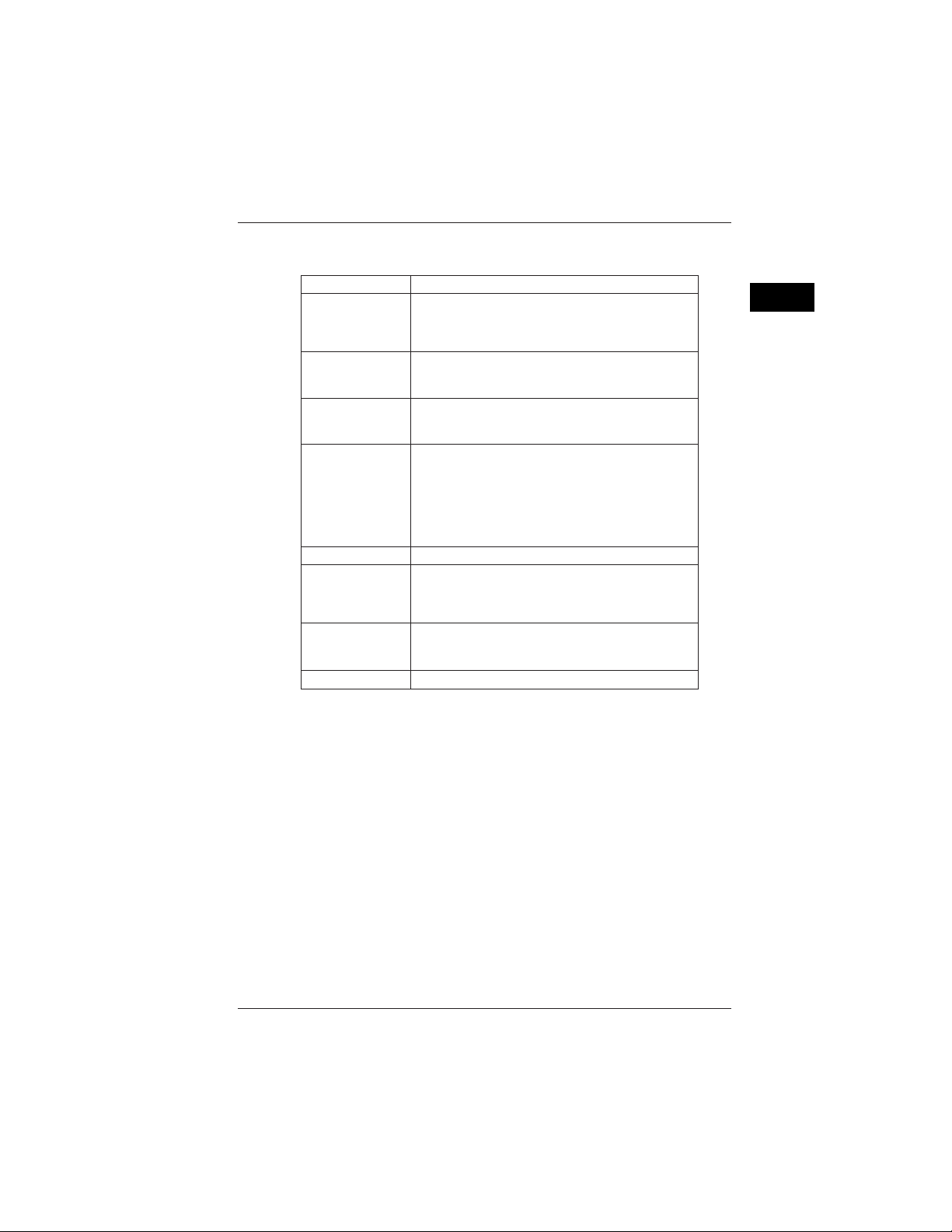

Model and Suffix Codes

Model

CW240

AC adapter

Option codes

Suffix Code

-D

-F

-R

-S

Specifications

Power cord: UL/CSA standard

VDE standard

SAA standard

BS standard

D/A output and analog input

/DA

Clamp-on current probe for 96030, 2 pcs./set

/C1

Clamp-on current probe for 96030, 4 pcs./set

/C2

Clamp-on current probe for 96031, 2 pcs./set

/C3

Clamp-on current probe for 96031, 4 pcs./set

/C4

Clamp-on current probe for 96032, 2 pcs./set

/C5

Clamp-on current probe for 96032, 4 pcs./set

/C6

Clamp-on current probe for 96033, 2 pcs./set

/C7

Clamp-on current probe for 96033, 4 pcs./set

/C8

Clamp-on current probe for 96036, 2 pcs./set

/C9

Clamp-on current probe for 96036, 4 pcs./set

/C10

Clamp-on current probe for 96034, 2 pcs./set

/C11

Clamp-on current probe for 96034, 4 pcs./set

/C12

Clamp-on current probe for 96035, 2 pcs./set

/C13

Clamp-on current probe for 96035, 4 pcs./set

/C14

NiMH battery pack + carrying case

/PM1

No. field: denotes the product number.

Refer to this number when inquiring about the product to the vendor.

2

IM CW240E

Page 9

Checking the Contents of the Package

Accessories

Make sure that the package contains all the accessories listed below and that

they are all free from any damage.

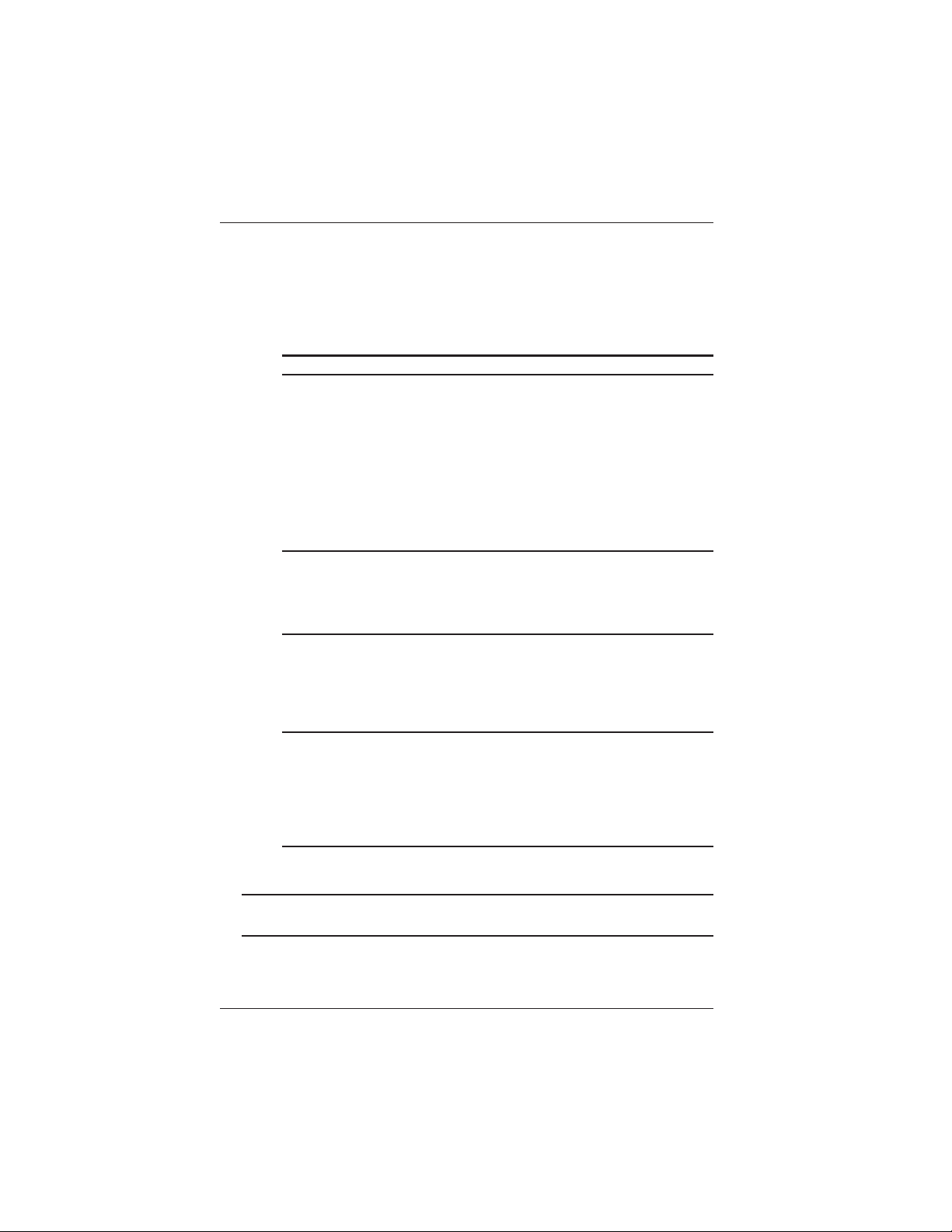

Product Name Part No. Q'ty Remarks

1. AC adapter for

power supply

2. AA-size alkaline

batteries

3. Voltage probes 91007 4 Color: black, red, yellow, blue

4. User's Manual IM CW240 1

5. Quick Setup

Manual

6. CD-ROM 1

1. 2. 3.

4. 5. 6.

788011 1set Yokogawa's AC adapter

- 6

IM CW240P 1

IM CW240E

3

Page 10

Checking the Contents of the Package

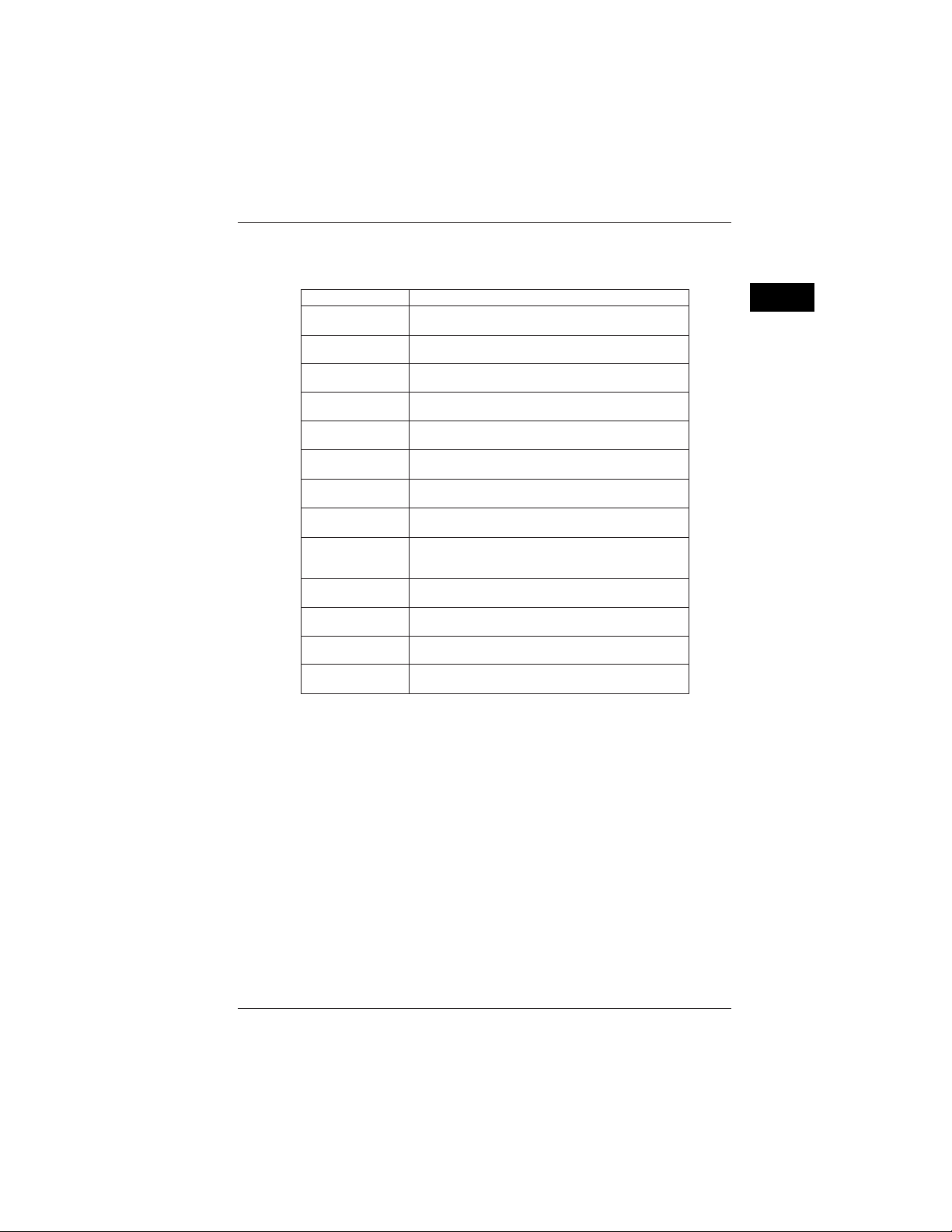

Peripherals (Optional)

The products listed below are available as optional peripherals. For technical

and ordering inquiries concerning peripherals, contact the vendor from whom

you purchased the product. If the product you purchased includes any one of

the optional peripherals, make sure it is free from any damage.

Product Name Part No. Min. Order Q'ty Remarks

Clamp-on Probe

for 200 A 96030 1

for 500 A 96031 1

for 700 A 96032 1

for 50 A 96033 1

for 3000 A 96034 1 Large-diameter type

for 3000 A 96035 1 Flexible type

for 2 A 96036 1

Voltage probe 91007 1 set 4

Carrying case 93020 1

AC adapter 788011 1 set Yokogawa's AC adapter

NiMH battery pack 94004

AC adapter for 96035 A1020UP 1 For clamp-on Probes

Printer 97010 1

AC adapter (for printer, Europe)

94006 1

AC adapter (for printer, USA)

94007 1

Thermal paper for printer 97080 10 rolls

Memory card

(with a PC card adapter)

16 MB 97030 1

32 MB 97031 1

128 MB 97033 1

256 MB 97034 1

512 MB 97035 1

Selectable from 3000 A, 2000 A,

and 1000 A

Selectable from 3000 A and 300 A

TIP

It is advisable that the packing box be saved, as it is useful when you transport the

product.

4

IM CW240E

Page 11

Checking the Contents of the Package

Housing the CW240 Main Unit and Accessories

An optional carrying case can accommodate the CW240 main unit with its

clamp-on probes and voltage probes connected to the unit. The case can also

house such accessories as the memory card, AC adapter, and User's Manual.

As such, it comes in handy for transporting a complete kit of tools necessary for

making measurements.

● Example of Housing:

User's Manual

NiMH

battery pack

AC adapter

Clamp-on probes

CW240 main unit

Voltage probes

IM CW240E

5

Page 12

Precautions for Safe Use of the

Instrument

When operating the instrument, be sure to observe the cautionary notes given below

to ensure correct and safe use of the instrument. If you use the instrument in any way

other than as instructed in this manual, the instrument’s protective measures may be

impaired. Yokogawa M&C Corporation is by no means liable for any damage

resulting from use of the instrument in contradiction to these cautionary notes.

The following safety symbols are used on the instrument and in this manual.

Danger! Handle with Care.

This symbol indicates that the operator must refer to an explanation in the

User's Manual in order to avoid risk of injury or death of personnel or damage

to the instrument.

Hazardous Voltage

➤

The operator must never attempt to touch equipment or parts marked with this

symbol.

Direct Current

This symbol indicates DC voltage/current.

Alternating Current

This symbol indicates AC voltage/current.

ON

This symbol indicates On (power).

OFF

This symbol indicates Off (power).

Double insulation

This symbol indicates double insulation.

WARN ING

Indicates a hazard that may result in the loss of life or serious injury of the user

unless the described instruction is abided by.

CAUTION

Indicates a hazard that may result in an injury to the user and/or physical

damage to the product or other equipment unless the described instruction is

abided by.

6

IM CW240E

Page 13

Precautions for Safe Use of the Instrument

NOTE

Indicates information that is essential for handling the instrument or, should be

noted in order to familiarize yourself with the instrument’s operating procedures

and/or functions.

TIP

Indicates information that complements the present topic.

SEE ALSO

Indicates the reference location(s) for further information on the present topic.

Strictly observe the following cautionary notes in order to avoid the risk of

injury or death of personnel or damage to the instrument due to hazards

such as electrical shock.

WARNI N G

● Removal of the Case from the Instrument

•Do not remove the case from the instrument or disassemble/modify the

instrument itself.

•Some parts of the inside of the instrument contain high voltage and,

therefore, access to the internal assembly is extremely hazardous. For

inspection and/or adjustment of the internal assembly, contact the vendor

from which you purchased the instrument.

● Use of the Instrument in a Gaseous Atmosphere

Do not operate the instrument in a location where any flammable or explosive

gas/vapor is present. It is extremely hazardous to operate it in such an atmosphere.

● Inspection of Power Source

•Before turning on the instrument, always make sure the voltage of the power

source to be applied matches the instrument's supply voltage.

•When using alkaline batteries or an NiMH battery pack, carefully read the

cautionary notes on battery handling later in this manual.

IM CW240E

7

Page 14

Precautions for Safe Use of the Instrument

WARN ING

● Use of Clamp-on Current Probes

•When using clamp-on current probes, keep the circuit voltage below operating circuit voltage in order to avoid possible shorts or accidents resulting

in an injury or death.

•Ensure that the rated current of the circuit you measure matches the rating

of the current probe.

•Avoid using the instrument if it has been exposed to rain or moisture, or if

your hands are wet.

•Do not use clamp-on current probes with any non-insulated conductors.

● Handling of Power Cord

•Use only the cord supplied from Yokogawa M&C to prevent electric shocks

and fire.

•Do not place any load on the power cord or allow the power cord to come

into accidental contact with any heat source. When unplugging the power

cord from the outlet, hold its plug, rather than holding and pulling the cord

itself.

•If the power cord is damaged, contact the vendor from which you purchased

the instrument.

● Measures in Case of Anomalies

If the instrument begins to emit smoke, becomes too hot, or gives off an

unusual smell, immediately turn it off and disconnect the power cord from

the outlet. Also turn of f power to the object under measurement that is

connected to the instrument’s input terminals. Never attempt to use the

instrument again. If any such anomalies as noted above occurs, contact

the vendor from which you purchased the instrument. Do not attempt to

repair the instrument yourself, as doing so is extremely dangerous.

8

IM CW240E

Page 15

Utilisation en Toute Securite

Les précautions suivantes doivent être prises pendant l'exploitation, la maintenance

et les réparations. YOKOGAWA M&C ne pourra en rien être déclaré responsable si

ces précautions ne sont pas respectées par l'utilisateur.

● Symboles utilisés sur les appareils et dans les Manuels d'instruction.

Explication: ce symbole indique que l'opérateur doit se reporter à une explication donnée par le manuel d'instruction afin d'éviter un accident au personnel ou de protéger l'appareil.

Haute tension: Ne pas toucher!

➤

Courant continu: Ce symbole indique une tension/intensité C.C.

Courant alternatif: Ce symbole indique une tension/intensité C.A.

MARCHE: Ce symbole indique la mise sous tension.

ARRET: Ce symbole indique la mise hors tension.

Double isolation: Ce symbole indique une double isolation.

AVERTISSEMENT

Indique un danger. Attire l'attention sur une utilisation, sur une procédure qui pourraît

être dangereuse pour le personnel.

ATTENTION

Indique un danger. Attire l'attention sur une utilisation, sur une procédure qui pourraît

être préjudiciable au produit.

IM CW240E

9

Page 16

Utilisation en Toute Securite

AVERTISSEMENT

● Retrait du boîtier de l'instrument

•Ne pas retirer le boîtier de l'instrument et ne pas essayer non plus de

démonter/modifier l'instrument lui-même.

•L'instrument renferme des composants parcourus par des tensions élevées.

Il est donc extrêmement dangereux d'accéder à ses circuits internes. Pour

vérifier et/ou régler les circuits internes, contacter le revendeur auprès duquel

a été acheté l'instrument.

● Utilisation de l'instrument dans une atmosphère gazeuse

Ne pas utiliser l'instrument dans un endroit qui renferme des gaz/vapeurs

inflammables ou explosifs. Il est extrêmement dangereux d'utiliser

l'instrument dans une telle atmosphère.

● Vérification de la source d'alimentation

•Avant de mettre l’instrument sous tension, toujours s’assure que sa tension correspond à celle de la source d’alimentation.

•En cas d’utilisation de piles alcalines ou d’un accumulateur NiMH, lire

attentivement les mises en garde relatives à la manipulation des piles/

accumulateurs, plus loin das ce manuel.

● Utilisation des sondes d'intensité à pince

•Lors de l'utilisation des sondes d'intensité à pince, maintenir la tension du

circuit au-dessous de operating circuit voltage afin d'écarter tout risque de

court-circuit ou d'accident susceptible de provoquer des blessures qui

peuvent éventuellement s'avérer mortelles.

•Assurez-vous d'utiliser un capteur de courant dont le calibre correspond au

niveau d'intensité à mesurer.

•Eviter d'utiliser l'instrument si celui-ci a été exposé à la pluie ou à l'humidité,

ou encore si vos mains sont humides.

•Ne pas utiliser les sondes d'intensité à pince avec des conducteurs non

isolés.

10

IM CW240E

Page 17

Utilisation en Toute Securite

AVERTISSEMENT

● Manipulation du cordon d'alimentation

•Afin de prévenir tout feu ou choc électrique, n'utilisez que le cordon fourni

par Yokogawa M&C.

•Ne déposer aucune charge sur le cordon d'alimentation et éviter tout contact fortuit entre celui-ci et une source de chaleur. Pour débrancher le cordon de la prise secteur, tirer sur sa fiche, mais jamais sur le fil proprement

dit. Si le cordon d'alimentation est endommagé, contacter le revendeur

auprès duquel a été acheté l'instrument.

● Mesures à prendre en cas d'anomalies

Si l'instrument est brûlant, dégage de la fumée ou une odeur inhabituelle, le

mettre immédiatement hors tension et débrancher le cordon d'alimentation

de la prise secteur. Mettre également hors tension le circuit sur lequel est

effectuée la mesure et qui est raccordé aux bornes d'entrée de l'instrument.

Ne surtout pas essayer d'utiliser l'instrument à nouveau. Si l'une de ces

anomalies est détectée, contacter le revendeur auprès duquel a été acheté

l'instrument. Ne pas essayer de le réparer soi-même, car cela est

extrêmement dangereux.

IM CW240E

11

Page 18

Chapter 1 Product Overview

Chapter 1 Product Overview

1.1 Product Overview ..................................... 1-2

1.2 System Configuration Diagram................ 1-4

Page 19

Chapter 1 Product Overview

1.1 Product Overview

The CW240 is a clamp-on power meter that measures items necessary for

various power measurements or power quality analyses to conduct an energysaving diagnosis or ISO 14001 testing.

The measurement items are as shown below and are all measured

simultaneously.

• Voltage rms Each phase and mean

For three-phase three-wire : line-to-line voltage or phase voltage from

the virtual mid-point

For three-phase four-wire : phase voltage

• Current rms Each phase and mean

• Power value (active, reactive, and apparent)

• Power factor Each phase and total

• Phase angle Each phase and total

• Frequency

• Electric energy(active, regenerative, lagging reactive, leading reactive)

• Power demand value

• Harmonics (1st to 50th order) Voltage rms, current rms, content,

• Voltage fluctuation Voltage dip, swell, momentary interruption

(Voltage quality) Data is saved by a threshold value-based

• Waveform Voltage and current waveform, full-voltage

Each phase and total

phase angle, power value, power content,

and power phase angle

Indication is available as a list, bar graph,

and vector diagram.

trigger.

waveform, full-current waveform

Features

1-2

● Supporting a Variety of Wiring Methods

• Wiring

Single-phase two-wire, single-phase three-wire, three-phase three-wire twocurrent, three-phase three-wire three-current, and three-phase four-wire

systems and Scott connection (three-phase three-wire and single-phase

three-wire)

• Loads

Single-phase two-wire systems can support up to four loads; single-phase

three-wire or three-phase three-wire two-current systems can support up to

two loads (shared voltage).

• Leakage current

In single-phase three-wire or three-phase four-wire systems, neutral line

current (leakage current) can also be measured.

IM CW240E

Page 20

1.1 Product Overview

● Wide measurement range

Voltage range: 150 V, 300 V, 600 V, and 1000 V

Current range: compatible with 7 types of clamp-on current probes

From 200 mA to 3000 A maximum

● Power quality analysis measurement

Power quality analysis can be made using harmonics (1st to 50th order), voltage

dip/swell/momentary interruption, and waveform measurement functions.

● Wiring check and setup check

• The wiring check function allows you to check a voltage phase sequence or

reverse connection of clamp-on current probes.

• The setup check function allows you to check settings for integration

measurements.

● Data management and communication

• Data can be saved using a personal computer (PC) card.

• Data can be transferred to a PC and setup can be made from the PC through

communications.

● Equipped with 4CH DA outputs and 2CH analog inputs (DC V) (optional)

• Measured values can be converted into DC voltage and then analog-output to

a recorder or other devices.

• Analog outputs from a thermometer or illuminometer can be connected to the

analog input terminals of the CW240 to measure power data and

environmental data together.

1

Product Overview

IM CW240E

1-3

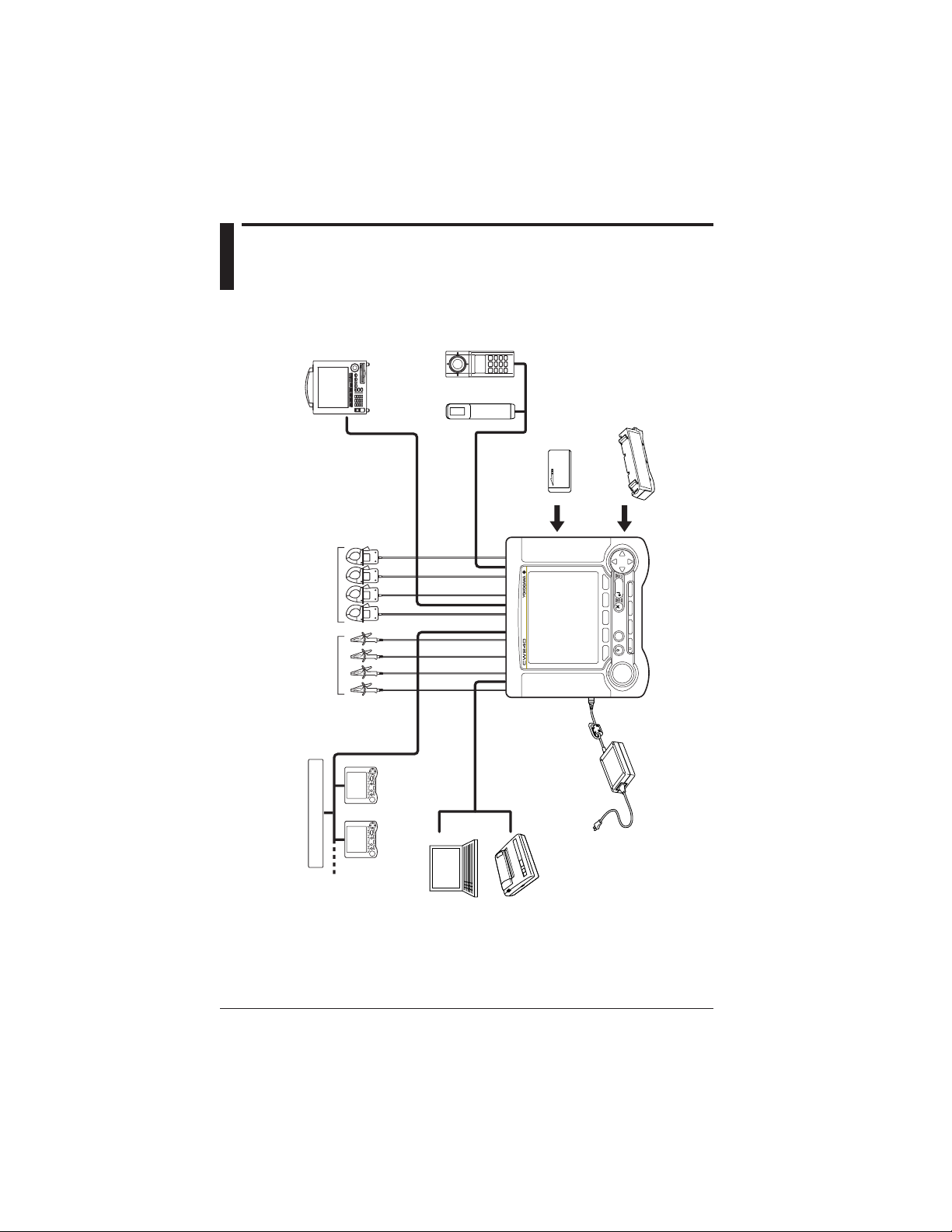

Page 21

CLAMP-ON POWER METER

LIGHT

TOP

MENU

SAVE

A

RANGE

START

&STOP

ESC

ENTER

DISP COPY

RANGE

START

&STOP

ENTER

START

&STOP

ENTER

Voltage inputs

Current inputs (clamps)

CW240: synchronized measurements

using multiple instruments

External control

input/output

RS-232

PC

Printer

AC adapter

MV series: recorders

DA outputs (4 CH)

Analog inputs (2 CH)

53003

thermometer

510 series

illuminometer

PC card

Alkaline batteries

NiMH battery pack

"Chapter 13, Section 6.9"

Chapter 3

"Sections 3.3 and 3.5" "Sections 3.4 and 3.5"

Chapter 3

"3.2.1"

"Chapter 10"

"Chapter 12"

Chapter 3

"3.2.2, 3.2.3"

"Chapter 11"

"Chapter 13, Section 6.9"

External contact signal

1.2 System Configuration Diagram

1-4

IM CW240E

Page 22

Chapter 2 Part Names and How to Use Parts

Chapter 2 Part Names and How to Use

Parts

2.1 Front Panel and Connector Block ............ 2-2

2.2 Operation Keys ......................................... 2-3

2.3 Side Faces ................................................. 2-4

2.4 Screen Configuration ............................... 2-5

2.5 Overrange/Error Indication during

Measurement ............................................ 2-6

2.6 Description of Mark Indication ................ 2-11

Page 23

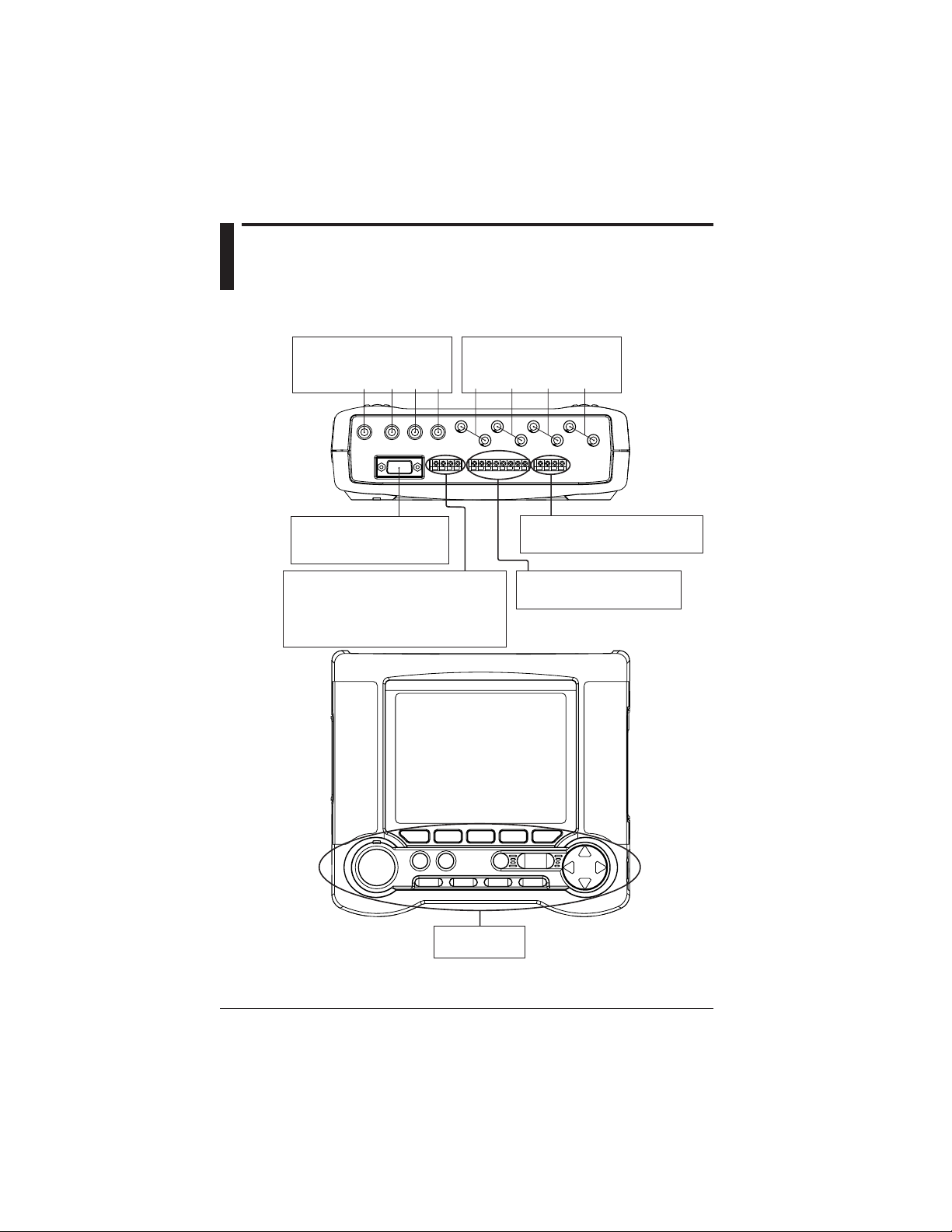

Chapter 2 Part Names and How to Use Parts

2.1 Front Panel and Connector

Block

Voltage input terminals Current input terminals

Connect the voltage

probes to these terminals.

N U1 U2 U3 CH1 CH2 CH3 CH4

Connect clamp-on current

probes to these terminals.

RS-232 connector

Connect a PC or printer using

a commercially available cable.

External control I/O terminals

Allows you start or stop integration

measurements using an external signal.

Also, a signal indicating that an integration

measurement is being made is output through

these terminals.

Display unit

Operation keys

Analog input terminals (optional)

Used for DC voltage inputs.

DA output terminals (optional)

Used for DC voltage outputs.

2-2

IM CW240E

Page 24

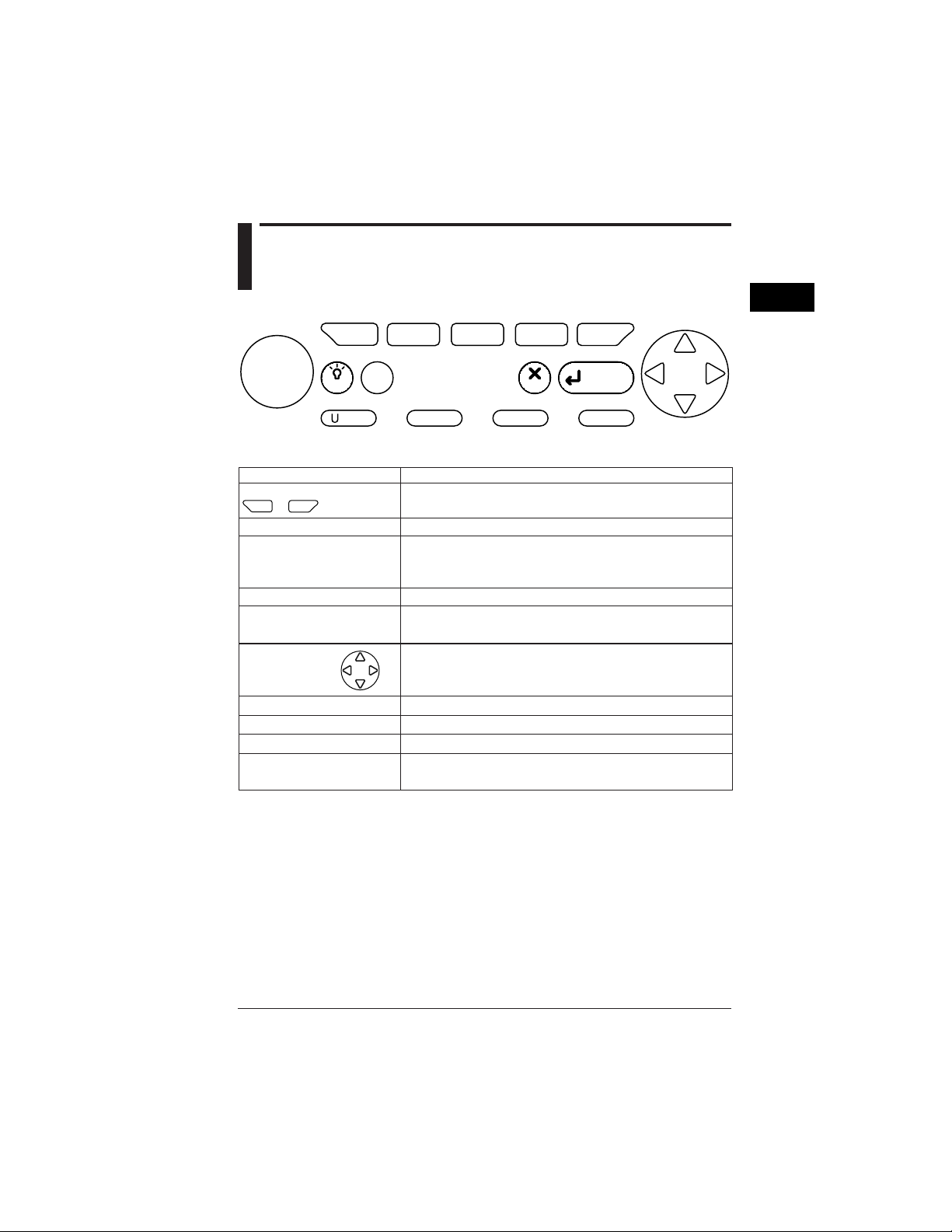

2.2 Operation Keys

F

F

F1F

1

2

3

2

Part Names and How to Use Parts

F

F

4

5

START

&STOP

Function keys

START & STOP key Starts/stops integration measurements.

LIGHT key Turns the backlight ON/OFF.

TOP MENU key Switches the display screen to the Top Menu.

ESC key

ENTER key

Cursor key Moves the cursor to the item you wish to select.

U RANGE key Changes the voltage range.

A RANGE key Changes the current range.

SAVE key Manually save or print measured data.

DISP COPY key

F

5

F

1

to

LIGHT

RANGE

TOP

MENU

RANGE

A

These are setting keys corresponding to the information displayed

in the bottom of the screen.

When held down for more than 3 seconds, it locks or unlocks the

operation keys.

Cancels setup conditions or other data.

Confirms setup conditions or other data.

Hard-copies information displayed on the screen.

Copy destination setting: PC card, internal memory, or printer

ESC

SAVE

Functional DescriptionKey Name

ENTER

DISP COPY

IM CW240E

2-3

Page 25

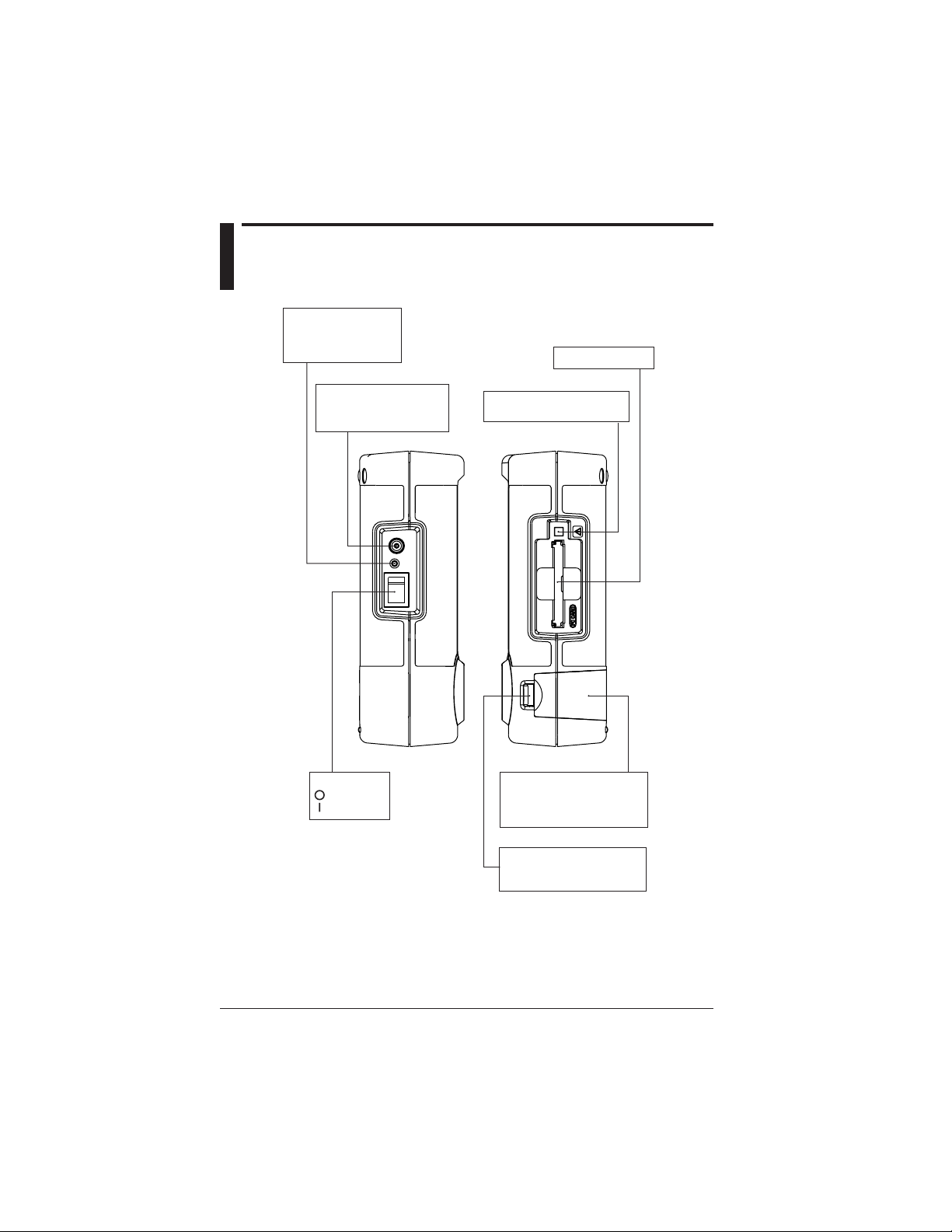

2.3 Side Faces

LED

Lights up while a NiMH

battery pack (optional)

is charged.

PC card slot

AC adapter jack

Connect the AC adapter

(accessorie) to this jack.

Power switch

: Power OFF

: Power ON

Button for extracting

a PC card

Battery holder

This part holds the alkaline

battery holder (accessorie) or

NiMH battery holder (optional).

2-4

Battery holder lock switch

Used to lock or unlock a

battery holder.

IM CW240E

Page 26

2.4 Screen Configuration

● Basic Screen Configuration

START

&STOP

MEASURE screen

F2 F3 F4 F5

F1

TOP

MENU

LIGHT

RANGE

RANGE

A

ENTER

ESC

SAVE

DISP COPY

SETUP screen FILE screen

2

Part Names and How to Use Parts

IM CW240E

LIST (instantaneous values)

POWER

INTEGRATE

DEMAND

ZOOM

HARMONIC

[LIST, GRAPH, VECTOR]

WAVEFORM

U & I WAVEFORM

U WAVEFORM

I WAVEFORM

VOLT. QUALITY

WIRING DIAGRAM

WIRING CHECK

GENERAL (1/2, 2/2)

SAVE (1/2, 2/2)

COMMUNICATION

VOLT. QUALITY

HARDWARE

ANALOG I/O (optional)

FILE NAME CHANGE

DELETE FILE

FORMAT

DATA COPY

SETTING FILE

BACKUP MEMORY COPY

BACKUP MEMORY DELETE

PROGRAM UPDATE

(normally not used)

2-5

Page 27

2.5 Overrange/Error Indication

during Measurement

● Overrange Indication during Measurement

: Conditions for voltage overrange indication

This mark appears if the peak value of an input signal exceeds 300%

(180% for a 1000 V range) of the rated voltage range or if the rms value of

measured voltage exceeds 110% of the rated range.

: Conditions for current overrange indication

This mark appears if the peak value of an input signal exceeds 400% of the

rated current range or if the rms value of measured current exceeds 110%

of the rated range.

TIP

• Voltage overrange mark appears if an input signal to one of terminals U1 to U3

satisfied the noted conditions.

• Current overrange mark appears if an input signal to one of terminals CH1 to

CH4 satisfies the noted conditions.

Indication of "OR" or "----" symbol

The CW240 indicates "OR" or "----" symbol instead of a usual four-digit value if

the measured value meets the noted conditions.

WARN ING

The CW240 shows an overrange mark in the maximum range only if the input

level exceeds the maximum allowable level. Do not apply any input level higher

than the maximum allowable level.

CAUTION

To measure an input signal level exceeding the rated range, use a voltage transformer (VT) or current transformer (CT).

When using a VT or CT, carefully read section 4.5, Wiring the Measurement

Circuit Using External VT/CT.

2-6

IM CW240E

Page 28

2.5 Overrange/Error Indication during Measurement

• Instantaneous value, electric energy, demand

Measurement Item Conditions and Indications

Voltage rms If the peak value of an input signal exceeds 300% (180% for

Current rms If the peak value of an input signal exceeds 400% of the

Active power

Reactive power

Apparent power

Power factor

Phase angle

Frequency

Interval electric energy

Electric energy

Reactive energy

Power demand

Reactive power demand

Analog input (optional)

the 1000 V range) of the measurement range, or if the rms

value of measured voltage exceeds 130% of the rated range,

"OR" appears.

measurement range, or if the rms value of measured current

exceeds 130% of the rated range, "OR" appears.

If power input (active, reactive, or apparent) exceeds 130%

of the rated range, "OR" appears. Also, if the measured value

exceeds the maximum displayable digits, 9999, "OR" appears.

If the peak value of a voltage input signal exceeds 300%

(180% for a 1000 V range) of the measurement range;

if the rms value of measured voltage exceeds 130% of the

rated range; if the peak value of a current input signal

exceeds 400% of the measurement range; or if the rms value

of measured current exceeds 130% of the rated range; "----"

appears.

If frequency exceeds 70 Hz, the fixed clock is selected.

Even if power input exceeds 130% of the rated range, an

excessive power value (active power, reactive power)

will be integrated. In this case, however, the accuracy of an

integrated value is not specified.

If a demand input exceeds 130% of the rated range, "OR"

appears. Also, if the measured value exceeds the maximum

displayable digits, 9999, "OR" appears.

If an input exceeds 130% of the rated range, "OR" appears.

2

Part Names and How to Use Parts

IM CW240E

2-7

Page 29

2.5 Overrange/Error Indication during Measurement

• Harmonics

Measurement Item Conditions and Indications

Voltage rms If the peak value of an input signal exceeds 300%

Voltage content

Voltage phase angle

Current rms If the peak value of an input signal exceeds 400% of the

Current content

Current phase angle

Power value If a power input exceeds 130% of the rated range,

Power content

Power phase angle

Total harmonic

distortion of voltage

Total harmonic

distortion of current

(180% for a 1000 V range) of the measurement range,

or if the rms value of measured voltage exceeds 130%

of the rated range, "OR" appears.

If the peak value of an input signal exceeds 300%

(180% for the 1000 V range) of the measurement range,

or if the rms value of measured voltage exceeds 130%

of the rated range, "----" appears.

measurement range or if the rms value of measured

current exceeds 130% of the rated range, "OR" appears.

If the peak value of an input signal exceeds 400% of the

measurement range, or if the rms value of measured

current exceeds 130% of the rated range, "----" appears.

"OR" appears.

Also, if the measured value exceeds the maximum

displayable digits, 9999, "OR" appears.

If the peak value of a voltage input signal exceeds

300% (180% for a 1000 V range) of the measurement

range; if the rms value of measured voltage exceeds

130% of the rated range; if the peak value of a current

input signal exceeds 400% of the measurement range;

or if the rms value of measured current exceeds 130%

of the rated range; "----" appears. Also, if the power

value exceeds the maximum displayable digits, 9999,

"----" appears.

If the peak value of a voltage input signal exceeds 300%

(180% for a 1000 V range) of the measurement range,

or if the rms value of measured voltage exceeds 130%

of the rated range, "----" appears.

If the peak value of a current input signal exceeds 400%

of the measurement range or if the rms value of

measured current exceeds 130% of the rated range,

"----" appears.

2-8

IM CW240E

Page 30

2.5 Overrange/Error Indication during Measurement

● Indication Provided if a Measured Value is Too Small

• Instantaneous value, electric energy, demand

Measurement Item

Voltage

Current

Active power

Reactive power

Apparent power

Electric energy

Reactive energy

Power factor

Phase angle

Frequency

Interval electric energy

Power demand

Reactive power

demand

Analog input (optional)

If an input level is below 0.4% of the rated range, the reading

becomes "0 V".

If an input level is below 0.4% of the rated range, the reading

becomes "0 A".

If an input level is 0.17% or less of the rated range, the

reading becomes "0 W".

If an input level is 0.17% or less of the rated range, the

reading becomes "0 Var".

If an input level is 0.17% or less of the rated range, the

reading becomes "0 VA".

If power input is 0.17% or less of the rated range, integration

stops.

If reactive power input is 0.17% or less of the rated range,

integration stops.

If the input level of either voltage or current is below 0.4% of

the rated range, "----" appears.

If frequency is 40 Hz or less or if the input level of a frequency

source is 10% or less of the rated range, the fixed clock is

selected, displaying the set fixed-clock frequency.

If power input is 0.17% or less of the rated range, integration

stops.

If power demand is 0.17% or less of the rated range, the

reading becomes "0 W".

If reactive power demand is 0.17% or less of the rated range,

the reading becomes "0 Var".

If an input level is below 0.4% of the rated range, the reading

becomes "0 V".

Conditions and Indications

2

Part Names and How to Use Parts

IM CW240E

2-9

Page 31

2.5 Overrange/Error Indication during Measurement

● Indications on the basis of other input conditions

Measurement Item

Electric energy

Reactive energy

Power factor

Power factor demand

Total power factor

Phase angle

Power phase angle

Reactive power

Apparent power

Legend

P : active power value

S : apparent power value

• When the display setting is any item other than AUTO, if the

integrated value exceeds "999999", the reading is reset to

"0", letting integration continue.

• When the display setting is AUTO, the position of a decimal

point or the unit of measurement is shifted by one digit to

continue integration.

Because of a computation error, if the power factor:

• Exceeds 1.0, the reading becomes "1.0."

• Is less than -1.0, the reading becomes "-1.0."

• Is S < |P|, the reading becomes "1.0."

Because of a computation error, if the power factor:

• Exceeds 1.0, the reading becomes "1.0."

• Is less than -1.0, the reading becomes "-1.0."

If the power factor exceeds 1.0 or is less than -1.0 due to a

computation error, the reading becomes "0°."

If the total power factor exceeds 1.0 or is less than -1.0 due to

a computation error, the reading becomes "0°."

Because of a computation error, if

• A value in is negative, the reading becomes "0."

• S < |P|, the reading becomes "0."

If S < |P| due to a computation error, S = |P|.

Conditions and Indications

2-10

IM CW240E

Page 32

2.6 Description of Mark Indication

Appears if a voltage overrange occurs.

Appears if a current overrange occurs.

Appears when integration measurement is made by external input control.

Appears in the event of loss of PLL synchronization. This automatically selects the

fixed clock.

Appears when a reactive power meter method is used.

Appears when display hold is enabled.

Appears if the amount of data exceeds the capacity of a PC card or the internal memory.

Appears when the CW240 is configured so that data is saved in a PC card. Also, this

mark flashes during an access to the PC card.

Appears when data has been saved in the backup memory.

Appears when the CW240 is configured so that data is saved in the internal memory.

Also, this mark flashes during an access to the internal memory.

Appears if the CW240 is in a key lock state.

Appears when the CW240 is configured so that the RS-232 connection destination is a

PC. Also, this mark flashes during communication with the PC.

Appears if the CW240 is configured so that the RS-232 connection destination is a

printer. Also, this mark flashes during communication with the printer.

Appears if the CW240 is powered through the AC adapter.

Appears when the CW240 is powered through alkaline batteries or a NiMH battery

pack. This mark indicates a battery voltage decrease (remaining capacity) in four steps.

2

Part Names and How to Use Parts

IM CW240E

2-11

Page 33

Chapter 3 Preparation for Safe Measurements

Chapter 3 Preparation for Safe

Measurements

3.1 Precautions for Use .................................. 3-2

3.2 Connecting a Power Supply ..................... 3-4

3.3 Connecting Voltage Probes .................... 3-14

3.4 Connecting Clamp-on Probes ................ 3-15

3.5 Connection Diagrams of Voltage Probes

and Clamp-on Probes ............................. 3-17

3.6 Turning ON the Power Switch ................ 3-22

3.7 Performing Measurements with Greater

Precision ................................................. 3-24

Page 34

Chapter 3 Preparation for Safe Measurements

3.1 Precautions for Use

If you are a first-time user, always read the "Precautions for Safe Use of the

CW240" on pages 6 through 11.

● Do not place any objects on the Instrument.

Do not place another device or a container filled with water on the instrument,

otherwise, the instrument may become defective.

● Moving the Instrument

Before moving the instrument, check that the power cord and all other cables

are disconnected. Hold the instrument with both hands when moving it.

● Input terminals

Do not bring a charged substance close to the signal terminals, otherwise the

internal circuitry may be destroyed. Do not apply any mechanical shock to the

signal terminals because it might be transformed into an electrical noise and

input into the instrument.

● Protection of the case or operation panel

Do not pour volatile chemicals on the case or operation panel or leave any

rubber or PVC product in contact with the case or operation panel for a

prolonged period, otherwise the case and/or operation panel may be discolored

or deformed.

3-2

● Cleaning

When cleaning the case and/or operation panel, disconnect the power cord from

the outlet and gently wipe the external surfaces with a soft clean cloth. Do not

use chemicals such as benzine or thinner, otherwise the instrument may be

discolored or deformed.

● Display screen

When the instrument is shipped from the factory, the LCD display screen is

covered with a protective film. Remove it before using the instrument.

● After use

Disconnect the power cord from the wall outlet after use.

● Long absence of use

If the instrument will not be used for a prolonged period, remove the batteries

(AA-size alkaline batteries or NiMH battery pack).

IM CW240E

Page 35

Precautions for Using Clamp-on Probes

CAUTION

3.1 Precautions for Use

• The clamping CT (current transformer) is precision assembled to ensure high

performance. When using a clamp, do not apply any intense mechanical shock,

vibration, or force to the clamping CT.

• If dust or any other foreign matter gets in the clamping CT, do not shut the

clamping cores tight. First remove dust and then make sure the clamping cores

on both sides close smoothly

3

Preparation for Safe Measurements

IM CW240E

3-3

Page 36

3.2 Connecting a Power Supply

To connect the instrument to a power supply, use the AC adapter(accessorie).

As backup power supply against a power failure, one of the following batteries

can be used. Use them together with the AC adapter.

• Alkaline batteries (accessorie)

See 3.2.2, Using Alkaline Batteries.

• NiMH battery pack (optional)

See 3.2.3, Using a NiMH (Nickel-Hydrogen) Battery Pack.

3.2.1 Connecting the AC Adapter

● Before Connecting a Power Supply

There is a danger of electrical shock or damage to the instrument. Observe the

following cautionary notes when handling the AC adapter.

WARN ING

• Use only the Yokogawa-supplied dedicated power cord.

• Check that the power source voltage matches the supply voltage rating of the

AC adapter, and then connect the power cord to the outlet.

• Check that the power switch of the CW240 is turned OFF and then connect the

power cord.

• If the CW240 is not used for a prolonged period, disconnect the AC adapter

power cord from the outlet.

• Do not use any AC adapter other than the one (part number: 788011) dedicated

to the CW240.

• Do not place any objects on the AC adapter or power cord, and do not let the

power cord come into contact with a heating element.

• Always hold the plug of the power cord rather than holding and pulling the

cord itself when disconnecting it from the outlet.

3-4

IM CW240E

Page 37

Attach the filter

to the cord.

3.2 Connecting a Power Supply

CW240 main unit

Approx. 10 cm

AC adapter

<4> Connect

<3> Connect

Clamp filter

A1193MN

<2> Connect

<1> Check that the power switch

is turned OFF.

● Procedure for Connecting the AC Adapter

Follow the steps below to connect the AC adapter.

<1> Check that the power switch of the CW240 is turned OFF.

(Attach the clamp filter to the output-side cable of the AC adapter.)

<2> Connect the AC adapter plug to the CW240's AC adapter jack.

<3> Connect the plug of the power cord supplied with the AC adapter to the

power connector of the AC adapter.

<4> Connect the other end of the power cord to the power outlet that meets the

power rating (requirements):

● AC adapter's Power Rating

Supply voltage ratin 100 to 240 V AC

Allowable supply voltage range 90 to 264 V AC

Power supply frequency rating 50/60 Hz

Allowable power supply frequency range 48 to 62 Hz

Maximum power consumption 70 to 90 VA

Output voltage rating of AC adapter 12 V DC

Maximum output current rating of AC adapter 2.6 A

3

Preparation for Safe Measurements

IM CW240E

3-5

Page 38

3.2 Connecting a Power Supply

3.2.2 Using Alkaline Batteries

NOTE

Alkaline batteries are the backup power for the AC adapter. Use them together

with the AC adapter.

Type of alkaline batteries LR6 AA-type, 1.5 V

● Handling Precautions

Observe the following cautionary notes when handling alkaline batteries.

WARN ING

• Install the alkaline batteries so that the positive and negative polarities are

correctly positioned. Otherwise, the battery fluid may leak or the batteries may

explode.

• Do not attempt to disassemble the batteries, heat them up, or dispose of them

in a fire.

• Do not short the batteries.

• Do not attempt to recharge the batteries.

• Do not solder the batteries.

• When replacing the batteries, replace all six units at the same time with new

ones (of the same manufacturer).

(Do not use manganese batteries as replacements.)

• If the CW240 will not be used for a prolonged period, remove the batteries.

3-6

● Backup Hours by Alkaline Batteries

The number of backup hours available using alkaline batteries varies with the

operating environment and conditions. Refer to the table below.

Operating Conditions Backup Hours Available

LCD backlight OFF

No access to a PC card

Approx. 30 minutes

IM CW240E

Page 39

3.2 Connecting a Power Supply

● Indication of a Battery Voltage Decrease

When the CW240 is operated using alkaline batteries, the following mark

appears. A decrease in the battery voltage (remaining capacity) is indicated in

the following four steps:

→ → →

NOTE

If you continue to operate the CW240 with this mark displayed, the

CW240 will be turned OFF automatically. Replace the alkaline

batteries with new ones before this mark appears.

3

Preparation for Safe Measurements

IM CW240E

3-7

Page 40

3.2 Connecting a Power Supply

● Procedure for Replacing Alkaline Batteries

Follow the steps below to replace alkaline batteries.

<1> Check that the power switch is OFF and no AC adapter has been

connected.

<2> Raise the battery holder lock switch at the back of the CW240 to remove

the alkaline battery holder.

<3> Remove the old batteries from the battery holder and insert six new alkaline

batteries.

<4> Place the battery holder into the holder inlet of the CW240. Then slide the

battery holder into the slot, so that the battery holder connector connects

properly with the battery connector.

<5> Lower the lock switch on the side of the CW240 to fix the holder.

(The indication changes to "䉭FREE".)

CAUTION

Place alkaline batteries into the holder with the positive (+) and negative (–)

polarities of the batteries agreeing with the polarity indications in the holder.

CW240 main unit

3-8

<1> Check that the

power switch is turned OFF.

CW240 main unit

Lock switch

<2> Remove

<3> Insert

<4>

Insert

<5> Lock

IM CW240E

Page 41

3.2 Connecting a Power Supply

3.2.3 Using a NiMH (Nickel-Hydrogen) Battery Pack

NOTE

A NiMH battery pack is backup power for the AC adapter. Use it together with

the AC adapter.

Charging type NiMH battery pack (optional) model: 94004

Specifications Voltage : 7.2 V

Capacity : 2100 mAh

Number of times chargeable (cycle life)

: approx. 300 times (depending on the operating

environment)

● Handling Precautions

Observe the following cautionary notes when handling the NiMH battery pack.

WARNI N G

• The electrolyte solution contained in the NiMH battery pack is alkaline. If it

comes into contact with any clothing or skin due to a leakage from or rupture

in the battery pack, the clothing or skin may be damaged. In particular, if the

solution gets into an eye, it may cause loss of eyesight. In such a case, do not

rub the affected eye, but thoroughly wash it immediately with clean water.

Then see a doctor quickly for treatment.

• When replacing the NiMH battery pack, always turn the CW240 power switch

OFF and disconnect the AC adapter power cord from the outlet to avoid

possible danger such as a short in the electric circuit or electrical shock.

• Do not use any battery pack other than Yokogawa's NiMH battery pack (model:

940 04).

• Do not leave the NiMH battery pack in strong direct sunlight, inside a vehicle

under the hot sun, or near a fire, otherwise it may result in a solution leakage

or deterioration in the performance and/or life.

• Do not disassemble or modify the NiMH battery pack, otherwise the protective

features of the battery pack may be damaged, resulting in a heating up or

rupture.

• Do not short the NiMH battery as this may cause burns due to the battery pack

heating up.

• Do not dispose of the battery pack in a fire or apply heat to it, otherwise there

is a risk that it will rupture or its electrolyte solution will scatter.

• Do not apply excessive shock to the battery pack, for example, by throwing it.

Doing so may cause solution leakage, battery pack heating, or rupture.

3

Preparation for Safe Measurements

IM CW240E

3-9

Page 42

3.2 Connecting a Power Supply

WARN ING

• Do not use a defective battery pack, such as any leaking solution, deformed,

discolored, or showing any other abnormality.

• Avoid any metal coming into contact with the battery pack when carrying it, as

there is a danger of a short.

• Do not immerse the battery pack in water or make it wet. Otherwise, it may

heat up or rust as well as leading to a loss of functions.

• If the battery pack is not used for a prolonged period, remove it from the CW240

and store it in the following environment.

Storage period of 1 year or less:

Temperature of -20°C to 35°C (in locations with low humidity)

Storage period of 3 months or less:

Temperature of -20°C to 45°C (in locations with low humidity)

● Procedure for Installing the NiMH Battery Pack

Follow the steps below to install the dedicated NiMH battery pack.

<1> Check that the power switch is turned OFF.

<2> If the AC adapter is in use, disconnect the power cord of the AC adapter

from the outlet.

CW240 main unit

3-10

<2> Check that the power plug

is disconnected.

AC adapter

<1> Check that the power switch

is turned OFF.

IM CW240E

Page 43

Lock switch

3.2 Connecting a Power Supply

<3> Remove

<4>

Insert

NiMH battery pack

<5> Lock

<3> If using alkaline batteries, raise the lock switch at the back of the CW240 to

remove them from the battery holder. Then install the NiMH battery pack

into the holder.

<4> Place the battery holder into the holder inlet of the CW240. Slide the battery

holder into the slot, so that the battery holder connector connects properly

with the battery connector.

<5> Lower the lock switch on the side of the CW240 to fix the holder.

(The indication changes to "䉭FREE".)

● Recharging the NiMH Battery Pack

When shipped from the factory, the dedicated NiMH battery pack (optional) is

not fully charged for safety reasons.

Recharge the battery pack to its full level before use.

When recharging it, use the CW240 and AC adapter.

WARNI N G

• When recharging the NiMH battery pack, always do so using the CW240 main

unit.

• When recharging the NiMH battery pack, keep the ambient temperature within

the range from 10°C to 35°C. Recharging the battery pack outside this range

may result in an insufficient amount of charge, solution leakage, or battery

heating.

3

Preparation for Safe Measurements

IM CW240E

3-11

Page 44

3.2 Connecting a Power Supply

● Procedure for Recharging the NiMH Battery Pack

Follow the steps below to recharge the NiMH battery pack.

<1> With the battery pack installed as instructed above, connect the AC adapter

to the CW240.

<2> The LED indicator on the side of the AC adapter jack comes on, indicating

that the battery pack is being recharged. When recharging is complete, the

LED indicator goes off.

NOTE

The NiMH battery pack will be recharged regardless of the ON/OFF of the power

switch. In this case, power is supplied through the AC adapter.

TIP

When the LED indicator is flashing, the CW240 is in a waiting-to-be-recharged state.

The CW240 falls into this state if:

• the ambient temperature is outside the 10°C to 35°C range,

• the battery performance is significantly low due to over-discharge or for other reasons,

• the battery temperature has exceeded 55°C during recharging, or

• the ambient temperature has changed abruptly.

3-12

● Indication that Recharging is Required

When the CW240 is operated using the NiMH battery pack, the following mark

appears. A decrease in the battery voltage (remaining capacity) is indicated in

the following four steps:

→ → →

NOTE

If you continue to operate the CW240 with this mark displayed, the

CW240 will be turned OFF automatically. Recharge the NiMH battery

pack before this mark appears.

IM CW240E

Page 45

3.2 Connecting a Power Supply

● Backup Hours with a NiMH Battery Pack

The number of backup hours available using a NiMH battery pack vary with the

operating environment and conditions. Refer to the table below.

Operating Conditions Backup Hours Available

LCD backlight OFF

No access to a PC card

● NiMH Battery Life

The NiMH battery pack can be recharged approximately 300 times, though the

frequency depends on the operating environment. The life of the battery pack is

over if the low-battery mark appears soon after the battery pack has been fully

recharged. Replace the battery pack with a new one.

Approx. 3 hours

3

Preparation for Safe Measurements

IM CW240E

3-13

Page 46

3.3 Connecting Voltage Probes

LL1

V INPUT

600V

MAX

TERMINALS 600V

MAX

O EAR

TH

CH

CH

CA

LOGIC NIPUT

ST

AR

T/ST

OP

5.5V MAX

LOGIC NIPUT

ST

OP

5.5V MAX

WARN ING

• For safety, connect voltage probes to the CW240 main unit and then to the

circuit under test.

• Before attaching a voltage probe to the circuit under test, turn off power to the

circuit under test. It is very dangerous to connect or disconnect a voltage

probe without turning off the circuit under test.

• Be sure to connect voltage probes to the secondary side of the circuit under

test such as current limiters (circuit breakers). Should an accident such as a

short occur, other circuits will be protected by these circuit breakers.

• Be extremely careful not to connect a voltage circuit to the current input ter-

minals or a clamp-on probe to the voltage input terminals. An improper connection may result in not only damage to the circuit or equipment under test

or the CW240, but also an injury to personnel.

• Voltage input terminals N, U1, U2, and U3 are not isolated from each other. Do

not connect any voltage probes not required (not used) for measurements.

Also, do not touch voltage input terminals not used.

• For measurements, do not use any voltage probes other than those supplied

with the product.

OP

T/ST

AR

HL H

ST

L

LOGIC NIPUT

ART/STOP

HL

ST

AX

L

5.5V M

H

H

2

CH

LOGIC NIPUT

AX

5.5V M

1

3

v

CH

L

2

v

L

1

v

TH

TO EAR

N

T.

〜 MAX

CA

TERMINALS 600V

〜MAX

600V

V INPUT

Voltage probes,

red, yellow, or blue

Voltage probe,

black (N terminal)

3-14

Insert the plug so that it is fastened

with a voltage input terminal securely.

IM CW240E

Page 47

3.4 Connecting Clamp-on Probes

LL1

V INPUT

600V

MAX

TERMINALS 600V MAX

O EAR

TH

CH

CH

CA

LOGIC NIPUT

5.5V MAX

LOGIC NIPUT

ST

OP

5.5V MAX

WARNI N G

• For safety, connect a clamp-on probe to the CW240 main unit and then to the

circuit under test.

• Before clamping a clamp-on current probe onto the circuit under test, turn off

power to the circuit under test. It is very dangerous to clamp or unclamp the

clamp-on probe without turning off the circuit under test.

• Be sure to connect a clamp-on probe to the secondary side of the circuit under test such as current limiters (circuit breakers). Should an accident such

as a short occur, other circuits will be protected by these circuit breakers.

• Be extremely careful not to connect a voltage circuit to the current input terminals or a clamp-on probe to the voltage input terminals. An improper connection may result in not only damage to the circuit or equipment under test

or the CW240, but also an injury to personnel.

• Do not connect any clamp-on probe not required (not used) for measurement.

• For measurements, do not use any current probes other than those dedicated

to the CW240.

• Do not use a clamp-on probe for a non-insulated conductor.

Ring markers

<1>

<2>

Clamp-on current probe

START/STOP

L H

LOGIC NIPUT

L H

ART/STOP

HL H

ST

X

A

L

.5V M

5

H

2

CH

LOGIC NIPUT

X

A

5.5V M

1

3

v

CH

L

2

v

L

1

v

TH

R

N

TO EA

AX

T.

CA

600V M

ALS

IN

ERM

AX

T

M

0V

60

V INPUT

3

Preparation for Safe Measurements

● Use of Ring Markers

• When using multiple clamp-on probes, attach ring markers (four colors) to the

probes. This allows inputs to be identified. Attach ring markers of the same

color to the current probe side <1> and connector side <2> of the cable of a

clamp-on probe.

• When attaching ring markers, exercise care not to damage the clamp-on

probes.

IM CW240E

3-15

Page 48

3.4 Connecting Clamp-on Probes

● Connecting Clamp-on Probes

When connecting a clamp-on probe to the CW240 main unit, connect the plug of

the clamp-on probe so that the groove in the plug agrees with the guide in the

CW240 main unit (that the H and L polarities are correctly connected).

● Types of Clamp-on Probes

Clamp-on probes that can be connected to the CW240 are available in the

following seven types. The CW240's current range setting changes depending

on the clamp-on probes in use.

Model

96036 (for 2 A)

96033 (for 50 A)

96030 (for 200 A)

96031 (for 500 A)

96032 (for 700 A)

1000 A (for 5 minutes)

96034 (for 3000 A)

96034-1

96034_2

96034_3

96035 (for 3000 A)

96035_1

96035_2

CW240 Current Range

200 mA/500 mA/1 A/2 A

5 A/10 A/20 A/50 A

20 A/50 A/100 A/200 A

50 A/100 A/200 A/500 A

200 A/500 A/1000 A

Current range is selectable using a switch.

300 A/750 A/1500 A/3000 A

200 A/500 A/1000 A/2000 A

100 A/200 A/500 A/1000 A

Current range is selectable using a switch.

300 A/750 A/1500 A/3000 A

30 A/75 A/150 A/300 A

CAUTION

When connecting a clamp-on probe, always check that the rating of the current

under test agrees with the rating of the clamp-on probe, including model number check.

3-16

IM CW240E

Page 49

3.5

Connection Diagrams of Voltage

Probes and Clamp-on Probes

Single-phase two-wire/Single load

(1P2W)

N1

Black

Red

Single-phase two-wire/Three loads

(1P2W)

N1

Black

Red

Load 1

Load 1 Load 2 Load 3

Single-phase two-wire/Two loads

(1P2W)

N1

Black

Single-phase two-wire/Four loads

(1P2W)

N1

Black

Load 1 Load 2

Red

Load 2 Load 3

Load 1 Load 4

Red

3

Preparation for Safe Measurements

IM CW240E

3-17

Page 50

3.5 Connection Diagrams of Voltage Probes and Clamp-on Probes

Single-phase three-wire/Single load

(1P3W)

N12

Black

Red

Yellow

Load 1 Load 2

Single-phase three-wire three-current

(1P3W3I)

<Measurement of neutral line current>

N12

Black

Red

Yellow

12 N

Single-phase three-wire/Two loads

(1P3W)

Load 1 Load 2

N12

Black

Red

Yellow

1212

3-18

IM CW240E

Page 51

3.5 Connection Diagrams of Voltage Probes and Clamp-on Probes

Three-phase three-wire two-current/

Single load (3P3W2I)

<Two-power-meter method>

SR T

Black

Red

RT

Blue

Three-phase three-wire two-current/

Two loads (3P3W2I)

<Two-power-meter method>

Load 1 Load 2

SR T

Black

Red

RTRT

Blue

3

Preparation for Safe Measurements

Three-phase three-wire three-current

(3P3W3I)

<Three-power-meter method>

RST R S T

Red

Yellow

Blue

IM CW240E

3-19

Page 52

3.5 Connection Diagrams of Voltage Probes and Clamp-on Probes

Three-phase four-wire (3P4W)

N1 32

Black

Red

Yellow

123

Blue

Three-phase four-wire four-current

(3P4W4I)

<Measurement of neutral line current>

N1 32

Black

Red

Yellow

123N

Blue

3-20

IM CW240E

Page 53

3.5 Connection Diagrams of Voltage Probes and Clamp-on Probes

Scott connection (3P3W+1P3W)

Single-phase (1P3W) connection: R-S

3

Preparation for Safe Measurements

Scott connection (3P3W+1P3W)

Single-phase (1P3W) connection: S-T

Three-phase

3-wire

NR TS

Black

Red

Single phase

1 (R)2 (S)R T

Yellow

Blue

Scott connection (3P3W+1P3W)

Single-phase (1P3W) connection: T-R

Three-phase

3-wire

NR TS

Black

Red

Single phase

1 (T)2 (R)R T

Yellow

Blue

NR TS

Black

Red

Single phase

1 (S)2 (T)R T

Yellow

Blue

Three-phase

3-wire

IM CW240E

3-21

Page 54

3.6 Turning ON the Power Switch

[ 1 Model Name Screen

When the power switch is turned ON, the CW240 displays the following startup screen for

approx. 2 seconds.

2 Message Screen

This screen displays the model, version number, the presence of options, and self-check

results.

CW240 Ver 1.00

FPGA Check OK

SDRAM Check OK

SRAM Check OK

Flash Disk Check OK

RTC Check OK

EEPROM Check OK

Setting Check OK

Option:Analog In/Out

3 When the self-check has been completed normally, the screen displayed when

you previously turned OFF the CW240 appears.

To switch to the Top Menu screen shown

on the left, press the TOP MENU key.

TOP

key

MENU

3-22

IM CW240E

Page 55

3.6 Turning ON the Power Switch

● Description of the Message Screen

Indications

1 CW240 VER 1.00

Self-check

2 FPGA Check OK

3 SDRAM Check OK

4 SRAM Check OK

5 Flash Disk Check OK

6 RTC Check OK

7 EEPROM Check OK

8 Setting Check OK

9 Option:Analog In/Out

Model and version number

FPGA check

SDRAM check

SRAM check

Check of the flash file system (internal memory)

Check of the real-time clock

EEPROM Check

Setting data check

Option specifications

The example shows the presence of analog I/O.

Description

CAUTION

If an error is detected by the self-check (3 to 8 items), the information about the

error is displayed. For countermeasures, see Chapter 16, Maintenance Troubleshooting.

3

Preparation for Safe Measurements

IM CW240E

3-23

Page 56

3.7 Performing Measurements

with Greater Precision

• After turning the power switch on, let the CW240 warm up (for more than 30

minutes) before starting to perform measurements.

• To perform measurements with higher precision, use the CW240 under the

following environment conditions:

Ambient temperature: 23 ± 5°C

Ambient humidity: 35 to 75% R.H (no condensation)

If the CW240 is installed in a location where the ambient humidity is less than

30%, use an antistatic mat, etc. to prevent electrostatic discharge.

If you move the CW240 from a location of low temperature and humidity to a

location of high temperature and humidity or, if there is an abrupt change in

the ambient temperature, condensation may occur in the CW240. If this

happens, let the CW240 stand still for at least an hour to allow it to adapt to

the new ambient temperature and for any condensation to dissolve. Then

begin operating the CW240.

• Supply the power of sine waves at 50 Hz/60 Hz.

• When using a clamp-on probe, pay attention to the following points:

<1> When performing measurements, hold the clamp-on probe so that the

conductor cable runs through the center of the clamping CT.

<2>

Ensure that the orientation of the clamp to the direction of the conductor

cable (from the power supply to the load) is correct, as shown on the right.

<3> Ensure that the clamping CT is properly closed.

Power supply side

Conductor cable

(SOURCE)

Joint section

Clamping CT

Load side

(LOAD)

TIP

The CW240 obtains the measured value from voltage and current inputs.

(For computation equations, see Chapter 17, CW 240 Specifications.)

There may be cases where the CW240 shows a measurement value different from

those obtained by other equipment with different operation principles or computation

equations.

3-24

IM CW240E

Page 57

Chapter 4 Wiring

Chapter 4 Wiring

4.1 Precautions for Wiring

to the Measurement Circuit ...................... 4-2

4.2 Installing the CW240 ................................. 4-3

4.3 Setting up Wiring ...................................... 4-5

4.4 Setting up the Number of Loads .............. 4-6

4.5 Carrying out Wiring .................................. 4-7

4.6 Wiring the Measurement Circuit

Using External VT/CT.............................. 4-23

4.7 Checking Wiring ..................................... 4-24

Page 58

Chapter 4

4.1 Precautions for Wiring to

the Measurement Circuit

WARN ING

• Before carrying out wiring, be sure to read through 3.3, Connecting Voltage

Probes, and 3.4, Connecting Clamp-on Probes.

• Do not apply an input exceeding the following value to the voltage input

terminals.

Maximum allowable input : 1000 V rms

For measurement category III : 600 V rms

• The maximum allowable input and maximum operating circuit voltage of the

clamp-on probes are as specified in the table below. Do not apply an input

exceeding the relevant value or use the CW240 at a circuit voltage

exceeding it.

Model Current Rating

96036 2 A 20 A 50 V/CAT.III

96033 50 A 60 A 300 V/CAT.III

96030 200 A 250 A 300 V/CAT.II, 600 V/CAT.II

96031 500 A 625 A 300 V/CAT.II, 600 V/CAT.II

96032 700 A (continuous) 700 A (continuous) 600 V

1000 A (for 5 min) 1000 A (for 5 min)

96034 1000/2000/3000 A 2400 A (continuous) 600 V/CAT.III

96035 300/3000 A 360/360 A 1000 V/CAT.III (area to be measured)

Maximum

Allowable Input

3600 A (for 10 min)

Maximum Operating Circuit Voltage/

Measurement Category

SEE ALSO

For more information, see Chapter 17, CW 240 Specifications.

WARN ING

• If using an external VT (voltage transformer) or CT (current transformer), make

sure the transformer can sufficiently withstand the voltage to be measured.

• Be careful not to allow the secondary side of CT to become open-circuited

while the CT is being energized. Otherwise, a high voltage may develop on the

secondary side, posing extreme risks.

4-2

IM CW240E

Page 59

4.2 Installing the CW240

Install the CW240 in locations meeting the following conditions:

● Location

Indoor

● Ambient Temperature and Humidity

• Ambient temperature : 5°C to 40°C

• Ambient humidity : 5 to 85% R.H

(no condensation)

● Operating Altitude

• 2000 m max. above sea level

● Measurement Category (CAT.)

The measurement category of the CW240 is III.

4

Wiring

Measurement

category

II

CAT.II

CAT.IIIIII

CAT.IV

IV

For measurements performed

on circuits directly connected

to the low voltage installation.

For measurements performed

in the building installation.

For measurements performed

at the source of the low-voltage

installation.

DescriptionRemarks

Appliances, portable

equipments, etc.

Distribution board, circuit

breaker, etc.

Overhead wire, cable

systems, etc.

Internal Wiring

T

Entrance

Cable

IV

III

Outlet

II

IM CW240E

4-3

Page 60

4.3 Installing the CW240

● Installation Category (CAT.)

The installation category of the CW240 is III.

Instrallation

Category

CAT.II

II

CAT.III

III

CAT.IV

IV

● Pollution degree

The pollution degree of CW240 is 2.

“Pollution degree” describes the degree to which a solid, liquid, or gas which

deteriorates dielectric strength or surface resistivity is adhering.

“2” applies to normal indoor atmosphere. Normally, only non-conducitve