Page 1

User's

Manual

IM CW140-E

CW140

CLAMP-ON POWER METER

3rd Edition July 2001 (YK)

IM CW140-E

Page 2

Page 3

Introduction

Thank you for purchasing our CW140 Clamp-on Power Meter. This User’s

manual explains the functions of the CW140, as well as its operating methods

and handling precautions. Before using the CW140, read this manual

thoroughly to ensure correct use of the instrument.

The Operation Guide manual is available separately, in addition to this

manual. The Operation Guide manual briefly describes the basic procedures

for performing such tasks as measurement operations and settings. Use the

manual together with this in-depth User’s manual.

When you have finished reading this manual, carefully store it in a place that

provides ease of access for later reference. This manual will come in handy

when you are unsure of how to operate the instrument.

Notices

The contents of this manual are subject to change without prior notice. In

addition, figures and illustrations representing display views in this manual

may differ from real views.

Every effort has been made to ensure accuracy in the preparation of this

manual. Should any doubts arise or errors come to your attention however,

please contact one of the Yokogawa M&C sales offices listed on the back

cover of this manual or the sales representative from which you purchased

the instrument.

The contents of this manual may not be transcribed or reproduced, in part or

in whole, without prior permission.

Trademark Acknowledgments

The company and product names referred to in this document are either

trademarks or registered trademarks of their respective holders.

Revision Information

February 2000: First edition

July 2001: 3rd edition

Disk No. CW140-E

3rd Edition: July 2001 (YK)

All Rights Reserved. Copyright © 2000, Yokogawa M&C Corporation

IM CW140-E

1

Page 4

Examining Items Contained in the Package

After opening the package, be sure to examine the product as instructed

below before use. Should the delivered product be the wrong model, lack any

item, or show any flaw in its appearance, contact the vendor from which you

purchased the product.

CW140 Main Unit

Check the model name and the suffix (specifications) code in the MODEL and

SUFFIX fields of the nameplate located at the back of the instrument to

ensure that the instrument is exactly as specified in your purchase order.

Model Name and Suffix Codes

Model Suffix Code Specifications

CW140

AC adapters D Power cord: UL/CSA standard

F VDE standard

R SAA standard

S BS standard

Option codes /DA D/A output

/C1 Clamp-on probe for 20/200A (2 pcs/set)

/C2 Clamp-on probe for 20/200A (4 pcs/set)

/C3 Clamp-on probe for 50/500A (2 pcs/set)

/C4 Clamp-on probe for 50/500A (4 pcs/set)

/C5 Clamp-on probe for 200/1000A (2 pcs/set)

/C6 Clamp-on probe for 200/1000A (4 pcs/set)

/PM1 NiMH (nickel-hydrogen) battery pack and carrying case

/PM2 “PM1” and FDD unit

No. field: Denotes the instrument number.

Refer to this number when inquiring to the vendor about the instrument.

Accessories

Make sure that the package contains all the accessories listed below and that

they are all free from any damage.

Product Name Part Number Qty Remarks

1. AC adapter for power supply 788011 1 set Yokogawa’s AC adapter

2. AA alkaline dry cells — 6 (alkaline batteries)

3. Voltage probes 91007 4 Supplied together with two sets of ring

4. Instruction manual IM CW140-E 1

5. Operation Guide manual IM CW140P-E 1

markers of three different colors.

1. 2. 3.

4. 5.

2

IM CW140-E

Page 5

Examining Items in the Package

Peripherals (Optional)

The products listed below are available as optional peripherals. For technical

and ordering inquiries concerning the peripherals, contact the vendor from

which you purchased the instrument. If the instrument you purchased

includes any one of the optional peripherals, make sure it is free from any

damage.

Product Name Part Number Minimum Order Qty Remarks

Clamp-on probe for 20/200 A 96030 1 * See the option codes for a choice of

Clamp-on probe for 50/500 A 96031 1 *

Clamp-on probe for 200/1000 A 96032 1 *

Voltage probe 91007 4

Floppy disk drive unit 97020 1 set FDD unit

Carrying case 93020 1

AC adapter 788011 1 set Yokogawa’s AC adapter

NiMH battery pack 94004 1

Printer 97010 1

AC adapter (for printer, Europe) 94006 1

AC adapter (for printer, USA) 94007 1

Thermal paper for printers 97080 10 rolls

TIP

It is advisable that the packing box be stored, as it is useful when you transport the instrument.

probe kits.

Instruction manual

NiMH battery pack

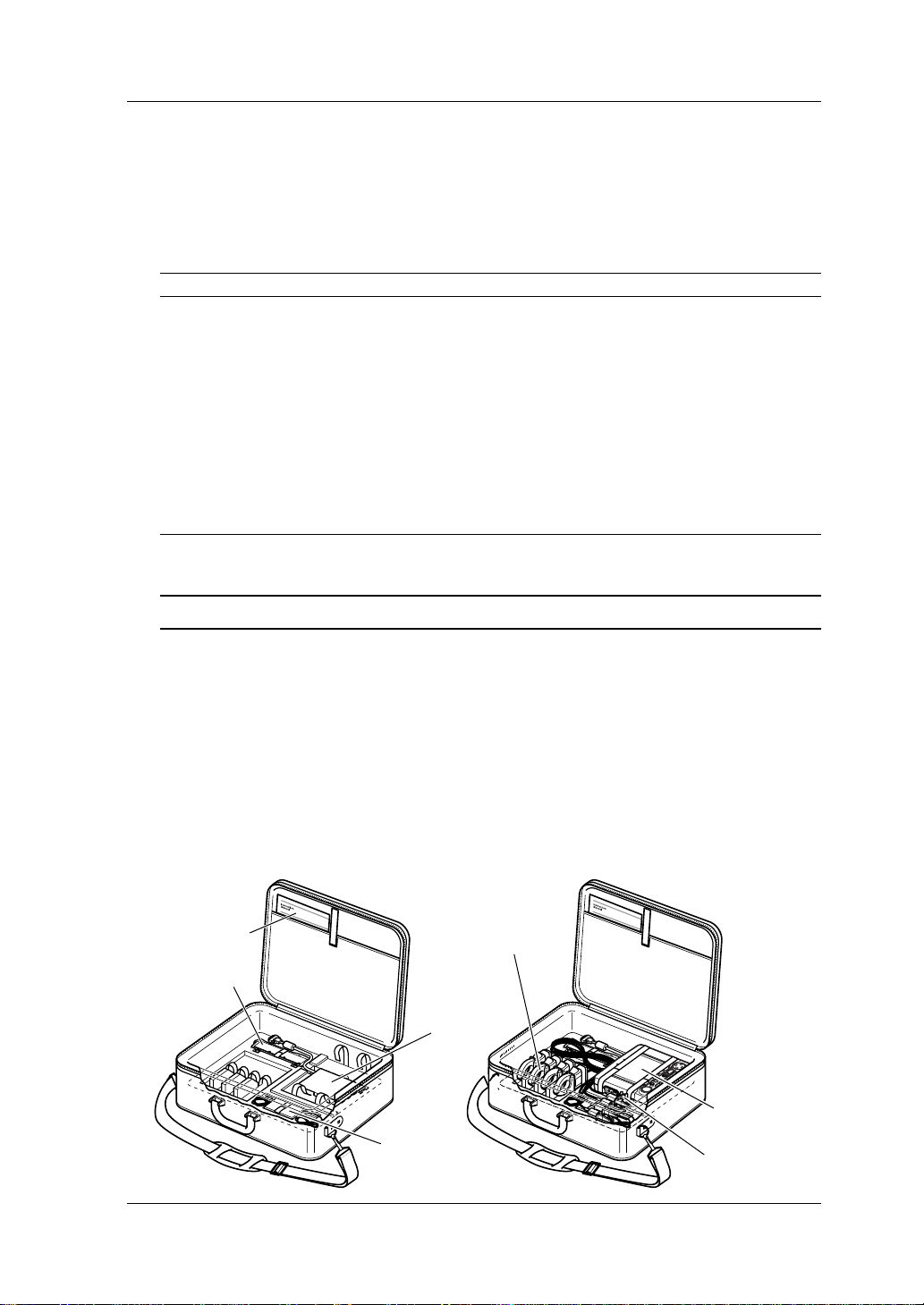

● Housing CW140 Main Unit and Accessories

An optional carrying case can accommodate the CW140 main unit with its

current-sensing clamp-on probes and voltage probes connected to the unit.

The case can also house such accessories as an AC adapter, NiMH battery

pack, floppy drive unit, instruction manual, floppy disks, recording paper, and

so on. It therefore comes in handy when transporting a complete kit of tools

necessary for your measurement.

Example of Housing:

Clamp-on probes

Floppy drive unit

CW140 main unit

AC adapter

Voltage probes

IM CW140-E

3

Page 6

Precautions for Safe Use of the Instrument

When operating the instrument, be sure to observe the cautionary notes given below

to ensure correct and safe use of the instrument. If you use the instrument in any

other way than instructed in this manual, the instrument’s protective measures may

be impaired. Yokogawa M&C Corporation is by no means liable for any damage

resulting from use of the instrument in contradiction to these cautionary notes.

The following safety symbols are used in the instrument and this manual.

Danger! Handle with Care.

This symbol indicates that the operator must refer to an explanation in the instruction manual in

order to avoid risk of injury or death of personnel or damage to the instrument.

Direct Current

This symbol indicates DC voltage/current.

Alternating Current

This symbol indicates AC voltage/current.

ON

This symbol indicates On (power).

OFF

This symbol indicates Off (power).

Double Insulation

This symbol indicates double insulation.

WARNING

Indicates a hazard that may result in the loss of life or serious injury of the user unless the

described instruction is abided by.

CAUTION

Indicates a hazard that may result in an injury to the user and/or physical damage to the pr oduct

or other equipment unless the described instruction is abided by.

NOTE

Indicates information that is essential for handling the instrument or should be noted in order to

familiarize yourself with the instrument’s operating procedures and/or functions.

TIP

Indicates information that complements the present topic.

SEE ALSO

Indicates the reference location(s) for further information on the present topic.

4

IM CW140-E

Page 7

Precautions for Safe Use of the Instrument

Strictly observe the following cautionary notes in order to avoid the risk of

injury or death of personnel or damage to the instrument due to such hazards

as electrical shock.

WARNING

● Removal of Case from the Instrument

• Do not remove the case from the instrument or disassemble/modify the instrument itself.

• Some parts of the inside of the instrument contain high-voltage and, therefore, access to the

internal assembly is extremely hazardous. For inspection and/or adjustment of the internal

assembly, contact the vendor from which you purchased the instrument.

● Use of the Instrument in a Gas Atmosphere

Do not operate the instrument in a location where any flammable or explosive gas/vapor is

present. It is extremely hazardous to operate the instrument in such an atmosphere.

● Inspection of Power Source

• Before turning on the instrument, always make sure the voltage of the power source to be

applied matches the instrument’s supply voltage.

• When using alkaline batteries or an NiMH battery pac k, carefully read the cautionary notes on

battery handling later in this manual.

● Use of Clamp-on Current Probes

• When using clamp-on current probes, keep the circuit voltage below 600 V AC in order to

avoid possible short-circuits or accidents resulting in injury or death.

• Avoid using the instrument if it has been e xposed to rain or moisture or if your hands are wet.

• Do not use clamp-on current probes with any non-insulated conductors.

● Measures In Case of Anomalies

If the instrument begins to emit smoke, becomes too hot, or gives off an un usual smell, immediately turn it off and disconnect the power cord from the outlet. Also turn off power to the

object under measurement that is connected to the instrument’s input terminals. Never attempt to use the instrument again. If any such anomalies as noted above occurs, contact the

vendor from which you purchased the instrument. Do not attempt to repair the instrument

yourself, as doing so is extremely dangerous.

● Handling of Power Cords

Do not place any load on the power cord or allow the power cord to come into accidental

contact with any heat source. Hold the plug of the po wer cord, rather than holding and pulling

the cord itself, when disconnecting it from the outlet. If the power cord is damaged, contact

the vendor from which you purchased the instrument. See page 2 for information on the AC

adapter that is necessary when ordering a replacement power cord.

IM CW140-E

5

Page 8

Contents

Introduction ..............................................................................................................1

Examining Items Contained in the Package..........................................................2

Precautions for Safe Use of the Instrument ..........................................................4

Chapter 1. Product Overview ...............................................................................1-1

1.1 Product Overview ........................................................................................ 1-1

Chapter 2. Components, Their Use and Overrange, and Error Indications ..... 2-1

2.1 Front Panel and Connector Block................................................................ 2-1

2.2 Operation and Functions Keys .................................................................... 2-2

2.3 Connecting Input Signals to Be Measured and External Input Terminals ... 2-3

2.4 Overrange and Other Marks Shown during Measurement.......................... 2-6

Chapter 3. Precautions for Safe Measurement...................................................3-1

3.1 Handling Precautions .................................................................................. 3-1

3.2 Installation Procedure.................................................................................. 3-3

3.3 Precautions for Wiring the Circuit under Test .............................................. 3-4

3.4 Diagrams of Basic Wiring ............................................................................ 3-5

3.5 Wiring the Circuit under Test Using External VT/CT.................................... 3-8

3.6 Connecting a Power Supply and Turning It On/Off ...................................... 3-9

3.7 Performing Measurements with Higher Precision ..................................... 3-18

Chapter 4. Basic Operation Flow and Top Menu Screen ...................................4-1

4.1 Basic Operation Flow .................................................................................. 4-1

4.2 Top Menu Screen ........................................................................................ 4-2

Chapter 5. System Settings..................................................................................5-1

5.1 System Settings .......................................................................................... 5-1

5.2 System Reset .............................................................................................. 5-4

Chapter 6. File Handling ....................................................................................... 6-1

6.1 File Handling ............................................................................................... 6-1

6.2 File Name and File Attribute........................................................................ 6-4

6.3 Entering a File Name................................................................................... 6-5

Chapter 7. Common Functions of All Modes .....................................................7-1

7.1 Wiring .......................................................................................................... 7-1

7.2 Checking Wiring .......................................................................................... 7-3

7.3 Ranges and Number of Digits ..................................................................... 7-6

7.4 Sampling Frequencies and Integration Periods......................................... 7-14

7.5 Frequency Measurement and Low-pass Filters ........................................ 7-16

7.6 Averaging Function.................................................................................... 7-18

7.7 Scaling Function (VT/CT) .......................................................................... 7-19

Chapter 8. Instant Measure Mode........................................................................8-1

8.1 Detailed View of Data Items on Instant Measure Mode Screen .................. 8-1

8.2 Working with the Function Keys .................................................................. 8-4

8.3 Expanded View of Data Items on Instant Measure Mode Screen ............... 8-5

6

IM CW140-E

Page 9

Contents

8.4 Logging in Instant Measure Mode ............................................................... 8-7

8.5 Setup Data Items of Instant Measure Mode.............................................. 8-10

8.6 Computational Expressions....................................................................... 8-15

Chapter 9. Electric Energy Measure Mode .........................................................9-1

9.1 Data Items on Electric Energy Measure Mode Screen ............................... 9-1

9.2 Working with the Function Keys .................................................................. 9-3

9.3 Integration in Electric Energy Measure Mode ............................................. 9-4

9.4 Setup Data Items of Electric Energy Measure Mode .................................. 9-7

Chapter 10. Key .............................................................................................10-1

10.1 Simple Electric Energy Measurement with Key .................................. 10-1

Chapter 11 Demand Measure Mode .................................................................11-1

11.1 About Demand .......................................................................................... 11-1

11.2 Data Items Shown on Demand Measure Mode Screen ............................ 11-2

11.3 Working with the Function Keys ................................................................ 11-4

11.4 Demand Measurement in Demand Measure Mode .................................. 11-5

11.5 Setup Data Items of Demand Measure Mode ........................................... 11-8

Chapter 12. Harmonics Measure Mode ............................................................. 12-1

12.1 Showing Tables in Harmonics Measure Mode .......................................... 12-1

12.2 Showing Graphs in Harmonics Measure Mode......................................... 12-3

12.3 Working with the Function Keys ................................................................ 12-5

12.4 Logging in Harmonics Measure Mode ...................................................... 12-6

12.5 Setup Data Items of Harmonics Measure Mode ....................................... 12-9

12.6 Computational Expressions..................................................................... 12-15

Chapter 13. File Functions .................................................................................13-1

13.1 Saving, Loading and Printing with File Functions...................................... 13-1

Chapter 14. External I/O Functions ...................................................................14-1

14.1 Optional D/A Output .................................................................................. 14-1

14.2 External Control Input ............................................................................... 14-8

14.3 Event Input ................................................................................................ 14-9

Chapter 15. RS-232C Communication Function ..............................................15-1

15.1 RS-232C Interface Specifications ............................................................. 15-1

15.2 Connecting CW140 through RS-232C Interface ....................................... 15-2

15.3 Handshake Methods ................................................................................. 15-4

15.4 Matching the Data Format......................................................................... 15-7

Chapter 16. In the Event of a Power Failure .....................................................16-1

16.1 In the Event of a Power Failure ................................................................. 16-1

Chapter 17. Auxiliary Functions ........................................................................17-1

17.1 Auxiliary Functions .................................................................................... 17-1

17.2 Floppy Disk Drive (Optional)...................................................................... 17-7

17.3 Printer (Optional) ....................................................................................... 17-8

Chapter 18. Troubleshooting .............................................................................18-1

18.1 Corrective Action in Case of Failure .......................................................... 18-1

18.2 Messages and Corrective Measures......................................................... 18-2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

App

Index

IM CW140-E

7

Page 10

Contents

Chapter 19. Specifications .................................................................................19-1

19.1 Specifications ............................................................................................ 19-1

19.2 Specifications of Current Clamps ............................................................ 19-15

Appendix.........................................................................................................App1-1

Appendix 1 Block Diagram of CW140 Main Unit............................................. App1-1

Appendix 2. Communication Commands.......................................................... App2-1

Appendix 3. Explanation of Data Item to be Saved/Printed .............................App3-1

Appendix 4. Terminology .................................................................................. App4-1

Appendix 5. Explanation of Reactive Power Method........................................App5-1

Appendix 6. Settings Check Sheet................................................................... App6-1

Index............................................................................................................... Index-1

8

IM CW140-E

Page 11

Chapter 1. Product Overview

1.1 Product Overview

The CW140 clamp-on power meter is basically designed for measuring rootmean-square voltage and current rms values and thereby electric energy. With its

computing capabilities, the CW140 can measure and analyze a wide variety of

parameters related to electric power.

This section explains the features of the CW140 and shows a schematic diagram

representing the functions of the CW140. It also explains the screen views (i.e.,

measuring objects) presented by each measurement mode of the CW140.

Features

● Supports a variety of measurement modes and continuous

measurement.

The CW140 has four measurement modes which support continuous

measurement.

• Instant Measure mode (logging)

• Electric Energy Measure mode (integration)

• Demand Measure mode (demand measurement)

• Harmonics Measure mode (logging)

● Efficient Measurement using the Wh Key

This feature simplifies operations required for the Electric Energy Measure mode

most often used.

● Supports a variety of wiring methods.

• Supports single-phase two-wire systems, single-phase three-wire systems,

three-phase three-wire two-current systems, three-phase three-wire threecurrent systems, and three-phase four-wire systems.

• Supports dual-load systems in a single-phase two-wire, single-phase threewire, or three-phase three-wire configuration (except when in the Harmonics

Measure mode).

● Data Management

• Measured values or measurement settings can be stored in internal memory

or on a 3.5-inch floppy disk inserted in an optional floppy drive attached

externally to the CW140.

• Allows simultaneous data saving to internal memory and a floppy disk, or

copying internal memory data to a floppy disk.

• An optional printer connected externally to the CW140 allows you to print

measured values or measurement settings.

● Communication

With an RS-232-C interface, it is possible to transfer data to or receive

measurement settings from a personal computer. The CW140 stores

measurement data in CSV format, facilitating data processing (such as creating

graphs) using commercial spreadsheet software.

● Setting Operations

• Easy-to-operate Display Screen

You can easily change settings by selecting items highlighted on the screen using

Range keys, Cursor key, and function keys.

● Settings Check Sheet

The settings check sheet in Appendix 6 lists required setting items for each

measurement mode. Use this sheet for reference and to improve efficiency when

making settings in the field.

1

Product Overview

IM CW140-E

1-1

Page 12

1.1 Product Overview

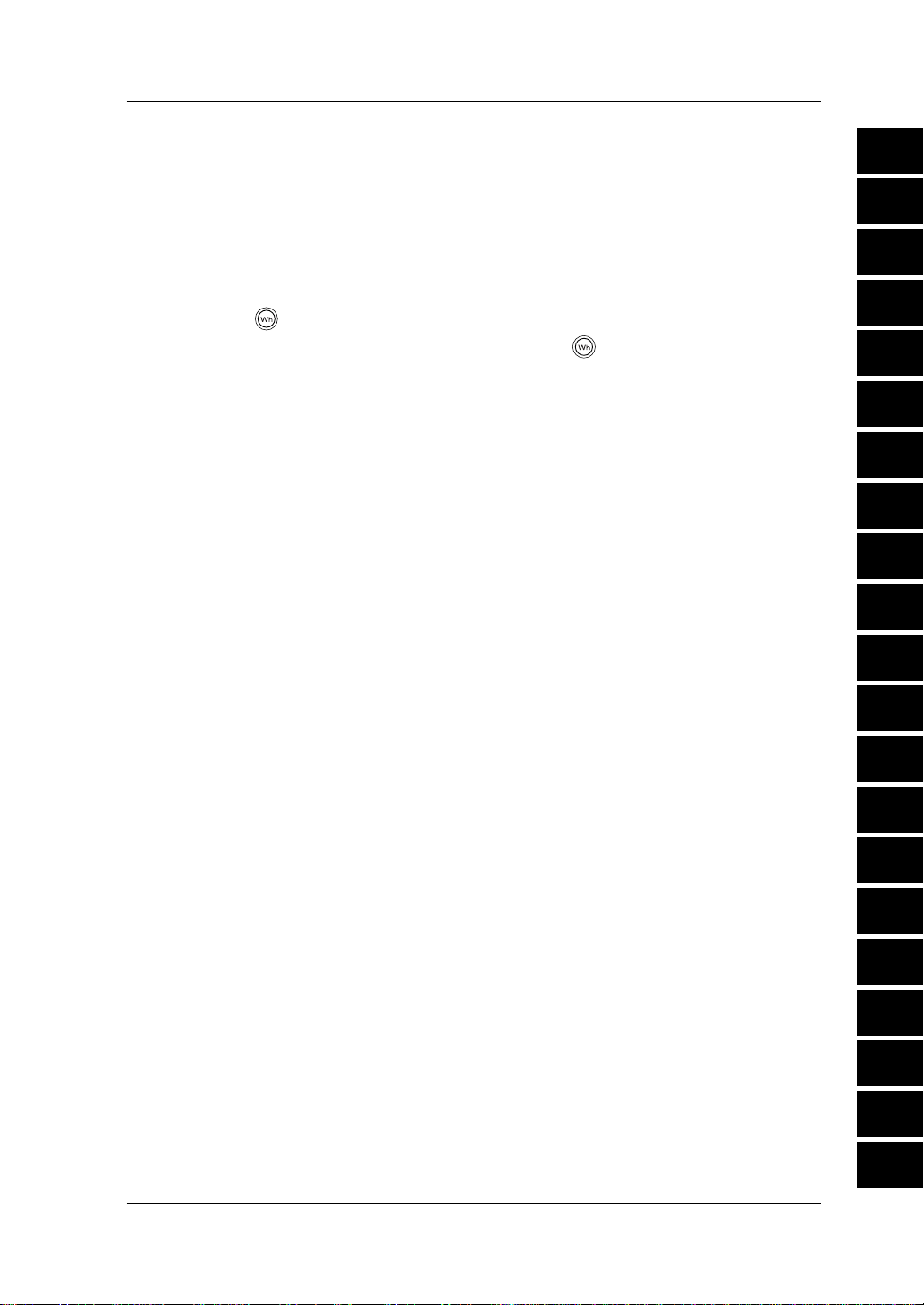

Schematic Function Diagram

key key

TOP MENU

screen

(Chapter 8) (Chapter 9) (Chapter 11) (Chapter 12)

Instant Measure

mode

Logging

Condition setting Condition setting Condition setting Condition setting

Averaging function (Section 7.6)

Scaling function (Section 7.7)

Low-pass filter function (Section 7.5)

Frequency measurement

Wiring check function (Section 7.2)

Power failure handling function (Chapter 16)

Auxiliary functions (Chapter 17)

Clock

Language selection (Japanese, English)

Hold of on-screen readings

NiMH battery recharging

LCD contrast

LCD backlight

Beep (confirmation of key operation)

Key locking

Power-saving mode

System reset

Low battery indicator

Testing backup batteries

Electric Energy

Measure mode

Integration

(Chapter 5) (Chapter 6)

System Setting

mode Screens

1/2 and 2/2

Demand Measure

mode

Demand

Internal

memory

for personal computer or printer

Floppy disk drive unit

(connected externally)

(Section 17.2)

File Handling

Harmonics

Measure mode

(Graph display)

Logging

Storage of data and setup conditions

Reading of setup conditions

RS-232C interface

mode

(Chapter 15)

(Section 17.3)

Event input function

(Chapter 10)

Electric Energy

Measure mode

Last condition

Setting condition 1

Setting condition 2

Setting condition 3

Setting condition 4

Saving set conditions

External trigger function

(Section 14.2)

(Section 14.3)

D/A

output

(Optional)

1-2

IM CW140-E

Page 13

1.1 Product Overview

Demand Measure mode

(Chapter 11)

Indication at the End of Demand

• Maximum demand and its time

• Average of respective demands

• Electric energy integrated from the

start to the end of demand

• Average power factor

• Average load factor

Indication During Demand Interval

• Maximum demand and its time

• Demand of one demand period earlier

• Electric energy integrated since the

start of demand

• Electric energy integrated during the

present demand period

• Power factor

• Load factor

• Remaining time of demand interval

On-screen Information (Data Items) Provided by Each Measurement Mode

In each measurement mode, you can measure and calculate on-screen data

items, as shown below.

Instant Measure mode

(Chapter 8)

Rms voltage value (V)

Rms current value (A)

Active power (W)

Reactive power 1 and 2 (Var)

1: With reactive power meter method

2: Without reactive power meter method

Apparent power (VA)

Power factor

Phase angle (°)

Frequency (Hz)

Three-phase unbalance factor (%) (for three-phase wiring only)

1

Product Overview

Electric Energy Measure mode

(Chapter 9)

Harmonics Measure mode

(Chapter 12)

Table displays

Graph displays

• Voltage/current Rms value, harmonic content, phase angle

• Power

• Voltage/current Rms value, harmonic content, phase angle

• Power

Active power (Wh)

Regenerative power (Wh)

Lagging reactive power (Varh)

Leading reactive power (Varh)

Analysis of 1st- through 13th-order harmonics

Total rms value (All-RMS)

Total harmonic distortion

IEEE (relative to fundamental wave);

CSA (relative to total rms value)

Fundamental wave frequency

Power value, power content, power phase angle

Total power value

Total power factor

Fundamental wave frequency

Power value, power content, power phase angle

IM CW140-E

(The CW140 does not support the Harmonics Measure mode when wired to

2-system load.)

NOTE

The CW140 can show a screen of instantaneous values whether it is in the Electric Energy Measure mode or the Demand Measure mode.

1-3

Page 14

Page 15

Chapter 2. Components, Their Use and Overrange, and Error Indications

)

2.1 Front Panel and Connector Block

Battery charge

LED indicator

(for optional

NiMH battery)

<Side View>

184 (7.24)

AC adapter

jack

Power

switch

N

START

&STOP

<Connector Block>

v

1

v

2

v

3

<Front View>

CLAMP ON POWER METER

FFF

Wh

LIGHT

KEY

LOCK

V

L

L

1

N

INPUT / OUTPUT

23

ESC

AW

L

L

2

3

4

N

N

L1NLNLN L2NL3NL4N

F

4F51

ENTER

TOP MENU

2

Product Overview

N

IM CW140-E

65 (2.56)

206 (8.11)

Unit: mm (approx. inches

2-1

Page 16

2.2 Operation and Functions Keys

Status LED

indicator* for

continuous

measurement

LIGHT

ESC

Name

Function keys

Key Symbol

to

Set data appropriate for information

shown in their respective

corresponding fields along the

Description

Display

bottom edge of the display.

START&STOP

key

Starts/stops logging when the CW140 is in the Instant Measure or Harmonics Measure

mode.

Starts/stops integration when the CW140 is in the Electric Energy Measure mode.

Starts/stops demand when the CW140 is in the Demand Measure mode.

Backlight key

LIGHT

Turns on/off the backlight.

Holding this key down for more than 3 seconds places the CW140 in a key

lock state. To cancel the state, hold this key down again for more than 3

seconds.

Watt-hour key

Allows you to measure electric energy easily without selecting the Electric

Energy Measure mode from the TOP MENU screen.

Escape key

Enter key

Cursor key

V Range key

Cancels such data as setup conditions.

ESC

Confirms such data as setup conditions.

Moves the cursor through on-screen data items so an item can be selected.

Shows/resets the voltage range.

(You can change the setpoint with a function key.)

A Range key

Shows/resets the current range.

(You can change the setpoint with a function key.)

Wiring key

Shows/resets the setting of a wiring method.

(You can change the setting with a function key.) Also see "Checking Wiring."

TOP MENU key

Changes the display to the TOP MENU screen for selecting each

measurement mode.

* Status LED indicator: Remains lit when the CW140 is performing continuous measurement (whether the

meter is in a stand-by state or taking measurements) in each measurement mode.

2-2

IM CW140-E

Page 17

2.3 Connecting Input Signals to Be

Measured and External Input Terminals

● Terminal Assignments

Voltage input terminals

Current (clamp) input terminals

2

Product Overview

v

1

v

N

FDD

Connector for connection with

an external floppy disk drive unit

2

RS-232C

RS-232C connector for

printer/personal computer

Event input terminals: Receive ON/OFF signals from equipment

External control input terminals: Receive START/STOP signals informing

D/A output terminals: Terminals for D/A output

L

CH

1

v

3

LOGIC INPUT START/STOP D/A OUTPUT

Event input terminals

External control (trigger)

input terminals

L

N

L

CH

2

N

L1NLNLN L2NL3NL4N

L

CH

3

D/A output terminals

CH

4

N

(optional)

under test.

of the start and end of logging,

integration or demand measurement.

(not available if the CW140 is not

equipped with a D/A output option).

N

IM CW140-E

2-3

Page 18

2.3 Connecting Input Signal Lines to Be Measured and External Input Terminals

LL1

V INPUT

600V~MAX

TERMINALS 600V ~ MAX

O EAR

TH

CH

CH

CA

FDD

RS-232C

LOGIC NIPUT

ST

AR

T/ST

OP

5.5V MAX

● Connection of Input Signal Lines to Be Measured and External Input

Terminals (Example)

Ring marker

Current clamp

OP

HL H

2

H

C

T/ST

AR

ST

L

LOGIC NIPUT

X

A

.5V M

5

H

1

H

C

L

RS-232C

3

v

FDD

2

v

L

1

v

TH

R

A

E

TO

N

X

A

T.

A

C

V ~ M

600

LS

INA

X

RM

A

E

T

M

V~

600

V INPUT

Voltage probe (red/yellow/blue)

Voltage probe (black)

WARNING

• Thoroughly read Section 3.3, "Precautions for Wiring the Circuit Under Test."

• When wiring the CW140, turn off the circuit under test.

It is extremely dangerous to connect or disconnect measuring lead wires without turning off

the circuit under test.

• Be extremely careful not to connect any voltage-mode cir cuit to the current input terminals or

any current-mode circuit to the voltage input terminals. Miswiring can result in not only damage to the circuit or equipment under test but also an injury to personnel.

• The CW140 can be connect to a maximum of four voltage input probes or four current-sensing

clamps. Do not connect any probe or clamp that is not necessary for measurement.

• Do not use any other probes or current-sensing clamps than those supplied with the CW140.

• Before connecting a current-sensing clamp to the CW140, make sure the H and L polarities are

correctly identified.

● Differentiating among Voltage Input Probes and among Current-

sensing Clamps

• Voltage Input Probes

Probe for Input terminal N: Black (one)

Probes for Input terminals V1 to V3: Three different colors: Red, Yellow and Blue.

• Current-sensing Clamps

Clamps for Input terminals CH1 to CH4: Differentiated by ring markers of four different

2-4

colors

IM CW140-E

Page 19

2.3 Connecting Input Signal Lines to Be Measured and External Input Terminals

● Use of Ring Markers (Standard Accessories)

Attach ring markers of the same color to both the terminal connection side

and alligator clip side of a voltage input probe or to both the terminal

connection side and clamping side of a current-sensing clamp. This enables

you to differentiate between the input signal lines.

CAUTION

Be careful not to damage a probe when attaching ring markers.

● Connection of External I/O Terminals

Signal wire

Tool such as a flat-tip screwdriver

● Connection Procedure

Insert the signal wire into the hole while pressing the rectangular area at the

bottom of the external I/O terminal using such a tool as a flat-tip screwdriver.

Removing the screwdriver from the terminal fixes the signal wire in place.

2

Product Overview

CAUTION

• Do not apply voltages outside the allowable input voltage range (-0.5 to 5.5 V), otherwise the

input circuit may be damaged.

• When wiring the CW140, be careful not to mistake an input terminal for an output terminal.

● Applicable Signal Wires

Standard wire: φ1.0 single-core wire (AWG18) or 0.75 mm

Adaptable wire: φ0.4 to 1.0 single-core wire (AWG26 to 18) or 0.35 to 0.75

mm2 stranded wire (AWG22 to 20) with a minimum strand

diameter of 0.18 mm; typical length of stripping = 10 mm

● Applied Terminals

LOGIC INPUT: Event input terminals (receive ON/OFF signals from

equipment under test)

START/STOP: Terminals for inputting signals informing the start and end of

logging, integration or demand measurement.

D/A OUTPUT: Terminals for D/A conversion output (optional)

IM CW140-E

2

stranded wire

2-5

Page 20

2.4 Overrange and Other Marks Shown

during Measurement

● Overrange Indications during Measurement

: Conditions for current overrange indication

This mark appears if the sampled value exceeds 300% of the rated

current range or if the rms value of the measured current exceeds

110% of the rated range. If a fixed range is used, step up the range.

: Conditions for voltage overrange indication

This mark appears if the sampled value exceeds 300% of the rated

voltage range or if the rms value of the measured voltage exceeds

110% of the rated range. If a fixed range is used, step up the range.

TIP

• The current overrange mark appears if an input signal to one of the terminals CH1 to CH4

satisfies the conditions noted above.

• The voltage overrange mark appears if an input signal to one of the terminals V1 to V3 satisfies

the conditions noted above.

Indication of Overrange Marks When Auto-ranging Is Used

The CW140 steps up or down the range, as discussed in Section 7.3,

"Ranges and Number of Digits." Then, the CW140 shows the or

mark if the conditions noted above become true under the maximum range.

Indication of OR Symbol

The CW140 shows the OR symbol, instead of a usual four-digit value, if the

result of measurement (calculation) satisfies the conditions noted above.

(If a fixed range is used, step up the range.)

Indication of OR Symbol When Auto-ranging Is Used

The CW140 steps up or down the range, as discussed in Section 7.3,

"Ranges and Number of Digits." Then, the CW140 shows the OR

symbol if the conditions noted above become true under the maximum

range.

WARNING

The CW140 shows an overrange mark under the maximum range only if the input level exceeds

the maximum allowable input level. Do not appl y an y input level higher than the maxim um allowable input level.

2-6

IM CW140-E

Page 21

2.4 Overrange and Other Marks Shown during Measurement

CAUTION

When measuring an input signal level exceeding the rated range, use a voltage transformer (VT)

or a current transformer (CT) - scaling function. When using a VT or CT, thoroughl y read Section

3.5, "Wiring the Circuit under Test Using External VT/CT."

● Frequency-related Overrange Indications

Normal measurement: The measurement range is from 45 Hz to 1 kHz.

The display shows "----" if the input signal is below 40 Hz or above 1.2 kHz.

Three-phase unbalance factor measurement:

The measurement range is from 45 to 440 Hz.

The display shows "----" if the input signal is below 40 Hz or above 440 Hz.

Harmonics measurement: The measurement range is from 45 to 65 Hz.

The display shows "----" if the input signal is below 40 Hz or above 70 Hz.

● Indications When the Measured Value Is Too Small

If either a voltage or current input level is below 0.4% of the rated range, the

CW140 gives the readings noted below. If a fixed range is used, step down

the range.

Reactive power 2 and apparent power: Read zero (0).

Power factor and phase angle: Read as "----".

2

Product Overview

If the level of active power or reactive power is below 0.7% of the rating, the

reading is displayed as shown below.

Active power or reactive power: Read zero (0). The integration stops.

In harmonics measurement, the display reads as shown below if the input

level of a frequency-measuring device is below 10% of the rated range.

All measurement data items: Read as "----".

If the voltage, current or power harmonic content in harmonics measurement

is below 0.1%, the phase angle of a harmonic component of that order reads

as "----".

TIP

Even if the instantaneous value overrange occurs and the OR symbol appears in the electric energy

measure mode, the integration processing continues. In this case, the level of accuracy of the on-screen

integrated value may become inaccurate (about two times) that of the rated accuracy.

NOTE

If continuous measurement (logging, integration, or demand) is performed when in AUTO range,

the range will be fixed to the value when the START&STOP key is pressed.

IM CW140-E

2-7

Page 22

2.4 Overrange and Other Marks Shown during Measurement

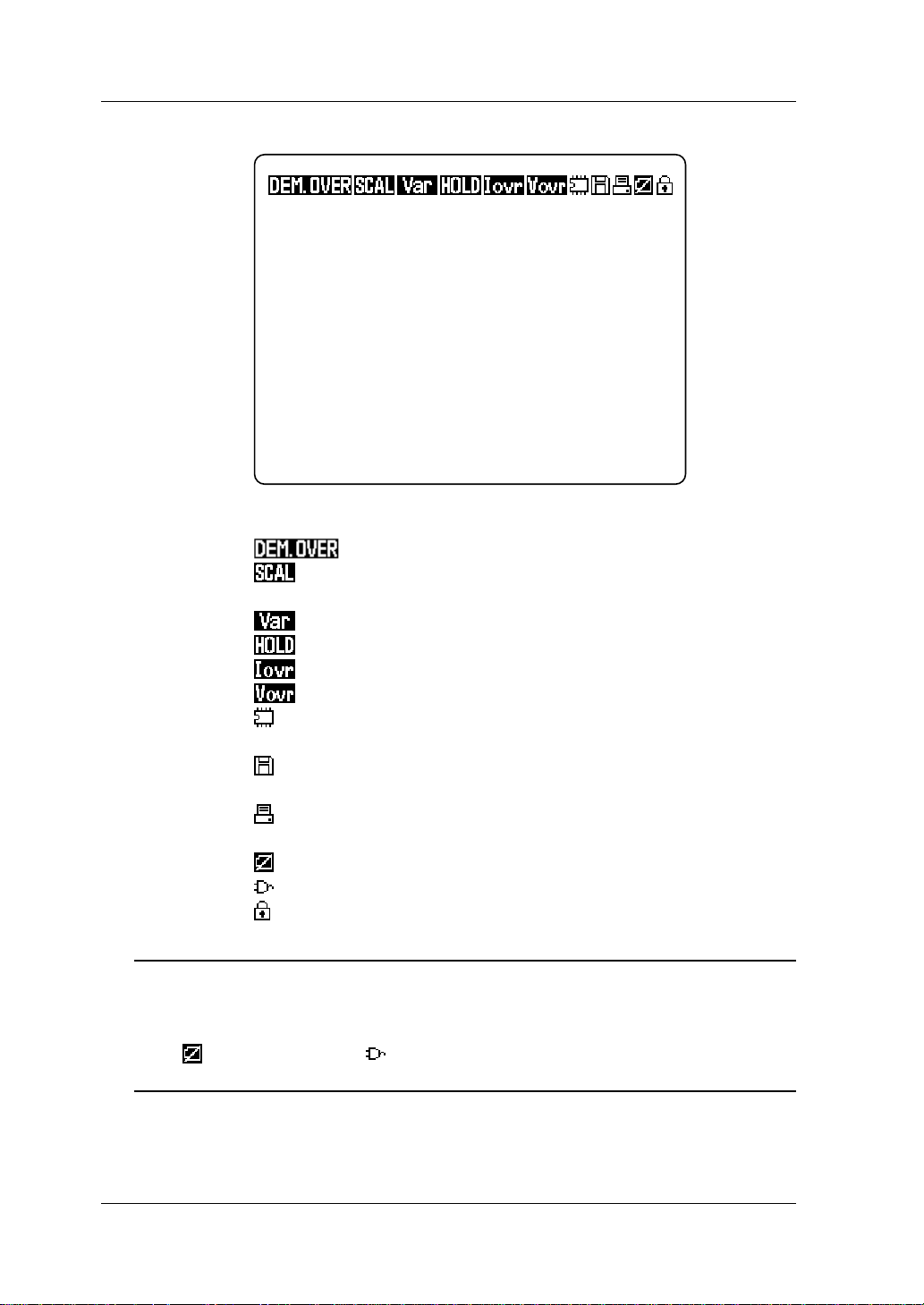

● Other Marks

Screen View

: Appears if the demand exceeds the reference power level.

: Denotes the scaling function.

Appears if either the VT or CT ratio is set at a value other than 1.

: Appears when the reactive power method is used.

: Appears when display hold is enabled.

: Appears when a current overrange occurs.

: Appears when a voltage overrange occurs.

: Appears when the CW140 is configured so that data is stored in

internal memory.

: Appears when the CW140 is configured so that data is stored

on a floppy disk.

: Appears when the CW140 is configured so that data is output to

a printer.

: Appears when the battery becomes low (low-battery mark).

: Appears when an AC adapter is used.

: Appears when the CW140 is in a key lock state.

TIP

• The Floppy Disk mark is only effective if an optional external floppy disk drive is used.

• The Printer mark is only effective if an optional external printer is used.

• The Low-Battery mark appears if either an optional NiMH battery pack or alkaline batteries are used.

• The (Low-Battery mark) and (AC Adapter mark) indications share the same position of view

on the display.

2-8

IM CW140-E

Page 23

Chapter 3. Precautions for Safe Measurement

3.1 Handling Precautions

If you are a first-time user, be sure to read "Precautions for Safe Use of the

Instrument" on pages 4 and 5.

● Do not place any load on the instrument.

Do not place any other equipment of a vessel filled with water on the

instrument. Otherwise, the instrument may become defective.

● Moving the instrument

Before moving the instrument, make sure the power cord and all other cables

are disconnected. When moving the instrument, hold it with both hands.

● Input Terminals

Do not bring any electrified substance close to the signal terminals.

Otherwise, the internal circuitry may be destroyed. Do not apply any

mechanical shock to the signal terminals. Otherwise, such impact may be

transformed into electrical noise and input to the instrument.

3

Precautions for Safe Measurement

● Protection of Case and Operation Panel

Do not spray any volatile chemical on the case or operation panel. Do not

leave any rubber or vinyl product in contact with the instrument for a

prolonged period. Otherwise, the instrument may be discolored or deformed.

● Cleaning

When cleaning the case and/or operation panel, disconnect the power cord

from the outlet. Then, wipe the surfaces of the case and/or operation panel

with a soft clean cloth. Do not use chemicals such as benzine or paint thinner.

Otherwise, the instrument may be discolored or deformed.

● Display Screen

When the instrument is shipped from the factory, the display screen is

covered with a protective film. Remove the film before you begin using the

instrument.

The LCD backlight lasts a approximately 10,000 hours when kept turned on at

room temperature. If it is used longer than that period, the brightness may

drastically decrease. If this occurs, the backlight needs to be replaced.

Contact the vendor from which you purchased the instrument.

IM CW140-E

3-1

Page 24

3.1 Handling Precautions

● After Use

After use, disconnect the power cord from the outlet.

● Long Absence of Use

If the instrument will not be used for a prolonged period, remove the batteries

(AA-size alkaline batteries or NiMH battery pack) from the instrument.

Precautions for Use of the Clamp

CAUTION

• The clamping CT (current transformer) is precision assembled to ensure high performance.

When using the clamp, do not apply any intense mechanical shock, vibration or force to the

clamping CT.

• If dust or any other foreign matter gets in the clamping CT, do not shut the clamping cores

tight. First remove the dust and then make sure the clamping cores on both sides close

smoothly.

3-2

IM CW140-E

Page 25

3.2 Installation Procedure

Install the instrument in a location that satisfies the following conditions.

● Ambient Temperature and Humidity

• Ambient temperature: 5°C to 40°C

• Ambient humidity: 35 to 80% RH (no condensation)

● Operating altitude

2000m max. above sea level

● Level Location

Do not install the instrument in an unstable or inclined location. Otherwise,

this may result in the failure to obtain precision measurements.

● Do not install the instrument in a location that is:

• exposed to direct sunlight or close to a heat source;

• close to such a noise source as high-voltage equipment or a motive power

supply;

• exposed to a relatively large amount of lampblack, steam, dust or

corrosive gas;

• exposed to frequent mechanical vibration;

• close to a source of strong electromagnetic fields; or

• unstable.

3

Precautions for Safe Measurement

IM CW140-E

3-3

Page 26

3.3 Precautions for Wiring the Circuit

under Test

WARNING

• When wiring the instrument or the instrument is turned off, turn off the circuit under test.

It is extremely dangerous to connect or disconnect measuring lead wires without turning off

the circuit under test.

• Be extremely careful not to connect any volta ge-mode circuit to the current input terminals or

any current-mode circuit to the voltage input terminals. Miswiring can result in not only damage to the circuit or equipment under test but also an injury to personnel.

• Do not apply any input level higher than the following to the v olta ge or current input terminals.

• Maximum allowable input (continuous)

Voltage input: 600 Vrms

Current input: 250 Arms Clamp A (96030)

625 Arms Clamp C (96031)

*700 Arms Clamp B (96032)

* Refer to Section 19.2, “Specifications of Current Clamps” for details.

In addition to the maximum allowable input, the rated input levels are specified as shown

below.

Voltage ratings: 150, 300 and 600 V

Current ratings: 20, 50, 100 and 200 A Clamp A (96030)

50, 100, 200 and 500 A Clamp C (96031)

200, 500 and 1000 A Clamp B (96032)

• If using an external VT (voltage transformer) or CT (current transformer), make sure the transformer can adequately withstand the voltage being measured.

• Be careful not to allow the secondary stage of the CT to become open-circuited while the CT is

being electrified. Otherwise, a high-voltage may develop on the secondary stage, causing

extreme danger.

• The maximum allowable input voltage range of the external input terminals (external control

input and event input terminals) is specified as –0.5 to 5.5 V.

Do not apply voltages exceeding this range, otherwise the input circuitry may be damaged.

(When wiring the input terminals, be careful not confuse them with the optional D/A output

terminals.)

• Do not use any probes or clamps other than those voltage input probes or dedicated clamps

supplied together with the CW140.

• Do not use a clamp with any non-insulated conductors.

TIP

After wiring the CW140, it is necessary to perform setting/operation for the wiring method using the

WIRING key.

SEE ALSO

Section 7.1, "Wiring," for details on how to set the wiring method.

3-4

IM CW140-E

Page 27

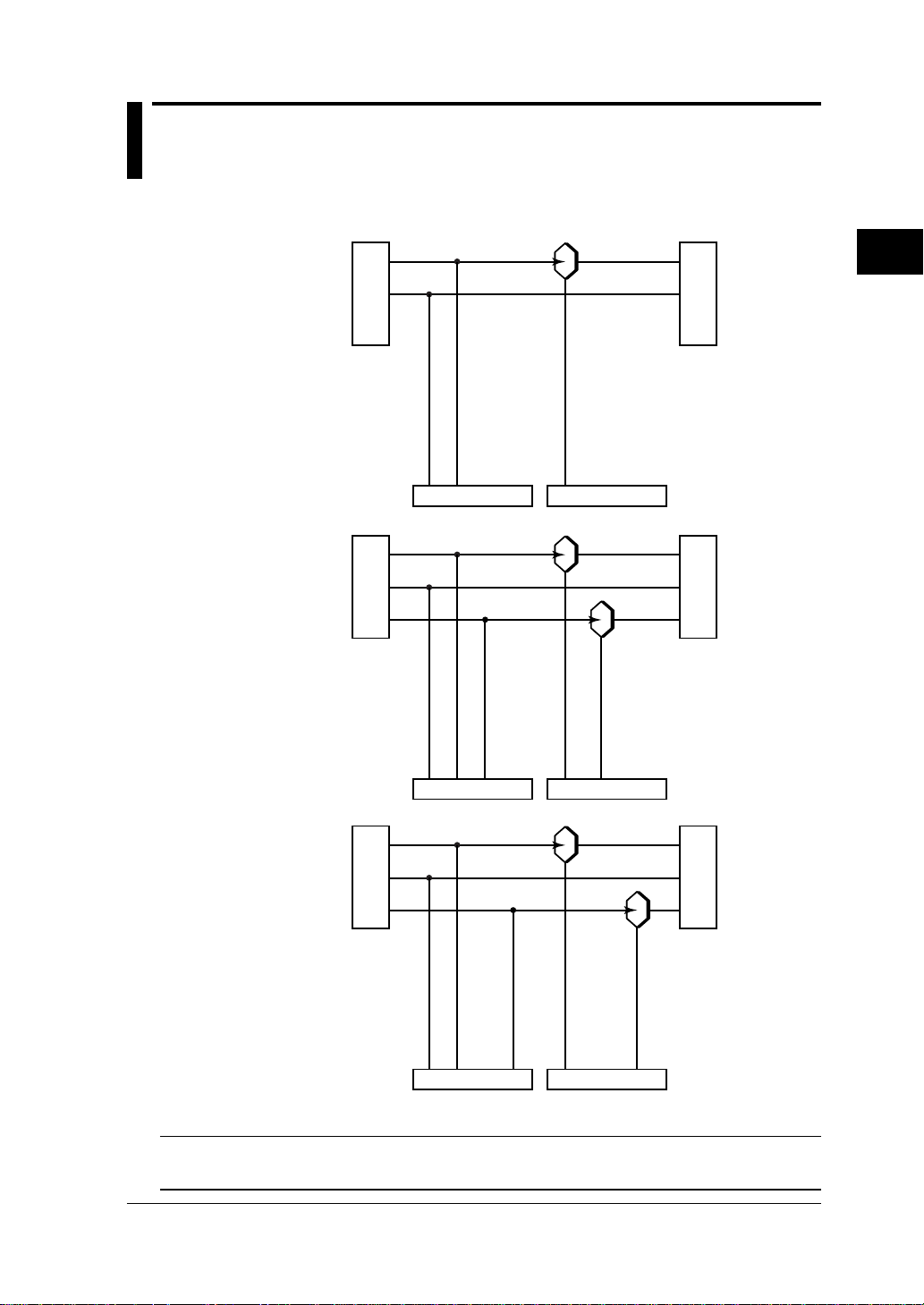

3.4 Diagrams of Basic Wiring

This section explains the methods of basic wiring using illustrations.

Current-sensing clamp

(1) 1

φφ

φ2W

φφ

S

1

O

U

N

R

C

E

L

O

A

D

3

Precautions for Safe Measurement

(2) 1

(3) 3

Voltage input terminals Current input terminals

φφ

φ3W

φφ

Voltage input terminals Current input terminals

φφ

φ3W2i

φφ

S

O

U

R

C

E

S

O

U

R

C

E

NV1 CH1

1

N

2

NV1 CH1

R

1

S

2

T

3

I1

V2 CH2

I2

I1

On-screen symbol

L

O

A

D

On-screen symbol

L

O

A

D

Voltage input terminals Current input terminals

TIP

In the case of a current-sensing clamp, the symbol of a current input terminal shown on the CW140 main

unit differs from that shown on the display, as indicated in the figures above.

IM CW140-E

NV1 CH1

V3 CH3

I1

I3

On-screen symbol

3-5

Page 28

3.4 Diagrams of Basic Wiring

(4) 3

(5) 3

φφ

φ3W3i

φφ

Voltage input terminals Current input terminals

φφ

φ4W

φφ

R

S

1

O

U

S

2

R

C

T

3

E

NV1 CH1

R

S

1

O

S

2

U

R

T

3

C

N

E

N

V3 CH3

CH2

I3

I2

I1

L

O

A

D

On-screen symbol

L

O

A

D

Voltage input terminals Current input terminals

V2 V3 CH3

NV1 CH1

I1 I3

CH2

I2

On-screen symbol

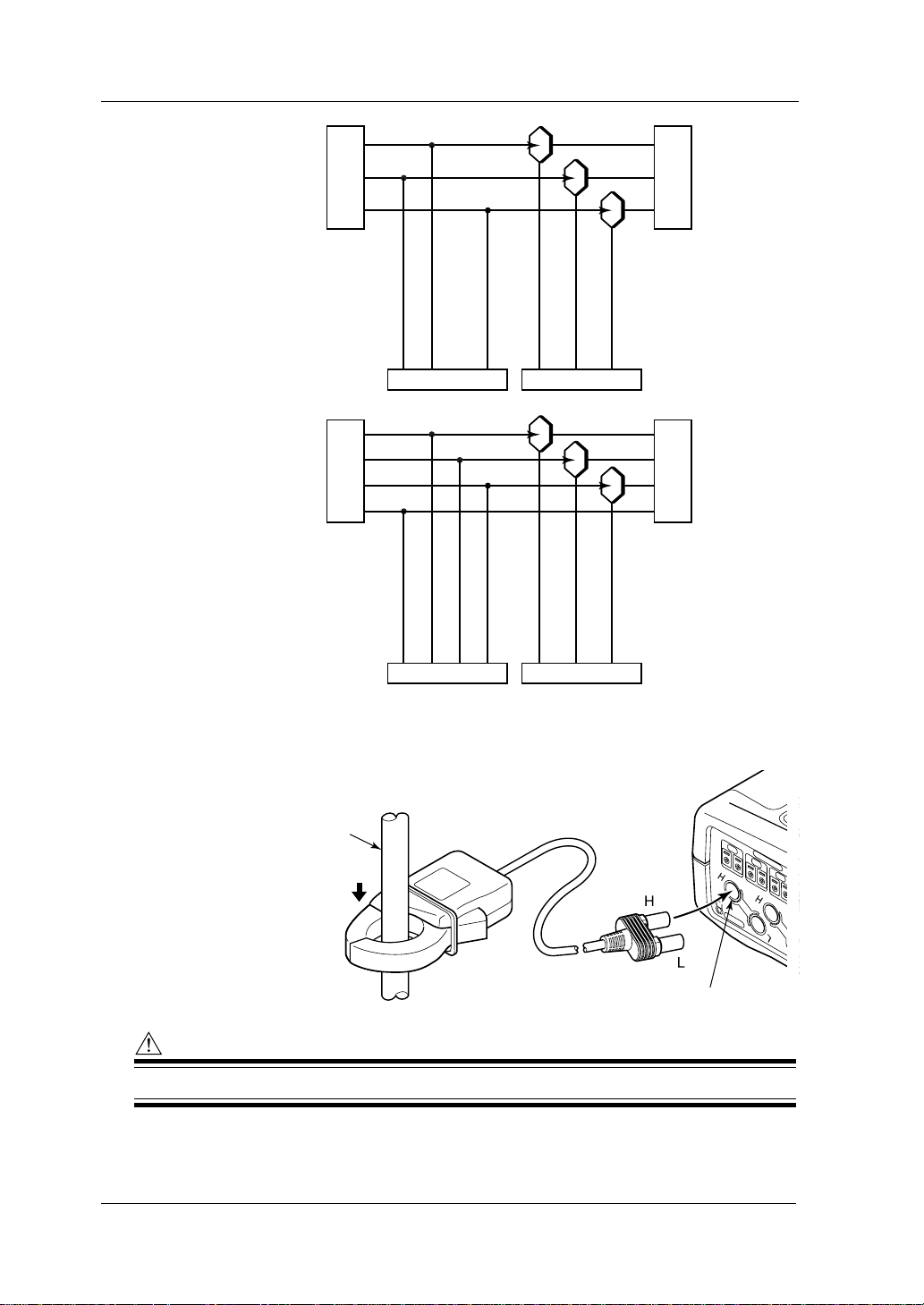

When connecting the current-sensing clamp, make sure the following polarities and clamp

position are correctly identified.

1 When connecting to

the CW140 main unit:

H and L polarities

Conductor

cable

Power supply side

(SOURCE)

2 The clamp should be

positioned in the

direction from the

power source side to

the load side, as

indicated by the

arrow.

Load side

(LOAD)

Connector on the main unit

WARNING

In addition to using the checking wiring function, be sure to verify the actual wiring connections.

3-6

IM CW140-E

Page 29

- 2-system load -

φφ

(6) 1

φ2W

φφ

××

×2

××

3.4 Diagrams of Basic Wiring

S

1

O

U

N

R

C

E

L

O

A

D

2

3

L

O

A

D

1

Precautions for Safe Measurement

(7) 1

(8) 3

Voltage input terminals

φφ

××

φ3W

×2

φφ

××

Voltage input terminals

φφ

××

φ3W

×2

φφ

××

Current input terminals

On-screen symbol

L

O

A

D

2

L

O

A

D

1

Current input terminals

CH4

On-screen symbol

I2-2

L

O

A

D

2

L

O

A

D

1

CH1

I1

CH2

I1-2

I1

CH3

CH2

I1-2

I2-1

NV1 CH1

S

1

O

U

N

R

C

2

E

NV1

V2

R

S

1

O

S

U

2

R

C

T

3

E

IM CW140-E

Voltage input terminals

NV1

V3

CH1

I1

CH2

I3-1

CH3

I1-2

Current input terminals

CH4

On-screen symbol

I3-2

3-7

Page 30

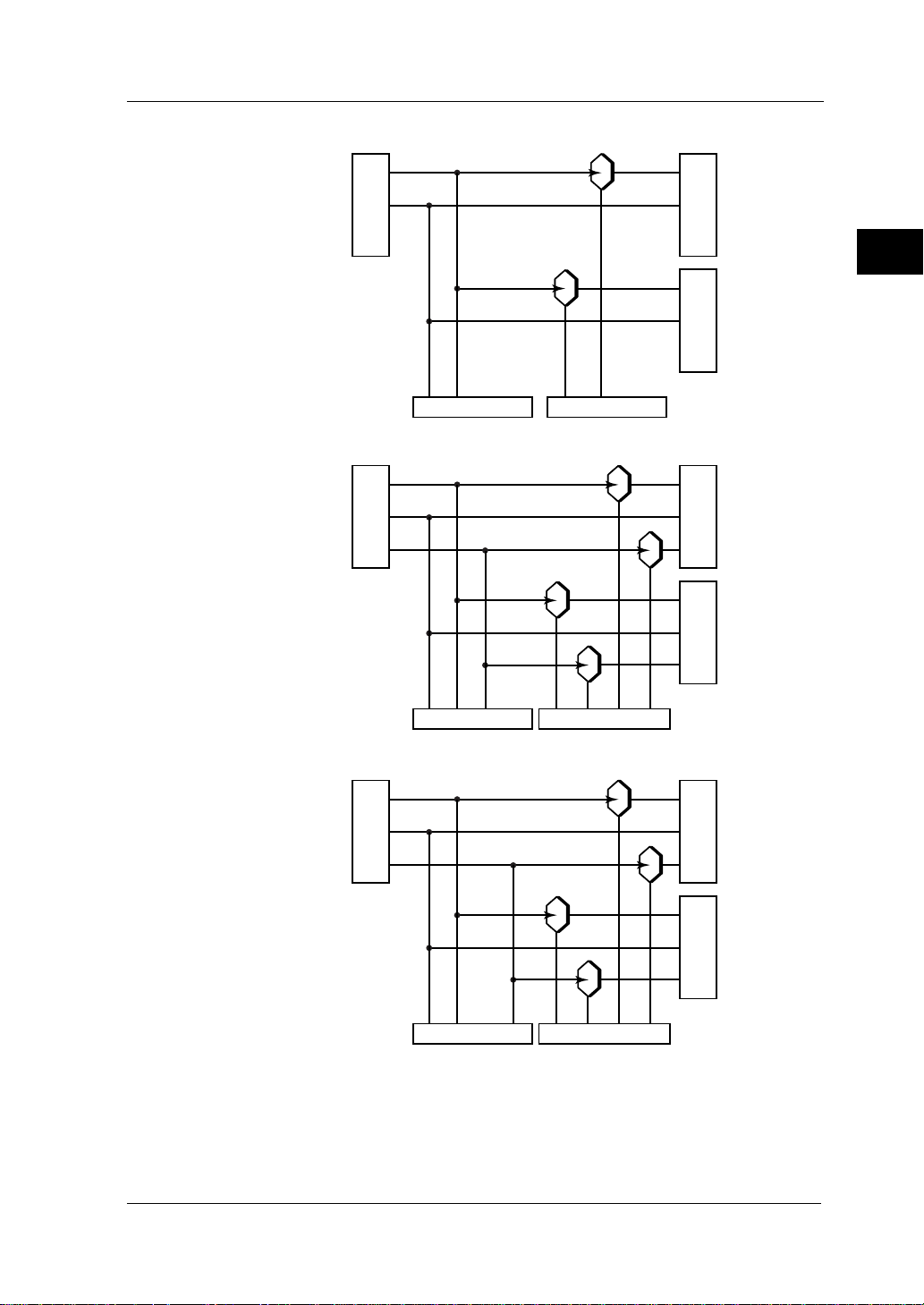

3.5 Wiring the Circuit under Test Using

External VT/CT

WARNING

• When using an external CT, be careful not to allow the secondary stage of the CT to become

open-circuited while the primary stage is being electrified. Otherwise, a high voltage may

develop on the secondary stage, causing extreme danger.

• The current under test flows through the bold lines shown in the figure below . For these lines,

use wire that has an adequate margin of current-carrying capacity.

If the maximum voltage or current level being measured exceeds the

maximum measurement range of the CW140, use an external VT and/or CT.

This strategy enables the measurement of voltage or current levels above the

maximum range.

If the maximum voltage level exceeds 600 V, attach an external VT. Then,

connect the secondary stage of the VT to the voltage input terminals.

If the maximum current level exceeds the following value, attach an

external CT. Then, connect the secondary stage of the CT to the currentsensing clamp.

200 A, when clamp A (20, 50, 100 and 200 A) is used

500 A, when clamp C (50, 100, 200 and 500 A) is used

1000 A, when clamp B (200, 500 and 1000 A) is used

Example of 1φ2W

S

O

1

U

R

N

C

E

Voltage

transfomer

TIP

• The CW140 can show the primarystage value even if the scaling function is applied using VT/CT.

SEE ALSO

Section 7.7, "Scaling Function," for details on how to use VT/CT.

• The lowest current range of the CW140 main unit itself is 20 A on full scale and the accuracy also

depends on this value. Note therefore that if a CT is used and its secondary output is too small when

compared with 20 A, then the error ratio will become higher.

V

VT

v

V1Voltage input terminals Current input terminalsN CH1

L

艎

L

O

A

D

CT

Current

transfomer

3-8

IM CW140-E

Page 31

3.6 Connecting a Power Supply and

Turning It On/Off

The CW140 can be operated with the following three types of power supply.

• Six AA-size alkaline batteries

• AC power supply through an AC adapter (standard accessory)

Part number: 788011 Yokogawa’s AC adapter

• Rechargeable NiMH battery pack (optional accessory)

part number: 94004

Using AA-size Alkaline Batteries

Alkaline Batteries: “AA”-size [LR6], 1.5V

● Handling Precautions

Observe the following cautionary notes when handling alkaline batteries.

WARNING

• Install the alkaline batteries with the positive and negative polarities correctly positioned, otherwise the battery fluid may leak or the batteries may explode.

• Do not disassemble the batteries, heat them, or throw them into a fire.

• Do not short-circuit the batteries.

• Do not attempt to recharge the batteries.

• Do not solder the batteries.

• When replacing the batteries, replace all of the six units at one time with new ones from the

same manufacturer. (Do not use manganese batteries as replacements.)

• If the instrument will not be used for a prolonged period, remove the batteries.

3

Precautions for Safe Measurement

IM CW140-E

● Operating Hours of Alkaline Batteries

The operating hours of an alkaline battery vary depending on its operating

environment and conditions. Refer to the following information.

Operating Hours: Approx. 3 hours

Operating Conditions: The LCD backlight is turned off and no floppy drive is connected.

3-9

Page 32

3.6 Connecting a Power Supply and Turning It On/Off

NOTE

• If the voltage of an alkaline battery falls below a given level, the mark appears in the upperright corner of the display (low-battery state). If you continue to operate the CW140 in this

state, the meter automatically turns off.

• If the low-battery mark appears during measurement, change the power suppl y to an AC sour ce.

Wait until the CW140 finishes or aborts measurement and therefore is ready for shutdown,

before replacing the batteries with new ones.

● Procedure for Replacing Alkaline Batteries

Follow the steps below to replace alkaline batteries.

1. Make sure the power switch on the CW140 is turned off and no AC

adapter is connected.

2. Remove the battery holder on the back of the CW140.

3. Place six new alkaline batteries in the battery holder.

SEE ALSO

The figure given below.

House the batteries with the positive and negative polarities of each battery positioned correctly.

4. Hold the battery holder so that the battery connector on the CW140

correctly mates with the battery holder connector. Then, slide the battery

holder into the slot on the CW140 with the holder's two guides engaged in

the groove of the slot. Finally, make sure both connectors are precisely

mated with each other.

5. Push down the lock switch on one side of the CW140 to fix the battery

holder in place.

(The label changes to "∆FREE".)

3-10

IM CW140-E

Page 33

3.6 Connecting a Power Supply and Turning It On/Off

Using the AC Adapter (Standard Accessory)

● Handling Precautions

There is a danger of electrical shock or damage to the meter. Observe the

following cautionary notes when handling the AC adapter.

WARNING

• Only use the manufacturer-supplied dedicated power cord.

• Before connecting the power cord, make sure the power-source voltage matches the supply

voltage rating of the AC adapter.

• Before connecting the power cord, also make sure the power switch on the CW140 is turned

off.

• If the CW140 is not to be used for a prolonged period, disconnect the power cord from the

outlet.

• Do not use any other AC adapter than the one (part number: 788011) dedicated to the CW140.

• Do not place any load on the power cord or allow the power cord to come into accidental

contact with any heat source.

• Be sure to hold the plug of the power cord, rather than holding and pulling the cord itself, when

disconnecting it from the outlet.

3

Precautions for Safe Measurement

IM CW140-E

3-11

Page 34

3.6 Connecting a Power Supply and Turning It On/Off

● Procedure for Connecting the AC Adapter

Follow the steps below to connect the AC adapter.

1. Make sure the power switch on the CW140 is turned off.

2. Attach the clamp filter supplied together with the AC adapter to the outputside cable of the power cord.

SEE ALSO

The figure given below.

Approx.

10 cm

part number: A1193MN

AC-input side

(for connection to the AC power outlet)

Side for connection

to the CW140

clamp filter

3. Connect the AC adapter plug to the AC adapter jack of the CW140.

4. Connect the plug of the power cord supplied together with the AC adapter

to the power supply connector of the AC adapter.

5. Connect the other end of the power cord to a power outlet that satisfies the

power ratings (requirements) shown below.

Power Ratings of AC Adapter

Supply voltage rating 100 to 240 V AC

Allowable supply voltage range 90 to 264 V AC

Power supply frequency rating 50/60 Hz

Allowable power supply frequency range 48 to 62 Hz

Maximum power consumption 70 to 90 VA

Output voltage rating of AC adapter 12 V DC

Maximum output current rating of AC adapter 2.6 A

3-12

IM CW140-E

Page 35

3.6 Connecting a Power Supply and Turning It On/Off

Using a NiMH (Nickel-Hydrogen) Battery Pack (Optional Accessory)

● Handling Precautions

Observe the following cautionary notes when handling the dedicated NiMH

battery pack.

Specifications

Voltage : 7.2V

Capacity : 2100mAh

Number of times can be changed (life cycle) :

Approx. 300times (varies with the operating environment)

WARNING

• Since the electrolyte solution inside the battery pack is alkaline, it may damage any clothing or

skin it comes into contact with due to a leakage from or rapture in the battery pack. In particular, if the solution enters an eye it may cause loss of eyesight. Therefore in such a case, thoroughly wash the affected eye with clean water immediately. Then, receive treatment from a

doctor right away.

• When replacing the NiMH battery pack, be sure to turn off the power switch of the CW140 meter

and remove the power cord from the outlet to avoid possible danger, such as a short in the

electric circuit or electrical shock.

• Do not use any other battery pack than the manufacturer-supplied NiMH battery pack (part

number: 94004).

• Do not leave the NiMH battery pack in a place that is subject to strong direct sunlight, inside a

vehicle under a blazing sun, or near a fire. Doing so may cause a solution leakage, or deterioration in the performance and/or the service life of the battery pack.

• Do not disassemble or modify the battery pack. Doing so may damage the protective properties of the battery pack and cause it to heat up and rapture.

• Do not short the battery electrodes, as this may cause burns due to the battery pack heating

up.

• Do not place the battery pack into a fire or apply heat to it. Doing so is dangerous, as there is

a risk that it will rupture, scattering electrolyte solution.

• Do not apply excessive shock to the battery pack, for example, by throwing it. Doing so may

cause solution leakage, battery pack heating, or a rapture.

• Refrain from using a defective battery pack, such as one with leaking solution, a deformation,

discoloring or any other abnormality.

• Avoid any metal coming into contact with the battery pack when carrying it, as there is the

danger of a short occurring.

• Do not immerse the battery pack in water or make it wet, as this may cause it to heat up or rust,

as well as lead to a loss of functions.

• If the battery pack is not used for a prolonged period, remove it from the CW140 main unit and

store it in the following environment:

Storage period of 1 year or less: Temperature of –20°C to 35°C

(in a place with low humidity)

Storage period of 3 months or less: Temperature of –20°C to 45°C

(in a place with low humidity)

3

Precautions for Safe Measurement

IM CW140-E

3-13

Page 36

3.6 Connecting a Power Supply and Turning It On/Off

● Procedure for Installing the NiMH Battery Pack

Follow the steps below to install the dedicated NiMH battery pack.

1. Make sure the power switch on the CW140 is turned off.

2. If the AC adapter is in use, disconnect the power cord of the AC adapter

from the outlet.

3. If alkaline batteries are in use, remove them from the battery holder and

install the NiMH battery pack.

4. Hold the battery holder so that the battery connector on the CW140

correctly mates with the battery holder connector. Then, slide the battery

holder into the slot on the CW140 with the holder's two guides engaged in

the groove of the slot. Finally, make sure both connectors are precisely

mated with each other.

5. Push down the lock switch on one side of the CW140 to fix the battery

holder in place.

(The label changes to "∆FREE".)

SEE ALSO

The figure given below.

3-14

IM CW140-E

Page 37

3.6 Connecting a Power Supply and Turning It On/Off

● Recharging the NiMH Battery Pack

The optional dedicated NiMH battery pack is not fully charged when shipped

from the factory. Before use, recharge the battery pack to its full level. When

recharging it, use the AC adapter.

WARNING

• When recharging the NiMH battery pack, be sure to do so through the CW140 main unit.

• When recharging the NiMH battery pack, keep the ambient temperature within the range from

10°C to 35°C. Recharging the battery pack outside this range may result in an insufficient

amount of charge, solution leakage, or battery heating.

● Procedure for Recharging the NiMH Battery Pack

Follow the steps below to recharge the NiMH battery pack.

1. With the battery pack installed as instructed earlier, connect an AC

adapter to the CW140.

2. At this point, keep the power switch on the CW140 turned off. The LED

indicator beside the AC adapter jack comes on, indicating that the battery

pack is being recharged. When recharging is complete, the LED indicator

flashes rapidly.

3

Precautions for Safe Measurement

NOTE

If the power switch on the CW140 is turned on, the NiMH battery pack is not recharged. In that

case, the CW140 is powered from the AC adapter.

IM CW140-E

3-15

Page 38

3.6 Connecting a Power Supply and Turning It On/Off

TIP

• The CW140 is in a wait-for-recharge state when the LED indicator is flashing slowly (lit for approximately one second when on). The meter falls into this state when:

• the ambient temperature is outside the range from 10°C to 35°C;

• the battery performance is remarkably low due to over-discharge or for other reasons; or

• the NiMH battery pack is not installed yet.

• The LED indicator flashes rapidly if:

• the battery temperature rises above 55°C, or

• the ambient temperature changes drastically,

indicating that the battery pack has been recharged to its full level.

However in practice, the battery pack may not have been recharged completely for some reason.

● Indication that Recharge Is Required

NOTE

• If the voltage of the NiMH battery pack falls below a given level, the mark appears in the

upper-right corner of the display (low-battery state). If you continue to operate the CW140 in

this state, the meter automatically turns off.

• If the low-battery mark appears during measurement, change the power suppl y to an AC sour ce.

Wait until the CW140 finishes or aborts measurement and therefore is ready for shutdown,

before replacing the batteries with new ones.

● Operating Hours of NiMH Battery Pack

The operating hours of an NiMH battery pack vary depending on its operating

environment and conditions. Refer to the following table.

Operating Hours: Approx. 7 hours

Operating Conditions: The LCD backlight is turned off and no floppy drive is connected.

● Service Life of NiMH Battery Pack

The NiMH battery pack can be recharged approximately 300 times, though

the frequency depends on its operating environment. The life of the battery

pack is over if the low-battery mark appears soon after the battery pack has

been fully recharged. Replace the battery pack with a new one.

3-16

IM CW140-E

Page 39

3.6 Connecting a Power Supply and Turning It On/Off

Startup Screen

When you turn on the power switch on the CW140 main unit, the display successively presents

the screens described in paragraphs (1) and (2) below.

(1) Model Name Screen

The CW140 first shows such a

screen as illustrated on the right,

then performs a self-test.

(2) Message Screen

1Indication of the model name

and version

2 Result of SRAM test

3 Result of backup SRAM test

4 Result of EEPROM

5Indication of function code

6 Result of RTC (real-time clock)

test

7 Result of floppy disk controller

test

8 Result of checking setup data

9 Result of internal flash memory

disk test

CW140 Ver.0.00

SRAM Check Ok

Battery Backup SRAM Check Ok

EEPROM OK

Function Code ...00000000

RTC Check Ok

FDC Check Ok

Setting Ok

Flash Disk Ok

3

Precautions for Safe Measurement

1

2

3

4

5

6

7

8

9

NOTE

If an error is found with any of the tests shown on the Message screen discussed in paragraph 2

above, the CW140 shows information about that error.

See Section 18.1, "Corrective Actions in Case of Failure," for more information.

IM CW140-E

3-17

Page 40

3.7 Performing Measurements with Higher

Precision

To perform measurements with higher precision, use the CW140 under the

following environmental conditions.

Ambient temperature: 23 ±5°C

Ambient humidity: 35 to 75% RH (no condensation)

If installing the CW140 in a location where the ambient humidity is 30% or

less, use such equipment as an anti-static mat to prevent electrostatic

discharge.

If you move the CW140 from an area of low temperature and humidity to an

area of high humidity and temperature or if there is a sudden change in the

ambient temperature, condensation may occur in the meter. If this happens,

let the meter stand still for at least one hour to allow it to adapt to the new

ambient temperature and for condensation to dissolve. Then, begin operating

the meter.

● Relationship between Clamp and Conductor

1 When performing a

measurement, hold the

clamp-on probe so that the

conductor cable runs

through the center of the

clamping CT.

2 Ensure that the orientation

of the clamp to the

direction of the conductor

cable (from the power

supply to the load) is

correct, as shown on the

right.

3 Ensure that the clamping

CT is properly closed.

Conductor

cable

Joint section

Clamping CT

Power supply side

(SOURCE)

Load side

(LOAD)

3-18

IM CW140-E

Page 41

Chapter 4. Basic Operation Flow and Top Menu Screen

4.1 Basic Operation Flow

AC adapter

Supply power to CW140

AA alkaline batteries

NiMH battely pack

Turn on power of CW140

Opening message

When you use the CW140 with

the most recently used settings.

Same status as last time

power was turned off

Press the TOP MENU key to

rertrieve the Top Menu.

Selection of mode

Measurement Mode

Instantaneous value measurement

Electric energy measurement

Demand measurement

Harmonics measurement

Press key (SETUP) to make

and modify settings each mode.

<Chapter 11>

TOP MENU

TOP MENU

<Chapter 8>

<Chapter 9>

<Chapter 12>

<Section 3.6>

<Section 4.2>

When you want to

modify settings

Setting Mode

System settings <Chapter 5>

File handling <Chapter 6>

Go to the Top Menu for first-time

use after delivery.

Handy for electric

energy measurement

Settings at end of last measurement

Setting condition 1

Setting condition 2

Setting condition 3

Setting condition 4

<Chapter 10>

4

Basic Operation Flow and Top Menu Screen

IM CW140-E

Calls up wiring settings <Section 7.1>

Calls up voltage range settings <Section 7.3>

Calls up current (ampere) range settings <Section 7.3>

Perform wiring

When you do not want

to check the wiring.

Press to check the wiring. <Section 7.2>

Perfoem measurement

Press key when you want to

perform measurement

continuously

4-1

Page 42

4.2 Top Menu Screen

The Top Menu is used to select measurement and setting modes. Press the

key to retrieve the Top Menu.

● Modes Displayed on Top Menu

Key operation

Measurement Mode See

Instantaneous value measurement Chapter 8

Electric energy measurement Chapter 9

Demand measurement Chapter 11

Harmonics measurement Chapter 12

● Top Menu Display and Selecting Modes

Retrieves the Top Menu.

Using the Cursor key,

select the desired mode.

(It becomes highlighted.)

Setting Mode See

System settings Chapter 5

File handling Chapter 6

TOP MENU

The selected mode screen appears.

TIP

You can also use the key to select the electric energy mode.

4-2

IM CW140-E

Page 43

Chapter 5. System Settings

5.1 System Settings

This section describes system settings, including calculation selection,

auxiliary function settings, and RS-232-C settings. Each setting has been set

to the default value before shipment and should be changed as required.

● Screen Configuration

The System Setting screen consists of 2 pages, pages 1/2 and 2/2.

SEE ALSO

For the contents of each screen and setting details, see Table "System Settings" on pages 5-2 and 5-3.

● Basic Operation for Setting/Modification

Key operation

Retrieves the Top Menu.

Using the Cursor key,

select the system setting.

(It becomes highlighted.)

SYSTEM SET

SYSTEM RESET

Select system setting.

(It becomes highlighted.)

System setting screen

appears.

Using the Cursor key,

select an item to set.

TOP MENU

5

System Setting

ESC

IM CW140-E

Using the function keys,

change the settings on

screen 1/2.

Press the F5 key, to

change the next screen.

Using the function keys,

change the settings on

screen 2/2.

Applies the changes you

made to the settings.

Press the escape key to cancel all

the changes you made.

5-1

Page 44

5.1 System Settings

System Settings 1/2

Screen

Reactive power

method

Frequency

source

Low-pass filter

(Frequency

measurement)

VT ratio

(Ratio of voltage

transformation)

CT ratio

(Ratio of current

transformation)

1/2

Item Items to be selected See also Default

ON (The method is used)

OFF (The method is not used)

To be changed →

Displays the selectable items in

the center of the screen.

ON (Selected)

OFF (Not selected)

Set to a value within 1 to 10,000.

Select the

desired setting.

Section 8.6,

"Computational

Expressions"

Section 7.5,

"Frequency

Measurement

and Low-pass

Filters"

Section 7.5, "Frequency

Measurement and Lowpass Filters"

Section 7.7,

"Scaling Function"

OFF:

The method is

not used

V1

OFF

1

Move to the digit to be changed.

+

Input values.

–

Set to a value within 0.01 to 10,000.

Section 7.7,

"Scaling Function"

1

Move to the digit to be changed.

+

Input values.

–

Clamp selection 20–200 A

Clamp A (20–200 A)

Clamp B (200–1000 A)

Clamp C (50–500 A)

Number of

averaging

cycles

Backlight (LCD)

auto-off when

LIGHT

key is ON

Contrast (LCD) Section 17.1,

Beep Section 17.1,

+ OFF

→

2 → 3 → ... 10 → OFF

→

– OFF

10 → 9 → ... 2 → OFF

ON (Auto-off when no key action is

performed for 10 minutes)

OFF (Not used)

Adjusts LCD's contrast (1 to 8).

+

Input values.

–

ON (Beeps for every key action)

OFF (Not used)

Power-saving

mode (LCD)

ON (Used)

OFF (Not used)

Section 7.6,

"Averaging

Function"

Section 17.1,

"Auxiliary

Functions"

"Auxiliary

Functions"

"Auxiliary

Functions"

Section 17.1,

"Auxiliary

Functions"

5-2

Clamp A

OFF

(Not used)

ON

4

ON

OFF

IM CW140-E

Page 45

System Settings 2/2

5.1 System Settings

Screen

RS-232C settings

2/2

Item Items to be selected See also Default

Connected

instrument

Baud rate

Data length

Parity Section 15.1,

Stop bit

Busy control OFF/OFF

Printer

PC

To be changed →

1200/2400/4800/9600/19200 bps

7

8

None

Odd

Even

1 bit

2 bit

For printer

OFF/OFF

XON/XOFF

CS/RS

Displays the selectable items

in the center of the screen.

For PC

Select to highlight

the desired setting.

OFF/OFF

XON/XOFF

XON/RS

CS/RS

Section 17.3,

"Optional Printer"

Section 15.1,

"RS-232C

Interface

Specifications"

Section 15.1,

"RS-232C Interface

Specifications"

"RS-232C

Interface

Specifications"

Section 15.1,

"RS-232C Interface

Specifications"

Section 15.3,

"Handshaking

Methods"

PC

9600 bps

8

None

1 bit

(No handshaking)

5

System Setting

Date/Time Section 17.1,

Language

IM CW140-E

+

Input values.

–

Applies the changes

Selects the item to be changed.

Year ↔ Month ↔ Day ↔ Time

(CHANGE) Press this key.

English Francais

Deutsch Italiano Español

Use the cursor key to select the language.

Press this key to confirm the selection.

"Auxiliary

Functions"

Section 17.1,

"Auxiliary

Functions"

JST

Japan Standard

Time

English

5-3

Page 46

5.2 System Reset

This section describes how to restore the default settings for all of the system settings (except for

date, time and language).

The language set before the reset can not be changed even if the system reset is executed. (Refer