Page 1

Models CW120,CW121 Model CW240 AP240E Data Analysis Program

AP240E Data Analysis Program

1

Bulletin CW-E

Page 2

Realization of Power & Power Quality

Realization of Power & Power Quality

Management using a CW240

Management using a CW240

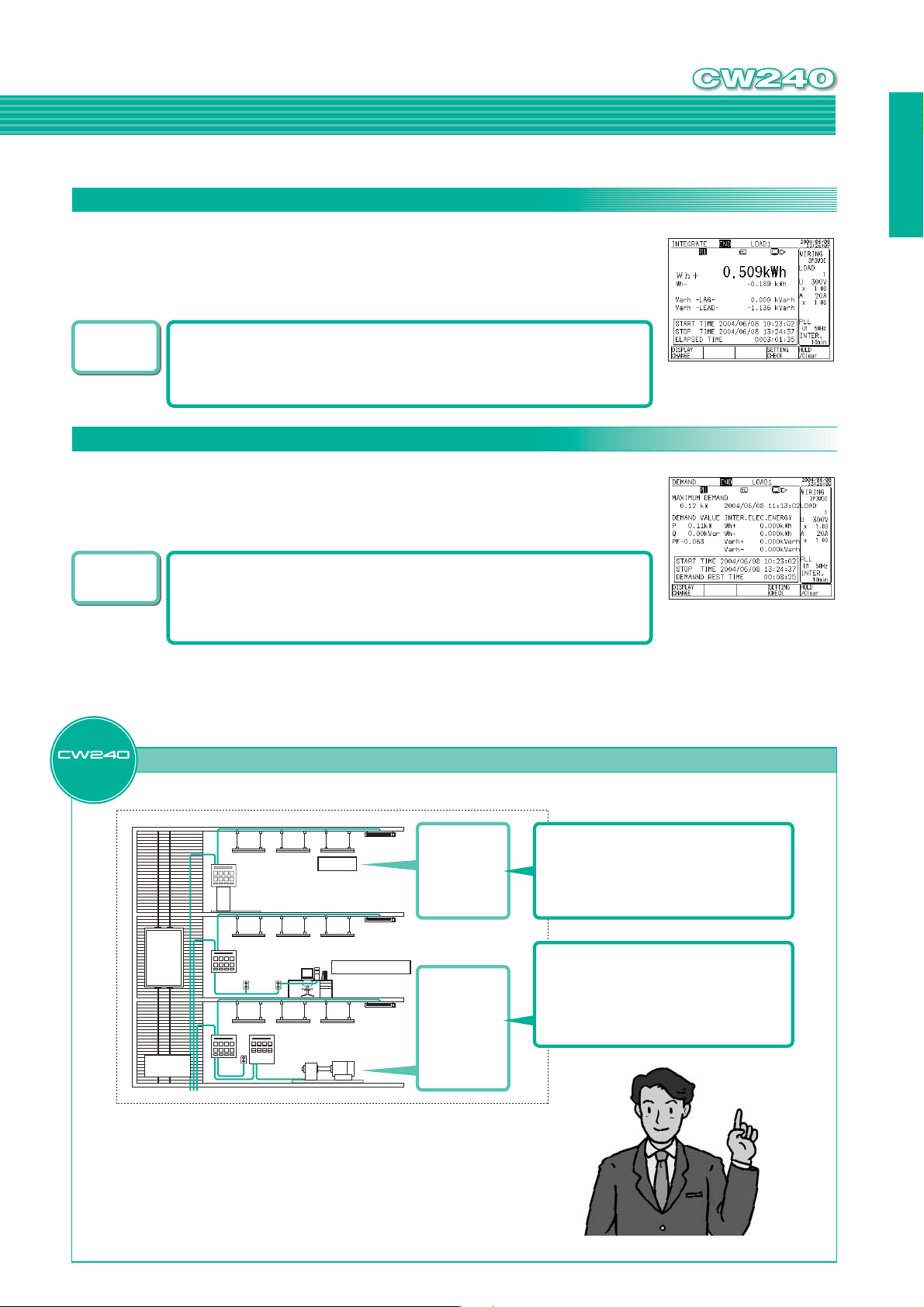

CASE 1

CASE 2

CASE 3

2

2

Get a view of energy consumption!

It is essential to measure energy and manage consumption of each sector such as

facility and production line for your energy saving activities and to minimize loss.

Contribute for improving productivity!

Constantly analyze productivity by managing unit consumption. Managing

voltage, current, electric power and power factor makes for good maintenance of

production facility.

Moreover, you can check operation management loss and enhance productivity.

Discover of electric power waste!

Measure and collect data of electric power consumption by short period.

The CW240 can figure out load of production process, and has the ability to check

wasteful time and current flow of standby load current.

CASE 4

Detect voltage fluctuation!

When trouble occurs on supply side of electric power, instantaneous voltage drop

can affect quality of produced goods at the factory. The CW240 is useful for

collecting data such as voltage fluctuation to prevent such problems.

Characteristics of CW240

Simultaneous measurement of instantaneous value, electric energy, demand, harmonics

and voltage fluctuation.

Simultaneous measurement of loads in 4 systems of up to 1P2W

Simultaneous measurement of loads in 2 systems of up to 1P/3P3W

Data saving interval can be set from 1 waveform (for instantaneous measurement) to 1

hour.

Measure up to 50th order harmonics

4ch leakage current measurement using newly released clamp probe 96036

Long time data logging by using compact flash memory.

Multi language for the display (English, German, French, Italian, Spanish, Korean and

Chinese)

2ch analog input (Optional)

Equipped with 4ch analog output (recorder output)

AC adaptor for power supply. NiMH rechargeable battery and alkaline battery for

backup

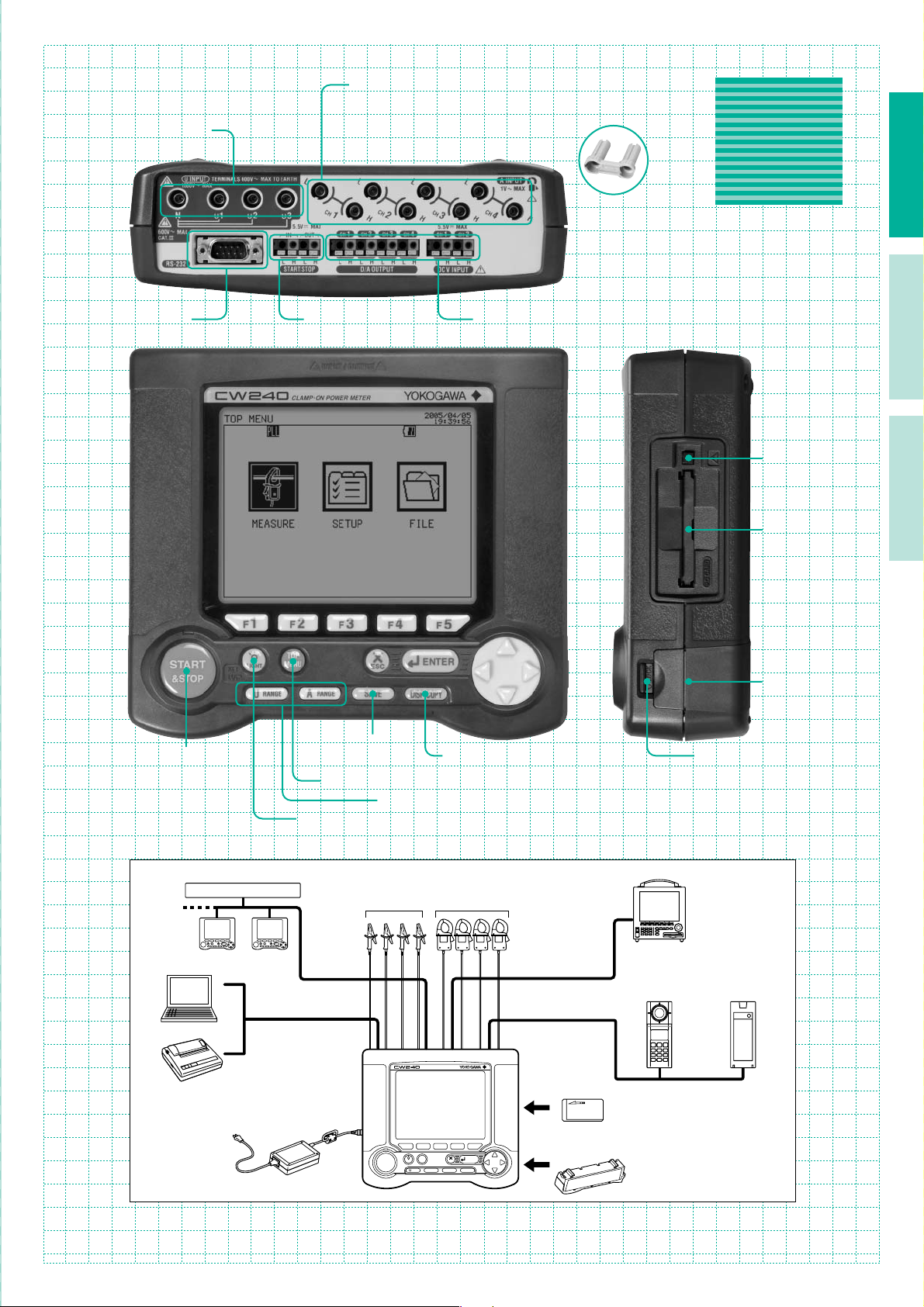

Page 3

Voltage input terminals

RS-232C connector

Current input terminals

●With protection against H/L reverse connection of current clamp-on probes

●With protection against connection of voltage cables

External control I/O

terminals

Analog I/O terminals

(Optional)

CW240

CW240

Protective cover

CW120 AP240E

Card ejection button

PC card slot

Starts/stops integration measurement.

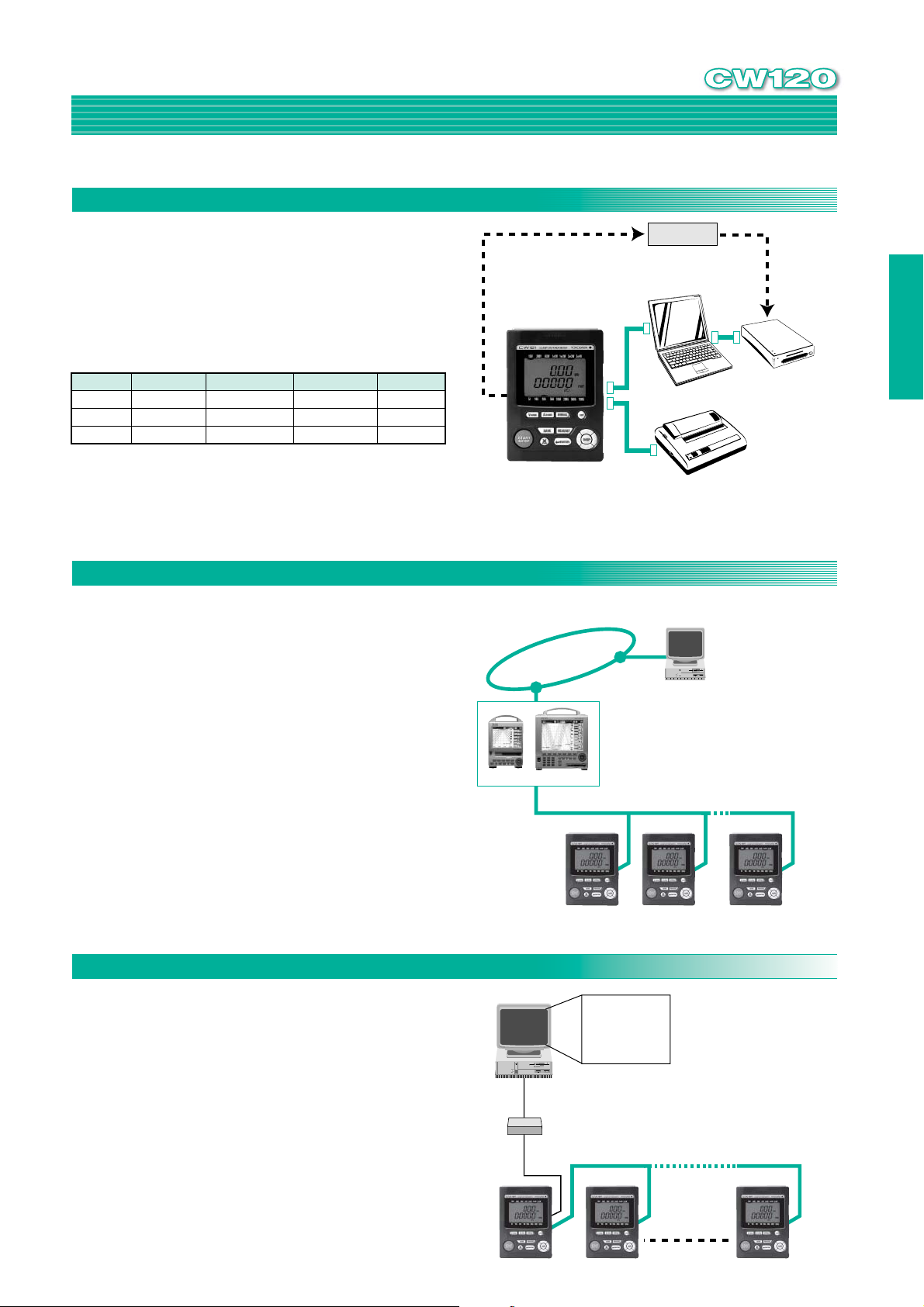

System Configuration Block Diagram

CW240: Simultaneous measurement using two or more CW240 units

External contact signal

ENTER

START

&STOP

PC

Printer

START

&STOP

RS-232

Saves or prints the

measured data.

Makes a screen hard copy.

Returns to the TOP MENU.

Switches the voltage/current range to another.

Turns ON/OFF the backlight (locked when held down for a while).

Current input

(clamp)

CLAMP-ON POWER METER

DA output

(4 channels)

Analog input

(2 channels)

PC card

ENTER

External

control I/O

terminals

Voltage input

Battery holder lock switch

MV series: Recorder

510 series

Illuminance

meter

Battery holder

JUXTA

Temperature

converter

3

AC adaptor

LIGHT

START

&STOP

510 series Illuminance meter

Product of Yokogawa Meters & Instruments Corporation

MV series: Recorder and JUXTA

Product of Yokogawa Electric Corporation

Alkaline battery

TOP

ENTER

MENU

ESC

RANGE

RANGE

A

SAVE

DISP COPY

NiMH battery pack

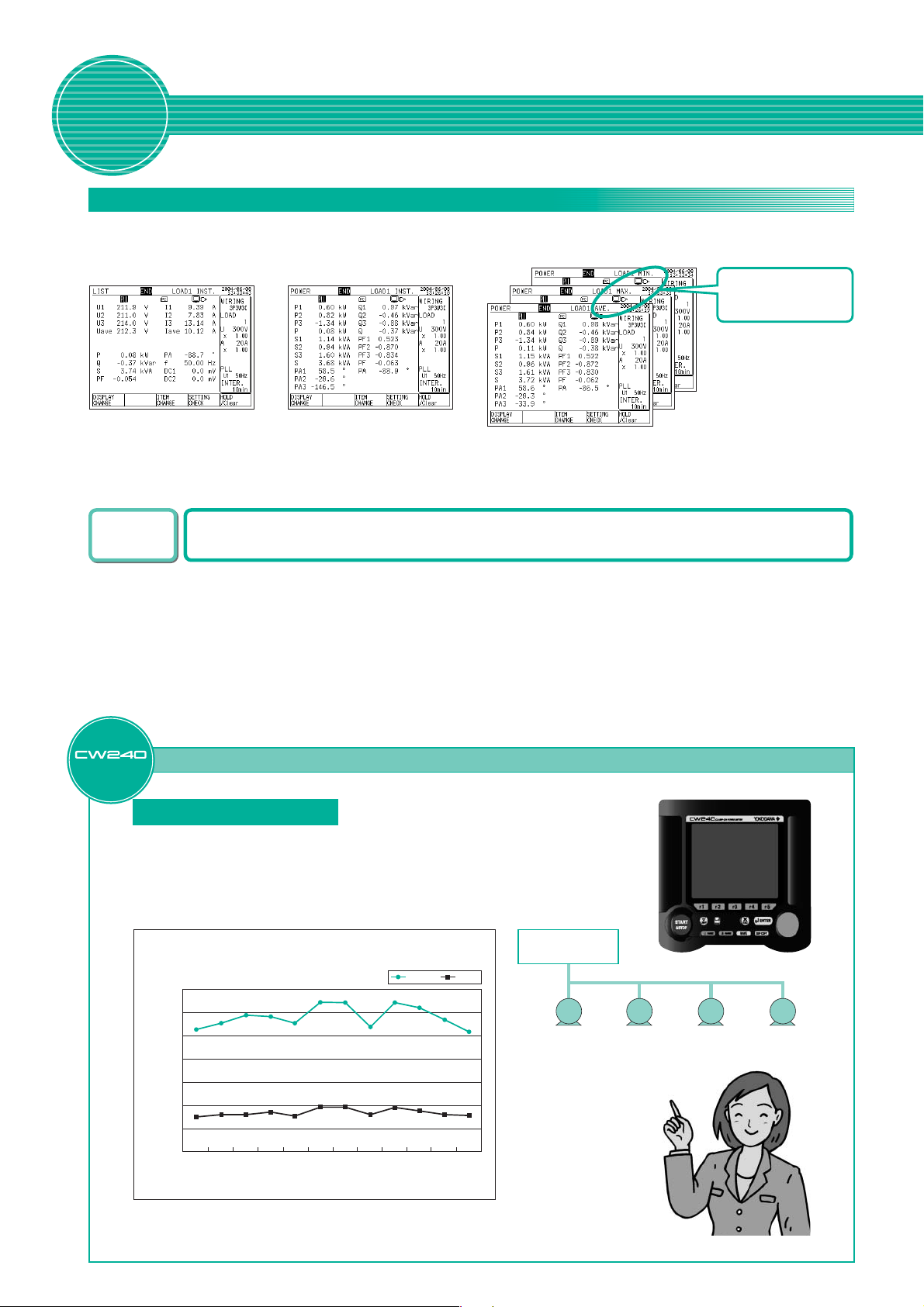

Page 4

Measurement of Instantaneous

Power

Investigation

Power Investigation Improves power Efficiency Through Detailed Data Coll

Measurement of Instantaneous

Value: For investigation of power consumption, maximum load factor and peak currentMeasurement of Instantaneous Value: For investigation of power consumption, maximum load factor and peak current

The CW240 can be used to carry out investigation regarding renewal of electric equipment such as transformers in

building, check load factors and demand factors, and to check current/voltage fluctuation at motor start-up.

(Example of screen display)

● Measurement elements : Voltage/current/electric power (active, reactive, apparent)/power factor/phase angle of each phase,

● Data collection time : 1/2/5/10/15/30 seconds, 1/2/5/10/15/30/60 minutes

Convenient

functions

average/minimum/maximum values of each measurement element.

One cycle (waveform), 100/200/500 ms (short time interval)

Use of the 3-wattmeter method enables display of instantaneous value of each

measurement element.

Allows switching data

from one to another

and saving data.

4

Solution

Food processing plant

Purpose : To review the current power equipment, and replace it

if necessary but with low investment cost

Solution 1 : Calculation of the amount of used water based on power

Solution 2 : Introduction of invert pump control

Power comparison before and after

implementation of the solution

14

12

10

8

6

Powe r (kw)

4

2

0

0:00

2:00

Investigation into Energy Saving at Factories and Buildings

Facility investigated: Pumps

consumption since flow meters are expensive

Power

measurement

before after

Water supply

pump

Water supply

pump

AP240 Suitable for

Data Analysis!

4:00

6:00

8:00

10:00

12:00

Time

14:00

16:00

18:00

20:00

22:00

CW240

Clamp-on power meter

Water supply

pump

Water supply

pump

Energy saving & Reduce electricity bill

Page 5

Demand Measurement:

wer Quantity Measurement:

ection.

CW240

Power Quantity Measurement:

For Power-Saving Diagnosis and Data Collection for ISO14001Power Quantity Measurement: For Power-Saving Diagnosis and Data Collection for ISO14001

The CW240 can measure and display the power quantity consumed up to the specified

time (from the start of integration until the end).

● Measurement elements : Active power quantity, regenerative power quantity, reactive power

quantity (leading/lagging)

● Data collection time : 1/2/5/10/15/30 seconds, 1/2/5/10/15/30/60 minutes

Convenient

functions

The number of display digits and display units can be selected.

●Standard (Voltage/current range is selected according to the phase)

●Arbitrary (Decimal point position and display unit can be specified)

●Auto (Decimal point position and display unit are selected automatically according to

the integration result)

Demand Measurement:

For Review and Investigation on Contract DemandDemand Measurement: For Review and Investigation on Contract Demand

● Measurement elements : Maximum power demand required since the start of logging measurement

and the time it occurs

Active power, reactive power (lag), power factor

Active power quantity (consumption, regeneration), reactive power

quantity (lagging/leading)

Convenient

functions

Normally, the demand time limit is set to 30 minutes in the

contract with a power company.

However, the CW240 allows you to set the desired demand

time limit in units of seconds/minutes.

Demand time limit setting : 1/2/5/10/15/30 seconds, 1/2/5/10/15/30/60 minutes

(Example of screen display)

CW120 AP240E

(Example of screen display)

● Demand

Demand time limit : Length of time set to obtain the average power (normally 30 minutes)

Demand power : Average power during the demand time limit

Solution

Energy Saving and Maintenance for Electric Equipment at Factories and Buildings

Investigation at

offices

●Air conditioning

●Lighting

●Office automation

equipment

●Elevator

Investigation at

production

departments

●Power quantity

●Investigation of

electric power

consumption rate

●Production

quantity

●Power factor

Elevator

Distribution

board

Cellulametal floor duct

Distribution board

Distribution

board

Personal computer

Control

panel

Lighting

Personal computer

CW240 solution (building)

1. For energy investigation/control for each application

and floor

2. For simple investigation for each shop and tenant

3. Diagnosis of operational status of equipment such as

elevator and air conditioner

4. Diagnosis regarding renewal of electric equipment

CW240 solution (factory)

1. Diagnosis of operational status of equipment such as

production equipment and air conditioner

2. For investigation of electric power consumption rate for

each production line

3. For energy investigation/control for privately-owned

electrical power facilities

4. For control of monthly target energy consumption

5

Page 6

Power Supply

● Harmonics for analysis : 1st to 50th

● Display data : List, bar graph (linear/log), vector (inflow/outflow judgment)

● Measurement elements : Level, content, phase angle (voltage/current/electric power of each harmonic), aggregate value (voltage,

current, electric power, power factor), aggregate harmonic distortion factors (THD-F or THD-R) of

voltage/current

● THD-F : Distortion factor for the fundamental wave, THD-R: Distortion factor for all rms values voltage/current

● Data collection time : 1/2/5/10/15/30/60 minutes

Quality Control

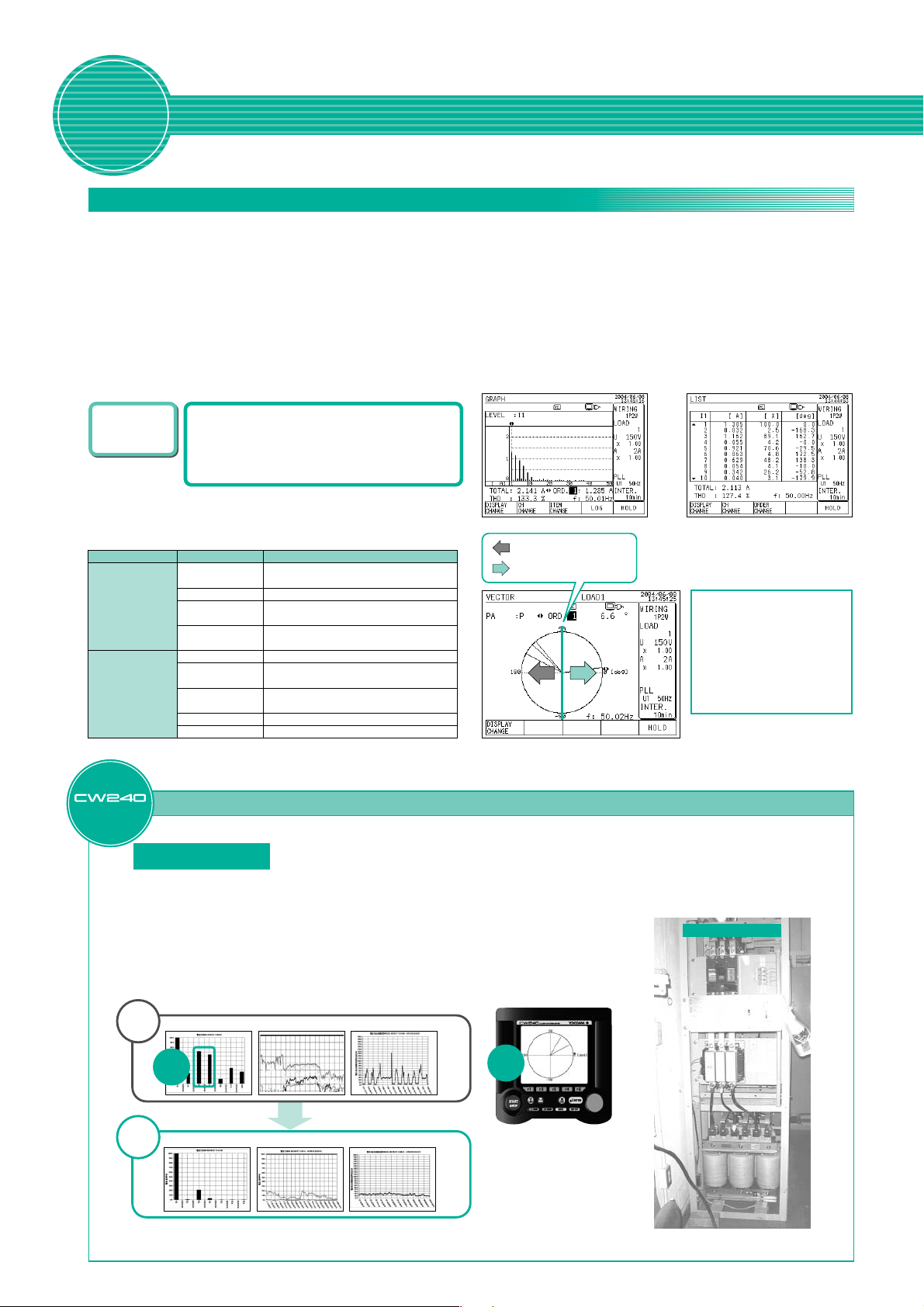

Harmonic Measurement

In many cases, inverter power supplies are used to drive air-conditioners and compressors. These power supplies

cause distortions in voltages and currents, leading to malfunctions and power loss. Therefore, investigation and

control of influences on the main power supplies by harmonics is necessary.

Discovers Failures in Power Supply Lines.

(Example of graph display) (Example of list display)

Convenient

functions

The harmonic whose data is

required to be saved can be selected.

Inflow/outflow of harmonics can be

checked.

●THD-F

Distortion factor for the fundamental wave, THD-R: Distortion

factor for all rms values

(Influences by harmonics)

Category Device Influence type

Power devices

6

Electronic/electrical

household

appliances

Solution

Capacitor, reactor

Transformer

Fuse, breaker

Induction motor

Protective relay

Electrical household

appliances

Fluorescent lamp,

mercury-arc lamp

Computer

Electronics device

Overheat, burn, vibration, noise due to

excessive current

Overheat, noise, increase in core/copper loss

Blow-out, malfunction due to excessive

current

Periodic fluctuation of revolution speed,

overheat, increase in loss

Malfunction

Flickering, noise, malfunction, breakdown

Burn of stabilizer/capacitor, flickering

Malfunction, out of control, breakdown

Malfunction of automatic control part

Improvement of Harmonic Measurement and Diagnosis

: Inflow of harmonic

: Outflow of harmonic

Explanation of vector diagram

● Vector length indicates the apparent

power of each harmonic in

proportion to that of the fundamental

harmonic.

● The horizontal axis shows active

power and the vertical axis indicates

reactive power. They are shown in a

logarithm.

● Frequencies shown are those of the

measurement element actually

measured.

Printing plant

Purpose: To investigate the cause for periodic breakdown of printing machine

Measurement: Advantages obtained by using the CW240

Result: Occurrence of harmonics in 5th and 7th was discovered!

Before

solution

Countermeasure: Installation of transformer filter for 5th and 7th harmonics

After

solution

It may be caused by harmonics generated in the power lines.

●

Compact and easy to carry ● Measurement of up to the 50th harmonic

●

Long-term data collection ● Vector diagram display

In addition, it became clear that harmonics are generated due to loads inside the factory.

In perticular, the 5th harmonic causes adverse effects such as burn-out of the serial reactor in the

capacitor used to improve the power factor.

Time series for

each harmonic for current 1

Discovery

of

the cause

Time series for

each harmonic for current 1

Content for

each harmonic for current 1

Content for

each harmonic for current 1

Total harmonics distortion for

current 1

Total harmonics distortion for

current 1

Confirmation

of

inflow

500kV transformer

Effects of countermeasures: The contents of 5th and subsequent harmonics decreased drastically

and the distortion ratio also dropped below 30%, resulting in elimination of breakdowns.

Page 7

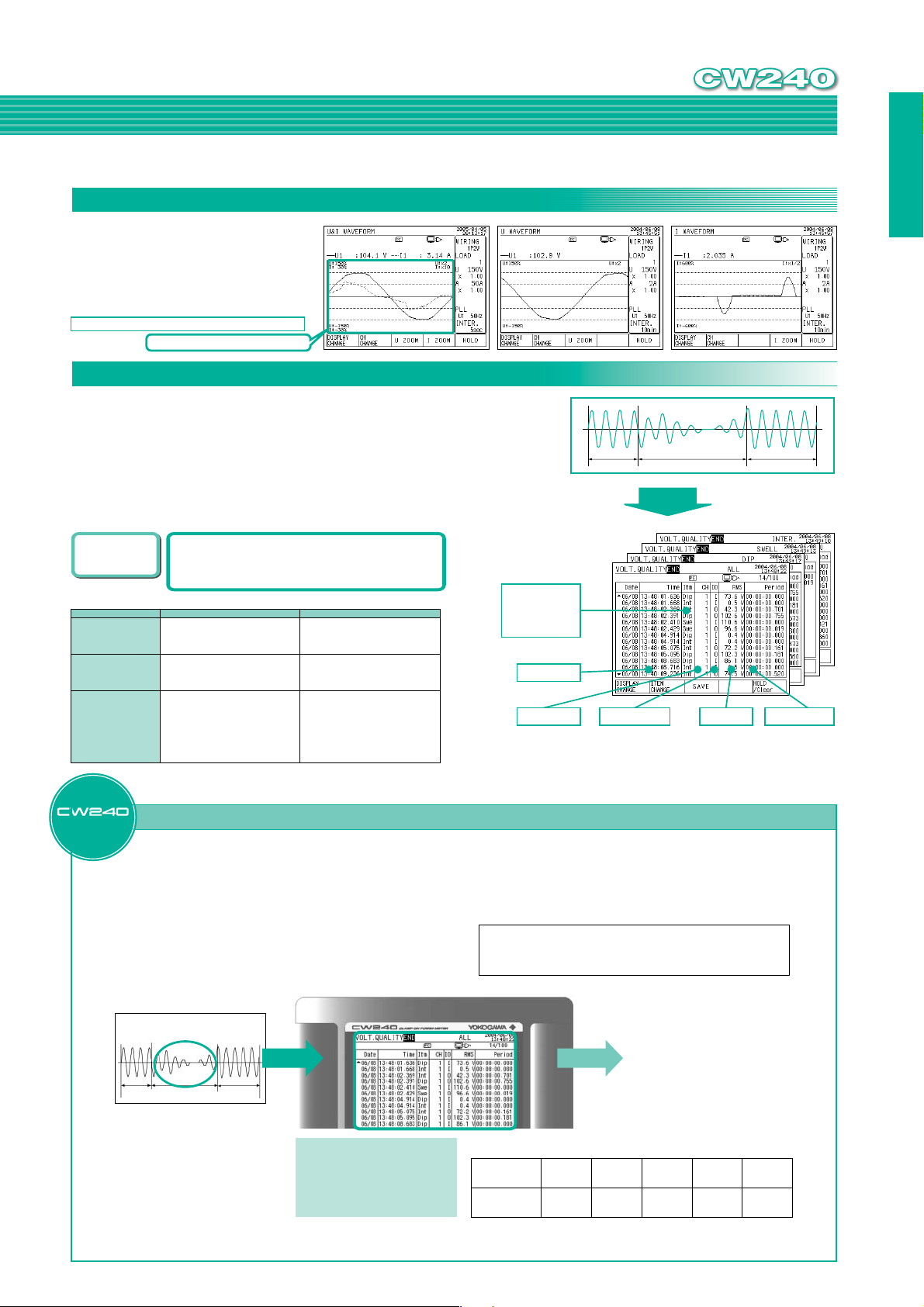

Waveform Measurement

Measurement results

● Measurement elements :

Voltage of each phase, current of each phase

Voltage and current of each phase

● Data saving format :

Binary (can be converted to CSV format

using a standard application program)

The scale of the vertical axis can be changed from x1/3 to x20.

Easy to understand waveform distortion.

Voltage Fluctuation Measurement

The CW240 detects dates/times of when fluctuations occur, fluctuation type,

channels where they occur, rms values, and periods between start and end. The

voltage threshold is set, and fluctuations exceeding the threshold are detected.

● Measurement element : Voltage dip (voltage drop), voltage swell (voltage rise),

instantaneous power failure

lData saving : Detected based on the voltage rms value of one waveform.

Up to 100 data sets can be saved.

CW240

CW120 AP240E

Normal period Fluctuation period Normal period

Measurement results

Convenient

functions

It is possible to provide a voltage

difference between start and end

by setting a hysteresis.

Failures in power supply lines

Item Phenomenon Problem

Voltage dip

(Sag, voltage drop)

Voltage swell

(Voltage rise)

Instantaneous

power failure

(Instantaneous stop

of power supply)

A voltage drop occurs for a short

time due to the occurrence of a large

inrush current, for example, when a

motor is started.

Voltage increases instantaneously,

for example, when lightning occurs

or when a power line with a heavy

load is turned ON/OFF.

Power supply is stopped

instantaneously or for a short/long

time, for example, when a problem

occurs in the power supply

(suspension of power supply due to

lightning, etc.) or due to the trip of a

breaker caused by short circuits in

the power supply, etc.

Solution

Quality check for power supplies used in

semiconductor manufacturing equipment in

accordance with the SEMI guidelines

Measure stability of the voltage of supplied power according to

SEMI S2-0302 (Environmental, Health, and Safety Guideline for

Semiconductor Manufacturing Equipment). If a sag (default:

within 2%) occurs, the wafer is removed from the line for

inspection so daily quality check for power supplies is necessary.

Item

Swe: Swell

Dip: Dip

Decrease of power supply voltage

may cause devices to stop or reset

operations.

Increase of power supply voltage

may cause devices to stop or reset

operations.

Instantaneous power failure may

cause devices to stop or reset

operations. Recently, various

preventive measures have been

taken for computers, thanks to

widespread use of UPS

(uninterruptible power source).

Int: Instantaneous

power failure

Occurrence date

Channel

I: Start 0: End

Power Supply Quality Check at Various Places

SEMI: Semiconductor Equipment and Materials International

SEMI guidelines are used at the time the contract is made, to

evaluate the safety of semiconductor manufacturing equipment

when exporting it from Japan to the USA.

rms value

7

Detection period

Voltage fluctuation image

Normal period Fluctuation period Normal period

Measurement

results

Advantages obtained by using the CW240

●Compact and easy to carry

●Detects voltage fluctuations in each cycle.

Instantaneous power failures and voltage

fluctuations are monitored continuously, and

the occurrence and recovery times are

reported.

Voltage level

(100% as reference)

Fall (rise) time

50% ~

Within 0.2 sec.

Result:

Occurrence date/time of the sag can

be reported so that semiconductor

quality can be improved.

Other:

Verification of instantaneous power failure

preventive measures implemented in

semiconductor manufacturing equipment

70% ~

Within 0.5 sec.

80% ~

Within 10 sec.

90% ~

110%

No limit

~ 120%

Within 0.5 sec.

Page 8

Convenient

functions

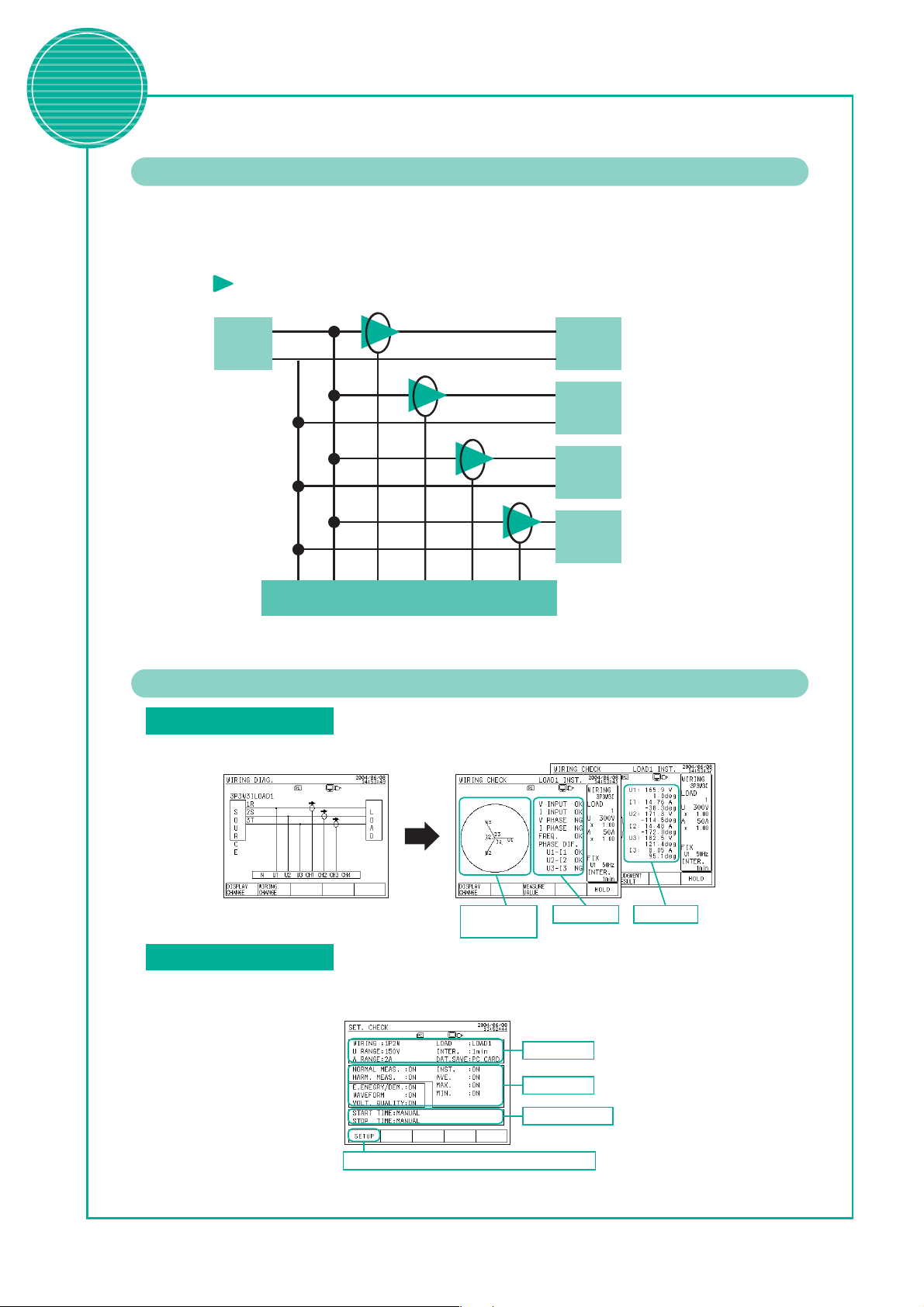

Measures Loads in Four Systems Simultaneously.

The CW240 enables simultaneous measurement of loads in four systems in the case of the

single-phase 2-wire system, and in two systems in the case of the single/three-phase 3-wire

system (common to voltage).

Current clamp probe/range can be set for each system.

This allows measurement according to the current flowing in each load.

(example)

200A

100A

10A

2A

Power

supply

1

N

Load 1

Load 2

Load 3

Load 4

NU1CH1 CH2 CH3 CH4

8

CW240 side Example of single-phase 2-wire system

Reduces Operation Errors at Work Site.

Wiring check function

Prior to start of measurement, the CW240 checks whether wiring is correct. Wiring errors, reverse connection of

current clamps, and phases to be checked can be displayed in a vector diagram.

Checking the

phases displayed in

a vector diagram

OK/NG judgment Measured values

Setting check function

Settings made for data saving can be checked in the screen. This prevents data acquisition errors that may occur due

to mistakes in voltage range setting, current clamp selection or data save item selection.

Phase/range etc.

Data save item

Measurement start/end

To change the settings, press this button to display the setting screen.

Page 9

Saving a Large Amount of Data

Use of an external memory card (compact flash)

makes it possible to save a large amount of data.

A memory card

the data is saved in CSV format.

In addition, the CW240 has a 1MB internal

memory.

*1: Memory cards purchased from Yokogawa should be

used.

*2: Data shorter than one second is saved in binary

format.

Screen copies can be made in bitmap format.

Voltage fluctuation data is saved in text format.

(*1)

of up to 2GB can be used, and

(*2)

Leakage Current Measurement

●Storage period when PC card (512MB) and internal memory (1MB) are used

When storing all items of measured data, measured power quantity/demand data, and measured

voltage fluctuation data

Wiring

Number of storable data items

Recording medium

PC card

(512MB)

Internal memory

(1MB)

When storing all items of measured data, measured power quantity/demand data, all items of

measured harmonics data, waveform data and measured voltage fluctuation data

Wiring

Number of storable data items

Recording medium

PC card

(512MB)

Internal memory

(1MB)

Interval time

1s

1min

60min

1s

1min

60min

Interval time

1min

60min

1min

60min

1P2W

4 systems

168

9 hrs

24 days

1471 days

8 min

8 hrs

21 days

1P2W

4 systems

5642

17 hrs

44 days

12 min

12 min

1P3W

2 systems

196

8 hrs

21 days

1304 days

7 min

7 hrs

18 days

1P3W

2 systems

5052

19 hrs

49 days

13 min

13 hrs

1P3W31

114

14 hrs

37 days

2223 days

12 min

12 hrs

32 days

1P3W31

3758

26 hrs

65 days

19 min

19 hrs

3P3W21

2 systems

208

8 hrs

20 days

1232 days

7 min

7 hrs

17 days

3P3W21

2 systems

6888

14 hrs

35 days

8 min

8 hrs

3P3W31,

3P4W

138

12 hrs

30 days

1852 days

10 min

10 hrs

26 days

3P3W31,

3P4W

4390

22 hrs

56 days

16 min

16 hrs

3P4W41

142

12 hrs

30 days

1802 days

10 min

10 hrs

26 days

3P4W41

5002

19 hrs

49 days

13 min

13 hrs

3P3W

+1P3W

216

7 hrs

19 days

1188 days

6 min

6 hrs

17 days

3P3W

+1P3W

7504

13 hrs

32 days

7 min

7 hrs

CW240

CW120 AP240E

- External magnetic field effect is 0.002A or less, at 400A/m -

Yokogawa's proprietary technology has achieved a magnetic field

impact amount of 30 ppm even in adjacent power lines. (At 100A)

Use of the 2A current clamp probe (96036) enables measurements

with 200.0 mA range.

Current clamp probe 96036

Analog Input/Output

- Besides power data -

Analog data such as temperature and illuminance data can be

saved simultaneously with power data by using the analog input

function (2 channels).

The available input ranges are 100 mV/1 V/5 V. In addition, the

analog output function (4 channels) acquires data to an external

recorder, allowing data duplexing. Output is ±1 VDC.

(The analog input/output function is optional.)

Digital illuminance meter 51001

Other Convenient Functions

Besides the AC adapter, it is possible to use a NiMH battery pack (94004) or alkaline

Power supply backup

Multi-lingual support

batteries (six AA batteries).

The CW240 will continue to operate even if supply of power is interrupted.

The CW240 supports Japanese, English, German, French, Spanish and Italian (available

in the near future).

1R

2S

Power

3T

supply

N

NU1U2U3CH1 CH2 CH3 CH4

CW240 side Three-phase 4-wire 4-current

Voltage,

current,

power etc.

Load

Temperature,

illuminance etc.

Analog output

2 channels

9

Manual data saving

Screen hard copy

Zoom function

The data for the selected items can be saved or printed using the SAVE key.

However, it cannot be saved during integrating measurement (and during standby).

The currently displayed screen can be saved or printed using the DISP COPY key.

Files are saved in bitmap format.

The measured data for the selected five items can be zoomed in.

The items to be displayed can be selected from instantaneous value and measured power

quantity data.

Page 10

Specifications

10

Inputs

Item Voltage Current

Input type Resistive potential division

Rated value

(range)

Phase to be

measured

Number of systems

to be measured

Input resistance

Maximum allowed

input (continuous)

A/D converter

150.0 V

300.0 V

600.0 V

1000 V

Single-phase 2-wire, single-phase 3-wire, single-phase 3-wire 3-current (current in neutral

line), three-phase 3-wire 2-current (2-power meter method), Three-phase 3-wire 3current (3-power meter method), three-phase 4-wire, three-phase 4-wire 4-current

(current in neutral line), Scott connection (three-phase 3-wire + single-phase 3-wire)

With the same voltage

Single-phase 2-wire: 4 systems, single-phase 3-wire: 2 systems, three-phase 3-wire 2current: 2 systems

Approx. 1.3MΩ Approx. 100KΩ (CW240 main unit)

1000 Vrms

Voltage/current input simultaneous conversion, PLL synchronized 128 samples/period,

16-bit resolution

Clamp detection

Varies with the clamp and range used.

96036 (2A) 200.0/ 500.0mA/1.000/ 2.000A

96033 (50A) 5.000/10.00/ 20.00/50.00 A

96030 (200A) 20.00/50.00 /100.0/200.0 A

96031 (500A) 50.00/100.0/ 200.0/500.0 A

96032 (1000A) 200.0/500.0 A /1.000 kA

96034 (3000A range) 300.0/750.0 A /1.500/3.000 kA

(2000A range) 200.0/ 500.0 A/1.000/2.000 kA

(1000A range) 100.0/ 200.0/500.0 A/1.000 kA

96035 (3000A range) 300.0/750.0 A /1.500/3.000 kA

(300A range) 30.00/75.00 /150.0/300.0 A

96036 (2A) 20Arms

96033 (50A) 130Arms

96030 (200A) 250Arms

96031 (500A) 625Arms

96032 (1000A) 700Arms

96034 (3000A range) 2400 Arms (

(2,000A range) 2400Arms

(1000A range) 1200 Arms

96035 (3000A range) 3600 Arms

(300A range) 360 Arms

Measurement Functions

Item Voltage

Method Digital sampling

Frequency range 45 to 65Hz (Measurement element is selected from U1, U2 and U3)

Crest factor Rated input: 3 (however, 1.8 when 1000V range is used)

±

Accuracy

Power factor

influence

Reactive factor

influence

Active input range 5 to 110% of each range (Max. 100% in the case of 1000V range)

0.2%rdg.

±

0.1%rng.

—

—

Voltage / current: 0.4 to 130% of each range

Display range

Temperature

coefficient

Display updating

interval

Power (active, reactive, apparent): 0 to 130% of each range

Harmonic level: 0 to 130% of each range

Frequency: 40 to 70Hz

±0.03%rng/°C ±0.05%rng/°C

Approx. 0.5 seconds

Current / Active power / Reactive power (reactive power meter method is used)

96030, 96031, 96033, 96036 ±0.6%rdg.±0.4%rng.

96032, 96034, 96035 ±1.0%rdg.±0.8%rng.

96030 ±1.0%rng (45 to 65Hz, power factor =±0.5)

Other than 96030 ±2.0%rng (45 to 65Hz, power factor =±0.5)

96030 ±1.0%rng. (

Other than 96030 ±2.0%rng (

45 to 65Hz, reactive factor =±0.5

45 to 65Hz, reactive factor =±0.5

(Zero suppression when below 0.4% of the range)

(Zero suppression when below 0.17% of the range

rating).

3600 Arms for 10 minutes

Equations

Active power, reactive power, apparent power, power factor and phase angle are

measured for each phase.

The average, maximum and minimum values of those obtained during

integrating measurement are calculated.

T

T

1

1

Voltage rms

Current rms

Active power

Reactive power 1 When the reactive power meter method is used

Equations for Each Phase

Measurement

Items

Average voltage

Umrms = um(t)2dt =

Imrms = im(t)2dt =

Pm = {um(t) ҂im(t)}dt =

Qm = {um(t)҂im(t + )}dt =

Wiring

∫

T

0

T

1

∫

T

0

T

1

∫

T

0

T

1

∫

T

0

Equation

Average current

Active power

Reactive power 2

)

Apparent power

Power factor

Phase angle

*1: Line voltage is measured in the case of 3-phase 3-wire system, and phase voltage in the case of 3-phase 4-wire

*2: I2 for three-phase 3-wire system (2-power meter method) is calculated by vector operation.

*3: This equation is applicable when the reactive power meter method is not used. Even in this case, the value is

*4: In the case of three-phase 3-wire system, the phase voltage from the virtual neutral point is used to calculate

*5: Multiplied by the polarity of Q for each phase calculated by the reactive power meter method.

*6: In the case of distorted waves and unbalanced inputs, there may be differences from other instruments that

)

)

(*3)

Q = S

S = U҂I

When the reactive

power meter method

is not used

When the reactive

power meter method

is used

(*5)

In the case of distorted waves, there may be differences from other instruments that

employ different measurement principles.

system.

multiplied by the polarity of Q for each phase calculated by the reactive power meter method.

each phase power.

employ different measurement principles.

P1, P3, Q1, Q3, S1, S3, PF1 and PF3 are obtained during calculations carried out by the 2-power meter

method, and do not exist as physical values.

2

(t)

u

∑

m

T

t=0

T

1

2

i

(t)

∑

m

T

t=0

T

1

{um(t)҂im(t)}

∑

T

t=0

T

T

1

∑

T

4

t=0

—

—

—

2

2

P

—

(*5)

—

{

um(t)҂im(t + )

Symbol

Uave

Iave

∑

P

∑

Q

∑

S

∑

PF

∑

PF

∑

PA

T

}

4

Single-phase

3-wire

(U1 + U2)/2

(1 + I2)/ 2

P1 + P2

Q1 + Q2

S1 + S2

Three-phase

2-current

∑S2 –∑P

∑

∑

∑

3-wire

P1 + P3

3

(S1 + S3)

2

PF =

PF =

PA = cos

*6

∑

P

∑

S

∑

P

–1

∑

u(t): Voltage input signal

i(t) : Current input signal

T:One cycle of input signal

m:Each phase

Three-phase

3-wire

3-current

(U1 + U2 + U3)/3

(I1 + I 2 + I3)/ 3

P1 + P2 + P3

2

Q1 + Q2 + Q3

S1 + S2 + S3

∑

P

2

2

+

∑

Q

PF

rdg: Reading rng: Range

Range Configuration for Active Power

For single-phase 2-wire system (X2 for single/three-phase 3-wire system, X3 for three-phase 4-wire system)

When 96030 / 96031/ 96032 / 96033/ 96036 is used

Voltage range

96036(2A) 96033(50A)

200.0 mA 500.0 mA 1.000 A 2.000 A 5.000 A 10.00 A 20.00 A 50.00 A 100.0 A 200.0 A 500.0 A 1.000 kA

150.0 V 30.00 W 75.00 W 150.0 W 300.0 W 750.0 W 1.500 kW 3.000 kW 7.500 kW 15.00 kW 30.00 kW 75.00 kW 150.0 kW

300.0 V 60.00 W 150.0 W 300.0 W 600.0 W 1.500 kW 3.000 kW 6.000 kW 15.00 kW 30.00 kW 60.00 kW 150.0 kW 300.0 kW

600.0 V 120.0 W 300.0 W 600.0 W 1.200 kW 3.000 kW 6.000 kW 12.00 kW 30.00 kW 60.00 kW 120.0 kW 300.0 kW 600.0 kW

1.000 kV 200.0 W 500.0 W 1.000 kW 2.000 kW 5.000 kW 10.00 kW 20.00 kW 50.00 kW 100.0 kW 200.0 kW 500.0 kW 1.000 MW

When 96034 / 96035 is used

Voltage range

96035_2(300A)

30.00 A 75.00 A 150.0 A 300.0 A 100.0 A 200.0 A 500.0 A 1.000 kA 2.000 kA 300.0 A 750.0 A 1.500 kA 3.000 kA

150.0 V 4.500 kW 11.25 kW 22.50 kW 45.00 kW 15.00 kW 30.00 kW 75.00 kW 150.0 kW 300.0 kW 45.00 kW 112.5 kW 225.0 kW 450.0 kW

300.0 V 9.000 kW 22.50 kW 45.0 kW 90.00 kW 30.00 kW 60.00 kW 150.0 kW 300.0 kW 600.0 kW 90.00 kW 225.0 kW 450.0 kW 900.0 kW

600.0 V 18.00 kW 45.00 kW 90.00 kW 180.0 kW 60.00 kW 120.0 kW 300.0 kW 600.0 kW 1.200 MW 180.0 kW 450.0 kW 900.0 kW 1.800 MW

1.000kV 30.00 kW 75.00 kW 150.0 kW 300.0 kW 100.0 kW 200.0 kW 500.0 kW 1.000 MW 2.000 MW 300.0 kW 750.0 kW 1.500 MW 3.000 MW

Current range

96032(1000A)

96031(500A)

96030(200A)

Current range

96034_3(3000A)

96034_2(2000A)

96034_1(1000A)

96035_1(3000A)

Three-phase

4-wire

*1

*2

*4

*4

*4

Page 11

Specifications of Each Function

Frequency Measurement Function

Measurement input Voltage input Selectable from U1, U2 and U3

Measurement frequency range 45 to 65 Hz

Display range 40.00 to 70.00 Hz

Accuracy ±0.1%rdg. ±1dgt

Low-pass filter function Cutoff frequency: Approx. 300 Hz OFF/ON selectable

Power Quantity Measurement Function

Measurement elements Active power quantity, regenerative power quantity, reactive

Measurement accuracy Measurement accuracy of active power and reactive power

Measurement range Active power quantity

Display digits setting function Selectable from automatic setting by rated power, minimum

Integration time accuracy ±20 ppm (Typ., 23°C)

Demand Measurement Function

Measurement elements Active power (consumption), reactive power (lagging), power

Measurement accuracy Measurement accuracy of active power and reactive power

Harmonic Measurement Function

Method PLL synchronization

Measurement frequency range Fundamental wave frequency 45 to 65 Hz

Harmonics for analysis 1st to 50th

Window width 1 cycle

Window type Rectangular

Analysis data quantity 128 points

Analysis rate 1 sample/16 cycles

Analysis items Harmonic level: Level of each harmonic of voltage, current and

Accuracy Harmonic level

Display data List, bar graph (linear/log), vector

Waveform Measurement Function

Measurement elements Selectable from voltage/current waveform of same phase, all

Magnification change x1/3 to x 20 in relation to the rating

Display data 1 waveform

Voltage Fluctuation Measurement Function

Measurement elements Voltage dip, voltage swell, instantaneous power failure

Measurement method Detected based on voltage rms of one waveform.

Threshold/hysteresis Can be set in percentage in relation to the reference voltage.

Accuracy Same as voltage rms accuracy

Detection period Time length during which the threshold is exceeded

Display data Occurrence date (year, month, day), voltage rms, detection

Number of events 100

Display Function

Display 5.7-inch STN monochrome LCD display (320 dots x 240 dots)

Backlight OFF/ON and auto OFF selectable

Contrast Automatically adjusted according to the ambient temperature /

Display digits Items other than power quantity: 4 digits

Language English, Japanese, German, French, Spanish, Italian, Korean and

Display average function Moving average

Display hold Hold / cancel

Save/Print Function

Data can be saved/printed manually or automatically.

Storage media Internal memory: 1MB or PC card

Printing Dedicated printer (via RS-232)

Save/print data Measured data, voltage variation data, waveform data, screen

Saving format Measured data: CSV format

Save/print interval

Standard interval: 1/2/5/10/15/30 seconds, 1/2/5/10/15/30/60 minutes

For 10% to 130% sine wave input of voltage range

power quantity (lead/lag)

±1dgt (When STANDARD is selected for display digits)

Consumption 0.00000 mWh to 999999 GWh

Regeneration -0.00000 mWh to -999999 GWh

Reactive power quantity

Lagging 0.00000 mvarh to 999999 GVarh

Leading -0.00000 mvarh to -999999 GVarh

resolution setting, and minimum resolution shift by integrated

value.

factor: Demand value within the interval time

Active power quantity (consumption, regeneration), reactive

power quantity (lagging), leading: Power quantity within the

interval time

Maximum demand (consumption power demand) required since

the start of integrating measurement and the time it occurs

±1dgt

(When STANDARD is selected as the standard number of

display digits)

Relative harmonic content: Content of each harmonic of

Harmonic phase angle: Phase angle of each harmonic of voltage,

Total value: Total value of all the harmonics up to the 50th

Total harmonic distortion rate:

1st to 20th: ±1.5%rdg. ±1.5%rng

21st to 30th: ±2.0%rdg. ±1.5%rng

31st to 50th: ±3.0%rdg. ±1.5%rng

Relative harmonic content:

Value calculated from harmonic level ±2dgt

Harmonic phase angle

The accuracy is guaranteed if both voltage and current levels

for each harmonic are 5% of the range or higher.

1st to 20th: ±5°

20th to 50th: ±(0.3° X k+1°) k: Order

The accuracy for current in relation to the fundamental wave

is not specified.

voltage waveforms, and all current waveforms.

period

with backlight

Settable in 8 steps.

Power quantity: 6 digits

Chinese

(Averaging count: selectable from 2, 5, 10 and 20)

data, setting data

(Binary format if short-time interval is set)

Voltage variation data: Text format

Waveform data: Binary format

Screen data: BMP format (bitmap)

Setting data: Text format

It is not possible to output/print measured harmonic and

waveform data if the interval is shorter than 30 seconds.

power

voltage, current and power

current and power

For voltage and current, the phase angle

of the fundamental wave or that of U1

can be selected as the reference.

harmonic of voltage, current, power and power factor

Voltage / current (THD-F or THD-R)

Short-time interval: 0.1/0.2/0.5 seconds for each waveform

Data storage time display

Unoccupied capacity in the storage destination

Data save items, calculated based on the interval time.

File operation

Rename File names in the internal memory and PC card can be changed.

Deletion File names in the internal memory and PC card can be deleted.

Format PC card and internal memory and can be initialized

Data copy Files in the internal memory can be copied to the PC card.

Setting file Setting file can be read, written, deleted and renamed.

Communication Function

Electrical specifications EIA RS-232

Synchronization system Asynchronous communication

Baud rates 1200/2400/9600/19200/38400 bps

Connector D-sub 9-pin

PC card interface

Slot PC card slot TYPE II (x1)

Compatible card ATA flash memory card

Data format MS-DOS format

Recording contents Measured data, voltage fluctuation data, waveform data, screen

External control I/O terminals

Used to control start/end of integrating measurement.

Control input TTL level or contact

Control output TTL level

Analog Input and DA Output Functions (Optional)

DA output

Output voltage ±1VDC of the rated value for each range

Number of output channels 4 channels

Output data

(Four items can be selected) Instantaneous value

Power quantity Active power quantity (consumption, regeneration), reactive

Harmonic Level, content, phase angle, total value, THD (THD-F or THD-R)

Accuracy ±(Measurement accuracy + 0.2%f.s.)

Resolution Polarity + 11 bits

Updating interval Other than harmonic measurement: 1 cycle of input signal

Temperature coefficient ±0.02%f.s./°C or less

Output resistance 22Ω±5%

Power quantity output route Selectable from 1V/1kWh, 1V/5kWh, 1V/10kWh, 1V/50kWh, 1V/

Analog input

Input ranges 100mV/1V/5VDC

Number of inputs 2 channels

Accuracy ±0.5% f.s

Resolution Polarity + 11 bits

Sampling rate Approx. 20ms

Input resistance Approx. 100kΩ

Clock Function

Automatic calendar, automatic leap-year setting, 24-hour system

Real-time accuracy ± 20 ppm (Typ., 23°C)

Wiring Check Function

Verification of validity of measurement of voltage/current input value, voltage/current phase

difference, voltage-to-voltage phase difference, current-to-current phase difference and frequency

Verification of single-phase load (in the case of Scott connection)

Wiring diagram, vector diagram display

Setting Check Window

Used to check data save items and start/end for integrating measurement.

Other functions

VT ratio/CT ratio setting, ID number setting, NiMH (nickel hydride battery) charge, remaining

battery voltage display, beep sound (key operation), key lock, system reset

General specifications

Location for use: Indoor, at an altitude of 2000 meters or less

Storage temperature and humidity ranges

Operating temperature and humidity ranges

Insulating resistance 500 VDC, 50MΩ or greater

Insulating withstand voltage

(50/60Hz, for one minute) 5.55 kVAC rms for one minute (Sensed current: 1mA)

Power supply AC adapter (standard accessory), 100 to 240 VAC, 50/60Hz

Backup battery (for power failure) Six AA size alkaline batteries (standard accessory)

Maximum rated power consumption

External dimensions Approx. 206 (W) ҂ 184 (H) ҂ 65 (D) mm

Weight Approx. 1.2 kg (without batteries)

Accuracy guarantee conditions

Warm-up time 30 minutes or more (within active input range, sine wave input,

Accuracy guarantee temperature and humidity ranges

Accuracy guarantee frequency range

Accuracy warranty period 1 year

Only instantaneous values can be input.

data, setting data

Power quantity depends on the output rate.

X1, X10 and X100 can be set for harmonics.

Frequency: 0.4 to 0.7V / 40 to 70 Hz

Voltage, current, average voltage, average current, active power,

reactive power, apparent power, power factor, phase angle,

frequency

power quantity (lagging/leading)

Harmonic measurement: 16 cycles of input signal

100kWh, 1V/500kWh and 1V/1000kWh.

-20 to 60°C, 90%RH (no condensation)

5 to 40°C, 5 to 80%RH (no condensation)

Between voltage input terminals and case

Between voltage input terminals and current input terminals /

DC power terminals / external interface terminals

Between voltage input terminals and case

3.32 kVAC rms for one minute (Sensed current: 1mA)

Between voltage input terminals and current input terminals /

DC power terminals / external interface terminals

One NiMH battery pack (optional)

Main unit: Approx. 10W (normal operation), approx. 20W

(during charging of NiMH battery pack)

AC adaptor: Approx. 30VA (normal operation), approx. 60VA

(during charging of NiMH battery pack)

(excluding projecting parts)

power factor=1, PLL synchronization)

23±5°C, 30 to 75%RH

45 to 65Hz

CW240

CW120 AP240E

11

Page 12

Model CW120 Clamp-on Power Meter

(integration start/stop signal: function to

start/stop multiple units simultaneously)

Model CW121- -1

CW120

Maintenance and long term monitoring

of electrical equipment and electrical

system.

Current input

Voltage input

(clamp)

12

Model CW121- -1

External I/O controller port

(integration start/stop signal: function to

(integration start/stop signal: function to

start/stop multiple units simultaneously)

start/stop multiple units simultaneously)

RS-232 connector

100-240VAC Power connection

PC card slot

Power switch

(8-pin)

(flash ATA memory)

Easy-to-recognize function icons

Page 13

wer measurement

Low-cost tools to support your energy conservation efforts

As energy conservation becomes increasingly important, we are pleased to present low-cost clamp-on power meters designed to meet user

needs for simple tools capable of measuring power values and instantaneous values.

Useful features for energy conservation and power measurement

Useful features for energy conservation and power measurement

CW240

●Periodically save data as often as once a

second

Data can be saved as low as 1-second interval.

This capability allows the CW120 Series to respond

quickly to load fluctuations and measure transient

responses in equipment.

●Check equipment operating conditions

The CW120 Series has an instantaneous value filing

function (enabling multiple data records to be saved in

a single file when multiple measurements are taken)

which is useful for determining equipment operating

conditions.

Details for Models CW120/CW121

Items

Measurement Mode

Display

Communication

Power supply

Size (W⫻H⫻D)

Weight

Input system

Instant mode

Electric Energy mode

Screen

Interface

Protocol

Monitoring by AP240E

CW120/CW121

Single-phase 2-wire to 3-phase 4-wire

(Up to 3 phase 3 wire for CW120)

Available

Segmented LCD with backlight

RS232 or RS485

MODBUS, PC-link, Power-Monitor, Proprietary

Available

100 to 240V AC, Supply the power from input.

117⫻161⫻51mm

600g

●Wiring error check function

This function helps ensure that measurement

operations are correct.

●Simultaneous measurement of multiple

facilities

Multiple CW120 Series units can start and stop

integration simultaneously through externally

controlled I/O.

●Works even with small electric energy

values

Easily change the decimal position (the number of

digits following the decimal point) and display unit (Wh,

kWh, MWh, GWh) on the electric energy display.

CW120 AP240E

13

Load measurements on multiple systems

● In addition to support for a variety of connection types,

The CW120 Series can simultaneously measure the

loads* (facilities, equipment) on multiple systems

sharing a common power supply.

CW120 (three-phase 3-wire model): 1ø2W⫻2

CW121 (three-phase 4-wire model): 1ø2W⫻2, ⫻3

1ø2W Three current systems (example)

Power supply side

1

2

(Facility 3)

Load 3 side

Load 2 side

(Facility 2)

Load 1 side

(Facility 1)

Page 14

Low-cost tools to support your energy conservation efforts

Compact design

14

● The CW120 Series is compact in size (117҂161҂51mm

(W҂H҂D)), making it ideal for installation in cubicles

and inside distribution panels. Installation is even easier

Approximately

70 mm

Current clamp (96033)

with the magnetic case (93023).

● Although the CW120 Series is small, it has a large

ø18 mm

backlit LCD.

● A new addition to the clamp lineup is a small-diameter

current clamp (model 96033, capable of measurements

in the range of 5–50 A) for measurements in tight spots

and locations where many wires are jumbled together.

Magnetic case (93023)

Measurements

● The CW120 Series can be used for voltage measurements up to 495 V.

● A variety of connection types are supported, from single-phase 2-wire to three-phase 4-wire

(CW120: three-phase 3-wire model; CW121: three-phase 4-wire model).

● Continuous measurement integration (accurate measurements can be obtained even if there are large load

fluctuations)

● Plus/minus signs are shown for reactive power and power factor.

● The data saving interval can be set in the range of one second to one hour.

Parameters setting tool (name: Toolbox)

The setting software allows you to set CW120 Series

measurement conditions through a PC and save

measurement data on a PC when the unit is connected to

the PC through RS-232 or RS-485 port.

●Measurement conditions setting function

This function makes it easy to set basic functions needed

for measurement, such as start/stop time and date, wiring

method, clamp type, voltage, and current range etc.

●File transfer function

The data file stored in CF pack can be transfered to PC.

Microsoft Excel can read transferred data file.

* Toolbox is included as a standard feature (on two floppy disks).

RS-232 comm. cable

Microsoft, Windows, and Excel are trademarks or registered

trademarks of Microsoft Corporation, the United States.

Setting screen

File transfer screen

Page 15

Advanced data management and communication

Data management and communication

CW240

1 You can connect CW120 to a PC through dedicated

RS-232 cable.

2 A printer (sold separately) can be connected through

RS-232 cable to print measurement data.

3 If you have a media reader connected to your PC or card

slot in notebook PC, measurement data and settings can

be uploaded directly to a PC from CF* pack.

Memory Card

97034

97035

97037

* Compact Flash cards with memory capacity up to 2 GB may be used.

Memory capacity

256MB

512MB

2GB

Interval Time 10sec

Approx. 103days

Approx. 206days

Approx. 2years

Interval Time 1sec

Approx. 70hours

Approx. 140hours

Approx. 560hours

Wiring Method

3system 1ø2W

3system 1ø2W

3system 1ø2W

Network Communication

CW120 In addition to proprietary communication also

supports, MODBUS, PC-link and Power Monitor protocols.

PC-link is a protocol for Yokogawa's Temperature

controllers and PLCs.

Power Monitor protocol is a protocol for Yokogawa's

Power Monitors. (PR201)

Model MV Model MV

Yokogawa's

Recorder

CF pack

3

Comm.

Cable

Model 91011

1

PC

2

Printer

Cable

Model 91010

Data Management by DAQLOGGER*

Internet

WEB function: Model MV100/200 can be

monitored by Internet Browser on PC.

E-mail Alarm function: The alarms from

Model MV100/200 can be sent to PC as an Email.

FTP function: Model MV100/200 can send

gathering data as a file to PC by using FTP

function.

Printer Model 97010

PC

RS485-MODBUS protocol

CW120 AP240E

Media reader

15

* DAQLOGGER is Yokogawa’s communication software for Windows

Remote monitoring

The RS-485 allows multiple use to be connected for

remote monitoring.

* RS-485/RS-232 converter is required to connect the CW120/CW121-m-2 (RS-

485 communication spec) to the RS-232 port on your PC.

Recommended brand and model: Yokogawa’s RS-232/RS-485 Converter

Model ML2.

PC

RS-232

RS-485

Monitoring

Software

Converter

Max 31 units, 1.2km

Page 16

Vrms=

T

1

T

0

=

T

1

T

t=0

Arms=

T

1

T

0

=

T

1

T

t=0

T

1

T

0

=

T

1

T

t=0

•Voltage rms

•Current rms

•Active power

•Reactive power and power factor

Single-phase

2-wire

Single-phase

3-wire

Three-phase

3-wire

(Note 3)

Three-phase

4-wire

Reactive power

(Note 2) Apparent power Power factor (Note 2)

Computation

range

Display

resolution

Rated value depends on V

and A ranges.

Rated value depends on V

and A ranges.

Internal computation only;

data not displayed or saved.

Same as for active power.

dt

dt

dt

Single-phase 3-wire, three-phase 3-wire

Three-phase 4-wire

(t), i(t): Input signals

T: One period for input signal

P= i

P = P1 + P2

P = P1 + P2 + P3

Note 1: In the case of distorted waves, there may be differences from other measuring instruments that are based

on different measurement principles.

Note 2: The polarity of each phase determined by the reactive power meter method is multiplied and the polarity

is displayed.

Note 3: In the case of three-phase 3-wire and unbalanced inputs, there may be differences from other measuring

instruments that are based on different measurement principles, or wiring.

Equations

Specifications

16

Inputs

Input type

Rated value

(range)

Wiring

Input

resistance

Maximum allowed

input

A/D converter

CW120

CW121

CW120

CW121

Resistive potential division

150/300/450 V

Single-phase 2-wire, single-phase 3-wire, three-phase 3-wire

Single-phase 2-wire, single-phase 3-wire, three-phase 3-wire, three-phase 4-wire

Approximately 1.5 MΩ

Approximately 1.3 MΩ

495 Vrms

Voltage/current input simultaneous conversion, 12-bit resolution

Voltage (V)Parameter

Current (A)

Clamp detection

Clamp 96033: 5/10/20/50 A

Clamp 96030: 20/50/100/200 A

Clamp 96031: 50/100/200/500 A

Clamp 96032: 200/500/1000 A

Approximately 100 kΩ

Clamp 96033: 130 Arms

Clamp 96030: 250 Arms

Clamp 96031: 625 Arms

Clamp 96032: 1000 Arms

Measurement Input functions

Parameter

Method

Frequency range

Crest factor

Active input range

Display

range

Temperature coefficient

Display updating interval

Instantaneous Value Measurement

•Measurement parameters: Voltage rms (V), current rms (A), active power (W), frequency

•Measurement accuracy (at power factor 1, including clamp)

Voltage: ±(0.3% rdg + 0.2% rng)

Current/active power: ±(0.8% rdg + 0.4% rng) when using clamps 96030, 96031, and

Frequency: ±(0.1% rdg + 1% dgt)

•Computation parameters: Reactive power (Var), power factor

•Computation accuracy: (value calculated from measurement) ±1 dgt

•Power factor influence: ±1.0% rng cosø = ±0.5 (relative to power factor 1) when using

Digital sampling

45–65 Hz (reciprocal system), detected from V1

150/300 V range

450 V range

10–110% of each range

All ranges 1.5 V

Lower limit

130% of each range, except 110% for 450 V range

Upper limit

±0.05% rng/˚C

Approximately one second

•Reactive factor influence: ±1.0% rng sinø = ±0.5 (relative to reactive factor 1) when using

Voltage Current/active power

Rated input: 2

Rated input: 1.56

Rated input: 3

0.4% of each range

130% of each range

±0.07% rng/˚C (including clamp)

(Hz)

96033

±(1.2% rdg + 0.8% rng) when using clamp 96032

clamp 96030

±2.0% rng cosø = ±0.5 (relative to power factor 1) when using

clamps 96031, 96032, and 96033

clamp 96030

±2.0% rng sinø = ±0.5 (relative to reactive factor 1) when using

clamps 96031, 96032, and 9603

Electric Energy Measurement

•Measured parameters:

Active electric energy, regenerative electric energy (regenerative electric energy is not displayed

on the screen; it is merely saved)

•Measurement accuracy: Active power measurement accuracy ±1 dgt (with standard settings)

•Integration function settings

Start/stop settings: Manual, timer, external trigger (control)

Output intervals: 1/2/5/10/15/30 seconds; 1/2/5/10/15/30 minutes; 1 hour

•Displayed digits:

This is set automatically based on the rated power, and the minimum resolution can be set

Saving items

•Saving items:

Voltage, current, active power, reactive power, power factor, frequency, active electric energy,

regenerative electric energy

Display Functions

•Display screen: Backlit segmented LCD

•Maximum number of displayed digits

Electric energy: 6 digits

Other parameters: 4 digits

•Range makeup: (rated values)

Voltage

150.0V

300.0V

450.0V

Wiring

1ø2W

1ø3W

3ø3W

3ø4W

1ø2W

1ø3W

3ø3W

3ø4W

1ø2W

1ø3W

3ø3W

3ø4W

5.000 A

750.0 W

1.500 kW

1.500 kW

2.250 kW

1.500 kW

3.000 kW

3.000 kW

4.500 kW

2.250 kW

4.500 kW

4.500 kW

6.750 kW

10.00 A

1.500 kW

3.000 kW

3.000 kW

4.500 kW

3.000 kW

6.000 kW

6.000 kW

9.000 kW

4.500 kW

9.000 kW

9.000 kW

13.50 kW

Clamp 96033

20.00 A

3.000 kW

6.000 kW

6.000 kW

9.000 kW

6.000 kW

12.00 kW

12.00 kW

18.00 kW

9.000 kW

18.00 kW

18.00 kW

27.00 kW

50.00 A

7.500 kW

15.00 kW

15.00 kW

22.50 kW

15.00 kW

30.00 kW

30.00 kW

45.00 kW

22.50 kW

45.00 kW

45.00 kW

67.50 kW

Clamp 96030

100.0 A

15.00 kW

30.00 kW

30.00 kW

45.00 kW

30.00 kW

60.00 kW

60.00 kW

90.00 kW

45.00 kW

90.00 kW

90.00 kW

135.0 kW

Clamp 96031

200.0 A

30.00 kW

60.00 kW

60.00 kW

90.00 kW

60.00 kW

120.0 kW

120.0 kW

180.0 kW

90.00 kW

180.0 kW

180.0 kW

270.0 kW

Clamp 96032

500.0 A

75.00 kW

150.0 kW

150.0 kW

225.0 kW

150.0 kW

300.0 kW

300.0 kW

450.0 kW

225.0 kW

450.0 kW

450.0 kW

675.0 kW

1.000 kA

150.0 kW

300.0 kW

300.0 kW

450.0 kW

300.0 kW

600.0 kW

600.0 kW

900.0 kW

450.0 kW

900.0 kW

900.0 kW

1.350 MW

Page 17

Communication Functions

•Electrical specifications: Conforms to EIA RS-232 or EIA RS-485.

•Protocols: CW120/121 proprietary protocol, Power Monitor protocol

•Synchronization system: Start stop synchronization

•Baud rates: 1200, 2400, 4800, 9600, 19200, 38400 bps

PC card interface

•Slot: PC card slot TYPE II

•Compatible card: ATA flash memory card

•Function specifications: Saving measurement data, saving and reading settings data

Faulty Wiring Checking Functions

•Check details:

Presence/absence of power input; check for frequency measurement range; voltage phase

sequence;

presence/absence of power input; whether current clamp is reverse-connected

Scaling Function

The VT ratio and CT ratio can be set.

•Settings ranges VT ratio: 1–10,000

External Control I/O (for RS-232 only; not provided for RS-485)

These input and output can be used as signals for starting and stopping integrating measurement.

•Control input: TTL level or contact

•Control output: TTL level

Other Functions

Clock (typical precision: ±100 ppm), key lock, system reset

General Specifications

•Environmental requirements: Indoor usage at an altitude of 2000 meters or less.

•Usage temperature and humidity ranges:

•Storage temperature and humidity ranges:

•Insulating resistance:

500 V DC, 50 MW or greater

Between voltage input terminals and case

Between voltage input terminals and current input terminals, communication terminals, and control

I/O terminals

Between power line and case

Between power line and current input terminals, communication terminals, and control I/O

terminals

•Insulating withstand voltage:

5550 V AC for one minute

Between voltage input terminals and case

3320 V AC for one minute

Between voltage input terminals and current input terminals, communication terminals, and

control I/O terminals

2300 V AC for one minute

Between power line and case

Between power line and current input terminals, communication terminals, and control I/O

terminals

•Power supply: 100–240 V AC ±10%, 50/60 Hz

•Consumed power: 8 VA maximum

•External magnetic field effects: Within accuracy levels at 400 A/m

•External dimensions: Approximately 117 ҂ 161 ҂ 51 mm (W ҂ H ҂ D)

•Weight: Approximately 0.6 kg

•Terminals:

Voltage input CW120: 3 terminals Banana terminals (safety terminals)

Current terminals CW120: 2 pairs Banana terminals (safety terminals)

(H/L) CW121: 3 pairs Banana terminals (safety terminals)

External control I/O 3 terminals (H/L/H) Screwless terminals

terminals RS-485 4 terminals (+/-/SG/TM) M3 screw terminals

•Connectors:

RS-232: Mini DIN 8-pin

AC power supply: 2-pin

•Accessories:

Voltage input probes: 3 for CW120, 4 for CW121

Power cord, user's manual, operation guide, Toolbox (setting software)

•Safety standards:

Compliant with EN61010-1, EN61010-2-031, UL3111-1 First Edition, CAN C22.2 No. 1010.1-92

–Voltage input line

Measurement (Overvoltage) category III (Max. input voltage : 600 Vrms)

– Power line

Installation category II (Max. input voltage : 264 Vrms)

Pollution degree 2

•EMC (emission):

Compliant with EN55011, Group1, ClassA; EN61326; EN61000-3-2; EN61000-3-3

•EMC (immunity):

Compliant with EN61326

(Standard protocol used for YOKOGAWA M&C's Power

Monitor)

PC link communication (Standard protocol used for

YOKOGAWA M&C’s Temperature Controllers)

MODBUS communication (ASCII or RTU)

CT ratio: 1–10,000 (in increments of 0.01)

0–50°C, 5–85% RH (no condensation)

0–40°C, 5–85% RH (no condensation) for UL, C-UL

-20–60°C, 90% RH (no condensation)

CW121: 4 terminals Banana terminals (safety terminals)

CW240

CW120 AP240E

17

Page 18

CW240 Model and Suffix Code

93020

CW240 main unit can be packed in the

carrying case with accessories like

current clamps and voltage probes,

without disconnecting them from the

main unit. It also holds the other

accessories.

To prevent error connection of clamp

probes.

Carrying case Protective Cover

91022

●Model name and suffix code

Model (Part No.)

CW240

Suffix code Option code

-D

-F

-H

-R

-S

Power Cord (UL/CSA Standard)

Power Cord (VDE Standard)

Power Cord (GB Standard)

Power Cord (SAA Standard)

Power Cord (BS Standard)

Description

●CW240 selection list for clamps

Notes for selecting type of clamp probesNumber of clampsAim wiring to measure

1phase2wire1load

1phase2wire2load

1phase2wire3load

1phase2wire4load

1phase3wire1load

1phase3wire2load

3phase3wire1load

3phase3wire2load

3phase3wire1load3currents

3phase4wire

Scott wiring

Standard accessories comes with main unit

91007 Voltage probes, AC adapter x1, AA size alkaline battery x6, ToolBox240(CD-ROM) x1,

User's Manual x1/CD-ROM version x1, Quick Manual x 1/CD-ROM version x1,

Communication function manual(CD-ROM) x1

1

2

3

4

2

4

2

4

3

3

4

Different clamps are selectable.

Same clamps must be selected.

Same clamps must be selected for each load.

Same clamps must be selected.

Same clamps must be selected for each load.

Same clamps must be selected.

Same clamps must be selected.

Same clamps must be selected.

●Accessories

Voltage probes (4 pcs/set)

NiMH battery pack

Memory Card (256MB)

Memory Card (512MB)

Memory Card (2GB)

Printer

AC adapter (for printer, Europe)

AC adapter (for printer, USA)

Thermal paper for printer (10 rolls)

AC adapter for 96035

CW viewer

91007

94004

97034

97035

97037

97010

94006

94007

97080

94013

B9108WB

AP240E

DescriptionModel No.Name

256MB CF with PC Card Adapter

512MB CF with PC Card Adapter

2GB CF with PC Card Adapter

Power Supply 200-240 VAC

Power Supply 100-120 VAC

For AC 120V

For AC 220-240V

18

CW120 Models and Suffix code

●Model name and suffix code

Model (Part No.)

CW120

CW121

Power cord

Communication

Suffix code Option code

-D

-F

-H

-R

-S

-1

-2

Three-phase 3-wire

Three-phase 4-wire

AC power cord (UL/CSA Standard)

AC power cord (VDE Standard)

AC power cord (GB Standard)

AC power cord (SAA Standard)

AC power cord (BS Standard)

RS-232 communication interface

RS-485 communication interface

●CW120/CW121 selection list for clamps

1phase2wire1load

1phase2wire2load

1phase2wire3load

1phase3wire1load

3phase3wire1load

3phase4wire

1

2

3

2

2

3

●Accessories supplied at no extra cost

Product Name Part No.

1. Power cord

2. Voltage probes (for CW 120)

Voltage probes (for CW 121)

3. User's Manual

4. Operation Guide

91018

91007

IM CW120-E

IM CW-120P-E

Description

Notes for selecting type of clamp probesNumber of clampsAim wiring to measure

Same clamps must be selected.

Same clamps must be selected.

Same clamps must be selected for CW121.

Same clamps must be selected.

Same clamps must be selected.

Same clamps must be selected for CW121.

Qty

1

3

4

1

1

●Accessories

Carrying case

CW120 main unit can be

packed in the carrying

case with accessories

like the current clamps

and voltage probes.

It also holds the other

accessories.

Power cable Printer

This cable supplies power from a

measurement circuit. length 1.5m

*Not applied to CE and UL.

Voltage probe

Voltage probe

Communication cable

Printer cable

Memory Card (256MB)

Memory Card (512MB)

Memory Card (2GB)

Printer

AC adapter (for printer, Europe)

AC adapter (for printer, USA)

Printer thermal paper

AC adapter for 96035

CW viewer

Includes magnet

and stand

91007

91018

91011

91010

97034

97035

97037

97010

94006

94007

97080

94013

B9108WB

AP240E

Main unit case

Portable case

9302393022 93024

98030 97010

DescriptionModel No.Name

Four per set

Three per set

RS232 communication cable for PC (9-pin)

RS232 printer cable, length 1.5 m

256MB CF with PC Card Adapter

512MB CF with PC Card Adapter

2GB CF with PC Card Adapter

Includes one roll of thermal paper and one battery pack

Power Supply 200-240 VAC

Power Supply 100-120 VAC

10 rolls

For AC 120V

For AC 220-240V

Page 19

Effective power supply quality and power saving management for PCs

CWViewer

Data Analysis Program for CW240/CW12x

AP240E report creation in line with your objectives.

Powerful & Accurate measurement

with the CW240

AP240E

CW240

CW120 AP240E

Increased quality and effectiveness of report creation

CW Viewer AP240E is data analyzing software for the CW240 Clampon Power Meter. Making full use of the rich measuring functions of the

CW240, this efficiently manages the large amounts of measurement

data that are required in order to implement power quality

management, energy management, and power saving measures.

Furthermore, the quality and efficiency of report creation has been

improved in order that reports to meet certain purposes can be easily

created.

Report creation in line with objectives

●Graph Display

●Daily Report Display, Weekly /

Monthly Report Display

●Harmonic Graph Display

Graph

●Harmonics Instant Value Display

●Waveform Data Display

●Voltage Change Display

19

Daily Report

Page 20

20

Report

Creation

Power quality and power saving management data measured with the CW240

AP240E report creation in line with your objectives

Increased quality and effectiveness of report creation

Bulk Data Management

In order to edit measurement data to create reports that meet objectives, it is necessary to sort the required elements

from a broad range of measurement data, and to set both the parameters for display, and items to display. CW Viewer

AP240E carries out bulk management of data by registering measurement data and display parameters. Easy data

registration, deletion, reference, and analysis means that the program is easy to use immediately, even for beginners.

●Bulk Management of Large Quantities of

Measurement Data

Using the AP240E, it is easy to register a large amount of data

measured with CW240 in the database, for integrated handling.

1 At the time of data registration, only the target files are displayed,

and detailed information can be confirmed by selecting these files.

2 Measurement data can be searched by measurement date or

group name.

3 Automatically links to measurement data such as that for

waveforms and voltage changes.

4 Group names and comments can be added and registered.

●Fast Reproduction of Past Reports

CW Viewer AP240E links display parameters for graphs and records with measurement data, and saves this in the

database, which means that reports that have been created in the past can be swiftly recreated in the same format.

Effective power supply quality and power saving management for PCs.

Registered

Data Details

1

2

3

dialog

4

Main screen

Simple Report Creation

Select measurement data, and click the Data Display button to edit reports. Settings of display items is easy, and items

such as graphs and daily reports are easy to create.

Simple Operation Clear Display

●Pick out target elements from large amounts of

data.

Items that can be selected when setting display items are displayed

in a list, which means that measurement data items that are required

for carrying out power management and power quality management

1

2

3

can be efficiently selected to meet objectives.

1Up to a maximum of 8 items can be set for both the left and right

axes.

4

Item Selection dialog

2 Display items, units, and scale, etc. can be selected from the list.

3 Desired maximum and minimum values for the graph scale can be set. Additionally, the Automatic Settings button

can be used to set optimal values.

4 This is also convenient for comparisons with power reduction targets, by setting standard values.

●Easy Setting of Focus Times

Setting the start and period of the focus times enables setting of a range of part (or all) of the measurement data.

1The display start time can be specified from the range of existing measurement data.

2 The specified display range can be moved easily using these

buttons.

3 The graph display period (the whole period or a desired period)

can be specified.

4 A desired range (more than the measurement cycle) can be

specified.

1

2

3

4

Focus Period settings

Page 21

Data Analysis Program

CWViewer

A

P

240EA

P

240E

Variety of Presentations in Line with Objectives

Report formats that can be selected as a result of the types of measurement data are displayed on tabs. Report formats

in line with objectives can be easily selected with tabs from a variety of report presentations.

●Selection of Report Formats with Tabs

Report formats such as graph display, daily report display,

harmonics graph and voltage change can be easily switched by

selection with tabs.

Superimposed Display of Multiple Waveforms

A channel, system, and type can be selected for each

measurement item such as power, voltage, and current, and up to

8 items can be simultaneously displayed on the graph for each of

the left and right vertical axes (a total of 16 items). This enables

the comparative display per channel and system of multiple data

items.

●Easy-to-see Graph Display

Graph display can be changed (line type, line thickness, and line

color, markers, etc.) in line with objectives, and multiple

measurement data can be displayed on the report in an easy to see

manner.

●Harmonics Data Analysis

Harmonics graphs are displayed by selecting the desired degree

from amongst 50. Harmonics trend graphs and harmonics instant

value graphs can be selected with tabs, and in the harmonics

instant value tab, all harmonics levels, harmonics content ratios,

and phase differences can be displayed. Vector display of power

phase differences is also possible.

●Waveform Data Display

Displays as a graph waveform data (maximum of 7 for each of

four systems) measured with the CW240. Irregularities in voltage

and current waveforms for each phase can be viewed at a glance,

making for effective management of electrical power quality

(current situation and confirmation of measures taken).

Graph Display

Harmonics Trend Display Harmonics Instant

Power Phase Difference

Vector Diagram Display

Val ue Display

Waveform Display

Tab Selection

CW240

CW120 AP240E

21

One-Touch Selection of Daily and Weekly Reports

●Daily Report Display

Demand measurement values for power consumption are

displayed in time units (30 minutes or 1 hour) as daily reports,

simply by selecting the desired demand measurement items.

Furthermore, load and demand ratio calculations are carried out

automatically by setting capacitance values for facilities.

●Weekly and Monthly Report Display

Demand measurement values for power consumption in 1 day

units are displayed as weekly and monthly reports. Load and

demand ratio calculations are carried out automatically in the

same way as with daily reports.

●Voltage Change Display

Displays in a list voltage drops, rises, and momentary power

interruption detection data and detection time. This enables

confirmation of the start, end, and period of voltage changes.

●Record Display

When the graph display, harmonics trend display, and harmonics

instant value display tabs have been selected, numerical data for

the displayed graph range can be displayed as a record.

Daily Report Display

Voltage Change Display

Records Display

Page 22

Report

AP240E Analysis Data can be Further Edited in MS Excel and Word

Creation

Report Creation Customization Functions

●Graph and Record Printing

Print graphs and records by using the Print buttons on the graph

display screen and records screen. Additionally, when printing, the

preview screen will allow confirmation of output.

●Selectable Printer Type

Printer configuration is possible in order that either color or

monochrome are printed correctly.

Effective power supply quality and power saving management for PCs.

Print Preview

22

●Graph Copy

The portion of the graph on the displayed screen can be copied to the

clipboard by using the Graph Copy button on the graph screen. This

enables graph images that are created in CW Viewer AP240E to be

pasted into Excel or Word documents. Power phase difference vector

diagrams and waveform data are also handled in the same way.

●Record Copy

By using the Record Copy button in the same way as with graphs,

record data can be copied to the clipboard. Record data is copied as

text data.

●Saving Record Data as CSV Format Files

The range of data displayed on the daily report, monthly report, and

record screens can be saved as CSV format files. CSV files can be used

in spreadsheet software; this is convenient for secondary analysis of

measurement data, and creation of original reports.

Useful Functions

●Analog Input Data

Scaling for analog input data settings, and unit settings can be carried

out. This enables comparison of measurement data such as