Page 1

User ’s

Manual

Model CM6G

Gas Calorimeter

IM 11R02A01-02E

IM 11R02A01-02E

6th Edition

Page 2

u Introduction

Thank you for purchasing Model CM6G Gas Calorimeter.

In order to have the product deliver its full capabilities, read this instruction manual thoroughly

before you use it.

On how to use the Gas density meter, read the instruction manual which comes with the product.

WARNING

Since the ignition starts until it completes, or right after the ame is extinguished, sample gas

mixed with the air will be released from the top of the equipment into the installation space. Even

though the sample gas will be diluted suciently by the air, great attention should be paid to the

following points if the sample gas contains harmful gases such as CO.

• Conrm that the air is supplied before introducing the sample gas.

• Use the equipment in a well-ventilated environment equipped with a ventilation system.

• Do not expose your face above the top of the calorie detector.

<INTRODUCTION>

i

n About This Manual

• This manual should be passed on to the end user so that the user can refer to the manual

whenever they need.

• If the product is not used in a manner specied in this manual, the safety of this product may

be impaired.

• The contents of this manual are subject to change without prior notice.

• The contents of this manual shall not be reproduced or copied, in part or in whole,without

permission.

• This manual explains the functions contained in this product, but does not warrant that they

are suitable for the particular purpose of the user.

• Every eort has been made to ensure accuracy in the preparation of this manual.

However, when you realize mistaken expressions or omissions, please contact the nearest

Yokogawa Electric representative or sales oce.

n Drawing Conventions

Some drawings may be partially emphasized, simplied, or omitted, for the convenience of

description.

n Inspection on delivery

After the delivery, open the product package carefully and inspect for damages caused during the

transport. Should there be any damage or breakage on the product, please contact YOKOGAWA

immediately. Retain all the packing materials, containers and boxes that came with the product.

After unpacking, make sure the delivered products include all of the component equipment you

ordered. When conrming the specications, refer to the model and sux codes indicated on the

nameplate on the product. The models are indicated on the name plates. Check also those of

accessories. For further information, please read subsection 1.2 of this document.

Media No.IM 11R02A01-02E 6thEdition : May 10, 2019 (YK)

All Rights Reserved Copyright © 2016, Yokogawa Electric Corporation

IM 11R02A01-02E 6th Edition :May 10, 2019-00

Page 3

u Safety Precautions

n Safety,Protection,ModicationoftheProduct

• In order to protect the system controlled by the product and the product itself and ensure

safe operation, observe the safety precautions described in this user’s manual. We assume

no liability for safety if users fail to observe these instructions when operating the product.

• If this instrument is used in a manner not specied in this user’s manual, the protection

provided by this instrument may be impaired.

• If any protection or safety circuit is required for the system controlled by the product or for

the product itself, prepare it separately.

• Be sure to use the spare parts approved by Yokogawa Electric Corporation (hereafter

simply referred to as YOKOGAWA) when replacing parts or consumables.

• Modication of the product is strictly prohibited.

• The following safety symbols are used on the product as well as in this manual.

WARNING

This symbol indicates that an operator must follow the instructions laid out in this manual in

order to avoid the risks for the human body and health including risk of injury, electric shock, or

fatalities. or the damages to instruments. The manual describes what special care the operator

must take to avoid such risks.

<INTRODUCTION>

ii

CAUTION

This symbol indicates that the operator must refer to the instructions in this manual in order to

prevent the operator or instrument from being injured, or damaged.

The following are signal words to be found only in our instruction manuals.

CAUTION

This symbol gives essential information to avoid damages of soft or hardware, or system failure.

NOTE

This symbol indicates information that complements the present topic.

n Warning and Disclaimer

• The product is provided on an “as is” basis. YOKOGAWA shall have neither liability nor

responsibility to any person or entity with respect to any direct or indirect loss or damage

arising from using the product or any defect of the product that YOKOGAWA can not predict

in advance.

n Trademark policy

All company or product and product names mentioned in this document are trade names,

trademarks or registered trademarks of their representative companies. In this document,

trademarks or trade names are not indicated with TM or ® as trademark symbols.

IM 11R02A01-02E 6th Edition :May 10, 2019-00

Page 4

u After-sales Warranty

n Do not modify the product.

n Yokogawa warrants the product for the period stated in the pre-purchase quotation Yokogawa

shall conduct dened warranty service based on its standard. When the customer site is located

outside of the service area, a fee for dispatching the maintenance engineer will be charged to the

customer.

n During the warranty period, for repair under warranty, carry or send the product to the local

sales representative or service oce. Yokogawa will replace or repair any damaged parts and

return the product to you.

• Before returning a product for repair under warranty, provide us with the model name

and serial number and a description of the problem. Any diagrams or data explaining the

problem would also be appreciated.

• If we replace the product with a new one, we won’t provide you with a repair report.

n In the following cases, customer will be charged repair fee regardless of warranty period.

• Failure of components which are out of scope of warranty stated in instruction manual.

• Failure caused by usage of software, hardware or auxiliary equipment, which Yokogawa

Electric did not supply.

• Failure due to improper or insucient maintenance by user.

• Failure due to modication, misuse or outside-of-specications operation which Yokogawa

does not authorize.

• Failure or damage caused by relocation of the instrument.

• Failure due to power supply (voltage, frequency) being outside specications or abnormal.

• Failure caused by any usage at location or its maintenance that Yokogawa does not

authorize.

• Any damage from re, earthquake, storms and oods, lightning, disturbances, riots, warfare,

radiation and other natural changes.

n Yokogawa does not warrant conformance with the specic application at the user site.

Yokogawa will not bear direct / indirect responsibility for damage due to a specic application.

<INTRODUCTION>

iii

n Yokogawa Electric will not bear direct / indirect responsibility for any damage an end user might

incur, when the user congures the product into systems or resells the product.

n Maintenance service and supplying repair parts will be covered for ve years after the

production ends. For repair for the product, please contact the nearest sales oce described in

this instruction manual.

IM 11R02A01-02E 6th Edition :May 10, 2019-00

Page 5

Blank Page

Page 6

Model CM6G

Gas Calorimeter

IM 11R02A01-02E 6th Edition

CONTENTS

u Introduction ....................................................................................................i

u Safety Precautions .......................................................................................ii

1. Outline ....................................................................................................... 1-1

1.1 StandardSpecications ................................................................................... 1-1

1.2 ModelandSuxCodes ...................................................................................1-3

1.3 ..............................................................Standard Systems for Each Application

1-4

1.4 ExternalDimensions ........................................................................................ 1-6

1.5 ....................................................................................Principle of Measurements

1-10

Toc-1

2. Installation, Piping, Wiring ...................................................................... 2-1

2.1 Installations .......................................................................................................2-1

2.2 Externalpiping .................................................................................................. 2-1

2.3 ExternalWirings ................................................................................................ 2-4

3. Construction and Function ..................................................................... 3-1

3.1 Air Pressure Regulating System ..................................................................... 3-1

3.2 Gas Pressure Control Section ......................................................................... 3-1

3.3 DierentialPressureDetectionPart ............................................................... 3-4

3.4 Calorie Detector ................................................................................................ 3-5

3.4.1 Burner Unit ......................................................................................... 3-8

3.4.2 High/Low Alarm Action ....................................................................... 3-9

3.4.3 Ignition ............................................................................................... 3-9

3.5 Computing Station .......................................................................................... 3-10

3.5.1 Display ............................................................................................. 3-10

3.5.2 Contents of the Data Display ........................................................... 3-13

3.5.3 Correcting Computation ................................................................... 3-14

3.6 Density Meter ................................................................................................... 3-16

4. Preparation of Operation ......................................................................... 4-1

4.1 Sampling Section (Outside panel) .................................................................. 4-1

4.2 Status of Valves ................................................................................................. 4-1

4.3 Water Supply (For Steel Mill Use) .................................................................... 4-1

4.4 Supply of the Air ................................................................................................ 4-2

4.5 Supply of Power ................................................................................................ 4-2

4.6 TheZeroAdjustmentoftheDierentialPressureTransmitter .................... 4-2

4.7 AirDierentialPressureAdjustment .............................................................. 4-3

IM 11R02A01-02E

6th Edition :May 10, 2019-00

Page 7

Toc-2

4.8 Pressure Adjustment of the Gas Line .............................................................4-3

5. Operation ................................................................................................... 5-1

5.1 Start Operation .................................................................................................. 5-1

5.2 Stopping Operations ........................................................................................ 5-2

6. Calibration ................................................................................................. 6-1

6.1 Supply of the Calibration Gas .......................................................................... 6-1

6.1.1 For Town Gas Use .............................................................................6-1

6.1.2 For Steel Mill Use ............................................................................... 6-2

6.2 Span Adjustment of the Calorie Detector.......................................................6-2

6.3 Calibration of the Computing Station ............................................................. 6-4

6.4 Calibration of the Density Meter ...................................................................... 6-4

7. Maintenance .............................................................................................. 7-1

7.1 Daily Check ........................................................................................................ 7-1

7.1.1 Air, Gas Dierential Pressure Adjustment ......................................... 7-1

7.1.2 Take Out the Water Out of the Drain Pot (Pump for Steel Mill Use) .. 7-1

7.1.3 Take Out the Drain from the Air Set ................................................... 7-1

7.2 Regular Check ................................................................................................... 7-2

7.2.1 Cleaning of the Orice Plate and Replacement of O-ring .................7-2

7.2.2 Fulo Filter (For Steel Mill Use)..........................................................7-3

7.2.3 Line Filter (For Town Gas Use) .......................................................... 7-3

7.2.4 Washing Bubbler or Pressure Regulating Pot ................................... 7-4

7.2.5 Dehumidier (For Steel Mill Use) ....................................................... 7-4

7.2.6 Density Meter ..................................................................................... 7-4

7.3 Check at the Regular Service .......................................................................... 7-5

7.3.1 Check the Burner Flame .................................................................... 7-5

7.3.2 Zero Adjustment of the Dierential Pressure Transmitter .................. 7-6

7.3.3 Others ................................................................................................ 7-6

8. Troubleshooting ....................................................................................... 8-1

8.1 Gas Sampling Pressure Regulating Section ................................................. 8-1

8.2 Air Pressure Adjustment Section ....................................................................8-2

8.3 DierentialPressureTransmitterSection ...................................................... 8-2

8.4 Signal Section ................................................................................................... 8-3

8.5 Computing Station ............................................................................................ 8-5

8.6 Other Troubleshooting ..................................................................................... 8-5

Revision Information ...............................................................................................i

IM 11R02A01-02E 6th Edition :May 10, 2019-00

Page 8

<1. Outline>

1. Outline

Model CM6G Gas calorimeter measures and controls a caloric value of gases, Wobbe-Index

(hereinafter referred to as WI), a theoretical air requirement, and a heat input for various kind of

gas burning furnaces.

It detects a temperature rise of a sample gas, whose pressure is normally controlled, by burning it

at a burner through the medium of air.

It picks up the ow rate of the sample gas and the air as the dierential pressure signal and

outputs a signal of WI after compensating calculation of the indication dierence caused by the

ow rate variation.

It also detects density of the sample gas by a density meter, and add to WI signal density

compensation, then, outputs a caloric signal.

1.1 StandardSpecications

EMC : EMC Regulatory Arrangement in Australia and New Zealand

Korea Electromagnetic Conformity Standard Class A

A급 기기 (업무용 방송통신기자재)

이 기기는 업무용(A급) 전자파적합기기로서 판매자 또는

사용자는 이 점을 주의하시기 바라며, 가정외의 지역에서

사용하는 것을 목적으로 합니다.

한국 전자파적합성 기준

1-1

n Town Gas Application

Measurement Object : Measurement and control of WI or the caloric value of fuel gas

Measuring Range : 3 to 62 MJ/Nm

Sample Conditions :

Dust ; 5 mg/Nm

Temperature ; 50°C or less

Humidity ; dew point of 0°C or less

Pressure ; (1) 10 to 20 kPa

Range : Select scale range (Span) :

General Gas ; 30 to 50% of maximum value of the span

Butane or Butene + Air ; 20 to 30% of maximum value of the span

Propane or Propylene + Air ;25 to 40% of maximum value of the span

Output : 1 to 5 V DC, 4 to 20 mA DC (simultaneously), non-isolated,

load resistance; 750 Ω or less

Alarm Contact Output :

Flame o alarm; 100 V AC, 5 A, closed when alarm occurs (resistance

Orice Temperature alarm; 100 V AC, 3 A, closed when alarm occurs

Contact Input : Remote ignition (Custom order); 24 V DC, 0.1A or more

for town gas.

3

3

or less

(2) 10 kPa or under: with pump

(3) 100 to 600 kPa: with pressure reducing valve

load) when contact is opened, the leakage current is 2

mA or less (100 V AC)

(resistance load)

IM 11R02A01-02E 6th Edition :May 10, 2019-00

Page 9

<1. Outline>

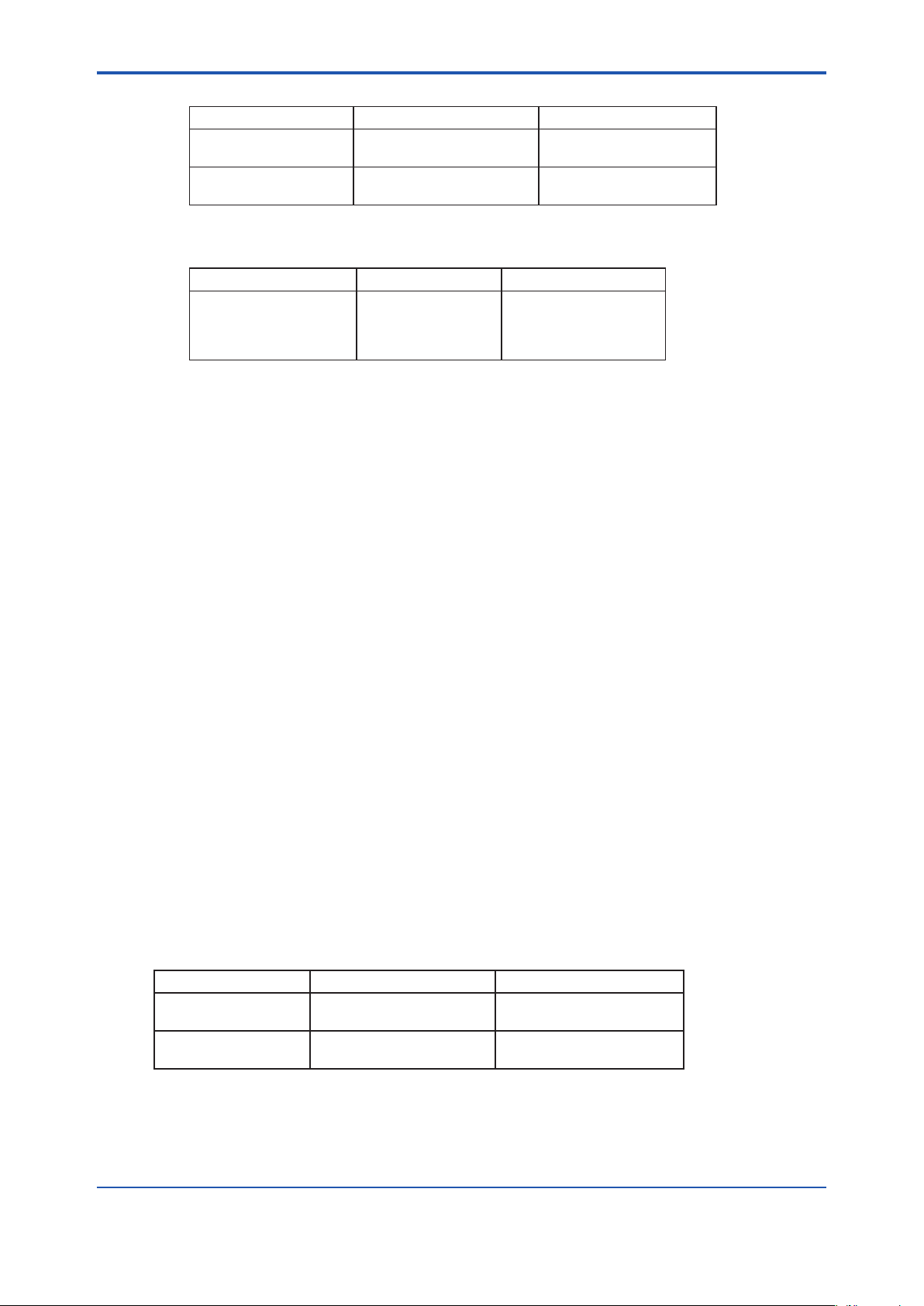

Repeatability

Measurement Measuring range (Note 1) Repeatability

WI

Caloric value

3

MJ/Nm

Note 1: High caloric value means 6.3 MJ/Nm3 or more. Low caloric value means below 6.3 MJ/Nm3.

High caloric value

Low caloric value

High caloric value

Low caloric value

± 0.5% of measured value

± 1.0% of measured value

± 1.0% of measured value

± 1.5% of measured value

Sample Gas Flow Rate : Approx. 10 l/min

Response Time (Note 2):

Max.WImeasured Dead time Response time (63.2%)

50 or more

32 or more, less than 50

13 or more, less than 32

Less than 13

Note 2: Response time varies depending on the WI of a sample gas. This is due to the dierent sample gas ow rate of the

calorimeter. The ow rate is preset depending on the WI of the sample gas to prevent the caloric value at the detector

burner from exceeding the upper limit.

Approx. 30 sec or less

Approx. 27 sec or less

Approx. 23 sec or less

Approx. 21 sec or less

Approx. 60 sec or less

Approx. 53 sec or less

Approx. 47 sec or less

Approx. 41 sec or less

Utility :

Instrument Air ; Approx. 50 Nl/min, pressure 300 to 700 kPa, dew point of 0°C or less

Power Supply ; 100 V AC ± 10%, single phase, 50/60 Hz (Note 3), 860 VA max.

Note 3: When you perform a low caloric value measurement, the frequency variation should be within ±0.4%. If the frequency variation

exceeds ±0.4% (especially for exporting overseas), consult with Yokogawa.

1-2

n Steel Mill Application

Measurement Object : Measurement and control of WI or the caloric value of fuel gas for a

Measuring range : 3 to 62 MJ/Nm

Sample Conditions:

Dust; 100 mg/Nm

Temperature; 50°C or less

Pressure; (1) 8 to 15 kPa

(2) 8 kPa or under: with pump

Range : Select scale range (Span):

General Gas; 30 to 50% of maximum value of the span

Butane or Butene + Air; 20 to 30% of maximum value of the span

Propane or Propylene + Air; 25 to 40% of maximum value of the span

Output : 1 to 5 V DC, 4 to 20 mA DC (simultaneously), non-isolated, load

resistance 750Ω or less

Alarm Contact Output :

Flame o alarm;

Temperature alarm; 100 V AC, 3 A, closed when alarm occurs (resistance load)

Contact Input: Remote ignition (Custom order); 24 V DC, 0.1A or more

Repeatability :

Measurement Measuring range (Note 1) Repeatability

WI

Caloric value

3

MJ/Nm

steel mill.

High caloric value

Low caloric value

High caloric value

Low caloric value

3

3

or less

100 V AC, 5 A, closed when alarm occurs (resistance load) when

contact is opened, the leakage current is 2 mA or less (100V AC)

0.5% of measured value

1.0% of measured value

1.0% of measured value

1.5% of measured value

Note 1: High caloric value means 6.3 MJ/Nm3 or more. Low caloric value means below 6.3 MJ/Nm3.

IM 11R02A01-02E 6th Edition :May 10, 2019-00

Page 10

<1. Outline>

Sample Gas Flow Rate :Approx. 10 l/min.

Response Time (Note 2):

Max.WImeasured Dead time Response time (63.2%)

50 or more

32 or more, less than 50

13 or more, less than 32

Less than 13

Note 2: Response time varies depending on the WI of a sample gas. This is due to the dierent sample gas ow rate of the

calorimeter. The ow rate is preset depending on the WI of the sample gas to prevent the caloric value at the detector

burner from exceeding the upper unit.

42 sec or less

39 sec or less

36 sec or less

30 sec or less

70 sec or less

60 sec or less

50 sec or less

45 sec or less

Utility :

Water ; Approx. 0.2 l/min, pressure 200 to 600 kPa

Instrument Air ; Approx. 50 Nl/min, pressure 300 to 700 kPa, dew point of 0°C or less

Power Supply ; 100 V AC ± 10%, single phase, 50/60 Hz (Note 3), 1100 VA max.

Note 3: In case of low caloric value measurement, frequency variation should be within ± 0.4%. If frequency variation exceeds ± 0.4%,

consult with Yokogawa.

Panel:

Construction : For indoor installation, rack panel

Paint Color: Munsell 3.2PB7.4/1.2 (inside and outside)

Ambient Temperature:

0 to 40°C (little temperature variation,particularly no

rapid change )

1-3

1.2 ModelandSuxCodes

n CM6G Gas Calorimeter

Model SuxCode Option Code Description

CM6G

Gas

Pressure

Measurement 00

Power supply -5

Range R - - - - - - - - - - Measuring range

Style *C - - - - - - - - - - Style C

Note: Measuring range and unit must be specied.

- - - - - - - - - - - - - - - - -

-S6 - - - - - - - - - - Always - S6

1

2

3

4

5

6

7

8

10

-6

- - - - - - - - - - Gas calorimeter

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

- - - - - - - - - -

Gas pressure 10 to 20 kPa for town gas, quake-proof

Gas pressure 10 to 20 kPa for town gas

Gas pressure 10 kPa or under for town gas

Gas pressure 100 ro 600 kPa for town gas

Gas pressure 8 to 15 kPa for steel mill, without preheating

Gas pressure 8 to 15 kPa for steel mill, with preheating

Gas pressure 8 kPa or under for steel mill, without preheating

Gas pressure 8 kPa or under for steel mill, with preheating

WI measurement

Caloric value measurement (GD400G should be purchased

separately)

100 V AC 50 Hz

100 V AC 60 Hz

l Standard Accessories

Followings are the standard accessories supplied.

• Calorie Detector

Name Q’ty Remarks

Mirror

Fuse

For burner ame inspection

1

2

3.15 A (A1113EF)

IM 11R02A01-02E 6th Edition :May 10, 2019-00

Page 11

<1. Outline>

• Orice Assembly

Name Q’ty Remarks

O-Ring

O-Ring

Hexagon Wrench

Hexagon Wrench

1

P16 (Viton) (Y9114XB)

3

P20 (Silicon) (L9817MT)

1

Nominal size 1.5 mm

1

Nominal size 2.5 mm

n Gas Density Meter

Gas Density Meter compensates a density value in caloric value measurement.

It is not required for WI measurement.

Converter: GD400G-N-10-N-/PA

Detector: GD300S-J-/KU

Measuring range and unit (specic gravity or density) should be specied. See GS 11T3E1-01E

for further information.

n Option

You must purchase options separately.

Name Part no. Description

Probe H7800HA Insertion length 650 mm

Probe H7800HB Insertion length 1150 mm

Probe H7800HC Insertion length 1650 mm

Fulo lter G7043XJ Element material: Polypropylene

Pressure reducing valve G7008XF Primary pressure: 15 MPa max.

Pore size: 50 μm

Body: SUS 316

Connection: Rc 1/2

Secondary pressure: 0 to 200 kPa

Material: Brass

1-4

1.3 Standard Systems for Each Application

Application Measurement Systemspecication Suxcode*

WI

Town Gas

Caloric value

3

MJ/Nm

WI

Steel Mill

Caloric value

3

MJ/Nm

* The code is basic for gas pressure and measurement.

Note: A wet sample gas in the town gas application is outside the scope of the standard specications. Consult

with Yokogawa.

Without

density

meter

With

density

meter

Without

density

meter

With

density

meter

Gas pressure 10 to 20 kPa: Standard

Gas pressure 10 kPa or under: With pump

Gas pressure 100 to 600 kPa: With pressure

reducing value

Gas pressure 10 to 20 kPa: Quake-proof

Gas pressure 10 to 20 kPa: Standard

Gas pressure 10 kPa or under: With pump

Gas pressure 100 to 600 kPa: With pressure

reducing value

Gas pressure 8 to 15 kPa: Without preheating

Gas pressure 8 to 15 kPa: With preheating

Gas pressure 8 kPa or under: Without preheating

Gas pressure 8 kPa or under: With preheating

Gas pressure 8 to 15 kPa: Without preheating

Gas pressure 8 to 15 kPa: With preheating

Gas pressure 8 kPa or under: Without preheating

Gas pressure 8 kPa or under: With preheating

-S6200

-S6300

-S6400

-S6110

-S6210

-S6310

-S6410

-S6500

-S6600

-S6700

-S6800

-S6510

-S6610

-S6710

-S6810

IM 11R02A01-02E 6th Edition :May 10, 2019-00

Page 12

<1. Outline>

n Instructions for System Selection

● The quake-proof type gas calorimeter is always equipped with the density meter.

● The CM6G Gas Calorimeter controls the ow rate under a constant dierential pressure. In

the caloric value measurement, if the density of a sample gas changes, a ow rate error

proportional to the reciprocal of the square root of the density of the sample gas,

will be generated, which directly aects the caloric value. Therefore, density compensation

is required using a density meter.

For the WI measurement, a density meter is not required since the WI is a value

proportional to

ρ

.

g

1/

1-5

ρ

g

1/

,

IM 11R02A01-02E 6th Edition :May 10, 2019-00

Page 13

<1. Outline>

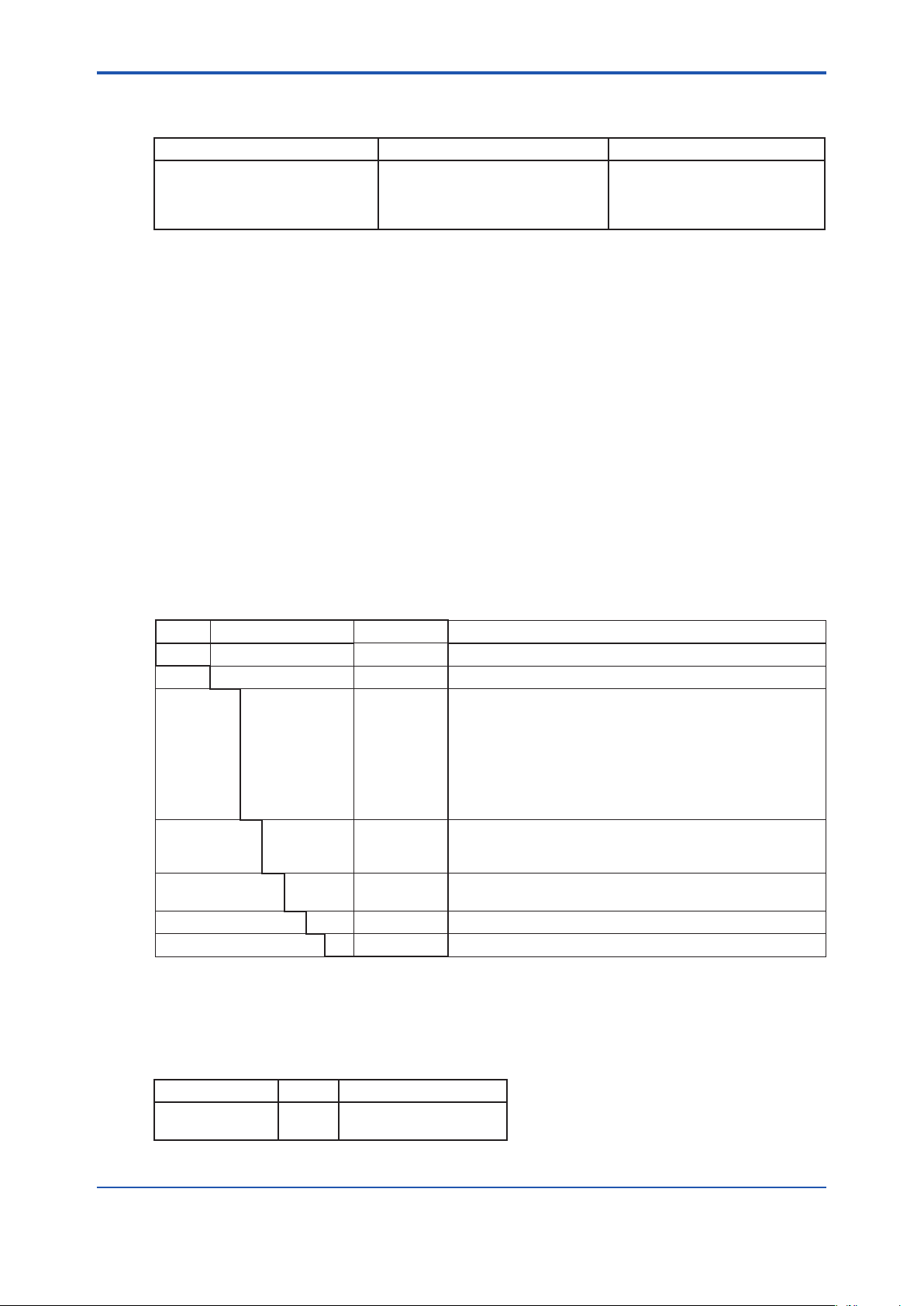

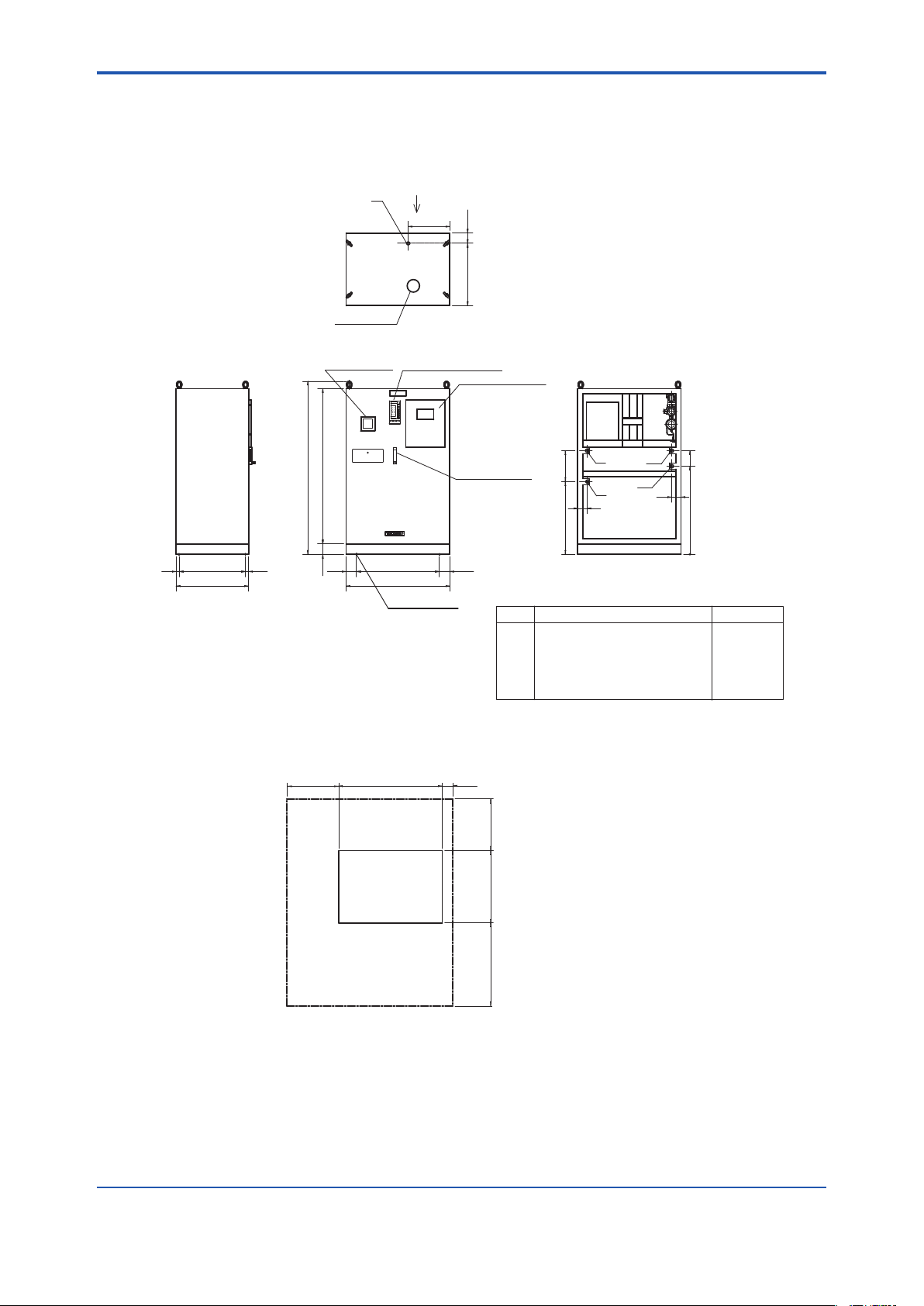

1.4 ExternalDimensions

n For Town Gas Applications

CM6G-S6200, S6210, S6300, S6310, S6400, S6410

1-6

Unit: mm

Mark Name Connection

A SAMPLE GAS IN Rc1/4

SAMPLE GAS OUT

B

C INST.AIR IN Rc1/4

D STD.GAS IN Rc1/4

E STD.GAS IN Rc1/4

B

D

E

A

C

250

View X

130

900

700

550

400

300

0

OR VENT Rc1/2

30

740

800

Density meter

converter

Computing

station

Approx.70

30

*

1800100

Approx.1970

100

4-Ø14 holes

X

* CM6G-S610 (with density meter) only

Density meter

detector

700

900

*

Calorie detector

Flowmeter for

density meter

100

*

Maintenance Space

100

800800 500

900

Back

Front

500

Weight: Approx. 300kg

Dim-6210.ai

IM 11R02A01-02E 6th Edition :May 10, 2019-00

Page 14

<1. Outline>

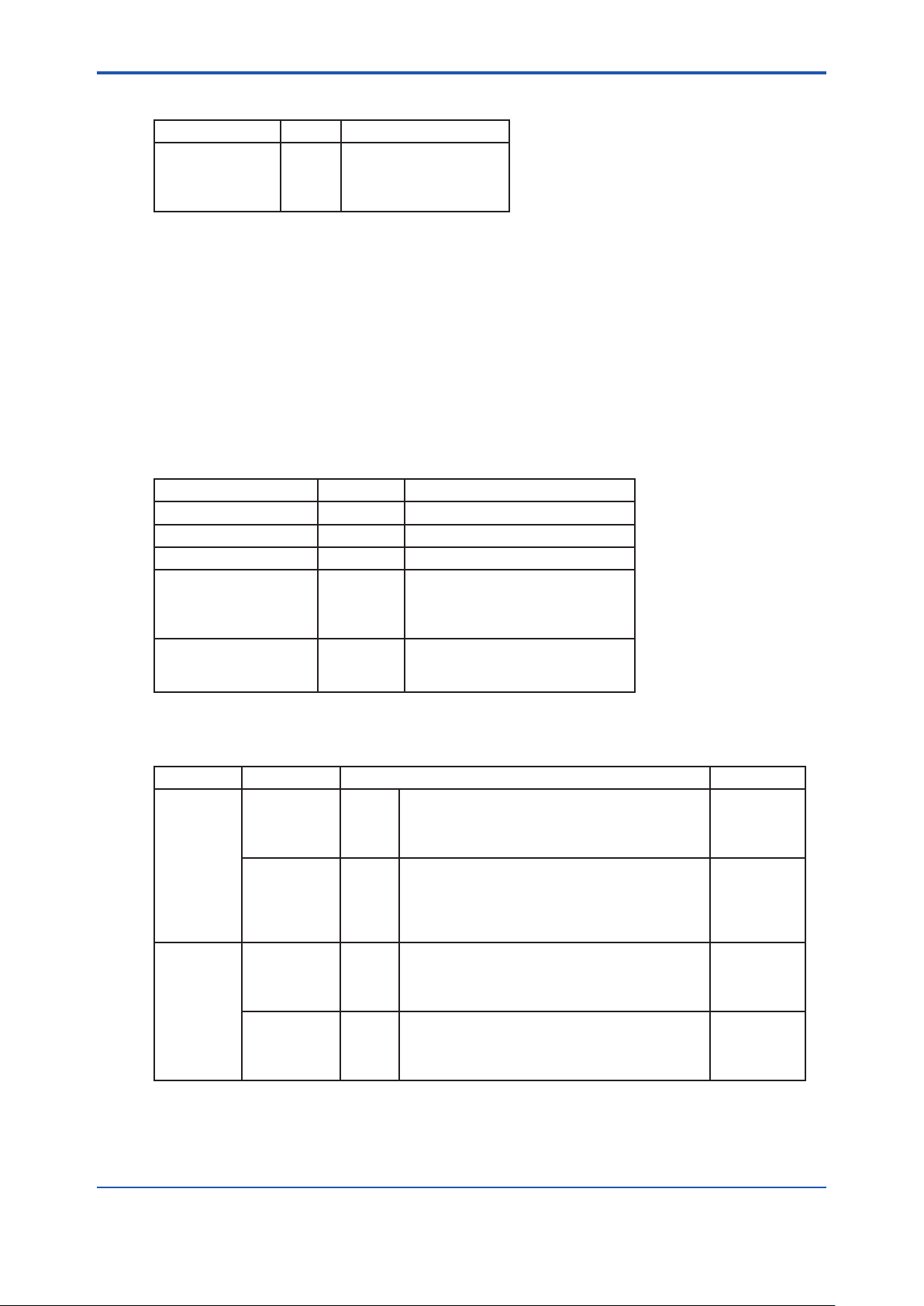

n For Town Gas Application (Quake-proof Type)

CM6G-S6110

1-7

30 640 30

700

Ø120 hole

Density meter

converter

1500100

Approx. 1670

X

D

400

Computing station

FAIL

---CM6G---

ALM

TREND 3

90.00

18.00

Y2Y1X3X1500.0

35.00

C

1000.0

37.67

100.00

23.02

A

M

▼▼▼

△

▽

PF

0.00

14.65

0.0

23.02

▼

C

O

SHIFT

<

<<<

YOKOGAWA◇

1000

4-Ø15 holes

100600

Calorie detector

Flowmeter for

density meter

100800100

300700

90

A

B

C2

View X

C1

90

Mark Name Connection

A SAMPLE GAS IN Rc1/4

B INST.AIR IN Rc1/4

C1 STD.GAS IN (ZERO) Rc1/4

C2 STD.GAS IN (SPAN) Rc1/4

D SAMPLE GAS OUT OR VENT Rc1/2

Wiring to switch box should be made

through the bottom.

Unit: mm

1000

850

0

Maintenance Space

1000 100500

Back

Front

500

700

800

Weight: Approx. 350kg

Dim-6110.ai

IM 11R02A01-02E 6th Edition :May 10, 2019-00

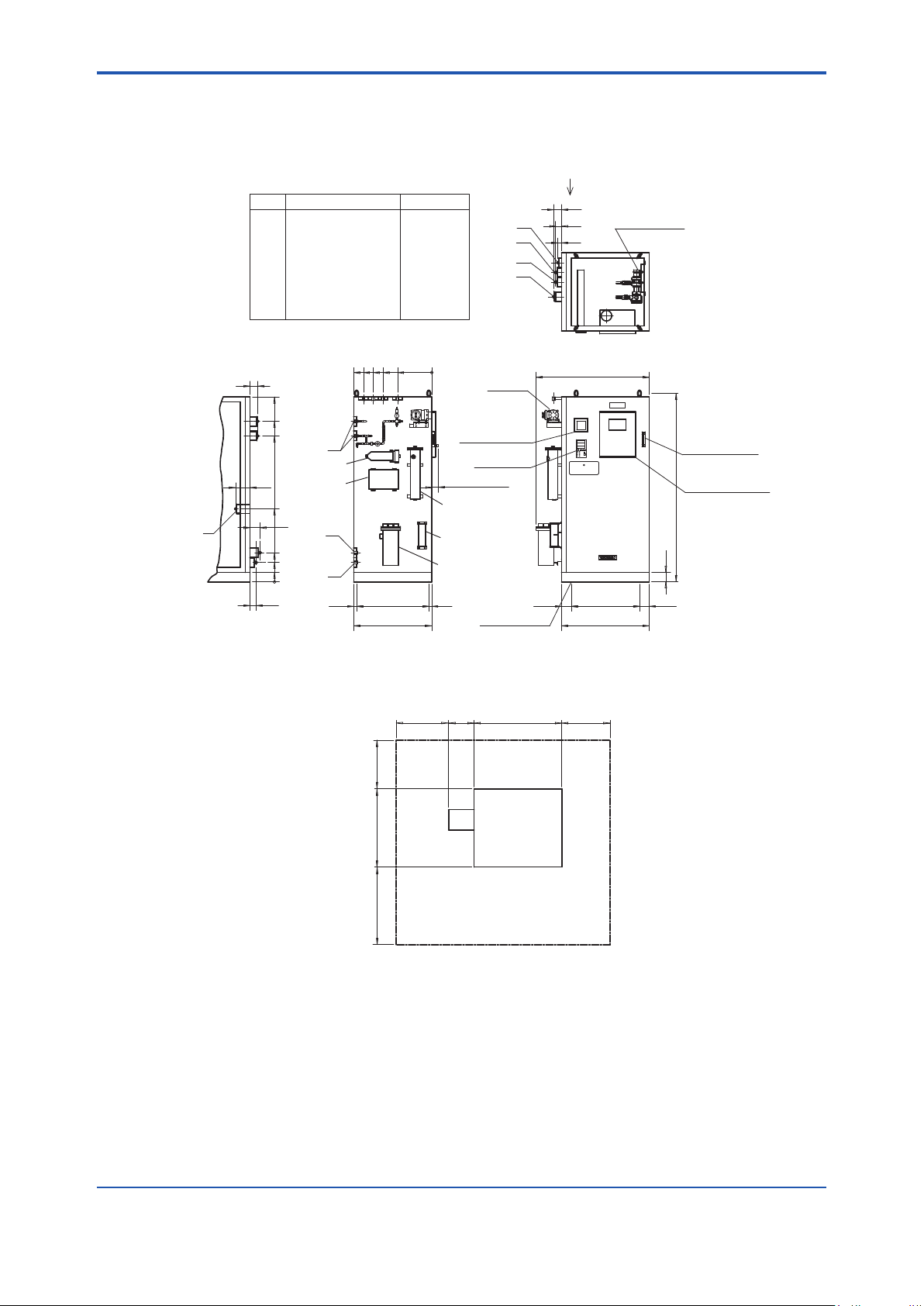

Page 15

<1. Outline>

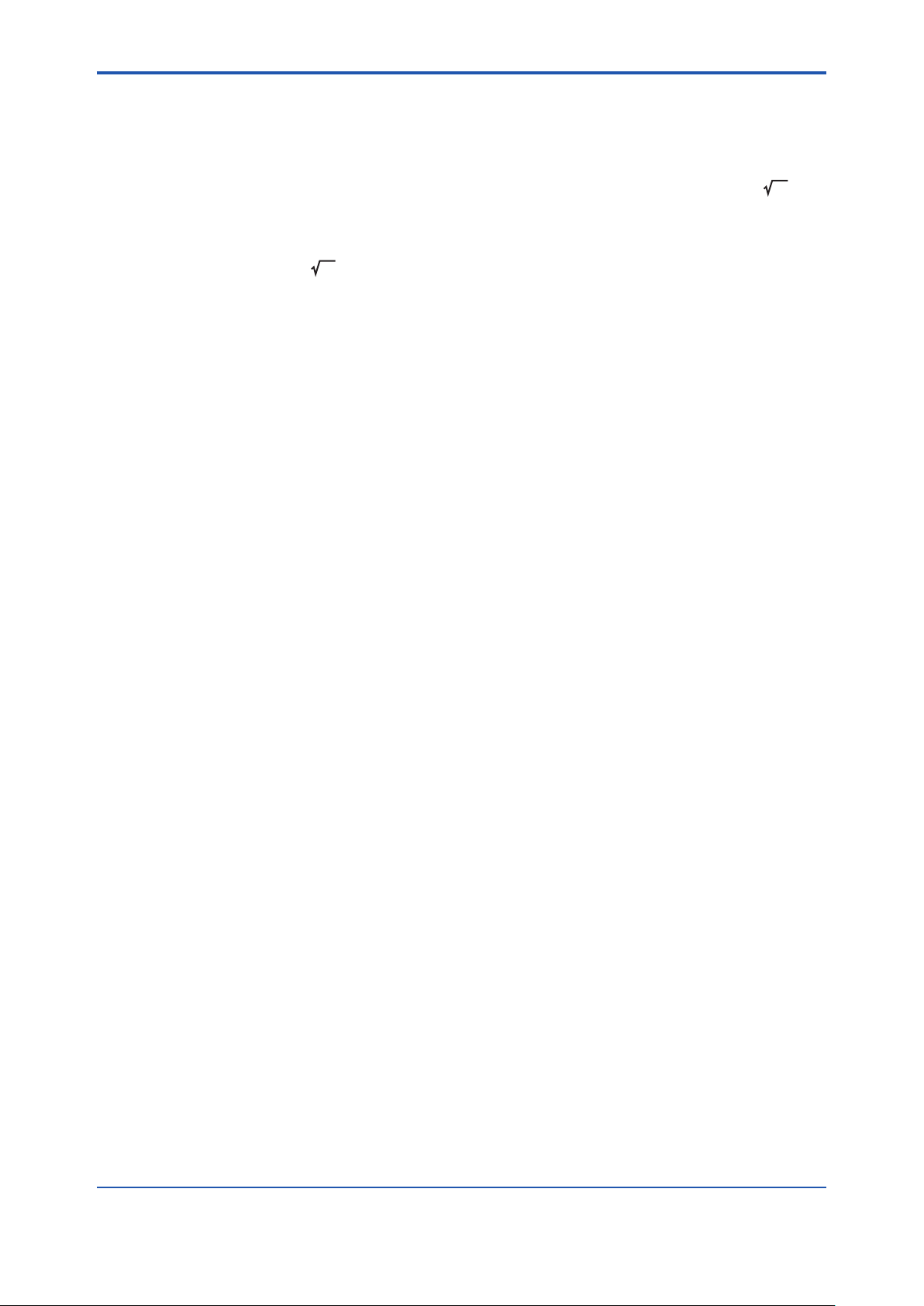

n For Steel Mill Application

CM6G-S6500, S6510, S6600, S6610, S6700, S6710, S6800, S6810

1-8

*

Flowmeter for

density meter

Calorie detector

Approx.1970

100

Unit: mm

*

X

Mark Name Connection

A SAMPLE GAS IN Rc1/2

B SAMPLE GAS OUT Rc1/2

C SAMPLE GAS OUT Rc1/2

D STD.GAS IN Rc1/4

E WATER IN Rc1/2

F DRAIN OUT Rc1/2

G INST.AIR IN Rc1/4

H SAMPLE GAS VENT Rc1/4

500

600

700

800

80

1900

1650

1500

150

750

View X

60

100

300

200

100

0

G

D

Fulflo filter

Dehumidifier

E

F

740 30(30)

800

0

350

Washing bubbler

Drain pot

Pressure regulating

pot

Density meter

converter

Approx. 70

H

B

C

A

**

Pump

*

Computing

station

4-Φ14 holes

80

60

40

Approx.1160

(100)

* CM6G-S610 (with density meter and flowmeter)

** CM6G-S670, CM6G-S680 (with pump)

Density meter

detector

700

900

100

500

800

800

Maintenance Space

540

900260

Back

Front

500

Weight: Approx. 350kg

Dim-6810.ai

IM 11R02A01-02E 6th Edition :May 10, 2019-00

Page 16

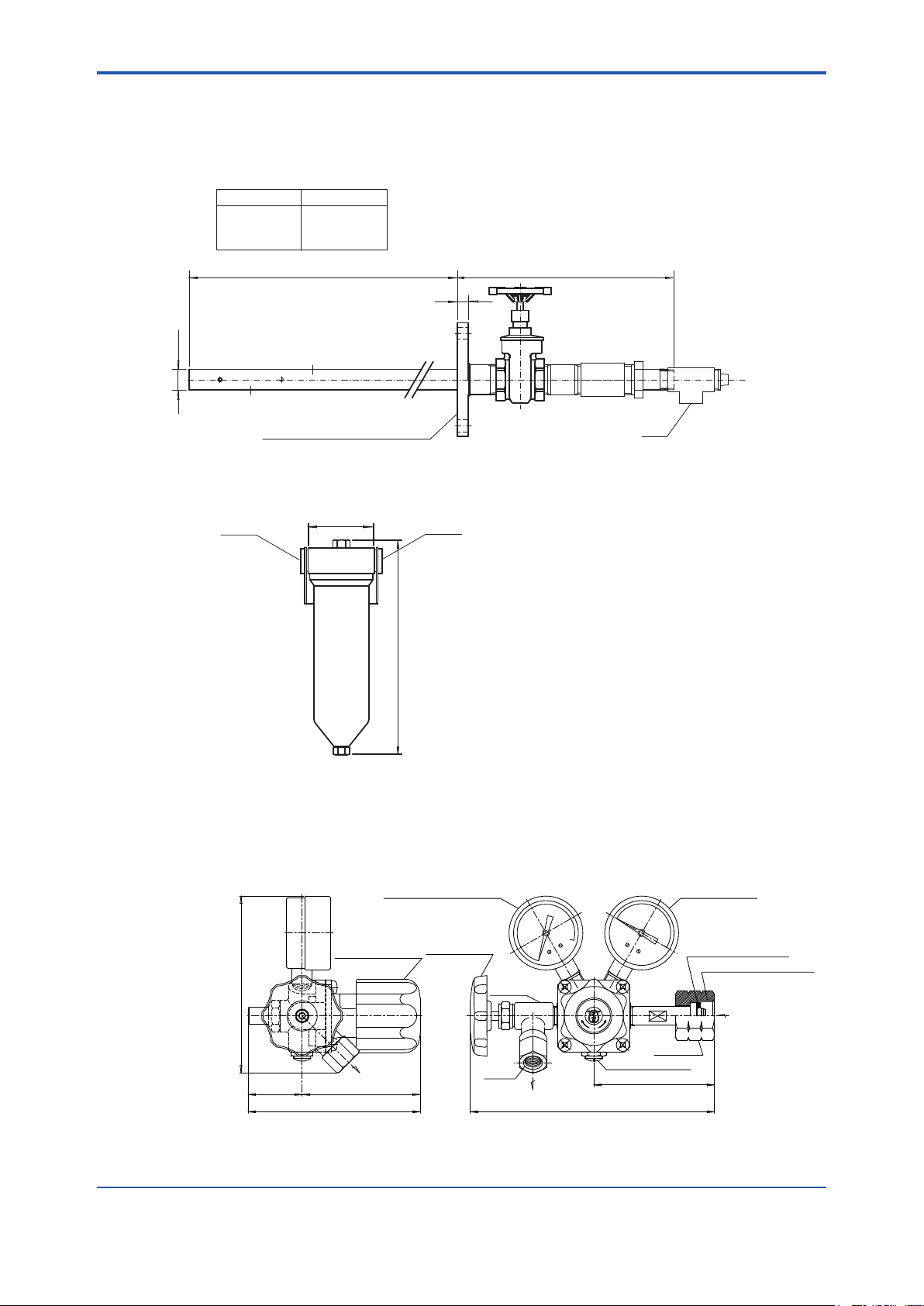

<1. Outline>

n Dimensions of Options

l Probe

Unit: mm

Part number L

H7800HA Approx. 650

H7800HB Approx. 1150

H7800HC Approx. 1650

)( 350Insertion length L

18

Φ34

1-9

JIS 10K-80-FF Equiv. SUS304

l FuloFilter(Partno.:G7043XJ)

108

Rc1/2Rc1/2

Approx. 350

Unit: mm

l PressureReducingValve(Partno.:G7008XF)

Secondary pressure

gauge

0.3MPaG

Rc1

Primary pressure

gauge

25MPaG

H7800HA.ai

Unit: mm

Approx. 119

Approx. 38

Handle for

pressure control

Approx. 62

Approx. 120

Outlet

Handle for

stop valve

Stop valve

Rc1/4

Outlet

H

C

I

A

H

K

O

A

T

開

閉

Safety valve

Approx. 166

Daiflon packing

W22 Left-hand thread

Inlet

Nut

Approx. 81

F2-8.ai

IM 11R02A01-02E 6th Edition :May 10, 2019-00

Page 17

<1. Outline>

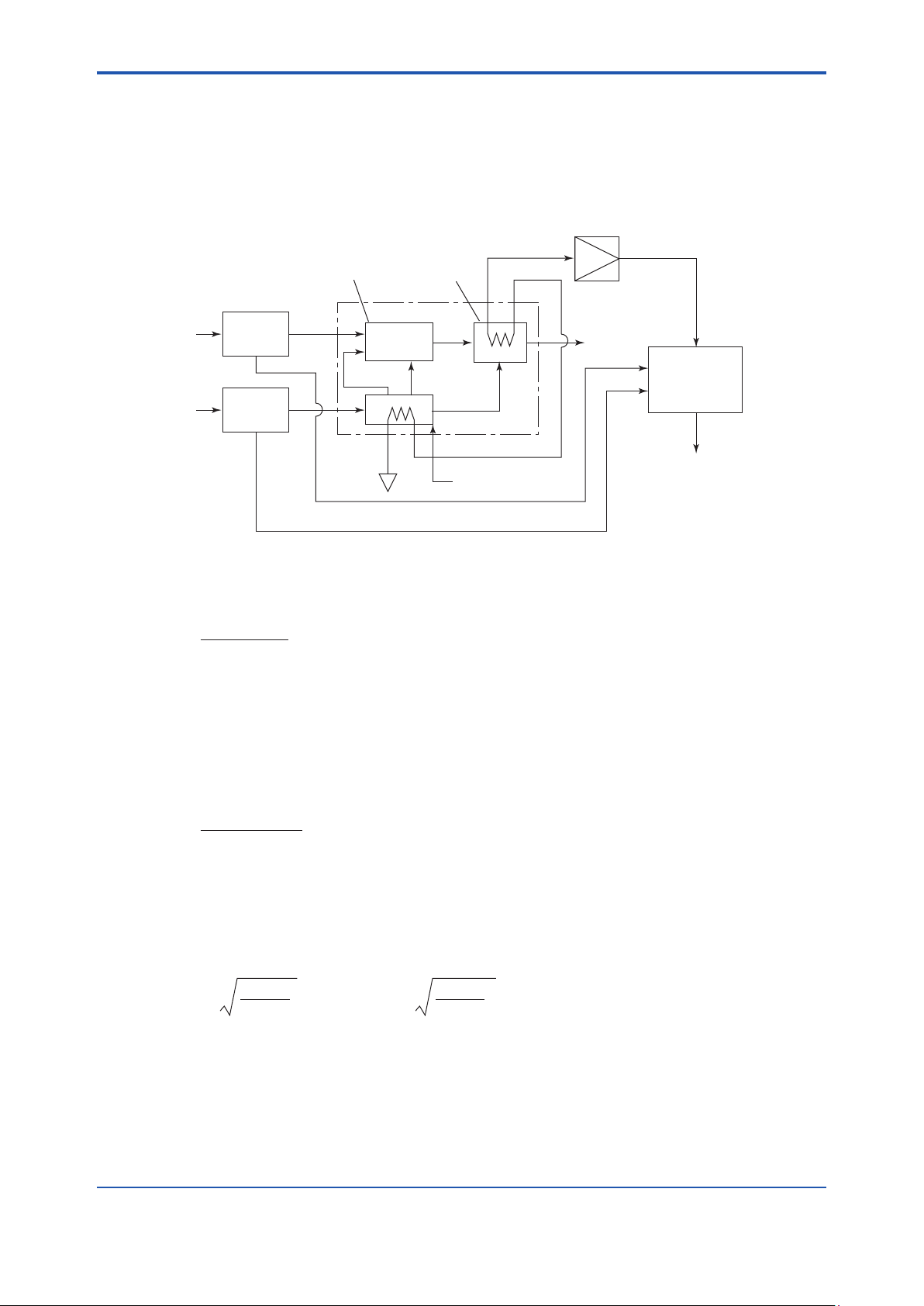

1.5 Principle of Measurements

The instrument detects the temperature dierence, using a thermocouple, between the exhaust

combustion gas made after sample gas is burnt in the burner, and the feed air at the inlet of

the burner. Then the instrument amplies the value of temperature dierence. It adds the

compensating calculation to the output signal and measures the caloric value of WI.

1-10

DIFFERENTIAL

PRESSURE

DETECTION

GAS

AIR

Figure 1.1 Measurement principle diagram

BURNING

PRIMARY

MIXING

SECONDARY

TERTIARY

AIR

DIVIDING

BLOW

COMPENSATING

CALCULATION

OUTPUT

SIGNAL

When the sample gas is completely burnt by the air, the formula of the increased temperature is

as follows:

∆θ = (1.1)

K • Fg

Cps • Fs

where K: Caloric value of the sample gas

Fg: Flow rate of the sample gas

Fs: Air-diluted combustion exhaust gas ow rate

Cps: Constant pressure heat ratio of air-diluted combustion exhaust gas

Air ow rate Fa is big enough compared with the sample gas ow rate Fg (Fa:Fg=50-200:1)

and Cps Cpa, Fs Fa+Fg=Fa ( 1 + g ), therefore, the formula (1.1) is as follows:

∆θ = (1.2)

K • Fg

Cpa • Fa (1 + g)

where Fa: Air ow rate

Cpa: Air constant pressure heat ratio

g: Fg/Fa

When using orice and take out Fa, Fg as a dierential pressure of before and after orice, Fa

and Fg are represented by the following formula:

Fa = Ka (1.3)

∆ Pa

ρ

a

Fg = Kg

∆ Pg

ρ

g

where: ∆Pa, ∆Pg: Air, gas dierential pressure between before and after orice

ρ

a, ρg: Density of the air and the gas

ka, kg: Orice constant gure of the air and the gas

(Orice coecient orice sectional area)

IM 11R02A01-02E 6th Edition :May 10, 2019-00

Page 18

<1. Outline>

If insert formula (1.3) into formula (1.2), ∆θ is represented by the following formula:

1-11

∆θ = C.K. (1.4)

1

ρ

•

g

(C =

∆ Pg

∆ Pa

1

Cpa (1+g)

Kg

• • )

Ka

ρ

a

According to formula (1.4), if ∆Pa, ∆Pg are constant, temperature dierence ∆θ is in proportion

ρ

g

to WI (

K/

) or caloric value (K). Thus we can measure continuously WI after ∆θ

measurement, and the caloric value after the measurement and calculation of the density.

IM 11R02A01-02E 6th Edition :May 10, 2019-00

Page 19

Blank Page

Page 20

<2. Installation, Piping, Wiring>

2. Installation, Piping, Wiring

2.1 Installations

Observe the following conditions when you install instruments.

(1) Adequate space for maintenance should be provided around the gas calorimeter.

* See “External Dimention” on 1.4.

(2) The base should be horizontal..

(3) Ambient temperature is 0 to 40°C and no rapid change in ambient temperature is allowed.

*Rapid change here means a change of approximately 10°C within 30 minutes.

(4) Install the instrument in the place where it is not directly exposed to the current of a

conditioned air.

(5) Minimal vibration( If much vibration is unavoidable, take an appropriate measure to absorb

shock, e.g, use of vibration-proof robber).

(6) A ventilation system should be provided.

(7) Corrosive gases and dust are present in small quantities and humidity is low.

(8) The water of the sampling system and the drain line do not freeze up.

2-1

WARNING

From the moment the ignition starts until it completes, or right after the ame extinction, sample

gas mixed with the air will be released from the top of the equipment into the installation space of

the equipment. Use the equipment in a well ventilated environment equipped with a ventilation

system.

2.2 Externalpiping

Refer to the drawing Figure 1.4. on the connections on the panel

The principal points to be taken care are as follows:

• Bent the outlet of the bent piping as U shape, and prevent it from the rain penetration. Set

the outlet at higher position as much as possible where there is little fear of physical danger.

• Drain piping shall be conducted below the level of drain outlet on the panel and conrm no

drain is accumulated on the panel bed.

• It is necessary for the sample line of the instrument for steel mill use to provide a slope of

more than 1/3, so that there is no blockade to the gas line by the drain at the bending part of

the piping. Make piping as short as possible. Equip the sample line with thermal insulation

so as to prevent the drain in the pipe line from freezing.

• Locate the standard gas cylinders at the place where they are comparatively cool and not

exposed to direct sunshine.

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 21

<2. Installation, Piping, Wiring>

Probe

Sampling Point

Steam for thermal

insulation

Water In

Vent to the

atmosphere

Drain

Safely vent to the atmosphere

Filter

Filter

Tetoron Braid

Hose

Pipe Φ6/Φ4 Cu

Pipe Φ6/Φ4 Cu

Zero Gas

Span Gas

Valves for maintenance

should be installed.

Pipe SUS 15A

Sample Gas Inlet

Std. Gas

Inlet

Pressure

Reducing

Valve

Wash water inlet

Pipe SUS 15A

Pressure:0.1-0.2MPa

Sample Gas Out

CM6G

Gas

Calorimeter

Pipe SUS 15A or greater

Sample Gas Vent

Sample Gas Out

Pipe SUS 15A

Drain Outlet

Pipe SUS 15A

Steam for

blowing back

Pipe SUS 15A

Pressure

Reducing

Valve

∆H

∆H: Water sealing greater than pressure at sampling point is required.

Seal pot

Note: denotes that piping should be installed at an angle that allows drain to flow downstream and smoothly. F4-1.ai

House Requirements

Temperature: 0 to 40˚C

Not rapid temperature change allowed.

Adequate ventilation and lighting provided.

Power Supply

100 V AC±10% 50/60Hz

Max. approx.1100 VA

Output Signal

Alarm Contact

Output Signal

Instrument Air

Pressure: 0.3-0.7MPa

Flow rate: Approx. 50Nl/min

Figure 2.1 Recommended Sampling for Steel Mill Use

2-2

Drain

• Sampling point shall be made at the location above or side of the transfer pipe. When the

instrument is mounted on wall, x it with a slope that the top end of the probe is facing

downward.

• When xing the probe, use a ange JIS 10K 80A.

• At the sample gas outlet of the probe, it is recommended to provide a gate valve of 1/2 inch.

Probe

Gate valve (1/2 inch)

Flange

100 or more

Figure 2.2 Mounting of the Probe

Transfer pipe

F4-2.ai

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 22

<2. Installation, Piping, Wiring>

• Fix lter vertically with their drain outlets facing downward. Mount it rmly to wall or to pillar

with U bolt-like bolts. Provide 1/2 inch gate valves at the sample gas inlet and outlet. Take an

ample space under lters so that checking and replacing of elements can be held easily. For

drain exhaust pipes, use exible pipes.

Gate valve (1/2 inch)

2-3

Rc1/2

Out

Fulflo filter

Bush

Flexible tube

Drain

Rc1/4

Drain

Figure2.3ExampleFuloFilterswiththePiping

In

Union (1/2 inch)

U-bolt

F4-3.ai

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 23

<2. Installation, Piping, Wiring>

2.3 ExternalWirings

External wires shall be connected from the terminal block of the switch box inside the

panel. Use M4 terminal screws. Use appropriate crimp terminals at the wire ends.

MAIN PANEL

DENSITY METER

CONVERTER

COMPUTING

STATION

SWITCH BOX

350

CALORIE

DETECTOR

2-4

200

Figure 2.4 SwitchBoxandEarth

SWITCH

NFB

POWER

TERMINAL

150

EARTH TERMINAL

SIGNAL TERMINAL

810

Figure 2.5 InsideaSwitchBox

FUSE

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 24

<2. Installation, Piping, Wiring>

n Notes on Wiring

• Turn o all power supplies while connecting cables and wires.

• An electrical wiring duct must not be used for the simultaneous connection of a large

capacity converter, motor, or power supply.

• When cables are connected in a place with high or low ambient temperatures, use cables

suitable for the place.

• The material of cables must be capable of withstanding harmful gases, lizids, oil , or

solvents when cables are used in the atmosphere where these harmful substances are

present.

• Use crimp terminals with insulated sleeve (M4 screws) for the wire ends.

n Wiring to Peripheral Equipment

l Power Supply

Use a 600 V insulated vinyl cabtyre cable (JIS C3312) with a cross-section area of 2 mm2 or

more, or a wire or cable that is the equivalent or better.

l Grounding

Connect a grounding wire to the grounding terminal inside the panel. A grounding wire must be

connected so that the grounding resistance becomes 100 Ω or less (equivalent to JIS Class D).

2-5

l Analog Output (4 to 20 mA DC)

Use a shielded twisted pair cable with a cross-section area of 0.5 mm2 or more, or a cable that is

the equivalent or better, and install it separately from the power supply and alarm output cables

and sources of electromagnetic interference. A shielded cable must be connected to the frame

ground (FG) beside each of the output terminals. The load resistance from the perspective of this

equipment must be 750 Ω or less.

l Contact Output

Use a 600 V insulated vinyl cabtyre cable (JIS C3312) with a cross-section area of 2 mm2 or

more, or a wire or cable that is the equivalent or better.

The ame extinction alarm contact and orice chamber temperature drop alarm contact must be

non-voltage dry contacts and the contact rating must be as follows.(when contact is opened, the

leakage current is 2 mA or less (100V AC))

Contact Rating

Flame distinction alarm contact 100 V AC 5 A

Orice chamber temperature drop alarm contact 100 V AC 3 A

l Contact Input (Remote Ignition: Made to order)

Input a non-voltage contact as a contact input signal. The contact rating is 24 V DC 1 A. The

open or closed state of the input is determined by the resistance value from the perspective of

this equipment. The resistance value also includes the wiring resistance.

Contact closed: 200 Ω or less.

Contact open: 100 kΩ or more.

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 25

<2. Installation, Piping, Wiring>

2-6

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 26

<3.Construction and Function>

F00.ai

3. Construction and Function

TypicalSystemConguration

Gas Calorimeter

Calorie Detector

Solenoid

Valve

Computing Station

---CM6G---

TREND 3

18.00

Y2Y1X3X1500.0

35.00

1000.0

100.00

0.00

0.0

▼

C

<<<

YOKOGAWA◇

Differential

Pressure

Transmitter

Orifice Assembly

FAIL

ALM

90.00

C

37.67

23.02

A

M

▼▼▼

△

▽

PF

14.65

23.02

O

SHIFT

<

Output

4-20mA DC

1 to 5V DC

Density Meter

Gas

Pressure

Regulating

Unit

Air

Pressure

Regulating

Unit

P

Calorific Value

WI (Wobbe Index)

Sample Gas

Instrument Air

3-1

Item Function / Description

Calorie detector

Detects WI or caloric value. Generates an alarm and takes protective

actions when the burner ame goes out or abnormal combustion occurs.

Computing station (digital) Calculates WI or caloric value. Displays selected parameters, e.g., each

dierential pressure and caloric value. Adjusts zero / span and others.

Density meter Measures density used for calculation of caloric value. Not required for

WI measurement.

Dierential pressure transmitter Detects dierential pressure of gas and air before and after orice, and

converts it to an electrical signal.

Orice assembly Gas and air orices housed in the constant temperature chamber.

Solenoid valve Serves as a safety valve to shut o the sample gas ow.

Figure 3.1 Components and Functions of Model CM6G Gas Calorimeter

3.1 Air Pressure Regulating System

Refer to Figure 3.2, 3.3 and 3.4. The instrument air pressure (300 to 700 kPa) is reduced by air

set (2-1) to about 200 kPa, further reduced to about 20 kPa by the pressure reducing valve (2-2).

Then the pressure is set by needle valve (V-16) to a dierential pressure of 500 Pa.

The air is controlled at 40°C in the preheater, which helps the temperature control by the orice.

When the temperature rises above 60°C, thermostat in the preheater operates and intercepts the

power supply of the heater. This air pressure regulating section is common to all systems.

3.2 Gas Pressure Control Section

Refer to Figure 3.2, 3.3 and 3.4.The gas pressure regulating section has two dierent types; town

gas use and steel mill use.

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 27

<3.Construction and Function>

l Town Gas Use

The sample gas, introduced through line lter (3-1), increases its pressure by pump, or

decreases by pressure reducing valves, according to the pressure at the sampling point. The

pressure gauge (3-2) indicates 8 to 18 kPa and the owmeter (3-3) approx. 10 l/min, respectively.

The sample gas, then, is set its dierential pressure to 500 Pa by pressure reducing valve (3-4)

and (3-6), and at this time the pressure gauge (3-5) indicates approx. 3 kPa. When the density

compensation system is equipped, the sample gas is introduced to the density meter with the ow

rate of 1 l/min, through the owmeter (5-3).

The standard gas is reduced its pressure to 8 to 18 kPa by the pressure reducing valve (4-1), and

supplied, same as the sample gas, with the ow rate approx. 10 l/min.

l Steel Mill Use

The pressure of the sample gas is increased, by the pump, according to that of the sampling

point.

The pressure gauge (3-1) indicates approx. 6 kPa. The sample gas then ows through the

washing bubbler (3-2) and the fulo lter (3-3), and then secure a constant pressure in the

pressure regulating pot (3-4) through the water sealed pipe from the dehumidier (3-5), then set

the dierential pressure by the pressure reducing valve (3-6) to 500 Pa.

To increase the pressure by the pump, a drain pot (3-9) is added. When the density

compensation system is equipped, the sample gas is supplied to the density meter with its ow

rate of 1 l/min, through the owmeter (5-3). The pressure of the standard gas is reduced by the

pressure reducing valve (4-1) to about 6 kPa and is supplied by the owmeter (4-2) with the ow

rate about 10 l/min.

3-2

Standard Flow Sheet

1. Town Gas Application (Standard Type)

CM6G-S6200, S6210, S6300, S6310, S6400, S6410

No. Item

1-1 Calorie detector

1-2 Solenoid valve

1-3 Orifice assembly

1-4 Differential pressure transmitter (air)

1-5 Differential pressure transmitter (gas)

1-6 Computing station

2-1 Air set

2-2 Pressure reducing valve

2-3 Pressure gauge

2-4 Preheating chamber

2-5 One touch coupler

V-1

V-2

SAMPLE GAS IN

SAMPLE GAS OUT

OR VENT

Maximum back pressure

is 1.5 kPa and no pressure

fluctuation is allowed.

A

B

No. Item

3-1 Line filter

3-2 Pressure gauge

3-3 Flowmeter

3-4 Pressure reducing valve

3-5 Pressure gauge

3-6 Pressure reducing valve

3-7 Diaphragm pump (when specified)

3-8 Pressure reducing valve (when specified)

4-1 Pressure reducing valve for standard gas

*3

3-8

V-4

3-1

*1

*2

3-7

V-5

V-3

P

DT

5-1

5-2

*1: CM6G-S610 (with density meter)

*2: CM6G-S630 (with diaphragm pump)

*3: CM6G-S640 (with pressure reducing valve)

V-11

V-6

V-13

5-3

V-7

3-2

3-3

3-4

3-6

3-5

V-12

GAS

DP.T

1-1

1-2

No. Item

5-1 Density meter detector (when specified)

5-2 Density meter converter (when specified)

5-3 Flowmeter for density meter (when specified)

6-1 Zero gas (supplied by customer)

6-2 Span gas (supplied by customer)

7-1 Pressure reducing valve for cylinder (optional)

7-2 Pressure reducing valve for cylinder (optional)

V1...16 Ball valve, needle valve

1-6

1-3

AIR

DP.T

1-5

1-4

V-16

4-1

2-4

2-3

V-15

2-1

V-14

2-2

2-5

V-9

V-8

V-10

FLOW-6410.ai

INST.AIR IN

0.3~0.7MPa

C

50Nl/min

STD GAS IN (ZERO)

7-1

7-2

D

E

6-2

STD GAS IN (SPAN)

6-1

Figure 3.2 Flow Sheet (for Town Gas)

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 28

<3.Construction and Function>

2. Town Gas Application (Quake-proof Type)

CM6G-S6110

No. Item

1-1 Calorie detector

1-2 Solenoid valve

1-3 Orifice assembly

1-4 Differential pressure transmitter (air)

1-5 Differential pressure transmitter (gas)

1-6 Computing station

2-1 Air set

2-2 Pressure reducing valve

2-3 Pressure gauge

2-4 Preheating chamber

2-5 One touch coupler

No. Item

3-1 Line filter

3-2 Pressure gauge

3-3 Flowmeter

3-4 Pressure reducing valve

3-5 Pressure gauge

3-6 Pressure reducing valve

4-1 Pressure reducing valve

5-1 Density meter detector

5-2 Density meter converter

5-3 Flowmeter for density meter

No. Item

6-1 Zero gas (supplied by customer)

6-2 Span gas (supplied by customer)

7-1 Pressure reducing valve for cylinder (optional)

7-2 Pressure reducing valve for cylinder (optional)

V1...16 Ball valve, needle valve

3-3

V-4

V-1

V-2

SAMPLE GAS IN

(10 to 20kPa)

SAMPLE GAS OUT

OR VENT

Maximum back pressure

is 1.5 kPa and no pressure

fluctuation is allowed.

A

D

V-3

3-1

5-1

5-2

Figure 3.3 Flow Sheet (for Town Gas)

1-5

1-3

AIR

DP.T

1-4

1-6

V-16

4-1

2-4

2-2

2-3

V-15

2-5

V-8

2-1

V-14

V-9

V-10

FLOW-6110.ai

INST.AIR IN

0.3 to 0.7MPa

B

50Nl/min

STD GAS IN (ZERO)

7-1

7-2

C1

C2

STD GAS IN (SPAN)

6-1

6-2

1-1

3-3

3-4

3-6

3-5

V-12

GAS

DP.T

1-2

3-2

V-11

V-5

V-6

V-7

V-13

P

5-3

DT

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 29

<3.Construction and Function>

3. Steel Mill Application

CM6G-S6500, S6510, S6600, S6610, S6700, S6710, S6800, S6810

No. Item

1-1 Calorie detector

1-2 Solenoid valve

1-3 Orifice assembly

1-4 Differential pressure transmitter (air)

1-5 Differential pressure transmitter (gas)

1-6 Computing station

2-1 Air set

2-2 Pressure reducing valve

2-3 Pressure gauge

2-4 Preheating chamber

2-5 One touch coupler

No. Item

3-1 Pressure gauge

3-2 Washing bubbler

3-3 Fulflo filter

3-4 Pressure regulating pot

3-5 Dehumidifier

3-6 Pressure reducing valve

3-7 Line filter

3-8 Diaphragm pump (when specified)

3-9 Drain pot (when specified)

4-1 Pressure reducing valve for cylinder

4-2 Flowmeter

No. Item

5-1 Density meter detector (when specified)

5-2 Density meter converter (when specified)

5-3 Flowmeter for density meter (when specified)

6-1 Water Flowmeter

7-1 Probe (optional)

7-2 Fulflo filter (optional)

9-1 Pressure reducing valve for cylinder (optional)

9-2 Pressure reducing valve for cylinder (optional)

10-1 Standard gas cylinder (supplied by customer)

10-2 Standard gas cylinder (supplied by customer)

11-1 Drain pot (supplied by customer)

V1...16 Ball valve, needle valve

3-4

WATER IN

DRAIN

9-1

9-2

7-1

10-2

SAMPLE GAS IN

11-1

STD.GAS IN

(SPAN)

STD.GAS IN

10-1

7-2

WATER IN

DRAIN OUT

(ZERO)

SAMPLE GAS

OUT

2-5

B

*1

*2

4-1

V-9

D

V-10

D

A

V-1

3-9

E

F

V-8

3-1

V-3

3-2

V-13

V-4

P

V-6

V-5

6-2

3-8

V-2

V-7

*1: CM6G-S610 (with density meter)

*2: CM6G-S670, CM6G-S680 (with diaphragm pump)

SAMPLE GAS VENT

SAMPLE GAS OUT

H

C

4-2

V-11

V-12

3-3

*1

5-3

3-6

3-7

3-5

3-4

1-2

5-1

5-2

1-1

1-5

1-3

V-16

1-4

2-4

2-2

P

1-6

V-15

2-3

2-1

V-14

INST.AIR IN

G

FLOW-6810.ai

Figure 3.4 Flow Sheet (Steel Mill Use)

3.3 DierentialPressureDetectionPart

In order to calculate the dierential pressure correction value, the ow rate is acquired from

the orice as a dierential pressure and converted to an electrical signal using the dierential

pressure transmitter. The orice is housed in a constant temperature chamber (orice assembly),

the temperature of which is maintained at approximately 50°C by the temperature controller, to

prevent the temperature drift of the actual ow rate.

When the temperature exceeds 90°C, the safety thermostat is activated to shut o the heater

power supply. When the temperature falls after the power supply is shut o, the alarm thermostat

is activated to provide an alarm (closed contact) output.

CAUTION

Power is supplied to the dierential pressure transmitter and the temperature controller from the

calorie detector. To operate the transmitter and the controller, turn on the calorie detector switch

of the switch box and the POWER switch on the front panel of the calorie detector.

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 30

<3.Construction and Function>

MAIN PANEL

ORIFICE ASSEMBLY

DIFFERENTIAL PRESSURE

TEMPERATURE

CONTROLLER

TRANSMITTER

Figure3.5DierentialPressureDetectionEquipment

3-5

3

9

4

19

16

15

8

10

18

No. Name

Air inlet

1

Gas inlet

2

Air outlet

3

Gas outlet

4

Air differential pressure take-out

5

Gas differential pressure take-out

6

Orifice section

7

No. Name

8

9

10

11

12

13

14

Figure3.6OriceAssembly

3.4 Calorie Detector

The calorie detector consists of a burner unit, which detects the temperature dierence before

and after the sample gas is burned, a detected signal amplication and ignition-and safety

sequence circuit, and distributor circuits of the transmitter for air and the transmitter for gas.

The detected signal is converted from approximately 0 - 20 mV to 1 - 5 V DC and input to the

computing station. If burner ame extinction or excessive combustion occurs, an alarm (closed

contact) output is produced.

7

12

11

Gas orifice section

Crotchet joint

Fitting screw

Heat conversion block

Heater plate

Safety thermostat (up)

Alarm thermostat (down)

13·14

5

6

2

17

No.

Thermistor (check)

15

Thermistor (control)

16

Temperature check terminal

17

Neon lamp

18

Terminal

19

1

Name

F0506.ai

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 31

<3.Construction and Function>

PRINTED CIRCUIT

BOARD ASSEMBLY

BURNER UNIT

IGNITION TRANS.

ASSEMBLY

Figure 3.7 Calorie Detector

3-6

POWER

Lamp

IGNIT

Lamp

0

Figure 3.8 Front Panel Assembly

SAFE EV

Switch

LOW AL

Volume

MEAS

Lamp

ALARM

Lamp

START

Switch

POWER

Switch

METER

Switch

SPAN

Volume

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 32

<3.Construction and Function>

Table 3.1 Function and operation procedure for each switch of the calorie detector

Name Function and operation procedures

“POWER” switch • Power supply switch.

• When the switch turns to “ON”, the power is supplied to the calorie detector and at the

same time the lamps, “POWER” and “ALARM” are lit on.

“START” switch • One push on “START” switch introduces gas to the burner unit and operates the ignition.

• At the same time, the lamp “IGNIT” is on while the lamp “ALARM” is lit o.

• If ignition occurs within the preset time, the lamp “IGNIT” is lit o but the lamp “MEAS”

turns on.

• If ignition does not occur within the preset time, the lamp “IGNIT” is lit o and the lamp

“ALARM” turns on again.

“SAFE EV” switch • Normally leave the switch at “SET”.

• When you adjust the dierential pressure, turn it to “RELEASE”. Then the lamp

“ALARM” is let o, alarm is released and solenoid valve of the gas line is opened.

• Switching over from “SET” to “RELEASE” during the operation does not aect anything.

However, if you leave the switch at “RELEASE”, no alarm signal is given even when the

burner ame is o.

• When the switch shows “RELEASE”, “START” switch does not start the operation.

“METER” switch •The indication of the indicator and the X5 display(*1) of the computing station switches

between “P.MEAS“ and “LOW AL“

• The switching does not aect the nal output and sequence action.

“SPAN” volume • With this span volume you can adjust the output of the calorie detector to 1 - 5 V DC.

• If you turn this to the right, the span point becomes bigger.

“LOW AL” volume • The level for the extinction alarm (lower alarm) is set by this volume.

• If you turn this to the right, the alarm level becomes higher.

“POWER” lamp • When the lamp is lit, power is being supplied to the calorie detector, dierential pressure

transmitter, and temperature controller.

“IGNIT” lamp • While the lamp is lit, the ignition proceeds.

“MEAS” lamp • While the lamp is lit, the system is under the measurement condition.

“ALARM” lamp • While the lamp is lit, alarm is being released.

(*1) The display range of X5 is 0 to 30.0 mV. “P.MEAS“ and “LOW AL“ indicate the following values.

3-7

Signal Name Display Value

“P.MEAS“ Thermocouple electromotive force 0 - 20.0 mV

“LOW AL“ Flame extinction alarm threshold value 0 - 10.0 mV (= 0 - 100%)

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 33

<3.Construction and Function>

3.4.1 Burner Unit

The sample gas burns inside the burner unit and a thermocouple detects the burning temperature increase.

The air is introduced from the air inlet and divided to the primary, secondary and tertiary air. The primary and

secondary ones are for burning the sample gas and the tertiary is for diluting and stirring the exhaust gas. The

sample gas is mixed with the primary air (In case of the low calorie gas, the primary air is throttled), and burnt

completely by the secondary air. Then, the combustion temperature generates, and burnt gas is promptly

diluted and stirred by the tertiary air. Finally the gas is exhausted out from the top of the calorie detector. The

increased temperature is measured with the dierence of the electromotive force between the cold junction

point (located at the air inlet) and the hot junction point (inside the mixed diluted exhaust gas). The heating

wire wound the burner tip is used for both ignition and preheating (when lower calorie gas is being used.)

Heater wire

Burner

tip

Lead wire

3-8

Figure 3.9 Burner Tip Assembly

1

14

13

12

11

10

2

3

4

6

5

9

7

8

Figure 3.10 Burner Unit

F0509.ai

No. Name

1 Hot junction detect point

2 Cold junction detect point

3 Air divider

4 Secondary air throttle screw

5 Primary air throttle screw

6 Air inlet

7 Gas inlet

8 Connector

9 Burner tip assembly

10 Combustion pipe

11 Stream contact pipe

12 Measuring pipe

13 Reverse flow pipe

14 External pipe

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 34

<3.Construction and Function>

Ignition action starts

3.4.2 High/Low Alarm Action

Higher and lower alarm limits are set for the amplied thermocouple output, respectively, to

execute a sequence.

The higher alarm limit is the point to alarm the excessive combustion of the burner, which is set to

approximately 120% of the span. The lower alarm limit is the point to alarm the ame extinction

of the burner. You can change the limit by “LOW AL”volume on the front panel of the calorie

detector. However, the lower alarm limit is set to an appropriate value in the nal adjustment test

at the factory before shipment.

If the higher or lower limit alarm occurs, the electromagnetic valve (EV) is closed to stop the

supply of gas

3.4.3 Ignition

Press START on the front panel of the calorie detector to start ignition. One cycle of an

ignition constitutes (T1) and (T2). (T1) is when the ignition voltage is applied to the heater

(T1). (T2) is when the voltage is not applied (when using low caloric value, the time when the

preheating voltage is applied). The cycle repeats ve times normally. (T1) time and (T2) time

are set independently within the range from approximately 2 to 20 seconds depending on the

measurement range and gas composition.

If the amplied thermocouple output exceeds the lower alarm limit, the burner is determined to

be ignited and the ignition action is stopped even if it is not completed. If the burner is not ignited

even after the ignition voltage is applied ve times, the ignition action is stopped after the ignition

voltage is applied for the fth time. In that case, press START to start the ignition again.

If the burner ame is extinguished in the event of an alarm, after removing the cause of the

failure, press START to start the ignition again. If the alarm occurs due to excessive combustion,

you cannot resume the ignition until the thermocouple output falls below the lower alarm limit (*1).

Indication lamps turn ON or OFF in accordance with each stage of the sequence.

Figure 3.11 shows the ignition sequence for which the lower alarm limit is set to 50%.

3-9

Thermocouple output

(Higher alarm limit)

(Lower alarm limit)

Ignition voltage

EV

ALARM lamp

IGNIT lamp

MEAS lamp

Figure 3.11 Ignition Sequence

120%

50%

Hi

Low

Open

Close

ON

OFF

ON

OFF

ON

OFF

Ignition action starts

T1T2

Ignition action

Alarm

status

Not ignition

Measurement

status

Ignitied

Ignition action

Alarm status

Excessive

combustion

Time

*1

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 35

<3.Construction and Function>

3.5 Computing Station

The computing station generates WI signal by calculating calorie detector signal with each

dierential pressure signal. It compensates the density with the density signal and generates the

caloric signal.

Each input signal is digitally computed after A to D conversion then D to A conversion. It

generates DC 4 to 20 mA (DC 1 to 5 V) output.

3.5.1 Display

n Display indication

FAIL lamp

TREND 3

Y1: Calorific value (green)

Y2: WI value (light blue)

X3: MAX range of gas

differential pressure(pink)

X1: MAX range of NON CORR. WI value(yellow)

X1: MIN range of NON CORR. WI value(yellow)

X3: MIN range of gas

differential pressure(pink)

Unused

---CM6G---

TREND 3

Y1

Y2

C

<

18.00

X1

35.00

X3

1000.0

100.00

0.00

0.0

SHIFT

YOKOGAWA

90.00

500.0

37.67

23.02

14.65

23.02

FAIL

ALM

C

A

M

PF

O

<

F0516.ai

ALARM lamp

X1: NON-CORR.WI% (yellow)

X3: Gas differential

pressure (Pa) (pink)

Y2: MAX range of WI

(light blue)

Y1: MAX range of

Calorific value (green)

Trend data (indicator 1 to 4)

Y1(green) : Calorific value

Y2(light blue): WI

X1(yellow) : NON-CORR. WI

X3(pink) : differential gas pressure Pa

Y1: MIN range of

Calorific value (green)

Y2: MIN range of WI

(light blue)

The key for switching screens.

Press this key to go to ALARM

screen. Push this again to return.

*1

3-10

Figure 3.12 Measuring Display

---CM6G---

ALARM

SYSTEM

PROCESS

*

*

*

*

*

*

STC EVENT

<

<

YOKOGAWA

X1

X2

X3

X4

Y1

CALC

SHIFT

FAIL

ALM

C

ALM

A

CLR

Left is ALARM screen you see when input or output is error.

Do as *1 of Fiigure 3.12 to go to ALARM.

M

EVT

ON

EVT

PF

CLR

<

<

Figure 3.13 Alarm Display

ALARM items, such as X1 to

X4,Y1 and Y2, are displayed.

F0517.ai

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 36

<3.Construction and Function>

n Switching to alarm display

3-11

---CM6G---

TREND 3

Y1

18.00

Y2

35.00

1000.0

100.00

X3X1500.0

FAIL

ALM

90.00

C

37.67

23.02

ALARM

PROCESS SYSTEM

A

M

Push key

Push key

<

C

<

<

0.00

0.0

SHIFT

YOKOGAWA

PF

14.65

23.02

O

<

<

(1) Measuring display (2) Alarm display

Figure 3.14 Switching operation to alarm display

n ConrmationofInput/outputdata

---CM6G---

TREND 3

Y1

Y2

C

FAIL

1000.0

100.00

ALM

90.00

X1

500.0

X3

C

37.67

23.02

A

Push key

SHIFT

with key.

M

18.00

35.00

---CM6G---

TUNING MENU

PID 1

PID 2

STC 1

STC 2

P&T REG

PF

14.65

0.00

23.02

0.0

O

I/O DATA

FAIL

ALM

PF

C

A

M

---CM6G---

X1

*

X2

*

X3

*

X4

*

*

Y1

*

CALC

EVENTSTC

SHIFT

YOKOGAWA

Push key

FAIL

ALM

C

ALM

A

CLR

M

EVT

ON

EVT

PF

CLR

<

F0518.ai

PF

---CM6G---

I/O DATA

X1

X2

X3

X4

X5

X6

X7

X8

Y1

Y2

Y3

Y4

Y5

Y6

DI01

0

DI02

0

DI03

0

DI04

0

DI05

0

DI06

0

DI07

0

DI08

0

DI09

0

DI10

0

FAIL

ALM

90.00

500.0

C

500.0

0.500

18.00

-25.0

-25.0

A

-25.0

18.00

35.00

-6.3

0.0

M

0.0

0.0

DO01

0

DO02

0

DO03

0

DO04

0

DO05

0

DO06

0

DO07

0

DO08

0

DO09

0

DO10

0

DO11

0

0

DO12

DO13

0

PF

DO14

0

DO15

0

DO16

0

<

<

SHIFT

YOKOGAWA

<

<

<

<

SHIFT

YOKOGAWA

<

<

(1) Measuring display

Figure 3.15 Switching operation to Input/output status display

SHIFT

<

<

YOKOGAWA

<

<

F0519.ai

(3) Input/Output status display(2) Tuning display

This screen is for confirming

Input/Output status and for setting

X1,X2 and X3.

Displayed characters become bigger

by pushing key.

A

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 37

<3.Construction and Function>

n Parameter setting

3-12

---CM6G---

TUNING MENU

PID 1

PID 2

STC 1

STC 2

P&T REG

I/O DATA

<

<

YOKOGAWA

FAIL

ALM

C

A

Push key

M

PF

SHIFT

<

<

---CM6G--- ---CM6G---

P&T REG 1/3

P01

P02

P03

P04

P05

P06

P07

P08

P09

P10

P11

P12

P13

P14

P15

P16

P17

P18

P19

P21

P22

P23

P24

P25

P26

P27

P28

P29

P30

<

<

YOKOGAWA

FAIL

ALM

60.00

2.500

C

0.00

100.0

7.00

100.0

7.00

A

5.00

0.0

0.0

0.0

0.0

0.0

M

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

PF

SHIFT

<

<

A

Push key

A

(Press key to enlarge

characters of parameter to

set.)

P&T REG 1/3

P01

P02

P03

P04

P05

P06

P07

P08

P09

P10

P11

P12

P13

P14

P15

P16

P17

P18

P19

P21

P22

P23

P24

P25

P26

P27

P28

P29

P30

<

<

FAIL

ALM

60.00

2.500

C

0.00

100.0

7.00

100.0

7.00

A

5.00

0.0

0.0

0.0

0.0

0.0

M

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

PF

SHIFT

<

<

YOKOGAWA

(1) Tuning display (2) Parameter setting display (3) Parameter setting display

Push key.

---CM6G---

TREND 3

18.00

Y2Y1X3X1500.0

35.00

C

<

YOKOGAWA

FAIL

ALM

90.00

C

1000.0

37.67

100.00

23.02

A

M

PF

0.00

14.65

0.0

23.02

O

SHIFT

<

(5) Measuring display

Push key

SHIFT

with

key twice.

The screen is for setting various

parameters such as ZERO and SPAN.

In setting

other parameters

Parameter setting is

finished. Return to the

measuring display.

(4) Input/Output status display

This screen is for confirming Input/Output status.

Select a parameter to confirm. Press key to enlarge the

character to display.

---CM6G---

I/O DATA

X1

X2

X3

X4

X5

X6

X7

X8

Y1

Y2

Y3

Y4

Y5

Y6

DI01

DI02

DI03

DI04

DI05

DI06

DI07

DI08

DI09

DI10

<

<

By using and key,

change the parameter value

which becomes larger characters.

After returning to Tuning

display (1) by pushing

key, push key.

90.00

500.0

500.0

0.500

18.00

-25.0

-25.0

-25.0

18.00

35.00

-6.3

0.0

0.0

0.0

0

0

DO01

0

0

DO02

0

0

DO03

0

0

DO04

0

0

DO05

0

0

DO06

0

0

DO07

0

0

DO08

0

0

DO09

0

0

DO10

0

DO11

0

DO12

0

DO13

0

DO14

0

DO15

0

DO16

SHIFT

YOKOGAWA

PF

FAIL

ALM

C

A

M

PF

<

<

F0520.ai

A

Figure3.16FlowChartofVariousParameterSettingandConrmation

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 38

<3.Construction and Function>

3.5.2 Contents of the Data Display

Contents of the data display are as follows:

Table 6.2 Contents of the data display

Kind Data abbreviated Data contents Data range

Input

X

N

Output

Y

N

Variable

data

P

N

X1 NON-CORR. WI [%] WI value before correction 0.0 to 100.0

X2 A-PRESS [Pa] Air dierential pressure 0.0 to 1000

X3 G-PRESS [Pa] Sample gas dierential pressure 0.0 to 1000

X4 SQT. DENSITY A square root of the sample gas

density

X5 TC or LOW ALARM *2[mV] Thermocouple electromotive force or

ame extinction alarm threshold value

X6~X8 Unused

Y1

cal [MJ/

Nm

3

Caloric value *1

]

Y2 WI Wobbe index *1

Y3 Option Option *1

Y4 BIAS CHECK Preheating check output 0.0 to 100.0

Y5, Y6

Unused

P01 ZERO Zero adjustment 0.0 to 100.0

P02 SPAN Span adjustment *1

P03 BIAS Preheating adjustment 0.0 to 100.0

P04 A-CORR. RATE [%] Air dierential pressure signal

computing correction rate

P05 A-TIME [sec] Time constant of air dierential

pressure signal delay time

P06 G-CORR. RATE [%] Sample gas dierential pressure

signal computing correction rate

P07 G-TIME [sec] Time constant of sample gas

dierential pressure signal delay time

P08 PRESS ALARM SET [%] Dierential pressure warning setting 0.0 to 100.0

P09 to P30 Unused

3-13

*1

0 to 30.0

0.0 to 200.0

0.0 to 100.0

0.0 to 200.0

0.0 to 100.0

*1: Diers depending on each specication.

*2: Press “METER” to switch.

IM 11R02A01-02E 5th Edition : Dec. 28, 2016-00

Page 39

<3.Construction and Function>

3.5.3 Correcting Computation

CM6G sets the dierential pressure of both sample gas (∆Pg) and air (∆Pa) to 500 Pa. In order

to correct the indication error due to the variation of the dierential pressure (Flow rate), the

correcting computation is practiced.

The detection signal is obtained through the measurement with the standard dierential pressure

of 500 Pa, but if each dierential pressure change to ∆Pg and ∆Pa (≠500 Pa), the detection

signal shall be changed from Eo to E’o.

3-14

E’o = Eo

Therefore, if you multiply the detection signal E’o by

∆ Pg

•

∆ Pa

/

, you can correct to the value

∆Pg∆Pa

(3.1)

at the standard dierential pressure.