Page 1

User’s

Manual

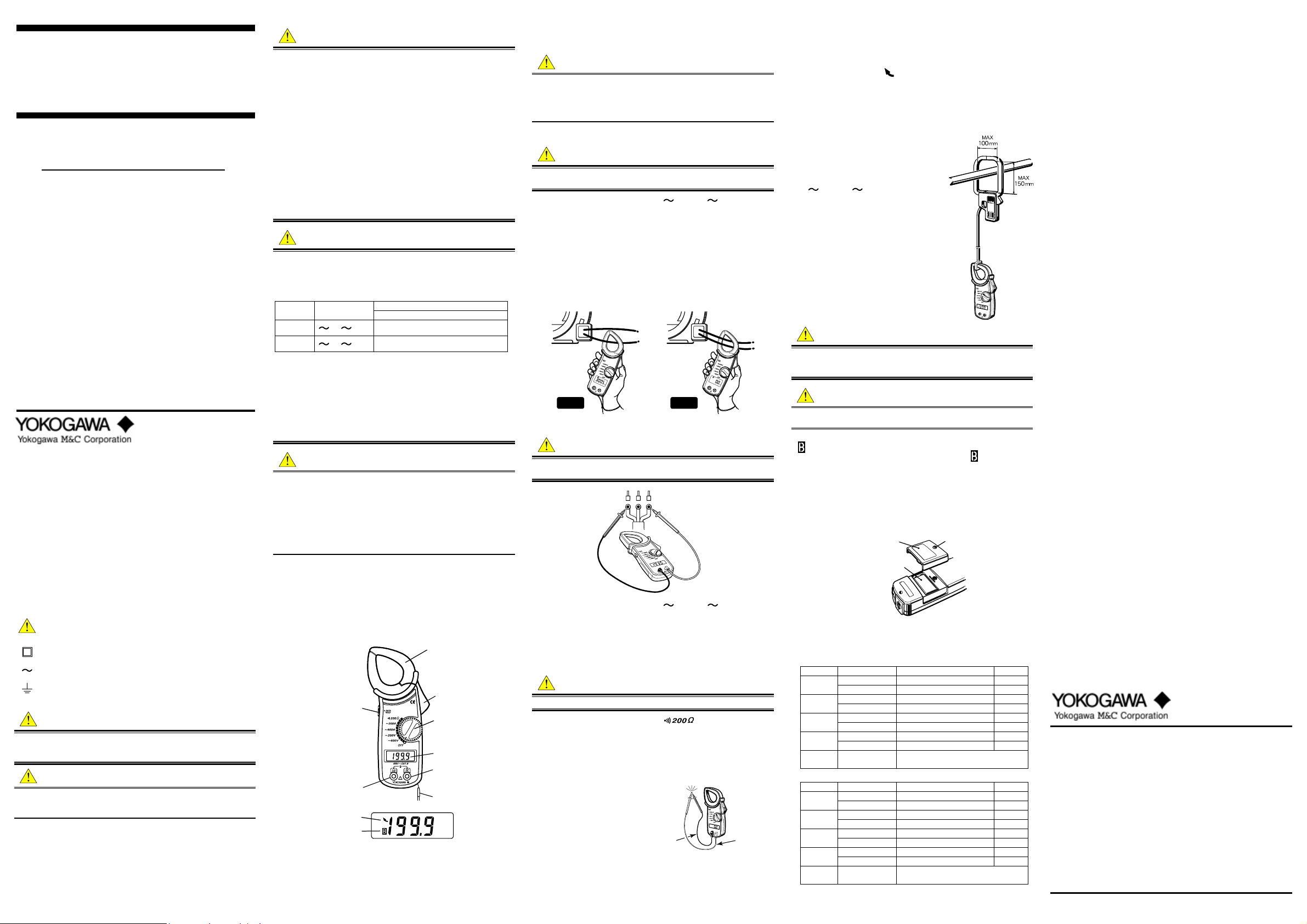

CL130/CL135

Clamp-on Tester

IM CL130

Contents

Precautions for Safety Use of the Instrument

1. Instrument Layout

2. Measurement

2.1 Preparation for Measurement

2.2 AC Current Measurement

2.3 AC Voltage Measurements

2.4 Resistance Measurement and Continuity Check

3. Other Functions

3.1 Data Hold Function

3.2 Optional Accessories

4. Battery Replacement

5. Specifications

6. Calibration and After-sales Service

2nd Edition: June 2003 (MC)

IM CL130

Precautions for Safe Use of the Instrument

When handling the instrument, ALWAYS observe all of the cautionary notes on

safety given below. Yokogawa M&C Corporation is not at all liable for damage

resulting from misuse of this p roduct by the user that is contra ry to these

cautionary notes.

Various symbols are used on the instrument and in this manual to ensure the

product is used safety and to protect operators and property from possible

hazards or damage. The following safety symbols are used where appropriate.

Read the explanations carefully and familiarize yourself with the symbols before

reading the text.

The instrument and this manual use the following safety symbols:

Danger! Handle with Care.

This symbol indicates that the operator must refer to an explanation in

the User’s Manual in order to avoid the risk of personal injury or death

and/or damage to the instrument.

Double Insulation

This symbol indicates double insulation.

AC Voltage/Current

This symbol indicates AC voltage or current.

Ground

Indicates that there is a possibility of serious personal injury or loss of life if the

operating procedure is not followed correctly and describes the precautions for

avoiding such injury or loss of life.

Indicates that there is a possibility of serious personal injury of damage to the

instrument if the operating procedure is not followed correctly and describes the

precautions for avoiding such injury or damage.

NOTE

Draws attention to information essential for understanding the operation and

features.

This symbol indicates ground (earth)

WARNING

CAUTION

WARNING

● Never make measurement on a circuit above 600V AC.

● Do not use the instrument in an atmosphere where any flammable or explosive

gas is present.

● The transformer jaws are made of metal and their tips are not insulated. Be

especially careful about the hazard of possible shorting where the equipment

under test has exposed metal parts.

● Avoid using the instrument if it has been exposed to rain or moisture or if your

hands are wet.

● Do not exceed the maximum allowabIe input of any measurement range.

● Never open the battery compartment cover when making measurement.

● Do not use the instrument if there is any damage to the casing or when the

casing is removed.

● Do not turn the Function Selector switch with plugged in test leads connected

to the circuit under test.

● Do not install substitute parts or make any modification to the instrument.

Return the instrument to Yokogawa M&C or your distributor for repair or

re-calibration.

● Always switch off the instrument before opening the battery compartment cover

for battery replacement.

WARNING

To avoid damage to the instrument or electric shock!

The restrictions on the maximum voltage level for which the CL130/CL135 testers

can be used, depend on the over-voltage categories specified by the safety

standards. These category specifications are formulated to protect operators

against transient impulse voltage in power lines.

Model Function

CL130 A, V

CL135 A, V

Over-voltage category I (CAT.I):

Signal level, special equipment or parts of equipment, telecommunication,

electronic etc., with smaller transient over-voltages than CAT.II.

Over-voltage category II (CAT.II)

Local level, appliance, portable equipment etc., with smaller transient

over-voltages than CAT.III.

Over-voltage category III (CAT.III):

Distribution level, fixed installation, with smaller transient over-voltages than

CAT.IV.

Maximum Allowable Input

OVERVOLTAGE CATEGORY III

Measuring circuit voltage : 600Vrms AC

Measuring circuit voltage : 600Vrms AC

600A AC

600A AC

CAUTION

● Always make sure to insert each plug of the test leads fully into the appropriate

terminal on the instrument.

● Make sure to remove the test leads from the instrument before making current

measurement.

● Be sure to set the Function Selector switch to the "OFF" position after use.

When the instrument will not be in use for a long period of time, Place it in

storage after removing the battery.

● Use a damp cloth and detergent for cleaning the instrument. Do not use

abrasives or solvents.

NOTE

● Radiation immunity affects the accuracy of CL130/CL135 testers under the

conditions specified in IEC 801-3: 1984 (CL130)/IEC 801-3: 1993 (CL135).

● If equipment generating strong electromagnetic interference is located nearly,

the testers may malfunction.

1. Instrument Layout

Transformer Jaws

Open/Close Lever

Data Hold Switch

Lo Terminal

LCD Display

Data Hold Mode

Low Battery Warning

Function Selector

Switch

Display

Hi Terminal

Safety Hand Strap

2. Measurement

2.1 Preparation for Measurement

CAUTION

● The jaw section is a delicate, precision sensor. Do not subject the jaw to

unreasonably strong shock, vibration, or force when using it.

● If dust gets into the tops of the jaws, remove it immediately. Do not close the

jaws when dust is trapped in its joints as the sensor may break.

● Please check that the Function Selector switch is set to the desired position

2.2 AC Current Measurement

WARNING

Never use the instrument on a circuit above 600V AC. This may cause electrical

shock hazard and damage to the instrument or the circuit under test.

(1) Set the Function Selector switch to the " 200A " or " 600A " position.

(2) Press the open/close lever to open the transformer jaws and clamp them onto

a single conductor and take the reading on the display. The most accurate

reading will be obtained by keeping the conductor at the center of the

transformer jaws.

NOTE

● During current measurement, keep the transformer jaws fully closed.

Otherwise, accurate measurements cannot be taken. Maximum conductor size

is 30mm in diameter.

● When measuring larger current, the transformer jaws may buzz. This in not a

fault and does not affect the accuracy either.

WrongCorrect

2.3 AC Voltage Measurements

WARNING

Never use the instrument on a circuit above 600V AC. This may cause electrical

shock hazard and damage to the instrument or the circuit under test.

Red lead

Black lead

(1) Set the Function Selector switch to the " 200V " or " 600V " position.

(2) Plug the red test lead into Hi terminal and the black test lead into the Lo

terminal.

(3) Connect the tip of the red and black test leads to the circuit under test and

take the reading on the display.

2.4 Resistance Measurement and Continuity Check

WARNING

Never use the instrument on an energized circuit.

(1) Set the Function Selector switch to the " " position.

(2) Plug the red test lead into Hi terminal and the black test lead into the Lo

terminal. Check that "1" (over indication) is indicated on the LCD display.

(3) Short the tip of the test leads and check whether the display reads "0".

(4) Connect the tip of the test leads to the circuit under test. If the resistance is

30.0

or less, the buzzer beeps.

Ω

NOTE

When shorting the tip of the

test leads, the display may

read a very small resistance

instead of "0". This is the

resistance of the test leads on

the display.

Black test lead Red test lead

3. Other Functions

3.1 Data Hold Function

This is a function used to freeze the measured value on the display. Press the

Data Hold button to freeze the reading. The reading will be held regardless of

subsequent variation in input. "

display while the instrument is in the Data Hold mode.

To exit the Data Hold mode, press the Data Hold button again.

" is shown on the upper right corner of the

3.2 Optional Accessories

Clamp Adapter Model 99025 (For AC current measurement only)

Clamp Adapter Model 99025 is designed to

increase the measuring capability of a clamp

meter. With the use of the Clamp Adapter, you

can not only extend current range over 3000A,

but also clamp on a large bus-bar or conductor.

(1) Set the Function Selector switch to the

200A " or " 600A " position.

"

(2) As shown in the figure below, clamp Model

CL130/CL135 onto the pickup coil of Model

99025.

(3) Clamp Model 99025 onto the bus-bar or

conductor under test.

(4) Take the reading on Model CL130/CL135

and multiply it by 10.

NOTE

For detailed specification, refer to the Clamp

Adapter User’s Manual.

4. Battery Replacement

WARNING

To avoid electric shock hazard, make sure to set the Function Selector switch to

"OFF" and remove the test leads from the instrument before trying to replace

battery.

CAUTIOIN

Make sure to install battery in correct polarity as indicated in battery

compartment.

If the battery voltage becomes too low for the instrument to operate normally,

" is shown on the display. Then, replace the battery. Note that when the

"

battery is completely exhausted, the display blanks without "

(1) Set the Function Selector switch to the "OFF" position.

(2) Unscrew and remove the battery compartment on the bottom of the

instrument.

(3) Replace the battery observing correct polarity. Use a new 6LR61 (Alkaline

battery) or 6F22 (Manganese battery).

(4) Re-place and screw the battery compartment cover.

Battery

compartment cover

Battery

Screw

" shown.

5. Specifications

Instrument Specifications

● Measuring Ranges and Accuracy (at 23±5°C, relative humidity up to 75%)

CL130

Range Frequency Accuracy

200A AC

600A AC

200V AC

600V AC

200Ω

CL135

200A AC

600A AC

200V AC

600V AC

200Ω

Conversion method : AC coupled, true rms responding, calibrated to the rms

50/60Hz 1.5% rdg +6dgt sin

40 to 1kHz 2% rdg +5dgt

50/60Hz 1% rdg +3dgt

40 to 1kHz 2% rdg +5dgt

50/60Hz 1% rdg +2dgt

40 to 1kHz 1.5% rdg +4dgt

50/60Hz 1% rdg +2dgt

40 to 1kHz 1.5% rdg +4dgt

Range Frequency Accuracy

50/60Hz 1.5% rdg +4dgt

40 to 1kHz 2% rdg +5dgt sin

50/60Hz 1.5% rdg +4dgt

40 to 1kHz 2% rdg +5dgt sin

50/60Hz 1% rdg +2dgt

40 to 1kHz 1.5% rdg +4dgt sin

50/60Hz 1% rdg +2dgt

40 to 1kHz 1.5% rdg +4dgt sin

1.2% rdg +4dgt

Beeps below about 30

1.2% rdg +4dgt

Beeps below about 30

Ω

Ω

Crest Factor

↑

↑

↑

↑

↑

↑

↑

Crest Factor

3

≤

3

≤

3

≤

3

≤

General Specifications

● Operating System : Dual integration

● Measurement Function : AC current, DC current, Resistance, Continuity check

● Display : Liquid crystal display with maximum counts of 1999

● Overrange Indication : "1" is displayed on the highest digit.

● Response Time : Approx. 1 second (approx.2 seconds on resistance range)

● Temperature and Humidity for Guaranteed Accuracy : 23°C ±5°C, relative

humidity up to 75% without condensation

● Operating Temperature and Humidity : -10 to 50°C (without condensation)

up to 30°C, 90% relative humidity

up to 40°C, 75% relative humidity

up to 50°C, 45% relative humidity

● Storage Temperature and Humidity : -20 to 60°C, relative humidity up to 75%

without condensation

● Effect of conductor position :

CL130 Within 2% of indicated value at the center to a 10 mm-dia conductor

carrying 100A, at every part inside the jaws

CL135 Within 3% of indicated value at the center to a 10 mm-dia conductor

carrying 100A, at every part inside the jaws

● Effect of external magnetic field : 2 A or less in AC magnetic field of 400 A/m

● Power Source : 6F22(9V DC) or equivalent battery

● Battery Life : Approx. 200 hours (continuous)

● Current Consumption : Approx. 2mA

● Withstanding Voltage : 5550V AC for 1 minute between housing case and

metal part of jaws

● Insulation Resistance : 10M

metal part of jaws

● Conductor Size : Approx. 30mm diameter max.

● Dimensions : Approx. 91(W) x 208(H) x 40(D) mm

● Weight : Approx. 400g (batteries included)

● Safety Standard: EN 61010-1

EN 61010-2-31

EN 61010-2-32

(600V AC CAT.III, Pollution degree2, indoor use)

● EMC Standard: EN 55022

● Radiation immunity : IEC 801-3

● Accessories : Test leads Model 98010····················· 1set

6F22 battery······································· 1

Carrying case Model 93032··············· 1

User’s Manual···································· 1

● Optional Accessories : Clamp adapter Model 99025

or greater at 1000V between housing case and

Ω

6. Calibration and After-sales Service

Should any failure occur while you are using the tester, follow the instructions

given below. If the tester still fails to operate correctly and needs repair, contact

the vendor from whom you purchased the instrument or the nearest Yokogawa

M&C sales office.

● Turn off the POWER switch once, then turn it back on again.

● If the tester does not turn on, replace the battery with a new one.

Calibration

It is recommended that the instrument be calibrated once every year.

YOKOGAWA M&C CORPORATION

International Sales Dept.

2-9-32 Nakacho, Musashino-shi, Tokyo, 180-8750 Japan

Phone: 81-422-52-5716 Facsimile: 81-422-55-8654

YOKOGAWA CORPORATION OF AMERICA (U.S.A.)

Phone: 1-770-253-7000 Facsimile: 1-770-251-2088

YOKOGAWA EUROPE B. V. (THE NETHERLANDS)

Phone: 31-334-64-1611 Facsimile: 31-334-64-16 10

YOKOGAWA AMERICA DO SUL S. A. (BRAZIL)

Phone: 55-11-5681-2400 Facsimile: 55-11-5681-1274

YOKOGAWA ENGINEERING INSTRUMENTS KOREA CORPORATION (KOREA)

Phone: 82-2-551-0660 to -0664 Facsimile: 82-2-551-0665

YOKOGAWA AUSTRALIA PTY. LTD. (AUSTRALIA)

Phone: 61-2-9805-0699 Facsimile: 61-2-9888-1844

YOKOGAWA BLUE STAR LTD. (INDIA)

Phone: 91-80-227-1513 Facsimile: 91-80-227-4270

LTD. YOKOGAWA ELECTRIC (RUSSIAN FEDERATION)

Phone: 7-095-737-7868 Facsimile: 7-095-737-7869

KIM3E-2003.2

Loading...

Loading...