Page 1

User ’s

Manual

AQ1210A, AQ1215A, AQ1210E,

AQ1215E, AQ1215F, AQ1216F

OTDR Multi Field Tester

IM AQ1210-01EN

2nd Edition

Page 2

Thank you for purchasing the AQ1210A, AQ1215A, AQ1210E, AQ1215E, AQ1215F, AQ1216F OTDR

(Optical Time Domain Reflectometer).

This user’s manual explains the features, operating procedures, and handling precautions of the

instrument. To ensure correct use, please read this manual thoroughly before operation. Keep this

manual in a safe place for quick reference.

The instrument comes with the following manuals. Please read all manuals.

Manual Title Manual No. Description

AQ1210A, AQ1215A, AQ1210E, AQ1215E,

AQ1215F, AQ1216F

OTDR Multi Field Tester

User’s Manual

AQ1210A, AQ1215A, AQ1210E, AQ1215E,

AQ1215F, AQ1216F

OTDR Multi Field Tester

Getting Started Guide

AQ1210A, AQ1215A, AQ1210E, AQ1215E,

AQ1215F, AQ1216F

OTDR Multi Field Tester

Communication Interface User’s Manual

Model 739884 Battery Pack Handling

Precautions

AQ1210A, AQ1215A, AQ1210E, AQ1215E,

AQ1215F, AQ1216F

OTDR Multi Field Tester User’s Manual

IM AQ1210-01EN This document. A PDF file of the manual is

contained in the internal memory of the instrument.

The manual explains all the features and how to

use them. For viewing instructions, see page 15 in

the Getting Started Guide, IM AQ1210-02EN.

IM AQ1210-02EN This guide explains the handling precautions, basic

operations, and specifications of this instrument.

IM AQ1210-17EN A PDF file of the manual is contained in the internal

memory of the instrument. The manual explains the

communication interface features and instructions

on how to use them. For viewing instructions, see

page 15 in the Getting Started Guide, IM AQ121002EN.

IM 739884-01EN This document explains the handling precautions of

the battery pack.

IM AQ1210-92EN Document for China.

The “-EN” in the manual number is the language code.

Contact information of Yokogawa offices worldwide is provided on the following sheet.

Document No. Description

PIM 113-01Z2 List of worldwide contacts

Notes

• The contents of this manual are subject to change without prior notice as a result of continuing

improvements to the instrument’s performance and functions. The figures given in this manual may

differ from those that actually appear on your screen.

• Every effort has been made in the preparation of this manual to ensure the accuracy of its

contents. However, should you have any questions or find any errors, please contact your nearest

YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual without the permission of

YOKOGAWA is strictly prohibited.

Trademarks

• Microsoft, Windows, and MS-DOS 10 are registered trademarks or trademarks of Microsoft

Corporation in the United States and/or other countries.

• Adobe, Acrobat, and PostScript are either registered trademarks or trademarks of Adobe Systems

Incorporated.

• Bluetooth is a registered trademark or trademark of Bluetooth SIG inc.

• In this manual, the ® and TM symbols do not accompany their respective registered trademark or

trademark names.

• Other company and product names are trademarks or registered trademarks of their respective

holders.

2nd Edition: April 2019 (YMI)

All Rights Reserved, Copyright © 2019, Yokogawa Test & Measurement Corporation

IM AQ1210-01EN

i

Page 3

Revisions

1st Edition: April 2019

2nd Edition: April 2019

ii

IM AQ1210-01EN

Page 4

Conventions Used in This Manual

Notes

The notes and cautions in this manual are categorized using the following symbols.

Improper handling or use can lead to injury to the user or damage to the

instrument. This symbol appears on the instrument to indicate that the user must

refer to the user's manual for special instructions. The same symbol appears

in the corresponding place in the user’s manual to identify those instructions.

In the manual, the symbol is used in conjunction with the word “WARNING” or

“CAUTION.”

WARNING

CAUTION

Calls attention to actions or conditions that could cause serious or fatal injury to

the user, and precautions that can be taken to prevent such occurrences.

Calls attention to actions or conditions that could cause light injury to the user or

damage to the instrument or user’s data, and precautions that can be taken to

prevent such occurrences.

French

AVERTISSEMENT

ATTENTION

Calls attention to information that is important for the proper operation of the

Note

Attire l’attention sur des gestes ou des conditions susceptibles de

Attire l’attention sur des gestes ou des conditions susceptibles

de provoquer des blessures graves (voire mortelles), et sur les

précautions de sécurité pouvant prévenir de tels accidents.

provoquer des blessures légères ou d’endommager l’instrument ou les

données de l’utilisateur, et sur les précautions de sécurité susceptibles

de prévenir de tels accidents.

instrument.

Symbols and Conventions Used in Procedural Explanations

The contents of the procedural explanations are indicated using the following symbols.

IM AQ1210-01EN

Procedure

Explanation

Carry out the procedure according to the step numbers. All procedures are

written under the assumption that you are starting operation at the beginning

of the procedure, so you may not need to carry out all the steps in a procedure

when you are changing the settings.

This section describes the setup items and the limitations regarding the

procedures. It may not give a detailed explanation of the feature. For a detailed

explanation of the feature, see chapter 1.

Character Notations

Panel Key Names and Button Names in Bold Characters

Indicate panel keys that are used in the procedure and buttons that appear on the screen.

Unit

k Denotes 1000. Example: 400 km

K Denotes 1024. Example: 400 KB (file size)

iii

Page 5

Contents

Conventions Used in This Manual ................................................................................................... iii

Chapter 1 Features

1.1 Overview .......................................................................................................................... 1-1

1.2 Optical Pulse Measurement (OTDR) ................................................................................ 1-6

1.3 Displaying Measured Data (OTDR) .................................................................................. 1-7

1.4 Analyzing Measured Data (OTDR) ................................................................................. 1-10

1.5 Pass/Fail Judgment (OTDR) .......................................................................................... 1-16

1.6 Utilities ............................................................................................................................ 1-17

1.7 Application ...................................................................................................................... 1-19

1.8 File Features .................................................................................................................. 1-28

1.9 System Features ............................................................................................................ 1-30

Chapter 2 Setting Up the OTDR Feature

2.1 Measurement (Measure) Conditions ................................................................................ 2-1

2.2 Analysis (ANALYSIS) Conditions ..................................................................................... 2-7

2.3 Display (OTDR) Conditions ............................................................................................ 2-13

2.4 File Conditions ................................................................................................................ 2-23

Chapter 3 Performing Real-time Measurement

3.1 Performing Real-time Measurement ................................................................................ 3-1

3.2 Measuring with Cursors .................................................................................................... 3-6

3.3 Cable Installation Completion Notification ........................................................................ 3-7

3.4 Rerouting Work............................................................................................................... 3-10

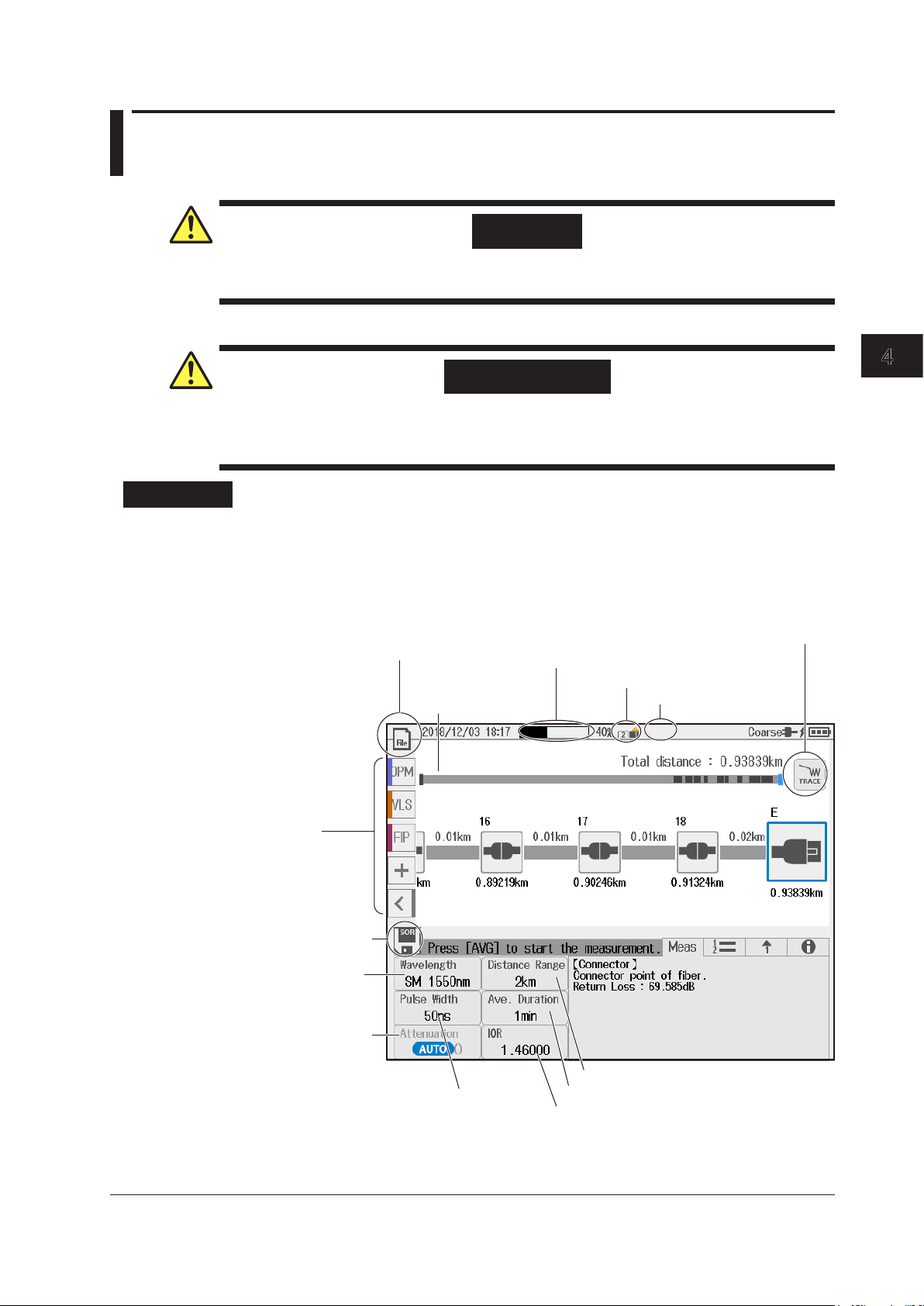

Chapter 4 Performing Averaged Measurements

4.1 Measuring in TRACE Mode .............................................................................................. 4-1

4.2 Measuring in MAP Mode .................................................................................................. 4-5

4.3 Performing Pass/Fail Judgments on Measured Results .................................................. 4-8

4.4 Saving Measured Data ................................................................................................... 4-10

Chapter 5 Analyzing Events

5.1 Analyzing in TRACE Mode ............................................................................................... 5-1

5.2 Analyzing in MAP Mode ................................................................................................. 5-13

Chapter 6 Analyzing Waveforms

6.1 Operating Cursors and Markers ....................................................................................... 6-1

6.2 Zooming In on or Out of Waveforms .............................................................................. 6-14

6.3 Displaying a Reference Trace ........................................................................................ 6-17

6.4 Analyzing Sections ......................................................................................................... 6-20

Chapter 7 Using the Utility Feature

7.1 Using the Light Source ..................................................................................................... 7-1

7.2 Using the Visible Light Source (/VLS option).................................................................... 7-6

7.3 Using the Optical Power Meter ....................................................................................... 7-10

7.4 Using the PON Power Meter (/PPM option) ................................................................... 7-23

7.5 Using the Power Checker (/PC option) .......................................................................... 7-29

7.6 Using the Fiber Inspection Probe (/FST option) ............................................................. 7-34

iv

IM AQ1210-01EN

Page 6

Contents

Chapter 8 Using the Application Feature

8.1 Displaying a Map of the Line Configuration and Events (OTDR Smart Mapper) ............. 8-1

8.2 Measuring a Multi-Core Optical Fiber Cable (Multi-Fiber Project) .................................... 8-8

8.3 Performing an Auto Loss Test (Auto Loss Test) .............................................................. 8-28

8.4 Performing a Multicore Loss Test (Multicore Loss Test) ................................................. 8-38

8.5 Performing Advanced Analysis (Advanced Analysis) ..................................................... 8-46

Chapter 9 Managing Data

9.1

9.2 Using the Instrument as a Mass Storage Device ............................................................. 9-2

9.3 Displaying the Data Management Buttons ....................................................................... 9-3

9.4 Saving and Loading Data ................................................................................................. 9-5

9.5 Creating Report Files ..................................................................................................... 9-10

9.6 Performing File Operations ............................................................................................ 9-14

Connecting USB Storage Device to the USB Ports ........................................................... 9-1

Chapter 10 System Setup

10.1 Displaying the System Setup Screen ............................................................................. 10-1

10.2 Using the Power Save Mode .......................................................................................... 10-3

10.3 Using the Network (LAN) ................................................................................................ 10-4

10.4 Using the WLAN Application .......................................................................................... 10-7

10.5 Specifying the Expiration Date ..................................................................................... 10-16

1

2

3

4

5

6

Chapter 11 Troubleshooting, Updating, and Storage

11.1

11.2 Error Message Display ....................................................................................................11-2

11.3 Viewing the Product Information......................................................................................11-5

11.4 Updating the Firmware ....................................................................................................11-7

11.5 Factory Default Settings ..................................................................................................11-9

11.6 Adding Options ..............................................................................................................11 -11

11.7 Mechanical Inspection and Operation Check ................................................................11-12

11.8 Routine Maintenance ....................................................................................................11-13

11.9 Storage Precautions ......................................................................................................11-15

Troubleshooting ................................................................................................................11-1

Appendix

Appendix 1 Using Open Source Software ............................................................................. App-1

Index

7

8

9

10

11

App

IM AQ1210-01EN

Index

v

Page 7

Chapter 1 Features

1.1 Overview

This instrument is an OTDR (Optical Time Domain Reflectometer) with the features listed below. It

is used in the optical fiber and line installation and maintenance servicing of access networks, which

link telephone exchanges and service providers with subscribers, and user networks, which enable

communication within a corporation or building.

Optical fiber cable

1

Features

AQ1210

Measurement

in cable

installations

Telephone

exchanges

Corporate user

Consumer

OTDR Features

OTDR stands for optical time domain reflectometer. The instrument displays waveforms (TRACE

mode) or icons (MAP mode) that you can use to detect fault locations in optical fiber cables and

monitor fault conditions (transmission loss, splice loss, etc.). It is mainly used in the following optical

fiber cable installation and maintenance situations.

• Access network connecting telecom carriers and subscribers, including service providers (SM

optical fiber cable)

• Network between telecom carriers

1 SM: Single mode

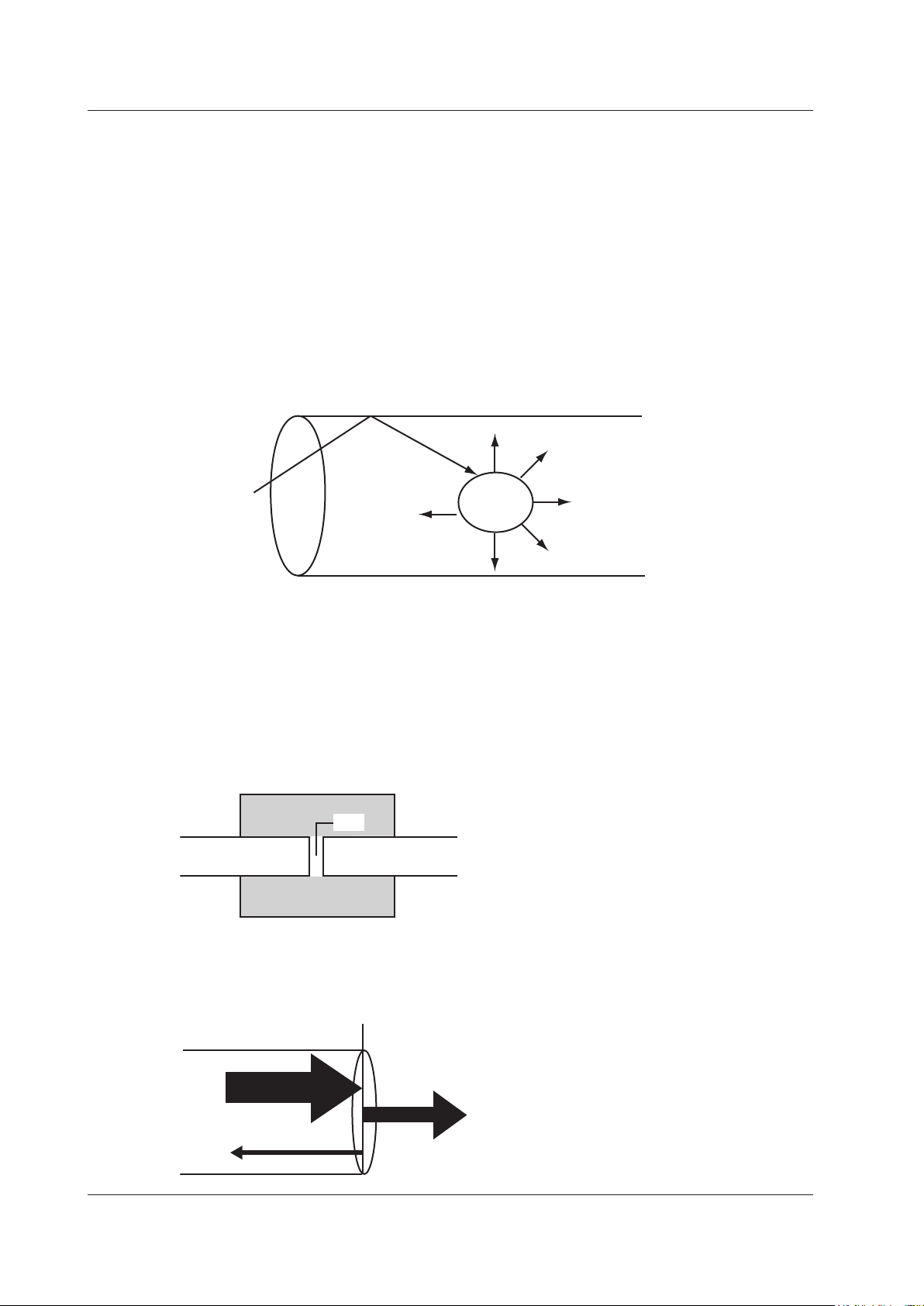

Optical Pulse Measurement

• Averaged Measurement (TRACE mode)

A measurement in which measurements are taken several times and the measured values are

averaged to display the waveform.

• Averaged Measurement (MAP mode)

After averaged measurement is performed, the OTDR waveform is automatically analyzed, and

the results are displayed using icons for each event type.

• Real-Time Measurement (TRACE mode)

While optical pulse measurement is in progress, measured values are updated and displayed as

a waveform in real time.

1

IM AQ1210-01EN

1-1

Page 8

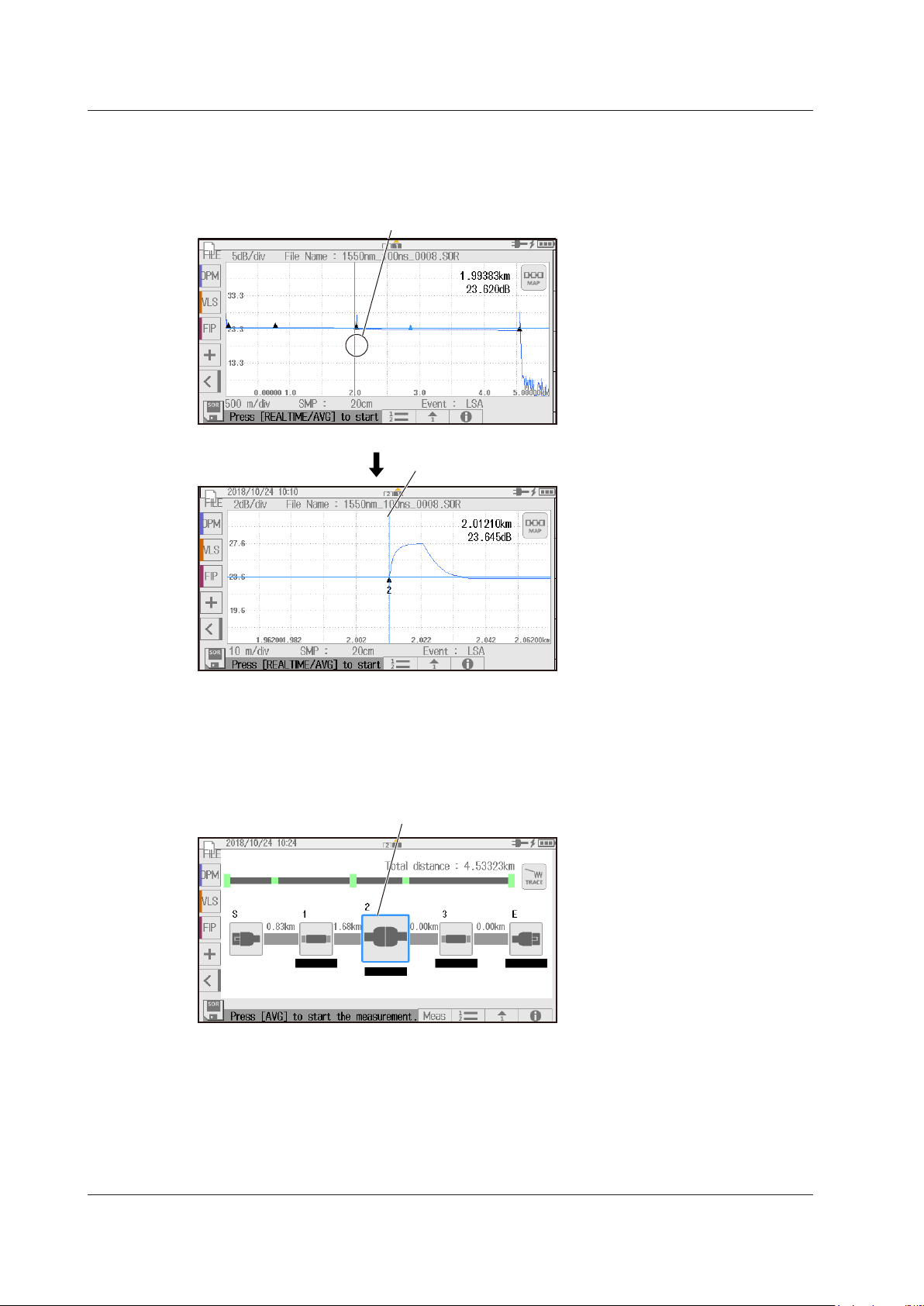

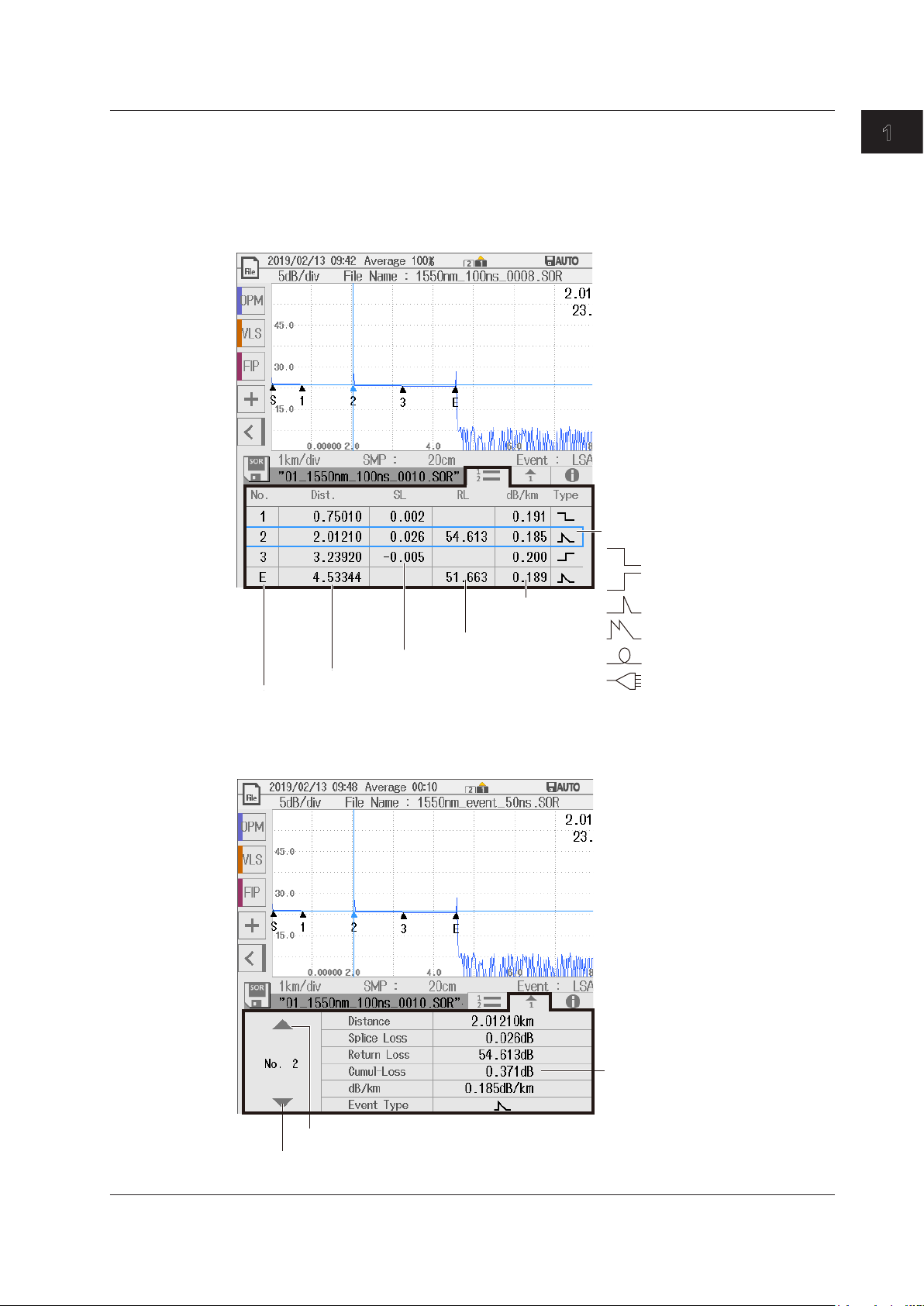

Analysis results are displayed on

Analysis results are displayed as icons.

1.1 Overview

Optical Pulse Waveform Display (TRACE mode)

The results of optical pulse measurement is displayed as a waveform. The displayed waveform can

be zoomed and moved.

the waveform as events.

Zoom the waveform at the cursor position

Event Icon Display (MAP mode)

The instrument can perform an averaged measurement and then automatically display the

measured result events as icons on the screen. In addition, if pass/fail judgment conditions are

specified, judgment results are displayed with icon colors. For details on the pass/fail judgment

function, see section 1.5.

Optical Pulse Analysis

• Waveform Analysis

The following events can be analyzed using cursors and markers.

• Distance

• Splice loss

• Return loss

Return loss between markers can be analyzed.

1-2

IM AQ1210-01EN

Page 9

1.1 Overview

• Event Analysis

Events are automatically detected. In addition, you can edit events. Adjustments can be made

when certain events cannot be detected or when noise is detected as events.

USB Feature

Connecting USB Storage Devices, Communication Dongles, and Fiber Inspection

Probes (Type A)

USB storage devices complying with USB1.0/1.1/2.0 can be used. Up to two devices can be

connected. You can save waveform data and measurement conditions to USB memory devices.

By using a communication dongle (LAN, WLAN), you can remotely control the instrument over a

network and transfer measured waveform data to an external server. You can connect a probe that

is used in Fiber Inspec Probe, which is an application of this instrument. For the recommended

communication dongles that can be used with this instrument, contact your nearest YOKOGAWA

dealer.

Connecting to a PC (Type C)

The instrument can be accessed as a mass storage device from a PC, and the files and folders

in the internal memory can be displayed and manipulated. You can also connect a PC to the

instrument and control it using communication commands. For details, see the communication

interface user’s manual, IM AQ1210-17EN.

Utility Features (simultaneous use of multiple functions)

On the OTDR screen, you can call up optical power meter, visible light source, and other features and

measure optical power and the like simultaneously with the OTDR measurement. In a measurement

that takes a certain time to complete such as in an OTDR averaged measurement, measurement of

other fibers can be executed simultaneously to effectively use the measurement wait time and improve

work efficiency.

1

Features

Light Source Feature (utility)

Stabilized Light Source

This is used as a light source for measuring optical loss or as a light source for optical fiber

identification. The measurement light (CW, CHOP) is emitted from the OTDR port. The wavelength

of the measurement light is the same as that of the optical pulse of the OTDR.

Visible Light Source (/VLS option)

This is used to view the fault locations or check the cores of multi-core optical fiber cables. The VLS

port transmits a visible light (CW, CHOP (2Hz)) with an emission wavelength of 650 nm.

Fiber in Use Alarm (utility)

Power Checker (/PC option)

The OTDR port enables you to check the presence of communication light (fiber in use) within the

optical fiber cable under measurement and view its power value.

Optical Power Meter Feature (utility)

Standard Optical Power Meter (/SPM option)

This feature is used to measure through the OPM port the optical power for loss measurement or

the optical power of a communication device. This is also used as an optical power meter for the

Auto Loss Test, which is an application of this instrument.

High Power Optical Power Meter (/HPM option)

This feature measures through the OPM port the high power (+27 dBm max.) optical power for

loss measurement. This is also used as an optical power meter for the Auto Loss Test, which is an

application of this instrument.

IM AQ1210-01EN

1-3

Page 10

1.1 Overview

PON Optical Power Meter (/PPM option)

This feature measures through the OPM port the optical power of a passive optical network (PON)

for three wavelengths (1310 nm/1490 nm/1550 nm) simultaneously.

Smart Mapper Feature (application)

This feature performs multiple measurements automatically with a single operation, combines the

measured results, and maps the events that occurred on the optical fiber cable as icons. Because

a map display is used in place of a waveform display, complex line configurations can be easily

understood even by inexperienced workers. You can also automatically judge measured results by

setting thresholds. Furthermore, you can view the multiple measured waveforms which are the bases

of the map display.

Events can also be displayed as icons on the map display of the OTDR feature, but the map display

of the OTDR feature converts the analysis results of averaged measurements. If multiple measured

waveforms, which form the bases, are required, the smart mapper feature is convenient.

Multi-Fiber Measurement Feature (application)

Multi-core fiber measurement takes time and effort. This feature makes it possible to efficiently

measure multi-core optical fiber cables through a dedicated menu.

Projects

Items required to make multi-fiber measurements such as measurement conditions, analysis

conditions, and core information are managed as projects. By creating a project before a

measurement, you can measure cores under the same conditions. You can save projects to files.

You can load a previously saved project and make measurements under the same conditions. In

addition, the AQ7933 Emulation Software can be used to create projects, and the project files can

be loaded into this instrument.

List

Cores are listed on the screen. You can identify cores that have been measured, cores that have

not been measured, and cores that are not to be measured. For each core in the list, you can

perform average measurement, real-time measurement, optical power management, and fiber

inspection probe operations. This prevents unintended omission in core measurements and allows

measurements to be performed efficiently.

Saving Measured Results

Measurement results of each core are automatically saved to a folder that is automatically created

in the folder that the project file is saved in. The folder will have the same name as the project file.

Fiber Inspec Probe (application)

A YOKOGAWA-specified fiber inspection probe can be used to view stains on the optical fiber cable

end face on the instrument screen. The fiber inspection probe is not included with the instrument.

Please purchase your own fiber inspection probe. For information about compatible fiber inspection

probes, contact your nearest YOKOGAWA dealer.

Loss Test/Multi-Core Loss Test (Application)

By using two instruments, one as a light source and another as an optical power meter, the optical fiber

loss can be measured. In a multi-core loss test, the loss of a multi-core optical fiber can be measured.

As a light source, the instrument automatically switches between two wavelengths (1310 nm and 1550

nm) and outputs them.

As an optical power meter, the instrument automatically detects the wavelength of the input light,

switches its wavelength setting, and measures the optical power.

1-4

IM AQ1210-01EN

Page 11

AQ1215F, AQ1216F

1.1 Overview

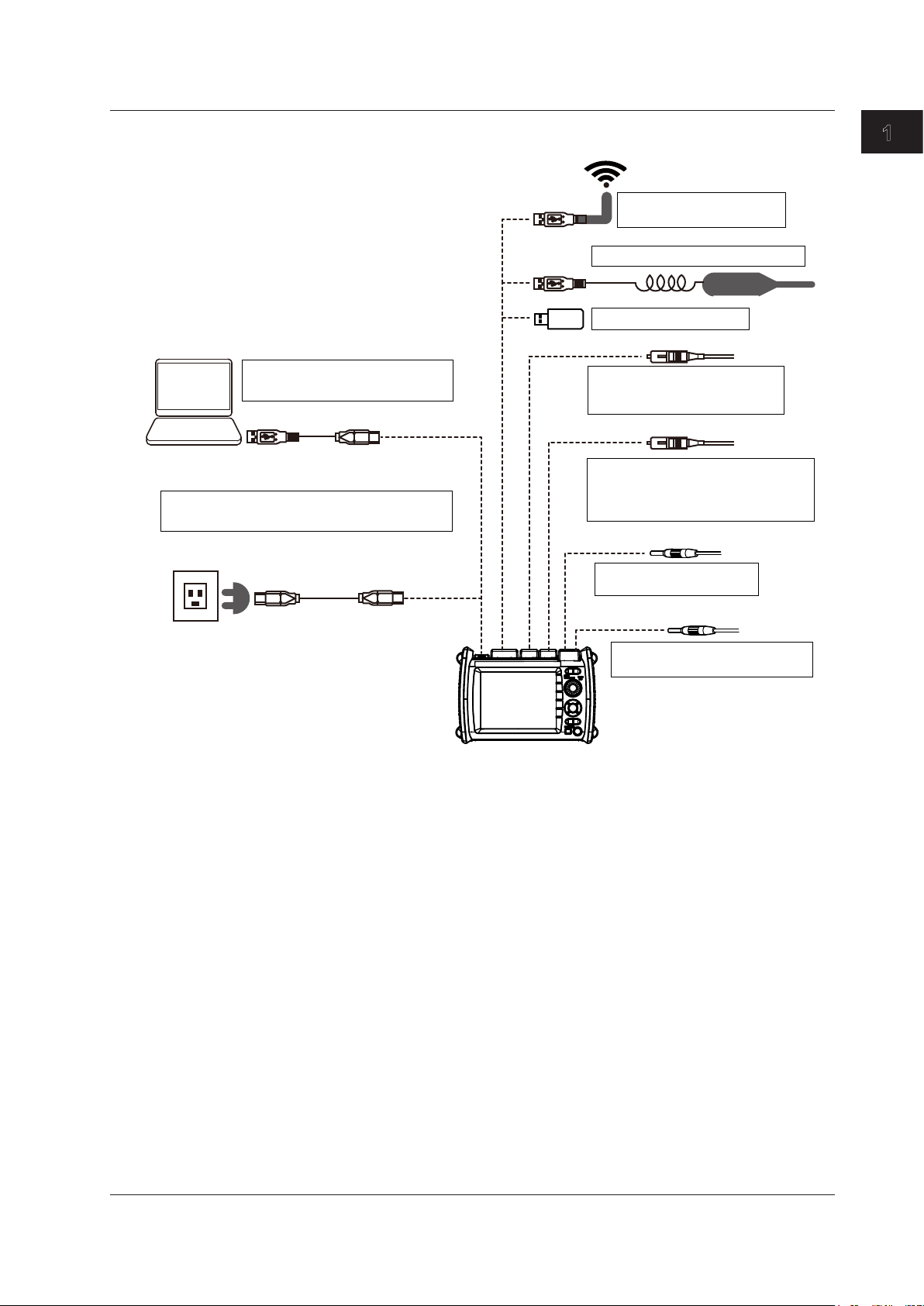

System Configuration

• Mass storage device (section 9.2)

PC

• Charging the instrument

See the Getting Started Guide, IM AQ1210-02EN.

Three-prong

outlet

• Remote control (section 10.4)

USB cable

USB cable (standard

accessory)

USB TypeC

USB TypeC

USB Type A

(2 ports)

Fiber inspection probe (section 7.6)

USB memory (section 9.1)

OTDR port 2

• OTDR measurement

• Light source output

OTDR port 1

• OTDR measurement

• Light source output, power checker

OPM port

Communication dongle

(section 10.3) (WLAN, LAN)

(wavelength 1625 nm, 1650 nm)

(wavelength 1310 nm, 1550 nm)

measurement

Optical power meter input

(/SPM, /HPM, /PPM option)

1

1

Features

1

1

USB-AC

adapter

VLS Port

AQ1210A, AQ1215A,

AQ1210E, AQ1215E,

VLS output (wavelength 650 nm)

(/VLS option)

See the top panel in “Component

1

Names and Functions” in the

Getting Started Guide, IM

AQ1210-02EN.

1

IM AQ1210-01EN

1-5

Page 12

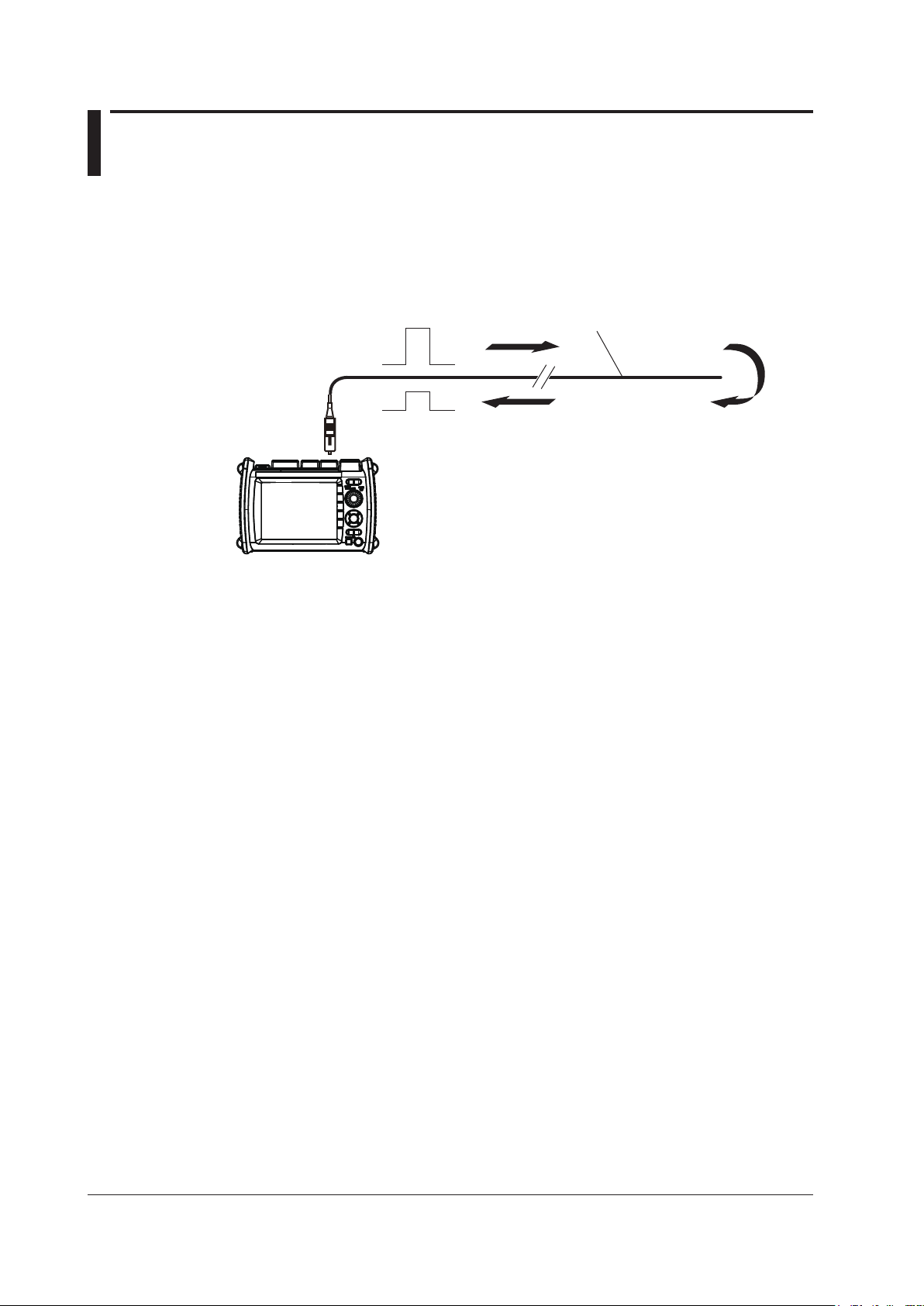

1.2 Optical Pulse Measurement (OTDR)

Optical fiber cable being measured

Optical pulse output

The instrument applies an incident optical pulse to the connected optical fiber cable and measures

the power level of the reflected light from the different sections of the optical fiber cable such as its

connections, bent sections, and the open end of the fiber. The instrument uses the measured power

level to determine the distance to the different points (splices, breaks, etc.) of the optical fiber cable

and the loss and other phenomena that occur at those points. For details on how to view optical pulse

waveforms, see section 1.3.

Reflection point

OTDR/light source port

Reflected light

Do not bend the optical fiber cable.

AQ1210A, AQ1215A,

AQ1210E, AQ1215E,

AQ1215F, AQ1216F

Real-time Measurement

Real-time measurement is a feature that measures optical pulses while updating and displaying

the measured values. You can monitor in real time events, such as splice loss and return loss,

while installing optical fiber cables. You can also view the changes in the waveform as you change

the measurement conditions, such as the wavelength, distance range, and pulse width. Real-time

measurement is not possible in MAP mode (the mode is automatically switched to TRACE mode

before making a measurement).

Averaged Measurement

Averaged measurement is effective when you want to detect reflections, splice loss, and other faint

events that are generated from connections or splice points but are buried in noise. The instrument

derives the measured data by averaging the specified number of optical pulse measurements or by

averaging optical pulse measurements over the specified duration. During averaged measurement,

you cannot change the measurement conditions. You can stop an averaged measurement before it

completes.

• Multi Wavelength Measurement

Two wavelengths, 1310 nm and 1550 nm, can be measured with one measurement operation.

When a measurement is started, an averaged measurement is performed at 1310 nm. Then, the

wavelength is automatically switched to 1550 nm, and another measurement is made.

1-6

Auto Check before Measurement

• Fiber-In-Use Alarm

The instrument uses the same wavelength that is used in real communication to measure optical

pulses. If communication light is present in the optical fiber cable that you want to measure, the

communication will be affected. When this communication light is present, we say that the fiber is

in use. The fiber-in-use alarm is a feature that checks if communication light is being transmitted

along the optical fiber cable that you are trying to measure. If the fiber is in use, a warning

message is displayed asking whether you want to continue the measurement.

• Connection Check

The connection check is a feature that checks the state of the connection between the

instrument and an optical fiber cable. When this feature is set to on, you can prevent light from

being transmitted from the instrument OTDR port if an optical fiber cable is not connected to the

instrument or if the cable is not connected correctly.

IM AQ1210-01EN

Page 13

1.3 Displaying Measured Data (OTDR)

Incident ray Backscatter Splice

Connector Bend

Icons of

each event

Incident ray Backscatter Splice

Connector Bend

Open end

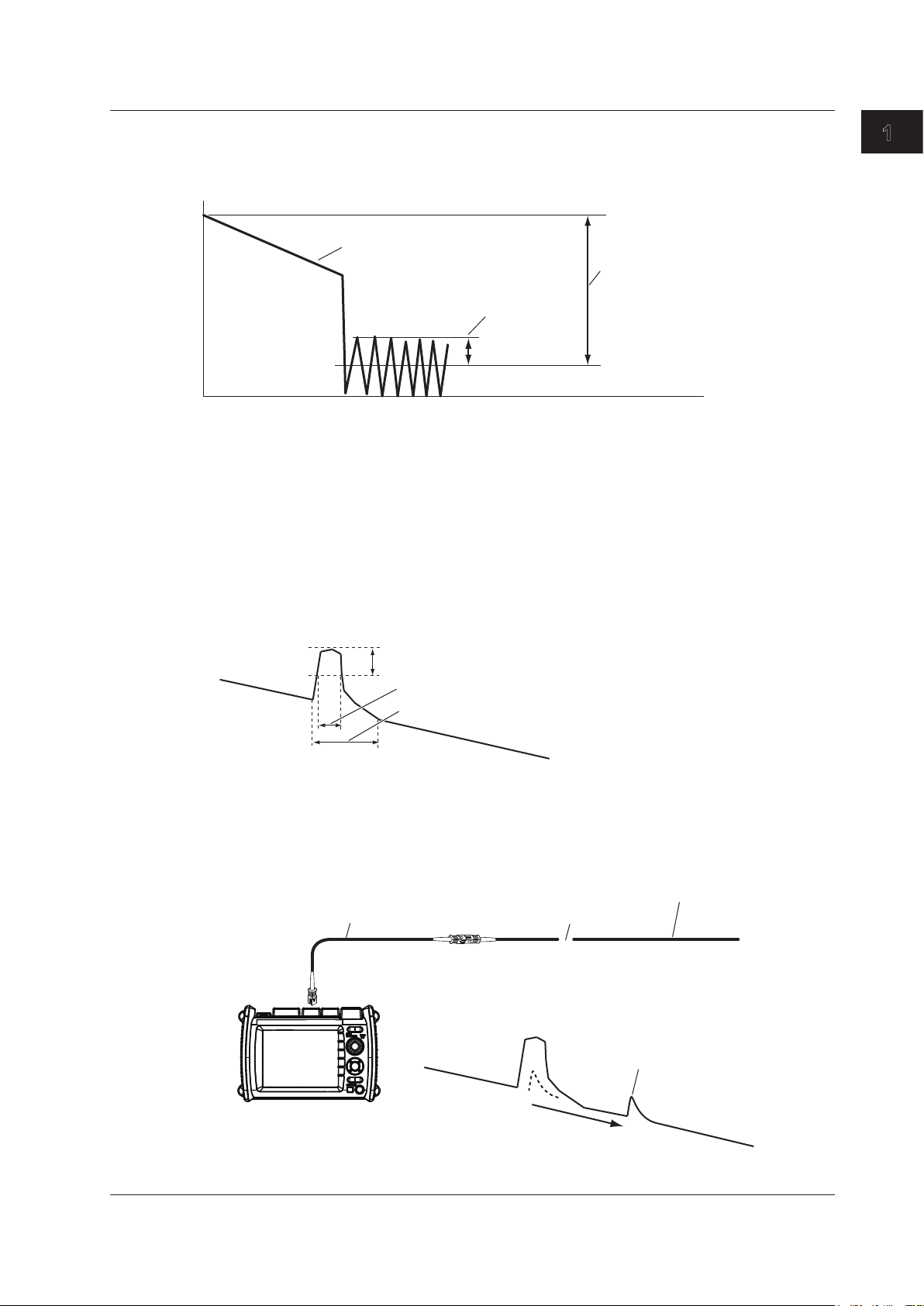

How to View Optical Pulse Waveforms (TRACE mode)

The optical pulse applied to the optical fiber cable is reflected at different points of the optical fiber such

as its connections, bent sections, and the open end of the fiber. These sections generate loss. The

measured result is displayed as a waveform that has distance represented in the horizontal direction

and loss level represented in the vertical direction. On the waveform, detected losses or reflections are

known as events.

1

Features

Optical fiber cable

Near-end reflection

Splice loss

Approximation line

Reflection caused by a connector

Loss caused by bending

Reflection at the open end (Fresnel reflection)

Dynamic range (SNR = 1)

Open end

How to View the Icon Display (MAP mode)

Losses and reflections that occur at connections, bent sections, and open ends are displayed using

icons. Events in the section from the measurement start point to the open end are displayed in order

from the start point.

IM AQ1210-01EN

Optical fiber cable

Start point

(Near-end

reflection)

Splice loss Return loss Bending loss Splitter End point

Splitter

(Fresnel

reflection)

1-7

Page 14

Incident ray

Optical fiber cable

Connector

1.3 Displaying Measured Data (OTDR)

Near-end Reflection

This is the reflection that occurs at the point where the instrument and the optical fiber cable are

connected. This also includes the instrument’s internal reflection. In the section where this near-end

reflection is detected, even if there are other connections, the loss and reflections that occur at these

points cannot be detected. This section is the near-end dead zone.

When you are measuring a short distance, connect a launch fiber cable to reduce the effect of the

near-end reflection.

Backscatter

When light travels through an optical fiber cable, Rayleigh scattering caused by changes in the density

of materials that are smaller than the light’s wavelength and inconsistencies in the fiber's composition

generates loss in the optical fiber itself. The portion of the scattered light that travels in the direction

opposite to the direction of propagation is known as backscatter.

Backscatter

Small

material

Splice Loss

Because spliced sections of optical fiber cables have a great number of changes in the material’s

density and inconsistencies in the cable’s composition, loss due to Rayleigh scattering becomes large,

and splice loss occurs in these sections.

Reflection at the Connection Point of Connectors

Using a connector to connect two optical fibers is different from splicing them together in that a small

gap remains between the two fibers. Because this gap has a different index of refraction, reflection

occurs.

Gap

Optical fiber cable Optical fiber cable

1-8

Fresnel Reflection at the Open End of the Fiber

This is the reflection that occurs at locations where the index of refraction changes (glass to air) such

as where there are tears in the optical fiber cable or at the end of it. When the optical fiber cable end

face is vertical, approximately 3% of the incident optical power (14.7 dB) is reflected.

Glass Air

Incident ray (100%)

Light (97%)

Reflected light (3%)

IM AQ1210-01EN

Page 15

RMS level of noise

Optical fiber cable

Small reflection that was hidden

AQ1215F, AQ1216F

1.3 Displaying Measured Data (OTDR)

Dynamic Range

Dynamic range refers to the range of optical power levels that can be measured. The larger the

1

Features

dynamic range, the greater the distance that optical pulses can be measured over.

Measured waveform

Dynamic range

(SNR=1)

Noise peak

2.6 dB

Dead Zone

An area where the influence of a large event such as a connector’s connection point makes it

impossible to recognize other events that exist in that area is a dead zone. There are the following

types of dead zones.

Event Dead Zone

An area where adjacent reflections cannot be separated. This is the area represented by the pulse

width between the two points on the waveform at the level that is 1.5 dB below the peak value.

Attenuation Dead Zone

An area where, because there is a large reflection, the surrounding splice losses cannot be

measured.

• Near-end Dead Zone Prevention

In sections where near-end reflection is detected, loss and reflections that occur at connections

cannot be detected. If you are measuring a short distance, connect a launch fiber cable to move

events that are hidden in the near-end reflection the distance of the launch fiber cable.

1.5 dB

Event dead zone

Attenuation dead zone

Launch fiber

Event generation

point

Do not bend the optical fiber cable.

being measured

within a large reflection

IM AQ1210-01EN

AQ1210A, AQ1215A,

AQ1210E, AQ1215E,

1-9

Page 16

1.4 Analyzing Measured Data (OTDR)

Measurement start position (marker )

Splice loss

1

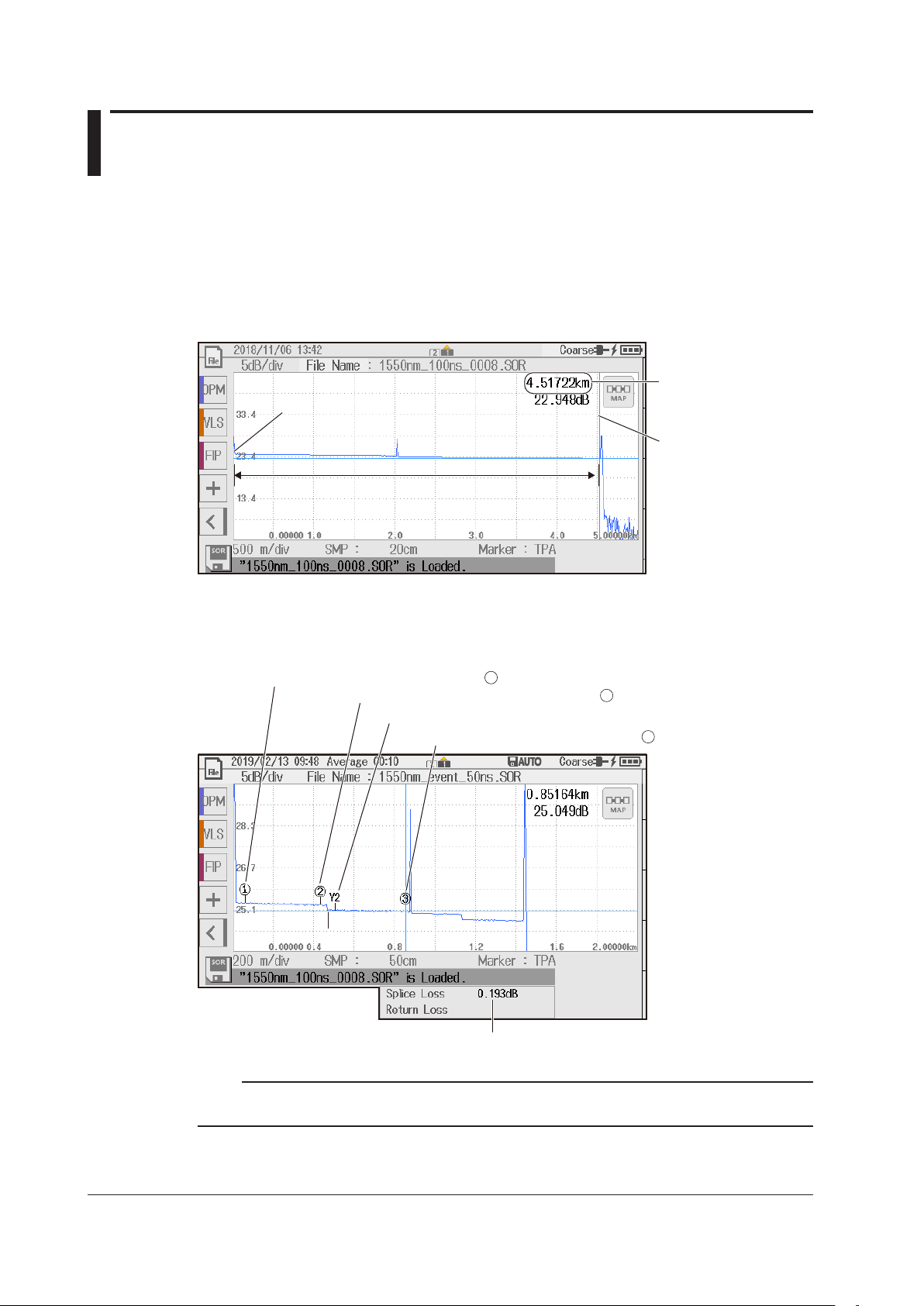

Marker Analysis (TRACE mode)

You can manually use cursors and markers to measure values such as the distance, splice loss, and

return loss between two points.

Distance between Two Points

The distance from the start point to the cursor position is displayed.

Start point

Distance from the start point to the cursor

Distance

Cursor

Splice Loss

When you place four markers as shown in the following figure, the splice loss from the measurement

start position to the measurement end position is calculated, and the value is displayed.

Position where splice loss starts (marker )

Position where splice loss ends (Y2 marker)

Measurement end position (marker )

Splice loss measurement point

2

3

1-10

Note

In addition to the above method, the splice loss can be measured by using six markers or by using line

markers. For details, see section 6.1.

IM AQ1210-01EN

Page 17

Return loss

Event’s rising start position (marker )

A B

start point to each

(between and )

1.4 Analyzing Measured Data

Return Loss

When you place two markers as shown in the following figure, the return loss is calculated, and the

value is displayed.

Splice Loss at Two Locations (4 Point Monitor)

Splice losses at two locations can be measured simultaneously using four markers.

1

Event’s falling end position (marker )

2

1

Features

Loss from the start

point to each marker

Loss

measurement at

splice point 1

Loss at splice point 1

Loss

measurement at

splice point 2

Loss at splice point 2

(between and )

Distance from the

marker

C D

IM AQ1210-01EN

1-11

Page 18

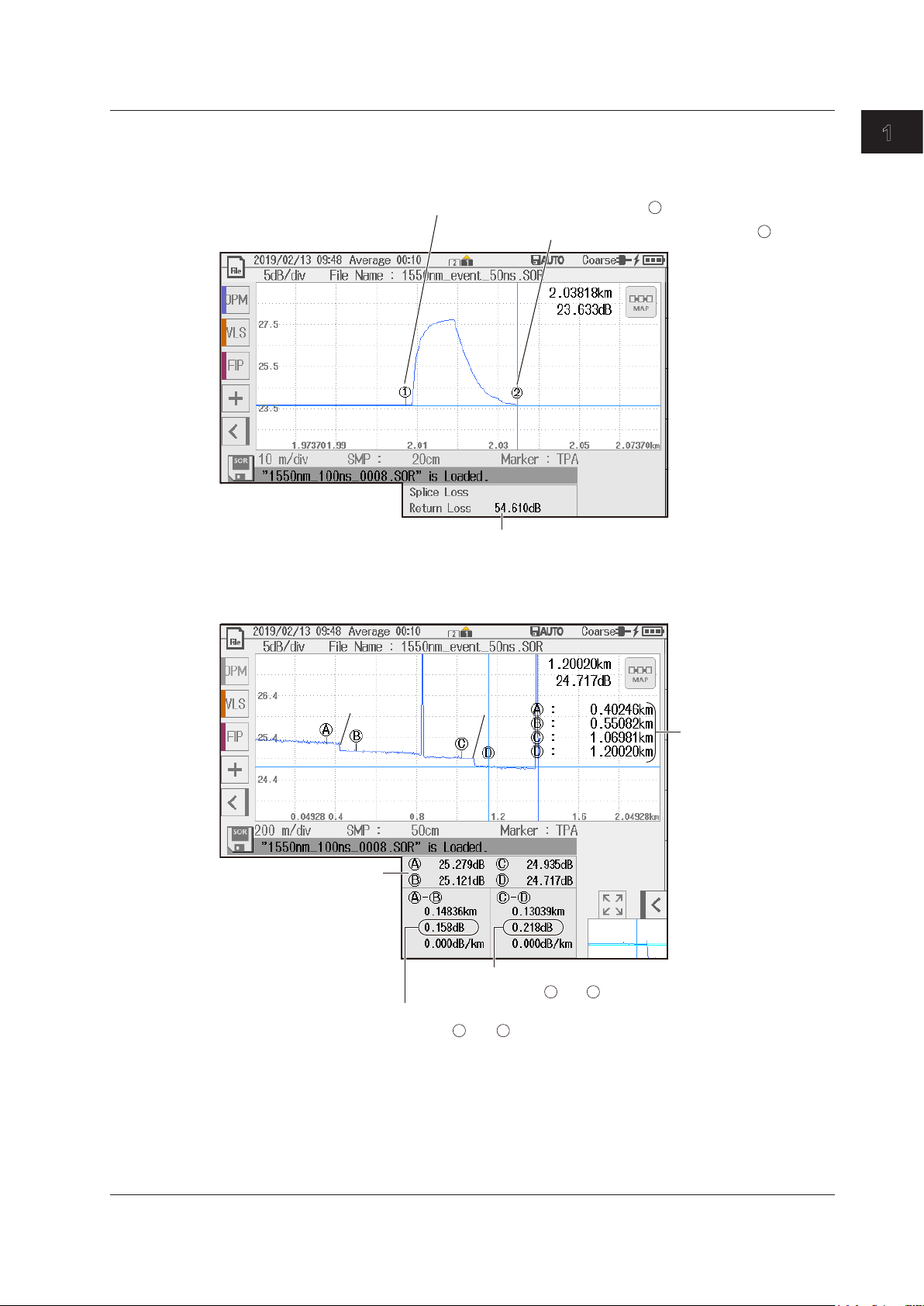

TRACE mode

1.4 Analyzing Measured Data

Event Analysis

All events are automatically detected from the waveform of optical pulse measurement, and the types

of each event and analysis results (splice loss, return loss, etc.) are displayed on the screen.

Event Display

In TRACE mode, detected events are displayed on the measured waveform. In MAP mode, the

types of events are displayed using icons along with the distances of each from the measurement

start position.

Event number

MAP mode

Relative position of the event

Distance between

events

Displays the event

type with an icon

Distance from start point S

Event number

1-12

IM AQ1210-01EN

Page 19

Cumulate loss from the measurement

Displays the previous event number

1.4 Analyzing Measured Data

Event Information Display

The distance, splice loss, return loss, and the like of each event are displayed. This is a feature

common to TRACE mode and MAP mode.

• List Display

All detected events are listed.

Event type

: Positive splice loss

: Negative splice loss

Loss per kilometer

between events

Return loss

Splice loss

Distance from the measurement start point (S)

Event number

: Reflection

: Superimposed reflections

: Bending loss (macro bending)

: Splitter insertion loss

1

Features

• Individual Event Information

The measured data of the selected event number is displayed.

start point (S)

Displays the next event number

IM AQ1210-01EN

1-13

Page 20

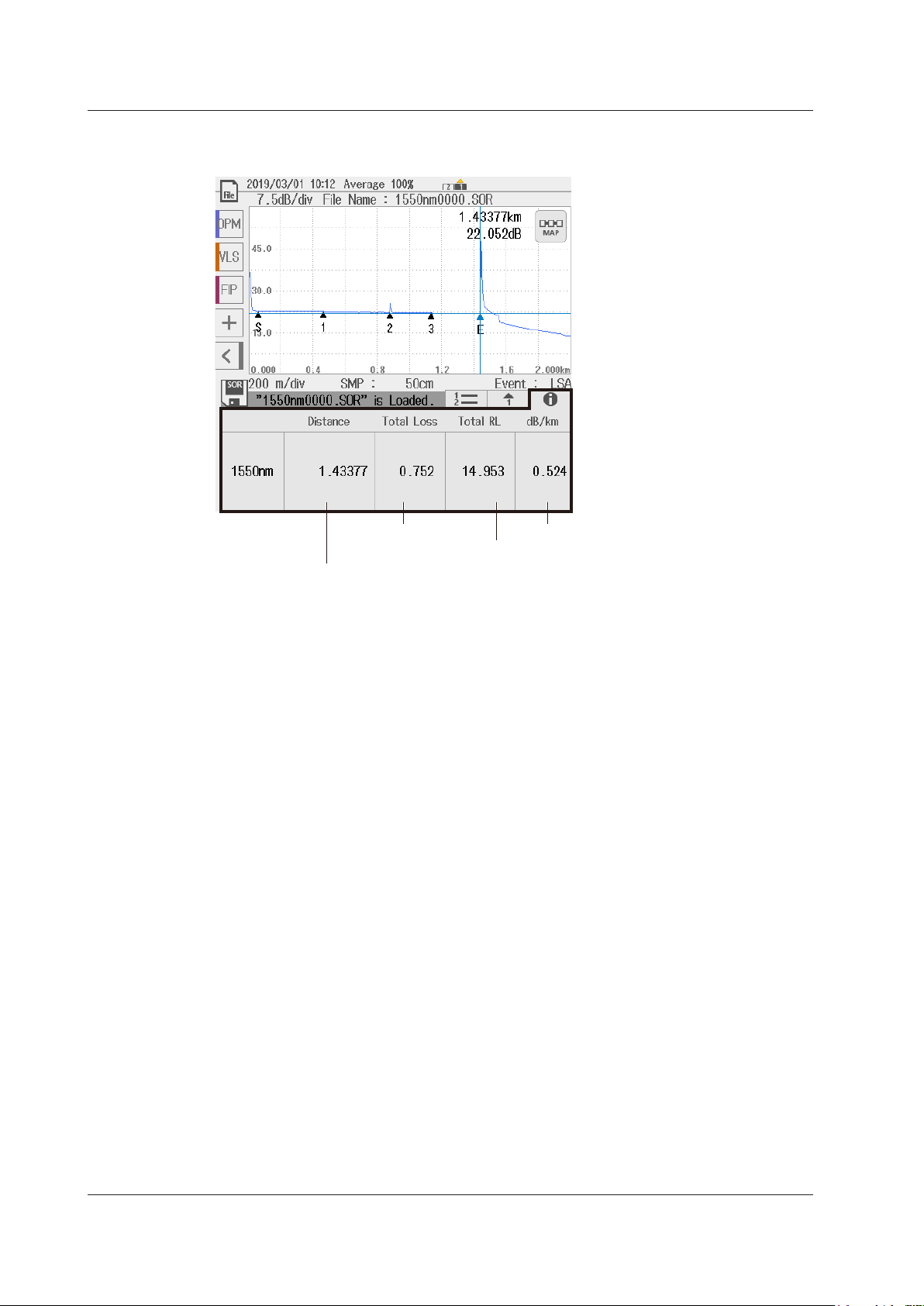

point (S) to the measurement end point (E)

Loss per kilometer between events

1.4 Analyzing Measured Data

• Measurement Total of Events

The total values of detected events are displayed.

Total loss

(cumulate loss)

Distance from the measurement start

Total return loss

Event Analysis Conditions

You can set event search conditions.

• Splice Loss (Splice/Connection)

The instrument recognizes that an event has occurred when it detects a measured result that is

greater than the specified value.

• Return Loss

The instrument recognizes that an event has occurred when it detects a measured result that is

less than the specified value.

• End of Optical Fiber

The instrument recognizes that an end-of-fiber (E) event has occurred when it detects a

measured result that is greater than the specified value.

• Bending Loss

You can select whether to detect bending losses. If you select to detect bending loss, the

instrument recognizes that an event has occurred when it detects a measured result that is

greater than the specified threshold.

• Near-end Dead Zone Prevention (Launch Fiber Setting)

To prevent near-end reflections, if a launch fiber is connected to the measurement start point, the

length of the launch fiber is automatically corrected in the calculations.

For details on near-end dead zone prevention, see “Dead Zone” in section 1.3.

• Splitter Loss

If splitters are inserted, you can select whether to detect the losses caused by them. If you select

to detect splitter loss, the instrument recognizes that an event has occurred when it detects a

measured result that is greater than the specified threshold.

1-14

IM AQ1210-01EN

Page 21

Reference trace (white: when Screen Color is set to Color1)

1.4 Analyzing Measured Data

Setting a Reference Trace

You can perform averaged measurements or real-time measurements while retaining the previous

waveform on the screen (reference trace). You can display the waveform being measured and the

reference waveform at the same time to compare them. Waveform data loaded from a file can also be

used as a reference trace.

Superimposed on the waveform currently being measured

1

Features

IM AQ1210-01EN

1-15

Page 22

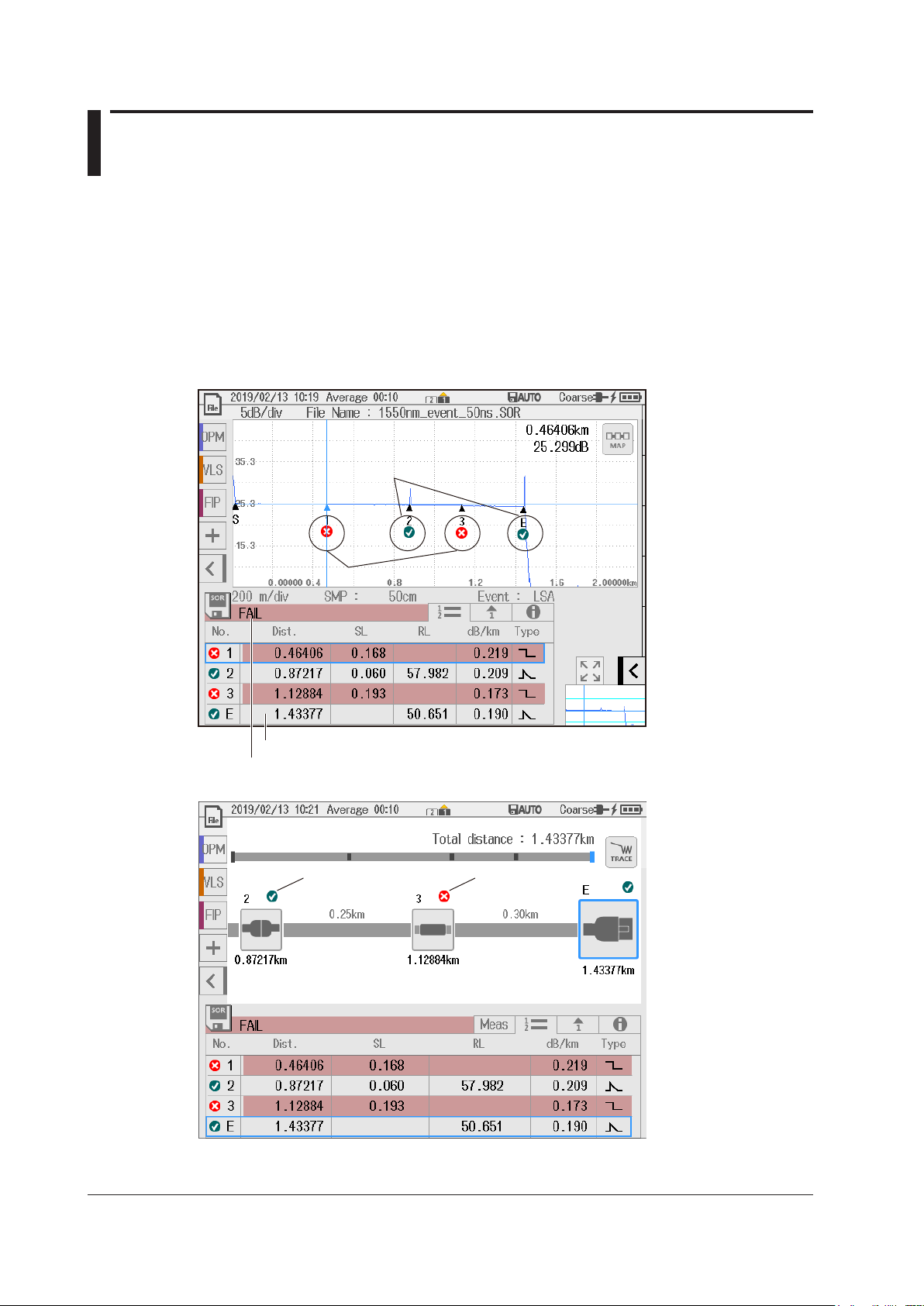

TRACE mode

1.5 Pass/Fail Judgment (OTDR)

In pass/fail judgment, the instrument automatically determines whether preset conditions are met

based on the event analysis data and displays the results on the screen.

Judgment Conditions

Set a pass/fail judgment threshold on each measurement item (splice loss, return loss, dB/km, total

loss). When the measurement value does not exceed the threshold, the corresponding event is

indicated as pass. When the measurement value is greater than the threshold, the corresponding

event is indicated as fail.

Pass judgment

Fail

MAP mode

When all events are judged as Pass, the bar turns green.

The pass judgment result and value of each event are displayed.

Pass

Fail

1-16

IM AQ1210-01EN

Page 23

1.6 Utilities

Light Source

The light source is used to make loss measurements. The following measurement light wavelengths

can be generated.

Model Measurement Light Wavelength

AQ1210A 1310 nm, 1550 nm

AQ1215A 1310 nm, 1550 nm

AQ1210E 1310 nm, 1550 nm, 1625 nm

AQ1215E 1310 nm, 1550 nm, 1625 nm

AQ1215F 1310 nm, 1550 nm, 1650 nm

AQ1216F 1310 nm, 1550 nm, 1650 nm

You can produce continuous light or light that has been modulated at the selected frequency (modulation

mode).

Visible Light Source

The features listed for the visible light source are available on models with the /VLS option.

A visible light source can be used for the following purposes.

• Determine visually breaks in the optical fiber cable under test

• Check the cores of multi-core optical fiber cables

Model Measurement Light Wavelength

AQ1210A

AQ1215A

AQ1210E

AQ1215E

AQ1215F

AQ1216F

650 nm

1

Features

Optical Power Meter

The optical power meter feature can be applied to models with the /SPM (standard), /HPM (high

power), or /PPM (PON) option. An optical power meter can be used for the following purposes.

• Measure the loss in an optical line that uses optical fibers

• Measure the optical signal power of an optical communication device

The following measurement lights can be measured.

Model Measurement Wavelength

/SPM option /HPM option /PPM option

AQ1210A

AQ1215A

AQ1210E

AQ1215E

AQ1215F

AQ1216F

Logging

You can measure short-term optical power stability. The optical power value during logging can be

displayed on a graph, and you can calculate the maximum, minimum, and average. In addition,

you can use cursors to calculate the optical signal power at a specified location or the maximum,

minimum, and average within a specified area. The logging results can be saved to a file in CSV

format.

800 nm to 1700 nm 800 nm to 1700 nm 1310 nm, 1490 nm, 1550

nm

IM AQ1210-01EN

1-17

Page 24

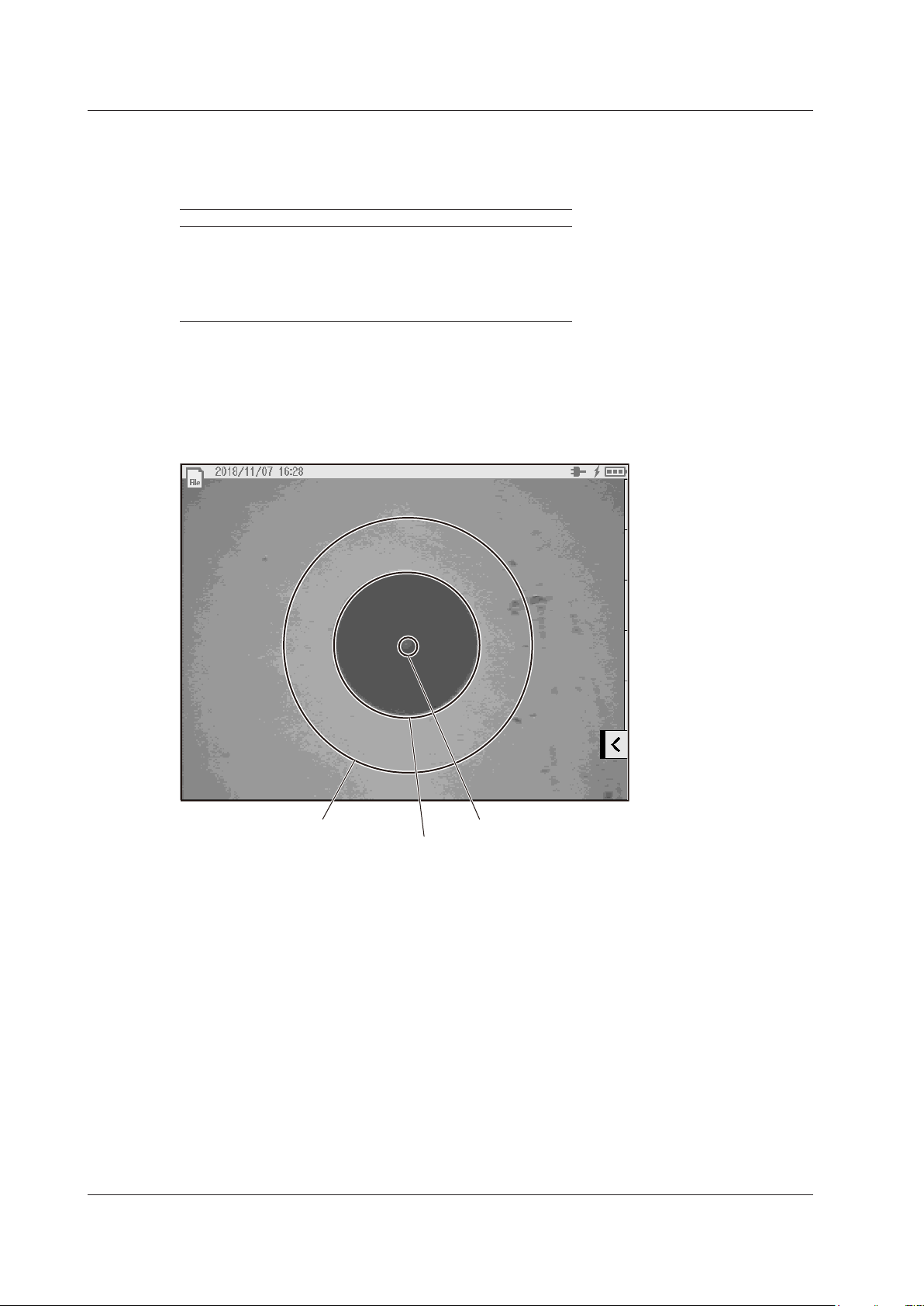

Example of an end face image of an optical fiber cable

Cladding area

1.6 Utilities

Power Checker (/PC option)

The power checker feature is used to check the power of the loss-measurement light source in a

simplified manner.

The following measurement lights can be measured.

Model Measurement Wavelength

AQ1210A

AQ1215A

AQ1210E

AQ1215E

AQ1215F

AQ1216F

1310nm, 1490nm, 1550nm, 1625nm, 1650nm

Fiber End Face Inspection (/FST option)

You can use a fiber inspection probe recommended by YOKOGAWA to take a photograph that shows

the state of a fiber end face. You can display this photograph on the instrument screen and save it. You

can also perform a pass/fail judgment on the state of the cable end face shown on the photograph.

Contact section

Pass/fail judgments can be performed separately on each of the contact areas, cladding areas, and

core areas.

Core area

1-18

IM AQ1210-01EN

Page 25

1.7 Application

The icon display method is the same as the display

See “Event Analysis” in section 1.4.

Smart Mapper

The Smart Mapper feature repeats the averaged measurements of the OTDR feature on the same

wavelength using different pulse widths, and then when measurements are completed, automatically

executes the event analysis of the OTDR feature.

Like the OTDR feature, when measurements are completed, you can select between MAP mode and

TRACE mode.

Event Analysis Using MAP Mode

When you select MAP mode, various events on the optical fiber cable path can be detected and

displayed as icons on the screen.

Relative position of the event

1

Features

in MAP mode of event analysis in section 1.4.

Distance between

events

Distance from start point S

Displays the event type with an icon

Event number

Event information display

IM AQ1210-01EN

1-19

Page 26

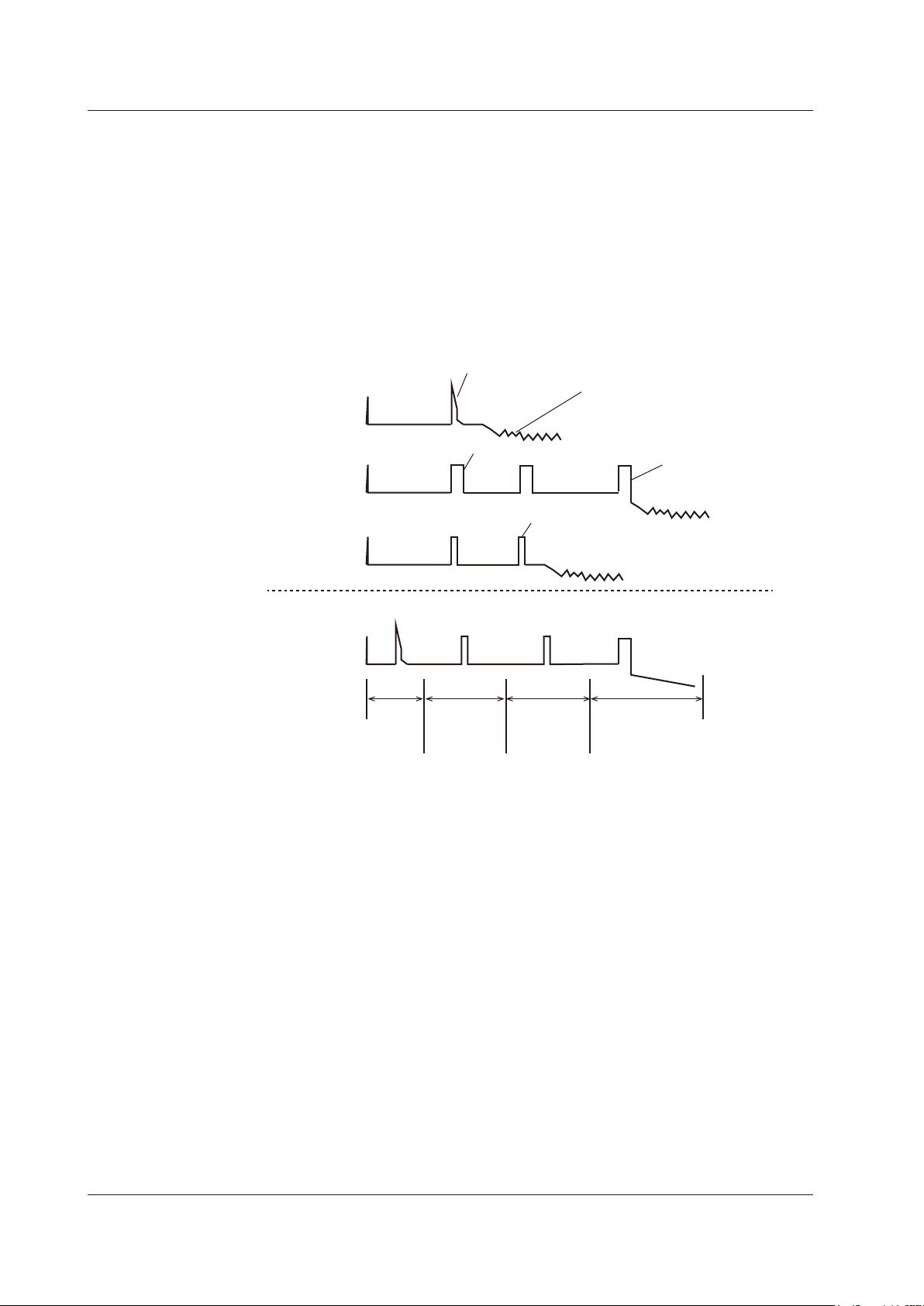

Increased waveform resolution

Measurement waveform using

an intermediate pulse width

(Trace2, Trace3)

1.7 Application

Adapt Trace Using TRACE Mode (waveform editing)

When you select TRACE mode, waveforms measured at different pulse widths can be displayed.

In an optical fiber cable measurement, reducing the pulse width of optical pulse measurement

increases the measurement resolution of the waveform in the near-end section but causes the

optical pulse to attenuate in the far-end section, preventing correct measurement. Conversely,

increasing the pulse width of optical pulse measurement allows correct measurement in the far-end

section but decreases the measurement resolution of the waveform in the near-end section.

The Adapt Trace feature compensates for these measurement accuracy degradations by performing

optical pulse measurement using multiple different pulse widths for the same wavelength and

combining the multiple waveforms on the screen. The instrument automatically determines the

pulse widths depending on the specified distance range and wavelength.

Measurement waveform

using a narrow pulse width

(Trace1)

Measurement waveform

using a wide pulse width

(Trace4)

Adapt Trace

When the distance is long,

measurement is not possible.

Decreased waveform resolution

Events in mid-range

can be measured.

Trace1

Trace2 Trace3 Trace4

Pulse

width

(narrow)

Pulse width

(intermediate)

Line 1 Line 2 Line 3

You can change the effective range of Trace1 to

Trace4 by moving the lines marking the sections.

Pulse width

(intermediate)

Events far away

can be measured.

Pulse width

(wide)

1-20

IM AQ1210-01EN

Page 27

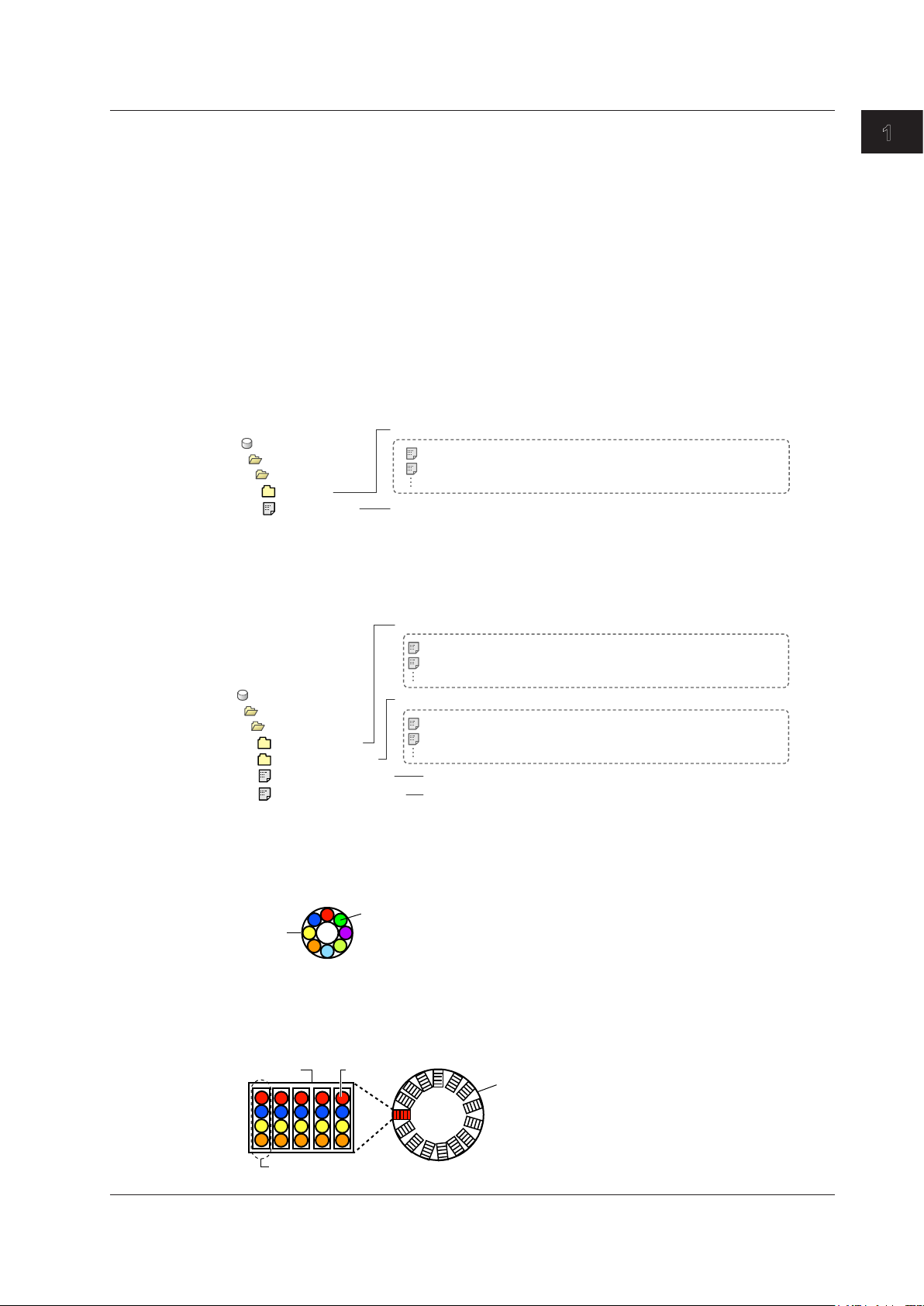

ABCDE.MPJ

The newly created project file

Measurement result files (.SOR extension)

Example of when the project file name is “ABCDE”

Folder for saving measurement result files (core numbers 1 to 10)

Folder for saving measurement result files (core numbers 101 to 200)

ABCDE_101_200.MPJ

The newly created project file (core numbers 101 to 200)

Normal core cable (example with eight cores)

Tape (example: 1a to 1d)

Ribbon slotted core cable (example of 300 fiber type 4-fiber ribbon)

This is an example of a 300 fiber type with 15 slots (20 fibers) containing five 4-fiber tapes.

The following settings need to be entered to set the information of this core cable in a project of this instrument.

• Num of Fibers (per slot): 20

• Tape No.: a-d(4)

1.7 Application

Optical Pulse Measurement of Multi-core Optical Fiber Cables

Projects

Projects are group of items for measuring multi-core fibers. The default project name is “NewProject.”

In the instrument internal memory, core information, measurement conditions, analysis conditions,

measured results, and the like are linked with the project name and saved. You can set up to 15

characters for the project name. For the types of strings and characters that you can use, see the

explanation in section 2.4.

• Project File Structure

When you create a new project name, a new project file (.MPJ extension) and a new folder

If the number of fibers exceeds 100, the folder for saving the project file and that for saving

for saving measurement result files (.SOR extension) are created. At this point, you can select

whether to inherit the fiber information, measurement conditions, and analysis conditions from an

existing project file or reset them to default values.

Internal Memory

DATA

MPJ

ABCDE

Folder for saving measurement result files

1310nm_0001.SOR

1310nm_0002.SOR

are automatically named and saved.

measurement result files will be divided. The folder is automatically divided every 100 fibers. The

divided folder names will be the project name followed by the start core number and end number

set in the project.

1

Features

Internal Memory

Number of Fibers, Number of Fibers in Each Division, Tape Number

The core number indications and settings vary depending on the type of multi-core fiber cable.

Eight cores are bundled into one.

Cable

DATA

MPJ

ABCDE_1_100

ABCDE_101_200

ABCDE_1_100.MPJ

Slot

Core

Core

1310nm_0001.SOR

1310nm_0002.SOR

1310nm_0101.SOR

1310nm_0102.SOR

The newly created project file (core numbers 1 to 100)

Cable

Measurement result files (.SOR extension)

are automatically named and saved.

Measurement result files (.SOR extension)

are automatically named and saved.

IM AQ1210-01EN

1-21

Page 28

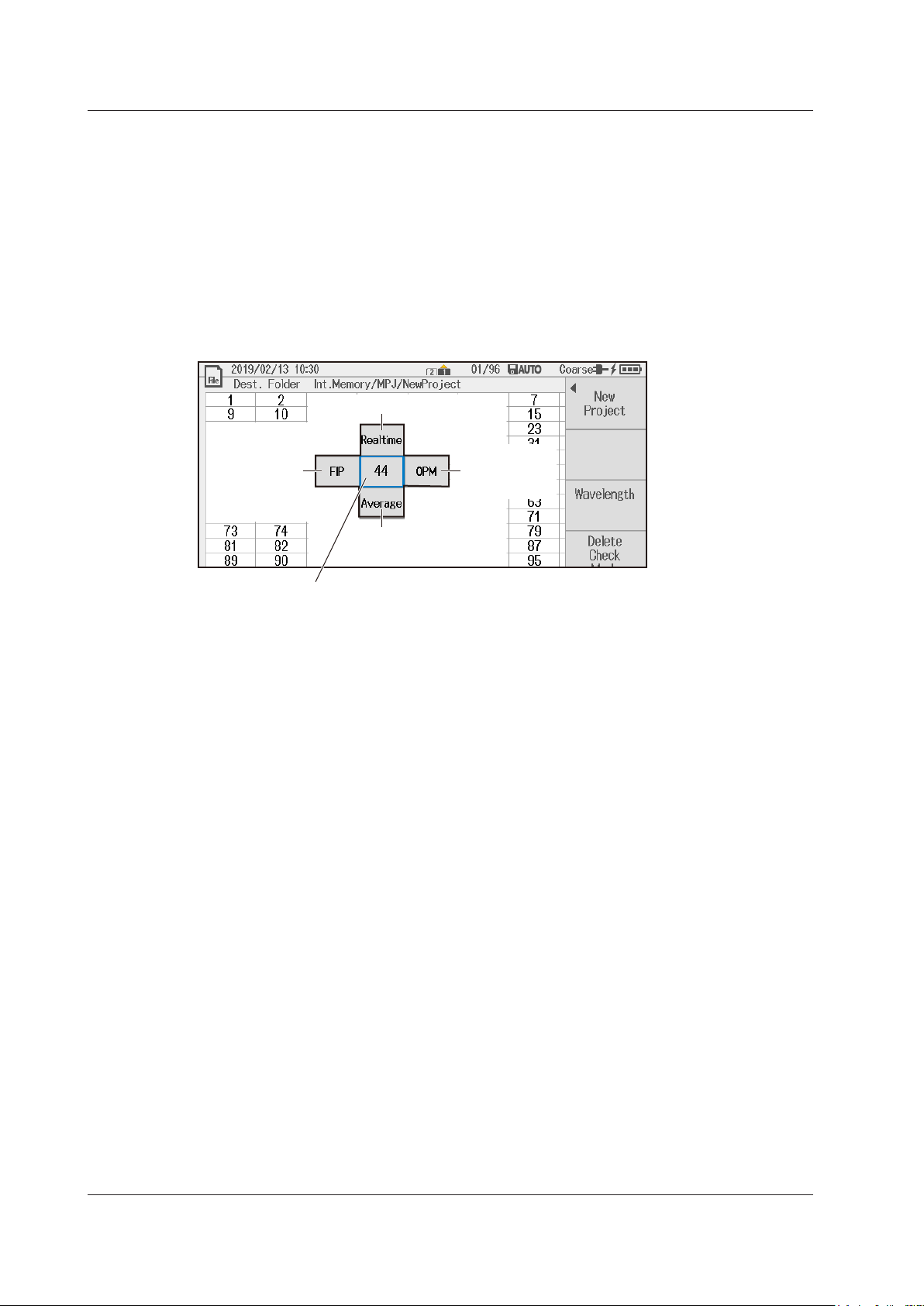

Example of measuring core number 44

1.7 Application

Multi-Fiber Measurement

The following four measurements can be performed in multi-fiber measurement.

• OTDR measurement (Realtime)

• OTDR measurement (Average)

• Optical power measurement

• Fiber Inspec Probe

The four measurement features use the same features as the OTDR feature for measuring a single

fiber explained in section 1.1, the optical power meter (excluding the logging feature) explained in

section 1.6, and the fiber end face inspection explained in section 1.6. You can run and use these

four measuring features from the main view screen of multi-fiber measurement.

OTDR feature (realtime)

Fiber inspection

probe

Saving Measurement Result Data

You can save the results of multi-fiber measurement for each fiber. The data is saved in the folder

explained in “Project File Structure” on the previous page. For details on the data format, see

section 9.4.

• OTDR Feature (Realtime, Average)

For each fiber, waveform data is saved in SOR format in a single file.

• Fiber Inspec Probe

For each fiber, screen capture data is saved in BMP format in a single file.

• Optical Power Meter

For each project, data is saved in tab-separated CSV format in a single file.

Optical power

meter

OTDR feature (average)

1-22

IM AQ1210-01EN

Page 29

AQ1210A, AQ1215A,

(this instrument)

(this instrument)

Optical fiber cable under loss test

OTDR port (PORT1)

Light source

Optical fiber cable under loss test

OTDR port (PORT1)

1.7 Application

Auto Loss Test (combination of light source and optical power

meter)

Using the instrument as a light source and optical power meter, you can easily measure optical fiber

cable and line degradation. You can also use the AQ1100/AQ1200A/AQ1200B/AQ1200C/AQ1200E/

AQ1205A/AQ1205E/AQ1205F in the multi-field tester series instead of this instrument as the light

source or optical power meter.

Light Source Feature

You can set up to two measurement light wavelengths and produce them in order. You can produce

a constant level of light if you use the optical power adjustment feature.

Optical Power Meter Feature

The instrument automatically identifies the measurement light from the opposing instrument

or AQ1100/AQ1200A/AQ1200B/AQ1200C/AQ1200E/AQ1205A/AQ1205E/AQ1205F that it is

connected to and measures the optical power.

AQ1210A, AQ1215A,

AQ1210E, AQ1215E,

AQ1215F, AQ1216F

1

Features

OPM port

AQ1210E, AQ1215E,

AQ1215F, AQ1216F

Loopback Feature

You can use the light source and optical power meter features on a single instrument to perform a

loop-back loss test on an optical fiber cable or line. To perform loss testing, connect one end of the

optical fiber cable that you want to perform loss testing on to the the instrument’s OTDR port (PORT1)

and the other end to the OPM port on the same instrument.

Light source

Optical power meter

OPM port

Optical power meter

AQ1210A, AQ1215A,

AQ1210E, AQ1215E,

AQ1215F, AQ1216F

IM AQ1210-01EN

1-23

Page 30

AQ1210A, AQ1215A,

Create a project

OTDR port (PORT1)

Transfer the project data

1.7 Application

Multicore Loss Test

You can efficiently measure multicore optical fiber cable and optical line degradation.

Projects

Projects are group of items for measuring multi-core fibers.

This feature is the same as that explained in “Optical Pulse Measurement of Multi-core Optical Fiber

Cables” on page 1-21.

• Number of Fibers, Number of Fibers in Each Division, Tape Number

The core number indications and settings vary depending on the type of multi-core fiber cable.

These features are the same as those explained in “Optical Pulse Measurement of Multi-core

Optical Fiber Cables” on page 1-21.

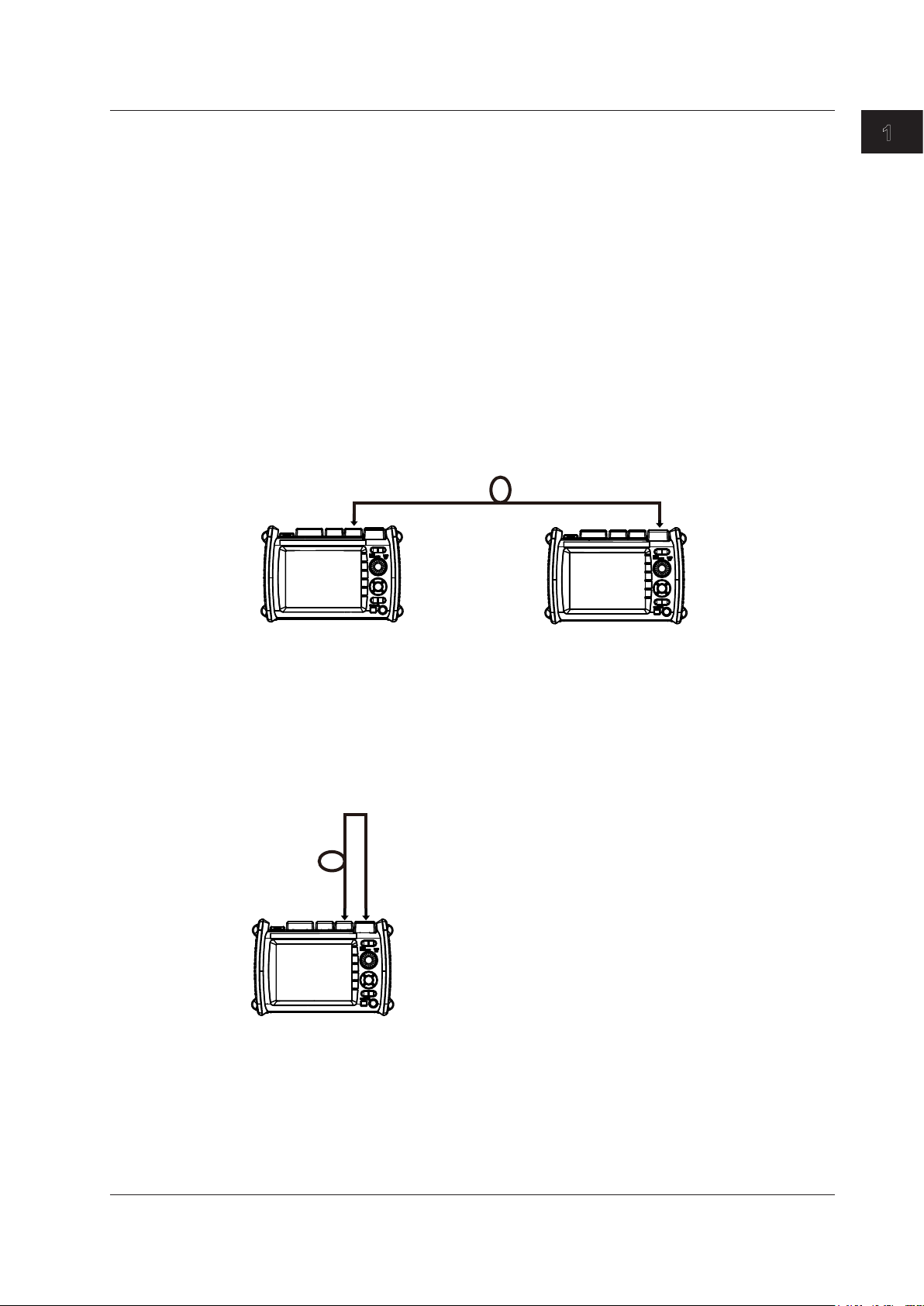

Master and Slave

Connect two instruments and specify the optical power meter as the master and the light source

as the slave. You can also use the AQ1100/AQ1200A/AQ1200B/AQ1200C/AQ1200E/AQ1205A/

AQ1205E/AQ1205F in the multi-field tester series instead of this instrument as the master or slave.

The preparation involves the following steps.

• Connecting an Optical Fiber Cable for Signal Transmission (step 1)

To transmit, between the master and slave, project setup information and information about the

fiber under loss test, you must specify a fiber cable from the multi-core optical fiber cable to use

for the signal transmission. Connect one end of the optical fiber cable for signal transmission to

the OTDR port (PORT1) of the instrument specified as the master (optical power meter side) and

the other end to the OPM port of the instrument specified as the slave (light source side).

• Transferring Object Information from the Master to the Slave (step 2)

On the master instrument, create a project. Transfer the project information to the slave

• Connecting the Optical Fiber Cable to Perform Multi-Core Loss Test On (step 3)

Multi-core loss test is performed on all optical fiber cables other than the optical fiber cable for

instrument through the optical fiber cable for signal transmission.

Optical fiber cable for signal transmission

AQ1210A, AQ1215A,

AQ1210E, AQ1215E,

AQ1215F, AQ1216F

Master (this instrument)

Slave (this instrument)

OPM port

AQ1210E, AQ1215E,

AQ1215F, AQ1216F

signal transmission. Connect one end of the optical fiber cable to be tested to the OPM port of

the master instrument and the other end to the OTDR port (PORT1) of the slave instrument.

1-24

IM AQ1210-01EN

Page 31

AQ1210A, AQ1215A,

Execute a multicore loss test

Transfer the results of the multicore loss test

Trace 1

Trace 2

Trace 3

Trace 4

Displays up to four waveforms simultaneously

You can move a waveform over another waveform to compare the two.

1.7 Application

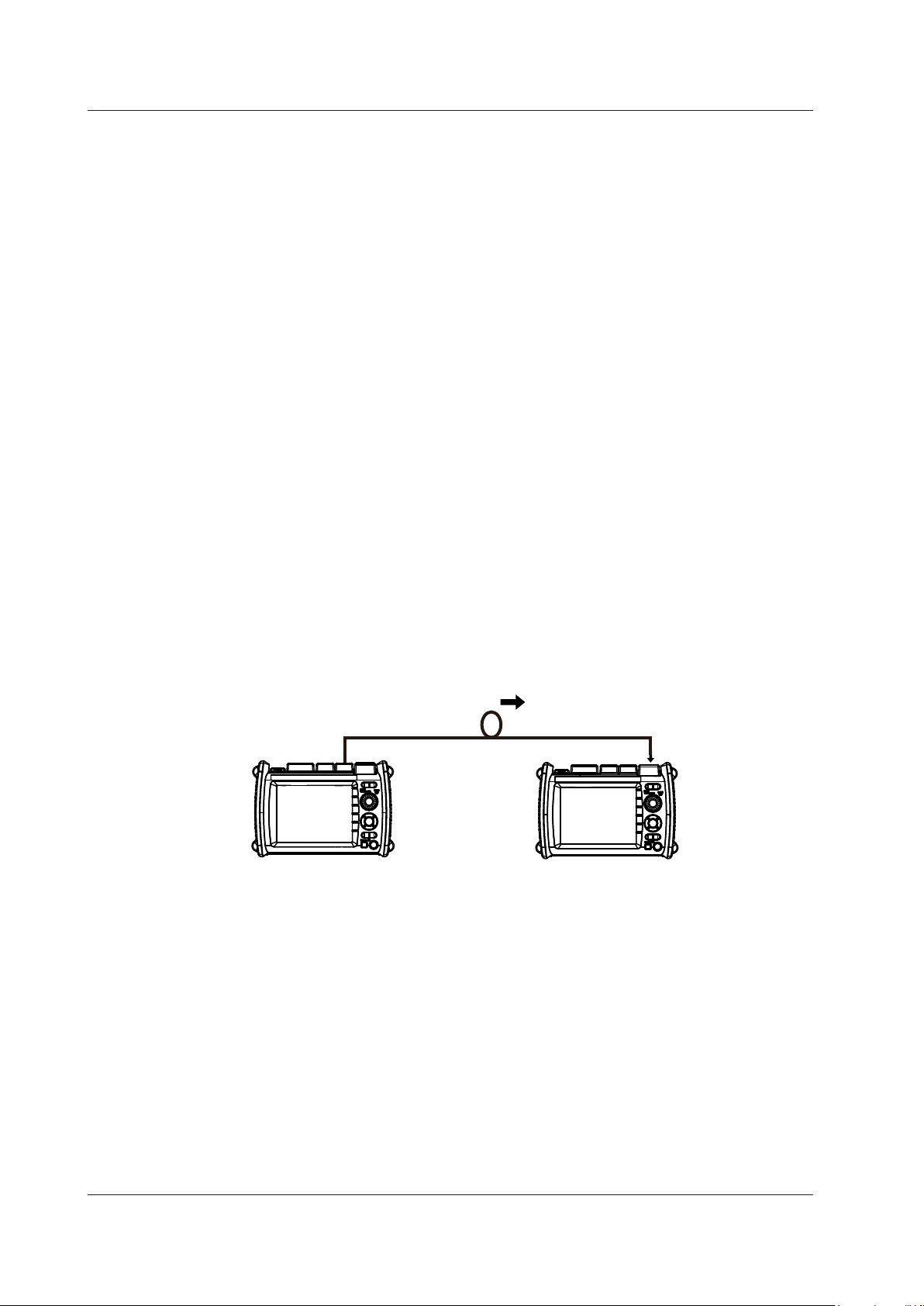

Executing the Multi-Core Loss Test

First, start the multi-core loss test on the master instrument. The core number information of the

1

Features

cores to be tested is transmitted from the master side through the optical fiber cable for signal

transmission. When the core numbers to be measured are received through the OPM port, the

slave instrument will be ready to execute a multi-core loss test.

Execute the multi-core loss test on the slave side. The light to be measured is output from the

OTDR port (PORT1) on the slave side. This light enters the OPM port on the master side, and

the loss in the optical fiber cable with the target core number is measured.

The measurement results are sent from the master to the slave instrument through the optical

fiber cable for signal transmission.

OTDR port (PORT1)

OPM port

AQ1210A, AQ1215A,

AQ1210E, AQ1215E,

AQ1215F, AQ1216F

Master (this instrument)

Optical fiber cable for signal transmission

Light being measured

Optical fiber cable under

multicore loss test

OPM port

OTDR port

(PORT1)

AQ1210E, AQ1215E,

AQ1215F, AQ1216F

Slave (this instrument)

If you cancel an ongoing multi-core loss test, the completed portion of the measurement results

are held, so you can resume the test from the optical fiber cable with the next target core

number.

Advanced Analysis

Multi Trace Analysis

You can load up to four waveforms that have been measured on the instrument and display

them simultaneously for comparison. You can adjust the vertical display position of each loaded

waveform.

IM AQ1210-01EN

1-25

Page 32

End A

End B

A

D

A

D

Trace 1

(Current trace)

Trace 2

(Differential trace)

(Trace 2) – (Trace 1)

The differential trace is the result of subtracting the values

You can perform marker analysis on the differential trace.

1.7 Application

2 way trace analysis

Waveform events that have been measured from optical fiber cable end A to end B and those

measured from end B to end A can be combined. This combination enables displaying of events

that could not otherwise be measured because of dead zones.

In the figure below, the event that is in the near-end dead zone (point S) when measured from end

A is detected as event number 5 when measured from end B. In the 2 way trace analysis display, it

is displayed as event number 1.

End A → End B

End A ← End B

2 way trace analysis

An event of the other waveform that exists within 6% of the position of an event of the current trace

will be considered part of the current trace event.

If multiple events of the other waveform that exists within 6% of the position of an event of the

current trace, the closest event will be considered part of the current trace event.

Waveforms that meet the following conditions can be combined.

• Both have the same wavelength.

• Both have the same pulse width.

• Their end position offset is within 6%.

• Both have event lists.

Differential Trace

You can load two waveforms that have been measured on the instrument and display their

difference as a waveform.

The screen can display the loaded waveforms and the differential trace simultaneously.

The differential trace is the result of subtracting the values of the current trace from those of the

other trace.

You can use markers to read the following values of the differential trace.

• Loss between markers (dB)

Loss between

• Distance to each marker

Distance between

This

instrument

▲ ▲ ▲ ▲ ▲ ▲

S 1 2 3 4 E

▲ ▲ ▲ ▲ ▲ ▲

5

▲ ▲ ▲ ▲ ▲ ▲

S

2 3 4 E5

1

and B and between C and

and B and between C and

This

instrument

S1234E

1-26

of the current trace from the target trace.

A

C

B

D

IM AQ1210-01EN

Page 33

S E

1.7 Application

Section Analysis

You can set two markers, start point S and end point E, to measure the return loss and total loss in

the section that you have specified. By setting reference point B, you can calculate the return loss

using the backscatter level you specify.

1

Features

B

IM AQ1210-01EN

1-27

Page 34

1.8 File Features

Measured results (waveform data), measurement and analysis conditions, system settings, and the

like can be saved as files to internal memory or external memory (USB memory). You can efficiently

configure multiple instruments to the same conditions by loading a file containing measurement and

analysis conditions, system settings, and the like. In addition, the instrument can save measured

waveform data as PDF data in report format.

Saving and Loading Files

Saving and Loading Files

The following types of files can be saved.

• .SOR

A file for saving optical pulse measurement results. Measurement and analysis conditions,

waveform data, event list data (when event analysis is executed) are stored in this file. When

an SOR file is loaded, the measurement and analysis data is loaded into the instrument, the

waveform data is displayed on the instrument screen. If event list data is stored, event analysis

results are also displayed. This file is useful when you want to save an SOR file at a site where

optical fiber cables are being installed and load the file into another instrument at a different site.

Only SOR files (waveform data) measured with conditions that are valid for the instrument can

be loaded.

• .PDF

A file for saving the current waveform displayed on the instrument screen or waveform data of an

already saved file in a PDF report format.

• .CFG

A file for saving the instrument system settings (device, connection, etc.). This file is useful when

you want to apply the same system settings to several instruments.

• .BMP, JPG

A file for saving a screen image of the instrument. This file is useful when you want to view the

screen content on the PC screen. BMP and JPG files cannot be loaded into the instrument.

• .SOZ

A file for saving multiple waveforms measured simultaneously.

• .SMP

A file for saving waveforms measured with a feature equivalent to Smart Mapper.

Selecting Drives

You can set the save destination to the following internal and external memories.

• Internal Memory

The memory inside the instrument. The size is about 256 MB. It cannot be removed.

• USB Memory

USB storage device.

1-28

IM AQ1210-01EN

Page 35

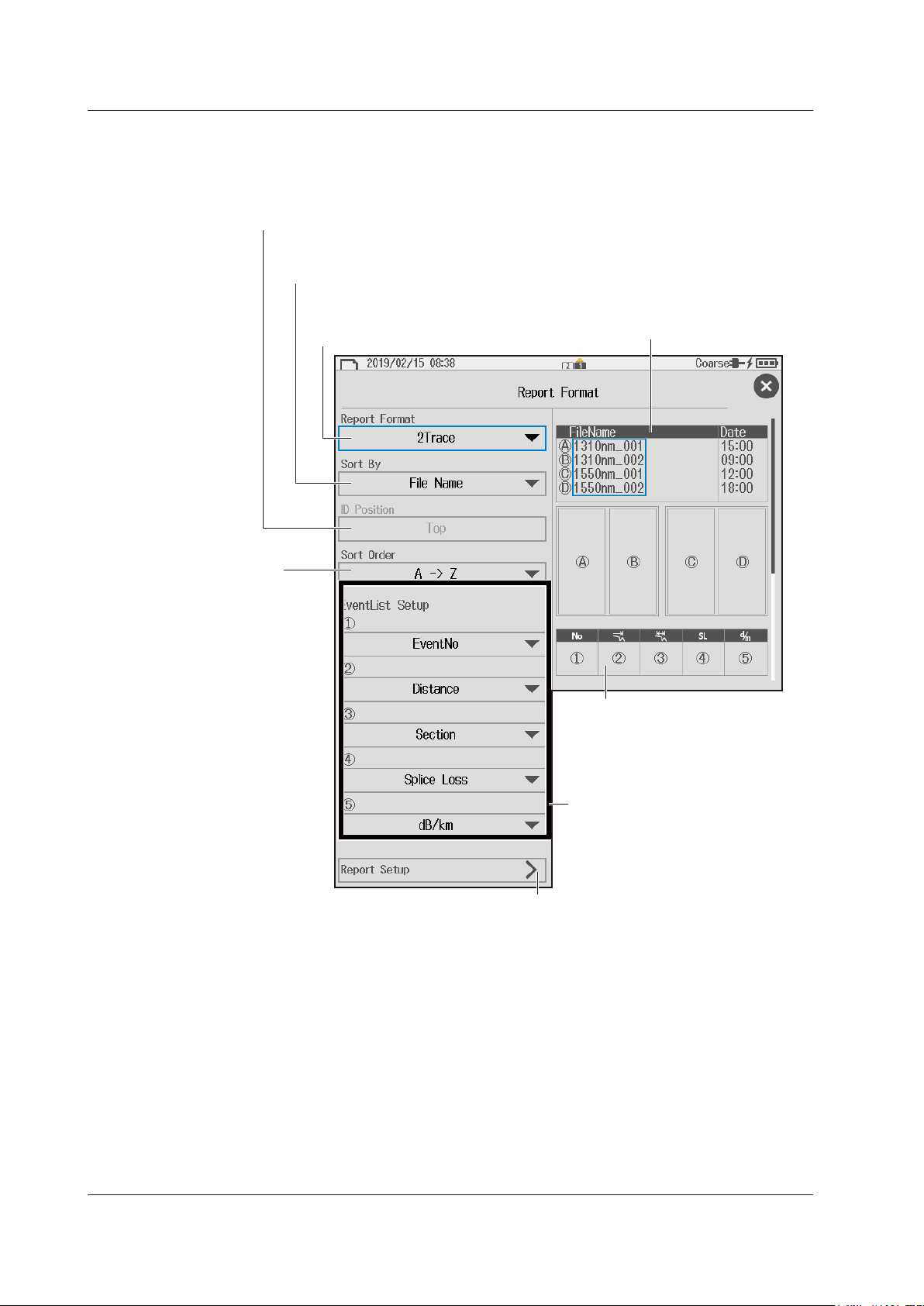

Event search conditions

Measurement

1.8 File Features

Creating Reports

Creating Reports

You can save the current optical pulse measurement and analysis conditions, waveforms, and

events as a report on a single sheet in a PDF file. You can choose which items to include in the

report.

Event icon display

Waveform display

Label information

1

Features

conditions

Event analysis results

File Reporting

You can specify several saved SOR files and save the content of the files one at a time as a report

on a single sheet in a PDF file. You can choose which items to include in the report.

File Operations

Copying and Deleting Files

You can copy or delete all the files and folders in the internal memory or external memory. You can

also copy or delete selected files or folders.

Renaming Files

You can rename existing files and folders.

Creating Folders

You can create a folder with a name of your choice in which optical pulse measurement results

are saved automatically. In the settings for automatically saving measure data explained in section

4.4, you can set the name of the folder in which to save the results automatically. When you

select a folder that you created with a name of your choice, measurement results can be saved

automatically to this folder.

IM AQ1210-01EN

1-29

Page 36

1.9 System Features

Power-Save Mode

To suppress battery consumption, you can set the screen brightness and a screen saver. You can set

different screen brightness levels for battery operation and USB-AC adapter operation.

LCD Brightness

You can select from four brightness levels (including OFF). You can choose the appropriate level

depending on the ambient light during outdoor use. You can turn off the display except when

viewing the measured data to suppress battery consumption.

Auto Sleep

If the instrument is turned on and is not accessed for a certain time, the instrument automatically

switches to sleep mode to suppress battery consumption.

Factory Default Settings

Setup

The following setup conditions are reset to their factory defaults. Note that files in the internal

memory are not deleted.

• OTDR feature setup (chapter 2)

• Utility feature (chapter 7)

• Application feature (chapter 8)

• System settings (chapter 10, except the date and time)

All

All the above setup conditions are reset to their factory defaults. All the files in the USER folder of

the internal memory are also deleted. The files in the following folders are not deleted.

• BACKUP (contains system files)

The files in this folder are deleted once, and factory default files are created again.

• USERS_MANUAL (contains the user’s manuals)

These files are not delete.

Configuring Network Settings

You can use a communication dongle (wired LAN adapter or wireless LAN adapter) to remotely control

the instrument from a PC (OTDR Remote Controller) and transfer measured results in the instrument’s

internal memory to a network server (File Transfer@OTDR Data Transporter).

• User Name and Password

Set user names and passwords for authenticating connections from PCs to the instrument.

• Timeout Period

If a communication command is not sent from a PC or measured results are not downloaded

within the timeout period, the instrument releases the network connection.

• TCP/IP

Set network address information.

• Enabling and Disabling Network Connection

Remote control can be disabled. When disabled, a PC cannot connect to the instrument.

1-30

IM AQ1210-01EN

Page 37

1.9 System Features

WLAN Application (wireless LAN)

You can use a communication dongle (wireless LAN adapter) to remotely control the instrument

from a PC (OTDR Remote Controller) and transfer measured results in the instrument’s internal

memory to a network server (OTDR Data Transporter).

• Application Setup

You can set user names and passwords for authenticating connections from PCs to the

instrument.

• Access Point Mode Setup

You can set network information for running the instrument as an access point. This is used

to connect the instrument and terminals directly without connecting a wireless router or other

network device.

Other Features

Language Selection

You can change the language used on the instrument screen.

Start Menu

You can select the screen that is displayed when the instrument starts.

• Trace

When the instrument starts, a screen with the data display area set to waveform display appears.

• Map

When the instrument starts, a screen with the data display area set to icon display appears.

• Setup Info.

When the instrument starts, the OTDR setup menu appears.

1

Features

Screen Color

You can set the screen color (color 1, color 2, or black and white).

Alarm

The instrument can generate sound when an operation error message is displayed.

USB (TypeC)

You can use USB port type C to send communication commands from a PC to the instrument or

download measured results from the instrument internal memory or SD card to a PC.

Operation Restrictions

You can set a PIN to restrict the following operations. This feature prevents settings from being

changed or laser light to be emitted by mistake.

• Mode

Changing from Simple Mode to another mode

• Laser light output

When an operation to emit the following laser light is performed

Optical pulse (OTDR), light source (measurement light), VLS

Expiration Date

This feature displays a message at startup or locks the instrument when the specified expiration

date arrives. You can display a message that urges you to calibrate the instrument or the like when

the recommended calibration period elapses.

IM AQ1210-01EN

1-31

Page 38

1.9 System Features

Version Update

You can update the firmware by storing a new firmware in a USB memory device and connecting it

to USB port type A.

Installing Options

You can install additional option licenses (sold separately) for the AQ1210.

For details on the available option licenses, see Getting Started Guide, IM AQ1210-02EN.

1-32

IM AQ1210-01EN

Page 39

1

Set wavelength 1 (1310nm,

1550nm, 1625nm/1650nm).

Set the distance range.

Set the attenuation

2^16, 2^17, 2^18, 2^19, 2^20)

Chapter 2 Setting Up the OTDR Feature

2.1 Measurement (Measure) Conditions

Procedure

Press MENU to display the MENU screen.

1.

For details on the MENU screen, see the Getting Started Guide, IM AQ1210-02EN.

Tap OTDR to display the OTDR screen.

2.

Press SETUP to display the setup screen.

3.

Tap the MEASURE tab to display the following screen.

4.

● AQ1210A, AQ1210E

(AUTO, 200m, 500m, 1km, 2km, 5km, 10km,

20km, 30km, 40km, 50km, 100km, 200km,

256km)

● AQ1215A, AQ1215E, AQ1215F, AQ1216F

(AUTO, 200m, 500m, 1km, 2km, 5km, 10km,

20km, 30km, 40km, 50km, 100km, 200km,

300km, 400km, 512km)

MEASURE tab

Set the sample interval

(Normal, Hi-Resolution).

( AUTO, 0.00dB, 2.50dB, 5.00dB,

7.50dB, 10.00dB, 12.50dB, 15.00dB,

17.50dB, 20.00dB, 22.50dB, 25.00dB,

27.50dB, 30.00dB).

Set the pulse width.

● AQ1210A, AQ1210E

(AUTO, 5ns, 10ns, 20ns, 30ns,

50ns, 100ns, 200ns, 300ns, 500ns,

1μs, 2μs, 5μs, 10μs, 20μs)

● AQ1215A, AQ1215E, AQ1215F,

AQ1216F

(AUTO, 3ns, 10ns, 20ns, 30ns,

50ns, 100ns, 200ns, 300ns, 500ns,

1μs, 2μs, 5μs, 10μs, 20μs)

2

Setting Up the OTDR Feature

Set wavelength 2

(OFF,

1310nm/1550nm).

Set the connection

check (OFF, ON).

Set the fiber-in-use alarm

(OFF, ON).

Set the event search (OFF, ON).

Set the average

method

(Hi-Speed,

Hi-Reflection).

Set the average duration

(when the average unit is set to Duration).

(AUTO, 5sec, 10sec, 20sec, 30sec, 1min,

3min, 5min, 10min, 20min, 30min)

Set the average times

(when the average unit is set to Times).

(AUTO, 2^10, 2^11, 2^12, 2^13, 2^14, 2^15,

Set the

average unit

(Duration,

Times).

Set auto save.

See the next

page.

Initializes the

measurement

settings

IM AQ1210-01EN

2-1

Page 40

Set auto save (OFF, ON).

Set the file name.

Set the file type (*.SOR).

The data save format is fixed to waveform data (SOR extension).

2.1 Measurement (Measure) Conditions

Configuring Auto Save (when averaged measurement is complete)

Tap Auto Save to display the Auto Save screen.

When the mode is set to Date

Select the destination drive (internal memory, USB memory).

This is displayed when the mode is set to Date, in which case you can set it.

Set the mode (Date, UserDefine).

Select how to specify the save destination

folder. You can set this when auto save is ON.

See section 2.4.

When the mode is set to UserDefine

Save destination folder

The current file path is displayed.

This is displayed when the mode is set to User Define.

Displays the file list of the folder displayed in the current file path.

For details on file operations, see section 9.6.

2-2

IM AQ1210-01EN

Page 41

1

Explanation

Wavelength

You can enter the following wavelengths.

Model Optical Pulse Wavelength

AQ1210A 1310 nm, 1550 nm, 1310 nm/1550 nm (multi wavelength measurement)

AQ1215A 1310 nm, 1550 nm, 1310 nm/1550 nm (multi wavelength measurement)

AQ1210E 1310 nm, 1550 nm, 1625 nm, 1310 nm/1550 nm (multi wavelength measurement)

AQ1215E 1310 nm, 1550 nm, 1625 nm, 1310 nm/1550 nm (multi wavelength measurement)

AQ1215F 1310 nm, 1550 nm, 1650 nm, 1310 nm/1550 nm (multi wavelength measurement)

AQ1216F 1310 nm, 1550 nm, 1650 nm, 1310 nm/1550 nm (multi wavelength measurement)

In a single measurement, 1310 nm and 1550 nm are measured one at a time.

If 1310 nm/1550 nm is selected, the wavelength of optical pulse being measured is displayed on the

Distance Range

Set the distance range according to the length of the optical fiber cable. The distance range that you

can select varies depending on the wavelength. Specify a distance range value that is greater than

the length of the optical fiber cable that you will measure. If you specify a shorter value, the instrument

will not be able to perform measurements properly. The longer the distance that you specify, the more

time measurements will take. When you specify the distance range, the optimum pulse width and

attenuation values are set automatically.

Cable Length Distance Range Cable Length Distance Range

Unknown Auto 16 km to 24 km 30 km

0 m to 160 m 200 m 24 km to 40 km 50 km

160 m to 400 m 500 m 40 km to 80 km 100 km

400 m to 800 m 1 km 80 km to 160 km 200 km

800 m to 1.6 km 2 km 160 km to 240 km 256 km, 300 km

1.6 km to 4 km 5 km 240 km to 320 km 400 km

4 km to 8 km 10 km 320 km to 400 km 512 km

8 km to 16 km 20 km

2.1 Measurement (Measure) Conditions

2

Setting Up the OTDR Feature

1310 nm/1550 nm (multi wavelength measurement)

screen.

Pulse Width

The pulse width has the following characteristics.

• A short pulse width enables you to measure with a high resolution, but you cannot measure long

distances.

• A long pulse width enables you to measure long distances, but you cannot measure with a high

resolution. Also, dead zones are larger with long pulse widths.

The pulse widths that you can select vary depending on the distance range, as shown in the

following table.

Distance Range Selectable Pulse Widths

200 m 3 ns/5 ns

500 m 3 ns/5 ns

1 km 3 ns/5 ns

2 km 3 ns/5 ns

5 km 3 ns/5 ns

10 km 3 ns/5 ns

20 km 3 ns/5 ns

30 km 10 ns 20 ns 30 ns 50 ns 100 ns 200 ns 300 ns 500 ns 1 µs 2 µs

50 km, 100 km 20 ns 30 ns 50 ns 100 ns 200 ns 300 ns 500 ns 1 µs 2 µs 5 µs 10 µs 20 µs

200 km 30 ns 50 ns 100 ns 200 ns 300 ns 500 ns 1 µs 2 µs 5 µs 10 µs 20 µs

300 km 50 ns 100 ns 200 ns 300 ns 500 ns 1 µs 2 µs 5 µs 10 µs 20 µs

1 The pulse width is 5 ns on the AQ1210A/AQ1210E and 3 ns on the AQ1215A/AQ1215E/AQ1215F/AQ1216F.

IM AQ1210-01EN

1

10 ns 20 ns 30 ns 50 ns 100 ns 200 ns 300 ns 500 ns

1

10 ns 20 ns 30 ns 50 ns 100 ns 200 ns 300 ns 500 ns

1

10 ns 20 ns 30 ns 50 ns 100 ns 200 ns 300 ns 500 ns 1 µs

1

10 ns 20 ns 30 ns 50 ns 100 ns 200 ns 300 ns 500 ns 1 µs

1

10 ns 20 ns 30 ns 50 ns 100 ns 200 ns 300 ns 500 ns 1 µs

1

10 ns 20 ns 30 ns 50 ns 100 ns 200 ns 300 ns 500 ns 1 µs

1

10 ns 20 ns 30 ns 50 ns 100 ns 200 ns 300 ns 500 ns 1 µs 2 µs

2-3

Page 42

If reflections are large, the waveform may saturate.

2.1 Measurement (Measure) Conditions

Sample Interval

The maximum number of sample data points is 256000. The shortest sample interval is determined by

the distance range.

Normal: The instrument uses the optimum sample interval for the measurement method to

perform measurements.

Hi-Resolution: The instrument uses a sample interval that would result in the greatest number of

data points.

If you use a short sample interval, you can measure for finer changes. However, the data size of the

measured result becomes large.

Attenuation

If large reflections are caused by connectors or by breaks in the optical fiber cable, the waveform may

be saturated. Specify attenuation to prevent the waveform from being saturated. The attenuations that

you can select vary depending on the pulse width, as shown in the following table.

Pulse Width (Example) Selectable Attenuations

3 ns/5 ns

30 ns, 50 ns

100 ns, 200 ns, 300 ns,

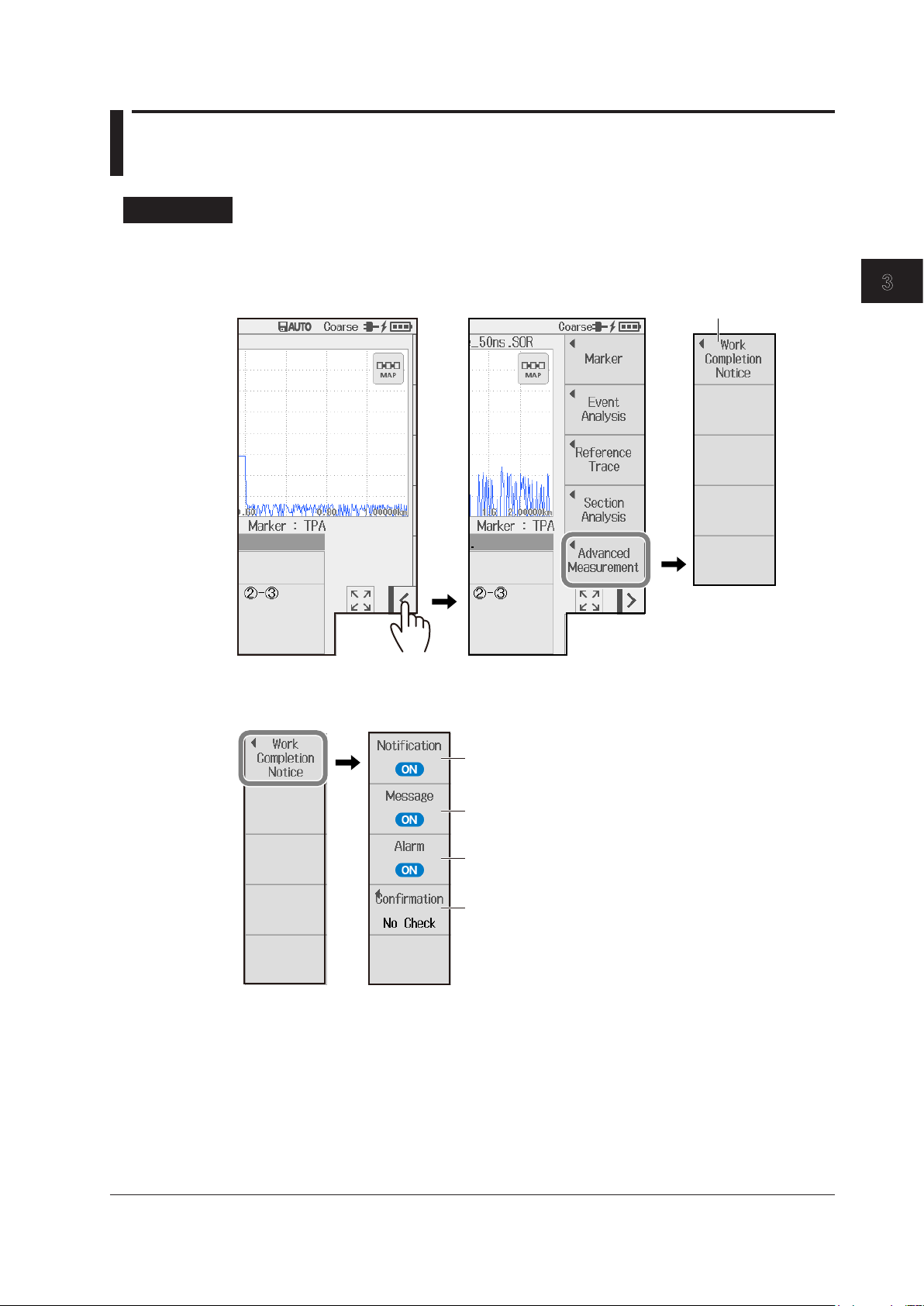

500 ns, 1 µs