Page 1

User’s

Manual

AQ1200 OTDR

Multi Field Tester

IM AQ1200-01EN

4th Edition

Page 2

Thank you for purchasing the AQ1200 OTDR (Optical Time Domain Reflectometer) Multi Field Tester.

This user’s manual explains the features, operating procedures, and handling precautions of the

AQ1200. To ensure correct use, please read this manual thoroughly before operation. Keep this

manual in a safe place for quick reference in the event that a question arises.

This manual is one of three AQ1200 manuals. Please read all the manuals.

Manual Title Manual No. Description

AQ1200 OTDR Multi Field Tester

Operation Guide

AQ1200 OTDR Multi Field Tester

User’s Manual (included in CD)

AQ1200 OTDR Multi Field Tester

Communication Interface User’s

Manual (included in CD)

IM AQ1200-02EN This guide focuses on the handling precautions, basic

operations, and specifications of the AQ1200.

IM AQ1200-01EN This manual. Explains all AQ1200 features, except for

the communication features, and how to use them.

IM AQ1200-17EN Explains the features related to using communication

commands to control the AQ1200.

Notes

• The contents of this manual are subject to change without prior notice as a result of continuing

improvements to the instrument’s performance and functionality. The figures given in this manual

may differ from those that actually appear on your screen.

•

Every effort has been made in the preparation of this manual to ensure the accuracy of its

contents. However

YOKOGAWA dealer.

• Copying or reproducing all or any part of the content of this manual without the permission of

YOKOGAW

, should you have any questions or find any errors, please contact your nearest

A is strictly prohibited.

Trademarks

• Microsoft, Windows, and Windows XP are either registered trademarks or trademarks of Microsoft

Corporation in the United States and/or other countries.

• Adobe, Acrobat, and PostScript are trademarks of Adobe Systems Incorporated.

•

In this manual, the TM and ® symbols do not accompany their respective registered trademark or

trademark names.

• Other company and product names are registered trademarks or trademarks of their respective

holders.

Revisions

1st Edition: February 2010

2nd Edition: February 2011

3rd Edition: July 2012

4th Edition: July 2013

4th Edition: July 2013 (YMI)

All Rights Reserved, Copyright © 2010, Yokogawa Electric Corporation

All Rights Reserved, Copyright © 2011, Yokogawa Meters & Instruments Corporation

IM AQ1200-01EN

i

Page 3

Conventions Used in This Manual

Notes

The notes and cautions in this manual are categorized using the following symbols.

Improper handling or use can lead to injury to the user or damage to the

instrument. This symbol appears on the instrument to indicate that the user must

refer to the user’s manual for special instructions. The same symbol appears

in the corresponding place in the user’s manual to identify those instructions.

In the manual, the symbol is used in conjunction with the word “WARNING” or

“CAUTION.”

WARNING

CAUTION

Calls attention to information that is important for proper operation of the

Note

Calls attention to actions or conditions that could cause serious or fatal injury to

the user, and precautions that can be taken to prevent such occurrences.

Calls attention to actions or conditions that could cause light injury to the user

or cause damage to the instrument or user’s data, and precautions that can be

taken to prevent such occurrences.

instrument.

Symbols and Conventions Used in Procedural Explanations

The contents of the procedural explanations are indicated using the following symbols.

Procedure

Explanation

Character Notations

Hard Key Names and Soft Key Names in Bold Characters

Indicate panel keys that are used in the procedure and soft keys and menu items that appear on the screen.

Carry out the procedure according to the step numbers. All procedures are

written under the assumption that you are starting operation at the beginning

of the procedure, so you may not need to carry out all the steps in a procedure

when you are changing the settings.

This section describes the setup items and the limitations regarding the

procedures. It may not give a detailed explanation of the feature. For a detailed

explanation of the feature, see chapter 2.

Unit

k Denotes 1000. Example: 12 kg, 100 kHz

ii

IM AQ1200-01EN

Page 4

3

2

1

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

App

Index

20

Contents

Conventions Used in This Manual .................................................................................................... ii

Chapter 1 Features

Chapter 2 Common Operations

1.1 Overview .......................................................................................................................... 1-1

1.2 Optical Pulse Measurement ............................................................................................. 1-3

1.3 Waveform Display ............................................................................................................ 1-5

1.4

1.5 Light Source and Optical Power Meters (Options) ......................................................... 1-12

1.6 Loss

1.7 Multi-Core Loss

1.8 Fault Locator .................................................................................................................. 1-16

1.9

1.10 IP T

1.11

1.12 Event Mapper ................................................................................................................. 1-20

1.13

2.1 Top Screen ....................................................................................................................... 2-1

2.2 Key, Rotary Knob, and Arrow Key Operations.................................................................. 2-5

2.3 Shortcut Keys ................................................................................................................... 2-8

2.4

aveform and Event Analysis .......................................................................................... 1-7

W

Test (Option)

Checking Fiber End Faces

est (Option) ............................................................................................................... 1-18

Multi-Core Fiber Measurement ....................................................................................... 1-19

Other Features ...............................................................................................................

Entering Strings .......................................................................................................

.......................................................................................................... 1-14

Test (Option) ......................................................................................... 1-15

............................................................................................. 1-17

1-21

....... 2-10

Chapter 3 Optical Pulse Measurement and Analysis Conditions

3.1 Selecting the Measurement Mode .................................................................................... 3-1

Simple (Full Auto) Mode

3.2 Selecting the Wavelength ................................................................................................. 3-3

3.3 Automatically Saving Measured Data .............................................................................. 3-4

3.4 Selecting the Approximation Method (Marker) ................................................................. 3-5

Detail Mode and Multi WL Mode

3.5 Setting Measurement Conditions ..................................................................................... 3-6

3.6 Setting Analysis Conditions ............................................................................................ 3-12

3.7 Setting the Pulse Light Output Level .............................................................................. 3-17

3.8 Giving Notifications When Installations

Are Complete ................................................... 3-18

Chapter 4 Measuring Optical Pulses

4.1 Performing Real-time Measurement ................................................................................ 4-1

4.2 Performing Averaged Measurements ............................................................................... 4-3

4.3 Displaying Snapshot Waveforms ...................................................................................... 4-5

Chapter 5 Waveform Display

5.1 Waveform Display Screen ................................................................................................ 5-1

5.2 Zooming the Waveform Display Scale ............................................................................. 5-2

5.3 Moving the Waveform Display Position ............................................................................ 5-5

5.4

Initializing the Waveform Display Scale ............................................................................ 5-6

5.5

Setting the Waveform Information Display ....................................................................... 5-7

IM AQ1200-01EN

iii

Page 5

iv

IM AQ1200-01EN

Contents

Chapter 6 Waveform Analysis

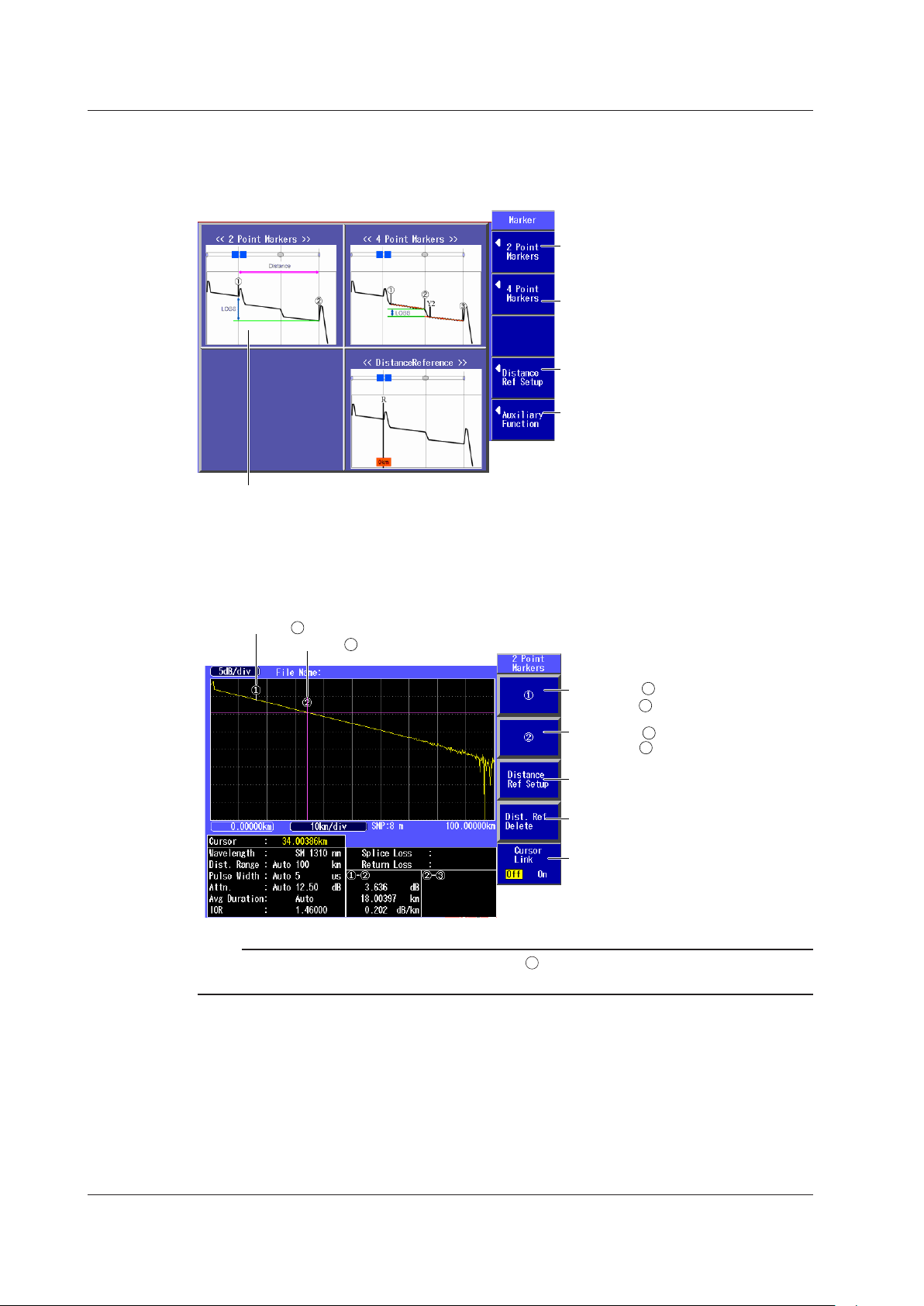

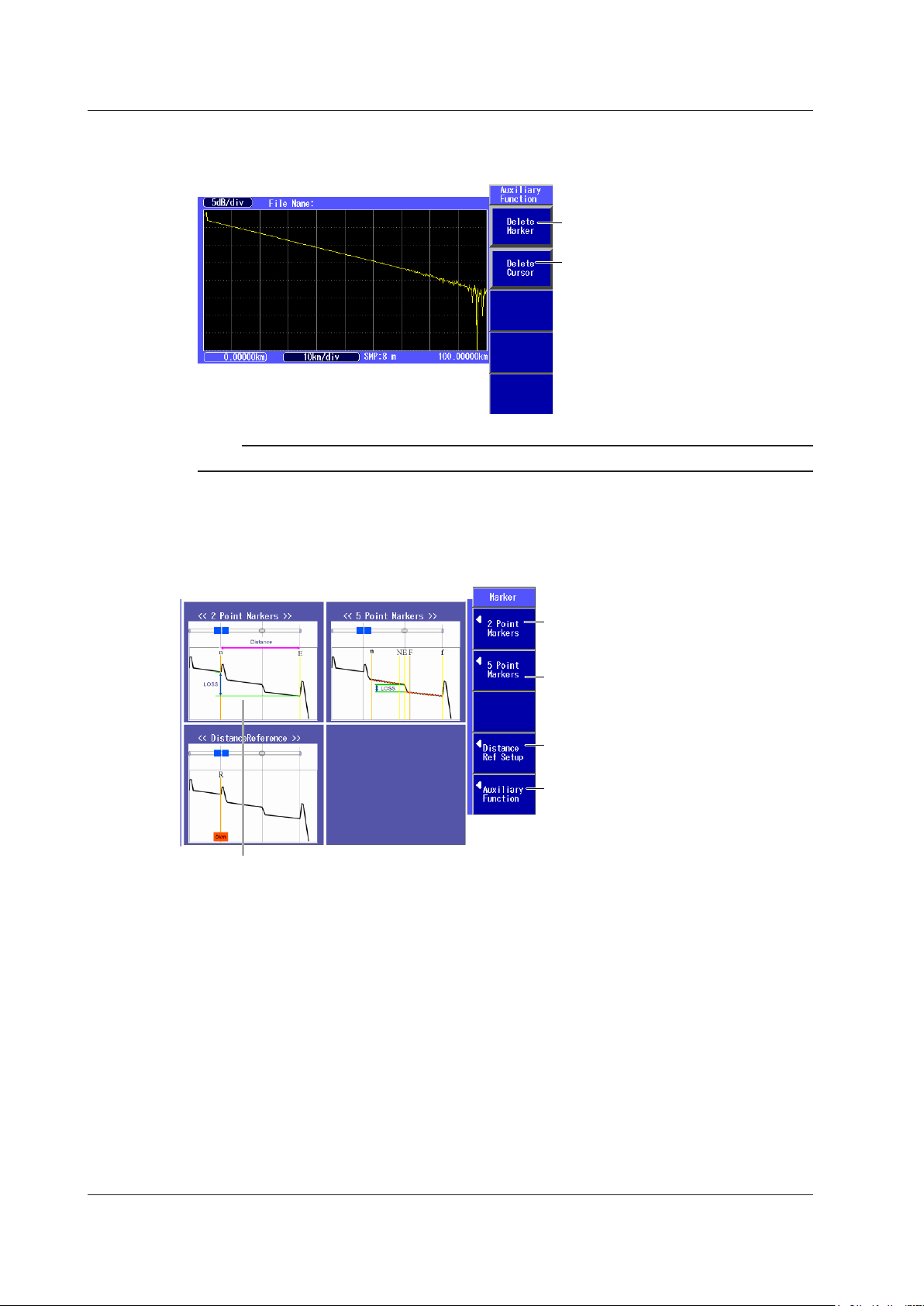

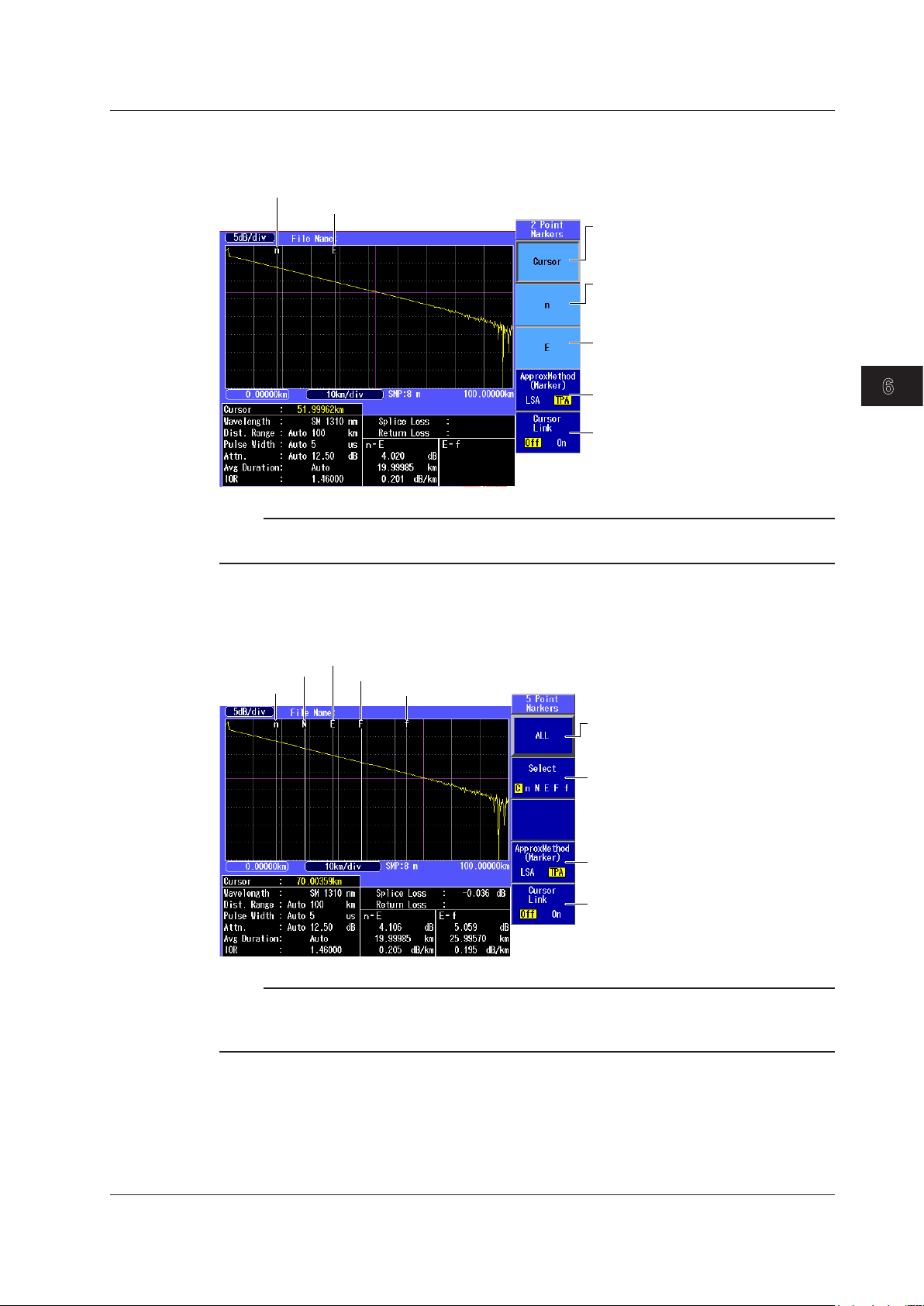

6.1 How to Operate the Cursor and Markers ......................................................................... 6-1

6.2 Measuring Distances ........................................................................................................ 6-8

6.3 Moving the Distance Measurement Reference Point ....................................................... 6-9

6.4 Measuring the Splice Loss .............................................................................................

6.5 Measuring the Return Loss .............................................................................................6-11

6.6

Displaying Multiple Traces

6.7 Combining Two

6.8 Displaying Differential T

6.9 Analyzing Sections ......................................................................................................... 6-18

Traces ................................................................................................... 6-14

.............................................................................................. 6-13

races ......................................................................................... 6-16

Chapter 7 Event Analysis

7.1 Displaying the Event Screen ............................................................................................ 7-1

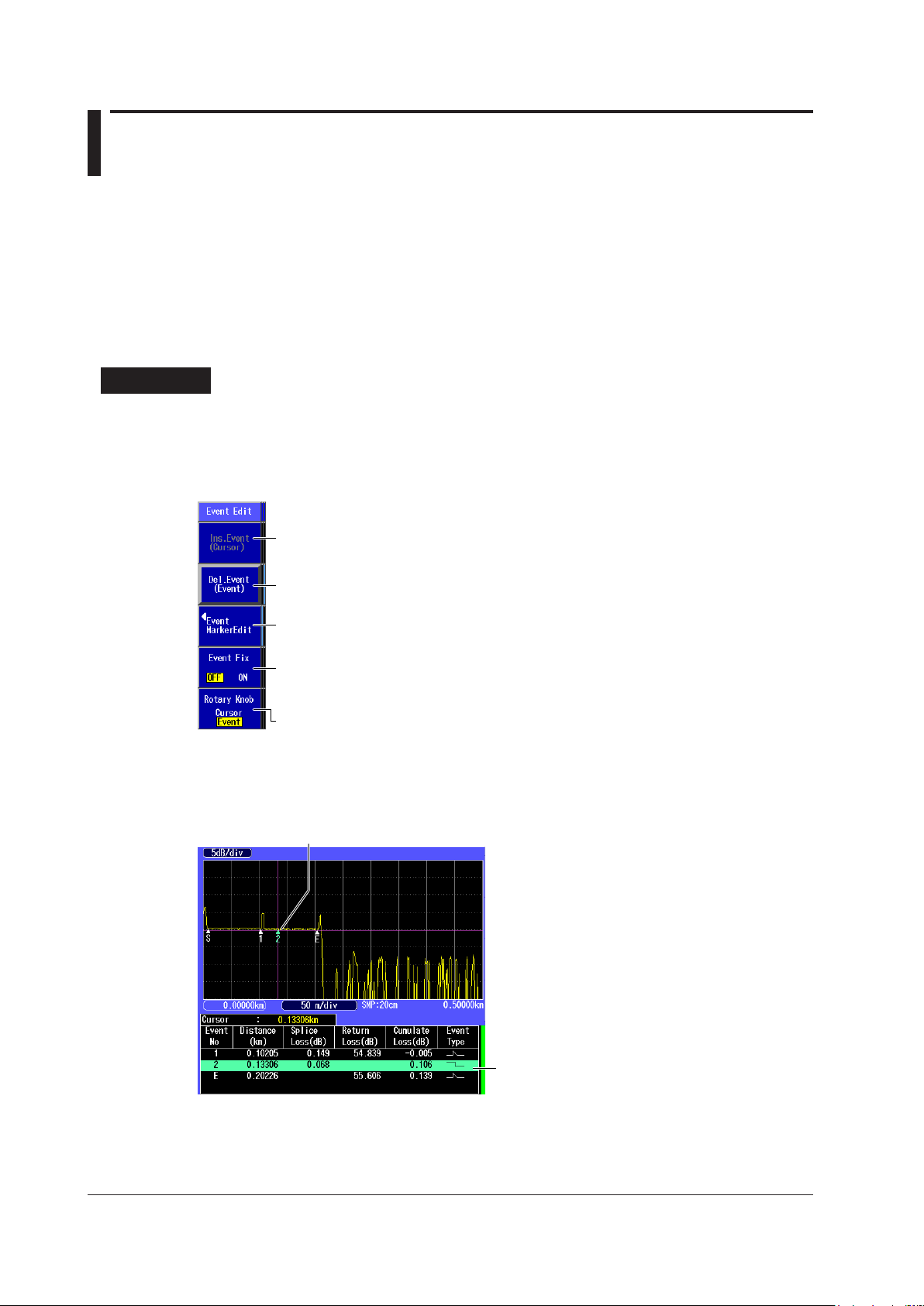

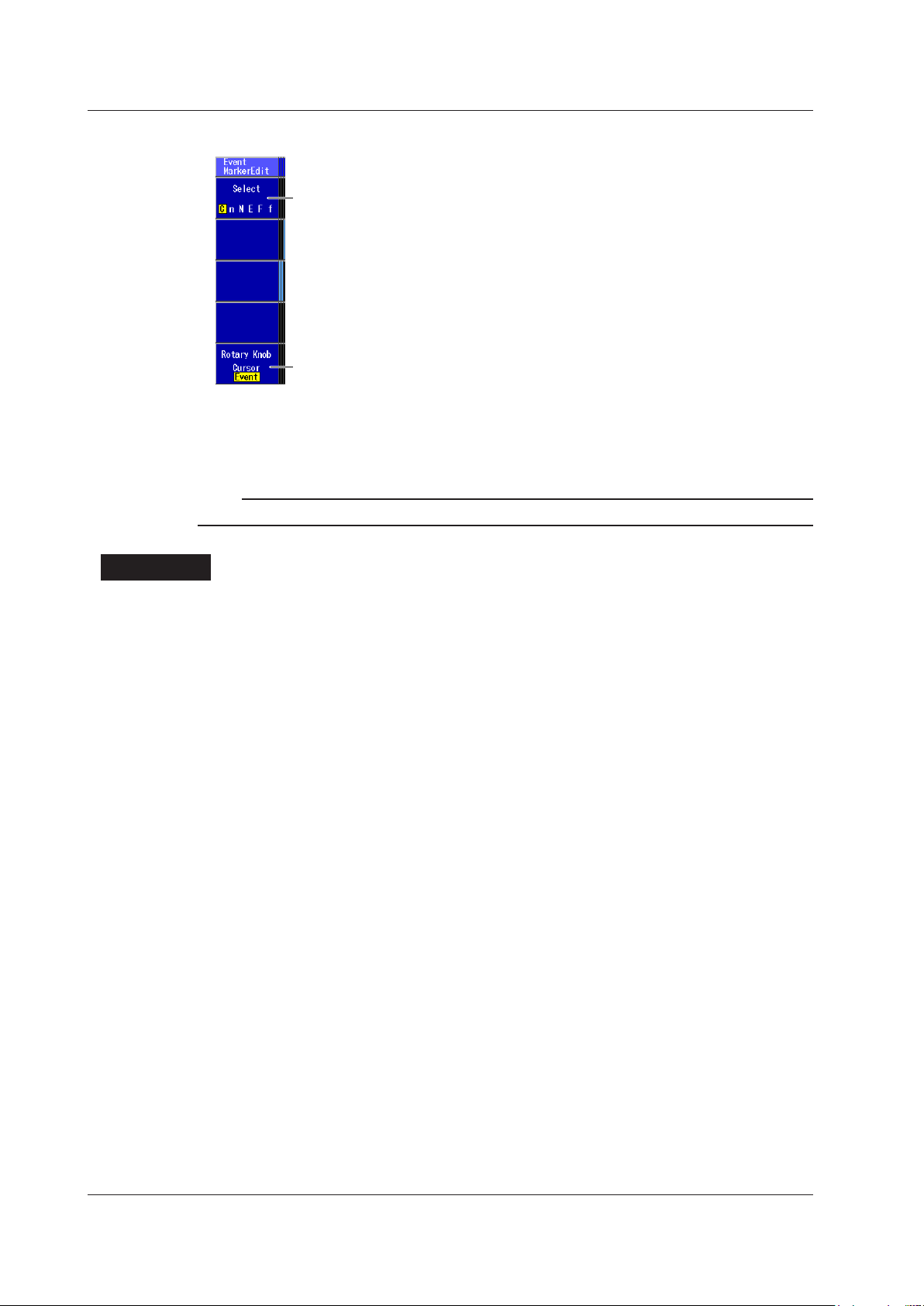

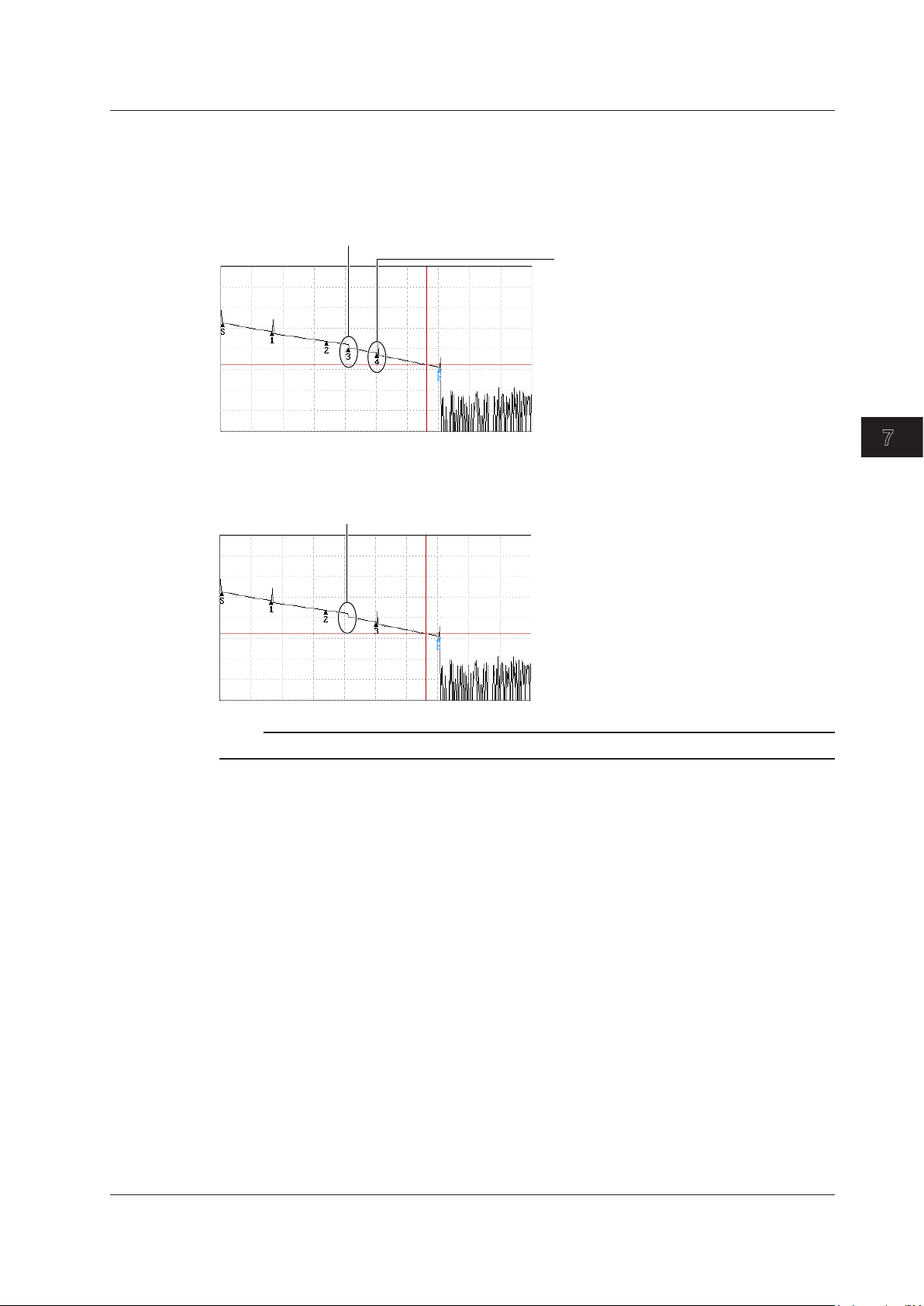

7.2 Editing Events .................................................................................................................. 7-4

7.3 Editing the Event List ........................................................................................................ 7-8

Chapter 8 Light Source (Option)

8.1 Producing Measurement Light ......................................................................................... 8-1

8.2 Turning On the Visible Light ............................................................................................. 8-3

Chapter 9 Optical Power Meter (Option)

9.1 Making Preparations for Measurements .......................................................................... 9-1

9.2 Setting Optical Power Measurement Conditions and Holding the Display ....................... 9-2

9.3 Logging Measured Values and Saving Logged Results ................................................... 9-5

9.4

Selecting and Saving Core and Tape Numbers .............................................................

6-10

9-10

Chapter 10 PON Power Meter (Option)

10.1 Making Preparations for Measurements ........................................................................ 10-1

10.2 Setting PON System Optical Power Measurement Conditions and Holding the Display 10-2

10.3 Selecting and Saving Core and Tape Numbers .............................................................

Chapter 11 Loss Testing (Option)

11.1 Making Preparations and Adjustments for Loss Testing ..................................................11-1

11.2 Performing an Auto Loss Test..........................................................................................11-3

11.3 Performing a Loop-Back Loss Test..................................................................................11-8

Chapter 12 Multi-Core Loss Testing (Option)

12.1 Creating New Projects .................................................................................................... 12-1

12.2 Sharing Projects ............................................................................................................. 12-3

12.3 Performing a Multi-Core Loss Test ................................................................................. 12-6

12.4 Optical Power Adjustment .............................................................................................. 12-9

Chapter 13 Fault Locator

13.1 Locating Breaks (Faults) in Optical Fibers ..................................................................... 13-1

Chapter 14 Checking Fiber End Faces

14.1 Using Fiber Inspection Probes to View the Status of Optical Fiber End Faces .............. 14-1

10-5

Chapter 15 IP Testing (Option)

15.1 Performing an IP Test ..................................................................................................... 15-1

Page 6

3

2

1

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

App

Index

20

Contents

Chapter 16 Multi-Core Fiber Measurement

16.1 Creating a New Project .................................................................................................. 16-1

16.2 Loading a Project ........................................................................................................... 16-8

16.3 Measuring Multi-Core Fibers .......................................................................................... 16-9

Chapter 17 Event Mapper

Chapter 18 File Operation and Printing

17.1 Displaying Optical Fiber Events as Icons ....................................................................... 17-1

18.1 Connecting a USB Storage Medium to the USB Port .................................................... 18-1

18.2 Saving and Loading Data ............................................................................................... 18-2

18.3 Deleting and Copying Files ............................................................................................ 18-8

18.4

Changing File Names ................................................................................................... 18-10

18.5 Creating Folders ........................................................................................................... 18-12

18.6

Deleting and Copying

18.7 Initializing the Internal Memory ..................................................................................... 18-15

18.8 Printing .........................................................................................................................

Specifying the Items That Are Displayed in the File List

18.9

Folders ...................................................................................... 18-13

18-16

............................................... 18-17

Chapter 19 Other Operations

19.1 Configuring the Language, Beep, Start Menu, USB Function, and Screen Color .......... 19-1

19.2 Configuring Power Save Settings ................................................................................... 19-2

19.3 Resetting the AQ1200 to Its Factory Default Settings ....................................................

19.4 Setting Operation Restrictions ........................................................................................ 19-4

19.5 Assigning Menus Items

19.6 Configuring Network Settings (Option) ........................................................................... 19-7

That Are Displayed on the

Top Menu ....................................... 19-6

Chapter 20 Troubleshooting, Maintenance, and Inspection

20.1 If a Problem Occurs ........................................................................................................ 19-1

20.2 Error Messages .............................................................................................................. 19-2

20.3 Viewing the Product Information.....................................................................................

20.4 Performing a Self Test

20.5 Updating the Firmware ................................................................................................... 19-8

20.6

Backing Up Necessary Files to a PC and Initializing the Internal Memory (Firmware

version 1.12 and later) .................................................................................................... 19-9

20.7

Performing a Mechanical Inspection and Checking Operations ...................................

20.8 Replacing the Battery Pack ...........................................................................................19-11

20.9 Replacing an Optical Adapter ....................................................................................... 19-14

20.10 Routine Maintenance ................................................................................................... 19-16

20.11 Storage Precautions ..................................................................................................... 19-17

20.12 Recommended Replacement Parts ............................................................................. 19-18

20.13 Calibration ....................................................................................................................

.................................................................................................... 19-7

Appendix

Appendix 1 Data File Formats ............................................................................................... App-1

19-3

19-6

19-10

19-19

Index

IM AQ1200-01EN

v

Page 7

1

Optical fiber cable

Telephone

exchanges

Measurement

in cable

installations

AQ1200

Consumer

Corporate user

Chapter 1 Features

1.1 Overview

This instrument is an OTDR (Optical Time Domain Reflectometer) with the features listed below. It

is used in the optical fiber and line installation and maintenance servicing of access networks, which

link telephone exchanges and service providers with subscribers, and user networks, which enable

communication within a corporation or building.

Features

OTDR Features

• Optical pulse measurement

Real-time, averaged measurement

• Waveform display

Can be zoomed and moved

• Waveform analysis

• Cursor/marker, distance, splice-loss, return-loss measurement

• Multi trace analysis

• 2 way trace analysis

• Differential trace

• Section analysis

• Event analysis

• Event editing

• Event list editing

Loss Testing (/SLT or /HLT option)

• Loss-measurement light source and visible light source

• Optical power meter

• Loss measurement (loss testing)

• Multi-core loss testing

Visible light source (/VLS option)

Generation of visible light

IM AQ1200-01EN

Fault Locator

Location of breaks (faults) in optical fibers

1-1

Page 8

1.1 Overview

Checking Fiber End Faces

You can use a fiber inspection probe* to photograph a fiber end face and display its state on the

screen.

* For information about compatible fiber inspection probes, contact your nearest YOKOGAWA dealer.

IP Testing (/LAN option)

Simple connection testing that uses PING

PON power meter (/PPM option)

Simultaneous measurement of the optical power of different signal wavelengths (1310 nm, 1490 nm,

and 1550 nm) of a PON system

Multi-Core Fiber Measurement

Using screens and menus specific to multi-core fiber measurement, you can efficiently and completely

measure multi-core fibers.

1-2

IM AQ1200-01EN

Page 9

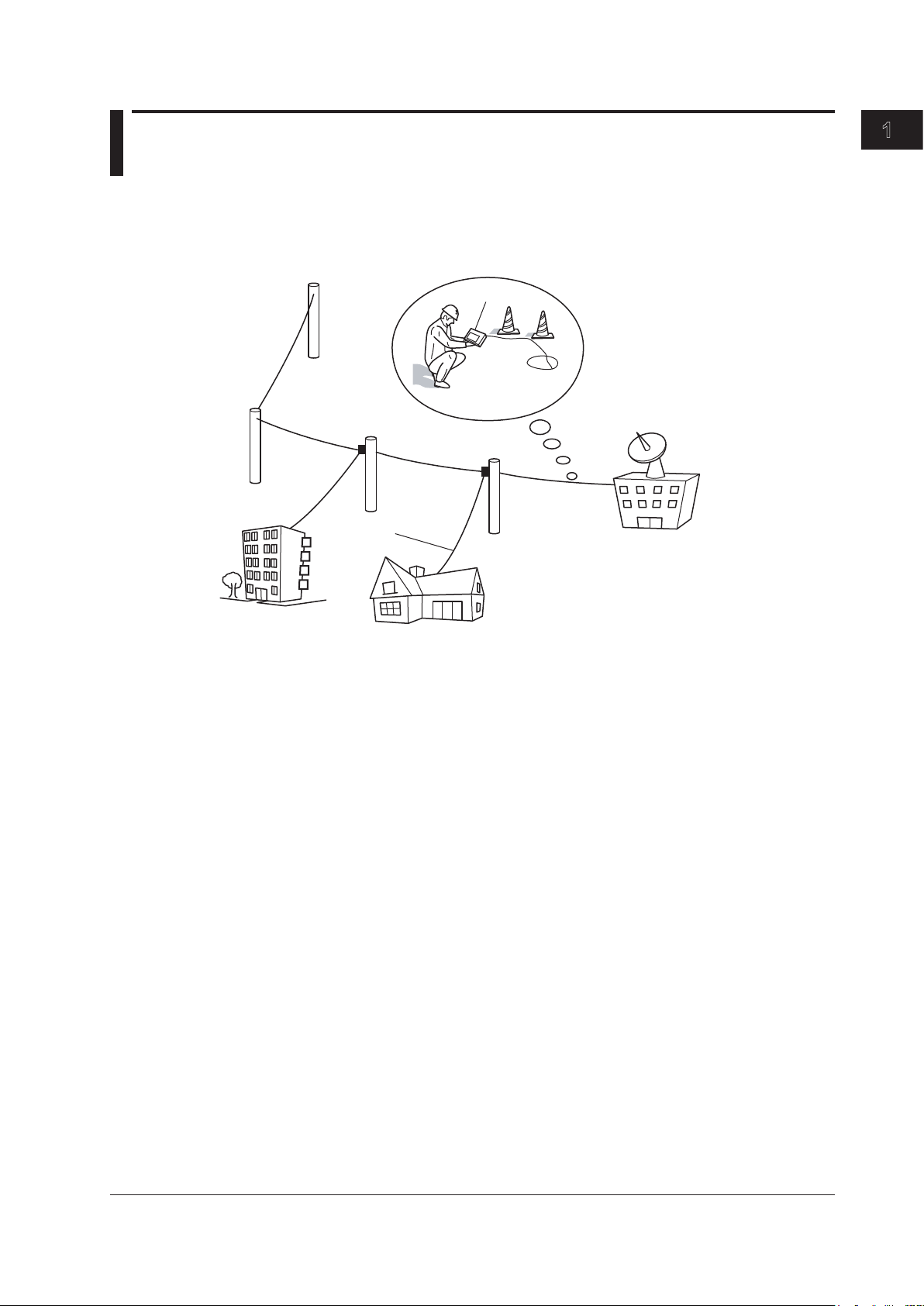

1

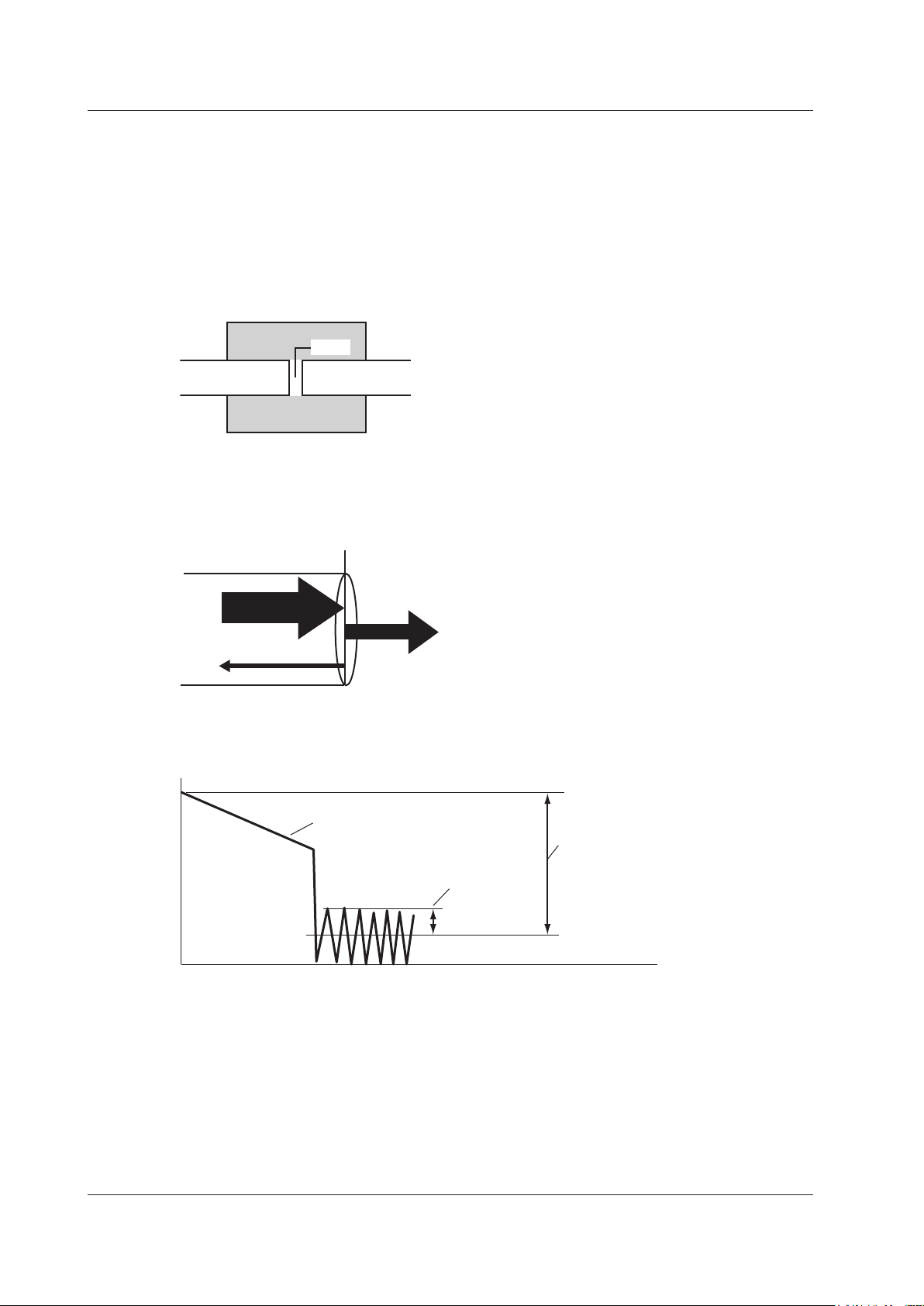

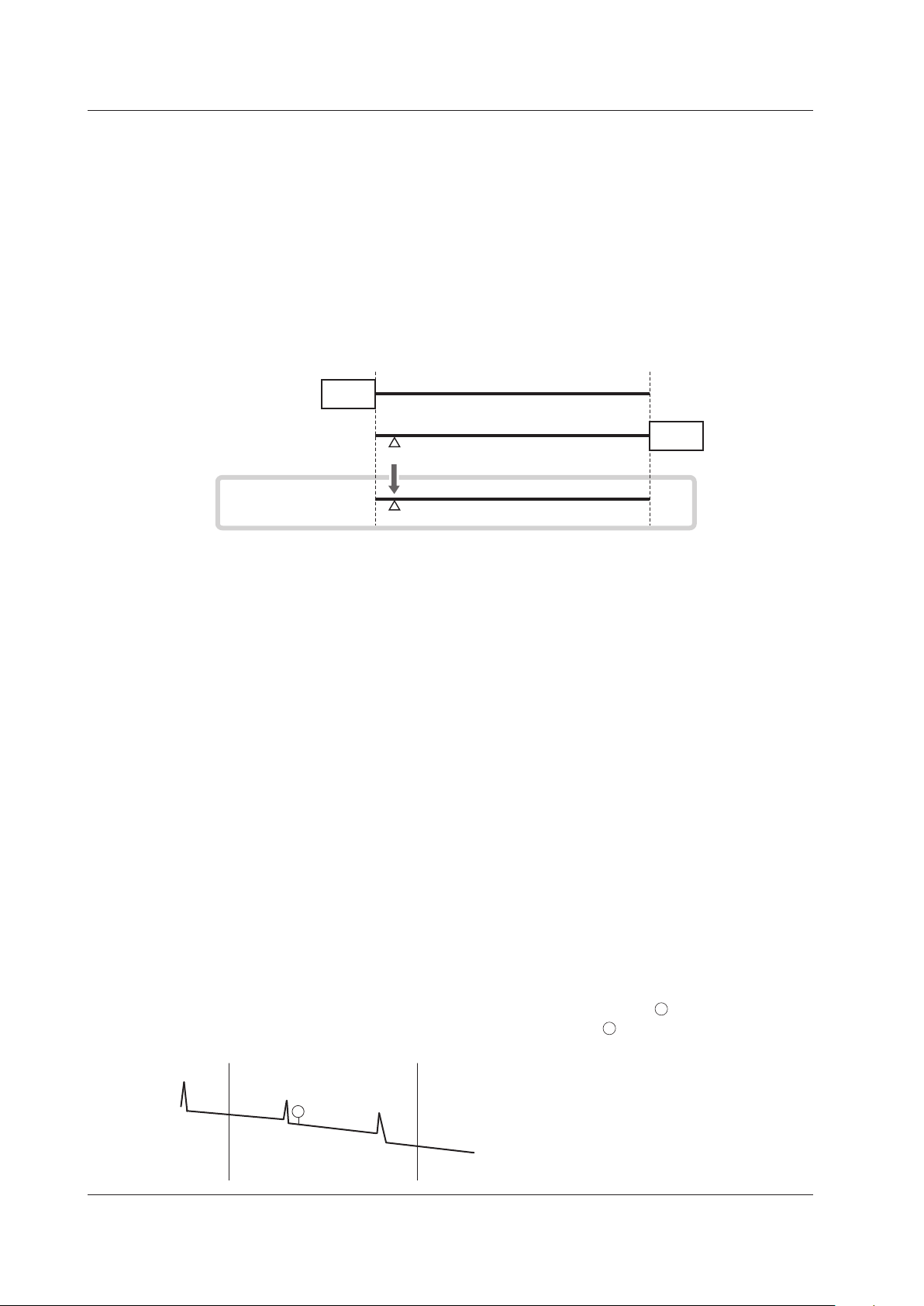

1.2 Optical Pulse Measurement

Reflection

point

Optical fiber being measured

Optical pulse generation

Reflected light

Do not bend the optical fiber.

AQ1200

OTDR/Optical port

(Optical port 2)

or

OTDR/Optical port

(Optical port 3)

The AQ1200 applies an incident optical pulse to the connected optical fiber and measures the power

level of the reflected light from the different sections of the optical fiber such as its splices, bent

sections, and the open end of the fiber. The AQ1200 uses the measured power level to determine

the distance to the different points (splices, breaks, etc.) of the optical fiber and the loss and other

phenomena that occur at those points.

Measurement Mode

The following three measurement modes are available depending on the items that you specify for

measurement conditions.

Simple

In this mode, you can set the optical wavelength and turn the automatic saving of measured data on

and off. All other measurement conditions are automatically configured or are fixed.

Features

Detail

In this mode, you can set all measurement conditions.

Multi WL

In this mode, in addition to the settings that you can specify in Detail mode, you can select up

to two optical wavelengths. The optical pulse whose wavelength you specified first is generated

and measured. Next, the optical pulse whose wavelength you specified second is generated and

measured. This operation is then repeated.

Analysis Mode

The following three analysis modes are available depending on the items that you specify for analysis

conditions.

Simple

In this mode, you can set the approximation method. All other analysis conditions are automatically

configured or are fixed.

Detail

In this mode, you can specify all analysis conditions.

Multi WL

In addition to the conditions in Detail mode, you can specify the index of refraction and the

backscattering light level for each of the two wavelengths that you specified in the measurement

Multi WL mode. You can also turn the macro bending (bending loss) display on and off.

IM AQ1200-01EN

1-3

Page 10

1.2 Optical Pulse Measurement

Real-time Measurement

In real-time measurement, you can change measurement conditions such as the wavelength, distance

range, and pulse width while waveform changes are being measured in real time.

* The measurement conditions that you can change vary depending on the measurement mode. For details

about the measurement conditions, see the explanation of the measurement modes in chapter 3.

Averaged Measurement

When you want to detect reflections, splice loss, and other faint events that are generated from

connections or splice points but are buried in noise, use averaged measurement. The AQ1200 derives

the measured data by averaging the specified number of optical pulse measurements or by averaging

optical pulse measurements over the specified duration. During averaged measurement, you cannot

change the measurement conditions. You can stop the averaged measurement before it completes.

Multi-Core Fiber Measurement

Using screens and setup menus specific to multi-core fiber measurement, you can efficiently and

completely measure multi-core fibers.

Fiber-in-Use

Some models in the AQ1200 Series use the same wavelength that is used in real communication to

make measurements.

If communication light is present in the optical fiber that you want to measure (the fiber is in use), the

communication will be affected. In this situation, the AQ1200 will not be able to perform measurements

correctly either. Take appropriate precautions to avoid communication interference. Check that there is

no communication light present in the optical fiber before you use the AQ1200.

The AQ1200 has a feature for checking whether there is communication light (fiber-in-use alarm; see

section 3.5).

*

1-4

IM AQ1200-01EN

Page 11

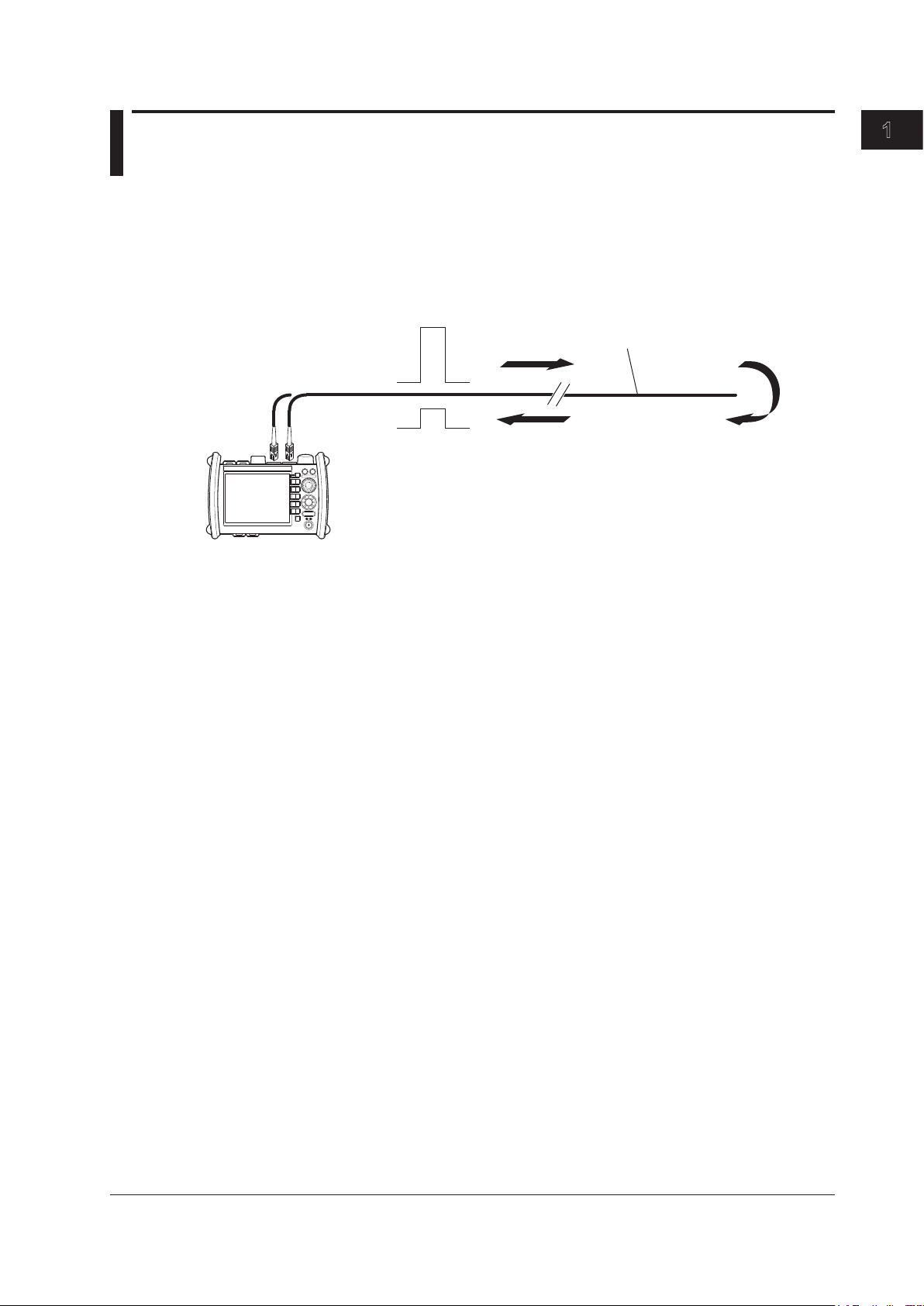

1

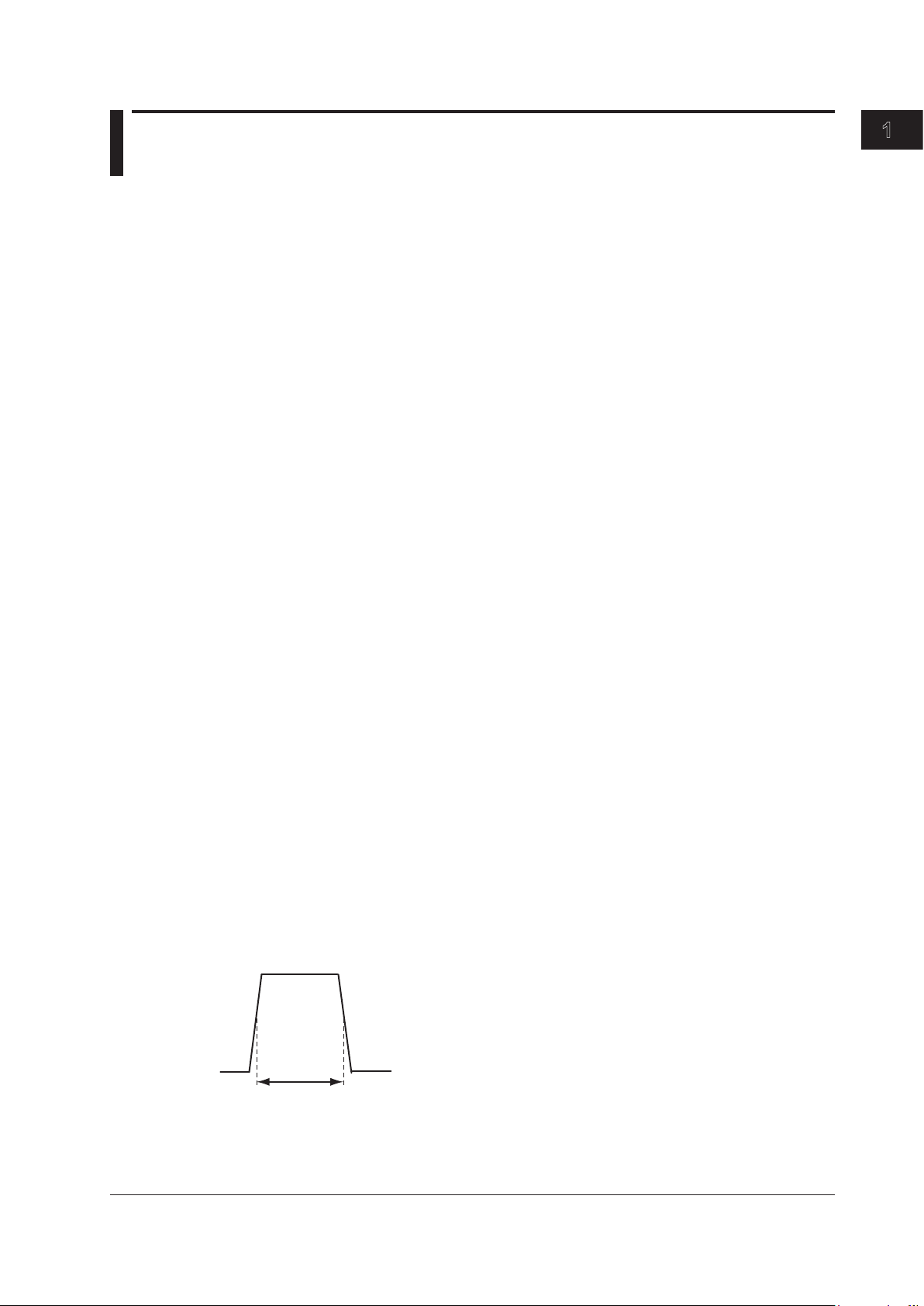

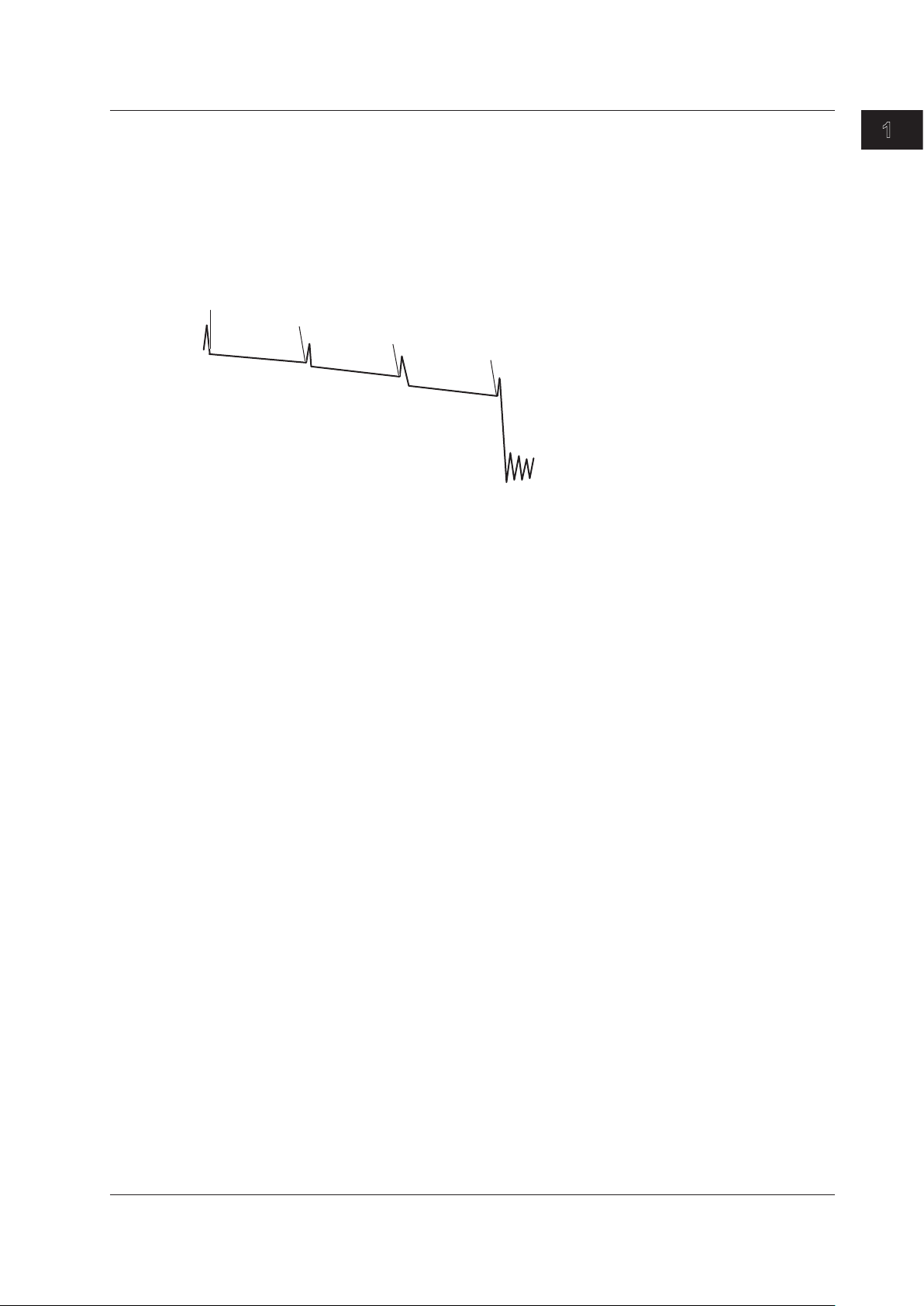

1.3 Waveform Display

Incident ray Backscatter Splice Connector Bend

Open end of

the fiber

Near-end

reflection

Splice loss

Approximated

line

Reflection caused

by a connector

Loss caused

by bending

Reflection at the open end

of the fiber (Fresnel reflection)

Dynamic range (SNR = 1)

Optical fiber

Small

material

Incident ray

Backscatter

Optical fiber

You can display the measured result as a waveform on the screen. You can zoom the displayed

waveform and move the position that is displayed.

How to View Optical Pulse Waveforms

The optical pulse applied to the optical fiber is reflected at different points of the optical fiber such

as its connections, bent sections, and the open end of the fiber. These sections generate loss. The

measured result is displayed as a waveform that has distance represented in the horizontal direction

and loss level represented in the vertical direction. On the waveform, detected points where loss or

reflection occurs are known as events.

Features

Near-end Reflection

This is the reflection that occurs at the point where the AQ1200 and the optical fiber are connected.

This also includes the AQ1200’s internal reflection. In the section where this near-end reflection is

detected, even if there are other connections, the loss and reflections that occur at these points cannot

be detected. This section is the near-end dead zone.

When you are measuring a short distance, connect a dummy fiber to reduce the effect of the near-end

reflection.

Backscatter

When light travels through an optical fiber, Rayleigh scattering caused by changes in the density of

materials that are smaller than the light’s wavelength and inconsistencies in the fiber’s composition

IM AQ1200-01EN

generates loss in the optical fiber itself. The portion of the scattered light that travels in the direction

opposite to the direction of propagation is known as backscatter.

1-5

Page 12

Optical fiber

Optical fiber

Connector

Gap

Glass Air

Incident ray (100%)

Reflected light (3%)

Light

(97%)

Measurement waveform

Noise peak

2.6 dB

RMS level of the noise

Dynamic range

(SNR = 1)

1.3 Waveform Display

Splice Loss

Because spliced sections of optical fibers have a great number of changes in the material’s density

and inconsistencies in the fiber’s composition, loss due to Rayleigh scattering becomes large, and

splice loss occurs in these sections.

Reflection at the Connection Point of Connectors

Using a connector to connect two optical fibers is different from splicing them together in that a small

gap remains between the two fibers. Because this gap has a different index of refraction, reflection

occurs.

Fresnel Reflection at the Open End of the Fiber

This is the reflection that occurs at locations where the index of refraction changes (glass to air) such

as where there are tears in the optical fiber or at the end of the optical fiber. When the optical fiber end

face is vertical, approximately 3% of the incident optical power (–14.7 dB) is reflected.

Dynamic Range

Dynamic range refers to the range of optical power levels that can be measured. The larger the

dynamic range, the greater the distance that optical pulses can be measured over.

Zooming the Waveform Display Scale

You can zoom the displayed waveform in the direction of the optical power level (vertically) or in the

direction of the distance (horizontally). A rectangular frame that shows the zoom position is displayed

on the overview screen that appears in the bottom right of the screen.

1-6

Moving the Waveform Display Position

You can move the displayed waveform in the direction of the optical power level (vertically) or in the

direction of the distance (horizontally). A rectangular frame that shows the display position is displayed

on the overview screen that appears in the bottom right of the screen. This is the same rectangular

frame that shows the zoom position.

IM AQ1200-01EN

Page 13

1

1.4 Waveform and Event Analysis

Pulse width

Waveform Analysis

You can use the cursor and markers to measure values such as the distance, splice loss, return loss,

or reflection level between two points.

Measuring Distance

The AQ1200 measures the time that it takes for an incident optical pulse to be reflected and return to

the device. It uses this information and the following equation to calculate the distance (L).

L = C×T/(2N) [m]

C:

The speed of light in a vacuum 2.99792 × 10

T: The time measured from when the incident pulse was generated to when the reflected light

was received [s]

N: Index of refraction

In the above equation, the division by two accounts for the fact that the measured time represents the

total time taken by the optical pulse to reach the reflection point and to return from it.

If the correct index of refraction is not specified, there will be errors in the distance measurement.

Setting the Index of Refraction

The AQ1200 has preset indices of refraction that correspond to each wavelength. For details on

the settings, see section 3.6. Contact the optical fiber manufacturer for the fiber’s correct index of

refraction.

8

[m/s]

Features

Distance Range

You must select a distance range that is longer than the cable length of the optical fiber that you

want to measure. As the distance becomes greater, the measurement time also increases. For

details on the setting range, see section 3.5.

Pulse Width

There are the following features depending on the length of the pulse width. The pulse width that

you can select varies depending on the distance range that you have specified. For details on the

settings, see section 3.5.

•

Short pulse width

You can separate and measure adjacent events (reflection points and losses). However

cannot measure long distances.

• Long pulse width

You can measure long distances. However, multiple adjacent

event.

events may be seen as one single

, you

IM AQ1200-01EN

1-7

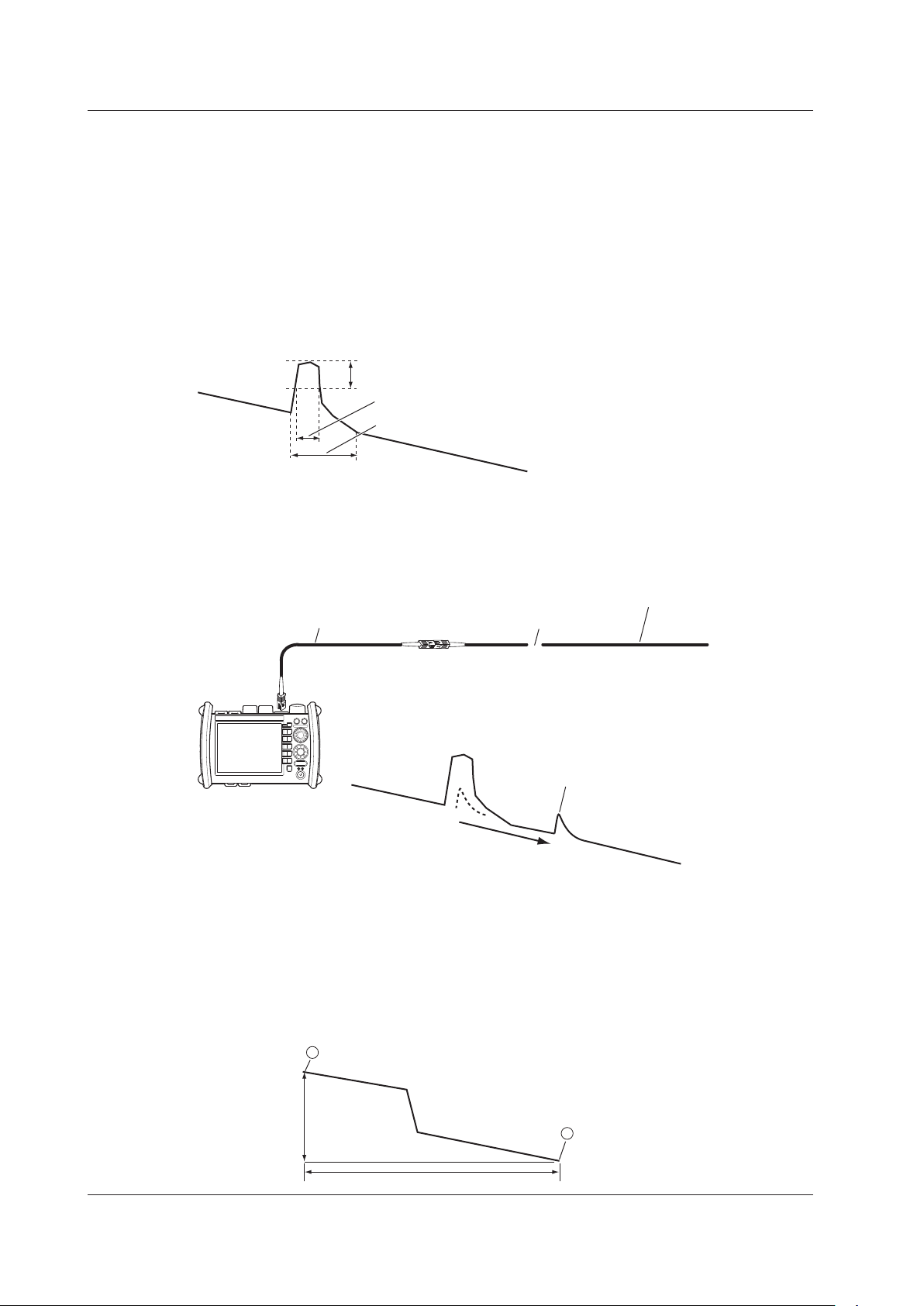

Page 14

Event dead zone

Attenuation dead zone

1.5 dB

Do not bend the optical fiber.

AQ1200

Optical fiber being

measured

Dummy fiber

Event generation

point

Small reflection that was hidden

within a large reflection

Splice loss a (dB)

(Total loss)

(n when Marker Mode is set to Line)

(E when Marker Mode is set to Line)

2

1

d (km)

1.4 Waveform and Event Analysis

Dead Zone

An area where the influence of a large event such as a connector’s connection point makes it

impossible to recognize other events that exist in that area is a dead zone. There are the following

two types of dead zones.

•

Event dead zone

An area where adjacent reflections cannot be separated. This is the area represented by the

pulse width between the two points on the waveform at the level that is 1.5 dB below the peak

value.

•

Attenuation dead zone

An area where, because there is a large reflection, the surrounding splice losses cannot be

measured.

Near-end Dead Zone Prevention

In sections where near-end reflection is detected, loss and reflections that occur at connections

cannot be detected. If you are measuring a short distance, connect a dummy fiber to move events

that are hidden in the near-end reflection the distance of the dummy fiber.

1-8

Splice Loss

The AQ1200 measures the distance and the loss between the specified points.

2 Point Markers

The AQ1200 measures the distance and the loss between two points. If reflection is detected

between the two points, the return loss is also measured. The splice loss value changes depending

on the approximation method that you have specified. This can be used when Marker Mode is set

to Marker or Line.

IM AQ1200-01EN

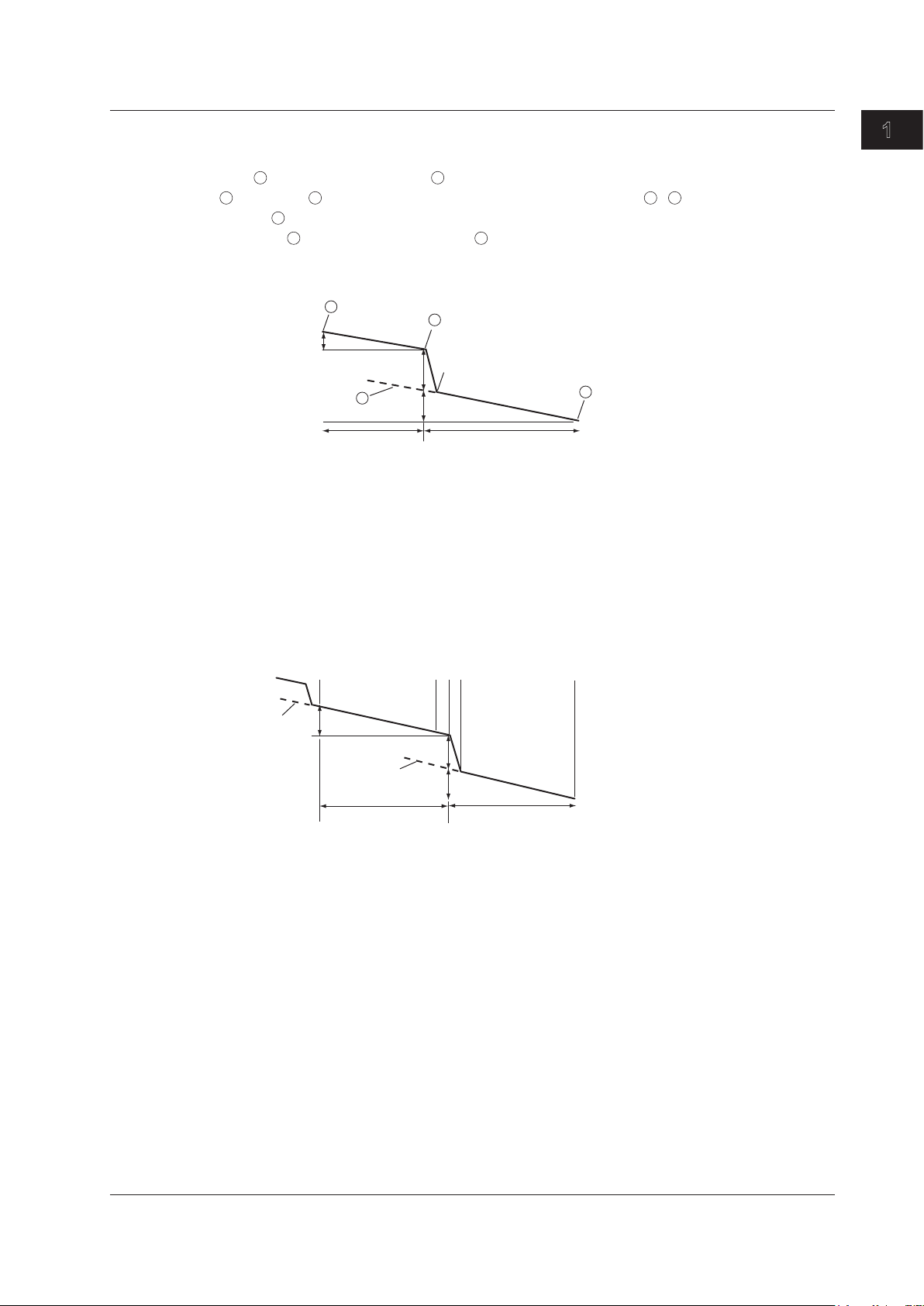

Page 15

1

1

3

3

2

Y2

b(dB)

e (dB)

c (km) f (km)

Approximated line Y2–

3

2

1

3

n

NfF

a (dB)

b (dB)

c (km)

e (dB)

f (km)

E

Approximated

line F–f

Approximated

line n–N

1.4 Waveform and Event Analysis

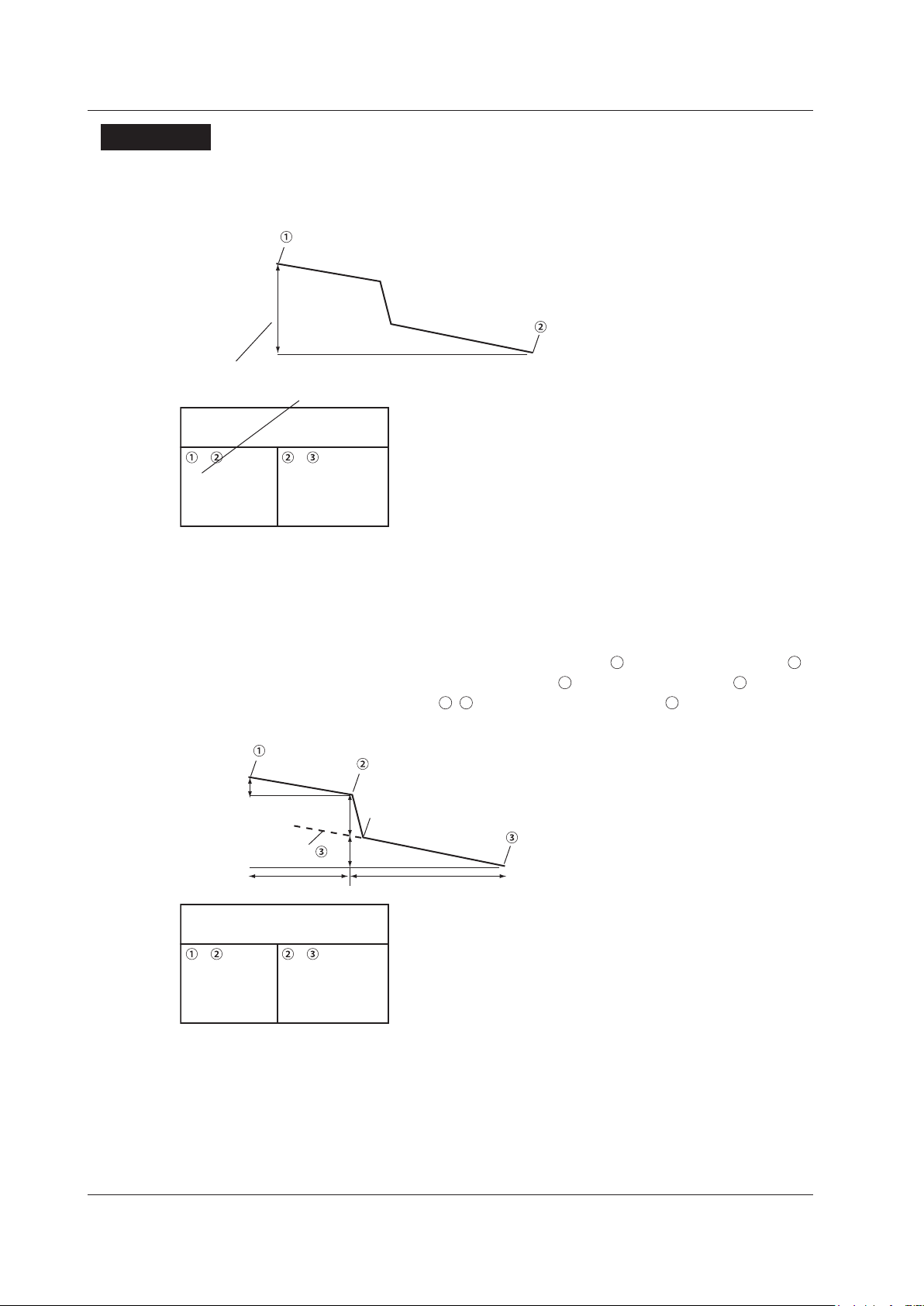

4 Point Markers

The AQ1200 uses the following four points to perform the measurement: the measurement start

point

, the splice loss start point 2, the splice loss end point Y2, and the measurement end point

. At position 2, the level difference between the approximated line 2–1 and the approximated

line Y2–

position of

is calculated as the splice loss. The splice loss changes greatly depending on the

. Set the correct position for 2. The splice loss value changes depending on the

approximation method that you have specified. This can only be used when Marker Mode is set to

Marker.

5 Point Markers

The AQ1200 uses the following five points to perform the measurement: the near-end point (n), a

point (N) that is used to calculate the near-end side’s approximated line, a point (E) where splice

loss is detected, a point (F) that is used to calculate the far-end side’s approximated line, and the

far-end point (f). At position E, the level difference between the approximated line n–N and the

approximated line F–f is calculated as the splice loss. The splice loss changes greatly depending

on the position of E. Set the correct position for E. The splice loss value changes depending on the

approximation method that you have specified. This can only be used when Marker Mode is set to

Line.

Features

IM AQ1200-01EN

Return Loss

Return loss RL is the ratio, in dB, of the reflected optical power level Pr to the incident optical power

level Pi. It is calculated using the following equation. The larger the return loss, the smaller the

reflected optical power. This implies that the performance of the measured optical line is good.

RL

= –10log(Pr/Pi) [dB]

1-9

Page 16

AQ1200

End A

End B

End A → End B

End A ← End B

▲ ▲ ▲ ▲ ▲ ▲

S 1 2 3 4 E

AQ1200

▲ ▲ ▲ ▲ ▲ ▲

S1234E

5

▲ ▲ ▲ ▲ ▲ ▲

S

1

2 3 4 E5

2 way trace analysis

B

B

S E

E

EE

B

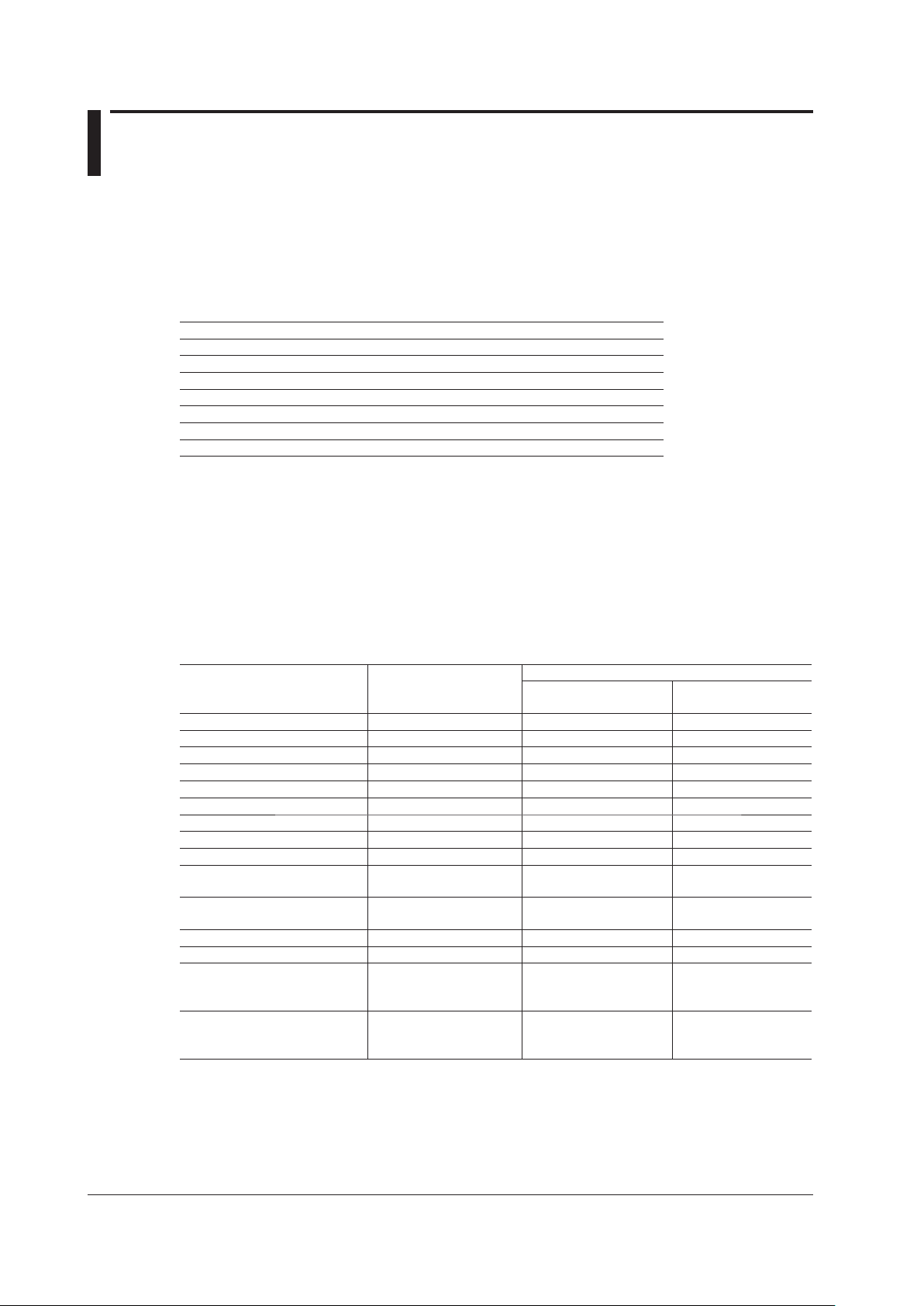

1.4 Waveform and Event Analysis

Multi Trace Analysis

You can load up to four traces that have been measured on the AQ1200 and display them

simultaneously for comparison.

You can adjust the vertical display position of each loaded trace.

2 Way Trace Analysis

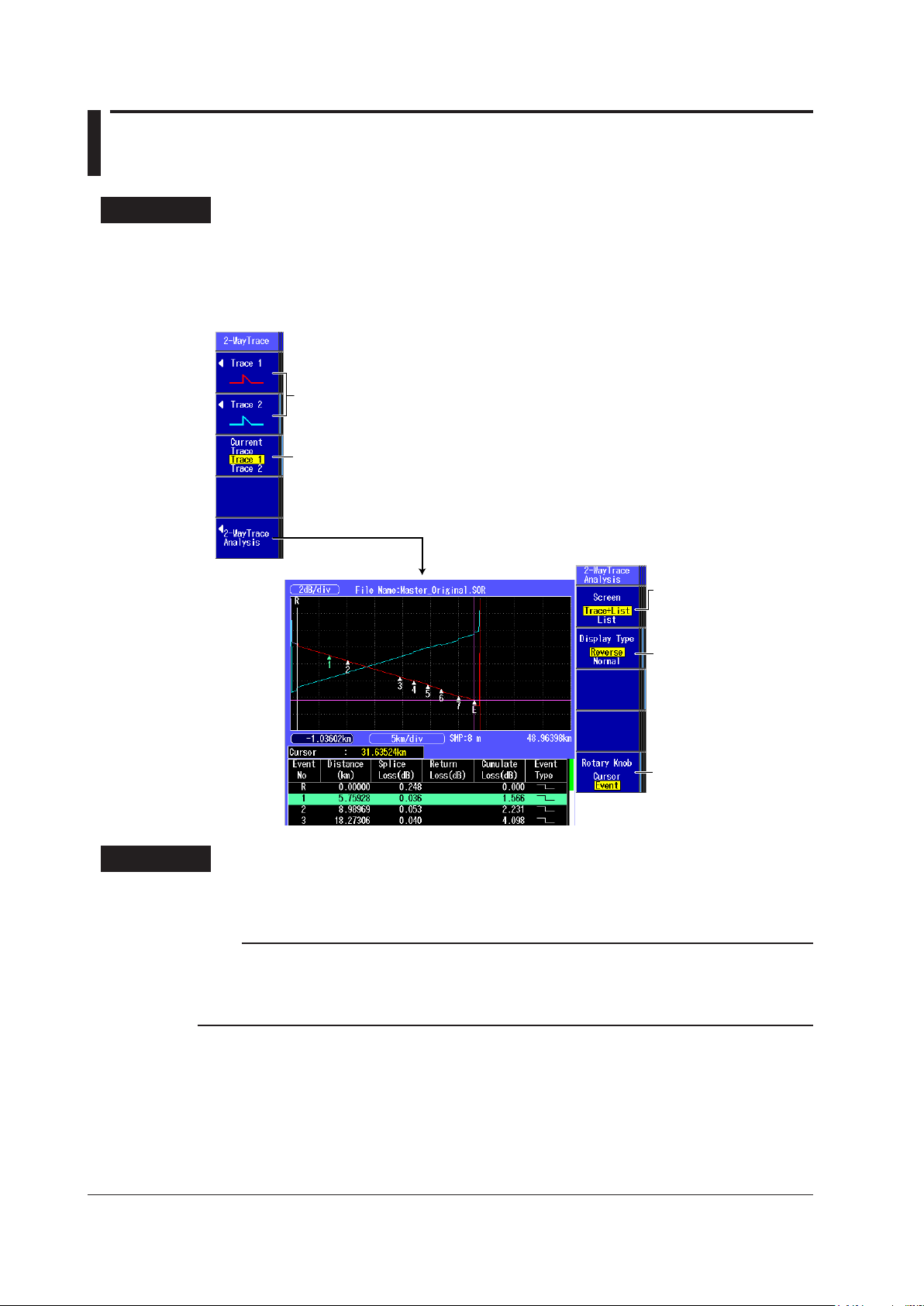

Trace events that have been measured from optical fiber cable end A to end B and those measured

from end B to end A can be combined. This combination enables displaying of events that could not

otherwise be measured because of dead zones.

In the figure below, the event that is in the near-end dead zone (point S) when measured from end A

is detected as event number 5 when measured from end B. In the 2 way trace analysis display, it is

displayed as event number 1.

An event of the other trace that exists within 6% of the position of an event of the current trace will be

considered part of the current trace event.

If multiple events of the other trace that exists within 6% of the position of an event of the current trace,

the closest event will be considered part of the current trace event.

Traces that meet the following conditions can be combined.

• Both have the same wavelength.

• Both have the same pulse width.

• Their end position of

fset is within 6%.

• Both have event lists.

Differential Trace

You can load two traces that have been measured on the AQ1200 and display their difference as a

trace.

The screen can display the loaded traces and the differential trace simultaneously.

The differential trace is the result of subtracting the values of the current trace from those of the other

trace.

You can use markers to read the following values of the differential trace.

Loss between markers (dB)

•

• Distance between markers (km)

• Loss per unit distance between markers (dB/km)

•

Distance to each marker

1-10

Section Analysis

You can set two markers, start point S and end point E, to measure the return loss and total loss in

the section that you have specified. If you specify the reference point marker

measurement, you can measure the return loss in the area between

and E.

for the return loss

IM AQ1200-01EN

Page 17

1

S

▲

▲

▲

▲

1

2

E

Measurement

reference point

Event number 1

Event number 2

Detected fiber-end event E

1.4 Waveform and Event Analysis

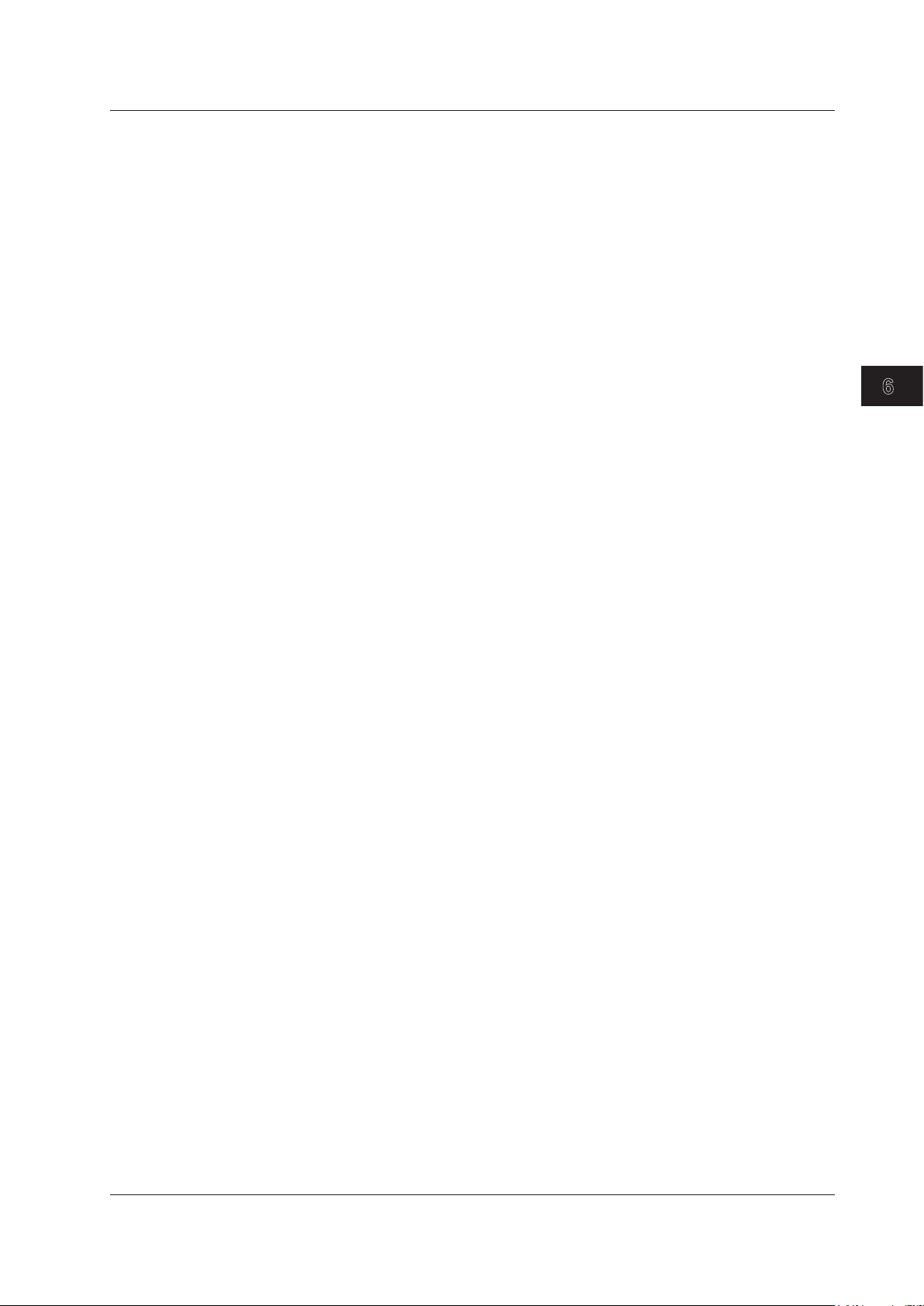

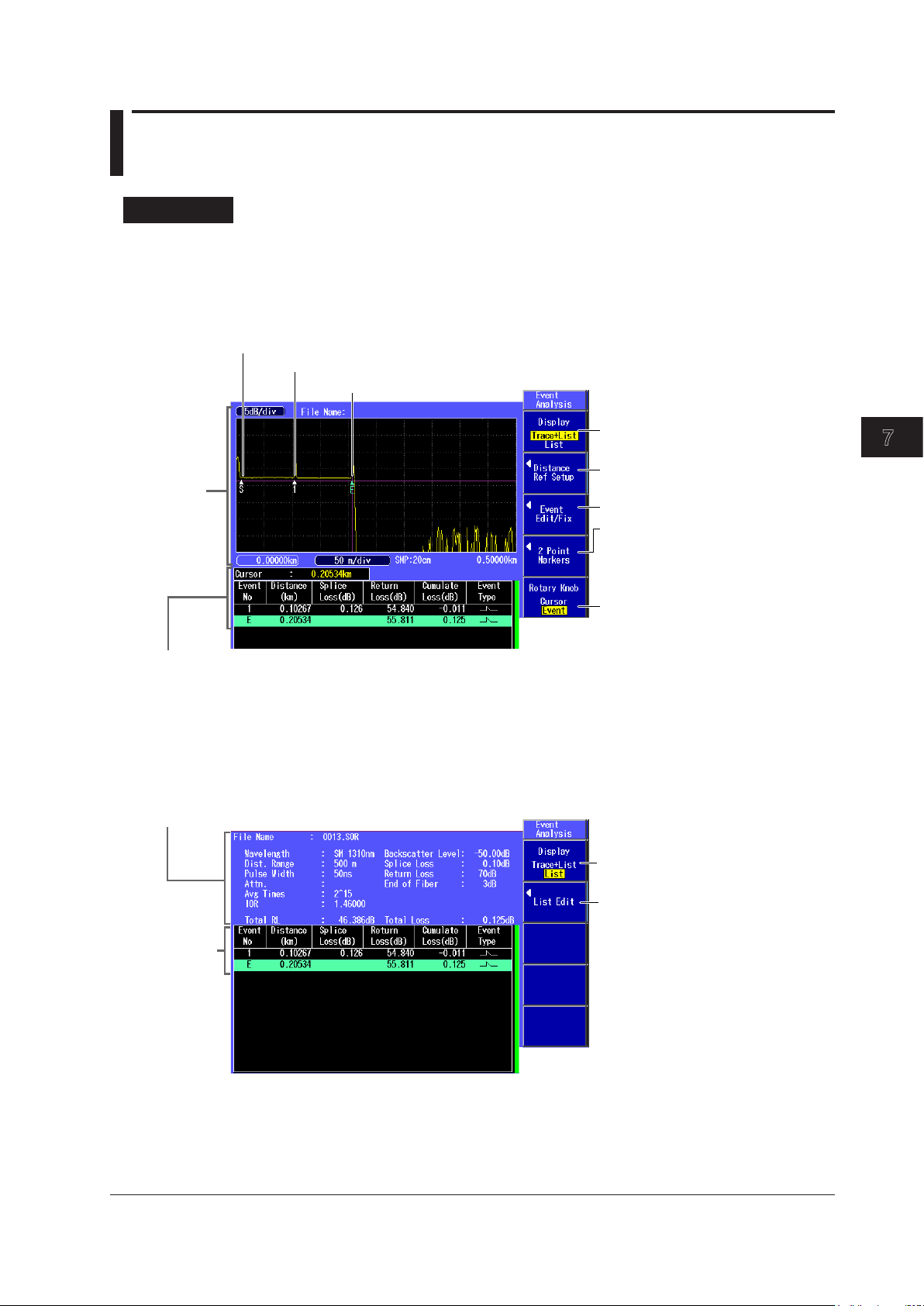

Event Analysis

You can search for events in the optical pulse measurement waveform and measure the splice loss

and the return loss.

Event Editing

You can insert and delete events on the event screen. When you edit an event marker, the splice loss

and the return loss can be recalculated.

Event List Editing

You can set indices of refraction for each event period on the event list. Setting the indices of refraction

in accordance with the connected fiber makes accurate distance measurements possible.

These indices only affect event analysis. The do not affect the waveform display.

You can also change event distances. However, the events shown on the screen will not change.

Features

IM AQ1200-01EN

1-11

Page 18

1.5 Light Source and Optical Power Meters (Options)

The features listed for the loss-measurement light source and optical power meters are available on

models with the /SLT, /HLT, or /PPM option. The features listed for the visible light source are available

on models with the /VLS option.

Loss-Measurement Light Source

The following measurement light wavelengths can be generated.

Model Measurement Light Wavelength

AQ1200A SM 1310 nm, SM 1550 nm

AQ1200B SM 1625 nm

AQ1200C SM 1650 nm

AQ1200E SM 1310 nm, SM 1550 nm, SM 1625 nm

AQ1205A SM 1310 nm, SM 1550 nm

AQ1205E SM 1310 nm, SM 1550 nm, SM 1625 nm

AQ1205F SM 1310 nm, SM 1550 nm, SM 1650 nm

You can produce continuous light or light that has been modulated at the selected frequency (modulation

mode).

Visible Light Source

You can produce visible light to visually identify breaks in the optical fiber under test. You can turn the

visible light on and off independently of the measurement light source.

Optical Power Meter

The two instrument types listed below are available for measuring different types of optical power.

Item

Wavelength Yes Fixed

Wavelength mode

Modulation mode

Unit

Reference

Measured value display hold Yes Yes Yes

Measured value logging Yes Yes —

4

Zero set

Average count

Maximum and minimum value

6

display

Interlocking of light source and

optical power meter settings

8

Offset

Threshold

Measurement of the optical

power from ONU to OLT for a

particular signal wavelength

Measurement of the optical

power from OLT to ONU for a

particular signal wavelength

1

2

3

5

9

Models with /SLT or /HLT

Suffix Codes

Yes (dB, dBm, W) Yes (dB, dBm, W) Yes (dBm, W)

7

10

11

Yes — —

Yes — —

Yes Yes —

Yes Yes Yes

Yes Yes Yes

Yes Yes —

Yes Yes —

Yes Yes Yes

Yes Yes Yes

— — Yes

— — Yes

Models with /PPM Suffix Codes

Normal power meter

selected

10, 11

Yes: Can be set or executed, —: Not available

PON power meter

selected

10, 11

Fixed

1-12

1 Wavelengths can be set with the wavelength mode set to Simple, Detail, or CWDM.

• Simple: You can select from a list of preset wavelengths.

• Detail: You can set the wavelength to a value from 800 to 1700 nm in 1 nm steps.

• CWDM: You can set the wavelength to a value from 1270 to 1610 nm in 20 nm steps along the CWDM

wavelength grid.

IM AQ1200-01EN

Page 19

1

1.5 Light Source and Optical Power Meters (Options)

2 You can select the modulation frequency of the incident rays from a list of presets. You can also select CW

(continuous).

3 You can make the displayed measured value the reference and display subsequent measured values as

relative values.

4 You can adjust the internal deviation of the optical power measurement section and obtain more accurate

absolute optical power values.

5 You can display averaged measured values.

6 You can display the maximum and minimum measured values.

7 You can interlock the light source and optical power meter settings when you connect an optical fiber

between the light source port of an AQ1200 and the optical power measurement port of another AQ1200.

8 You can add a specified value (the offset value) to measured optical power values.

9 You can set upper and lower threshold values and determine whether or not the measured values fall within

them.

10 You can measure the optical power of an upstream signal from the ONU (optical network unit: the user’s

optical terminal) to the OLT (optical line termination: the telephone exchange’s optical terminal). The optical

power of the 1310 nm (data wavelength) signal is measured.

11 You can measure the optical power of downstream signals from the OLT to the ONU. The optical power of

the 1490 nm (data wavelength) and 1550 nm (video wavelength) signals is measured.

Logging

You can measure short-term optical power stability. The optical power value during logging can be

displayed on a graph, and you can calculate the maximum, minimum, and average. In addition, you

can use cursors to calculate the optical power at a specified location or the maximum, minimum, and

average within a specified area. The logging results can be saved to a file in CSV format.

Features

IM AQ1200-01EN

1-13

Page 20

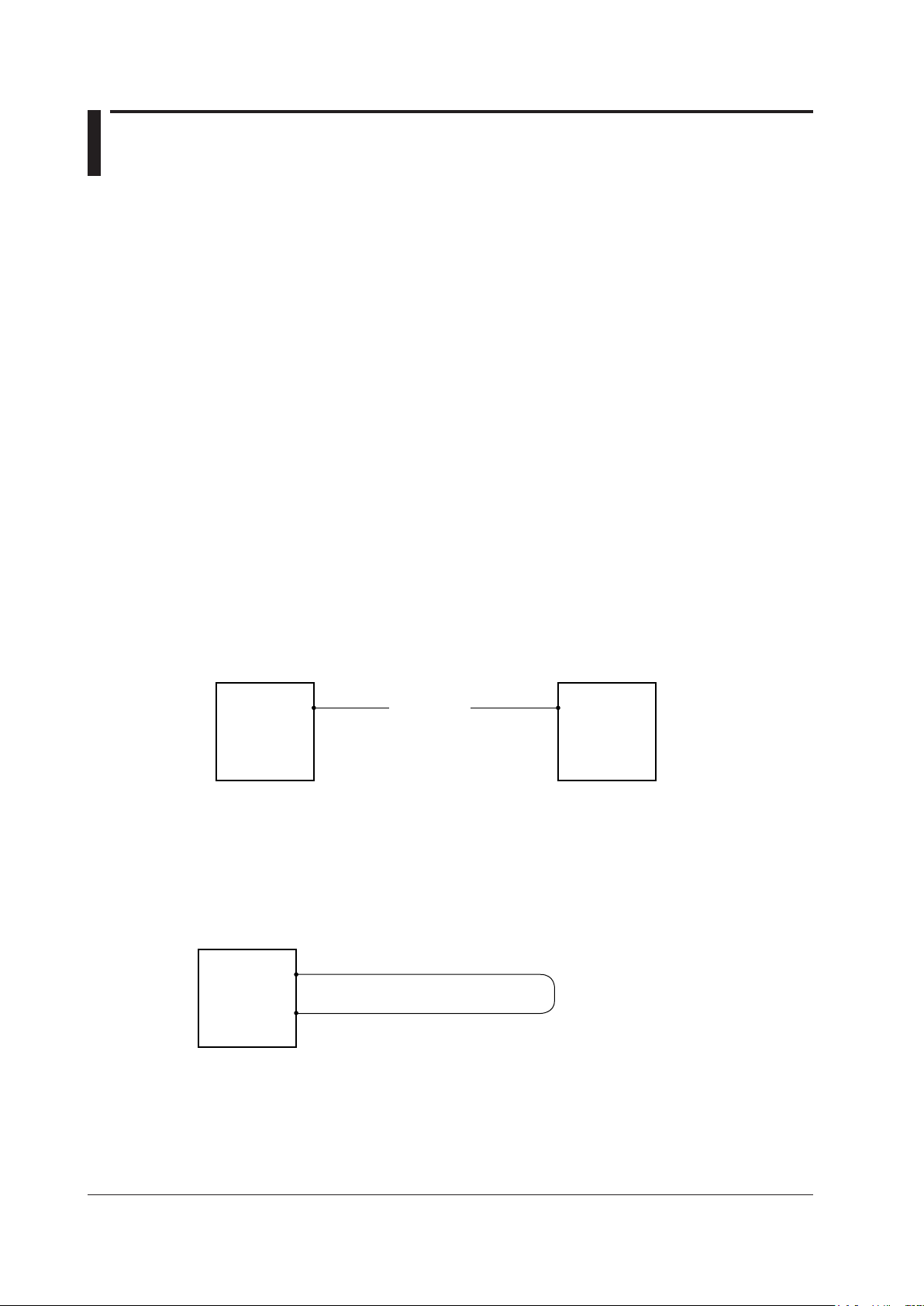

1.6 Loss Test (Option)

Light source (AQ1200)

Light source

port

Optical power meter (AQ1200)

Optical power

measurement

port

Fiber under

loss test

Light source and optical power meter

(AQ1200)

Light source

port

Optical power

measurement

port

Fiber under

loss test

You can easily measure optical fiber and optical line degradation. This feature is available on models

with the /SLT or /HLT option.

Auto Loss Test (Using one AQ1200 as the light source and another

as the optical power meter)

Using the AQ1200 as a light source and optical power meter, you can easily measure optical fiber and

line degradation. You can also use the AQ1100 multi-field tester series instead of the AQ1200 as the

light source or optical power meter.

Light Source

You can set up to two measurement light wavelengths and produce them in order. You can produce

a constant level of light if you use the optical power adjustment feature.

Optical Power Meter

The AQ1200 automatically identifies the measurement light from the AQ1200 that it is connected to

and measures the optical power.

• The following items can be specified or executed. For details about these items, see section 1.5.

The unit, reference, offset, and threshold values can be specif

The zero set and measured value display hold operations can be executed.

• You can attach

* Because the AQ1200 is capable of identifying optical fiber and line cores, it is possible to number cores

and tapes.

fiber information to the measured values and save them.

ied.

*

Loop-Back Loss Test (Using one AQ1200)

You can use the light source and optical power meter features on a single AQ1200 to perform a loopback loss test on an optical fiber or line. To perform loss testing, connect one end of the fiber that

you want to perform loss testing on to the AQ1200 light source port, and connect the other end to the

optical power measurement port of the same AQ1200.

1-14

IM AQ1200-01EN

Page 21

1

1.7 Multi-Core Loss Test (Option)

Master (AQ1200)

Light source port

(optical port 2)

Optical power

measurement port

Slave (AQ1200)

Light source port

Optical power

measurement port

(optical port 1)

Fiber under

loss test

Communication fiber

You can efficiently measure multi-core optical fiber and optical line degradation. This feature is

available on models with the /SLT or /HLT option.

Master and Slave

Connect two AQ1200s and specify the optical power meter as the master and the light source as the

slave. You can also use the AQ1100 multi-field tester series instead of the AQ1200 as the master or

slave.

Specifying the Optical Communication Fiber

To transfer, between the master and slave, project setup information and information about the fiber

under loss test, you must specify a fiber from the multi-core optical fiber to use for communication.

Connect one end of the optical communication fiber to the master’s light source port (optical port 2),

and connect the other end to the slave’s optical power measurement port (optical port 1).

Information That Is Transferred from Master to Slave

The following information can be transferred through the optical communication fiber from the

master to the slave.

• Project information (see below for further details)

• Loss test results

* Each time that the selected fiber’s loss test finishes, that fiber’s loss test result is automatically transferred.

*

Features

IM AQ1200-01EN

Connecting the Optical Fiber under Loss Test

All fibers other than the optical communication fiber can be tested. For each optical fiber under

loss test, connect one end to the master’s optical power measurement port, and connect the other

end to the slave’s light source port. The core and tape numbers of the fibers under loss test are

transferred from the master to the slave.

Executing a Loss Test

Transmit light from the slave. The master will automatically identify different wavelengths in the light

from the slave and measure the optical power. Continue the loss test, switching the cores between the

master and the slave in order.

Projects

You can create projects with the master. You can specify the following project information:

The project name, the number of the core to start loss testing at, the tape number type, the number

of cores, and the transmitted or measured measurement light wavelengths (up to 2).

• You can transfer projects from the master to the slave and share information.

When the master and the slave share a project and use that project to perform loss testing, if testing

•

is stopped, the data up to the stop point is saved and you can begin testing again from the next

core.

•

You can save and load projects as CSV files.

1-15

Page 22

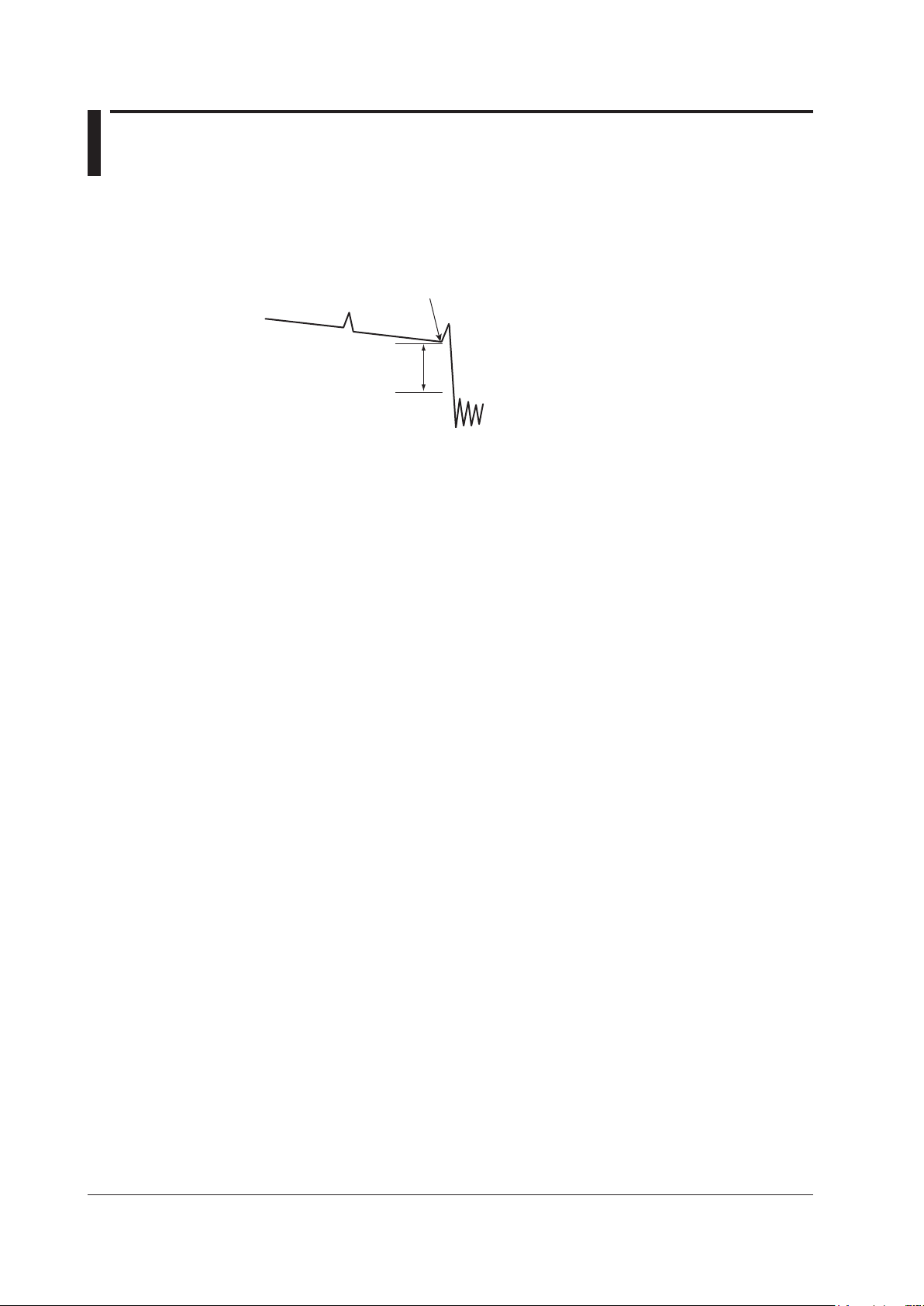

1.8 Fault Locator

Loss level that is used to determine

whether this is the fiber end face or not

Break (fault)

This feature enables you to search for breaks (faults) in an optical fiber or line. If there are no faults in

the middle of a fiber, the fiber end face is detected as a fault. You can specify the wavelength and the

loss level that is used to determine if a fault is a fiber end face or not when the AQ1200 searches for

faults. You can also zoom the display scale of the measured waveform and move the display position.

You can make measurements on the selected route.

The following five routes are available.

• Normal

Searches for faults in the fiber that connects the OLT

• OLT -> Splitter

Searches the route from the OLT to the splitter

• OLT -> Splitter -> ONU

Searches the routes from the OLT through the splitter to each ONU

• ONU -> Splitter

Searches the route from an ONU to the splitter

• ONU -> Splitter -> OLT

Searches the route from an ONU through the splitter to the OLT

1

and ONU

2

1 OLT (optical line termination): the telephone exchange’s optical terminal

2 ONU (optical network unit): the user’s optical terminal

1-16

IM AQ1200-01EN

Page 23

1

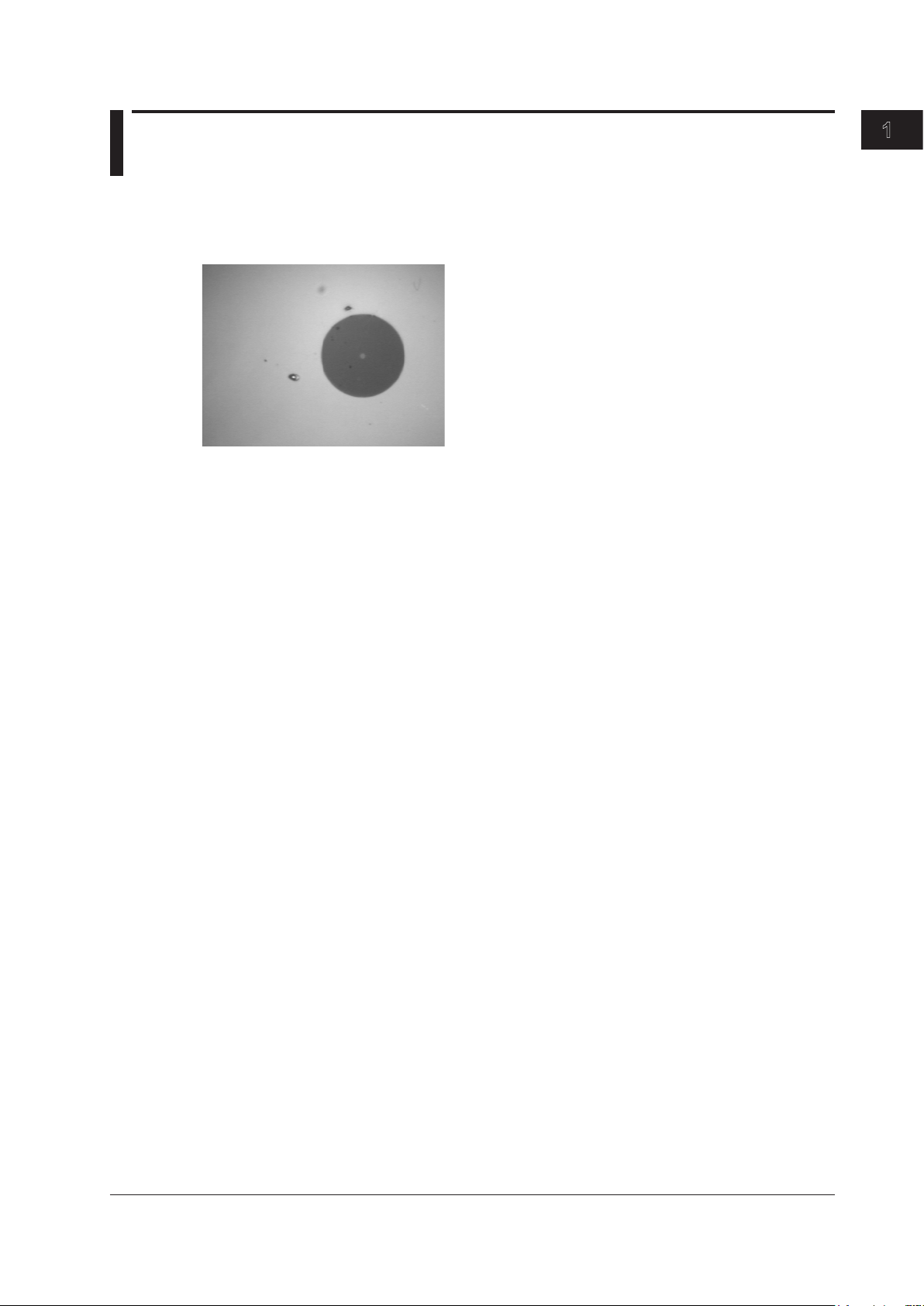

1.9 Checking Fiber End Faces

You can use a fiber inspection probe* to take a photograph that shows the state of a fiber end face.

You can display this photograph on the AQ1200 screen and save it.

* For information about compatible fiber inspection probes, contact your nearest YOKOGAWA dealer.

Features

IM AQ1200-01EN

1-17

Page 24

1.10 IP Test (Option)

You can check whether or not the network layer of an Ethernet LAN line is established. Before

performing an IP test, make sure that the optical fiber or line is connected physically.

IP testing is available on models with the /LAN option.

Ping Test

To ping an address (perform a simple IP test), specify the address and configure the Tx frame settings

listed below. The results of pinging the address appear on the screen.

The frame length, Tx mode (continuation, number of frames to send, and transmission time), and

measurement interval

1-18

IM AQ1200-01EN

Page 25

1

1.11 Multi-Core Fiber Measurement

Multi-core fiber measurement takes time and effort. This feature makes it possible to efficiently

measure multi-core fibers through a dedicated menu.

Projects

Items that you need to specify in order to make multi-core measurements such as measurement

conditions, analysis conditions, and core information are managed in projects.

By creating a project before a measurement, you can measure cores under the same conditions.

You can save projects to files. You can load a previously saved project and make measurements under

the same conditions.

List

Cores are listed. You can easily distinguish between cores that have been measured, cores that have

not been measured, and cores that do not to be measured. This list prevents you from forgetting

measurements and from making unnecessary measurements. (You can make measurements

efficiently.)

Measurement Result Storage

Measurement results of each core are automatically saved to a folder that is automatically created in

the folder that the project file is saved in. The folder will have the same name as the project file.

Features

IM AQ1200-01EN

1-19

Page 26

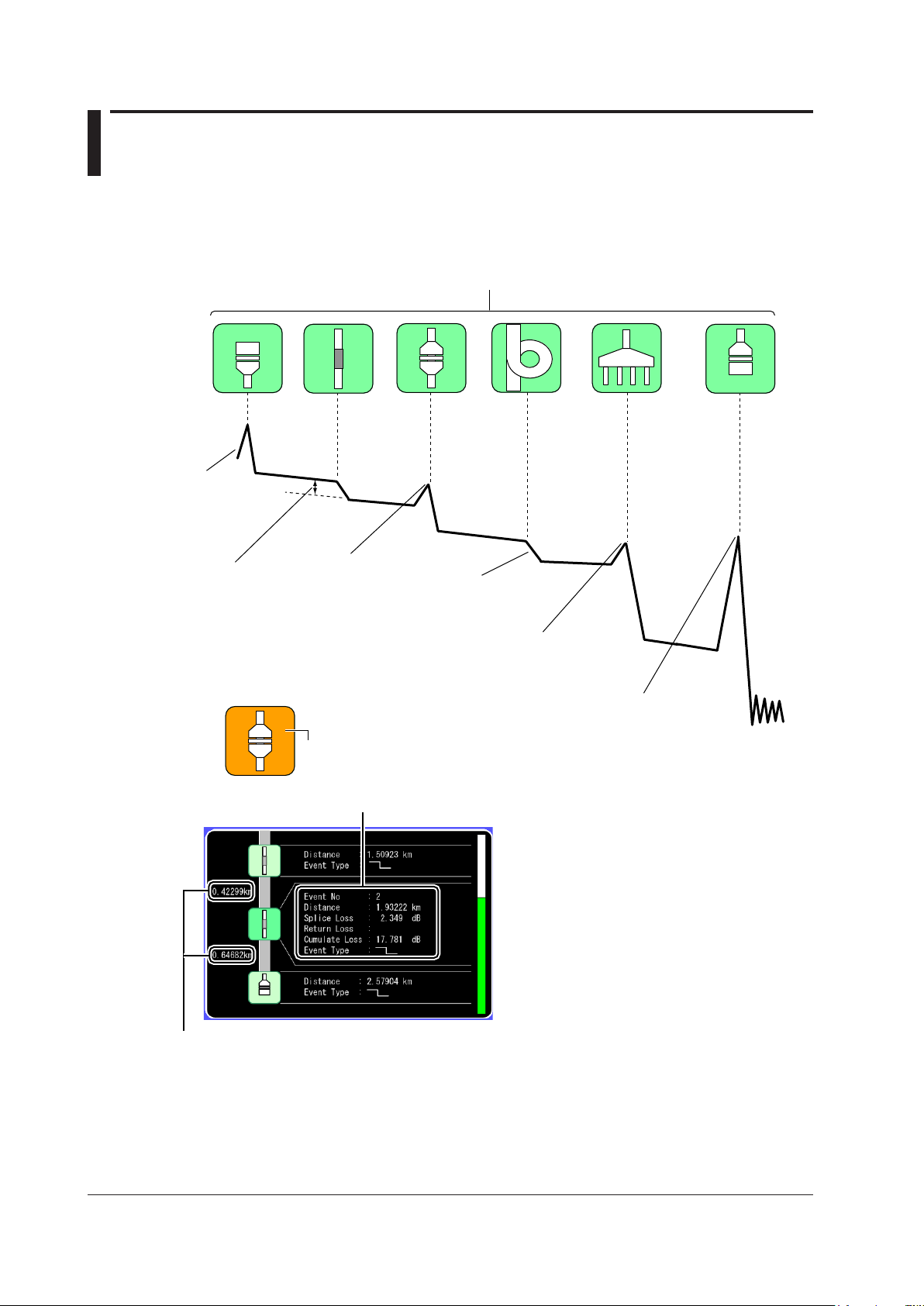

1.12 Event Mapper

Near-end

reflection

Splice loss

Reflection caused

by a connector

Loss caused

by bending

Reflection at the open end

of the fiber (Fresnel reflection)

Reflection caused

by a splitter

Each event is displayed as an icon. You can also switch to the waveform display using soft keys.

If an event is determined to be a fault event,

the icon background is displayed in orange.

Detailed analysis results of the selected icon (event)

Distance between events

You can display measured result events as icons on the screen. Detailed event analysis results are

displayed along with the displayed icons. In addition, if fault events (see section 3.6) are specified,

icons are displayed in different colors depending on the results of pass/fail judgments.

1-20

IM AQ1200-01EN

Page 27

1

1.13 Other Features

The AQ1200 also has the following features.

• Data saving and loading

• Language selection

• Beep on/off

• Startup menu selection

• USB function selection (storage/communication)

• Screen color selection

• Current date and time configuration (see the operation guide, IM AQ1200-02EN)

• Power save settings

• Network settings (on models with the /LAN option)

• Setup information initialization (to the factory default values)

• AQ1200 information display (model, serial no., suffix code, version, etc.)

• Self test execution

• Firmware version updating

Features

IM AQ1200-01EN

1-21

Page 28

2

1

Displays a term that

represents the selected

feature

• OTDR

• LS_OPM

• Auto Loss Test

• Multi-Core Loss Test

• IP Test

•

Fiber Inspection Probe

• Fault Locator

• Visible Light Source

• PON_OPM

• Multi-Core Fiber Meas

• OTDR Event Mapper

Top Menu

Displays an image that shows

the selected feature

Rotary knob

ENTER key

The center

of the rotary

knob

Displays an explanation of the selected feature

Chapter 2 Common Operations

2.1 Top Screen

When you turn the AQ1200 on and it starts, the top screen appears. First select a feature from this top

screen, and then configure the feature or carry out the measurement that corresponds to the feature

you have selected.

Turn on the AQ1200.

1.

Use the rotary knob to select the feature.

2.

An image that shows the selected feature is displayed, and the feature name is displayed in the upper left

of the screen.

Press the center of the rotary knob or ENTER to confirm your selection.

3.

The setup or measurement operation menu for the selected feature is displayed.

In this manual, steps 2 and 3 above are described as shown below.

Example: To select the OTDR feature and confirm it:

“Using the

rotary knob and ENTER, select OTDR.”

Common Operations

IM AQ1200-01EN

Procedural Explanations of Features

For explanations of the procedures to perform after you have selected and confirmed a feature, see

the chapters or sections that are listed in the following table.

Function Reference

OTDR (optical pulse measurement) Chapters 3 to 7

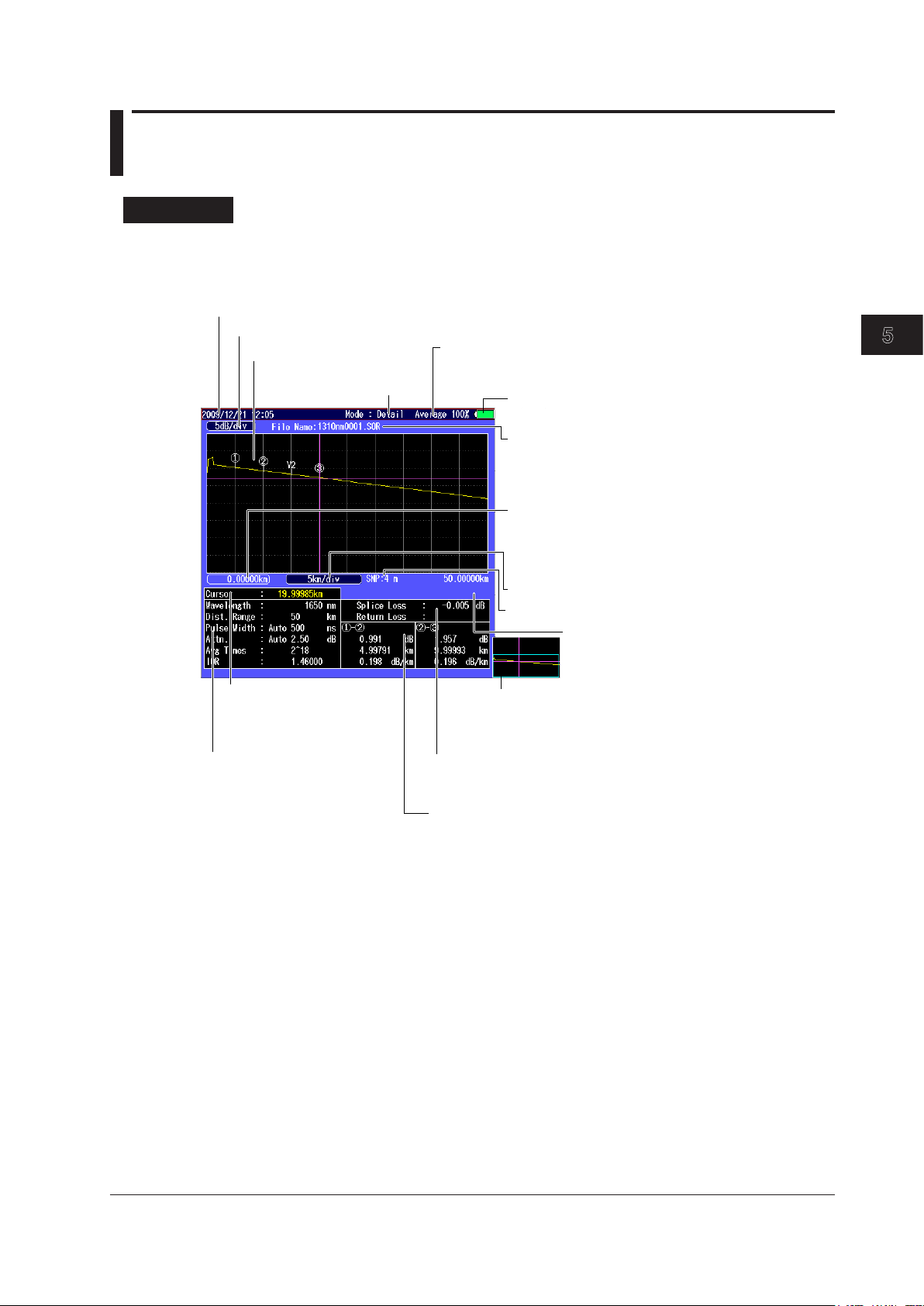

LS_OPM (power meter and light source) Chapters 8 and 9

Auto loss test (auto loss test and loopback loss test) Chapter 11

Multi-core loss test Chapter 12

IP test Chapter 15

Fiber inspection probe (fiber end face check) Chapter 14

Fault locator Chapter 13

Visible light source Section 8.2

PON_OPM (PON power meter)

Multi-Core Fiber Meas (multi-core fiber measurement)

OTDR Event Mapper

1

3

1 AQ1200 firmware versions 1.10 and later support this feature.

2 AQ1200 firmware versions 2.01 and later support this feature.

3 AQ1200 firmware versions 2.03 and later support this feature.

2

Chapter 10

Chapter 16

Chapter 17

2-1

Page 29

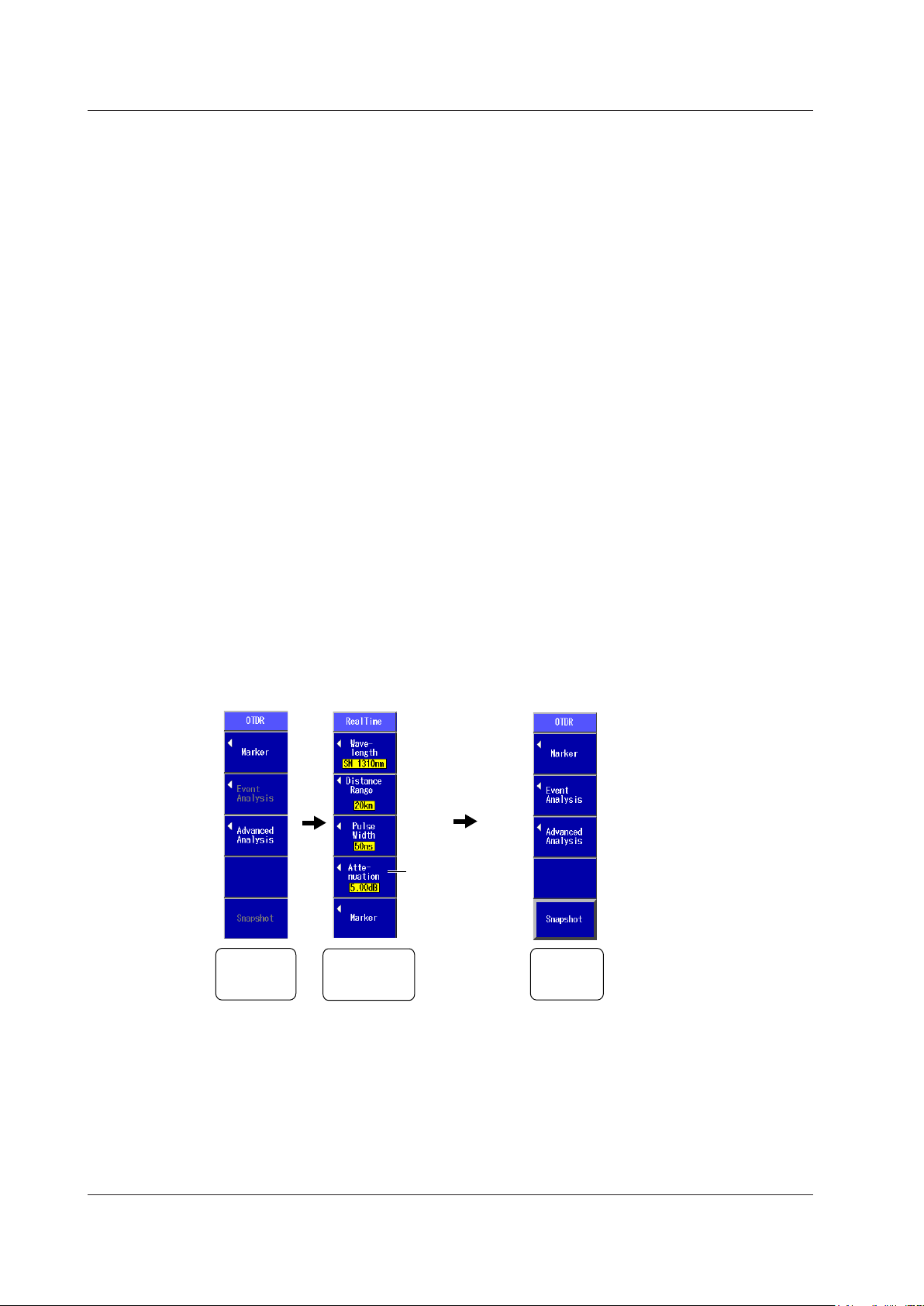

• OTDR Top Menu (during real-time measurement)

When not

measuring

During real-time

measurement

After real-time

measurement

Attenuation

command

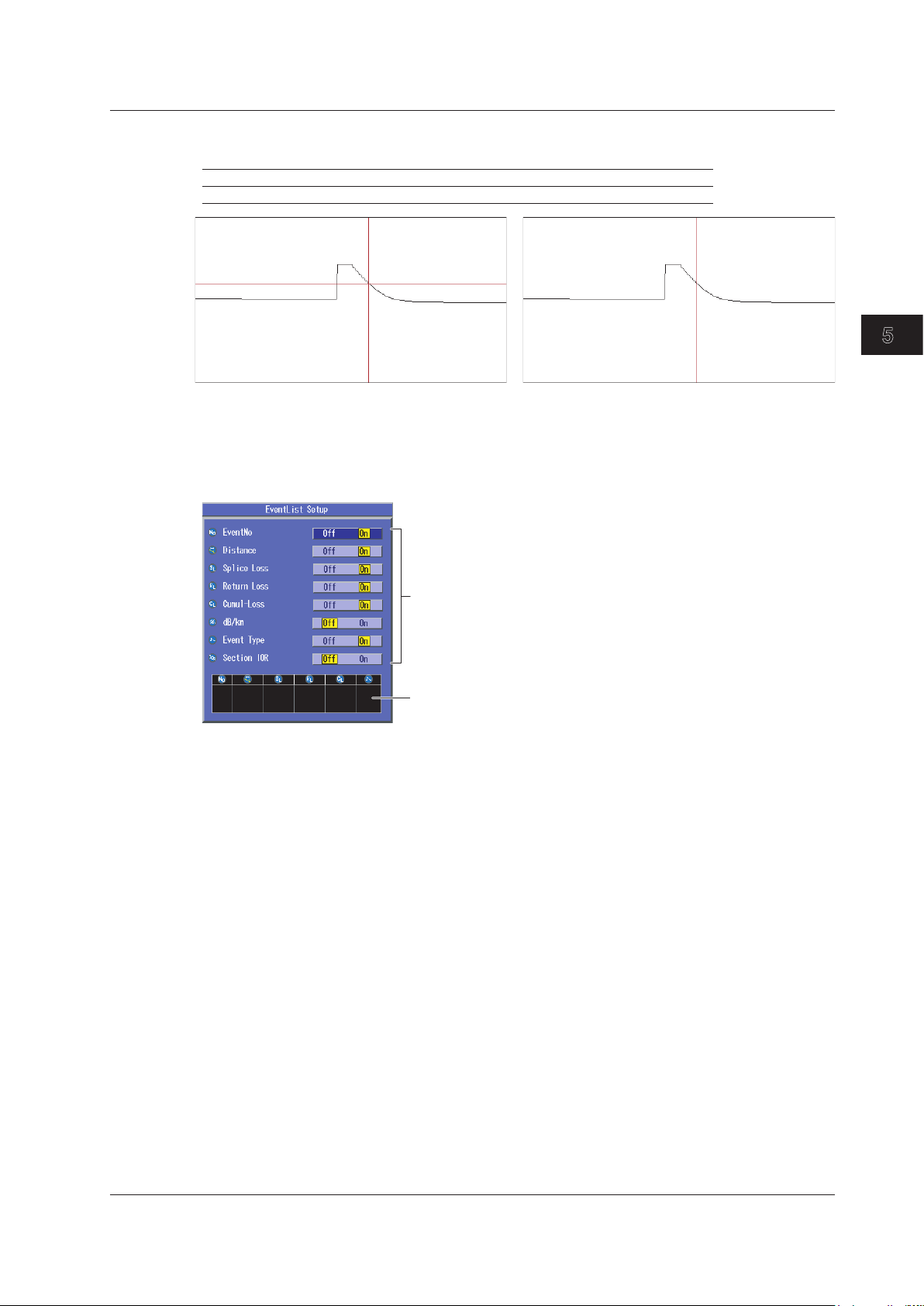

Waveform

Analysis

Command

Measurement

Condition

Command

Waveform

Analysis

Command

2.1 Top Screen

Top Menu

• You can also use the soft keys (F1 to F5) on the right side of the top menu to select a feature and

display its setup or measurement operation menu.

• The feature that you have used the rotary knob and ENTER to select is displayed in the top position

(soft key F1) of the top menu.

• If you use the rotary knob and ENTER to select a feature that is already displayed in the top menu,

the feature will move to the top position of the top menu. If you press a soft key (F1 to F5), the

feature that you have selected will also be moved to the top position.

• Up to five features can be displayed. When you exceed this number, the feature that was displayed

in the position by soft key F5 is deleted from the top menu.

• You can configure the top menu that is displayed when the AQ1200 starts. For details, see section

19.1.

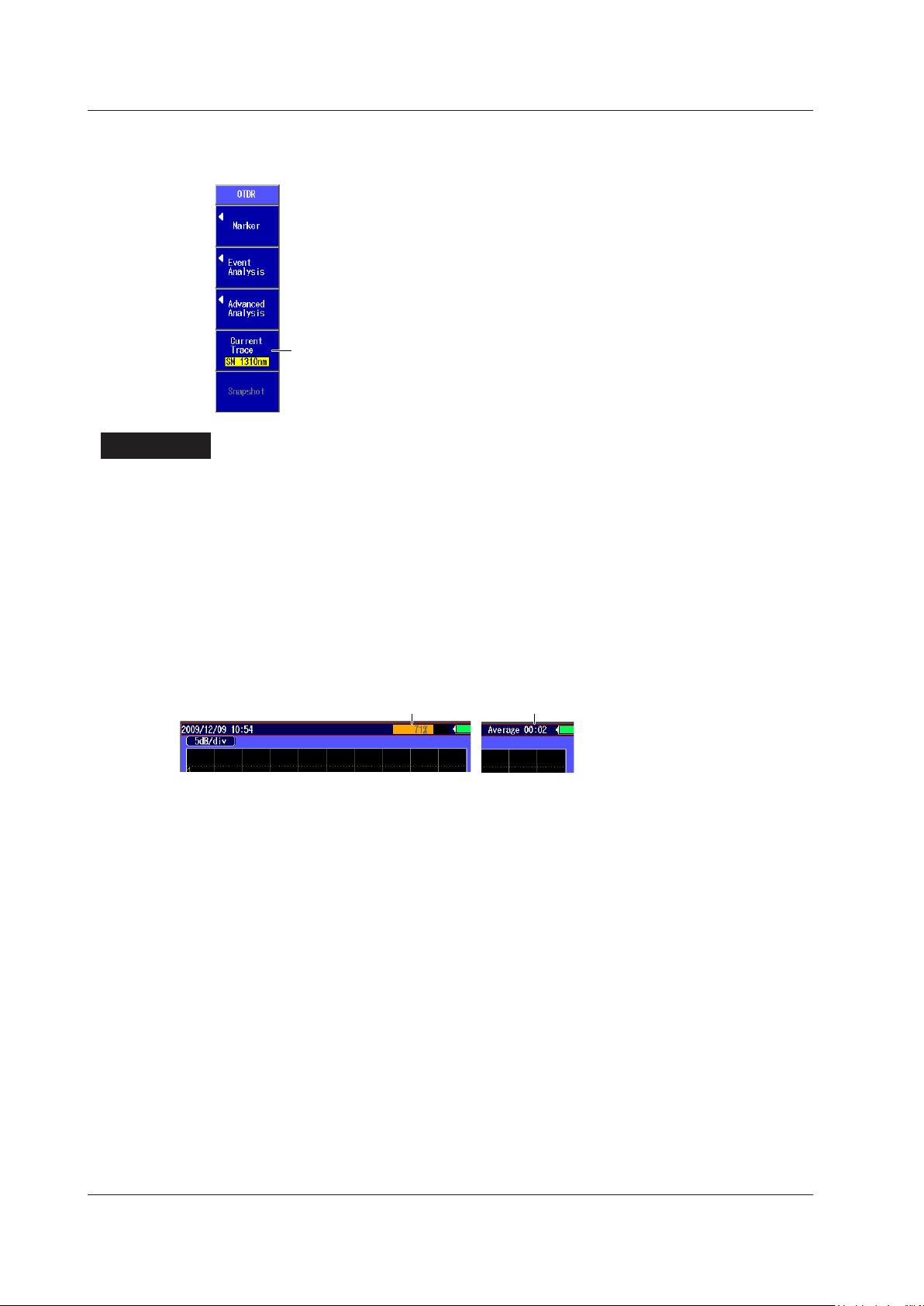

OTDR Top Menu

If you select the OTDR feature from the top menu, the OTDR menu (OTDR top menu) will appear.

On AQ1200s with firmware version 2.03 and later, the OTDR top menu varies depending on the suffix

code.

If the Suffix Code Is Not -HE (-HJ for example)

The OTDR top menu is the same as that of the previous version.

• The OTDR top menu will contain waveform analysis commands.

• During real-time measurement, marker and measurement condition commands appear.

The F4 soft key will show the attenuation command.

• When real-time measurement finishes, the menu will return to displaying waveform analysis

commands.

• During averaged measurement, the marker command appears.

• When averaged measurement finishes, the menu will return to displaying waveform analysis

commands.

2-2

IM AQ1200-01EN

Page 30

2

1

Waveform Analysis

Command

Marker

Command

Waveform Analysis

Command

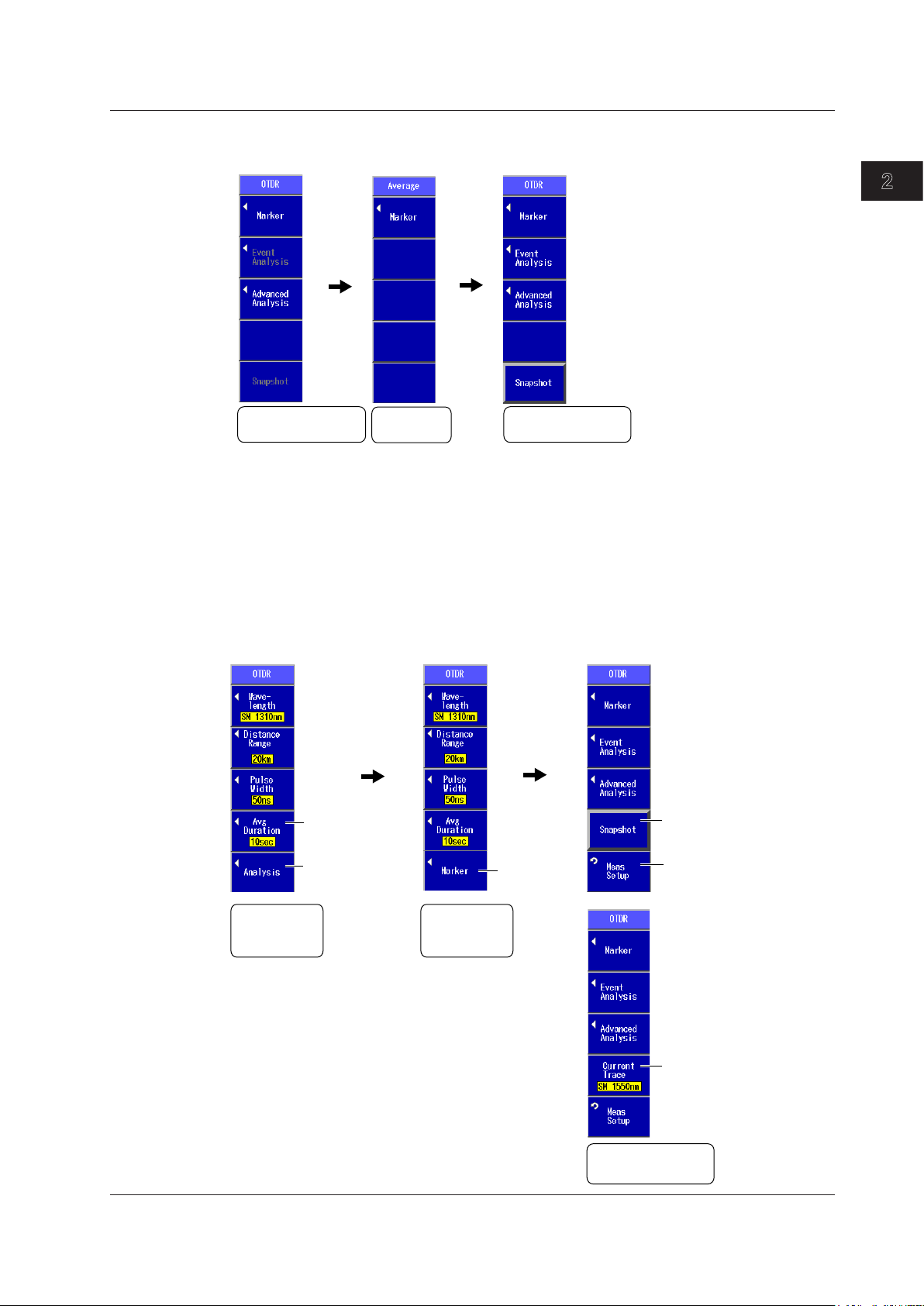

• OTDR Top Menu (during averaged measurement)

When not

measuring

During averaged

measurement

After averaged

measurement

[Detail mode]

• OTDR Top Menu (during real-time measurement)

When not

measuring

During real-time

measurement

After real-time

measurement

Average duration

command

(see section 3.5)

Switches to

waveform analysis

commands

Marker

command

Displays/clears

snapshot waveforms

Switches to measurement

condition setting commands

Multi WL mode

Switches the

displayed waveform

Measurement

Condition

Command

Measurement

Condition

Command

Waveform Analysis

Command

2.1 Top Screen

Common Operations

If the Suffix Code Is -HE

• The OTDR top menu will contain measurement condition setting commands.

The F4 soft key will show the average duration command.

The F5 soft key will show a command for switching to waveform analysis commands.

• During real-time measurement, measurement condition setting commands appear.

• When real-time measurement finishes, the menu will change to displaying waveform analysis

commands.

IM AQ1200-01EN

2-3

Page 31

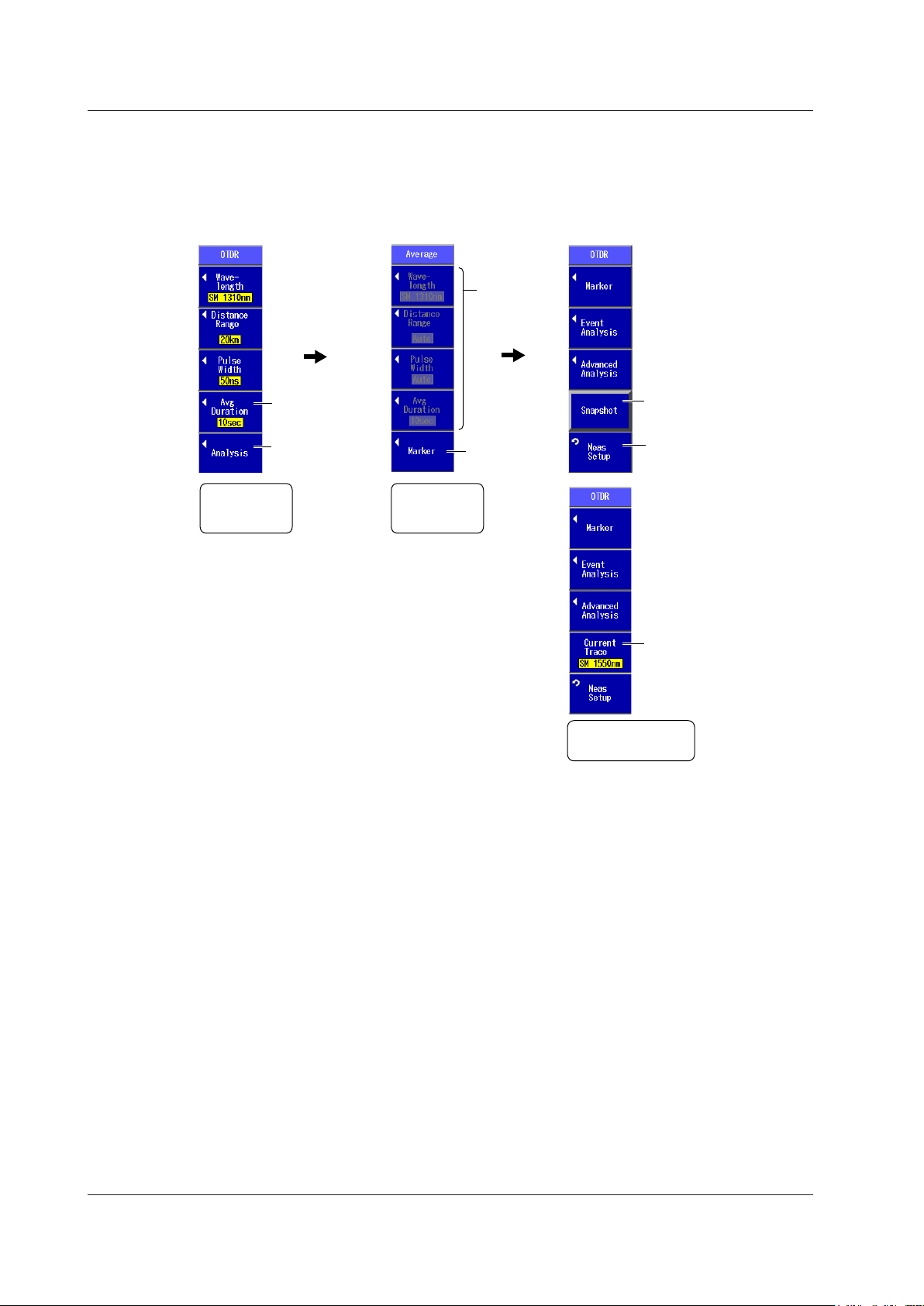

Detail mode

• OTDR Top Menu (during averaged measurement)

When not

measuring

During averaged

measurement

After averaged

measurement

Average duration

command

(see section 3.5)

Switches to

waveform analysis

commands

Marker

command

Displays/clears

snapshot waveforms

Switches to

measurement condition

setting commands

Multi WL mode

Switches the

displayed waveform

Measurement

Condition

Command

Measurement

Condition

Command

Waveform Analysis

Command

During

measurement,

the operation

can not be

perform.

2.1 Top Screen

• During averaged measurement, marker and measurement condition commands (cannot be used

during measurement) appear.

• When averaged measurement finishes, the menu will display waveform analysis commands.

2-4

IM AQ1200-01EN

Page 32

2

1

2.2 Key, Rotary Knob, and Arrow Key Operations

Below are the different types of menu

operations that you may encounter.

When you press a soft key,

the selected setting switches. The setting

changes each time you press the soft key.

a selection menu appears.

When you press a soft key that corresponds

to an option, the selected item is confirmed,

or the selected operation is executed.

the selected item is confirmed, or the

operation is executed.

Soft keys

MENU

MENU

ESC ESC

The settings that the soft keys are used to

configure and the actions that pressing them

cause are explained.

Options and ranges are listed afterwards.

Set the start point.

Set the start point marker to the cursor position.

Set the end point.

Set the end point marker to the cursor position.

Specify from markers.

When the and markers or the n and E

markers are already present, change these

markers to the start point and end point markers.

1 2

Press to configure more settings.

Change the reference point, or delete all the

specified markers from the displayed menu.

Set the approximation method (LSA, TPA).

Key Operations

Key operations are explained below using an example. Here we will examine the steps you would take

to select the section analysis menu from the top screen.

Use the rotary knob and ENTER to select OTDR. Or, press the OTDR soft key on the top

1.

menu.

The OTDR menu appears.

Press the Advanced Analysis soft key.

2.

The waveform analysis menu appears.

Press the Section Analysis soft key.

3.

The section analysis menu appears.

Common Operations

In this manual, the above key operation is described as shown below.

Example of an Explanation in This Manual

Use the rotary knob and ENTER to select OTDR.

1.

Press the Advanced Analysis soft key.

2.

Press the Section Analysis soft key. The following screen appears.

3.

Or

Press the

menu appears.

IM AQ1200-01EN

OTDR soft key > Advanced Analysis soft key > Section Analysis soft key. The following

2-5

Page 33

2.2 Key, Rotary Knob, and Arrow Key Operations

This manual explains procedures in accordance with the following guidelines.

• The following types of procedures are simplified.

- Repetitive operations.

- Detailed operations for proceeding to the desired setup menu or dialog box and information

about the accompanying screen changes.

• Step numbers are used in soft key explanations when there are many operations and when

operations must be performed in different menus.

The explanation for returning to the previous menu is omitted.

•

2-6

IM AQ1200-01EN

Page 34

2

1

To return to the top menu, press .

The item at the cursor location is highlighted.

Below are the different types of setup operations that you may encounter.

Pressing ENTER display a menu.

Each time you press ENTER, the selected setting switches.

Pressing ENTER displays a text box.

Pressing ENTER confirms the selected item or executes its corresponding

action.

• Using the rotary knob or the up and down arrow

keys, move the cursor to the item you want to select.

• Press ENTER to confirm the selected item.

• To reset the selected item to its previous setting, press

ESC.

• To increase or decrease a value, use the rotary

knob or the up and down arrow keys.

To move between digits, use the left and right

arrow keys.

• Press ENTER to confirm the entered value.

• To reset the selected item to its previous setting,

press ESC.

MENU

Performs zero set

Set the wavelength mode (Simple, Detail, CWDM).

Set the average count (1, 10, 50, 100).

Turns the display of the max/min value menu on and

off

Turns the interlocking of the light source and optical

power meter settings on and off

Set the offset (–9.900 to 9.900 dB).

Set the upper threshold value (–80.00 to 40.00 dB).

Set the lower threshold value (–80.00 to 40.00 dB).

The settings that the items are used to configure and the

actions that selecting them cause are explained.

Options and ranges are listed afterwards.

2.2 Key, Rotary Knob, and Arrow Key Operations

Rotary Knob and Arrow Key Operations

We will use the dialog box that appears when you press the OPM Setup soft key as an example to

explain the rotary knob and arrow key operations.

Press the OPN Setup soft key.

1.

The OPN Setup dialog box appears.

Use the rotary knob or the arrow keys to move the cursor to the item that you want to

2.

configure or execute.

The item at the cursor location is highlighted.

Press ENTER.

3.

Common Operations

In this manual, the above rotary and arrow key operations are described as shown below.

Example of an Explanation in This Manual

Press the OPN Setup soft key. The following screen appears.

This manual omits the following descriptions.

• How to operate the rotary knob, arrow key, and ENTER key

• How to reset the selected item to its previous setting

• How to return to the previous menu

IM AQ1200-01EN

2-7

Page 35

2.3 Shortcut Keys

Set the action that is executed when you press the

rotary knob.

(No action, file menu, print menu, scale menu, visible

light source menu, save, print, coarse/fine)

Set the action that is executed when you hold down

the SETUP key.

(No action, file menu, print menu, scale menu, visible

light source menu, save, print, coarse/fine, light

source menu)

Rotary knob indicator SETUP key indicator

An indicator that represents the action that has

been assigned to the SETUP key is displayed.

An indicator that represents the action that has

been assigned to the rotary knob is displayed.

If no action is assigned, nothing is displayed.

An indicator that represents

the setup status of the pulse

light output level is displayed.

An indicator that represents the setup

status of the marker approximation

method is displayed.

The AQ1200’s OTDR feature has a shortcut key feature. You can use the rotary knob and the SETUP

key as shortcut keys. You can assign actions to each shortcut key.

Using the rotary knob and ENTER, select OTDR.

1.

Press SETUP, the System Setup soft key, and then the OTDR soft key to display the following

2.

screen.

Note

• The shortcut feature is only enabled when you are operating the OTDR feature. Also, you can only make

shortcut assignments when you are using the OTDR feature.

• The shortcut feature does not function on the top screen.

• You can assign the same action to both the rotary knob and the SETUP key.

Status Indicators

The indicators that represent the following AQ1200 actions and statuses are displayed in the lowerright of the screen.

• The actions assigned to the rotary knob and the SETUP key

• Status of the pulse light output level

•

Status of the marker approximation method

2-8

IM AQ1200-01EN

Page 36

2

1

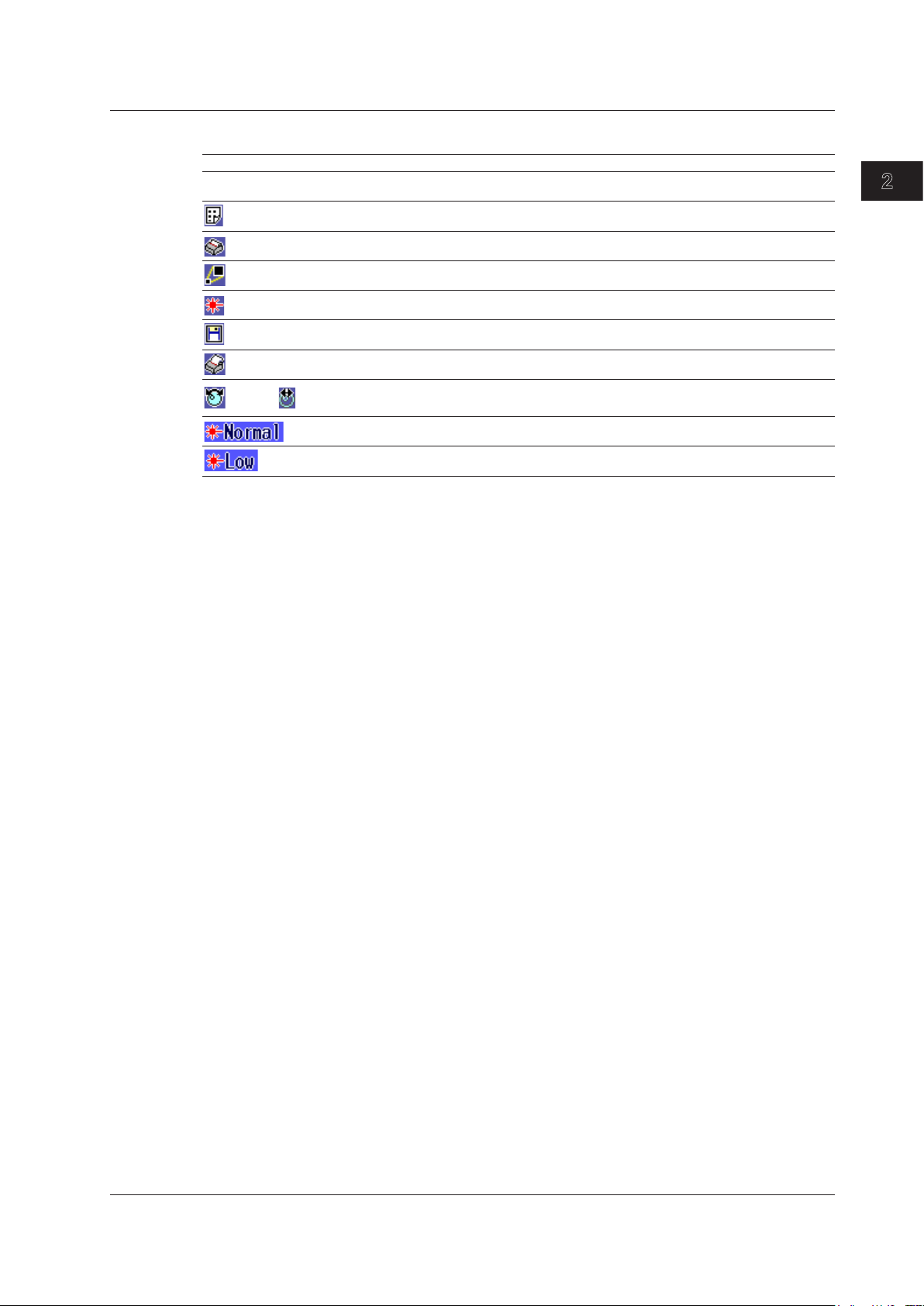

Meaning of the Status Indicators

Status Indicator Meaning

None No action assigned

Displays the file menu

Displays the print menu

Displays the scale menu

Displays the visible light source menu

Starts saving

Starts printing

Coarse / Fine

Switches the resolution between coarse and fine for the cursor movement that you control

by turning the rotary knob

Normal pulse light output level

Low pulse light output level

2.3 Shortcut Keys

Common Operations

IM AQ1200-01EN

2-9

Page 37

2.4 Entering Strings

Character input dialog box

Edit screen

Confirms

the input

SpaceSwitches between

uppercase and

lowercase letters

Keyboard

Input history

Strings that you have entered in the past remain in

the input history. You can enter these strings (see

the next page).

Moves the cursor to the left

Moves the cursor to the right

Deletes the previous character

Confirms the entered string

After you have selected a setup item and pressed ENTER, a character input dialog box will appear if it

is necessary. This section explains the operations that you can perform after the dialog box appears.

Entering Strings

Using the rotary knob and ENTER, enter a string. The string that you entered appears in the

1.

edit screen.

Press the various soft keys to edit the string as necessary.

2.

After you have finished entering and editing the string, press the OK soft key to confirm the

3.

string that you entered and close the character input dialog box. The string be applied to the

relevant item.

You can also confirm the string by moving the cursor to ENT on the displayed keyboard and then pressing

ENTER.

Note

• If there is a limit to the length of the string, you will not be able to enter characters after the limit is

reached.

• You can also enter strings using a USB keyboard.

2-10

IM AQ1200-01EN

Page 38

2

1

2.4 Entering Strings

Entering Strings from the History

Using the rotary knob and ENTER, select to display the input history screen.

1.

Using the rotary knob and ENTER, choose the string that you want to enter. The string

2.

appears in the edit screen.

Note

Entered strings are saved to the input history when you confirm them. Up to 50 strings can be saved. Newer

strings appear at the top of the input history.

Common Operations

IM AQ1200-01EN

2-11

Page 39

3

2

1

Set the measurement mode (Simple, Detail, Multi WL, PON).

The Multi WL option is not available on the AQ1200B

and AQ1200C.

Chapter 3

Optical Pulse Measurement and Analysis Conditions

3.1 Selecting the Measurement Mode

Procedure

Measurement Screen

Explanation

Simple Mode

In this mode, the absolute minimum amount of measurement conditions are set manually. You only

have to set the wavelength.

The following measurement conditions are set to the optimum values when measurement starts.

•

Distance range

• Pulse width

• Event search

The measurement conditions that are available when the

listed below. You can view these conditions in the measurement condition information (see section 5.1)

that is displayed on the screen.

Item Setup

Distance range Automatic

Pulse width Automatic

Attenuation Automatic

Duration to average over Automatic

Average method Hi-reflection

Average unit Time

Sample interval Standard

Using the rotary knob and ENTER, select OTDR.

1.

Press SETUP and then the Meas Setup soft key to display the following screen.

2.

AQ1200 is in Simple (Full Auto) mode are

Optical Pulse Measurement and Analysis Conditions

For the procedures to set the Simple mode measurement conditions, see sections 3.2 to 3.4.

Detail Mode

In this mode, all measurement conditions are set manually.

For the procedures to set the Detail mode measurement conditions, see sections 3.5 and 3.6.

Multi WL Mode

You can perform consecutive measurements over multiple wavelengths.

Depending on the AQ1200 model, the wavelengths that can be measured and the number of

waveforms that can be displayed vary.

For the procedures to set the Multi WL mode measurement conditions, see sections 3.5 and 3.6.

IM AQ1200-01EN

3-1

Page 40

Set the number of splitter stages (1, 2).

Image when the route is set to ONU -> OLT

Select the number of splits

from the following:

2, 4, 8, 16, 32, 64, 128

The maximum total number of

splits is 128.

Set the route (OLT -> ONU or ONU -> OLT).

The settings change to values

that are suitable for the

measurement of the specified

number of stages and splits.

You can also change the settings

according to your measurement

conditions.

3.1 Selecting the Measurement Mode

PON Mode

In PON mode, you can set the measurement route details such as the number of splitter splits and

measurement direction. In addition, an image of the specified route is displayed.

3-2

IM AQ1200-01EN

Page 41

3

2

1

3.2 Selecting the Wavelength

Set Mode to “Simple.”

Set the wavelength .

The available options vary depending on the model.

For details, see the explanation in section 3.5.

<Simple (Full Auto) Mode>

Procedure

Measurement Screen

Explanation

Selecting the Measurement Wavelength

For details, see “Explanation” in section 3.5.

Using the rotary knob and ENTER, select OTDR.

1.

Press SETUP and then the Meas Setup soft key.

2.

Using the rotary knob and ENTER, set Mode to Simple to display the following screen.

3.

Optical Pulse Measurement and Analysis Conditions

IM AQ1200-01EN

3-3

Page 42

3.3 Automatically Saving Measured Data

Turns automatic saving of the measured result on or off

Set Mode to “Simple.”

<Simple (Full Auto) Mode>

Procedure

Measurement Screen

Using the rotary knob and ENTER, select OTDR.

1.

Press SETUP and then the Meas Setup soft key.

2.

Using the rotary knob and ENTER, set Mode to Simple to display the following screen.

3.

Explanation

Automatically Saving the Measured Results

For details, see “Explanation” in section 3.5.

3-4

IM AQ1200-01EN

Page 43

3

2

1

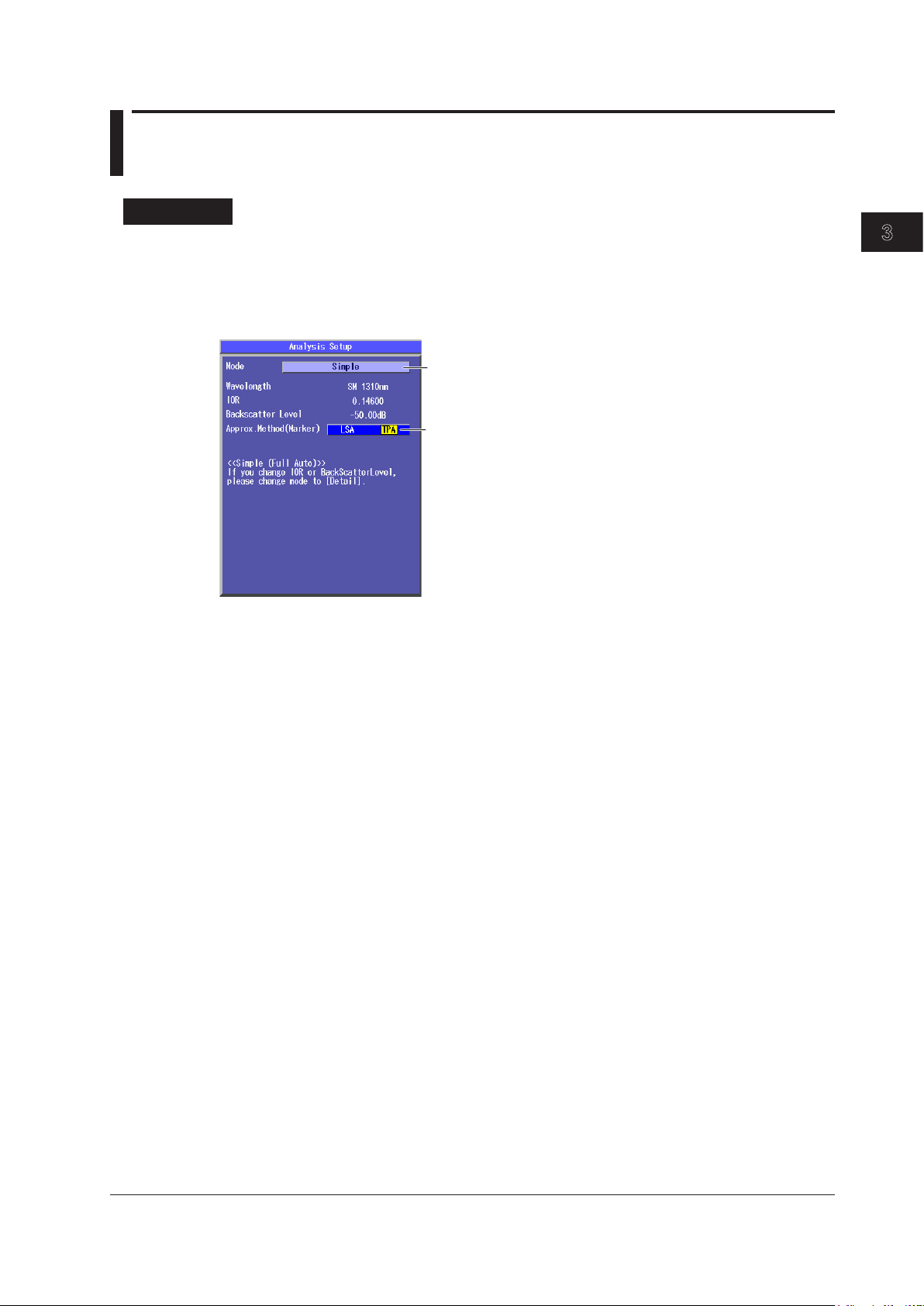

3.4 Selecting the Approximation Method (Marker)

Set the approximation method (LSA, TPA).

Set Mode to “Simple.”

<Simple (Full Auto) Mode>

Procedure

Analysis Setup Screen

Using the rotary knob and ENTER, select OTDR.

1.

Press SETUP and then the Analysis Setup soft key.

2.

Using the rotary knob and ENTER, set Mode to Simple to display the following screen.

3.

Approximation Method (Marker)

For details, see section 3.6.

Optical Pulse Measurement and Analysis Conditions

IM AQ1200-01EN

3-5

Page 44

3.5 Setting Measurement Conditions

Set the average method (Hi-Speed, Hi-Reflection).

Set the average unit (Times, Duration).

Set the event search (Auto, Manual).

Turns the fiber-in-use alarm on or off

Turns the plug check on or off

Initializes the settings

Press to reset the settings

to their factory defaults.

Set Mode to “Detail” or “Multi WL.”

The Multi WL option is not available on the AQ1200B and AQ1200C.

Set the distance range (Auto, 500m, 1km, 2km, 5km, 10km, 20km, 50km, 100km,

200km, 300km, 400km, 512km).

Set the pulse width (Auto, 3ns, 10ns, 20ns, 50ns, 100ns, 200ns, 500ns, 1µs,

2µs, 5µs, 10µs, 20µs).

Set the attenuation (Auto, 0.00dB, 2.50dB, 5.00dB, 7.50dB, 10.00dB,

12.50dB, 15.00dB, 17.50dB, 20.00dB, 22.50dB, 25.00dB, 27.50dB, 30.00dB).

Set the sample interval (Normal, High Resolution, 5cm, 10cm,

20cm, 50cm, 1m, 2m, 4m, 8m, 16m, 32m).

Set the average count or the duration to average over.

• When the unit is times:

(Auto, 2^10, 2^11, 2^12, 2^13, 2^14, 2^15, 2^16, 2^17, 2^18,

2^19, 2^20)