Page 1

User's

Manual

Model AE14

Magnetic Flow Converter

[Style:S1]

IM 1E7C1-E

IM 1E7C1-E

13th Edition

Page 2

CONTENTS

Contents

1. INTRODUCTION ................................................................................................... 1-1

2. HANDLING PRECAUTIONS...............................................................................2-1

2.1 Checking Model and Specifications ................................................................ 2-1

2.2 Accessories ...................................................................................................... 2-1

2.3 Storage Precautions ......................................................................................... 2-1

2.4 Installation Location Precautions .................................................................... 2-1

3. INSTALLATION ..................................................................................................... 3-1

3.1 Installing Magnetic Flow Converter ................................................................ 3-1

3.2 Wiring Precautions .......................................................................................... 3-1

3.2.1 Protective Grounding............................................................................... 3-1

3.2.2 General Precautions ................................................................................. 3-1

3.2.3 Cable Types.............................................................................................. 3-2

3.2.4 DC Connections....................................................................................... 3-3

3.2.5 Wiring Ports............................................................................................. 3-3

3.2.6 Connecting to External Instruments ........................................................ 3-4

4. BASIC OPERATING PROCEDURES.................................................................. 4-1

4.1 Liquid Crystal Display..................................................................................... 4-1

4.2 Types of Display Data ..................................................................................... 4-2

4.2.1 Flow Rate Data Display Mode................................................................. 4-3

4.2.2 Setting Mode............................................................................................ 4-6

4.2.3 Alarm Display Mode ............................................................................... 4-9

5. FUNCTION AND DATA SETTINGS....................................................................5-1

5.1 Setting Nominal Size ...................................................................................... 5-2

5.2 Setting Flow Span............................................................................................ 5-3

5.3 Setting Meter Factor ........................................................................................ 5-6

5.4 Power Frequency (For DC version only) ......................................................... 5-7

5.5 Other Functions and Settings........................................................................... 5-7

5.5.1 Pulse Output............................................................................................. 5-7

5.5.2 Display of Internal Totalization Values.................................................... 5-9

5.5.3 Resetting for Totalization Display ......................................................... 5-10

5.5.4 Damping Time Constant........................................................................ 5-10

5.5.5 Current Output During Alarm Occurrence ............................................ 5-11

5.5.6 Reversing Flow Direction ...................................................................... 5-11

5.5.7 Limiting Current Output ........................................................................ 5-11

5.5.8 Forward and Reverse Flow Measurement ............................................. 5-13

5.5.9 Automatic Two Range Switching .......................................................... 5-14

5.5.10 Alarm Output at Low Flow Limit (Flow Switch) .................................. 5-15

5.5.11 Totalization Switch Output .................................................................... 5-16

5.5.12 Alarm Output ......................................................................................... 5-17

5.5.13 Data Setting Enable / Inhibit.................................................................. 5-17

5.5.14 Procedure of Selecting Special Application Items................................. 5-18

5.5.15 Rate Limit .............................................................................................. 5-18

5.5.16 Pulsating Flow ....................................................................................... 5-19

FD No. IM 1E7C1-E

13th Edition: Dec., 2003(YK)

All Rights Reserved, Copyright © 1994, Yokogawa Electric Corporation

i

Page 3

CONTENTS

6. OPERATION VIA BRAIN TERMINAL .............................................................. 6-1

6.1 Operation Via the BT200 ................................................................................. 6-1

6.1.1 BT200 Connections ................................................................................. 6-1

6.1.2 BT200 Keypad Layout............................................................................. 6-2

6.1.3 Major BT200 Key Functions ................................................................... 6-3

6.1.4 Displaying Flow Rate Data...................................................................... 6-5

6.2 Setting Parameters ........................................................................................... 6-6

6.2.1 Setting Nominal Size ............................................................................... 6-6

6.2.2 Setting Flow Span Via the BT200............................................................ 6-7

6.2.3 Setting Meter Factor ................................................................................ 6-8

6.2.4 Power Frequency ..................................................................................... 6-9

6.2.5 Pulse Output (Refer to 5.5.1) ................................................................... 6-9

6.2.6 Display of Internal Totalization Values (Refer to 5.5.2) ........................ 6-10

6.2.7 Resetting for Totalization Display (Refer to 5.5.3) ............................... 6-10

6.2.8 Damping Time Constant (Refer to 5.5.4) .............................................. 6-11

6.2.9 Current Output during Alarm Occurrence (Refer to 5.5.5) ................... 6-11

6.2.10 Reversing Flow Direction(Refer to 5.5.6) ............................................. 6-11

6.2.11 Limiting Current Output (Refer to 5.5.7) .............................................. 6-11

6.2.12 Forward and Reverse Flow Measurement (Refer to 5.5.8) .................... 6-12

6.2.13 Automatic Two Range Switching (Refer to 5.5.9) ................................ 6-13

6.2.14 Alarm Output at Low Flow Limits (Flow Switch) (Refer to 5.5.10) ..... 6-13

6.2.15 Totalization Switch Output (Refer to 5.5.11) ........................................ 6-14

6.2.16 Alarm Output (Refer to 5.5.12) ............................................................. 6-14

6.2.17 Data Setting Enable / Inhibit (Refer to 5.5.13)...................................... 6-15

6.2.18 Procedure of Selecting Special Application Items (Refer to 5.5.14) ..... 6-15

6.2.19 Rate Limit (Refer to 5.5.15) .................................................................. 6-15

6.2.20 Pulsating Flow (Refer to 5.5.16)............................................................ 6-15

6.2.21 User-Defined Units Via the BT200........................................................ 6-16

6.2.22 Other Important Points to Note.............................................................. 6-17

7. ACTUAL OPERATION.......................................................................................... 7-1

7.1 Pre-Operation Zero Adjustment....................................................................... 7-1

7.1.1 Zero Adjustment Using Data Setting Keys .............................................. 7-1

7.1.2 Zero Adjustment Via the BT200.............................................................. 7-2

7.2 Self-diagnostics Functions............................................................................... 7-3

7.2.1 Display and Output Status during Alarm Occurrence ............................. 7-3

7.2.2 Error Description and Countermeasures.................................................. 7-3

8. MAINTENANCE .................................................................................................... 8-1

8.1 Loop Test (Test Output)................................................................................... 8-1

8.1.1 Settings for Test Output Using Data Setting Keys................................... 8-1

8.1.2 Setting for Test Output Via the BT200 .................................................... 8-1

8.2 Fuse Replacement............................................................................................ 8-2

8.3 Trouble Shooting ............................................................................................. 8-2

9. OUTLINE................................................................................................................. 9-1

10. PARAMETER SUMMARY ................................................................................. 10-1

ii

IM 1E7C1 -E

Page 4

CONTENTS

11. EXPLOSION PROTECTED TYPE INSTRUMENT ........................................ 11-1

11.1 ATEX Directive ............................................................................................. 11-1

11.2 FM ................................................................................................................. 11-2

11.3 CSA ............................................................................................................... 11-2

11.4 SAA ............................................................................................................... 11-3

iii

IM 1E7C1 -E

Page 5

1. INTRODUCTION

NOTE

1. INTRODUCTION

This instrument has been already adjusted at the

factory before shipment.

To ensure correct use of the instrument, please read

this manual thoroughly and fully understand how to

operate the instrument before operating it.

Regarding This Manual

•This manual should be passed on to the end user.

• Before use, read this manual thoroughly to comprehend its contents.

• The contents of this manual may be changed

without prior notice.

• All rights reserved. No part of this manual may be

reproduced in any form without Yokogawa’s written

permission.

•Yokogawa makes no warranty of any kind with

regard to this material, including, but not limited to,

implied warranties of merchantability and suitability

for a particular purpose.

• All reasonable effort has been made to ensure the

accuracy of the contents of this manual. However, if

any errors are found, please inform Yokogawa.

• Yokogawa assumes no responsibilities for this

product except as stated in the warranty.

• If the customer or any third party is harmed by the

use of this product, Yokogawa assumes no responsibility for any such harm owing to any defects in the

product which were not predictable, or for any

indirect damages.

The following safety symbol marks are used in

this manual and instrument;

WARNING

A WARNING sign denotes a hazard. It calls

attention to procedure, practice, condition or the

like, which, if not correctly performed or adhered

to, could result in injury or death of personnel.

CAUTION

A CAUTION sign denotes a hazard. It calls

attention to procedure, practice, condition or the

like, which, if not correctly performed or adhered

to, could result in damage to or destruction of

part or all of the product.

IMPORTANT

A IMPORTANT sign denotes an attention to

avoid leading to damage to instrument or system

failure.

Safety Precautions

• The following general safety precautions must be

observed during all phases of operation, service, and

repair of this instrument. Failure to comply with

these precautions or with specific WARNINGS

given elsewhere in this manual violates safety

standards of design, manufacture, and intended use

of the instrument. YOKOGAWA Electric Corporation assumes no liability for the customer’s failure to

comply with these requirements. If this instrument is

used in a manner not specified in this manual, the

protection provided by this instrument may be

impaired.

A NOTE sign denotes a information for essential

understanding of the operation and features.

Protective grounding terminal.

Function grounding terminal. This terminal

should not be used as a “Protective grounding

terminal”.

Alternating current.

Direct current.

1-1

IM 1E7C1-E

Page 6

1. INTRODUCTION

Warranty

• The guaranteed term of this instrument is described

in the quotation. We repair the damages that

occurred during the guaranteed term for free.

• Please contact with our sales office when this

instrument is damaged.

• If the instrument has trouble, please inform us

model code, serial number, and concrete substances

or situations. It is preferable to be attached a outline

or data.

• We decide after the examination if free repair is

available or not.

• Please consent to the followings for causes of

damages that are not available as free repair, even if

it occured during the guaranteed term.

A:Unsuitable or insufficient maintenance by the

customer.

B: The handling, using, or storage that ignore the

design and specifications of the instrument.

C: Unsuitable location that ignore the description in

this manual.

D:Remaking or repair by a person except whom we

entrust.

E: Unsuitable removing after delivered.

F: A natural disaster (ex. a fire, earthquake, storm and

flood, thunderbolt) and external causes

For Safety Using

For safety using the instrument, please give attention

mentioned below.

WARNING

(1) Installation

• The instrument must be installed by expert

engineer or skilled personnel. The procedures

described about INSTALLATION are not

permitted for operators.

• The Magnetic Flowmeter is a heavy instrument.

Please give attention to prevent that persons

are injured by carrying or installing. It is preferable for carrying the instrument to use a cart

and be done by two or more persons.

• In case of high process temperature, care

should be taken not to burn yourself because

the surface of body and case reach a high

temperature.

• When removing the instrument from hazardous

processes, avoid contact with the fluid and the

interior of the flow tube.

• All installation shall comply with local installation requirement and local electrical code

(2) Wiring

• The instrument must be installed by expert

engineer or skilled personnel. The procedures

described about WIRING are not permitted for

operators.

•Please confirm voltages between the power

supply and the instrument before connecting

the power cables. And also, please confirm

that the cables are not powered before connecting.

• The protective grounding must be connected to

the terminal in order to avoid personal shock

hazard.

(3) Operation

• Wait 10 min. after power is turned off, before

opening the covers.

(4) Maintenance

•Please do not carry out except being written to

a maintenance descriptions. When these

procedures are needed, please contact to

nearest YOKOGAWA office.

• Care should be taken to prevent the build up of

drift, dust or other material on the display glass

and data plate. In case of its maintenance, soft

and dry cloth is used.

(5) Explosion Protected Type Instrument

• For explosion proof type instrument, the

description in Chapter 11 “EXPLOSION

PROTECTED TYPE INSTRUMENT” is prior to

the other description in this user's manual.

• Only trained persons use this instrument in the

industiral location.

• The protective grounding must be connected

to a suitable IS grounding system.

• Take care not to generate mechanical spark

when access to the instrument and peripheral

devices in hazardous locations.

1-2

IM 1E7C1-E

Page 7

1. INTRODUCTION

ATEX Documentation

This procedure is only applicable to the countries in

European Union.

GB

All instruction manuals for ATEX Ex related products

are available in English, German and French. Should

you require Ex related instructions in your local

language, you are to contact your nearest Yokogawa

office or representative.

DK

Alle brugervejledninger for produkter relateret til

ATEX Ex er tilgængelige på engelsk, tysk og fransk.

Skulle De ønske yderligere oplysninger om håndtering

af Ex produkter på eget sprog, kan De rette

henvendelse herom til den nærmeste Yokogawa

afdeling eller forhandler.

I

Tutti i manuali operativi di prodotti ATEX

contrassegnati con Ex sono disponibili in inglese,

tedesco e francese. Se si desidera ricevere i manuali

operativi di prodotti Ex in lingua locale, mettersi in

contatto con l’ufficio Yokogawa più vicino o con un

rappresentante.

E

Todos los manuales de instrucciones para los productos

antiexplosivos de ATEX están disponibles en inglés,

alemán y francés. Si desea solicitar las instrucciones de

estos artículos antiexplosivos en su idioma local,

deberá ponerse en contacto con la oficina o el

representante de Yokogawa más cercano.

NL

Alle handleidingen voor producten die te maken

hebben met ATEX explosiebeveiliging (Ex) zijn

verkrijgbaar in het Engels, Duits en Frans. Neem,

indien u aanwijzingen op het gebied van

explosiebeveiliging nodig hebt in uw eigen taal, contact

op met de dichtstbijzijnde vestiging van Yokogawa of

met een vertegenwoordiger.

SF

Kaikkien ATEX Ex -tyyppisten tuotteiden käyttöhjeet

ovat saatavilla englannin-, saksan- ja ranskankielisinä.

Mikäli tarvitsette Ex -tyyppisten tuotteiden ohjeita

omalla paikallisella kielellännne, ottakaa yhteyttä

lähimpään Yokogawa-toimistoon tai -edustajaan.

P

Todos os manuais de instruções referentes aos produtos

Ex da ATEX estão disponíveis em Inglês, Alemão e

Francês. Se necessitar de instruções na sua língua

relacionadas com produtos Ex, deverá entrar em

contacto com a delegação mais próxima ou com um

representante da Yokogawa.

F

Tous les manuels d’instruction des produits ATEX Ex

sont disponibles en langue anglaise, allemande et

française. Si vous nécessitez des instructions relatives

aux produits Ex dans votre langue, veuillez bien

contacter votre représentant Yokogawa le plus proche.

D

Alle Betriebsanleitungen für ATEX Ex bezogene

Produkte stehen in den Sprachen Englisch, Deutsch

und Französisch zur Verfügung. Sollten Sie die

Betriebsanleitungen für Ex-Produkte in Ihrer

Landessprache benötigen, setzen Sie sich bitte mit

Ihrem örtlichen Yokogawa-Vertreter in Verbindung.

S

Alla instruktionsböcker för ATEX Ex (explosionssäkra)

produkter är tillgängliga på engelska, tyska och

franska. Om Ni behöver instruktioner för dessa

explosionssäkra produkter på annat språk, skall Ni

kontakta närmaste Yokogawakontor eller representant.

GR

ATEX Ex

, .

Ex

Yokogawa .

1-3

IM 1E7C1-E

Page 8

2. HANDLING PRECAUTIONS

2. HANDLING PRECAUTIONS

This instrument has been already tested thoroughly at

the factory. When the instrument is delivered, please

check externals and make sure that no damage

occurred during transportation.

In this chapter, handling precautions are described.

Please read this chapter thoroughly at first. And please

refer to the relative matter about other ones.

If you have any problems or questions, please make

contact with Yokogawa sales office.

2.1 Checking Model and Specifications

The model and specifications are shown on the Data

Plate. Please confirm the specifications between the

instrument that was delivered and the purchase order

(refer to the chapter 10. Outline).

Please let us know Model and Serial No. when making

contact with Yokogawa sales office.

• Plug (for DC power supply only) : 1-piece

• Hexagonal wrench : 1-piece

(for special screw of hazardous duty type converter.)

2.3 Storage Precautions

In case the instrument is expected to be stored over a

long term, please give attention to the followings;

• The instrument should be stored in its original

packing condition.

• The storage location should be selected according to

the following conditions:

1) The location where it is not exposed to rain or

water.

2) The location where there is few vibration or

shock.

3) Temperature and humidity should be:

Temperature: –20 to 60˚C (–4 to 140˚F)

Humidity: 5 to 80% RH (no condensation)

Preferable ambient temperature and humidity

are 25˚C(77˚F) and about 65% RH.

MAGNETIC FLOW

CONVERTER

MODEL

SUFFIX

STYLE

SUPPLY

CURRENT

OUTPUT

PULSE

OUTPUT

AMB.TEMP.

NO.

Figure 2.1 Data Plate

V AC~47–63Hz 36VA 12.5W

V DC 12.5W

4 - 20mA

(0 - 750Ω)

30V DC 0.2 Amax

–20~60 °C

Made in Japan

N200

2.2 Accessories

When the instrument is delivered, please make sure

that the following accessories are in the package.

Spare fuse can be applied only to this product.

• Fuse (250V,2A time lag) : 1-piece

*The spare fuse is taped to the converter.

•Mounting hardware

•Data sheet : 1-sheet

• Unit labels : 1-sheet

2.4 Installation Location Precautions

Please select the installation location considering the

following items to ensure long term stable operation of

the flow tube.

• Ambient Temperature:

Please avoid to install the instrument at the location

where temperature changes continuously. If the

location receives radiant heat from the plant, provide

heat insulation or improve ventilation.

•Atmospheric Condition:

Please avoid to install the instrument in an corrosive

atmosphere. In case of installing in the corrosive

atmosphere, please keep ventilating sufficiently and

prevent rain from entering the conduit.

•Vibration or shock:

Please avoid to install the instrument at the location

where there is heavy vibration or shock.

2-1

IM 1E7C1-E

Page 9

3. INSTALLATION

3. INSTALLATION

WARNING

This instrument must be installed by expert

engineer or skilled personnel. The procedures

described in this chapter are not permitted for

operators.

3.1 Installing Magnetic Flow Converter

A signal cable (AM011) is used between the remote

type flow tube and the converter. The maximum signal

cable length is 30m (98ft).

The converter is mounted on a 2 inch (60.5mm outer

dia.) vertical or horizontal pipe. See Figure 3.1.1

Vertical Mounting

2-inch pipe

U-Bolt

3.2 Wiring Precautions

CAUTION

Please confirm that all conncetions are correct

before applying power to the instrument.

Improper wiring may damage the flowmeter.

The external signal wirings are connected into the

terminal inside the converter. Please connect to each

terminal (Please refer to Figure 3.2.1) by taking off a

cover backside the converter.

Excitation Cable

Dedicated Cable

AM011-4

A

B

C

Converter AE14

Converter

Terminals

A

B

C

(See NOTE below)

(See NOTE below)

SA

EX2

EX1

SB

Ex1

Ex2

NOTE : Terminate those shielding wire

terminals using tape.

Power supply

Protective ground

4 to 20 mA DC output

Pulse or alarm output

Flow Tube

AE***D

A

B

C

Ex1

Ex2

Bracket

Horizontal Mounting

Nut

Bracket

2-inch pipe

Figure 3.1.1 Magnetic Flow Converter Installation

Nut

U-Bolt

Figure 3.2.1 Wiring

3.2.1 Protective Grounding

CAUTION

Please be sure to connect protective grounding

of ADMAG AE with cable of 2mm2 or larger

cross section in order to avoid the electrical

shock to the operators and maintenance engineers and prevent the influence of external

noise. And further connect the grounding wire to

the mark (100Ω or less).

3.2.2 General Precautions

Please give attention to the followings in wiring.

3-1

IM 1E7C1-E

Page 10

3. INSTALLATION

NOTE

CAUTION

• Please pay attention to avoid the cable is

bended excessively.

• Please do not connect cables outdoors in case

of rain to prevent damages from dew formation

and to keep insulation inside the terminal box

of the flowmeter.

• The all cable ends are to be provided with

round crimp-on terminal.

•The power cables and signal cables must be

routed in separate steel conduit tubes or

flexible tubes.(except 4-core 24VDC cable

wiring.)

• When waterproof glands, union equipped

waterproof glands are used, the glands must be

properly tightened to keep the box watertight.

•Please install a external switch or circuit

breaker as a means of power off (capacitance;

15A, conform to IEC947-1 and IEC947-3). The

preferable location is either near the instrument

or other places to easy operation. Furthermore, please indicate "power off equipment" on

the those external switch or circuit breaker.

•Please be sure to fully tighten the terminal box

cover before the power is turned on.

•Please be sure to turn off the power before

opening the terminal box cover.

• In case of DC power supply, a plug is attached.

When 4-core cable is used, please put that

plug into unused electrical connection port.

3.2.3 Cable Types

(1) Dedicated Signal Cable(AM011)

The flow signal is transmitted via this dedicated cable.

The cable is constructed with double shielding over the

two conductors, and used heat-resistant vinyl as the

outer jacket material.

IMPORTANT

If the cable is longer than required, cut off any

extra length, rather coiling it up, and terminate

the conductors as shown in Figure 3.2.3. Avoid

using intermediate terminal boards to extend the

cable length, or this will interrupt the shielding.

ACB

SA

On the converter

Figure 3.2.3 Treatment of Dedicated Signal Cable

25 (0.98)

(WHITE) (BLACK) (RED)

side

150

(5.9)

SB

50 (1.97)

8 (0.3) Max.

20 (0.8)

70 (2.76)

80 (3.15)

L (SPECIFIED LENGTH)

AM011*A

ACB

55 (2.2)

90 (3.5)

(WHITE) (BLACK) (RED)

8 (0.3) Max.

150

(5.9)

On the flow tube

ø10.5 (0.4)

F030203.EPS

CAUTION

Since A, B, SA, SB, and C all operate at different electrical potentials, securely insulate them

from each other so they do not touch.

The shields must not be allowed to touch each

other or to touch the case.

Cover each shield with vinyl tube or wrap in vinyl

tape.

90 (3.5)

side

Finished diameter: 10.5 mm (0.413”)

Maximum length: 30 m (98 ft)

Maximum temperature: 80°C (176°F)

Figure 3.2.2 Dedicated Signal Cable AM011

Conductors A and B carry the signal from the

electrodes, and C is at the potentials of the liquid

it self (signal common) . Shields SA and SB are

kept at the same potentials as the individual

electrodes (these are actively driven shields).

This is done to reduce the effect of the distributed capacitance of the cable at long cable

length. Note that, since the signals from the

individual electrodes are impedance converted

inside the converter, errors will result if they

come in contact with any other component.

Great care must be taken in the cable end

treatment.

3-2

IM 1E7C1-E

Page 11

3. INSTALLATION

(2) Power, Excitation, or Output Cable

Power Cable

• Crimp-on Terminal

• Green/Yellow covered conductors shall be used only

for connection to PROTECTIVE CONDUCTOR

TERMINALS.

• Conform to IEC277 or IEC245 or equivalent

national authorization.

Excitation or Output Cable

•Please use Polyvinyl chloride insulated and sheathed

control cables (JIS C3401) or Polyvinyl chloride

insulated and sheathed portable power cables (JIS

C3312) or equivalents.

Outer Diameter

• 6.5 to 12mm in diameter (10.5 to 11.5 mm for

waterproof gland / ECG, /ECU)

Nominal Cross Section

•Single wire; 0.5 to 2.5mm2 , Stranded wire; 0.5 to

2

2.5mm

EX1

EX2

(2.4)

60

85

(3.3)

EX1

Unit: mm (inch)

EX2

Supply Voltage and Cable Length

20

22

24

Usable range E(V)

26

2

28

Cable cross section area : 2mm

Allowed

cable

length

m(ft)

1000

(3300)

900

(2970)

800

(2640)

700

(2310)

600

(1980)

500

(1650)

400

(1320)

300

(990)

200

(660)

100

(330)

0

Cable cross section area : 1.25mm

(3)Setting Power Supply Frequency

IMPORTANT

In case of DC power supply, the frequency of

the power supply has to be adjusted. Please

adjust for the local power frequency. The power

supply frequency is set in parameter B12 (or

Power freq for HART). Refer to 5.4 or 6.2.4 for

data setting procedure.

3.2.5 Wiring Ports

2

On the converter side On the flow tube side

Figure 3.2.4 End Treatment of Excitation Cable

3.2.4 DC Connections

(1)Connecting Power Supply

IMPORTANT

In case of 24VDC power supply, AC power

supplies or reversed polarities cannot be connected. It will cause the fuse to burn out.

(2)Supplied Voltage Rating for 24VDC

IMPORTANT

In case of 24VDC power supply, the specification for the supply voltage is 24VDC (-15 to

+20%), but the input voltage of the converter

drops due to cable resistance so it should be

used within the following range.

Please select the most suitable standard of wiring

procedure for the wiring ports by customer’s own.

(1)Using the Waterproof Gland

IMPORTANT

To prevent water or condensate from entering

the converter housing, waterproof glands are

recommended. Do not over-tighten the glands or

damage to the cables may result. Tightness of

the gland can be checked by confirming that the

cable is held firmly in place.

Waterproof gland

Optional specification

cade : / ECG

Gasket

Tightening gland

Figure 3.2.5 Waterproof Gland

Waterproof gland with union

joint Optional specification

cade : / ECU

JIS G 1/2

Washer

Tightening gland

JIS G 1/2

Gasket

3-3

IM 1E7C1-E

Page 12

3. INSTALLATION

(2)Conduit Wiring

In case of conduit wiring, please use the waterproof

gland to prevent water flowing through the conduit

pipe into the wiring connection.

Please slope the conduit pipe down, and install a drain

valve at the low end of the vertical pipe.

Please open the drain valve regularly.

Figure 3.2.6 Conduit Wiring

3.2.6 Connecting to External Instru-

ments

CAUTION

All the devices to be connected to current

output and pulse output must be conformed to

CSA1010, CSA950, or IEC950.

• In case of input impedance of electric counter is

large inductive noise from power supply bring

bad influence to measurement. To calculate

correctly, it is recommended to use shield cable

or to make input impedance small enough within

the limits of pulse output of flowmeter.

AE 14

PULSE OUT

AE 14

PULSE OUT

Figure 3.2.8 Pulse Output Connection

P +

P –

P +

P –

30 V DC, 0.2A. max

Protective diode

Mechanical counter

Load

Electronic counter or Universal counter

(3)Alarm Output

IMPORTANT

This is a transistor contact(insulated type) so

attention must be paid to voltage and polarity

when making connections.

This output can not switch an AC load. To do

this, another relay (see the figure below) is

required.

* The alarm output works from "close"(Normal) to

"open"(Alarm).

(1)Analog Signal Output(4 to 20mADC)

I +

AE 14

I –

Figure 3.2.7 Connection for Analog Singal Output

Receiving instrument

Load resistance max 750Ω

(max.600Ω for BRAIN Communication)

(2)Pulse Output

IMPORTANT

Please give attention to voltage and polarity in

wiring, because it is transister contact (insulation type).

•In case of the filtering constant of Electric

Counter is more than the pulse width, it makes

signal decreases and can not be calculated

correctly.

AE 14

AE 14

Figure 3.2.9 Contact Output Connection

P+

Load

P–

This connection cannot be made.

P+

External

P–

Power supply

30 V DC, 0.2A. max

3-4

Protective diode

Magnetic

AC power supply

valve

IM 1E7C1-E

Page 13

4. BASIC OPERATING PROCEDURES

4. BASIC OPERATING PROCEDURES

All data settings can be performed with the three keys on the front panel (SET, SHIFT and

INC) or using a handheld BRAIN (BT) terminal.

The following sections describe basic data configurations and how to use the three panel

keys. (See chapter 6 for information on BT operations.)

4.1 Liquid Crystal Display

Figure 4.1 shows the configuration of the ADMAG AE display panel (if equipped).

(The figure shows display when fully lit)

(1) LED (red)

Normal operation : off

During alarm: flashes

(2) Delimiter

(4) Unit Label Location

(5) Data Display

(6) Decimal Points

(7) Setting Keys

(3) Unit Display

Units displayed:

l : liter

gal : gallon

3

: cubic meters

m

/h: hour

/m: minute

If other units are to be used,

attach labels giving the specific unit.

l gal m3 /h /m

SET

SHIFT

%

INC

Figure 4.1 Configuration of Display

(1) LED (red) : This LED is off during normal operation and flashes when an

alarm condition has occurred.

(2) Delimiter : The delimiter " : " (colon) indicates that the displayed data is in

setting mode.

(3) Unit Display : Displays flow rate units. In order to display other units, the

required unit label should be selected from the provided data

sheets and attached as shown.

(4) Unit Label Location : To display units not on the LCD, select the required label from

the provided data sheets and attach it here.

(5) Data Display : Displays flow rate data, setting data and type of alarm gener-

ated.

(6) Decimal Point : Displays decimal point in the data.

(7) Setting Keys : These keys are used to change flow rate data displays and type

of setting data.

4-1

IM 1E7C1-E

Page 14

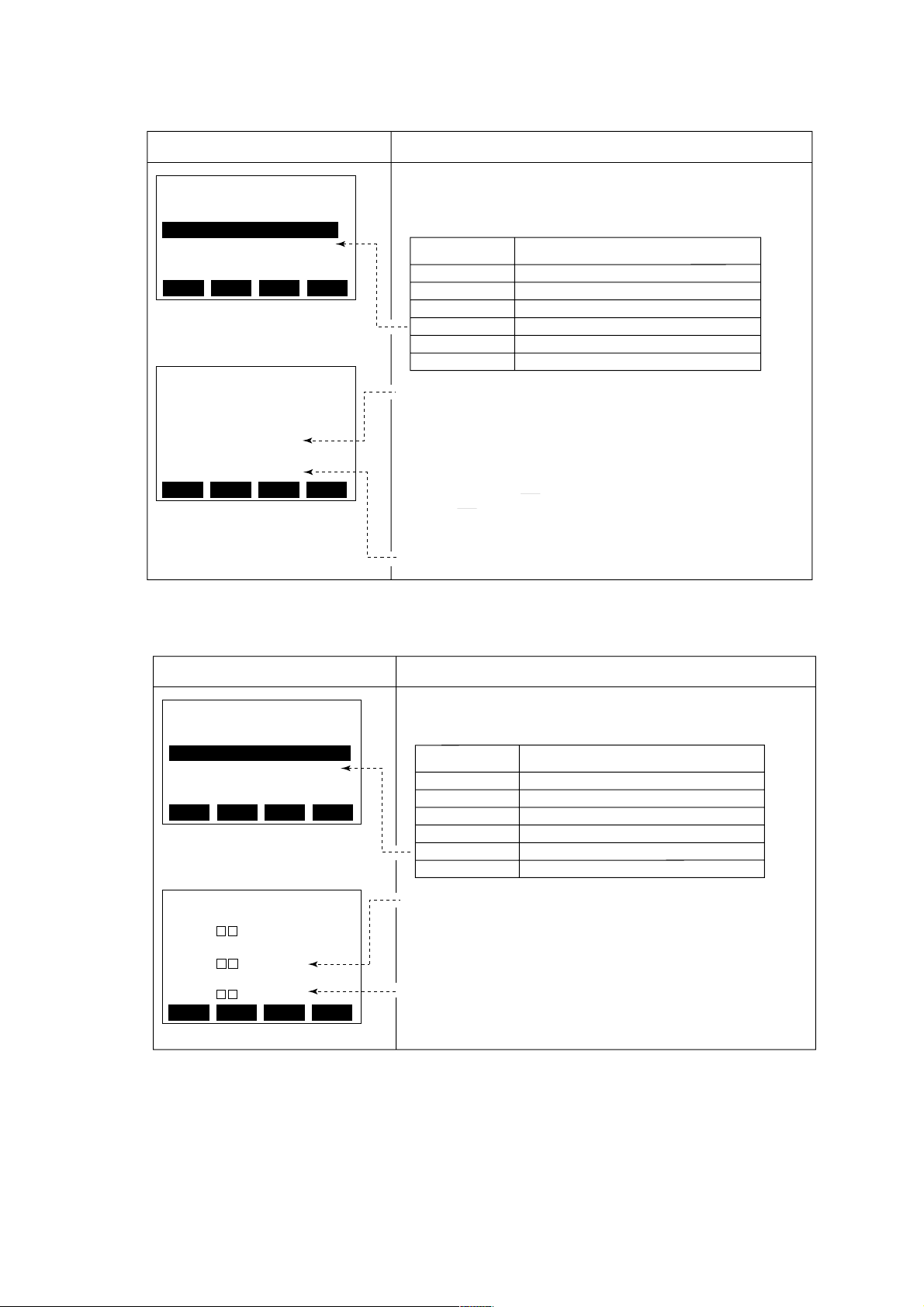

4.2 Types of Display Data

Three major types of data are displayed.

4. BASIC OPERATING PROCEDURES

1. Flow Rate Data

Display Mode

This mode displays flow

rates and totalization date.

Go to the setting mode

and use parameter "d1" to

change display items.

This mode can be called up by

pressing "SET" key while

pressing "SHIFT" key when

setting mode is displayed.

Display Example)

%

(Flow rate %)

3

m

/h

(Actual flow rate)

(Flow rate totalization value)

(Alternate display of

flow rate % and flow

rate totalization value)

(Alternate display of

actual flow rate and flow

rate totalization value)

2. Setting Mode

This mode is used to check

parameter content and

rewrite data. This mode

can be called up from the

flow rate data display mode by

pressing the "SET" key.

Display Example)

(Data item 02: 3 sec.dumping)

(Data item 03: Span 50.0)

(Data item C1: Zero adjust not possible)

(Data item d1: Selection of display items)

3. Alarm Display Mode

When an alarm situation

occurs, this mode will

replace the current mode

(flow rate or setting mode)

to show what type of

alarm has occurred.

Display Example)

(Error 07: Coil open)

(Error 06: Input signal error)

(Error 08: Incorrect span setting)

(Error 20: Metering tube not

filled with water)

(Alternate display of

actual flow rate and

flow rate %)

(Data item E1: Selection of totalization units)

4-2

IM 1E7C1-E

Page 15

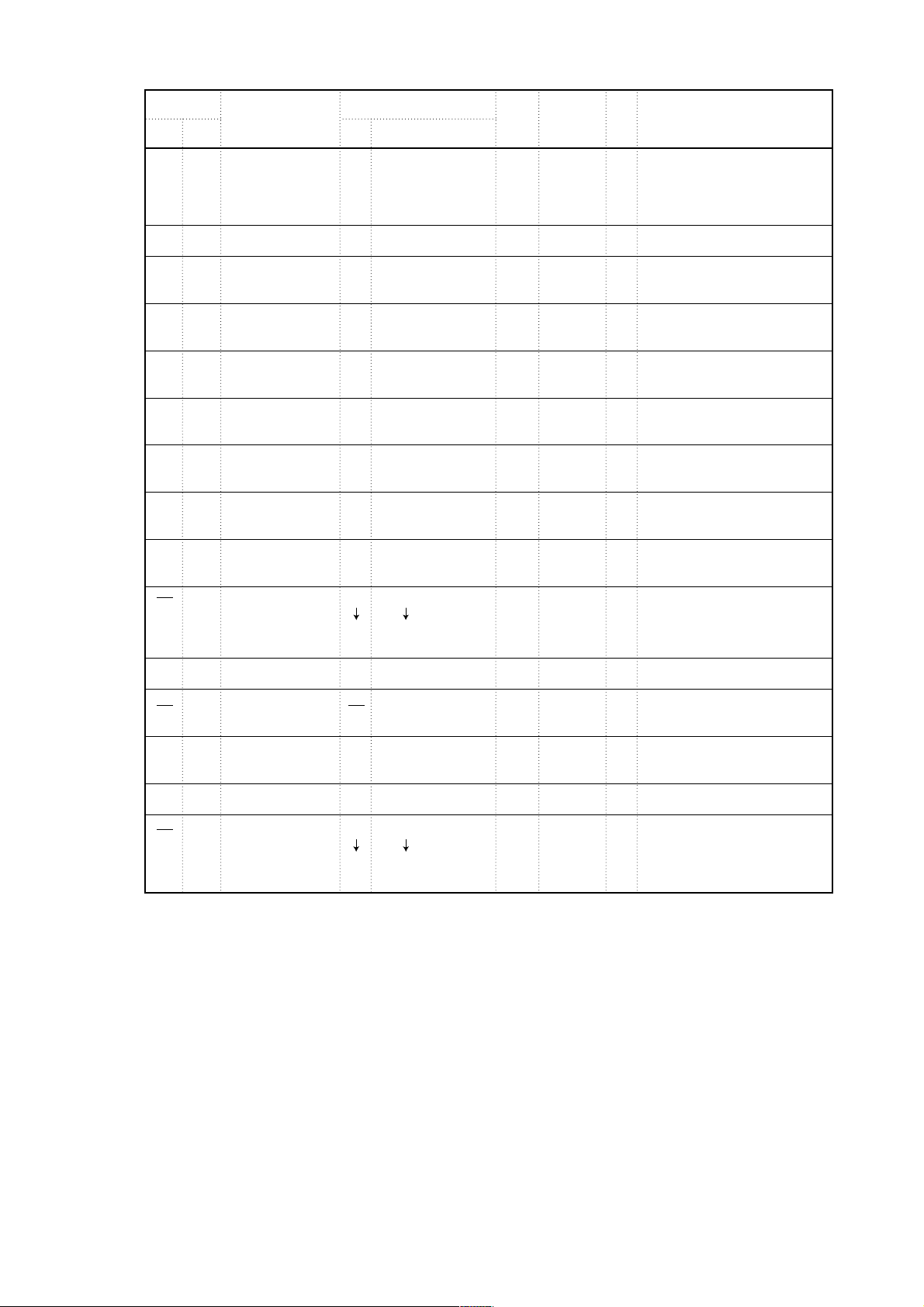

4.2.1 Flow Rate Data Display Mode

• The flow rate data display mode indicates instantaneous flow and totalized flow

values.

The ADMAG AE can display 12 types of flow rate data.

• This functions can be set in the parameter "d1" key of the flow converter.

• For changing from setting mode to flow rate data display mode, press "SET" key

while pressing "SHIFT" key.

•When a BT is used, call up the "D01 DISP SELECT" parameter to select functions.

4. BASIC OPERATING PROCEDURES

Display item Content

Forward

Flow Rate %

Actual forward

Flow Rate

Forward flowrate

totalization values

Reverse flowrate

totalization values

Differential

Between the

forward and

reverse

totalization

values

Forward flowrate

( %) and Forward

totalization values

Instantaneous flow rate is displayed within a

range of -8.0(-108.0) to 108 for the span.

The actual meter rate of instantaneous flow rate

is displayed. (See note 1.)

The decimal place is the same as for the span

setting. However,since a decimal point set at the

most significant bit cannot be displayed.

It is automatically shifted 1 digit to the right. (BT setting

of 0.0001 is displayed as 0.000 on the ADMAG.)

Display forward flow rate totalization value

Display reverse flow rate totalization value

Differential totalization, between forward

totalization and reverse totalization,

is displayed.

Display alternately between display of

"RATE(%)" and "FOR. TTL"

every 4 second interval.

ADMAG AE Setting

BT Setting

D01 : DISP SELECT

RATE(%)

D01 : DISP SELECT

RATE

D01 : DISP SELECT

FOR.TOTAL

D01 : DISP SELECT

REV.TOTAL

D01 : DISP SELECT

DIF. TOTAL

D01 : DISP SELECT

RATE%/FOR.TTL

Note 1 : The LCD can display the following combination of units (by selecting a parameter)

Units other than those shown below can be displayed by attaching the provided unit labels .

l (liters) /h, l (liters) /m, m3/h, m3/m, gal/h, gal/m

4-3

IM 1E7C1-E

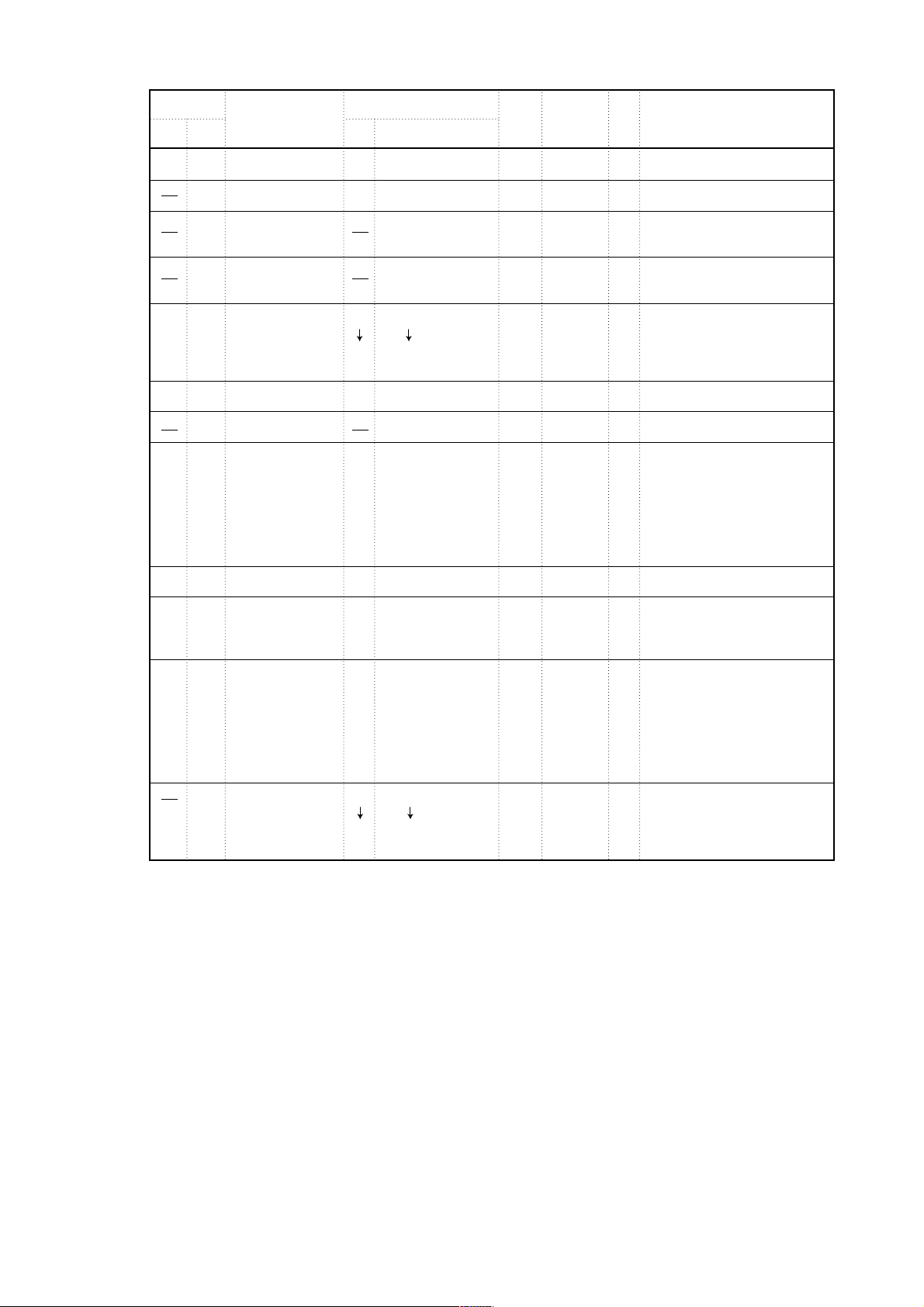

Page 16

4. BASIC OPERATING PROCEDURES

Display item Content ADMAG AE Setting BT Setting

Alternate

display of actual

forward

flowrate and

flowrate

totalization

values

Alternate

display of actual

forward

flowrate and

forward

flowrate (%)

Alternate

display

of forward

flowrate (%)

and reverse

totalization

values

Alternate

display of

forward

flowrate and

reverse flowrate

totalization

values

Alternate display

of forward

flowrate (%) and

differential between

the forward

and reverse

totalization values

Display alternately between

display of "RATE" and "FOR.

TTL" every 4 second interval.

Display alternately between

display of "RATE" and "RATE(%)"

every 4 second interval.

Display alternately between

display of "RATE(%)" and "REV.

TTL" every 4 second interval.

Display alternately between

display of "RATE" and "REV.

TTL" every 4 second interval.

Display alternately between

display of "RATE(%)" and "DIF.

TTL" every 4 second interval.

D01 : DISP SELECT

RATE/FOR.TTL

D01 : DISP SELECT

RATE/RATE(%)

D01 : DISP SELECT

RATE(%)/REV.TTL

D01 : DISP SELECT

RATE/REV.TTL

D01 : DISP SELECT

RATE(%)/DIF.TTL

Alternate display

of forward

flowrate and

differential between

the forward

and reverse

totalization values

Display alternately between

display of "RATE" and "DIF.

TTL" every 4 second interval.

D01 : DISP SELECT

RATE/DIF.TTL

4-4

IM 1E7C1-E

Page 17

(1) Changes in Flow Data Display Items

•Shows how the display changes when the flow converter switches are pressed.

• See chapter 6 for information on changes using the BT200.

%

SET SHIFT INC SET SHIFT INC SET SHIFT INC

4. BASIC OPERATING PROCEDURES

The display shown when the

power is turned on.

Selection

00 : Instantaneous flow rates (%)

01 : Instantaneous flow rates (actual

meter values)

02 : Forward flowrate totalization values

03 : Reverse flowrate totalization values

04 : Differetial Between the forward and

reverse totalization values

05 : Alternate display of forward flowrate

% and forward flowrate totalization

values

06 : Alternate display of forward flowrate

and flowrate totalization values

07 : Alternate display of forward flowrate

and forward flowrate (%)

08 : Alternate display of forward flowrate

(%) and reverse totalization values

09 : Alternate display of forward flowrate

and reverse flowrate totalization

values

10 : Alternate display of forward flowrate

(%) and differential between the

forward and reverse totalization

values

11 : Alternate display of forward flowrate

and differential between the forward

and reverse totalization values

Press the SET key to go to the

data mode shown above.

SET SHIFT INC SET SHIFT INC

Press the INC key to select

the number of the desired display

type.

SET SHIFT INC SET SHIFT INC

Press the SET key once and all

data starts to flash.

Press the INC key twice to

display d1:00.

Press the SET key to move the

hached portion (flashes)

to the last digit.

Wait 2 to 3 seconds and press the

SET key again to return the hatched

portion to its original position.

4-5

%

SET SHIFT INC

When all setting have been made,

hold down the SHIFT key while

pressing the SET key to return to

original display mode.

IM 1E7C1-E

Page 18

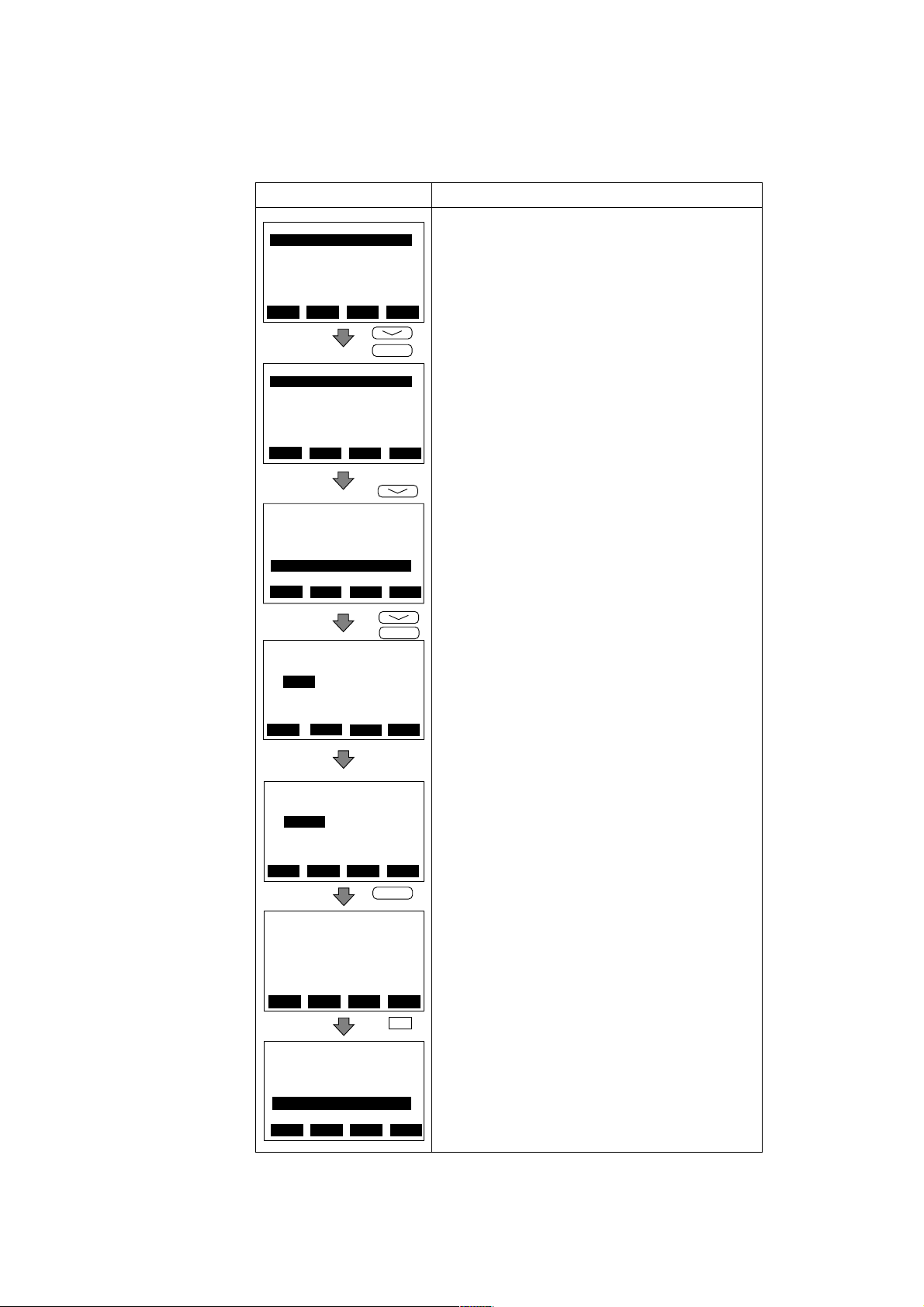

4.2.2 Setting Mode

• The setting mode is used for checking parameters and rewriting data.

• The following is an overview of the setting mode. See Section 5 "Function and Data

Settings" for detailed information.

(1) Structure of Setting Mode Display

• The display consists of two areas ; two digits to the left of the colon and four digits to

the right of it.

• Two types of data can be entered : direct entry of numerals and entry of desired data

items using codes.

Refer to "Parameter list" in chapter 11 for information on how to change settings.

Parameter number Data number

(2) Procedures for Setting and Changing Data

Example of parameter change : Changing the span (number 03) from 1.000 to 1.200

Item Display Content

4. BASIC OPERATING PROCEDURES

① Switch to

"Setting Mode"

② Parameter

Selection

➂ Data Rewrite

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

Press the SET key to go from the flow rate data display to the

setting mode.The delimiter ":" is displayed to indicate that the

mode has been swiched.

Press the SHIFT key to move the flashing segment (the selected

item)

Use the INC key to change the items displayed in the flashing

segment(the selected item).

Parameter 03 contains 5-digit data which cannot be

*

displayed as shown on the left but has to be scrolled.

Use the SET key to move the flashing segment (the selected item)

to the most significant location of the data area.

Use the SHIFT key to move the flashing segment (the selected

item) within the data area.

---Continued---

SET SHIFT INC

Use the INC key to change the data area (numeric data) in the

flashing segment (the selected item).

4-6

IM 1E7C1-E

Page 19

4. BASIC OPERATING PROCEDURES

Item Display Content

➃ Data Input

SET SHIFT INC

First time

SET SHIFT INC

Second time

➄ Switching to Flow

Data Entry

SET SHIFT INC

(3) Procedures for Changing Decimal Place

Before starting this procedure check in the data list if the position of the decimal point

for the desired parameter decimal places can be changed.

Example of parameter change : Changing the span from 1.000 to 10.00

Press the SET key twice to enter data.

(All data will start flashing when the key is pressed the first time.

Then wait 2 to 3 seconds before pressing the key the second time.)

Hold down the SHIFT key and press the SET key to switch to

the flow rate data display.

%

Item Display Content

① Selecting

Decimal

Position

➁ Moving

Decimal

Portion

➂ Data Entry

Press the SHIFT key to move the flashing segment to the decimal

point.

SET SHIFT INC

Press the INC key to move the decimal point to the right.

SET SHIFT INC

Press the SET key twice to enter data.

(All data will start flashing when the key is pressed the first time.

Then wait 2 to 3 seconds before pressing the key the second tme.)

SET SHIFT INC

First time

SET SHIFT INC

Second time

4-7

IM 1E7C1-E

Page 20

(4) Display of 5-digit Data

• The data display area has four digits and

•When the flashing segment is aligned with

can therefore not display span and other 5digit data parameters.

To display such data, the data is automatically shifted (scrolled) to the left one digit

at a time .

When a 5-digit parameter is selected, the

delimiter " : " starts to flash.

the last digit and the data includes a space,

the data is displayed as shown ④ on the

right.

4. BASIC OPERATING PROCEDURES

Display example : Display of span 123.45

①

3 seconds

➁

➂

➃

(Space)

1 second

1 second

(Space)

1 second

(5) Display of 6-digit Data

• The data display area has four digits and can therefore not display span and other 6digit data parameters. (E05 TL SET VALUE is the only 6-digit parameter.)

Like 5-digit data, 6-digit data is displayed by automatically shifting (scrolling) it to

the left one digit at a time.

(6) Display and Setting Coded Data

• Example of change : Changing from +120 to -120

Item Display Content

1. Selecting

Coded Data

➄

1 second

➅

1 second

➆

1 second

The display on right indicates "+120".

2. Coded Data

Flashes

3. Change of

Coded Data

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

Cause the "+" sign to flash.

Press the INC key to change the "+" sign to a "-" sign.

Press the SET key twice.

4-8

IM 1E7C1-E

Page 21

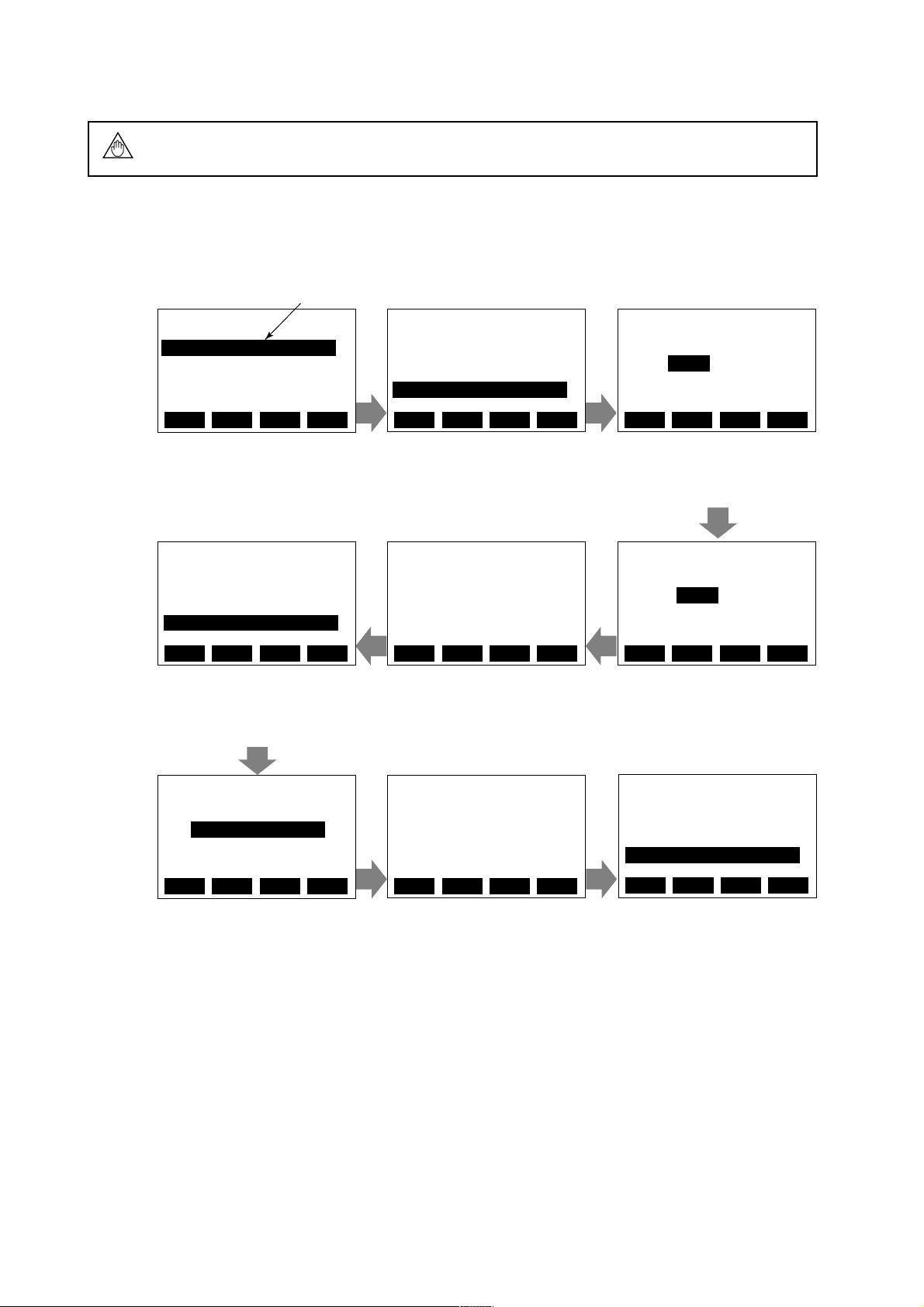

4.2.3 Alarm Display Mode

• When an alarm occurs, an alarm number indicating is displayed in place of the normal

display mode.

However, this happens only when the current display mode is the flow rate data

display mode or when parameter number are being changed in the setting mode.

(Alarms are not displayed when data items are being changed.)

4. BASIC OPERATING PROCEDURES

Alarm (Err) 06 and Alarm (Err) 20 have occurredAlarm (Err) 06 has occurred

Flow rate data displayed

%

4 seconds

Alarm 06 is displayed

2 seconds

Flow rate data is displayed

%

4 seconds

Flow rate data displayed

%

4 seconds

Alarm 06 is displayed

2 seconds

Flow rate data is displayed

%

4 seconds

Alarm 20 has occurred

2 seconds

Flow rate data is displayed

%

4 seconds

• See the section 7.2 "Self diagnostics function for information on alarm numbers.

4-9

IM 1E7C1-E

Page 22

5. FUNCTION AND DATA SETTINGS

5. FUNCTION AND DATA SETTINGS

A magnetic flowmeter calculates volume flow rate from minute voltage that corresponds

to the flow velocity of a fluid and outputs a 4 to 20mA signal.

The three parameters must be set to obtain a correct signal. Nominal size, flow span and

NOTE

NOTE

meter factor must be set.

This chapter explains how to set flow span and other functions.

Please set data correctly.

You cannot set the leftmost digit of display to numeric value greater than "4". If the leftmost

digit of the span must be "4" or more, set the numeric value beginning from the digit

second from the left on the display (the fourth digit). If the leftmost digit of the display is set

to "3", the digits to its right can be set to "0" only , regardless of the decimal point position.

Basic Key Operations

How to change the display into the setting mode?

How to move the cursor on the display during parameter setting?

How to change the display into the data changing mode?

How to move the cursor in the data changing mode?

How to change the data?

How to input the set data?

Key OperationItem

SET

SHIFT

SET

SHIFT

INC

SET (Twice)

5-1

IM 1E7C1-E

Page 23

5.1 Setting Nominal Size

Data Example : flowtube size 50mm

Switch Operation Display Description

5. FUNCTION AND DATA SETTINGS

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

Twice

SET SHIFT INC

Press the SET key during flow rate data display mode

to display setting mode shown in the left figure.

Press the SHIFT key to cause the second digit from

the left to flash.

Press the INC key to call up parameter number 06.

Press the SET key to move the flashing segment to

the data area.

Press the INC key to select

code "0" or "01" to display

"mm" or " inch".

Press the SET key twice.

Press the INC key to call up parameter number 07.

Code Size Unit

Code Size Unit

00 mm

01

inch

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

Twice

Press the SET key to move the flashing segment to the

first digit in the data area.

Set Flowtube size to number 07.

After completing the changes, press SET key twice ( wait slightly

between presses), the setting is completed.

5-2

IM 1E7C1-E

Page 24

5.2 Setting Flow Span

(1) Determining the Flow Rate Span Value

The flow rate span is the instantaneous flow rate value at which the output current is to

be 20 mA.

Please determine the span under considering the followings.

• Please set the maximum flow rate at the most variable flow rate line. If the flow rate

of the fluid exceeds the flow rate span value, the flow rate that exceeds this value

(20mA or more) is not output and the meter will not display the correct flow rate

(108% or more cannot be output).

• In a line where the flow rate is comparatively stable, set a value that is 1.5 to 2.0

times larger than the normal flow rate.

• Set a value that will correspond to a flow velocity of 0.3 to 10m/s.

The flow velocity is checked using sizing data or parameter number "13". (Parameter

number "13" displays the set span in flow velocity values.)

• The display of data is based on the input flow rate span value. It is recommended that

the accuracy of the first digit is in a 0.05 to 0.1%. For example, 30 m3/h should be set

as 30.00m3/h.

• The maximum numeric value that can be set is "30000" except any relation with

decimal position.

5. FUNCTION AND DATA SETTINGS

5-3

IM 1E7C1-E

Page 25

(2) Span Setting using Display Keys (Example setting: 30.00 m3/h)

• Span Value Setting

Switch Operation Display Description

5. FUNCTION AND DATA SETTINGS

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

Press the SET key during flow rate data display mode

to display setting mode shown in the left figure.

Press the SHIFT key to cause the second digit from

the left to flash.

Press the INC key to call up parameter number 03.

Default is set as 1.0000. Change this into 030.000

Press the SET key to move the flashing segment to

the first digit in the data area.

Press the INC key to set the first digit to 0.

Press the SHIFT key to move the decimal point.

Press the INC key to move the decimal point to "000.00".

*To set a "00000." as the data area is a four digit LCD,

the three digits and the space will be displayed as "000".

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

Note : 5-digit span data can be displayed, but only 4 digits will be supplyed at one time. As a result, when the

Press the SHIFT key to move the flashing segment two

digits to the right.

Press the INC key to enter "3".

Press the SET key once to cause all the data to flash.

*As the data display now will be scrolled, it may not

appear as shown in the left figure.

Wait 2 to 3 seconds when the data starts flashing. Then

press the SET key to return the flashing segment to the

leftmost digit.

*This display will also be scrolled to display 5-digit data.

(Setting is now completed)

last digit is changed, the last digit and the space will be displayed as the last three digits. (See 4.2.2

"Display of 5-digit data".)

5-4

IM 1E7C1-E

Page 26

5. FUNCTION AND DATA SETTINGS

• Setting Volume Measurement (m3) and Time Unit (/h)

Switch Operation Display Description

( Selecting m3)

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

( Selecting /h)

Press the SHIFT key to cause the second digit from the

left to flash.

Press the INC key to call up parameter number 04.

Code Volume Unit

Press the SET key to move the

flashing segment to the

data area.

Press the INC key to select

"01" to display m

3

.(See the

table on the right.)

Press the SET key once to

casue all the data to flash.

00

01

02

03

04

05

06

07

08

09

10

11

12

13

3

km

(103m3)

3

m

l(liter)

3

cm

(10

Mgal

kgal

gal

mgal

kbbl

bbl

mbbl

µbbl

m

ft

Wait 2 to 3 seconds when the data starts flashing.

Then press the SET key to return the flashing segment

to the lesfmost digit.

-

2

m)

3

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

(Setting is now completed.)

Press the SHIFT key to cause the second digit from the

left to flash.

Press the INC key to call up parameter number 05.

Press the SET key to move the flashing segment to the

data area.

Time Unit

/d

/h

/m

/s

Press the INC key to select

the code "01" to display /h.

(See the table on the right.)

Code

00

01

02

03

Press the SET key once to cause all the data to flash.

Wait 2 to 3 seconds when the data starts flashing.

Then press the SET key to return the flashing segment

to the leftmost digit.

5-5

IM 1E7C1-E

Page 27

5.3 Setting Meter Factor

The meter factors are engraved on the data plate of the combined flow tube.

Data Example : Meter factor (L) : 1.1200

Meter factor (H) : 1.2300

Switch Operation Display Description

5. FUNCTION AND DATA SETTINGS

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

Press the SET key during flow rate data display mode

to display the setting mode shown in the left figure.

Press the SHIFT key to cause the second digit from

the left to flash.

Press the INC key to call up parameter number 08.

Press the SET key to move the flashing segment to

the data area.

Press the SHIFT key to move the flashing segment two

digits to the right.

Press the INC key to enter "1".

Press the SHIFT key to move the flashing segment to

the right.

SET SHIFT INC

SET SHIFT INC

SET SHIFT INC

Press the INC key to enter "2".

After completing the changes, press SET key twice

(wait slightly between presses) , the data setting is completed.

Set meter factor(H) to number 09. Set in the same way.

5-6

IM 1E7C1-E

Page 28

5. FUNCTION AND DATA SETTINGS

5.4 Power Frequency (For DC version only)

IMPORTANT

the frequency differs.

Display

Set the value in area where the frequency differs in

parameter number "12".

Setting Range : 47.00 to 53.00Hz.

Default:50.00Hz

5.5 Other Functions and Settings

5.5.1 Pulse Output

(1) Pulse Output Overview

•By setting a pulse weight, a scaled pulse is transmitted to external counters and

measuring instruments.

Pulse Output Overview

metItnetnoC

tuptuO

snoitacificeps

- When using these for pulse output, alarm output or status output are not available

In case of DC power supply version, setting power frequency is required in areas where

gnitcennoC

slanimret

P,+P

as the terminals are used commonly.

Description

)Am002,CDV03siyticapactcatnoc(tuptuotcatnocrotsisnarT

htdiwesluP sm001,05,33,02,1,5.0,%05YTUD:noitceleS

etartuptuO s/P0001.xaMs/P1000.0.niM

* See "3.2.7 Connecting external instruments" for information on how to connect external instruments.

P+, P- terminals are for common use with pulse, alarm and other status output functions.

NOTE

Therefore, in case this function is used, other functions are not available to use.

(2) Procedures for Setting Pulse Output

Example setting :10 liter output per pulse in a flow rate span of m3/h

Display Description

Select "Pulse output" in parameter number "10".

Code

00

Pulse output

01

Alarm output

02

Forward/reverse flow measurement

03

Automatic two range switching

04

Alarm output at low flow limit

05

Totalization switch

Contents

5-7

IM 1E7C1-E

Page 29

Display Description

Select the volume unit for pulse weight using parameter number "F1".

5. FUNCTION AND DATA SETTINGS

Default :

3%

Code

00

Volume unit in that for the flow rate span ×10

Volume unit in that for the flow rate span ×10

01

Volume unit in that for the flow rate span ×10

02

Volume unit in that for the flow rate span ×1

03

Volume unit in that for the flow rate span ×10

04

Volume unit in that for the flow rate span ×10

05

Number of pulses output per second at 100% of output

06

Example : When pulses are to be output per same liter with the flowrate

span of m3/h, select "02" since L(liter) = 10

Volume Unit

-9

-6

-3

3

6

-3 × m3

Set pulse weight "10 (L)" in parameter number "E2".

Since parameter number "F2" is a 5-digit data item, scrolling is

necessary to display all the data. Mind the decimal point when

setting are made. (The decimal point can be moved if required.)

Set the low cut range percentage in parameter "F3".

Range of setting : 0 to 100% (of span)

Select the pulse width in parameter number "F4".

Default :

50%DUTY

Code Pulse Width

50%DUTY (Max. 1000P/s min. 0.0001P/s)

00

0.5ms (Max. 1000P/s min. 0.0001P/s)

01

1ms (Max. 500P/s min. 0.0001P/s)

02

20ms (Max. 25P/s min. 0.0001P/s)

03

33ms (Max. 15P/s min. 0.0001P/s)

04

50ms (Max. 10P/s min. 0.0001P/s)

05

100ms (Max. 5P/s min. 0.0001P/s)

06

Normally, these are all required settings. The following settings are made depending on the applications

that are used.

Select instantaneous flow rate or flow rate after damping for the pulse output.

(The damped value is the value set in "02".)

Default : 01

(Damped flow rate value)

Set parameter "n2" to "01" when the pulse output transistor is to be off active.

Default : 00(ON ACTIVE)

*The "n" item can be opened by entering "55" in paramter number "L2".

5-8

IM 1E7C1-E

Page 30

5.5.2 Display of Internal Totalization Values

•The flow converter can display totalization values by setting the pulse weight.

(1) Setting Totalization Pulse Weight

Example : Display 10 liter output per pulse in a flow rate span of m

Display Description

Select the volume unit for pulse weight using parameter number "E1".

Code Volume Unit

00

Volume unit in that for the flow rate span ×10

Volume unit in that for the flow rate span ×10

01

Volume unit in that for the flow rate span ×10

02

Volume unit in that for the flow rate span ×1

03

Volume unit in that for the flow rate span ×10

04

Volume unit in that for the flow rate span ×10

05

Number of pulses output per second at 100% of output

06

Example : When pulses are to be output per same liter with the flow

rate span m

5. FUNCTION AND DATA SETTINGS

-9

-6

-3

3

6

3

/h, select "02" since L(liter) = 10-3× m

3

/h

3

Default : 3%

Default : 01

(Damped flow rate value)

*Item "n" can be opened by entering "55" in parameter number "L2".

Set pulse weight "10 (L)" in parameter number "E2".

Since parameter number "E2" is a 5-digit data item, scrolling is

necessary to display all the data. Mind the decimal point when

setting are made. (The decimal point can be moved if required.)

Set the low cut range percentage in parameter "E3".

Range of setting : 0 to 100% (of span)

Select pulse output calculation of instantaneous flow rate or flow rate after

damping. (Use parameter "02" to set damping constant.)

5-9

IM 1E7C1-E

Page 31

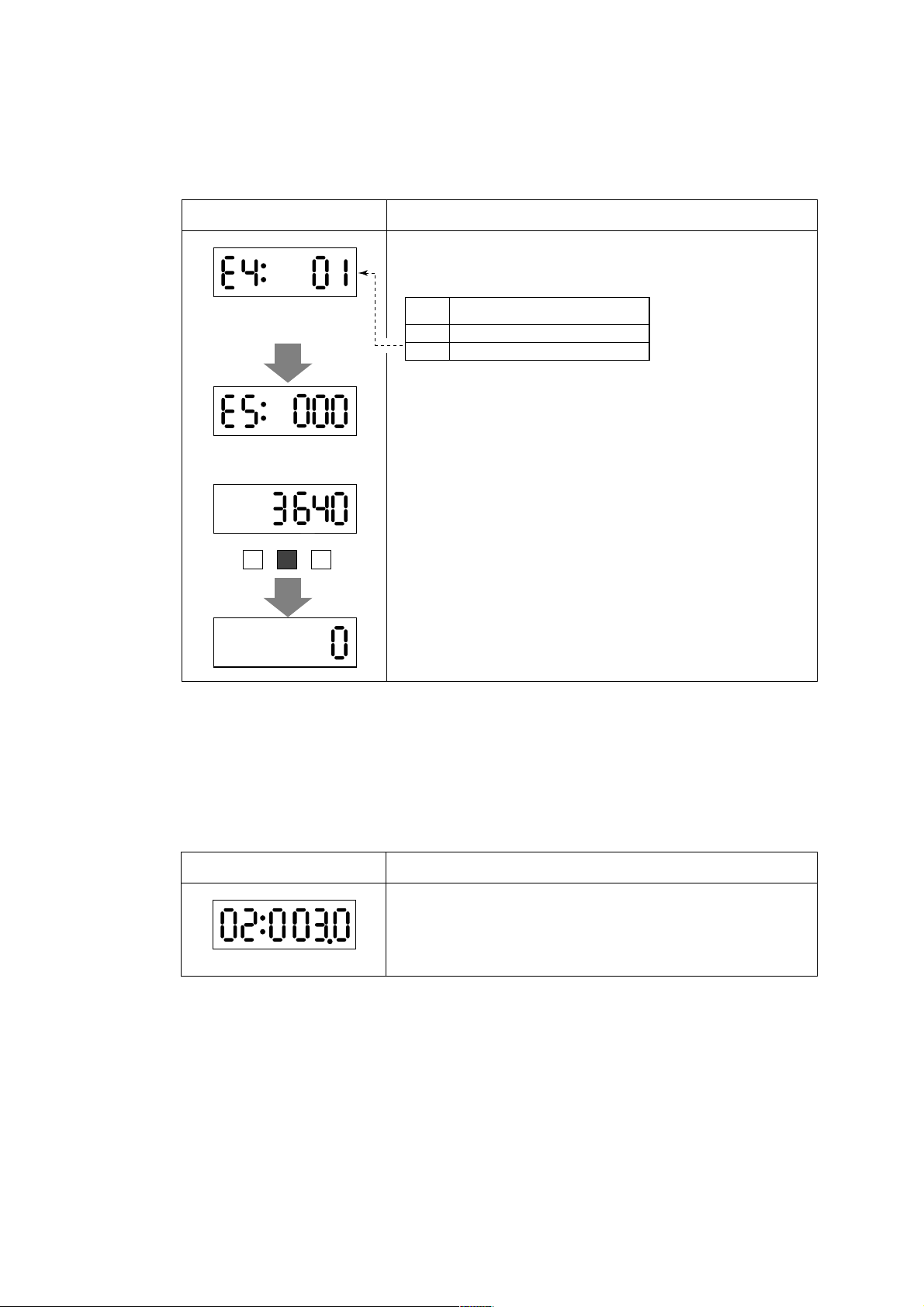

5.5.3 Resetting for Totalization Display

• This function is used to reset or preset totalization values of the display.

• Hold down the SHIFT key for more than 2 seconds while the totalization values of

the flow rate are displayed to set the totalization value to the value set in parameter

number "E5".

Display Description

Select totalization enable in parameter number "E4"

5. FUNCTION AND DATA SETTINGS

Default : 00 (inhibit)

Default : 0

SET SHIFT INC

5.5.4 Damping Time Constant

Code Description

0001Totalization presetting inhibit

Totalization presetting enabled

Set the totalization preset value in parameter number "E5". The initial value

is 0, if it is no setting, the function is zero setting.

Hold down the SHIFT key for more than 2 seconds while the totalization

values of the flow rate reading are displayed to set the totalization value to

the value set in parameter number "E5"

• The time constant can be changed by setting the parameter number "02" to suppress a

fluctuation or change a response time.

• The time constant influences to flow rate, pulse output and internal totalization.

However, in case "00" is selected in parameter number "N1", the pulse output and

internal totalization are not influenced by it.

Display Description

Set the value in parameter number "02".

Range of possible settings : 0.1 to 200.0 seconds.

Default : 3 seconds

5-10

IM 1E7C1-E

Page 32

5.5.5 Current Output During Alarm Occurrence

• The current output and display values during alarming can be selected in advance.

Display Description

Set a value for current output to be used during alarms in parameter number "11"

5. FUNCTION AND DATA SETTINGS

Default : 00

(2.4 mA or less)

5.5.6 Reversing Flow Direction

• The flow direction is set to "FORWARD" at the factory. This function enables to set

flow direction from "FORWARD" to "REVERSE"

Display Description

Default : 00

5.5.7 Limiting Current Output

Code Contents

00

2.4mA or less

01

4.0mA

02

Hold

03

21.6mA or more

Set the flow direction in parameter "14".

Code Contents

0001Forward direction

Reverse direction to flow arrow

(1) 4 to 20 mA low cut output (Current Output near by 0% Range)

• This function makes it possible to reduce fluctuations in the 0% region to reduce it to

0%.

Display Description

Output Set value

5.6mA(10%)

Default : 0(%)

4mA

Setting range : 0 to 10%

Input

0.5% 0.5%

Hysteresis : 1% fixed

5-11

IM 1E7C1-E

Page 33

(2) 4 to 20mA Low Limit

• This function limits the low end of the analog output.

• The default value is -20%, and a -10% (2.4mA) as reverse flow limit. Please set in

•2.4mA or less output in alarming is also limited.

5. FUNCTION AND DATA SETTINGS

case other setting is required.

Display Description

Output

Default : -20(%)

(3) High Limit on Current Output

• This function limits the high end of analog output.

• The default value is 120% (23.2mA). Please set in case other setting is required.

• 21.6mA or more output in alarming is also limited.

Display Description

Default : 120(%)

5.6mA(10%)

4mA

18.4mA(90%)

Setting Range

: -20 to 100%

Output

Setting range : 0 to 120%

5-12

IM 1E7C1-E

Page 34

5.5.8 Forward and Reverse Flow Measurement

• This function enables to measure forward and reverse flow rate without change the

flow tube direction.

•By setting reverse range, in case fluids flow to reverse direction the flow tube

measures it as reverse direction range automatically. In this time, a status signal that

shows changing into the reverse direction is output.

• To set the internal totalizing function for forward direction can also show it for

reverse direction by parameter settings.

• P+, P– terminals are used for output connection.

P+, P– terminals are for common use with pulse, alarm and other status output

NOTE

functions. Therefore, in case this function is used, other functions are not

available to use.

Display Description

F and R flow rate measurement can be selected as “02” in

parameter No. “10”.

5. FUNCTION AND DATA SETTINGS

(Default : 2%)

Code

00

Pulse output

01

Alarm output

02

Forward / reverse flow measurement

03

Automatic two range switching

04

Alarm output at low flow limit

05

Totalization switch

Reverse direction span can be set in parameter

No. “30”.

Flow rate unit is the same as forward direction span.

Futher reverse range span should be set in the same

number of places of decimals as forward range span.

Example: forward flow rate : 1.000 then revers flow rate

should be 4.000.

Hysteresis width at switching direction can be set in

parameter No. “31”.

It is the rate (%) of the smaller span, either forward or

reverse span.

Content

0%

Flow Rate

Hysteresis

Forward flow measurement: OFF

Reverse flow measurement: ON

When using reversed status (ON/OFF)

is required, it can be set in “n2 Output Mode”.

5-13

Status output

IM 1E7C1-E

Page 35

5.5.9 Automatic Two Range Switching

• When an input exceeds 100% of the first range, the range is automatically transferred

to the second range and the status output changes state.

• P+, P– terminals are used for output connection.

P+, P– terminals are for common use with pulse, alarm and other status output

NOTE

functions. Therefore, in case this function is used, other functions are not

available to use.

Display Description

5. FUNCTION AND DATA SETTINGS

Automatic two range transfer can be selected “03” in

parameter No. “10”.

Default : 00

Default : 10%

Code

Pulse output

00

Alarm output

01

Forward / reverse flow measurement

02

Automatic two range switching

03

Alarm output at low flow limit

04

Totalization switch

05

Forward second range can be set by calling up parameter

No. “33”.

Setting restrictions: First range ≤ 2nd range.

Further second range span should be set in the same

number of places of decimals as first range span in

parameter No. “03”.

Example: First range : 1.000 then second range should be

4.000

Hysteresis width at switching range can be set in

parameter No. “34”.

It is the rate (%) of first range span.

Output

100%

Content

2nd range1st range

0 %

1st range: OFF

2nd range: ON

When using reversed status (ON/OFF)

is required, it can be set in “n2 Output Mode”.

Status Output ON

Hysteresis (%)

Status Output

5-14

Flow Rate

IM 1E7C1-E

Page 36

5.5.10 Alarm Output at Low Flow Limit (Flow Switch)

• In case flow rate decrease under set level, an status signal is output.

P+, P– terminals are for common use with pulse, alarm and other status output

NOTE

functions. Therefore, in case this function is used, other functions are not

available to use.

Display Description

Alarm output at low flow limits can be selected “04” in

parameter No. “10”.

Default : 00

Code

00

Pulse output

01

Alarm output

02

Forward / reverse flow measurement

03

Automatic two range switching

04

Alarm output at low flow limit

05

Totalization switch

The Low Limit value can be set in parameter No. “36”

as parcentage for 4 to 20 mA.

5. FUNCTION AND DATA SETTINGS

Content

(Default : -10%)

(Default : 5%)

Hysteresis width is set in parameter No. “37”.

Output

low flow

limits

value.

Status

Output

On

When using reversed status (ON/OFF)

is required, it can be set in “n2 Output Mode”.

Hysteresis

5-15

IM 1E7C1-E

Page 37

5.5.11 Totalization Switch Output

• In case the Internal Totalization Value increase over set level, an alarm signal is

output.

P+, P– terminals are for common use with pulse, alarm and other status output

NOTE

functions. Therefore, in case this function is used, other functions are not

available to use.

Display Description

Default : 00

5. FUNCTION AND DATA SETTINGS

Totalization switch can be selected as “05” in parameter

No. “10”.

Code

00

Pulse output

01

Alarm output

02

Forward / reverse flow measurement

03

Automatic two range switching

04

Alarm output at low flow limit

05

Totalization switch

Switch level can be selected by calling up parameter No.

“06”.

Content

Default : 0

Totalization

999999

Setting value

10000

Status

Output

ON

When using reversed status (ON/OFF)

is required, it can be set in “n2 Output Mode”.

Input

5-16

IM 1E7C1-E

Page 38

5.5.12 Alarm Output

• This function is for status output from P+, P– terminals, when an alarm occurs.

P+, P– terminals are for common use with pulse, alarm and other status output

NOTE

functions.

Therefore, in case this function is used, other functions are not available to use.

•All of the alarms are able to output except empty pipe detection function that can be

• The status goes from close to open (OFF) during alarming.

Default : 00

Default : 00

selected in parameter No. “n7” as out of selection.

Display Description

The alarm output can be selected “01” in parameter No.

“10” and P+, P– terminals are only for alarm output.

Code

00

Pulse output

01

Alarm output

02

Forward / reverse flow measurement

03

Automatic two range switching

04

Alarm output at low flow limit

05

Totalization switch

The empty pipe output selection can be set in parameter

No. “n7”.

Code

00

ALARM

01

NO ALARM

Content

Content

5. FUNCTION AND DATA SETTINGS

* Item "n" can be opened by entering "55" in parameter number "L2".

5.5.13 Data Setting Enable / Inhibit

• This function can inhibit to change all data except parameter No. “ L1”.

However, auto zero adjustment function can work, if it has been set in parameter No.

“C1”.

And the preset totalization value function also can work, if it has been set in parameter

No. “E4”.

Display Description

Default : 01

The data setting inhibit item can be set "00" in parameter number "L1".

Code Content

0001INHIBIT

ENABLE

5-17

IM 1E7C1-E

Page 39

5.5.14 Procedure of Selecting Special Application Items

• Only the special application (“n” items) shipped being unpublished.

In case the “n” items should be used, it can be set “55” in parameter No. “L2”.

Display Description

It is possible to open up to item n when "55" is entered in parameter number

"L2".

Default : 00

Code Content

0001Accessible up to L parameters

Accessible up to n parameters

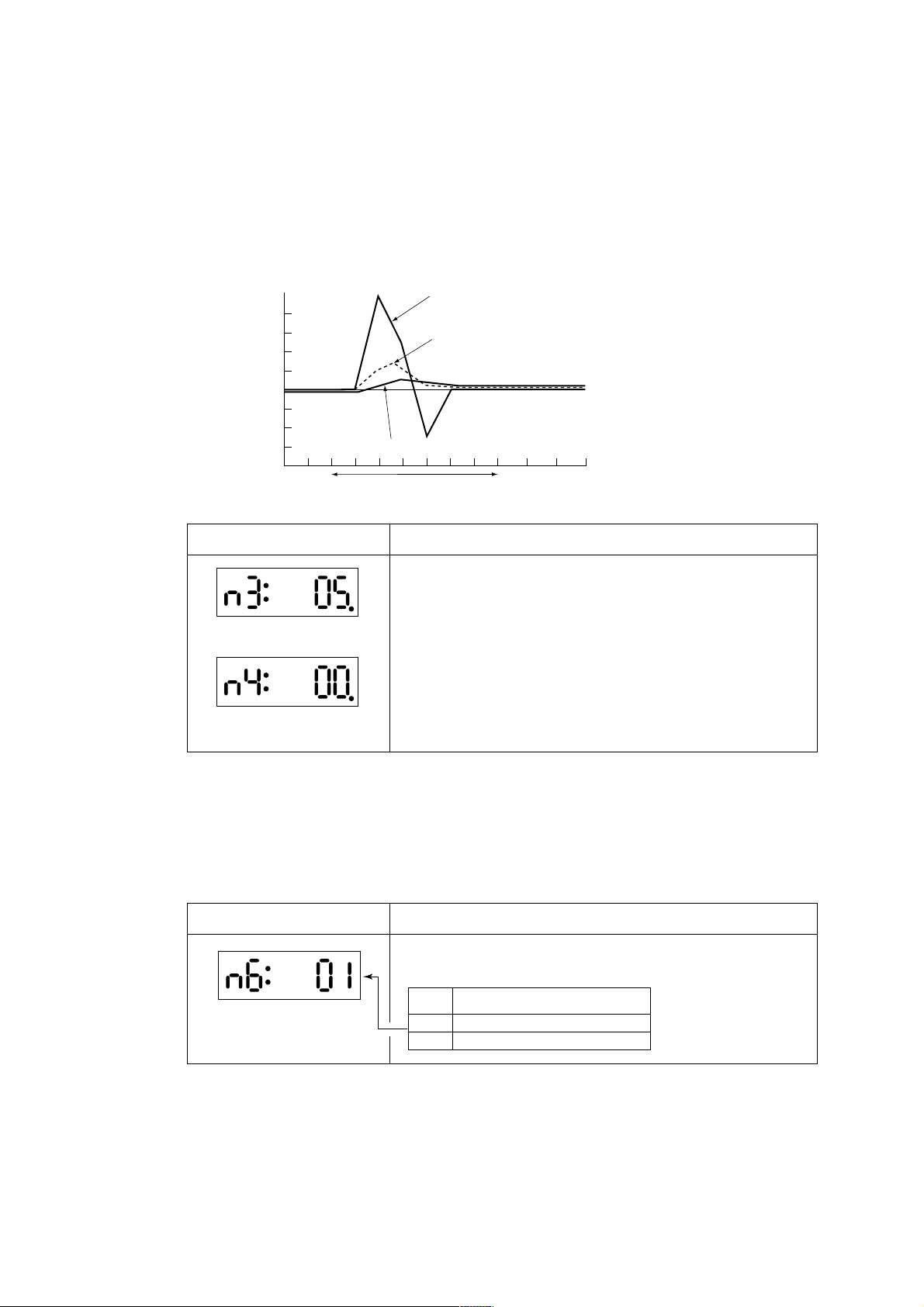

5.5.15 Rate Limit

• This function is used to remove noise that cannot be removed by increasing the

damping time constant.

• In case unexpected noise from step signal or slurry is entered, a basis is set to